Patents

Literature

153 results about "Oil concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oil concentration determining means for low concentrations performs the process of determining the oil concentration based on a measured value of the absorbance at a predetermined wavelength in a similar manner to the process performed by the conventional oil concentration measurement system.

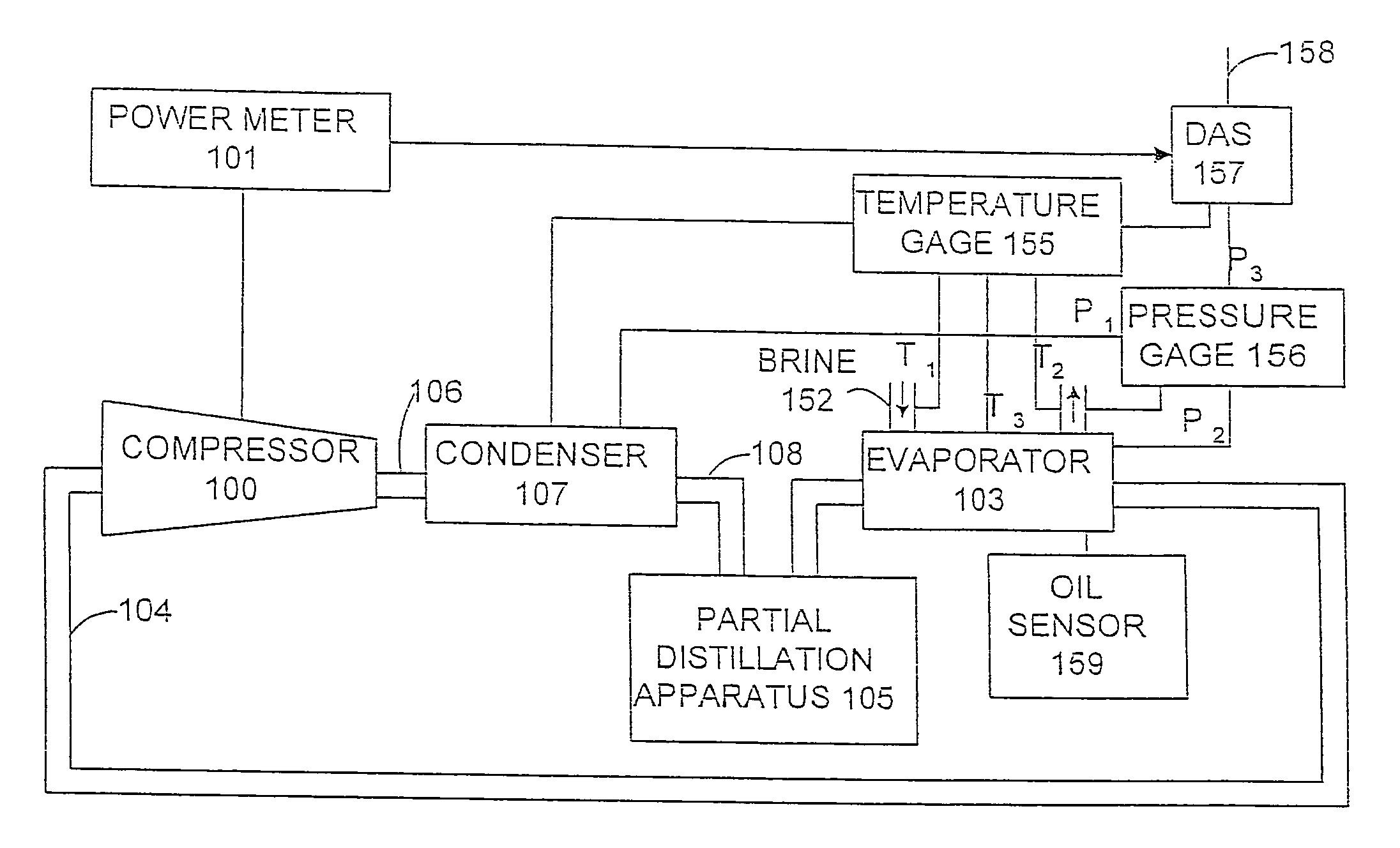

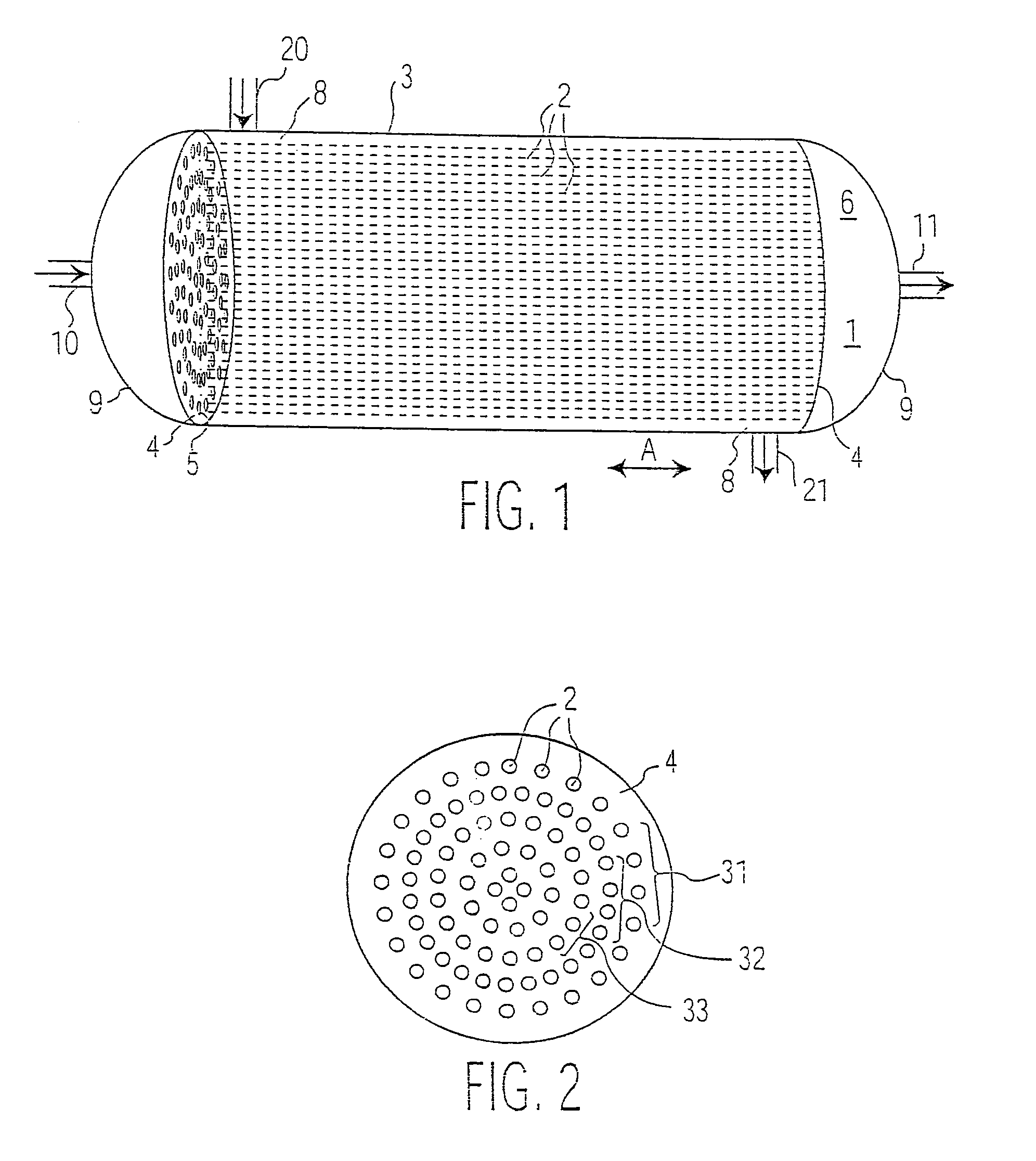

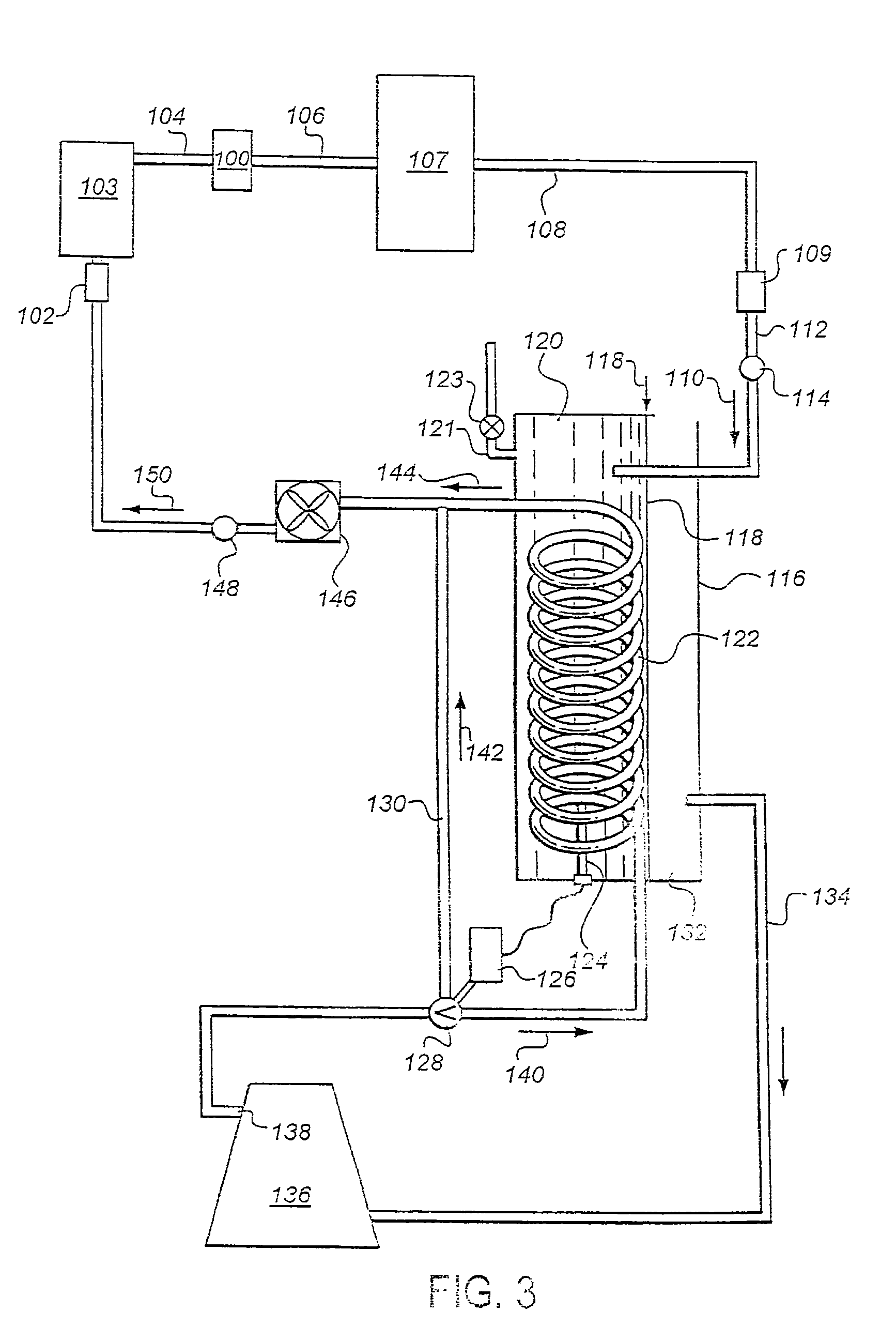

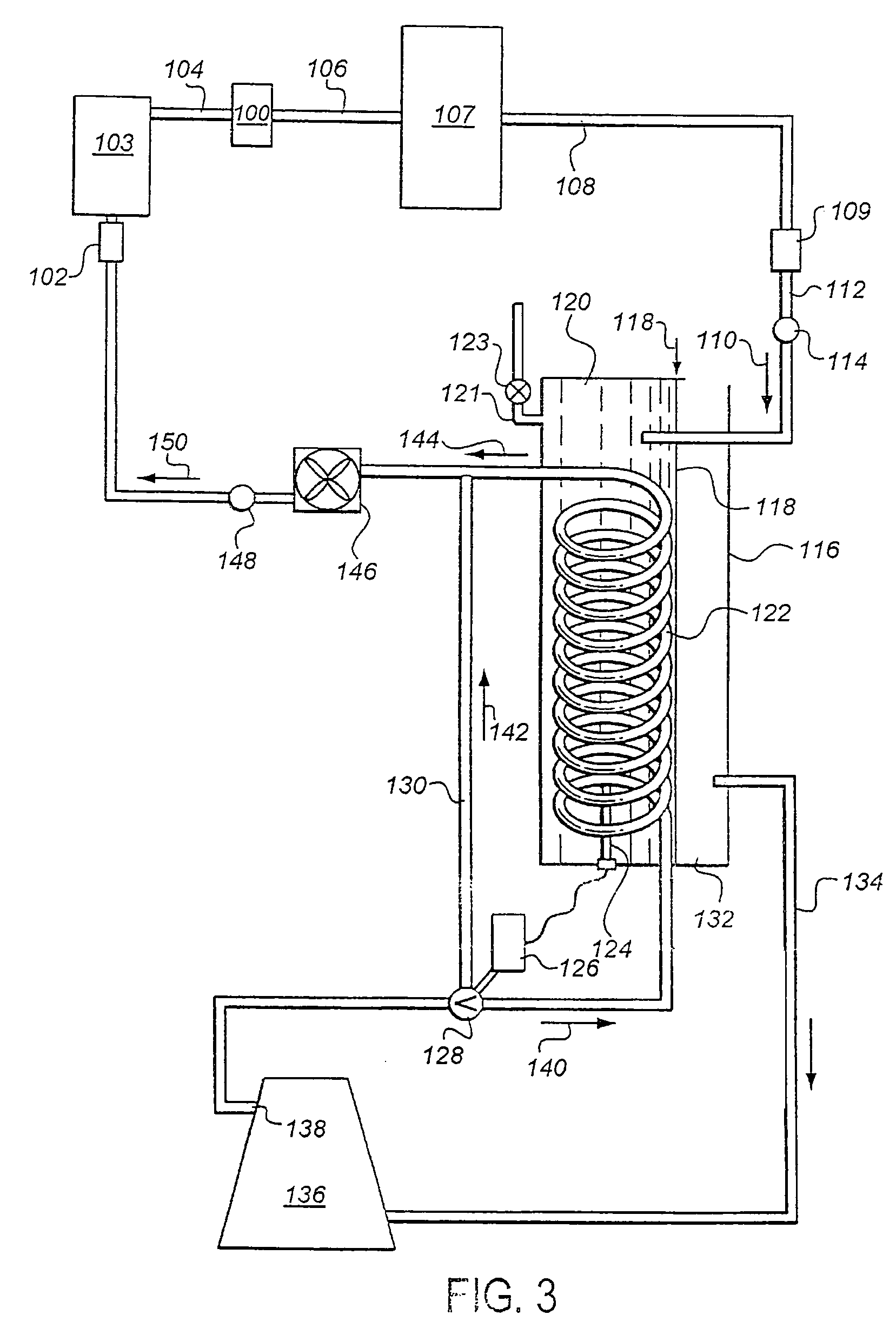

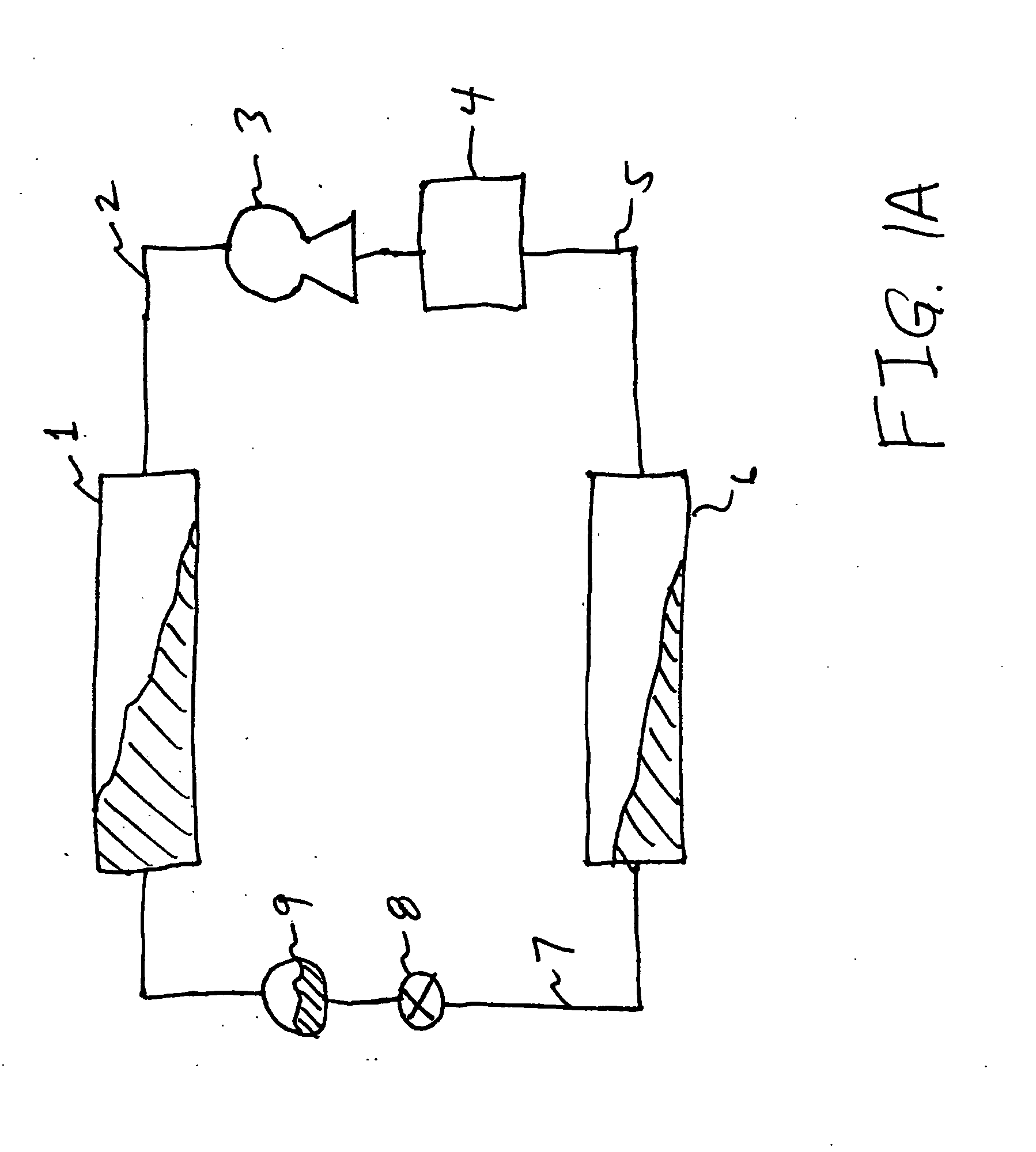

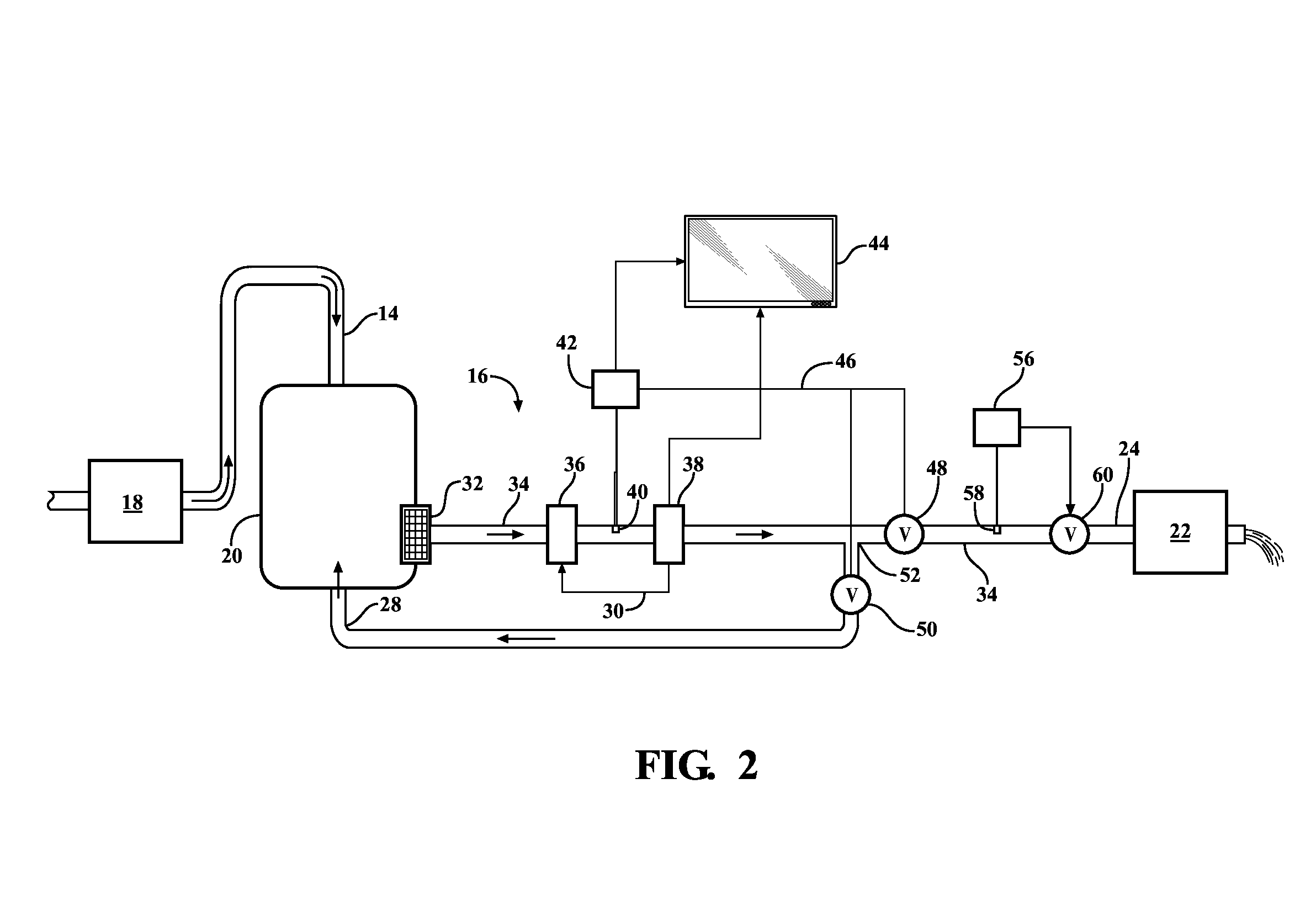

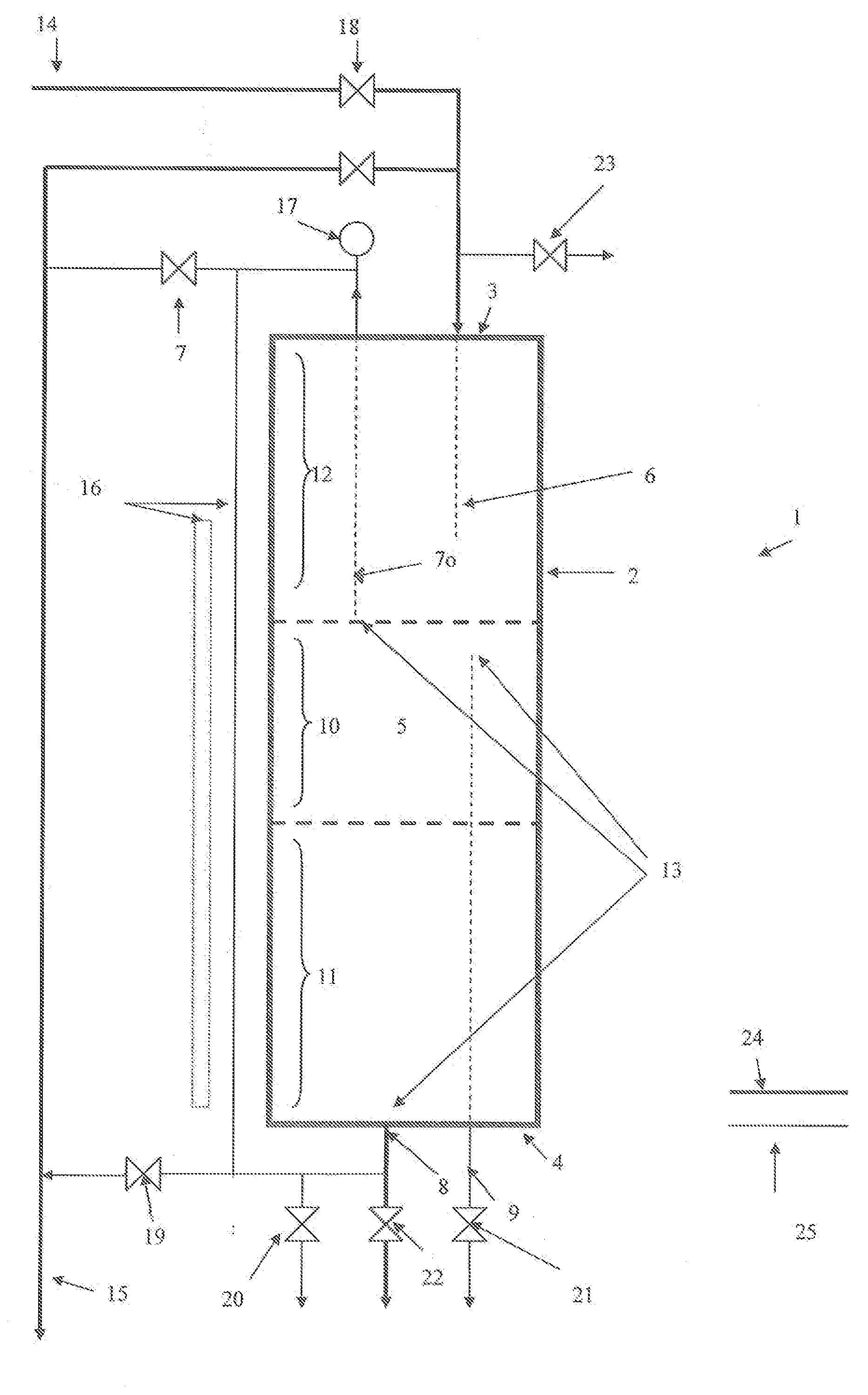

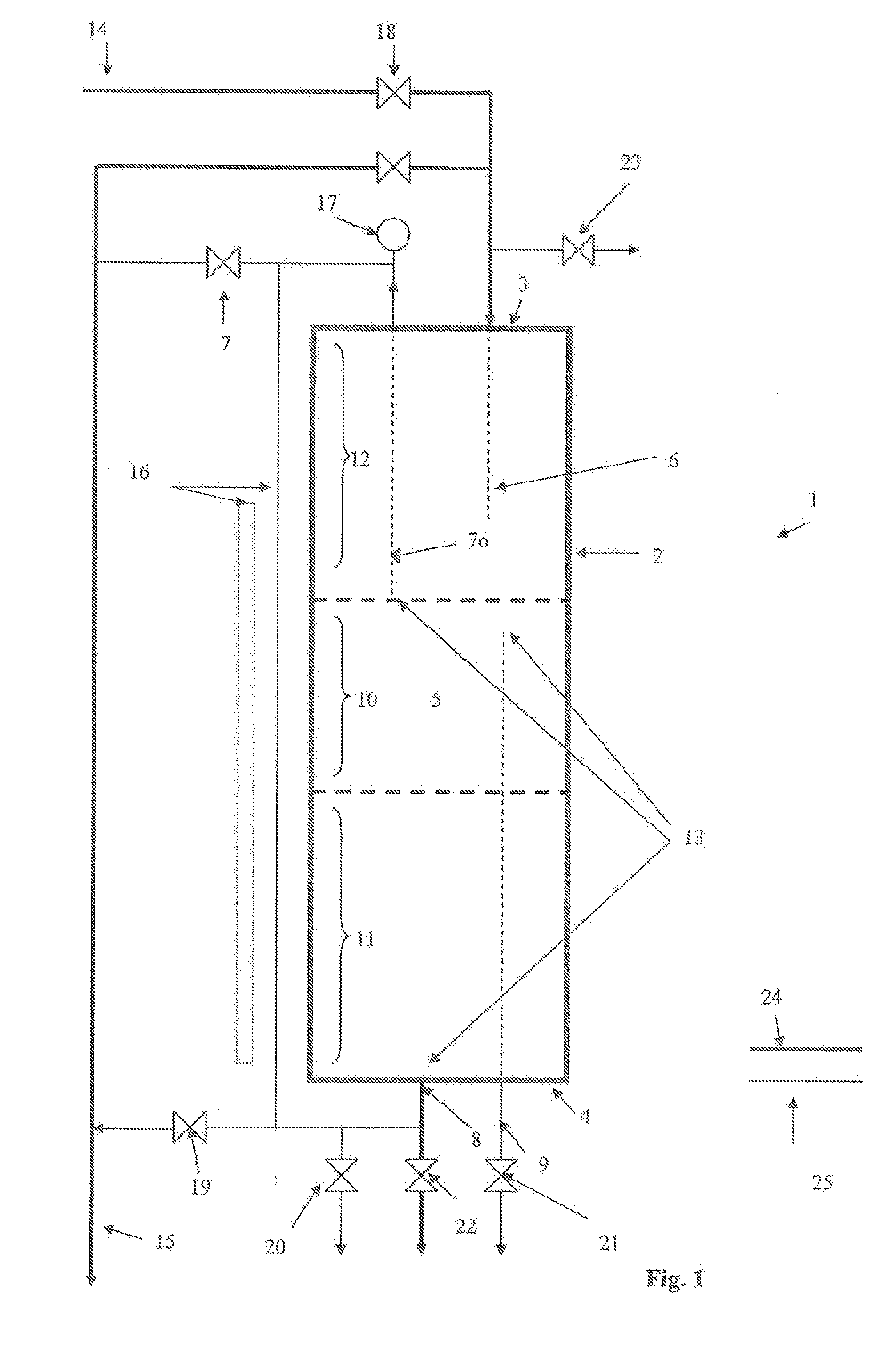

Method and apparatus for measuring and improving efficiency in refrigeration systems

InactiveUS7086240B1Improve performanceCompressorMechanical apparatusProcess engineeringRefrigeration

An apparatus for optimizing an efficiency of a refrigeration system, comprising means for measuring a refrigeration efficiency of an operating refrigeration system: means for altering a process variable of the refrigeration system during efficiency measurement: and a processor for calculating a process variable level which achieves an optimum efficiency. The process variables may include refrigerant charge and refrigerant oil concentration in evaporator.

