Patents

Literature

2874results about How to "Reduce wear rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

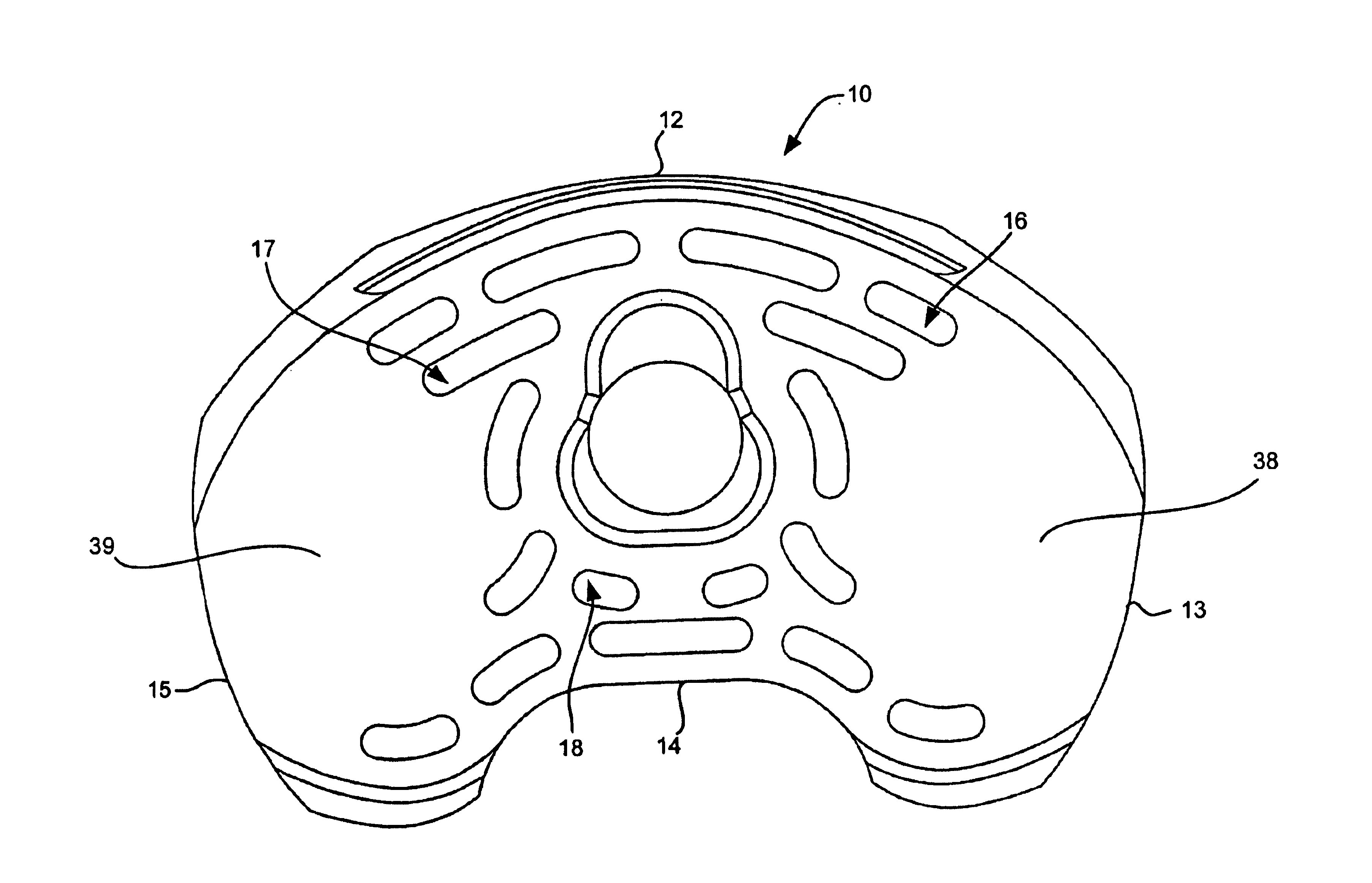

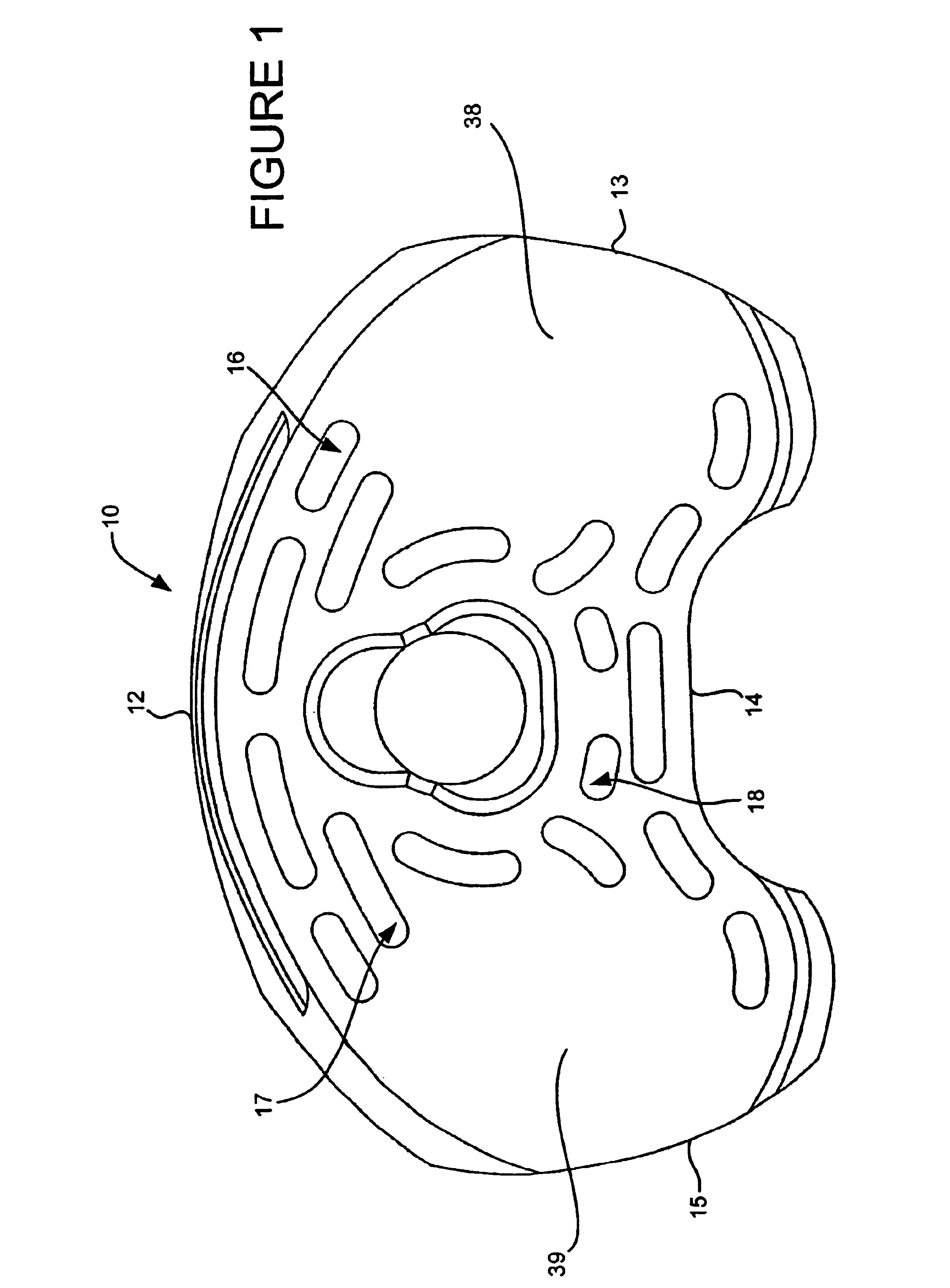

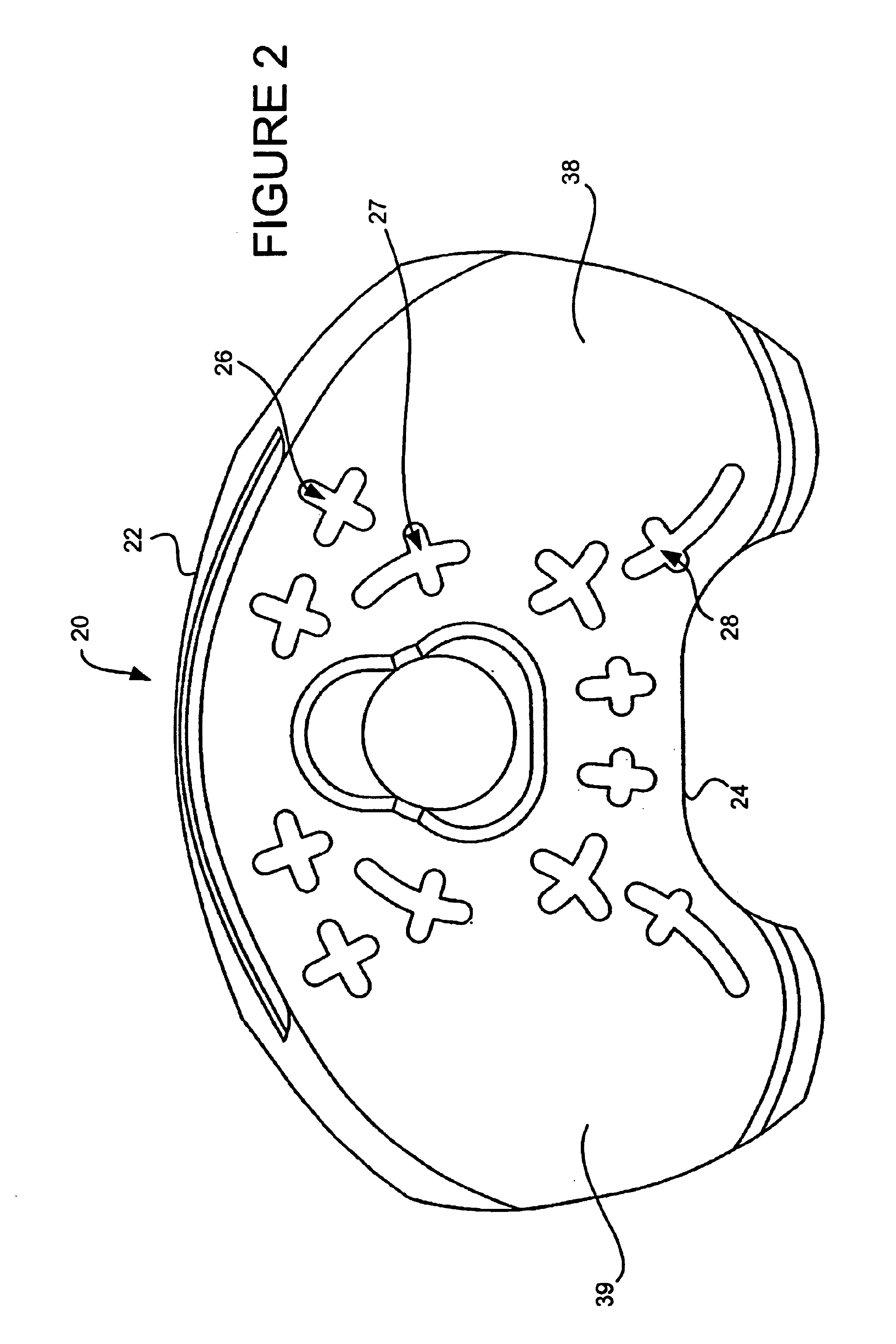

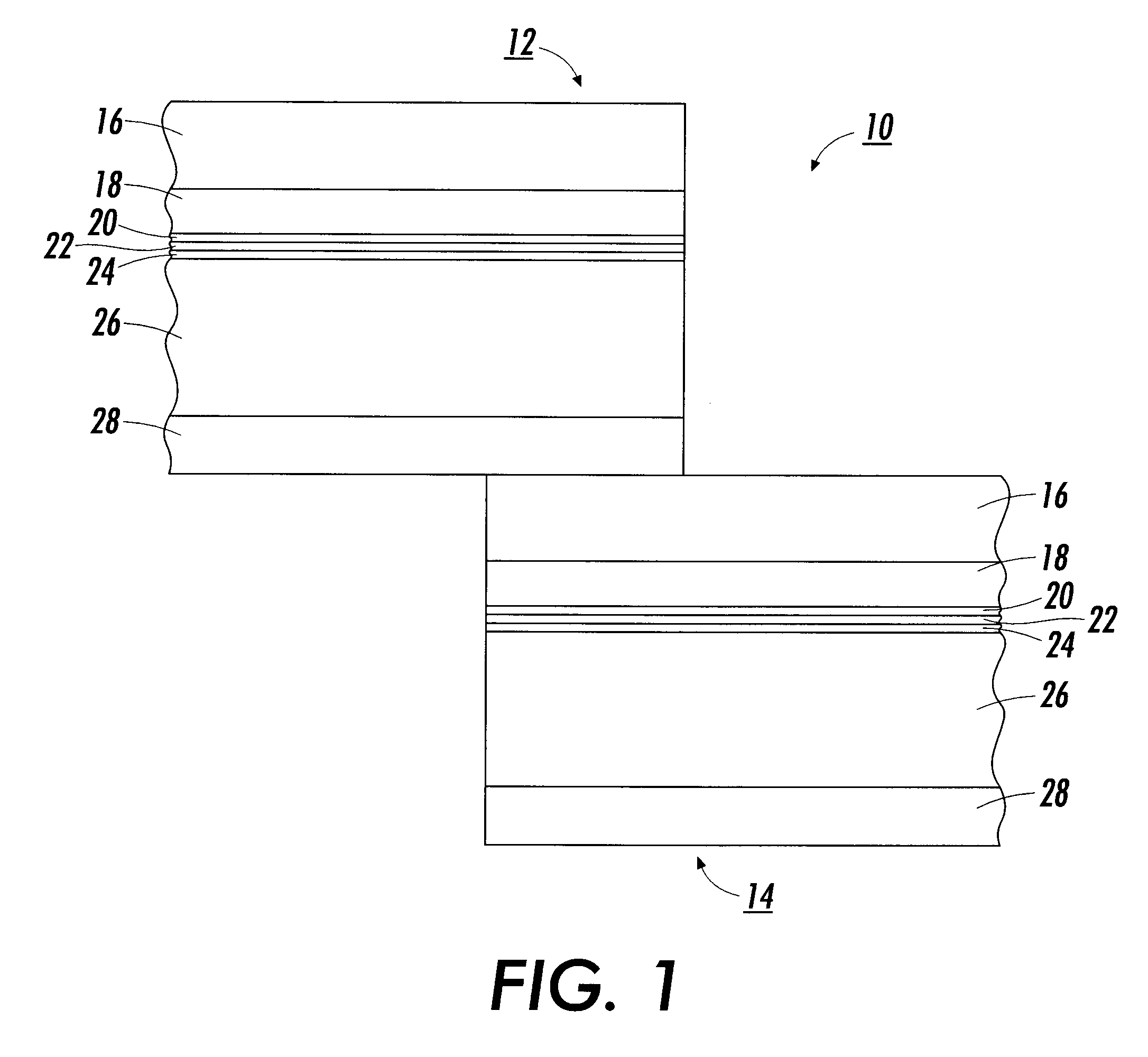

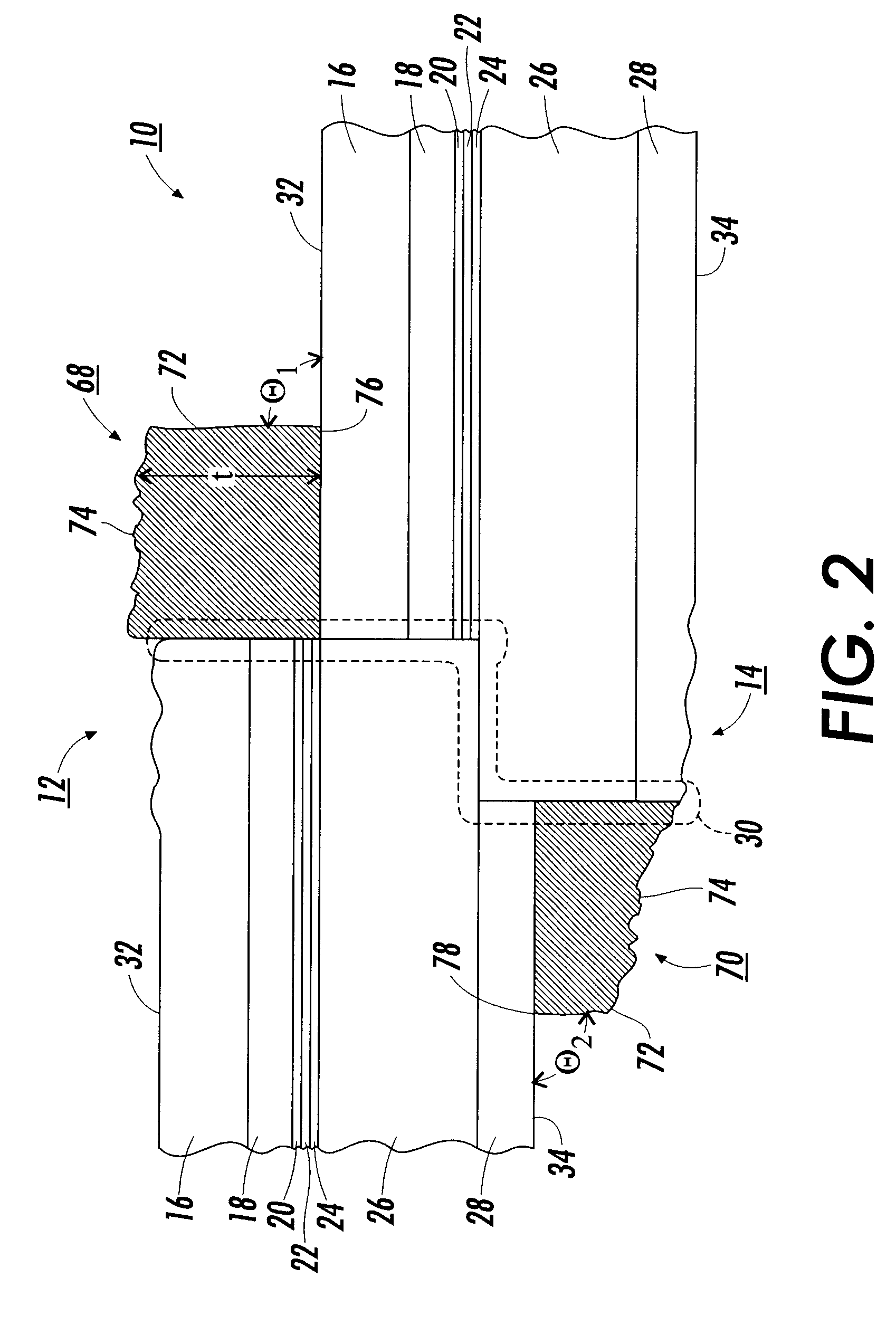

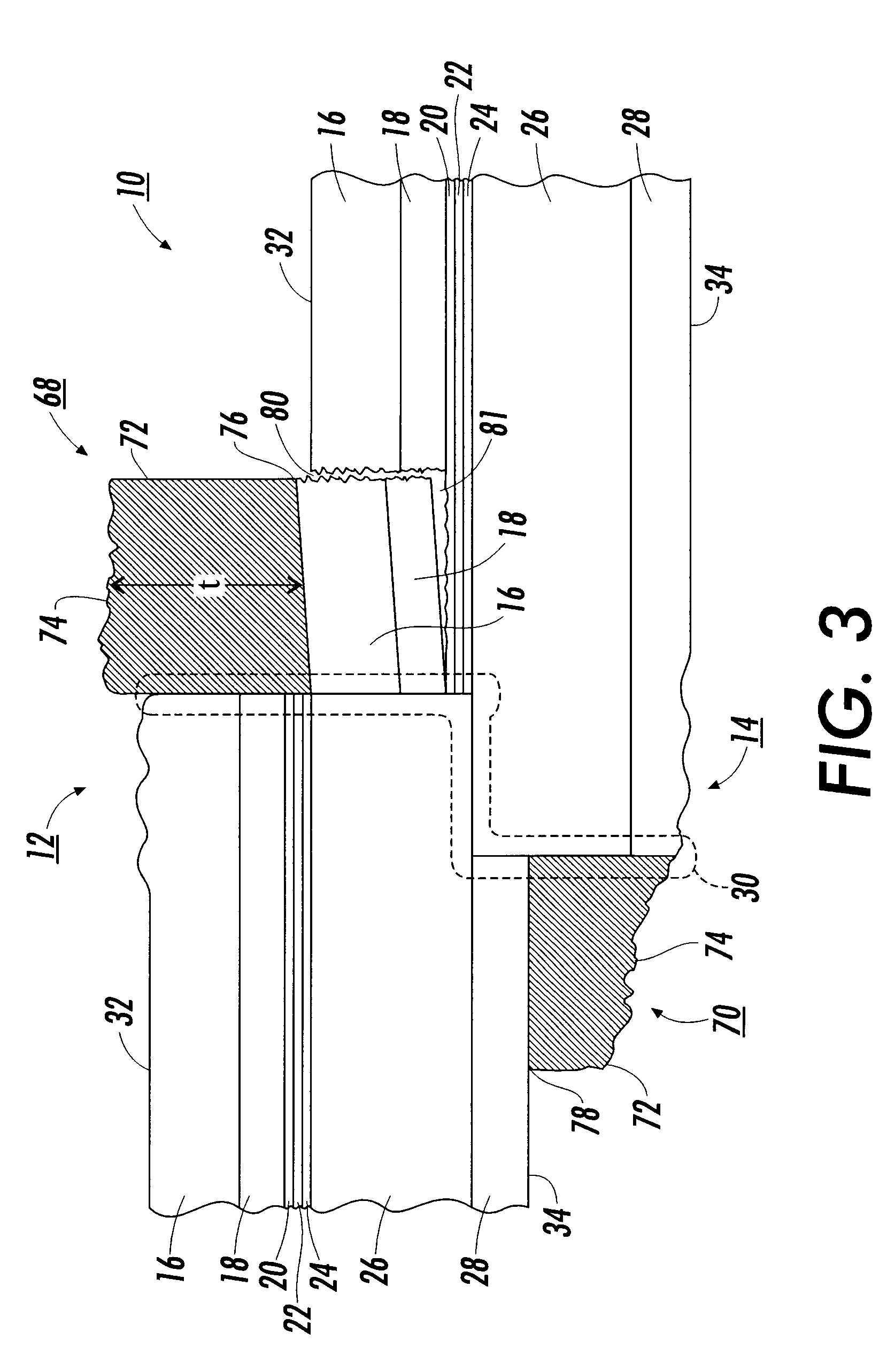

Surfaces and processes for wear reducing in orthopaedic implants

Artificial implants having reduced area to provide reduced wear are provided. The reduced area is particularly located at areas where greatest wear is exhibited. In a particular embodiment of a mobile bearing knee implant, the area is reduced on the mobile bearing insert underside, where it contacts a tibial component. The reduced area may be any shape of indentations, for example, grooves, dimples, straight patterns, curved patterns, crossing patterns, holes, channels or slots. The indentations may be various sizes, and have been found to be particularly effective if covering about 10% to about 20% of the insert at depths between about 1-2 mm.

Owner:SMITH & NEPHEW INC

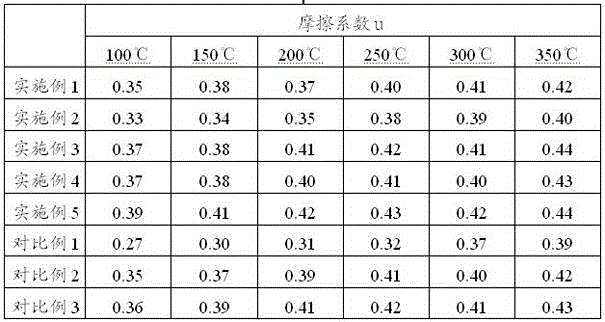

Formula of ceramic radical friction material for automobile braking friction facing

InactiveCN101113204AImprove braking effectImprove yieldFriction liningFilling materialsMaterials processing

The invention discloses a prescription of a ceramic-based friction material used in a vehicle braking friction pad, comprising the components (by weight): adhesives 5 percent-15 percent, intensifier 23.5 percent-33.5 percent, grinding aid 0 percent-7 percent anti-wearing lubricant 11.3 percent-21.3 percent, elastic toughening agent 5.7 percent-15.7 percent and filling material 27.5 percent-37.5 percent. The total amount of the components is 100 percent. The materials of the invention can be processed and molded into the vehicle braking pad that is applicable to friction braking on a vehicle braking device. The anti-wearing performance of the pad can be greatly enhanced, thereby reducing noise pollution and promoting the performance of the braking system of the vehicle.

Owner:SHAANXI LIZHIQUAN IND TRADE

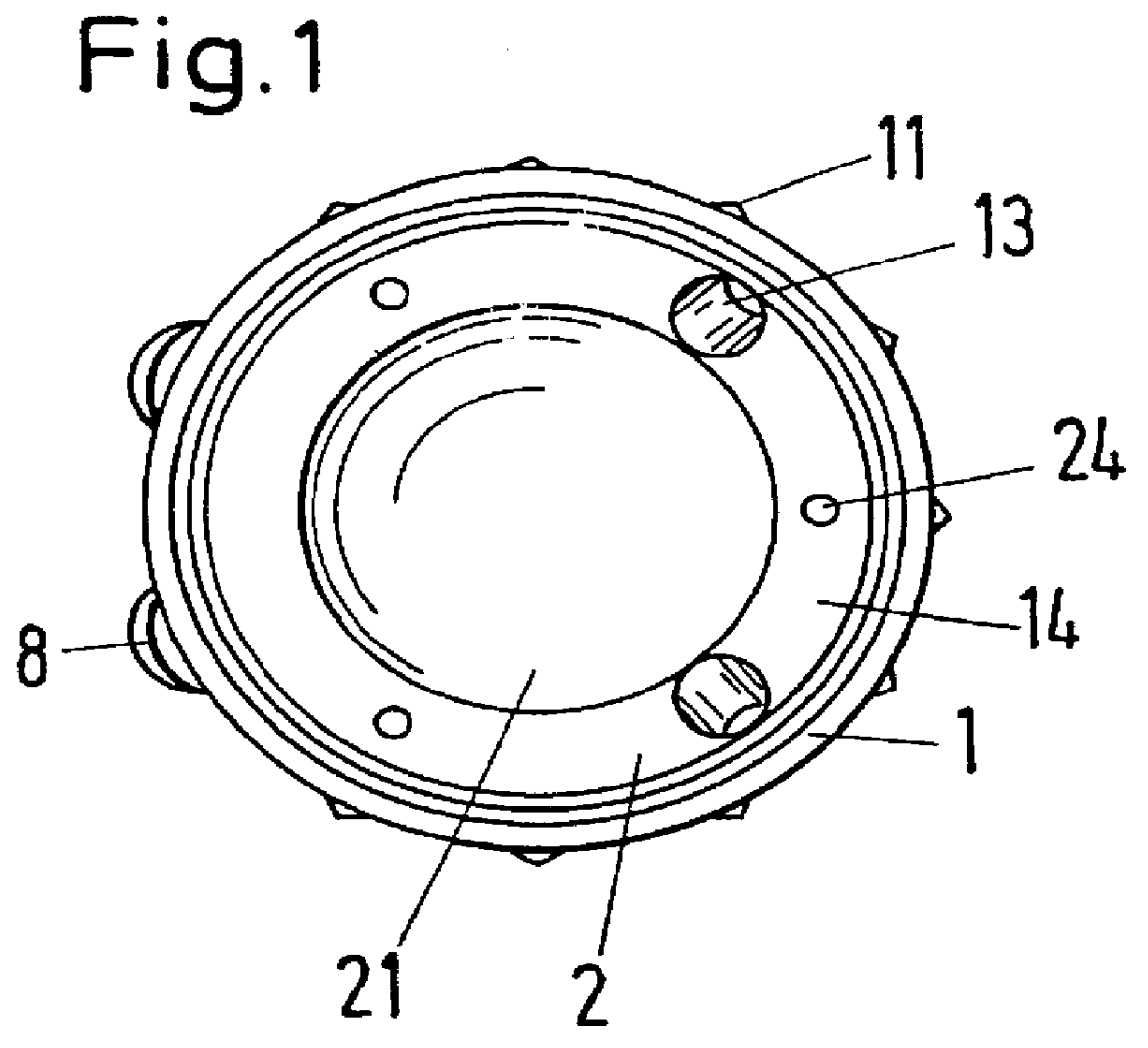

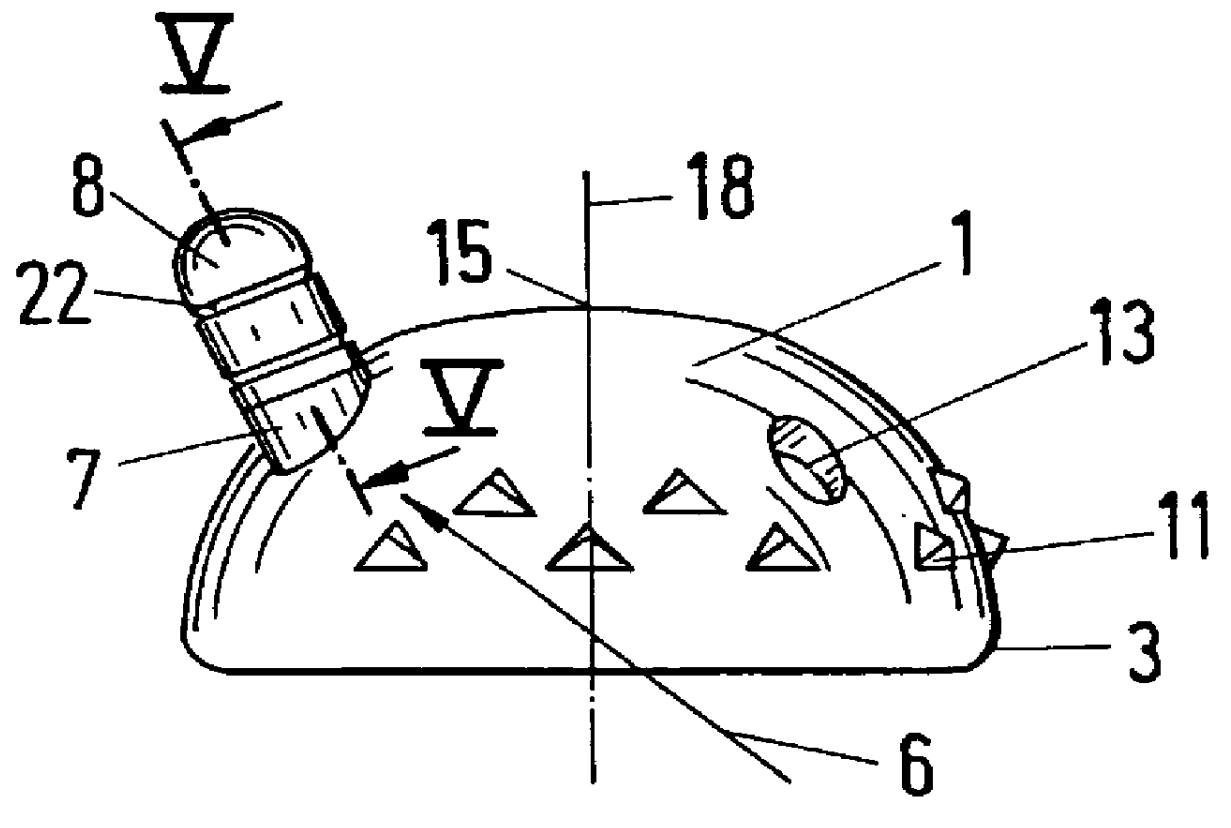

Twin-shelled artificial hip joint and its manufacture

InactiveUS6045583AHigh degree of polymerizationReduce wear rateJoint implantsCoatingsArtificial hip jointsCoxal joint

The invention shows a hip joint socket and its manufacture, with the hip joint socket including a thin walled metallic outer shell with anchoring pins which is firmly connected to an inner shell of plastic. Since the bearing surface of the inner shell is not produced until after the assembly, a high accuracy of shape of the bearing surface results together with a relatively elastic outer shell and with good anchoring aids for a primary anchoring.

