Patents

Literature

635results about How to "Facilitate chemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

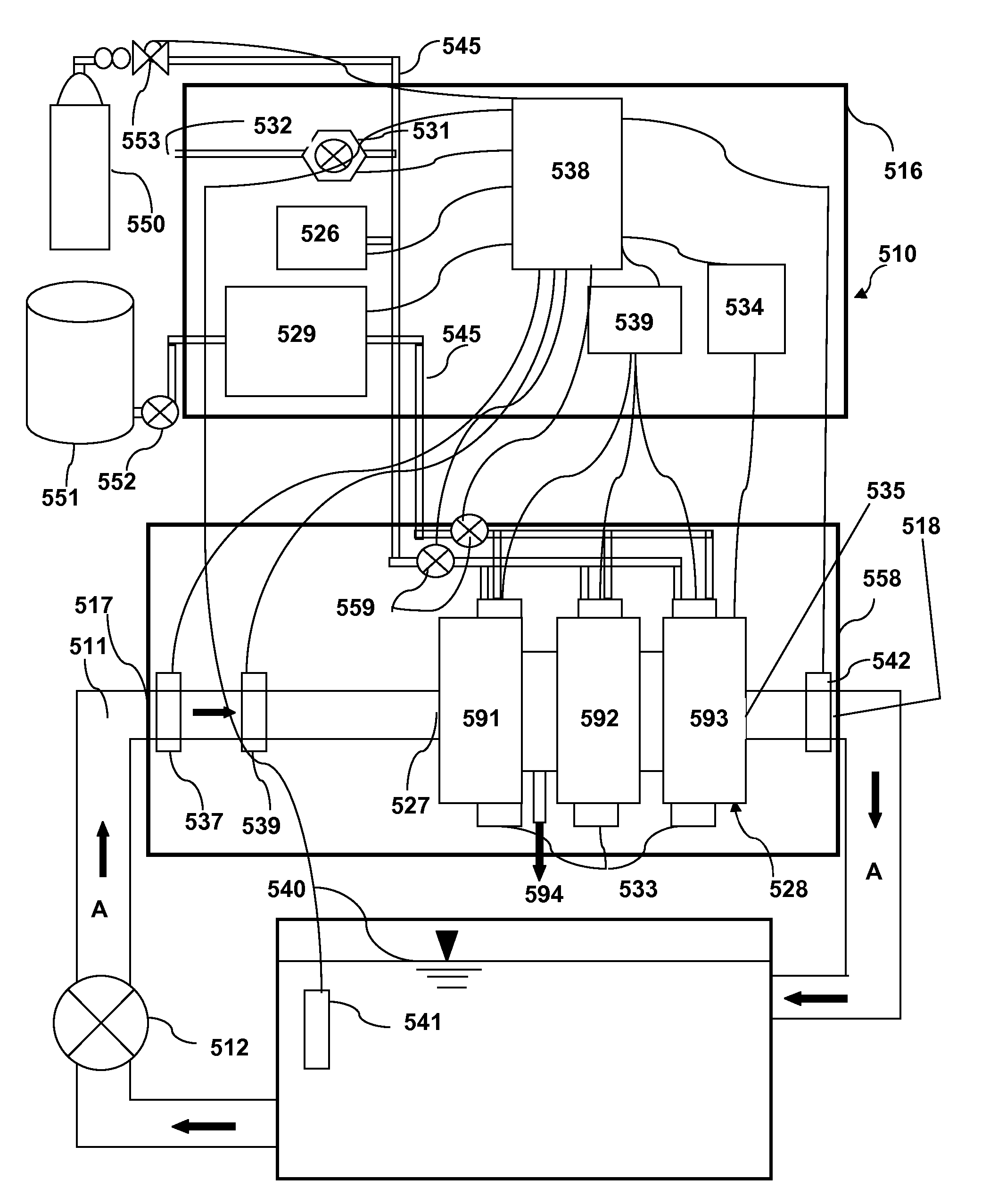

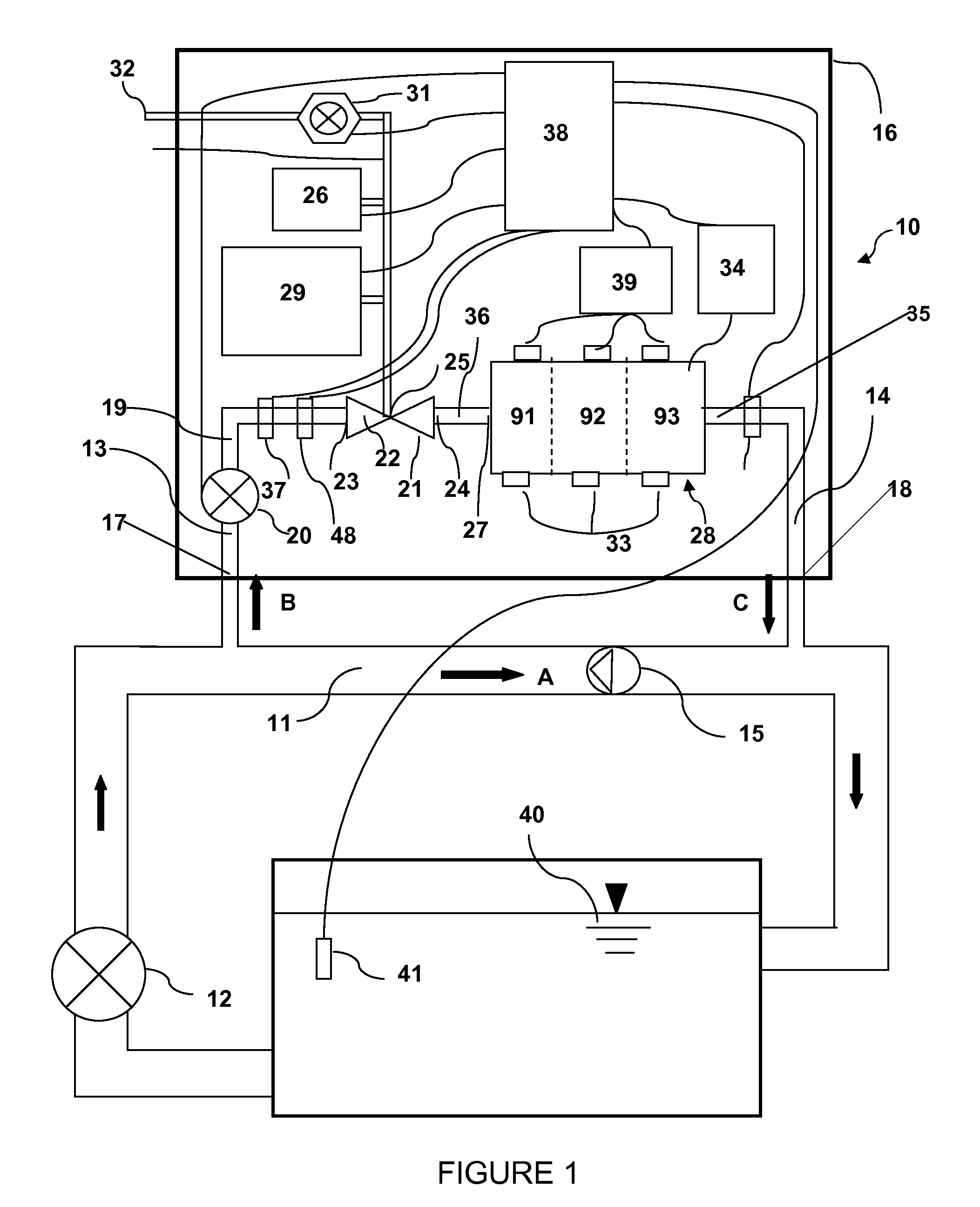

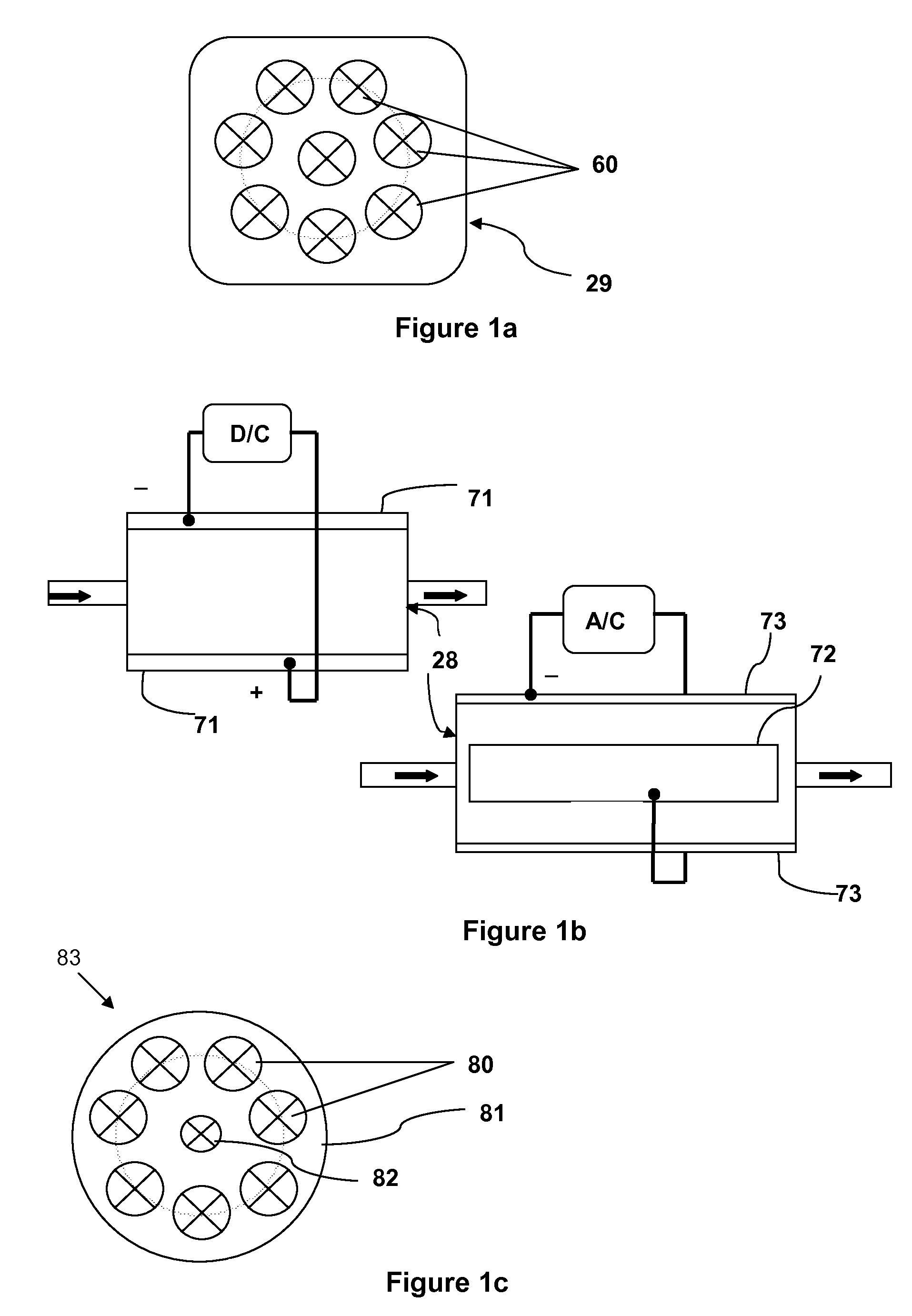

Aqueous treatment apparatus utilizing precursor materials and ultrasonics to generate customized oxidation-reduction-reactant chemistry environments in electrochemical cells and/or similar devices

ActiveUS20110024361A1Prevent precipitationReduce maintenance costsFrom normal temperature solutionsLiquid separation by electricityEnvironmental chemistrySet point

An electrochlorination and electrochemical system for the on-site generation and treatment of municipal water supplies and other reservoirs of water, by using a custom mixed oxidant and mixed reductant generating system for the enhanced destruction of water borne contaminants by creating custom oxidation-reduction-reactant chemistries with real time monitoring. A range of chemical precursors are provided that when acted upon in an electrochemical cell either create an enhanced oxidation, or reduction environment for the destruction or control of contaminants. Chemical agents that can be used to control standard water quality parameters such as total hardness, total alkalinity, pH, total dissolved solids, and the like are introduced via the chemical precursor injection subsystem infrequently or in real time based on sensor inputs and controller set points.

