Patents

Literature

141 results about "China stone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

China stone is a medium grained, feldspar-rich partially kaolinised granite characterized by the absence of iron-bearing minerals. It is mainly used for making porcelain, hence the name, and coatings for paper.

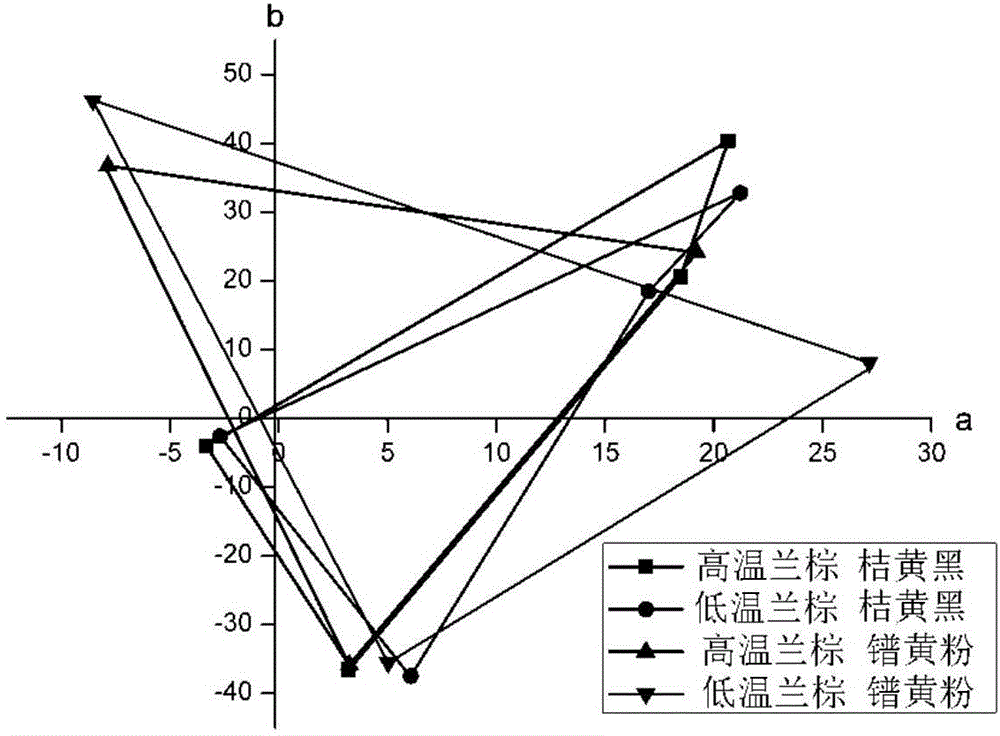

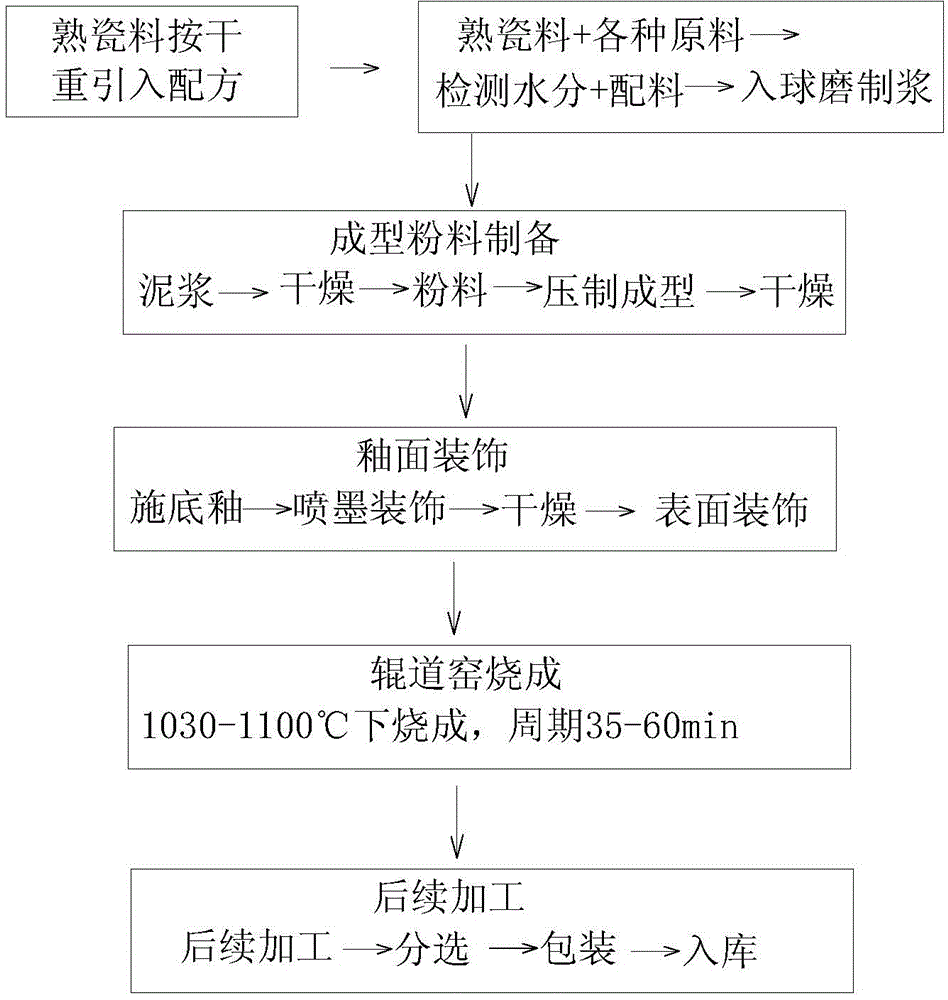

Wide-color-gamut inkjet glaze decorated ceramic floor tile and production process thereof

The invention relates to the technical field of ceramic tiles, and in particular relates to a wide-color-gamut inkjet glaze decorated ceramic floor tile and a production process thereof. A floor tile billet comprises the following components in parts by weight: 40-75 parts of a cooked porcelain material, 0-38 parts of porcelain stone, 20-30 parts of clay and 0-5 parts of a mineralizing agent; and a production method comprises the following steps: firstly performing conventional processes such as wet-process ball-milling, spray drying and dry-pressing molding on architectural ceramics to prepare a billet, by taking titanium series engobe as a ground glaze, combining engobe with a low-temperature ink-jet ink composition of interior wall tiles to perform inkjet decoration, and performing firing in a roller hearth kiln under the conditions that the firing temperature is 1030-1100 DEG C and the firing cycle is 35-60min to prepare a finished product, wherein the water absorption rate of the finished product is 0-3%, and the quality of the product can meet the national standard requirements. The wide-color-gamut inkjet glaze decorated ceramic floor tile disclosed by the invention has the beneficial effects that energy conservation and emission reduction can be achieved, and the firing temperature can be reduced by 50-100 DEG C compared with that of the same category of products; the technology bottleneck that titanium series opacified engobe can be yellowed when being applied in the floor tiles in a conventional high-temperature process can be effectively solved; and the color gamut range of an inkjet decorative layer of a glaze decorated ceramic tile can be significantly broadened.

Owner:JIANGXI HEMEI CERAMICS +1

Preparation of iron tailing based light heat-preservation foamed ceramic material

InactiveCN106588081ASolve the pollution of the environmentImprove mechanical propertiesCeramic materials productionCeramicwareFoaming agentEconomic benefits

The invention discloses preparation of an iron tailing based light heat-preservation foamed ceramic material. The iron tailing based light heat-preservation foamed ceramic material is prepared from the following components in parts by weight: 30-70wt% of iron tailings, 10-15wt% of chinastone, 5-20wt% of feldspar, 5-20wt% of clay, 5-10wt% of a foaming agent, 0.5-2.3wt% of an additive foaming agent and 0.5-1wt% of an additive grinding aid. The iron tailing based light heat-preservation foamed ceramic material disclosed by the invention has relatively low heat conduction coefficients and relatively good mechanical properties, the raw material cost can be lowered, the economic benefits of companies can be increased, and comprehensive utilization of resources can be achieved.

Owner:UNIV OF JINAN

Low temperature semi-porcelain and its preparation method

The invention relates to a low-temperature semi-ceramic, which comprises: 50-65% clay of Al2O32SiO22H2O, 0-10% fine ceramic waste, 3-20% lithium China stone, 3-25% diopside, 5-20% talc, and 0-15% feldspar. Wherein, breaking the hard material, removing impurity; preparing material according to said weight share; grinding material, ball stone and water as proportion of 1:1.8-2:0.8 for 18-20h; screening off iron from 250 items sieve with residue under 0.2wt%; pressure filtering, forming; colored drawing on blank; glazing; finally, using low-temperature one-time calcination technique at 1020-1030Deg with oxidation atmosphere for 5-6h. This invention has well property, and decreases greatly energy consumption.