Owner:SULZER ORTHOPAEDIC

Electrostatographic imaging member

InactiveUS6303254B1Improve thickness uniformityReduces undesirable dirtElectrographic process apparatusMicrometerPolymer chemistry

An electrostatographic imaging member including: a flexible supporting substrate; an imaging layer having an optional adjacent ground strip layer coated on one side of the substrate; and an anti-curl backing layer coated on the other side of the substrate which layer is comprised of a film forming polymer binder, an optional adhesion promoting polymer, and a dispersion of polytetrafluoroethylene particles which dispersion has particles with a narrow diameter particle size distribution of from about 0.19 micrometer to about 0.21 micrometer, and an average diameter particle size of about 0.20 micrometer. The optional ground strip layer can include the same dispersion of polytetrafluoroethylene particles as the anti-curl backing layer.

Owner:XEROX CORP

High wear-resistant wood-plastic composite and preparation method thereof

The invention provides a high wear-resistant wood-plastic composite and a preparation method thereof, and relates to a composite obtained by mixing modified plant fiber powder, modified nano ceramics particles and plastic powder. The high wear-resistant wood-plastic composite comprises the modified plant fiber powder, the modified nano ceramics particles, the recycled plastic powder and the like, wherein the modified nano ceramics particles comprises modified nano Al2O3, modified nano Si3N4, modified nano SiC or the mixture thereof, which can obviously improve the microhardness of the wood-plastic composite, reduce the wear rate and improve the mechanical property. The high wear-resistant wood-plastic composite is prepared from the components by the common melt-mixing method in the plastic processing. The surface hardness and the wearability of the wood-plastic composite are greatly increased, and the strength and the toughness are also greatly improved, so that the overall performance of the wood-plastic composite is greatly enhanced. The wood-plastic composite can be used in the fields of construction material, furniture, package and the like.

Owner:GUANGDONG XINXIU NEW MATERIAL CO LTD

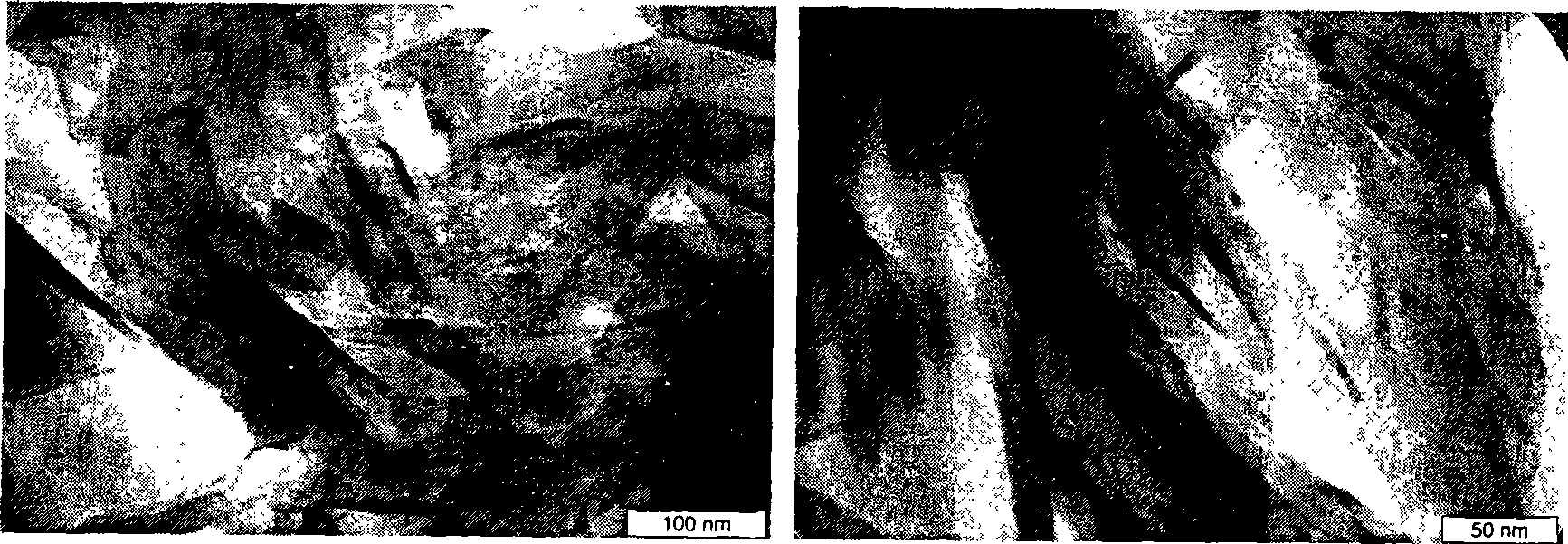

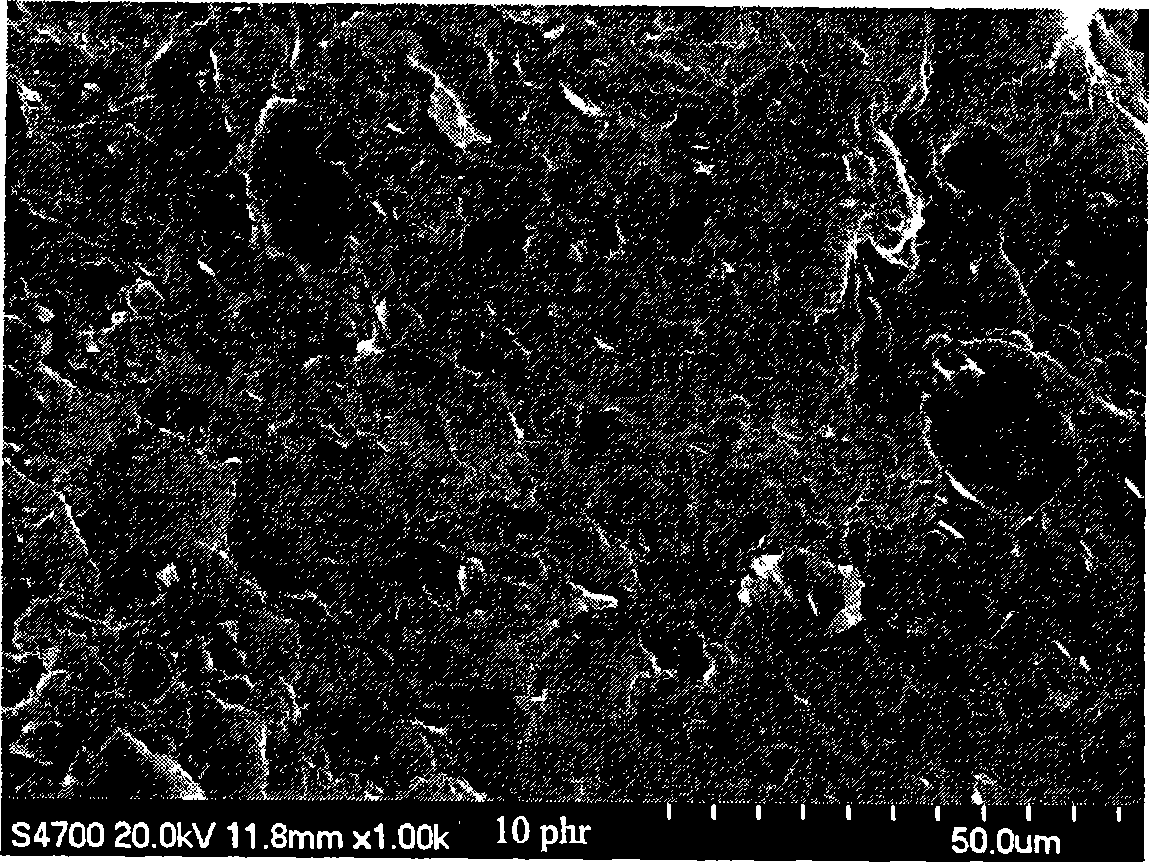

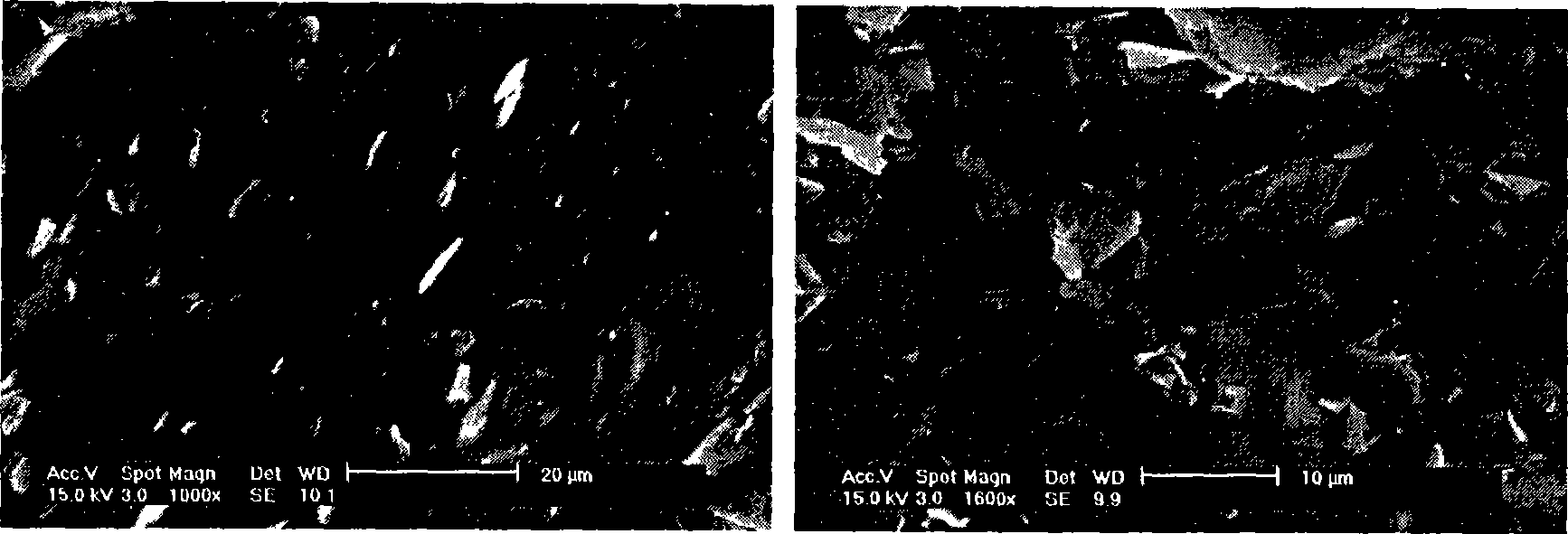

Preparation of wear resistant rubber composite material

InactiveCN101463149AImprove mechanical propertiesImprove recycling efficiencyOrganic solventPolymer science

The invention relates to a preparation method of a graphite-modified abrasive resistant rubber composite material. The method comprises the following steps: soaking expandable graphite with laminar crystal layer structure in water or an organic solvent containing a surfactant; preparing a suspension system of nano flaky graphite by stirring and ultrasonic treatment; mixing the suspension system with rubber latex or rubber solution, and then adding a flocculant for breaking latex and flocculating or adding a poor solvent for precipitation; and drying flocculate or precipitate, mixing and vulcanizing to obtain the graphite / rubber composite material. The latex (solution) blending process is introduced into preparation of the graphite / rubber nano-composite material to realize homogeneous dispersion of the graphite in a rubber matrix compound system by a nanoscale size, to cause good strengthening effect and prepare the rubber composite material with excellent mechanical property, low frictional coefficient and high abrasive resistance.

Owner:BEIJING UNIV OF CHEM TECH

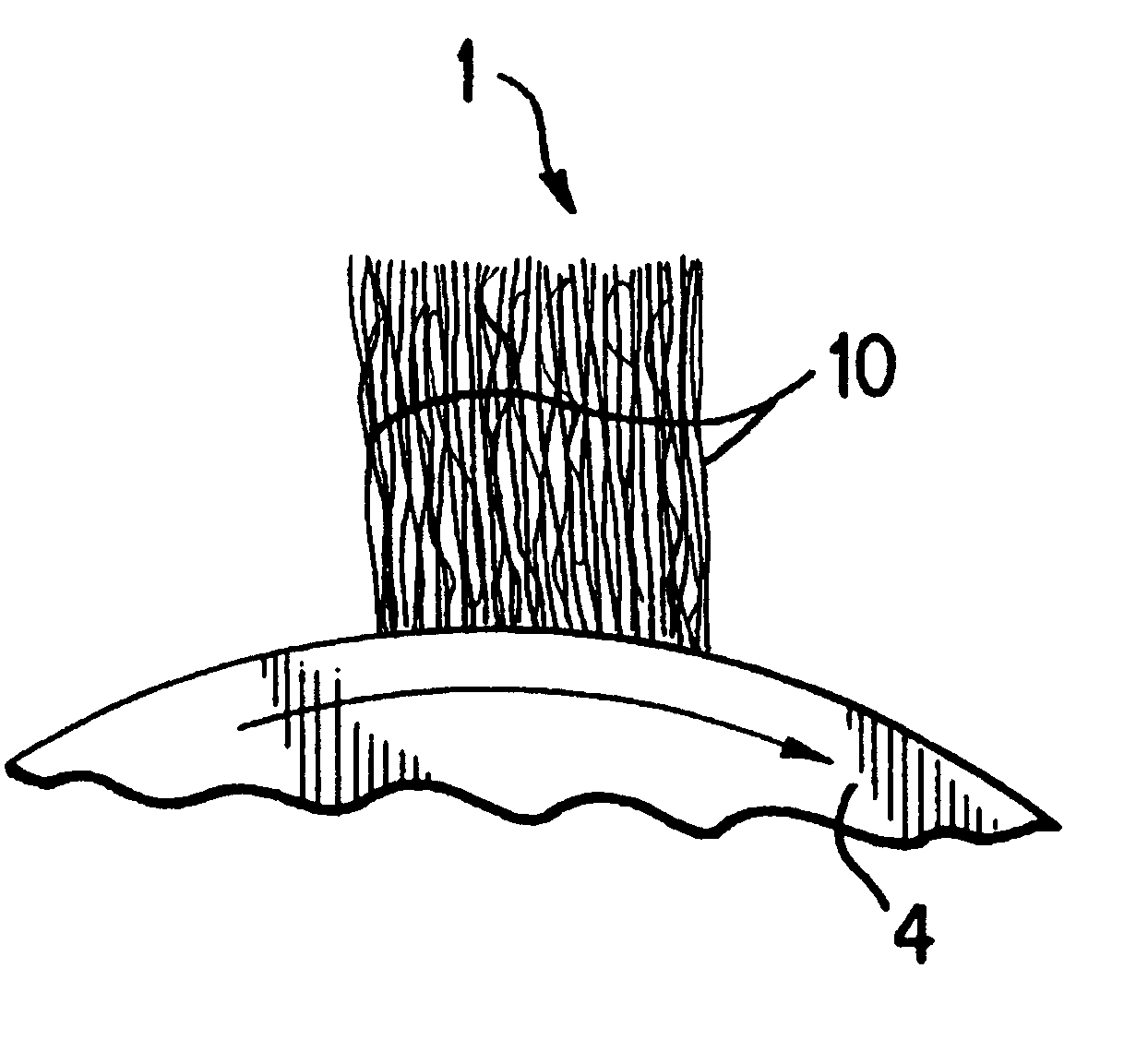

Continuous metal fiber brushes

InactiveUS6245440B1Avoid large gapsSuppressing advanceRotary current collectorMagnetic materialsMetal fiberLubrication

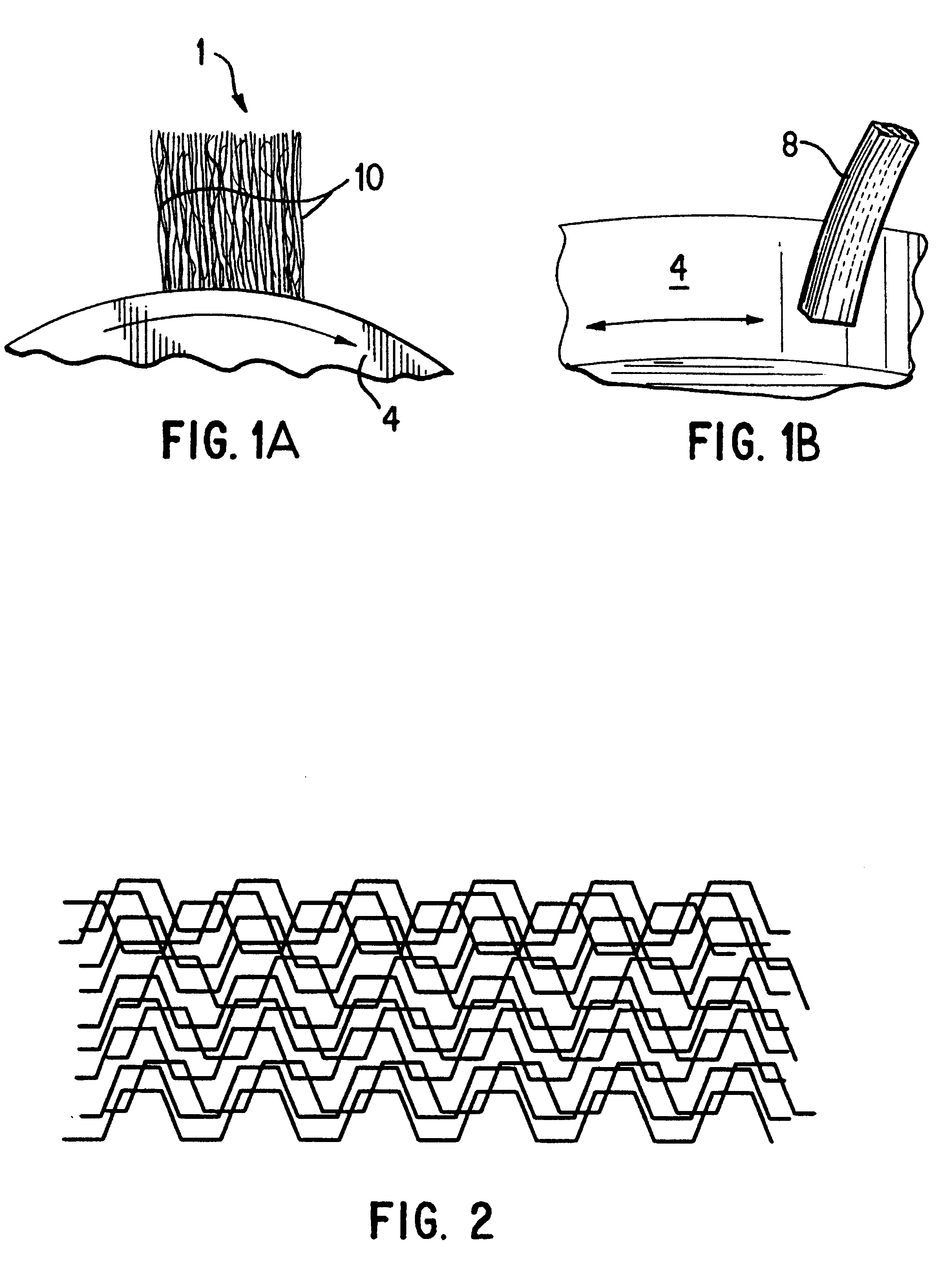

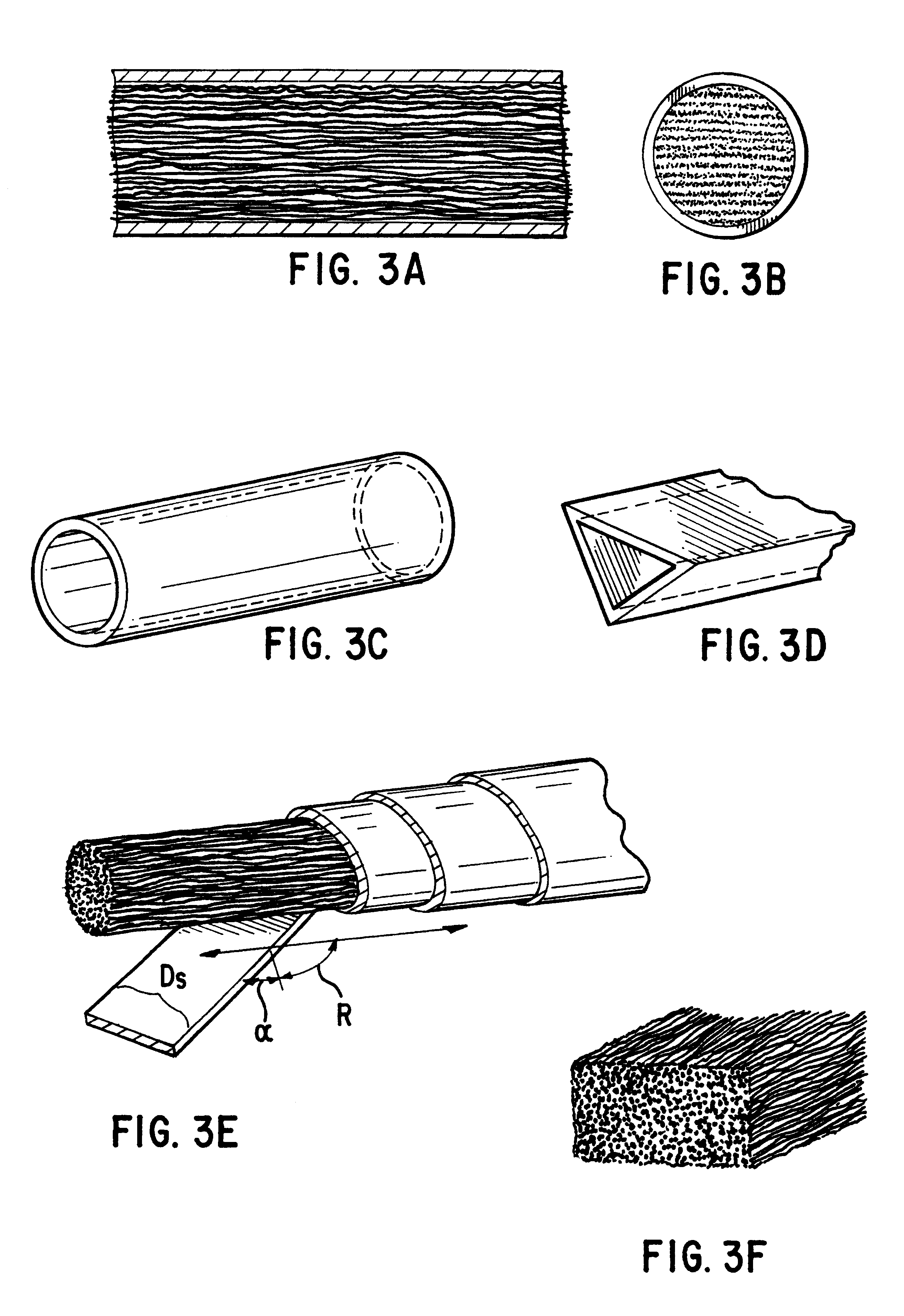

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the leg of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:VIRGINIA UNIV PATENT FOUND OF

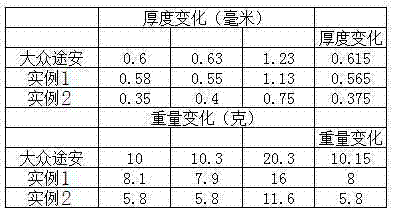

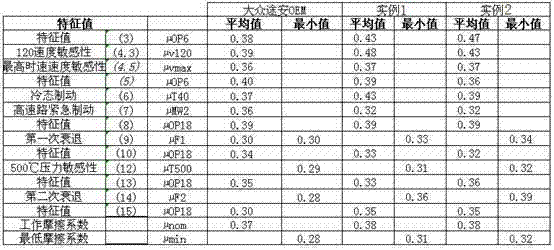

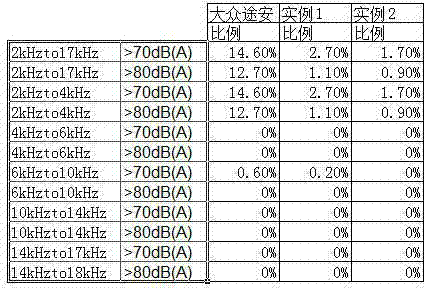

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

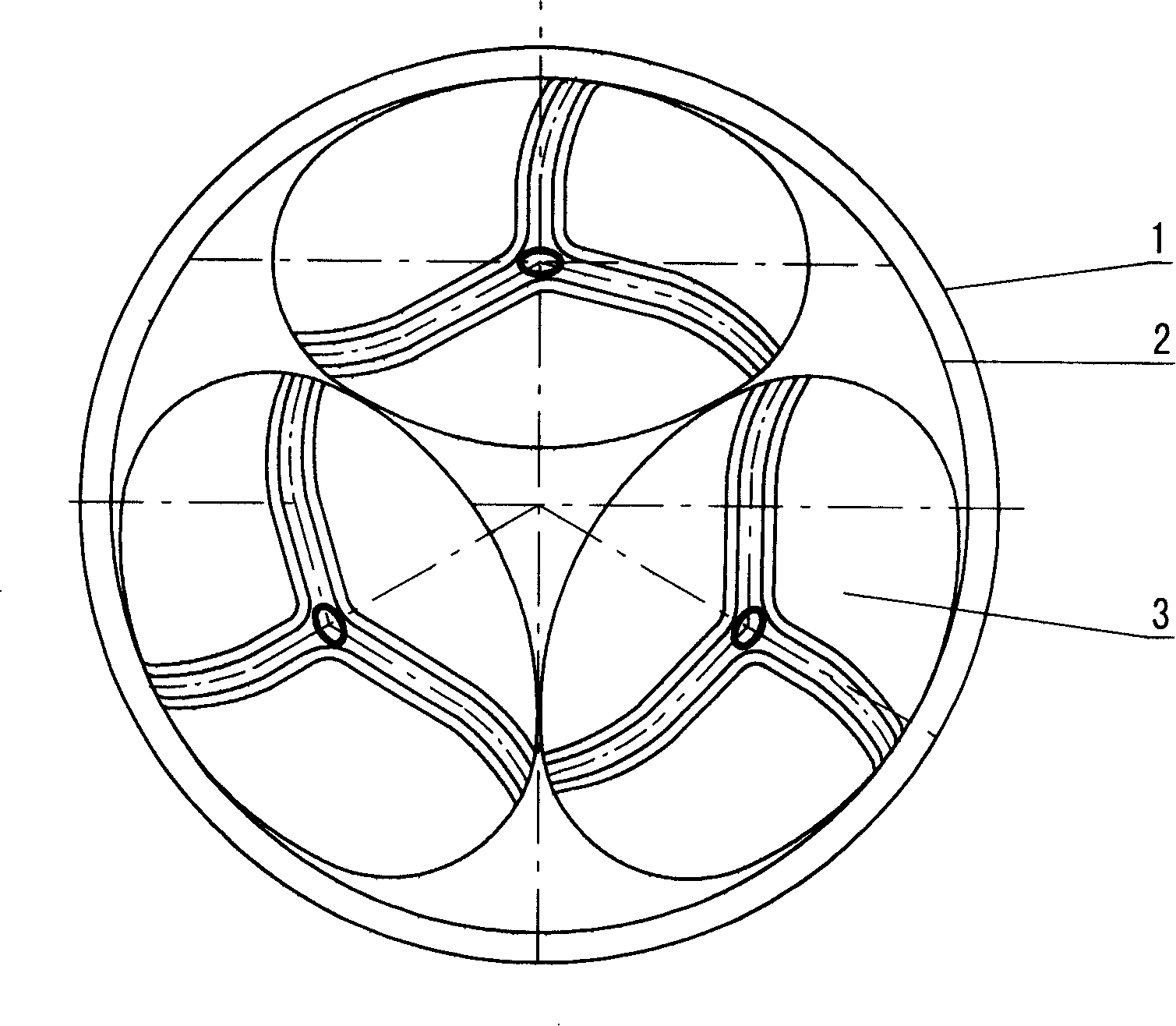

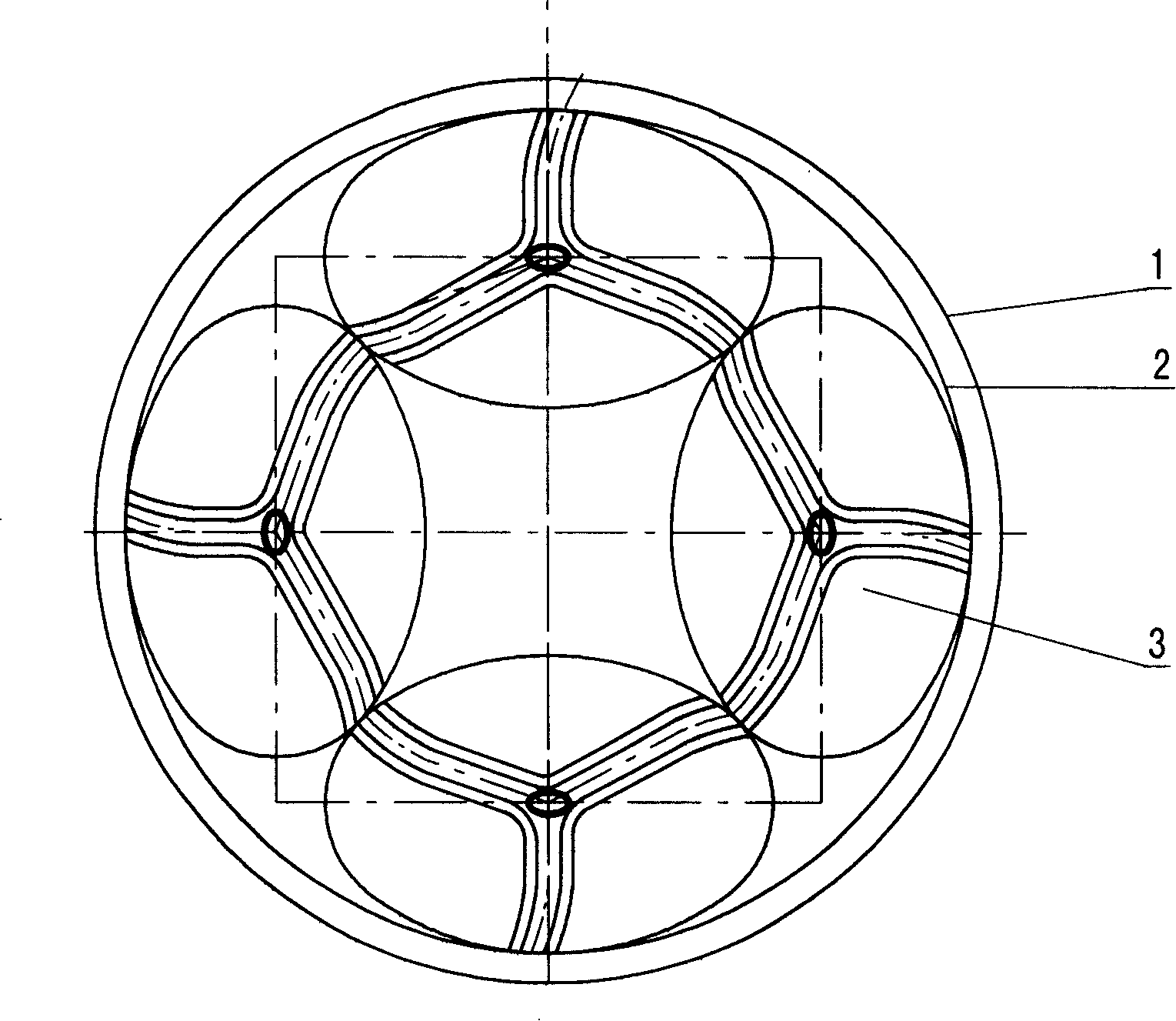

Vertical multi-impeller washing machine and washing method

InactiveCN101191285ASolve the entanglementImprove cleanlinessWashing machine with receptaclesTextiles and paperImpellerEngineering

The invention relates to a vertical multi-impeller washing machine which comprises an inner barrel, an outer barrel, impellers, a motor, a speed reducer and a transmission gear. The invention is characterized in that: the impellers are three or four impellers which are pivotally arranged on the periphery of the inner wall of the inner barrel and correspondingly arranged at 120 DEG or 90 DEG; the impellers take the shape of a basin and are provided with convex ribs with smooth edges; gear rings are arranged on reverse surfaces of the impellers; the transmission gear is provided with three or four output shafts on which the impellers are arranged. A washing method of the invention is characterized in that: during the washing process, washing can be carried out when water inlet quantity only reaches one third of impeller height, and all the impellers can rotate positively or reversely simultaneously for washing clothes. Due to adoption of multi-impeller structure, the clothes can be overturned and thrown in the three-dimensional direction, thereby effects of non winding, high cleanliness and low abrasion are realized. Because the inner barrel and the outer barrel are designed into the shape of a basin and the size of the bottom part of the outer barrel is small, the aim of water conservation is reached.

