Patents

Literature

78results about How to "Anti-stick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weak solvent aliphatic polyurethane resin for synthetic leather and preparation method thereof

The invention relates to the technical field of materials for synthetic leather, in particular to weak solvent aliphatic polyurethane resin for synthetic leather and a preparation method thereof. The weak solvent aliphatic polyurethane resin for synthetic leather is prepared from the following components by weight percent: 2-30 percent of aliphatic diisocyanate compound, 5-40 percent of polyester or polyether polyalcohol compound, 0-10 percent of micromolecule polyol chain extender, 0.1-13 percent of micromolecule polyamine chain extender, 0.01-1.0 percent of catalyst, 0.05-5.0 percent of assistant and 45-85 percent of organic mild solvent. The invention also discloses the preparation method of the weak solvent aliphatic polyurethane resin for synthetic leather. By adopting the technical scheme, the polyurethane resin with different solid contents, different viscosities and different modulus can by synthesized, the requirement of the synthetic leather is satisfied, and the synthetic leather product with high temperature resistance, cold resistance, anti-sticking performance and better external tensility of pigment can be prepared.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

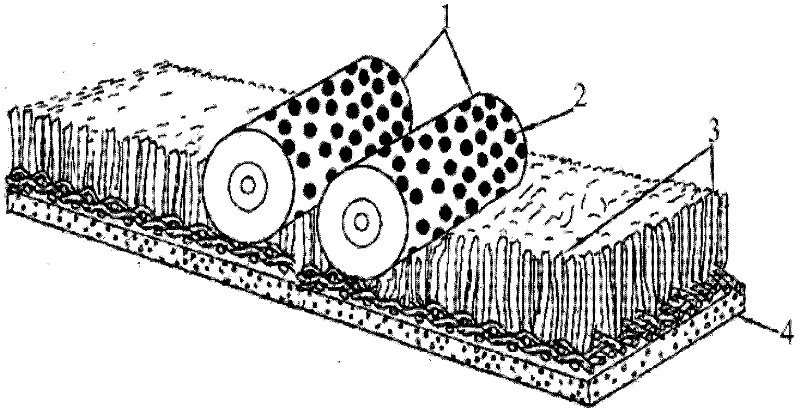

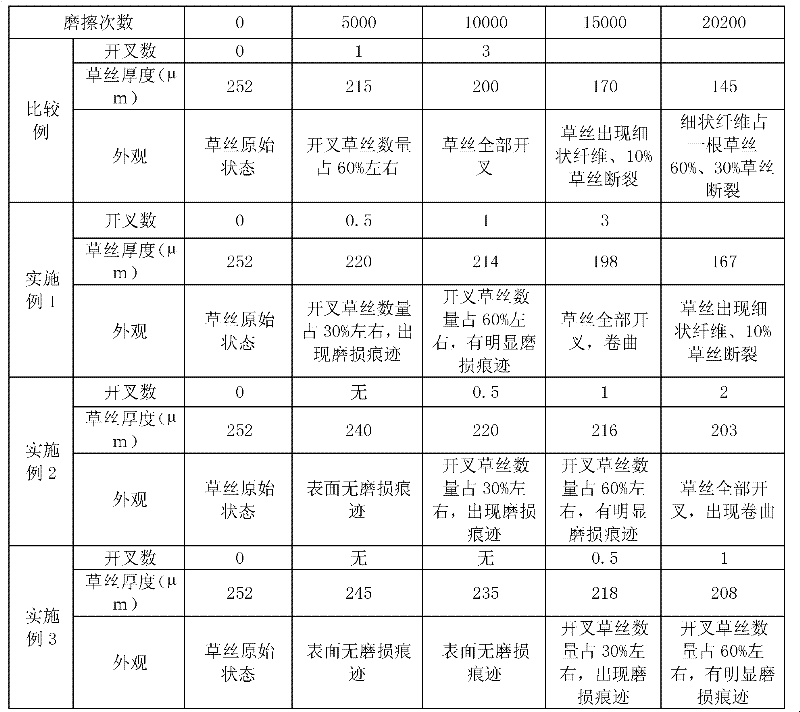

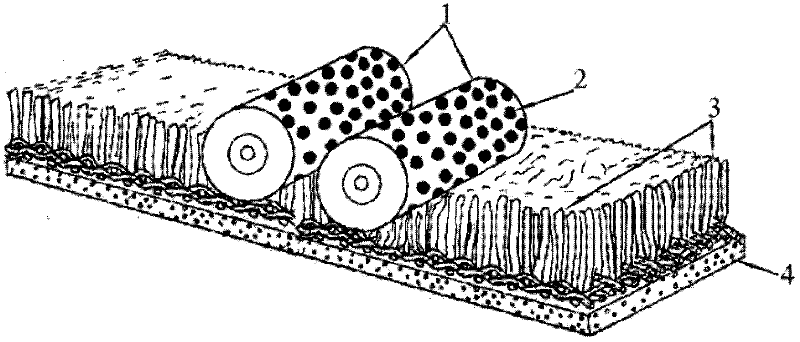

Wear-resistant artificial turf fiber

ActiveCN102493011AReduce wear rateImprove wear resistanceArtificial filament heat treatmentGround pavingsMasterbatchFiber

The invention relates to a wear-resistant artificial turf fiber made of the following raw materials by weight: 60 to 95 parts of matrix resin, 1 to 10 parts of wear-resistant masterbatch, 1 to 10 parts of color masterbatch, and 2 to 5 parts of age resister; and the wear-resistant masterbatch contains silicone powder. The wear-resistant artificial turf fiber has a greatly improved wear resisting property, thereby being suitable for places such as schools and the like where the wear-resistant artificial turf fiber is required to be used frequently for a long time. The wear-resistant artificial turf fiber has the advantages that the preparation method is simple; and the cost is low.

Owner:TAISHAN SPORTS IND GRP +1

Super-hydrophobic self-cleaning paint

InactiveCN101205439ASuperhydrophobicSelf-cleaningPolyurea/polyurethane coatingsPolyether coatingsEngineeringSolvent

The invention relates to super-hydrophobic self-cleaning paint suitable to be used in various surfaces. The paint comprises the following components: 100 portions of filler, 30 to 50 portions of polyurethane, 300 to 500 portions of mixed solvent and 1 to 5 portions of Gamma-aminopropyltrimethoxysilane. The invented paint has the advantages of super-hydrophoby, self cleaning, antifouling, antisticking, denoise and drag reduction, etc.; meanwhile, the paint has low price cost, convenient construction and less environmental pollution.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Matte flame-retardant cold-resistant covering cloth

ActiveCN104401084AImprove flame retardant performanceGood mechanical propertiesFibre typesSynthetic resin layered productsEngineeringFire retardant

The invention relates to matte flame-retardant cold-resistant covering cloth. The covering cloth is prepared by performing gumming dipping and drying on base cloth, employing a PVC surface membrane and a PVC bottom membrane to bond with two faces of the base cloth, performing cooling fixing, then employing a fluorosilicone finishing agent to perform surface function processing, and then performing drying and reeling. A double-face bonding production technology of plain base cloth and the PVC surface membrane and the PVC bottom membrane is employed, also a flame retardant and a cold-resisting agent are added into the formula of the PVC membrane, so that the flame retardation performance and the cold resistant performance of the product are improved. The covering cloth possess good flame retardation performance, mechanical properties, cold resistance and the like, and also is greatly improved in applicability and added value by coating the covering cloth surface with a layer of the fluorosilicone finishing agent.

Owner:ZHEJIANG BOTAI PLASTIC

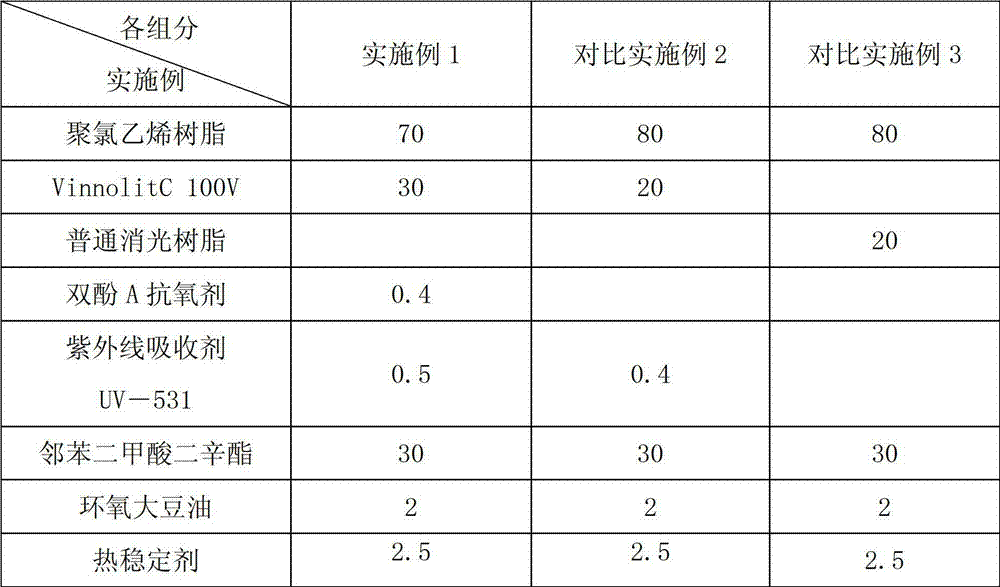

Matting resin modified polyvinyl chloride (PVC) matt film

The invention relates to a matting resin modified polyvinyl chloride (PVC) matt film, belonging to the technical field of PVC matt films. The matting resin modified PVC matt film comprises the following components: 60 to 90 weight parts of polyvinyl chloride resin, 10 to 40 weight parts of matting resin (VinnolitC 100V), 20 to 50PHR of dioctyl phthalate, 2 to 10PHR of epoxy soybean oil, 2 to 5PHR of a thermal stabilizer, 0.3 to 0.5PHR of an antioxidant, and 0.1 to 1.0PHR of an ultraviolet absorbent. The modified matt film can achieve surface effects of anti-sticking, matting, grain forming and the like, has a good surface matting effect, has high adaptability to processing conditions, and has the advantages of good matting effect and the like in a broad plasticizing temperature range.

Owner:TIANJIN TIANSU SCI & TECH GROUP

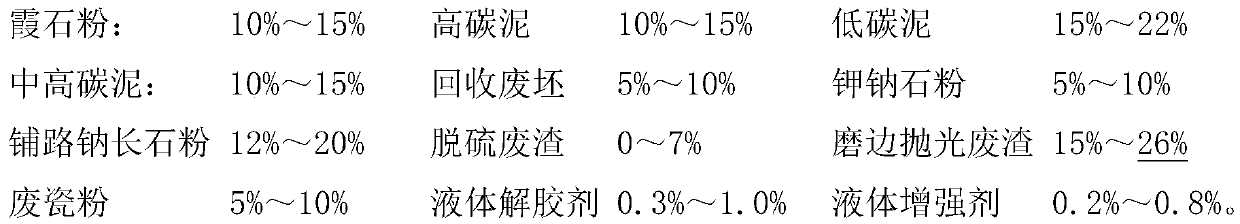

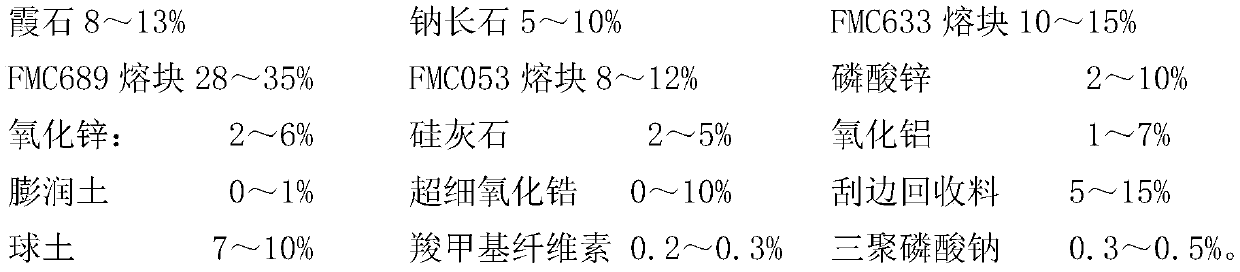

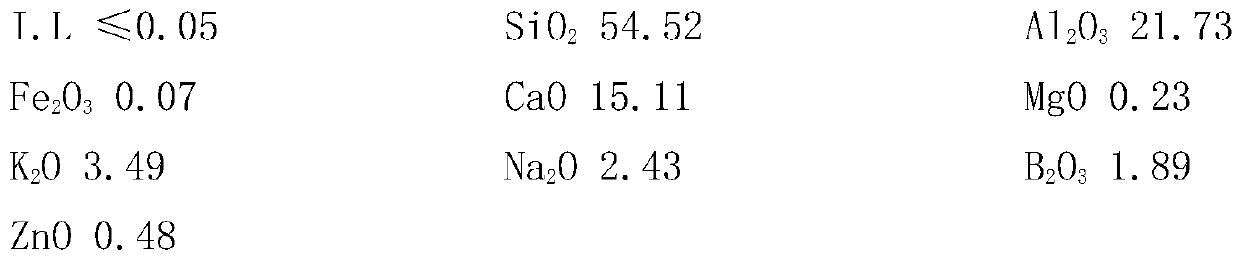

Silky fine matt ceramic tile and production method thereof

ActiveCN110204306AReduce consumptionSimplify product processCeramic shaping apparatusCeramic materials productionCeramic tilesPotassium

The invention relates to a silky fine matt ceramic tile and a production method thereof. The blank material of the ceramic brick comprises 10-15% of nepheline powder, 5-10% of high-carbon mud, 20-25%of low-carbon mud, 10-15% of medium-and-high-carbon mud, 5-10% of recovered waste blanks, 5-10% of potassium and sodium stone powder, 20-25% of paving albite powder, 5-10% of waste porcelain powder, 0-7% of desulfurization waste residues, 20-30% of edging and polishing waste residues, 0.3-1.0% of a liquid dispergator and 0.2-0.8% of a liquid reinforcing agent. The production method comprises the following processes: proportioning and ball milling of blank raw materials, spray drying, aging, blank compression molding, drying, blank polishing, water spraying, glazing, pattern decoration and firing.

