Patents

Literature

1027results about How to "Good filling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

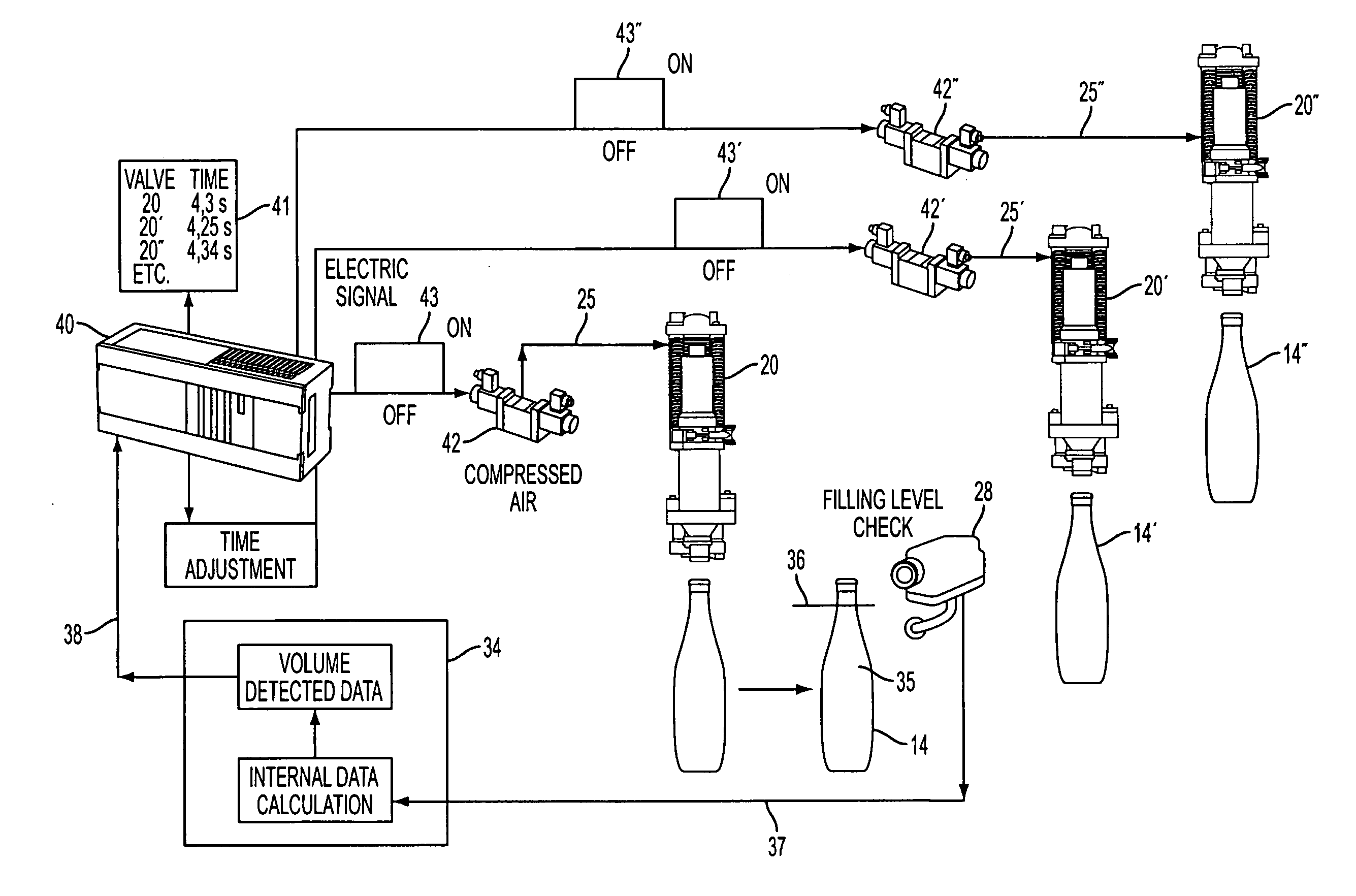

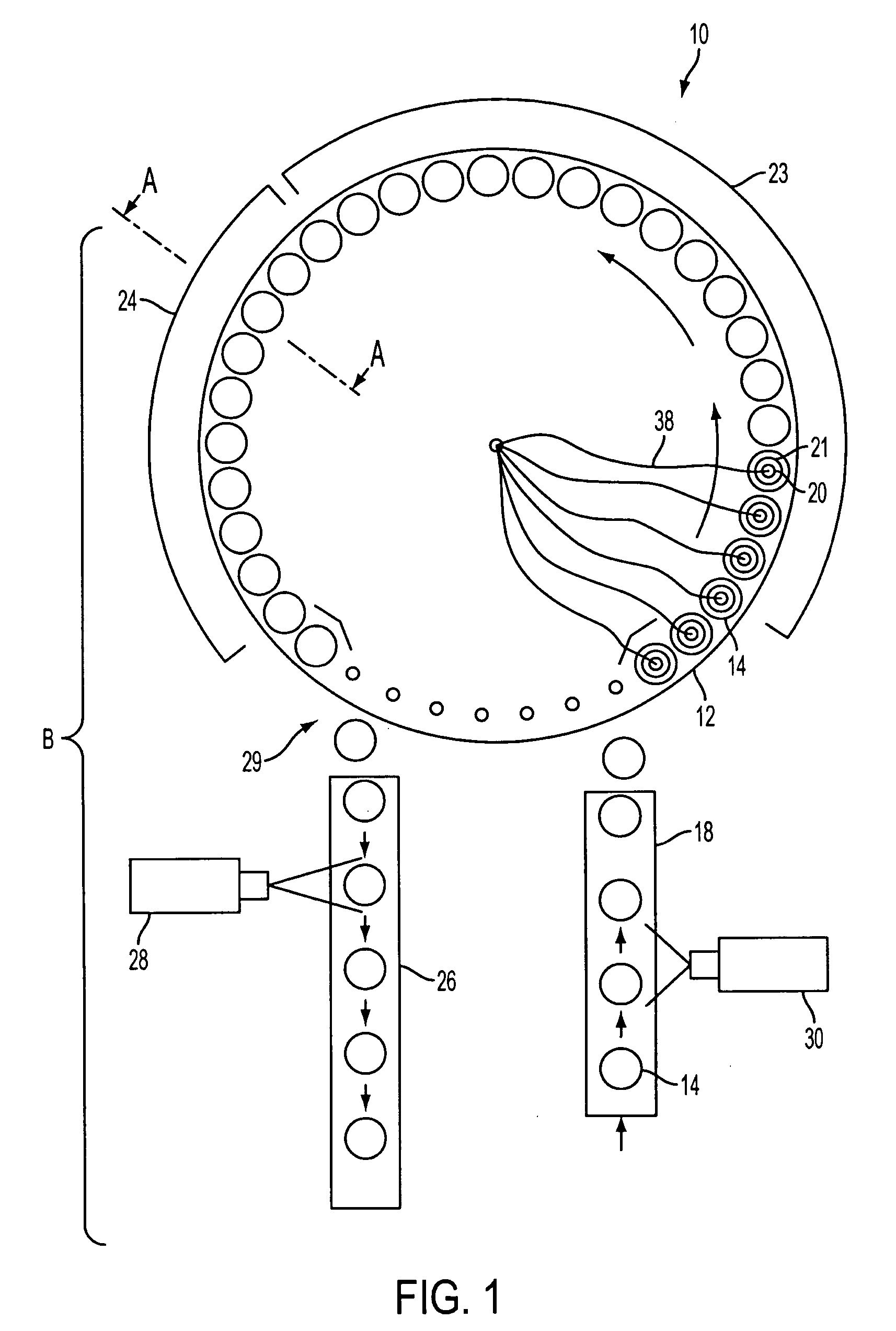

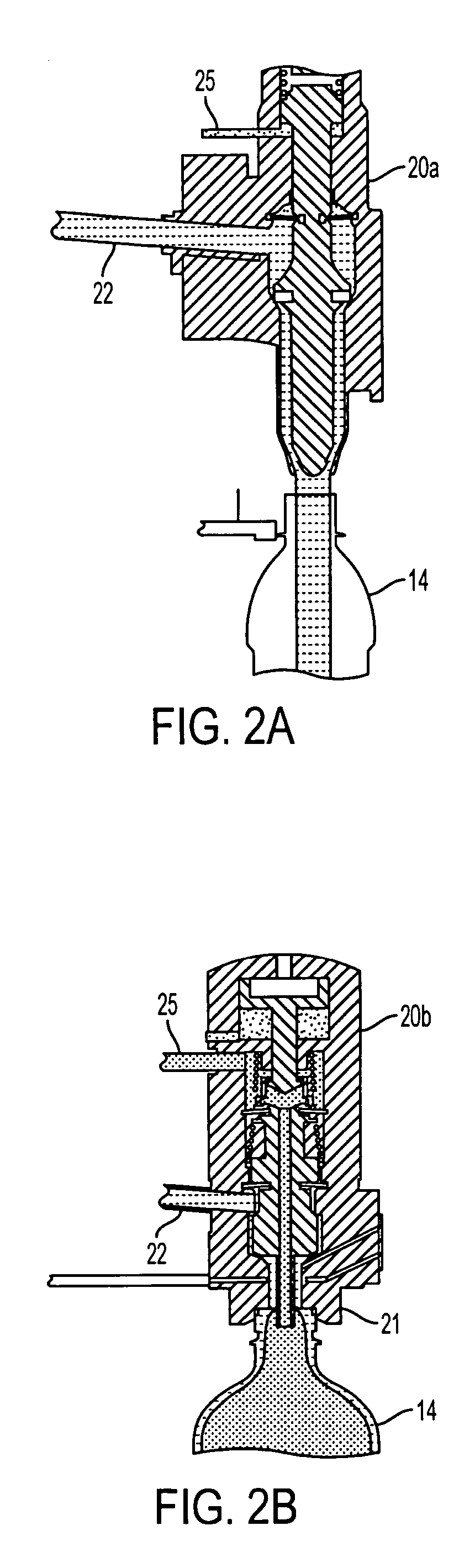

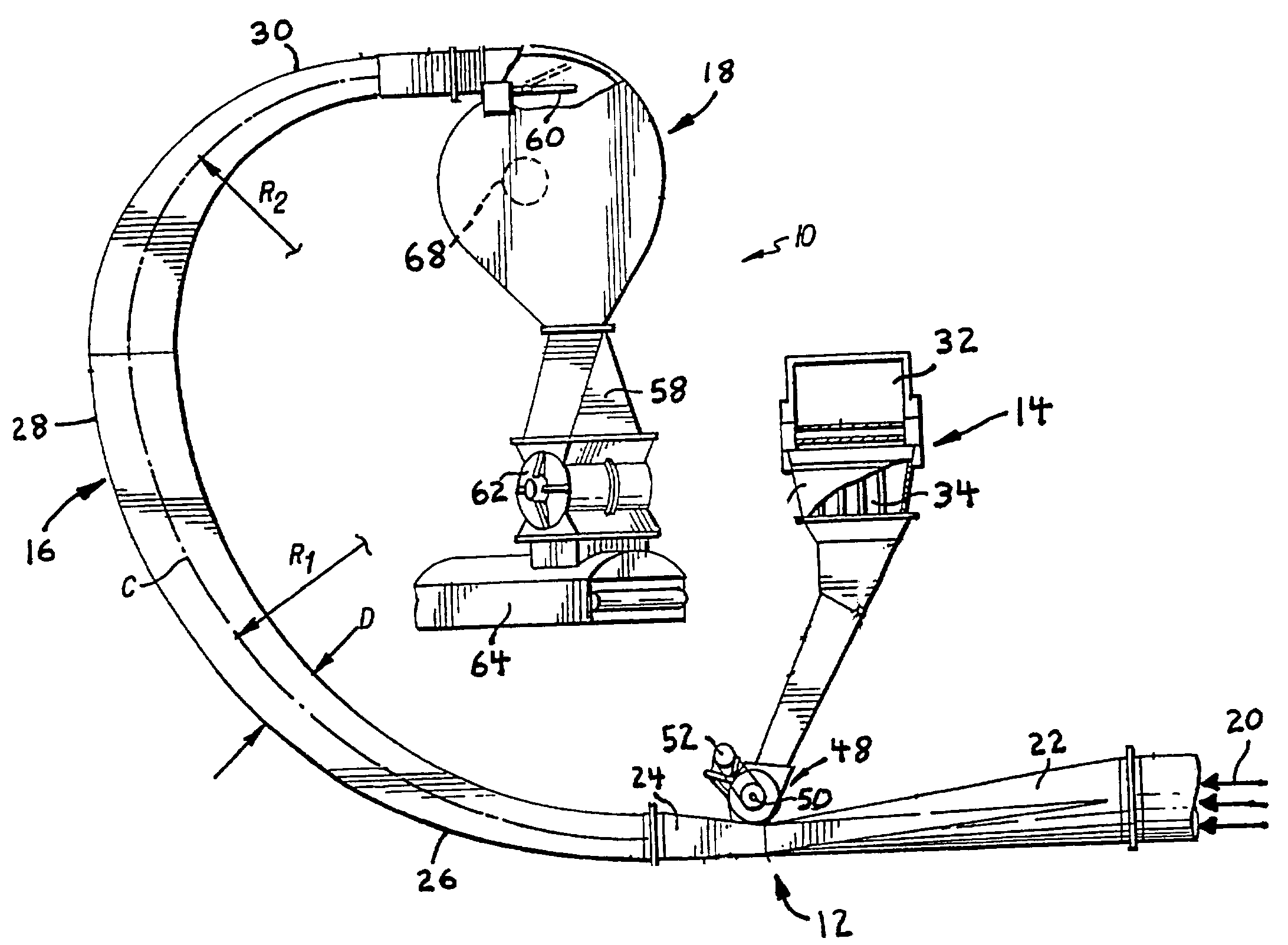

Bottle filling machine with sensor and method thereof

InactiveUS20070107801A1Reduce generationImprove trustVolume measurement and fluid deliverySafety device in filling machineryEngineeringBottle

A filling apparatus and method including a carrier for transporting containers and having a plurality of valves, each of the valves being opened for an individual, specific period of time to control a flow of liquid into the respective containers, while the containers are transported by the carrier. An exit feed path transports the containers after the containers have been filled, and a sensor, such as a camera, detects a level of liquid in the respective containers, while the containers are on the exit feed path. The sensor produces a signal that is stored as data representing the level of liquid for the individual containers. The data is then tracked and used for valve optimization. A period of time that each individual valve is opened for subsequent fillings is adjusted based on the signal and the historical performance of each valve.

Owner:SIDEL PARTICIPATIONS SAS +1

Method of expanding tobacco using steam

ActiveUS7556047B2Increasing filling powerImprove filling capacityTobacco preparationTobacco treatmentEngineeringTobacco use