Owner:揭阳恒成陶瓷科技有限公司

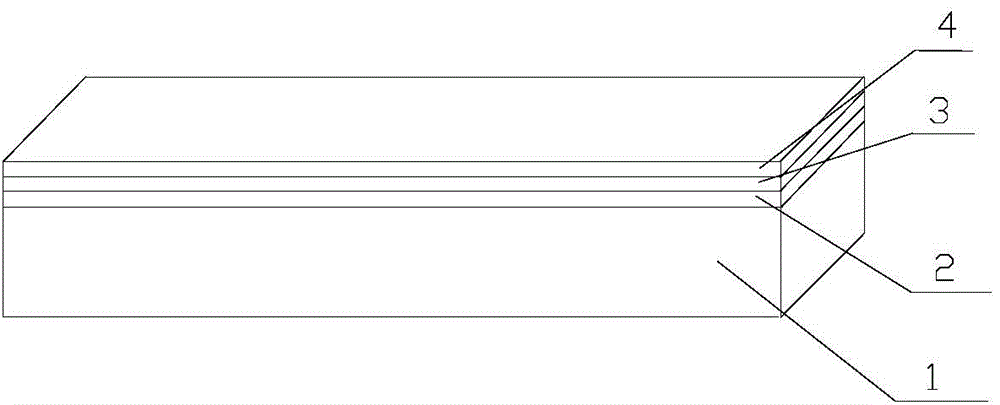

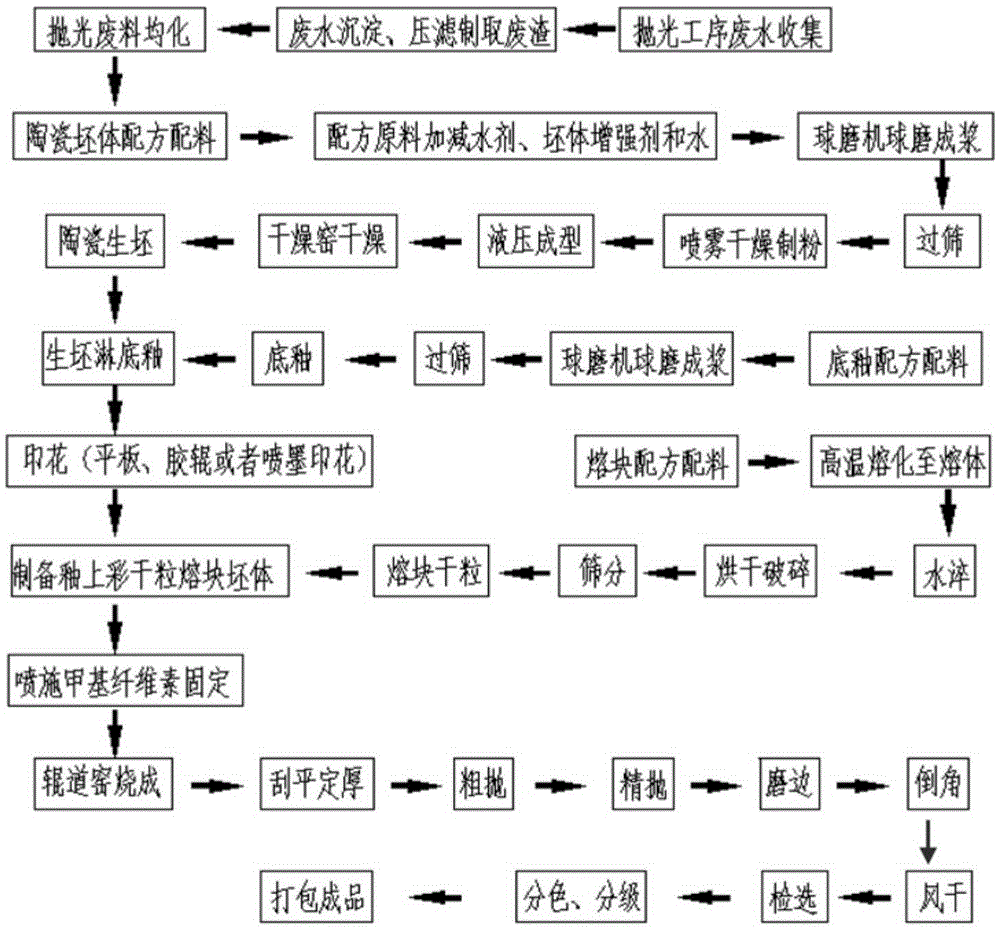

Single-fired glass ceramic composite brick and production method thereof

ActiveCN105272160AAvoid foamingAchieve recyclingCeramic materials productionClaywaresBrickChina stone

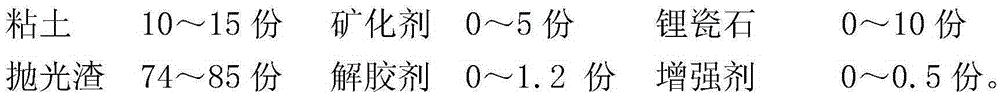

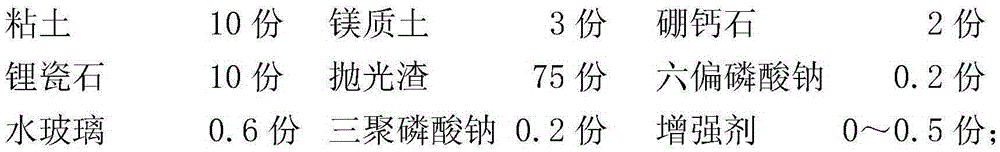

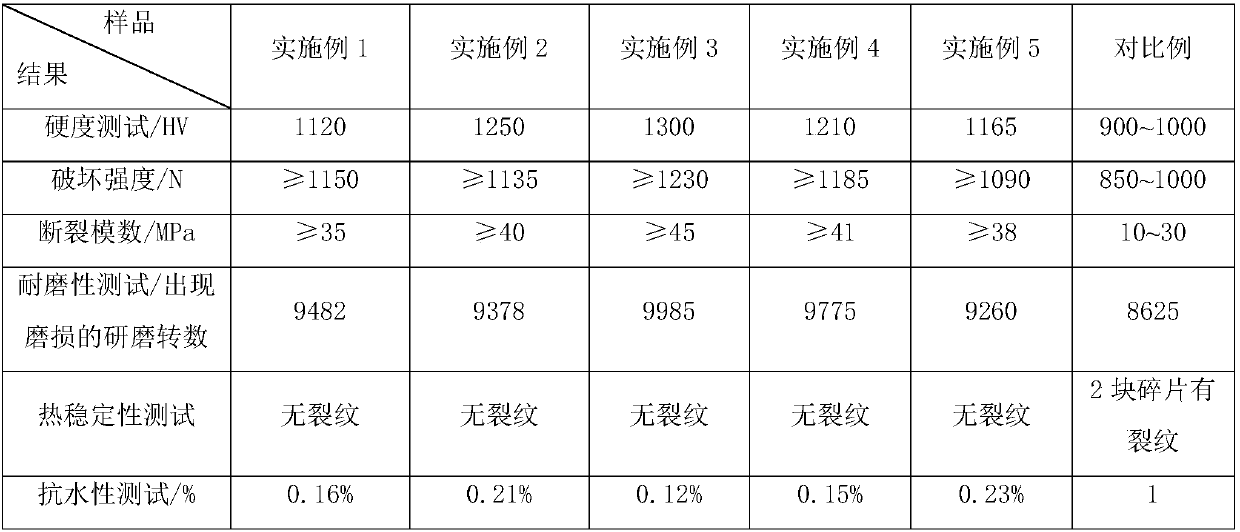

The invention relates to a single-fired glass ceramic composite brick and a production method. A blank of the ceramic brick is prepared from, by weight, 10-15 parts of clay, 0-5 parts of mineralizing agents, 0-10 parts of lithium china stones, 74-85 parts of tile-polished waste, 0-1.2 parts of peptizers and 0-0.5 part of reinforcing agents. The production method comprises the steps that the blank is processed through procedures of wet ball milling and spray drying and then processed through dry pressing to prepare a ceramic green blank; 2, the ceramic green blank is coated with a ground glaze after being dried and decorated through printing to form an overglazed color blank, and then microcrystalline glass frit dry grains are coated on the overglazed color blank to form a dry grain layer; 3, methylcellulose is sprayed and fixed on the surface of the dry grain layer, then the blank is put into a roller kiln to be fired, the firing temperature is set at 1000 DEG C-1048 DEG C, the firing time is set for 65-150 minutes, and a semi-finished product is prepared; 4, the semi-finished product out of the kiln is prepared into a finished produce after being processed through strickling for thickness fixation, rough polishing, fine polishing, edging, chamfering, air drying, inspecting and sorting, color separating and grading.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

Archaized bricks produced by using polished brick factory waste materials and preparation method thereof

InactiveCN103044009AImprove surface wear resistanceExtended service lifeCeramic materials productionClaywaresEnvironmental resistanceBreaking strength

The invention discloses archaized bricks produced by using polished brick factory waste materials. The bricks comprise the following components in part by weight: 8 to 10 parts of polished brick waste materials, 10 to 12 parts of raw materials for blanks, 0.04 to 1 part of raw materials for glazes and 10 to 15 parts of water, wherein the raw materials for the blanks are one of clay, quartz and chinastone or combinations thereof. The bricks have the benefits that the water absorptivity is about 1-3 percent, the breaking strength can achieve 2,050 N, the surface wear resistance is high, grinding marks are visible by level 4 and 2,100 r, and the service life is long; and at the same time, as the archaized bricks are produced by using the polished brick factory waste materials, the wastes are turned into the wealth, and the environment-friendly industrial production and the sustainable development can be achieved.

Owner:李建顺

Wear-resistant and high-hardness ceramic product and preparation method thereof

PendingCN109608168AHigh densityImprove corrosion resistanceCeramic materials productionClaywaresWear resistantCalcite

The invention discloses a wear-resistant and high-hardness ceramic product and a preparation method thereof. The wear-resistant and high-hardness ceramic product comprises a green body and a glaze layer applied on the green body. The green body comprises the following raw materials by weight: 45-55 parts of kaolin, 5-10 parts of zirconia, 12-18 parts of bentonite, 15-25 parts of waste ceramic residue, 10-15 parts of silicon nitride, 17-23 parts of potassium feldspar, and 8-16 parts of albite. The glaze layer consists of the following raw materials by weight: 25-35 parts of kaolin, 12-16 partsof talc powder, 10-15 parts of spodumene, 6-12 parts of lithium china stone, 10-15 parts of quartz, 5-10 parts of silicon carbide and 7-14 parts of calcite. By the above way, the ceramic product provided by the invention has high hardness and wear resistance, high compressive strength and strong thermal stability.

