Patents

Literature

117results about How to "Ingredients Science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

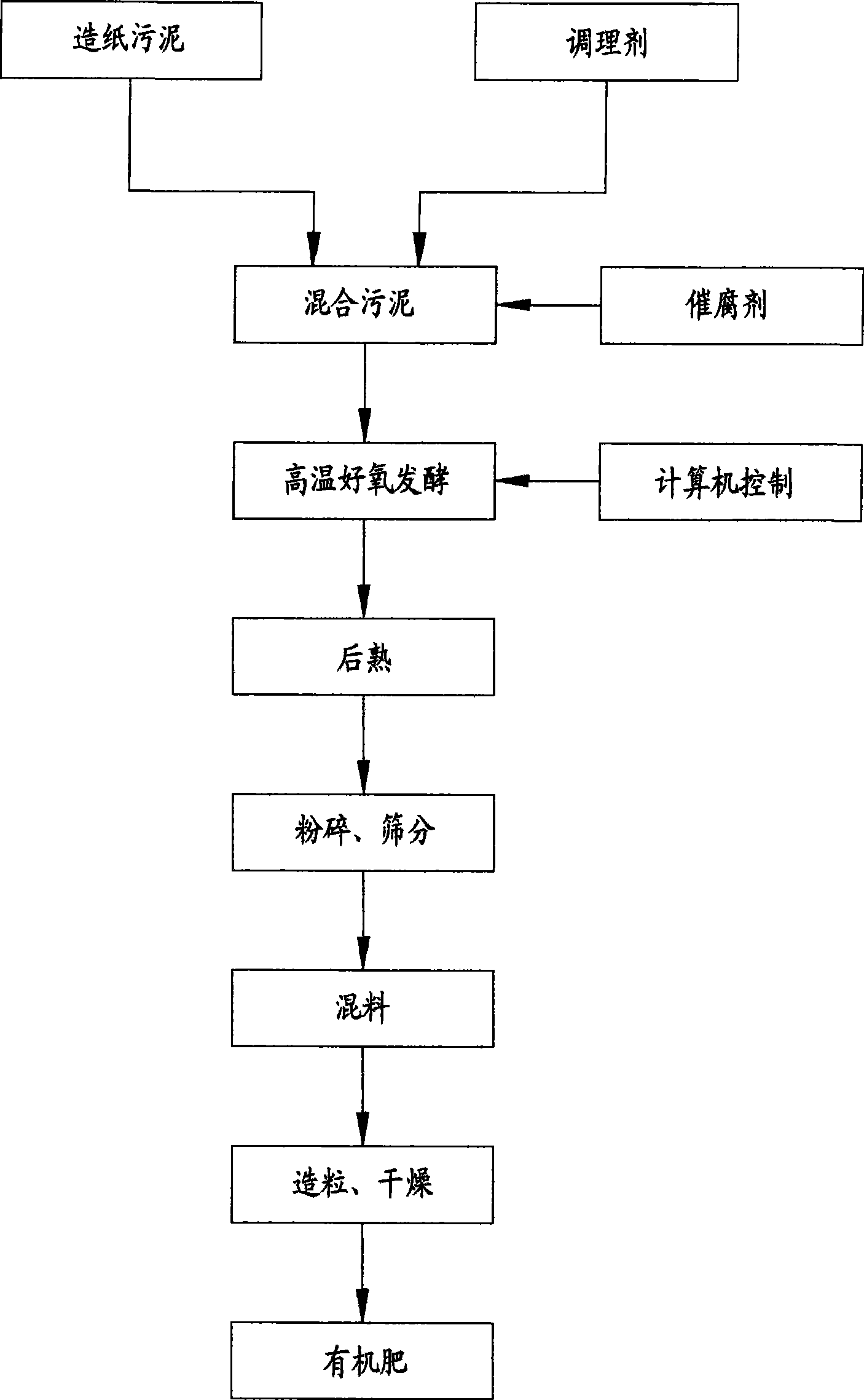

Method for producing fertilizer with papermaking sewage sludge

InactiveCN101429066ARealize comprehensive utilizationSolve processing problemsBio-organic fraction processingOrganic fertiliser preparationSludgePotassium

The invention discloses a method for preparing organic fertilizer from paper-making sludge. The materials such as paper-making sludge, amendment are mixed, subjected to high-temperature aerobic fermentation, post maturation and crushing, screened, and mixed with fertilizer of nitrogen, phosphorus, potassium and the like and medium and micro elements to prepare the organic fertilizer. The method has the advantages of simple process, easy operation, obvious innocuous effect, no environmental pollution and little nutrient loss; and the organic fertilizer prepared by the method is widely applied to industrial crops such as vegetables, fruit trees, Chinese herbal medicines, flowers and field crops such as wheat, corn, paddy rice.

Owner:SHOUGUANG CAILUN ZHONGKE FERTILIZER

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Chinese herbal medicine type green concentrated feed for raising fattening pig

The present invention belongs to the field of feed technology, and is especially one kind of Chinese herbal medicine type green concentrated feed for raising fattening pig. The Chinese herbal medicine type green concentrated feed is compounded with bean dregs 50-77 weight portions, cotton seed dregs 4-16 weight portions, fish meal 2-7 weight portions, yeast 2-11 weight portions, lysine 0.2-0.6 weight portions, rock dust 3-8 weight portions, calcium biphospate 3-9 weight portions, table salt 1.3-1.8 weight portions, 1 % concentration premixed material 2.5-5.0 weight portions, and Chinese herbal material 1.3-2.4 weight portions. It has comprehensive nutritious components, scientific recipe, low production cost and capacity of promoting the growth of pig and raising the pork quality.

