Patents

Literature

53results about How to "Detoxify thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

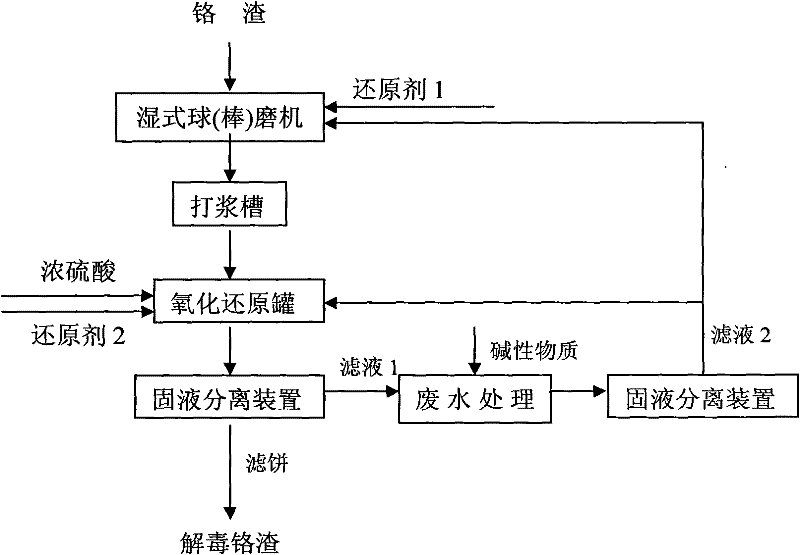

Chromium residue detoxifying process

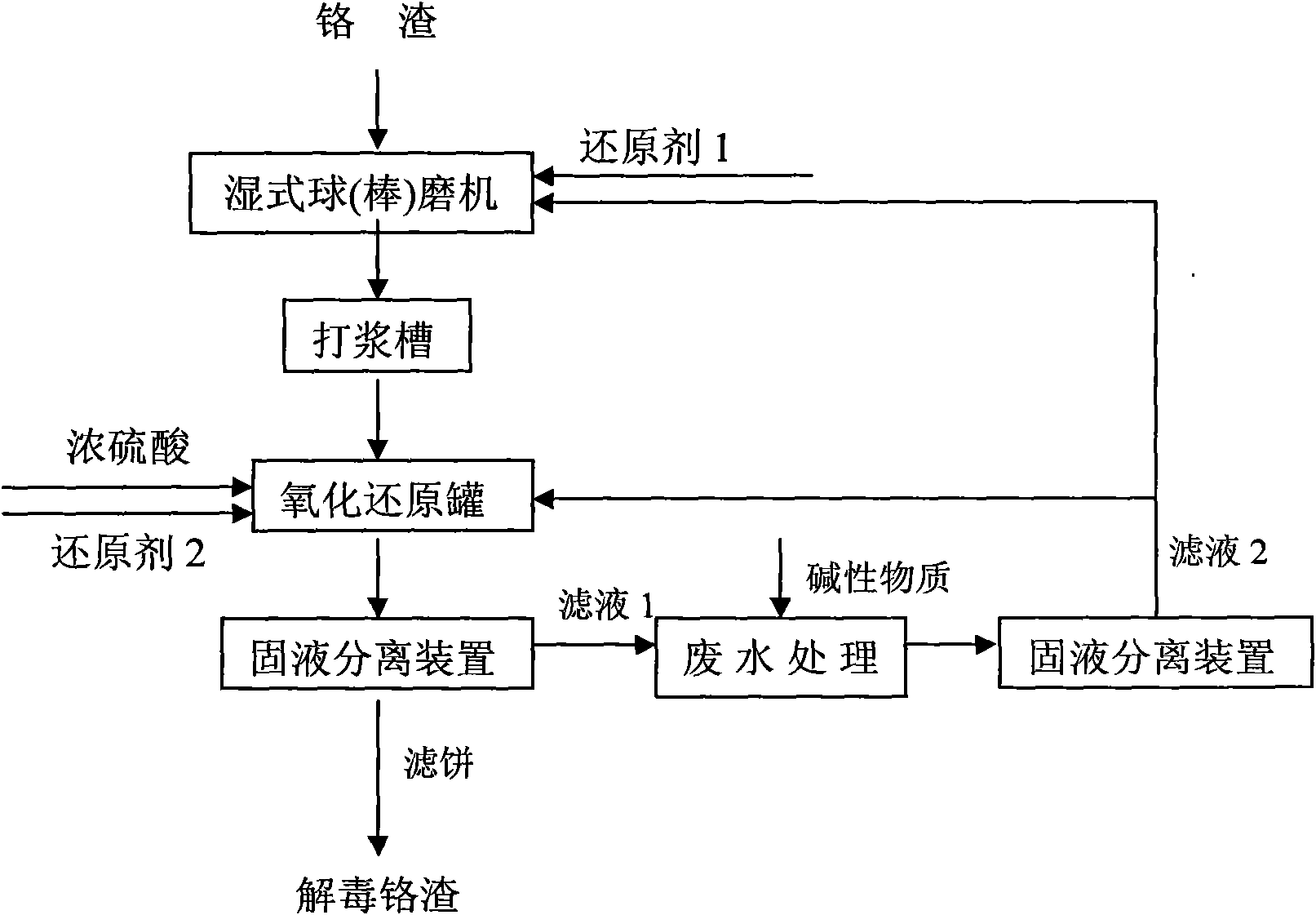

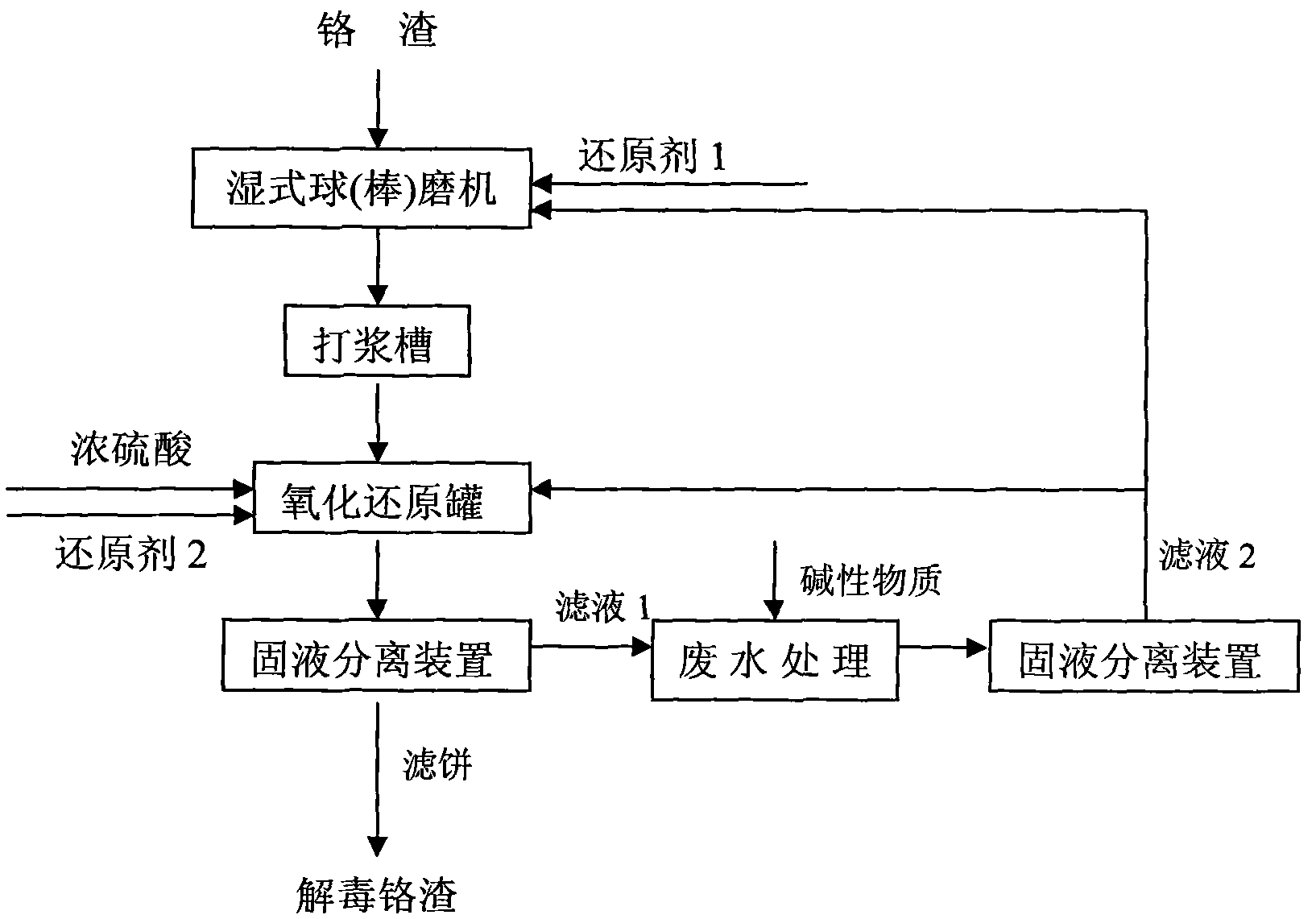

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

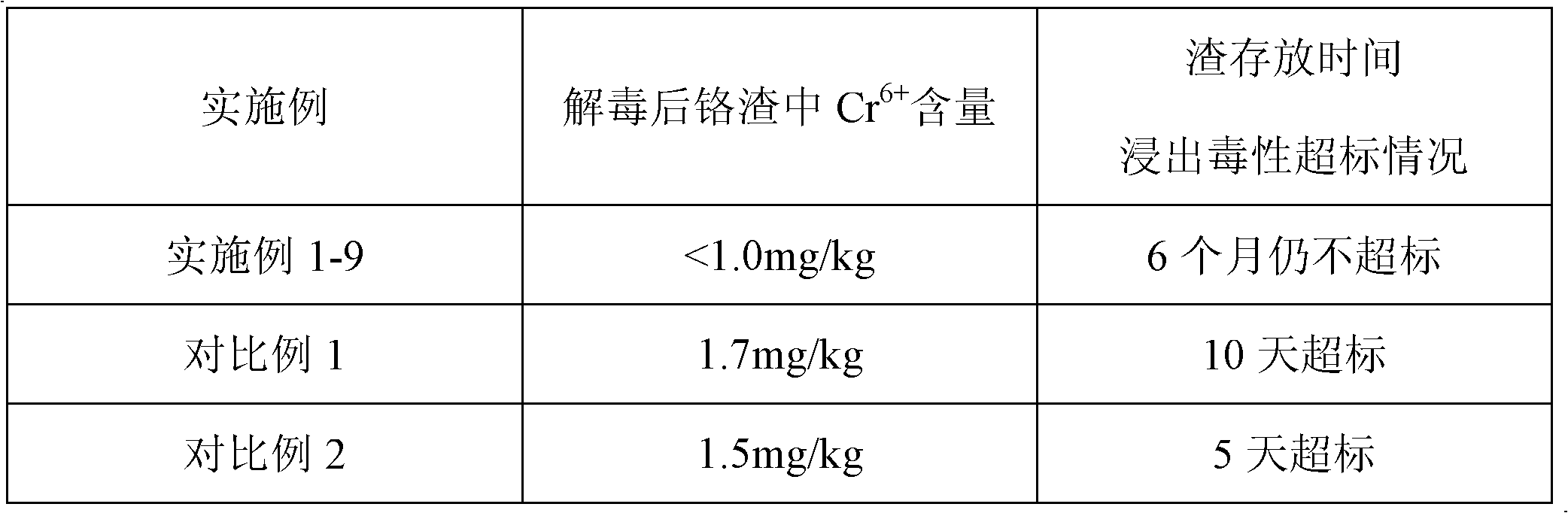

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

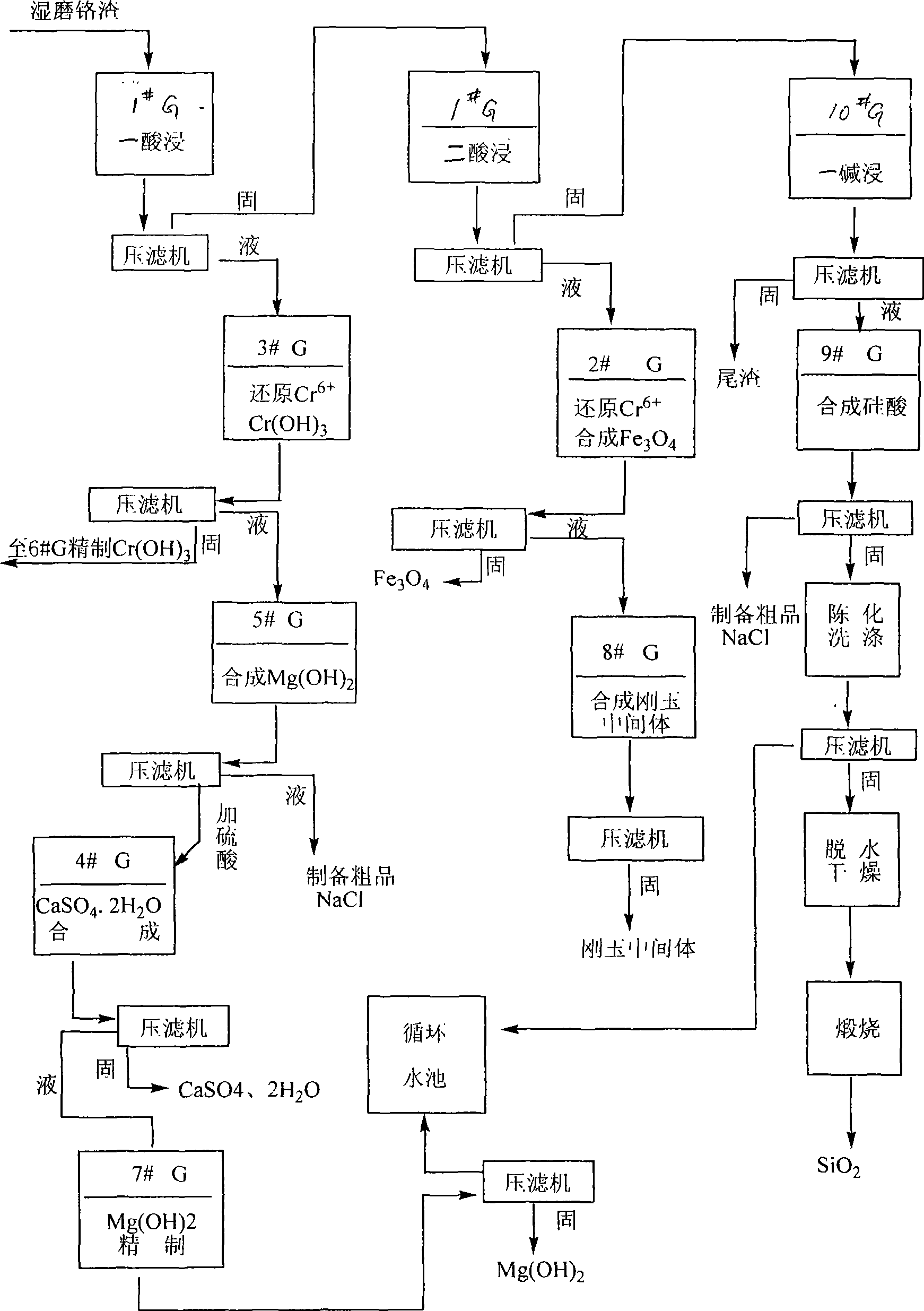

Chromic slag wet method detoxifcation and resource comprehensive utilization new technique

InactiveCN101380510ADetoxify thoroughlyAchieve detoxificationCalcium/strontium/barium sulfatesFerroso-ferric oxidesAmmonium hydroxideHexavalent chromium

A new harmless comprehensive utilization technique for wet processing chromic slag comprises steps as follows: ball milling chromic slag to 80-200 meshes, adding water to prepare slurry, immersing the slurry in hydrochloric acid solution, regulating the pH to 5-6, performing solid-liquid separation with filter press, in the immersion liquid after separation, the hexavalent chrome is reduced to trivalent chromium, adding sodium hudroxide aqueous solution, regulating the pH to 4-6, roughly preparing chromic hydroxide, adding sulfuric acid into filtrate, regulating the pH to 5-6, removing the calcium coprecipitated with magnesium in the rest filtrate, preparing the 2-water calcium sulphate whisker, adding alkali to the filtrate after filter-pressing to regulate the pH to 9-12 to synthesize super-fine magnesium hydroxide powder; the solution after filter-pressing is concentrated to prepare sodium chloride. The main contents of extracts within the chromic slag treated by wet processing all can meet primary, secondary or even accredited national or ministerial standard. The technique can thoroughly detoxicate Cr<6+> in chromic slag and can prepare nine products, includiing chromic hydroxide, magnesium hydroxide, ammonium hydroxide, silicon dioxide, magnetic ferrous ferricoxide, 2-water calcium sulphate, corundum intermediate, sodium chloride, and tailings-chromite; and the extracts after processing chromic slag have high quality.

Owner:杨恩清 +1

Wet detoxification method of hexavalent chromium contained alkali waste residues

InactiveCN102614620ATo achieve the purpose of reduction and detoxificationEasy to restore and detoxifyProcess efficiency improvementChemical industryReaction temperature