Owner:GLOBAL WATER INVESTMENTS LLC

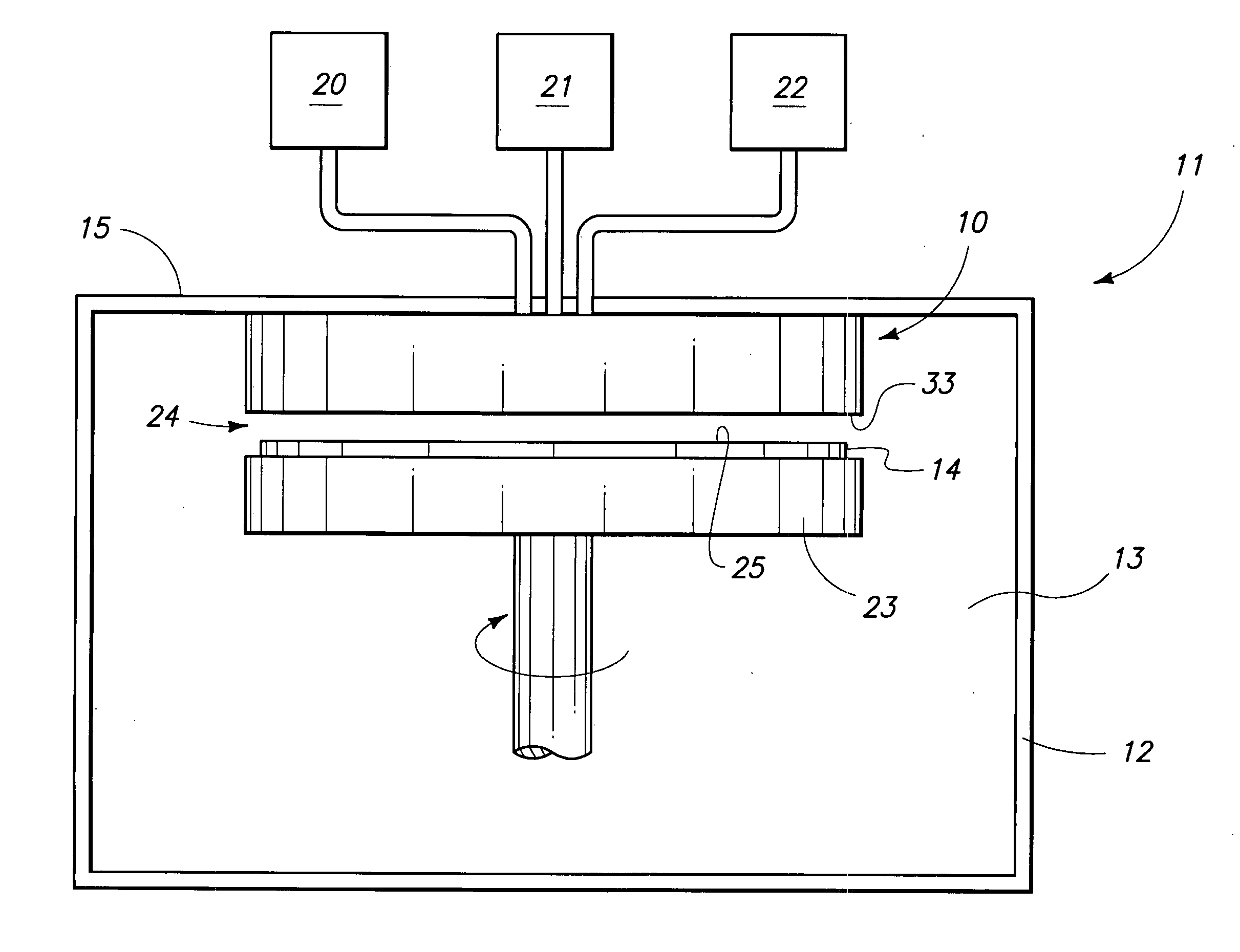

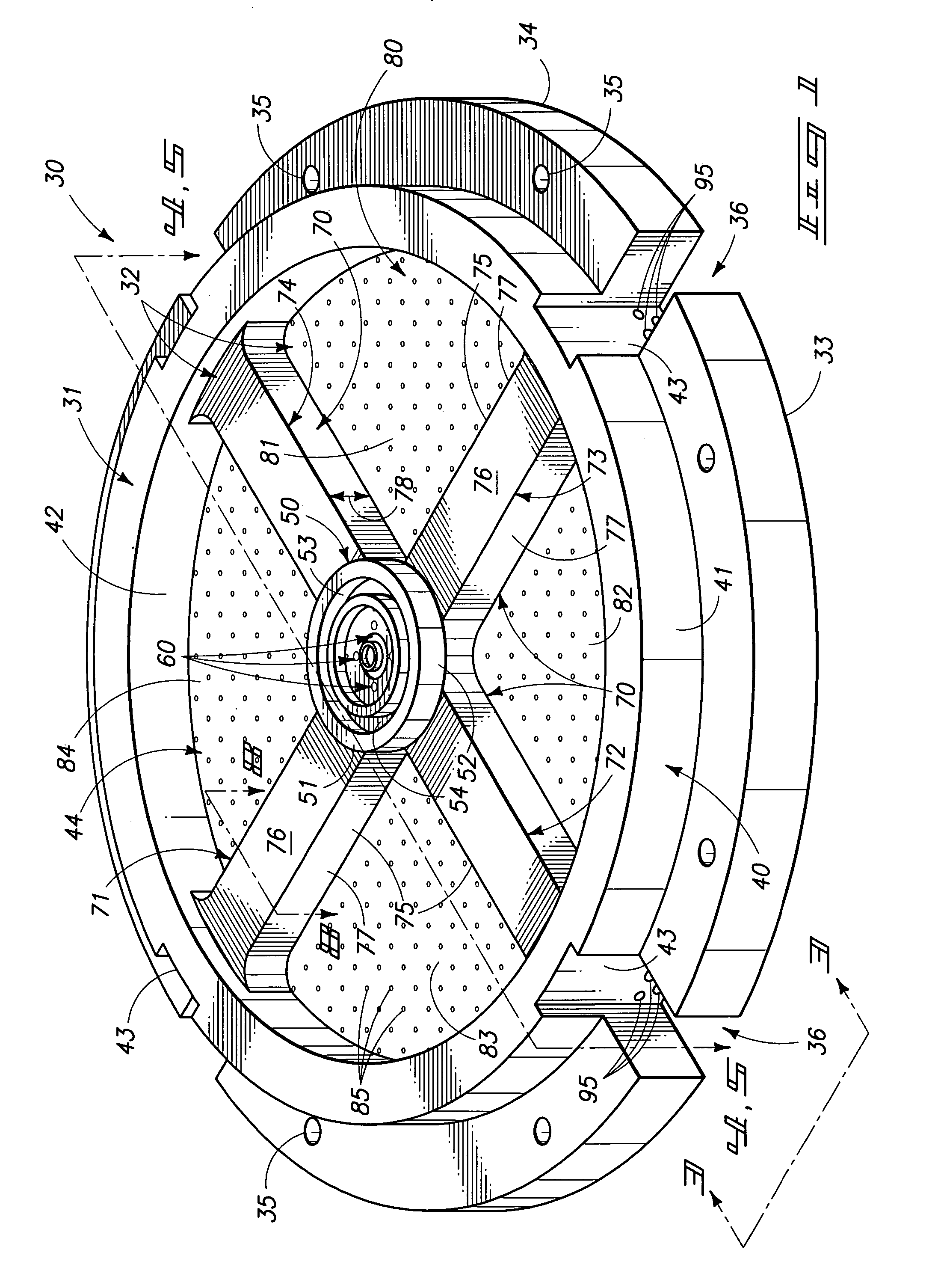

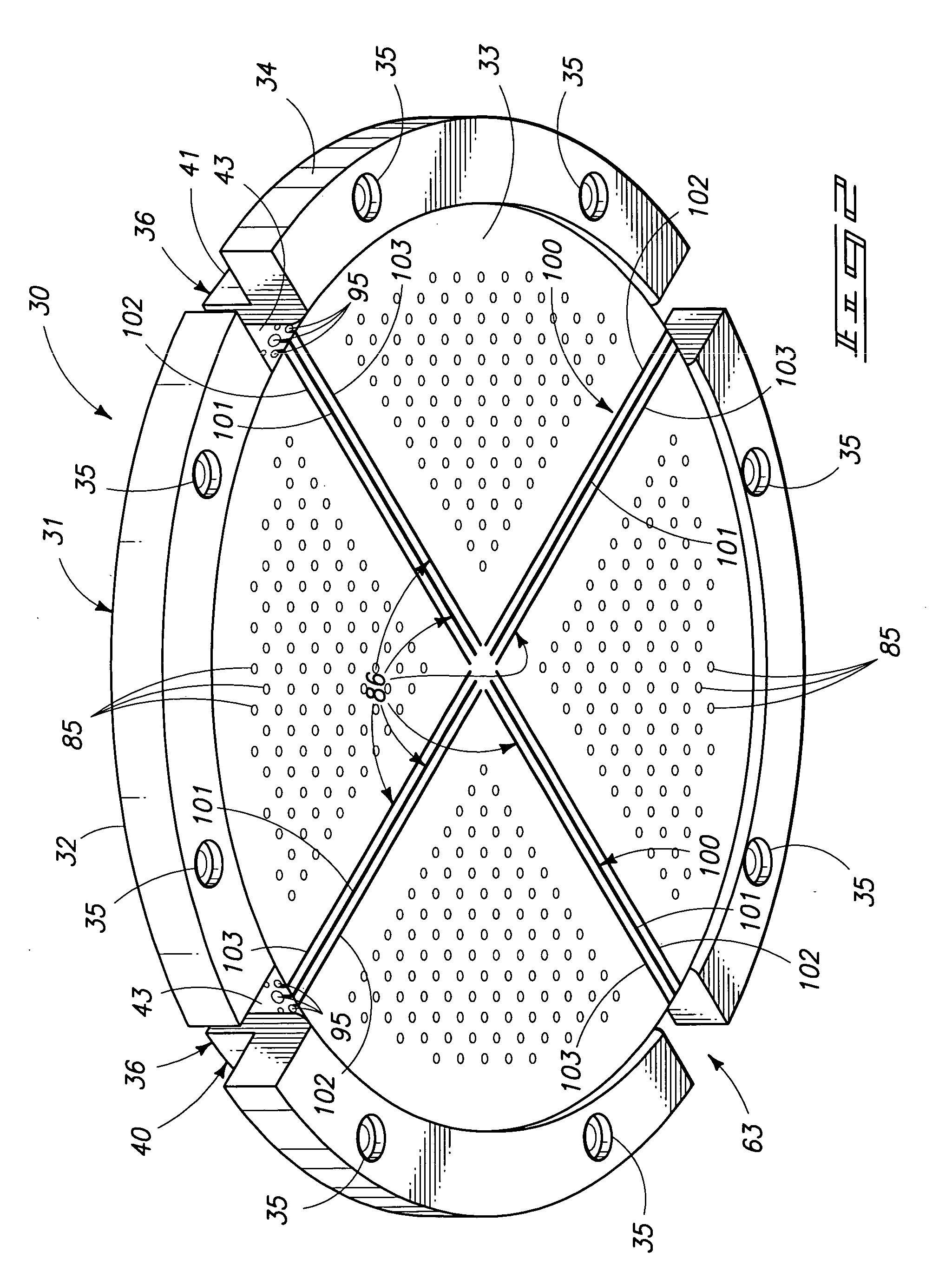

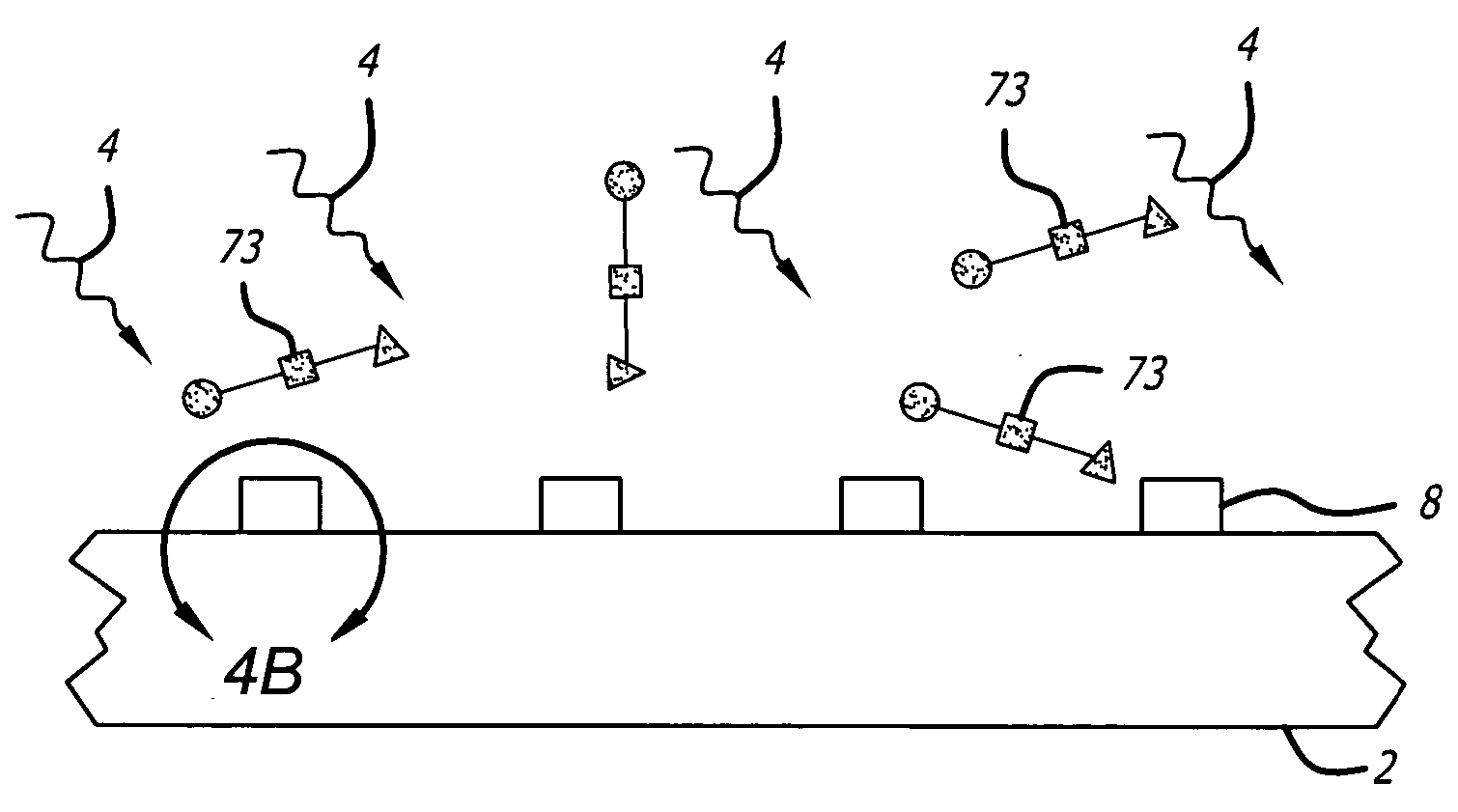

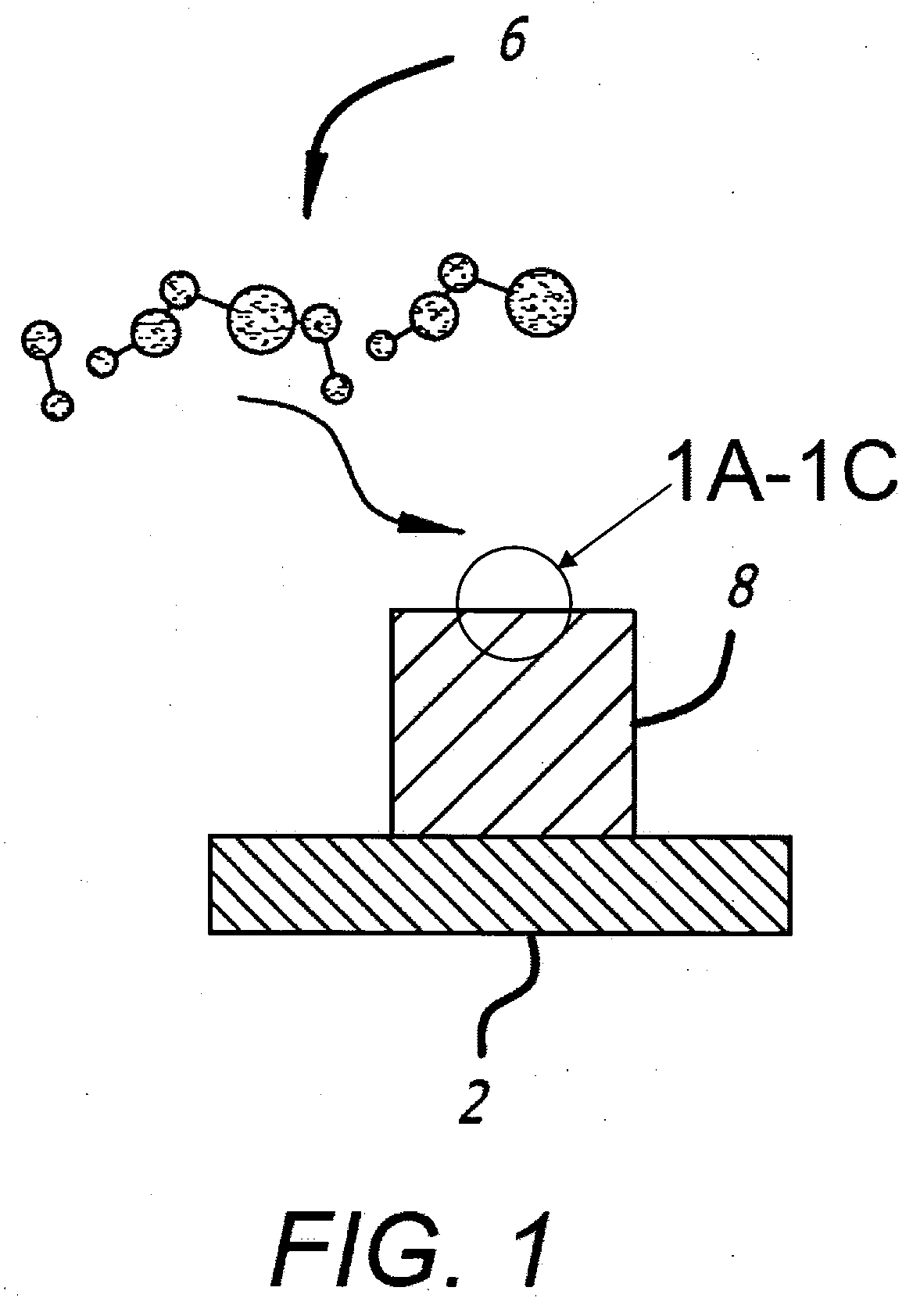

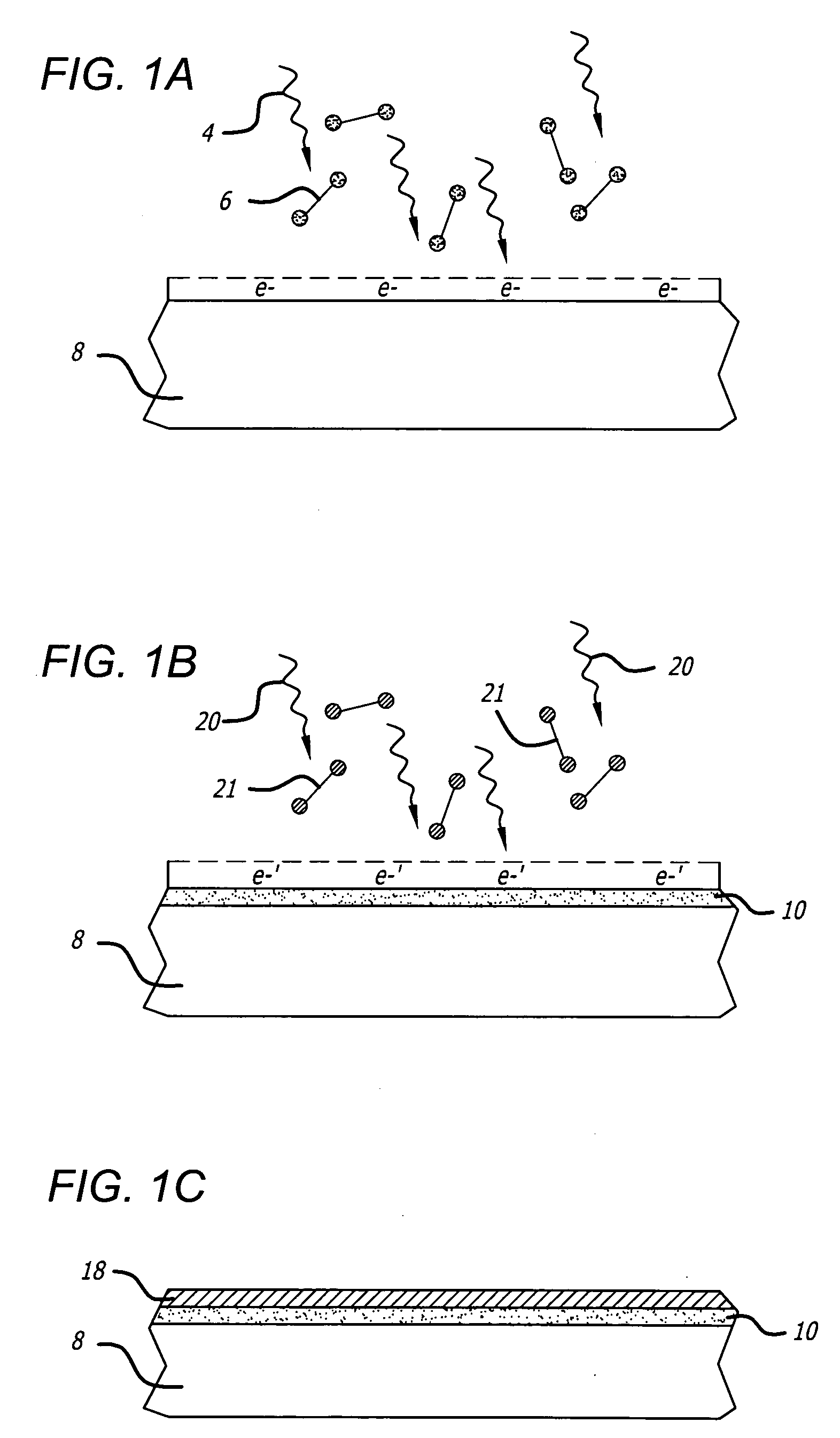

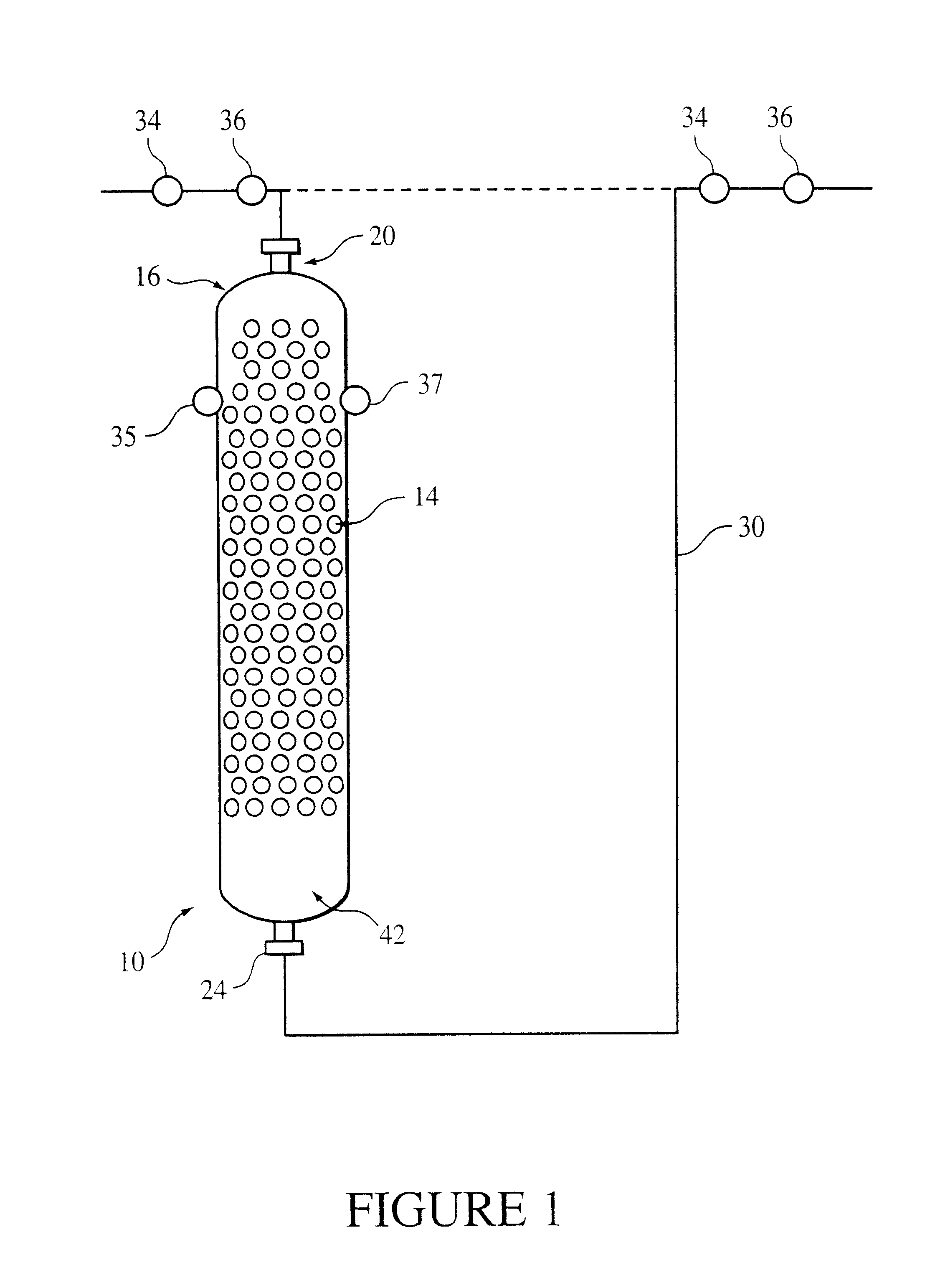

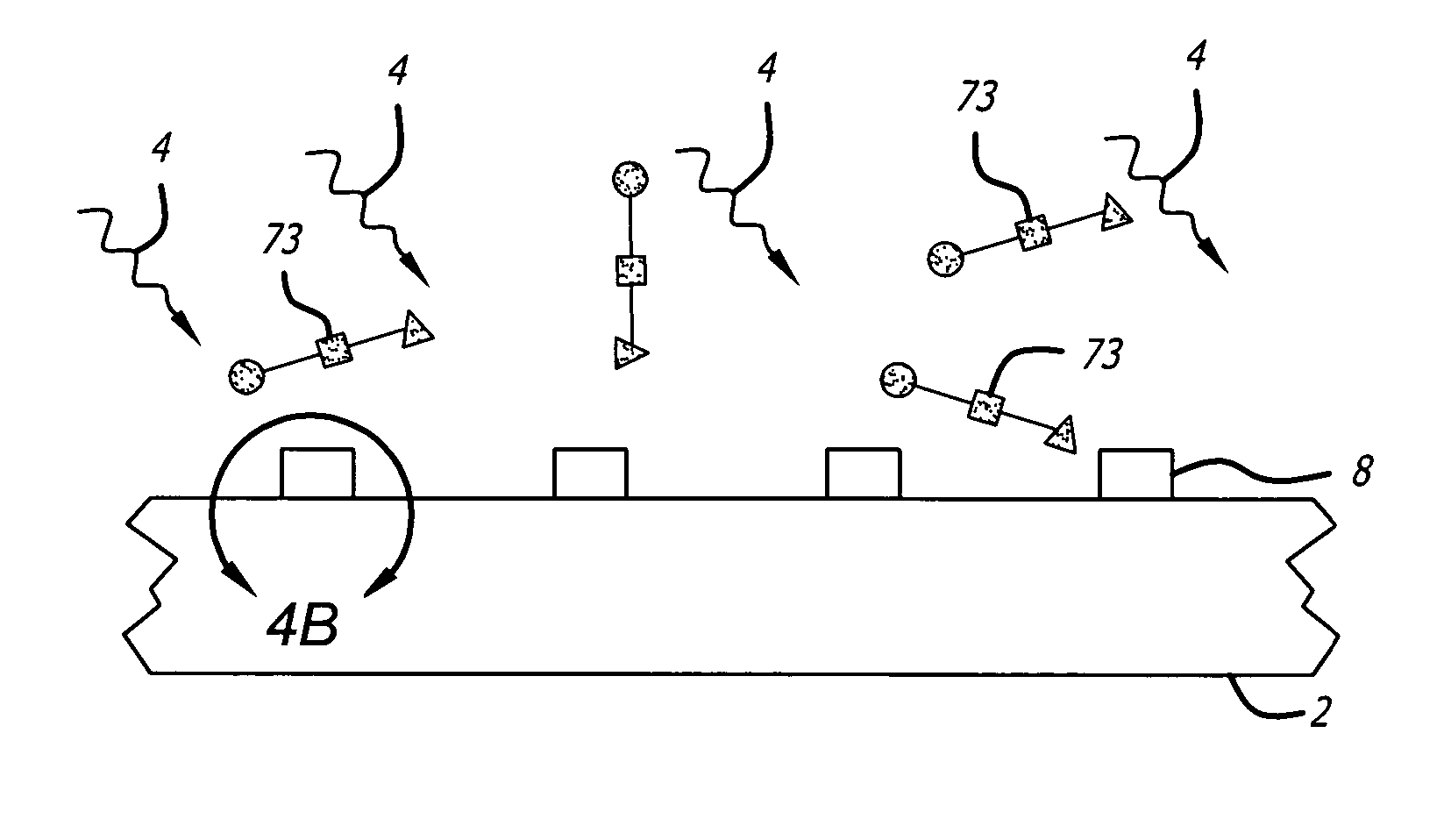

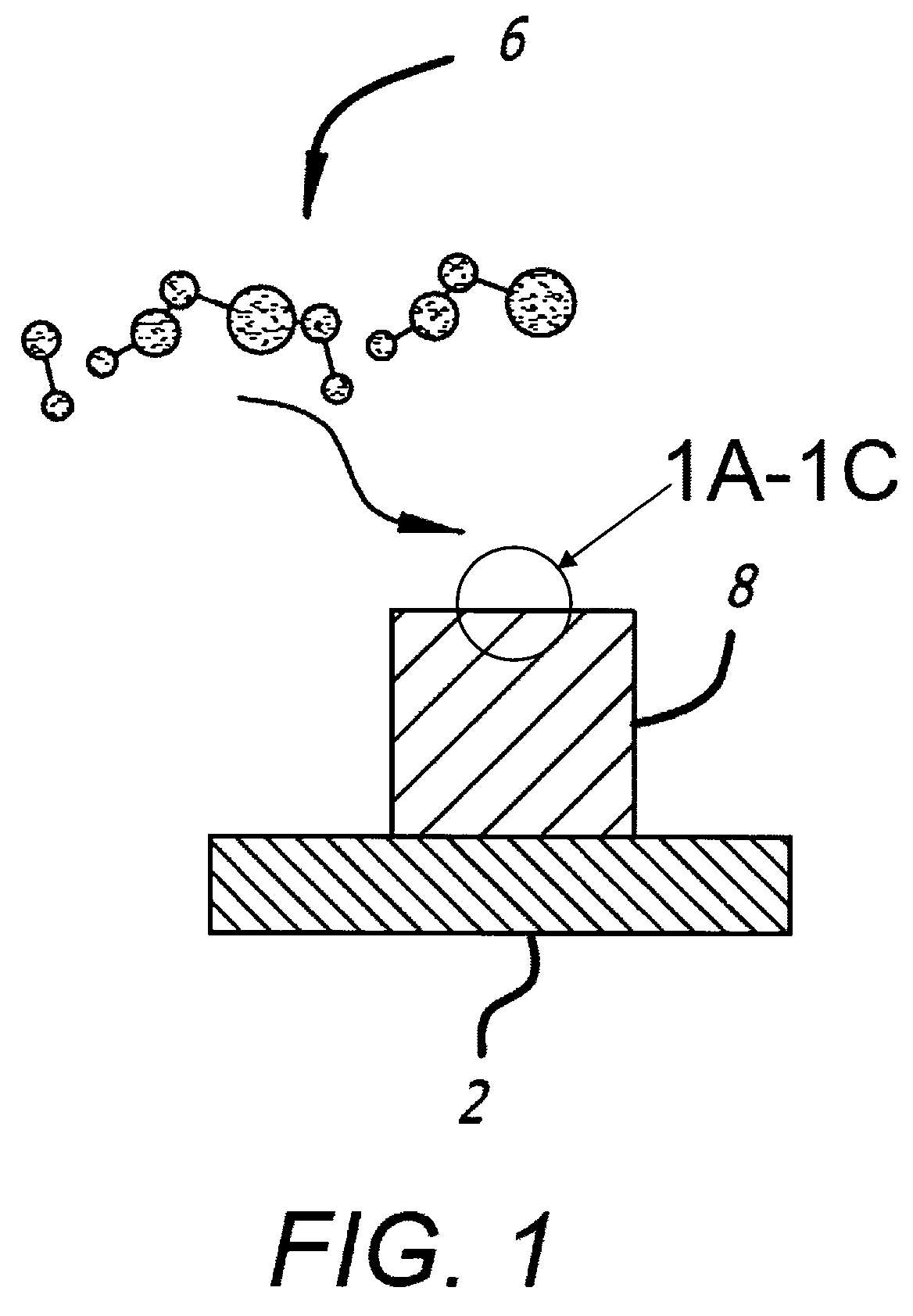

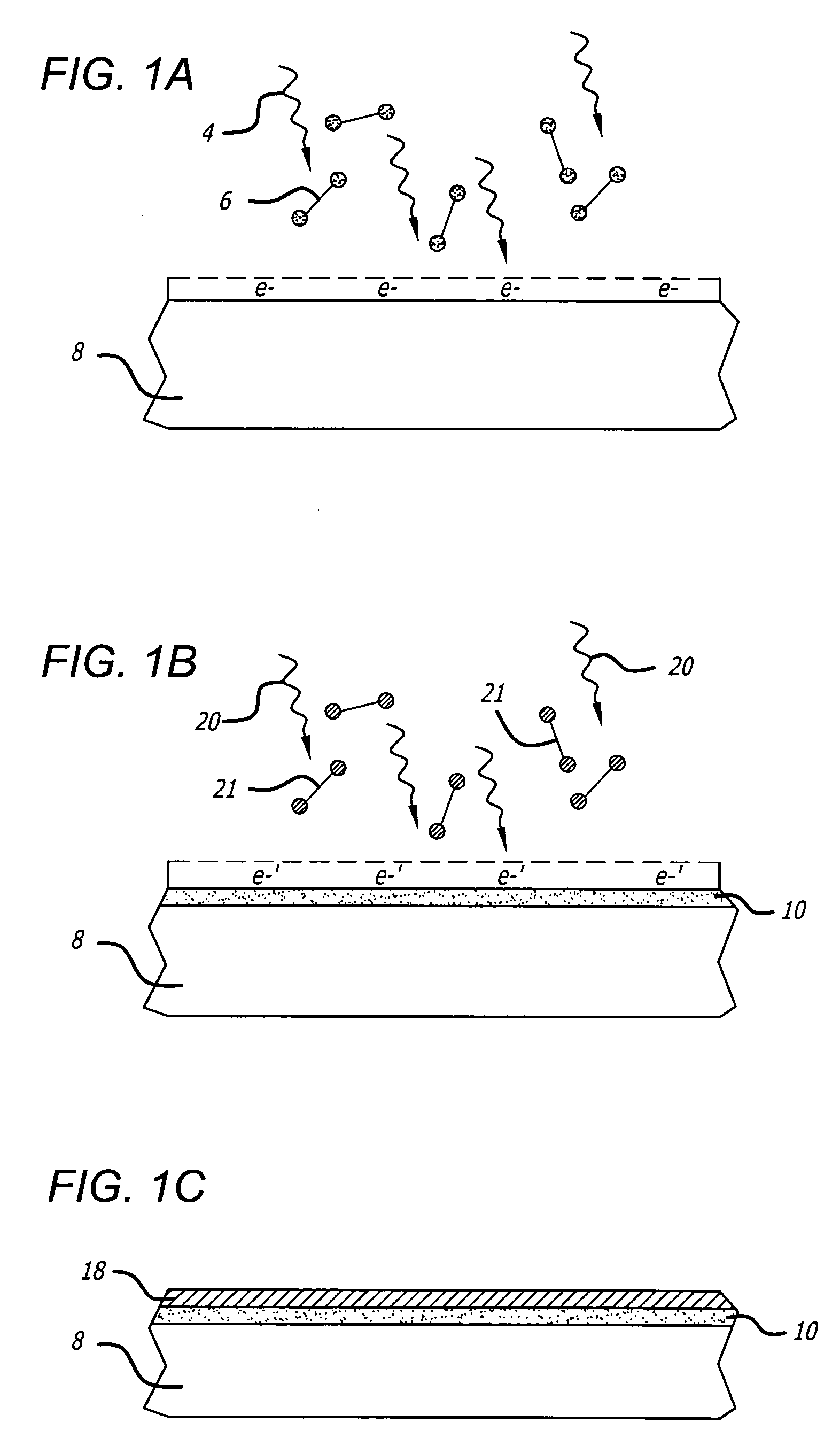

Assembly and method for delivering a reactant material onto a substrate

InactiveUS20070166459A1Facilitate depositionFacilitate chemical reactionsChemical vapor deposition coatingBiomedical engineering

An assembly and method for delivering a reactant material onto a substrate is described and which includes a delivery member which has a first surface, and an opposite second surface, and wherein the second surface is positioned adjacent to a substrate, and wherein an elongated substantially continuous channel is formed in the second surface of the delivery member, and which is coupled in fluid flowing relation relative to a source of reactant material, and wherein the elongated substantially continuous channel delivers the reactant material onto the substrate.

Owner:ADVANCED MICRO-FABRICATION EQUIP INC ASIA

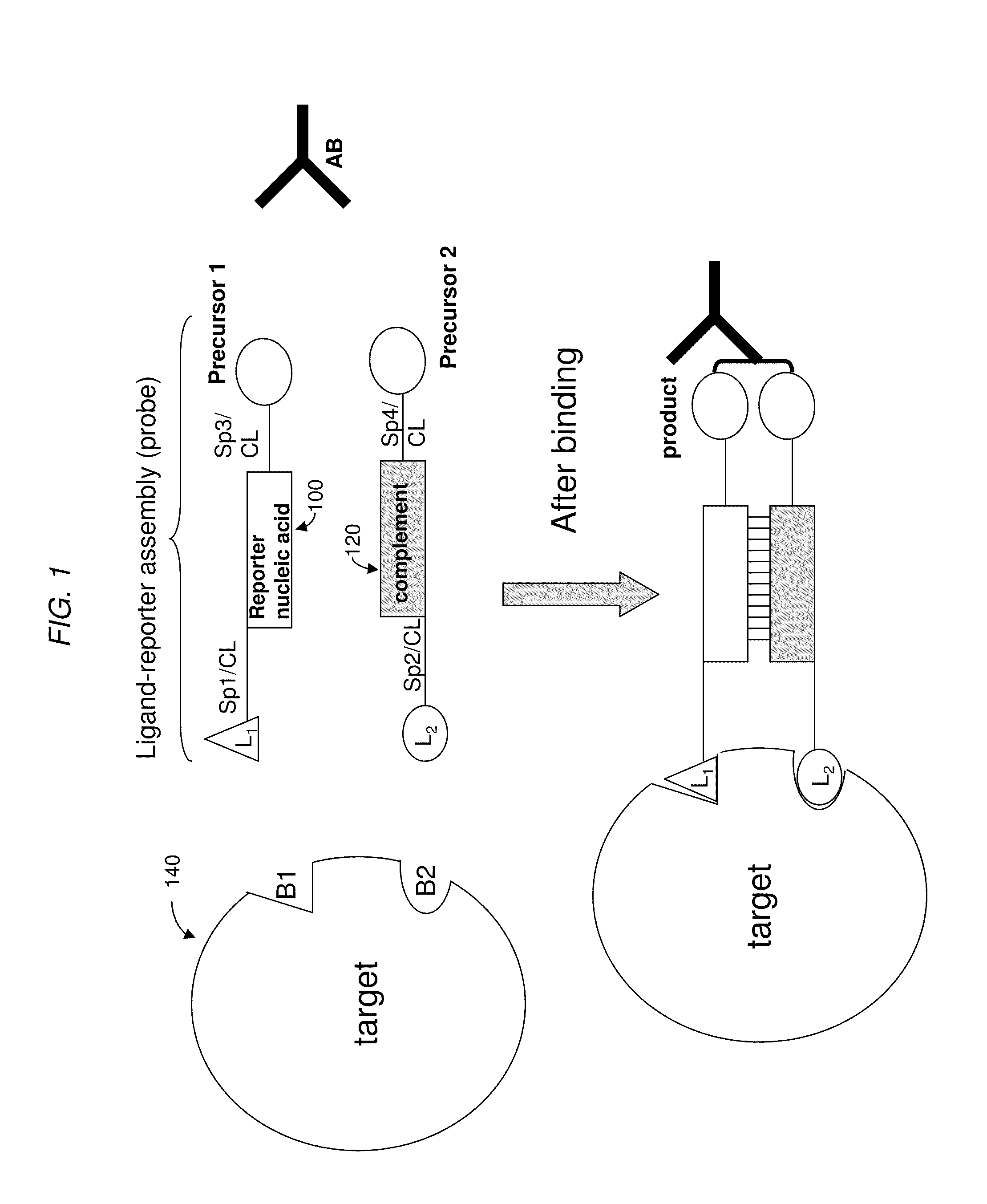

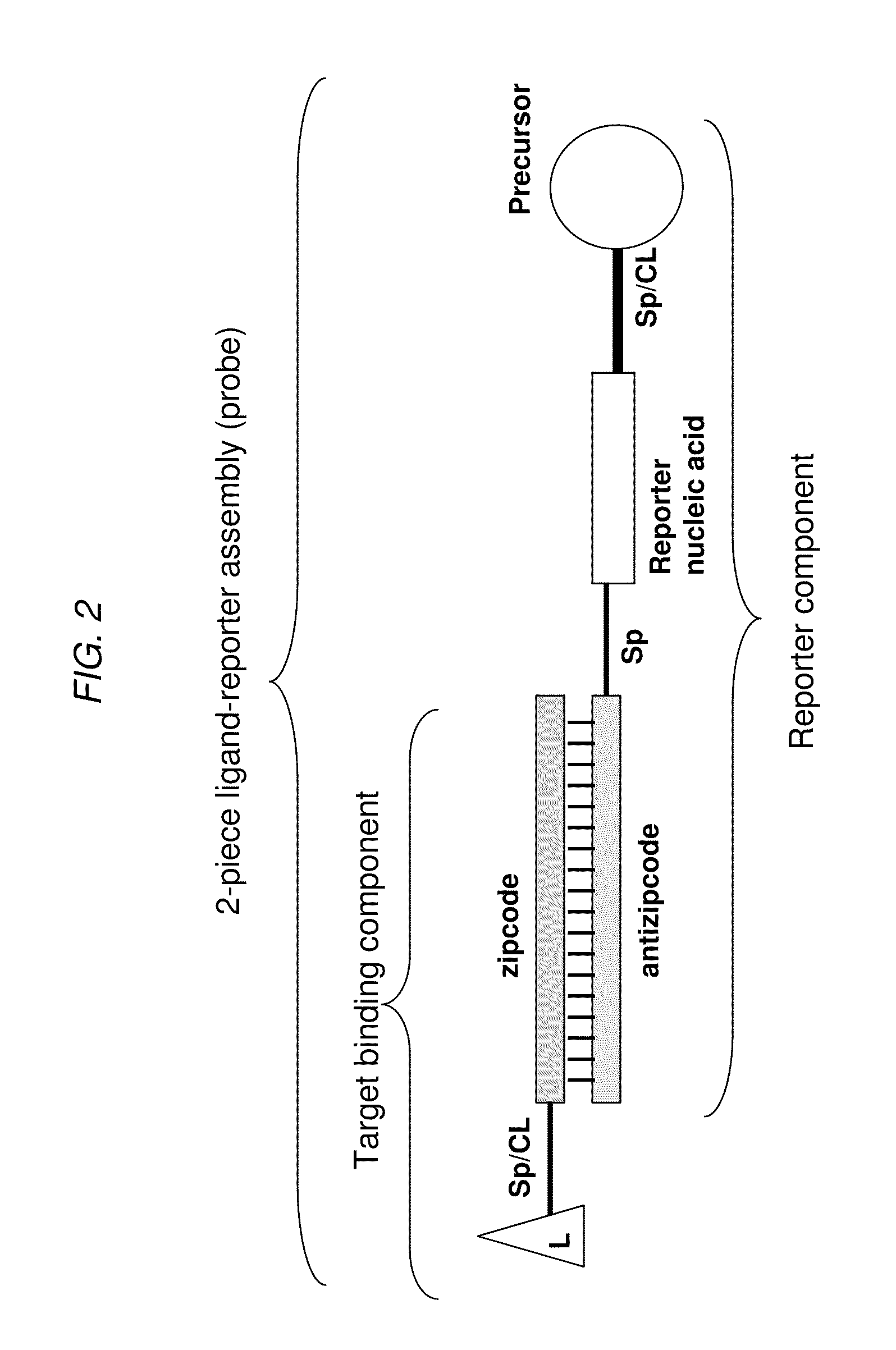

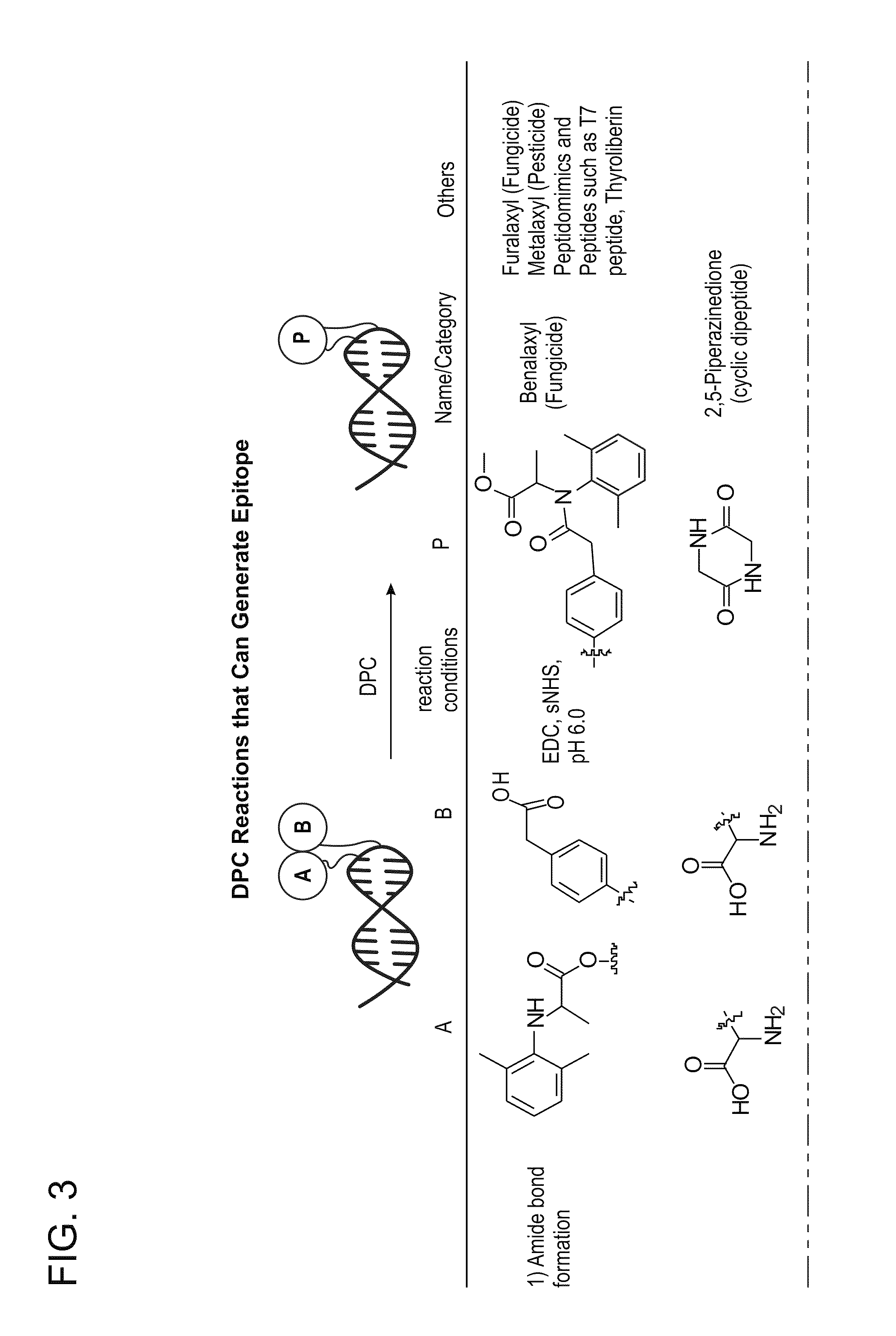

Detection Assays and Use Thereof

InactiveUS20100159446A1Detection is limitedHigh sensitivityCompound screeningApoptosis detectionEpitopeBiological target

The invention provides compositions and methods for the detection and / or quantification of biological targets (e.g., nucleic acids and proteins) by the nucleic acid-templated creation of one or more reaction products, for example, epitopes, enzyme substrates, enzyme activators, and ligands. The reaction products can be detected and / or quantitated after signal amplification using an amplification system.

