Patents

Literature

328results about How to "Improve anti-static" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional viscose and preparation method thereof

ActiveCN104831389AGood far infraredImproves UV resistanceGrapheneArtificial filaments from viscoseViscoseAntibacterial activity

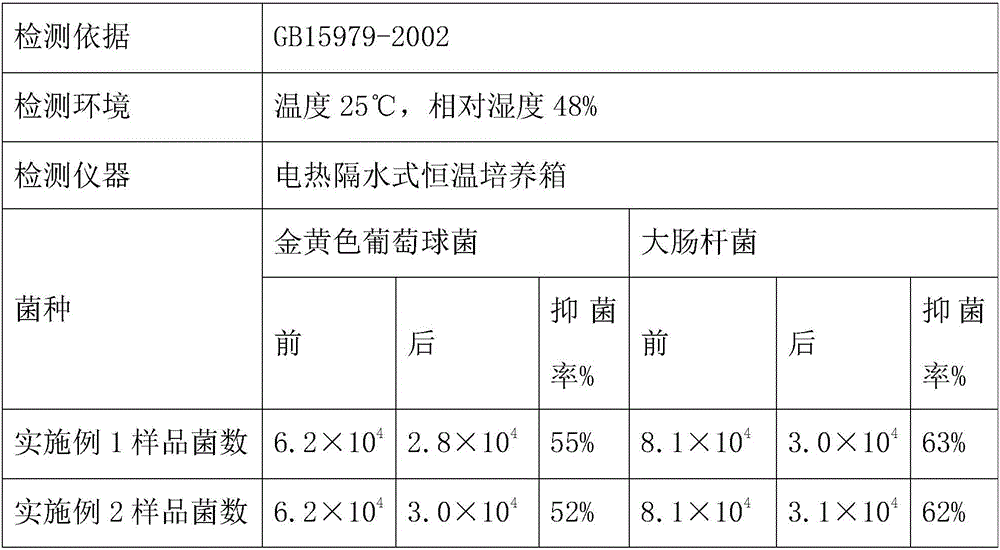

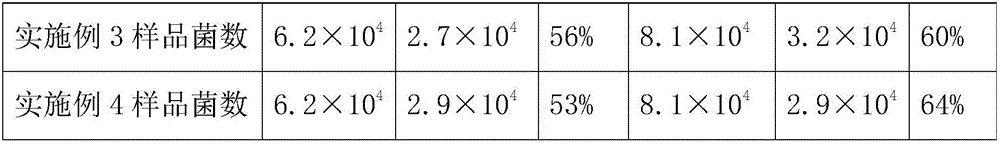

The invention provides multifunctional viscose. The multifunctional viscose comprises viscose, graphene and nano-silver, wherein nano-silver is loaded to a graphene slice layer in situ. The invention further provides a preparation method of the multifunctional viscose. The preparation method is characterized by comprising the following steps: (a) dispersing graphene in a water solution, so as to obtain a graphene dispersion liquid; (b) dissolving silver salt into the graphene dispersion liquid, adding a reducing agent, and carrying out reduction reaction, so as to obtain nano-silver-loaded graphene dispersion liquid; and (c) uniformly mixing the nano-silver-loaded graphene dispersion liquid with viscose liquid, and carrying out spinning, so as to obtain the multifunctional viscose. An experimental result shows that compared with viscose which is not added with nano-silver-loaded graphene, the multifunctional viscose has the advantages that the far infrared temperature increase performance is increased by not less than 100%, the ultraviolet protecting coefficient is increased by not less than 70%, and the antibacterial activity reaches 99.9% and is increased by not less than 100%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

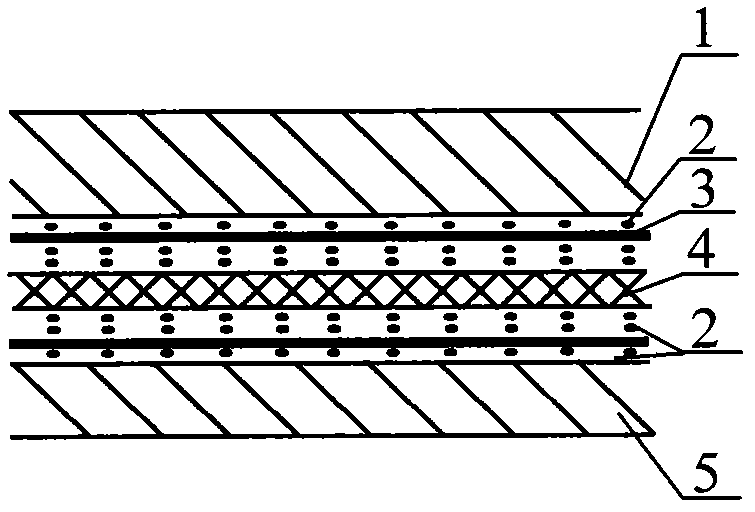

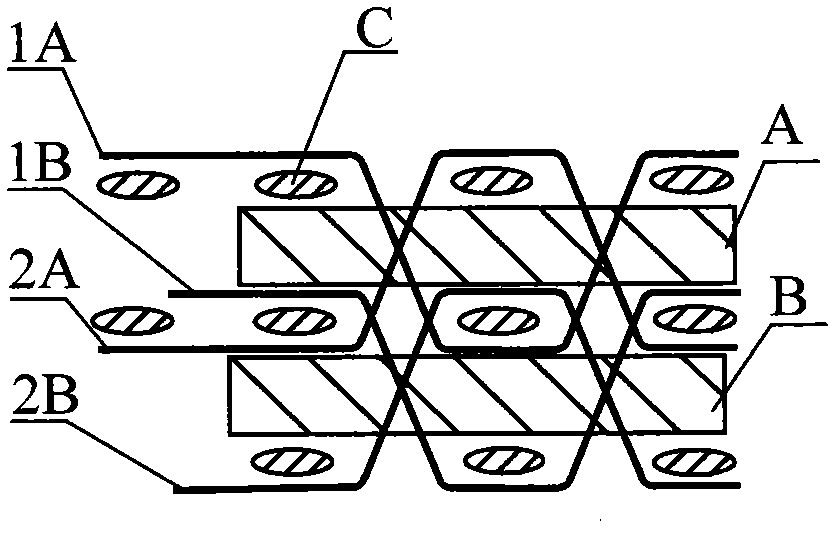

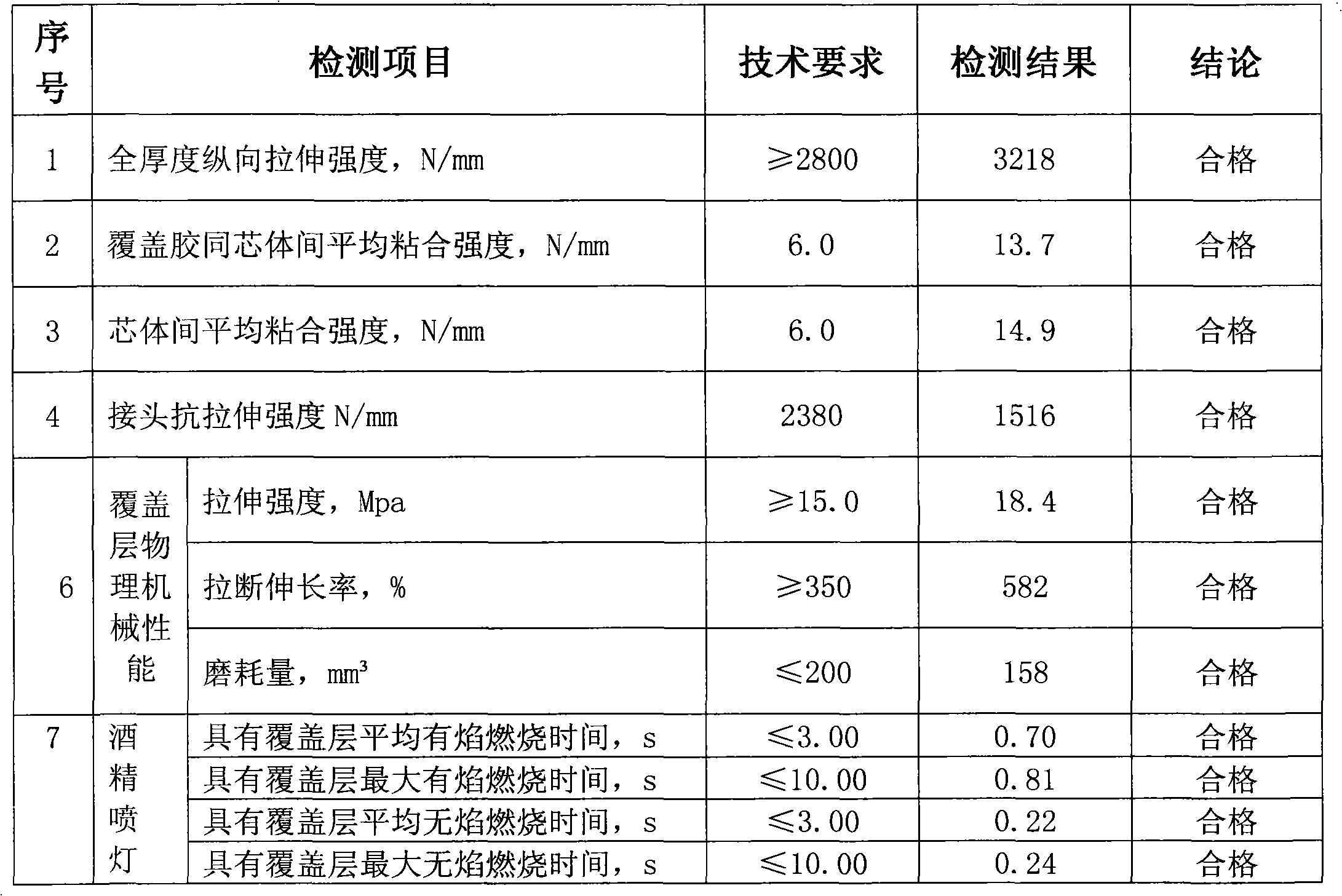

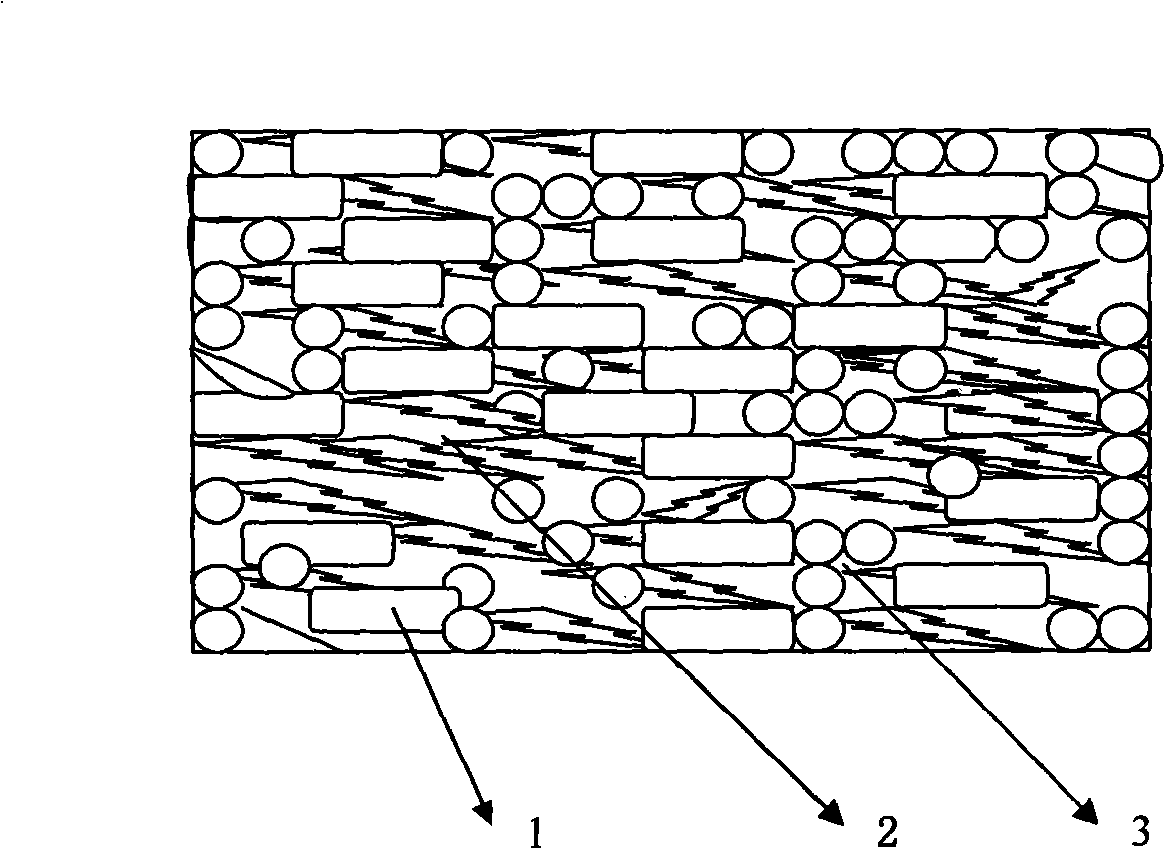

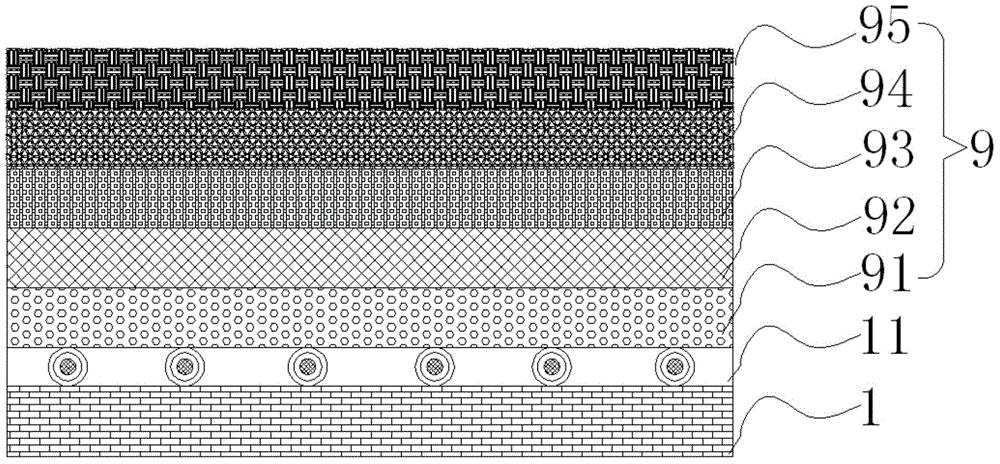

Flameretardant conveyor belt for aramid fiber core

The invention discloses a flameretardant conveyor belt for an aramid fiber core. A pull-resistant framework layer made from aramid fiber fibre. The flameretardant conveyor belt comprises an aramid fiber framework layer, two buffer layers and a flameretardant coverage glue layer, wherein the aramid fiber framework layer is a straight-longitude and straight-latitude structure, two sides of the aramid fiber framework layer are respectively provided with the buffer layer, two sides of the aramid fiber framework layer and the buffer layers are respectively glued with flameretardant bonding glue, the aramid fiber framework layer is bonded with the buffer layers by the flameretardant bonding glue, and the buffer layers are bonded with the flameretardant coverage glue layer by the flameretardant bonding glue. The flameretardant conveyor belt is good in integrated performance, high in the strength of a belt body, light in weight, good in adhesive force, flameretardant, static electricity-resistant, and good in corrosion resistance; the flameretardant conveyor belt is long in service life, low in operation kinetic energy consumption, small in the diameter of a transmission roller, and low in equipment cost; and the flameretardant conveyor belt is less in long-distance jointing times, low in integrated cost, convenient to joint, and good in jointing durability, so that the transportation requirement of multi-variety under a coal mine well can be met.

