Patents

Literature

196results about How to "No flying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of steroid hormone coating agent and preparation method thereof

ActiveCN102258455ASimple preparation processNo flyingOrganic active ingredientsPharmaceutical delivery mechanismSurvivabilityPlasticizer

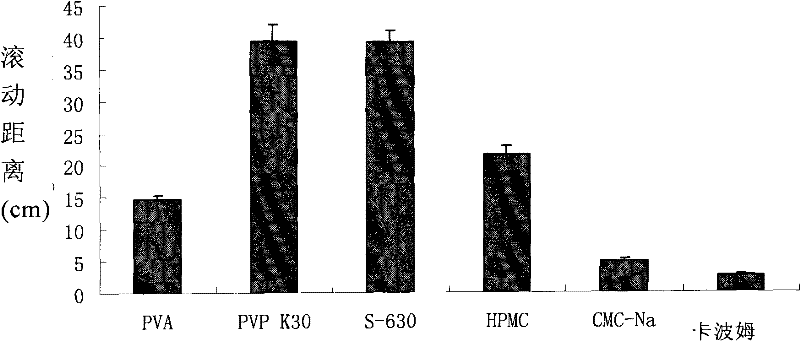

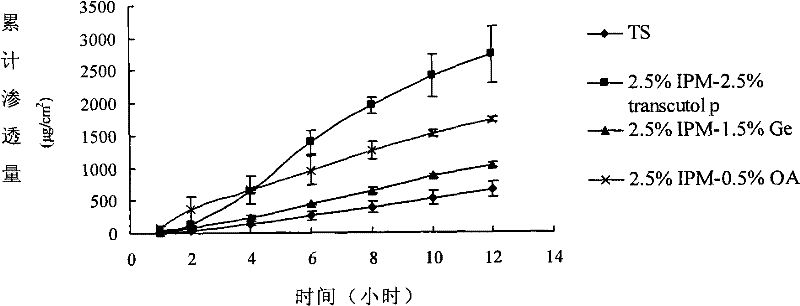

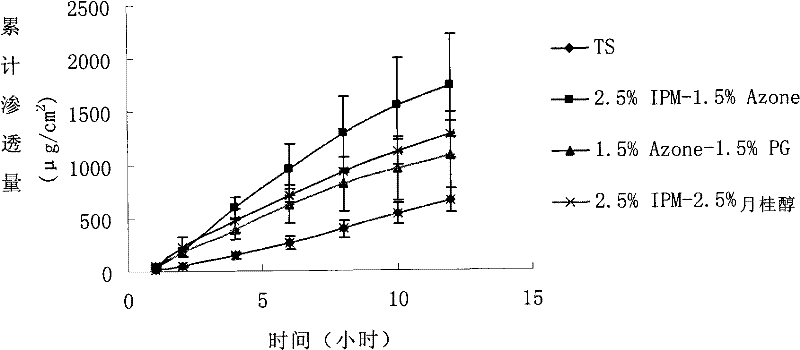

The invention relates to a film coating agent containing steroid hormone, which comprises 1 part of steroid hormone medicament, 1-50 parts of film forming materials, 0.5-10 parts of plasticizer, 0.5-10 parts of biological adhesive materials and 1-50 volumes of transdermal enhancer. The preparation of the present invention is capable of raising the efficiency of conveying steroid hormone medicament into the body by permeating skin and improving the irritation to the skin, and has good survivability. The invention also relates to a preparation method of the film coating agent, and the preparation method has the advantages of simple process, convenient operation and less energy consumption.

Owner:上海市生物医药技术研究院

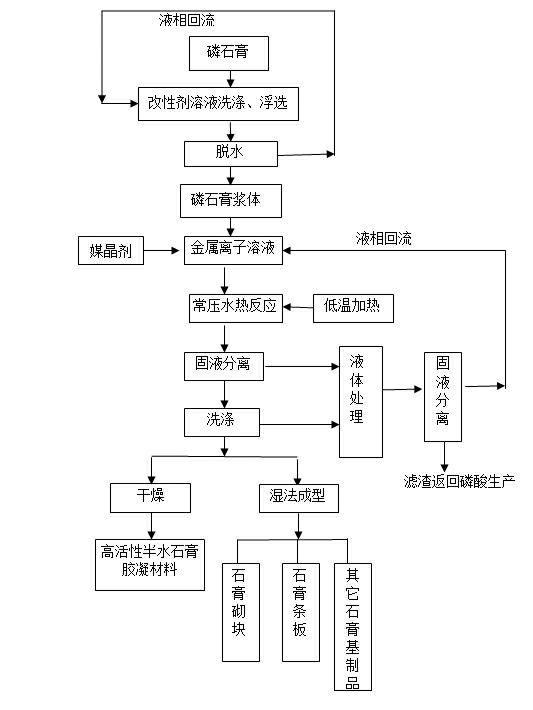

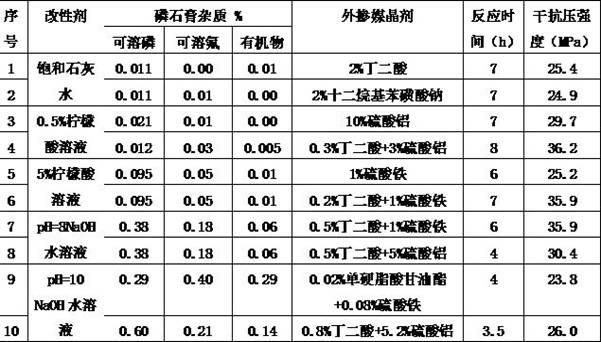

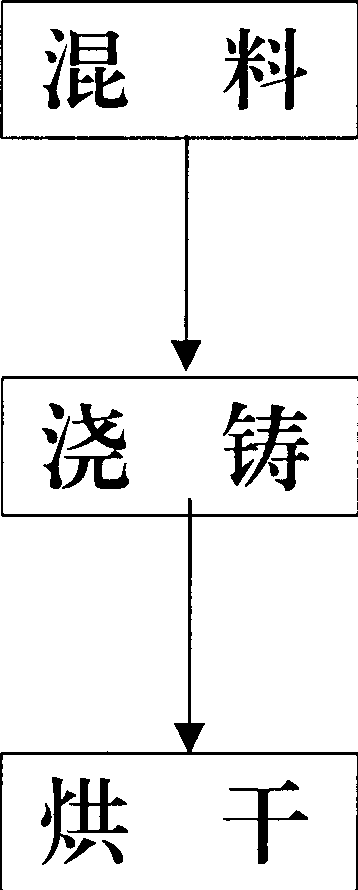

Process for preparing high-activity semi-hydrated gypsum cementing material and gypsum product by aid of phosphorous gypsum

The invention relates to a process for preparing a high-activity semi-hydrated gypsum cementing material and a gypsum product by the aid of phosphorous gypsum. The process includes technical processes of 1) a pretreatment process for the phosphorous gypsum; 2) a normal-pressure water heating reaction process; 3) a slurry preparation process; and 4) a preparation process for the high-activity semi-hydrated gypsum cementing material and the gypsum product. The process for preparing the high-activity semi-hydrated gypsum cementing material and the gypsum product by the aid of the phosphorous gypsum has the advantages that a process for preparing the high-performance semi-dehydrated gypsum cementing material by the aid of the phosphorous gypsum is completed under the normal-pressure mild condition, the process can be combined with an independent gypsum product manufacturing process to produce gypsum blocks, gypsum plates or other semi-hydrated gypsum products, and production flexibility of the technical processes is realized. In addition, owing to normal-pressure conversion, investment cost and running cost are saved, the processes are easily controlled, reliability is improved, performances of the product are excellent, materials are wet during the process which adopts wet phosphorous gypsum raw materials and produces the product, flying dust is prevented, waste is utilized, and effects of saving energy and protecting environments are realized.

Owner:WUHAN UNIV OF TECH

Method for preparing powdered rubber in stuffing type with extra fine calcium carbonate

A superfine calcium carbonate filled powdered rubber is prepared from dry rubber, superfine calcium carbonate, surfactant, operating oil, antioxidant, emulsifier, coagulant and deionized water through proportioning, emulsifying, heat treating, coagulating and post-treating. Its advantages are high coating effect, high pulverizing rate (99% or more), and high mechanical performance, flowability and storage stability of product.

Owner:SOUTH CHINA UNIV OF TECH

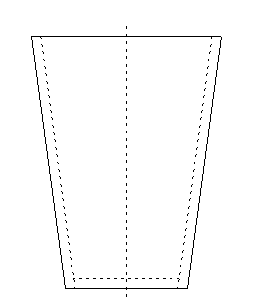

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

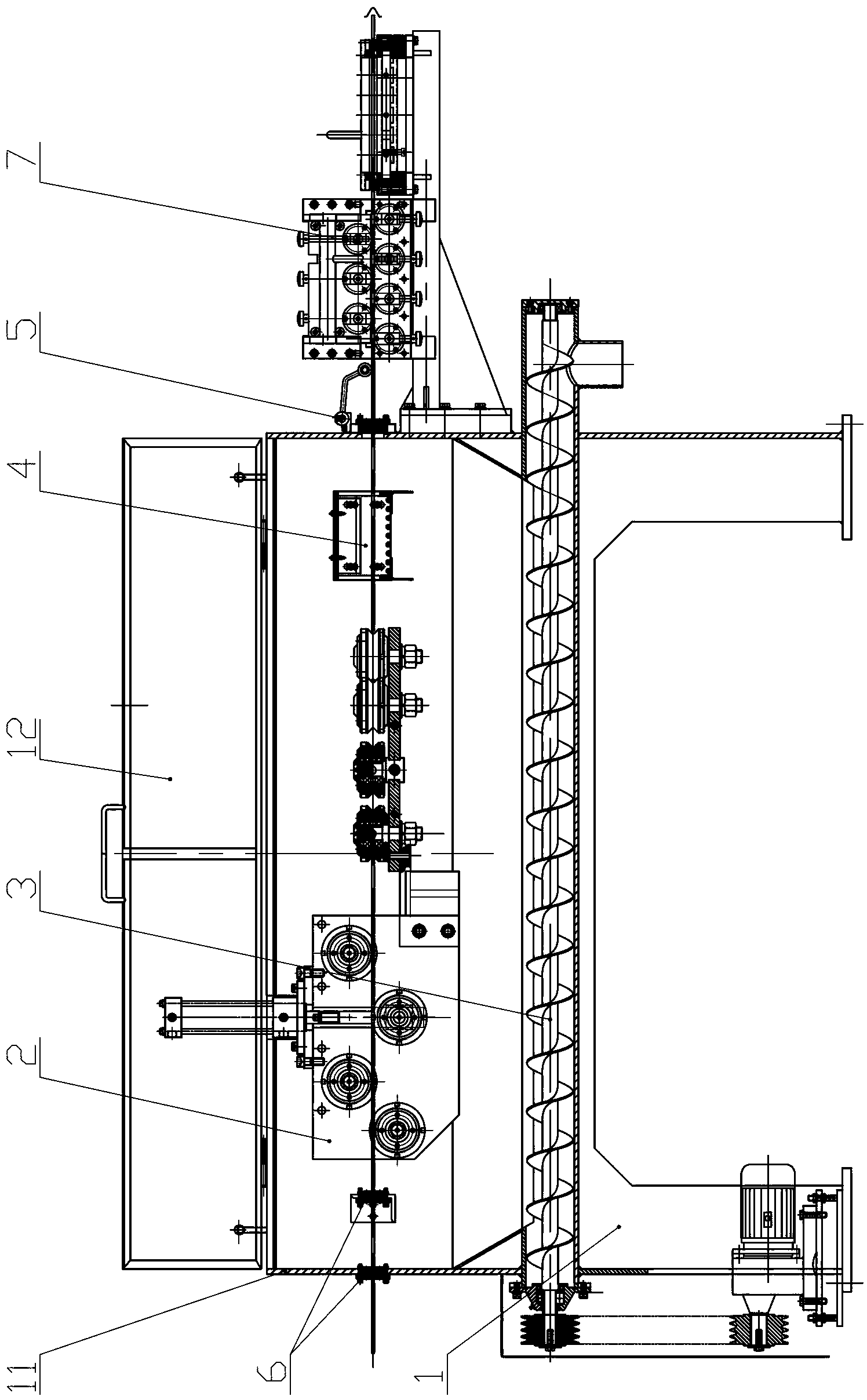

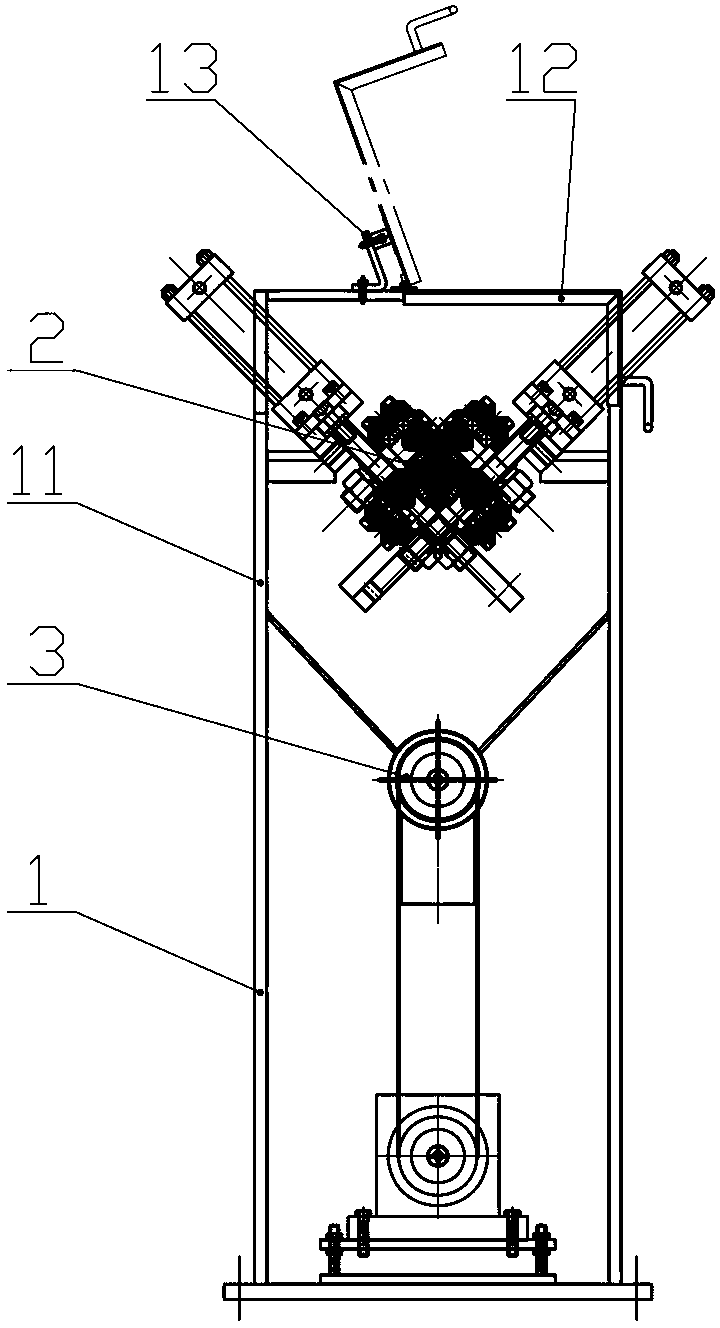

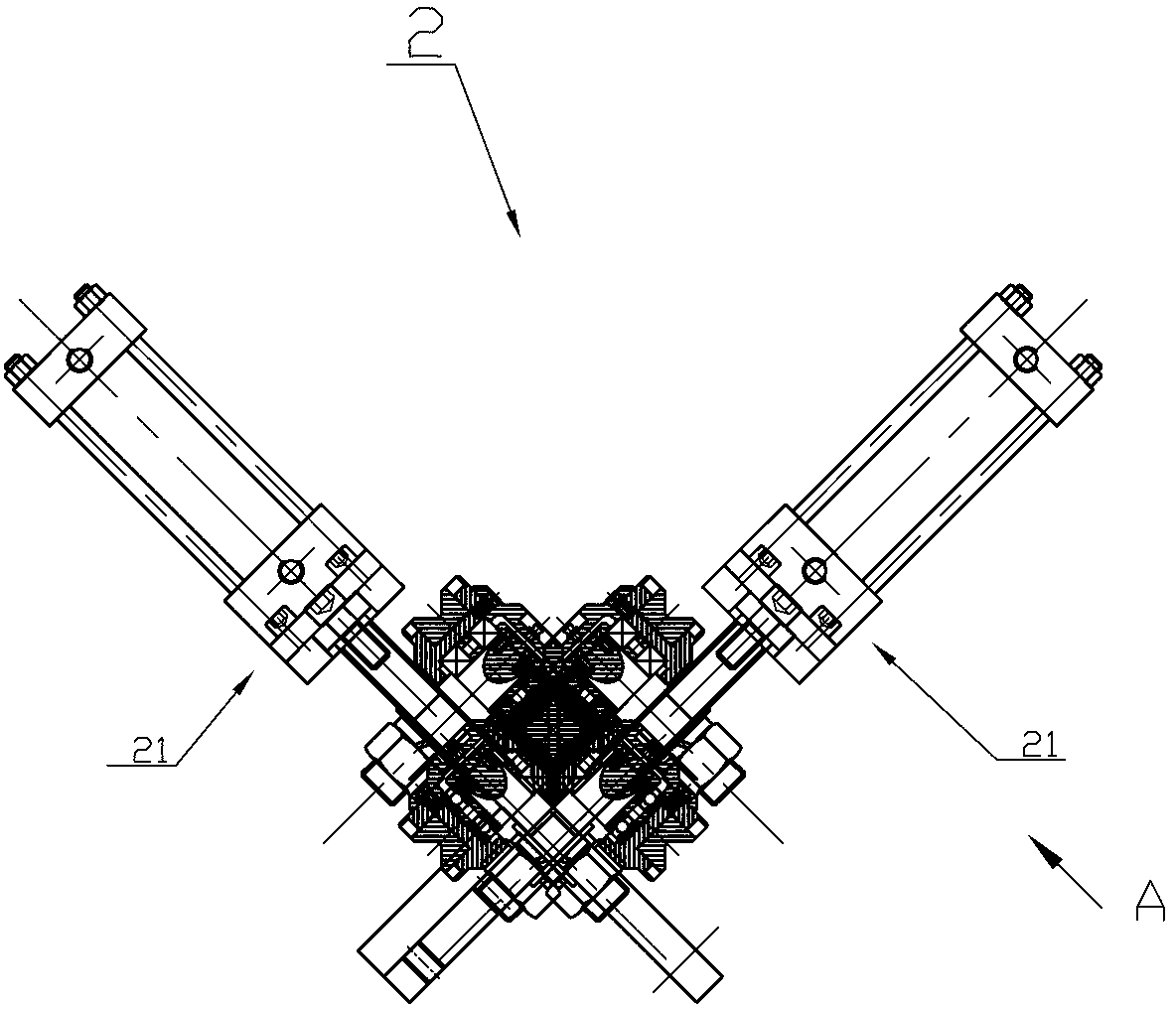

Husking machine

The invention relates to a husking machine used for a continuous acid-free wiredrawing production line. The husking machine comprises a machine frame, wherein an unshelling device and an aligner are mounted on the machine frame; the machine frame is provided with a case body; material guide devices are mounted on two opposite lateral walls of the case body respectively; the unshelling device and a dust removing device are mounted between the two material guide devices; a residue discharging device is mounted on the bottom part of the case body; and the aligner is mounted outside the case body and is located on the downstream position of the dust removing device. According to the invention, the material guide devices, the dust removing device and the residue discharging device are added; wire rods are guided through the material guide devices and can be unshelled initially, and abrasion of the wire rods to the unshelling device can be reduced; husked wires are polished by the dust removing device so that the wires have glabrous surfaces; abrasion of the wires to the aligner can be reduced; service life of the husking machine is prolonged; shells and rust residue dropped from the wire rods are collected by the residue discharging device; a whole machine is worked without blown powder dust; therefore, cleaning of working environment of the husking machine can be ensured.