Owner:R J REYNOLDS TOBACCO COMPANY

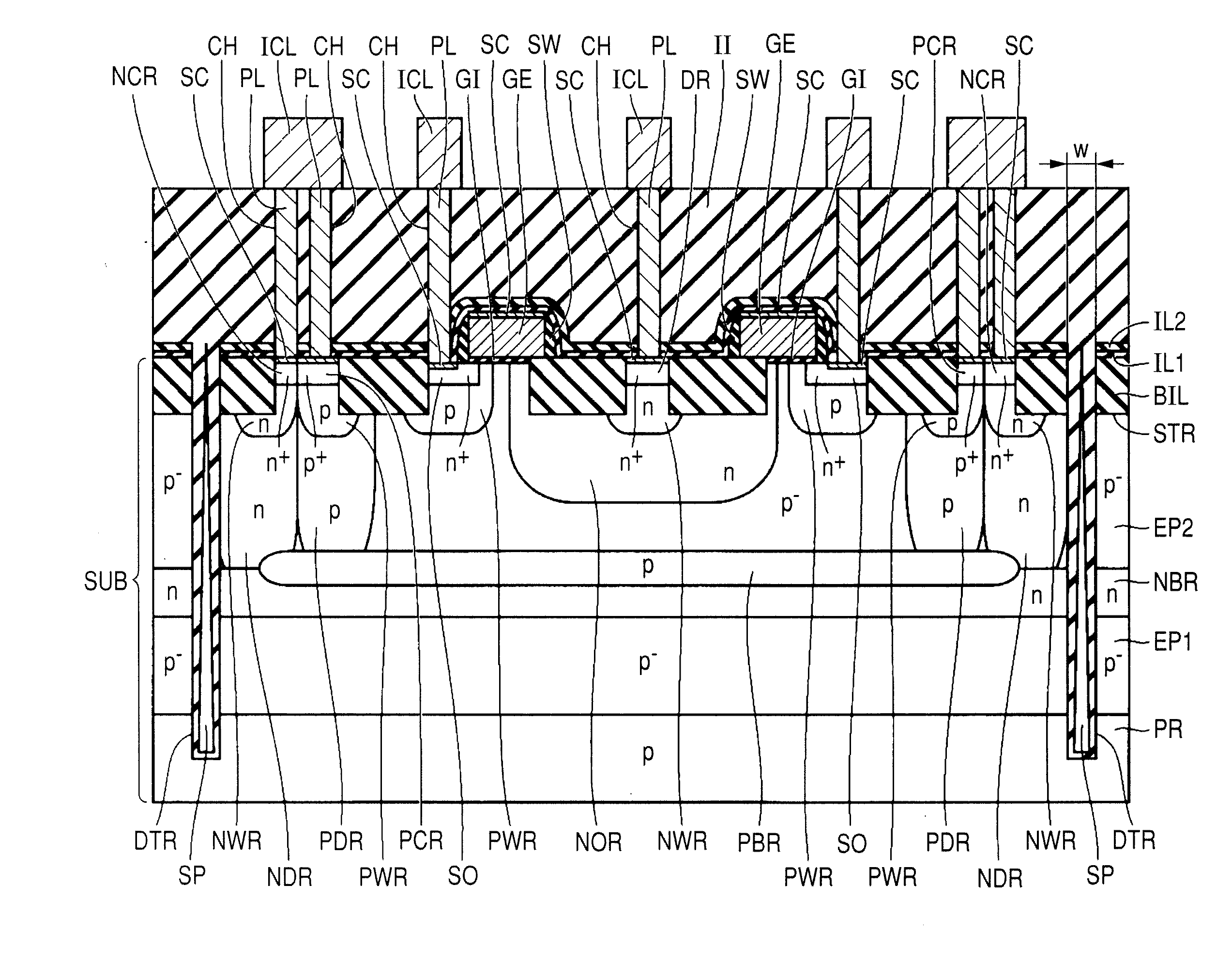

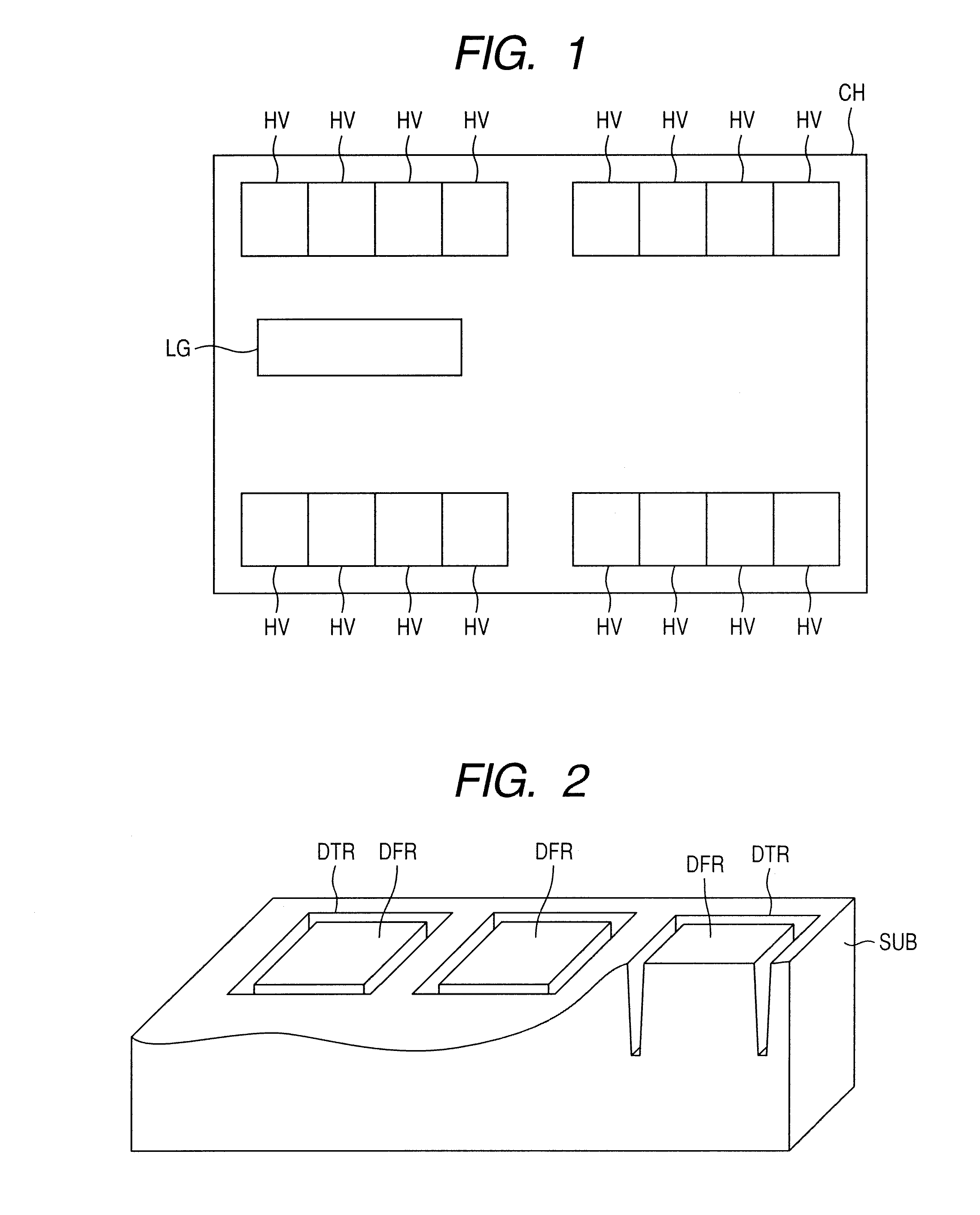

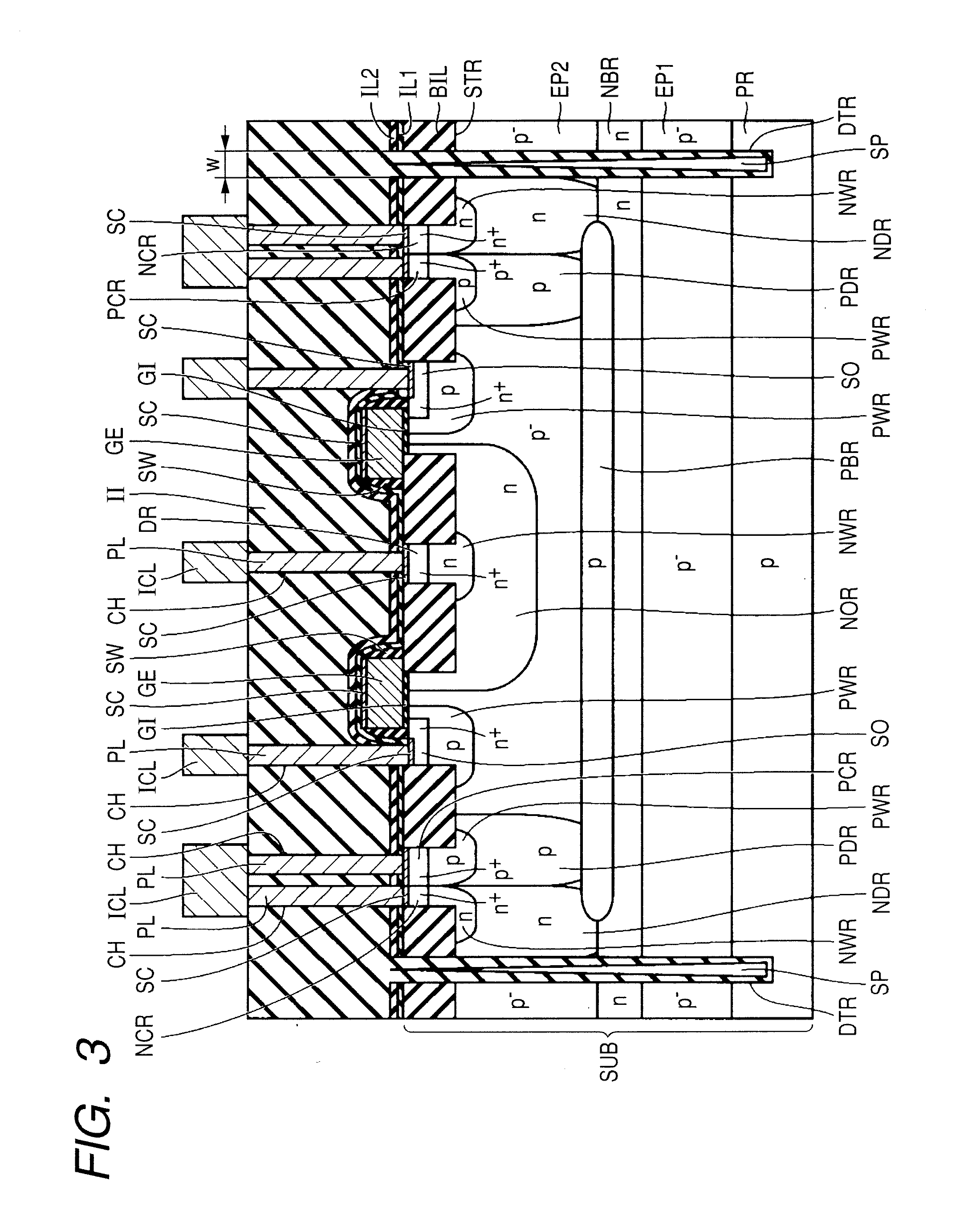

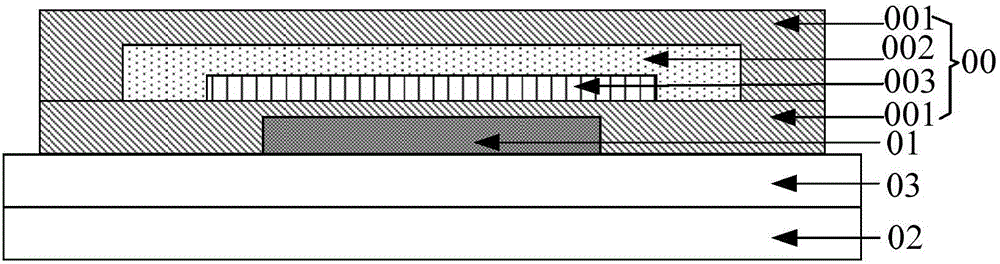

