Patents

Literature

63results about How to "The production process is environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

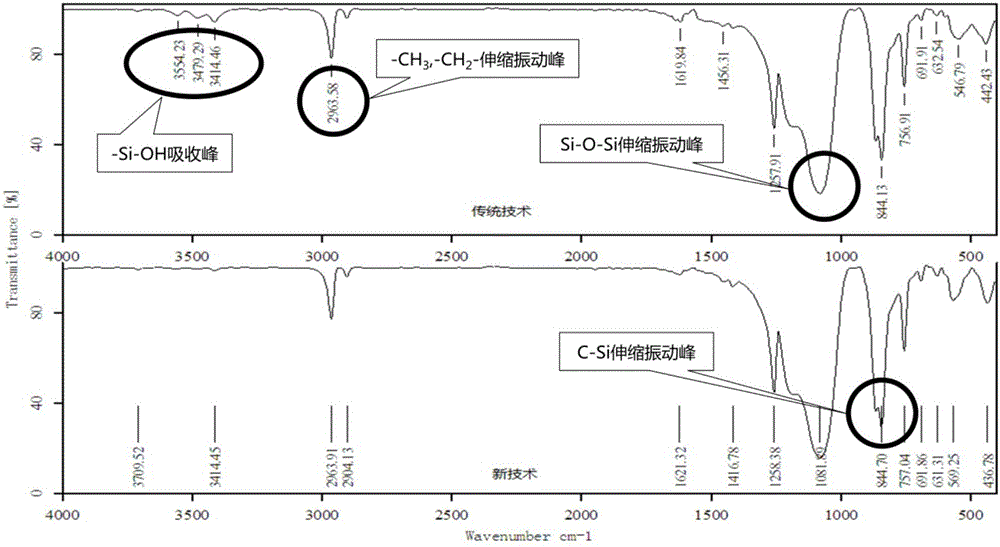

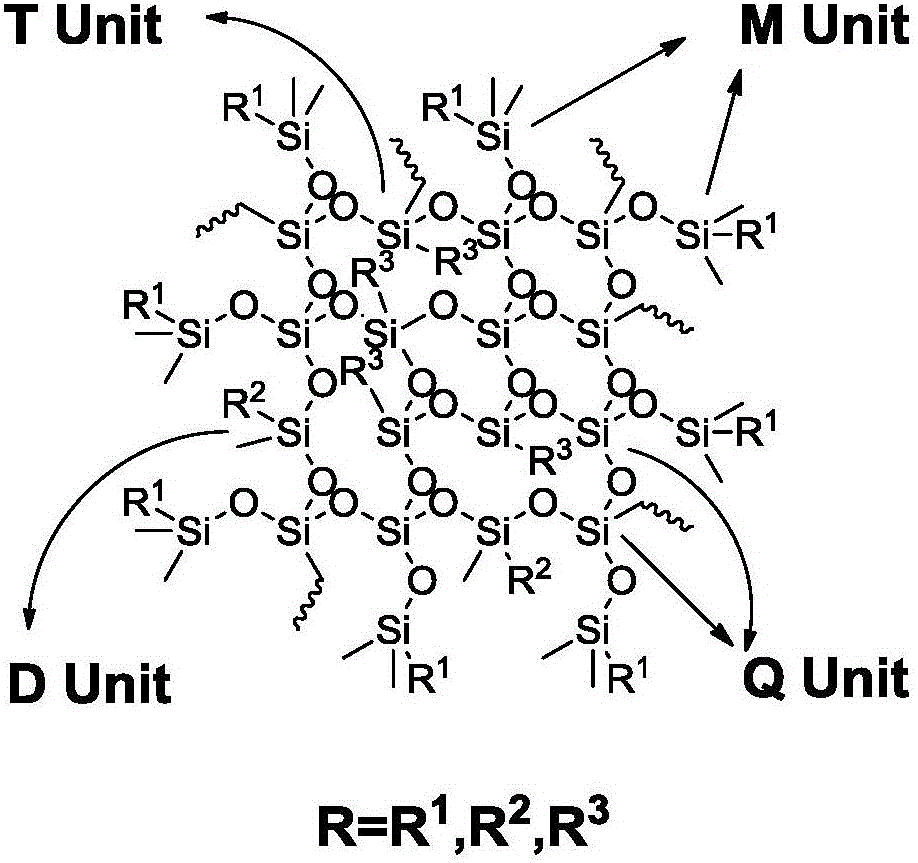

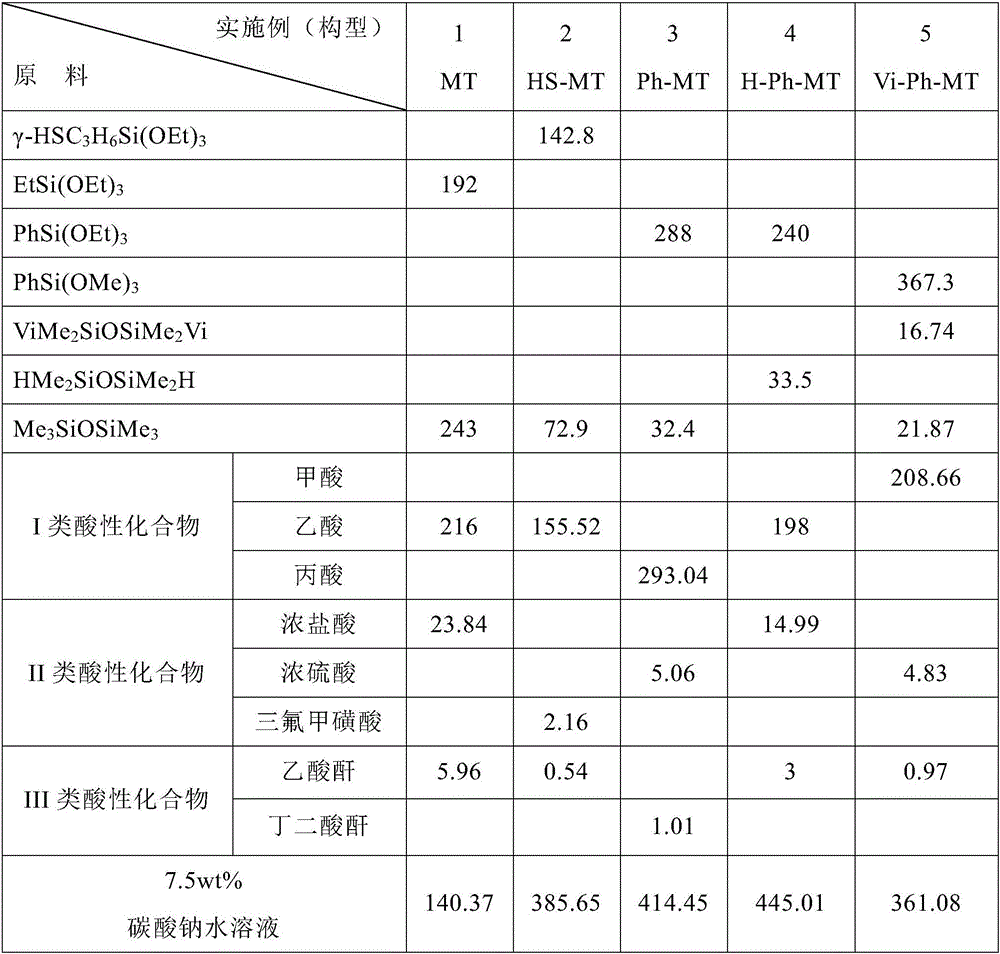

Preparation method of organopolysiloxane resin

The invention discloses a preparation method of organopolysiloxane resin. The preparation method includes the steps of (1), taking alkoxyorganosilane, an end-capping reagent and an acidic compound as preparation raw materials; (2), feeding the preparation raw materials with uniform stirring, wherein the feeding molar ratio of the end-capping reagent to the alkoxyorganosilane to the acidic compound is (0-40):1:(0.2-5); (3), adjusting the temperature at 40-150 DEG C at which condensation polymerization reaction is conducted for 2-20 hours; (4), terminating the condensation polymerization reaction, adjusting a reaction mixture to be neutral, and purifying a reaction product so as to obtain the organopolysiloxane resin. The preparation method of the organopolysiloxane resin has the advantages of environmental protection and no pollution during production, low energy consumption, short period, high product yield and the like and is more excellent in performance.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD

Solar cell module rear panel and manufacturing method thereof

ActiveCN103158312AEasy to processImprove the environmentSynthetic resin layered productsPhotovoltaic energy generationEnvironmental resistanceAcrylonitrile

The invention provides a solar cell module rear panel which can be in a single-layer structure or a multi-layer structure. At least an outmost film which directly contacts the environment is mainly composed of one or more of acrylonitrile-styrene-acrylate copolymer (ASA), acrylonitrile-ethylene-styrol copolymer (AES) and polymethyl methacrylate (PMMA), or the outmost film is mainly composed of ASA, AES, PMMA, and polycarbonate (PC) or polyamide (PA) or polybutylene terephthalate (PBT) or polyvinyl chloride (PVC). The invention further provides a manufacturing method of the rear panel, namely layers are directly glued to form a rear film or the layers are subjected to coextru-lamination through fusion. The solar cell module rear panel has good machining property and reliable weather resistance property, use of fluorine-containing materials is avoided, cost of a solar cell module is lowered, and the rear panel is environmental-friendly and safe.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

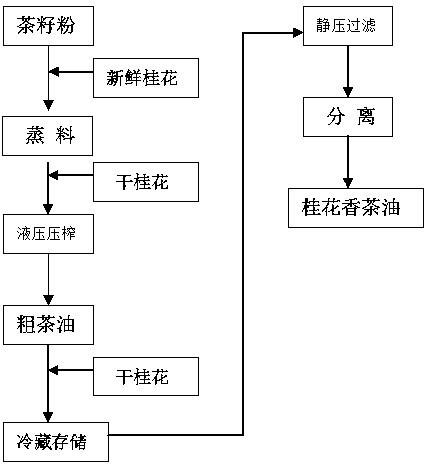

Natural osmanthus fragrans fragrant tea seed oil and preparation method thereof

ActiveCN103642583AGreen smellEnvironmental protectionFatty-oils/fats refiningFatty-oils/fats productionCAMELLIA SINENSIS SEED OILChemistry

The invention discloses natural osmanthus fragrans fragrant tea seed oil and a preparation method thereof. The preparation method comprises the steps: firstly, respectively filling water, fresh osmanthus fragrans flowers and tea seed powder into a bottom layer, a middle layer and an upper layer of a steam cooker; secondly, raising the temperature by heating to enable the bottom layer to generate vapor, introducing the vapor into the fresh osmanthus fragrans flowers at the middle layer, enabling the vapor to penetrate through the osmanthus fragrans layer and enter the tea seed powder, and enabling the tea seed powder to fully absorb osmanthus fragrans fragrance to obtain osmanthus fragrans fragrant tea seed powder; thirdly, mixing the osmanthus fragrans fragrant tea seed powder and dry osmanthus fragrans flowers, and squeezing a mixture to obtain crude osmanthus fragrans fragrant tea seed oil; fourthly, pouring the crude osmanthus fragrans fragrant tea seed oil into a stainless steel barrel which contains the dry osmanthus fragrans flowers with a proper amount, sealing, and storing at low temperature; fifthly, filtering to obtain a natural osmanthus fragrans fragrant tea seed oil product. The fragrance of the natural osmanthus fragrans fragrant tea seed oil product is mixed by strong natural osmanthus fragrans fragrance and light natural tea seed oil fragrance. The natural osmanthus fragrans fragrant tea seed oil is simple in the process, is green, is environment-friendly and has the actions of refreshing the brain, raising up the spirit, tenderizing the skin, delaying senescence and the like; the quality and the taste of the natural osmanthus fragrans fragrant tea seed oil are obviously superior to those of ordinary tea oil.

Owner:湖南金叶油业有限公司

Method for producing alumina through mineral containing aluminum

InactiveCN102718240AEnergy saving productionThe production process is environmentally friendlyChemical industryAluminium oxide/hydroxide preparationSlagAluminium hydroxide

The invention discloses a method for producing alumina through mineral containing aluminum, and relates to a method for economically and effectively recycling alumina from low-quality mineral resources containing aluminum. The method is characterized in that the production process comprises the following steps: (1), the mineral containing the aluminum are mixed with lime and sodium carbonate, and the mixture is processed into chamotte through dry-method sintering; (2), after being pulverized, the sintered chamotte is dissolved out, and the dissolved-out slurry is separated and cleansed to obtain the sodium aluminate solution and red mud slag; (3), aluminium hydroxide is decomposed and separated out after the silicon of the sodium aluminate solution is removed, the mother liquid after the decomposition returns to the dissolve-out work procedure, and the aluminum hydroxide is roasted to obtain the alumina product; (4), and the red mud slag is directly used for cement production. The method can be used for processing the low-quality mineral resources containing the aluminum, which is not in the concept scope of bauxite. The production technical flow is energy-saving and environmental-friendly, and all heat resources used in the production process are the residual heat of clinker kilns, lime kilns and calcinators. In the production flow, the red mud is used as the raw material for producing cement, no red mud slag is piled, and clean production is realized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