Owner:JIANGXI HEMEI CERAMICS +4

Easily-collapsible mud core molding sand and preparation method thereof

InactiveCN103521690AImprove smoothnessImprove breathabilityFoundry mouldsFoundry coresFiberEthyl acetate

The invention discloses easily-collapsible mud core molding sand. The easily-collapsible mud core molding sand is prepared from the following raw materials in parts by weight: 200-240 parts of chromite sand, 20-25 parts of sepiolite, 50-56 parts of kaolin powder, 2-5 parts of steel fibers, 20-25 parts of sawdust, 10-15 parts of gypsum powder, 2-3 parts of quick lime, 10-14 parts of corn meal powder, 3-5 parts of furan resin, 1-2 parts of benzenesulfonic acid, 5-7 parts of ethyl acetate and an appropriate amount of water. According to the easily-collapsible mud core molding sand disclosed by the invention, the chromite sand, the sepiolite, the kaolin and the like are roasted and roasted at a high temperature dispersing and grinding of added gypsum powder and the like are combined, so that the molding sand not only has excellent smoothness, gas permeability, cohesiveness, toughness and plasticity, but also has cohesiveness resistance; the steel fibers are used to increase strength of the molding sand; the sawdust is used to increase collapsibility and environment is not polluted. High polymer resin is used as a binding agent, so that the easily-collapsible mud core molding sand is easily collapsible at the high temperature. Besides, the molding sand disclosed by the invention is suitable for facing sand and mud core sand of a large cast steel piece.

Owner:HEFEI CITY TENVER PRECISION CASTING

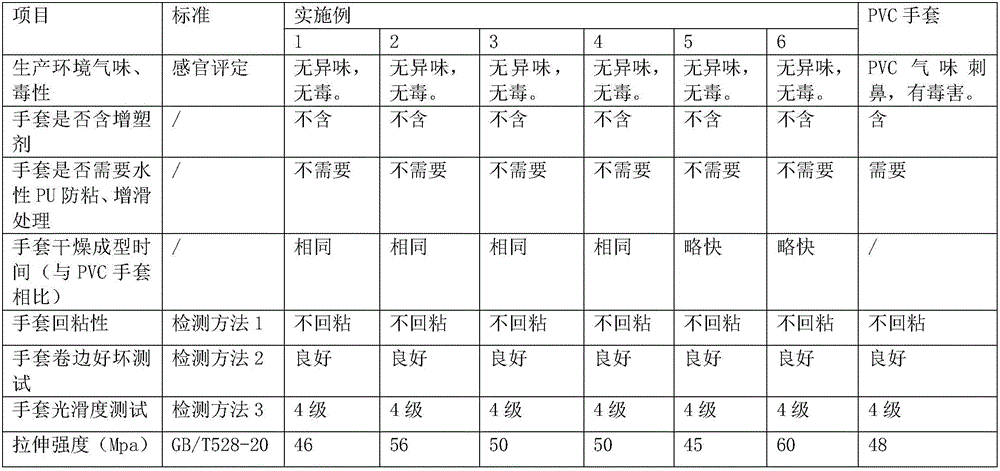

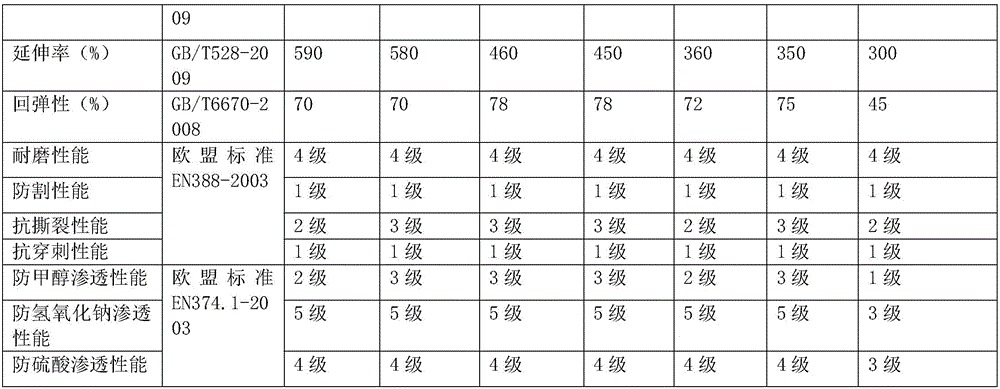

Waterborne polyurethane gloves slurry, preparation method thereof, and waterborne polyurethane gloves prepared from the same

InactiveCN106380829AImprove high temperature resistanceIncrease resistance to ethanolGlovesProtective garmentWater basedSlurry

The invention relates to a waterborne polyurethane gloves slurry, a preparation method thereof, and waterborne polyurethane gloves prepared from the same. The slurry includes: 4.9-10.2 parts of epoxidized soybean oil, 68.4-239.7 parts of macromolecular polyol, 4.5-67 parts of isocyanate, 2.4-11 parts of a hydrophilic chain extender, 2.0-8.6 parts of a small molecular chain extender, 0.028-0.08 part of a catalyst, 0.6-1.0 part of an antioxidant, 20-60 parts of a solvent, 254-300 parts of water, 6.4-7.8 parts of a neutralizing agent, 1.0- 6.0 parts of an amine chain extender, 3.6-7.0 parts of a water-based silane coupling agent, 2-13 parts of filler, 1.2-3.1 parts of a wetting agent, 1.2-3.1 parts of a leveling agent, 1.2-3.1 parts of a defoaming agent, 3.1-6.2 parts of a dispersing agent, 1.2-3.1 parts of an organosilicon slipping additive, 12.5-320.0 parts of a wax emulsion, and 0.3-0.8 part of a thickening agent. The gloves have the advantages of high solid content, fast drying molding, ultrahigh elasticity, high elongation, and simplified process, and also have methanol permeability resistance, sodium hydroxide permeability resistance, and sulfuric acid permeability resistance, etc.