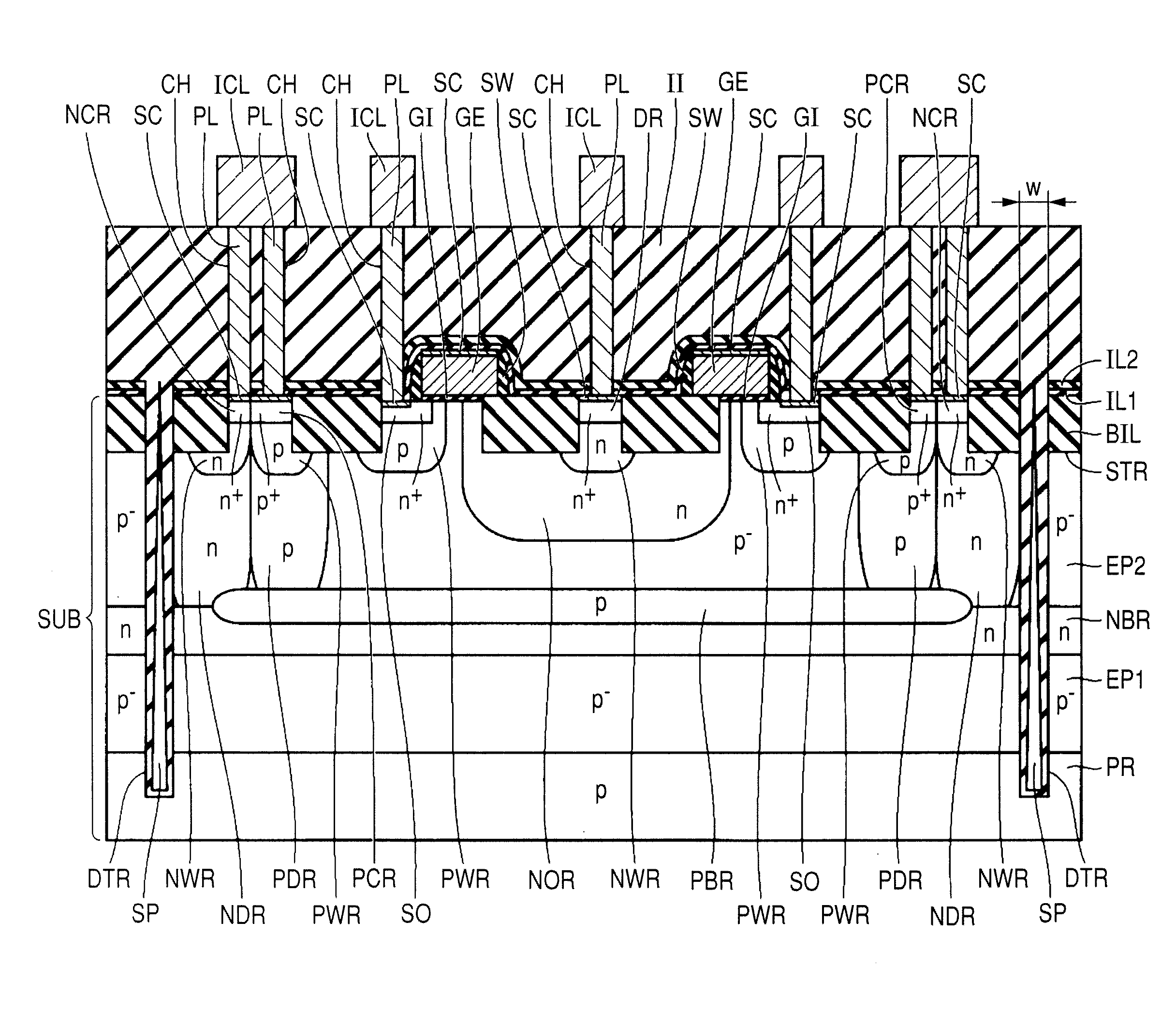

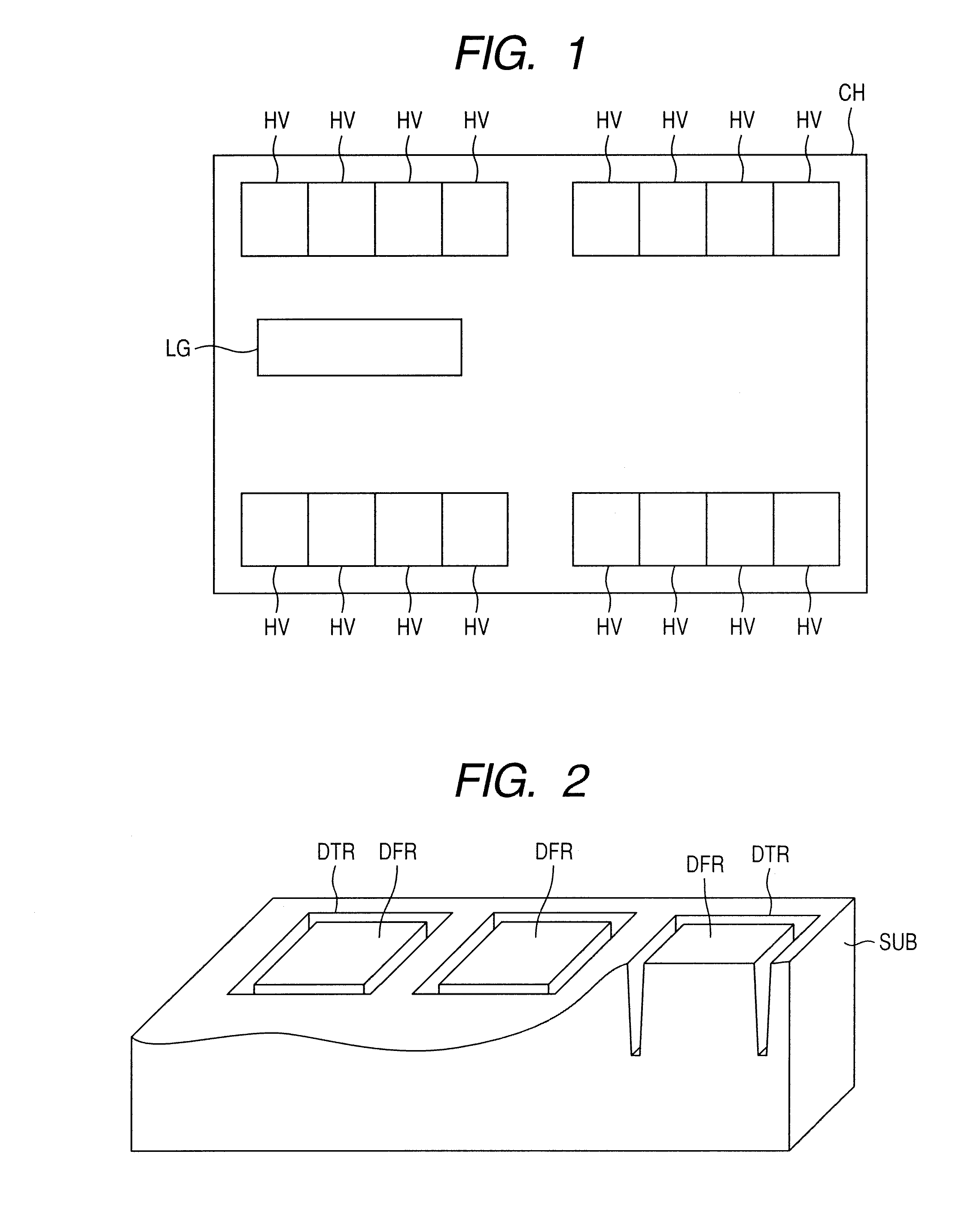

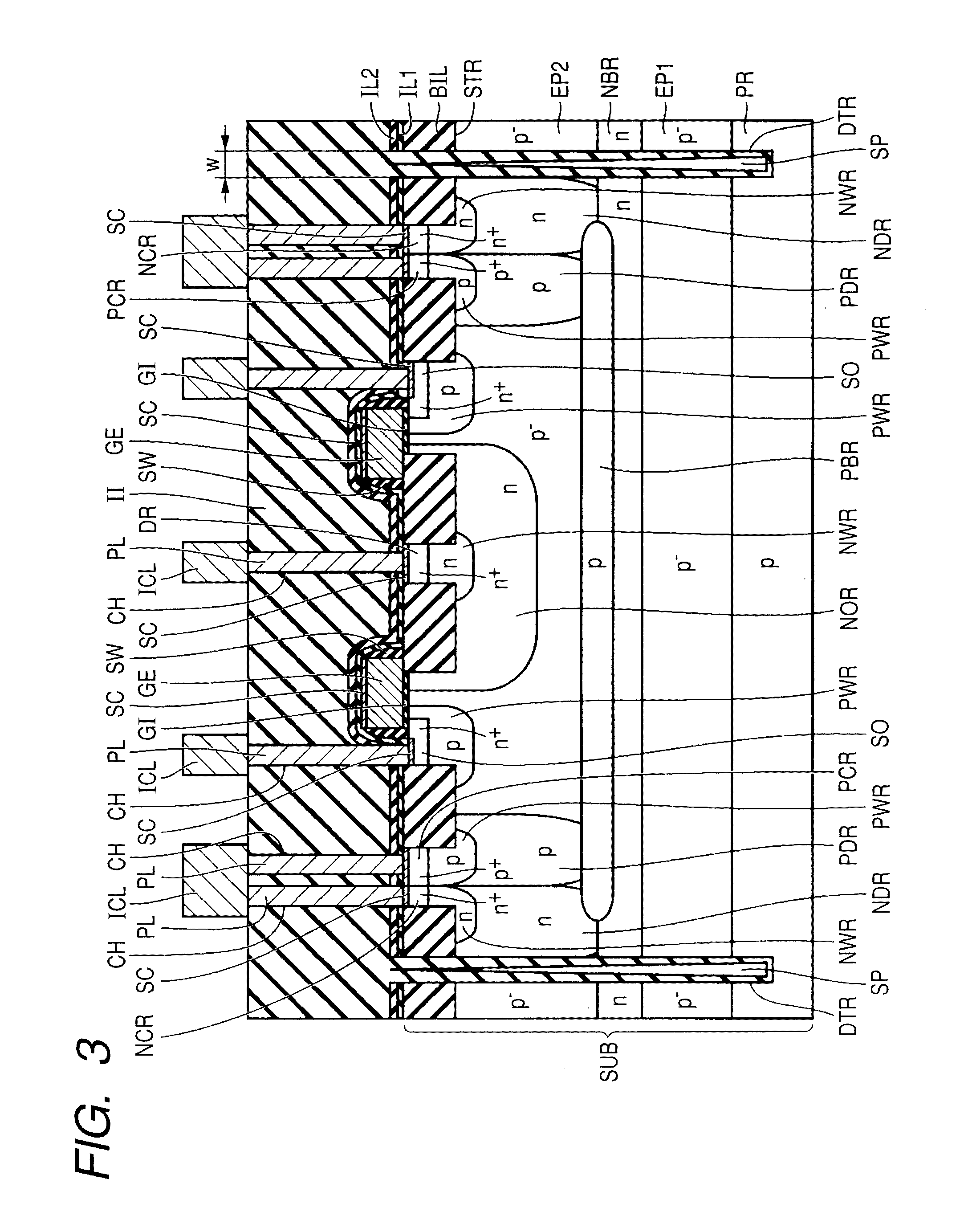

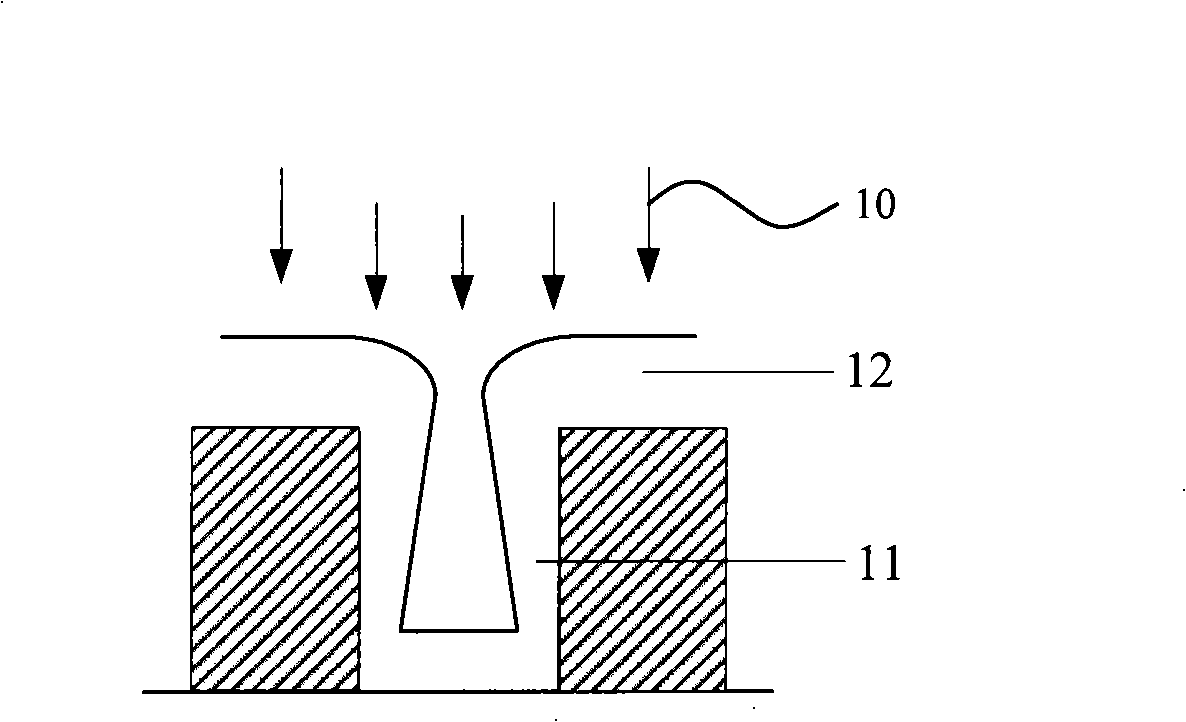

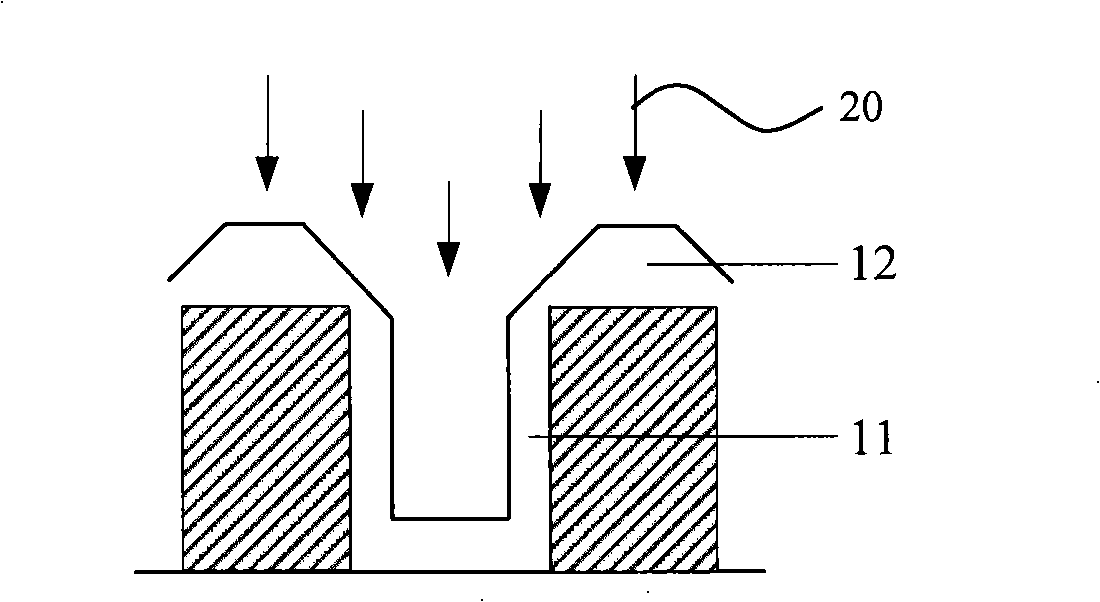

