Patents

Literature

2185results about How to "Strong toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

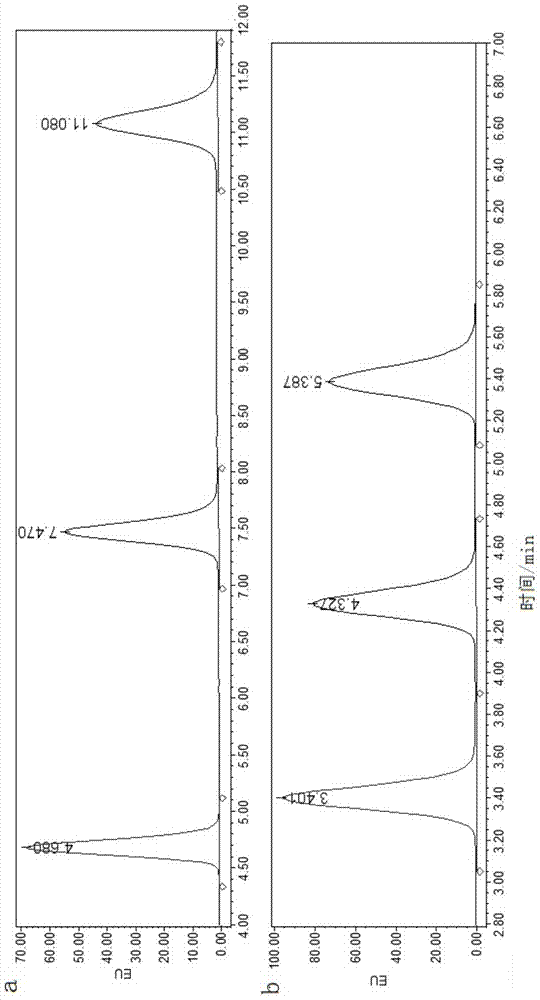

Method for preparing Ag-carrying bacterial cellulose hydrogel antimicrobial dressing and product thereof

The invention discloses a method for preparing an Ag-carrying bacterial cellulose hydrogel antimicrobial dressing and a product thereof. The method comprises the following steps of: soaking a bacterial cellulose hydrogel film in solution of silver metal precursor; then heating the film to be between 121 and 135 DEG C in a high-pressure sterilizing pot, and pressurizing between 0.205 and 0.313MPa; standing bacterial cellulose for 5 to 30min; and then taking the treated bacterial cellulose out for washing, partial dehydration, packaging and sterilization to obtain an Ag-carrying bacterial cellulose hydrogel antimicrobial dressing which is formed by compounding silver metal nano-particles and bacterial cellulose and is attached with 0.01 to 10 weight percent of the silver metal nano-particles in a bacterial cellulose three-dimensional porous network structure. The preparation process of the invention has the advantages of simplicity, easiness, convenient operation, controllable preparation technology, no pollution and low cost; and the prepared nano-particles have the advantages of high purity, small particle size, uniform size and good dispersity. The obtained Ag-carrying bacterial cellulose hydrogel antimicrobial dressing has the characteristics of good antimicrobial property, high water content, good water-retaining property, strong toughness, good air permeability and the like, and can meet the requirements of treating various wounds by a wet method.

Owner:DONGHUA UNIV +1

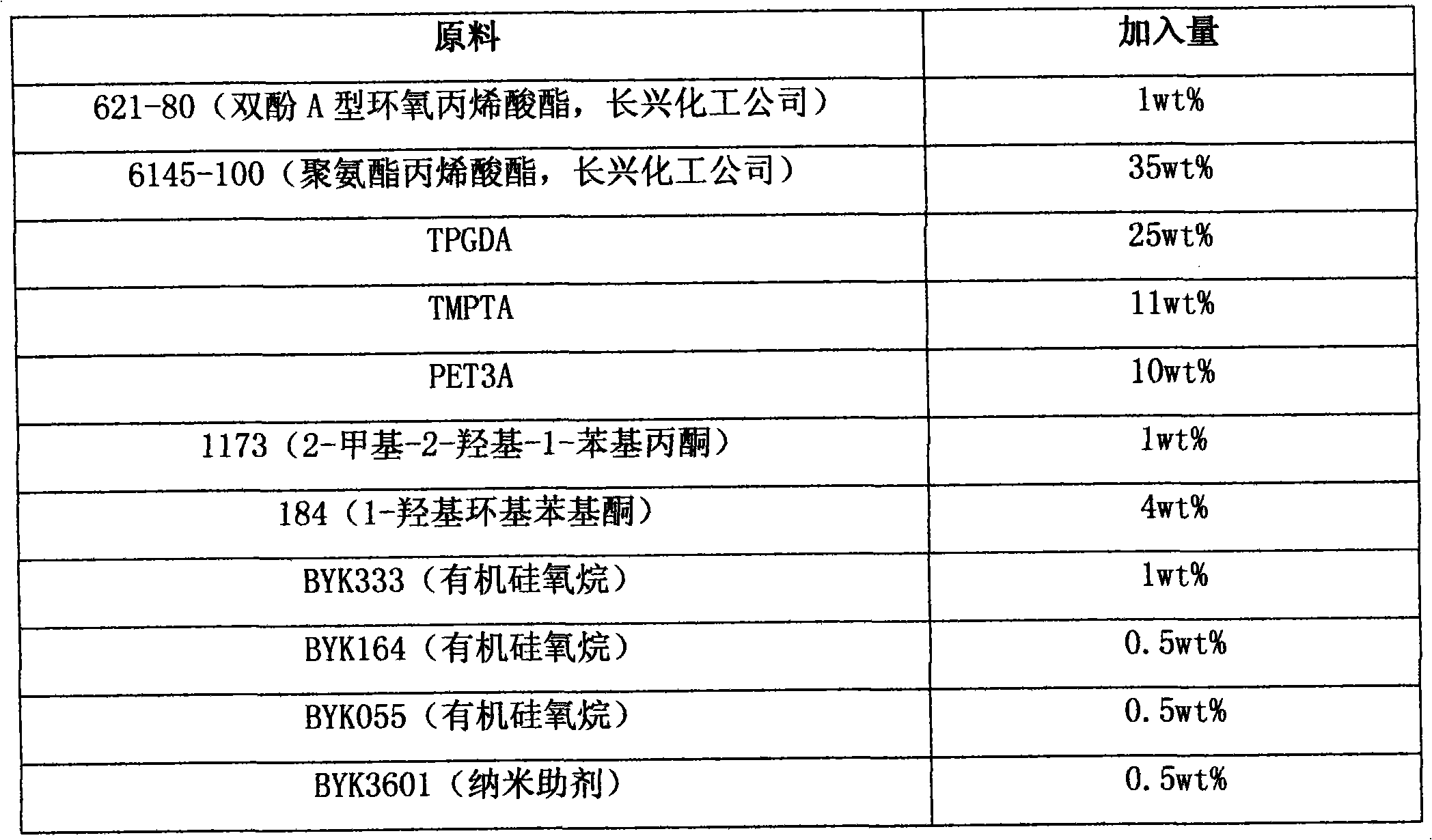

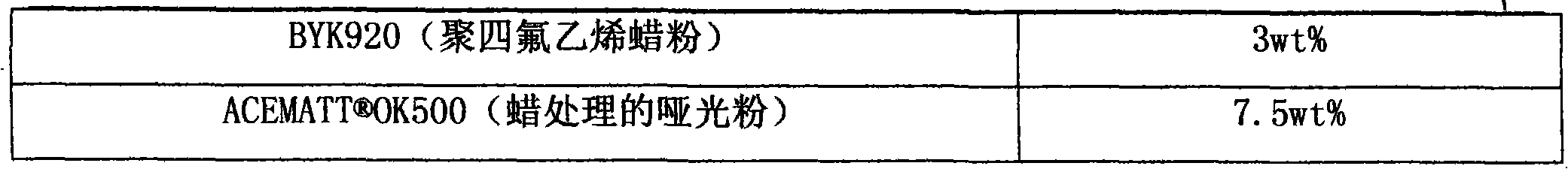

Ultraviolet curing coating

InactiveCN101638554AImprove anti-pollution performanceEasy to cleanPolyurea/polyurethane coatingsEpoxy resin coatingsUrethane acrylatePhotoinitiator

The invention relates to an ultraviolet curing coating which is characterized in that the ultraviolet curing coating comprises 1-35 wt% of epoxy acrylate, 1-35wt% of urethane acrylate, 20-50wt% of polyfunctional acrylate monomer, 1-15wt% of additive and 1-10wt% of photoinitiator. The coating formed by ultraviolet curing coating obtained by adopting the technical scheme has the advantages of good pollution resistibility, easy cleaning, high strength, strong adherence, high toughness and difficult stripping.

Owner:FOSHAN SHUNDE HEYGEY LIGHT CURING MATERIALS

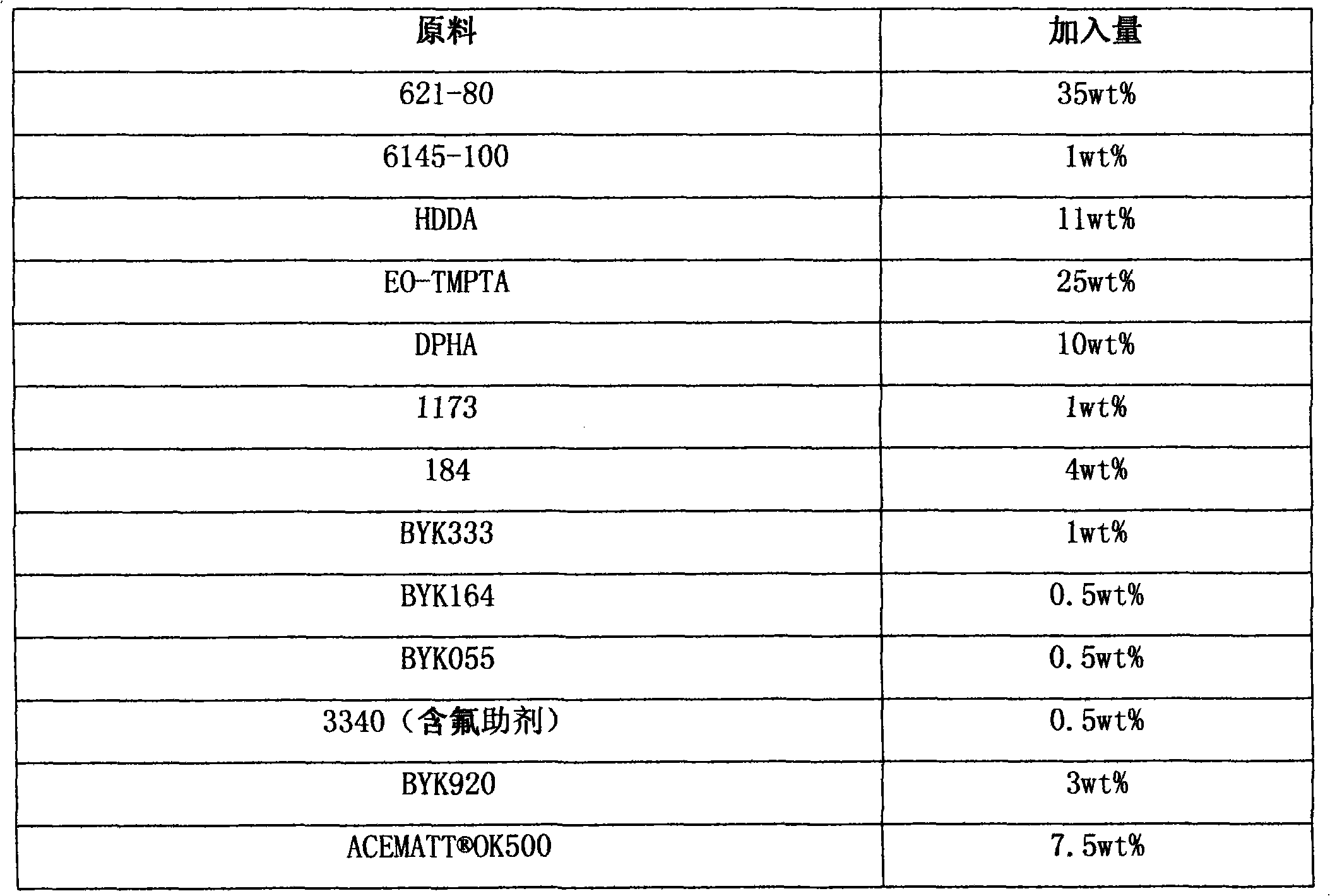

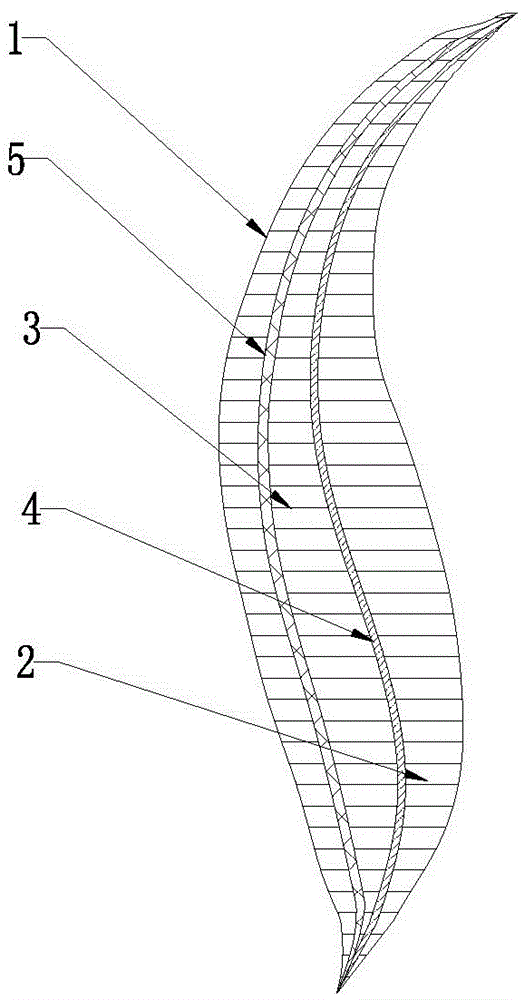

Preparation method of superfine fiber high-imitation grain synthetic leather

ActiveCN102304858AUniform cell size and distributionImprove qualityLamination ancillary operationsSynthetic resin layered productsWoven fabricDimethylformamide

The invention discloses a preparation method of superfine fiber high-imitation grain synthetic leather. The preparation method comprises the following steps of: spinning sea-island composite fibers by utilizing nylon 6 and low-density polythene as raw materials, manufacturing non-woven fabric by utilizing the sea-island composite fibers, coating one surface of the non-woven fabric by utilizing high-solid-concentration polyurethane slurry, infiltrating the non-woven fabric by utilizing low-solid-concentration polyurethane slurry, enabling the non-woven fabric to pass through an aqueous solution of dimethylformamide after infiltrating, solidifying polyurethane and forming a cellular structure to obtain synthetic leather semi-finished products, enabling the synthetic leather semi-finished products to pass through methylbenzene to separate sea-component low-density polythene out of the sea-island fibers, peeling off the sea-island composite fibers to be superfine fibers, washing away methylbenzene through boiling water, and drying to obtain the superfine fiber high-imitation grain synthetic leather. The product manufactured by the method disclosed by the invention has the advantages of strong gradient, abundant hand feeling, fine and smooth surface wrinkles and strong toughness after being bent, and has the beneficial effects on aspects of pollution reduction, animal protection, ecological protection and the like.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

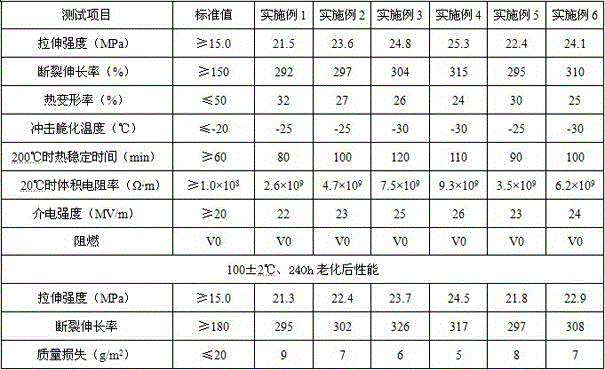

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

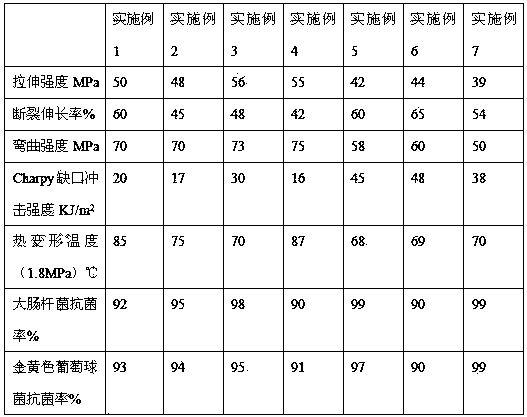

Antibacterial masterbatch, nano antibacterial super-tough plastic added with antibacterial masterbatch and preparation and application of plastic

The invention discloses an antibacterial masterbatch, nano antibacterial super-tough plastic added with an antibacterial masterbatch and preparation and an application of the plastic and relates to the technical field of high molecular materials. The nano antibacterial super-tough plastic is characterized by being prepared from the following raw materials in parts by weight through blending and extruding: 70-93 parts of resin, 2-10 parts of antibacterial masterbatch, 5-20 parts of a flexibilizer, 0.1-1.0 part of an antioxidant and 0.2-1.0 part of a lubricant. The preparation method comprises the following steps: firstly, preparing the antibacterial masterbatch, then, weighing the raw materials in proportion, adding into a high speed mixer and mixing for 2-10 minutes; and then, extruding and granulating the obtained mixture through a twin-screw extruder to obtain the nano antibacterial super-tough plastic. The nano antibacterial super-tough plastic disclosed by the invention has an efficient, lasting, broad-spectrum and safe antibacterial effect, can be applied to preparation of spectacle frames and can satisfy the requirements on characteristics of the spectacle frames such as great elasticity, strong toughness and difficulty in breakage.

