Roof contacting process in goaf filling treating procedure

A technology for processing processes and gobs, applied to filling materials, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficulty in filling and roofing, low efficiency of roofing, high cost of roofing, etc., and save the cost of filling and roofing , Guarantee normal production and high efficiency of top connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below through embodiment.

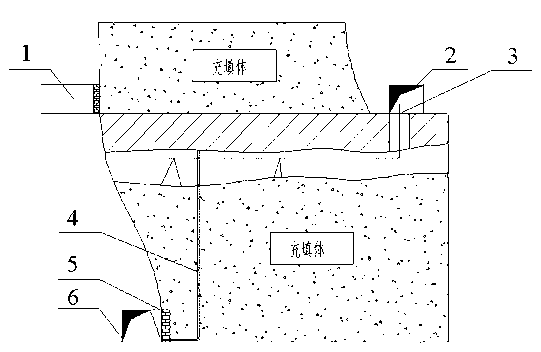

[0012] In the example, a large-scale open-pit mining of an iron mine began in 1975. In July 2001 and October 2003, the mineral resources in the middle of -60 meters were developed and constructed twice, and in 2010 Phase III mining construction at -120m level. The third phase of mining adopts the method of subsequent filling, a two-step mining method, segmented open space and subsequent filling mining method, mining pillars first, filling them with tailing sand to form artificial pillars, and then mining large mine rooms. If the artificial ore pillar cannot be connected to the roof, the high height of the empty roof will add difficulty to the recovery of the second-step mine, resulting in a passive situation in production.

[0013] Preparation before filling

[0014] When mining the last stratum, certain adjustments are made to the blasting parameters and mining technology. The specific metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com