Owner:HEFEI GOOLU TECH WASHER

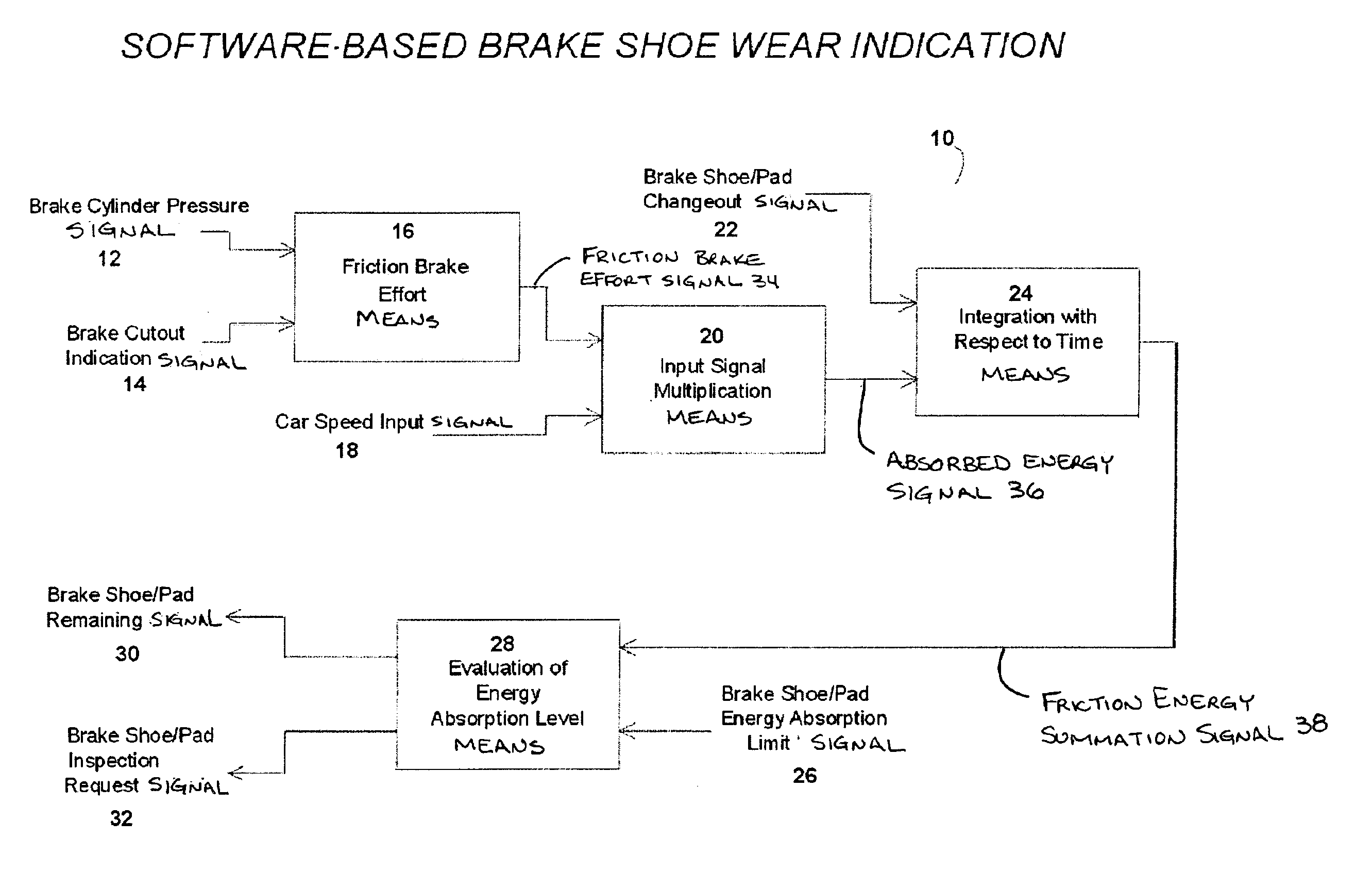

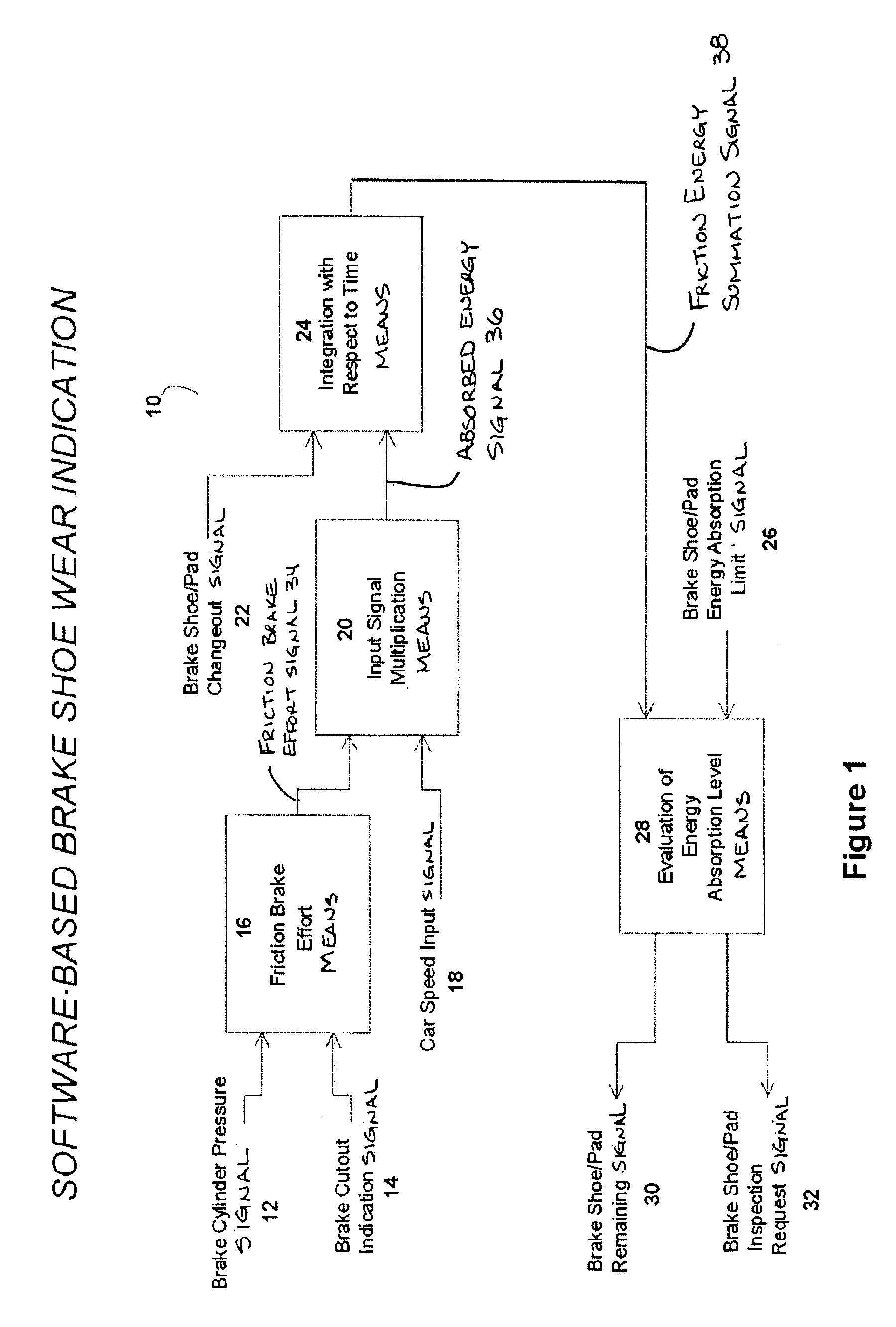

Software based brake shoe wear determination

InactiveUS6847869B2Reduce harmReduce amount of friction brake effort suppliedVehicle testingRegistering/indicating working of vehiclesEngineeringEnergy supply

