Patents

Literature

261 results about "Peptization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Peptization or Deflocculation is the process responsible for the formation of stable dispersion of colloidal particles in dispersion medium. In other words it may be defined as a process of converting a precipitate into colloidal sol by shaking it with dispersion medium in the presence of small amount of electrolyte. The electrolyte used in this process is called as peptizing agent.

Macropore alumina supporter and its preparation method

ActiveCN1765509ALarge apertureConcentrated hole distributionCatalyst carriersCatalyst activation/preparationPhosphorRoom temperature

The invention discloses a micro-porous alumina carrier and relative preparing method, which contains boric oxide and another agent selected from phosphor, silicon, zirconium, and titanium. The invention adds the boric acid into water or peptizate acid whose temperature is higher than room temperature, then adds the mixture of alumina leading material and physics expanding-hole agent to be molded, dried, and burnt to attain the final carrier. The inventive carrier contains a proper agent, with the characters of large aperture, centralized distribution hole and a certain acid. And its surface acid and aperture can be adjusted easily. Therefore, the invention can overcome the defects of present technique which can not have aforementioned characters at the same time. The inventive alumina carrier can be used in variable hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

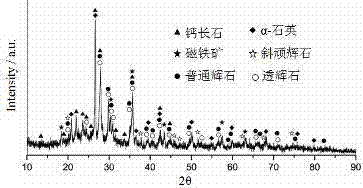

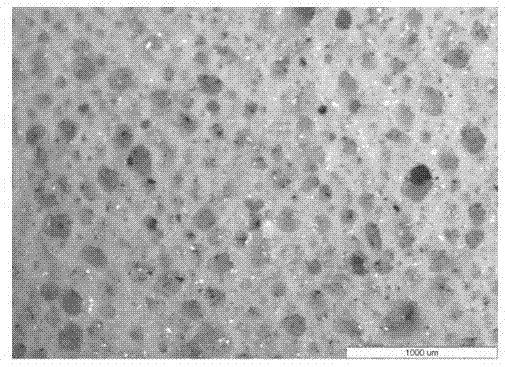

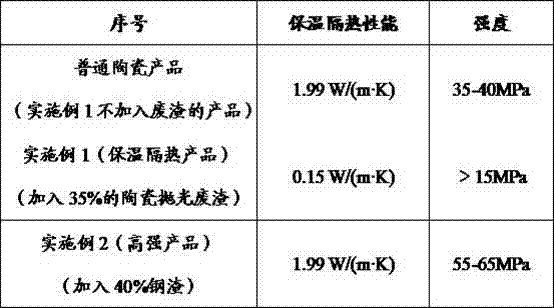

Architectural ceramic prepared from industrial solid waste through dry method and process for preparing architectural ceramic

ActiveCN103570340AReduce the cost of degummingSave the drying processCeramic materials productionClaywaresFluidized bed dryingThermal insulation

The invention discloses architectural ceramic prepared from industrial solid waste through a dry method and a process for preparing the architectural ceramic. The architectural ceramic comprises the following components in percentage by mass: 30-60% of solid waste, 40-70% of ceramic raw material and 1-3% of ceramic additive, wherein the ceramic raw material is selected from one or a composition of multiple of clay raw material, feldspar raw material or talc, and the ceramic additive is one or a combination of multiple of sodium tripolyphosphate, sodium silicate, ammonium chloride, ammonium citrate, sodium humate, sodium lignin sulfonate sodium, ethylenediamine tetraacetic acid disodium and edetic acid. After being pretreated, the granules of the solid waste are fine and are mixed evenly in a dry mixing manner and a spray drying manner and are directly used for pressing of green bricks or stored in a bin for standby, so that the ball milling energy consumption and the peptization cost are reduced, the humidification pelleting and fluidized bed drying procedures are omitted, the formula can be quickly adjusted according to the functional characteristics of the architectural ceramic, the process is simple and convenient to control, and the architectural ceramic has such good properties as heat preservation, thermal insulation and high strength.

Owner:FOSHAN OCEANO CERAMICS +1

Self-dispersion type nanometer gamma A100H and its preparation method and use

A gamma-AlOOH nanocrystal powder able to be automatically dispersed in aqueous and some organic solvents for preparing self-dispersing superfine non-toxic aluminum hydroxide flame-retarding agent, or the high-molecular polymer / inorganic nano-material composition, or the microcrystalline alumina ceramics or high-performance alumina ceramics as grinding medium is prepared through reaction of sodium aluminate or Al salt solution in alkaline medium, extracting the generated deposit, adding peptizing agent and disperser, peptizing and dispersing to obtain aluminum hydroxide colloid, reacting on additive and surfactant for surface modifying, and spray drying.

Owner:GUANGXI UNIV FOR NATITIES

High temperature-resistant activated alumina material and preparation method thereof

ActiveCN102745729AEase of mass productionSimple processAluminium oxide/hydroxide preparationRoom temperaturePeptization

The present invention provides a high temperature-resistant activated alumina material and a preparation method thereof. The alumina material is prepared by the following steps: mixing macroporous pseudo-boehmite, high viscosity pseudo-boehmite and an additive by using water; uniformly stirring at a rotation speed of 100-1000 r / min; adding dilute nitric acid with a concentration of 30% to carry out a reaction until the pH value is 2.0-5.5 and the solution is at the peptization state, and then aging for 3-6 hours at a temperature of 80-100 DEG C while stirring; adding a pore-forming agent at a room temperature, and carrying out uniform stirring, pulping, spraying and drying; and carrying out calcination at a temperature of 900 DEG C to prepare the alumina. The alumina material of the present invention has advantages of convenient mass production, high specific surface, and the like, wherein the specific surface of the alumina material of the present invention can be maintained more than 110 m<2> / g for a long time at a temperature of 1000-1100 DEG C. In addition, the preparation method of the alumina material has characteristics of simple process and low cost.

