Patents

Literature

8240 results about "Vapor–liquid separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vapor–liquid separator is a device used in several industrial applications to separate a vapor–liquid mixture. A vapor–liquid separator may also be referred to as a flash drum, breakpot, knock-out drum or knock-out pot, compressor suction drum or compressor inlet drum. When used to remove suspended water droplets from streams of air, it is often called a demister.

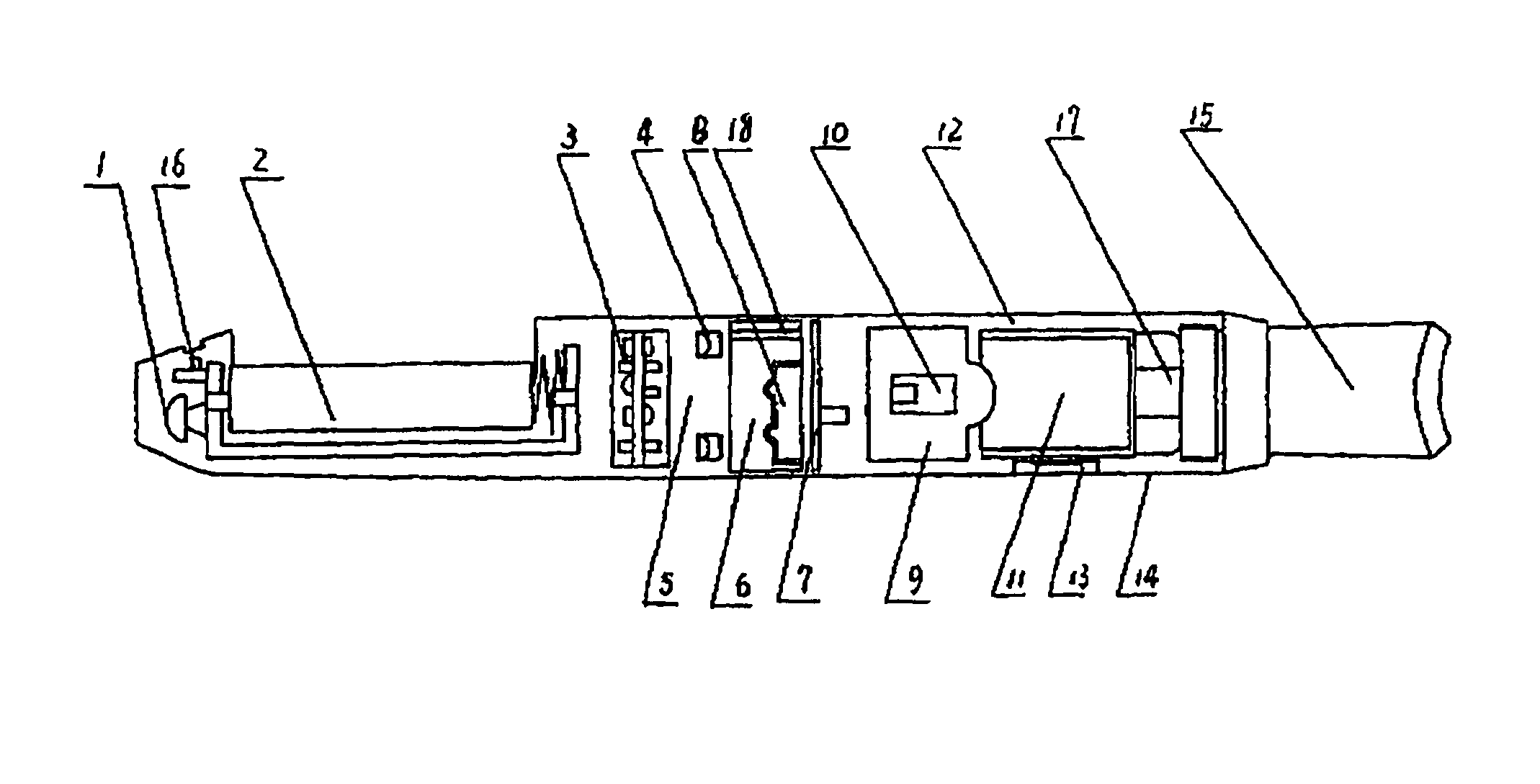

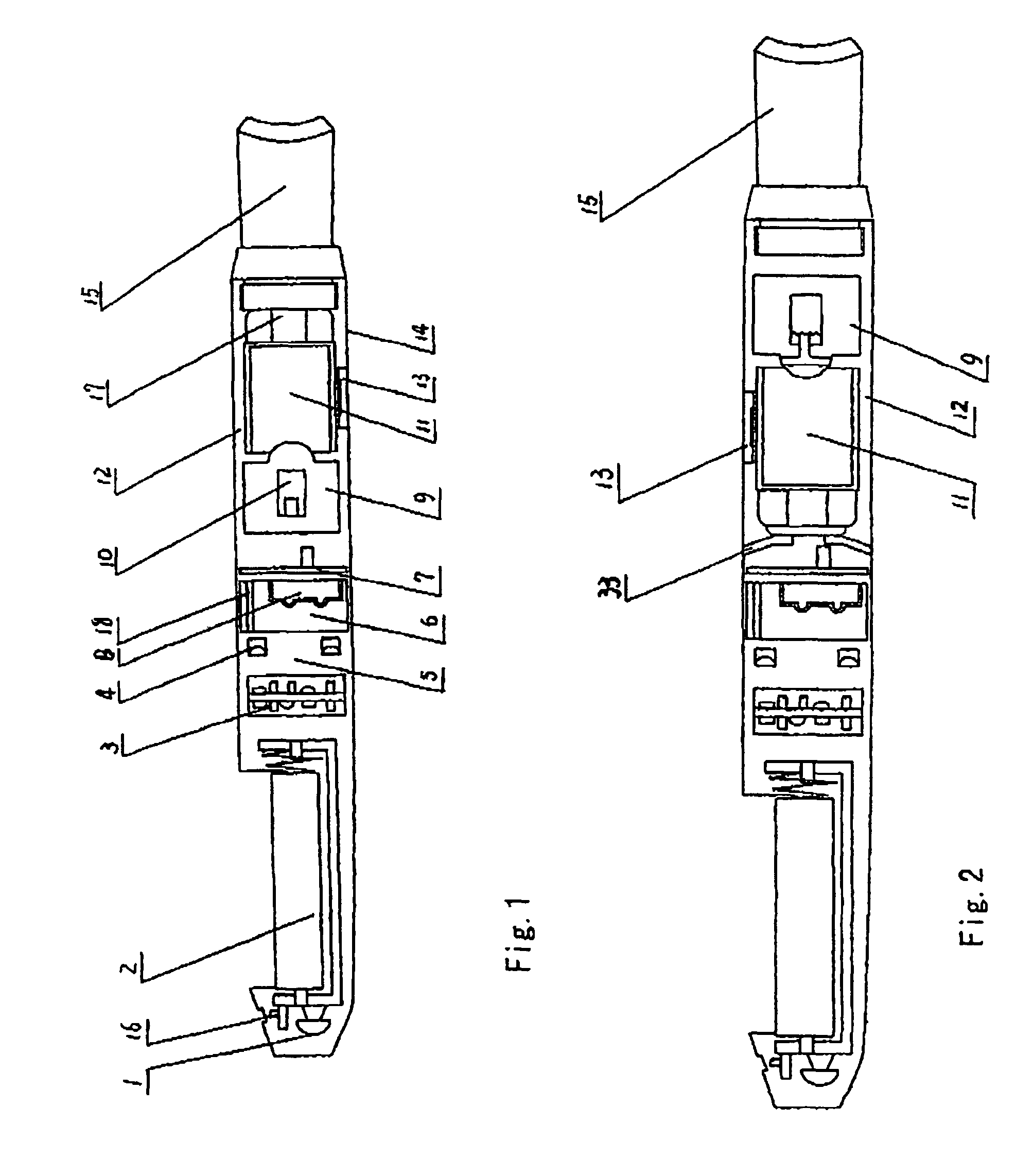

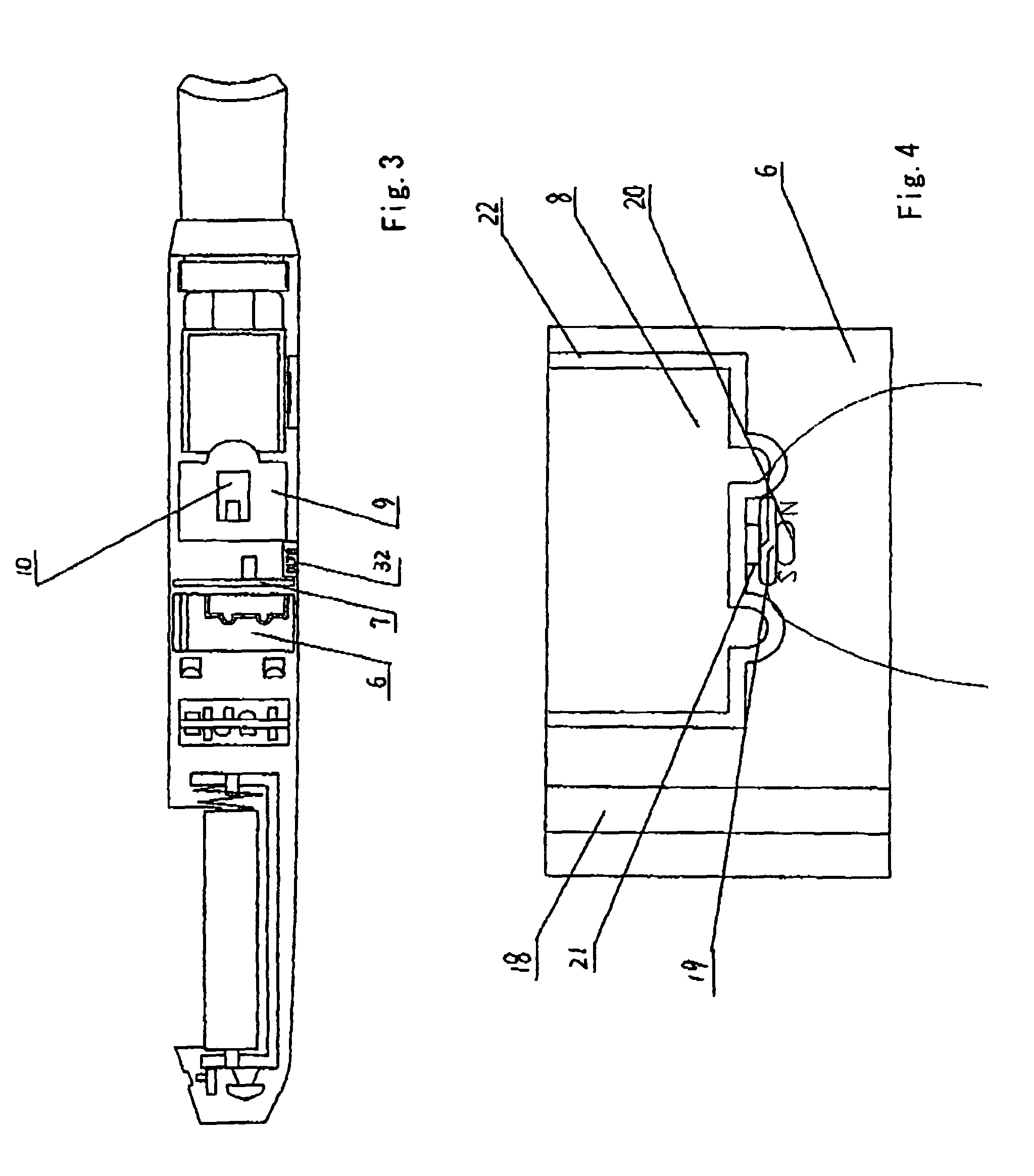

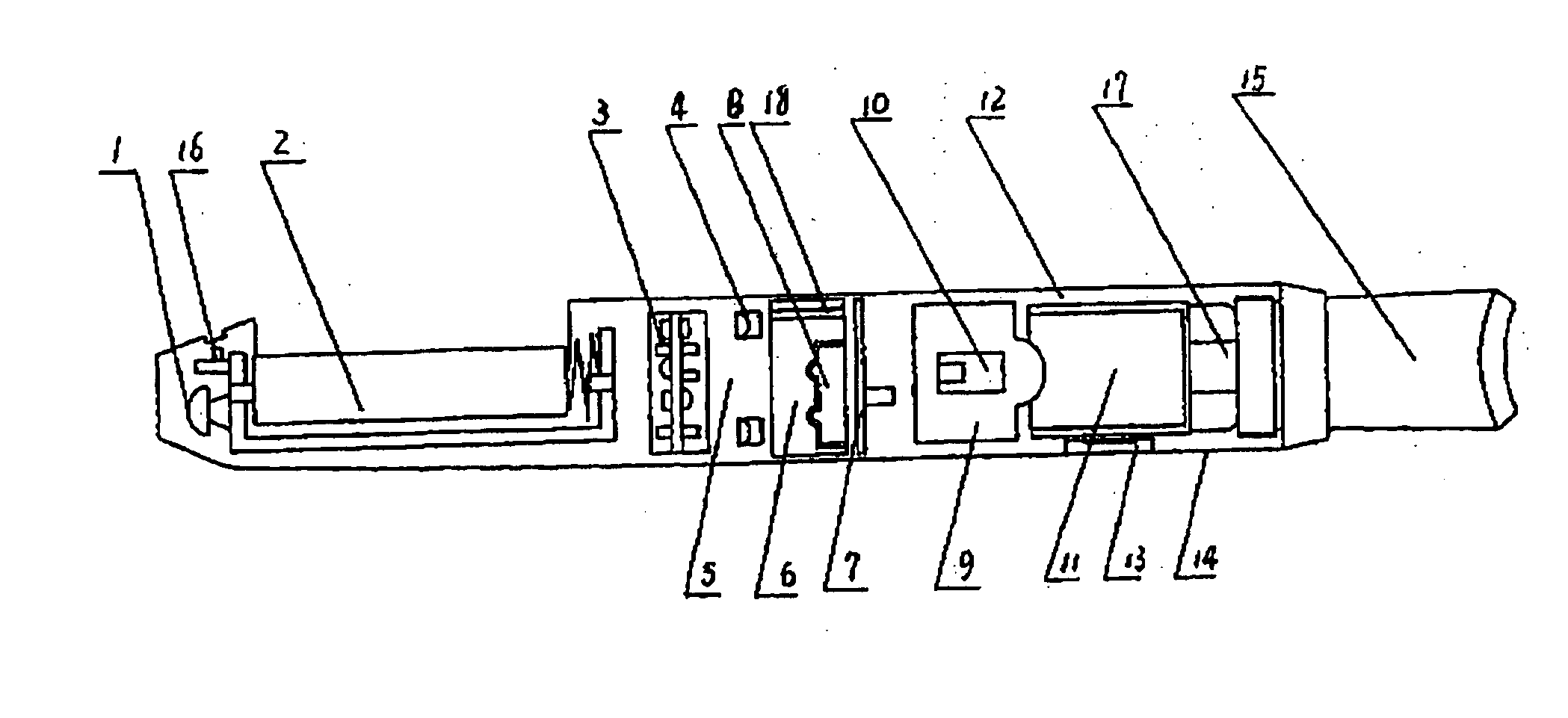

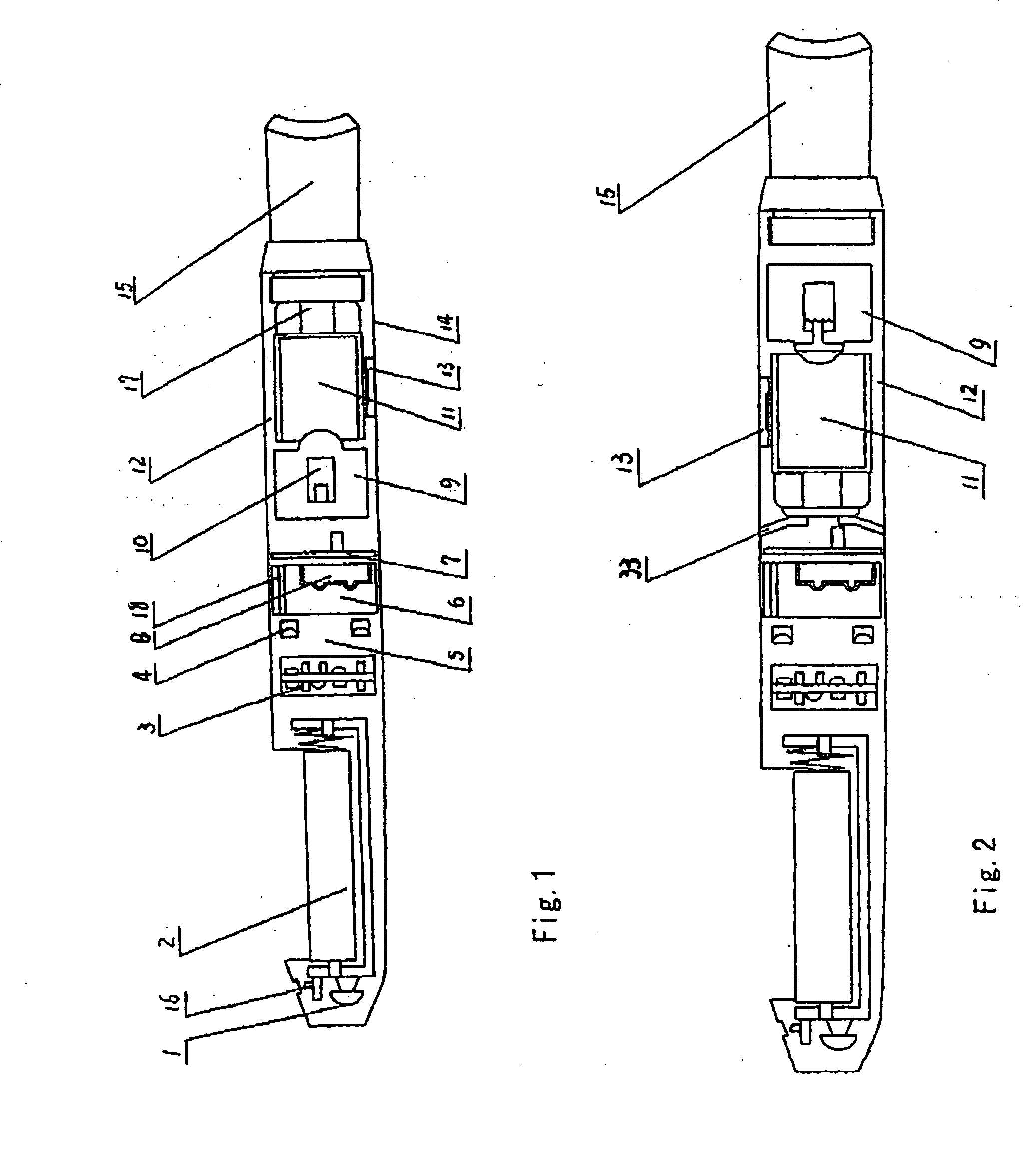

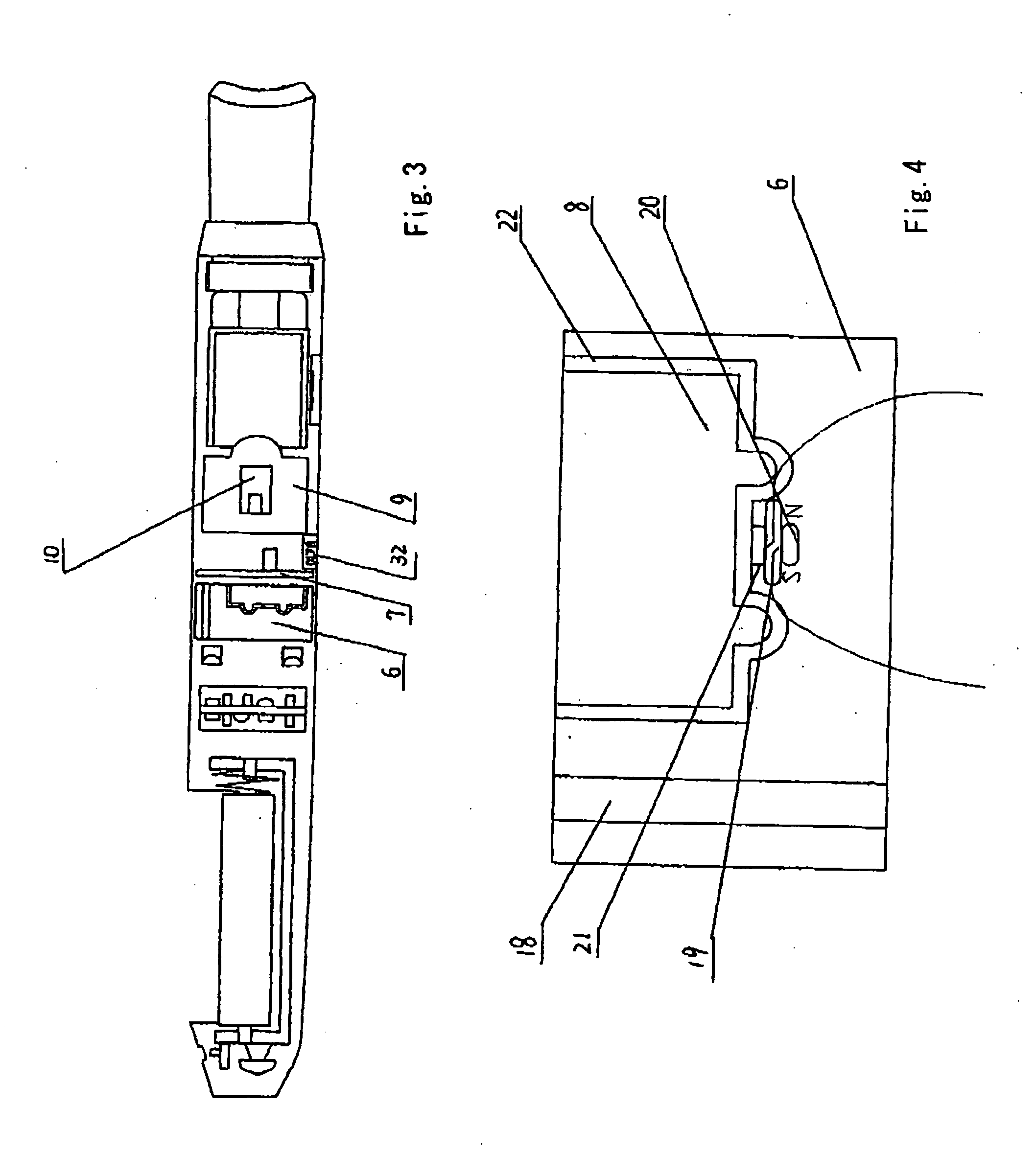

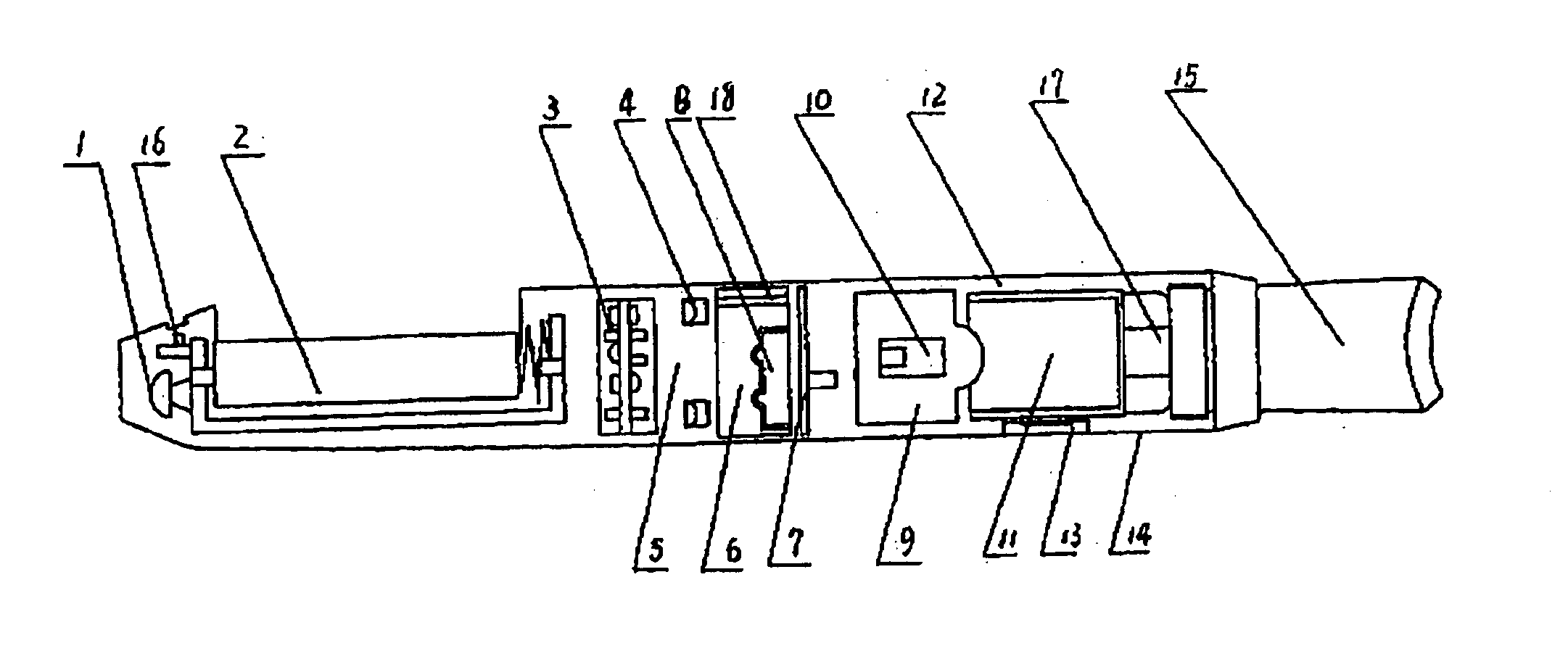

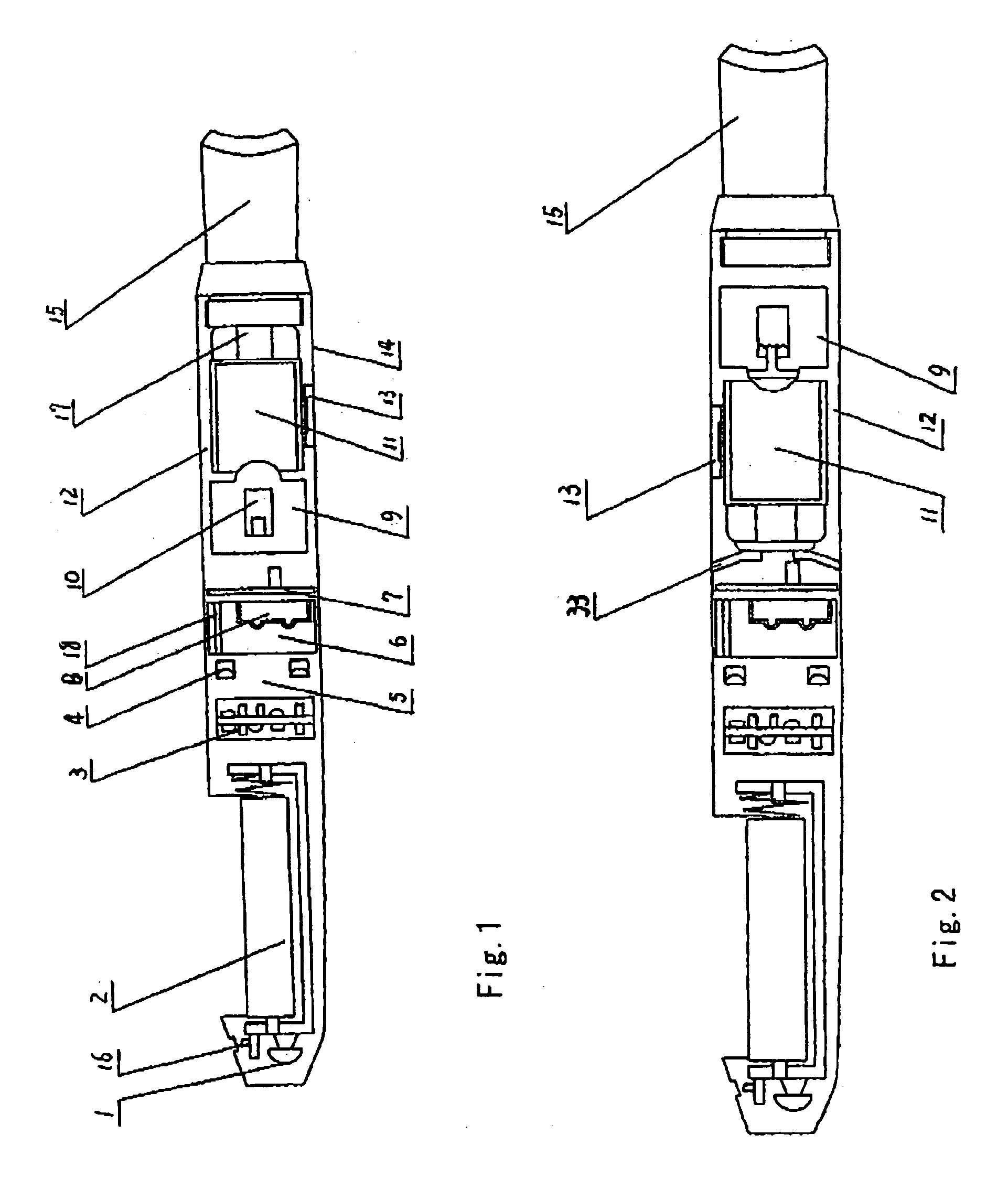

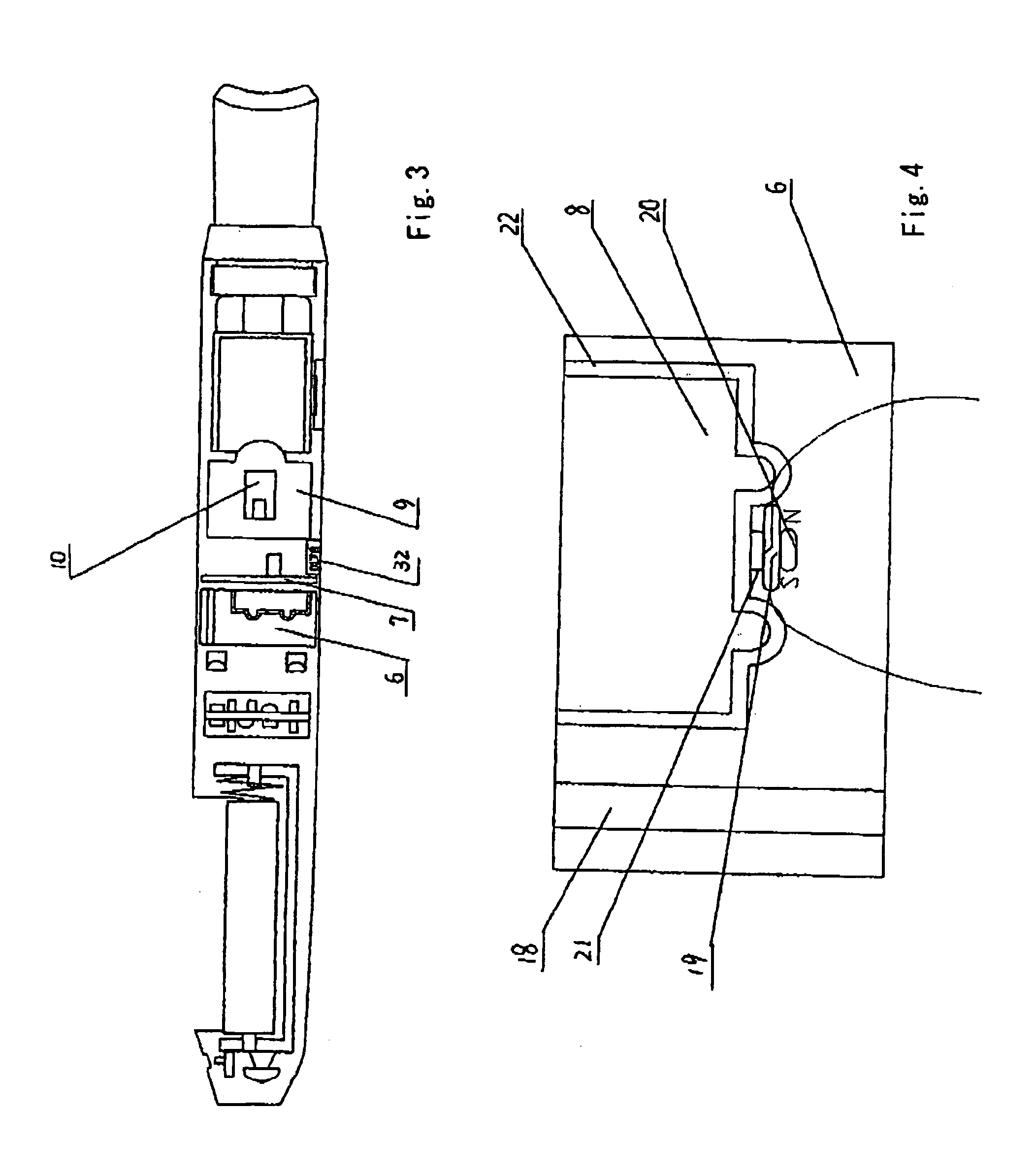

Electronic atomization cigarette

ActiveUS7832410B2Reduce cancer riskTobacco preparationNervous disorderVapor–liquid separatorEngineering

