Preparation method for modified starch comb-shaped copolymer

A comb-like copolymer and starch technology, applied in the field of materials, can solve the problems of large amount of water reducing agent, low molecular anion charge, and the electrostatic repulsion cannot be fully exerted, and achieves excellent performance, avoids excessive retardation, and has good performance. Beneficial effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

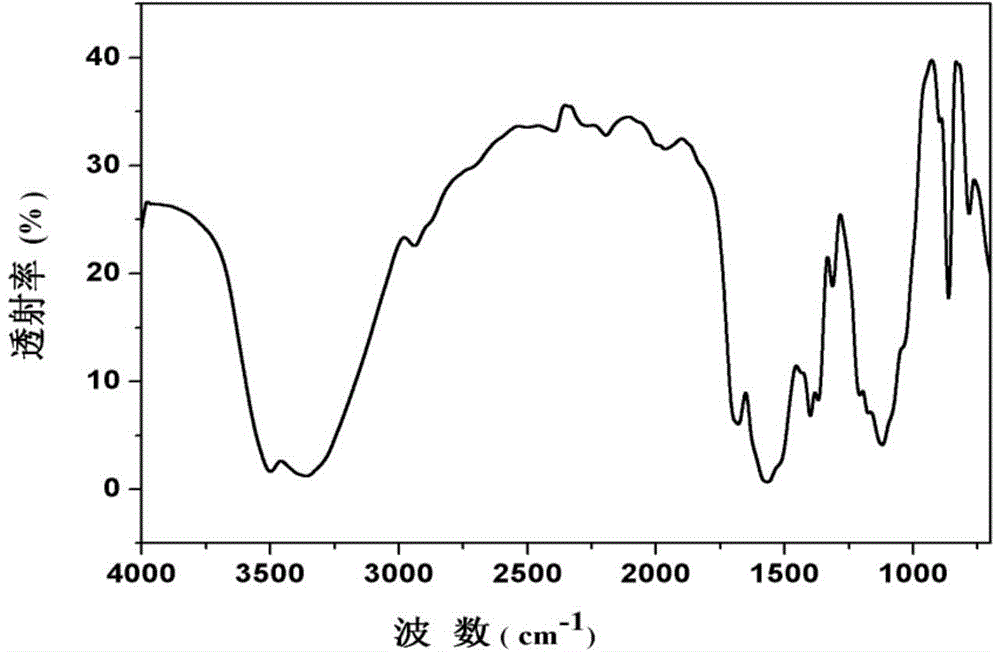

Image

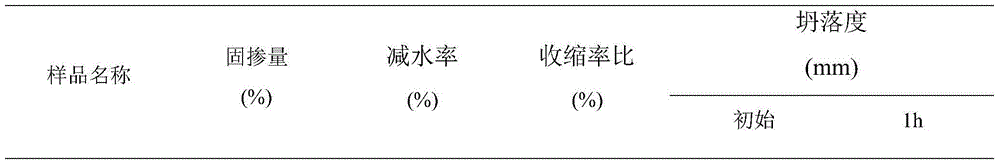

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method of modified starch type comb copolymer comprises the following steps:

[0031] a, preparation of sulfonated starch

[0032] Take amylose with a number average molecular weight of 12,000, add water to prepare starch milk with a starch weight percentage of 30%, then add concentrated sulfuric acid 1.5 times the weight of the starch, react at 50°C for 40 minutes, and then wash and dry. Prepare sulfonated starch;

[0033] b. Preparation of esterified starch

[0034] Take sulfonated starch, add water to prepare sulfonated starch milk with 30% by weight of sulfonated starch, add dropwise aqueous solution of maleic anhydride with 50% by weight of maleic anhydride at 50°C within 0.5h, The molar ratio of acid anhydride to sulfonated starch is 1.2:1, followed by heat preservation for 3 hours, followed by washing and drying to obtain esterified starch;

[0035] c, preparation of modified starch type comb copolymer

[0036] Prepare este...

Embodiment 2

[0037] Embodiment 2: a kind of preparation method of modified starch type comb copolymer, comprises the following steps:

[0038] a, preparation of sulfonated starch

[0039] Take amylose with a number average molecular weight of 26,000, add water to prepare starch milk with a starch weight percentage of 30%, then add concentrated sulfuric acid 1.5 times the weight of the starch, react at 45°C for 40 minutes, and then wash and dry. Prepare sulfonated starch;

[0040] b. Preparation of esterified starch

[0041] Take sulfonated starch, add water to prepare sulfonated starch milk with 30% by weight of sulfonated starch, add dropwise aqueous solution of maleic anhydride with 50% by weight of maleic anhydride at 50°C within 0.5h, The molar ratio of acid anhydride to sulfonated starch is 1.5:1, followed by heat preservation for 3 hours, followed by washing and drying to obtain esterified starch;

[0042] c, preparation of modified starch type comb copolymer

[0043] Prepare est...

Embodiment 3

[0044] Embodiment 3: a kind of preparation method of modified starch type comb copolymer, comprises the following steps:

[0045] a, preparation of sulfonated starch

[0046] Take amylose with a number average molecular weight of 20,000, add water to prepare starch milk with a starch content of 30% by weight, then add concentrated sulfuric acid twice the weight of the starch, react at 50°C for 40 minutes, and then wash and dry. Prepare sulfonated starch;

[0047] b. Preparation of esterified starch

[0048] Take sulfonated starch, add water to prepare sulfonated starch milk with 30% by weight of sulfonated starch, add dropwise aqueous solution of maleic anhydride with 50% by weight of maleic anhydride at 50°C within 0.5h, The molar ratio of acid anhydride to sulfonated starch is 1.5:1, followed by heat preservation for 3.5 hours, followed by washing and drying to obtain esterified starch;

[0049]c, preparation of modified starch type comb copolymer

[0050] Prepare esteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com