Owner:SHANDONG TIANQING TECH DEV

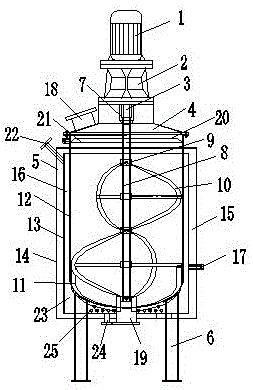

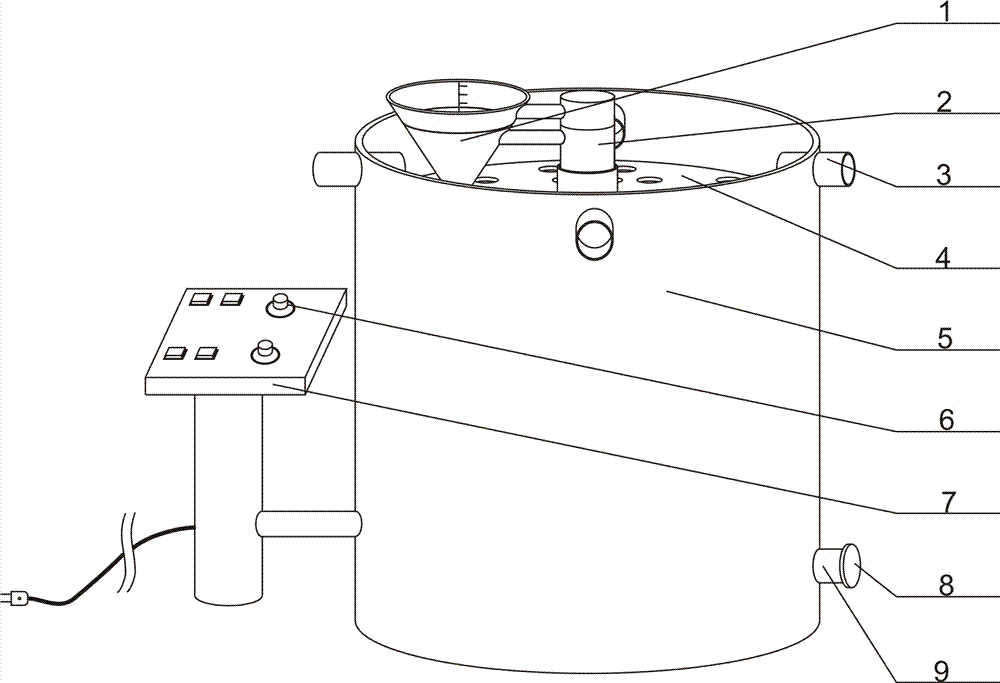

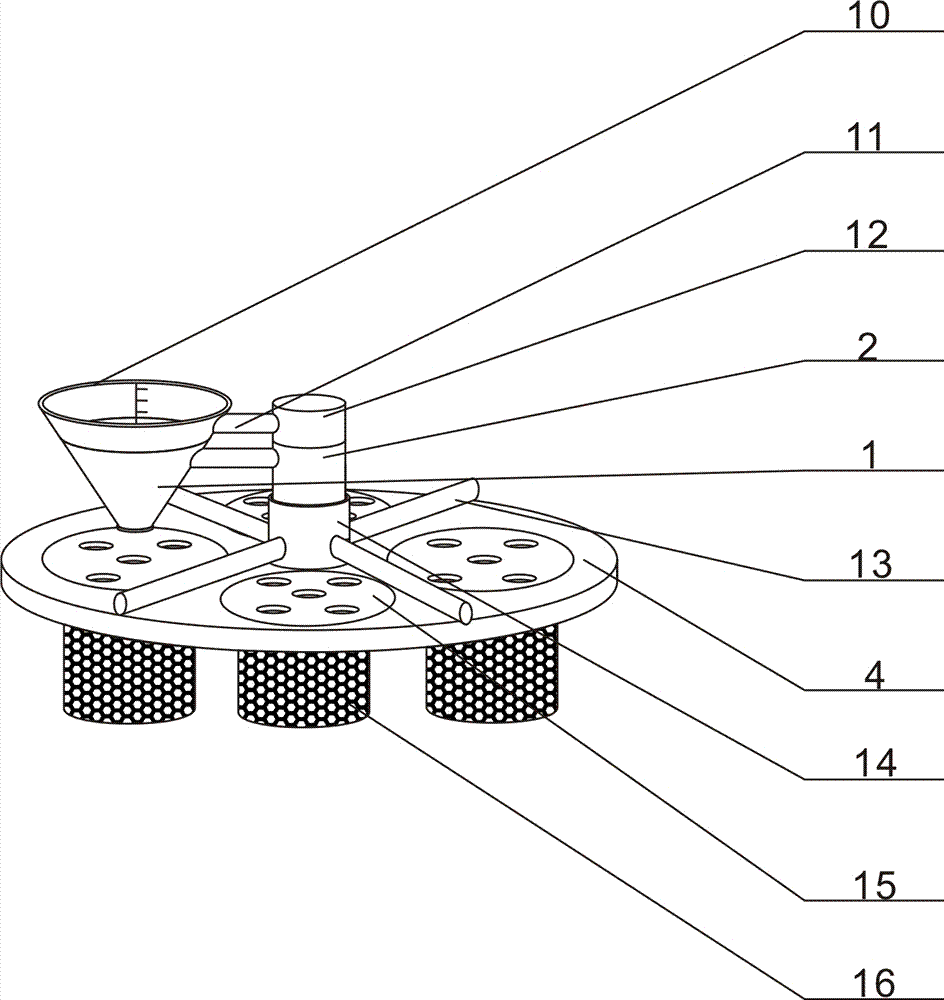

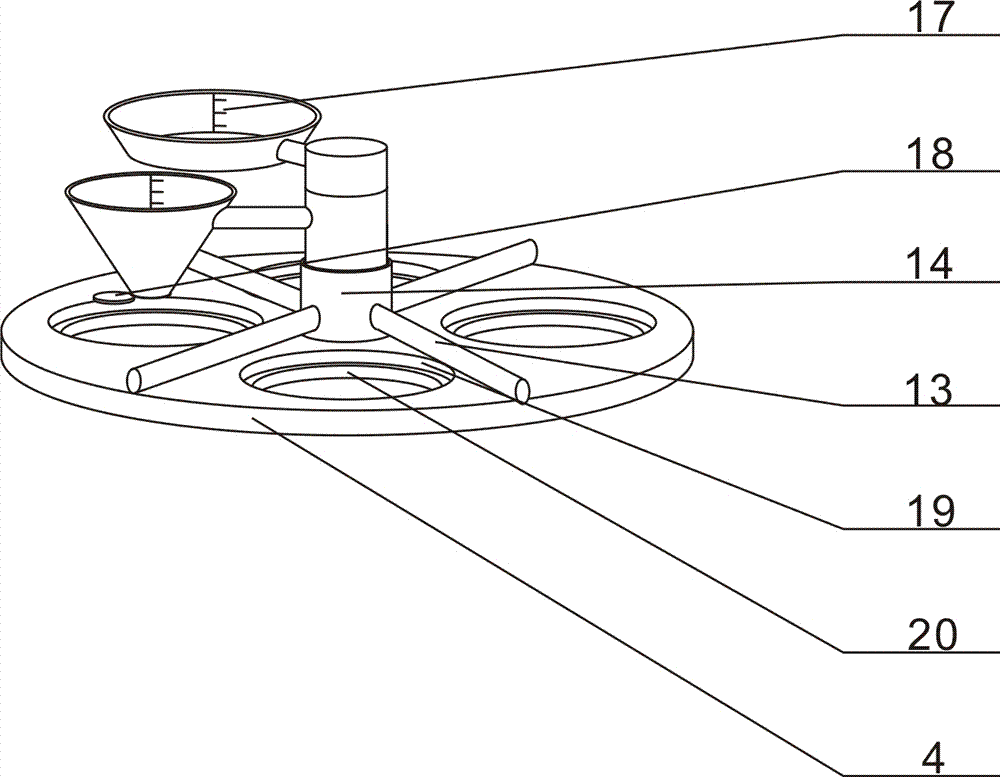

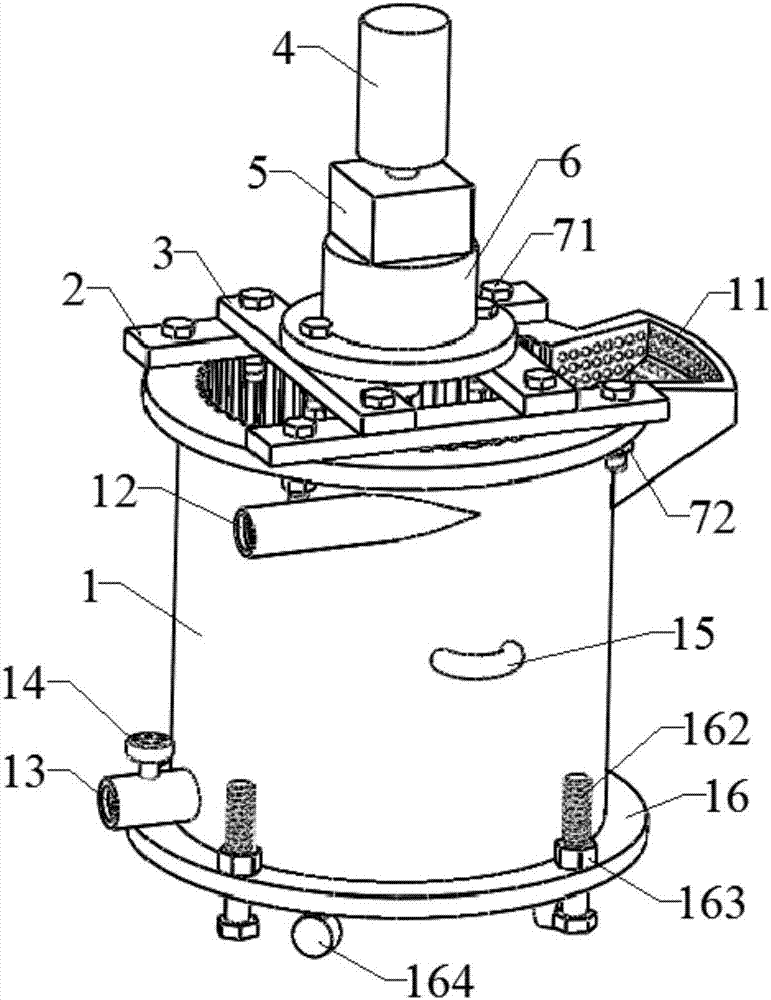

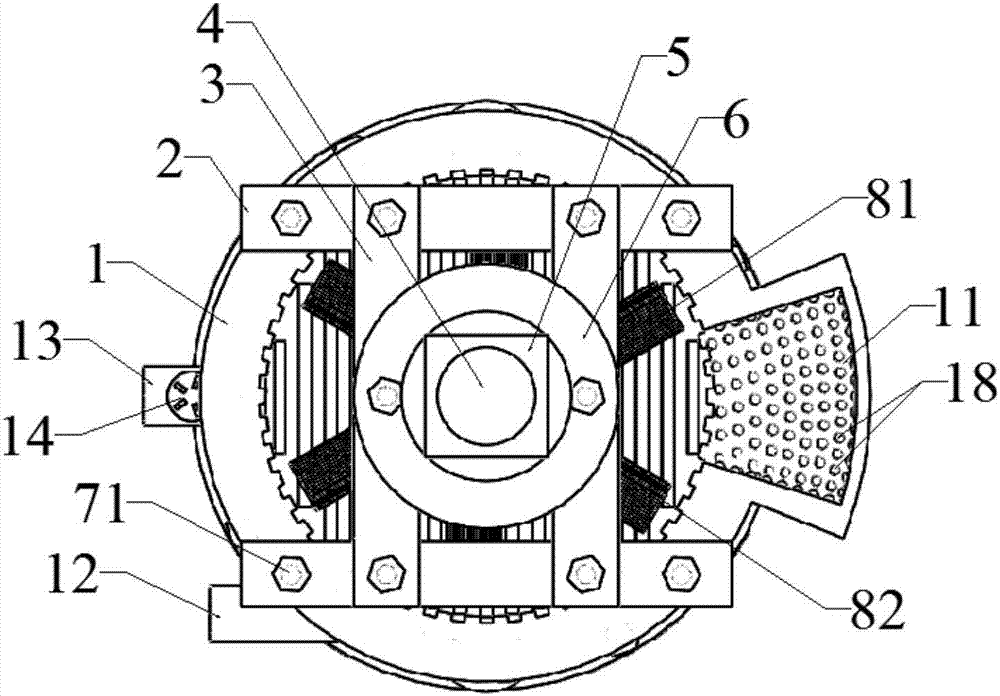

Biological fermentation tank

ActiveCN105886388AImprove wear resistanceImprove rust resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringFermentation

The invention relates to a biological fermentation tank which comprises a motor, a speed reducer, a stirring device, an upper cover, a fermentation bucket and a support. The upper cover is arranged at the upper end of the fermentation bucket and provided with a stirring opening, and the stirring device is arranged in the stirring opening and comprises a stirring shaft and stirring blades arranged on the stirring shaft. The stirring blades comprise the first stirring blade and the second stirring blade, the second stirring blade is arranged at the lower end of the stirring shaft, the first stirring blade is a flood dragon rotary blade, and the second stirring blade is a frame type stirring blade. Coatings are arranged on the outer sides of the stirring blades, the fermentation bucket is provided with an inner barrel body, an outer jacket and a shell in sequence from inside to outside, a heat preservation device is arranged between the outer jacket and the shell, a heating device is arranged between the inner barrel body and the outer jacket, and a sensor is arranged in the heat preservation device. The stirring blades are formed by combining the flood dragon rotary blade and the frame type stirring blade, therefore, reactants can be comprehensively stirred and can be effectively prevented from being pasted to the inner wall of the fermentation bucket, and the reaction rate is increased.

Owner:YANCHENG JIANFENG MACHINERY

Inflammation-eliminating, pain-stopping, bacteria-resisting, pain-relieving soluble hemostatic gauze and its processing method

ActiveCN1799639AAnti-stickWith sterilizationAbsorbent padsSynthetic polymeric active ingredientsCelluloseAntimicrobial drug

A soluble hemostatic gauze for anti-inflammation and pain relieving and the preparing method, relating to field of medical sanitary goods. The hemostatic gauze comprises the following substance according to the percentage by weight: dibasic sodium phosphate 0.1-0.3%, sodium alginate 1-1.8%, carbomu 0.5-25, antibacterial drugs 1-10%, polyethylene glycol 1-2%, tuwen 1-4%, dimethicone 0.1-1%, sodium carboxymethylcellulose 0.2-0.8%, americaine 0.05% and the left is ethanol solution. The product possesses functions of special pain relieving, preventing adhesion after surgery besides functions of hemostatic, broad spectrum antibiotic and promoting wound healing, which is of great importance for relieving patient pain and improving their survival quality.

Owner:青岛中惠圣熙生物工程有限公司

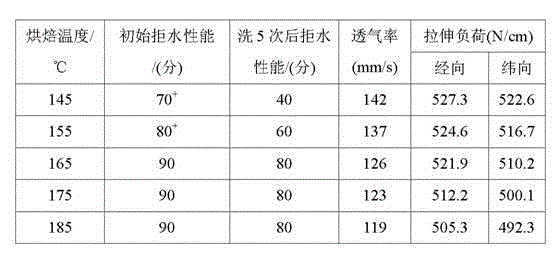

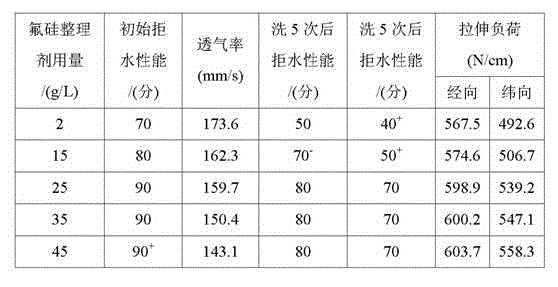

Three-prevention one-resistance method for finishing all terylene/cotton fabrics using teflon and anti UV agent

The present invention relates to a kind of dressing method for all terylene / cotton fabrics through the treatment of Teflon and anti-ultraviolet ray solution to achieve waterproof, oil-prevention, adhesion-prevention and anti-ultraviolet ray effects. The method pertains to the steps of first putting all terylene / cotton fabrics into the Teflon dressing solution with 40-60g / L of Co content for dipping and rolling; then letting them be pre-baked for 1-2 minutes under the temperature of 100-120 degrees C; again putting them into the anti-ultraviolet ray E solution with 30-50g / L content for dipping and rolling; and finally letting them be baked for 3-5 minutes under the temperature of 160-180 degrees C. After the above treatment, all terylene / cotton fabrics can attain the 6th grade of waterproof, 6th grade of oil-prevention, 6th grade of adhesion-prevention and the 5th grade of anti-ultraviolet ray and also are durable and washable. The invention is reliable in technology, easy in operation, low in cost and can be widely used.