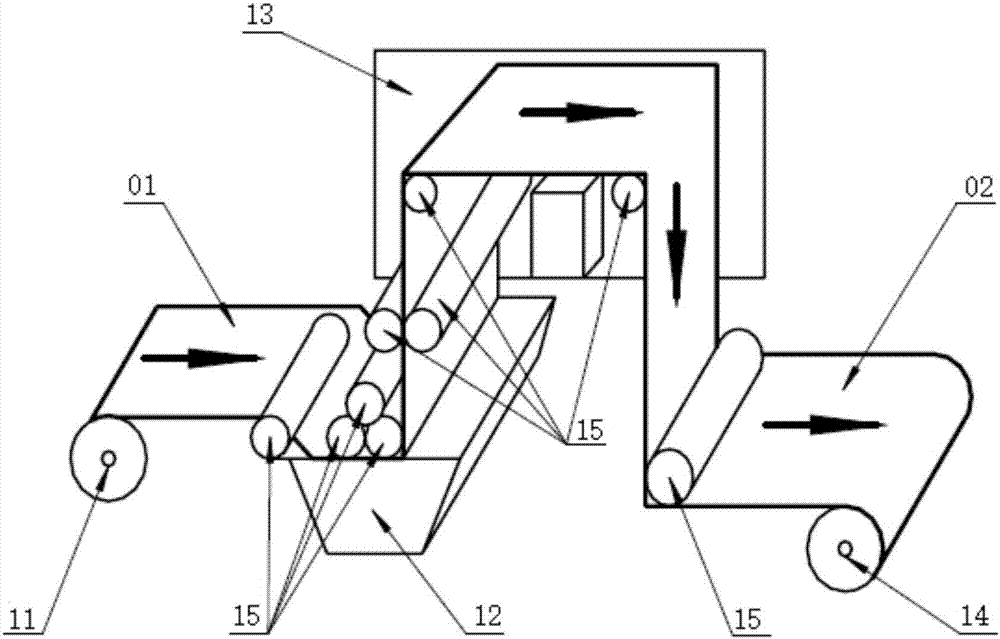

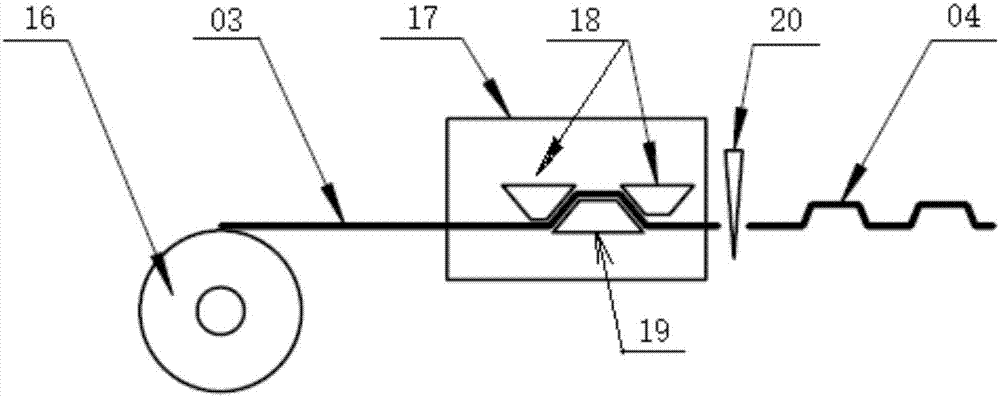

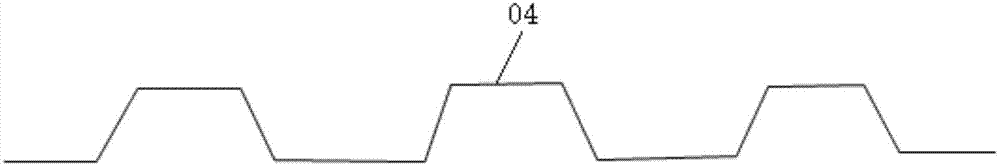

Manufacturing method for honeycomb structure made of composite material and equipment used for manufacturing honeycomb structure made of composite material

PendingCN107244087AThe production process is environmentally friendlyRealize automated productionDomestic articlesHoneycomb structureFiber

The invention provides a manufacturing method for a honeycomb structure made of a composite material. The manufacturing method comprises the following steps of: step 1, soaking fiber cloth with a resin material to prepare prepreg; step 2, performing mould pressing on the prepreg obtained in step 1 to form corrugated sheets with needed shapes; and step 3, stacking and jointing the corrugated sheets obtained in step 2 to form the honeycomb structure made of the composite material. The invention further provides equipment used for manufacturing the honeycomb structure made of the composite material. According to the manufacturing method for the honeycomb structure made of the composite material and the equipment used for manufacturing the honeycomb structure made of the composite material, the fiber cloth is sequentially soaked with resin and cured by the equipment, the resin adopts thermosetting resin or thermoplastic resin, viscidity of the resin can be reduced by a heating mode, and the resin is changed into a flowable state and is conveniently soaked onto the fiber cloth. In a production process, a solvent does not need to dilute, so that the pollution problem due to absence of the solvent is avoided, and therefore, the production process is environmentally friendly.

Owner:苏州云逸航空复合材料结构有限公司

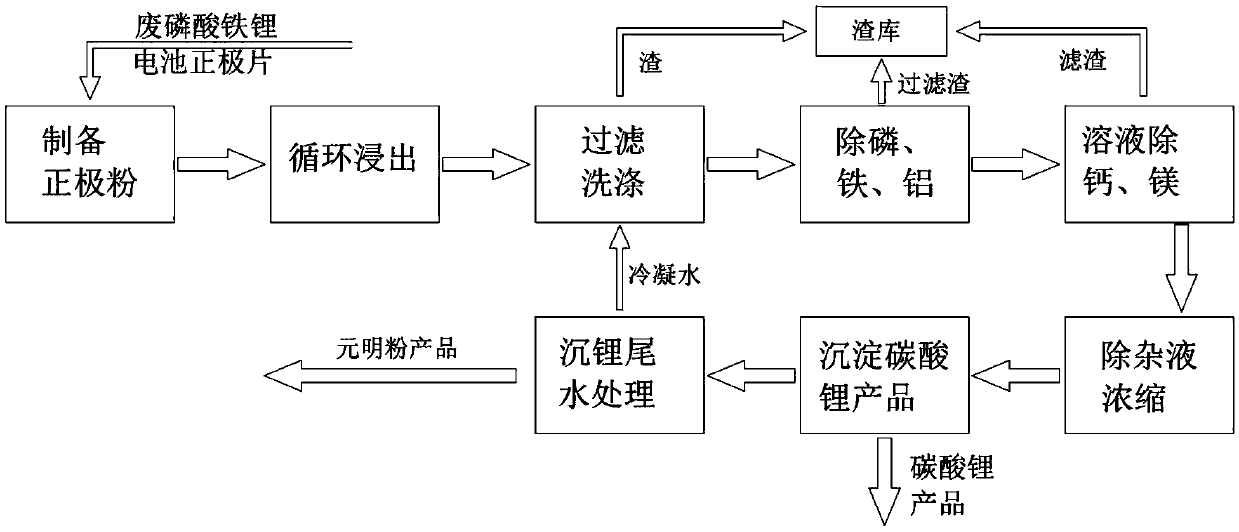

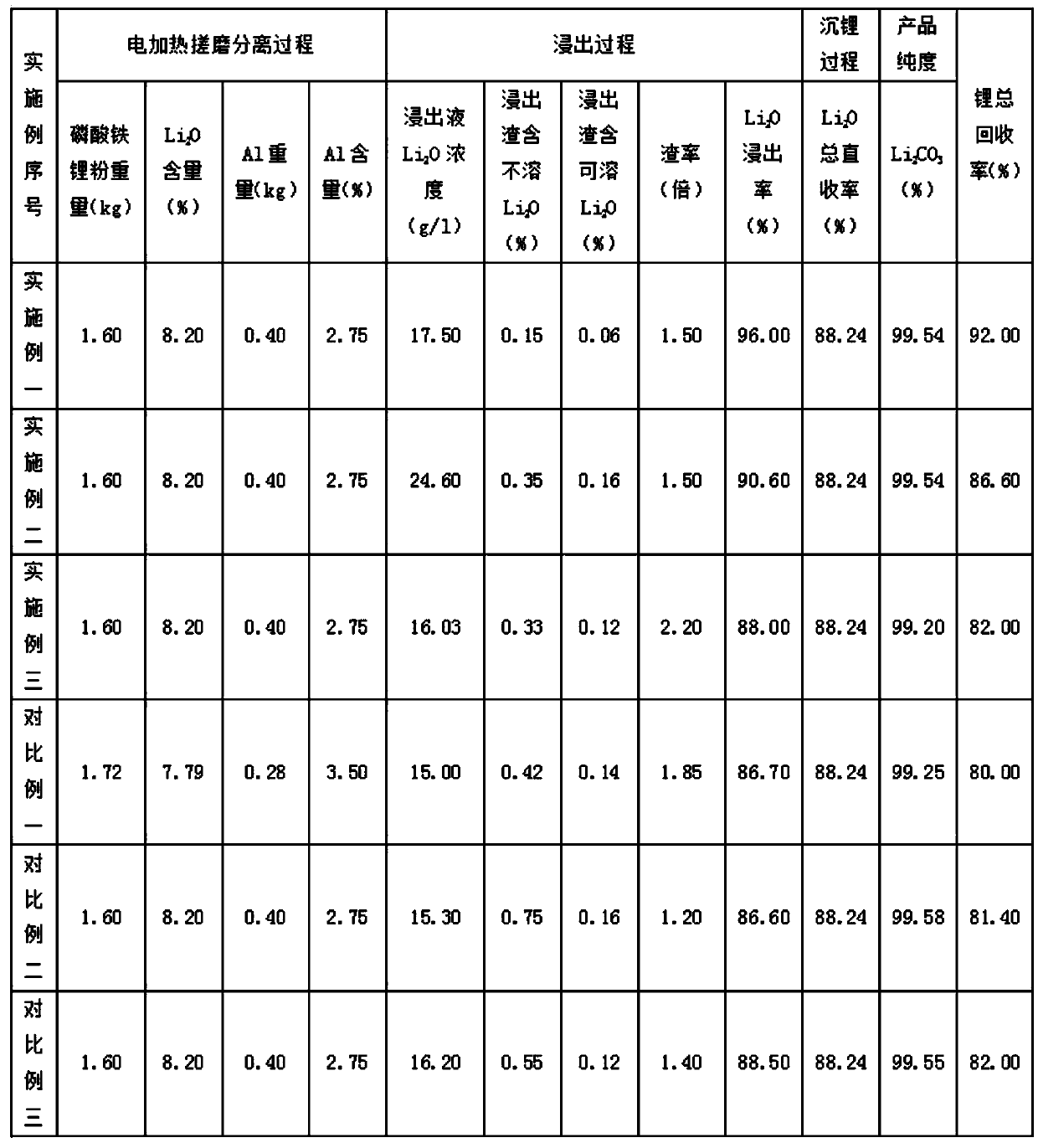

Method for extracting lithium carbonate from scrapped lithium iron phosphate battery positive electrode powder

ActiveCN109650415ANo decomposition guaranteeSolve environmental problemsSulfate/bisulfate preparationWaste accumulators reclaimingLithium iron phosphateLithium carbonate

The invention discloses a method for extracting lithium carbonate from scrapped lithium iron phosphate battery positive electrode powder. The method comprises the eight steps of preparation of positive electrode powder, circulating leaching, filtering and washing, and other five steps. The purpose of the present invention is to provide the method for extracting lithium carbonate from the scrappedlithium iron phosphate battery positive electrode powder. The method has the advantages of environmental protection, low energy consumption, low production cost, small dirt discharging capacity, highefficiency in realization of comprehensive utilization of resources, and meeting of industrial production.

Owner:湖南天泰天润新能源科技有限公司

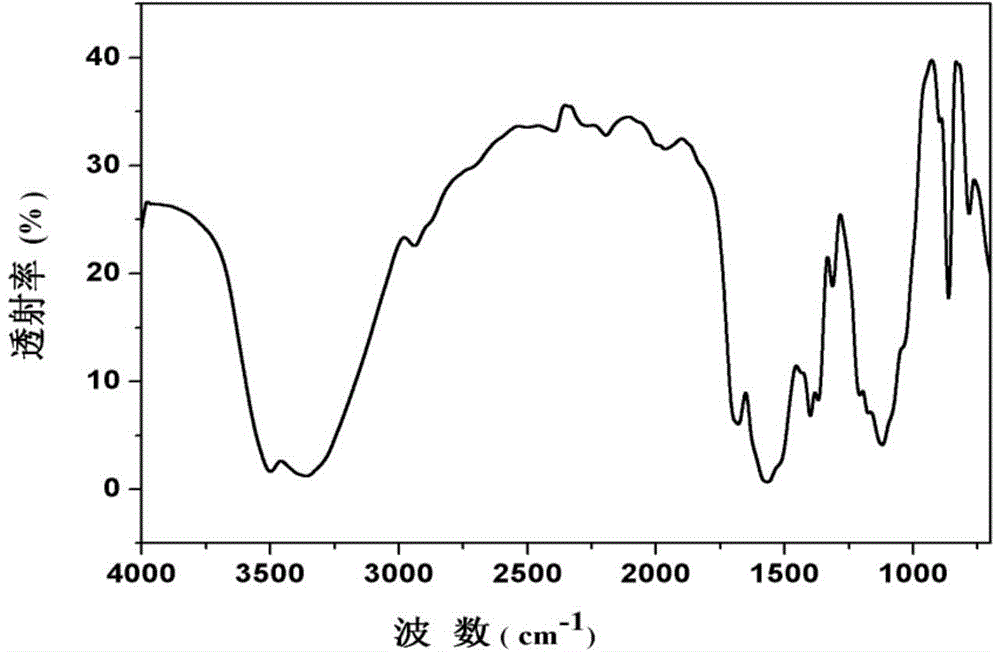

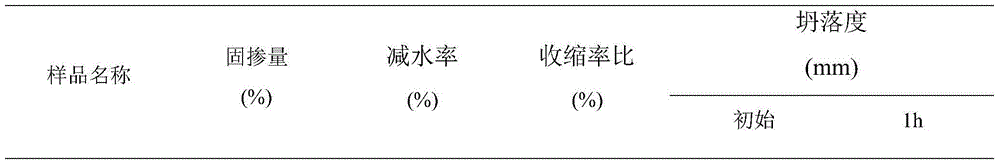

Preparation method for modified starch comb-shaped copolymer

InactiveCN105273137AAvoid excessive retardationReduce anion chargeEsterification reactionMaleic anhydride

The invention discloses a preparation method for a modified starch comb-shaped copolymer. The preparation method comprises: sulfonated starch is prepared, an esterification reaction with maleic anhydride is carried out, esterified starch is prepared, finally, a copolymerization reaction is carried out and a modified starch comb-shaped copolymer product is obtained. The prepared comb-shaped copolymer forms strong steric hindrance on outer surfaces of cement particles, is beneficial for dispersion effects, and has a high water-reducing rate and shrinkage ratio.

Owner:YANCHENG INST OF TECH

Near-field radio frequency identification (RFID) reader plane opening dual-ring antenna for ultra high frequency (UHF) band

InactiveCN102820535ASimple structureStructure miniaturizationRadiating elements structural formsAntenna earthingsFrequency spectrumResonance

The invention discloses a near-field radio frequency identification (RFID) reader plane opening dual-ring antenna for an ultra high frequency (UHF) band. The antenna is in a plane structure and comprises an antenna radiating unit, a dielectric substrate and a matching patch, wherein the antenna radiating unit is attached to one surface of the dielectric substrate and is a radiating body of the antenna, and the matching patch is attached to the other surface of the dielectric substrate and is a ground terminal of the antenna. The antenna is simple in structure and easy to produce. Frequency points and bandwidths of resonance frequency of the antenna can be changed within broad radio-wave spectrum through the adjustment of antenna structural parameters. The antenna can meet RFID system radio-wave spectrum which is regulated by different nations and is applied to near-field mobile terminal RFID application such as mobile payment and article anti-faking and tracing.

Owner:SOUTH CHINA UNIV OF TECH

Carbon nanotube anticorrosive paint

InactiveCN112574606AImprove water resistanceImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNanotube

The invention discloses an anticorrosive paint for carbon nanotube-containing metal. The anticorrosive paint is composed of epoxy resin, organic bentonite, dibutyl phthalate, titanium dioxide, mediumchrome yellow, talcum powder, barium sulfate, zinc oxide, carbon nanotubes, temperature-sensitive powder and matched assistants. According to the invention, a special high-strength one-dimensional linear structure of the carbon nanotubes is utilized to form a high-strength interlaced reticular structure in the coating, so that the coating is more compact; and meanwhile, by utilizing the nano effect of the carbon nanotubes, the binding force between the coating and the material is improved, pores in the coating are reduced, and a solution is prevented from entering the coating, so that the weather resistance and the corrosion resistance of the coating are effectively improved. The material is environmentally friendly, the production process is environmentally friendly, the obtained paint film is excellent in water resistance and corrosion resistance, high in bonding strength and excellent in alkali resistance and corrosion resistance, the application range of the paint is greatly widened, and the cost performance of the paint is greatly improved.