Owner:FOSHAN UNIVERSITY

Coal ash ceramic brick and manufacturing method thereof

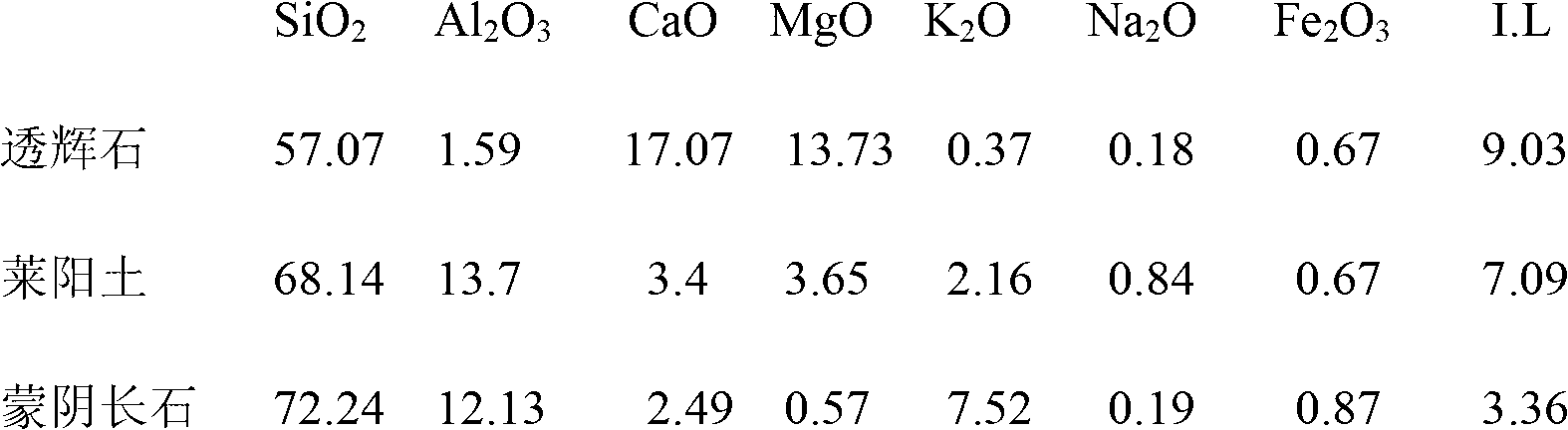

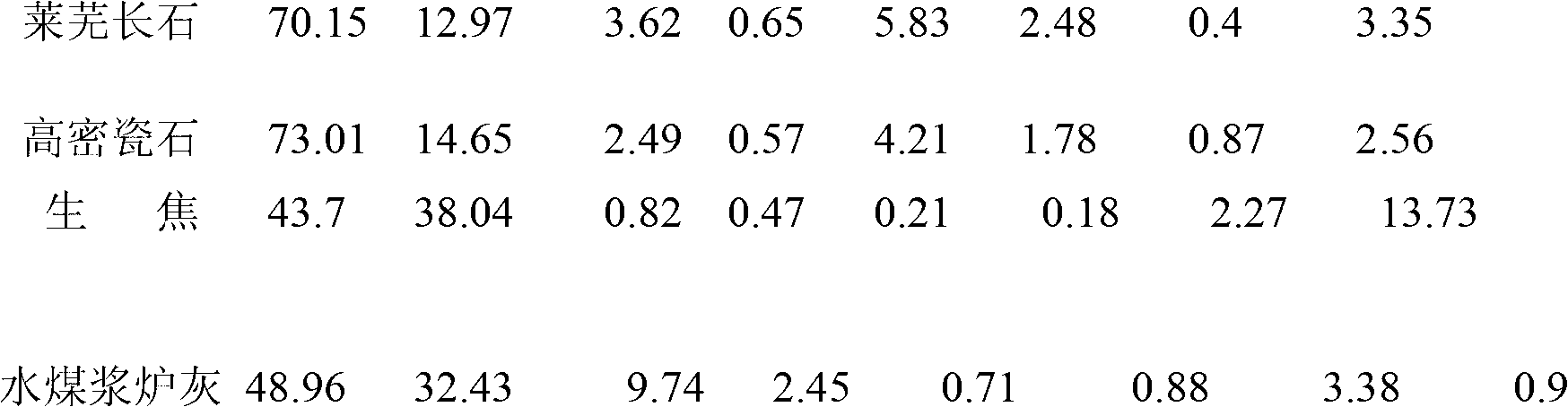

The invention relates to a coal ash ceramic brick and a manufacturing method thereof, and belongs to the field of ceramic preparation methods. The coal ash ceramic brick is characterized by being prepared by the following raw materials by mass percent: 4% of diopside, 27% of Laiyang soil, 23% of Mengyin feldspar, 24% of Laiwu feldspar, 7% of green coke, 8% of high-density china stone and 7% of water coal slurry ash. The water coal slurry ash is no longer discharged to the outside, so that the production cost is greatly reduced. As the water coal slurry ash has no plasticity but a higher iron content, the ligand strength is enabled to meet the standards through adjusting a formula. The color of the produced blank body is slightly yellow than before, but the physicochemical indexes are all not less than those before. During operation, a production line can be applied without any change after the formula of the blank body is adjusted only.

Owner:淄博新空间陶瓷有限公司

Preparation method of reinforced jade-based porcelain and product made of reinforced jade-based porcelain

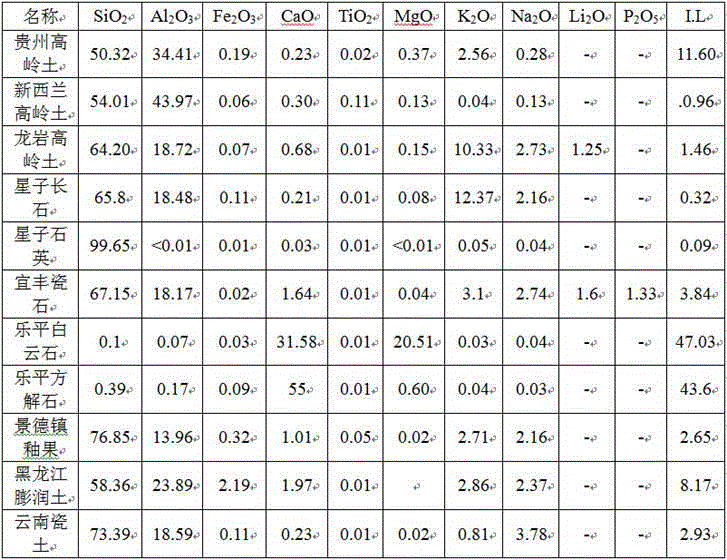

The invention relates to a preparation method of reinforced jade-based porcelain and a product made of the reinforced jade-based porcelain. The reinforced jade-based porcelain comprises a blank material and a glaze material, wherein the blank material comprises the following raw materials by weight: 10 to 15 percent of Longyan kaolinite, 8 to 15 percent of Guizhou kaolinite, 5 to 10 percent of New Zealand kaolinite, 10 to 15 percent of Xingzi feldspar, 40 to 50 percent of Xingzi quartz, 5 to 10 percent of Yifeng low-temperature porcelain stone, 3 to 5 percent of Jingdezhen glaze stone, 3 to 5 percent of Heilongjiang bentonite, and 3 to 5 percent of Yunnan porcelain clay; the glaze material comprises the following raw materials by weight: 8 to 12 percent of Longyan kaolinite, 3 to 5 percent of New Zealand kaolinite, 10 to 15 percent of Xingzi feldspar, 30 to 37 percent of Xingzi quartz, 8 to 12 percent of Yifeng low-temperature porcelain stone, 15 to 20 percent of Leping dolomite, 5 to 10 percent of Leping calcite, 8 to 10 percent of Jingdezhen glaze stone, and 5 to 10 percent of Yunnan porcelain clay. The preparation method and the product have the advantages that the production method is scientific and reasonable; the production cost is relatively low; the implementation is easy; the yield is high; the product quality is good. Therefore, the market prospect is wide.

Owner:景德镇红叶陶瓷股份有限公司

Ceramic product, and preparing and sintering process thereof

The invention relates to a ceramic product which is characterized in that raw material components comprise washing kaolin, Changxing white mud, Fujian pottery stone, feldspar and burned talcum, wherein after blending, sodium humate and sodium silicate are added and ball-milled in a cylinder to obtain a grouting blank of the ceramic product, and the ceramic product is obtained by screening iron, molding, biscuiting, glazing and sintering. According to the invention, a reasonable blank formula, and a preparing and sintering process are adopted, the sintered ceramic product has the advantages of high intensity, high compactness, low water absorption, high dimensional accuracy, corrosion resistance, leakage resistance, good heat stability, no deformation, no crack, and smooth and clear glaze, and has no vices such as pinholes, thin glaze and contracted glaze, so that the defective percentage is reduced, the production efficiency is improved, the production cost is decreased, the artistic degree of the appearance of the ceramic product is promoted; and the method is suitable for high-level ceramic products such as high-grade ceramic wine bottles.

Owner:江苏省宜兴彩陶工艺厂

Preparation method of reinforced bone china and product prepared therefrom

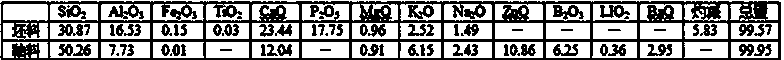

The invention relates to a preparation method of reinforced bone china and a product prepared therefrom. According to the preparation method, a green body formula comprises the following components in percentage by weight: 15 to 20% of kaolin I, 15 to 20% of kaolin II, 10 to 15% of feldspar, 5 to 10% of quartz, 8 to 10% of kaolin III, 2 to 5% of kaolin IV, 35 to 40% of high calcium powder, and 5 to 10% of low-temperature cornish stone; a glaze formula comprises the following components in percentage by weight: 10 to 15% of kaolin I, 30 to 40% of feldspar, 5 to 10% of quartz, 8 to 13% of borax, 5 to 10% of zinc oxide, 10 to 15% of cornish stone, 3 to 6% of dolomite, 8 to 12% of calcite, and 5 to 8% of barium carbonate. The production method is scientific and reasonable, advanced in process technology, high in rate of finished products, and high in product quality, realizes firing at medium and low temperatures and has the advantages that a lot of gas and fuel is saved, the defect rate caused by the glaze firing at high temperature is greatly reduced, the production cost is remarkably reduced, and thus a wide market prospect is brought.

Owner:景德镇恩达陶瓷有限公司

Ceramic light insulation decorative exterior wall tile and productive process

InactiveCN102718549AImprove insulation effectReduce processing timeClimate change adaptationHeat proofingPorosityBrick

The invention relates to a ceramic light insulation decorative exterior wall tile and a productive technology. The ceramic light insulation decorative exterior wall tile with good foaming effects is prepared by, by weight, 15-20 parts of clay, 20-30 parts of quartz sand tailings, 15-25 parts of low-temperature porcelain sand, 30-35 parts of lithium china stone, 3-5 parts of talc and 1-5 parts of silicon carbide powders with the content of silicon carbide larger than or equal to 90 %. The production steps include mixing raw materials according to a proportion, and subjecting the raw materials to ball milling in a 250 mesh sieve to occupy 1%-3% of fineness; drying the raw materials to obtain powders with water ratio from 5.5 %-6.5 %; and performing molding, drying and sintering, wherein the highest temperature of the sintering is from 1170 DEG C to 1230 DEG C, and the sintering period is from 35 minutes to 45 minutes. According to the exterior wall tile, uniform and fine closed air holes are formed, the water absorption is from 1% to 3%, the porosity can reach 40% to 50%, and the thermal coefficient is 0.5-0.8 W / (M.K). The exterior wall tile is good in insulation performance and decoration effect and convenient to use.