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

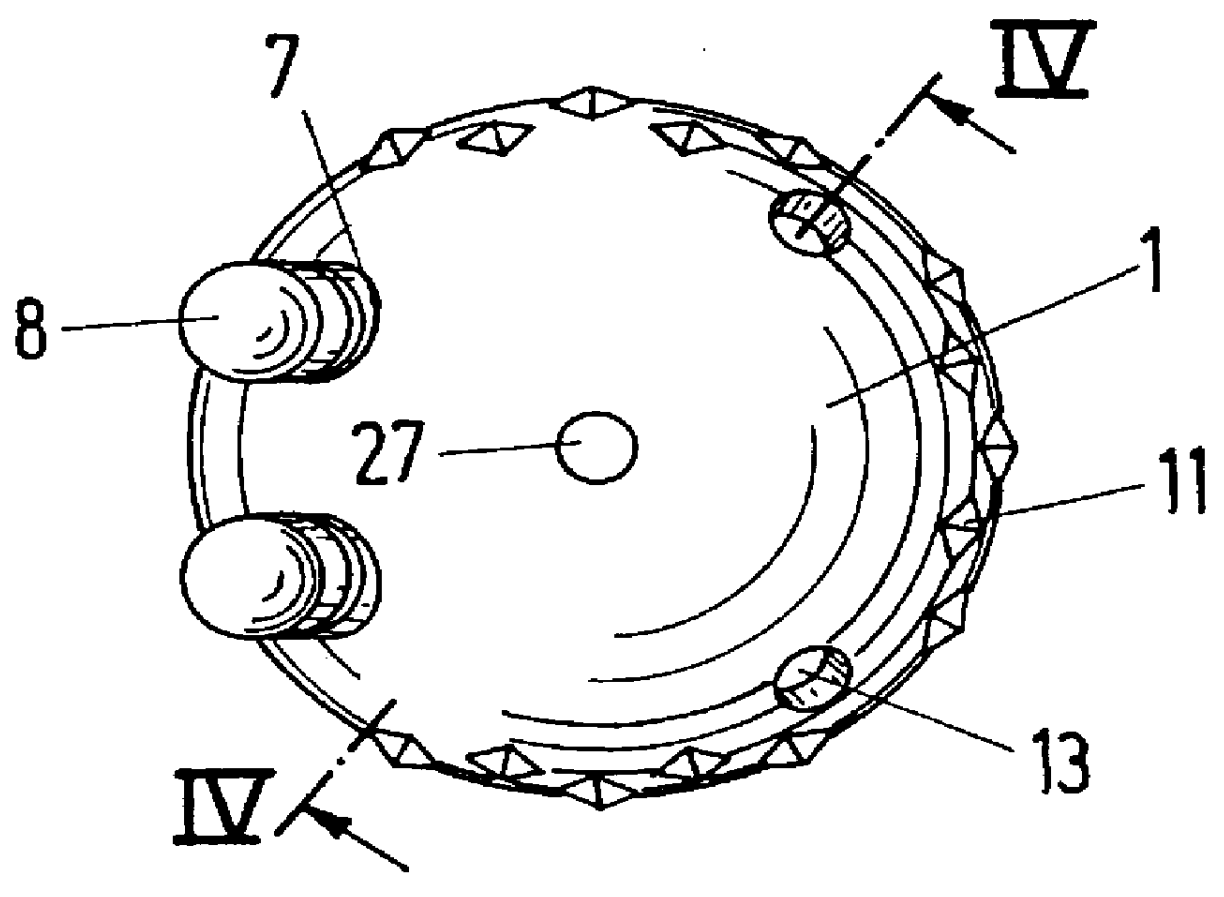

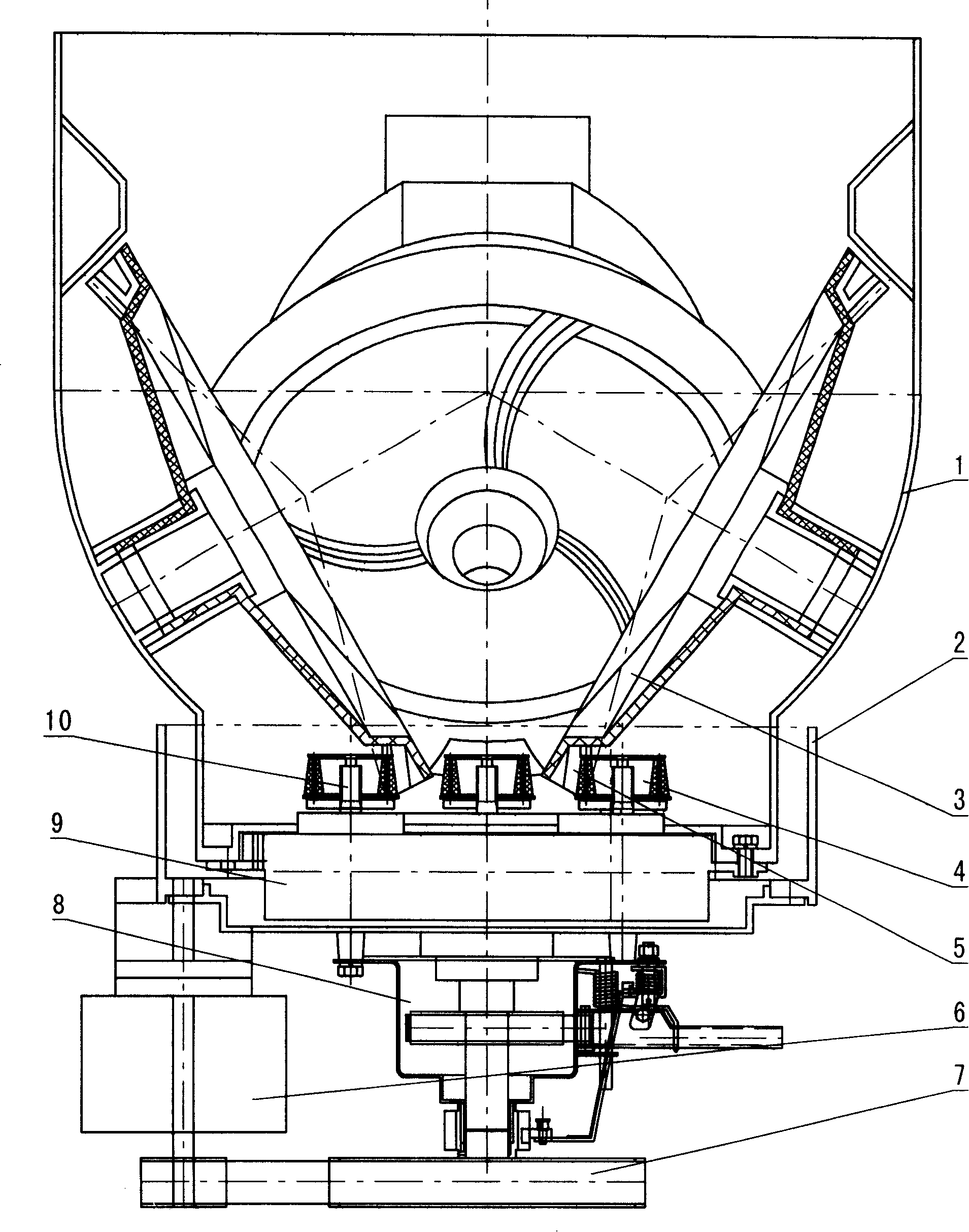

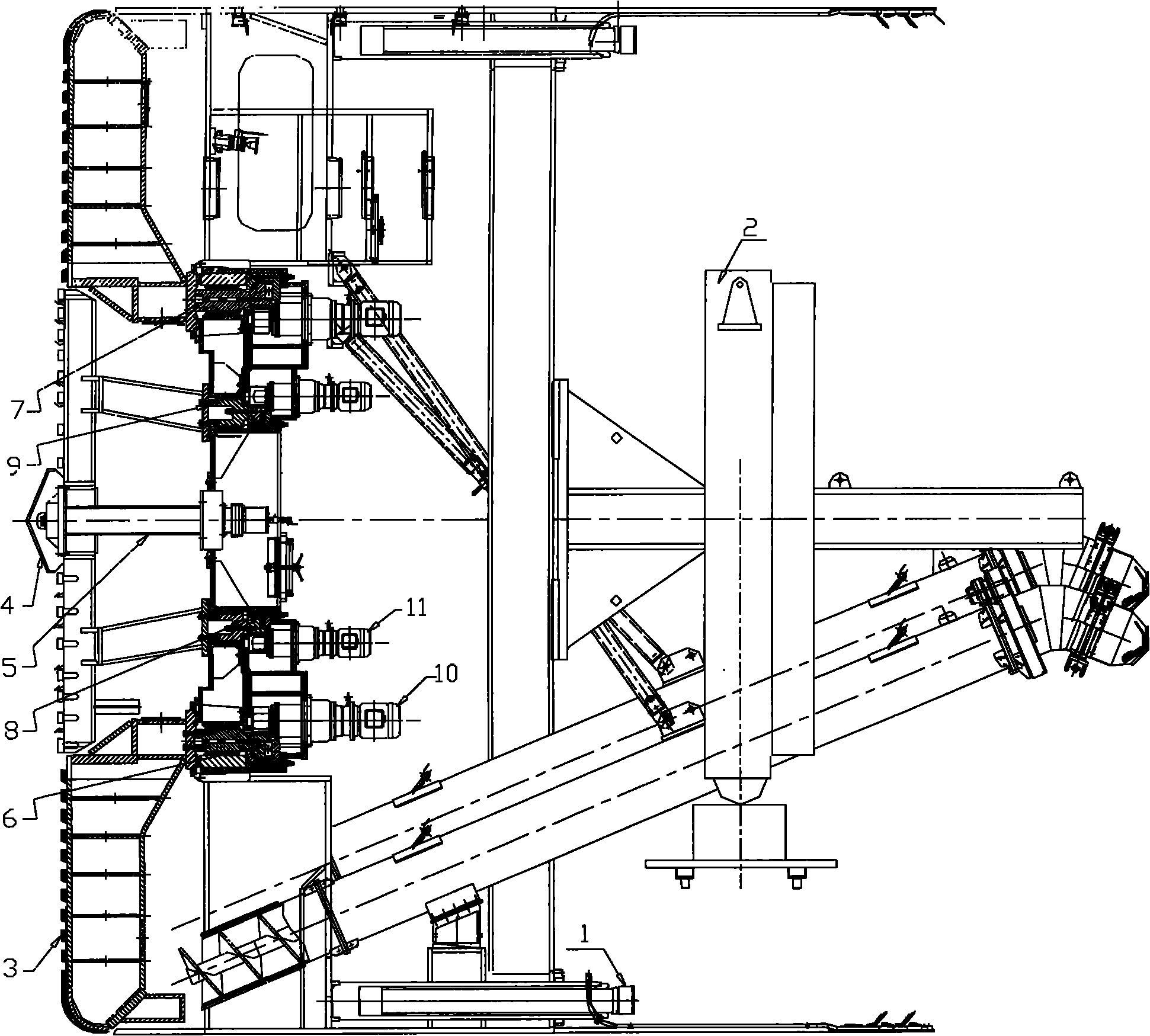

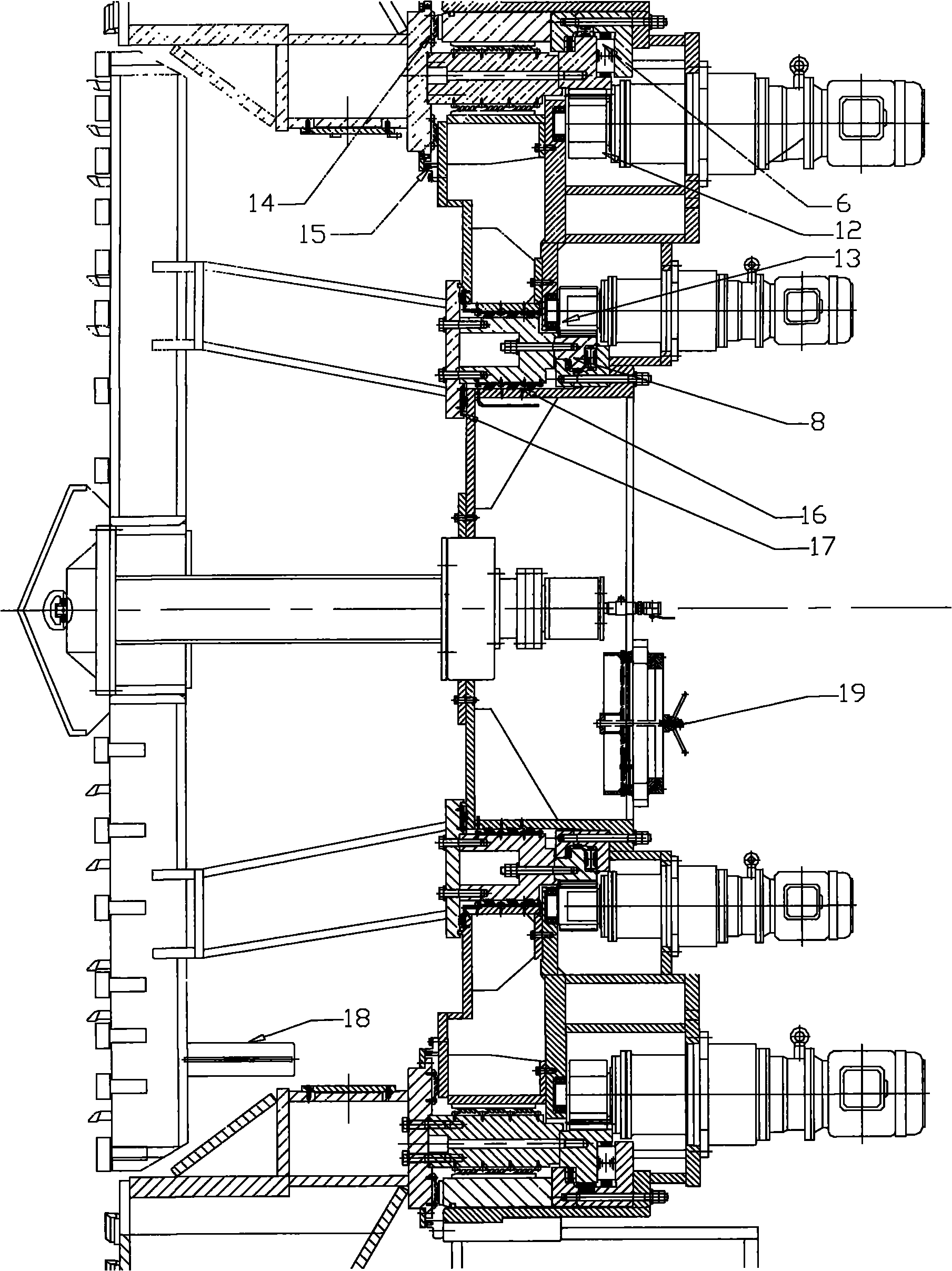

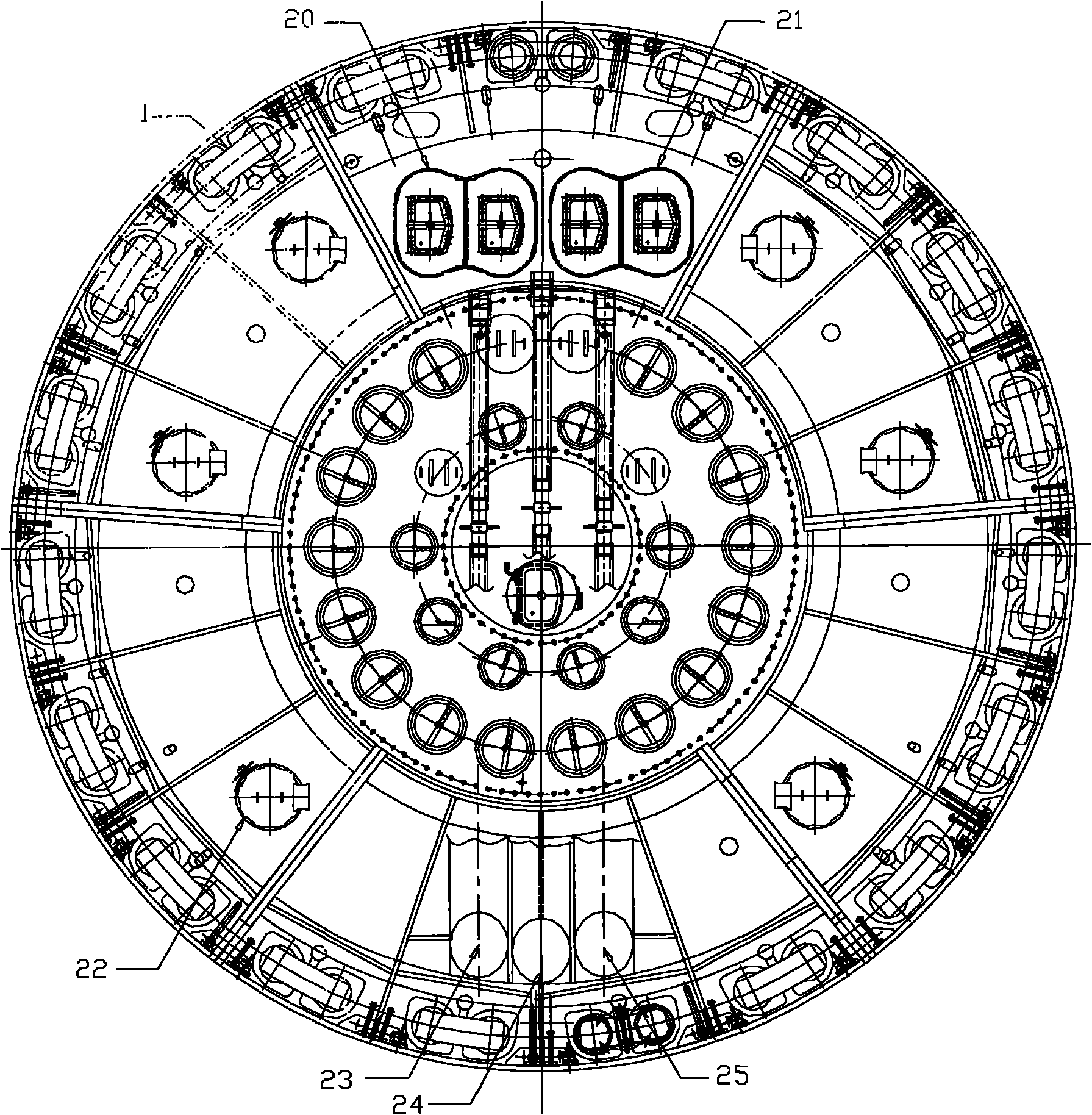

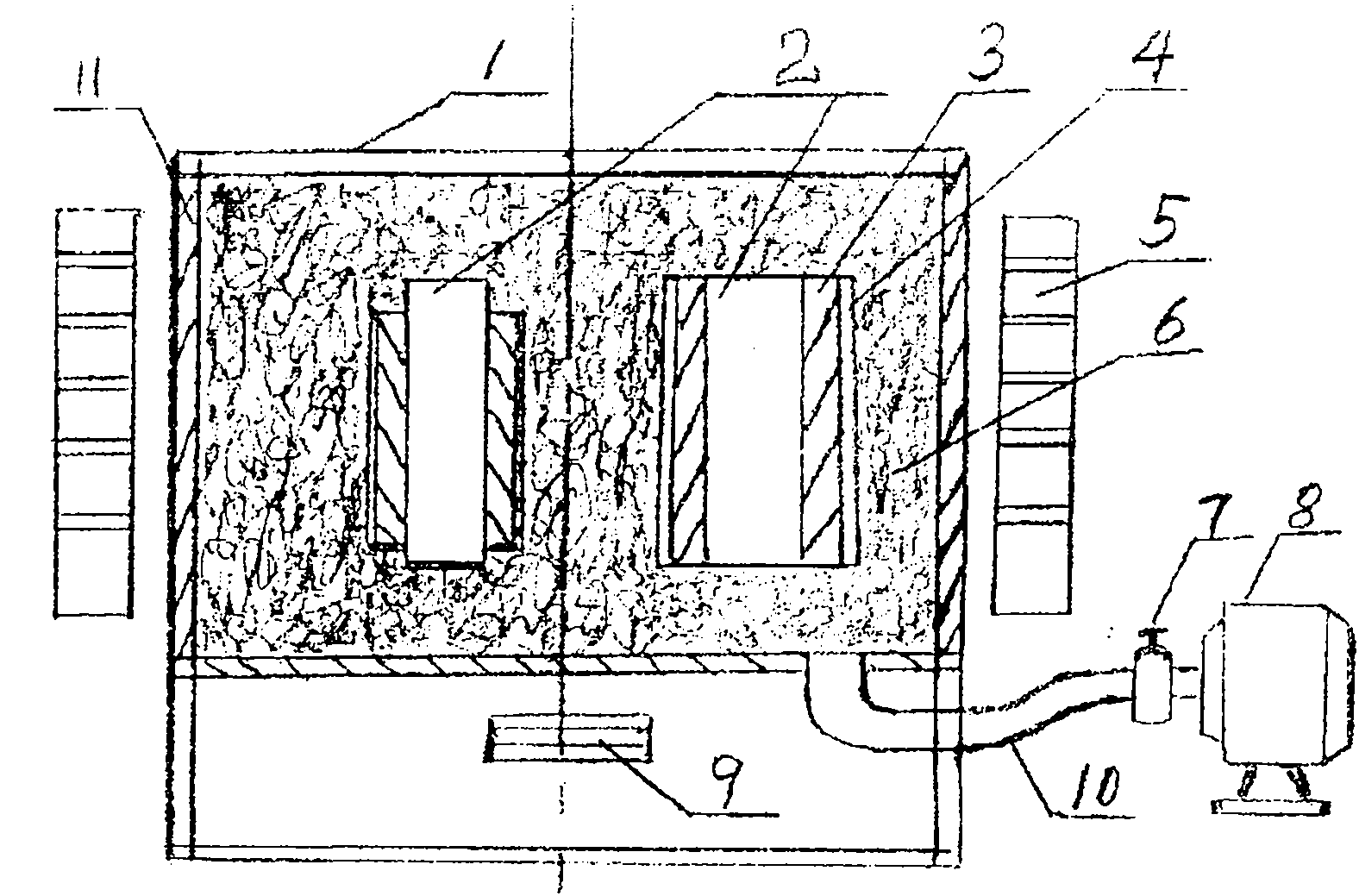

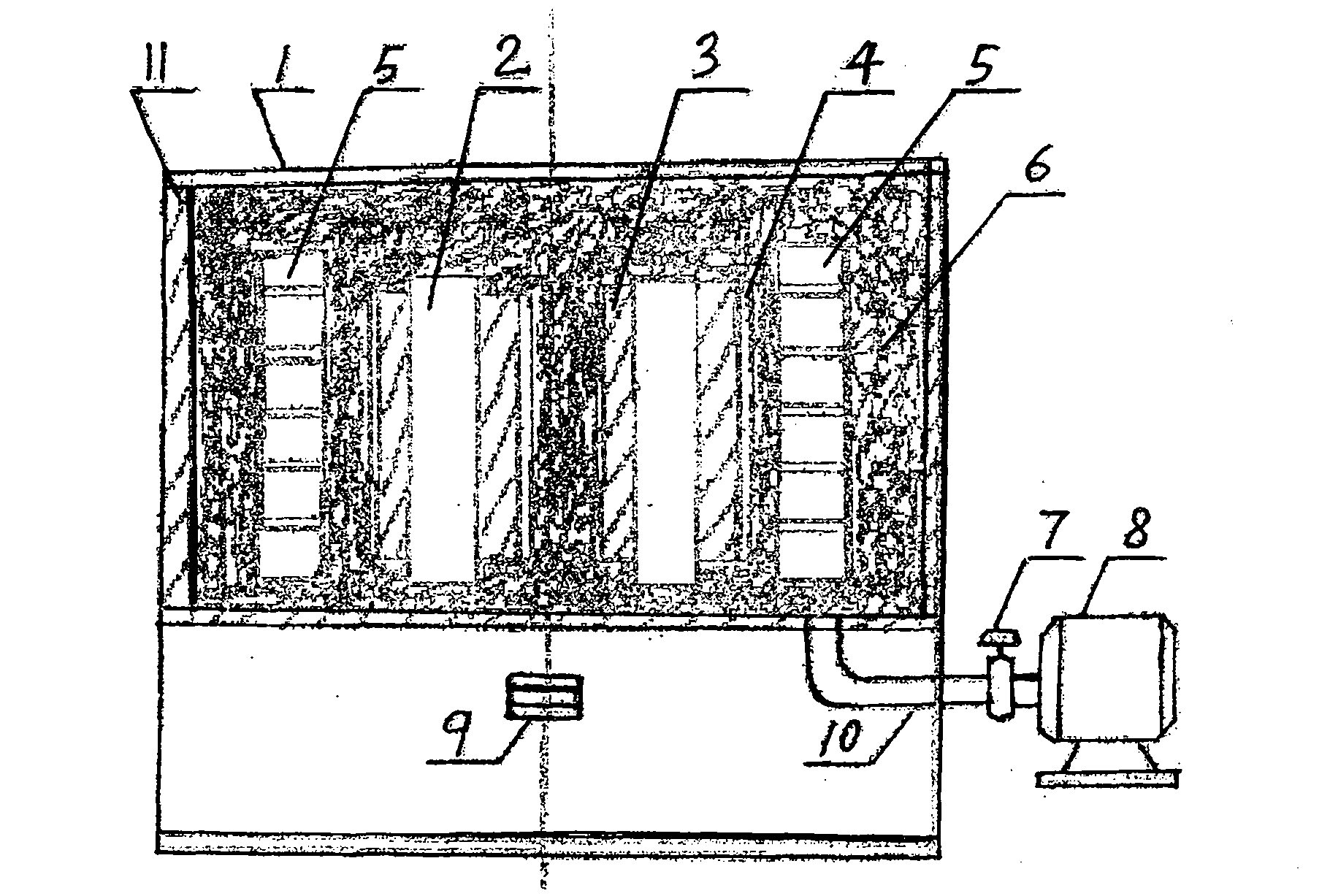

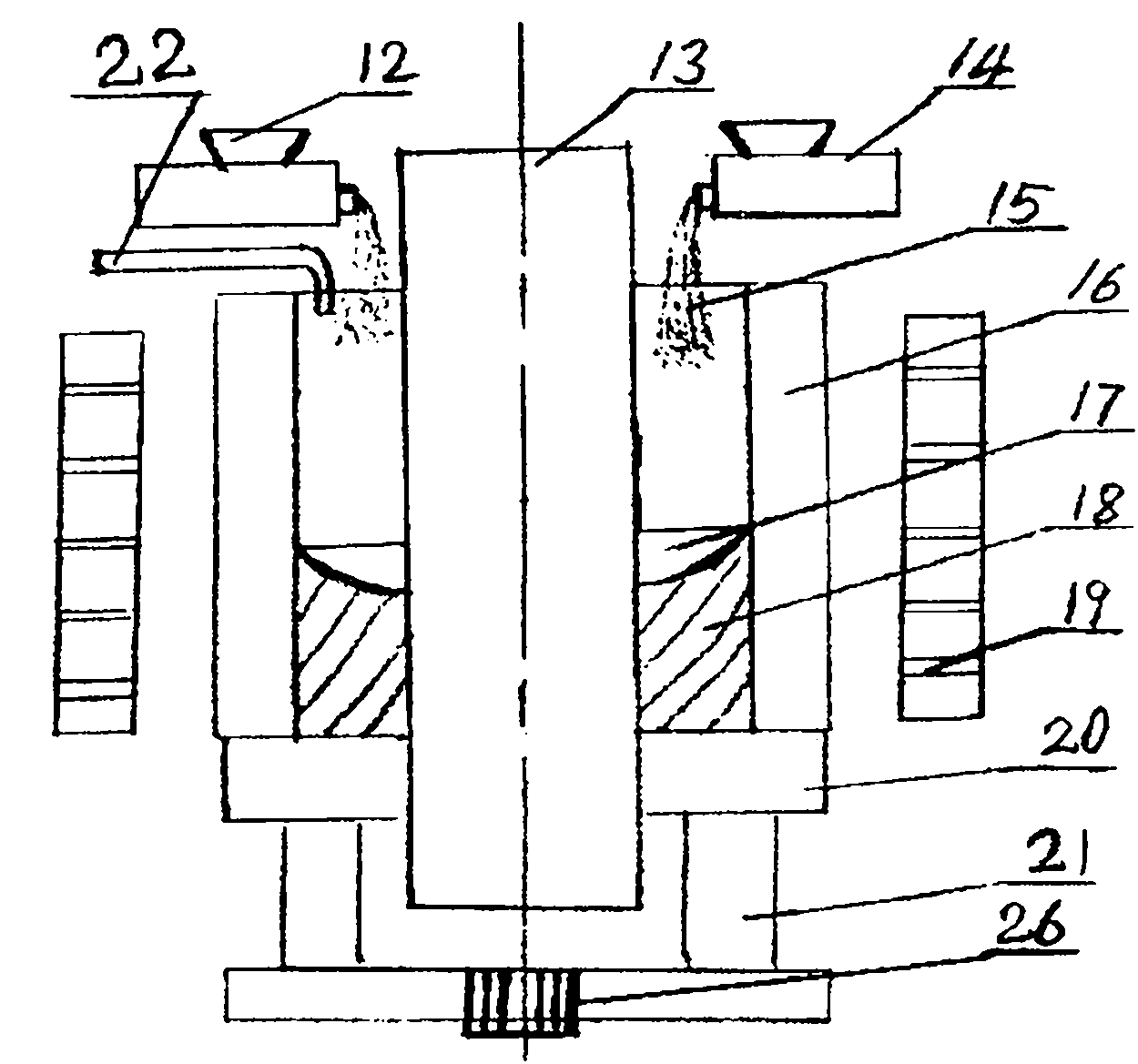

Large-diameter earth pressure balance shield machine

InactiveCN101798928AReduce wear rateChange the situation of uneven damageTunnelsControl theoryEarth pressure balance

The invention relates to a large-diameter earth pressure balance shield machine. The machine comprises a cutterhead, a cutterhead drive part, a propulsion oil cylinder, an erector, spiral conveyors and a frame; the cutterhead is a double-cutterhead which comprises a peripheral large cutterhead and an independent central cutterhead; the cutterhead drive part comprises two driving mechanisms which drive the peripheral large cutterhead and the independent central cutterhead respectively; and the peripheral large cutterhead and the independent central cutterhead rotate independently and bidirectionally. Compared with the prior art, the shield machine adopts the double-cutterhead design, greatly optimizes a cutting speed of the cutterhead on a soil body, further improves a propulsion speed of the shield, optimizes the disturbance effect of the cutterhead on the soil body, and prevents the rolling of a shield machine body; different opening rates are designed on the cutterhead and are suitable for different situations of a central part and a peripheral part when a tunnel is advanced; and three spiral conveyors discharge soil, effectively control the posture of the shield, and prevent the deviation of a tunnel axis.

Owner:SHANGHAI LIXING ENG TECH DEV

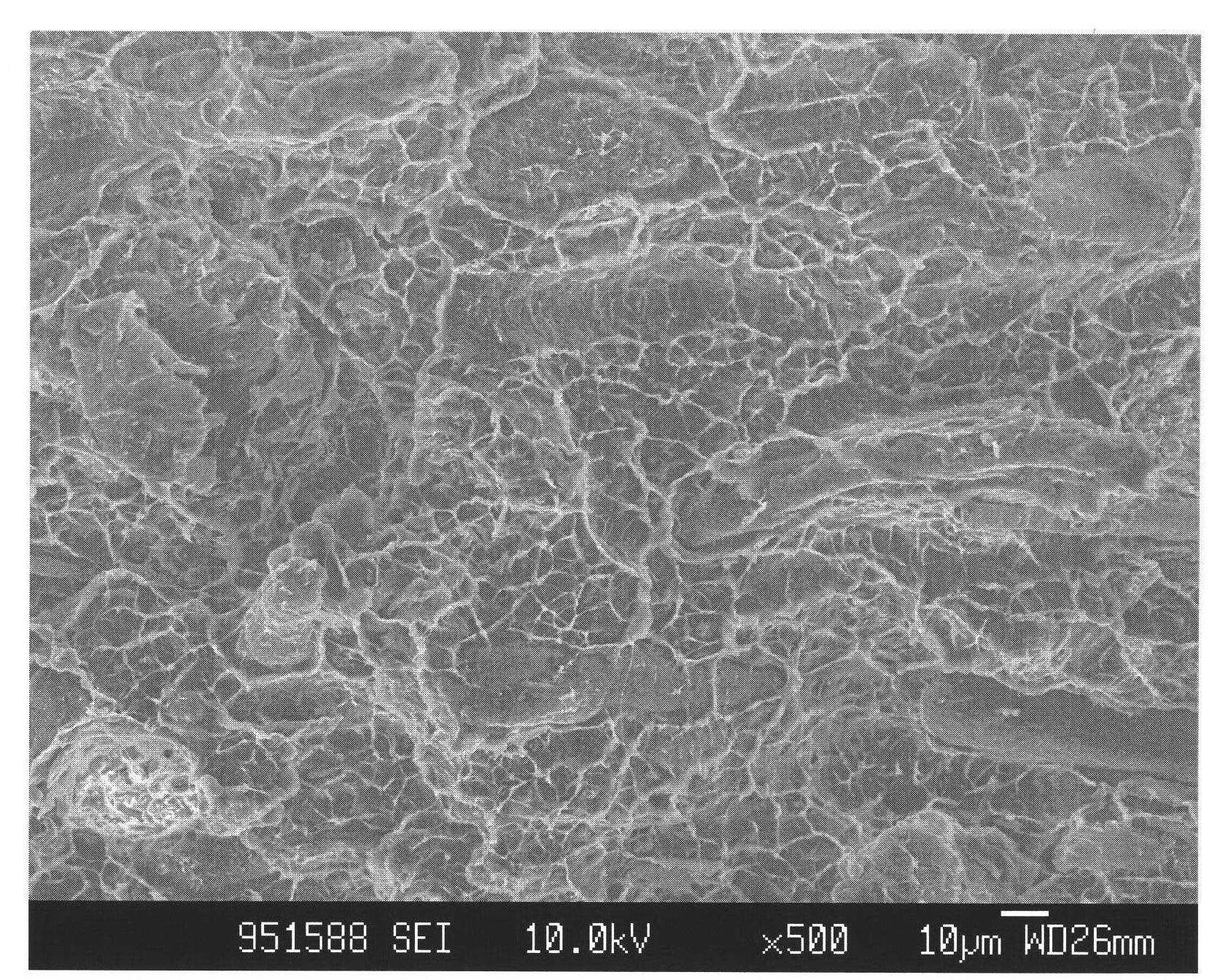

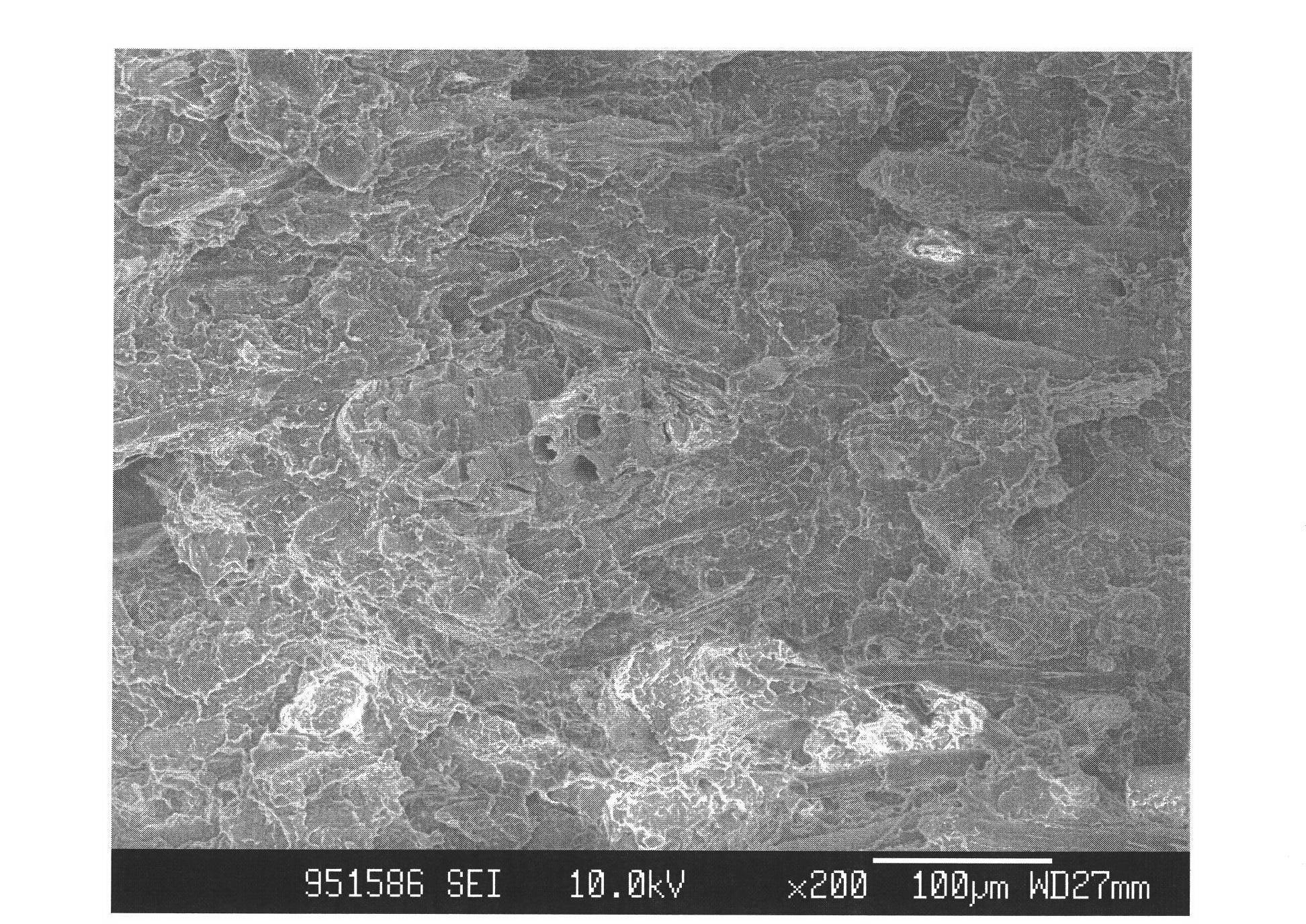

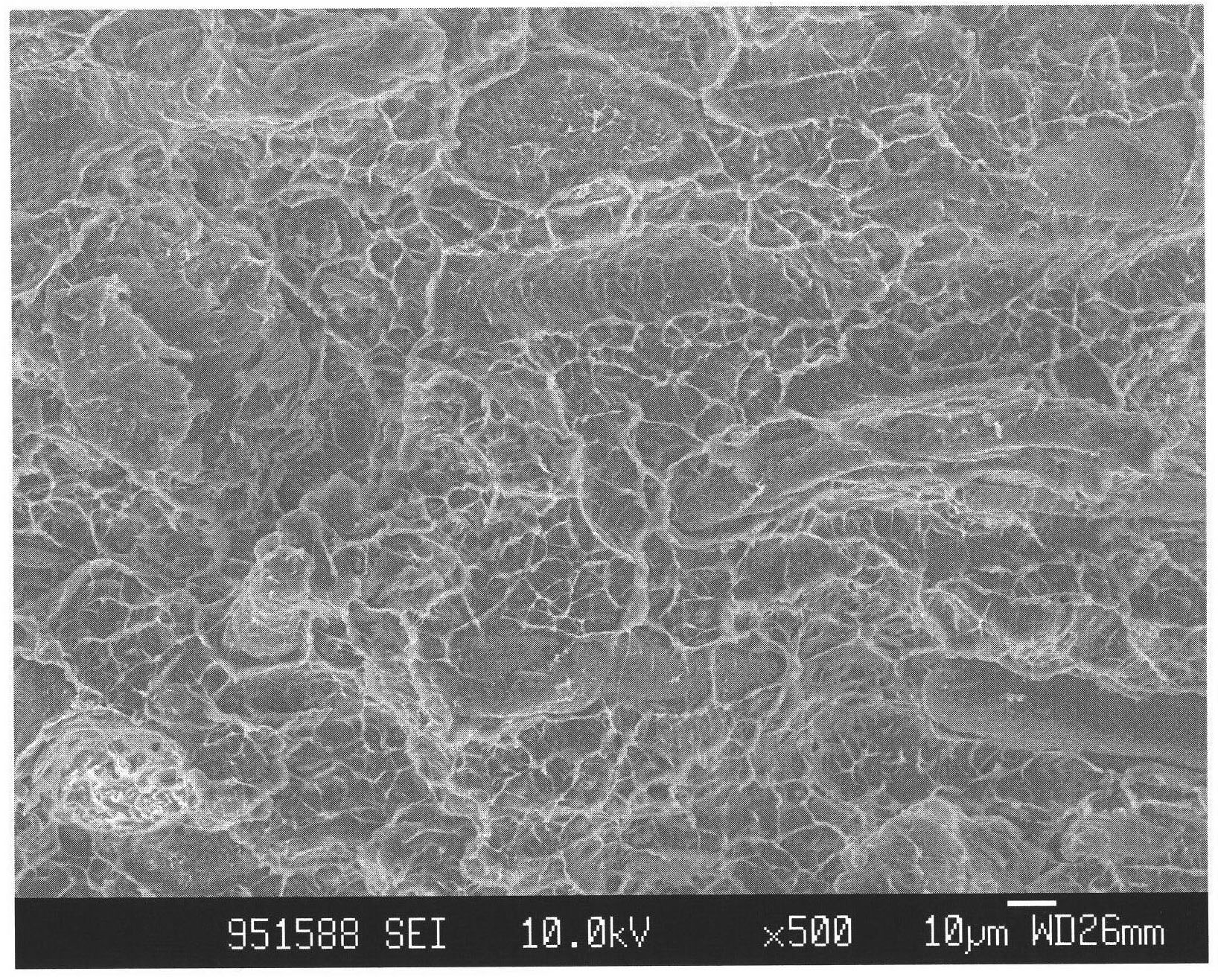

Boron carbide based ceramic matrix composites

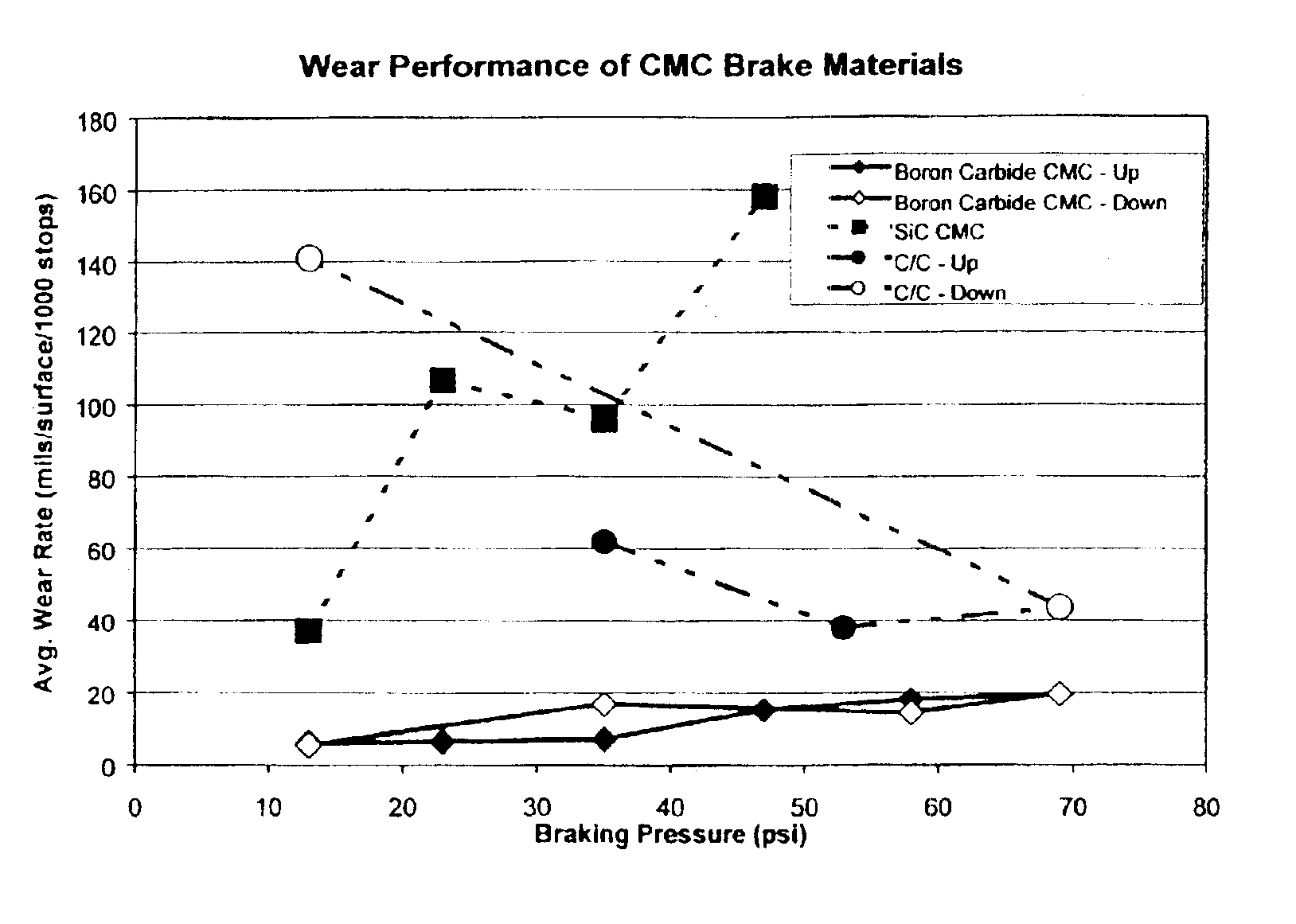

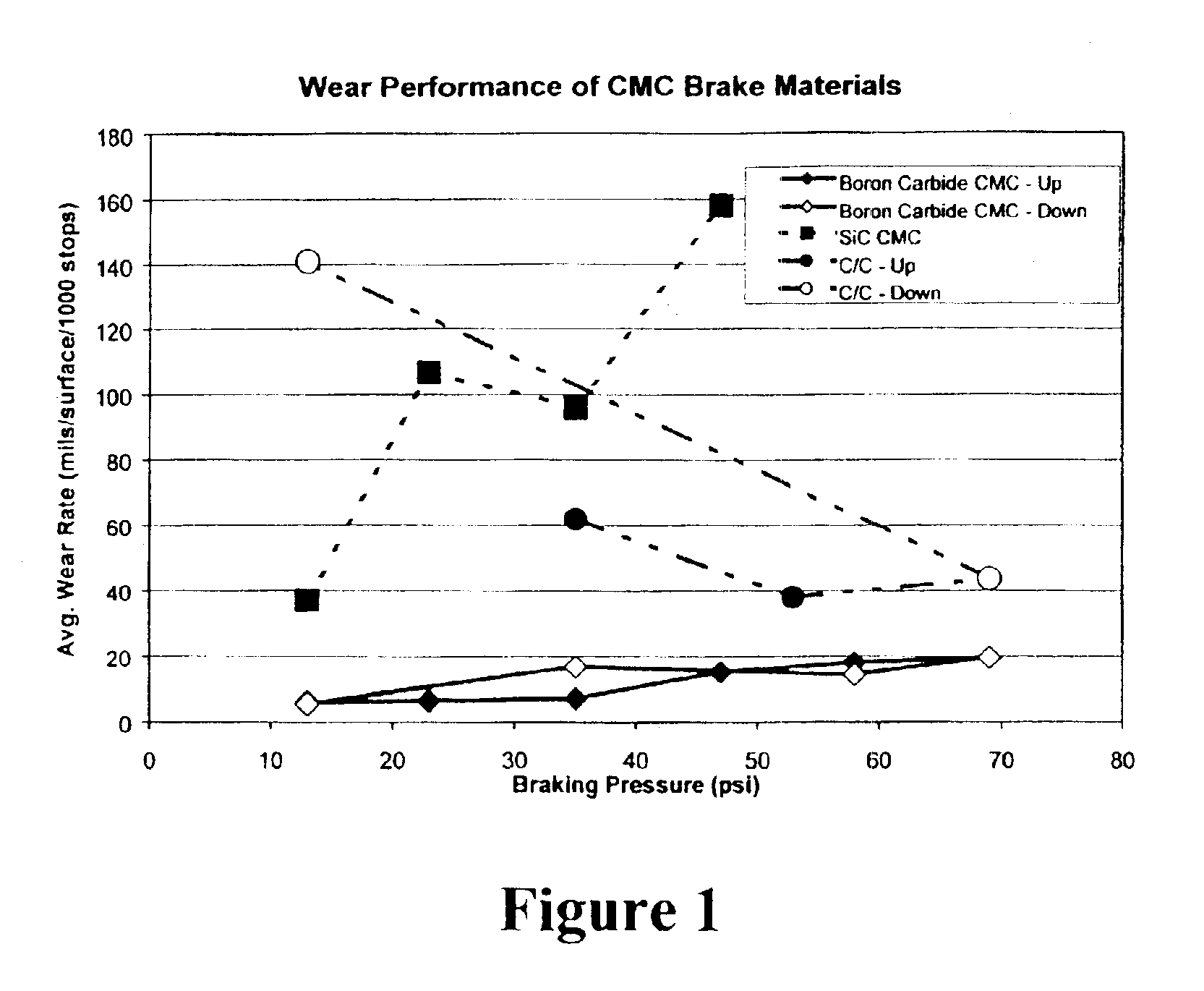

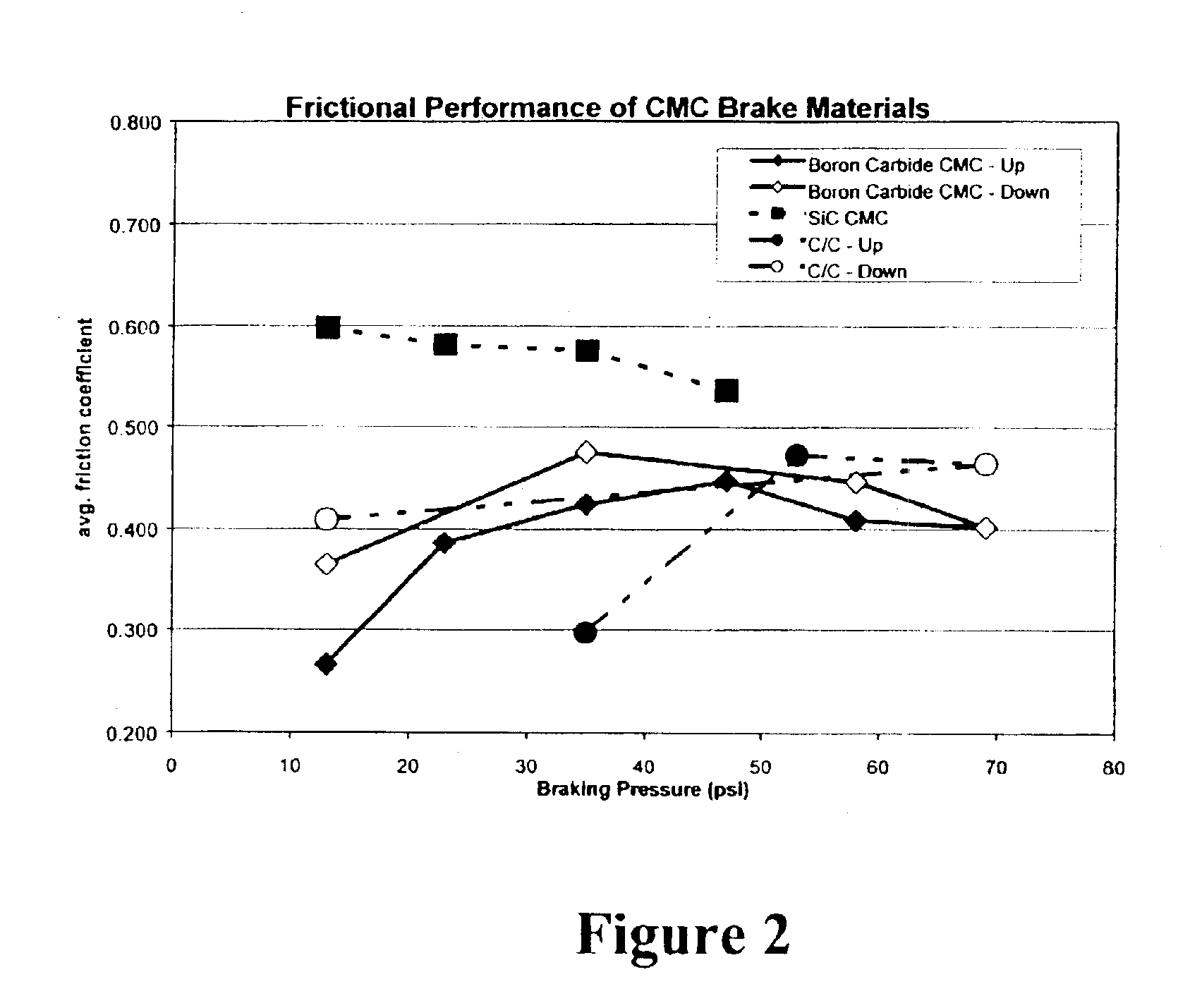

InactiveUS6855428B2Big advantageReduce wear rateBraking discsPretreated surfacesSilicon matrixBoron carbide

The present invention is a composite material and process to produce same. That material comprises a fibrous structure which is initially predominantly coated with elemental carbon; that fibrous structure is then subsequently predominantly coated with at least one ceramic material, e.g., boron carbide, which is non-reactive with silicon. The composite material also comprises a silicon matrix which is continuous and predominantly surrounds the fibrous structure, which has been initially predominantly coated with elemental carbon and subsequently predominantly coated with at least one ceramic material. The matrix which has a fine grain crystalline structure of predominantly 20 microns or less in size. The at least one ceramic material is discontinuous within that matrix. The fibrous material pulls out of the elemental carbon, which initially predominantly coats that fibrous structure, when the composite is subjected to fracture.