Owner:HEFEI GENIUS NEW MATERIALS

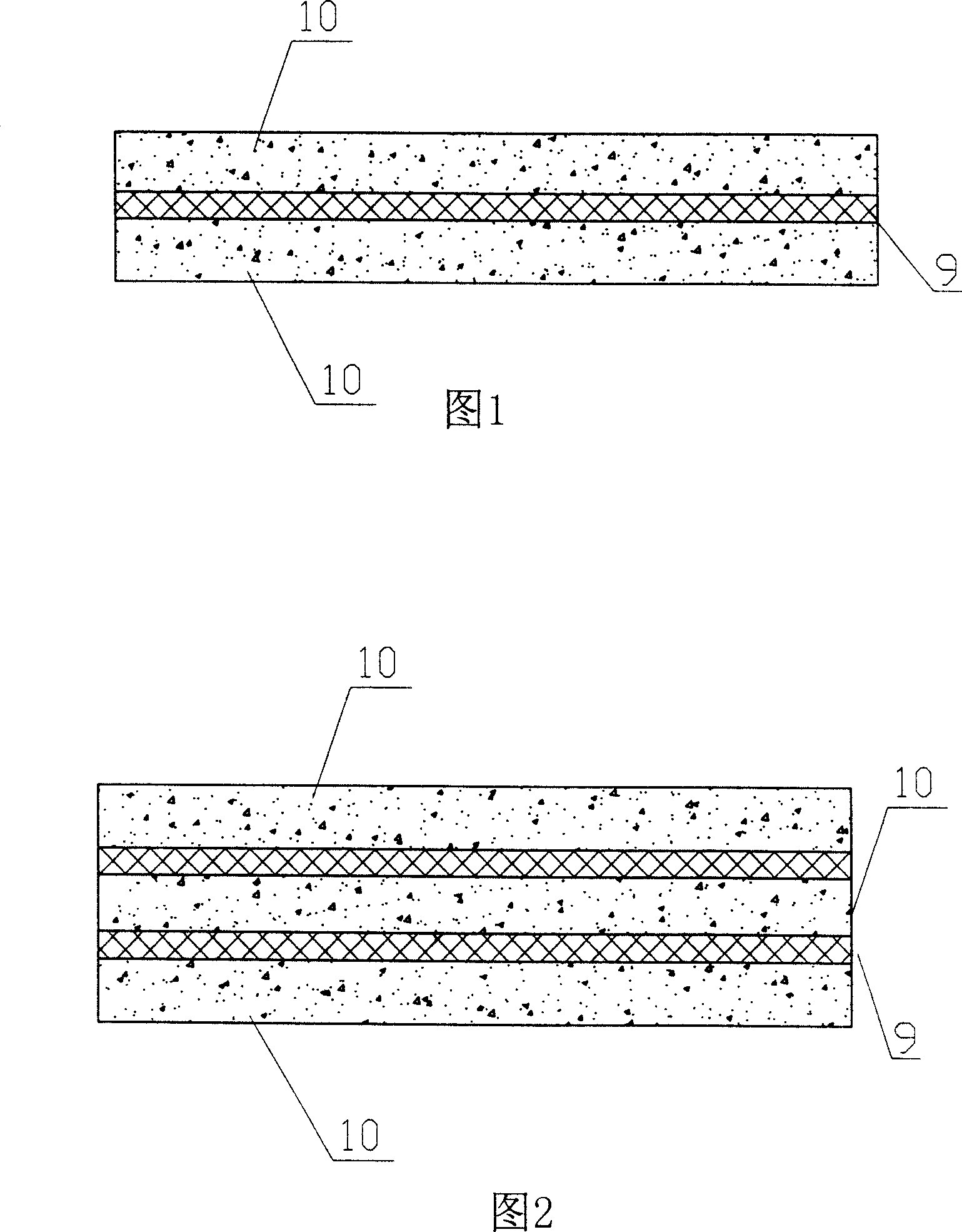

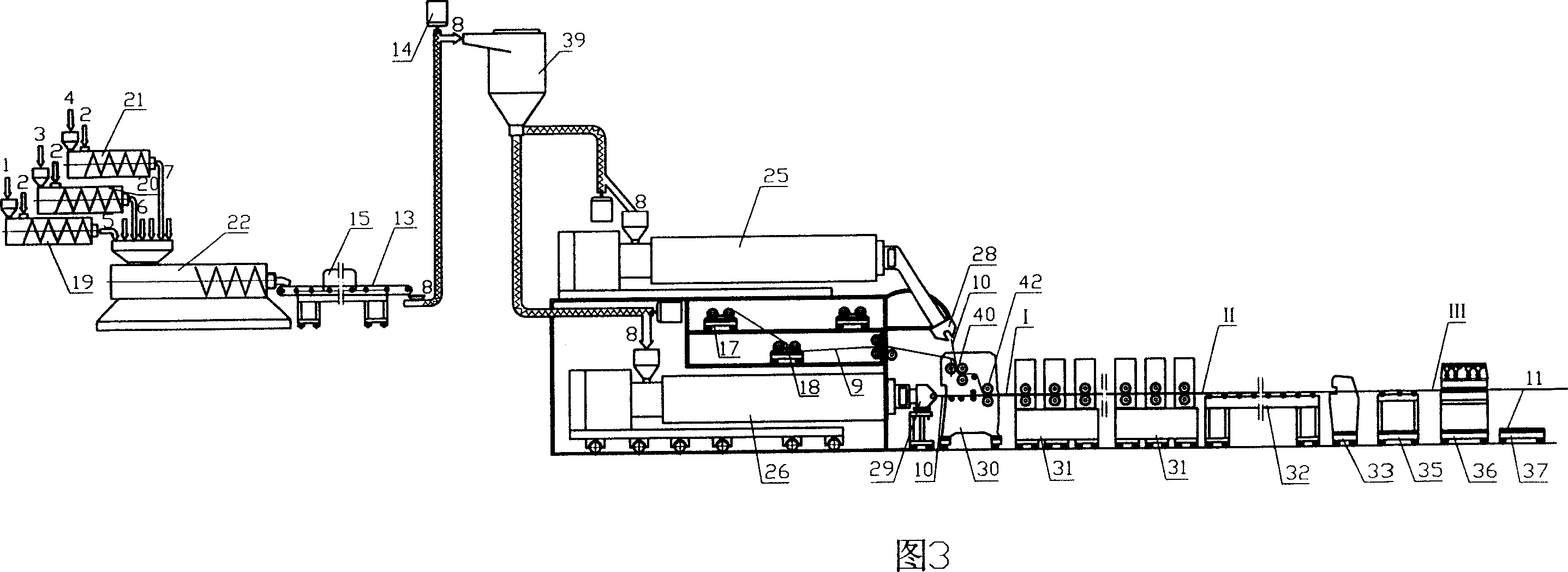

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

Water-soluble insulating varnish and preparation method thereof

InactiveCN101270256AGood transparency and stabilityLong application periodPolyurea/polyurethane coatingsEmulsion paintsWater basedDiluent

The invention relates to water-soluble insulating varnish and a preparation method thereof. The water-soluble insulating varnish of the invention consists of water-soluble resin, water-borne curing agent, water-base defoamer, water-base flow agent, water-base catalyst and water; the proportion of the components is as below: 30 percent to 50 percent of water-soluble resin; 10 percent to 30 percent of water-base curing agent, 1 percent to 1.0 percent of water-base catalyst, 0 percent to 0.5 percent of water-base defoamer, 0 percent to 0.5 percent of water-base flow agent and 20 percent to 60 percent of water; the water-soluble insulating varnish has the advantages of environmental protection and safety; no harmful solvent released to the atmosphere; no inflammability and explosion, no corrosion; no transparent or translucent paint liquid, good stability, long application service life under normal temperature; simple solidifying process, good insulating performance of the paint film after solidification, high strength and strong toughness; technical indexes meeting or exceeding the technical indexes of the prior solvent-type insulating varnish; the most important is that the insulating varnish takes water as solvent or diluent, which does not bring pollution and reduces the cost.

Owner:SHANGHAI BAOQING TONGYONG ELECTRICAL

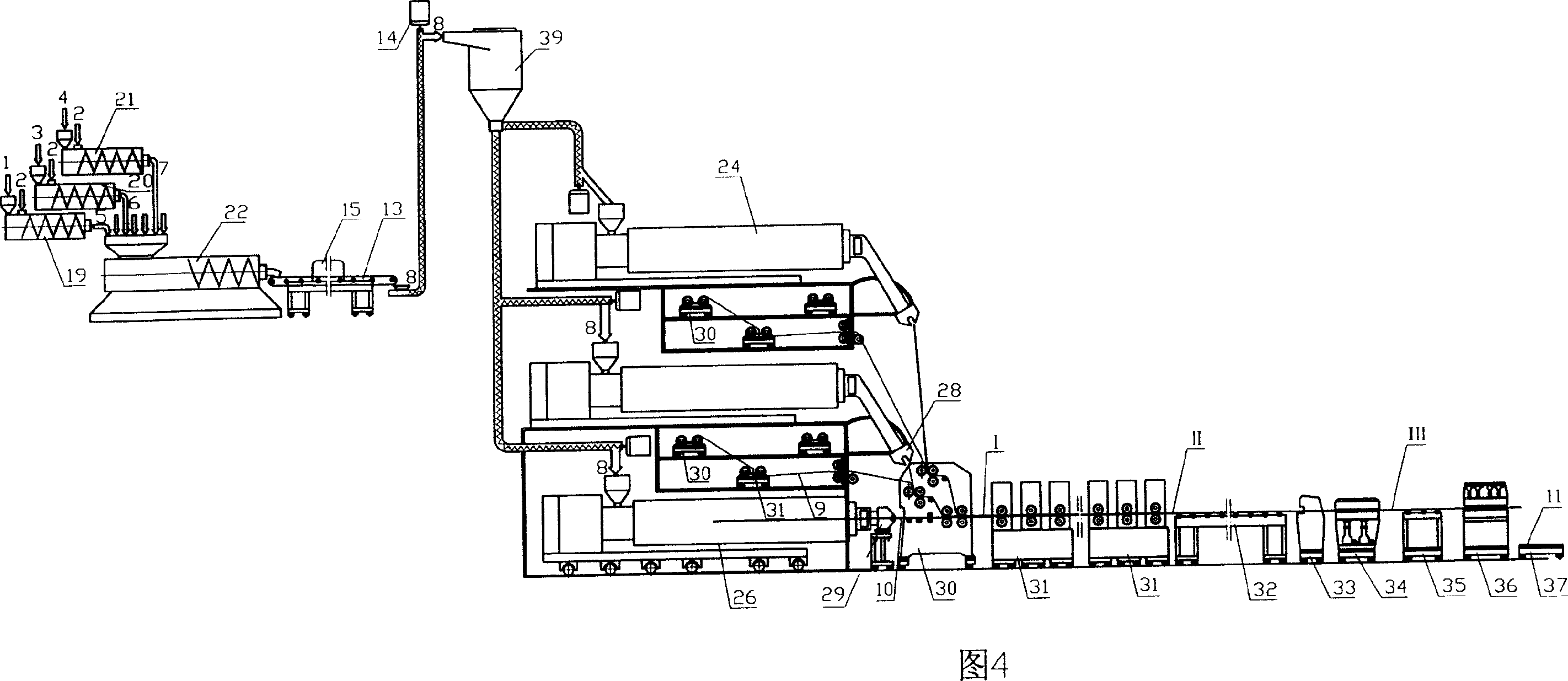

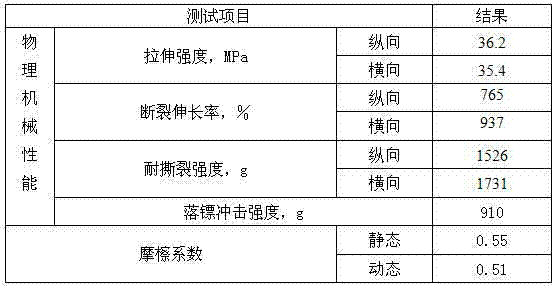

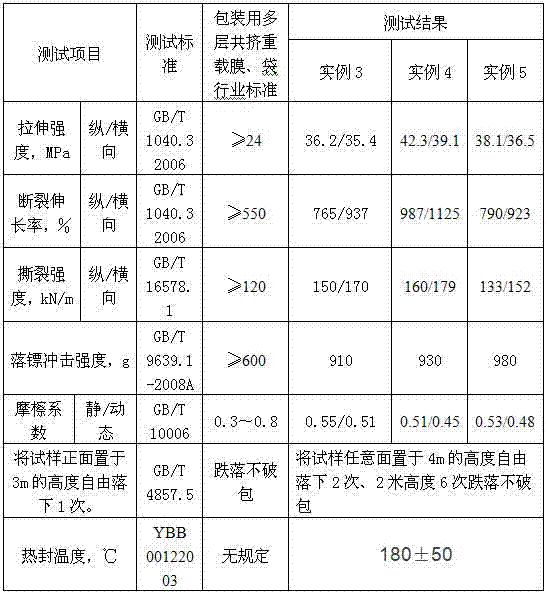

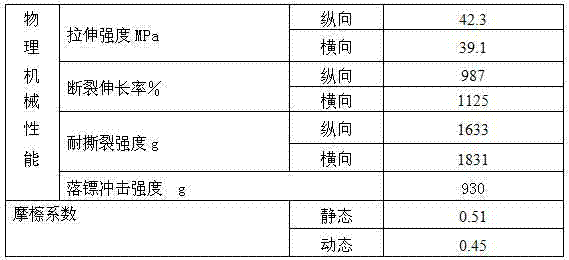

Three-layer coextrusion heavy packaging membrane and fabrication method thereof

The invention relates to the technical field of heavy packaging membranes, in particular to a three-layer coextrusion heavy packaging membrane and a fabrication method thereof. An inner layer of the three-layer coextrusion heavy packaging membrane contains LLDPE (linear low density polyethylene) and m-LLDPE (metallocene-linear low density polyethylene); a middle layer thereof contains m-LLDPE, LLDPE, MDPE (medium density polyethylene), EVA (ethylene-vinyl acetate) and a color masterbatch; and an outer layer thereof contains LLDPE, LDPE (low density polyethylene) and m-LLDPE. The fabrication method of the three-layer coextrusion heavy packaging membrane adopts the proportioning, and a product is fabricated on a certain technological condition. Compared with the prior art, the membrane has the characteristics that the membrane is excellent in mechanical property and good in deflexion; a skin-friction coefficient of the membrane is moderate; and a heat-seal window can reach 180 minus / plus 50 DEG C. The membrane can fully meet the requirement of normal use of downstream packaging, is particularly suitable for high-speed FFS (form-fill-seal) packaging, and has a good economic benefit and a social benefit.

Owner:GUANGDONG SUNION CHEM & PLASTIC

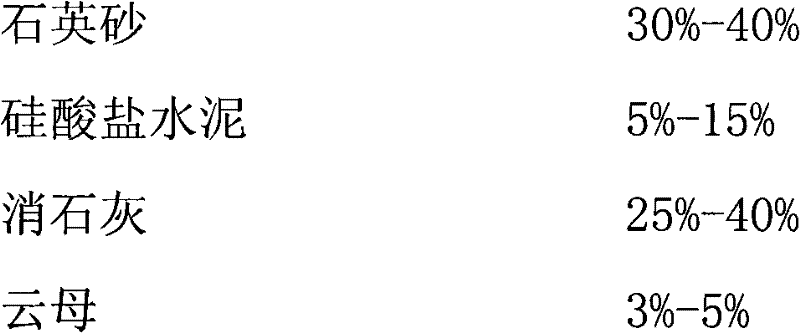

Novel thermal insulation fireproof wall calcium silicate board and preparation method thereof

InactiveCN102515675AGood stabilityStrong elasticity and toughnessCeramic shaping apparatusThermal insulationMica

The invention discloses a novel thermal insulation fireproof wall calcium silicate board and a preparation method thereof. The novel thermal insulation fireproof wall calcium silicate board comprises the following components in percentage by mass: 30-40% of quartz sand, 5-15% of portland cement, 25-40% of slaked lime, 3-5% of mica, 8-13% of vermiculite and 7-8% of wood pulp fiber. The preparation method comprises the following steps of: preparing raw materials by using all the components in percentage by mass; shredding paper; pulping; discharging pulp; forming; carrying out three-working-position operation; demoulding; autoclave curing; drying; and sanding to obtain the novel thermal insulation fireproof wall calcium silicate board. The novel thermal insulation fireproof wall calcium silicate board remains the favorable universality of a calcium silicate board and has an extremely low coefficient of heat conduction. The coefficient of heat conduction of the novel thermal insulation fireproof wall calcium silicate board provided by the invention is (31+273)K, 0.154W / mk; (100.5+273)K, 0.164W / mk.