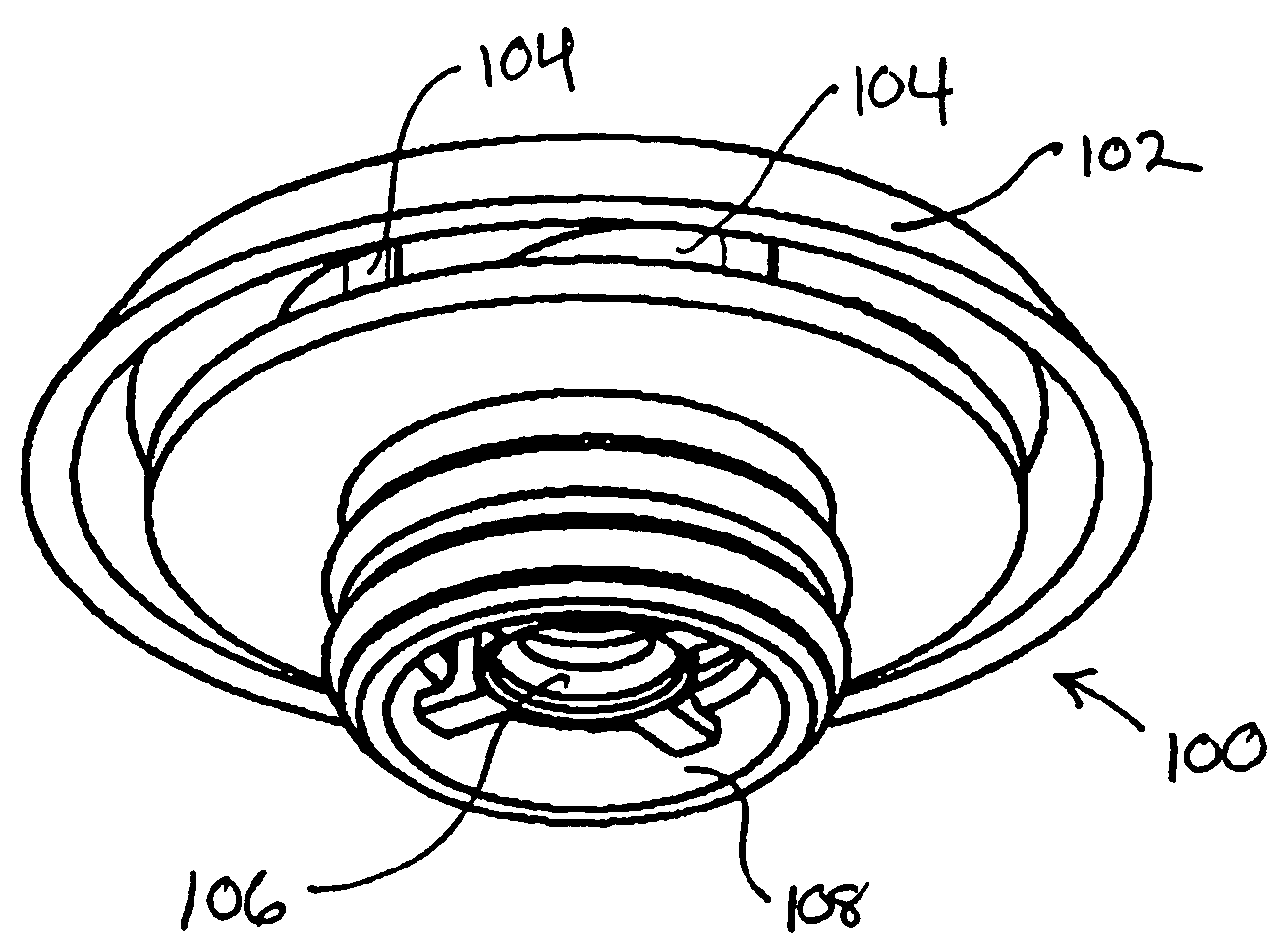

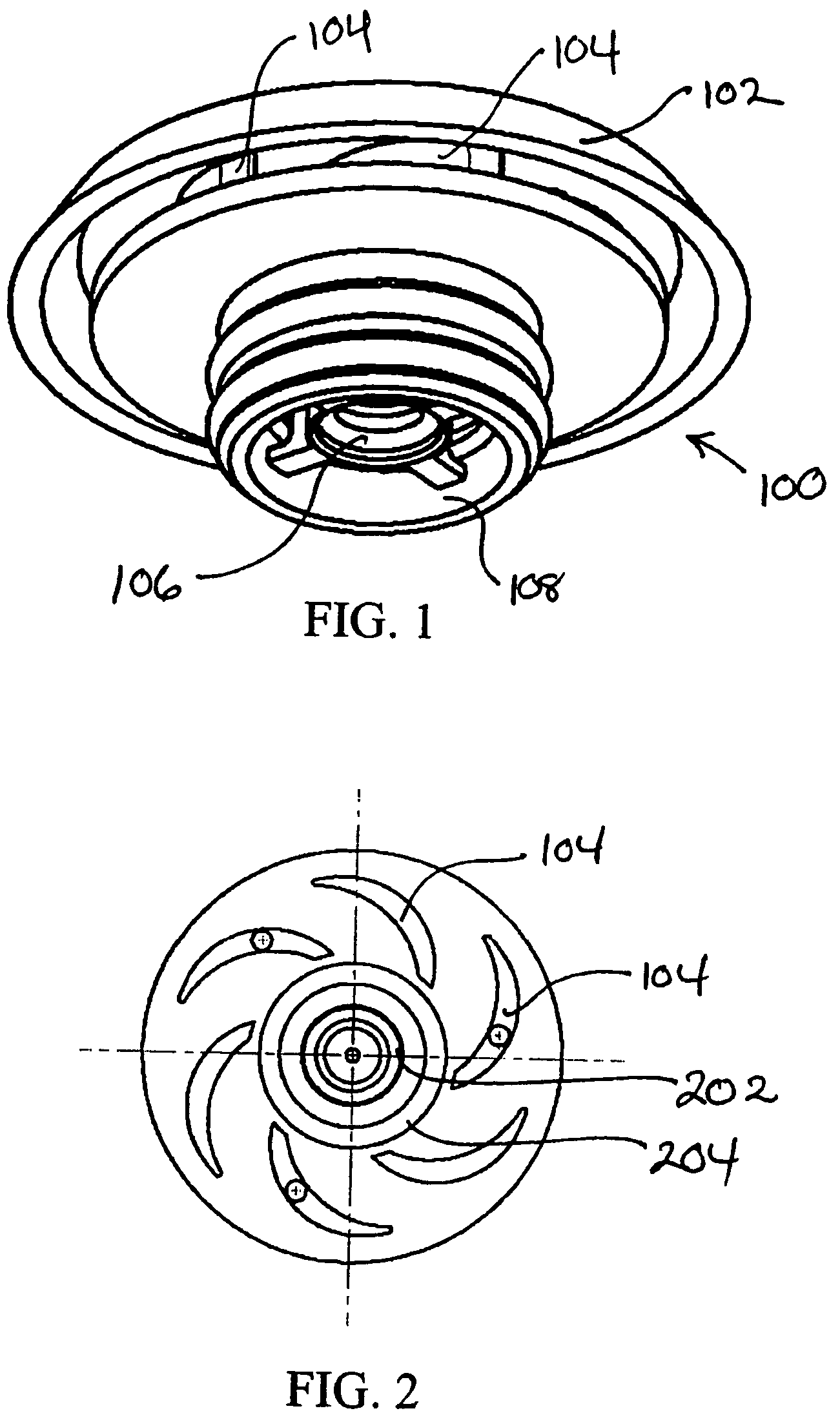

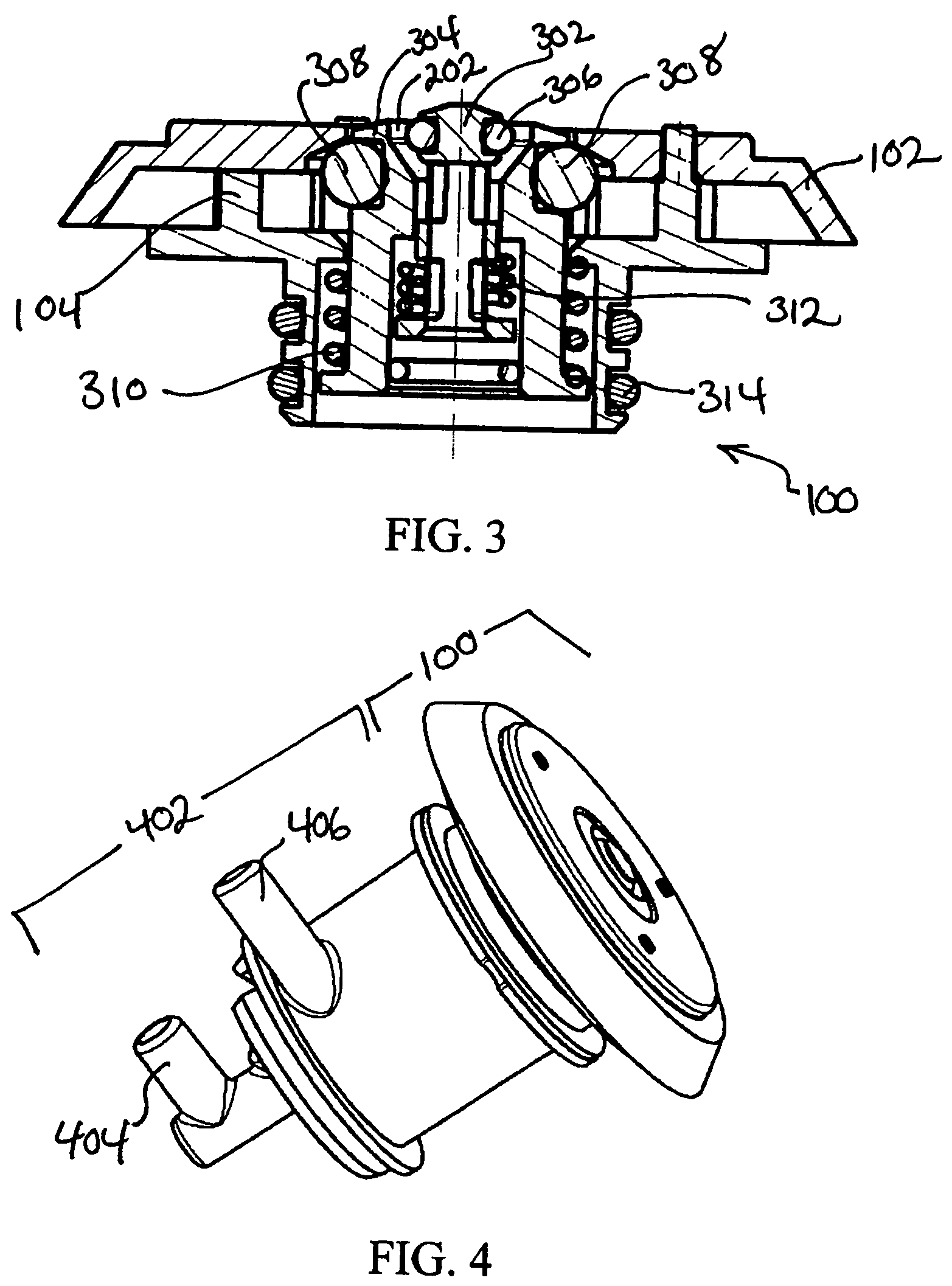

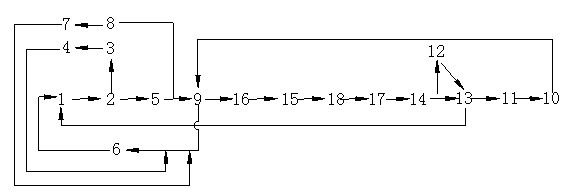

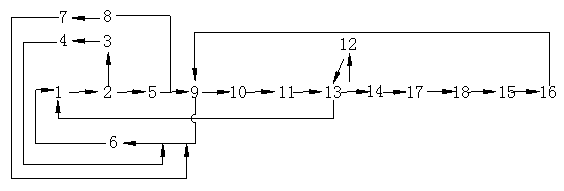

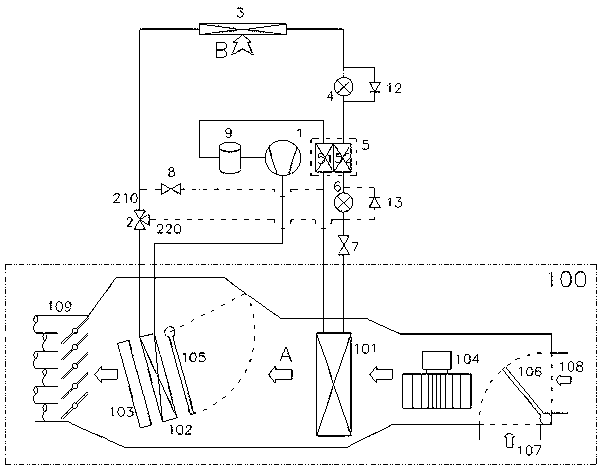

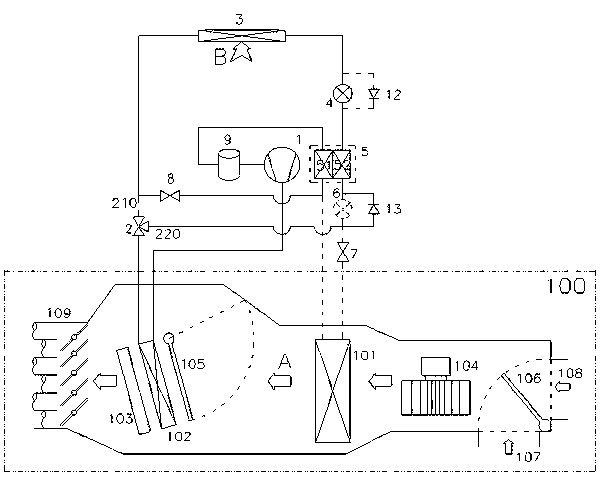

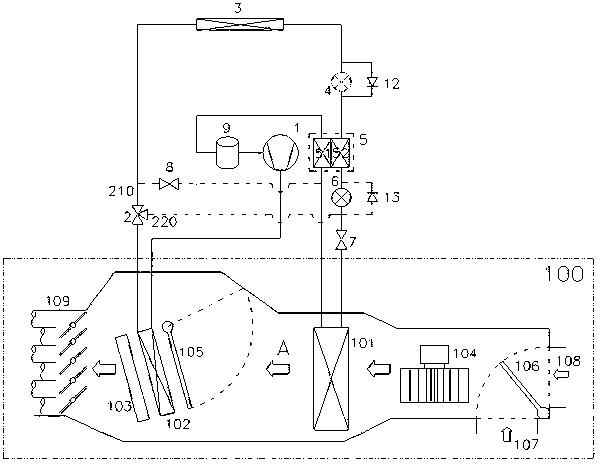

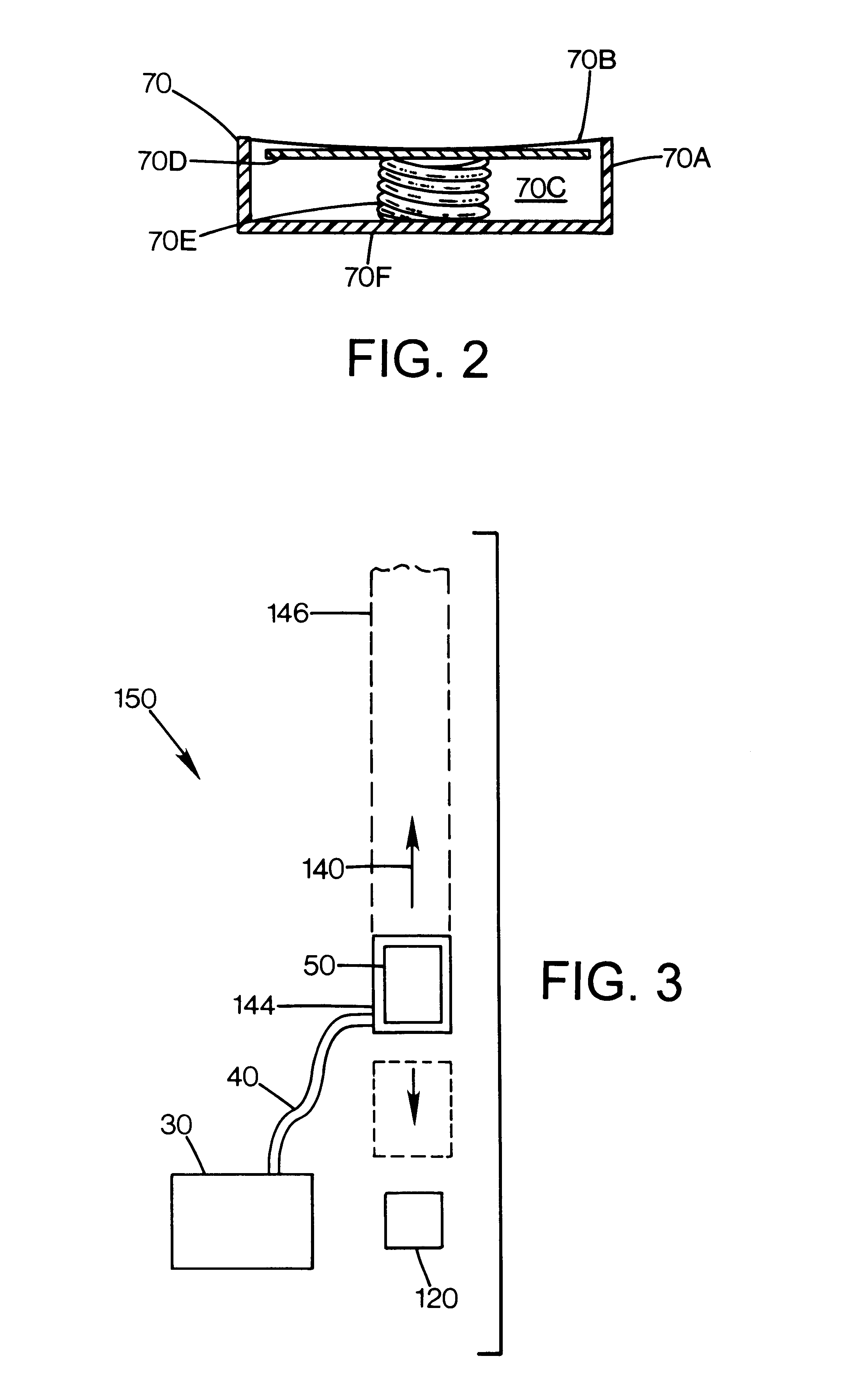

The invention relates to an electronic atomization cigarette which only contains nicotine without harmful tar. The electronic atomization cigarette includes a shell and a mouthpiece. The external wall of the shell has an air inlet. An electronic circuit board, a normal pressure cavity, a sensor, a vapor-liquid separator, an atomizer, a liquid-supplying bottle are sequentially provided within the shell, wherein the electronic circuit board comprises an electronic switching circuit and a high frequency generator. A stream passage of the sensor is provided on one side of the sensor, and a negative pressure cavity is provided in the sensor. The atomizer and the liquid-supplying bottle is in contact with each other. An atomization cavity is arranged in the atomizer. A retaining ring for locking the liquid-supplying bottle is provided between one side of the liquid-supplying bottle and the shell, and an aerosol passage is provided on the other side of the liquid-supplying bottle. The air inlet, normal pressure cavity, vapor-liquid separator, atomizer, aerosol passage, gas vent and mouthpiece are sequentially interconnected.

Owner:FONTEM VENTURES

Electronic Atomization Cigarette

The present invention relates to an electronic atomization cigarette which only contains nicotine without harmful tar. The electronic atomization cigarette includes a shell and a mouthpiece. The external wall of the shell has an air inlet. An electronic circuit board, a normal pressure cavity, a sensor, a vapor-liquid separator, an atomizer, a liquid-supplying bottle are sequentially provided within the shell, wherein the electronic circuit board comprises an electronic switching circuit and a high frequency generator. A stream passage of the sensor is provided on one side of the sensor, and a negative pressure cavity is provided in the sensor. The atomizer and the liquid-supplying bottle is in contact with each other. An atomization cavity is arranged in the atomizer. A retaining ring for locking the liquid-supplying bottle is provided between one side of the liquid-supplying bottle and the shell, and an aerosol passage is provided on the other side of the liquid-supplying bottle. The air inlet, normal pressure cavity, vapor-liquid separator, atomizer, aerosol passage, gas vent and mouthpiece are sequentially interconnected. The advantages of the present invention include smoking without tar, significantly reducing the cancerogenic risk. Furthermore, users still feel as if they are smoking and experiencing the same excitement, and the cigarette is no need to be lit and is no fire risk.

Owner:FONTEM VENTURES

Electronic atomization cigarette

ActiveUS20110168194A1Reduce cancer riskRespiratorsNervous disorderVapor–liquid separatorAerosol spray

The present invention relates to an electronic atomization cigarette which only contains nicotine without harmful tar. The electronic atomization cigarette includes a shell and a mouthpiece. The external wall of the shell has an air inlet. An electronic circuit board, a normal pressure cavity, a sensor, a vapor-liquid separator, an atomizer, a liquid-supplying bottle are sequentially provided within the shell, wherein the electronic circuit board comprises an electronic switching circuit and a high frequency generator. A stream passage of the sensor is provided on one side of the sensor, and a negative pressure cavity is provided in the sensor. The atomizer and the liquid-supplying bottle is in contact with each other. An atomization cavity is arranged in the atomizer. A retaining ring for locking the liquid-supplying bottle is provided between one side of the liquid-supplying bottle and the shell, and an aerosol passage is provided on the other side of the liquid-supplying bottle. The air inlet, normal pressure cavity, vapor-liquid separator, atomizer, aerosol passage, gas vent and mouthpiece are sequentially interconnected. The advantages of the present invention include smoking without tar, significantly reducing the cancerogenic risk. Furthermore, users still feel as if they are smoking and experiencing the same excitement, and the cigarette is no need to be lit and is no fire risk.

