Patents

Literature

4021results about How to "Good acid and alkali resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent-free expansion type fire-proof epoxy coating and its preparation method

The invention discloses the inflatable fire-resisting paint, comprising A and B. The A comprises epoxide resin, modified resin, catalyst, foamable agent, fire retarding agent, fluxing agent, color filler and smog inhibiting agent, and the B comprises color filler, curing agent and auxiliary agent. The fire-resisting paint has the advantages of good heat-insulating property, adhesion force and intensity. The coating has good water resistance, acid- alkali resistance, corrosion resistance and tenacity, and is not easy to drop. The paint can be used in rolled steel and aluminum products, especially the fireproof situation of oil factories.

Owner:MARINE CHEM RES INST

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

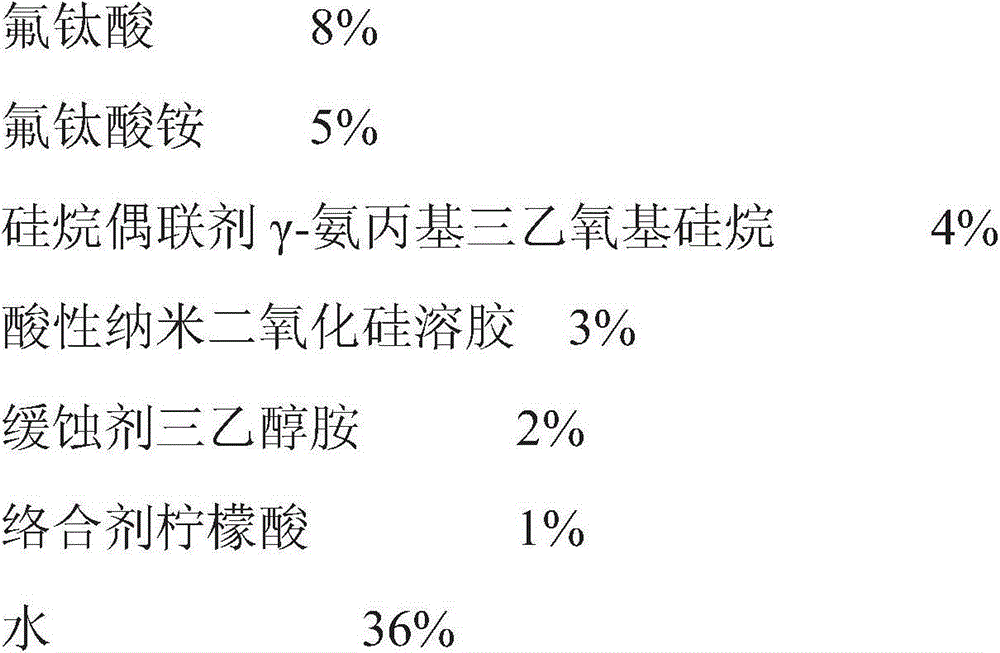

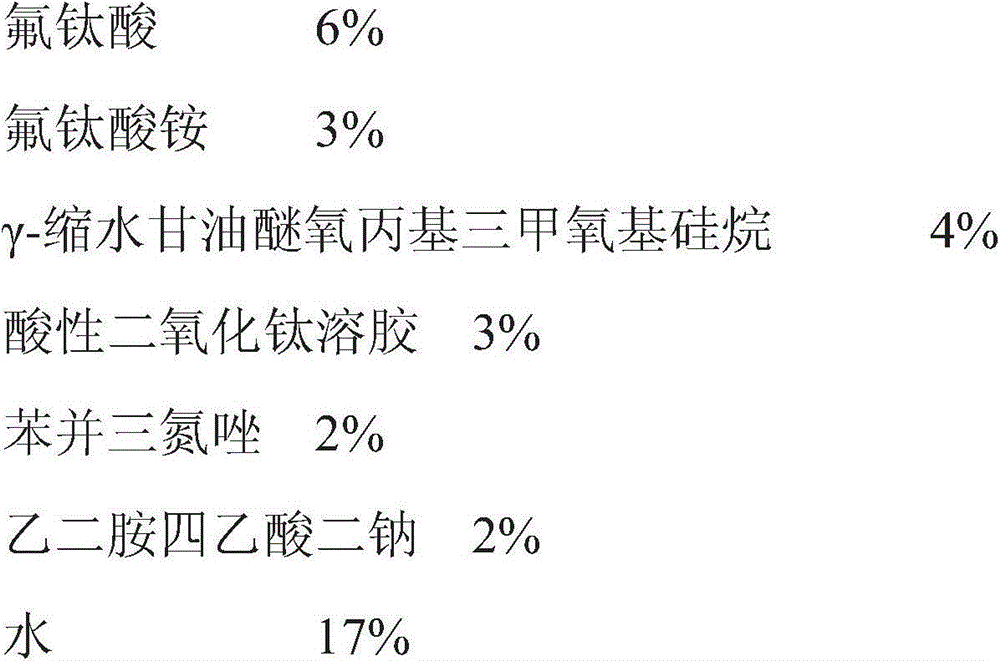

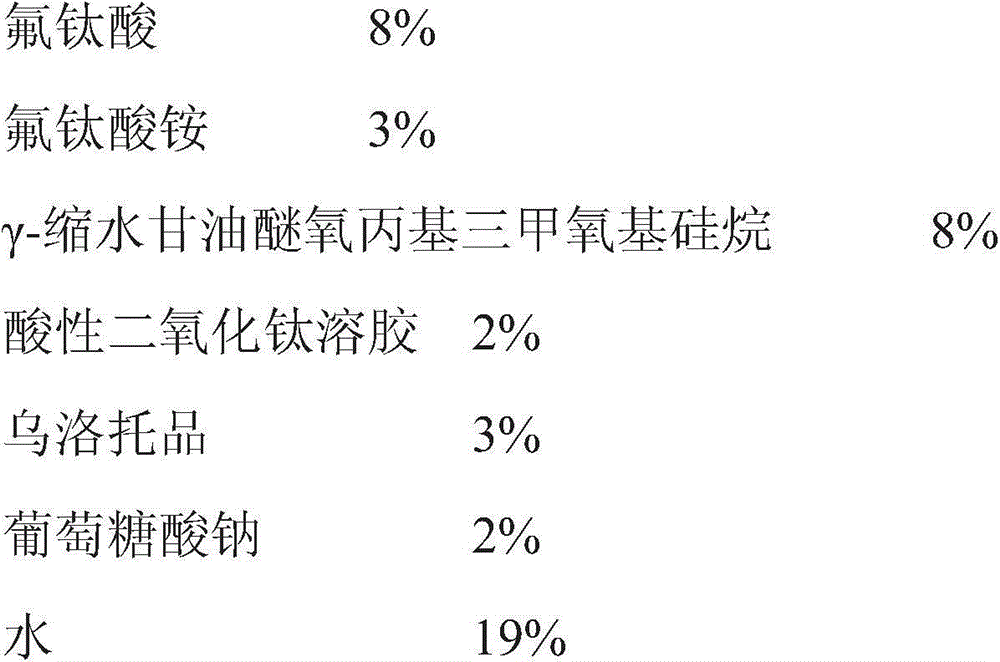

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

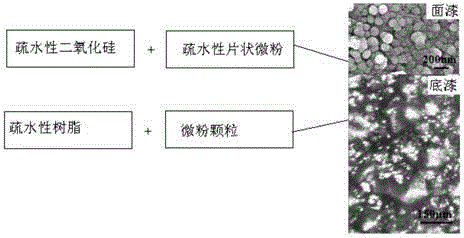

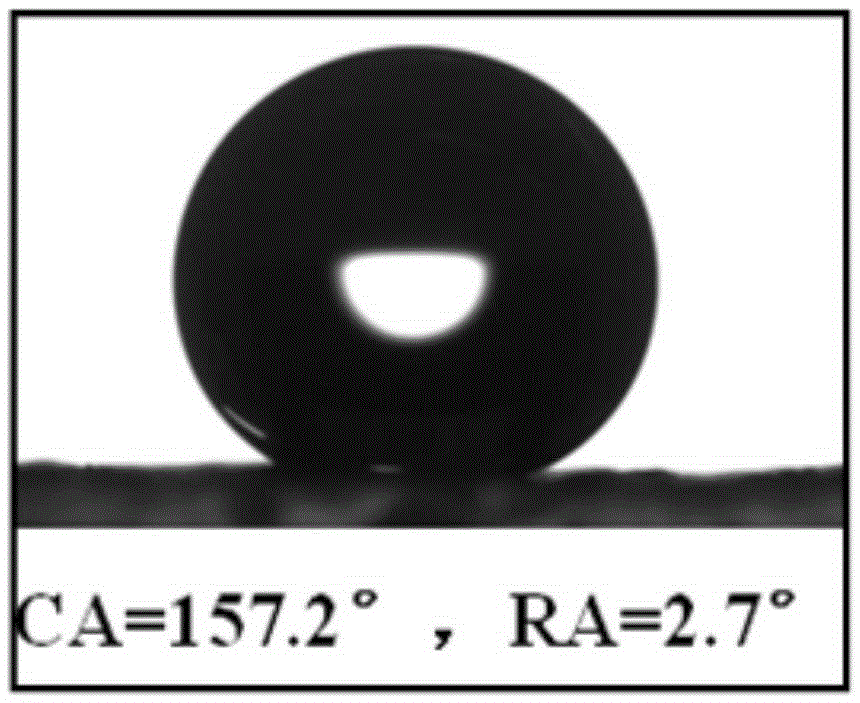

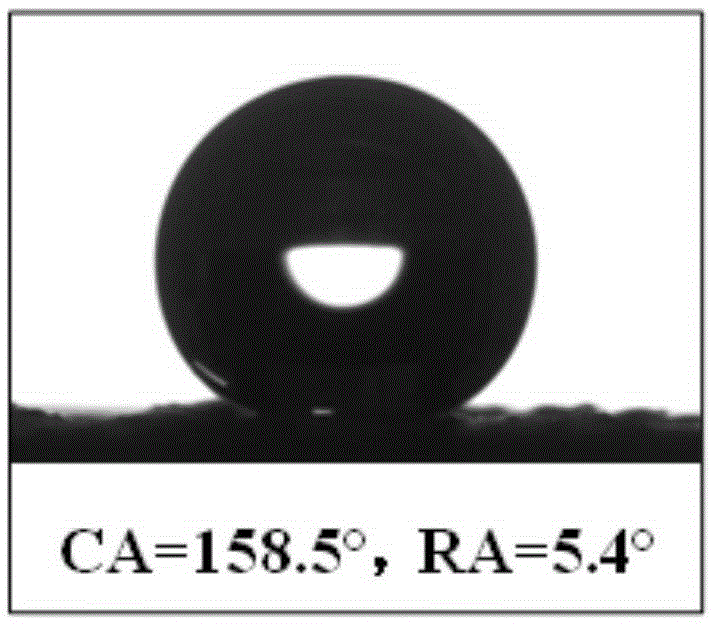

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

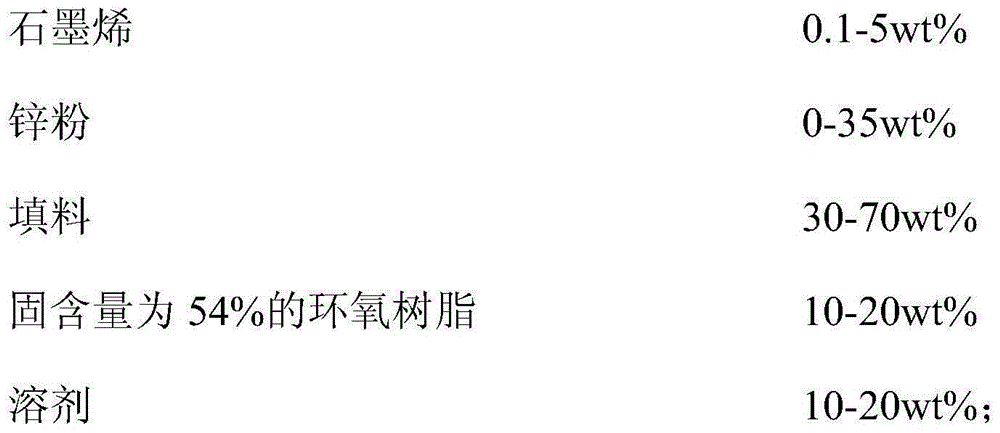

Zinc-rich epoxy anticorrosion paint and preparation method thereof

ActiveCN103173095AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene

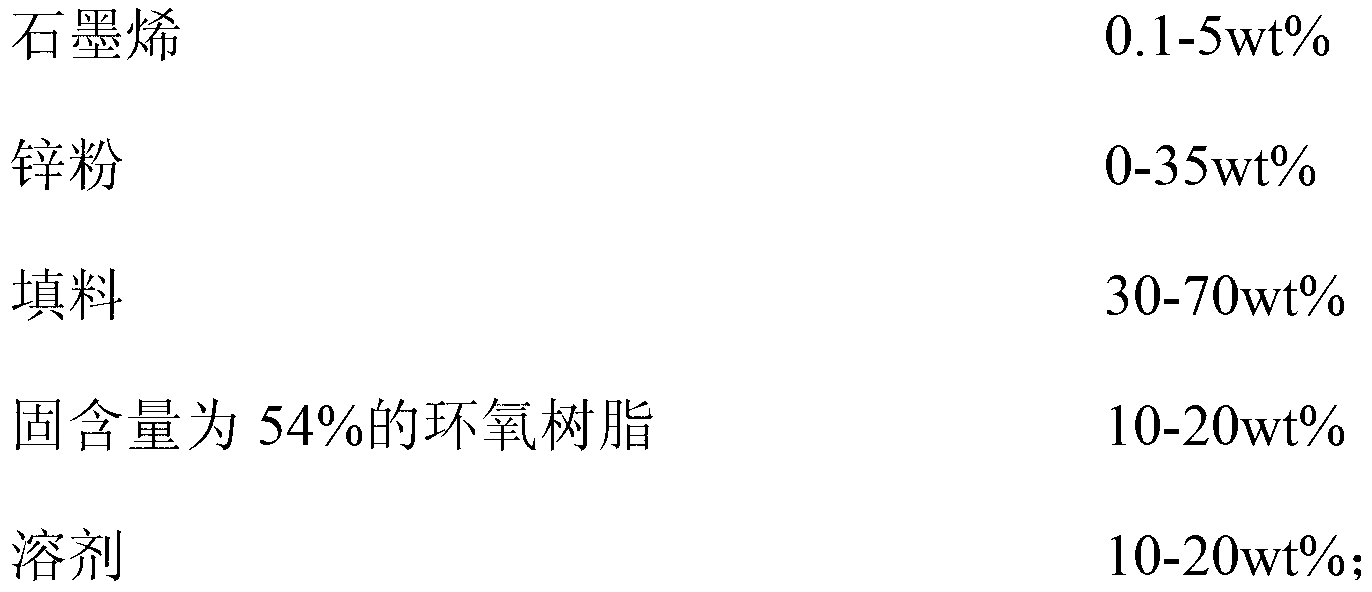

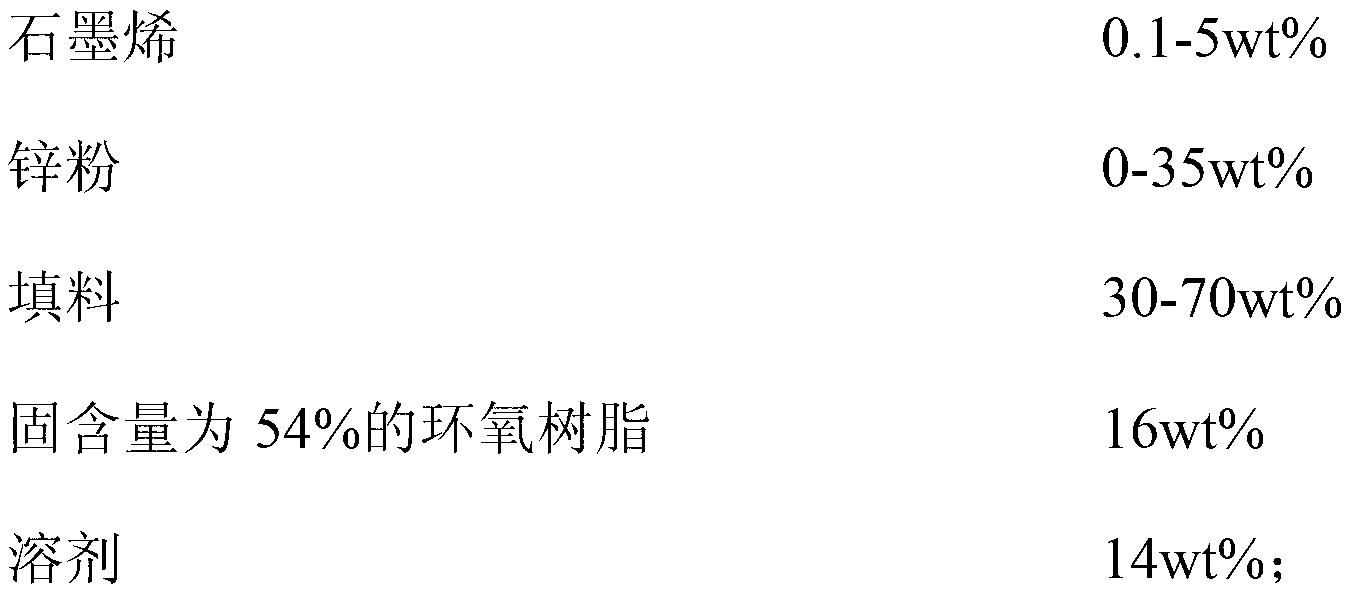

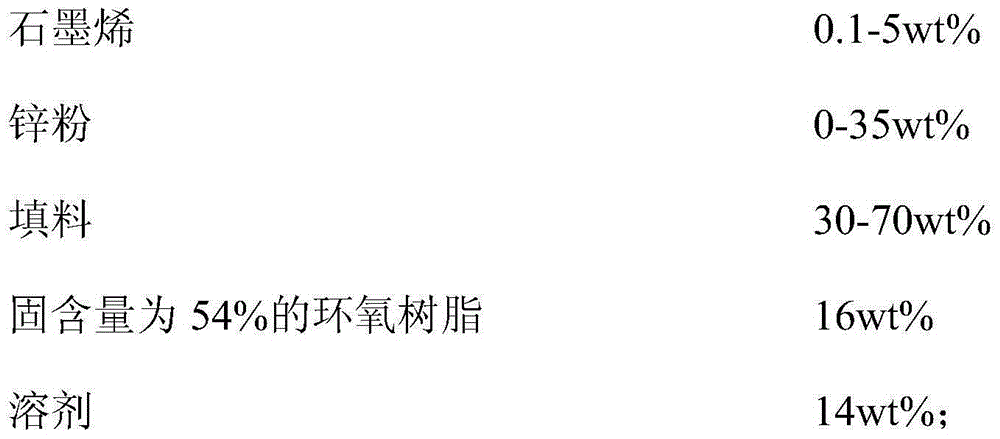

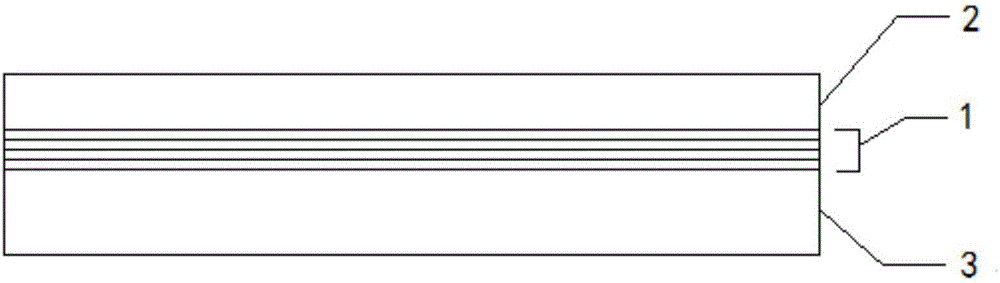

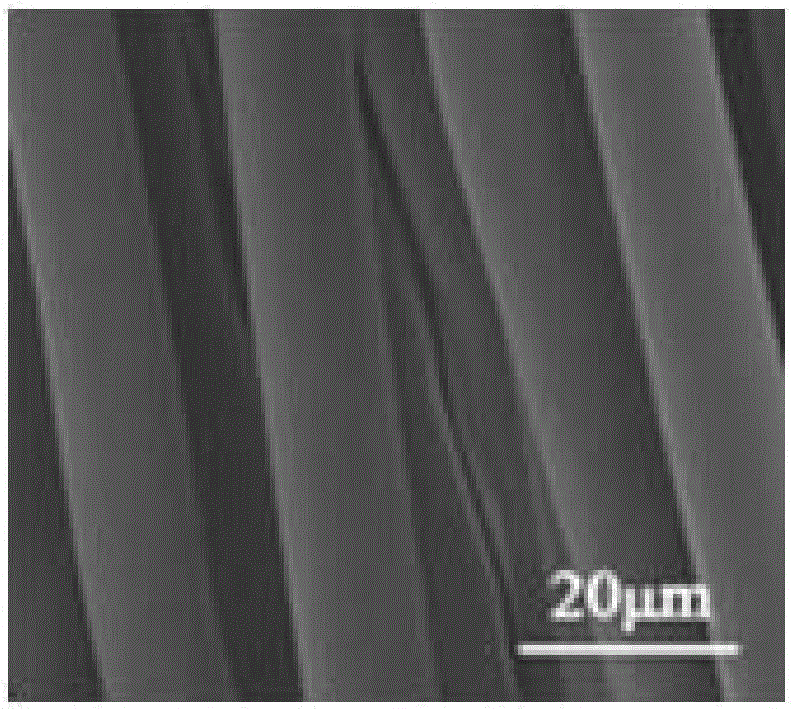

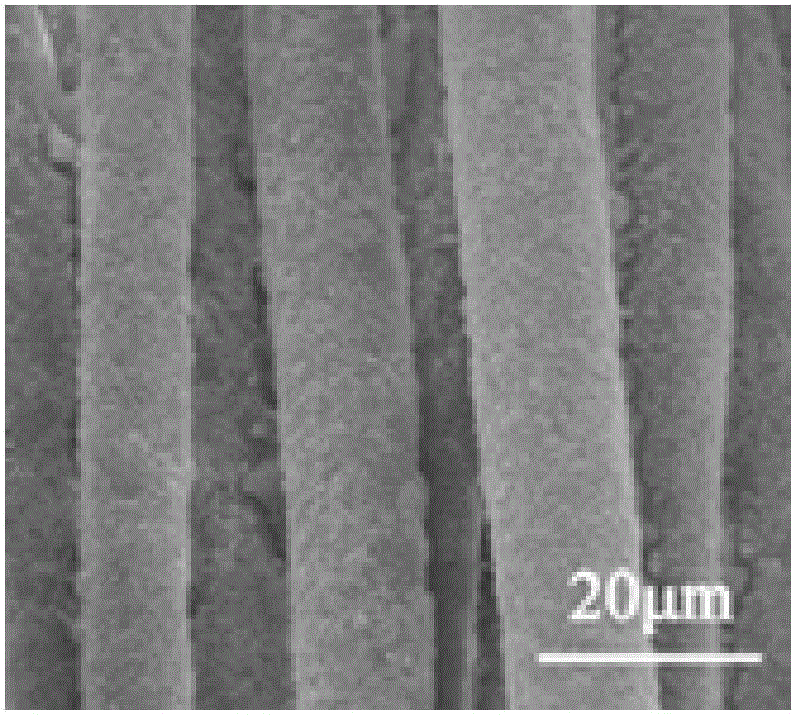

The invention relates to a zinc-rich epoxy anticorrosion paint. The paint comprises a component A which can be cured into a film and a component B comprising a curing agent. The component A comprises the components of, by mass, 0.1-5wt% of graphene, 0-35wt% of zinc powder, 30-70wt% of a filling material, 10-20wt% of epoxy resin with a solid content of 54%, and 10-20wt% of a solvent, wherein a total mass percentage of graphene, zinc powder, and the filling material is 60-80wt%, and a total mass content of the component A is 100wt%. According to the invention, graphene is added into the anticorrosion paint, such that paint film thickness is greatly reduced. Through the selection of the components, the anticorrosion effect is improved, and zinc powder content is greatly reduced. Therefore, a zinc-rich paint anticorrosion manner with the cost of sacrifice of zinc powder is overcome, and zinc oxide mist produced during welding is greatly reduced. The paint is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

High degree of substitution quaternary ammonium cationic starch flocculating agent and method for synthesizing same