Owner:JIANGSU KEHUI ENVIRONMENTAL TECH CO LTD

Composite leather and manufacturing method thereof

ActiveCN108505350APrevent penetrationImprove breathabilityFibre treatmentSurface finishFoaming agent

The invention relates to the field of feather manufacturing and provides a composite leather and a manufacturing method thereof, which is used for solving the problem of increasing leather permeability and strength. The composite leather and the manufacturing method thereof include the following steps: (1) preparing a base cloth, using inorganic hybrid liquid to impregnate the base cloth, rollingliquid and drying;(2) preparing slurry, adding 5-8 parts of foaming agent to 40-80 parts of waterborne polyurethane, evenly mixing and obtaining waterborne polyurethane slurry;(3) scratching the slurry, scratching the waterborne polyurethane slurry on the base cloth, drying and cooling, then obtaining waterborne polyurethane leather bayes;(4) processing surface, conducting surface-finishing processing on the waterborne polyurethane leather bayes by using finishing agent, and obtaining the composite leather. The base cloth impregnated by the inorganic hybrid liquid can effectively prevent the waterborne polyurethane slurry from permeating into the base cloth, and the leather with surface processing has good permeability and feel.

Owner:广州可那派英皮具有限公司

Anti-bacterial viscose fiber and preparation method thereof

InactiveCN105177747ARest assuredNot easy to cause damageMonocomponent cellulose artificial filamentArtifical filament manufactureUltravioletSilver colloid

The invention relates to a method for preparing an anti-bacterial viscose fiber by taking a nano-silver colloid solution as an additive. The method comprises the steps of meal mixing, colloid preparing, spinning, bundling, cutting, refining, drying and packaging; the additive nano-silver colloid solution is formed by mixing a honewort extract solution with silver nitrate in proportion and then performing incubation on the mixture. The viscose fiber produced through the method has the higher anti-bacterial, sterilizing and ultraviolet-proof effects, is lasting in anti-bacterial effect and has no toxic or side effect on a human body.

Owner:NINGBO XINTAISHENG TEXTILE SCI & TECH

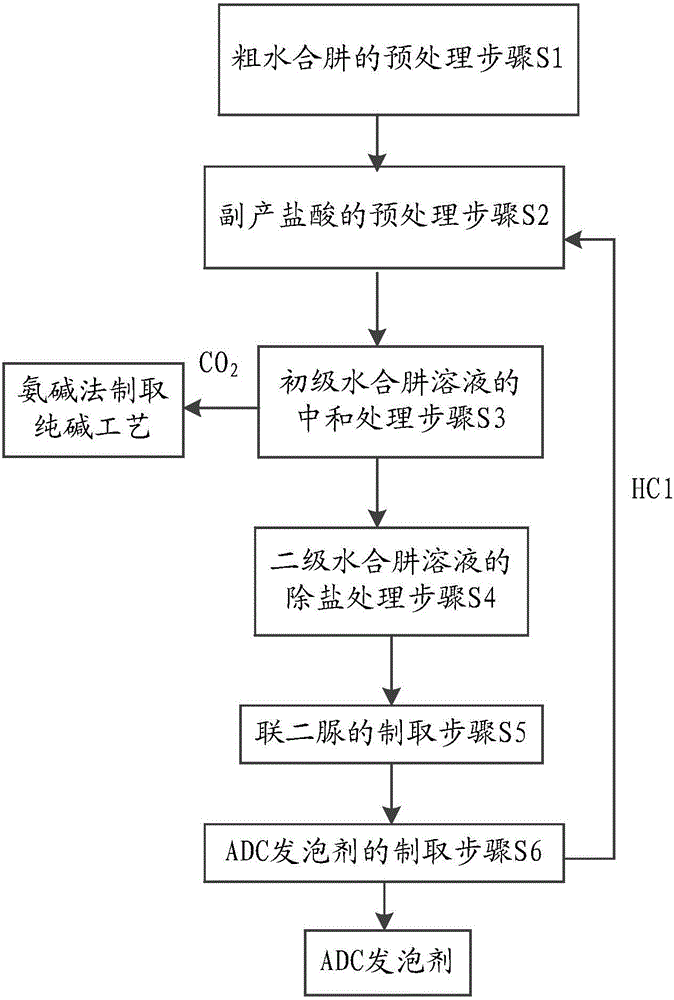

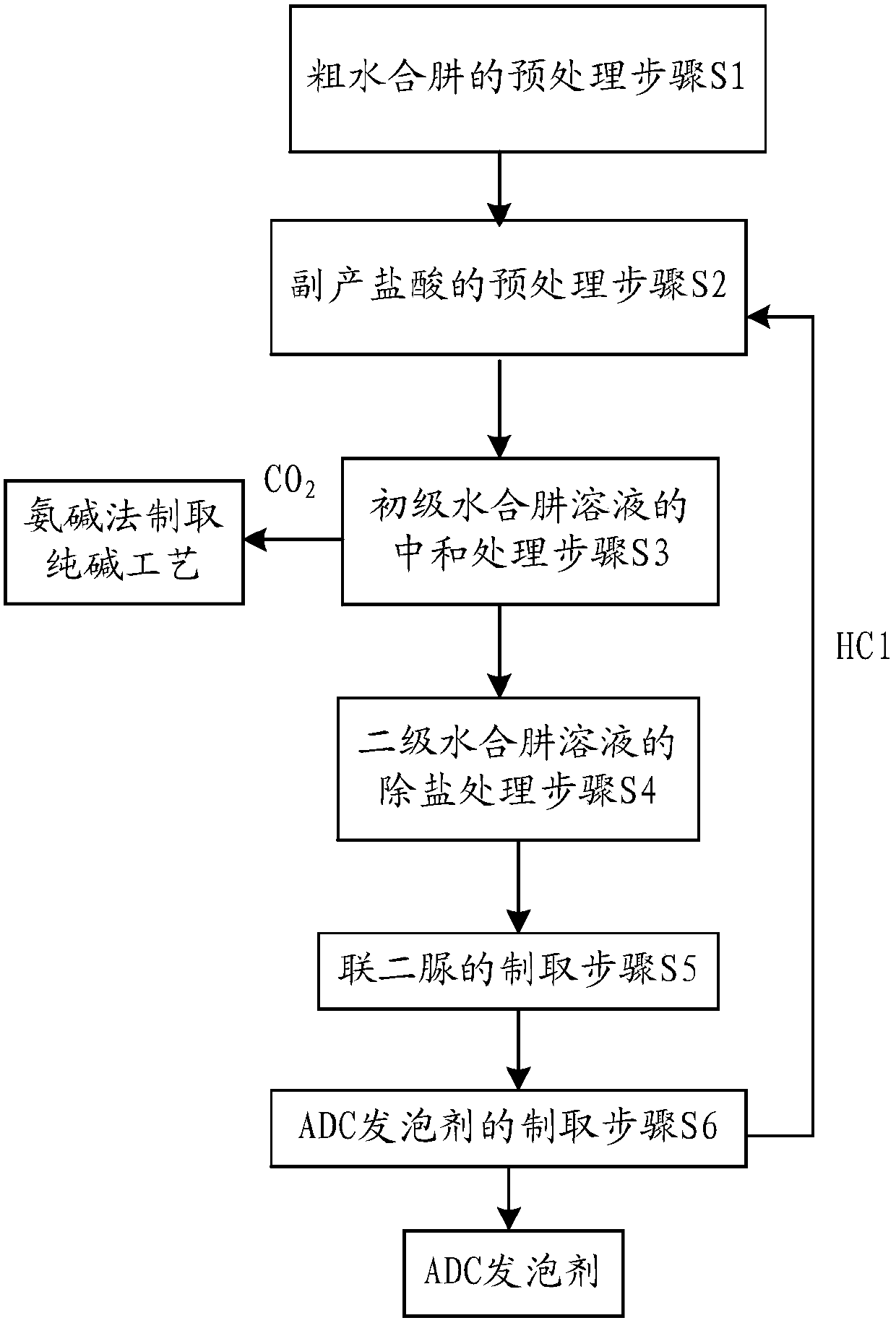

Method for recycling coproduct hydrochloric acid in ADC (azodicarbonamide) foaming agent preparation process

ActiveCN105859592ASimple processLow purity requirementOrganic chemistryAlkali metal chloridesEconomic benefitsProduct gas

The invention discloses a method for recycling a coproduct hydrochloric acid in an ADC (azodicarbonamide) foaming agent preparation process. The method comprises the following steps: S1. pretreatment of crude hydrazine hydrate; S2. pretreatment of coproduct hydrochloric acid; S3. neutralizing treatment of primary hydrazine hydrate solution; S4. desalting treatment of secondary hydrazine hydrate solution; S5. preparation of biurea; and S6. preparation of ADC foaming agent. The coproduct hydrochloric acid produced in the step S6 is recycled, and treated by the step S2 to form hydrogen chloride gas; and the hydrogen chloride gas is introduced into the hydrazine hydrate solution in the step S3 to remove abundant sodium carbonate in the hydrazine hydrate solution, thereby implementing the cyclic utilization on the coproduct hydrochloric acid. The method solves the problem of the disposition of the coproduct hydrochloric acid, and avoids the environmental pollution caused by the hydrochloric acid. The sodium carbonate in the hydrazine hydrate solution is treated, and the formed main waste sodium chloride can be discharged to the salt field, so that the ADC foaming agent preparation process is more environment-friendly. The hydrogen chloride treatment technique is simple, and has the advantages of low energy consumption and obvious economic benefits.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Preparation method for cellulose-polyvinyl alcohol degradable composite film and antibacterial strengthening method for cellulose-polyvinyl alcohol degradable composite film

ActiveCN110818937ASimple processThe production process is green and environmentally friendlyAntifouling/underwater paintsPaints with biocidesFilm materialPolymer chemistry

The invention discloses a preparation method for a cellulose-polyvinyl alcohol degradable composite film. The preparation method comprises the following steps: A, preparation of a cellulose film: dissolving, film preparation, water washing and plasticizing; B, preparation of a polyvinyl alcohol reinforcing solution; and C, compounding of the cellulose membrane and polyvinyl alcohol. The preparation method provided by the invention has the characteristics of simple process and green and environmentally-friendly preparation process, and does not pollute the cellulose solvent so as to realize recycling. The invention also provides an antibacterial reinforced preparation method of the cellulose composite membrane. The polymer ionic liquid antibacterial agent can be compounded with the polyvinyl alcohol reinforcing liquid to form a compound film-forming reinforcing liquid with good film-forming property and long-term antibacterial property, and the compound film-forming reinforcing liquid is prepared on the film material base layer through a dip-coating method to form a composite layer, so the mechanical property and the antibacterial property of the film material can be improved.

Owner:SHIJIAZHUANG UNIVERSITY

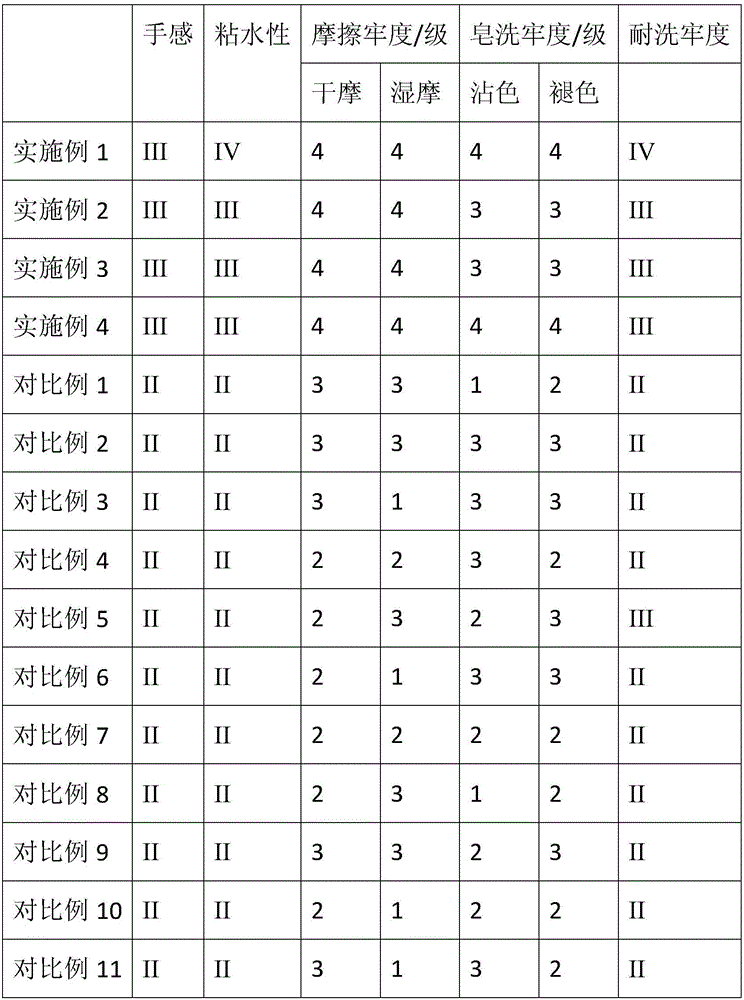

Environment-friendly emulsion-like textile size composition and preparation method and application thereof

