Coating for cooling surface of light-emitting diode (LED) radiator

A heat sink and coating technology, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of high power LED light source heat generation, LED light source life, poor heat dissipation, etc., to achieve good coating process, protection The effect of good equipment and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] The preparation method is as follows:

[0026] (1) Weighing each component of the formula ratio, then adding the carbon nanotubes into ethanol at a temperature of 50-80°C, and stirring evenly;

[0027] (2) Then the inorganic colloidal particles are added, and the epoxy resin and methyl methacrylate mixing system are stirred evenly;

[0028] (3) Mix the solutions of step (1) and step (2), then add spinel after electronic transition, rare earth element oxide and stabilizer and stir evenly to obtain the heat dissipation coating for the surface of LED heat sink.

[0029] The spinel electron radiation mentioned above has an energy range of 1-1.5 MeV and a beam power of 2-20Kw for 0.2-3h to achieve electron transition. The spinel is ground to a particle size of less than 1000nm after electronic transition.

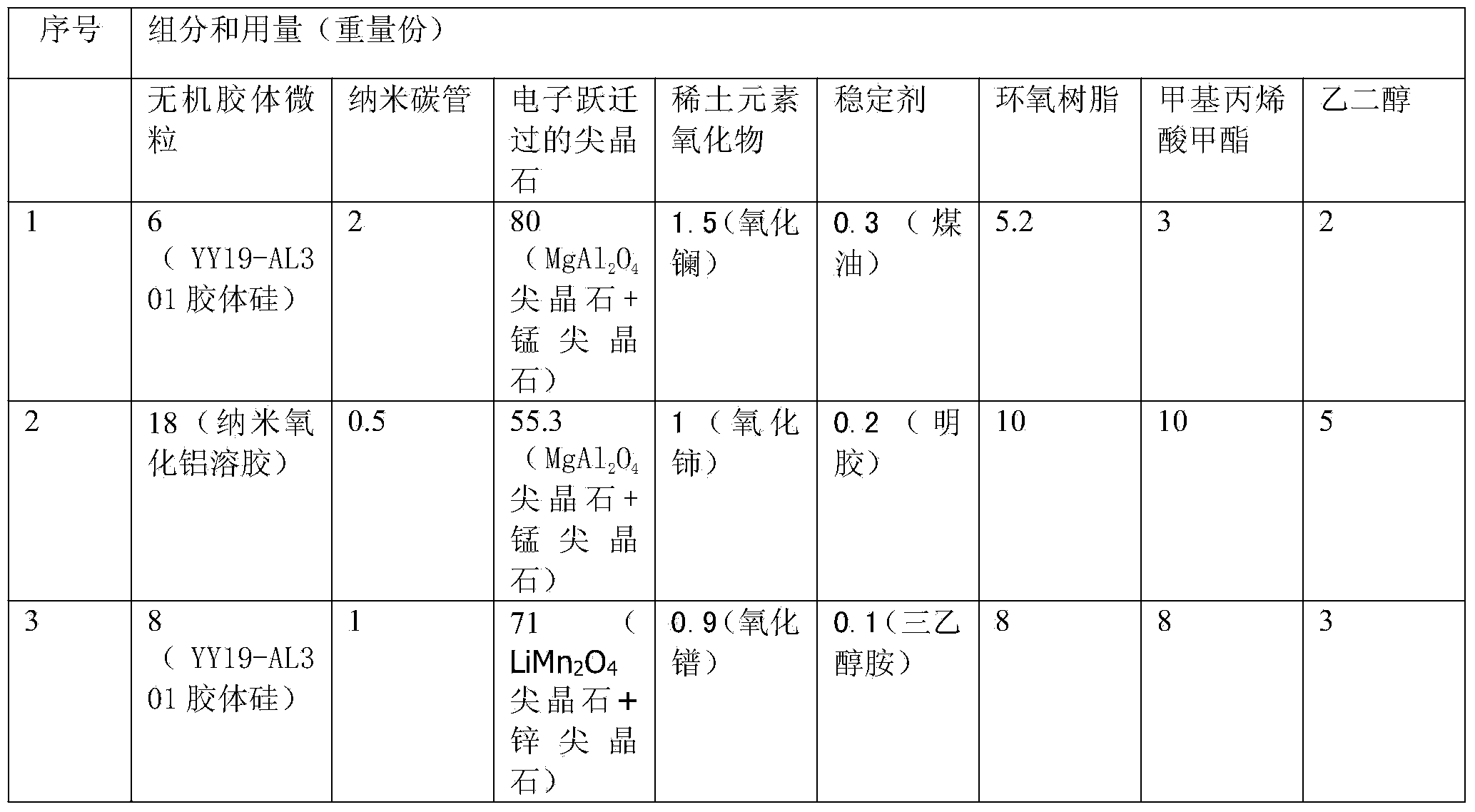

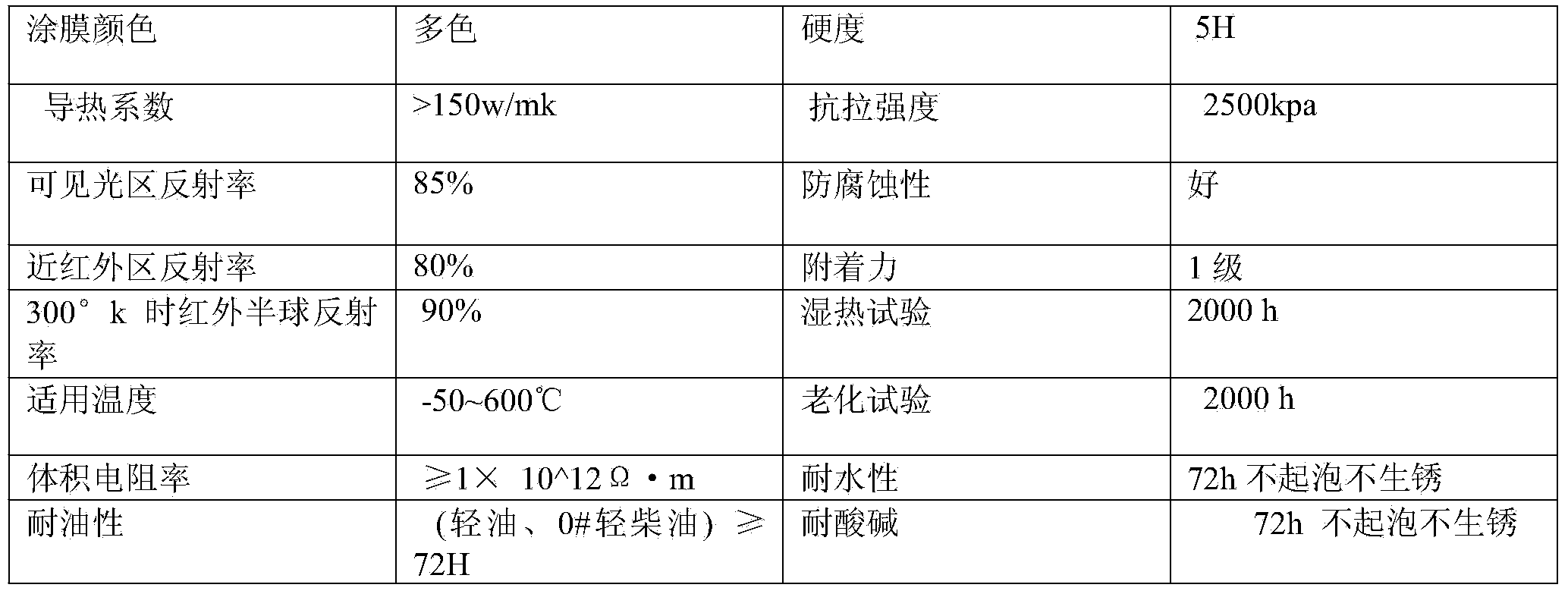

[0030] Table 1 embodiment 1-3 each component consumption

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com