Owner:浙江欧信环保科技有限公司

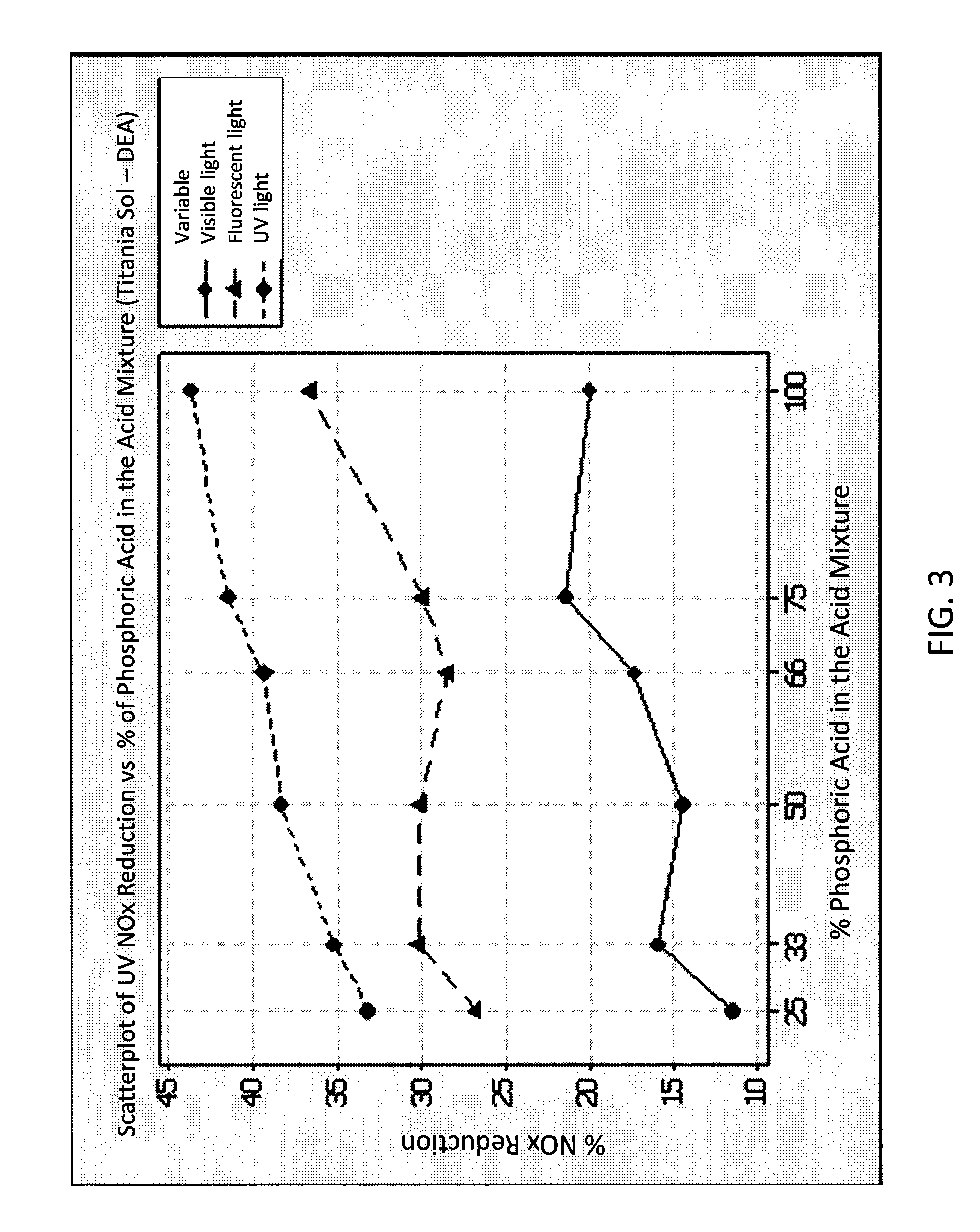

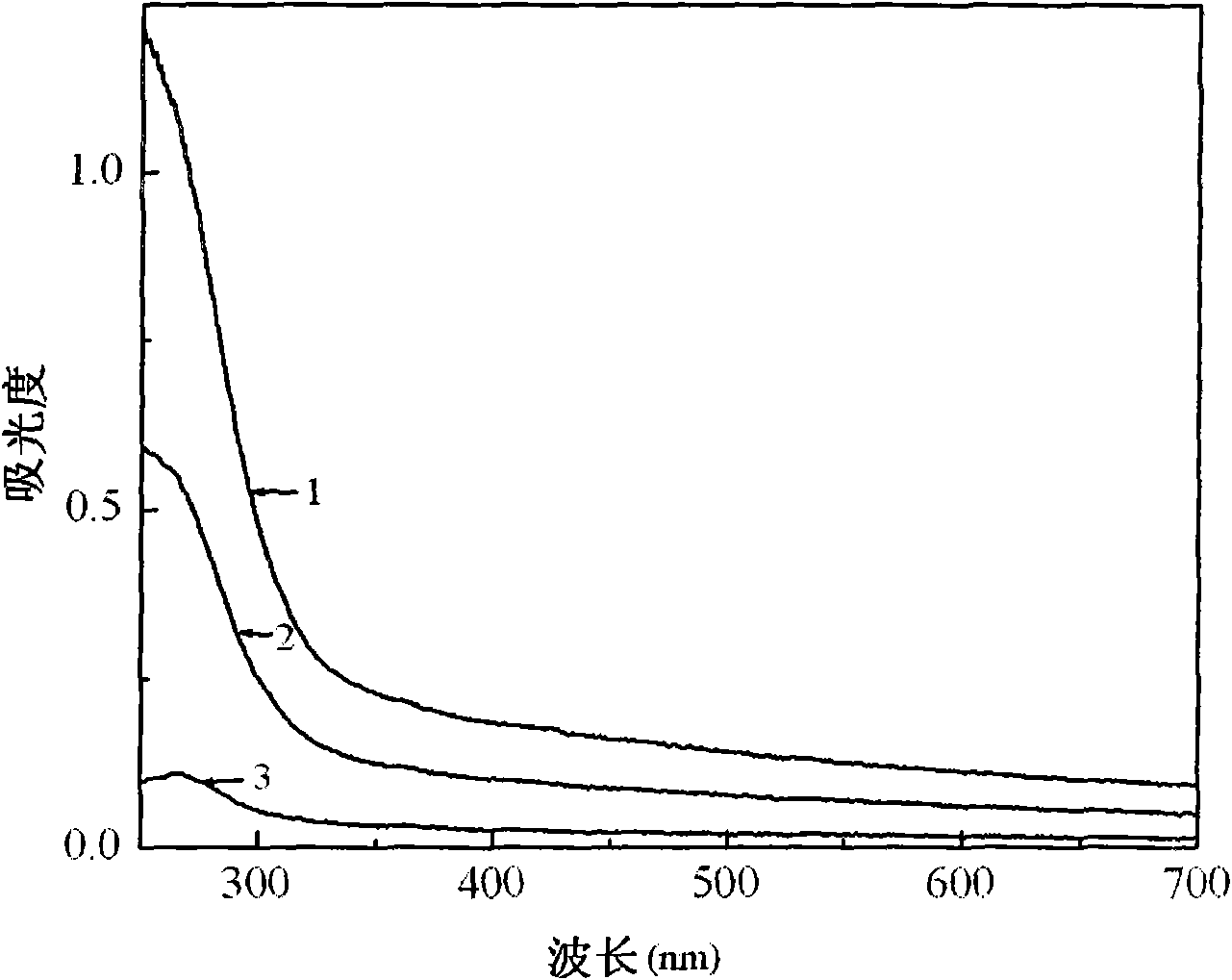

Neutral, Stable and Transparent Photocatalytic Titanium Dioxide Sols

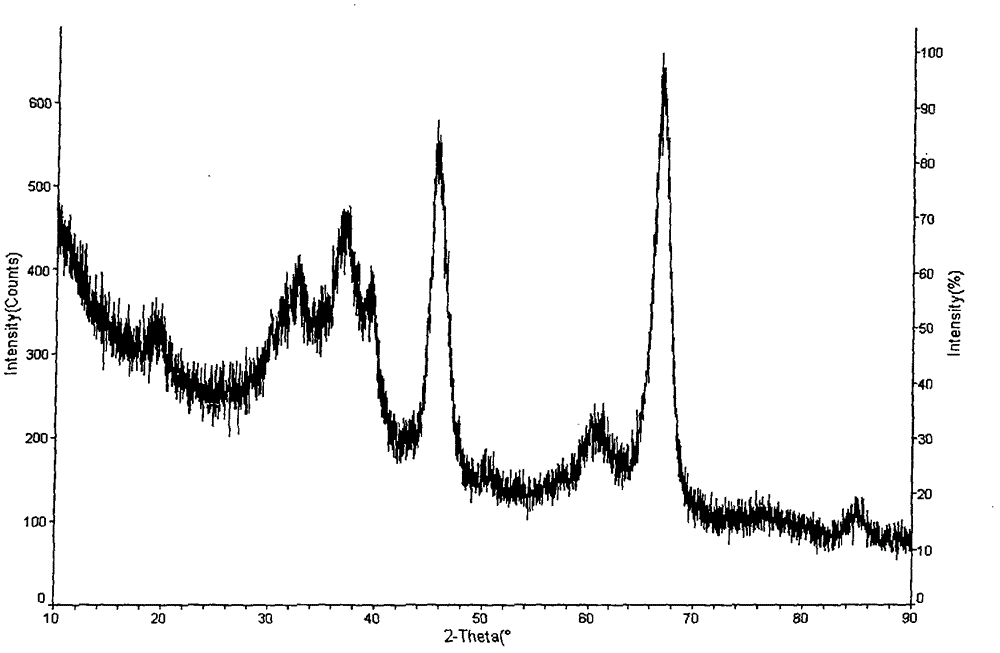

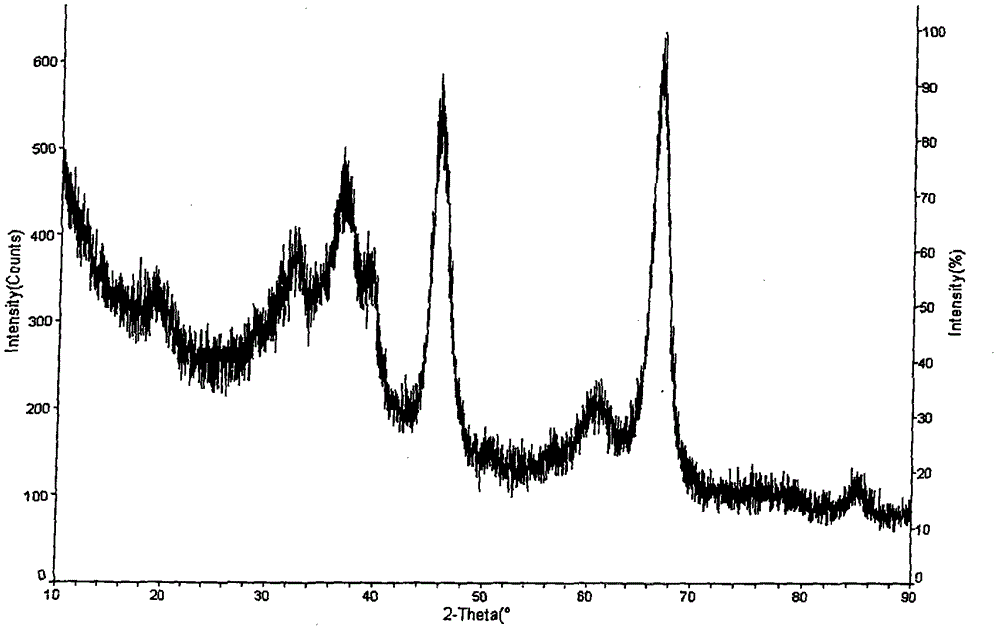

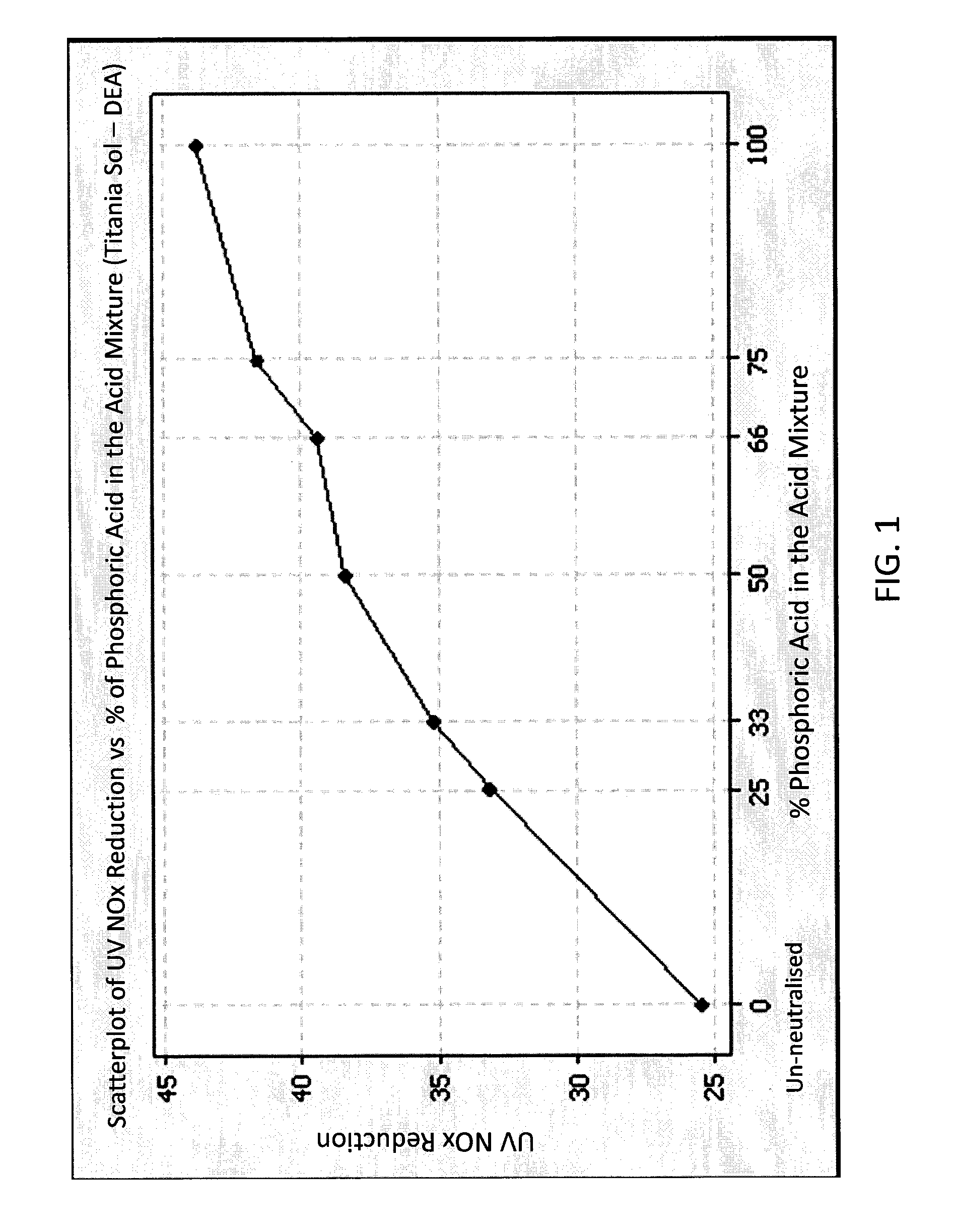

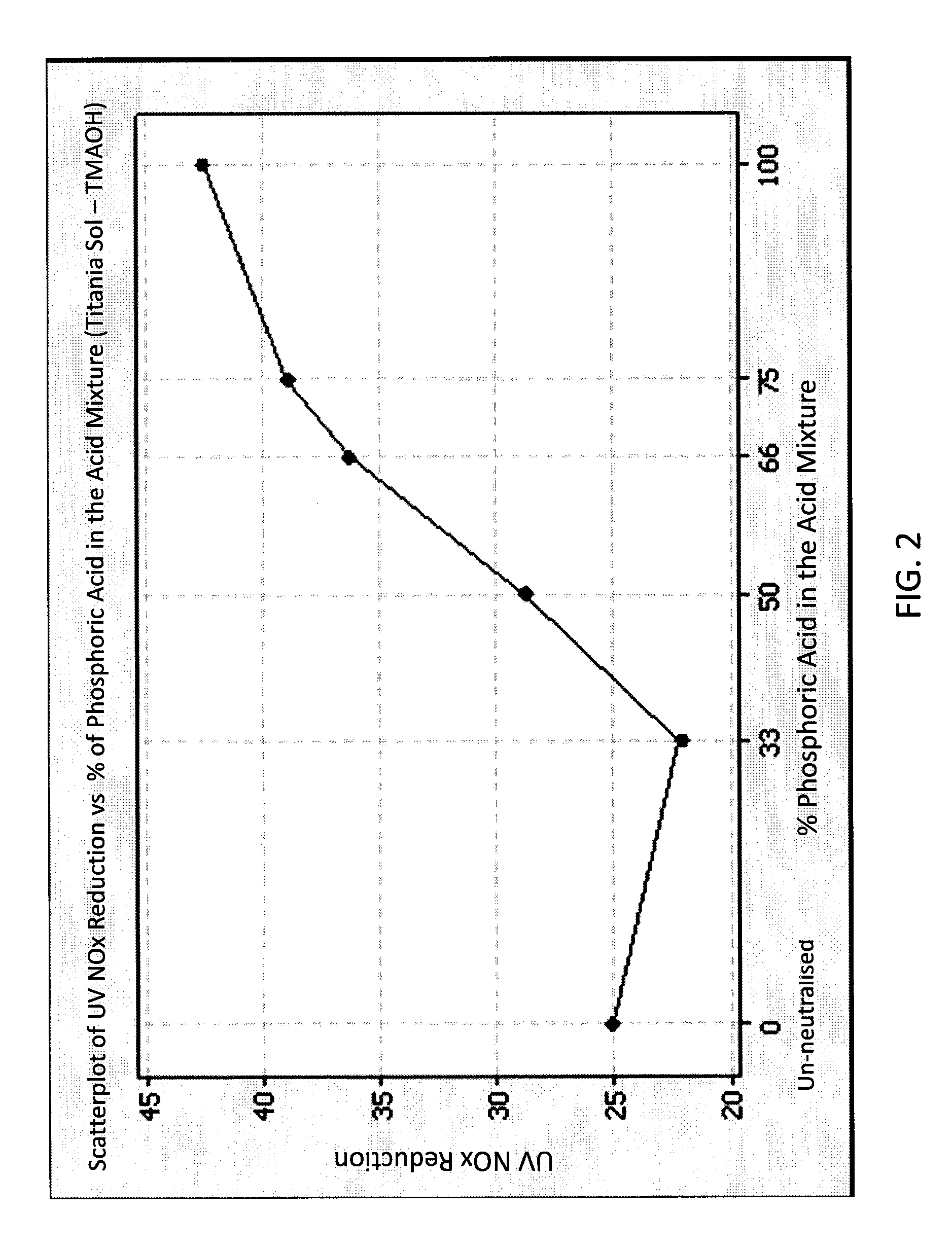

ActiveUS20130122074A1Easy to useLong stabilityHeavy metal active ingredientsBiocidePeptizationHYDROSOL

A method for preparing a neutral, stable and transparent photocatalytic titanium dioxide sol is provided. The method comprises (1) contacting an alkaline titanium dioxide sol with an alkaline peptizing agent to provide a peptized alkaline titanium dioxide sol; (2) neutralizing the peptized alkaline titanium dioxide sol; and (3) obtaining or collecting the neutral, stable and transparent photocatalytic titanium dioxide sol. The titanium dioxide sol is stable and transparent over a range of pH of about 7.0 to about 9.5. The titanium dioxide sol may include crystallites of titanium dioxide having an average particle size of less than about 10 nm with at least 90% of the crystallites being in the anatase form.

Owner:TRONOX LLC

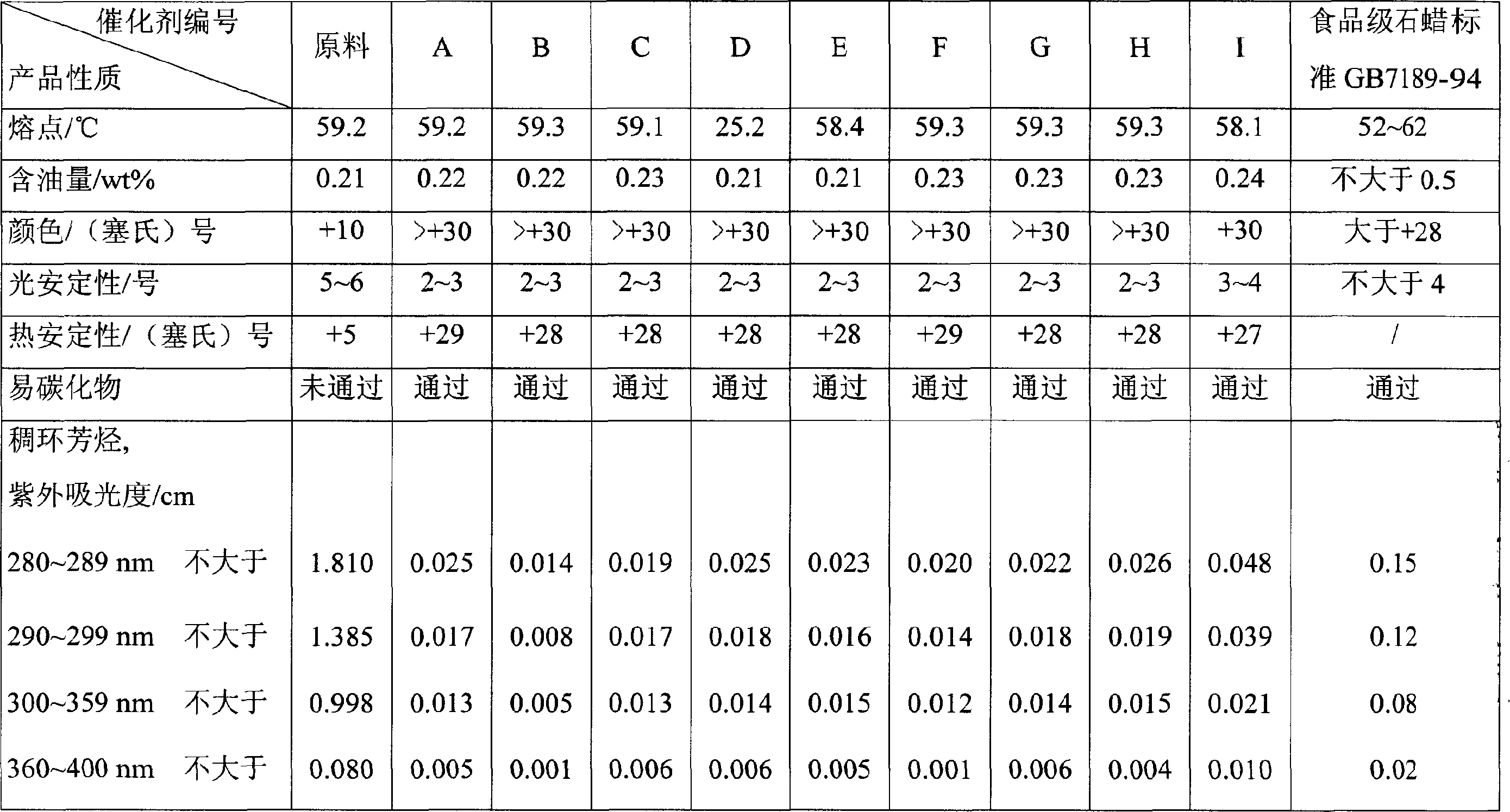

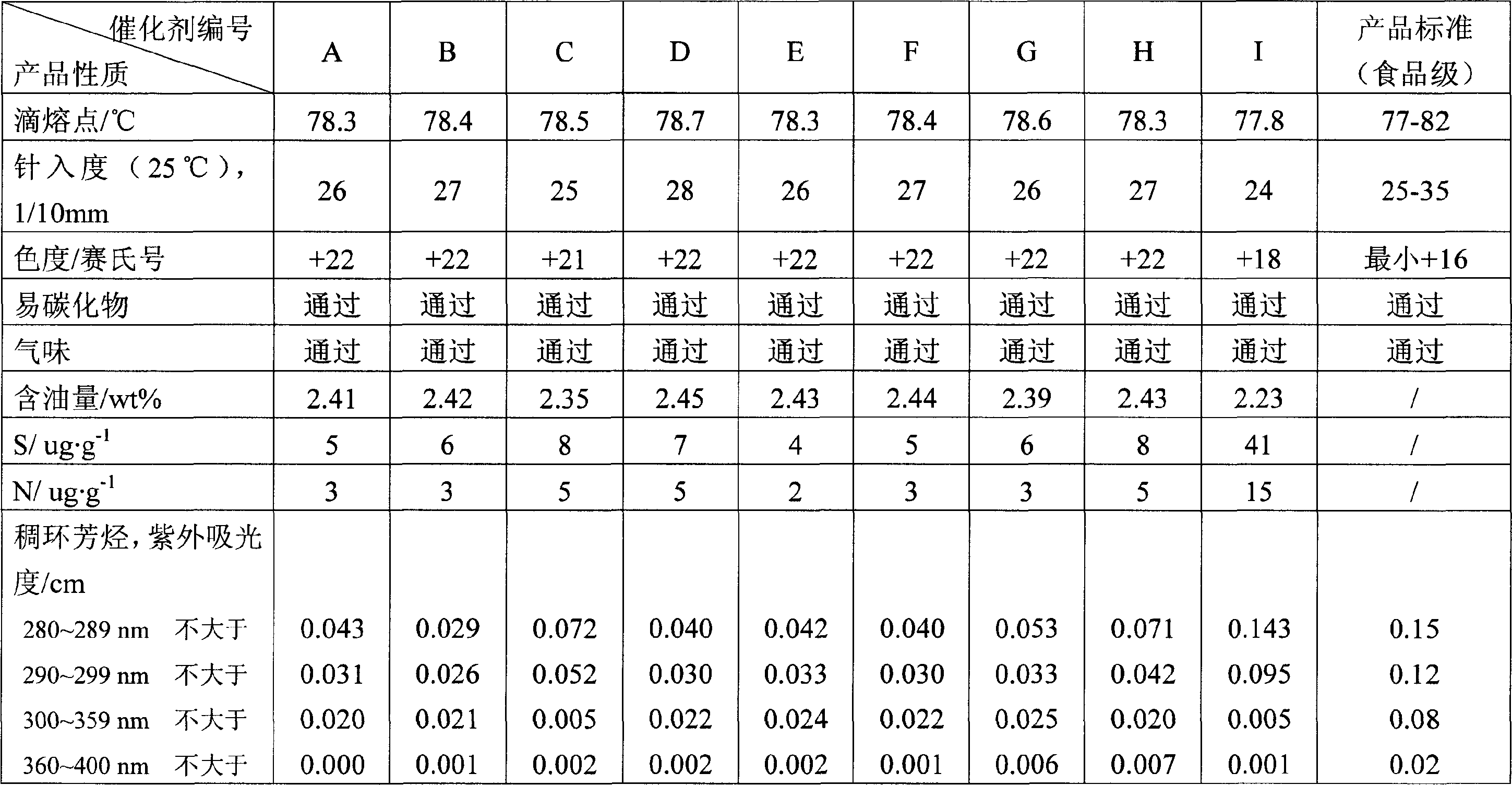

Hydrogenating catalyst for petroleum wax and its preparation process

ActiveCN1597868AGood physical and chemical propertiesLarge aperturePetroleum wax refiningAluminateWax

The invention discloses a petroleum wax hydrogenation catalyst and its preparing method, adopting the Si- and P- containing aluminum hydroxide prepared by CO2 netur neutralization process to act as a carrier material of catalyst, where the Si and P auxiliaries are added in steps, some Si- and P- containing compounds mix with sodium meta-aluminate solution to form a glue, some Si-containing compounds are added after the glue is formed or in the ageing process, and most P-containing compounds are added in the process of peptizing or pulping the produced aluminum hydroxide after washed, thus making most Si and P are distributed on the surface of aluminum hydroxide, effectively give full play to the Si and P cooperatively regulating surface physico-chemical property and hole structure of the catalyst. Its preparing process is simple and low-cost. It has good activity and selectivity as processing petroleum waxes including high-melting point petroleum wax.