Owner:JIANGSU YUHAO TEXTILE

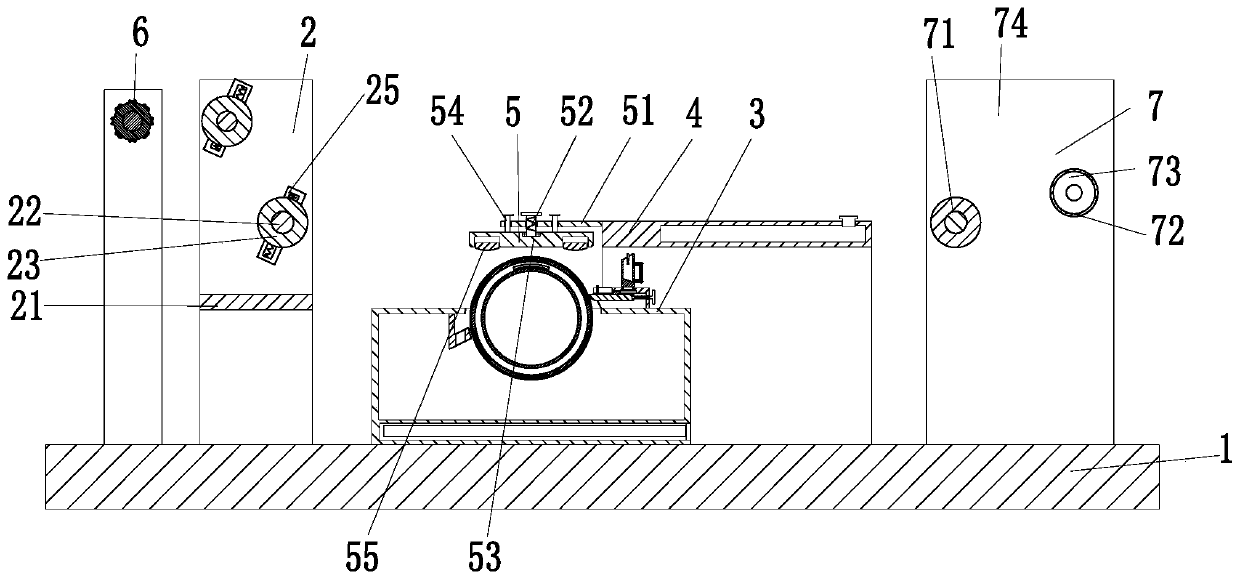

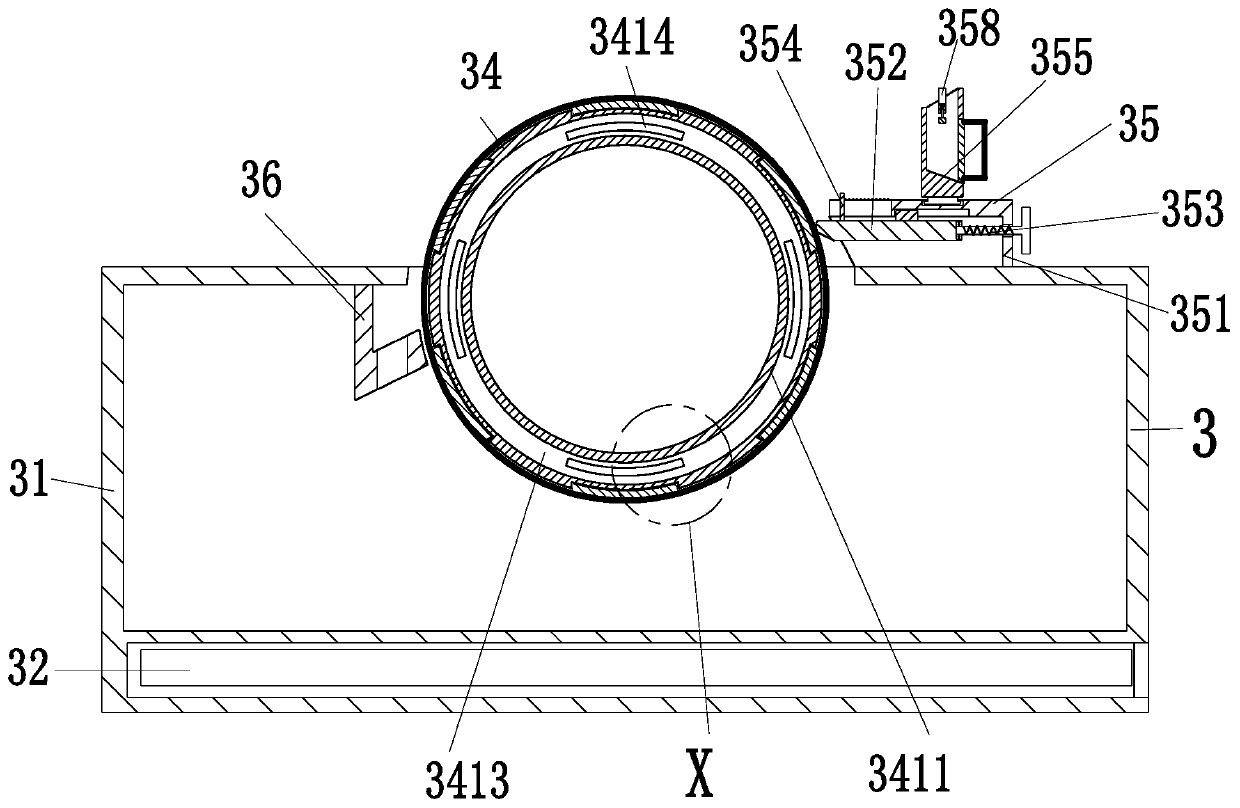

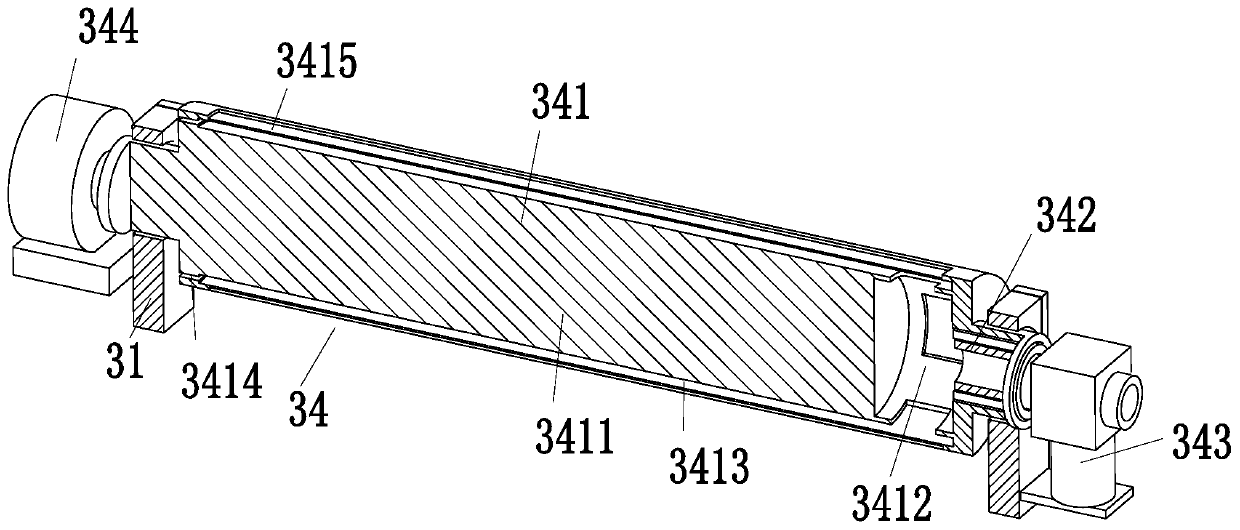

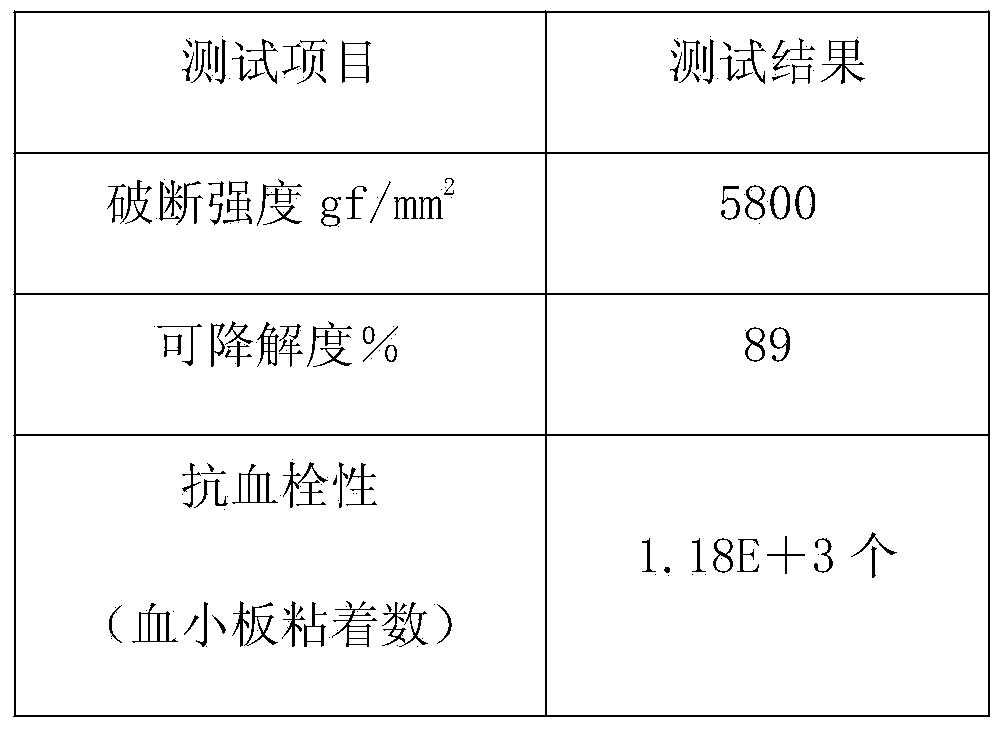

Anti-counterfeiting self-adhesive label coating system and coating treatment method

InactiveCN111346793AIncrease surface thicknessReduce cooling ratePretreated surfacesCoatingsCoating systemEngineering

The invention relates to an anti-counterfeiting self-adhesive label coating system and a coating treatment method. The anti-counterfeiting self-adhesive label coating system comprises a base, a tightening frame, a coating device, a cooling frame, a pressing device, a sleeving set and a winding set, wherein the coating device is mounted in the middle of the base; the sleeving set is mounted at theleft end of the base; the tensioning frame is arranged between the sleeving set and the coating device and mounted on the base; the winding set is mounted at the right end of the base; the cooling frame is arranged between the winding set and the coating device and mounted on the base; and the pressing device is arranged on the left side of the cooling frame. Through the anti-counterfeiting self-adhesive label coating system and the coating treatment method, the problems that the surface of a commonly-used coating roll is cold, a hot melt adhesive adhering to the surface of the coating roll may directly solidify on the surface of a roll body at low temperature, the adhesion force between the hot melt adhesive and the coating roll is large in the coating process, much hot melt adhesive is difficult to be transferred to the surfaces of labels, and remaining hot melt adhesive not processed in time directly solidifies on the roll body can be solved.

Owner:郭东东

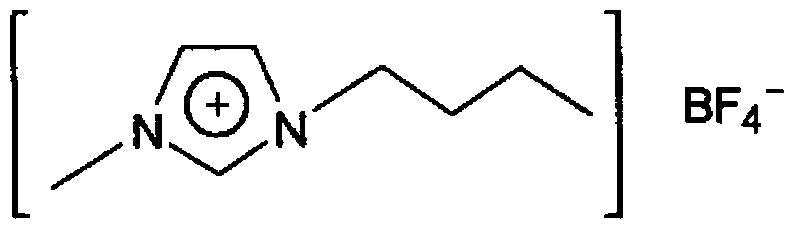

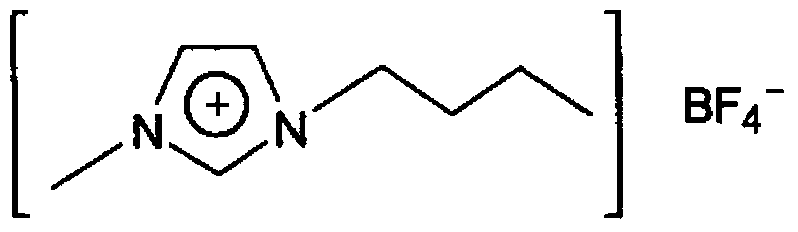

Nano-carbon sol and application thereof

The invention discloses nano-carbon sol and application thereof; the nano-carbon sol is characterized in that the carbon particle size is in the range from 1 to 500 nm; the nano-carbon sol is prepared by adding sodium lignin sulfonate, which is 0.08-0.12% of the total weight of sol and is 6500 Dalton in molecular weight, into the nano-carbon sol obtained by electrolyzing water by taking a graphite electrode as the anode; the carbon content in the sol is 0.6 wt%. The nano-carbon sol disclosed by the invention is applied to petrochemical industries, medicines, environmental protection, antiviral protection and catalysts; in the aspect of medicines, the nano-carbon sol can be used as a medicine additive and a film wrapped for external injury; in the aspect of petrochemical industries, the nano-carbon sol can be used as a dispersing agent in the refining process; in the aspect of environmental protection, the nano-carbon sol can be used as a flocculating agent and bactericide for water treatment; in the aspect of antiviral protection, the nano-carbon sol not only can be used as an antiviral filtering material but also can be used as a chemical catalyst; the nano-carbon sol disclosed by the invention has the antiinflammation effect; a nano-carbon sol medical catheter has excellent mechanical strength, good low-friction of the sliding surface and antithrombus; in addition, the nano-carbon sol disclosed by the invention has excellent biological degradability.

