Patents

Literature

470results about How to "High in iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

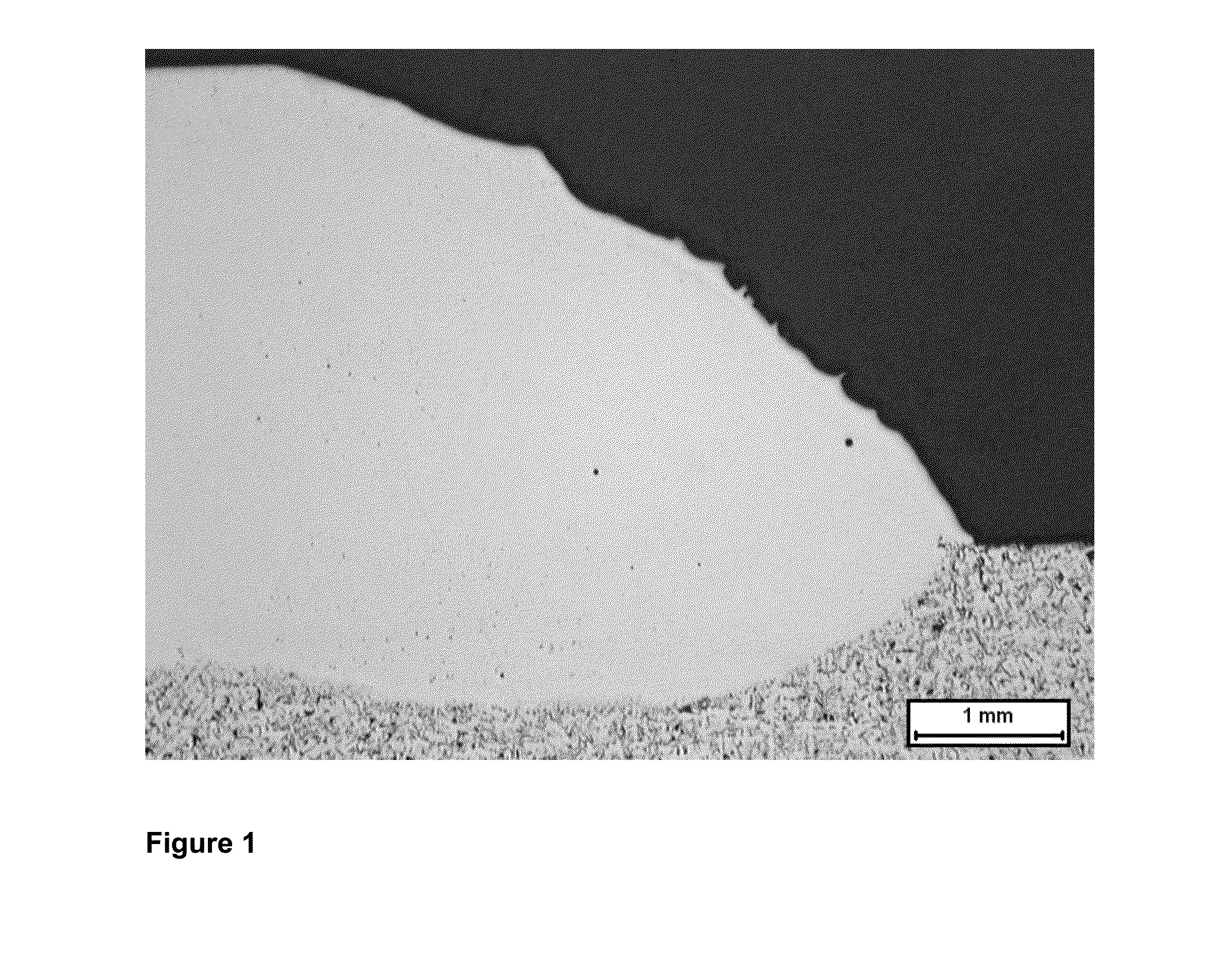

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

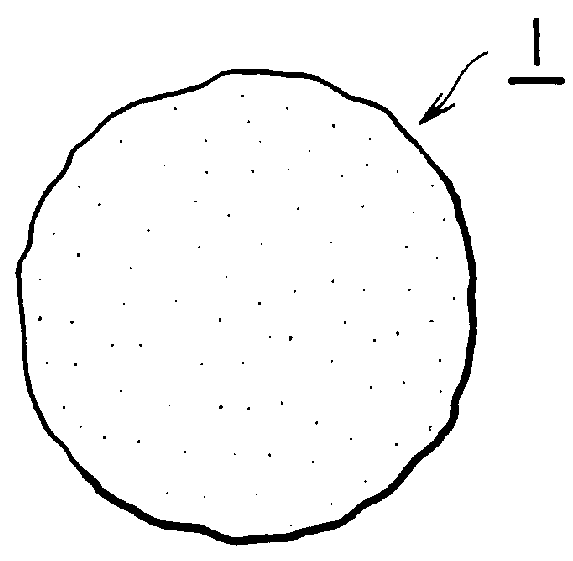

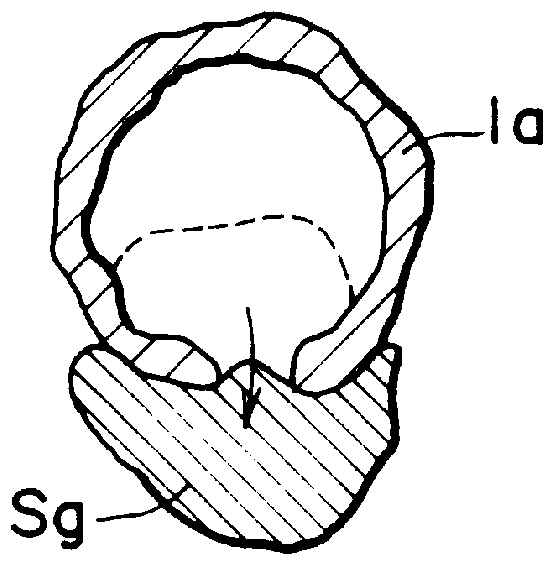

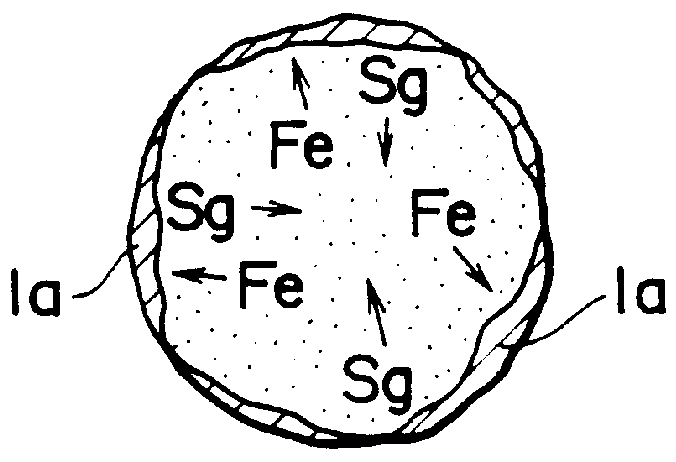

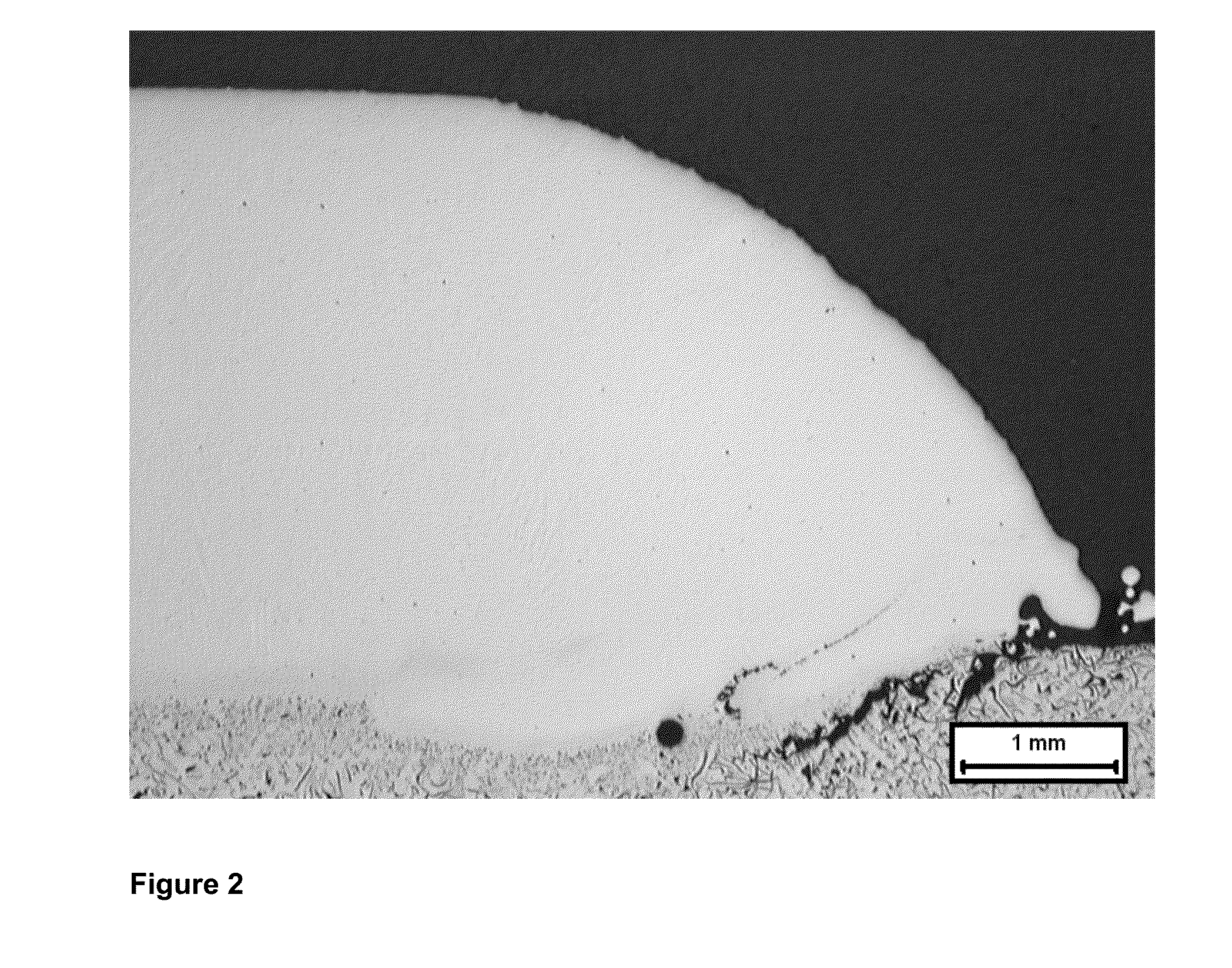

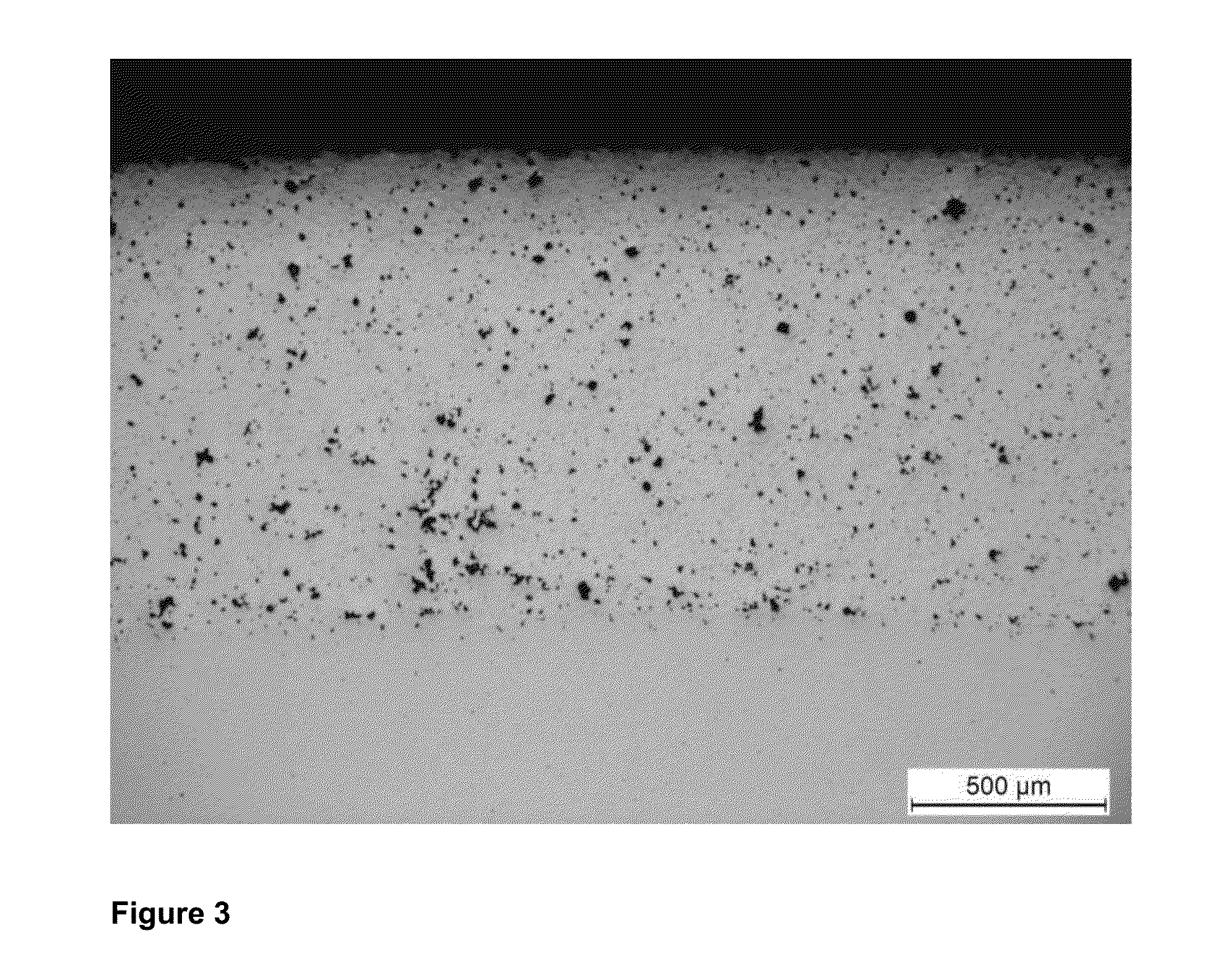

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

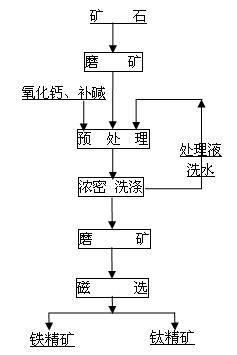

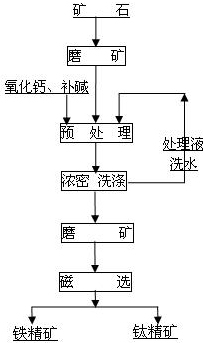

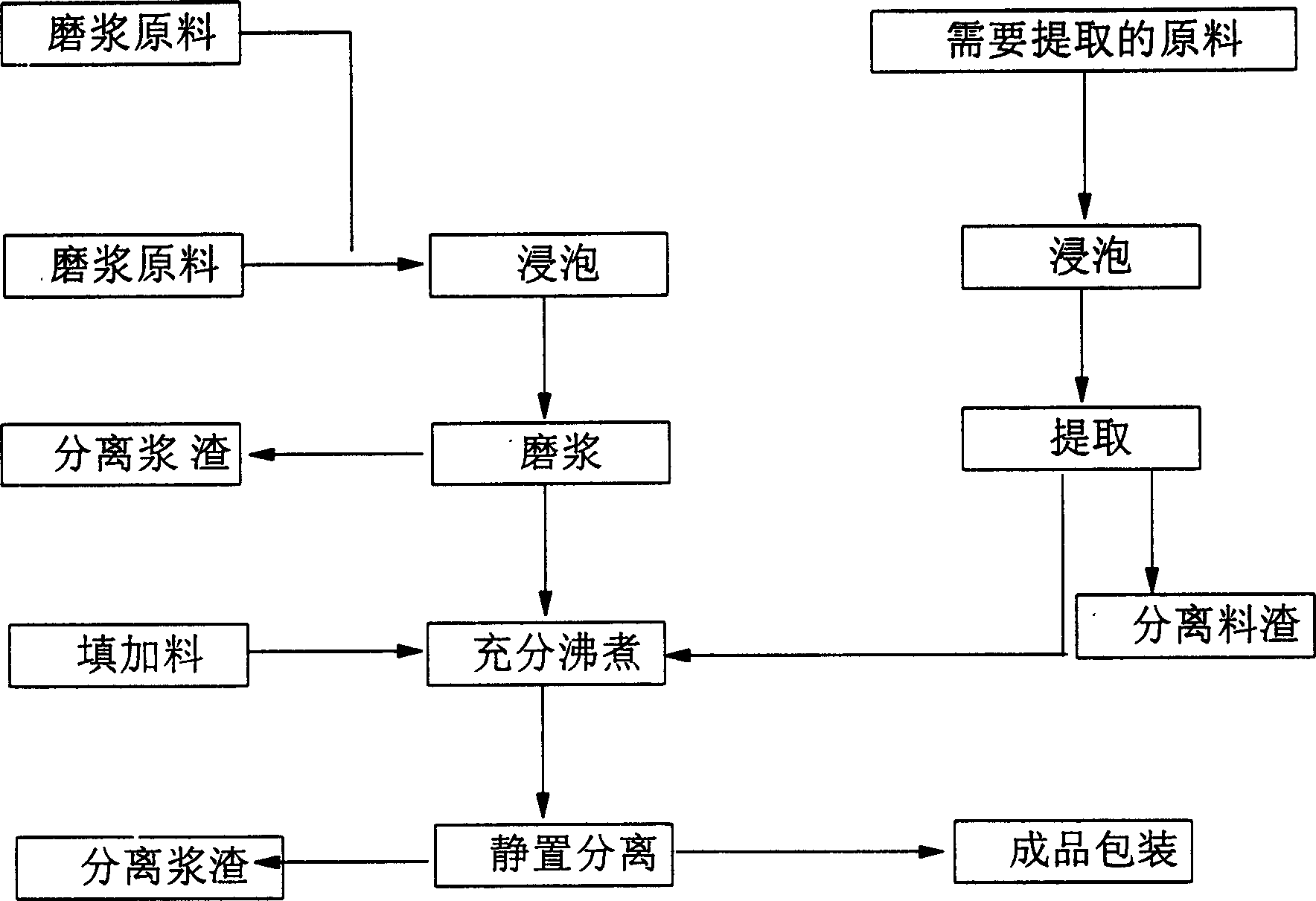

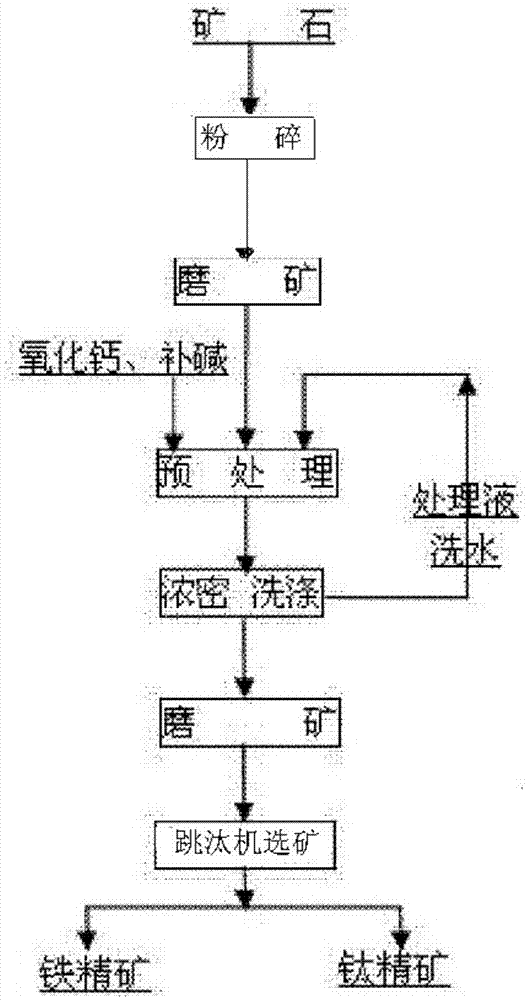

Beneficiating method for ilmenite

ActiveCN102181626AIncrease alkali concentrationHigh in ironBlast furnace detailsProcess efficiency improvementMagnetiteIlmenite