Owner:FONTEM VENTURES

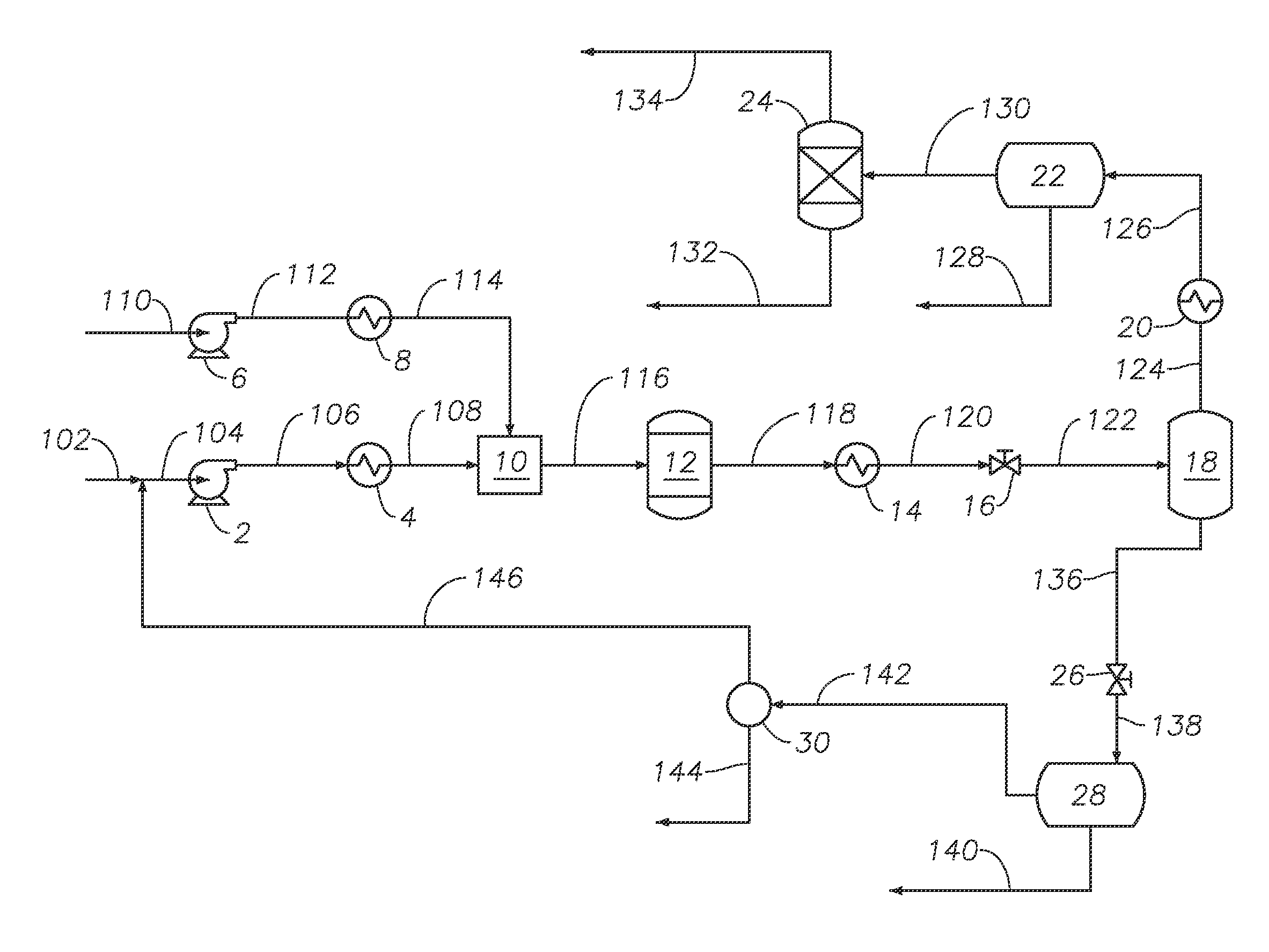

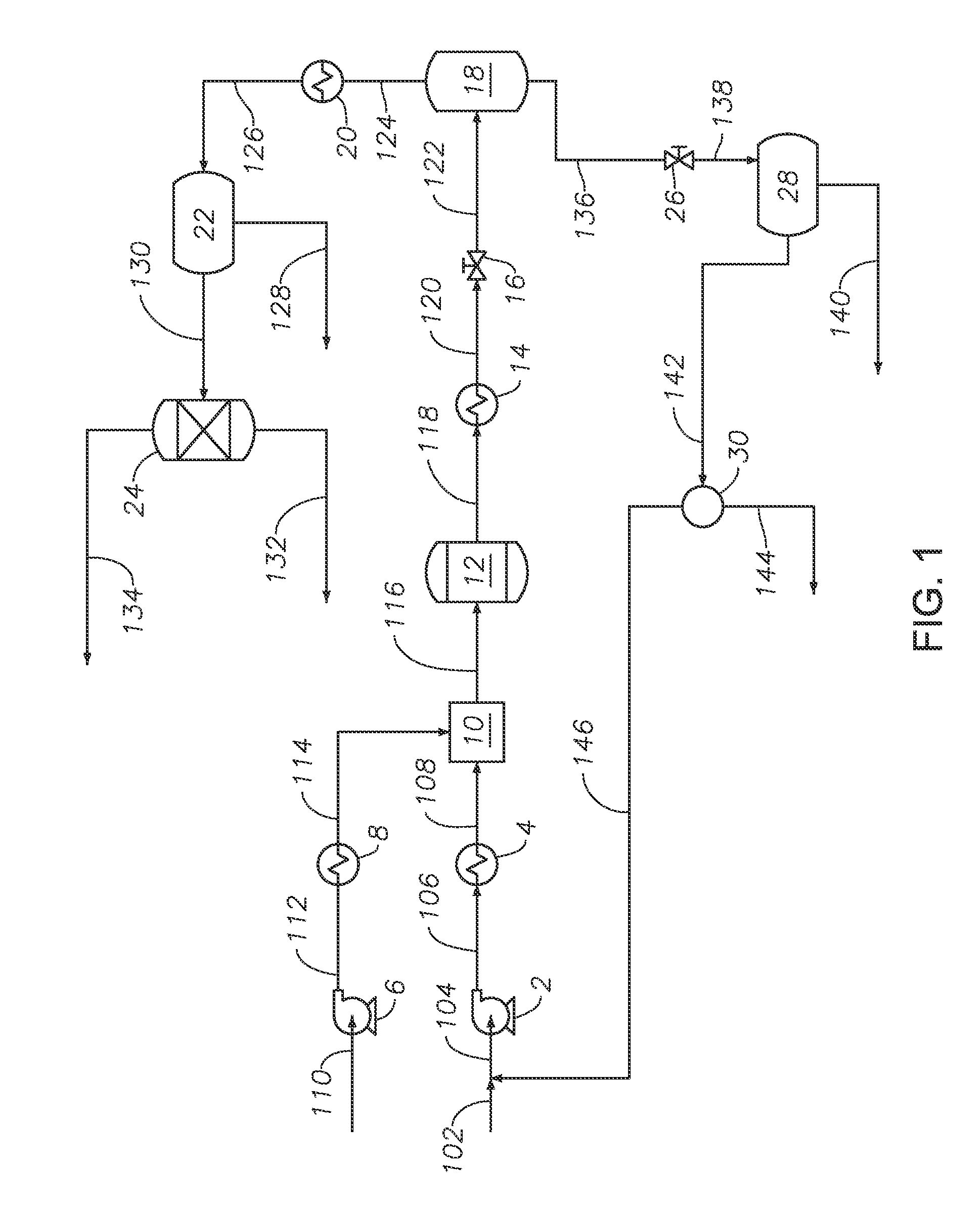

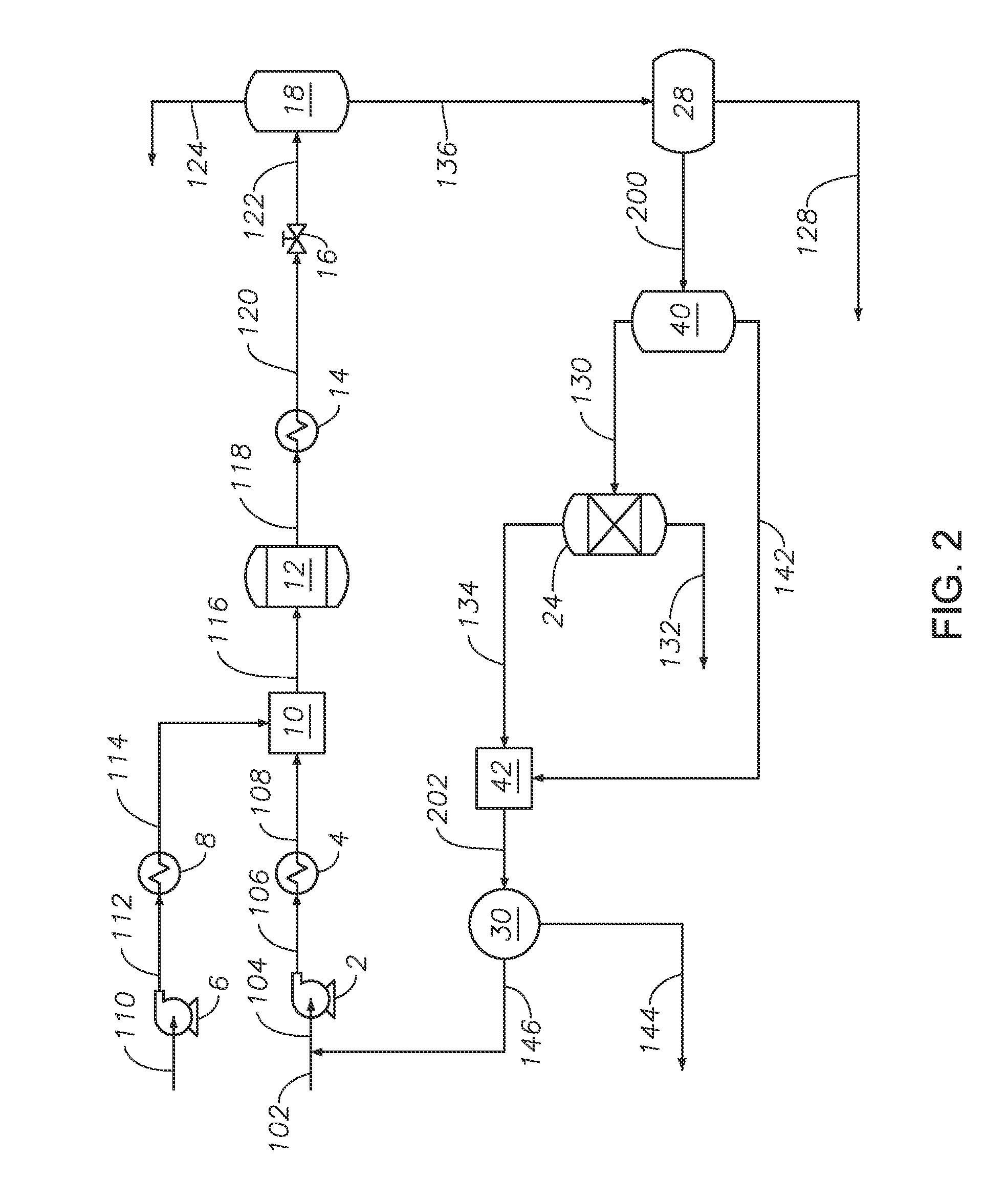

Process to produce aromatics from crude oil

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

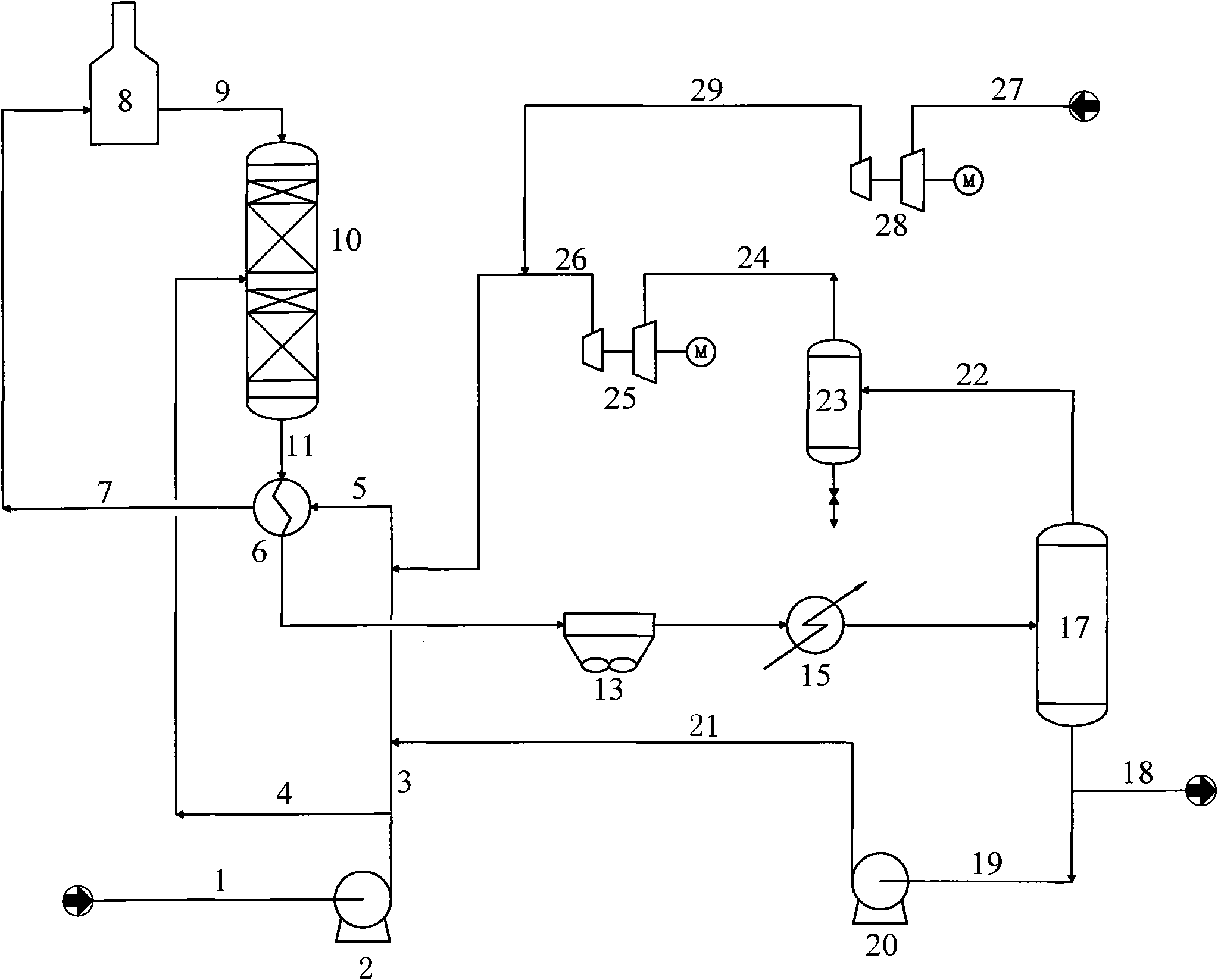

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

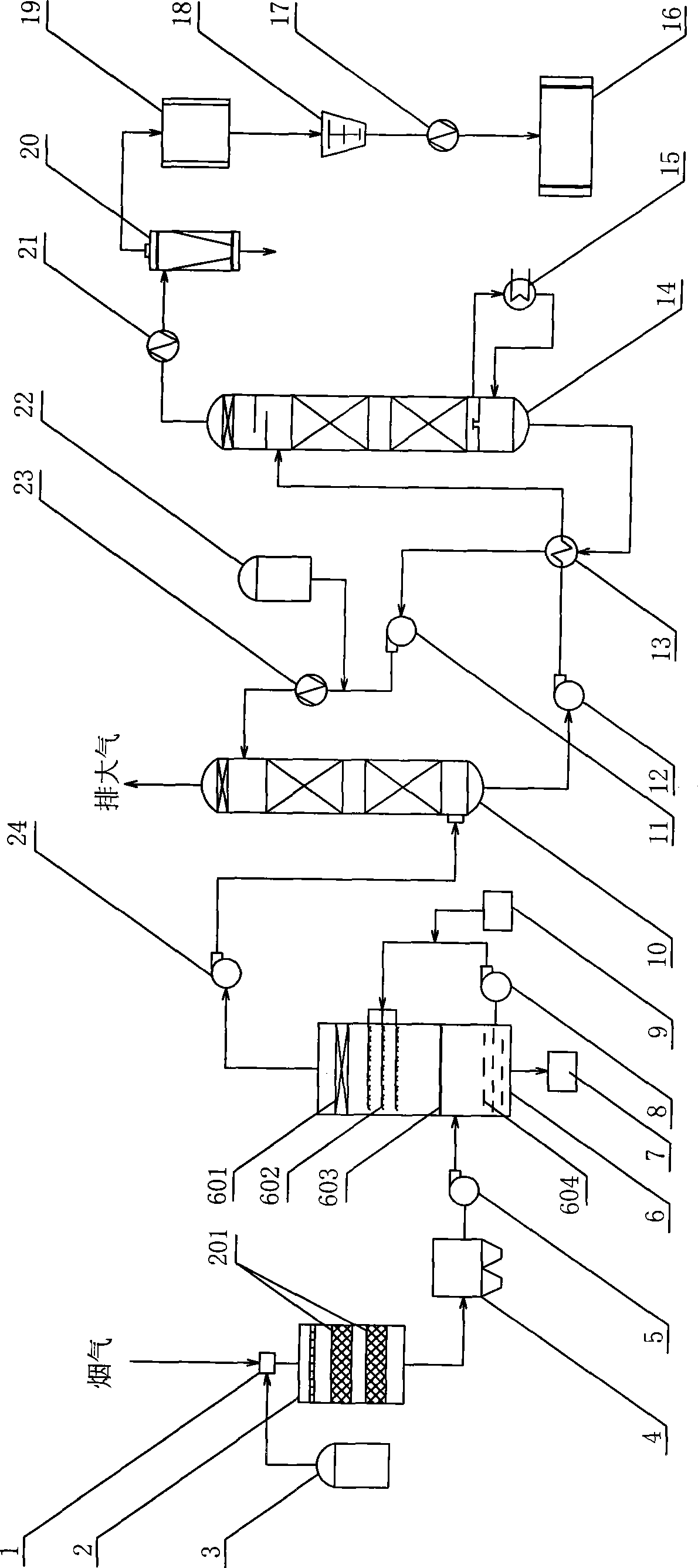

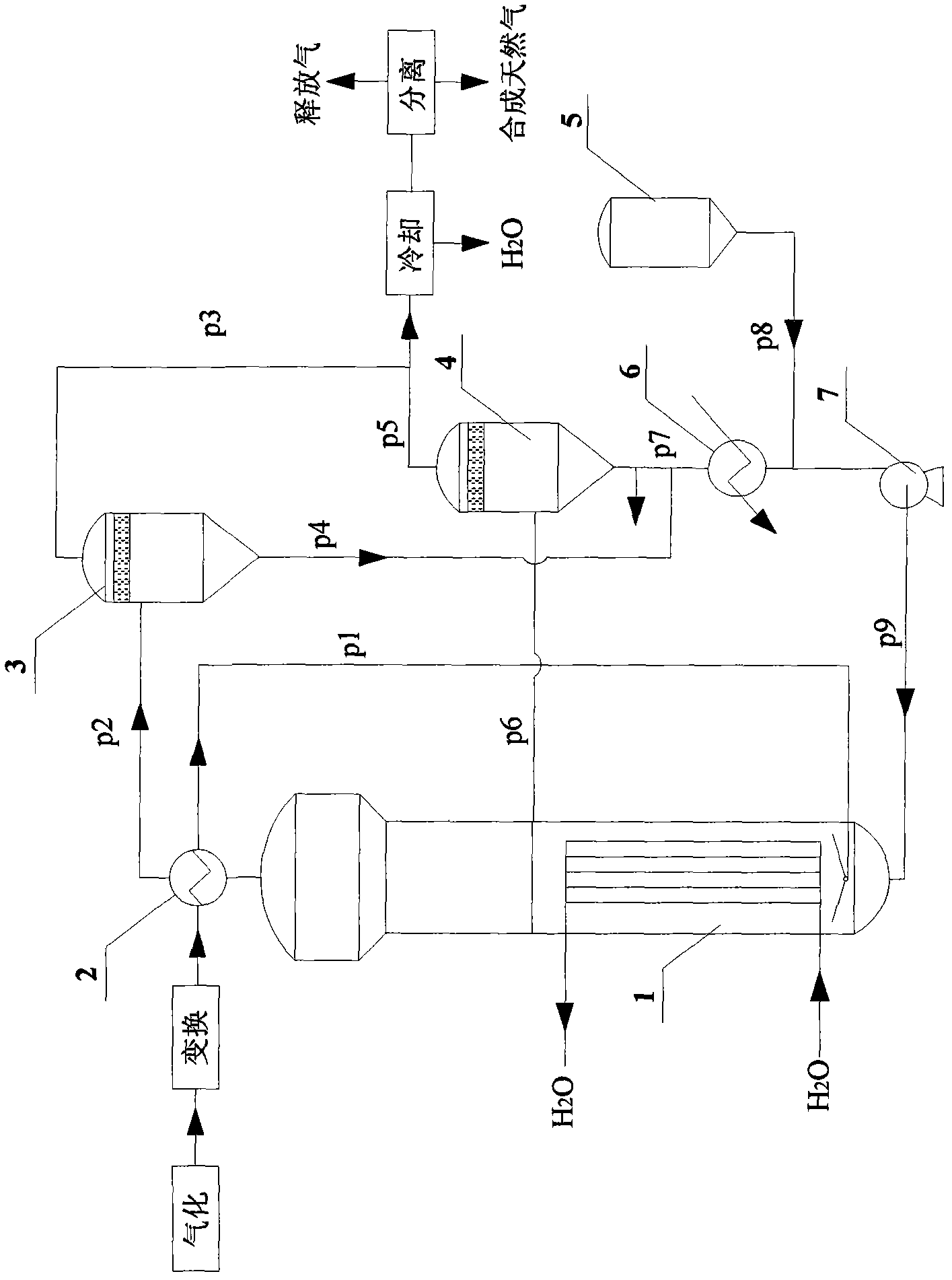

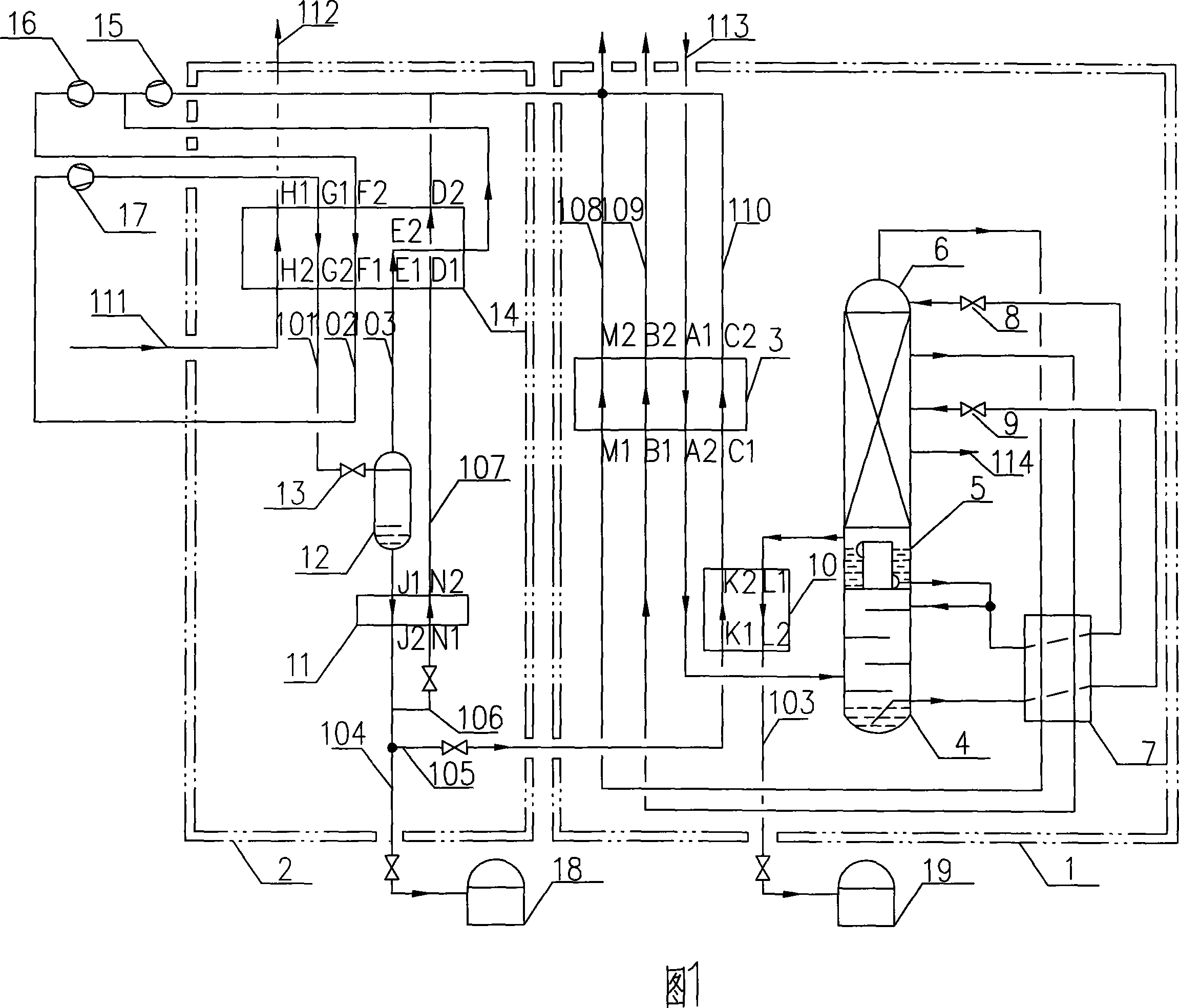

Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

The invention provides a method and a device for collecting carbon dioxide in smoke gas of a coal-fired power plant. The device consists of a smoke gas pretreatment system, absorption towers, a regeneration tower, an exhaust scrubbing system, a solution heating recoverer, a product gas processing system (comprising a condenser, a gas-liquid separator and a compressor). The device is integrated with the prior smoke gas purification device of the coal-fired power plant, and is provided with a high-efficiency whirlcone and a chemical absorption system, so that mass carbon dioxide gas exhausted from a coal-fired boiler can be collected, and the emission of greenhouse gas can be reduced; the special arrangement of double absorption towers ensures more flexible operation of a collecting system, and improves the operational reliability; an absorption solution reclaiming process reduces the consumption of the solution; the arrangement of a lean-rich solution heat exchanger and a product gas rich solution heat exchanger reduces the energy consumption of the collecting system; and the steam consumption can be effectively reduced by adopting a built-in solution boiling unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Improvement method of needle coke used refined aromatic hydrocarbon oil

InactiveCN104560082AIncrease contentSimple processCoke ovensTreatment with polymerisationVapor–liquid separatorRoom temperature

The invention relates to an improvement method of needle coke used refined aromatic hydrocarbon oil. The improvement method of the needle coke used refined aromatic hydrocarbon oil comprises the following steps: taking oil rich in aromatic hydrocarbon, heating the oil to 400-490 DEG C by a heating furnace, introducing the oil into a polymerization tower, taking the material at the bottom of the polymerization tower and introducing the material into a flash tower, taking the flashed material at the bottom of the flash tower, cooling the material to the room temperature, introducing the material into a gas-liquid separator, controlling the vacuum degree in the gas-liquid separator to be 5-10kpa, taking the material at the bottom of the gas-liquid separator, and enabling the material to flow into a refined aromatic hydrocarbon oil buffering tank to prepare the raw material which is refined aromatic hydrocarbon oil for producing needle coke. The improvement method of the needle coke used refined aromatic hydrocarbon oil is simple in process; the oil rich in aromatic hydrocarbon with low content of aromatic hydrocarbon in domestic oil refining plant is processed, the content of the aromatic hydrocarbon is increased; the prepared refined aromatic hydrocarbon oil is applicable to production of the needle coke.

Owner:SHANDONG YIDA NEW MATERIAL

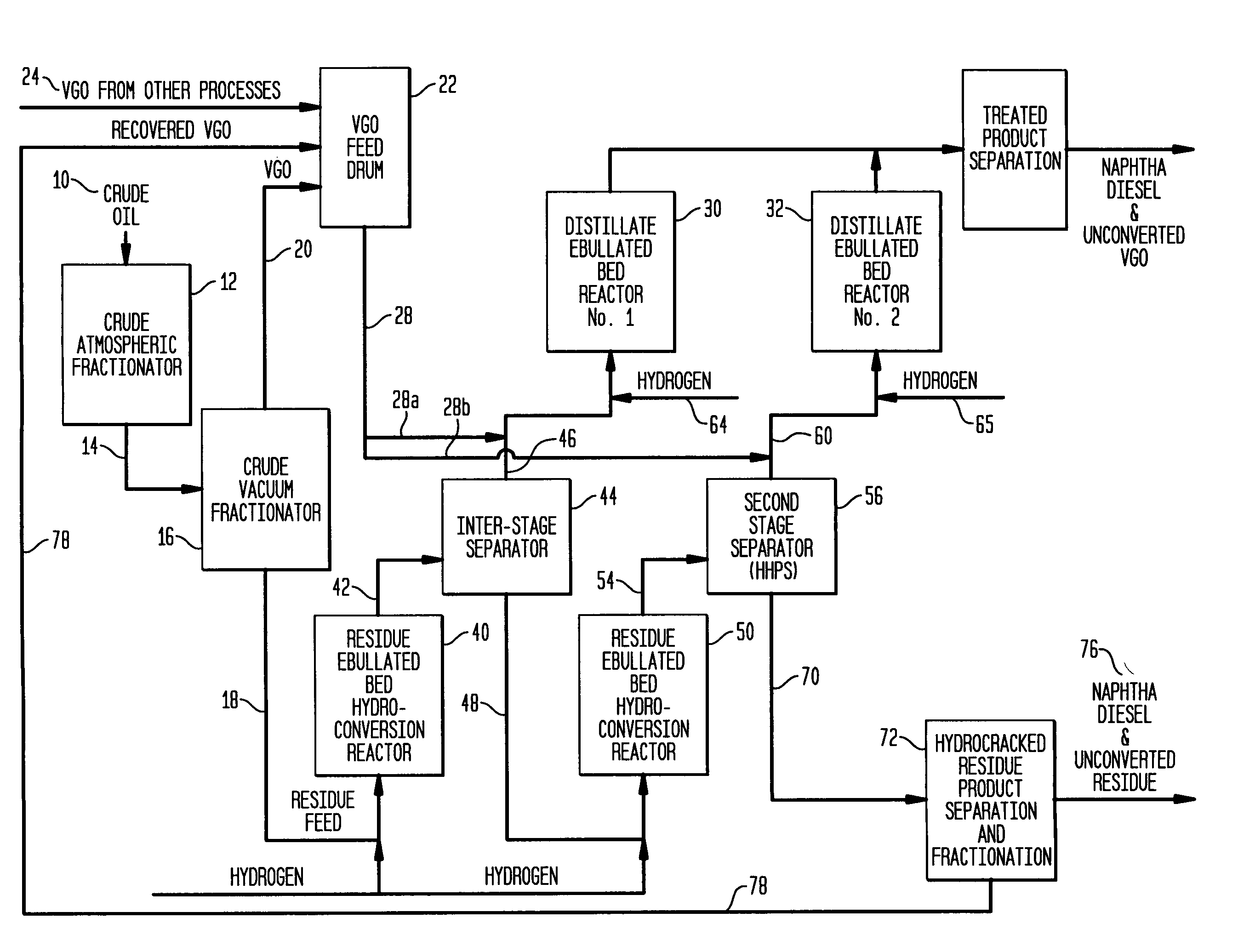

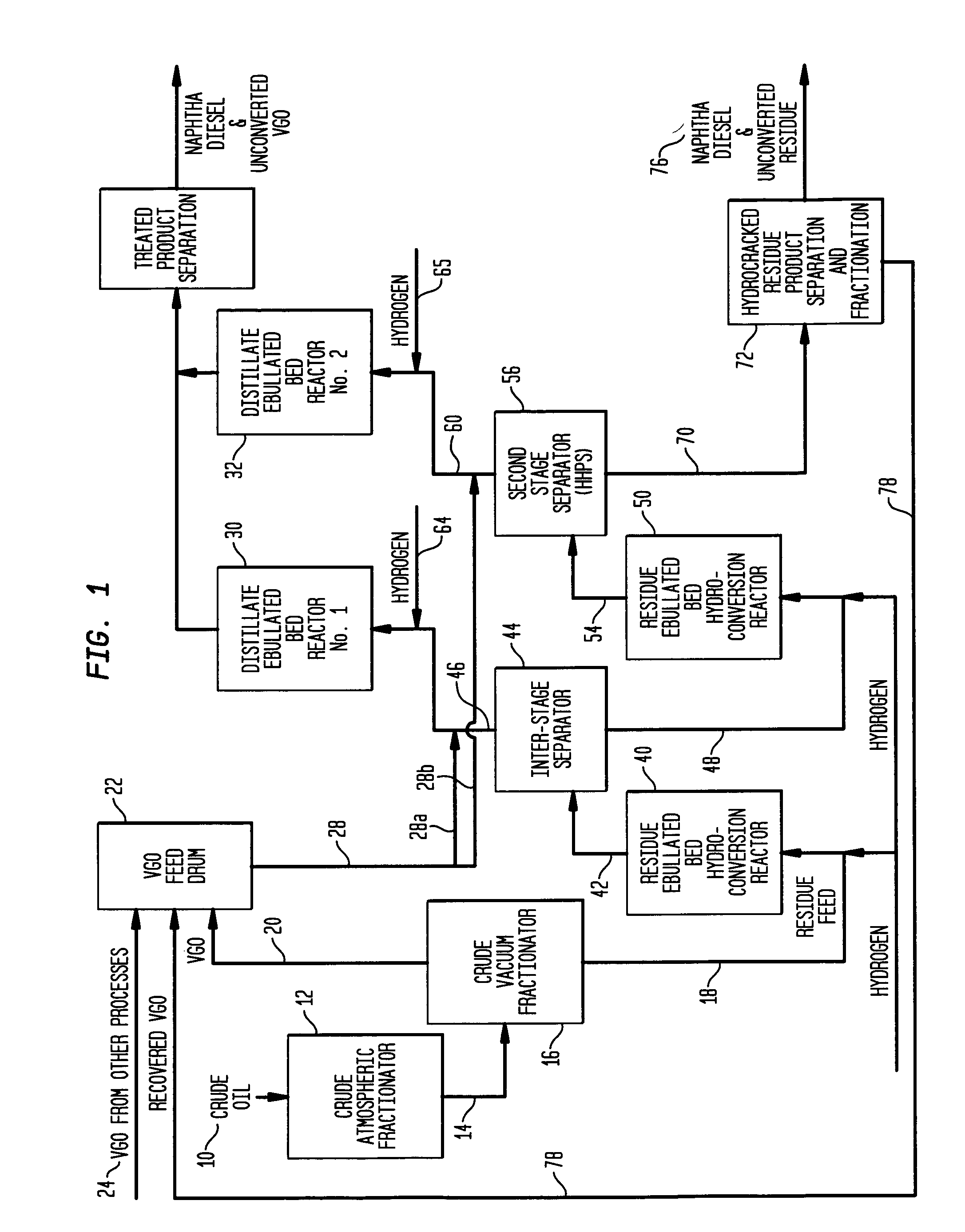

Process for multistage residue hydroconversion integrated with straight-run and conversion gasoils hydroconversion steps

InactiveUS7938952B2Improve throughputMitigate issueTreatment with plural serial cracking stages onlyMolecular sieve catalystsVapor liquidLiquid product

This invention relates to a novel integrated hydroconversion process for converting heavy atmospheric or vacuum residue feeds and also converting and reducing impurities in the vacuum gas oil liquid product. This is accomplished by utilizing two residue hydroconversion reaction stages, two vapor-liquid separators, and at least two additional distillate ebullated-bed hydrocracking / hydrotreating reaction stages to provide a high conversion rate of the residue feedstocks.

Owner:INST FR DU PETROLE

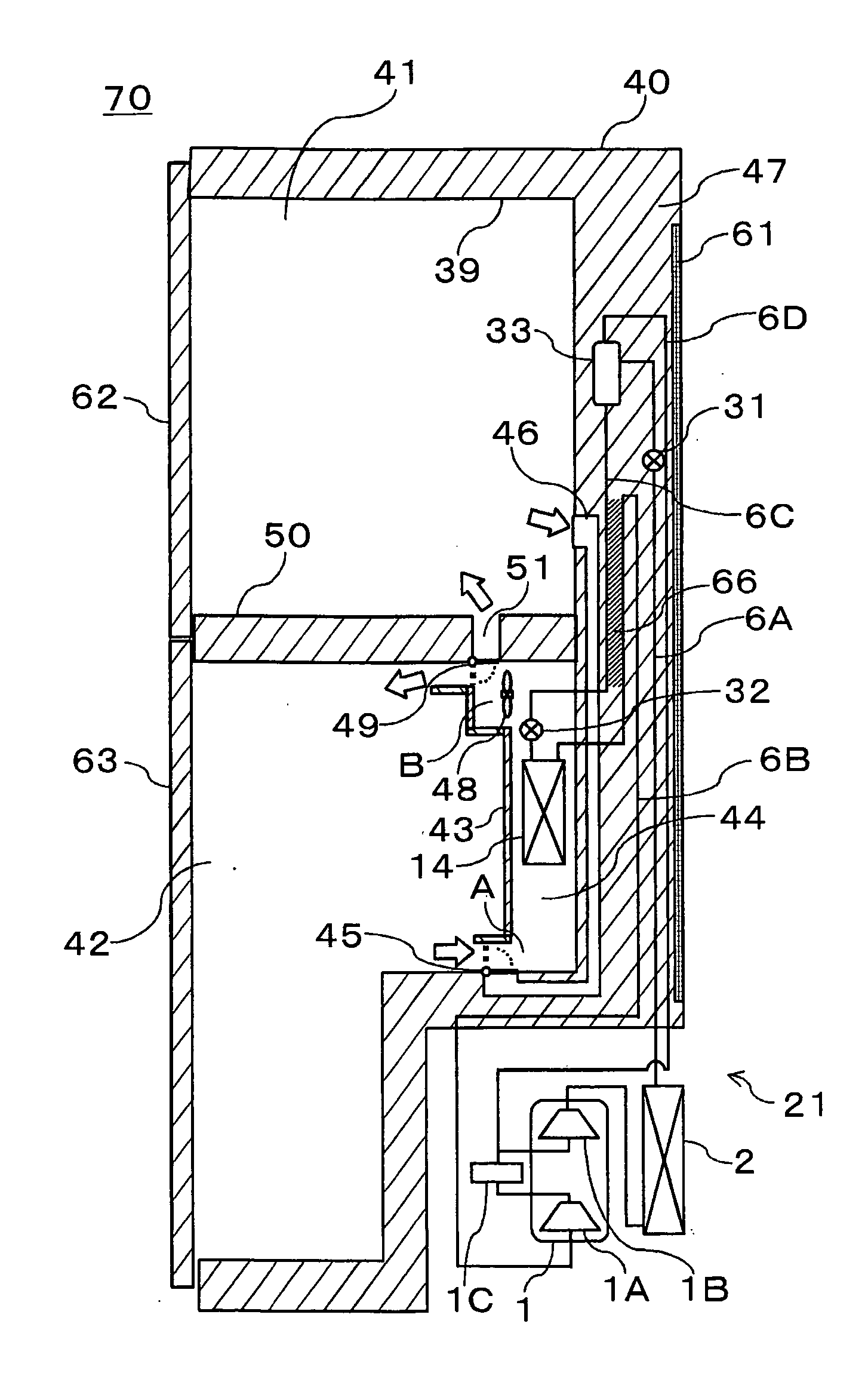

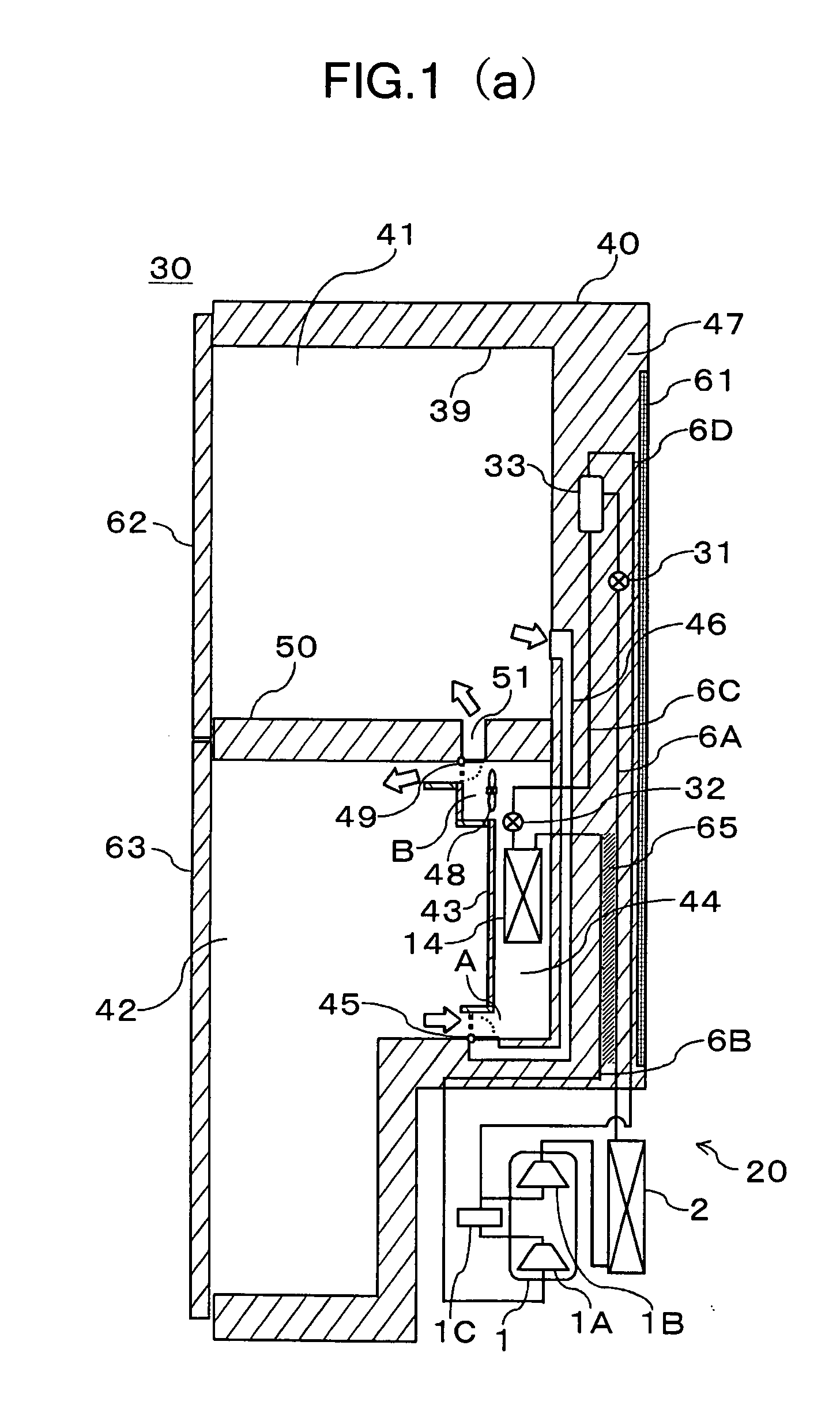

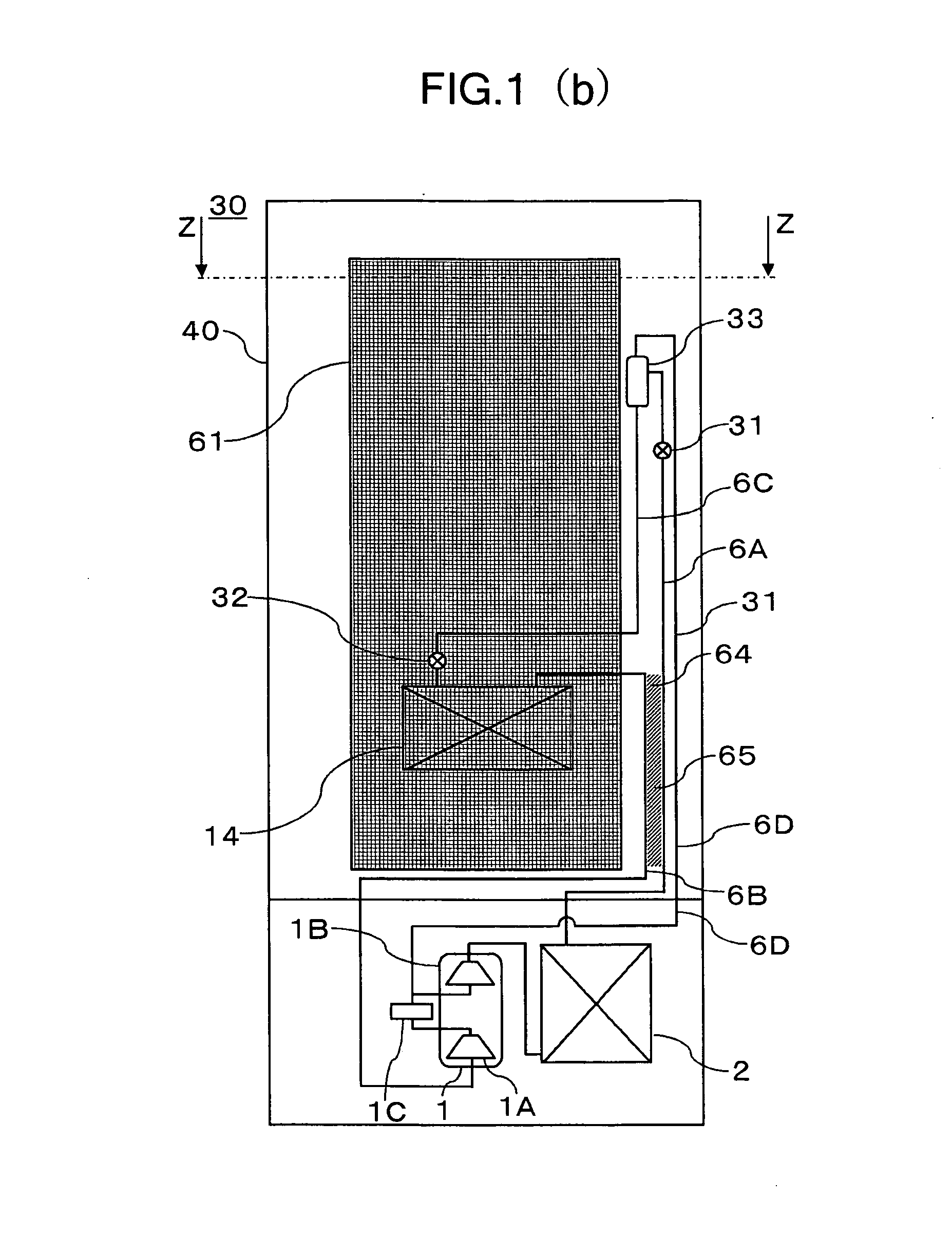

Refrigerator

InactiveUS20060266075A1Improve cooling effectLow thermal conductivityCompression machines with non-reversible cycleDomestic refrigeratorsVapor–liquid separatorLiquid state