Owner:安徽天地人科技集团有限公司

Ultraviolet curing nano transparent heat-insulation composite coating

InactiveCN101760110AImprove aging resistanceExcellent stain resistance and self-cleaningAntifouling/underwater paintsPaints with biocidesUltravioletContamination

The invention discloses an ultraviolet curing nano transparent heat-insulation composite coating belonging to the field of ultraviolet curing coatings and containing the following substances in percentage by weight: 30-75 percent of oilopolymer, 0.01-15 percent of photosensitive curing agent and 10-55 percent of activated monomer, as well as 0.1-15 percent of stannic oxide. The transparent heat-insulation coating can be prepared in 1 minute under ultraviolet irradiation at room temperature, and the curing speed is high and the cost is low. The coating has selectivity to a solar spectrum, and a coating film which is about 5-70 micrometers is formed on the material surface. When the coating is used for glass, the visible light transmissivity of the glass is still higher than 75 percent, and the infrared thermal screening factor is higher than 70 percent, thereby not only keeping the transparency of the original glass, but also effectively isolating the infrared thermal radiation of sunlight. The coating has good ageing resistance, contamination resistance, anti-static performance, anti-dazzle performance, radiation protection, quick curing, environmental protection and the like.

Owner:南京海泰纳米材料有限公司

Rubber-wood-cement composite material

ActiveCN101298379AShorten the production cycleHigh degree of continuitySolid waste managementWear resistantAdhesive

The invention provides a rubber-timber-cement functional environment-friendly compound material, which belongs to the field of cement-base compound material. The material adopts the waste tire rubber, waste rubber products, woody material and silicate cement as raw materials, an isocyanate-based adhesive is coated on the surface of the waste rubber particles, then the woody material is soaked and dried, and the treated rubber particles, the woody material and cement are mixed to form a blank material, which is finally laid, pressed and cured so as to obtain the compound material. The compound material provided by the invention can absorb and insulate sound, has high shock resistance and damping property, and is wear-resistant, antistatic, mothproof, waterproof and anticorrosive; also the material is heat-insulating and friendly to the environment, etc.; the production process has no chemical pollution source, no radioactivity, no light pollution and no noise. The invention blazes a new path for solving the 'black pollution' of increasing waste tires, which is a global problem; additionally, the compound material can be used for producing structural lumber.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

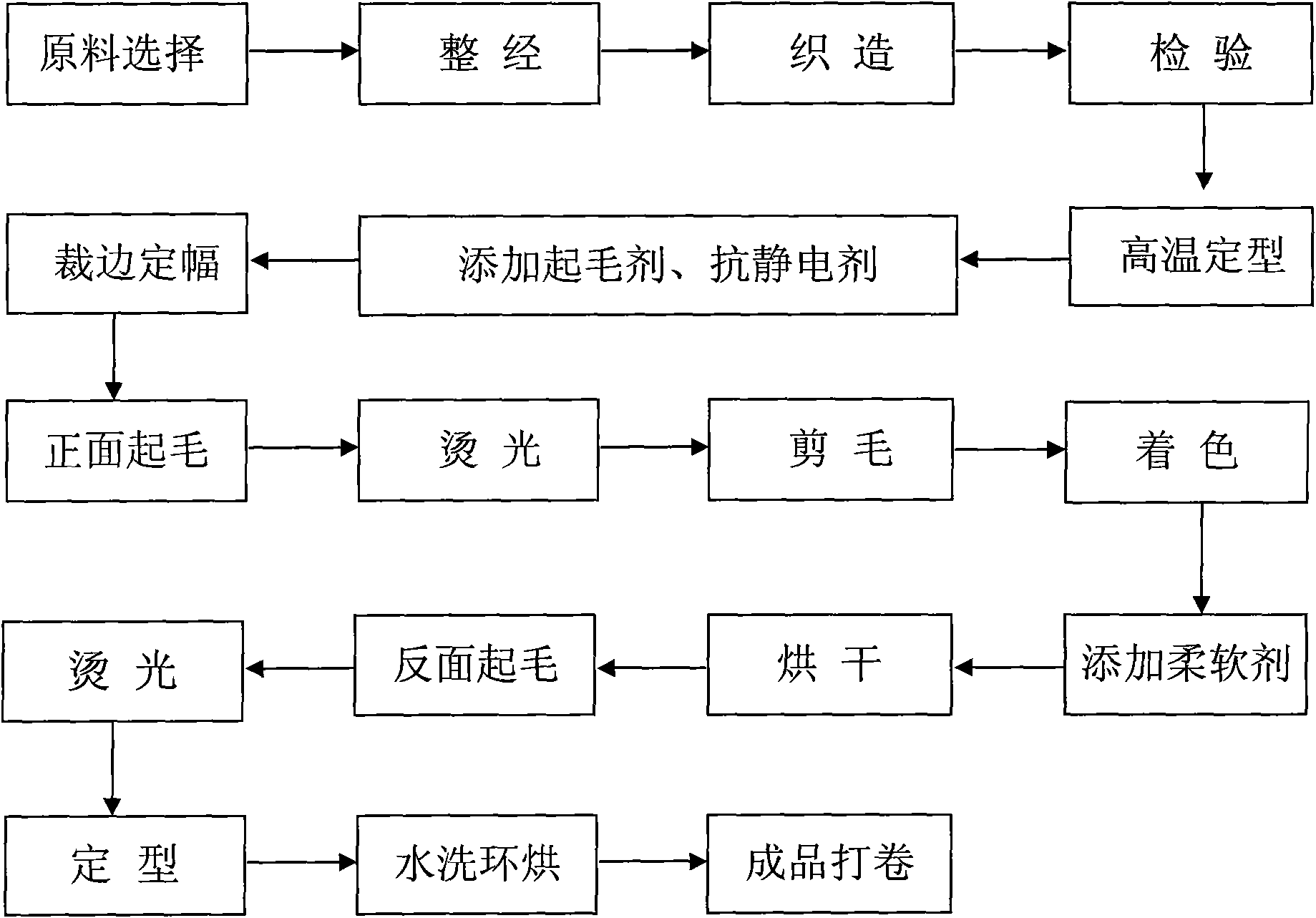

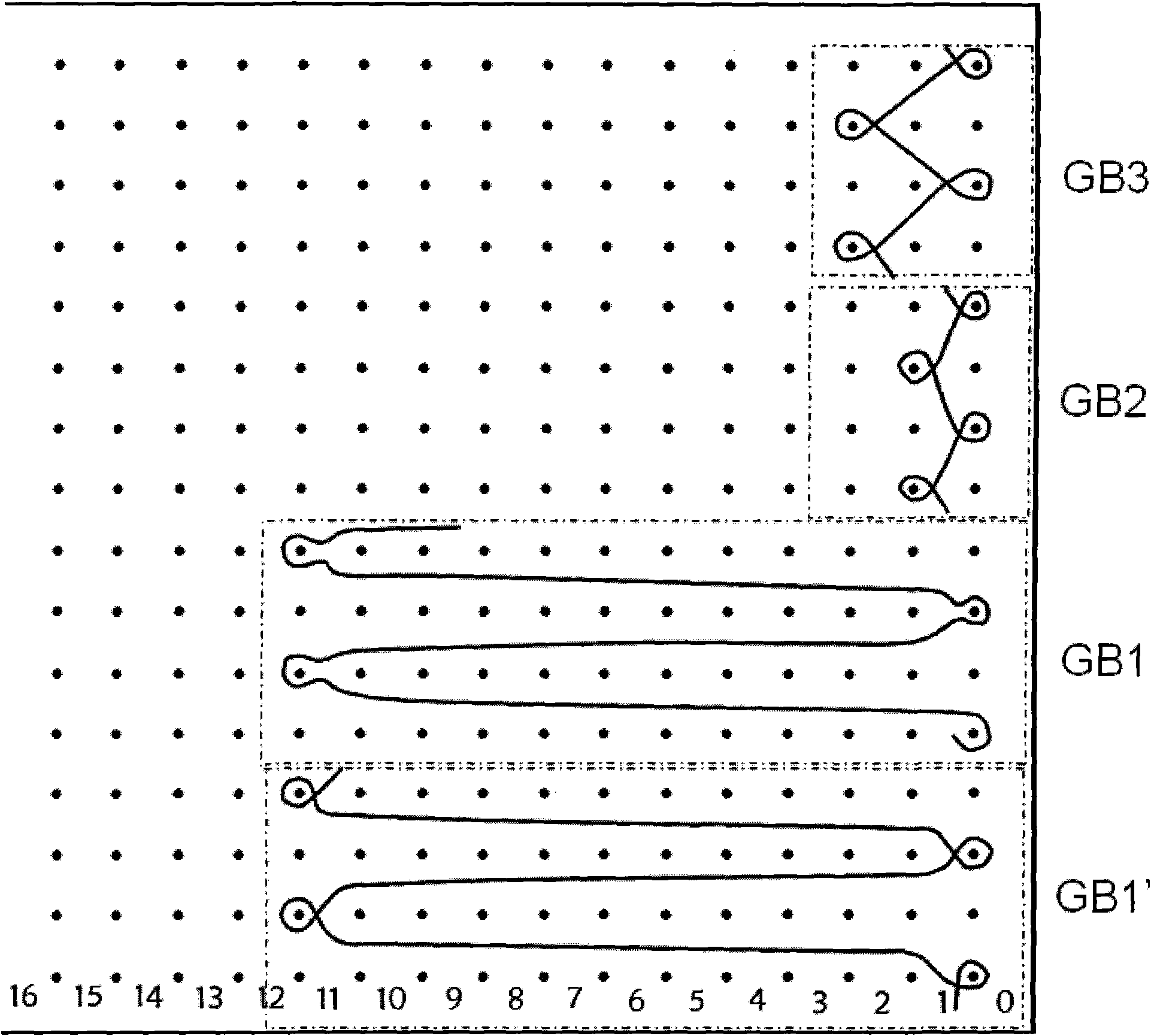

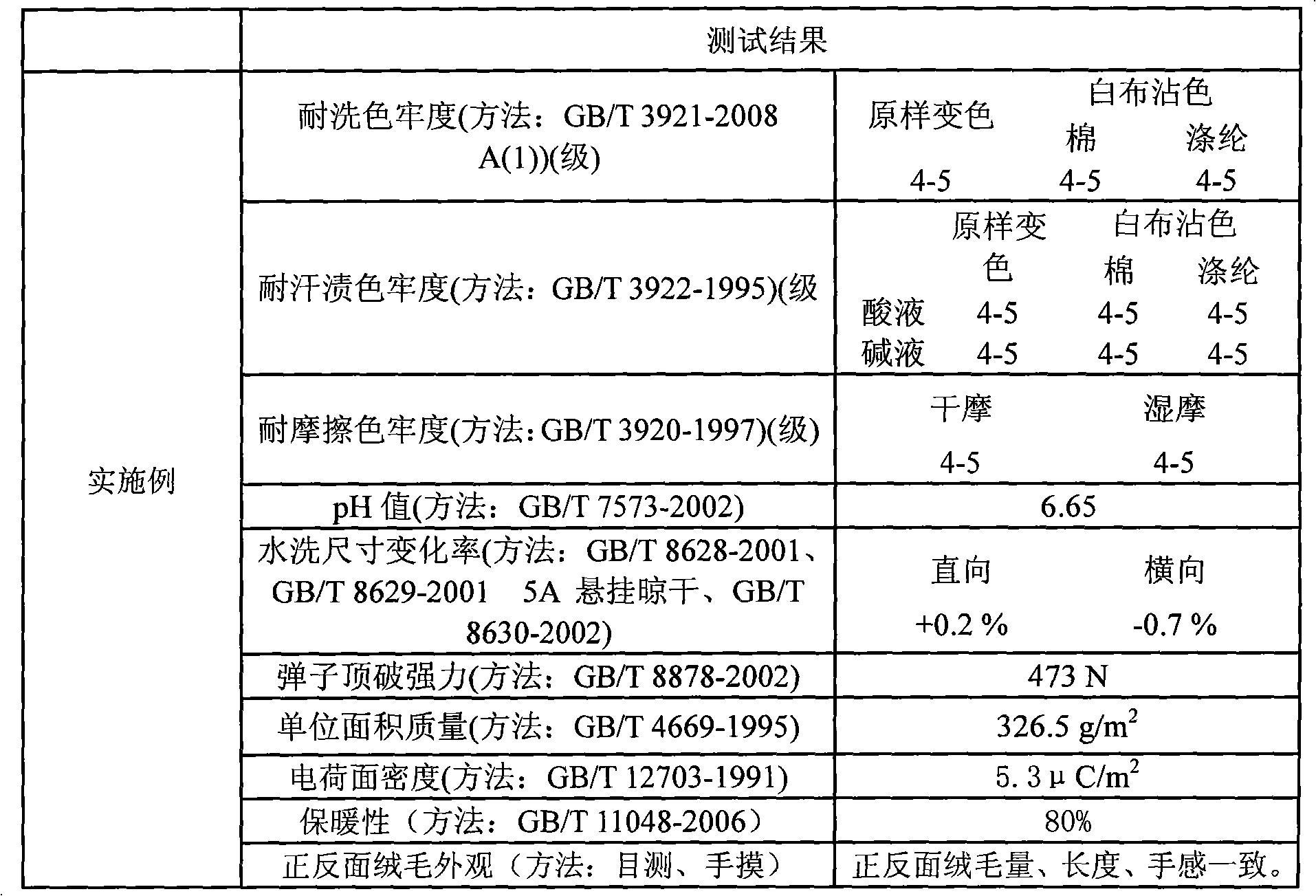

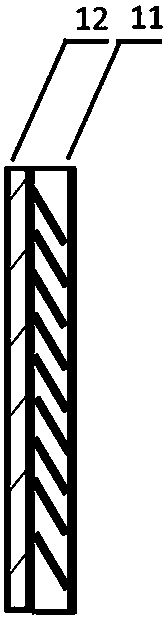

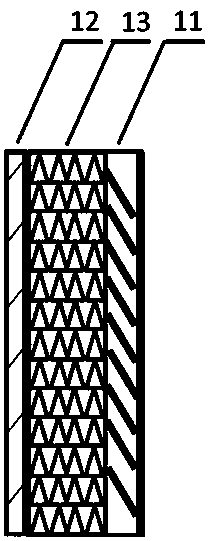

Method for producing double-sided ultrafine supersoft floss fabric

InactiveCN101603240ASame lengthExcellent fluff finenessFibre treatmentWarp knittingAntistatic agentEngineering

