Patents

Literature

1660results about How to "Guarantee normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron coke for blast furnace and preparing method thereof

InactiveCN103468289AEnsure Strength IndexBest heating speedCoke ovensBlast furnace detailsCoke ovenUltimate tensile strength

The invention relates to iron coke for a blast furnace and a preparing method thereof. The iron coke comprises 5wt%-20wt% of iron ore powder and 80wt%-95wt% of mixed coal; the mixed coal is formed by mixing 25wt%-29wt% of one third of coking coal, 40wt%-44wt% of coking coal, 7wt%-11wt% of lean coal, 6wt%-10wt% of gas-fat coal and 12wt%-16wt% of fat coal; the iron ore powder and the mixed coal are mixed uniformly with water and tamped before entering the blast furnace, and are placed into the blast furnace when the temperature is 800 DEG C, the temperature is increased at the speed of 2 DEG C per minute to 3 DEG C per minute, the iron ore powder and the mixed coal are discharged from the blast furnace when the temperature is 950-1050 DEG C, and the iron coke is obtained by adopting a wet way of quenching the coke. According to the iron coke and the preparing method, the performance, the ratio, the particle size and the composition and the like of the iron ore powder and the mixed coal are optimized, and the strength and the reactivity of the iron coke can meet the requirement of the blast furnace process under the circumstance of not adding binding agents.

Owner:WUHAN UNIV OF SCI & TECH

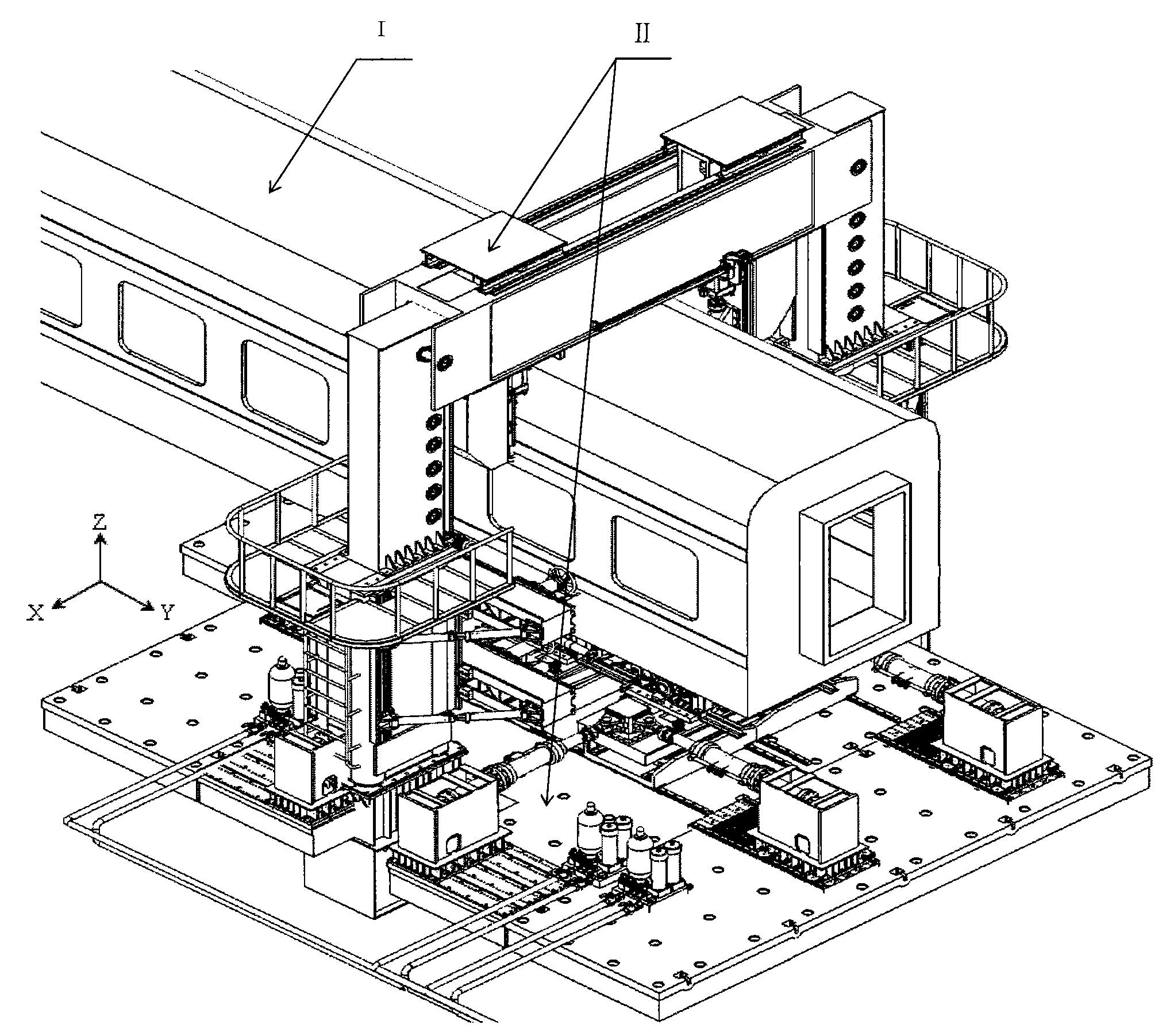

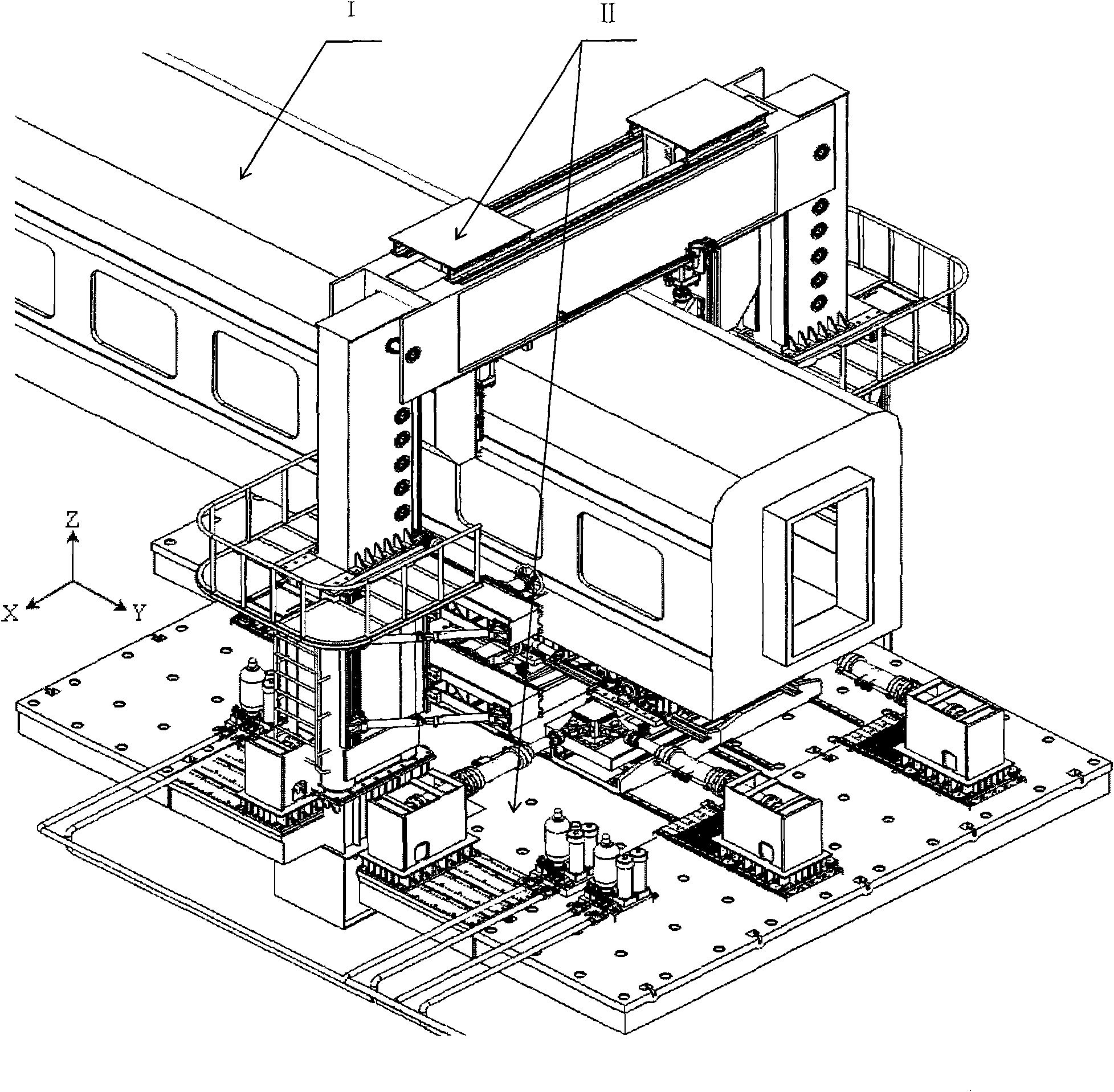

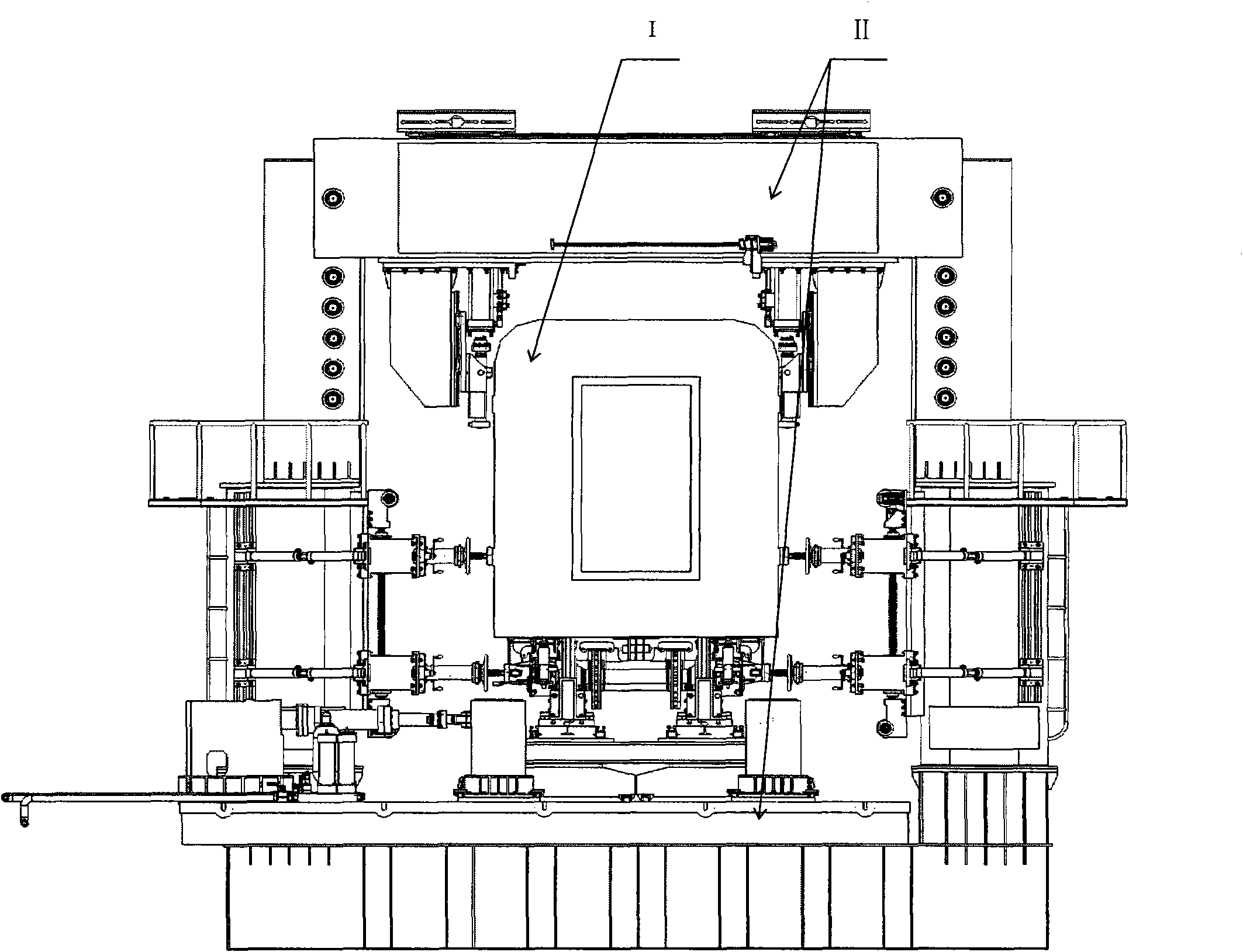

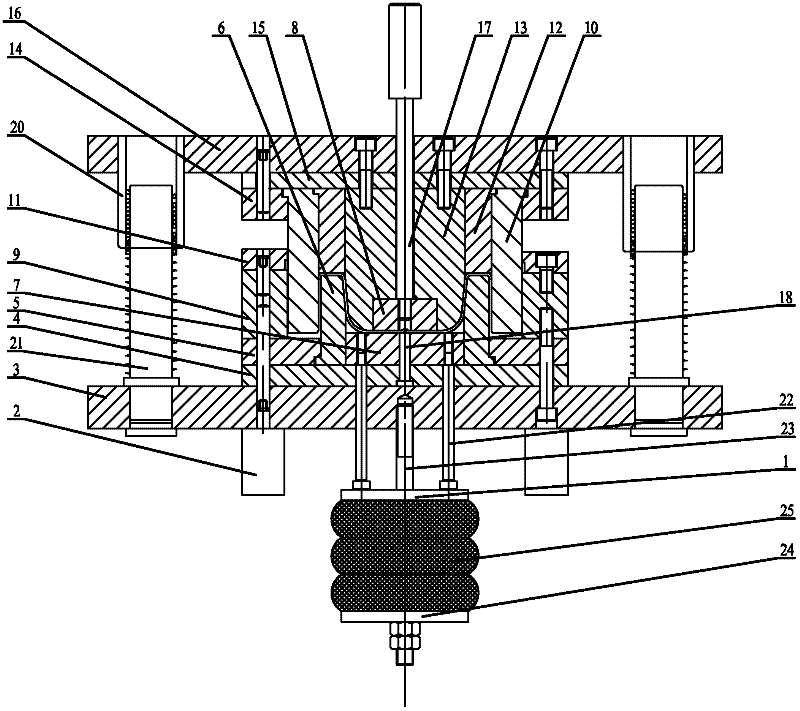

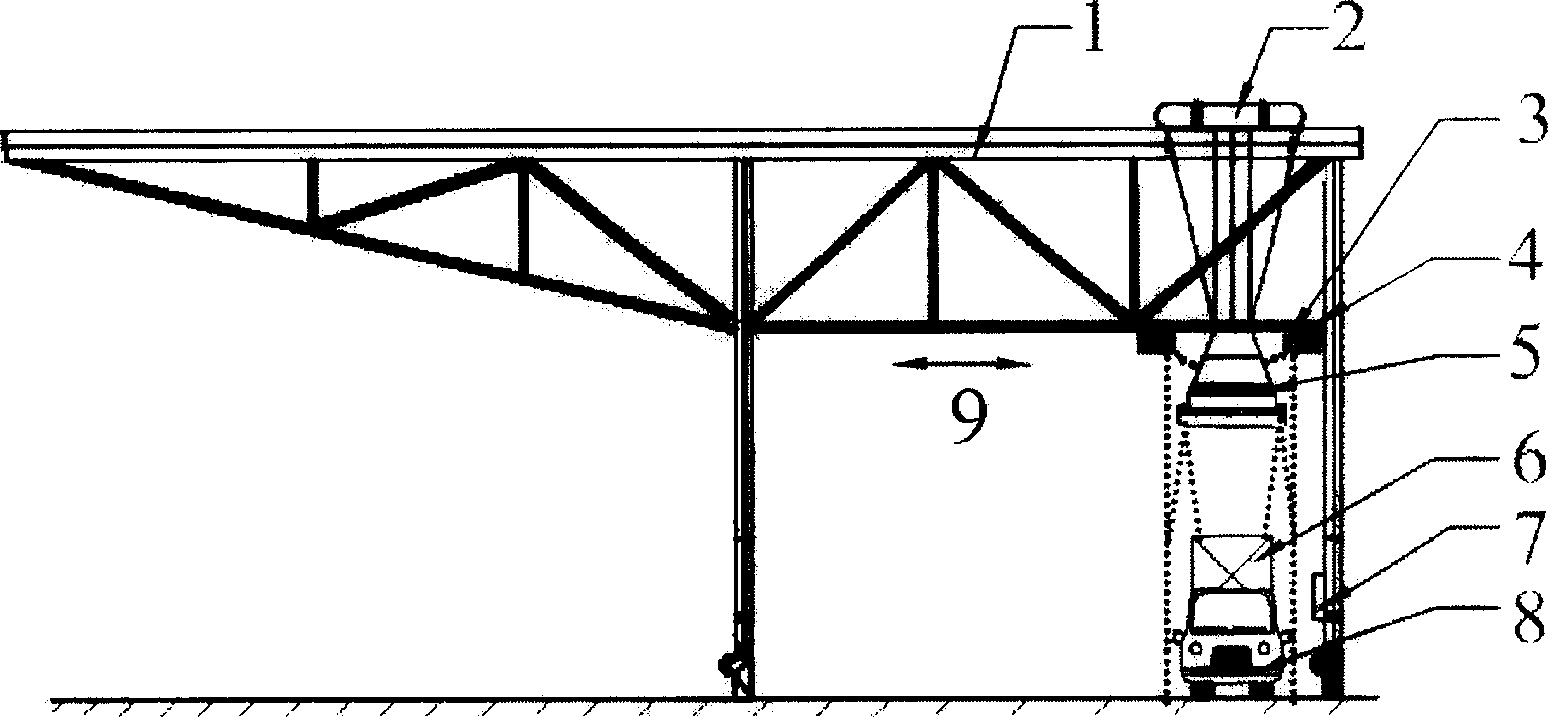

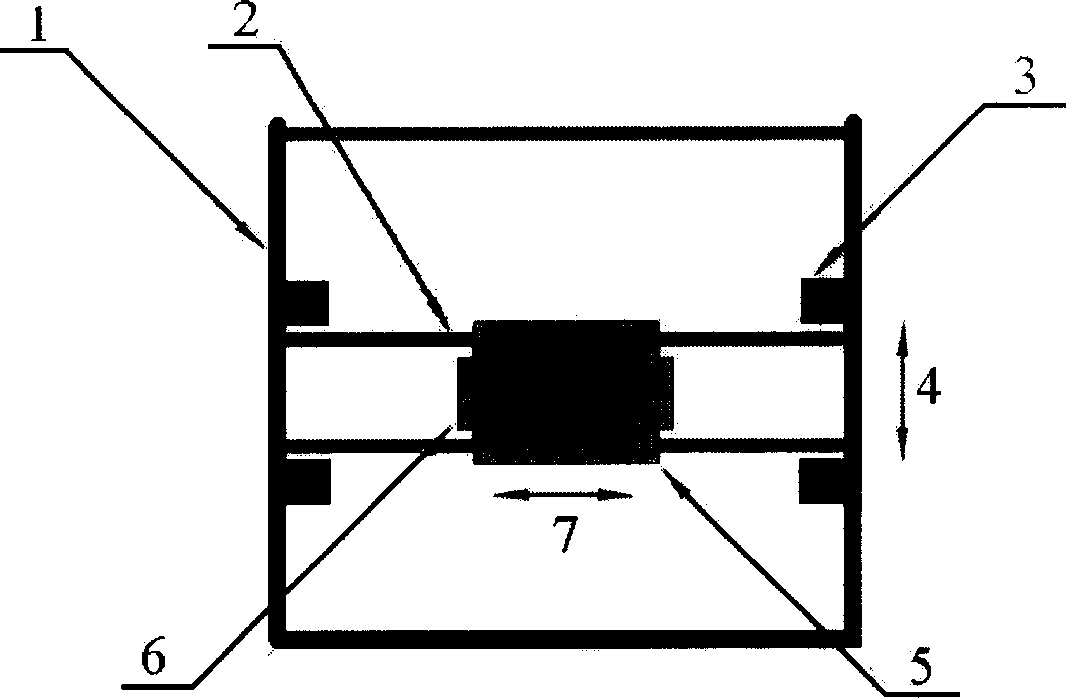

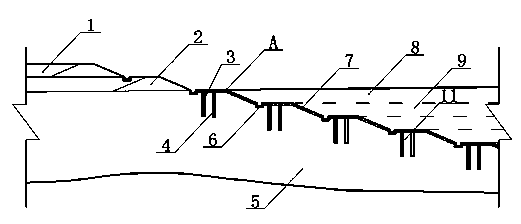

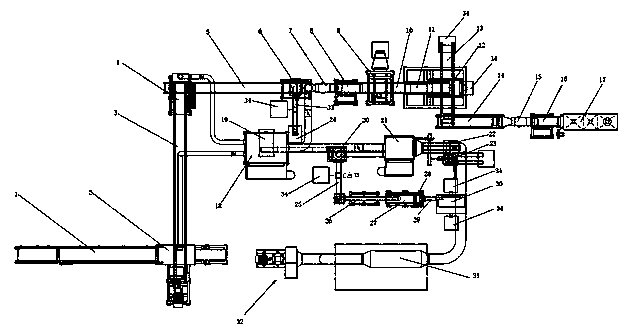

Integrated dynamic testboard of parameter of bogie of railway car

InactiveCN101813550ASolve the single functionProgrammatic highWork measurementRailway vehicle testingBogieEngineering