Owner:THE BF GOODRICH CO

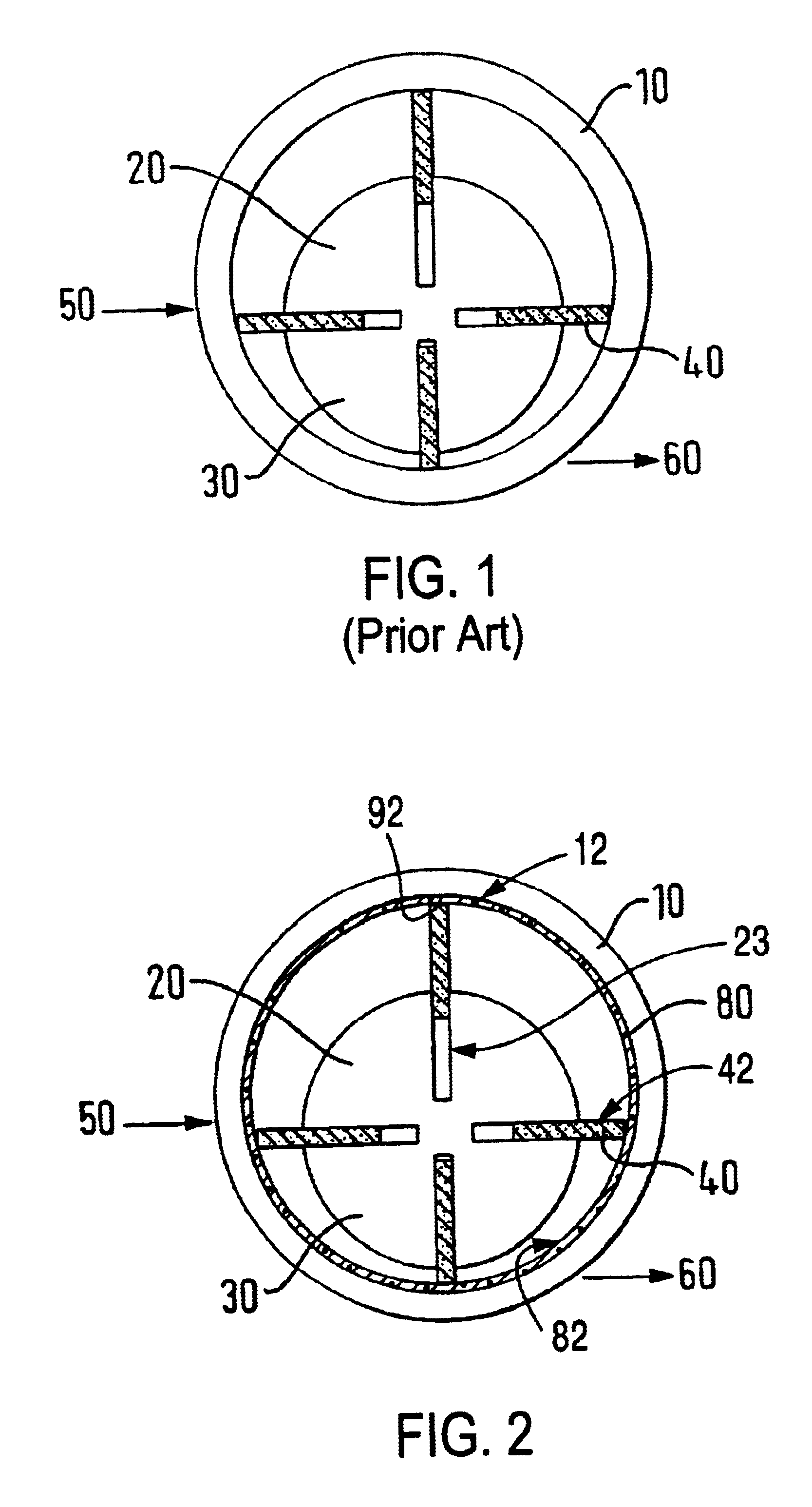

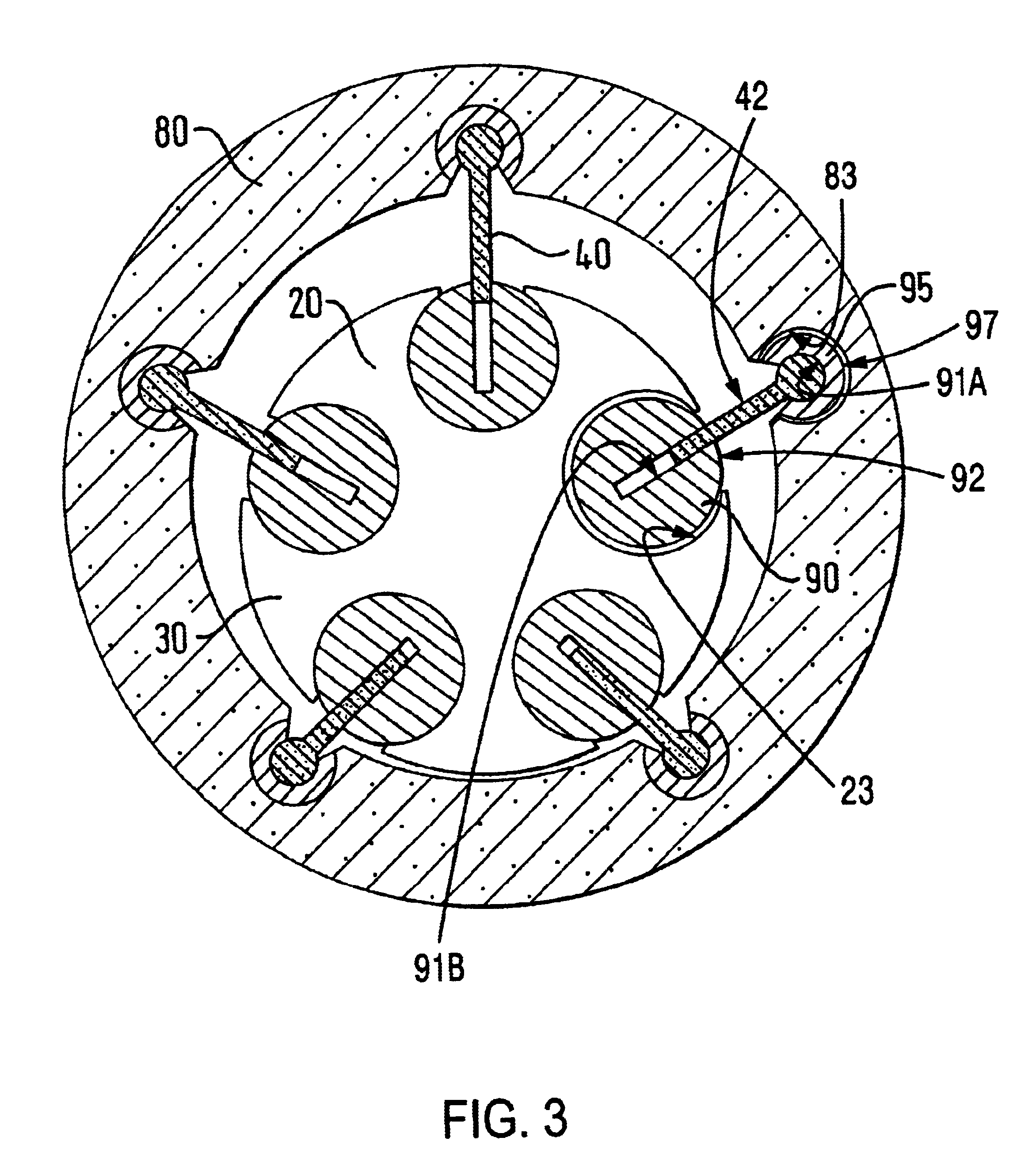

Rotary pump

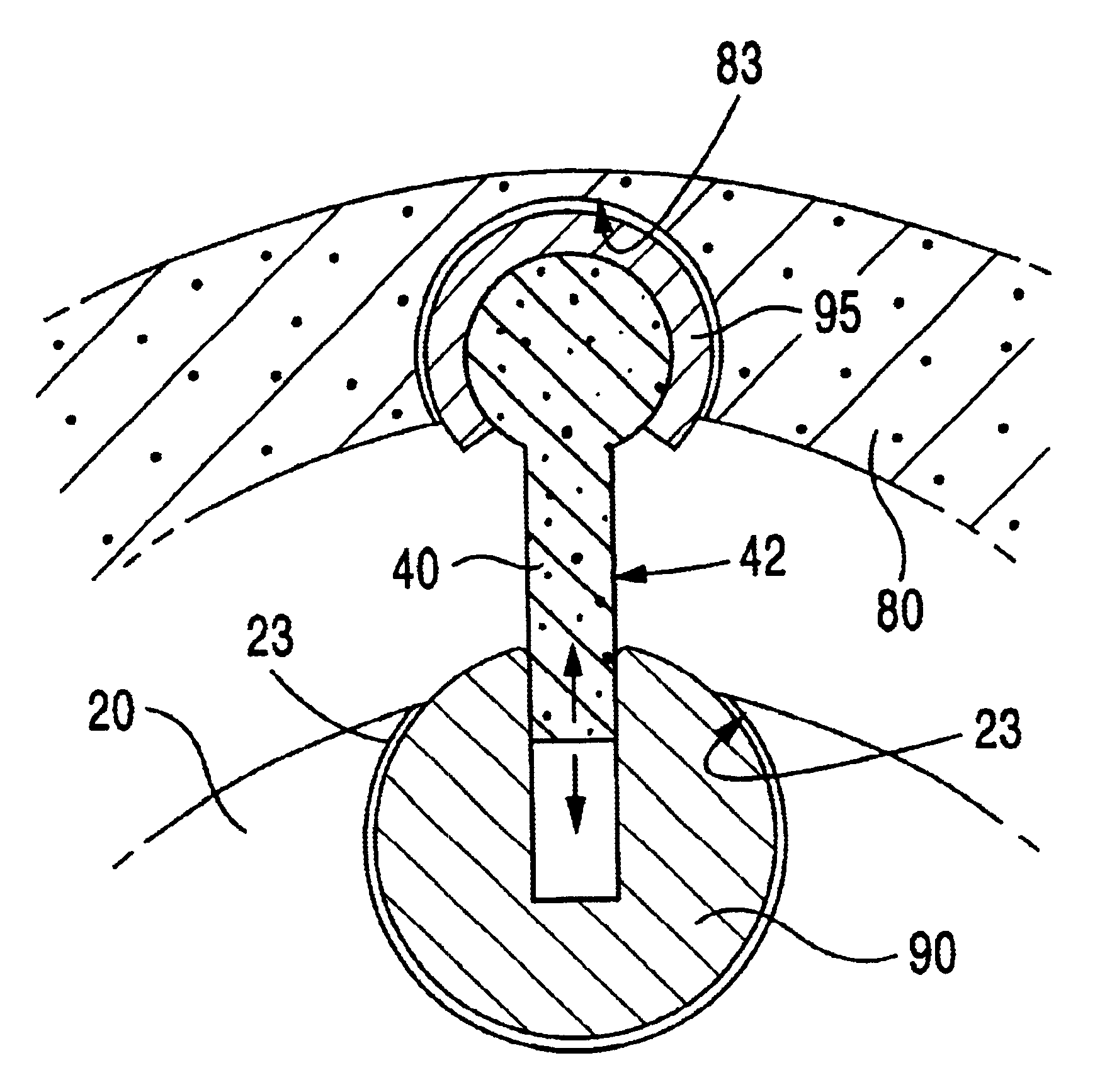

InactiveUS6666671B1Shorten speedReduce wear rateOscillating piston enginesSealing arrangement for pumpsRotary pumpFree rotation

A rotary pump for pumping compressible fluid comprising an eccentrically mounted rotor 20 and a stator 10. The stator 10 comprises a stator inner liner 80 that is free to rotate, driven directly or in response to rotation of the rotor 20 such that the relative velocity between the outer surface of the rotor 20 and the inner surface of the stator 10 is reduced. The vanes 40 are held at each end by sockets 90, 95 in the rotor 20 and stator 10. The vane 40 and socket 90, 95 coupling provides fluid sealing without liquid lubricant. Opposing solid lubricant and hard surfaces are used on contact surfaces between the elements.

Owner:IC INNOVATIONS

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

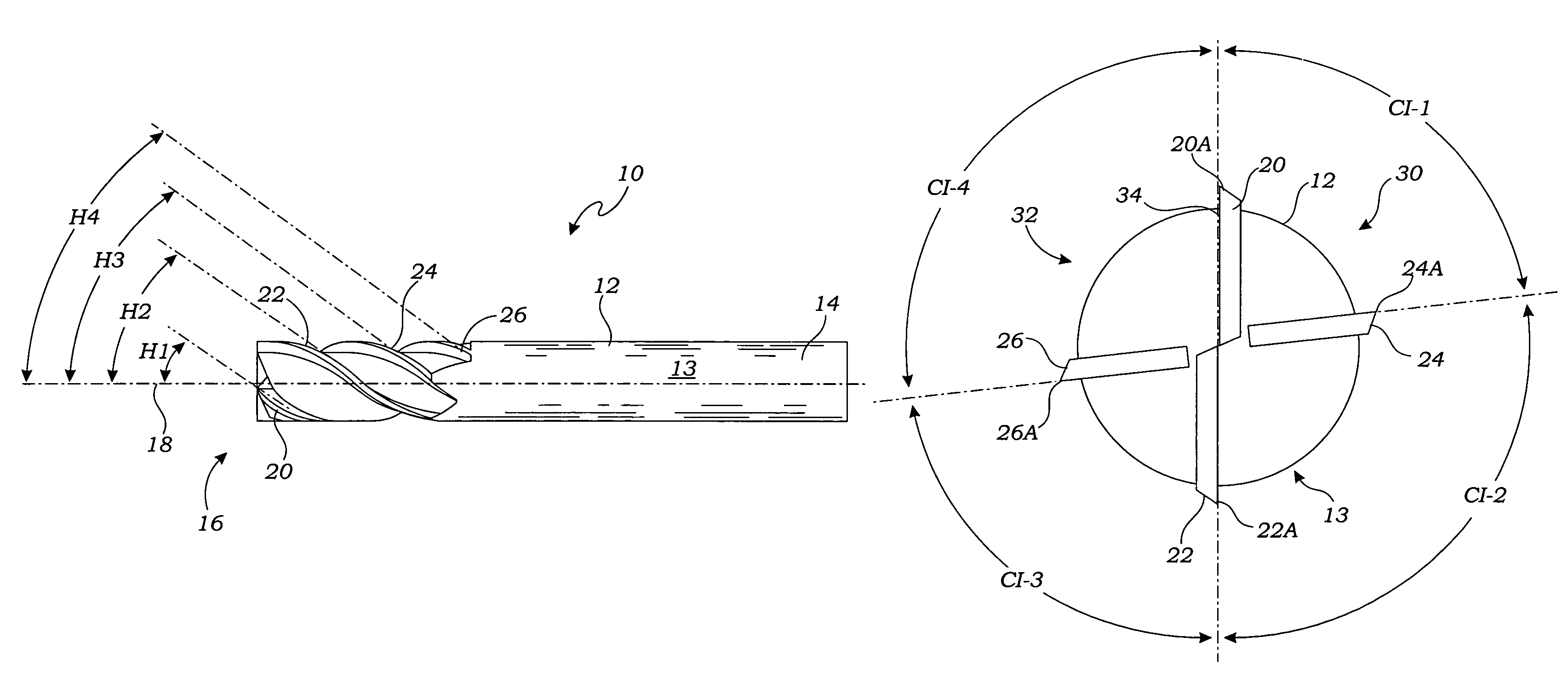

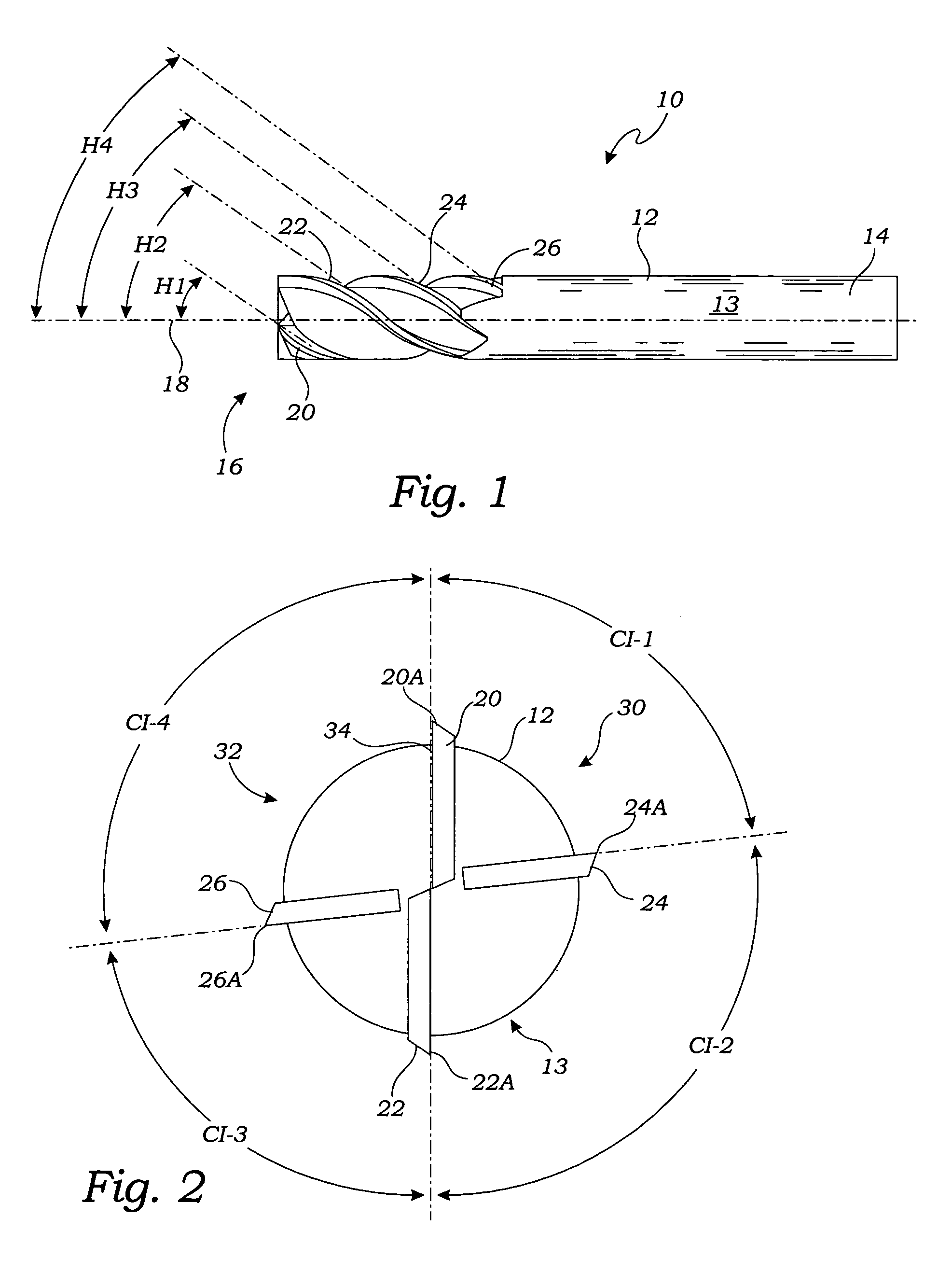

Variable helix rotary cutting tool

A rotary cutting tool has a substantially cylindrical main body and four flutes. The main body has a shank end, a cutting end formed integrally opposite the shank end, and a longitudinal axis of rotation. The four flutes include a pair of flutes comprising a first flute and a second flute formed on opposite sides of the main body, and each of the pair of flutes are symmetrical and have the same helix angle. A third flute is formed on one side of the main body between the pair of flutes, and defines a helical cutting edge having a helix angle that is different than the helix angle of the pair of flutes. A fourth flute is formed on the other side of the main body, and defines a helical cutting edge having a helix angle that is different than the helix angle of the pair of flutes and different than the helix angle of the third flute.

Owner:CARBIDE GRINDING CO INC +1

Method for electroplating magnesium and magnesium alloy

The present invention provides an electroplating method of magnesium and magnesium alloy. The technology comprises dehydrogen, chemical degreasing, shining, neutralization, activation, pre-plating, functional plating, decorative plating and post treatment. The cast workpiece must be water-washed between every two procedures. The current density of pre-plating is 5-15 A / dm2, cell voltage 4-12 V, pH value of pre-plating solution 1.0-1.2, and Baume degree at room temperature is 30-35. Pre-plating solution recipe contains: copper fluoborate, fluoboric acid, alanine, polyethylene glycol and alizarin dye, mixture of itaconic acid and MBT, 3-S isothiourea onium salt propane sulfonate ,R-S-S(CH2)SO3Na and deionization water. The pre-plating solution of the present invention is cyanogen free, non-toxic and non-hazardous. Bond strength between pre-plating layer and substrate material and between pre-plating layer and the post functional plating layer or decorative plating layer is good. The plating layer is bright and has good corrosion resistance, wear resistance and decorative effect.

Owner:SHENYANG POLYTECHNIC UNIV

Reinforced wear-resistant automobile brake composite material and preparation method thereof

ActiveCN103059504AImprove wear resistanceLow costOther chemical processesFriction liningWear resistantCoupling

The invention discloses a reinforce wear-resistant automobile brake composite material which is prepared from the following components in parts by weight: 85-100 parts of resin matrix, 100-150 parts of composite reinforcing fiber, 80-120 parts of filler, 25-40 parts of toughening material, 6-10 parts of curing agent, 4-6 parts of curing accelerator, 30-85 parts of frictional property regulator, 30-40 parts of noise reducer and 4.5-6 parts of releasing agent. The resin matrix is reinforced by the composite reinforcing fiber and matched with proper frictional property regulator, filler, toughening material and noise reducer to display the synergic coupling actions among the resin matrix, reinforcing fiber, filler and frictional property regulator, thereby obtaining the novel automobile brake composite material which has the advantages of stable friction factor, small wear rate, high heat fade resistance, favorable braking effect, shock absorption, noise reduction, high mechanical strength, low cost, long service life and favorable braking property at different temperatures.

Owner:江苏裕铭铜业有限公司

Double hot-rolling composite friction material and its production

A bi-hot pressing composite friction material and its production are disclosed. The process is carried out by the first hot-press forming, crushing for composite friction material, sifting, mixing composite friction material 40-70 wt% and high-temperature-resisting modified resin 15-35 wt% with reinforced fiber 5-15 wt%, rubber powder 5-15 wt% and residual lubrication material, putting them into mould, hot-press forming at 140-165 degree and 12-20 Mpa and keeping temperature to obtain final product. It has stable friction coefficient, less wear rate and friction noise, better surface toughness and higher gas-pocket coefficient.

Owner:SOUTH CHINA UNIV OF TECH

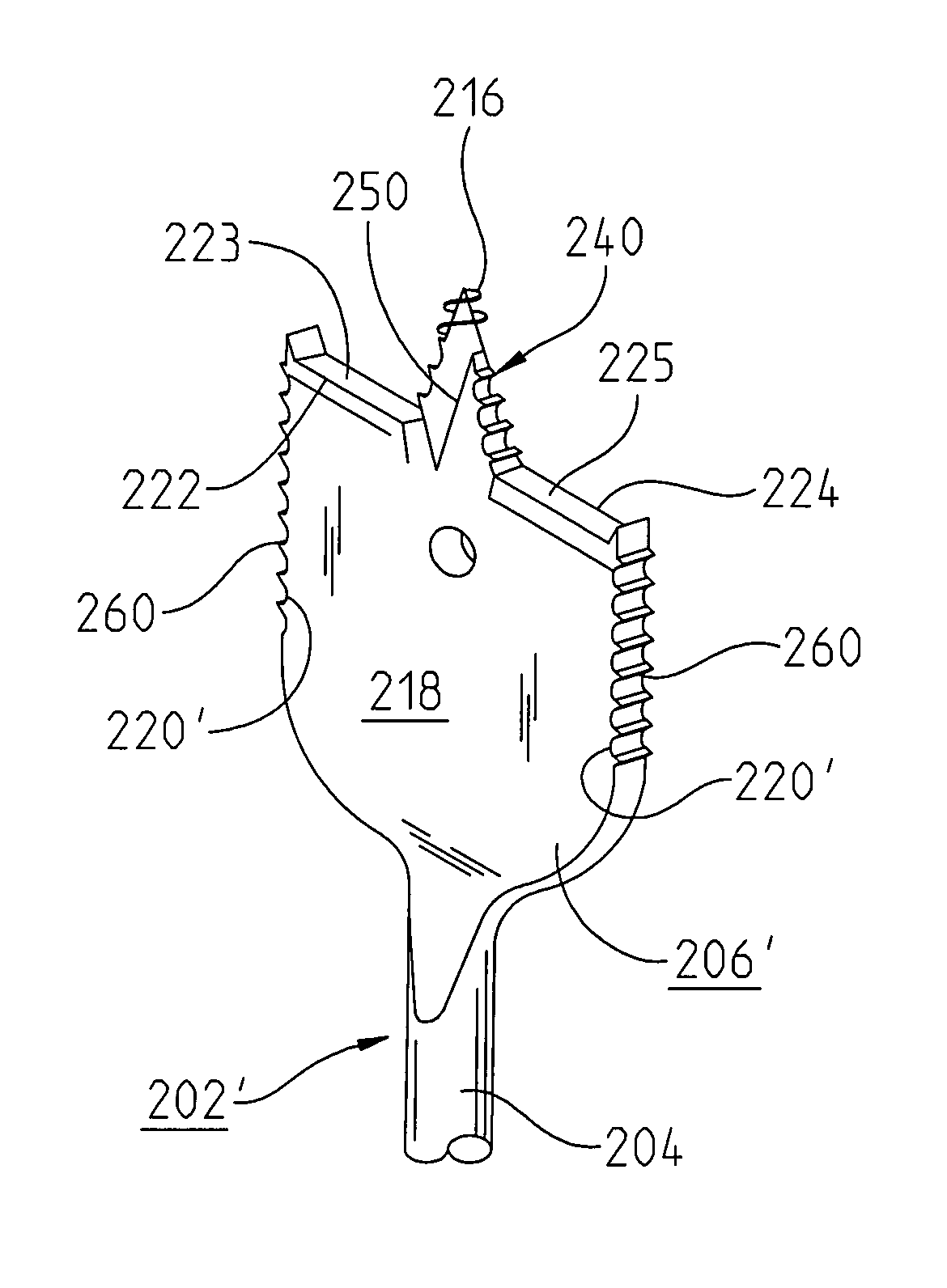

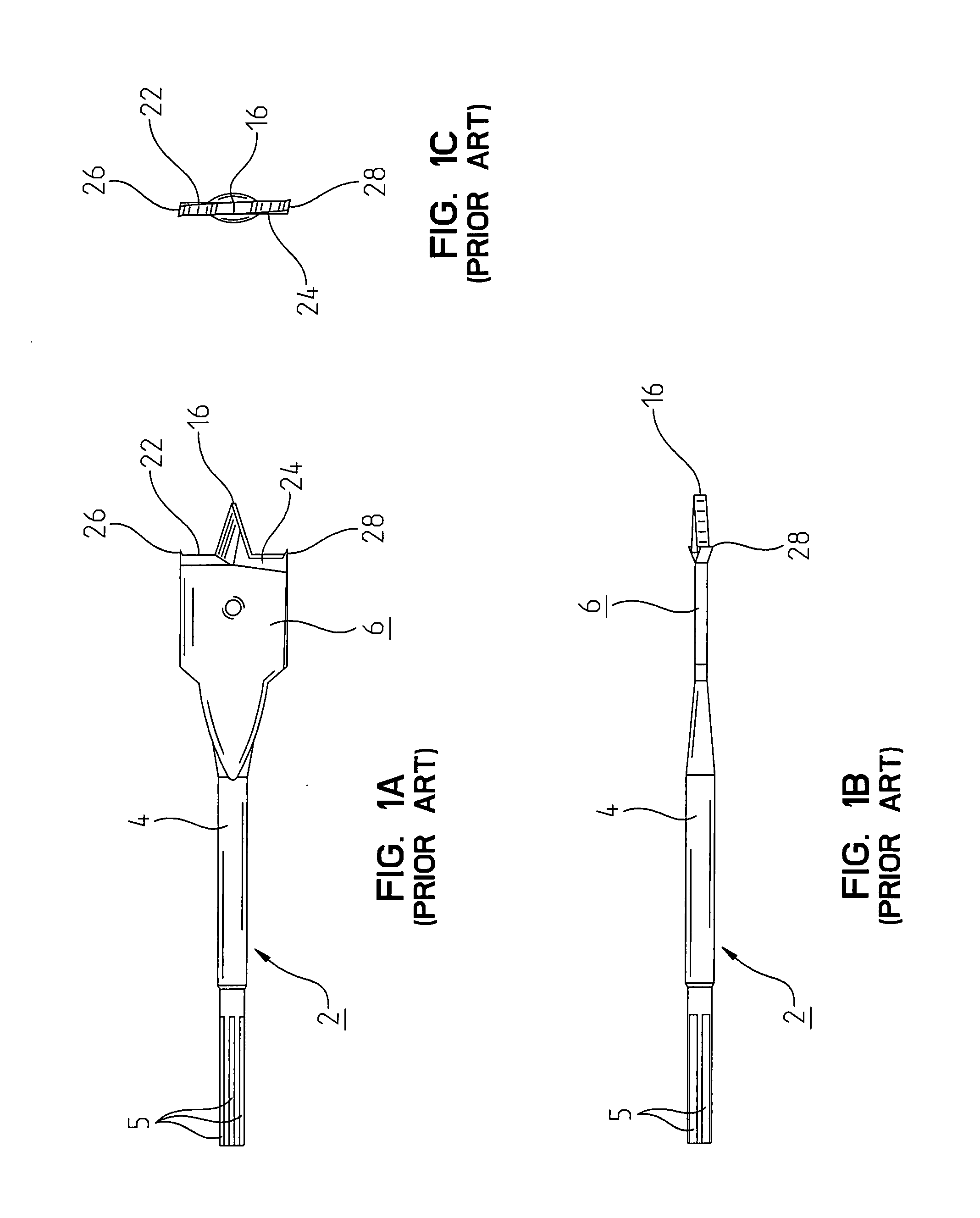

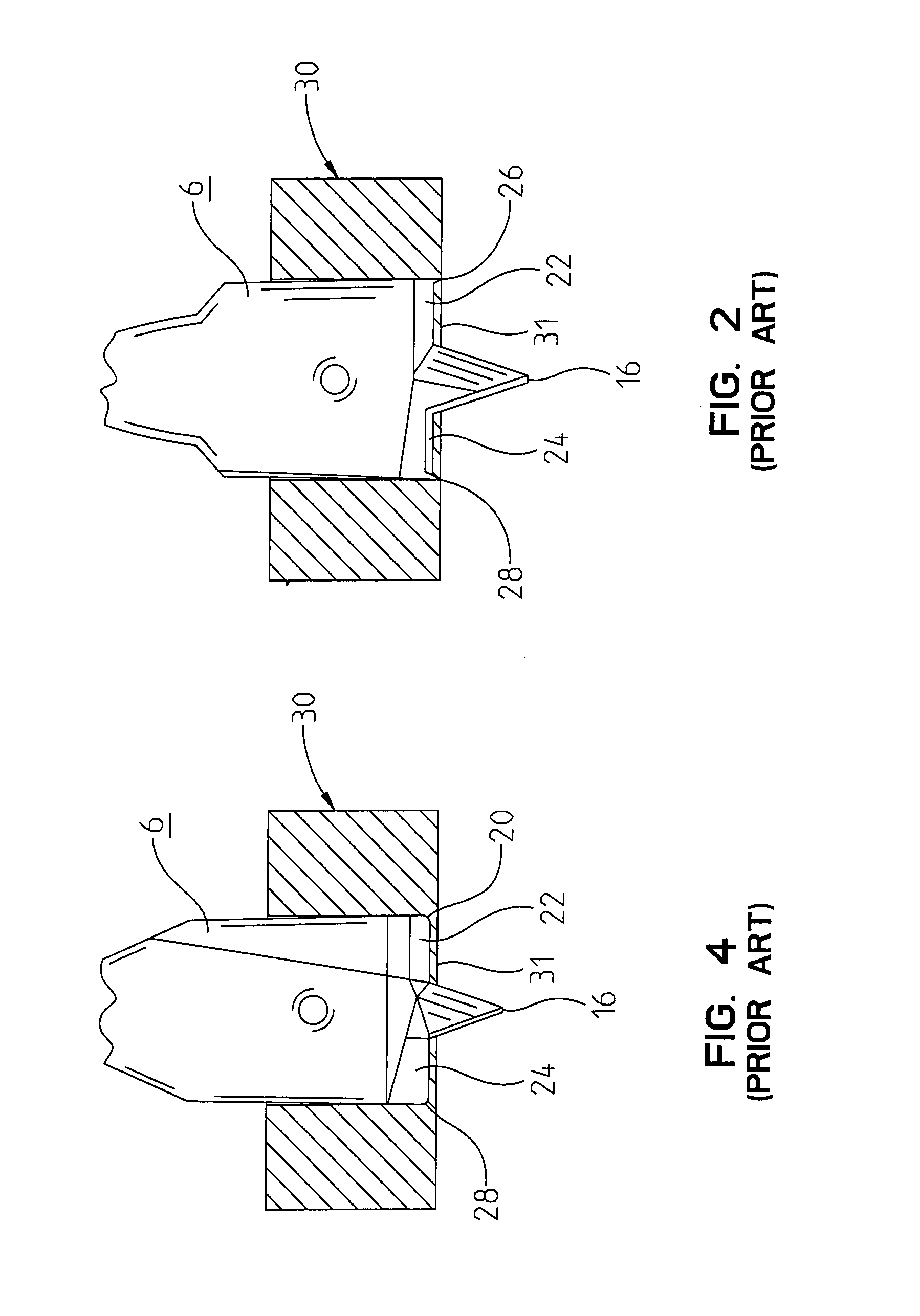

Spade drill bit

InactiveUS7267513B2Easy to removeEnergy efficiencyWood turning toolsTransportation and packagingEngineeringMechanical engineering

A spade drill bit (202) comprises a shaft (204) having one end (205) configured to be engaged to a driving tool and a cutting head (206) attached at an opposite end of said shaft (204). The cutting head (206) includes a center point (216) having threads (240) defined thereon, including continuous threads (247) adjacent the tip and discontinuous threads (242) thereafter toward the base.