InactiveCN1990392AReduce operating linksReduce manufacturing costWater/sewage treatment by flocculation/precipitationCorn starchChemistry

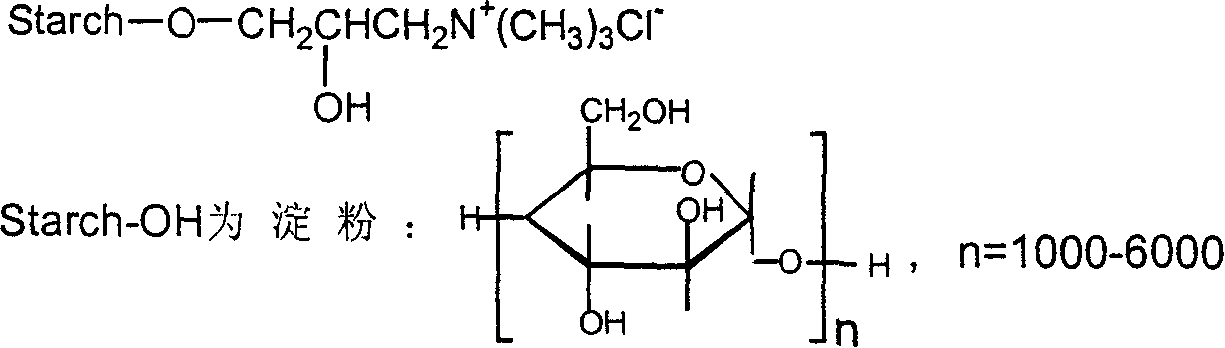

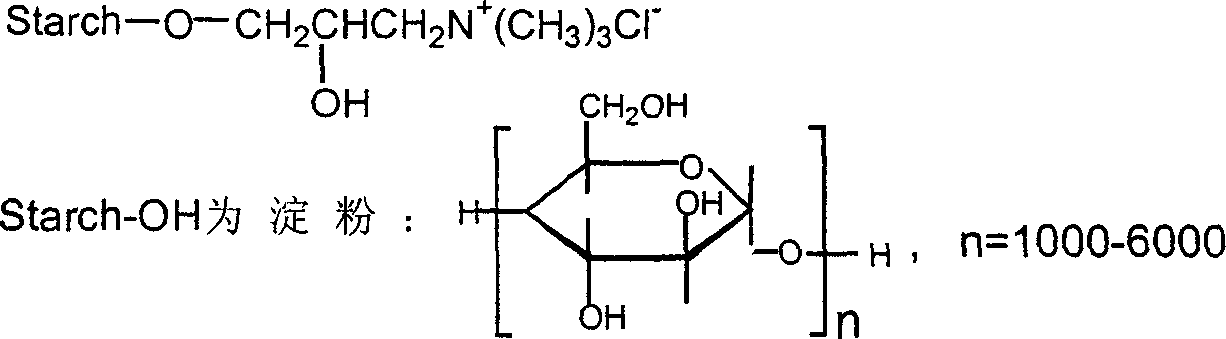

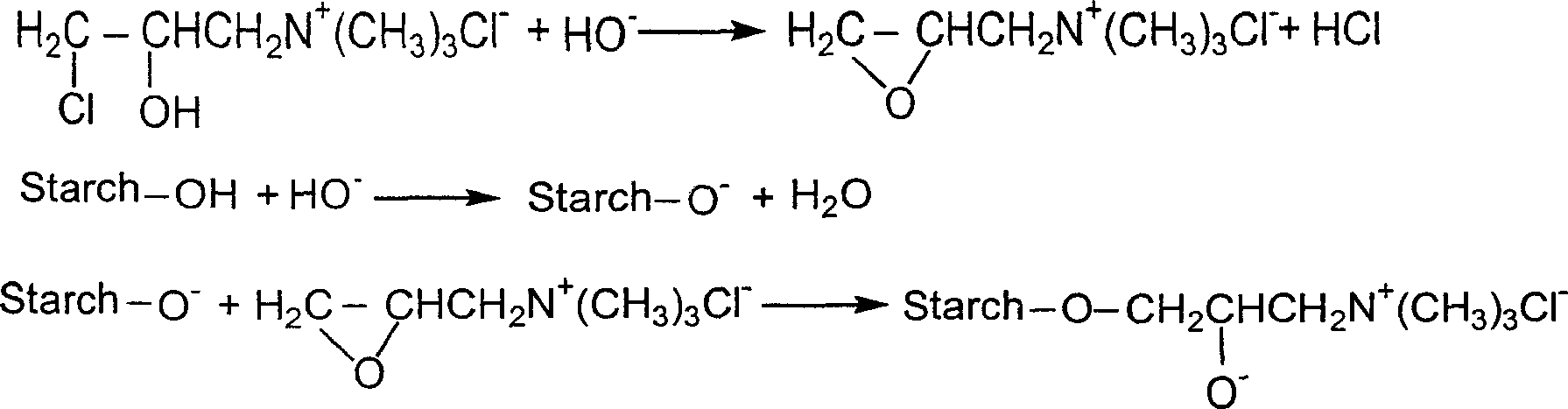

The invention relates to a green flocculant- ammonium type cation starch flocculant with high replace degree. Said flocculant employs one of corn starch, wheat starch, tapioca starch, potato starch or any of mixture of them as raw material, takes 3-Chloro-2-hydroxypropyl-trimethylammonium Chloride, or epoxypropyl trimethyl ammonium chloride as cationic etherifying agent, and employs dry method to synthesize said flocculant by using sodium hydroxide and co-catalyst as complex catalyst system. The invention combines the advantage of dry method and semi-dry method, overcomes problem of agglomeration of starch during solution ejection, and solves problems of pasting and agglomeration of starch during reaction process when together with base. The invention is characterized by non post treatment, non three waste, simple processes, short reaction period, mild reaction condition, high efficiency and low cost. The flocculant is characterized when compared with normal ones by less consumption, fast settling speed, high transparency, and wide use for wastewater treatment and sludge waterless in industries such as paper making, dyeing, leathering making and petrochemical industry.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Permanent resist composition, cured product thereof, and use thereof

InactiveUS20050260522A1High densityImprove film adhesionNanoinformaticsPhotomechanical apparatusPolymer sciencePhotoacid generator

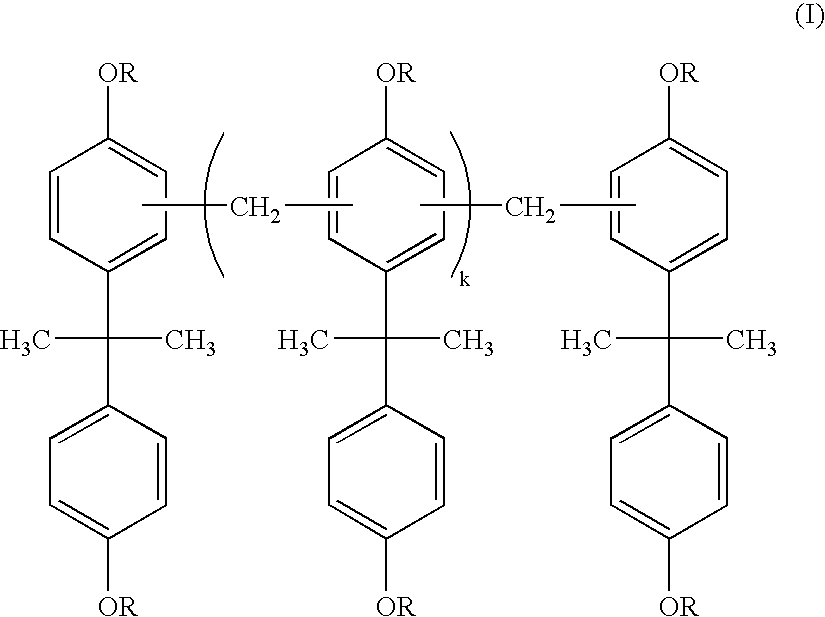

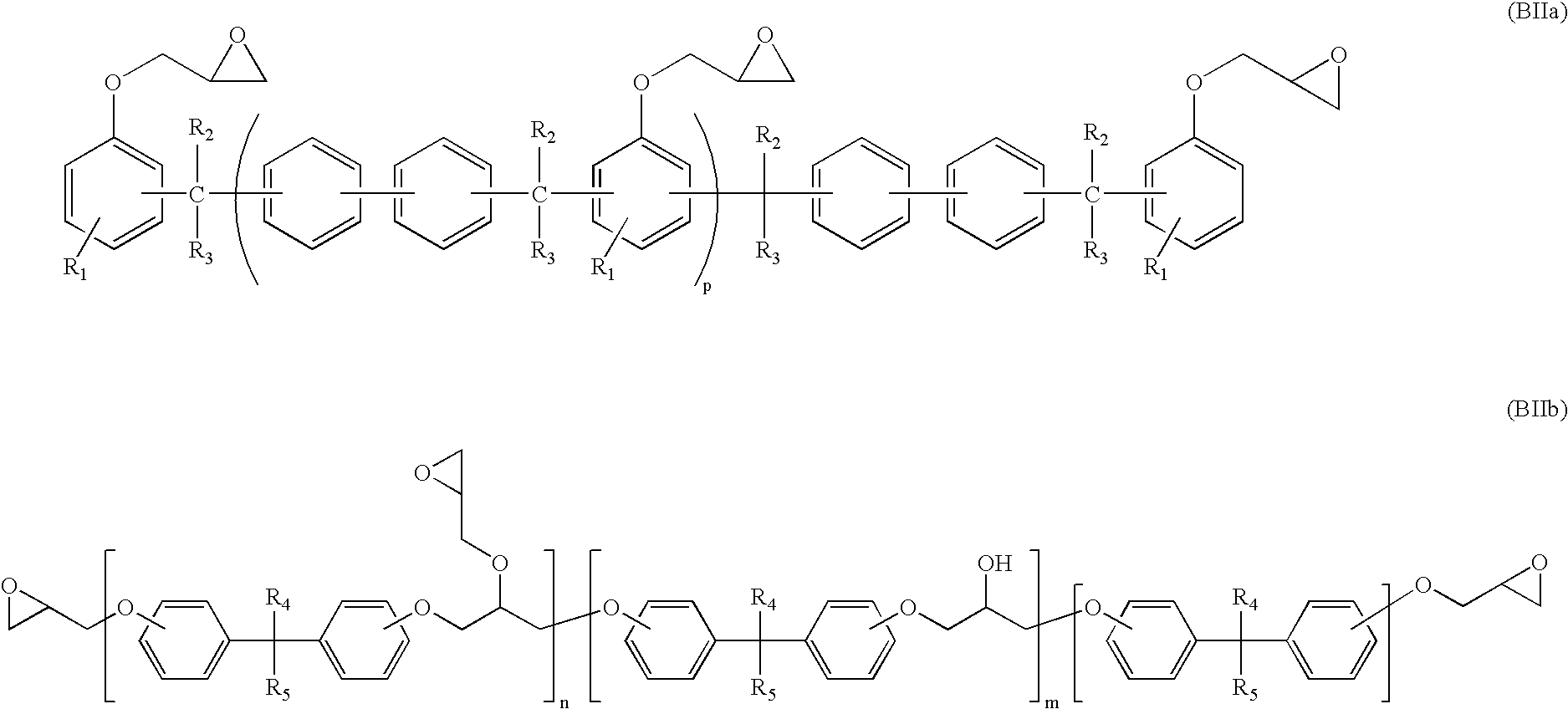

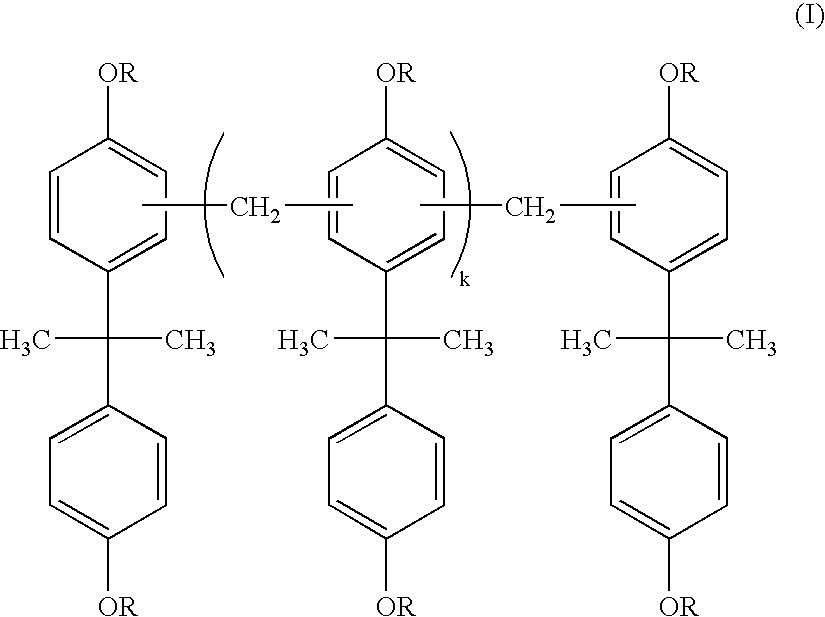

A permanent photoresist composition comprising: (A) one or more bisphenol A-novolac epoxy resins according to Formula I; wherein each group R in Formula I is individually selected from glycidyl or hydrogen and k in Formula I is a real number ranging from 0 to about 30; (B) one or more epoxy resins selected from the group represented by Formulas BIIa and BIIb; wherein each R1, R2 and R3 in Formula BIIa are independently selected from the group consisting of hydrogen or alkyl groups having 1 to 4 carbon atoms and the value of p in Formula BIIa is a real number ranging from 1 to 30; the values of n and m in Formula BIIb are independently real numbers ranging from 1 to 30 and each R4 and R5 in Formula BIIb are independently selected from hydrogen, alkyl groups having 1 to 4 carbon atoms, or trifluoromethyl; (C) one or more cationic photoinitiators (also known as photoacid generators or PAGs); and (D) one or more solvents.