Owner:HUDSON TECHNOLOGIES

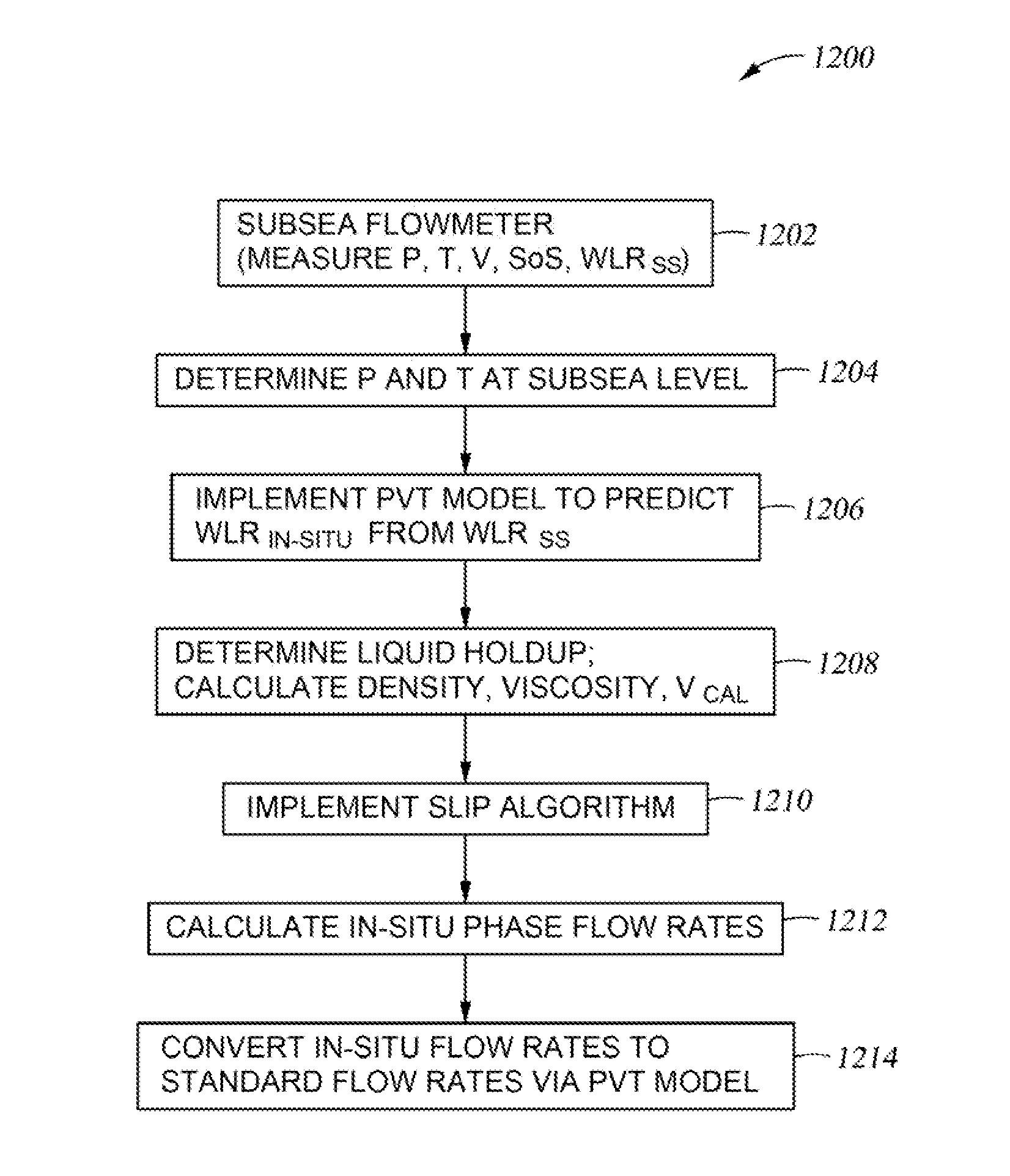

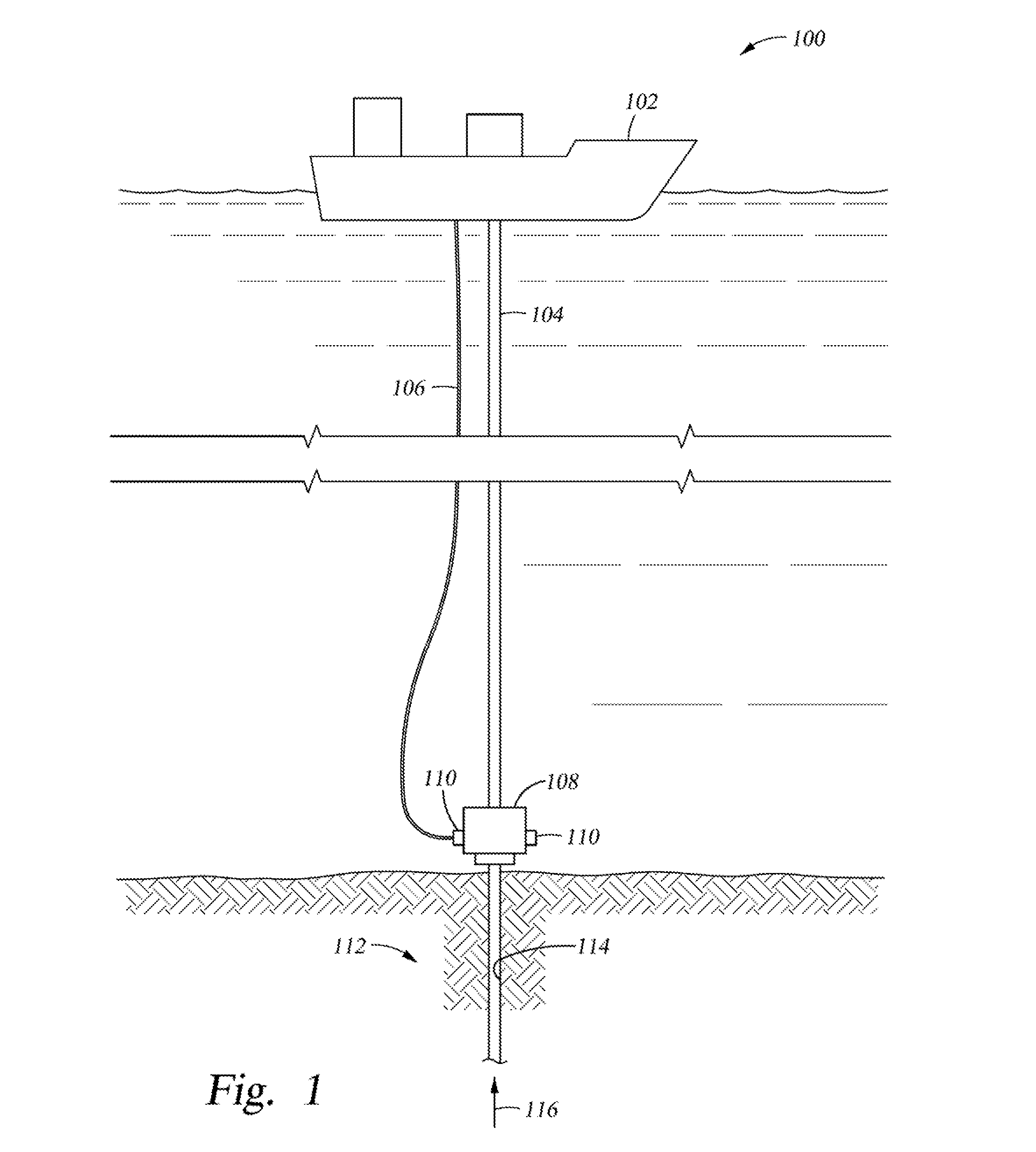

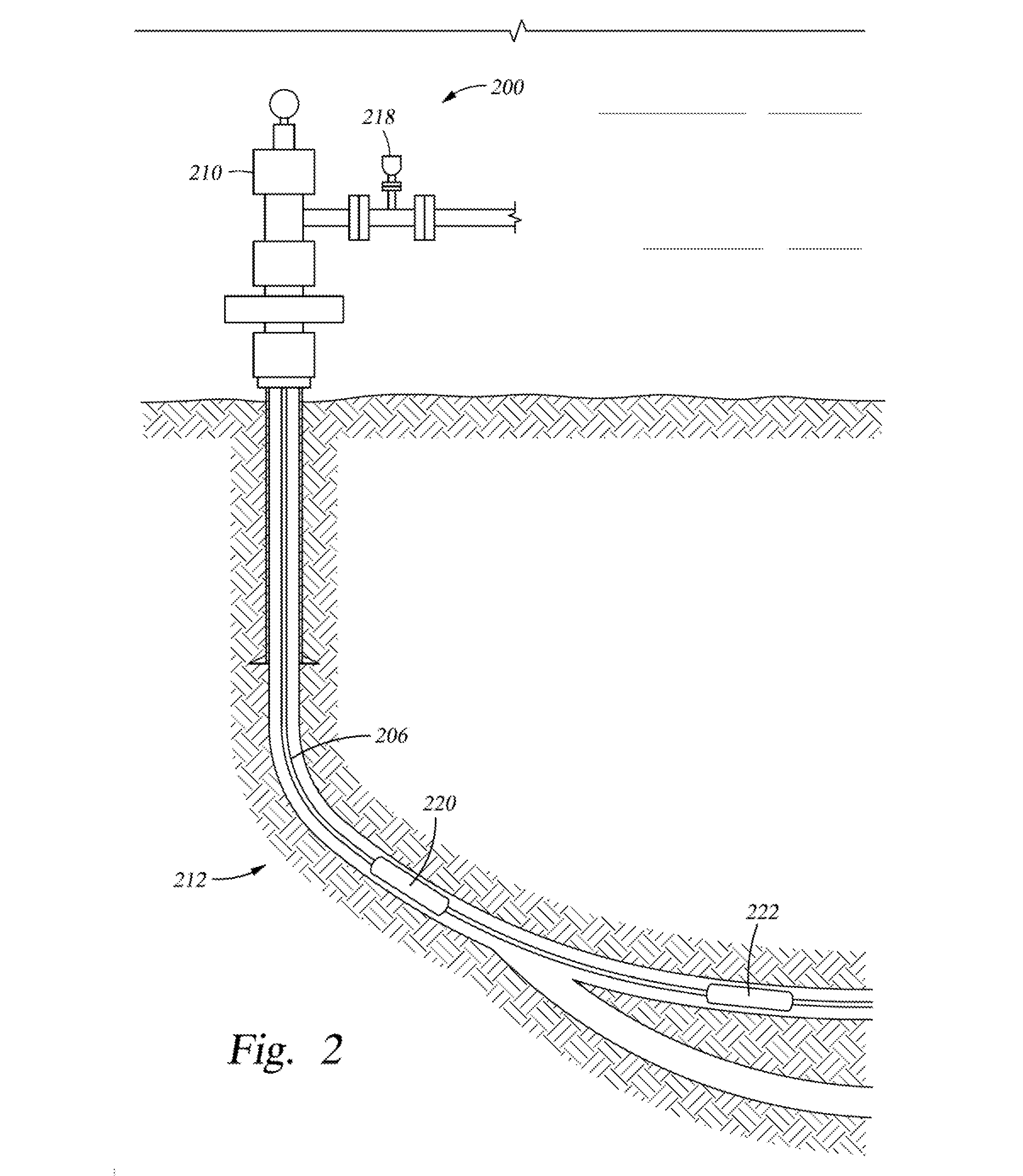

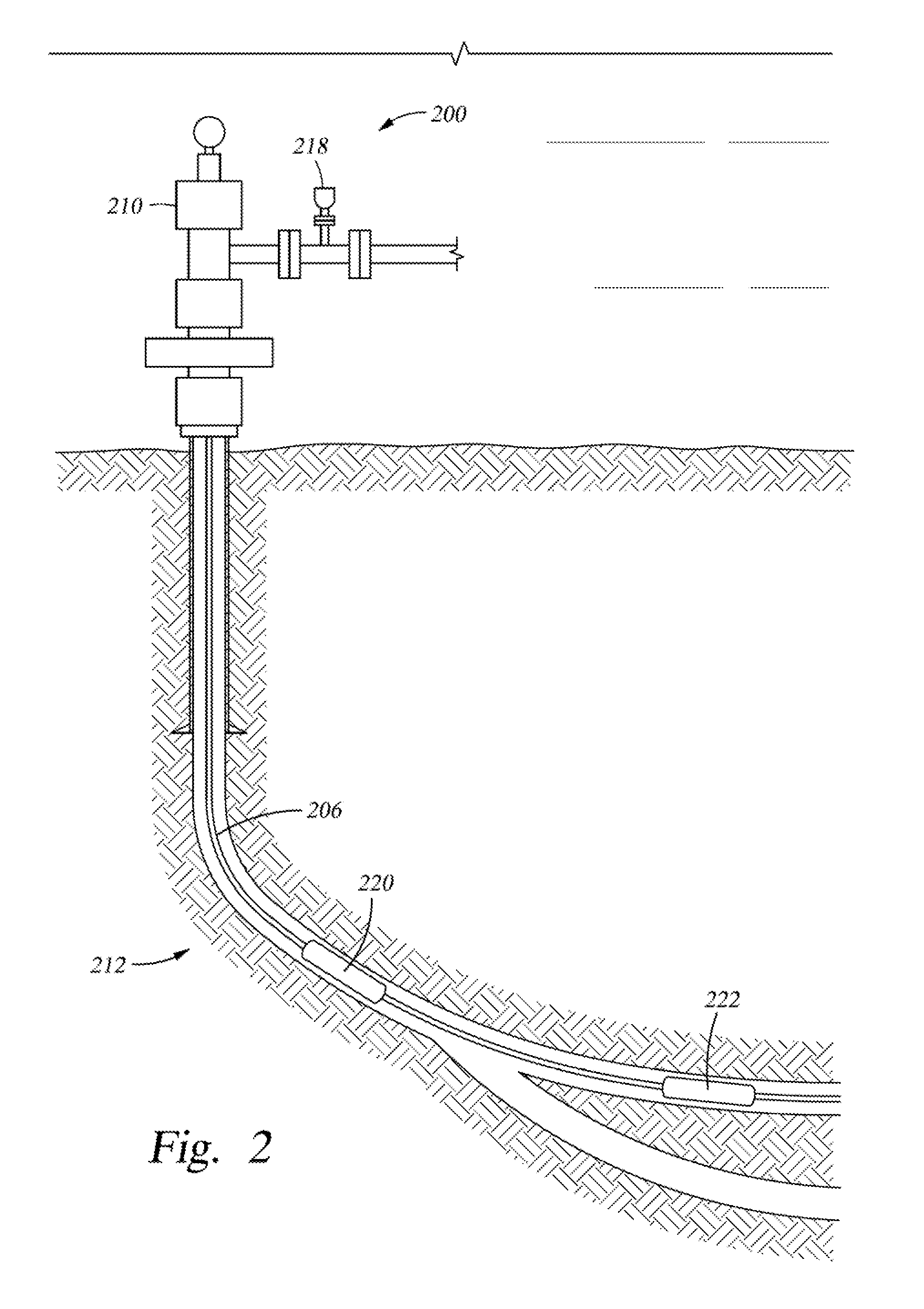

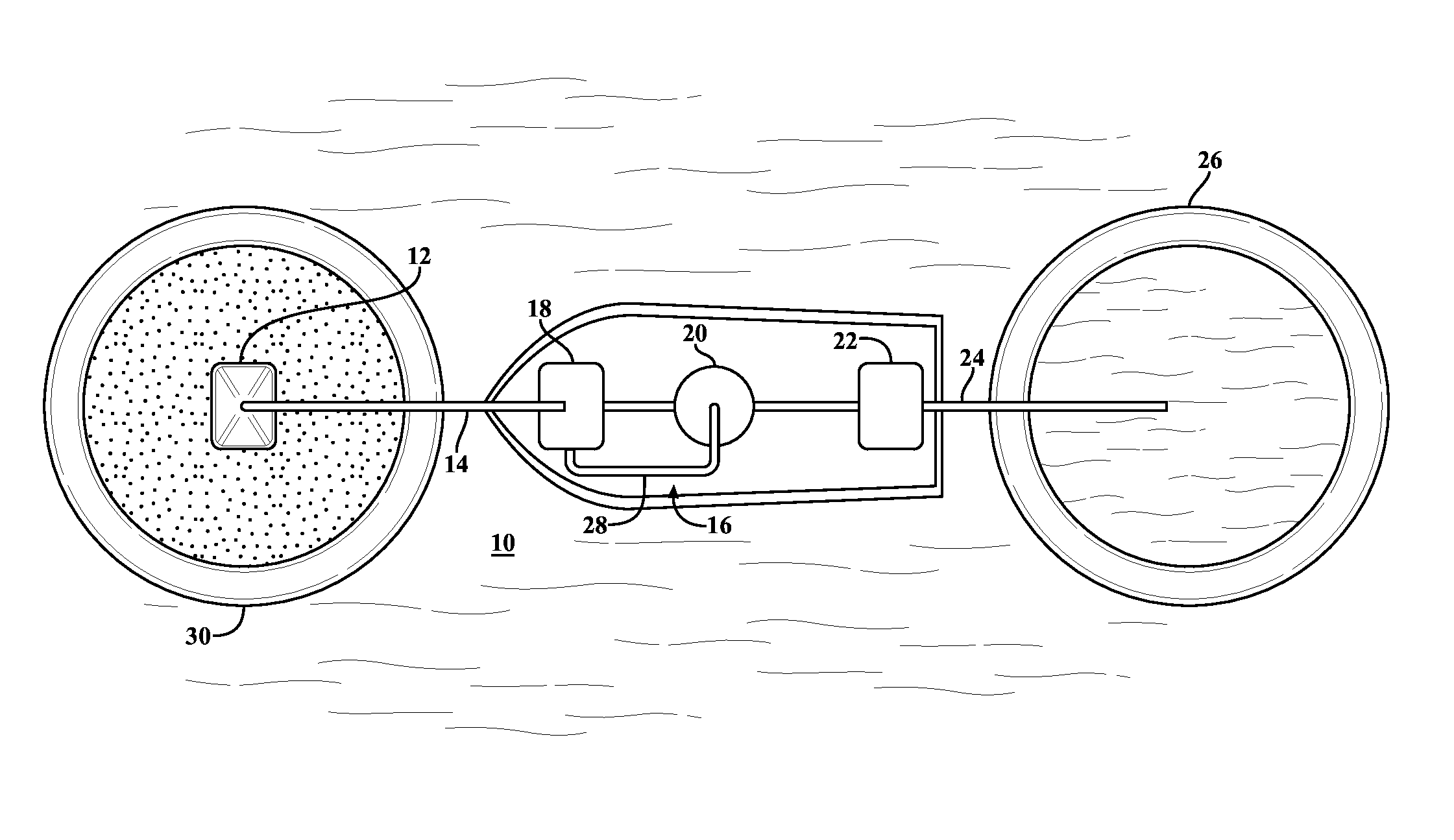

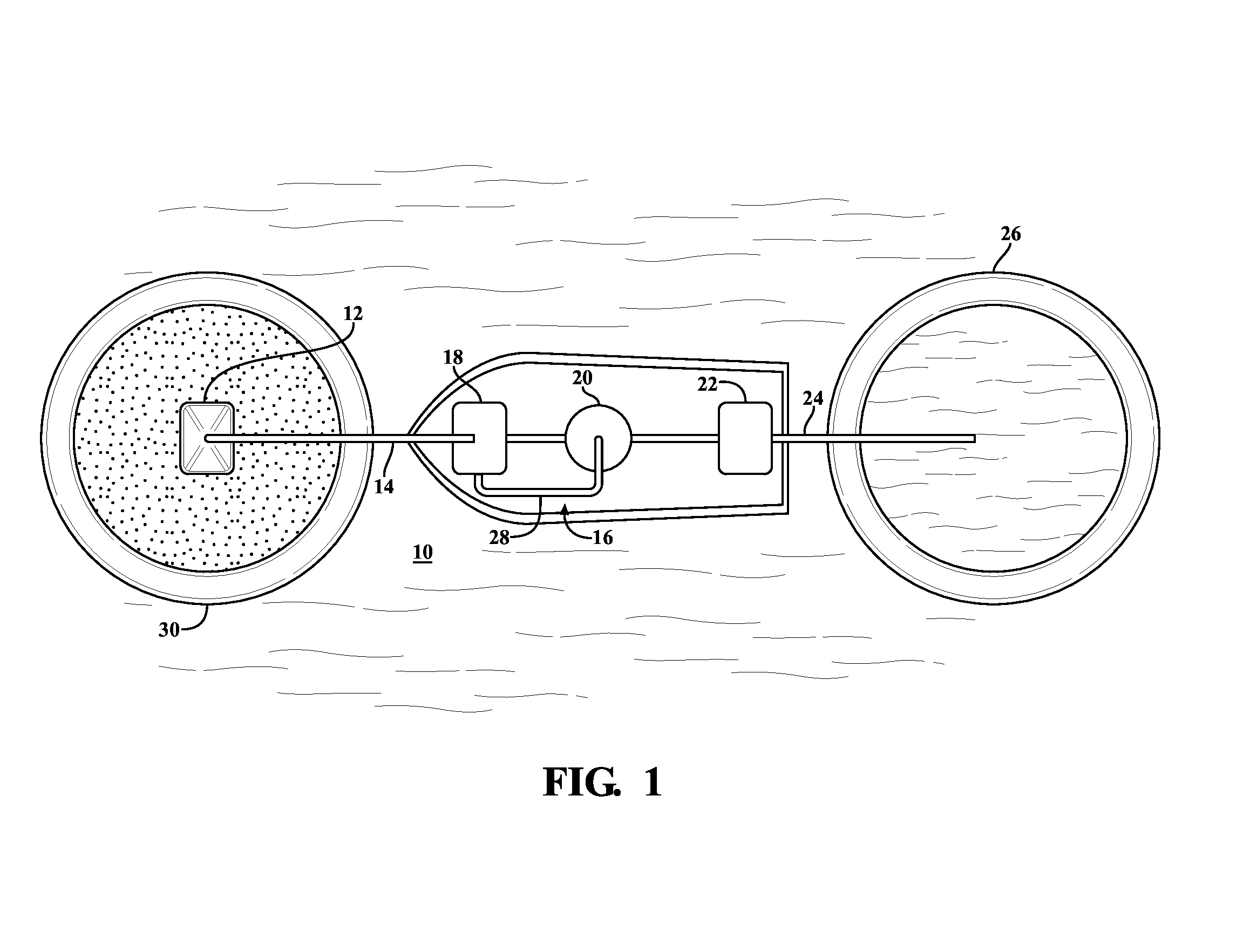

Multiphase flowmeter for subsea applications

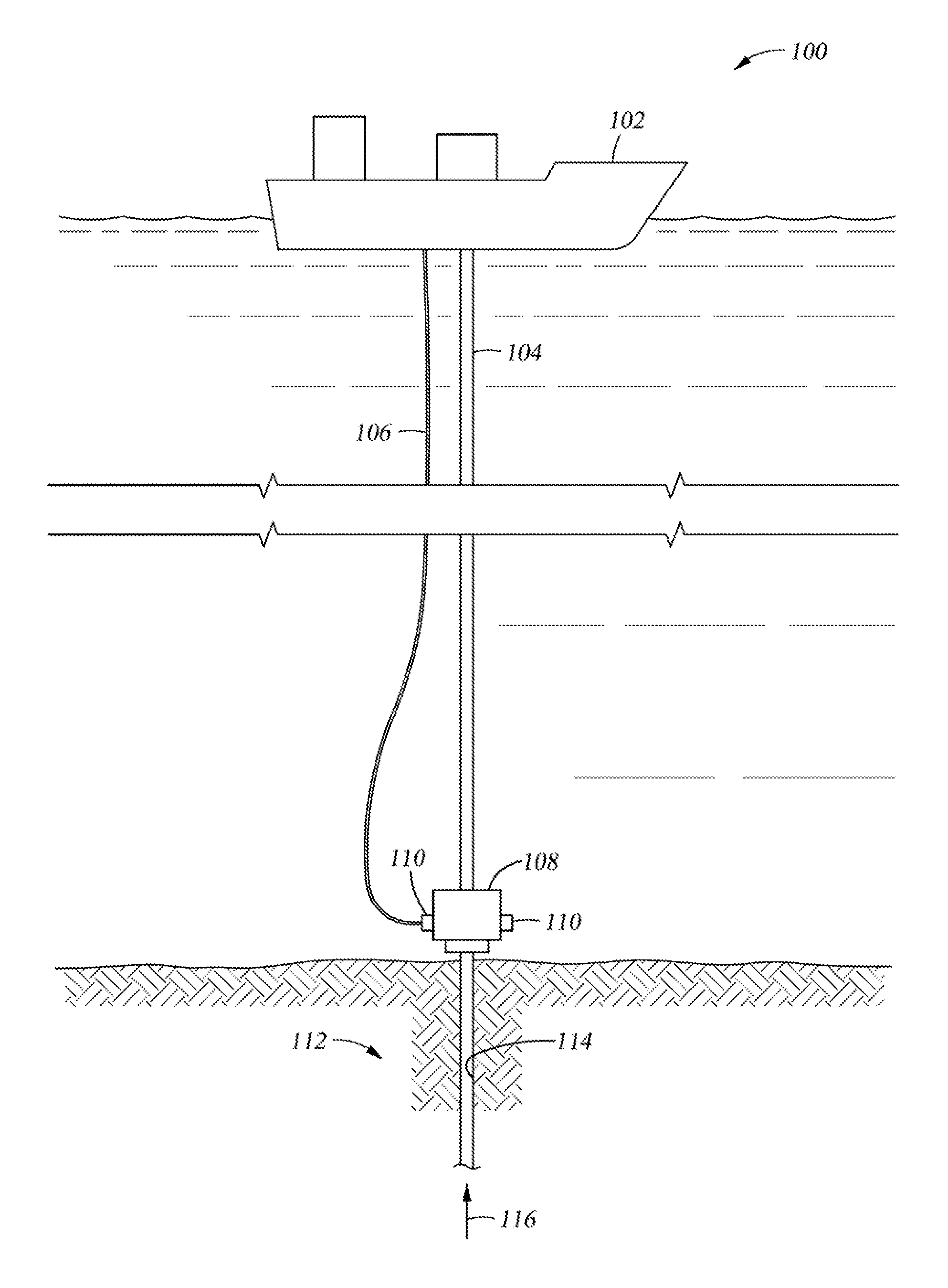

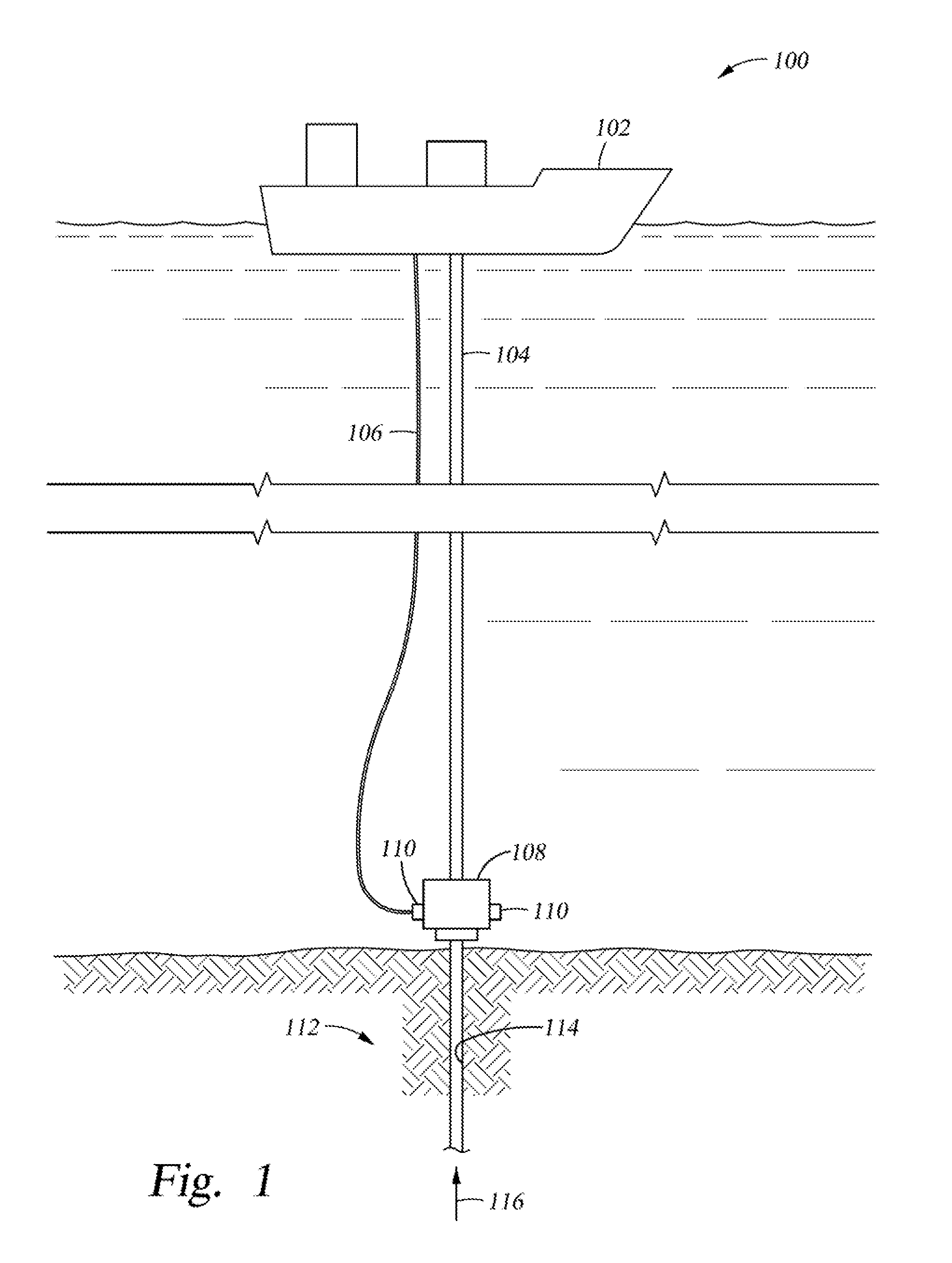

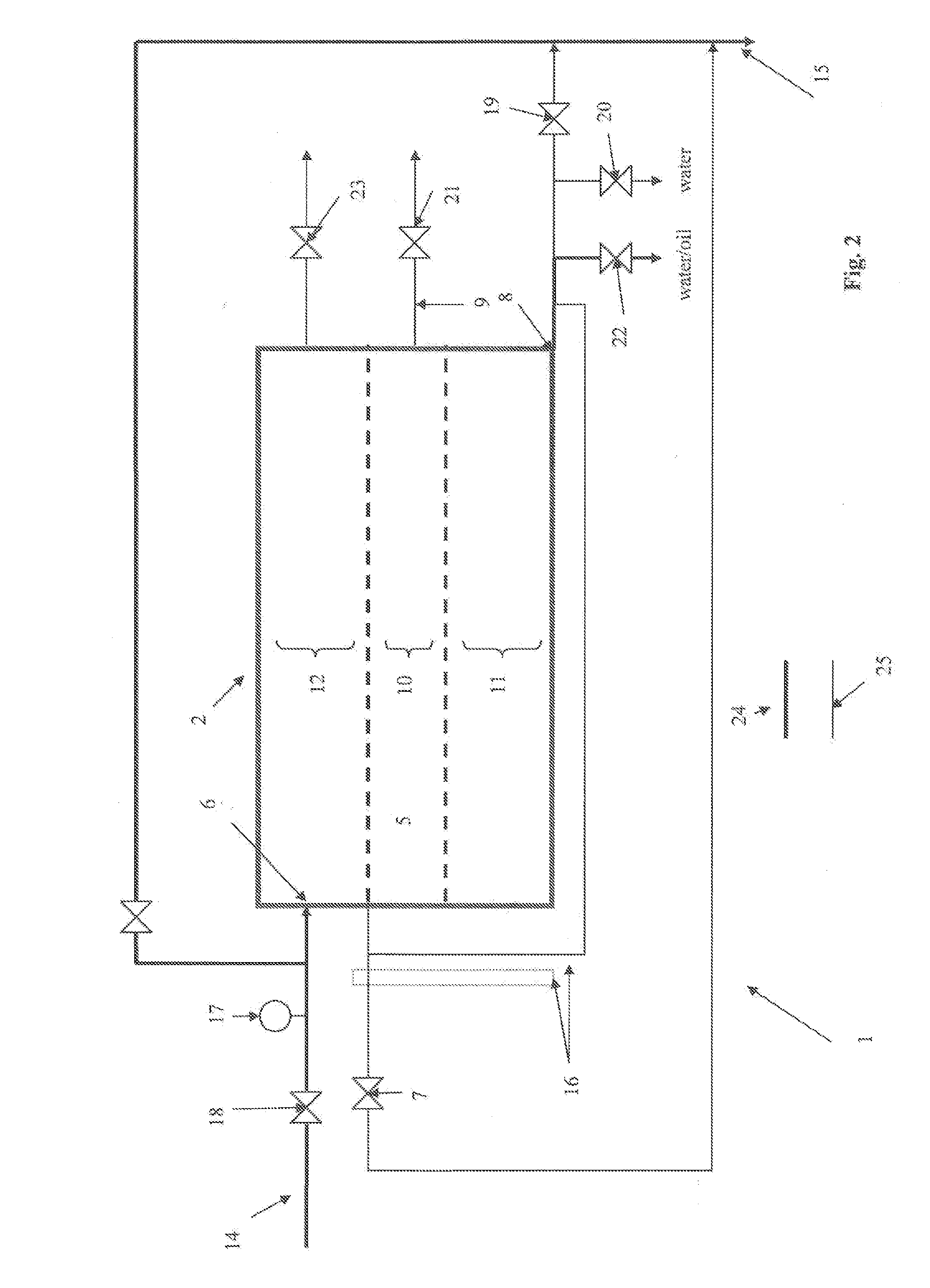

Multiphase flow measurement in extreme environments such as subsea or in-well is a difficult task for many reasons including reliability, survivability, and longevity issues; accessibility to the equipment; and complexity of the varying flow field as a function of position and time. Embodiments of the present invention provide techniques and apparatus for performing subsea multiphase flow measurement by combining two technologies. One is based on infrared water-cut measurement technology which is capable of measuring water and oil concentrations in multiphase flow with up to 99.5% gas volume fractions. The second technology is based on in-well fiber-optic flow measurement capable of resolving gas and total liquid flow through the measurements of flow velocity, fluid mixture speed of sound, and absolute pressure and temperature at meter location. This hybrid system represents an approach to subsea multiphase metering that may offer advantages compared to traditional systems for some applications.

Owner:WEATHERFORD TECH HLDG LLC

Method and apparatus for measuring and improving efficiency in refrigeration systems

InactiveUS7059143B1Reduce noiseReduce complexityCompressorMechanical apparatusProcess engineeringRefrigerant

An apparatus for optimizing an efficiency of a refrigeration system, comprising means for measuring a refrigeration efficiency of an operating refrigeration system; means for altering a process variable of the refrigeration system during efficiency measurement; and a processor for calculating a process variable level which achieves an optimum efficiency. The process variables may include refrigerant charge and refrigerant oil concentration in evaporator.