Owner:CREDO TECH CORP

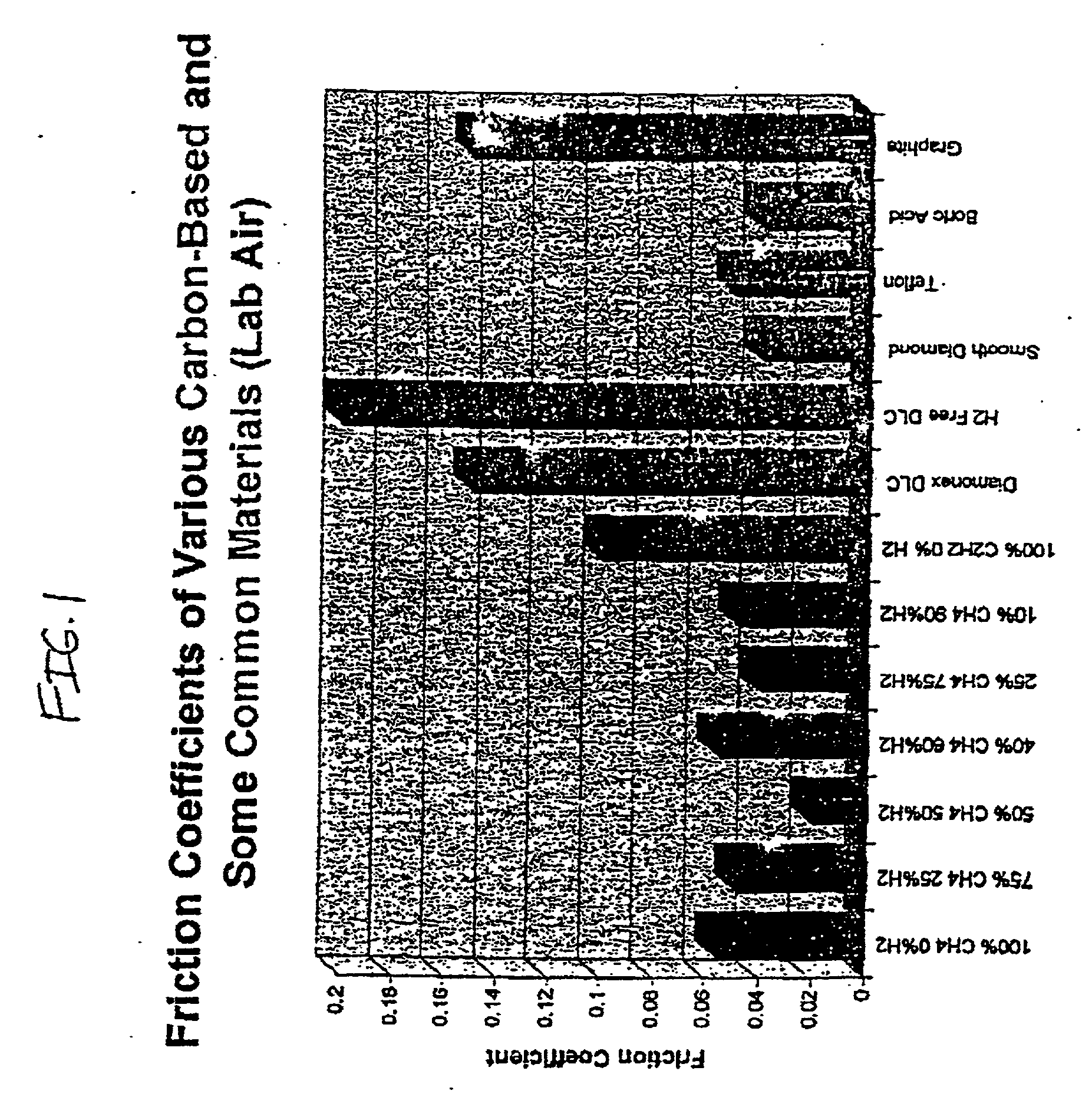

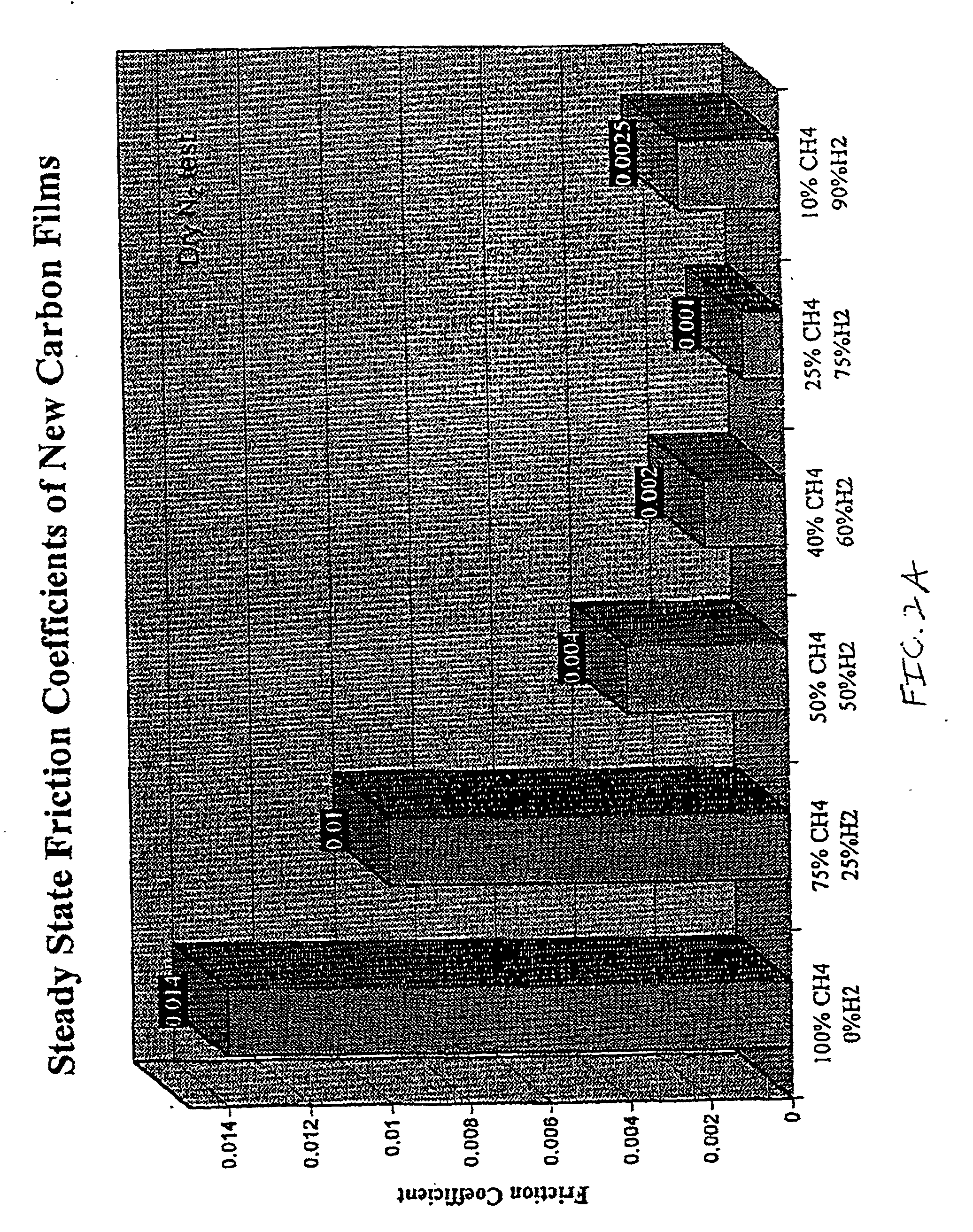

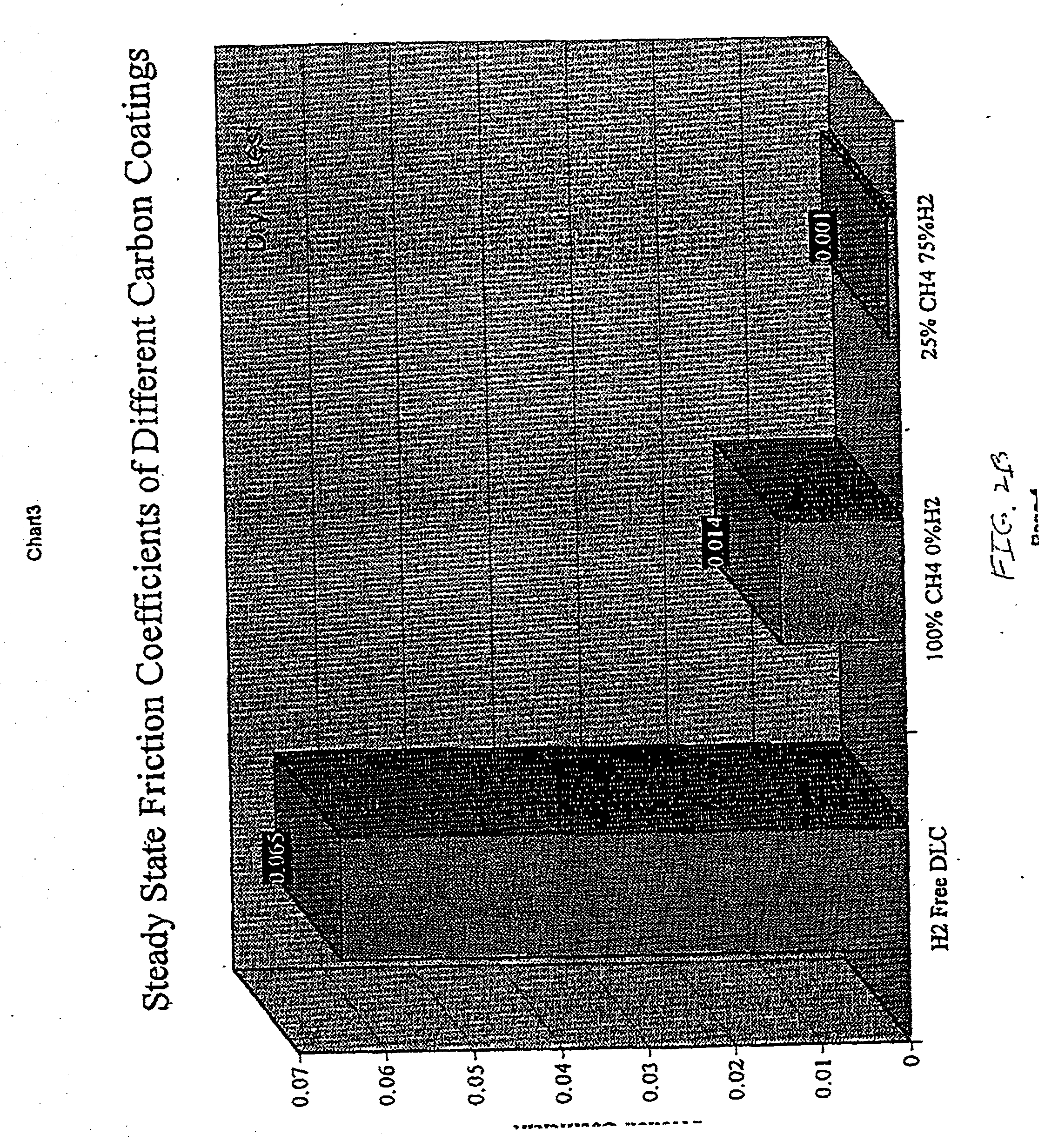

Method to produce ultra-low friction carbon films

InactiveUS20020041930A1Ultra-low frictionUltra-low wear propertyLiquid surface applicatorsRecord information storageCarbon filmDiamond-like carbon

A method and article of manufacture of amorphous diamond-like carbon. The method involves providing a substrate in a chamber, providing a mixture of a carbon containing gas and hydrogen gas with the mixture adjusted such that the atomic molar ratio of carbon to hydrogen is less than 0.3, including all carbon atoms and all hydrogen atoms in the mixture. A plasma is formed of the mixture and the amorphous diamond-like carbon film is deposited on the substrate. To achieve optimum bonding an intervening bonding layer, such as Si or SiO2, can be formed from SiH4 with or without oxidation of the layer formed.

Owner:UCHICAGO ARGONNE LLC

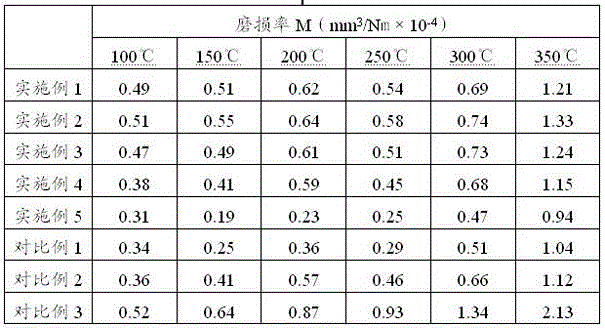

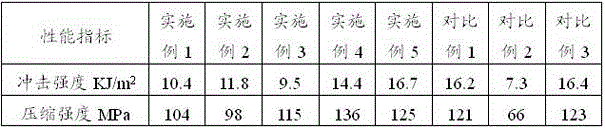

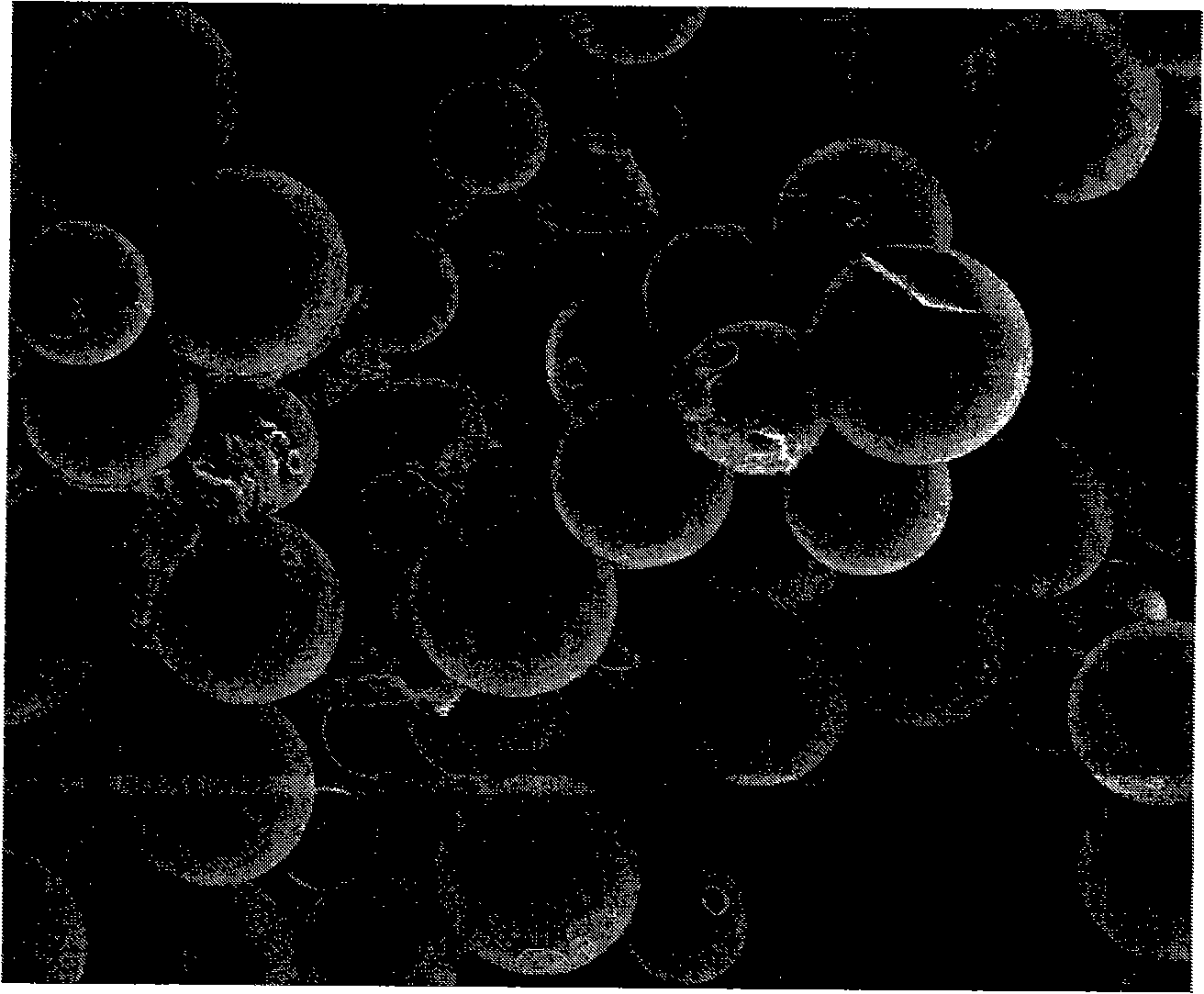

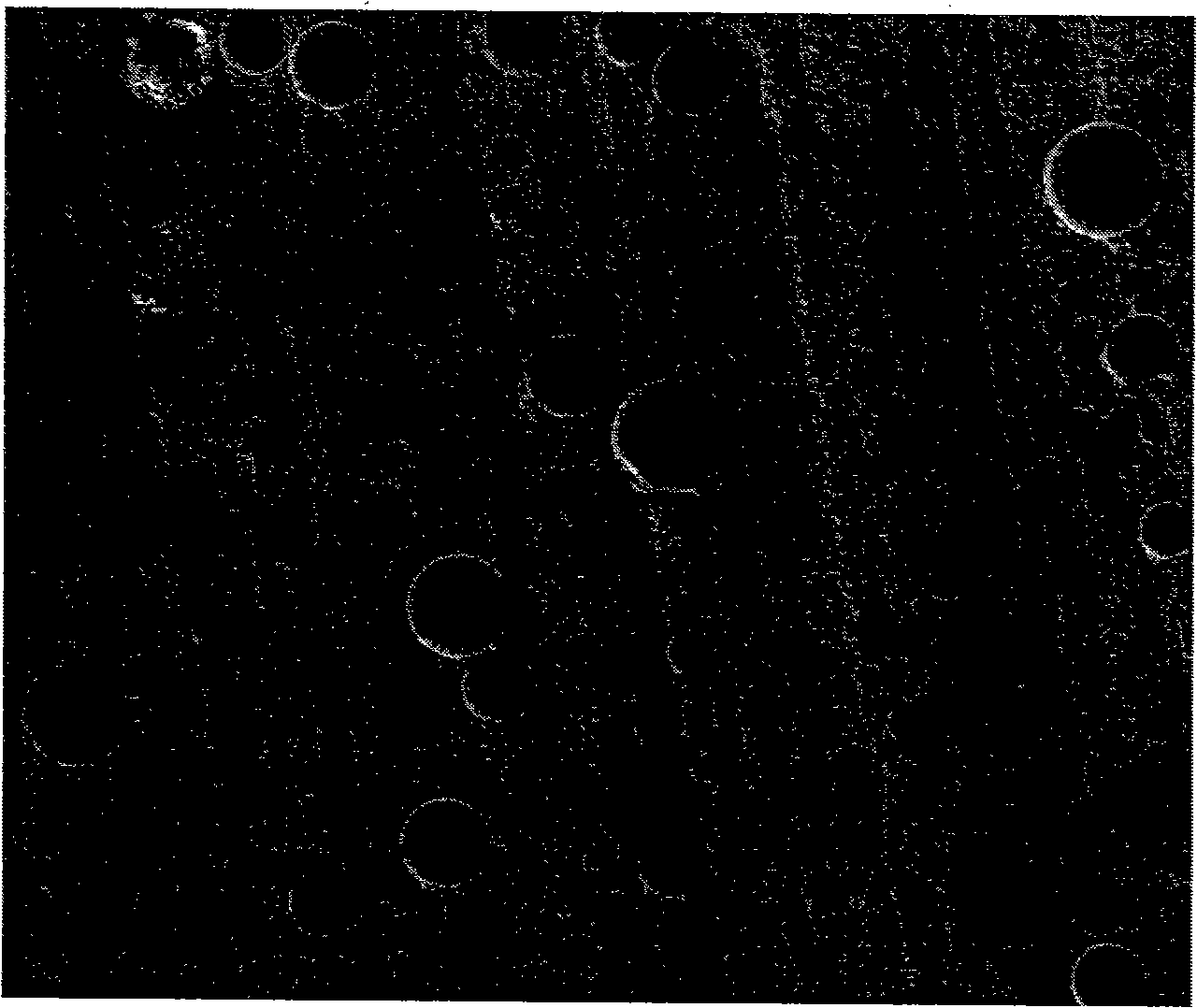

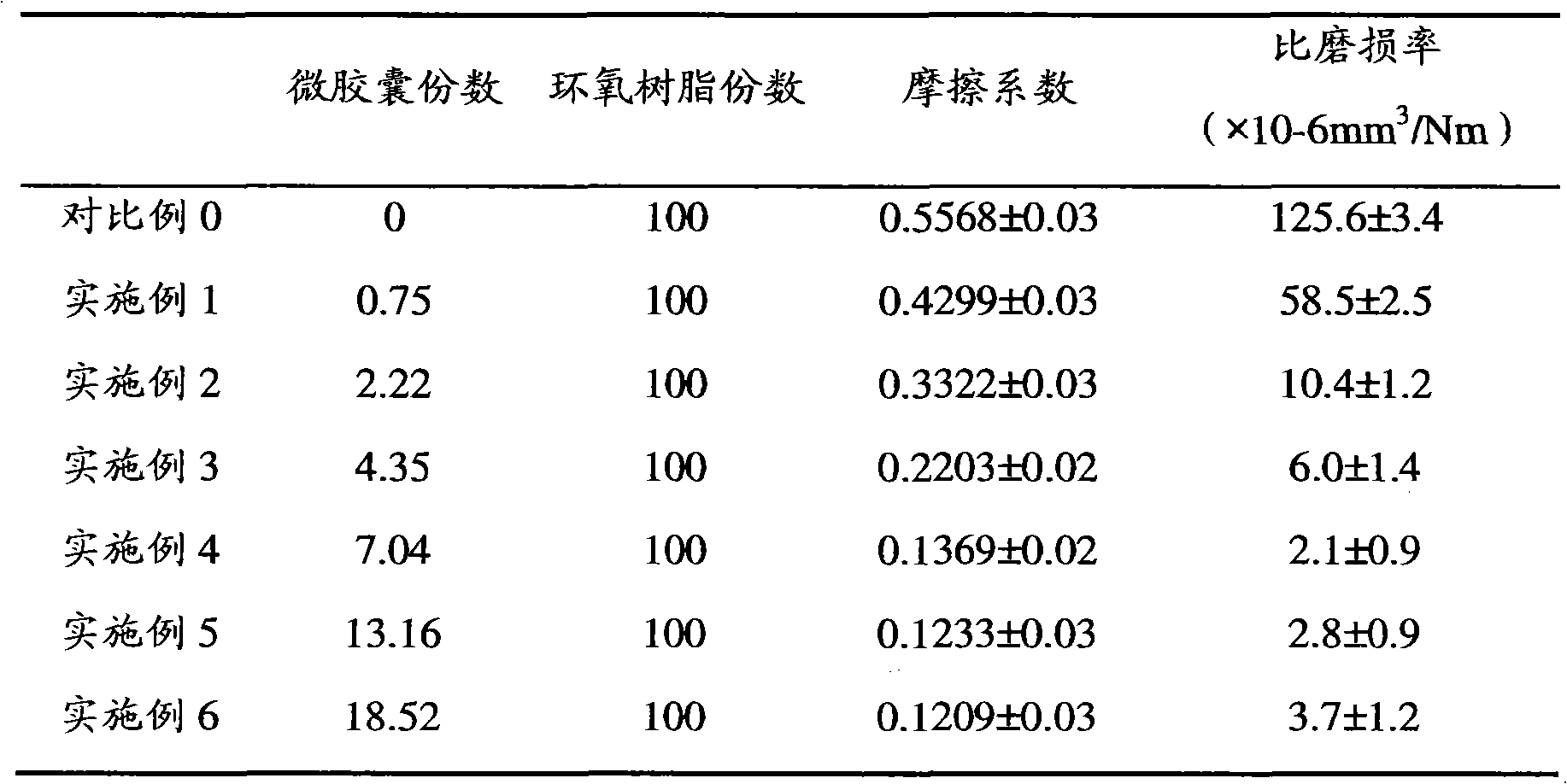

Self-lubricating type epoxide resin material and preparation thereof

InactiveCN101348600AImprove stabilityReduce pollutionMicroballoon preparationLubricant compositionFirming agentEpoxy resin composite

The invention discloses a self-lubricating type epoxy resin material and a preparation method thereof, belonging to the polymer material field. The self-lubricating type epoxy resin material comprises the following components in weight percentage: 60 to 80 percent of epoxy resin, 0.5 to 25 percent of lubricating oil microcapsules and 15 to 35 percent of curing agents. The preparation method for the self-lubricating type epoxy resin material comprises the following steps of well mixing the lubricating oil microcapsules, the epoxy resin with the curing agents and casting rapidly when to-be-mixed matter has gel phenomena, so as to obtain the self-lubricating type epoxy resin material. The invention also provides a lubricating oil microcapsule needed in the preparation of the epoxy resin material and a preparation method for the lubricating oil microcapsule. A technical proposal provided by the invention adds the lubricating oil microcapsules to the epoxy resin so as to prepare the epoxy resin compound material, which can remarkably improve the wear reducing-resisting performance of the epoxy resin material and has broad application prospects.