Owner:GUIZHOU TELIDA NANO CARBON SCI & TECH +1

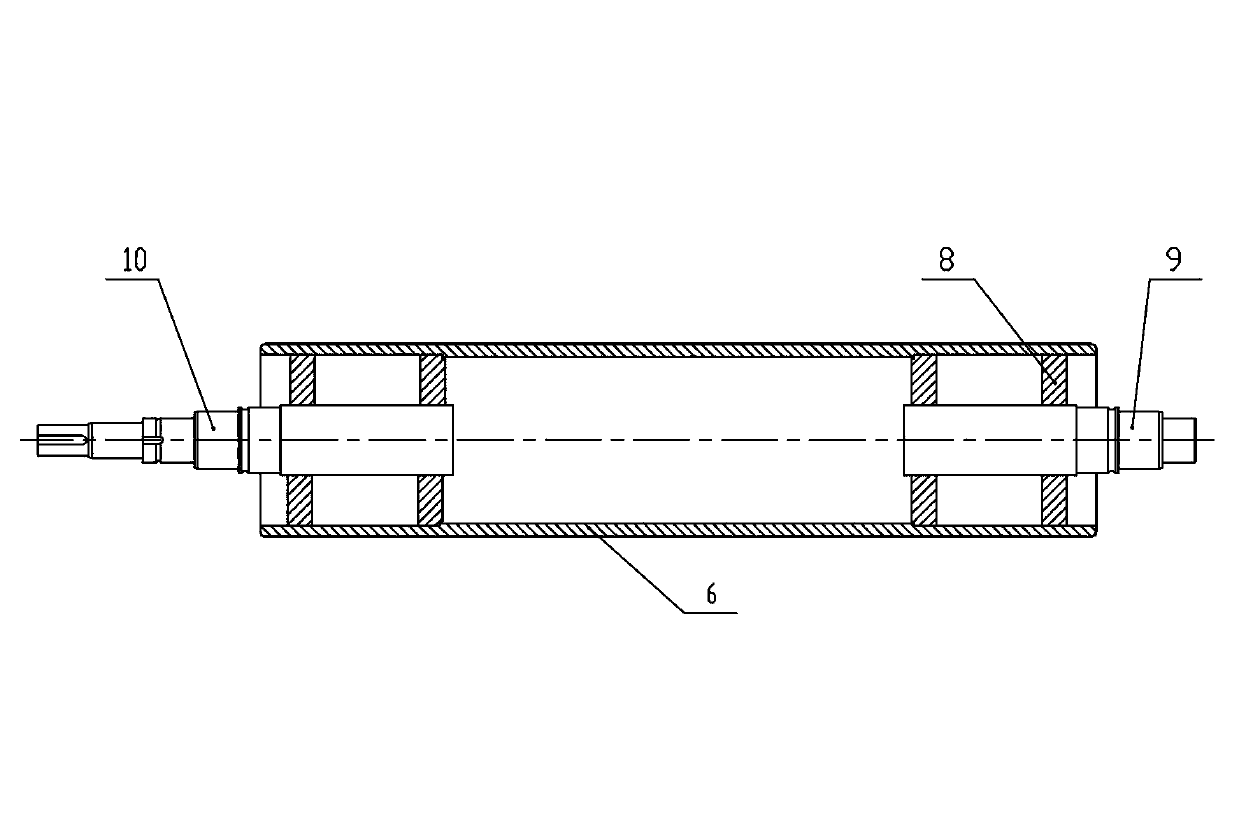

Spray-welding coating technology for hot-rolling laminar cooling roller and use fixture for technology

ActiveCN103695831AGuaranteed to be heatedGuaranteed spraying effectMolten spray coatingCarbide coatingLaminar cooling

The invention relates to a spray-welding coating technology for a hot-rolling laminar cooling roller. The spray-welding coating technology comprises the following steps: 1) blanking a roller and processing before spraying; 2) preheating a workpiece; 3) conducting spray-welding coating: adjusting the velocity of the roller to be 15-20 revolutions per minute, adjusting the position of a spray gun and opening the spray gun, adjusting the powder delivery volume and flame, and meanwhile, moving the roller forwards at a constant speed of 280 mm / min, so as to ensure that the hard alloy in the spray gun is uniformly sprayed on the outer circumference of the roller; 4) auto-rotating the sprayed roller in the environment at the temperature of 370 DEG C to enable the hard alloy on the roller to remelt, and after the hard alloy coating is molten, placing the roller to be subjected to air cooling to obtain the roller with the hard alloy coating. The cooling roller sprayed and welded by adopting the technology and the fixture for spray-welding coating has the functions of abrasion resistance, thermal barrier, antioxidation, corrosion protection, scaffolding resistance, caking inhibition and the like, as well as the service life longer than that of a roller bed in market application.

Owner:ANSHAN ZHENGFA SURFACE TECHN & ENG CO LTD

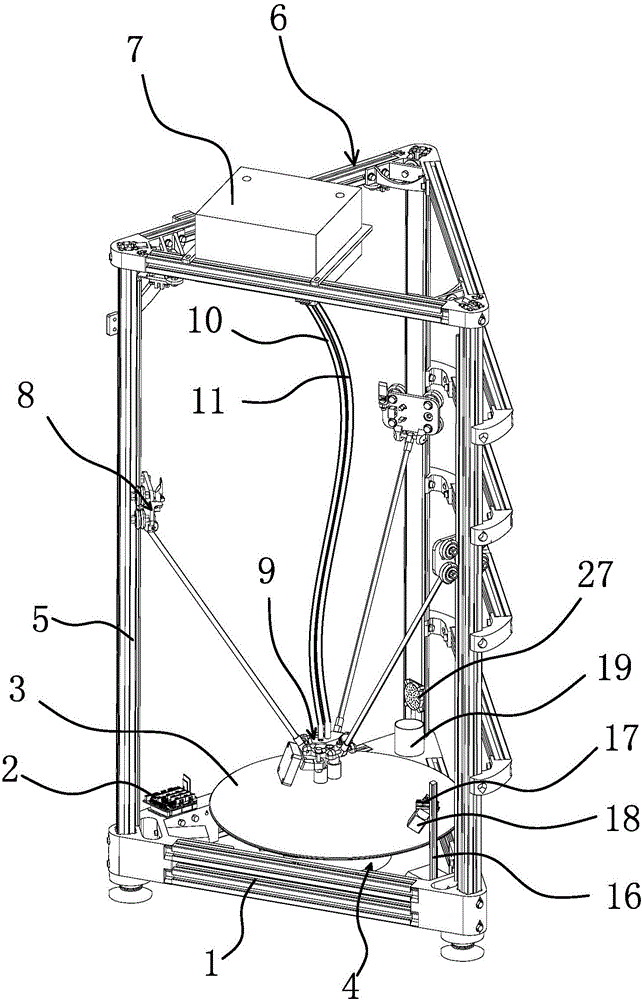

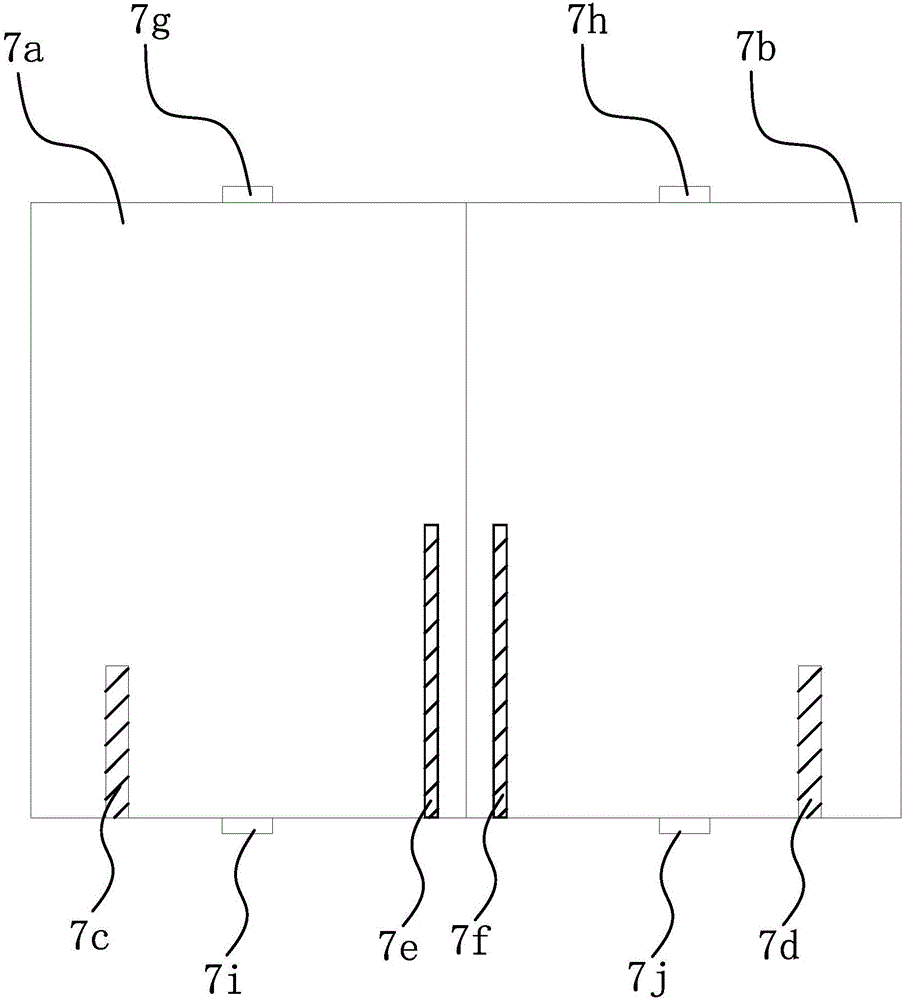

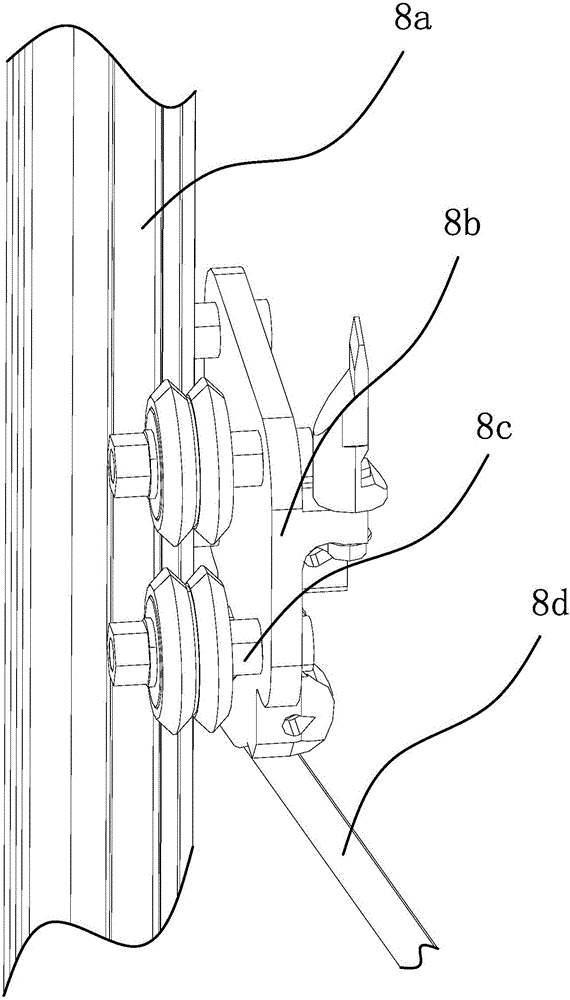

Printing platform of 3D printer

ActiveCN105922594AExtend your lifeHigh temperature resistantAdditive manufacturing apparatusGear wheelElectric machinery

Owner:泰安正豪物业管理有限公司

Sprayable super-hydrophobic self-cleaning coating

ActiveCN103897515AAntifoulingAntifreezePolyurea/polyurethane coatingsEthyl acetatePollution prevention

The invention relates to the technical field of super-hydrophobic coating, and particularly relates to sprayable super-hydrophobic self-cleaning coating. The sprayable super-hydrophobic self-cleaning coating comprises base coat and filler, wherein the base coat comprises 20-40 parts of polyurethane, 100-200 parts of mixed solvent I and 5-10 parts of 3-aminopropyl triethoxysilane, the filler comprises 40-50 parts of polytetrafluoroethylene powder, 100-200 parts of mixed solvent II and 5 parts of 3-aminopropyl triethoxysilane, and the mixed solvent I and the mixed solvent II comprise reagent-grade acetone, reagent-grade ethyl acetate and reagent-grade dimethylformamide, the volume ratio of which is 1: 1: 1. The sprayable super-hydrophobic self-cleaning coating has excellent performances such as super hydrophobicity, pollution prevention, freezing resistance, sticking prevention, resistance reduction and radiation prevention. Meanwhile, the sprayable super-hydrophobic self-cleaning coating is low in cost, low-pollution and easy to store for a long term and can be sprayed.