The invention belongs to the technical field of chromium chemical industry and chromium salt clean production, and in particular relates to a wet detoxification method of hexavalent chromium contained alkali waste residues. According to the method, the method comprises the following steps of: first, slurrying the chromium residues; and then adjusting the pH value of the slurry to 7-10; adding a stabilizing agent and a reducing agent to the completely slurried slurry at 20-150 DEG C; and reducing the hexavalent chromium to trivalent chromium, wherein the trivalent chromium can stably exist in the chromium residue for a long period. The leaching toxicity of the obtained chromium residue, which conforms to State Environmental Protection Industrial Standard issued by the Ministry of Environmental Protection, is less than 3 mg / L. Compared with the prior art, the wet detoxification method of the hexavalent chromium contained alkali waste residues, provided by the invention, has the advantages of simple process, less usage of the reducing agent, low cost, complete reduction of the hexavalent chromium, no rebound, low reducing reaction temperature, suitability for industrial production and better promotion and application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

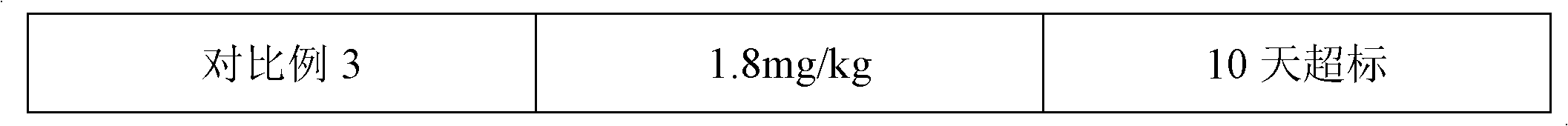

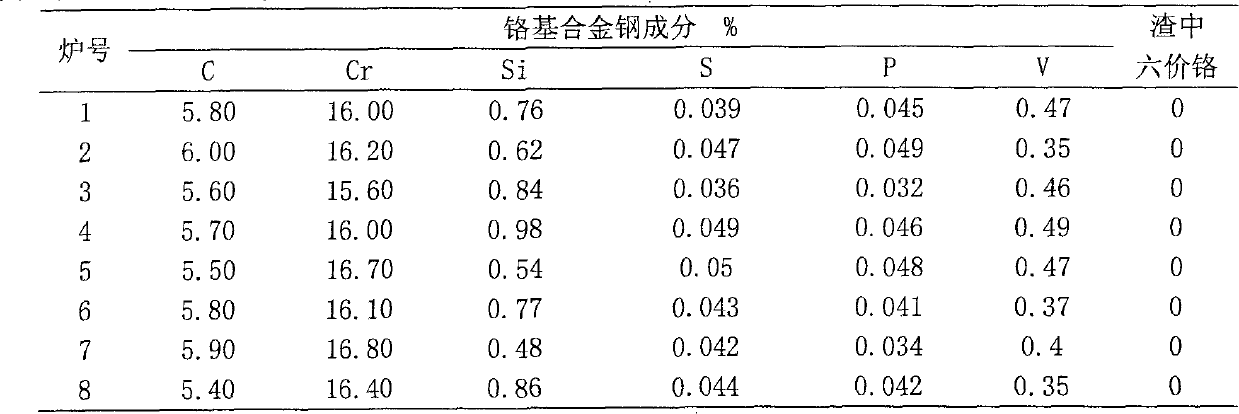

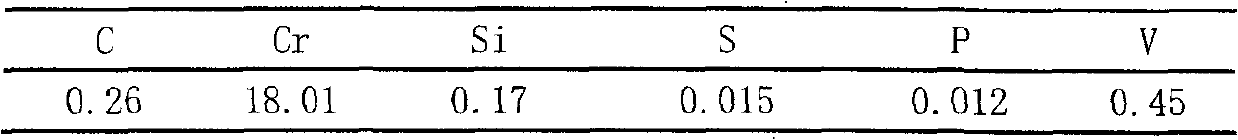

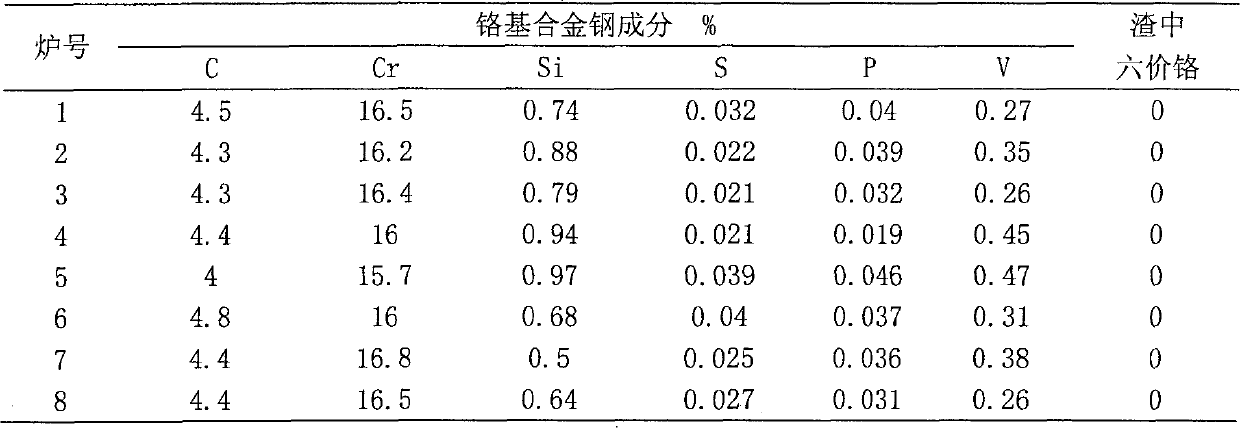

Method for directly producing chrome-base alloy steel by comprehensively using calcium-free chrome slag

ActiveCN101906500AEat a lot of dregsDetoxify thoroughlyProcess efficiency improvementElectric furnaceWear resistantSteel ball

The invention discloses a method for directly producing chrome-base alloy steel by comprehensively using calcium-free chrome slag, which is implemented by the steps of weighing, material preparation, reduction smelting, slag discharge, iron discharge, refining pouring and the like. The chrome-base alloy steel is prepared by the following steps of: adding a reducing agent into the calcium-free chrome slag; smelting the calcium-free chrome slag in a smelting furnace; and directly introducing the molten chrome and iron into a refining furnace to perform oxygen blowing decarburization refining. The chrome-base alloy steel comprises the following main components: 0.2 to 6.0 percent of carbon (C), 8.0 to 50.0 percent of chromium (Cr), 0.3 to 1.0 percent of silicon (Si), less than or equal to 0.05 percent of sulphur (S), less than or equal to 0.05 percent of phosphorus (P) and 0.1 to 0.5 percent of vanadium (V). The alloy steel can be directly used for manufacturing or forging various wear resistant materials, such as cement, wear resistant steel balls for power and mineral separation, forging steel or liners and the like. In the method, the chrome-base alloy steel product is directly produced by using the calcium-free chrome slag as a raw material, so that the calcium-free chrome slag is completely detoxified and the limited chrome resource is recycled. Thus, the method has a great significance for clean chrome salt production and waste slag recycling.