Owner:ENSEMBLE THERAPEUTICS CORP

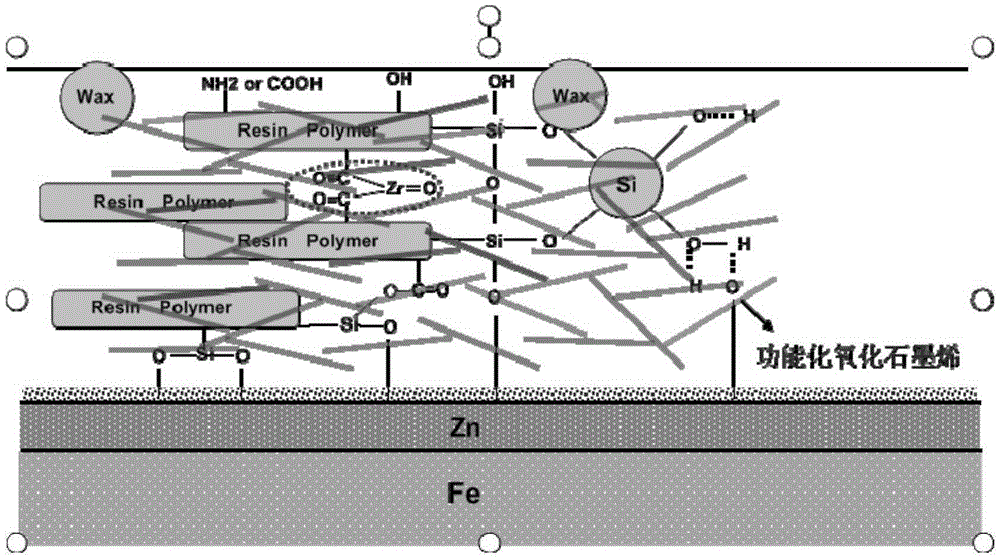

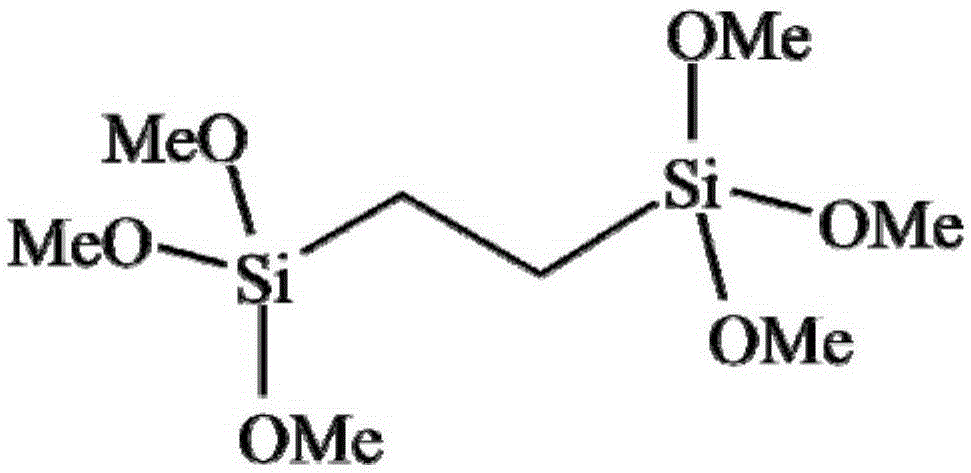

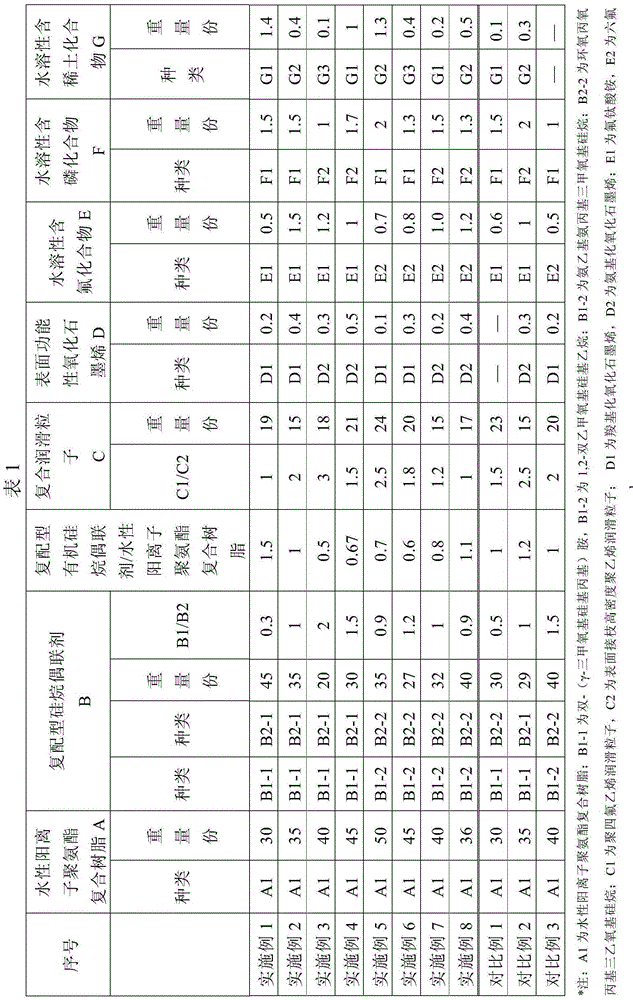

Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

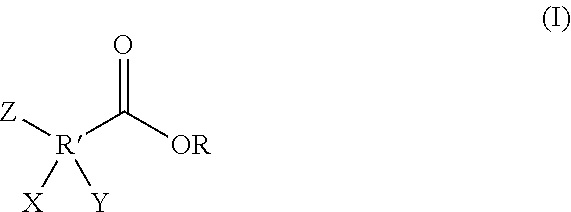

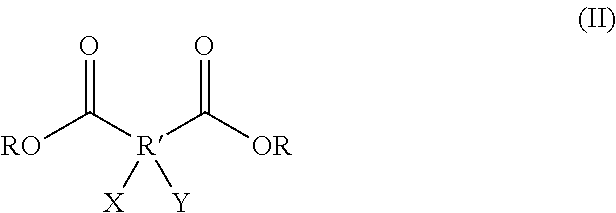

ActiveCN105255338AGood acid and alkali resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCompound organic

The invention relates to a galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and a water-based surface treating agent. The surface of a galvanized steel sheet is coated with the surface treating agent in a solidified mode, wherein the surface treating agent includes water-based positive ion polyurethane composite resin, compound organic silane coupling agents containing bis-organic silane coupling agents and mono-organic silane coupling agents, compound lubrication particles containing teflon-surface modification high-density polyethylene particles, oxidized graphene, water-soluble fluorine-containing compounds, water-soluble phosphorous compounds, water-soluble rare earth salt compounds and other components, and therefore the surface treatment galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance is obtained. Meanwhile, the surface treatment galvanized steel sheet has good resistance, such as solvent resistance, to all kinds of chemical media.

Owner:BAOSHAN IRON & STEEL CO LTD

Freeze-dried scent compound and a method of preparation

InactiveUS20060263326A1Facilitate chemical reactionsChange compositionBiocideCosmetic preparationsFlavorFreeze dry

A freeze-dried scent compound comprises at least one carrier material and at least one active ingredient. The selected carrier material and active ingredient are combined and freeze-dried. The scent compound may be a granular or powdered product. The active ingredient may be at least one of an animal product, a food product, a natural fragrance product or a synthetic fragrance product. The scent compound is freeze-dried which enhances the stability and potency of the scent compound. The scent compound is not significantly affected by environmental conditions and does not significantly evaporate, freeze or absorb into the ground. The scent compound may be used as an attractant, a repellent or an air fragrance material.

Owner:WEISER GRP

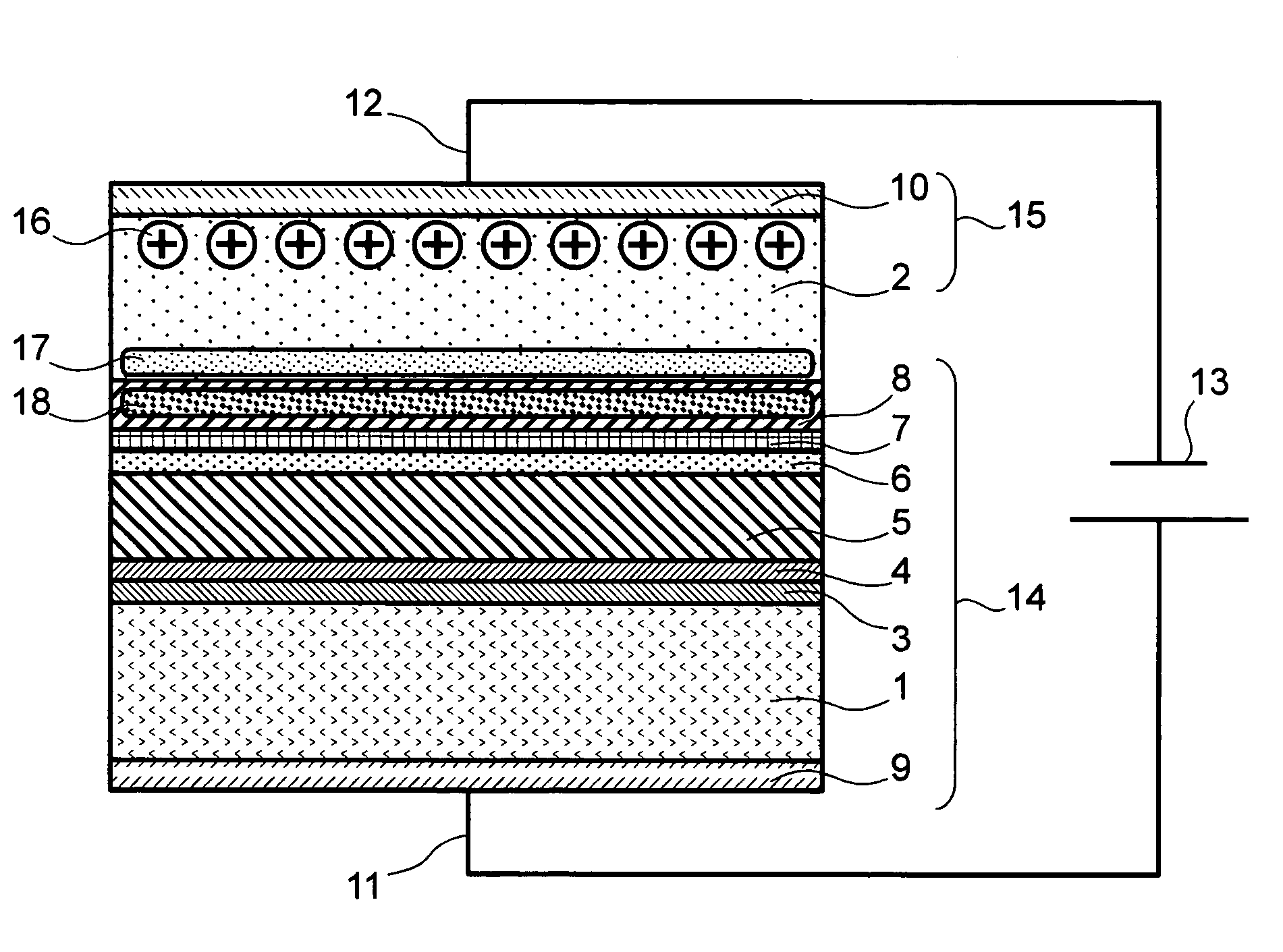

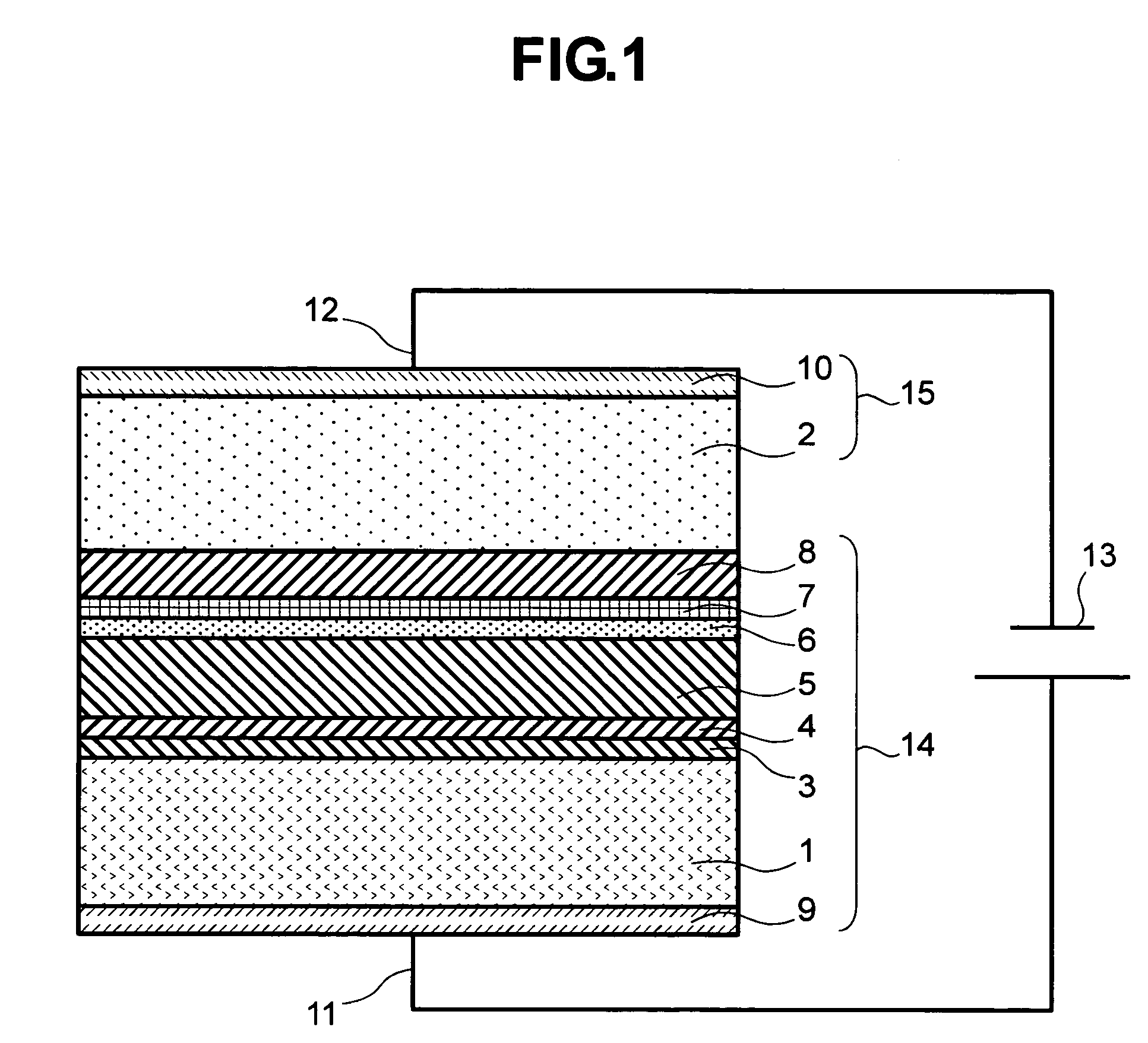

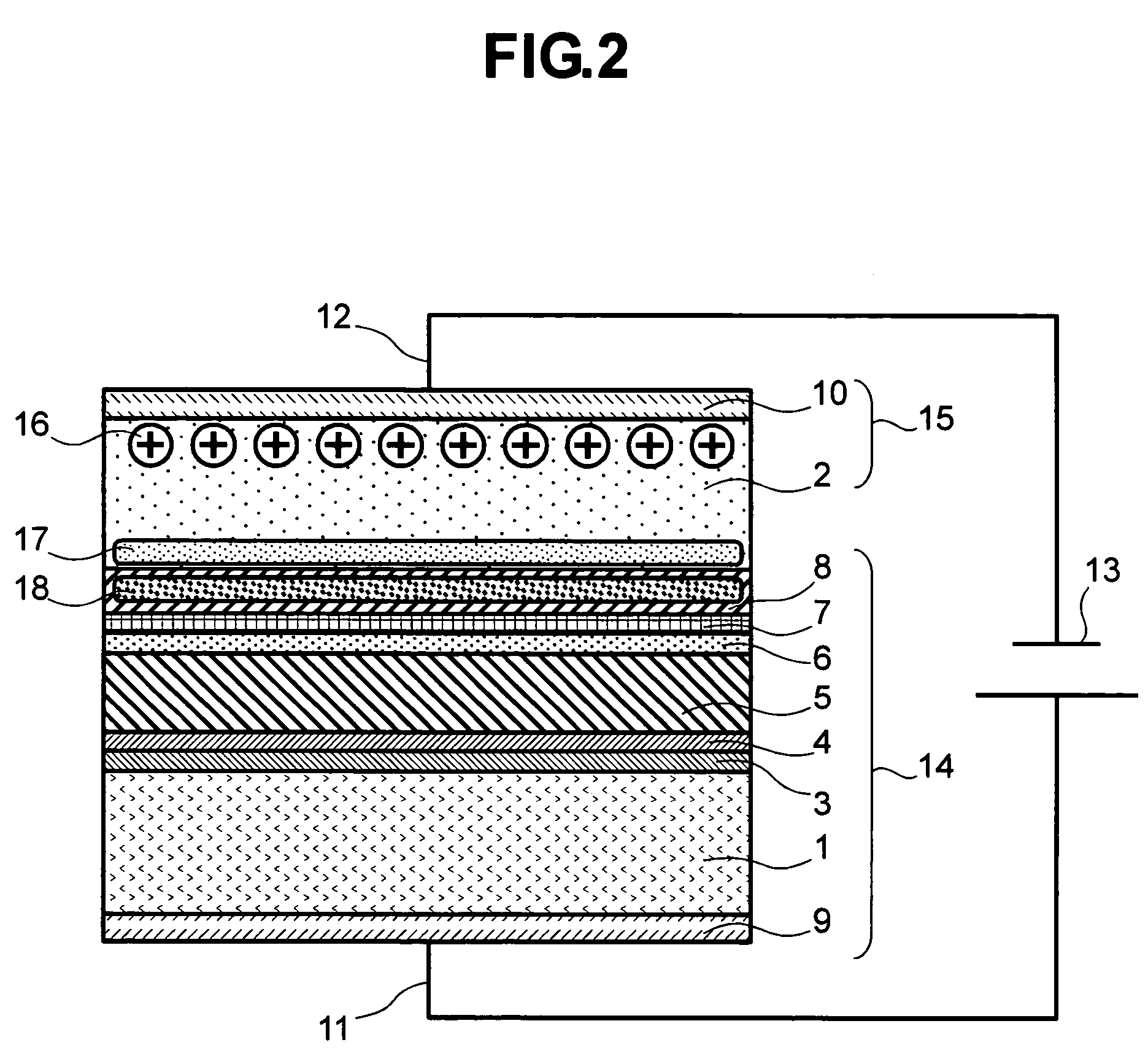

Anodic bonding method and electronic device having anodic bonding structure

InactiveUS7153758B2Good close adhesionBond be not deteriorateLamination ancillary operationsLaminationAnodic bondingElectrical conductor

In anodic bonding between a conductor or semiconductor and glass, in order to attain good adhesion at a lower bonding temperature than usual and improve the toughness at its boundary to obtain higher reliability for a bonded portion even in a case where bonded members are warped or dust is present at the bonding boundary, a soft metal film is formed on the surface of a conductor or semiconductor on which an active metal film having high reactivity with oxygen is formed, whereby a warp or dust, if any, can be absorbed by the deformation of the soft metal film, thereby to improve the adhesion at the boundary. Adhesion at the bonding boundary is improved even at a low bonding temperature of, e.g., about 200° C. Further, the toughness at the bonding boundary can be improved to increase reliability by roughening the bonded surface on the side of the glass.

Owner:HITACHI LTD

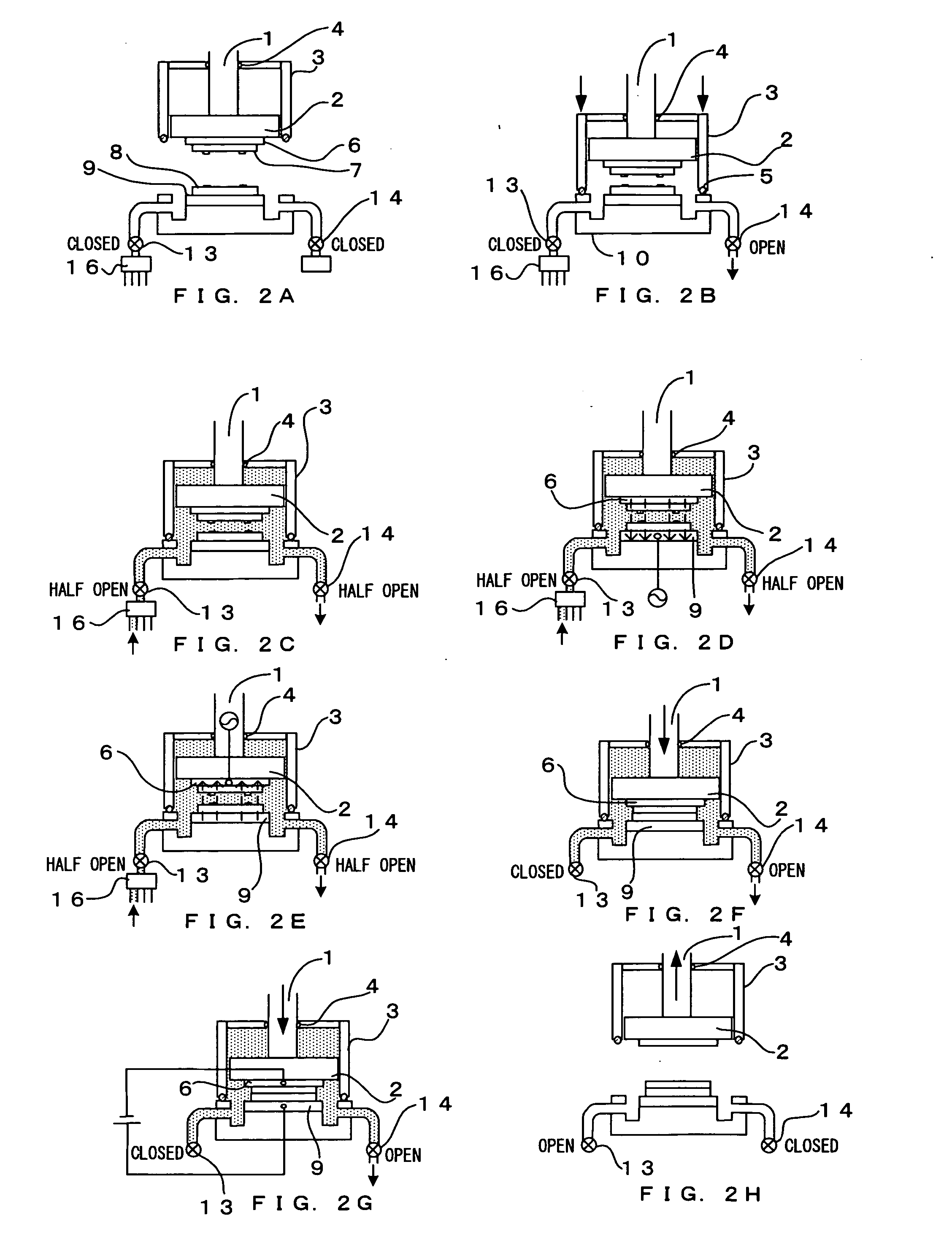

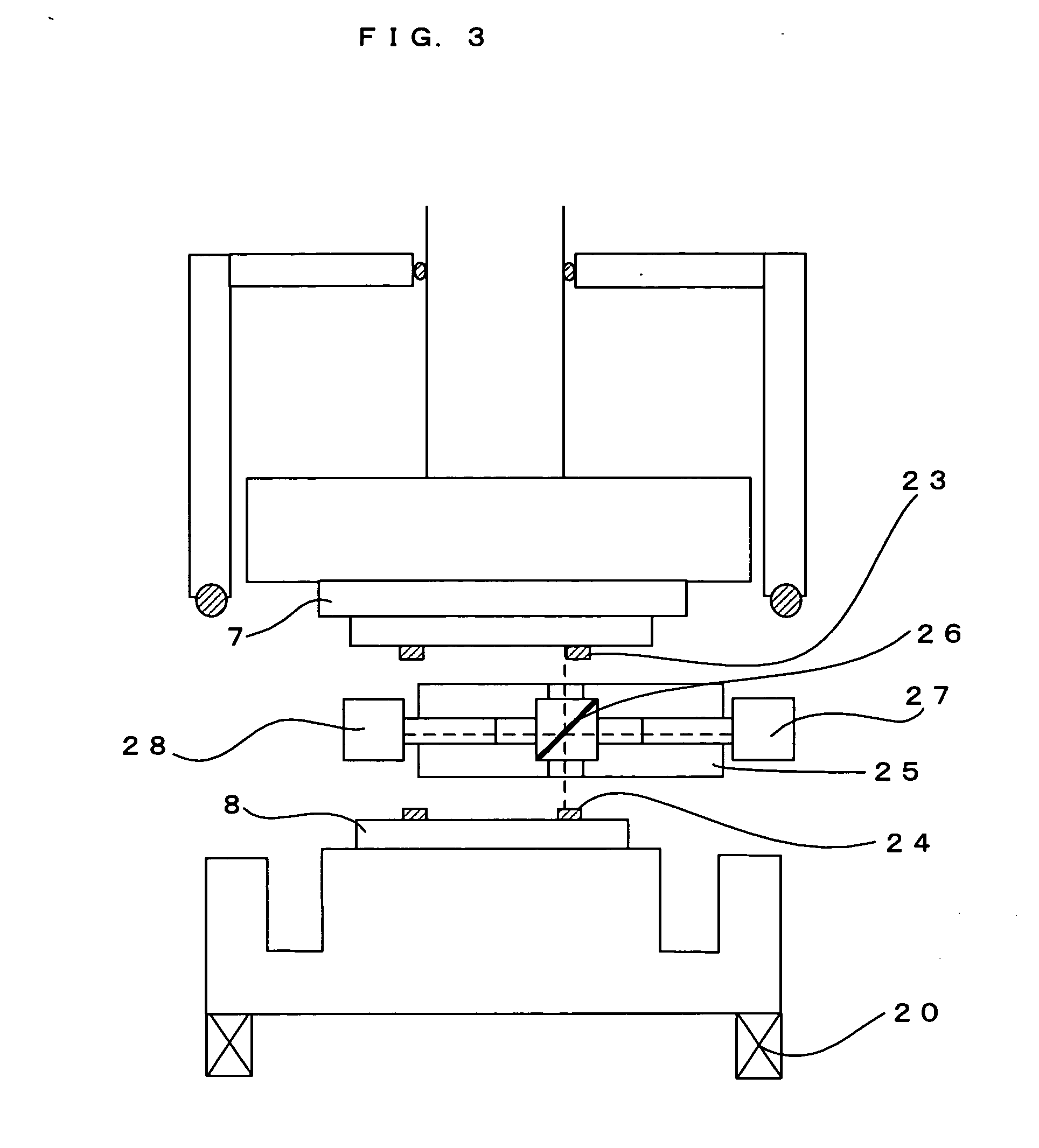

Bonding method, device formed by such method, surface activating unit and bonding apparatus comprising such unit

InactiveUS20070110917A1High bonding strengthReduce the impactSemiconductor/solid-state device detailsSolid-state devicesChemical treatmentDevice form

In a method of bonding objects to be bonded together in a solid phase at low temperature after subjecting bonding surfaces of the objects to be bonded to a hydrophilic treatment using a plasma, the objects to be bonded are conventionally handled in the atmospheric air for bonding, so that adhesion of organic substances in the atmospheric air leads to a reduction in bonding strength. Therefore, diffusion bonding needs to be performed at a temperature of as high as 1100° C. in the conventional art. According to the present invention, firm bond can be achieved at low temperature. In a method for bonding objects to be bonded together in a solid phase after subjecting bonding surfaces of the objects to be bonded to a hydrophilic treatment using a plasma, a chemical treatment step of subjecting both the objects to be bonded to the hydrophilic treatment using the plasma without exposure to the atmospheric air is performed after a physical treatment step of subjecting both the objects to be bonded to a physical treatment using an energy wave, such as an atom beam, an ion beam or a plasma, thereby bonding both the objects to be bonded together. Therefore, satisfactory bonding can be achieved without adhesion of organic substances or the like, thereby making it possible to achieve firm bond at a low temperature of 500° C. or less.