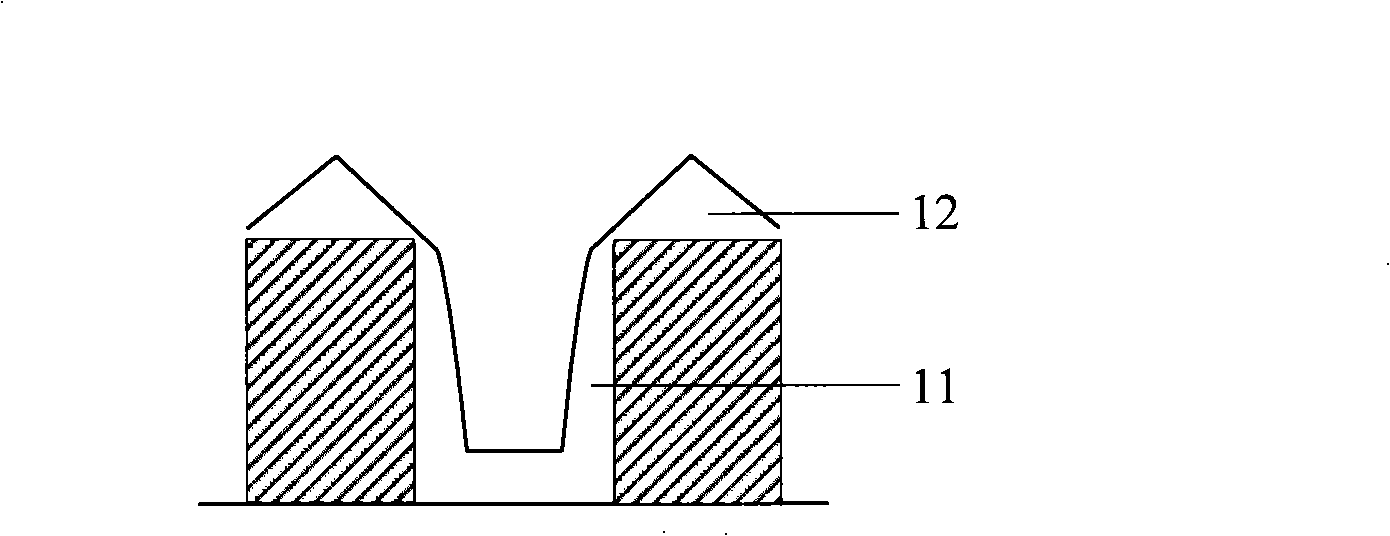

Semiconductor device and method for manufacturing the same

ActiveUS20110062547A1Good filling effectEliminate needSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorBreakdown voltage