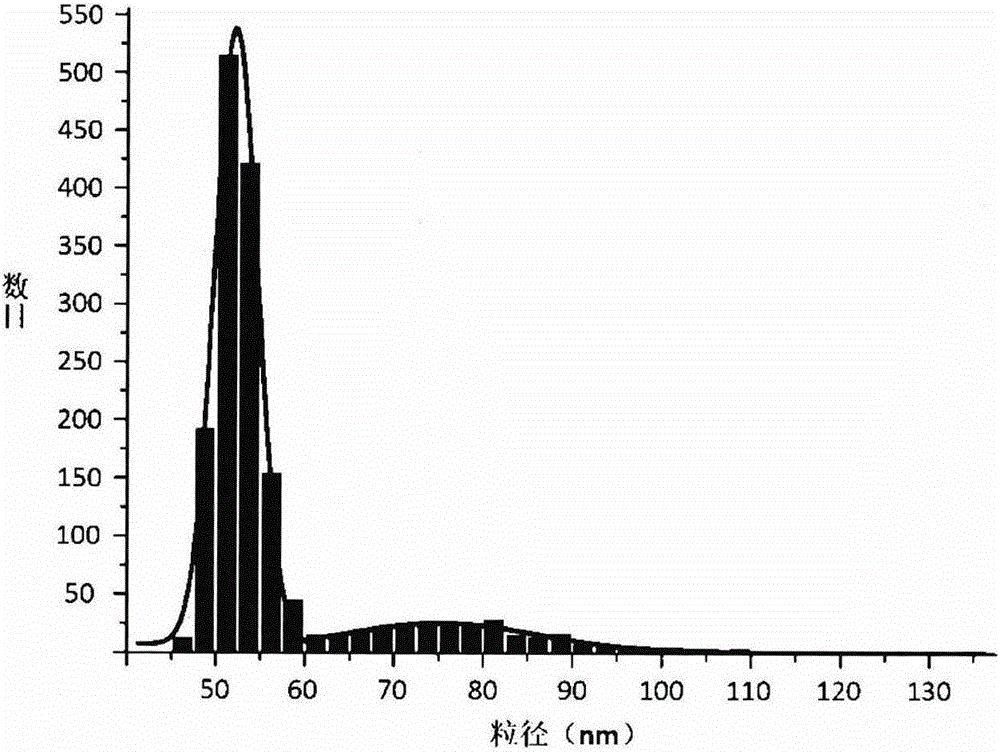

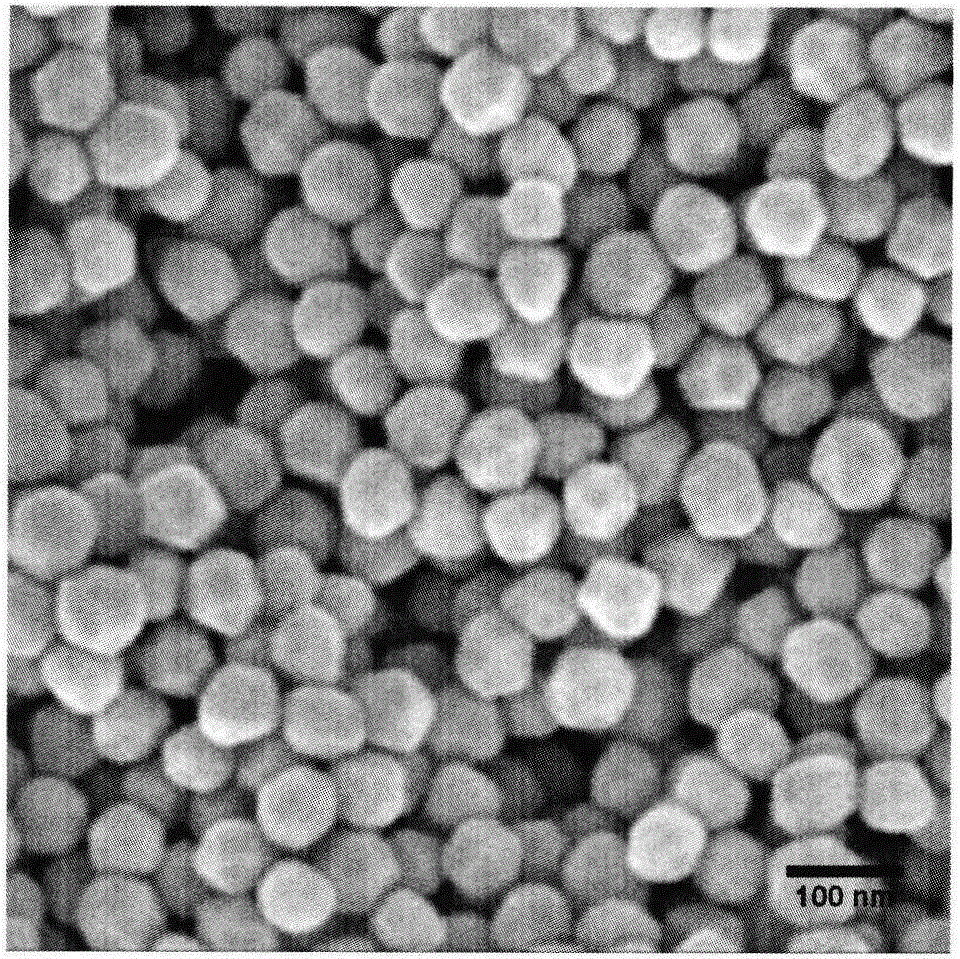

InactiveCN106436356AGood rubbing fastnessExcellent wash fastnessDyeing processMicroballoon preparationPolymer scienceAdhesive

The invention relates to an environment-friendly emulsion-like textile size composition and a preparation method and application thereof. The composition is prepared from, by weight, 80-100 parts of adhesive, 1-8 parts of thickening agent and 10-45 parts of microcapsule powder. The adhesive is a mixture of acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acrylic acid, methacrylic acid and acrylamide. The thickening agent is an associative type waterborne polyurethane thickening agent or a polyacrylic acid type synthetic thickener so that the viscosity of the composition at 25 DEG C can be adjusted to be 11-13 centipoises. The textile size composition is mainly used as paint for textile, the technical problems that the textile is hard in handfeel, poor in crock fastness, not high in rubbing fastness, high in after-dyeing textile hardness, poor in viscosity and pollutes the environment are solved, and the effects of being excellent in crock fastness, high in rubbing fastness, soft in after-dyeing textile handfeel, good in after-dyeing textile hydrophilia, especially excellent in adhesive force and friendly to the environment in the production process are achieved.

Owner:西达(无锡)生物科技有限公司

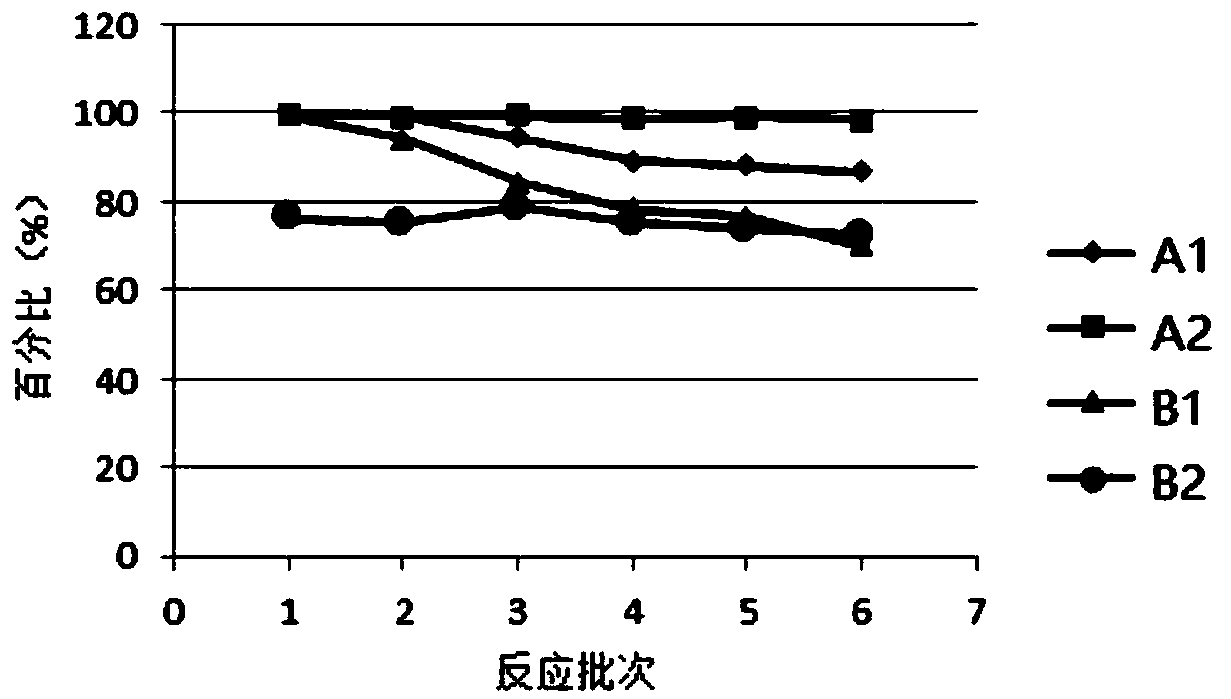

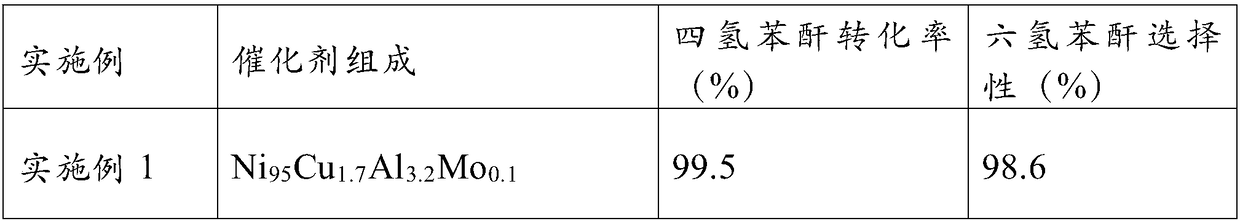

Hydrogenation catalyst, preparation method and application thereof

ActiveCN108144618AImprove conversion rateThe preparation conditions are simpleOrganic chemistryCatalyst activation/preparationRaney nickelMetal

The invention provides a hydrogenation catalyst. The hydrogenation catalyst is prepared from the following elements: 70-95wt% of Ni, 1-10wt% of Cu, 3-20wt% of Al and 0.1-6wt% of modified metal elementM, wherein the modified metal element M is selected from one or more of Ca, La, Mo, Ti, Fe and Co. Compared with the conventional raney-nickel catalyst, the hydrogenation catalyst prepared by adopting a preparation method has the beneficial effects that the conversion rate of tetrahydrophthalic anhydride and the selectivity of preparation of hexahydrophthalic anhydride are improved, the catalystpreparation condition is simple and convenient and the cost is low; in addition, the invention also provides a preparation method of the hydrogenation catalyst and application of the hydrogenation catalyst to production of the hexahydrophthalic anhydride by adopting the tetrahydrophthalic anhydride as a raw material.

Owner:SHANGHAI XUNKAI NEW MATERIAL TECH

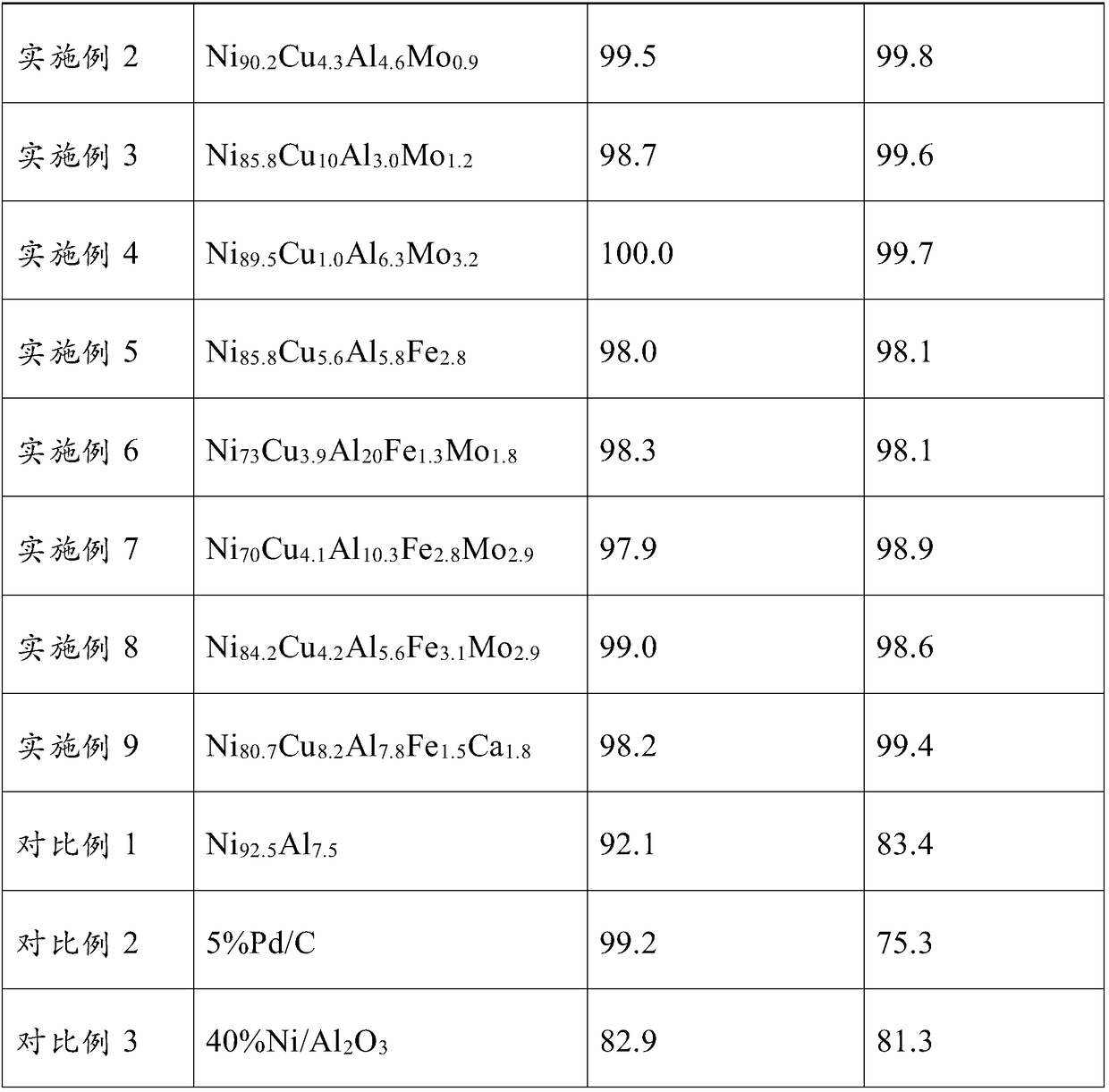

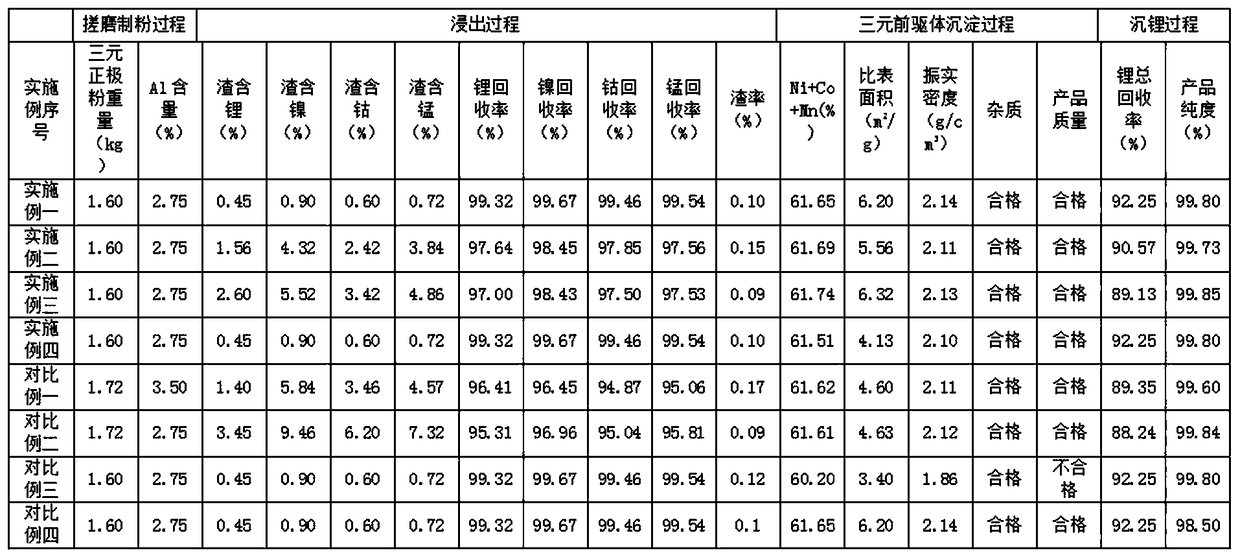

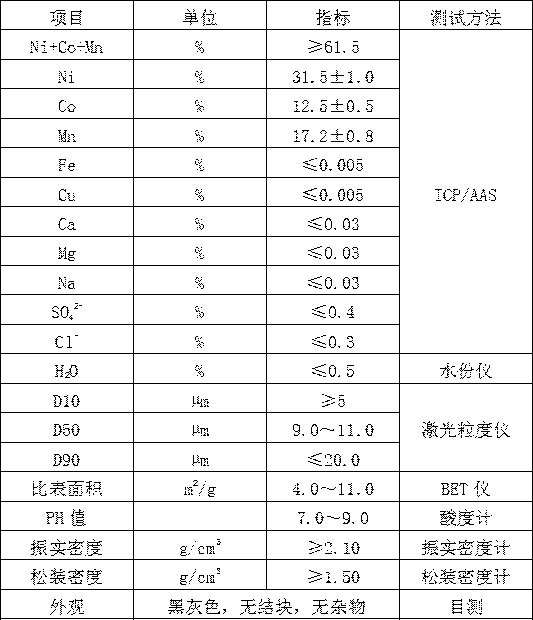

A method for producing ternary precursor and high-purity lithium carbonate from a waste ternary lithium battery

ActiveCN109244588ASolve environmental problemsGuarantee normal productionCell electrodesWaste accumulators reclaimingLithium carbonateEnergy consumption

The invention discloses a method for producing a ternary precursor and high-purity lithium carbonate from a waste ternary lithium battery, which comprises eight steps of preparing cathode powder, reducing cycle leaching, filtering and washing, etc. The purpose of the invention is to provide a method for producing ternary precursor and high-purity lithium carbonate from waste ternary lithium battery, which is environmentally friendly, low in energy consumption, low in production cost, low in pollutant discharge amount, highly effective in realizing comprehensive utilization of resources and satisfying industrial production.