Owner:BONDTECH

Process for relaxing or straightening hair, using weak dicarboxylic acids with heat

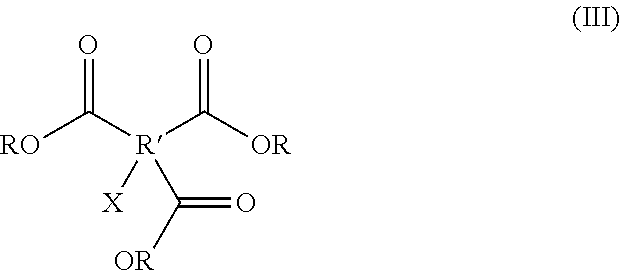

ActiveUS8513200B2Facilitates straightening and relaxingLess irritating and damaging to a user's skin and hair.Cosmetic preparationsHair cosmeticsHair straighteningTricarboxylic acid

A process for straightening or relaxing hair comprising the following steps: (a) providing a hair straightening or relaxing composition having a pH ranging from 8 to 11.5, and containing, in a cosmetically acceptable medium, at least one weak acid chosen from monocarboxylic, dicarboxylic and tricarboxylic acids, their salts, and mixtures thereof; (b) contacting the hair with the hair straightening or relaxing composition to form treated hair; and (c) straightening or relaxing the treated hair by applying heat, wherein hydroxide-containing compounds are not used. Disclosed herein is also a preferred hair straightening or relaxing composition.

Owner:LOREAL SA

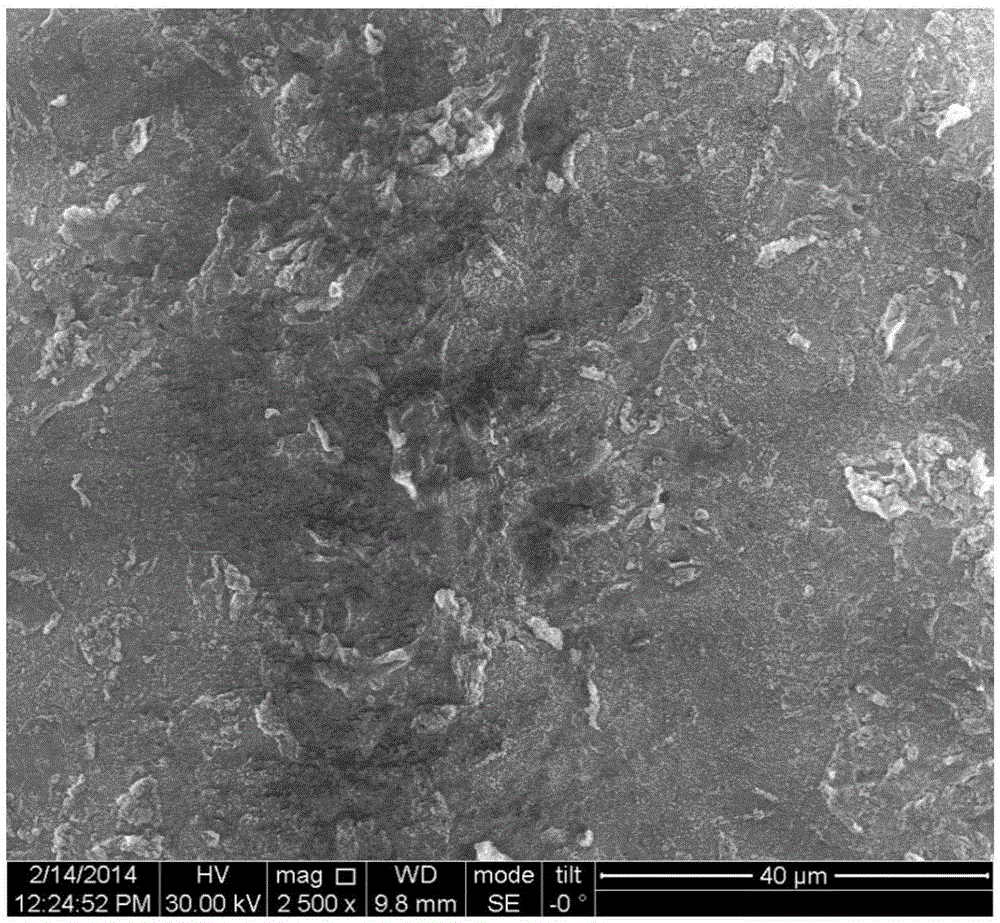

Method of supersonic chemical plating nickel phosphorus of powder metallurgy material

InactiveCN1410592AUniform thicknessImprove corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingPowder metallurgy

In the invention, the sodium hypopphosphite is as the reducing agent of the bath, nickel sulfate as the main salt, with the complexing agent, accelerating agent and stabilizing agent being added. Theultrasonic chemical plating is adopted that utilizes the mechanical energy of the ultrasonic vibration, making the bath deposit nickel and phosphor under the catalysis of the metal surface and the chemical reduction method controlled. The plating procedure includes the steps of oil removal, rust removal, activation, chemical plating and post treatment. The multiple complexing, accelerating and stabilizing agents raises the stability of the bath. The plating speed is adjustable. The even, compact nickel and phosphor plating layer covers the surface of the base body of powder metallurgical material so as to increase the service life of the material and provide wide application area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electromagnetic control of chemical catalysis

ActiveUS20050202185A1Rapid coolingHigh degreeMaterial nanotechnologySolid state diffusion coatingChemical reactionElectron resonance

The present disclosure methods and systems that provide heat, via at least Photon-Electron resonance, also known as excitation, of at least a particle utilized, at least in part, to initiate and / or drive at least one catalytic chemical reaction. In some implementations, the particles are structures or metallic structures, such as nanostructures. The one or more metallic structures are heat at least as a result of interaction of incident electromagnetic radiation, having particular frequencies and / or frequency ranges, with delocalized surface electrons of the one or more particles. This provides a control of catalytic chemical reactions, via spatial and temporal control of generated heat, on the scale of nanometers as well as a method by which catalytic chemical reaction temperatures are provided.

Owner:CALIFORNIA INST OF TECH

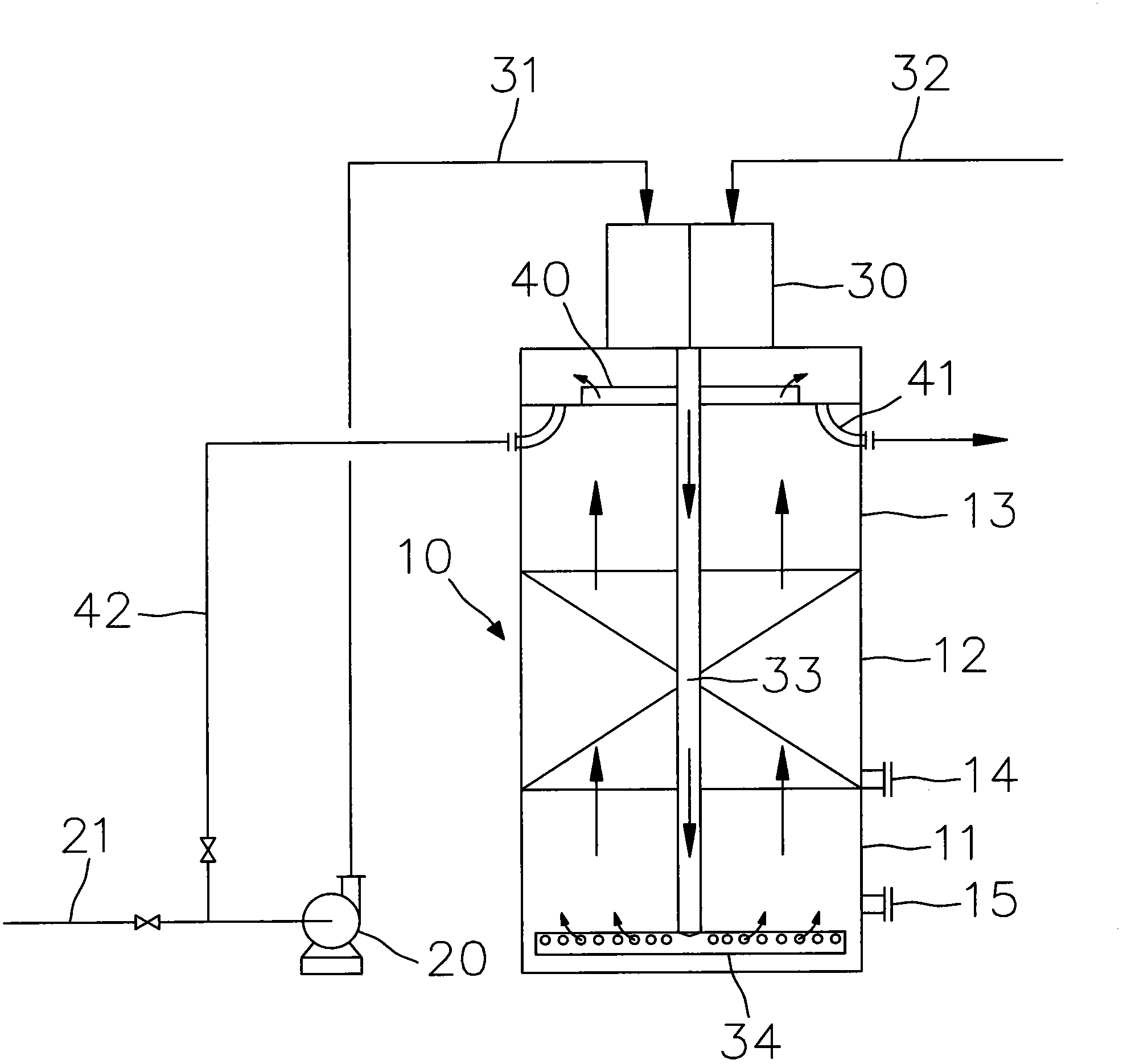

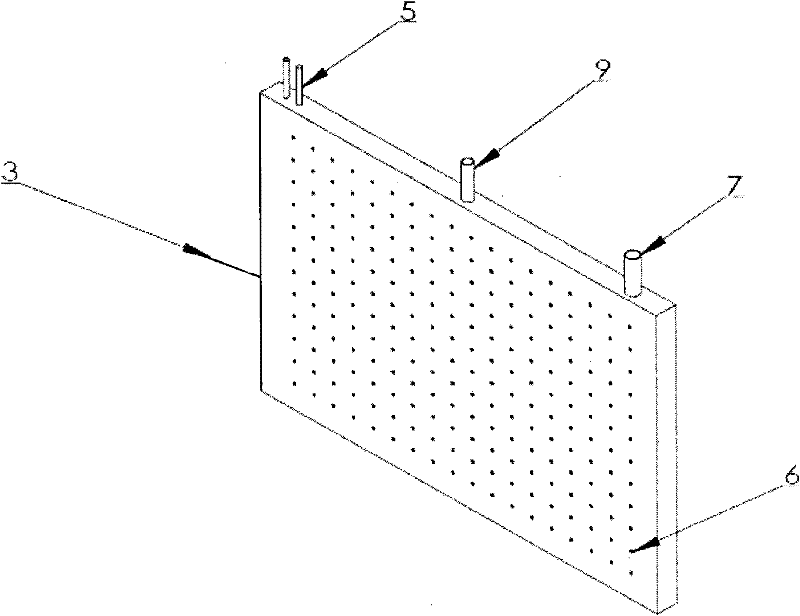

Microelectrolysis-fenton oxidizing reaction device

ActiveCN103663802AReduce the additional amountPlay a catalytic roleMultistage water/sewage treatmentWater/sewage treatment by oxidationElectrochemical responseElectrolysis

The invention belongs to the technical field of sewage treatment, and in particular relates to a microelectrolysis-fenton oxidizing reaction device. The oxidizing reaction device comprises a wastewater supply device, and a hollow-out reactor made of anti-corrosive materials; a barrel body of the reactor is internally divided into a fenton oxidizing reaction area, a microelectrolysis reaction area and a flocculoreaction area from bottom to top; the microelectrolysis reaction area is full of iron-carbon fillers. The device also comprises a draining device arranged at the upper side of the reactor. The draining device is convenient for draining the treated wastewater to the outside of the oxidizing reaction device. The microelectrolysis-fenton oxidizing reaction device has the advantages that the microelectrolysis technology and the fenton oxidizing technology are integrated, so that the effective space of the reactor can be furthest utilized, i.e.,, the electrochemical reaction and the oxidization-reduction reaction can be carried out synchronously within the effective space of every independent unit device, therefore, the wastewater treatment process can be greatly simplified, the impact of various factors on wastewater treatment operation can be reduced, the purification performance of unit equipment in wastewater treatment can be improved, and as a result, an ideal treatment effect can be obtained.

Owner:安徽南风环境工程技术有限公司

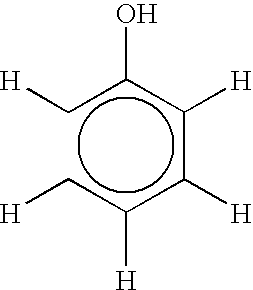

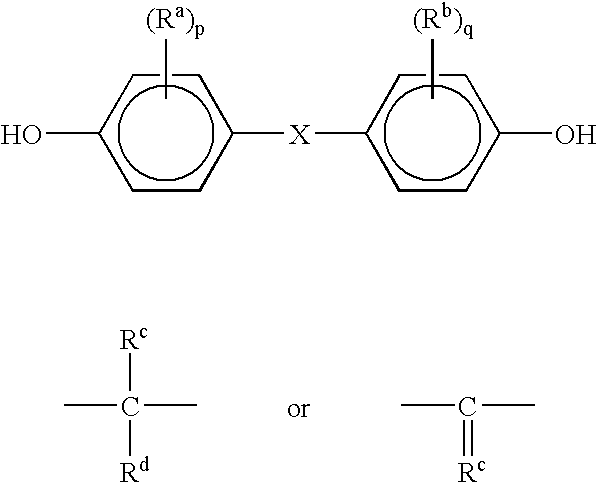

Chemical reactor system and process

InactiveUS6703530B2Large effective void fractionLower overall pressure dropOrganic compound preparationOrganic chemistry methodsReactor systemChemical reactor

A method for producing bisphenol includes introducing a phenol and a ketone into a fixed, supported catalytic bed reactor system in a downflow mode, reacting the phenol and the ketone to form a reaction mixture, and recovering the bisphenol isomer from the reaction mixture. The preferred bisphenol isomer is bisphenol A, or p,p'-bisphenol A, produced from the reaction of phenol and acetone. The reactor for producing the bisphenol A from the reaction of phenol and acetone includes an ion exchange resin catalyst disposed in a bed and packing randomly distributed throughout the ion exchange resin catalyst to improve heat transfer efficiency and reduce compression of the catalyst bed.

Owner:SABIC GLOBAL TECH BV

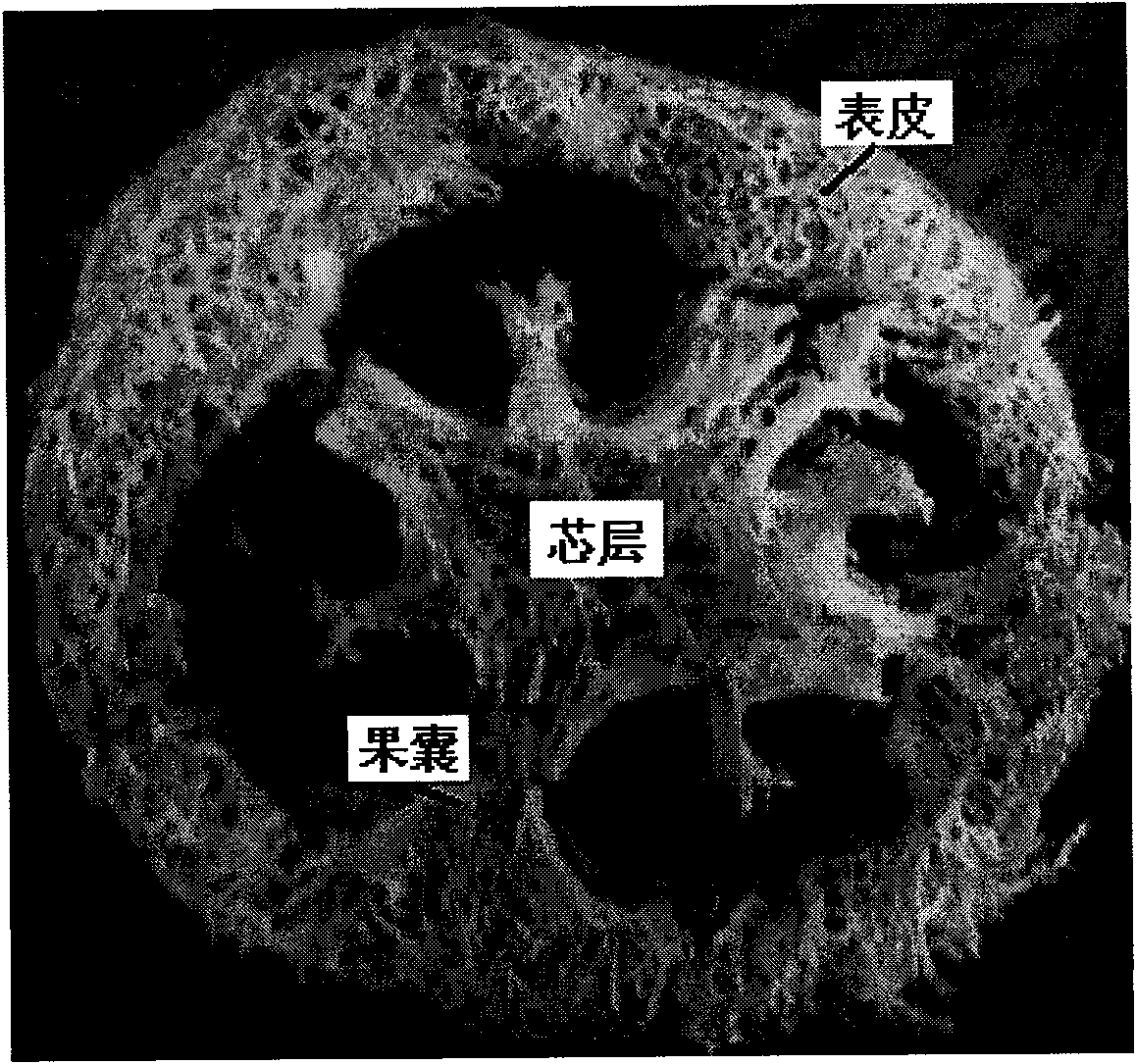

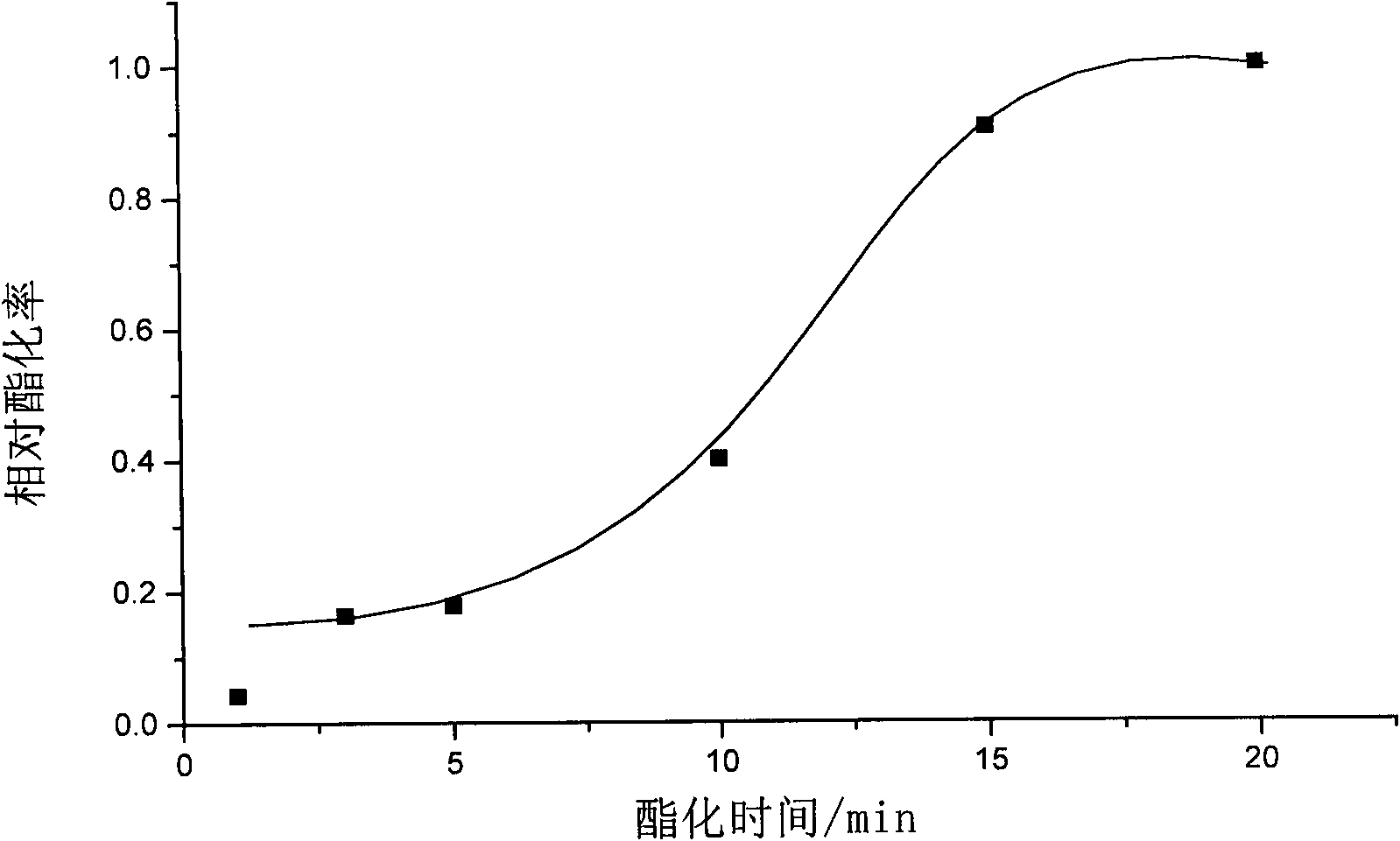

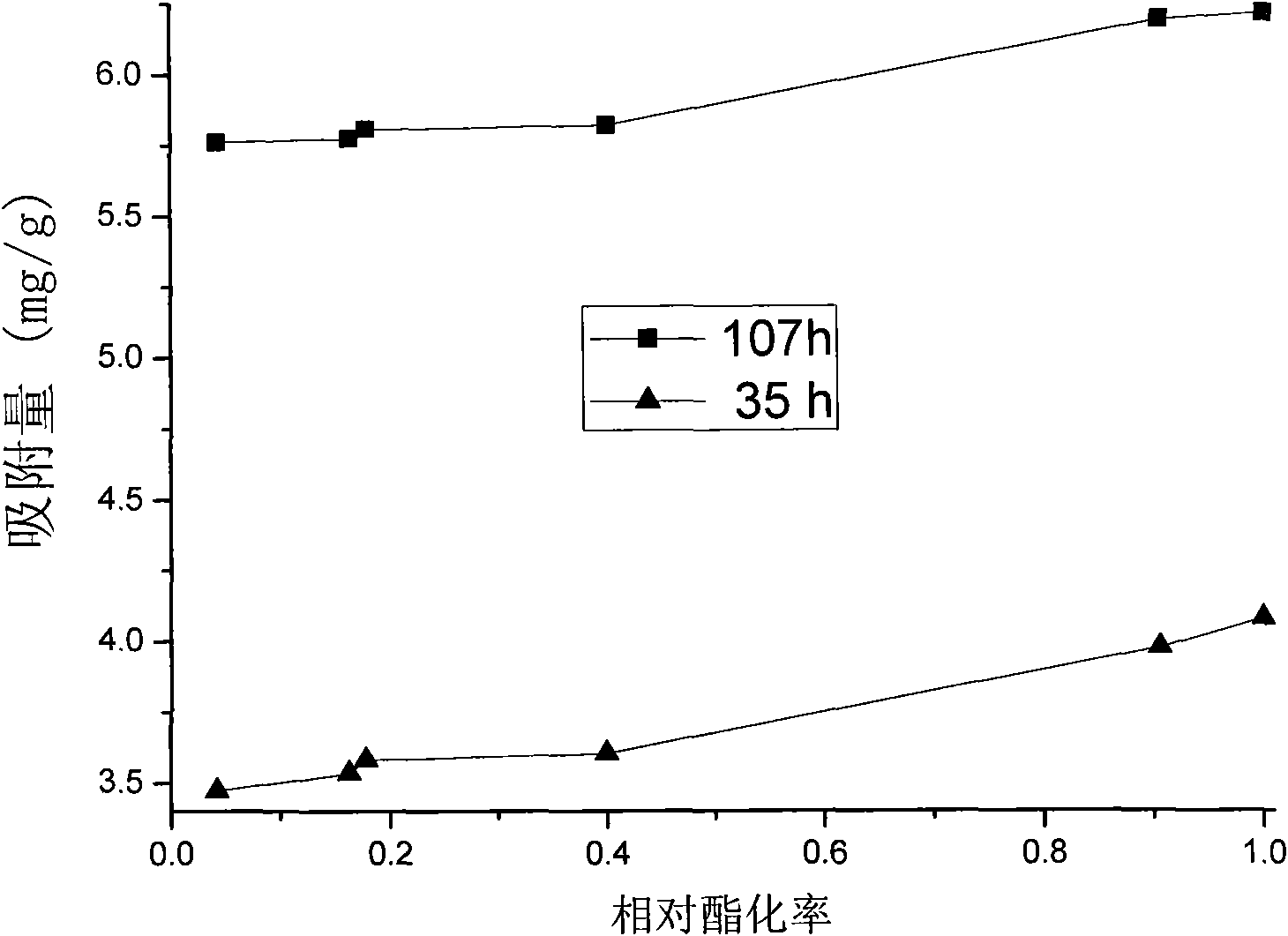

Preparation method of esterified vegetable sponge and application thereof in organic matter absorption

InactiveCN101664671AFacilitate chemical reactionsInhibit side effectsOther chemical processesWater/sewage treatment by sorptionEnvironmental chemistryAcetic anhydride

The invention discloses a preparation method of esterified vegetable sponge and the application thereof in organic matter, particularly in organic matter absorption in water system, belonging to the technical fields of natural high molecular material modification and wastewater treatment. The method comprises the following steps of: dipping natural vegetable sponge with proper NaOH / ethanol solution; basifying by means of microwave intermittent radiation; reflowing, washing and drying in thermostatic waterbath; and dipping with acetic oxide; intermittently reacting under the condition of microwave radiation, washing and drying to obtain the esterified vegetable sponge. The esterified vegetable sponge has relative simple process technology, has the better performance of organic pollutant absorption than that of the natural vegetable sponge, can partially replace synthetic high molecular material in wastewater treatment, and has the characteristics of wide source, low cost, biological degradation, environmental protection and the like.