The invention relates to a method for producing double-sided ultrafine supersoft floss fabric, which comprises the following steps: (1) raw material selection, (2) beam-warping, (3) weaving, (4) inspection, (5) high-temperature shaping, (6) addition of a raising agent and an anlistatig, (7) drying, (8) positive fuzzing, (9) ironing, (10) shearing, (11) coloring, (12) addition of a softener, (13) drying, (14) reverse fuzzing, (15) ironing, (16) high-temperature shaping; (17) water washing and loop drying so that a product obtains the effect of consistent handle of the positive and the reverse loop, (18) coiling of a finished product; the method has the advantages of adopting a special tissue structure and solving the problems that the prior floss fabric product has rare fluff and different lengths of the positive fluff and the reverse fluff through a weaving process and a manufacturing procedure; and a product has the advantages of consistent fluff amount and length of the positive fluff and the reverse fluff, enlarges the service occasions of the class of the product and improves the attractiveness and warm keeping performance of the product.

Owner:HAINING SHUNDA WARP KNITTING

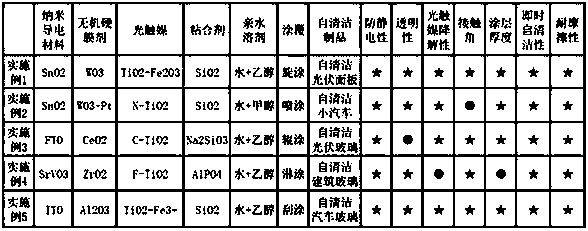

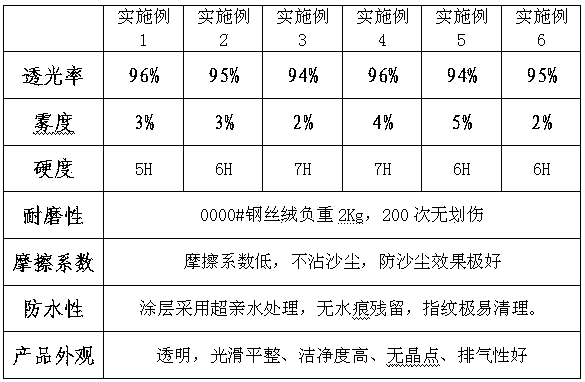

Composite self-cleaning nanometer coating, inorganic transparent coating layer and self-cleaning product

InactiveCN107892826AImprove hydrophilic propertiesImprove anti-staticAntifouling/underwater paintsPaints with biocidesSpecific functionBird droppings

The invention reveals a composite self-cleaning nanometer coating, an inorganic transparent coating layer and a self-cleaning product. The coating, the coating layer and the product have anti-static,super-hydrophilic and photocatalytic functions at a same time. The composite self-cleaning nanometer coating containing 0.01-20 parts of conductive particles, 0.01-20 parts of a photocatalyst, 0.01-20parts of a hard film agent, 0.01-20 parts of an inorganic binder and 20-99.96 parts of a hydrophilic solvent is prepared. The surface of an object is coated with the composite self-cleaning nanometercoating, and the composite self-cleaning nanometer coating is solidified for forming a hydrophilic inorganic transparent coating layer. Because of specific functions of static electricity conductionand static electricity dissipation of the coating layer, static electricity generated when the surface of the object rubs flowing air can be instantly eliminated, and the surface of the object loses the attraction to particles in the surrounding environment in microstructure, so that sand, dust, pollen, haze and the like are difficult to attach to the surface of the object, and thus an instant self-cleaning effect of keeping the surface of the object clean at any time is achieved. The coating layer also has a photocatalyst degradation function and can be used for remarkably solving the problemof high-adhesive-force dirt caused by non-electrostatic adsorption of bird droppings, ink, artificial scrawling and the like.

Owner:ZHANGJIAGANG ALIEN NEW MATERIAL TECH CO LTD

Self-cleaning nano-coating protective film and preparation method thereof

InactiveCN103740292ADifferent curing methodsSimple processFilm/foil adhesivesCoatingsPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to the technical field of optical protective films, and in particular relates to a self-cleaning nano-coating protective film and a preparation method thereof. The preparation method comprises the following processing steps: I, preparing a nano-paint having a self-cleaning function; II, coating a PET (Polyethylene Terephthalate) substrate with the nano-paint by using a micro-concave anilox roller; III, forming a layer of nanofilm on the PET substrate by adopting a heat curing way; and IV, coating silica gel and sticking a stripping layer. The PET substrate is coated with the nano-paint having the self-cleaning function by using the micro-concave anilox roller, and the PET substrate is dried and cured in a drying oven, so that the nano-coating having a self-cleaning function is formed on the surface of the PET substrate. The self-cleaning nano-coating protective film can be used by peeling the PET stripping layer off and sticking an adhesive layer to a screen. The self-cleaning nano-coating protective film is convenient to use and easy to operate.

Owner:NALI OPTICAL MATERIAL DONGGUAN

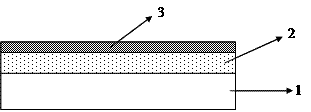

Antistatic, anti-dazzle and anti-reflection optical film and manufacture method for the same and application thereof

InactiveCN107203013AWith anti-reflection propertiesAntifoulingOptical elementsCoated surfaceAntistatic agent

The invention discloses an antistatic, anti-dazzle and anti-reflection optical film and a manufacture method for the same and an application thereof. The antistatic, anti-dazzle and anti-reflection optical film comprises a transparent film base material, an antistatic and anti-dazzle hard coating which is at least coated on the transparent film base material and an anti-reflection coating on the surface of the antistatic and anti-dazzle hard coating; the antistatic and anti-dazzle hard coating comprises a medium the refractive rate UV solidified resin with a refractive index ranging from 1.45-1.53, an active diluent, transparent anti-dazzle particles, a photoinitiator, an antistatic agent and a diluent; the anti-reflection coating consists of a low refractive rate material with a refractive index lower than 1.45 and a high refractive rate material with a refractive index higher than 1.52; the anti-reflection coating is formed through coating the antistatic and anti-dazzle hard coating on the surface of the transparent film base material and then performing one-time coating on the antistatic and anti-dazzle film after the film is formed. The antistatic, anti-dazzle and anti-reflection optical film and the manufacture method for the same and the application thereof can have functions of preventing static electricity, preventing dazzling, preventing scratching and fouling and can be applied to polarized plates of various kinds of flat displayers and display screen surface protection.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Ultraviolet curing nano transparent heat-insulating composite coating

InactiveCN102120900AHigh visible light transmittanceHigh infrared heat shielding rateCoatingsUltravioletMaterials science

The invention relates to an ultraviolet curing nano transparent heat-insulating composite coating. The ultraviolet curing nano transparent heat-insulating composite coating mainly comprises the following substances in percentage by weight: 30 to 75 percent of oligomer, 0.01 to 15 percent of photoinitiator, 10 to 55 percent of activated monomer, 0.1 to 15 percent of tin stibium oxide and 0.01 to 10 percent of nano material. The ultraviolet curing nano transparent heat-insulating composite coating can be prepared into a transparent heat-insulating coating within one minute through ultraviolet irradiation at normal temperature, so the curing speed is high and the cost is low. The coating has selectivity on solar spectrum and forms a coating film of about 2 to 7 mu m on the surface of a material. When the coating is applied to glass, visible light transmissivity of the glass is still more than 75 percent and the infrared heat shielding rate is more than 70 percent, so the coating maintains the transparency of the original glass, can effectively isolate infrared heat radiation of sunlight, and has the advantages of excellent aging resistance, stain resistance, self cleaning, static resistance, glare resistance, radiation resistance, high curing speed, environmental friendliness and the like.

Owner:高建宾

PA/ABS alloy material and preparation method thereof

The invention falls into the technical field of polymer composite material, and discloses PA / ABS alloy material and a preparation method thereof. The PA / ABS alloy material comprises (by weight parts) PA 30-80, ABS 10-50, an antioxidant 0.1-0.5, a compatilizer 3-10, a lubricant 0.1-0.5, an antistatic agent 2-10 and a flame retardant 10-20. The preparation method includes putting all above raw materials in a high-speed mixer, mixing for 2-5 minutes, and extruding and granulating by a screw extruder to obtain the PA / ABS alloy material. The inventive PA / ABS alloy material has stable size, high strength, good appearance, high fluidity and resistance to chemicals, and possesses antistatic and flame retardant effects at the same time, and therefore, can be widely applied in fields of electronics, automobile, etc.; owing to the antistatic and flame retardant functions of the PA / ABS alloy material, the PA / ABS alloy material can play a role of electrostatic prevention, dust prevention and flame retardance during application process.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation method of mineral graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe

The invention relates to a preparation method of a mineral graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe. The pipe is prepared from the following raw materials: 100 parts of ultra-high molecular weight polyethylene, 2-5 parts of nano-graphene sheets, 5-10 parts of a coupling agent, 0.1-1 part of a foaming agent, 0.1-1 part of a compatibilizer, 1-2 parts of a lubricating agent, 6-10 parts of a halogen-free flame retardant, 3-6 parts of an antistatic agent, 2-4 parts of a flow modifier, 1-3 parts of a nucleating agent, and the like; the graphene reinforced ultra-high molecular weight polyethylene double-resistant pipe is prepared by the processes of extruding, sizing, and the like. According to the preparation method, nano-graphene, the antistatic agent and the flame retardant are dispersed into ultra-high molecular weight polyethylene resin medium gaps by means of the coupling agent, the compatibilizer, the flow modifier, the lubricating agent, the nucleating agent, and the like; the nano-graphene sheets have significant synergistic flame retardation after being compounded with the flame retardant, and can reduce the resistivity of the pipe after being compounded with the antistatic agent. The prepared pipe has the characteristics of being light in weight, high in strength, flame-retardant, antistatic, and the like, thus being used in the operating environments such as coal mines, downhole and mines in which a great deal of gas exists.

Owner:JIUJIANG UNIVERSITY

Graphene modified waterborne polyurethane-epoxy resin and preparation method thereof

InactiveCN109608610AImprove performanceNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyDibutyltin dilaurate

The invention relates to a graphene modified waterborne polyurethane-epoxy resin and a preparation method thereof. The graphene modified waterborne polyurethane-epoxy resin is composed of, in parts byweight, 8.0-20.0 parts of polyisocyanate, 2.0-6.0 parts of polyol, 0.5 to 2.0 parts of polyamine chain extender, 4.0-10.0 parts of oligomer polyether polyol, 1.5-4.5 parts of dimethylolpropionic acid, 4.0-15.0 parts of epoxy resin, 0.01-0.1 part of dibutyltin dilaurate, 0.5-2.5 parts of graphene, 4.0-10.0 parts of acetone, 1.0 to 3.0 parts of neutralizer and 48.0 to 68.0 parts of distilled water.The graphene modified waterborne polyurethane-epoxy resin disclosed by the present invention is characterized by good adhesion, corrosion resistance, water resistance, alkali resistance, wear resistance, anti-static property, high hardness and the like, and can be widely used in the field of ocean engineering, iron components, wood coatings, anti-static coatings, conductive coatings, and antifouling and waterproofing coatings with enormous application potential.