Owner:CHINA PETROLEUM & CHEM CORP +1

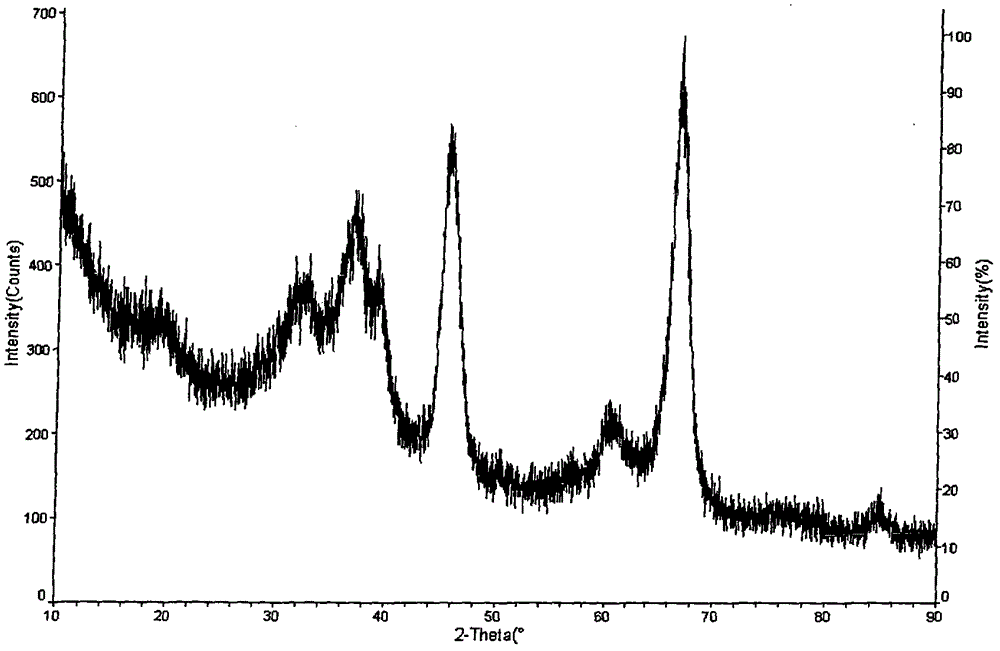

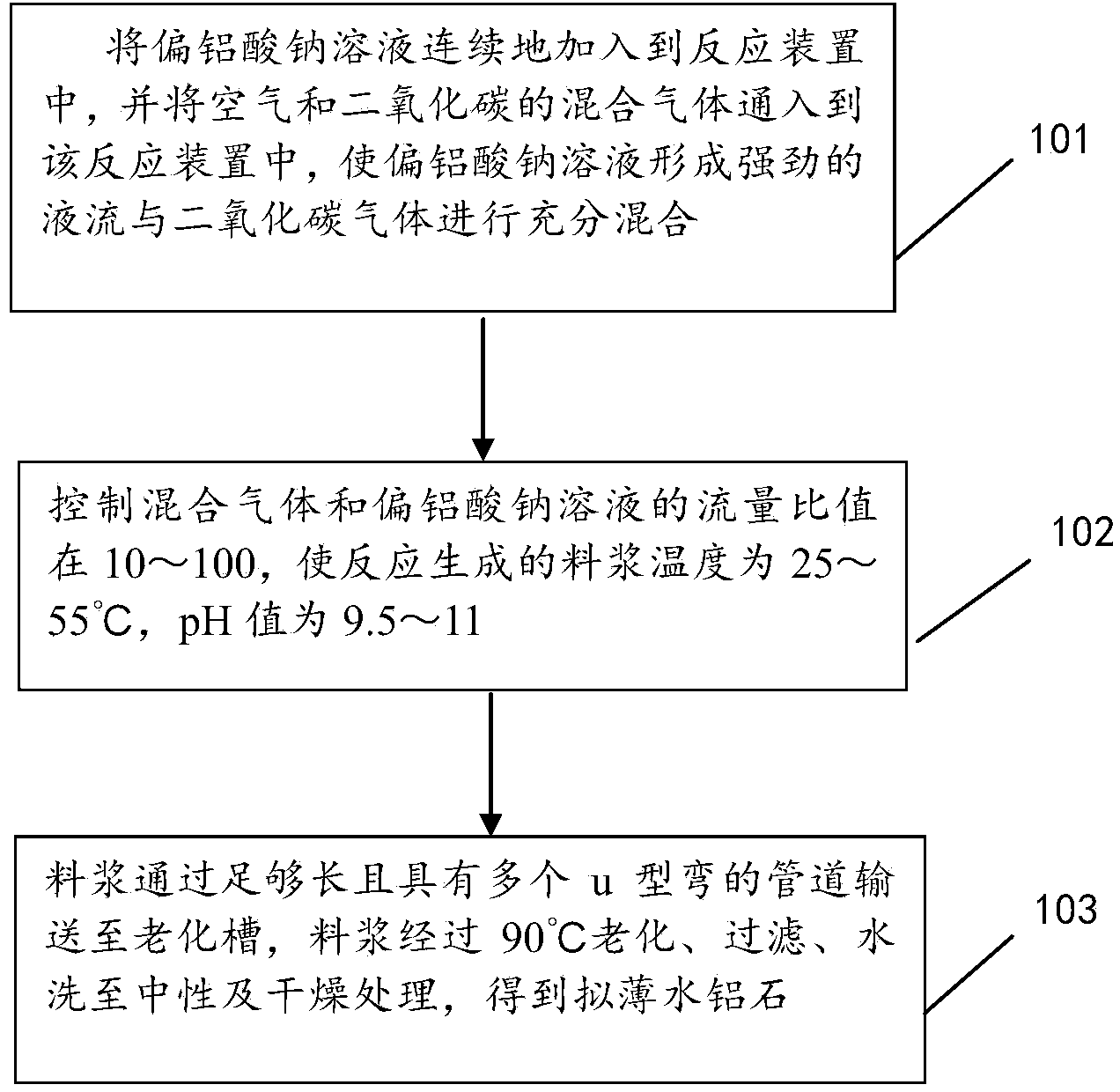

Method for continuously producing pseudoboehmite

ActiveCN103449484ASmall pore volumeLarge specific surface areaAluminium oxides/hydroxidesPseudoboehmiteSlurry

The invention discloses a method for continuously producing pseudoboehmite, belonging to the technical field of boehmite preparation. The method comprises the following steps: continuously adding a sodium metaaluminate solution into a reactor while introducing an air-carbon dioxide gas mixture, and forming a strong liquid flow of the sodium metaaluminate solution to be thoroughly mixed with the carbon dioxide gas; controlling the flow rates of the gas mixture and the sodium metaaluminate solution to control the temperature of the slurry generated by reaction at 25-55 DEG C and the pH value at 9.5-11; and after the slurry passes through a pipeline with a plurality of U-shaped bends, aging the slurry, filtering, washing with water, and drying to obtain the pseudoboehmite. The pseudoboehmite prepared by the method has the characteristics of large specific area and pore volume, reasonable peptization, continuous production, simple technique, high production efficiency, stable product quality, low equipment investment, reliable operation, low energy consumption, low labor intensity and the like, is convenient to operate and maintain, and is especially suitable for producing common pseudoboehmite, superfine aluminum hydroxide or aluminum oxide.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

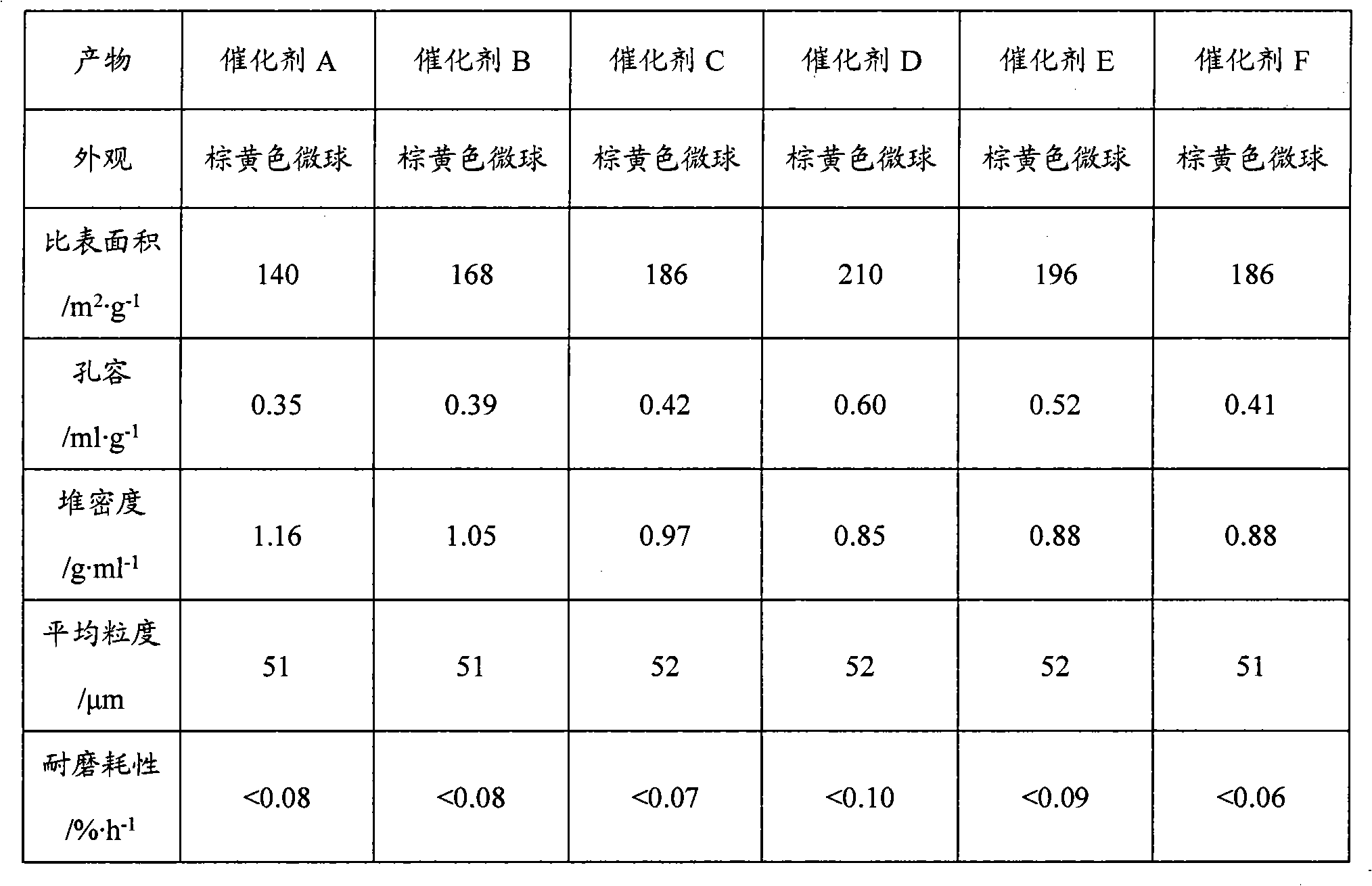

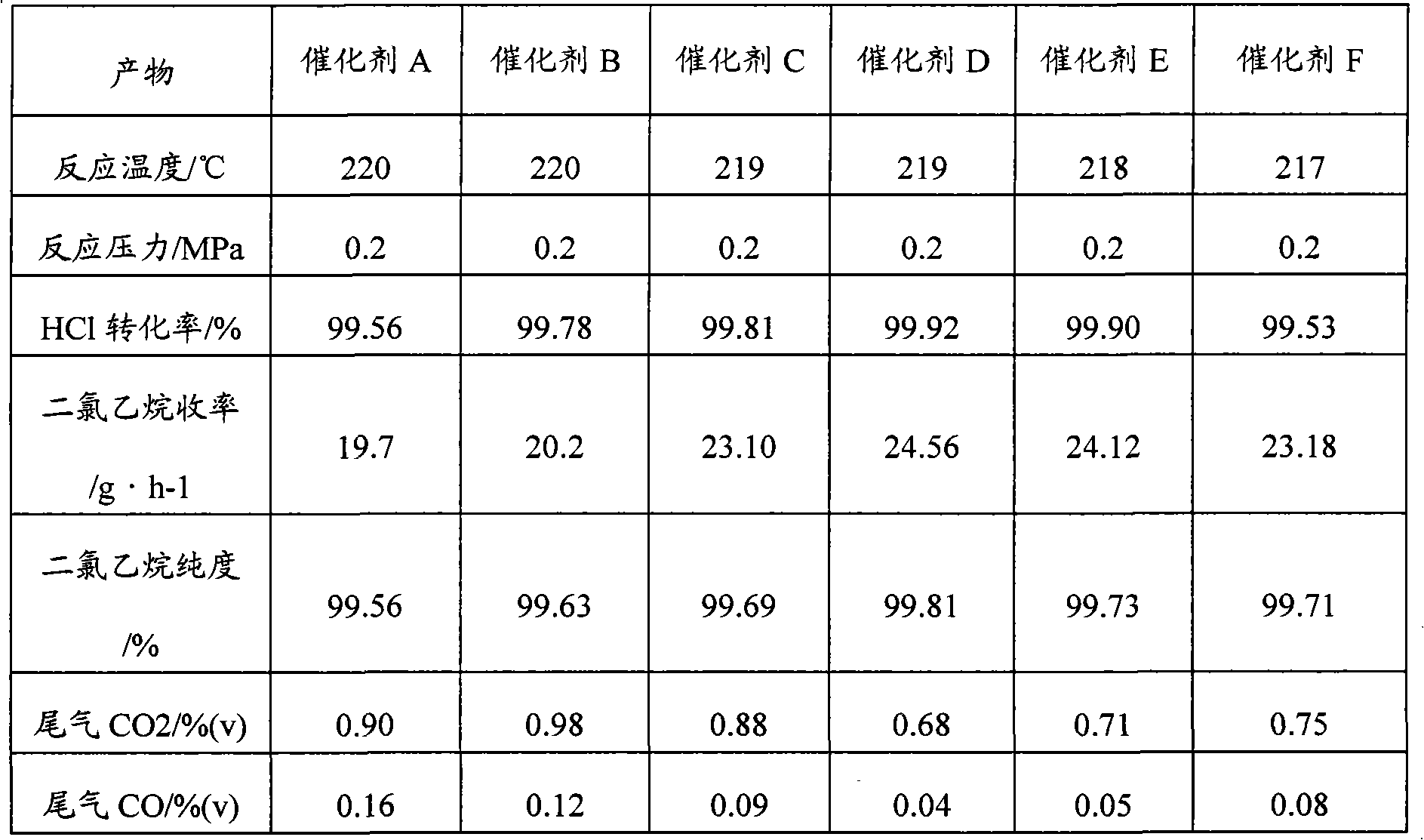

Microspherical ethylene oxychlorination catalyst preparation method

ActiveCN102049314AMaintain catalytic activityProblems Affecting Catalytic PerformanceCatalyst activation/preparationHalogenated hydrocarbon preparationTime extensionMicrosphere

The invention discloses a microspherical ethylene oxychlorination catalyst preparation method, which comprises the following six steps: solution preparation; precipitation and reaction; peptization; active component and assistant component homogenization; spray forming; and post-treatment. Solution of an active component and solution of an assistant component are dissolved in peptized pulp; a proper amount of dispersant and pore-expanding agent are added into the pulped sol solution to ensure the active component and the assistant component are uniformly distributed in the sol solution; the dispersant can prevent active and assistant component deposition caused by the prolongation of spray time; and the added proper amount of pore expanding agent can expand formed pore passage with a microspherical structure in a spraying process of the sol solution so as to improve the volume of the pore passage of a catalyst carrier and improve the pore volume and specific area of the catalyst.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