Owner:SHANGHAI UNIV

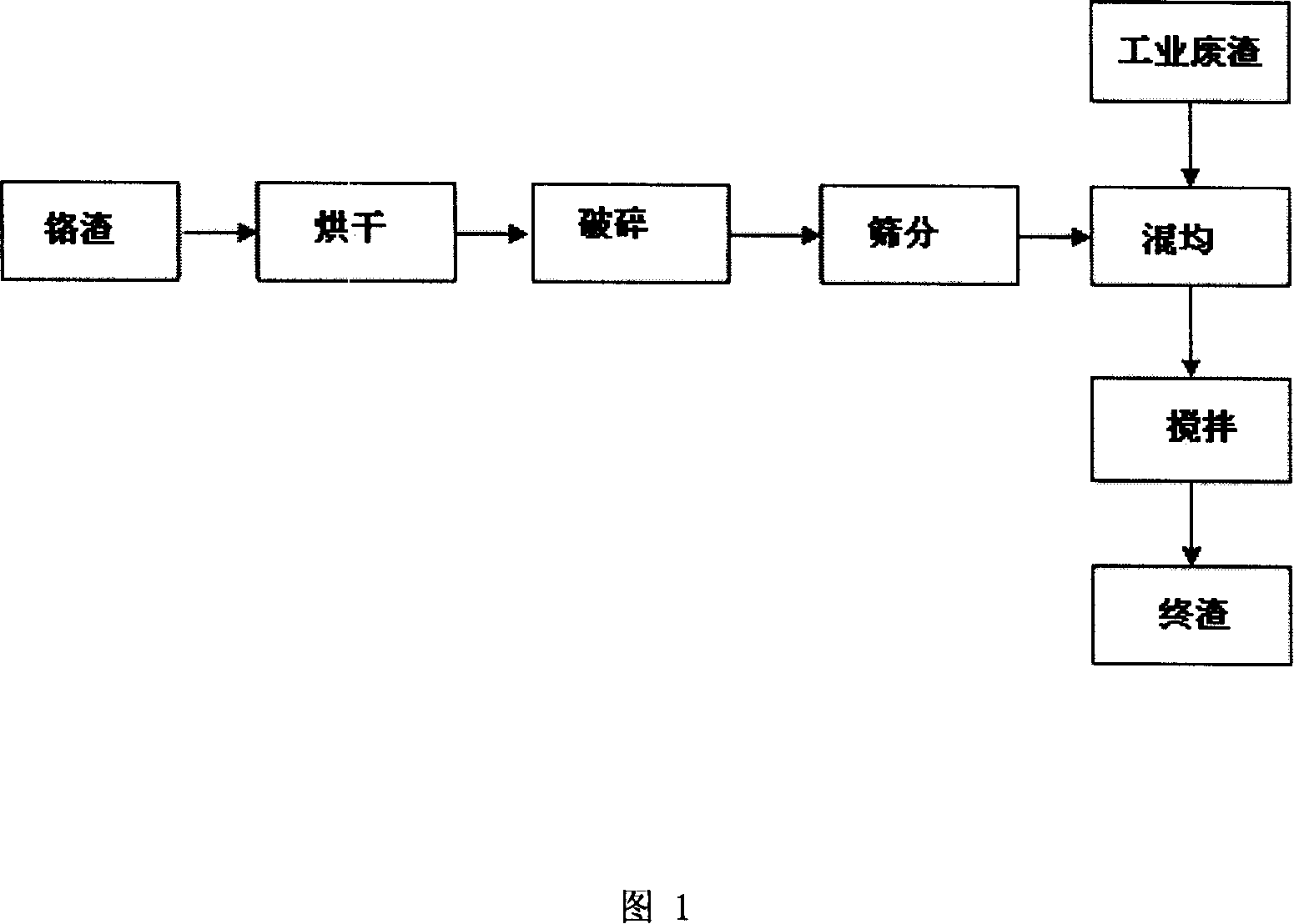

Novel process of the high temperature reduction and detoxication of industrial chromic slag

InactiveCN101138670ALarge physical heat capacityEfficient use ofChemical protectionSlagHigh-temperature corrosion

The present invention relates to a method for reducing detoxification of chromium residue under a high temperature with industrial wastes. Reducing metallurgy wastes in a waste tank are heated and melted. When the temperature becomes constant, the chromium residue is added into the tank. The toxicant in the chromium residue is Cr6 mainly in the form of water-soluble Na (SUB)2( / SUB)CrO (SUB)4 ( / SUB) and acid-soluble CaCrO (SUB)4( / SUB). Under the high temperature, Cr6 is reduced into intoxicant Cr3. After the chromium residue is cooled down to the room temperature naturally, the removal rate of Cr6 reaches over 99 percent in the final residue. The method is provided with an appropriate process flow, and the device is simple and easy for operation. Heat of the material itself is fully used, so the high efficiency is high, which is beneficial to the high-temperature reducing of chromium residue. The chromium residue is thoroughly detoxicated. Moreover, no environmental pollution is caused and the cost is low, so the method is applicable for scaled detoxification of chromium residue in the industry.

Owner:隋智通

Water-based transparent super-amphiphobic nano-paint and preparation method and application thereof

The invention relates to water-based transparent super-amphiphobic nano-paint and a preparation method and application thereof. Under the room temperature condition, hydrophilic silica nanoparticles and tetraethoxysilane or carbon tetrachloride serve as raw materials to synthesize oily nanoparticles with the concentration of 1-10 mg / mL; the oily nanoparticles and fluorocarbon resin are compounded according to the volume ratio of 1:1, a rotary evaporator is utilized for rotary evaporation for 30-60 min under the condition of a water bath at the temperature of 60-90 DEG C, and high-solid-content oily nano-paint concentrated liquor with the concentration of 20-40 mg / mL is obtained; water and surfactant are added, and the water-based transparent nano-paint with the super-amphiphobic surface is obtained. The prepared paint is soluble in water, the preparation process is simple, and the paint is suitable for large-area spraying, is high in adaptability to a base material and transparency, good in protective performance, environmentally friendly and capable of improving the working environment, and saves energy.

Owner:SOUTHEAST UNIV

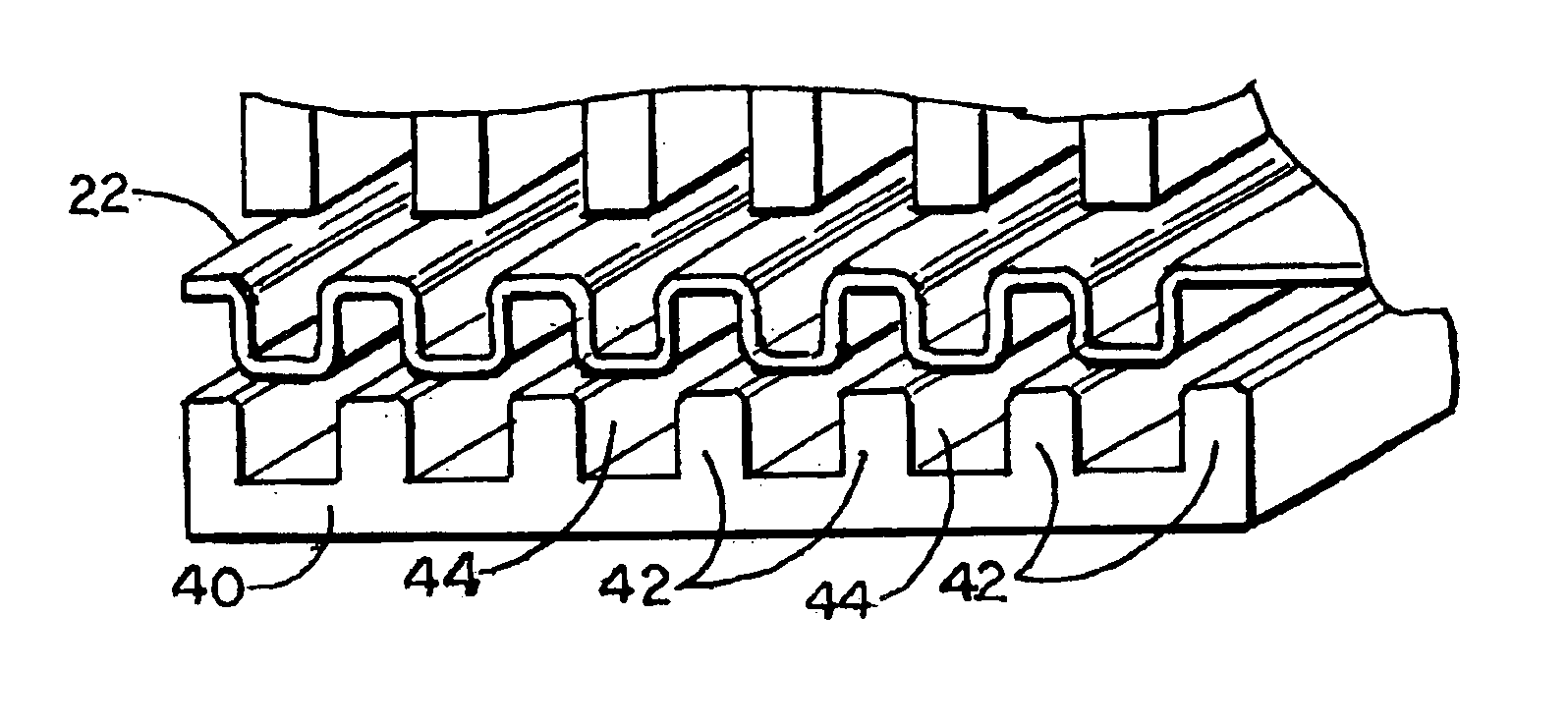

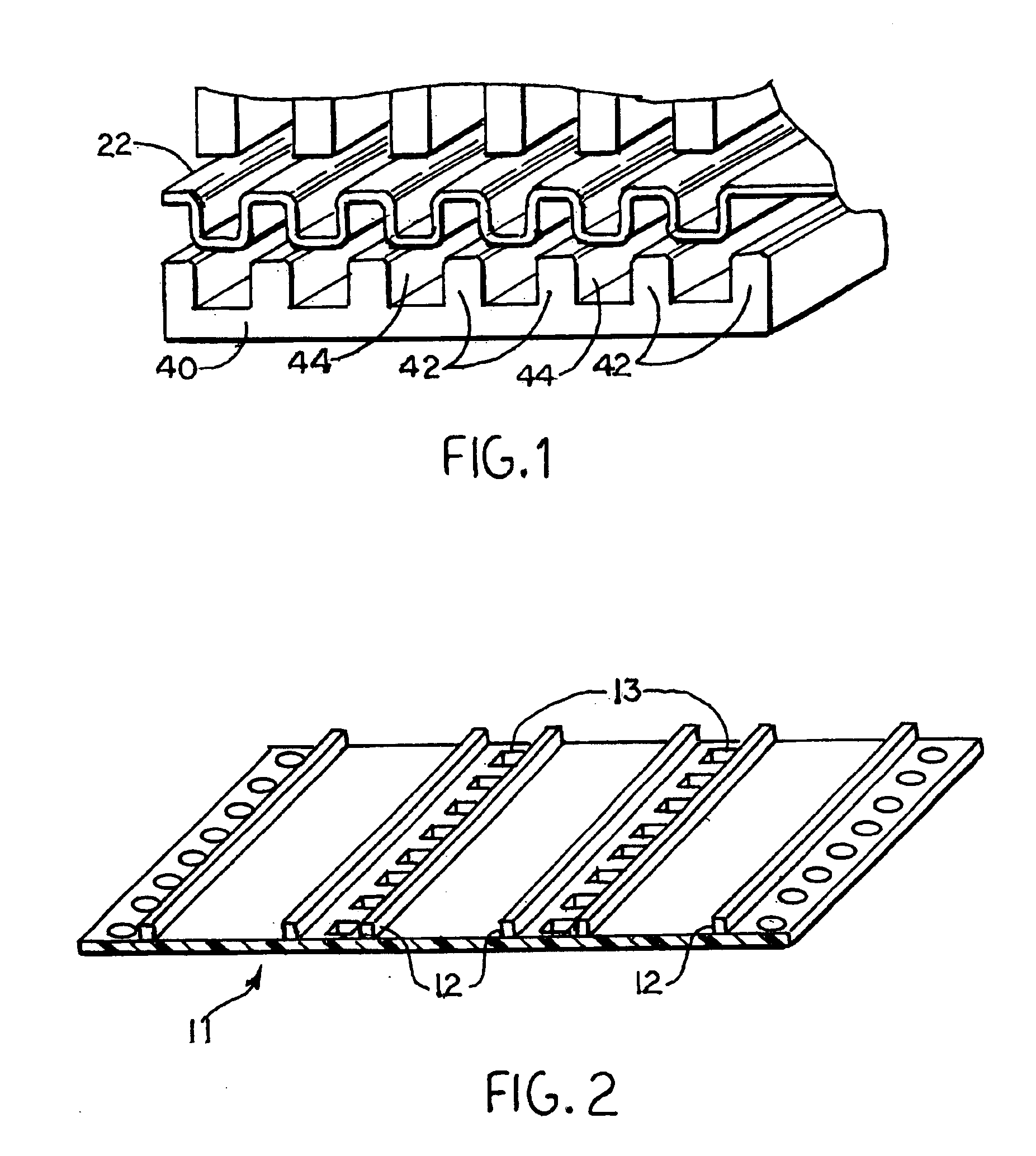

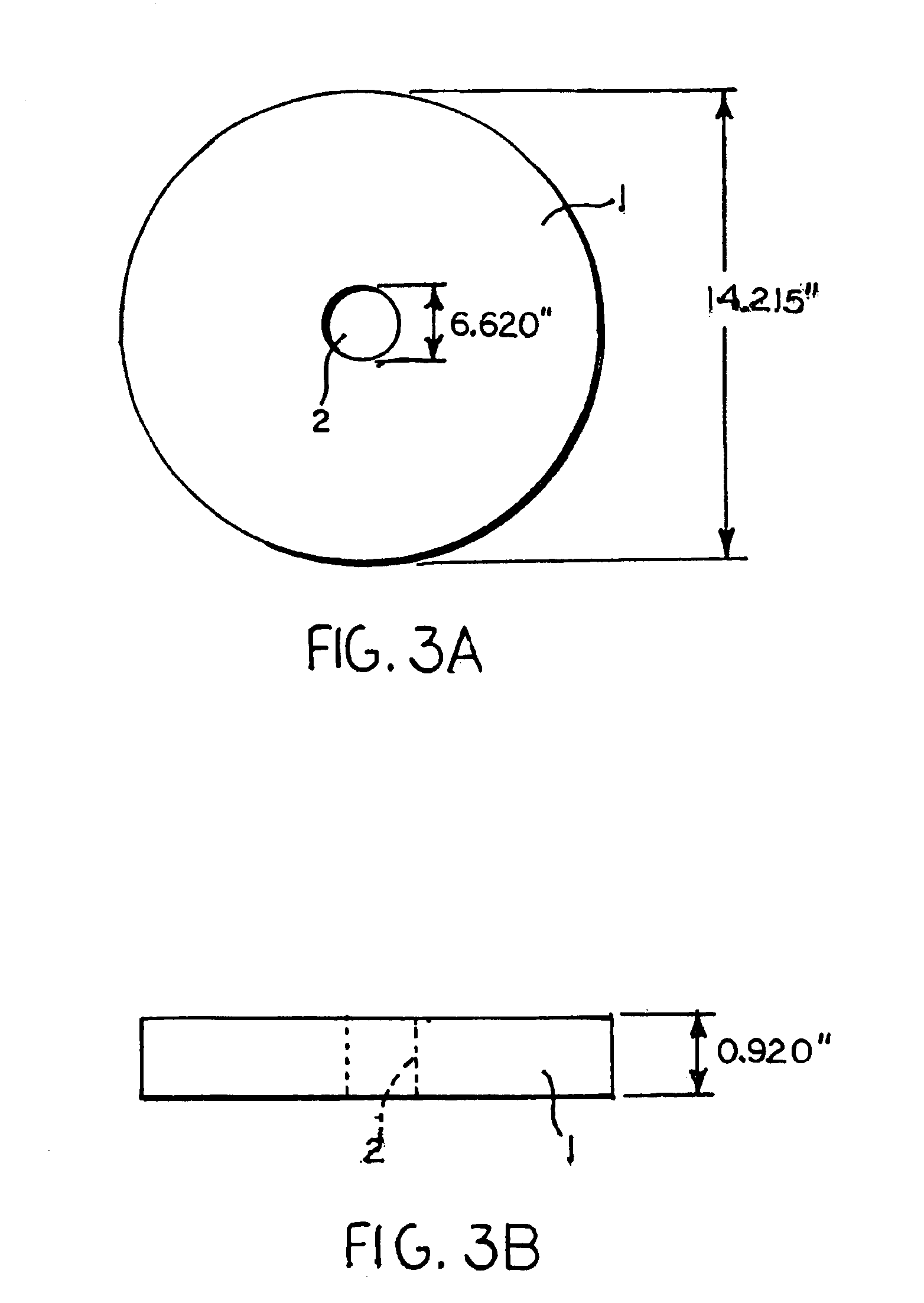

Fluidizing oxidation protection systems

InactiveUS6913821B2Facilitate chemical reactionsRelieve pressureFilm/foil adhesivesPretreated surfacesProtective barrierAlkali hydroxide

Carbon composite components (1, 11, 22, 30), which may be aircraft brake discs, heat exchanger cores, and so on, are covered by protective coating 32. Component (1, 11, 22, 30) is immersed in liquid bath precursor of fluidized glass (step 55). After immersion step, glass-coated component (1, 11, 22, 30) is removed and annealed. Heat treatment gradually increases temperature to 250-350° C. at the rate of 1-2° C. per minute (step 60). Heat treatment is followed by soak at temperature of 250-350° C. for 1-10 hours (step 65). Temperature is then increased to 550-650° C. (step 70). Temperature is maintained at 550-650° C. for 1-10 hours (step 75). After completion of second prolonged heat treatment, the component is cooled until reaching room temperature (step 80). Upon completion of the annealing step, the fluidized glass coating converts to solid glass coating (32) enveloping and forming a protective barrier against undesirable oxidation of the C—C component (1, 11, 22, 30). For application to thin-gauge composites, the glass precursor components contain 20-60 weight-% water, 25-50 weight-% phosphoric acid, 2-20 weight-% alkali metal hydroxide, 1-10 weight-% manganese phosphate, 1-10 weight-% boron nitride, 0-5 weight-% elemental boron, and 10-28 weight-% boron carbide.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