Owner:韩思文

Coarse cereal fried flour

ActiveCN101791088AHigh nutritional valuePrevent indigestionFood preparationCamellia oleiferaVegetable oil

The invention discloses coarse cereal fried flour, which adopts five common cereals as raw materials and is prepared with the following raw materials in parts by weight: 6-90 of wheat flour, 5-8 of soybean flour, 5-8 of corn flour, 5-8 of black rice flour, 5-8 of millet flour, 16-20 of vegetable oil, 60-90 of white soft sugar, 1-5 of peanuts, 1-5 of sesame seeds, 1-5 of candied seasoning and 3-10 of shelled melon seeds. The manufacturing method comprises the following steps: respectively filling low-gluten wheat flour of 60-80 meshes, corn flour, black rice flour, millet flour and soybean flour into a frying pan, and frying for 15-20 minutes at the temperature of 160-180 DEG C; peeling baked peanuts, frying sesame seeds and oil-frying molten seeds for preparation; and mixing the fried standby wheat flour and other ingredients according to a proportion, thereby obtaining the coarse cereal fried flour. The manufacturing method has the advantages of scientific mixing proportion and fine processing of coarse cereals, and maintains the specific nutrients and real flavor of the five common cereals. The coarse cereal fried flour is naturally yellow, intensely fragrant and properly sweet, and is a popular food which has rich nutrients and the health care function and is applicable to both the elderly and the young.

Owner:北票市海丰食品有限公司

Green general-purpose cleaning agent

InactiveCN101531954AReduce pollutionImprove protectionInorganic/elemental detergent compounding agentsDetergent solventsGeneral purposeEther

The invention relates to a green general-purpose cleaning agent which is a compound composed by solvent, washing assistant, surface active agent and deionized water. The solvent is a carbonic ether type green solvent, the surface active agent contains at least one or more kinds of AEO, APG and EMS. The cleaning agent is used for cleaning various hard surfaces and is suitable for home cleaning andpublic location cleaning. The cleaning agent has advantages of simple operation, rapid and convenient. The cleaning agent is no-poisonous and no-harm to environment and biology which accords cleaningagent developing current and has better application prospect.

Owner:徐博

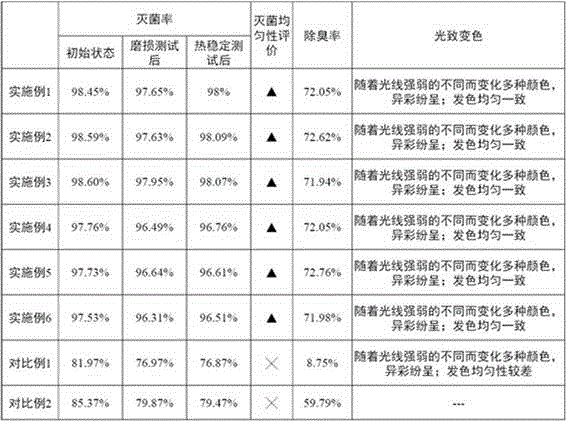

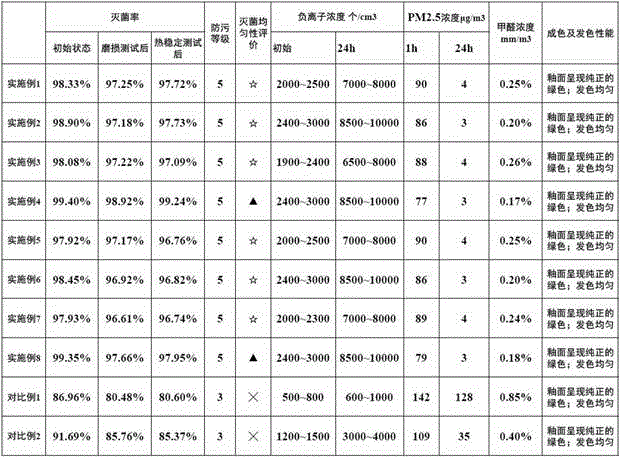

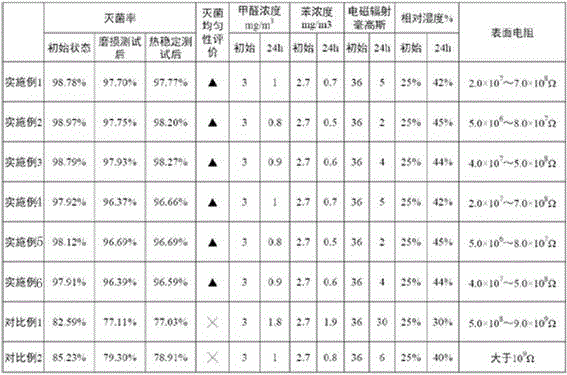

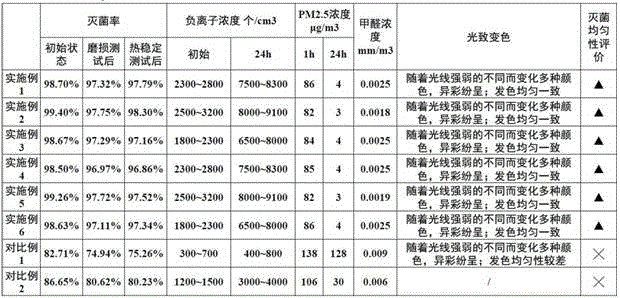

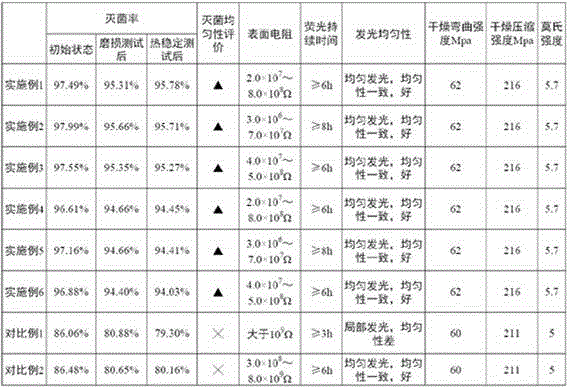

Antibacterial deodorizing ceramic tile and preparation method thereof

InactiveCN106242297AIngredients ScienceReasonable ingredientsDispersed particle separationBrickBall mill