Owner:宁波易和绿色板业有限公司

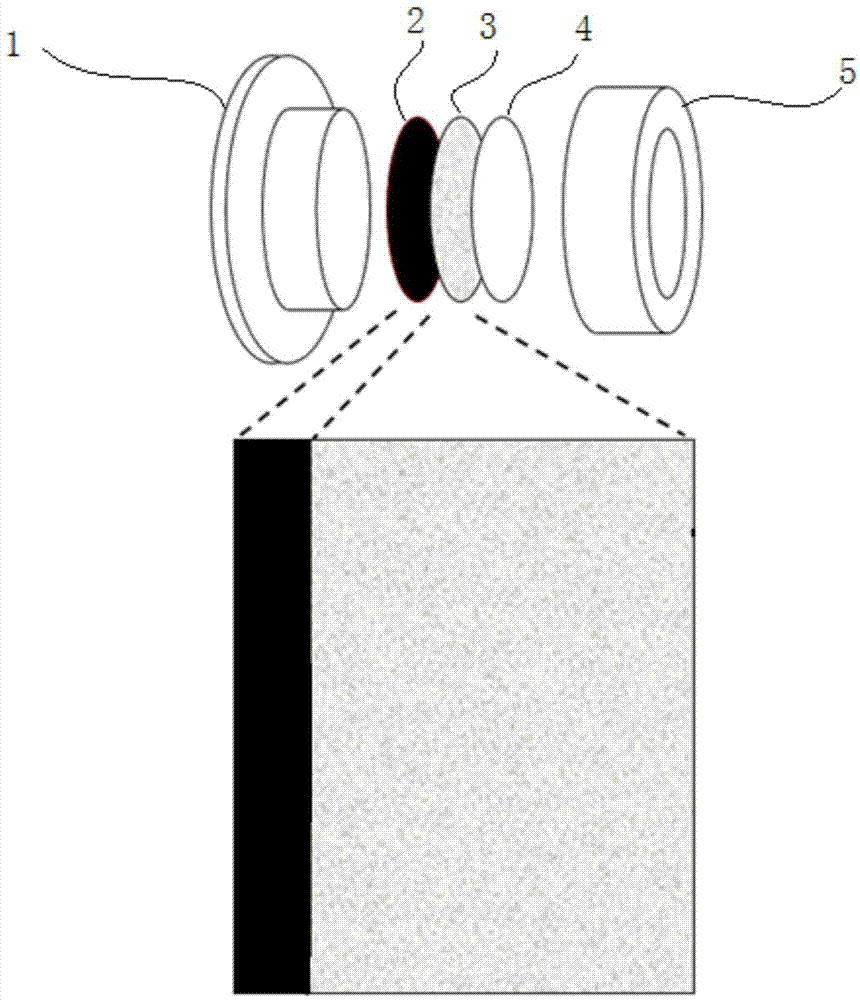

Preparation method of activated carbon adsorption film and method for measuring bisphenol substances in wetland soil or sediment based on thin-film diffusion gradient technique

InactiveCN104492376AStrong toughnessLarge adsorption capacityOther chemical processesComponent separationSorbentBisphenol

The invention discloses a preparation method of an activated carbon adsorption film and a method for measuring bisphenol substances in wetland soil or sediment based on a thin-film diffusion gradient technique, and belongs to the fields of environmental sciences and earth sciences. According to the preparation method of the activated carbon adsorption film, the activated carbon adsorption film is prepared by mixing activated carbon as an adsorbent with agar, and then is overlapped on an agar diffusion film and a PTFE filter film to form a DGT device; after nitrogen introduction pretreatment, the DGT device is put into the wetland soil or the sediment to be tested for 24 hours, and then the activated carbon adsorption film is taken out and eluted by use of an eluent which is the mixed solution of methanol and sodium hydroxide; next, the adsorbing capacity of the bisphenol compounds in the adsorption film is measured and the concentration of the bisphenol substances in the wetland soil or the sediment is calculated according to the Fick's first law of diffusion. The preparation method of the activated carbon adsorption film is simple in process, the adsorbent is even in distribution, the adsorbing capacity is high and the quality guarantee period is long; the DGT technique based on the adsorption film is simple and easy to operate and the testing result is representative, and therefore, the DGT technique is suitable for in-situ detection of the bisphenol substances in the wetland soil or the sediment.

Owner:NANJING UNIV

Method for recycling zirconium oxide and yttrium oxide from yttrium oxide steady zirconium oxide solid fused mass waste matter

ActiveCN101244843ASignificant progressTo achieve the effect of resource utilizationRare earth metal compoundsZirconium oxidesZirconium hydrideYttria-stabilized zirconia

The invention relates to a method for recovering zirconia and yttria from the yttria-stabilized zirconia solid solution waste, which comprises the following steps: mixing the solid solution waste powder, sulfate and salt; acidizing and calcining at 200 to 320 DEG C; leaching the acidizing water and / or mother liquor under self-heating conditions; concentrating the leaching solution to leach zirconium sulfate; dissolving the zirconium sulfate in the water and purifying; neutralizing the zirconium hydroxide with alkali and precipitating; calcining the zirconium hydroxide to obtain zirconia; precipitating zirconium mother liquor to produce by-product of ammonium sulfate; neutralizing yttrium rich mother liquor and precipitating to obtain yttrium; dissolving yttrium rich residue with acid and purifying; precipitating oxalate to obtain yttrium oxalate; calcining to obtain the yttria. The method has the advantages of effectively separating the yttria from the zirconia in stable zirconia solid solution waste with optional yttrium ion under low temperature condition, changing the zirconia solid solution waste into valuables and utilizing the resources.

Owner:SHANDONG LEIBAO ZIRCONIUM SCI&TECH

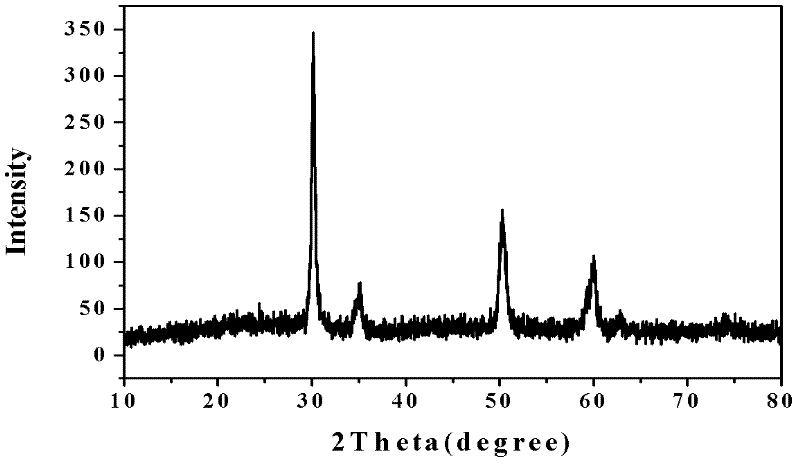

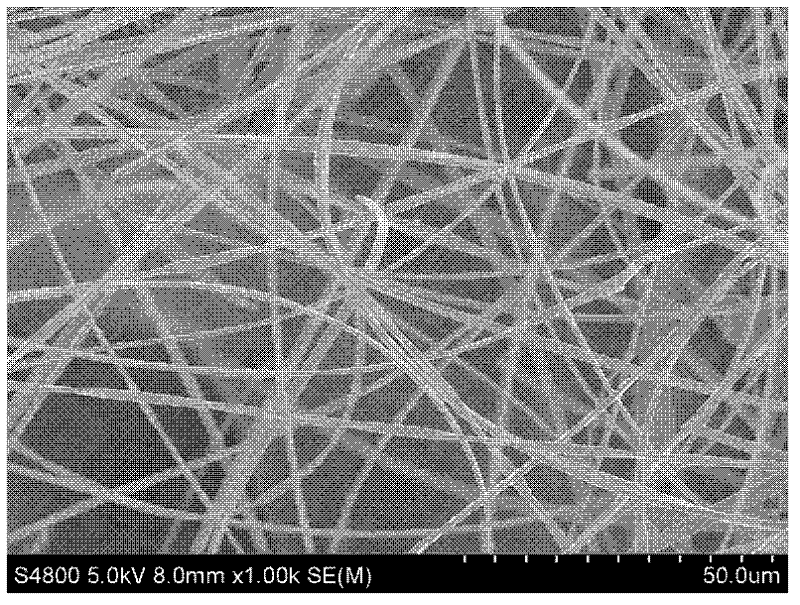

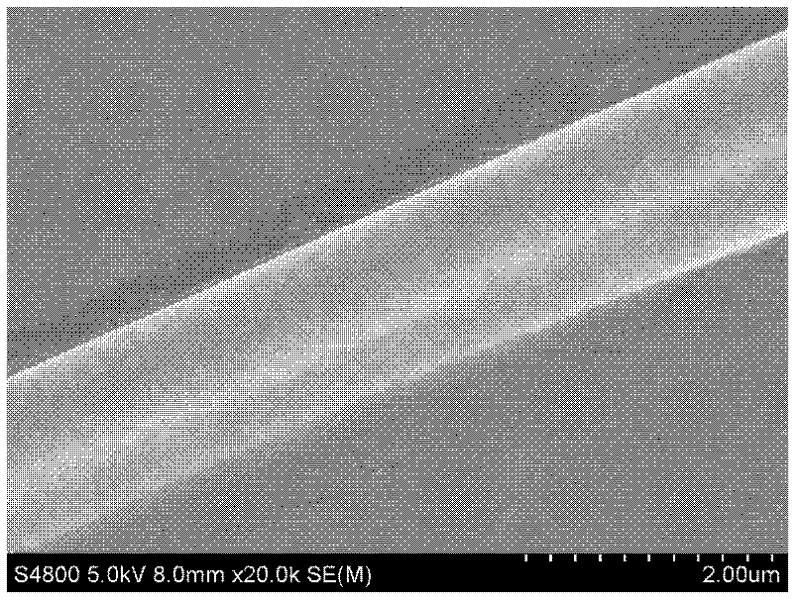

Flexible yttrium stable zirconium oxide ceramic fiber and preparation method thereof

The invention relates to a flexible yttrium stable zirconium oxide ceramic fiber and a preparation method thereof. The particle diameters of zirconium oxide particles constructing the ceramic fiber are 10-400 nanometers, the diameter of the ceramic fiber is 0.5-3 mum, and the fiber is uniform and continuous, is prevented from being broken easily and has high flexibility. A zirconium oxide gel fiber is prepared by combining a sol-gel method with an electrostatic spinning technology, and the yttrium stable zirconium oxide ceramic fiber is obtained by calcining the gel fiber. The obtained yttrium stable zirconium oxide ceramic fiber has high thermal stability and excellent mechanical property, can be taken as a high-temperature catalyst carrier, a high-temperature heat insulating material aswell as a battery membrane, and can be applied to high-temperature filtering and the like. A process disclosed by the invention has high operability, and is suitable for large-scale production.

Owner:SHANDONG UNIV

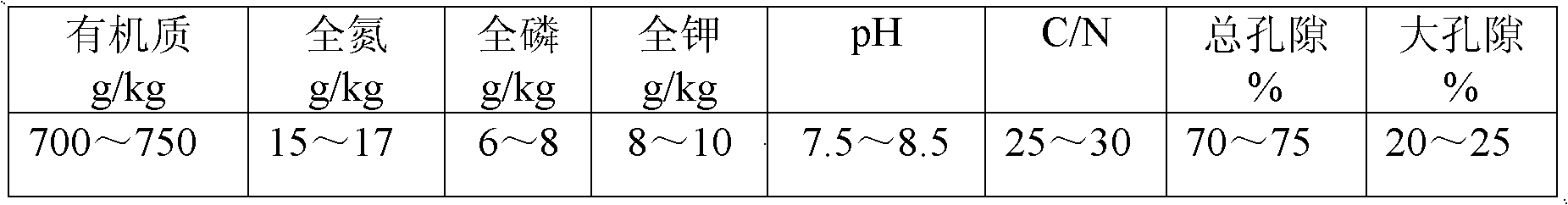

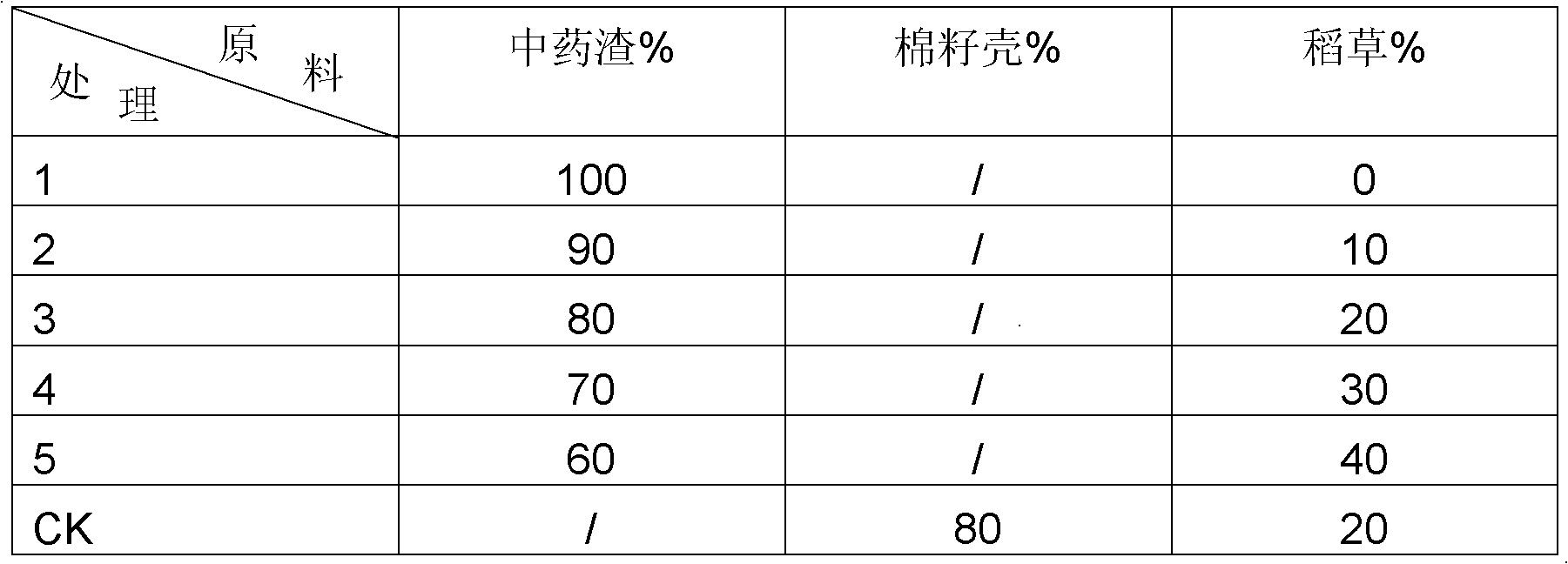

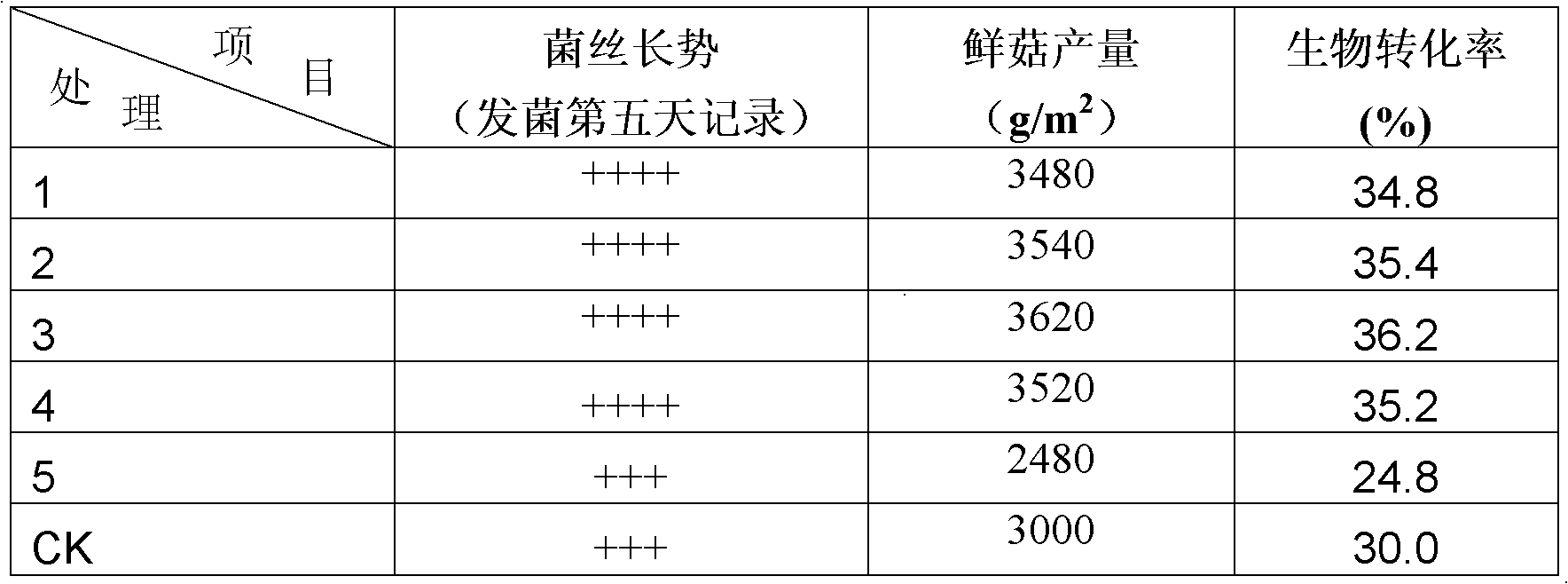

Straw mushroom culture medium and method for circularly cultivating straw mushrooms

InactiveCN102173949ANo pollutionImprove ventilationHorticultureFertilizer mixturesBiotechnologySulfate

The invention discloses a straw mushroom culture medium and a method for circularly cultivating straw mushrooms. The straw mushroom culture medium comprises 70 to 90 weight percent of Chinese medicament dreg, 10 to 30 weight percent of straws and a production increasing agent with the dose of 5 to 10 kg / m<3>, wherein the production increasing agent is prepared by mixing the following components in percentage by weight: 0.006 to 0.01 percent of vitamin B1, 15 to 20 percent of superphosphate, 40 to 60 percent of quick lime, 1.5 to 2 percent of magnesium sulfate, 0.2 to 0.4 percent of zinc sulfate, 0.2 to 0.3 percent of boric fertilizer, 0.2 to 0.4 percent of triacontanol and 22 to 37 percent of starch. By the straw mushroom culture medium and the method for circularly cultivating the straw mushrooms, resources can recycled; energy is saved due to short fermentation time of the medium; the medium can increase yield of the straw mushroom, can improve the quality of the straw mushroom and can increase the flavonoid content of the straw mushrooms; and by the multi-time circularly cultivating method, the utilization ratio of the medium is increased and production cost is reduced.