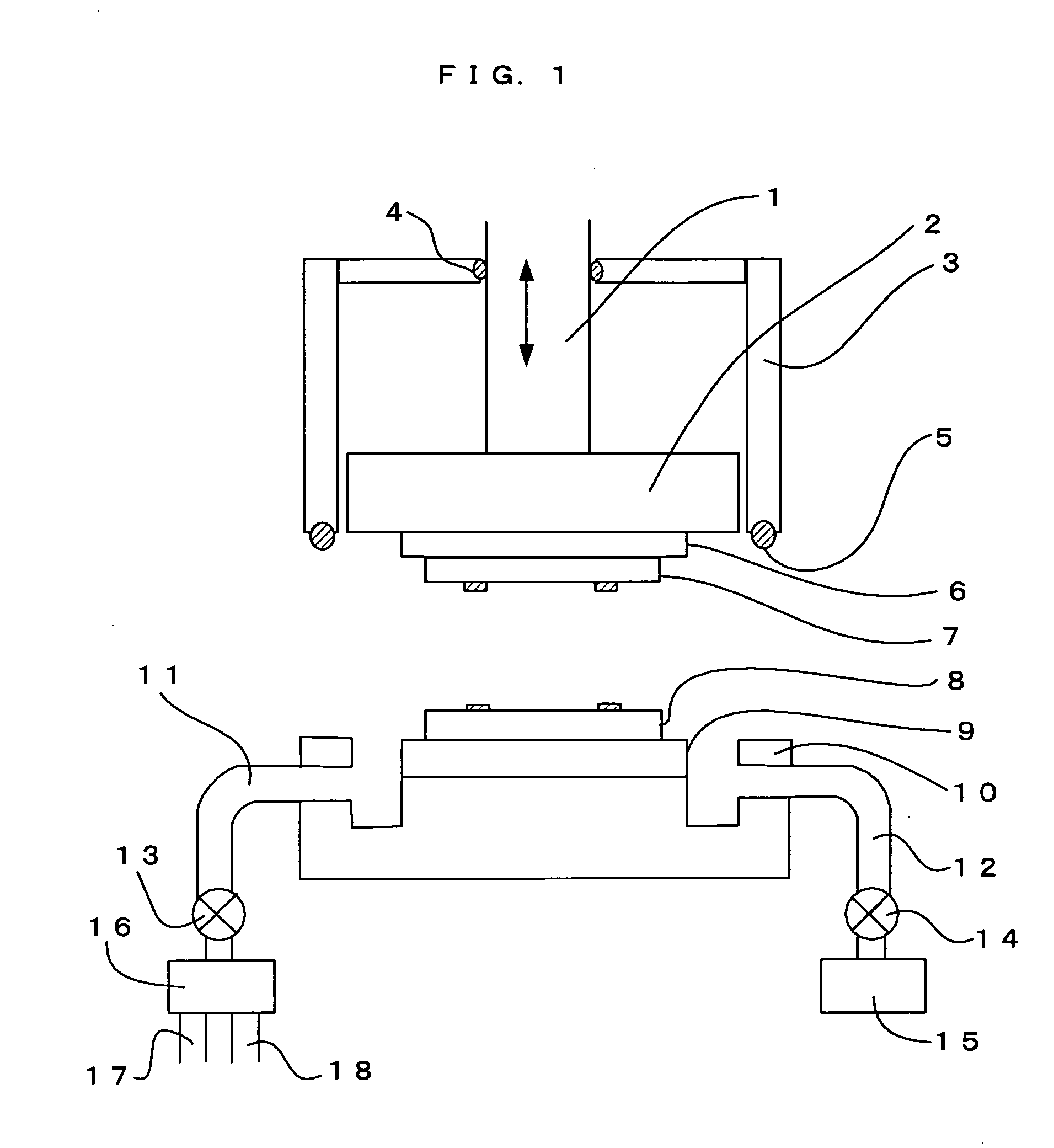

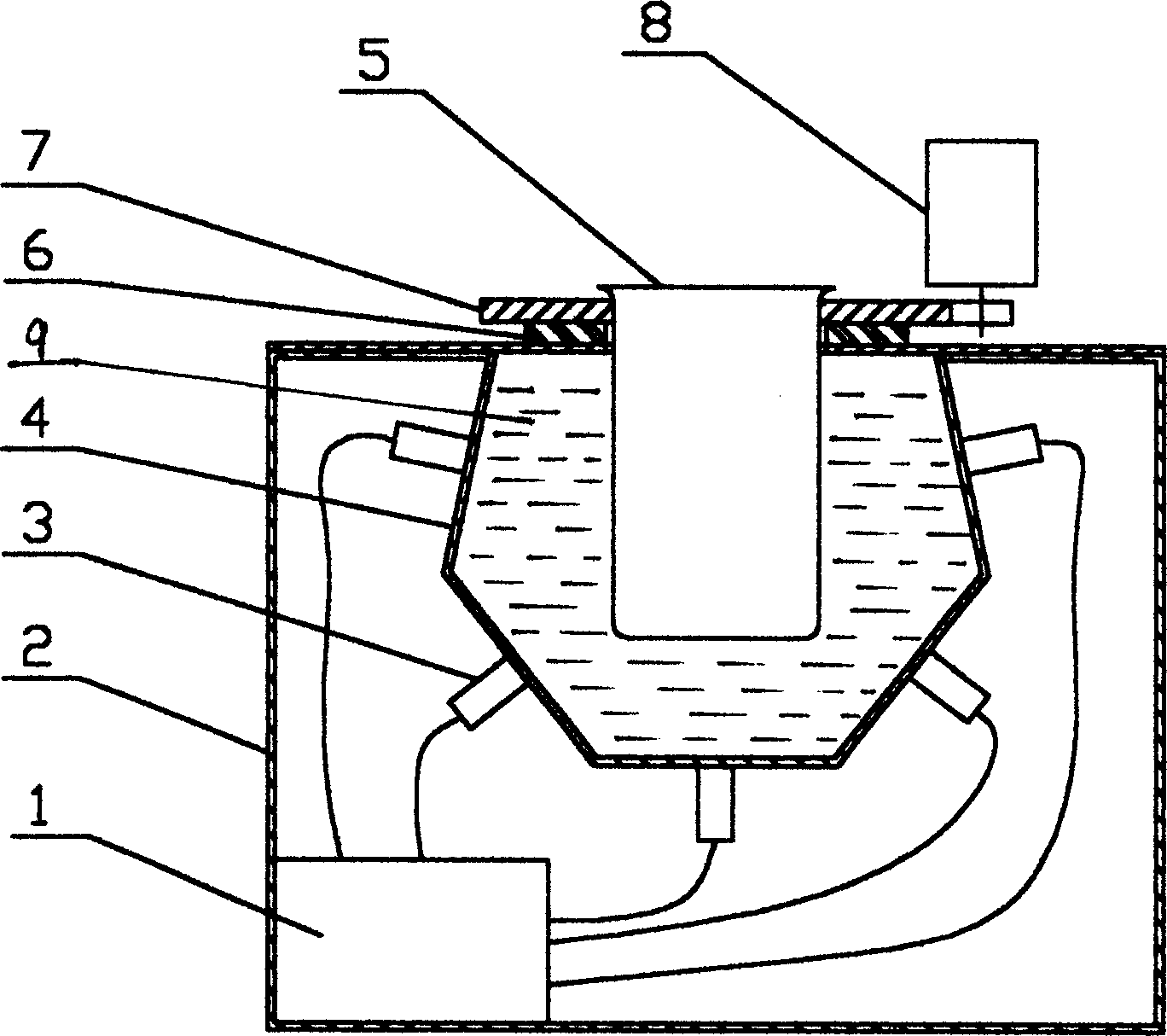

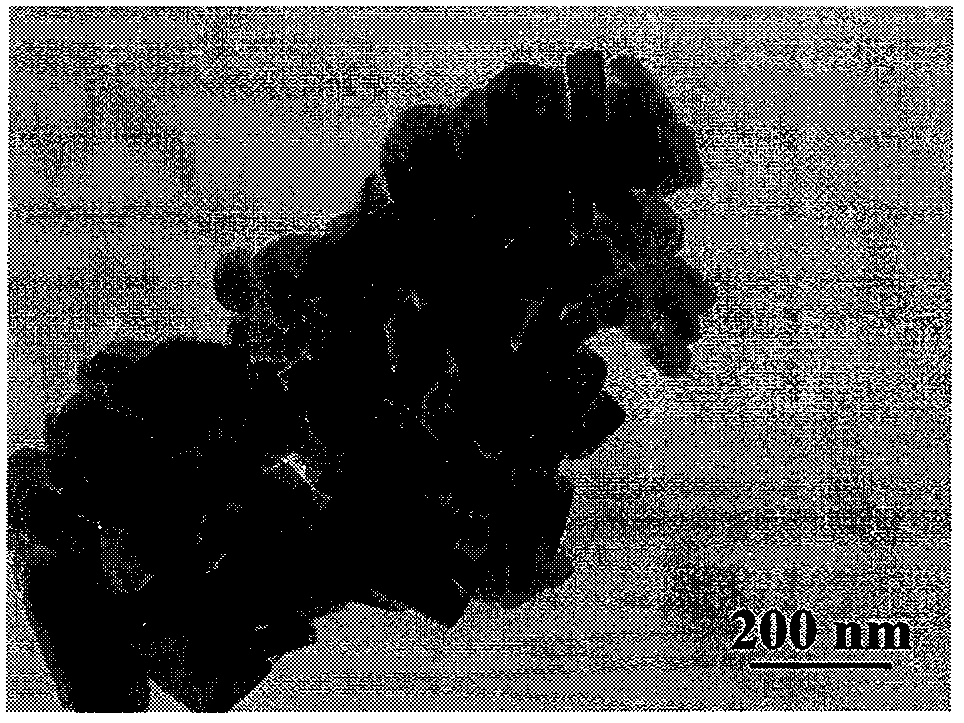

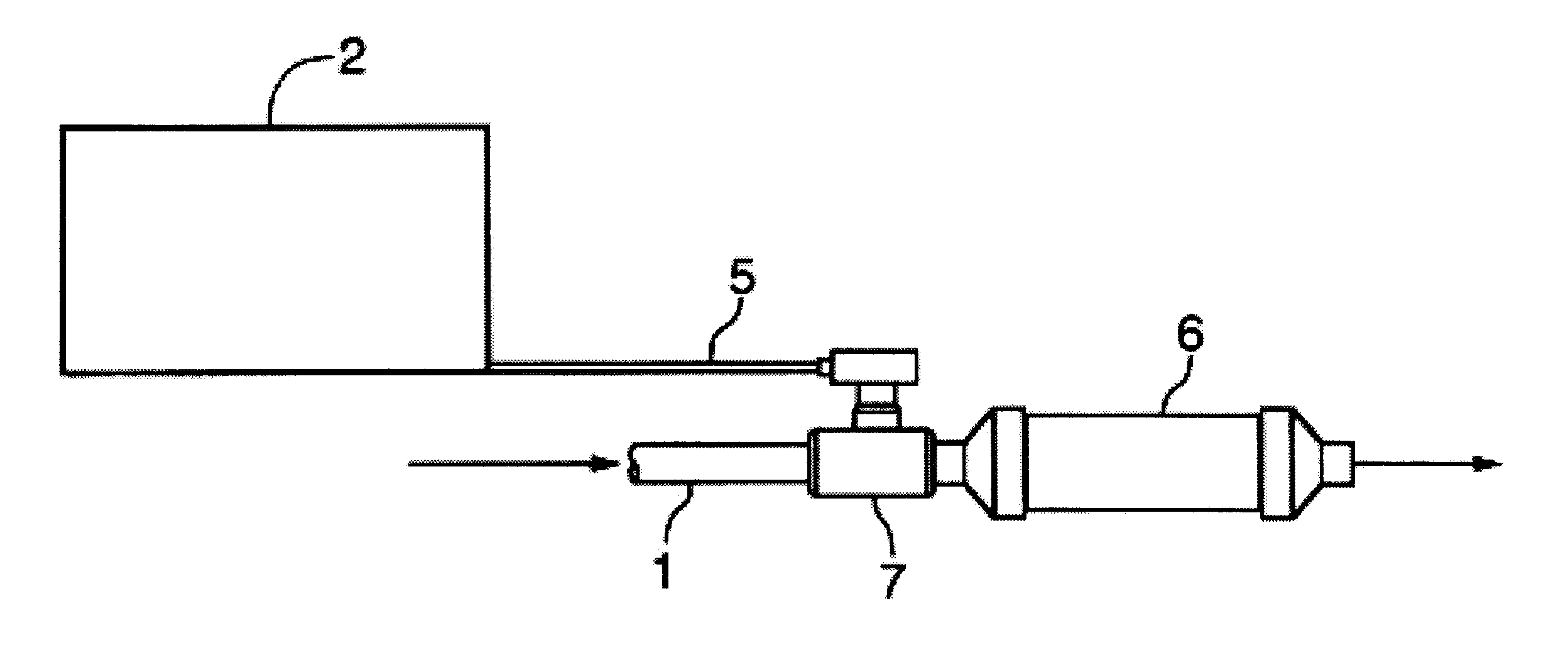

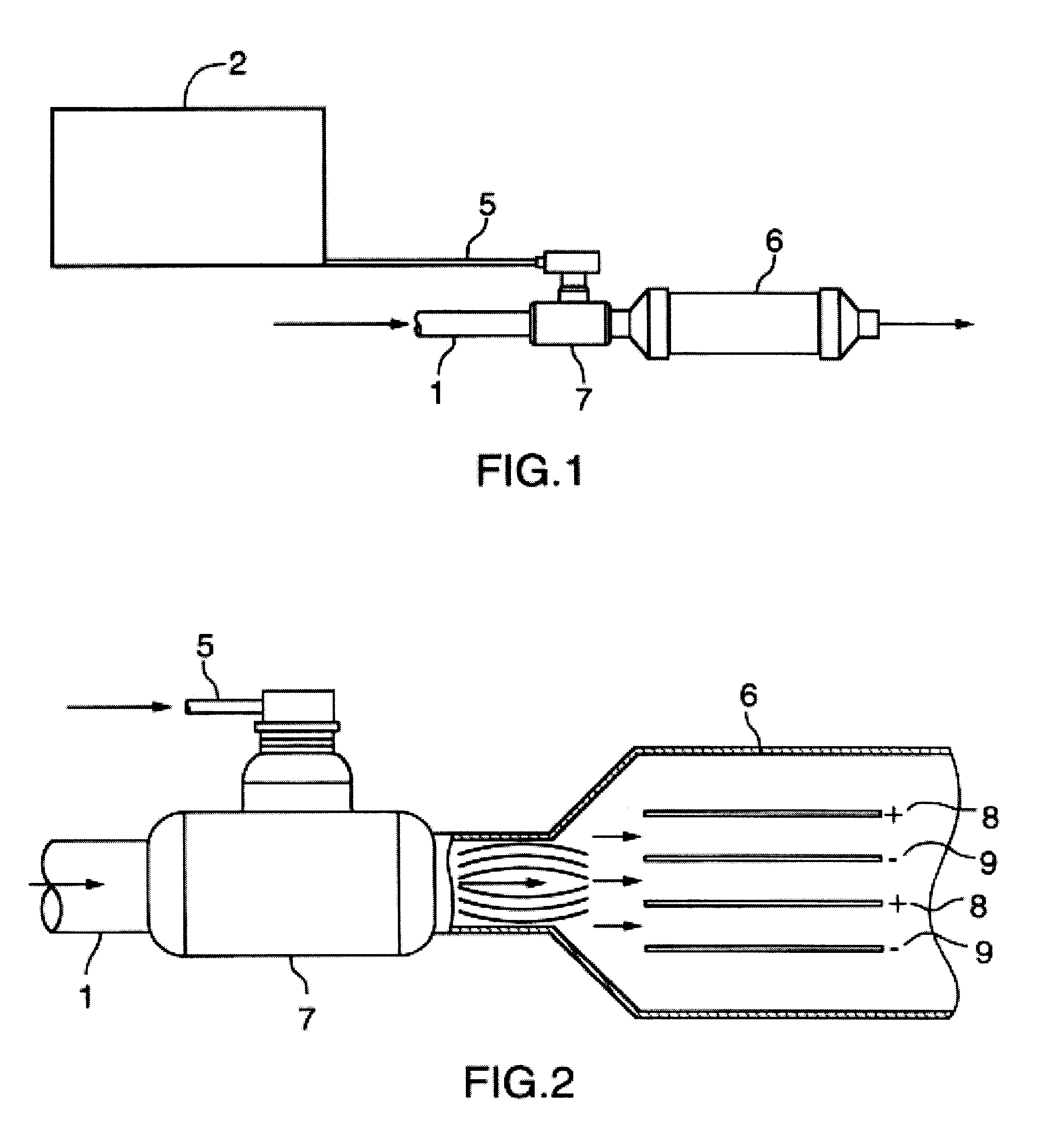

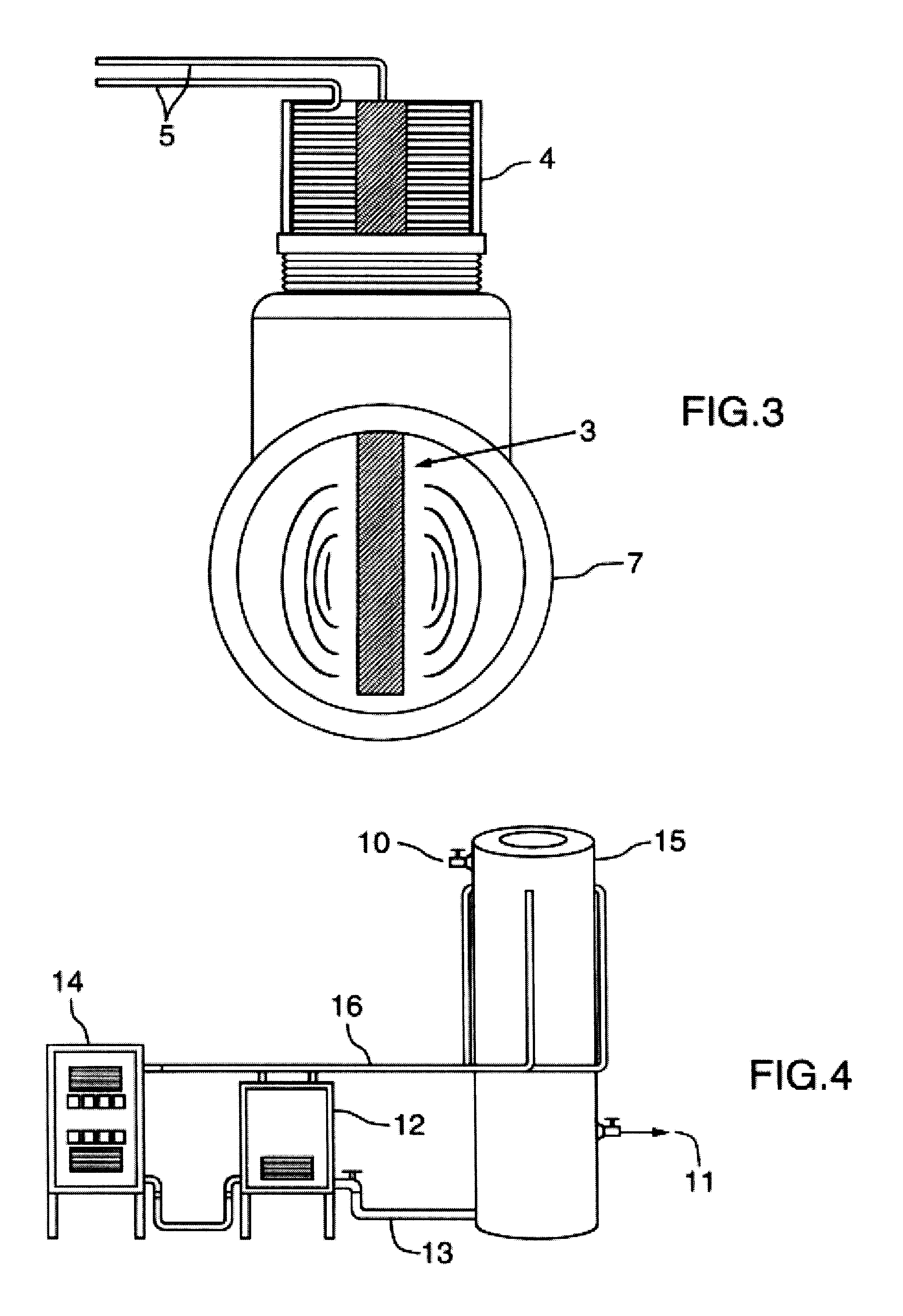

Supersonic technological method and apparatus for preparing nano material

InactiveCN1398663AQuality assuranceEasy to manufactureEnergy based chemical/physical/physico-chemical processesSupersonic wavesTransducer

The present invention includes: one supersonic functional tank with supersonic transducer heads to emit supersonic energy to the center of the tank; one reaction container to hold material inside the functional tank; a liquid filled in the gap between the functional tank and the reaction container; and one supersonic wave generator to supply supersonic waves of the same or different adjustable frequency to the supersonic transducer heads. Compared with the existing technology, the present invention has the features of capability of producing homogeneous nanometer inserting material and multiple crystal material; and it is simple, safe, and energy saving.

Owner:严卓理 +2

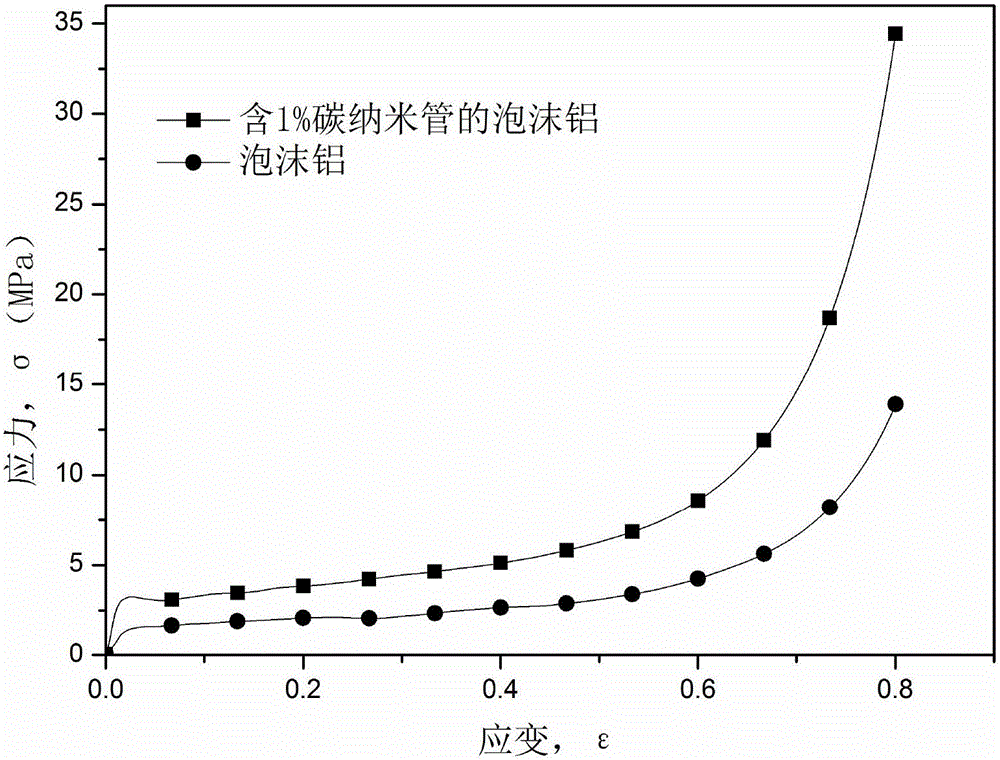

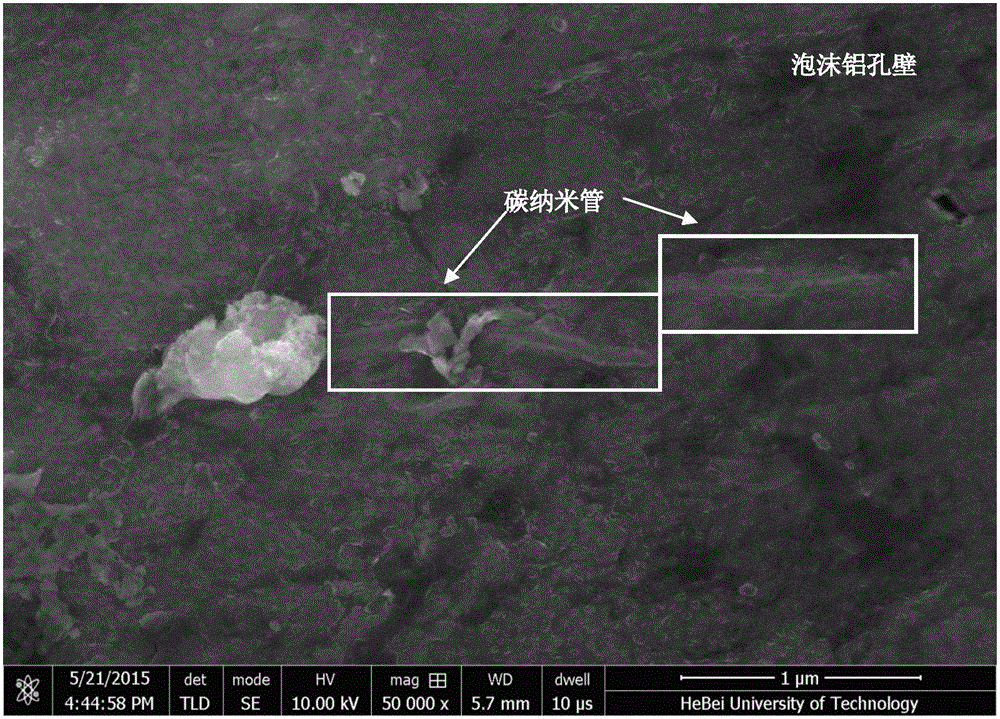

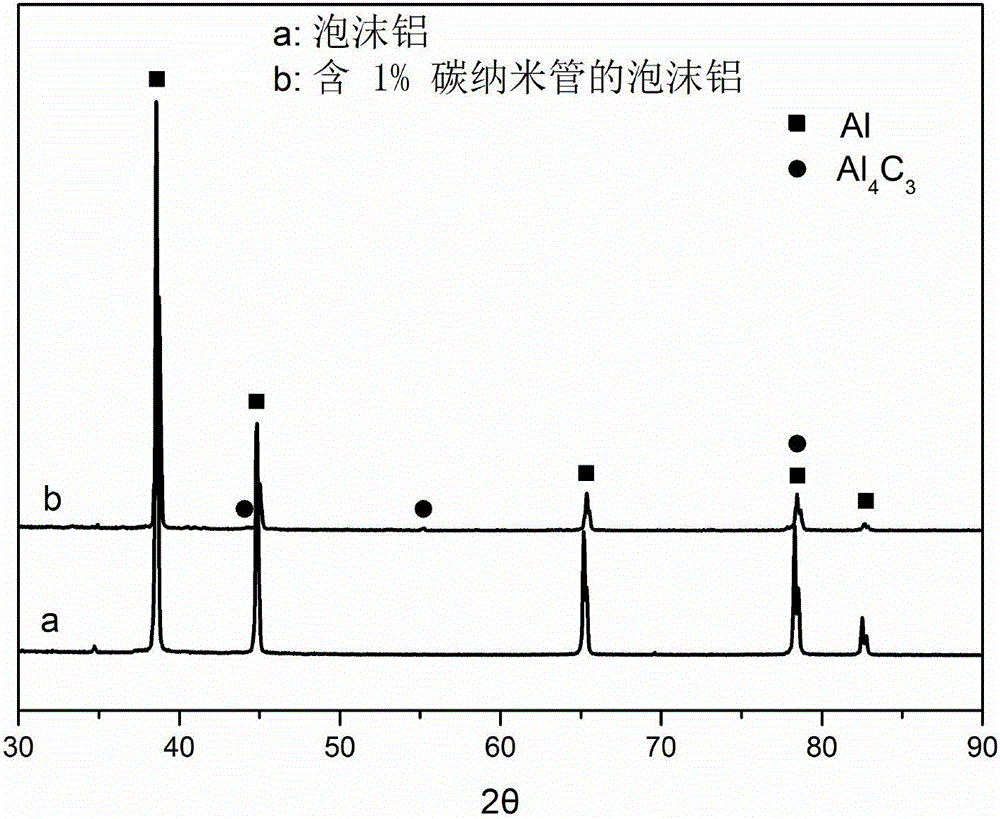

Preparing method for foam metal composite material

The invention discloses a preparing method for a foam metal composite material. The method includes the following steps that firstly, a metal ingot is cut into metal sheets the same in thickness; carbon nanometer tubes and metal powder with the components the same as those of metal pretreated in the first step are mixed, and the mixture is subjected to ball grinding on a planetary ball grinding machine for 0.5 h-6 h to obtain mixed powder; thirdly, one metal sheet is added to the bottom of a crucible, one layer of mixed powder is then evenly added, the manner of adding one metal sheet and then one layer of mixed powder cyclically is adopted, the topmost part is the corresponding metal sheet, and the crucible is put into a resistance furnace to be smelted; fourthly, a thickening agent is added; fifthly, a foaming agent is added; and sixthly, the crucible is taken out and cooled, and the closed-cell foam metal composite material containing the carbon nanometer tubes is obtained. The carbon nanometer tubes are evenly scattered in the foam metal, and the compression performance and the energy absorbing capability are obviously improved.

Owner:HEBEI UNIV OF TECH

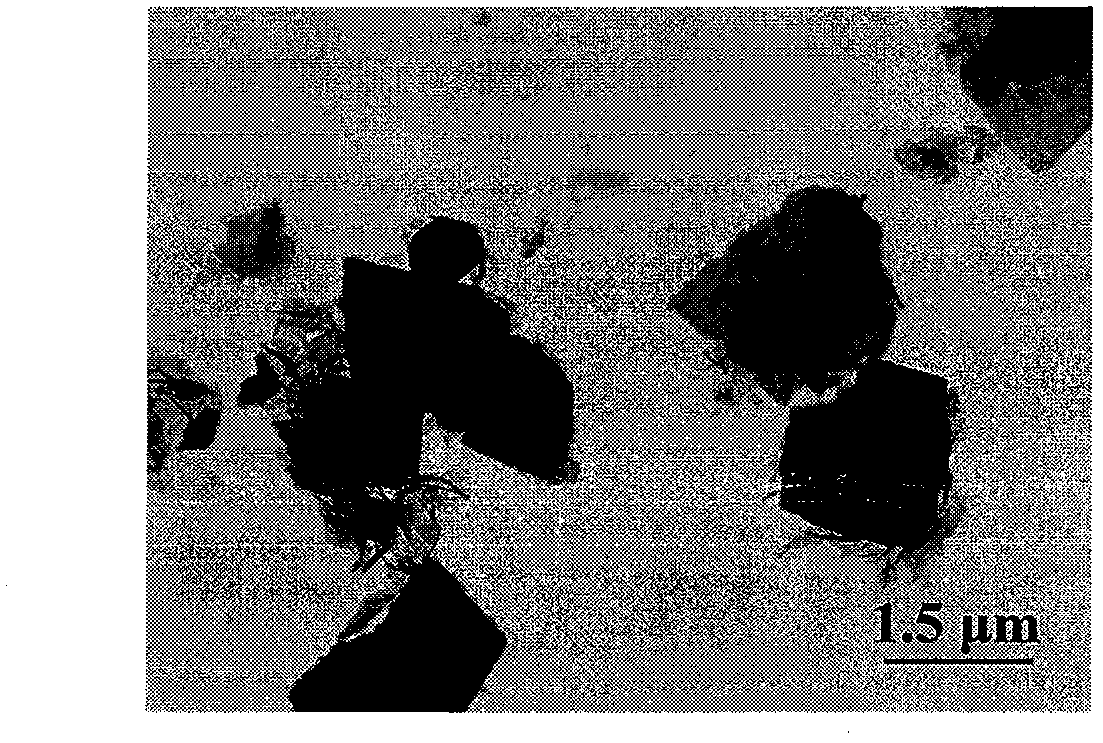

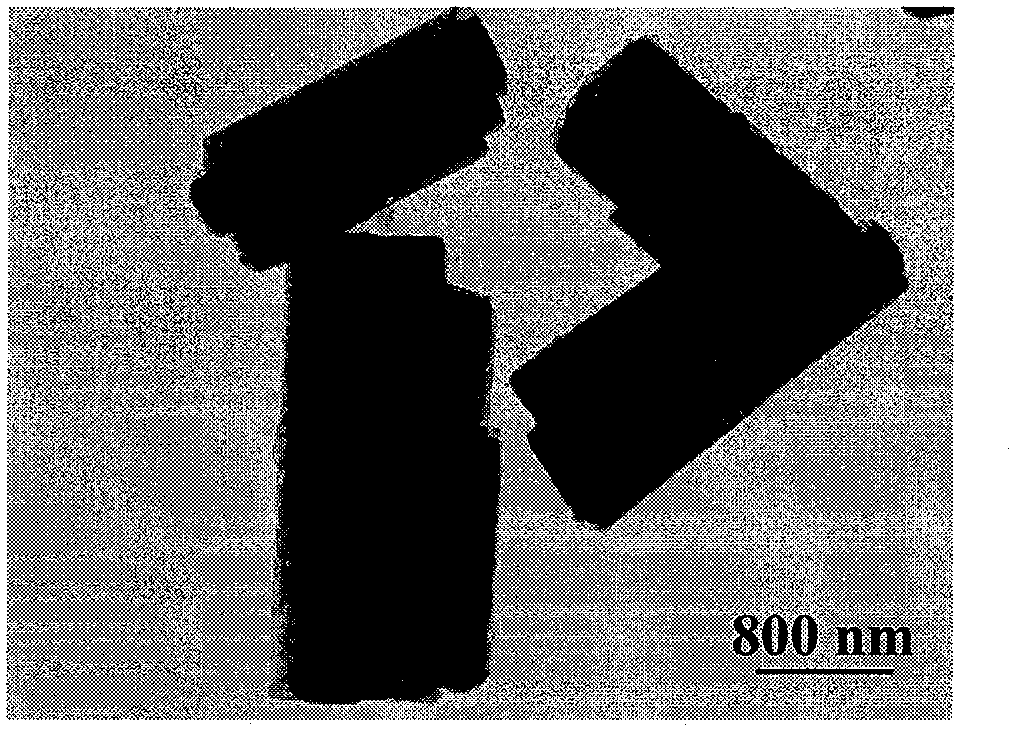

Efficient zinc phosphate micro-nano anticorrosion agent preparation method

InactiveCN103896235AUniform sizeGood dispersionMaterial nanotechnologyAnti-corrosive paintsWater bathsMicro nano

The invention belongs to the field of inorganic chemistry, and particularly relates to an efficient zinc phosphate micro-nano anticorrosion agent preparation method, wherein the product is applied in the field of metal heavy corrosion. According to the present invention, a cycle ultrasonic cavitation effect and a high-temperature high-pressure water bath thermal effect are adopted to perform synchronous and synergetic regulation to prepare the efficient zinc phosphate micro-nano anticorrosion agent, wherein the synchronous and synergetic effect of the two effects is adopted so as to make the product system be well dispersed, ensure the uniformity of crystal nucleation and effectively solve the difficult problem of difficult synchronous regulation on the particle size and the crystallization degree of the nanometer crystal, and a microwave heating mode is adopted to dry the product so as to reduce the agglomeration; the prepared micro-nano zinc phosphate product has advantages of high purity, complete crystallinity, narrow particle size distribution, good dispersion and the like, wherein the effective corrosion protection time of the zinc phosphate micro-nano anticorrosion agent is up to 1056 h and is far superior to the effective corrosion protection time of the commercially available zinc phosphate anticorrosion material; and the method has characteristics of simple process and low cost, and is suitable for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalytic simulation using radio frequency waves

InactiveUS6217712B1Facilitate chemical reactionsEliminate needAnalysis using nuclear magnetic resonanceElectric/magnetic detectionPlatinumNMR - Nuclear magnetic resonance

The invention relates to a method of using radio frequency waves to artificially create catalytic action in a catalyst-free chemical reaction within a substance. To mimic or imitate the catalyst, radio frequency waves are transmitted through the substance at a signal strength sufficient to electronically reproduce the effect of the physical presence of a selected catalyst. The radio frequency waves have a selected transmission frequency substantially equal to a catalyst signal frequency of the selected catalyst, defined as the signal frequency determined by nuclear magnetic resonance of the selected catalyst. It is commonplace to use nuclear magnetic resonance to identify elements within a substance and the signal frequencies of various elements (including catalysts) are listed in widely published tables. To date, the mechanism by which catalysts bring about chemical reactions has been unknown. The inventor has recognised that the physical presence of a catalyst brings about a chemical reaction due to the emission of low intensity radio frequency waves from the catalyst with the signal frequency that is emitted being the signal frequency of the catalyst that is commonly determined by nuclear magnetic resonance. Therefore, the invention can be used to eliminate the need for expensive metallic catalysts, such as platinum. The invention electronically reproduces the effect of the physical presence of a catalyst by transmission of a radio frequency wave with a signal frequency equal to that signal frequency emitted by the catalyst and as determined by nuclear magnetic resonance of the catalyst.

Owner:2141582 ONTARIO

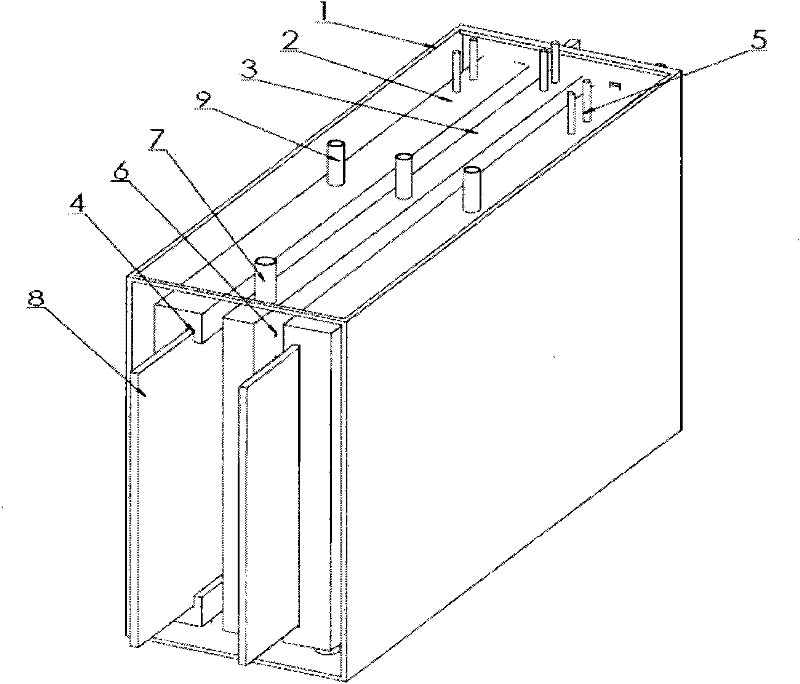

Plasm-aided selenium sulfuration treatment device and process

InactiveCN102051603ALow heating temperatureImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingFilm materialVacuum chamber

The invention relates to a plasm-aided selenium sulfuration treatment device arranged in a vacuum chamber. The plasm-aided selenium sulfuration treatment device comprises a shell, a cathode plate and an anode plate, wherein the cathode plate and the anode plate are alternately stacked to form a plasm generator, the cathode plate is provided with a groove for fixing a semiconductor film substrate, and small holes are uniformly distributed on the surface of the anode plate which is provided with a gas pipe, an independent internal heating electrode and an anode temperature-measuring point. The process based on the treatment device comprises the following steps of: (1) precasting a metal layer on the semiconductor film material according to the proportions of a chemical formula and then putting in the groove of the cathode plate; and (2) putting in the vacuum chamber to vacuumize, switching on a power supply to heat the cathode plate and the anode plate, switching on a power supply of the plasm generator and adding the mixed gases of selenium or sulfur, hydrogen and argon. The invention has the advantages that selenium ions have high reaction activity, the selenizing reaction of the metal precast layer is complete, the photoelectric conversion efficiency is high, and the substrate has lower heating temperature and is hardly deformed. An electronic mode is adopted to monitor the change of capacitive reactance between the two electrodes, know the conversion development and reduce the defective index of the industrial production.