Owner:WUXI CHANGXIN TECH

Modified plant fiber material type glass moldproof parting powder

ActiveCN102924942AImprove adsorption capacityPrevent mildewBiocideFungicidesOrganic acidMaterial type

The invention discloses a modified plant fiber material type glass moldproof parting powder which is prepared by carrying out surface modification on plant fiber pulverized substances. The preparation method comprises the following steps: screening plant fiber pulverized substances, mixing with a modifier solution, standing, treating under the absolute pressure of 100-500kPa at the temperature of 0-300 DEG C for 0.1-48 hours, and finally, directly drying to obtain the modified plant fiber material type glass moldproof parting powder. The modifier is selected from one or mixture of organic acids, inorganic acids or acid salts. The moldproof parting powder has the advantages of favorable flowability, adsorptivity and natural degradability, can postpone the glass from becoming moldy, basically does not generate flying ash, and is clean and convenient. The glass using the product can be easily cleaned after long-term storage, and can not influence the subsequent processing and use of the glass.

Owner:南京汉旗新材料股份有限公司

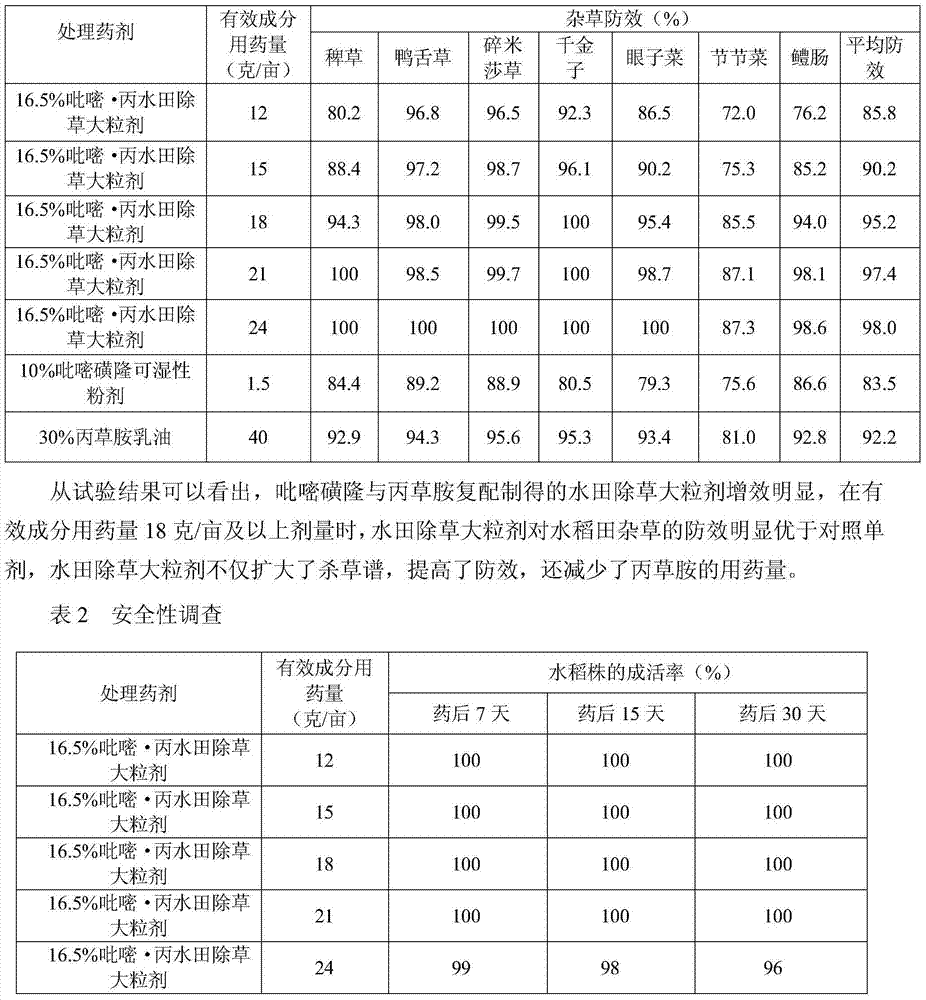

Weeding macro granule for paddy field and preparation method thereof

ActiveCN103688971ALong-lasting and uniform effectGood prevention effectBiocideAnimal repellantsPesticidePaddy field

The invention provides a weeding macro granule for a paddy field. The weeding macro granule comprises the following raw materials in parts by weight: 1-30 parts of pretilachlor, 1-25 parts of adsorbents, 0.5-5 parts of pyrazosulfuron, 0.5-25 parts of surfactants, 1-30 parts of oily substances, 10-80 parts of a solid core material, 10-20 parts of additives and 10-20 parts of fillers. The weeding macro granule for the paddy field disclosed by the invention utilizes a floating material, floating glass beads, and thus the granules can float on water, and can automatically diffuse under the action of wind and assistants of the granules; a high-performance dispersing agent is introduced into the formula, and thus the effective components of the granule can diffuse to the overall field within a short period of time. Thus, the pesticide effect is lasting, and labor and time are saved.

Owner:NANJING GAOZHENG AGROCHEM

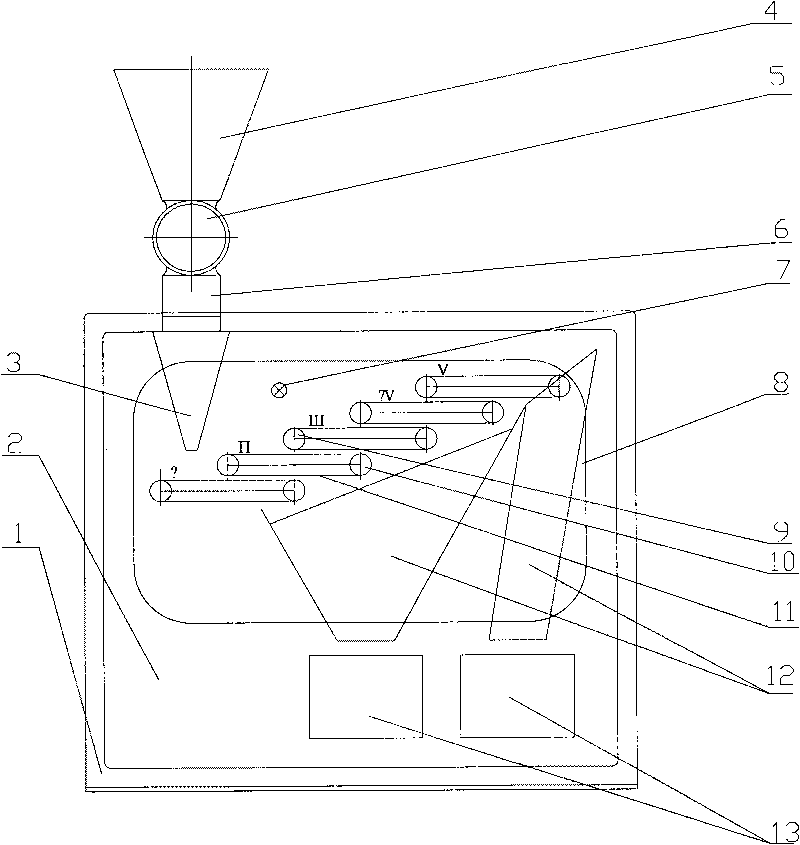

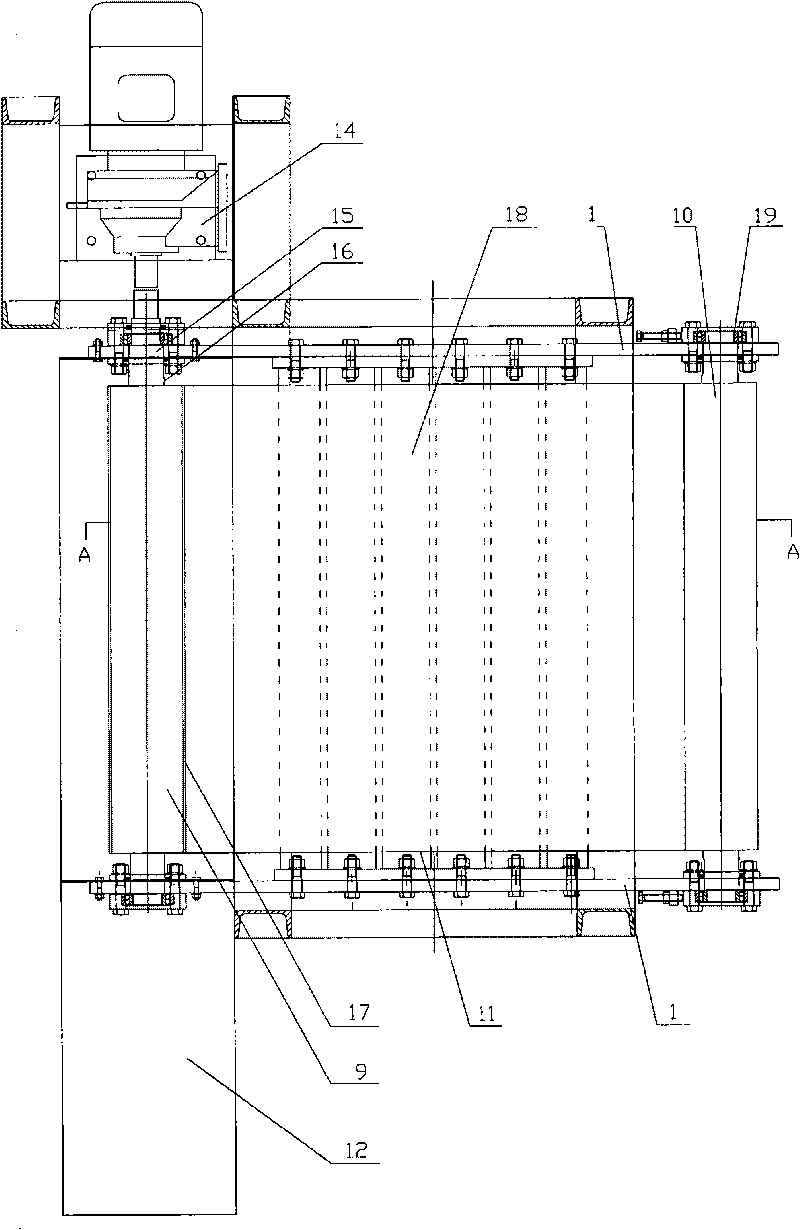

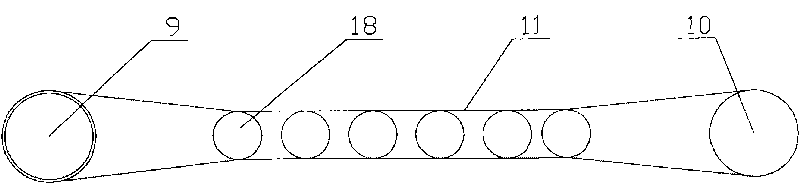

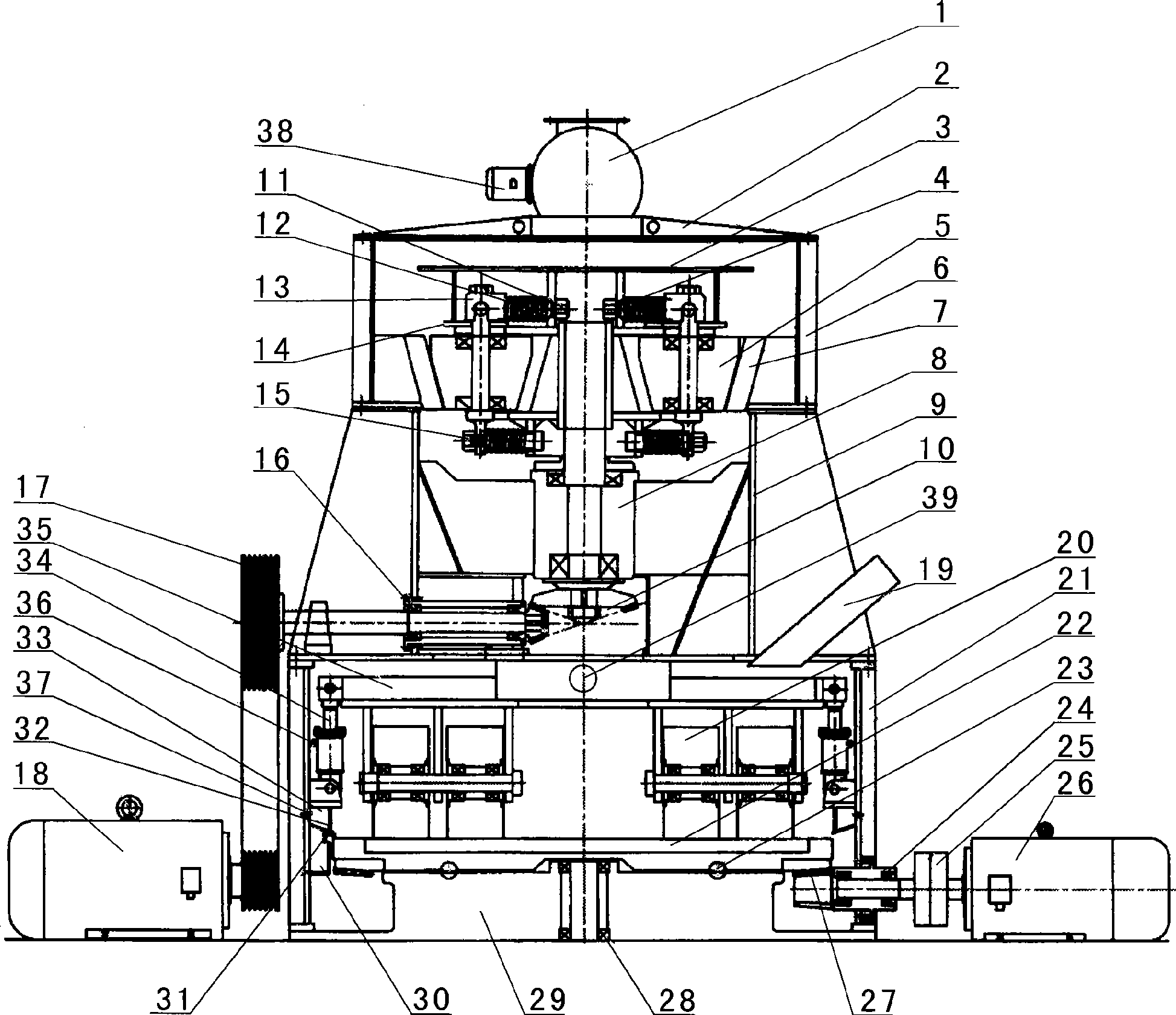

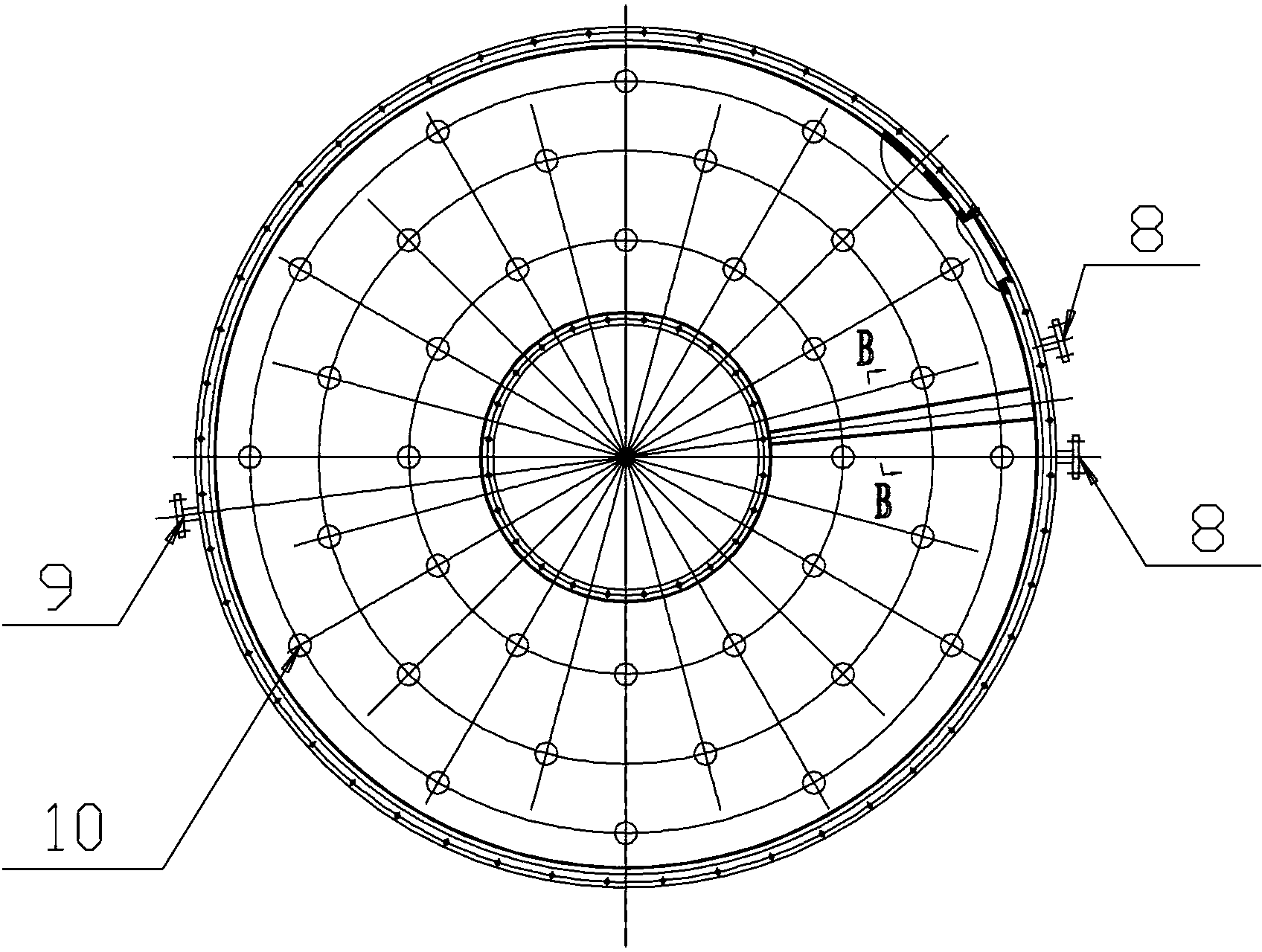

Module type permanent magnetic separation rolling machine

InactiveCN101693223AReduce wasteIncrease flexibilityMagnetic separationMechanical engineeringMagnetic separation