Owner:重庆歌德陶瓷玛赛克制造有限公司

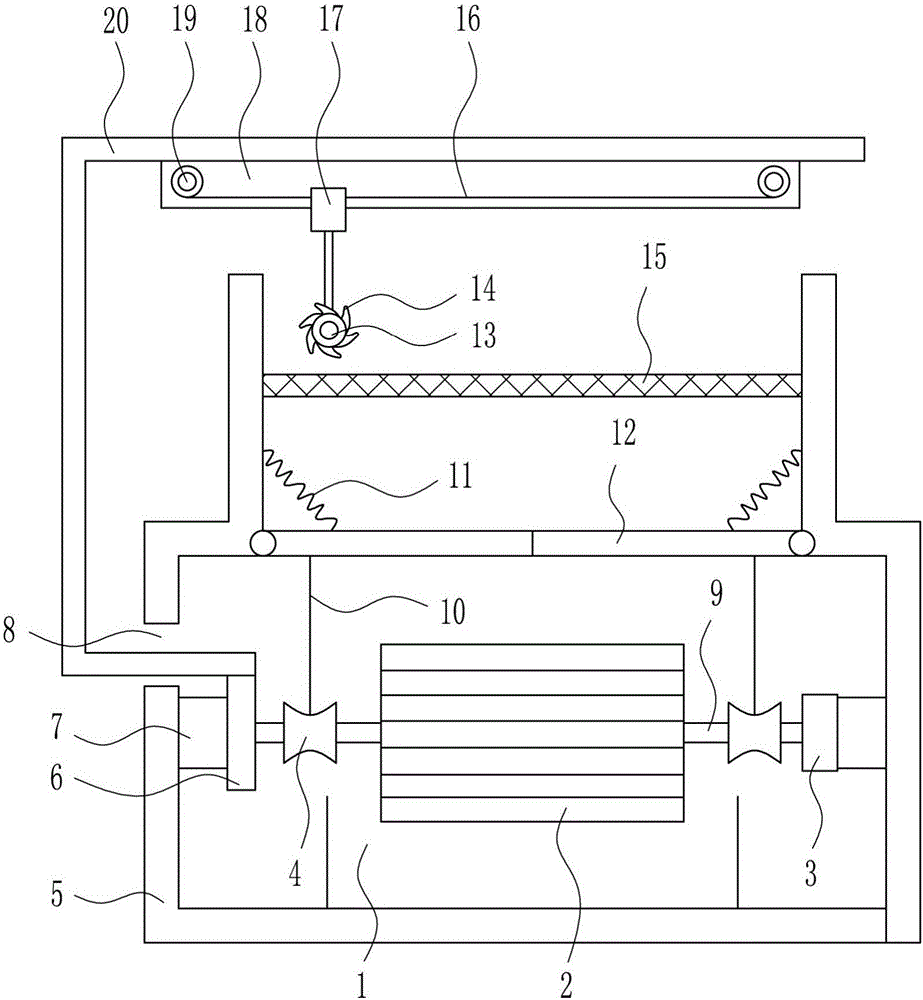

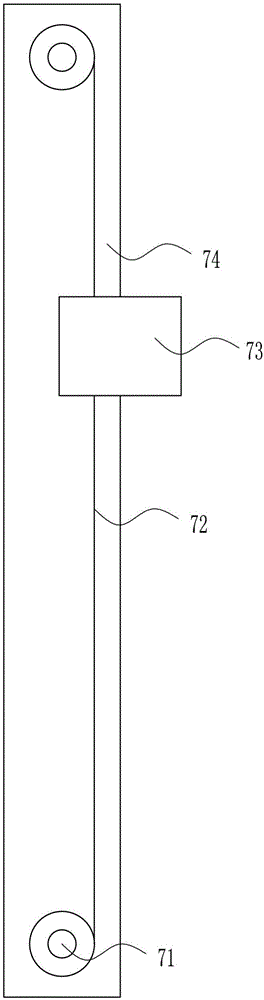

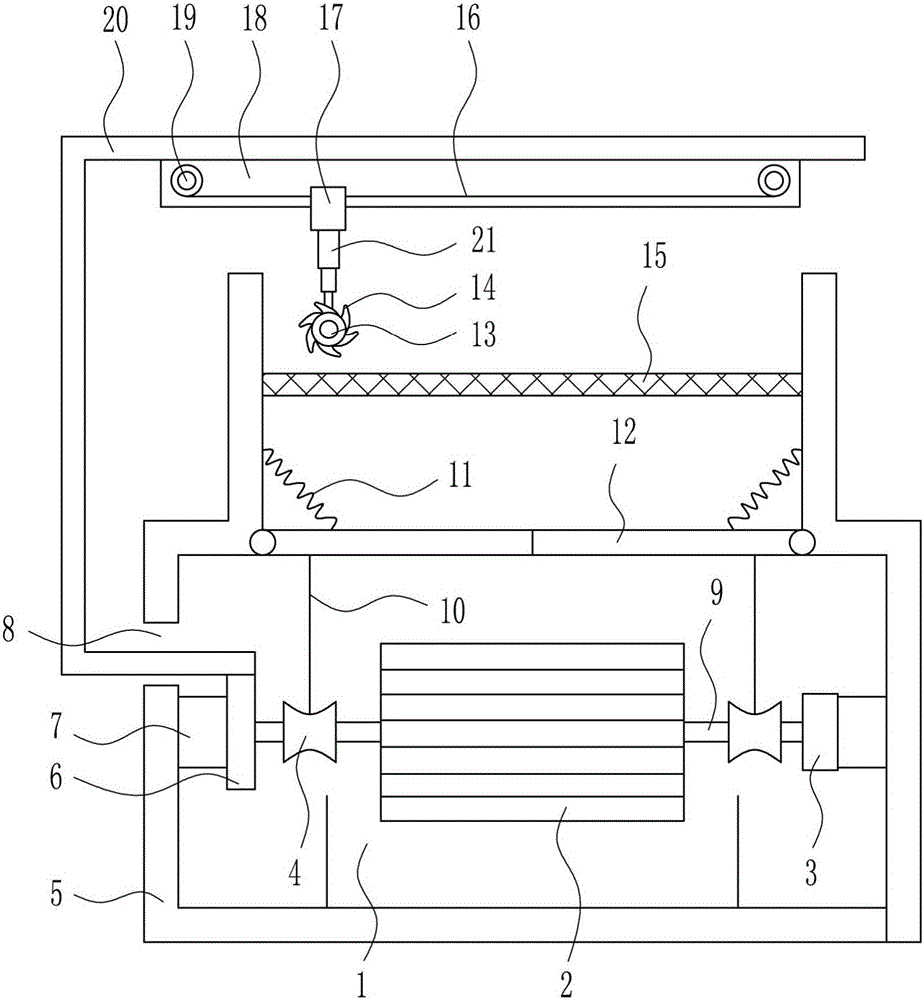

High-efficiency china stone grinding apparatus used for mosaic tiles

The invention relates to a grinding apparatus, and especially relates to a high-efficiency china stone grinding apparatus used for mosaic tiles. The technical problem to be solved in the invention is to provide the high-efficiency china stone grinding apparatus used for mosaic tiles, with a high china stone grinding efficiency. The high-efficiency china stone grinding apparatus used for mosaic tiles comprises a collecting box, a grinding wheel, a first motor, a reel, a grinding box, a bearing seat, translation devices, a rotating shaft, a third stay wire, springs, a baffle plate, a second motor, a breaking wheel, a filter screen, a first stay wire, a first slide block, a first slide rail, a first electric wheel and a support; and the translation devices are symmetrically arranged under the left wall and the right wall in the grinding box. The grinding apparatus greatly improves the mosaic tile grinding efficiency.

Owner:佛山市爱鑫建材有限公司

High efficiency ceramic blank casting slip and processing method thereof

The invention relates to a high efficiency ceramic blank casting slip. The ceramic blank casting slip comprises the following raw materials, by weight, 8-9 parts of Zhangcun soil, 6-7 parts of Zhangwu clay, 8-9 parts of Tangshan knag, 9-10 parts of Shanxi knag, 13-14 parts of Qinyang soil, 2-3.5 parts of Guangdong ball clay, 0.7-1.3 parts of Guangdong black mud, 1.4-1.7 parts of dolomite, 5-6 parts of Weichang clay, 9-10 parts of Fengrun sandstone, 14-15 parts of Luanxian feldspar, 3-4 parts of porcelain powder, 1-2.5 parts of Zhanjiang porcelain clay B, 7-8.5 parts of Xuanhua porcelain stone, 3-4 parts of northeast black mud, and 1.5-3 parts of Zhanjiang porcelain clay A, wherein dolomite in the raw materials is ground into a dolomite slurry, and the dolomite slurry and other raw materials, which are mixed, are ground in a ball mill according to a raw materials: balls: water ratio of 1:1.8:0.4. The raw materials of the casting slip are easy to obtain, a large ceramic product is subjected to slip casting twice each day, the slip suction speed is fast, the ceramic product production efficiency is improved, and the output is increased, so the ceramic blank casting slip is suitable for the large scale production.

Owner:TANGSHAN HUALI CERAMICS CO LTD

Anti-static ceramic tile and production method thereof

The invention discloses an anti-static ceramic tile and a production method thereof. The anti-static ceramic tile is formed by the following raw materials of, by weight, 27 to 41 parts of river sand, 19 to 33 parts of lithium China stone, 16 to 28 parts of dickite, 15 to 25 parts of pebble chips, 12 to 24 parts of steel slags, 14 to 22 parts of composite clay, 10 to 15 parts of colloidal graphite powder, 8 to 14 parts of molybdenum disilicide, 3 to 6 parts of tin antimony oxide, 5 to 7 parts of liquid phenolic resin, 2 to 3 parts of sodium lauryl sulfate and 3 to 4 parts of chitosan. According to the anti-static ceramic tile and the production method thereof, the colloidal graphite powder, the molybdenum disilicide, the tin antimony oxide and the other components are added and accordingly the high anti-static function is achieved through the produced ceramic tile, the national anti-static ceramic tile standard GB26539-2011 requirements for the anti-static property are met, the strength is high, the heat stability is good, the abrasion resistance is good, the corrosion resistance is good, the service life of the anti-static ceramic tile is extended, and the use range of the anti-static ceramic tile is expanded.

Owner:安徽省亚欧陶瓷有限责任公司

Matt glaze as well as preparation method and application thereof

The invention discloses a matt glaze as well as a preparation method and application thereof. The matt glaze is prepared from the following raw materials in parts by weight: 8-15 parts of aluminum oxide, 5-11 parts of boric acid, 24-29 parts of potassium feldspar, 9-14 parts of albite, 24-30 parts of dolomite, 5-10 parts of barium carbonate, 20-38 parts of lithium china stone and 3-8 parts of calcium fluoride. Due to improvement of the formula of a matt glaze, the glaze amount on the surface can be increased without affecting anti-flouring properties and textures, the glossiness degree of 12 or lower can be easily achieved after polishing treatment of a subdued light ceramic tile, and the subdued light ceramic tile is free of light reflection generally when being looked with naked eyes under radiation of light. In addition, the matt glaze is made of purely dry granules, is small in gas generation and good in gas exhaust in the production process, is small in pore residue in surfaces, and thus is good in anti-flouring effect.