Owner:MICROCHEM CORP +1

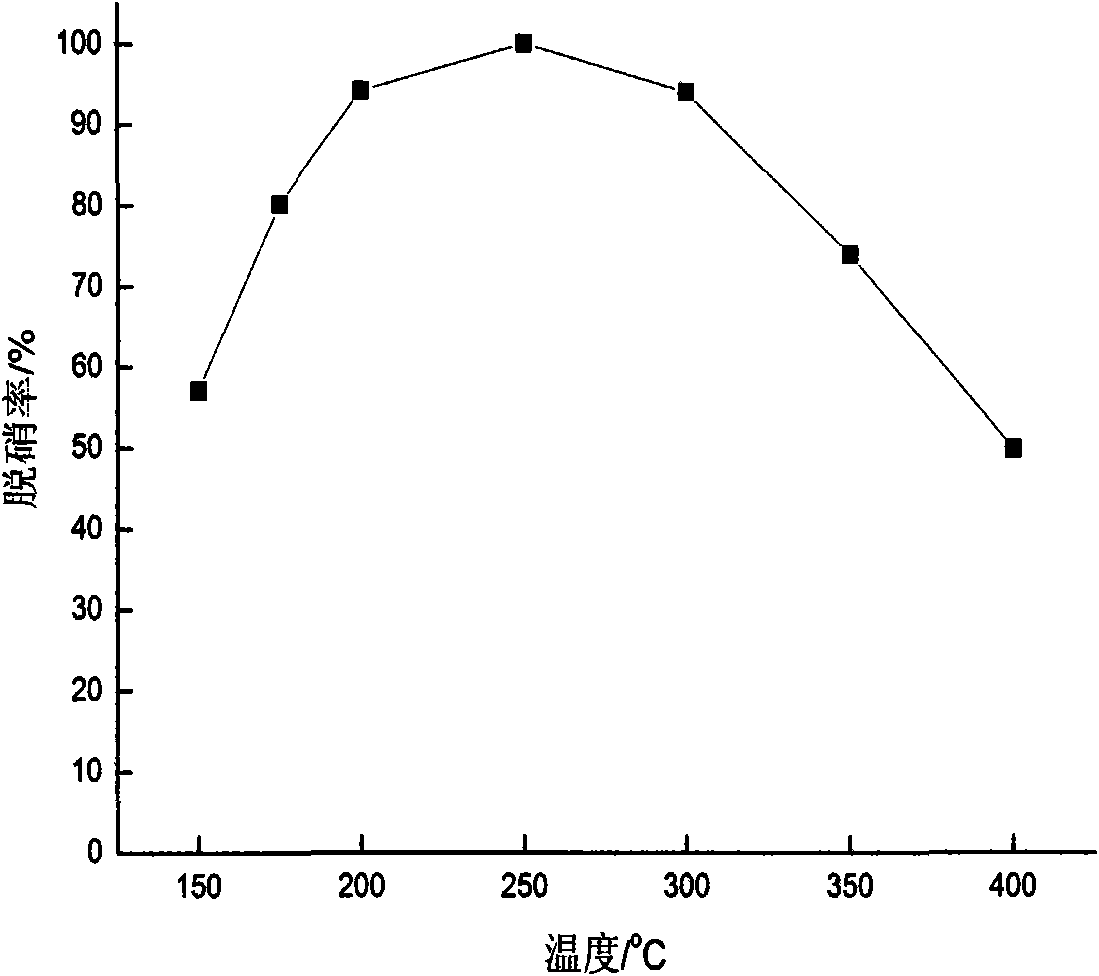

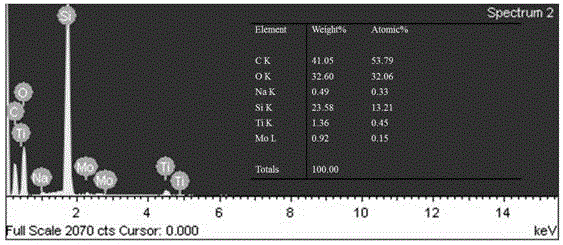

Low-temperature selective catalytic reduction denitration catalyst and preparation method thereof

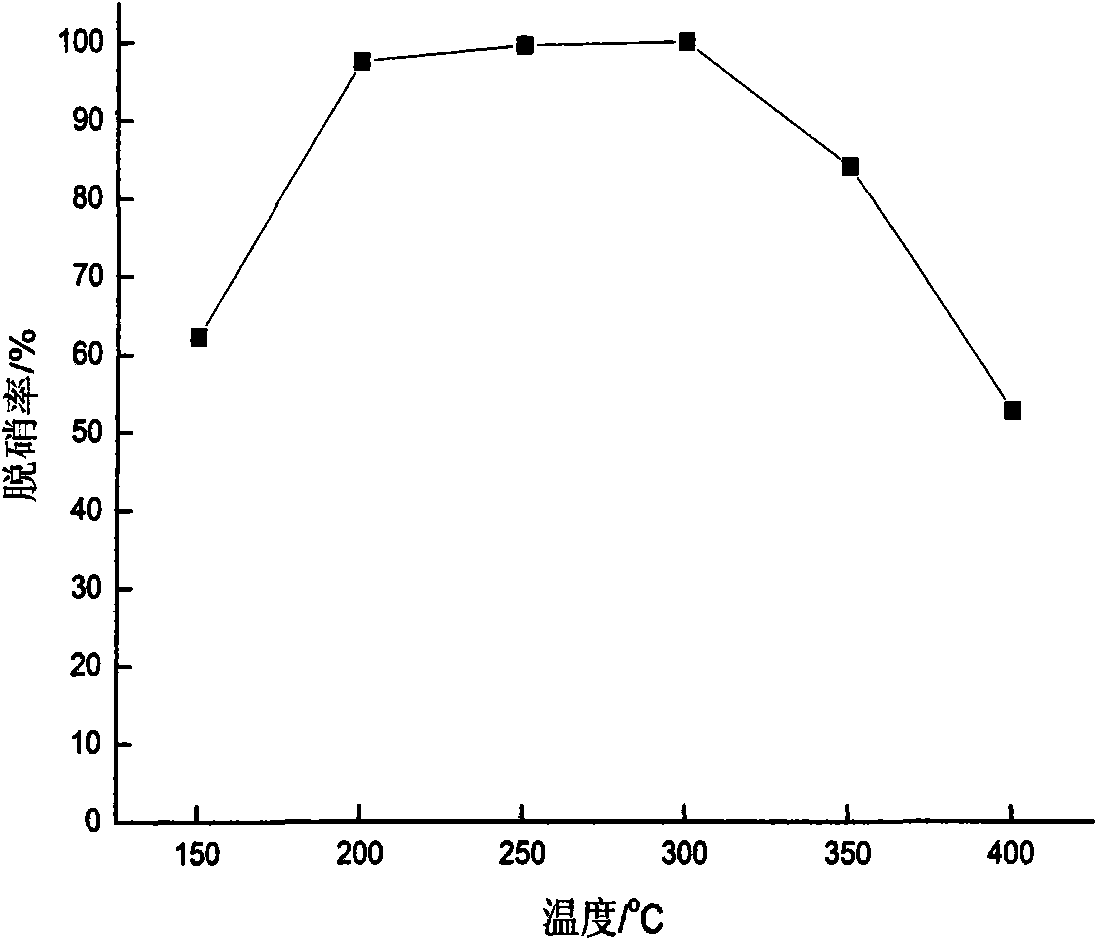

ActiveCN101658787ALow costWide variety of sourcesDispersed particle separationCatalyst activation/preparationManganese oxideHigh activity

The invention discloses a low-temperature selective catalytic reduction denitration catalyst and a preparation method thereof, wherein the catalyst takes an attapulgite as a carrier to load nano-composite materials of manganese oxide nano-particles; the structure thereof is as follows: manganese oxide particles with the particle diameter of less than 20nm are loaded on the rod-shaped crystal surface of the attapulgite with the diameter of 40-50nm; one or more types from iron, copper and nickel are added as an additive; and calculated according to the mass percentage of manganese, the content of the manganese oxide in the catalyst is 0.1-20. The preparation method comprises the steps of: firstly extruding, drying and crushing the attapulgite clay, and then preparing attapulgite clay powderinto suspension liquid; adding acid solution to wash and remove carbonate impurities, adding manganese salt, and then adding alkali solution for stirring so as to lead the manganese ion to be hydrolyzed and precipitated and loaded onto the crystal surface of the attapulgite, and finally obtaining the product after centrifugal washing, dewatering, drying and calcinations. The catalyst takes ammoniaas a reducing agent, and has higher activity of catalyzing NH3 and reducing NO reaction within the scope of 120 DEG C to 350 DEG C.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

Electromagnetic shielding conductive coating and preparation method thereof

InactiveCN102618145AReduce dosageImprove shielding effectEpoxy resin coatingsElectrically-conductive paintsConductive coatingElectromagnetic shielding

The invention provides an electromagnetic shielding conductive coating and a preparation method thereof. The electromagnetic shielding conductive coating comprises film-forming substances, conductive powder, thickening agents, coupling agents and curing agents. The mass ratio of the film-forming substances to the conductive powder to the thickening agents to the coupling agents to the curing agents is 5-20:50-75:5-30:0.7-4:6.5-15. Auxiliaries are added into the film-forming substances and stirred to be completely dissolved, the thickening agents are added into mixture, the coupling agents are then added into the mixture, the conductive powder is added into the mixture after stirring, and the curing agents are added into the mixture, so that the electromagnetic shielding conductive coating is obtained. By means of composition and proportioning for the conductive coating, the prepared coating is excellent in electric conductivity and resistant to acid, alkaline and oxidization. Besides, the resistivity of the conductive coating prepared by the preparation method is continuously reduced, and conductive high molecular polymer for the conductive powder in the conductive coating is well compatible with organic resin, so that air bubbles and needle holes in the coating can be decreased.

Owner:KUNMING UNIV OF SCI & TECH

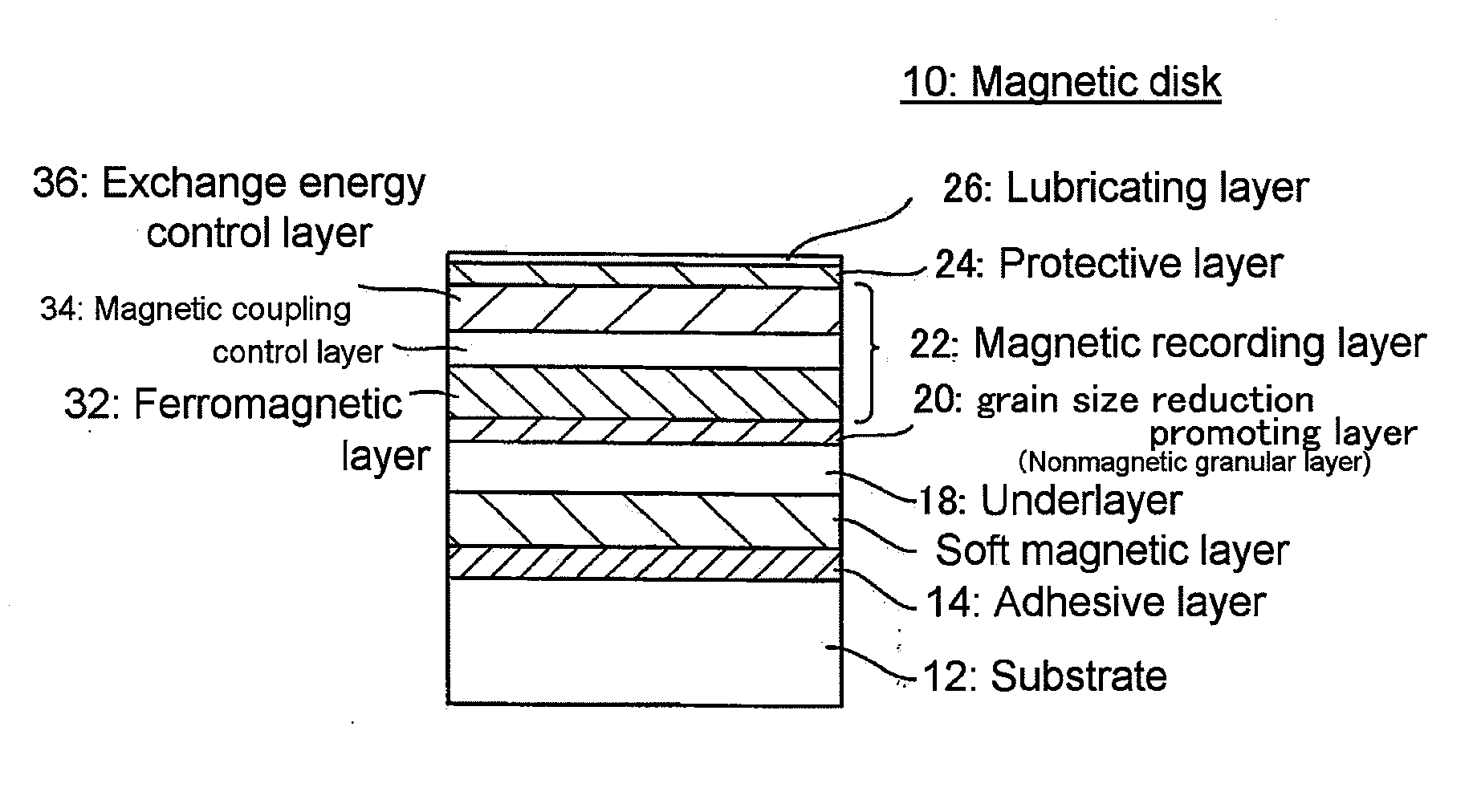

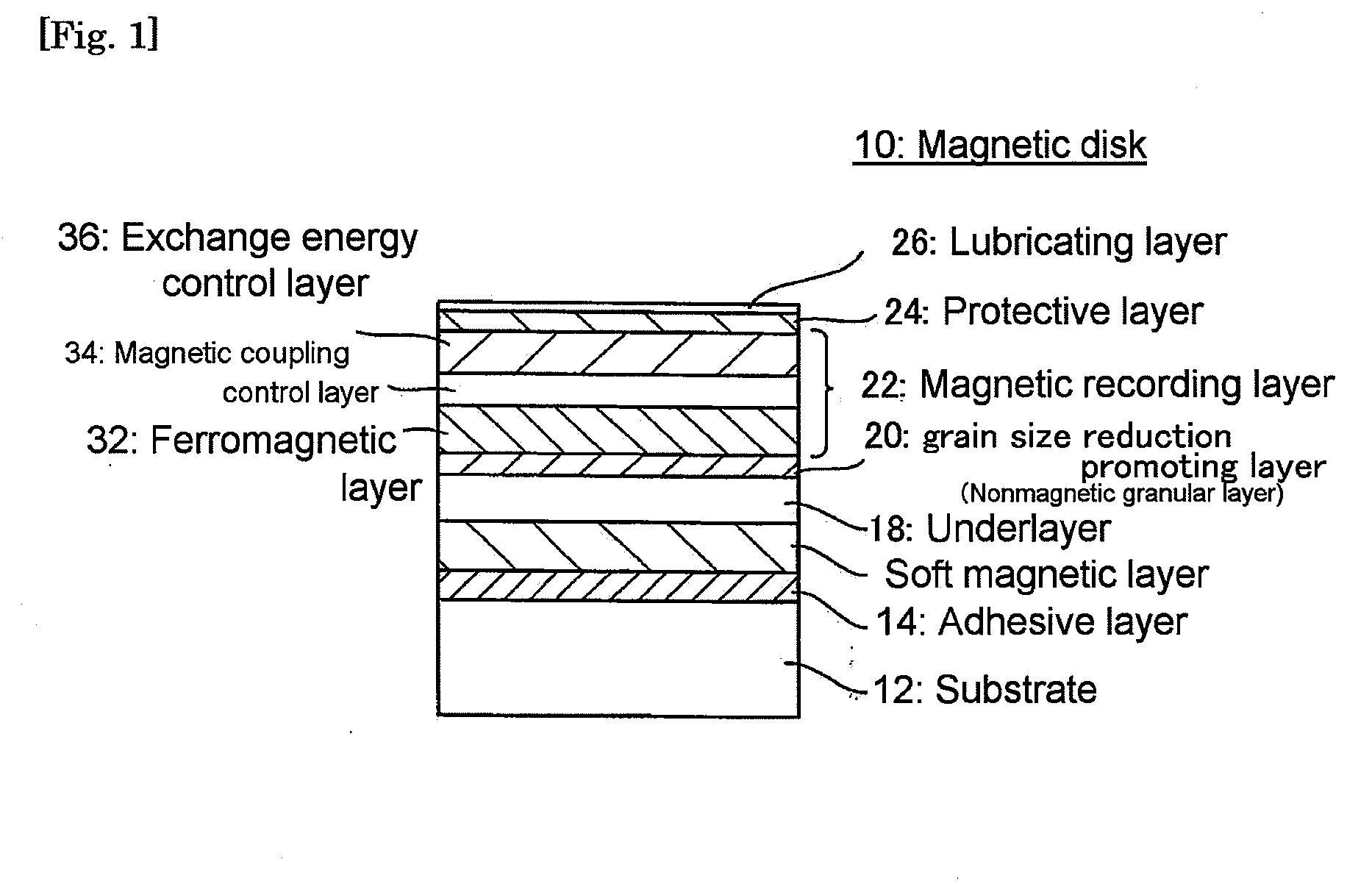

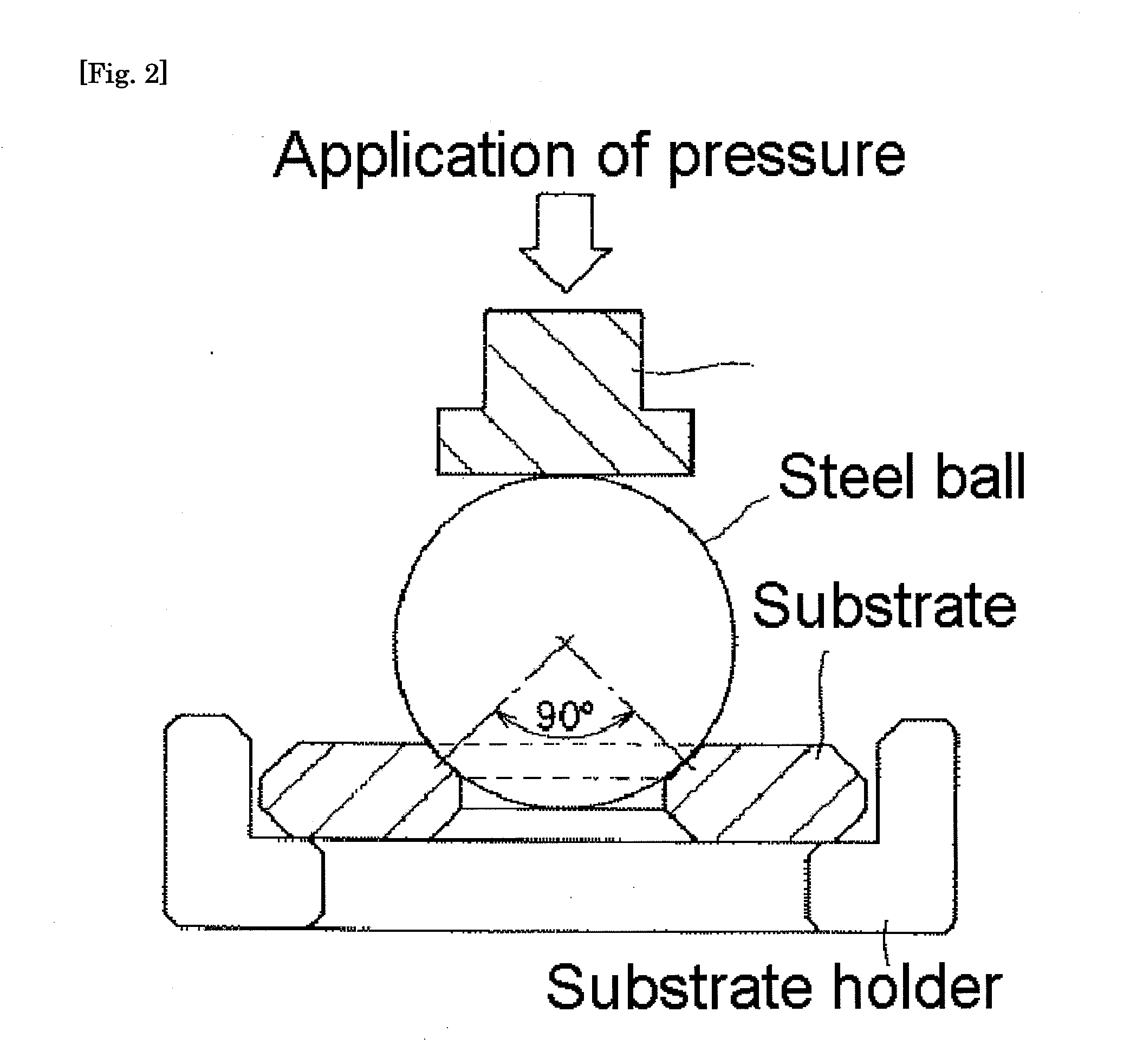

Glass for use in substrate for information recording medium, substrate for information recording medium and information recording medium, and their manufacturing method

ActiveUS20100167091A1Good resistance to acidityIncrease alkalinityMagnetic materials for record carriersBase layers for recording layersMetallurgyPhysical chemistry

According to one aspect of the present invention, provided is glass for use in substrate for information recording medium, which comprises, denoted as molar percentages, a total of 70 to 85 percent of SiO2 and Al2O3, where SiO2 content is equal to or greater than 50 percent and Al2O3 content is equal to or greater than 3 percent; a total of equal to or greater than 10 percent of Li2O, Na2O and K2O; a total of 1 to 6 percent of CaO and MgO, where CaO content is greater than MgO content; a total of greater than 0 percent but equal to or lower than 4 percent of ZrO2, HfO2, Nb2O5, Ta2O5, La2O3, Y2O3 and TiO2; with the molar ratio of the total content of Li2O, Na2O and K2O to the total content of SiO2, Al2O3, ZrO2, HfO2, Nb2O5, Ta2O5, La2O3, Y2O3 and TiO2 ((Li2O+Na2O+K2O) / (SiO2+Al2O3+ZrO2+HfO2+Nb2O5+Ta2O5+La2O3+Y2O3+TiO2)) being equal to or less than 0.28. Further provided are the substrate for information recording medium, information recording medium and their manufacturing methods according to the present invention.