Owner:HUDSON TECHNOLOGIES

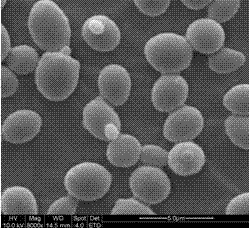

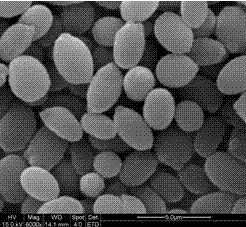

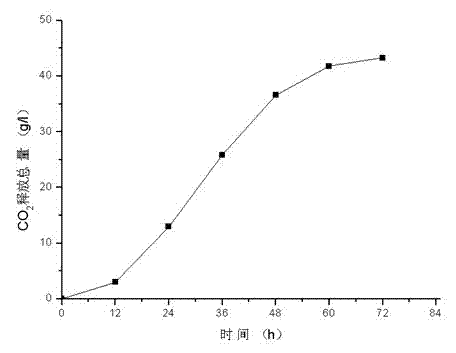

Screening and application of yeast with high ethanol yield and low fusel oil yield in Chinese Maotai-flavor liquor production

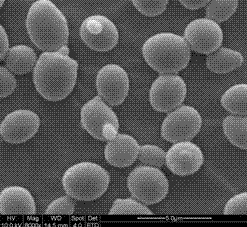

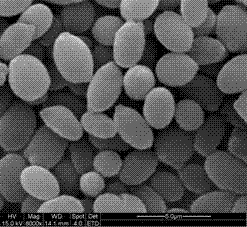

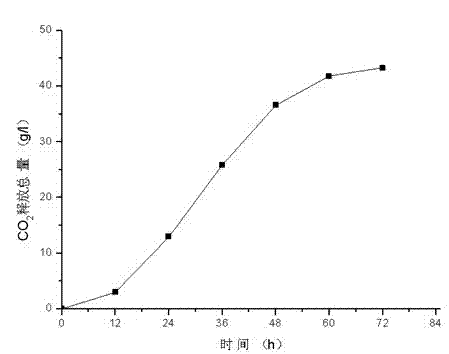

InactiveCN102226155AReduce manufacturing costSimple production processFungiMicrobiological testing/measurementDistillationScreening method

Screening and application of yeast with high ethanol yield and low fusel oil yield in Chinese Maotai-flavor liquor production belong to the technical field of biological engineering. The strain is any one strain selected from pichia anomala CGMCC4740, schizosaccharomyces pombe CGMCC4744, zygosaccharomyces bailii CGMCC4745, trichosporon asahii CGMCC4746, saccharomyces cerevisiae CGMCC4747, kazachstania exigua CGMCC4748, pichia fermentans CGMCC4750. The strain is separated from various Daqu, fermented grains, brewing raw materials and brewing environment of several Chinese famous distilleries; the screening method comprises the following steps: diluting distiller yeast samples, fermented grains, brewing raw materials or brewing environment substances, coating on a TTC primary screening plate, selecting a colony with an obvious red color, inoculating the colony in a shake flask for culture, performing secondary screening, determining the contents of ethanol and fusel oil of the fermentation broth by a distillation specific gravity method and HS-SPME-GC-MS respectively, screening the strain with high ethanol concentration and low fusel oil concentration. The strain is applicable to food industry and brewed wine industry.