Owner:UNION FOSHAN CHEM +1

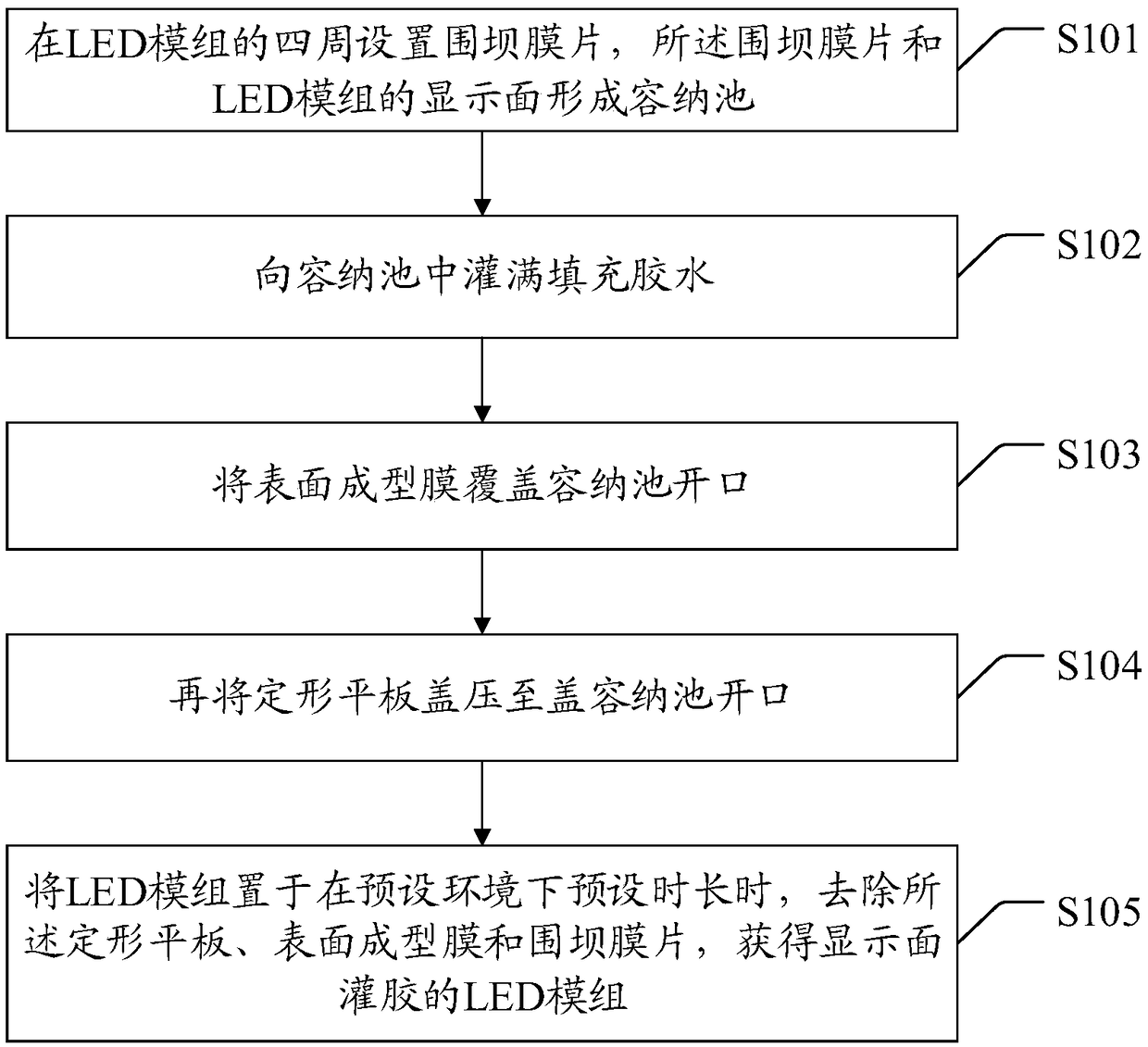

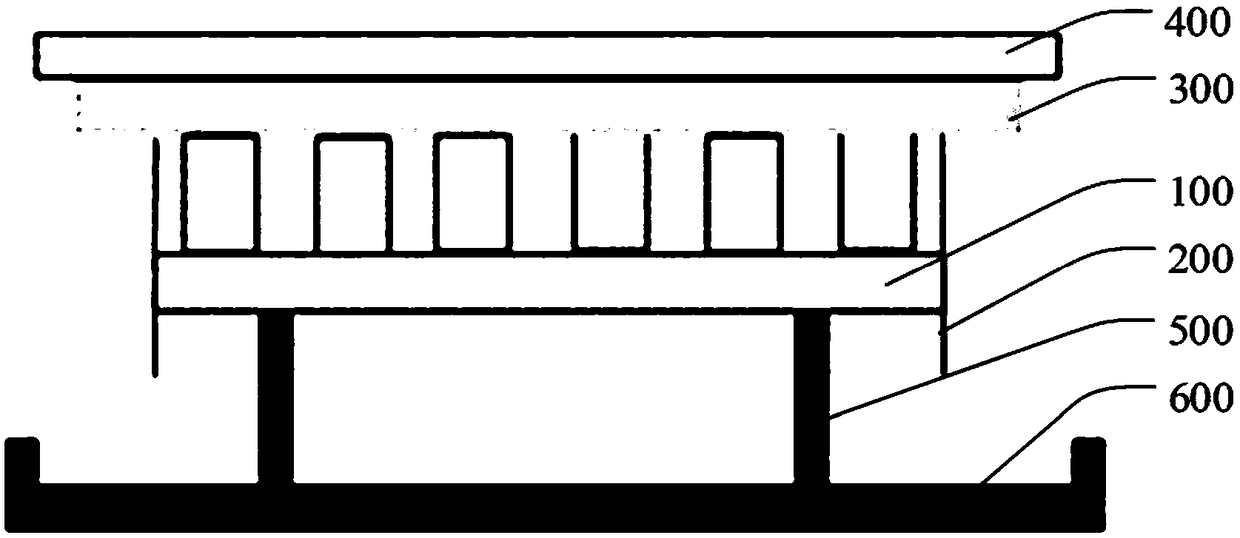

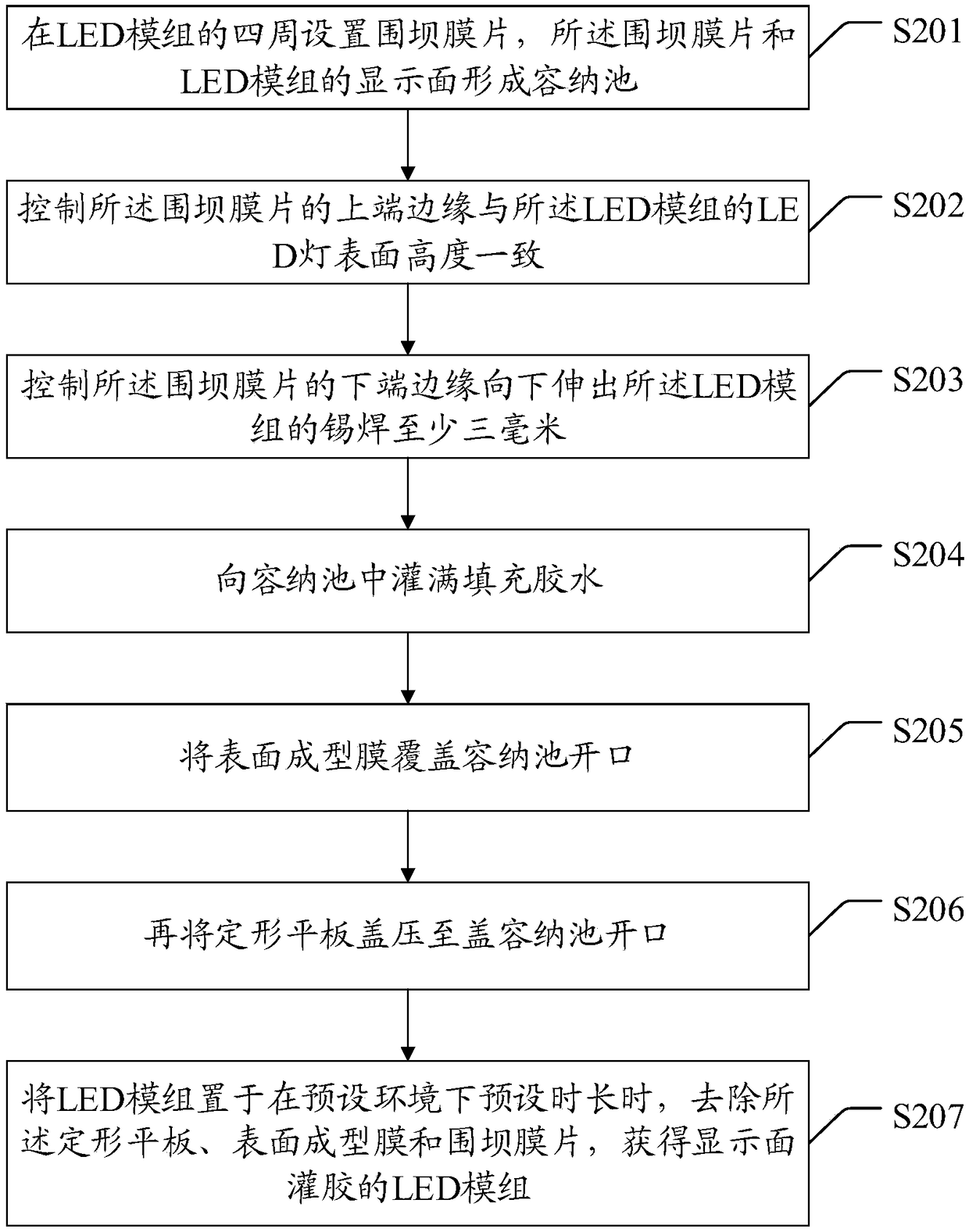

LED module glue-filling method and LED module with display surface subjected to glue filling

ActiveCN109004077AImprove anti-staticEnhance anti-static abilitySemiconductor devicesEngineeringCuring time

The invention discloses an LED module glue-filling method and an LED module with a display surface subjected to glue filling. The LED module glue-filling method comprises the following steps: a box dam diaphragm is arranged around the LED module, and the box dam diaphragm and the display surface of the LED module form an accommodation pool; the accommodation pool is with filled with filling glue;a surface forming film is utilized to cover a mouth of the accommodation pool; then a shaping flat plate pressed to the mouth of the accommodation pool; and when waiting for preset curing time in preset environment, the shaping flat plate, the surface forming film and the box dam diaphragm are removed to obtain the LED module with the display surface subjected to glue filling. The LED module glue-filling method provided by the invention has the effect of improving the anticollision performance of the LED module.

Owner:UNILUMIN GRP

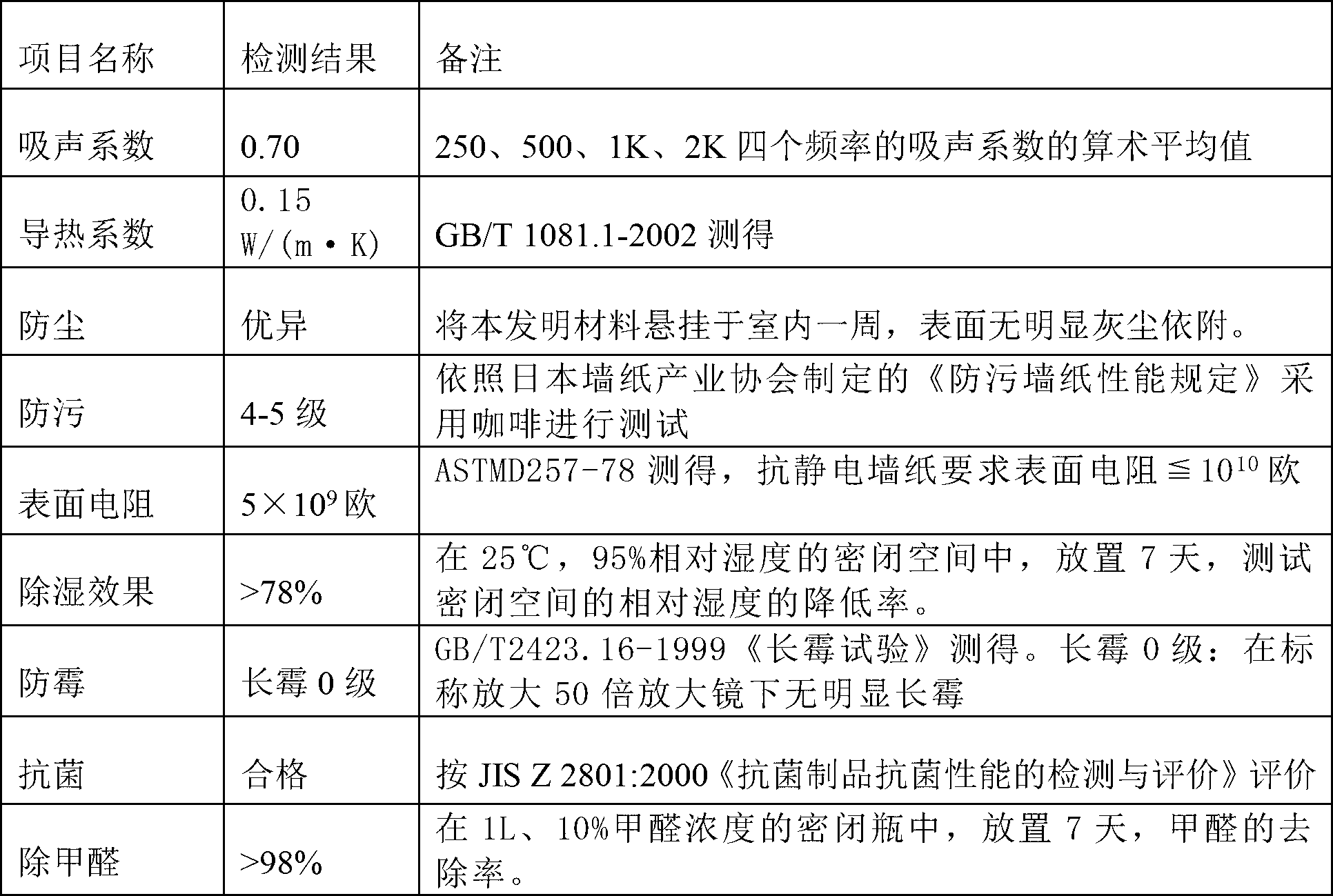

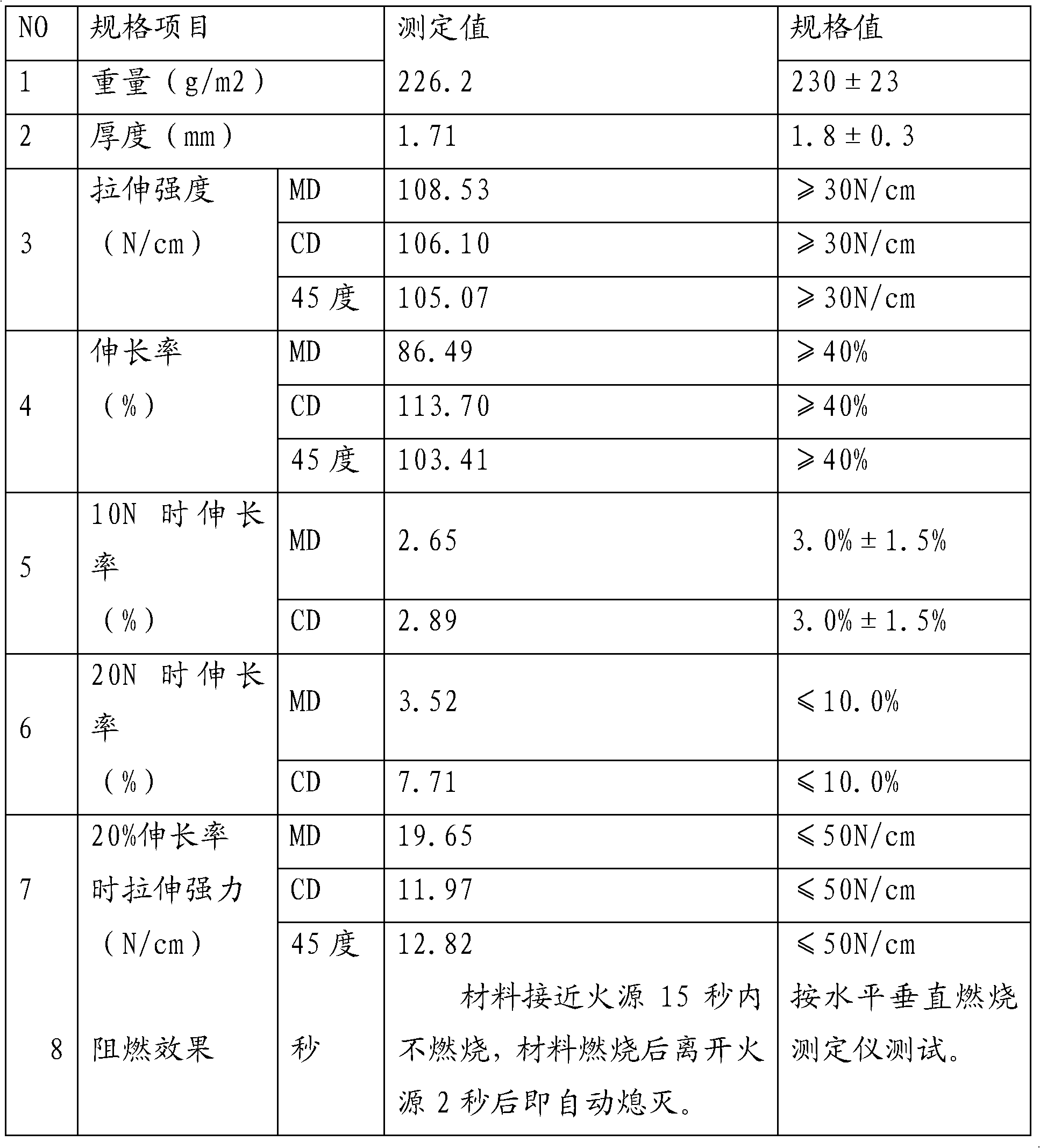

Infusorial earth environment-friendly interior wall decoration polyurethane synthetic leather and production method thereof