Owner:SUN YAT SEN UNIV

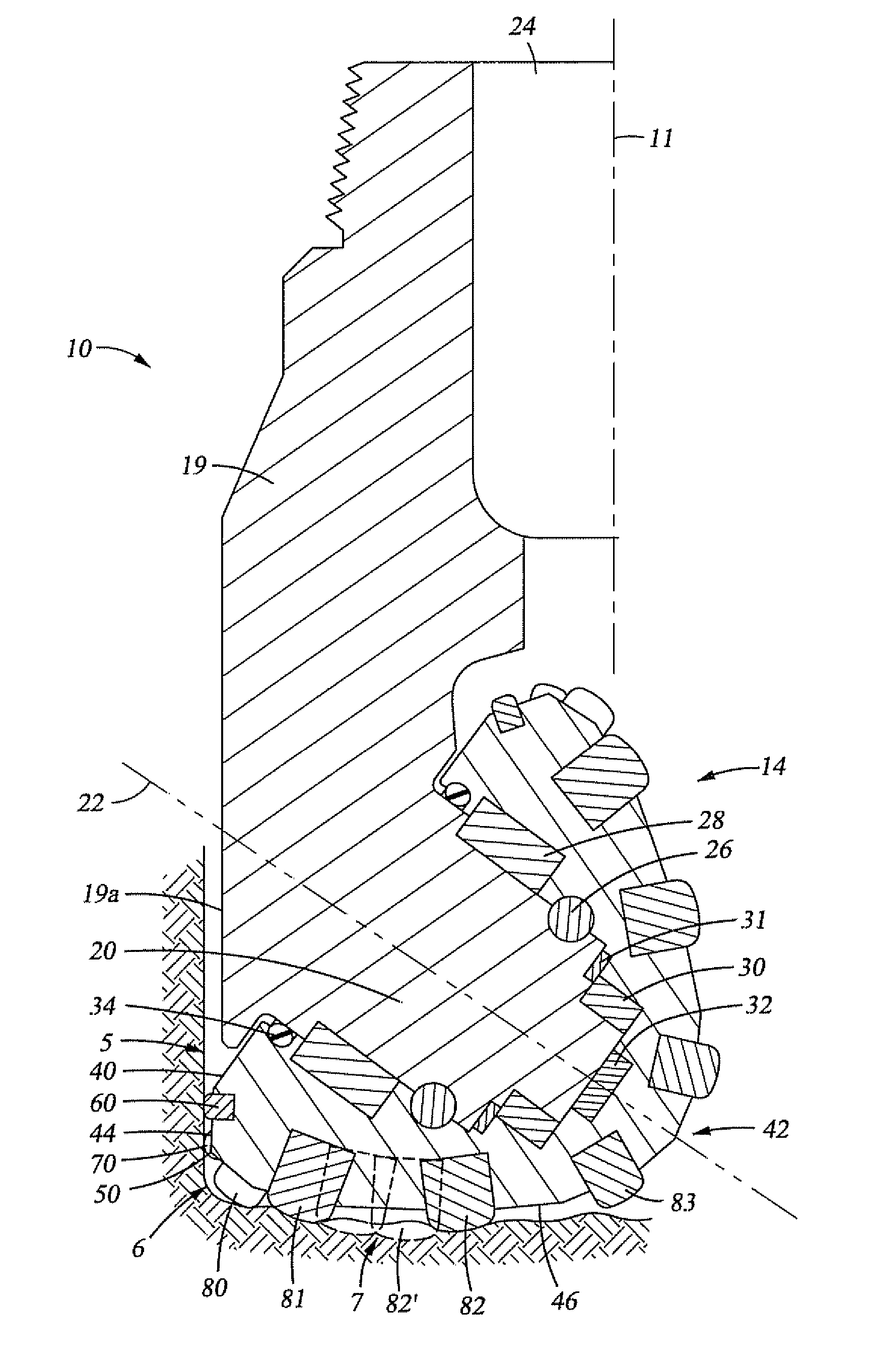

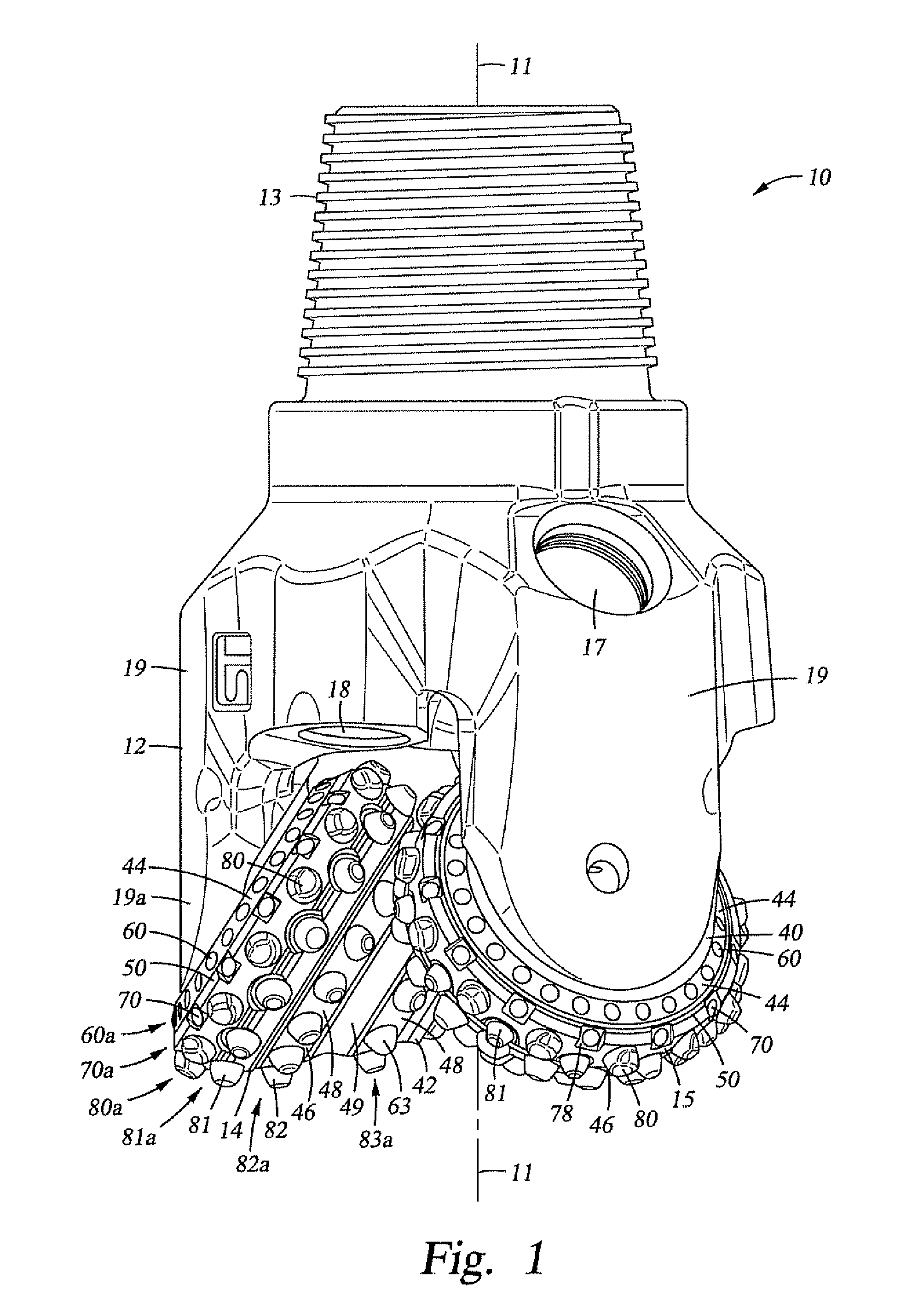

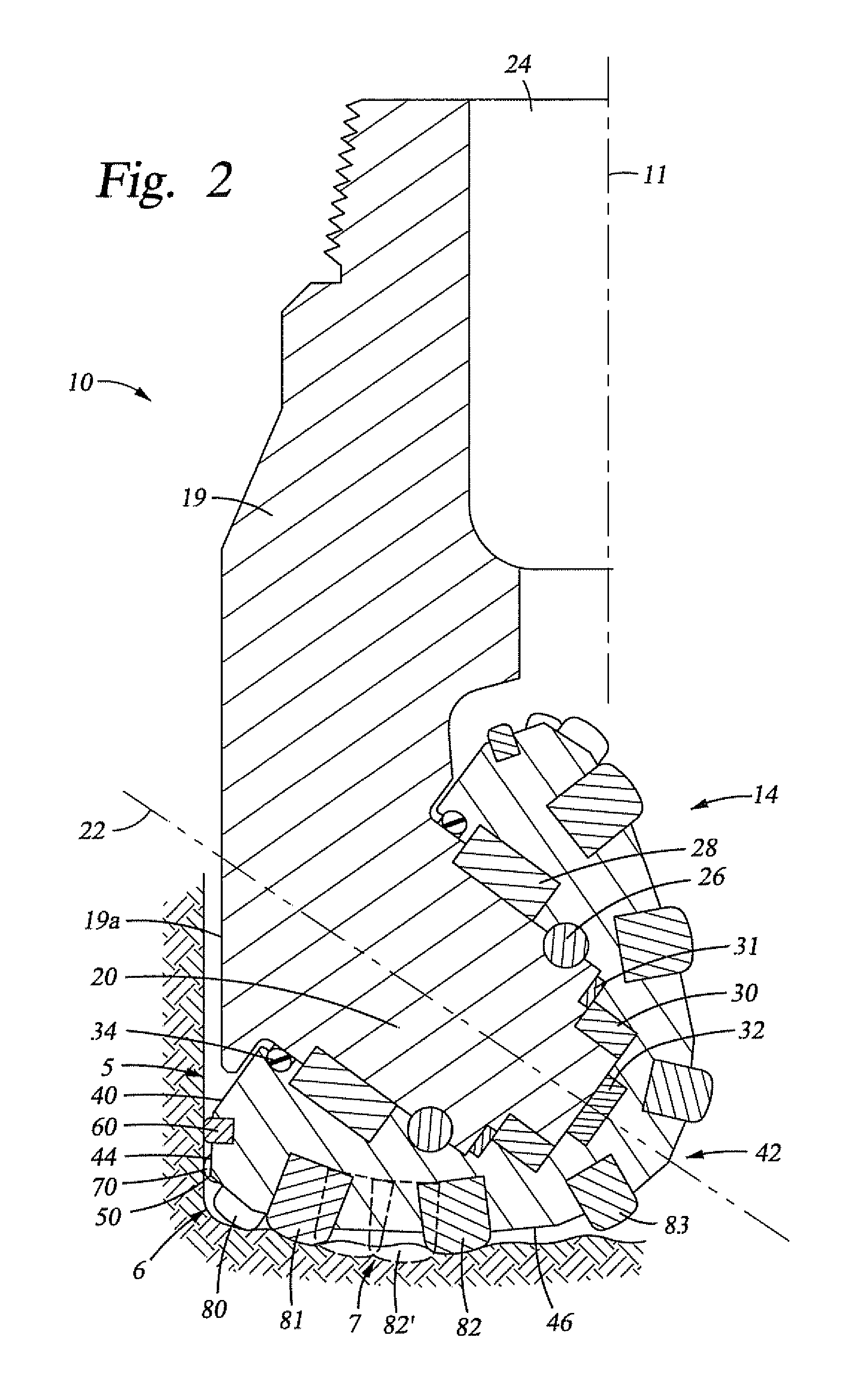

Drill Bit and Cutting Inserts For Hard/Abrasive Formations

ActiveUS20060260846A1Increase ROPIncreased durabilityDrill bitsMetal-working drilling toolsCircular coneEngineering

A rolling cone drill bit comprises a plurality of bottomhole cutter elements positioned in a first circumferential row, wherein at least one of the cutter elements comprises a cutting portion extending from a base portion to a point furthermost from the base portion, defining an extension height. The ratio of the cross-sectional area of the cutter element at a point equal to ninety-four percent of the extension height to the cross-sectional area of the cutter element base is greater than 0.2. Moreover, the ratio of the extension height to the base diameter is not greater than 0.75.

Owner:SMITH INT INC

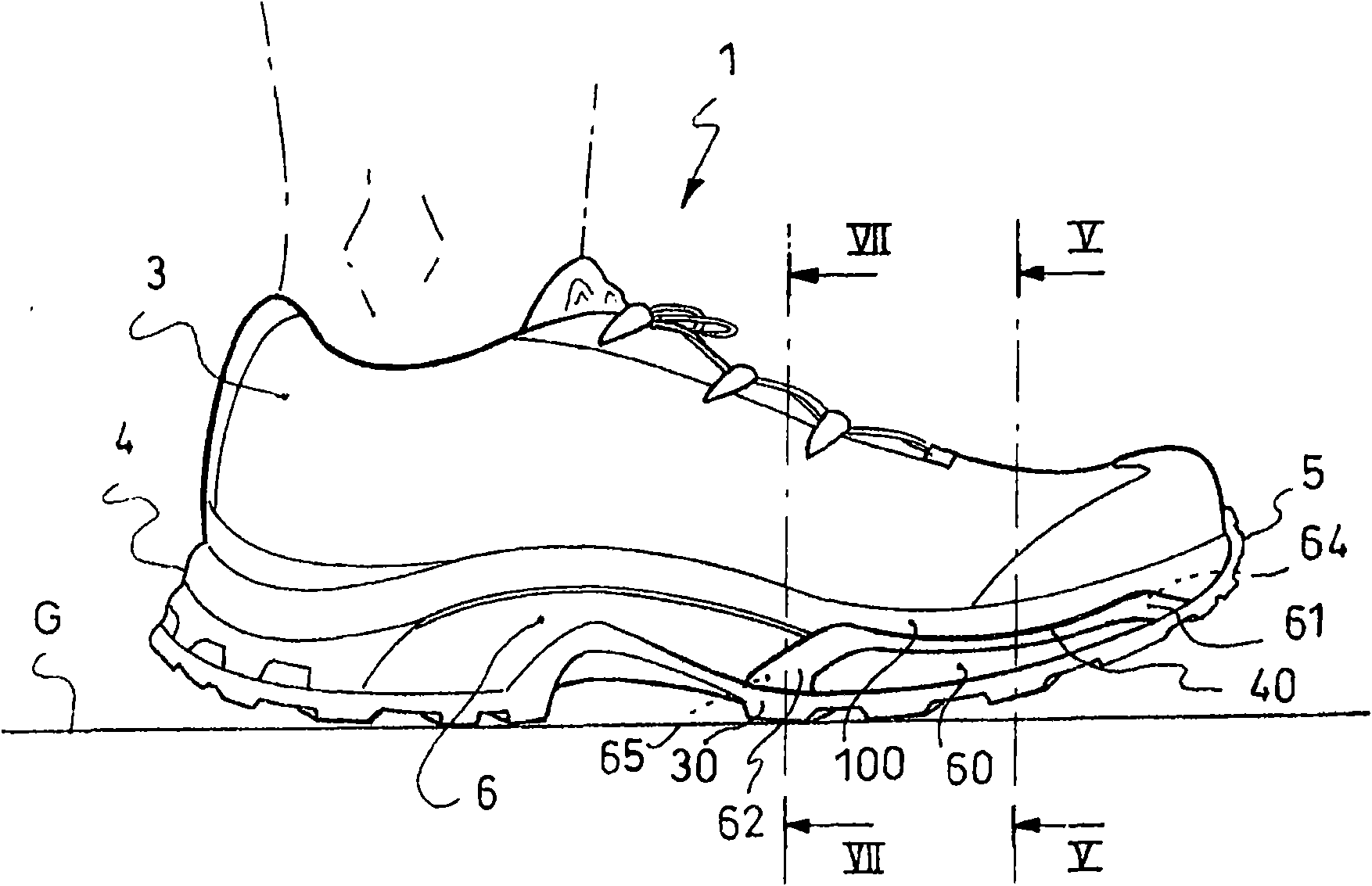

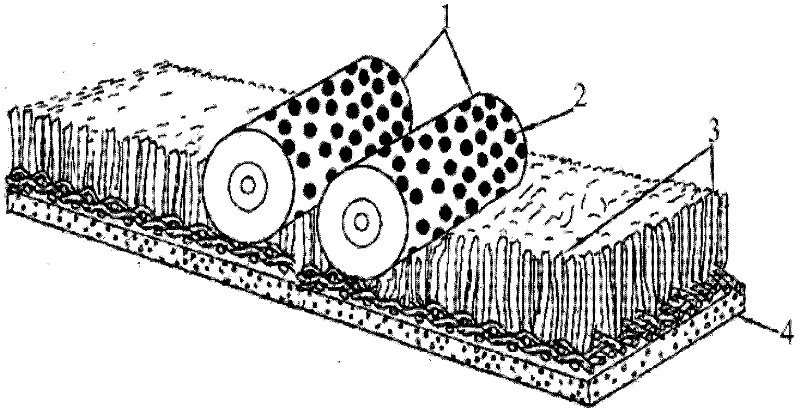

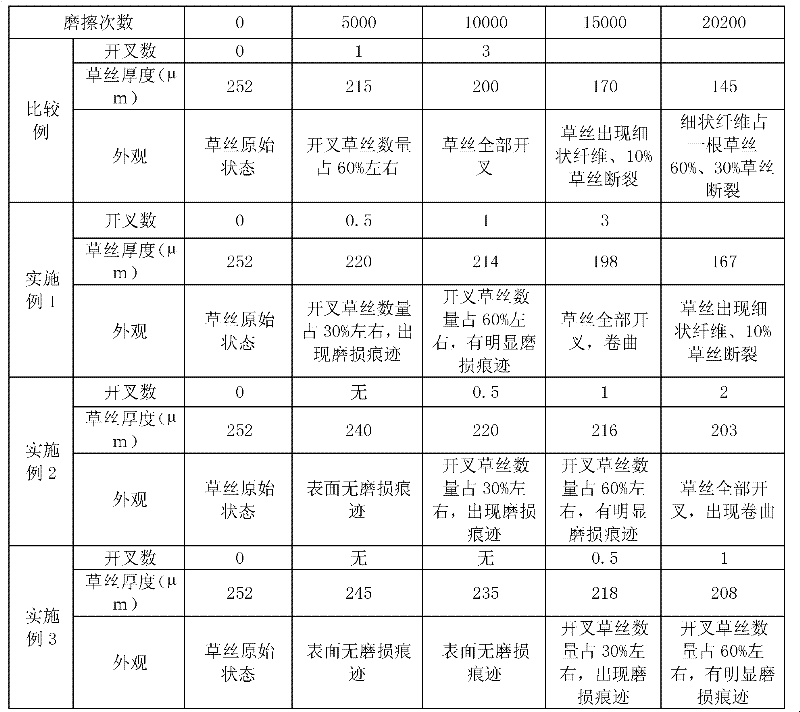

Wear-resistant artificial turf fiber

ActiveCN102493011AReduce wear rateImprove wear resistanceArtificial filament heat treatmentGround pavingsMasterbatchFiber

The invention relates to a wear-resistant artificial turf fiber made of the following raw materials by weight: 60 to 95 parts of matrix resin, 1 to 10 parts of wear-resistant masterbatch, 1 to 10 parts of color masterbatch, and 2 to 5 parts of age resister; and the wear-resistant masterbatch contains silicone powder. The wear-resistant artificial turf fiber has a greatly improved wear resisting property, thereby being suitable for places such as schools and the like where the wear-resistant artificial turf fiber is required to be used frequently for a long time. The wear-resistant artificial turf fiber has the advantages that the preparation method is simple; and the cost is low.

Owner:TAISHAN SPORTS IND GRP +1

Silicon carbide carbonized complex phase ceramic sealing material and preparation method thereof

InactiveCN101591169AImproved dry friction propertiesGood self-lubricating performanceWater basedHigh density

The invention relates to a silicon carbide carbonized complex phase ceramic sealing material, which comprises the following component in portion by weight: 100 portions of silicon carbide powder, 0.1 to 1 portion of boron carbide, 5 to 30 portions of carbon powder, 0.5 to 3 portions of binding agent PVA, and 0.5 to 1.5 portions of dispersing agent. A preparation method comprises the following steps in turn: (1) blending the raw materials in proportion and then adding the mixture into deionized water, and after ball milling and mixing, preparing the mixture into a water-based silicon carbide composite slurry of which the solid phase weight content is between 40 and 60 percent; (2) adopting a spraying granulating process to perform spray drying on the slurry to obtain silicon carbide granulated powder; (3) adopting a two-step mode of 140 MPa dry pressing pre-compaction and 200 MPa isostatic cool pressing final compaction to carry out forming on the granulated powder to obtain a high-density sealing material blank; and (4) putting the blank into a vacuum pressureless sintering furnace, raising the temperature to between 2,000 and 2,100 DEG C, keeping the temperature for 1 to 1.5 hours, and sintering the blank to obtain the silicon carbide carbonized complex phase ceramic sealing material.

Owner:东新密封有限公司

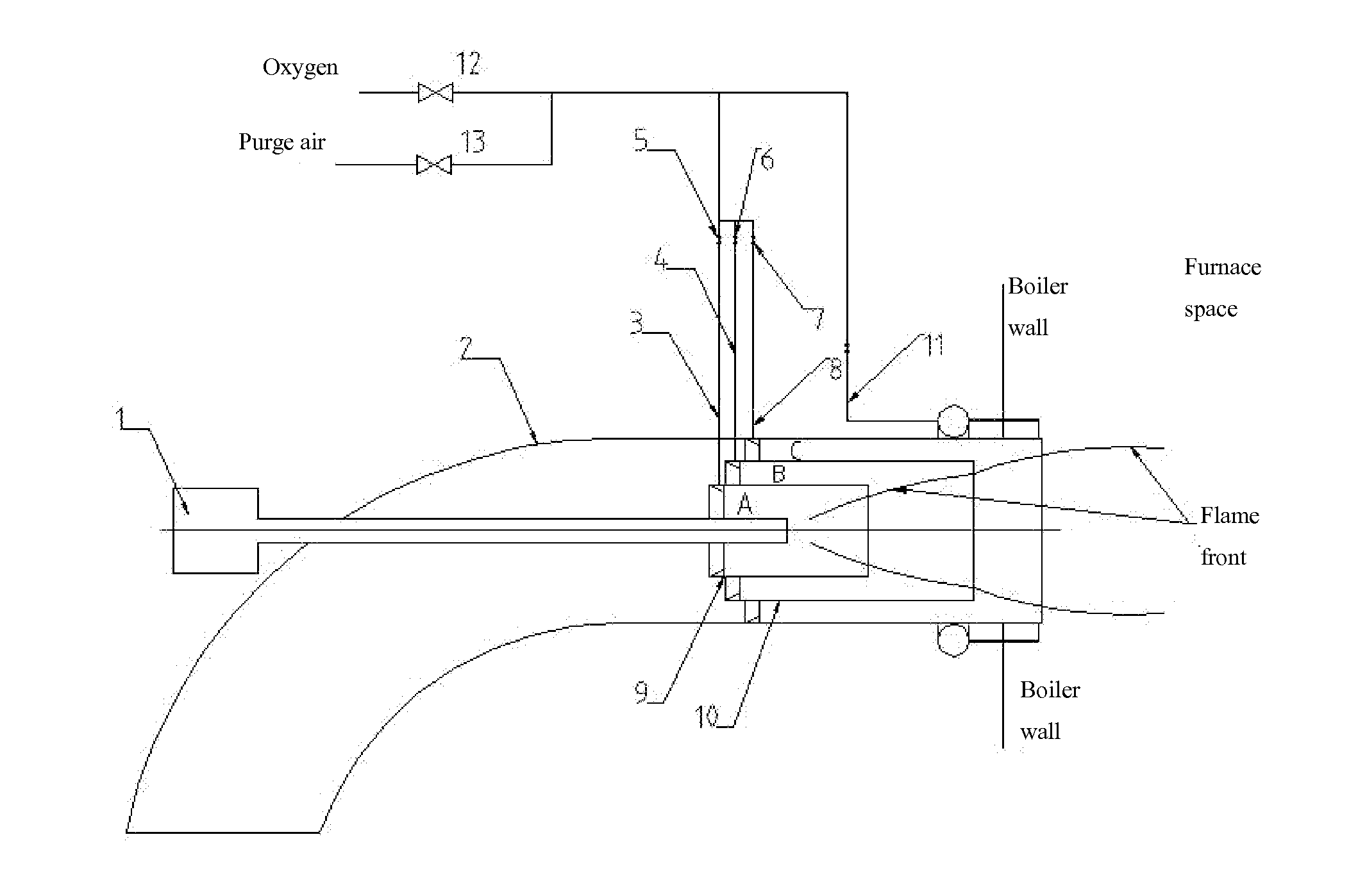

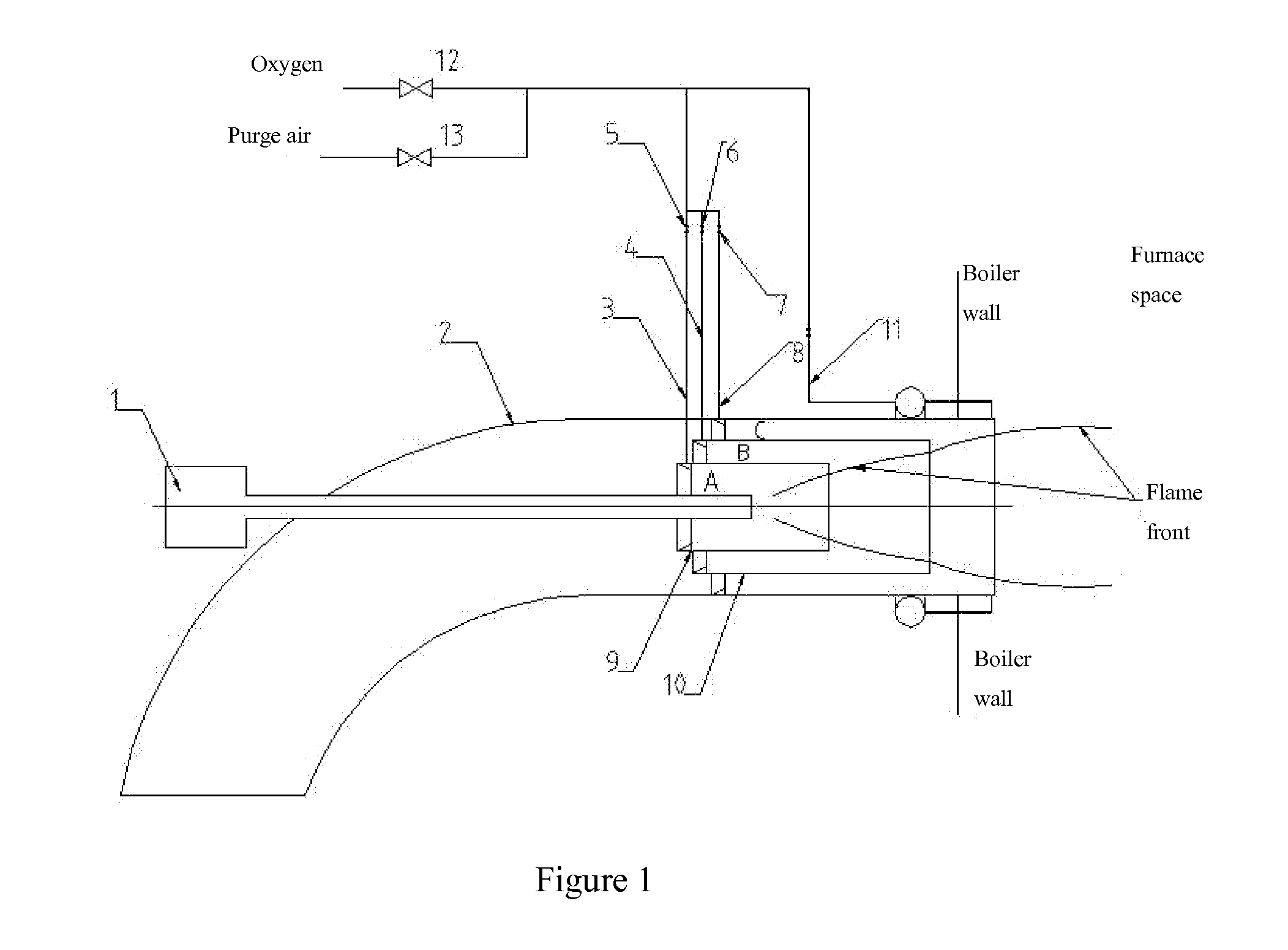

Dense Phase Swirl Pulverized Coal Burner

InactiveUS20130112120A1Simple primary air channel structureImprove wear resistancePulverulent fuel combustion burnersCombustionFlue gas

A dense phase swirl pulverized coal burner comprises a primary air channel, a direct flow secondary air channel and a outermost swirl secondary air channel; and multiple levels of pulverized coal concentration rings are arranged axially at intervals along the oil gun casing in a straight tube section of the primary air channel, so that pulverized coal air flow is distributed thickly outside and thinly inside the primary air nozzle. In the invention, dense phase pulverized coal outside the primary air nozzle passes through guide vanes, forms disturbed flow, is ejected into a furnace and mixes with high temperature backflow flue gas rapidly and sufficiently at an outlet. Meanwhile, dilute pulverized coal air flow at the center is ejected into the furnace by direct flow, ensuring subsequent mixing and combustion of pulverized coal flow. The primary air nozzle and the secondary air nozzle are provided with cone flaring structures with certain angle to effectively control appropriate mixing of secondary air and pulverized coal. The invention has advantages of strong ignition and combustion stability, good coal adaptability, low nitric oxide emission, simple primary air channel structure and small resistance, which effectively slows wear rate of parts.