It is an object of the present invention to provide a refrigerator which is able to improve the efficiency of the refrigerating cycle while avoiding causing the structure of the refrigerator to be complicated, and avoiding a cost increase. Refrigerator 30 includes a refrigerating cycle device 20 having a compressor 1, a radiator 2 connected to a discharge side of the compressor 1, a first expansion valve 31 connected to an exit side of the radiator 2, a gas-liquid separator 33 for separating a refrigerant, which is in a mixed gas-liquid state by being decompressed by the first expansion valve 31, into a gas refrigerant and a liquid refrigerant, a heat absorber 14 into which the liquid refrigerant discharged from the gas-liquid separator 33 flows, and a refrigerant pipe 6D for delivering the gas refrigerant discharged from the gas-liquid separator 33 into the middle pressure portion of the compressor 1; an outer case 40; an inner case 39; and a heat insulating material. The gas-liquid separator 33 is arranged in the heat insulating material 47.

Owner:SANYO ELECTRIC CO LTD

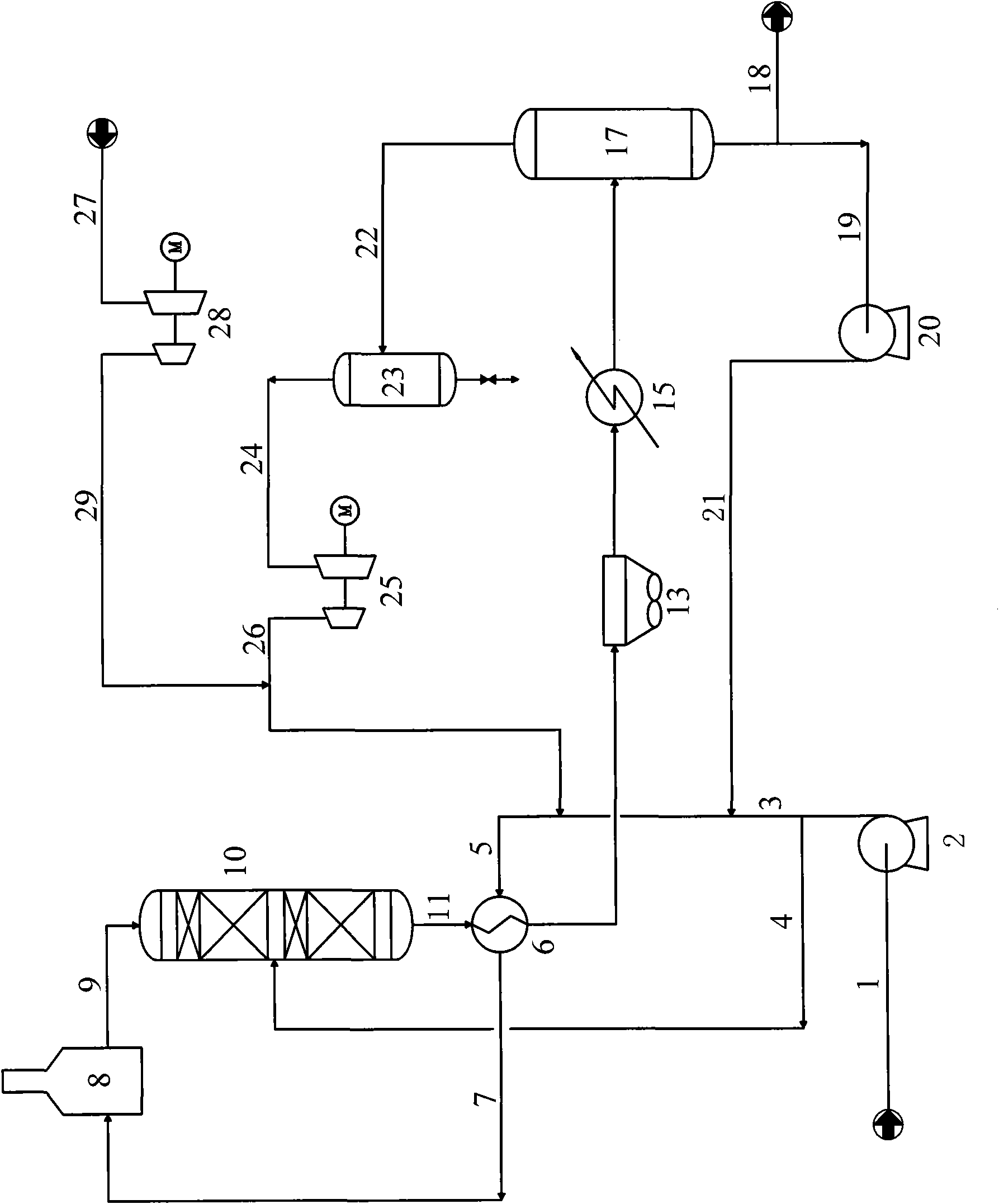

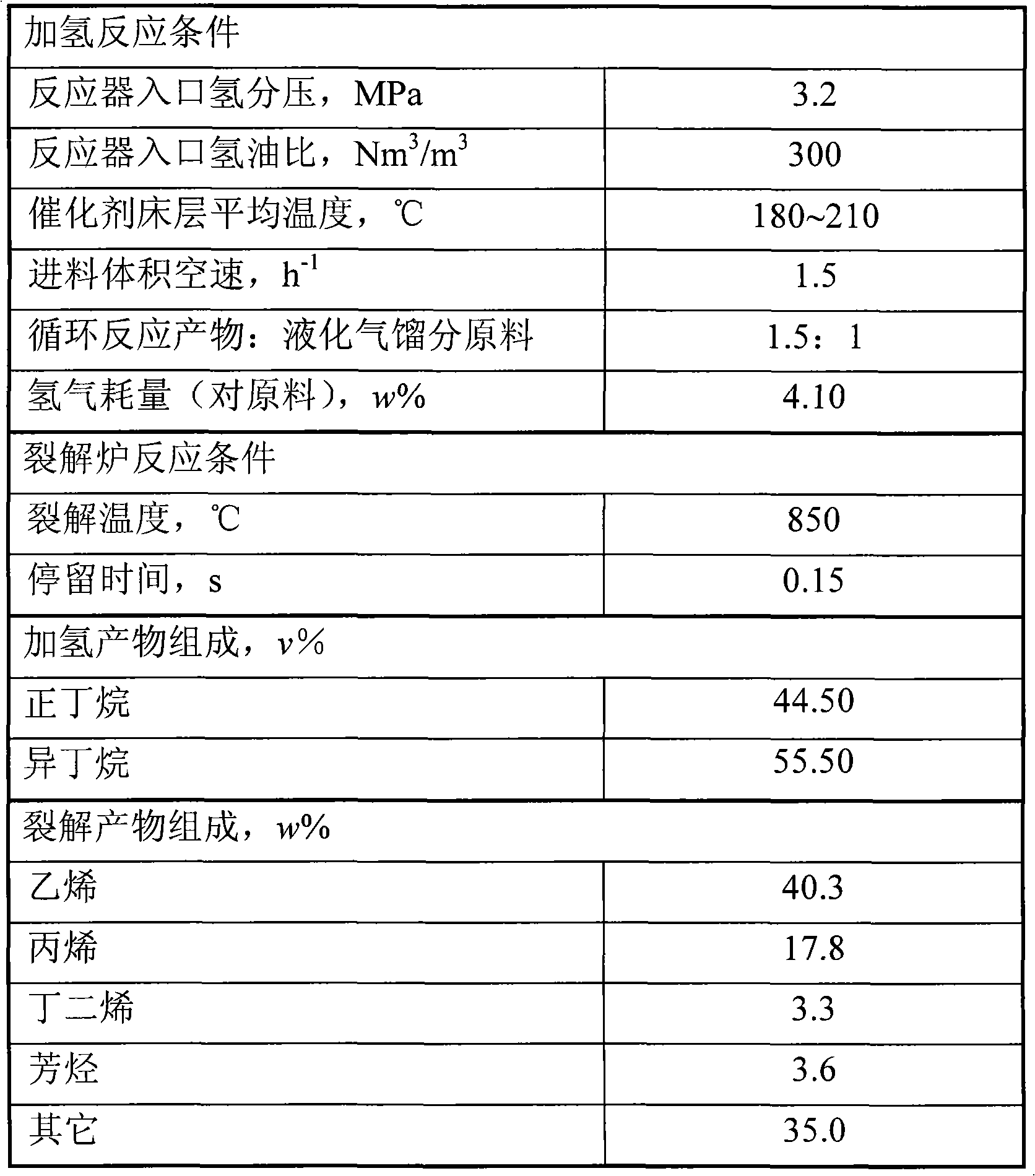

Hydrogenation method for liquefied gas fraction

InactiveCN101880549AExpand application channelsExpand sourceHydrocarbon by hydrogenationTreatment with hydrotreatment processesAlkaneGas phase

The invention discloses a hydrogenation method for liquefied gas fraction, which is characterized by comprising the following steps of: filling at least one section of catalyst bed layer into a reactor, introducing a liquefied gas fraction raw material and hydrogen into the reactor from one or more sections of catalyst bed layers to contact a catalyst and perform hydrogenation saturation reaction, and reacting olefin in the liquefied gas fraction and the hydrogen to generate alkane and release a large amount of heat; after heat exchange, feeding the reaction product into a gas-liquid separator and separating the reaction product into a gas phase and a liquid phase, and introducing the separated gas phase flow into the reactor to perform repeated use; and introducing a part of separated liquid phase flow serving as a cyclic reaction product back to the reactor, and introducing the other part of the separated liquid phase flow serving as a liquefied gas fraction hydrogenation product out of the reactor to perform reuse. The hydrogenation product obtained by the method is saturated light hydrocarbon fraction which can be directly used as a raw material for an ethylene cracking device and also can be fractionated and cut into propane, n-butane and iso-butane and the like serving as high value-added chemical base raw materials so as to increase the economic benefit of an oil refining enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

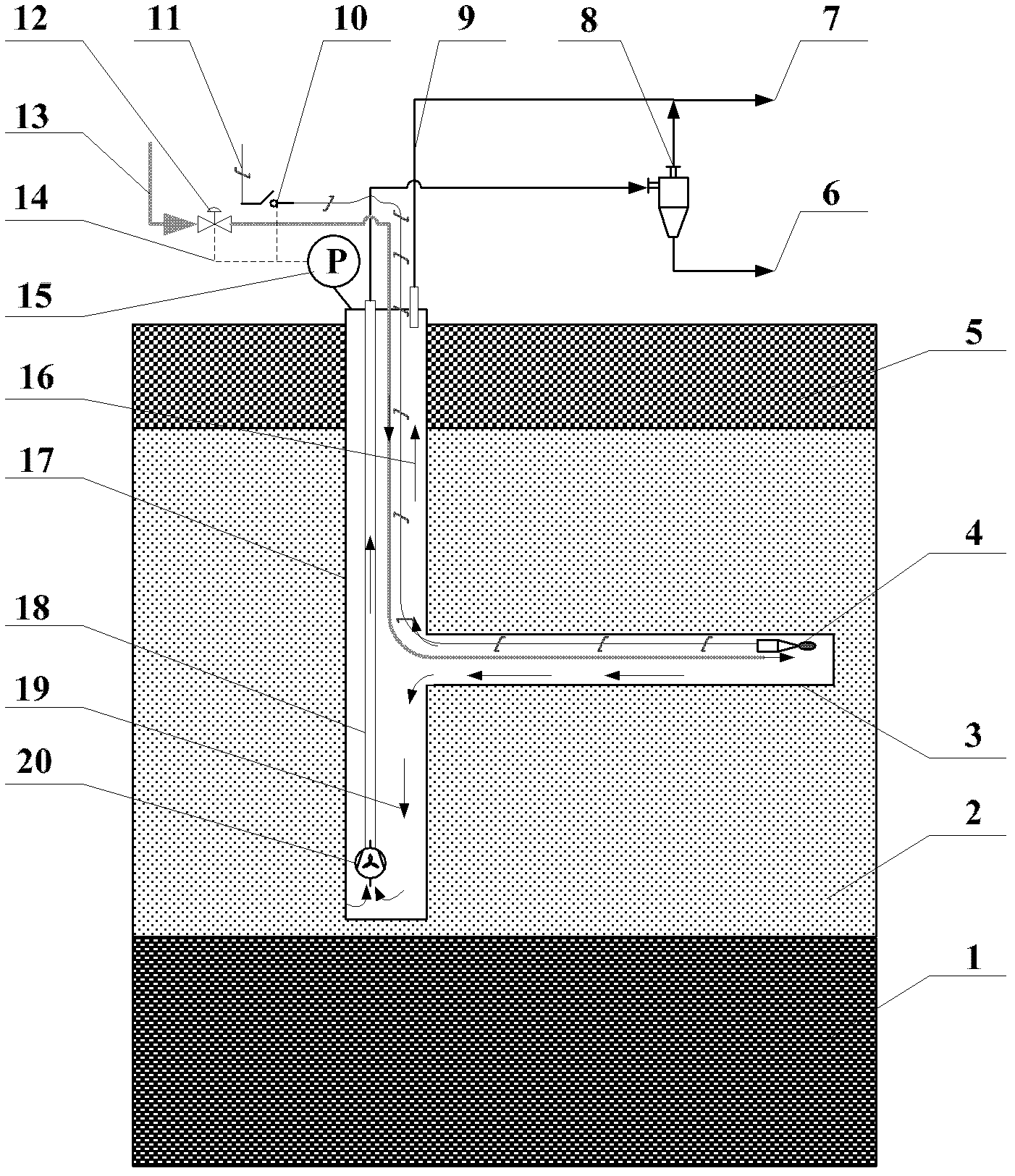

Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

ActiveCN103410488ASpeed up decompositionReduce moisture contentConstructionsFluid removalElectricityVapor–liquid separator

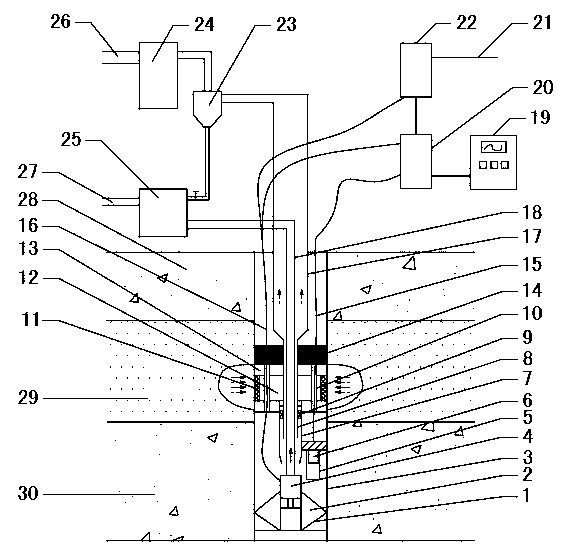

The invention provides a natural gas hydrate water discharge gas production exploitation device and an exploitation method of the natural gas hydrate water discharge gas production exploitation device, and belongs to the technical field of natural gas hydrate exploitation. A feeding cavity (12) communicated with a natural gas hydrate layer (29) is connected with an in-well gas-liquid separator (7), an exhaust cavity (8) of the in-well gas-liquid separator (7) is communicated with a gas production sleeve pipe (17), and a water discharge opening of the in-well gas-liquid separator (7) is communicated with a liquid storage cavity (2) arranged at the lower part. According to the exploitation method adopting the device, the natural gas hydrate layer (29) is firstly heated, the in-well gas-liquid separator (7) is utilized for separating gas-water mixture generated in the natural gas hydrate decomposition process, meanwhile, a liquid level monitoring device is utilized for regulating the water discharge speed of an electric submersible pump (4), and the decomposition speed of the natural gas hydrate is controlled. The device and the method have the advantages that the natural gas hydrate exploitation well liquid accumulation can be effectively prevented, the gas production efficiency is improved, the work is safe and reliable, the environment is protected, the service life is long, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