Owner:常州纳浩新材料科技有限公司

Soluble hemostatic gauze for diminishing inflammation, killing bacteria and calming pain, and its making method

ActiveCN1803203AAnti-stickWith sterilizationAbsorbent padsAmine active ingredientsPolyethylene glycolSurface-active agents

Disclosed is a soluble hemostatic gauze for diminishing inflammation, killing bacteria and calming pain, and its making method, which comprises the following raw materials (by weight portion), 0.1-0.3% of disodium hydrogen phosphate, 1-1.8% of sodium alginate, 0.5-2% of Carbomer, 1-10% of cationic surface active agent, 1-2% of polyethylene glycol, 1-4% of Tween-80, 0.1-1% of dimethyl silicon oil, 0.2-0.8% of sodium carboxymethylcellulose, 0.05% of benzocain and balancing ethanol solution.

Owner:青岛中惠圣熙生物工程有限公司

Bromfenac sodium eye drops and preparation technology thereof

PendingCN107375207AStir wellAvoid accumulationOrganic active ingredientsSenses disorderFiberSodium bisulfate

The invention provides bromfenac sodium eye drops and preparation technology thereof, and relates to eye drops and preparation technology thereof. The eye drops comprise the following components in percentages by weight: 0.001-0.15% of a bacteriostat potassium sorbate, 0.10-3.25% of an anti-oxidant sodium bisulfite, 0.04-2.52% of a lubricant magnesium lauryl sulfate, 0.15-0.55% of bromfenac sodium, a pH conditioning agent and injection water. A series of mixing and stirring steps are used in order to prepare the bromfenac sodium eye drops. A stirring mechanism on a base plate as well as stirring fans on a vertical plate and stirring fiber bars arranged on the stirring fans are used for realizing partial stirring in one cubic centimeter, partial stirring can be used for substantially reducing suspended solids, stirring time is shortened, uniform dissolving is realized, content of each component in bromfenac sodium eye drop bulk pharmaceutical chemicals is uniform, stirring efficiency of bulk pharmaceutical chemicals is substantially improved, and current speed during stirring is substantially improved.

Owner:LIAONING MEILIN PHARMA

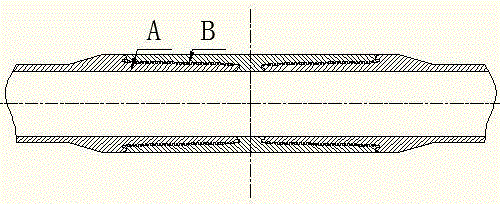

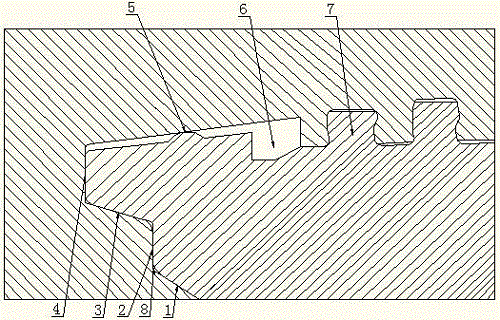

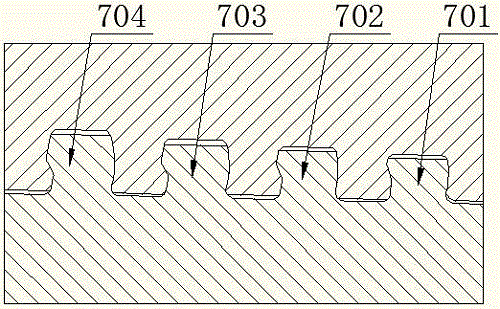

Special-thread gas seal oil sleeve joint for ultra-deep wells

InactiveCN105927167AStrong anti-torsion abilityImprove sealing performanceDrilling rodsDrilling casingsDirectional wellCorrosion

The invention relates to a special-thread gas seal oil sleeve joint for ultra-deep wells. The special-thread gas seal oil sleeve joint comprises a pipe portion and a coupling portion. The joint is composed of two main seals (conical / conical sealing structure and spherical / conical sealing structure), three auxiliary seals (-15-degree-angle torque shoulder and two right-angle torque shoulders), a deformation release space, a tool withdrawal groove and a connecting thread. The technical problem that an ultrahigh-pressure oil-gas well threaded joint is prone to thread gluing, sealing invalidation and torque shoulder shearing invalidation, low in resistance to stress corrosion and threaded connection strength and nonuniform in stress distribution is solved, and the special-thread gas seal oil sleeve joint can be used for high-temperature high-pressure oil-gas wells, deep wells, the ultra-deep wells, directional wells and horizontal wells.

Owner:SOUTHWEST PETROLEUM UNIV +2

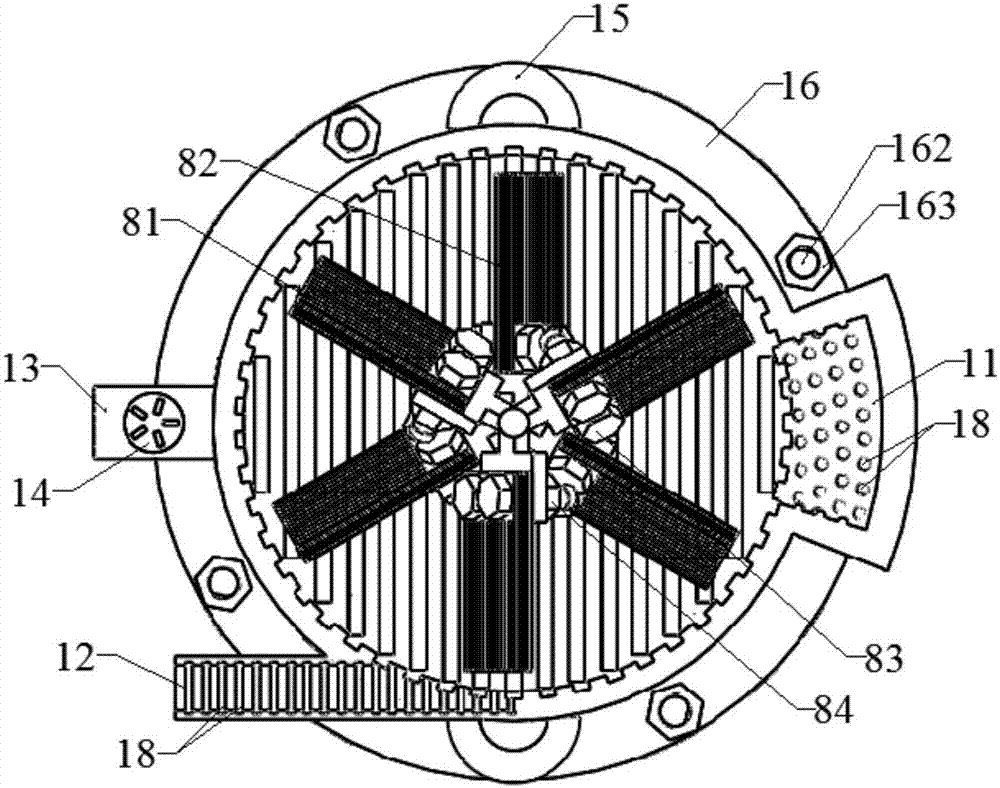

Bionic stirring machine for injection grout, hybrid power bionic stirring system and slurrying method of hybrid power bionic stirring system

ActiveCN107053468AIncrease smoothnessImprove efficiencyMixing operation control apparatusFoundation engineeringProcess engineeringSlurry

The invention discloses a bionic stirring machine for injection grout, a hybrid power bionic stirring system and a slurrying method of the hybrid power bionic stirring system. The bionic stirring machine for injection grout comprises a stirring tank with a feed inlet and a slurry discharge pipe. The bottom face of the stirring tank is an inclined face which is inclined towards the slurry discharge pipe. The upper end of the stirring tank is fixedly provided with a power portion through a supporting frame. The power output end of the power portion is connected with a stirring shaft in the stirring tank. A stirring paddle is vertically or obliquely arranged on the stirring shaft. When the stirring paddle is obliquely arranged on the stirring shaft, the inclination direction of the stirring paddle is opposite to the rotation direction of the stirring shaft. The inner surface of the stirring tank, the inner surface of the feed inlet, the inner surface of the slurry discharge pipe and the stirring paddle are each provided with a plurality of bionic non-smooth units. The superficial area of faces, making contact with the bionic non-smooth units, of the stirring tank, the feed inlet and the slurry discharge pipe is 20-50% of the superficial area of the inner surfaces of the components, and the superficial area of the faces, making contact with the stirring paddle, of all the bionic non-smooth units on the stirring paddle is 20-60% of the superficial area of all surfaces of the stirring paddle.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Synthetic leather for touch screen gloves and preparation method thereof

The invention belongs to the field of the preparation of synthetic leather and particularly relates to synthetic leather for touch screen gloves. The synthetic leather comprises a base (1), a face layer (2) and a face layer (3) from bottom to top, wherein the base (1) is a washer wrinkle fabric, the face layer (2) is prepared from, by weight, 30 parts of PC-8030 elastic resin, 70 parts of PC-8010 elastic resin, 100 parts of N,N-dimethyl formamide, 3 parts of touch-screen powder and 5 parts of toner, and the face layer (3) is prepared from, by weight, 100 parts of PC-8010 elastic resin, 100 parts of N,N-dimethyl formamide, 4 parts of touch-screen powder and 6 parts of toner. In addition, the formula of the touch-screen powder is improved, and the touch-screen powder has the silky feeling, flow-leveling abrasion-resisting and anti-sticking effects. After the touch-screen powder is added in the synthetic leather, the synthetic leather for the touch screen gloves has the advantages of being soft and flexible, is flexible in touch and does not scratch touch screens.

Owner:福鼎市永大合成革有限公司

Polyurethane resin preparation method

The invention relates to the technical field of materials for synthetic leather, in particular to a polyurethane resin preparation method. The method includes the steps: 1) increasing the temperature of 145 parts of polyneopentanediol adipate with the molecular weight of 2000 to 100 DEG C, performing vacuum dehydration for about 1h and cooling to 50 DEG C; 2) adding 150 parts of methylbenzene, 251 parts of IPDI (isophorone diisocyanate) and 5 parts of organic bismuth catalysts into a reactor with stirring uniformly, increasing the temperature to 90 DEG C and reacting for 2h; 3) adding 46 parts of 1,6-hexanediol to continue reaction for 2h at the temperature of 90 DEG C; 4) cooling to 50 DEG C, adding 100 parts of methylbenzene, 100 parts of normal butanol and 100 parts of isopropyl alcohol with stirring uniformly, slowly tackifying with 53 parts of isophorone diamine, and stopping adding the isophorone diamine when the viscosity is increased to 150000cps; and 5) continuing to stir for 30 minutes and cooling to 30 DEG C to discharge so that weak-solvent aliphatic polyurethane resin with 50% of solid content and 220kgf / cm<2> of modulus is obtained.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Printing missing word repairing method

The invention relates to a printing missing word repairing method. The printing missing word repairing method comprises the following steps of: (A) preparing a printing plate of words to be repaired, moving out a word missing part of a book, typesetting the word missing part and reserving an appropriate space convenient for operation in the future repairing; (B) making a repairing printing film according to four layers of a transparent film base material, a mold release agent, transfer printing ink and hot melt adhesive in sequence and printing the words needed to be transferred onto the transparent film by using a screen printing method; (C) making a transfer printing iron board according to the range of the repaired words; (D) heating a heating body to 180-200 DEG C and placing the transfer printing iron board on the heating body for 10-20 minutes; (E) placing the machined transfer printing film at a part needed to be repaired, aligning positions of the transfer printing film and the part needed to be repaired, impressing the heated transfer printing iron board onto the words needed to be thermoprinted, and moving out the transfer printing iron board after heated for 2-3 seconds; and (F) cooling the transfer printing film for 10-15 seconds and rapidly uncovering the thermoprinting film with heavy force. The method provided by the invention has the advantages of simplicity and convenience for operation, cost reduction, high repairing speed and the like.

