Preparation method of superfine fiber high-imitation grain synthetic leather

A technology of imitating top layer skin and ultra-fine fiber, which is applied in the directions of fiber processing, chemical instruments and methods, synthetic resin layered products, etc. problems such as the price of the top layer of leather, to achieve the effect of enhancing international competitiveness, uniform cell size and distribution, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

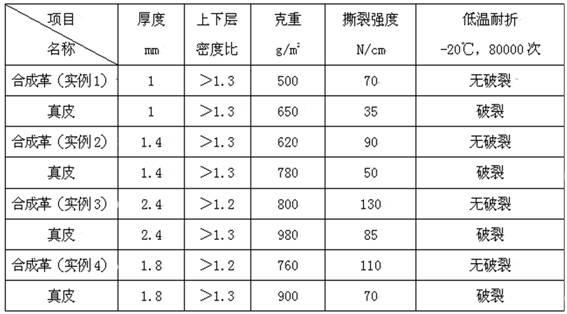

Examples

Embodiment 1

[0029] (1) Spinning of composite fibers

[0030] Nylon 6 slices and low-density polyethylene are mixed according to the mass ratio of 50:50, extruded and melted by a screw extruder, and the spinning temperature range is controlled at 245-285°C, after cooling and blowing (air temperature 25°C), pulling Stretching (drawing ratio 4.5 times), oiling (oil concentration 4.0%), crimping (the number of crimps is 20 / 25mm) and cutting, spinning 6D×51mm sea-island composite fibers, nylon 6 in the composite fibers For the island component, low density polyethylene is for the sea component.

[0031] (2) Production of non-woven fabrics

[0032] Use the island-in-the-sea composite fiber prepared in step (1) to make a non-woven fabric with a width of 1.55m and a thickness of 1.50-1.70mm. Its density reaches 0.29g / cm 3 , The thickness reaches 1.48mm. The process parameters of non-woven fabric production are needle punching frequency 500-1000 punches / min, needle punching density 1000-1500 p...

Embodiment 2

[0043] (1) Spinning of composite fibers

[0044] Nylon 6 slices and low-density polyethylene are mixed according to the mass ratio of 55:45, extruded and melted by a screw extruder, and the spinning temperature range is controlled at 245-285°C, and cooled and blown (air temperature 20°C) , drafting (drawing ratio 4 times), oiling (oil concentration 6.0%), crimping (17 crimps / 25mm) and cutting, and spinning a 7D×38mm sea-island composite fiber. Nylon 6 is the island component, and low-density polyethylene is the sea component.

[0045] (2) Production of non-woven fabrics

[0046] Use the island-in-the-sea composite fiber prepared in step (1) to make a non-woven fabric with a width of 1.65m and a thickness of 1.95-2.15mm. Its density reaches 0.30g / cm 3 , The thickness reaches 1.75mm. The process parameters of non-woven fabric production are needle punching frequency 1000-1500 punches / min, needle punching density 1500-2000 punches / m 2 , The number of laying layers is 40 laye...

Embodiment 3

[0057] (1) Spinning of composite fibers

[0058] Nylon 6 slices and low-density polyethylene are mixed according to the mass ratio of 60:40, extruded and melted by a screw extruder, and the spinning temperature range is controlled at 245-285°C, and cooled and blown (air temperature 16°C) , drafting (drawing ratio 6 times), oiling (oil concentration 10%), crimping (the number of crimps is 22 / 25mm) and cutting, and spinning a sea-island composite fiber of 5D×64mm, the composite fiber Nylon 6 is the island component, and low-density polyethylene is the sea component.

[0059] (2) Production of non-woven fabrics

[0060] Use the island-in-the-sea composite fiber prepared in step (1) to make a non-woven fabric with a width of 1.70m and a thickness of 3.10-3.30mm. Its density reaches 0.28g / cm 3 , The thickness reaches 3.0mm. The process parameters of non-woven fabric production are acupuncture frequency 800-1200 punches / min, acupuncture density 900-1700 punches / m 2 , The number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com