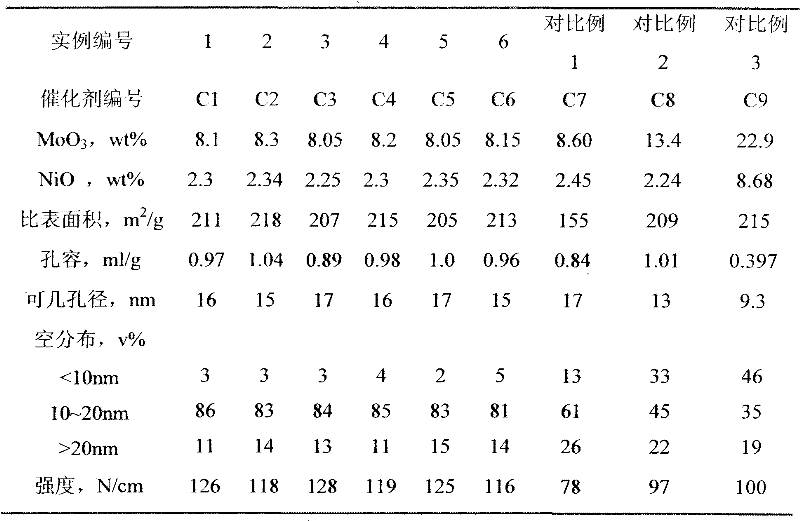

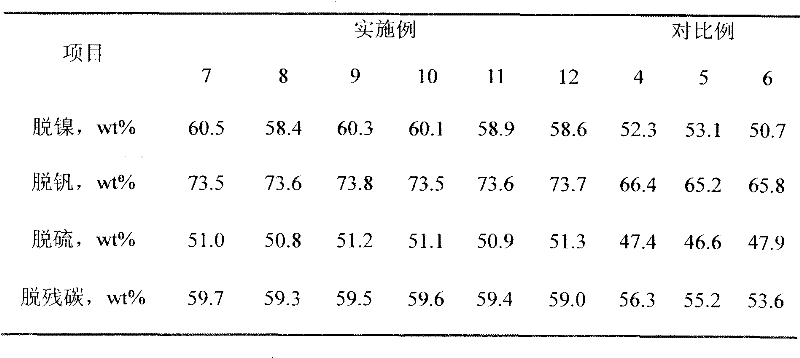

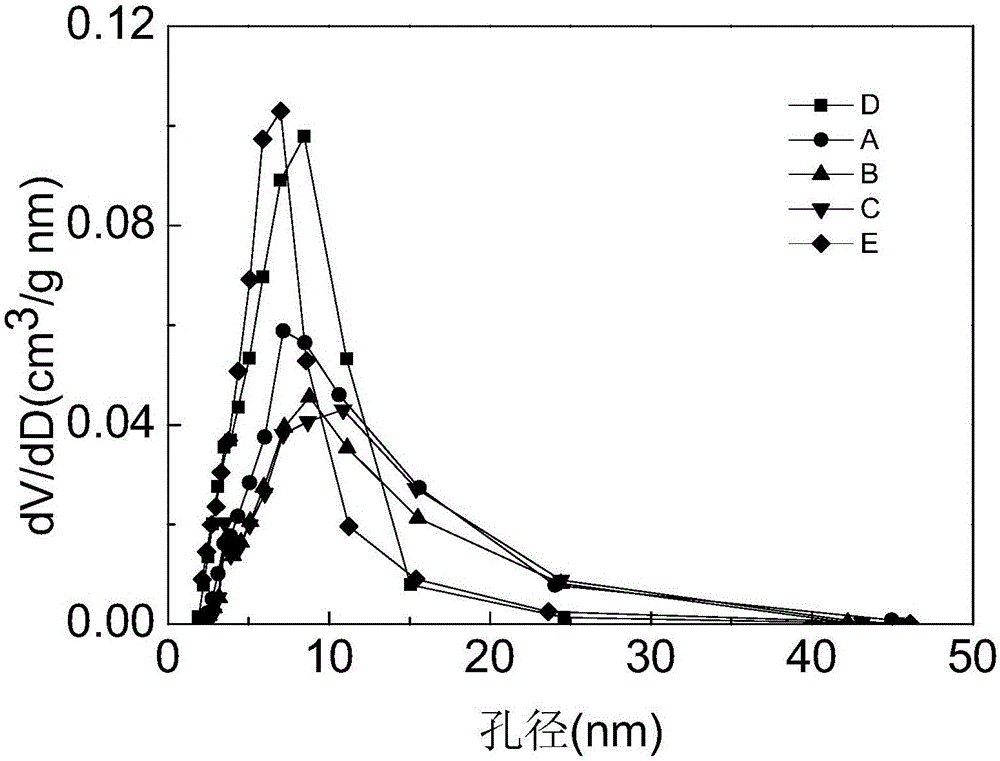

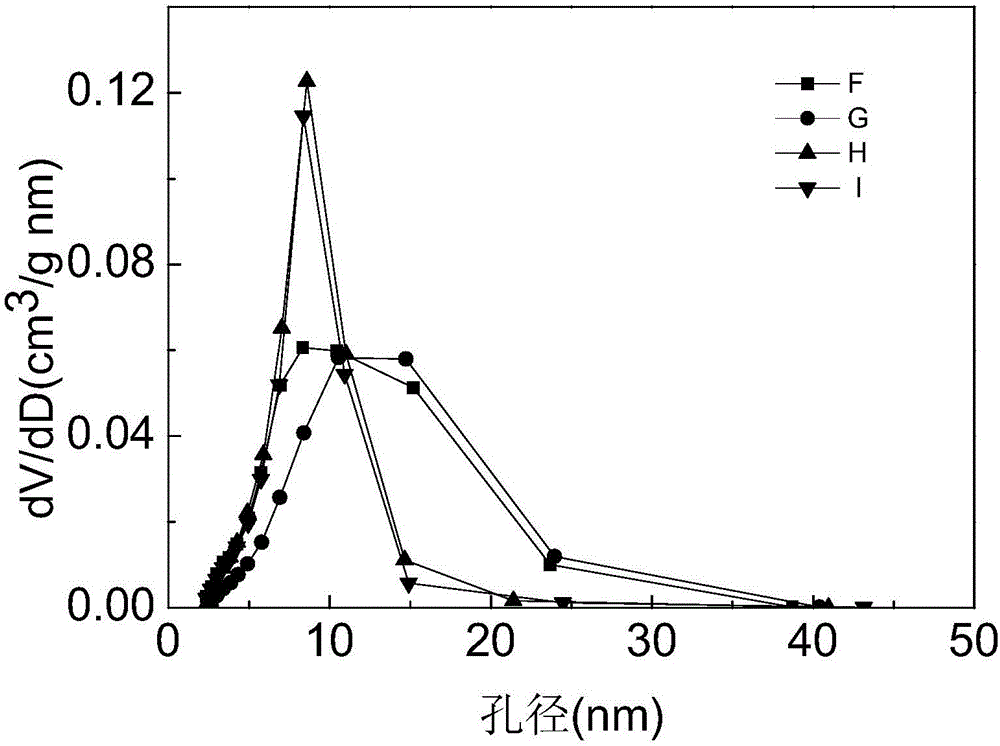

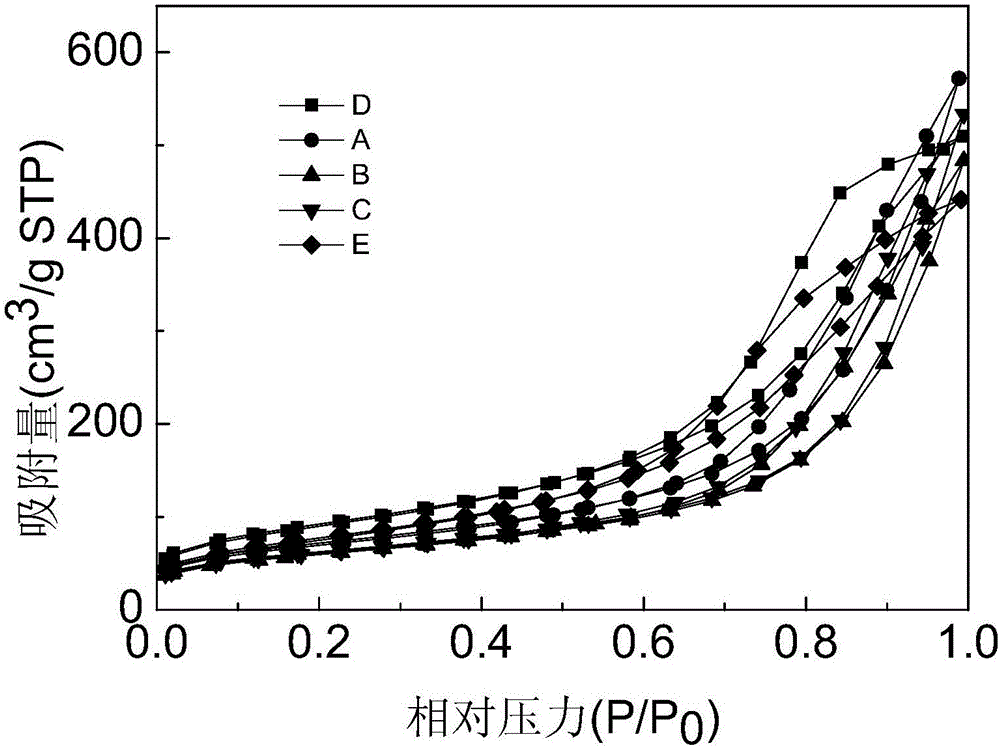

Method for preparing hydro-demetalization catalyst

ActiveCN102441398ALarge hole volumeLarge apertureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionWater vapor

The invention discloses a method for preparing a hydro-demetalization catalyst, which comprises the following steps of: (1) weighing two kinds of pseudoboehmite dry colloidal powder with different natures, evenly mixing, adding an extrusion aid, then, carrying out peptization, forming, drying, and roasting to prepare an alumina carrier; (2) preparing a dipping solution from a VIB metallic compound and / or a VIII metallic compound; and (3) dipping the alumina carrier prepared in the step (1) by using the dipping solution prepared in the step (2), drying an obtained wet catalyst, and then, roasting the catalyst in water-vapor-contained atmosphere to prepare the final catalyst. With the adoption of the method disclosed by the invention, the hydro-demetalization catalyst with a large pore diameter, large pore volume and concentrated pore distribution can be prepared under the condition of not using a pore-expanding agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Normal temperature solidified titania sol

InactiveCN1530326ALow costNo operating temperatureTitanium dioxideColloidal chemistry detailsPhysical chemistryPeptization

A TiO2 sol able to be solidified at ordinary temp to become anatase crystal type TiO2 is prepared through hydrolyzing the compound of inorganic titanium to obtain spontaneous crystal seed, ordinary-pressure hydrolyzing inorganic titanium compound under the action of said crystal seed to obtain white deposit, and dissolving in inorganic acid. Its advantages are low cost, low operation temp, and no pollution.

Owner:INST OF CHEM CHINESE ACAD OF SCI

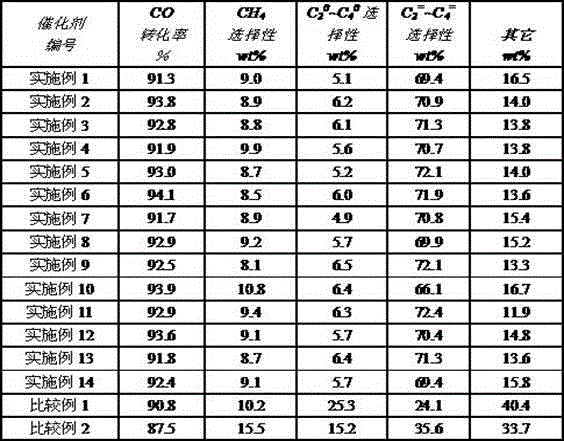

Catalyst for directly preparing low-carbon olefin from microspherical synthesis gas, as well as preparation method thereof

ActiveCN104549296AImprove wear performanceReduce wear rateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasFluidized bed

The invention relates to a catalyst for directly preparing a low-carbon olefin from a microspherical synthesis gas, and is mainly used for solving the problems that the existing co-precipitation Fischer-Tropsch catalyst preparation technology comprises the following steps: firstly co-precipitating and then pulping and spray-forming, so that the slurry is substantially a non-homogenous body dispersed by adopting a physical method, the finial catalyst finished product is uneven and the hydrocarbon products on the catalyst are widely distributed. The problems are well solved by adopting the technical scheme that the preparation method comprises the following steps: firstly precipitating a part of components, then carrying out peptization on the obtained precipitates by using the salt solution of non-precipitated components to obtain chemically evenly dispersed sol, then spray-drying the sol, and then roasting at high temperature. The preparation method can be used for industrial production for a catalyst for synthesizing the low-carbon olefin from the synthesis gas. The catalyst is applicable to but not limited to such reactors as a fluidized bed and a slurry-state bed in which catalyst grains are required to be distributed according to the certain distribution rule.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for making improved zeolite catalysts from peptized aluminas

This invention relates to a process of preparing a catalyst from zeolite and peptized alumina. The invention comprises adding a yttrium compound to the zeolite, either prior to, during, or after its combination with the peptized alumina. The yttrium compound can be added to the zeolite via exchange of yttrium onto the zeolite prior to addition of peptized alumina, or the yttrium can be added as a soluble salt during the combination of the zeolite and peptized alumina. In either embodiment, the zeolite catalyst is then formed from the zeolite, yttrium and peptized alumina, optionally containing other inorganic oxide. This invention is suitable for preparing fluid cracking catalysts.

Owner:WR GRACE & CO CONN

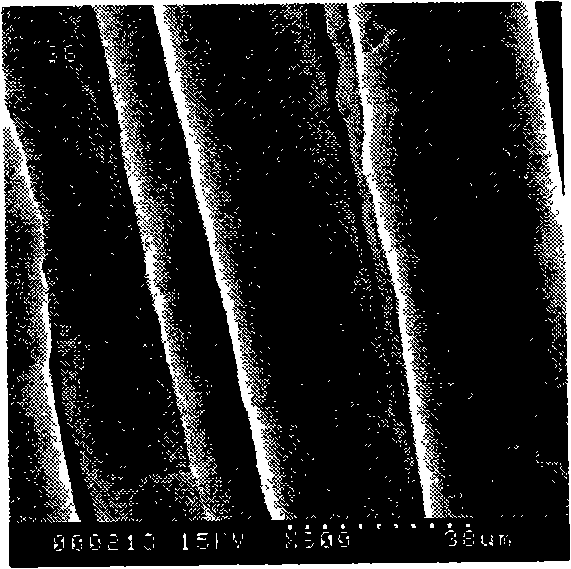

Preparation method for alumina coat on quartz fibre surface

The invention relates to a preparation method for an alumina coat on quartz fibre surfaces, and belongs to the technical field of special functional ceramics. The preparation method comprises the following steps: respectively adding aluminum ion, nitric acid and chelating agent in solvent according to the molar ratio of 1: (0.03-0.28): (0.5-1) till all the materials are hydrolyzed to generate sediments; then, adding peptizator to carry out peptization; carrying out reflux heating and stirring for 8 to 24h at a temperature of between 50 and 100 DEG C to obtain transparent and stable Al2O3 sol; putting quartz fibre into a steeping vat of Al2O3 sol for steeping and then heating up and gradually drying the quartz fibre at a temperature of between room temperature and 80 DEG C; and finally, carrying out heat treatment at a temperature of between 450 and 850 DEG C to obtain the quartz fibre coated with the alumina coat. The preparation method is scientific, reasonable and easy to implement; moreover, the Al2O3 coat coated on the surface of the quartz fibre increases material mechanical property and reduces material brittle fracture.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Ferromagnetic microsphere medium made from urea-formaldehyde resin and its preparation method

A microspherical medium of ferromagnetic urea-formaldehyde resin is composed of the urea-formaldehyde resin with 0.5-20 microns of granularity and uniformly dispersed Fe3O4 nanoparticles (0.1-200 nm). Its preparing process includes preparing magnetic fluid, preparing its sol, separating and preparing magnetic microspheres. Its advantages are simple and easily controllable process and high stability.

