Patents

Literature

510 results about "Lime kiln" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide). The chemical equation for this reaction is...

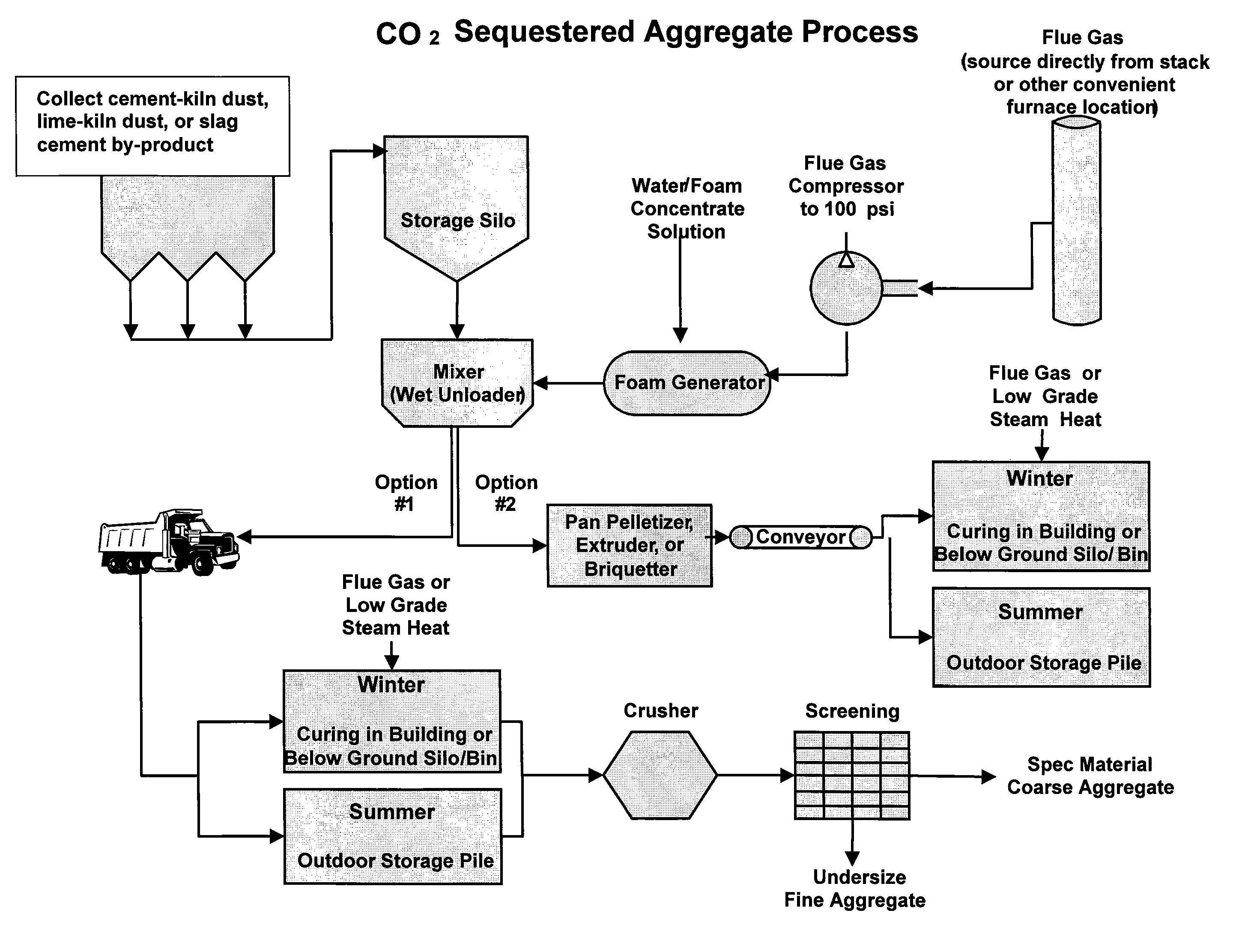

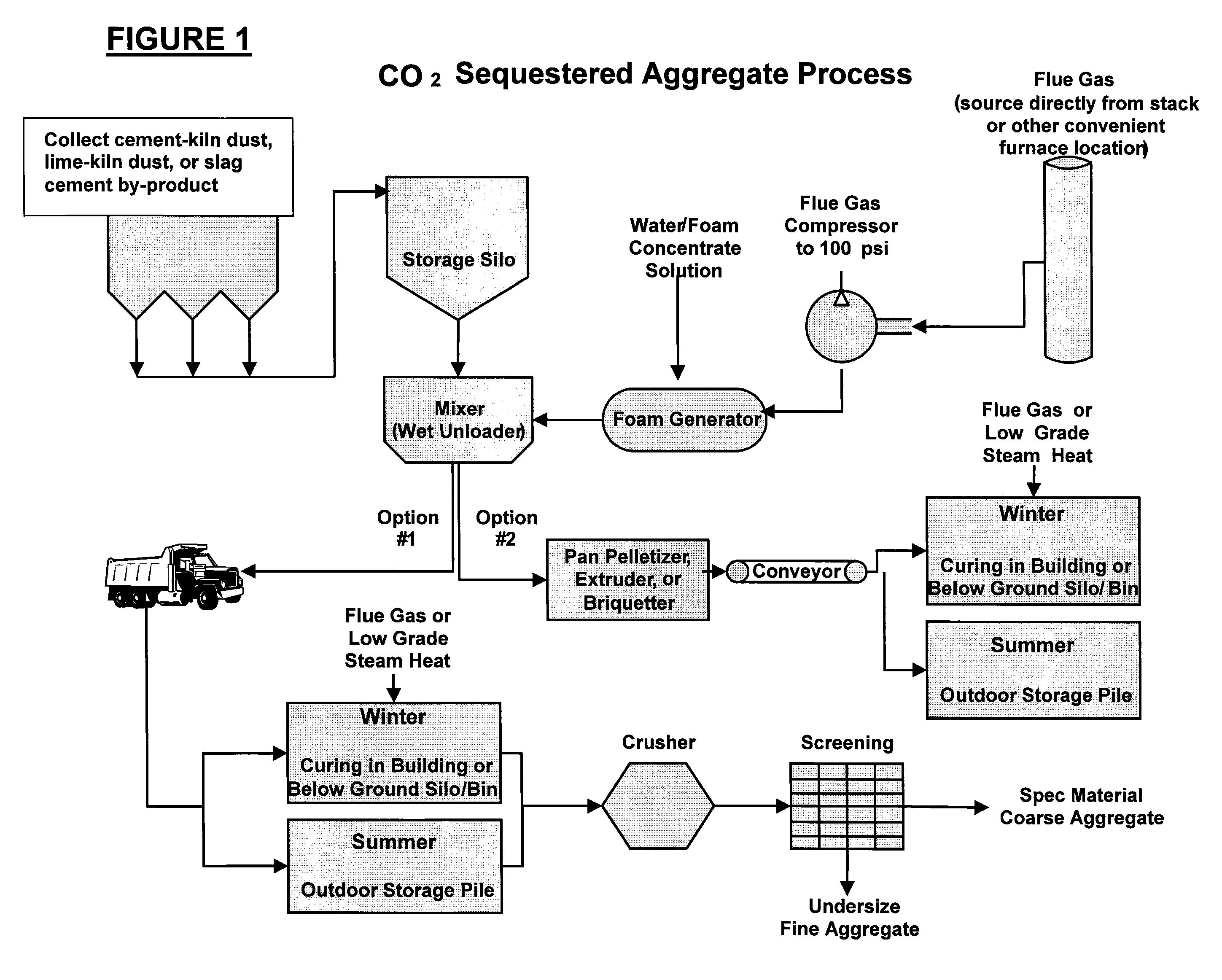

Carbon Dioxide Sequestration in Foamed Controlled Low Strength Materials

A process for sequestering carbon dioxide from the exhaust gas emitted from a combustion chamber is disclosed. In the process, a foam including a foaming agent and the exhaust gas is formed, and the foam is added to a mixture including a cementitious material (e.g., cement-kiln dust, lime kiln dust, or slag cement) and water to form a foamed mixture. Thereafter, the foamed mixture is allowed to set, preferably to a controlled low-strength material having a compressive strength of 1200 psi or less. The carbon dioxide in the exhaust gas reacts with hydration products in the controlled low-strength material and in turn sequesters the carbon dioxide.

Owner:WISCONSIN ELECTRIC POWER

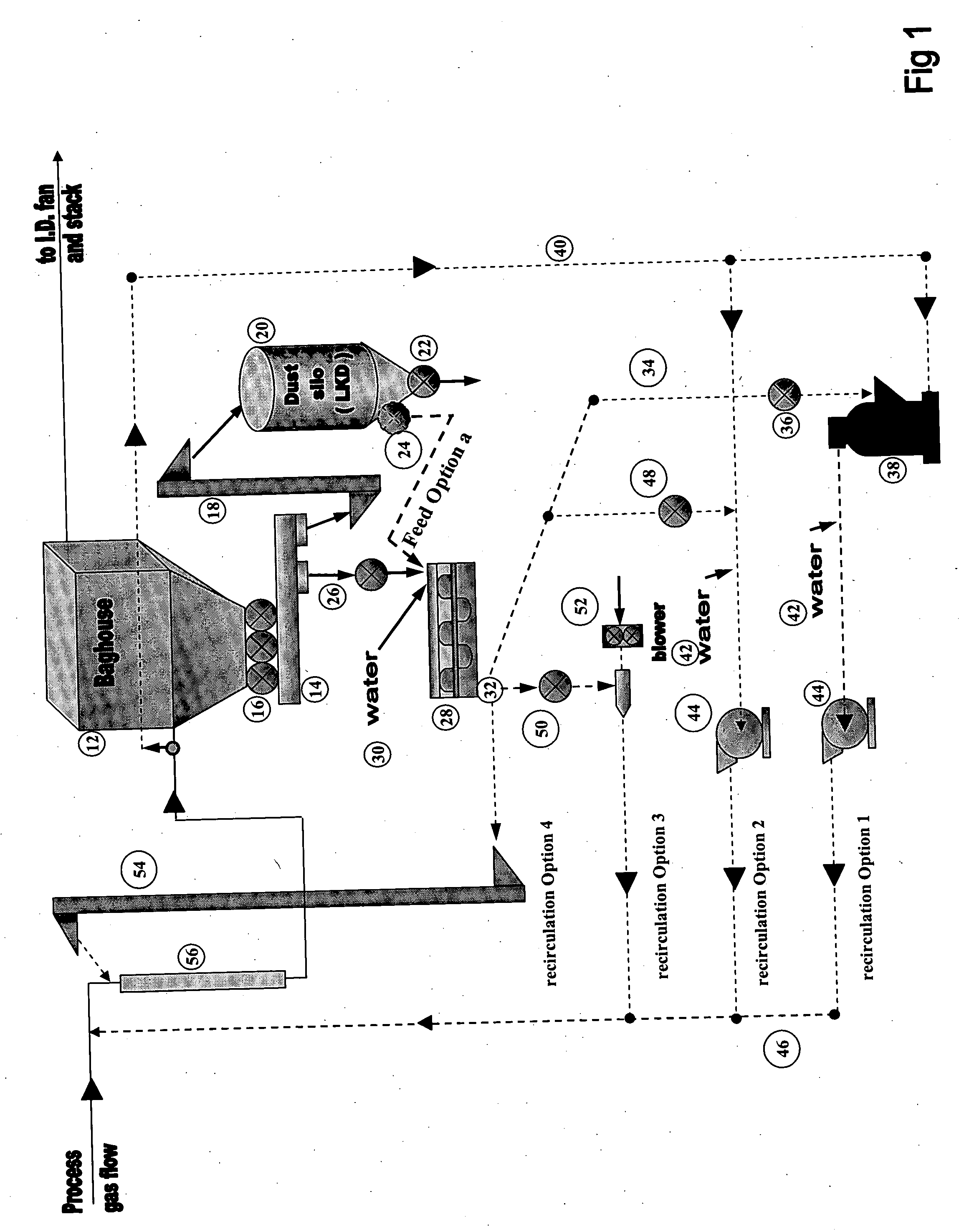

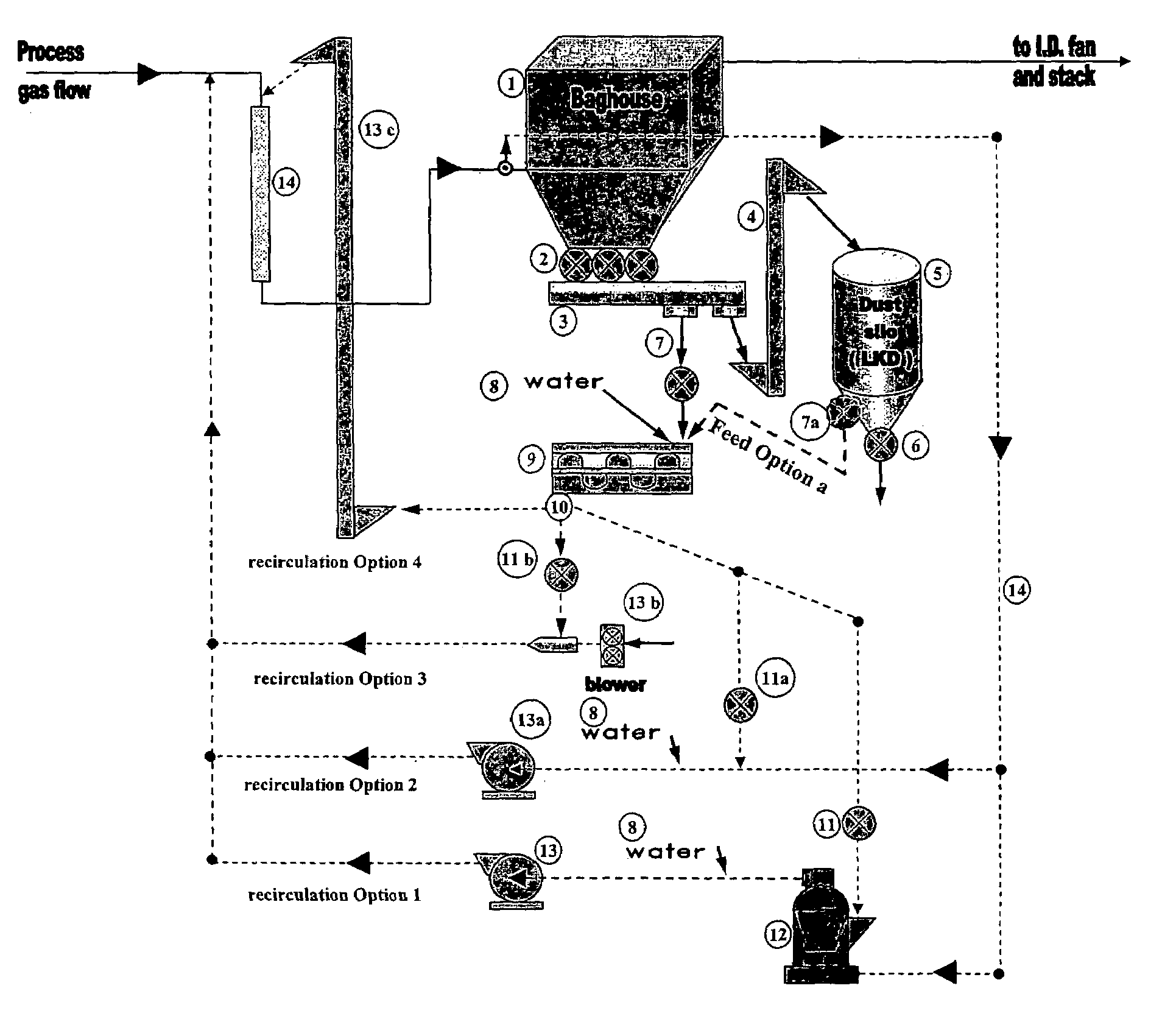

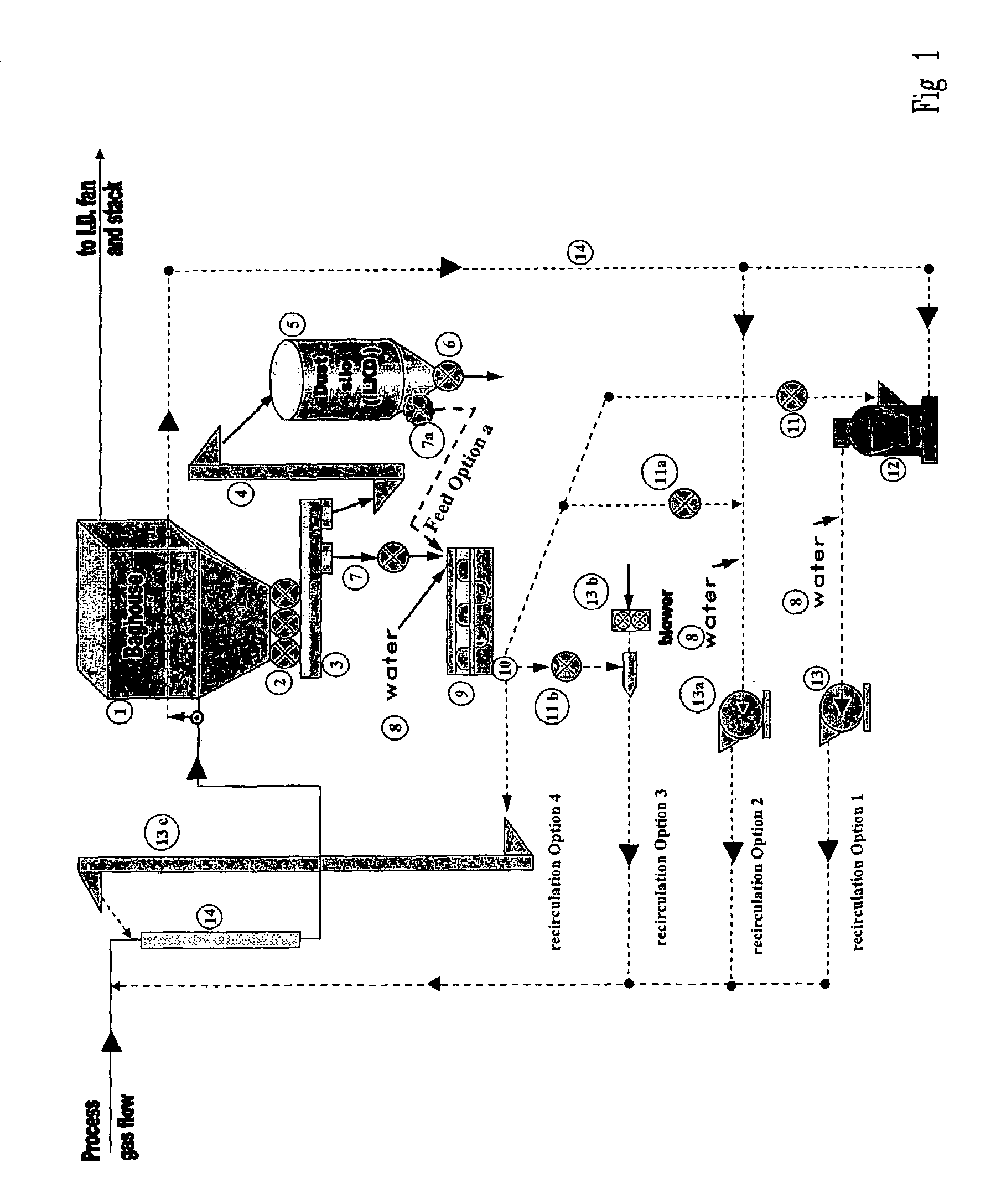

Hydrated lim kiln dust recirculation method for gas scrubbing

ActiveUS20050031515A1Effectively self-cleaningEffective sorbentGas treatmentIsotope separationFlue gasSorbent