Owner:HOYA CORP

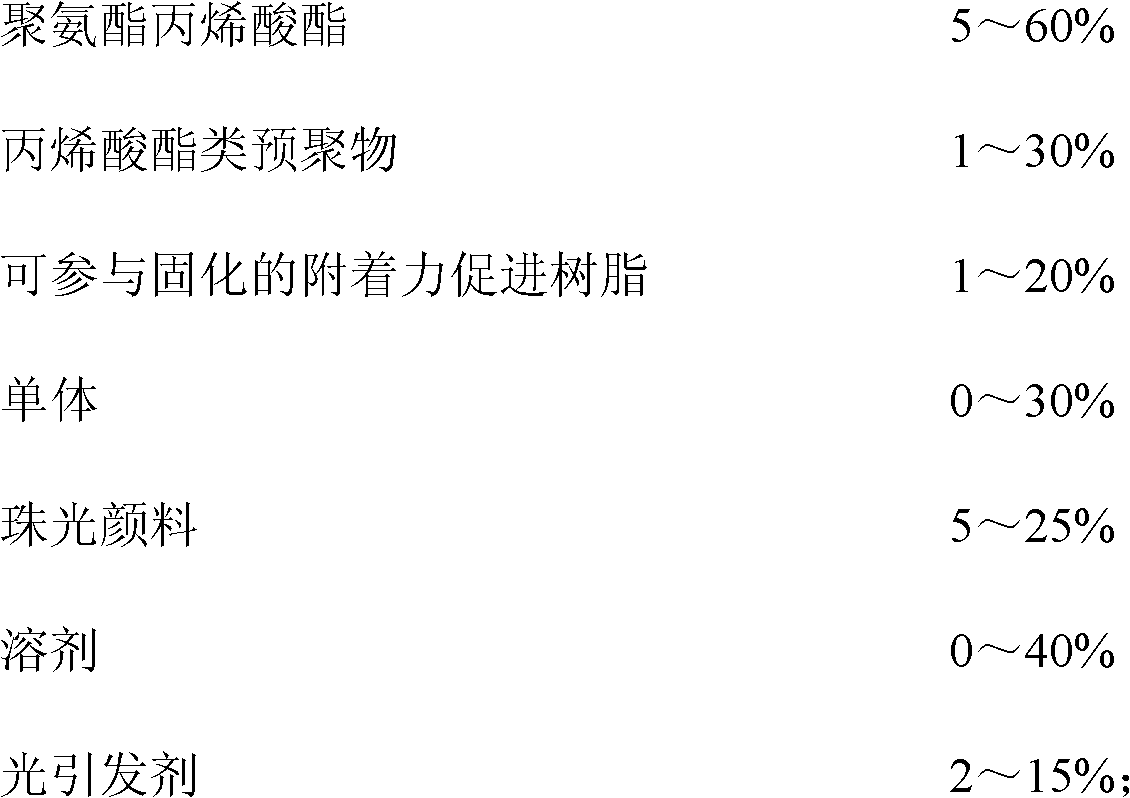

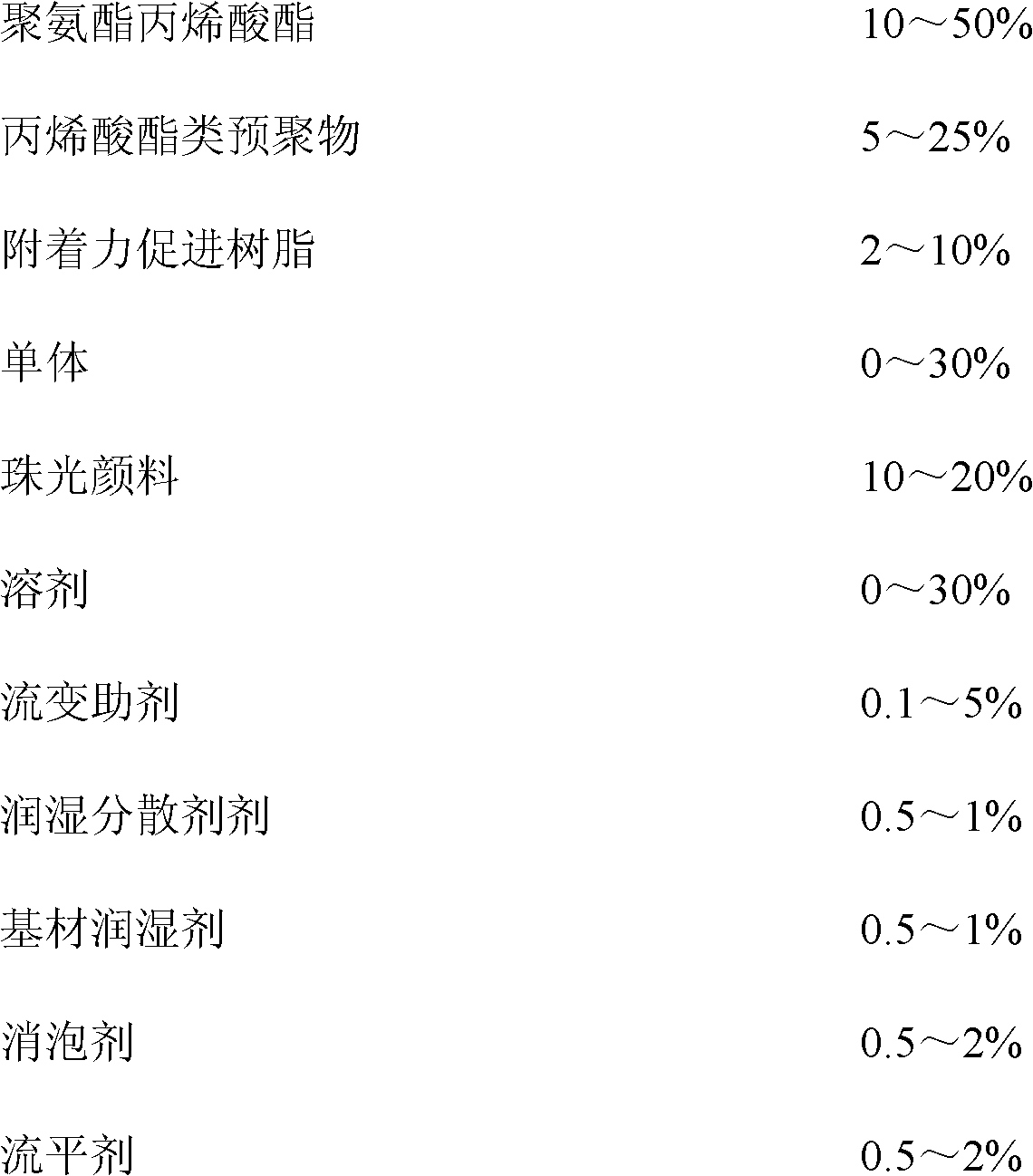

Photo-curing silk screen pearly-luster ink applicable to different printing substrates and preparation method thereof

ActiveCN102634251AGood flexibility and abrasion and scratch resistanceGood acid and alkali resistanceInksSolventPrepolymer

The invention provides a photo-curing silk screen pearly-luster ink applicable to different printing substrates and a preparation method of the photo-curing silk screen pearly-luster ink. The ink is prepared from the following components in percentage by weight: 5-60% of polyurethane acrylate, 1-30% of acrylates pre-polymer, 1-20% of adhesive force accelerating resin capable of participating curing, 0-30% of monomer, 5-25% of pearly-luster pigment, 0-40% of a solvent and 2-15% of a light initiator. The photo-curing silk screen pearly-luster ink applicable to the different printing substrate disclosed by the invention can be suitable for the different printing substrates at the same time and comprises plastic substrates including paper, PET (Poly Ethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), PP (Propene Polymer), PE (Poly Ethylene) and the like, and metal substrates; an adhesive force between the photo-curing silk screen pearly-luster ink and the printed materials is good and the photo-curing silk screen pearly-luster ink has good flexibility and wear-resisting and scrape-resisting strength; the acid-resisting and alkali-resisting performance is excellent and the performance for resisting each type of solvent is good, so that the requirements on silk-screen printing can be met.

Owner:CHINA BANKNOTE INK +1

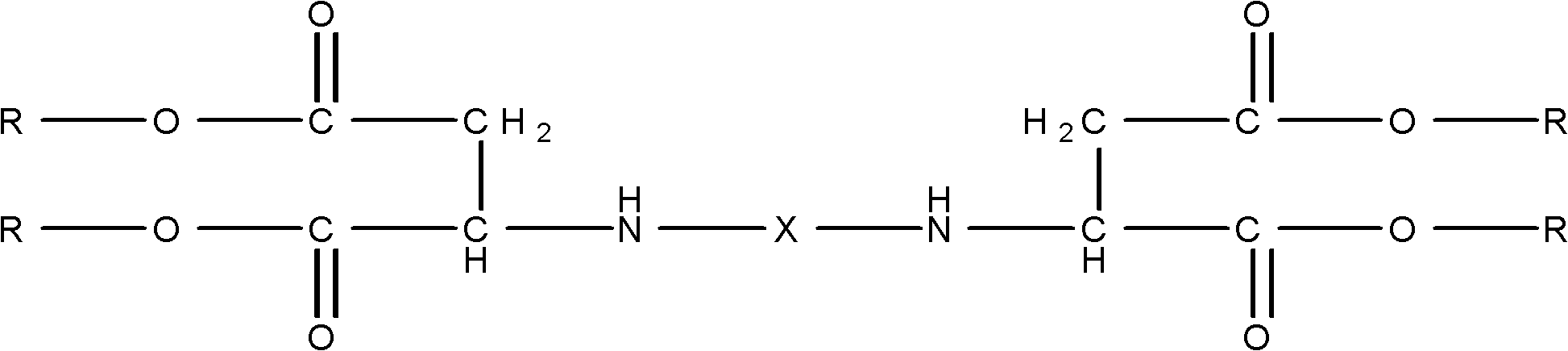

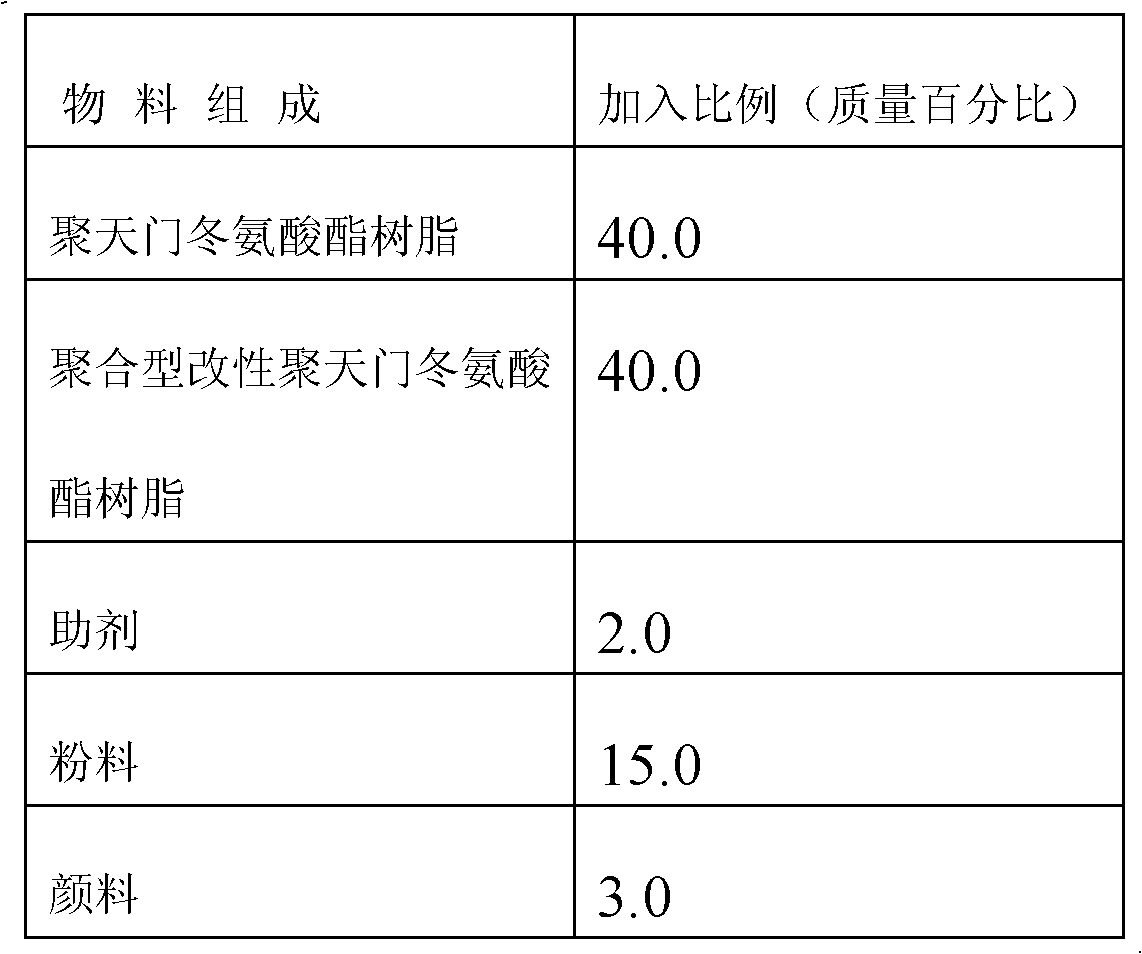

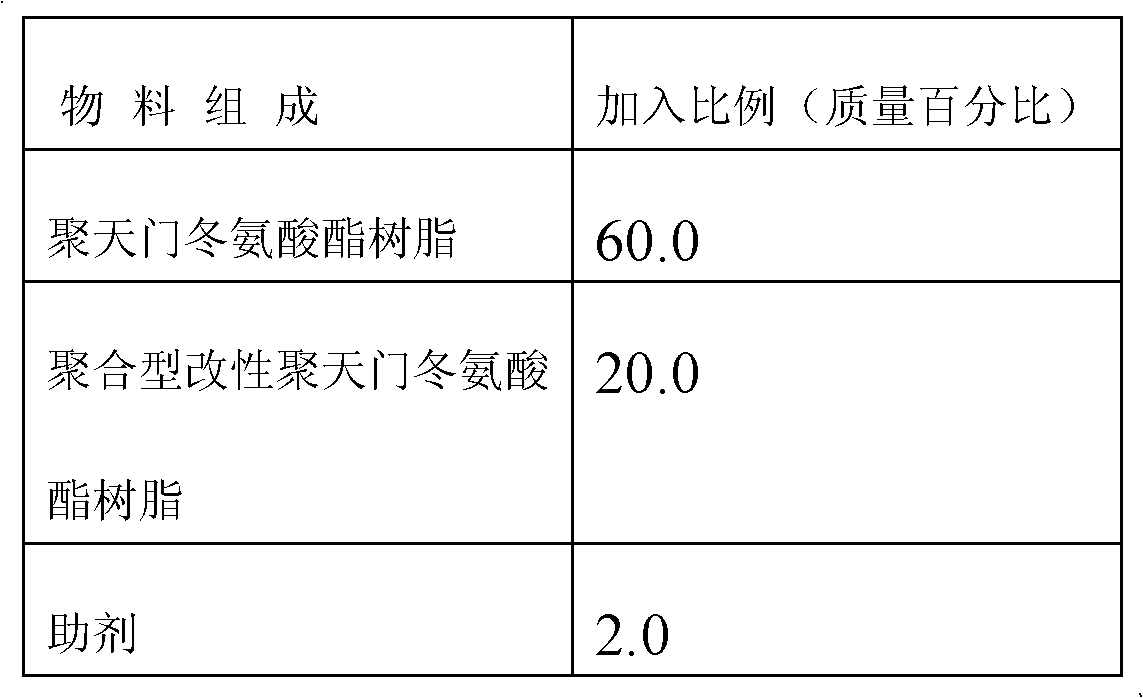

Solvent-free polyaspartic acid ester polyurea elastic waterproof paint

ActiveCN103031045AGood elongation at breakEasy constructionPolyurea/polyurethane coatingsSolventIsocyanate

The invention relates to paint and a preparation method thereof and discloses solvent-free polyaspartic acid ester polyurea elastic waterproof paint. The solvent-free polyaspartic acid ester polyurea elastic waterproof paint is composed of a component A and a component, wherein the component A comprises 2%-35% of polyisocyanate and 65%-98% of end seal isocyanate prepolymer by weight percent; and the component B comprises 20%-60% of polyaspartic acid ester, 10%-40% of polymeric modified poly aspartic acid ester, 5%-30% of stuffing and a small amount of additives by weight percent. Compared with the polyurea paint processed by the polyaspartic acid ester, the solvent-free polyaspartic acid ester polyurea elastic waterproof paint processed by raw materials has the advantages that the construction is convenient, a special large-scale spraying device is not needed, the gelation time is prolonged, the surface drying time is shortened, the tensile strength is enhanced, the elongation at break is increased, and the elastic coating film hardness is increased, does not have a solvent, is environment-friendly and harmless to a human body.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Colored aluminum pigment with high color depth and preparation method thereof

InactiveCN101445675AGood acid and alkali resistanceColorfulInorganic pigment treatmentMetallic aluminumKetone solvents

The invention relates to a colored aluminum pigment with high color depth and a preparation method thereof. The colored aluminum pigment is obtained by depositing a layer of silicon dioxide on a flaky metallic aluminum sheet substrate and then depositing one or more layers of metal oxide on the surface of the silicon dioxide, and the colored aluminum pigment exists in the form of dry powder. The preparation method comprises the following steps: a. stirring to disperse commercially available aluminum pigment slurry in alcohol, alcohol ether or a ketone solvent; b. regulating the temperature to 30-80 DEG C, respectively adding tetraethoxysilane and aqueous solution to the dispersed aluminum pigment slurry with the mol ratio of the tetraethylorthosilicate to the water ranging from 1:0.5 to 1:20, adding a catalyst such as ethylenediamine solution or aqueous ammonia, and obtaining aqueous aluminum pigment slurry by vacuum filtration and washing after the reaction; and c. cladding the aqueous aluminum pigment slurry obtained in the step b with the hydrated metal oxide on the powdered aluminum surface in a liquid phase. The preparation method help prepare the colored aluminum pigment with diversified colors and high color depth without reducing brightness of the original aluminum pigment slurry.

Owner:WENZHOU YOUNGBIO CHEM

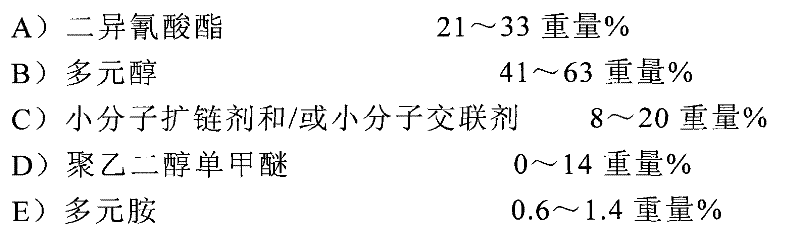

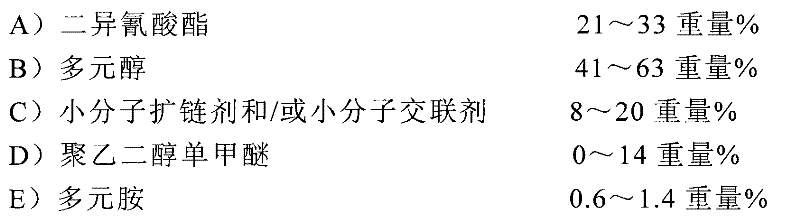

Nonionic waterborne polyurethane dispersoid and preparation method thereof

InactiveCN102690404AWide range of usesGood acid and alkali resistancePolyurethane dispersionPolymer science

The invention discloses a nonionic waterborne polyurethane dispersoid and a preparation method thereof. The dispersoid is mainly made from raw materials of A) diisocyanate, B) one or more than two polyols containing at least two hydroxy groups, wherein number average molecular weight of the polyols is 1000-4000, C) a small molecule chain extender and / or a small molecule cross-linking agent, D) methoxy polyethylene glycol with medium-low molecular weight, and E) one or more than one polyamines with number average molecular weight smaller than 500. According to the invention, the prepared dispersoid is with a small particle size, has long storage time and has great stabilities of acid tolerance, alkali tolerance and salt tolerance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

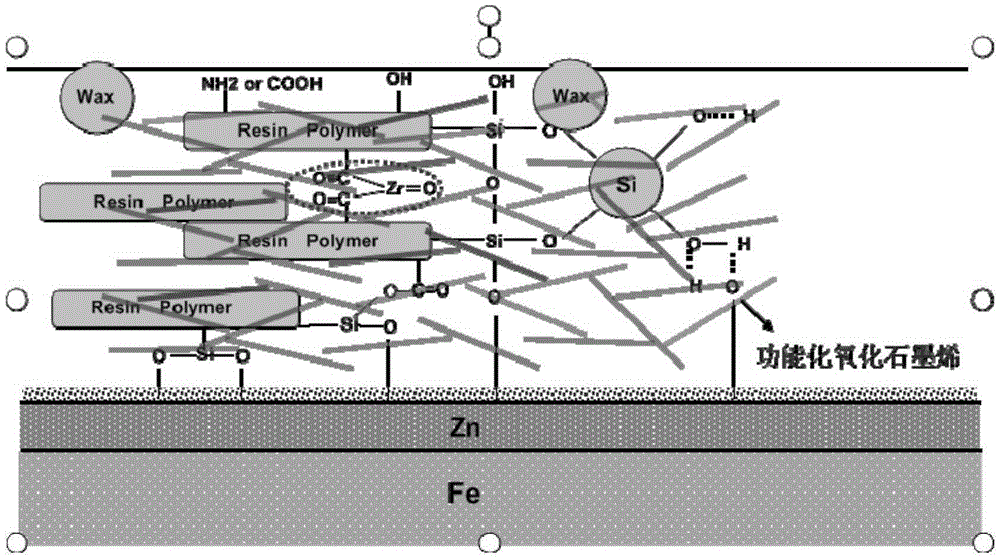

Galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and water-based surface treating agent