Owner:GANSU JINSHI CHEM

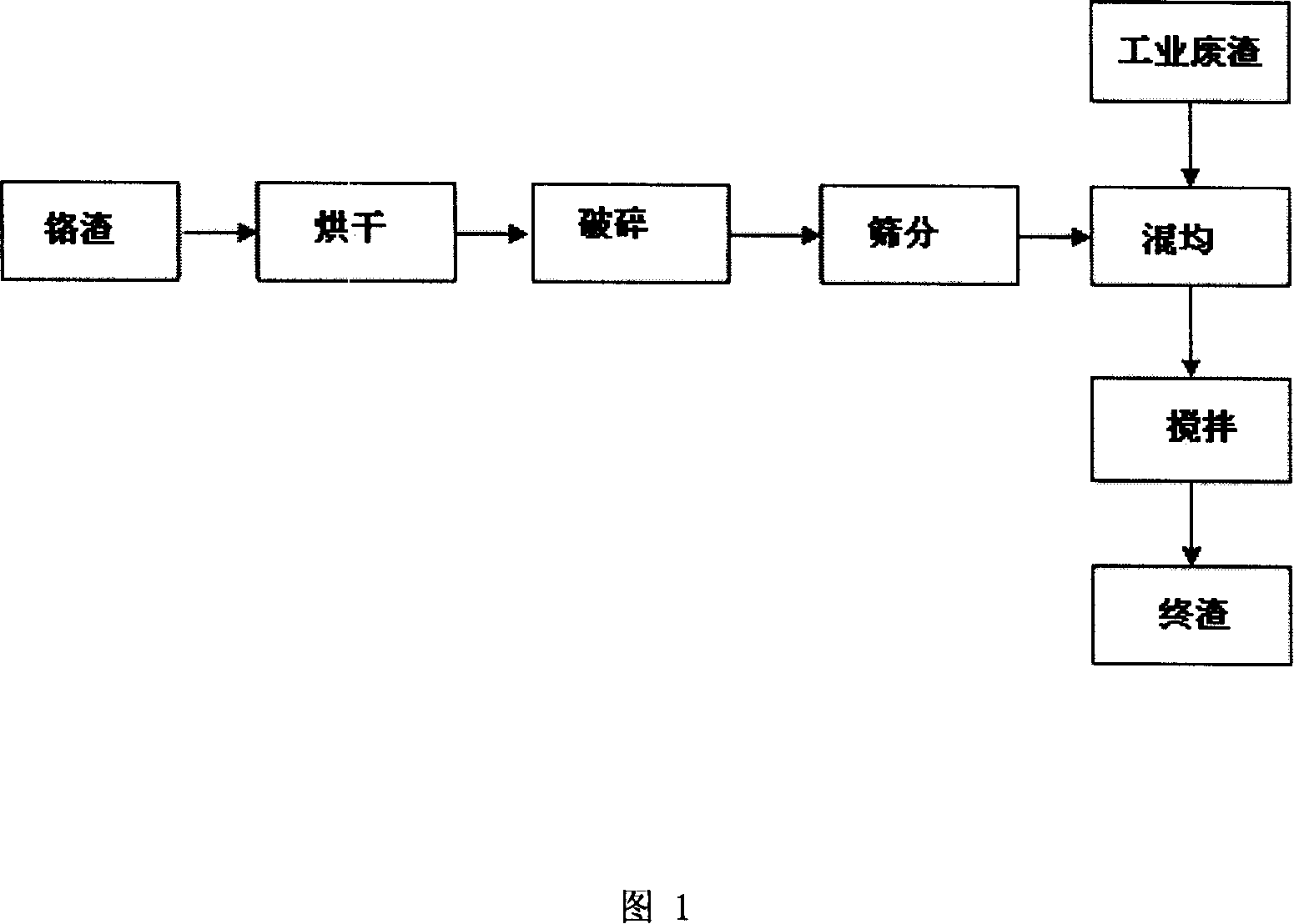

Novel process of the high temperature reduction and detoxication of industrial chromic slag

InactiveCN101138670ALarge physical heat capacityEfficient use ofChemical protectionSlagHigh-temperature corrosion

The present invention relates to a method for reducing detoxification of chromium residue under a high temperature with industrial wastes. Reducing metallurgy wastes in a waste tank are heated and melted. When the temperature becomes constant, the chromium residue is added into the tank. The toxicant in the chromium residue is Cr6 mainly in the form of water-soluble Na (SUB)2( / SUB)CrO (SUB)4 ( / SUB) and acid-soluble CaCrO (SUB)4( / SUB). Under the high temperature, Cr6 is reduced into intoxicant Cr3. After the chromium residue is cooled down to the room temperature naturally, the removal rate of Cr6 reaches over 99 percent in the final residue. The method is provided with an appropriate process flow, and the device is simple and easy for operation. Heat of the material itself is fully used, so the high efficiency is high, which is beneficial to the high-temperature reducing of chromium residue. The chromium residue is thoroughly detoxicated. Moreover, no environmental pollution is caused and the cost is low, so the method is applicable for scaled detoxification of chromium residue in the industry.

Owner:隋智通

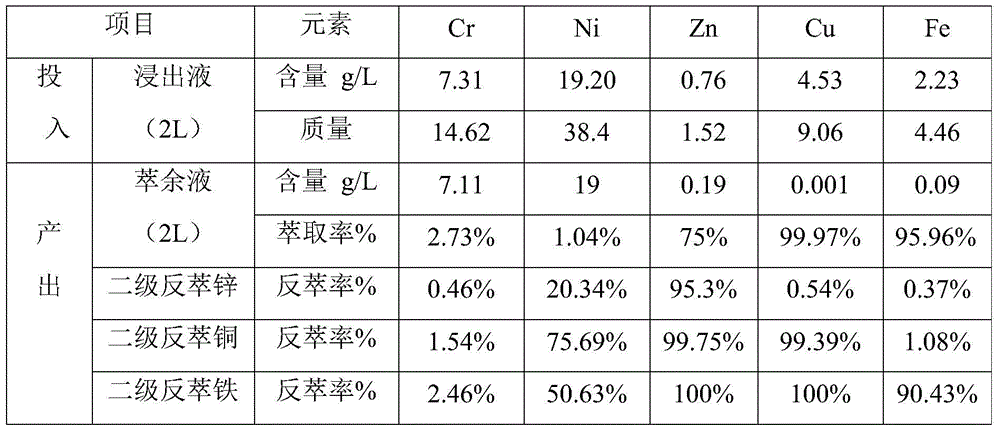

Harmless disposal and resource utilization method for electroplating sludge

InactiveCN105734294ADetoxify thoroughlyAdaptableProcess efficiency improvementResource utilizationSludge

The invention provides a harmless disposal and resource utilization new technology for electroplating sludge and particularly for complex electroplating sludge rich in copper, iron, nickel, zinc and chromium. Selected microorganisms are high in adaptation to the electroplating sludge and good in leaching performance; one-step extraction is adopted to extract copper, iron and zinc, follow-up nickel and chromium separation and purification are facilitated, in the whole technology, the iron cannot form any solid phase, and the problem that according to an existing reported technology, during iron separation, entrainment is serious or iron precipitation is not thorough is solved; a metallurgical method is adopted to carry out separating and recycling on extraction raffinate, the separation effect is good, and an obtained product is high in purity; and according to the technological process, cleaning and efficient high-value recycling of valuable metal in the electroplating sludge are achieved, the method is high in adaptation to various kinds of electroplating sludge, the electroplating sludge meets the harmless requirement, and the method extremely has the industrialized utilization value.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