Owner:NANKAI UNIV

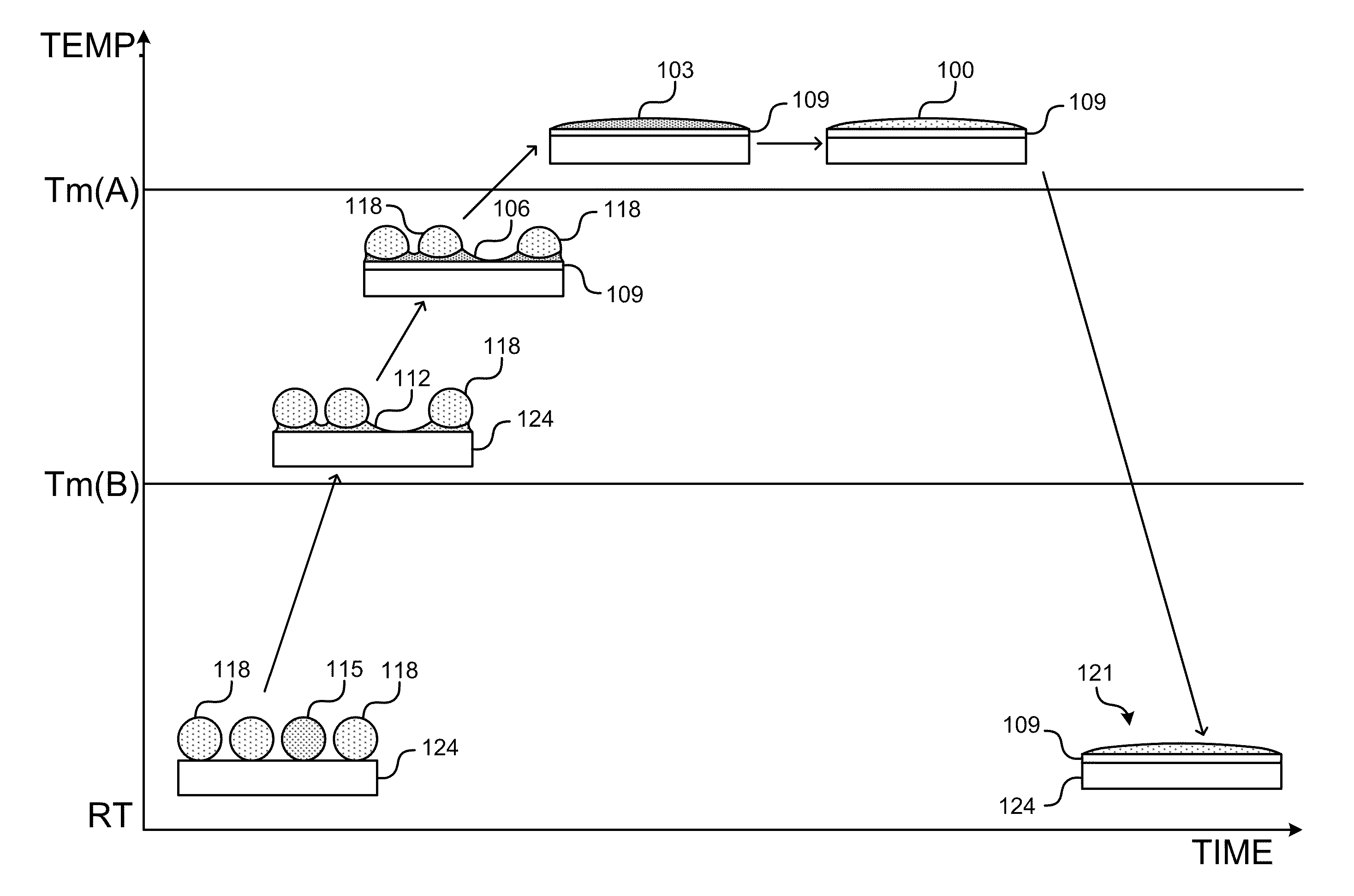

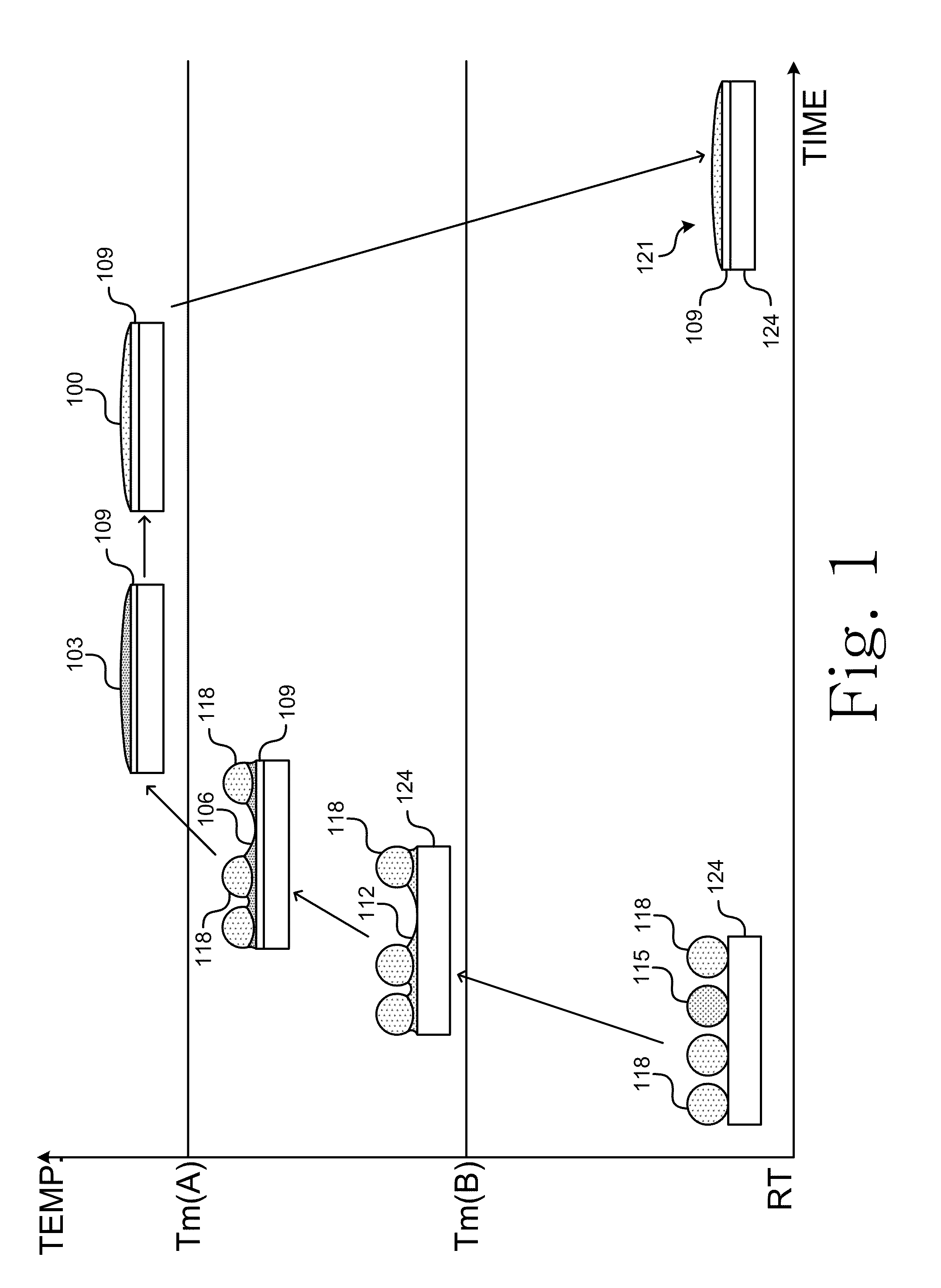

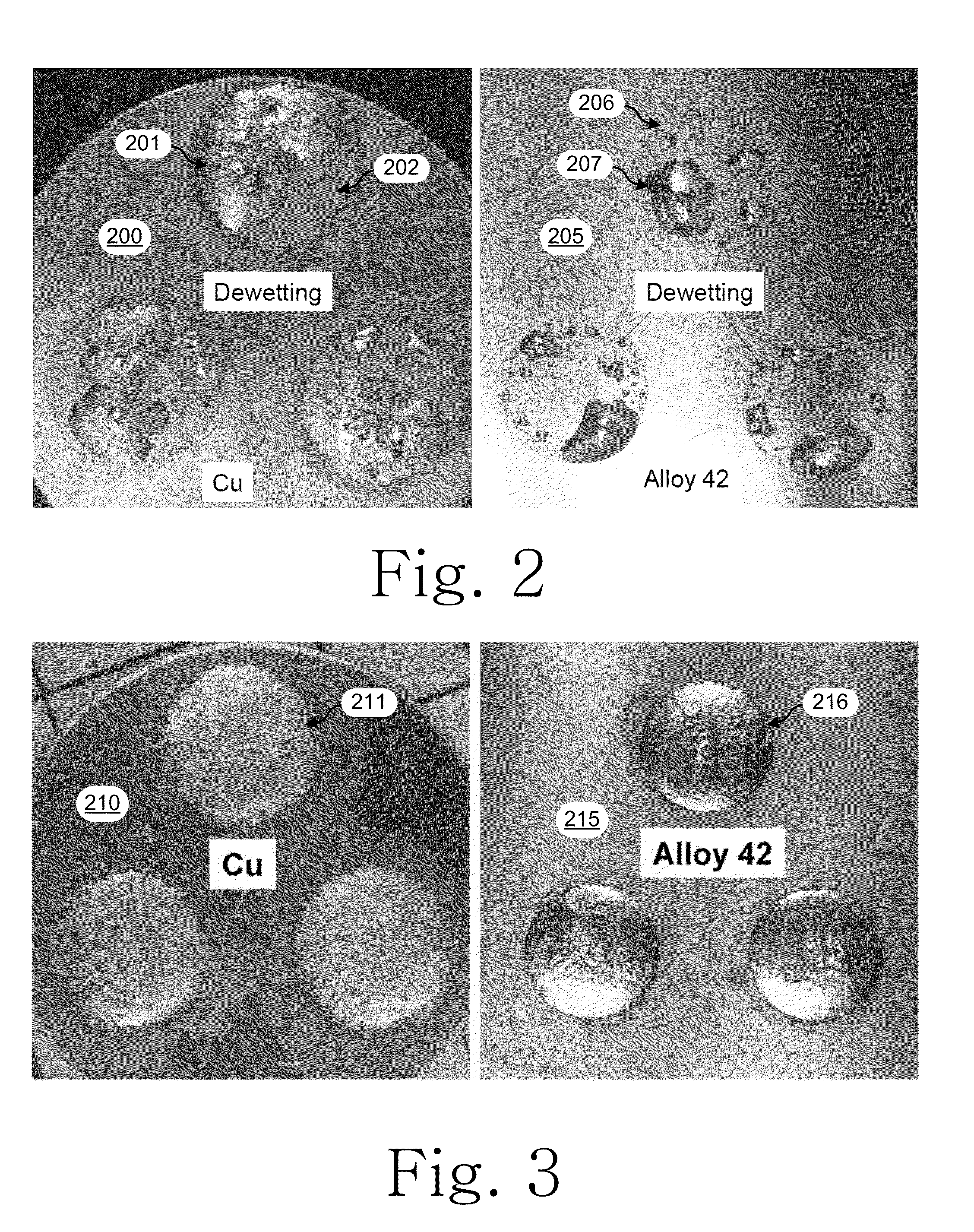

Mixed alloy solder paste

ActiveUS20110268985A1Improved reaction chemistryWell-controlled IMC layer thicknessSolid-state devicesPrinted circuit manufactureSolder pasteMaterials science

A solder paste comprises an amount of a first solder alloy powder between about 60 wt % to about 92 wt %; an amount of a second solder alloy powder greater than 0 wt % and less than about 12 wt %; and a flux; wherein the first solder alloy powder comprises a first solder alloy that has a solidus temperature above about 260° C.; and wherein the second solder alloy powder comprises a second solder alloy that has a solidus temperature that is less than about 250° C.

Owner:INDIUM CORPORATION

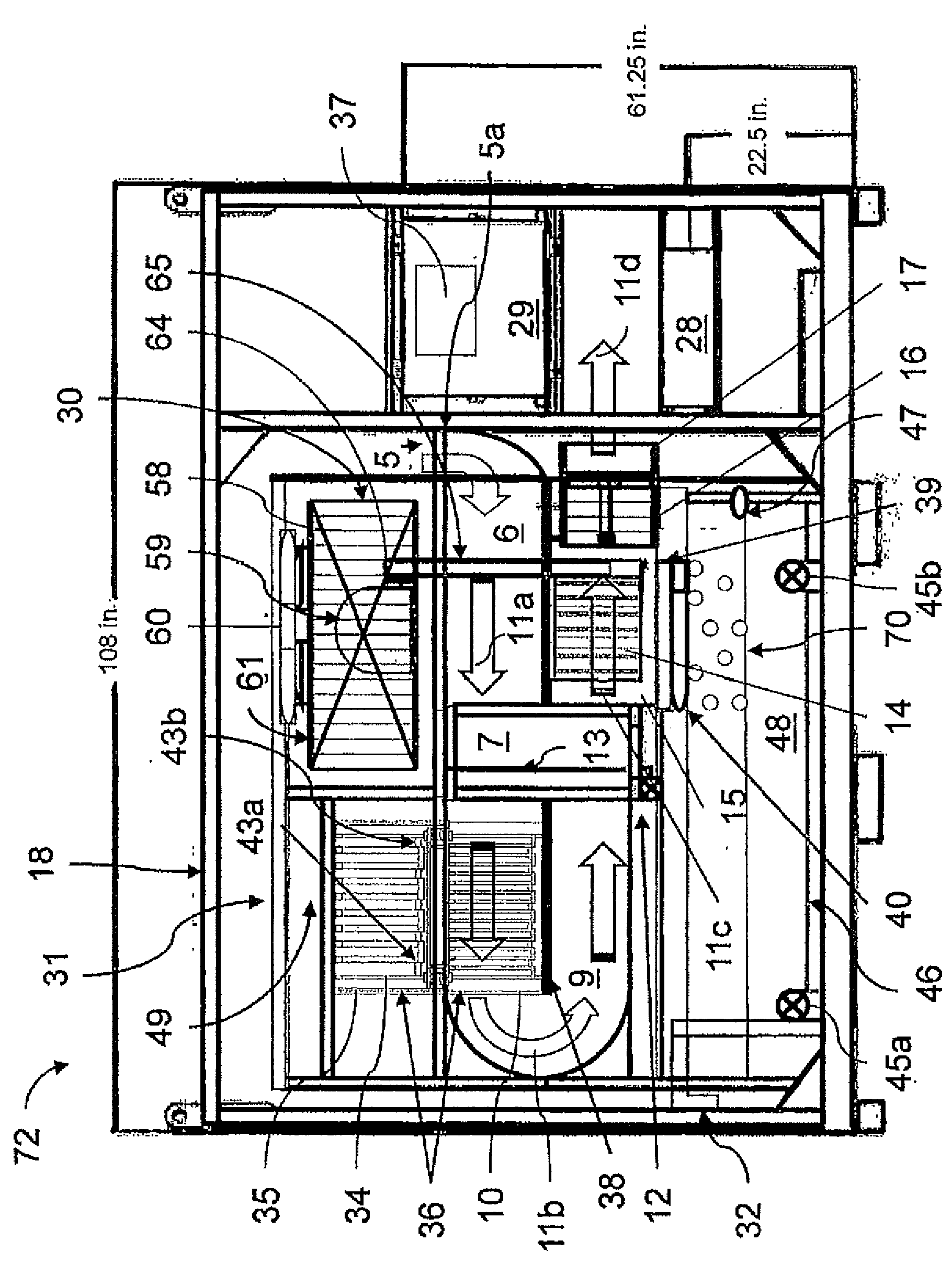

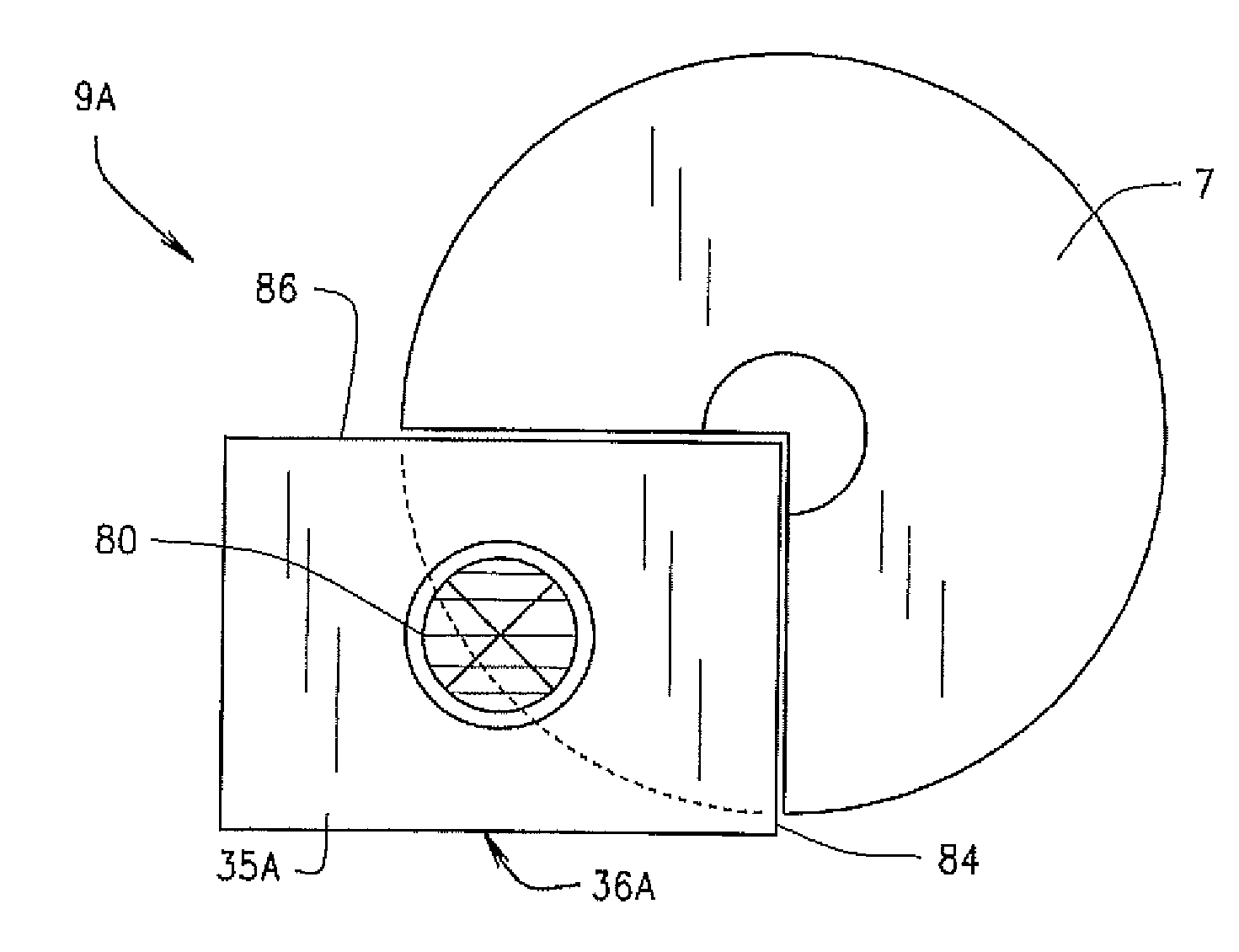

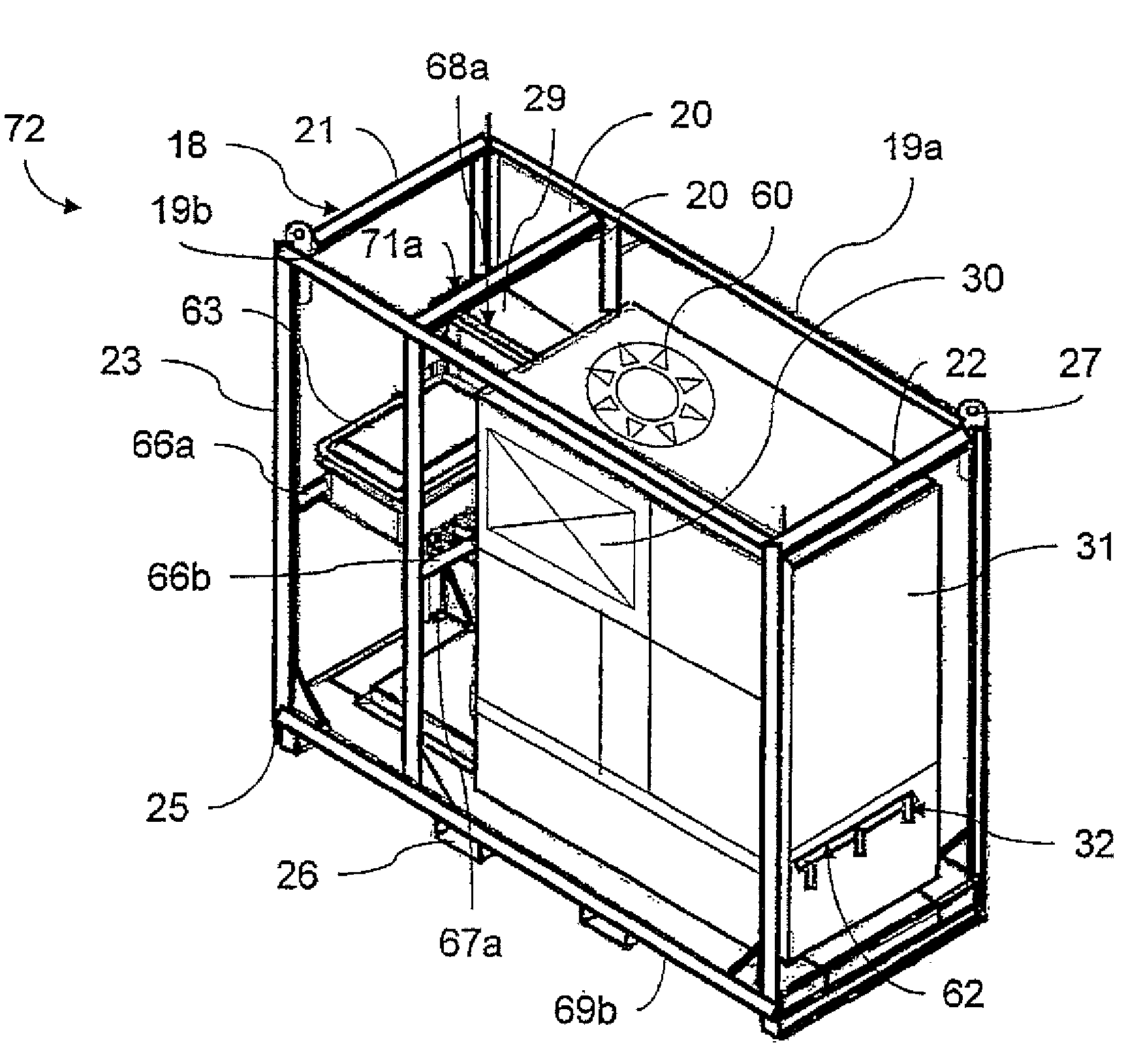

Ph20cp-portable water and climatic production system

ActiveCN103889892AReduce Disposal-Associated ProblemsFacilitate chemical reactionsGas treatmentDispersed particle separationAridWater vapor

The present invention relates to a portable water and climatic production system ("PH2OCP"). In the preferred embodiment, the system utilizes a desiccant rotor wheel to capture water vapor. The desiccant rotor wheel then rotates through a microwave heating chamber to release the water therefrom and heat the airflow as it rehydrates with the water released from the rotor wheel. The heated, moistened airflow then passes through a cooling and condensation system to create air conditioned airflow and water. The "PH2OCP" system is designed to operate and produce water in a wide range of global climatic conditions, including the most arid of environments. This is made possible due to the highly effective performance capabilities of the desiccant rotor technology in the extraction of water vapor molecules from any existing ambient air. The desiccant technology is designed to operate in combination with the microwave reactivation system in the regeneration or reactivation section and cooling coils assembly located in the condensation section.

Owner:9143173加拿大公司

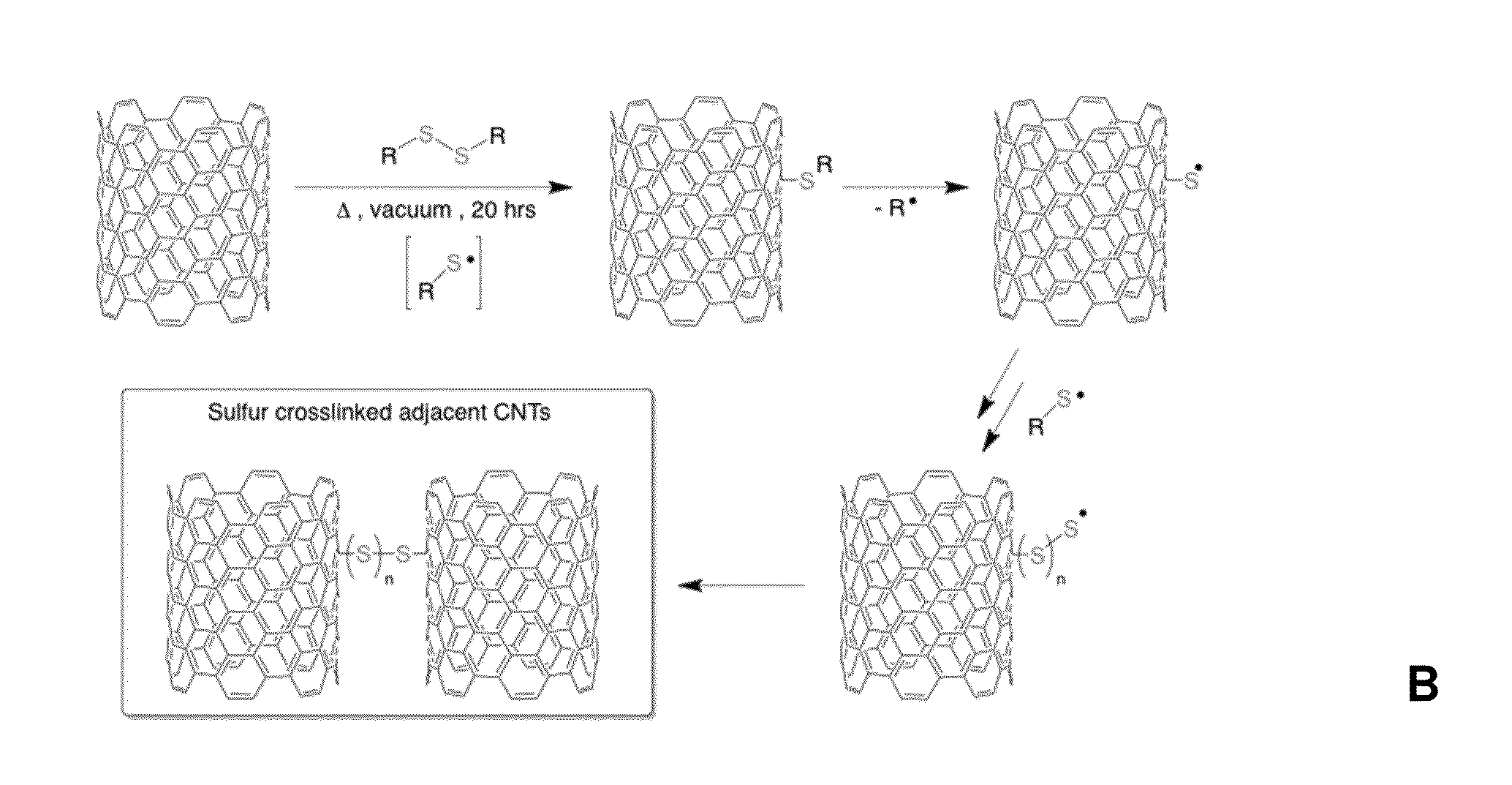

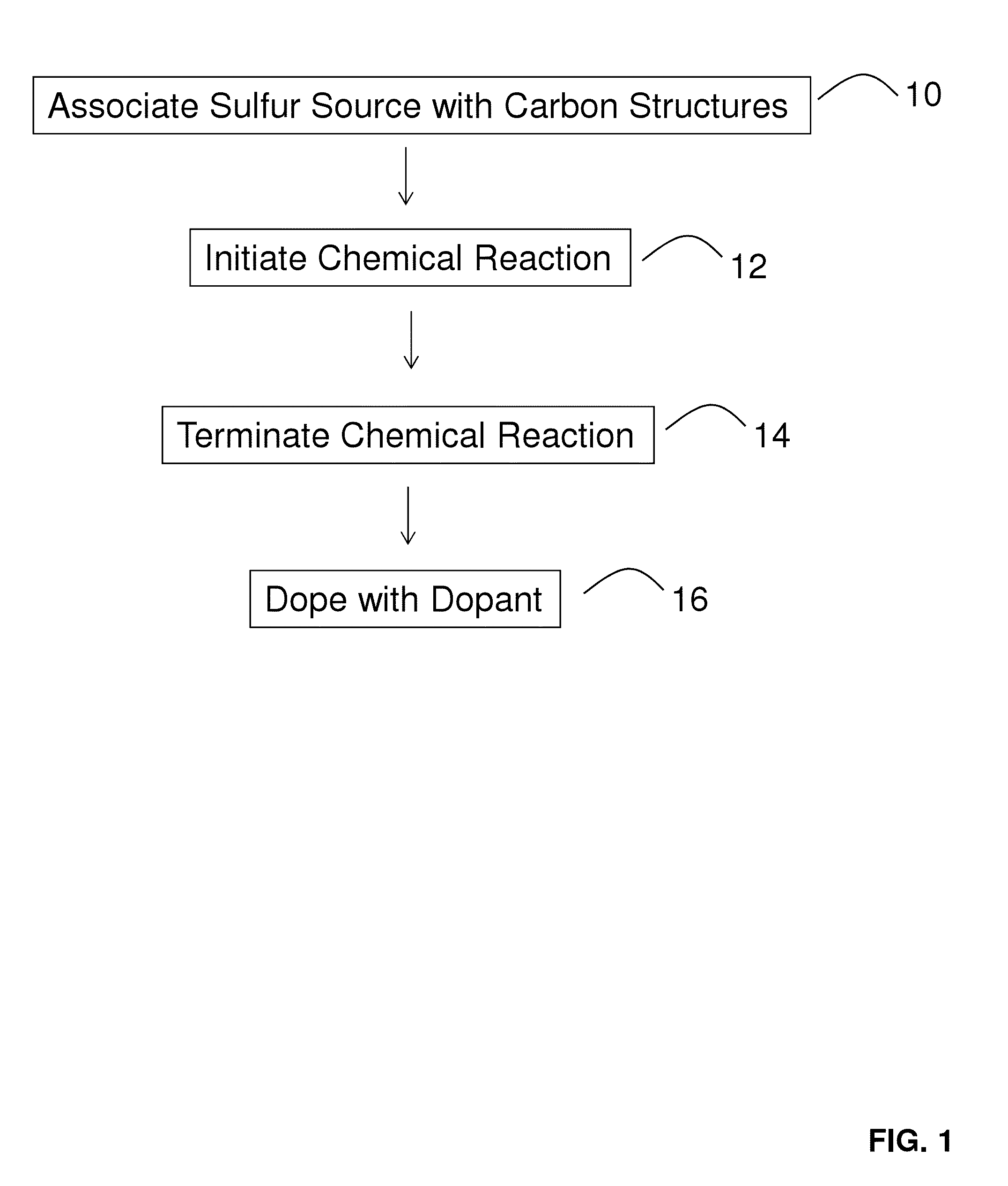

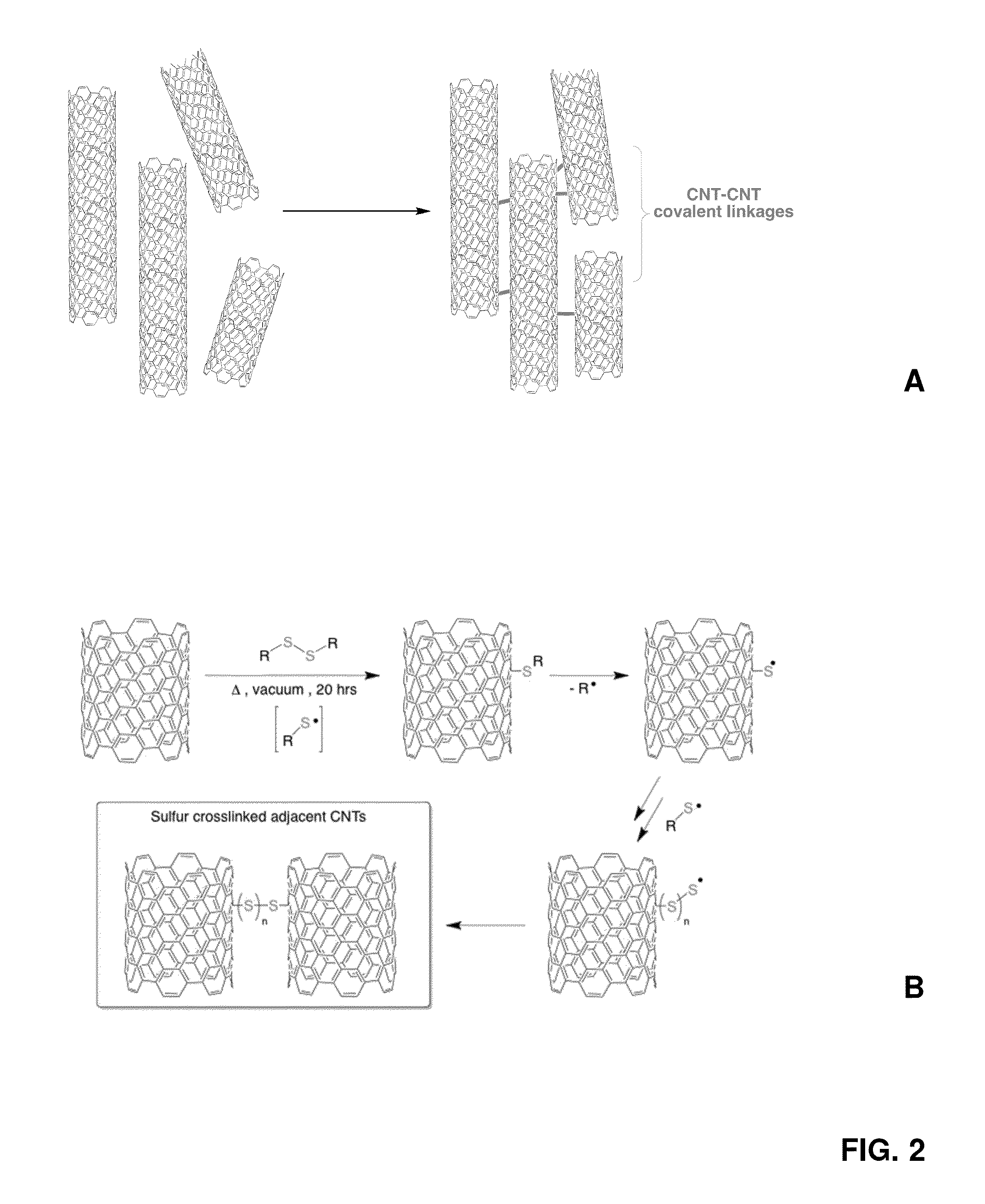

Covalent modification and crosslinking of carbon materials by sulfur addition

InactiveUS20140138587A1Facilitate chemical reactionsIncrease vapor pressureCarbon compoundsConductive materialSolventCarbon nanotube