The invention discloses an antibacterial deodorizing ceramic tile and a preparation method thereof. The preparation method comprises the following steps: step A, preparing a ground coat: evenly mixing a frit, a functional agent, a lithium chinastone, zirconium silicate, kaolin and quartz according to mass percent, ball-milling through a wet method, and screening to obtain the pulpous ground coat; step B, preparing a surface glaze: evenly mixing a frit, a deodorant, the kaolin, aluminum oxide, zinc oxide and zirconium silicate, ball-milling through a wet method, and screening to obtain the pulpous surface glaze; step C, sequentially applying the ground coat and the surface glaze prepared in the step A and the step B on a tile clay, and firing to obtain the ceramic tile. Compared with an existing ceramic pile, the ceramic pile prepared through the preparation method is scientific in material collocation, reasonable in preparation and stable in performances; with reasonably allocated photochromic compound, deodorant and antibacterial powder, the ceramic tile has excellent antibacterial performance, air purification performance and photochromic performance, so that the application scope of the ceramic tile is further expanded.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

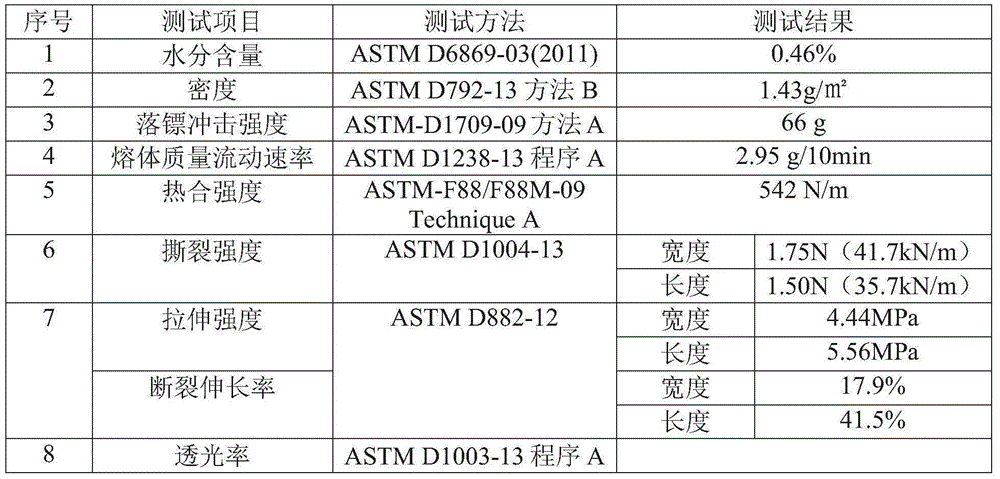

Biodegradable material and preparation method and use thereof

The present invention belongs to the field of polymer materials, and in particular relates to a biodegradable material, a preparation method and use thereof in preparation of a film container. The biodegradable material is prepared from the following components in parts by weight: 5 to 40 parts of polylactic acid, 5-40 parts of inorganic powder, 10-60 parts of PBAT, and 0.2-12.6 parts of an aid. The biodegradable material is prepared from good biodegradable polylactic acid and PBAT recycled materials and second line materials as main components with a large amount of inorganic powder and a plurality of finely-selected additives, physical and chemical modification are performed by mixing, molecular structure modification and self-combination and compounding are performed, and application performance is improved to achieve the characteristics of water resistance, oil resistance, leakage resistance, high impact resistance, strong rigidity, and good flexibility and achieve the performance of traditional plastics, cost is greatly reduced, and the biodegradable material is an ideal alternative of the traditional plastics.

Owner:邓铁军 +1

Rice food and production method thereof

The invention discloses a rice food and a production method thereof. The rice food comprises the following raw material components in part by weight: rice, soy sauce, disodium ribonucleotide, white sugar, garlic powder and the like. The production method comprises the following steps: rinsing, soaking, steaming and refrigerating the rice to form a rice cake; cutting the rice cake, drying, baking,sorting, and seasoning with seasoning liquid; and drying, sorting, metering and packaging finished products, and storing in a finished product warehouse. The puffing degree and mouthfeel of the rice food are greatly improved, so the rice food is more crispy and delicious; and the rice food is particularly added with nutrition elements of calcium, iron and zinc, so the applicable users of the ricefood are widened to the old with weak chewing capacity from the main users of children and the youth, and the leisure food has the function of supplementing the nutrition elements.

Owner:安徽阿幸食品有限公司

Wall-flow type honeycomb ceramic carrier batching and sludge mixing method

ActiveCN101117288AMeet stickinessMeet the bondCatalyst carriersExhaust apparatusMethylcellulose PowderSludge

The invention relates to a proposal of a wall flow type honeycomb ceramics carrier billet ingredient for collection of diesel engine tail gas particles and a mud-stirring method. The steps of the method are as follows: firstly, a mixture power of pure silicon carbide and methylcellulose is stirred evenly, and is poured into a stirring mill and then is stirred to make silicon carbide power and methylcellulose mixed evenly; secondly, the mixture power of the pure silicon carbide and the methylcellulose is stirred for a plurality of minutes, then flour water solution mixed by water and flour is stirred evenly and poured into the stirring mill with stirring, pug is stirred evenly enough after all the flour water solution is poured into the stirring mill; thirdly, tung oil is added into the stirred pug, and is stirred for a plurality of minutes, when the pug can be felted together, the pug is put into a container and is sealed to guarantee that the water in the pug can not be vaporized, and can be kept for a plurality of days before getting musty.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