The invention discloses a beneficiating method for ilmenite, relating to a method for preparing titanium concentrate and iron concentrate by beneficiating crude ilmenite. The method is characterized in that: a beneficiating process of the method orderly comprises the following steps of: (1) grinding the crude ilmenite; (2) performing alkaline leaching pretreatment under the conditions of heating, oxygenating and pressurizing; (3) filtering pulp which is subjected to the alkaline leaching pretreatment; (4) washing filter residue and grinding; and (5) performing magnetic separation to obtain the titanium concentrate and the iron concentrate. In the method provided by the invention, the characteristic of iron and titanium compact symbiosis and the isomorphism occurrence characteristic of vanadium are damaged from the source of vanadium titano-magnetite by adopting the pretreatment process, so that mineral transformation of the vanadium titano-magnetite is realized, dissociation on lattice layers of titanium and iron is realized, high-quality iron concentrate and titanium concentrate with lower iron content are obtained through grinding and the magnetic separation process, an alkaline medium used in the pretreatment can be recycled, and the process has a small influence on environment and a bright application prospect.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

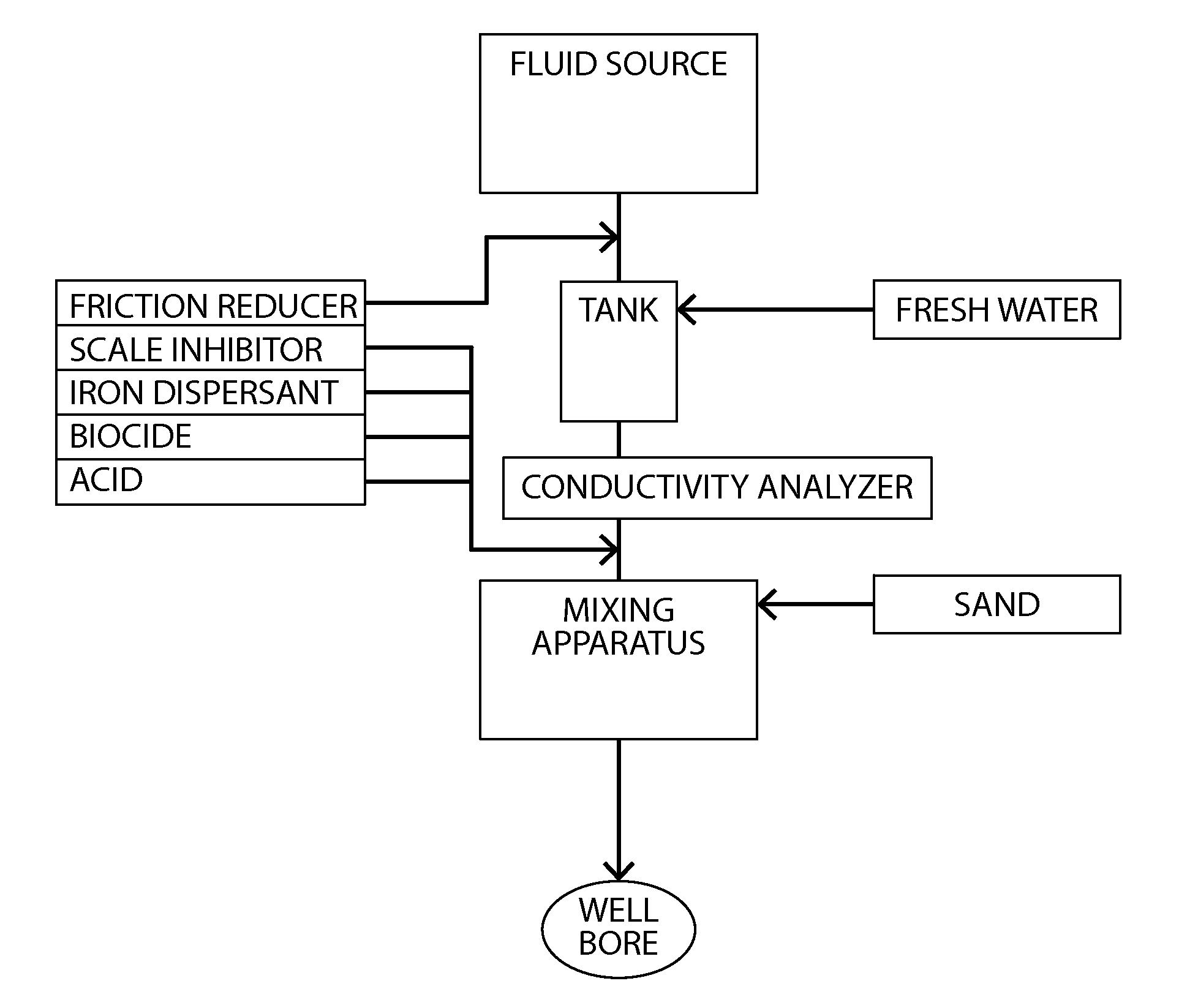

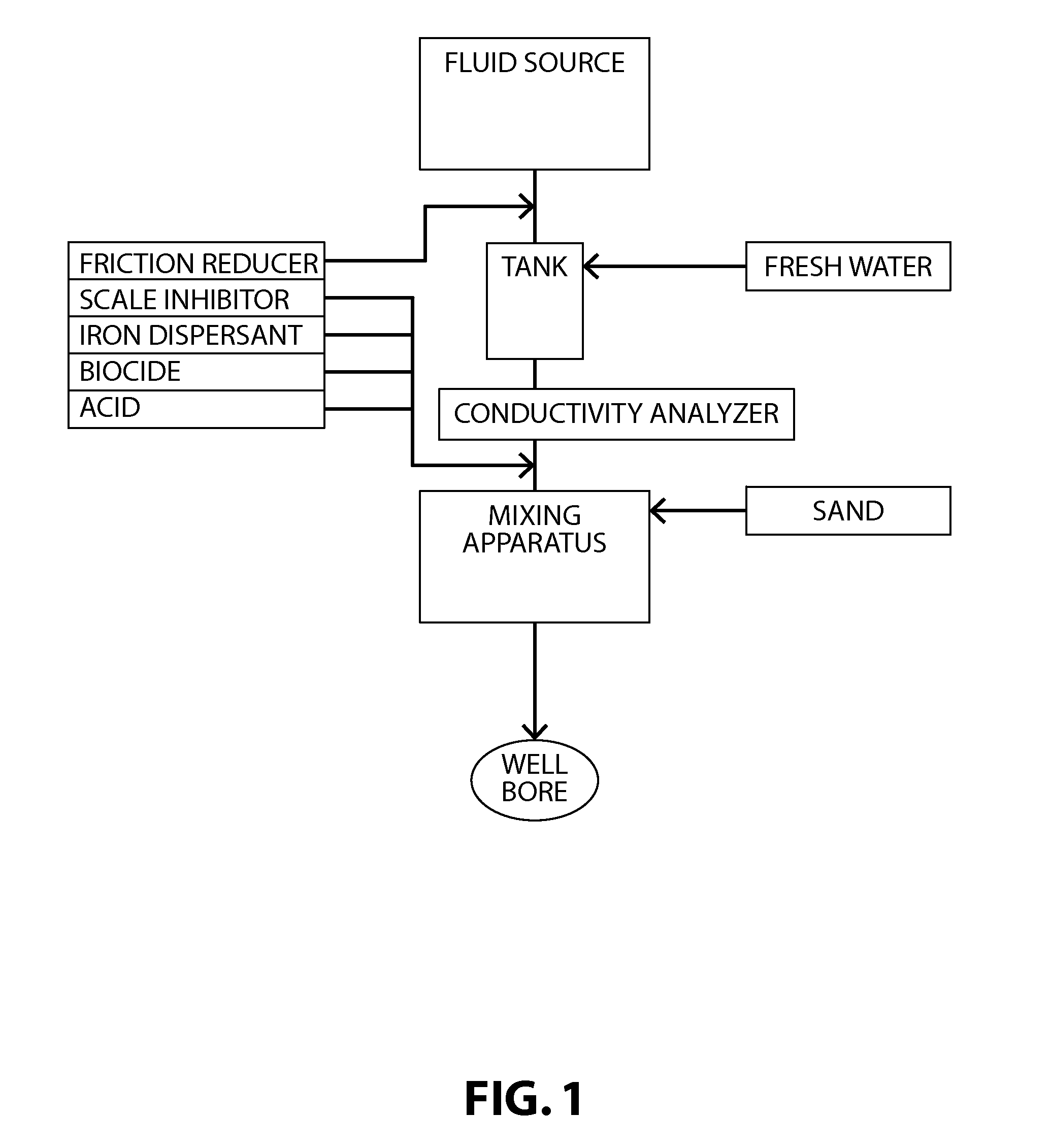

Fracturing fluid water reuse system and method

ActiveUS20120024525A1Low costIncreasing well productionFluid removalMixer accessoriesFracturing fluidHydraulic fracturing

Methods of processing a fluid recovered from an oil or gas extraction operation for reuse in a hydraulic fracturing fluid are described. The methods include providing an amount of a produced fluid composition containing iron and suspended solids and controlling at least one of the conductivity, iron content, oxidative strength, and pH of the composition, such that Fenton's reagent is formed in situ. Also described are hydraulic fracturing fluids produced using fluid recovered from an oil or gas production process and treated in accordance with the methods described herein as well as systems for preparing a hydraulic fracturing fluid having, as a fluid source, fluid recovered from an oil or gas production process that has been treated in accordance with the methods described herein.

Owner:CHEVROU USA INC

Iron-Containing Human Milk Fortifier With Improved Antimicrobial Properties

InactiveUS20080274230A1Reducing and eliminating inherent activityHigh iron concentrationNervous disorderAntipyreticHuman milk fortifierMicroorganism

Disclosed are human milk fortifier compositions, in either powder or liquid forms, comprising nutrients and selected iron-containing materials, wherein the fortifiers when added to human milk do not significantly inhibit or otherwise eliminate the inherent, in-vitro antimicrobial properties of the milk. This is accomplished by formulating the compositions with iron-containing insoluble iron, soluble bound iron, or combinations thereof, with little or no soluble unbound iron. Also disclosed are methods of providing nutrition to infants, especially preterm infants, by adding the human milk fortifier described herein with human milk to form a fortified human milk, and then administering the fortified human milk to the infant. The fortifier can also be used to fortify other infant formulas.

Owner:JOHNS PAUL W +2

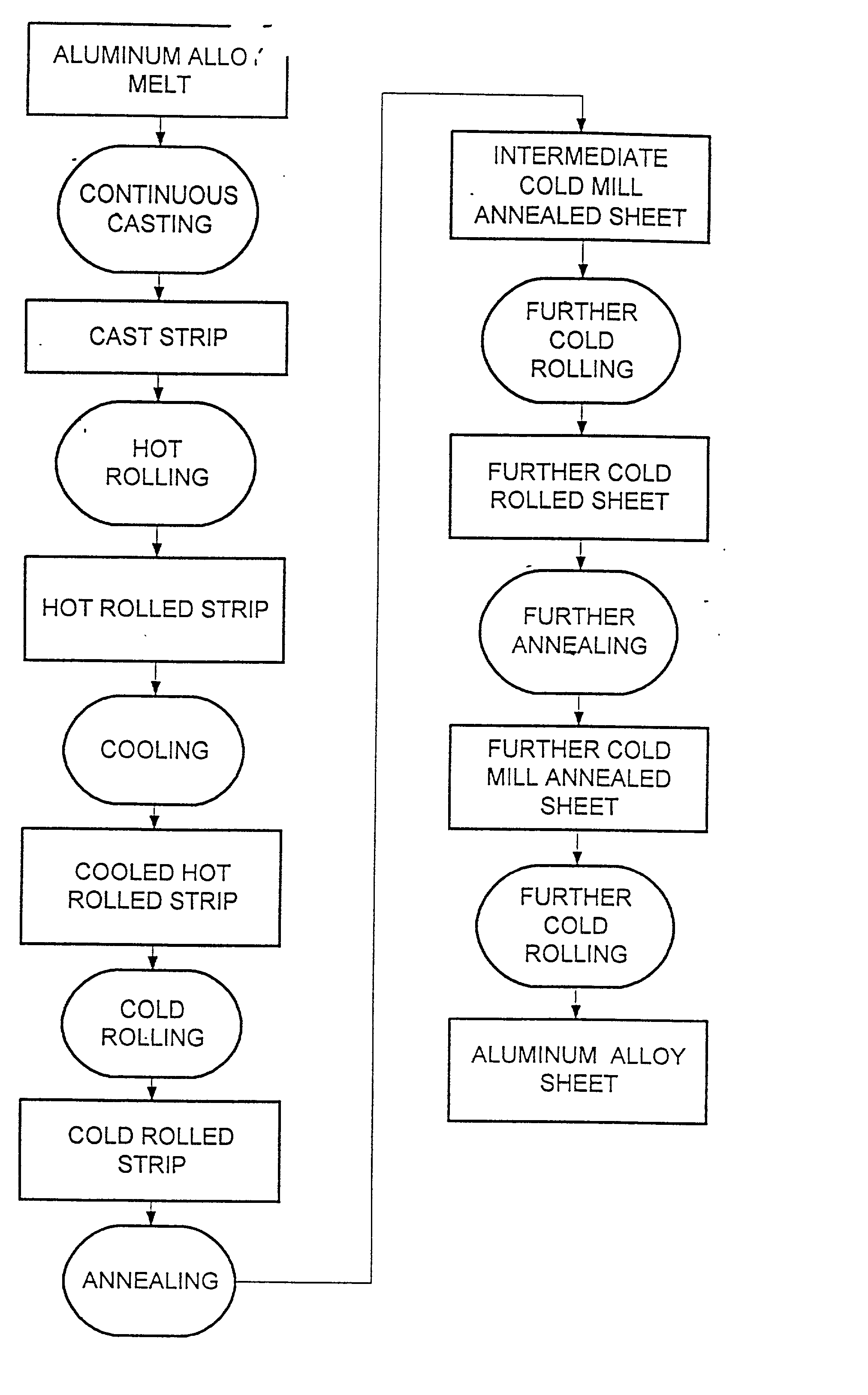

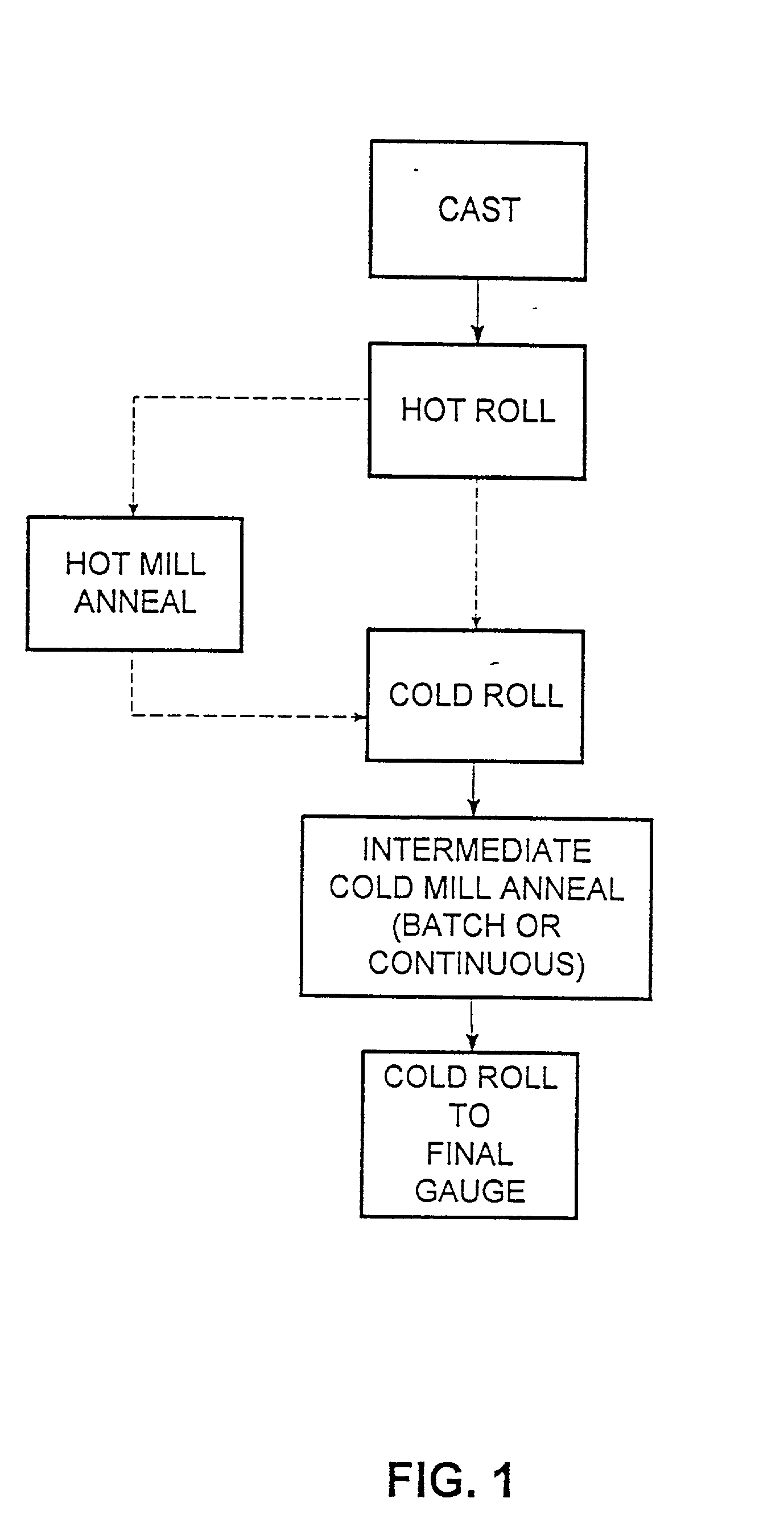

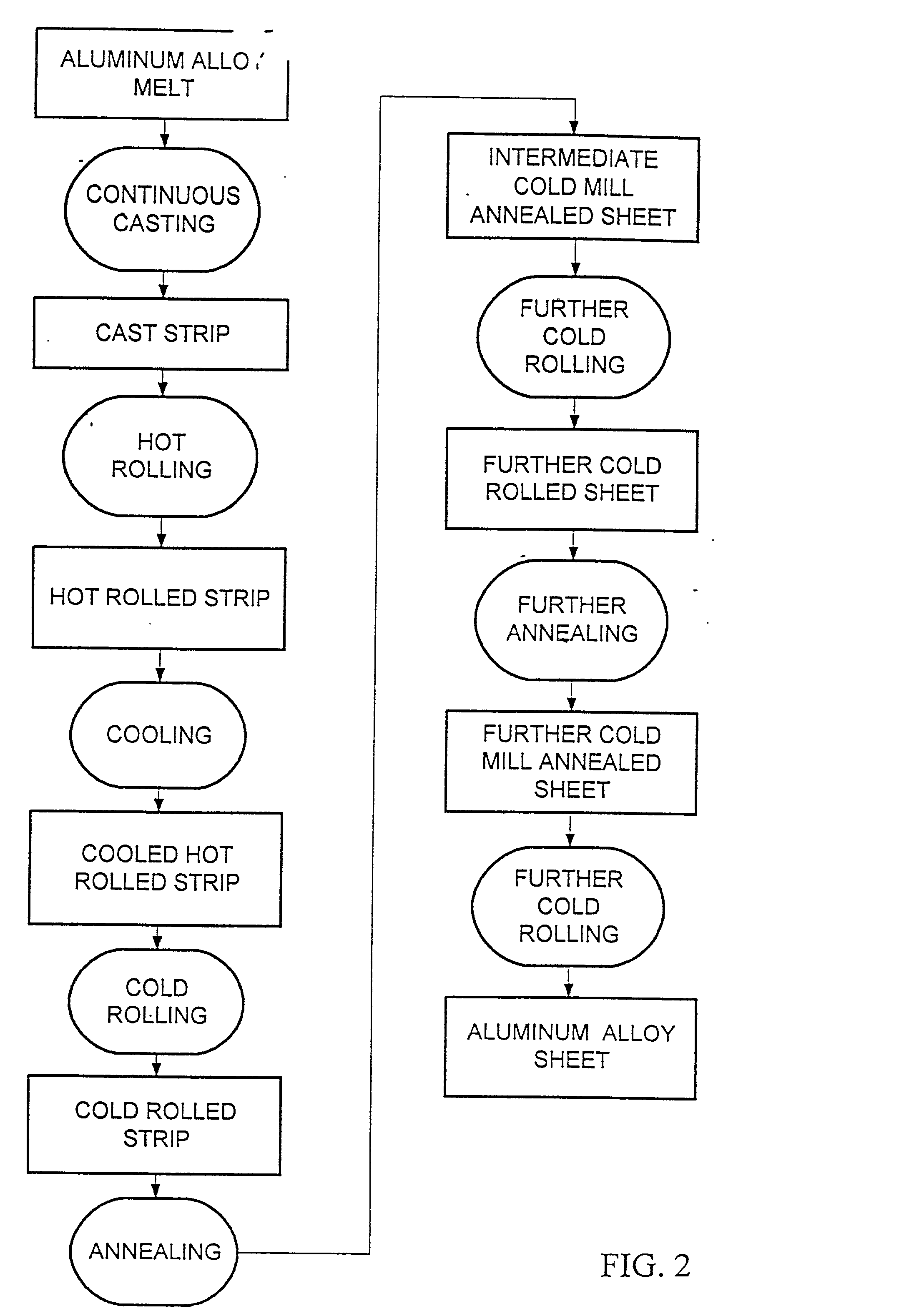

Method for making an improved aluminum alloy sheet product

InactiveUS20020043311A1High reductions in gaugeGreater hot mill and cold mill reductionsUltimate tensile strengthAluminium alloy

An aluminum alloy sheet and a method for producing an aluminum alloy sheet. The aluminum alloy sheet is useful for forming into drawn and ironed container bodies. The sheet preferably has an after-bake yield strength of at least about 37 ksi and an elongation of at least about 2 percent. Preferably, the sheet also has earing of less than about 2 percent.