Owner:GRAYMONT PA INC

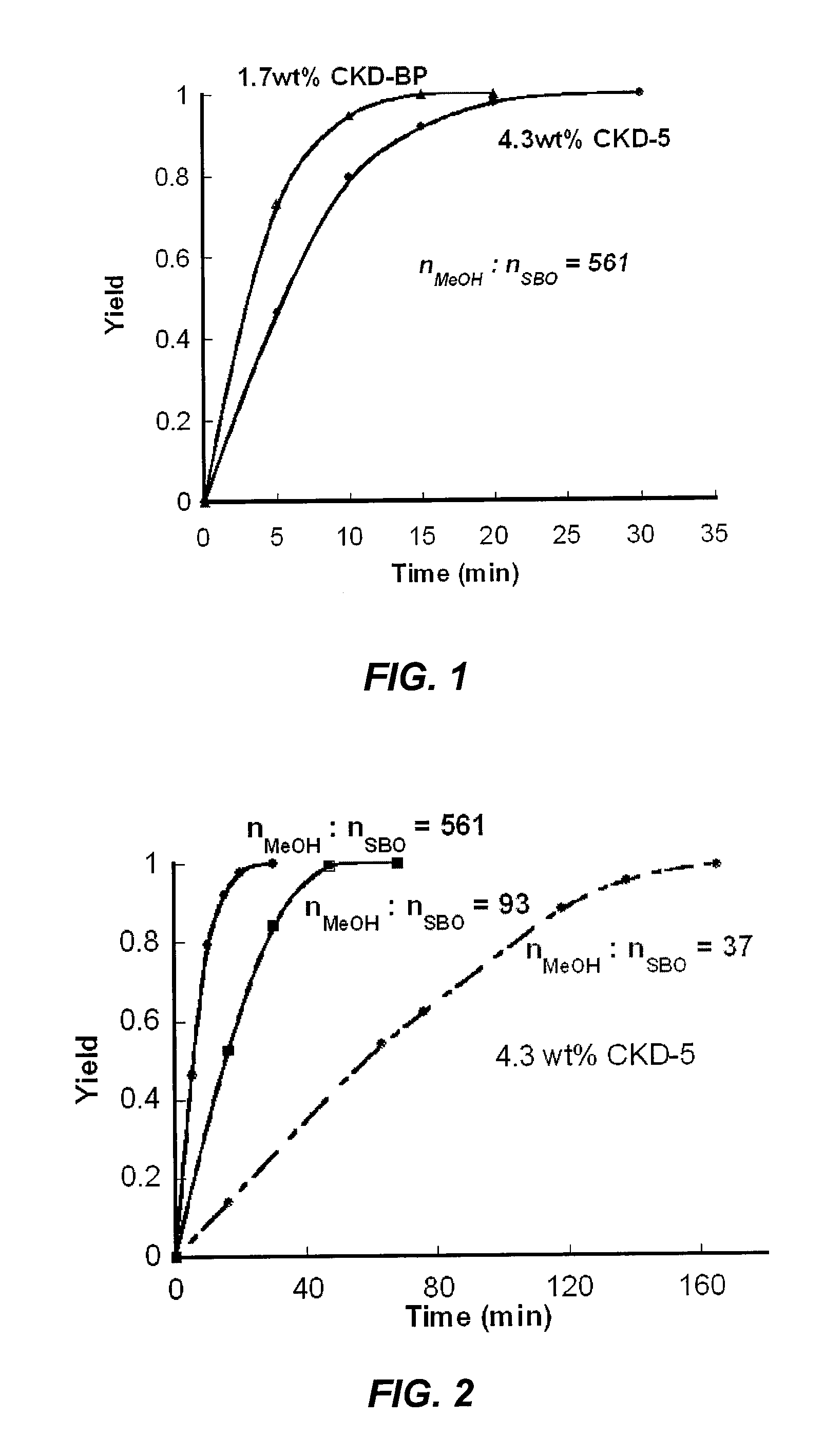

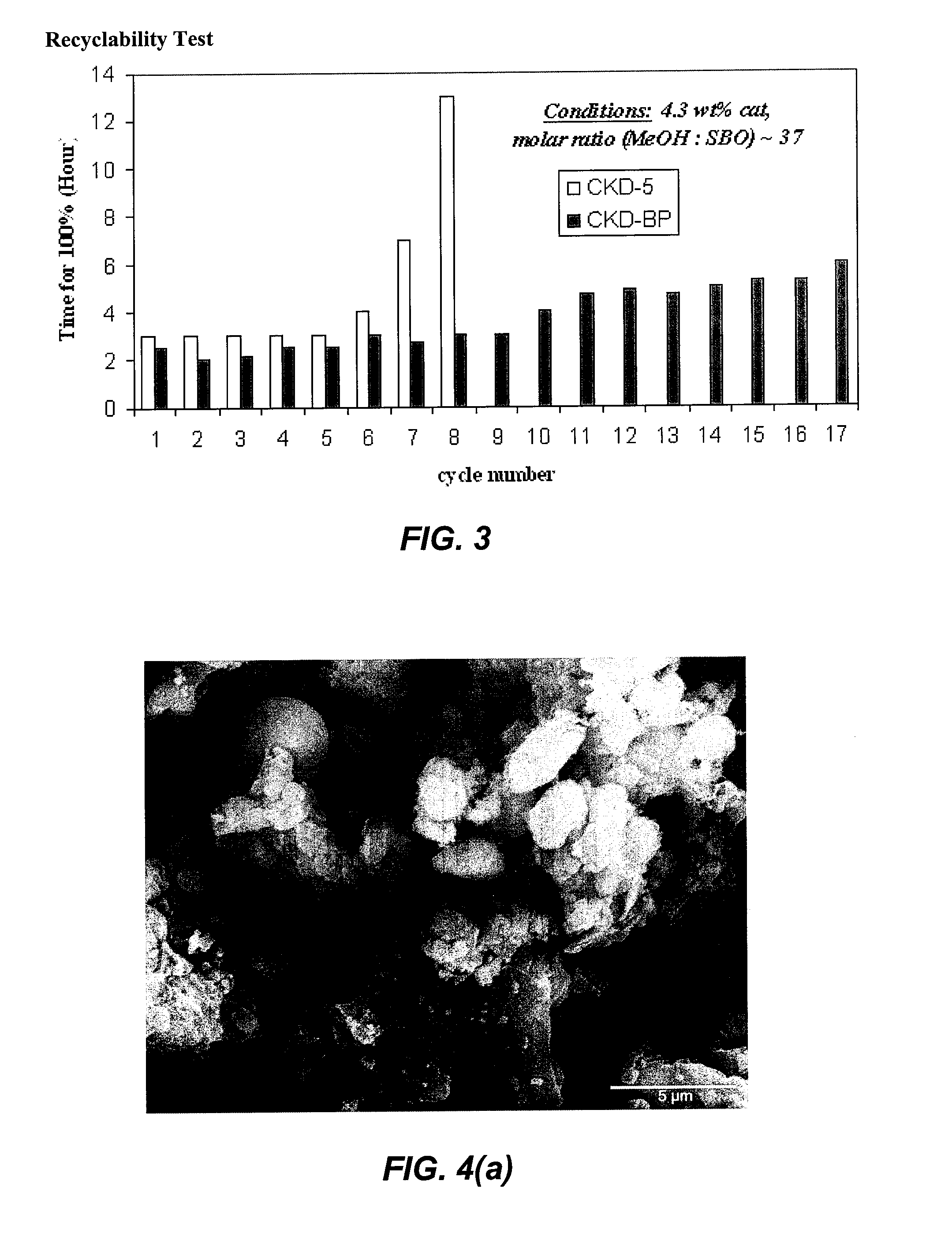

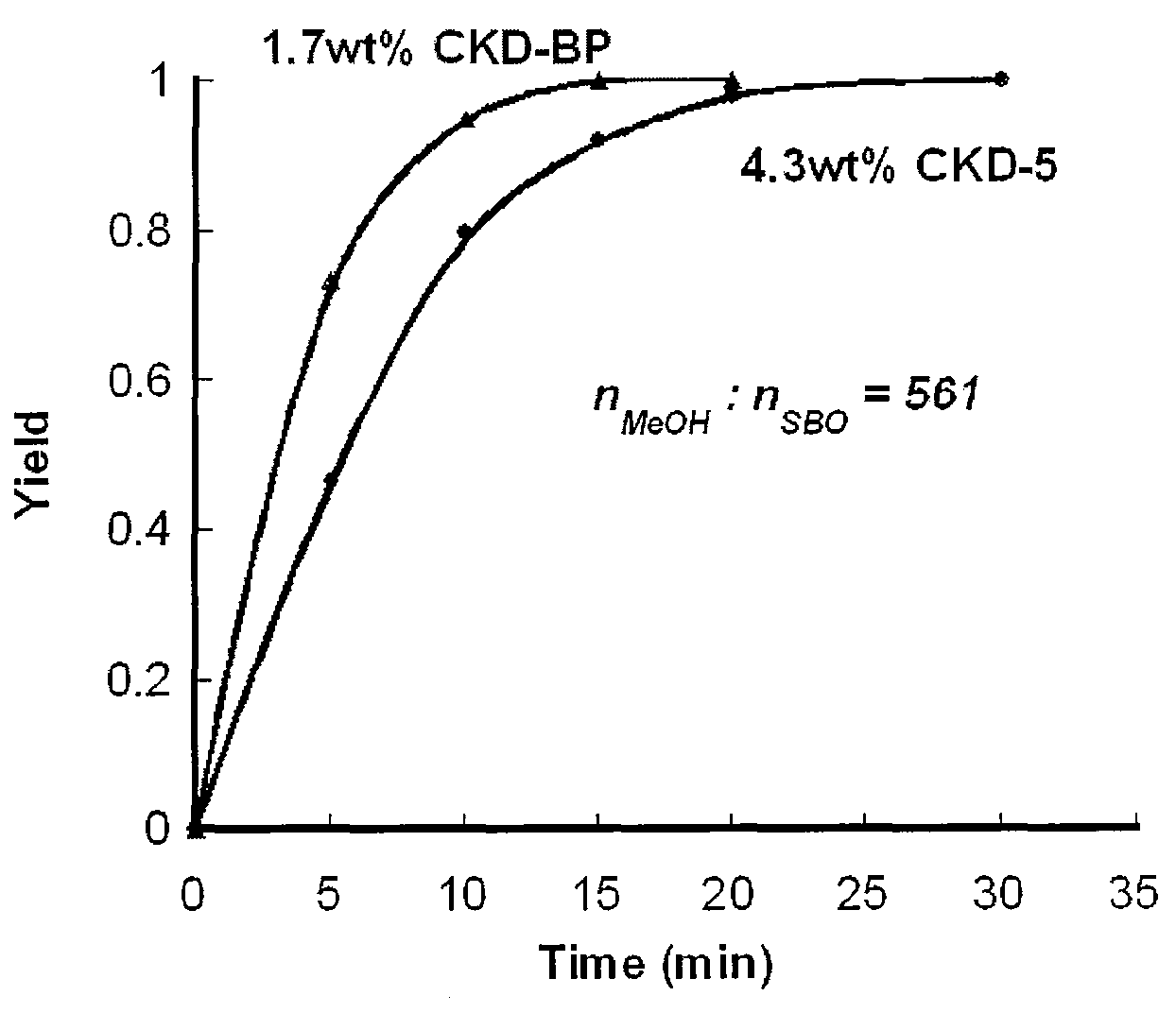

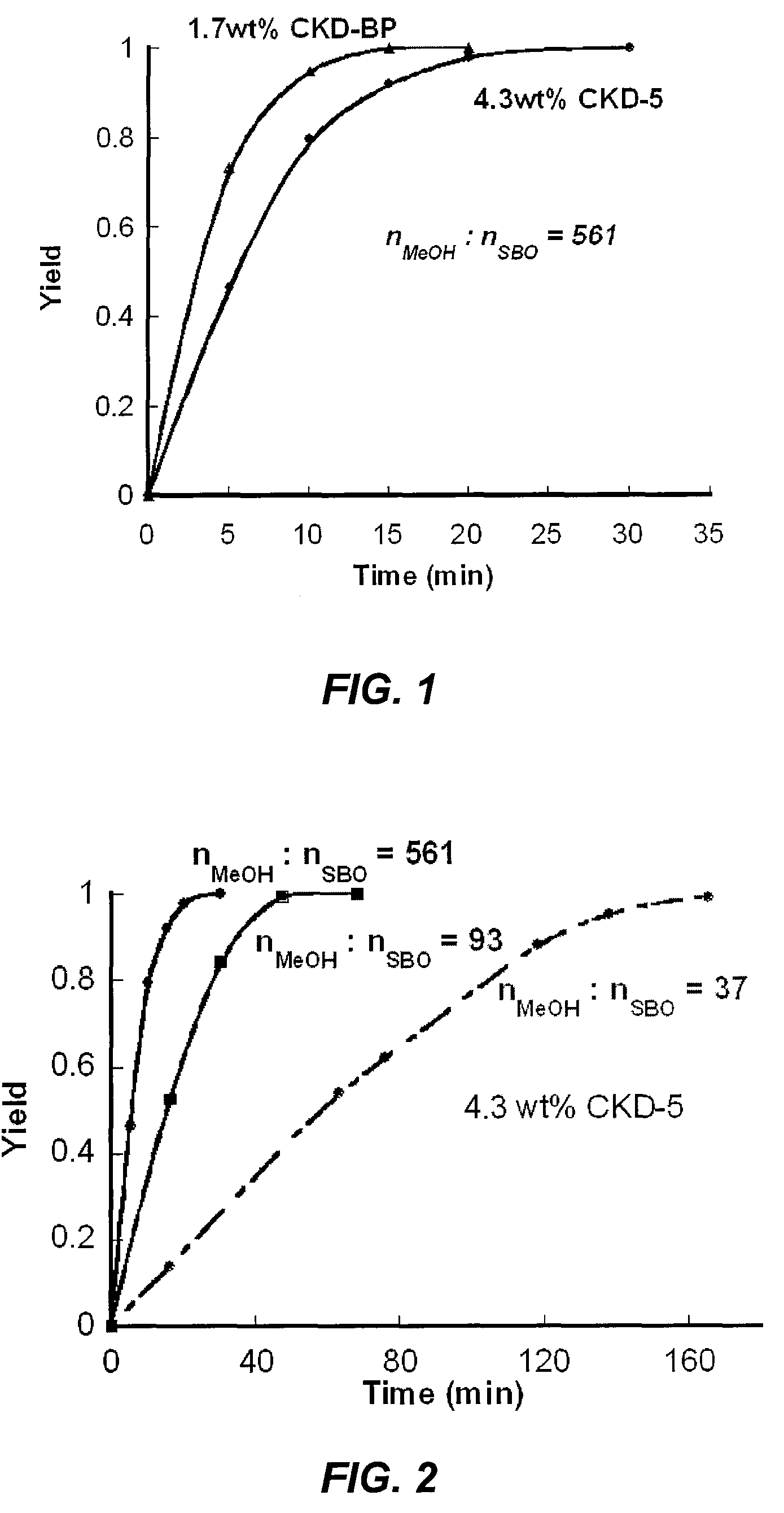

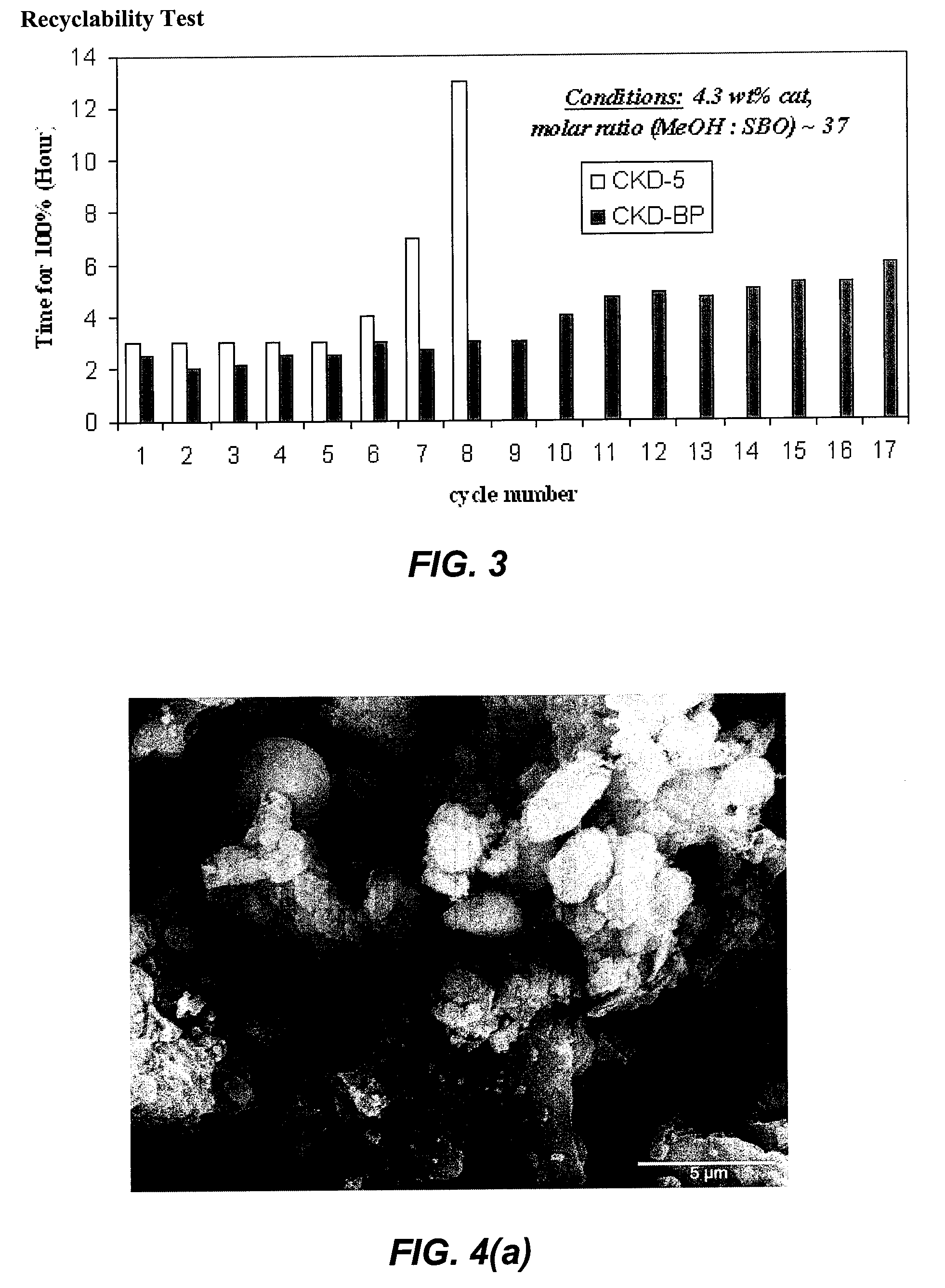

Solid catalyst system for biodiesel production

ActiveUS20090112007A1Increase contact areaRapid responseFatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

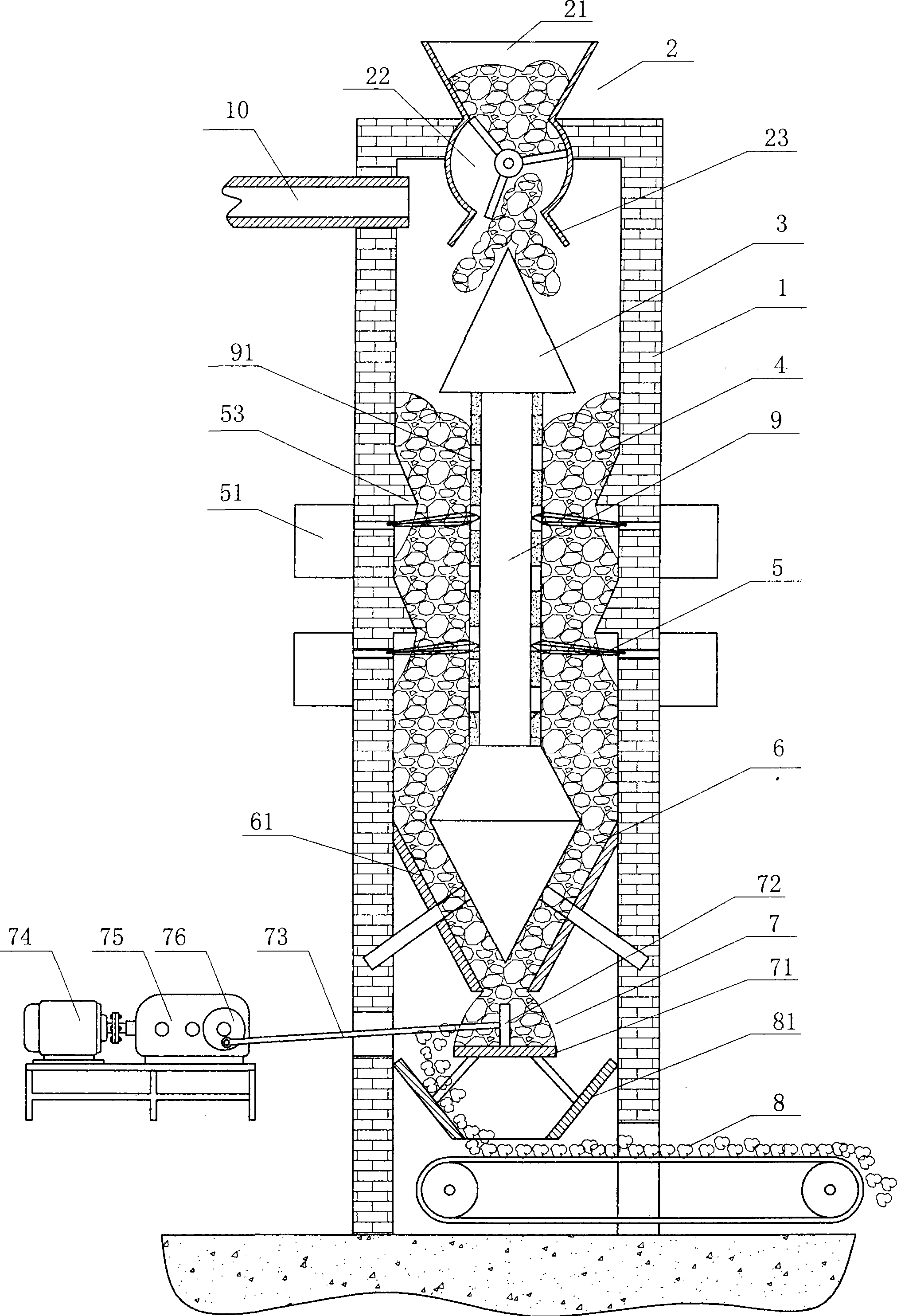

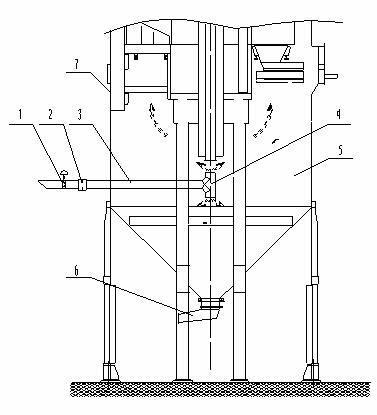

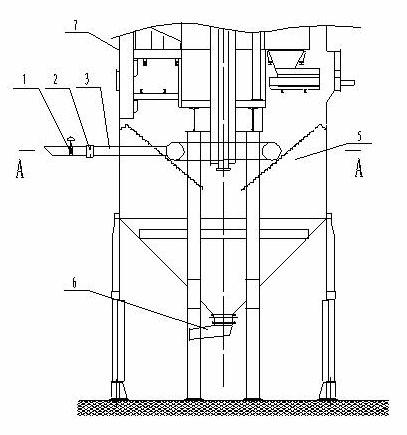

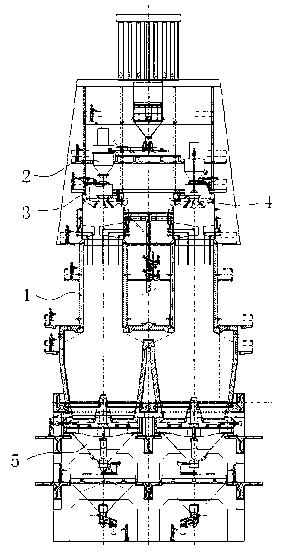

Vertical continuous calcination lime burner

InactiveCN101195520AHigh activityCalcination process is reasonableLime productionInterior spaceLime kiln

The invention discloses a vertical and continuously calcining lime kiln, including a cylindrical kiln body. From the top down, the kiln body is successively provided with an air-lock feeding device, a distributing device, a preheating zone, calcining zone, cooling zone and a continuously discharging device. The air-lock feeding device is located on the top of the kiln body, the distributing device is located on the upper of the inner chamber of the kiln body, the preheating zone is located below the distributing device, the calcining zone is located below the preheating zone, the cooling zone is located below the calcining zone and the continuously discharging device is located below the discharge port but at the cooling zone. The top of the kiln body is equipped with air discharge pipe, heat wind exhaust passage which is devised axially along the kiln body and can extend to the preheating zone is equipped in the inner space of the kiln body, and a plurality of air outlets and inlets are equipped on the copper wall of the heat wind exhaust passage. The invention enables to continuously manufacture, can control the lime in the kiln to drop with a uniform speed, has no sintering phenomenon, can control the lime to fall with constant speed on every level surface in the kiln and completely put an end to undersintering and oversintering.