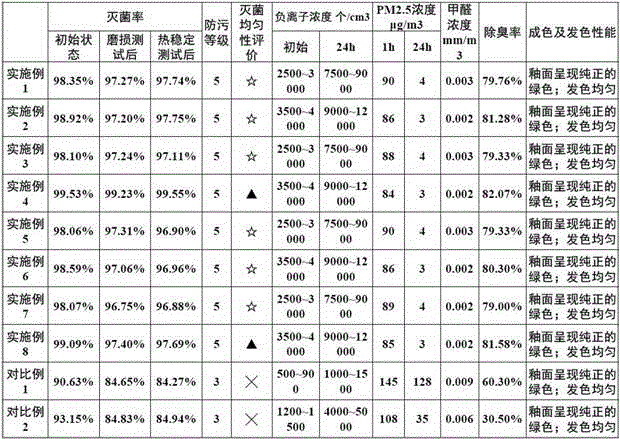

Antibacterial and anti-static ceramic tile and preparing method thereof

The invention discloses an antibacterial and anti-static ceramic tile and a preparing method thereof. The preparing method includes the following steps of A, ground coat preparing, wherein ground coat is prepared from, by mass, 30%-35% of frits, 2%-8% of a functional agent, 20%-28% of lithium China stone, 5%-10% of silicic acid zirconium, 20%-25% of kaolin and 10%-12% of quartz, the materials are mixed to be even, subjected to wet ball grinding and screened, and the pasty ground coat is obtained; B, overglaze preparing, wherein overglaze is prepared from, by mass, 70%-80% of frits, 1%-5% of conductive powder, 10%-20% of kaolin, 5%-8% of aluminum oxide, 1%-2% of zinc oxide and 1%-5% of zirconium silicate, the mixture is mixed to be even, subjected to wet ball grinding and screened, and the pasty overglaze is obtained; C, the ground coat prepared in the step A and the overglaze prepared in the step B are sequentially glazed to a ceramic tile blank soil, and the ceramic tile is obtained in a sintered mode. Compared with an existing ceramic tile, the ceramic tile prepared with the method is scientific in mixing, reasonable in preparing and stable in performance; the conductive powder, a deodorant and antibacterial powder are reasonably matched, the ceramic tile has the excellent antibacterial, anti-static and air purifying properties accordingly, and the application range of the ceramic tile is further broadened.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

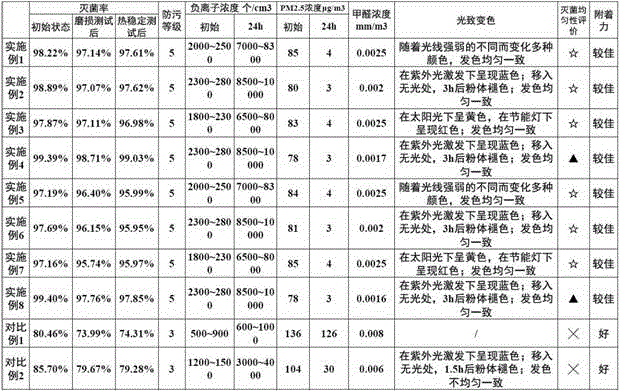

Ecological ceramic tile and preparation method thereof

The invention discloses an ecological ceramic tile and a preparation method thereof. The preparation method comprises the steps of: A, glaze slurry preparation; B, glaze slurry impregnation: impregnating cordierite honeycomb ceramic in the glaze slurry, conducting vacuum pumping, and carrying out pressurized circulation treatment at least 1 time, and then performing first firing at 500-600DEG C; C, glaze slurry spraying: spraying the glaze slurry on the fired honeycomb ceramic surface, and then conducting second firing at 700-800DEG C, thus obtaining the ecological ceramic tile. Compared with existing ceramic tiles, the ceramic tile provided by the invention has the advantages of scientific compounding, reasonable preparation, stable performance, and no lead, cadmium or other extremely toxic substances. Also through reasonable collocation of the photochromic compound, negative ion compound and antibacterial composite material, the ceramic tile has excellent antibacterial, air purification and photochromic characteristics, thus further broadening the application scope of ceramics.

Owner:佛山市高明区诚睿基科技有限公司

Manufacture method of spicy dried radish strips

InactiveCN103404818AKeep active ingredientsScience flavorClimate change adaptationFood preparationSalinityCold storage

The invention discloses a manufacture method of spicy dried radish strips. According to the manufacture method, the spicy dried radish strips are prepared through special brine. The method comprises the following steps: the fibrous roots and leaves of radishes are cut away; the radishes are washed cleanly, cut into blocks and aired; the radish blocks are stored in a refrigerating chamber for reservation; the radish blocks are rinsed with clear water and then cut into strips after being taken out from the refrigerating chamber; the radish strips are poured to the special brine for marinating for 10-12 hours; the marinated radish strips are fished out and drained off; the drained radish strips are mixed with condiments; the mixture is stirred until the mixture is uniform; the radish strips are packaged through a machine; after sterilization, the radish strips can be put on sale. According to the manufacture method, the dried radish strips are prepared through the special brine and the marinating method. In the marinating process, not only is high salinity, which can affect human bodies, lowered but also the effective components of the radishes are reserved. The manufacture method has the advantages that industrialized production is realized, the burdening is scientific, and the dried radish strips are unique in taste, delicious, palatable in salinity, and crispy. The spicy dried radish strips are suitable for serving as food in hotels and homes as well as during traveling.