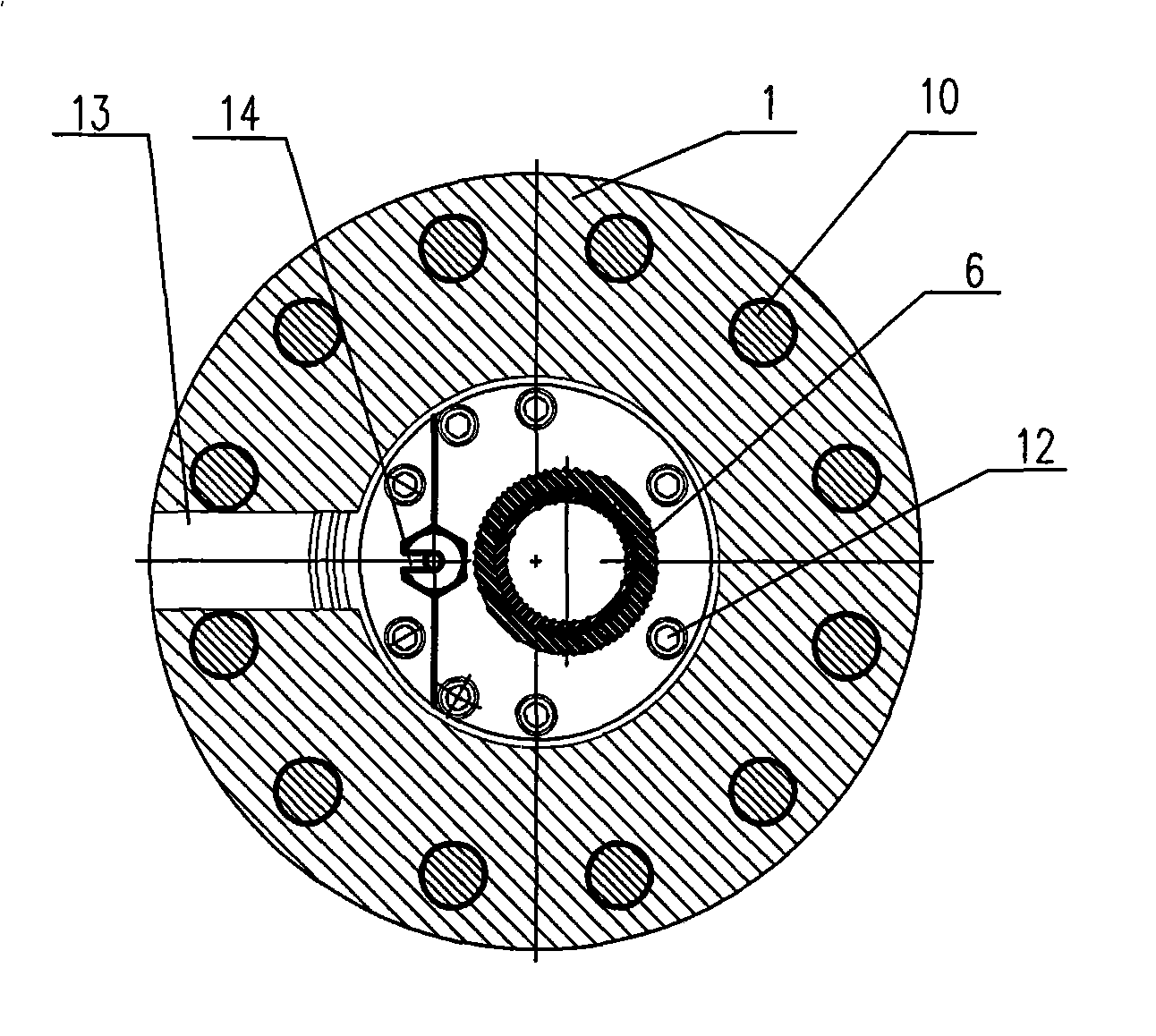

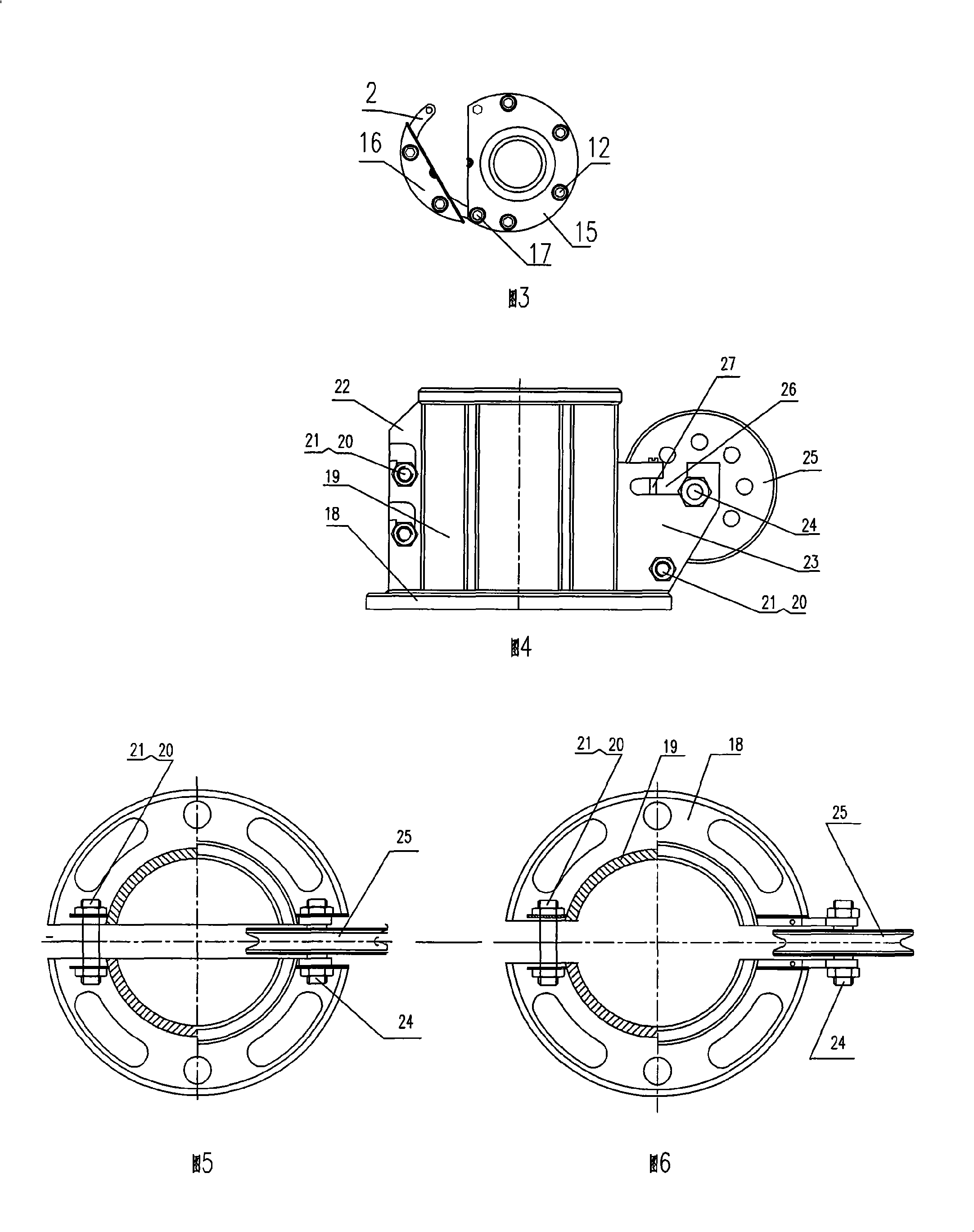

The invention relates to detection equipment of a kinetic parameter of a railway car, in particular to an integrated dynamic testboard of a parameter of a bogie of a railway car, which comprises a multi-freedom degree dynamic loading platform (A) and a lift type loading gantry (B), wherein the multi-freedom degree dynamic loading platform (A) mainly comprises a combined type cast steel reference platform (a), a peripheral hydraulic unit (b), a truss longitudinal limit device (c) and a multi-freedom degree sliding table loading device (d); the lift type loading gantry (B) mainly comprises a lift type gantry side beam assembly (e), a lift type gantry cross beam (f), a vertical loading assembly (g) and a lift type gantry sill beam (h). The testboard can carry out dynamic test on the rigidity parameter of a bogie under two states of carload completion and independence by regulating the truss longitudinal limit device (c), the lift type gantry cross beam (f) and the vertical loading assembly (g) without disassembly, and thereby, the goal of integrated multi-function test is achieved.

Owner:JILIN UNIV

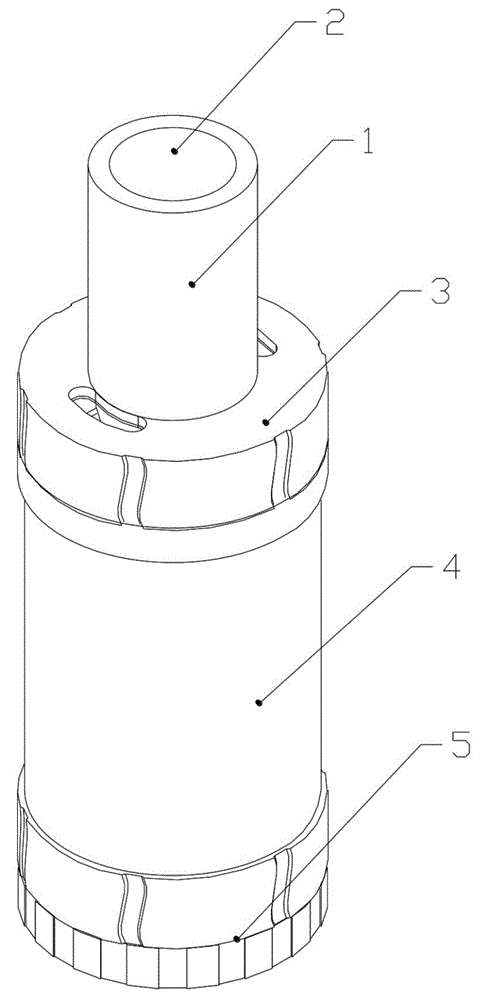

Electronic cigarette atomizer

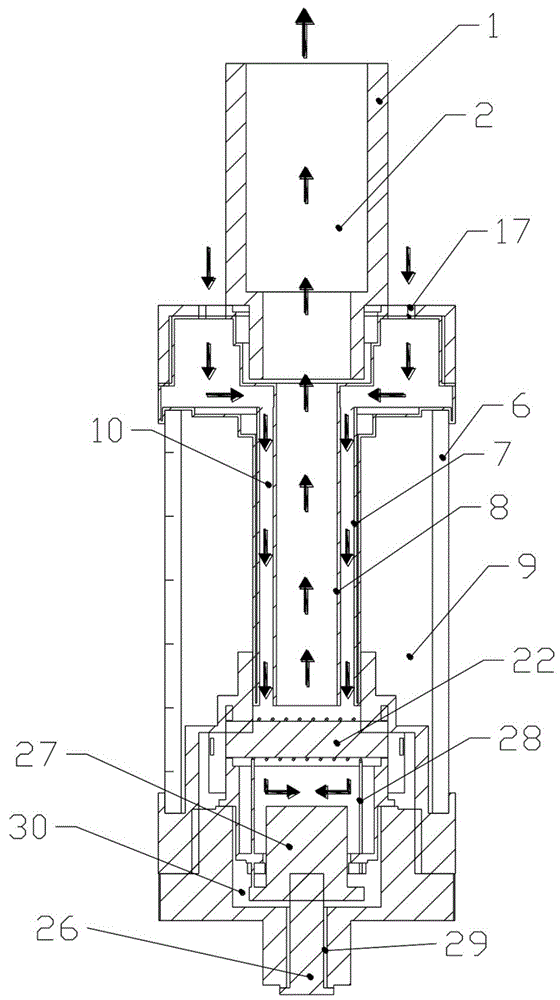

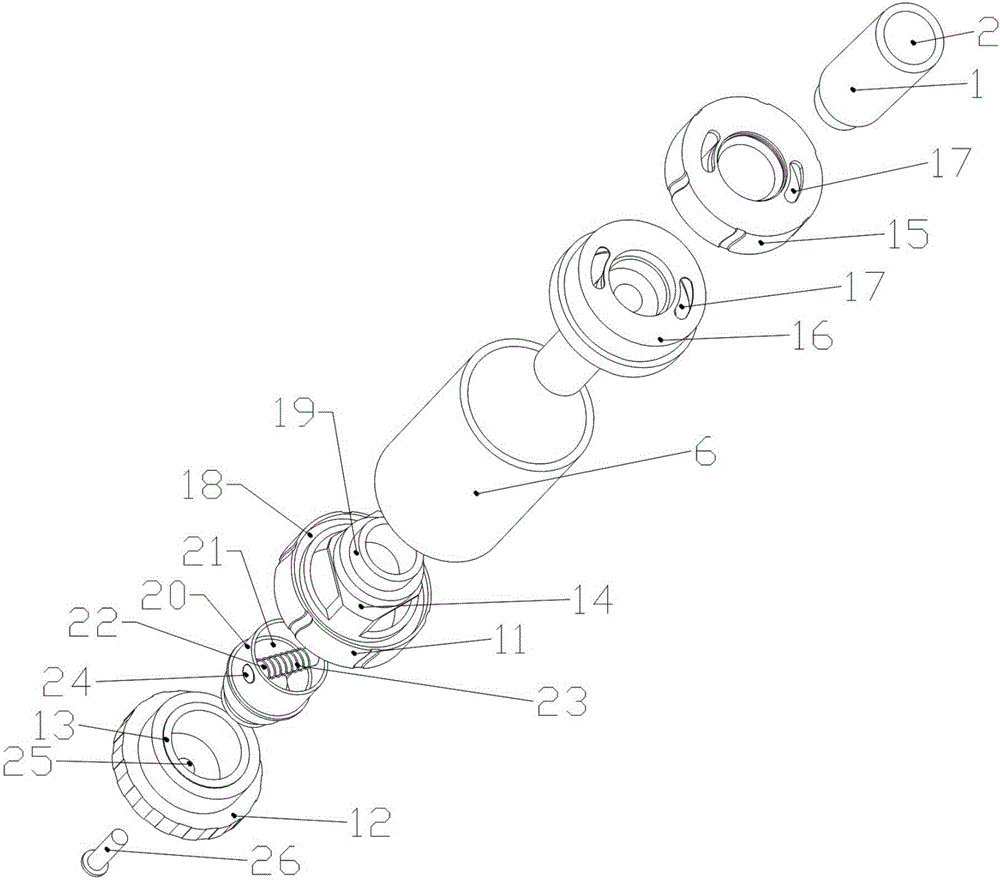

InactiveCN104939326AAvoid Leakage ProblemsExtended service lifeTobacco devicesEngineeringElectronic cigarette

The invention discloses an electronic cigarette atomizer which is characterized by including a cigarette holder with a smoking hole and an atomizer body detachably connected with the cigarette holder, wherein the cigarette holder includes a cigarette holder body and a sealing part; the cigarette holder body is in threaded connection with the sealing part; the atomizer body includes an atomizing bin and a fixing base; the atomizing bin is in threaded connection with the fixing base. According to the electronic cigarette atomizer provided by the invention, air inlets are formed in the top of the electronic cigarette atomizer, which utilizes the theory that air inflows through the top of the atomizer to form air recirculation, and inner pipes inside the atomizer are connected with an atomizing core at the bottom of the atomizer in a sealing manner, so that liquid leakage of an electronic cigarette is avoided; a liquid guide structure is adopted for sucking nicotine liquid automatically from a liquid storage chamber, so that a large amount of external air enters an atomizing chamber, sufficient air is provided for the atomization of nicotine liquid, the nicotine liquid can be fully atomized to ensure that a large amount of smoke is generated, the dry burning problem caused by insufficient supply of nicotine liquid is avoided, and the service life of the atomizer is prolonged.

Owner:杨卫东

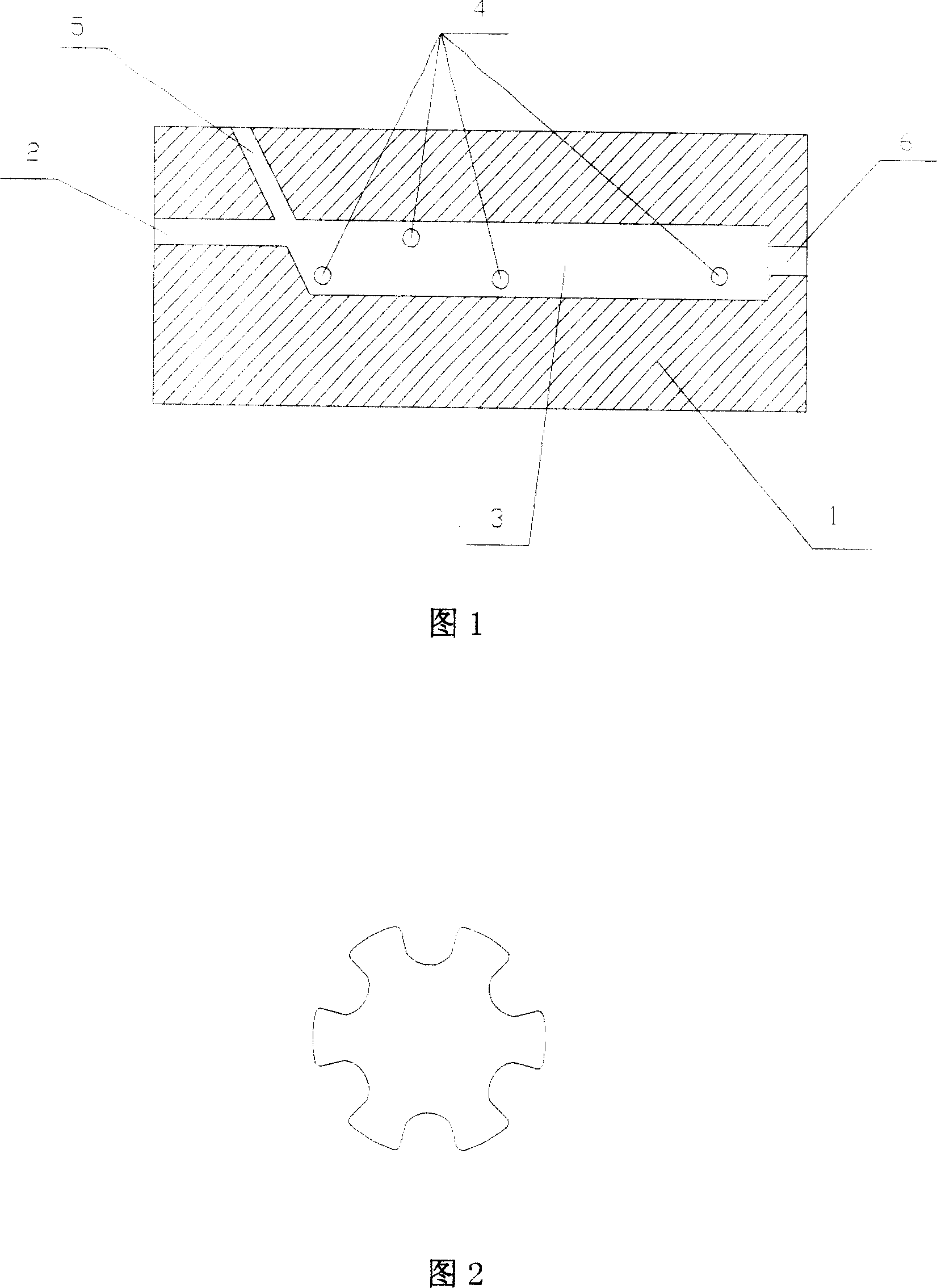

Method for shaping continuous fiber reinforced thermoplastic resin and shaping equipment thereof

ActiveCN101152767AAvoid mutual interferenceContinuous and stable productionFiber bundleFree rotation

The present invention discloses a molding method and molding equipment for a continuous fiber reinforced thermoplastic resin. The molding equipment of the present invention comprises a melting soakage mould. The melting soakage mould comprises a soakage mould outer body and a thermoplasticity resin fused mass crack flow passage, a soakage independent flow passage, a continuous fiber inlet passage and a soakage outlet which are arranged in the soakage mould outer body. The thermoplasticity resin fused mass crack flow passage is arranged on upstream end and forms an angle with the continuous fiber inlet passage. The thermoplasticity resin fused mass crack flow passage and the continuous fiber inlet passage are both communicated with the soakage independent flow passage. The soakage outlet is arranged on downstream end and is communicated with the end of the soakage independent flow passage. The soakage independent flow passage is also provided with at least one tension roller group which is capable to rotate freely. Using the molding equipment of the present invention for manufacturing continuous fiber reinforced thermoplastic resin avoids the interference and impairment between fiber bundles, guarantees the stable and continuous production and improves the dipping effect, so fiber reinforced thermoplastic resin with excellent performance can be obtained.