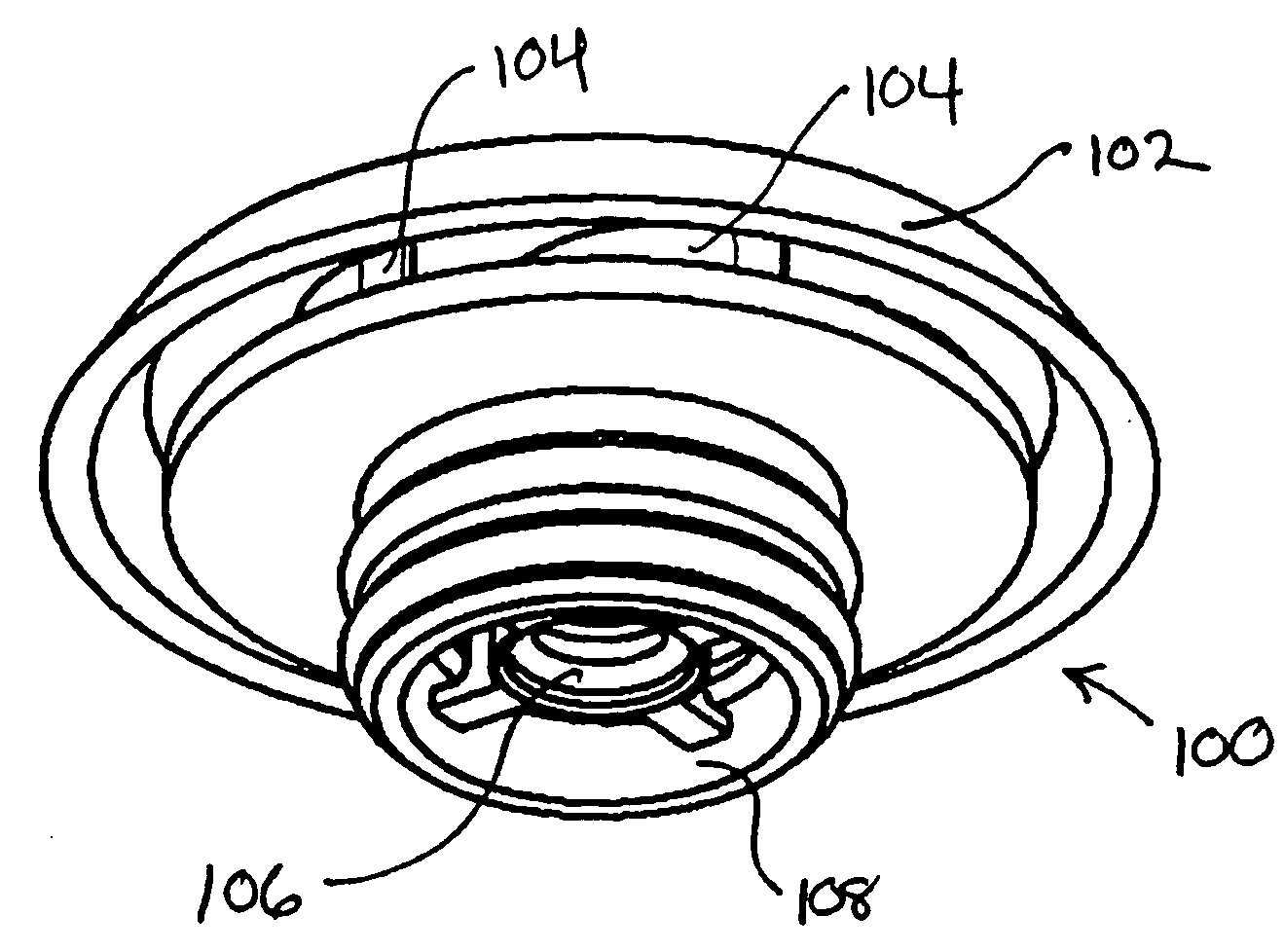

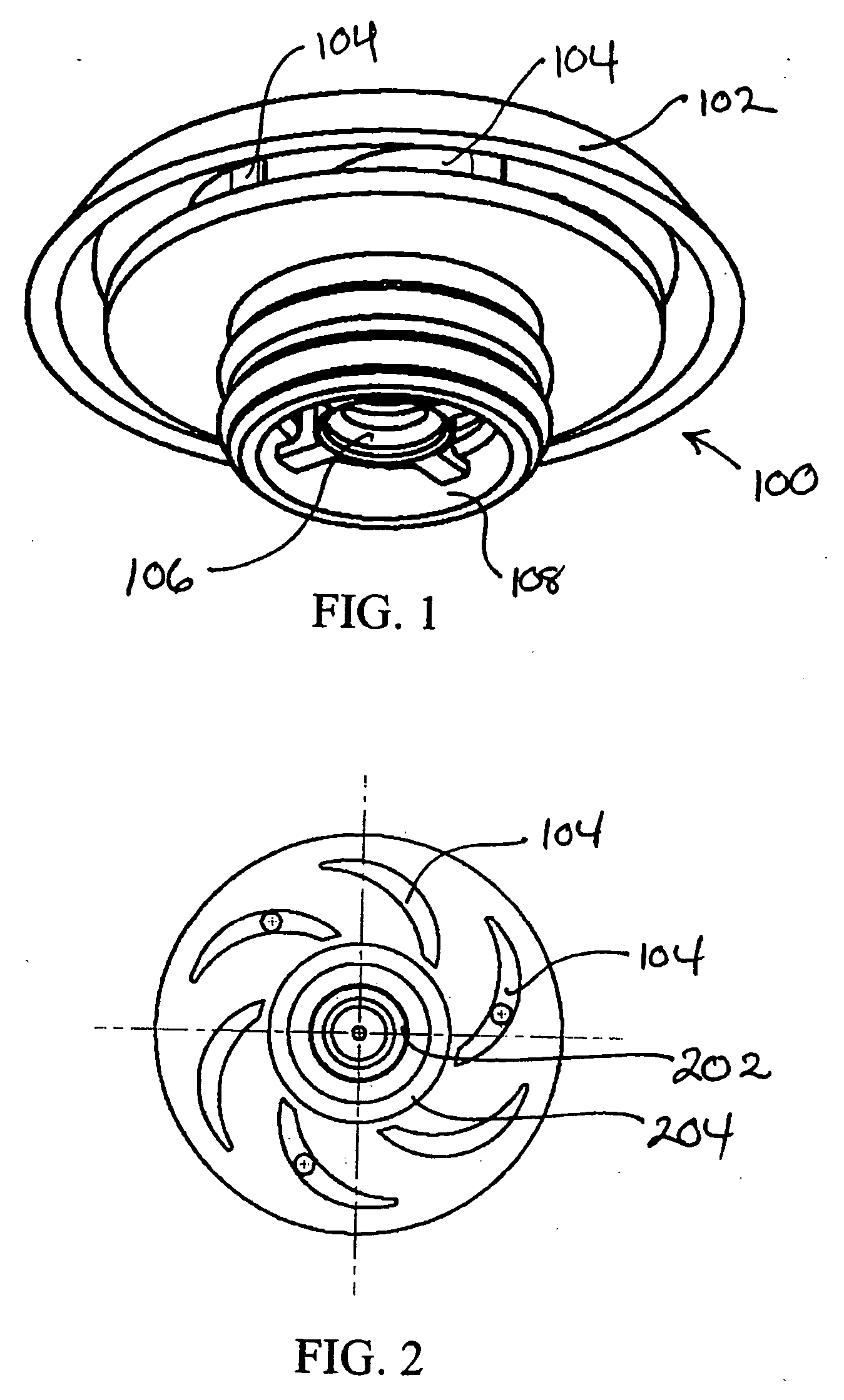

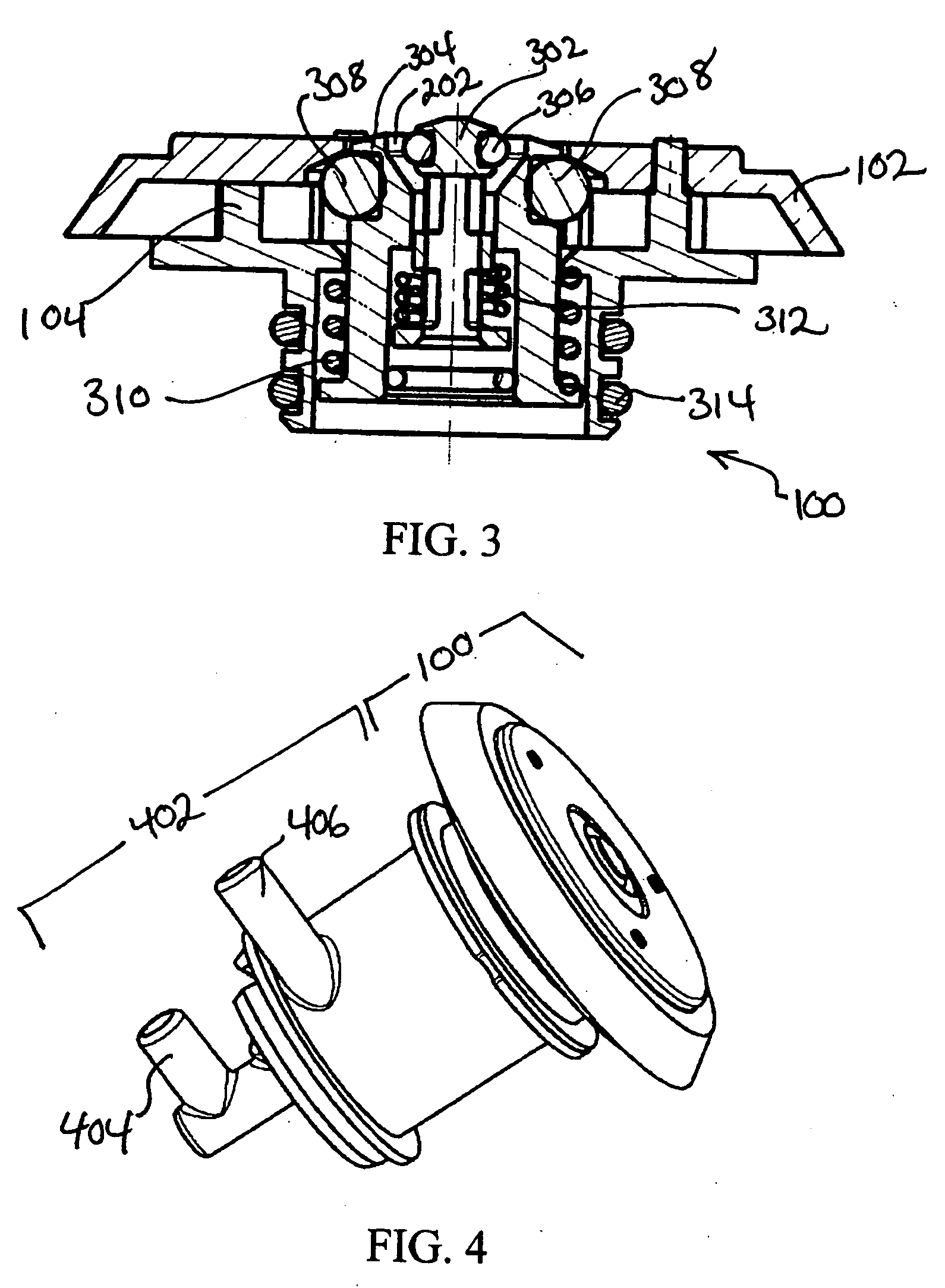

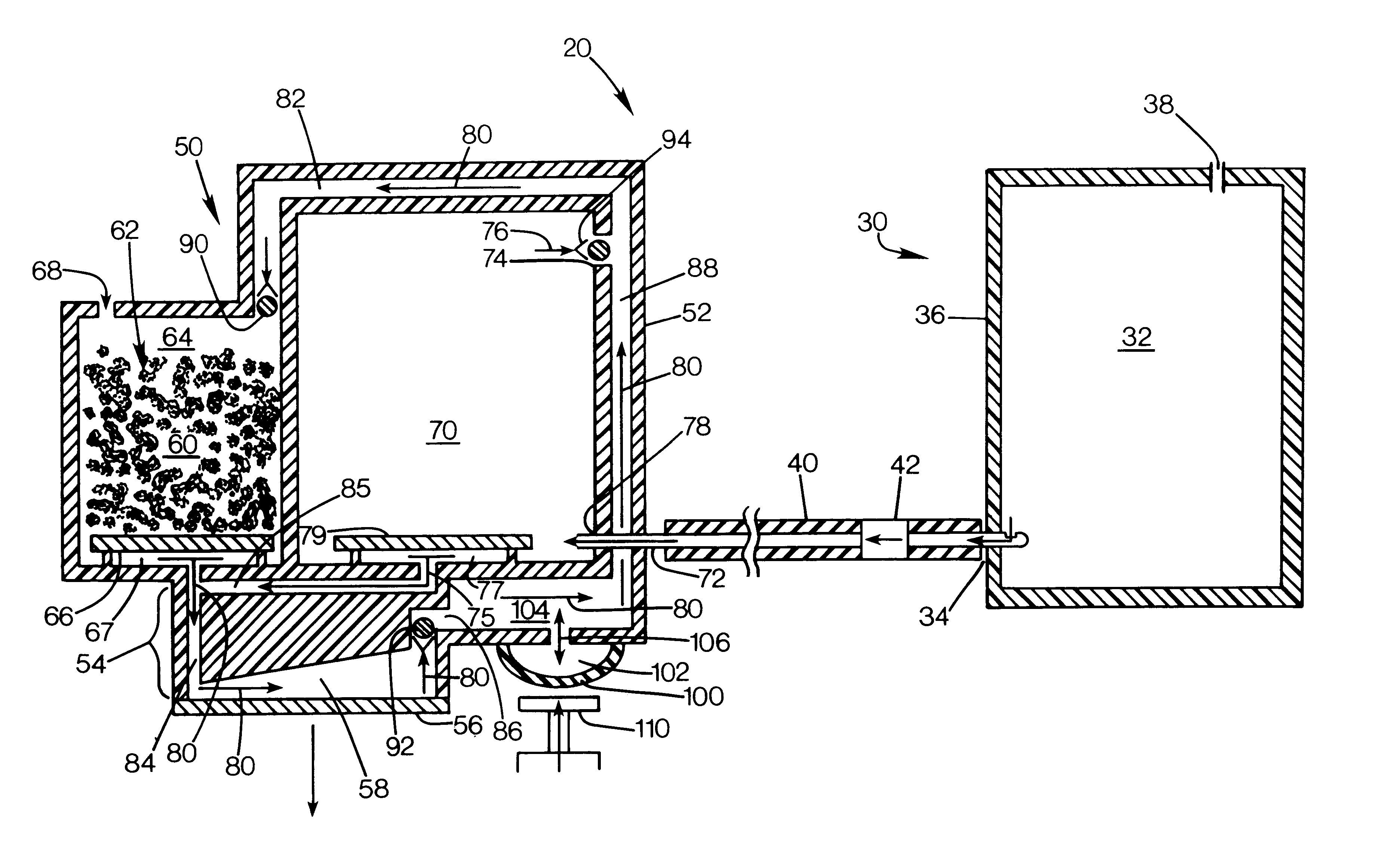

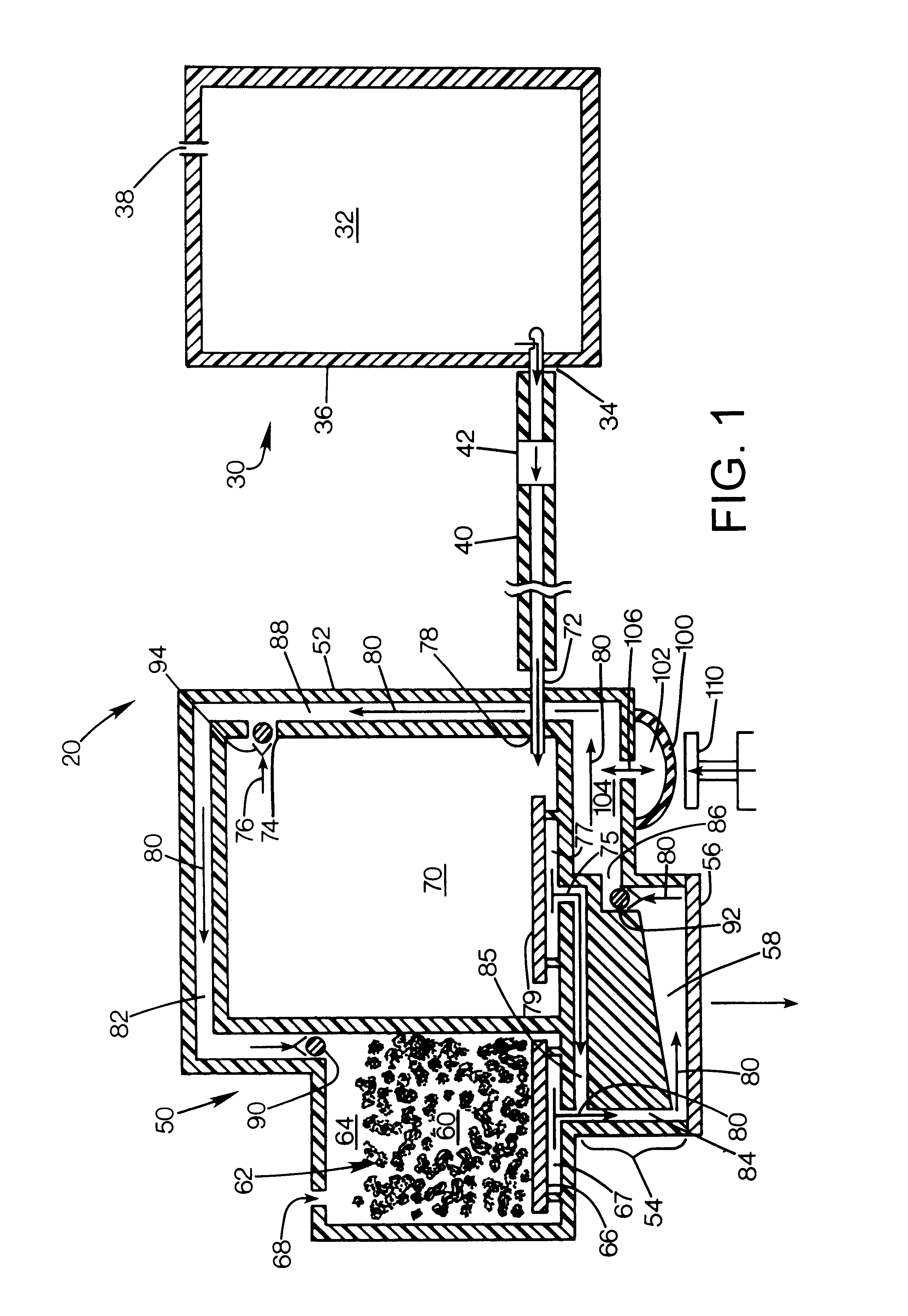

Sanitization system and system components

InactiveUS7767168B2Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

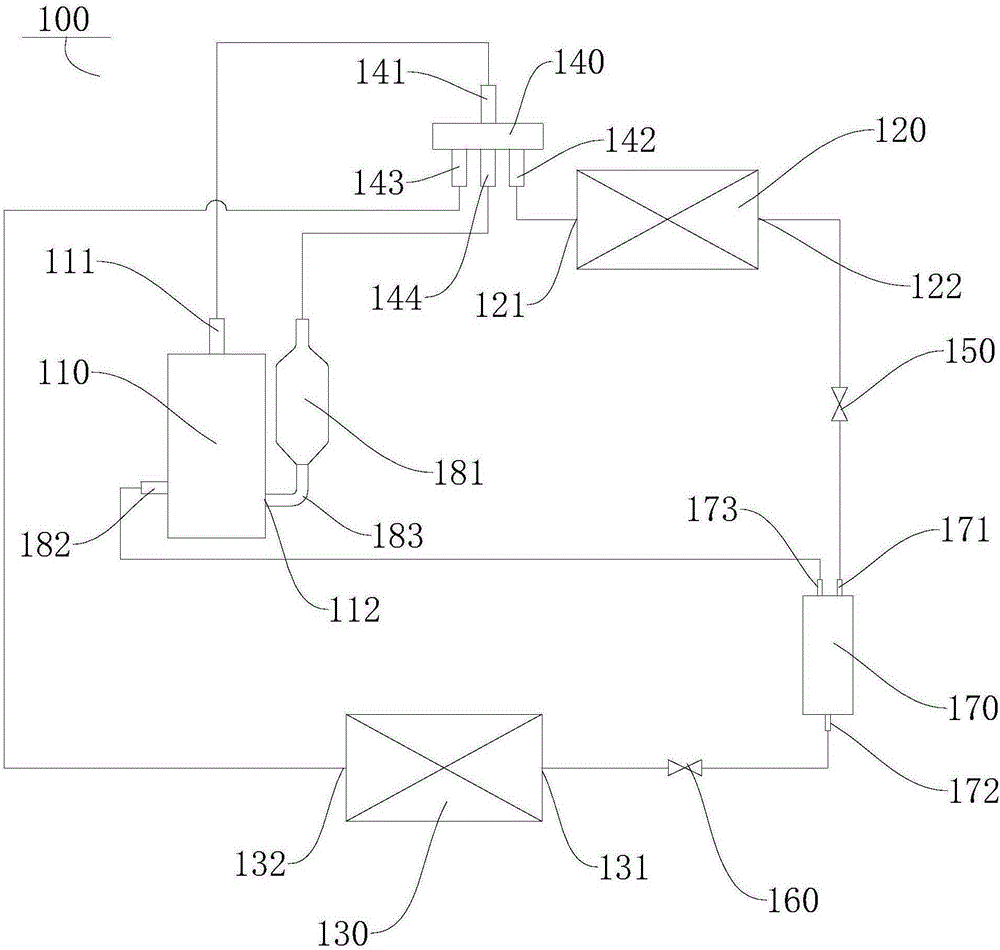

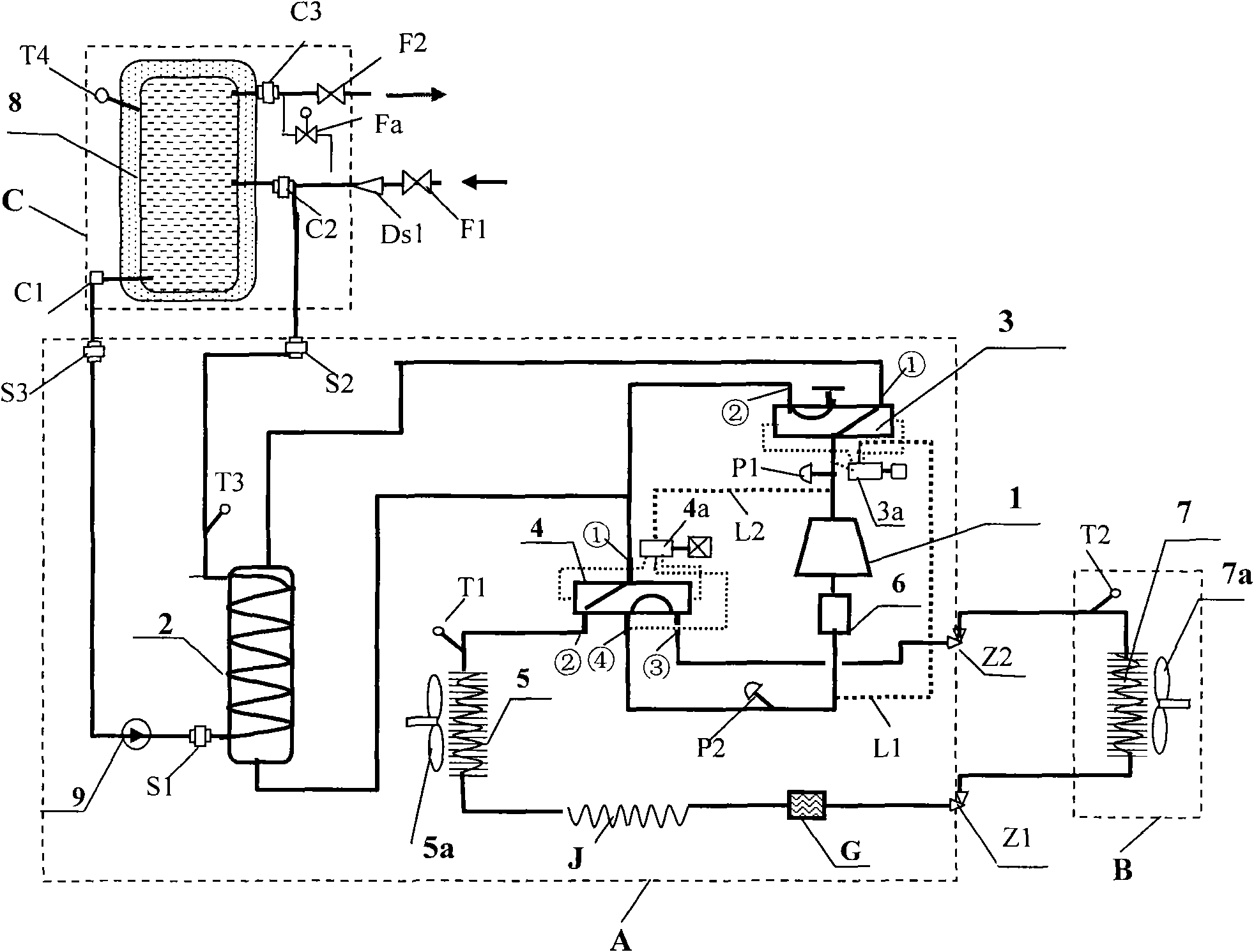

Air conditioner system and air conditioner provided with same

ActiveCN105202796AImprove performanceCanon Efficiency StatusCompression machines with reversible cycleHeating and refrigeration combinationsVapor–liquid separatorEngineering

The invention discloses an air conditioner system and an air conditioner provided with the same. The air conditioner system comprises a compressor, an indoor heat exchanger, an outdoor heat exchanger, a reversing assembly, a first throttling element, a second throttling element, a gas-liquid separator and a liquid storage device. The compressor comprises a first air cylinder, a second air cylinder, an exhaust opening and an air return opening. The exhaust volume ratio of the second air cylinder to the first air cylinder is smaller than or equal to 0.1. The reversing assembly comprises a first valve opening, a second valve opening, a third valve opening and a fourth valve opening. When the air conditioner system conducts cooling, the first valve opening is communicated with the second valve opening, and the third valve opening is communicated with the fourth valve opening. When the air conditioner system conducts heating, the first valve opening is communicated with the third valve opening, the second valve opening is communicated with the fourth valve opening, and a gas outlet of the gas-liquid separator is communicated with the second air cylinder. According to the air conditioner system, the exhaust volume ratio of the second air cylinder to the first air cylinder is made to be smaller than or equal to 0.1, so that the performance of the air conditioner system can be effectively improved, and the air conditioner can reach the optimal state of energy efficiency easily.

Owner:GUANGDONG MEIZHI COMPRESSOR

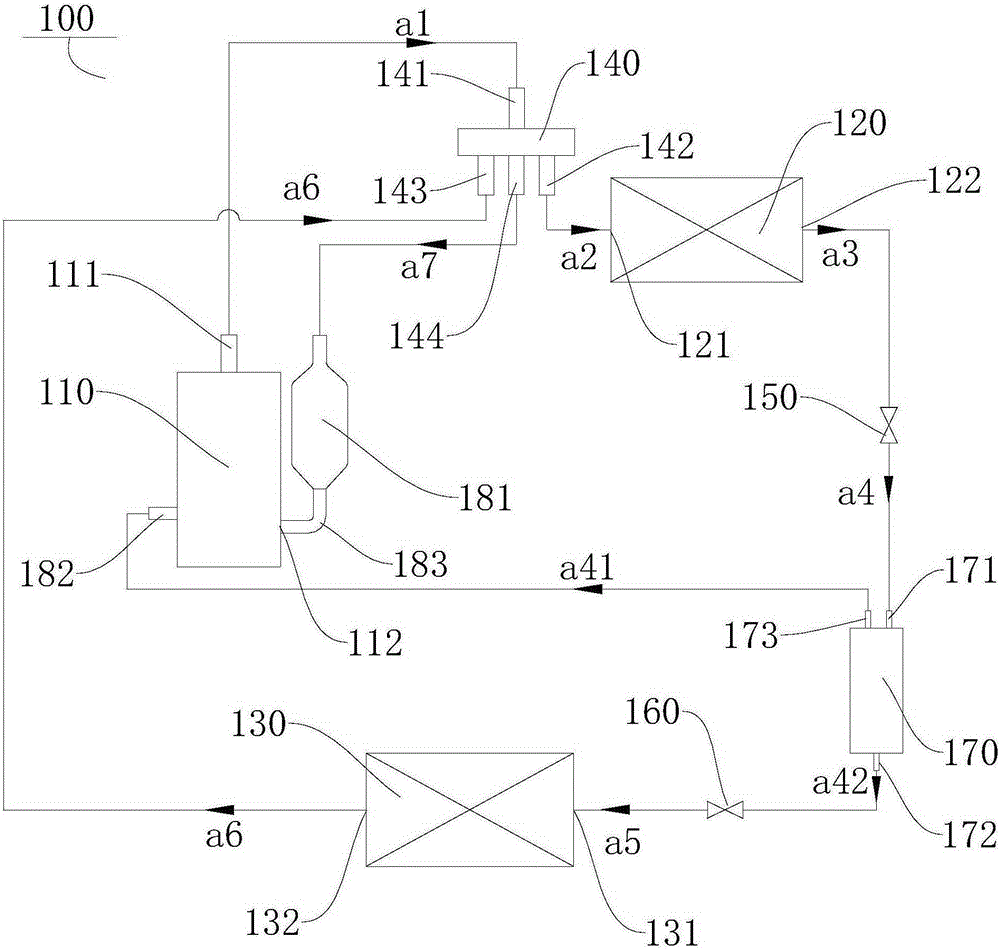

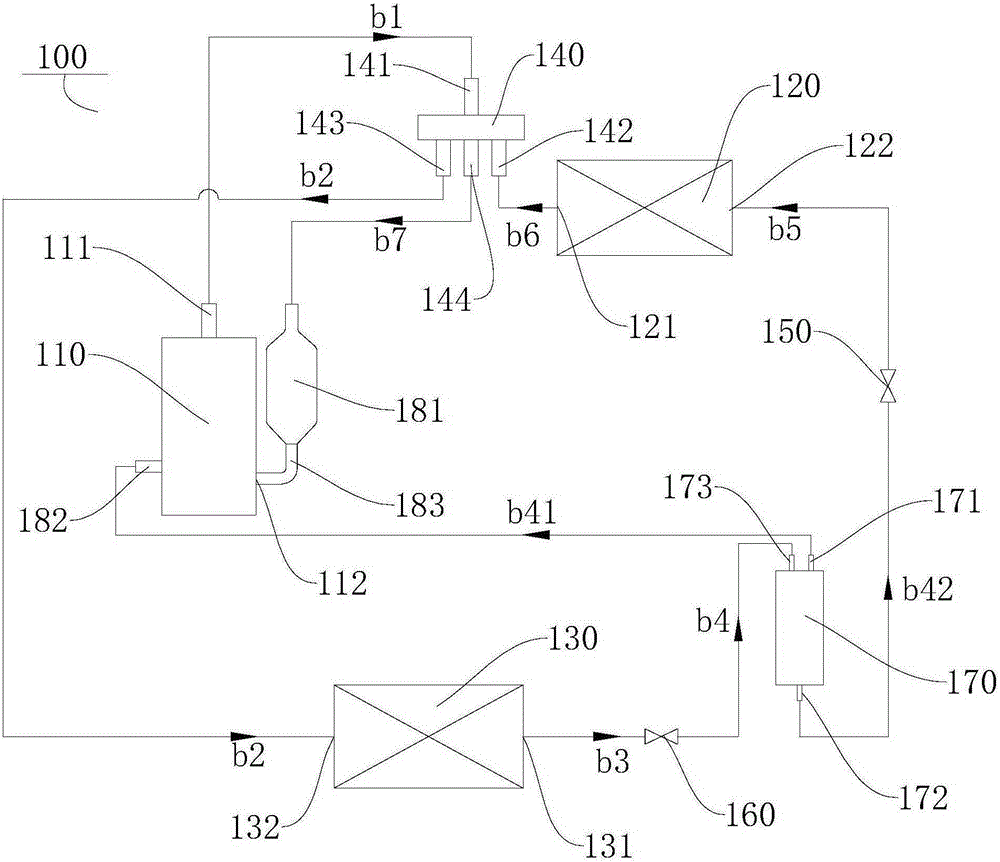

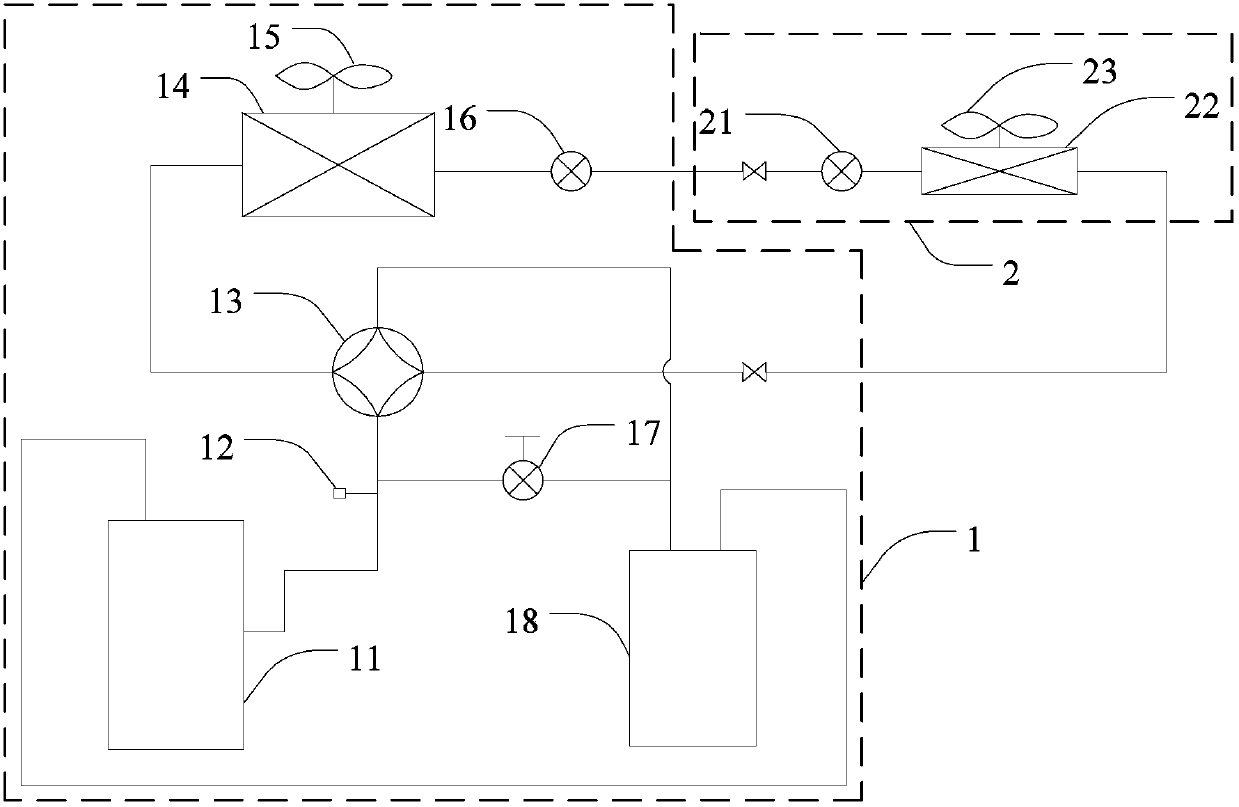

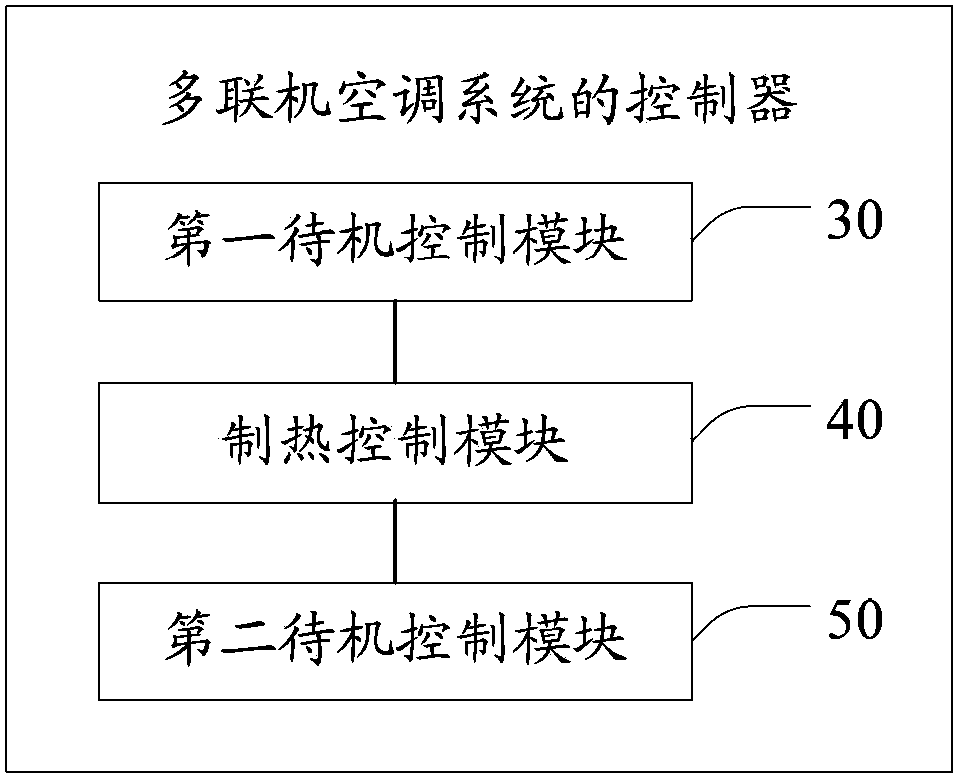

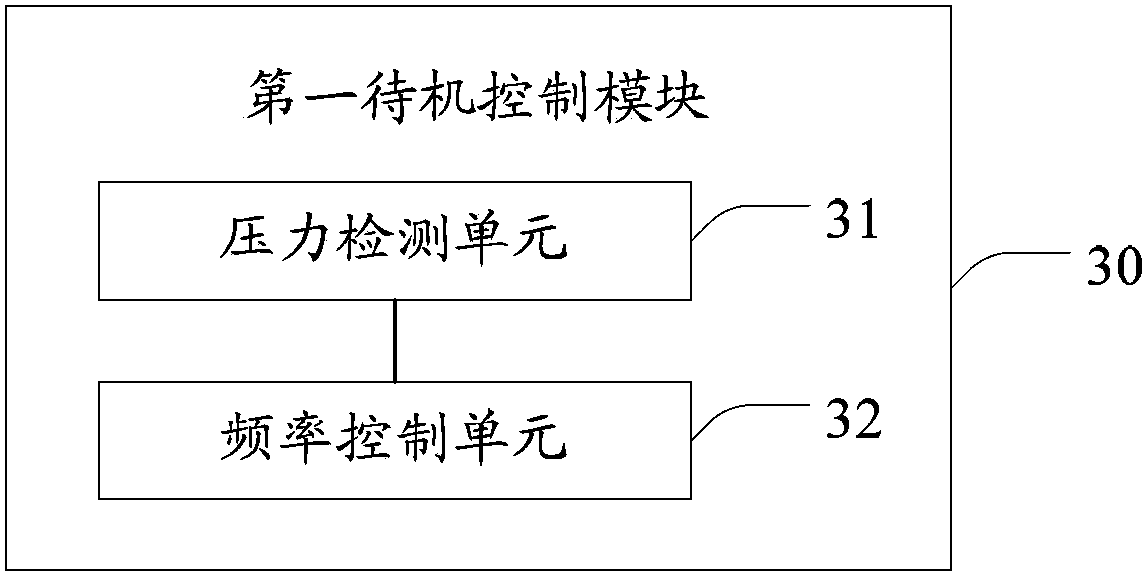

Multi-split air conditioner system and quick-starting heat generation method

ActiveCN103388856AShorten the timeImprove experienceSpace heating and ventilation safety systemsLighting and heating apparatusCold airVapor–liquid separator

The invention discloses a multi-split air conditioner system. When the temperature of an indoor environment reaches the preset temperature, the multi-split air conditioner system is controlled through a controller of the multi-split air conditioner system to run in a standby-ready mode, a refrigerant circulates between a compressor and an air and liquid separator, the capacity output of the compressor is controlled, and the pressure of a refrigerant outlet of the compressor is maintained within certain range, so when the multi-split air conditioner system is restarted to generate heat, the phenomenon of raising the lower pressure of the refrigerant to the working pressure is avoided, the cold air prevention time of an indoor unit is shortened, and the better user experience can be obtained. In addition, by setting the time of the multi-split air conditioner system entering the standby-ready mode through the controller, when the time of entering the standby-ready mode reaches the preset value, the multi-split air conditioner system is controlled to enter the standby mode, and the compressor is closed, so as to save the electric energy. The invention also provides a quick-starting heat generation method suitable for the multi-split air conditioner system.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