A semiconductor device which eliminates the need for high fillability through a simple process and a method for manufacturing the same. A high breakdown voltage lateral MOS transistor including a source region and a drain region is completed on a surface of a semiconductor substrate. A trench which surrounds the transistor when seen in a plan view is made in the surface of the semiconductor substrate. An insulating film is formed over the transistor and in the trench so as to cover the transistor and form an air-gap space in the trench. Contact holes which reach the source region and drain region of the transistor respectively are made in an interlayer insulating film.

Owner:RENESAS ELECTRONICS CORP

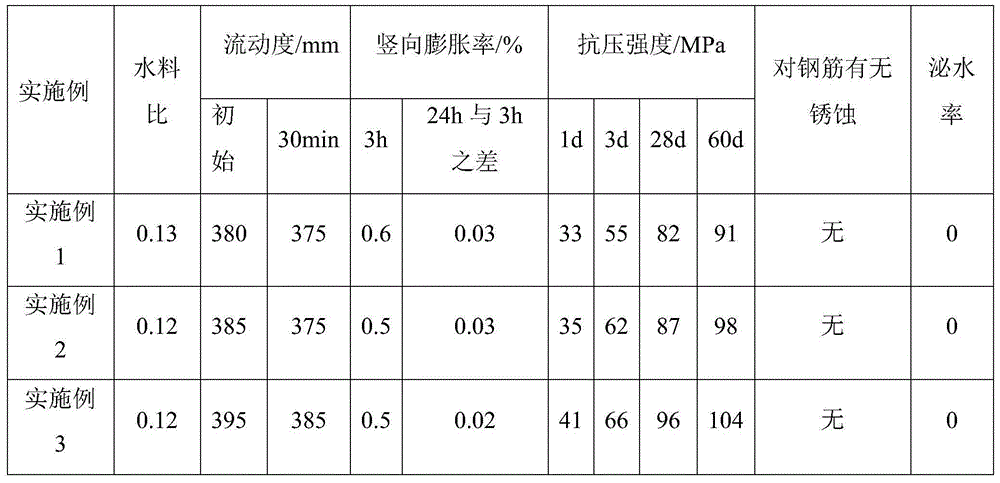

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

Graphene-modified heat conduction film

The present invention relates to a graphene-modified heat conduction film, which comprises, by weight, 10-60% of a polyimide emulsion, 0-10% of a binder, 30-90% of graphene, 0-5% of an auxiliary agent and 0-10% of a solvent. According to the present invention, based on characteristics of high strength, high specific surface area, high chemical reaction activity, high thermal conductivity coefficient and high filling property of graphene, the heat conduction film is added with graphene so as to improve the strength of the heat conduction film, and the graphene has the good lubrication effect so as to improve the mechanical property and the thermal conductivity of the heat conduction film.

Owner:NINGBO MORSH NEW MATERIALS

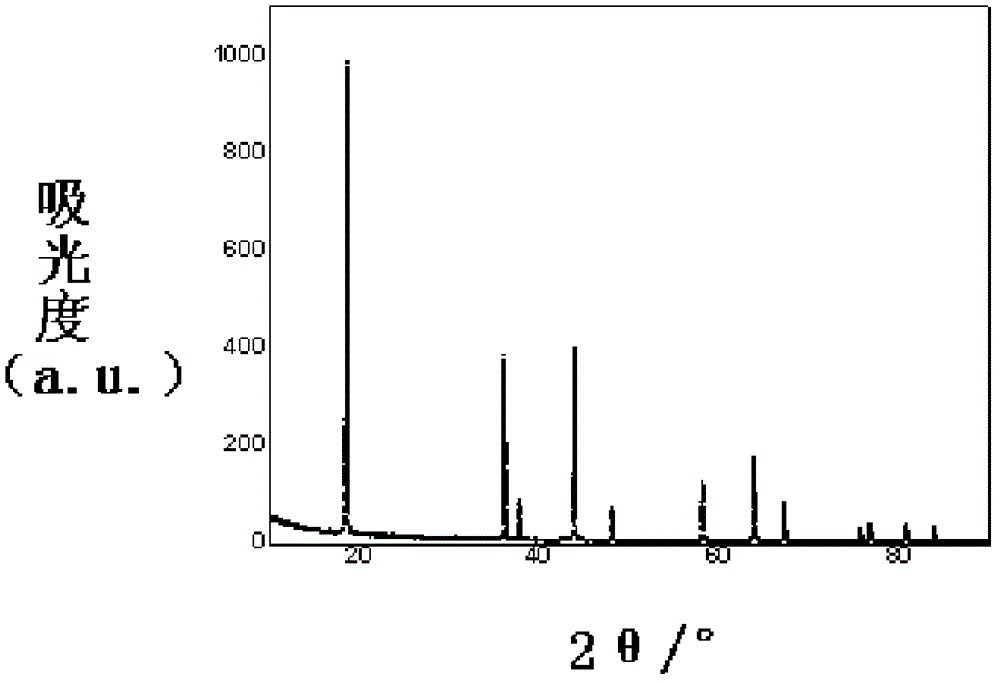

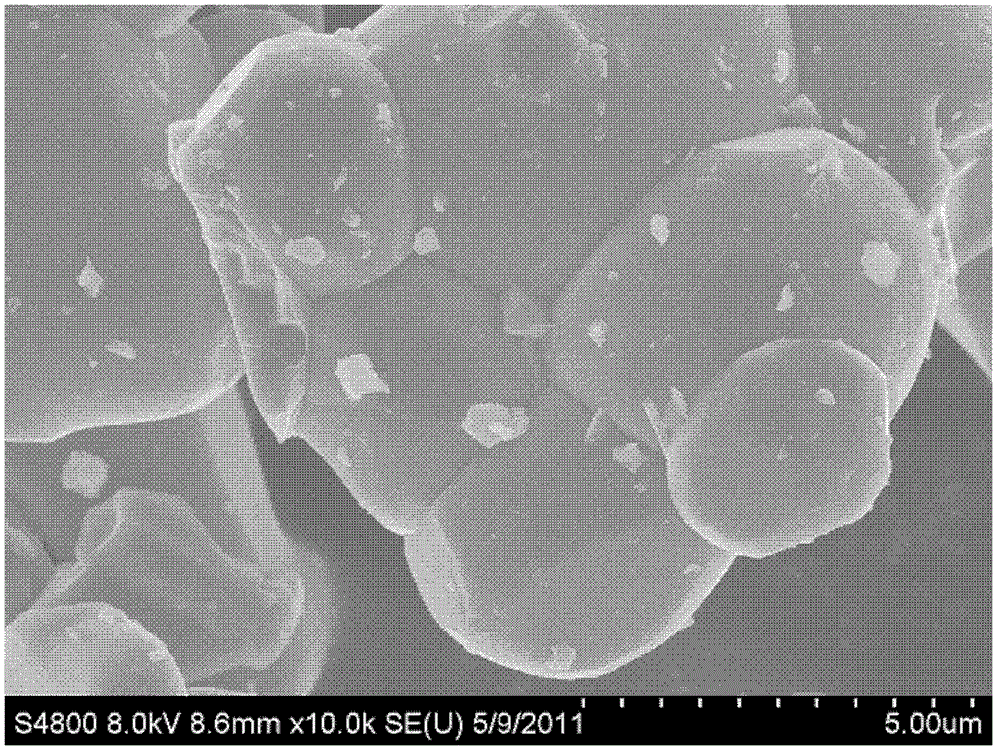

Cathode material of lithium ion battery, and preparation method thereof and lithium ion battery

ActiveCN102800840ANot easy to dissolveGood high temperature cycle performanceCell electrodesSecondary cellsTemperature cyclingLithium electrode

The invention provides a cathode material of a lithium ion battery. The cathode material is composed by the atomic ratio shown in formula (I): Lia(MxMn2-x)(O4-yZy), wherein a is greater than or equal to 0.8 and less than or equal to 1.2; x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; M is one or more selected from Li, Na, K, Ca, Mg, Al, Ti, Sc, Ge, V, Cr, Zr, Co, Ni, Zn, Cu, La, Ce, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, Pb and Si; and Z is one or more selected from OH, halogens, N, P, S and O. Primary particles of the cathode material have sphere-like morphologies, wherein (111) face is connected with adjacent equivalent crystal face through a curved surface having no clear edges. The invention also provides a preparation method for the cathode material of the lithium ion battery and the lithium ion battery. The cathode material provided by the invention has good high-temperature cycling performance and good filling property.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