Owner:湖南天泰天润新能源科技有限公司

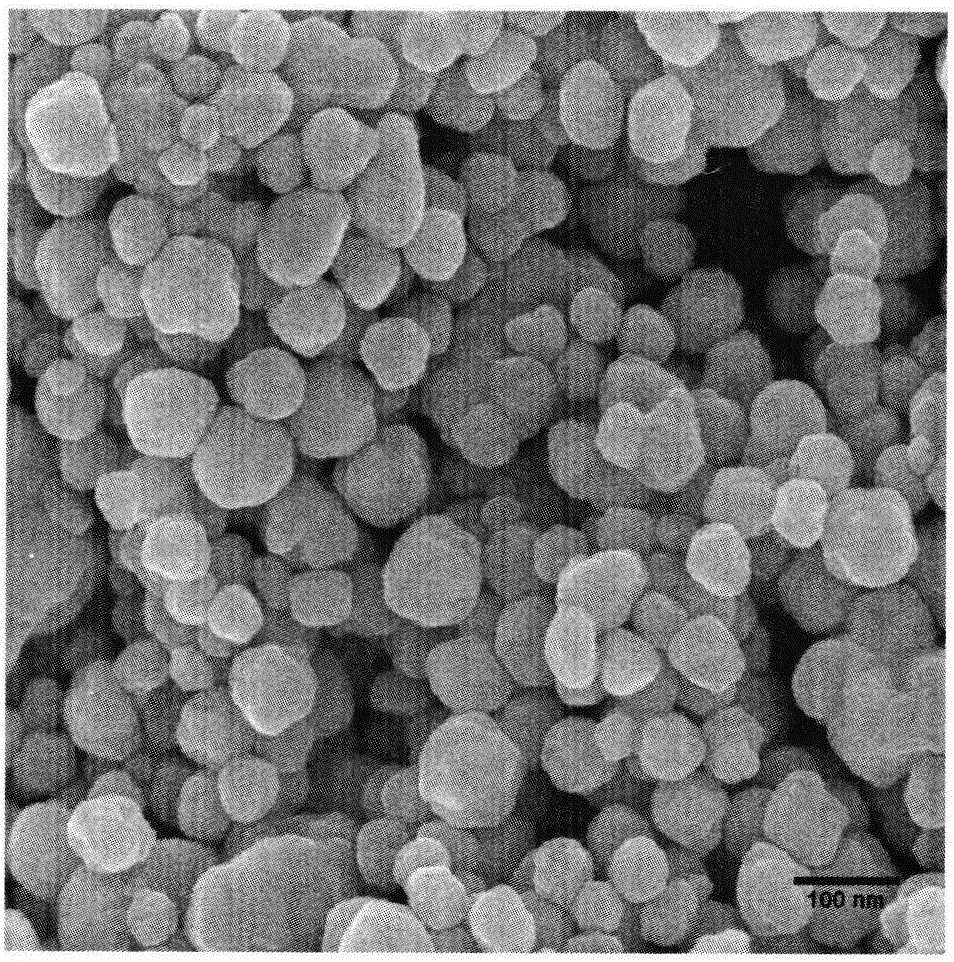

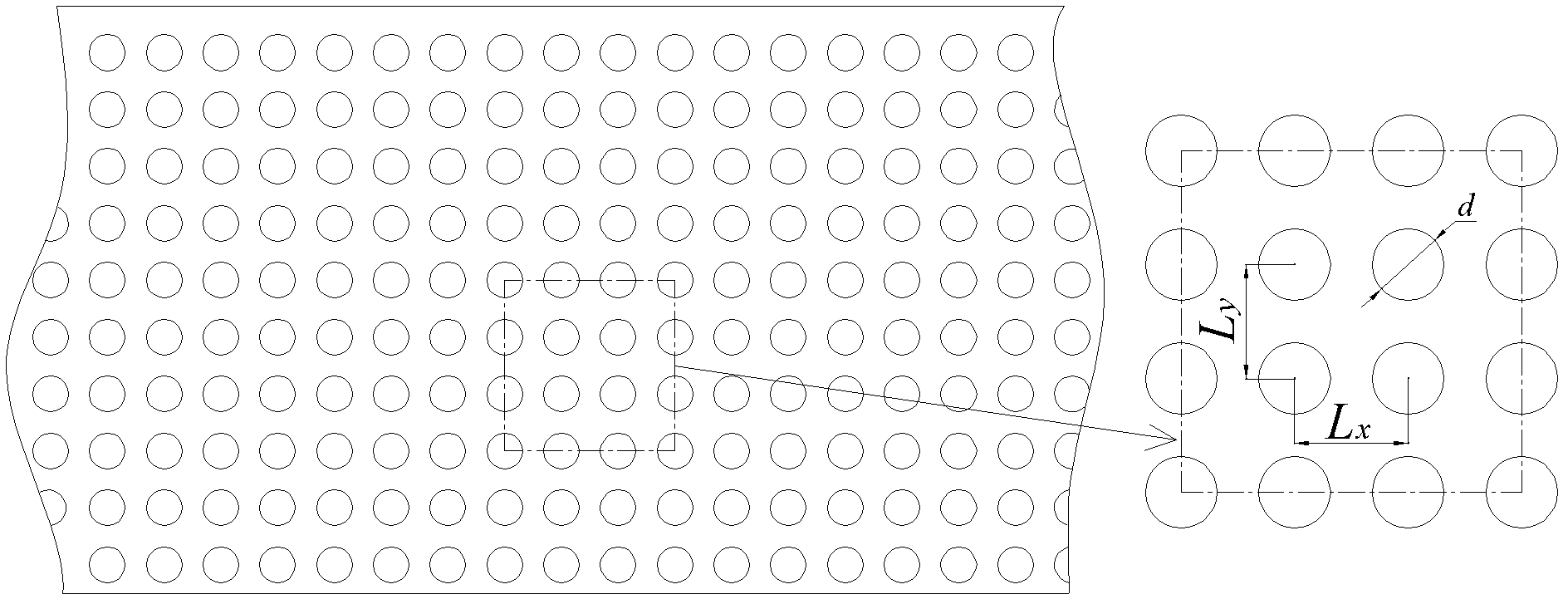

Ultrasonic motor with microstructures on surface

InactiveCN102624280AThe production process is environmentally friendlyIncrease frictionPiezoelectric/electrostriction/magnetostriction machinesWear resistanceUltrasonic motor

The invention discloses an ultrasonic motor with microstructures on a surface, and belongs to the technical field of ultrasonic motors. The problem of poor abrasion resistance of a friction pair of the conventional ultrasonic motor is solved. Two technical schemes are provided, wherein one is that: the ultrasonic motor comprises a stator and a rotor, and the microstructures are uniformly arranged on the contact surface area of the stator which contacts the rotor, and are convex body microstructures, micro pits or micro slots; and the other is that: the ultrasonic motor comprises the stator and the rotor, and the microstructures are uniformly arranged on the contact surface area of the rotor which contacts the stator, and are the convex body microstructures, the micro pits or the micro slots. The invention is applied to the ultrasonic motor.

Owner:HARBIN INST OF TECH

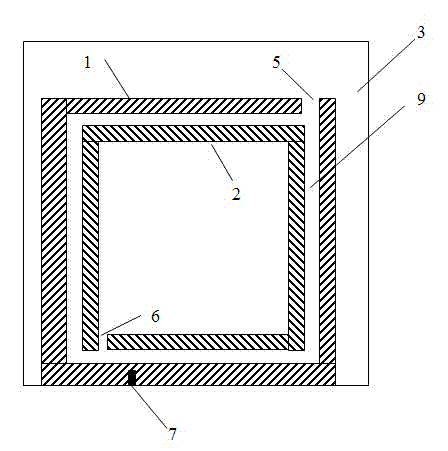

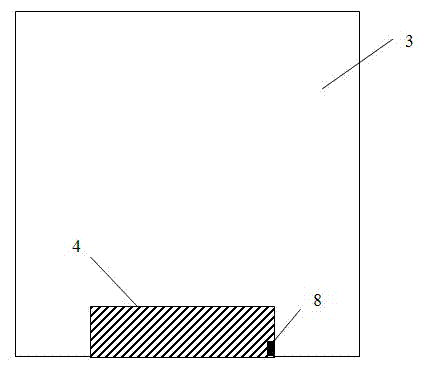

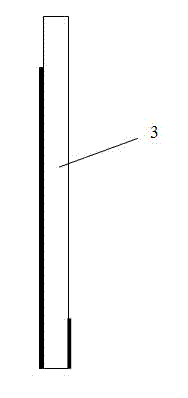

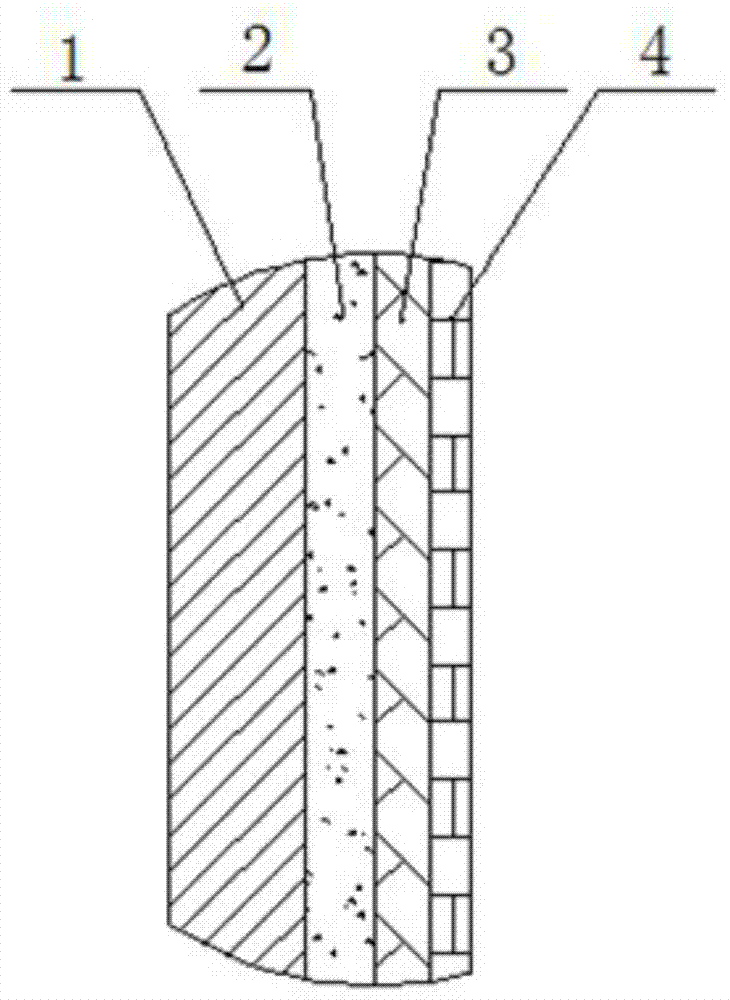

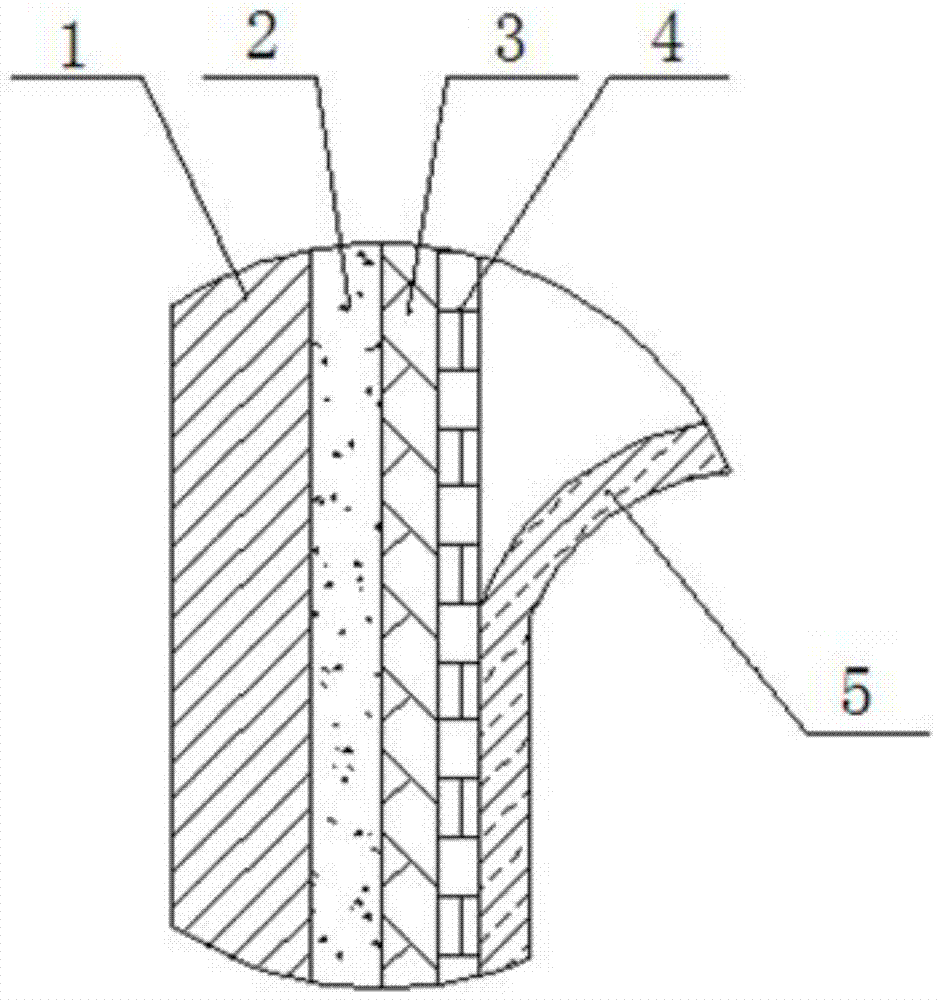

Composite resin metal mold and manufacturing method thereof

ActiveCN106938509ASolve pollutionLow heat resistanceIncreasing energy efficiencyState of artHeat resistance

The invention discloses a composite resin metal mold and a manufacturing method thereof. The composite resin metal mold includes a metal layer (1), a resin fiber layer (2) and a metal bracing frame (3), wherein the resin fiber layer (2) is arranged at the back layer of the metal layer (1), one end of the metal bracing frame (3) is in fixed connection to an inner side of the metal layer (1) through the resin fiber layer (2), and the other end extends out of the resin fiber layer (2). Through adoption of the metal layer and the resin fiber layer, the technical problem that a traditional resin mold doesn't resist to wear or temperature and is complicated in processing and the technical problem that a 3D-printed metal layer is too thin and low in strength are solved. The composite resin metal mold is good in dimensional stability, hardness, tensile strength, wear resistance and thermal resistance.