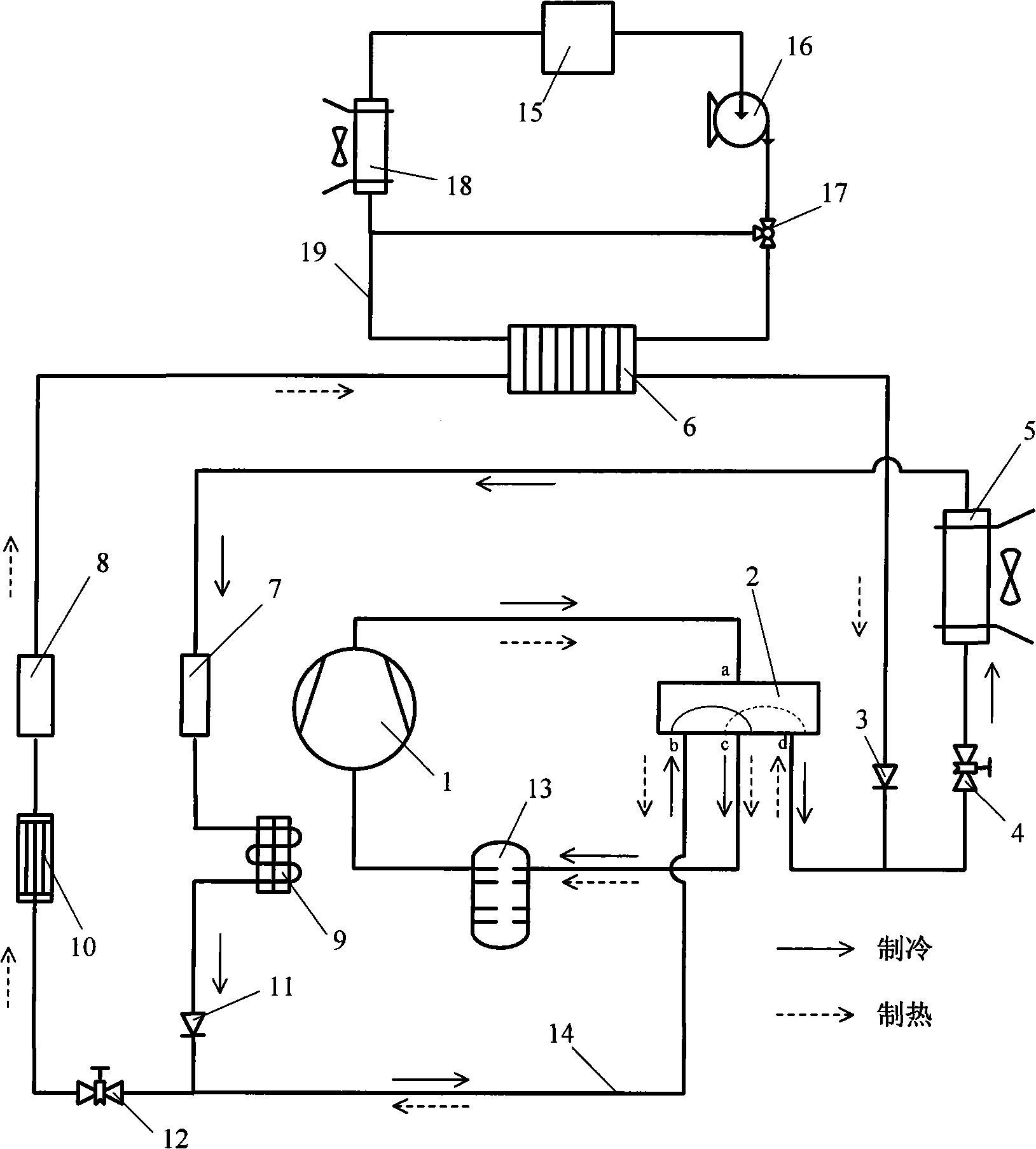

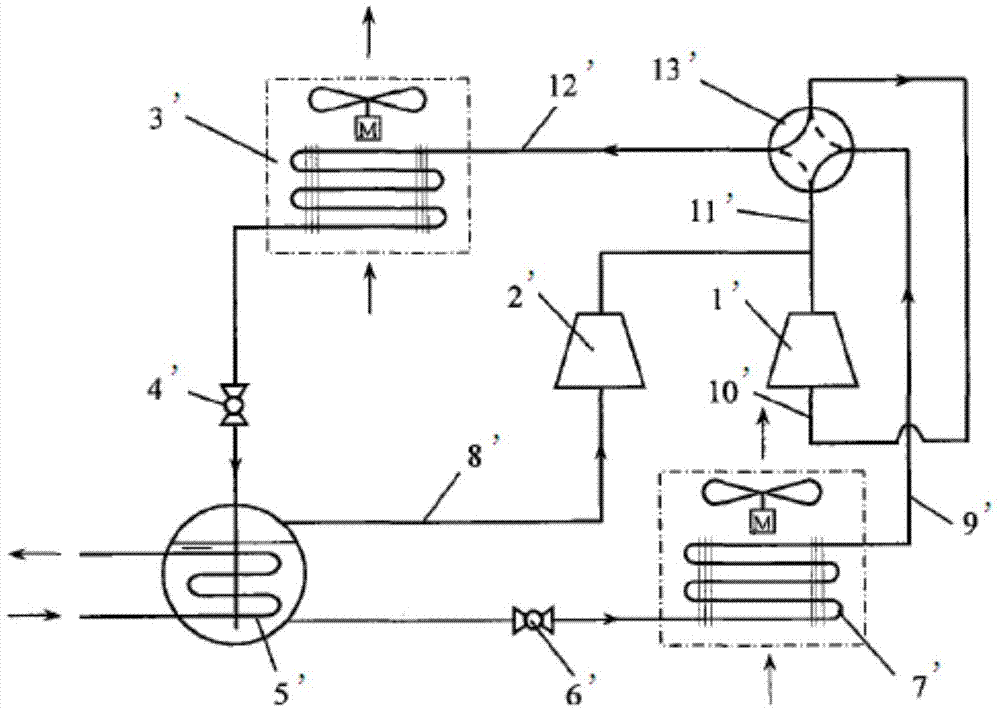

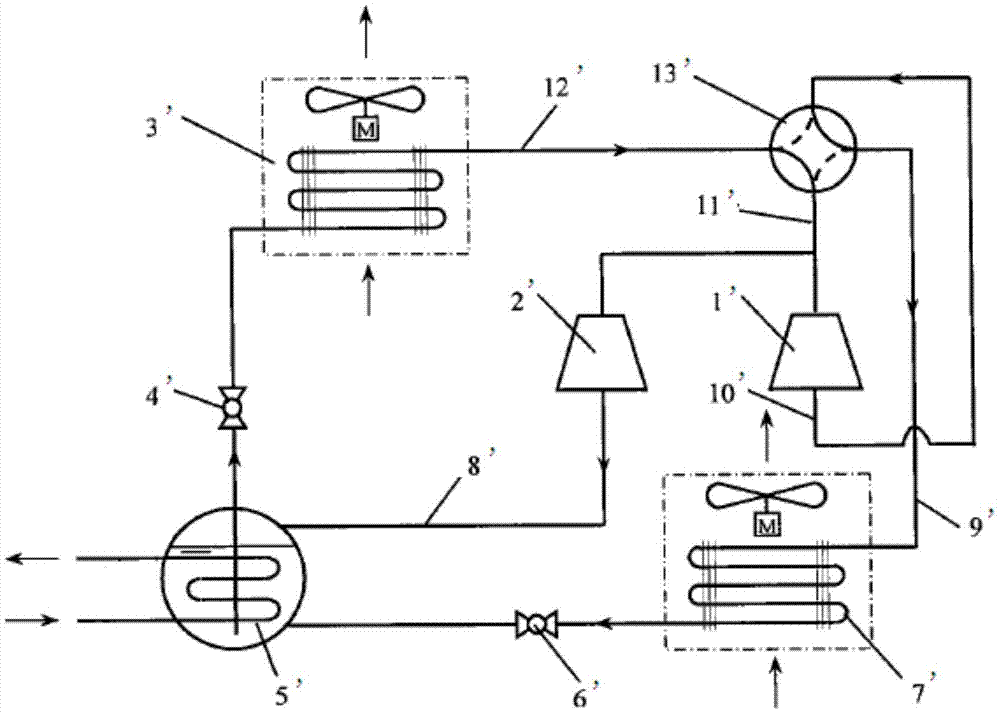

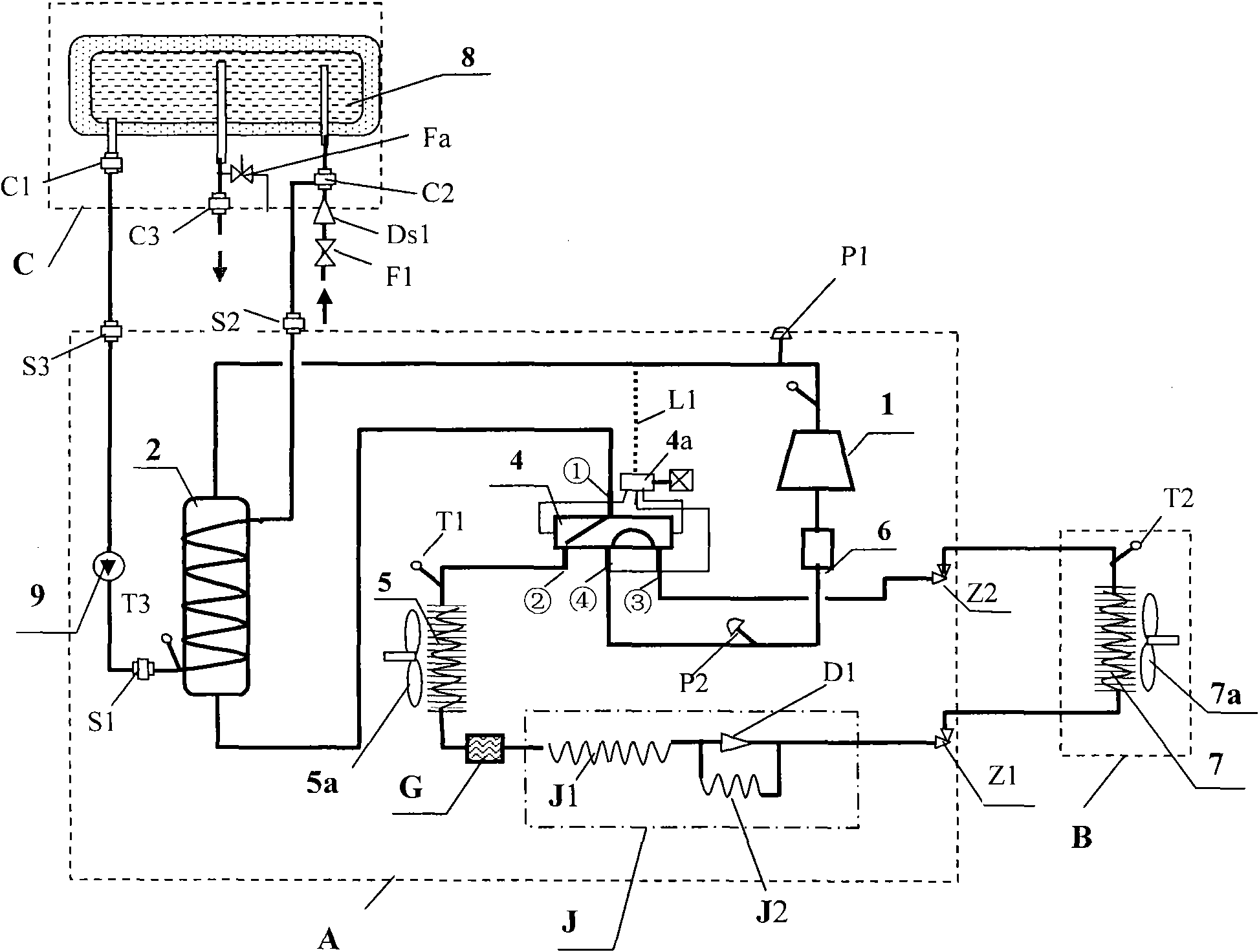

Residual heat pump air conditioner system for fuel-cell vehicle

InactiveCN101279580AAchieve the desired purposeAir-treating devicesHeat recovery systemsFuel cellsVapor–liquid separator

The invention relates to a residual heat pump air conditioning system for fuel cell vehicle, which belongs to the technical field of the air conditioner for fuel cell vehicle. The invention is characterized in that the residual heat pump air conditioning system comprises a refrigerating circuit and a heating circuit, the refrigerating circuit and the heating circuit are connected with a compressor via a four-way valve, an inlet of the four-way valve is connected with an outlet of the compressor, a first outlet and a second outlet of the four-way valve are connected with the refrigerating circuit and the heating circuit, and a third outlet of the four-way valve is connected with the inlet of the compressor via a gas-liquid separator; the heating circuit comprises an external evaporator, the heat side of the external evaporator is connected in a cooling circuit of the fuel cell and the cool side is connected in the heating circuit; the cooling circuit of the fuel cell also comprises an electric control three-way valve, one end of which is connected with the fuel cell via a water pump and a second end and a third end respectively are connected with the inlet and the outlet at the heat side of the external evaporator. The air conditioning system can use the residual heat of the fuel cell for heat supply and has the advantages of energy saving, simple structure and wide adaptability to use area, etc.

Owner:TSINGHUA UNIV

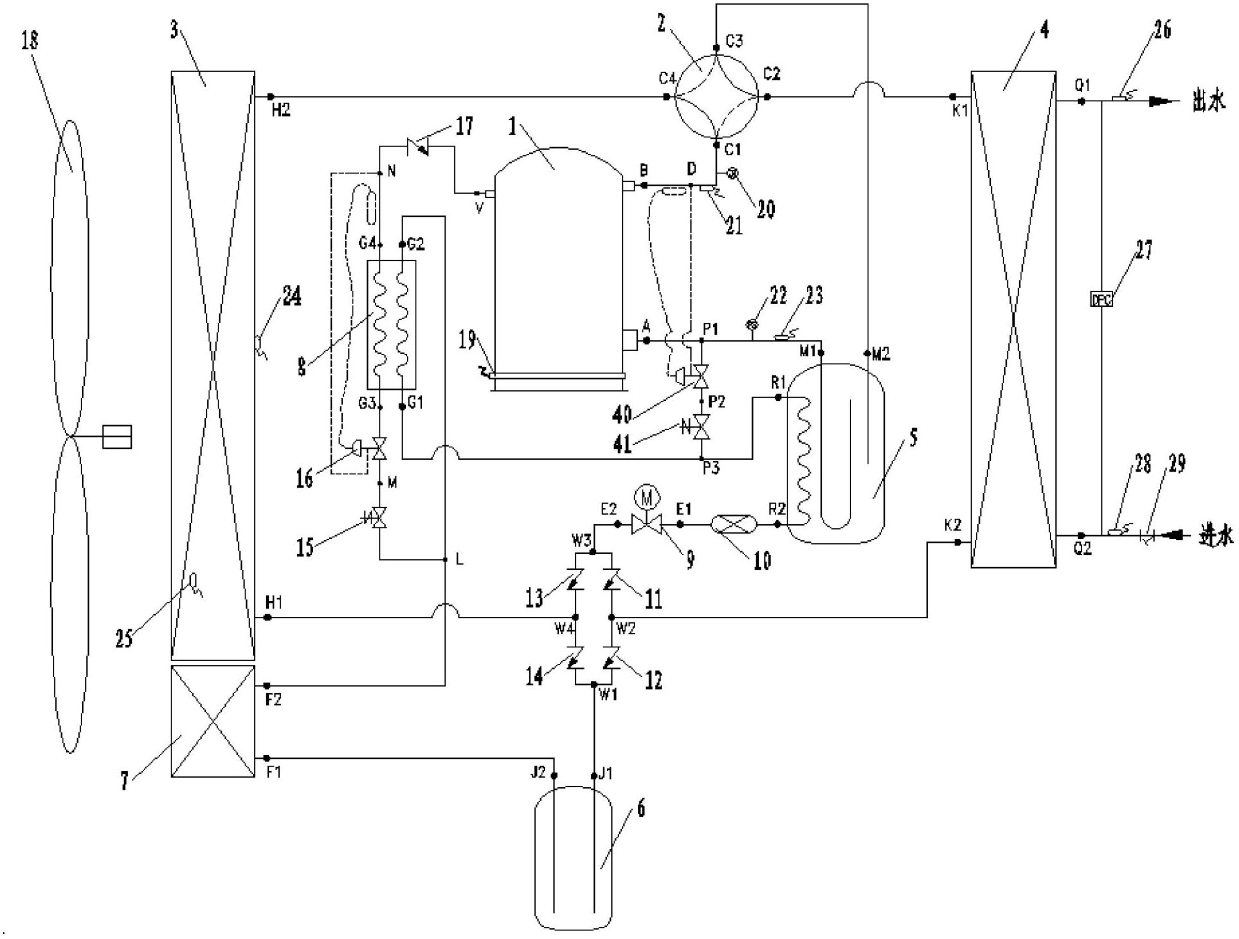

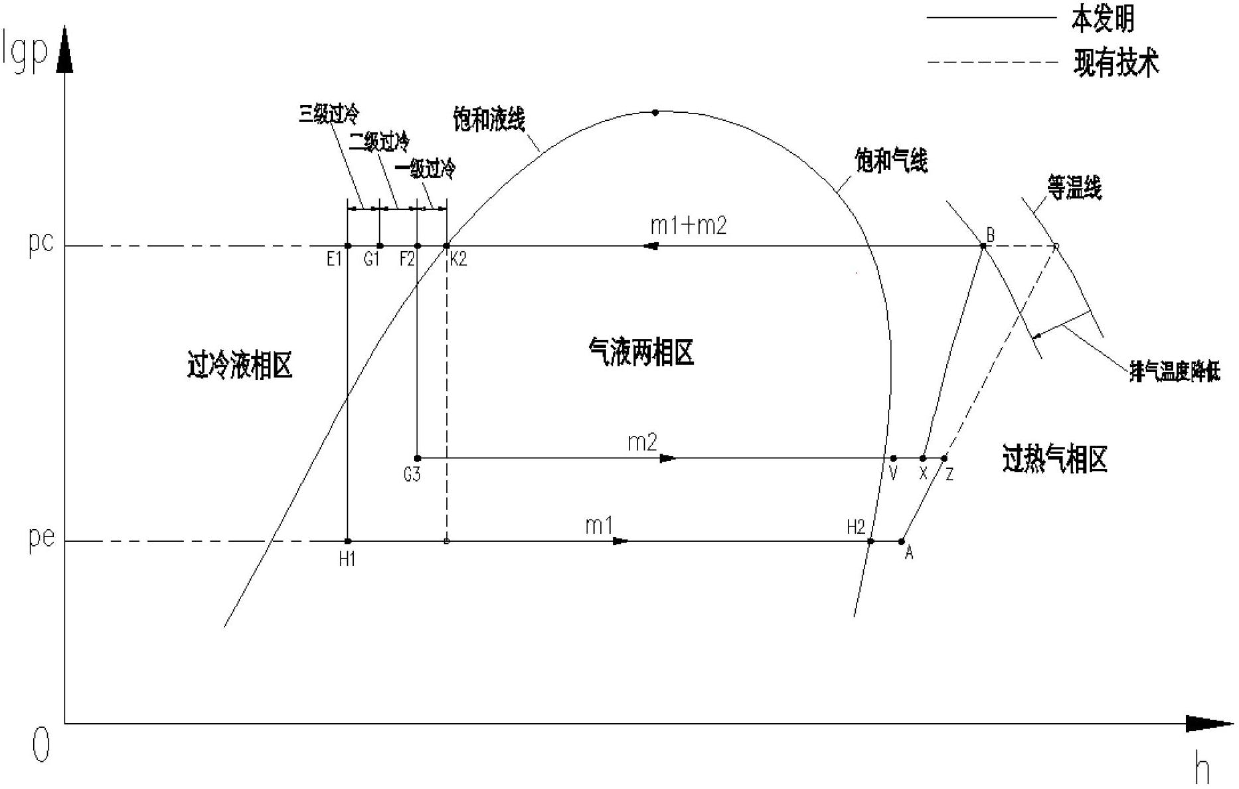

Air-cooled heat pump air conditioner

InactiveCN102679609AIncrease subcoolingLow heat recovery functionSubcoolersFluid circulation arrangementLiquid lineVapor–liquid separator

The invention discloses an air-cooled heat pump air conditioner which comprises a compressor, an outdoor coil, a heat exchanger, a main liquid line and supercooling devices, wherein the supercooling devices comprise two or three of a supercooling coil, an economizer and a liquid-vapor separator with a supercooling function, the supercooling devices are arranged on the main liquid line, and liquid state refrigerants which circulate in the main liquid line can achieve repeatedly the supercooling through the supercooling devices. According to the air-cooled heat pump air conditioner, the performance of cooling / heating circulation of the air-cooled heat pump air conditioner is effectively improved, so that the air-cooled heat pump air conditioner is stable and reliable in operation and energy saving in a low-temperature environment.

Owner:四川同达博尔置业有限公司

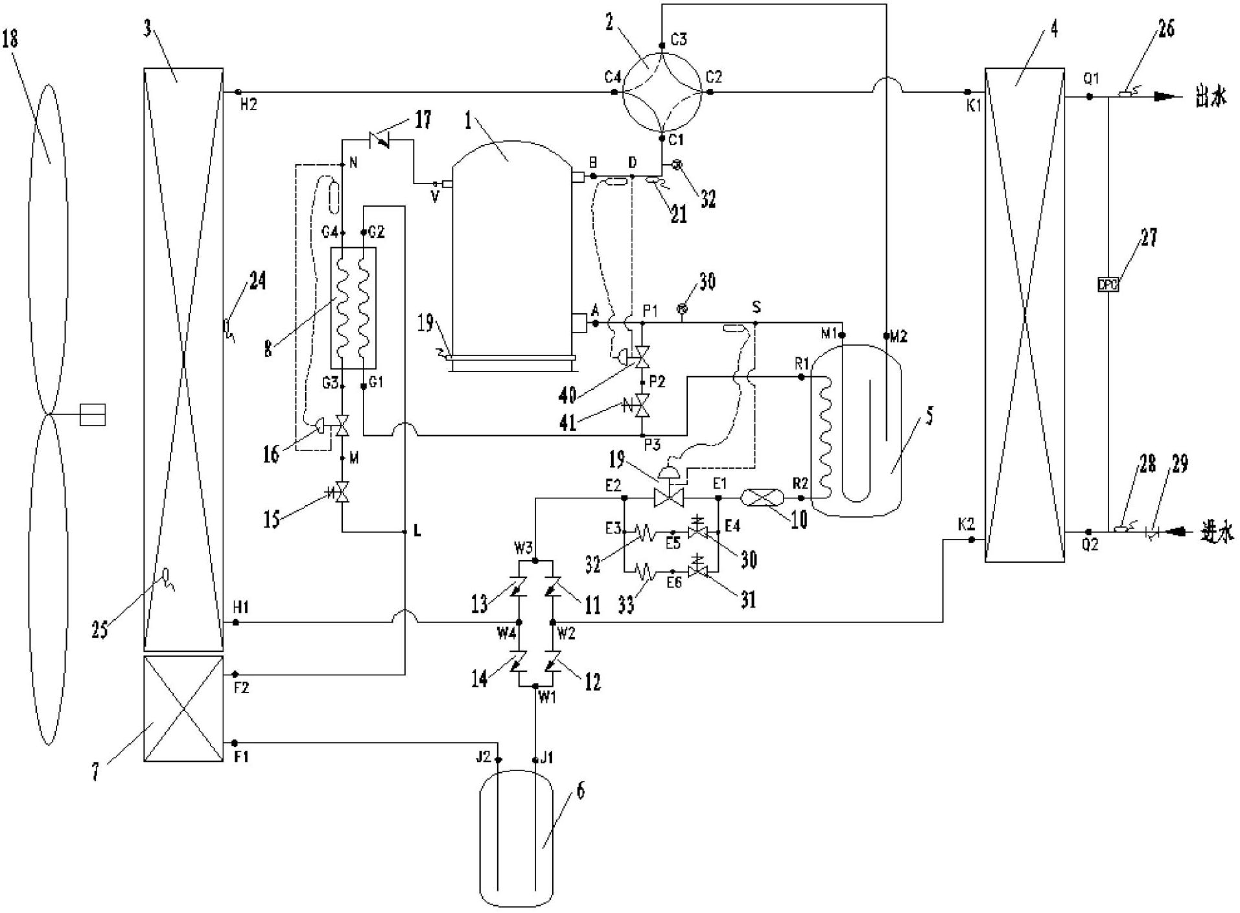

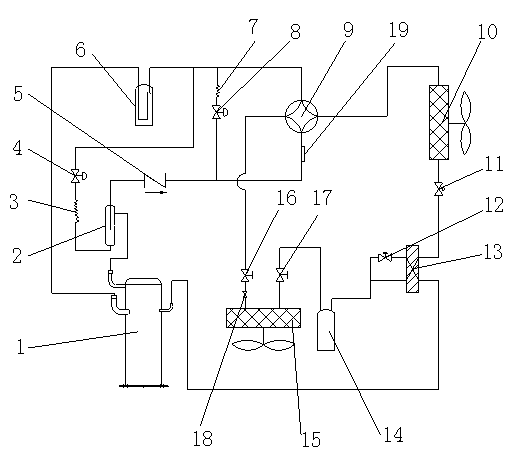

High-heat-discharge-quantity refrigerating and heating temperature control system for reaction kettle

ActiveCN103983041ACompact structureReasonable structureMechanical apparatusEfficient regulation technologiesExpansion tankVapor–liquid separator

The invention relates to a high-heat-discharge-quantity refrigerating and heating temperature control system for a reaction kettle. The high-heat-discharge-quantity refrigerating and heating temperature control system comprises a reaction kettle, wherein one end of the reaction kettle is sequentially connected with a heating pipe, an electric proportioning regulating valve, a first cold storage tank and an evaporation heat exchanger through a fourth pipeline, the output end of the evaporation heat exchanger is sequentially connected with a first circulation pump, a first one-way valve, an expansion tank and an exhaust valve through a first pipeline, the exhaust valve is connected to the other end of the reaction kettle through a fifth pipeline, the two ends of the evaporation heat exchanger are connected with a refrigerating machine, the refrigerating machine is structurally characterized in that one end of the evaporation heat exchanger is sequentially connected in series with a gas-liquid separator, a compressor, an oil separator, a condenser, a drying filter, a second cold storage tank, an electromagnetic valve and an expansion valve through a third pipeline, the outer end of the expansion valve is connected with the other end of the evaporation heat exchanger through an eighth pipeline, the refrigerating machine is positioned between the electromagnetic valve and the second cold storage tank and is connected with the third pipeline through the second pipeline, and an electronic expansion valve is arranged on the second pipeline. The work reliability is good.

Owner:WUXI GUANYA REFRIGERATION TECH

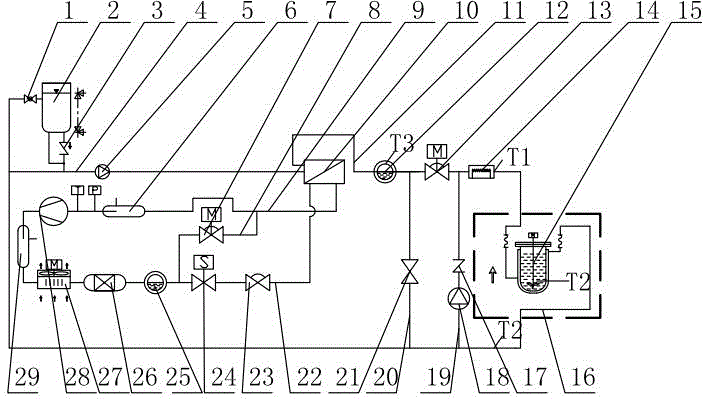

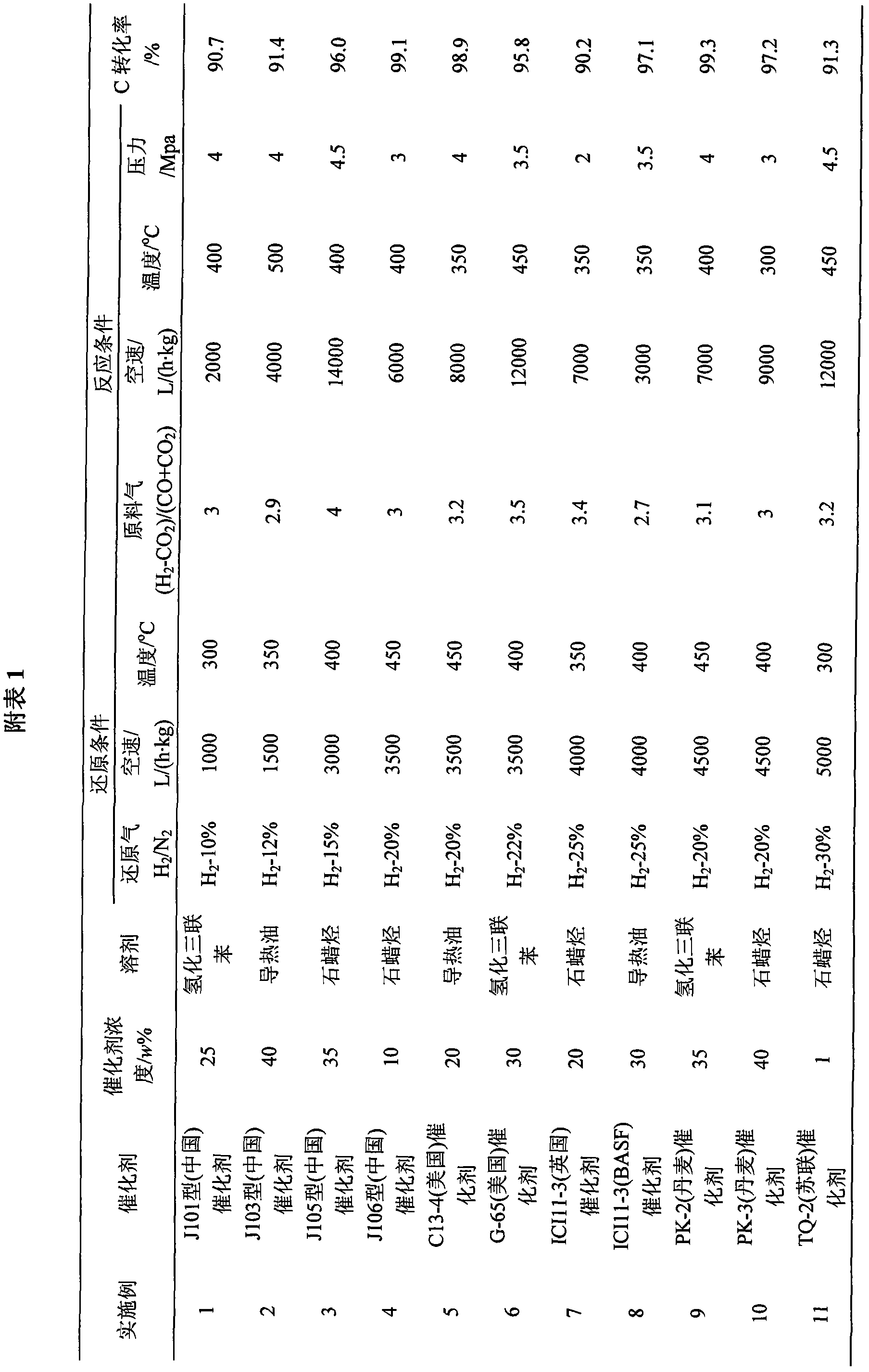

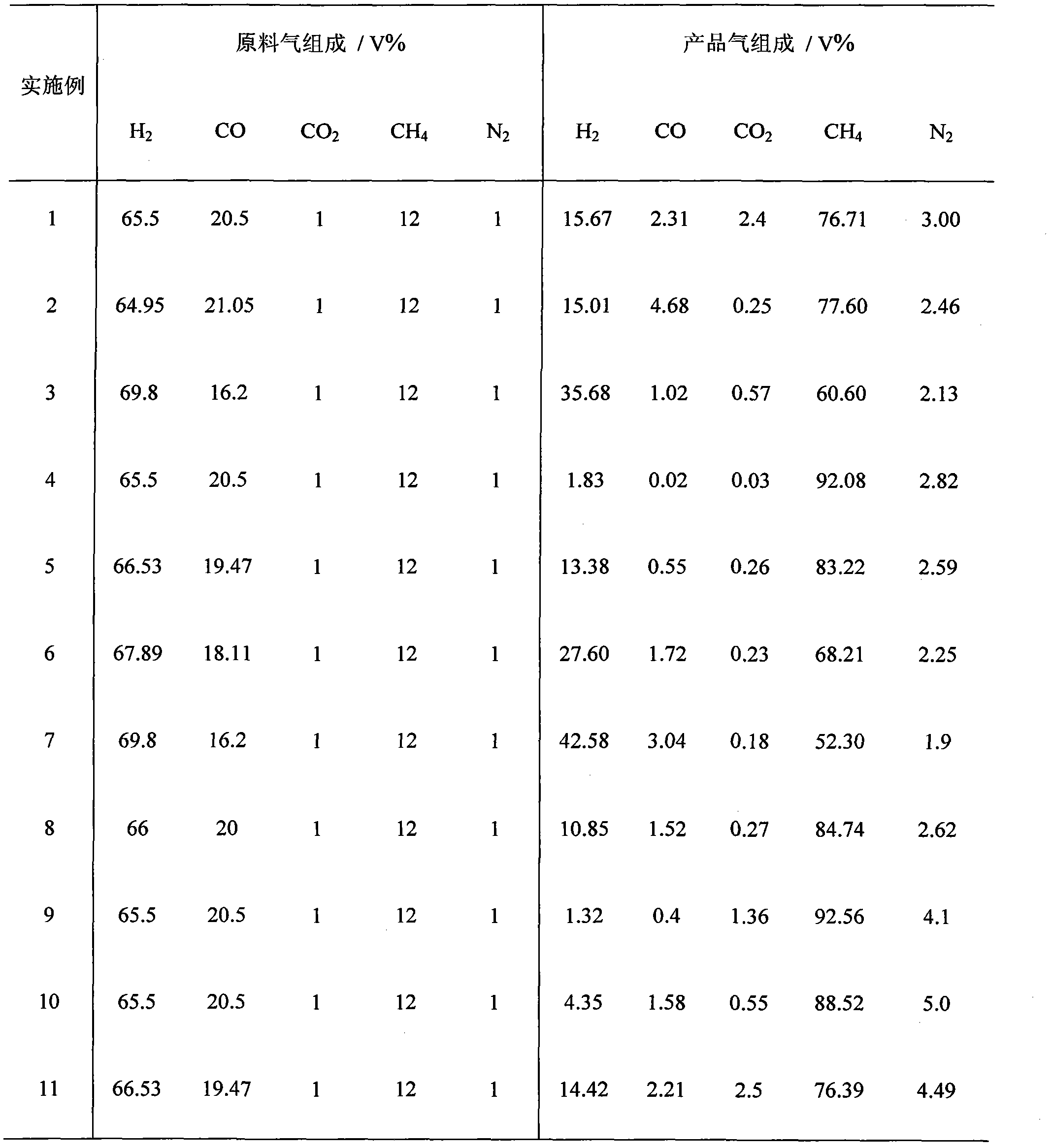

Process for synthesizing natural gas by methanation of coal synthesis gas

The invention discloses a process for synthesizing natural gas by methanation of coal synthesis gas, which comprises the following steps of: dispersing a fresh methanation catalyst into an inert liquid medium, delivering the medium into a slurry bed methanation reactor to perform reduction, performing methanation reaction on the transformed methanation raw gas after the reduction is finished, delivering the tail gas to a gas-liquid separator I, discharging the slurry liquid component and the catalyst in the tail gas from the bottom of the gas-liquid separator I, discharging the gas phase in the tail gas from the top of the gas-liquid separator I, delivering partial slurry liquid component containing the catalyst into a gas-liquid separator II, discharging the gas phase from the top of thegas-liquid separator II, merging the gas phases discharged from the tops of the gas-liquid separators I and II, cooling and purifying the gas phases to obtain synthesized natural gas, discharging theslurry liquid component containing the catalyst from the bottom of the gas-liquid separator II, merging the slurry liquid component discharged from the bottom of the gas-liquid separator II and the slurry liquid component and the catalyst discharged from the bottom of the gas-liquid separator I, discharging 1 to 5 percent of the weight sum of the slurry liquid component and the catalyst separatedfrom the two gas-liquid separators, and performing methanation reaction on the cooled rest slurry liquid component and catalyst and the fresh methanation catalyst dispersed into the insert liquid medium together. The process has the advantages of low power consumption and low equipment investment, and is easy to operate.