Owner:KINGFA SCI & TECH CO LTD +1

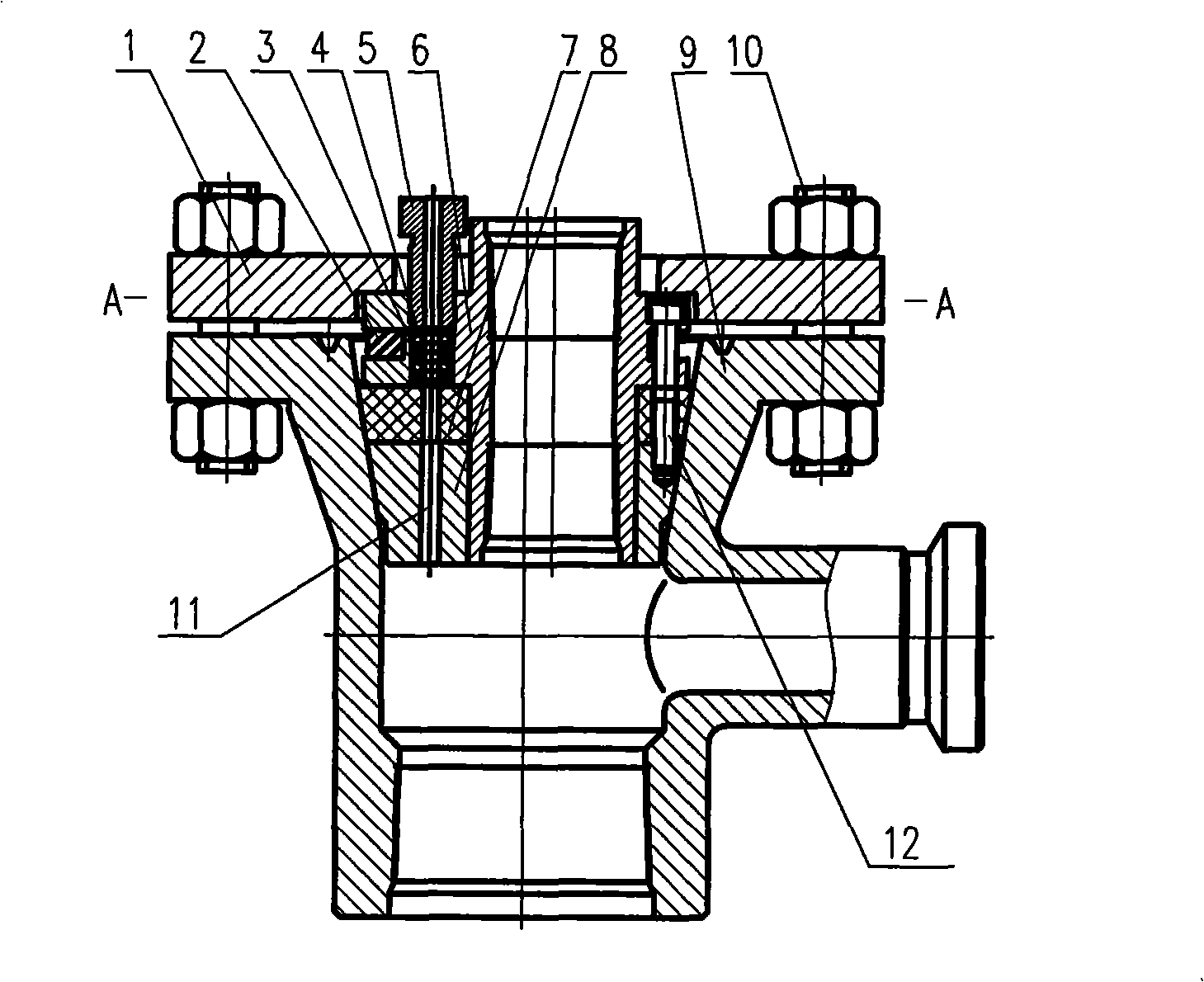

Preset production fluid section plane test method of mechanical mining horizontal well and special shaft mouth test apparatus

ActiveCN101403291AEasy to get up and downSo as not to damageSurveySealing/packingSection planeTubing hanger

The invention relates to a mechanical recovery horizontal well preset produced fluid profile testing method and a special wellhead testing device thereof, mainly aiming at solving the problem of the downhole testing of a mechanical recovery horizontal well. The invention is characterized in that: the special wellhead testing device comprises an eccentric type tubing hanger body connected with a tubing string, wherein, the side wall of the tubing hanger body is divided into a body and splits which are completely matched with each other, and the splits are fixed on a locking arm which is fixed on the body though bolts; and a corresponding matched cable penetrating a channel is arranged at the splitting seam of the body and the splits, the channel is internally provided with a cable gasket, a spacer and a pressing cap. By being matched with a special wellhead support, under the condition that a testing cable and a tester are pre-arranged in the horizontal well to test a target layer, an oil pipe does not touch the cable during the up and down process of the oil pipe. The method and the special wellhead testing device can realize the produced fluid profile testing of the mechanical recovery horizontal well, and ensure the accuracy of normal testing and data of the mechanical recovery horizontal well with simple and reliable operation method.

Owner:DAQING OILFIELD CO LTD +1

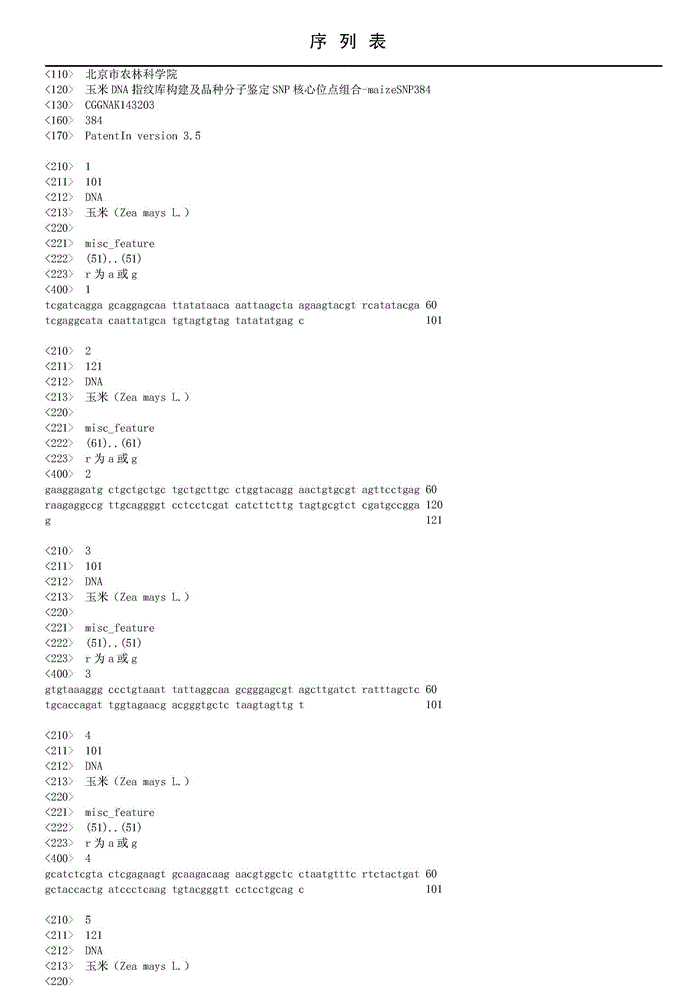

Core SNP sites combination maizeSNP384 for building of maize DNA fingerprint database and molecular identification of varieties

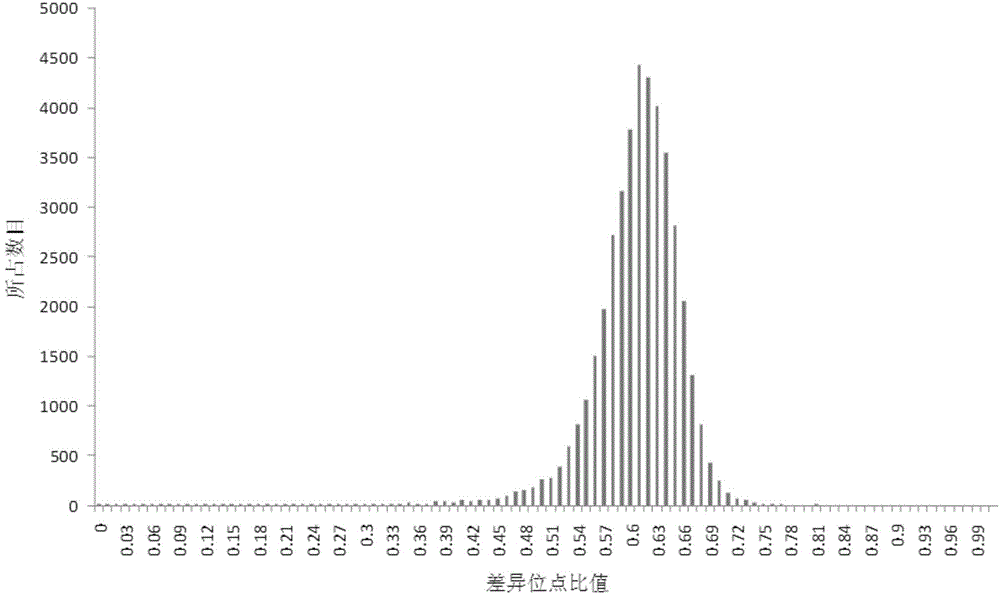

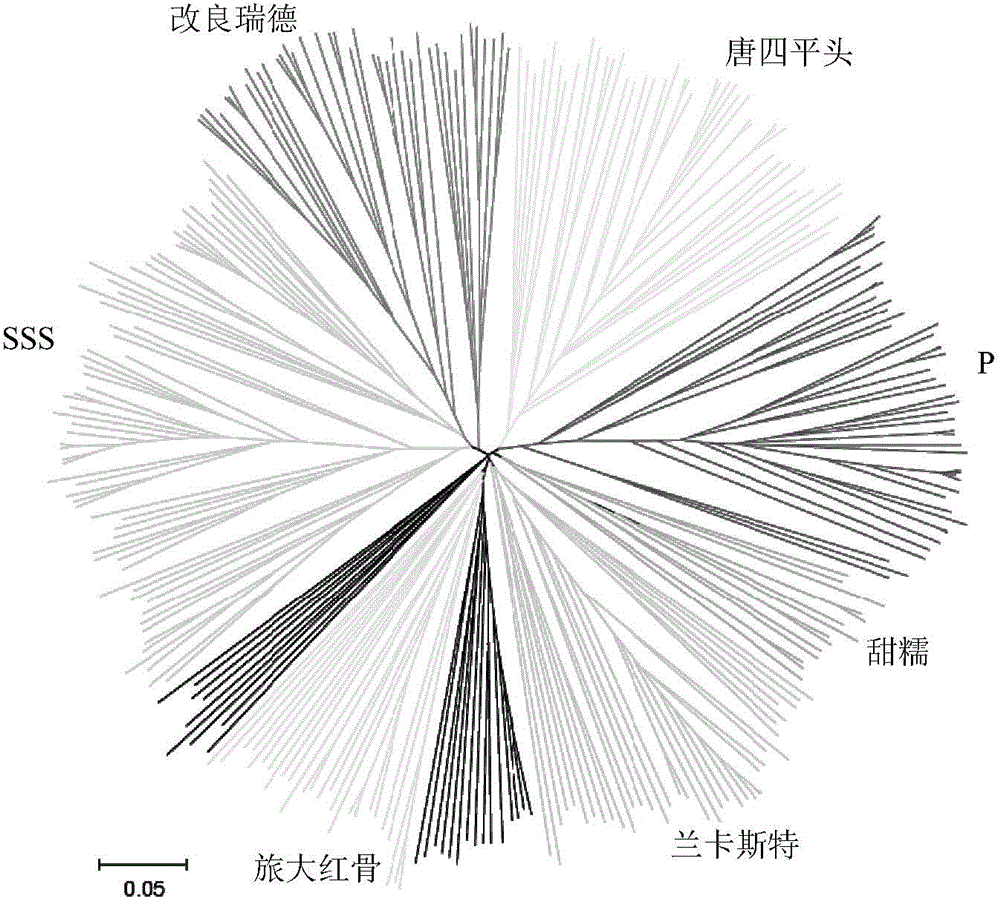

ActiveCN104532359AImprove stabilityGood repeatabilityNucleotide librariesMicrobiological testing/measurementMolecular identificationAgricultural science

The invention discloses a core SNP sites combination maizeSNP384 for building of a maize DNA fingerprint database and molecular identification of varieties, and an application of the core SNP sites combination. The invention provides applications of 384 SNP sites in any one of the following conditions: (1) building of the maize DNA fingerprint database; (2) detecting of the authenticity of maize varieties; (3) genetic analysis of corn germplasm resources; and (4) molecular breeding of maize, wherein the physical positions of the 384 SNP sites are determined by comparison on the basis of a whole genome sequence of the maize variety B73; the version number of the whole genome sequence of the maize variety B73 is B73 RefGen V1; and the 384 SNP sites are MG001-MG384. An experiment proves that the 384 SNP sites can be applied to building of the maize variety DNA fingerprint database, identification of the variety authenticity, dividing of germplasm resource groups, and other related researches.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

PVC (polyvinyl chloride) coated fabric paste and preparation method thereof

The invention discloses a functional PVC (polyvinyl chloride) paste. The functional PVC paste comprises the following components: PVC paste resin, PVC doped resin, a plasticizing agent, a filling agent, a heat stabilizer, a light stabilizer, an antioxidant, a mildew-proof antibacterial agent, a gas-phase silicon dioxide and the like. A preparation method of the functional PVC paste comprises the following steps of: (1) stirring: firstly mixing and stirring a part of the plasticizing agent and a liquid component uniformly, then adding a solid component, stirring uniformly, finally adding coloring stock and the remaining plasticizing agent, and stirring uniformly, so as to obtain plasticized paste; (2) grinding: grinding the plasticized paste on a three-roll grinding machine; and (3) defoaming and ageing. The paste has the advantages that the viscosity stability is good; and the paste can remain low viscosity under the action of the shearing force of a scraper in the process of producing PVC coated fabric, so that the normal production of the PVC coated fabric is guaranteed, and the surface of the prepared PVC coated fabric is smooth without the phenomena of pin holes and the like.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

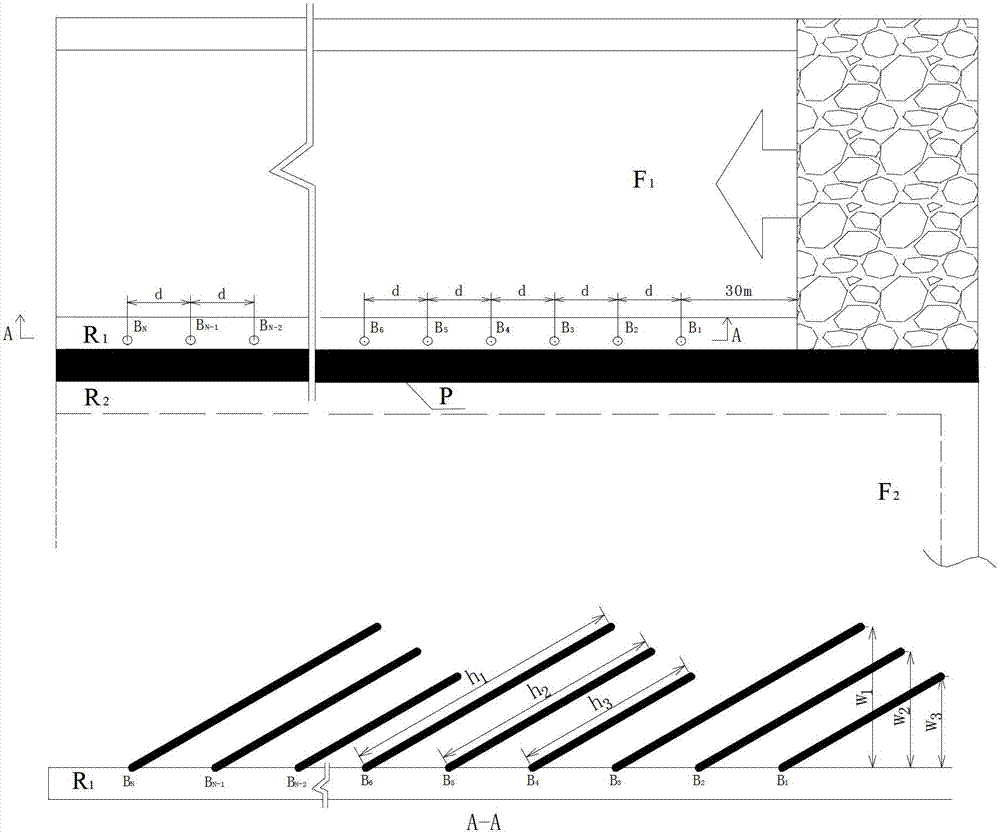

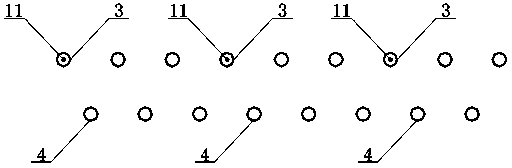

Beside-roadway escribing pressure relief method of roadway driving along gob of small coal pillar influenced by dynamic pressure

InactiveCN102778182AShorten exercise timeEliminate mining dynamic pressureBlastingEngineeringCoal pillar

The invention discloses a beside-roadway escribing pressure relief method of roadway driving along a gob of a small coal pillar influenced by dynamic pressure. The method includes the following steps: adopting roadway roof deep hole blasting as the escribing method, arranging escribing shot holes within the overall length range of an adjacent working surface crossheading of the roadway driving along the gob, and implementing stage blasting operation during back production of the working surface, wherein the escribing shot holes need to be close to the small coal pillar as far as possible, the depth of the escribing shot holes is determined according to the mining height of the back production working surface and the free caving height of the roof of the working surface, the shot holes need to be arranged with a distance away from the working surface, and the distance among the shot holes need to be determined reasonably; then performing explosive filling and hole blocking; performing ahead blasting operation in front of the working surface or lag blasting operation after the shot holes enter a gob area; and instantly performing roadway driving along the gob when the bad influence on the essence of the roadway driving along the gob of the small coal pillar caused by dynamic pressure of the working surface can be basically eliminated when back production of the adjacent working surface is finished. By means of the beside-roadway escribing pressure relief method, normal production of a back production working surface is ensured, and the cost and difficulty in roadway support along the gob are greatly reduced.