Owner:TIANJIN UNIV

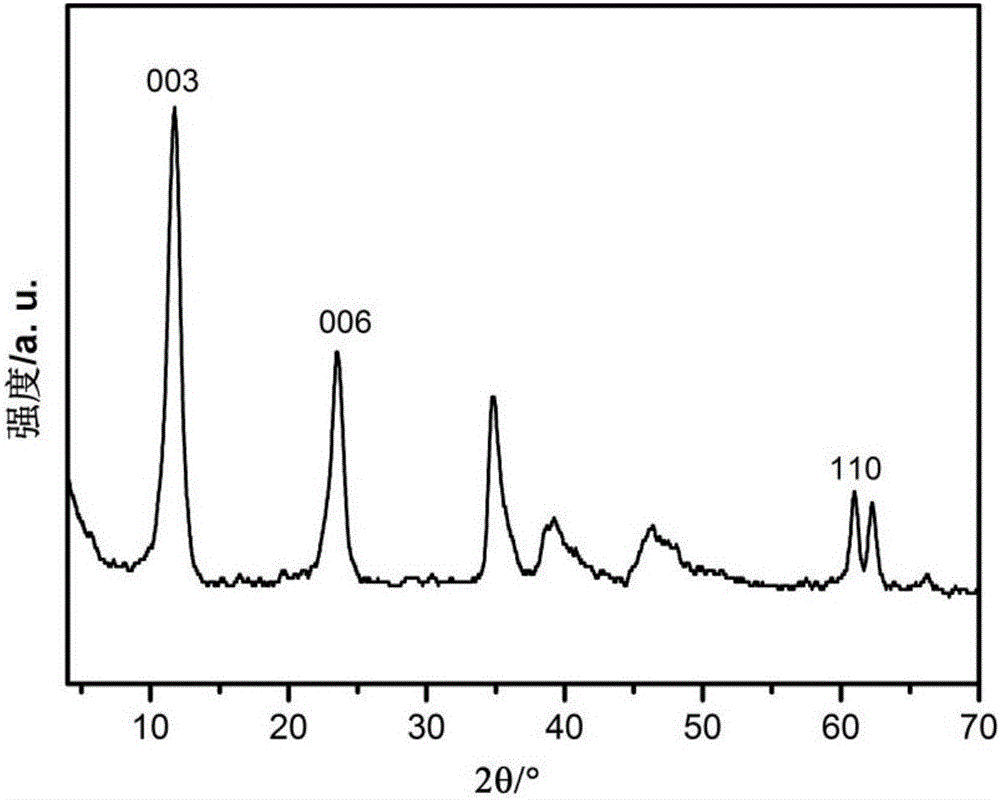

Clean preparation method of magnalium based laminated composite hydroxide

ActiveCN105836769ARich sourcesIncrease spawn rateAluminium compoundsZinc compoundsEnvironmental resistanceReaction temperature

The invention provides a clean preparation method of a magnalium based laminated composite hydroxide. The method uses magnesium hydroxide, magnesium oxide, pseudo boehmite, inorganic acid and a material containing functional anions as raw materials, uses magnesium chloride or magnesium nitrate as a circulation medium, and uses the property of peptization under acidic condition of boehmite to improve the reaction activity of pseudoboehmite; the concentration of magnesium ions in solution is increased by using magnesium chloride or magnesium nitrate. The method accelerates the formation rate of laminated composite hydroxide, promotes the dissolution of magnesium hydroxide and magnesium oxide, shortens the reaction time, overcomes the defects of high reaction temperature and long time consumption in hydrothermal method for synthesis of laminated composite hydroxide, and can rapidly prepare magnalium based laminated composite hydroxide under mild conditions. Magnesium chloride and magnesium nitrate can be recycled; and the preparation process has no waste discharge, and is green and environment-friendly. The method has the advantages of abundant raw materials, low cost, simple preparation process, mild reaction conditions, and easiness to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

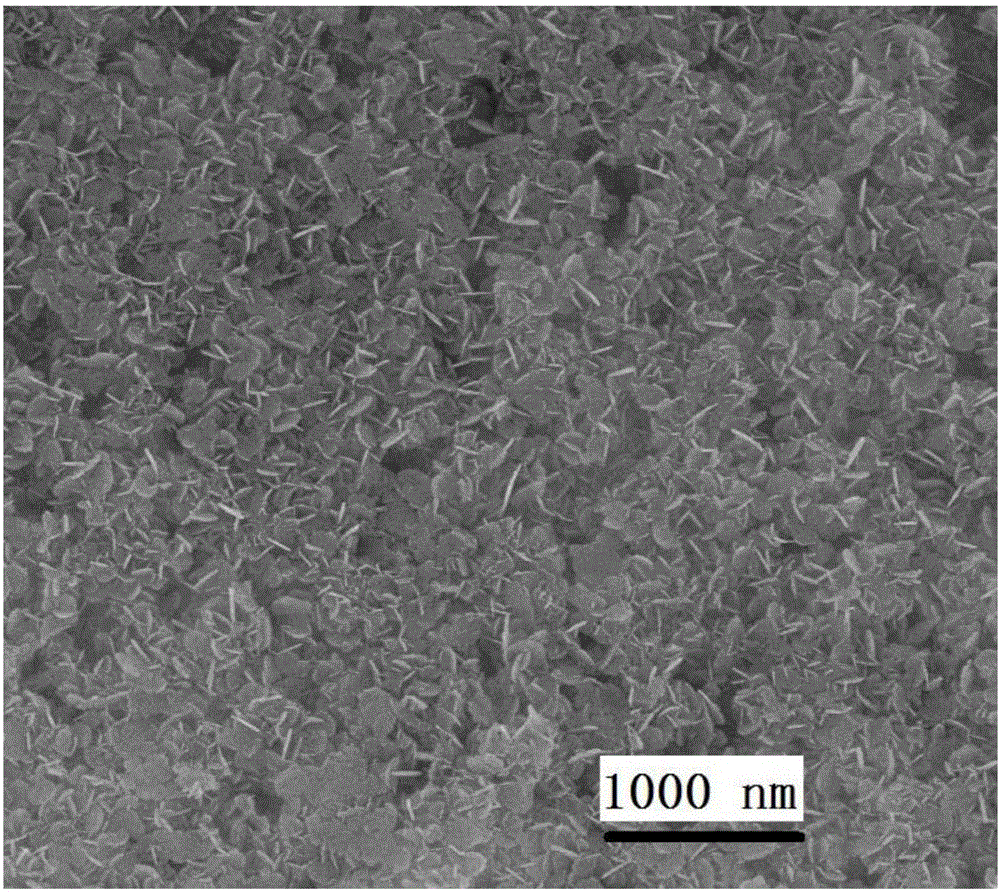

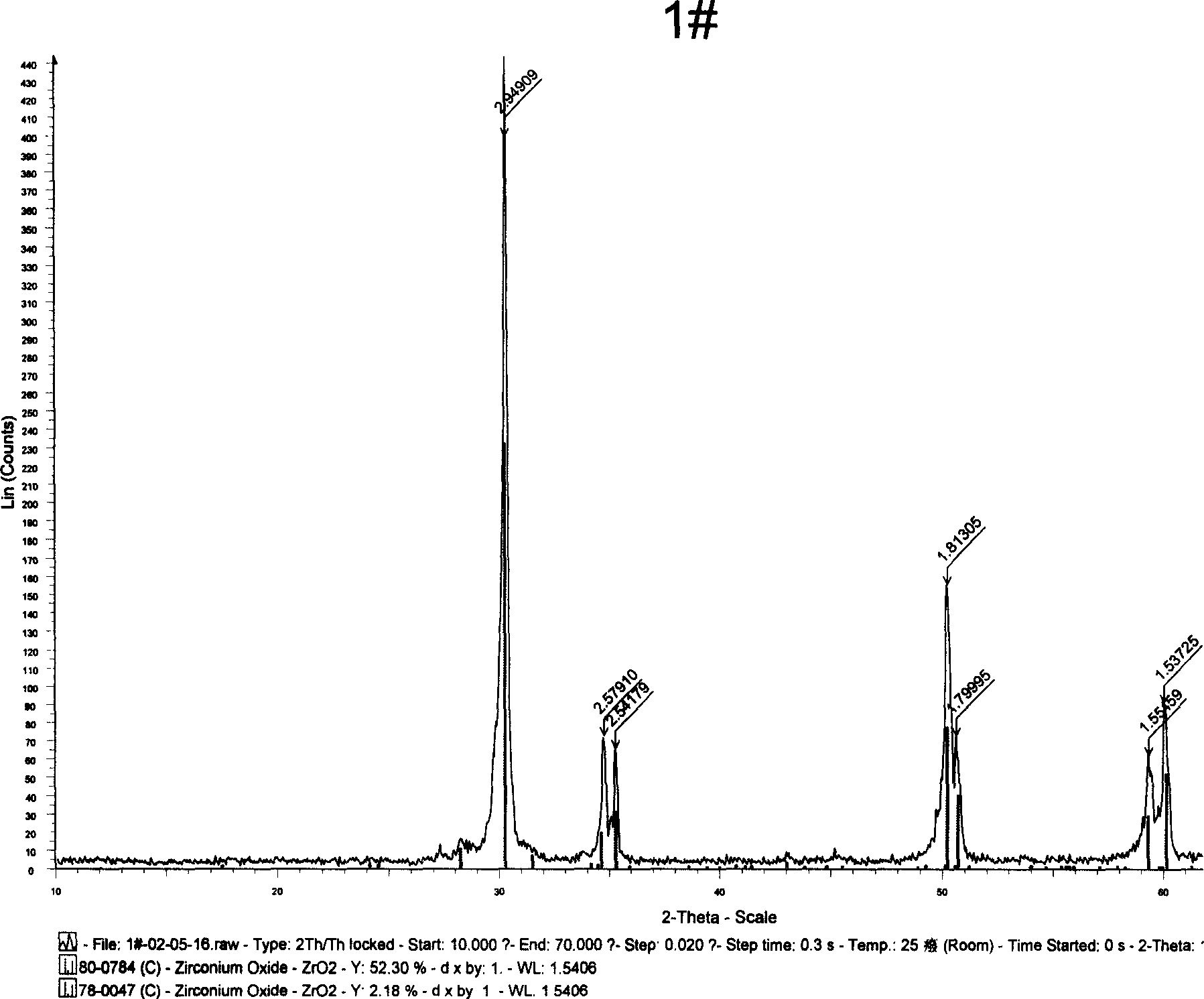

Method for preparing zirconium oxide micro powder

A process for preparing superfine zirconium oxide powder includes such steps as reaction between ammonia water and Zr salt in solution to obtain deposit, washing, filtering, adding it to the solution of zirconium chloride oxide to generate sol, heating while hydrolyzing to obtain deposit, washing, calcining and grinding. Its advantages are controllable and uniform granularity, and low cost.

Owner:河北恒博新材料科技股份有限公司

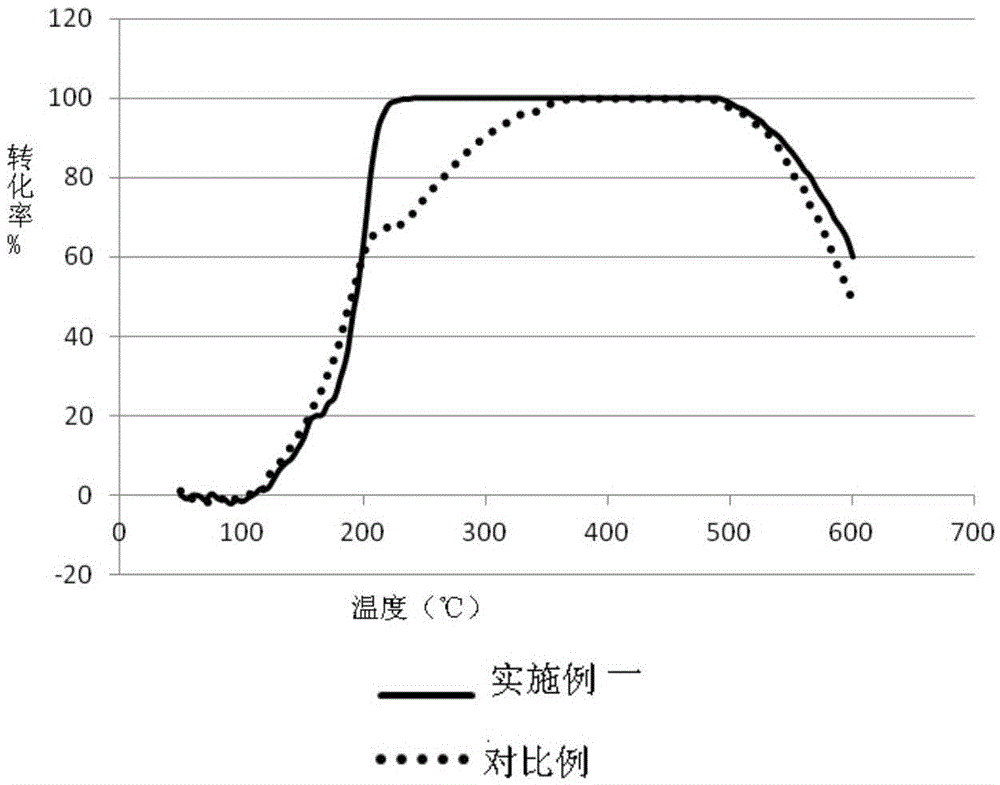

High-efficiency Fe-SCR integrated catalyst preparation method

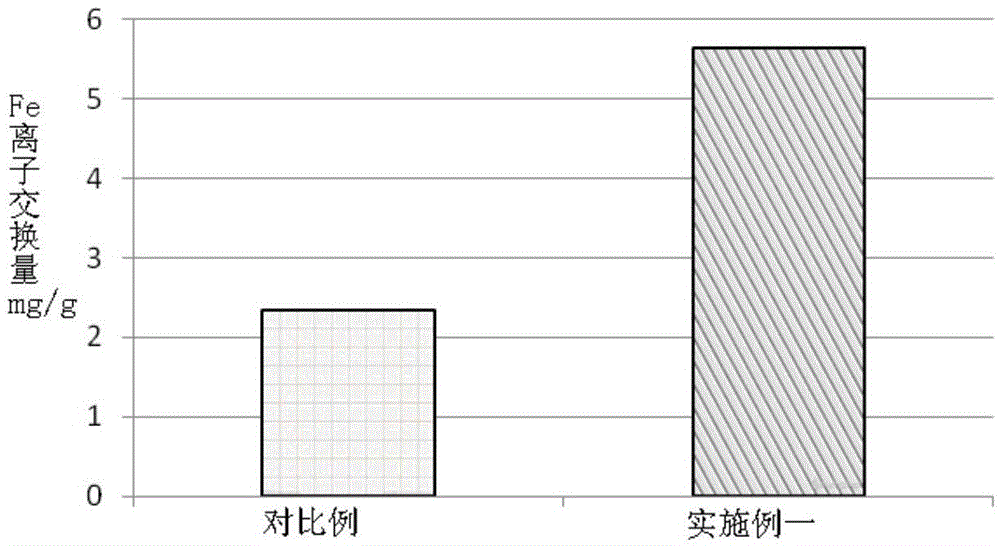

The invention relates to a high-efficiency Fe-SCR integrated catalyst preparation method. The method includes: using a Fe source for preparation to obtain an exchange solution, adding a molecular sieve into the exchange solution to realize ion exchange, and drying and roasting to obtain a high-exchange-capacity molecular sieve; well mixing pseudo-boehmite in deionized water, slowly adding nitric acid, and adding nanometer SiO2 powder to regulate a pH value after the pseudo-boehmite is peptized completely; reheating in water bath and ageing to obtain an aluminum-silicon compound adhesive serving as a bonding agent, adding the exchanged Fe molecular sieve into an aqueous solution of the bonding agent to prepare a slurry solution, and stirring for 3h; loading the slurry solution to a carrier to obtain a Fe-SCR integrated catalyst according to a dip coating method. The high-efficiency Fe-SCR integrated catalyst preparation method is simple and easy to operate; since the bonding agent is prepared by mixture of the pseudo-boehmite and the nanometer SiO2 powder, adhesive power of the Fe-SCR integrated catalyst can be increased, and low-temperature catalytic performance of the catalyst can be improved.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