Owner:WAFANGDIAN RIRUI DIE CASTING

Juicy peach flavored honey dry powder and preparation method therefor

InactiveCN104824501AThe production process is environmentally friendlyFull of nutritionFood preparationPeach FlavorPouteria campechiana

The present invention discloses juicy peach flavored honey dry powder and a preparation method therefor. The juicy peach flavored honey dry powder is prepared from the raw materials: honey, juicy peaches, pleurotus eryngii, rye, exocarpium citrulli, burdock roots, corn flour, pouteria campechiana, purslane, purple cabbage, mangosteen, sweet potato rattan, lotus nut starch, yogurt and the like. The juicy peach flavored honey dry powder has the beneficial effects that the manufacturing process is environment-friendly; the sweet and fruity juicy peaches are combined with the sweet and delicious honey so that the honey dry powder is rich in nutrition, tastes soft and silky, and is easy to digest and absorb; and the honey dry powder has full-bodied and pleasant fruit flavor when being brewed, enabling people to feel sweet taste of the juicy peaches anytime and anywhere.

Owner:WUHU HYK FOOD CO LTD

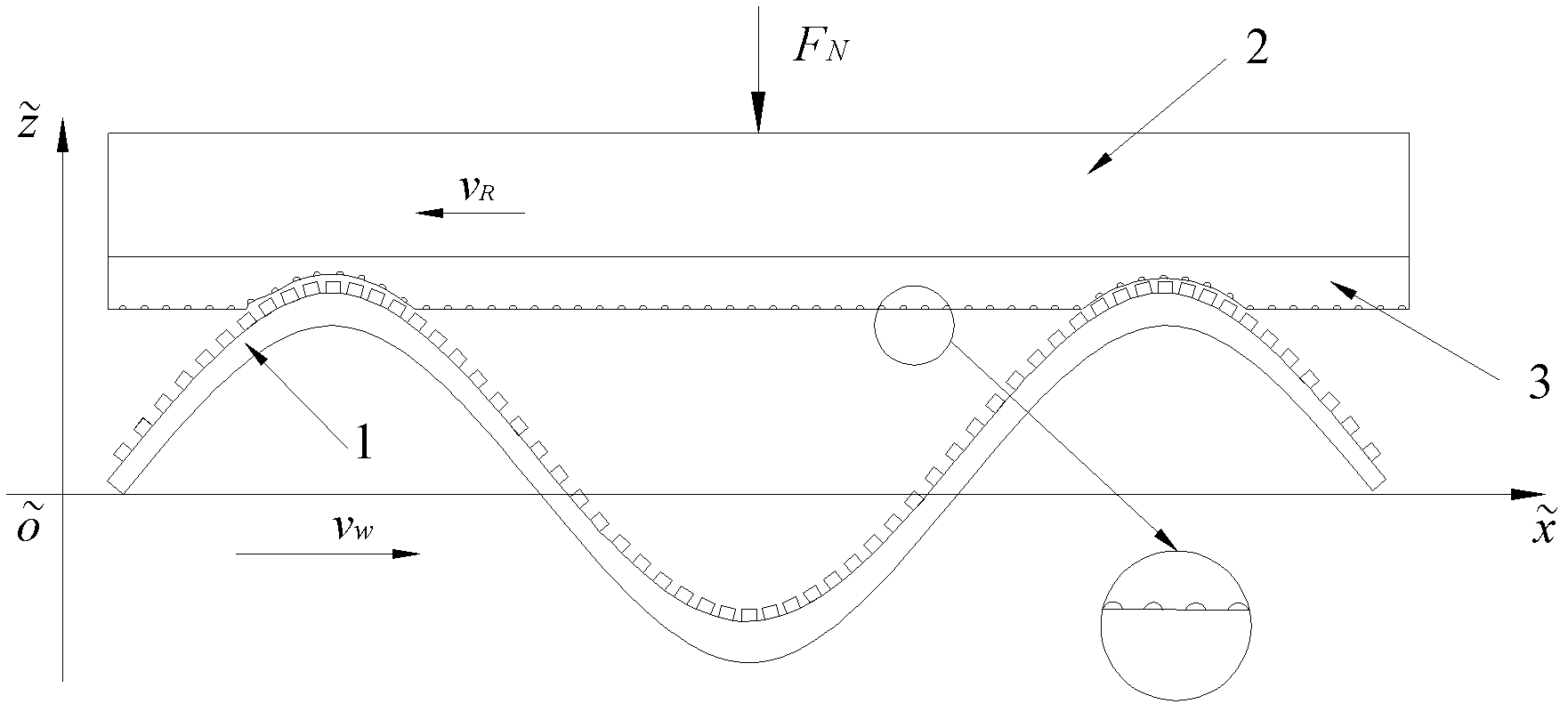

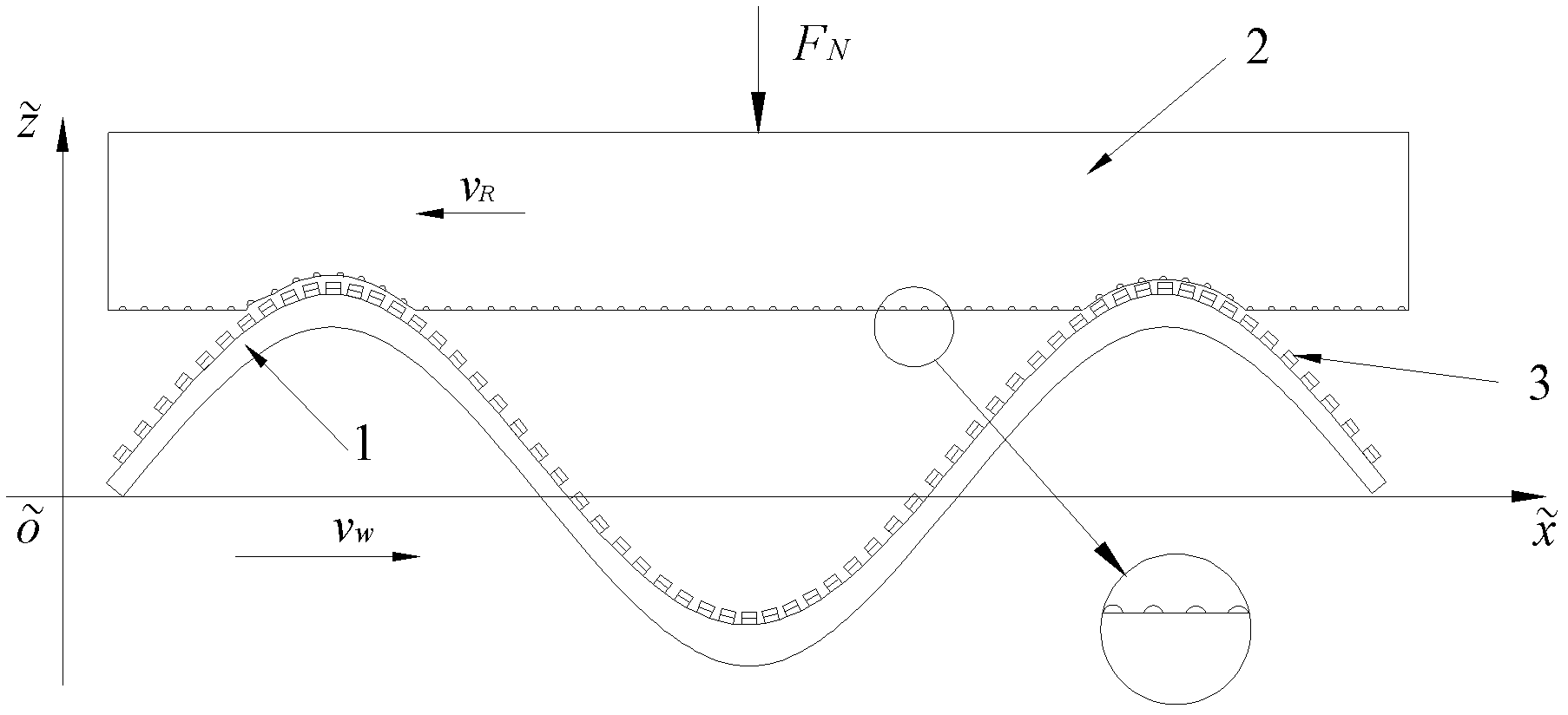

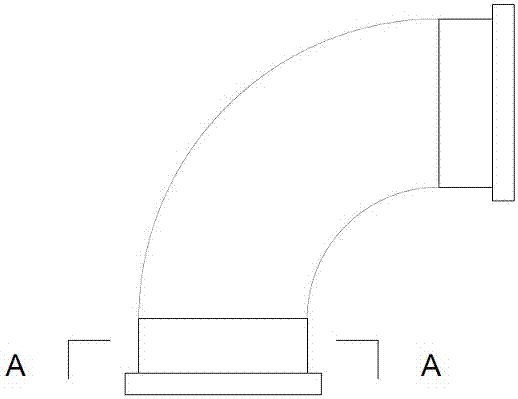

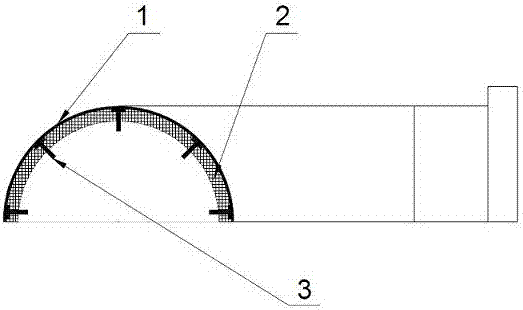

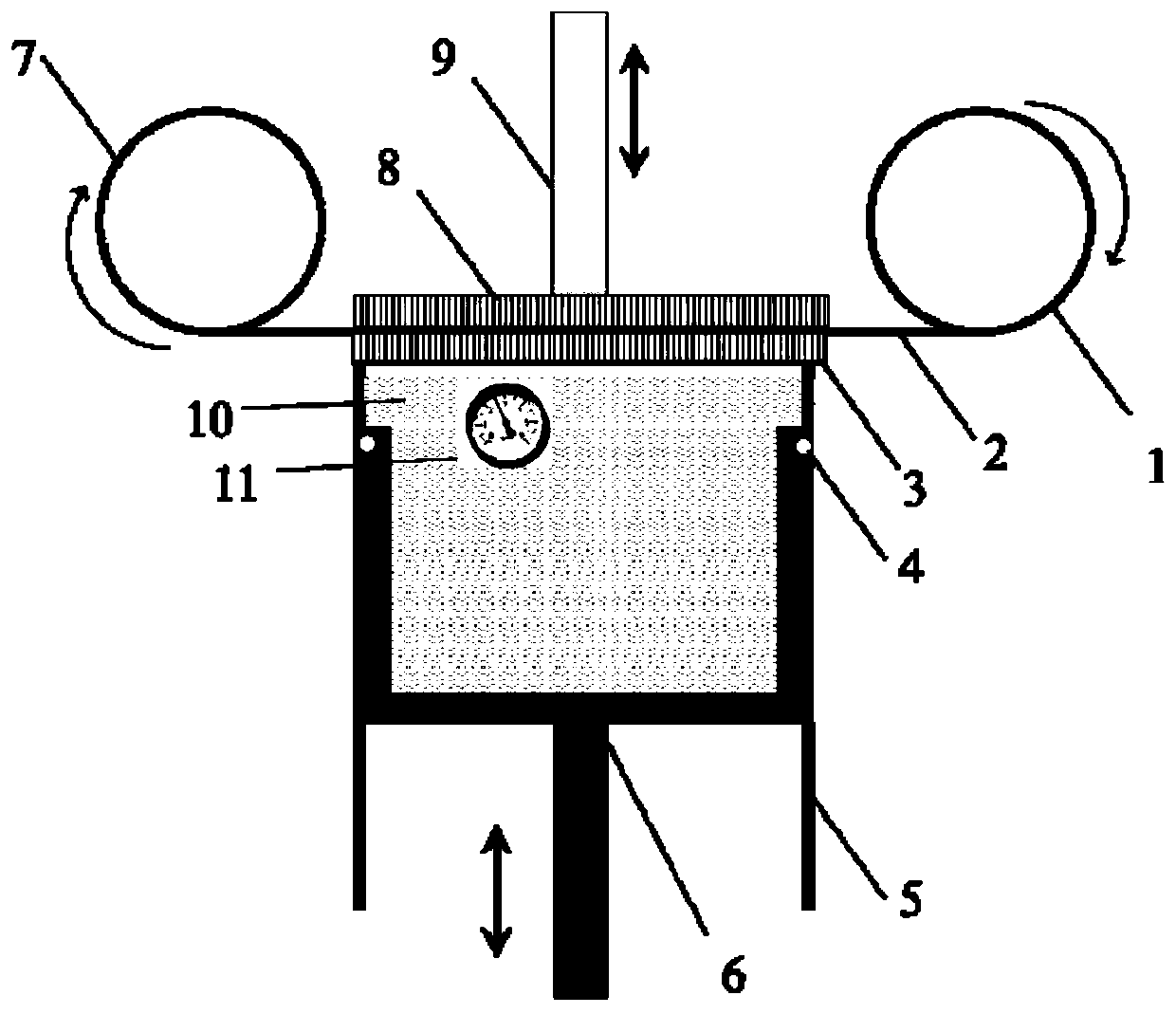

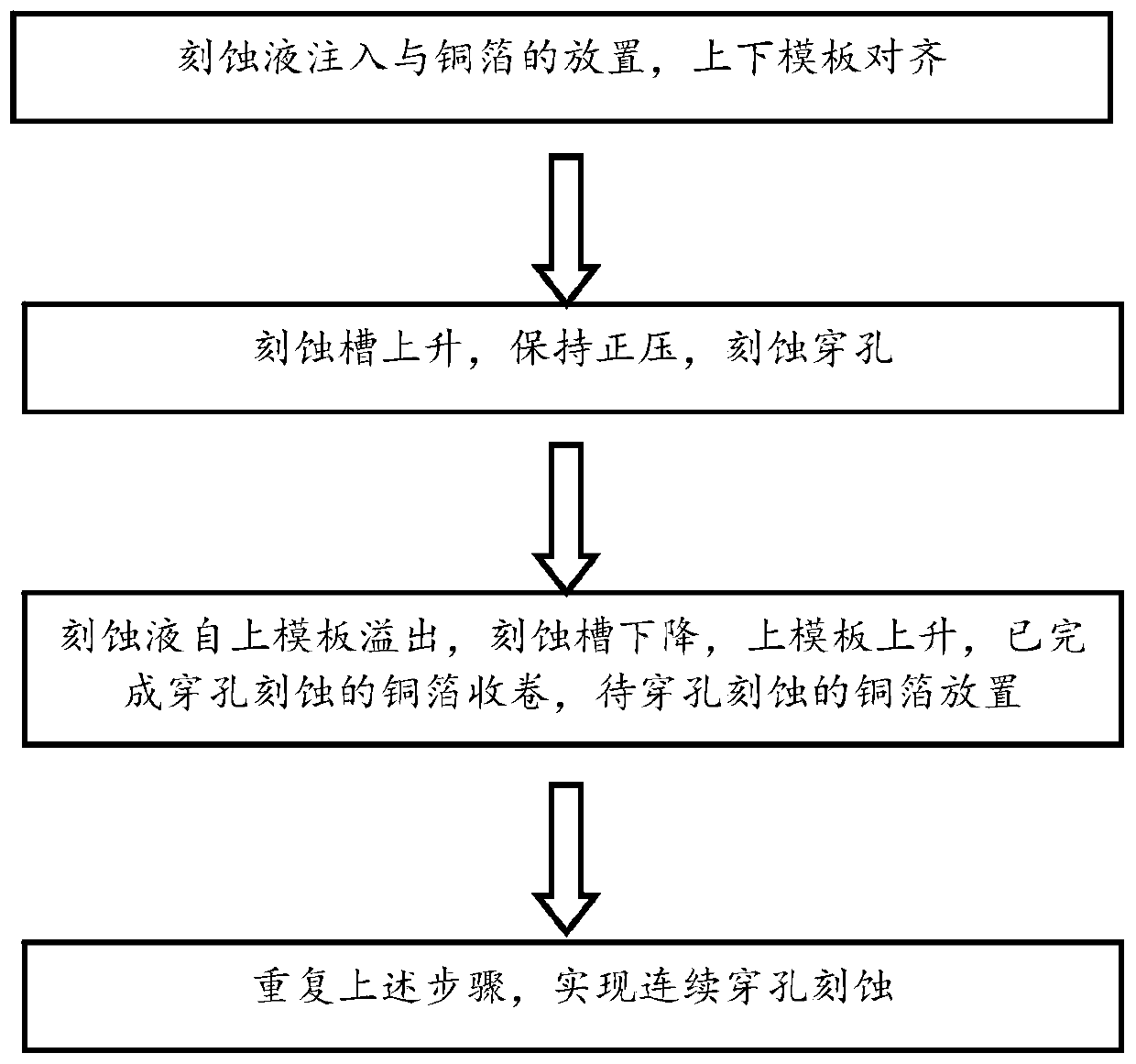

A copper foil perforator based on chemical etching and its production process

The invention discloses a copper foil perforating machine based on chemical etching. The copper foil perforating machine comprises a copper foil unwinding wheel, a stainless steel lower template, sealing rings, a perforating machine jacket, an etching tank which can be moved up and down, a copper foil winding wheel, a stainless steel upper template, an upper template connecting rod which can be moved up and down, an etching groove internal pressure gage. The invention further provides a production technology for perforated copper foil based on the copper foil perforating machine. The production technology comprises the following step (1) of filling the etching tank with etching liquid, and placing the lower template on the upper edge of the perforating machine jacket; spreading the copperfoil on the lower template flat, and placing the upper template for pressing the copper foil; aligning the upper template to the lower template; the step (2) of pushing the etching tank to rise so that the liquid level rises and is in contact with the copper foil for perforation and etching; and the step (3) of declining the etching tank when the etching liquid overflows from the upper template, and finishing perforation and etching. According to the copper foil perforating machine and the production technology thereof, porous copper foil with high perforation quality and low extent of mechanical damage can be produced, and the quality of finished products is improved; and continuous production is performed so that the production efficiency is improved, and the production process is more environmentally friendly.

Owner:ZHEJIANG UNIV

Matte silver foil and production method thereof

InactiveCN104846700AReduce processThe production process is environmentally friendlyFlexible coversWrappersAdhesive cementSilver paste

The invention provides matte silver foil. The matte silver foil is characterized by comprising a base paper layer, an adhesive layer coated on the base paper surface, a matte silver layer coated on the adhesive layer and a surface coating coated on the matte silver layer. The matte silver foil has the advantages that the adhesive layer is provided and coated with the matte silver layer, and accordingly, matte silver paste does not contact with the paper directly, and deformation of the paper can be avoided during drying; additionally, a BOPET (bi-axially oriented polyester film) used during production can be used repeatedly, so that a production process is more environment friendly.

Owner:SHANGHAI ZIJIANG METALLIZATION ENVIRONMENTAL PROTECTION MATERIAL

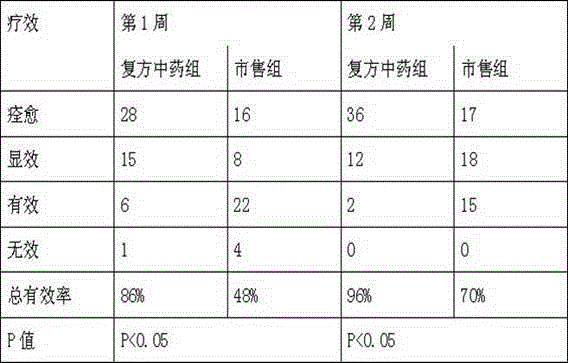

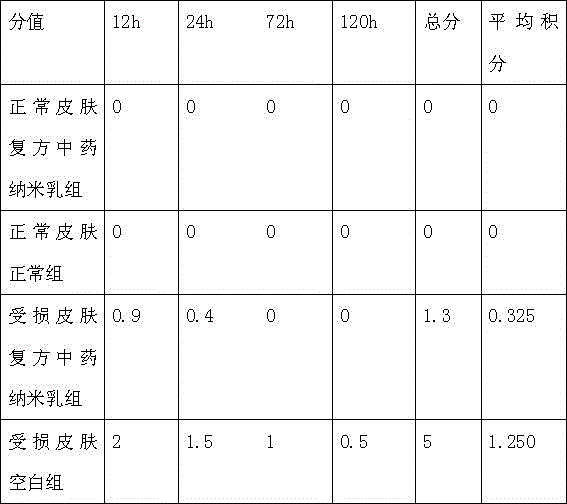

Compound traditional Chinese medicine nanometer emulsifiable paste for treating skin chap

InactiveCN106138083AReasonable formulaGood storage stabilityOrganic active ingredientsEmulsion deliveryWater bathsBletilla striata