Owner:佛山市登羽科技有限公司

Medium and low temperature fine porcelain and its preparing method

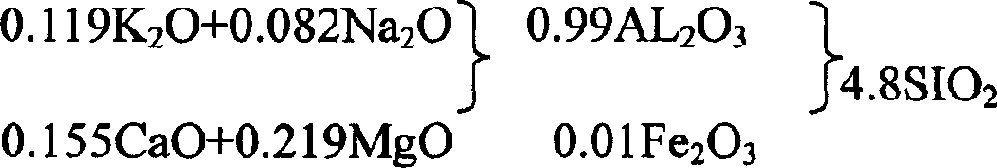

InactiveCN1616380ABroaden your optionsGuarantee normal performance quality indicatorsClaywaresAlkaline earth metalChina stone

The present invention relates to medium and low temperature fine porcelain and its preparation process, and especially a kind of medium and low temperature fine porcelain of high alkali metal element and alkali earth metal element content and with relatively lower sintering temperature and its preparation process. The base material has two basic components of sericite china stone and kaolin, and includes three main kinds of oxides, SiO2 50-70 wt%, Al2O3 20-30 wt% and R2O+RO 7.3-12 wt%, where R2 and R are alkali metal element and alkali earth metal element separately. The very large amount of alkali metal element and alkali earth metal element results in the sintering temperature lowered to 1150-1230 deg.c, saving in energy, great color selecting range and flexible processing mode.

Owner:景德镇景德陶瓷集团有限公司

Color ceramic and its preparing method

The color ceramic contains kaolin over 20.0 wt%, china stone 7.0-60.0 wt%, and pigment 0.2-12.0 wt%, and has vitrification temperature of 1100-1250 deg c. The present invention also discloses the preparation process of the color ceramic. The preparation process includes preparing ceramic mud and slurry via pre-treatment of the components, mixing to obtain slurry, sieving to eliminate iron, press filtering to eliminate water and to form color mud cake and mixing; forming; and mixing partial color mud cake and liquefacient to obtain slurry for injection. The present invention has wide material source, wide ceramic mud compounding range, high color adaptability, and capacity of making ceramic product with high decoration effect and bright color.

Owner:景德镇景德陶瓷集团有限公司

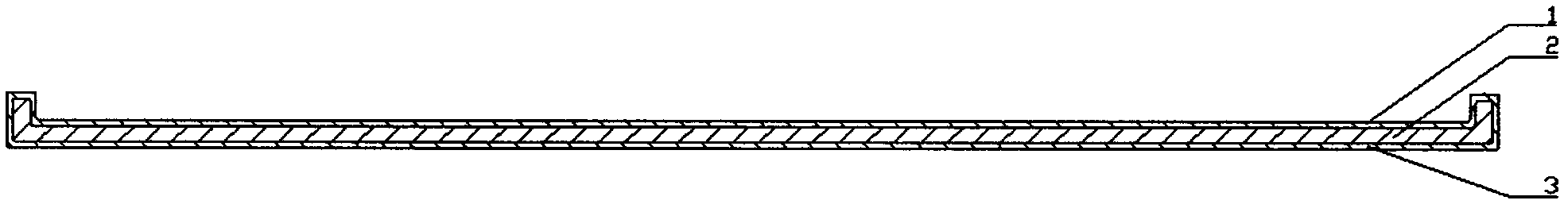

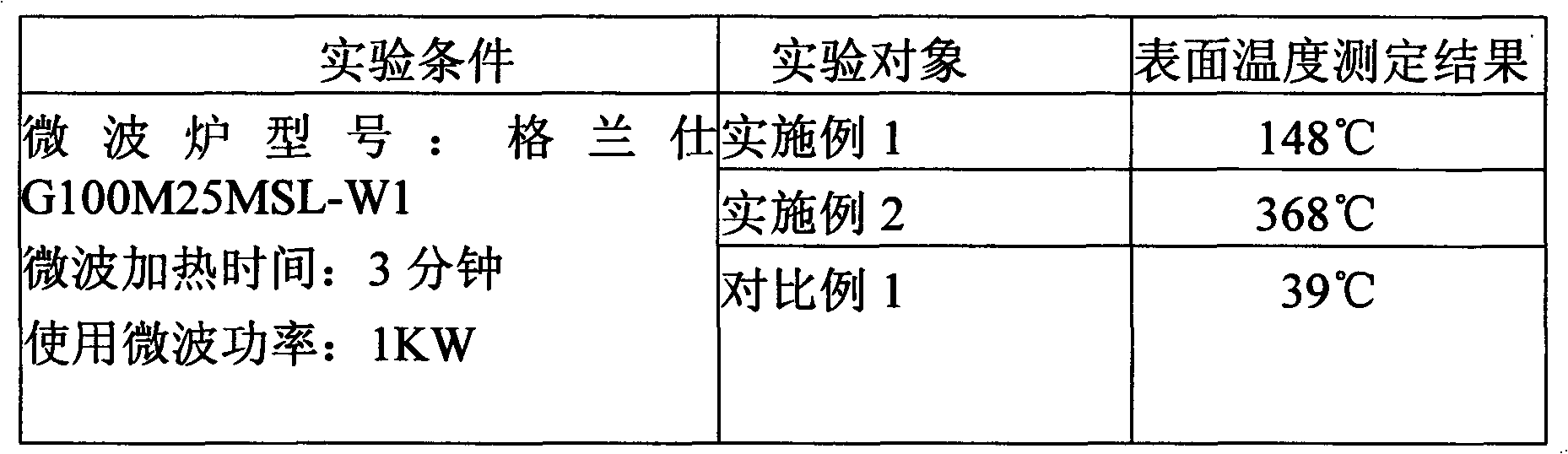

Composite ceramic baking tray for microwave oven and preparation method for composite ceramic baking tray

The invention provides a composite ceramic baking tray for a microwave oven. An interlayer (2) of the composite ceramic baking tray is a wave-absorbing heating layer, and is mainly prepared from the following raw materials in percentage by weight: 25 to 70 percent of tetra-needle like ZnO whisker and 75 to 30 percent of ceramic paste preform, wherein the ceramic paste perform comprises one or a mixture of several of kaolin, clay, feldspar, quartz, chinastone and china clay; and upper and lower layers (1 and 3) of a section structure are ceramic glaze layers. In the composite ceramic baking tray for the microwave oven, the tetra-needle like ZnO whisker is adopted as a wave-absorbing heating material and can absorb microwaves in short time to generate heat quickly, so that foods during microwave heating are re-heated, frying and roasting effects are achieved, and the foods are more delicious. The composite ceramic baking tray for the microwave oven is directly contacted with the bottom of a food, and high temperature conduction and microwave heating are simultaneously performed, so the food cooking time is greatly shortened.

Owner:蔡立君

Antibacterial and anti-static ceramic tile and preparing method thereof

The invention discloses an antibacterial and anti-static ceramic tile and a preparing method thereof. The preparing method includes the following steps of A, ground coat preparing, wherein ground coat is prepared from, by mass, 30%-35% of frits, 2%-8% of a functional agent, 20%-28% of lithium China stone, 5%-10% of silicic acid zirconium, 20%-25% of kaolin and 10%-12% of quartz, the materials are mixed to be even, subjected to wet ball grinding and screened, and the pasty ground coat is obtained; B, overglaze preparing, wherein overglaze is prepared from, by mass, 70%-80% of frits, 1%-5% of conductive powder, 10%-20% of kaolin, 5%-8% of aluminum oxide, 1%-2% of zinc oxide and 1%-5% of zirconium silicate, the mixture is mixed to be even, subjected to wet ball grinding and screened, and the pasty overglaze is obtained; C, the ground coat prepared in the step A and the overglaze prepared in the step B are sequentially glazed to a ceramic tile blank soil, and the ceramic tile is obtained in a sintered mode. Compared with an existing ceramic tile, the ceramic tile prepared with the method is scientific in mixing, reasonable in preparing and stable in performance; the conductive powder, a deodorant and antibacterial powder are reasonably matched, the ceramic tile has the excellent antibacterial, anti-static and air purifying properties accordingly, and the application range of the ceramic tile is further broadened.

Owner:FOSHAN GAOMING DISTRICT MINGCHENG TOWN NEW ENERGYNEW MATERIAL IND TECH INNOVATION CENT

Low-water absorption stoneware and production method thereof

A low-water absorption stoneware product is prepared from the following components in parts by weight: 30 to 40 parts of sodaclase, 15 to 25 parts of quartz, 40 to 50 parts of kaolinite and 1 to 2 parts of additive; the percentage content of K, Na, Fe and Ti in the stoneware product is guaranteed to be the followings in percentage by weight: 1 to 1.5 percent of K, 2.5 to 3 percent of Na, less than 0.9 percent of Fe, and less than 0.15 percent of Ti. The additive is a mixture formed by mixing lithium porcelain stone or lithium porcelain stone with soapstone; the mixing ratio of the lithium porcelain stone and the soapstone is optional, and can be selected according to the requirements of the cost and the quality of a product. The production method of the low-water absorption stoneware product comprises the steps of sorting, batching, ball milling, slurry discharging, squeezing, primary refining, refining, staling, blank making and burning; according to the invention, through rationally selecting raw material formulation and adding moderate lithium porcelain stone or lithium porcelain stone to be mixed with the soapstone to form the mixture serving as the additive, not only is the conventional firing temperature of the stoneware followed, but also the water absorption can be effectively lowered, and the product quality is ensured.

Owner:HUNAN HUALIAN CHINA IND

Low-temperature fired high-strength building ceramic green body and preparation method thereof