The invention relates to a module type permanent magnetic separation rolling machine which is characterized by comprising a stand, a belt conveyer, a feeding mechanism and a collecting hopper, wherein the belt conveyer is sequentially arranged on a plurality of layers in the stand from bottom to top in ladder type derangement and is horizontally arranged and driven by an actuating device, the feeding mechanism is arranged above the feeding end of the belt conveyer, the collecting hopper is arranged below the feeding outlet of the belt conveyer; a driving roll of every layer of the belt conveyer positioned in the feed end is of a magnetic roll structure. The complete machine is controlled by a PID control chamber which can conveniently and rapidly regulate all operation systems of the complete machine and ensure that the separation process runs continuously according to the set program, thereby realizing the automatic regulation of parameters.

Owner:HENAN POLYTECHNIC UNIV

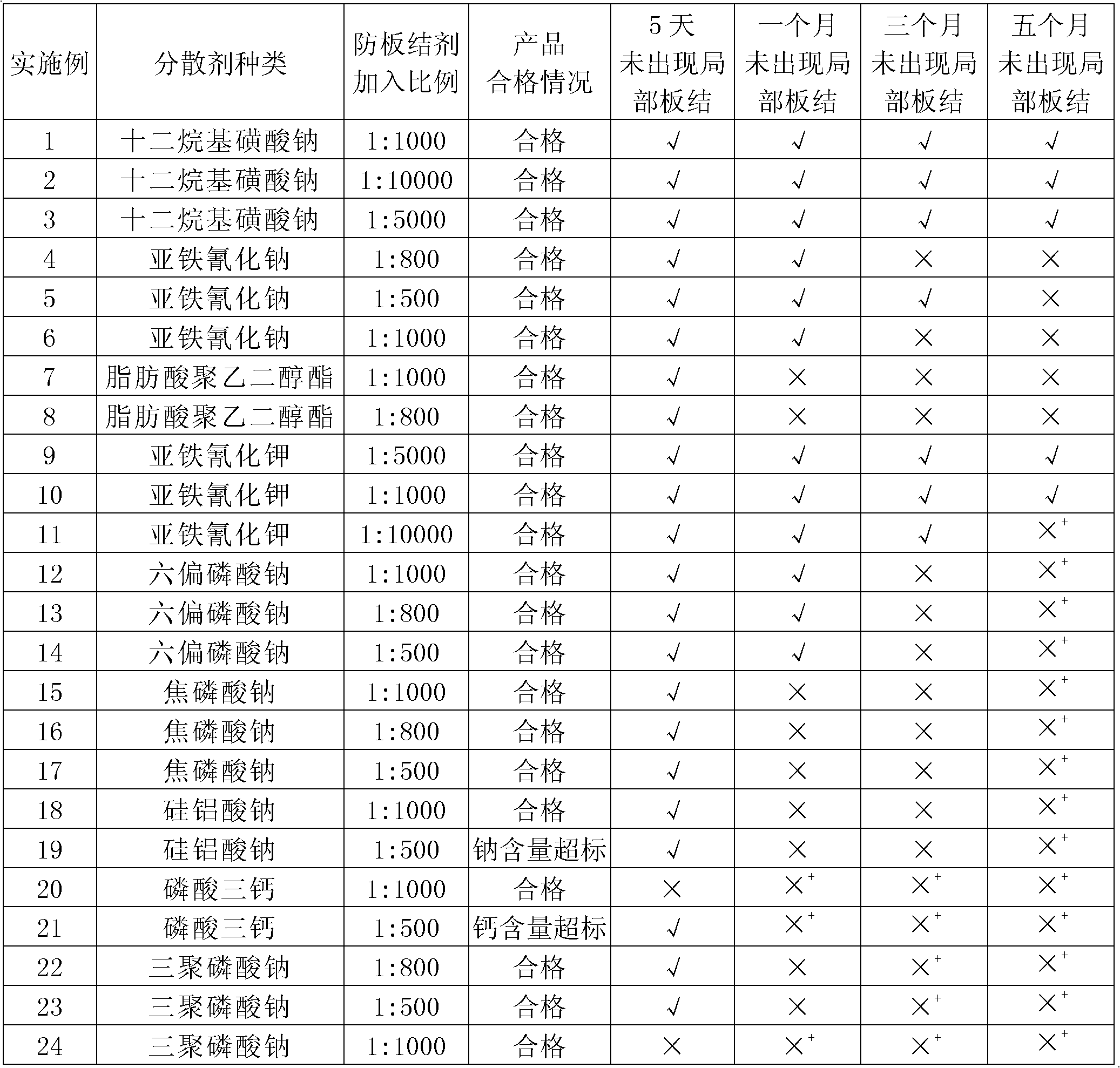

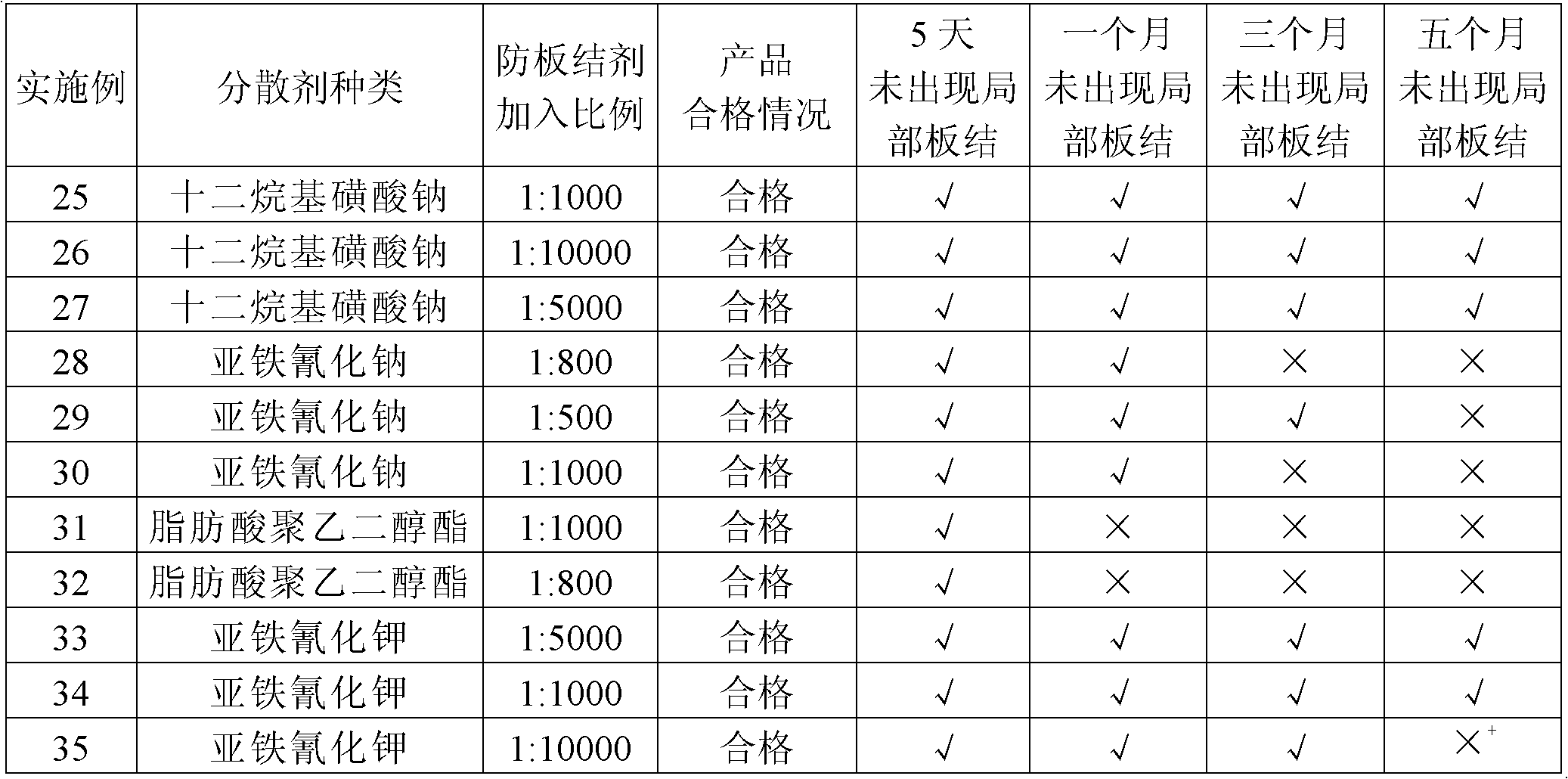

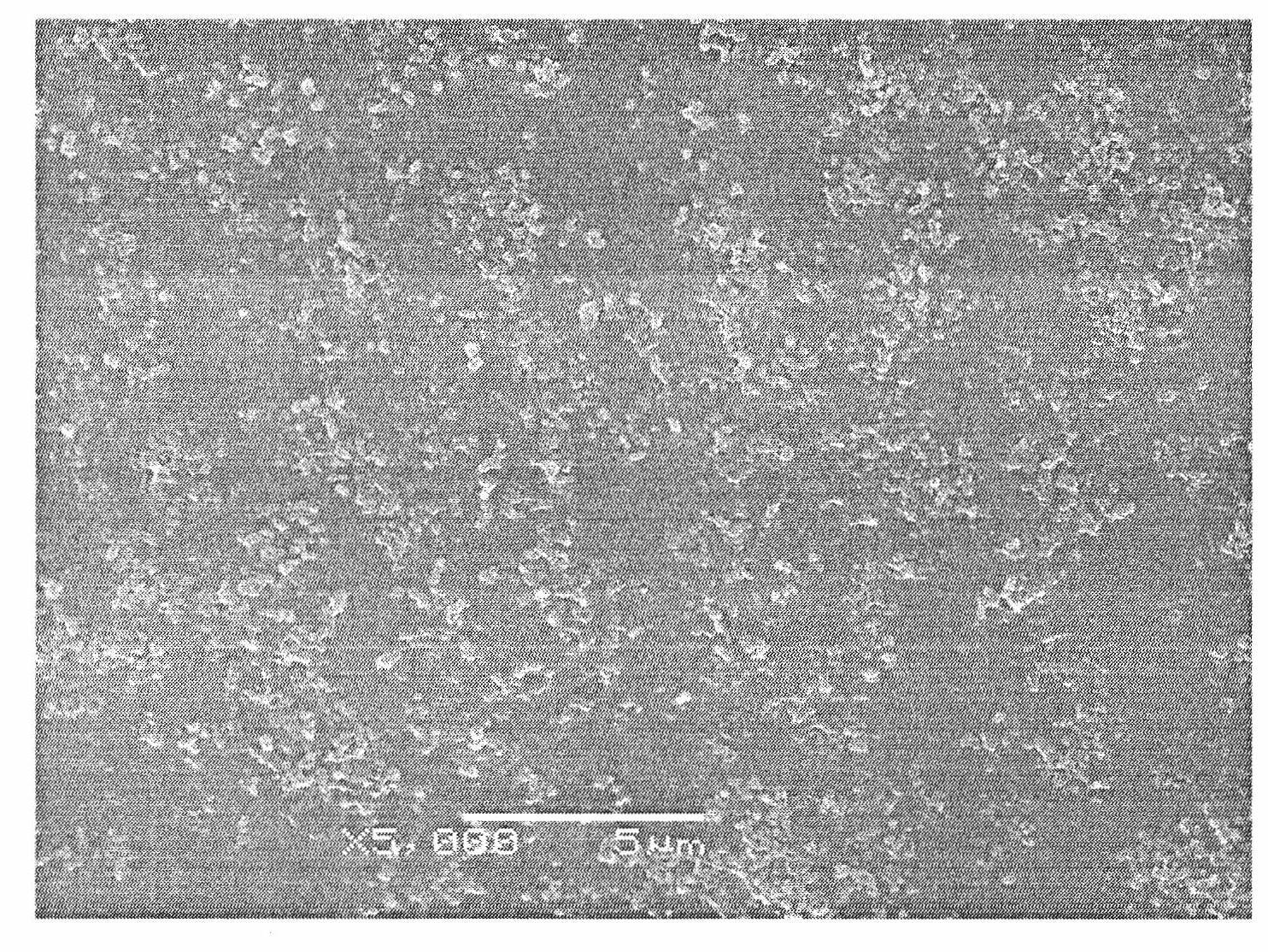

Lithium hydroxide monohydrate and preparation method thereof

ActiveCN102020294ANo flyingMeet the qualityTransportation and packagingLithium oxides/hydroxidesCalcium hydroxideDust explosion

The invention refers to a dust-free lithium hydroxide monohydrate and a preparation method thereof, belonging to the technical field of lithium hydroxide. The technical problems to be solved by the invention are that wet LiOH.H2O has a problem of hardening and dry LiOH.H2O has a problem of dust explosion in the prior art. The invention provides a novel LiOH.H2O, that is, dust-free lithium hydroxide monohydrate without hardening. The lithium hydroxide monohydrate is a loosened granular wet product, wherein the content of water is less than or equal to 3.5%, and the surface of the lithium hydroxide monohydrate is coated with a little anti-hardening agent. The dust-free lithium hydroxide monohydrate is prepared by the following methods: (1) preparing a LiOH solution having a Li2O concentration of 70+-5g / l, and the concentration of SO42- is less than or equal to 15g / l; (2) evaporating the LiOH solution obtained in the step (1) until the ratio of liquid to solid is 1: (0.8-1.5); adding a little anti-hardening agent; uniformly stirring; separating and washing the mixture to obtain dust-free wet LiOH.H2O; and carrying out vacuum seal and packing the wet product, wherein the obtained product is not hardened within 3-5 months.