Owner:SEDIN ENG +1

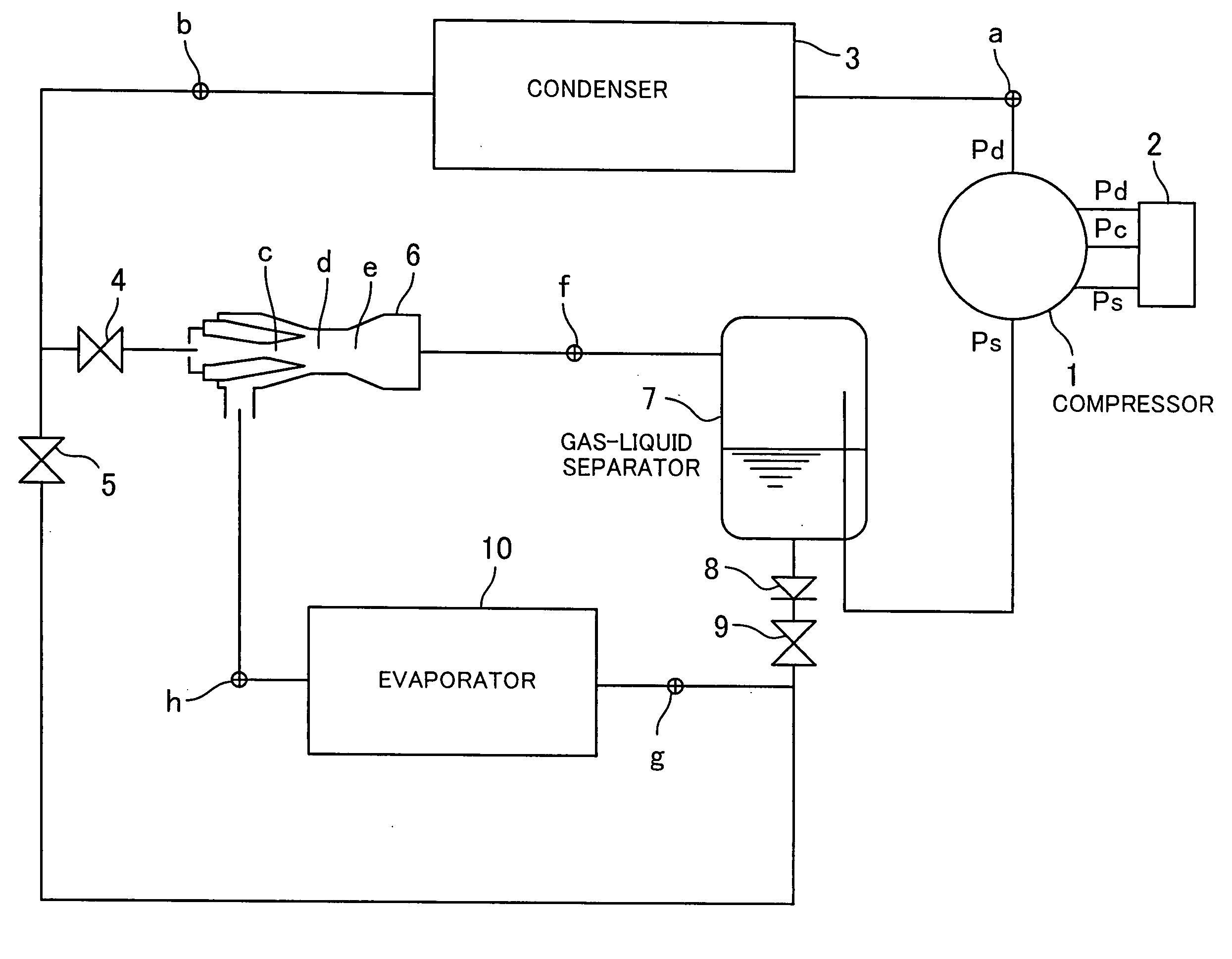

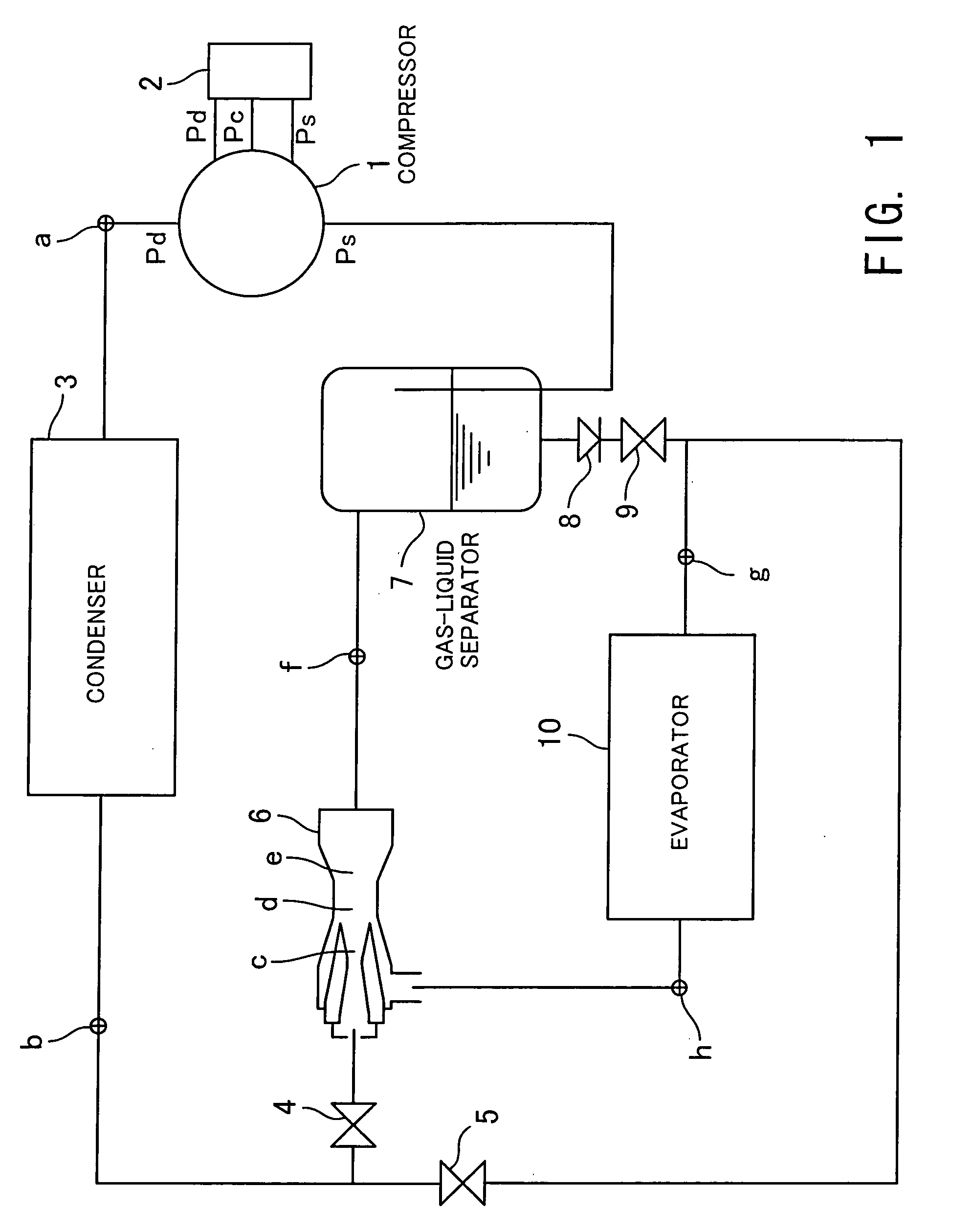

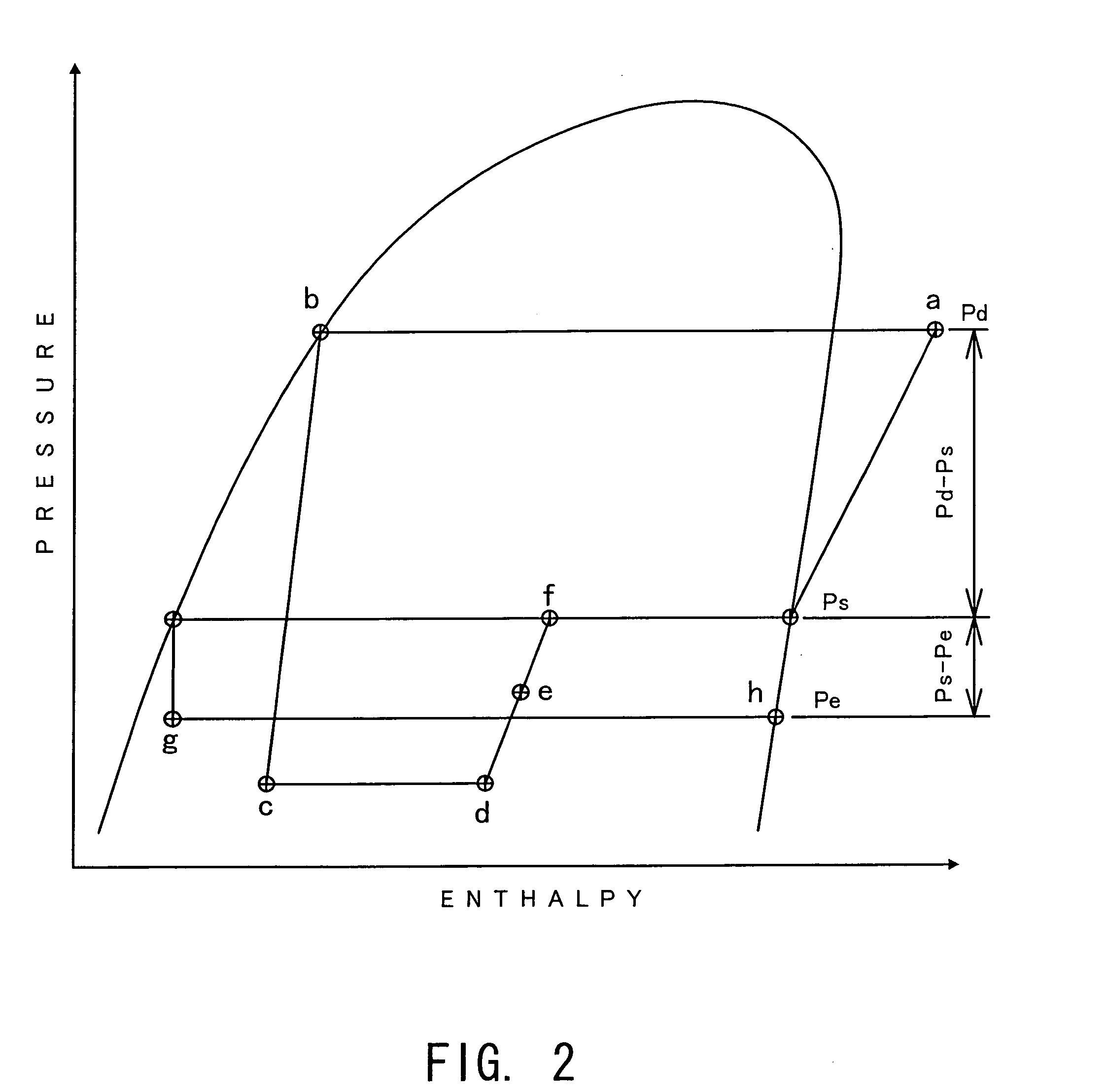

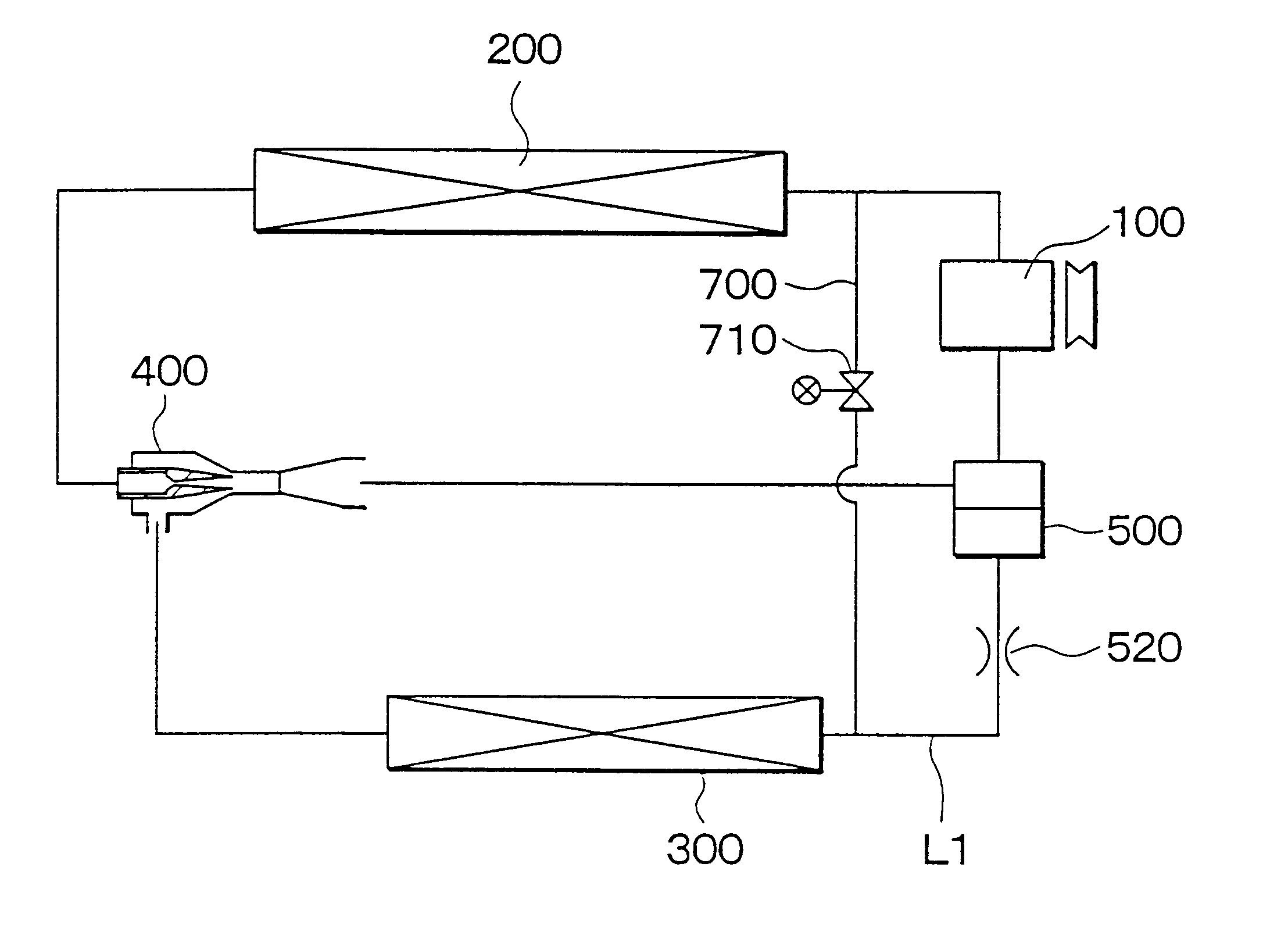

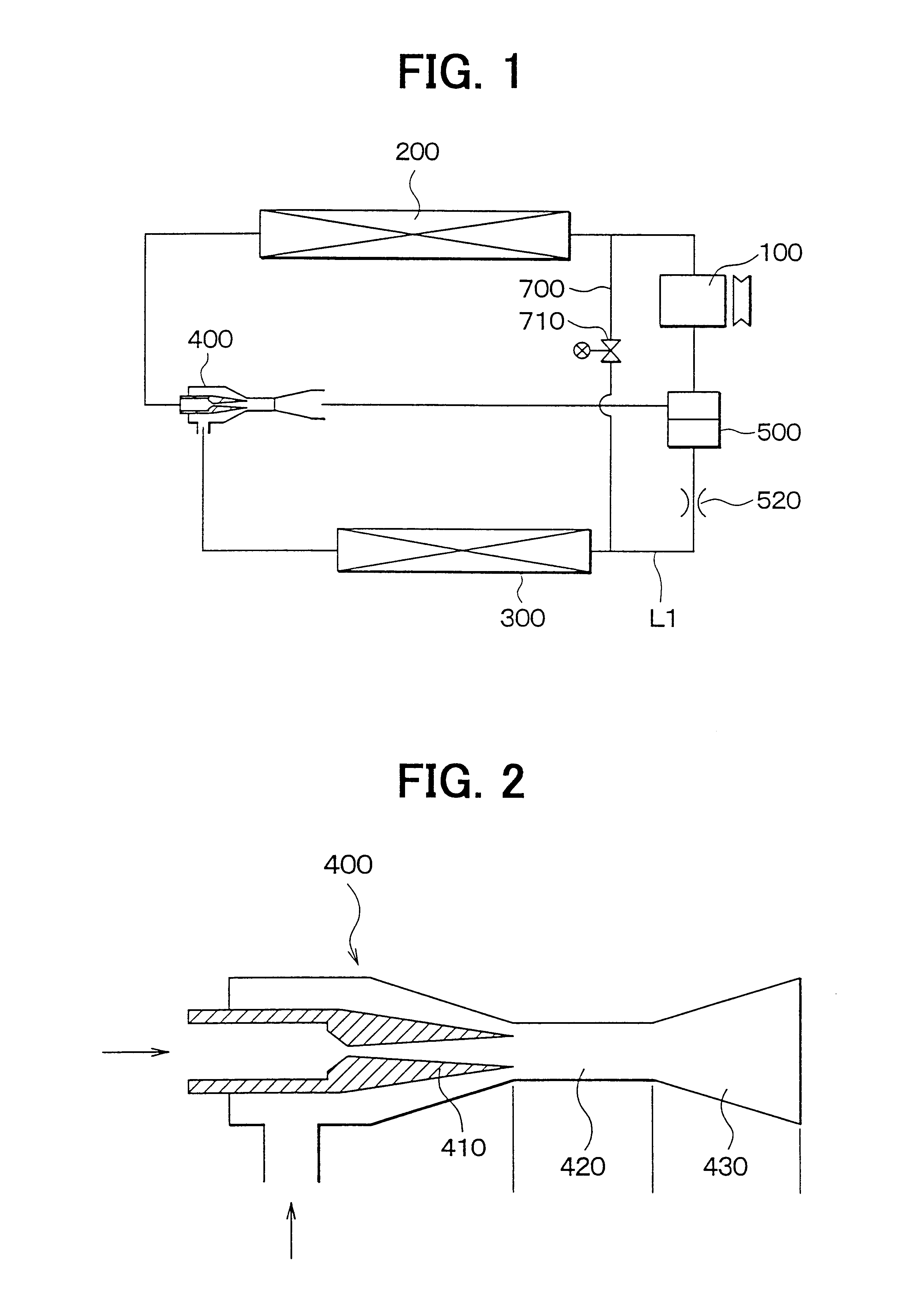

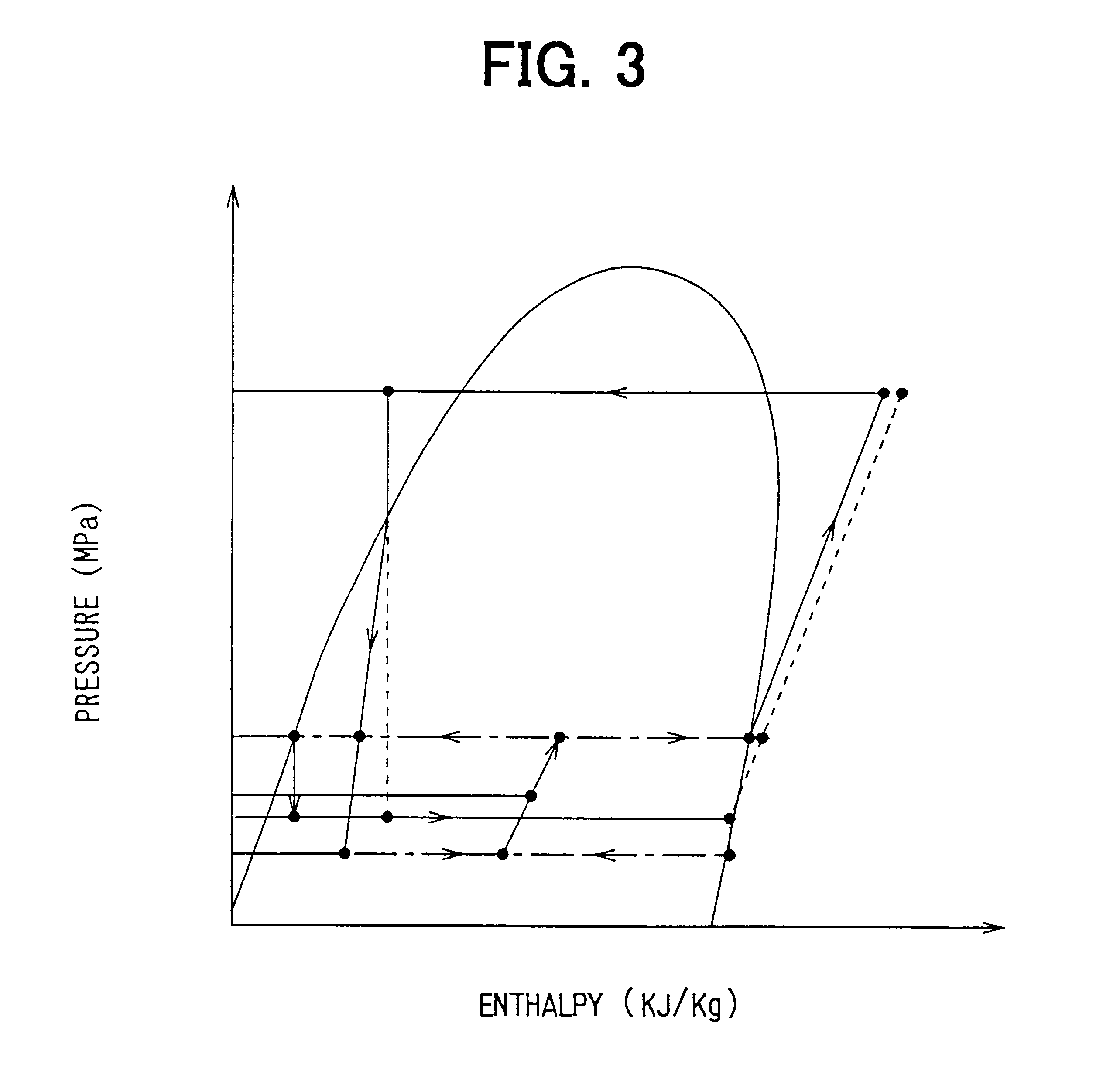

Refrigeration cycle

InactiveUS20050011221A1Low costAir-treating devicesCompression machines with non-reversible cycleMobile vehicleVapor–liquid separator

The object of the present invention is to provide a refrigeration cycle for an automotive air conditioner, which is reduced in costs and uses an ejector. A variable displacement compressor driven by an engine for driving an automotive vehicle is used as a compressor, and the capacity of the compressor is controlled by a capacity control valve such that the differential pressure between discharge pressure and suction pressure of refrigerant becomes equal to a predetermined differential pressure determined by an external signal. Pressure substantially equal to pressure applied across the compressor is applied across the ejector, and therefore to control the differential pressure across the compressor is to control the differential pressure across the ejector. A differential pressure valve disposed between a gas-liquid separator and an evaporator is set to a differential pressure approximately proportional to the differential pressure across the ejector. A differential pressure set to the differential pressure valve is estimated from the differential pressure across the compressor which corresponds to the differential pressure across the ejector, and the differential pressure can be directly and accurately determined from the external signal for controlling the capacity control valve.

Owner:TGK

Double-temperature refrigerating and heating system

ActiveCN105444453AImprove energy efficiencyCompression machines with reversible cycleHeating and refrigeration combinationsFour-way valveEngineering

The invention relates to the technical field of air conditioning equipment, and in particular, discloses a double-temperature refrigerating and heating system, wherein a first cylinder, a first four-way valve, a first-grade throttle valve, an outdoor heat exchanger, a first-grade indoor heat exchanger, a gas-liquid separator, a second-grade throttle valve and a second-grade indoor heat exchanger of a compressor are connected through a pipeline to form a low-temperature evaporation loop; and a second cylinder, a second four-way valve, a first-grade throttle valve, an outdoor heat exchanger, a first-grade indoor heat exchanger and a gas-liquid separator of the compressor are connected through a pipeline to form a middle-temperature evaporation loop. The double-temperature refrigerating and heating system realizes switchover of refrigerating / heating modes through reversing of two four-way valves, realizes double-evaporation temperature refrigeration or double-condensation temperature heating, and effectively improves whole system energy efficiency; and obtained double-evaporation or double-condensation temperature can be widely applied to such places as freezing and refrigeration, air conditioner cold radiation and dehumidification, double-temperature heat source heat pump, air conditioner heat radiation and hot air or air conditioner heat radiation and living hot water.

Owner:GREE ELECTRIC APPLIANCES INC

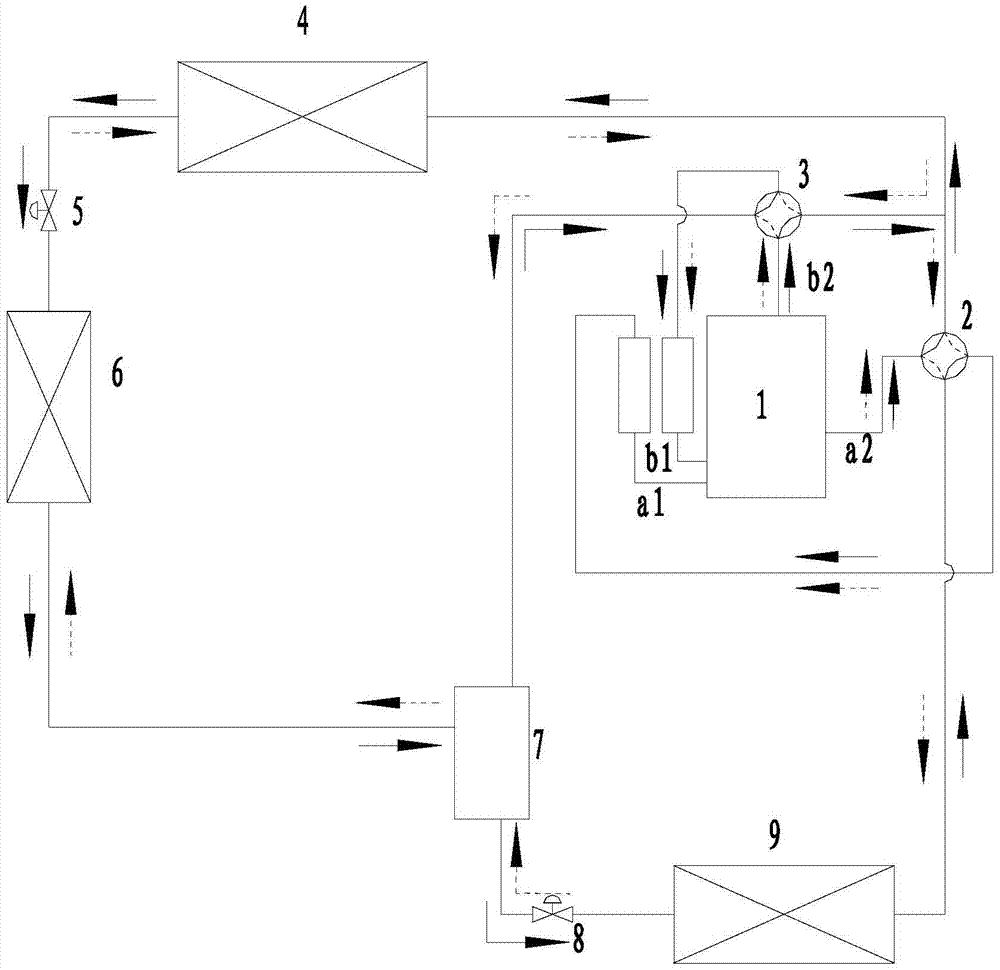

Enhanced vapor injection air-conditioning circulating system and control method thereof

ActiveCN103471275AImprove heating effectGuaranteed uptimeCompression machines with reversible cycleRefrigeration safety arrangementVapor–liquid separatorFour-way valve

The invention relates to a central air-conditioning system, in particular to a duct air conditioner, namely an enhanced vapor injection air-conditioning circulating system. A vapor injection side electronic expansion valve of the system is subject to discharge superheat control instead of vapor injection superheat control; high discharge superheat is guaranteed, and heating capacity of the system can be further improved by vapor injection; the system is especially applicable to variable frequency compressors; high heating capacity is kept even under different operating frequencies; the system operates stably and fluctuates little. The enhanced vapor injection air-conditioning circulating system comprises a controller, a compressor, a four-way valve, a vapor-liquid separator, an economizer, a solenoid valve and a coolant pipe. The compressor is a variable frequency compressor. The economizer is a plate economizer. The electronic expansion valve controls vapor injection. The vapor injection electronic expansion valve is subject to discharge superheat control instead of vapor injection superheat control; accordingly, high discharge superheat is guaranteed, and heating capacity of the system is further improved by vapor injection. The system is especially applicable to variable frequency compressors; the heating capacity is kept even under different operating frequencies; the system operates stably and fluctuates little.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Air separation system for generating liquid oxygen and liquid nitrogen

This kind of air separation system obtaining liquid oxygen and liquid nitrogen at least includes an air separator mainly consisting of a fractionating tower and at least includes an equipment for recovering cold energy of liquefied natural gas mainly consisting of an liquefied natural gas heat exchanger, which still includes main heat exchanger, liquid-oxygen heat exchanger and liquid-nitrogen liquid air subcooler; oxygen is drawn out from the underpart of the upper column on the fractionating tower, and cools and liquefied in the liquid-oxygen heat exchanger as the liquid oxygen products; after nitrogen from the top of the upper column passes through a liquid-nitrogen liquid air subcooler and is reheated by main heat exchanger, some nitrogen enters into liquefied-natural-gas heat exchanger to recool and exchange heat to become high pressure nitrogen through primary compression and pressurization at least. And through throttling expansion and air-liquid separator, nitrogen and liquid nitrogen participate in recycling and other nitrogen as liquid-nitrogen products; energy consumption is reduced notably after using actually, power consumption which produces liquid oxygen of 1kg is 0.39kwh, while the power consumption of the traditional equal air separator is 1.0 to 1.25kwh, which is 2.4 to 3 times than the separator. And it is easy to popularize and apply.

Owner:HANGZHOU HANGYANG

Sanitization system and system components

InactiveUS20050017380A1Easy to adaptUsing liquid separation agentMixing methodsOzone generatorVapor–liquid separator

A multi-use sanitization system is disclosed which includes one or more containers in fluid communication with other system components. Components of the system include an ozone contacting device, such as a vortex-venturi or a sparger, for incorporating ozone into a liquid, an ozone generator to provide ozone to the vortex-venturi, a fluid transfer valve to allow simultaneous flow of liquid into and out of the container, and a pump to promote fluid flow through the system. Optionally, a gas-liquid separator with an optional integral gas release valve, an ozone destructor, an oxidation-reduction potential ozone sensor, or a pour-through type pre-filter may be incorporated into the system.