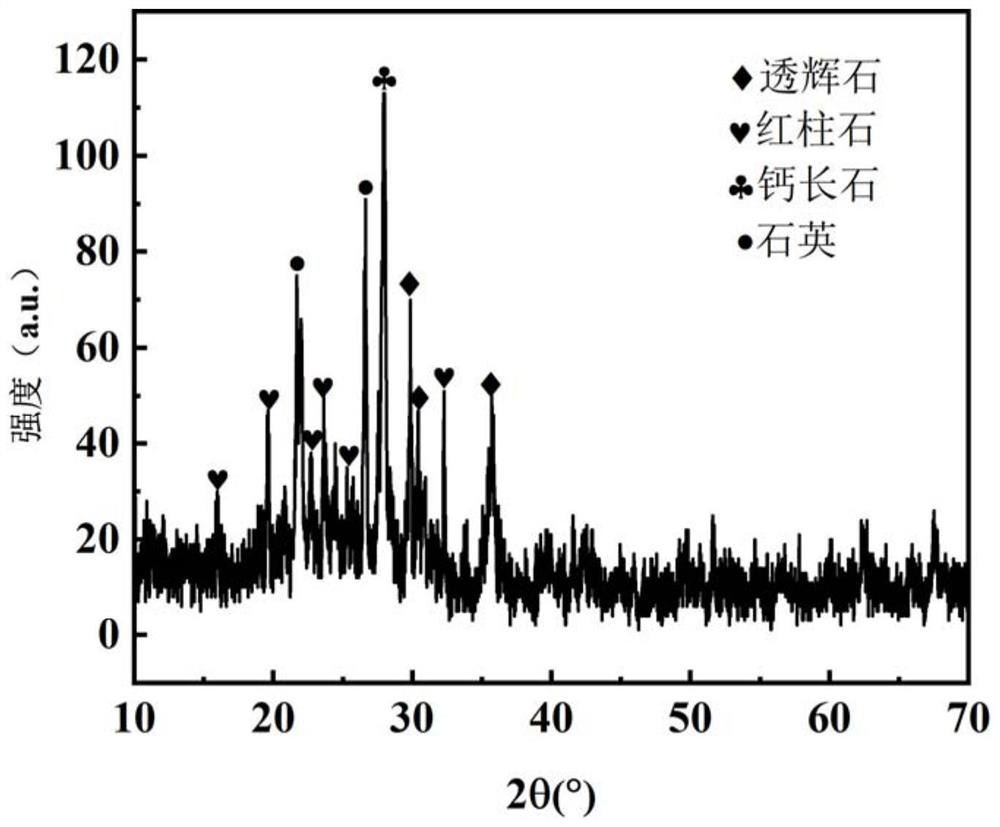

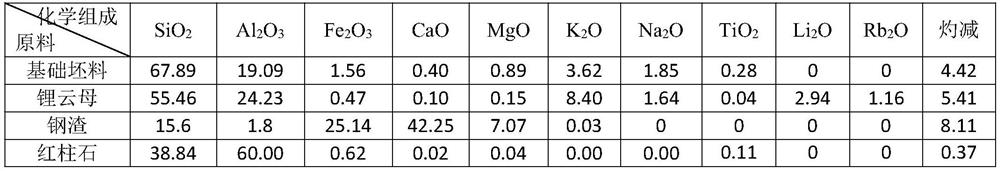

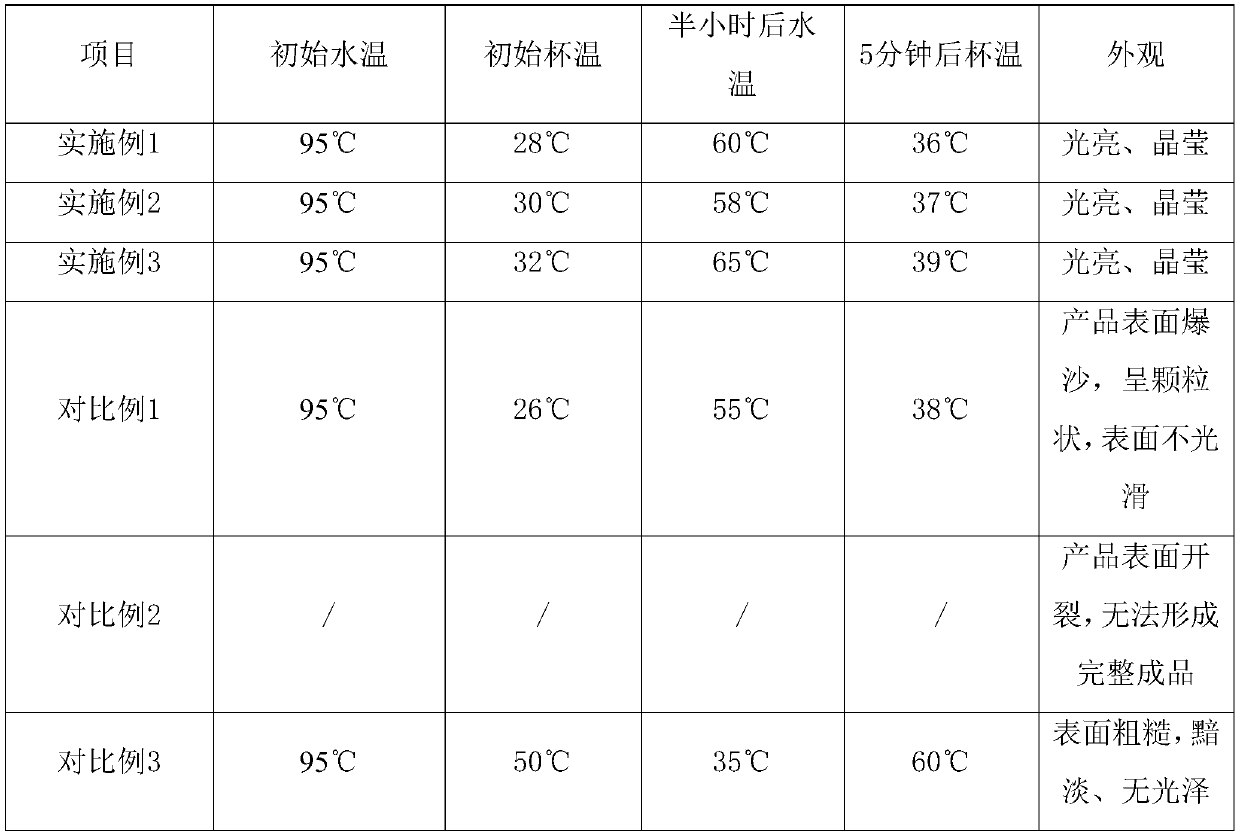

The invention discloses a low-temperature fired high-strength building ceramic green body, which is prepared from the following raw materials: 70 to 80 weight percent of basic green body, 1 to 8 weight percent of lepidolite, 5 to 10 weight percent of steel slag and 8 to 19 weight percent of andalusite, the basic blank is prepared from the following raw materials: 28 to 32 weight percent of chinastone, 10 to 12 weight percent of potassium feldspar, 6 to 14 weight percent of albite, 20 to 24 weight percent of kaolin, 8 to 14 weight percent of black mud, 12 to 16 weight percent of white mud and 1 to 3 weight percent of talc. In addition, the invention also discloses a preparation method of the low-temperature fired high-strength building ceramic green body. By optimizing a formula system, the breaking strength of the ceramic green body can be effectively improved, so that the thickness of a product is reduced, thin-wall light weight and low-temperature firing of the building ceramic green body are realized, the national strategy of green and sustainable development is met, and the ceramic green body has a wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Thermal insulation agate porcelain and preparation method thereof

The invention discloses thermal insulation agate porcelain. According to a formula, the agate porcelain comprises the following materials in parts by mass: 60 to 70 parts of agate, 5 to 10 parts of crystal, 6 to 8 parts of feldspar, 2 to 6 parts of soapstone, 2 to 5 parts of clay, 5 to 10 parts of bentonite, 3 to 8 parts of kaoline and 1 to 5 parts of pottery stone. The invention further disclosesa preparation method of the thermal insulation agate porcelain. The thermal insulation agate porcelain has the advantages that the dosage of argil (feldspar, soapstone, clay, bentonite, kaoline and pottery stone) is reduced by taking natural minerals, such as the agate, crystal, feldspar, soapstone, clay, bentonite, kaoline and pottery stone, as raw materials and taking the agate as a main component, and the agate and crystal are molten in a whole formula system through high temperature, so that the smooth and moist characteristics of agate and crystal can be given in full play, a whole ceramic product has a gentle and crystal clear ornamental value, through the mixing of the different types of raw materials, the formed ceramic product has the property of thermal insulation, the materialsin the formula are environmentally-friendly, hazardous substance does not produce during burning, and the ceramic product formed through burning is ensured to be environmentally-friendly, healthy andnontoxic.