Owner:SHANDONG UNIV OF SCI & TECH

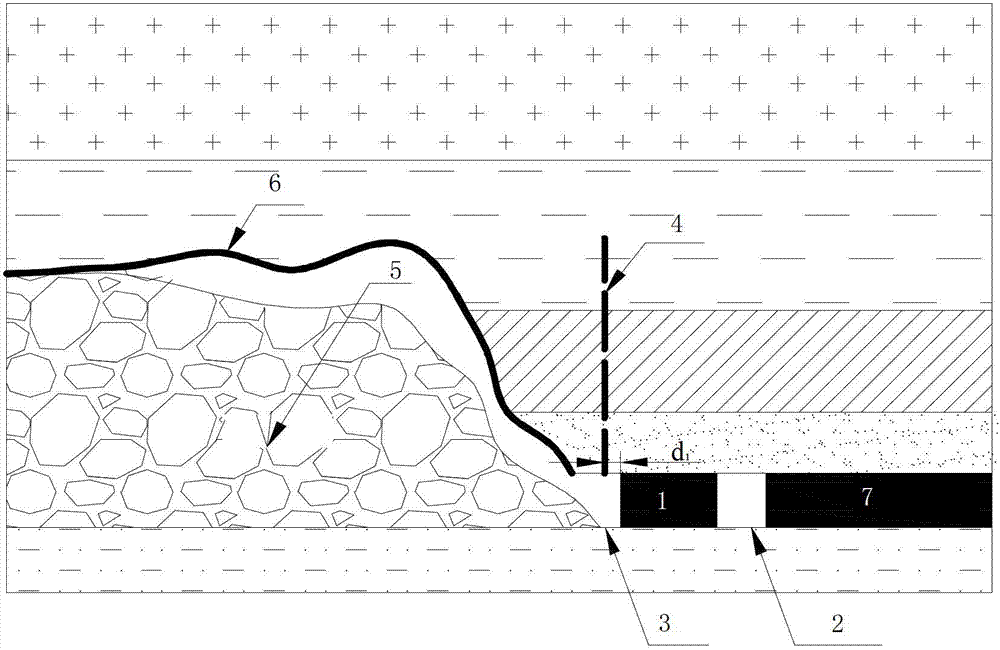

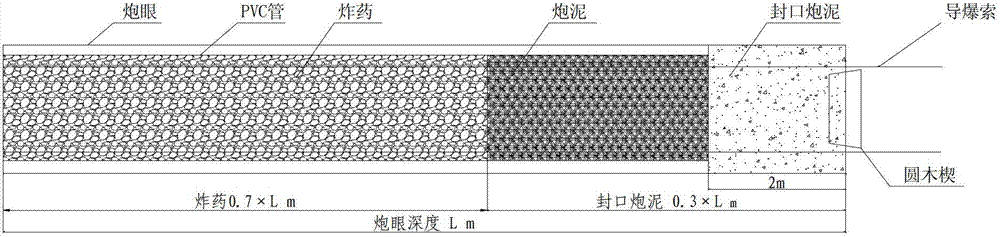

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

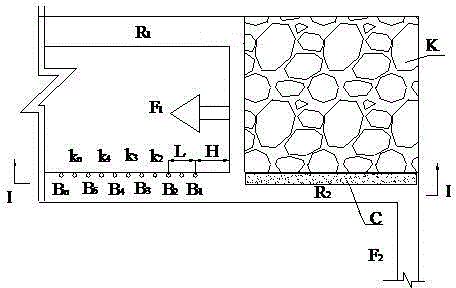

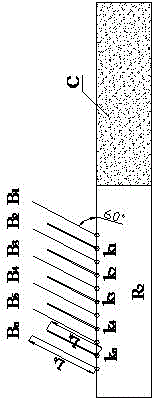

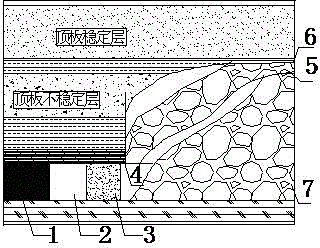

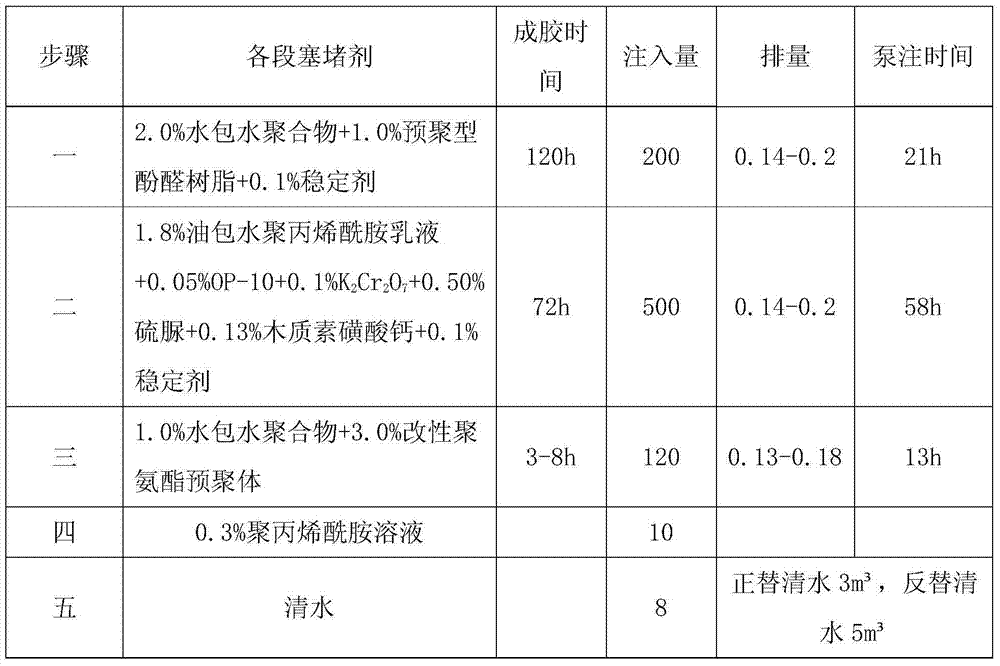

Composite slug deep water plugging method for oil pool with high water content

ActiveCN103498643ATo achieve the purpose of water controlReduce moisture contentDrilling compositionSealing/packingEnvironmental resistanceHigh intensity

The invention relates to a composite slug deep water plugging method for an oil pool with a high water content, and belongs to the technical field of oilfield development. The composite slug deep water plugging method for the oil pool with the high water content is characterized in that a composite slug is designed by using different plugging agent characteristics, high-strength plugging agents are filled into a near-wellbore zone slug, middle-strength plugging agents are filled into a transitional zone slug, and low-strength plugging agents are designed in a far-wellbore zone slug; foaming gel plugging agents are adopted as the high-strength plugging agents, inorganic chrome jelly plugging agents are adopted as the middle-strength plugging agents, and phenolic aldehyde jelly plugging agents are adopted as the low-strength plugging agents. The composite slug deep water plugging method has the advantages of being reasonable in process, easy to construct, long in water plugging validity period, free of poison, environmentally friendly, capable of achieving selective deep water storage, capable of plugging high-water-content zones and not damaging oil layers and long in water plugging validity period, effectively reducing the water content of oil well produced liquid, guaranteeing the normal production of an oilfield and the like.

Owner:陕西越洋石油技术服务有限公司

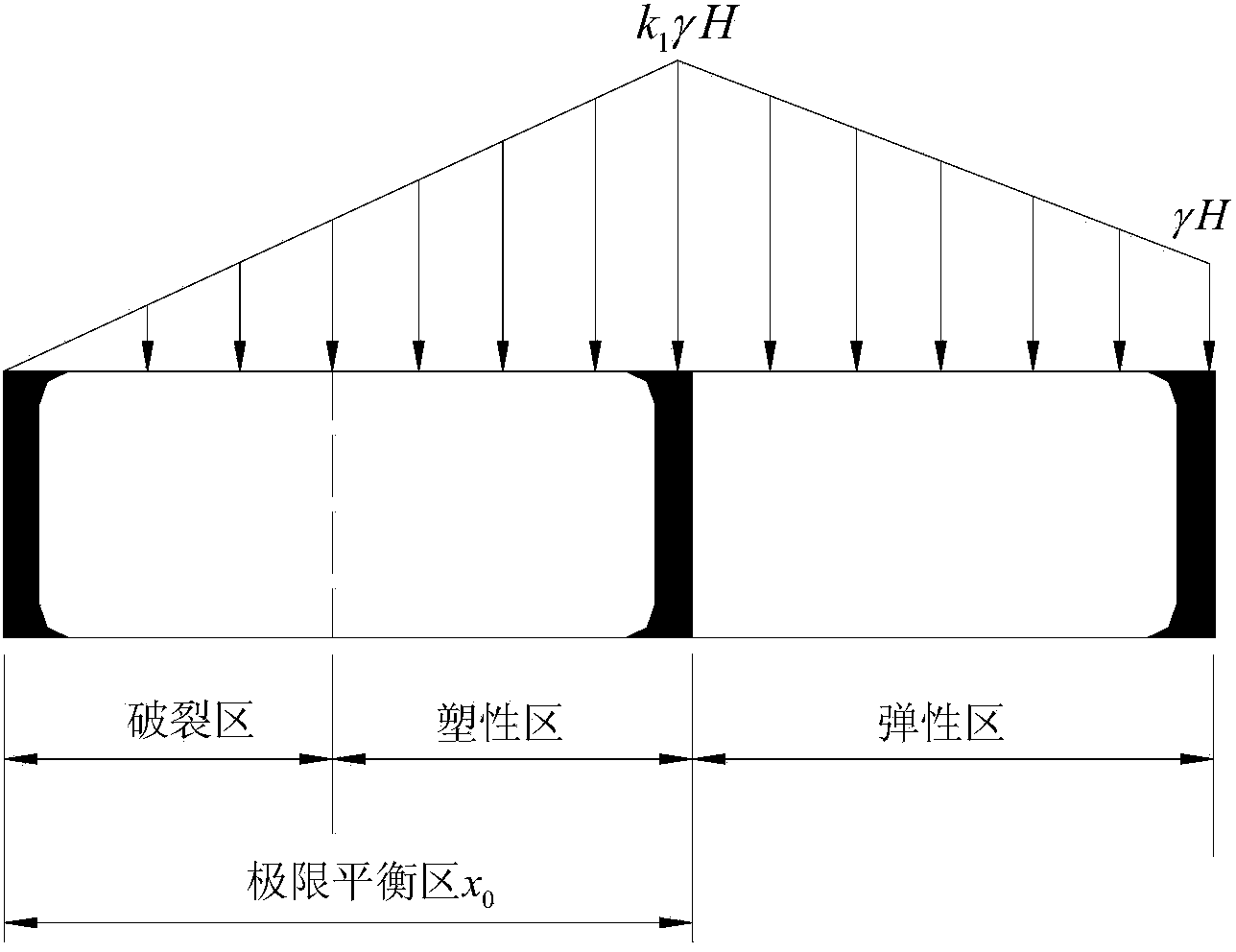

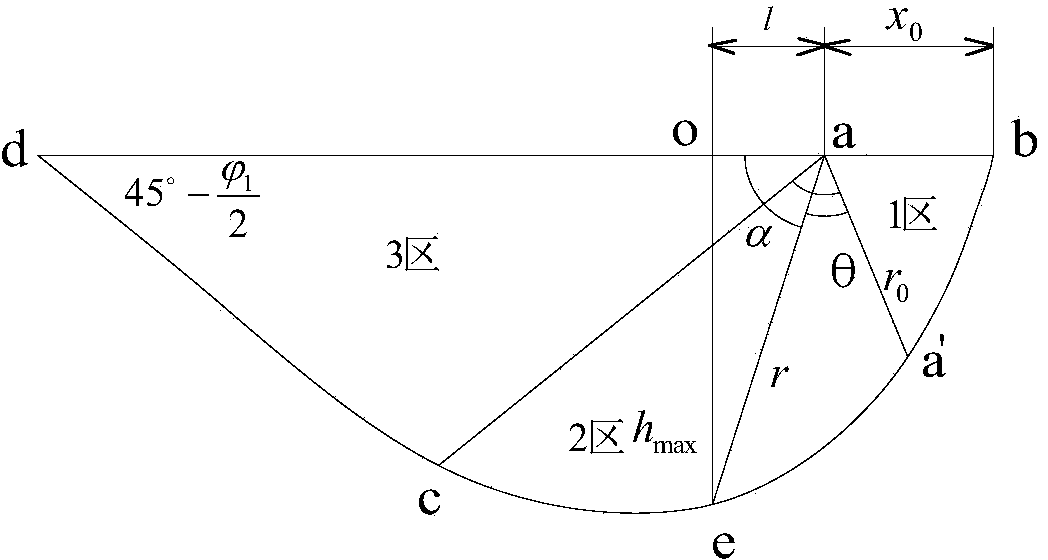

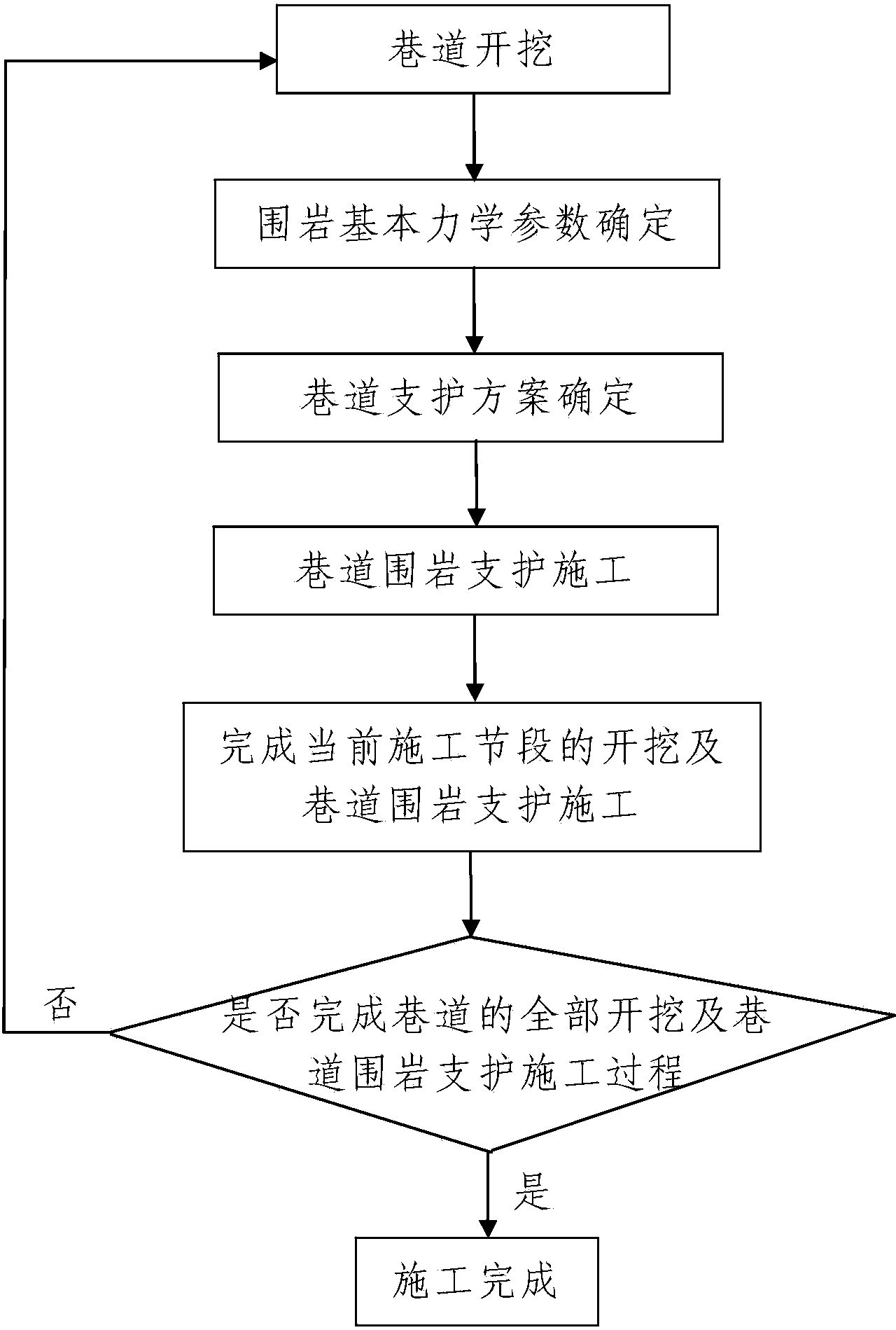

Rectangular roadway surrounding rock deformation and failure control method

The invention discloses a rectangular roadway surrounding rock deformation and failure control method which comprises steps as follows: 1), a roadway is excavated; 2), basic mechanical parameters of a surrounding rock are determined; 3), a roadway support scheme is determined as follows: roadway side unstability is judged, the caving arch rise is determined when the roadway side is in a stable state, the width of roadway side olistolith, the caving arch rise, the roadway side limit equilibrium area width, the maximum failure depth of a roadway bottom board and a horizontal distance between the maximum failure depth position and an adjacent roadway side wall are determined when the roadway side is in an unstable state, and a roadway support unit structure is determined; 4), a roadway surrounding rock support is constructed; 5), the next section is excavated, and the roadway surrounding rock support is constructed; and 6), the step 5) is repeated until all excavation and roadway surrounding rock support construction processes of the rectangular roadway are completed. The method is simple in step, convenient to implement and good in use effect, the roof caving and bottom swelling problems of the rectangular roadway can be effectively solved, and deformation and failure of the roadway surrounding rock can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

High-temperature high-pressure artifical sandproof well wall and construction technology thereof

A high-temp high-pressure artificial sand-controlling well wash for the oil well to recover thick oil by injecting steam is formed through pressure cracking of underground target stratus, high-pressure injecting of working liquid to form cracked seams in the stratum, carrying the quartz sand and refractory sand-controlling material into the seams by carrying liquid, closing the well and hydrating reacting to form a whole stratum.

Owner:LIAONING TIANYI IND CO LTD

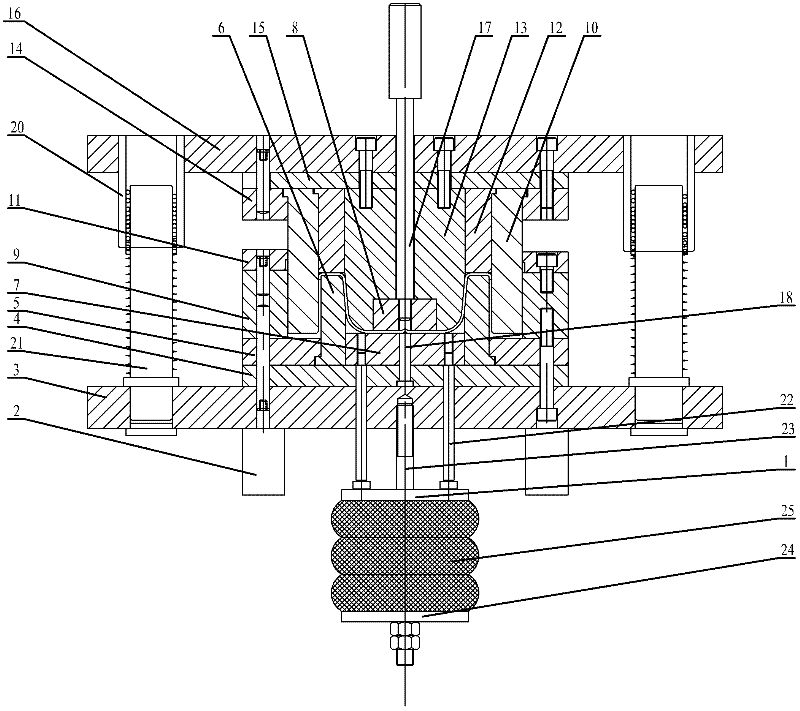

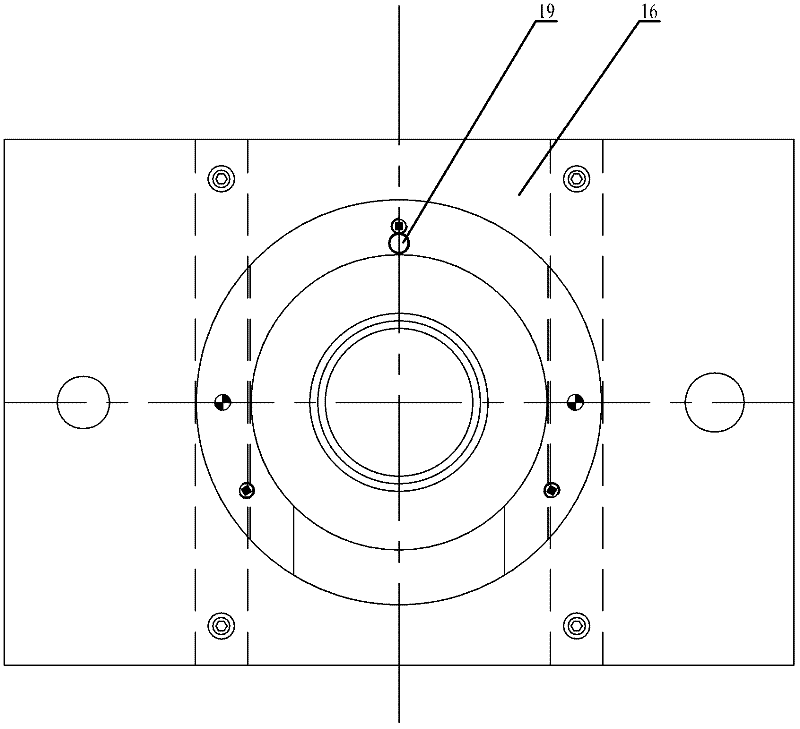

One-piece forming die with multiple functions

The invention relates to a one-piece forming die with multiple functions, in particular to one-piece forming cup die for use in fields of blanking, stretching, raising, lettering, flanging and the like. In the technical scheme, the one-piece forming die with multiple functions comprises an upper die plate and a lower die plate, wherein a guide sleeve is fixed to the edge part of the upper die plate; a stretching male die is fixedly arranged on the middle part of the lower surface of the upper die plate; a punching block is arranged inside the bottom end part of the stretching male die; a flanging female die insert is sleeved outside the stretching male die; a blanking flanging female and male die is sleeved outside the flanging female die insert; an upper fixed plate is sleeved outside the blanking flanging female and male die; a punching rod is arranged in the stretching male die and the upper die plate in a sliding mode; and the bottom end part of the punching rod is connected with the punching block. By the one-piece forming die, products can be formed in one piece, so that the yield and quality of the products can be improved.