In some embodiments, the present disclosure pertains to methods of forming cross-linked carbon materials by: (a) associating a sulfur source with carbon materials, where the sulfur source comprises sulfur atoms; and (b) initiating a chemical reaction, where the chemical reaction leads to the formation of covalent linkages between the carbon materials. In some embodiments, the covalent linkages between the carbon materials comprise covalent bonds between sulfur atoms of the sulfur source and carbon atoms of the carbon materials. In some embodiments, the chemical reactions occur in the absence of solvents while carbon materials are immobilized in solid state. In some embodiments, the carbon materials include carbon nanotube fibers. In some embodiments, the methods of the present disclosure also include a step of doping carbon materials with a dopant, such as iodine. Further embodiments of the present disclosure pertain to cross-linked carbon materials formed in accordance with the above methods.

Owner:RICE UNIV

Electromagnetic control of chemical catalysis

ActiveUS7998538B2High degreeFast decayMaterial nanotechnologyOrganic chemistryChemical reactionElectron resonance

The present disclosure relates to methods and systems that provide heat, via at least Photon-Electron resonance, also known as excitation, of at least a particle utilized, at least in part, to initiate and / or drive at least one catalytic chemical reaction. In some implementations, the particles are structures or metallic structures, such as nanostructures. The one or more metallic structures are heated at least as a result of interaction of incident electromagnetic radiation, having particular frequencies and / or frequency ranges, with delocalized surface electrons of the one or more particles. This provides a control of catalytic chemical reactions, via spatial and temporal control of generated heat, on the scale of nanometers as well as a method by which catalytic chemical reaction temperatures are provided.

Owner:CALIFORNIA INST OF TECH

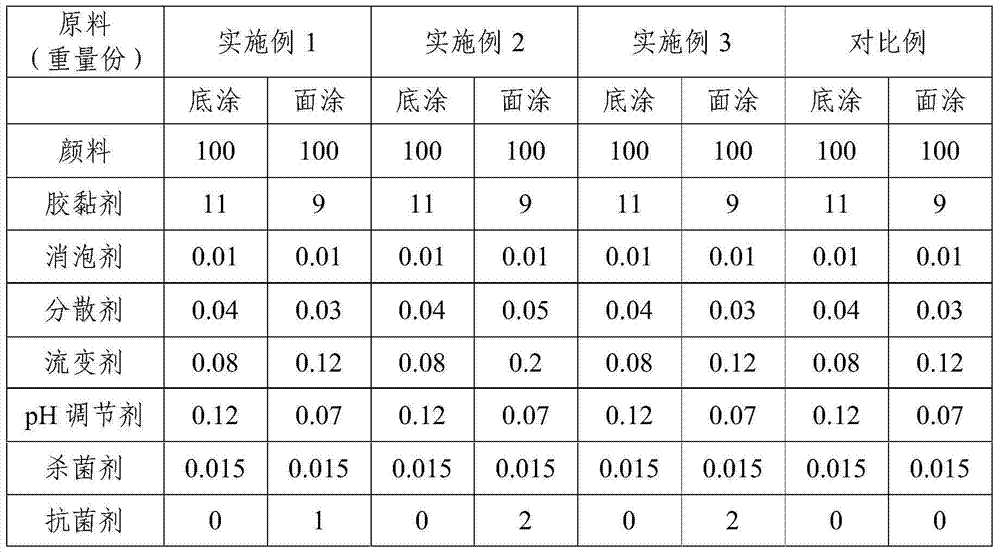

Antibacterial chromo board coating and antibacterial chromo board

InactiveCN103614948AAchieve antibacterial effectImprove efficiencyDefoamers additionCoatings with pigmentsAdhesiveBULK ACTIVE INGREDIENT

The invention provides an antibacterial chromo board coating, which comprises the following active ingredients in parts by weight: 100 parts of pigment, 8-12 parts of adhesive, 0.01-2 parts of defoaming agent, 0.01-2 parts of dispersing agent, 0.01-2 parts of rheological agent, 0.01-3 parts of pH regulator, 0.01-2 parts of bactericide, and 0-3 parts of antibacterial agent. According to the antibacterial chromo board coating, the nanometer material antibacterial agent is added on the basis of the existing chromo board coating, and bacteria resistance can be carried out by utilizing nanotechnology. After the antibacterial agent is added in the coating, the paper achieves a certain antibacterial effect, the antibacterial rate can be increased to more than 99.99% from 80%, thus meeting the special demand of customers, and also promoting the benefit of a company.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

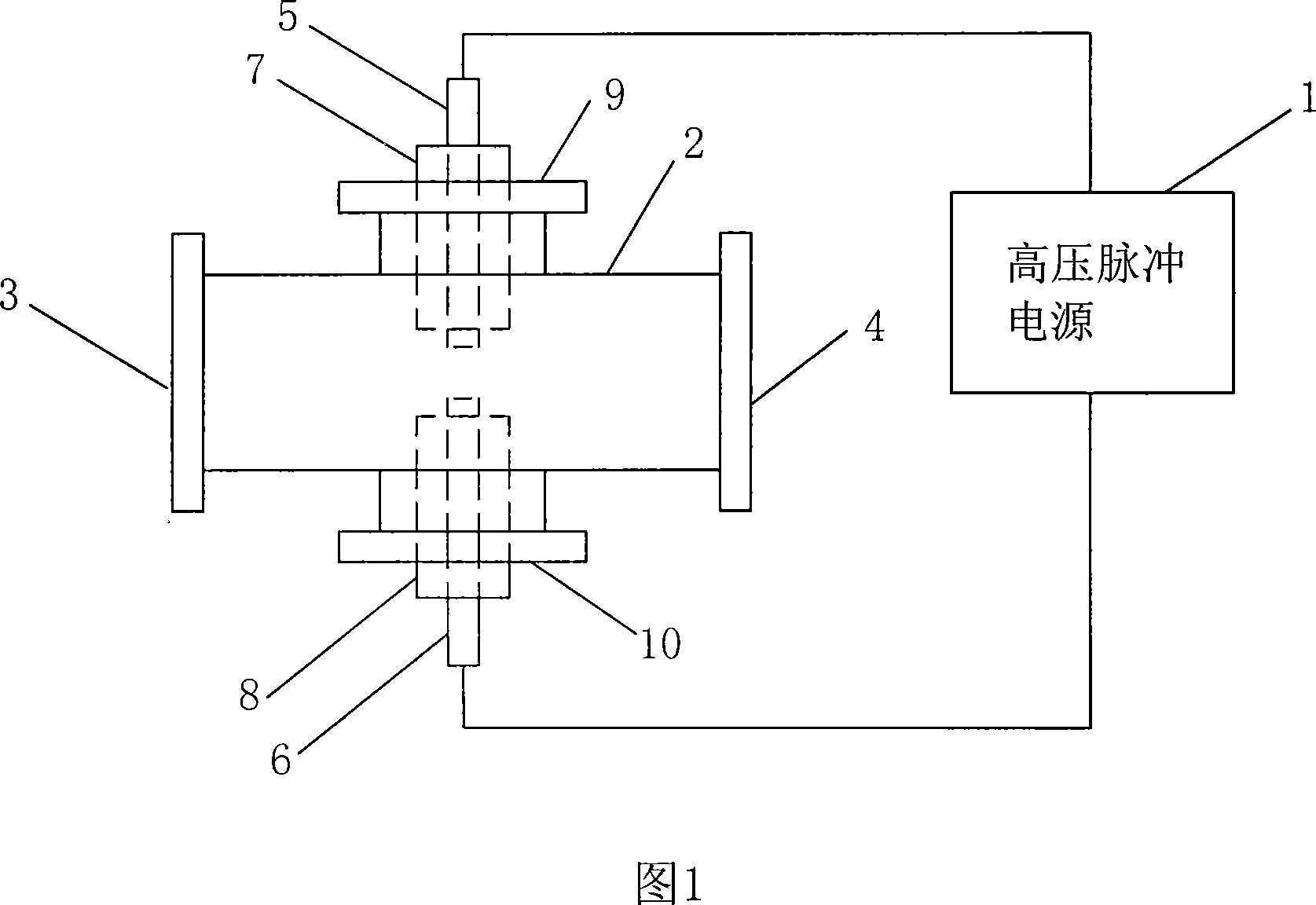

Method for treating ship ballast water

InactiveCN101074138AEasy to handleFacilitate chemical reactionsMultistage water/sewage treatmentNature of treatment waterShock waveChemical reaction

A method for treating ship ballast water and its treating device are disclosed. The process is carried out by immersing two discharge electrodes into ship ballast water, applying high-voltage pulse voltage between two electrodes, producing liquid-phase discharge to generate shock wave, ultraviolet ray and various active free radicals and sterilizing mono-cell, bacterium, protozoon and other harmful living things. It utilizes shock-wave pressure and oxidation effect, ultraviolet sterilizing effect and accelerating chemical reaction, and hydroxyl-free radical, active oxy-bromide species and other free-radical high oxidation processes, the treating device consists of high-voltage power supply, discharge electrode and discharge container. It's cheap and simple and has no chemical dispensing residue. It can be used for ship ballast water transfer and shore-base treatment.

Owner:DALIAN MARITIME UNIVERSITY

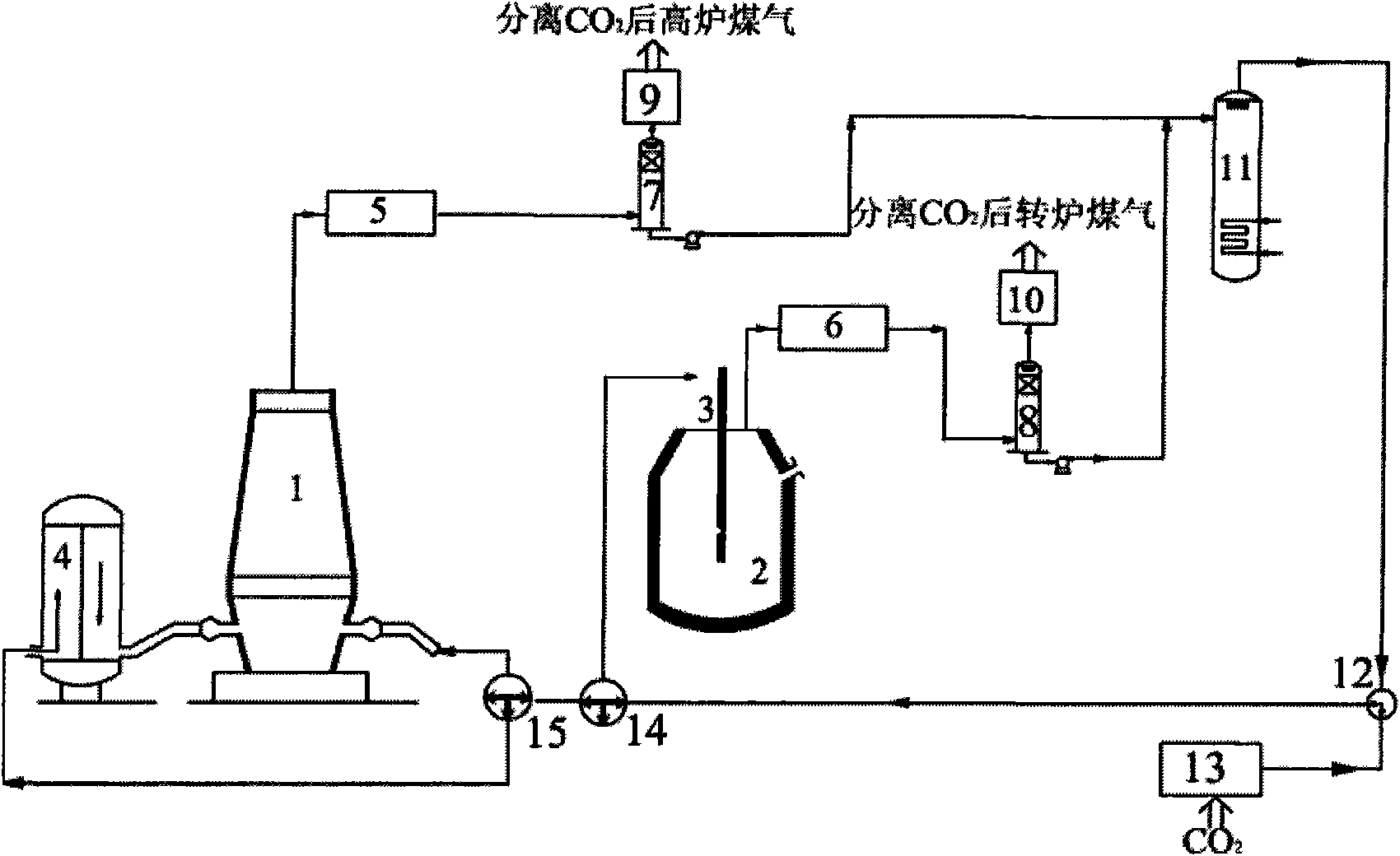

Method for separating, reclaiming and recycling CO2 in gas of blast furnace and converter

InactiveCN101603104AEmission reductionReduce consumptionBlast furnace detailsManufacturing convertersSlagTower

The invention relates to a method for separating, reclaiming and recycling CO2 in gas of a blast furnace and a converter respectively, belongs to the fields of ferrous metallurgy and greenhouse gas discharge reduction, and provides an energy-saving technique for improving the mass energy of the gas and reducing the discharge of CO2. The method integrates and optimizes the reclamation and recycle of the gas of the blast furnace and the converter; the reclamation and separation of the CO2 in the gas are executed by a gas treatment system, an absorption tower and a regeneration tower with a built-in boiler, and a chemical absorption system is additionally provided; and the reclaimed CO2 and partial external CO2 can be used for blasting in a hot-blast stove of the blast furnace and carrying gas for injection fuel, and the reclaimed CO2 also can be used for replacing N2 to carry out slag splashing protection for the converter. The method realizes the recycle of the CO2 during iron making in the blast furnace and steel making in the converter, also can use the external CO2 reclaimed from the industrial waste gas in the industries of power, chemical engineering and the like, reduces the discharge of the CO2, realizes an environment-friendly steel production process, and has remarkable social and environmental benefits.

Owner:PEKING UNIV

Method for using pennisetum hydridum lignin for preparation of active carbon and application of active carbon

ActiveCN105399872ALoose structureFacilitate chemical reactionsLignin derivativesPaper material treatmentActivated carbonPhosphoric acid

The present invention discloses a method for using pennisetum hydridum lignin for preparation of active carbon and application of the active carbon, the method comprises the following steps: hydrothermal coke can be prepared from the pennisetum hydridum lignin as a raw material by a hydrothermal method, the hydrothermal coke is impregnated with a solution of phosphoric acid, then the impregnated hydrothermal coke is put into a muffle furnace for carbonization, and finally the impregnated hydrothermal after the carbonization is activated by a hydrochloric acid solution, washed and dried to obtain the active carbon. The active carbon prepared from a pennisetum hydridum waste residue is just suitable for detoxification and decoloration of a hydrolyzate after pennisetum hydridum hydrolysis due to the pore size of the active carbon, and compared with the decolorization effect of purchased commodity active carbon, the decolorization effect of the active carbon is better.

Owner:QILU UNIV OF TECH

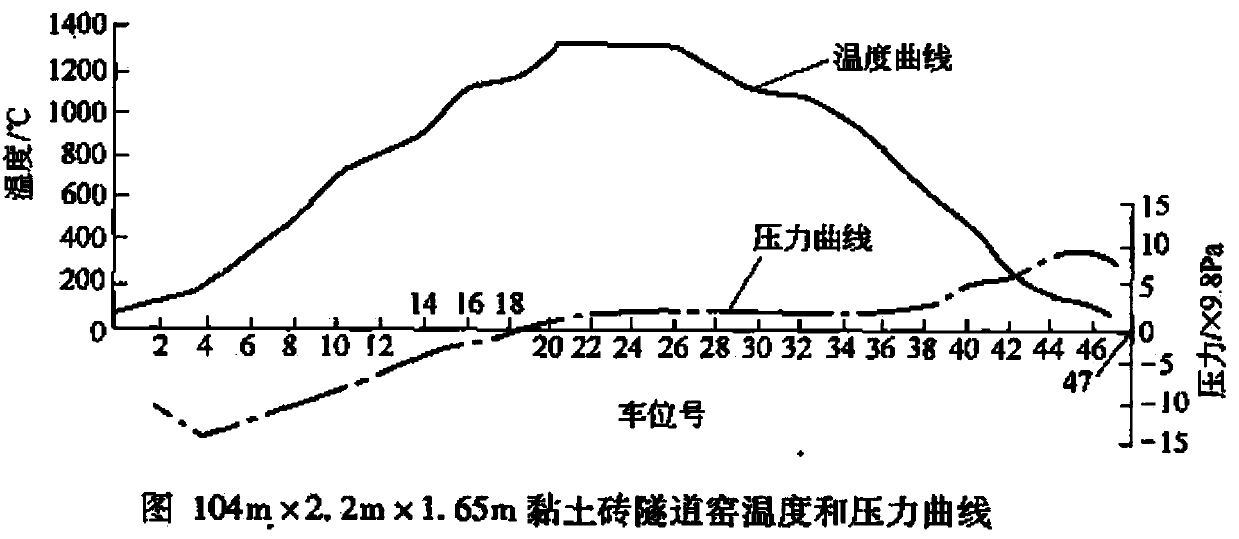

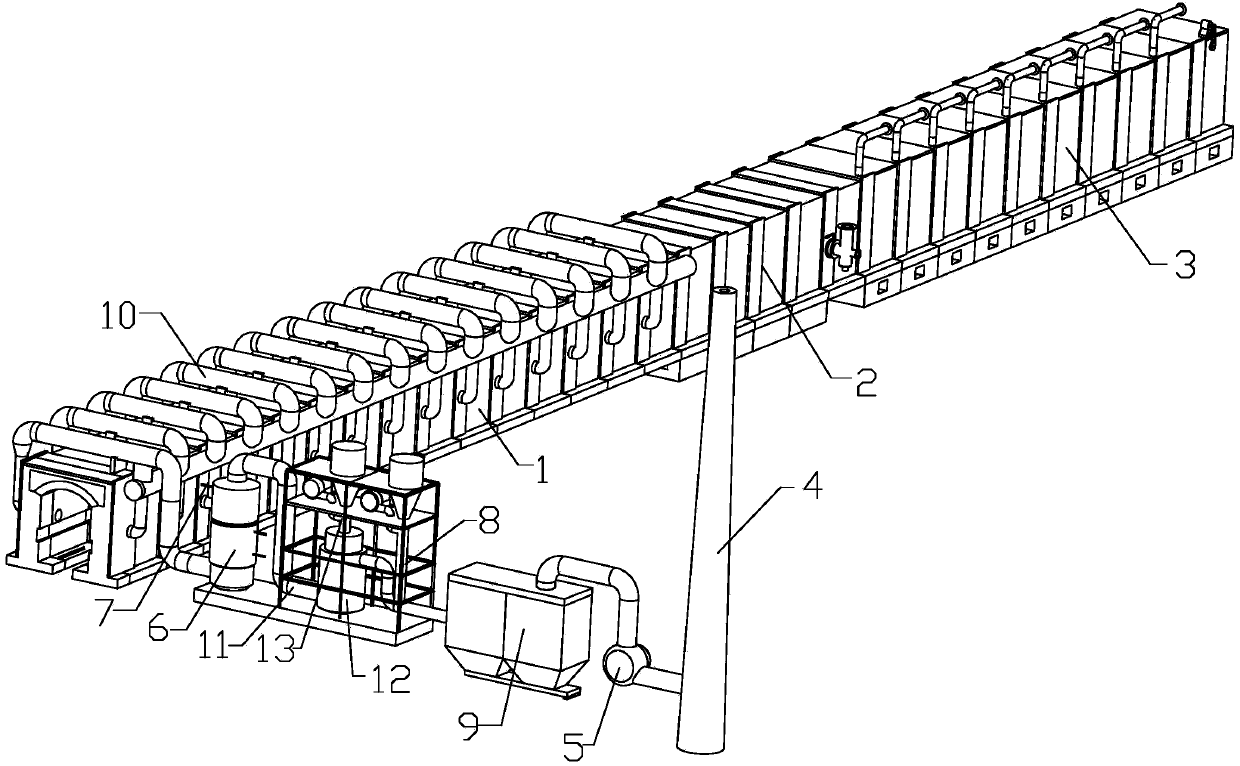

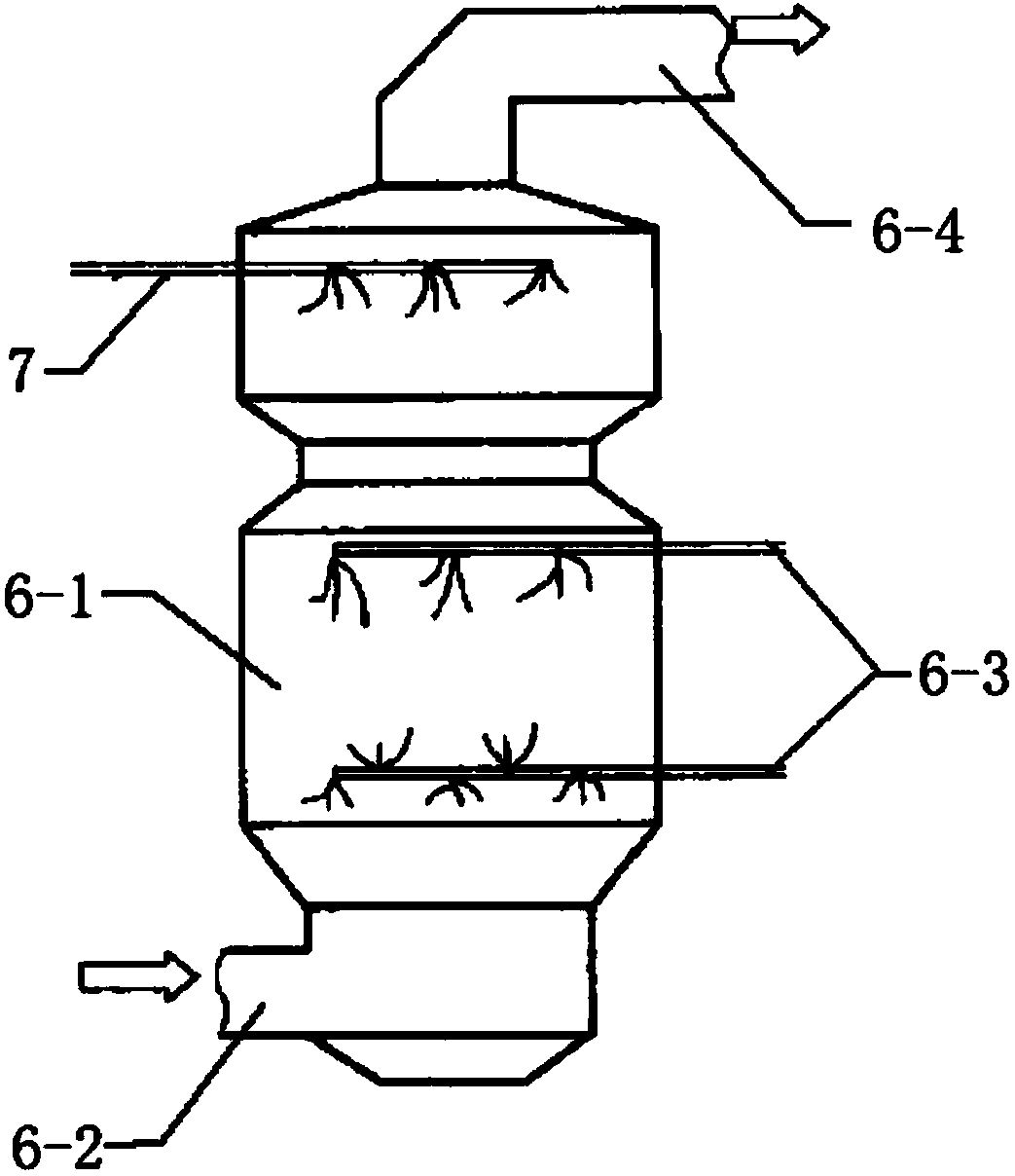

Novel tunnel kiln structure and method for tunnel kiln to process organic polluted soil

ActiveCN104197702ASpeed up temperature riseImprove smoke exhaust effectFurnace typesCeramic materials productionTunnel kilnBrick

The invention provides a novel tunnel kiln structure and a method for processing organic polluted soil. The method comprises the steps of detecting types and contents of mineral substances in the organic polluted soil, then adding required materials according to the tile firing requirements or the firing requirements, adding internal fuel, adding water to mix the materials to obtain raw pug materials, sequentially pugging, pelletizing, extruding and forming the raw pug materials, decaying or curing the raw pug materials for 5-10 days, drying the raw pug materials, sending the raw pug material into the tunnel kiln to be fired, sequentially keeping green bricks or green tiles in a preheating zone kiln body at the temperature of 150-750 DEG C for 30 minutes to 1 hour and in a firing zone kiln body at the temperature of 750-1350 DEG C for 2-3 hours, then sending the green bricks or the green tiles into a cooling zone kiln body to be naturally cooled to the normal temperature and outputting the green bricks or the green tiles. The method can completely remove toxic substances like various pesticide residues in the soil through high temperature and is high in processing efficiency, low in cost, free of secondary pollution and obvious in environmental-friendly benefit.

Owner:WUHAN HUIZHONG DACHUAN AUTOMATIC CONTROL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com