Oil circulation observer for HVAC systems

a technology of hvac systems and oil circulation observer, which is applied in the direction of refrigeration machines, lighting and heating apparatus, and refrigeration safety arrangements, etc. it can solve the problems of high oil viscosity, insufficient oil in the compressor, and insufficient lubrication of the compressor

Inactive Publication Date: 2005-05-19

MASSACHUSETTS INST OF TECH

View PDF6 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0009] In one embodiment, the first component of the vapor compression cycle system is a compressor. The plurality of other components of the vapor compression cycle system can comprise at least one of an evaporator, an accumulator, a suction gas line, a discharge gas line, a

Problems solved by technology

For example, this may happen when the defrost operation is turned on during the heating season, since under such conditions, the indoor fan is typically shut down, and liquid in the evaporator may not be evaporated.

As a result, large amounts of liquid refrigerant may enter the compressor chamber and mix with the lubricating oil.

However, in an evaporator, when superheat is large and evaporating temperature is low, oil viscosity may become high because liquid refrigerant becomes vapor in the superheat range.

If vapor velocity is not sufficient to transport the oil, some oil may remain in the evaporator.

Similarly, in suction lines, oil retention may be

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

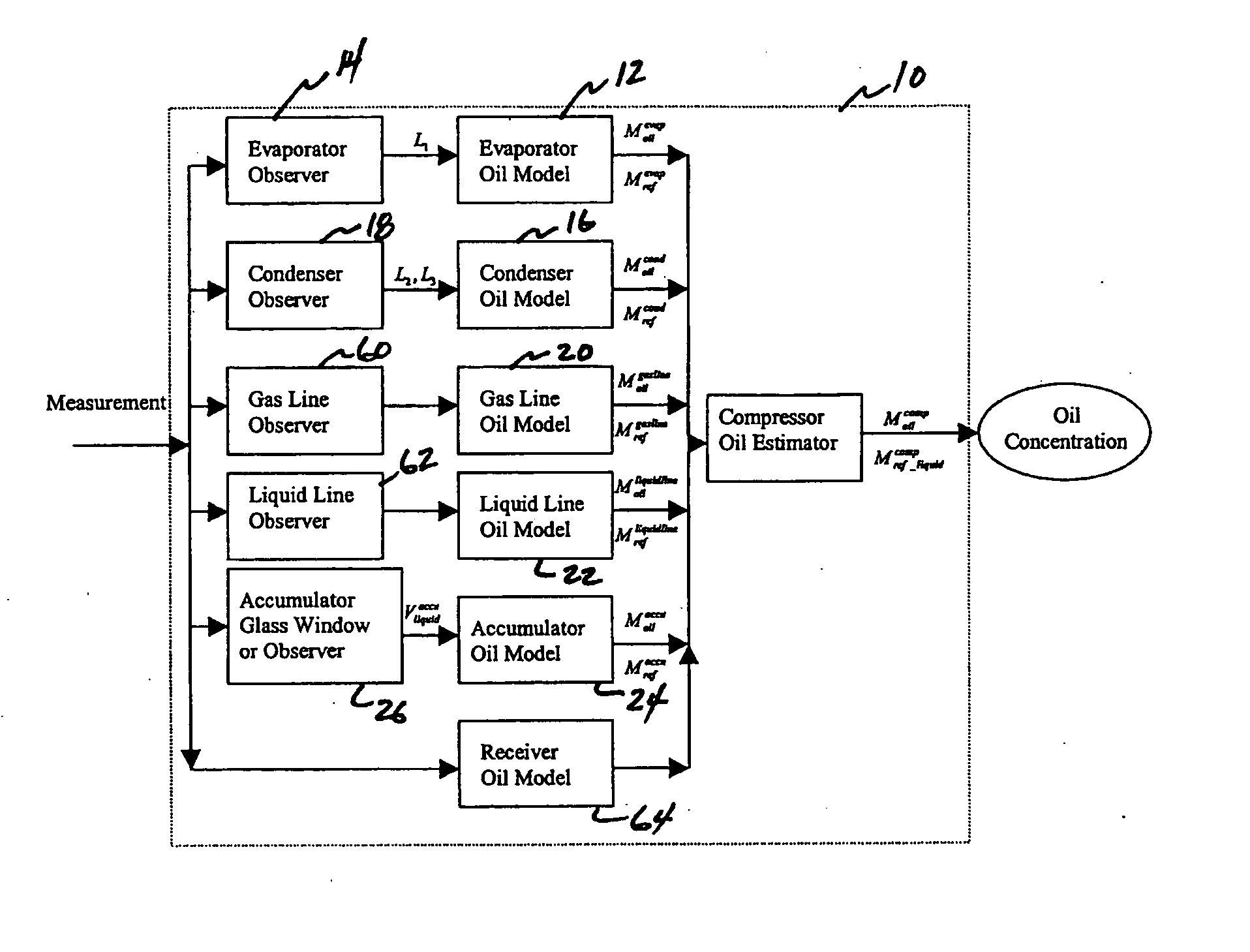

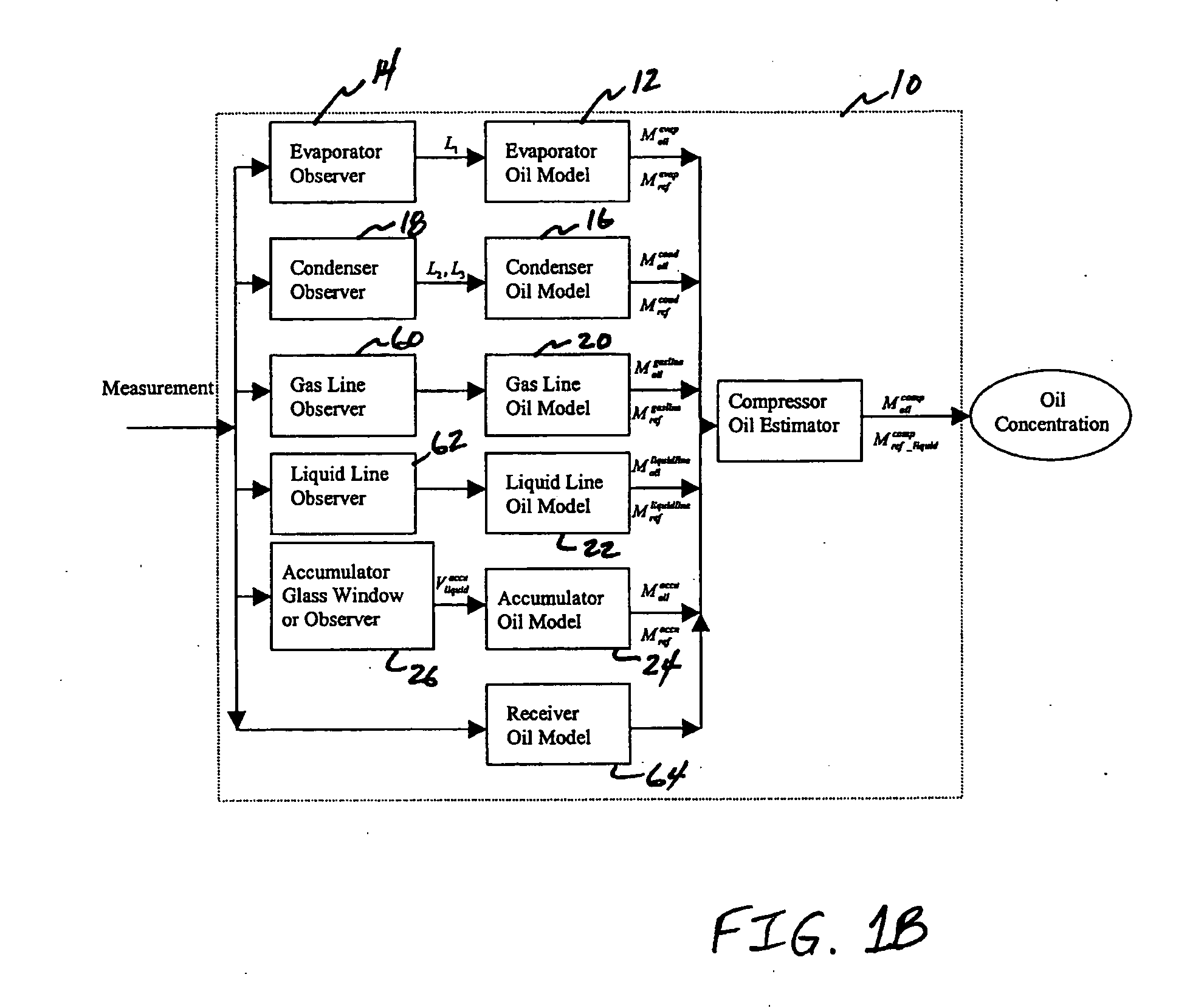

An innovative oil observer for estimating oil concentration and oil amount in a refrigerant compressor in a vapor compression cycle is described. The invention ensures the safe operation of the compressor by ensuring that adequate lubricant is present in the compressor. This oil observer is based on oil models for components of air conditioning and refrigeration systems. Oil models for HVAC components estimate oil mass and refrigerant mass in each component. With all component oil models and heat exchanger observers which provide the estimation of inner geometric lengths of two-phase flow heat exchangers, a system-level oil observer is established by integrating all component models. Experimental testing has been conducted to verify the performance of this oil observer for steady state operation and dynamic processes. The invention has direct applications in residential and commercial air conditioning and refrigeration systems.