Owner:无锡绿缘汽车零部件有限公司

Large-range goaf group filling method

InactiveCN103046955AGuarantee normal productionSimple filling processMaterial fill-upDrainagePipeRetaining wall

The invention relates to a large-range goaf group filling method and belongs to the technical field of mining engineering. According to the technical scheme, the method includes: dividing filling units, selecting filling material, and laying out filling pipes; calculating to determine the thickness of a filling retaining wall, performing site construction, reserving drain holes and filter holes in the filling retaining wall, and stacking a hillock inverted filter layer behind the filling retaining wall; laying filter pipes, allowing the filter pipes to extend out from the drain holes of the filling retaining wall; constructing a filling borehole, 133mm-150mm in diameter, at a highest point, applying the filling borehole as an overhead discharge point, ensuring roof contact, constructing the corresponding number of filling boreholes according to practical situation, and performing alternating filling. The large-range goaf group filling method has the advantages that filling process is simplified, filling efficiency is increased, plugging amount is decreased, filling amount is decreased, filling period is shortened, filling cost is lowered, and normal mine production is guaranteed.

Owner:HEBEI IRON & STEEL GRP MINING +2

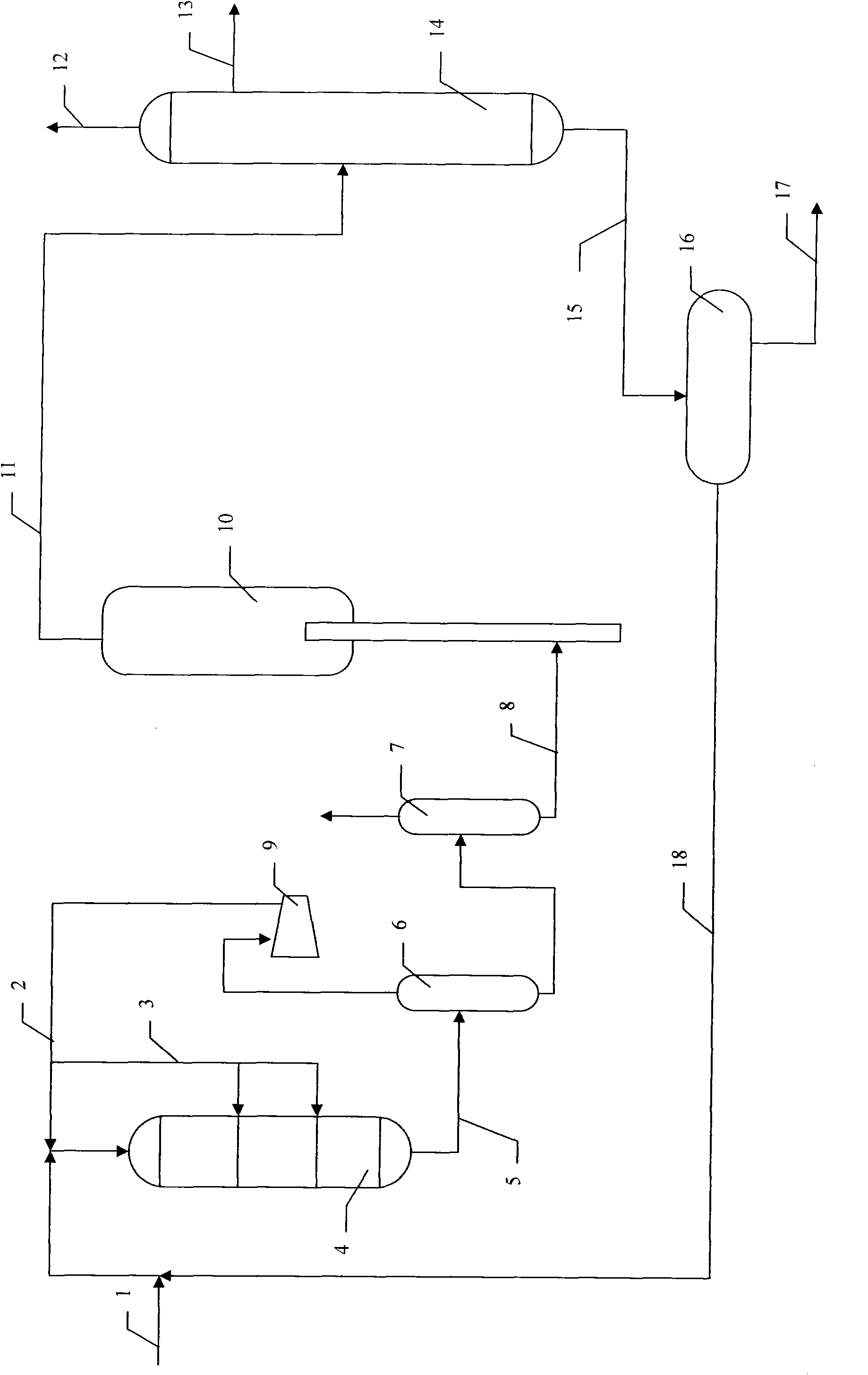

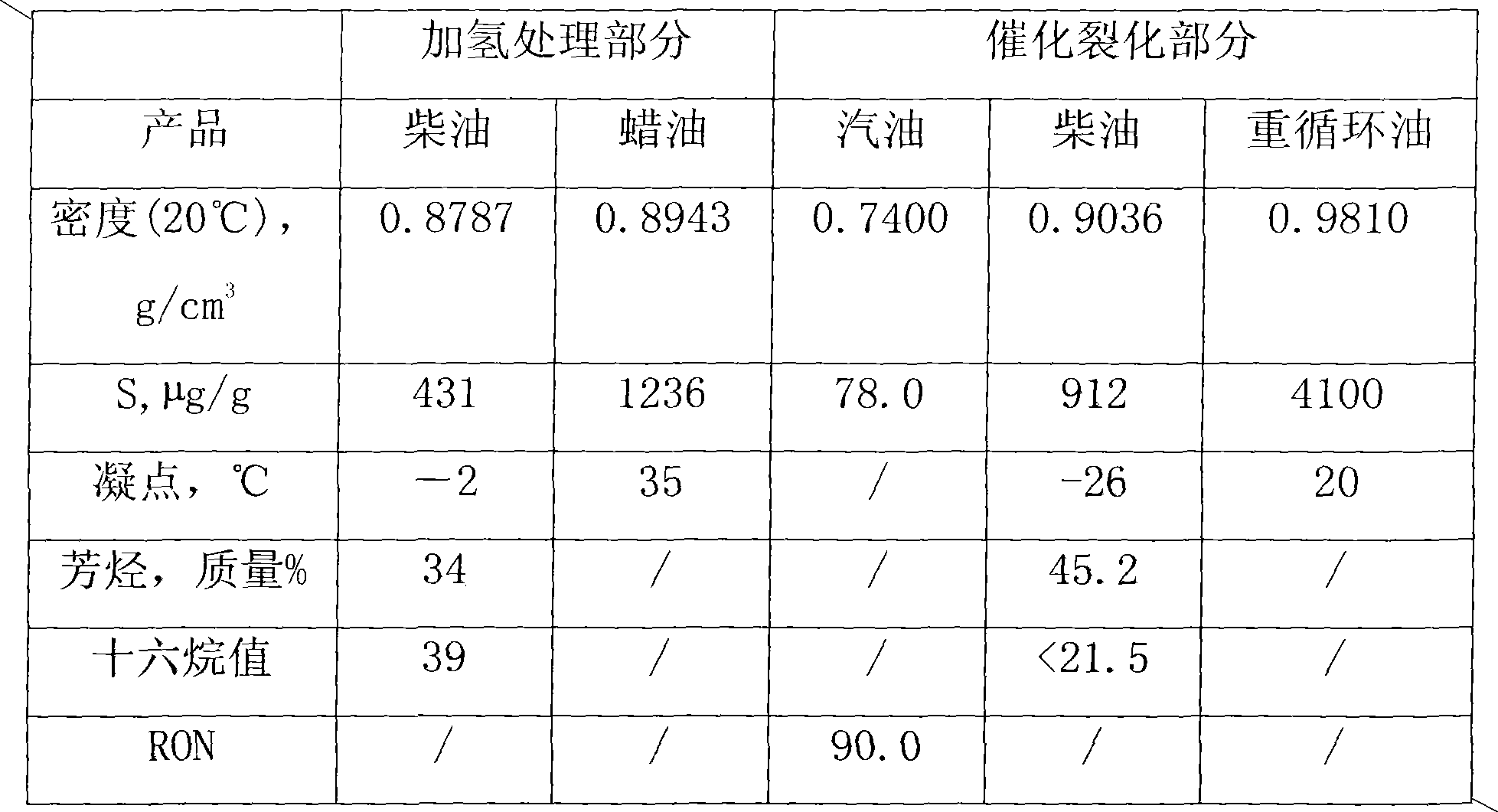

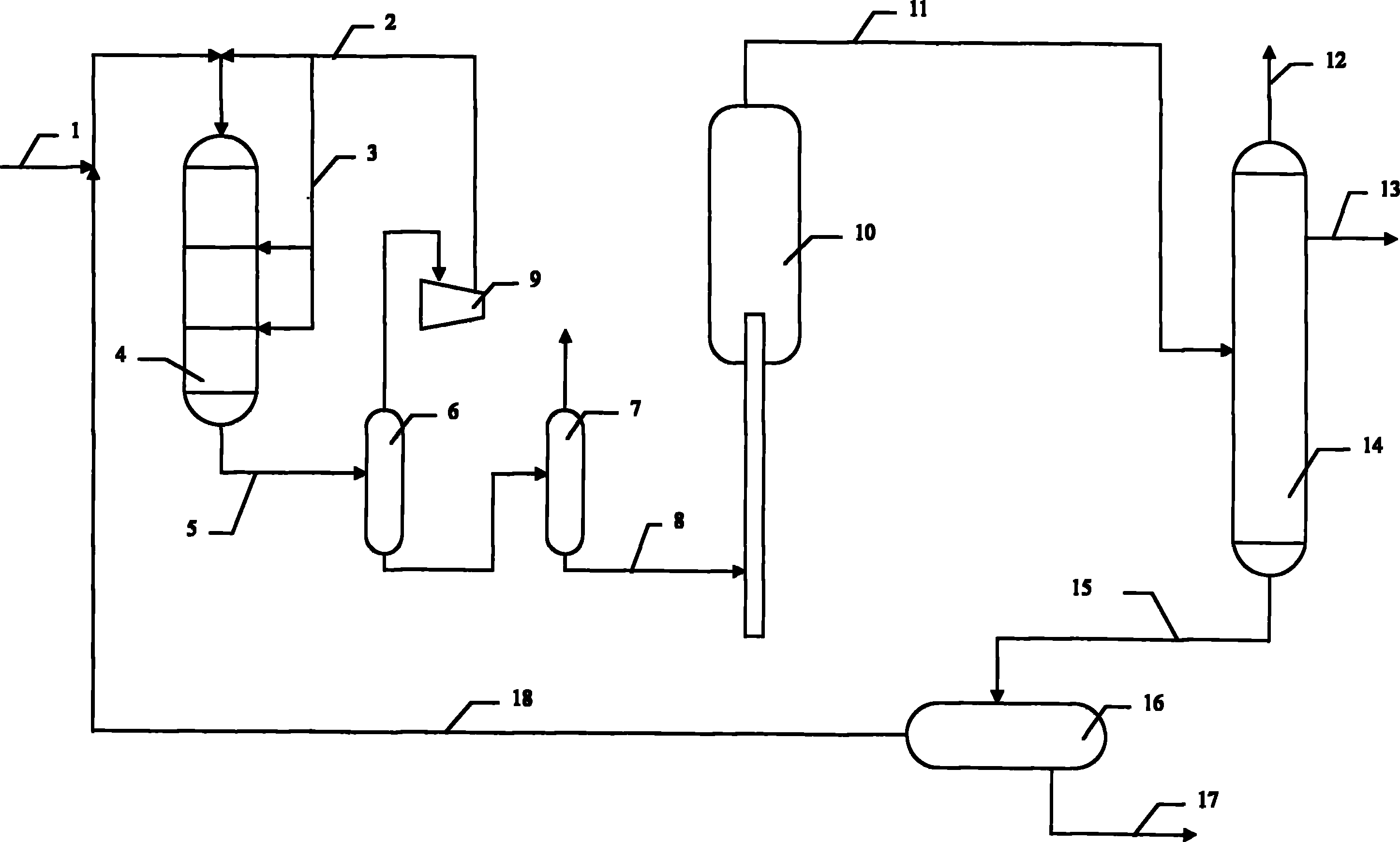

Wax oil hydrogenated treatment and catalytic cracking combined method

ActiveCN101875856AGuarantee normal productionSolve the problem that it is difficult to separate the catalyst solid powderTreatment with hydrotreatment processesGas phaseCombined method

The invention discloses a wax oil hydrogenated treatment and catalytic cracking combined method, which comprises the following steps of: performing hydrogenated reaction on hydrogenated treatment raw materials in the presence of hydrogen and hydrogenated treatment catalyst, performing gas-liquid separation on the hydrogenated reaction effluent, circulating the gas phase for the hydrogenated reaction, directly feeding the liquid phase into a catalytic cracking device without fractionation, and mixing dry gas and liquefied gas separated from the catalytic cracking reaction effluent, catalytic cracking heavy fraction formed by catalytically cracking gasoline and the hydrogenated treatment raw materials to perform hydrogenated reaction. Compared with the prior art, the method can produce maximum gasoline, meanwhile saves equipment investment, makes full use of reaction heat energy and reduces the production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

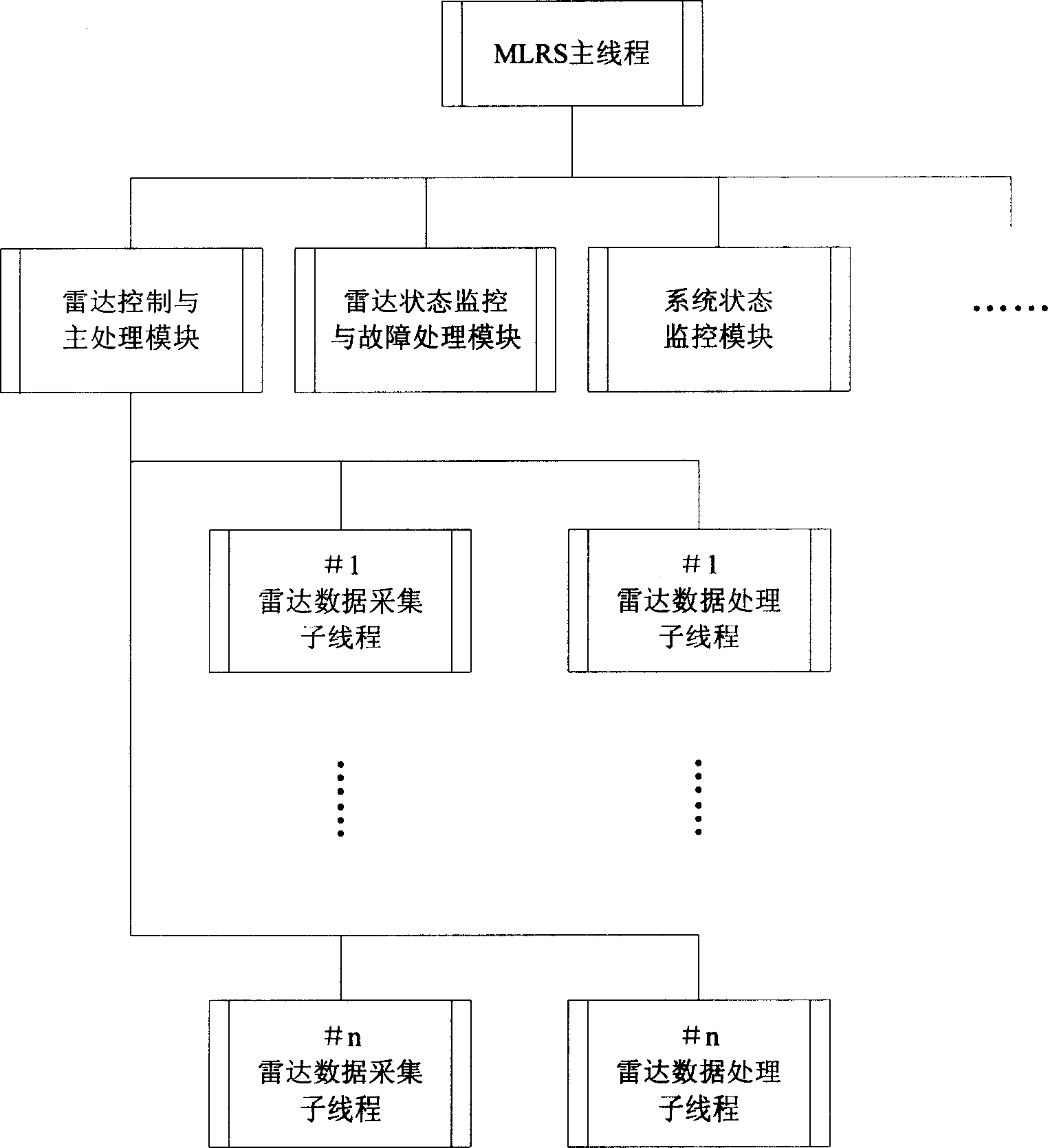

Collaborative work of multiple lidars, and dat processing method

InactiveCN1916659AImprove scanning accuracyHigh precisionElectromagnetic wave reradiationICT adaptationRadarProcess module

A method for making multilaser radar be operated coordinately includes enabling each radar to finalize object blocking scan and dynamic weighted treatment of scanning data independently under coordination control of master controlling and processing module (MCPM), carrying out effectiveness verification on data collected by each radar in real time and stopping linear grogram of the radar as well as shielding its function if certain radar is fault, feeding radar state back to system sate display module, carrying out dynamic data treatment of error compensation and coordinate matching adaptively and finalizing scan and identification task of object multiple surfaces by MCPM according to system topological structure.

Owner:SHANGHAI JIAO TONG UNIV

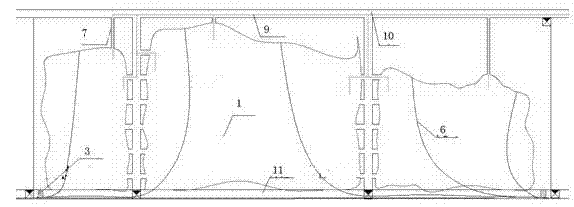

Roof contacting process in goaf filling treating procedure

InactiveCN103233771ALow costGuarantee normal productionMaterial fill-upEngineeringUltimate tensile strength

The invention relates to a roof contacting process in a goaf filling treating procedure and belongs to the technical field of mining engineering. The technical scheme of the roof contacting process in the goaf filling treating procedure includes: detecting a goaf to obtain the coordinate of the top point position of a top plate; drilling a filling drill hole at the top point position of the top plate, and performing cementing filling; installing a three-way plug valve on a filling pipe of the filling drill hole, and guiding a washing pipeline out on the filling pipe through the three-way plug valve; when the position with 1m away from the top point of the top plate is filled, extending the filling pipe to the position farthest from the filling drill hole, and simultaneously, arranging a 1-1.5m temporary retaining wall on the filling drill hole portion; when cement body is full, continuing to fill; and finally opening the three-way plug valve, guiding water away through the washing pipeline and finishing the filling roof contacting work. The roof contacting process is particularly suitable for filling the goaf generated during the filling exploitation process afterwards, is good in filling roof contacting effect and low in working intensity, saves filling roof contacting cost, achieves the roof contacting maximumly, is high in roof contacting efficiency, and ensures normal production of mines.