Owner:JIANGNAN UNIV

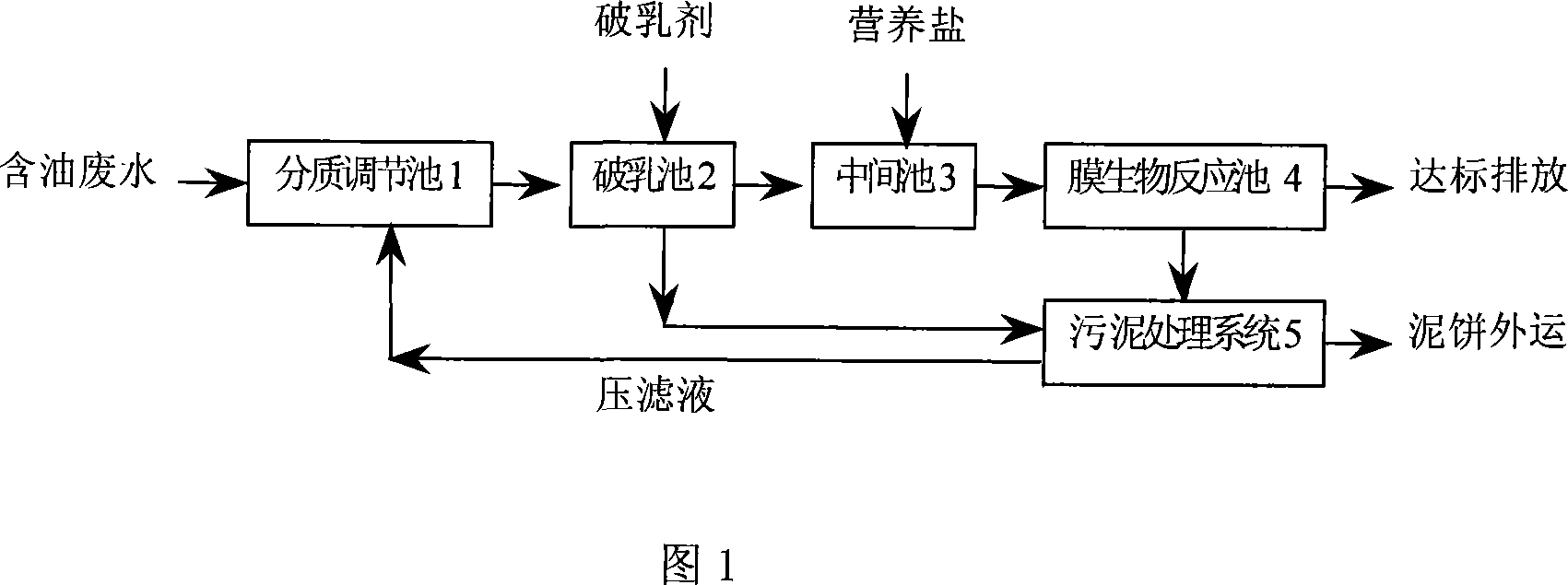

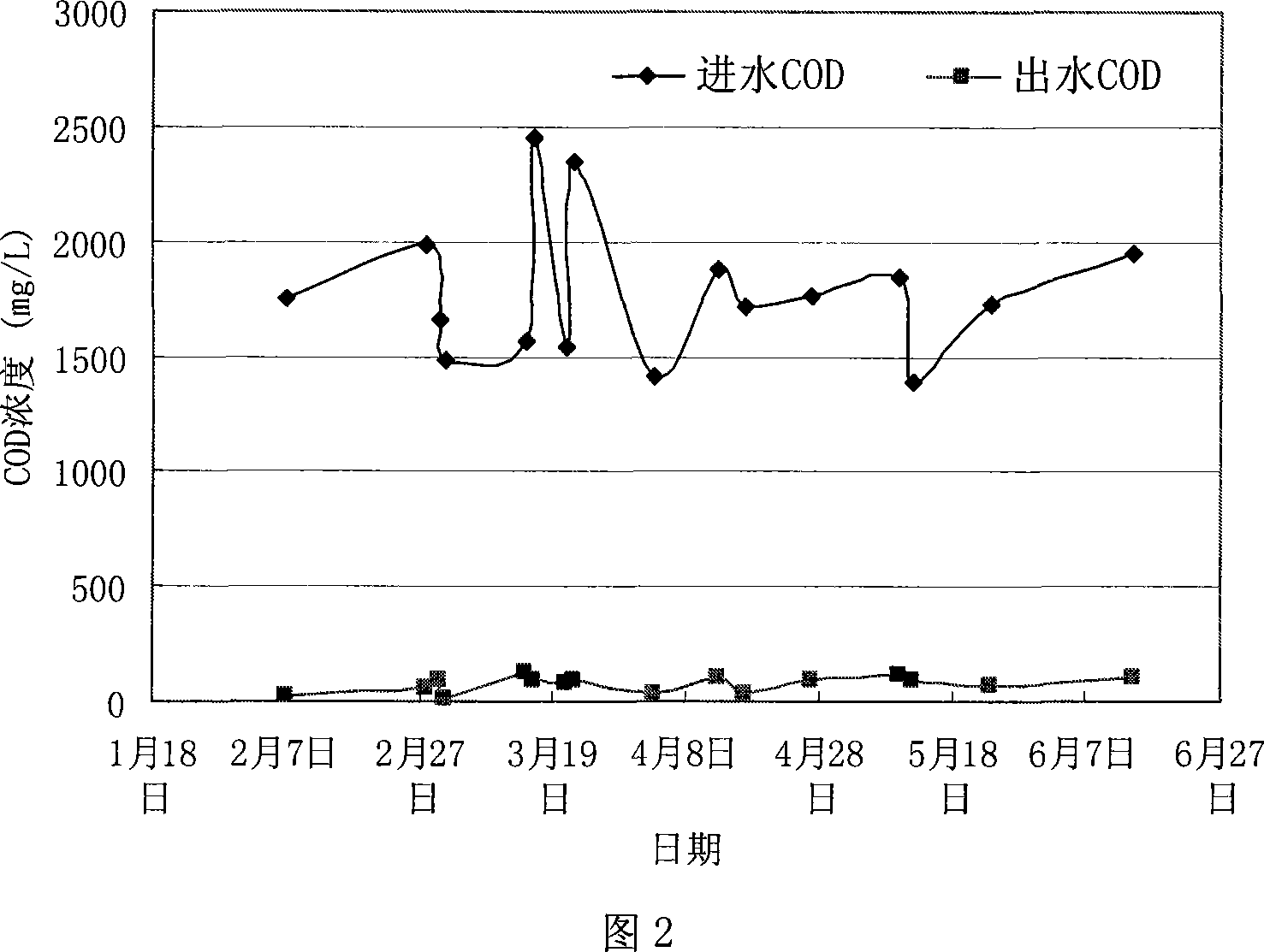

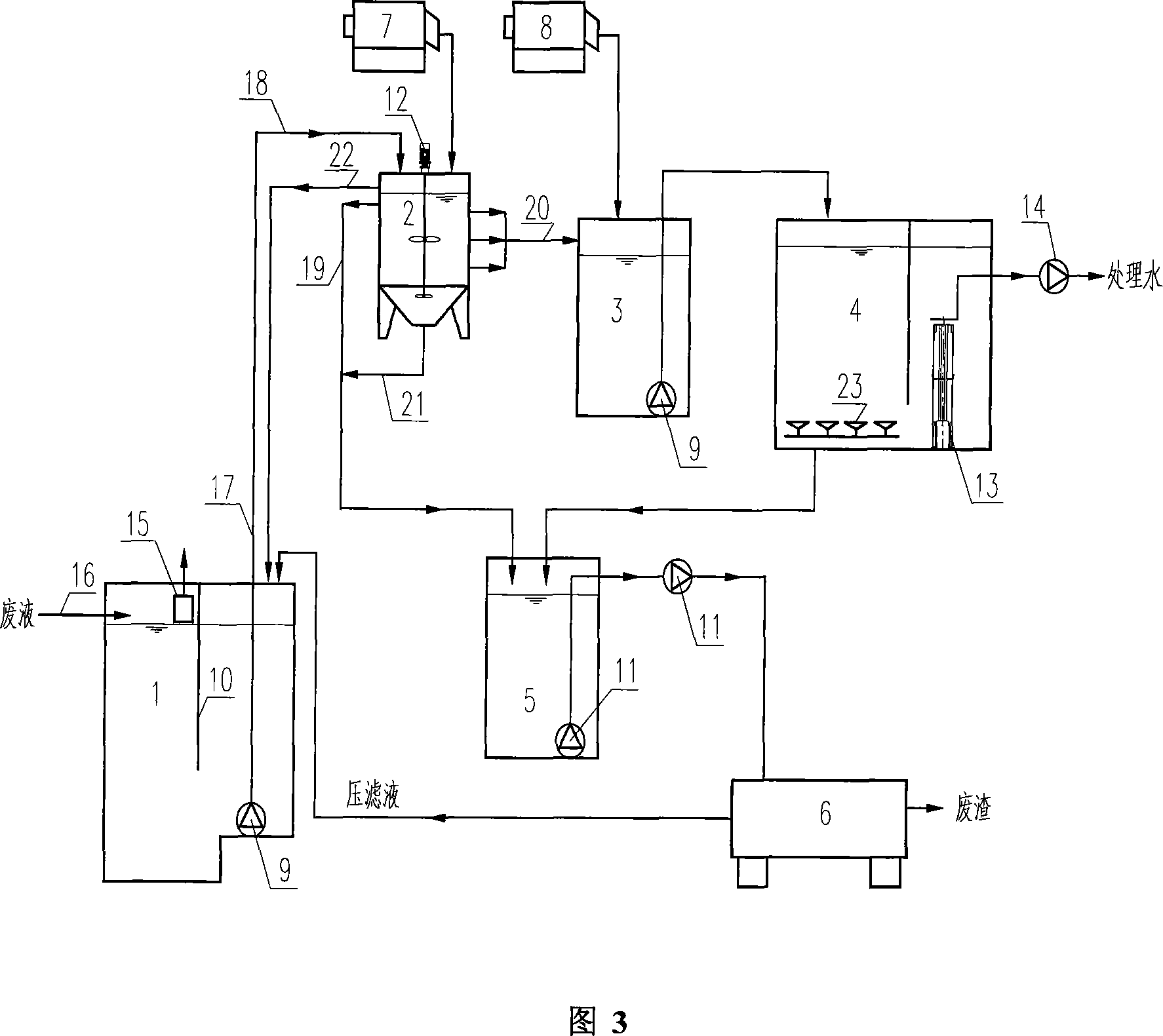

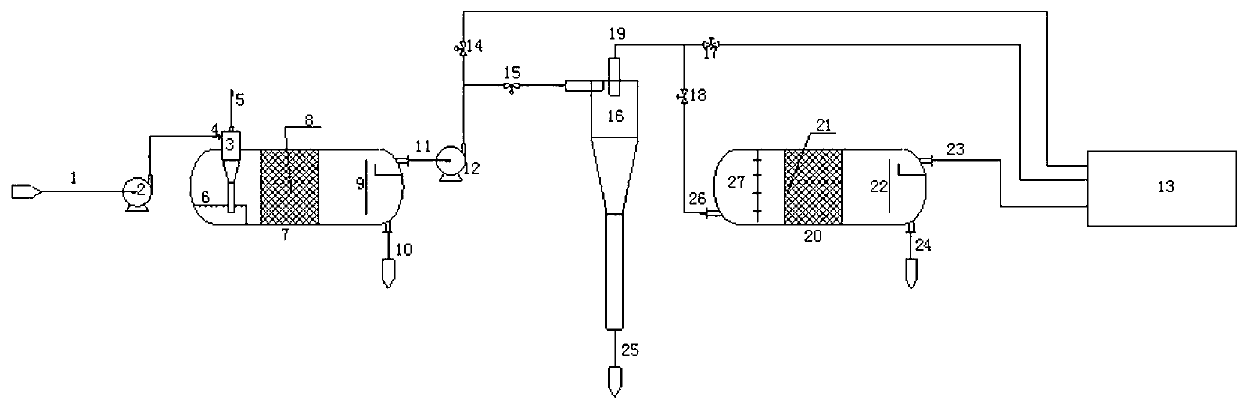

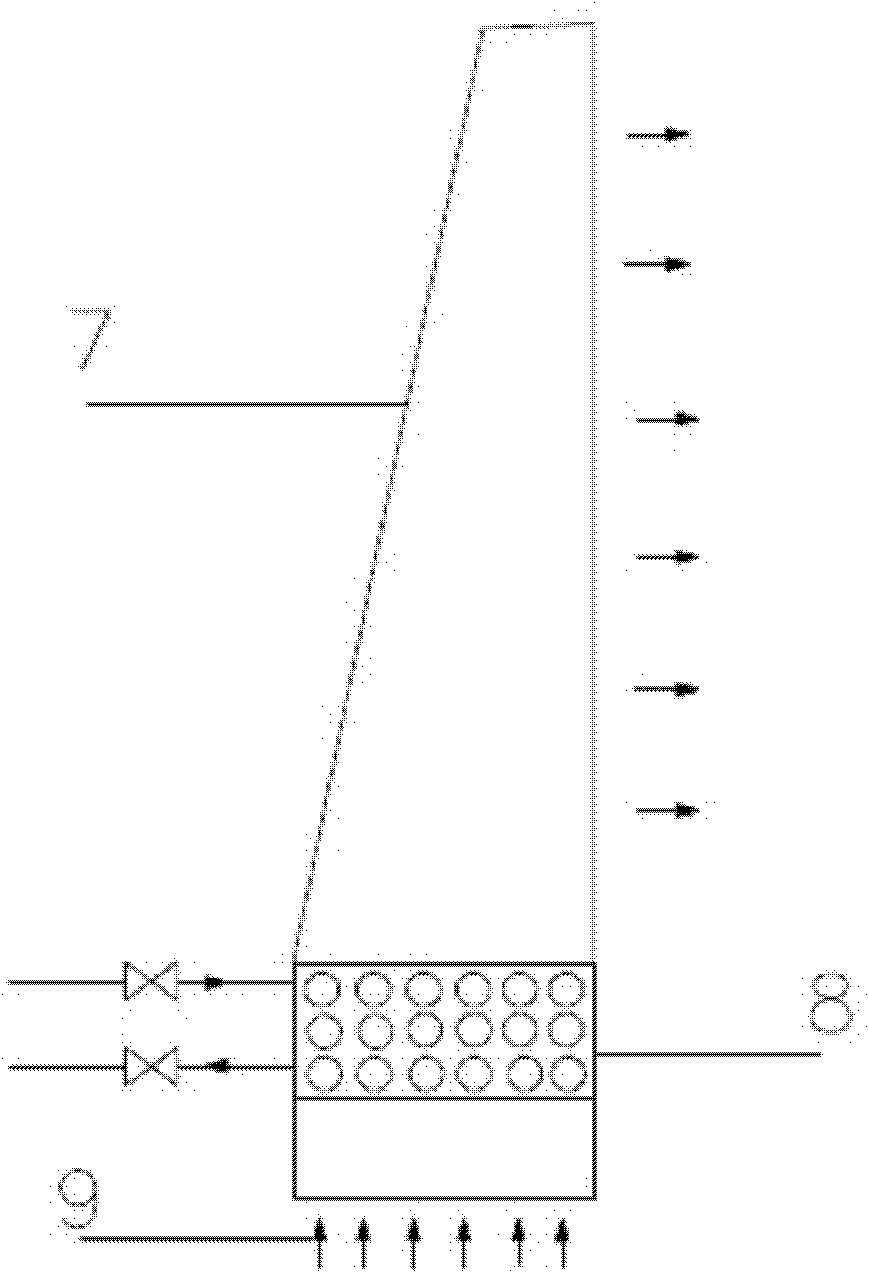

Method and apparatus for treating emulsified oil waste water

ActiveCN101054254ADemulsification and degreasing method is simpleEasy to operateSludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesWater processingOil concentration

The invention discloses a emulsified oil waste water processing method, comprises five steps such as separating oil and emulsion breaking, adding easy degrading material, deoiling by codegradation membrane biological method and mud processing, the invention combines codegradation mechanism with the application of a membrane bioreactor based on biological treatment of oily wastewater, has strengthened ability of biological processing oil contamination, has broken through the inhibition of oil for microorganism. The invention also discloses a emulsified oil waste water processing device, comprises a separating equalizing tank, a emulsion breaking tank, a middle tank and a membrane biological reaction tank connected successively, the produced mud is sent in a mud storing tank, a hydroextractor successively, a demulsifier feeding apparatus is arranged out of the emulsion breaking tank, a nutrient salt feeding apparatus is arranged out of the middle tank. The device requires widely for influent oil concentration of the bioreactor, COD concentration, has strong degradation ability to contaminant, processed effluent can reach the standard, produces a little mud and a little secondary pollution, has simple device technological process and saves investment and operating costs.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

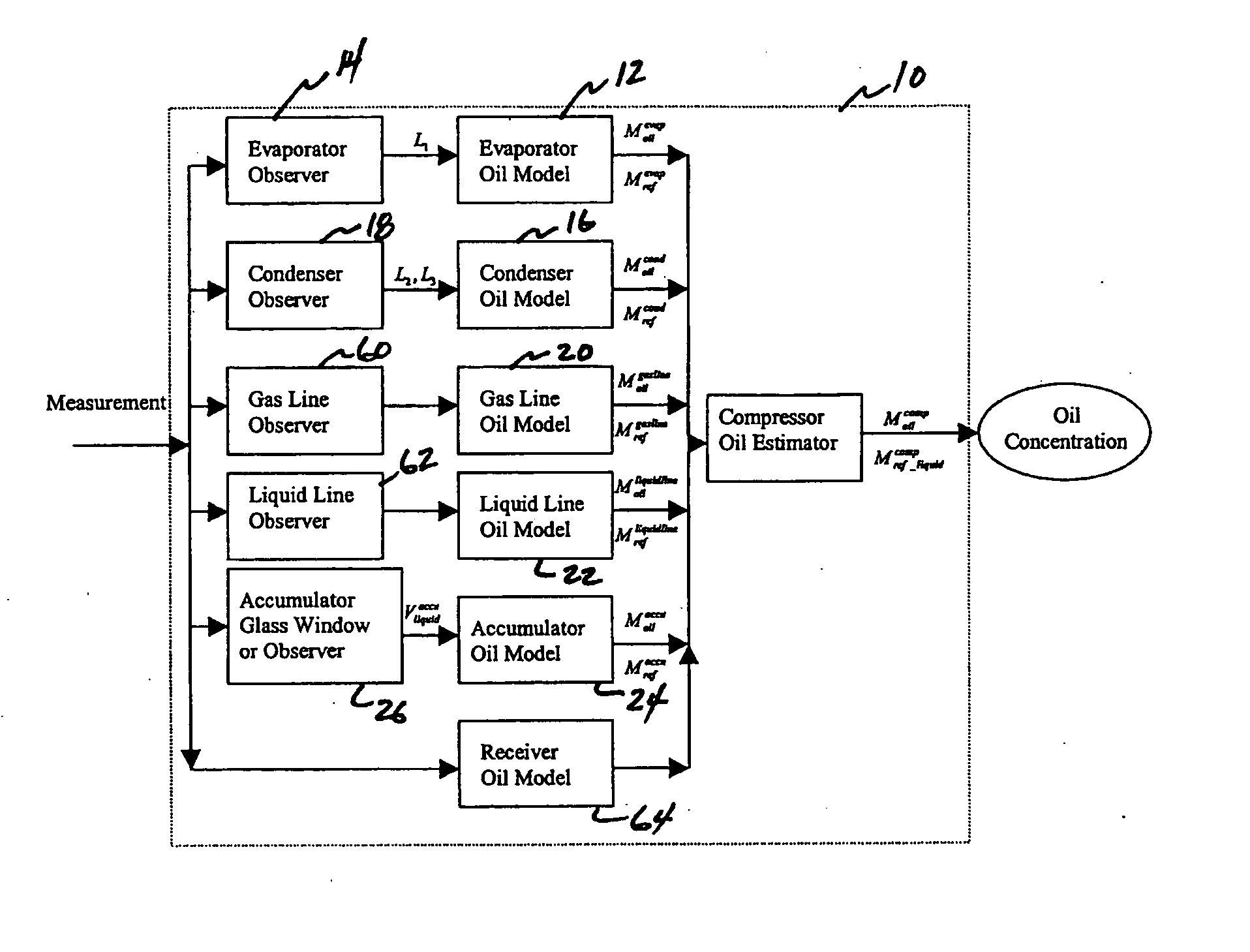

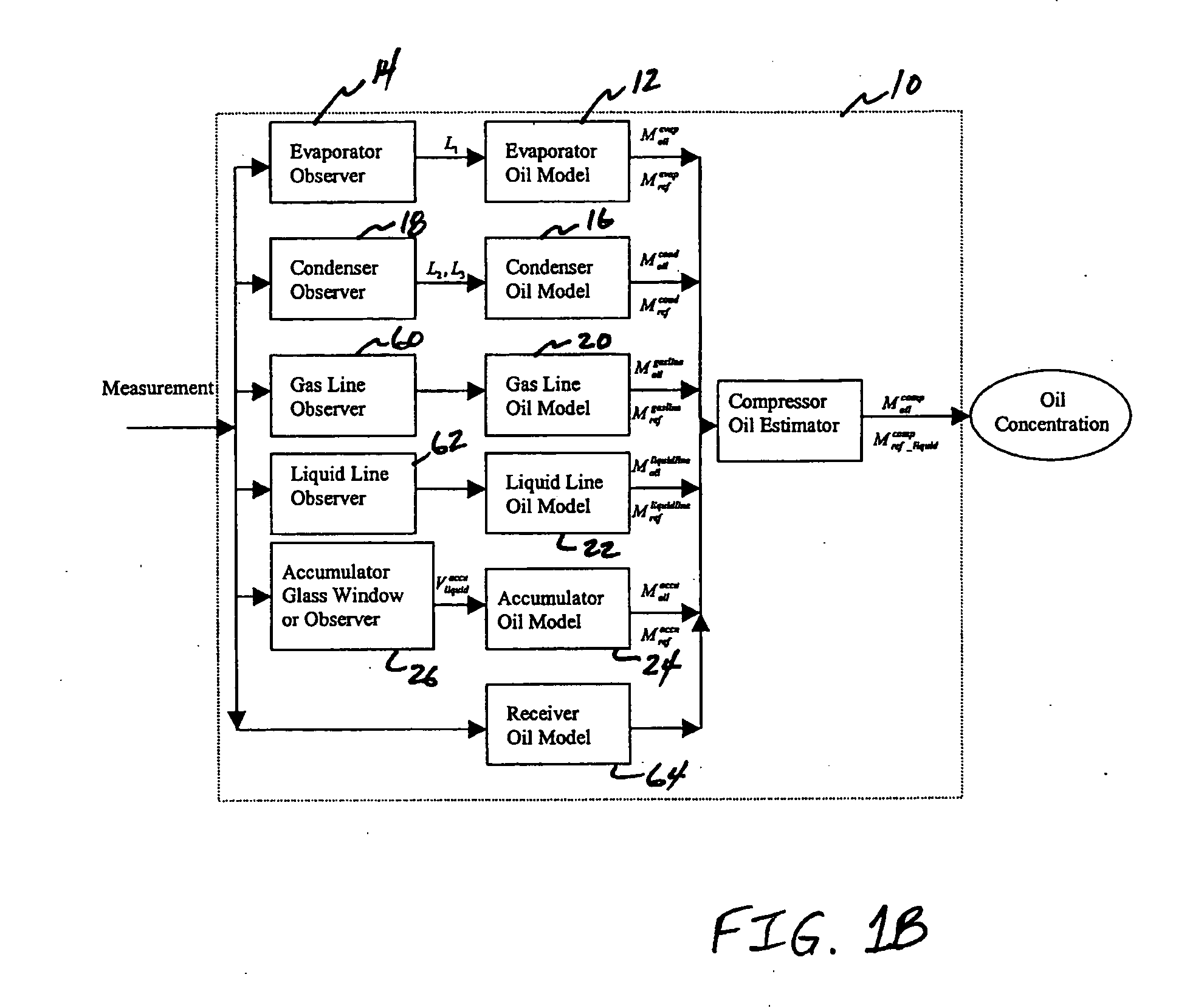

Oil circulation observer for HVAC systems

InactiveUS20050103035A1CompressorRefrigeration safety arrangementRefrigeration compressorExperimental testing

Owner:MASSACHUSETTS INST OF TECH

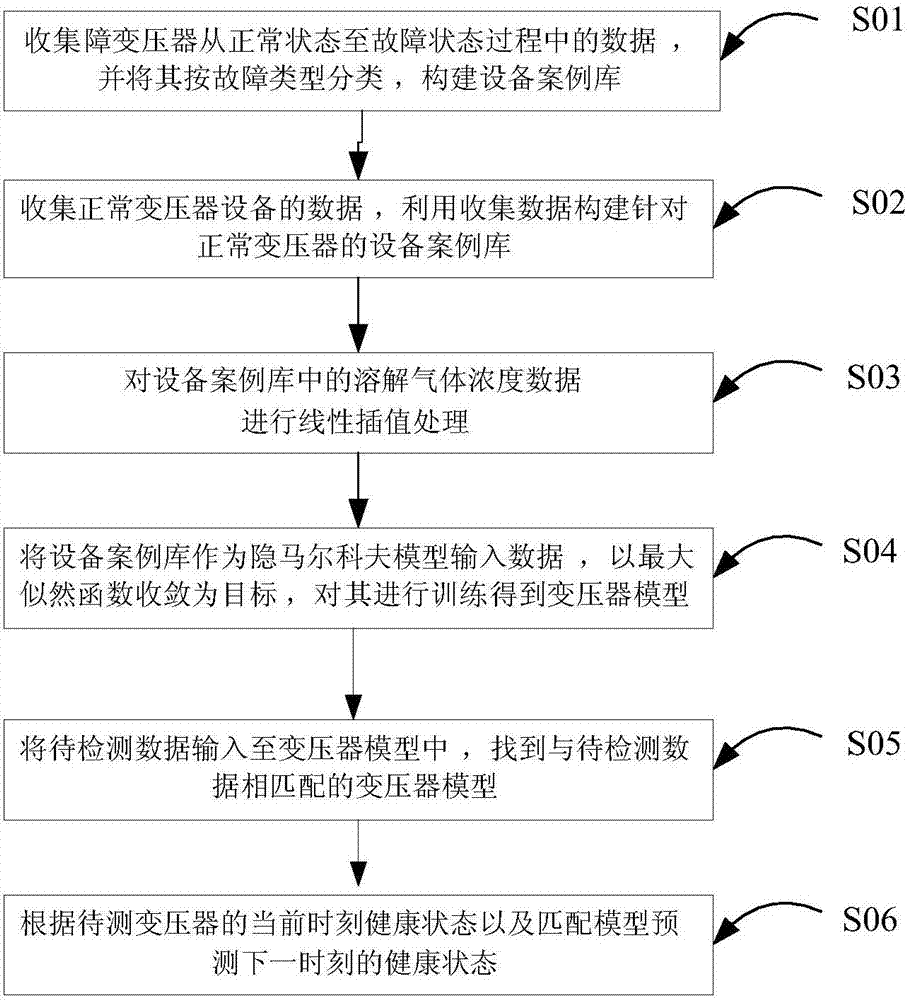

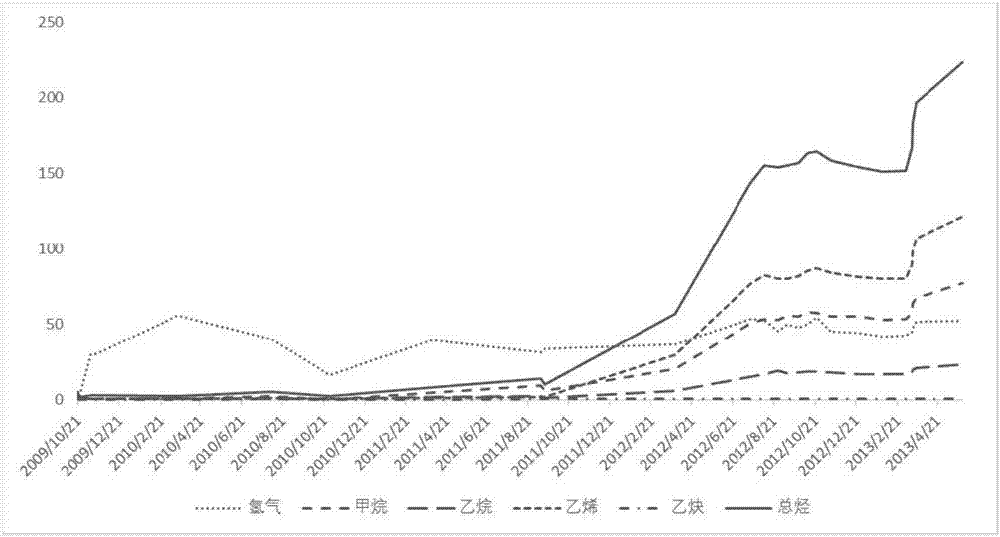

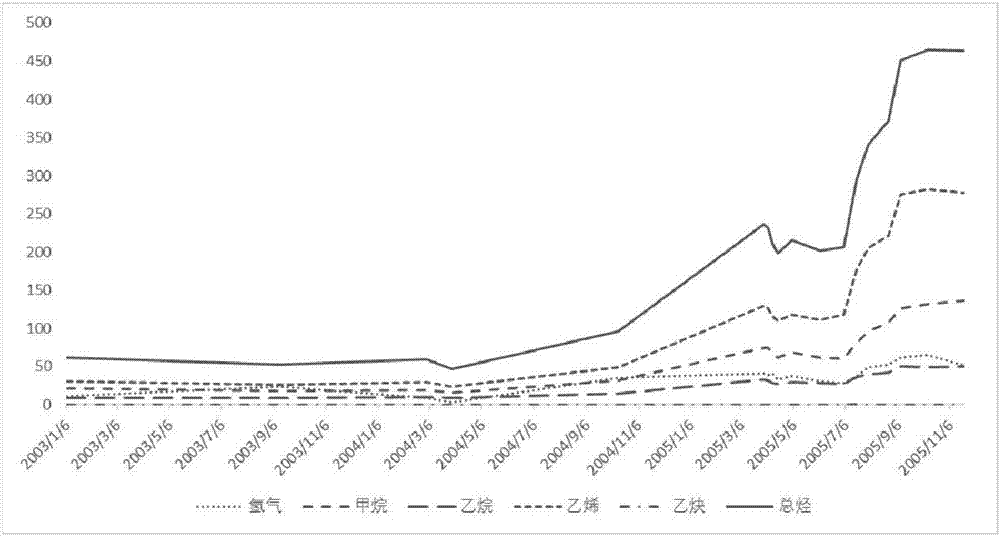

Transformer fault dynamic early warning method based on Markov model

ActiveCN107037306ARealize dynamic early warning functionTransformers testingCharacter and pattern recognitionHide markov modelTransformer

The invention discloses a transformer fault dynamic early warning method based on a Markov model. The method comprises steps of (1) training the hidden Markov model by using gas dissolved in oil concentration data from the normal state to the fault state of a fault transformer and gas dissolved in oil concentration data of a normal transformer, to obtain a transformer fault model Mm and a transformer normal model M fitting each type of fault; and (2) using the transformer fault model Mm and the transformer normal model M to find a model M' which matches the gas dissolved in oil concentration data of a to-be-tested transformer after the linear interpolation process, and according to the model M', the current health state and data of the to-be-tested transformer, predicting the health state of the next moment of the to-be-tested transformer. The method can predict the future operation condition of the transformer by extracting the dynamic characteristics, and realize the dynamic early warning function of the transformer equipment. The method has a wide application prospect in the equipment maintenance.