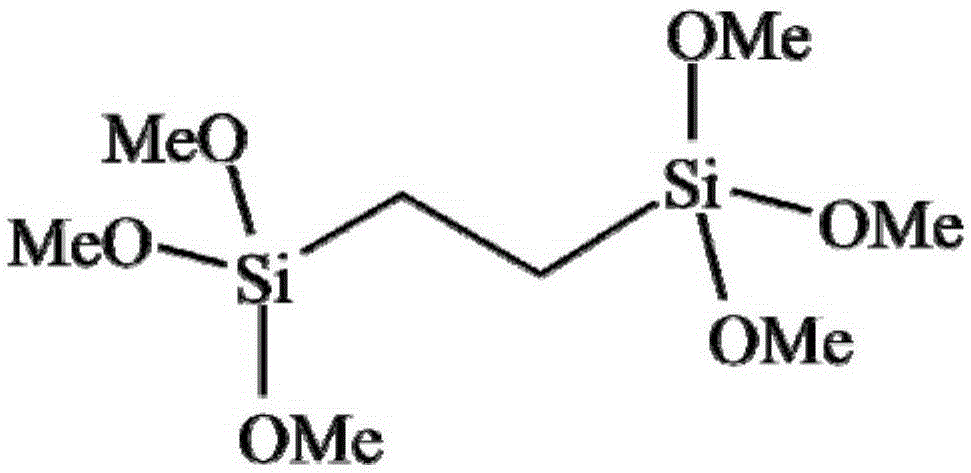

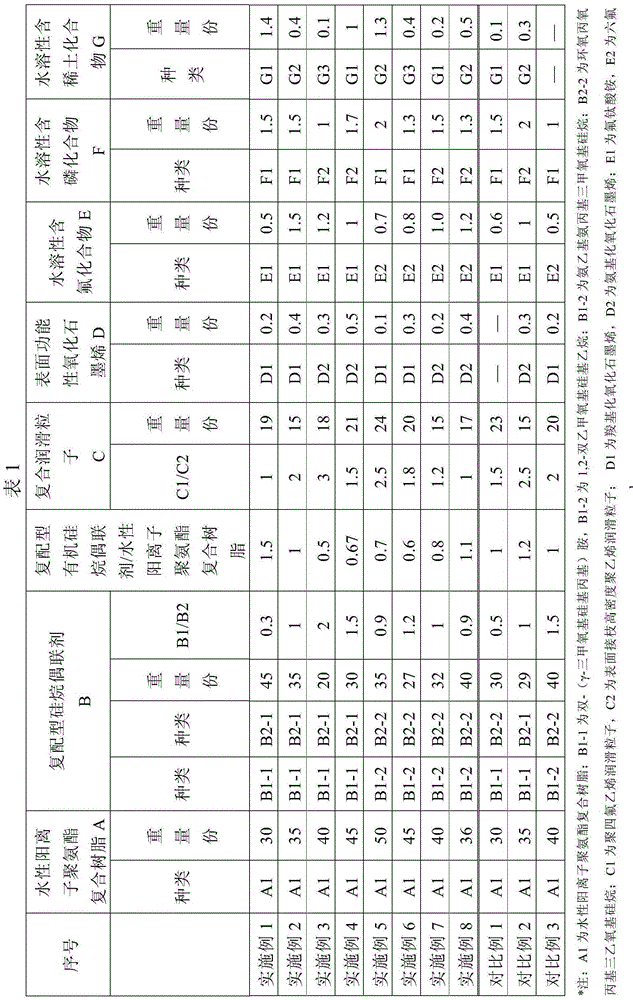

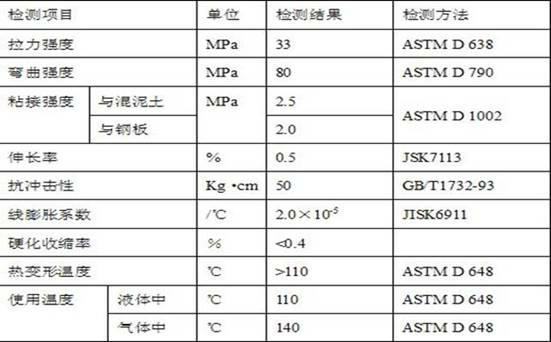

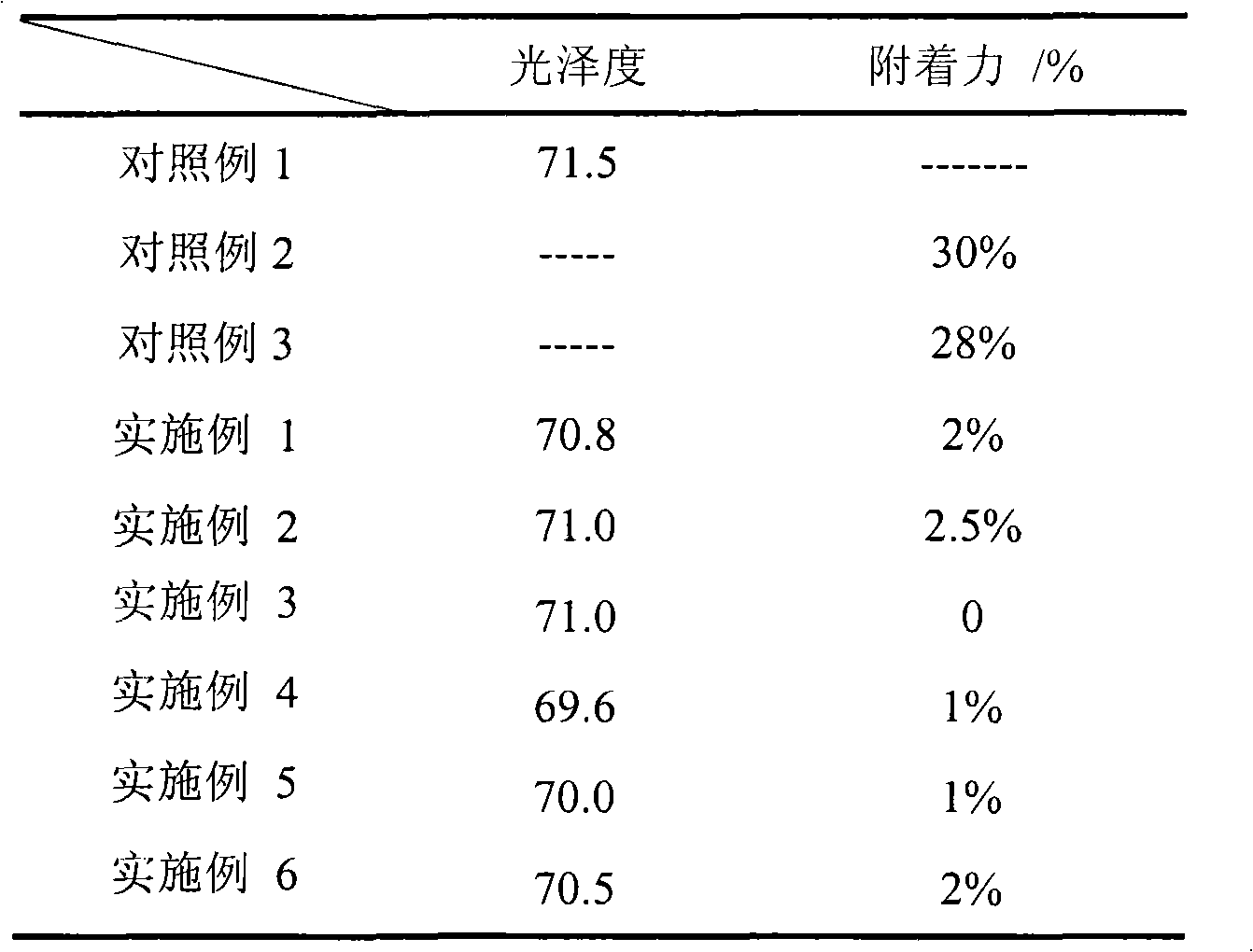

ActiveCN105255338AGood acid and alkali resistanceIncrease the degree of cross-linkingAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedCompound organic

The invention relates to a galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance and a water-based surface treating agent. The surface of a galvanized steel sheet is coated with the surface treating agent in a solidified mode, wherein the surface treating agent includes water-based positive ion polyurethane composite resin, compound organic silane coupling agents containing bis-organic silane coupling agents and mono-organic silane coupling agents, compound lubrication particles containing teflon-surface modification high-density polyethylene particles, oxidized graphene, water-soluble fluorine-containing compounds, water-soluble phosphorous compounds, water-soluble rare earth salt compounds and other components, and therefore the surface treatment galvanized steel sheet excellent in surface abrasion resistance, corrosion resistance and acid and base resistance is obtained. Meanwhile, the surface treatment galvanized steel sheet has good resistance, such as solvent resistance, to all kinds of chemical media.

Owner:BAOSHAN IRON & STEEL CO LTD

Heavy-duty anticorrosive coating for flue gas desulphurization equipment and preparation technology thereof

InactiveCN102690586AStrong adhesionImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses a heavy-duty anticorrosive coating for flue gas desulphurization equipment and a preparation technology thereof. The heavy-duty anticorrosive coating comprises components of a novolac epoxy vinyl ester resin, a plasticizer, a diluent, a curing agent, a promoter, glass flakes, rutile titanium dioxide, nano-silica, alumina powder, silicon carbide, talcum powder and auxiliary agents. The preparation technology comprises that the components are dispersed by a high-speed dispersion kettle and then are mixed into the heavy-duty anticorrosive coating. The heavy-duty anticorrosive coating is convenient for construction, can be cured at a normal temperature, has good mechanical properties and excellent anti-permeability performances, is stable in an acid medium for a long time and has good protection effects on a matrix material.

Owner:BEIJING UNIV OF CHEM TECH

Organic-inorganic hybrid nanometer film coating aluminum powder pigment and preparation method and application thereof

InactiveCN101580653AGood acid and alkali resistance and water resistanceGood metallic lusterCoatingsPigment treatment with organosilicon compoundsDouble bondChemistry

The invention discloses organic-inorganic hybrid nanometer film coating aluminum powder pigment and a preparation method and application thereof. The preparation method comprises the followings steps: by utilizing organic-inorganic hybrid technology and taking aluminum powder pigment as nuclear, firstly performing free radical polymerization on polymerisable carbon-carbon double bond reaction monomers and polymerisable carbon-carbon double bond organosiloxane; and bonding the obtained polymer and ethyl orthosilicate with the surface of the aluminum powder pigment in a hydrolysis mode, and further coating a layer of organic-inorganic hybrid nanometer film on the surface of the aluminum powder. On the basis of maintaining the lustrousness of the aluminum powder, the prepared organic-inorganic hybrid nanometer film coating aluminum powder pigment has excellent compatibility with resin and good acid and alkaline resistance properties, simultaneously well solves the problem of 'powder falling' when the conventional aluminum powder and single-layer or two-layer costing aluminum powder pigment are applied to metallic coatings, and provides a foundation for applying modified aluminum powder pigment and developing high performance metallic coatings.

Owner:SOUTH CHINA UNIV OF TECH

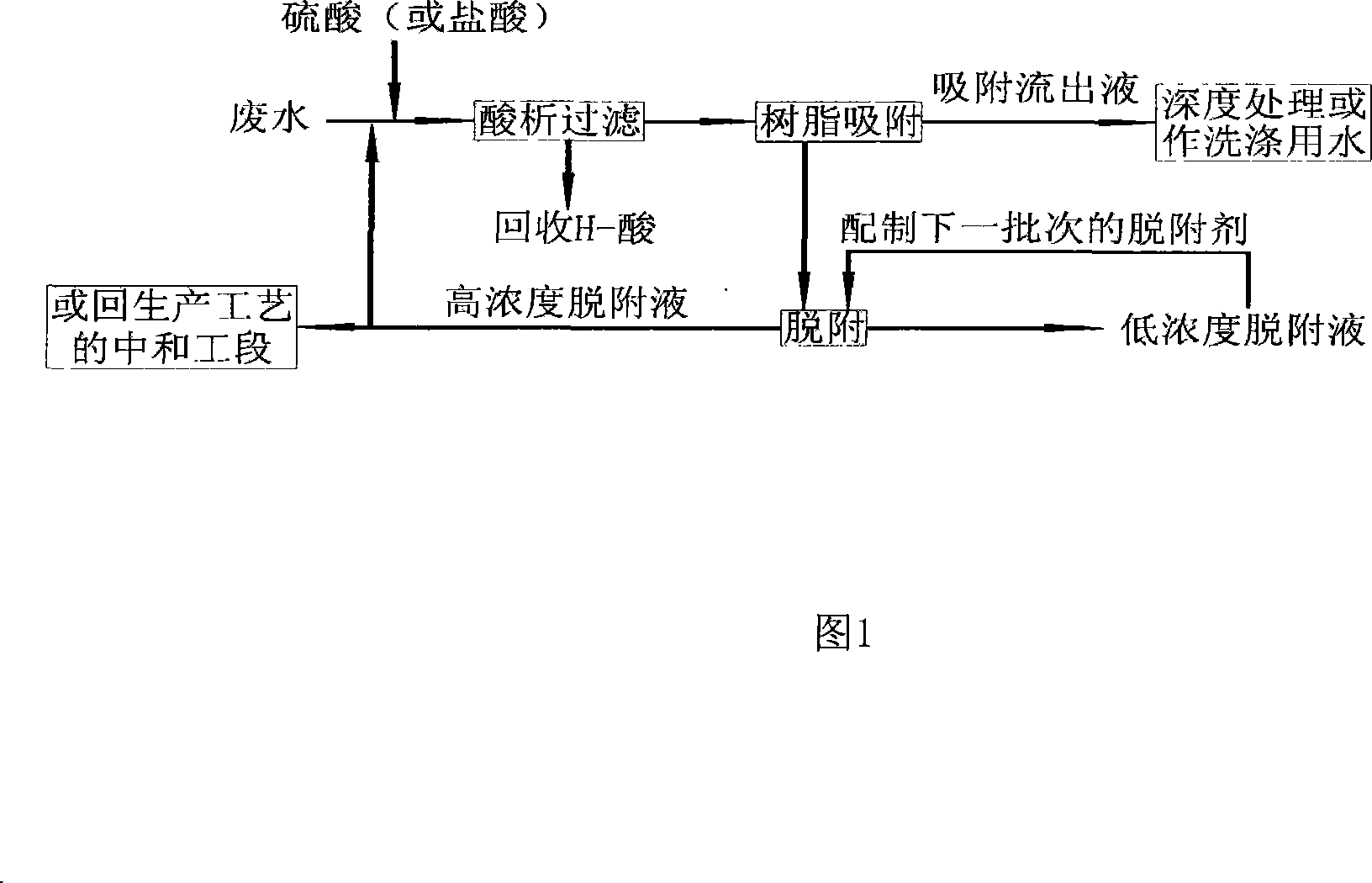

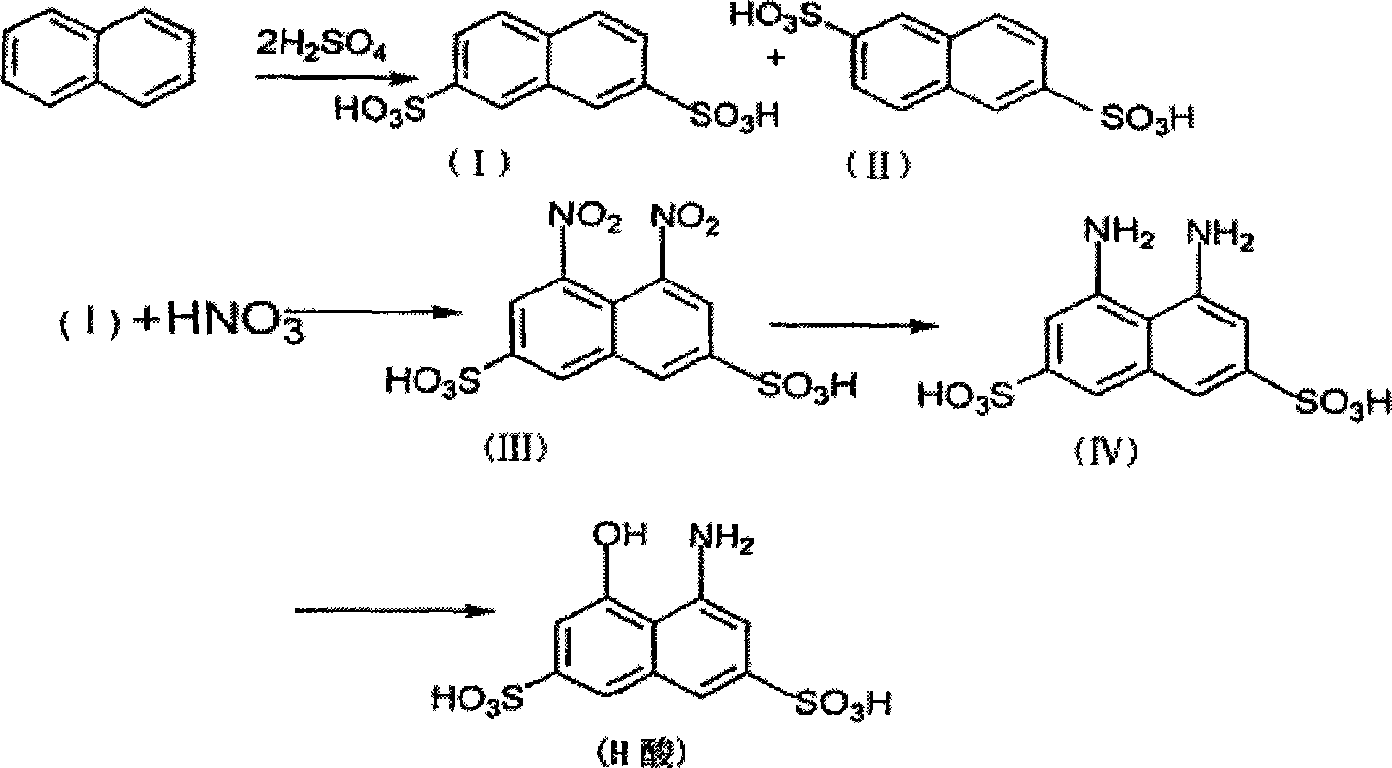

Method for treating waste water of H-acid production

InactiveCN101104533ANot affected by the adsorption effectImprove practicalityOrganic chemistryIon-exchange column/bed processesResource utilizationDesorption

The present invention is a treatment method for naphthalene dye intermediate H-acid production wastewater. After H-acid pretreatment wastewater is preprocessed, organic compounds such as, 1-amido-8- naphthol-3, 6-disulfonic acid (H-acid) and intermediate products, are adsorbed on the resin through alkalescence macroporous adsorption resin; the adsorbed water is added with lye for desorption regeneration and the regenerated liquid will be back into the previous production process for application. The CODcr of the treated wastewater can be effectively reduced to reach the national emission standards; the reclaimed H-acid sodium salt can be used. The resin can be desorbed and regenerated through lye for repeated use. The desorbed liquid is distilled and reclaimed, and the distilled effluent can be used repeatedly. The H-acid sodium salt and the intermediate products reclaimed through the invention can be used as raw materials for the original production process; therefore, the invention not only helps treating wastewater but also realizes waste resource utilization.