InactiveCN102936851AGood antibacterial, mildew and moth resistanceImprove wear resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsInfusorial earthPigment

The invention discloses infusorial earth environment-friendly interior wall decoration polyurethane synthetic leather and a production method thereof. The synthetic leather comprises base cloth, a waterproof agent layer which is coated on one side of the base cloth and a waterborne polyurethane layer which is coated on the waterproof agent layer and contains infusorial earth, wherein the waterborne polyurethane layer containing the infusorial earth comprises, by weight, 100 parts of waterborne polyurethane, 1-20 parts of anti-settling agent, 1-20 parts of ricinate, 50-300 parts of infusorial earth and 1-50 parts of waterborne pigment paste. According to the synthetic leather and the production method, the used raw materials are environment-friendly materials, the produced infusorial earth environment-friendly interior wall decoration polyurethane synthetic leather has good durability, feels comfortable, is elegant in appearance, can be widely applied to interior wall decoration of upscale wine-shops and hotels, fashionable Karaok telsvision (KTV), senior clubs, senior villas or mansions, and has great market prospect.

Owner:HUAFON MICROFIBER SHANGHAI

Environmentally friendly differential fiber non-woven automotive interior trim material and preparation method thereof

ActiveCN101851863AImprove spinnabilityAvoid it happening againFibre typesNeedling machinesFoam rubberEngineering

The invention belongs to automotive non-woven textiles, in particular to an environmentally friendly differential fiber non-woven automotive interior trim material and a preparation method thereof. The preparation method comprises the following steps of: preparing needle-punched grey cloth through feeding fibers, roughly opening, mixing fibers, fine opening, carding the fibers into a net, crosswise spreading the net and needling by using environmentally friendly colored flame retardant terylene short fibers as a raw material; and then carrying out foam gum dipping in flame retardant polyacrylate foaming rubber latex to obtain the differential fiber non-woven automotive interior trim material, wherein the adhesion quantity of the rubber latex is controlled to be 12-18g / m<2>. The environmentally friendly differential fiber non-woven automotive interior trim material has good property, high quality, environmental protection and high safety; and the preparation method provided by the invention has low energy consumption, no pollution and low cost.

Owner:福建福能南纺卫生材料有限公司

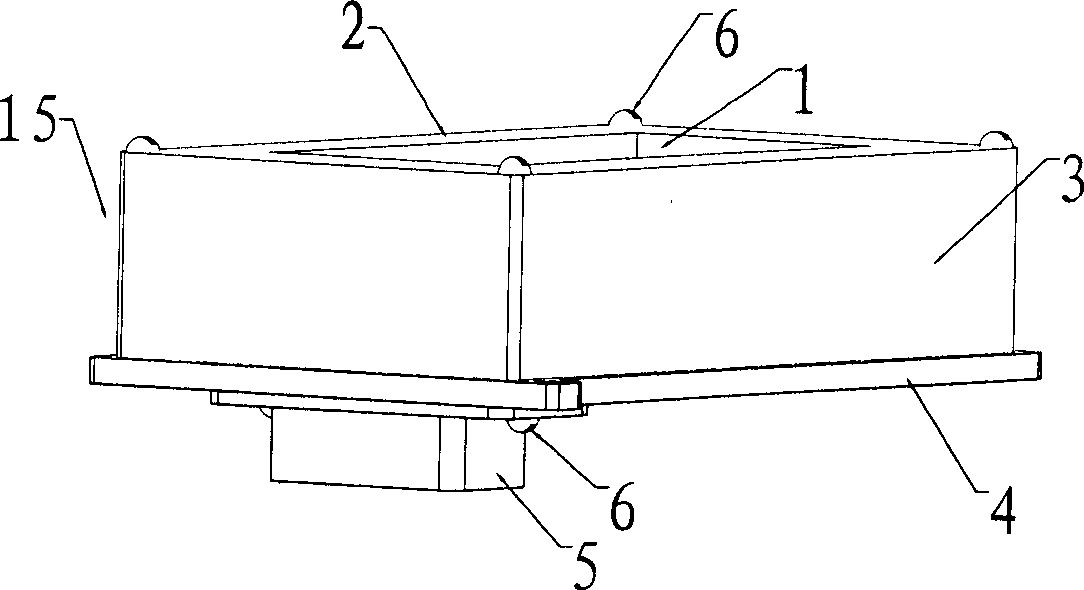

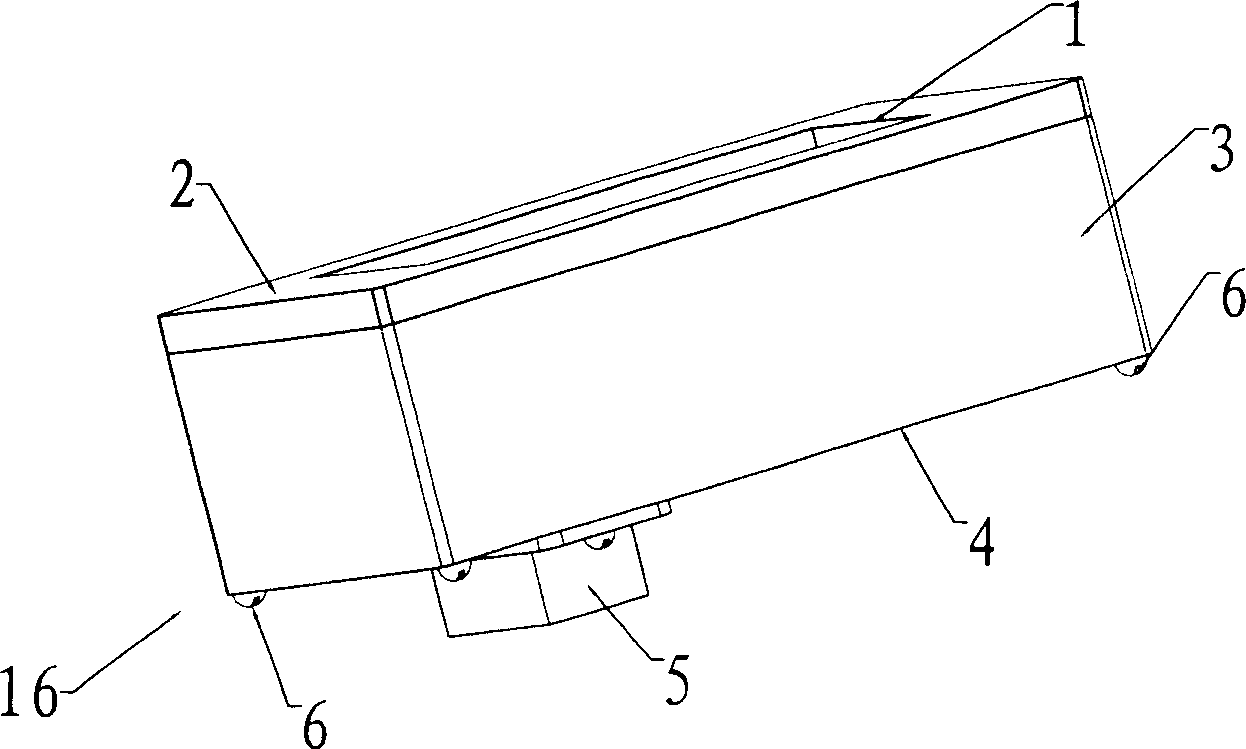

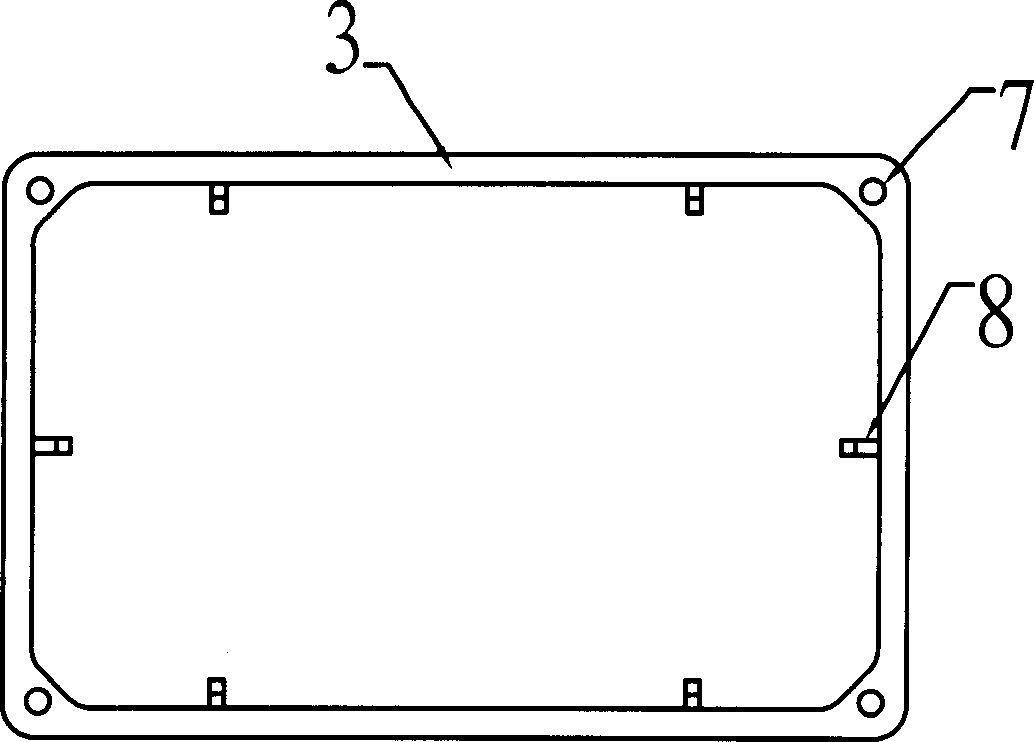

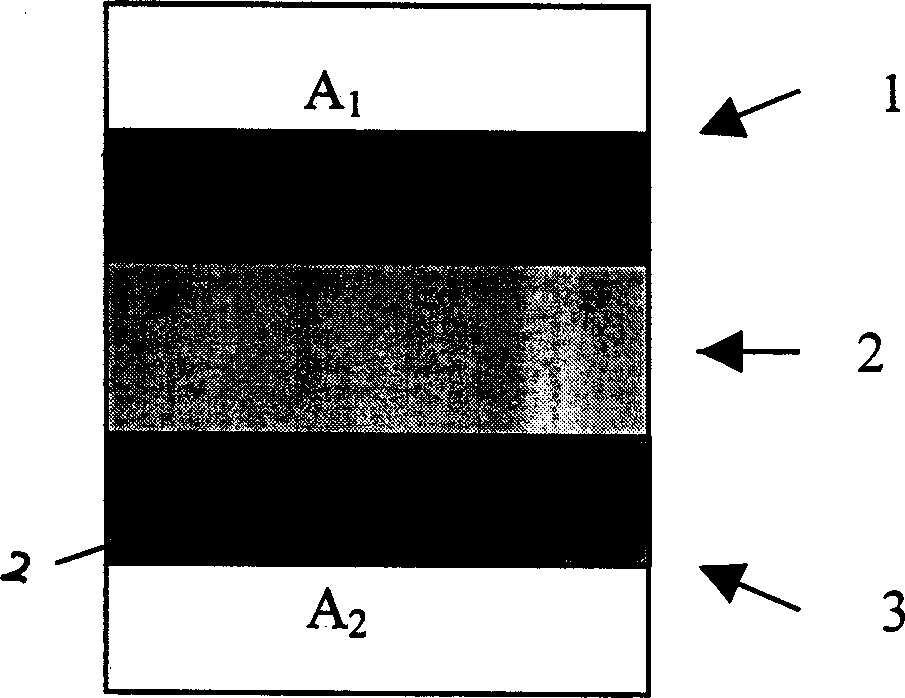

Electromagnetic compatible protector for display device and display device

ActiveCN1901793AImprove anti-staticStrong anti-staticMagnetic/electric field screeningIdentification meansElectricityElectromagnetic interference

This invention relates to an electromagnetic compatible protection device and a display, in which, the protection device is composed of a shell forming a closing structure, a display region is set on the shell, a conductive light transmission material covers on the inside wall of the display region and an electromagnetic wave shield material with conduction function covers the inside wall of the display apart from the display region and an electric connector is set on the shell, a TVS tube or a piezeoresistor is set on the CB apart from the protection device and the control chip is packaged by a ceramic shell.