Owner:TIANQI LITHIUM CORP

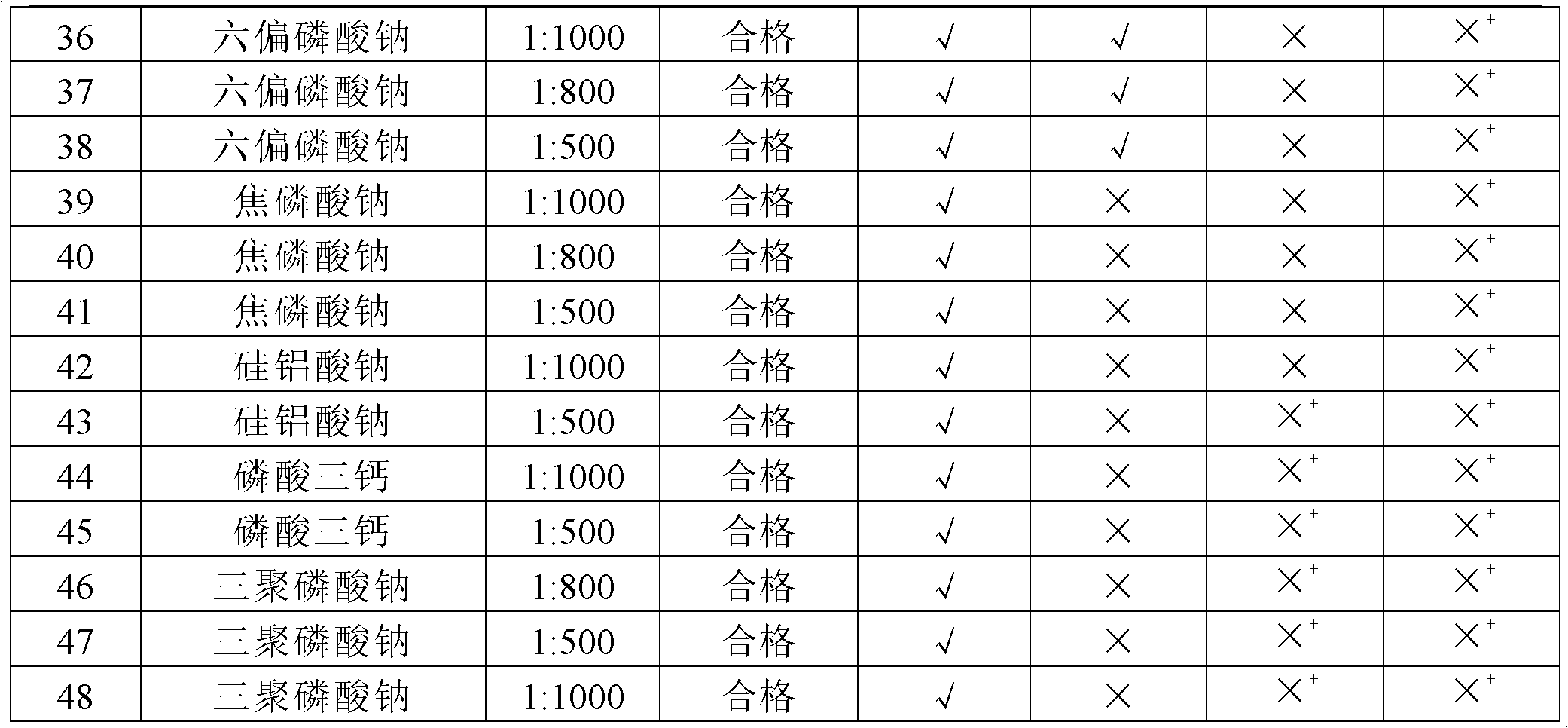

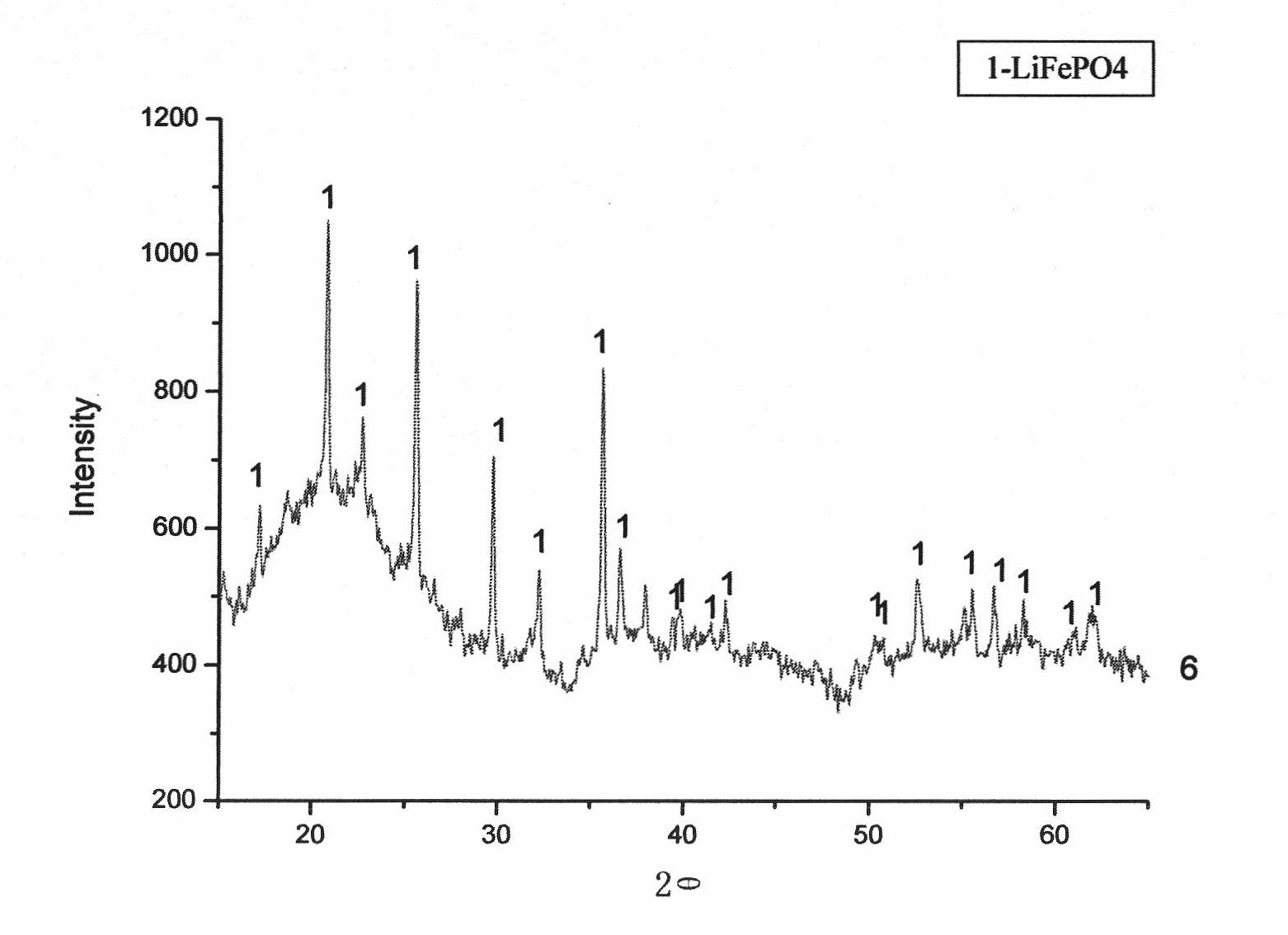

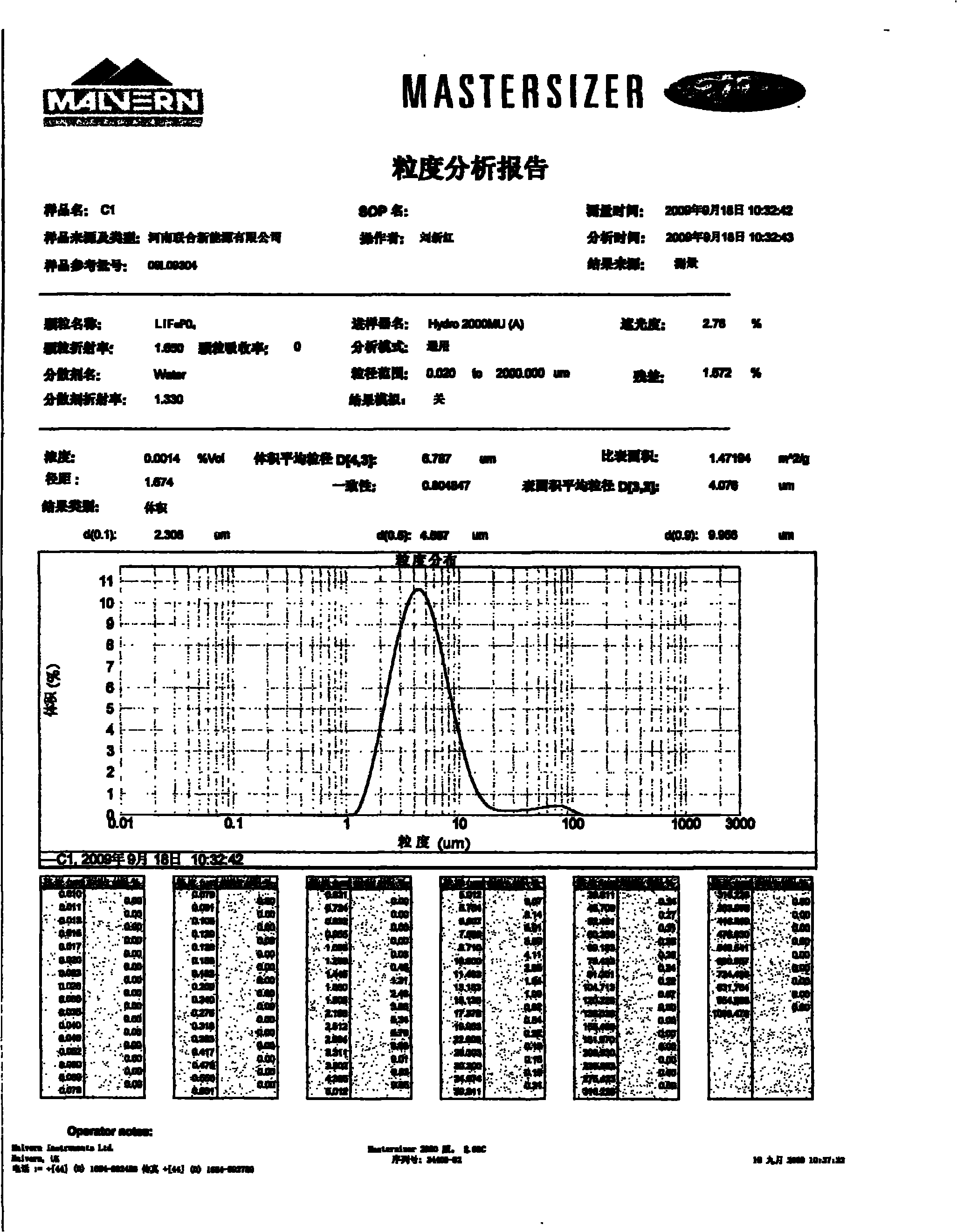

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

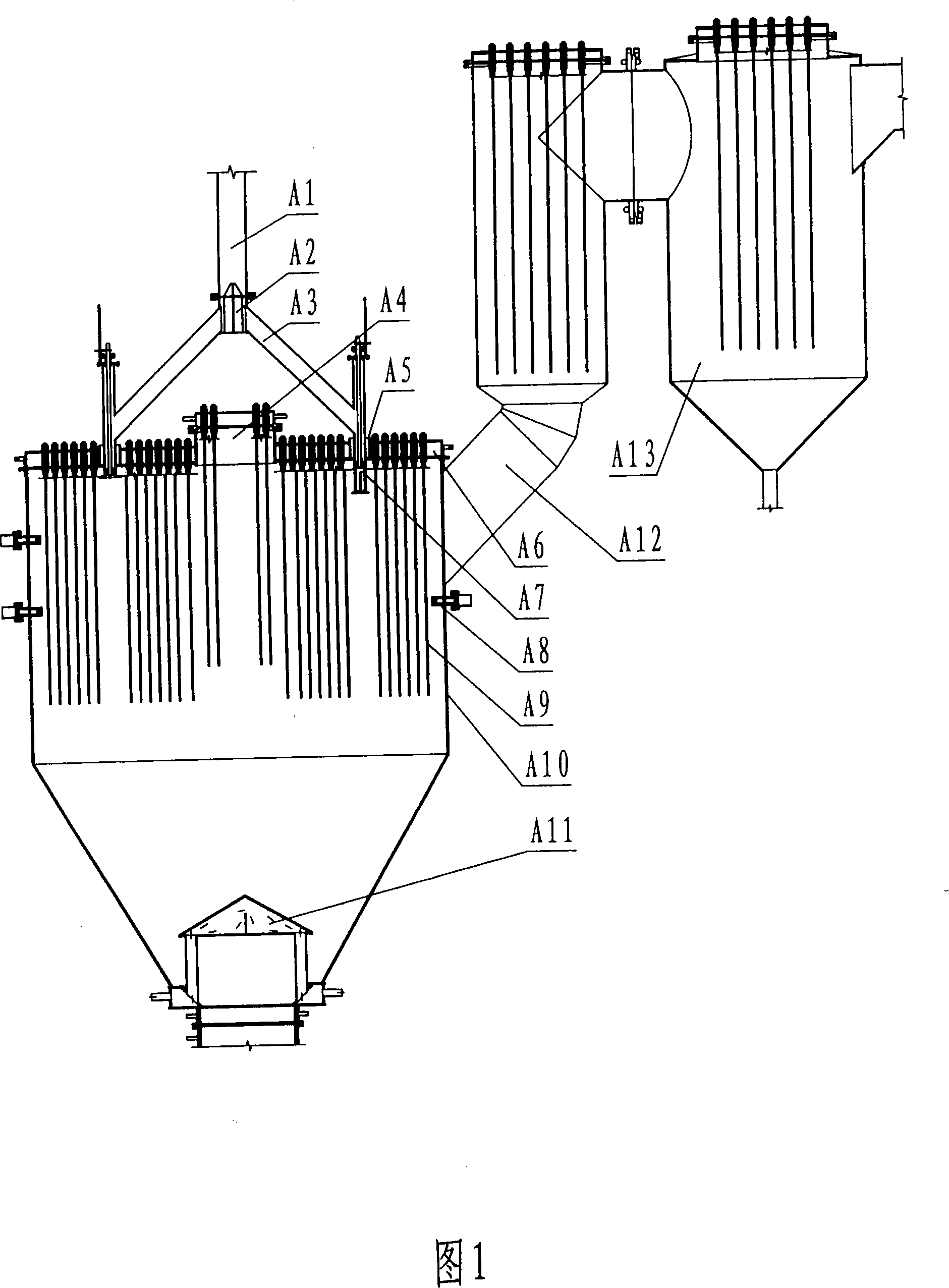

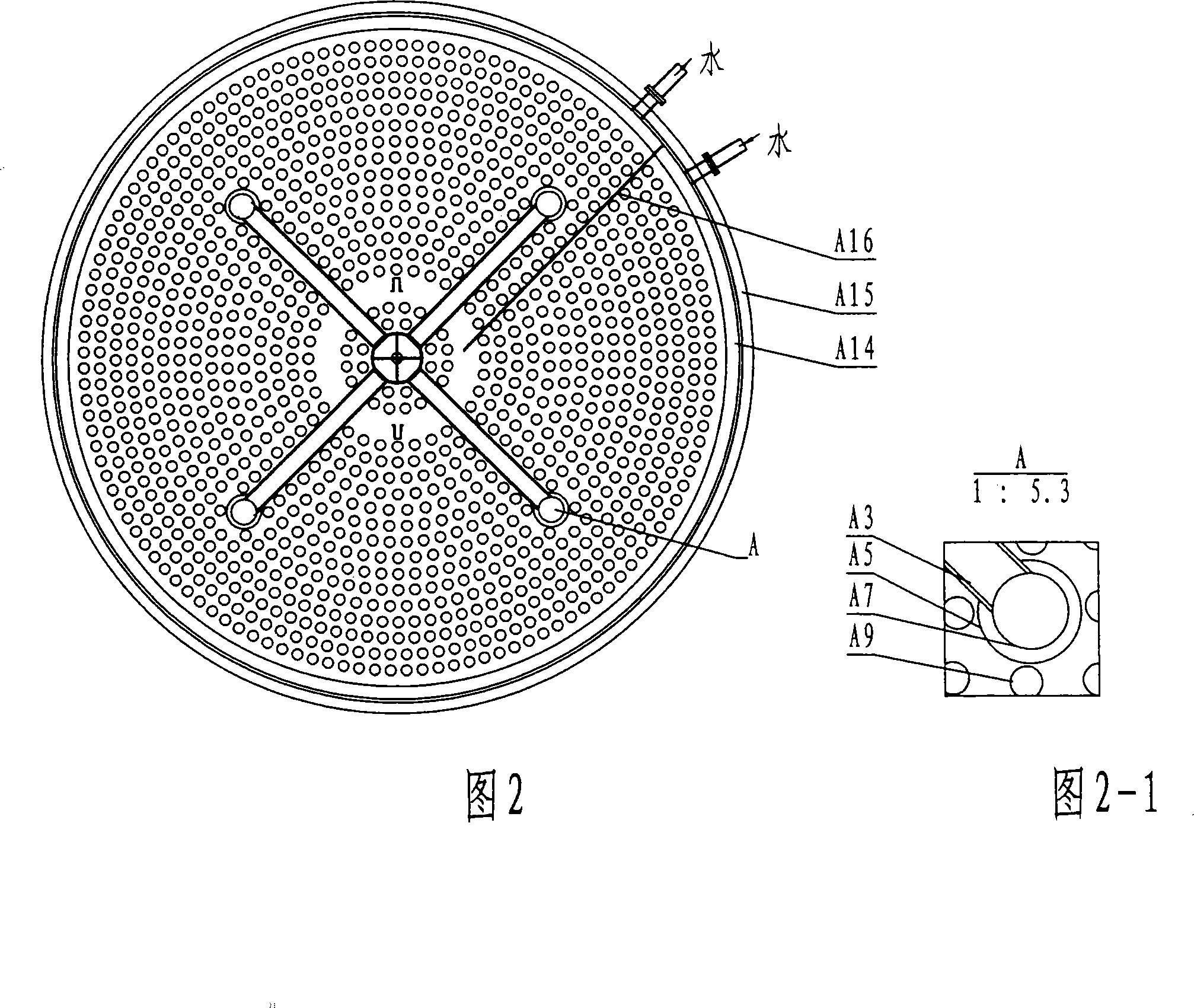

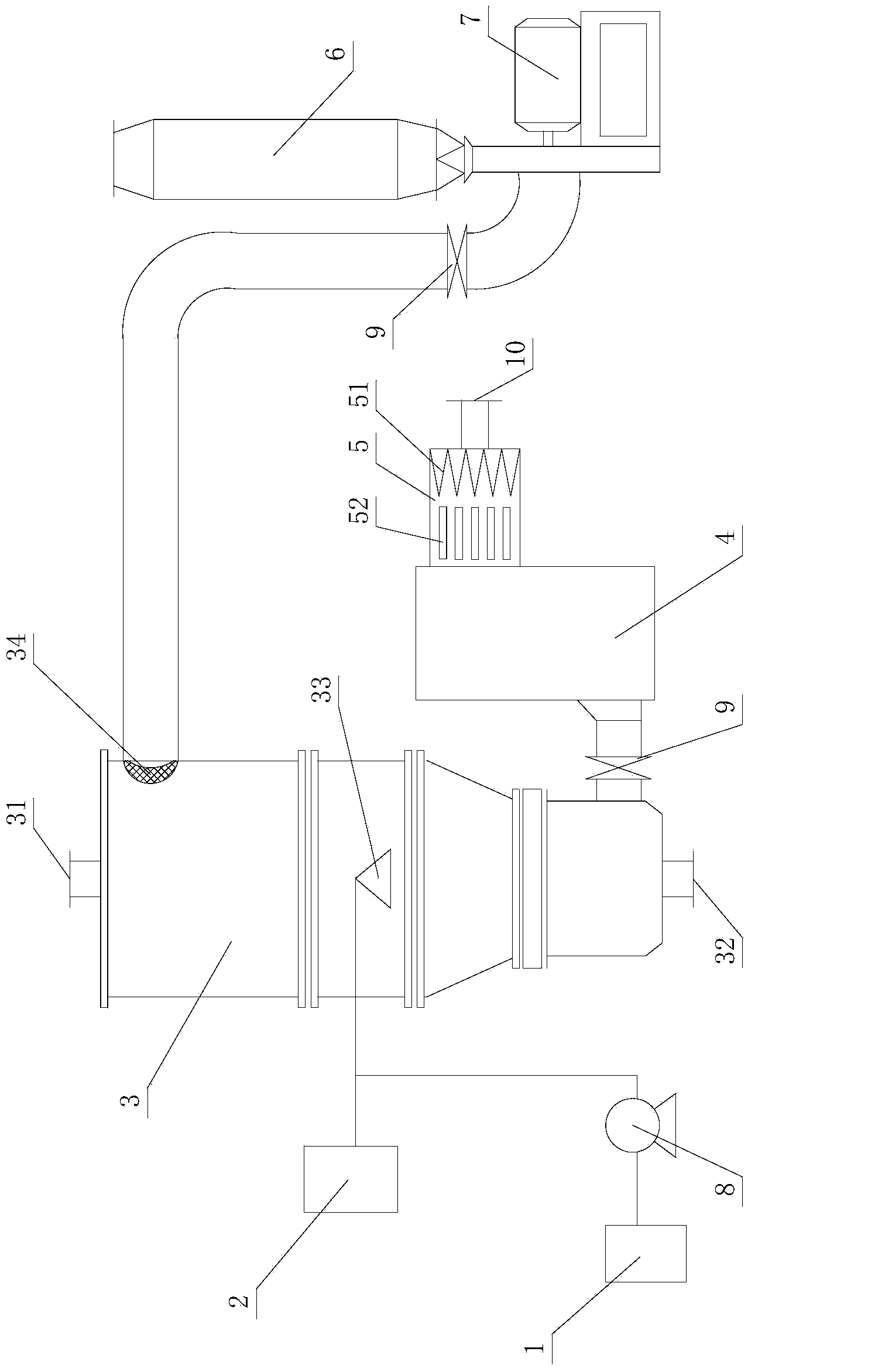

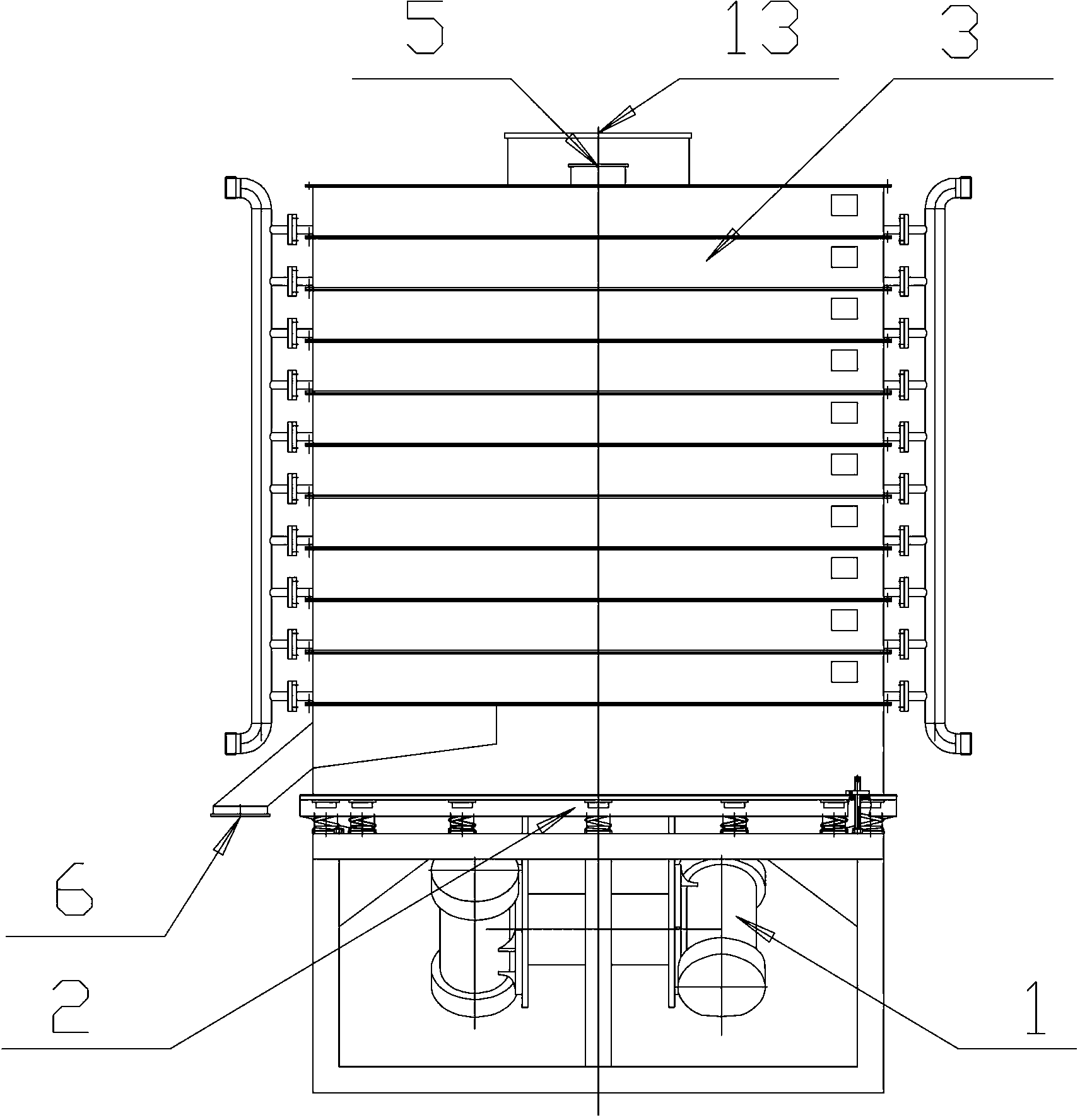

Fluid bed granulating drier and drying process thereof

InactiveCN104014278ANo flyingSimple structureDrying solid materials with heatChemical industryChemical industryGas compressor

The invention discloses a fluid bed granulating drier applied in various fields such as pharmacy, food, feeds, pigments and chemical industry and a drying process thereof. The fluid bed granulating drier comprises an adhesive tank, an air compressor and a fluid bed, wherein a hot air inlet is formed in the lower half part of the fluid bed and is connected with a heater; an air outlet of the fluid bed is connected with an exhaust fan via a pipeline; a filter is connected with the upper half part of the heater and is provided with an air inlet; filter cloth and a muffler are arranged at the air outlet of the fluid bed. The drier has a simple structure, is reasonable in design, completes the processes of mixing, granulating and drying in the same equipment, is quick in mass heat transfer, is operated at closed negative pressure, thus avoiding dust flying, is uniform in granules, does not have dead angles, is cleaned thoroughly, is free from cross pollution and is energy-saving and environment-friendly.

Owner:张家港市进润彩印包装有限公司

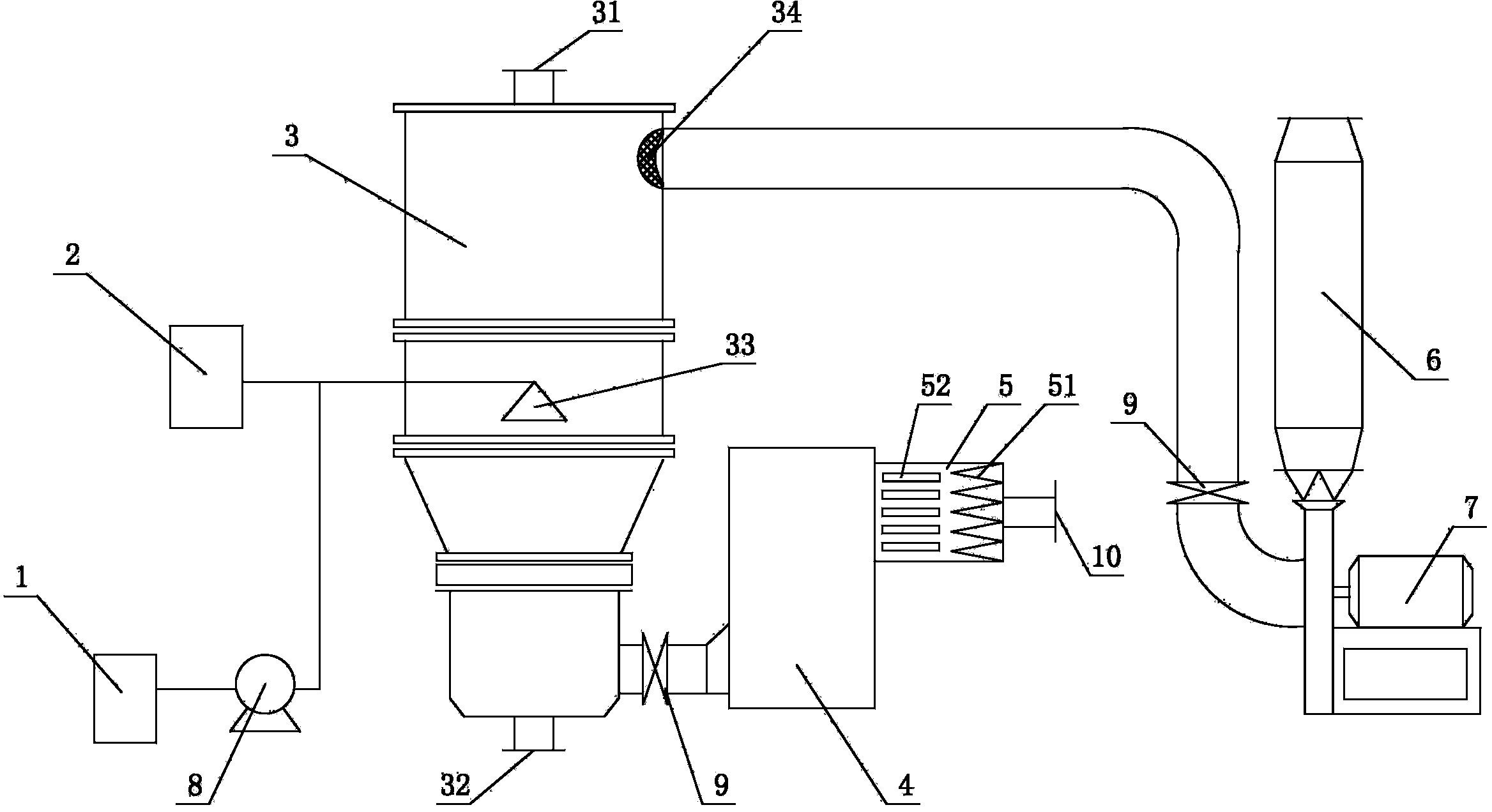

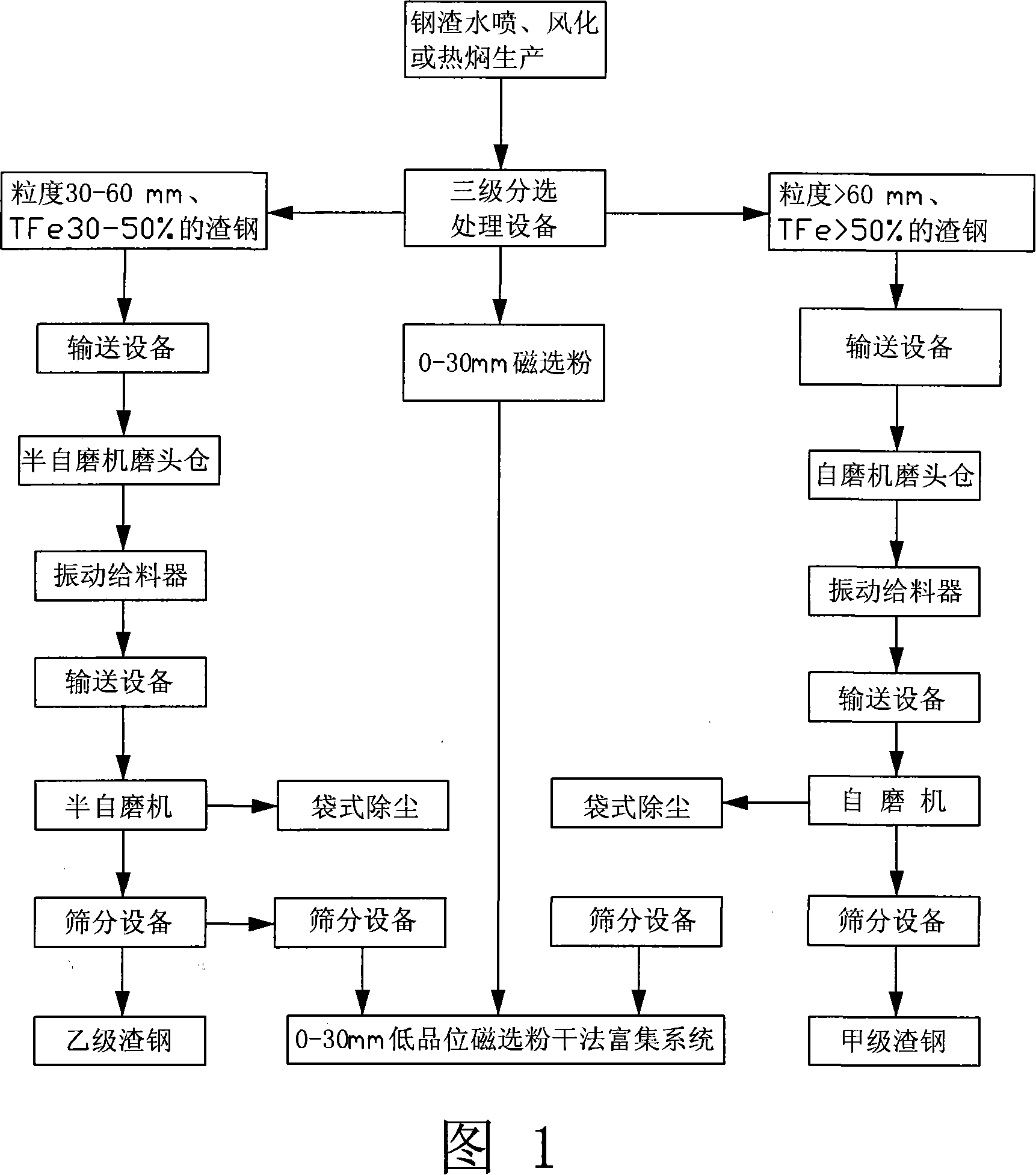

Method for purifying granular slag steel

The invention relates to a purifying method for a particle type slag steel, wherein, an autogenous tumbling mill is used to mill without media the particle type slag steel that is weathered, smoldered and in particle size >60 mm, TFe>50%, and an semi-autogenous tumbling mill is used to mill with media the particle type slag steel that is weathered, smoldered and in particle size 30-60 mm, TFe 30 swung dash 50%. During the milling, the non magnetic slag and small steel particles attached on the slag steel surfaces separate from the substrates due to the bumping and