Owner:南京爱德印刷有限公司

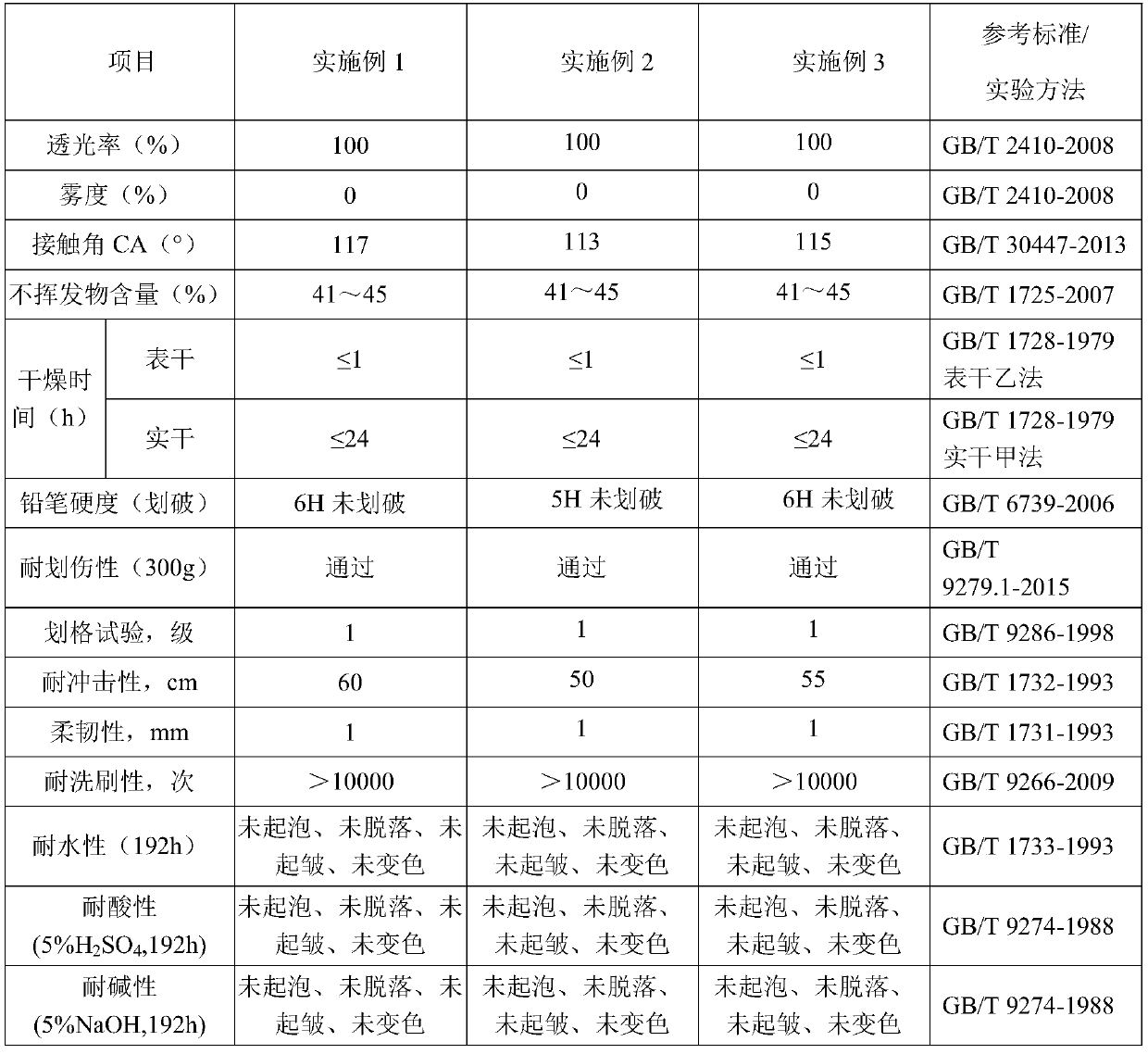

Waterborne anti-doodling coating

The invention discloses a waterborne anti-doodling coating. The waterborne anti-doodling coating is characterized by comprising the following components in parts by weight: 50-80 parts of pure acrylate emulsion, 0.5-1 part of wax emulsion, 0.05-0.1 part of fluoride additive, 15-20 parts of filler, 0.1-0.2 part of dispersant, 0.05-0.1 part of wetting agent and 1.0-2.0 parts of coalescing agent. The waterborne anti-doodling coating disclosed by the invention has excellent antifouling and anti-doodling functions and contaminants can be easily cleaned.

Owner:关锦池

Aliphatic polyurethane resin preparation method

The invention relates to the technical field of materials for synthetic leather, in particular to an aliphatic polyurethane resin preparation method. The method includes the steps: 1) increasing the temperature of 35 parts of poly adipic acid glycol-butanediol ether glycol and 35 parts of polycaprolactone glycol to 100 DEG C, performing vacuum dehydration for about 1h and cooling to 50 DEG C, wherein the molecular weight of the poly adipic acid glycol-butanediol ether glycol is 3000, and the molecular weight of the polycaprolactone glycol is 1000; 2) adding 150 parts of methylbenzene, 83 parts of IPDI (isophorone diisocyanate), 19 parts of H12MDI (dicyclohexylmethane 4,4- diisocyanate) and 0.2 part of stannous octoate into a reactor with stirring uniformly, increasing the temperature to 90 DEG C and reacting for 3h; 3) adding 5 parts of 1,4-butanediol and 9 parts of neopentyl glycol to continue reaction for 3h at the temperature of 90 DEG C; 4) cooling to 50 DEG C, adding 250 parts of methylbenzene, 200 parts of isobutyl alcohol and 200 parts of ethyl acetate with stirring uniformly, slowly tackifying with 13.8 parts of IPDA (isophorone diamine), and stopping adding the isophorone diamine when the viscosity is increased to 3000cps; and 5) continuing to stir for 30 minutes and cooling to 30 DEG C to discharge, so that weak-solvent aliphatic polyurethane resin with 20% of solid content and 180kgf / cm<2> of modulus is obtained.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

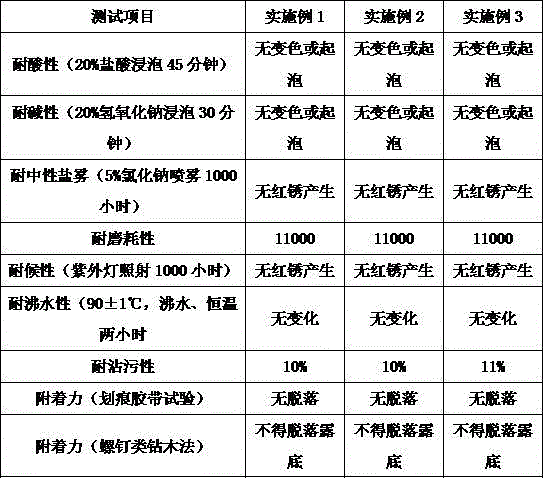

Water-base anti-sticking paint

InactiveCN104031532AAnti-stickAnti-graffitiAntifouling/underwater paintsPaints with biocidesAdhesion forceWater based

The invention relates to water-base anti-sticking paint. The water-base anti-sticking paint is characterized by being produced by mixing a component A and a component B in a mass ratio of 1: (6-10), wherein the component A comprises 62 to 90 parts by weight of acrylic acid epoxy resin, 5 to 16 parts by weight of an emulsifier, 2 to 7 parts by weight of a catalyst, 1.5 to 5 parts by weight of a surface active agent, 0 to 9.8 parts by weight of a diluting agent and 0.2 to 0.6 parts by weight of organic silicon; the component B comprises 30 to 48 parts by weight of a water-base amine hardener, 24 to 38 parts by weight of deionized water, 0.2 to 0.4 part by weight of a dispersion agent, 1 to 5 parts by weight of a diluting agent, 0.2 to 0.6 part by weight of a thixotropic agent, 17 to 24 parts by weight of body pigment, 3 to 6 parts by weight of modified plastic powder, 0.2 to 0.4 part by weight of a leveling agent and 0.1 to 0.5 part by weight of a surface active agent. The water-base anti-sticking paint is water-based, environmental friendly, strong in adhesion force, resistant to solvent corrosion, resistant to contaminant, self-cleaned, good in outdoor aging resistance, anti-sticking, resistant to doodling and the like.

Owner:SUZHOU DEODAR SPECIAL BUILDING MATERIALS

Multi-effect anti-fouling coating and construction method thereof

ActiveCN110437723ALower surface energyStrong water and oil repellencyFireproof paintsCovering/liningsPolyester resinAlgae

The invention discloses multi-effect anti-fouling coating. The multi-effect anti-fouling coating is prepared from a component A and a component B; the component A is prepared from the following components in parts by weight: 40-45 parts of fluorine-silicon modified polyester resin, 0.5-2 parts of an anti-static agent, 0.5-2 parts of a hydrophobic restorer, 0.5-2 parts of an anti-mold and anti-algae agent, 0.5-2 parts of a leveling agent, 0.5-2 parts of a wetting dispersant and 2-5 parts of a defoaming agent; the component B is prepared from 30-50 parts of a polyisocyanate pre-polymer; the massratio of the component A to the component B is (4 to 10):1; and the fluorine-silicon modified polyester resin contains hydroxyls. Through the synergistic effect of the fluorine-silicon modified polyester resin, the polyisocyanate pre-polymer and the multiple functional additives, the multi-effect anti-fouling coating has the functions of corrosion prevention, fouling prevention, self-cleaning, scrawling prevention and pasting prevention, and has excellent overall performance. The invention further discloses a construction method of the multi-effect anti-fouling coating.