Owner:NANKAI UNIV

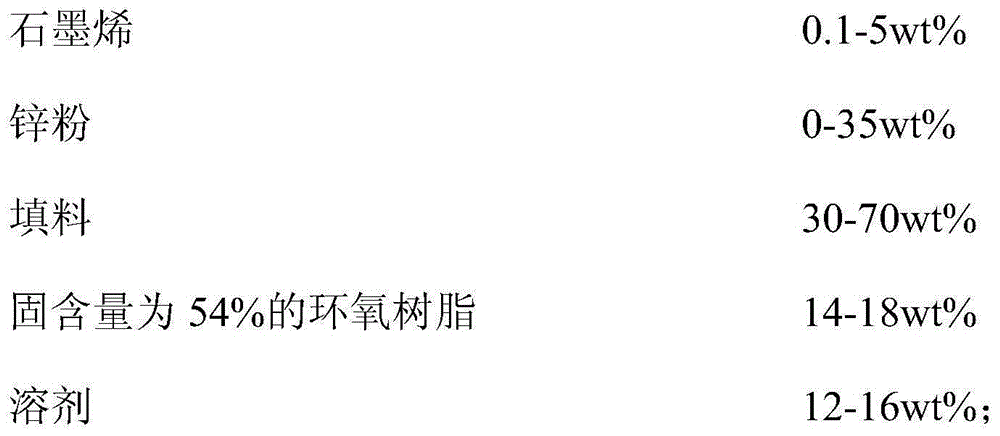

Double-component graphene anticorrosive coating

ActiveCN105086754AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

A zinc-rich epoxy anti-corrosion coating, including a component A, capable of being cured into a film, and a component B containing a curing agent; component A contains, by weight percentage, graphene (0.1-5wt%), zinc powder (0-35wt%), filler (30-70wt%), 10-20wt% epoxy resin having 54wt% solids content, and solvent (10-20wt%), wherein the sum of the weight percentages of the graphene, zinc powder and filler is 60-80wt% and the sum of the weight percentages of all components of compenent A is 100wt%. The present invention adds graphene into an anti-corrosion coating, thus decreasing the thickness of the coating film, increases the anti-corrosion effect while decreasing zinc powder contents, reduces the amount of zinc oxide vapor generated during welding, and is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Super-hydrophobic coating, super-hydrophobic coating layer, and preparation method thereof

InactiveCN106366907AImprove environmental adaptabilityImprove friction resistanceCoatings with pigmentsFiltration separationFiberSolvent

The invention provides a preparation method of a super-hydrophobic coating layer. The preparation method includes the steps of: 1) according to mass percentage of a final solution, dissolving 0.5-10% of hydrophobic nano particles and 1-15% of hydrophobic resin in a solvent, performing ultrasonic dispersion for 15-60 min to obtain a mixed solution; 2) forming the mixed solution on the surface of a substrate material and in internal microstructures of the substrate material; 3) naturally air-drying the substrate material to form the super-hydrophobic coating layer. According to the method, the preparation process of the coating layer is free of assistance of external equipment, such as heating and the like, so that the method is simple and low-cost. The method can achieve preparation of the super-hydrophobic coating layer on various fiber surfaces and porous material surfaces, has excellent universality and is easy to achieve in industrial large-area preparation.

Owner:TIANJIN RES INST FOR ADVANCED EQUIP TSINGHUA UNIV

Method for preparing silicon dioxide coating type water aluminum-silver slurry

InactiveCN101235226AGood acid and alkali resistanceAvoid hydrogen evolution reactionInorganic pigment treatmentPigment pastesSolventSilicon alkoxide

The invention discloses a preparation process of silica dioxide coated waterborne aluminum paste. The characteristics of the process are that self-assembling silica dioxide gel particle, conducting the electric potential regulation and control for the surface of aluminum powder in order to make the surface of aluminum powder positive, generating negative charged SiO2 gel particles through dripping silicon alkoxide to generate silicon alkoxide, wherein negative charged SiO2 gel particles are evenly compactly absorbed on the positive charged aluminum paste surface which is regulated and controlled by aluminum salt, therefore realizing the self-assemly of the SiO2 gel particle on the surface of aluminum powder, and making the surface of aluminum powder be coated with a layer of even compact and transparent silica dioxide film, and finally obtaining silica dioxide coated waterborne aluminum paste. The waterborne aluminum paste has the following characteristics of excellent dispersion in alcohol solvent and water solvent, wonderful properties of acid resistance and alkali resistance, and the particle diameter change of aluminum powder is smaller than 1 micron back and forth coating, and metal sense decrease is smaller 5%. The product of silica dioxide coated waterborne aluminum paste which is prepared can be used as an environment-friendly metallic pigment which can be extensively applied on environment-friendly waterborne pigment and waterborne ink.

Owner:CENT SOUTH UNIV

Printing strippable protective ink, and preparation method and application thereof

The invention discloses a printing strippable protective ink, and a preparation method and application thereof. The ink comprises the following components in parts by weight: 50-80 parts of thermoplastic film-forming resin, 20-50 parts of low-viscosity plasticizer, 1-10 parts of filler and pigment, and 1-3 parts of functional assistant. The printing strippable protective ink has 100% solid rate, does not volatilize any solvent, is a green environment-friendly material, and satisfies the increasingly higher ecological environmental requirements. The ink has the advantages of no irritating smell, moderate viscosity and no voids, is not sticky to the printing screen, and is easy for printing operation; the ink can form a film by thermosetting at medium / low temperature, so the energy consumption is low; the thermosetting film has high flexibility, favorable heat resistance, favorable insulativity and favorable acid / alkali resistance, and effectively solves the influence on the resistance when etching the circuit on a transparent conductive film with acid and alkali in the touch screen manufacturing process; and after the conductive film protecting technique is finished in the touch screen manufacturing process, the protective ink layer can be easily stripped, and does not leave any residue, thereby effectively solving the problem of protection of the conducting film in the existing touch screen manufacturing process.

Owner:PANYU NANSHA YAN TIN CHEM

Water soluble adhesive

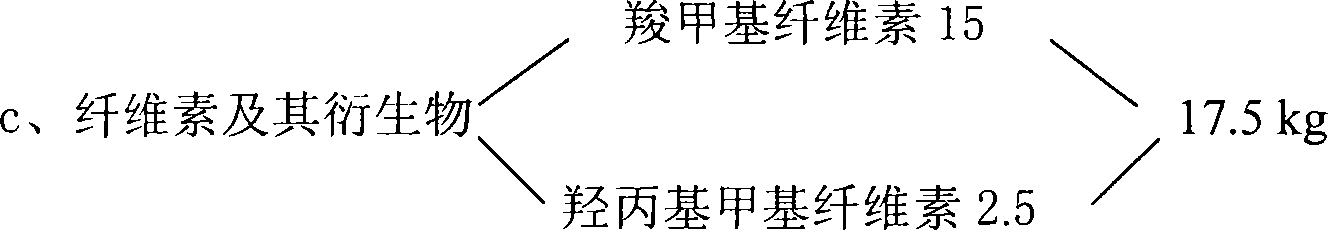

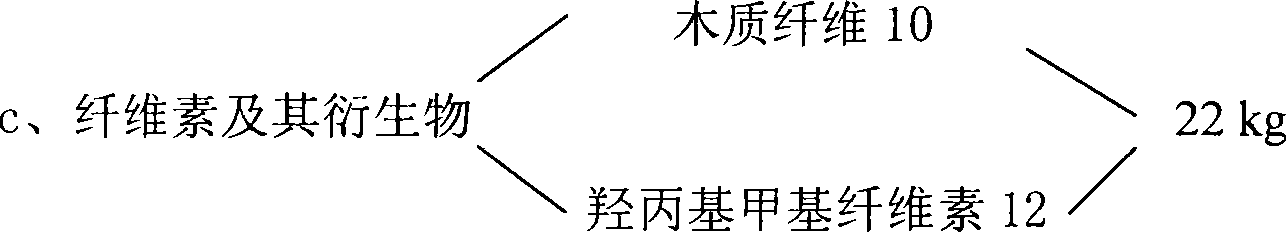

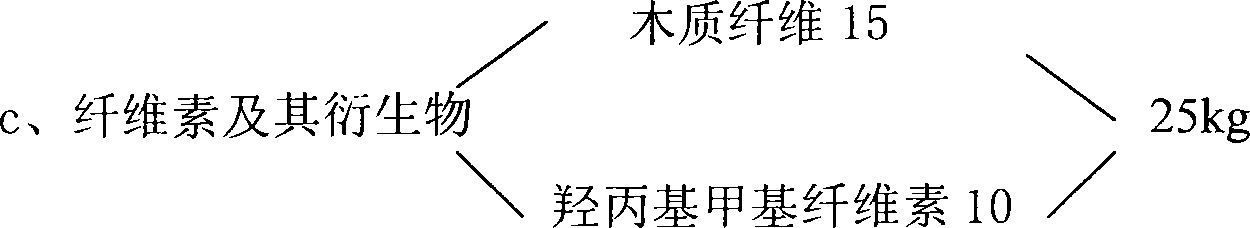

InactiveCN101058701AGood adhesionStrong adhesionNon-macromolecular adhesive additivesStarch adhesivesCellulosePolymer science

The invention discloses a water-soluble adhesive, which comprises the following parts: 30-65% pregelatinized starch, 10-20% 2488 polyvinyl alcohol, 13-37% cellulose and its derivant, 0-20% redispersion emulsion powder, 0. 15-0. 5% thickener and 0. 3-0. 8% high-activity zinc oxide, wherein each component is stirred evenly under the drying condition to form the product; the grain size of pregelatinized starch is 20-40 or 80-100 order, which can be allocated into gel powder to form common glue with 6% water after stirring 30min or interior-exterior wall putty powder adhesive after blending diflying powder or cement with weight at 0. 2: 10 directly.

Owner:陈峰磊

Graphene masterbatch

InactiveCN105017742AExcellent mechanical propertiesImprove antioxidant capacityNon-conductive material with dispersed conductive materialChemical LinkageMasterbatch

Disclosed is a graphene masterbatch including a base resin, electrically conductive carbon black, graphene nanoplatelets with modified surface and a dispersant. The modified surface of graphene nanoplatelet is formed by a modifying agent containing a coupling compound so as to possess hydrophobic and hydrophilic functional groups, which help graphene nanoplatelets form chemical bonding with carbon black and the base resin. Since the modified surface makes graphene nanoplatelets evenly dispersed in the base resin, the graphene masterbatch of the present invention is suitably melt blended with a polymer material to form a composite material such that graphene nanoplatelets are evenly dispersed in the polymer material, thereby enhancing junction strength, increasing mechanical properties, and improving anti-oxidation, acid / base resistance, and thermal conductivity.

Owner:北京烯创科技有限合伙企业(有限合伙)

Multifunctional graphene/high-molecular composite material water permeable membrane, preparation method, and application thereof

InactiveCN106492654AGood acid and alkali resistanceImprove antibacterial and anti-pollution abilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceFiltration

The invention relates to a multifunctional graphene / high-molecular composite material water permeable membrane, a preparation method, and an application thereof. A high-molecular moisture-conductive polymer and a graphene-based composite material are organically bonded in a manner of forming effective chemical bonds, such as a hydrogen bond, an ionic bond, a covalent bond and the like, through polar functional groups, thereby forming a water permeation channel with reinforced hydrophilic-hydrophobic groups on the basis of the moisture-conductive polymer, and meanwhile, significantly improving the mechanical strength, anti-friction strength and acid- and alkali-resistant property, anti-bacterial and anti-fouling capabilities, heat conductivity and heat resistance and the like characters. The multifunctional composite water permeable membrane has long service life, is free of replacement during operation and has self-cleaning capability, and can be applied in the field of whole-heat exchanger, humidity conditioner, sewage treatment and other fields requiring water permeation or water filtration.