Owner:BEIJING VISIONOX TECH +1

Transparent metal dielectric composite material

InactiveCN1425555ADelay decayImprove transmittanceOther chemical processesLayered productsDielectricMicrowave

The transparent composite metal dielectric material consists of two inducing layers and one functional layer between the two inducing layers and features that each inducing layer consists of two layers of different transparent dielectric film and the two inducing layers may have different optical thickness. The function layer may have doped inducing layer material to form multiple quantum well structure. By means of multiple reflection and quantum well-like resonant effect, the composite material anti-reflects the electromagnetic wave in required wave band while reflecting electromagnetic waves of other wavelengths. The present invention may be used as windoe material or transparent body material a well as in producing metal semiconductor photoelectronic detector and other relevant device.

Owner:张会琴 +1

Nano-multifunctional washing sheet

ActiveCN102965223ASave waterReduced burden and storage spaceInorganic/elemental detergent compounding agentsSurface-active non-soap compounds and soap mixture detergentsNano zinc oxideActive agent

The invention relates to a nano-multifunctional washing sheet. The washing sheet comprises the following components: a surfactant, nano-carbon dioxide powder, composite powder of nano-zinc oxide and nano-silicon oxide, nano-silver, a washing agent, a bonding agent, a color covering agent, a disintegrating agent, spice, pigments and deionized water. The nano-multifunctional washing sheet disclosed by the invention adopts the nano-powder, so that the traditional washing habit is optimized; natural properties of washings are fully protected; mildewing and pollution of a washing machine are solved; the great waste of water for rinsing is avoided; and the secondary pollution of washing wastewater is thoroughly solved.

Owner:江苏常泰纳米材料有限公司

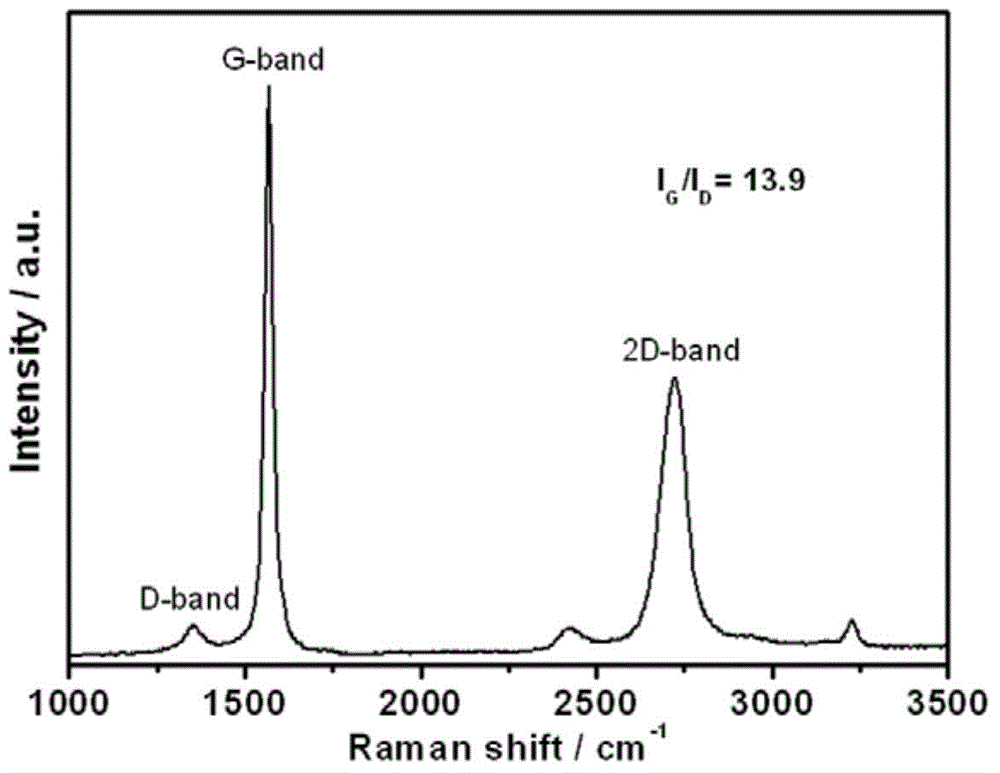

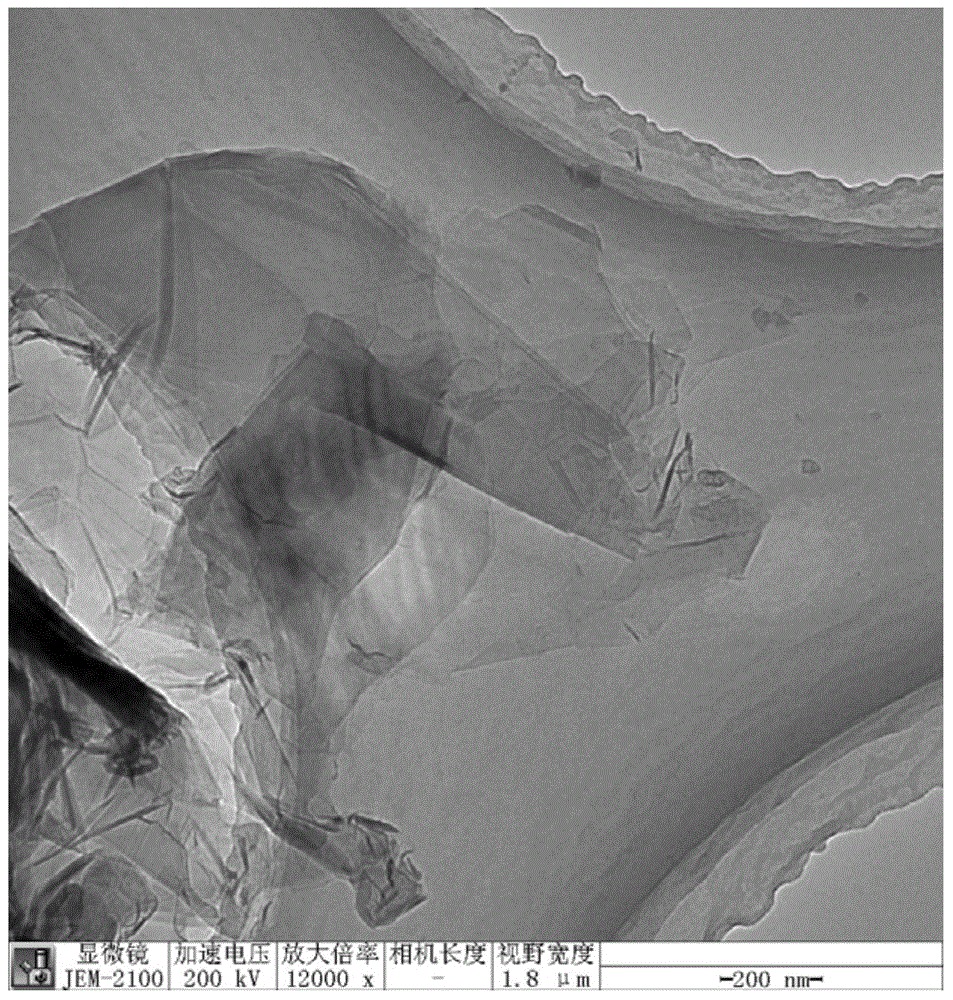

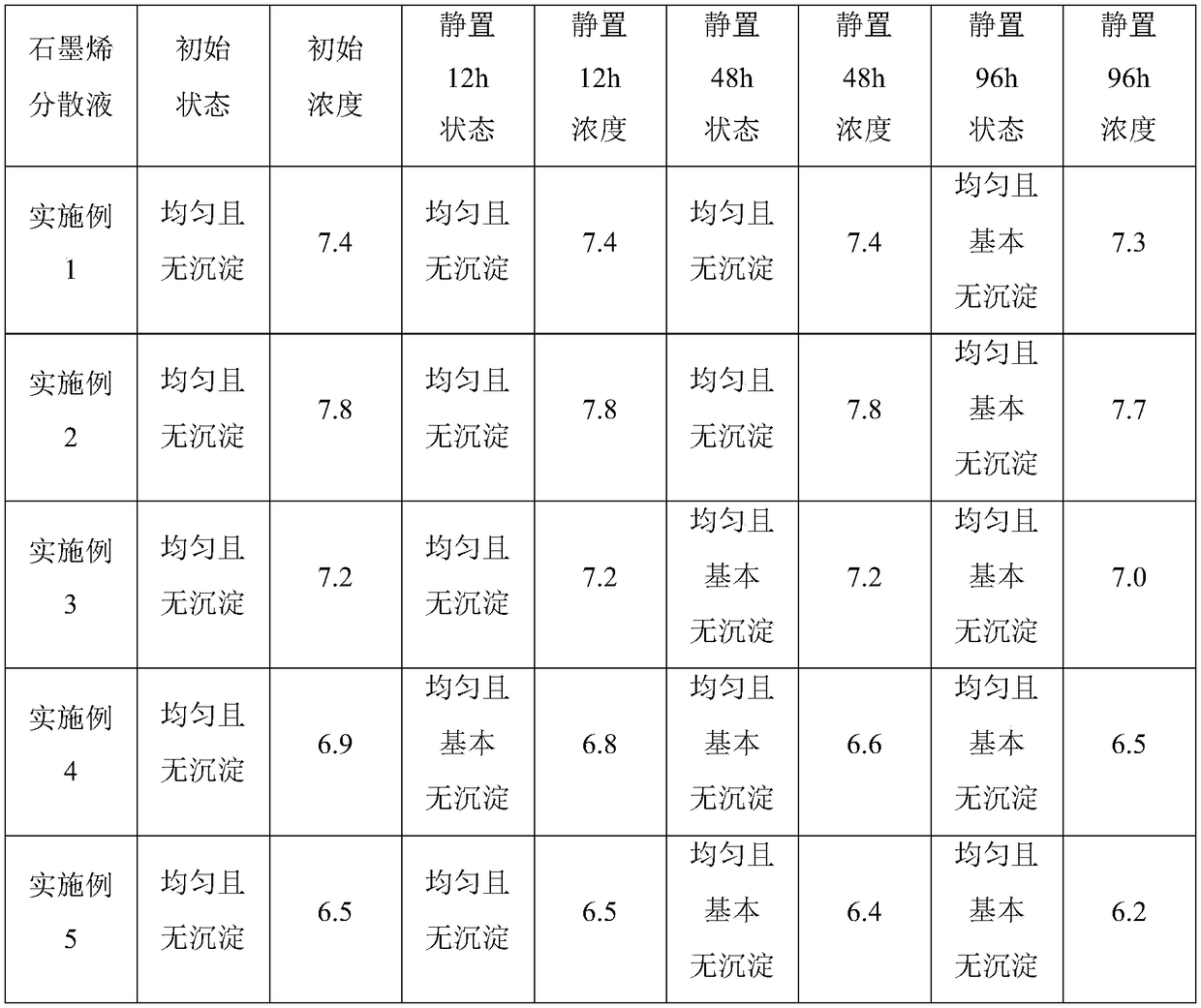

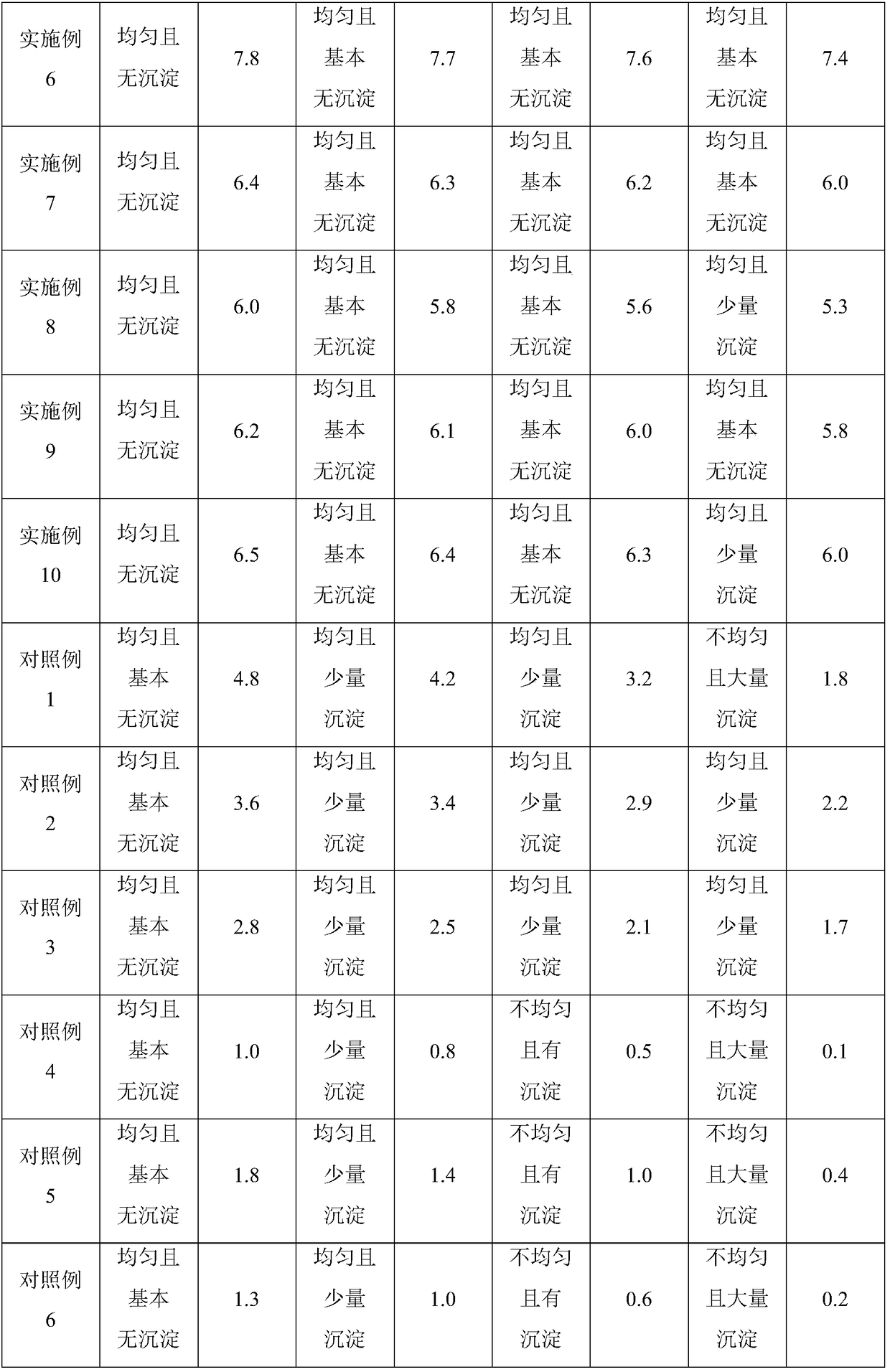

Graphene composite fiber yarn, preparation method and application thereof

ActiveCN109402815AGood spinnability and continuityGood spinnabilityArtificial filaments from viscoseYarnIonYarn

The invention provides a graphene composite fiber yarn and a preparation method and application thereof. The method comprises the steps of dispersing graphene in deionized water to obtain a graphene dispersion; mixing a viscose with the graphene dispersion to obtain a spinning glue; conducting wet spinning on the spinning glue to obtain a graphene composite fiber; conducting spinning on the graphene composite fiber to obtain a graphene composite fiber yarn. The preparation method can prepare the graphene dispersion with high concentration and stable dispersion, the crystal structure of the graphene is complete, the spinnability is good when spinning with the glue, the spinning quality is high, and convenience is provided for the graphene composite fiber yarn to be widely used in the textile field.