rubbing between the milling body and the raw materials, and between the raw materials. After being discharged from the mills, the raw materials smaller than 30 mm are sieved away to obtain class A slag steel with TFe>=90% and class B slag steel with TFe>=80%. The invention has the advantages of the compact structure, the small footprint, the no waste water, waste slag and waste gas discharging and the no dust flying during the production, and the realization of clean production while realizing hi-efficiency use of steel slag resources. The class A / B slag steel sieved from the particle slag steel can be directly used by steel and iron making plants.

Owner:郭心岭

Composite molten steel slag washing agent based on LF (ladle furnace) refining waste slag and preparation method thereof

The invention discloses a composite molten steel slag washing agent based on LF (ladle furnace) refining waste slag and a preparation method thereof. The composite molten steel slag washing agent consists of 65 to 95% of LF refining slag, 10 to 30% of active lime and 5 to 15% of industrial soda. The LF refining slag is composed of 50 to 60% of CaO, 25 to 35% of Al2O3, 4 to 8% of SiO2, 4 to 7% of MgO, 0.5 to 1.0% of MnO and FeO, 0.005 to 0.02% of P2O5, and 0.01 to 0.3% of S; the active lime includes 90 to 94% of CaO, and HCl with activity of 350 to 380 ml / 4N and granularity of 0.5 to 3.0 mm; and the industrial soda includes 99.2% of Na2CO3 with granularity of 0.5 to 1.0 mm. The preparation method comprises the following steps of: processing the LF refining slag and the active lime into the powder with the granularity of 0.5 to 3.00 mm; uniformly mixing and stirring the materials according to the percentage, dry-pressing and moulding the materials with granularity of 25 to 35 mm and applying the waterproof packaging to the materials. On the condition that the adding quantity is 4 to 6 kg / t, the desulfurization rate of the invention achieves more than 30%, the reduction rate of the total oxygen content is more than 25% and the qualified rate of the thermal top forge is improved from 80% to 95%, so that the invention realizes the resource recycling of the LF refining waste slag and is beneficial to the energy-saving and emission reduction of the iron and steel enterprises.