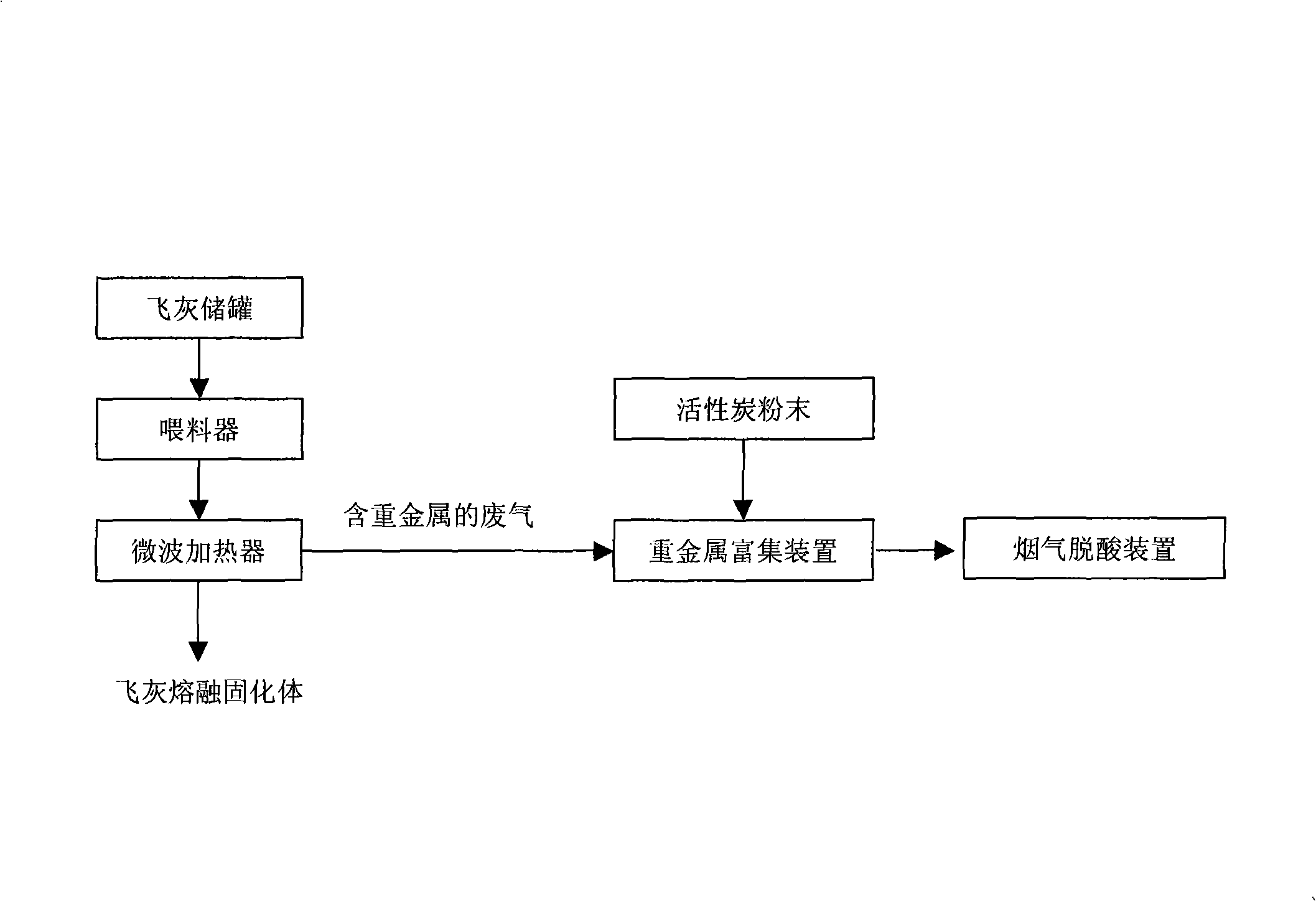

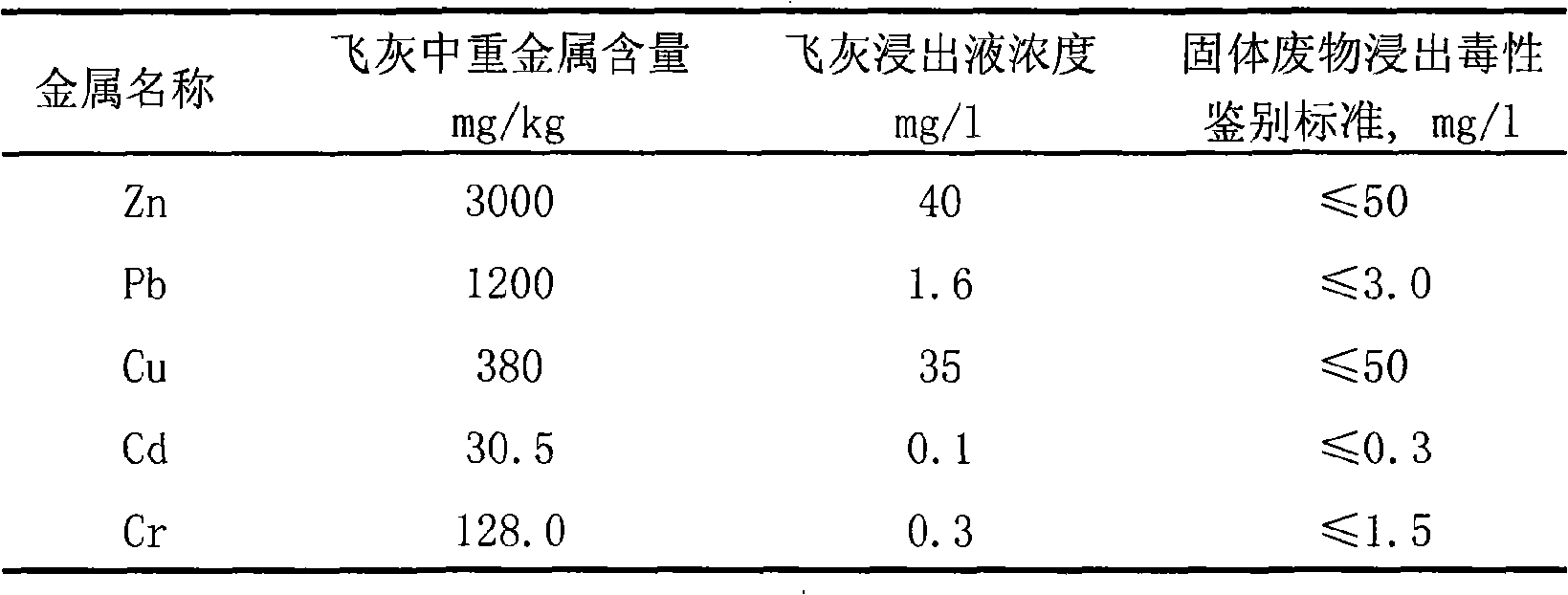

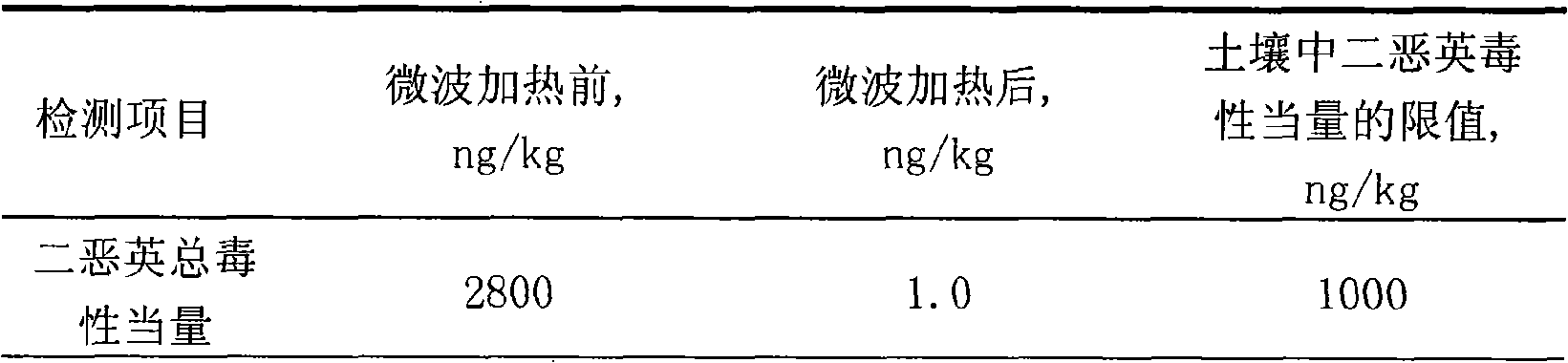

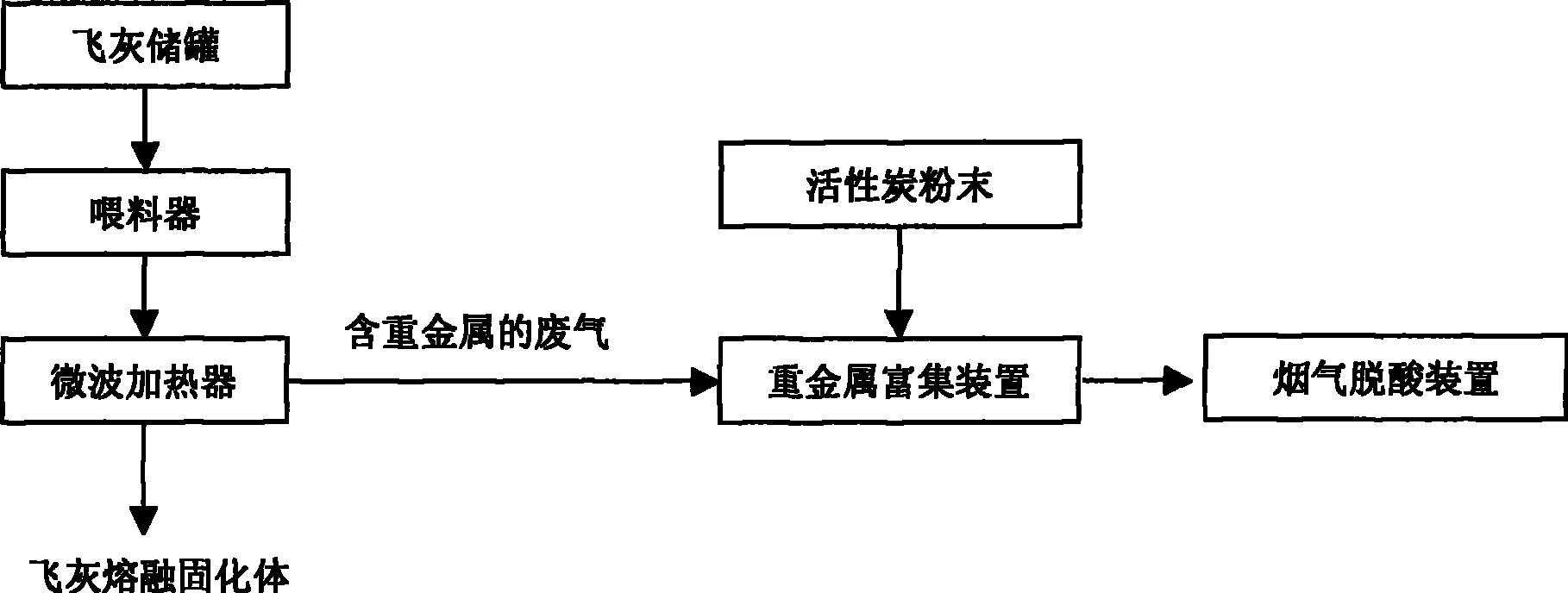

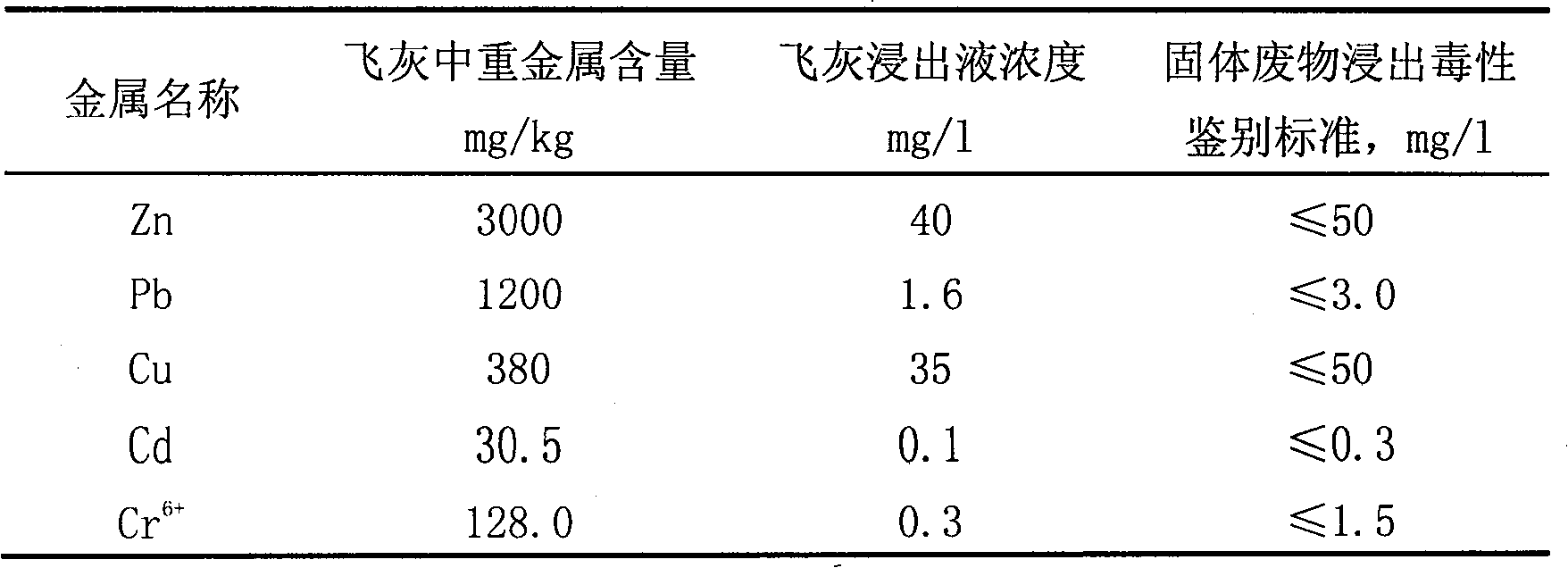

Method for microwave heating detoxication for flying ash from incineration of refuse

ActiveCN101318189AAccelerateReduce energy consumptionSolid waste disposalMunicipal solid waste incinerationActivated carbon

The invention discloses a method for detoxicating municipal solid waste incineration fly ash by microwave heating, which includes the following steps: (1) the heavy metal leaching content of the municipal solid waste incineration fly ash is sampled and detected; (2) the municipal solid waste incineration fly ash is fed into a microwave heater through a feeder; (3) the municipal solid waste incineration fly ash is heated under a temperature of 850-1200 DEG C; (4) the detention time of the fly ash in the microwave heater is controlled within 10-60 minutes; (5) the heavy metal is absorbed and enriched by activated carbon, then waste gas generated is pumped into Mg(OH)2 solution for deacidification treatment and is discharged into the atmosphere; and (6) the fly ash after treating is discharged in the form of a cloddy solidified body and is detected according to a standard. The processing method of the invention has fast speed, low energy consumption, and complete detoxification, is especially suitable for treating the fly ash which simultaneously contains a plurality of heavy metals, and has no special requirements on heating atmosphere. The method of the invention is suitable for the harmless treatment of the municipal solid waste incineration fly ash and poisonous and harmful powder solid wastes which contain heavy metal, dioxin and the like, in the environmental protection industry.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Chromium slag processing method for chemical-biological coupling reduction of hexavalent chrome

The invention relates to a chromium slag treatment when coupling and reducing hexavalent chromium from chromium slag, wherein said method comprises using wet method to break, and adding the solution with acid and reducer, controlling the pH value, reducing the density of hexavalent chromium; transferring the liquid-solid mixture to another reactor, adding acid and reducer, mixing to reduce the hexavalent chromium; adding anaerobe, emerging. The acid can be sulfuric acid, etc; the reducer can be sulfite, etc; the anaerobe can be the mixture of SRB, Pseudomonas putida and Escherichia coli.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

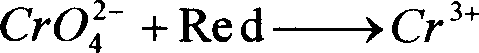

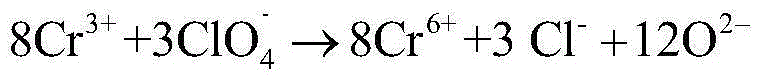

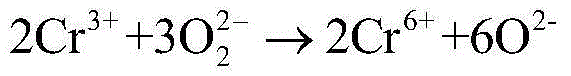

Processing method for recovering nickel, chromium and iron from stainless steel factory waste residue

ActiveCN104098148AHigh recovery rateEasy to separateIron oxides/hydroxidesChromates/bichromatesFerric hydroxideNickel sulfide

The invention discloses a processing method for recovering nickel, chromium and iron from stainless steel factory waste residue. The method is as below: adding mixed acid into the stainless steel factory waste residue, leaching out nickel, chromium and iron in the waste residue, and filtering to separate a pickle liquor and leaching residue; adding sodium sulfide to the pickle liquor under normal temperature, and after reaction conducting solid-liquid separation to obtain nickel sulfide and a filtrate; heating the filtrate, and adding a sodium hydroxide solution and a hydrogen peroxide solution; converting trivalent chromium into hexavalent chromium to stay in the supernatant by an alkali leaching oxidation method, and converting trivalent iron into a ferric hydroxide precipitate, conducting solid-liquid separation to obtain a sodium chromate solution; and recovering the chromium, smelting down the ferric hydroxide precipitate for smelting utilization, and subjecting the acid leaching residue to natural air drying for agricultural landfill. The whole process of the invention does not produce contaminants, and realizes complete recovery and utilization of resources; and the process is simple, easy to operate and low in cost, can effectively solve the problem of waste residue pollution in the production of stainless steel, and has high economic benefit and environmental benefit.