Owner:NICHOLS ALUMINUM - GOLDEN

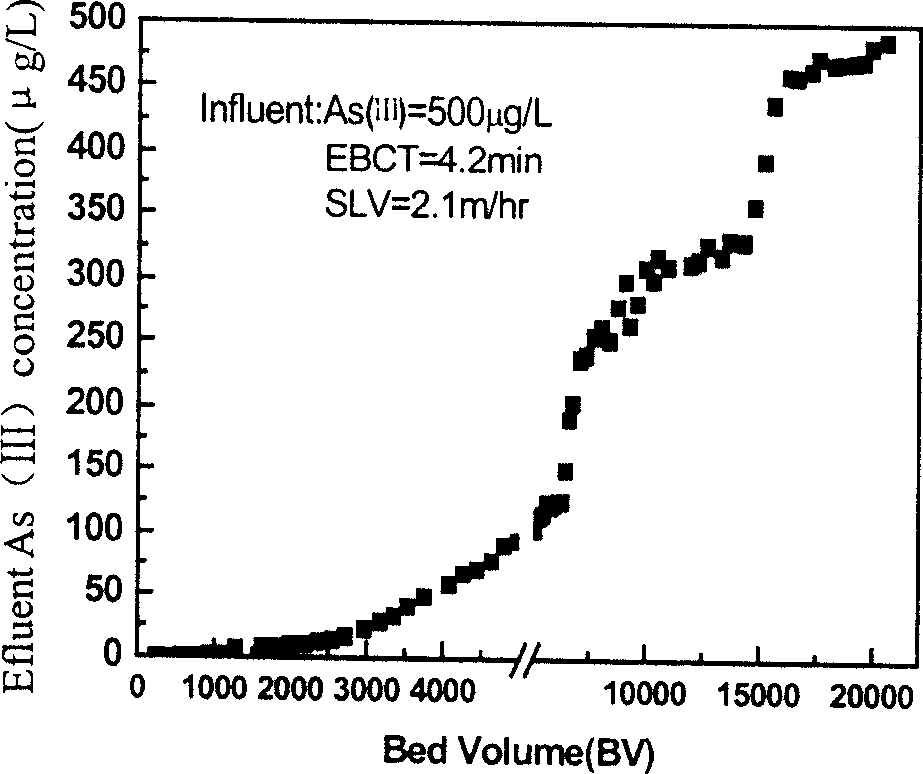

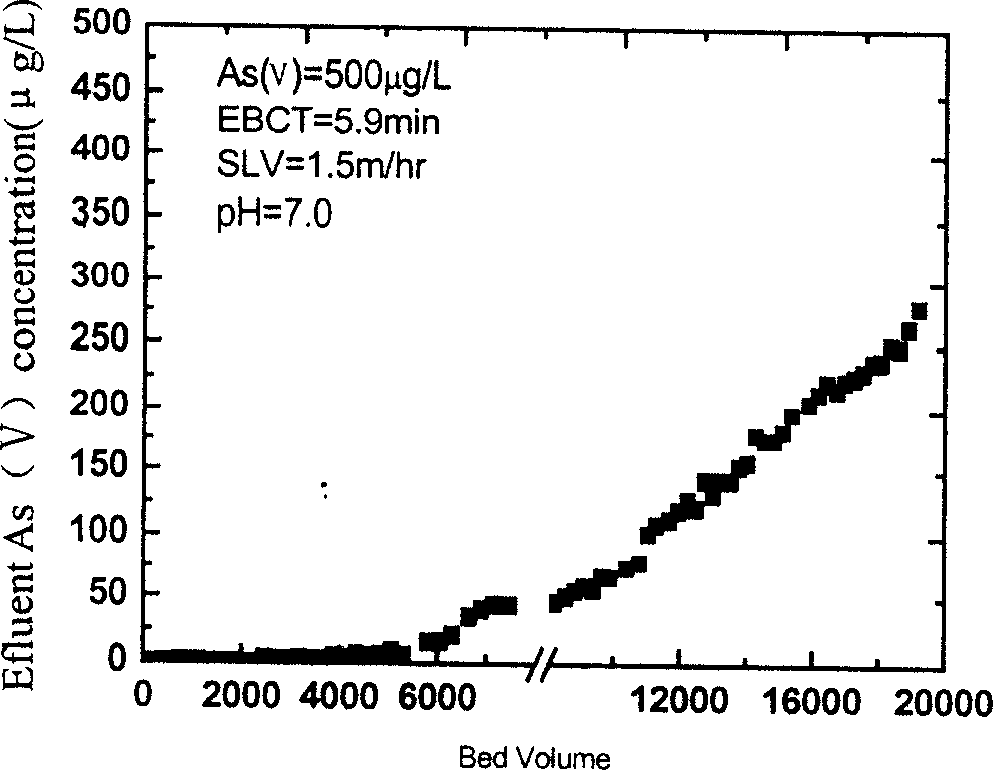

Ferrum carried spherical cellulose adsorbent, preparation and application thereof

InactiveCN1593745ASuccessfully removedImprove hydrophilicityOther chemical processesCelluloseHigh absorption

The invention relates to a kind of globe-form cellulose absorbent with iron carrying and its manufacturing and application. The carrying agent of the invention is globe-form cellulose, and the active center is the hydroxide of iron in the specific form, which has the high absorption activity. The manufacturing feature is as follows: dropwise alkali solution tardily into the solution of cellulose bead and molysite; in stirring condition, iron can load the cellulose bead by dispersing and hydrolyzing; after loading repeatedly and frequently, use the alkali solution to stabilize the ferruginous form. The manufacturing method of the absorbent has the advantages of environmental protection, novelty, simplicity and low cost. Moreover, it can remove arsenic, fluorine and other heavy metal with high efficiency and high selectivity, and the absorbent has excellent usage-prospect in nowadays.

Owner:NANKAI UNIV

PROCESS FOR HYDRAULIC FRACTURING WITH pH CONTROL

InactiveUS20130206398A1High in ironSufficient mechanical propertySurveyFluid removalPh controlFracturing fluid

A process for hydraulic fracturing including the steps of (a) providing a fracturing fluid by combining water, proppant, an oxidizing biocide, and a friction reducer; (b) introducing the fracturing fluid into a well; and (c) controlling the pH of the fracturing fluid to a pH of at least about 4.5.

Owner:THE CHEMOURS CO FC LLC

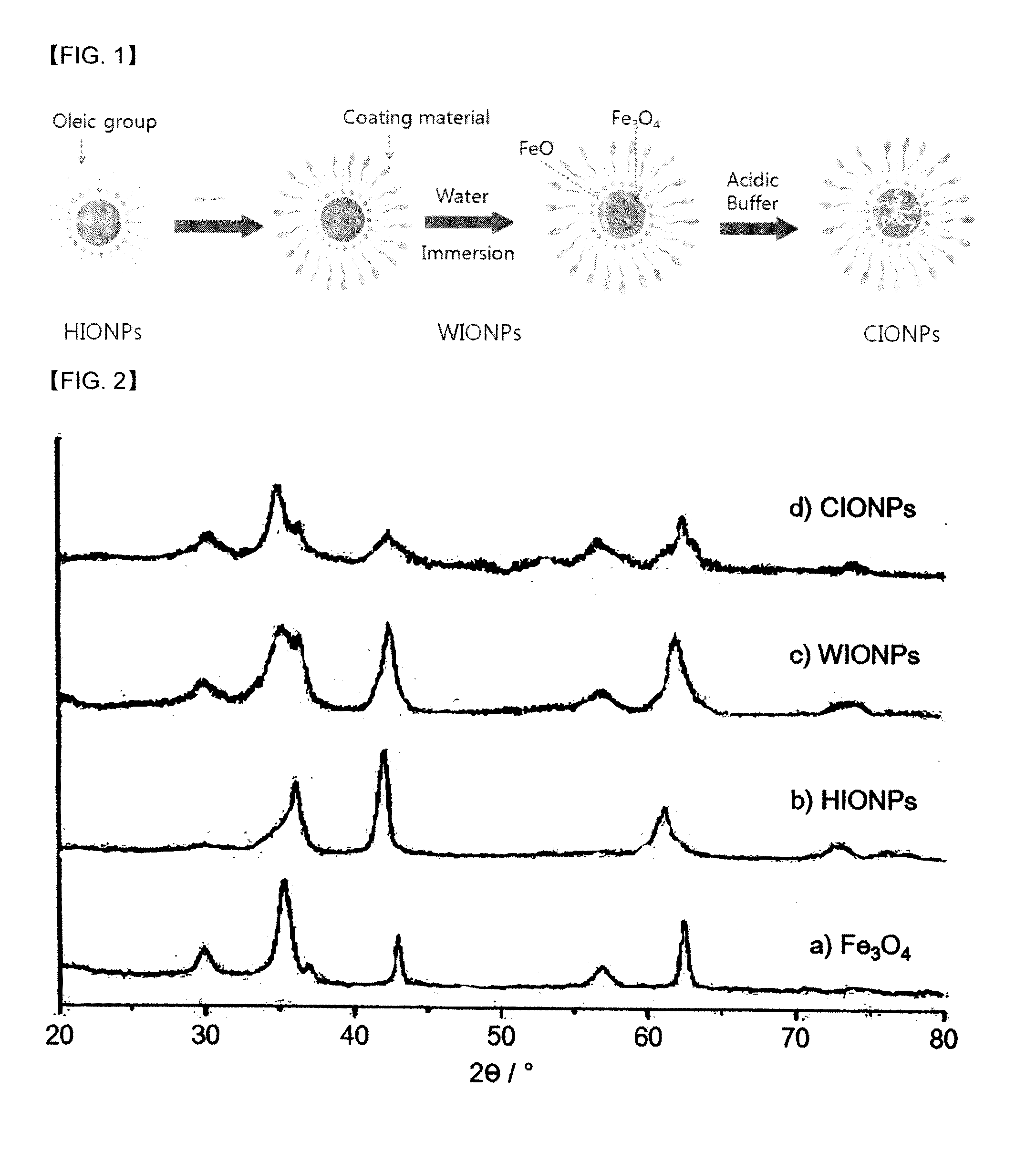

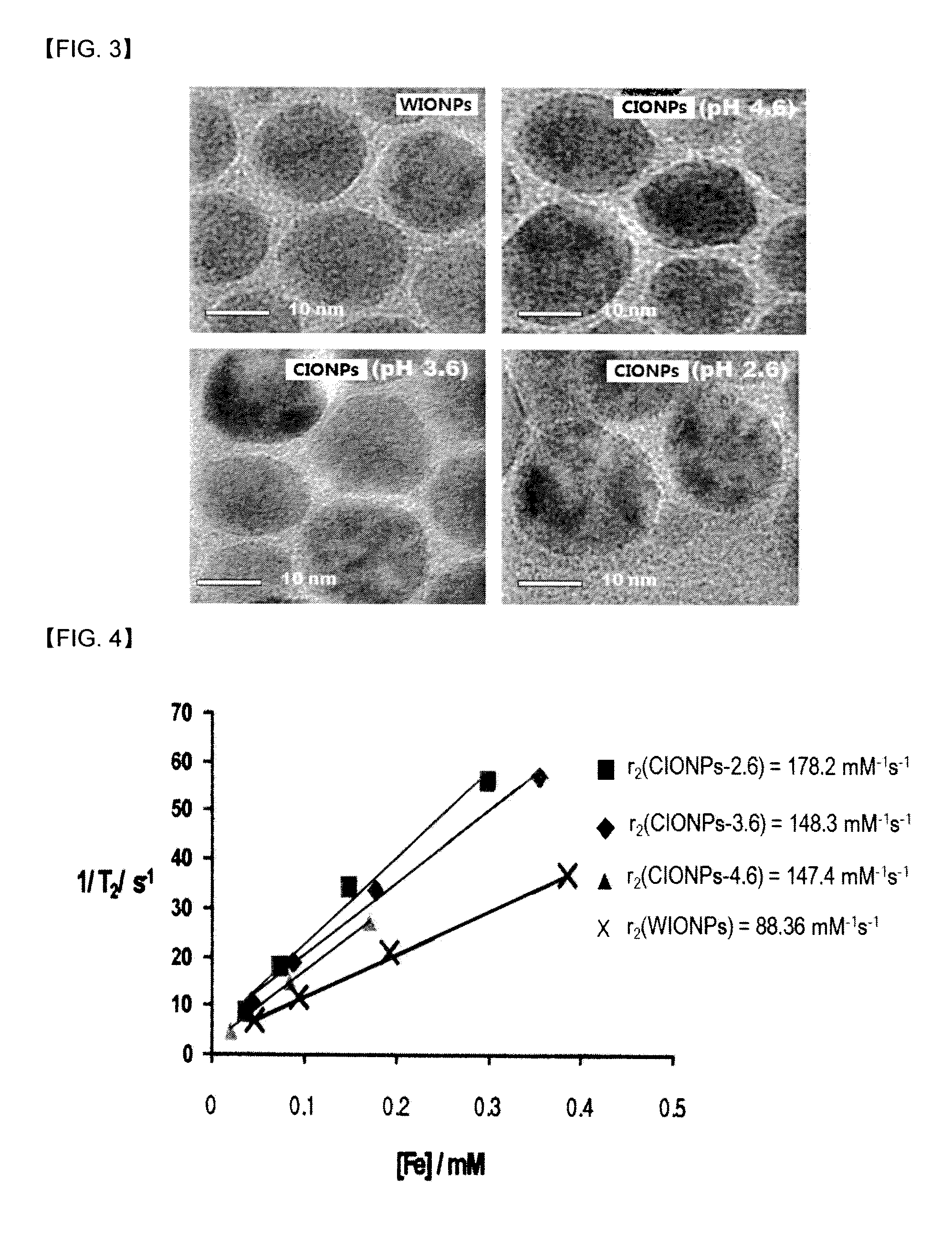

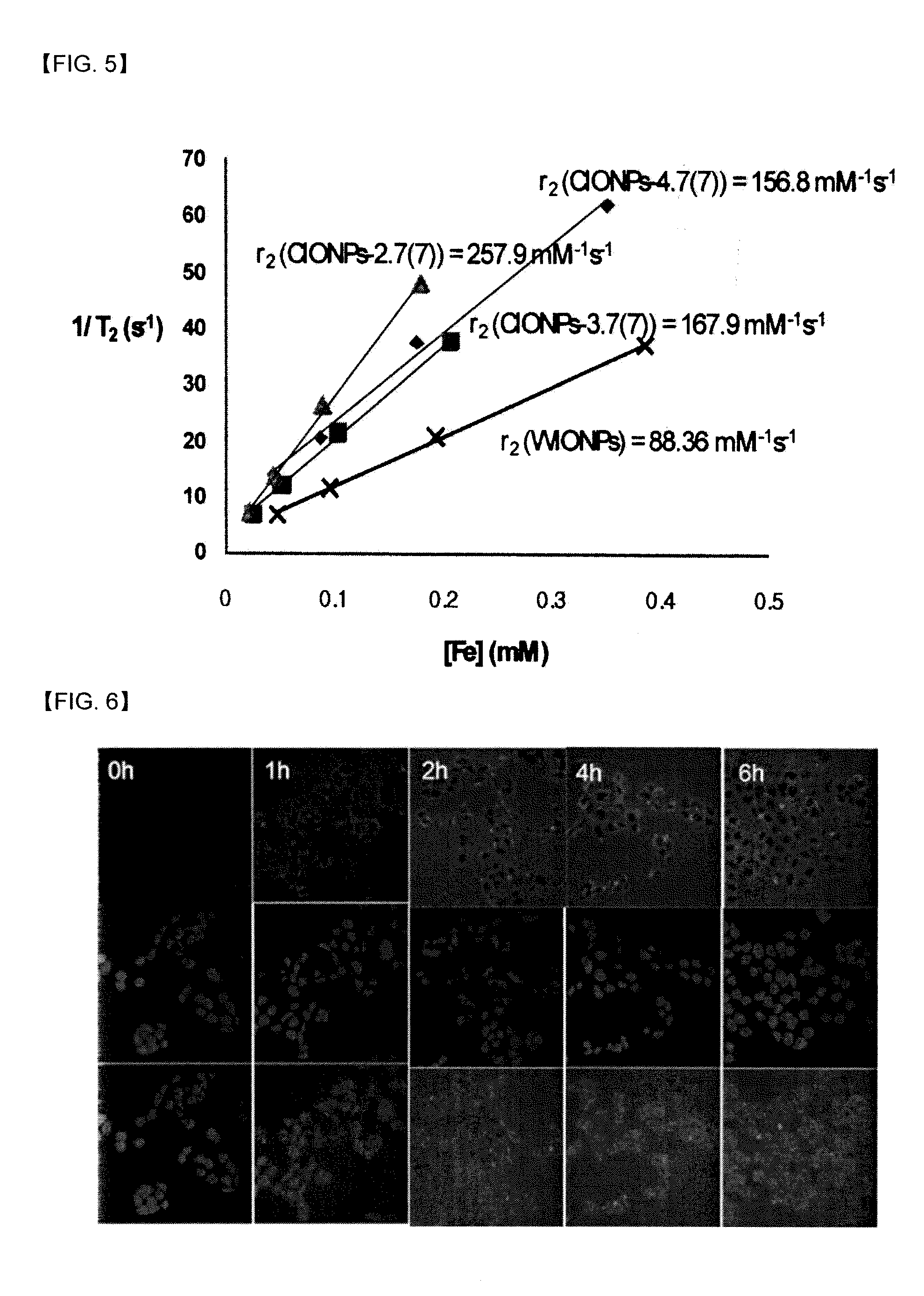

Iron oxide nanoparticles as MRI contrast agents and their preparing method

InactiveUS20110165086A1Low toxicityHigh in ironMaterial nanotechnologyGenetic material ingredientsMRI contrast agentPolyethylene glycol

Iron oxide nano contrast agents for Magnetic Resonance Imaging which have superior T2 contrast effect, and also can be used as a storage or a carrier for drugs and so on, are disclosed. The iron oxide nano contrast agents can be prepared by the steps of: coating surfaces of hydrophobic FeO nanoparticles with a coating material selected from the group consisting of polyethylene glycol-phospholipid conjugate, dextran, chitosan, dimercaptosuccinic acid and mixtures thereof in an organic solvent to form hydrophilic FeO nanoparticles having hydrophilic surfaces and dispersibility in water; dispersing the hydrophilic FeO nanoparticles in water to oxidize FeO; and exposing the oxidized hydrophilic FeO nanoparticles to an acidic buffer to dissolve and remove interior unoxidized FeO portions, and thereby to form Fe3O4 nanoparticles having an interior space.