Owner:ZHEJIANG UNIV

Device of oil-sewage ship for treating sewage and method thereof

InactiveCN101234797ASimple processLess investmentFatty/oily/floating substances removal devicesLiquid separationEconomic benefitsOil separation

The invention relates to a device for treating oil stain water in an oil stain vessel and a method thereof, which belongs to the field of vessel sewage treatment and environment protection. The oil stain water treating device and the method treat the oil stain water by combining the pretreatment, middle treatment and post-treatment together. The pretreatment is finished in a multilevel oil separation and sedimentation chamber. The time between entering and flowing out is about 42 hours; the middle treatment is finished in the inclined board oil separation chamber and the gas floating chamber; the post-treatment adopts the multilevel filtering device. After the oil stain water in the vessel is treated through the multilevel oil separation and sedimentation, the inclined board oil separation, the gas floating and a multilevel filtering, in the drained oil stain water, the oil concentration is less than or equal to 5mg / L, even the oil concentration is less than or equal to 2mg / L. The oil stain treating device has the advantages of low investment, stable operation with safety and reliability, as well as simple, reliable and economic process of treating the oil stain water. The oil stain can be recycled with remarkable economic benefits.

Owner:DALIAN UNIV OF TECH

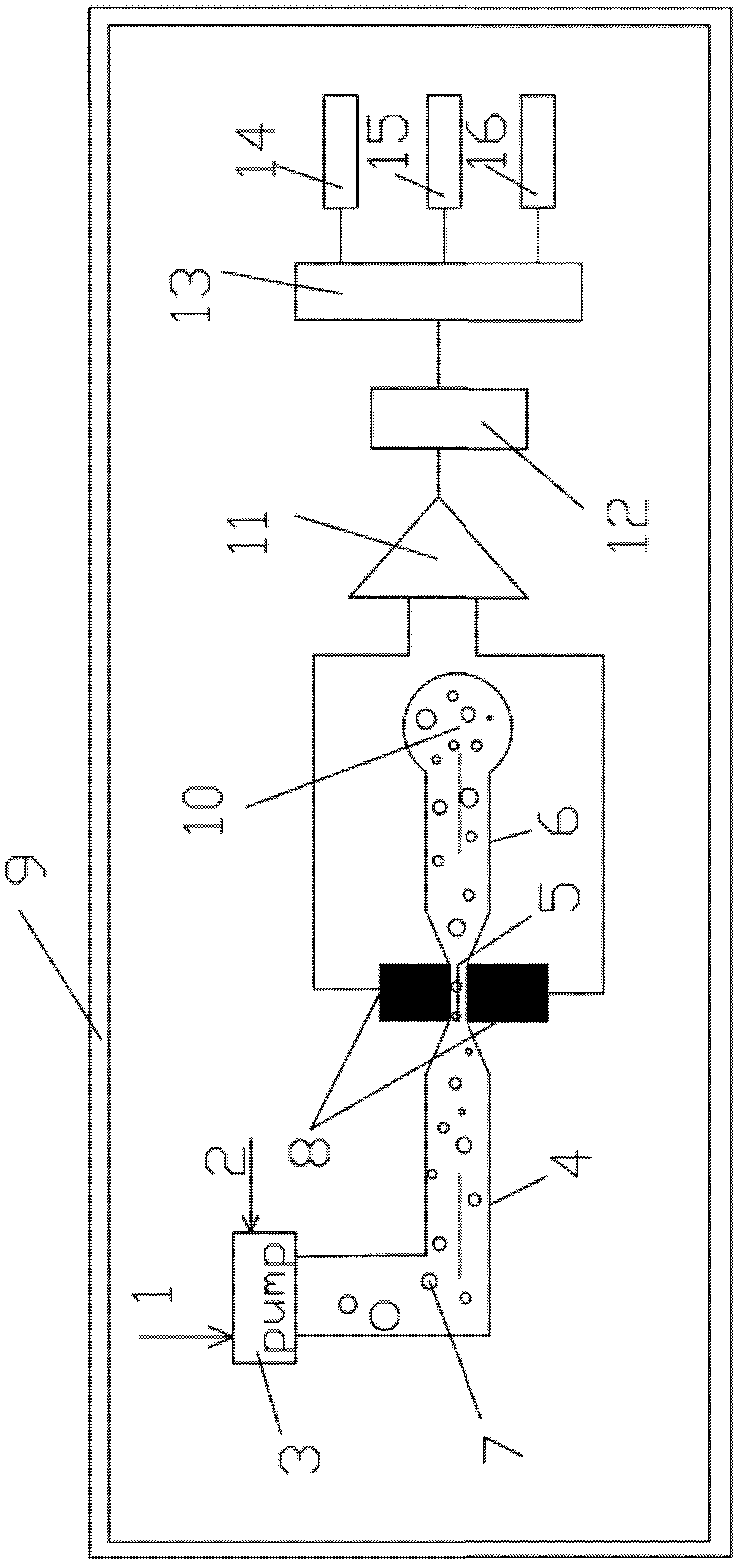

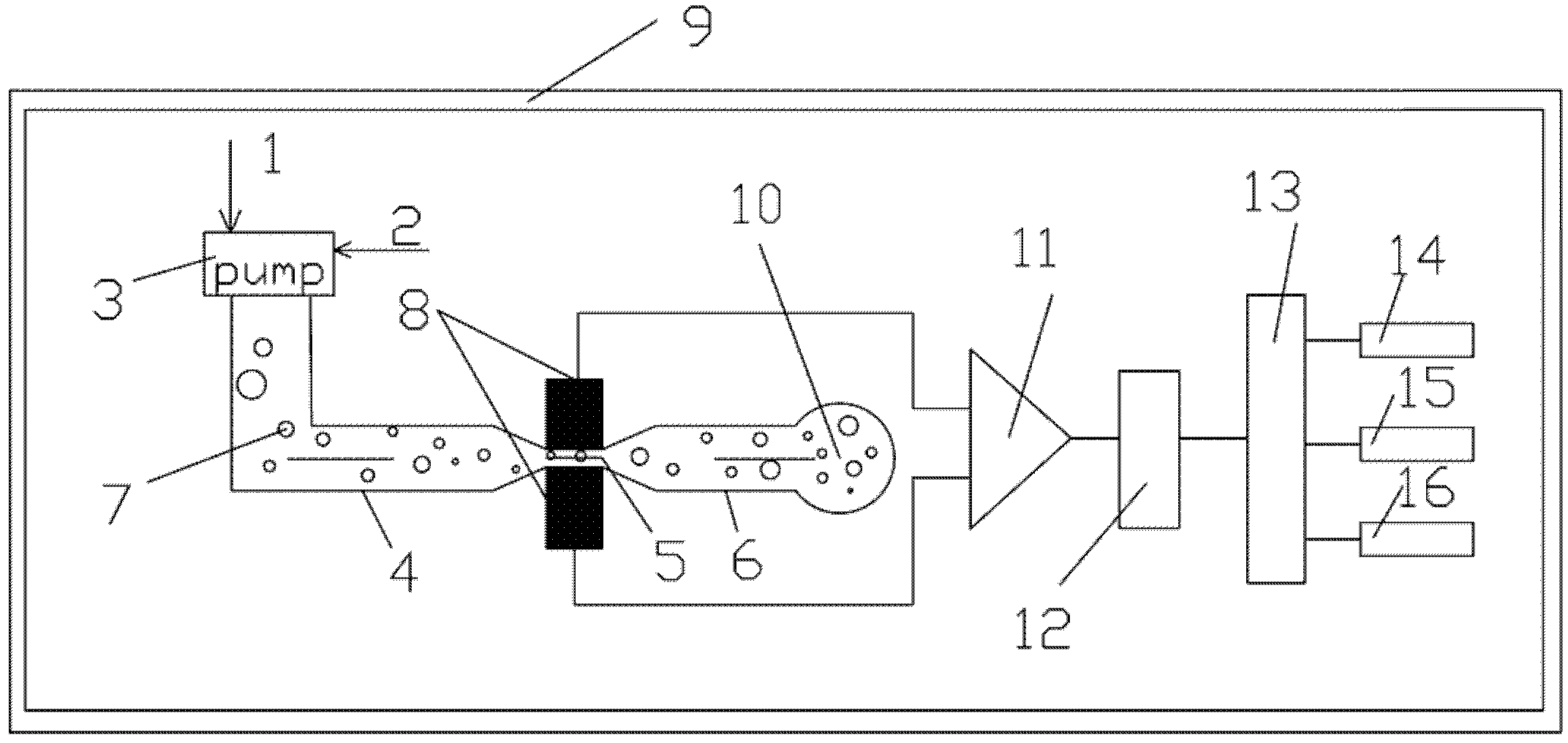

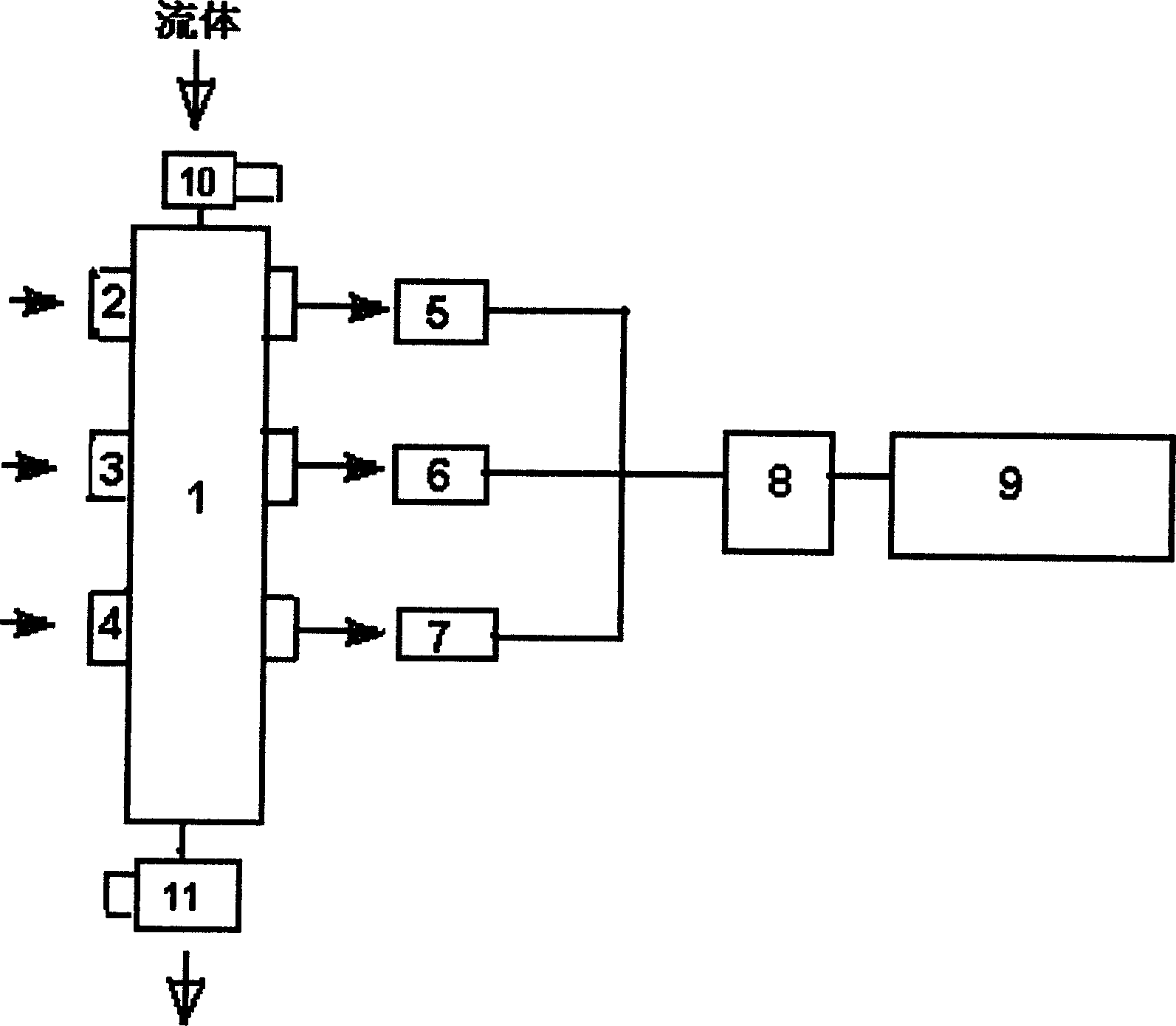

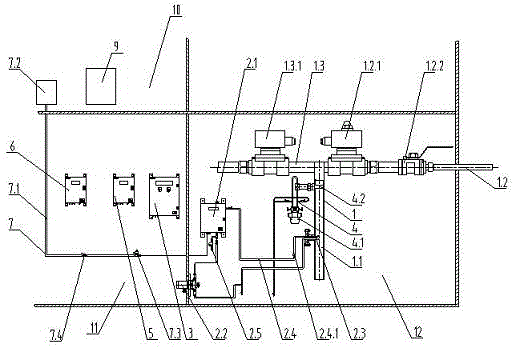

Oil concentration rapid detection apparatus for oily sewage

The invention discloses an oil concentration rapid detection apparatus for oily sewage, comprising a micropump, a capacitance detection electrode, a micro-channel chip, a body case, a capacitance amplifier, a signal acquisition card, a microprocessor, a display, a printer, and an alarm. A micro channel and the capacitance detection electrode are integrated in the micro-channel chip. A cross section of the micro channel has a rectangular shape. The micro channel comprises an inlet section, a detection section, and an outlet section. The microprocessor is provided with built-in programs of signal acquisition, filtering, comparison, analysis and counting, and data processing. In the invention, the micro-channel chip technology is used, detection members have small sizes, a detection circuit has high integration, signal processing and computing are mainly completed by the microprocessor, and therefore equipment has a relatively simple structure. The micro-channel chip of the invention can be repeatedly used, is rapid in detection, has little sample consumption, has low energy consumption, has common and relatively cheap equipment working parts, and therefore overall cost is relatively low. The oil concentration rapid detection apparatus for oily sewage is simple to operate, has a circuit board of high integration, has a compact structure, is convenient for carrying, and is convenient for on-site detection.

Owner:DALIAN MARITIME UNIVERSITY

Multiphase flowmeter for subsea applications

Owner:WEATHERFORD TECH HLDG LLC

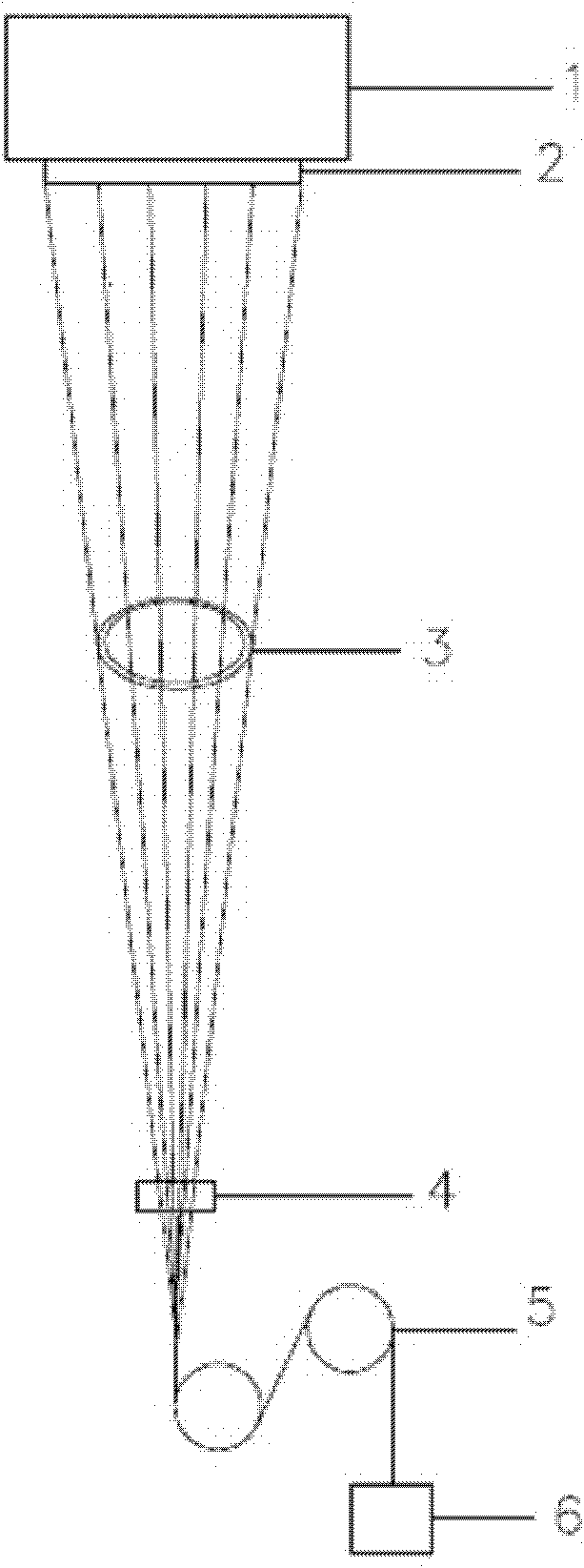

Online method for measuring oil density in oil containing sewage and device thereof

InactiveCN1687746AAvoid inhomogeneityEnsure stabilityPreparing sample for investigationColor/spectral properties measurementsUltrasonic emulsificationDisplay device

The invention discloses the online measuring the oil concentration of the sewage and its equipment. The method adopts the ultrasonic emulsification oil-water mixture and uses the optical nephelo method to test the oil concentration. The equipment comprises the measuring section vertically put on the sewage pipeline, the ultrasonic oscillator set at the input and the output ends of the measuring section; three pairs of white gem windows transmitting beams set at the outside pipe wall, and the windows arrange in 120 Deg angle mutually; three groups of photoelectric converters are set corresponding to the windows; connect the industrial controller with a displayer through the signal receiver and the amplifier. When the sewage flows through the test section, the ultrasonic oscillator emulsificates the sewage and mixes it evenly; the testing beam is the violet beam with fixed wavelength; the photoelectric converter converses the optical signal into the electric signal and the optical nephelometer calculates the oil concentration of the sewage.

Owner:XI AN JIAOTONG UNIV

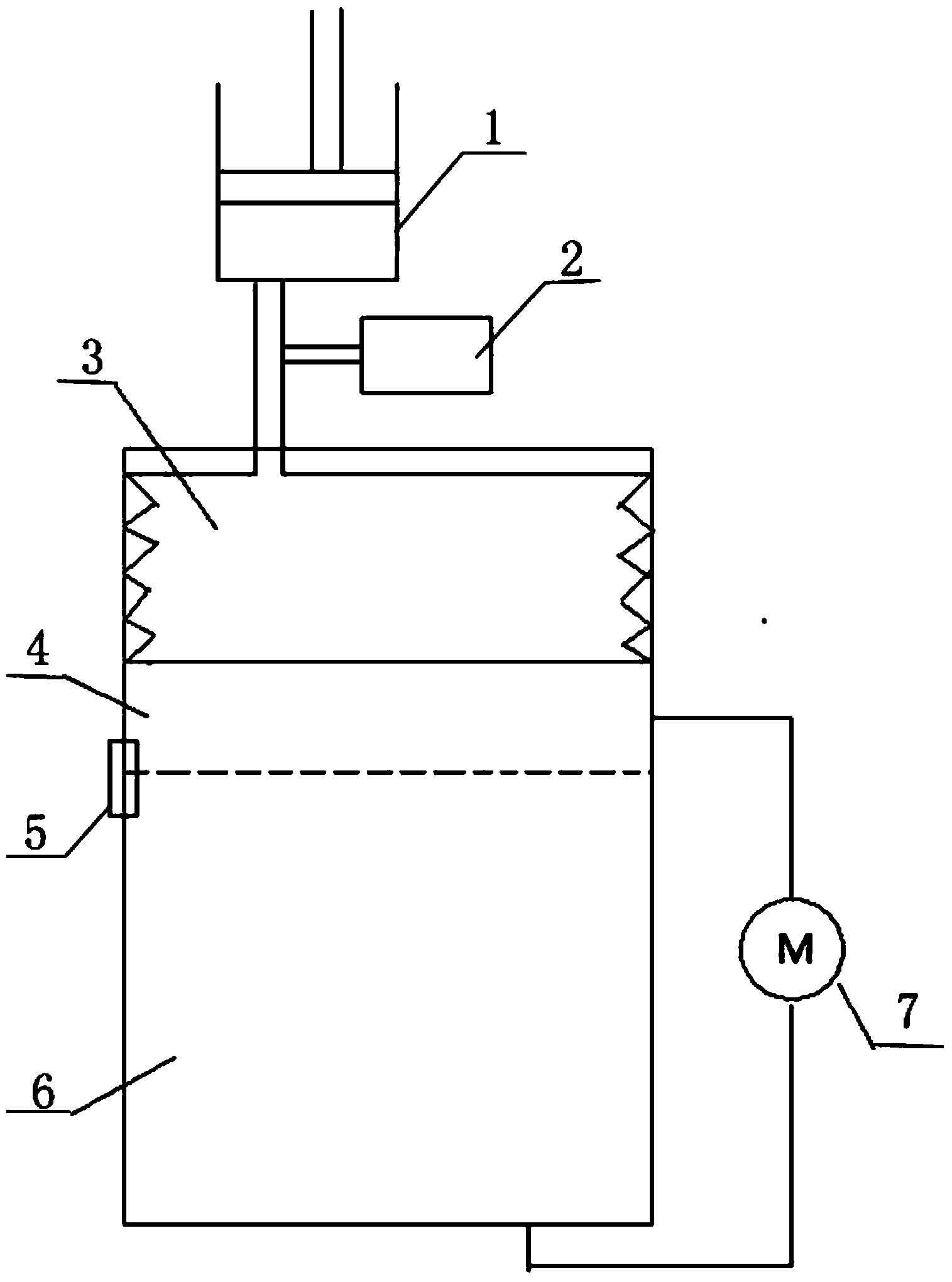

Oil-water separation technology and equipment for spilled oil recovery robot

InactiveCN102989200AImprove the ability to adapt to sea conditionsIncrease concentrationNon-miscible liquid separationAutomatic controlSeparation technology

The invention relates to an oil-water separation technology and equipment for a spilled oil recovery robot. The equipment comprises an oil transfer pump, a cyclone separator, a primary oil-water separator, a screw pump, a liquid distributor, a secondary oil-water separator, a tertiary oil-water separator, a rectifier and a plurality of automatic control valves. The primary oil-water separator and the tertiary oil-water separator are coalescence-type gravity oil-water separators, the secondary oil-water separator is a hydrocyclone separator, and the cyclone separator is arranged at an inlet part of the primary oil-water separator. Whether oil water directly enters an oil storage bag or the next oil-water separator can be decided by detecting the oil content of the oil water separated by the primary oil-water separator and the secondary oil-water separator. According to the oil-water separation technology and equipment for the spilled oil recovery robot, the flexibility is high, the energy consumption is low, the oil concentration in the oil storage bag can be greatly improved, the adaptive capacity, operation efficiency and operation speed of the small robot can be improved, and the market competitiveness of the robot can be promoted.