Owner:NANJING INST OF VEGETABLE SCI

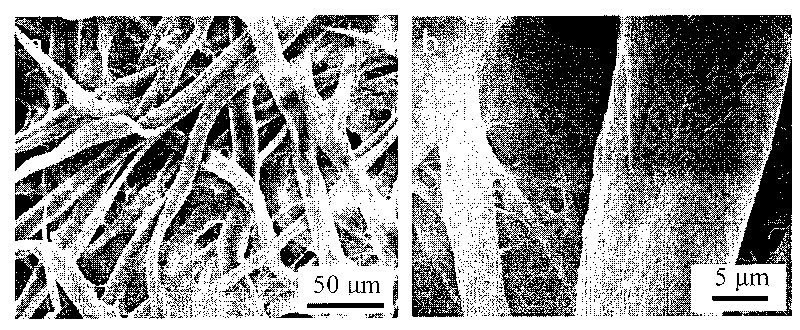

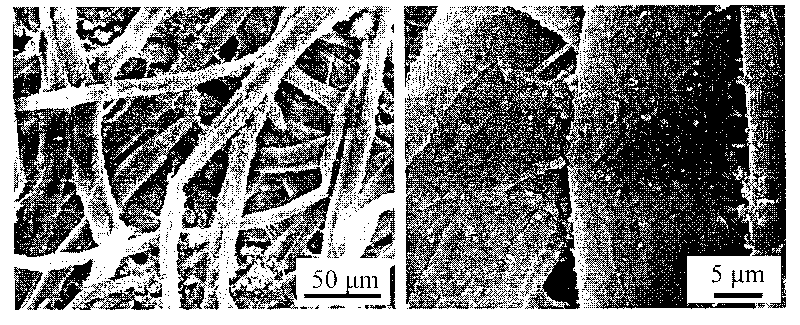

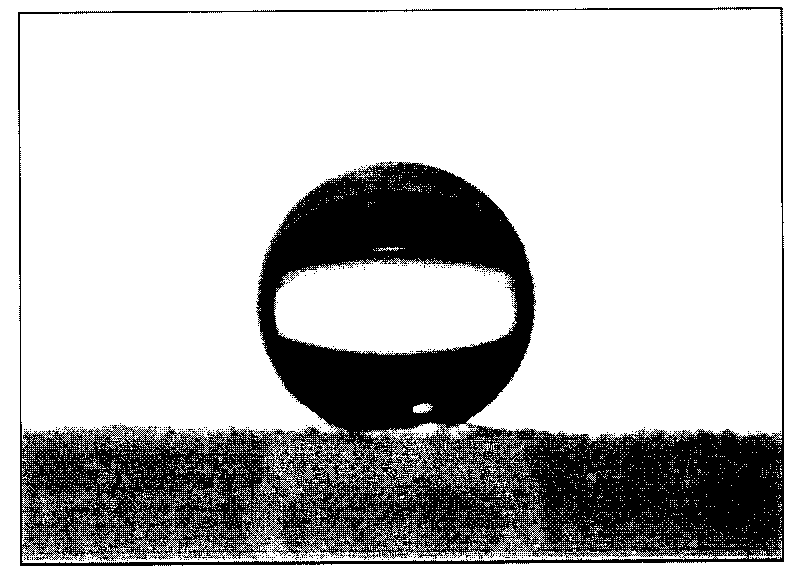

Method for preparing super-hydrophobic nano modified cellulose material

InactiveCN101694057AStrong toughnessHigh mechanical strengthDry-cleaning apparatus for textilesVegetal fibresCellulose fiberNatural fiber

The invention relates to a method for preparing a super-hydrophobic nano modified cellulose material, which comprises the following steps: adopting tetrabutyl titanate as a precursor, adopting a natural cellulose fiber as a substrate substance and depositing a nano-layer titanium dioxide film on the surface of the natural cellulose fiber by a sol-gel method; and then self-assembling a silane single layer containing long chain alkyl to obtain the super-hydrophobic nano modified cellulose material. The nano modified cellulose material has obvious super-hydrophobicity, durable chemical stability and self-cleaning capacity and wide application prospect in the production of the fiber materials for preventing water, damp, dirt, dust, and the like in a textile industry.

Owner:ZHEJIANG UNIV

Ring forging and rolling processing method of bearing ring parts used for large-scale wind turbine unit

The invention discloses a ring forging and rolling processing method of bearing ring parts used for a large-scale wind turbine unit. The technical scheme of the invention is that the processing method comprises the following steps: (1) blanking; (2) heating by a first heating number; (3) forging and making a blank forming; (4) heating by a second heating number; (5) chambering and reforming; (6) heating by a third heating number; (7) carrying out diameter expansion and ring rolling; (8) cutting two connected bearing ring part workblanks which are obtained in the step (7) to obtain a single workblank; and (9) thermally treating: normalizing, quenching and tempering. The processing method disclosed by the invention has the following beneficial effects: compared with the prior art, four heating numbers are decreased to three heating numbers; two ring parts can be obtained by one-time rolling and expanding processing through the improvement of a mold, so that the production efficiency is improved, the cost is lowered, and good combination property of a flange is ensured; and the bearing ring parts processed by the processing method of the invention have high strength, good hardenability, strong toughness, small deformation in the quenching, and stronger creep strength and persistent strength at the high temperature, and are applied to a large-scale wind turbine unit in a severe environment.

Owner:SHANDONG IRAETA HEAVY IND

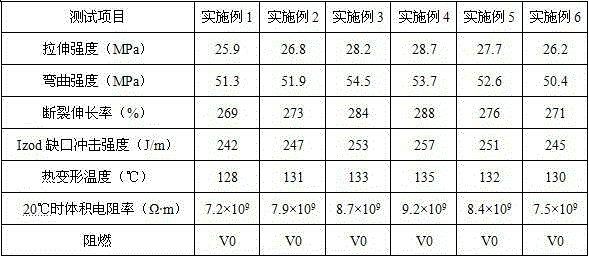

Waste PVC (Polyvinyl Chloride) and fly ash composite material and preparation method thereof

The invention relates to the technical field of PVC (Polyvinyl Chloride) composite materials and particularly relates to a waste PVC and fly ash composite material and a preparation method thereof. The waste PVC and fly ash composite material comprises the following raw materials according to parts by weight: 80-120 parts of waste PVC, 35-55 parts of fly ash, 3-10 parts of plasticizer, 1-2 parts of flame retardant, 0.5-2 parts of stabilizer, 0.5-2 parts of impact modifier, 0.3-1 part of lubricant and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps of: weighing all the raw materials according to the parts by weight, mixing, stirring, extruding through a twin-screw extruder for granulation, chopping and air-cooling to obtain the waste PVC and fly ash composite material. The waste PVC and fly ash composite material prepared by the preparation method has excellent heat resistance, high strength, good flame retardant effect, high compression performance and toughness, and excellent processing performance and comprehensive performance; and the additive amount of renewable resources in the waste PVC and fly ash composite material reaches 90%-95%, thus lowering the production cost, reducing the environmental pollution, and bringing good economic benefit and social benefit.

Owner:广东祺龙科技有限公司

Shield tail seal grease of shield excavating machine

The invention discloses a shield tail seal grease of a shield excavating machine, which is used for passing through sand soil, rivers and lakes in the process of excavating construction of an underground project. The shield tail seal grease is combined by the following raw materials in parts by weight: 15-25 parts of plant oil, 15-25 parts of viscosity index modifying agents, 50-60 parts of stuffing, 5-10 parts of thickening agent, 0.8-1.2 parts of mildewproof agents, 0.5-1.0 part of wet dispersing agents and 2-6 parts of bamboo fibres. The seal grease has good seal performance and pumping ability and no pollution to the environment, can particularly play a favorable seal role in the sand soil or a deeper soil layer with more water content and solve the problem of easy slurry leakage or large dosage in the sand soil, which commonly exists in the grease in the current market.

Owner:SHANGHAI CIFU NEW BUILDING MATERIALS CO LTD

High strength concrete and preparation method thereof

InactiveCN105367026AHigh strengthSolution to short lifeSolid waste managementHigh strength concreteAggregate (composite)

The invention discloses high strength concrete and its preparation method, and relates to the technical field of building materials. 1 m<3> of the high strength concrete comprises the following ingredients: 200-300 kg of ordinary Portland cement, 40-50 kg of mineral powder, 15-30 kg of rubber particles, 500-800 kg of fine aggregate, 600-900 kg of coarse aggregate, 20-60 kg of a concrete composite additive, 50-100 kg of polypropylene fiber, 100-200 kg of water, 45-90 kg of phosphorous slag powder, 2-3 kg of a corrosion inhibitor, 5-10 kg of a water reducing agent, and 10-20 kg of a reinforcing agent. According to the prepared concrete product, compressive strength is remarkably raised, cracks are minimized, and life of concrete structures is prolonged. In addition, the preparation method is simple, and production efficiency is high.