Owner:黄官禹

Hydrated lime kiln dust recirculation method for gas scrubbing

ActiveUS7141093B2Effectively self-cleaningEffective sorbentGas treatmentIsotope separationSorbentFlue gas

Owner:GRAYMONT PA INC

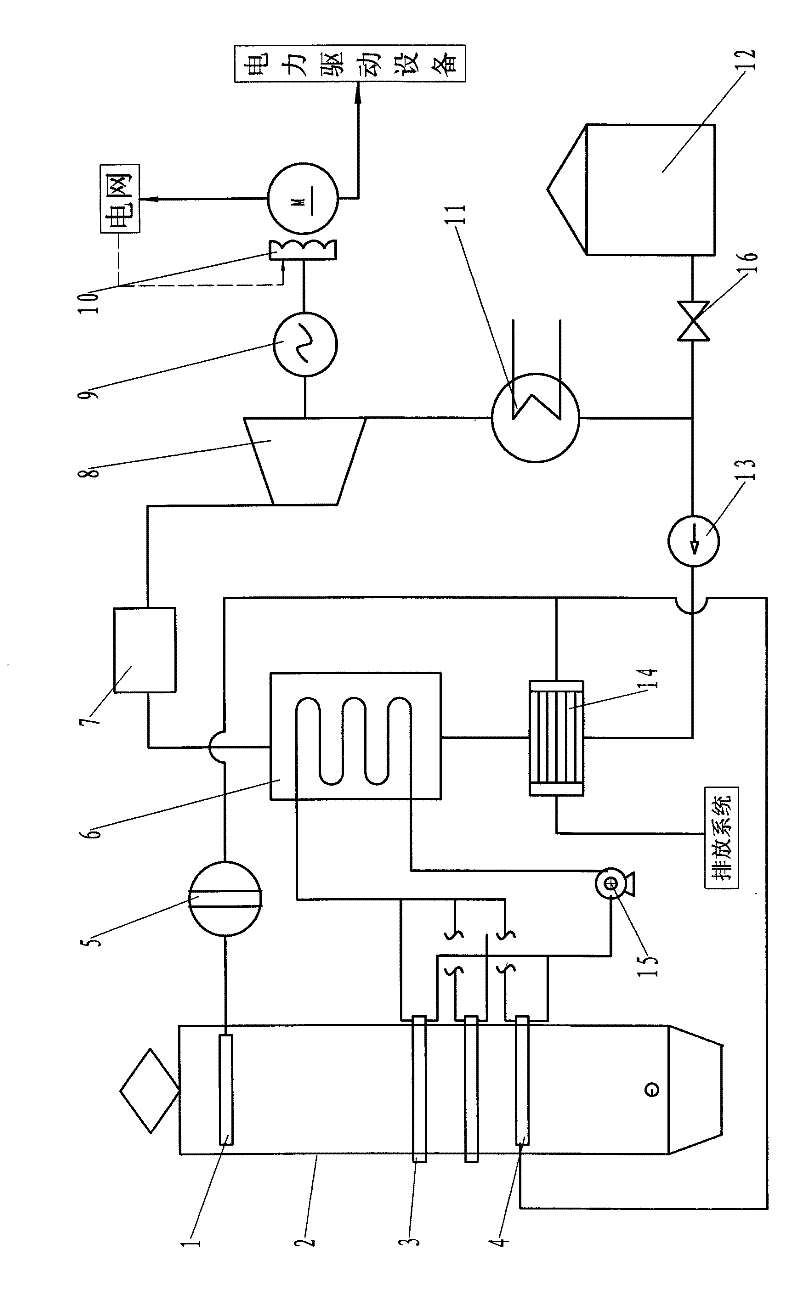

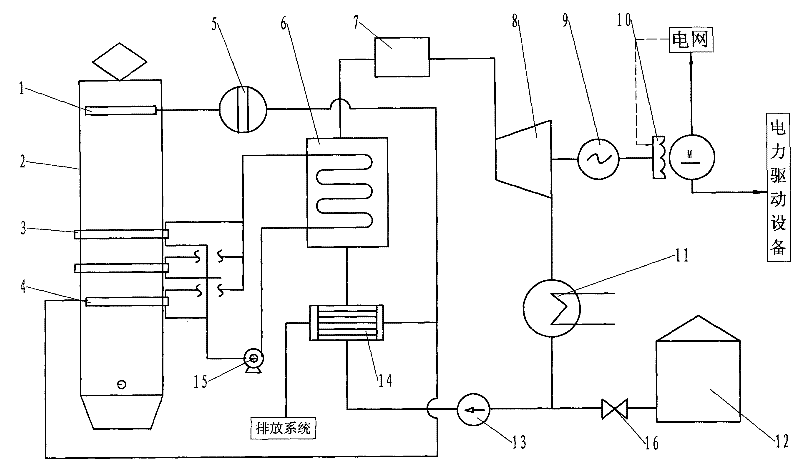

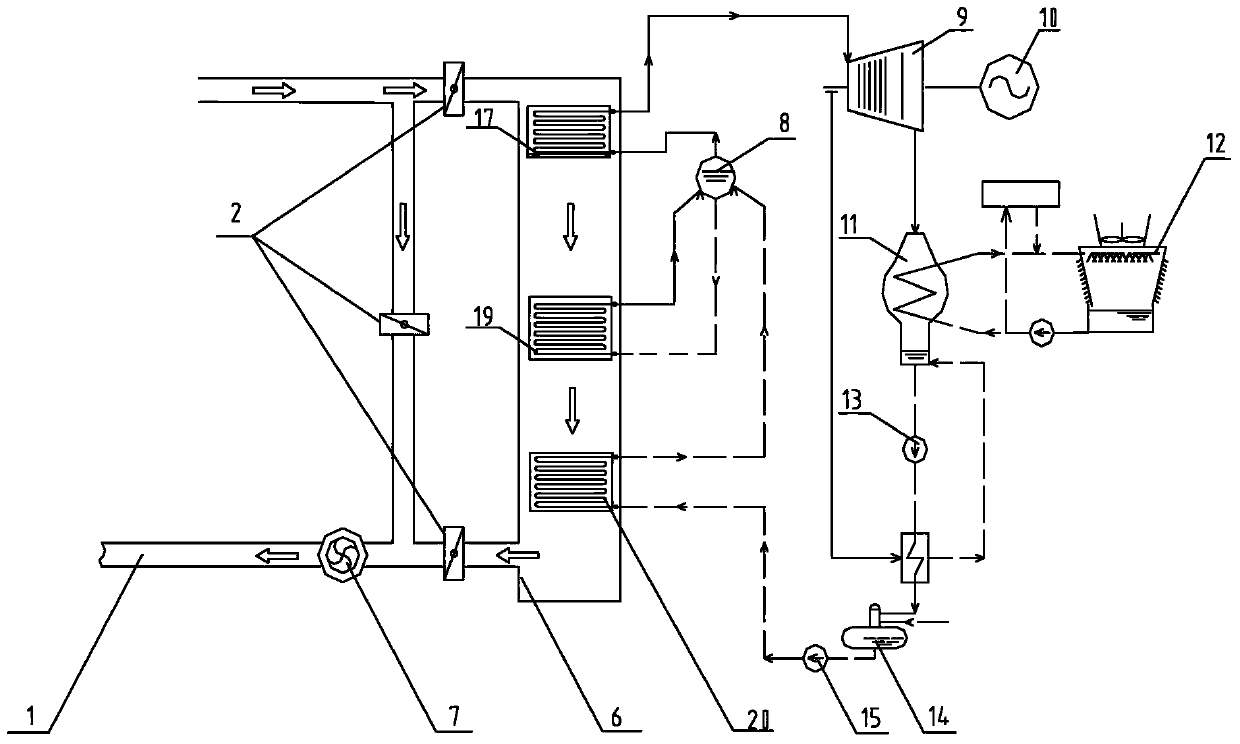

Equipment for recycling low-temperature heat of lime kiln

ActiveCN102338565ALow costTake advantage ofIncreasing energy efficiencySteam engine plantsThermal energyHeat conducting

The invention provides equipment for recycling low-temperature heat of a lime kiln; the equipment mainly comprises the lime kiln, a working medium storage tank, a working medium preheater, a steam generator, a steam adjusting device, a steam turbine, a generator, a transmitter and a condenser. A working medium is preheated by using low-temperature gas of the lime kiln through the working medium preheater; the preheated working medium is converted into steam by using the heat discharged by heat-conducting oil through the steam generator; and then the generator is driven to generate power by utilizing the steam turbine, and the generated power can be supplied to electrical equipment of the lime kiln device, and also can be merged into a general power grid. When the power is insufficient, the power from the general power grid can be supplemented to power driving equipment of the lime kiln, therefore, the operation flexibility is high. By adopting the equipment, the low-temperature heat of the lime kiln can be fully utilized, meanwhile, the emission of greenhouse gases is reduced, and the production cost of lime is reduced. The equipment can be used for recycling the low-temperature heat of the lime kiln and also can be used for recycling the energy of other low-temperature heat source systems.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

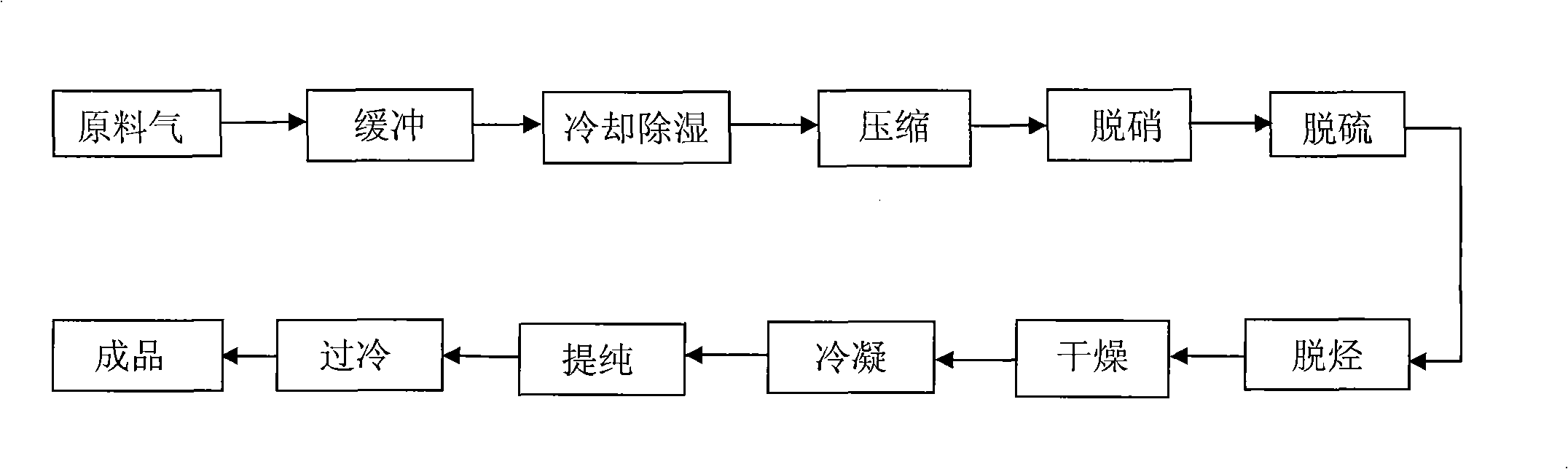

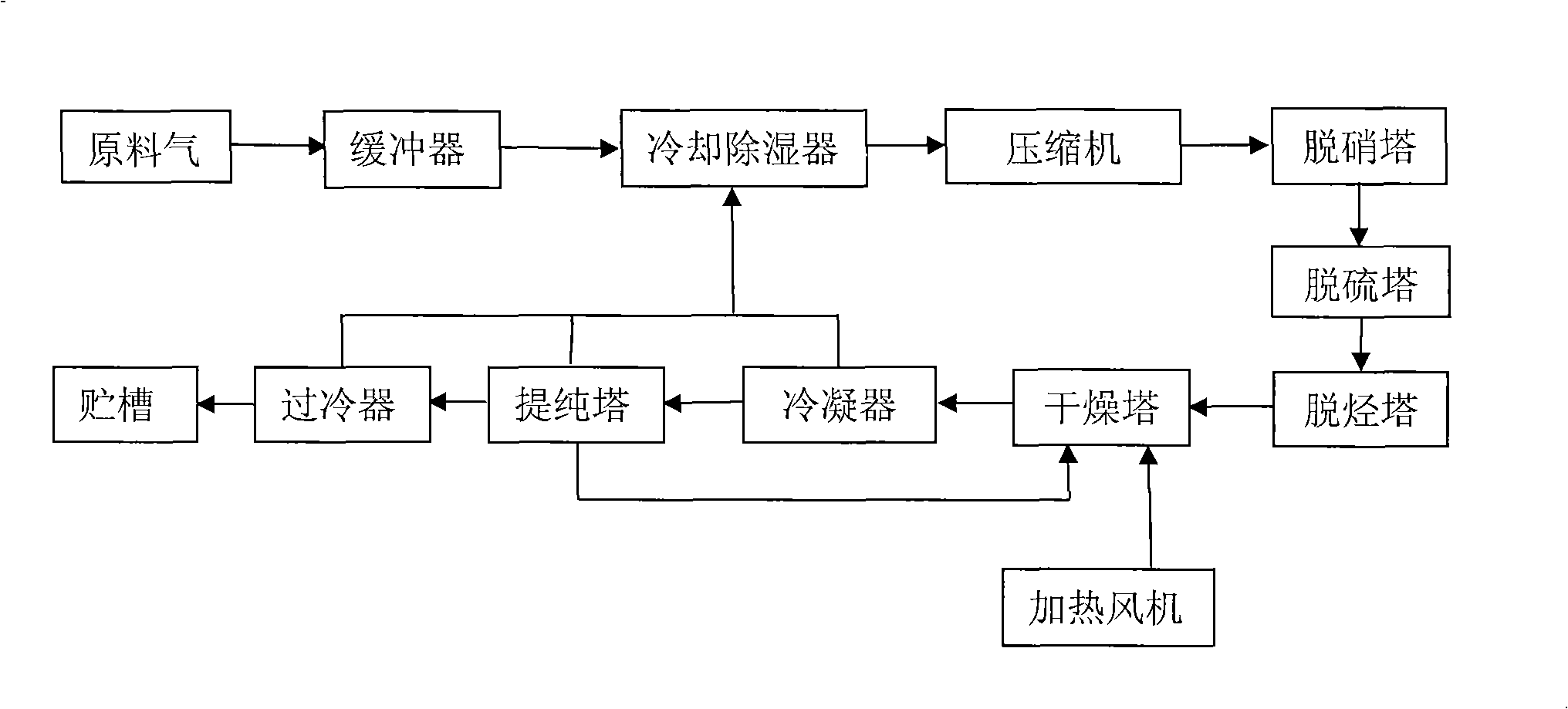

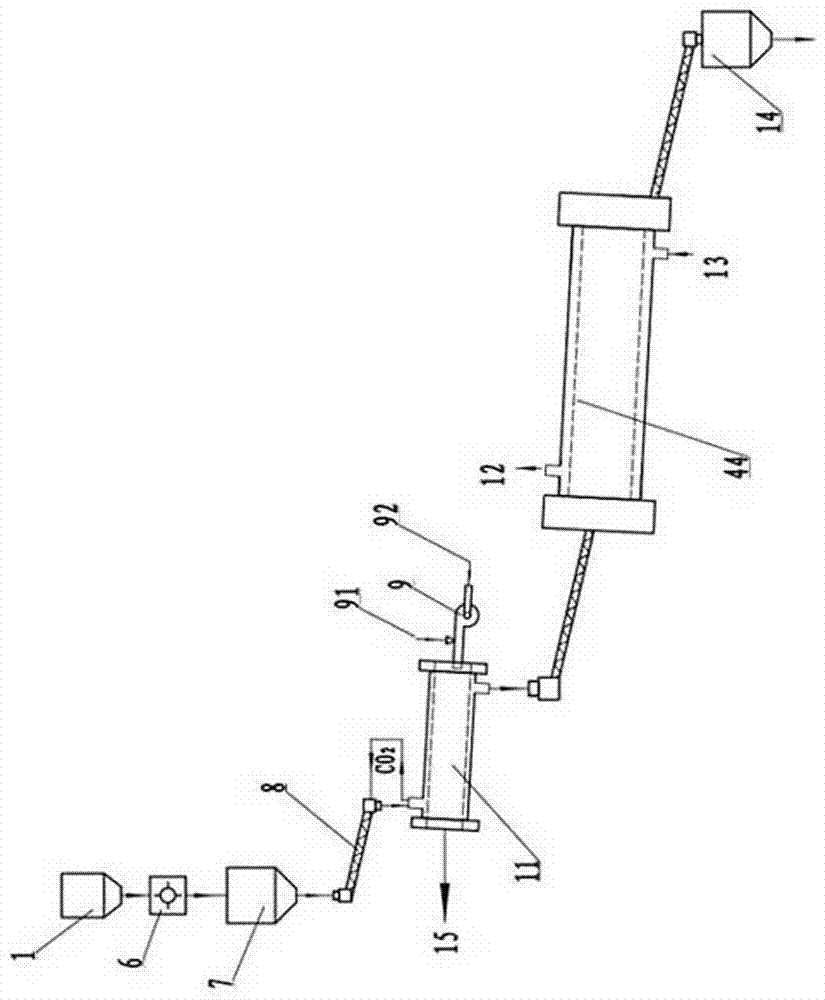

Method and apparatus for preparing food level liquid carbon dioxide with flue gas

The invention discloses a method of using flue gas to prepare food-grade liquid carbon dioxide, comprising steps that the carbon dioxide is collected and recovered as raw material to be treated by cooling, drying, compression, denitration, desulfurization and de-hydrocarbon, and is further treated by drying, purification and cooling to obtain the food-grade liquid carbon dioxide; a device to be adopted comprises a cooling dehumidifier, a compressor, a denitration tower, a desulfurization tower, a de-hydrocarbon tower, a drying tower, a condenser, a purification tower, a subcooler and a storage tank, etc., which are all connected by pipelines; the food-grade liquid carbon dioxide prepared by using the method and the device has advantages of high purity, small power consumption and low cost, etc.; the method can be widely used in the occasions of making use of the flue gas which is emitted from coal-fired power plants, cement factories, lime plants and coal-fired boilers and then collected and recovered to prepare food-grade liquid carbon dioxide.