Owner:JIANGYONG CHARACTERISTIS AGRI & SIDELINE PROD DEV

Low temperature antique glaze with cleaner air effect and preparing method thereof

The invention discloses a low temperature antique glaze with cleaner air effect and preparing method thereof, the preparing method comprises the steps of: A, preparing low temperature frit; B, preparing glaze, mixing low temperature frit, colorant, potassium feldspar, quartz, calcite, talc, calcium phosphate, anion compounds and antibacterial composite to obtain the mixing powder, putting sodium tripolyphosphate and carboxymethyl cellulose into powder and mixing the powder evenly, fine grinding, and then adding water so as to obtain the glaze; C, applying the glaze evenly on the body, and then putting the body into the reducing atmosphere furnace, cooling the natural glaze to room temperature after heat preservation, and the low temperature antique glaze with cleaner air effect is obtained. Compared with the prior antique glaze, the antique glaze produced by the invention has the advantages of scientific ingredients,reasonable preparing method, pure color and stable performance; at the same time with a reasonable combination of negative ions and antibacterial composite materials, the synergistic action of the two making the antique glaze has characteristics of excellent anti-bacterial, anti-fouling and air purification, the scope of the application of the antique glaze is further broaden.

Owner:佛山市高明区诚睿基科技有限公司

Coarse cereal flour nutritional food convenient to eat

InactiveCN106858296ARich in nutrientsImprove immunityFood ingredient functionsPolygonum fagopyrumNutritional status

The invention relates to coarse cereal flour nutritional food convenient to eat, which belongs to the technical field of healthcare food. The product is prepared from 11 raw materials such as buckwheat, oats, millets, sorghum, corns, purple rice, black rice, red beans, green beans, peas and black beans, and the raw materials are selected, impurity separated, crushed, weighed, proportioned, mixed, pulped, cured at a high temperature, regulated in a pot, enzyme deactivated, sterilized, homogenized, spraying dried, finished product selected, and packaged to prepare the coarse cereal flour nutritional food convenient to eat. The coarse cereal flour nutritional food is scientific in material proportioning, advanced in process, rich in vitamins and various trace elements, high in nutritional value, capable of improving the high blood fat, high blood glucose or the nutritional condition of people with imbalance nutrition, and capable of helping sub-health people to be recuperated as soon as possible after being eaten for a long time; and an anti-aging effect can be realized for healthy people after the healthy people eat the coarse cereal flour nutritional food.

Owner:丁强

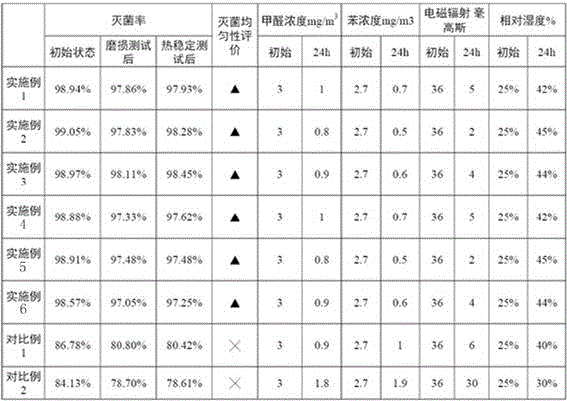

Anti-radiation ceramic tile and preparing method thereof

The invention discloses an anti-radiation ceramic tile and a preparing method thereof. The preparing method includes the following steps of A preparing ground glaze, wherein by mass, 30-35% of frit, 5-10% of functional agent, 20-28% of lithium chinastone, 5-10% of zirconium silicate, 20-25% of kaolin and 10-12% of quartz are mixed uniformly, wet ball grinding is carried out on the mixture, and the slurry ground glaze is obtained after screening; B preparing overglaze, wherein by mass, 70-80% of frit, 3-8% of nanometer bamboo charcoal, 10-20% of kaoline, 5-8% of aluminum oxide, 1-2% of zinc oxide and 1-5% of zirconium silicate are mixed uniformly, wet ball grinding is carried out on the mixture, and the slurry overglaze is obtained after screening; C applying the ground glaze prepared in the step A and the overglaze prepared in the step B on a tile blank, and firing the tile blank to obtain the tile. Compared with the existing ceramic tile, the manufactured ceramic tile is scientific in matching, reasonable in preparation and stable in performance; the ceramic tile has excellent antibacterial, anti-static and anti-radiation performance by reasonably matching conducting powder, nanometer bamboo charcoal and antibacterial powder, and the application range of the ceramic tile is further broadened.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

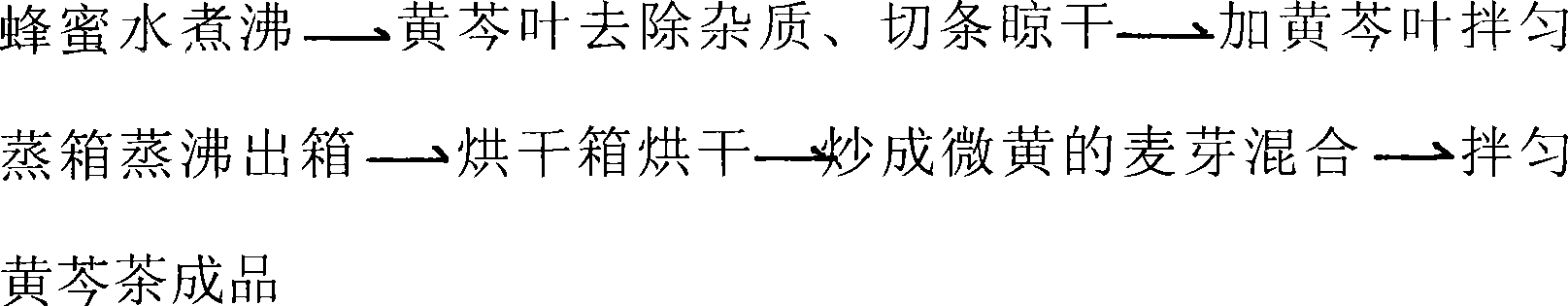

Scutellaria tea and production method thereof

InactiveCN101444301AIngredients ScienceSimple production methodTea substituesFood preparationFlavorAcute hyperglycaemia