Owner:江苏森力威冶金设备有限公司

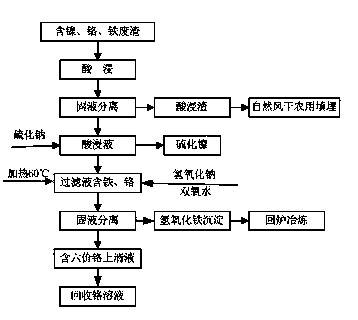

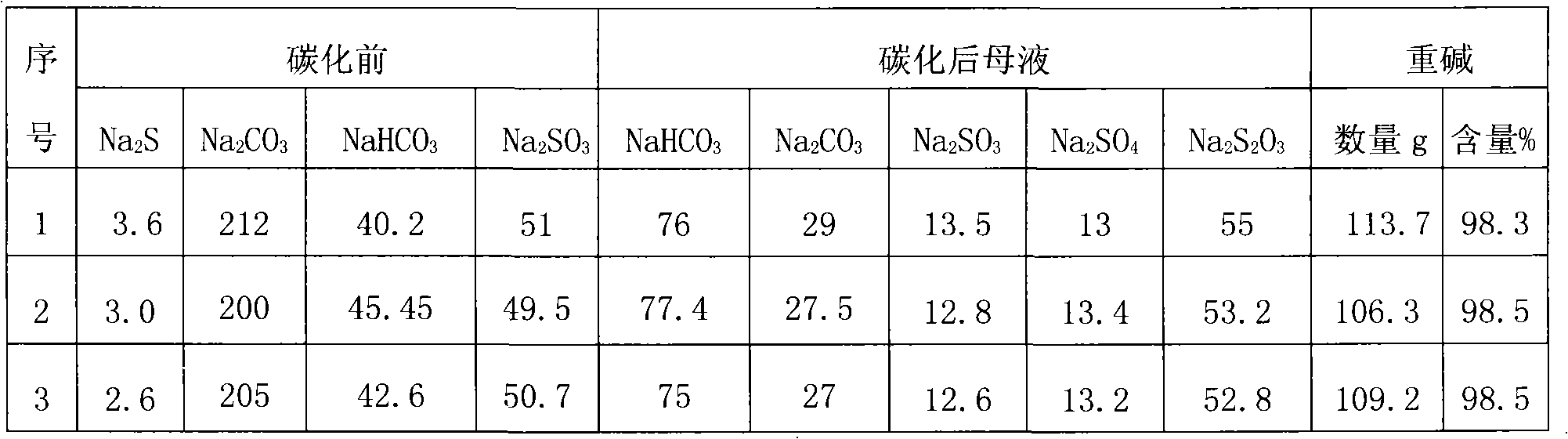

Method for producing sodium bicarbonate and sulfur from mirabilite by wet process

InactiveCN101264904AAchieving zero emissionsAchieve recyclingBicarbonate preparationSulfur preparation/purificationSodium bicarbonateCarbonization

The invention discloses a method for clean method for producing sodium bicarbonate and sulphur by means of Glauber salt wet method for reducing the emission of CO2 and avoiding the discharge of wastewater, which comprises the following steps: A, sodium sulphide preparing process, B, hot carbonatation process, C, sulphur preparing process, D, cold carbonization process, and E, mother liquor purifying. Glauber salt coal is reduced and calcined into sodium sulphide, and the sodium sulphide solution is heated and carbonized into a mixed solution with the soda as the main component by use of sodium bicarbonate, then the mixed solution is cold-carbonated by CO2 to separate out NaHCO3 crystal, which is dried to finally obtain the soda in conformity with relevant standard. The production method has the advantages of simple process, environmental friendliness, no pollution, full circulation of the mother liquor, and no wastewater discharged.

Owner:GANSU JINSHI CHEM

Chromium resource recycling and detoxification processing method for chromium slag

ActiveCN106011482ASolve processingSolve the costProcess efficiency improvementWater useSocial benefits

The invention discloses a chromium resource recycling and detoxification processing method for chromium slag, and belongs to the field of detoxification processing and resource recycling for chromium slag. The method comprises the specific steps that 1, water is added into the chromium slag, and the water and the chromium slag are mixed to be uniform; 2, a mineralizing agent is added into the solution obtained in the step 1, sufficient stirring is carried out, and a mixed solution is obtained, wherein the mineralizing agent is prepared from potassium sulphate, potassium peroxodisulfate and sodium carbonate; 3, the mixed solution is processed through a hydrothermal method or a direct heating method; 4, after heating processing is finished, the solid-liquid mixture is naturally cooled to be at room temperature for standing; 5, solid slag is separated from liquid supernatant containing chromium, and the filter slag is washed with water and dried again; and 6, the solution containing chromium is recycled and returned into a workshop section, or chromium is recycled. The method is simple in process, low in cost, capable of becoming effective rapidly, large in processing capacity, thorough in detoxification and capable of achieving whole slag utilization, and has high social benefits and economic benefits.

Owner:SOUTH CHINA UNIV OF TECH

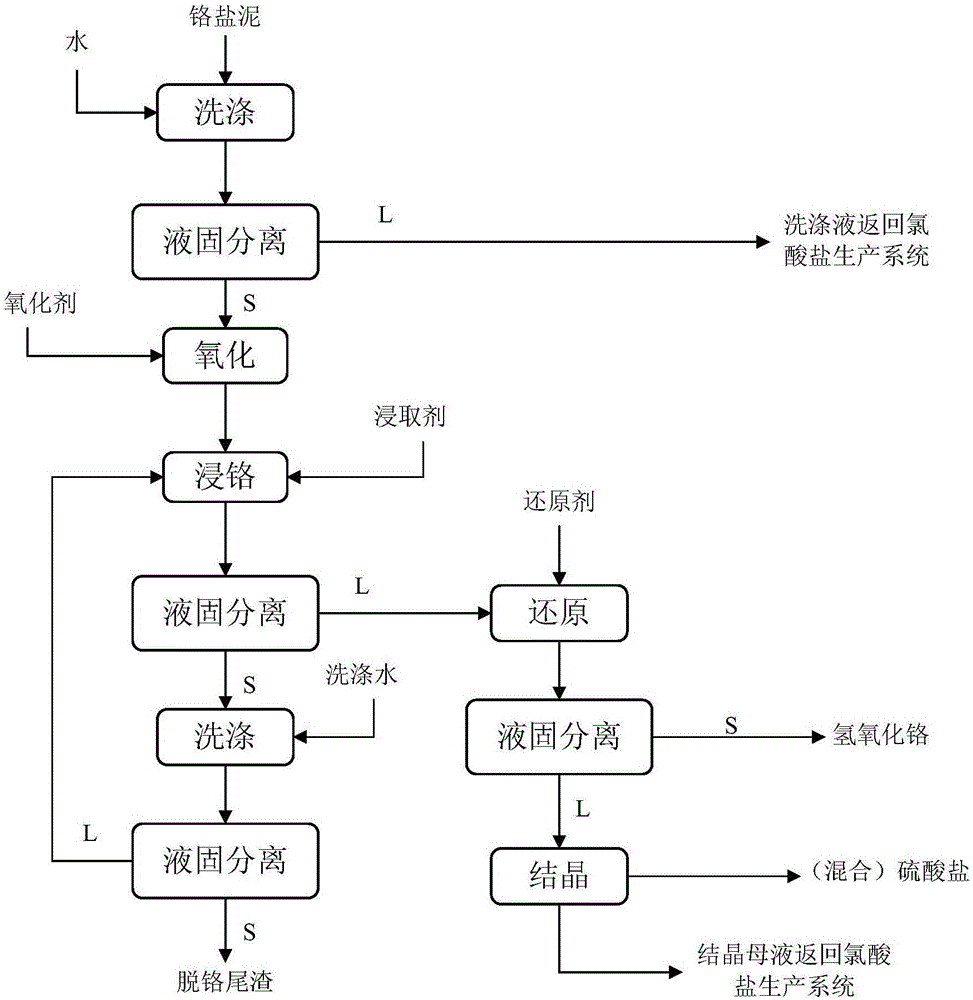

Chromium salt mud treatment method

ActiveCN105016387AAchieving processing powerRealize comprehensive utilizationChromium compoundsRecovery methodPregnant leach solution

The invention relates to a chlorate factory chromium salt mud harmless treatment and chromium separation and recovery method. The method comprises mixing chromium salt mud and water, heating the mixture, carrying out elution, carrying out solid-liquid separation to obtain filtrate and filter residue, mixing the filter residue and water to obtain a uniform mixture, carrying out oxidation and chromium impregnation, carrying out solid-liquid separation to obtain leachate and leaching residue, washing the leaching residue to obtain dechromed tailings, recycling the washing solution after washing, adjusting pH of the leachate, adding a reducer into the leachate for reduction chromium removal, carrying out solid-liquid separation to obtain a dechromed solution and chromium hydroxide, carrying out crystallization separation on the dechromed solution to obtain sulfate and recycling the mother liquid obtained by crystallization separation. The method can realize high efficiency separation and recovery of chromium in chlorate factory chromium salt mud and thorough removal of toxicity of the dechromed tailings. The method has simple processes, a low cost and a good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for synergistically treating heavy metal sludge