Owner:张进

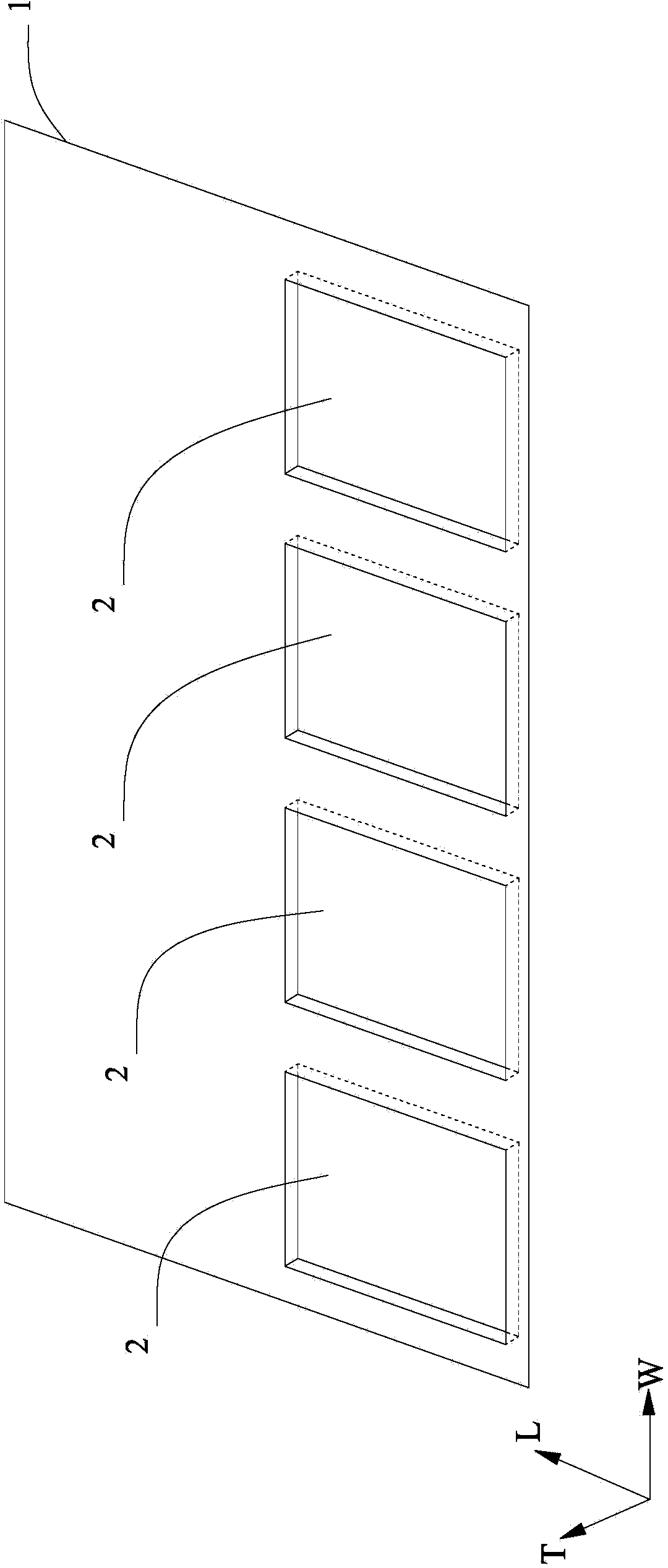

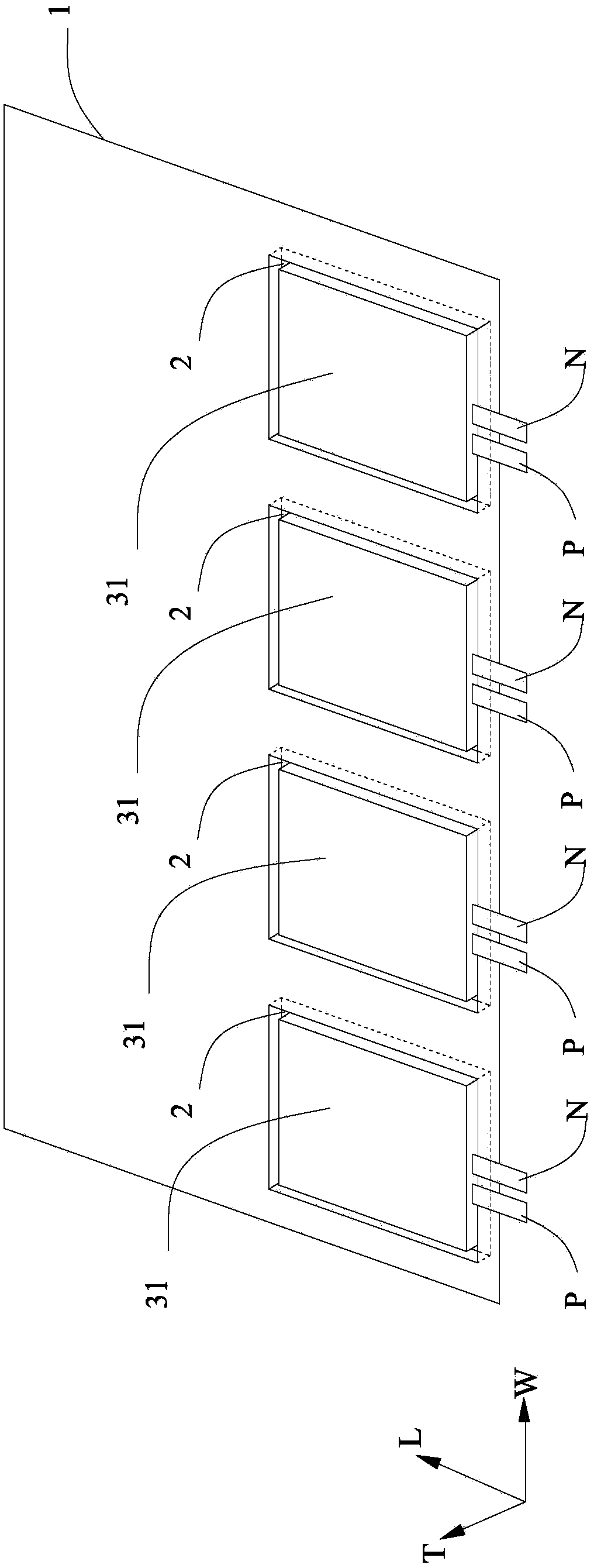

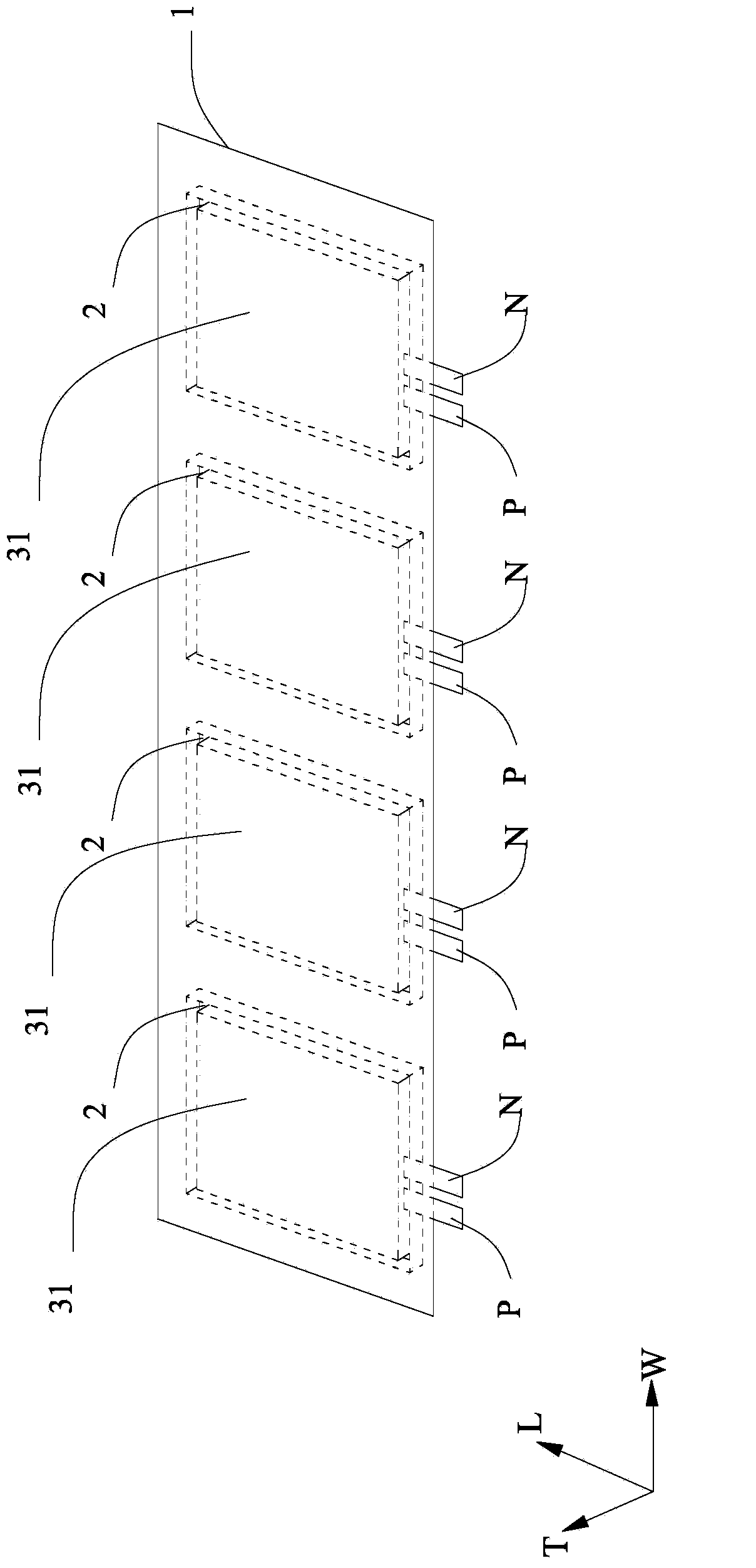

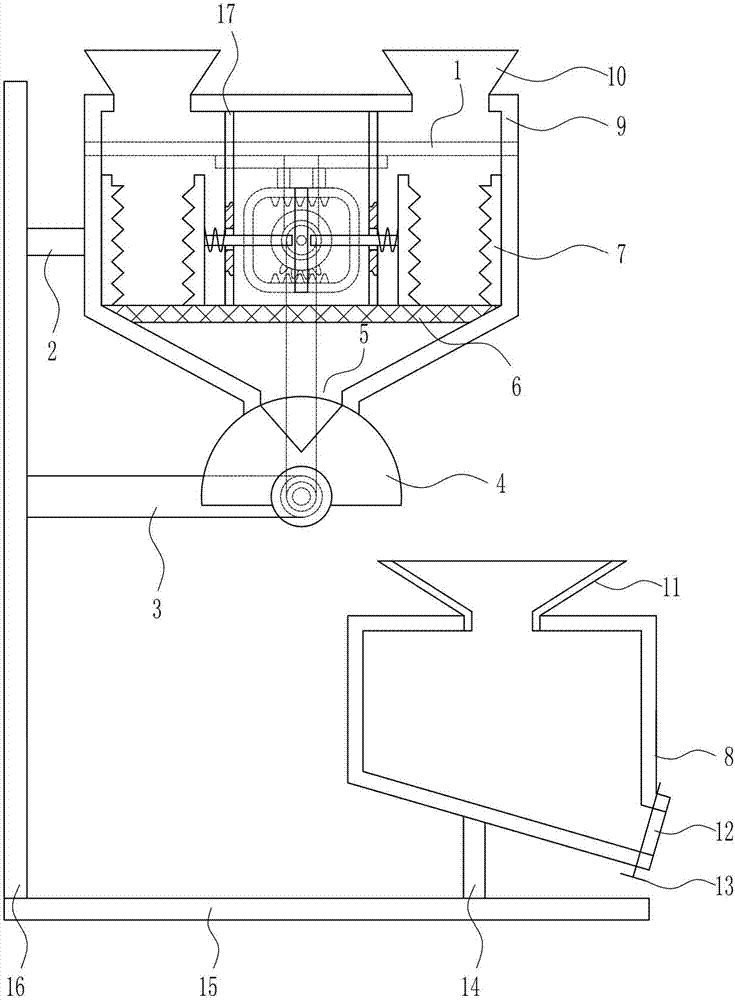

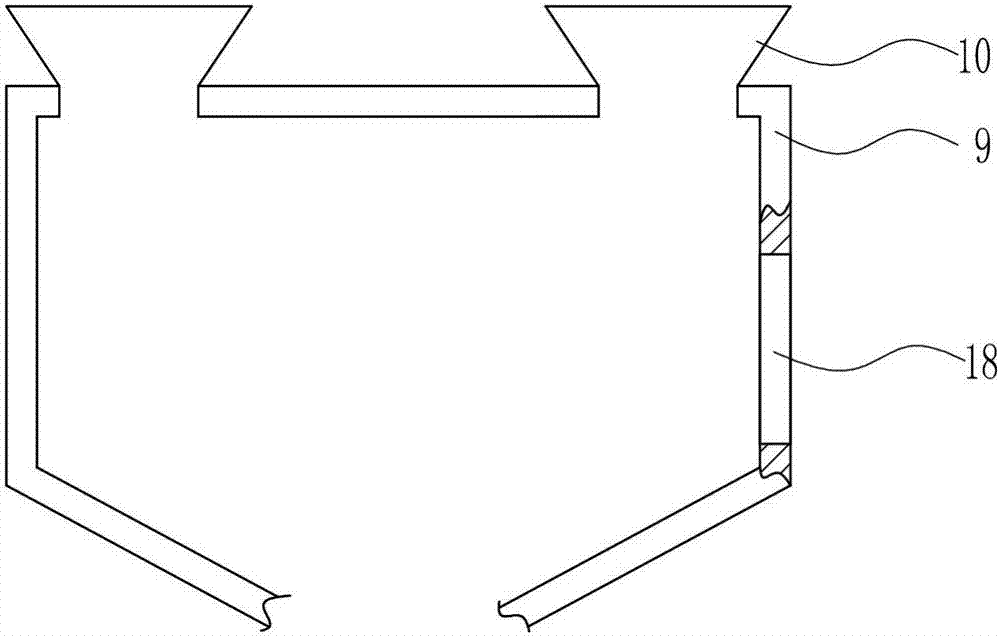

Flexible battery pack and preparation method thereof

ActiveCN103824985AStrong toughnessHigh fatigue strengthFinal product manufactureBattery isolationPlastic filmSilica gel

The invention provides a flexible battery pack and a preparation method thereof. The flexible battery pack comprises an aluminium plastic film, a plurality of batteries and a plurality of silica gels, wherein a plurality of scouring pits are arranged on the aluminium plastic film along the width direction; each battery is hermetically arranged in each scouring pit on the aluminium plastic film and is provided with a cell, a positive electrode tab, a negative electrode tab and injected electrolyte, the positive electrode tabs of the batteries are connected together, the negative electrode tabs of the batteries are connected together, and the adjacent batteries are isolated from each other; each silica gel is bonded with the aluminium plastic film parts on the sides of the scouring pits of the adjacent batteries on the two sides of the silica gel and the aluminium plastic film parts between the scouring pits of two adjacent batteries via glue. The flexible battery pack has the beneficial effects that the buckling capacity of the battery pack can be improved by adopting the silica gels, so that the safety of the batteries in the flexible battery pack can be improved; meanwhile, the silica gels are arranged outside the aluminium plastic film and the released stress is transferred from the silica gels to the aluminium plastic film when the aluminium plastic film deforms, therefore, the force finally borne by the aluminium plastic film is reduced, thus being more beneficial for the flexibility of the battery pack.

Owner:DONGGUAN AMPEREX TECH

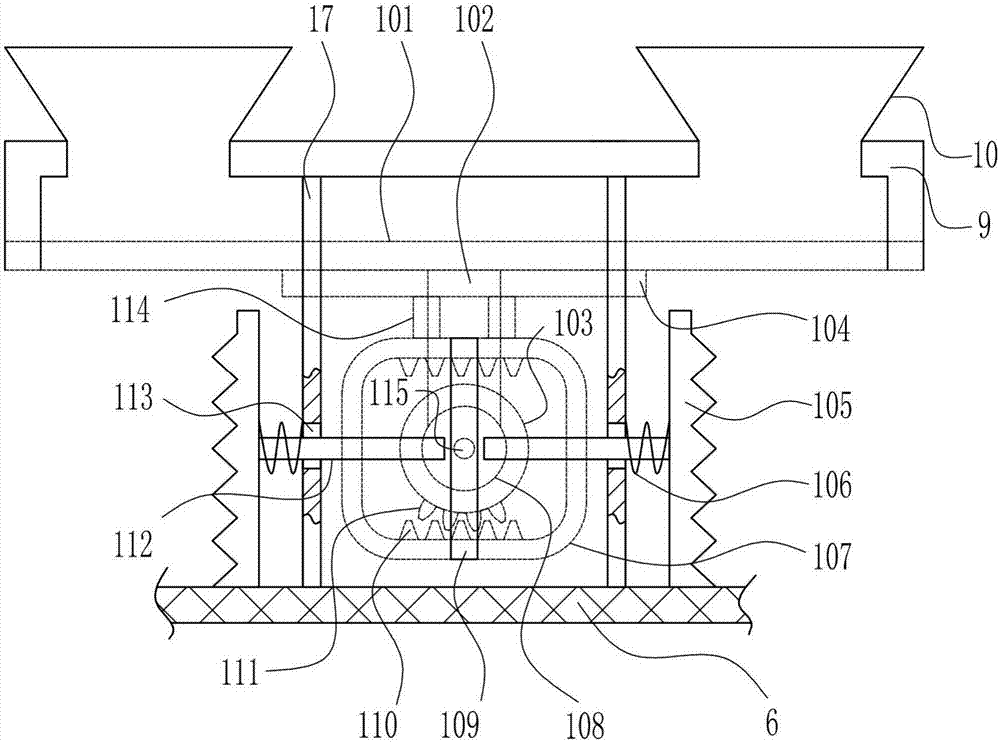

Efficient shell crushing device for electronic technology

InactiveCN107511954AEfficient and convenient recyclingAccelerate secondary rolling workPlastic recyclingGrain treatmentsEngineeringExtrusion

The invention relates to a crushing device, in particular to an efficient shell crushing device for an electronic technology. The technical problem to be solved by the invention is to provide the efficient shell crushing device for the electronic technology with high crushing efficiency, fine crushing and preferable development of the subsequent work. In order to solve the technical problem, the invention provides the efficient shell crushing device for the electronic technology. The device comprises an extrusion device, a first support rod, a second support rod, an emptying device, a first filter screen, a second crushing plate, a collecting box, a crushing box, a first feeding hopper, a second feeding hopper and the like; a left bracket is arranged on the left side of the top of a baseplate; the first support rod and the second support rod are arranged on the right side of the left bracket; and the crushing box is arranged at the right end of the first support rod. The device achieves the effects of high crushing efficiency, fine crushing and preferable development of the subsequent work, uses the extrusion device for extrusion crushing, and uses the emptying device for precise limit emptying.

Owner:钟苡苇

Compound double-wall corrugated pipe and preparation process thereof

InactiveCN101761710AIncreased ring stiffnessImprove toughnessFlexible pipesPolymer scienceEngineering

The invention discloses a compound double-wall corrugated pipe, which is prepared from the following components in part by weight: 100 parts of mixture of polythene and polypropylene, 3-10 parts of coupling agent, 3-10 parts of rigid particle, 2-6 parts of master batch, 2-6 parts of blue batch and 3-9 parts of defoaming agent. The preparation process comprises the following steps of: evenly mixing the components in a high-speed mixer; after evenly mixing in a cold mixer, extruding tubes by using a double-host single screw extruder; modulizing, vacuumizing and cooling the tubes to form; and fixing the length and cutting and packaging the tubes. With the blending and the modification of polypropylene and polythene and the use of the rigid particles, the compound double-wall corrugated pipe well solves the problem of strong and unyielding balance, i.e. the tubes has higher toughness while having high annular rigidity. The tubes are made of completely non-toxic raw material and have good sanitary performance as well as the characteristic of simple production process.

Owner:山东华信塑胶股份有限公司

Method for improving quality of kiwi fruit and special high-quality fruit comprehensive agents

The invention provides a method for improving quality of kiwi fruit and special high-quality fruit comprehensive agents. According to the method, a high-quality fruit agent No.1 capable of increasing color, sugar, hardness and yield and preventing diseases is used after fruit picking, before and after blooming an during base fertilizer application; a high-quality fruit agent No.2 capable of thickening cell walls and increasing cell density is used in a fruit swelling period, a fruit strengthening period and a fertilizer application period, wherein weight ration of the high-quality fruit agents No.1 and No.2 to water is 1:400-600, the high-quality fruit agent No.1 can be sprayed on leaves or applied to soil once after fruit picking, before and after blooming an during base fertilizer application, the high-quality fruit agent No.2 can be applied twice, once every a half month, in the fruit swelling period, the fruit strengthening period and the fertilizer application period. Through adoption of the method and the special high-quality fruit comprehensive agents, the internal quality and external fruit shape, color, storability and freeze injury resistance of kiwi fruit can be improved, the use is convenient, the cost is reduced, kiwi fruit trees become strong and can bloom and bear fruits easily, the quality of fruits is improved greatly, the disease resistance is enhanced and yellows can be prevented and controlled.