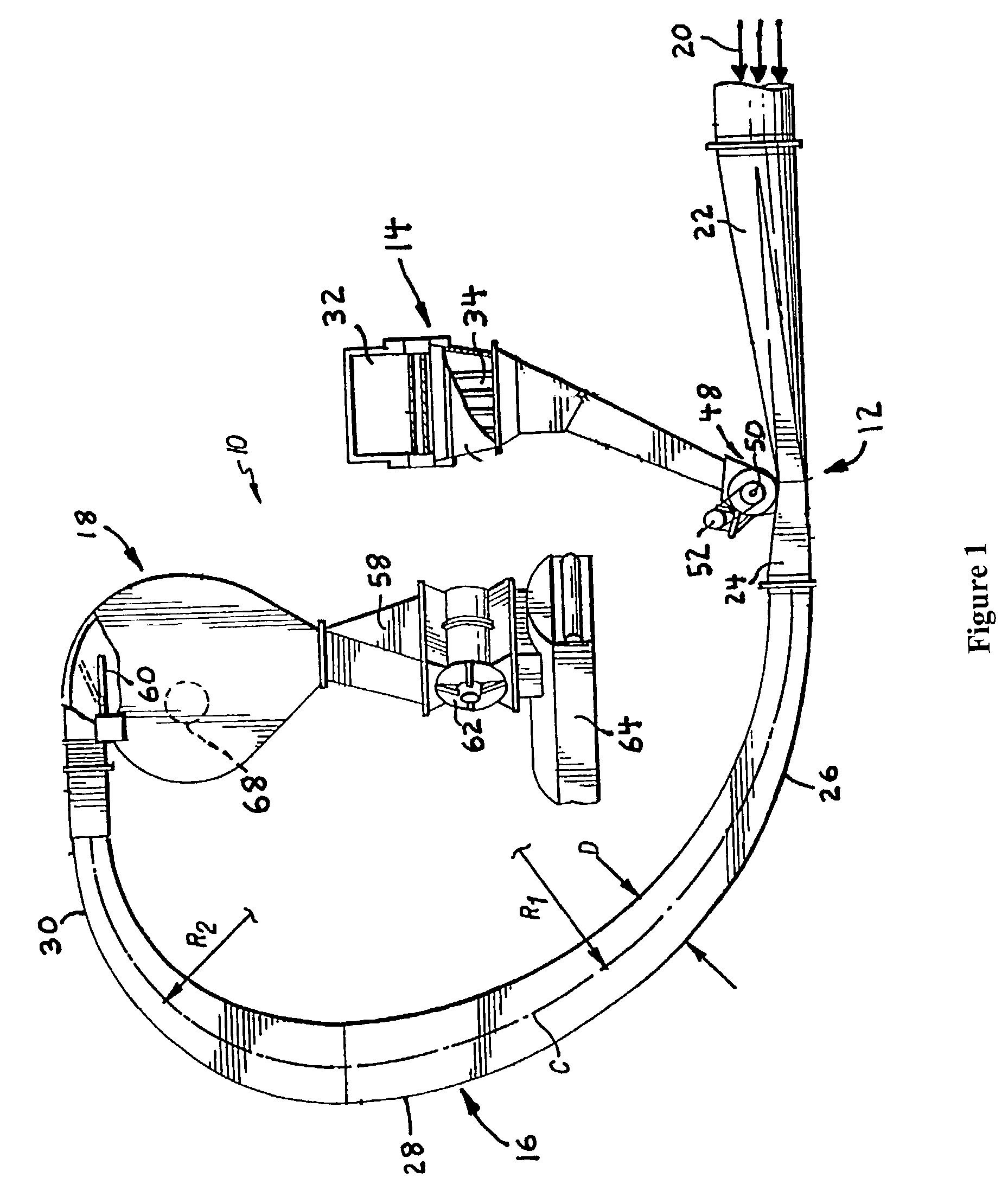

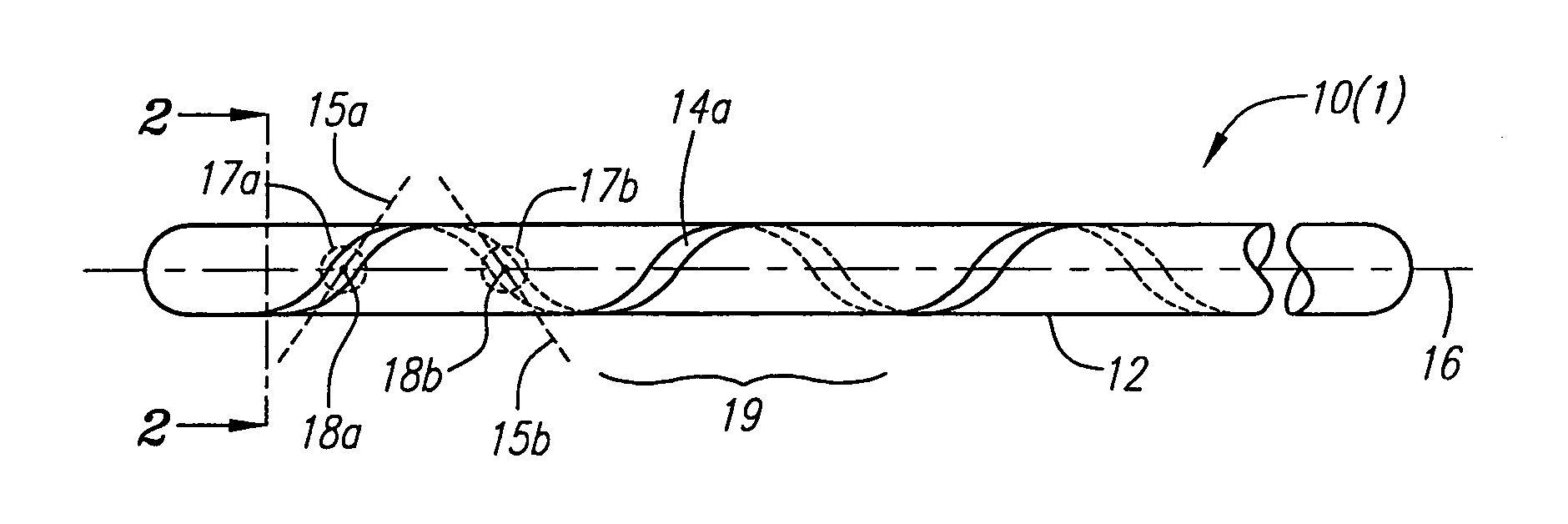

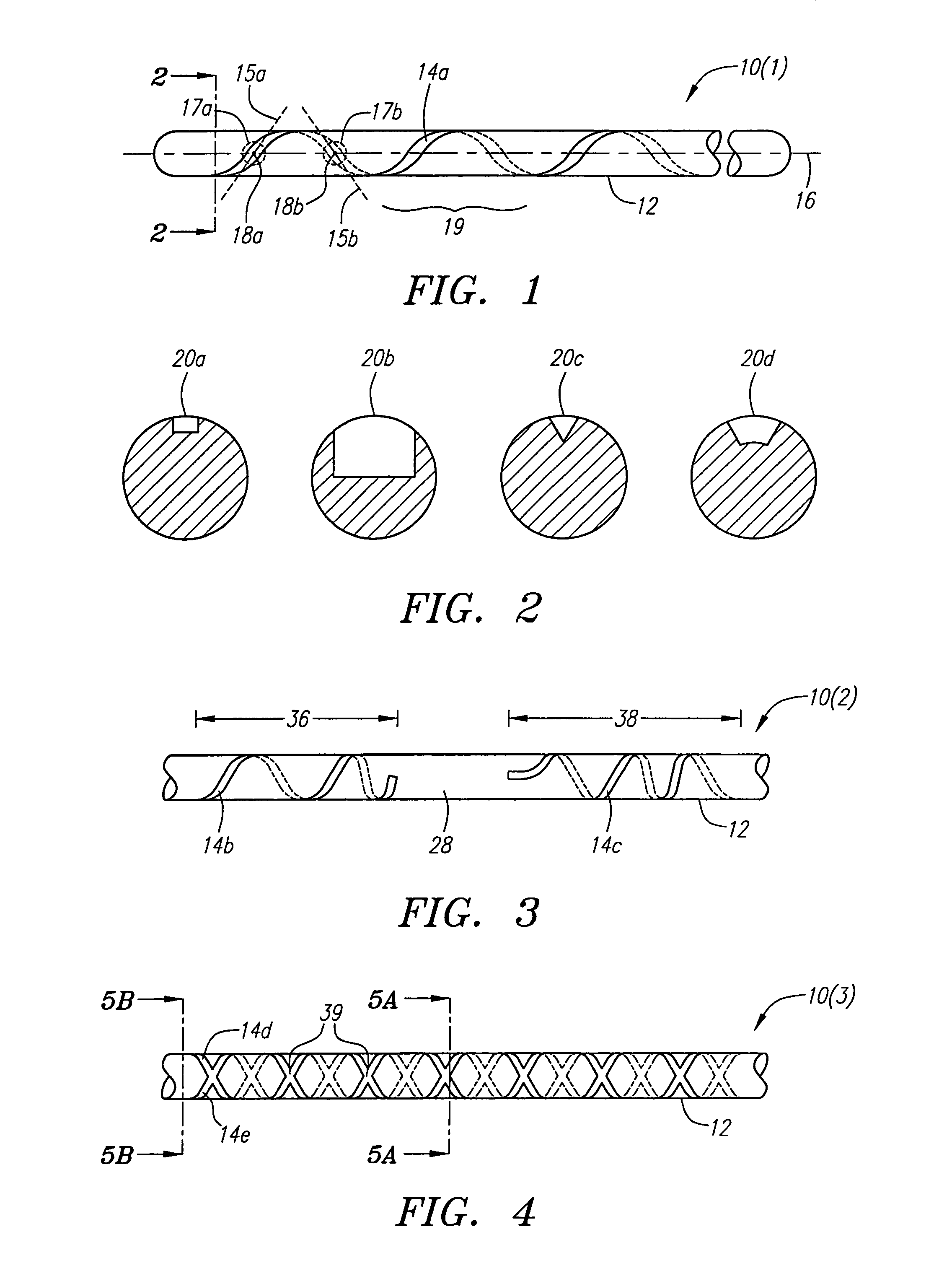