Owner:SHENYANG LIGONG UNIV

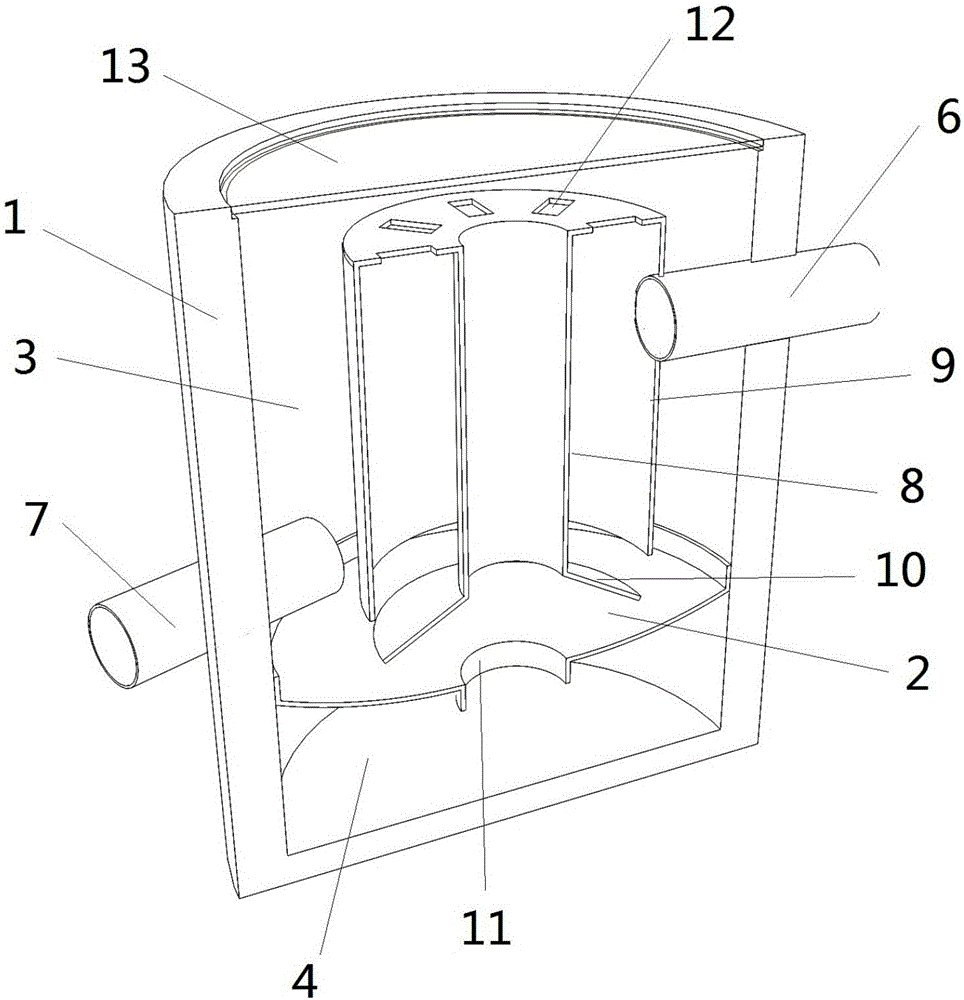

Desilting and deoiling device

InactiveCN105668700AReduce sediment contentReduce concentrationFatty/oily/floating substances removal devicesRunoff/storm water treatmentSewageUrban water

The invention discloses a sand settling and deoiling device, which comprises a separation well, a bottom baffle is arranged inside the separation well, a separation area is above the bottom baffle, and a sand settling area is below the bottom baffle, and the separation area is provided with a separator, drainage Pipe and tangential water inlet pipe, the separator is located in the center of the separation zone, including inner and outer cylinders that are concentric and connected at the top, the bottom of the inner cylinder is connected with an inclined deflector, and the drain pipe communicates with the cavity between the inner cylinder and the outer cylinder And outside the separation well, the tangential water inlet pipe connects the external sewage and the cavity between the outer cylinder and the inner wall of the separation well, and the tangential water inlet pipe is tangent to the outer wall of the outer cylinder; the bottom baffle has the same cross-sectional size as the inner wall of the separation well, and is located in The position directly below the cylinder is provided with a grit chamber, and the grit chamber connects the separation area and the grit chamber. The invention can effectively reduce the silt content and oil concentration in the rainwater, and reduce the non-point source pollution discharged into urban water bodies.

Owner:SHENZHEN ECO VISTA TECH CO LTD

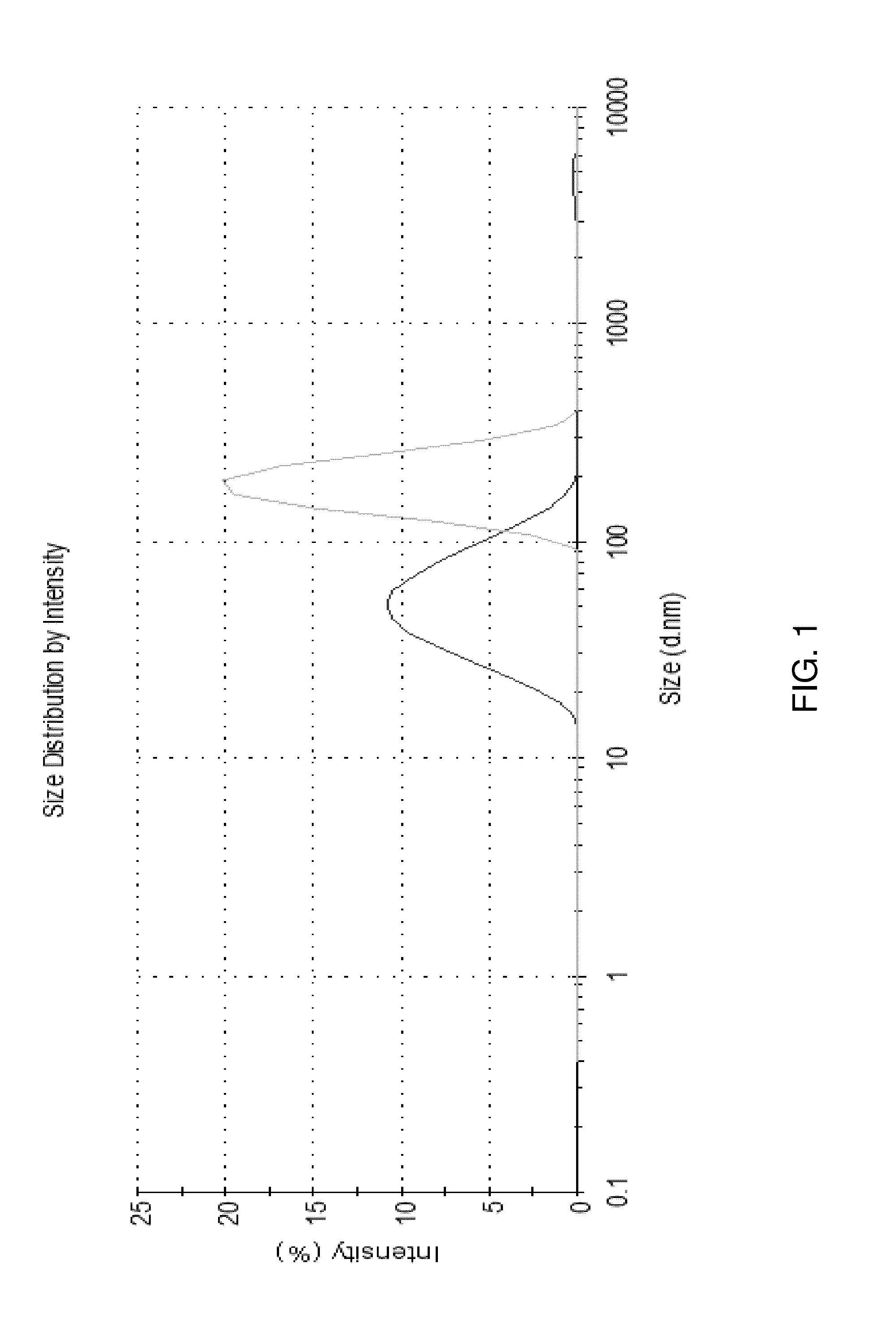

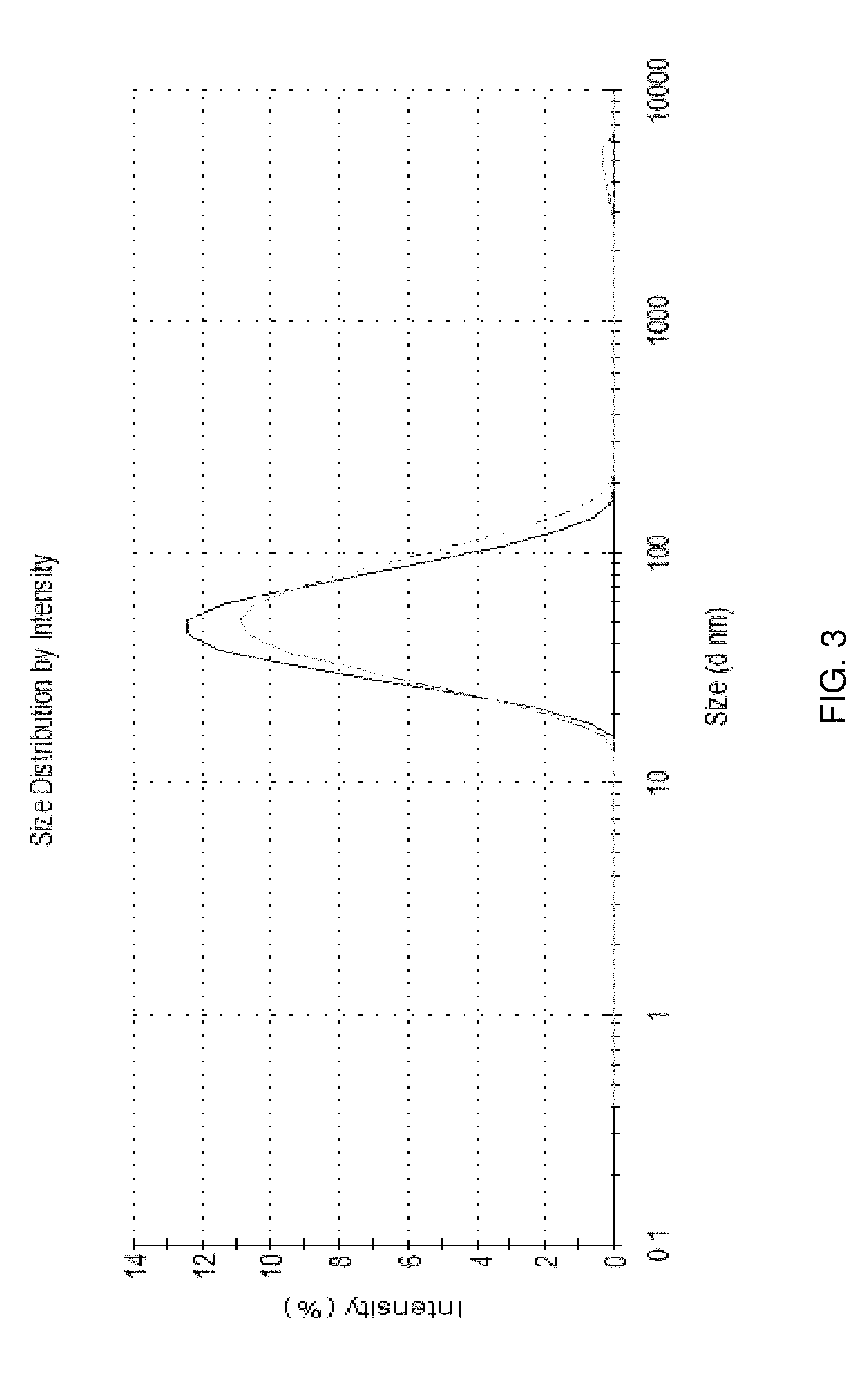

Compositions for Nanoemulsion Delivery Systems

ActiveUS20150231070A1Improve stabilityEliminate useSenses disorderInorganic non-active ingredientsSolubilityOptical transparency

The present disclosure provides a pharmaceutically acceptable, stable, and optically clear oil-in-water nanoemulsions (intensity-averaged diameter<100 nm) with an oil phase comprising >10% w / v of long chain triglyceride, total surfactant and cosurfactant concentration less than that of oil phase and without the use of alcohol as cosolvent in the aqueous phase. The nanoemulsions of this disclosure have extremely favorable particle size distribution, optical clarity, and product stability against Ostwald ripening with high levels of oil concentrations. Poorly water soluble, therapeutically active agents and others can be incorporated in the nanoemulsion systems to improve their solubility / stability in aqueous medium or to enhance their delivery for use in pharmaceutical, food, cosmetic, and other applications by oral, intravenous, subcutaneous, intra muscular, inhalation, nasal, topical, ocular, and transdermal routes.

Owner:ASCENDIA PHARMA

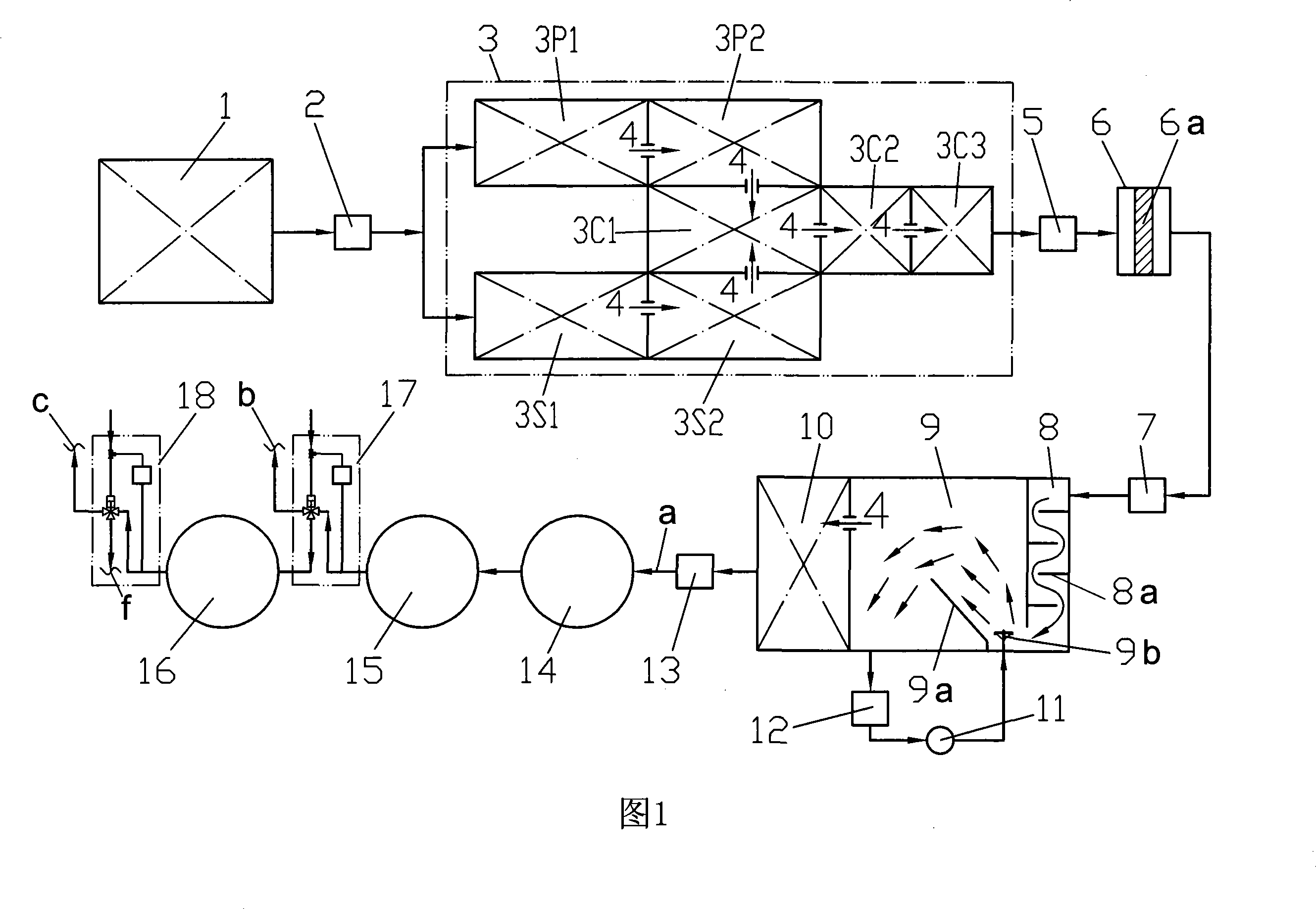

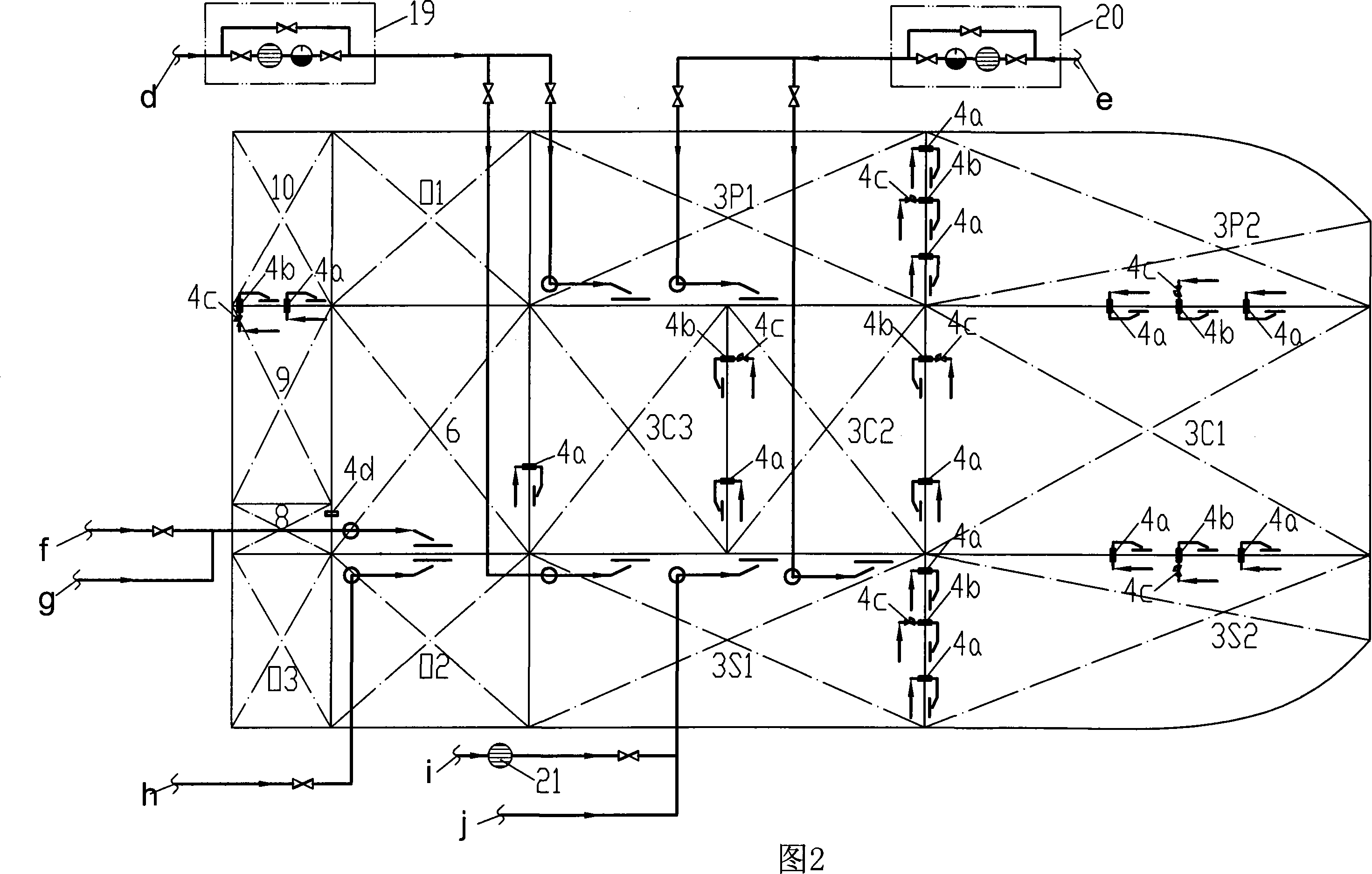

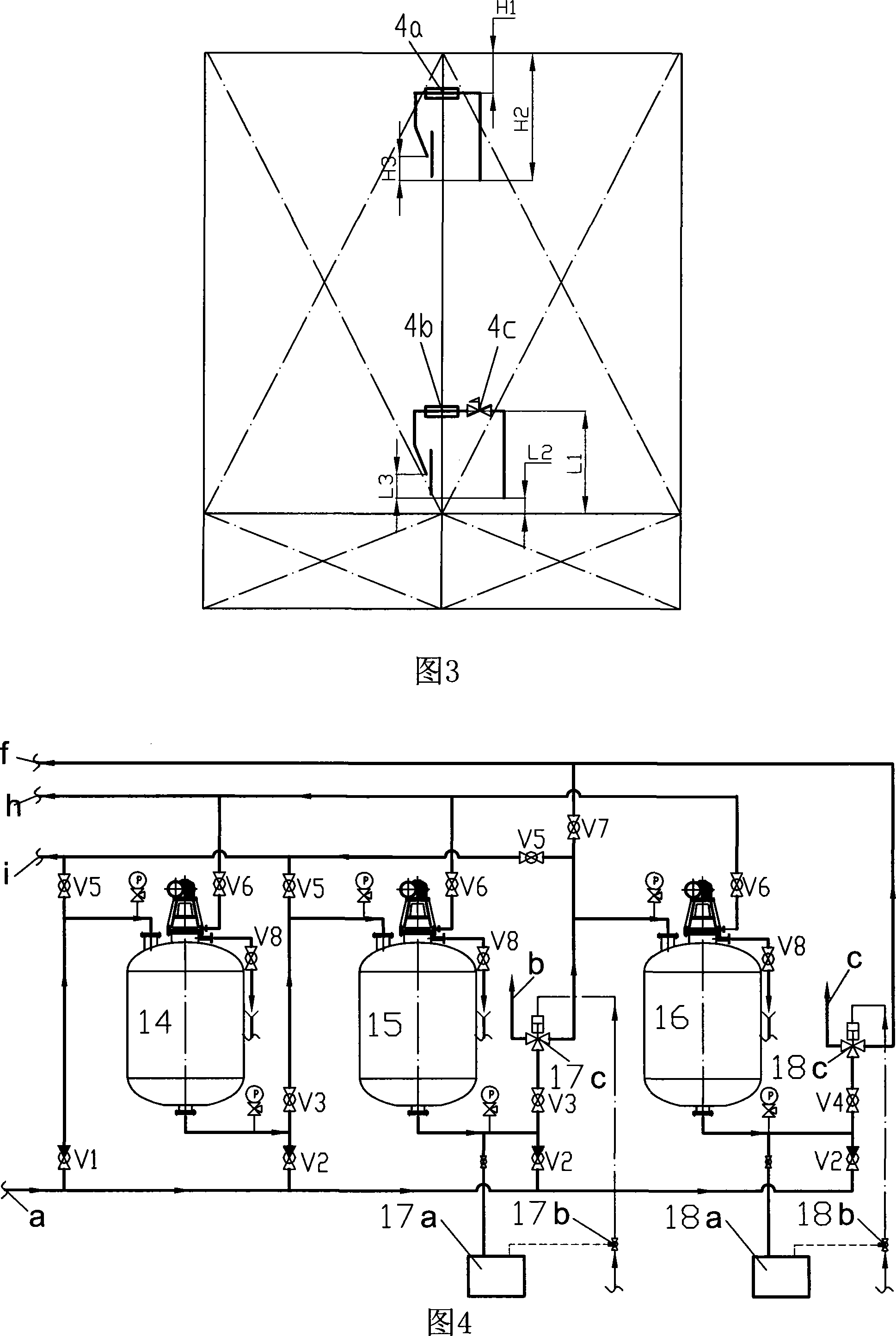

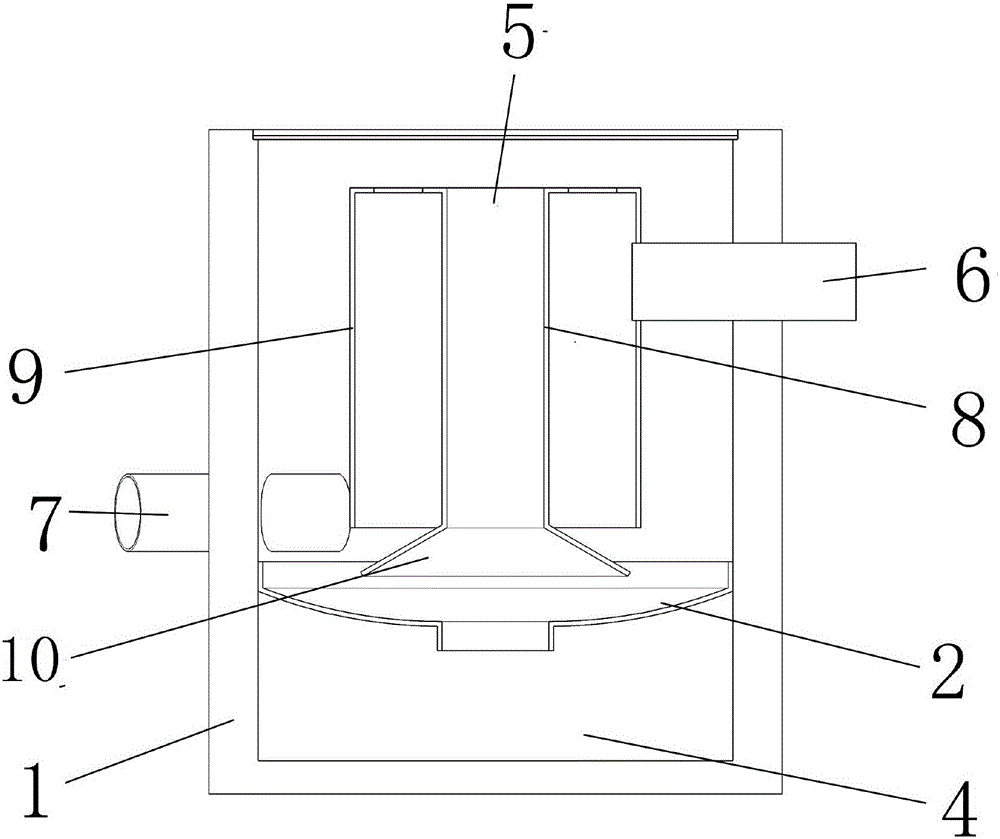

Negative-pressure transformer oil chromatographic analysis standard oil preparation device and method

ActiveCN103558316AGuaranteed stabilityGuaranteed reliabilityComponent separationFuel tankLinear motor

The invention discloses a negative-pressure transformer oil chromatographic analysis standard oil preparation device and method. The device comprises a standard oil preparation tank and an air cylinder, wherein the standard oil preparation tank is provided with an overflow opening; the top in the standard oil preparation tank is provided with an air bag; the air bag is connected with the air cylinder; a standard gas is arranged below the air bag; transformer oil is arranged below the standard gas; the overflow opening is positioned at the junction of the standard gas and the transformer oil and used for quantifying the transformer oil; the standard oil preparation tank is provided with a linear motor; two ends of the linear motor are connected to the bottom and the middle standard gas part of the standard oil preparation tank for oil and gas circulation. The negative-pressure transformer oil chromatographic analysis standard oil preparation device and method, which are provided by the invention, are used for overcoming the defects that transformer oil chromatographic analysis standard oil prepared at normal pressure is difficult to store, the concentration of standard oil prepared from standard gases with the same concentration is single, and the like, and have the characteristics of convenience in preparation, adjustable standard oil concentration range, and long-term storage of standard oil.