Owner:杭州快凯高效节能新技术有限公司

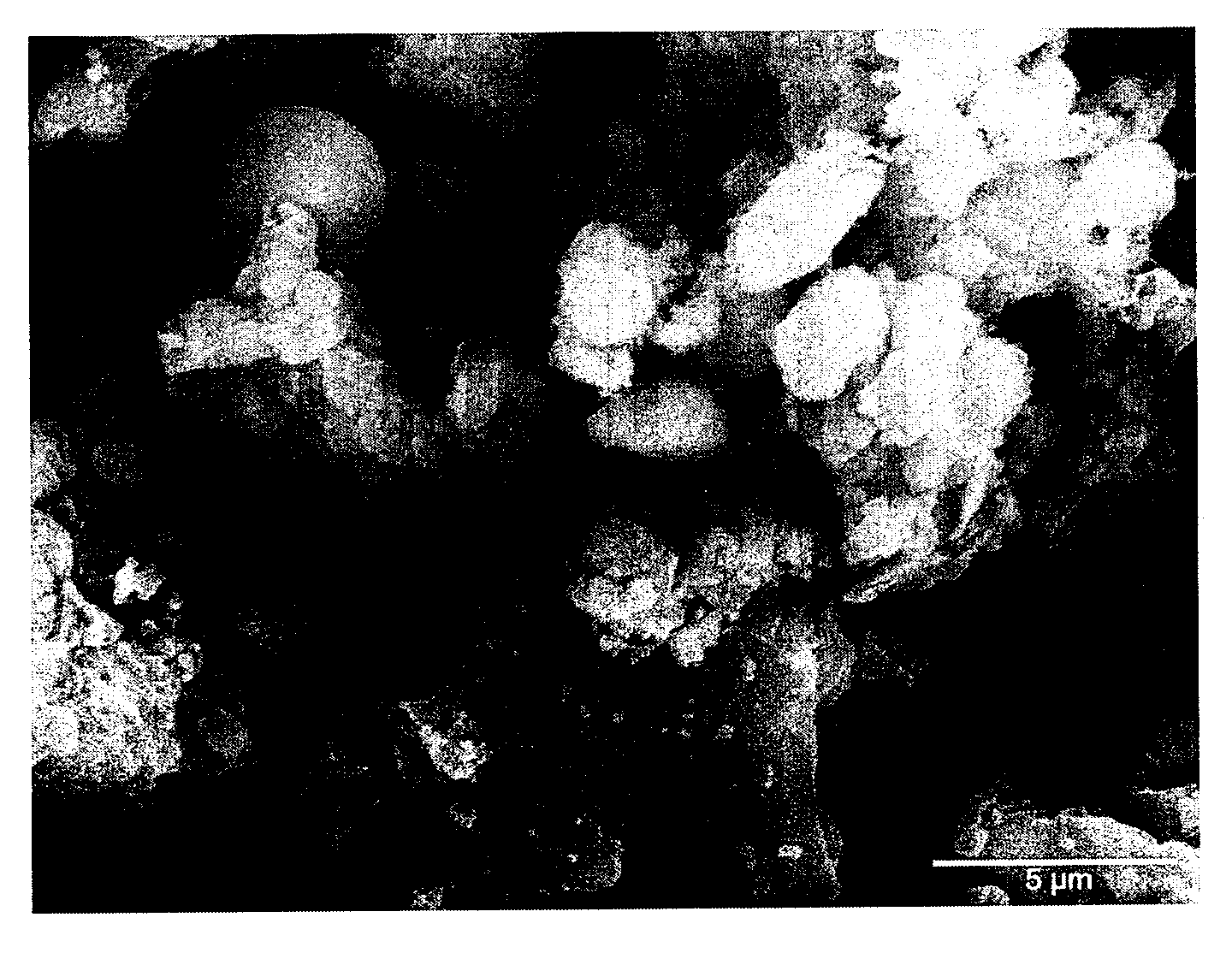

Solid catalyst system for biodiesel production

ActiveUS7906665B2Fatty acid chemical modificationFatty acids production/refiningMETHYL SOYATEVegetable oil

The invention provides efficient, inexpensive, and environmental friendly catalysts and catalyst systems. The catalysts can be used to catalyze esterification and / or transesterification reactions, for example, for the preparation of biodiesel. Kiln dust, such as cement kiln dust (CKD) or lime kiln dust (LKD) can be used to convert a variety of feedstock acids and / or esters to biodiesel in high yield under mild conditions. The CKD and LKD catalyst systems are recyclable esterification or transesterification catalysts that can be used to prepare biodiesel, such as methyl soyate, from various feedstocks, including vegetable oils and animal fats.

Owner:PINNAVAIA THOMAS J PH D +1

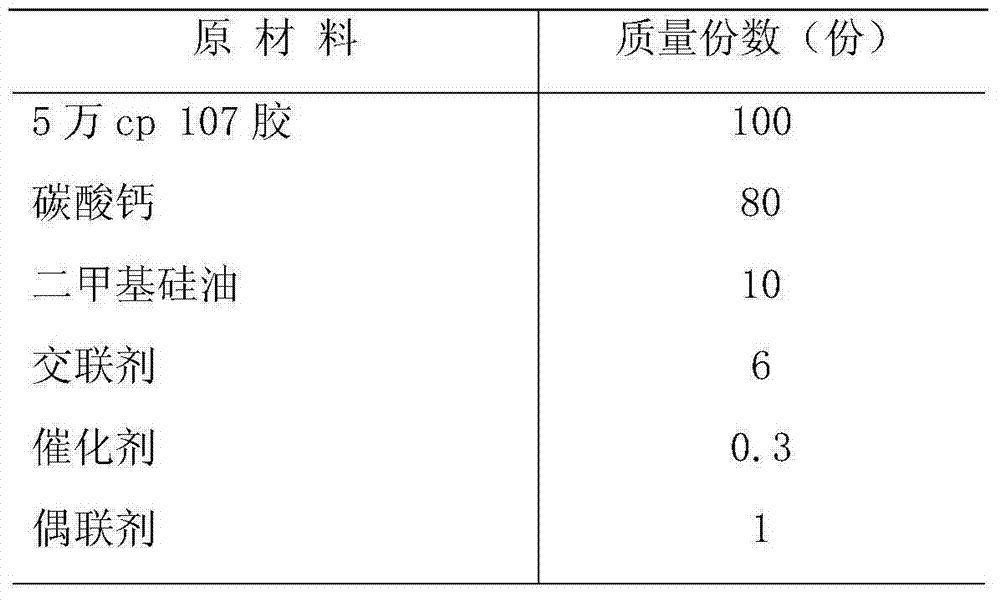

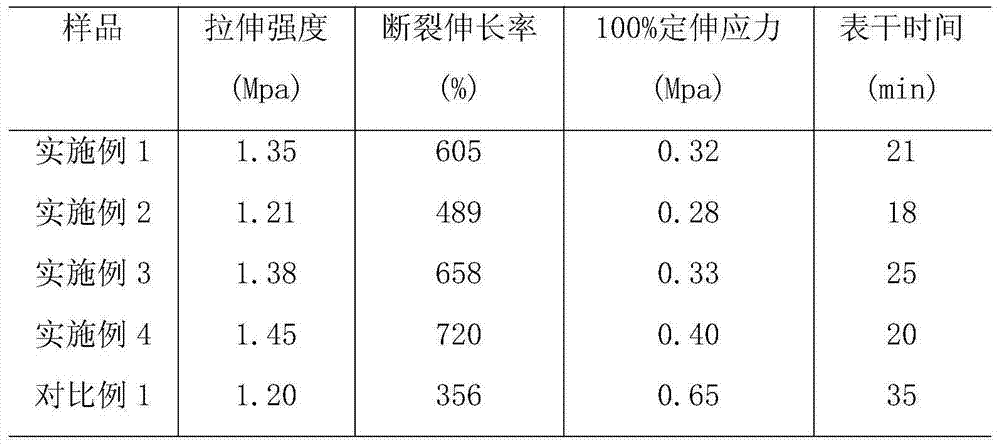

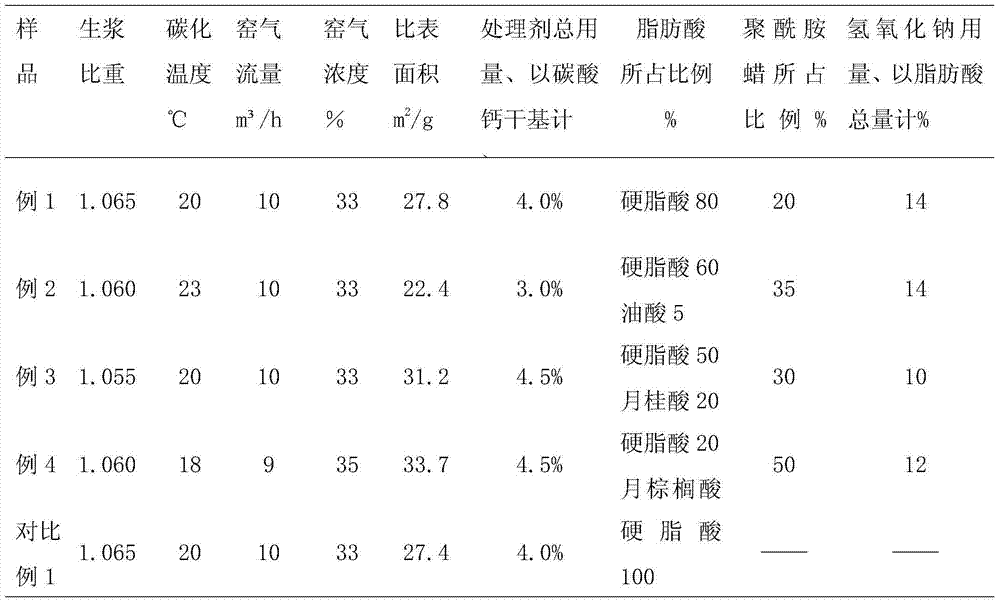

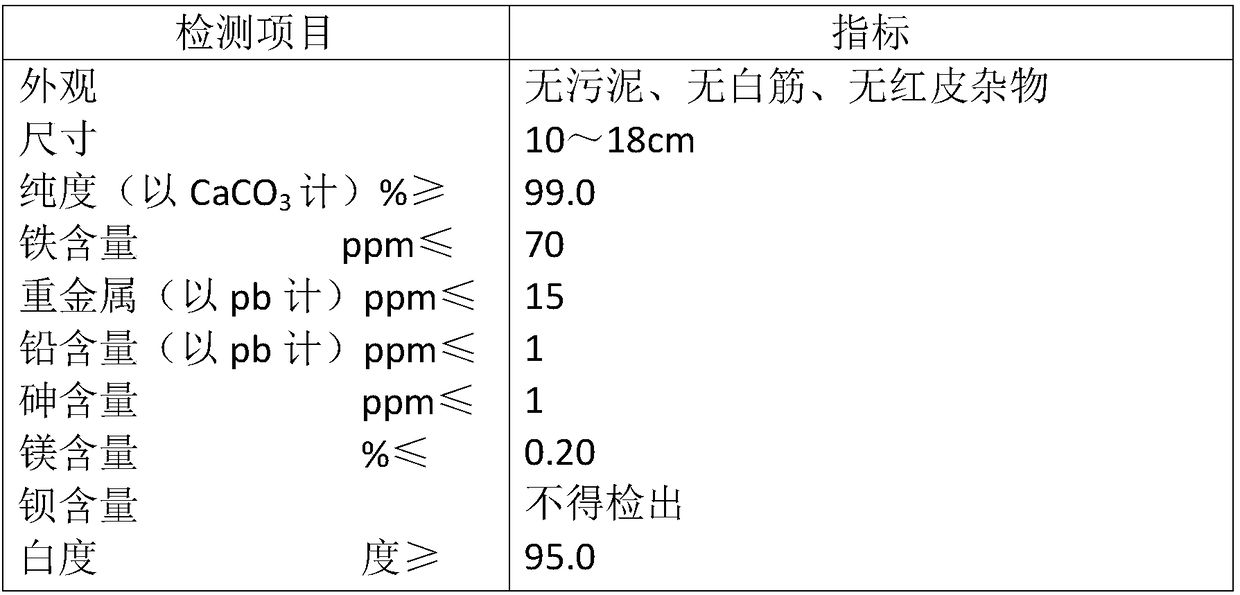

Preparation method of nano calcium carbonate used for weather proofing silicone sealant

ActiveCN104497634AShorten drying timeLow modulusNon-macromolecular adhesive additivesPigment treatment with macromolecular organic compoundsPolyamideDrying time

The invention discloses a preparation method of nano calcium carbonate used for a weather proofing silicone sealant, the proportion of lime milk aged for 36-72h is adjusted to 1.055-1.070, the temperature is controlled between 18 to 28 DEG C, lime kiln gas is introduced into for carbonation reaction, the lime kiln gas flow is controlled to 6-10m<3> / h, the carbon dioxide volume content is 25-40%, when the reaction solution pH is reduced to 7, the reaction solution is heated to 50 to 90 DEG C, 12-20g of fatty acid saponified solution and polyamide wax compounded surface treatment agent is added for coating, and after 60-120min of stirring, the product is obtained by completion of surface modification, dehydration, drying, crushing and grading. The nano calcium carbonate prepared by the method can significantly shorten surface drying time, reduce the curing silicone sealant modulus, and improve the filling silicone sealant thixotropy, processing and adhesion properties, and the process is easy and feasible, low in production cost, and good in economic benefit.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

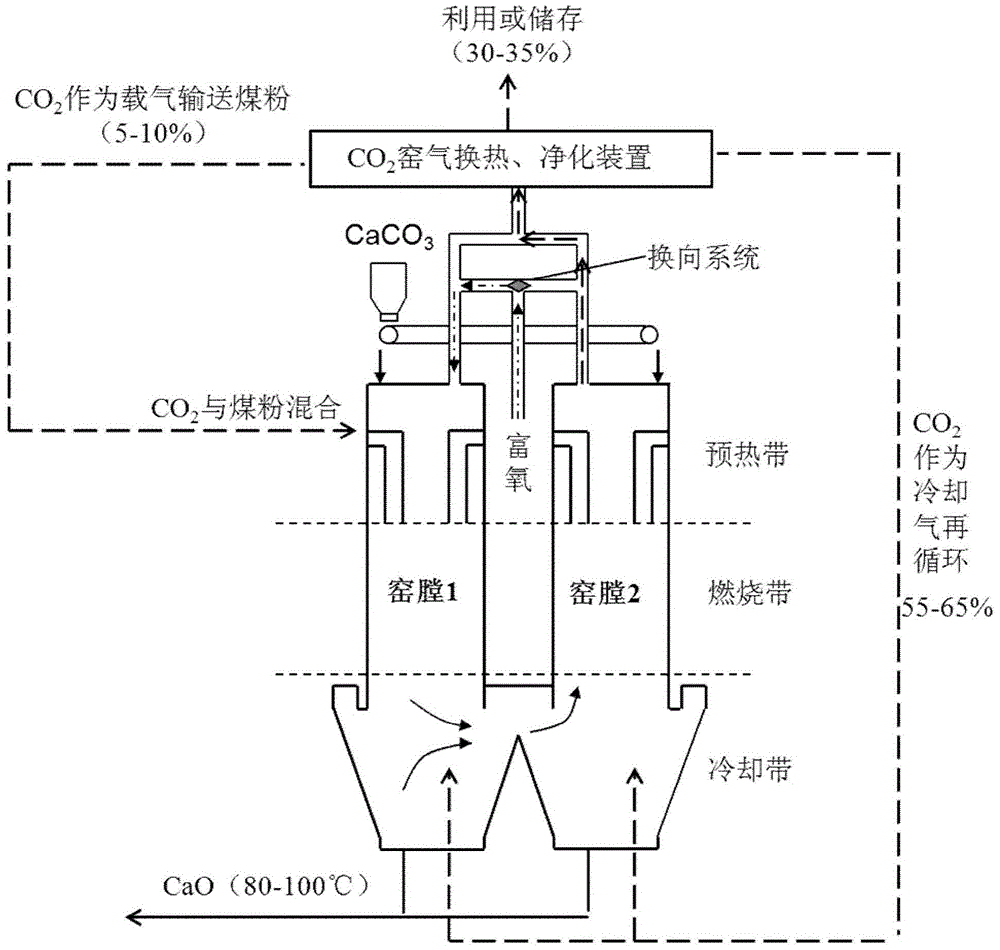

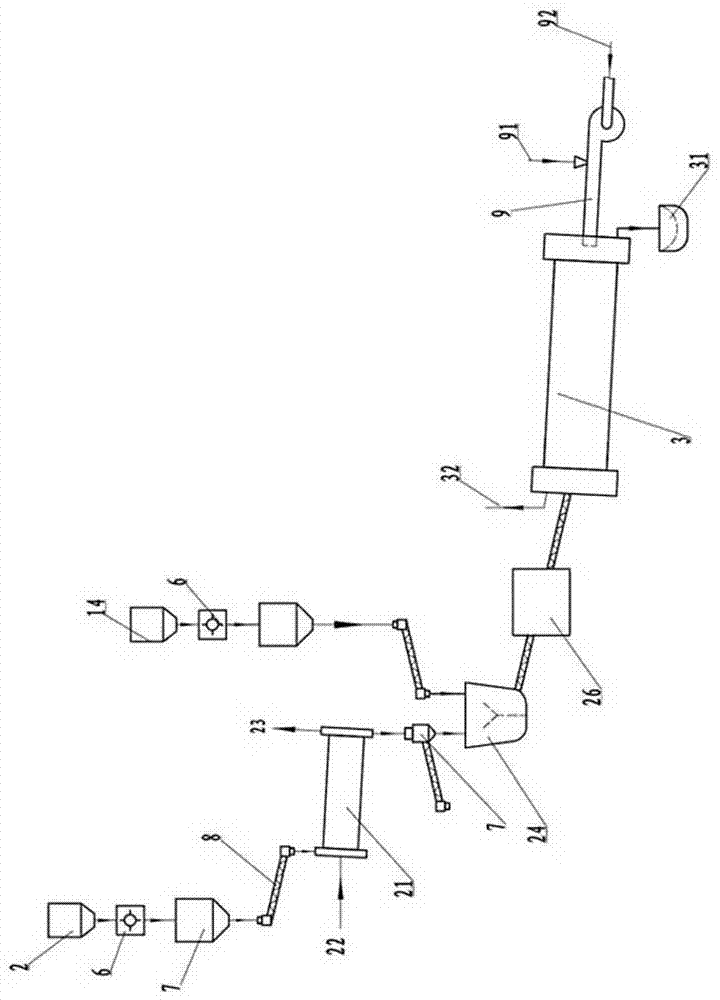

Parallel flow heat accumulating type lime kiln production technology based on CO2 accumulation

The invention discloses a parallel flow heat accumulating type lime kiln production technology based on CO2 accumulation. The parallel flow heat accumulating type lime kiln production technology includes the steps that limestone raw materials are fed into two kiln chambers of a parallel flow heat accumulating type lime kiln; carrier gas is sprayed into the kiln chambers; combustion supporting gas is fed; in a combustion zone of the current kiln chamber, limestone absorbs the heat generated by fuel combustion to be decomposed to generate quick lime and CO2 gas; the quick lime is discharged after being cooled to 80 DEG C to 100 DEG C; cooling gas, the CO2 gas generated by decomposing the limestone and CO2 gas generated by fuel combustion are mixed to enter the other kiln chamber to preheat limestone; flue gas generated by preheating releases heat to the limestone, then the temperature of the flue gas is reduced, the flue gas is exhausted, and CO2 gas with the volume concentration larger than 95% is generated; the parallel flow heat accumulating type lime kiln starts reversing work. By means of the parallel flow heat accumulating type lime kiln production technology, the high-purity CO2 gas is obtained while the high-quality lime is prepared. Compared with an existing technology, circulation of N2 in a system is avoided, the energy used for heating the N2 is saved, and the flue gas is recycled to achieve the aims of increasing the product added value, saving energy and reducing consumption.