Owner:黑龙江省辽金源陶瓷有限公司

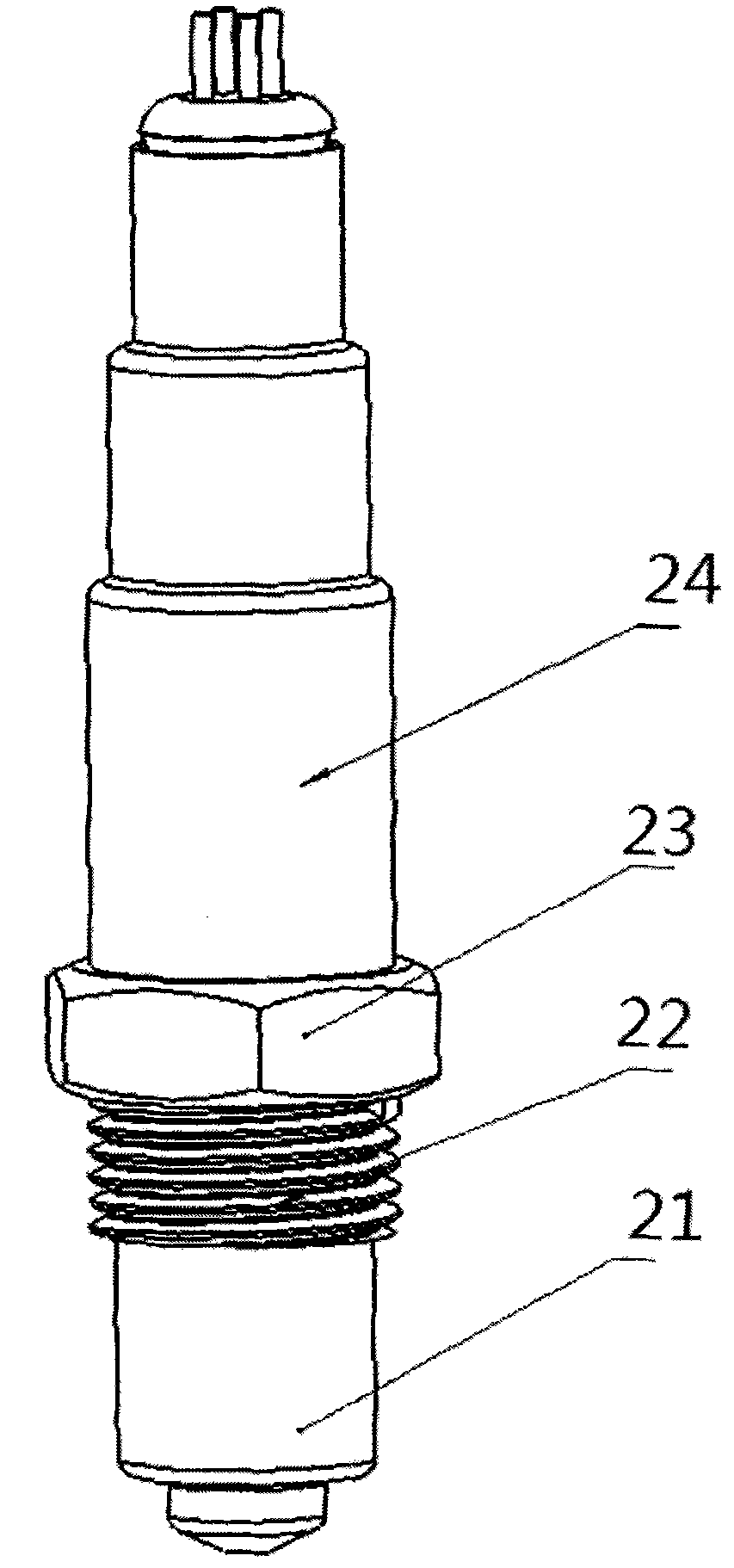

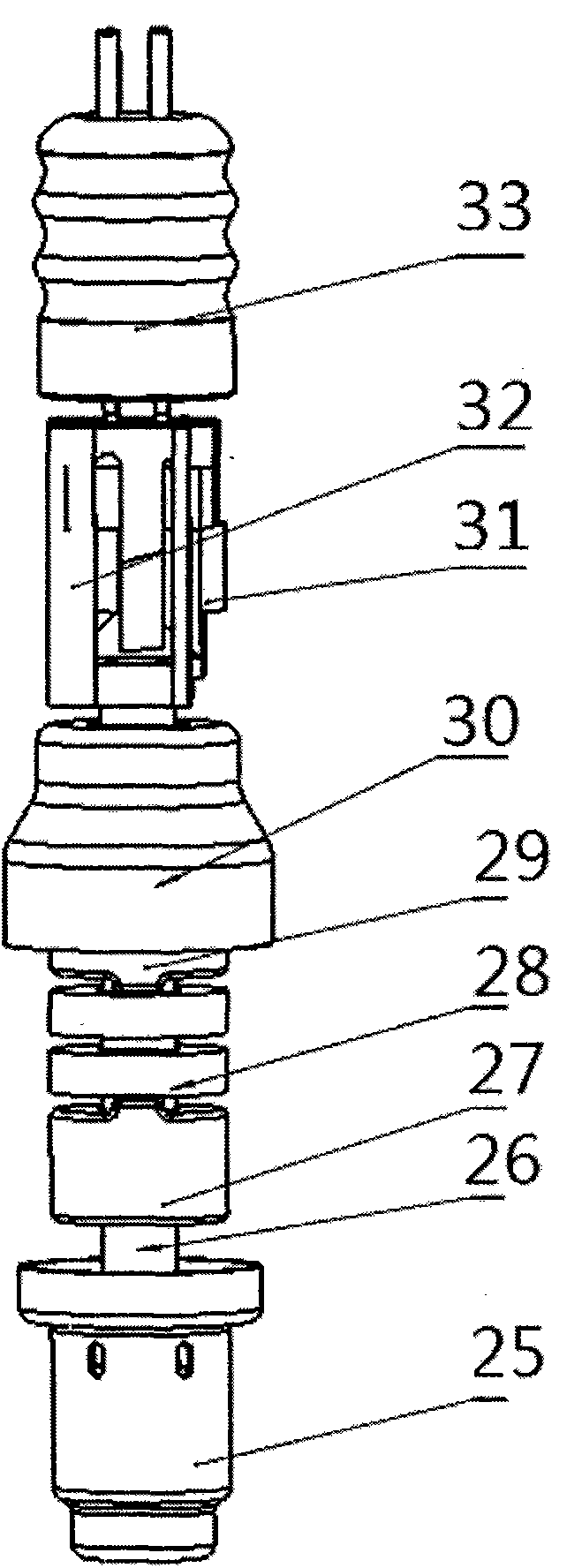

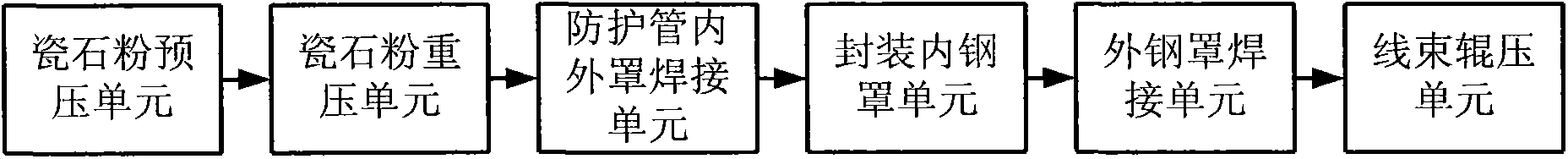

Automatic production line device for packaging oxygen sensor

ActiveCN103949891ARealize the assemblyIn line with the status quo of production technologyOther manufacturing equipments/toolsProduction lineOxygen sensor

The invention provides an automatic production line device for packaging an oxygen sensor. The automatic production line device comprises a China stone powder pre-pressing unit, a China stone powder repressing unit, a protective inner and outer cover welding unit, an inner steel cover packaging unit, an outer steel cover welding unit and a wire harness rolling unit, wherein the structures of the protective inner and outer cover welding unit and outer steel cover welding unit are the same, a laser beam is used for welding a protective pipe inner cover, a protective pipe outer cover and an outer steel cover with a hexagonal base together so as to protect an interior sensor chip. According to the automatic production line device, the units are sequentially connected according to the assembling technology of the oxygen sensor, and semi-automatic and full-automatic assembling of the oxygen sensor product is realized, so that the product quality can be stabilized and improved, the working conditions are improved, the occupied area for production is reduced, the production cost is reduced, and the production cycle is shortened.

Owner:WENZHOU UNIVERSITY

Method for preparing medium aluminum grinding balls by secondary ball milling

InactiveCN102443377AIncrease productionImprove grinding efficiencyOther chemical processesPolyvinyl alcoholSodium phosphates

The present invention relates to a method for preparing medium aluminum grinding balls by a secondary ball milling process. According to the method, raw materials are weighed according to a certain ratio, wherein the raw materials comprise, by weight, 85-90% of sintered bauxite, 2-5% of dolomite, 2-5% porcelain stone, 2-5% of clay and 0.5-2% of sodium humate; the massive raw materials are crushed, and added to a ball mill; water, a dispersion agent sodium tripolyphosphate and a polyvinyl alcohol solution are added to the ball mill; treatments of ball milling, screening, staling are performed; a secondary ball milling treatment and a screening treatment are performed; the resulting slurry is subjected to spray drying and pelletizing by a high tower to obtain a powder material; the powder material is screened; the screened powder material is subjected to pressing formulation under isostatic pressure to obtain a blank material; the blank material is placed into a kiln, and is subjected to high temperature firing to obtain the finished product. According to the present invention, the secondary ball milling treatment is adopted, such that the grinding efficiency and the grinding ball yield can be improved, and the production cost can be reduced; the AL2O3 content in the product is more than 70%, the compression strength is more than 1800 MPa, the volume density is 3.0-3.03 g / cm<3>, the abrasion loss is less than or equal to 0.03%, and the performance of the product of the present invention is superior to the similar products.

Owner:HENAN GOLD SOURCE NEW MATERIAL TECH

Thermal shock resistance refractory brick and preparation method thereof

InactiveCN106542834AImprove fire resistanceImprove performanceCeramic materials productionClaywaresFiberSlag

The invention discloses a thermal shock resistance refractory brick and a preparation method thereof. The refractory brick is prepared from the following raw materials in parts by weight: 12-19 parts of crushed gravels, 13-22 parts of blast furnace slag, 10-15 parts of alumina-silicatechromere fibers, 18-29 parts of cinerite, 14-26 parts of sericite, 8-14 parts of potassium silicate, 32-38 parts of filter mud of sugar refinery, 5-10 parts of yellow dextrin, 6-12 parts of borax, 24-36 parts of sodium silica slag, 11-17 parts of flake graphite powder, 15-25 parts of china stone tailing, 10-15 parts of aluminum titanate and 16-28 parts of satin stones. According to the refractory brick, alumina-silicatechromere fibers, flake graphite powder, aluminum titanate and other raw materials are mixed, and the advantages of the raw materials are sufficiently utilized to achieve the synergistic effect, so that a higher refractoriness is achieved, and the thermal shock resistance of the refractory brick can be effectively improved. The thermal shock resistance refractory brick has the advantages of good high temperature resistance, excellent thermal shock resistance and long service life.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

Underground anti-static ceramic roller and preparation method thereof

The invention relates to an underground anti-static ceramic roller and a preparation method thereof and belongs to the technical field of large-scale belt conveying mechanical accessories. The preparation method comprises the following steps of: preparing china stone, kaolin, knar clay, soda feldspar, smonite, potassium feldspar, silicon carbide powder and other raw materials in a certain weight ratio; preparing slurry; homogenizing the slurry; filtering to obtain mud; smelting the mud and decomposing; extruding to form blank; turning green bodies; firing at high temperature; and accurately grinding to obtain the roller. Silicon carbide which has the electrical property of semiconductor, high-temperature oxidation resistance, heat conduction and melting resistance is doped with a certain amount of impurities which have the characteristic of heat conduction, so that the ceramic roller has the characteristics of heat conduction and anti-static performance, light weight, high hardness, wear resistance, acid and alkaline resistance, water resistance and the like. The problem that the conventional ceramic roller which is made of common ceramic materials without heat conduction cannot release charges timely, so that static sparks are generated to cause gas explosion, and the life safety of coal miners and the production operation safety are threatened can be solved. The underground anti-static ceramic roller can be used safely and reliably, and is long in service life.

Owner:HUBEI EARTH ENVIRONMENTAL PROTECTION EQUIP CO LTD

Weather resistant sand-based water permeable bricks with high water permeability and preparation method thereof

The invention discloses weather resistant sand-based water permeable bricks with high water permeability. The water permeable bricks are prepared from the following raw materials in parts by weight: 39-40 parts of desert sand, 10-12 parts of talcum powder, 12-14 parts of lithium china stone, 14-16 parts of red clay, 11-13 parts of waste asphalt particles, 13-15 parts of sugar filter mud, 2.3-2.7 parts of hydroxyethyl cellulose, 0.7-0.9 part of aluminium chloride, 1.5-1.8 parts of superfine barium sulfate, 7-9 parts of tea dregs, 3-4 parts of sawdust, 4-6 parts of waste gear oil and proper amount of water.