Owner:JIANGSU ELECTRIC POWER RES INST +3

Method and system for achieving automatic water cutting and oil return through petrochemical storage tank water drainage pipe

The invention relates to a method and system for achieving automatic water cutting and oil return through a petrochemical storage tank water drainage pipe. In order to solve the problem of oil entrainment of water cutting equipment, an automatic water cutting tank or an automatic water cutting pipe which communicates with the lower portion of a storage tank through the water drainage pipe is used for water cutting, and when the oil concentration, detected by an oil-water detection sensor, in liquid exceeds a specified value, a water cutting control valve on a water cutting pipeline led out by the automatic water cutting tank or the water cutting pipe is closed by an intelligent controller; when water appears on the lower portion of the storage tank again, an oil return control valve on an oil return pipe enabling the automatic water cutting tank or the water cutting pipe to communicate with the storage tank is opened and an oil return pump is started by the intelligent control for oil return, or an oil return pump on an oil return pipe enabling the water cutting tank and a check valve of the storage tank is opened by the intelligent controller of water cutting equipment for oil return; when a medium, detected by the oil-water detection sensor, is water, the oil return pump is stopped, and the oil return control valve is closed, or the oil return pump is stopped, and the oil return process is completed; and water cutting is conducted after settling for a certain time or immediately. The method and system have the advantages that oil cannot adhere to the interior of the pipeline of the automatic water cutting equipment during water cutting, entrainment and adhering of oil do not exist during water cutting, and the water cutting purity degree is high.

Owner:KAITAI (CHUZHOU) FLUID CONTROL CO LTD

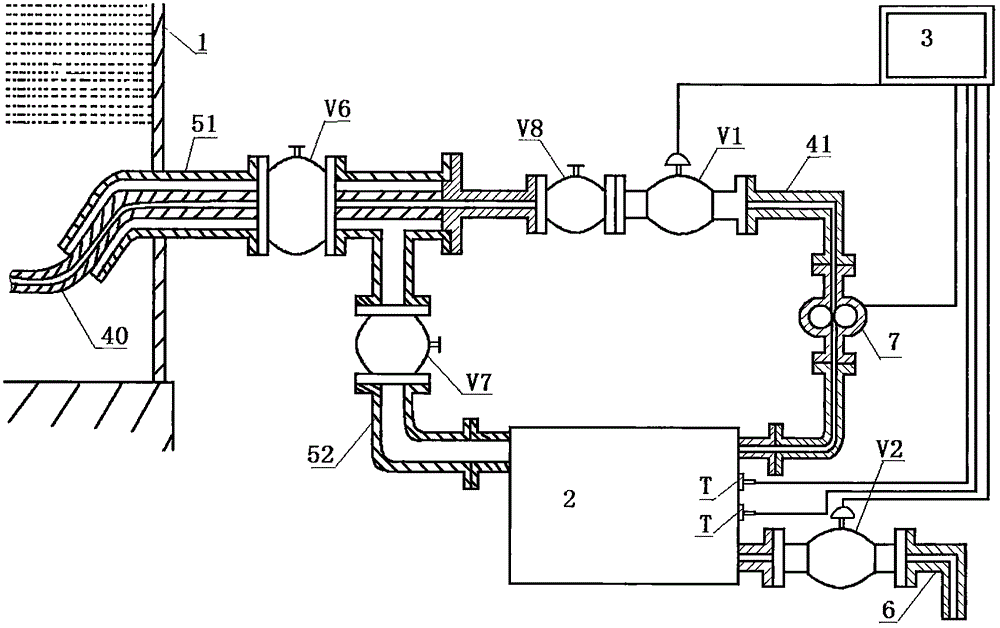

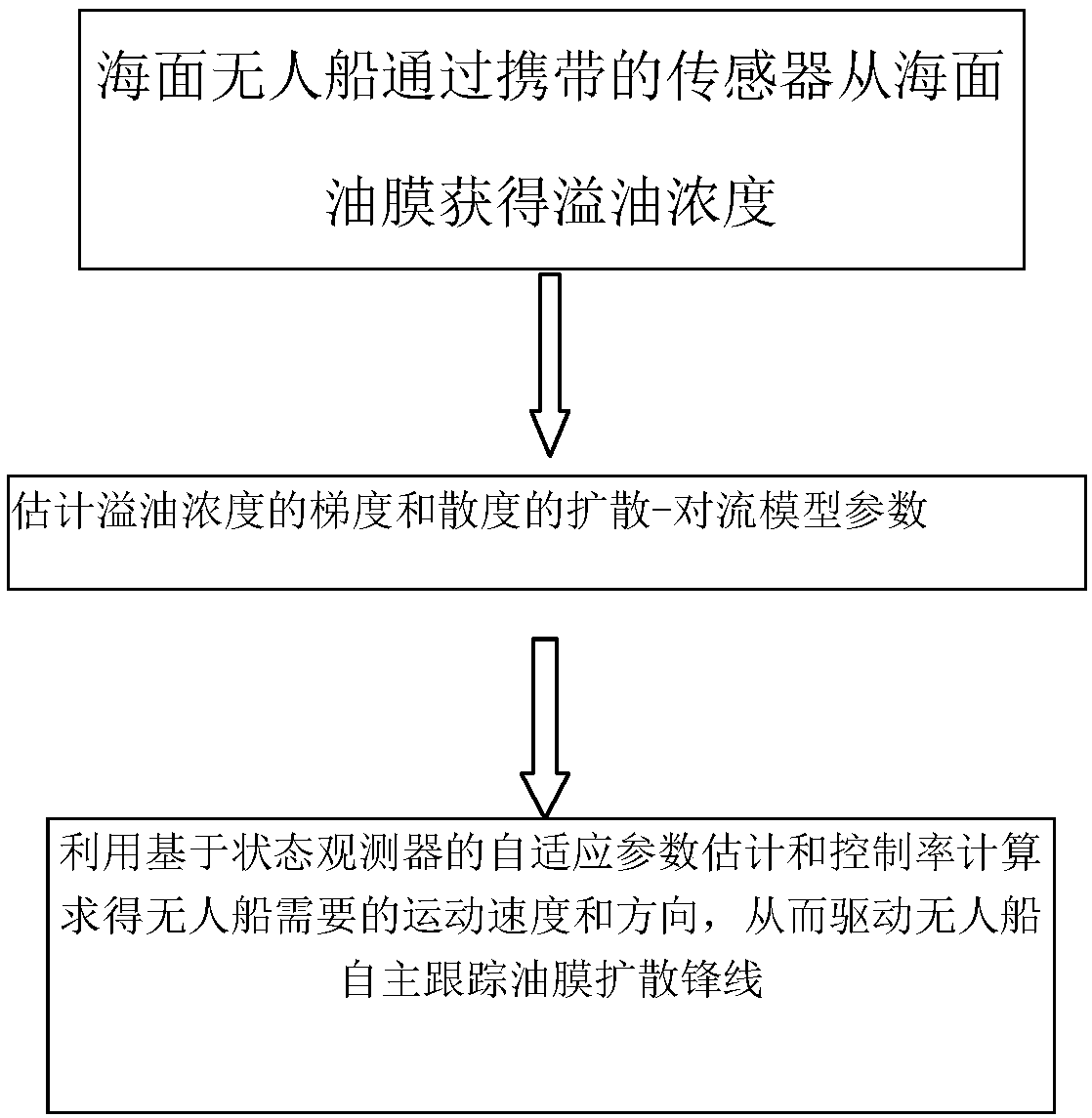

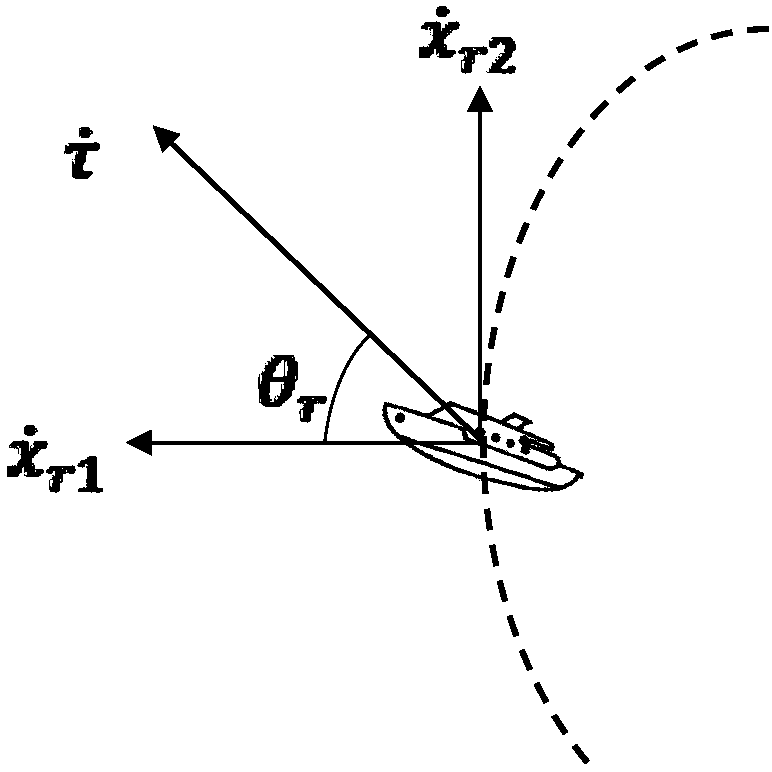

Littoral spilled oil adaptive tracking and controlling method and system

InactiveCN107807069AReal-timeGuaranteed real-timeSurface/boundary effectTarget-seeking controlState observerMarine engineering

The invention provides a littoral spilled oil adaptive tracking and controlling method and system, and relates to the field of control of unmanned ships. The method comprises the following steps: (1)carrying a sensor by an unmanned ship to obtain the concentration of spilled oil of oil slick; (2) calculating to obtain the model parameters of spilled oil concentration; and (3) utilizing adaptive parameter estimation of a state observer and adaptive control rate to calculate the moving speed and direction of the unmanned ship so as to drive the unmanned ship to automatically trace the forward line of oil slick. The method has a real time property, an adaptive property, and robustness, and can trace the forward line of spilled oil by using an unmanned ship without using parameters of an oilslick diffusion-convection model.

Owner:SHANDONG UNIV

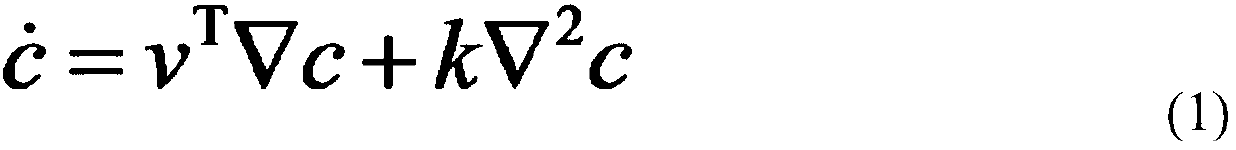

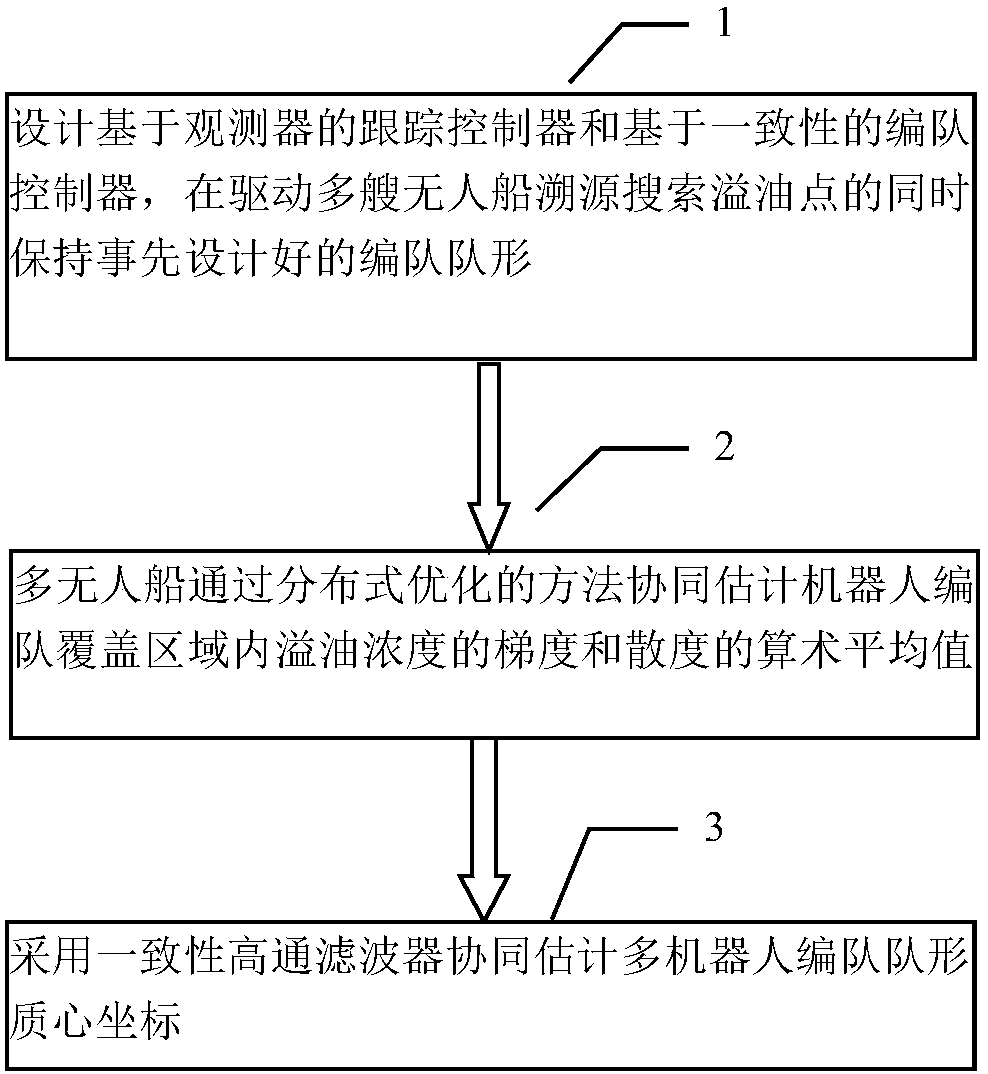

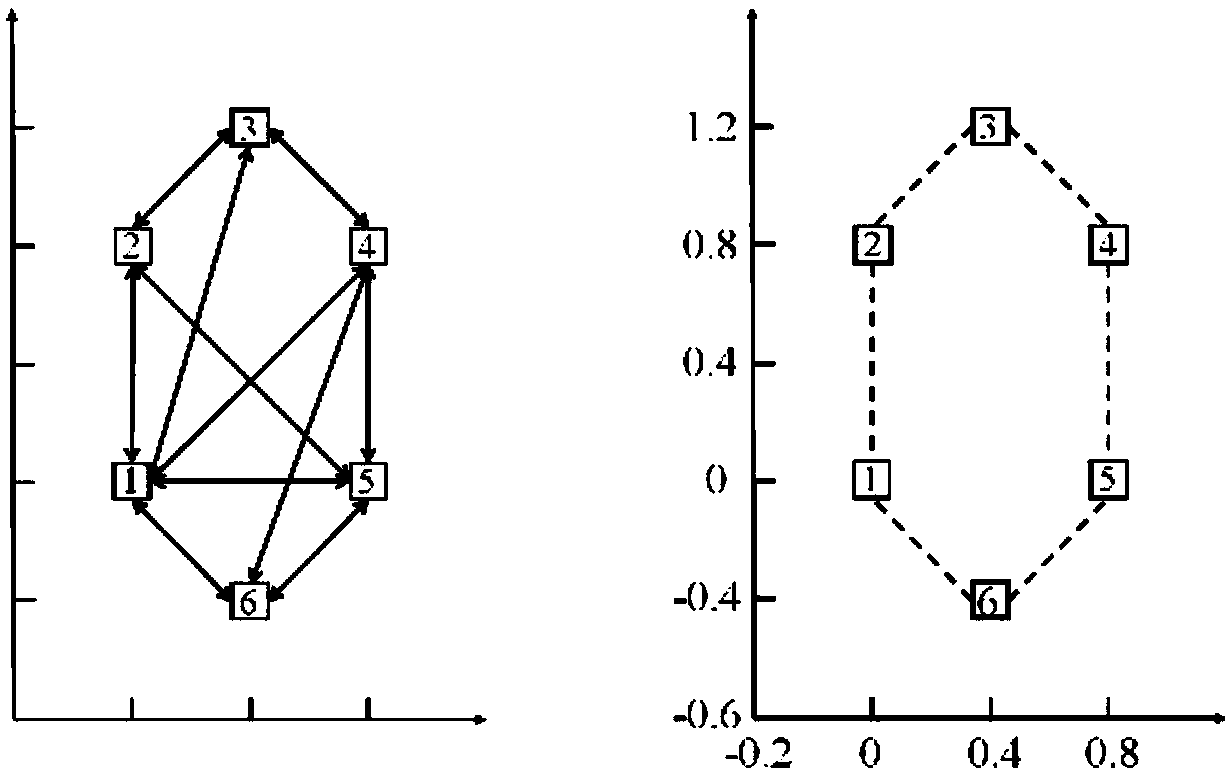

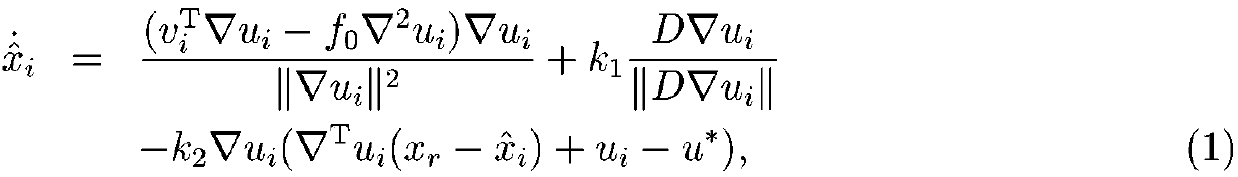

Multi-robot formation traceability control method for sea surface spill oil

InactiveCN108181928ATarget-seeking controlPosition/course control in two dimensionsDiffusionObservation data

The invention provides a multi-robot formation traceability control method for the sea surface spill oil. The method comprises steps that 1), an observer-based tracking controller and a consistency-based formation controller are designed, multiple unmanned ships are driven to trace oil spilling points on the condition that the pre-designed formation shape is kept; 2), under the control framework designed in the step 1), the multiple unmanned ships are utilized to carry out cooperation estimation through a distributed optimization method to acquire the arithmetic mean of the gradient and the divergence of the oil spill concentration in the coverage area of the robot formation area; and 3), under the distributed estimator framework of the step 2), a consistent high-pass filter is utilized torealize cooperation estimation of a centroid coordinate of the multi-robot formation shape. The method is advantaged in that properties of the large search scope, strong mobility and strong robustness are realized, under the condition of limited observation data, based on an oil film diffusion and convection model, oil spill point formation search control of the multiple unmanned ships can be realized.