Owner:中山市创思泰新材料科技股份有限公司

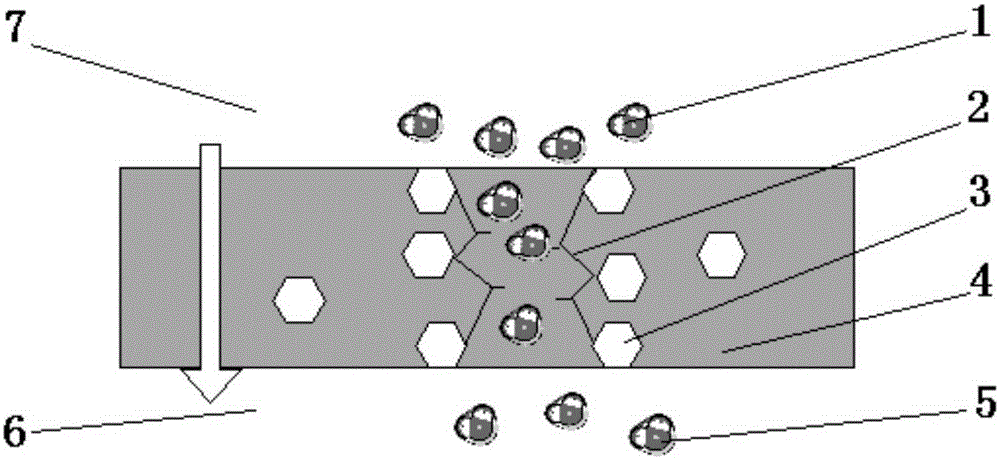

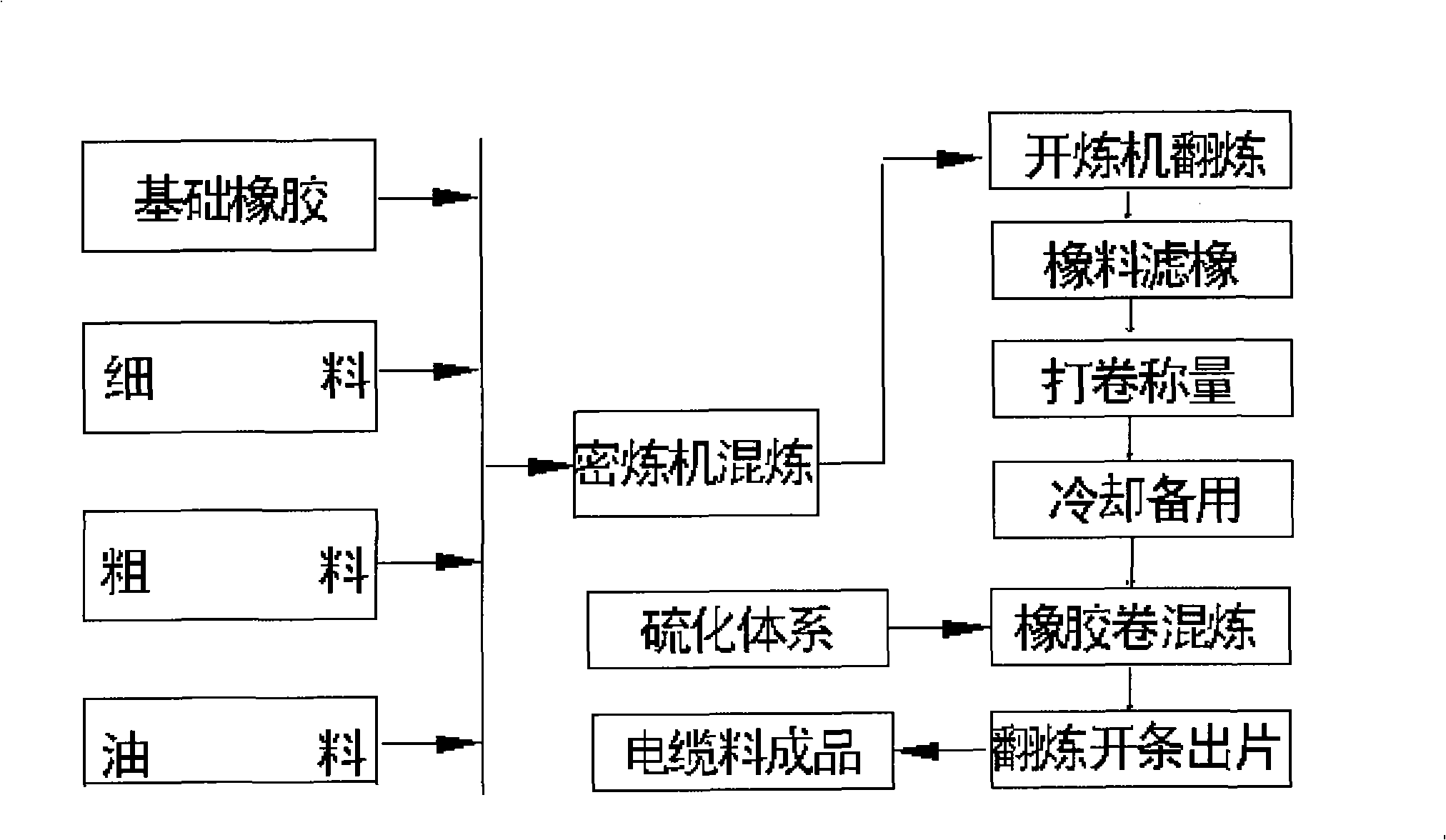

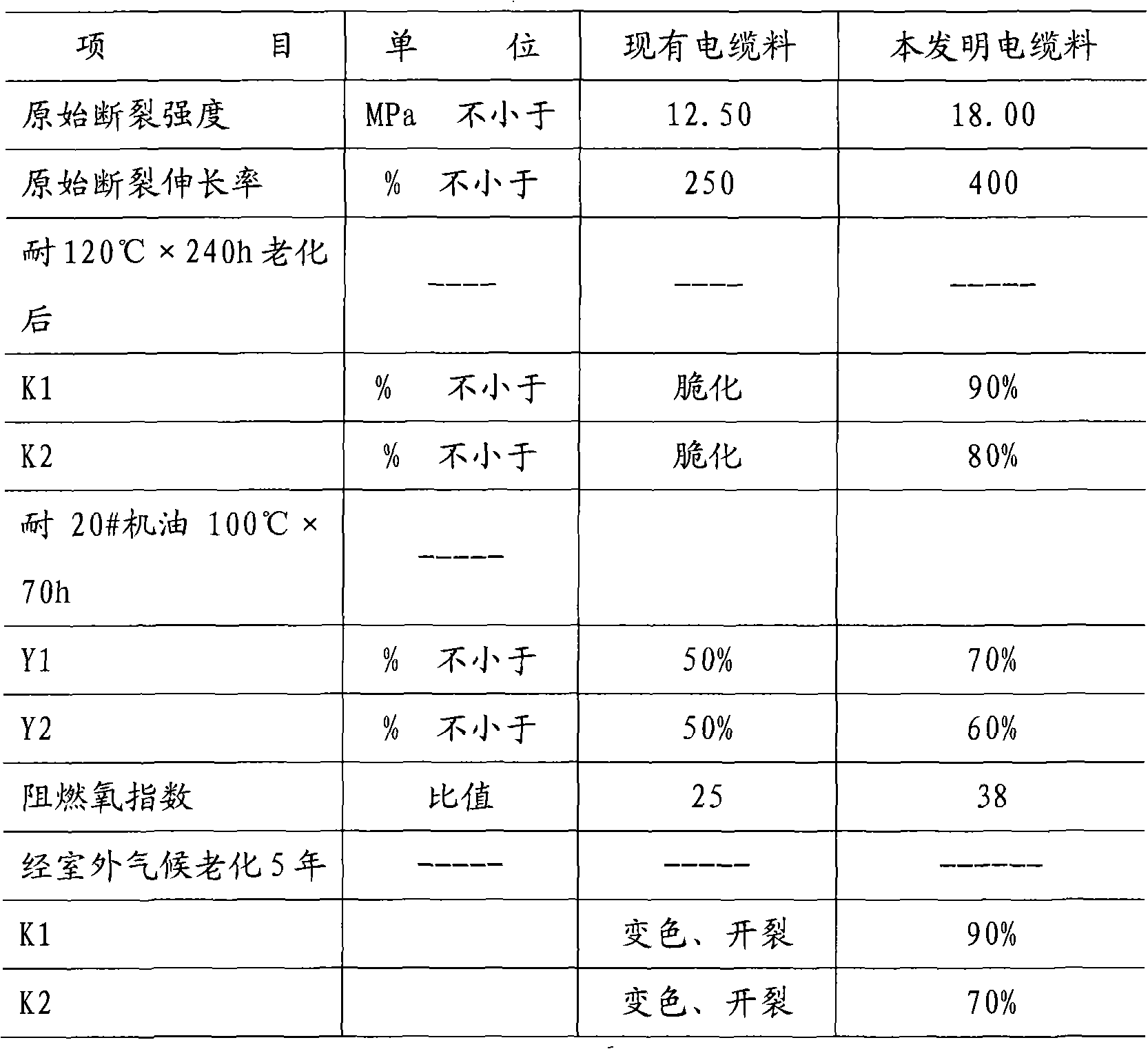

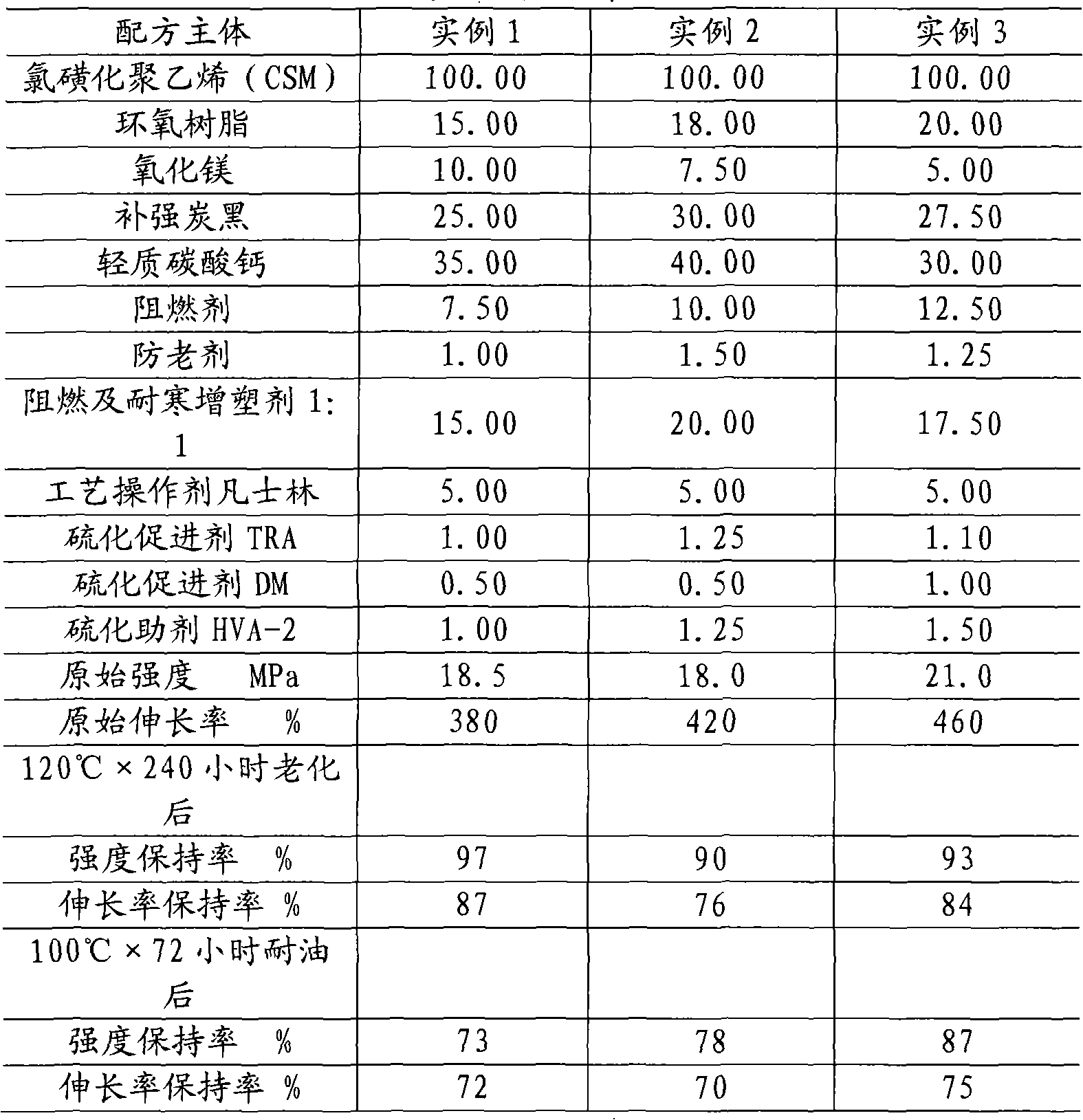

External rubber sleeve material of cable for wind power generation

InactiveCN101538391AEasy to operateImprove water resistanceInsulated cablesInsulated conductorsEpoxyVulcanization

The invention discloses an external rubber sleeve material of a cable used for wind power generation, comprising the following components by weight parts: 100.00 parts of chlorosulfonated polyethylene rubber, 15.00-20.00 parts of vulcanizing agent epoxy resin, 5.00-10.00 parts of magnesium oxide acid acceptor, 1.00-1.50 parts of vulcanization aid, 0.20-1.50 parts of vulcanization accelerator, 10.00-15.00 parts of fire-retardant plasticizer, 5.00-10.00 parts of cold resistant plasticizer, 30.00-40.00 parts of reinforcing agent, 40.00-50.00 parts of filling agent, 0.50-2.00 parts of anti-ageing agent, 0.50-2.00 parts of process operation agent, and 10.00-15.00 parts of flame retardant. The external rubber sleeve material of the cable used for wind power generation has the greatest advantages of extremely high physical and mechanical performance, excellent oil resistance and climate resistance, extremely softness and flame retarding, and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

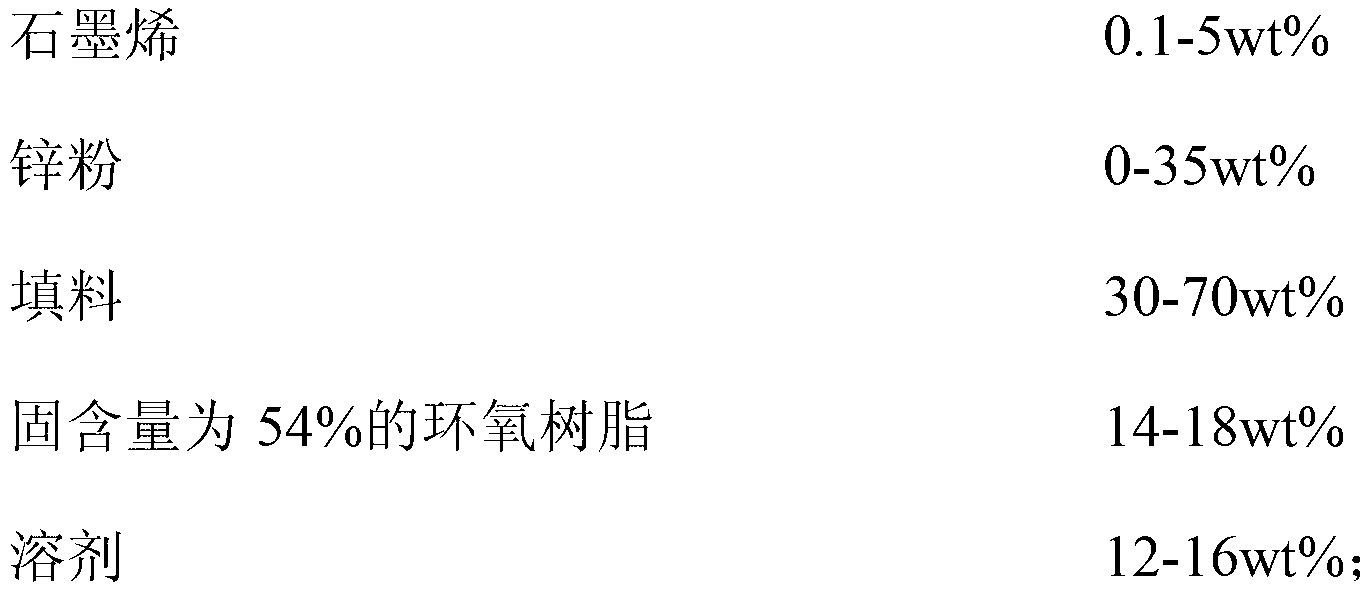

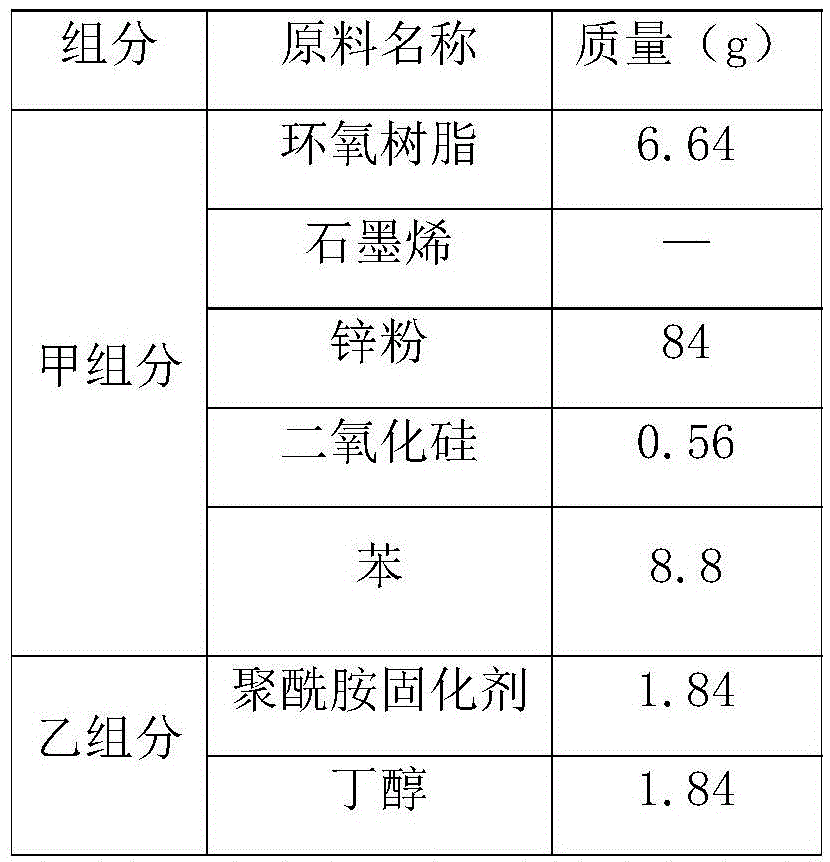

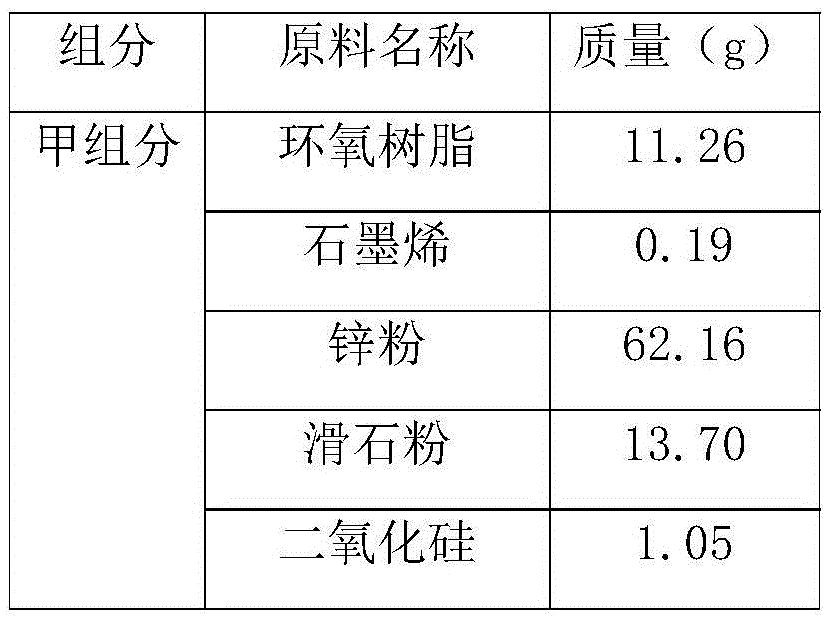

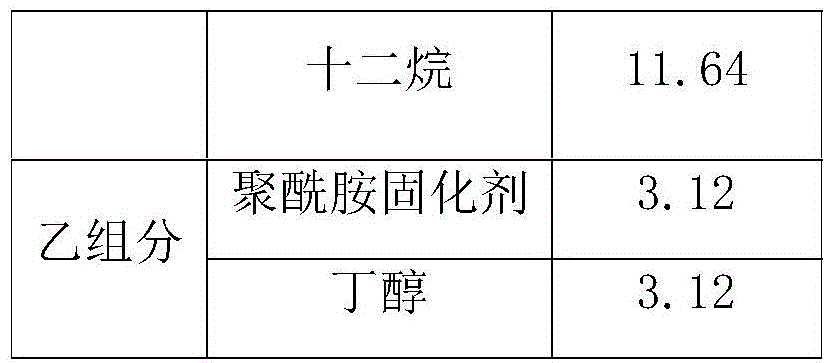

Epoxy resin-graphene-zinc powder anticorrosive coating and preparation method thereof

InactiveCN105623471AReduce contentWays to overcome corruptionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention relates to epoxy resin-graphene-zinc powder anticorrosive coating and a preparation method thereof. The coating comprises a component A capable of forming a film in a curing mode and a component B containing a curing agent, wherein the component A is prepared from 14.64-20.24% of epoxy resin, 0.33-0.56% of graphene, 19.63-37.67% of zinc powder, 23.74-40.37% of filler, 1.41-2.0% of silicon dioxide and the balance a solvent. The component B is prepared from 50% of polyamide and 50% of butanol. Graphene is added into the anticorrosive coating, the anticorrosive effect is improved and the content of the zinc powder is greatly reduced by means of selection of the components, the anticorrosive mode, at the cost of zinc powder, of zinc-rich coating is avoided, zinc oxide fog generated during welding is greatly reduced, and the coating is environmentally friendly. The novel composite coating is good in anti-corrosive effect, free of toxin and pollution and wide in application range.

Owner:TIANJIN XITENG SCI & TECH CO LTD

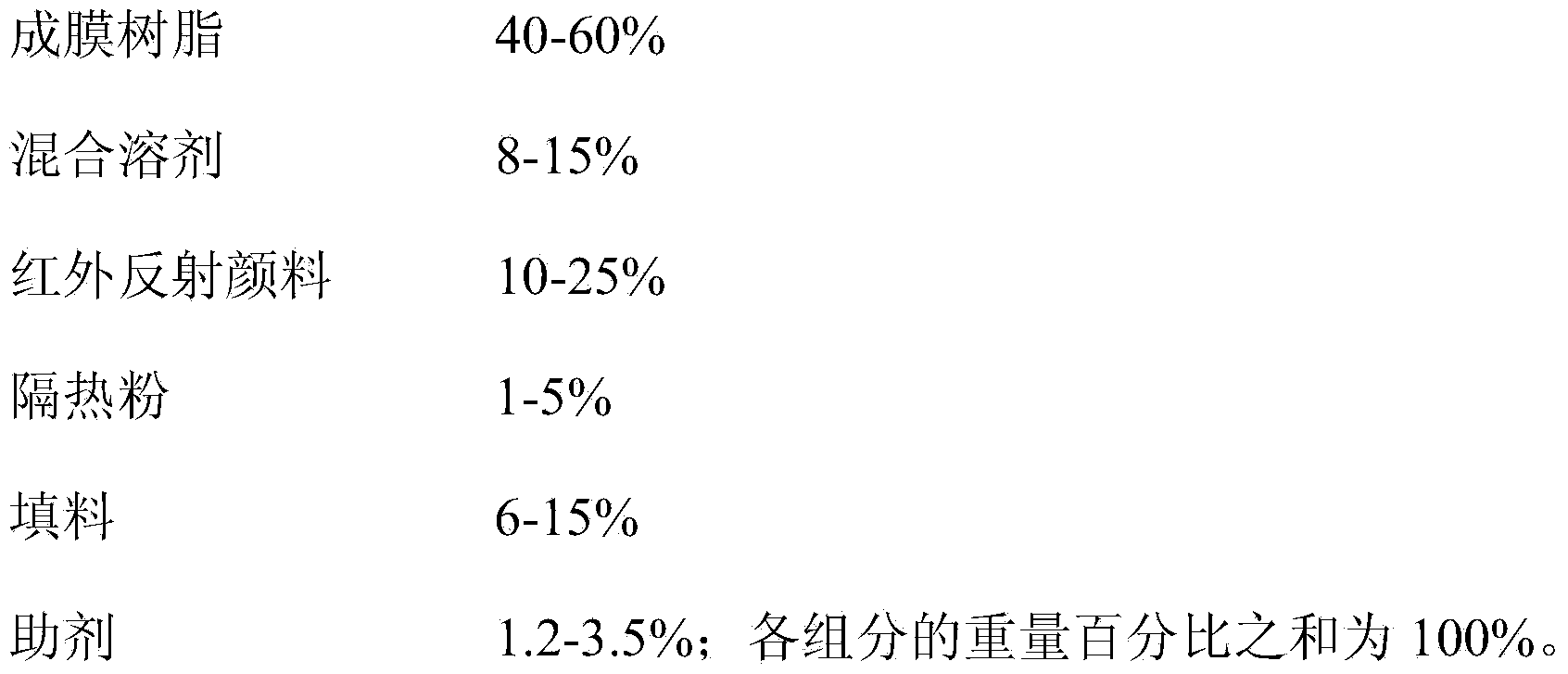

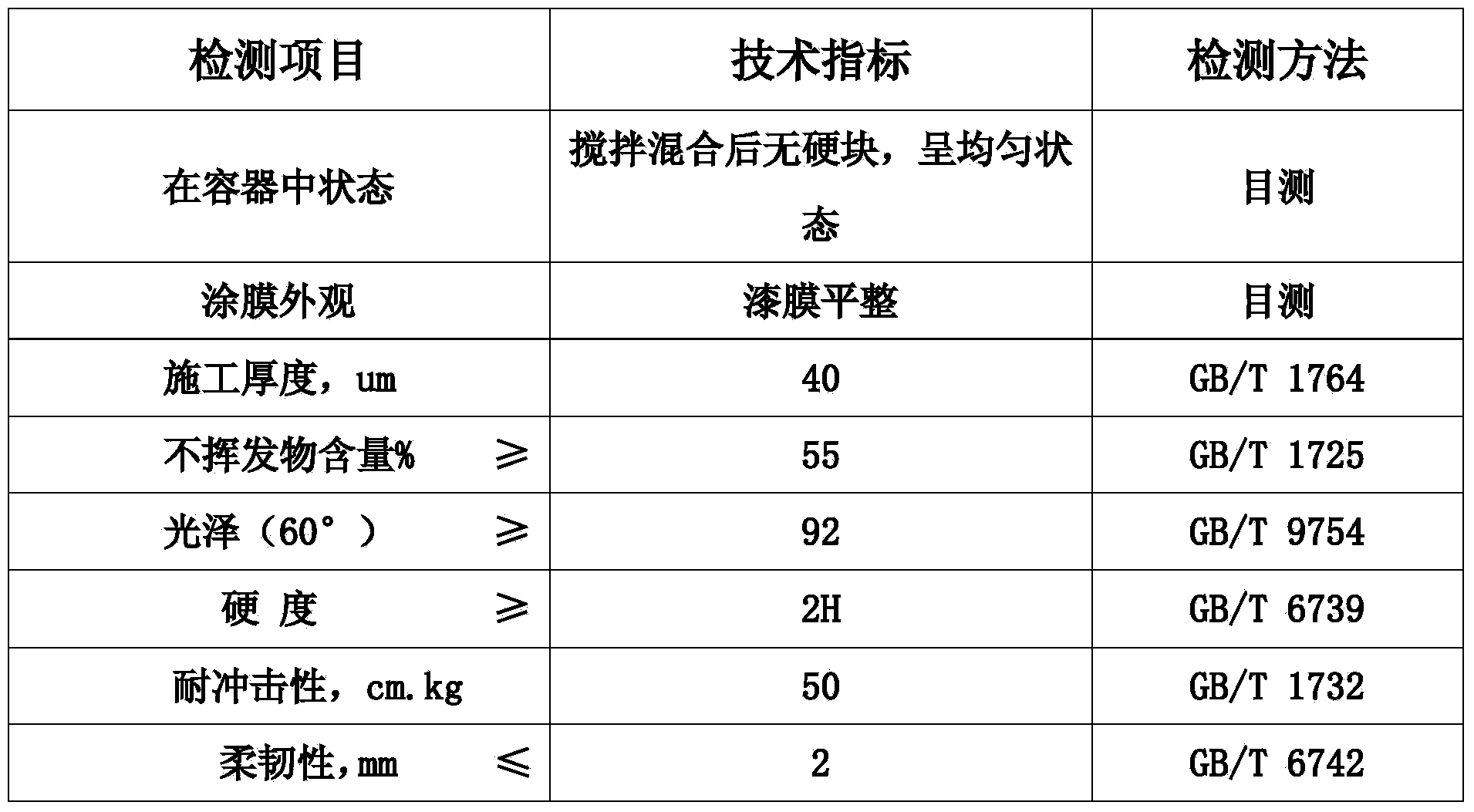

Heat reflective insulating stoving varnish coating and preparation method thereof

ActiveCN104109438AHigh strengthImprove impact resistancePolyester coatingsReflecting/signal paintsAcrylic resinSolvent

The invention discloses a heat reflective insulating stoving varnish coating and a preparation method thereof. The stoving varnish coating comprises the following components in percentage by weight: 40-60% of a film-forming resin, 8-15% of a mixed solvent, 10-25% of an infrared reflective pigment, 1-5% of insulating powder, 6-15% of filler and 1.2-3.5% of an auxiliary, totaling 100%, wherein the film-forming resin comprises a mixture of thermosetting acrylic resin, acrylic resin and amino resin. As the film-forming resin contains the above three main resins, the stoving varnish coating has good weather ability, mechanical property and chemical resistance. As the infrared reflective pigment and heat insulating powder are added into the raw material, the coating is high in reflection efficiency of sunlight and good in insulating effect.

