Glass polishing wheel and its preparing method and using method

A polishing wheel and glass technology, applied in grinding/polishing equipment, grinding/polishing safety devices, manufacturing tools, etc., to achieve high luminosity, fast luminous speed, and good grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Put 40g of mixing type polyurethane, 100g of cerium oxide, 3g of accelerator MBT, 3g of accelerator MBTS, 8g of magurone, 4g of phthalic acid-butyl fat into the internal mixer and mix at 95°C Refining for 15-20 minutes, deglue to make polyurethane masterbatch;

[0020] 2), 30g of styrene-butadiene rubber, 30g of butadiene rubber, 150g of cerium oxide, 1g of accelerator MBT, 1g of accelerator MBTS, 8g of magurone, 4g of phthalic acid-butyl ester, 0.8g of stearic acid, zinc stearate Put 0.8g into an internal mixer and knead for 13-15 minutes at a temperature of 125°C, then discharge the glue to make a rubber masterbatch;

[0021] 3) Cool the above two masterbatches to below 50°C and put them into the internal mixer at the same time, add 4g of magnesium oxide, 5g of zinc oxide, and 1.6g of sulfur, and mix them in the internal mixer without heating for 10-13 minutes to remove the glue Prepare ready-to-use mixture;

[0022] 4) Put the mixed material into a polishing whe...

Embodiment 2

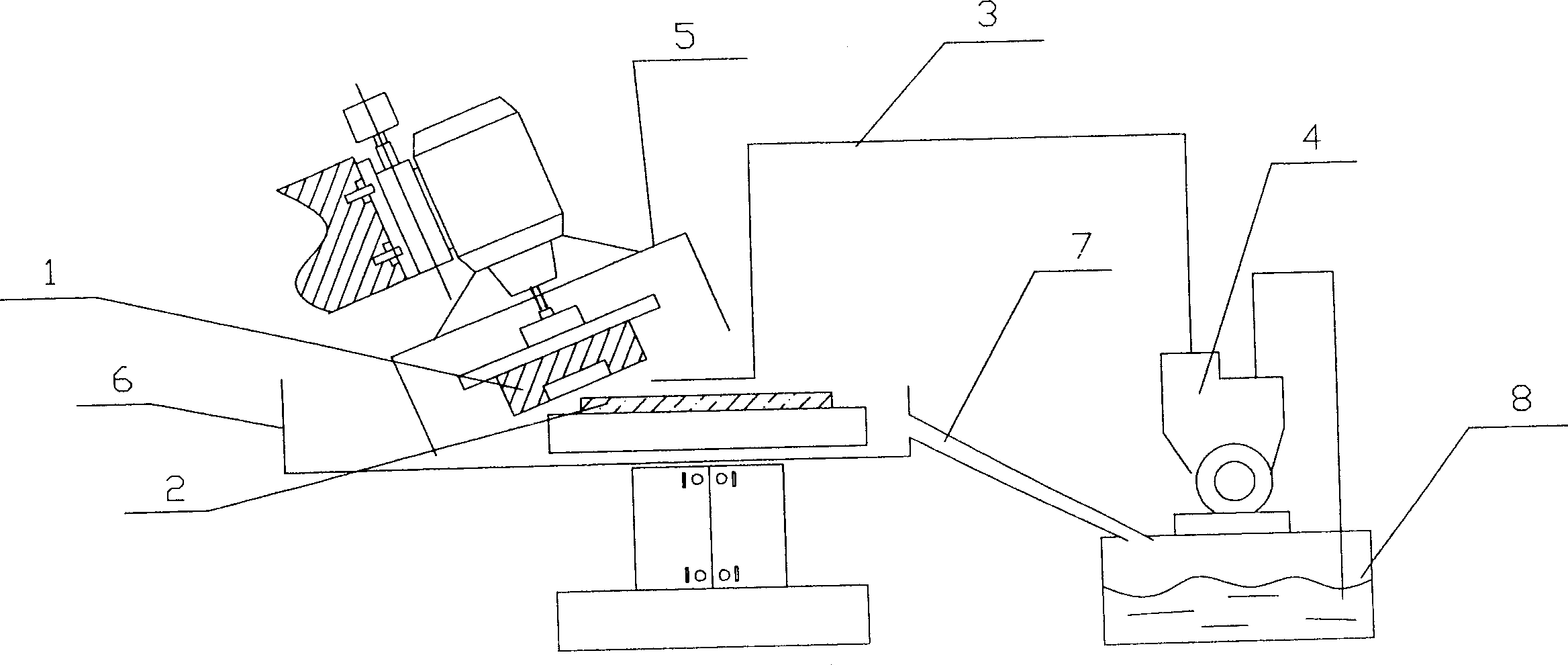

[0024] Such as figure 1 As shown, the polishing wheel 1 prepared in Example 1 is installed on the polishing machine, and the polishing machine for installing the polishing wheel is equipped with a 0.3M 3 Above the water tank 8, a 150W-200W high-pressure water pump 4 is installed on the water tank, and the water flow of the water pump shoots to the contact point between the polishing wheel and the polished glass surface 2 through the rubber hose 3, and the water shield 5 and the water catcher are installed around the polishing wheel Box 6, the water receiving box is provided with return water pipe 7, and water flows back to the water tank through the return water pipe for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com