Owner:SHANDONG UNIV

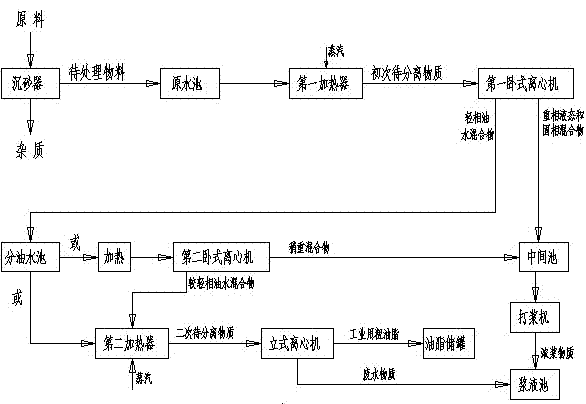

Oil-water separation process of pulpifying centrifugal treatment system

ActiveCN102583855AEasy to separateIncrease digestion rateEnergy based wastewater treatmentMultistage water/sewage treatmentOil and greaseWear resistant

The invention discloses an oil-water separation process of a pulpifying centrifugal treatment system. The pulpifying centrifugal treatment system comprises a pulp beater, a sand settling device, a horizontal centrifuge, a heater, a vertical centrifuge and a pulp tank. The oil-water separation process comprises the steps as follows: a preparation step, a primary heating step, a primary centrifugation step, a secondary heating step, a secondary centrifugation step and a hydration and pulp-beating step. Hydrated beaten pulp continuously and mutually collides with wear-resistant material in the equipment at a high speed and is ground into thickened pulp material, so that the digestion rate of a back-section anaerobic fermentation system and the biogas yield are increased; a secondary centrifugation step is added, so that the design flow of the oil-water separation process is reasonable, the next step vertical centrifugation effect is facilitated, and the outlet oil concentration and the operation efficiency are increased; a good centrifugal oil outlet effect is achieved, and the water content of obtained thick oil and the oil content of wastewater material are low; and the back-section anaerobic fermentation efficiency is improved, oil-water separation of the material is conducted more thoroughly and re-consumption of energy is avoided.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

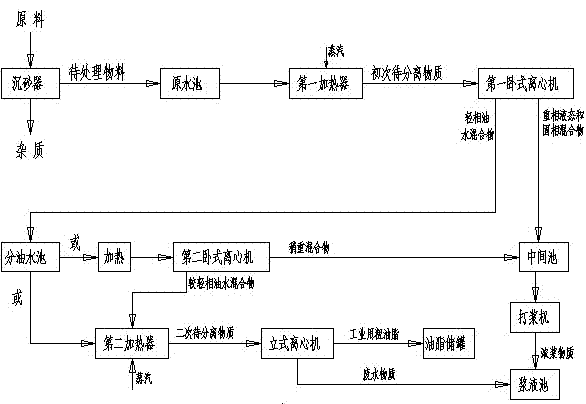

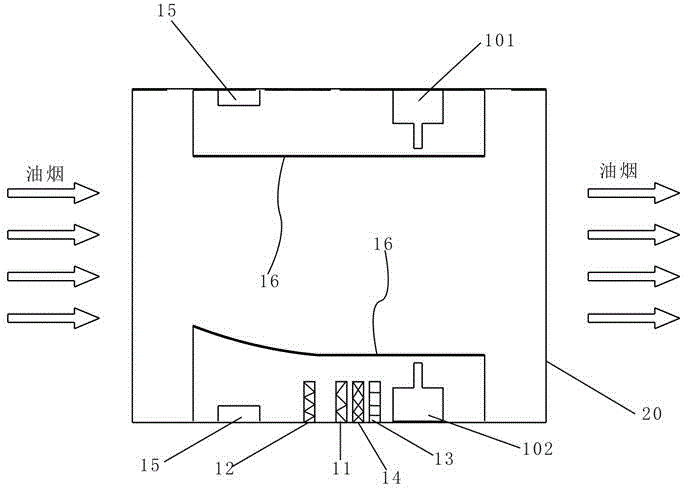

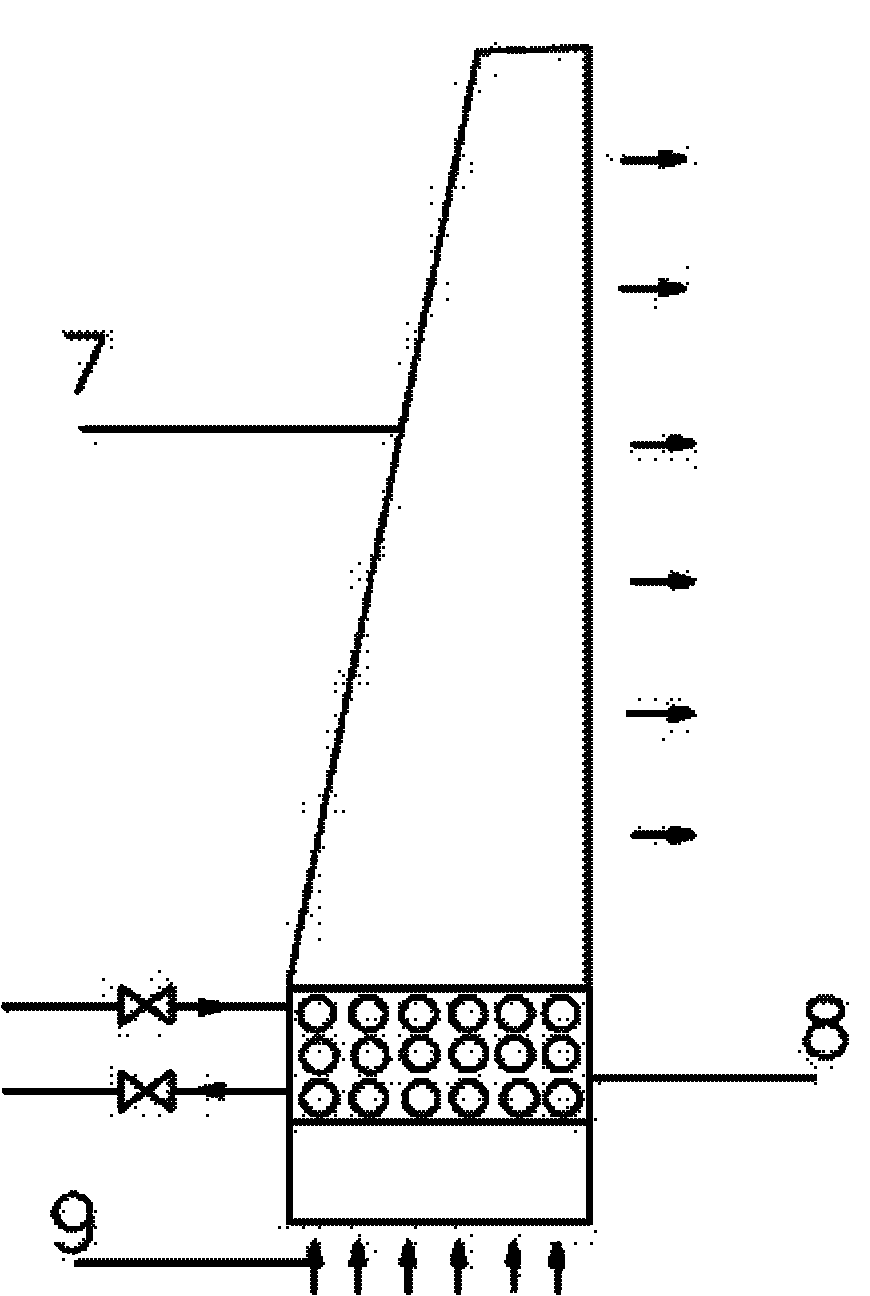

On-line oil smoke detection system and online oil smoke concentration detection method

ActiveCN104655536AReduce distractionsPromote degradationMaterial moisture contentParticle suspension analysisDifferential pressureOil concentration

The invention discloses an online oil fume detection system and an on-line oil fume concentration detection method; the system comprises an oil fume concentration detector, an anemograph, purification equipment, a single chip microcomputer and an intelligent monitoring terminal, wherein the oil fume concentration detector, the anemograph, the purification equipment and the single chip microcomputer are arranged in a ventilation pipeline; the intelligent monitoring terminal is in interactive communication connection with the communication end of the single chip microcomputer; the oil fume concentration detector comprises a light sensitive oil fume sensor and a dry and wet ball sensor; the anemograph comprises a micro differential pressure sensor, a pressure sensor and a temperature sensor; and the purification equipment comprises ultraviolet lamps and photocatalyst layers of the light sensitive oil fume sensor, the dry and wet ball sensor, the micro differential pressure sensor, the pressure sensor and the temperature sensor. The online oil fume detection system disclosed by the invention has the functions of strongly catalyzing and degrading through the photocatalyst layers, and therefore, interference of ambient light to all the sensors can be effectively reduced; oil fume adsorbed on all the sensors and probes of all the sensors can be degraded and purified well, and therefore, the purification effect is enhanced, the multifunctional and energy-saving effects of the purification equipment are satisfied, and furthermore, the on-line real-time detection of oil fume concentration and the oil fume exhaust efficiency can be realized.

Owner:SHENZHEN TIANDEYI ENVIRONMENT TECH

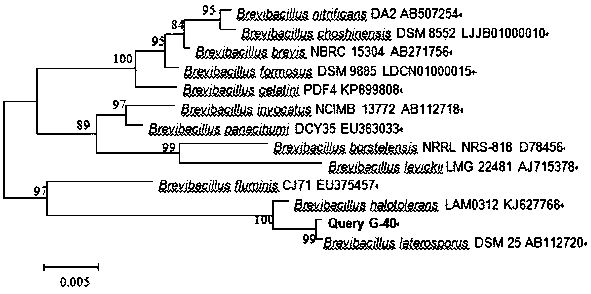

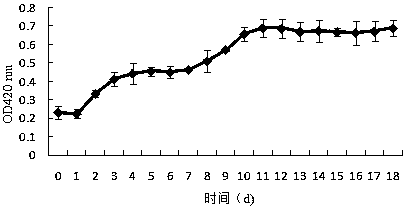

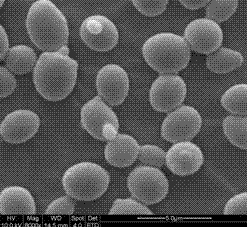

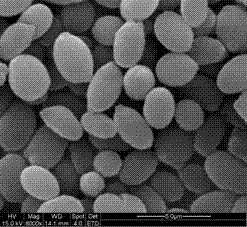

Strain of petroleum aromatic hydrocarbon degrading bacterium and applications thereof

ActiveCN107893047AEfficient degradation abilityWide temperatureBacteriaWater contaminantsBioremediationOil concentration

The invention discloses a petroleum aromatic hydrocarbon degrading bacterium (G-40), which is named as brevibacillus laterosporus G-40 and belongs to brevibacillus. The strain has been saved in ChinaCenter for Type Culture Collection (CCTCC), Wuhan university, China in June 30, 2017. The preservation number is CCTCC No. M2017400. The strain is screened from petroleum polluted soil in the oil producing region of Guanghua oil field in Qianjiang city. The strain (G-40) has an ellipsoidal shape. The result of gram staining is positive. The strain (G-40) can degrade 53.02% of petroleum aromatic hydrocarbons after the strain is cultured for 30 days under following conditions: temperature: 35 DEG C; pH value: 7.3; oil concentration: 0.6%; salt concentration: 0.5%; inoculation amount: 10%; nitrogen source: (NH4)2SO4; and phosphor source: Na2HPO4. The strain (G-40) can adapt with wide ranges of temperature, pH value, and salinity, and has a good prospect and economic value in fields such as petroleum pollutant elimination, biological restoration of petroleum aromatic hydrocarbon polluted soil and water, and the like.

Owner:YANGTZE UNIVERSITY

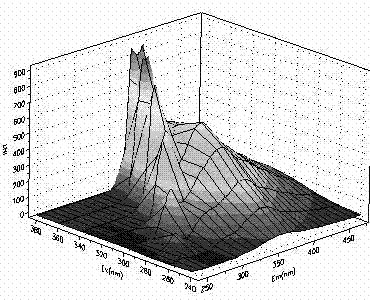

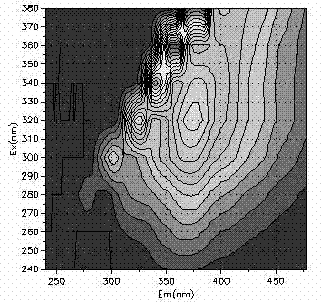

Three-dimensional quantitative fluorescence spectrum total volume integral method

InactiveCN102128817AHigh sensitivityHigh selectivityFluorescence/phosphorescenceBorehole/well accessoriesGeological explorationFluorescent light

The invention relates to the technical field of explanation and evaluation of a geological log in petroleum geological exploration, in particular to a three-dimensional quantitative fluorescence spectrum total volume integral method. The method comprises the following steps of: A, continuously applying excitation waves with the wavelengths of between 240 nanometers and 380 nanometers to a collected sample by using a fluorescence analyzer; B, receiving fluorescent light with the wavelengths of between 240 nanometers and 480 nanometers by using the fluorescence analyzer; C, establishing an excitation wavelength-receiving wavelength-fluorescence intensity three-dimensional space system; D, randomly generating random numbers distributed in a three-dimensional space according to a Monte-Carlo principle by using a computer; E, accumulating relative fluorescence intensities corresponding to each random number and accumulating and describing the volume integration values of the sample; and F, calculating an oil concentration value of the sample through a formula shown in the specifications by using the volume integration value of the sample. The invention provides a three-dimensional quantitative fluorescence spectrum total volume integral method which can determine the concentration of a single component fluorescent substance and quantitatively explain and distinguish the contents of various hydrocarbons in an oil-gas zone.

Owner:中国石油集团川庆钻探工程有限公司长庆录井公司

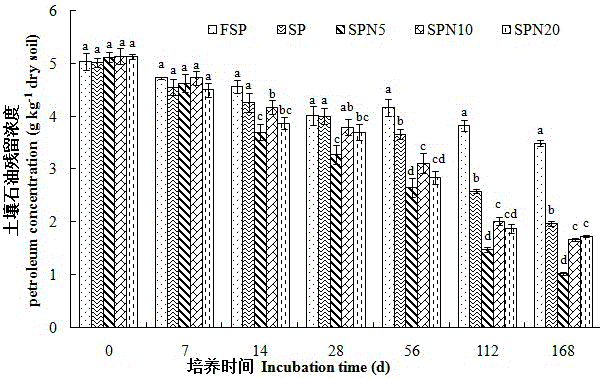

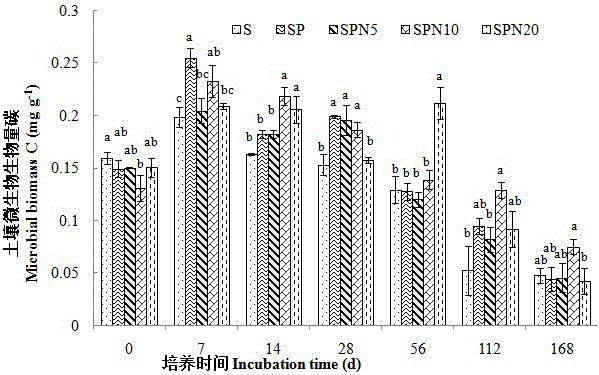

Remediation method for oil-contaminated soil

ActiveCN106424131AReduce concentrationRealize regeneration and reuseContaminated soil reclamationSoil remediationNematode

The invention discloses a remediation method for oil-contaminated soil, and relates to the technical field of contaminated soil remediation. Bacterial-feeding nematodes are used for remediating the oil-contaminated soil. The method is simple, convenient to use and easy to implement, the oil concentration of the contaminated soil can be effectively reduced, therefore, the function of purifying the soil is achieved, and regeneration and reutilization of the contaminated soil are achieved. Under the conditions that at present, the agricultural acreage is increasingly reduced and land pollution is increasingly severe, the method has very outstanding social and economic benefits.

Owner:NANCHANG INST OF TECH

Oil decanting system

ActiveUS20140083950A1Water cleaningFatty/oily/floating substances removal devicesFuel tankWater flow

A method and apparatus for operating on skimmed oil / water picked up from a body of water to separate the oil from the water and discharge the oil-free water back into the body of water, first feeds the skimmed oil / water into a gravity settling tank wherein the oil tends to settle above the water, removing relatively oil-free water from the bottom of the tank and measuring its oil content with an oil concentration sensor, and either returning the oil / water flow to the settling tank for further processing if the measured concentration of oil exceeds predetermined limits or discharging the water back into the body of water if the oil concentration is measured to be less than the predetermined value.

Owner:MARINE POLLUTION CONTROL CORP

Method for screening yeast CGMCC 4746 capable of producing ethanol in high yield and producing fusel oil in low yield in production of maotai-flavor Chinese distilled spirits and application of method

InactiveCN102766584AReduce manufacturing costSimple production processFungiMicroorganism based processesDistillationScreening method

The invention relates to a method for screening yeast CGMCC 4746 capable of producing ethanol in high yield and producing fusel oil in low yield in the production of maotai-flavor Chinese distilled spirits and application of the method, and belongs to the technical field of biological engineering. According to the yeast, a strain is trichosporon asahii CGMCC 4746 and is separated from various massive raw starters for alcoholic liquor, fermented grains, brewing raw materials and brewing environmental matters of multiple famous distilleries in China. The screening method comprises the following steps of: taking starter samples, the fermented grains, the brewing raw materials or the brewing environmental matters, diluting, and coating to a triphenyl tetrazole hydrochloride (TTC) preliminary screening flat plate; selecting bacterial colonies with an obvious red color, transferring the red bacterial colonies to a shake flask for culturing, and screening repeatedly; and measuring the content of the ethanol and the fusel oil in fermentation liquor respectively by a distillation specific gravity method and using a headspace-solid-phase micro-extraction-gas chromatography-mass spectrometer (HS-SPME-GC-MS), and screening to obtain the strain with high ethanol concentration and low fusel oil concentration. The strain can be applied to industries of foods and brewed liquors.

Owner:JIANGNAN UNIV

Method for preparing super-thick denier polyester monofilament

ActiveCN101831718AMeet the process requirementsSolve the problem that cannot be produced at the same timeArtificial filament heat treatmentMelt spinning methodsPolyesterEngineering

The invention discloses a method for preparing super-thick denier polyester monofilament, which comprises the following steps: polyester melt, booster pump, melt transmitting pipeline, spinning tank body, metering pump, spinning assembly, spinning side blowing, oiling, drafting for typing and winding, wherein, in the step of spinning side blowing, air-conditioning air blown from a side blowing air-conditioner is re-cooled, and the parameters of the side blowing after re-cooling are controlled as follows: temperature is 17 DEG C to 19 DEG C, the humidity is 75% to 90%, the wind speed is 0.7m / s to 0.9m / s; in the step of oiling, filament after side blowing and re-cooling is oiled and cooled two times, and the total oiling rate of the filament is controlled to be 0.7 to 0.9%; the oiling parameters for the first time are as follow: the oiling rate is 0.2% to 0.3%, and the oil concentration is 13% to 18%; the oiling parameters for the second time are as follows: the oiling rate is 0.5% to 0.6%, and the oil concentration is 18% to 22%. The method can be used for producing conventional FDY products and super-thick denier master monofilament at the same time.

Owner:新凤鸣集团股份有限公司

Multiphase sample container and method

ActiveUS20140366653A1Reduce shearSlow changeWithdrawing sample devicesTesting organic contamination in waterProduct gasEngineering

The invention provides a sample container arrangement for collecting multiphase samples of gas and liquid, particularly oil in water samples that are representative with respect to oil concentration, oil droplet size and oil droplet size distribution, the sample container arrangement comprises a sample container with an upper end, a lower end and a container volume for sample collection, such as a standing cylinder, distinctive in that the container arrangement further comprises: one inlet connected to the upper end or part of the container volume, one outlet with a valve with bleeding function, connected to the upper end or part of the container volume, and one outlet connected to the lower end of the container volume.

Owner:TYPHONIX

Intelligent ship sewage discharge monitoring device

InactiveCN105158174ARealize high-precision measurementLong adjustment intervalColor/spectral properties measurementsCleaning using liquidsMeasurement deviceExtinction

The invention discloses an intelligent ship sewage discharge monitoring device. The device comprises a computer control unit, a value control box, a signal acquisition control box, an oil concentration measurement unit and a sewage discharge pipe, wherein the oil concentration measurement unit comprises an oil concentration measurement device, a sampling pump and a sampling head; the sewage discharge pipe comprises a sewage absorption pipe, a branch pipe I and a branch pipe II, and a drain valve and a return valve are arranged in the branch pipe I and the branch pipe II respectively; a sampling pump control box is electrically connected with the sampling pump; the drain valve and the return valve are electrically connected with the valve control box; the sampling pump control box and the valve control box are electrically connected with the signal acquisition control box; the signal acquisition control box is electrically connected with the computer control unit; the oil concentration measurement device adopts an oil concentration sensor adopting a double-wavelength correlative extinction measurement method. The device is further improved and characterized by further comprising a flow meter and a washing unit. The intelligent ship sewage discharge monitoring device can monitor the concentration and the discharge capacity of sewage of various oil products discharged by a ship, and is high in measurement precision and good in stability.

Owner:JIANGSU YUANWANG INSTR

Screening and application of yeast CGMCC (china general microbiological culture collection center) 4748 with high ethanol yield and low fusel oil yield in production of Chinese Maotai-flavor liquor

InactiveCN102766583AReduce manufacturing costSimple production processFungiAlcoholic beverage preparationBiotechnologyScreening method

The invention relates to screening and application of yeast CGMCC (china general microbiological culture collection center) 4748 with high ethanol yield and low fusel oil yield in production of Chinese Maotai-flavor liquor, and belongs to the technical field of biological engineering. The yeast strain is Saccharomyces exiguous CGMCC4748 and is obtained by separating in various yeasts for making hard liquor, fermented grains, fermenting materials and fermenting environments from many Chinese manufacturers of famous liquors. A screening method of the yeast strain includes thinning the yeasts, the fermented grains, the fermenting materials or fermenting environmental materials, coating to a TTC (triphenyltetrazolium chloride) primary-screening flat plate, selecting remarkably red colonies, and transferring the colonies to shaking culture for secondary screening, measuring content of ethanol and fusel oil in fermentation broth by distilling and proportioning process and HS-SPME-GC-MS (head space solid-phase micro-extraction and gas chromatography-mass spectrometry), and screening to obtain the strain with high ethanol concentration and low fusel oil concentration. The strain is applicable to food industry and liquor-making industry.

Owner:JIANGNAN UNIV

Process and device for deeply purifying waste emulsion

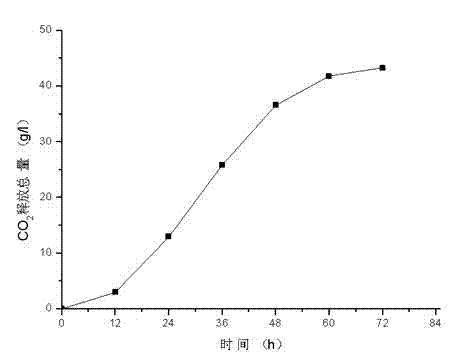

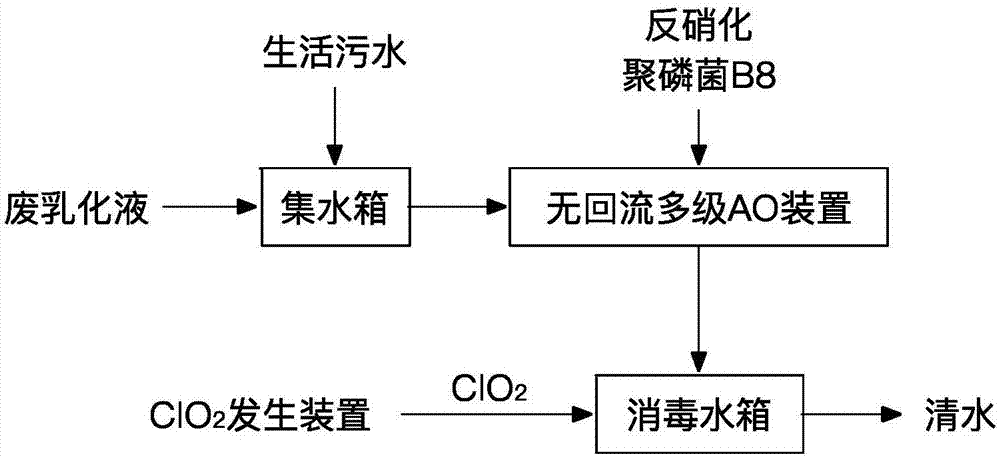

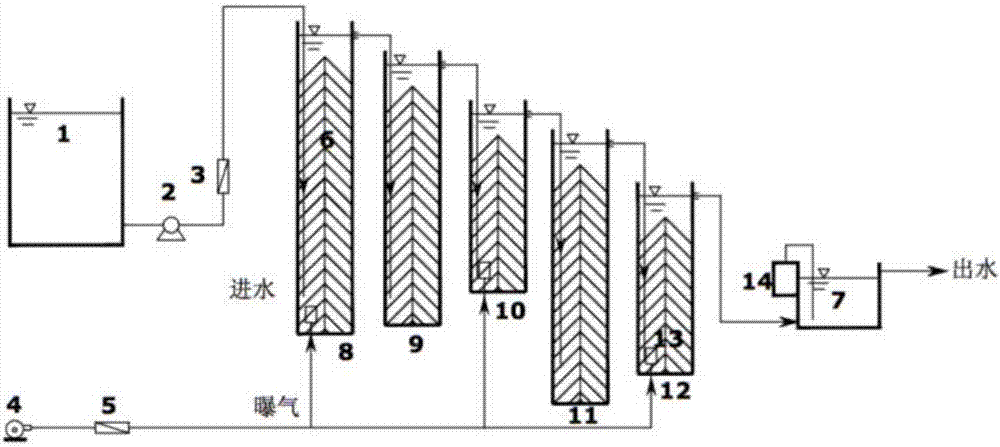

InactiveCN107055950APromote growthPromote enrichmentWater contaminantsWaste water treatment from metallurgical processAmmoniacal nitrogenEmulsion

The invention discloses a process and device for deeply purifying waste emulsion. The process comprises the following steps: firstly, collecting waste emulsion in a water collection tank, diluting by introducing domestic sewage, serially connecting non-reflux multi-stage AO reactors, and leading a certain liquid level difference among the reactors; and filling elastic silky filler, opening a fan, introducing gas into the reactors through micro-porous aerators, opening a water pump, injecting mixed liquid into the lower end of a primary aerobic reactor, dosing a synchronous denitrification phosphorous removing bacterial agent B8 to enable the mixed liquid to be in sufficient contact with the elastic silky filler on which a microorganism membrane grows, deeply purifying the waste emulsion through adsorption, deposition, decomposition and other effects of microorganisms in the aerobic-anaerobic repeated alternating processes, enabling the purified clear water to flow into a disinfecting water tank, and discharging the disinfected clear water into a water body. By adopting the process, the clear water in the disinfecting water tank has COD concentration of 87.34mg / L, total oil concentration of 3.96mg / L, total phosphorous concentration of 0.65mg / L, total nitrogen concentration of 3.78mg / L and ammonia-nitrogen concentration of 1.17mg / L, and meets the requirements of I-level discharge of the Integrated Wastewater Discharge Standard (GB 8978-1996).

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com