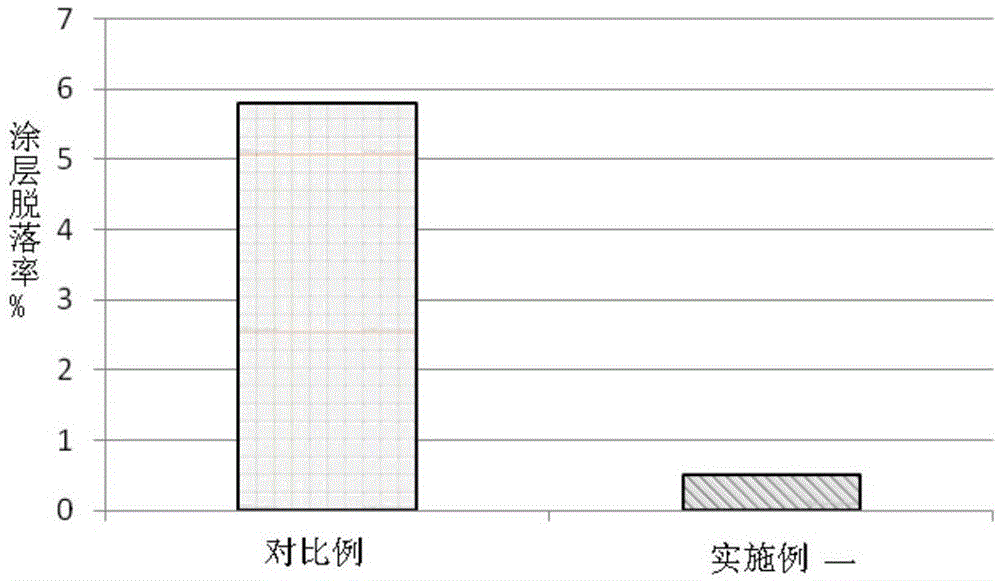

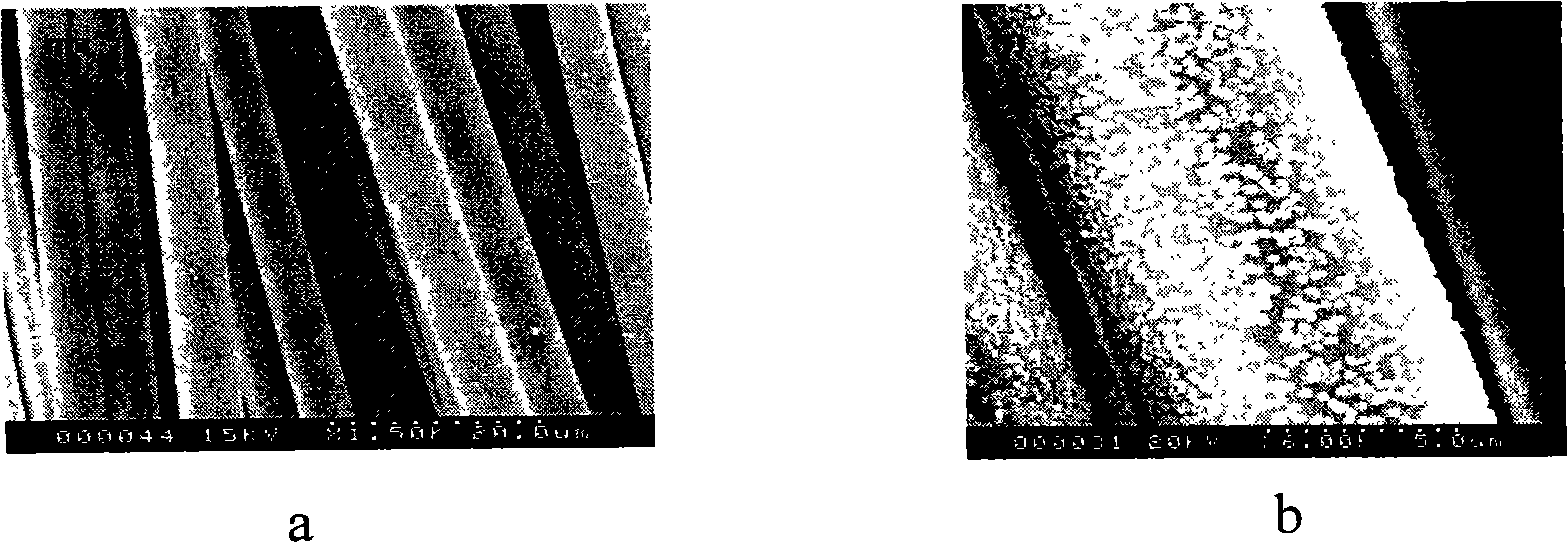

Pretreatment method of chemical plating conductive magneto-conductive glass fibre

The invention relates to a pretreatment method for chemical plating electric conducting and magnetic conducting glass fibre, which has the characteristics that: alkali-free glass fiber undergoes ultrasonic dispersion and cleaning, is washed by stilled water and then undergoes dispersion treatment, roughening treatment, coupling treatment, sensitizing and activating treatment, peptization treatment and oven drying treatment. The method has the advantages that: firstly, the self-made activator is adopted to complete the sensitizing and activating in one step and has the effect better than the two-step method, thereby optimizing the pretreatment process; secondly, the combined coupling agent is used to strengthen the glass fibre and the chemical adsorption capacity of Pa <2+> in the activator, thereby the coating has good combination property.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

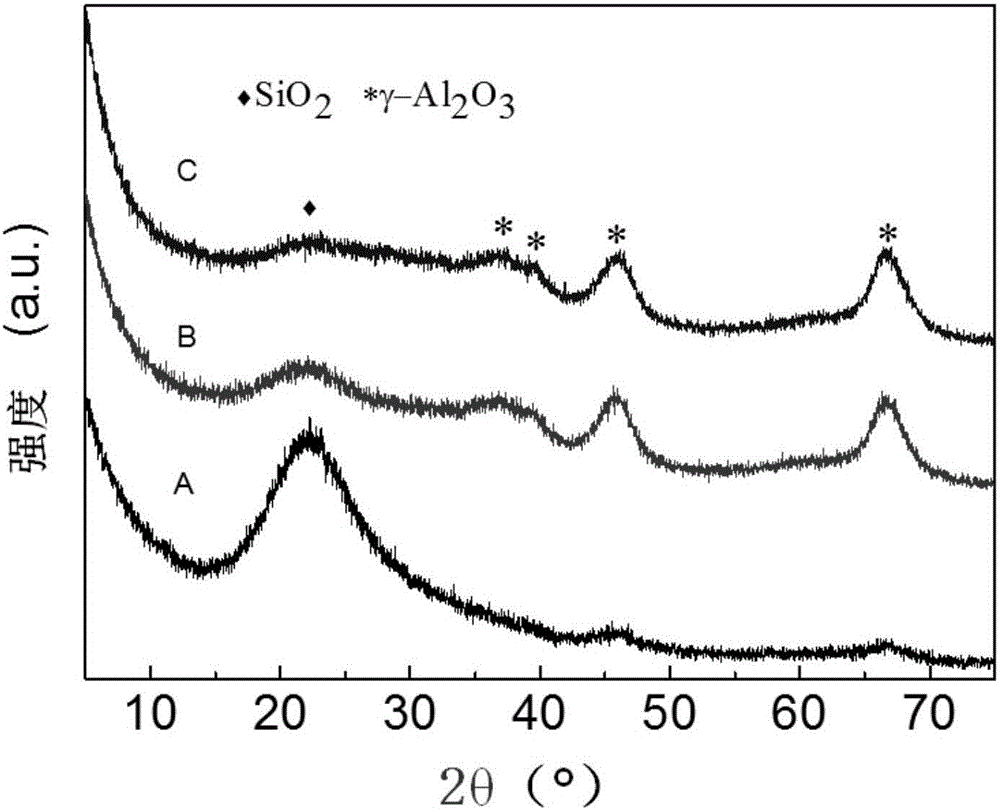

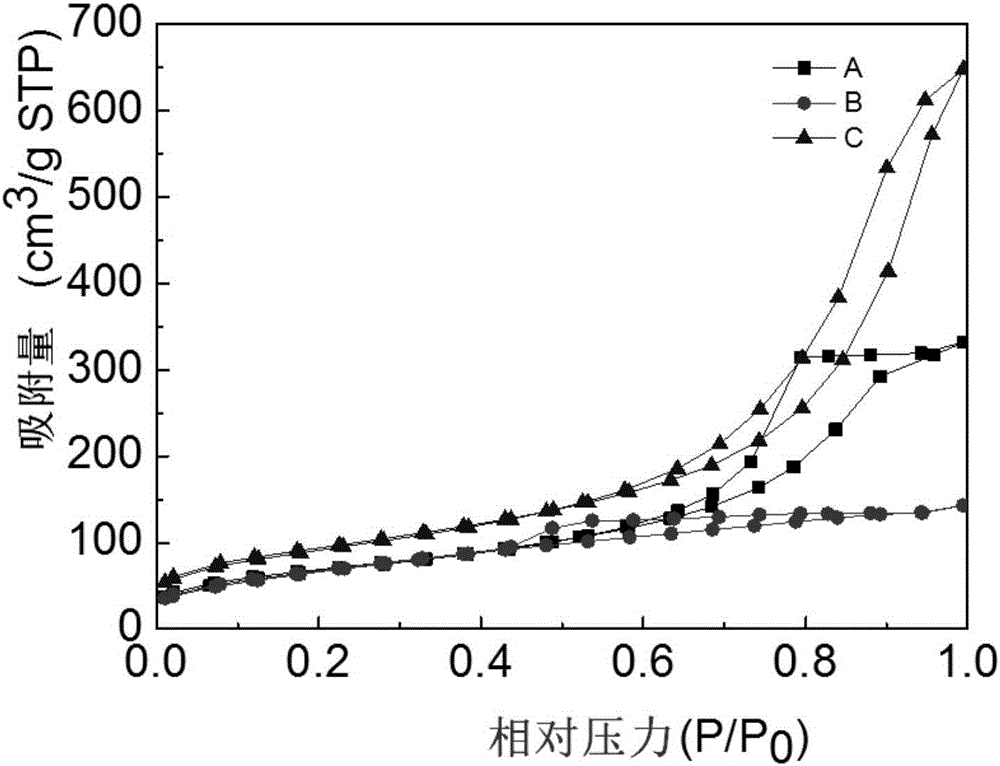

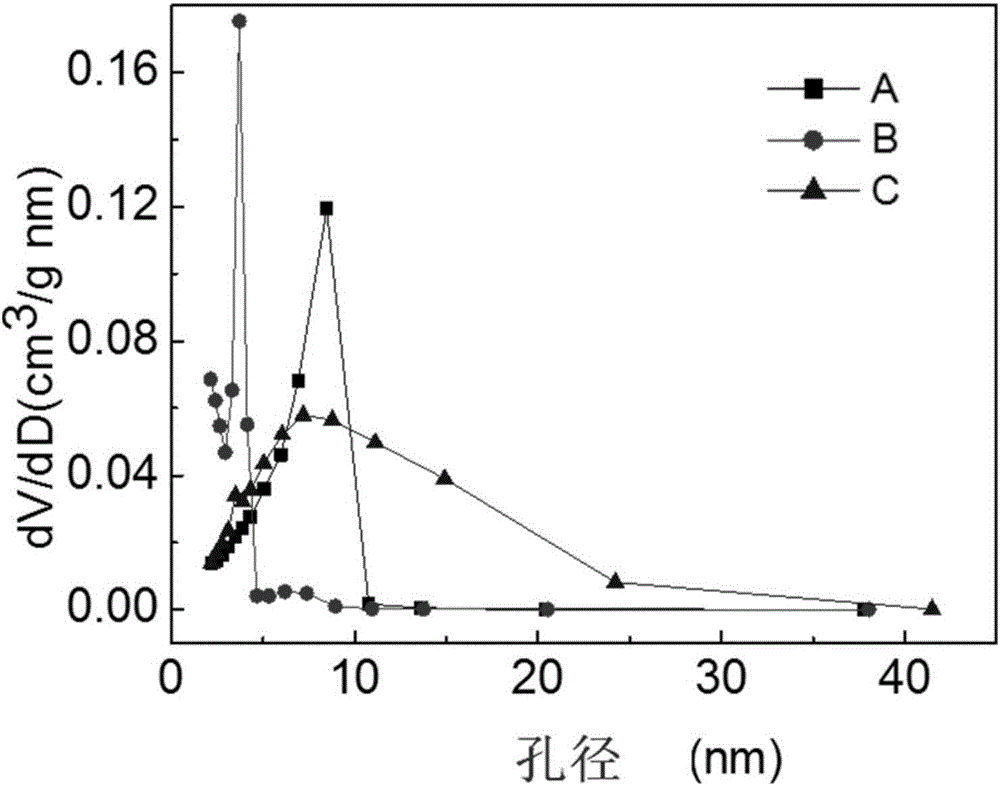

Silicon-modified alumina, as well as preparation method and application thereof

ActiveCN106582597AImprove performanceFlexibly adjust the focus of modificationCatalyst carriersSlurrySilicon

The invention provides silicon-modified alumina, as well as a preparation method and application thereof. Alumina modified by silicon sol comprises the following steps of (1) acidifying and peptizing pseudo-boehmite slurry with inorganic acid to obtain pseudo-boehmite sol; (2) adding silica sol into the pseudo-boehmite sol to obtain a first mixture; (3) regulating the pH value of the first mixture in a range that the pH is 1 to 11 according to different requirements for the content of surface bronsted acid and pore volume improvement degree of alumina, and conducting a reaction for a period of time under a heating condition to obtain a second mixture; (4) crystallizing the second mixture to obtain a third mixture; and (5) filtering, washing, drying and roasting the third mixture to obtain the silicon-modified alumina. Flexible conversion between emphasizing pore volume improvement and bronsted acid content improvement can be realized by regulating the pH value of the first mixture, so that the method has a wide application prospect.

Owner:PETROCHINA CO LTD +1

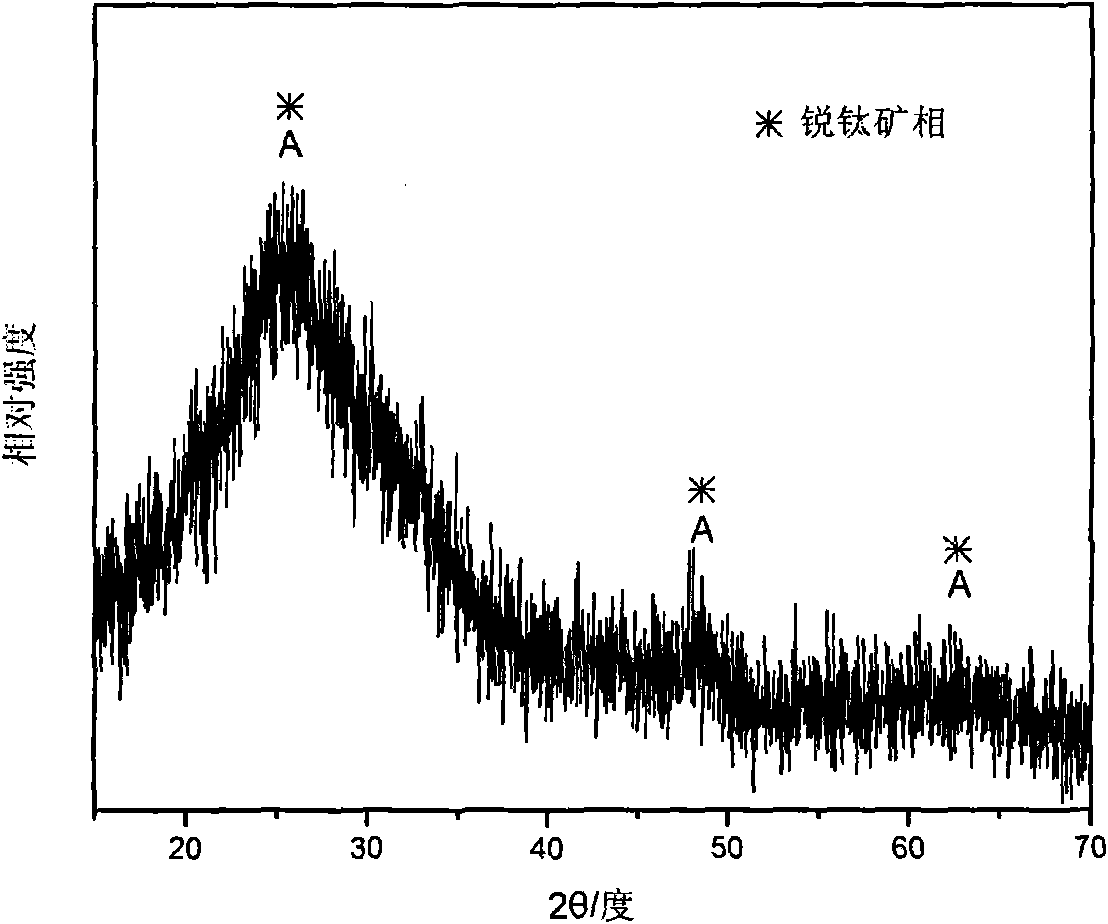

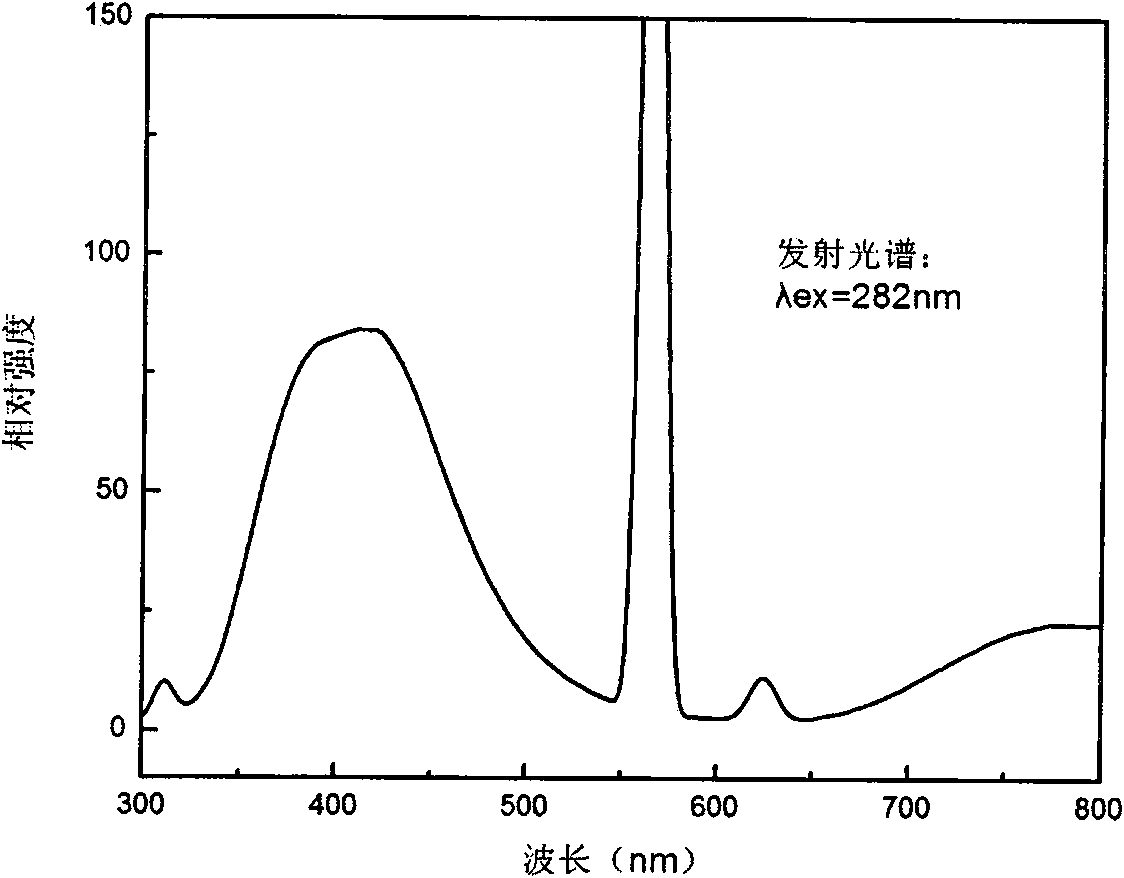

Method for synthesizing anatase phase titanium dioxide nanometer particle by microreactor