Owner:KOREA BASIC SCI INST

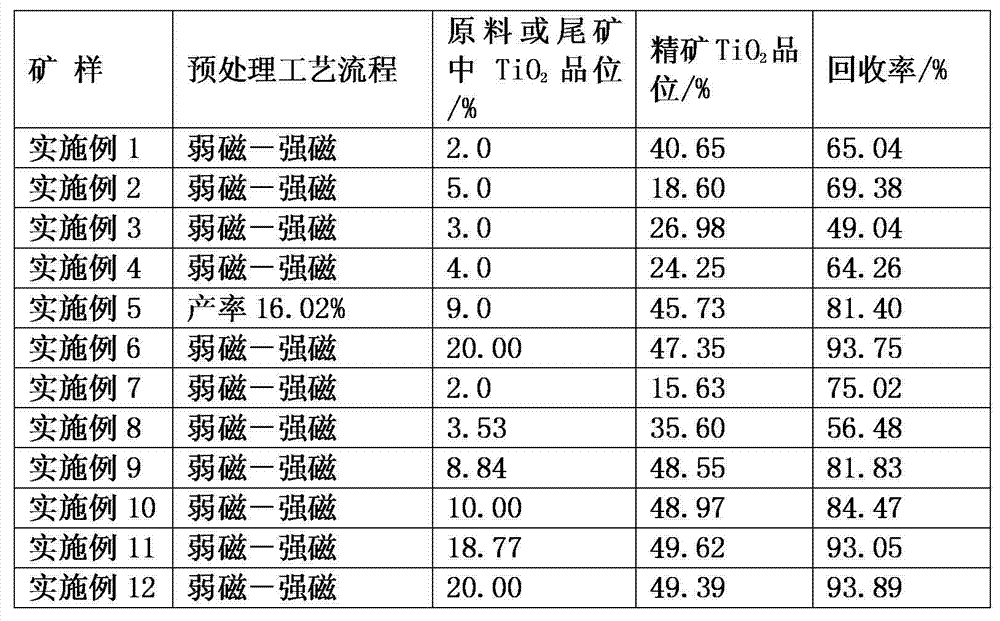

Combined mineral processing technology of low-grade laterite type weathering titanium placers

The invention relates to a combined mineral processing technology of low-grade laterite type weathering titanium placers and belongs to the technical field of mineral processing. The combined mineral processing technology includes subjecting raw materials with the titanium dioxide content of below 5% to low-intensity magnetic-high-intensity magnetic pre-treatment technologies, then gravity separation-regrinding-gravity separation, gravity separation-regrinding-flotation processing and regrinding-flotation processing. According to the combined mineral processing technology of the low-grade laterite type weathering titanium placers, by means of the low-intensity magnetic-high-intensity magnetic pre-treatment technologies, a large number of slurries which are rich in kaolin minerals can be cast, technological procedures can be simplified, obtained rough titanium concentrates have few slurries, and follow-up treatment can be easily performed, for example, the interference of the slurries is avoided when technologies such as flotation and tabling gravity separation are performed; the grade and the recovery rate of the obtained titanium concentrates are high, and high intensity magnetic separation is beneficial to recovery of fine-particle grade titanium particles; and by means of the technologies of gravity separation-regrinding-gravity separation, gravity separation-regrinding-flotation processing and regrinding-flotation processing, the recovery rate of titanium is high, simultaneously, the content of iron in mineral samples is increased, and additional values of products are improved.

Owner:KUNMING METALLURGY INST

Health care nutritious soybean milk

InactiveCN1602754AReduce contentIncrease proteinUnknown materialsFood scienceAdditive ingredientVitamin

The invention called healthy and nutritional soya-bean milk relates to the field of healthy and nutritional food. It uses elements of eatable invigorant and invigorant to adjust the proportion of the nutrition component in the soya-bean milk in order that it can be fit for the nutrition need of any age or any degree of the laborhood. When adjust the proportion of the nutrition component, we choose the most food-like medicine to the best on the base that we use the mild medicine when the foundation of the medicines is the same. For instance, when we produce healthy and nutritional soya-bean milk for brain care and increasing memory, we choose walnut, meat and honey containing abundant protein, unsaturated fatty acid, lecithin and vitamin. Therefore, it is good at curing the brain weaken, insomnia and increasing memory.

Owner:陈跃华

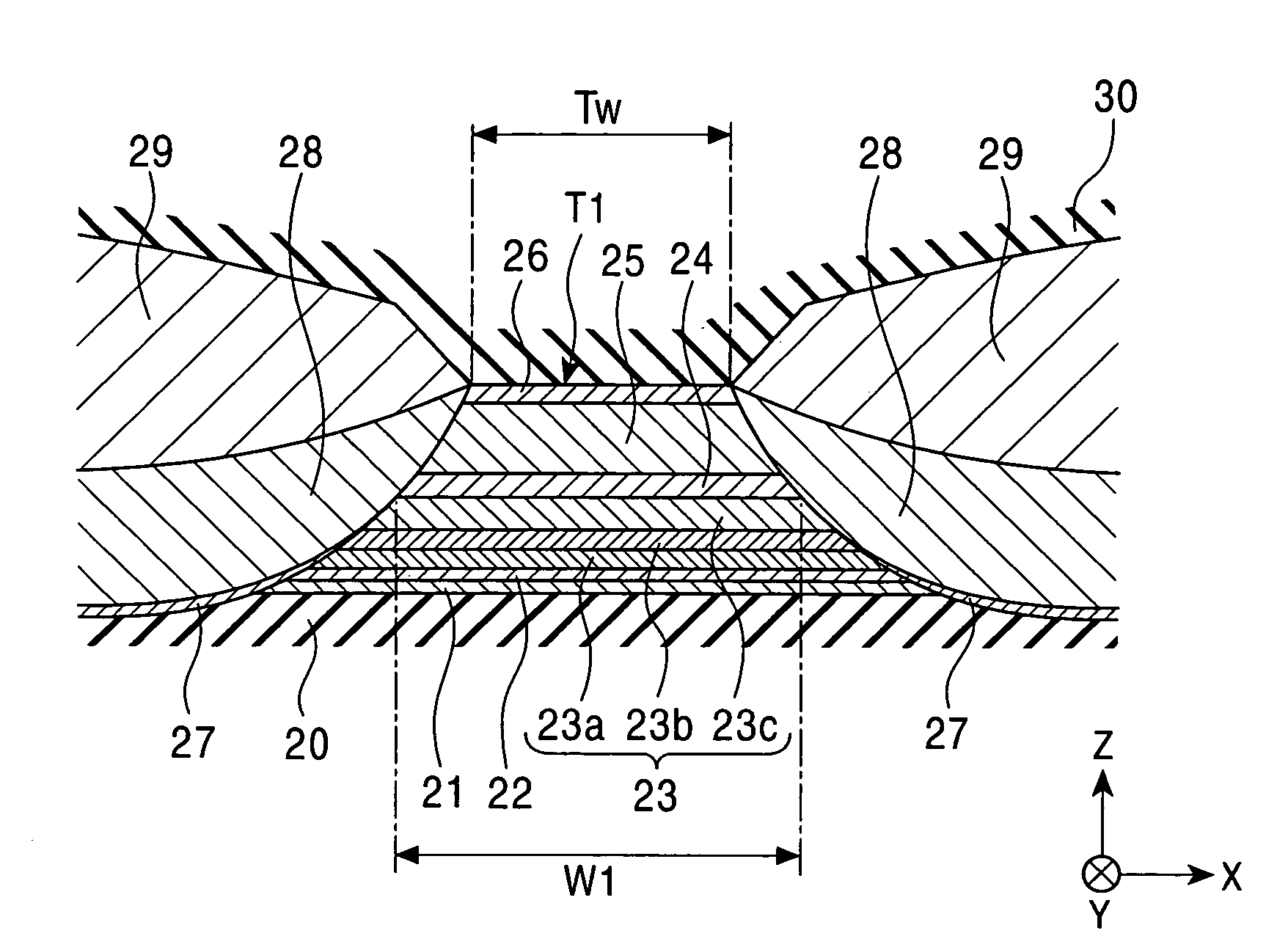

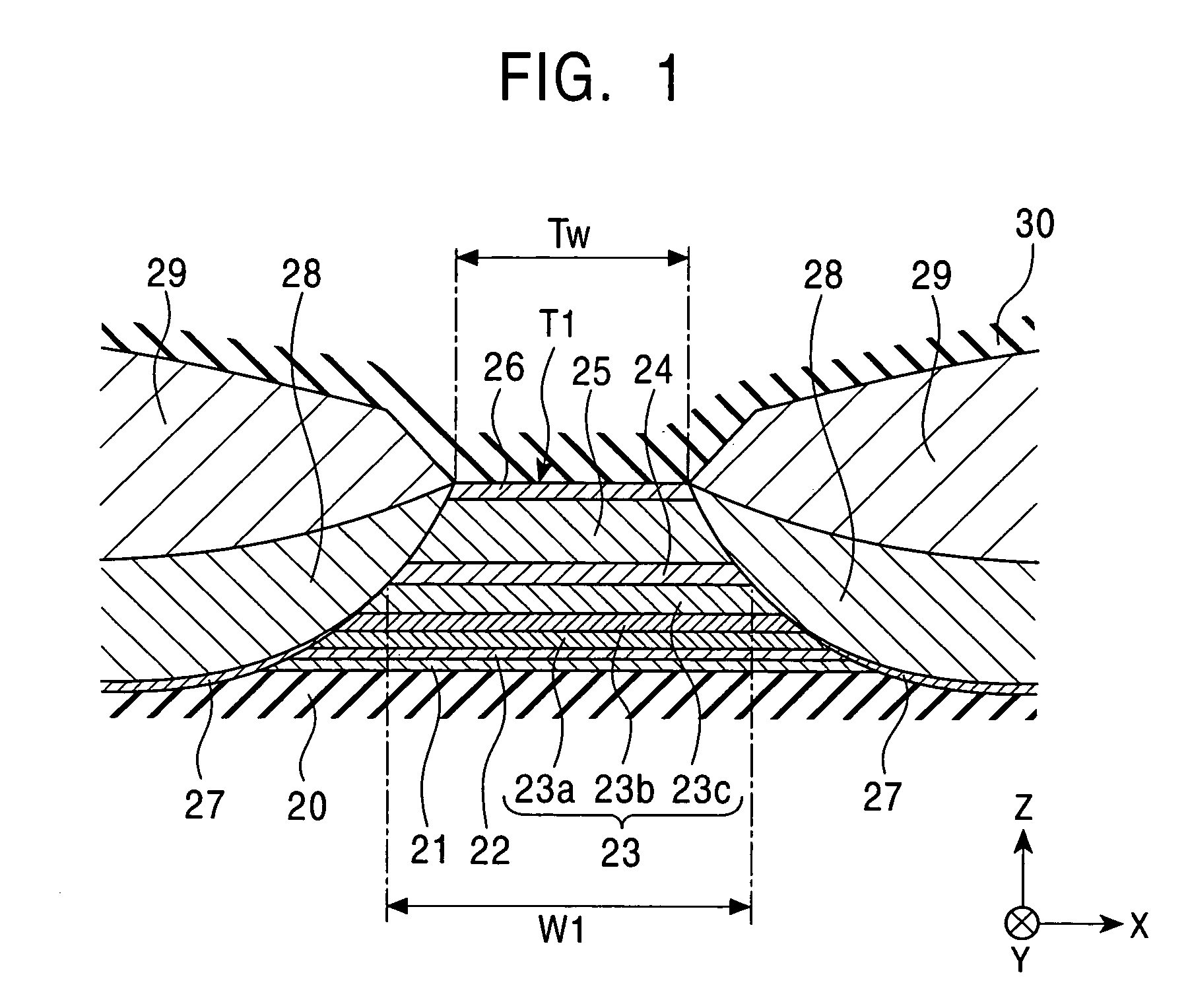

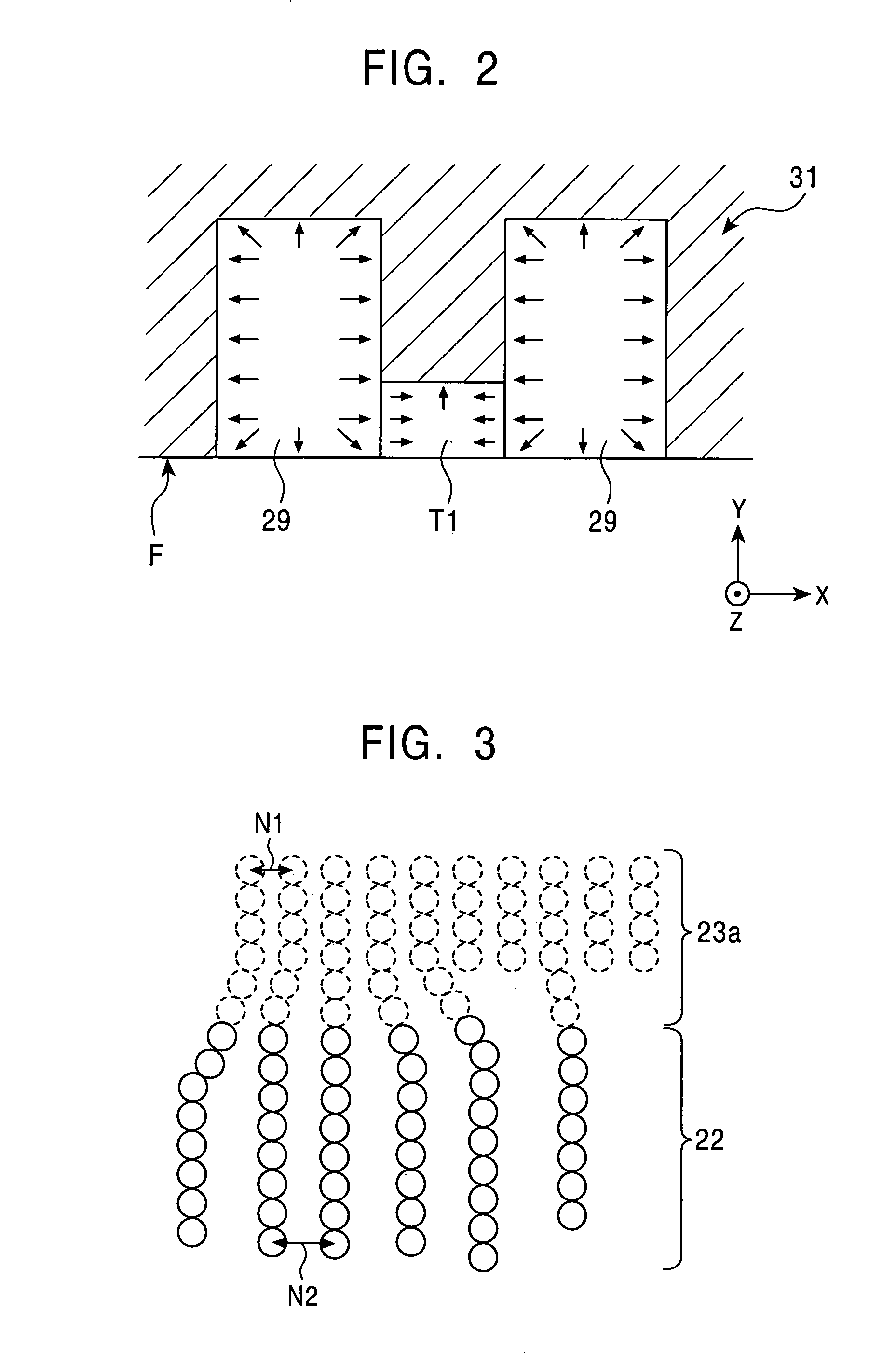

Spin valve magnetoresistive element having pinned magnetic layer composed of epitaxial laminated film having magnetic sublayers and nanomagnetic interlayer

InactiveUS7126797B2High in ironShunt loss can be smallNanostructure applicationNanomagnetismMagnetic reluctanceCrystal structure

A magnetic sensor includes a pinned magnetic layer having first and second magnetic sublayers sandwiching a nonmagnetic metal layer. The nonmagnetic metal layer contains at least one of Ru, Re, Os, Ti, Rh, Ir, Pd, Pt, and Al. The atoms in the first magnetic sublayer and the atoms in the nonmagnetic metal layer overlap with each other, while each of the crystal structures is deformed. The deformations in the crystal structure of the first magnetic sublayer increase the magnetostriction constant, thereby increasing the magnetoelastic effect of the magnetic sensor.

Owner:TDK CORPARATION

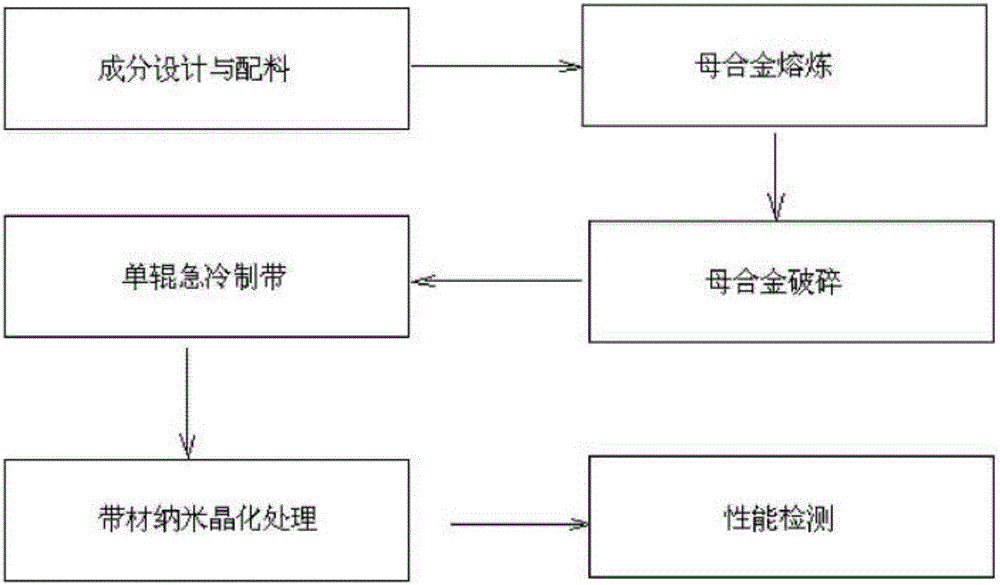

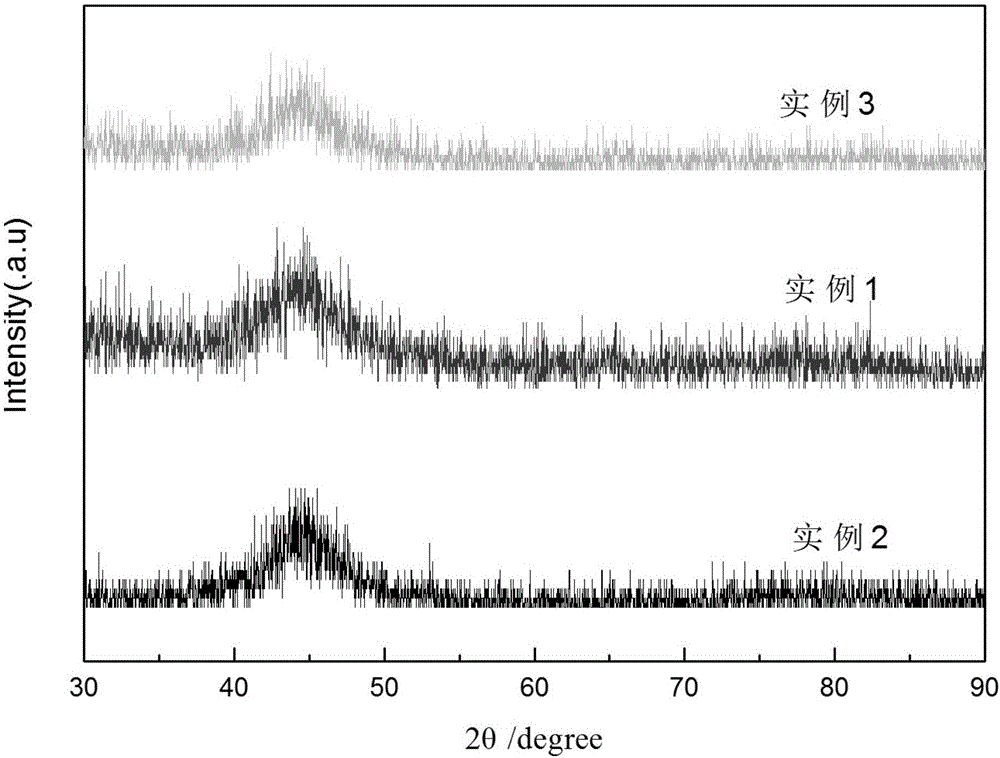

Iron-based amorphous and nano-crystalline soft magnetic alloy and preparation method thereof

The invention provides an iron-based amorphous and nano-crystalline soft magnetic alloy which has a general formula as shown in formula I, FexSiyBzPnCumCw, wherein x is greater than or equal to 84.0 and smaller than or equal to 85.0, y is greater than or equal to 0 and smaller than or equal to 2, z is greater than or equal to 8.5 and smaller than or equal to 10.5, n is greater than or equal to 3 and smaller than or equal to 4, m is greater than or equal to 0.3 and smaller than or equal to 1, w is greater than or equal to 0 and smaller than or equal to 1, and x+y+z+n+m+w is equal to 100. By adding special elements and supplementing with a corresponding proportion, the invention discloses the novel iron-based amorphous and nano-crystalline soft magnetic alloy with has high statured magnetic induction intensity. The alloy has excellent soft magnetic performances such as high magnetic induction intensity and low coercive force, does not contain a dear metal element B and greatly reduces cost of the material.