Owner:HEBEI IRON & STEEL GRP MINING +2

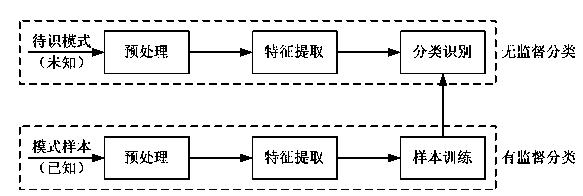

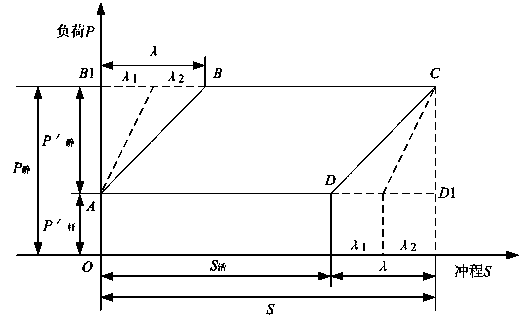

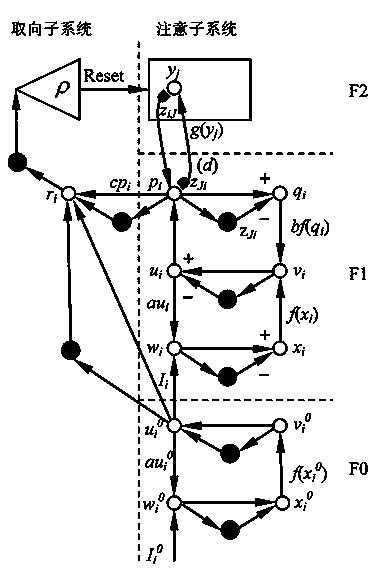

Pumping unit indicator diagram identification method based on ART2

InactiveCN104110251AEfficient identificationAccurate identificationConstructionsCharacter and pattern recognitionTime changesIndicator diagram

The invention discloses a pumping unit indicator diagram identification method based on an ART2. By collecting load and suspension center displacement signals of a pumping unit, a closed curve formed along with time changes in a pumping period is drawn with polished rod displacement signals serving as an x-coordinate and loading signals serving as a y-coordinate, and a pumping unit indicator diagram sample is obtained. If the category of the pumping unit indicator diagram sample is known, the pumping unit indicator diagram sample is identified through a mode with a supervision module. If the sample category of the pumping unit indicator diagram sample is unknown in advance, the pumping unit indicator diagram sample is identified through a mode without the supervision module. The pumping unit indicator diagram sample is identified through an ART2 neural network, according to an identification result, fault diagnosis and underground work condition judgment are performed on the pumping unit, and a judgment result is displayed. The pumping unit indicator diagram identification method based on the ART2 has the advantages of performing fault diagnosis and underground work condition judgment on the pumping unit, identifying the indicator diagram stably, efficiently and accurately, and the like.

Owner:ANHUI DORJE ELECTRIC

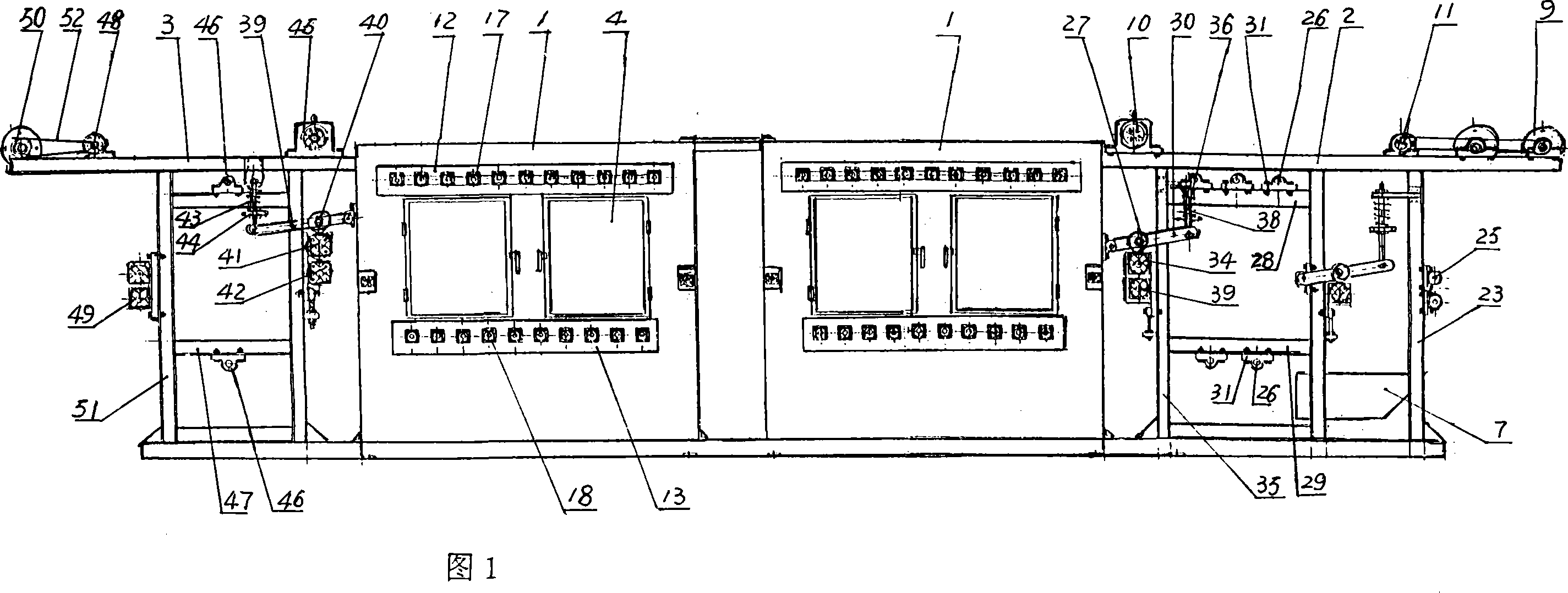

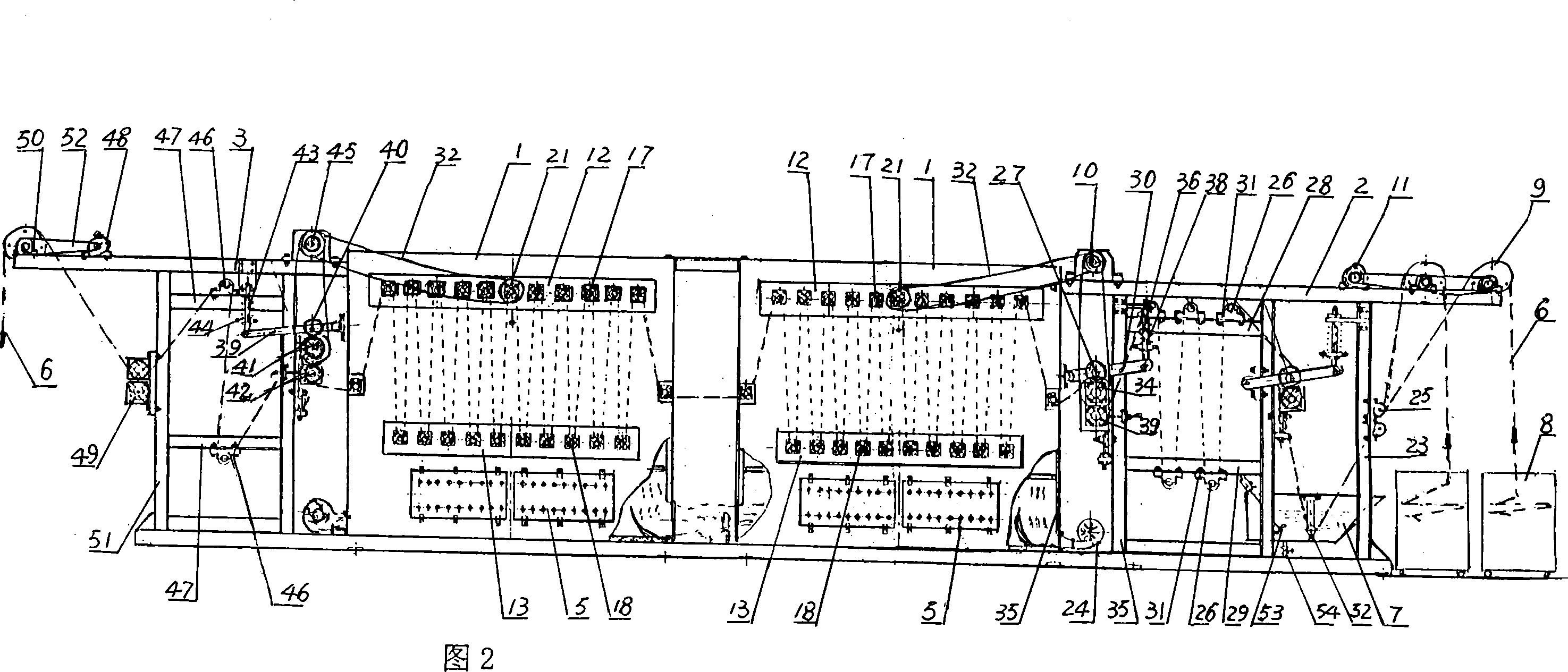

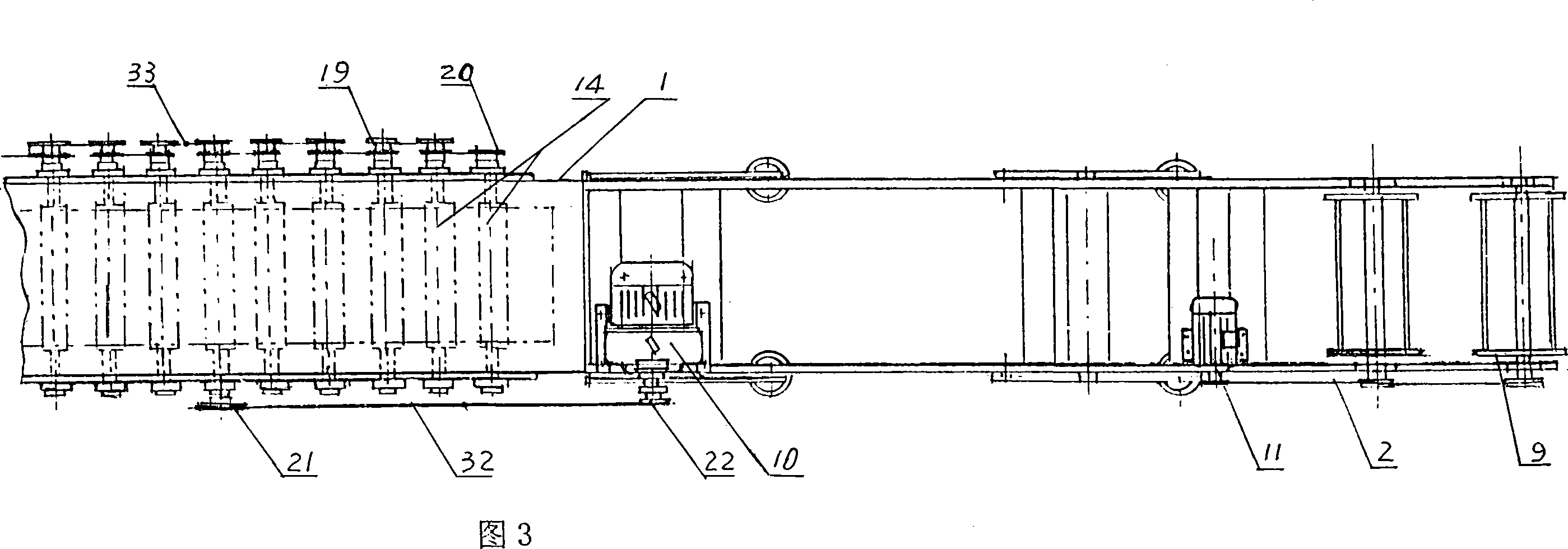

Equipment for dyeing and finishing polyester fibre flat woven tape

InactiveCN101220549ANo deformationUniform thicknessSucessive textile treatmentsTextile treatment containersPolyesterEngineering

The invention discloses a dyeing and finishing device of a terylene flat meshbelt, relating to a high speed continuous dyeing and finishing device of the terylene flat meshbelt which is a dyeing dryer that collects coloring, dyeing, fixation, drying, ironing and sizing into a whole. The device comprises a front straining trestle, a back straining trestle, a carding belt device, a staining trough, a front draughting and pressing device, a drying box, a back draughting device, a cooling device, and a tape-out device. The front straining trestle is arranged on the front of the drying box while the back straining trestle is arranged on the back of the drying box; the carding belt device comprises a meshbelt freight lorry, a squirrel cage typed carding belt drum, a speed reduction motor, and a carding belt drum; and the staining trough is arranged on the lower part of the front straining trestle; the front draughting and pressing device which is arranged on a middle column of the front straining trestle comprises a frequency control motor I, a press roll, a draughting and driving roller, a pressure adjusting rod, a pressure spring, and a pressure adjusting ejector pin; the drying box is provided with a drying chamber and a heating chamber, and the back draughting device is arranged on a back column which is on the lower part of the back straining trestle, and the cooling device is provided with a plurality of cooling rollers.

Owner:杨军

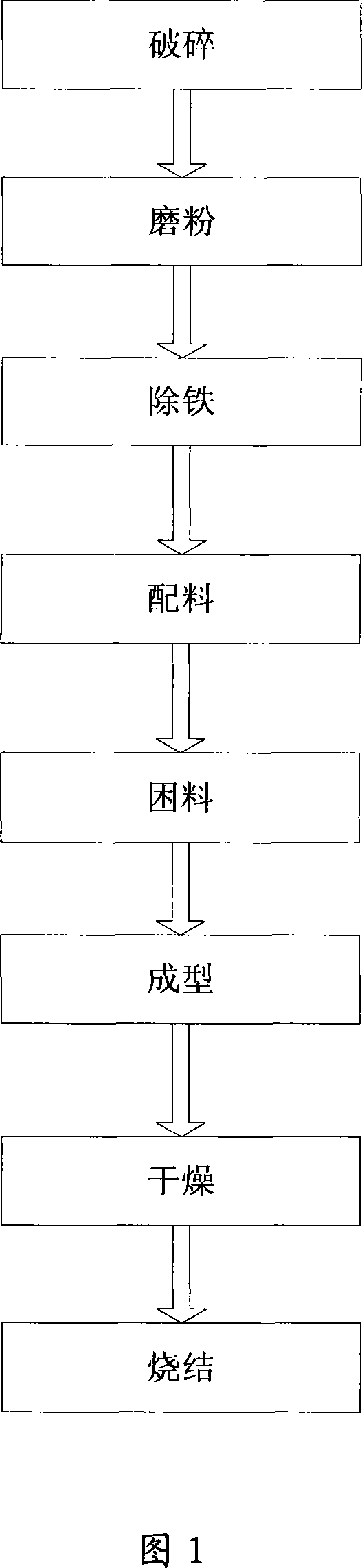

Resintered fused silica brick and method of producing the same

InactiveCN101172872AGood thermal stability and thermal shock resistanceGuaranteed uptimeMicroliteFused quartz

The invention discloses a re-sintering meltdown quartz brick and the manufacturing method thereof, and solves the problem that the fire resisting material of the prior microlite glass melt kiln flame space position deforms and cracks due to the expansion and the shrinking under the temperature changing condition so as to damage the glass melt kiln. The re-sintering meltdown quartz brick of the invention comprises the components according to the following weight parts: meltdown quartz of 50 to 60 parts with granularity of 3 to 1 mm, meltdown quartz of 10 to 20 parts with granularity of 1 to 0 mm, mineralized powder of 1 to 2 parts and caking agent of 4 to 7 parts. The invention is suitable for the fire resisting material of the microlite glass melt kiln flame space position.

Owner:孙邢哲

Hydroprocessing catalyst and preparing method thereof

InactiveCN1488716AIncrease acidityImprove denitrification activityRefining to eliminate hetero atomsNano siliconHigh activity

The present invention discloses a hydrogenation treatment catalyst and its preparation method. It is applicable to hydrogenation treatment of heavy oil, specially hydrogenation treatment of heavy fraction. Said catalyst is prepared by loading molybdenum, nickel and phosphorus on silicon-contained aluminium oxide carrier prepared by adopting a special method, and said silicon-contained aluminium oxide carrier is prepared by adding nano silicon-containing compound, for example nano silicon dioxide. As compared with existent catalyst it has higher activity for hydrodesulfurization and hydro-denitrification.

Owner:CHINA PETROLEUM & CHEM CORP +1

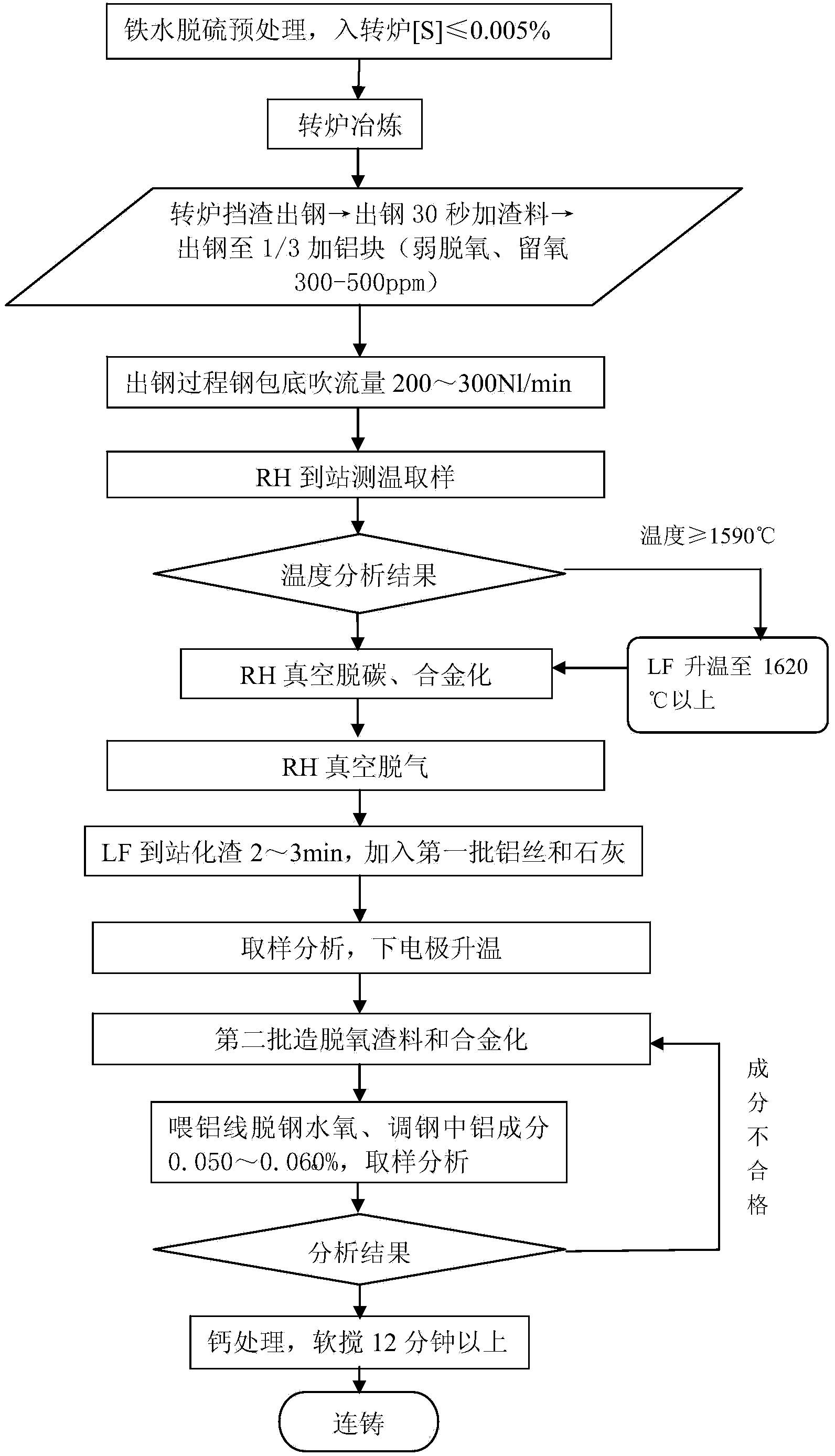

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

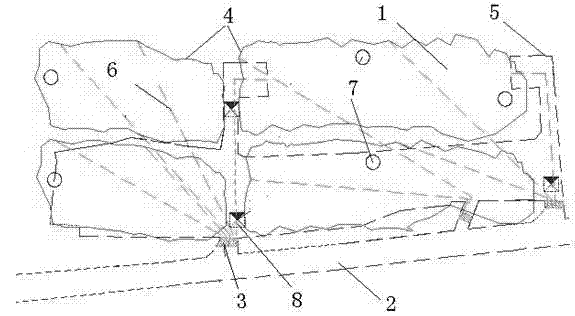

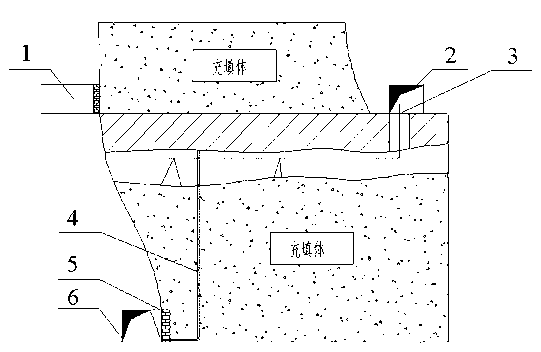

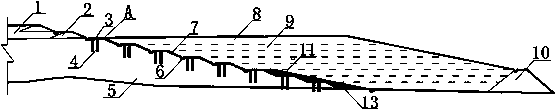

Stoping technology for dam slope tailing of tailing dam

ActiveCN103967495AAddressing Stability ImpactsGuarantee normal productionUnderground miningSurface miningTailings damMineral Sources