Description

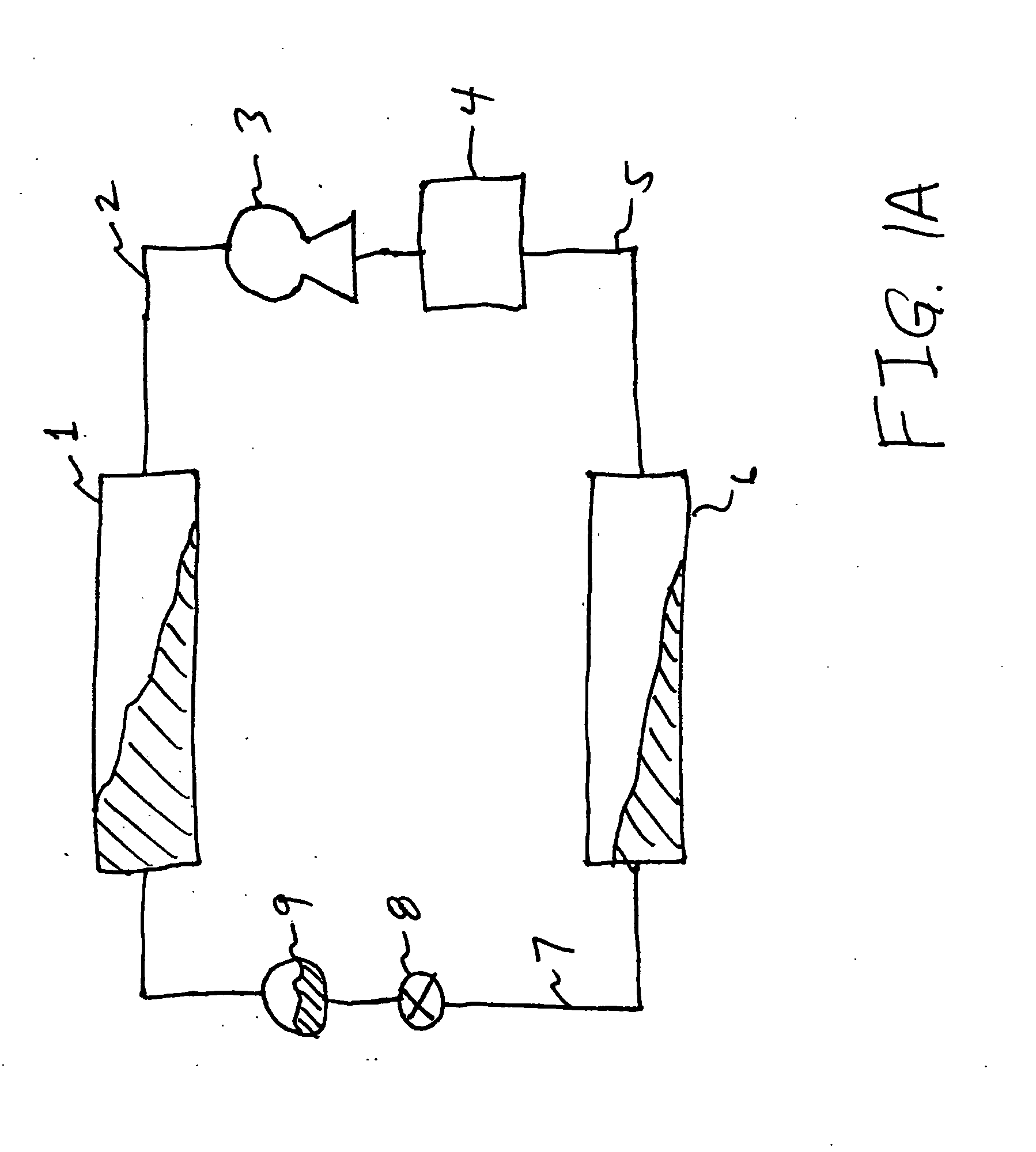

RELATED APPLICATION [0001] This application is based on U.S. Provisional Application Ser. No. 60 / 523,447, filed on Nov. 19, 2003, the contents of which are incorporated herein in their entirety by reference.BACKGROUND OF THE INVENTION [0002] Lubricating oil in the compressor of a heating, ventilation and air conditioning (HVAC) system provides lubrication for moving parts in the compressor. Good lubrication ensures the safe operation of the compressor. For a refrigerant compressor, the oil lubricating capability decreases when the oil is mixed with liquid refrigerant. For example, this may happen when the defrost operation is turned on during the heating season, since under such conditions, the indoor fan is typically shut down, and liquid in the evaporator may not be evaporated. As a result, large amounts of liquid refrigerant may enter the compressor chamber and mix with the lubricating oil. [0003] To quantify how much liquid refrigerant is mixed with oil in the compressor, an imp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F25B49/02F25B31/00

CPCF25B31/002F25B2700/03F25B2500/16

Inventor HE, XIANG-DONGASADA, H. HARRYCHENG, TAO

Owner MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com