The invention aims at providing compound traditional Chinese medicine nanometer emulsifiable paste for treating skin chap. The compound traditional Chinese medicine nanometer emulsifiable paste contains a nanometer emulsion substrate and a traditional Chinese medicine extract, wherein the nanometer emulsion substrate contains an isopropyl palmitate substance and a mixed surfactant; isopropyl palmitate and the traditional Chinese medicine extract are put into 80-DEG C constant temperature water bath for heating melting; a surfactant and a cosurfactant are put into the isopropyl palmitate; stirring, dissolving, placing and cooling are performed; the mixed surfactant is a composition of the surfactant and the cosurfactant; the surfactant is prepared from Tween-80 and polyoxyethylene hydrogenated castor oil; the cosurfactant is one of glycerol, absolute ethyl alcohol or polyethylene glycol 400; the traditional Chinese medicine extract is a compound of rhizoma bletillae polysaccharide and alkannin. The nanometer emulsifiable paste has the advantages that the formula is reasonable; the storage stability is good; in the use process, the oily feeling is avoided; the emulsion droplet grain diameter is small; the emulsifiable paste can be fast absorbed in the medicine use position. The recipe process of the compound traditional Chinese medicine nanometer emulsifiable paste is reasonable; green and environment-friendly effects are achieved in the manufacturing process; the carrying and the use are convenient; the auxiliary materials are safe; the price is moderate.

Owner:HENAN UNIV OF CHINESE MEDICINE

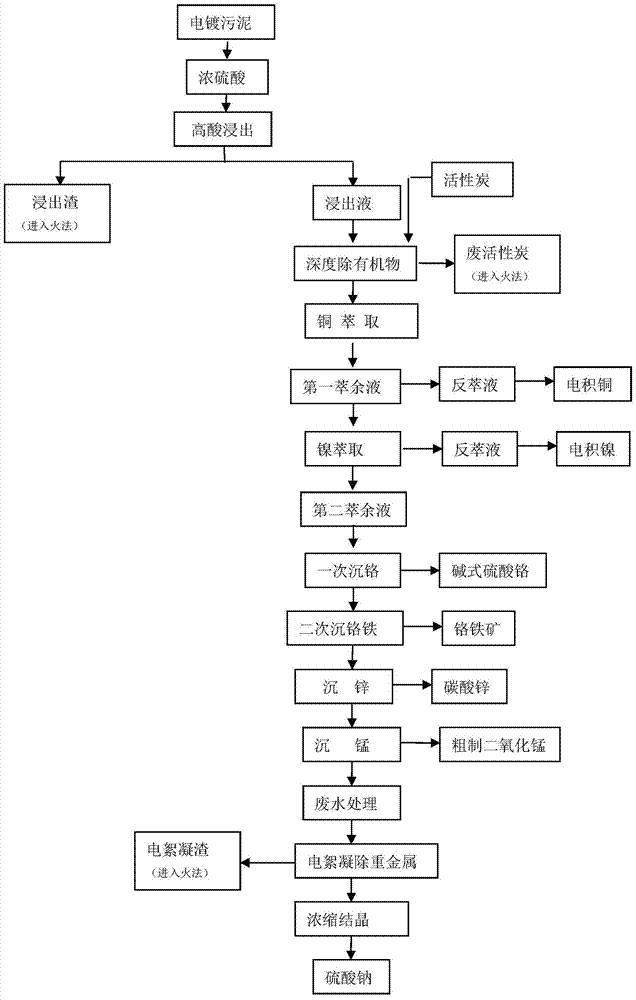

A method for resourceful treatment and comprehensive recycling of electroplating sludge

ActiveCN105256141BEfficient recyclingThe production process is environmentally friendlyProcess efficiency improvementSludgePhosphoric acid

The invention discloses an electroplating-sludge resourceful treatment and comprehensive recycling method. The method mainly includes the steps of pretreatment, acid leaching, copper extracting, nickel and cobalt extracting, chrome taking through precipitating, precipitated zinc neutralizing, manganese taking through adsorbing and sodium salt recycling. According to the method, under the condition of the low pH value, valuable metal such as copper, nickel, cobalt, chrome, zinc, manganese and the like is effectively and sequentially recycled, chrome is deeply removed through one-time chrome precipitating and magnetic fluid flawing growing with a phosphoric acid method, virose hexavalent chromium is not produced in the period, and therefore the chrome is produced in a high-value-added chemical product manner and becomes available resources. After being treated, waste water can be discharged outwards or reused when meeting the national standard, resourceful-and-innocent treatment and comprehensive recycling of electroplating sludge are achieved accordingly, the technological process is short, the adaptability of raw materials is high, and the metal recovery percent can be higher than 90%. In this way, the comprehensive process cost is markedly reduced, and economic benefits and social benefits are obvious.

Owner:广西银亿再生资源有限公司 +1

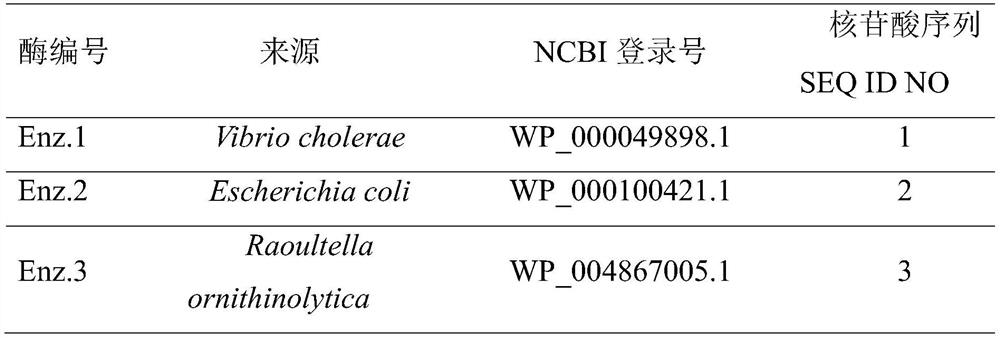

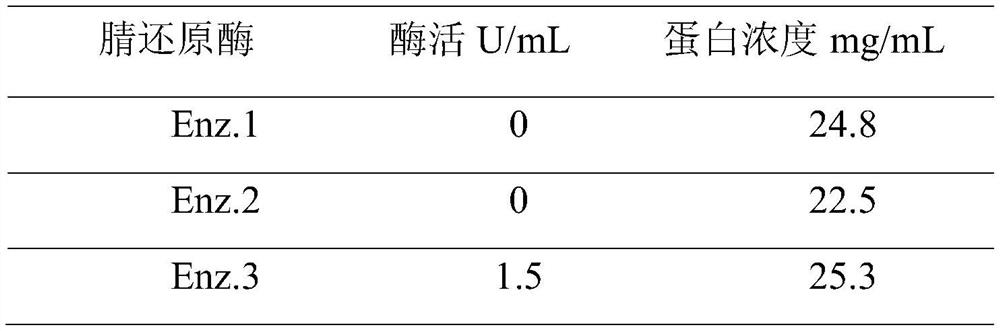

Preparation method of 2,4-difluorobenzylamine

PendingCN112410380ARaw material safetyThe production process is environmentally friendlyFermentationRedox enzymesBiochemical engineering

The invention discloses a preparation method of 2,4-difluorobenzylamine, which comprises the following steps: contacting 2,4-difluorobenzonitrile with nitrile oxidoreductase, and reducing 2,4-difluorobenzonitrile into 2,4-difluorobenzylamine. The nitrile oxidoreductase is nitrile oxidoreductase with an NCBI (National Center of Biotechnology Information) login number of WP_004867005.1. The invention also discloses an application of the nitrile oxidoreductase in preparation of dolutegravir or an intermediate of dolutegravir. According to the preparation method provided by the invention, the conversion rate of can reach 70%, the raw materials are safe, the production process is environmentally friendly, and the preparation method is suitable for large-scale industrial production.