Owner:建宁县富农果蔬专业合作社

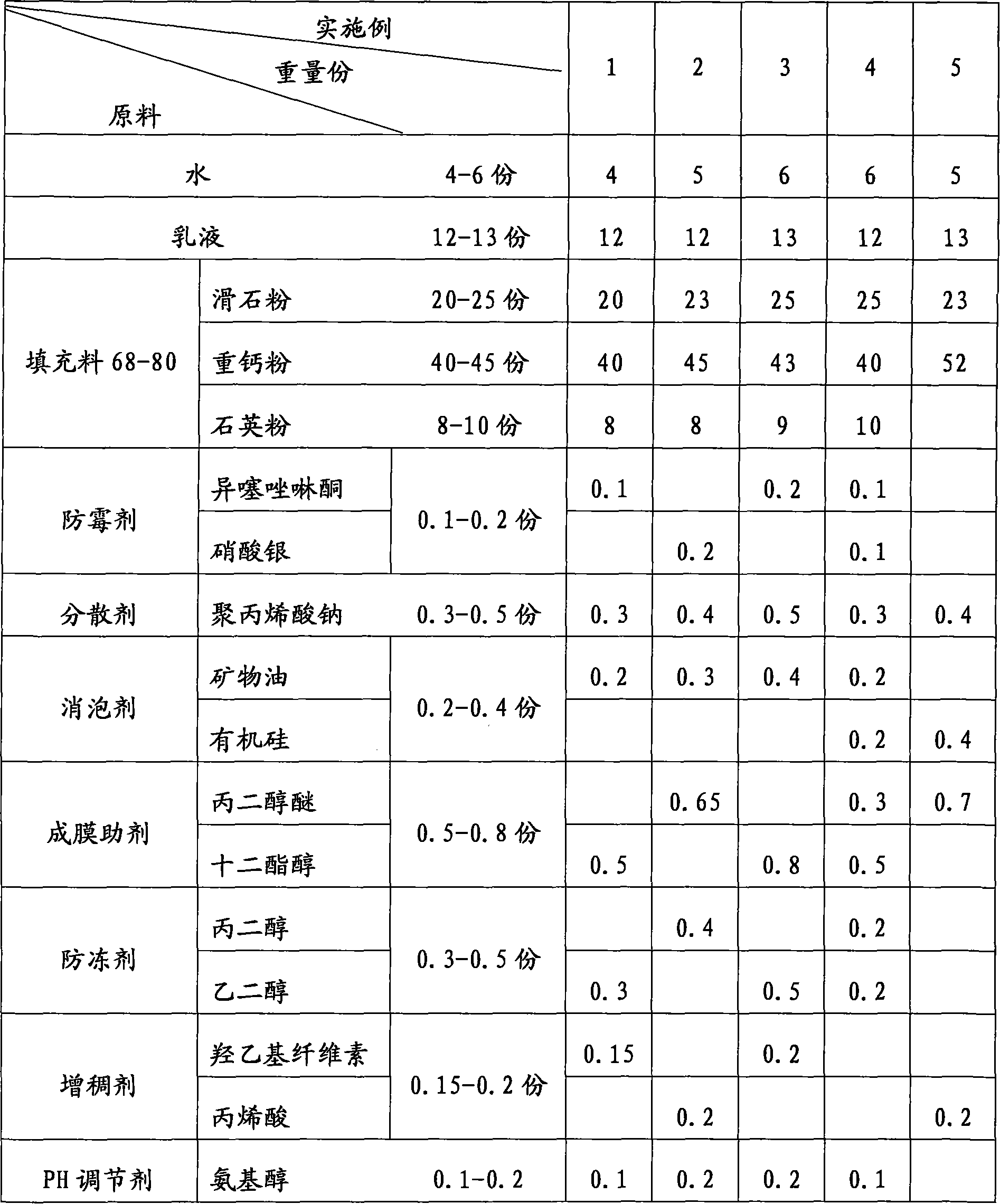

Method of producing and painting stone similar paint for flexible flat surface

InactiveCN101108943ANot easy to accumulate dustLow costLiquid surface applicatorsCoatingsEmulsionLacquer

A production method of a flexible stone-like paint is provided, which consists of the following raw materials and weight portion mixture ratios: 4 to 6 of water, 12 to 13 of waterborne pure acrylic acid emulsion, 68 to 80 of fillers and 0.65 to 2.8 addition agents. The method is that water, emulsion and addition agents are mixed first and are dispersed for 5min to 10min at medium speed, and are dispersed for 20min to 30min at low speed after adding the fillers; each half of antifoamers are added into the above two procedures respectively and are mixed with color and stirred evenly to form the stone-like paint. The wall is neatened first when painting and then sprayed by primer or rendered by roller coat, and tackiness paper tapes are stuck in grids; the stone-like paint is adopted to spray spots which are polished by abrasive paper after drying; the stone-like paint is adopted to level and polish twice until the spots are completely set off, to remove the dust and rip off the tackiness paper tapes and spray finishing varnish finally. The stone-like paint is applied in the decoration of the walls of construction or the table-board of the kitchens and toilets, and is beneficial for environment protection, light in quality and strong in toughness, which can be directly coated on the wall with surface low cost and energy-saving, therefore, the wall surface is not easy to store dust and the shapes and colors of the plane-imitating marble slab and the granite slab are lifelike.

Owner:浙江华特新材料有限公司

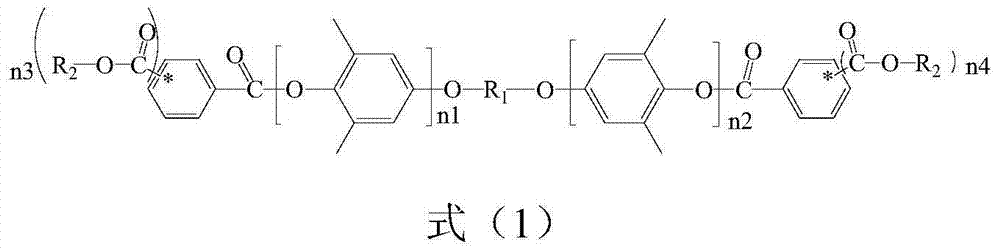

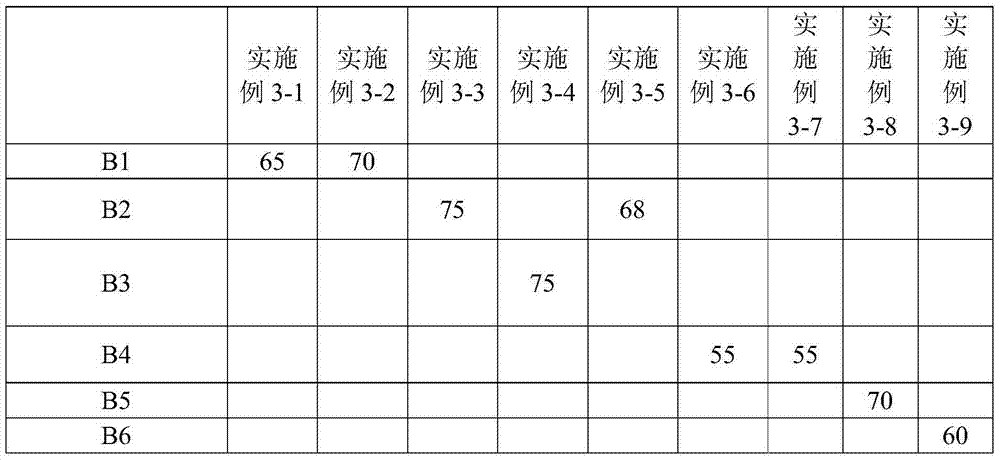

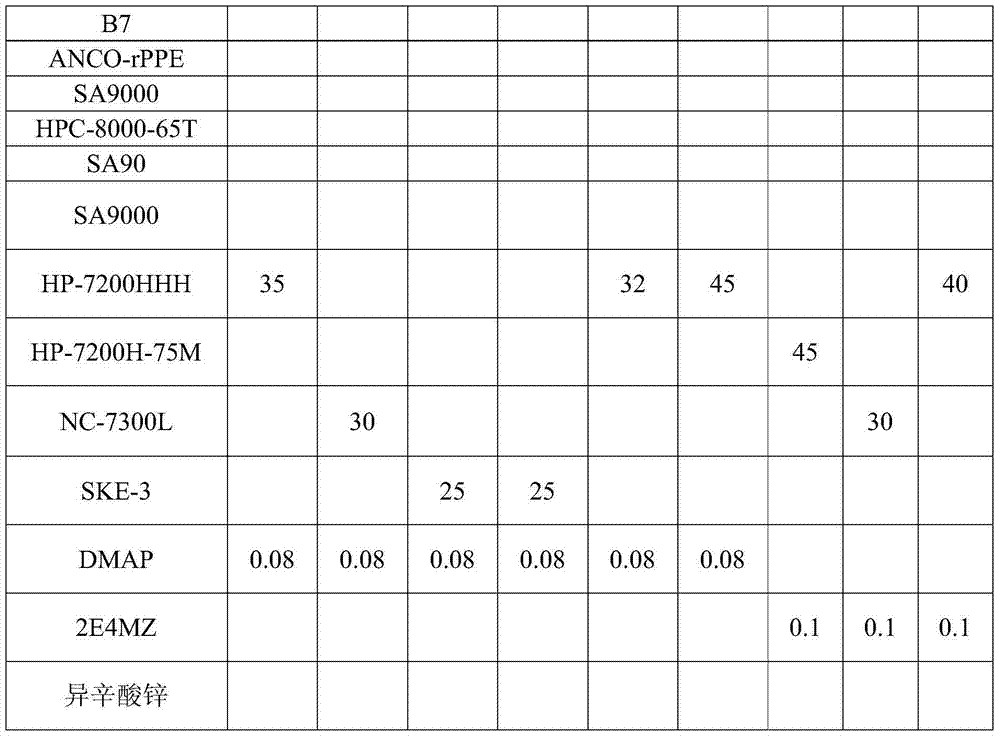

Active ester, thermosetting resin composition containing active ester, prepreg and laminated board

InactiveCN104761719AImprove heat resistanceStrong heat resistanceSynthetic resin layered productsPrinted circuit aspectsEpoxyHeat resistance

The invention provides active ester, a thermosetting resin composition containing the active ester, a prepreg and a laminated board. The active ester is a double-ended polyfunctional active ester containing a PPO main chain, and the thermosetting resin composition comprises epoxy resin and the double-ended polyfunctional active ester containing the PPO main chain. The prepreg, the laminated board and a copper-clad plate prepared from the thermosetting resin composition containing the double-ended polyfunctional active ester containing the PPO main chain has excellent dielectric properties, damp-heat resistance, heat resistance, extremely low water absorption and high bending strength.

Owner:GUANGDONG SHENGYI SCI TECH

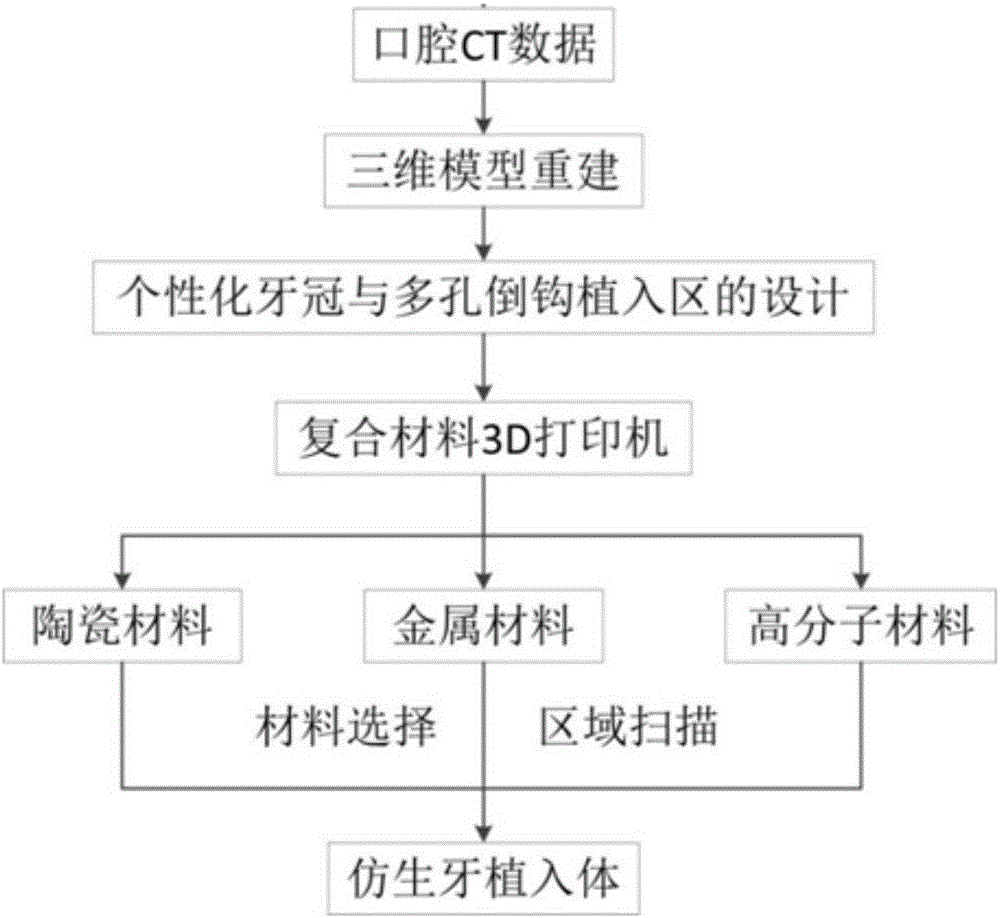

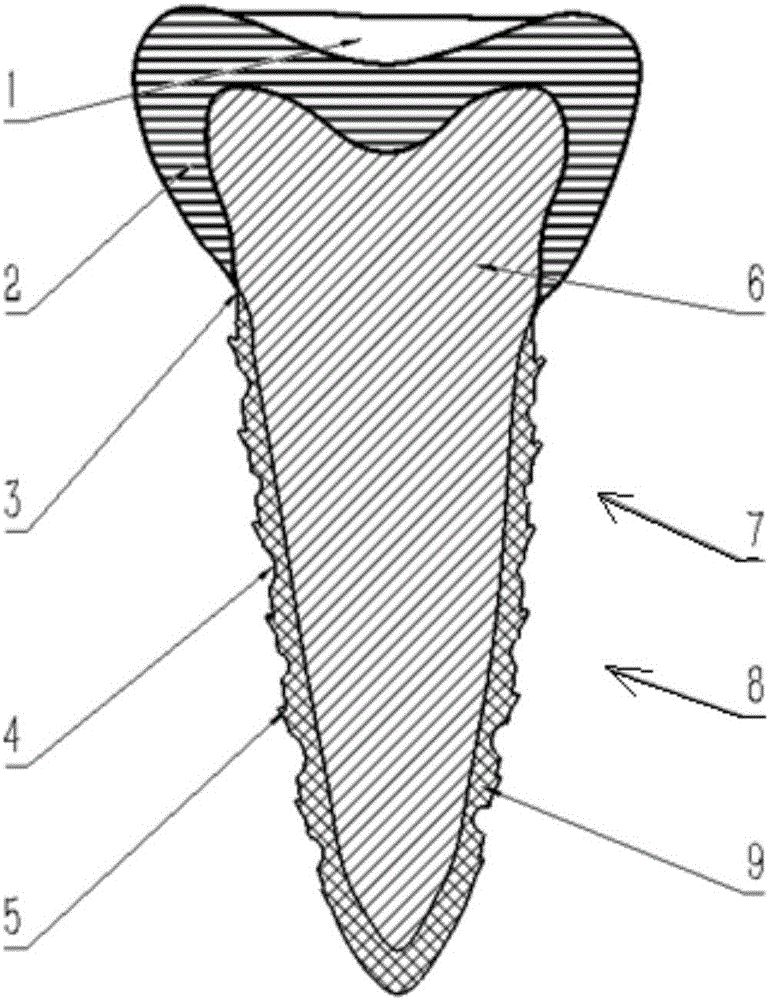

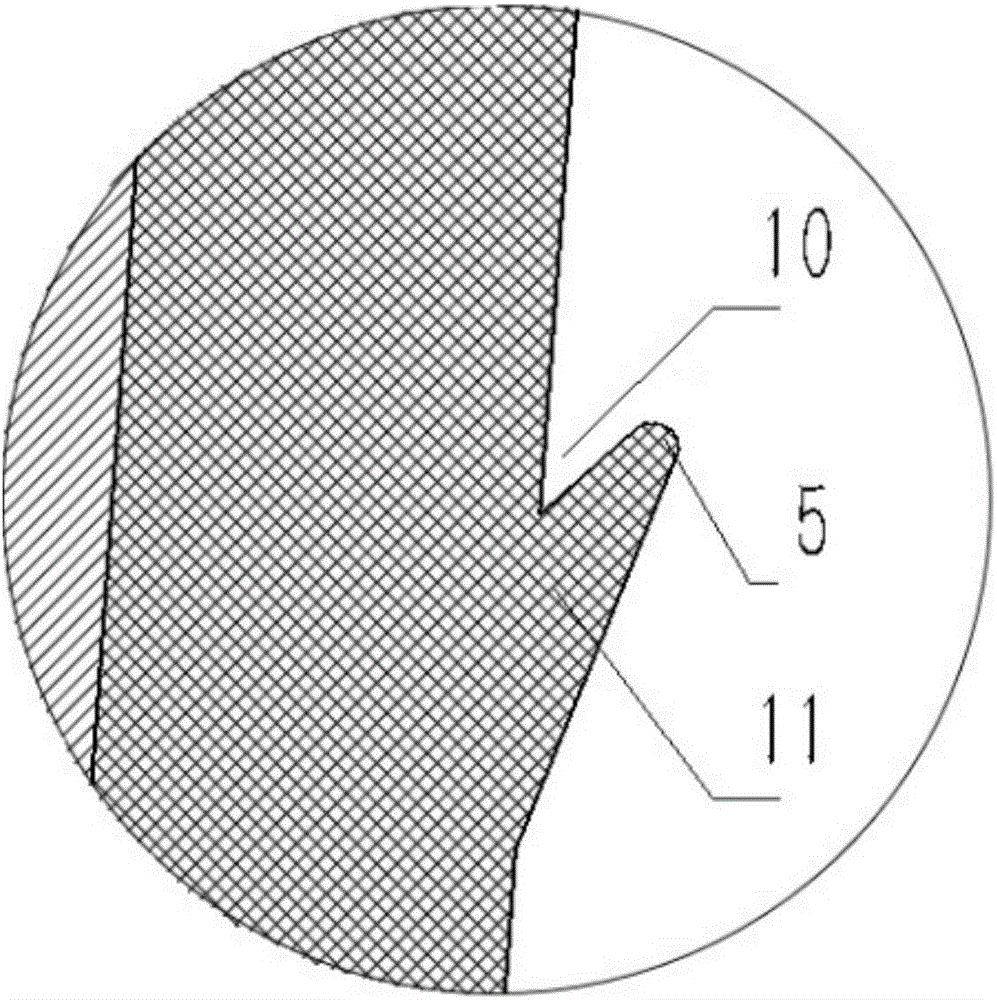

3D printing-based bionic artificial tooth and manufacturing method thereof

InactiveCN105919683AStrong toughnessHigh strengthDental implantsAdditive manufacturing apparatusCell adhesionFall risk

The invention discloses a 3D printing-based bionic artificial tooth and a manufacturing method thereof. The 3D printing-based bionic artificial tooth comprises a bionic dentin main body, a bionic enamel layer coating the upper end surface of the bionic dentin main body and a bionic cementum layer coating the bionic dentin main body, the bionic enamel layer is connected to the bionic cementum layer through a transition region, the outer surface of the bionic cementum layer is covered with a microstructure layer, and the microstructure layer comprises porous structures and barb structures staggered or irregularly distributed on the bionic cementum layer. According to bionic characteristics, solids with different gradient strength are molded in different implantation material areas so that stress interference between an implantation material and an alveolar bone is reduced. Through combination with a high freedom degree molding capability of the 3D printing technology, a completely personalized bionic dental implant is directly molded so that wearing comfort is improved. The barb structures and the porous structures are conducive to cell adhesion, growth and fixation, improve a bonding capacity of an implant and an alveolar bone and reduce adverse effects such as a dental implant falling risk after an operation.