Owner:LI YUEHUA

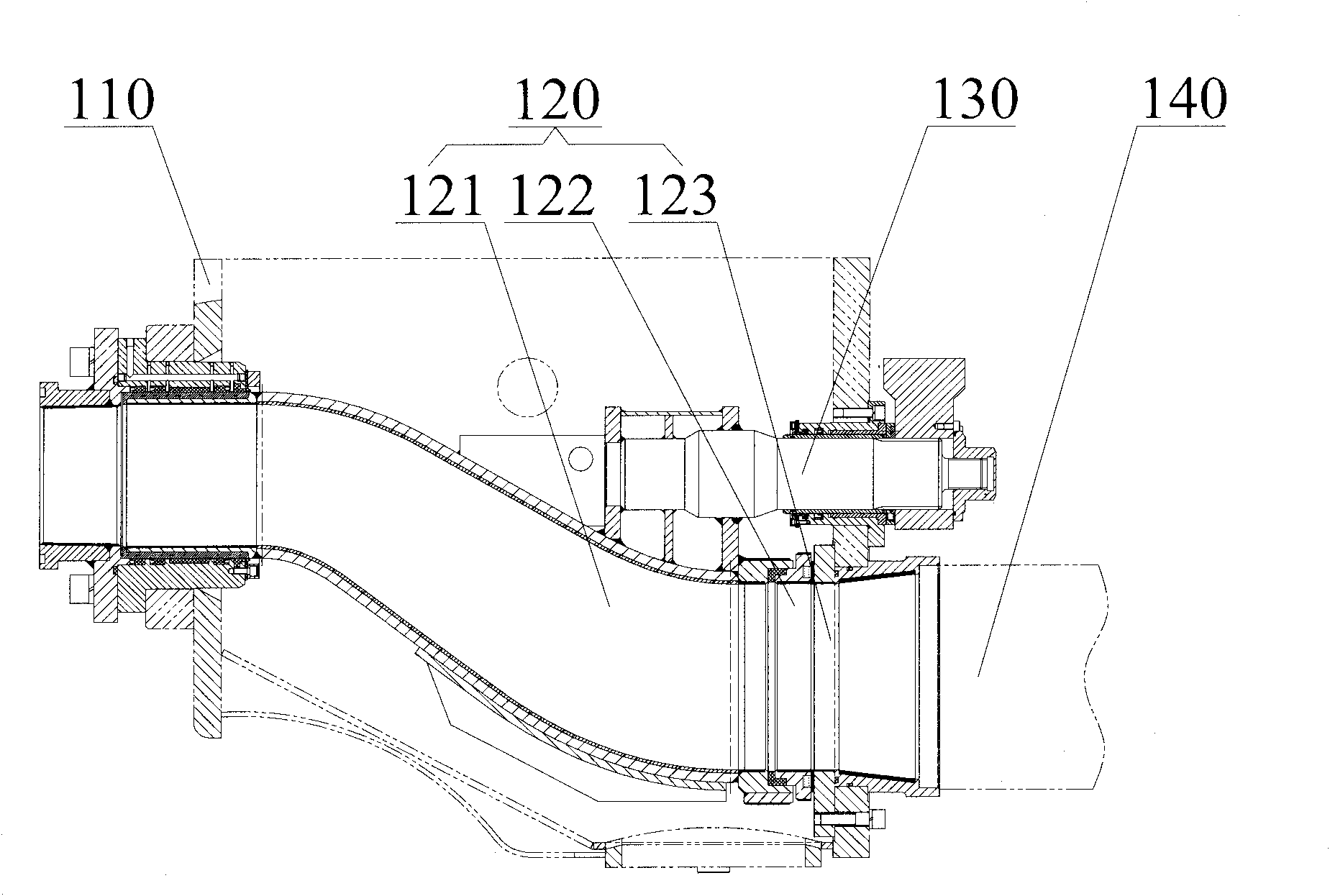

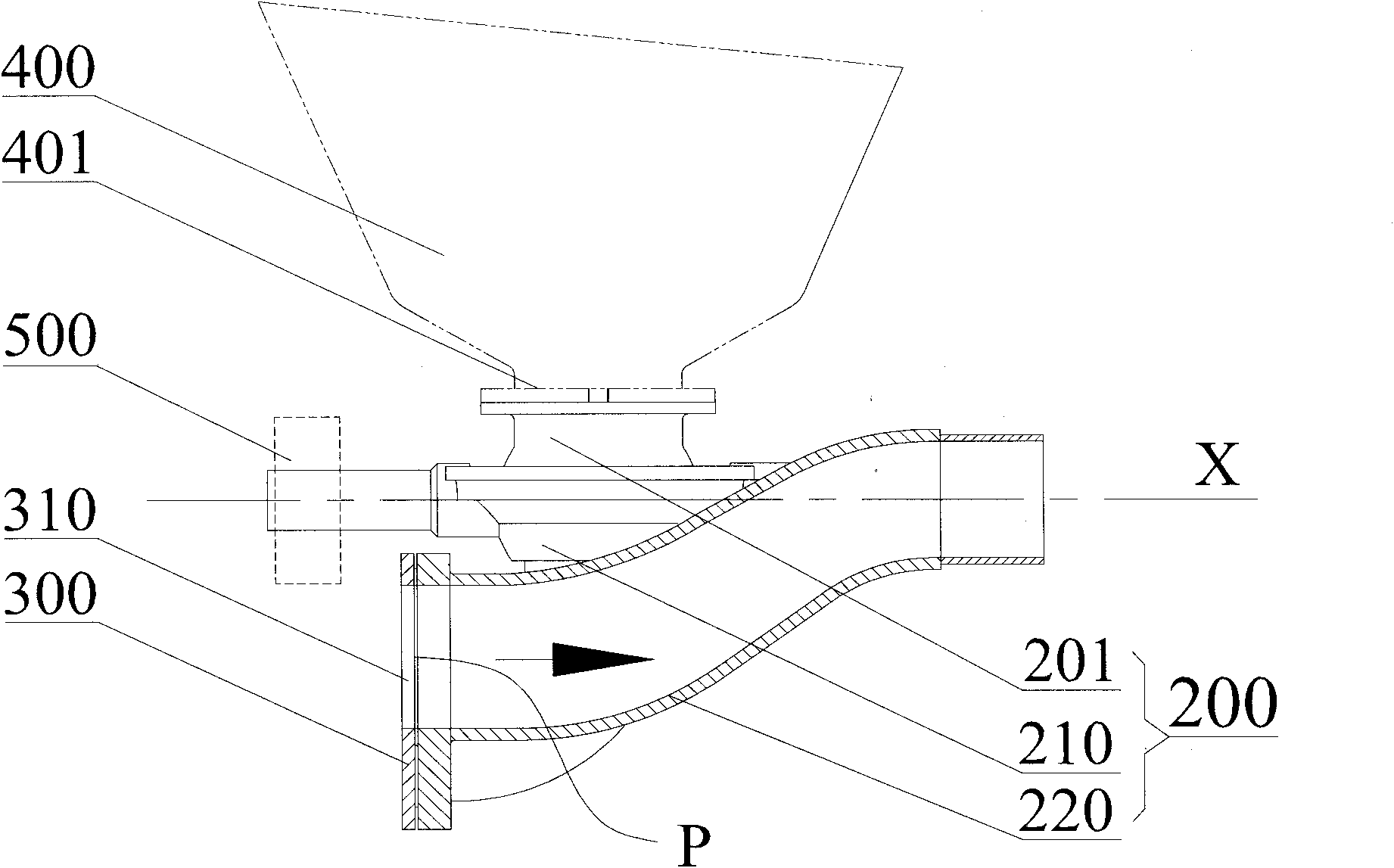

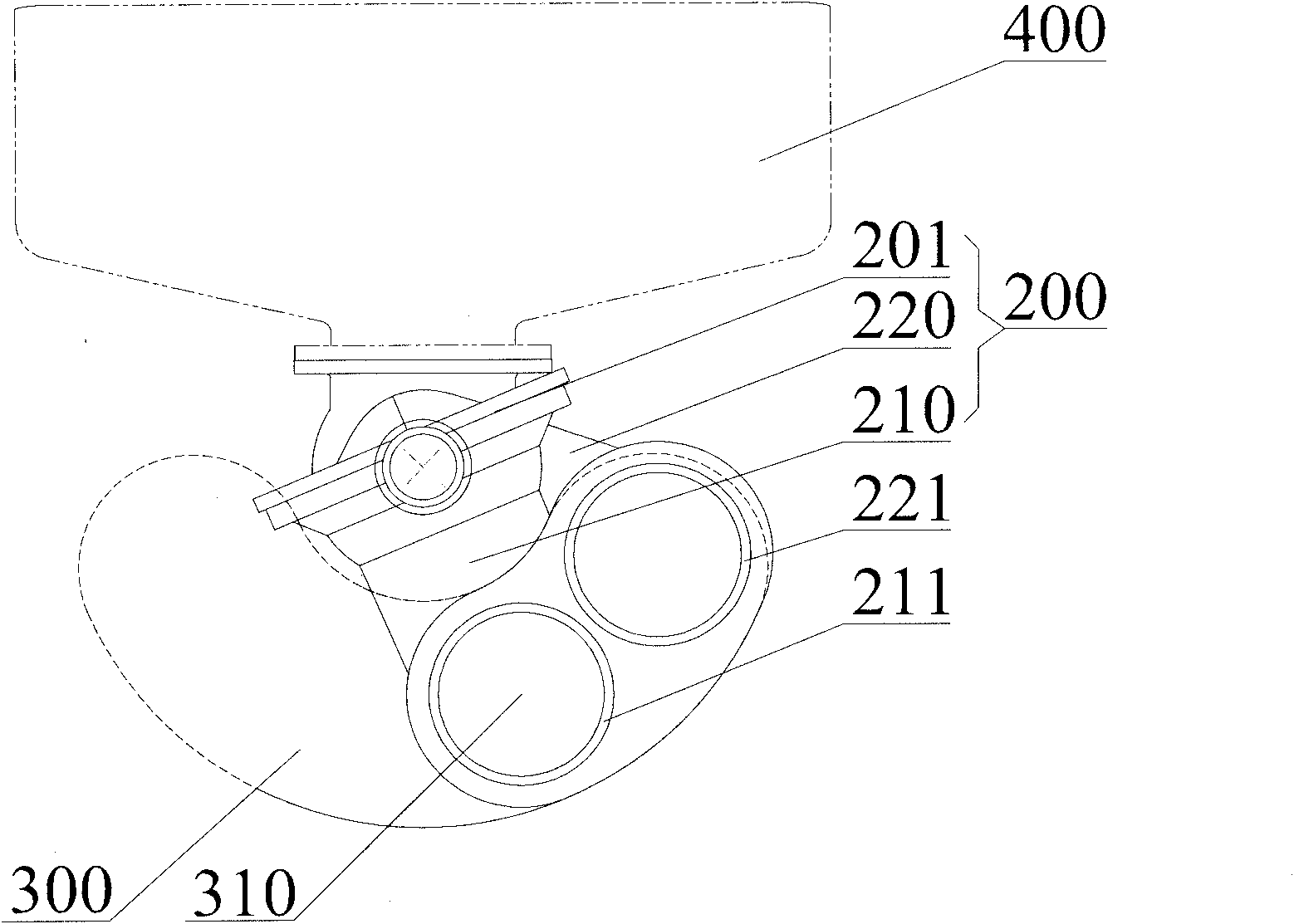

Distributing valve for concrete pump, concrete pump, control method thereof and concrete pump truck

InactiveCN101787973AReduce wear rateImprove suction performancePositive displacement pump componentsPump controlSlurryHigh pressure

The invention discloses a distributing valve for a concrete pump, the concrete pump, a control method thereof and a concrete pump truck. The distributing valve for the concrete pump comprises a valve body and a wear-resisting plate. The valve body comprises a first suction pipe and a first pumping pipe, wherein the back end of the first suction pipe is communicated with an outlet of a hopper so as to communicate the hopper and a delivery cylinder, and the back end of the first pumping pipe is rotatably connected with a delivery pipe of the concrete pump so as to communicate the delivery cylinder and the delivery pipe. The valve body can be switched between a first state and a second state under the driving of a drive mechanism, in the first state, concrete slurry is sucked into the delivery cylinder through the first suction pipe, and in the second state, the delivery cylinder pumps over the concrete slurry through the first pumping pipe. Because of the distributing valve with the structure, the concrete pump can thoroughly employ the self-flowing capacity of the concrete slurry in order to increase the suction performance of the concrete pump. The distributing valve has higher pressure bearing capacity, and the concrete pump can ensure that the concrete slurry has higher pressure through the delivery cylinder, thereby meeting the needs of high-pressure pumps to pump over the concrete slurry.

Owner:三一西北重工有限公司

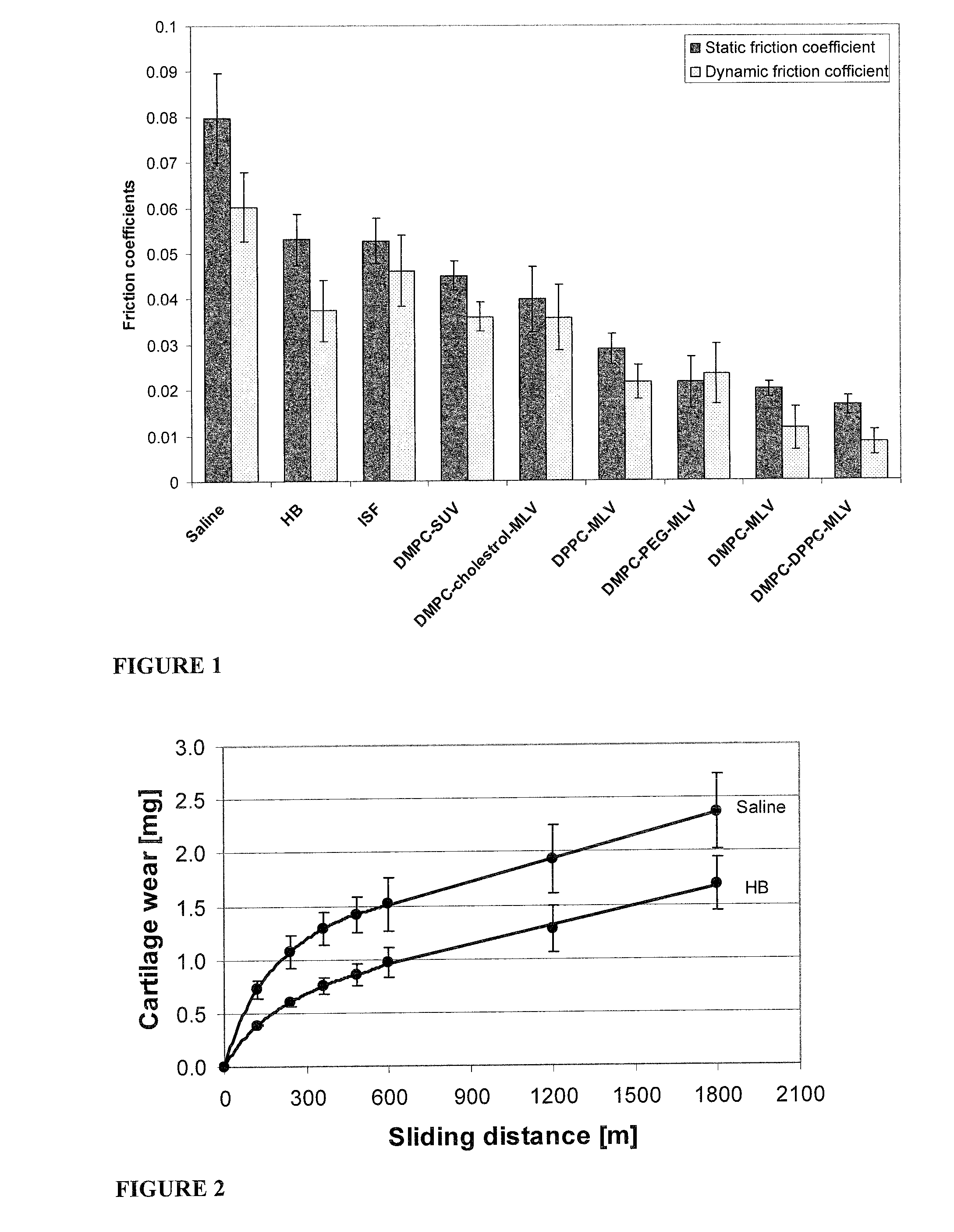

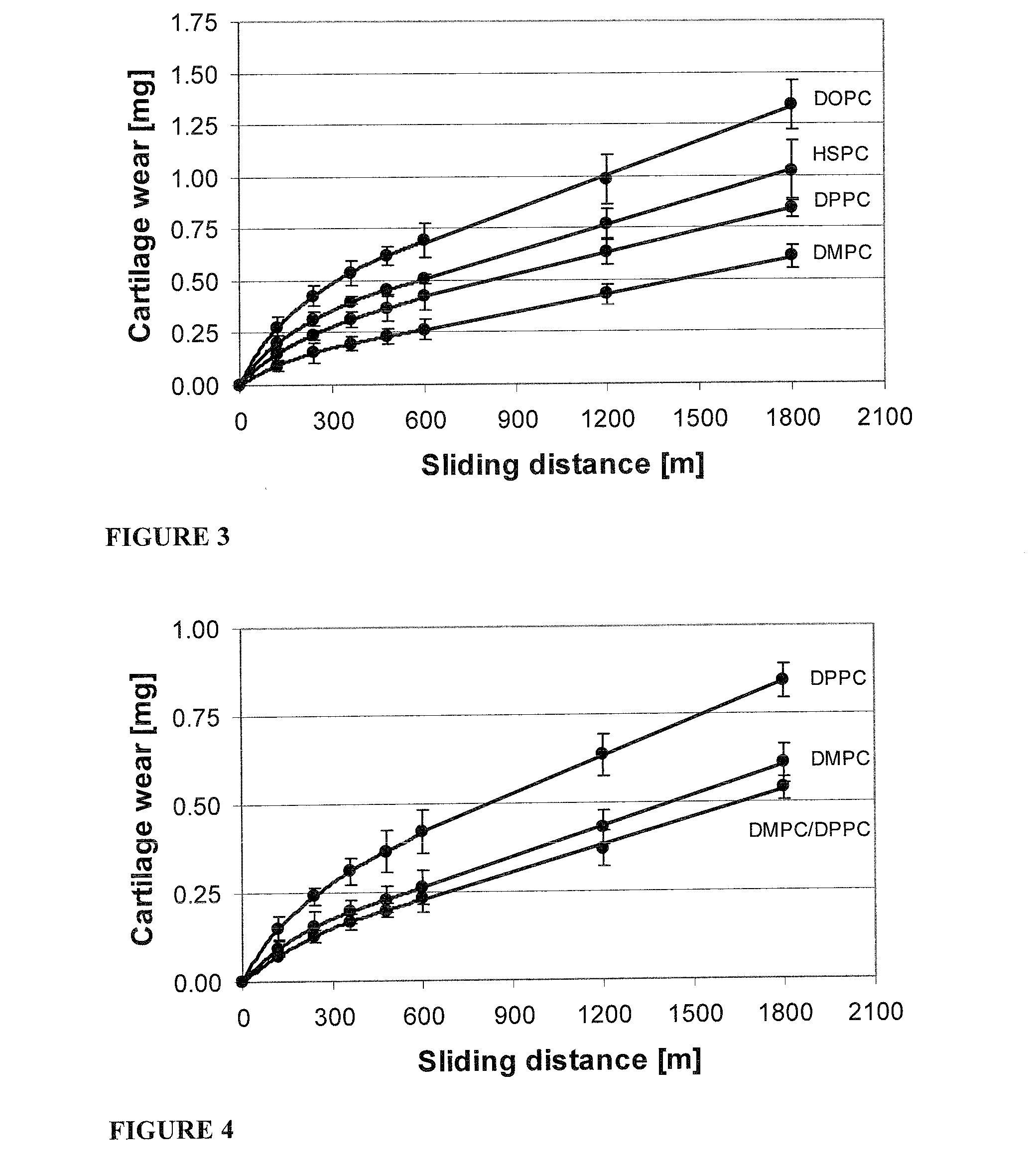

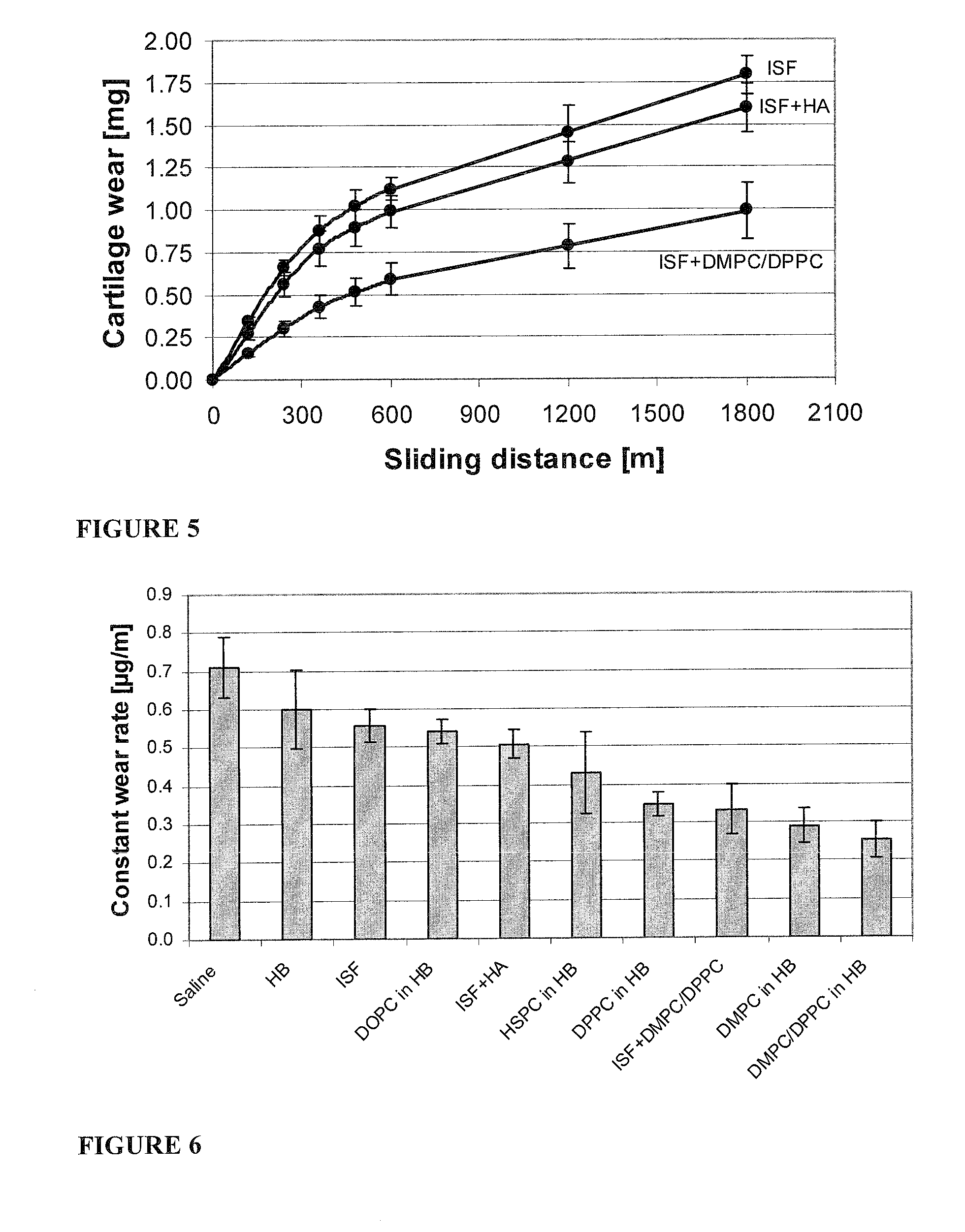

Methods for joint lubrication and cartilage wear prevention making use of glycerophospholipids

ActiveUS20100098749A1Improve and restore joint mobilityReduce wearOrganic active ingredientsAntipyreticLubricationLiposome

The present invention concerns methods of joint lubrication and / or prevention of cartilage wear making use of liposomes having membranes with at least one phospholipid (PL) of the group consisting of a glycerophospholipid (GPL) having two, being the same or different, C12-C16 hydrocarbon chain and a sphingolipid (SPL) having a C12-C15 hydrocarbon chain, the one or more membranes having a phase transition temperature in which solid ordered (SO) to liquid disordered (LD) phase transition occurs, the phase transition temperature being within a temperature of about 20° C. to about 39° C. for lubrication of joints.

Owner:TECHNION RES & DEV FOUND LTD +2

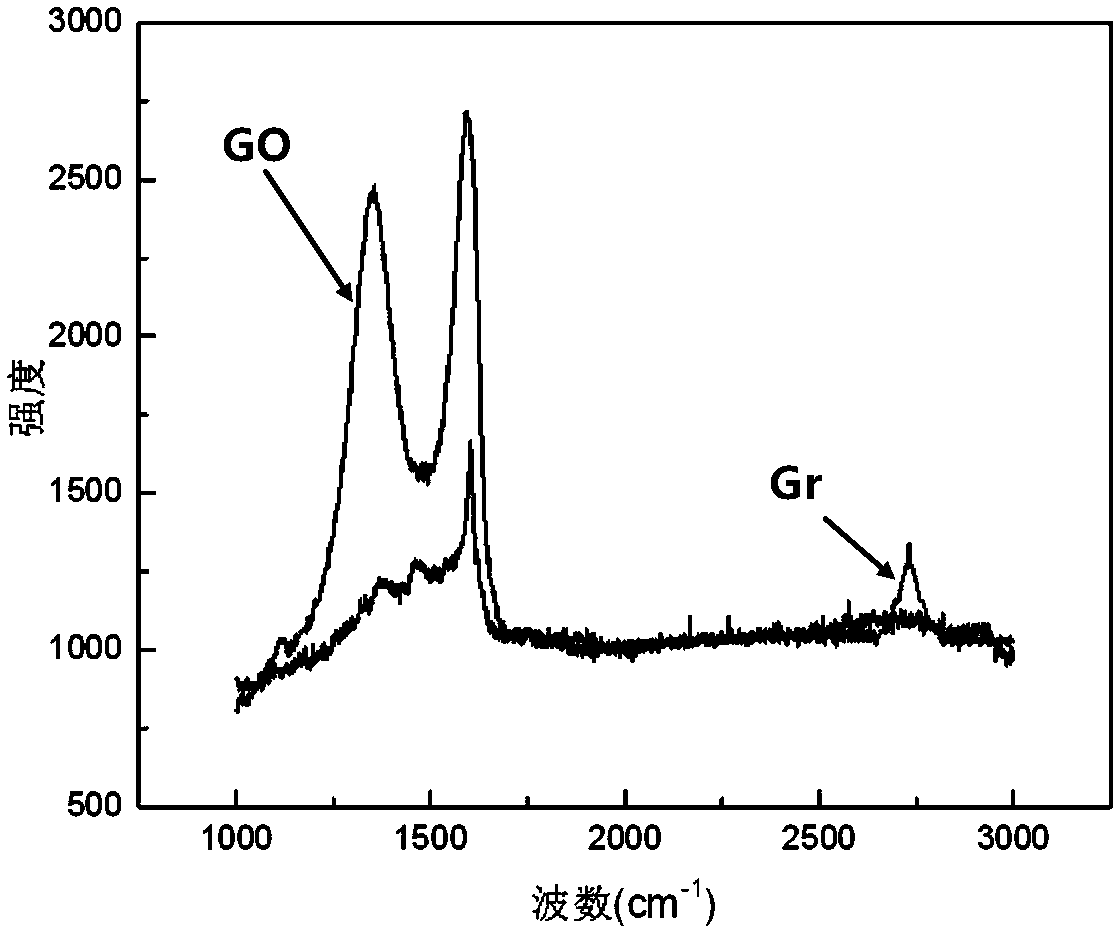

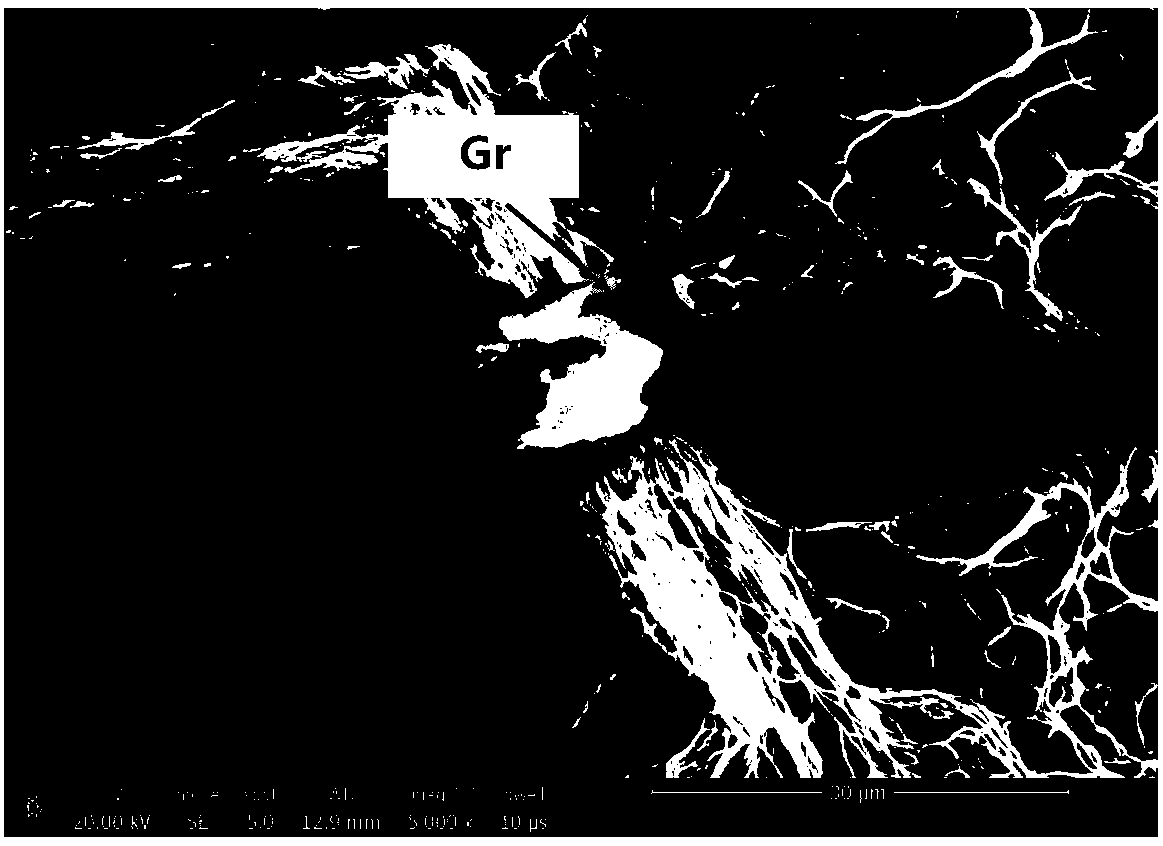

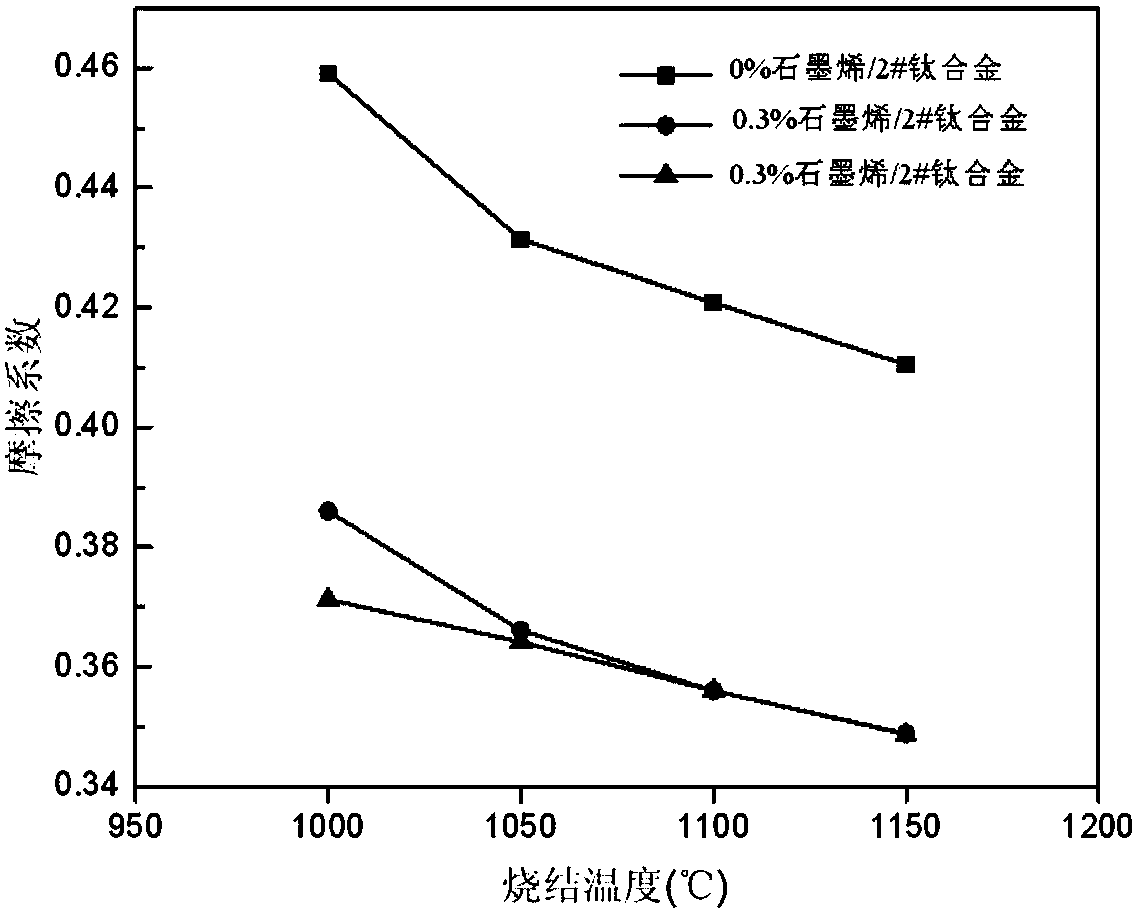

Graphene-reinforced titanium-based nanocomposite material and preparation method

The invention belongs to the technical field of graphene composite materials and relates to a titanium-based nanocomposite material reinforced through graphene and a preparation method, in particularto a graphene-reinforced titanium-based nanocomposite material and a preparation method. Firstly, oxidized graphene nanosheets of 0.01 wt%-1.0 wt% of titanium alloy powder are weighed to be added intoabsolute ethyl alcohol to be stirred and mixed, then disperse treatment is conducted through an ultrasonic cell pulverizer, and an oxidized graphene solution is prepared; then the titanium alloy powder with the alloying element content being larger than 10 wt% and the oxidized graphene solution are stirred and mixed under inert protection, and oxidized graphene and titanium alloy powder compositepowder is obtained; and finally, the composite powder is loaded into a graphite mold to be sintered, through vacuum pumping and sintering forming, oxidized graphene is basically decomposed to form graphene, and therefore the graphene-reinforced titanium-based nanocomposite material with the excellent mechanical property is prepared. In the graphene-reinforced titanium-based nanocomposite material, the graphene is uniformly dispersed, and the preparation method is simple, efficient and suitable for batch preparation.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com