The invention discloses a stoping technology for a dam slope tailing of a tailing dam. The stoping technology comprises the following steps: assigning 1-2 rows of gravel piles (4) in the front of each stoping step; assigning a row of unwatering, pumping and reinforcing facilities comprising unwatering pump drainage water wells (3) and the gravel piles (4) at intervals; adopting submersible pumps to conduct groundwater pump drainage in the unwatering pump drainage water wells (3); excavating a tailing in the area on a first construction separated layer (8) of the tailing stoping in a dry type; conducting construction on slope surface protection measures (7) after the tailing stoping of the tailing pound tailing stacking dam slope; constructing tailing stacking dam side slope stepped drainage ditches (6); repeating the constructing steps, and excavating a tailing in the area on a second construction separated layer (9) of the tailing stoping of tailings stacking dam slope. The stoping technology solves the problem of safety and stability of the stacking dam side slope during tailing stoping of a valley type tailing stacking dam slope, reduces vast capital cost and land-use cost of new-building a tailing pond, realizes recovery of the most valuable tailings in the tailing pond, and improves mineral resource utilization ratio and economic benefits.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

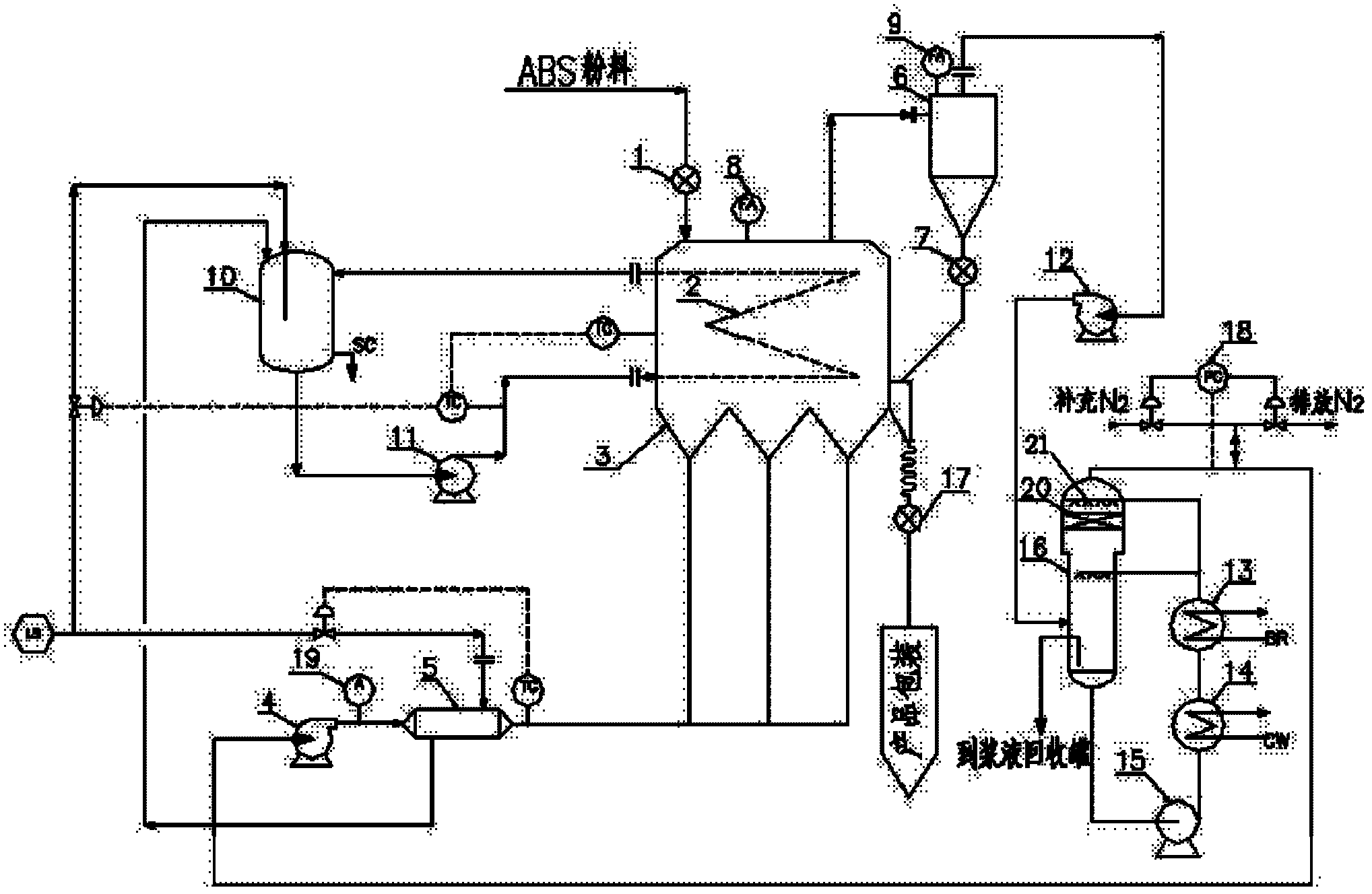

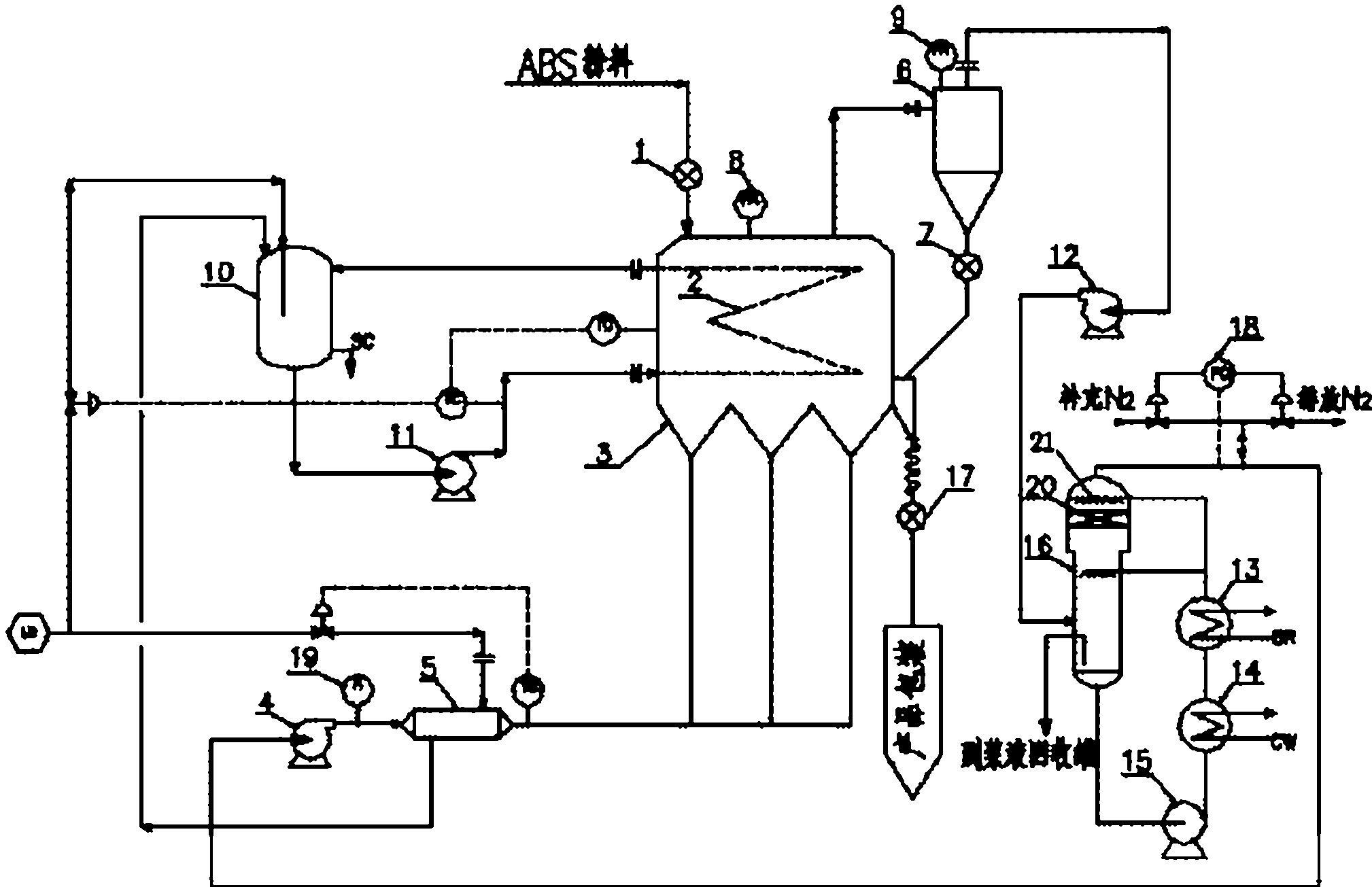

ABS powder drying method

ActiveCN102626965AEasy to separateImprove securityDrying solid materials with heatDrying gas arrangementsFluidized bed dryingNitrogen

The invention provides an ABS powder drying method, comprising a step of powder drying and a step of powder recovery. In the step of powder drying the technology of utilization of waste heat of condensed water comprises conveying the steam condensed water in a nitrogen heater to a buffer hot water tank as heating medium hot water in a heater. A slurry recovery tank is connected to a bottom portion of a washing tower. The upper portion diameter of the washing tower is slightly bigger than the bottom portion diameter. No filling material and no tray floor are arranged inside the washing tower. The washing tower is provided with a demister, and second spray water in the upper portion of the washing tower. A split-range controller is arranged on the top portion of the washing tower. A first fire extinguishing device is installed in a fluidized bed dryer. A second fire extinguishing device is installed at the exit port of a cyclone separator. An oxygen detector is installed at a nitrogen inlet side of the nitrogen heater. The method of the invention has the advantages of full utilization of the waste heat, energy saving and consumption reduction, heat utilization efficiency improvement, short process flow, reduction of powder loss, reduction of equipment investment, high operation flexibility and stability in the whole technology process, a good ABS separating effect, and good safety performance.

Owner:CHINA TIANCHEN ENG +3

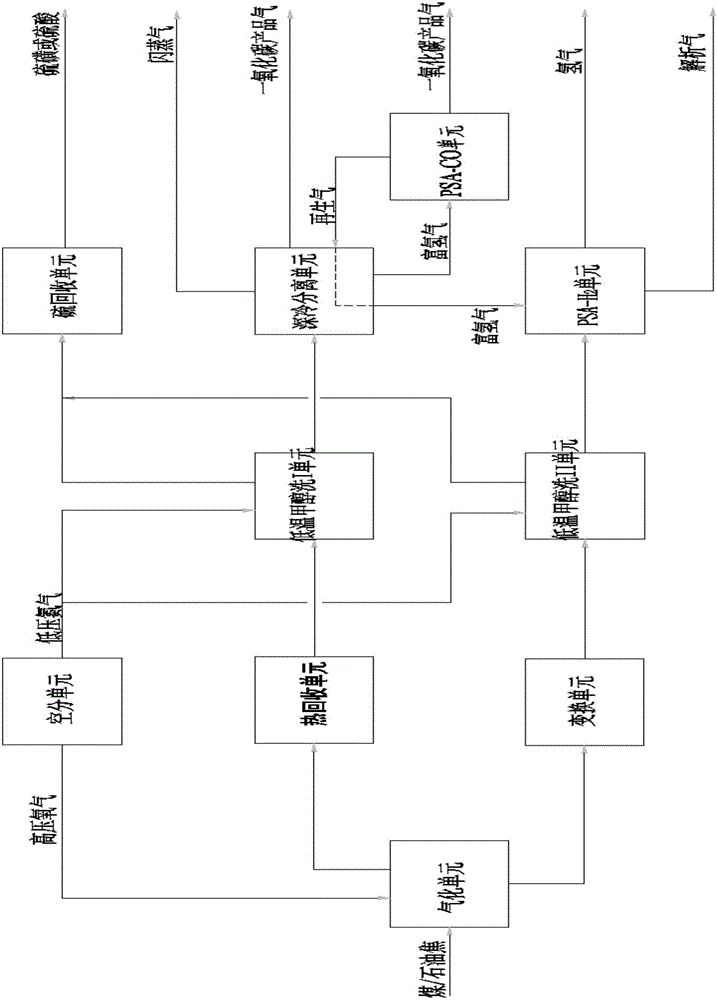

Method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation

ActiveCN105948046AFlexible scale adjustmentHigh recovery rateHydrogen separation by selective and reversible uptakeGas treatmentSyngasPhysical chemistry

The invention discloses a method for simultaneously preparing pure hydrogen and pure carbon monoxide by gasification without desorbed gas circulation. The crude synthetic gas prepared by the gasification unit is divided into two parts, one part is used for preparing pure carbon monoxide, and the other part is preparing pure hydrogen. The process of preparing pure carbon monoxide is divided into two parts: one part is used for preparing pure carbon monoxide with the crude synthetic gas prepared by gasification by a heat recovery unit, a low temperature methanol washing I unit, and a cryogenic separation unit; and the other part is used for preparing pure carbon monoxide by the hydrogen rich gas from the outlet of the cold box of the cryogenic separation unit sending into a PSA-CO unit. The feedstock of preparing hydrogen is divided into two parts: one part is the converted gas which is purified by a conversion unit and a low temperature methanol washing II unit with the crude synthetic gas prepared by gasification and contains carbon monoxide -1% (mol), and the other part is the hydrogen rich gas from a resurgent TSA device of the cryogenic separation unit, and the two parts of the gas are mixed and sent into the PSA-H2 unit to prepare pure hydrogen. The method has high recovery rates of carbon monoxide and hydrogen, has no desorbed gas circulation and no resurgent gas introduced by environment, has small investment and low energy consumption, and can adjust product gas scale of hydrogen and carbon monoxide flexibly.

Owner:HUALU ENG & TECH

Recycling system for waste electrical and electronic products

InactiveCN103722003AReduce vacancy rateImprove efficiencySolid waste disposalGrain treatmentsProduction lineCollection system

The invention discloses a recycling system for waste electrical and electronic products. The recycling system is characterized by comprising a control system as well as a crushing system, a separation system, a dust collection system, a waste gas collection system and a draught fan which are controlled by the control system, wherein the crushing system comprises a knocking crusher, the separation system comprises a winnower and a plastic and metal separation device, and the knocking crusher, the winnower and the plastic and metal separation device are connected through conveyer devices sequentially to form a plastic and metal separation production line; the knocking crusher and an air outlet of the winnower are connected with the dust collection system respectively for collecting light materials and dust of the whole recycling system; an air outlet of the dust collecting system is connected with the waste gas collection system; and the draught fan is connected with the waste gas collection system, so that the knocking crusher, the winnower, the dust collection system and the waste gas collection system are in negative pressure states. The system can be applied to crushing and separation treatment of various waste electrical appliances such as a refrigerator, a circuit board and the like respectively.

Owner:CHINA NAT ELECTRIC APP RES INST +1

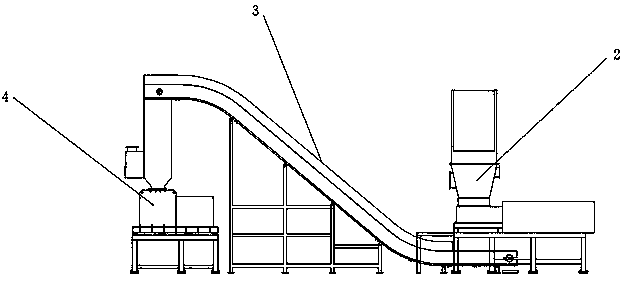

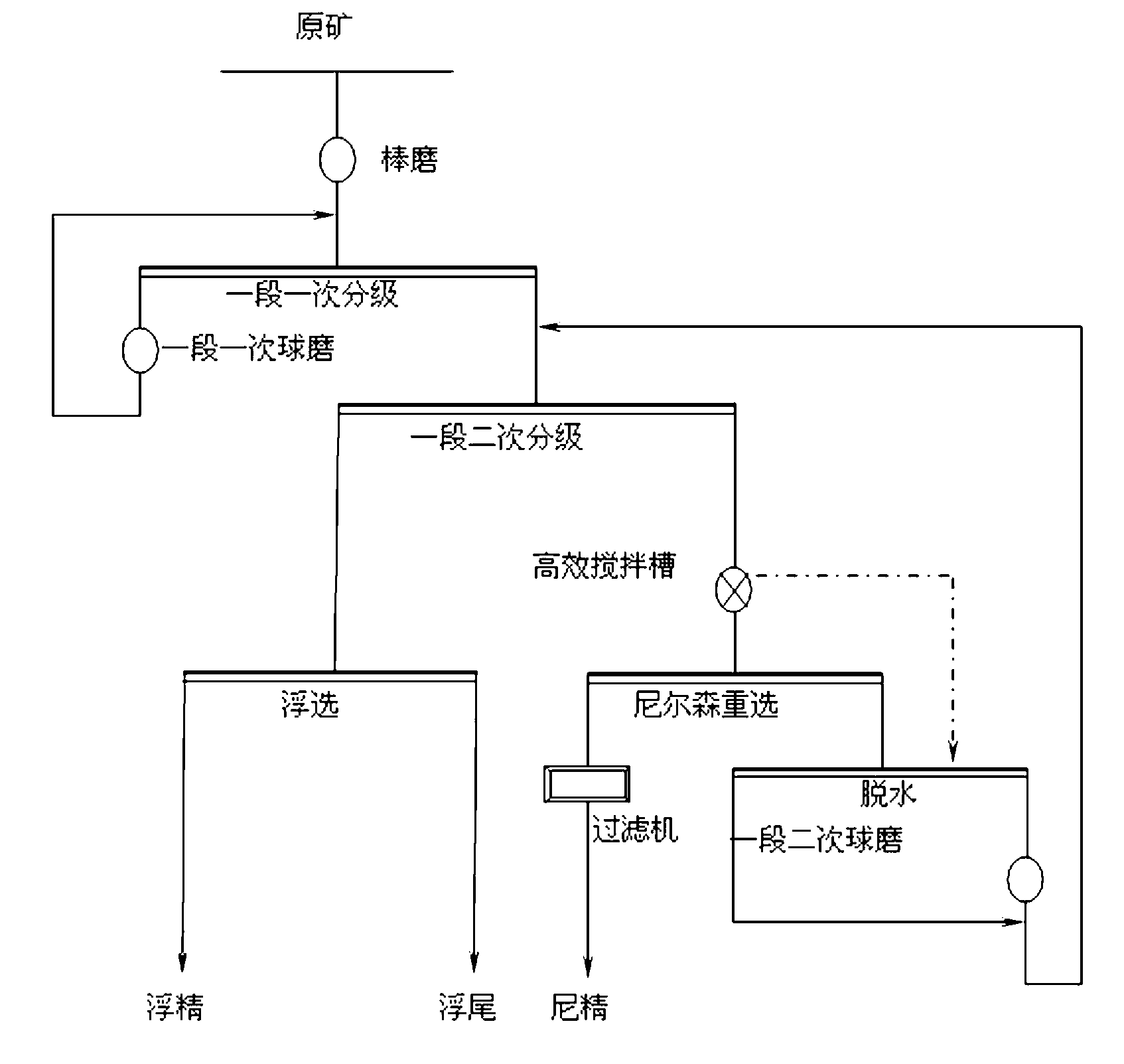

Method for improving recovery rate of copper nickel associated precious metals

The invention provides a method for improving the recovery rate of high copper nickel associated precious metal. A Nielsen centrifugal ore separator is utilized for a section of secondary grading sand setting and a section of secondary ball milling ore discharge to recover sperrylite separated in a monomer mode and ore containing the precious metals such as gold and silver. The technical principles include that in a high power strengthened gravity field, the gravity difference of ores large in specific gravity and ores small in specific gravity is enormously amplified so as to enable separation between the heavy oars and the light oars to be easier than that in a natural gravity field, and therefore ore particles sorted according to specific gravities is realized. A part of precious metals are enriched and recovered in advance, and ore concentrate after ore dressing directly enters an alloy vulcanizing oven to be processed, and therefore the recovery rate of the gold, the silver and other precious metals is improved by a large margin, and normal production and stable operation of an original production system can be ensured. Compared with the indexes of the original production system, concentrate grades of precious metals aurum and platinum are respectively improved by 1.1g / t and 2.0g / t, and recovery rates of the precious metals aurum and platinum are respectively improved by 5% and 10%.

