Frozen food packaging paper as well as manufacturing method and application thereof

A technology of frozen food and manufacturing method, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of environmental degradation, hidden dangers of food safety, etc., and achieve the effect of improving fine control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

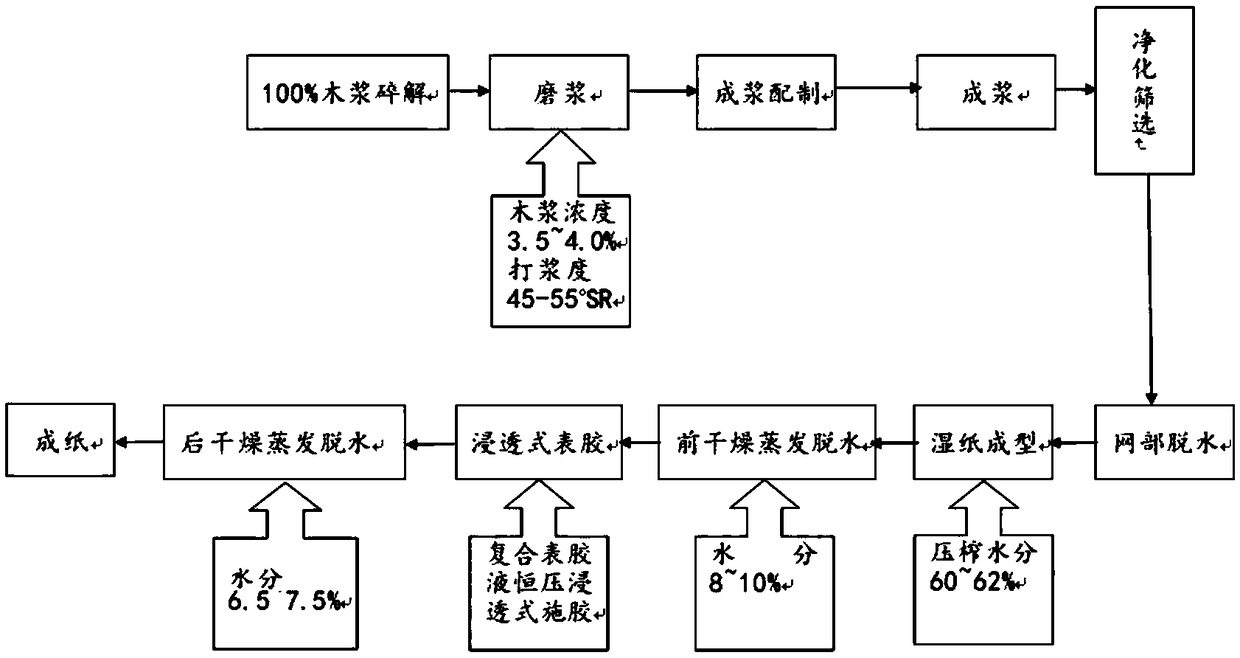

[0029] like figure 1 Shown, a kind of manufacture method of frozen food wrapping paper is characterized in that, comprises the following steps:

[0030] 1) Select 100% imported kraft softwood pulp that does not contain fluorescent whitening agent substances, and obtain a pulp with a concentration of 3.5% and an average fiber number length of more than 1mm after pulping and beating;

[0031] 2) Add filter aid, water-resistant agent, reinforcing agent and bactericide to the slurry mixing tank, and mix slurry with the slurry in step 1);

[0032] 3) Purify and screen after pulping, and then go online to dehydrate the wire part;

[0033] 4) The pressing part adopts three presses with a positive pressure of 0.45MPa, a second pressure of 0.3MPa and a double pressure of 0.4MPa to form the wet paper. The water content of the press is controlled at 62%, and then enters the drying front to evaporate and dehydrate to a water content of 10%;

[0034] 5) Use compound surface glue liquid t...

Embodiment 2

[0042] like figure 1 Shown, a kind of manufacture method of frozen food wrapping paper is characterized in that, comprises the following steps:

[0043] 1) Select 100% imported kraft softwood pulp that does not contain fluorescent whitening agent substances, and obtain a pulp with a concentration of 4.0% and an average fiber number length of more than 1mm after pulping and beating;

[0044] 2) Add filter aid, water-resistant agent, reinforcing agent and bactericide to the slurry mixing tank, and mix slurry with the slurry in step 1);

[0045] 3) Purify and screen after pulping, and then go online to dehydrate the wire part;

[0046] 4) The pressing part adopts three presses with a positive pressure of 0.45MPa, a second pressure of 0.3MPa and a double pressure of 0.4MPa to form the wet paper. The water content of the press is controlled at 60%, and then enters the drying front to evaporate and dehydrate to a water content of 8%;

[0047] 5) Use compound surface glue liquid to...

Embodiment 3

[0055] like figure 1 Shown, a kind of manufacture method of frozen food wrapping paper is characterized in that, comprises the following steps:

[0056] 1) Select 100% imported kraft softwood pulp that does not contain fluorescent whitening agent substances, and after pulping and beating, obtain a pulp with a concentration of 3.8% and an average fiber number length of more than 1 mm;

[0057] 2) Add filter aid, water-resistant agent, reinforcing agent and bactericide to the slurry mixing tank, and mix slurry with the slurry in step 1);

[0058] 3) Purify and screen after pulping, and then go online to dehydrate the wire part;

[0059] 4) The pressing part adopts three presses with a positive pressure of 0.45MPa, a second pressure of 0.3MPa and a double pressure of 0.4MPa to form the wet paper. The water content of the press is controlled at 61%, and then enters the drying front to evaporate and dehydrate to a water content of 9%;

[0060] 5) Use compound surface glue liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com