Owner:GUANGDONG UNIV OF TECH +1

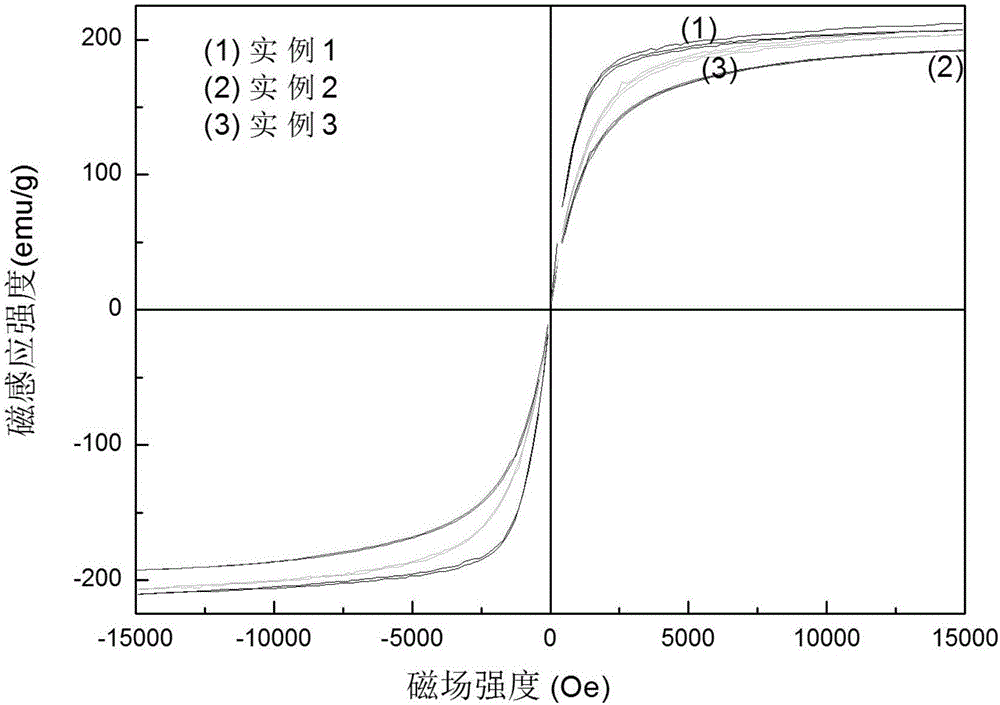

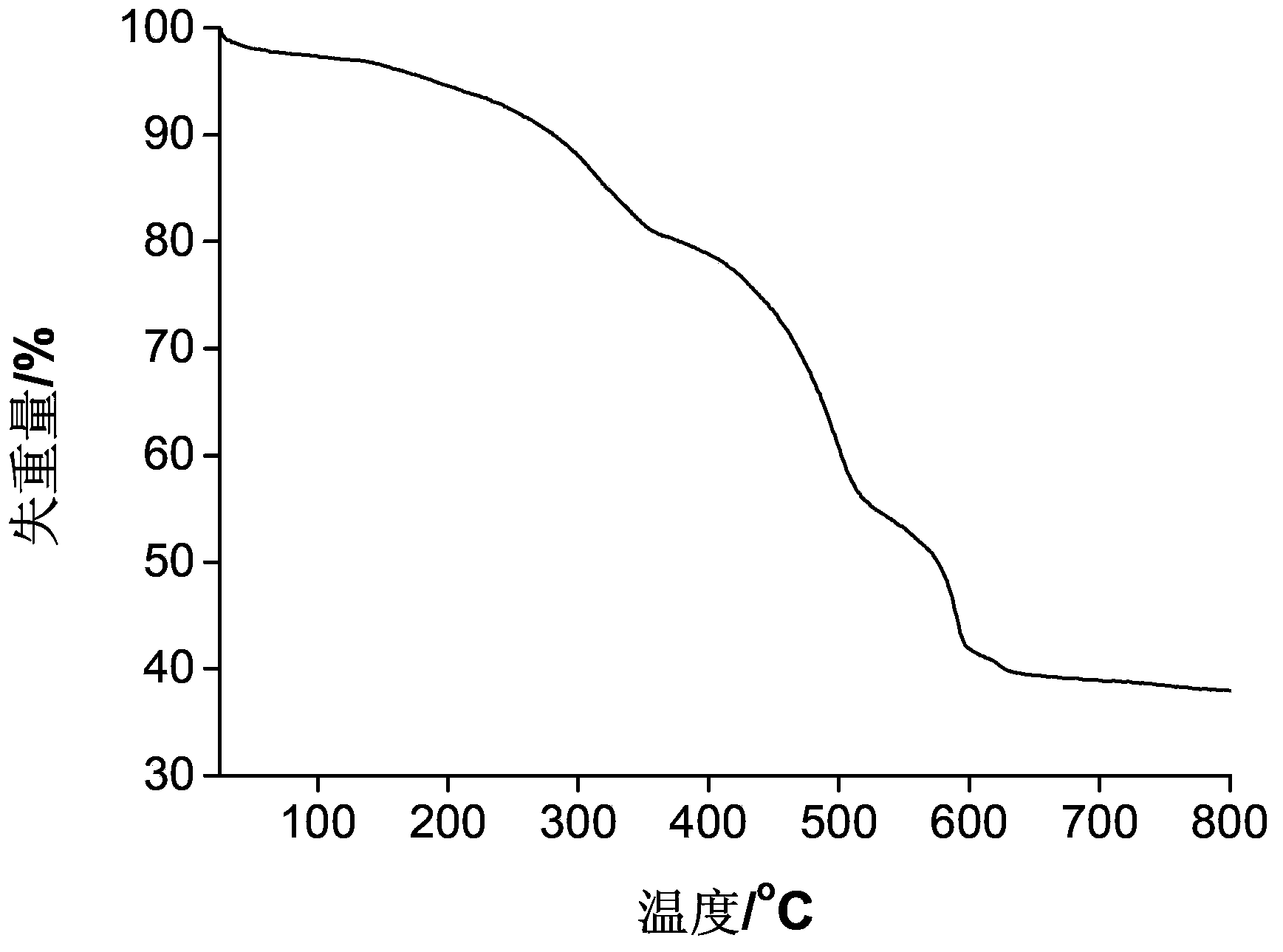

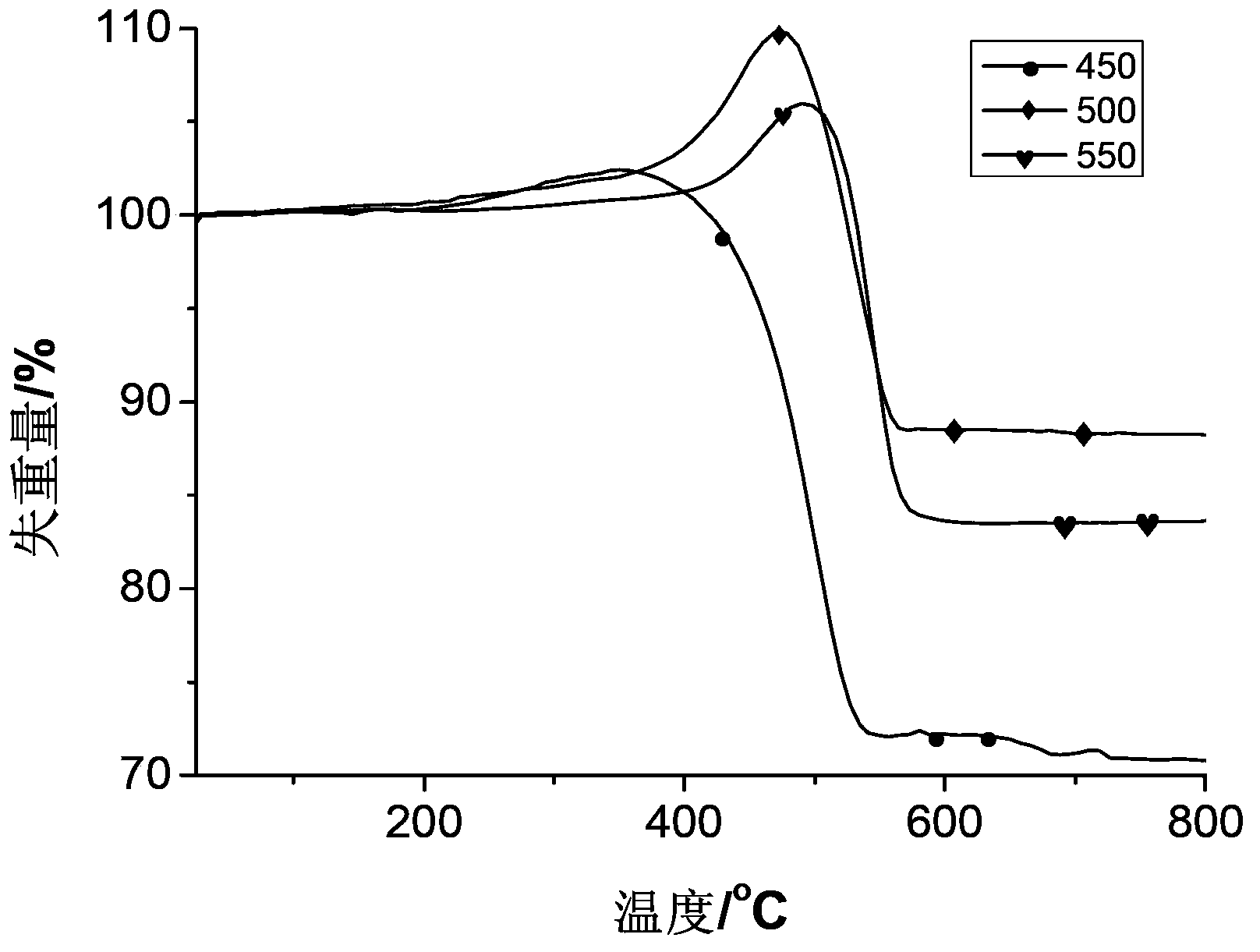

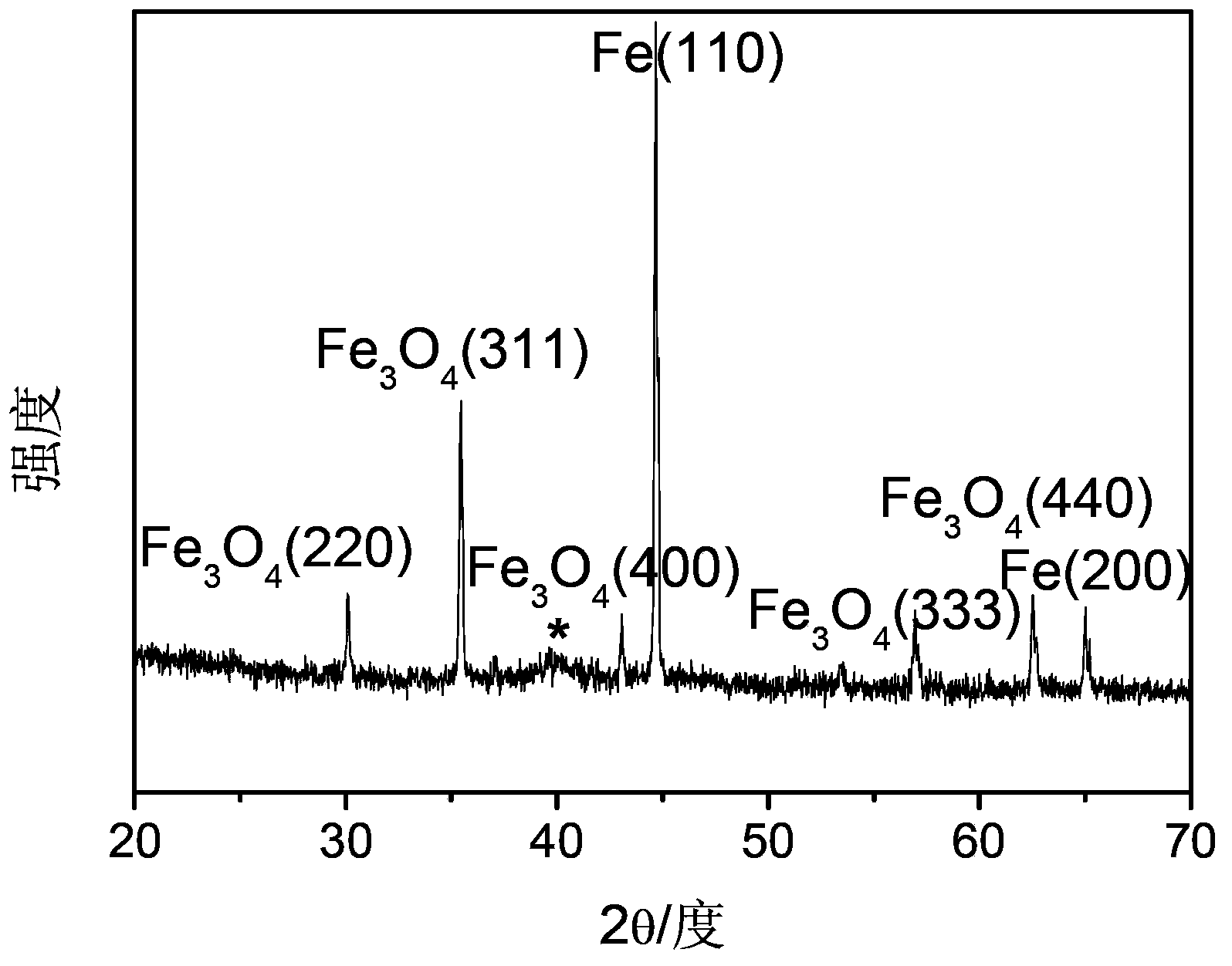

Magnetic iron-carbon composite material, preparation method and application thereof

InactiveCN103623824AEasy to separateGood orientationOrganic compound preparationHydrocarbon by hydrogenationCarbon compositesIron nanoparticle

A disclosed magnetic iron-carbon composite material comprises carbon-coated metallic iron nanoparticles and nanometeriron oxide particles, wherein the iron content is 45%-90% by weight and the specific surface area is 100-500 m<2> / g, and further the composite material comprises a compound composed of the carbon-coated metallic iron nanoparticles and the nanometeriron oxide particles. The invention also discloses a preparation method and application of the magnetic iron-carbon composite material. The magnetic iron-carbon composite material provided by the invention is relatively high in iron content, resistant to 400 DEG C high-temperature oxidation, excellent in magnetic property, easy for magnetic separation and guiding role and high in specific surface area; employed precursors are nontoxic and the preparation conditions are mild; and the material loaded with precious metals has extremely good activity on catalytic hydrogenation reactions, and the composite material is applicable to different catalytic reactions as an excellent catalyst carrier.

Owner:西安荣轩分析测试技术服务有限公司

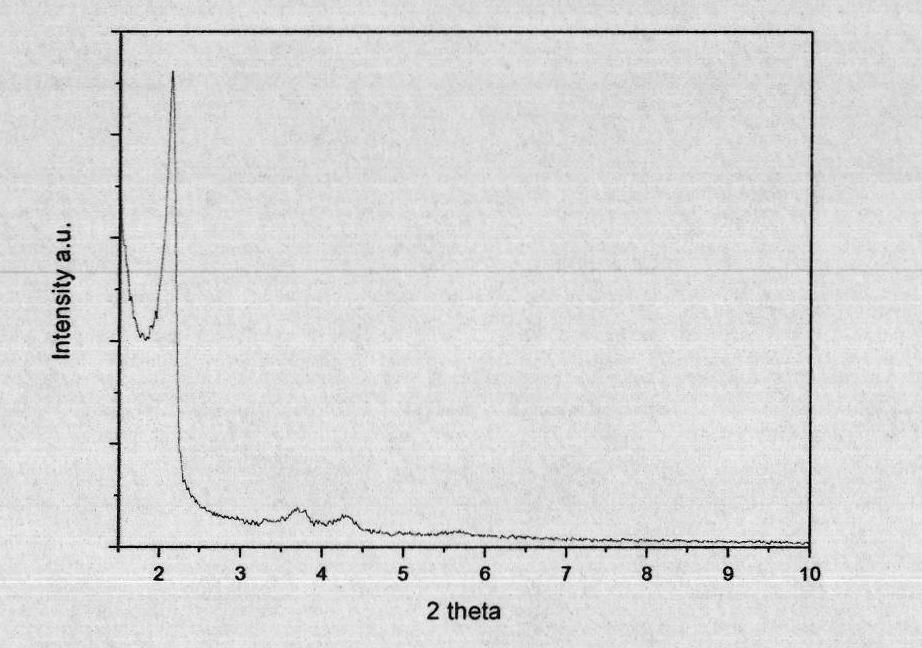

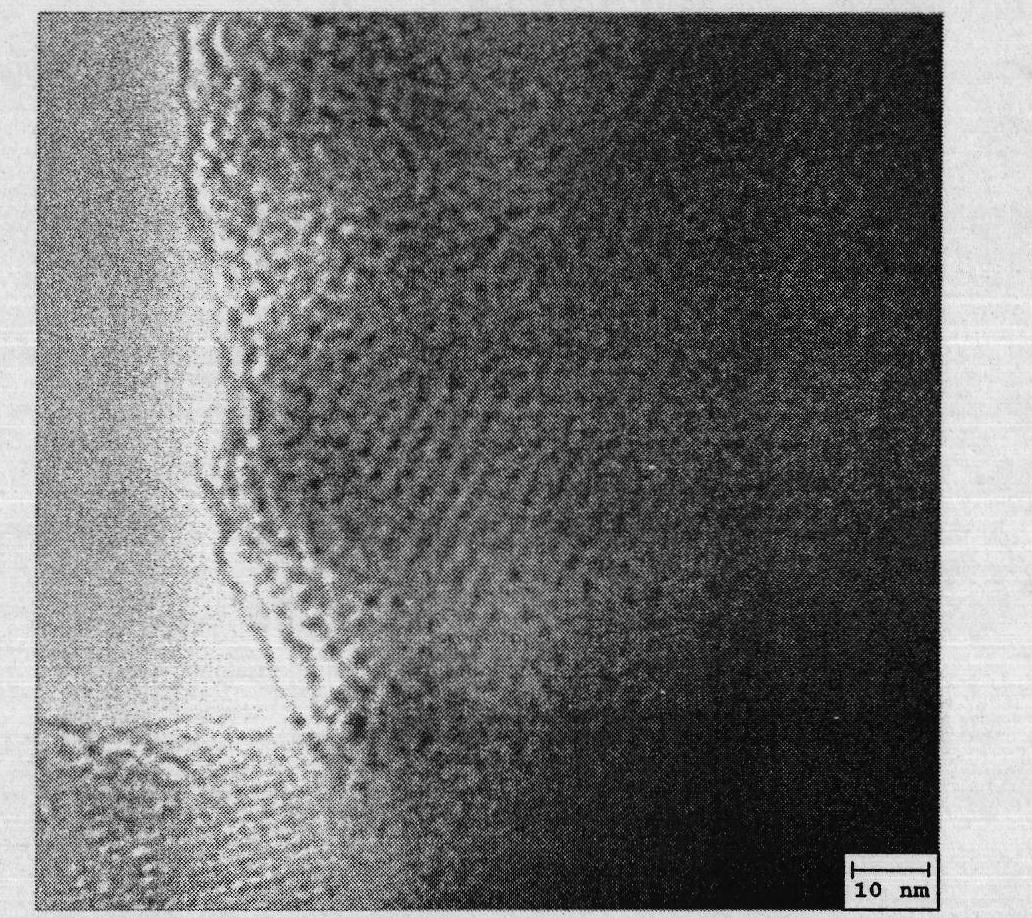

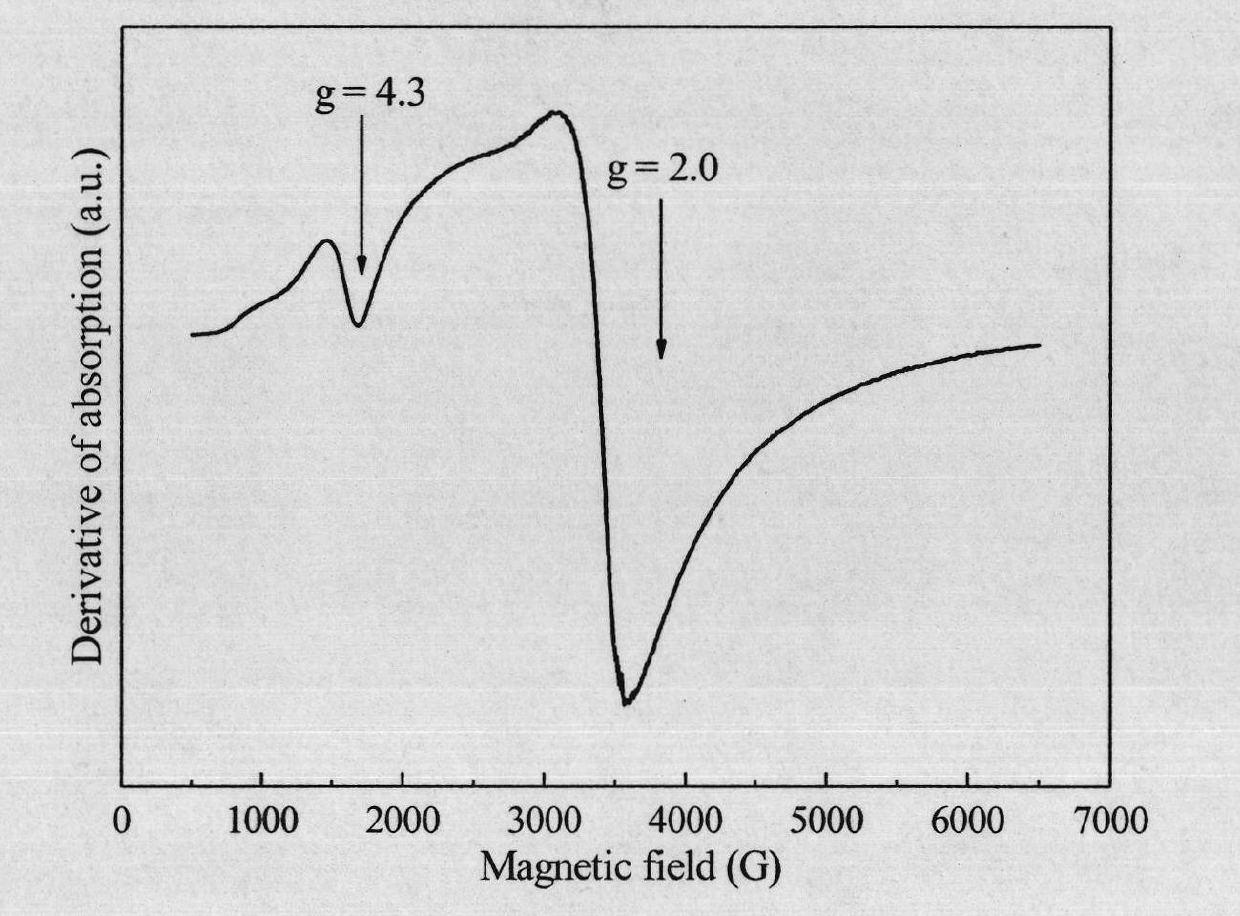

Method for preparing mesoporous molecular sieve Fe-MCM-41 with high iron content

InactiveCN102198948AIncrease acidityHigh selectivityMolecular sieve catalystsCrystalline aluminosilicate zeolitesHydrothermal synthesisThermal stability

The invention relates to a method for preparing a mesoporous molecular sieve Fe-MCM-41 with high iron content. In the method, the problem that iron is easily aggregated to generate a precipitate in the process of synthesizing the molecular sieve is solved by controlling the pH value in the synthesis process, an iron atom is directly introduced into a framework of the MCM-41 molecular sieve under the mild hydrothermal synthesis condition, and the Fe-MCM-41 molecular sieve with the iron content of 10 percent is successfully synthesized. The mesoporous molecular sieve material with the high iron content has a regular structure, a uniform pore size, large specific surface area and pore volume and high heat stability.