Owner:ZHANG ZHOU SAN PAINTS

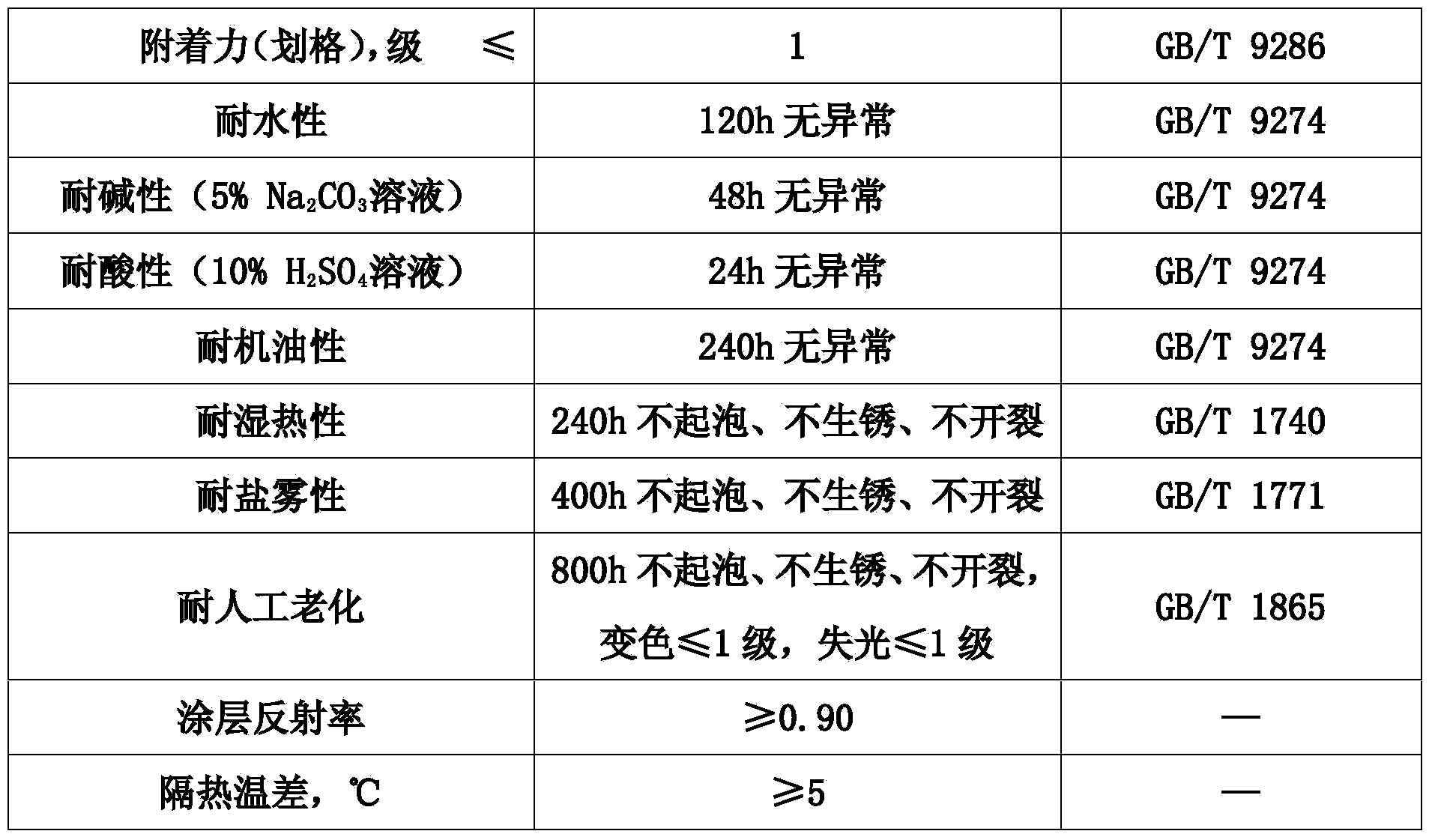

Coating for cooling surface of light-emitting diode (LED) radiator

ActiveCN103965671AGood self-cleaningEasy constructionReflecting/signal paintsRare-earth elementCorrosion

The invention discloses a coating for cooling the surface of a light-emitting diode (LED) radiator. The coating is characterized by being prepared from the following components in parts by weight: 6-20 parts of inorganic colloidal particle, 0.5-2 parts of carbon nano-tube, 15-80 parts of electron transition spinel, 0.05-2 parts of rare-earth element oxide, 0.1-0.3 parts of stabilizer, 3-10 parts of epoxy resin, 3-10 parts of methyl methacrylate and 2-5 parts of ethylene glycol. The coating has obvious heat dissipating and cooling effects, is not affected by surrounding medium when taking the cooling effect, can be used in a vacuum environment, also has the advantages of good self-cleaning property, corrosion resistance, waterproofness, fire retardancy, insulativity, and acid and alkali resistance, and convenient construction when taking a radiation cooling effect.

Owner:NINGBO AISHI ELECTRIC EQUIP

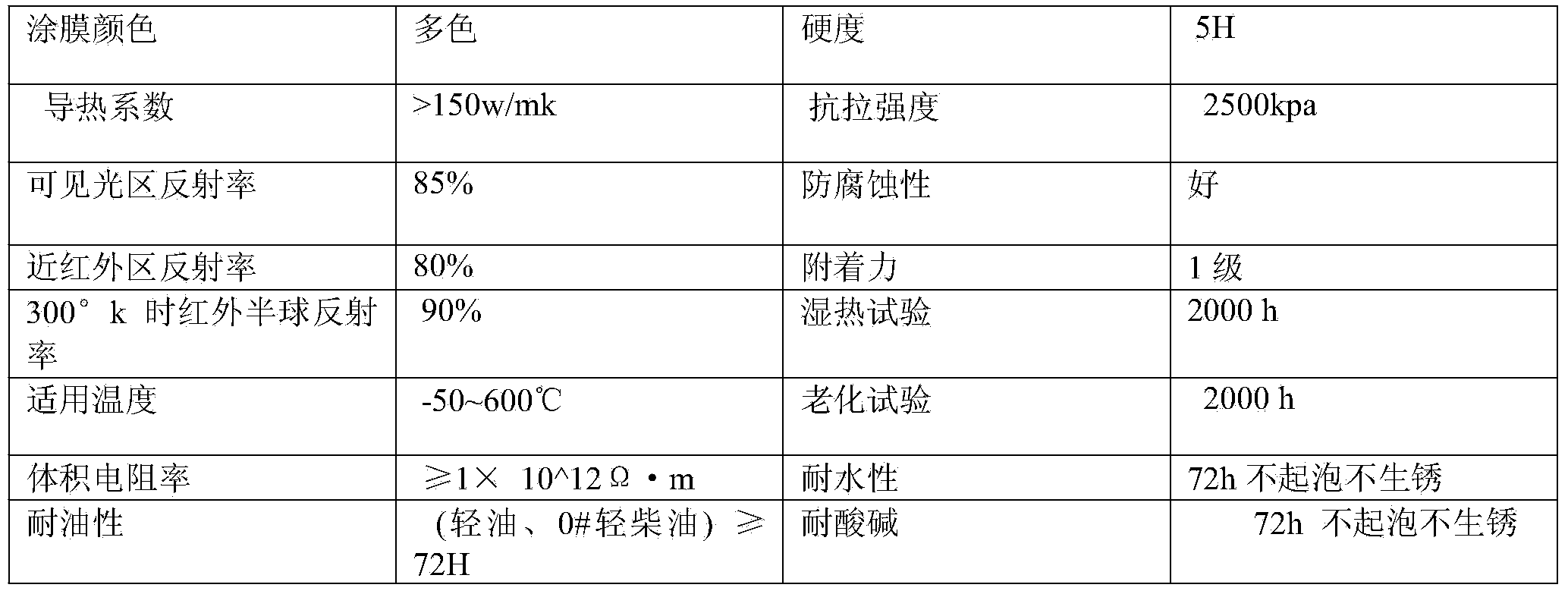

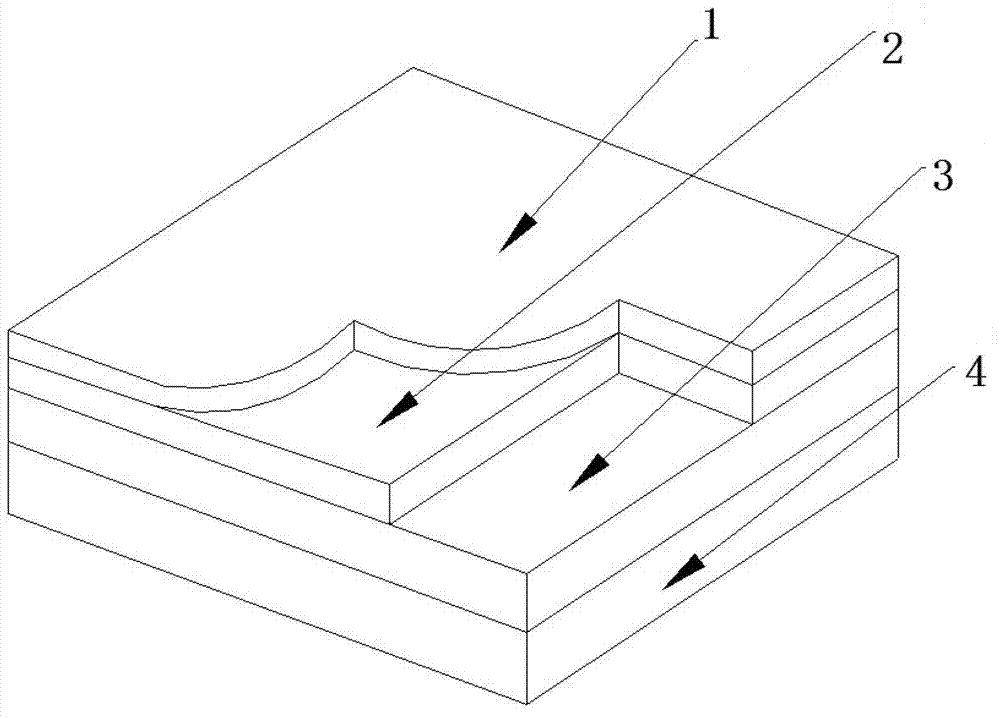

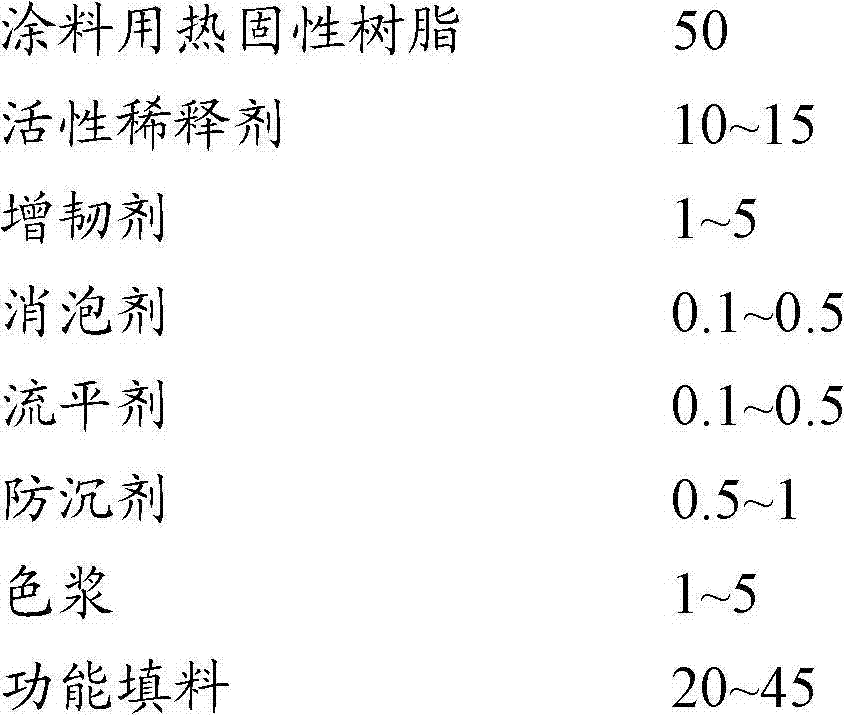

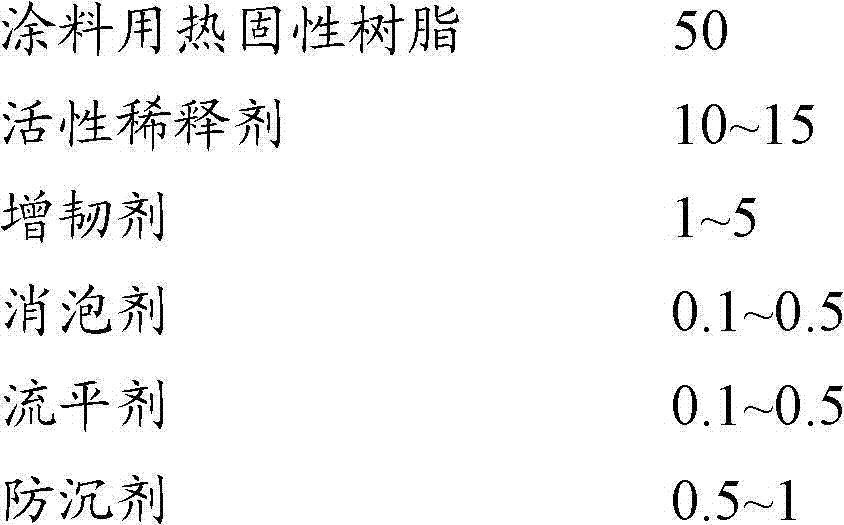

Thermosetting resin composite facing material and preparation method thereof

ActiveCN102808334AIncrease the physical and chemical properties of instant noodlesImprove scratch resistanceSynthetic resin layered productsTextiles and paperResin coatingHigh integrity

The invention discloses a thermosetting resin composite facing material, which comprises a fiber reinforced layer, and a decorative layer and a basic layer which are respectively coated on the upper surface and the lower surface of the fiber reinforced layer. The decorative layer and the basic layer are made of functional thermosetting resin coating. By using the thermosetting resin composite facing material, the organic combination of a thermosetting resin coating layer and a fiber fabric layer is realized, and the obtained material has the advantages of high integrity, uniform performance, convenience in field laying, fewer gap and excellent performance. The excellent physical and chemical performance of thermosetting resin is inherited, the toughness of the material is increased, the material is more convenient and rapid to install and the application scope is wider. The invention additionally discloses a preparation method of the thermosetting resin composite facing material.

Owner:HANGZHOU JIUHE NEW MATERIAL

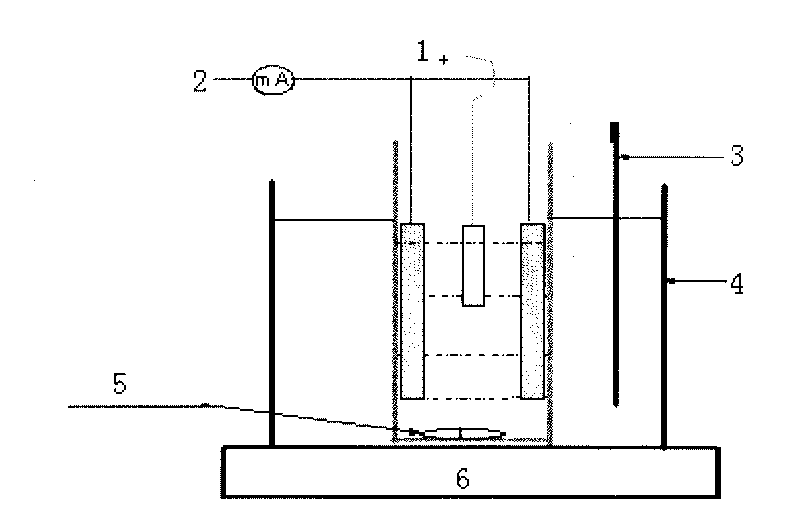

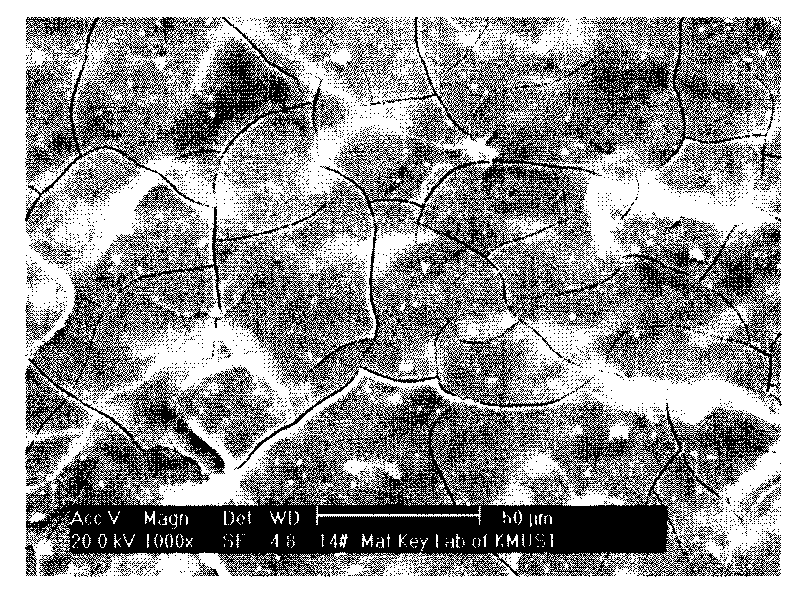

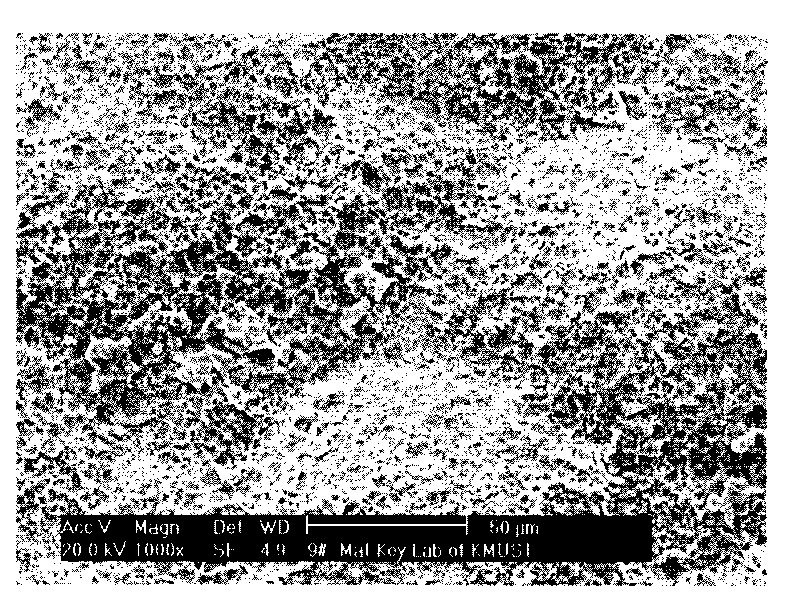

Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

InactiveCN101736369ASolution to short lifeStrong acid resistancePhotography auxillary processesElectrolytic inorganic material coatingLead dioxideSand blasting

The invention discloses a method for preparing a novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition, which is characterized by sequentially plating conductive coating, an alpha-PbO2-CeO2-TiO2 layer and a beta-PbO2-MnO2-WC-ZrO2 layer outside an aluminum matrix of a composite lead dioxide-manganese dioxide anode from inside to outside. The method comprises the following steps of: carrying out quenching, oil removal and sand blasting processing on the aluminum matrix; spraying the conductive coating on a matrix material; then carrying out alkaline composite plating on the alpha-PbO2-CeO2-TiO2 layer and carrying out acidic composite plating on the beta-PbO2-MnO2-WC-ZrO2 layer to obtain the composite lead dioxide-manganese dioxide anode. The aluminum-based composite lead dioxide-manganese dioxide anode manufactured by the process and method of the invention can obviously reduce the voltage of an electrode bath and energy consumption; and meanwhile, a plating layer and a matrix have strong binding force and small internal stress, and the service life of an electrode is long.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com