Owner:NORTHEASTERN UNIV

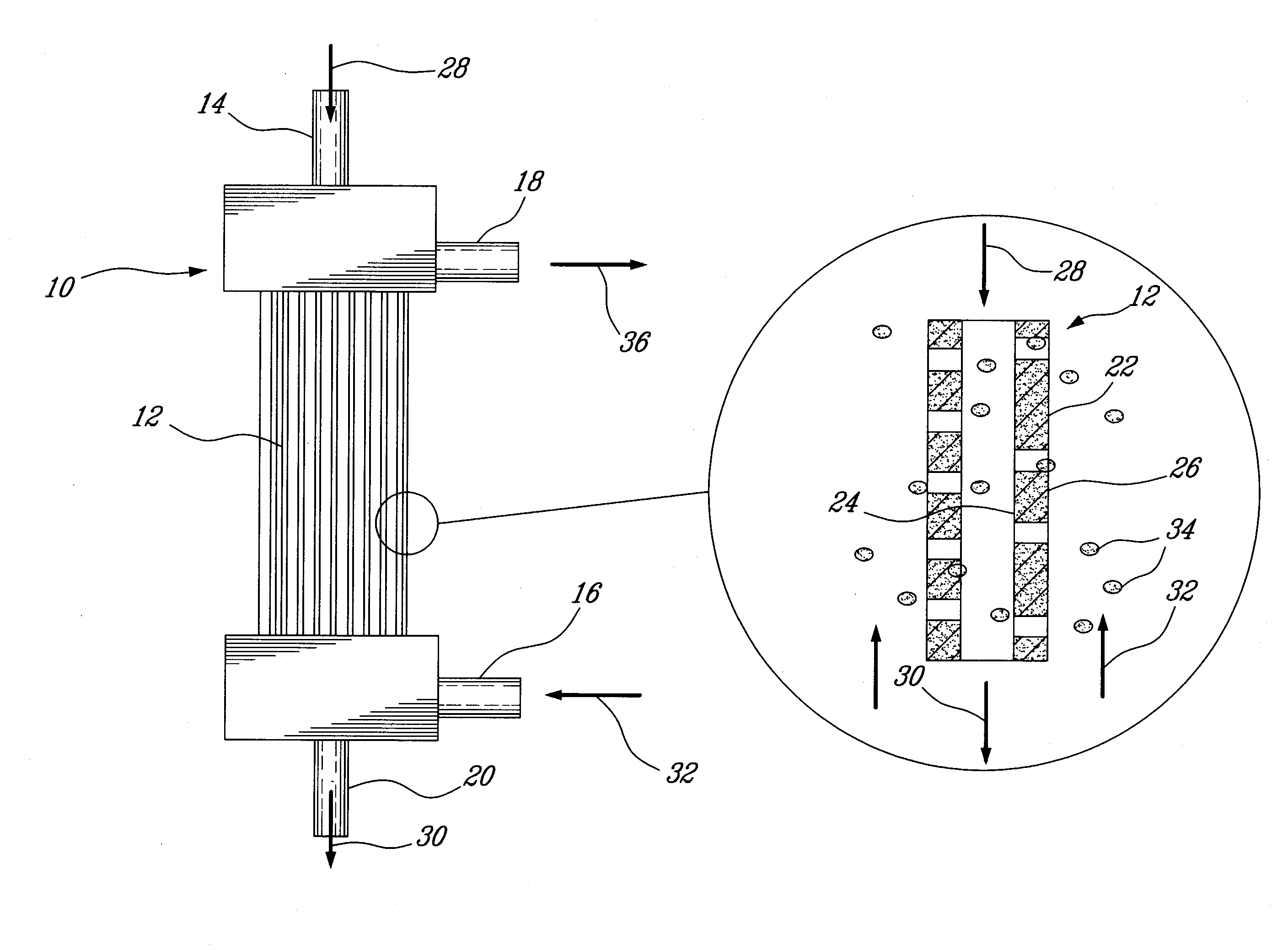

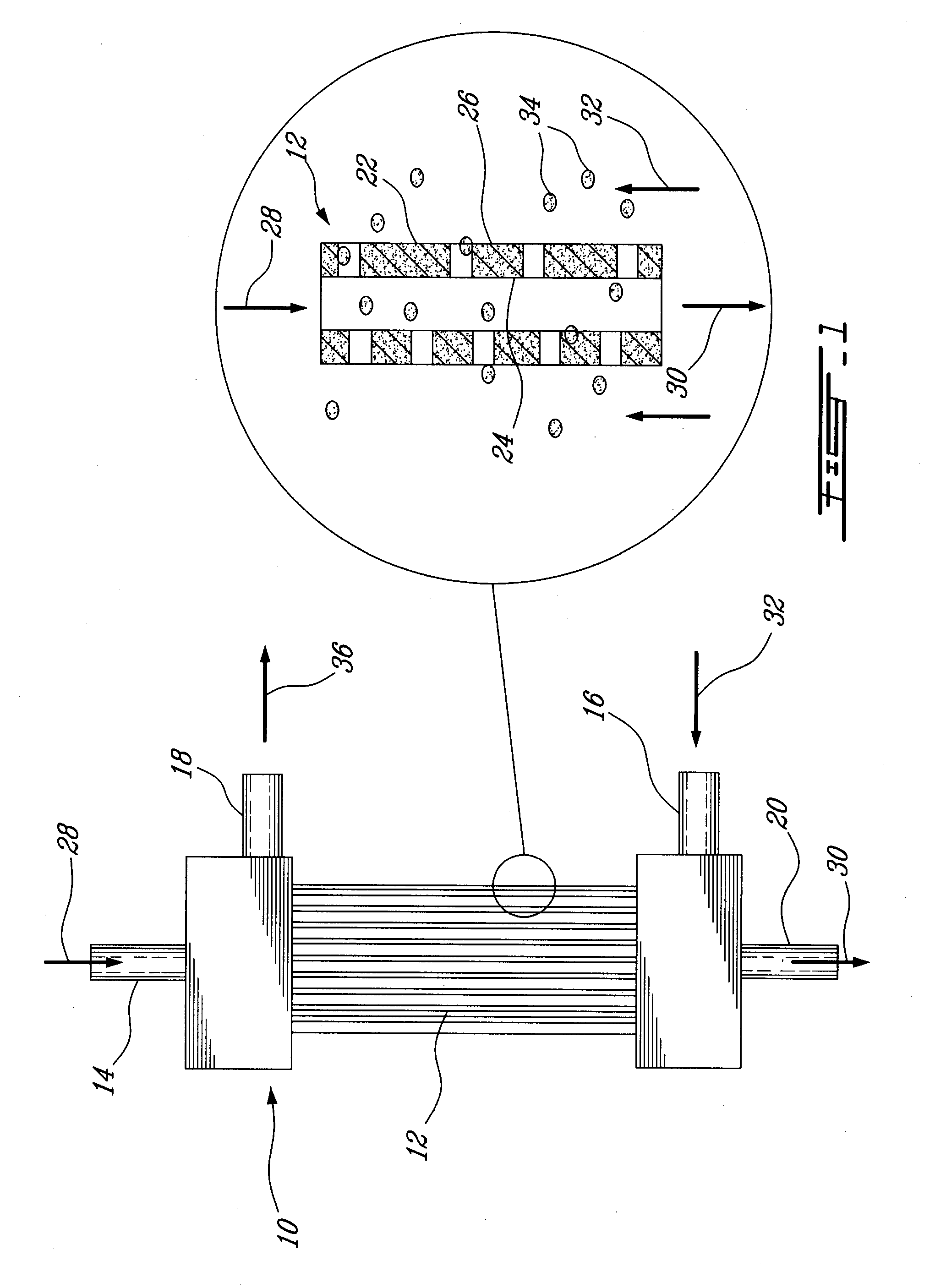

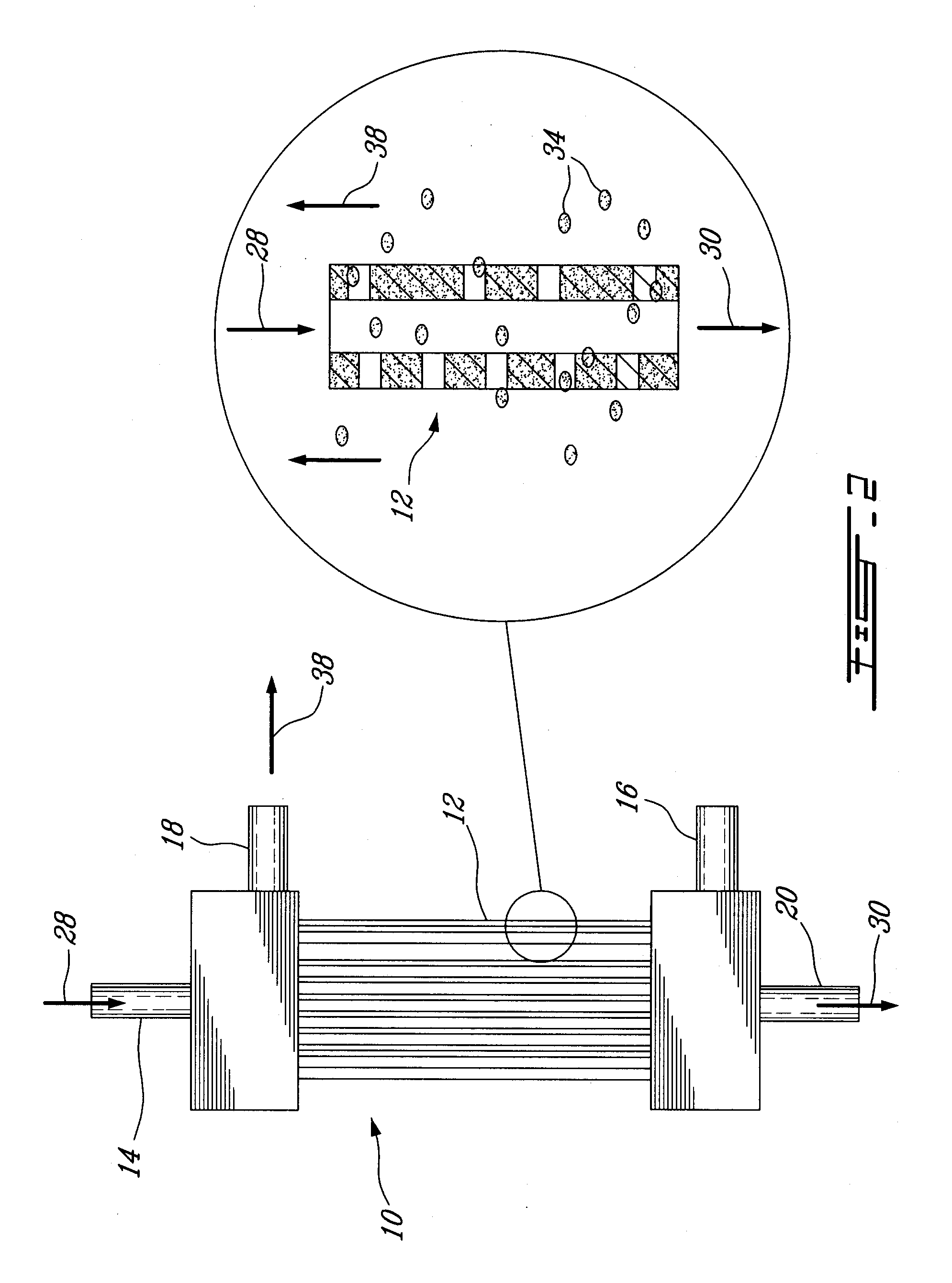

Process for treating pulp mill condenstates using a hollow fiber contactor

A method and apparatus for the treatment of pulp mill condensates is described. A hollow fiber contactor, incorporating a hydrophobic membrane, was used to remove several undesirable compounds from pulp mill condensates. For example, TRS compounds and SO2 were efficiently stripped from kraft and sulphite mill evaporator condensates, respectively. Methanol was also removed from kraft mill condensates but at a lower efficiency than TRS. Furthermore, other undesirable compounds found in condensates of pulp mills that contribute to the BOD and COD loading to effluent treatment systems were also removed. These contactors are cost effective since air, vacuum or a suitable solvent or scrubbing solution can be used as the stripping medium to drive off through the membrane several undesirable compounds from the feed solution. The undesirable compounds removed can thus be burned in the recovery boiler, lime kiln or a dedicated boiler.

Owner:FPINNOVATIONS INC

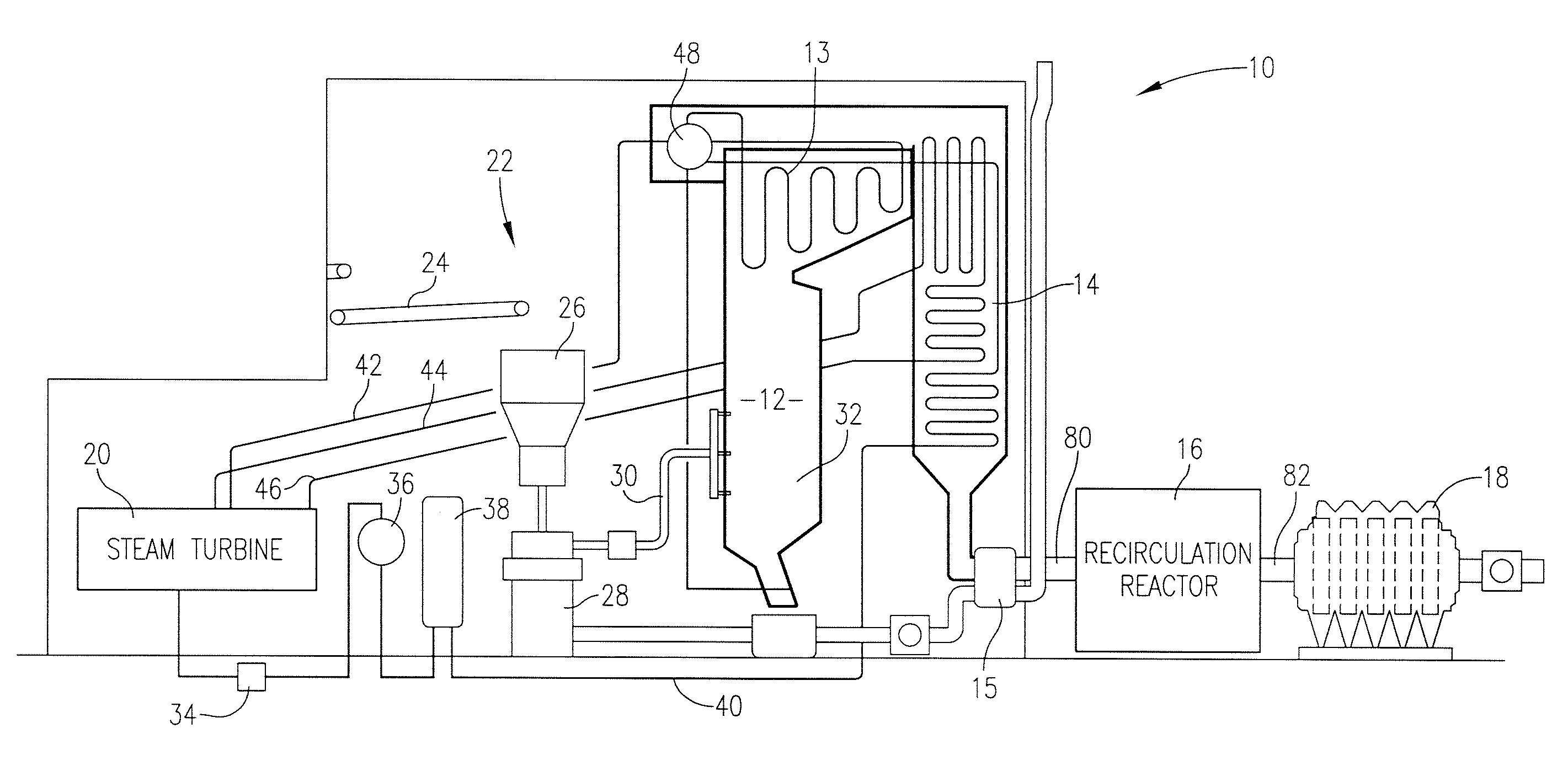

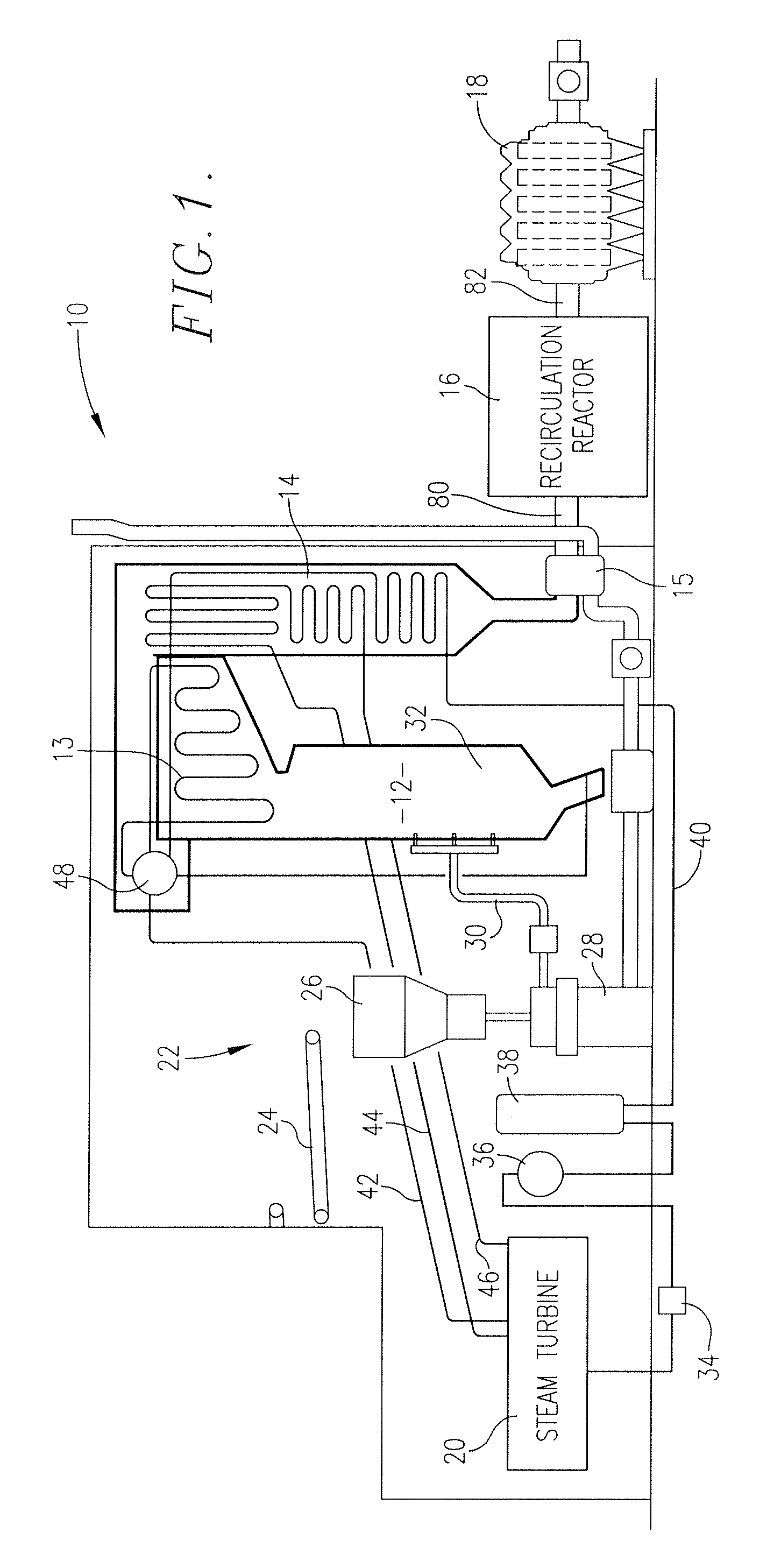

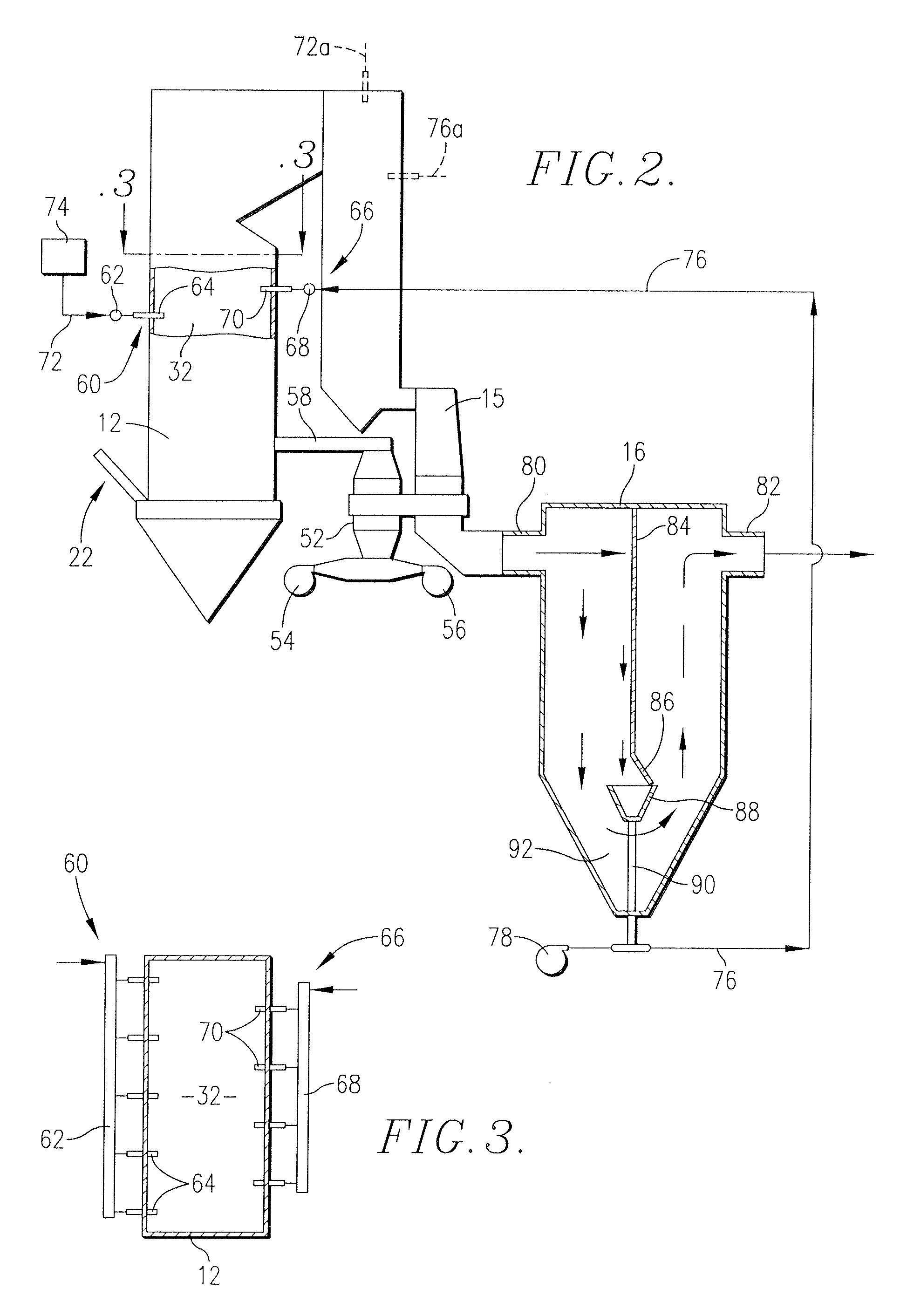

Pollution abatement process for fossil fuel-fired boilers

InactiveUS20100263577A1High degreeLow-cost operationGas treatmentSteam generation heating methodsParticulatesSodium bicarbonate

The present invention provides improved boiler assemblies (10) with enhanced pollution abatement properties through injection and recycling of particulate sorbent materials including sodium bicarbonate, trona, and mixtures thereof. The assemblies (10) include a boiler (12), economizer (14), air heater (15), and recirculation reactor (16). Fresh sorbent material is introduced via assembly (60) into the boiler assembly (10) at one or more injection locations, and serves to sorb NOx, SOx, and other pollutants in the flue gas. The flue gas and entrained sorbent material then pass through reactor (16) for separation of sorbent, which is then recycled for injection back into the assembly (10) upstream of reactor (16).The present invention can also be used in industrial applications where the same emissions are generated and are needed to be controlled. Examples of such applications are Cement and Lime Kilns.