Owner:BEIJING UNIV OF CHEM TECH

Novel powder

InactiveUS20160138144A1High in ironInhibits the formation of cracksMolten spray coatingArc welding apparatusMetallurgyMetal powder

The present invention concerns a new metal powder which is useful for coating cast iron parts. The invention also relates to a method for coating cast iron parts by using the new metal powder. Of special importance is the possibility to use the metal powder for coating the surfaces of glass moulds. The invention also relates to metal parts, such as cast iron parts, or glass moulds which are coated by the metal powder.

Owner:HOGANAS AB

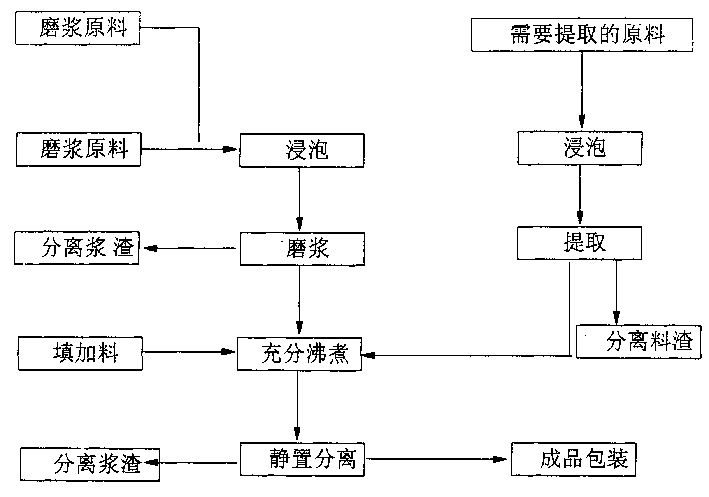

Beneficiation method of ilmenite

The invention discloses a beneficiation method of ilmenite and relates to the method for performing beneficiation on an ilmenite raw ore to prepare iron ore concentrate and ilmenite concentrate. The beneficiation method is characterized in that the beneficiation process comprises the following steps of (1) smashing the ilmenite raw ore; (2) grinding the ilmenite raw ore; (3) performing alkaline leaching pretreatment under conditions of water adding, temperature rising, oxygen adding and pressurization; (4) filtering ore pulp after the alkaline leaching pretreatment; (5) washing a filtered filter residue phase and performing ore grinding; (6) utilizing a washbox and performing magnetic separation to obtain the iron ore concentrate and the ilmenite concentrate. According to the method, dense symbiosis features of titanium and iron and isomorphism occurrence features of vanadium are damaged from the source of vanadium titanium magnetite ores by means of the treatment procedure, mineral transformation of the vanadium titanium magnetite is achieved, dissociation on lattice levels of titanium and iron is achieved, and the high-quality iron ore concentrate and the low-iron ilmenite concentrate can be obtained through a magnetic separation process and ore grinding. Alkali medium utilized by pretreatment can be recycled, therefore, influence of the process on the environment is small, and the beneficiation method has good application prospects.

Owner:GUANGXI KESHENGDA MACHINERY MFG

Technology for zinc wet-process clean smelting and resource comprehensive recycling

InactiveCN102978391AEnhanced leaching processHigh recovery ratePhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention belongs to the technical field of zinc smelting of the nonferrous metal smelting industry, in particular relates to a technology for valuable metal comprehensive recycling and iron element separating and concentrating during a zinc clean smelting process. Zinc calcine which is produced through calcinating zinc concentrate is separated out through neutral leaching and low-acid leaching and is then fed into a wet-process reinforced leaching system to separate acid soluble metals from insoluble substances; the separated zinc and soluble impurity-containing liquid enters a valuable metal separating and concentrating system to separate out indium, gallium, germanium and the like, the separated valuable metal sludge enters a special recycling system; and the liquid enters a zinc and iron separating system to completely separate out zinc and iron, iron is output in a high-grade iron ore concentrate mode, zinc enters the next process in a zinc sulfate mode, and the liquid enters an electrolyzing system after deep purification to output metal zinc. The technology has high metal zinc recovery rate, good valuable metal comprehensive recycling effect, a good environment-friendly effect and high iron content of hematite sludge, the hematite sludge can be treated to be used as a raw material for smelting iron, so that 'non-sludge' smelting is realized, and the smelting process is compact.

Owner:HENAN YUGUANG ZINC IND

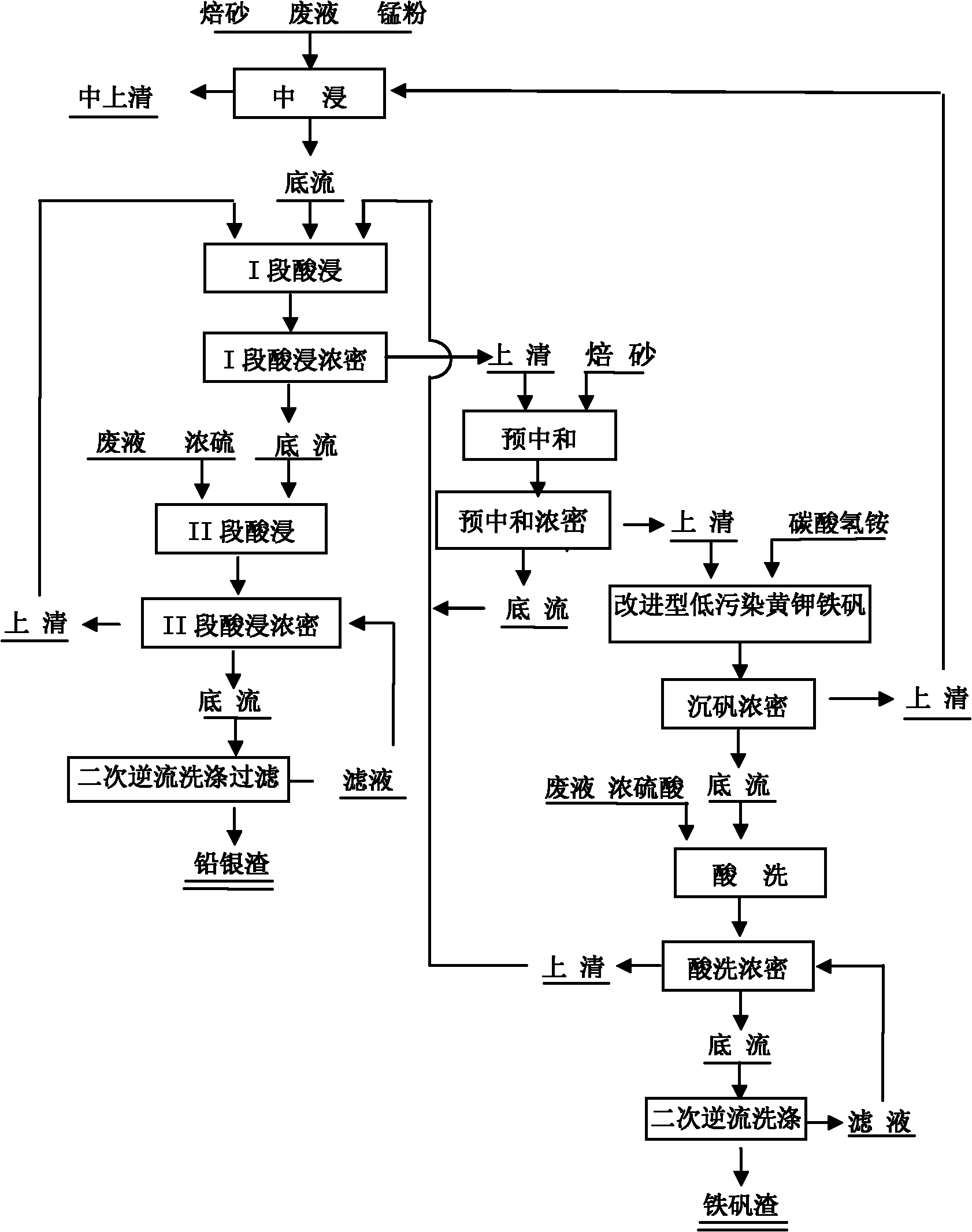

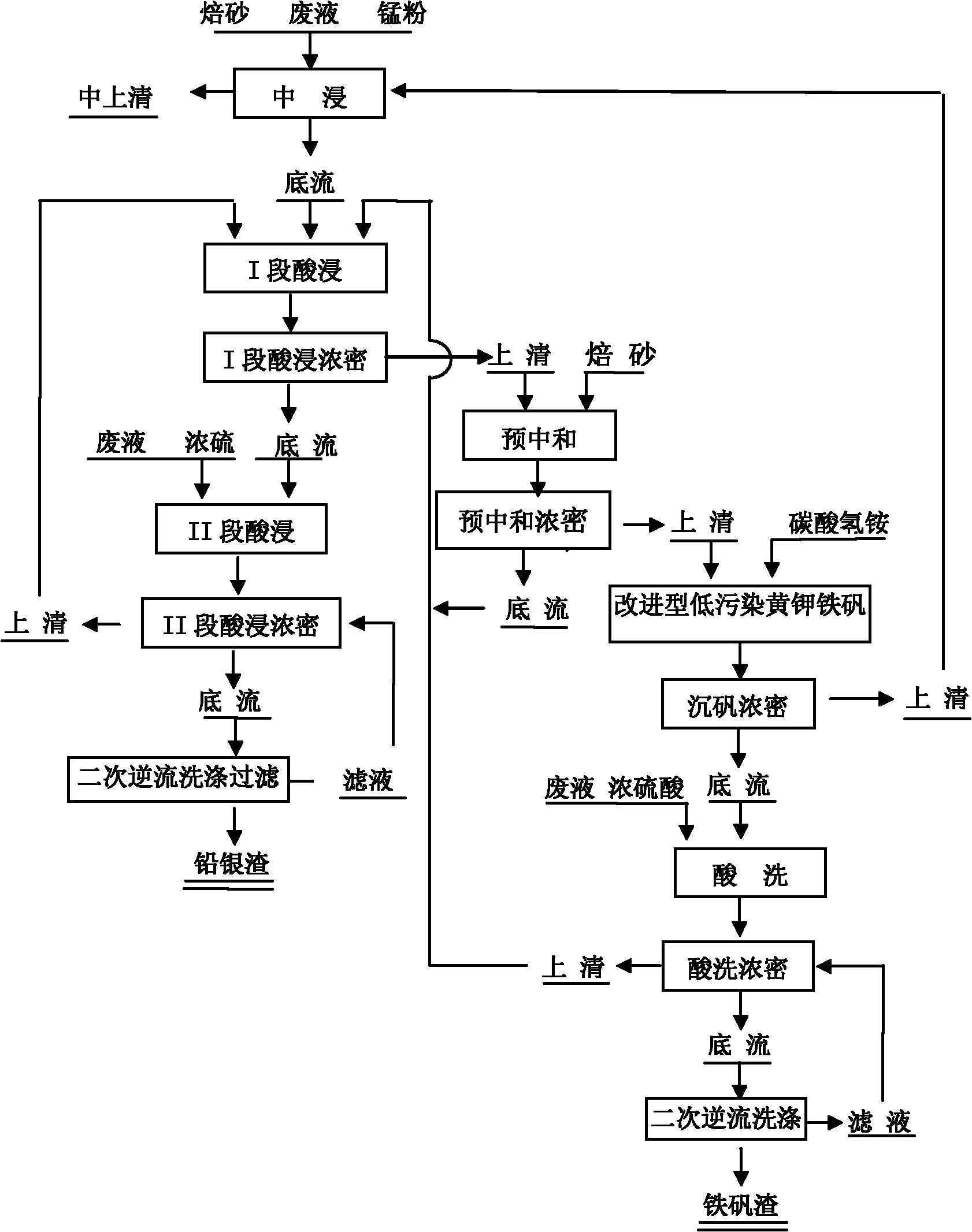

Process for smelting zinc with wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling by two stages

InactiveCN102094126AImprove leaching rateHigh recovery rateProcess efficiency improvementSlagZinc metal

The invention provides a process for smelting zinc with a wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling at two stages, belonging to the technical field of non-ferrous metal smelting. The process comprises the following steps of neutral leaching, acid leaching at the first stage, acid leaching at the second stage, pre-neutralizing, settling vitriol and pickling to obtain zinc metal with a high recovery rate. The total recovery rate of zinc metal is 94.45%. The loss of valuable metal in iron vitriol slag is less, the recovery rate of metal is high, and the pollution of vitriol slag to the environment is improved.