Owner:JINCHUAN GROUP LIMITED

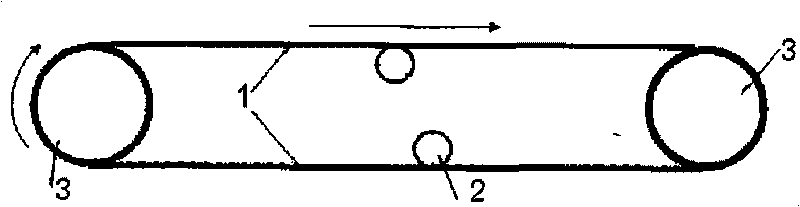

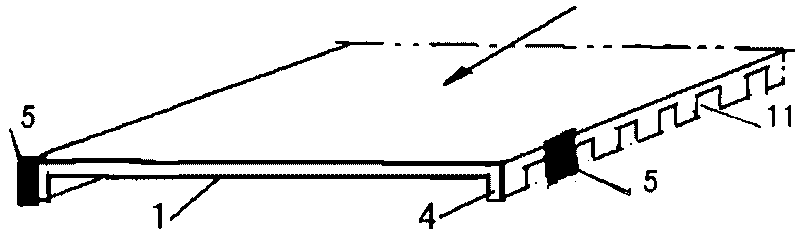

New correcting method and device of metal conveyor belt

The invention discloses new correcting method and device of a metal conveyor belt, belonging to the correction field of mechanical devices. In the invention, by adopting a correction mode of a permanent magnet or an electromagnet, the conveyor belt is limited in deviation by magnetic force or the deviated conveyor belt is pulled back to a normal track, i.e. grooves or convex edges are arranged at two ends of a driving roller of the metal conveyor belt, magnetic correcting devices with magnetism opposite to or same as that of the corresponding sides of the metal conveyor belt are arranged on two inner sides of the grooves or the convex edges, two sides of the metal conveyor belt are folded into folded edges with the depth corresponding to the depths of the grooves or the convex edges or small magnets are arranged at intervals on two sides of the metal conveyor belt so as to increase the magnetic action and strengthen the magnetic action effect. The invention is simple and feasible, effectively overcomes the defects of side deformation and cracking of the metal conveyor belt caused by the deviation in the background art and ensures normal production.

Owner:CHINA CHEM ENG SECOND CONSTR

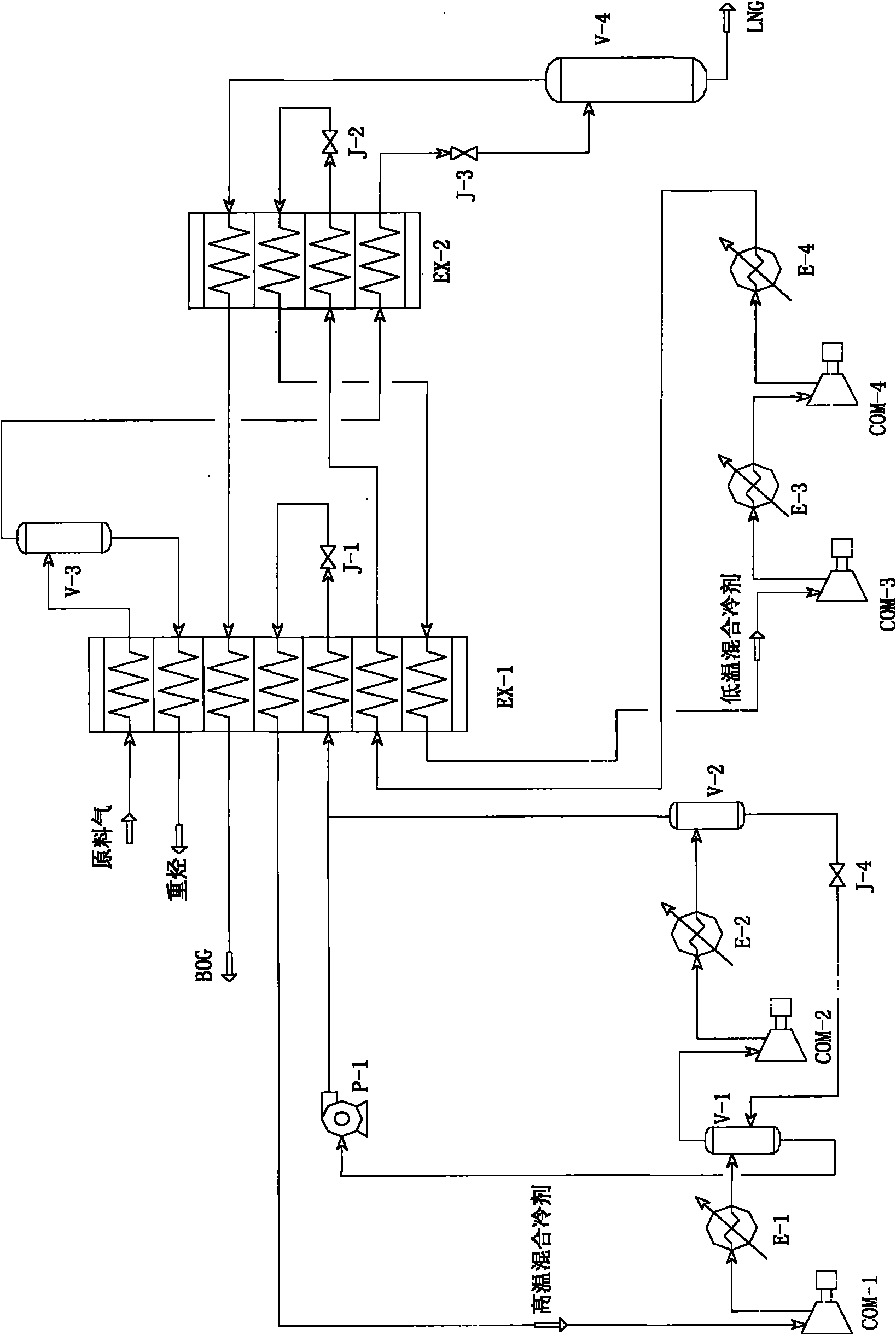

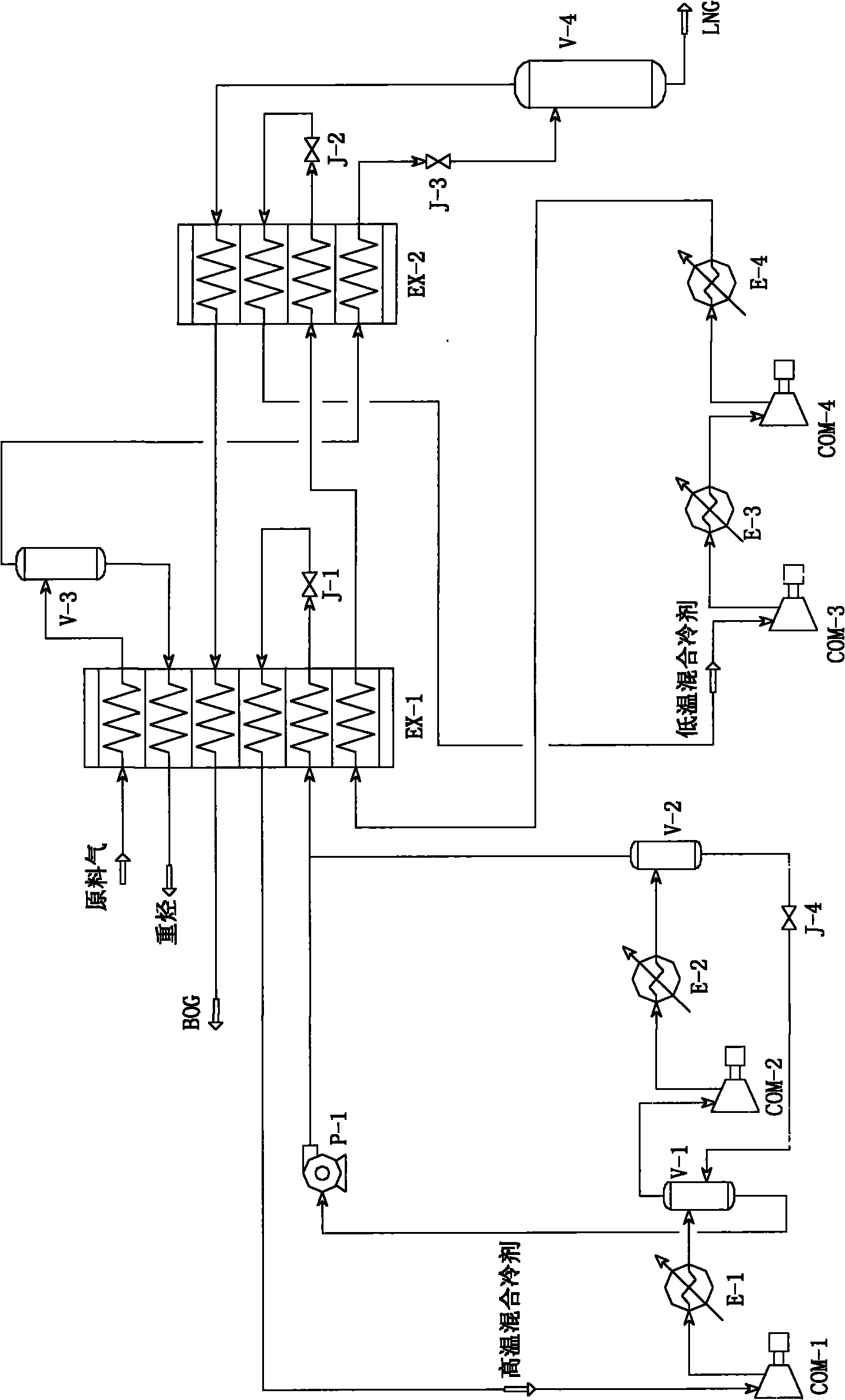

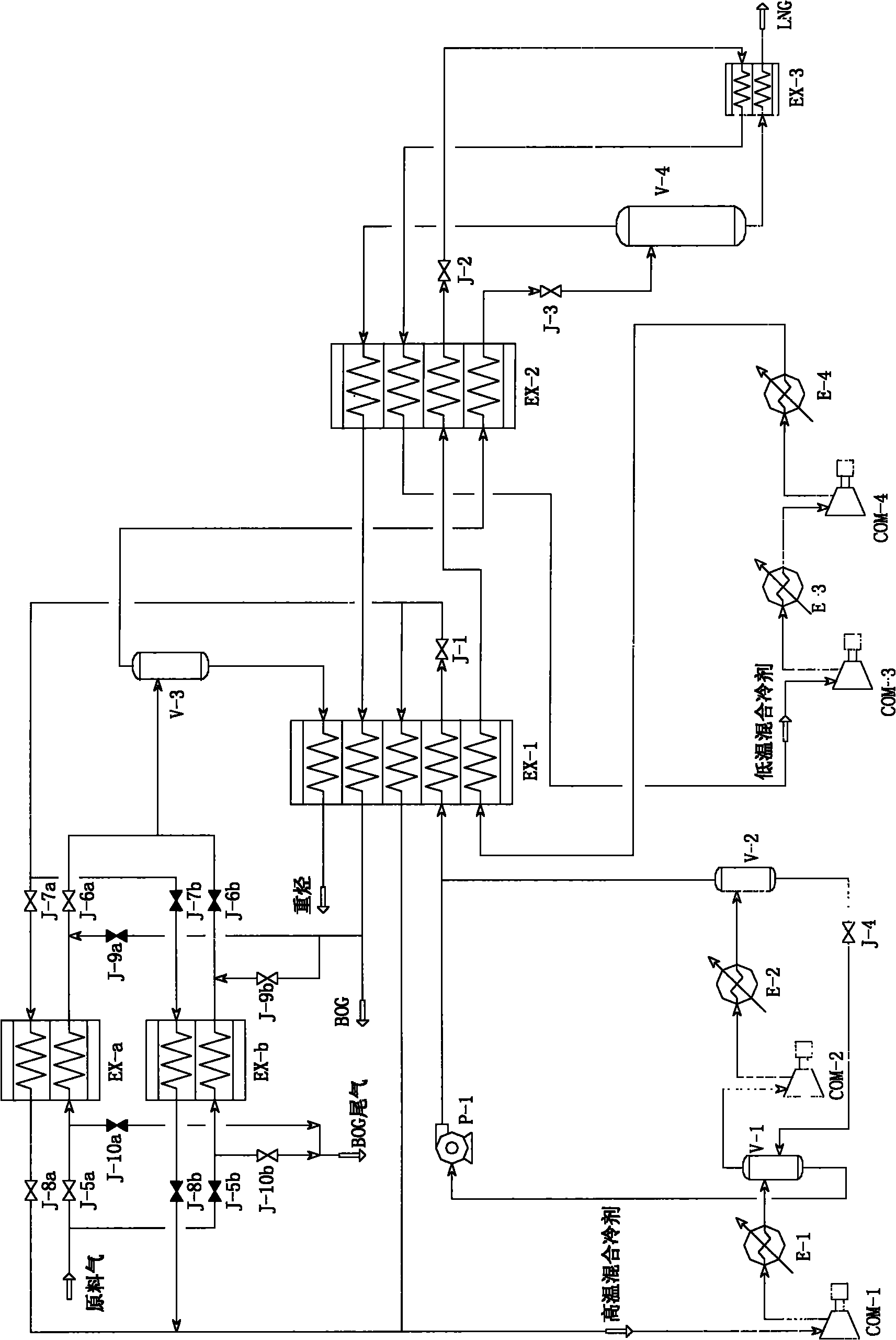

Method for producing liquefied natural gas

InactiveCN102115683ASimple designLower manufacturing requirementsCompression machines with non-reversible cycleGaseous fuelsLiquid stateRecuperator

The invention provides a process for producing liquefied natural gas, which comprises the following steps of: introducing purified feed gas into a first heat exchanger for precooling; introducing the precooled feed gas into a heavy hydrocarbon separator for gas-liquid separation; introducing the separated gaseous fluid into a second heat exchanger, and liquefying to obtain liquid-state fluid; and depressurizing and throttling to obtain the liquefied natural gas, wherein a refrigeration cycle consists of two independent mixed working medium refrigeration cycles in a high temperature area and a low temperature area; the feed gas can pass through a reversing heat exchanger to enter the first heat exchanger; and the separated heavy hydrocarbons and BOG return to the heat exchanger for reheating. In the process, the energy consumption is low; each mixed working medium refrigeration cycle is controlled by only one throttle valve in a cold box, and the operation is simpler; due to the reversing heat exchanger, the production process is more stable and safe; and the cold quantity of the separated heavy hydrocarbons and BOG is fully recycled and discharged out of the cold box, and the energy consumption is reduced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

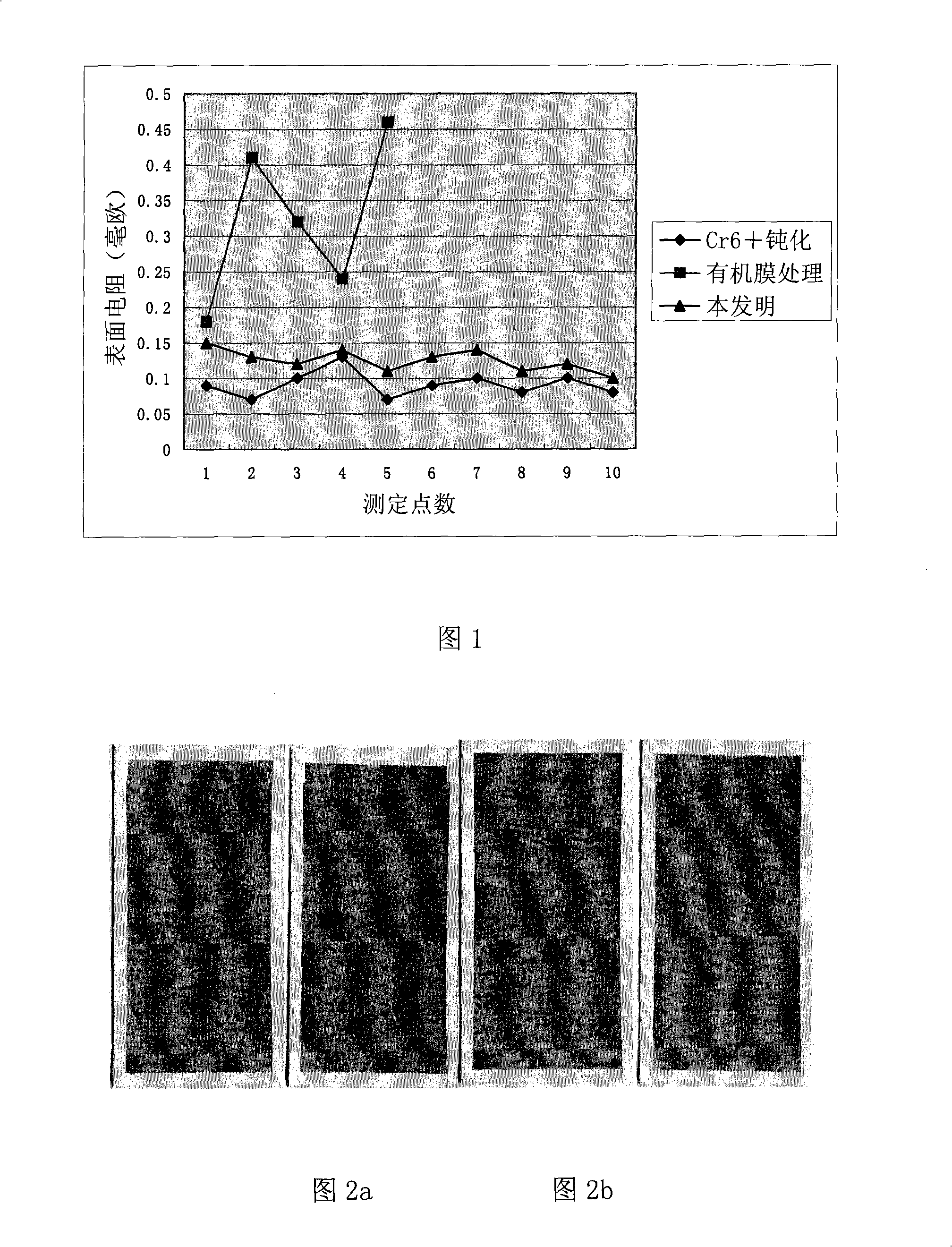

Hot-dip aluminizing zinc chrome-free passivated steel-plate and technique thereof

InactiveCN101332692ASmall white rust rateSmall color difference ΔEMetallic material coating processesSpecial surfacesFilm-forming agentOxygen

The invention provides a hot-dipped Al-Zn no-Co passivation steel plate, which is characterized in that the steel plate is provided with a film which uses fluoro acid salt and oxygen chlordimeform-hydrochloride of third and fourth subgroup elements as a main film forming agent and combines with the passivation disposal of compounds containing phosphorus. The invention also provides a passivation process used for the hot-dipped Al-Zn no-Co passivation steel plate, comprising a roll plating and solidifying process or a spraying, dry extruding and solidifying process.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com