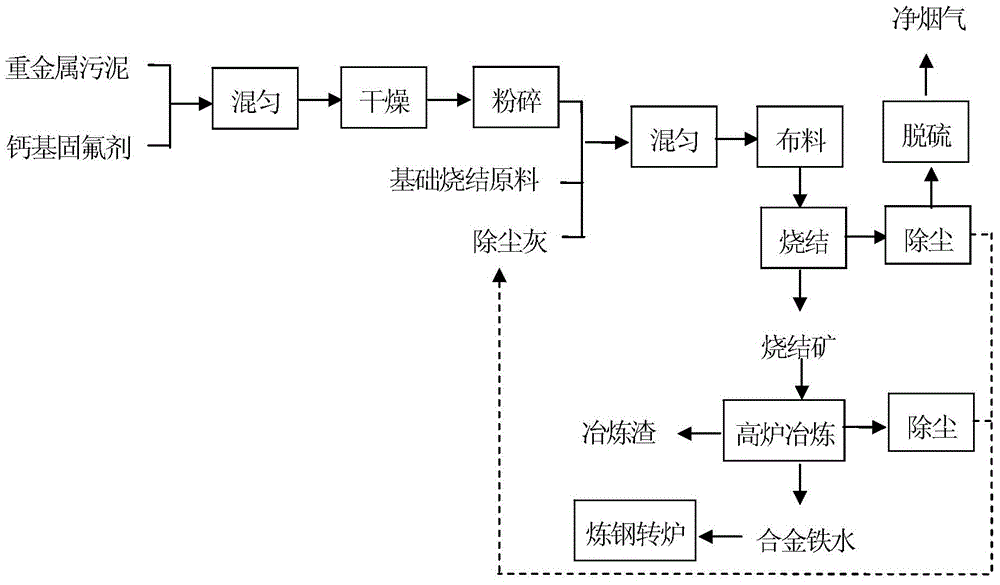

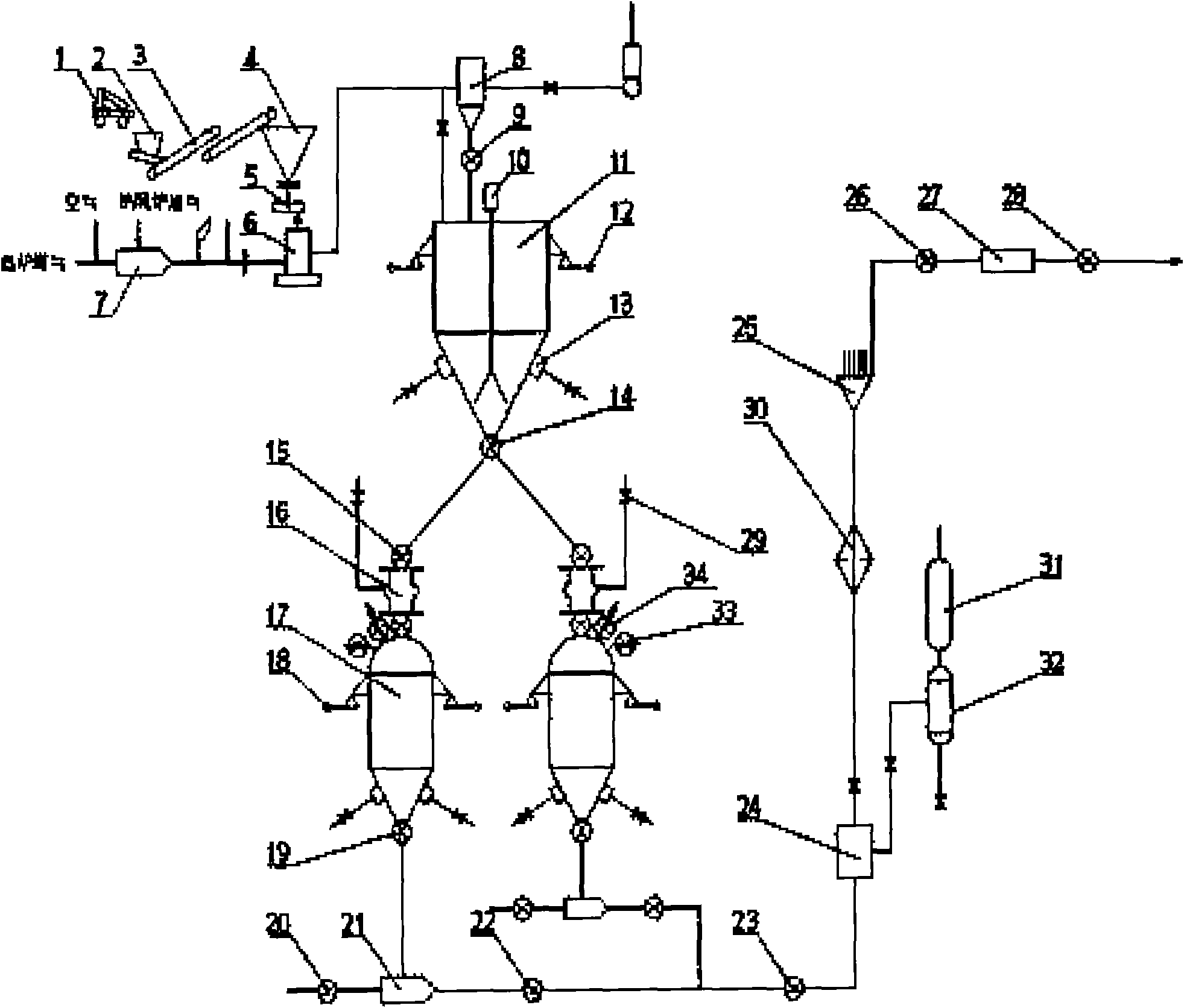

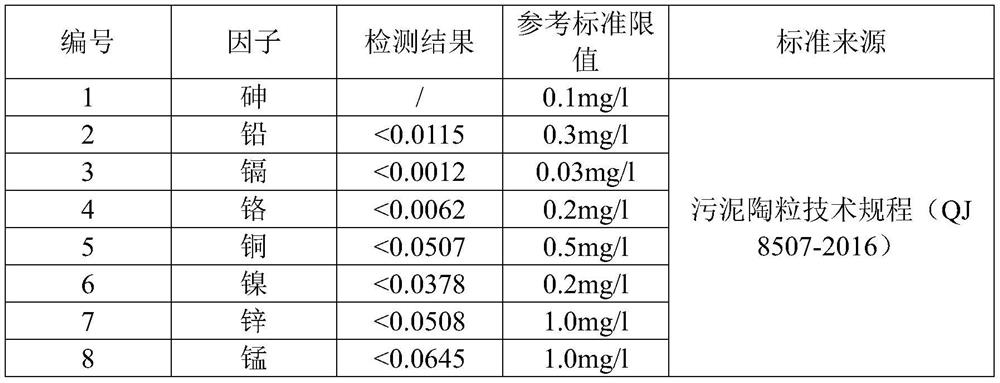

ActiveCN105271624AEfficient recyclingNo slag effectSludge treatmentWaste water treatment from metallurgical processSteelmakingSludge

The present invention provides a method for synergistically treating heavy metal sludge. The method comprises: uniformly mixing heavy metal sludge with a water content of 20-50% and a calcium-based fluorine fixing agent, drying, crushing to obtain calcium-based sludge, uniformly mixing with a base sintering raw material and dust removing ash, granulating, and distributing the material, wherein a mass ratio of the base sintering raw material to the heavy metal sludge to the calcium-based fluorine fixing agent to the dust removing ash is 50-120:0.3-20:0.1-2:0.5-5; sintering the granulated mixing material to obtain sintered ore, wherein the flue gas produced during the sintering process passes through a dust removing and desulfurization device, and the purified flue gas is externally discharged through a chimney; and conveying the sintered ore into a blast furnace, and smelting, wherein the flue gas is externally discharged after the dust removing, the smelting residue is comprehensively utilized, and the alloy hot metal enters the steelmaking converter of the stainless steel enterprise. According to the present invention, dust, gas and wastewater can be discharged into the existing facilities so as to be treated; and with the synergetic treatment of the sintering process and the blast furnace smelting, most of the metal elements can be effectively recovered so as to achieve harmlessness and resources.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Direct blast furnace innocent treatment method of chromic slag pressure block

The invention discloses a direct blast furnace innocent treatment method of a chromic slag pressure block. The method comprises the steps of: adding water and evenly mixing chromic slag, an adhesive and rolling scale, or adding water and evenly mixing the chromic slag, the adhesive, the rolling scale and quick lime, adding water and evenly mixing the chromic slag, the adhesive and coal to prepare into blocks; baking or naturally drying and condensing, adding to a blast furnace with reducing atmosphere to smelt, and restoring hexavalent chromium into trivalent chromium and / or metal chromium. By adopting the treatment method disclosed by the invention, the chromic slag can be thoroughly detoxified and fully utilized; the treatment method has an obvious innocent treatment effect, and obvious social benefit, is free of any secondary pollution, and plays important roles in protection of soil texture, water quality and human health; the phenomenon that the chromium oxide value ascends due to the fact that the chromic slag is sintered at a high temperature firstly in the prior art is avoided; namely chromium is increased to sexavalence from trivalence; and the substance with larger toxicity is manufactured. Therefore, the direct blast furnace innocent treatment method has obvious social benefit and economic benefit.

Owner:赖红君

Method for comprehensively treating waste iron oxide desulfurizer and chromium slag

The invention discloses a method for comprehensively treating waste iron oxide desulfurizer and chromium slag so as to solve the problems that the conventional waste iron oxide desulfurizer contains FeS, the treating process is complex, the safety is low, the investment is high, the running expense is high and certain defects are existent in the conventional chromium salt detoxifying method. The method comprises two steps of pre-treating and mixing for reaction. According to the method, the two wastes are skillfully treated by each other and interact with each other to achieve the purpose of treating wastes with wastes; harmless treatment on the waste iron oxide desulfurizer and the chromium slag is effectively achieved while no other additive is used, so that the treatment cost is effectively reduced; the method is simple in process and convenient to operate, and has the characteristics of energy conservation, economy and environmental protection; the method is of important significance for solving the problem of the treatment of the waste iron oxide desulfurizer and the chromium slag, and especially can be used for effectively treating the chromium slag to effectively reduce harm of the chromium slag to the environment.

Owner:李平

Detoxification method of chromium-containing slag entering metallurgical blast furnace by using coal spraying process form

ActiveCN101775449AWell mixedFully recycleBlast furnace detailsProcess efficiency improvementSlagReducing atmosphere

The invention provides a detoxification method of chromium-containing slag entering metallurgical blast furnace by using coal spraying process form. The method comprises the following steps: first drying and grinding the chromium-containing slag, then uniformly blending chromium-containing slag in an amount of 1 to 15 percent of the weight of coal powder into the coal powder, spraying the coal powder blended with the chromium-containing slag into a blast furnace cylinder from a blast furnace coal-spraying system, detoxifying the hexavalent chromium in the chromium-containing slag at the high temperature of the blast furnace under the reducing atmosphere, reducing the hexavalent chromium into trivalent chromium, and finally reducing the trivalent chromium into a chromium metal, wherein 92 to 98 percent of the chromium metal is melted into molten iron and 2 to 8 percent of the chromium metal enters the furnace slag; and meanwhile, reducing the iron oxide in the chromium-containing slag into iron metal for entering the molten iron. By utilizing the sealed blast furnace coal-spraying system to directly spray the chromium-containing slag into the blast furnace cylinder, the method has the advantages of few links, no pollution, thorough detoxification due to direct and full utilization of the high-temperature reducing atmosphere, full recycling and lowest cost compared with that of the conventional methods for treating chromium-containing slag.

Owner:CHONGQING ANGRUIYUE SCI & TECH

Method for lowering chromium pollution risk in electric furnace slag

The invention discloses a method for lowering chromium pollution risk in electric furnace slag. The method includes: putting molten stainless steel slag into a slag tank, adding a modifier, and stirring to enable the modifier and the molten stainless steel slag to be mixed well; cooling at a cooling speed of smaller than 20 DEG C / min to below 1300 DEG C to realize chromium-direct-stable spinel phase enrichment; performing hot braising on the slag. The stainless steel slag is thorough in detoxification; after the molten stainless steel slag is well mixed with the modifier, cooling is performed,so that chromium-direction-stable spinel phase enrichment can be realized, and environmental discharging standards can be met completely. The treatment process is low in energy consumption, sensibleheat of the molten stainless steel slag is utilized, and external adding of energy consumption and equipment is not needed, so that the method has great advantage in the aspect of treatment cost. Treated stainless steel slag can be further recycled, and hot-braised stainless steel slag can be safely used in products like cement and roadbed materials.

Owner:WISDRI ENG & RES INC LTD

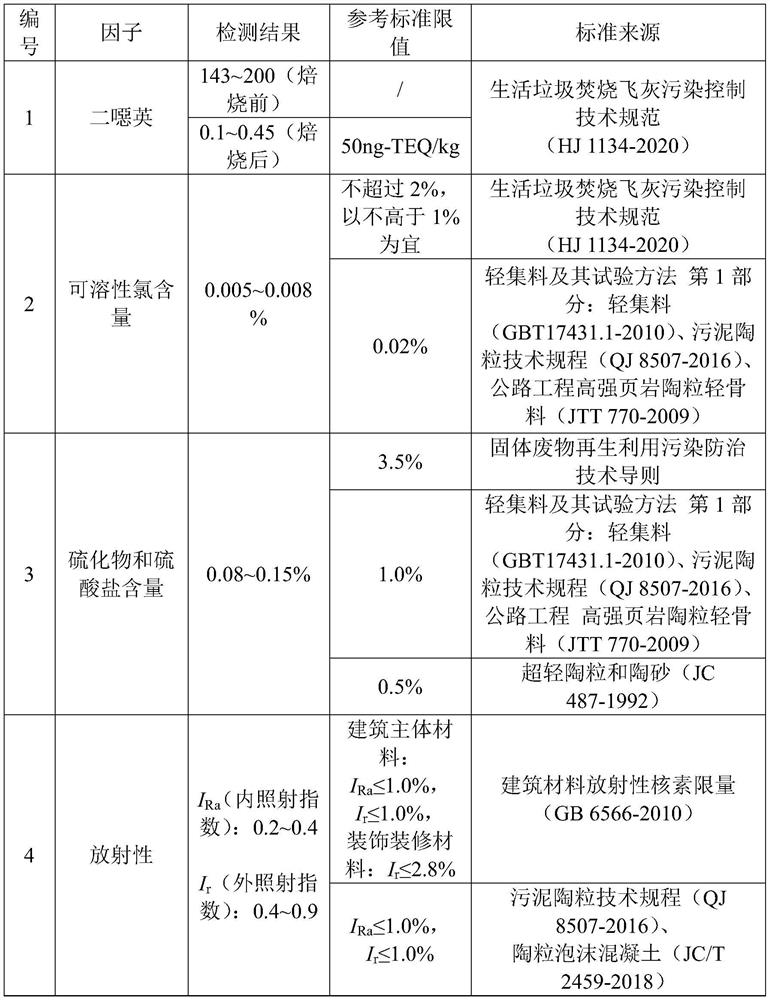

Ceramsite preparation method using waste incineration fly ash and ceramsite prepared by method

PendingCN113213891ALower the build temperatureAids in melt solidificationCeramic materials productionClaywaresProcess engineeringEnvironmental engineering

The invention discloses a preparation method of ceramsite by utilizing waste incineration fly ash and the ceramsite prepared by the preparation method. According to the invention, the waste incineration fly ash is used as a raw material, limestone and a high-silicon substance are added, and the generation amount of a liquid phase in a roasting process is controlled by regulating and controlling the mass ratio of the main components as follows: CaO / SiO2=0.2-0.35, and (SiO2+Al2O3) / (CaO+Fe2O3+MgO)=5-8. Therefore, the cylinder compressive strength of the ceramsite is improved, and the roasting temperature is reduced. The waste incineration fly ash, the limestone, the high-silicon substance and water are uniformly mixed according to the mass ratio, pelletizing is conducted, drying is conducted, and roasting is conducted at the temperature of 800-1200 DEG C for 5-30 minutes to obtain the ceramsite with excellent performance. The method has the advantages of being simple in process, low in production cost, high in resource utilization rate, environmentally friendly and the like, thorough detoxification and efficient resource utilization of the waste incineration fly ash can be synchronously achieved, raw materials can be provided for the ceramsite industry, and dependence on natural raw materials is reduced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Wet detoxification method of hexavalent chromium contained alkali waste residues

InactiveCN102614620BEasy to restore and detoxifyGood value for moneyProcess efficiency improvementChemical industryReaction temperature

The invention belongs to the technical field of chromium chemical industry and chromium salt clean production, and in particular relates to a wet detoxification method of hexavalent chromium contained alkali waste residues. According to the method, the method comprises the following steps of: first, slurrying the chromium residues; and then adjusting the pH value of the slurry to 7-10; adding a stabilizing agent and a reducing agent to the completely slurried slurry at 20-150 DEG C; and reducing the hexavalent chromium to trivalent chromium, wherein the trivalent chromium can stably exist in the chromium residue for a long period. The leaching toxicity of the obtained chromium residue, which conforms to State Environmental Protection Industrial Standard issued by the Ministry of Environmental Protection, is less than 3 mg / L. Compared with the prior art, the wet detoxification method of the hexavalent chromium contained alkali waste residues, provided by the invention, has the advantages of simple process, less usage of the reducing agent, low cost, complete reduction of the hexavalent chromium, no rebound, low reducing reaction temperature, suitability for industrial production and better promotion and application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