The invention relates to a method for synthesizing anatase phase titanium dioxide nanometer particle by a microreactor, comprising the following steps: (1) titaniferous inorganic substance is confected into water solution, and is heated, and inorganic alkali solution is added; (2) after precipitate is washed with water, the clean precipitate is put into perhydrol liquid, is stirred and is scattered with ultrasound, the temperature is preserved for 12-24h after rising, and peptization is carried out to obtain potassium peroxytitanate solution or collosol; (3) after diluted with polyalcohol, the potassium peroxytitanate solution or the collosol is injected into the microreactor to be treated with oil bath to obtain titanium dioxide collosol; (4) the collosol is mixed with acetone, titanium dioxide colloid particles are performed with precipitation and decentralization to obtain light white titanium dioxide powder bodies. The invention has simple technology and short reaction time and is suitable for industrialized production; the obtained titanium dioxide collosol has the characteristics of small particle, even distribution, favourable crystallinity, favourable stability, high transparency and the like.

Owner:DONGHUA UNIV

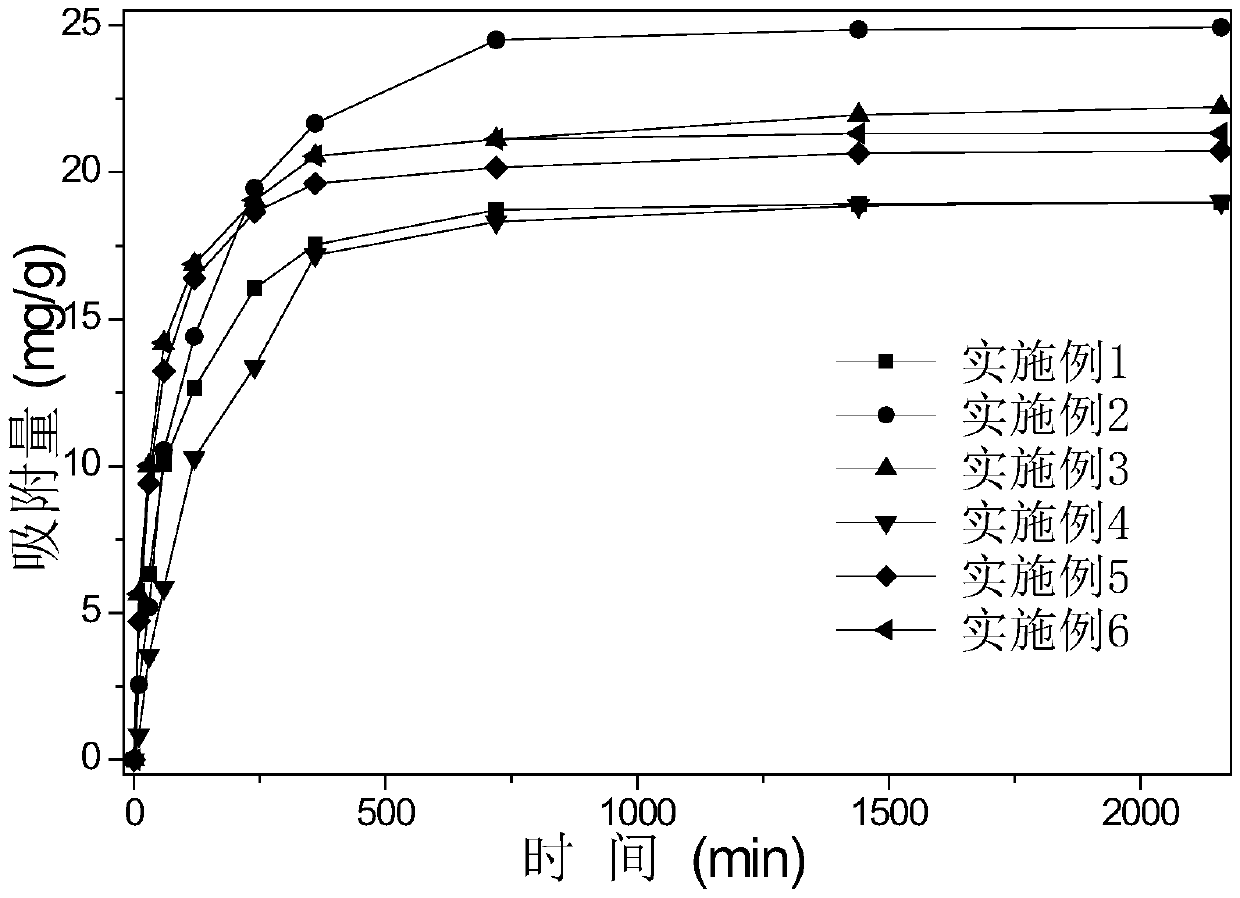

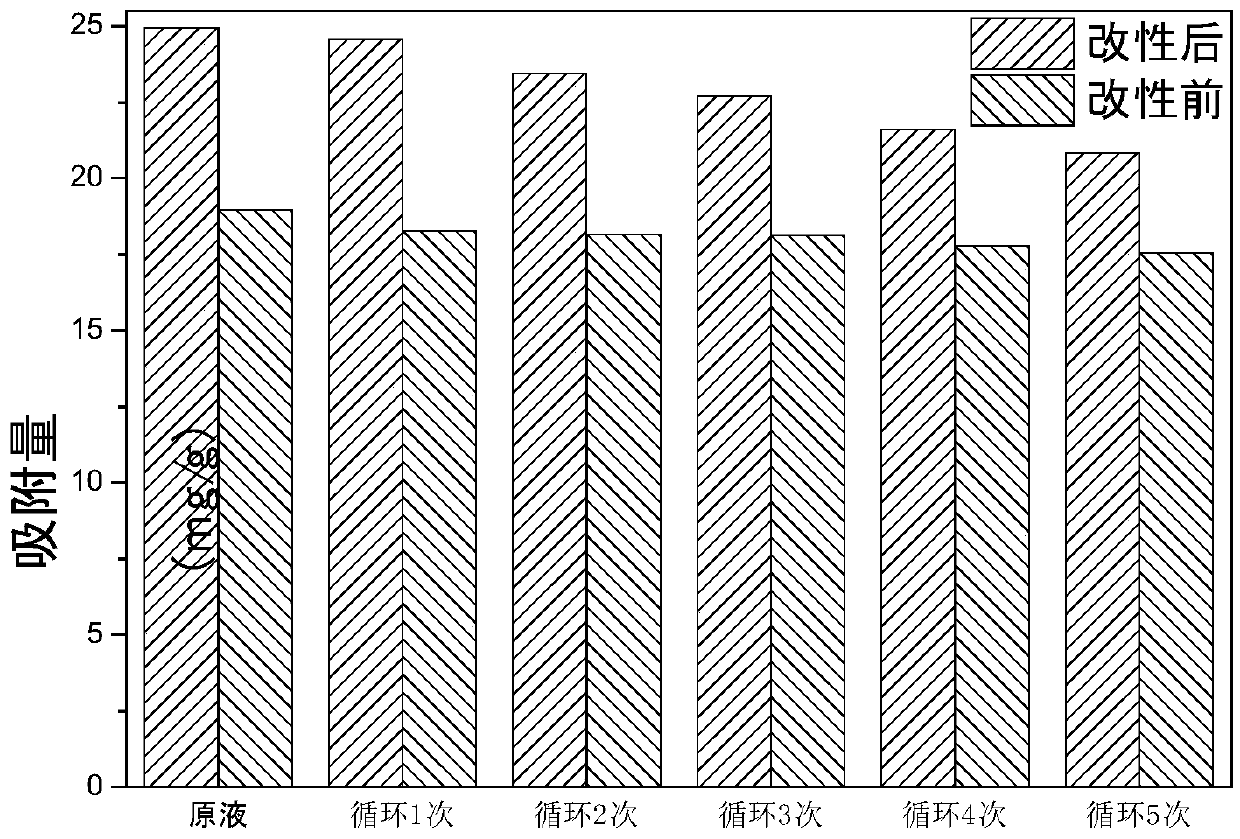

Preparation method of amino silane modified gamma-Al2O3 thin film

InactiveCN105498699ALarge adsorption capacityHigh removal rateOther chemical processesWater contaminantsSilanesPolyvinyl alcohol

The invention relates to a preparation method of an amino silane modified gamma-Al2O3 thin film for toxic Cr (VI) adsorption. The preparation method comprises the following steps: firstly, under an acidic condition, peptizing industrial pseudo-boehmite powder, adding polyvinyl alcohol serving as a coalescing agent while peptizing, mixing for a period of time, performing hydrothermal treatment on sol, and performing tape casting, drying and baking on a sol product to prepare a gamma-Al2O3 thin film; and then, under the protection of N2, refluxing the gamma-Al2O3 thin film in a solvent with amino silane for a period of time, and washing and drying to obtain the amino silane modified gamma-Al2O3 thin film. Compared with the gamma-Al2O3 thin film before modification, the amino silane modified gamma-Al2O3 thin film prepared by the method is higher in removal rate and higher in adsorption performance for toxic Cr (VI) in water; meanwhile, the thin film adsorbing toxic Cr (VI) can be easily separated from water, so that the problem of a complicated process for separating and recycling a powdered adsorbent is solved, and the separation efficiency is greatly improved.