The invention discloses a scutellaria tea and a production method thereof. The scutellaria tea comprises three components of scutellaria leaves, honey and malt. The production method is as follows: at first, the impurities of the scutellaria leaves are removed and the scutellaria leaves are cut into strips and air-dried; diluted honey is boiled and then the scutellaria leaves is added and stirred uniformly; then the mixture is arranged in a steam box for boiling and taken out of the box; then the mixture is arranged into a drying box for drying and is mixed uniformly with the malt fried which is fried to be micro-yellow, thus becoming a finished scutellaria tea. The scutellaria tea is scientific in dosage and the production method is simple and easy to operate. The scutellaria tea has excellent nutrition values and functions for controlling diseases and health care. The flavor thereof is abundant and pure; the scutellaria tea has the effects of clearing heat and drying damp, moistening lung and quenching thirst, reinforcing spleen to promote digestion as well as relaxing bowel. The scutellaria tea has better control effect for the diseases like hypertension, hyperlipemia, hyperglycemia, hepatitis, cholecystitis, and the like.

Owner:INNER MONGOLIA MENG QING AGRI TECH DEV CO LTD

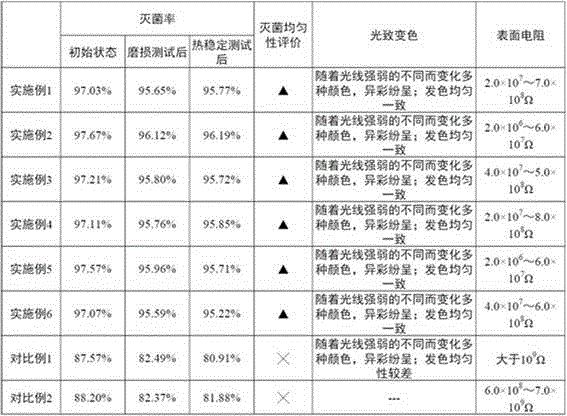

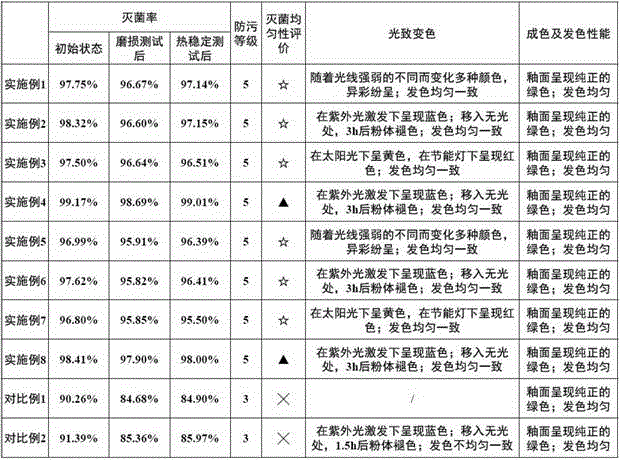

Photochromic ceramic tile and preparation method thereof

The invention discloses a photochromic ceramic tile and a preparation method thereof. The preparation method comprises the steps of: A, preparation of ground glaze: by mass percentage, mixing 30-35% of frit, 3-7% of a functional agent, 20-28% of lithium porcelain stone, 5-10% of zirconium silicate, 20-25% of kaolin and 10-12% of quartz evenly, conducting wet ball-milling, and performing sieving to obtain slurry ground glaze; B, preparation of surface glaze: by mass percentage, mixing 70-80% of frit, 1-4% of conductive powder, 10-20% of kaolin, 5-8% of alumina, 1-2% of zinc oxide and 1-5% of zirconium silicate evenly, performing wet ball-milling, and conducting sieving so as to obtain slurry surface glaze; and C, applying the ground glaze and surface glaze prepared by step A and step B respectively to a tile blank in order, and performing firing so as to obtain the ceramic tile. Compared with the existing ceramic tiles, the ceramic tile prepared by the method provided by the invention has the characteristics of scientific compounding, reasonable preparation and stable performance. Also through reasonable collocation with conductive powder, photochromic compounds and antibacterial powder, the ceramic tile has excellent antibacterial, antistatic and photochromic properties, thus further broadening the application scope of ceramic tiles.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Qishanshaozi noodle soup materials

The invention relates to a kind of Qishan reed noodle soup stock, comprising reed meat bun, tart and delicious flavoring bun, and flavoring vegetable bun, the weight proportion of them is 5-50: 5-50: 2-10.The flvoring vegetable is dewatered and dried, reed meat, tart and delicious bun are boiled, disinfected and packed at high temperature. The product is instant food using boiling water, and is characterized by fast, time saving, abundant nutrition, scientific batching and easy carrying, etc. The preservative period at normal temperature is up to 12 months.

Owner:李伟

Beverage for relieving summer heat and its prepn. method

InactiveCN1792279AGreat tasteIngredients ScienceDrug compositionsPlant ingredientsSummer heatAqueous extract

A beverage for clearing the summer heat is prepared from mung bean, chrysathemum flower, liquorice root, beverage additive and water through proportional mixing, immersing, boiling it for extracting, centrifugal filtering, adding the beverage additive and dispensing.

Owner:吴维罡

Method of producing sodium tungstate solution using scheelite powder as raw material

InactiveCN1455008AIngredients ScienceRaw material adapts to a wide rangeProcess efficiency improvementScheeliteDecomposition

The present invention belongs to a method for producing sodium wolframate solution by using calcium-containing wolfram ore powder, and said method includes the following steps: adding NaOH and P3PO4 into the raw material ore powder WO3 and CaWO4 in low duplication of Ca cotained in the above-mentioned raw material ore powder and a certain quantity of Al2O3 and NaNO3 to make them into slurry material, under the condition of 0.4-0.9 MPa and 140-180 deg.C stirring them and making decomposition treatment for 2-3 hr., filtering, separating and washing residue to obtain the invented product sodium wolframate solution. Said invention is high efficiency and its product quality is good.