Owner:NANJING IRON & STEEL CO LTD +1

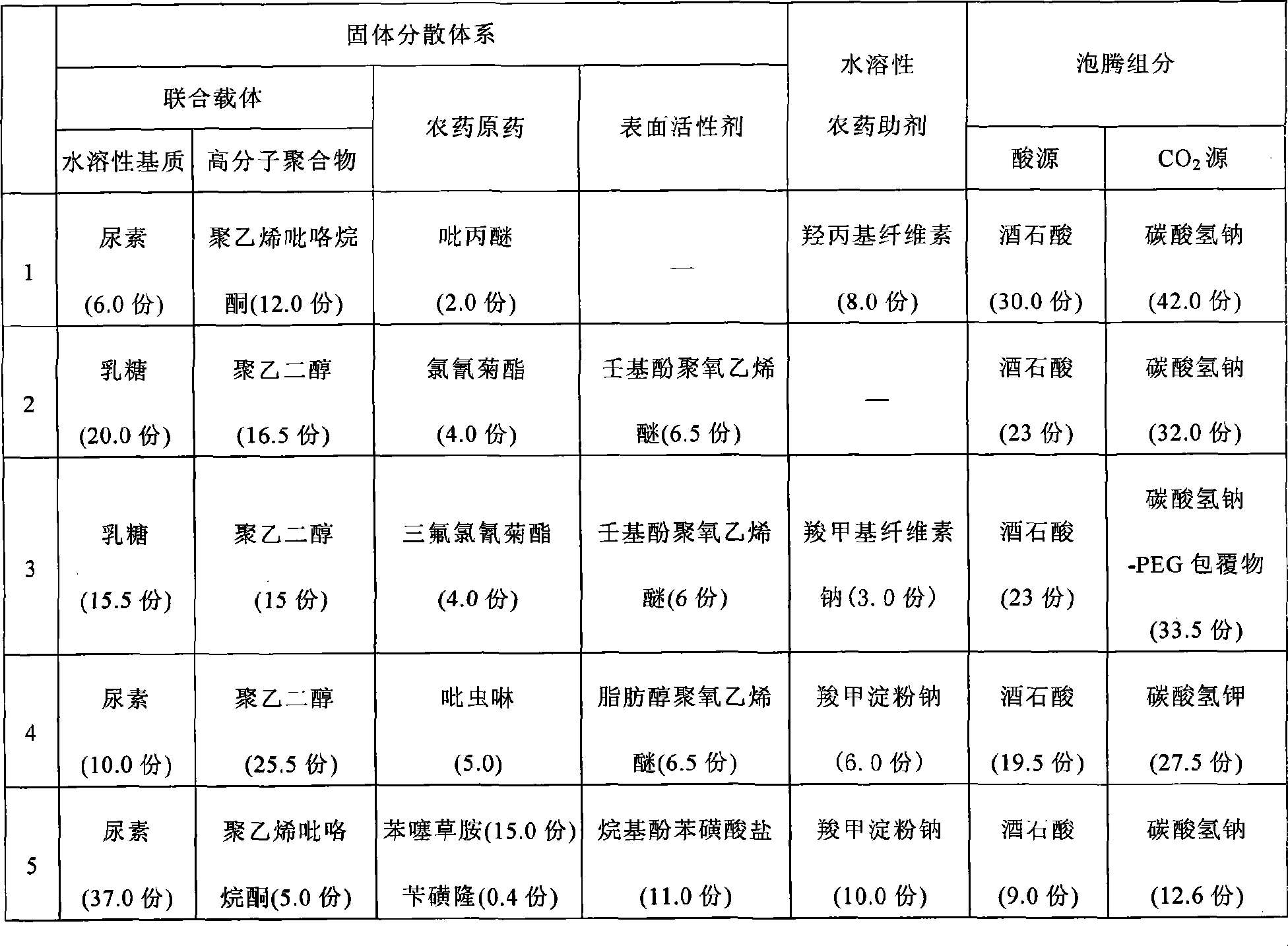

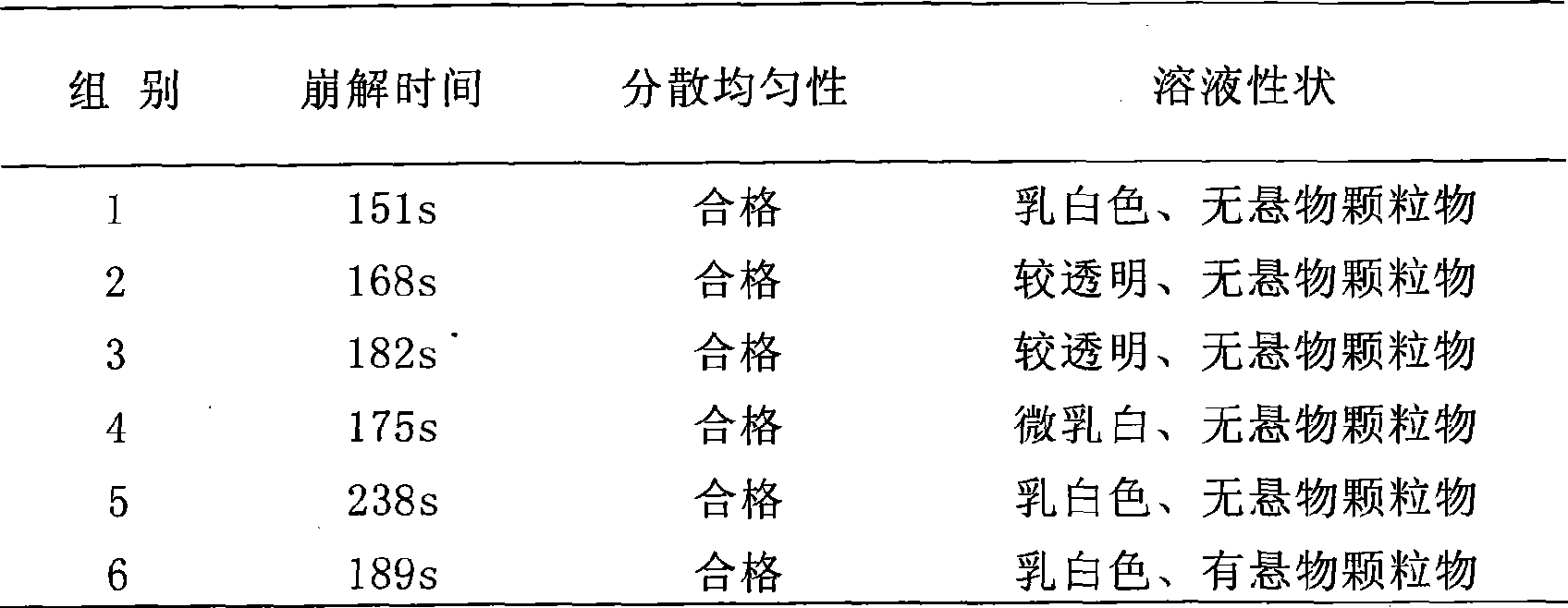

Pesticide effervescence combination and preparation method thereof

InactiveCN101455196AMeet the No Trace RequirementsIncrease dissolution rateBiocideAnimal repellantsParticulatesWater dispersible

The invention relates to a agricultural chemicals branch of technology, specifically to an agriculture chemicals effervescence composition and a preparation method thereof.The invention discloses an agricultural chemicals effervescence composition comprising effervescence components, active compounds of agricultural chemicals, and the invention is characterized in that, taking the total weight as the basic reference, the agricultural chemicals effervescence composition also comprises the following components that water soluble base with a percentage by weight of 5-45% and water-soluble high molecular polymer with percentage by weight of 3-30% which form a united vector, and the active ingredients of agricultural chemicals are coated by the carrier to form a solid highly dispersed system.Every type of matters in the agricultural chemicals effervescence composition of the present invention has a better water-soluble performance, active compounds of agricultural chemicals can be highly dispersed into particles with a size of 0.001-0.1micrometre, the particle size of the active compounds of agricultural chemicals is much smaller than that of water-dispersion granulas, water dispersible powder and the like, the composition does not include any water-insoluble matters such as waterproofing agents, thinning agent and the like that are used by conventional effervescing agents, and once in water, the obtained effervescence composition is disintegrated instantly and rapidly and can be diffuse easily.Therefore, suspending particulate matters will never appear in the obtained solution, and if the prescription is reasonable, the solution will be clear and transparent; therefore, the composition can not only be used for expelling agriculture disease, but also be extensively used in the filed of expelling sanitation disease.

Owner:NAVY MEDICINE RES INST OF PLA

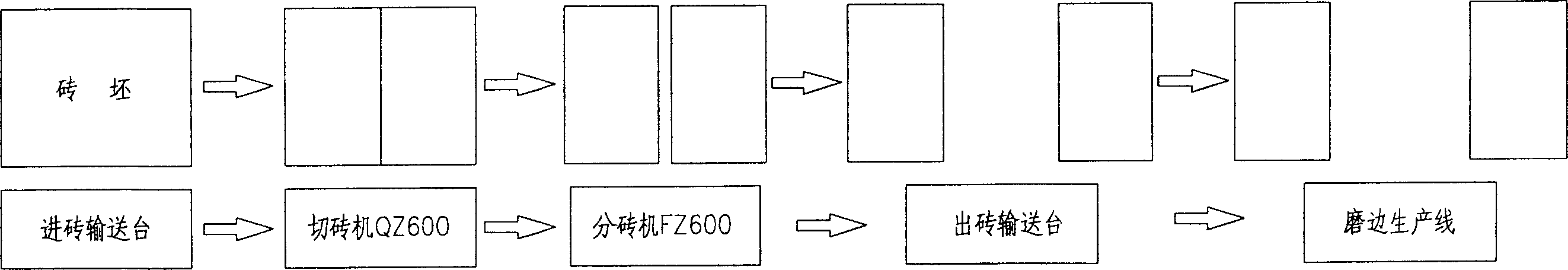

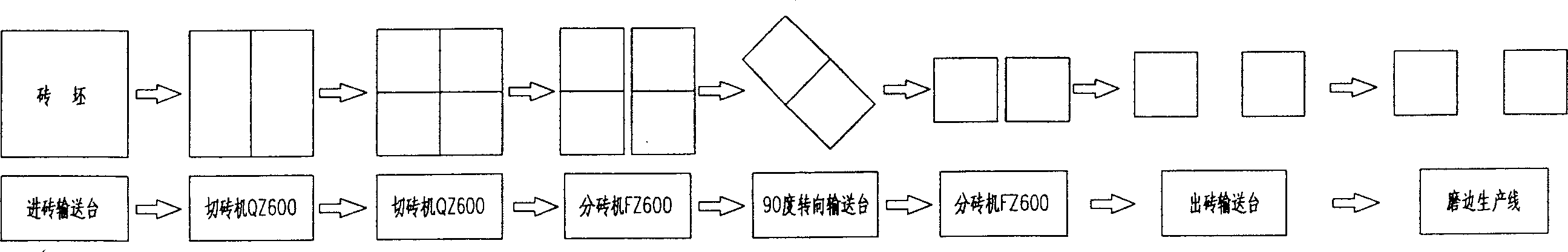

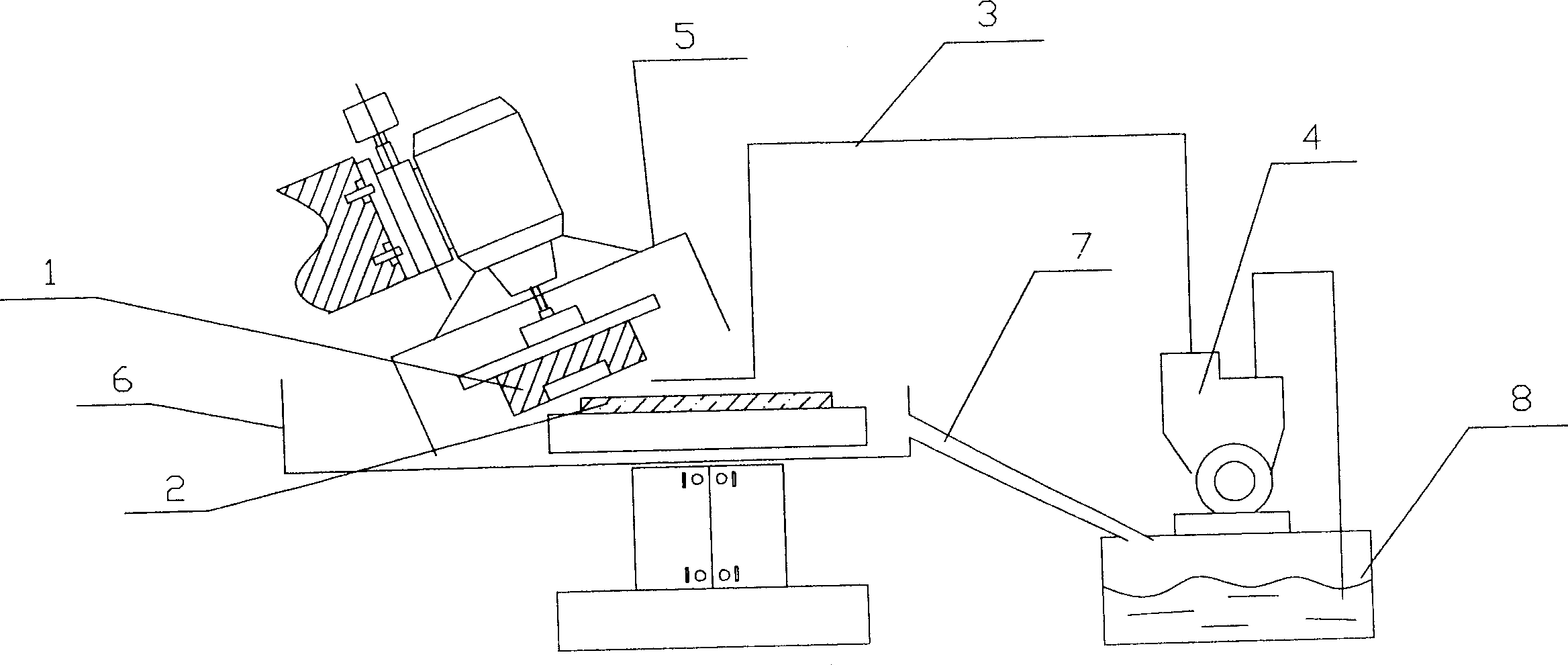

Ceramic tile making method

InactiveCN1891420AReduce the type of specificationReduce processing costsCeramic shaping apparatusStone-like material working toolsBrickEngineering

This invention provides a method for manufacturing tiles including: sending adobes into a feeding platform then to a brick cutter and utilizing a knife flywheel to cut cut-lines on the surfaces of the adobes, sending the adobes with cut-lines into a brick separating machine then to knock on them with a knocking device, the adobes are cut off along the cut-lines, the separated adobes are sent to an edge-grind production line from the platform to grind the edges, in which, the method reduces the specifications of dies to reduce the process cost of tiles in small scale.

Owner:KEDA INDUSTRIAL GROUP CO LTD

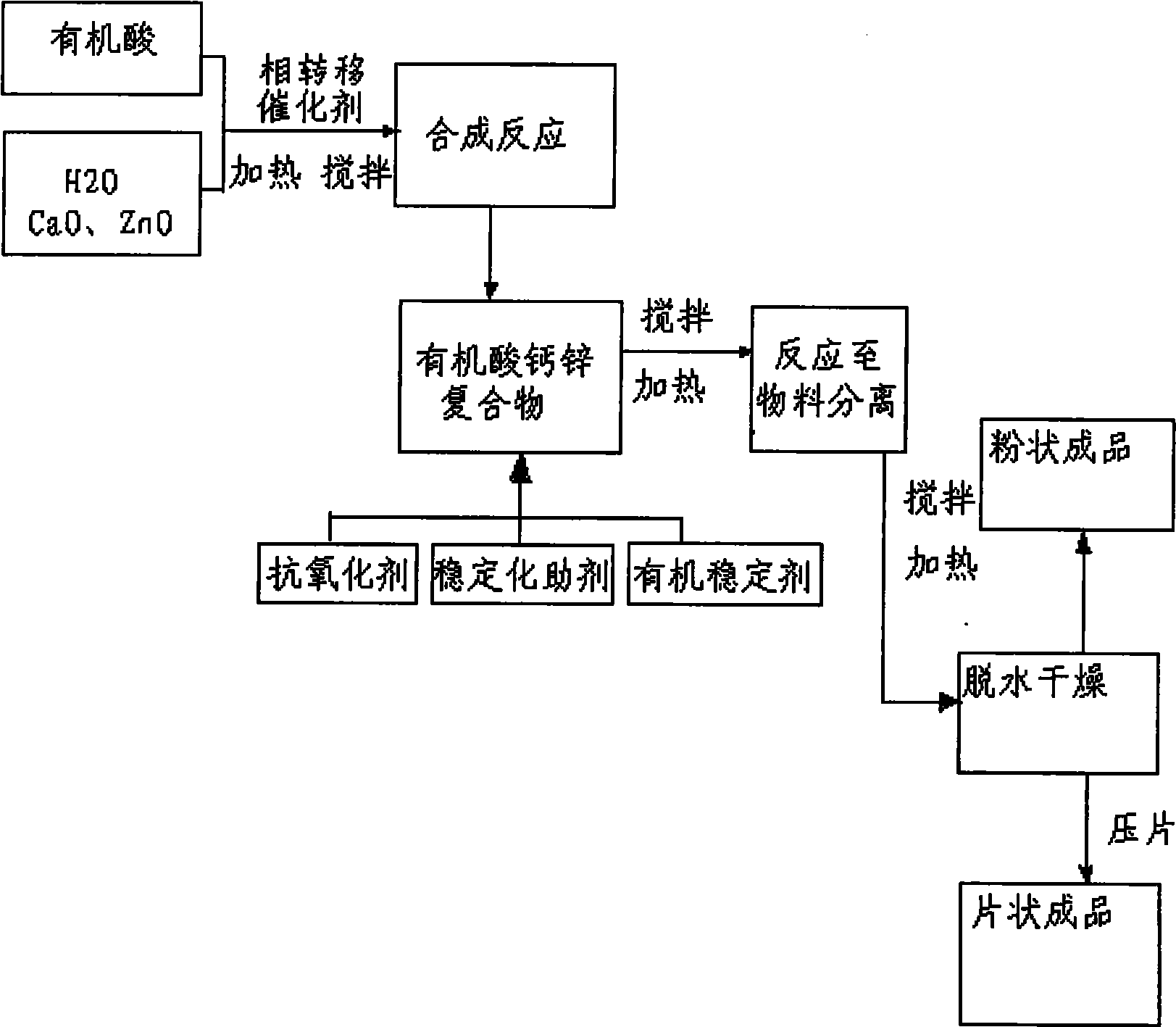

Preparation of calcium zinc composite stabilizer for processing plastic

The invention discloses a method for preparing calcium zinc compound stabilizer used for the processing of PVC plastic; the invention is characterized by comprising: (1) organic acid, calcium oxide, and zinc oxide powder are dispersed in a water phase, and then under the function of a phase transfer catalyst, an organic acid calcium zinc compound is generated by reaction; (2) the compound which is obtained in step (1) is heated and added with an oil and grease substance, and then stirred until the material is completely separated from the water phase; and (3) the product which is obtained by separation is placed in a two-roll kneading machine, later heated to 130 DEG C, and then stirred and gradually added with antioxidant, stabilizing additives, and organic stabilizer; after tabletting and forming, a finished product is obtained. The invention is finished by one step, has short flow process, and does not produce waste; the formula of the method is optimized, the obtained composite calcium zinc stabilizer has high thermal efficiency, and the stabilizing time is improved by 50-100% compared with the products sold in the market; and the product takes the shape of a tablet or small particle, and has the advantages of no dust pollution, low beginning melting temperature, and wide adaptability.