Owner:INDAL ACCESSORIES

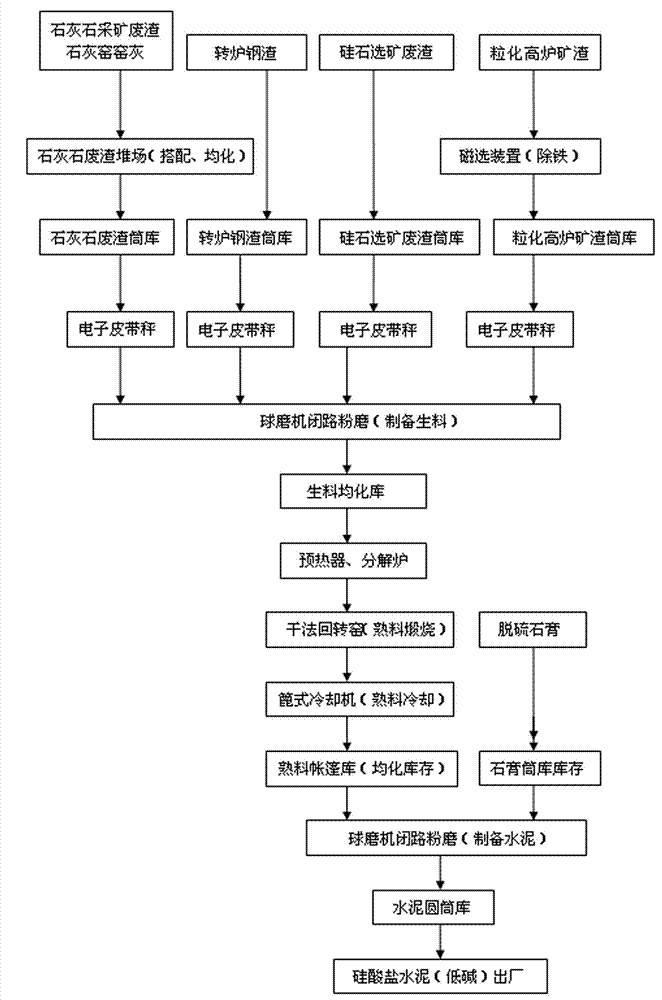

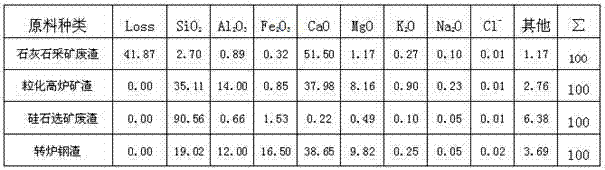

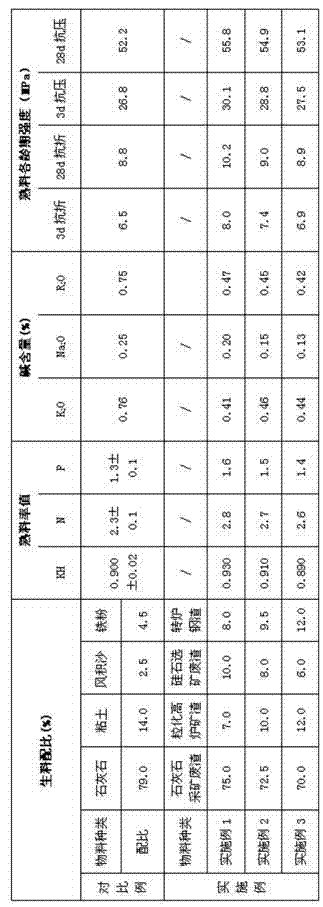

Method for producing low-alkali Portland cement by using industrial solid waste

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

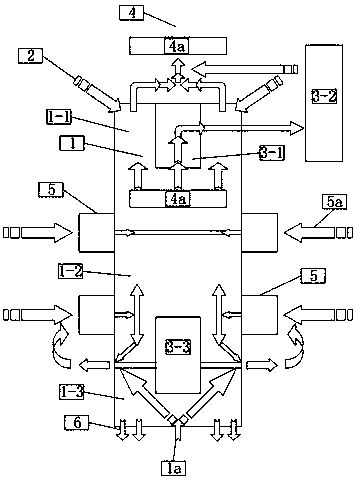

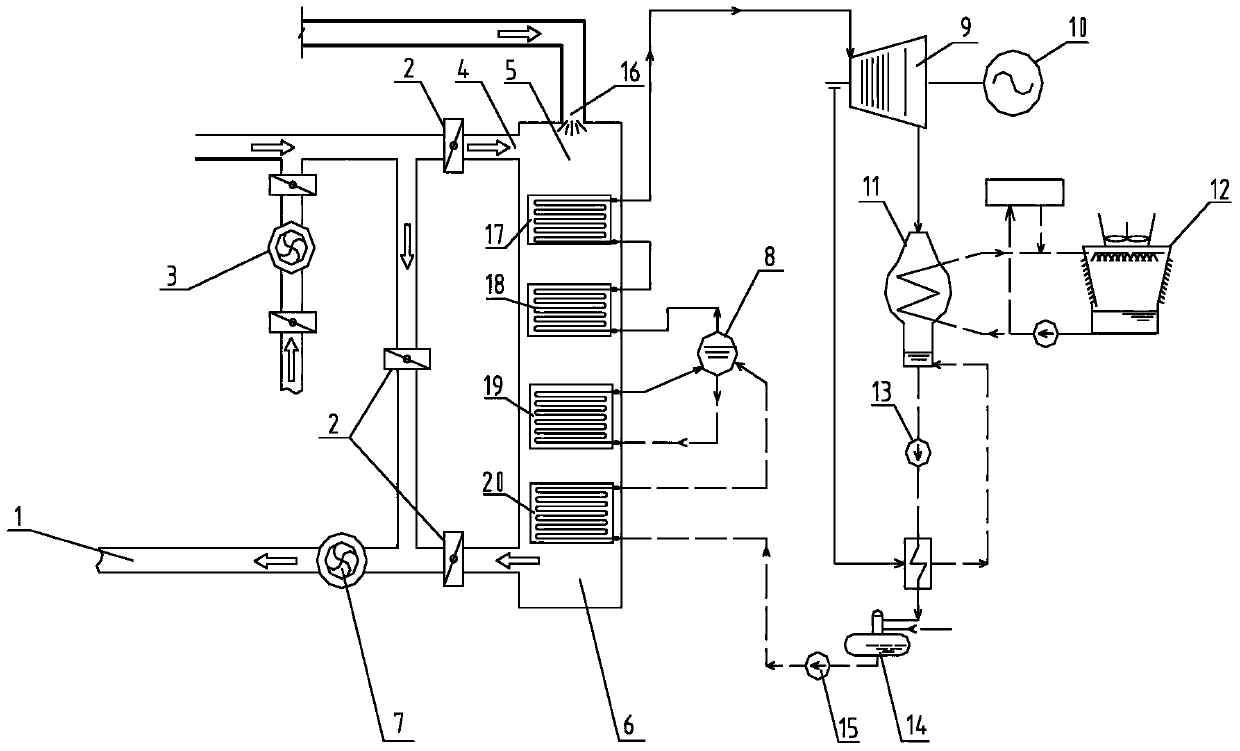

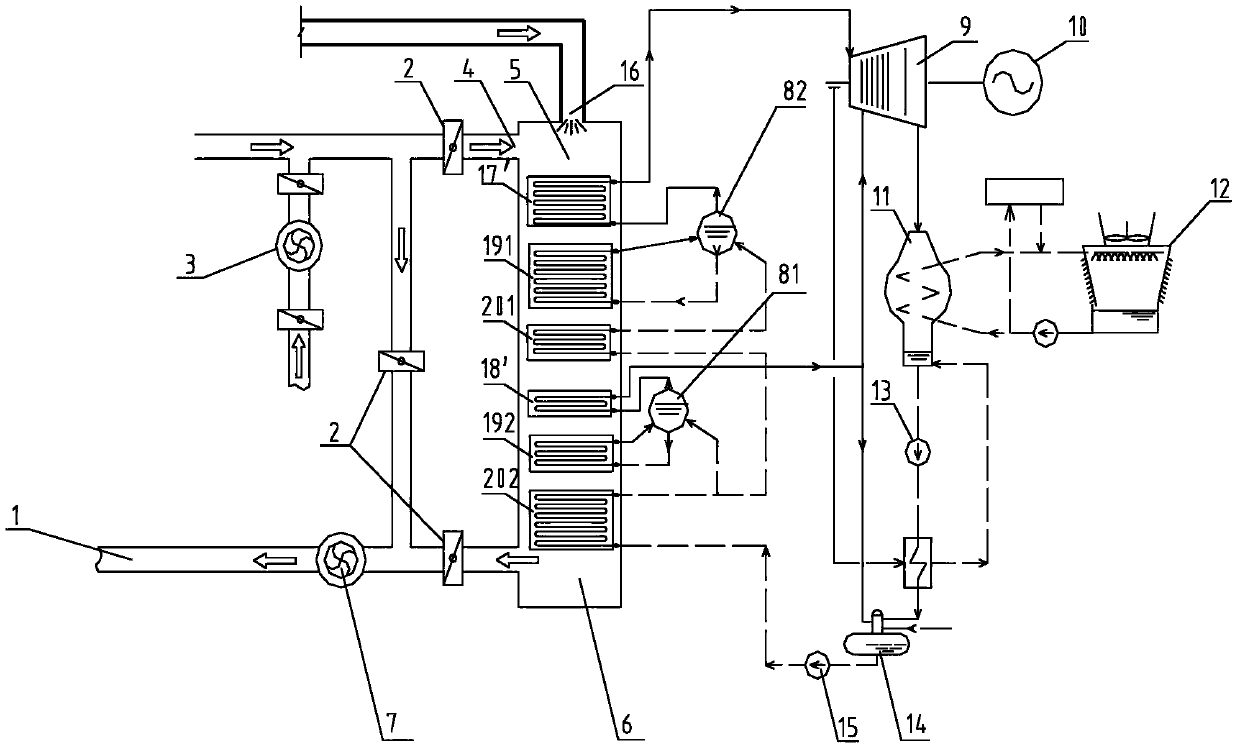

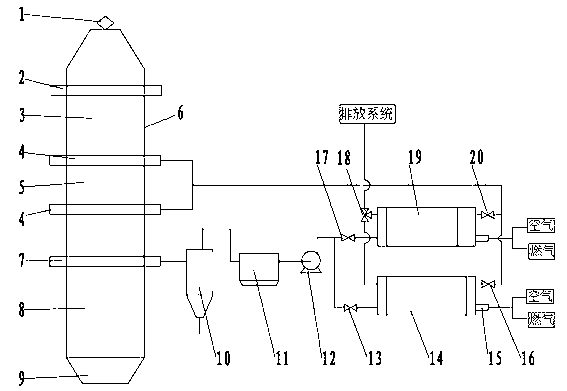

Lime kiln device adopting circulating hot air

The invention relates to a lime kiln device adopting circulating hot air and a production method for industrial lime. According to the lime kiln device adopting the circulating hot air and the production method for the industrial lime, in the preparation process of the lime, limestone is calcined by using the circulating hot air, the calcined waste circulating hot air is used for preheating limestone ore, and the preheated waste circulating hot air is cooled, is subjected to dust removal, then is conveyed to a regenerative heating furnace set, is heated to a set calcining temperature and thenis sent back to a lime kiln system for calcining. The lime kiln device adopting the circulating hot air and the production method for the industrial lime have the advantages that the limestone is calcined by using the circulating hot air, so that the quality of the lime can be remarkably improved, the yield of the lime can be increased, the productivity can be improved, and high-purity CO2 can beconveniently recycled; and the lime kiln system adopts the regenerative heating furnace set for heating, a lime kiln is not provided with a burner system, regenerative heating furnaces can utilizes low-heating-value blast furnace gas as fuel, and therefore the structure of a kiln body can be conveniently simplified, and the operation cost of the lime kiln can be lowered.

Owner:王长春 +3

Method for producing alumina through mineral containing aluminum

InactiveCN102718240AEnergy saving productionThe production process is environmentally friendlyChemical industryAluminium oxide/hydroxide preparationSlagAluminium hydroxide

The invention discloses a method for producing alumina through mineral containing aluminum, and relates to a method for economically and effectively recycling alumina from low-quality mineral resources containing aluminum. The method is characterized in that the production process comprises the following steps: (1), the mineral containing the aluminum are mixed with lime and sodium carbonate, and the mixture is processed into chamotte through dry-method sintering; (2), after being pulverized, the sintered chamotte is dissolved out, and the dissolved-out slurry is separated and cleansed to obtain the sodium aluminate solution and red mud slag; (3), aluminium hydroxide is decomposed and separated out after the silicon of the sodium aluminate solution is removed, the mother liquid after the decomposition returns to the dissolve-out work procedure, and the aluminum hydroxide is roasted to obtain the alumina product; (4), and the red mud slag is directly used for cement production. The method can be used for processing the low-quality mineral resources containing the aluminum, which is not in the concept scope of bauxite. The production technical flow is energy-saving and environmental-friendly, and all heat resources used in the production process are the residual heat of clinker kilns, lime kilns and calcinators. In the production flow, the red mud is used as the raw material for producing cement, no red mud slag is piled, and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

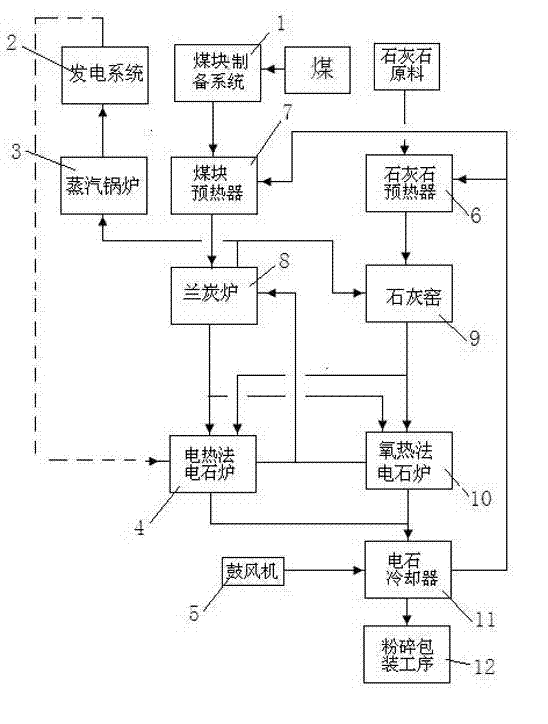

Production device for coproduction of calcium carbide by electrothermal method and oxygen thermal method

The invention relates to a production device for coproduction of calcium carbide by an electrothermal method and an oxygen thermal method. The production device comprises an oxygen thermal method calcium carbide furnace, an electrothermal method calcium carbide furnace, a semi-coke furnace, a lime kiln and a power generation system. A coal briquette preparation system is connected to the semi-coke furnace through a coal briquette preheater, and the semi-coke furnace is connected to the electrothermal method calcium carbide furnace and the oxygen thermal method calcium carbide furnace. A limestone supply device is connected to the lime kiln through a limestone preheater, and the lime kiln is connected to the electrothermal method calcium carbide furnace and the oxygen thermal method calcium carbide furnace. Calcium carbide furnace gas outlets of the calcium carbide furnaces are connected to a fuel inlet of the semi-coke furnace, a semi-coke tail gas outlet of the semi-coke furnace is connected to the fuel inlet of the lime kiln and the fuel inlet of a steam boiler, and a waste heat boiler is connected to a steam turbine. A power generator set is connected to the wiring end of the electrothermal method calcium carbide furnace through a power transmission device. The production device provided by the invention fully utilizes byproducts and waste heat of the calcium carbide furnaces and the semi-coke furnace, reduces the energy consumption and the calcium carbide production cost and improves the comprehensive economic benefits of an enterprise by combining the oxygen thermal method calcium carbide furnace and the electrothermal method calcium carbide furnace with the semi-coke furnace, the lime kiln and the power generation system.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

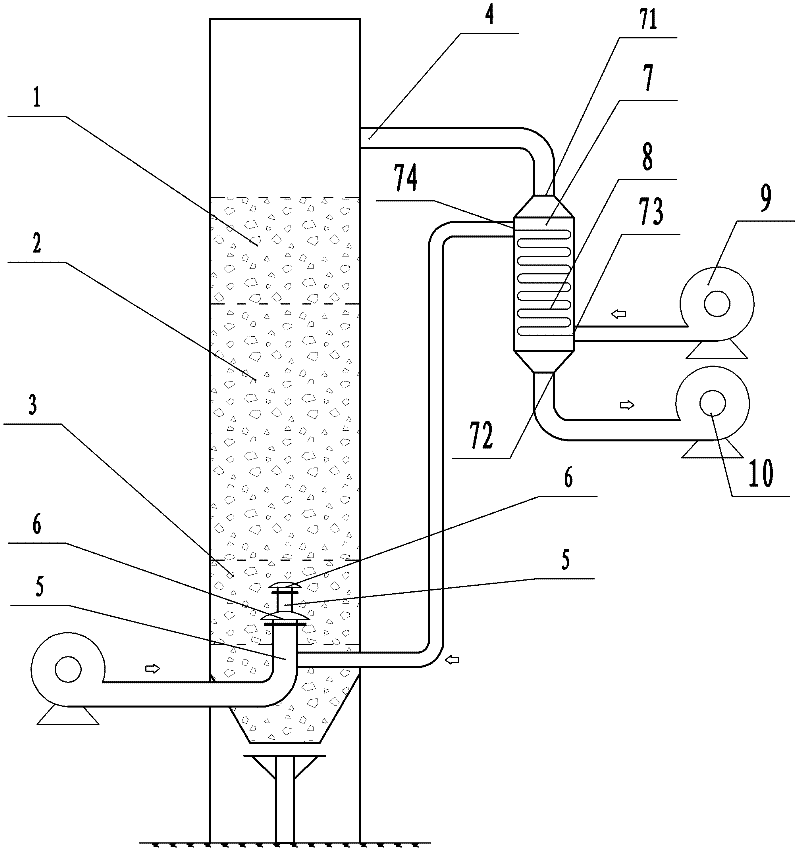

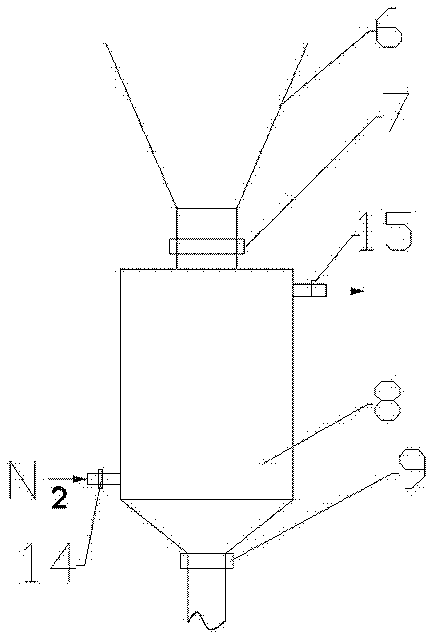

Energy-saving lime kiln

The invention discloses an energy-saving lime kiln, which aims to solve the problems that heat energy is wasted because smoke discharged by the conventional lime kiln is not utilized and fuel consumption is increased because the preheating temperature of combustion-supporting air of the lime kiln is low. The energy-saving lime kiln comprises a kiln body, wherein a preheating zone, a calcining zone and a cooling zone are sequentially on the kiln body from top to bottom; a kiln gas outlet pipe is arranged above the preheating zone; a normal-temperature air input device and a preheated air inputdevice fixed on the normal-temperature air input device are arranged in the cooling zone; each of the normal-temperature air input device and the preheated air input device comprises an air pipe and an air cap connected with an air outlet of the air pipe; the air cap of the preheated air input device is arranged above the air cap of the normal-temperature air input device; the two air caps form adouble-layer air cap structure; the kiln gas outlet pipe is connected with an air inlet of a heat exchanger; a heat exchange pipe is arranged in the heat exchanger; a cold air inlet of the heat exchange pipe is connected with an air blower; a hot air outlet of the heat exchange pipe is connected with the air pipe of the preheated air input device; and an air outlet of the heat exchanger is connected with a draft fan.