Owner:ZIGONG CEMENTED CARBIDE CORP

Photo chromic ceramic glaze and preparation method thereof

InactiveCN106336119AIngredients ScienceReasonably preparedMaterial nanotechnologyGrapheneFritCalcite

The invention discloses a photo chromic ceramic glaze and a preparation method thereof. The preparation method comprises the steps of preparation of photo chromic glaze, glazing, sintering of ceramic glaze, wherein the method for preparing photo chromic glaze comprises the steps of preparing the mixed powder, by mass, mixed with 25-35% of low temperature frit, 30-40% of potash feldspar, 10-20% of quartz, 3-6% of calcite, 3-6% of speck stone, 2-5% of calcium orthophosphate, 1-5% of kaolin, 5-10% of calcined clay, adding the function agent into the mixed powder and uniform mixing. The addition of the function agent is 1-8% of the mass of the mixed powder. The glaze is prepared by fine grinding and water adding, so that the photo chromic ceramic glaze is obtained. Compared with the existing ceramic glaze, the ceramic glaze of the invention has the advantages of scientific ingredients, reasonable preparation, stable performance, without toxic substances such as lead and cadmium. The ceramic glaze also has the advantages of antibacterial properties of uniform persistent spectrum, air purification and photo chromic function, thereby further broadening the scope of application of ceramic glaze.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Acroleic acid polymerization solution and preparation thereof

The invention relates to an acrylic acid polymerized solution used for water-borne flexible and intaglio printing ink and water-borne oil polish and a preparation method thereof. The compositions by weight percentage of the acrylic acid polymerized solution are: 8 to 12 percent of acrylic ester polymer, 2 to 3 percent of ethanolamine, 25 to 30 percent of water, 20 to 30 percent of butyl acrylate, 7 to 10 percent of styrene, 2 to 5 percent of dimethyl ester, 4 to 6 percent of emulsifier, 10 to 12 percent of water, 0.2 to 0.5 percent of initiator and 2 to 8 percent of water. The acrylic acid polymerized solution is prepared by respective mixture and heat treatment of the various compositions according to corresponding proportions. The acrylic acid polymerized solution has high glaze, good film-forming property, good transfer printing property, low glass temperature and low wettability and dispersity on pigment, is compatible with most water-borne ink resins, and has novel compositions, scientific mixture, simple preparation and low cost.

Owner:广东佳景科技股份有限公司

Antistatic bionic quartzite and preparation method thereof

InactiveCN106365516AImprove fire performanceAvoid it happening againWork in processMaterial distribution

The invention discloses antistatic bionic quartzite and a preparation method thereof. The preparation method includes the following steps that firstly, modified resin is prepared; secondly, by weight, 80-90% of quartz, 8-12% of modified resin, 0.01-1% of a curing agent, 0.01-1% of a coupling agent, 3-5% of conductive powder, 1-3% of aluminum hydroxide powder and 0.1-2% of pigment are stirred to be uniform, and a mixture is obtained; thirdly, the mixture is distributed on a mould plate for the first time, vibratory compacting forming, demoulding and cutting are carried out, arrangement is carried out according to a preset pattern to obtain a semi-finished product, material distribution is carried out for the second time, vibratory compacting forming and drying forming are carried out, and then aftertreatment is carried out to obtain a finished product. Compared with existing bionic quartzite, the prepared bionic quartzite is scientific in blending, reasonable in preparation, stable in performance, high in mechanical strength and not prone to deformation or ageing; besides, by reasonably matching conductive powder, a luminous composite and antibacterial powder, the bionic quartzite has excellent antibacterial, luminous and antistatic properties, and the application range of the bionic quartzite is further widened.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Preparation method of copper-based pantograph slide plate blank

InactiveCN107584123AEvenly distributedImprove friction and wear performanceTurbinesOther manufacturing equipments/toolsAbrasive agentGraphite

The invention discloses a preparation method of a copper-based pantograph slide plate blank. The method includes the steps that powder mixing is conducted on 5-15 % by mass of Sn, 1-5% by mass of Bi,0-5% by mass of Cr, 0%-8% by mass of Mo2C, 0-8% by mass of WC, 1-10% by mass of graphite, 0.1-0.8% by mass of P, 0-5% by mass of MoS2, 0.2-0.8% by mass of powder lubricant and the balance of Cu, and forming, sintering, re-pressing and re-sintering are conducted on mixed powder in sequence to obtain the copper-based pantograph slide plate blank. According to the method, primary sintering, re-pressing and re-sintering are conducted on a green body, so that combination between the anti-abrasive agent, namely, the graphite and a matrix is further enhanced; moreover, the reinforcement elements of Cr, WC and Mo2C and the low-melting-point anti-abrasive component Bi are added into the ingredient, so that the frictional wear performance of a slide plate is further improved; the method has the advantages that the technology is simple, operation is convenient, and the cost is low; meanwhile, pollution of the environment is low, and mass production is available.

Owner:NBTM NEW MATERIALS GRP

Barley almond dairy product and preparation method thereof

InactiveCN101715827AIngredients ScienceRegulate acid-base balanceMilk preparationDiseaseCoronary heart disease

The invention discloses a barley almond dairy product and a preparation method thereof. The barley almond dairy product is prepared into the dairy product by using barley bud powder, almond, milk and the like as main raw materials, adding partial auxiliary materials, scientifically mixing the materials, homogenizing under high pressure and instantly sterilizing. The barley almond dairy product can regulate acid-base balance of human bodies, relax bowels, eliminate fire, expel toxin, and maintain metabolic balance of the human bodies. The barley almond dairy product can prevent 'three diseases' such as hypertension, high fat and high cholesterol and has the effects of preventing and curing coronary heart diseases and atherosis.