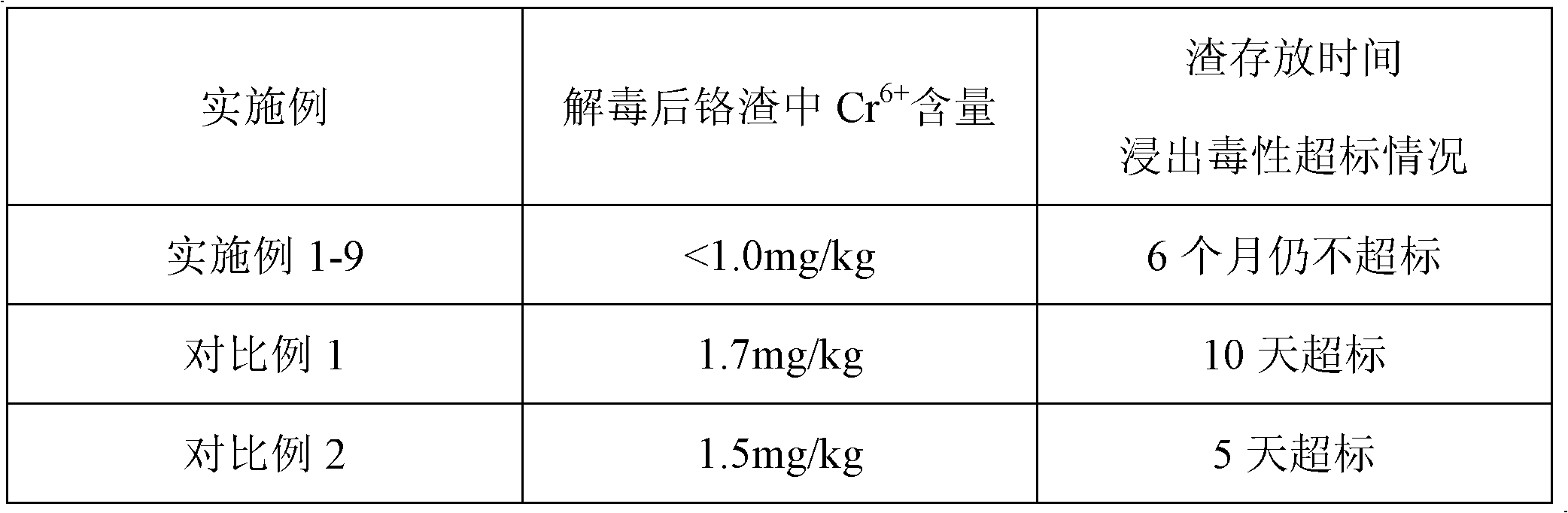

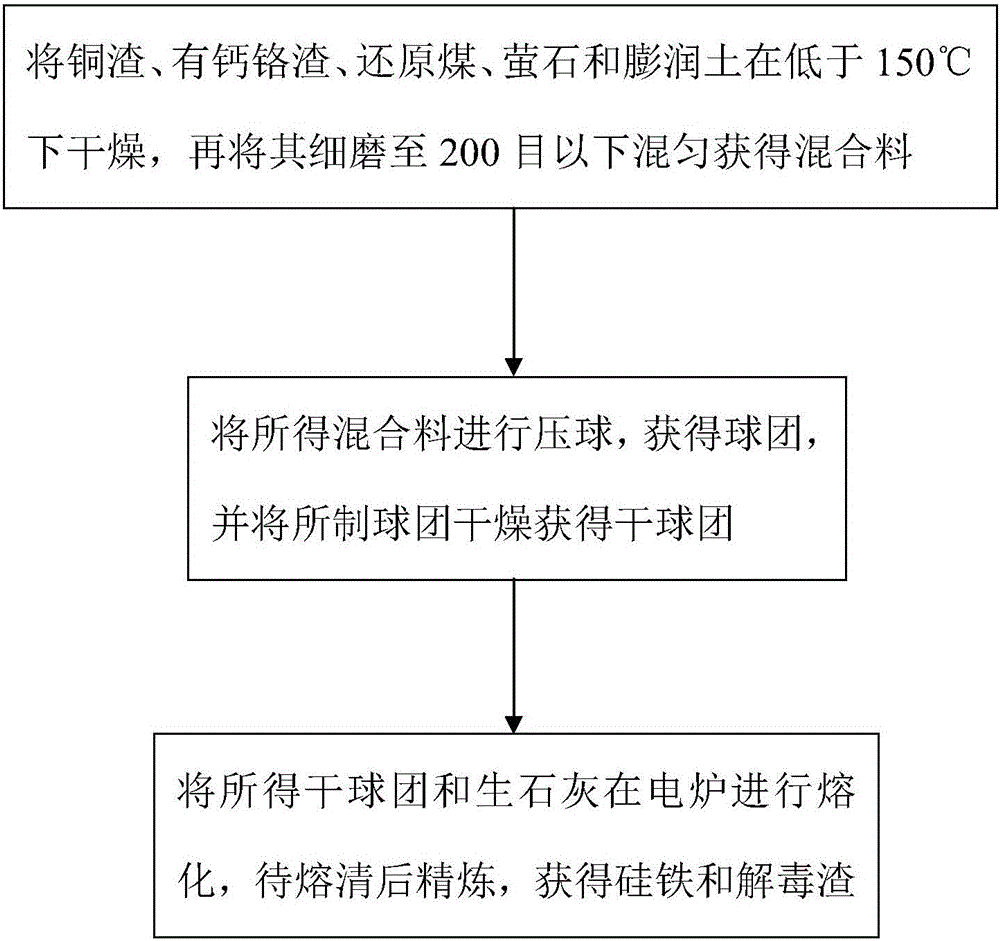

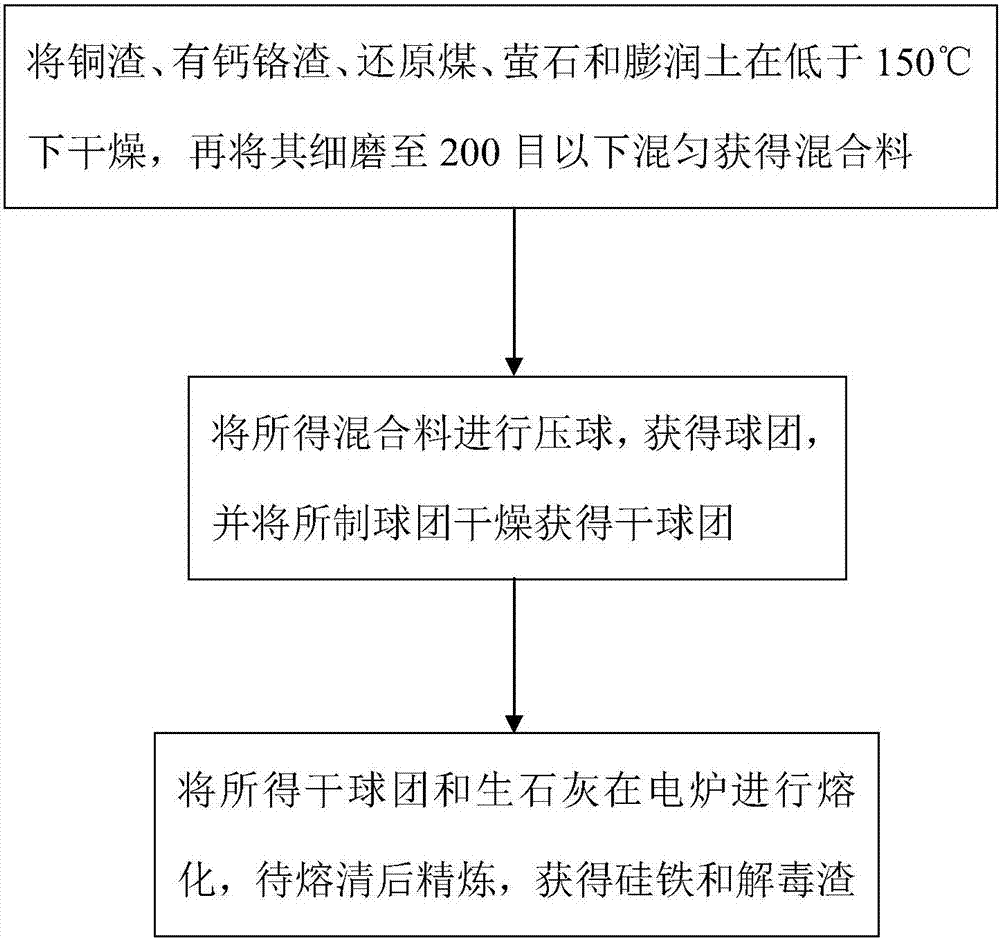

Method for combined treatment of copper slags and chromium slags

ActiveCN105861833ADetoxify thoroughlyRealize recyclingSolid waste disposalProcess efficiency improvementFerrosiliconCoal

The invention discloses a method for combined treatment of copper slags and chromium slags. The method comprises the following steps that A, copper slags, calcium-contained chromium slags, reduction coal, fluorite and bentonite are dried under the temperature lower than 150 DEG C, finely ground to 200 meshes or below, and mixed to be uniform to obtain a mixture; B, the mixture is pressed into balls, and the obtained balls are dried to obtain dry balls; C, the dry balls and quick lime are molten in an electric furnace, refining is performed after melting down, and ferrosilicon and detoxicated slags are obtained. According to the method for combined treatment of copper slags and chromium slags, copper slags, calcium-contained chromium slags, reduction coal, fluorite, bentonite and quick lime are adopted as raw materials, and ferrosilicon and detoxicated slags are obtained; Cr6+ in chromium slags is detoxicated thoroughly, and copper slags and calcium-contained chromium slags are comprehensively recycled.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Method for extracting ultra-fine ferric oxide by using waste slag

The present invention provides a method of industrial residue recycle, especially a method of extracting superfine ferric oxide from waste residue. The technical solution is divided into three process of the method of extracting superfine ferric oxide from waste residue, firstly a detoxifcation process, adopting rotary kiln incineration and detoxifcation; secondly an extracting manufacturing ferric oxide, preparing iron oxide red by LAUX method; thirdly a process of preparing nanometer superfine ferric oxide, using chemical reaction method. The invention can produce beneficial results: a method of extracting superfine ferric oxide utilizing toxic waste residue ''chrome residue'' which being a material of extracting superfine ferric oxide, changing waste into valuable, and also utilzing industrial acid waste, protecting environment. The invention has a strong operability, complete detoxifcation, high economic value, evident predominance; the method is easy to control, the prepared nanometer iron oxide yellow has a small granularity, evenly distribution.

Owner:徐惠峰

Chromium residue detoxifying process

InactiveCN101816829BReduce dosageImprove mixing uniformityChemical protectionSodium bisulfideSodium hydrosulfide

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environmentof the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

Method for separating and recovering chromium from waste residue containing hexavalent chromium

ActiveCN101209873BSolve the problem of difficult leachingLow in chromiumSolid waste disposalWater/sewage treatmentSodium bicarbonateSocial benefits

The invention discloses a method for separating and recycling chromium from the waste residue containing hexavalent chromium. The waste residue containing hexavalent chromium which has fine particles and is difficult to subside is added with mineralizer and then is subject to hydrothermal method or heating treatment to generate the waste residue which can subside, the upper clear liquid is separated from the waste residue and then the waste residue is cleaned and dried. Sodium bicarbonate or salt-mixture of sodium carbonate and sodium bicarbonate is adopted as mineralizer. The invention has simple process, low cost, quick results, large throughput, complete detoxification and no secondary pollution and can make use of all the residue, thereby bringing comparatively high social benefit andeconomic benefit.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

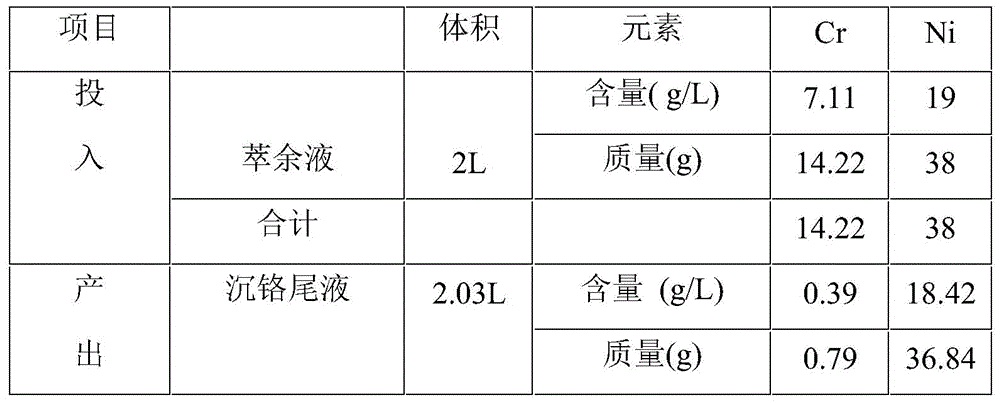

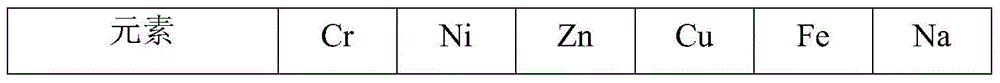

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

Method for microwave heating detoxication for flying ash from incineration of refuse