Owner:浙江天石纳米科技股份有限公司

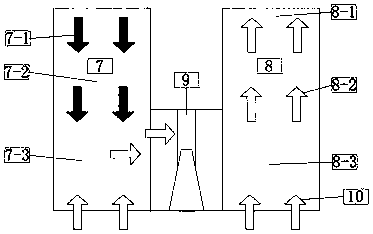

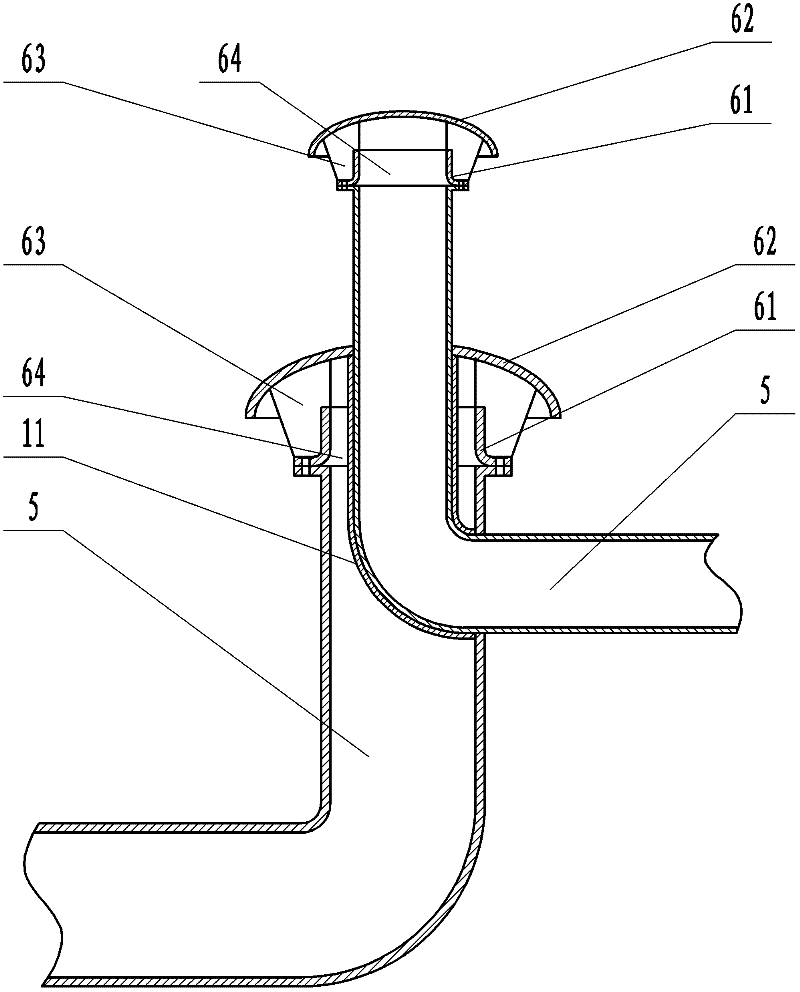

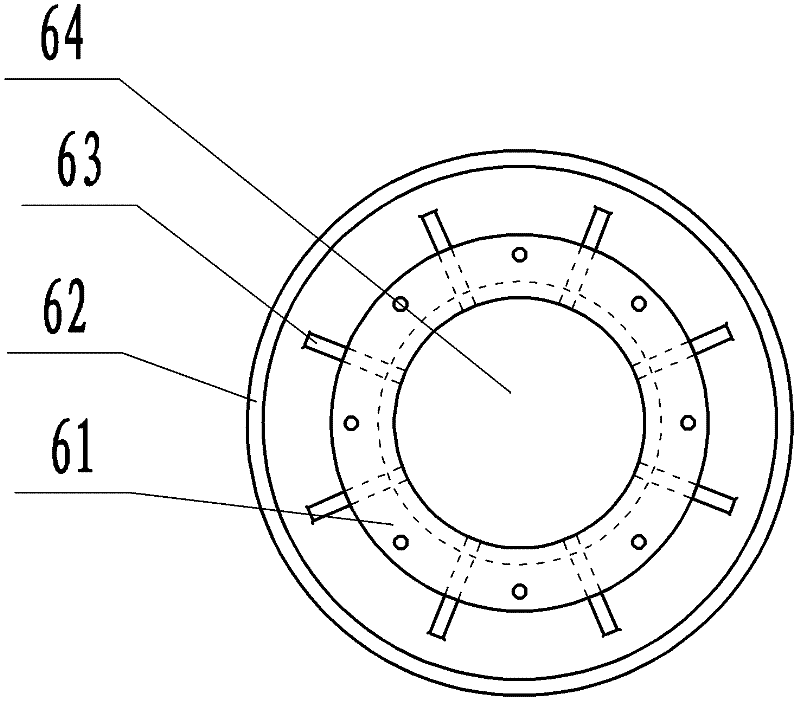

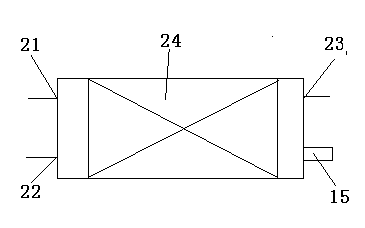

Lime cooling equipment of sleeve kiln

The invention relates to lime cooling equipment of a sleeve kiln. The lime cooling equipment comprises a ventilation pipe and a distributor. A flow meter and a regulating valve are installed on the ventilation pipe. The ventilation pipe is inserted into a lime storage chamber at the lower part of a kiln body from the side wall of the kiln body and is connected with the distributor. The distributor is a flow guide pipe or an annular distribution pipe. The flow guide pipe is a straight pipe structure with an open upper end and an open lower end and is arranged in the center of the kiln body. The annular distribution pipe and the kiln body are concentrically arranged. Air outlets are arranged on the upper side and the lower side of the annular distribution pipe. The quantity and the size of the air outlets are determined according to the size and process requirements of the sleeve kiln. By installing the distributor at the outlet of the ventilation pipe of a cooling zone, cooling air is evenly distributed on the entire cross section of the cooling zone of the lime kiln. Since the cooling air is evenly distributed, the air is prevented from being segregated or passing through a short path, lime is fully cooled, the cooling speed is high, the lime output temperature is stable and the activity of the lime is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

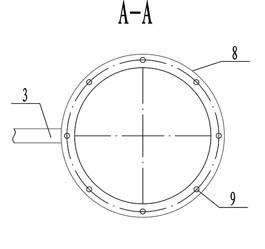

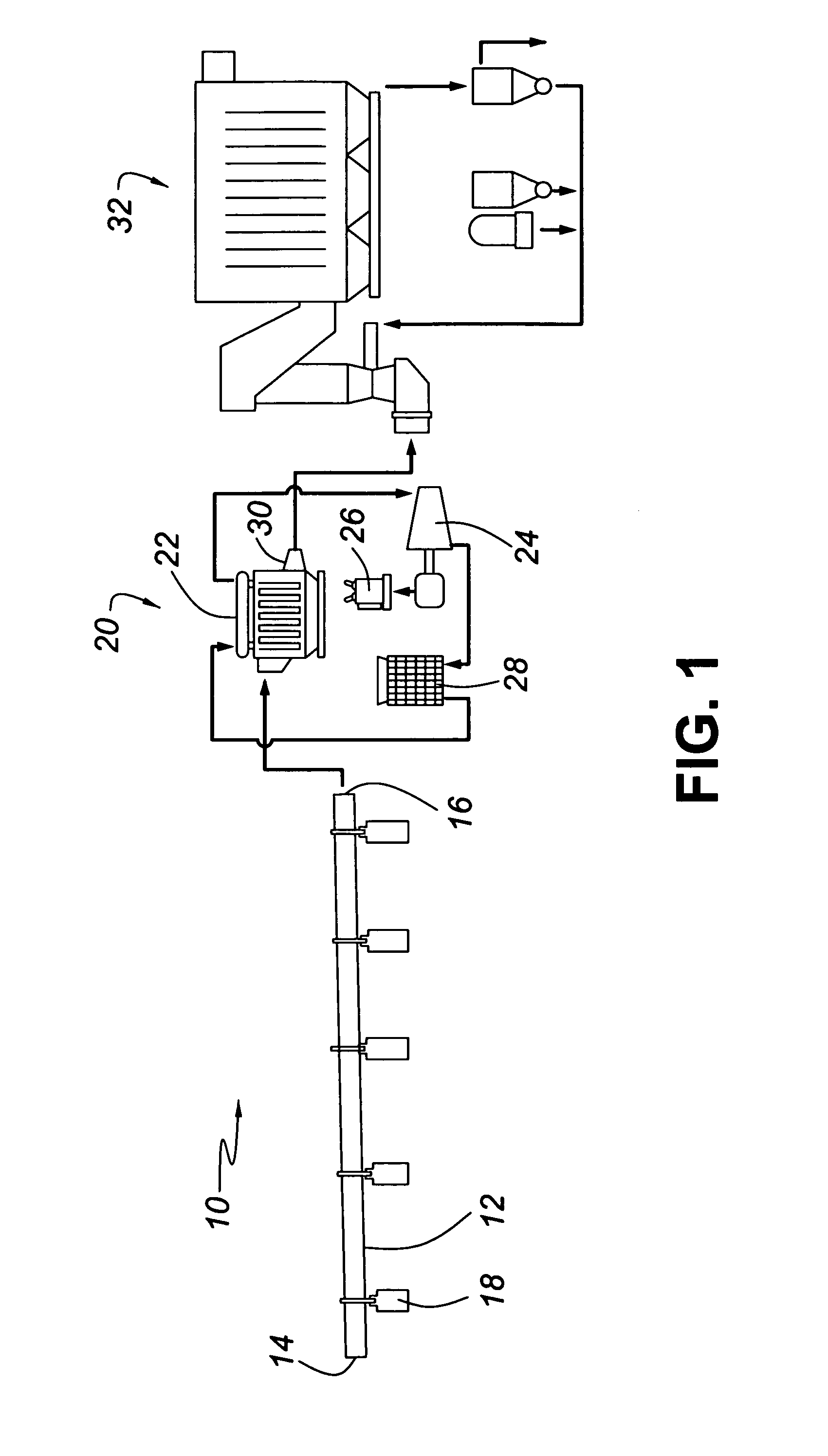

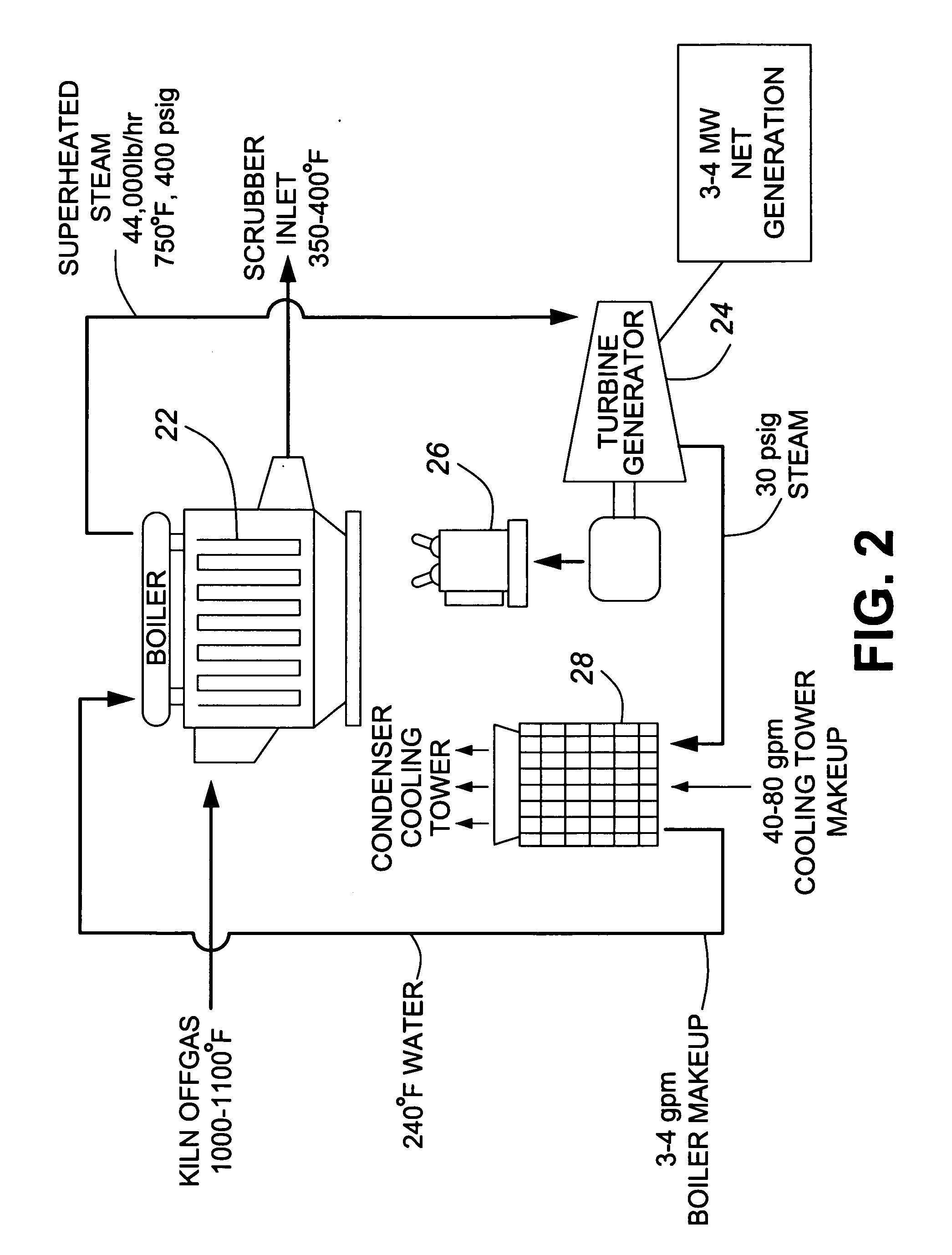

Integrated lime kiln process

ActiveUS20080031794A1Optimizing pollutantSimple technologyUsing liquid separation agentRotary drum furnacesWaste heat recovery unitPlate heat exchanger

A process and system for recovering waste heat from a kiln used for lime or cement production. The system unifies the kiln, a waste heat recovery and power generation circuit and a dry scrubber for scrubbing the pollutants from the kiln offgas. Essentially, the system employs the boiler component of the waste heat recovery and power generation circuit as a heat exchanger to recover the waste heat from the kiln, which is used to drive the steam turbines. The heat absorption from the latter stage lowers the temperature of the kiln offgas sufficiently for optimum performance from the scrubber. The presence of lime particles in the offgas effectively protects the boiler tube surfaces from corrosion which would occur at optimum scrubber temperatures, and subsequently provides the lime required as a scrubbing medium for the dry scrubber. Further, the efficient scrubbing allows for the use of any fuel for firing the kiln inclusive of high sulphur content compounds. A process for effecting the technology is also provided.

Owner:GRAYMONT PA INC

Preparation method for rice-grain-shaped light calcium carbonate

ActiveCN108083314ALarge specific surface areaGood dispersionCalcium/strontium/barium carbonatesNanotechnologyLongest DiameterCarbonization

The invention discloses a preparation method for rice-grain-shaped light calcium carbonate. The preparation method comprises the following steps: calcining lime stones with natural gas, adding digesting water to complete digesting reaction, performing screening, impurity-removal and ageing, adding a crystal form controller, introducing lime kiln kiln-gas to perform carbonization, pumping into a homogenizing tank to perform re-aging, and introducing purified, cooled and compressed lime kiln kiln-gas to perform secondary carbonation reaction, thereby preparing calcium carbonate slurry; and adding a modifying agent into the calcium carbonate slurry and stirring, and performing filter-pressing and dehydrating, drying, crushing and grading, thereby obtaining the rice-grain-shaped light calciumcarbonate. The light calcium carbonate crystal form prepared by the preparation method is rice-grain-shaped, has a long diameter of 150-200 nm, a short diameter of 30-50 nm, a BET specific surface area of 20-22 m<2> / g, a small length-diameter ratio, a high specific surface area and good dispersion, and can be used for manufacturing food and cosmetics; and moreover, the process is simple and feasible, the cost is low, the price is low, and the economic benefits are relatively good.

Owner:山东宇信纳米科技有限公司

Low heat value gas oxygen-enriched burning process in rotary lime kiln

The oxygen-enriched low heat value gas burning process in rotary lime kiln includes adopting low heat value gas of (1700-2000)x4.18 kJ / cu m, such as converter gas and coke oven gas, burning in oxygen-enriched air of oxygen content 23-25 % to reach over 100 deg.c higher calcining temperature, compressing oxygen in a compressor and blending oxygen into the comburant air for burning, and increasing the oxygen content to reinforce burning, concentrate high temperature area and speed the decomposition of limestone.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

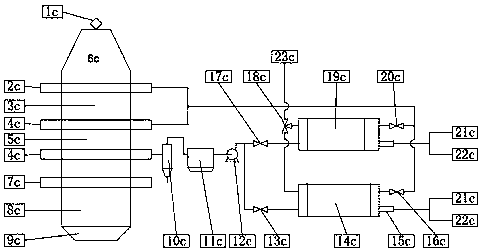

Lime kiln waste gas waste heat electricity generating system with by-product coal gas afterburning function

InactiveCN103344124AIncrease temperatureImprove working abilityIncreasing energy efficiencyMachines/enginesCooling towerSuperheater

The invention discloses a lime kiln waste gas waste heat electricity generating system with a by-product coal gas afterburning function. The lime kiln waste gas waste heat electricity generating system comprises a smoke valve, a waste heat boiler, a steam pocket, a turbine, a boiler water feeding pump, a condenser, a condensate water pump, a cooling tower, a deaerator, an electricity generator, an induced draft fan, an air blower, and a chimney. A combustion hearth, a high temperature super-heater, a low temperature super-heater, an evaporator and a coal economizer are sequentially arranged in the waste heat boiler from top to bottom, an outlet of the high temperature super-heater is connected with a steam inlet of the turbine through a pipeline, the waste heat boiler is provided with a lime kiln waste gas inlet and a by-product coal gas inlet, and an air blowing opening is additionally formed in an air inlet smoke pipe so as to provide oxygen needed by coal gas burning. The lime kiln waste gas waste heat electricity generating system with the by-product coal gas afterburning function can greatly increase smoke temperature, so that the temperature and the pressure of superheated steam at the inlet of the turbine are increased, and electricity generating capacity is improved.

Owner:广州智光节能环保有限公司

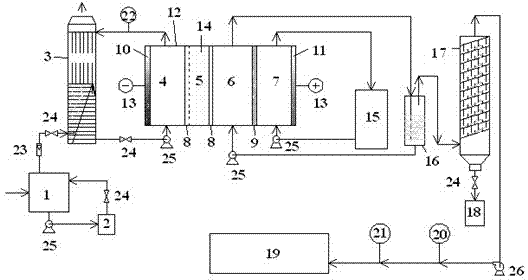

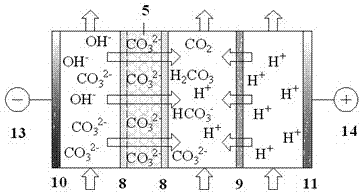

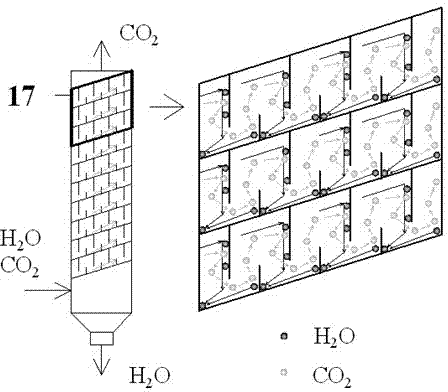

Device and method for electrically acquiring and purifying carbon dioxide

ActiveCN103191633AAchieve recyclingEnergy saving and environmental protectionProductsElectrolysis componentsCo2 absorptionOrganic fuel

The invention discloses a device and method for electrically acquiring and purifying carbon dioxide. The device comprises the following main parts: a carbon dioxide absorbing tower, an electric concentration and extraction device and a gas-liquid separation tower. Carbon dioxide contained in a waste gas is absorbed by electrically-generated alkali liquor in the carbon dioxide absorbing tower to become a carbonate solution, after the carbonate solution enters the electric concentration and extraction device, carbonates are transferred to enter a concentration chamber and converged with electrically-generated hydrogen ions to gradually form carbonic acid, the carbonic acid continuously overflows after being saturated, and after the carbonic acid is separated and purified through the gas-liquid separation tower, the carbon dioxide is compressed and stored. The device disclosed by the invention has the advantages of no pollution, easiness for operation and recycling of electrically-generated alkali liquor, and the like and can be widely applied to industrial departments, namely coal-fired power generation, coke oven combustion of a coke making enterprise, lime kiln forging, and the like which generate carbon dioxide waste gases; and the obtained carbon dioxide gas is pure and can be used as an industrial raw material, such as organic fuel methanol, a fire extinguishing agent, a refrigerant, an artificial rainfall agent, and the like.