Owner:TERSANO INC

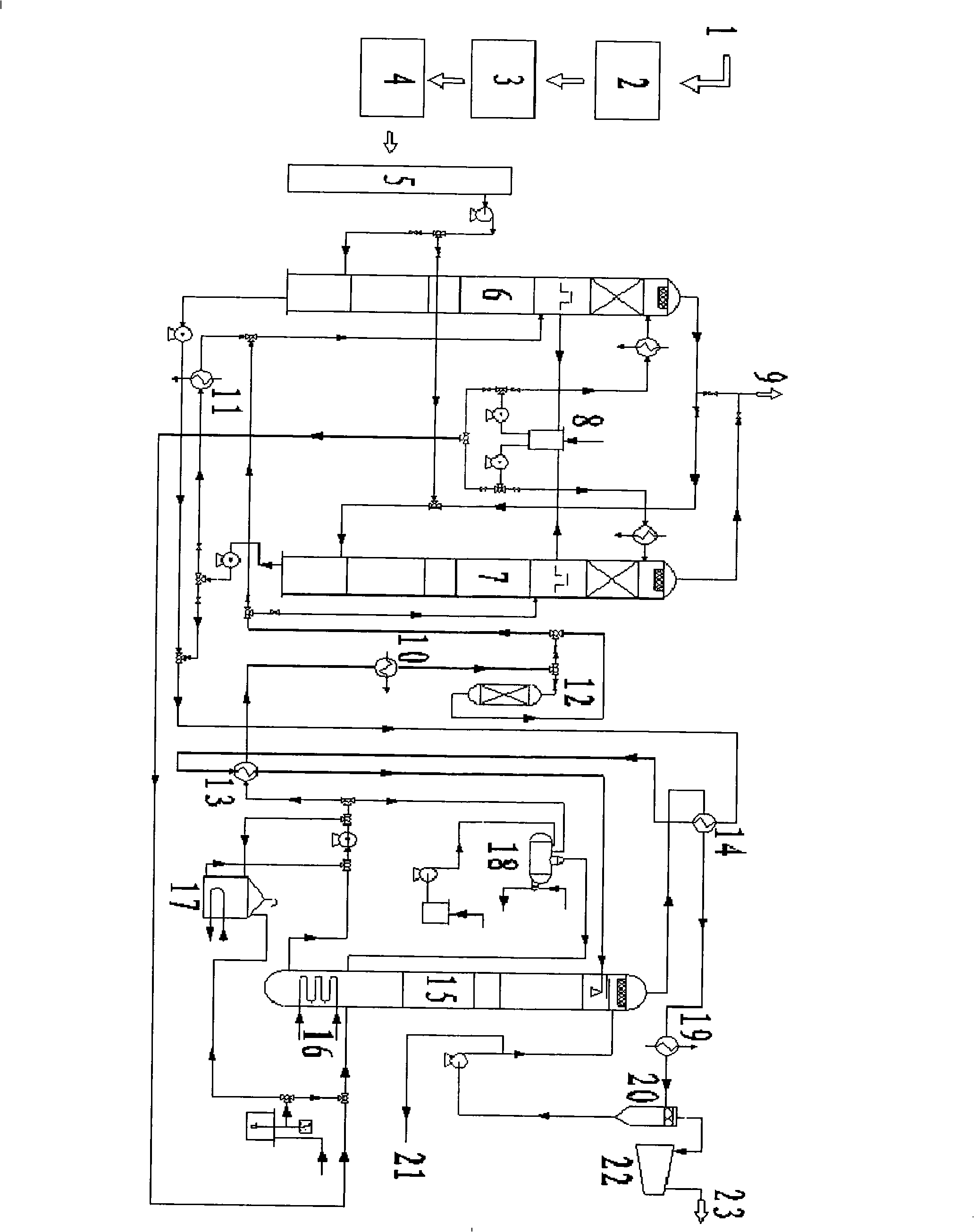

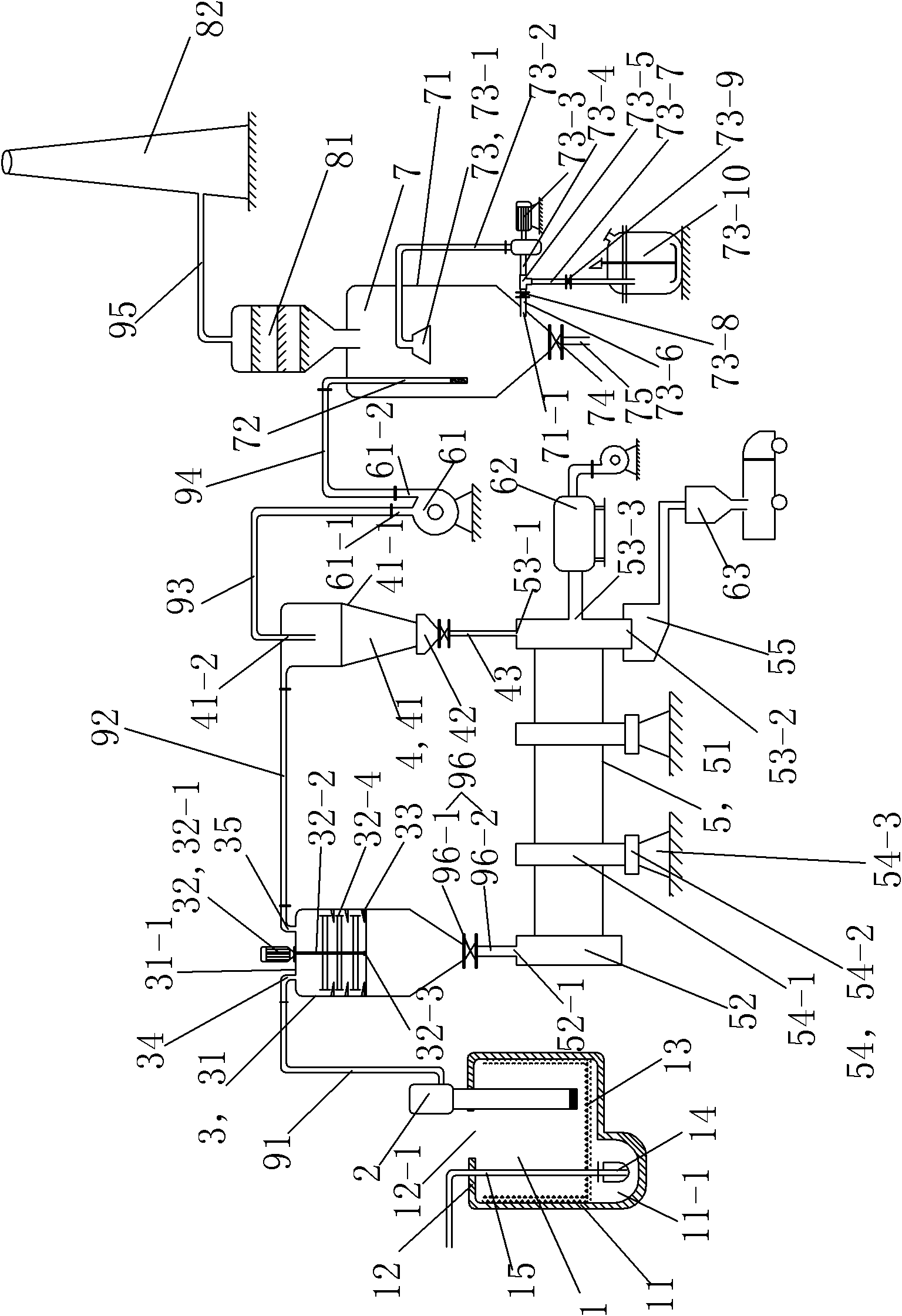

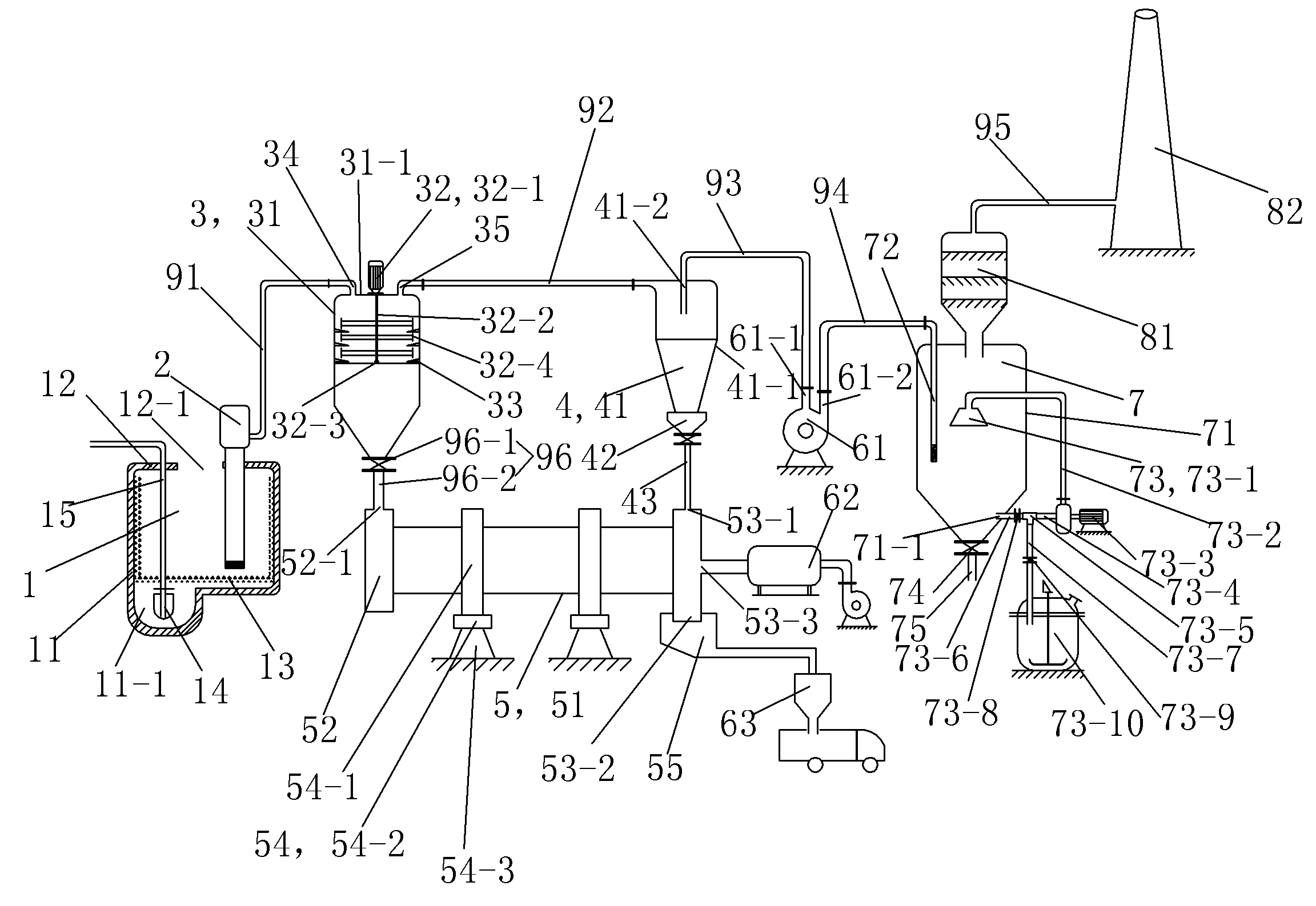

Sludge resource treatment device and method for treating sludge

ActiveCN102276130ASave drying energyGuaranteed drynessSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeCyclonic separation

Owner:陈海渊

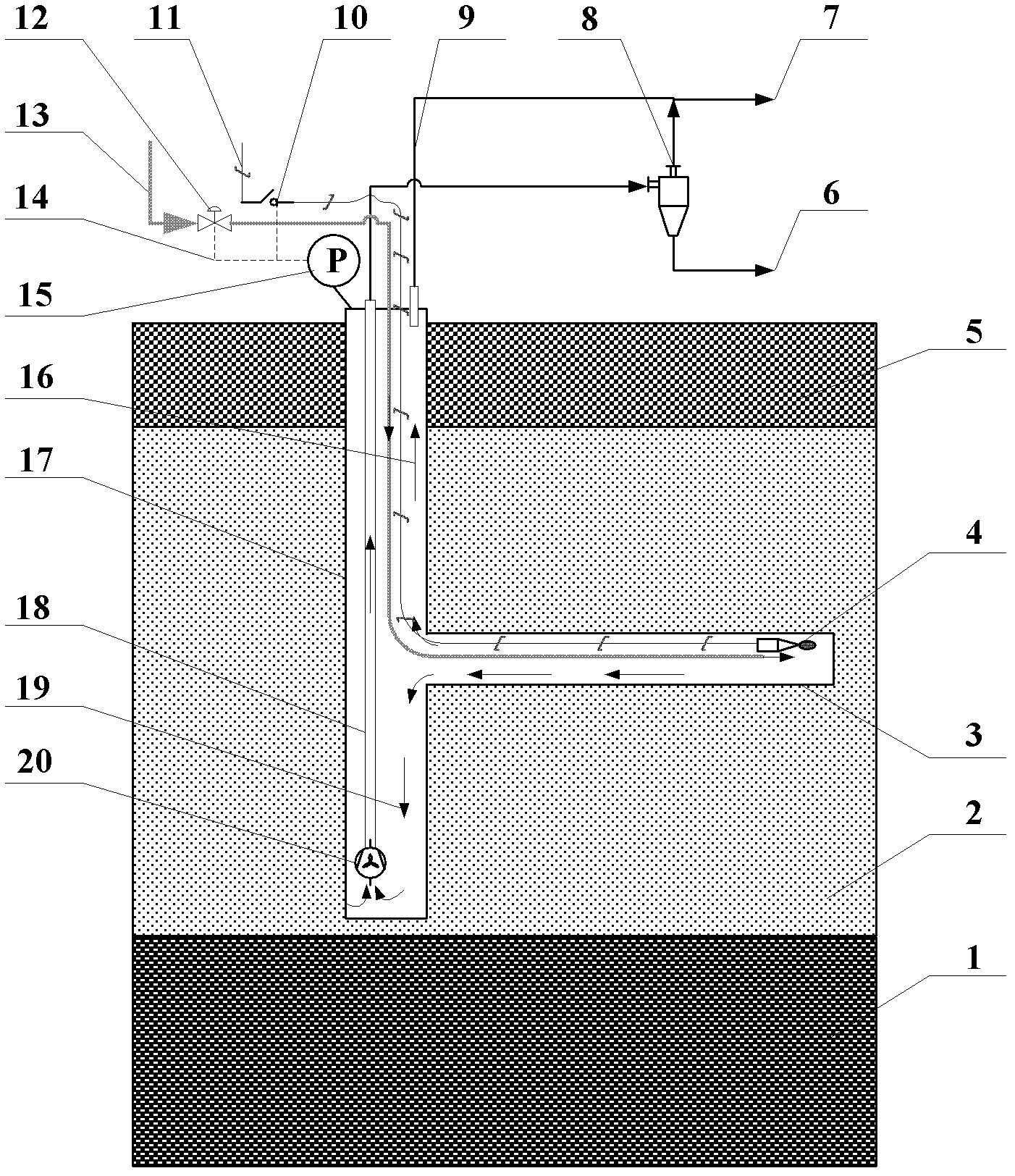

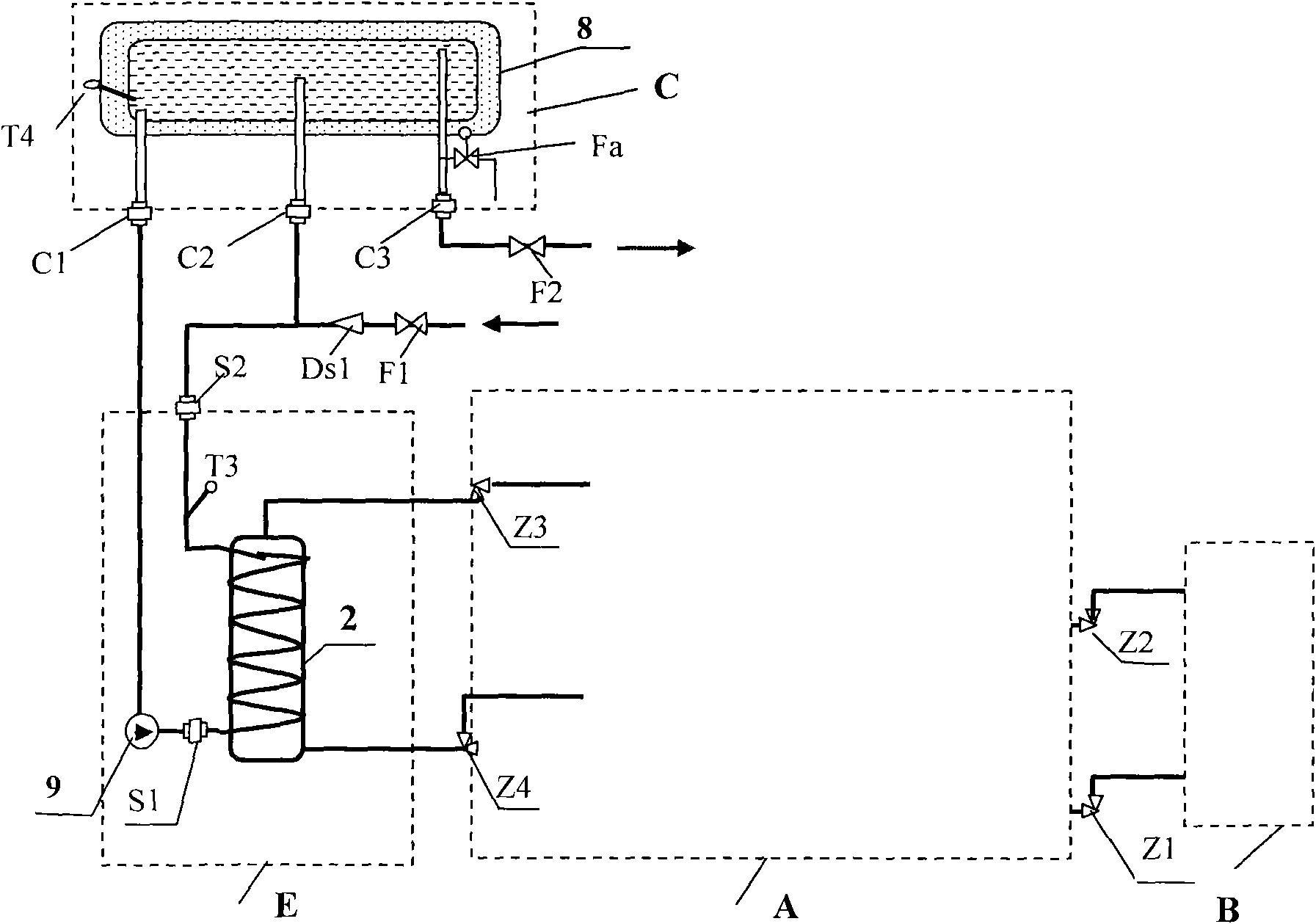

Method and device for exploiting natural gas hydrate in permafrost region

ActiveCN102213090APromote decompositionLower the water levelConstructionsFluid removalCollection systemOxygen

The invention discloses a method and a device for exploiting natural gas hydrate in a permafrost region. The device comprises a water-pumping depressurization system, an underground in-situ combustion heating system, a gas collection system and a control system. The water pumping depressurization system comprises a water delivery pipe, a deep-well pump and a gas-liquid separator, wherein the deep-well pump is arranged at the bottom of a vertical well; and the gas-liquid separator is connected with the deep-well pump by the water delivery pipe. The underground in-situ combustion heating system comprises an electronic ignition device and an oxygen-containing gas conveying pipe, wherein the electronic ignition device is connected with a ground power supply by a power switch; and the oxygen-containing gas conveying pipe is connected with an external gas supply system and paved from the ground to the electronic ignition device through the vertical well. The gas collection system comprises a gas collection pipe which is arranged at a well head of the vertical well. The control system comprises a pressure sensor, the power switch and a regulation valve, wherein the regulation valve is arranged on the oxygen-containing gas conveying pipe; and the control system controls the aperture of the regulation valve and the on and off of the power switch according to a pressure, which is measured by the pressure sensor, of the vertical well. By the invention, the synchronous continuous exploitation of depressurization and underground in-situ combustion heating can be realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

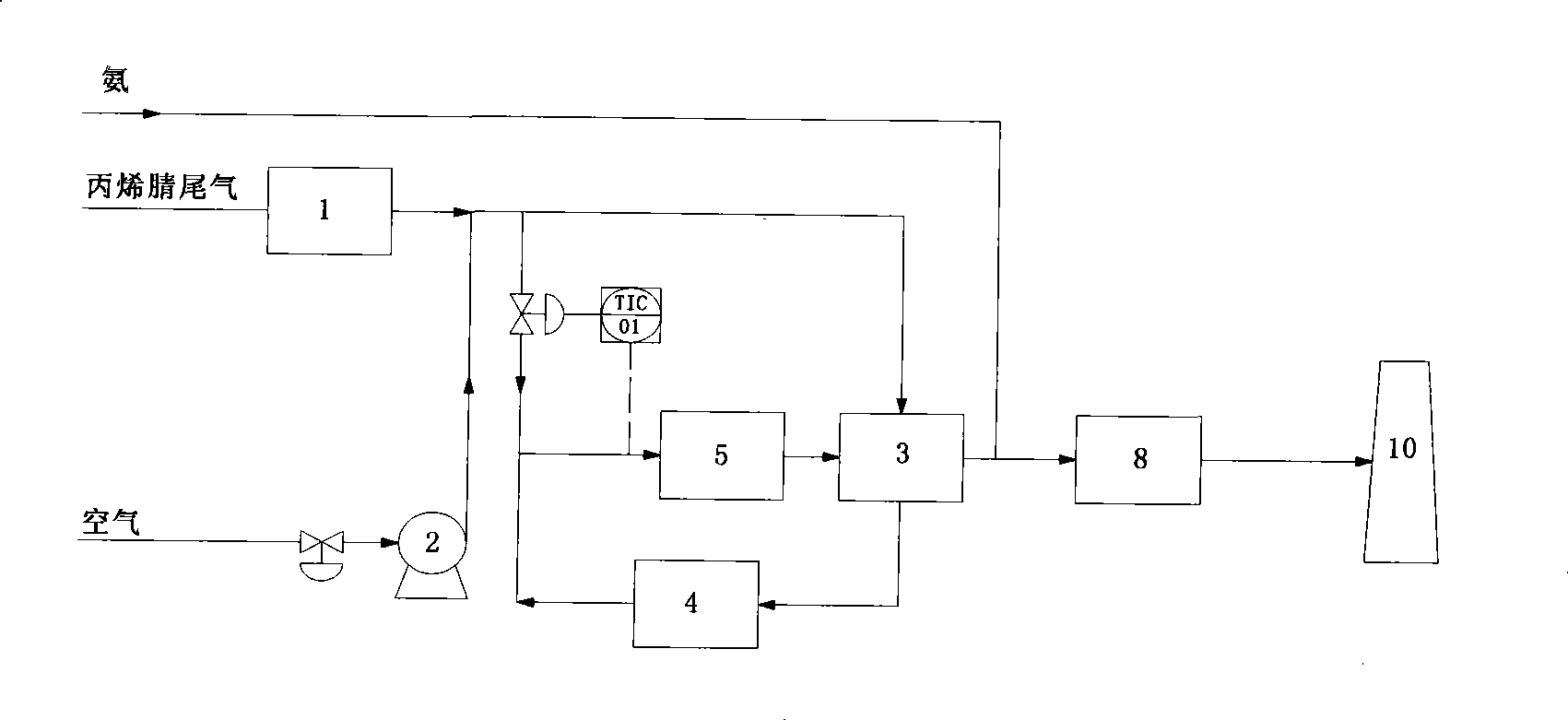

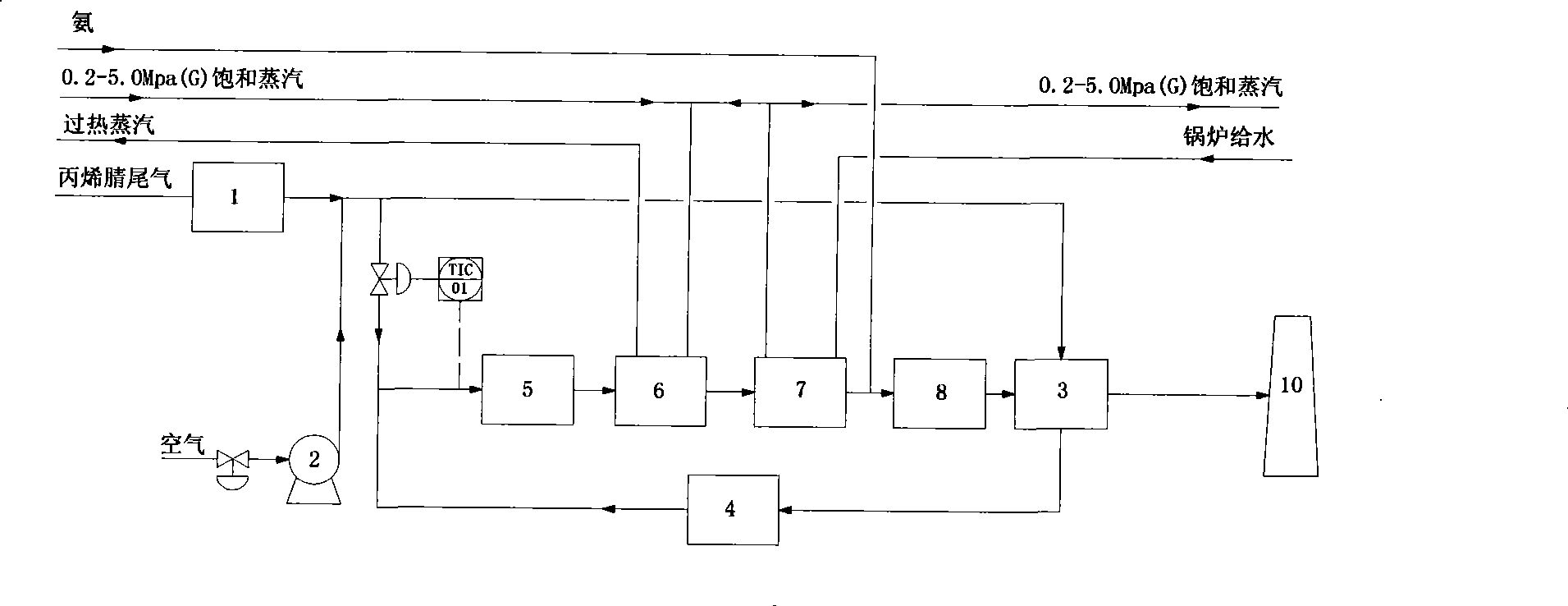

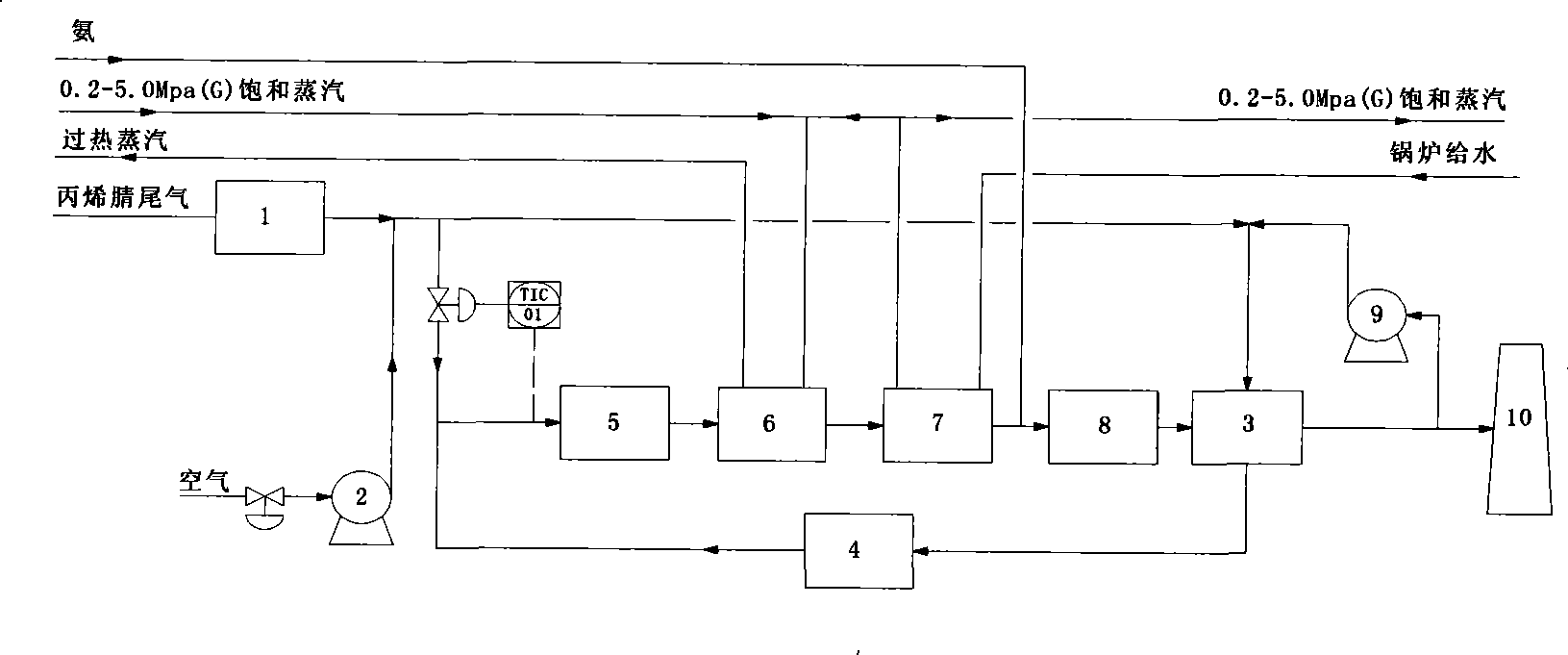

Acrylonitrile device tail-gas treatment technique

InactiveCN101362051AHigh mechanical strengthExtended service lifeChemical industryDispersed particle separationAcrylonitrileCatalytic oxidation

The invention discloses a technique for treating the tail gas of an acrylonitrile device, which is suitable for treating acrylonitrile tail gas discharged by the acrylonitrile device. The technique is characterized in that: after free water is separated out by a gas-liquid separator, the acrylonitrile tail gas is mixed with air, a noble metal monolithic catalyst is taken as a catalyst and catalytic oxidation reaction is carried out to turn harmful volatile organic compounds into carbon dioxide and water; then a selective reduction monolithic catalyst is taken as a catalyst and selective catalytic reduction reaction with added ammonia is carried out to reduce nitrogen oxide in the tail gas into nitrogen and water. The technique has the advantages of simple technique, turning the harmful volatile organic compounds and nitrogen oxide in the tail gas into carbon dioxide, nitrogen and water, without secondary pollution, the test results totally meeting the environmental protection control requirements of the State Standard of China, adopting a tail gas heat exchanger to recycle reaction heat to heat input tail gas, needing no additional fuel during the normal operation process, small system resistance and low operation cost.

Owner:SHANGHAI DONGHUA ENVIRONMENT ENG

Ejector cycle system

InactiveUS6584794B2Shorten the time periodEasy to operateCompression machines with non-reversible cycleCorrosion preventionVapor–liquid separatorFrost

In an ejector cycle system, hot gas refrigerant discharged from a compressor is introduced into an evaporator through a bypass passage while bypassing an ejector and a gas-liquid separator in a defrosting operation for defrosting frost generated on the evaporator. In addition, a throttle or a check valve is provided in a refrigerant passage from the gas-liquid separator to a refrigerant inlet side of the evaporator. Accordingly, in the defrosting operation, the hot gas refrigerant from the compressor can be accurately introduced into the evaporator through the bypass passage without flowing toward the gas-liquid separator.

Owner:DENSO CORP

Automobile air-conditioning system

ActiveCN103256746AReduce the temperatureImprove operational efficiencyAir-treating devicesMechanical apparatusVapor–liquid separatorIntermediate heat exchanger

An automobile air-conditioning system comprises a compressor, a vapor liquid separator, a first heat exchanger, a second heat exchanger, a third heat exchanger and an intermediate heat exchanger. The third heat exchanger selectively exchanges heat with an external environment, the intermediate heat exchanger is provided with a first portion and a second portion which can exchange heat, and a throttling element is arranged in a pipeline passing through the second portion of the intermediate heat exchanger. When the automobile air-conditioning system is in at least one of a refrigerating mode and a heating mode, low-temperature and low-pressure refrigerants before returning to the compressor pass through the first portion of the intermediate heat exchanger, refrigerants before throttling pass through the second portion of the intermediate heat exchanger, the low-temperature and low-pressure refrigerants before returning to the compressor exchange heat with the refrigerants before throttling in the intermediate heat exchanger, the temperature of the refrigerants before throttling is further reduced, and the temperature of the low-temperature and low-pressure refrigerants before returning to the compressor is increased, so that the operating efficiency of a heat pump system is improved.

Owner:HANGZHOU SANHUA RES INST CO LTD

Simple, high-efficiency and reliable cold-warm air-conditioning water heater

InactiveCN102313326ASimple structureEasy to switchFluid heatersSpace heating and ventilation safety systemsFour-way valveLow voltage

The invention relates to a simple, high-efficiency and reliable cold-warm air-conditioning water heater, which comprises a refrigerant loop, a hot-water condensing heat exchanger, a hot-water storing box and a signal acquisition and circuit control system. A scheme I of the invention is characterized in that: an exhaust opening of a compressor is connected with an air inlet of a three-way valve; a first air outlet of the three-way valve is connected with a refrigerant inlet of the hot-water condensing heat exchanger, and a second air outlet is connected and communicated with a first interfaceof a four-way valve and a refrigerant outlet of the hot-water condensing heat exchanger; a second interface, a third interface and a fourth interface of the four-way valve are respectively connected with the upper ports of an outdoor-wind heat exchanger and an indoor-wind heat exchanger and an air inlet of an air-liquid separator, and a capillary is connected in series between the lower ports of the outdoor-wind heat exchanger and the indoor-wind heat exchanger; an air outlet of the air-liquid separator is connected with an air inlet of the compressor; and an electromagnetic guide-valve low-voltage air-outlet pipe of the three-way valve is communicated with an air-sucking pipe of the compressor, and an electromagnetic guide-valve high-voltage air-inlet pipe of the four-way valve is communicated with an exhaust pipe of the compressor. A scheme II of the invention is characterized in that: the hot-water condensing heat exchanger is added between the exhaust opening of the compressor of a refrigerant-circulating loop of a cold and warm air conditioner and an air inlet of the four-way valve, and the electromagnetic guide-valve high-voltage air-inlet pipe of the four-way valve is communicated with the exhaust pipe of the compressor; and the two technical schemes both have four functions of hot-water making and refrigerating, hot-water making, refrigerating and heating.

Owner:JIASHAN YONGNING PLASTICS

Re-circulating fluid delivery system

A fluid delivery system includes a print cartridge and a fluid supply. The print cartridge includes a housing structure, an air-fluid separator structure within the housing structure, including an air vent region in communication with the seperator structure. A fluid ejector is mounted to the housing structure, and a fluid plenum within the housing structure is in fluid communication with the fluid ejector. A fluid reservoir in the housing structures is in fluid communication with the plenum for supplying fluid to the plenum under negative pressure. A fluid re-circulation path is provided in the housing structure through the separator structure and the fluid plenum. A pump structure re-circulates fluid and air through the re-circulation path during a pump mode. The fluid supply is continuously or intermittently fluidically coupled to the fluid reservoir.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com