Owner:合肥李诺新材料贸易有限公司

High-silicon high-temperature strengthened domestic porcelain and preparation method thereof

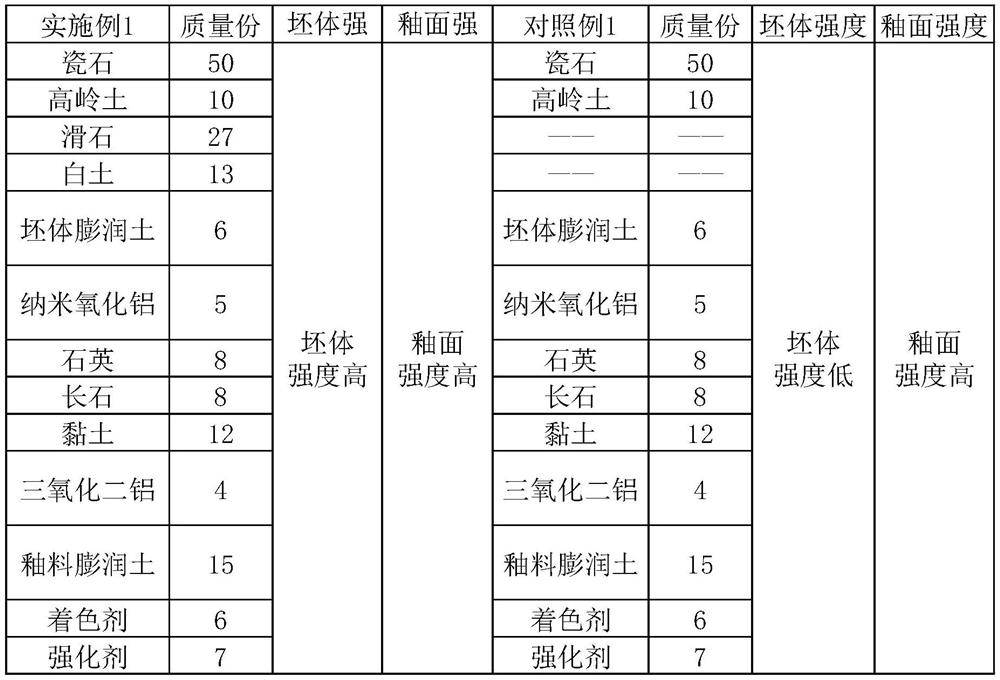

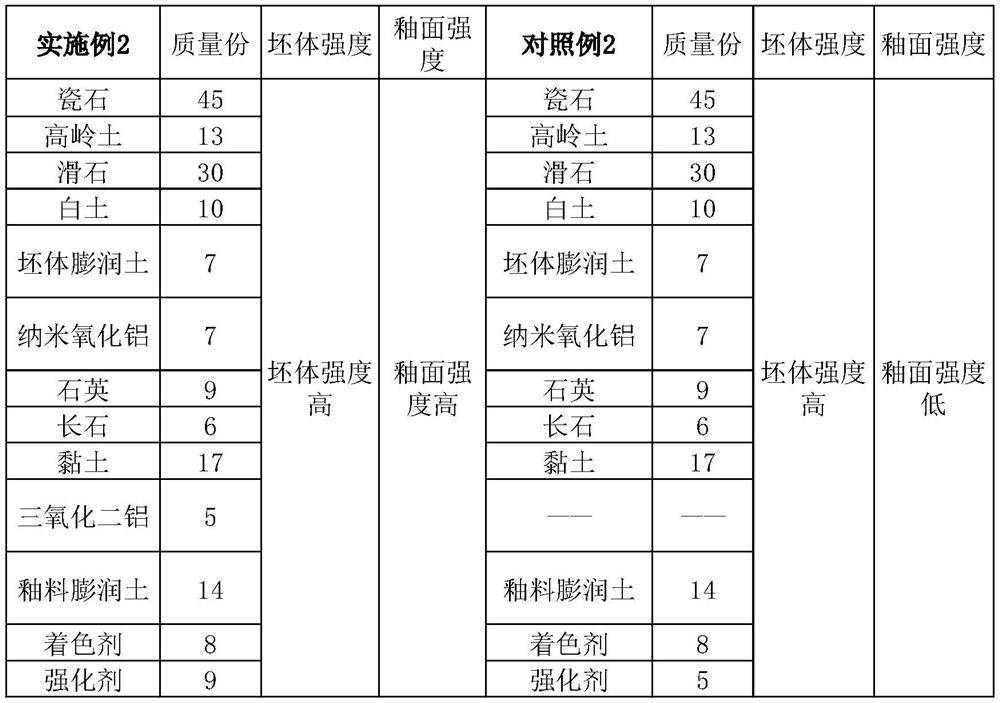

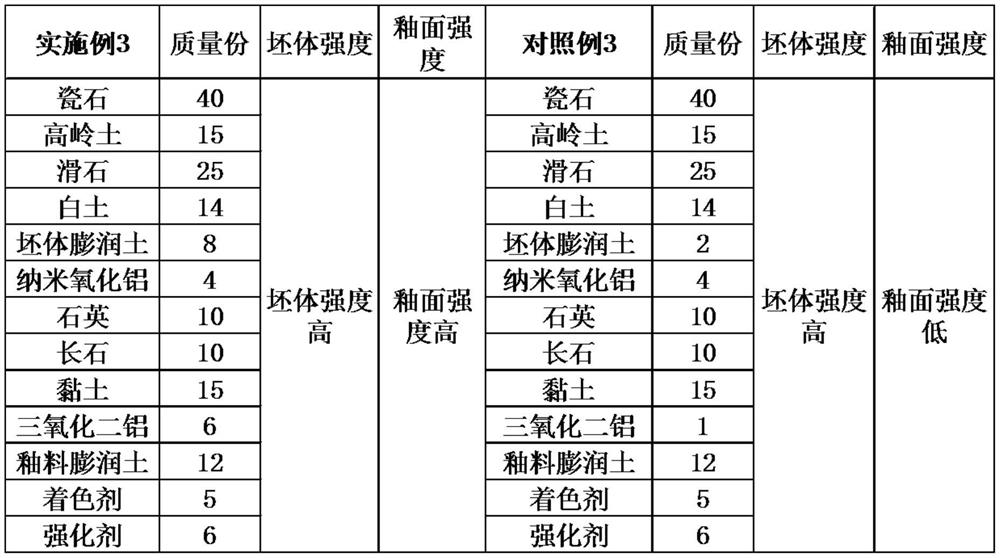

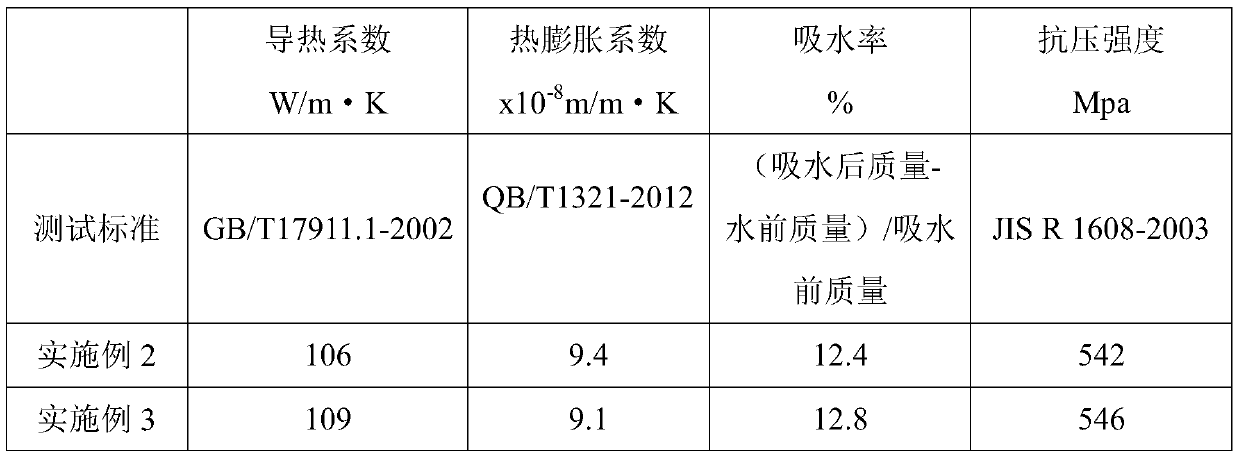

The invention relates to the technical field of ceramics, in particular to high-silicon high-temperature strengthened domestic porcelain and a preparation method thereof. The high-silicon high-temperature strengthened domestic porcelain comprises a green body and glaze, and the green body is prepared from, by mass, 40-50 parts of chinastone; 10-15 parts by mass of kaolin; 25-30 parts by mass of talc; 10-15 parts by mass of carclazyte; 5-8 parts by mass of green body bentonite; and 3-7 parts by mass of nano aluminum oxide. The high-silicon high-temperature strengthened domestic porcelain has the beneficial effects that the green body bentonite is added into the green body raw materials, so that a green body is not prone to cracking in the forming process, the talcum powder and the carclazyte obtained after the talcum powder is crushed are arranged, so that the overall strength of the formed green body is improved, the glaze bentonite is added into the glaze, the glaze layer is conveniently prevented from cracking, the strength of the glaze layer is conveniently improved to the maximum extent by adding the enhancer and aluminum oxide into the glaze, the color of the glaze is conveniently changed according to different use conditions by arranging the coloring agent, and the practicability of the glaze is improved.

Owner:FUJIAN WILL CERAMIC CO LTD

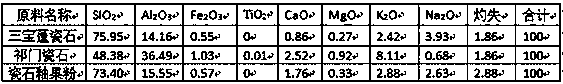

Ceramic glaze which is easy to clean and is not easy to oil

The invention discloses ceramic glaze which is easy to clean and is not easy to oil. The ceramic glaze comprises, by mass, bottom glaze: 25-35% of porcelain glaze stone powder, 10-15% of albite, 3-6%of limestone, 5-10% of wollastonite, 10-15% of Fuzhou kaolin, 5-10% of Sanbaopeng porcelain stone, 5-10% of Qimen porcelain stone, 10-15% of quartz, 2-6% of magnesium carbonate, 2-6% of dolomite and 2-6% of barium carbonate, and overglaze: 30-40% of porcelain glaze stone powder, 10-18% of lithium feldspar, 5-15% of talc, 6-8% of Fuzhou kaolin, 6-12% of Sanbaopeng porcelain stone, 6-10% of Qimen porcelain stone, 5-10% of quartz, 2-6% of zinc oxide, 2-8% of lithium carbonate, 2-6% of dolomite and 10-15% of additive titanium oxide powder. Through bottom glaze and surface glaze preparation, bottomglaze application, primary high temperature glaze burning, surface glaze application and secondary high temperature glaze burning, the product is obtained. The ceramic glaze product has a good glazesurface, good cleanability, a low production cost and broad market prospects.

Owner:景德镇富玉青花玲珑陶瓷有限公司

Porous water-absorbing red pottery steaming block and preparation method thereof

InactiveCN110803913AImprove thermal conductivitySmall coefficient of thermal expansionBaking vesselsCeramicwareGlass fiberThermal dilatation

The invention discloses a porous water-absorbing red pottery steaming block and a preparation method thereof. The porous water-absorbing red pottery steaming block is prepared from the following raw materials in parts by weight: 300-350 parts of laterite, 50-60 parts of diatomite, 25-32 parts of jade red soil, 45-55 parts of clay, 70-82 parts of feldspar, 30-38 parts of lithium china stone, 14-20parts of glass fibers and 5-7 parts of superfine stainless steel fibers. The porous water-absorbing red pottery steaming block disclosed by the invention is low in firing temperature, belongs to a low-temperature fired ceramic product, and is high in heat conductivity coefficient and good in heat conductivity; the thermal expansion coefficient is small, the thermal shock resistance is good, and the material can be used in cold-hot alternating environments; the water absorption rate is high, water can be provided for bread and other food when food is baked, and the baked bread and other food are prevented from being too dry; the compressive strength is high, and the durability is achieved.

Owner:德化县嘉祥陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com