The invention discloses a method for detoxicating municipal solid waste incineration fly ash by microwave heating, which includes the following steps: (1) the heavy metal leaching content of the municipal solid waste incineration fly ash is sampled and detected; (2) the municipal solid waste incineration fly ash is fed into a microwave heater through a feeder; (3) the municipal solid waste incineration fly ash is heated under a temperature of 850-1200 DEG C; (4) the detention time of the fly ash in the microwave heater is controlled within 10-60 minutes; (5) the heavy metal is absorbed and enriched by activated carbon, then waste gas generated is pumped into Mg(OH)2 solution for deacidification treatment and is discharged into the atmosphere; and (6) the fly ash after treating is discharged in the form of a cloddy solidified body and is detected according to a standard. The processing method of the invention has fast speed, low energy consumption, and complete detoxification, is especially suitable for treating the fly ash which simultaneously contains a plurality of heavy metals, and has no special requirements on heating atmosphere. The method of the invention is suitable for the harmless treatment of the municipal solid waste incineration fly ash and poisonous and harmful powder solid wastes which contain heavy metal, dioxin and the like, in the environmental protection industry.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

A method for detoxification of chromium-containing waste residue and recovery of chromium

ActiveCN108220604BHigh puritySimple processProcess efficiency improvementSodium bicarbonateSocial benefits

Owner:SOUTH CHINA UNIV OF TECH

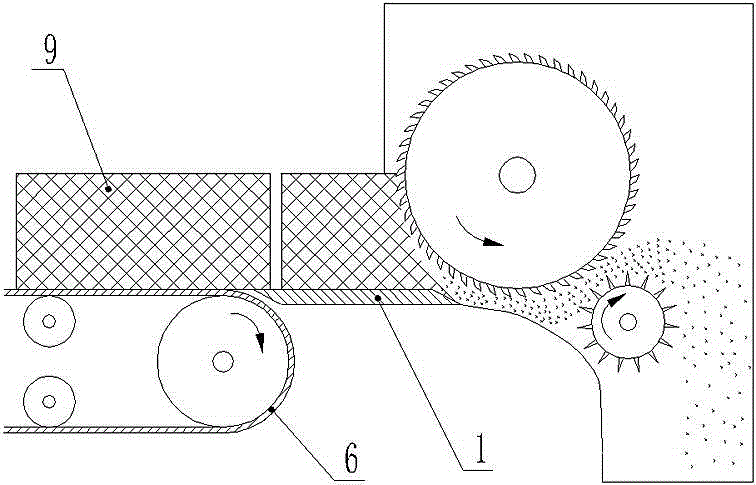

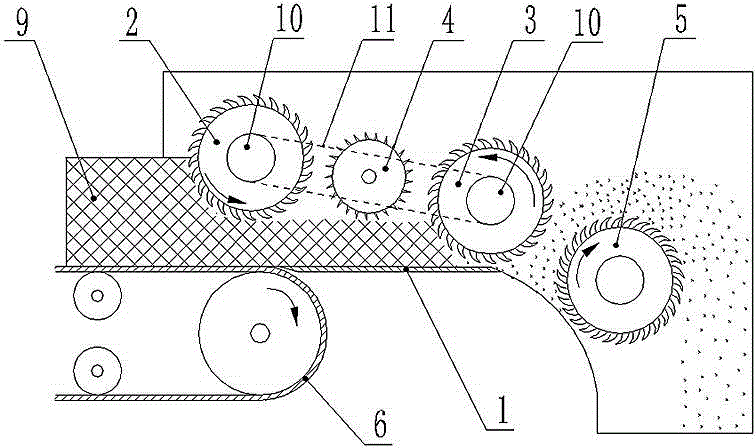

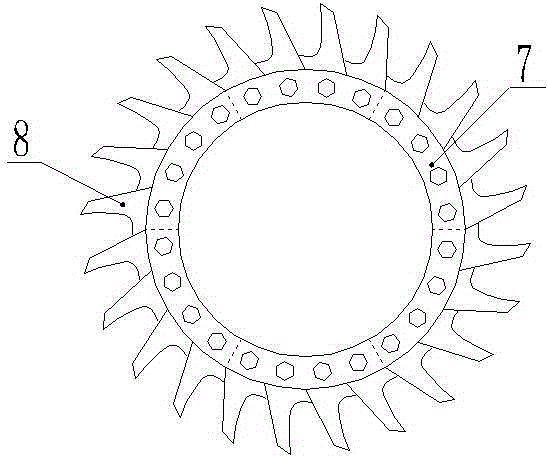

Refined cotton opening machine high in cotton opening efficiency

ActiveCN105297185AReduce workloadAvoid situations where the evacuation is insufficientFibre cleaning/opening by toothed membersEngineeringUltimate tensile strength

The invention relates to the technical field of refined cotton and discloses a refined cotton opening machine high in cotton opening efficiency. The refined cotton opening machine high in cotton opening efficiency is used for decomposing a cotton package (9) into sheet matter or floccule. The refined cotton opening machine high in cotton opening efficiency comprises a feeding device, a defibering device and a feeding plate (1) arranged between the feeding device and the defibering device. The defibering device comprises at least two stages of defibering rollers used for defibering of the cotton package (9), the defibering rollers are sequentially arranged in a staggered mode from the feeding end to the discharging end, defibering teeth are arranged on the outer layers of the defibering rollers, the defibering device comprises the two stages of defibering rollers used for defibering of the cotton package (9), the defibering rollers are composed of the first-stage defibering roller (2) and the second-stage defibering roller (3), and a pre-pressing roller (4) is arranged between the first-stage defibering roller (2) and the second-stage defibering roller (3). By means of the refined cotton opening machine high in cotton opening efficiency, defibering efficiency is improved, the labor intensity of workers is lowered, and it is also guaranteed that defibering quality meets the technological requirement.

Owner:SICHUAN NITROCELLULOSE CORP

Digital persuasion system for assisting detoxification

The invention relates to a digital persuasion system for assisting detoxification, which comprises a value field, an emotion field, an action field, an information field and a knowledge field. The value field influences the emotion field, the action field, the information field and the knowledge field. The knowledge field includes personal long-term memory and group long-term memory. The information field includes personal short-term memory and group short-term memory. Under the guidance of the value field, the knowledge field oriented to specific problems is established and is fed back and applied to the human-machine interactive information field, and by continuously and repeatedly correcting the personal short-term memory, the personal long-term memory is modified. The digital persuasion system, for an auxiliary detoxification system which is a social technical system, exerts influences on drug addicts to abandon drugs from inside to outside by means of computer technology and information technology as a technical means, persuades the drug addicts to change wrong thoughts and ideas, and assists the drug addicts to develop the correct values, cultivate good habits, to achieve rapid and thorough detoxification.

Owner:SHANGHAI DIANJI UNIV

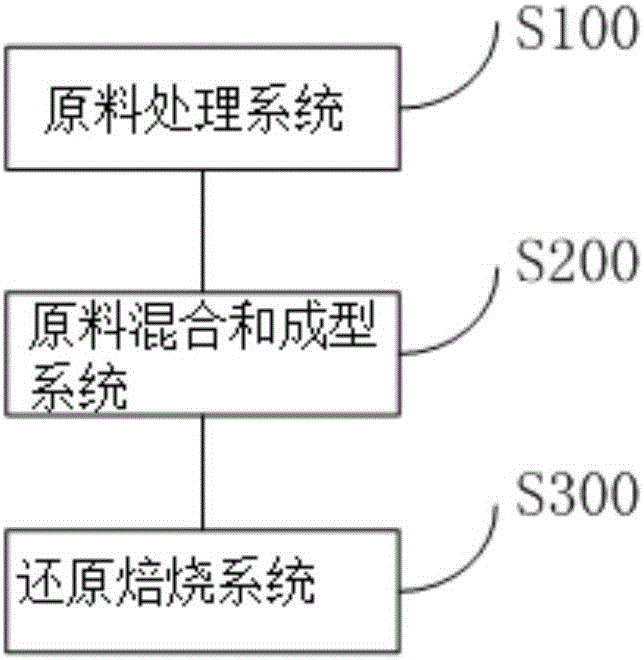

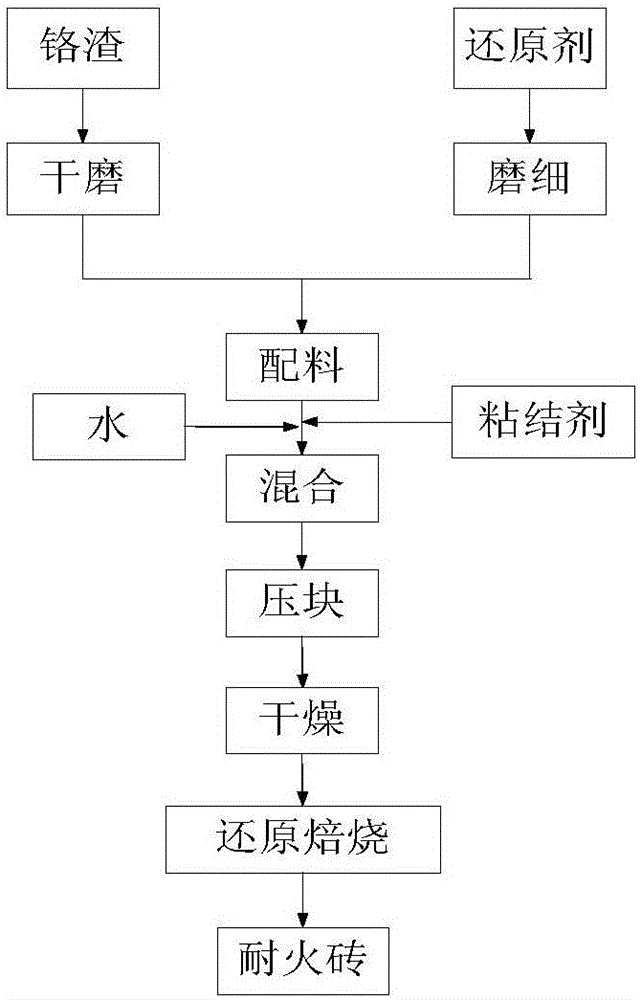

Method for preparing compact refractory material from chromium slag and special system of method

The invention discloses a method for preparing a compact refractory material from chromium slag and a special system of the method, and belongs to the field of chromium slag reutilization. The method comprises the following steps that (1) the chromium slag, reducing coal, a bonding agent and water are mixed to obtain a mixed material; the mixed material is pressed into a wet brick blank; (2) the wet brick blank is dried and then is subjected to reducing roasting in a high-temperature kiln; after the roasting is finished, cooling along with the kiln is performed to obtain the chromium slag compact refractory material. The invention further discloses the special system for realizing the method; the special system comprises a raw material treatment system, a raw material mixing and forming system and a reducing roasting system. The waste chromium slag is used as a major raw material; a compact refractory brick with the specific gravity of 2.3 to 2.7 g / m<3> is prepared by using the chromium slag as the major raw material through a pyrogenic process; the hexavalent chromium content is smaller than 2ppm; high temperature of 1300 DEG C can be resisted. The method has the advantages that the operation is simple; the process is feasible; the chromium slag detoxification is very thorough; the full reutilization of the chromium slag is realized.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

A method for joint treatment of copper slag and chromium slag

ActiveCN105861833BDetoxify thoroughlyRealize recyclingSolid waste disposalProcess efficiency improvementFerrosiliconCoal

The invention discloses a method for combined treatment of copper slags and chromium slags. The method comprises the following steps that A, copper slags, calcium-contained chromium slags, reduction coal, fluorite and bentonite are dried under the temperature lower than 150 DEG C, finely ground to 200 meshes or below, and mixed to be uniform to obtain a mixture; B, the mixture is pressed into balls, and the obtained balls are dried to obtain dry balls; C, the dry balls and quick lime are molten in an electric furnace, refining is performed after melting down, and ferrosilicon and detoxicated slags are obtained. According to the method for combined treatment of copper slags and chromium slags, copper slags, calcium-contained chromium slags, reduction coal, fluorite, bentonite and quick lime are adopted as raw materials, and ferrosilicon and detoxicated slags are obtained; Cr6+ in chromium slags is detoxicated thoroughly, and copper slags and calcium-contained chromium slags are comprehensively recycled.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com