Owner:JINGJIANG XUGUANG PLASTIC

Large vacuum furnace for processing arsenic-containing gold ore or arsenic concentrate and continuous operation method thereof

The invention discloses a large scale vacuum furnace and continuous operation method for processing arsenical gold ore or arsenic concentrate; wherein, the vacuum furnace comprises a vertical furnace body, a horizontal furnace roof and a conical furnace bottom; a discharge tube, a flow rate control device and an electrical heating tube are arranged on the furnace roof; a vertical exhaust tube is extended from a skew joint on the lateral face of the furnace; a materiel level control observation window is arranged on the furnace body; a slag-guiding cone is arranged on the furnace bottom; a feeding system, a slag discharge system and a product collection system are arranged in the vacuum furnace, which are operated in vacuum. The large scale vacuum furnace and continuous operation method for processing arsenical gold ore or arsenic concentrate has the advantages of maximization of vacuum furnace, protecting electrical heating element, no air leakage, corrosion resistance of furnace mantle, sealed and degassed feeding, continuous feeding with the discharge tube fully filled with materials in the entire operation process, no dead angle in the slag discharge, stepwise product collection and automatic packing, and no three waste pollution in the production process and surrounding environment.

Owner:伍耀明 +1

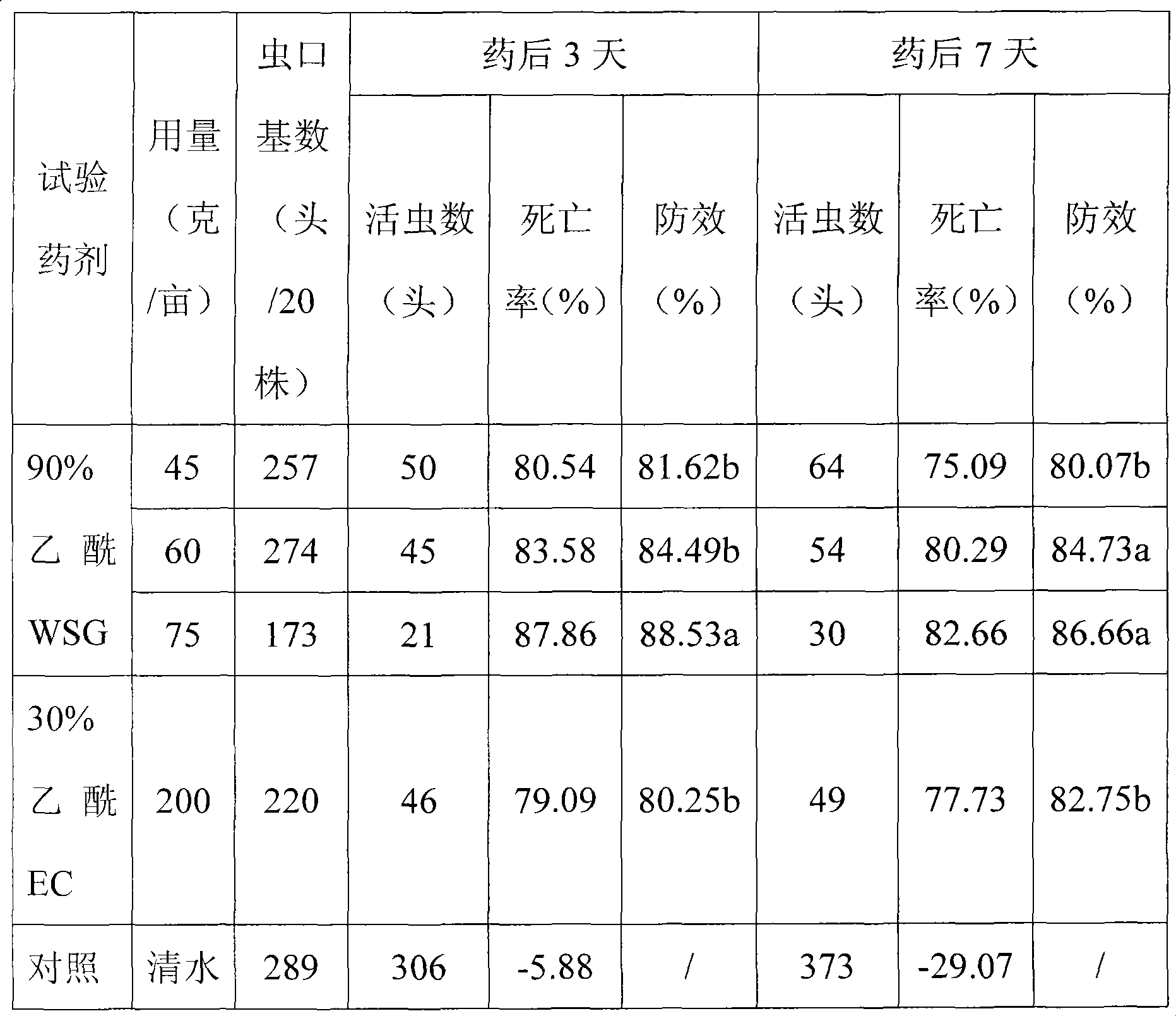

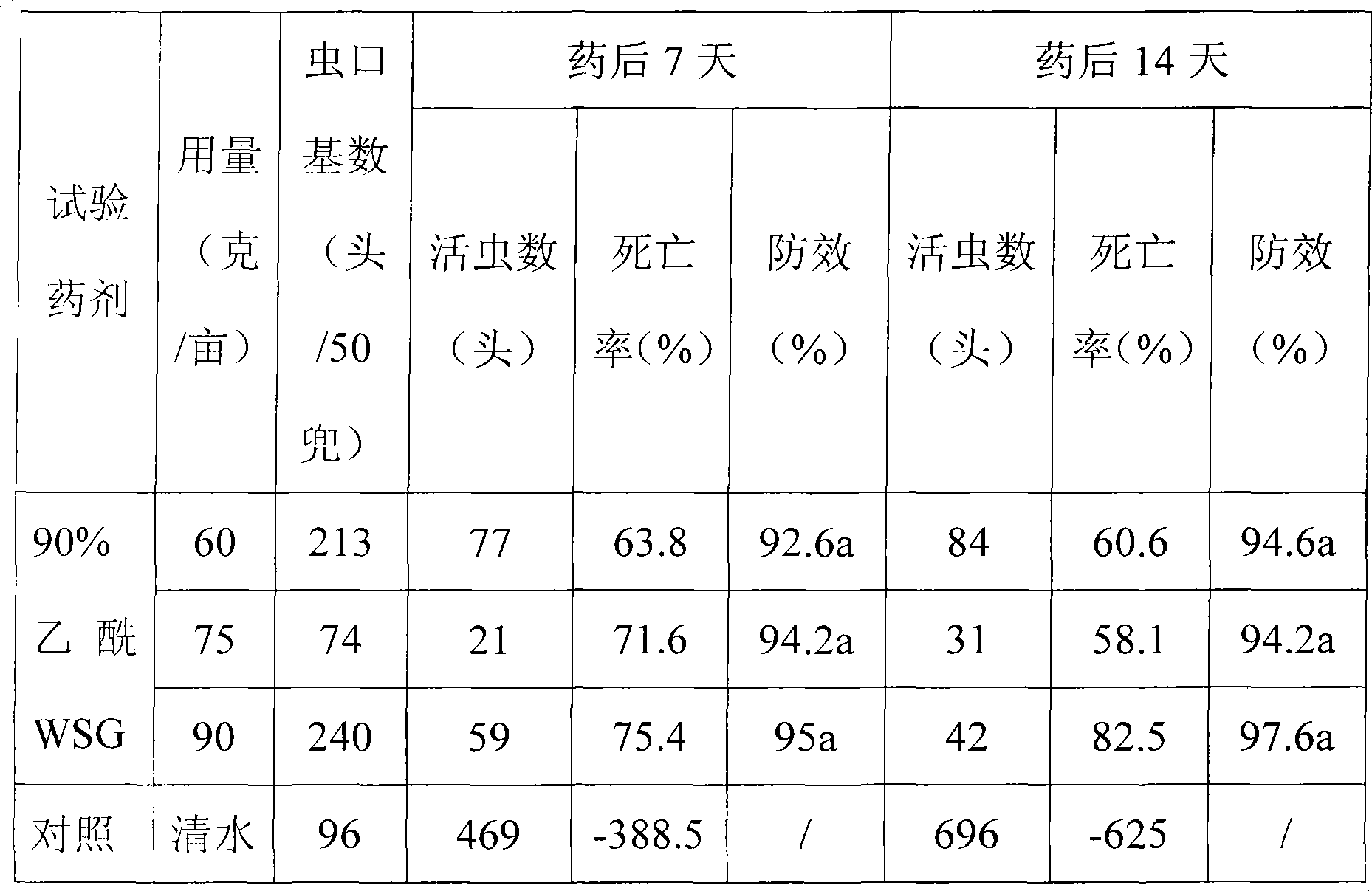

Stable acephate soluble granula and method of producing the same

The invention relates to a preparation method of acephate pesticide formulation, specifically a stable acephate soluble granule and preparation method thereof, comprising the following components: 5-97 weight% of acephate, 1-10 weight% of stabilizer, 1-15 weight% of binder, 1-20 weight% of synergist. The acephate granule can enwrap the effective component acephate in the middle of the granule, which can prevent effective component from decomposing with good solubleness and no flying-dust. Thus the preparation method has features of strong stabilization, good drug efficacy, small environmental pollution, simple preparation method and is very suitable for processing pesticide formulation of high content.

Owner:荆州沙隆达控股有限公司

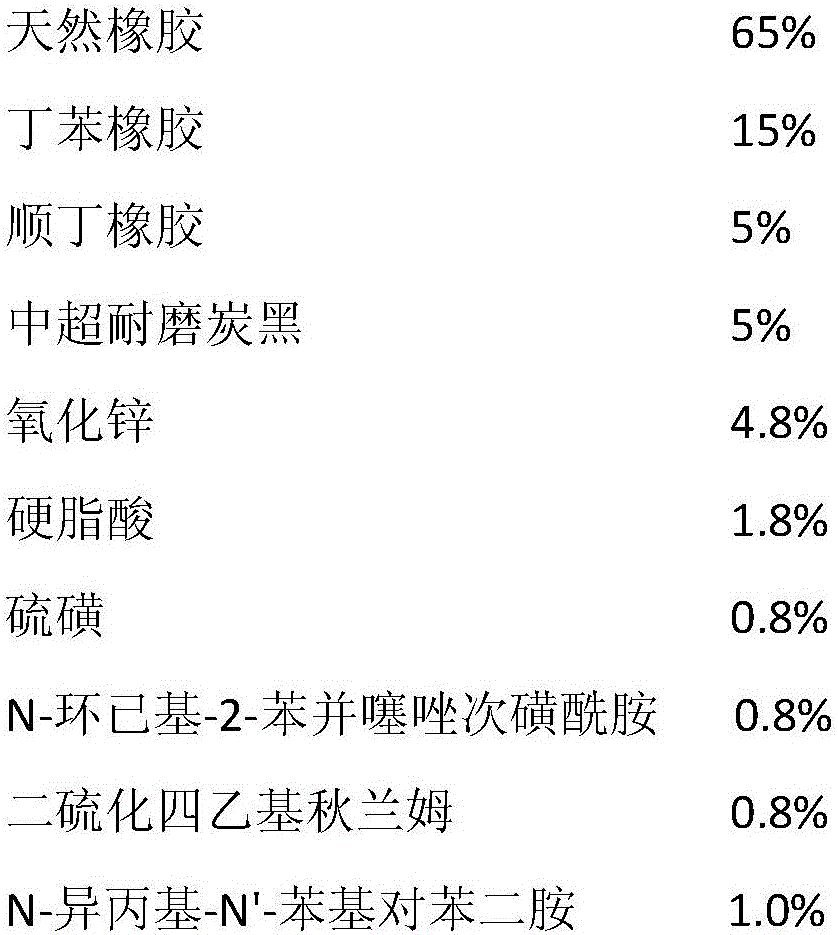

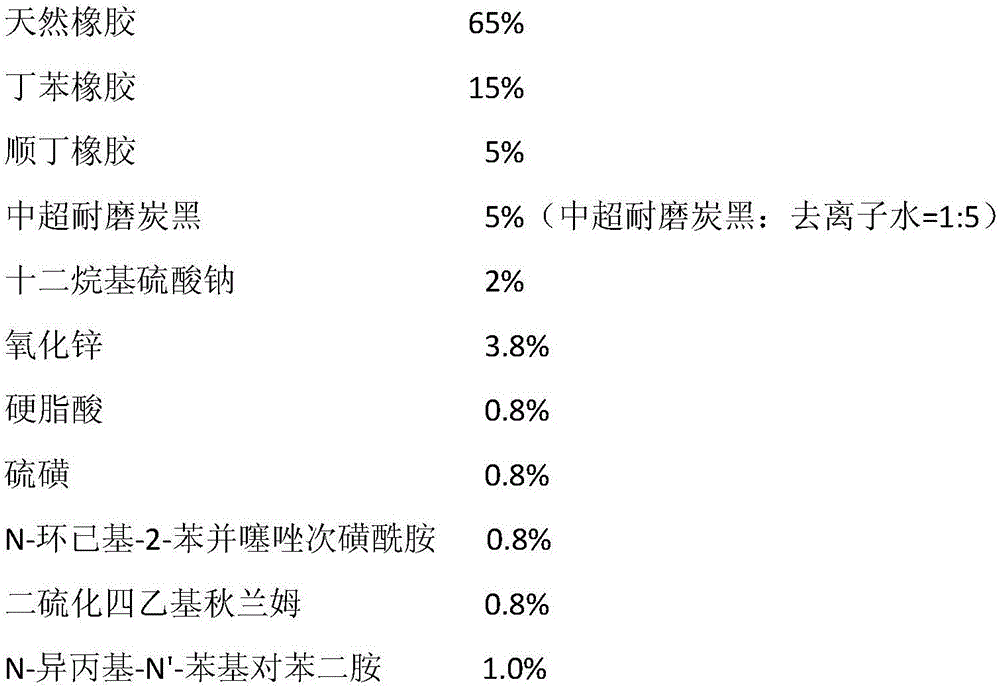

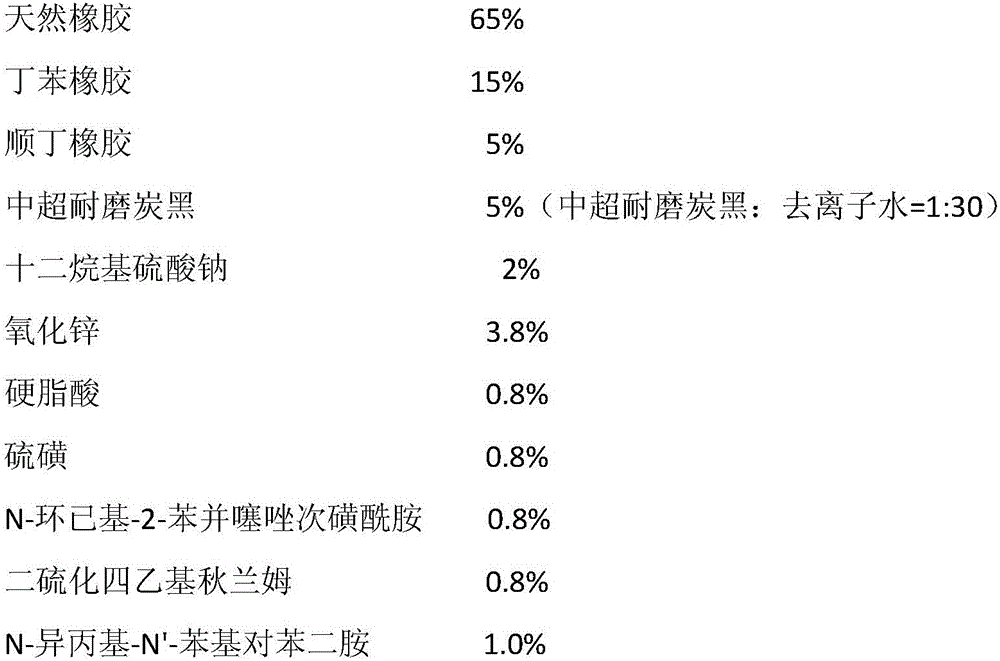

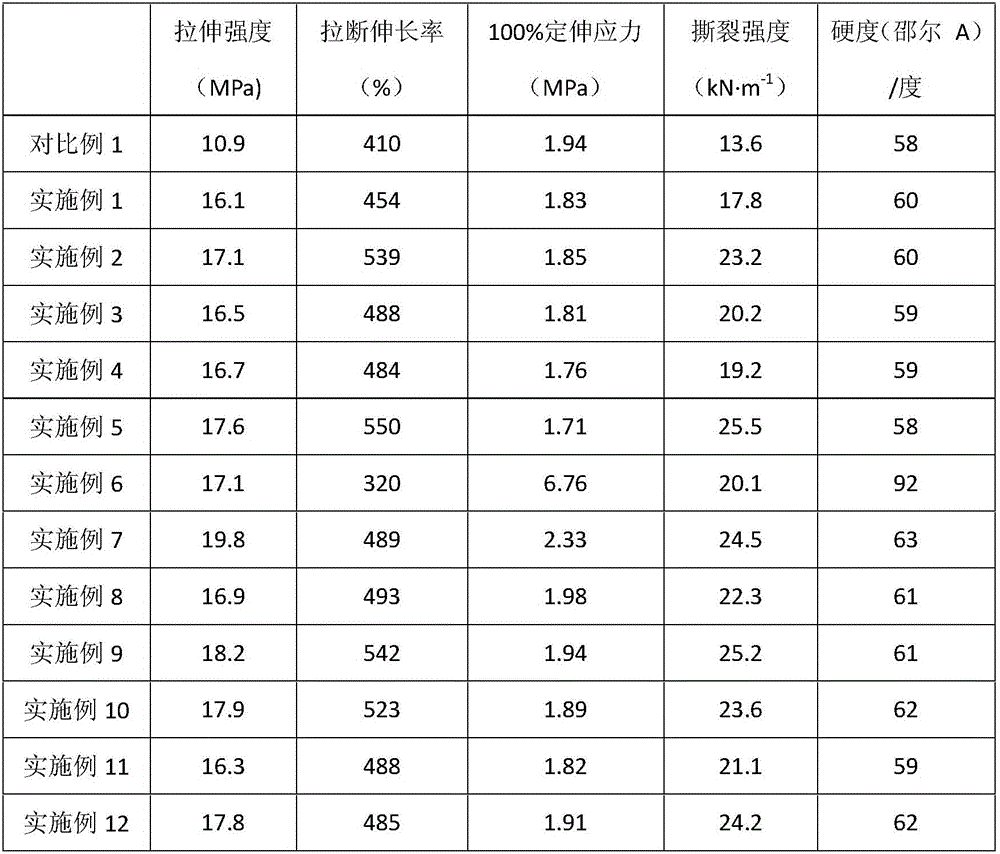

Preparation method of olefin rubber/filler blend vulcanized rubber

The invention discloses a preparation method of olefin rubber / filler blend vulcanized rubber. The method comprises the following steps: preparing a filler predispersion solution; plasticizing unvulcanized natural rubber by a rubber Banbury mixer, mixing with styrene-butadiene rubber and cis-1,4-polybutadiene rubber, increasing the temperature of the Banbury mixer to 110-160 DEG C, adding the filler predispersion solution into the rubber Banbury mixer, compounding, evaporating to remove water, and drying with hot air to obtain an olefin rubber / filler mixture; adding zinc oxide, stearic acid, a vulcanizing agent, an accelerator and an anti-aging agent into a rubber open mill or Banbury mixer, compounding uniformly, discharging, and standing to obtain the olefin rubber / filler compounded rubber; and vulcanizing the olefin rubber / filler compounded rubber on a flat vulcanizing machine to obtain the olefin rubber / filler blend vulcanized rubber. The method has the advantages of simple technique, no solvent pollution and no flying dust, is green and environment-friendly, and can be widely used for mixing multiple fillers and rubber.

