Coal ash ceramic brick and manufacturing method thereof

A technology of ceramic bricks and fly ash, which is applied in the removal of solid waste and other directions, can solve problems such as pollution of the environment, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment:

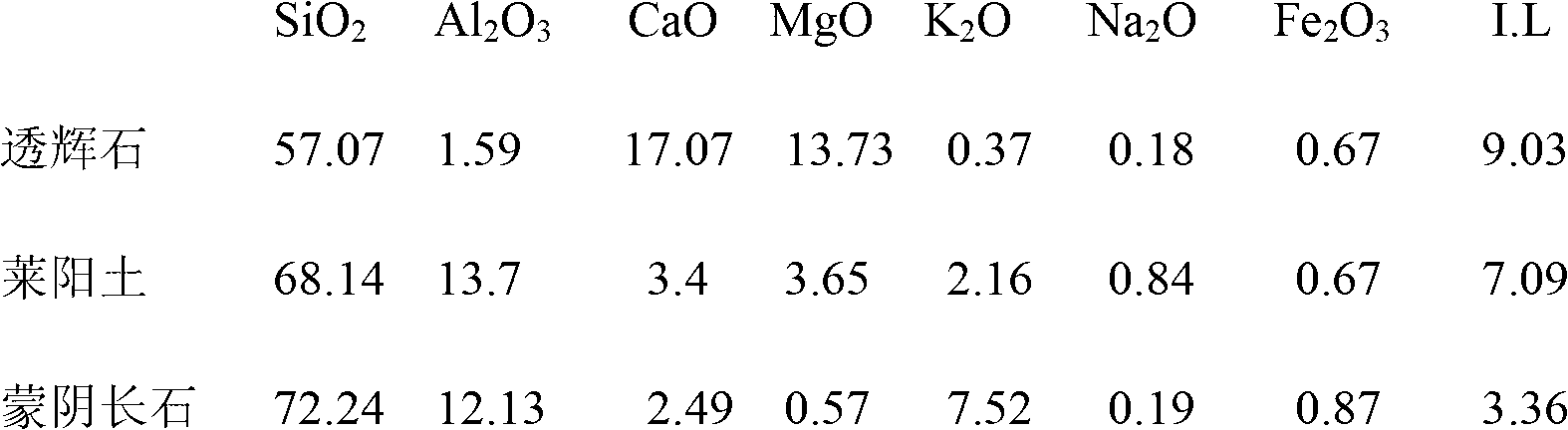

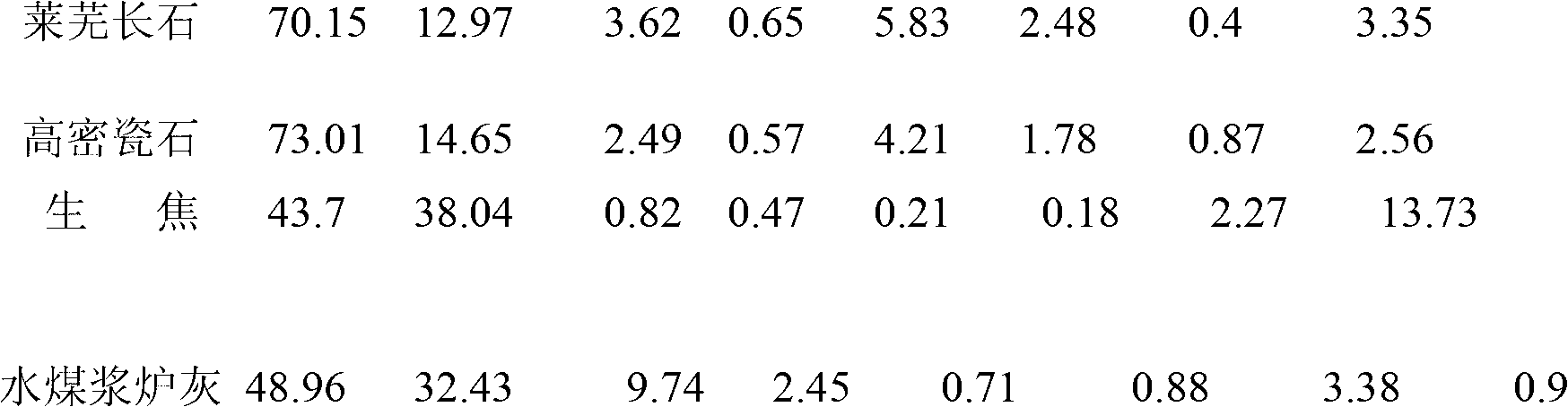

[0025] Fly ash ceramic bricks are prepared from raw materials with the following mass fractions:

[0026] Diopside 4%

[0027] Laiyang soil 27%

[0028] Mengyin feldspar 23%

[0029] Laiwu feldspar 24%

[0030] Raw coke 7%

[0031] High-density porcelain stone 8%

[0032] CWS furnace ash 7%.

[0033] In the preparation process of fly ash ceramic bricks, 5% of the total mass of the above-mentioned raw materials is added to waste bricks.

[0034] The preparation method of fly ash ceramic brick is:

[0035] The above raw materials were mixed and ground, and the fineness of the mud grinding was 250 mesh sieve with a residue of 5%, the firing temperature was 1170°C, and the firing temperature was 40 minutes.

[0036] Product testing indicators are as follows.

[0037] Product implementation standard: Appendix K of GB / T4100—2006, tested by the Bureau of Technical Supervision, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com