Owner:福建祥业生物工程技术有限公司

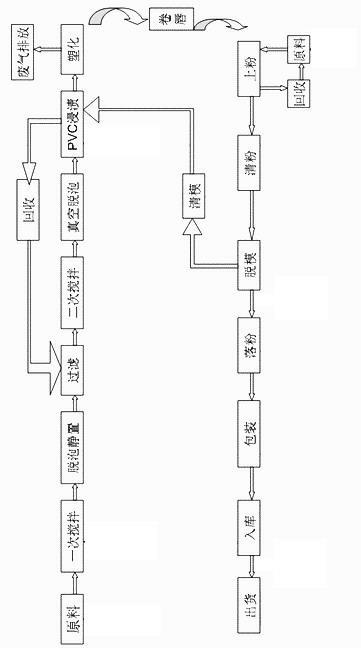

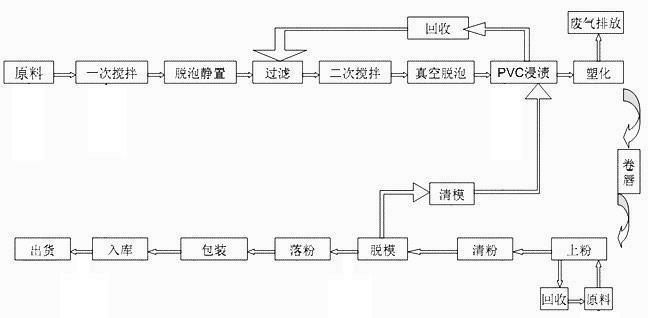

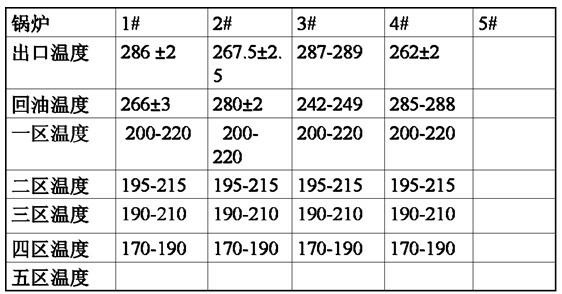

Nutritional skin-care skin-moisturizing powder-containing polyvinyl chloride (PVC) glove and manufacturing method thereof

The invention discloses a manufacturing method of a nutritional skin-care skin-moisturizing powder-containing polyvinyl chloride (PVC) glove, which comprises the following steps: preparing materials, filtering, defoaming under vacuum, immersing, dropping, plasticizing, cooling, rolling edge, preparing powder, adhering powder and demoulding. The method is characterized in that: collagen and vitamin E are added during material preparation; and submicron wall-broken powder of pearl powder, dandelion, witch hazel, aloe, peach blossom and pear blossom is added into corn starch in a powder adhering process. The glove has the advantages of overcoming the drawbacks of the conventional PVC gloves, integrating sanitation, environment protection, safety, nutrition, skin care and skin moisturizing, offering comfortable wear and flexible use experience, avoiding any natural latex components and avoiding causing allergic reaction, along with good nutritional skin-care and skin-moisturizing functions.

Owner:辽宁尚威医疗用品有限公司

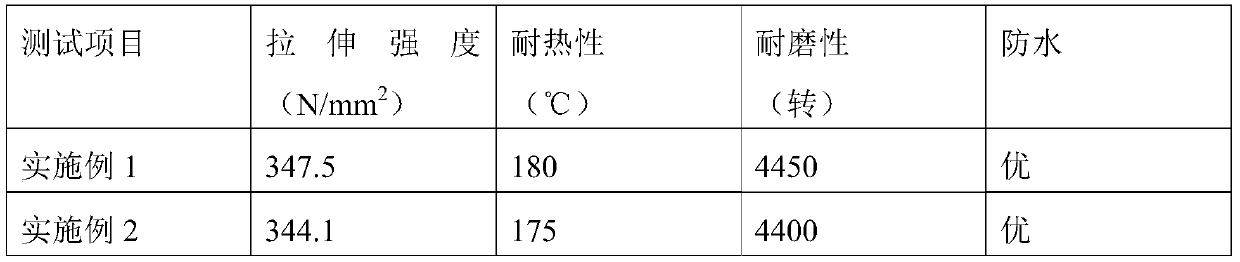

Inorganic nano-material modified polyurethane resin and preparation method thereof

The invention discloses inorganic nano-material modified polyurethane resin. The inorganic nano-material modified polyurethane resin is prepared from components in percentage by weight as follows: 35%-40% of isocyanate, 35%-40% of a polyol compound, 1.5%-6.5% of a chain extender, 15%-20% of a solvent, 2.0%-6.0% of an inorganic nanomaterial, 1.0%-5.0% of a silane coupling agent and 0.01%-0.05% of acatalyst. After polyurethane is modified with an inorganic nano-material, stretch strength of polyurethane resin is enhanced by 30%-40%, tensile strength is improved by 30%-50%, heat resistance is improved by 10%-20%, wear resistance is improved by 20%-30%, and besides, waterproof, moisture-permeable, anti-static and self-cleaning properties of the polyurethane resin are improved.

Owner:广东大盈新材料科技有限公司

Preparation method of conductive plastics master batch containing stainless steel fibers

ActiveCN101840745AElectromagnetic shielding effect hasHas antistatic effectNon-conductive material with dispersed conductive materialCable/conductor manufactureElectromagnetic shieldingStainless steel fiber

The invention discloses a preparation method of a conductive plastics master batch containing stainless steel fibers. The stainless steel fibers in the plastics master batch are isolated by macromolecular materials and completely packed by the macromolecular materials. When the plastics master batch as raw materials is mixed with plastics for secondary granulation or a conductive plastic work-piece is formed, the stainless steel fibers can resist high shear force when the plastics are processed, and are easily and uniformly dispersed in the plastic work-piece and overlap to each other to form a three-dimensional conductive network. By adopting the conductive plastics master batch, the ideal antistatic and electromagnetic screen effects can be achieved under the circumstance of low content of the stainless steel fiber.

Owner:HUNAN HUITONG ADVANCED MATERIALS

Preparation method and application of ecological finishing agent used for cellulose and protein fiber fabrics

InactiveCN103603195AImprove stabilityInhibition of agglomerationVegetal fibresAnimal fibresCelluloseNatural fiber

The invention relates to a preparation method and application of a deacetylated chitosan ecological finishing agent used for finishing natural fibers and regenerated natural fiber fabrics. The invention aims to solve the technical problems of a crosslinking problem, size and uniformity of chitosan acetic acid sol particles and stability of the finishing agent. The method is technically characterized by comprising the following steps: mixing chitosan and lacial acetic acid to form an acetic acid aqueous solution with the acetic acid concentration of 1.5-3 percent, dripping a 10g / L of ion stabilizer agar solution, regulating the size of the chitosan colloid particles to be in a distribution range of 60-100nm, forming a uniform and stable acetic acid-chitosan colloid solution of which the colloid size is in a nanoscale, controlling the pH value to be 4-7, wherein the viscosity of the colloid solution is 2-60mPa.s. The method has good chitosan fixation effect, does not have harmful or chemical residues and is environment-friendly, high-efficiency, harmless to human bodies and rich in raw material source.