Owner:SOUTH CHINA UNIV OF TECH

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

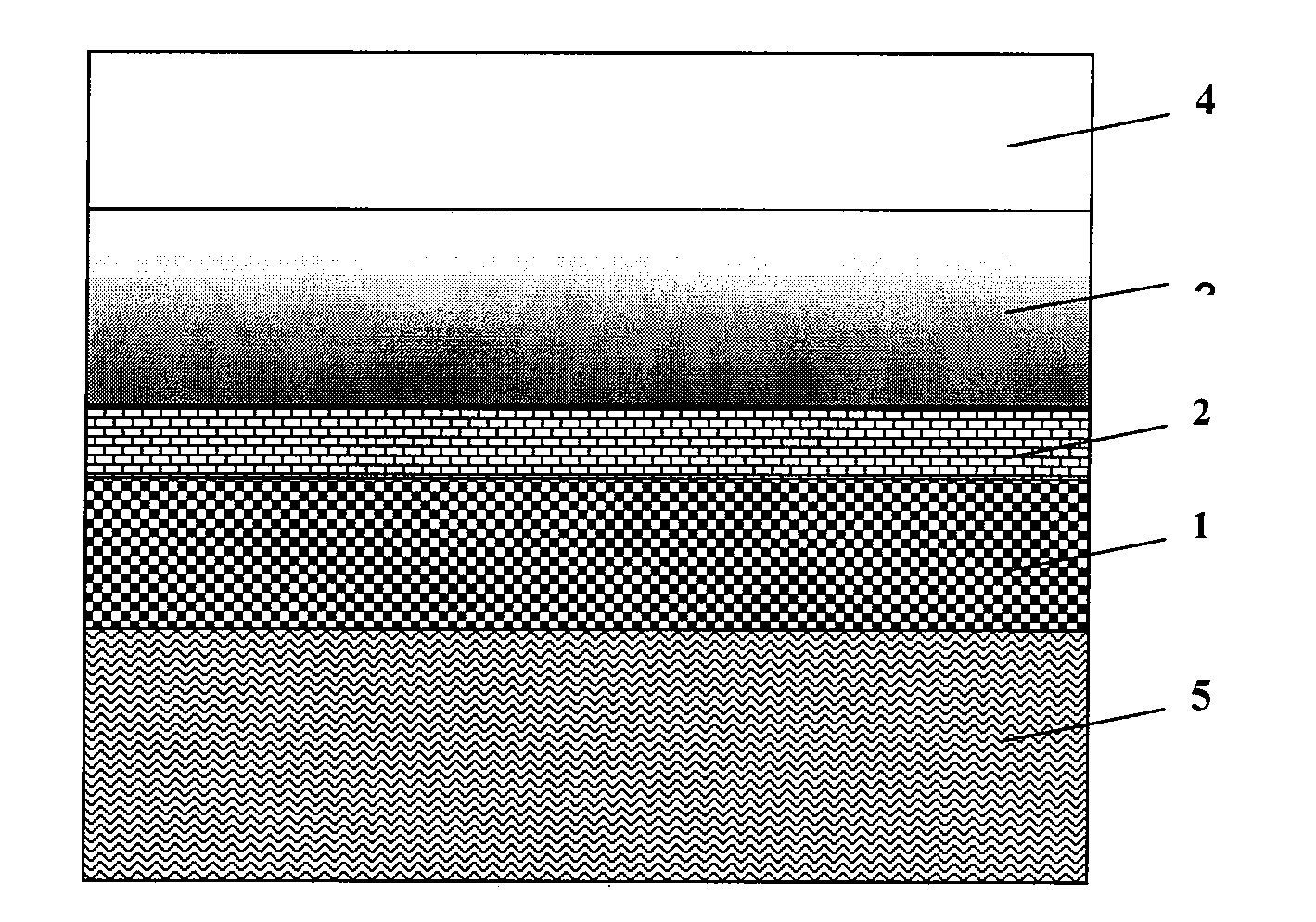

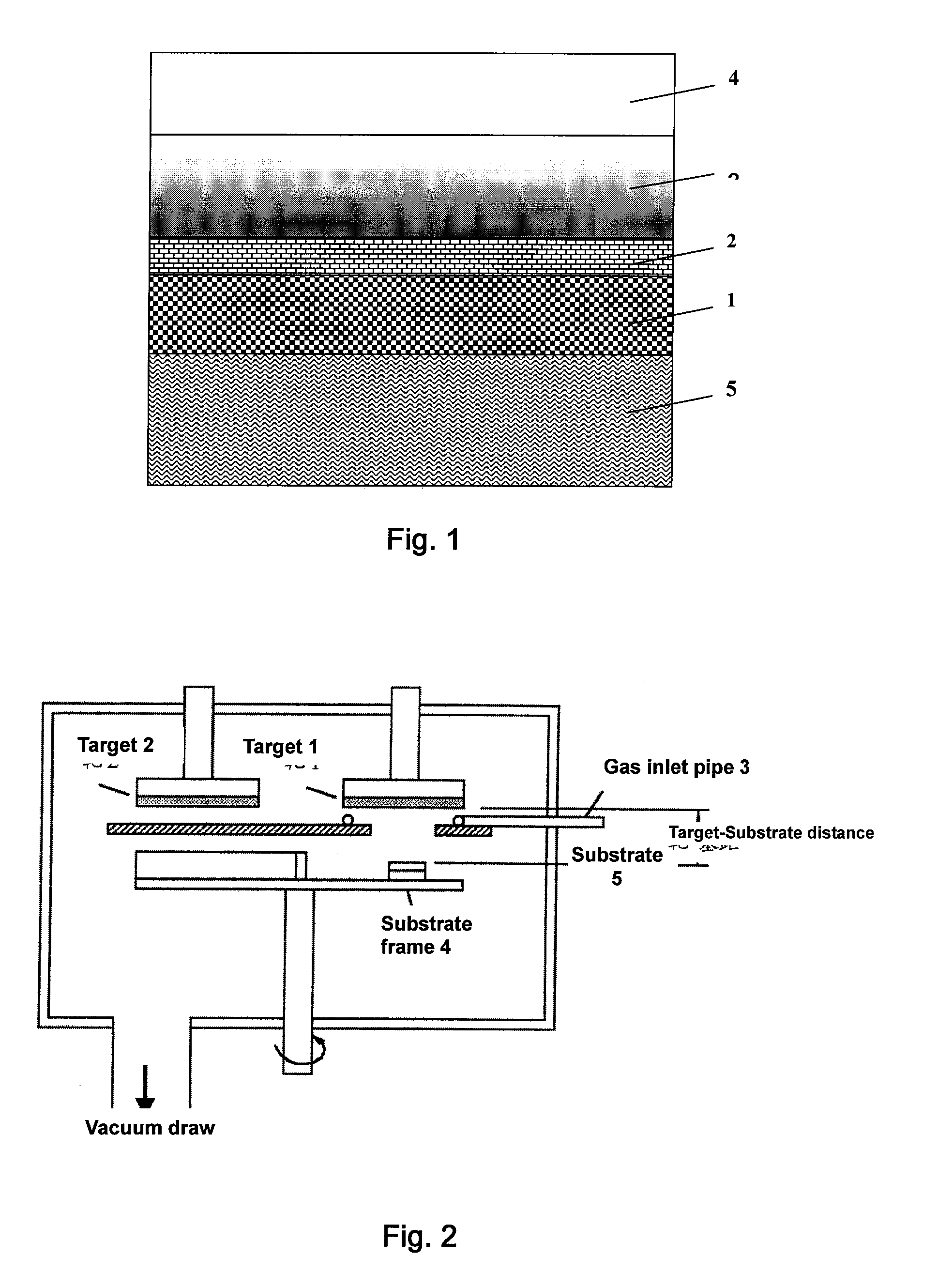

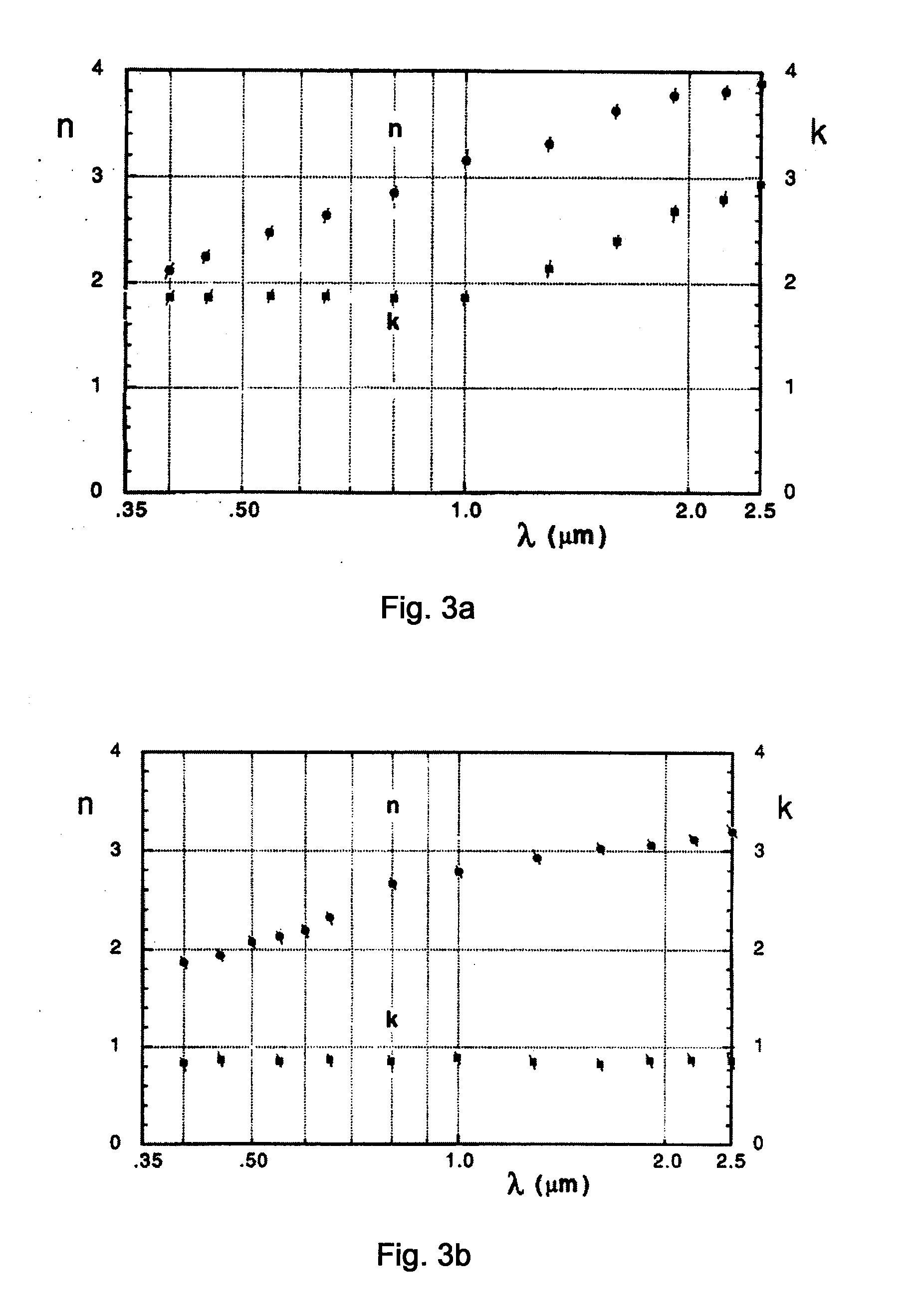

Light selective absorbing coating and its process

InactiveUS20100035034A1Easy to controlExcellent property of corrosion resistance and workability and compatibilitySolar heat devicesSynthetic resin layered productsCoating systemNitrogen

The present invention relates to a light selective absorbing coating and a production process thereof. The light selective absorbing coating consists of a composite material film deposited by reaction of iron chromium alloy and a non-metal gas with vacuum deposition technology. Said non-metal gas comprises gases of nitrogen and oxygen elements. The present invention also relates to a solar energy heat collecting element or solar energy selective absorbing coating system comprising said light selective absorbing coating and a production process thereof. The present invention further relates to use of said composite material film as a light selective absorbing coating of a solar energy heat collecting element or of a solar energy selective absorbing coating system.

Owner:SHENZHEN COMMONPRAISE SOLAR

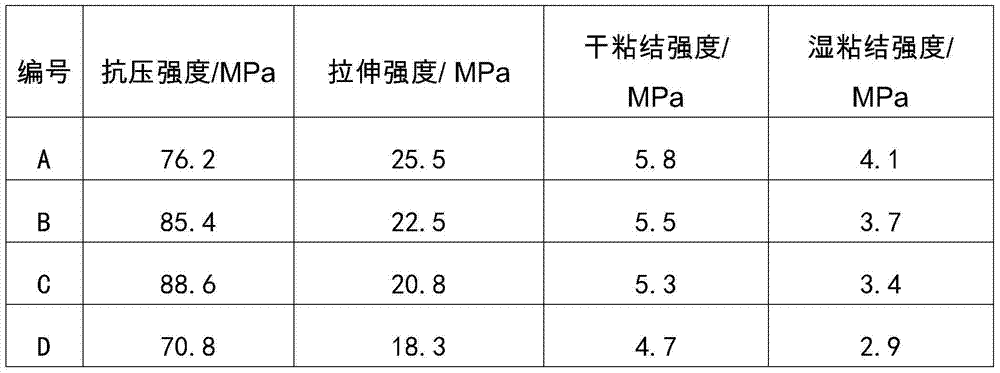

Preparation method of polyurethane modified epoxy resin and grouting material based on resin

The invention provides a preparation method of polyurethane modified epoxy resin. The preparation method comprises the following steps: firstly performing reaction on isocyanate and a hydroxyl group on epoxy resin to obtain polyurethane graft epoxy resin, further terminating isocyanate on the polyurethane graft epoxy resin with monohydric alcohol, and further grafting a polyurethane short branch chain on the epoxy resin by utilizing the unit termination of isocyanate so as to increase the intermolecular distance of the epoxy resin, reduce the intermolecular action force, improve the motion ability of a chain segment and simultaneously realize the effects of reducing viscosity of slurry and toughening; furthermore, a grouting material based on the polyurethane modified epoxy resin provided by the invention can effectively reduce the intermolecular physical crosslinking and realize strong permeability and good toughness; data shows that the compressive strength exceeds 70MPa, the tensile strength is more than 20MPa, the dry bonding strength is more than 5MPa, and the wet bonding strength is more than 3MPa.