Antibacterial radiation-proof ceramic tile and preparation method thereof

The invention discloses an antibacterial radiation-proof ceramic tile and a preparation method thereof. The preparation method comprises the steps of: A, preparing ground glaze: by mass percentage: mixing 30-35% of frit, 1-6% of antibacterial powder, 20-28% of lithium chinastone, 5-10% of zirconium silicate, 20-25% of kaolin and 10-12% of quartz evenly, conducting wet ball milling, and performing sieving to obtain pulp ground glaze; B, preparing surface glaze: by mass percentage, mixing 70-80% of frit, 1-5% of nano bamboo charcoal, 10-20% of kaolin, 5-8% of alumina, 1-2% of zinc oxide and 1-5% of zirconium silicate evenly, conducting wet ball milling, and then performing sieving to obtain pulp surface glaze; and C, applying the ground glaze and the surface glaze obtained in step A and step B to a tile blank in order, and performing firing to obtain the ceramic tile. Compared with the existing ceramic tiles, the ceramic tile prepared by the method provided by the invention has the advantages of scientific compounding, reasonable preparation, and stable performance. Also through reasonable collocation of nano bamboo charcoal and the antibacterial powder, the two play a synergistic role and endow the ceramic tile with excellent antibacterial, radiation-proof and air purification performance, thus further broadening the application scope of the ceramic tile.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Coarse grain powder nutritious food capable of being conveniently eaten

InactiveCN107751789AImprove human immunityProduct ingredient scienceFood ingredient functionsHigh cholesterolPopulation

The invention discloses a coarse grain powder nutritious food capable of being conveniently eaten and belongs to the technical field of health foods. The product is made by the following steps: takingthe following eleven grains as raw materials: buckwheat, oat, millet, sorghum, corn, purple rice, black rice, phaseolus anagularis, mung beans, peas and black beans, screening the raw materials to remove impurities, grinding, weighing, proportioning and mixing, pulping, high-temperature curing, size-mixing in a kettle, performing enzyme inactivation, sterilizing, homogenizing, spray drying, screening the finished product, and packaging, thereby obtaining the coarse grain powder nutritious food capable of being conveniently eaten. The coarse grain powder nutritious food disclosed by the invention is scientific in ingredients, advanced in process, enriched in vitamins and various trace elements and high in nutritive value, can well improve the nutritional status of crowds suffering from hyperlipidemia and hyperglycemia or nutritional imbalance, can help sub-health population to restore health as fast as possible when eaten for a long time, and achieves an anti-aging effect when eaten byhealthy people for a long time.

Owner:WEIHAI HONGYIN FOOD TECH CO LTD

Method for photochromic low temperature antique glaze and preparing method thereof

The invention discloses a photochromic low temperature antique glaze and a preparing method thereof. The preparing method comprises the steps of: A, preparing low temperature frit; B, preparing glaze, mixing low temperature frit, colorant, potassium feldspar, quartz, calcite, talc, calcium phosphate, photochromic compounds and antibacterial composite to obtain the mixing powder, putting sodium tripolyphosphate and carboxymethyl cellulose into powder and mixing the powder evenly, fine grinding, and then adding water so as to obtain the glaze; C, applying the glaze evenly on the body, and then putting the body into the reducing atmosphere furnace, cooling the natural glaze to room temperature after heat preservation, and the photochromic low temperature antique glaze is obtained. Compared with the prior antique glaze, the method has the advantages that the ingredients are scientific, the preparing method is reasonable.

Owner:佛山市高明区诚睿基科技有限公司

Low-temperature archaized glaze and preparation method thereof

The invention discloses low-temperature archaized glaze and a preparation method thereof. The preparation method comprises the following steps: Step A, preparing a low-temperature frit; Step B, preparing glaze slip: mixing the low-temperature frit, a colouring agent, potash feldspar, quartz, calcite, talcum, calcium phosphate, a deodorant, a negative ion compound and an antibacterial compound to obtain mixed powder, adding sodium tripolyphosphate and carboxymethyl cellulose into the mixed powder and uniformly mixing, grinding, and adding water to obtain the glaze slip; and Step C, uniformly applying the glaze slip onto a green body, putting the green body into a reducing atmosphere furnace, carrying out thermal insulation and naturally cooling to room temperature so as to obtain the low-temperature archaized glaze. In comparison with existing archaized glaze, the manufactured archaized glaze in the invention has advantages of scientific batching, reasonable preparation, pure color and stable performance. Through reasonable cooperation of the deodorant, the negative ion compound and the antibacterial composite material, the archaized glaze has excellent antibacterial antifouling and air purification characteristics. According to the invention, the application range of the archaized glaze is further widened.

Owner:佛山市高明区诚睿基科技有限公司

Donkey hide gelatin powder nutritious food capable of being eaten conveniently

InactiveCN106901353ARich in nutrientsImprove immunityFood ingredient functionsAdditive ingredientPuerarin

The invention provides a donkey hide gelatin powder nutritious food capable of being eaten conveniently, and belongs to the technical field of health-care foods. The donkey hide gelatin powder nutritious food is prepared by taking donkey hide gelatin powder as a main raw material and scientifically combining adjuvant materials of red date powder, longan powder, fructus lycii powder, yam flour, poria cocos powder and puerarin powder. The donkey hide gelatin powder nutritious food is prepared by the following processes: weighing and mixing of all ingredients, enzyme deactivation, sterilization, homogeneity, drying, packaging and the like. The donkey hide gelatin powder nutritious food is scientific in ingredients matching, advanced in the processes, abundant in vitamins and various microelements and high in the nutritional value in blood replenishing, patients with hemorrhage and anemia can be well nourished, and a patient can be recuperated as soon as possible after the donkey hide gelatin powder nutritious food is eaten for a long time; additionally, the donkey hide gelatin powder nutritious food has a function of anti-aging after being eaten by healthy people for a long time.

Owner:丁强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com