Owner:ABIOCHEM BIOTECH CO LTD

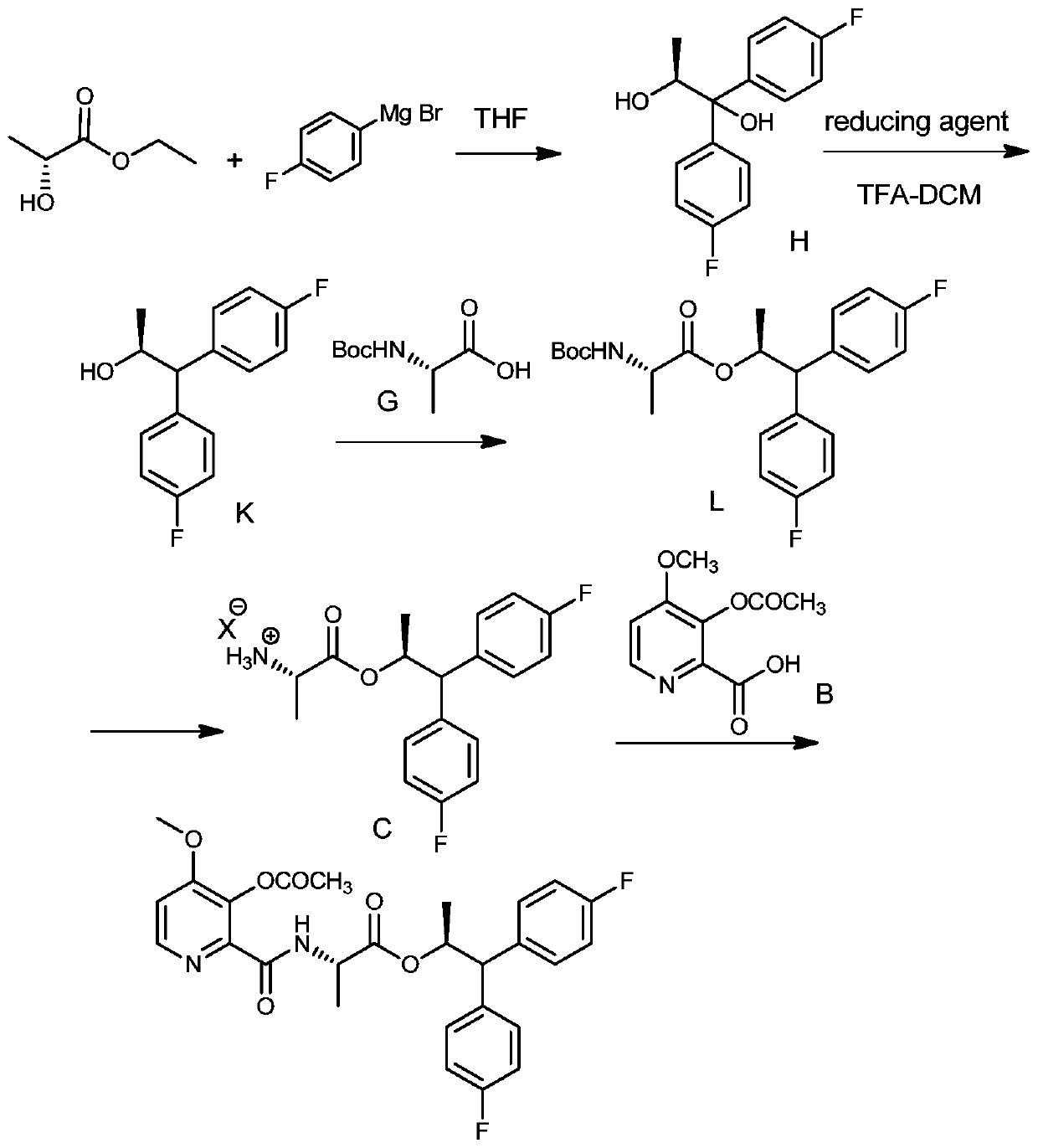

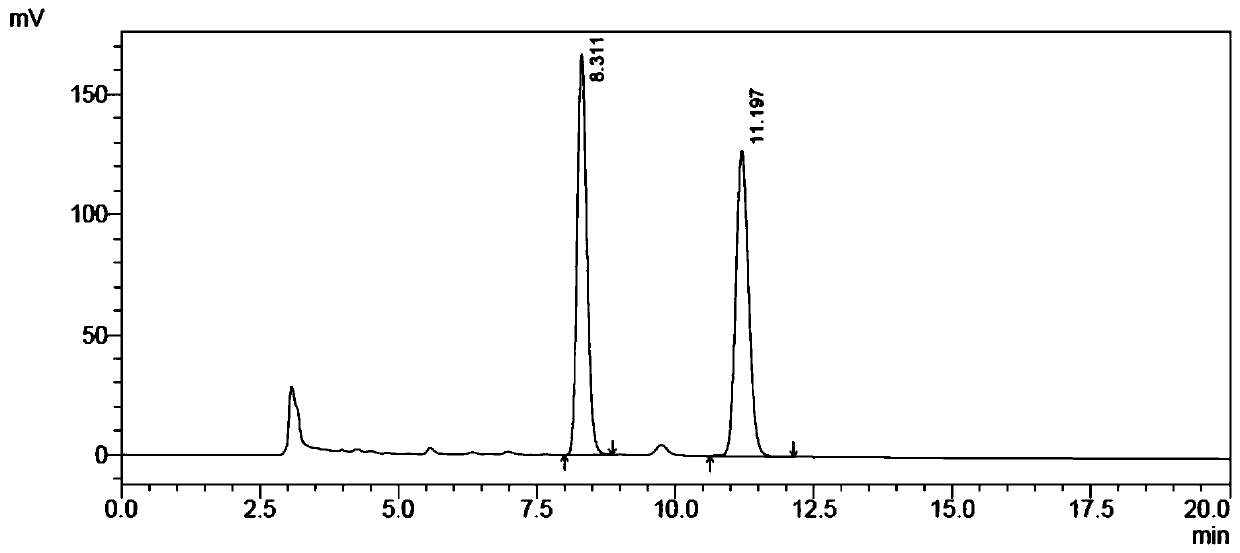

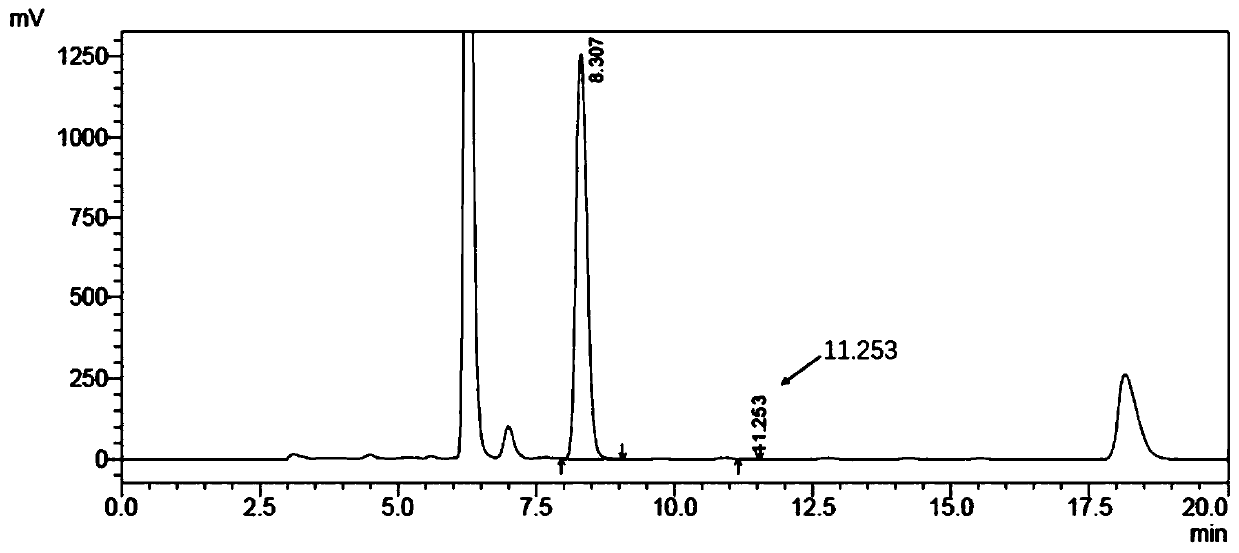

Application of ketoreductase in preparation of (S)-1,1-bis(4-fluorophenyl)-2-propanol, and preparation method of (S)-1,1-bis(4-fluorophenyl)-2-propanol

PendingCN111057725ALow costThe production process is environmentally friendlyFermentationEthyl lactatePropanol

The invention provides a preparation method of (S)-1,1-bis(4-fluorophenyl)-2-propanol. The preparation method is characterized in that a compound of a formula 2 is catalyzed in a reaction system by using ketoreductase to obtain a compound of a formula 1, that is the (S)-1,1-bis(4-fluorophenyl)-2-propanol, and the structural formula of the compound of the formula 2 is as shown in the specification.The invention also provides application of the ketoreductase, the compound of formula 2, 1,1-bis(4-fluorophenyl)-1,2-propylene glycol and / or ethyl lactate in the preparation of (S)-1,1-bis(4-fluorophenyl-2-propanol) or a picolinamide bactericide Florylpicoxamid. The preparation method, adopting an enzyme catalysis method to replace a chemical method in the prior art, has the advantages of reduction of the cost of used raw materials, environmentally friendly production process, and high stereoselectivity of the prepared product.

Owner:ABIOCHEM BIOTECH CO LTD

A method for recovering and utilizing by-product hydrochloric acid in the process of preparing ADC blowing agent

ActiveCN105859592BSimple processLow purity requirementOrganic chemistryAlkali metal chloridesBiureaHydrazine compound

The invention discloses a method for recycling a coproduct hydrochloric acid in an ADC (azodicarbonamide) foaming agent preparation process. The method comprises the following steps: S1. pretreatment of crude hydrazine hydrate; S2. pretreatment of coproduct hydrochloric acid; S3. neutralizing treatment of primary hydrazine hydrate solution; S4. desalting treatment of secondary hydrazine hydrate solution; S5. preparation of biurea; and S6. preparation of ADC foaming agent. The coproduct hydrochloric acid produced in the step S6 is recycled, and treated by the step S2 to form hydrogen chloride gas; and the hydrogen chloride gas is introduced into the hydrazine hydrate solution in the step S3 to remove abundant sodium carbonate in the hydrazine hydrate solution, thereby implementing the cyclic utilization on the coproduct hydrochloric acid. The method solves the problem of the disposition of the coproduct hydrochloric acid, and avoids the environmental pollution caused by the hydrochloric acid. The sodium carbonate in the hydrazine hydrate solution is treated, and the formed main waste sodium chloride can be discharged to the salt field, so that the ADC foaming agent preparation process is more environment-friendly. The hydrogen chloride treatment technique is simple, and has the advantages of low energy consumption and obvious economic benefits.

Owner:QINGHAI SALT LAKE IND

Non-toxic pesticide and preparation process thereof

InactiveCN107410378ANo pollution in the processHigh-efficiency bactericidal and insecticidal effectBiocideFungicidesAlkaloidTributyl citrate

The invention discloses a non-toxic pesticide and a preparation process thereof. The non-toxic pesticide is prepared from the following components: 8 to 20 parts of eucalyptus citriodora, 8 to 15 parts of pomegranate peel, 10 to 20 parts of xanthoxylin, 10 to 20 parts of zinc oxide, 5 to 10 parts of common andrographis herb, 12 to 25 parts of matrine, 10 to 20 parts of chitin, 8 to 20 parts of rangooncreeper fruit, 7 to 18 parts of ormosia seed, 5 to 15 parts of alkaloids from tripterygium wilfordii, 10 to 20 parts of acetyl tributyl citrate, 3 to 10 parts of emulsifier and 1 to 3 parts of nano silver ion powder. The preparation method has the advantages of simple process, and environmental protection and no pollution during the whole production process, and the obtained pesticide has high sterilization and deinsectization effects, can improve yield of crops, has no pollution to the environment and no residue, and has good economic value and social value.

Owner:冯新平

Areca taro and spirulina compound taro crisp and production method thereof

InactiveCN102907480ANutritional balanceHigh nutritional valueBakery productsAdditive ingredientAquatic animal

The invention discloses areca taro and spirulina compound taro crisp and a production method thereof. The areca taro and spirulina compound taro crisp consists of two parts such as a skin and a crisp core, wherein the skin is prepared from flour, butter, salt and sugar; and the crisp core is prepared from areca taro, spirulina, dried small shrimp powder, dried scallop powder, butter, salt, sugar, a small amount of vanillin and the like. The areca taro and spirulina compound taro crisp has the crisp skin, the core has unique flavors of arecas and the spirulina, and the content of sugar is low, so that the areca taro and spirulina compound taro crisp is low in sweetness and suitable for children, the elderly and other groups. In addition, the areca taro and spirulina compound taro crisp makes use of the unique ingredients of terrestrial plants and aquatic animals such as the areca taro, the spirulina, dried small shrimps and dried scallops, is rich in nutrition and good in favor and facilitates the body health of human if being often eaten.

Owner:芋魁食品(福建)股份有限公司

Energy storage agent and preparation method thereof

InactiveCN104893668AMeet the requirements of environmental protection and high efficiencyThe production process is environmentally friendlyHeat-exchange elementsSodium polyacrylateSodium carboxymethylcellulose

The invention provides an energy storage agent and a preparation method thereof. The energy storage agent comprises the following components by weight percent: 0.5-6% of a mixture of at least two of gelatinized starch, sodium alginate, sodium polyacrylate and carboxymethyl cellulose sodium, 0.2-4% of sodium chloride, 0.1-2% of borax, 0.2-3% of silicon dioxide, and the balance of water. The components used in the energy storage agent are non-toxic, odorless, energy-saving, environment-friendly, temperature-controllable, large in thermal capacity, long in heat preservation time, and wide in application range.

Owner:周锦泉

Antibacterial degradable composite fiber preparation method

PendingCN110846898AImprove antibacterial propertiesProcess environmental protectionBiochemical fibre treatmentVegetal fibresCellulosePolymer science

The invention discloses an antibacterial degradable composite fiber preparation method. The method includes steps: A, cellulose spinning; B, compound fluid preparation / compound sizing enhancement solution preparation; C, antibacterial cellulose-polyvinyl alcohol composite fiber preparation. By improvement and development of a traditional lyocell fiber process, an antibacterial composite fiber is obtained, a technical process is environmentally friendly, and the obtained composite fiber is stable in antibacterial performance and applicable to cloth and rope products. In addition, the compositefiber applied to fields of agriculture, clothing and the like is not only excellent in antibacterial performance but also high in environmental friendliness due to easiness in degradation under natural conditions, and the environmental problem caused by white pollution can be hopefully improved from the source by popularization of materials like the composite fiber in the future.

Owner:SHIJIAZHUANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com