Owner:BEIJING TIEKE SHOUGANG RAIL TECH CO LTD

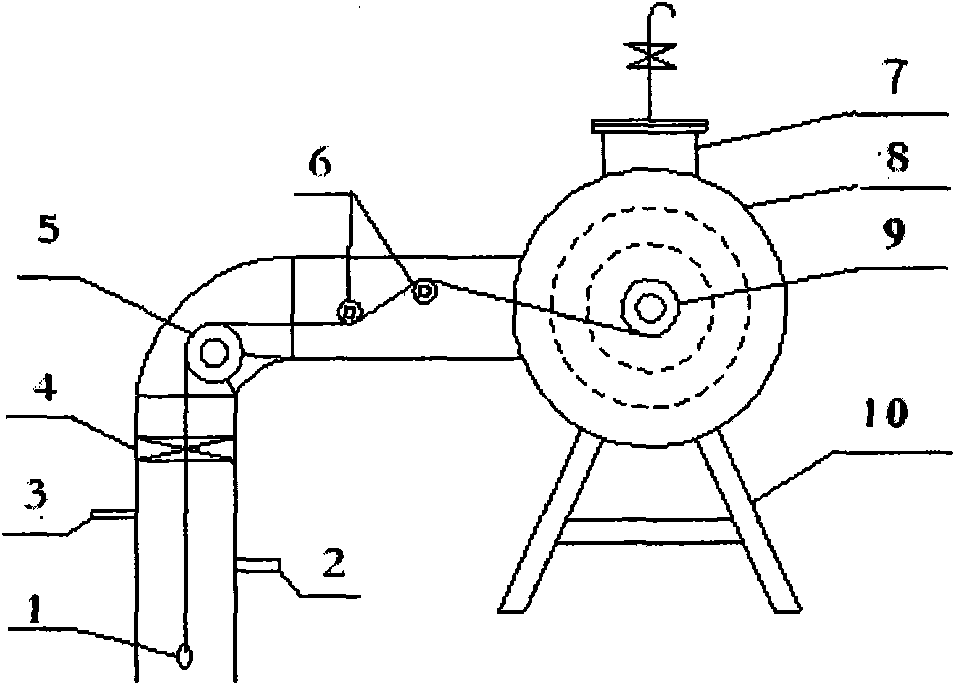

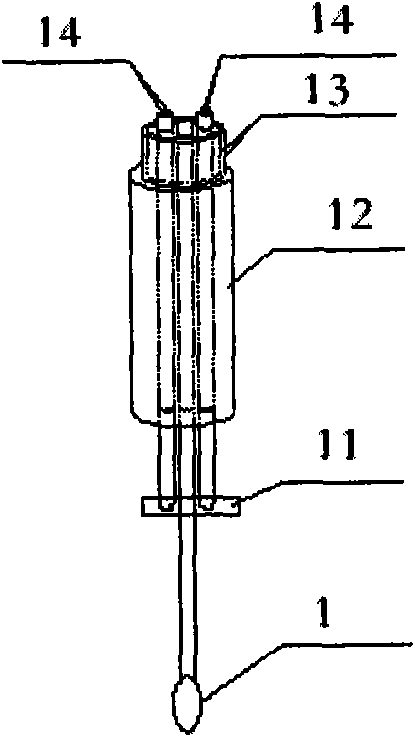

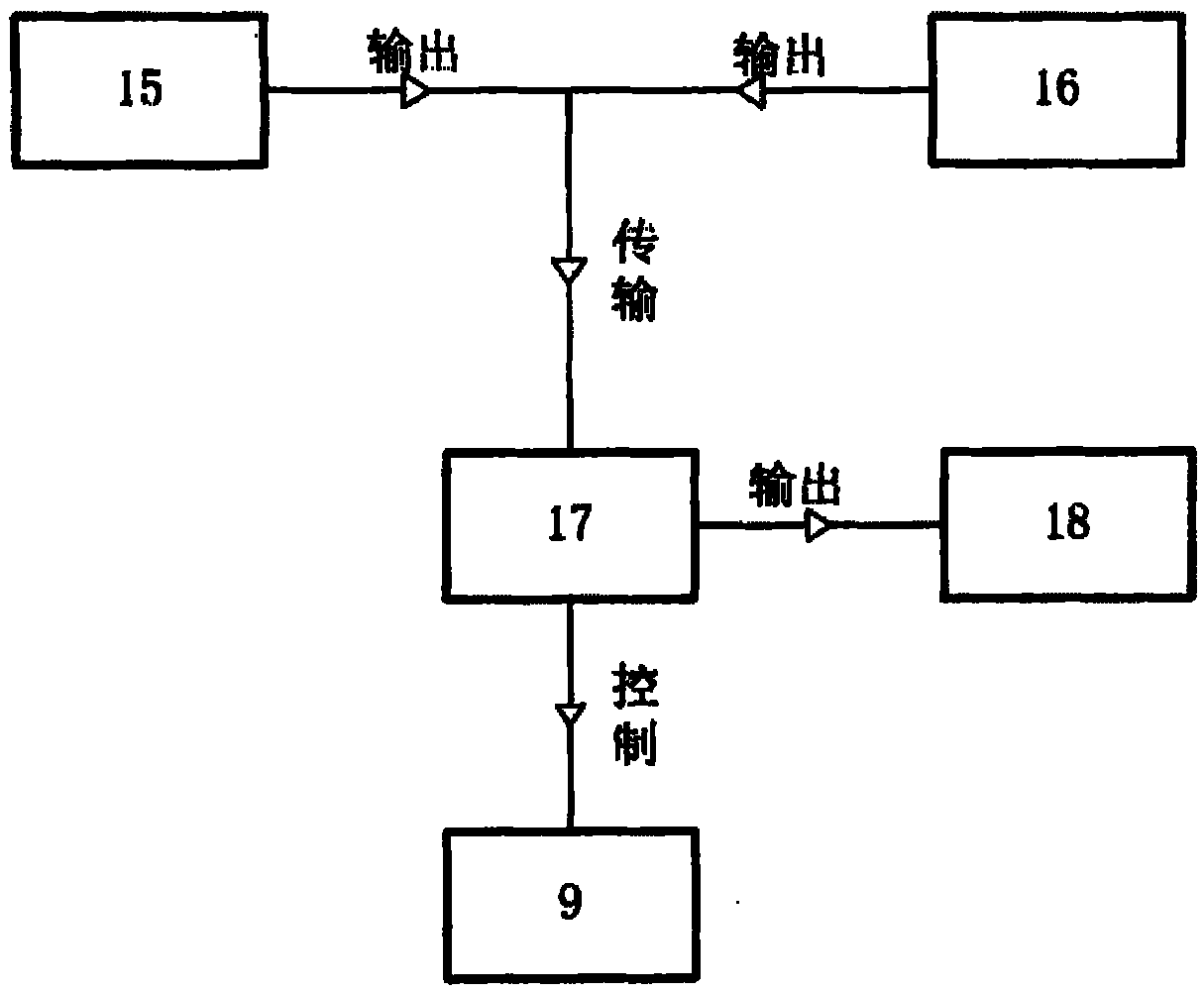

On-line underground temperature measurement system

ActiveCN101942990AAvoid short circuit problemsHigh strengthSurveyConstructionsThermocouple WireEngineering

The invention relates to an underground temperature measurement system. The system comprises a thermocouple, a compensating lead and a heavy hammer, wherein the compensating lead is positioned above the thermocouple, and the lower end of the compensating lead is connected with the upper end of the thermocouple; the heavy hammer is positioned below the thermocouple, connected with the lower end of the thermocouple and used for guiding the thermocouple to advance in a temperature measurement passage; and the thermocouple is a sheathed thermocouple manufactured by combined assembly of a thermocouple wire, an insulating material and a metal protective sleeve and stretching, and the length of the sheathed thermocouple corresponds to the thickness of a highest temperature interval in an underground high temperature layer to be measured. The temperature measurement system can greatly reduce the manufacturing cost of the thermocouple, effectively prolong the service life of the thermocouple and improve the automation degree of temperature measurement, and is convenient for repair and maintenance of the system per se.

Owner:ENN SCI & TECH DEV

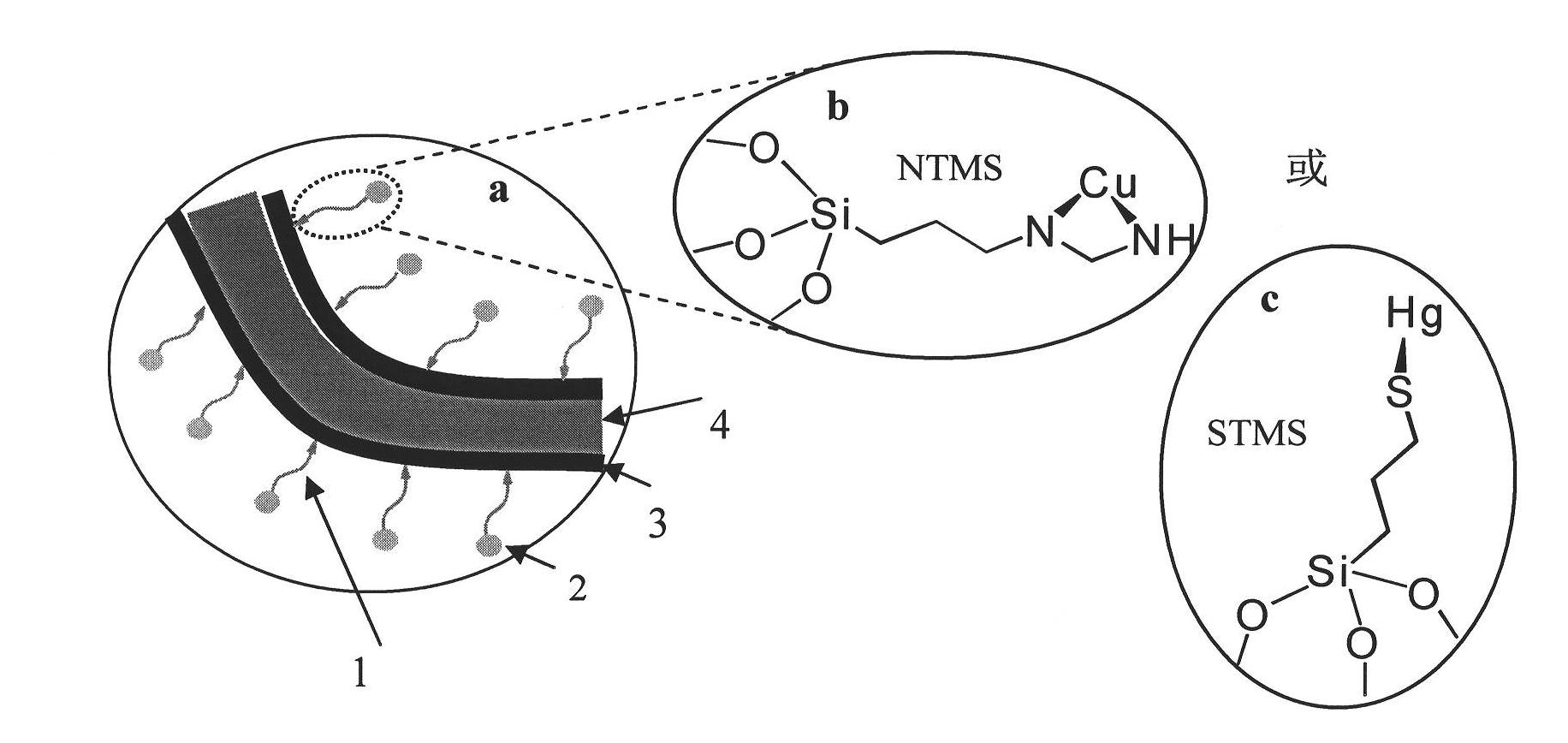

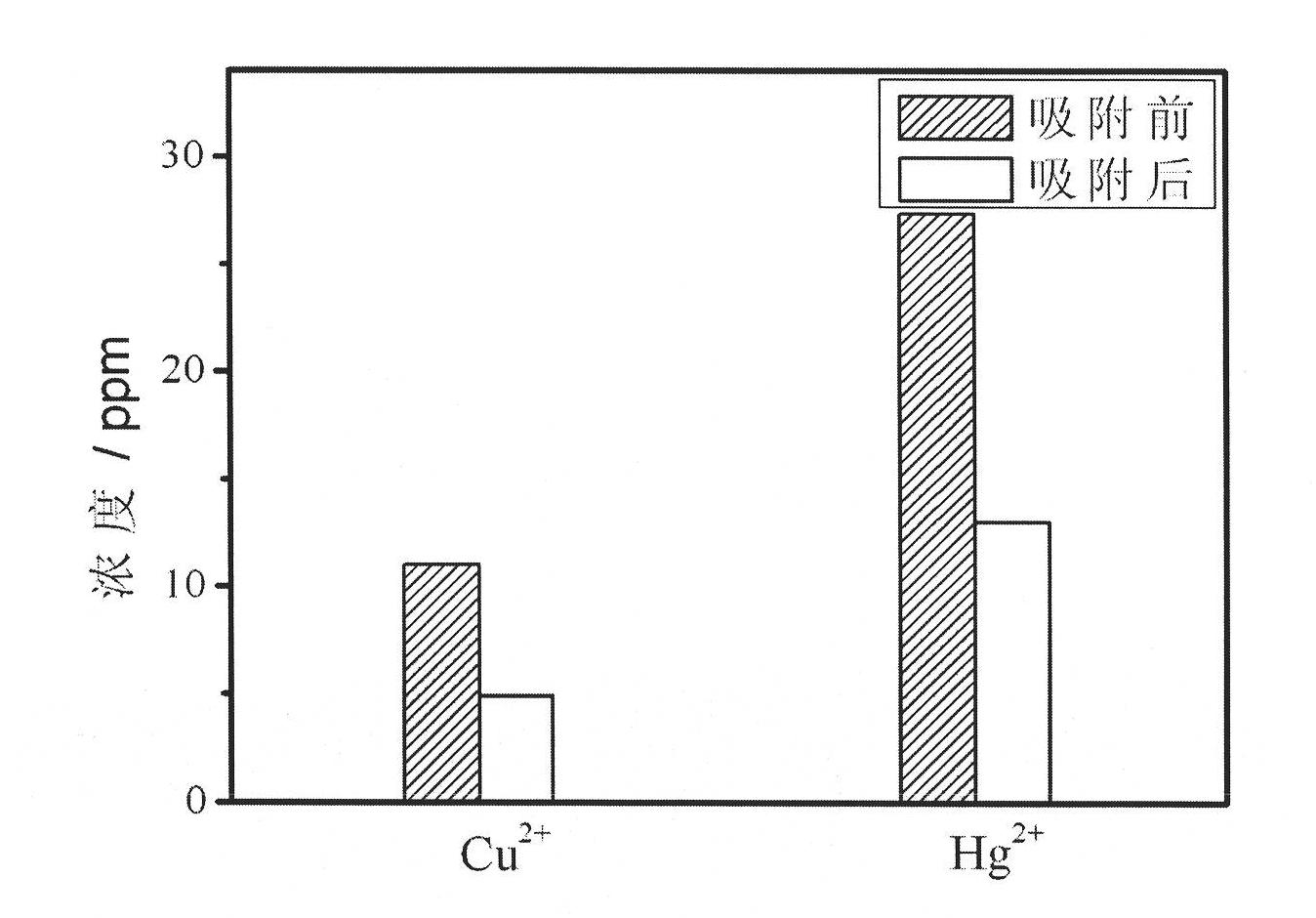

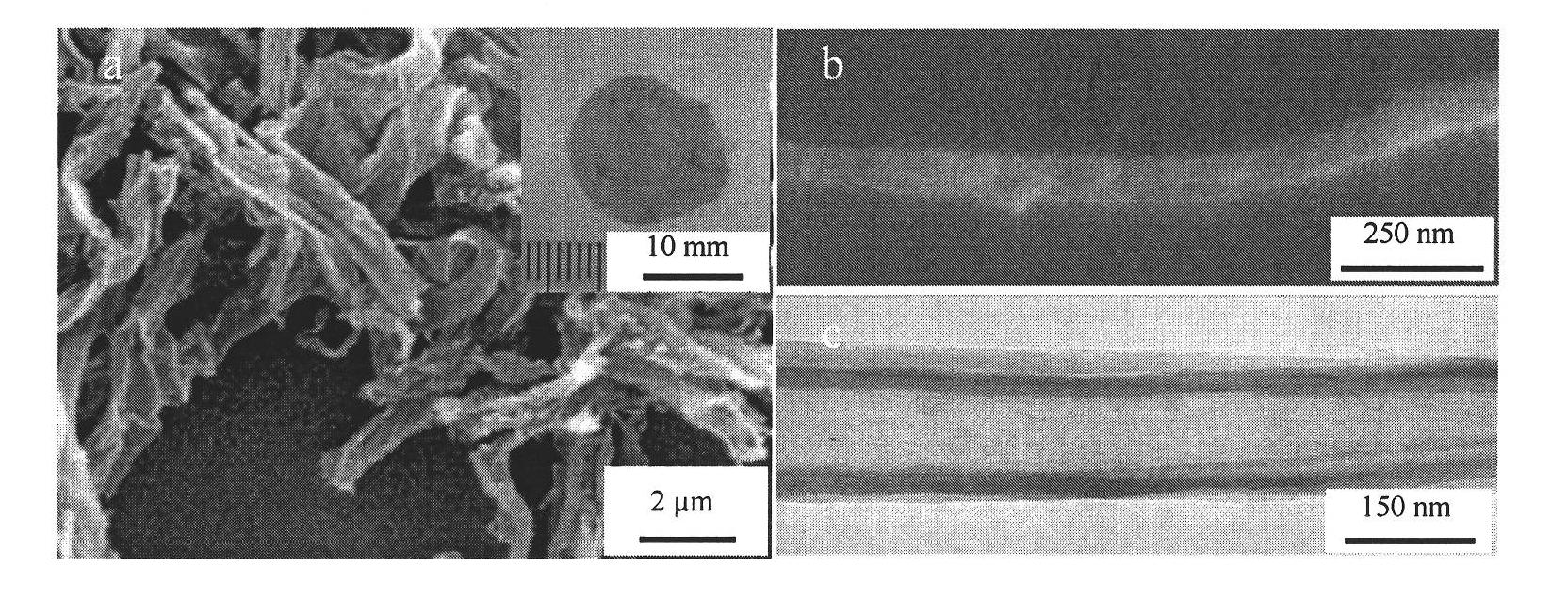

Preparation method of heavy metal ion enrichment cellulosic material

InactiveCN101787654AStrong toughnessHigh mechanical strengthFibrous raw materialsHigh absorptionSilanes

The invention relates to a preparation method of heavy metal ion enrichment cellulosic material; in the method, natural cellulosic material fiber is adopted as the matrix, tetramethyl silane is take as the precursor and the surface sol-gel method is utilized to deposit silica film on the surface of the filter paper fiber; subsequently, ligand molecule monolayer sensitive to copper ion and mercury ion are introduced through self-assembly to obtain the heavy metal ion enrichment cellulosic material; the heavy metal ion solution can be simply filtered by the material prepared by the method of the invention to realize the absorption effect. The heavy metal ion enrichment cellulosic material has superior heavy metal ion enrichment performance, broad raw material source range, low price, simple preparation method, high absorption speed, high sensitiveness and can realize the treatment of waste water containing heavy ions simply, rapidly and economically.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com