Owner:BAIYIN NONFERROUS GROUP

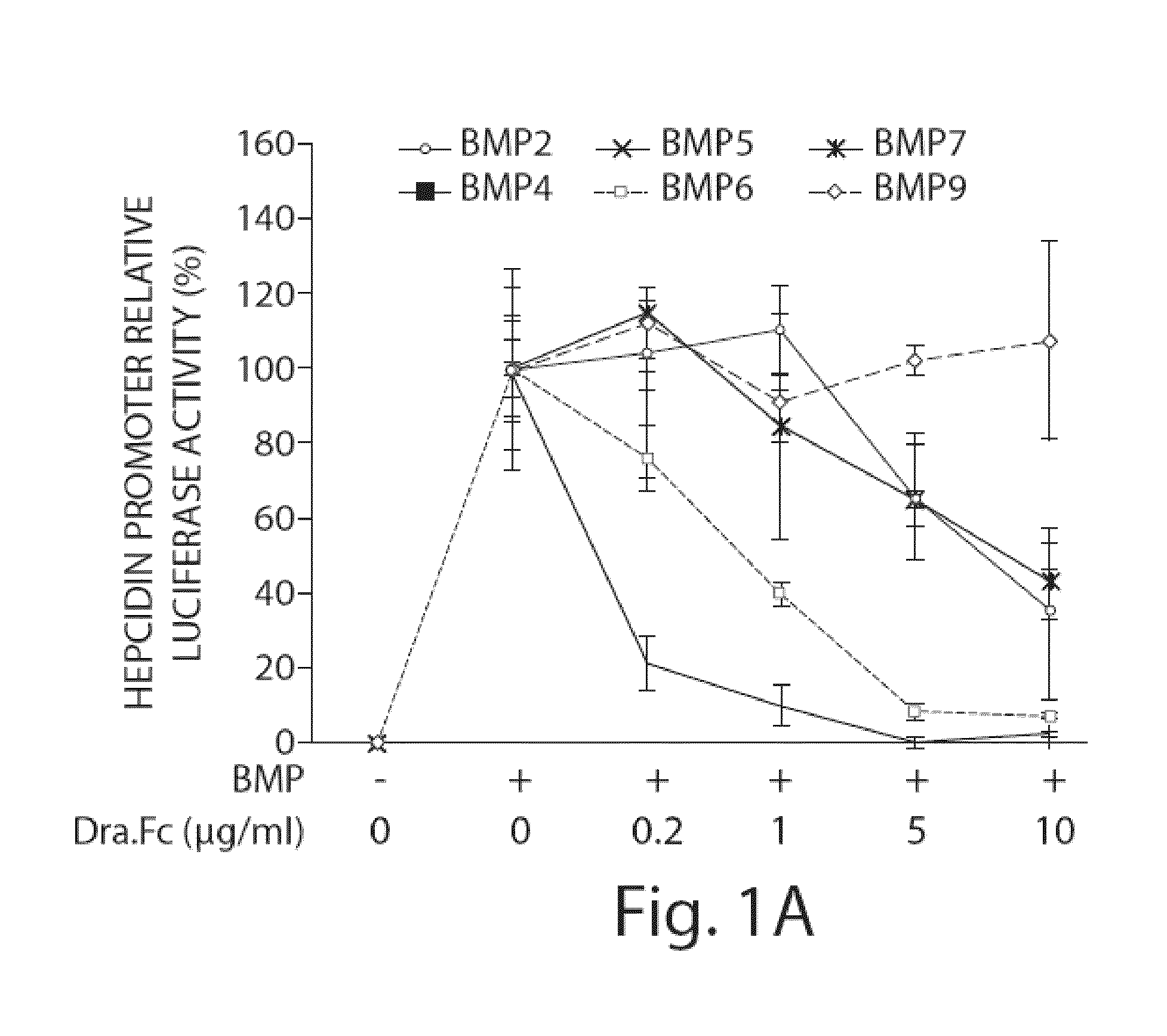

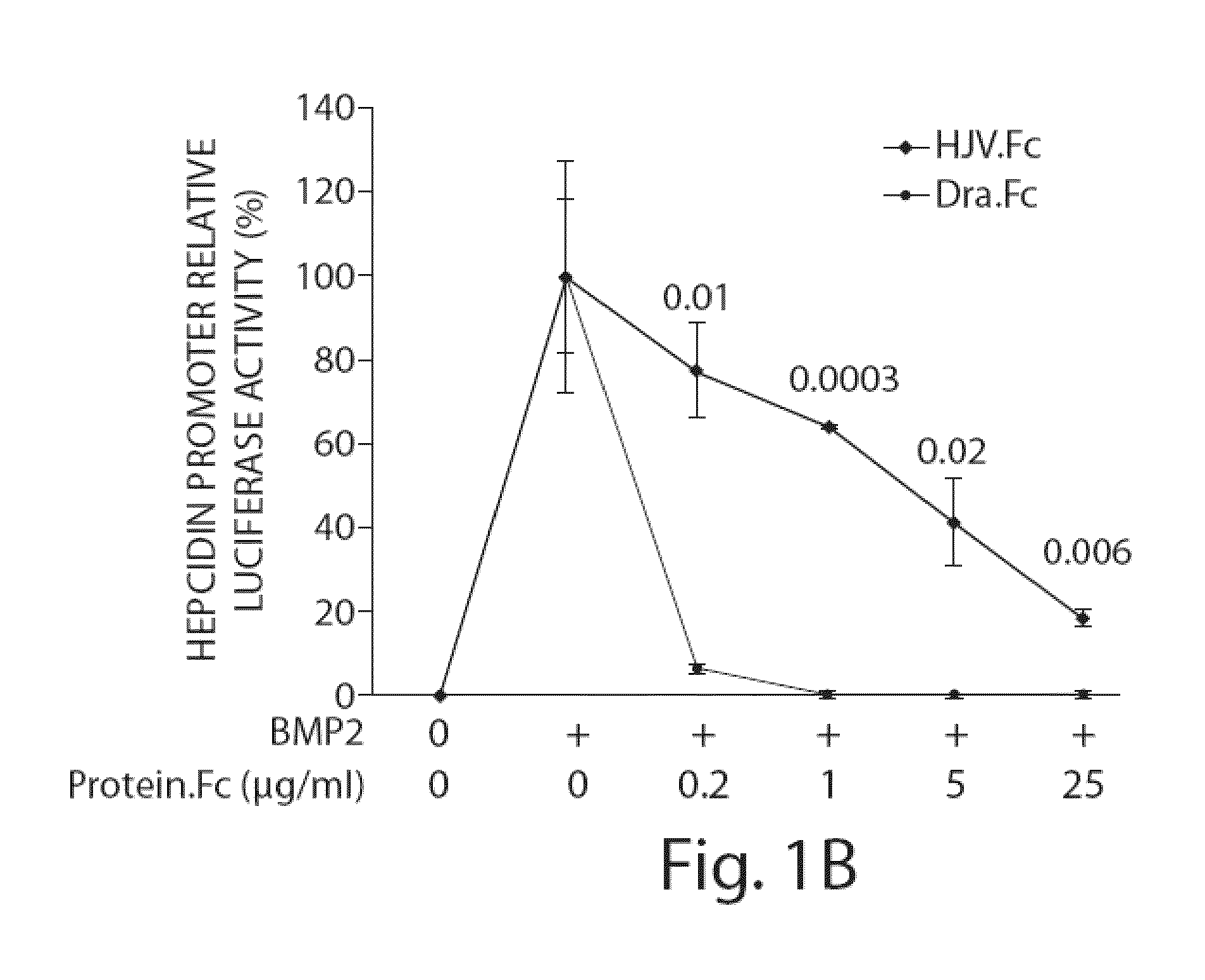

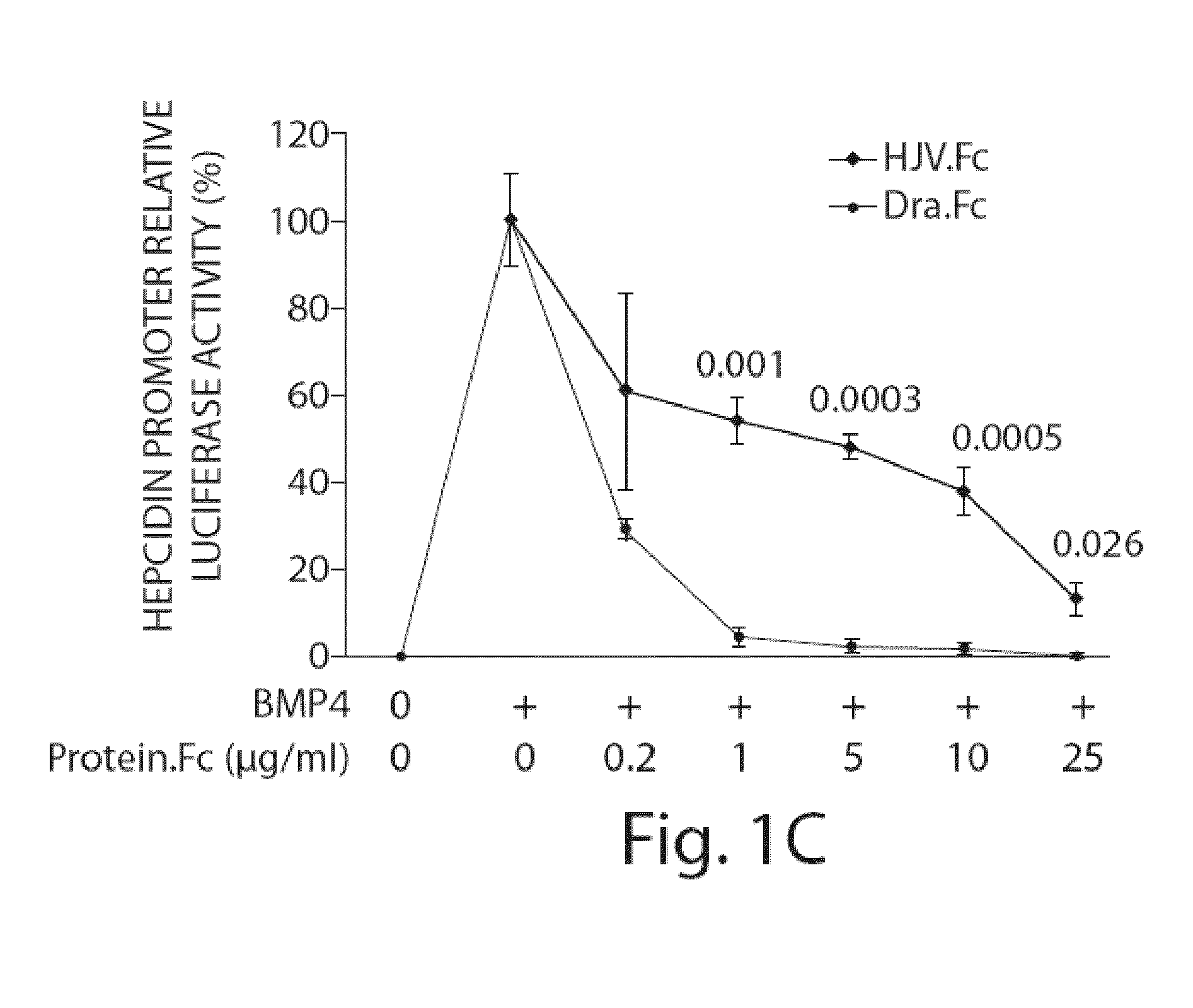

Methods and compositions for regulating iron homeostasis by modulation of BMP-6

ActiveUS8318167B2High in ironHigh saturationAntibody mimetics/scaffoldsImmunoglobulins against growth factorsPhysiologySerum iron tests

Modulation of iron homeostasis by regulating BMP-6 activity is provided. Methods of using BMP-6 and BMP-6 protein-specific reagents, such as antibodies, for altering serum iron levels in humans are provided. Such antibodies are useful in pharmaceutical compositions for the prevention and treatment of hemochromatosis and anemia of inflammation.

Owner:THE GENERAL HOSPITAL CORP

Smelting method for Al-Mg-Mn-Cu-Ti aluminum alloy

The invention discloses a smelting method for an Al-Mg-Mn-Cu-Ti aluminum alloy. The smelting method comprises the following steps of (1) preparing before smelting; (2) batching; (3) smelting, namely preheating a cast iron crucible furnace, and adding a covering agent; adding partial raw materials into a cast iron crucible after the covering agent is completely dissolved, and increasing the temperature and adding pure Mn ingots after the raw materials are completely smelted; continuously stirring and gradually increasing the temperature after the pure Mn ingots are smelted, slagging off, transferring melt to a graphite crucible heat preserving furnace, sampling and performing stokehole chemical component analysis; (4) preserving the heat and refining; namely adjusting the components of the melt, controlling the temperature of the furnace, pressing a refining agent into an aluminum alloy melt, degassing and refining; and (5) casting, namely covering a coating agent without magnesium on the surface of the aluminum alloy melt, slagging off after standing, and finally casting. The Al-Mg-Mn-Cu-Ti aluminum alloy produced by the smelting method has the advantages of less casting defects, high yield, low content of impurities of produced products, and good mechanical performance.

Owner:威瑞泰科技发展(宁波)有限公司

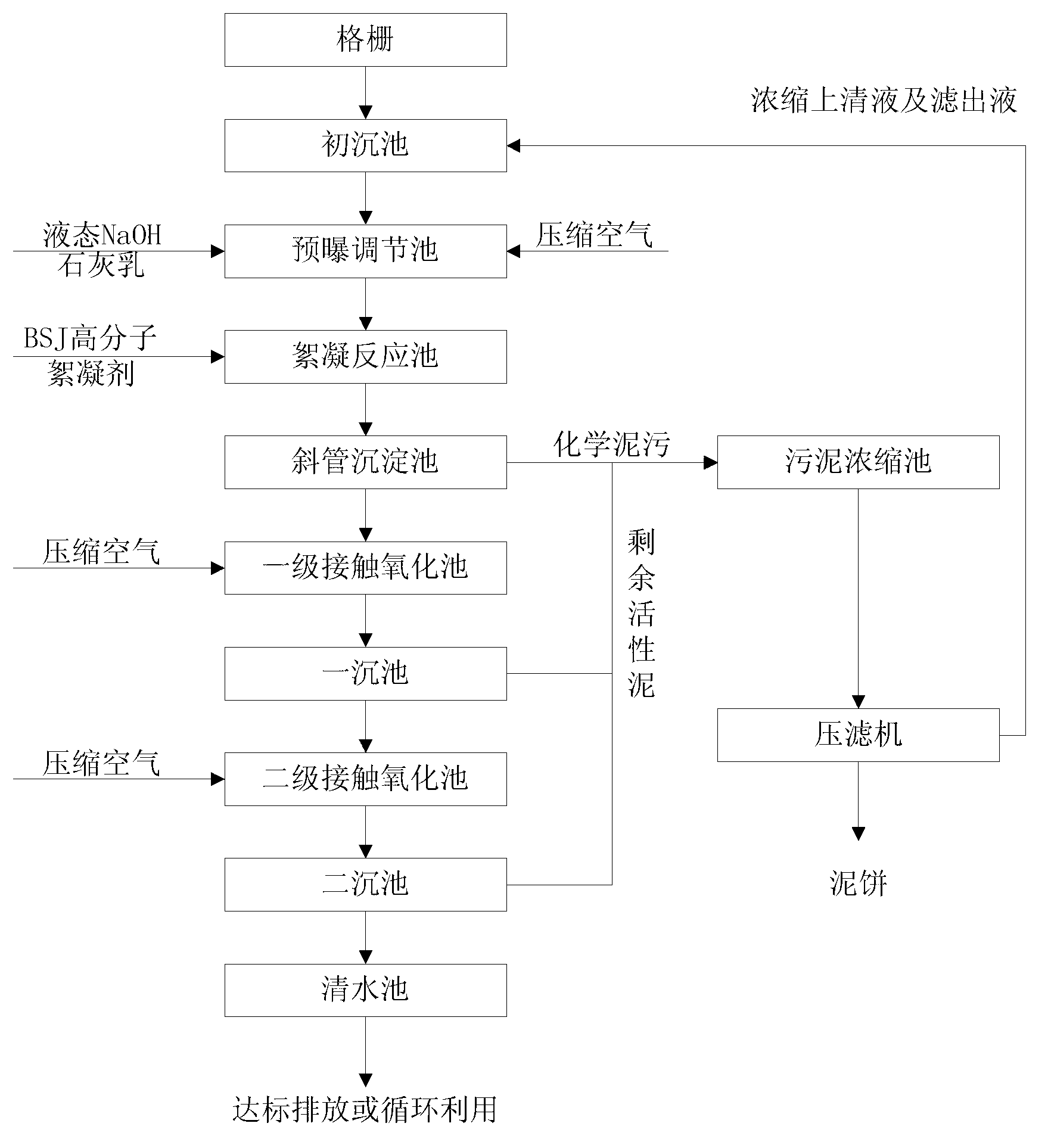

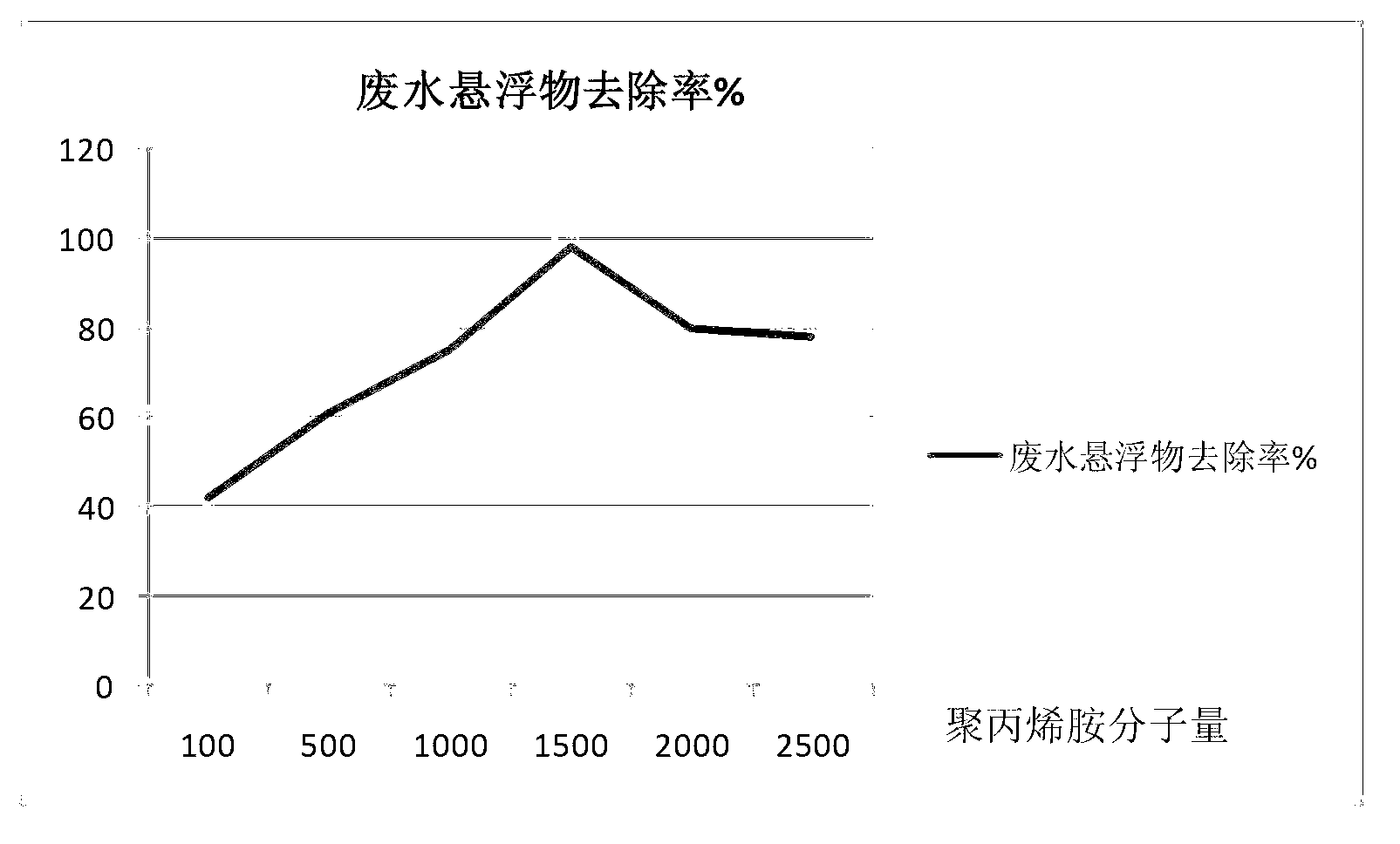

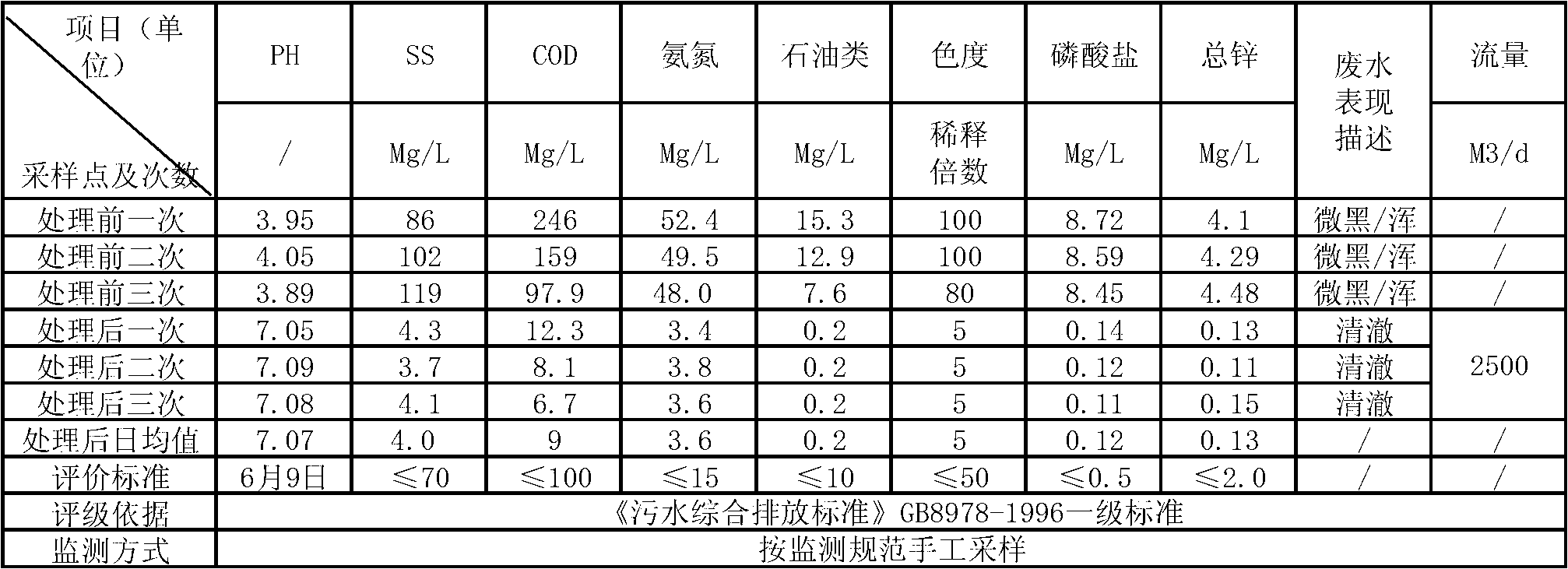

Waste water treatment process

InactiveCN102795747AHigh removal rateFast flocculationMultistage water/sewage treatmentPolyacrylamideSewage

The invention discloses a waste water treatment process which comprises the following steps that 1) waste water enters a primary sedimentation tank through a grid to remove suspended matters; 2) the waste water overflows from the primary sedimentation tank into a regulating tank after the suspended matters are removed, and lime milk is added to adjust the pH value of the waste water to be neutral; 3) the waste water of which the pH value is adjusted to be neutral naturally flows into a neutral aeration tank and is mixed with compressed air in the aeration tank, and Fe<2+> in the waste water is converted to Fe<3+>; 4) the waste water in the aeration tank is injected to a flocculation reaction tank, polyacrylamide flocculant is added to the waste water, and then the waste water is pumped to an inclined tube sedimentation tank; and 5) supernate of the waste water in the inclined tube sedimentation tank overflows into a contact oxidation tank and is mixed with the compressed air filled into the contact oxidation tank, organic matters in the waste water are subjected to oxygenolysis, and the waste water in the contact oxidation tank is deposited through a sedimentation tank and then overflows into a clean water tank. After being treated by the waste water treatment process, the waste water can reach the standard of Integrated Waste Water Discharge Standard (GB 8978-1996); and in addition, the operating cost of a waste water treatment system is lower, and the waste water treatment volume is large .

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Red mud superconducting high-gradient magnetic separator

InactiveCN101837321AHigh in ironHigh recycling valueHigh gradient magnetic separatorsChemical industryRed mud

The invention discloses a red mud superconducting high-gradient magnetic separator which aims to solve the problem of low magnetic separation efficiency of the traditional magnetic separator. The red mud superconducting high-gradient magnetic separator comprises a superconducting magnet, a separator and a drive device, wherein the superconducting magnet is used for generating a background magnetic field; the separator is provided with two separating chambers connected into a whole, and each separating chamber is a closed container provided with a slurry inlet, a slurry outlet, a rinse water inlet and a rinse water outlet; both ends of the separator are respectively provided with a supporting guide rail; and the drive device is used for driving the two separating chambers to alternately enter and exit the background magnetic field along the guide rails. The red mud superconducting high-gradient magnetic separator can be used for various occasions such as the iron removal of kaolin, the iron removal before smelting metallic ores, the iron removal of chemical industry raw materials, and the like and is broad-spectrum equipment for removing iron by utilizing a strong magnetic field.

Owner:王小军

Repairing method of chromium polluted soil

InactiveCN103316904AHigh removal rateHigh in ironContaminated soil reclamationFiltrationPotassium hydroxide

The invention relates to a repairing method of chromium polluted soil. The repairing method is characterized by comprising the following steps: (1) smashing the chromium polluted soil to a granularity of 1-2 cm; (2) adding aluminum sulfate and ferric subsulfate into the chromium polluted soil, blending uniformly, wherein aluminum sulfate accounts for 14-18% by mass of the chromium polluted soil, and ferric subsulfate accounts for 6-10% by mass of the chromium polluted soil; (3) adding water, stirring the chromium polluted soil mixture, immersing for 2 days, filtering and collecting the filtrate, wherein the mass ratio of water to the chromium polluted soil mixture is 1.5:1-2:1, drying the obtained soil after filtration and getting repaired soil; (4) adding sodium hydroxide or potassium hydroxide into the collected filtrate, adjusting pH of the filtrate to 10-11, adding a flocculating agent to deposit chromium in the filtrate at the same time, standing and filtering out chromium in the filtrate, and the filtrated liquid is used as the water required in step (3). The beneficial effects of the repairing method comprise raising repair rate, preventing secondary pollution and maintaining soil matrix.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Purification technique of steel scoria magnetic separation product

The invention discloses a purification technique of steel slag magnetic separation products, which comprises the following steps: (1) the steel slag magnetic separation product is put into a ball mill and water is added, (2) full grinding is processed, the product is discharged from the exhaust end of the ball mill naturally and divided into up-screen product and below-screen product through a cylinder screen, (3) the up-screen product is divided into block iron and tailings by magnetic pulley, the block iron is dried by dryer to make water content below 2%, (4) the product below screen is divided into overflow and sand-returning by a classifier, and the overflow grade of the classifier is controlled by the size of the spray water, which controls the sand-returning grade of the classifier, and (5) the sand-returning is conveyed into the fine powder feed chute through belt, the classifier overflow is conveyed to the thickener through a pump, and the underflow of the thickener is filtered by the filter and conveyed into the tail powder feed chute. The purification technique of steel slag magnetic separation products has the advantages of no non-magnetic and weakly magnetic material loss, full and complete recovery, raising the content of iron of luppen from 60% to 65% to above 90%, raising the grade of the magnetic separation powder from 40% to 50% to above 60%, raising the content of iron of steel slag product completely, and raising the comprehensive utilization ratio of the steel slag.