Owner:SOUTH CHINA UNIV OF TECH

Fluid bed granulating drier

InactiveCN104014279ANo flyingSimple structureChemical industryGranulation by powder suspensionChemical industryGas compressor

The invention discloses a fluid bed granulating drier applied in various fields such as pharmacy, food, feeds, pigments and chemical industry. The fluid bed granulating drier comprises an adhesive tank, an air compressor and a fluid bed, wherein a hot air inlet is formed in the lower half part of the fluid bed and is connected with a heater; an air outlet of the fluid bed is connected with an exhaust fan via a pipeline; a filter is connected with the upper half part of the heater and is provided with an air inlet; filter cloth and a muffler are arranged at the air outlet of the fluid bed. The drier has a simple structure, is reasonable in design, completes the processes of mixing, granulating and drying in the same equipment, is quick in mass heat transfer, is operated at closed negative pressure, thus avoiding dust flying, is uniform in granules, does not have dead angles, is cleaned thoroughly, is free from cross pollution and is energy-saving and environment-friendly.

Owner:张家港市进润彩印包装有限公司

Glass polishing wheel and its preparing method and using method

InactiveCN1748941AGood gripLight fastAbrasion apparatusGrinding/polishing safety devicesScrapCerium oxide

The glass polishing wheel is made with polyurethane, rubber, cerium oxide and assistant, and through mixing and pressing. It is used together with circulating water, and has the advantages of no dust, capacity of recovering waste material, no environmental pollution, high attachment of glass, etc.

Owner:游国力

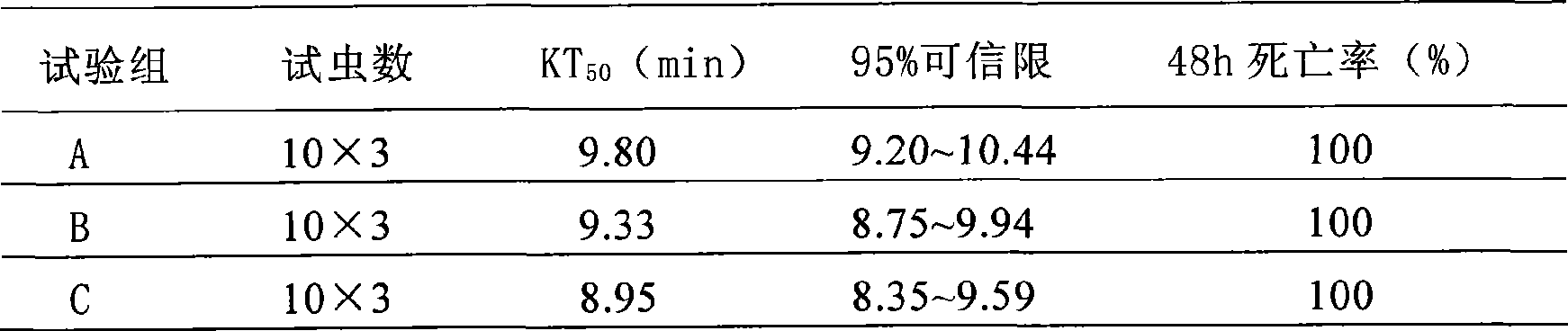

Niclosamide insecticide and molluscacide suspension and its prepn. process

InactiveCN1389112AReduce stimulationReduce pollutionBiocideAnimal repellantsOrganic solventNiclosamide

The present invention relates to a suspending agent formed from niclosamide as chemical active substance and several auxiliary materials and its preparation method. Its preparation method includes: using niclosamide as raw material medicine, adding moistening agent, dispersing and suspending aid, tack-producing agent, antifreezing agent, preservative, defoaming agent and water, uniformly mixing them, pulverizing by means of high shearing emulsifying machine in a barrel, grinding for once or at twice, and quality test and packaging so as to obtain the invented niclosamide pesticide spirillicide suspending agent.

Owner:JIANGSU PESTICIDE RES INST +1

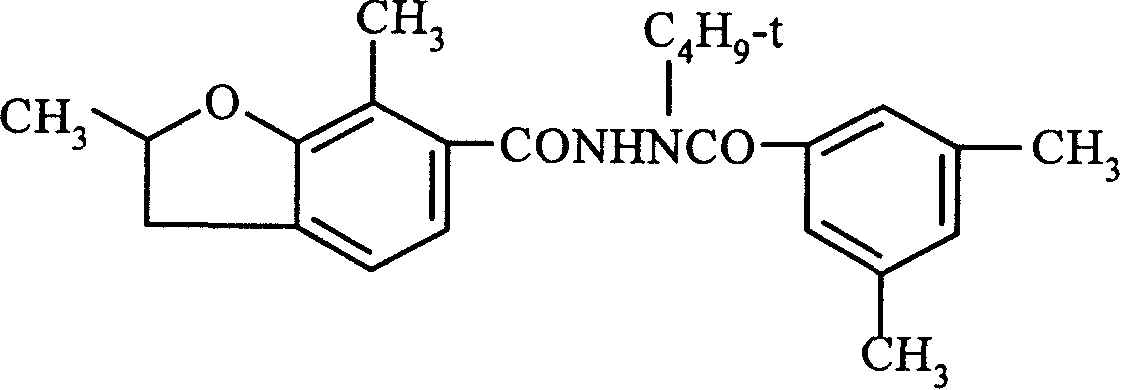

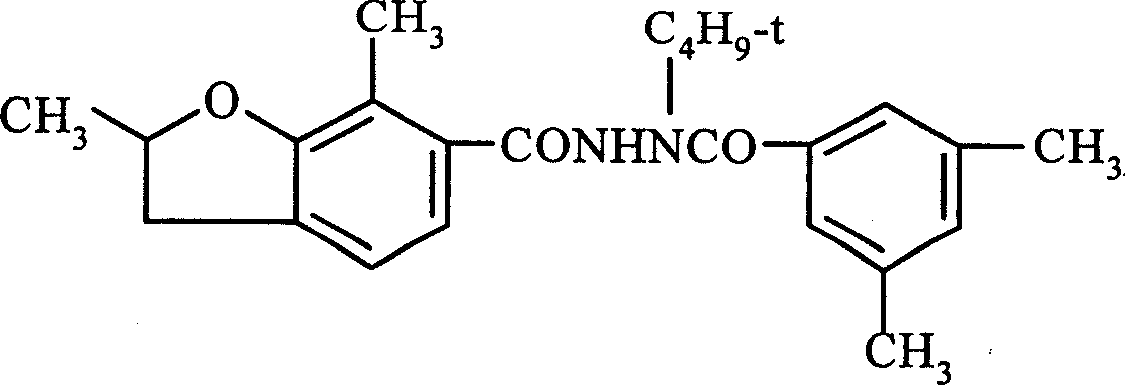

Furanfenozide insecticidal suspending agent and its preparation method

The invention discloses a furfuran hydrazide insecticidal suspending agent and preparing method, which is composed of furfuran hydrazide with structural formula as formula (I) and suspending agent. The preparing method comprises the following steps: placing furfuran hydrazide and insecticidal suspending agent in the cutting autoclave, staring high-cutting emulsifying machine, blending the cut material evenly, grinding for 1-2 times.

Owner:JIANGSU PESTICIDE RES INST

Preparing method of fluororubber/nanofiller composite material

The invention discloses a preparing method of a fluororubber / nanofiller composite material. The method comprises the steps of firstly preparing nanofiller hydrosol or nanofiller pre dispersion liquid; then using a rubber internal mixer to conduct plastify on the fluororubber, raising the temperature of the internal mixer to 120-200 DEG C after plastification, gradually adding the nanofiller hydrosol or the nanofiller water pre dispersion liquid into the rubber internal mixer, mixing, and adopting hot air to dry the material after evaporation of water finishes so as to prepare fluororubber / nanofiller mixture; adding the fluororubber / nanofiller mixture, zinc oxide, triallyl isocyanurate, dicumyl peroxide in a rubber mix mill, mixing evenly, conducting out slice, and stopping putting so as to prepare a fluororubber / nanofiller rubber compound; conducting vulcanization of the fluororubber / nanofiller rubber compound on a press vulcanizer to prepare the fluororubber / nanofiller composite material. The preparing method of the fluororubber / nanofiller composite material is simple in technology, free of pollution of solvent, free of dust flying upward, green and environmentally friendly, and capable of being applied to various recombination of nanofiller and rubber and being popularized.

Owner:SOUTH CHINA UNIV OF TECH

Rubber accelerator TMTM predispersion master batch and preparation method thereof

The invention discloses a rubber accelerator TMTM predispersion master batch which is composed of the following components in parts by weight: 75-85 parts of tetramethylthiuram monosulfide, 10-20 parts of rubber matrix, 1-10 parts of rubber oil and 1 part of fatty acid alcohol ester. The preparation method is simple and easy to operate. The rubber matrix is previously compounded and prepared to effectively shorten the compounding time required by the subsequent master batch preparation process. The prepared master batch has no impurity or dust, can effectively maintain the original activity of TMTM, does not cake at room temperature, is easy for proportioning and compounding, has the advantages of favorable flowability, no flying dust and high utilization ratio of raw materials, and can not cause skin allergy of operating personnel. The master batch is dispersed uniformly in the rubber product after proportioning and compounding, can ensure the production efficiency and quality of the rubber product, and has important meanings for sustainable development of rubber manufacturing industry.

Owner:NINGBO ACTMIX POLYMER

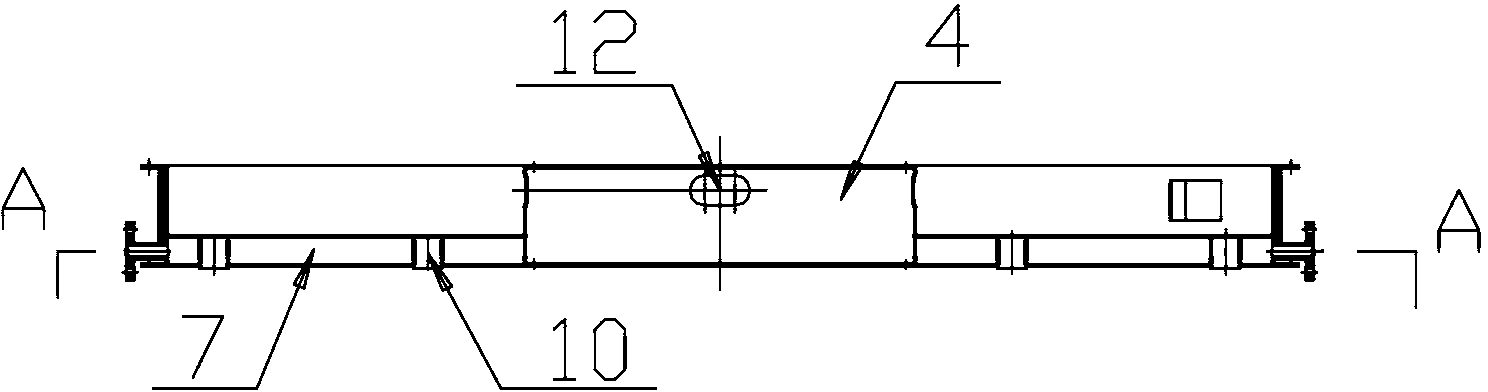

End milling equipment instead of ball mill

The invention relates to finish grinding equipment for replacing a ball grinder, which comprises a vane feeding mechanism used for feeding and sealing, a pregrinding structure used for finely grinding materials and a finish crushing structure used for grinding again, wherein the vane feeding mechanism used for feeding and sealing comprises a vane feeding machine (1) and a motor B (38). Furthermore, the lower end of the vane feeding machine (1) is connected to the upper surface of a cover (2), and any side of the vane feeding machine (1) is provided with the motor B (38) connected with an inner impeller of the vane feeding machine (1). The invention integrates the fine crushing and the grinding into a whole, occupies small floor area, saves the capital investment by a half, has low equipment expense, reduces the equipment investment by a half, has high equipment efficiency, and reduces the power consumption by a half. In addition, no severe relative moment exists between materials and all abrasion resistant materials, the abrasion of the abrasion resistant materials is a little, and the consumption of the abrasion materials is reduced by 90 percent.

Owner:付庚有

Dendrobe film agent

InactiveCN101632455ASimple preparation processEasy to solve the problem of incompatibilityMetabolism disorderDigestive systemMedicineFilm-forming agent

The invention relates to a dendrobe film agent which belongs to the class of food, medicaments and health care products and comprises the components of a dendrobe extract, a film forming agent and the like. For regulating tastes and colors, a flavoring agent and a toner can also be added. All the components and portions are prepared into the film agent by required contents. The film agent has the characteristics of accurate medicament contents, good stability, light weight, small volume, convenient application and the like and is suitable for the application of various administration purposes. Different film forming materials can be prepared into film agents with different medicament release rates, release control films and slow release films. A multilayer compound film agent is also convenient for solving the problem of incompatibility among medicaments.

Owner:阳瑞鸿

Vibrating disk type drier with burbling function

InactiveCN102706117APlay a disturbing roleEvenly heatedDrying chambers/containersHeating arrangementHeat transmissionHardness

The invention relates to a vibrating disk type drier with a burbling function. The vibrating disk type drier comprises a vibration motor, a vibration chassis and a vibration spring arranged between the vibration motor and the vibration chassis, wherein vibrating disks are arranged above the vibration chassis, the upper and lower surfaces of each vibration chassis are respectively provided with an inlet and an outlet; the bottom of each vibrating disk is provided with an interlayer, and the interlayers are communicated with oil inlets and oil outlets formed in the outer periphery of the vibrating disks; and the inner periphery of each interlayer is provided with a plurality of peripheries which are at equal intervals, each periphery is provided with a plurality of burbling pillars which are uniformly distributed, and the burbling pillars of the adjacent two peripheries are distributed in an overlapping manner. The drier adopts a receiving broken vibration mode to ensure that a material can do horizontal circle operation, the conjugation generated friction in mechanical movement is avoided, and high-purity and high-hardness particle material can be continuously dried; and meanwhile, the power consumption is small so that the energy-saving purpose can be realized as no machine driving member exists, and a burbling structure does a disturbing action on the flow of heating a medium in the vibrating disks so that the heat transmission is enhanced.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Manufacturing method of beaded polytrifluorochloroethylene resins

The invention relates to a manufacturing method of beaded polytrifluorochloroethylene resins, which comprises the following steps of: taking trifluorochlor oethylene, high-purity water, an organic dispersant and an initiator under the condition that the mass ratio of the trifluorochlor oethylene, the high-purity water, the organic dispersant and the initiator is 100:(500-1000): (50-200): (0.1-1); placing the high-purity water, the organic dispersant and the initiator in a reaction kettle, and at a stirring speed of 400-500 rmp, feeding the trifluorochlor oethylene into the reaction kettle; carrying out reaction on the obtained mixture for 4-6 hours under the conditions of 0.2-1 Mpa and 20-30 DEG C; and then continuing to react for 2-4 hours at a temperature of 50 DEG C and at a stirring speed of 100-200 rmp; and carrying out washing and drying on the obtained product so as to obtain a beaded polytrifluorochloroethylene resin with a diameter of 0.5-5 mm. The method disclosed by the invention is stable in polymerization rate and narrow in molecular weight distribution, no dust flying occurs in the process of production, and no further granulation treatment is required; the obtained polytrifluorochloroethylene resin is excellent in performances, and can be prepared into tubes, bars and profiles with more complicated shapes through melt injection molding; and no yellowing phenomenon occurs, therefore, the method has good social, economic and environmental benefits.

Owner:山东森福新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com