Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

A technology of drainage gas production and drainage device, which is applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low production efficiency, unsafe heating, small decomposition driving force, etc., and achieve high energy utilization rate , Improve the efficiency of gas production, the effect of safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

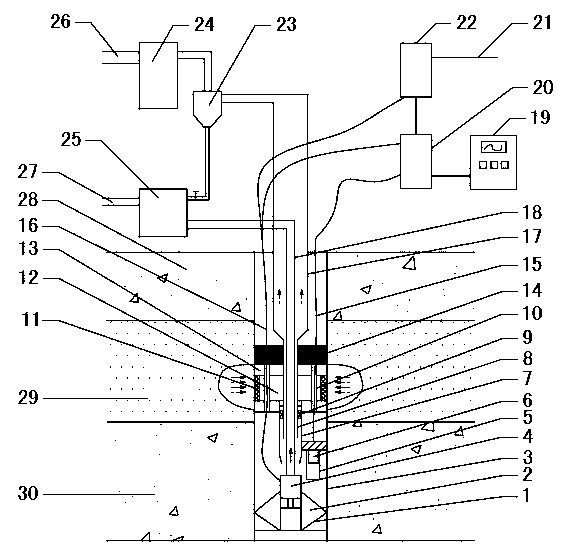

[0035] Figure 1~2 It is the best embodiment of the natural gas hydrate drainage gas production device and its mining method of the present invention, below in conjunction with the attached Figure 1~2 The present invention will be further described.

[0036] Refer to attached figure 1 : The natural gas hydrate drainage and gas production device includes a natural gas hydrate production well 3 connected to the natural gas hydrate layer 29, an electric submersible pump 4 fixed at the bottom of the natural gas hydrate production well 3 and a gas hydrate production well 3 fixed in the middle The microwave generator 14 is connected to the gas-liquid separator 7 in the well above the electric submersible pump 4. The microwave generator 14 heats the natural gas hydrate layer 29, and the gas and water generated by the decomposition of the natural gas hydrate are separated by the gas-liquid separator 7 in the well. The gas is transported to the ground through the gas production casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com