Owner:WUHAN UNIV OF TECH

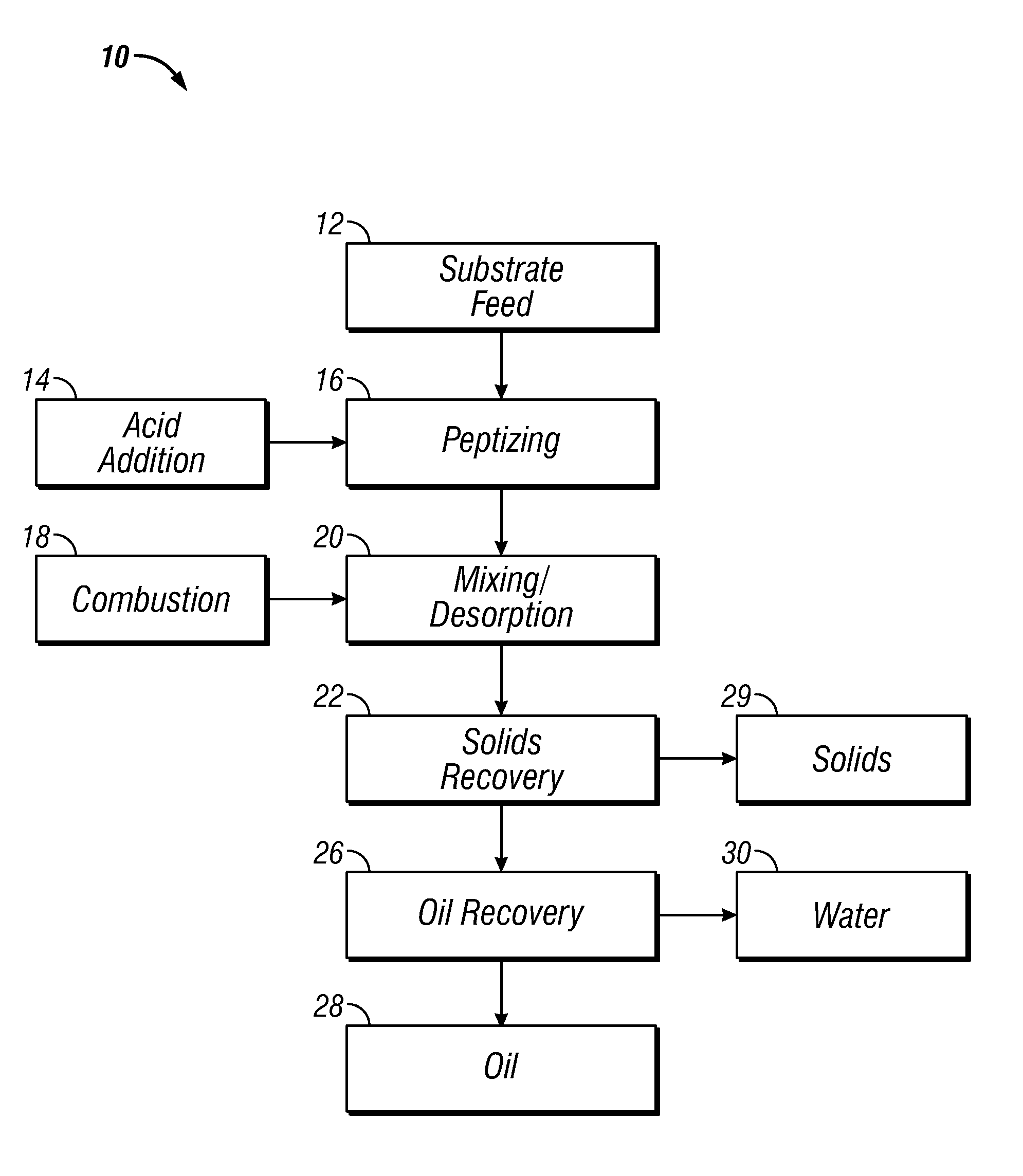

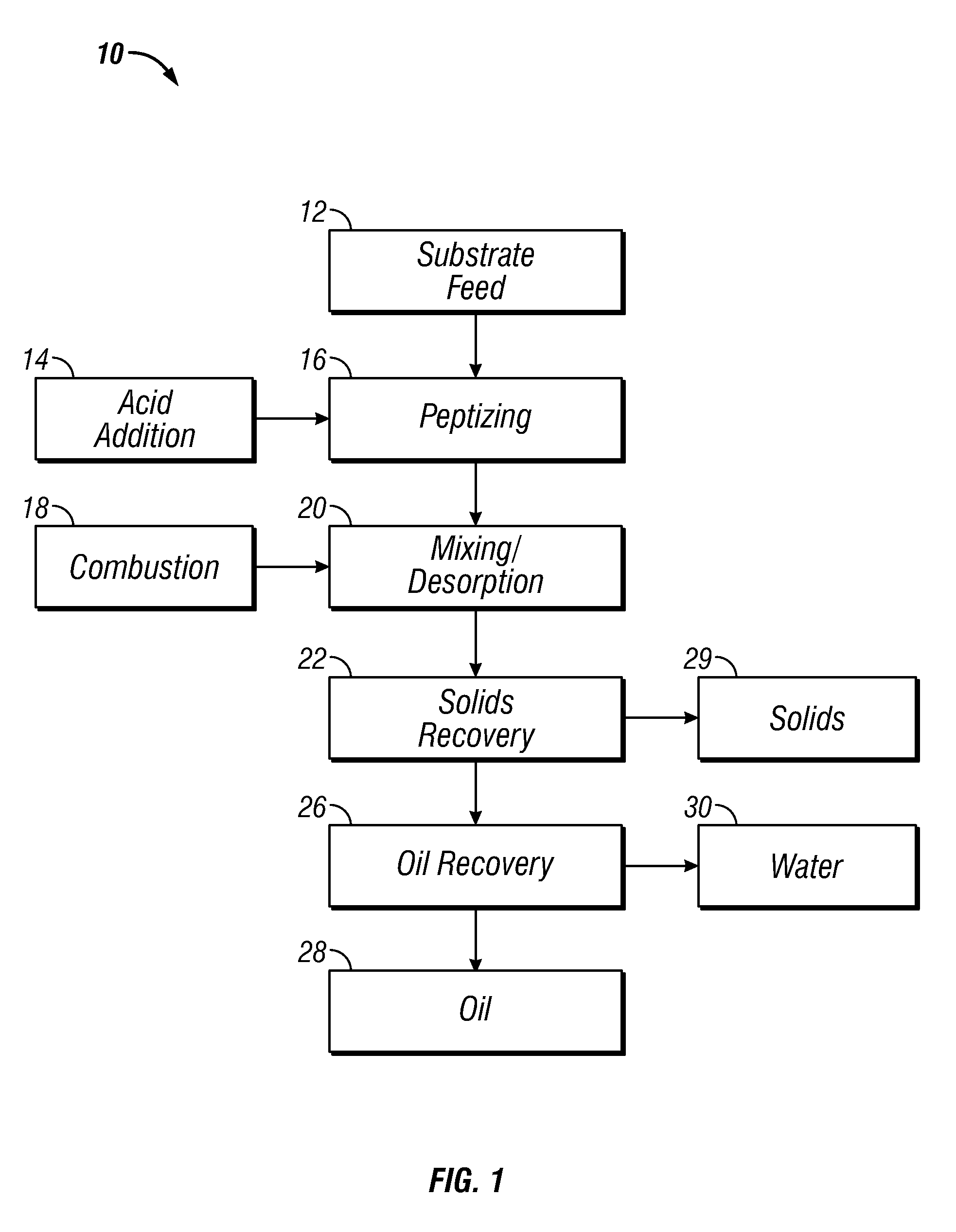

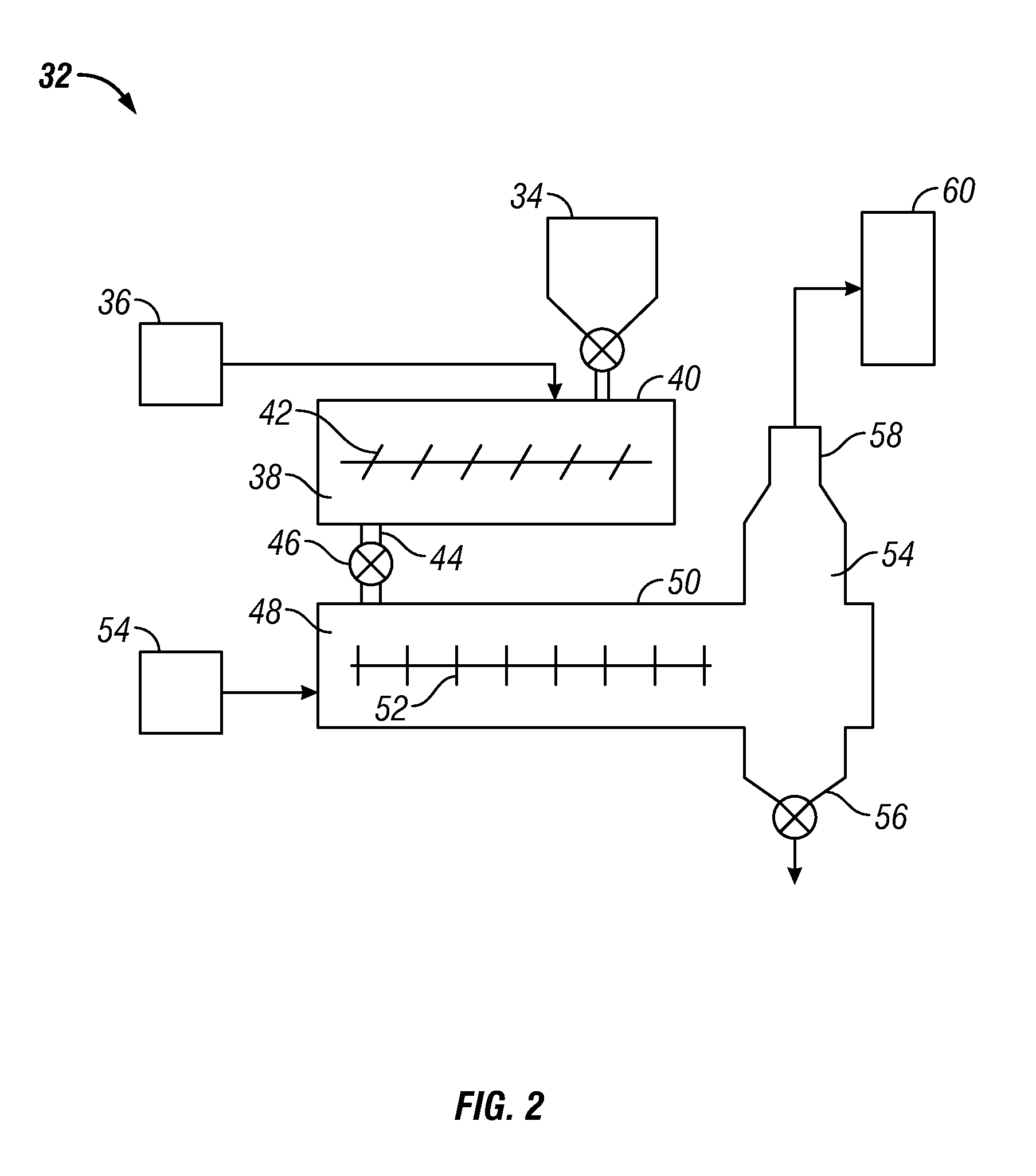

Oil recovery method and apparatus

Owner:RACIONAL ENERGY & ENVIRONMENT

Technology for preparing pseudo-boehmite by sodium bicarbonate neutralization method

ActiveCN101665261AReduce manufacturing costNo corrosionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium bicarbonateChemical industry

The invention discloses a technology for preparing pseudo-boehmite by a sodium bicarbonate neutralization method, which comprises steps: using NaHCO3 solution and sodium aluminate solution to carry out acid-alkali neutralizing reaction so as to prepare pseudo-boehmite; and after neutralizing reaction, separating, ageing, washing, drying and grinding material to prepare pseudo-boehmite. As reactionmother solution does not contain acid radical ions, processes and devices are not corroded, and simultaneously CO2 gas is pumped into mother solution for depth carbonization to form NaHCO3 solution,and neutralization reaction can be conducted repeatedly, thus fully using production raw material and reducing production cost. The pseudo-boehmite prepared by the technology has good peptization property, fast peptization speed, high peptization rate, low peptization viscosity, concentrated product pore diameter distribution, good caking property and wide application in oil refining, petroleum and chemical industries, environmental protection and chemical fertilizer catalytic agent manufacture.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Four-grain highly-flavored white spirit and preparation method thereof

The invention relates to the technical field of white spirit processing, especially to a multi-koji five-grain highly-flavored white spirit and a preparation method thereof. According to the present invention, four grains such as sorghum, glutinous rice, rice, corn and wheat are adopted as raw materials to mix so as to prepare the four-grain highly-flavored white spirit, wherein the prepared highly-flavored white spirit has characteristics of rich nutrients, excellent taste, sweet aftertaste after drinking, and fragrant and soft odor; raw material treatment, steaming gelatinization, spread cooling-koji stirring, boxing-saccharification, lees preparing-pitting, pit sealing-fermentation, pit exposing-distillation, warehousing storage and other process steps are combined so as to carry out complete peptization on the raw materials such as sorghum, the glutinous rice, the rice and the corn, such that the starch can be completely exposed; and with the steaming gelatinization step, the raw materials can be cooked and do not stick in hand, and it is ensured that the raw materials have no raw core so as to increase the highly-flavored white spirit yield and improve the highly-flavored white spirit quality.

Owner:GUIZHOU HUANGGUOSHU LIQUOR

Method of using TiCl4 to prepare high-activity double-effect crystal seed and control titanium dioxide particle size

InactiveCN104129813AReduce usageSmall particle sizeTitanium dioxidePhysical chemistryHydrolytic Process

The invention provides a method of using TiCl4 to prepare a high-activity double-effect crystal seed and control titanium dioxide particle size. Specifically, the method employs TiCl4 as a raw material, a precipitate is prepared through a certain proportion and rapid neutralization of a dilute base solution, the precipitate is subjected to peptizing, curing and quenching and then is adjusted to have a proper pH value, then soluble salt compositions are removed through washing, so that the high-activity double-effect crystal seed, which is applied to hydrolysis process and calcining process of production of sulfuric-acid-process titanium dioxide, is prepared. The prepared crystal seed is uniform in particle size and high in activity, and also during application of hydrolysis of a titanium solution, by adjusting the addition amount of the seed crystal and cooperating with addition of a proper salt treating agent and control on calcining intensity, rutile type titanium dioxide with different particle sizes can be prepared, and thus the particle size demands on different products are satisfied. The preparation technology is simple, not high in equipment investment and high in operation controllability, and the prepared double-effect crystal seed is capable of producing titanium dioxide hydrate primary particles with uniform particle size, so that the uniformity of calcined product particle size is guaranteed, and optical performances and pigment performances of titanium dioxide are perfectly exhibited.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

Polyacrylamide gel peptization instant solid composite and preparing method thereof

ActiveCN105232467AReduce preparation timeEasy to storePowder deliveryPill deliveryPolymer sciencePeptization

The invention relates to the technical field of polyacrylamide gel, in particular to a polyacrylamide gel peptization instant solid composite and a preparing method thereof. The composite comprises a monomer which is capable of achieving free radical polymerization and contains acrylamide, a monomer capable of achieving crosslinking, a gel making buffer agent, a pH regulator and a solid forming auxiliary material. The peptization instant solid composite is prepared by mixing the solid forming auxiliary material with a polyacrylamide gel making reagent. In use, polyacrylamide gel can be obtained simply by dissolving the polyacrylamide gel peptization instant solid composite in water as needed, operation is easy and convenient, polyacrylamide gel preparing time is saved greatly, property and performance are stable, storage is convenient, and retention cycle is long; meanwhile, tablets are easy to prepare, dosage is accurate, and bulk production can be conducted to enable the polyacrylamide gel to be more stable and reliable, batch difference to be smaller, repeatability to be higher and cost to be lower.

Owner:广东易优生物医药有限公司

Fluid/slurry bed cobalt-alumina catalyst made by compounding and spray drying

ActiveUS20060035783A1High cobalt concentrationOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereRuthenium

A method for producing a cobalt on alumina catalyst is disclosed. The catalyst is prepared by thoroughly mixing cobalt nitrate into a peptized alumina slurry, and then spray-drying the slurry to form attrition resistant microspheres. The cobalt prepared by this invention is fully reducible. Optionally, metals such as ruthenium can be added to the cobalt / alumina catalyst by impregnation or methods known in the prior art.

Owner:CLARIANT INT LTD

Fluid/slurry bed cobalt-alumina catalyst made by compounding and spray drying

ActiveUS7560412B2Other chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsMicrosphereRuthenium

Owner:CLARIANT INT LTD

B acid-enriched mesoporous alumina, as well as preparation method and application thereof

ActiveCN106669646AHigh B/L ratioHigh pore volumePhysical/chemical process catalystsCatalytic crackingMesoporous silicaSlurry

The invention provides a B acid-enriched mesoporous alumina, as well as a preparation method and application thereof. The preparation method of the B acid-enriched mesoporous alumina comprises the following steps: (1) acidifying and peptizing pseudo-boehmite slurry by using an inorganic acid solution to obtain pseudo-boehmite sol; (2) adding an aqueous solution of an acidic modifying agent into the pseudo-boehmite sol and then adding an aqueous solution of a pore-enlarging agent to obtain a first mixture; (3) performing a reaction on the first mixture for a period of time under the heating condition, and after the reaction, sequentially cooling, adjusting the pH value to 9 to 11 and ageing to obtain a second mixture; (4) directly drying the second mixture at 60 to 110 DEG C for 12 to 24 hours without filtering and washing the second mixture, and roasting at 500 to 700 DEG C for 4 to 8 hours to prepare the B acid-enriched mesoporous alumina. The B acid-enriched mesoporous alumina provided by the invention has the characteristics of high B / L ratio, high pore volume and large aperture.

Owner:PETROCHINA CO LTD +1

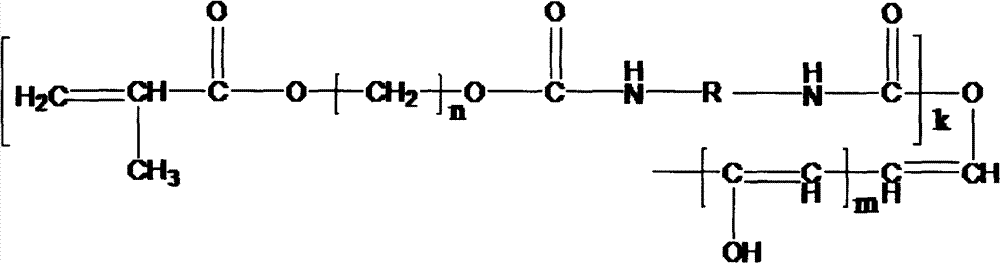

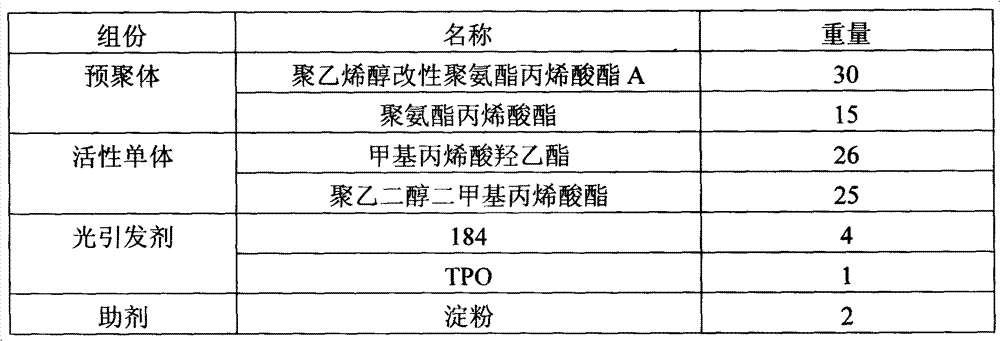

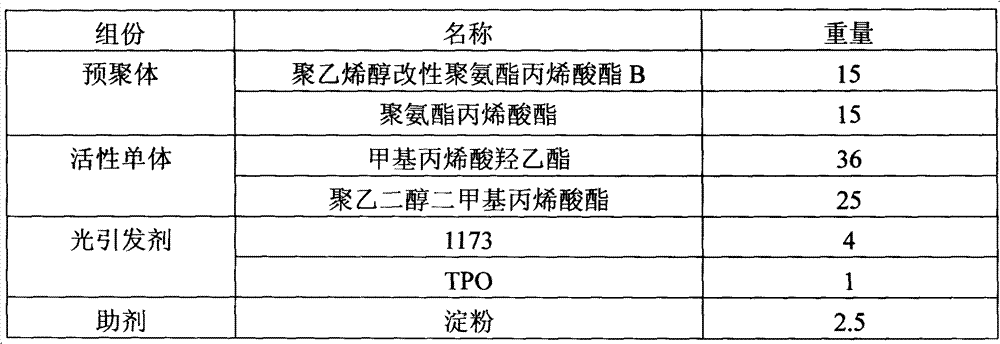

Hydrolysable ultraviolet curing adhesive and method for preparing same

InactiveCN102807835ALiquidityBroaden applicationPolyureas/polyurethane adhesivesPolyether adhesivesAdhesiveUltraviolet

The invention relates to the technical field of ultraviolet curing adhesive, in particular to a hydrolysable ultraviolet curing adhesive and a method for preparing the same. The curing adhesive comprises the following components in part by weight: 30 to 70 parts of prepolymer, 15 to 60 parts of reactive diluent, 0 to 10 parts of coupling agent, 1 to 10 parts of photoinitiator and 0.1 to 2.5 parts of auxiliary agent, wherein the prepolymer has a unique structural formula. The preparation method comprises the following steps of: performing vacuum dehydration on the reactive diluent at the temperature of between 110 and 120 DEG C for 1 to 2 hours; cooling the reactive diluents; adding the prepolymer, the coupling agent and the photoinitiator into the reactive diluents when the temperature is reduced to the room temperature; stirring the mixture for dissolution; and finally adding the auxiliary agent. The ultraviolet curing adhesive is high in fluidity, easy to coat and quick in curing, the curing matters have the characteristics of hardness, crispness and low shrinkage ratio, and the curing adhesive is suitable for mechanical processing; and the curing adhesive is high in water adsorption, susceptible to peptization in water, low in cost and wide in application range. The preparation method is characterized by simple synthetic reaction process, and is easy to operate.

Owner:HB FULLER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com