Wear-resistant artificial turf fiber

A technology of artificial turf and fiber, applied in rayon manufacturing, heat treatment of artificial filament, single-component polyolefin artificial filament, etc. Unsatisfactory abrasive performance, uneven surface dispersion of artificial turf fibers, etc., to achieve the effects of reducing friction coefficient, reducing adhesion, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

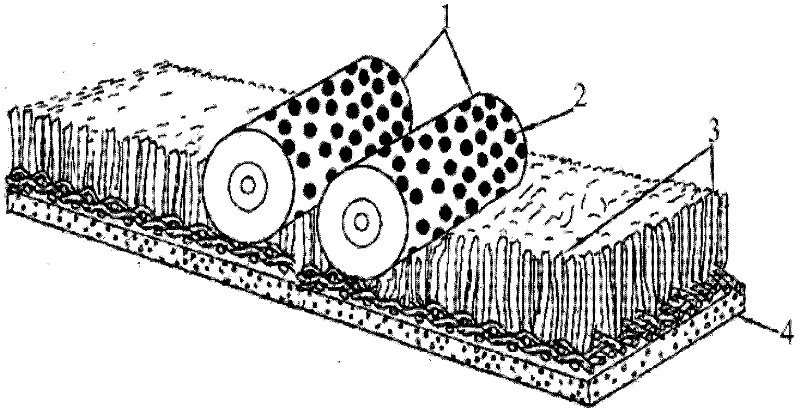

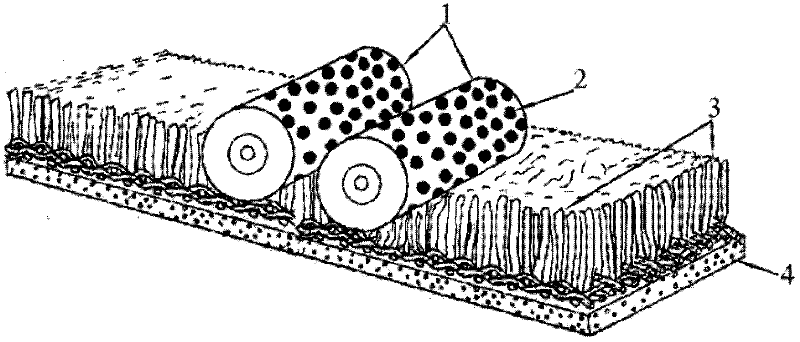

Image

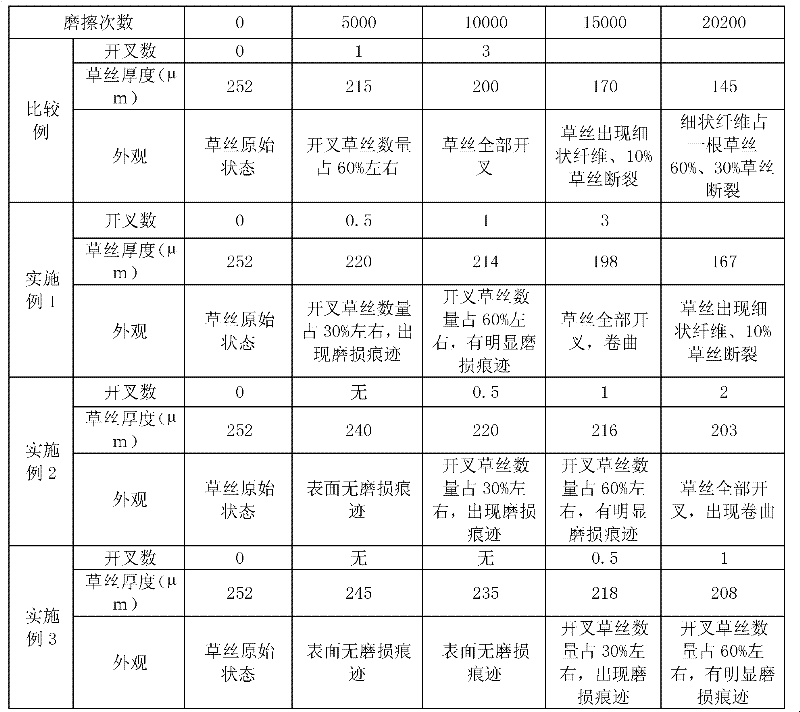

Examples

Embodiment 1

[0039] (1) Preparation of wear-resistant masterbatch

[0040] LDPE (1F7B) 50kg,

[0043] PE wax 8kg,

[0044] Put LDPE, PE wax, silicone powder, and zinc stearate into a high-speed mixer and mix evenly. The mixing temperature is controlled at 75°C, and the mixing time is 25 minutes; The first to seventh zones of discharge temperature are 150°C, 150°C, 160°C, 170°C, 180°C, 180°C, 180°C respectively, and the screw speed is 30r / min;

[0045] (2) Preparation of wear-resistant artificial turf fiber

[0046] Mix the prepared wear-resistant masterbatch with LLDPE (7042), color masterbatch and anti-aging agent according to the following weight ratio:

[0047] LLDPE (7042): 89%

[0048] Wear-resistant masterbatch: 2%

[0049] Masterbatch: 6%

[0050] Anti-aging agent: 3%

[0051] Put it into the single-screw hopper, the temperature of each section of the screw extruder is 200°C, 210°C, 220°C, 220°C, 220°C, 220°C, the s...

Embodiment 2

[0055] (1) Preparation of wear-resistant masterbatch

[0056] LDPE(1F7B)55kg

[0057] Silicone powder 40kg

[0059] PE wax 8kg

[0060] Put LDPE, PE wax, silicone powder, and zinc stearate into a high-speed mixer and mix evenly. The mixing temperature is controlled at 75°C, and the mixing time is 30 minutes; The first to seventh zones of discharge temperature are 150°C, 150°C, 160°C, 170°C, 180°C, 180°C, 180°C respectively, and the screw speed is 30r / min;

[0061](2) Preparation of wear-resistant artificial grass fiber

[0062] Mix wear-resistant masterbatch, LLDPE(7042), color masterbatch and anti-aging agent according to the following weight ratio, add LLDPE(7042): 87%

[0063] Wear-resistant masterbatch: 4%

[0064] Masterbatch: 6%

[0065] Anti-aging agent: 3%

[0066] into the single-screw hopper, the temperature of each section of the screw extruder is 210°C, 220°C, 230°C, 235°C, 235°C, 235°C, and the screw speed is 42.9r / min. Cool in ...

Embodiment 3

[0070] (1) Preparation of wear-resistant masterbatch

[0071] LDPE(1F7B)60kg

[0072] Silicone powder 50kg

[0073] Zinc stearate 2kg

[0074] PE wax 10kg

[0075] Put LDPE, PE wax, silicone powder, and zinc stearate into a high-speed mixer and mix evenly. The mixing temperature is controlled at 78°C, and the mixing time is 35 minutes; The first to seventh zones of discharge temperature are 150°C, 150°C, 160°C, 170°C, 180°C, 180°C, 180°C respectively, and the screw speed is 30r / min;

[0076] (2) Preparation of wear-resistant artificial turf fiber

[0077] Mix wear-resistant masterbatch, LLDPE (7042), color masterbatch, anti-aging agent, processing aid masterbatch according to the following proportions, add

[0078] LLDPE (7042): 85%

[0079] Wear-resistant masterbatch: 6%

[0080] Masterbatch: 6%

[0081] Anti-aging agent: 3%

[0082] In the single-screw hopper, the temperature of each section of the screw extruder is 220°C, 225°C, 230°C, 235°C, 235°C, 235°C. The scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com