Novel process of the high temperature reduction and detoxication of industrial chromic slag

A technology of industrial waste residue and chromium residue, which is applied in the direction of protection devices against harmful chemicals, can solve problems such as immature technology, and achieve the effects of simple equipment, promotion of chemical reactions, and large physical heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

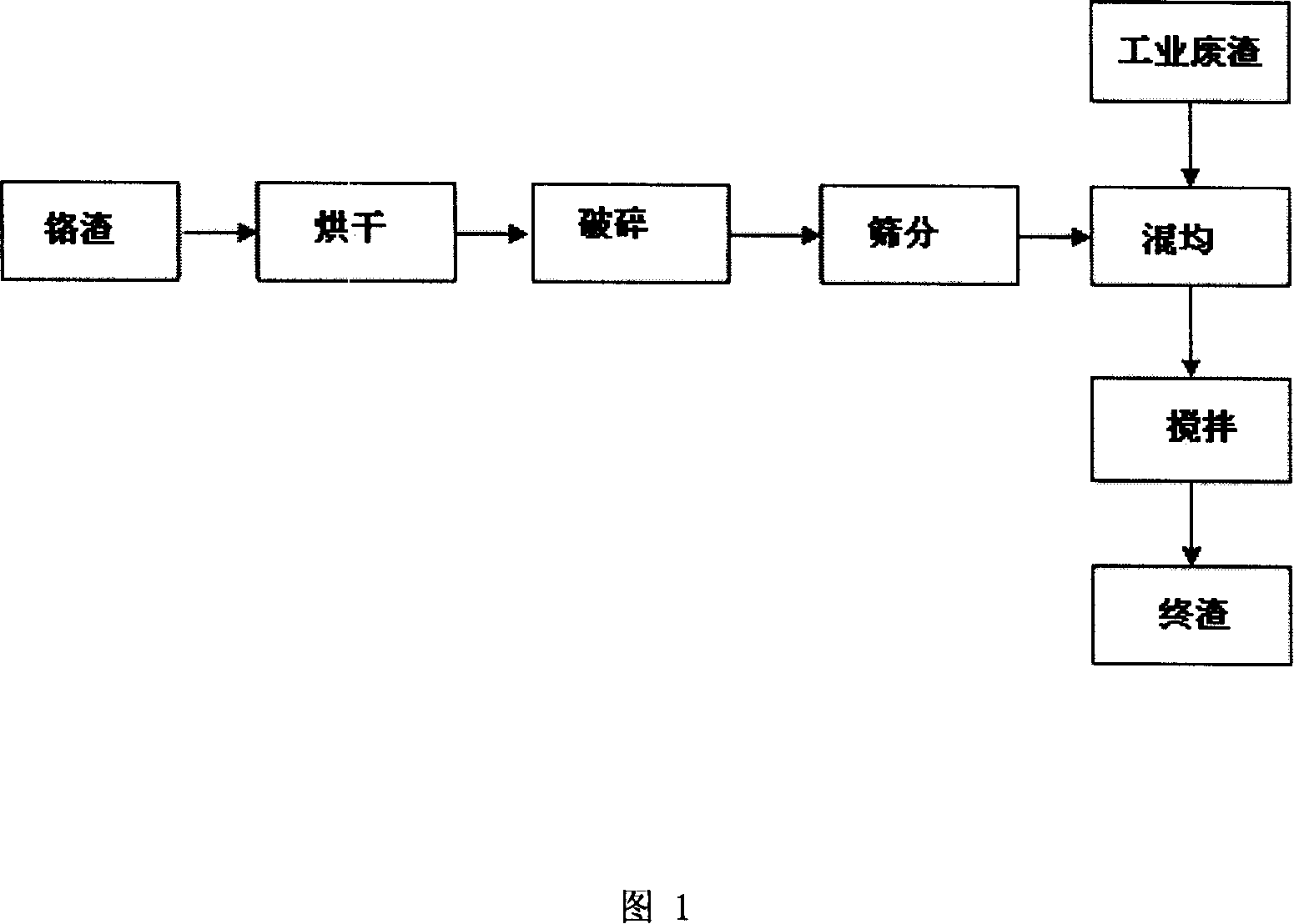

Method used

Image

Examples

Embodiment approach (1

[0026] A certain amount of reducing metallurgical slag is weighed and filled in a slag pot, heated and melted, and the temperature after melting is controlled at 1200°C. When the temperature is constant, add chromium slag to the slag tank, and the water-soluble sodium chromate (Na 2 CrO 4 ) and acid-soluble calcium chromate (CaCrO 4 ) content are 0.5% and 0.2% respectively, the particle size of chromium slag is controlled below 20 mesh, the addition amount is 2% of the total amount of metallurgical slag, the reaction time is controlled at 5min, and naturally cooled to room temperature, in the obtained final slag, Cr(VI ) removal rate of 99.93% of the final slag.

Embodiment approach (2

[0028] A certain amount of reducing metallurgical slag is weighed and filled in a slag pot, heated and melted, and the temperature after melting is controlled at 1200°C. When the temperature is constant, add chromium slag to the slag tank, and the water-soluble sodium chromate (Na 2 CrO 4 ) and acid-soluble calcium chromate (CaCrO 4 ) content is 0.5% and 0.2% respectively, the particle size of chromium slag is controlled below 20 mesh, the addition amount is 2% of the total amount of metallurgical slag, the reaction time is controlled at 15min, and naturally cooled to room temperature, in the obtained final slag, Cr(VI ) removal rate of 99.95% of the final slag.

Embodiment approach (3

[0030] A certain amount of reducing metallurgical slag is weighed and filled in a slag pot, heated and melted, and the temperature after melting is controlled at 1200°C. When the temperature is constant, add chromium slag to the slag tank, and the water-soluble sodium chromate (Na 2 CrO 4 ) and acid-soluble calcium chromate (CaCrO 4 ) content is 0.5% and 0.2% respectively, the particle size of chromium slag is controlled below 20 mesh, the addition amount is 6% of the total amount of metallurgical slag, the reaction time is controlled at 5min, and naturally cooled to room temperature, in the obtained final slag, Cr(VI ) removal rate of 99.91% of the final slag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com