Owner:鞍钢绿色资源科技有限公司 +1

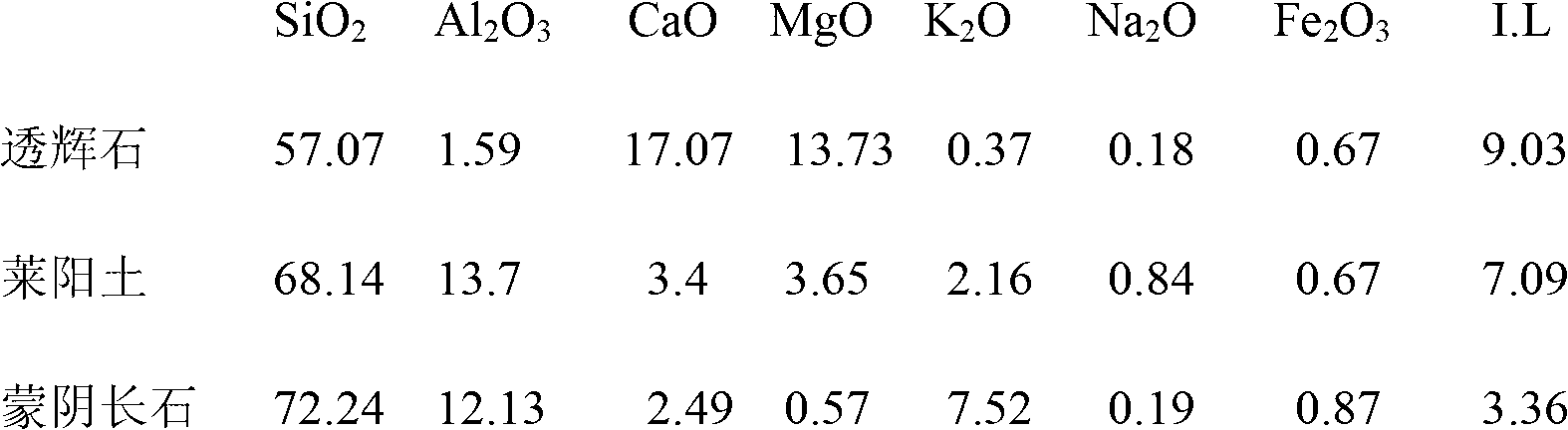

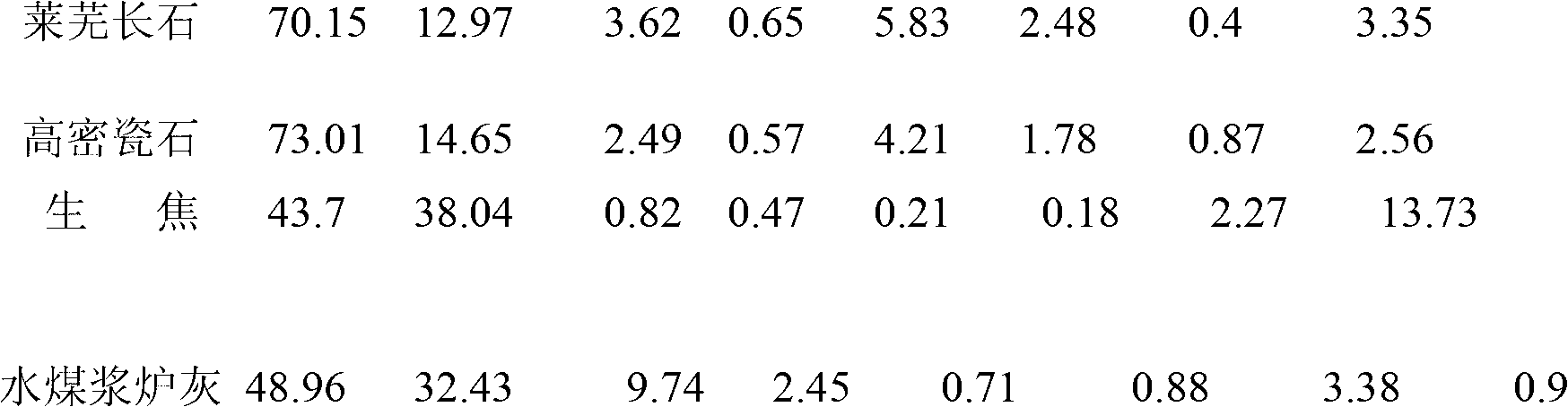

Coal ash ceramic brick and manufacturing method thereof

The invention relates to a coal ash ceramic brick and a manufacturing method thereof, and belongs to the field of ceramic preparation methods. The coal ash ceramic brick is characterized by being prepared by the following raw materials by mass percent: 4% of diopside, 27% of Laiyang soil, 23% of Mengyin feldspar, 24% of Laiwu feldspar, 7% of green coke, 8% of high-density china stone and 7% of water coal slurry ash. The water coal slurry ash is no longer discharged to the outside, so that the production cost is greatly reduced. As the water coal slurry ash has no plasticity but a higher iron content, the ligand strength is enabled to meet the standards through adjusting a formula. The color of the produced blank body is slightly yellow than before, but the physicochemical indexes are all not less than those before. During operation, a production line can be applied without any change after the formula of the blank body is adjusted only.

Owner:淄博新空间陶瓷有限公司

Zinc smelting technology for low-zinc high-iron roasting ore by wet method

InactiveCN104233373ASolving Quantitative SeparationsOptimizing Process ParametersPhotography auxillary processesProcess efficiency improvementZinc smeltingImpurity

The invention relates to a zinc smelting technology for a low-zinc high-iron roasting ore by a wet method. The technology comprises a leaching process, a purifying process and an electrolyzing process. The technology employs a smelting method that a wet method can solve the problem of lean impurity high-iron raw material, iron removal efficiency is high, and various production consumption and production cost are not increased. The quality of 58% qualified high-purity zinc is greater than or equal to 99.995%, and quality of 42% qualified high purity zinc is greater than or equal to 99.99%.

Owner:无锡市森信精密机械厂

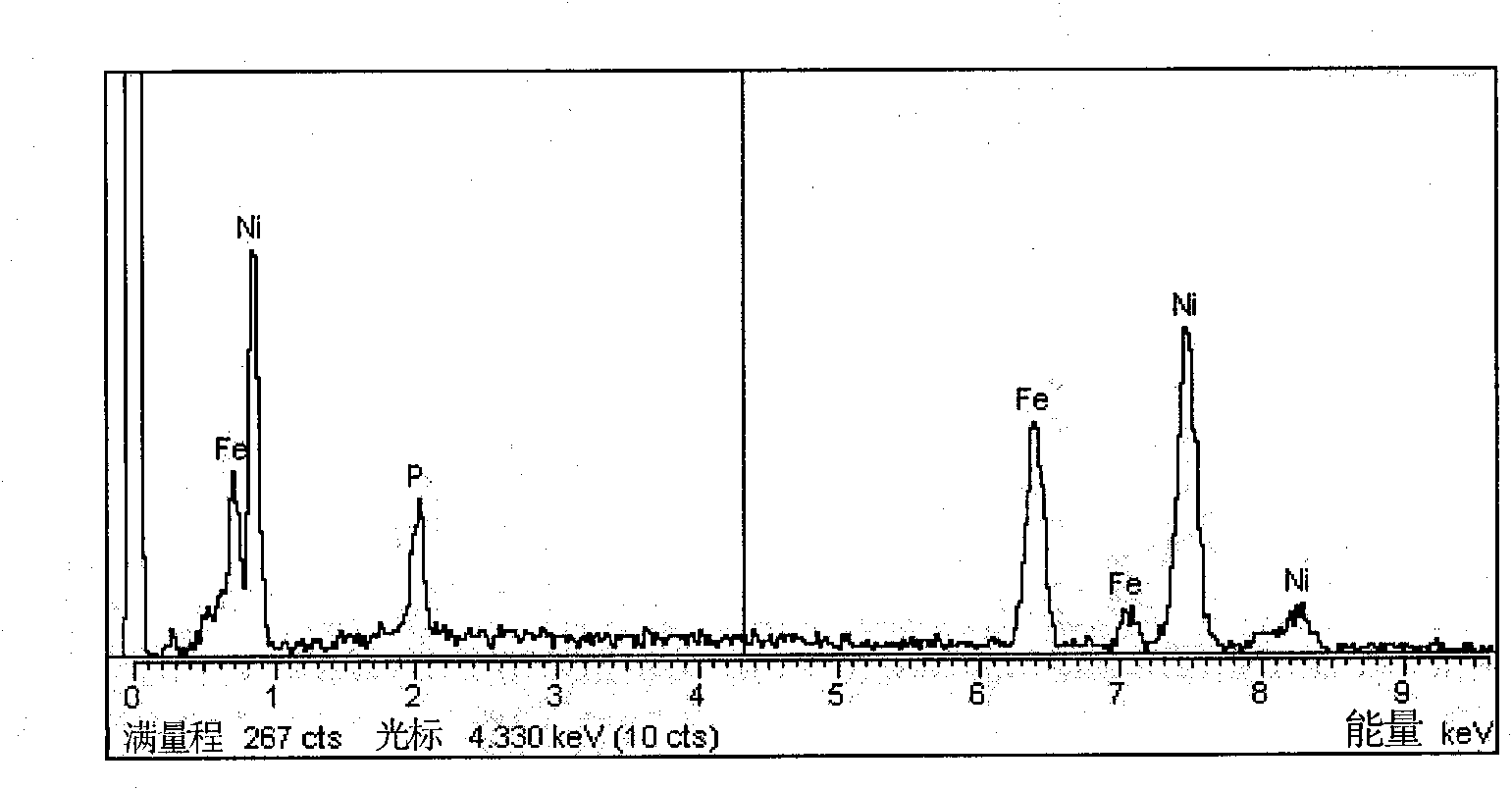

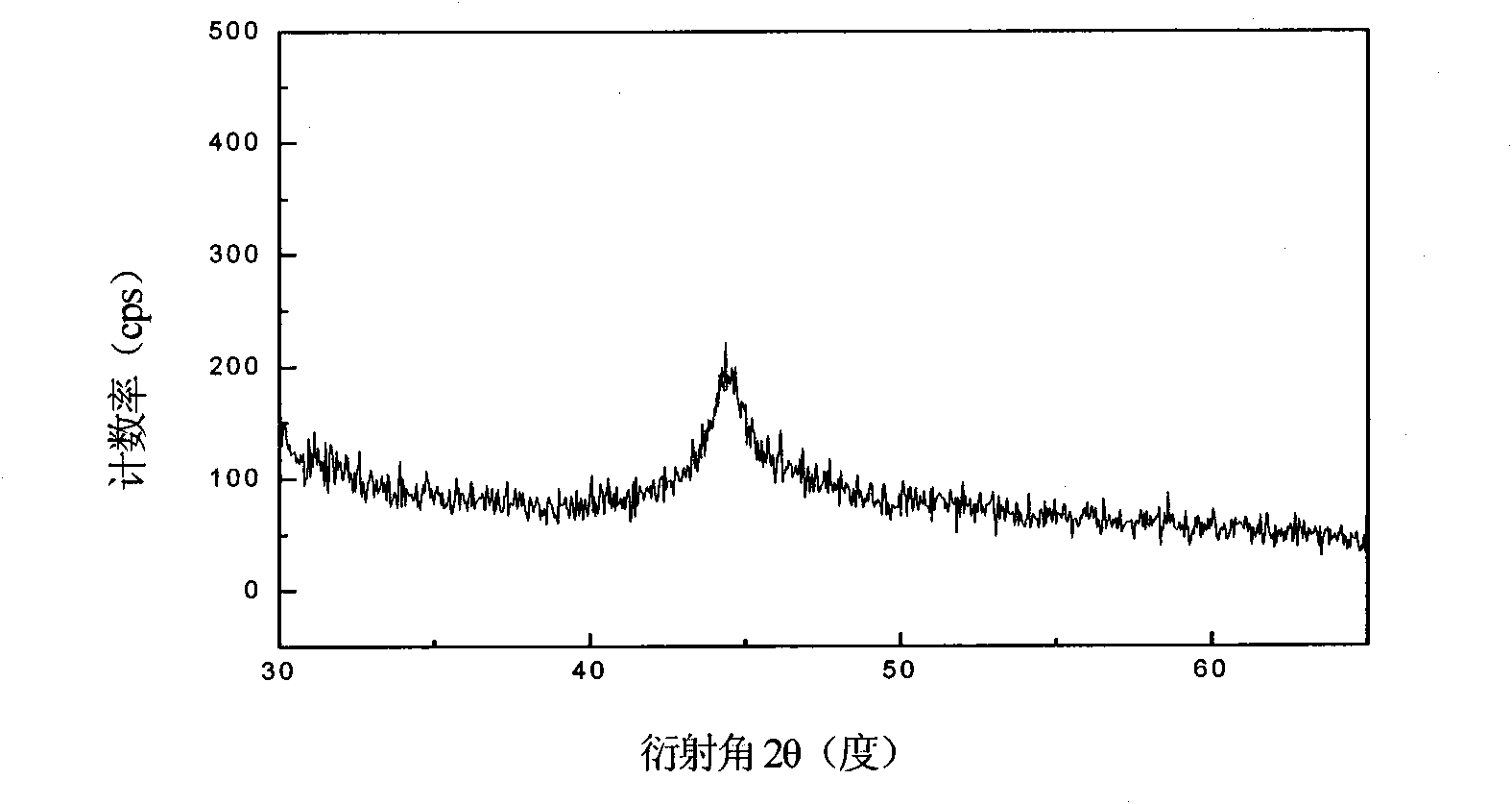

Method for preparing iron-nickel-phosphorus chemical plating

InactiveCN101906624AHigh in ironAdjust reaction speedLiquid/solution decomposition chemical coatingChemical platingSodium potassium tartrate tetrahydrate

The invention belongs to the technical field of chemical deposition, in particular to a new method for preparing an iron-nickel-phosphorus chemical plating. The plating can be widely used in (micro) electronic industry and space navigation and general projects. In the method, a compound complex system consisting of sodium potassium tartrate tetrahydrate, trisodium citrate, two organic mixed additives having N(CH2COOH)2 groups and ammonia water is used for controlling Fe<2+> and Ni<2+> concentrations, reducing the reduction speed of nickel and improving the reduction speed of iron so as to improve the iron content of the plating; the compound complex system can be complexed with impurity ions to improve the containable metal impurity ion concentration of the solution. The method is particularly suitable for preparing high-iron content iron-nickel-phosphorus chemical plating on silicon chips or copper surfaces. The plating on a silicon chip surface comprises 0 to 50 percent (controllable) of iron atoms, 2 to 18 percent of phosphorus atoms and the balance of nickel; and the plating on a copper surface contains 0 to 90 percent (controllable) of iron atoms, 2 to 16 percent of phosphorus atoms and the balance of nickel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

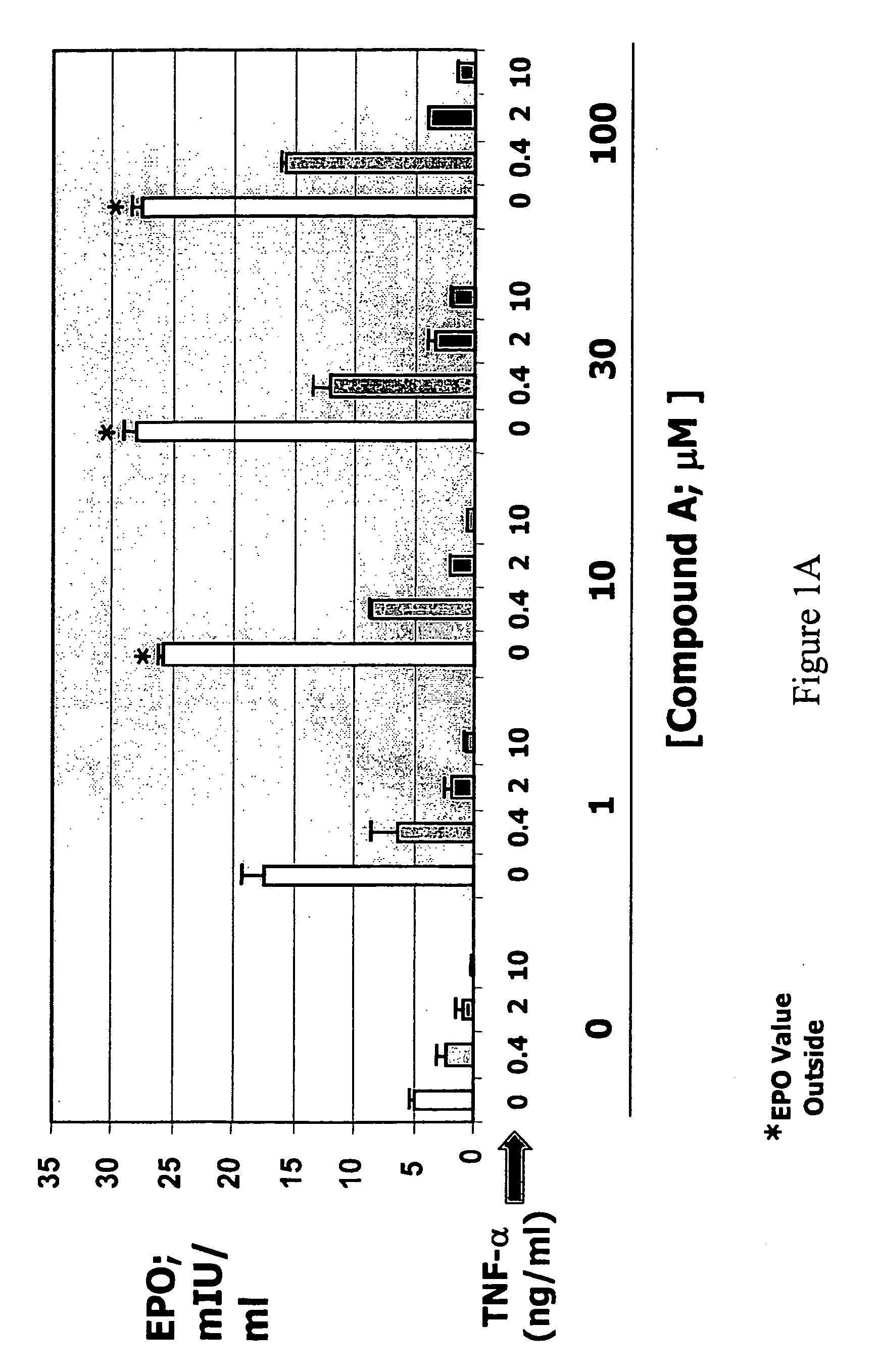

Enhanced erythropoiesis and iron metabolism

ActiveUS20100278941A1Increase productionTo promote metabolismBiocideHeavy metal active ingredientsDiseaseRed blood cell

The present invention relates to methods and compounds for regulating or enhancing erthropoiesis and iron metabolism, and for treating or preventing iron deficiency and anemia of chronic disease.

Owner:FIBROGEN INC

Preprocessing method of raw materials for ferrosilicon smelting

InactiveCN101280356AReduce the degree of deteriorationGood volatileSocial benefitsPretreatment method

The invention relates to the smelting technology, in particular to silicon iron smelting raw material and a preprocessing method. The preprocessing method comprises the following steps: firstly, silicon contained raw material is mixed with the carbonaceous reducing agent according to a certain ratio; secondly, a 40 to 80 mm oval or oblate pellet is pressed into form through a mechanical way; thirdly, after drying, the percentage of moisture is controlled for less than two percent, and then the raw material can be used as silicon iron smelting raw material. The silicon iron smelting raw material and the preprocessing method have the advantages that the raw material resource is rich, the price is inexpensive, and the energy saving effect is obvious, simultaneously, because a great amount of , the silicon fine powder and siliceous colliery waste are adopted by the technology, the social benefit and the environmental benefit are quite good.

Owner:樊玉山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com