Owner:安徽甲特生物科技有限公司

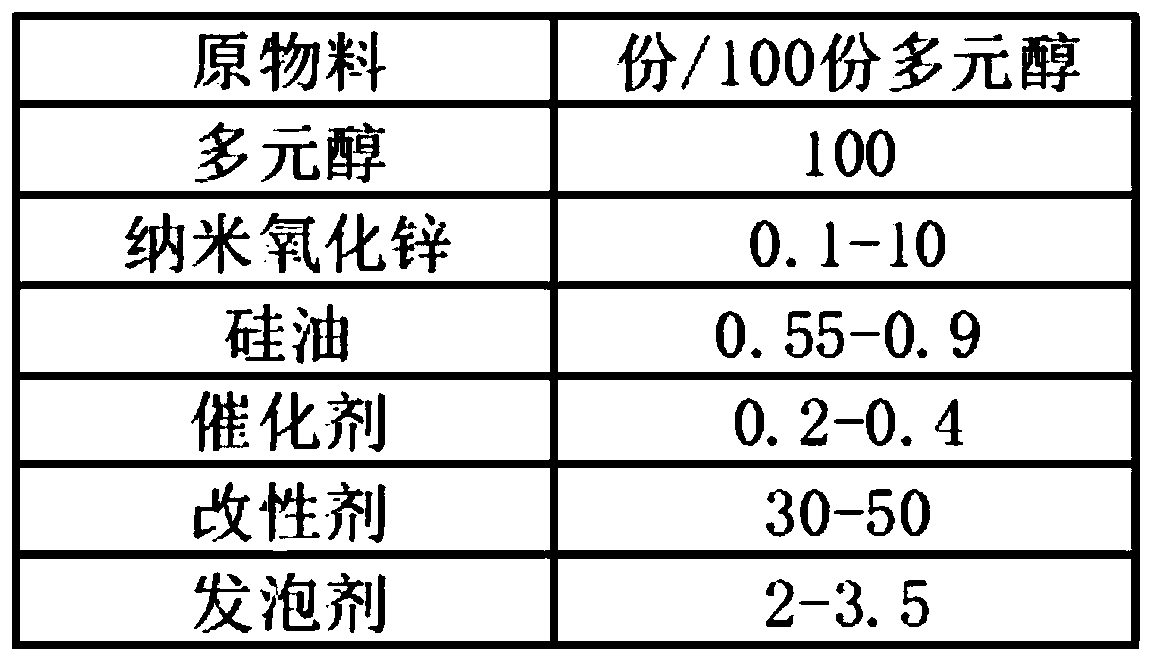

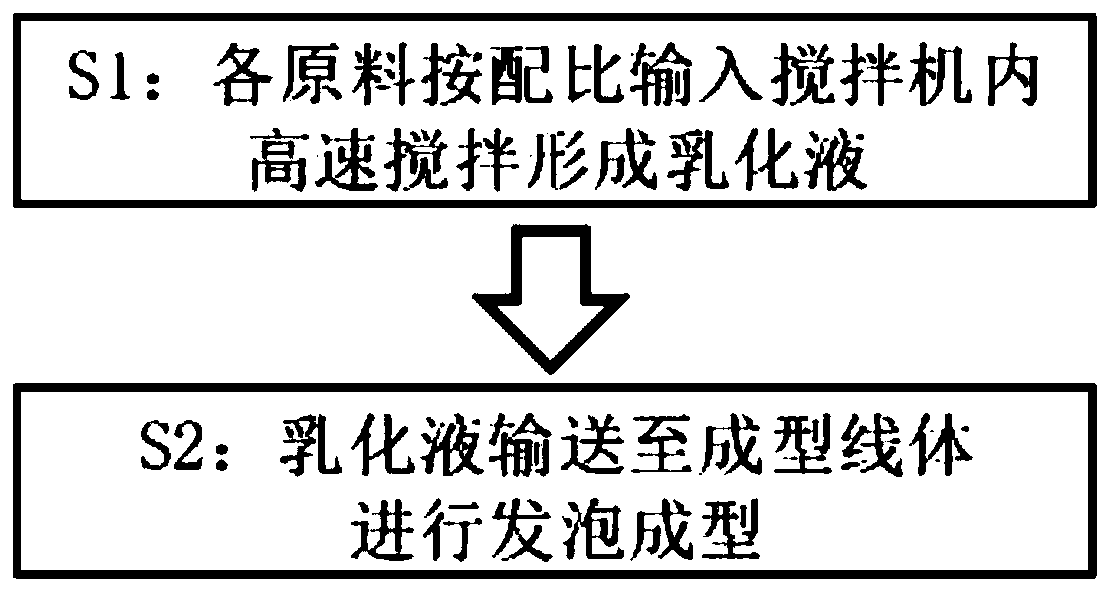

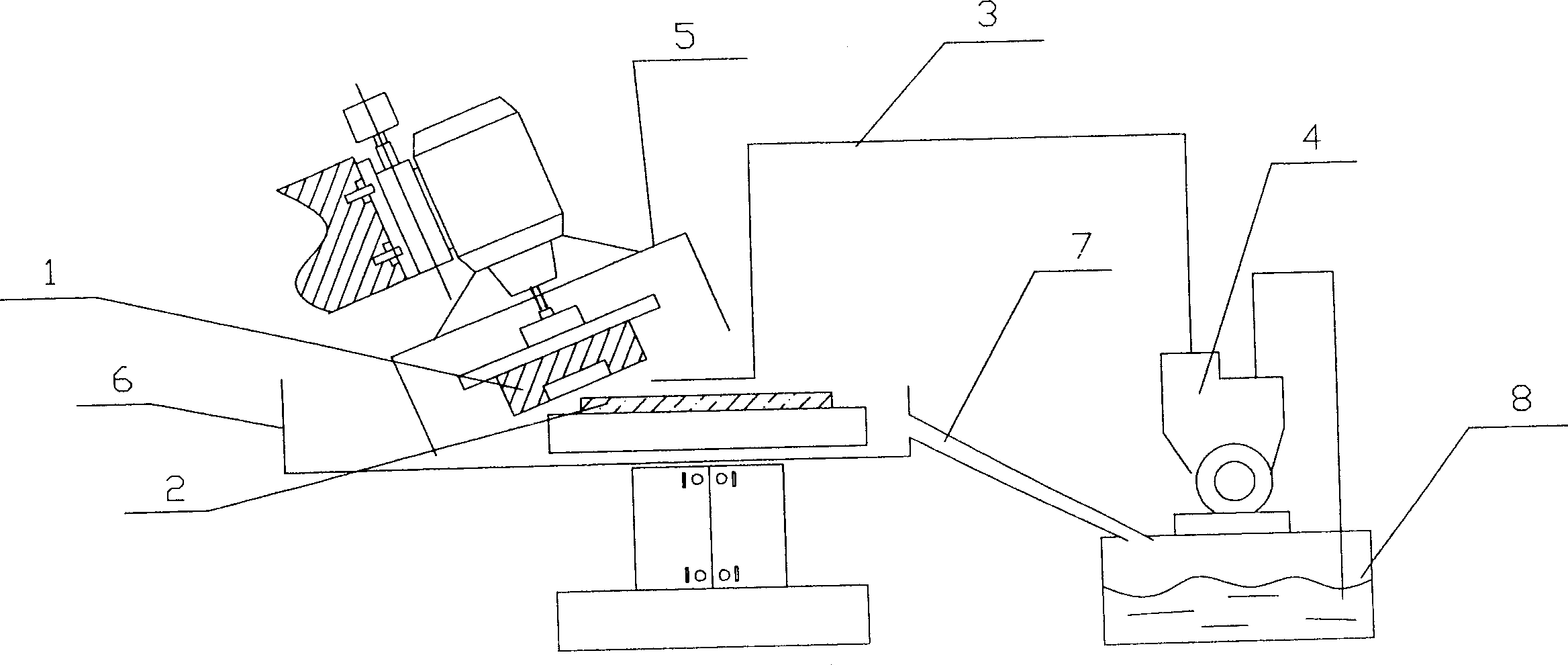

Antibacterial anti-mite sponge and preparation method thereof

The invention discloses a bacteriostatic anti-mite sponge. The bacteriostatic anti-mite sponge is generated by foaming of a mixture comprising the following materials: polyhydric alcohols including polyether polyol, polymer polyol and polyester polyol; and nanometer zinc oxide with a particle size in a range of 1 nanometer to 100 nanometers, wherein 0.1 part to 10 parts of the nanometer zinc oxideis added into every 100 parts by mass of the polyhydric alcohol. According to the invention, the antibacterial zinc oxide is added into an emulsion for producing the sponge, so the breeding of bacteria such as mould can be inhibited, the purpose of blocking mite food chains is achieved, and a sponge product is capable of fundamentally preventing and inhibiting mites; through the combined reactionof various polyols, a catalyst, a modifier and the nanometer zinc oxide, the sponge has the characteristics of excellent insulation, static prevention and dust prevention, and has soft hand feeling.

Owner:东莞市腾崴塑胶制品有限公司

Glass polishing wheel and its preparing method and using method

InactiveCN1748941AGood gripLight fastAbrasion apparatusGrinding/polishing safety devicesScrapCerium oxide

The glass polishing wheel is made with polyurethane, rubber, cerium oxide and assistant, and through mixing and pressing. It is used together with circulating water, and has the advantages of no dust, capacity of recovering waste material, no environmental pollution, high attachment of glass, etc.

Owner:游国力

Antibacterial and anti-static ceramic tile and preparing method thereof

The invention discloses an antibacterial and anti-static ceramic tile and a preparing method thereof. The preparing method includes the following steps of A, ground coat preparing, wherein ground coat is prepared from, by mass, 30%-35% of frits, 2%-8% of a functional agent, 20%-28% of lithium China stone, 5%-10% of silicic acid zirconium, 20%-25% of kaolin and 10%-12% of quartz, the materials are mixed to be even, subjected to wet ball grinding and screened, and the pasty ground coat is obtained; B, overglaze preparing, wherein overglaze is prepared from, by mass, 70%-80% of frits, 1%-5% of conductive powder, 10%-20% of kaolin, 5%-8% of aluminum oxide, 1%-2% of zinc oxide and 1%-5% of zirconium silicate, the mixture is mixed to be even, subjected to wet ball grinding and screened, and the pasty overglaze is obtained; C, the ground coat prepared in the step A and the overglaze prepared in the step B are sequentially glazed to a ceramic tile blank soil, and the ceramic tile is obtained in a sintered mode. Compared with an existing ceramic tile, the ceramic tile prepared with the method is scientific in mixing, reasonable in preparing and stable in performance; the conductive powder, a deodorant and antibacterial powder are reasonably matched, the ceramic tile has the excellent antibacterial, anti-static and air purifying properties accordingly, and the application range of the ceramic tile is further broadened.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

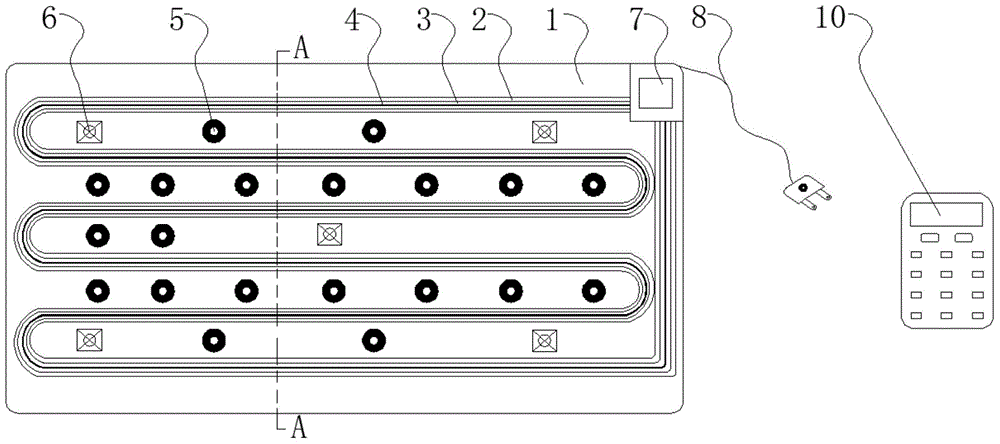

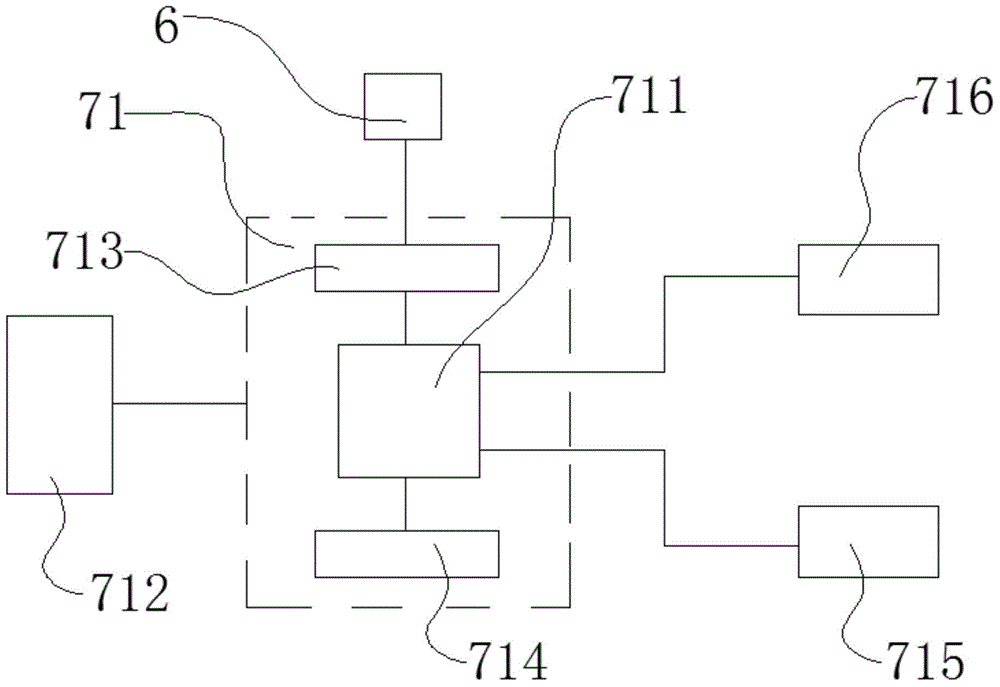

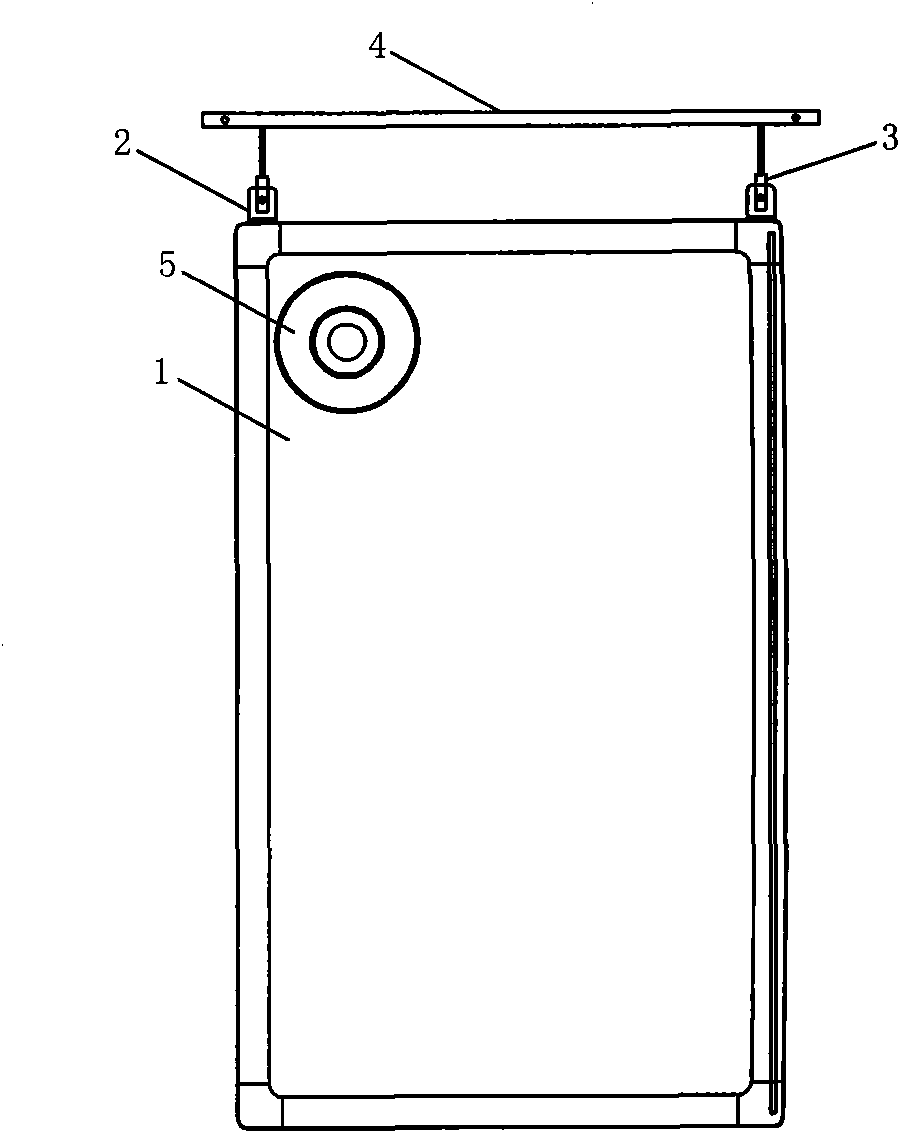

Medical multifunctional health-care electric blanket

InactiveCN104605682AReasonable structural designImprove anti-staticElectrotherapyBlanketTemperature controlComputer module

Owner:天曦医学技术(广州)有限公司

Processing method for screen sealing panel

InactiveCN101835015AExcellent surface hardnessImprove scratch resistanceTelevision system detailsColor television detailsRainbowTransmittance

The invention relates to the technical field of shell frame-free processing of consumable electronic products and provides a processing method for a screen sealing panel. The method comprises the following steps of: (1) designing a clamping process structure; (2) producing an injection molding element; (3) carrying out annealing processing; (4) carrying out hardening processing and static electricity prevention processing; (5) carrying out edge cutting or cleaning procedure; (6) printing the panel by silk and sticking a middle frame; and (7) sticking or installing a decorative strip and assembling and packaging the whole panel. The screen sealing panel created by the invention has more favorable performance, such as surface hardness, scratching prevention, static electricity prevention, light transmittance, no rainbow veins, and the like and can meet the modeling design, production and use of the screen sealing panel of a more complex electronic product; meanwhile, the creating process has low construction difficulty and high yield as well as production cost reduction.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Anion health-care viscose fabric

ActiveCN106087104AImprove spinnabilitySolve defects such as low strength and easy to generate static electricityConjugated cellulose/protein artificial filamentsHeating/cooling textile fabricsYarnMoisture absorption

The invention discloses an anion health-care viscose fabric. The anion health-care viscose fabric is formed by weaving yarns which are formed by blending anion health-care viscose and cotton fibers; a preparation technology of the anion health-care viscose fabric comprises the steps that sodium alginate colloid is prepared; anion powder is added into the sodium alginate colloid, and uniform stirring is conducted, colloid containing the anion powder is obtained; bamboo fibers, taxus chinensis fibers and microporous lignocellulose are added into sodium hydroxide for soaking, CS2 is added, a stirring reaction is conducted, and a viscose solution is obtained; the colloid containing the anion powder is added into the viscose solution to be stirred to be uniform, grinding is conducted, and a viscose mixed solution before spinning is obtained; filtering, defoaming, curing, spinning, desulfurization, water washing, oiling and drying are conducted, and the anion health-care viscose fabric is obtained. The anion health-care viscose fabric has the advantages of being good in skin adaptability, moisture absorption and liberation and air permeability, resistant to bacteria, healthy, green, environmentally friendly and the like.

Owner:江苏华拓纺织科技有限公司

Graphene-organosilicon modified waterborne polyurethane resin

The invention relates to graphene-organosilicon modified waterborne polyurethane resin. The graphene-organosilicon modified waterborne polyurethane resin is prepared from polyisocyanate, polyol, a polyamine chain extender, oligomeric polyol, dimethylolpropionic acid, organosilicon, dibutyltin dilaurate, graphene, acetone, a neutralizing agent and deionized water through a reaction. The invention provides the graphene-organosilicon modified waterborne polyurethane resin and a preparation method thereof. The graphene-organosilicon modified waterborne polyurethane resin prepared by using the method provided by the invention can be prepared into a one-component waterborne coating, a two-component waterborne coating and a normal-temperature curing coating, has good performances like adhesion force, corrosion resistance, water resistance, alkali resistance, wear resistance, electrostatic resistance and high hardness, is extensively applied to ocean fields, iron components, woodware coatings, antistatic coatings, electric-conductive coatings and antifouling and waterproofing coatings, and has great application potentials.

Owner:康伦国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com