Owner:ZHEJIANG UNIV

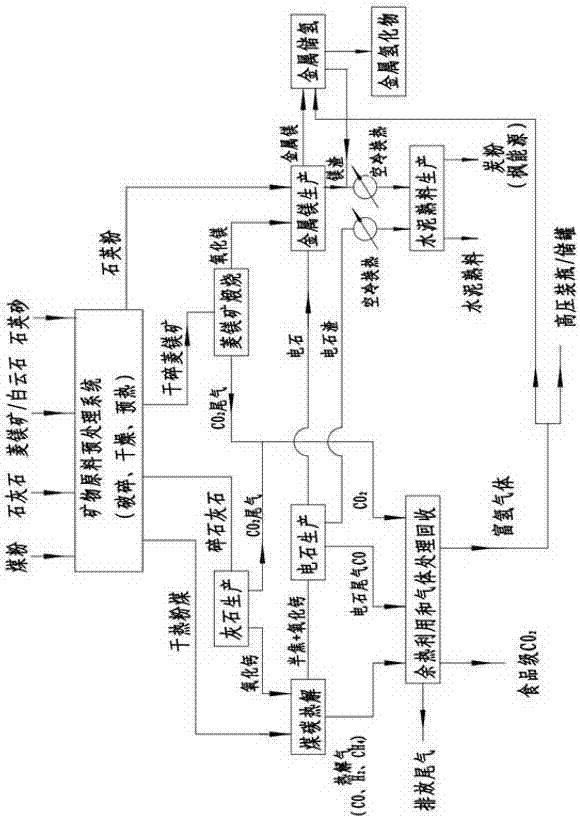

Rotary kiln and poly-generation system utilizing rotary kiln for producing metal hydride

InactiveCN107091569ARealize continuous productionNo emissionsFurnace componentsAlkali/alkaline-earth/beryllium/magnesium hydridesHigh concentrationBrick

The invention discloses a rotary kiln and a poly-generation system utilizing the rotary kiln for producing metal hydride. The poly-generation system comprises a lime production sub-system, a pulverized coal production sub-system, a calcium carbide production sub-system, a magnesium metal production sub-system, a waste heat utilizing and gas recycling sub-system, a metal hydrogen storage sub-system and a cement clinker production subsystem. Limestone, magnesite / dolomite, quartz sand and coal serve as raw materials, and the limestone is roasted into lime; in a lime kiln built through zirconia bricks, the lime and the coke powder are subjected to the high-temperature reaction so that liquid calcium carbide can be obtained; the magnesite / dolomite is roasted into magnesium oxide, and the calcium carbide, the magnesium oxide and the quartz sand are mixed to generate magnesium; high-concentration carbon dioxide, coal pyrolysis gas and calcium carbide tail gas obtained through decomposing of the limestone and the magnesite are recycled and processed, and hydrogen and food-level carbon dioxide are obtained; magnesium hydride is generated through union of hydrogen and magnesium; and carbide slag and magnesium slag are processed, and cement clinker and carbon powder are obtained. According to the poly-generation system, emission of solid waste is avoided, and carbon emission is greatly reduced.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Beam type heat storage lime kiln

The invention relates to a beam type heat storage lime kiln. The beam type heat storage lime kiln comprises a kiln body, a feeding system, an air supply system, a discharging system, a cyclone dust collector, a bag-type dust collector, a draught fan, two heat accumulators with burners, a waste gas discharging system and a control system, wherein an outlet of a lower suction beam is connected into an inlet of the draught fan through the cyclone dust collector and the bag-type dust collector; an outlet of the draught fan is divided into two paths which are respectively connected into a combustion air inlet of a combustion beam through valves and the heat accumulators; a gas pipeline and an air pipeline are connected to the burners of the heat accumulators; and waste gas outlets of the heat accumulators are respectively connected to the waste gas discharging system through three-way valves; and the two heat accumulators are used for alternatively accumulating heat and preheating gases, and the reversing operation is realized through the opening and closing of each valve. The beam type heat storage lime kiln has the advantages that the high-temperature gases pumped out by the lower suction beam are dedusted, purified and preheated by the cyclone dust collector, the bag-type dust collector and the heat accumulators to serve as the combustion air, the burning temperature of a low-heat value fuel is increased, the full utilization of the low-heat value fuel is facilitated, and the quality of calcined products is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Double-O-shaped lime kiln

InactiveCN102849967AEnvironmentally friendlyHigh degree of automationLime productionBrickEngineering

The invention discloses a double-O-shaped lime kiln which comprises a raw material delivering mixing distributing system, a kiln main body structure, a discharging system, a dust removing system and a power device. The power device is configured with each system; the kiln main body structure is double-O-shaped; and the wall of the kiln main body structure is a fully sealed calcination structure and sequentially composed of a high-alumina brick layer, a light-weight insulating brick layer, a heat insulation fiber layer and a steel furnace shell from inside to outside. The double-O-shaped lime kiln has the advantages of being obvious in energy saving, high in automation degrees, high in qualities of finished products, low in construction costs, short in construction periods and capable of reaching the standard of environmental protection; the use ratio of fuel thermal values can reach over 80%, electric energy can be averagely saved by over 40%, and a microcomputer network control system is used so that production and activity are improved, labor intensity of workers is reduced, and working environment is improved; and according to the trail use, the double-O-shaped lime kiln is stable, reliable, low in fault rate, high in capability of interference resistance, high in accuracy of a weighing system, complete in functions and simple in operating.

Owner:ZHAOYANG PNEUAMTIC HYDRAULIC MECHANICAL EQUIP JIANGSU

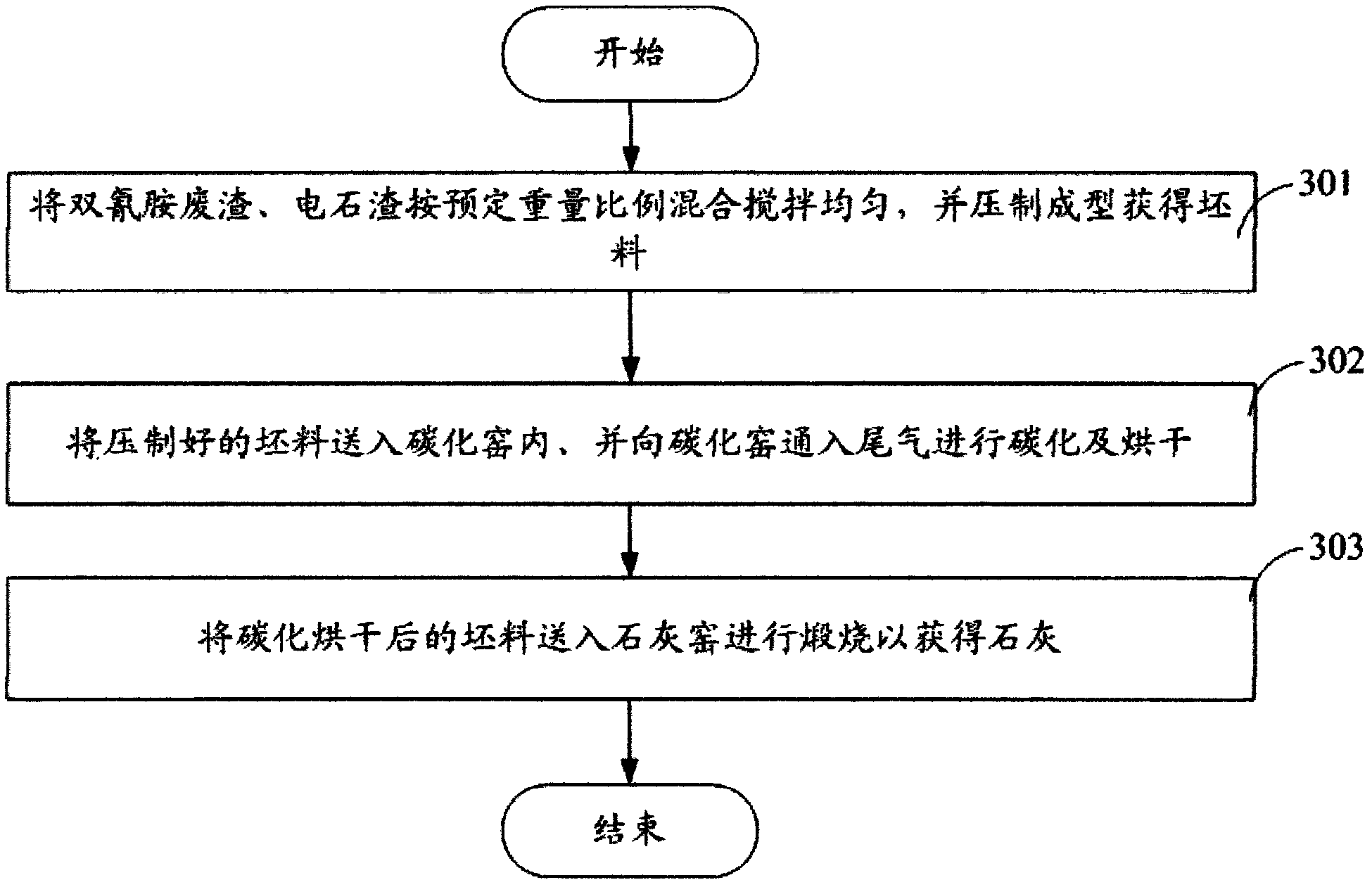

Method of utilizing dicyandiamide waste residues and carbide slag to produce lime

A method of utilizing dicyandiamide waste residues and carbide slag to produce lime comprises the following steps: evenly mixing and stirring the dicyandiamide waste residues and the carbide slag according to a scheduled weight ratio, obtaining blank through compression moulding, wherein the scheduled weight ratio is 95 to 39 percent of the dicyandiamide waste residues and 5 to 70 percent of the carbide slag; sending the pressed blank into a carbonization furnace, passing tail gas into the carbonization furnace to conduct carbonization and drying, wherein carbonization time is 4 to 8 hours, moisture of the dried blank is less than 5 percent; and sending the carbonized and dried blank to a lime kiln to conduct calcination to obtain lime, wherein calcination temperature is 800 to 1000 DEG C. The dicyandiamide waste residues and the carbide slag can be utilized to produce lime with high purity through the method of utilizing the dicyandiamide waste residues and the carbide slag to produce lime.

Owner:李黔 +1

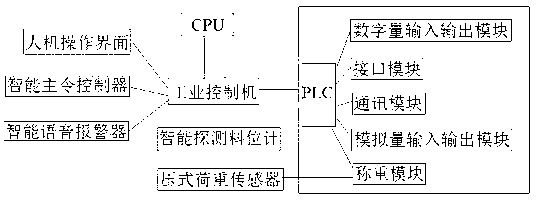

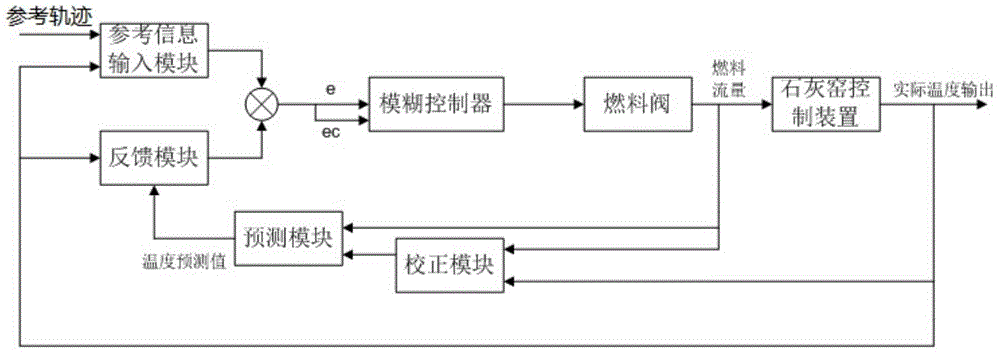

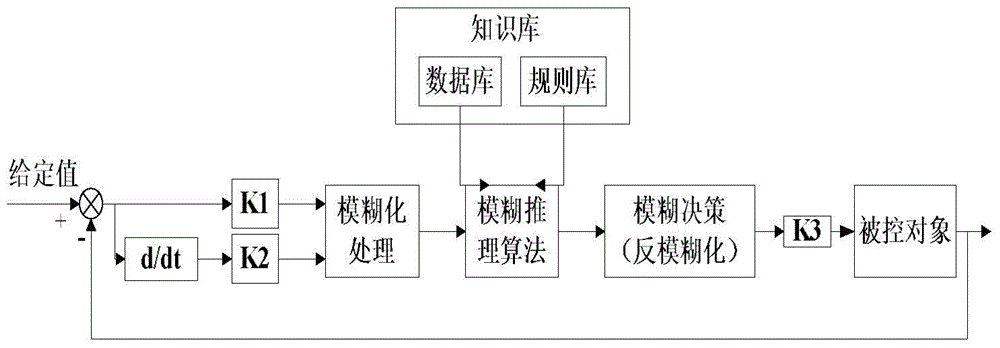

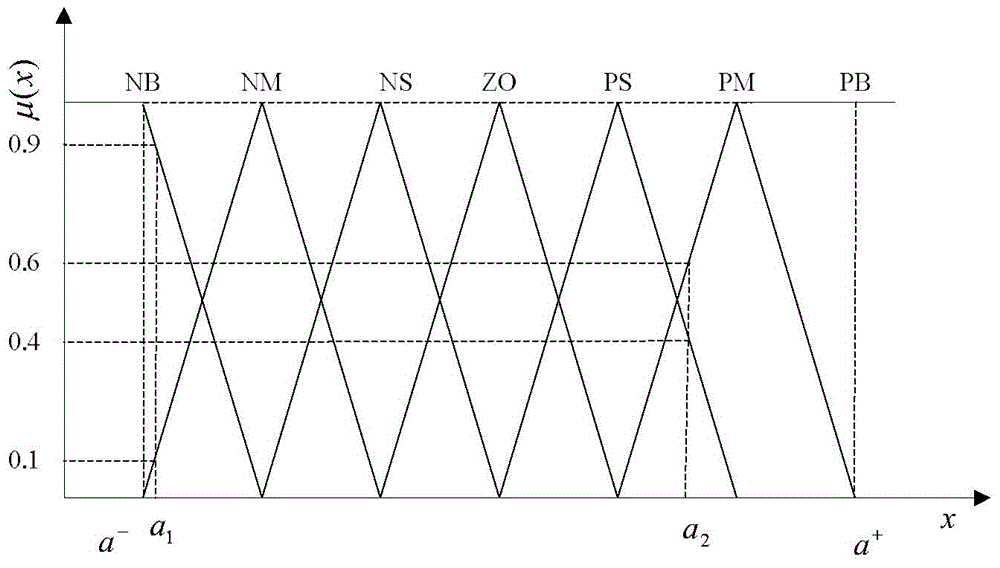

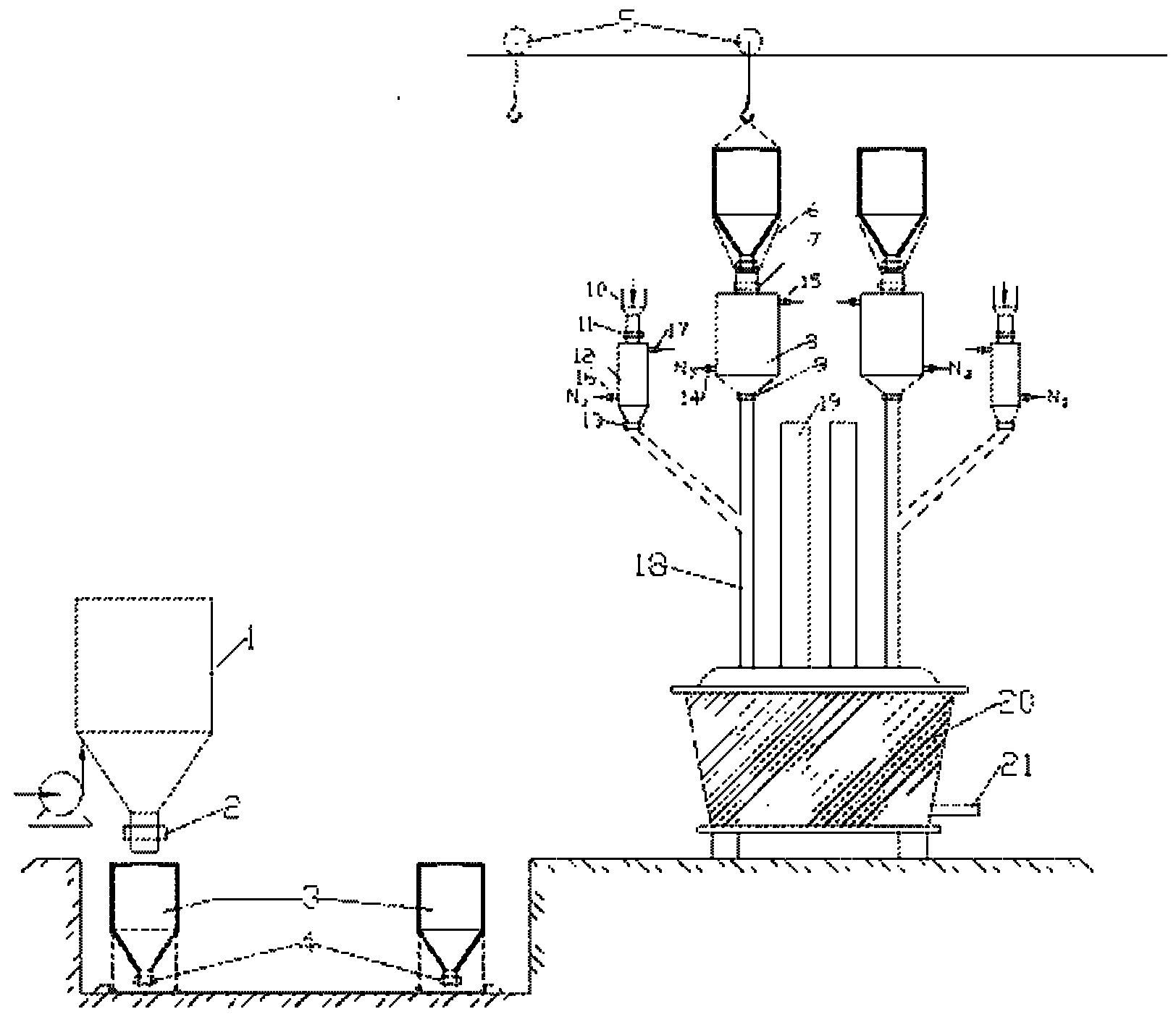

Fuzzy predictive control system for combustion process of lime kiln as well as control method of system

InactiveCN104950681ASolve temperature controlHigh activityAdaptive controlOptimal controlEngineering

The invention discloses a fuzzy predictive control system for a combustion process of a lime kiln as well as a control method of the system and belongs to the field of control on the combustion process. The fuzzy predictive control system comprises a reference information input module, a fuzzy controller, a fuel valve, a lime kiln control device, a prediction module, a feedback module and a correction module. A combustion temperature control system of the lime kiln has the characteristics of nonlinearity, time variability, model structure uncertainty and the like, a predictive control and fuzzy decision combined control method is adopted, an advanced prediction function of predictive control and the optimal control effect of fuzzy control in a large deviation range are integrated, and the temperature control problem of a large-time-delay nonlinear system is solved; the system can be put into actual production operation, the dynamic quality in the lime calcining temperature adjustment process is effectively improved, and the good actual application effect is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing nano calcium carbonate for weather-resistant ink

ActiveCN106634049AReduce yellowingGood weather resistanceCalcium/strontium/barium carbonatesInksFiltrationSlurry

The invention discloses a method for preparing nano calcium carbonate for weather-resistant ink. The method comprises the following steps of diluting an aged lime emulsion, adding a crystal form control agent into the diluted aged lime emulsion, then conveying slurry into a carbonating reaction kettle, and controlling the temperature of lime mortar to be 15 to 18 DEG C; introducing kiln gas of a lime kiln into the lime mortar, carrying out a carbonating reaction until pH (potential of Hydrogen) is decreased to 7.0, then heating obtained slurry to 30 to 35 DEG C, and repeating the step for 3 to 5 times; afterwards, heating nano calcium carbonate suspending liquid, adding a compound surface treating agent, which is prepared from saturated fatty acid saponified liquid, levopimaric acid and acrylic polyurethane, into the nano calcium carbonate suspending liquid, and agitating an obtained mixture; carrying out pressure filtration, drying and disintegration on obtained calcium carbonate slurry by using conventional methods, so that a product is obtained. The method has a simple and feasible process and is simple to operate; the quality of the product is stable; the application effect is good; not only can the flowability and the glossiness of the ink be effectively improved, but also the yellowing of the nano calcium carbonate can be effectively reduced; the weather resistance of the ink is improved; moreover, the moisture of the product can be effectively maintained; the method has better economic benefit and social benefit.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Thermal feeding method and device for calcium carbide furnace

The invention relates to a thermal feeding device for a calcium carbide furnace. The device is used for directly feeding calcium oxide of 400-500 DEG C discharged from a lime kiln stewing tank into a dump truck without cooling, crushing or screening, carrying into an improved annular stock cabin through a track and a crane, mixing with coke in a feed pipe, and feeding a mixture into an enclosed calcium carbide furnace for producing calcium carbide. Due to the adoption of a process disclosed by the invention, the conveying and feeding ways of calcium carbide furnace charge are improved, and the conveying and feeding safety of the calcium carbide furnace charge is enhanced; and meanwhile, the temperature of calcium oxide entering the calcium carbide furnace can be up to 400-500 DEG C, so that heating time in the calcium carbide furnace is reduced, and the energy consumption of the calcium carbide furnace is lowered.

Owner:王全祥 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com