Owner:武汉长弢新材料有限公司

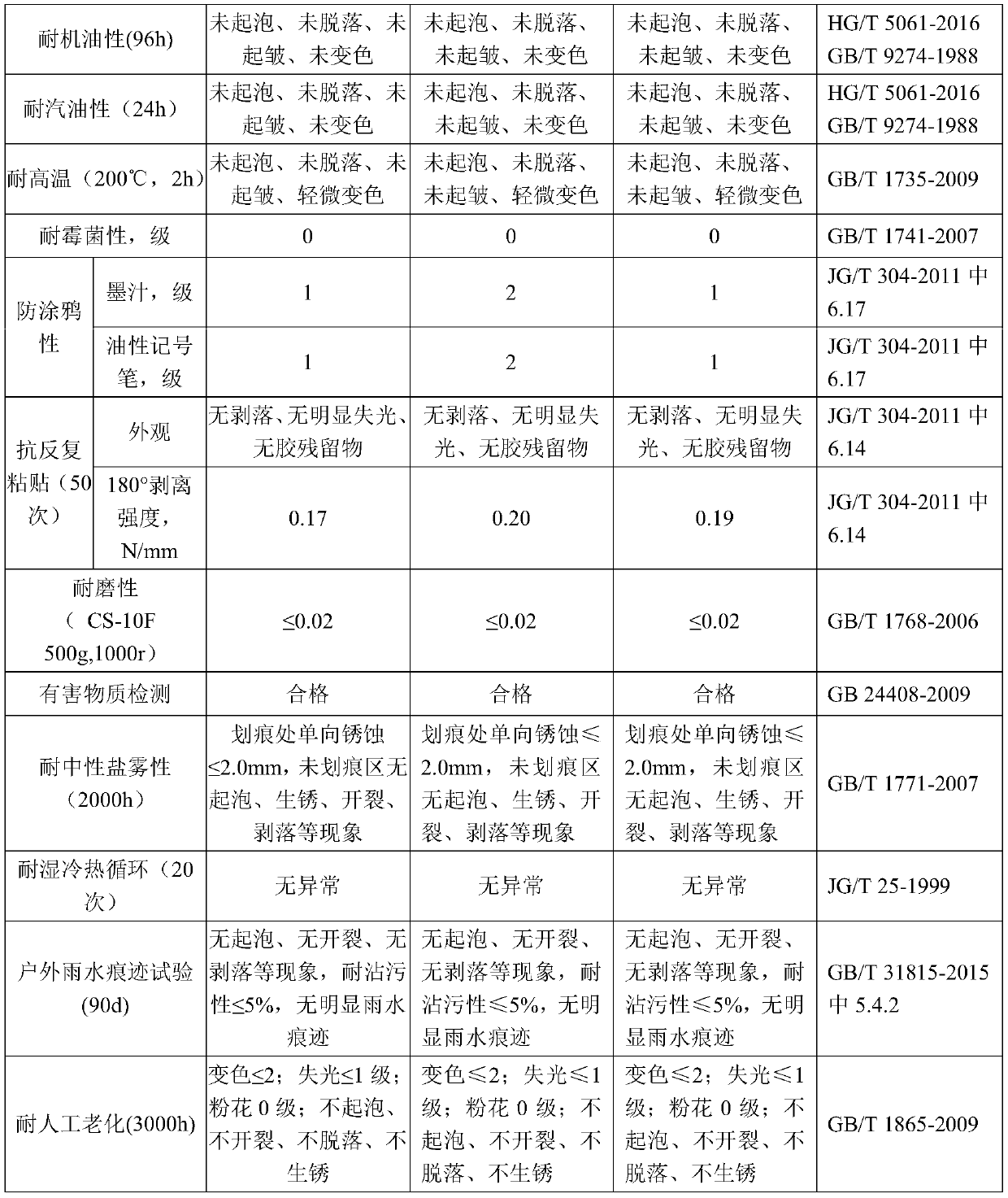

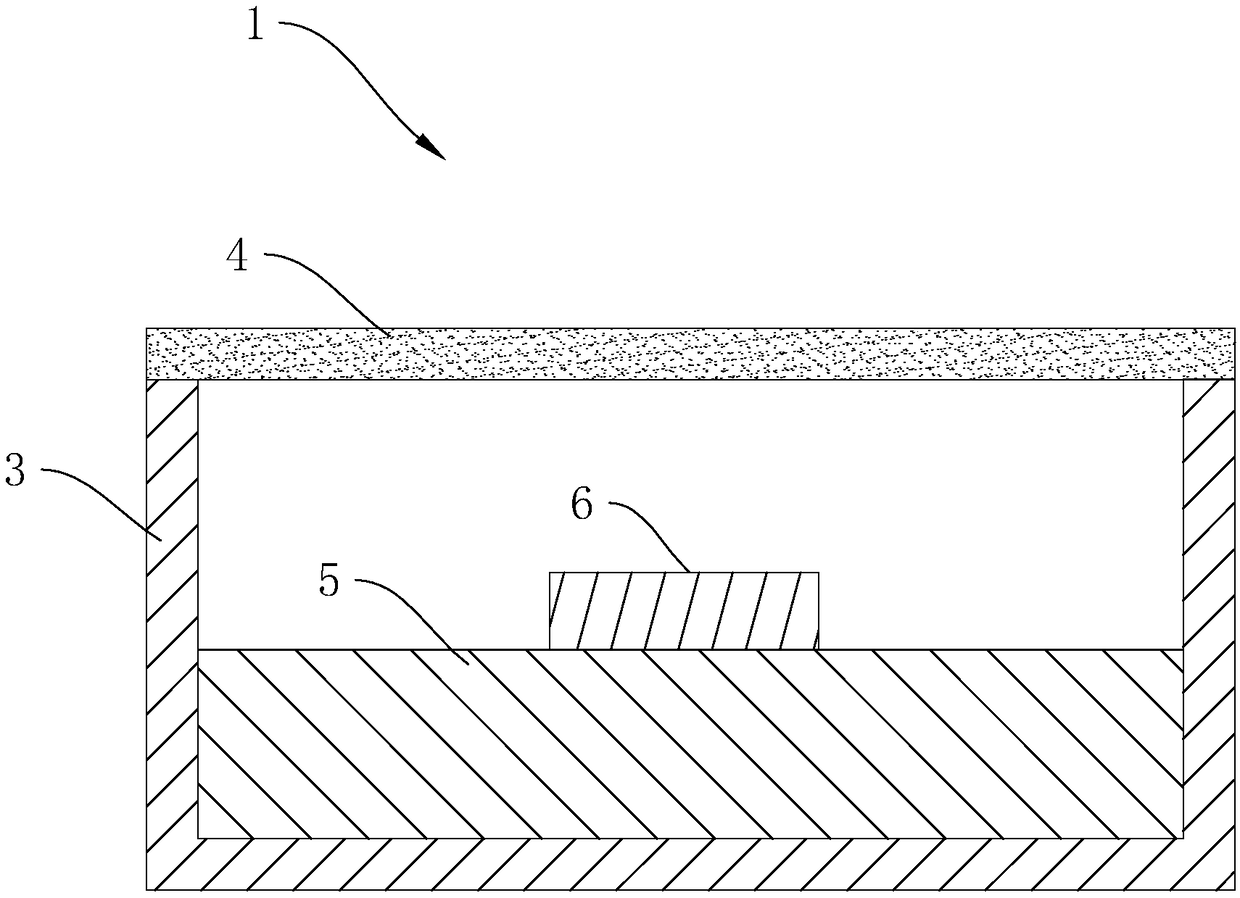

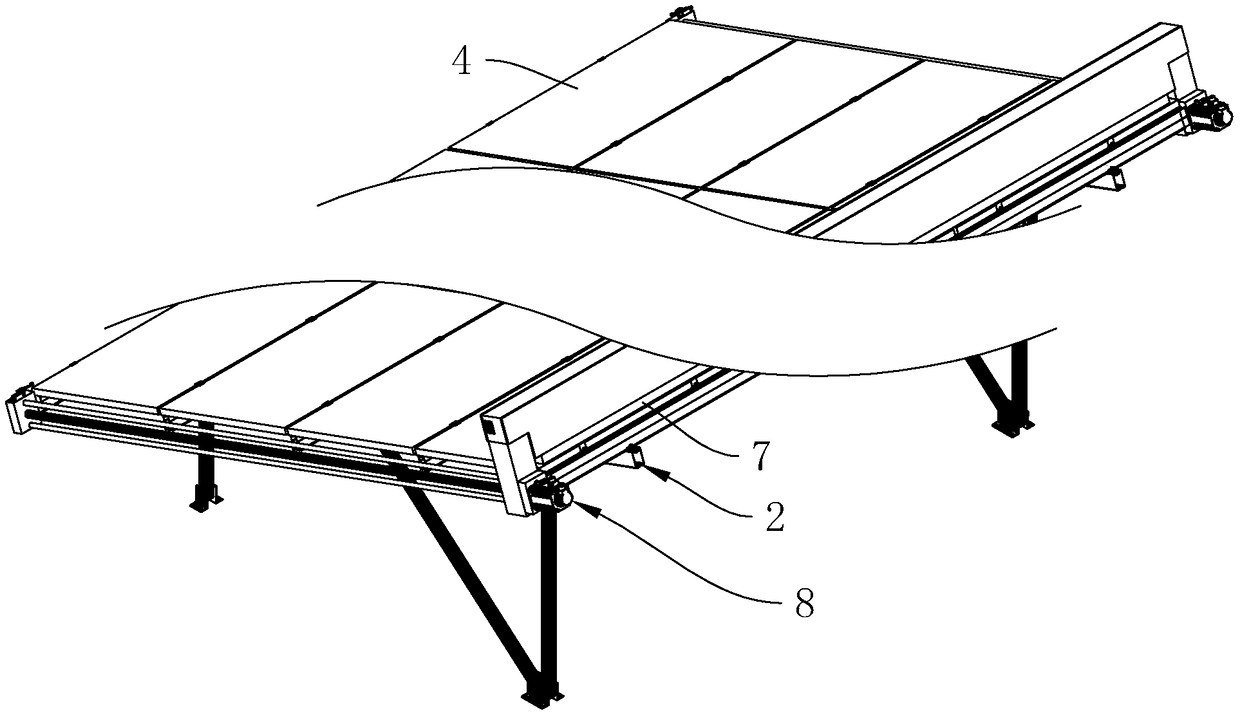

A photovoltaic panel dedusting system

InactiveCN109167566AGuaranteed photoelectric conversion efficiencyReduce consumptionPhotovoltaicsPhotovoltaic energy generationElectricityGlass cover

A system for remove dust from photovoltaic panel belonging to the field of solar photovoltaic technology, A technical scheme comprise a plurality of groups of photovoltaic panel and photovoltaic scaffolds, the photovoltaic panel includes a frame, a glass cover plate and a heat absorbing plate, wherein the glass cover plate is located on an upper end surface of the frame, the heat absorbing plate is arranged in the frame, a brush bar for cleaning dust on the surface of the glass cover plate and a driving assembly for driving the brush bar to move are arranged on the photovoltaic support, and the opening and closing of the driving assembly is controlled by a control system; A light-sensitive response module is arrange in that frame for detecting whet dust blocks the surface of the glass cover plate and outputting an induction signal, The photosensitive response module is electrically connected with the control system. When the photosensitive response module senses that dust is blocked, the control system outputs a control signal for starting the driving component. The invention can automatically remove the dust on the surface of the photovoltaic panel and maintain the power generation efficiency of the photovoltaic panel.

Owner:厦门通盛达工贸有限公司

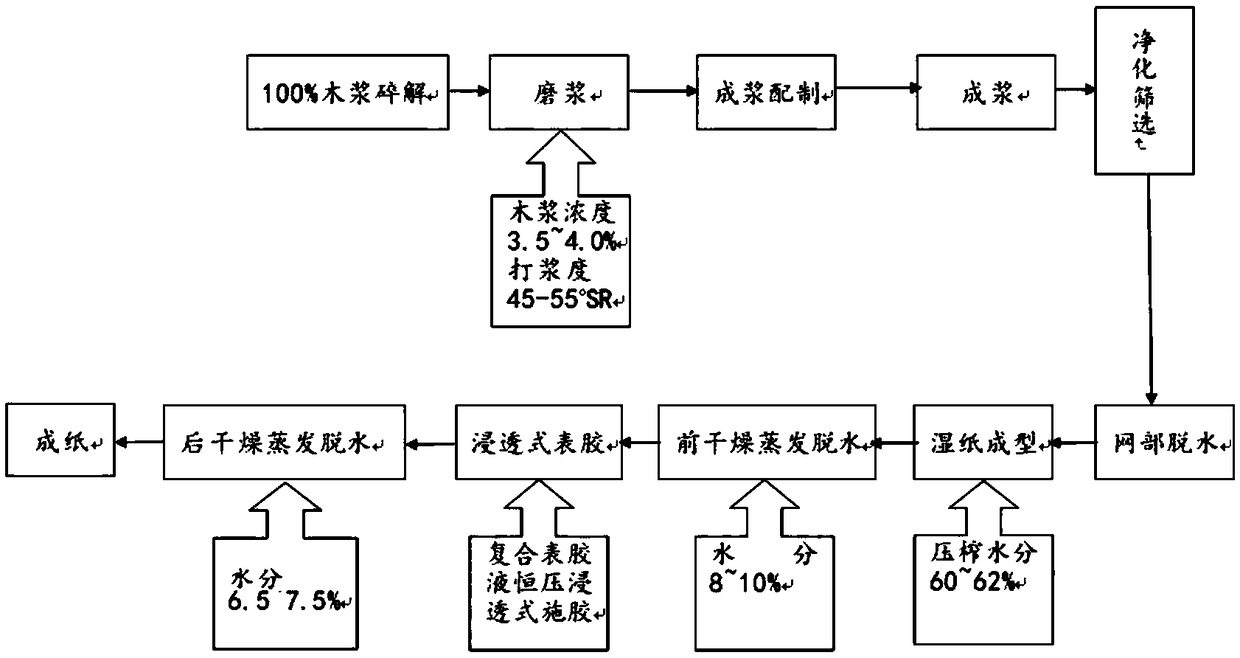

Frozen food packaging paper as well as manufacturing method and application thereof

ActiveCN109487629AImprove fine-grained controlLow temperature resistanceFlexible coversWrappersPlastic materialsSulfate

Sulfate softwood pulp is selected as a raw material, fine control of the technical process is improved by pulping, beating and adding various environmental-friendly additives, and the frozen food packaging paper with advantages of being low-temperature-resistant, oil-resistant, waterproof, anti-adhesion and wet cracking resistant can be prepared. The traditional waxed paper, coated paper and plastic materials can be replaced, and foods contacted with the paper can be safe and environmental-friendly.

Owner:沈阳思特雷斯纸业有限责任公司

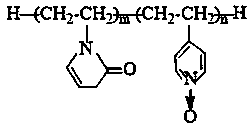

Low-temperature non-foaming anti-staining soaping agent as well as preparation method and application thereof

ActiveCN108977282AGood dispersionImprove adsorption capacityInorganic/elemental detergent compounding agentsCationic surface-active compoundsColour fastnessFoaming agent

The invention discloses a low-temperature non-foaming anti-staining soaping agent as well as a preparation method and application thereof. The low-temperature non-foaming anti-staining soaping agent is prepared from 25-30 parts of copolymer of vinyl pyrrolidone and vinylpyridine-N-oxide, 2-5 parts of alkaline substance, 10-15 parts of a cationic modifier, 1-3 parts of an organic silicon defoamer and 45-60 parts of water. The low-temperature non-foaming anti-staining soaping agent has good low-foaming and defoaming capability, the number of washing times can be reduced, and the low-temperaturenon-foaming anti-staining soaping agent has a good anti-staining effect, good colour fastness to washing and good color fastness to rubbing at low temperatures.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com