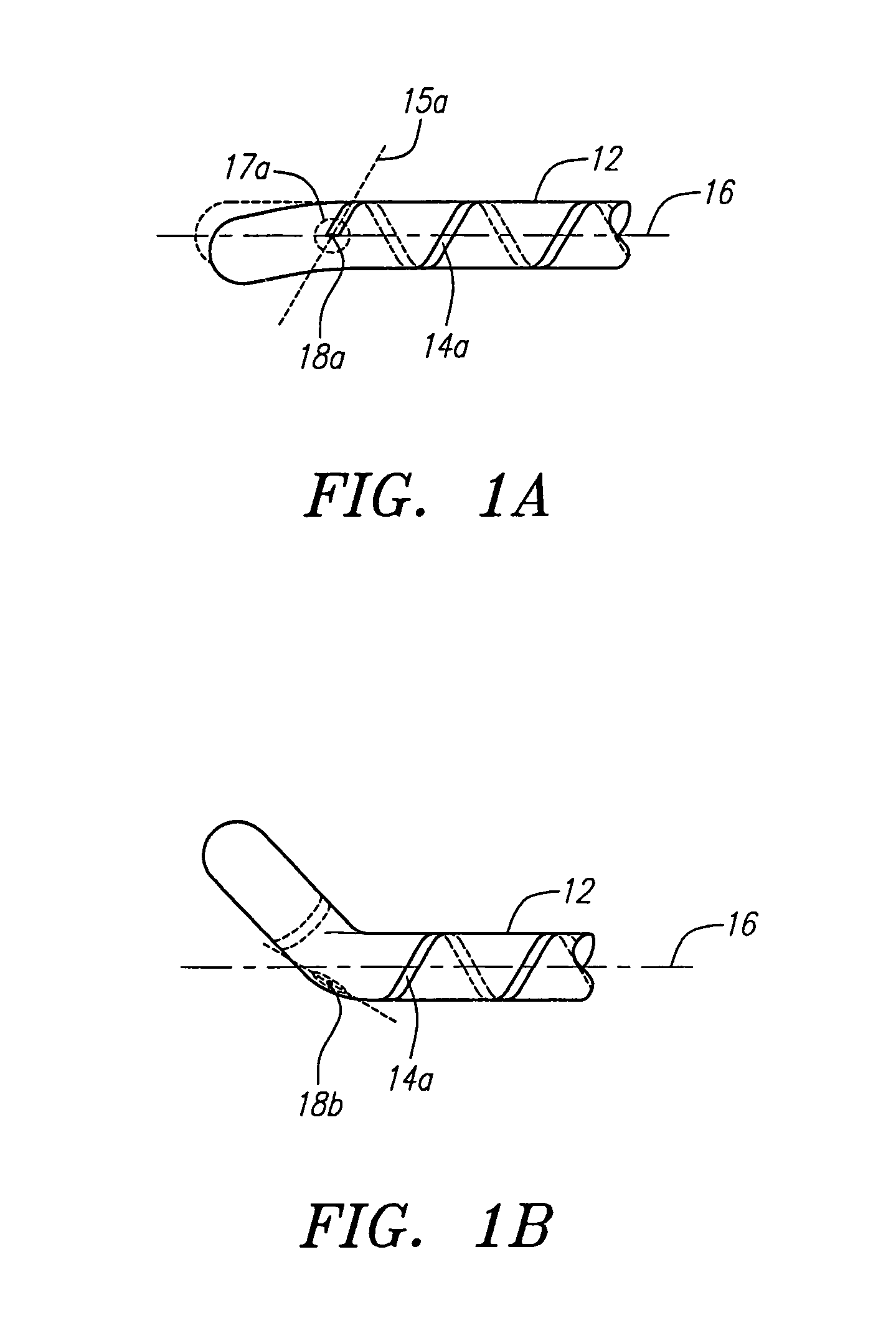

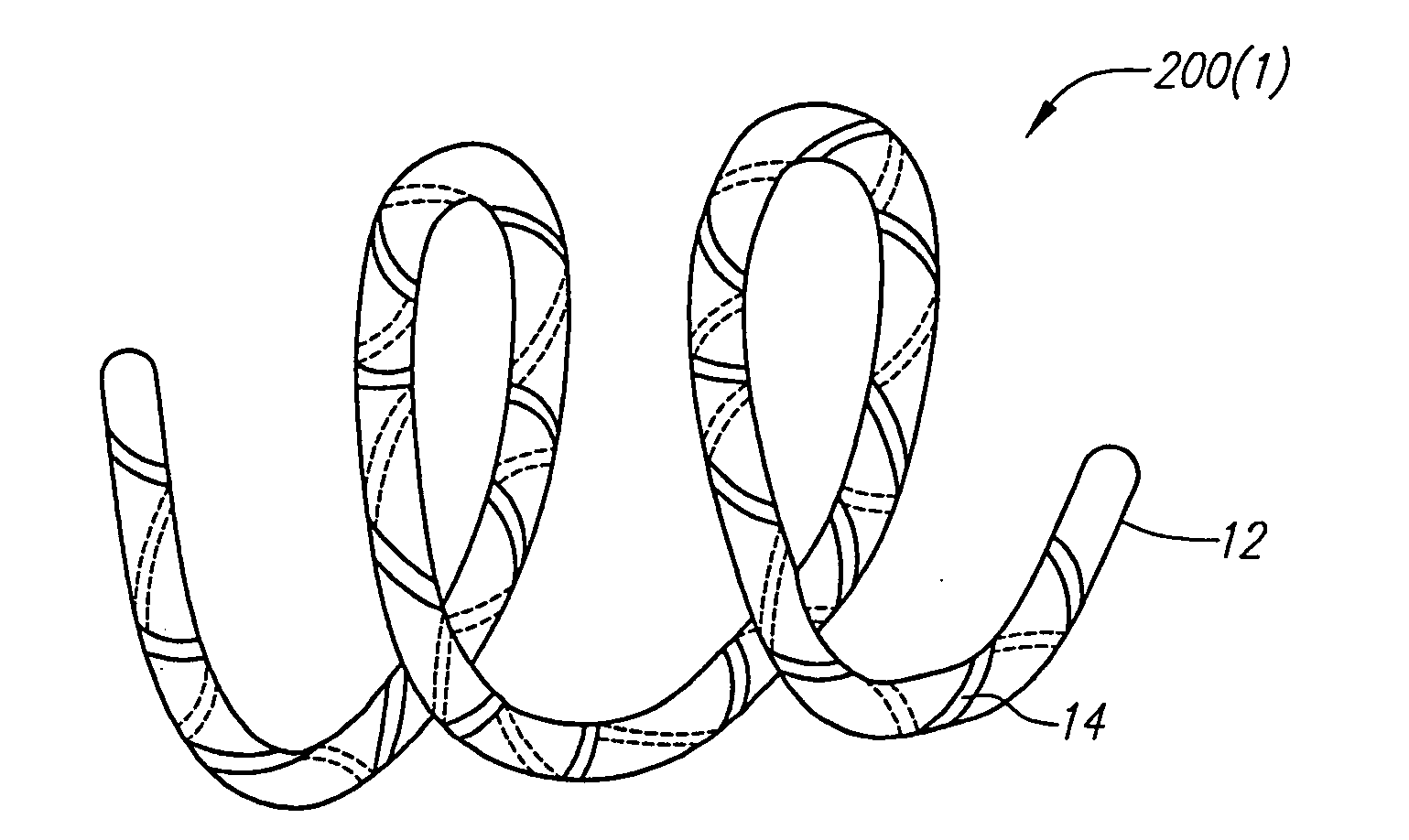

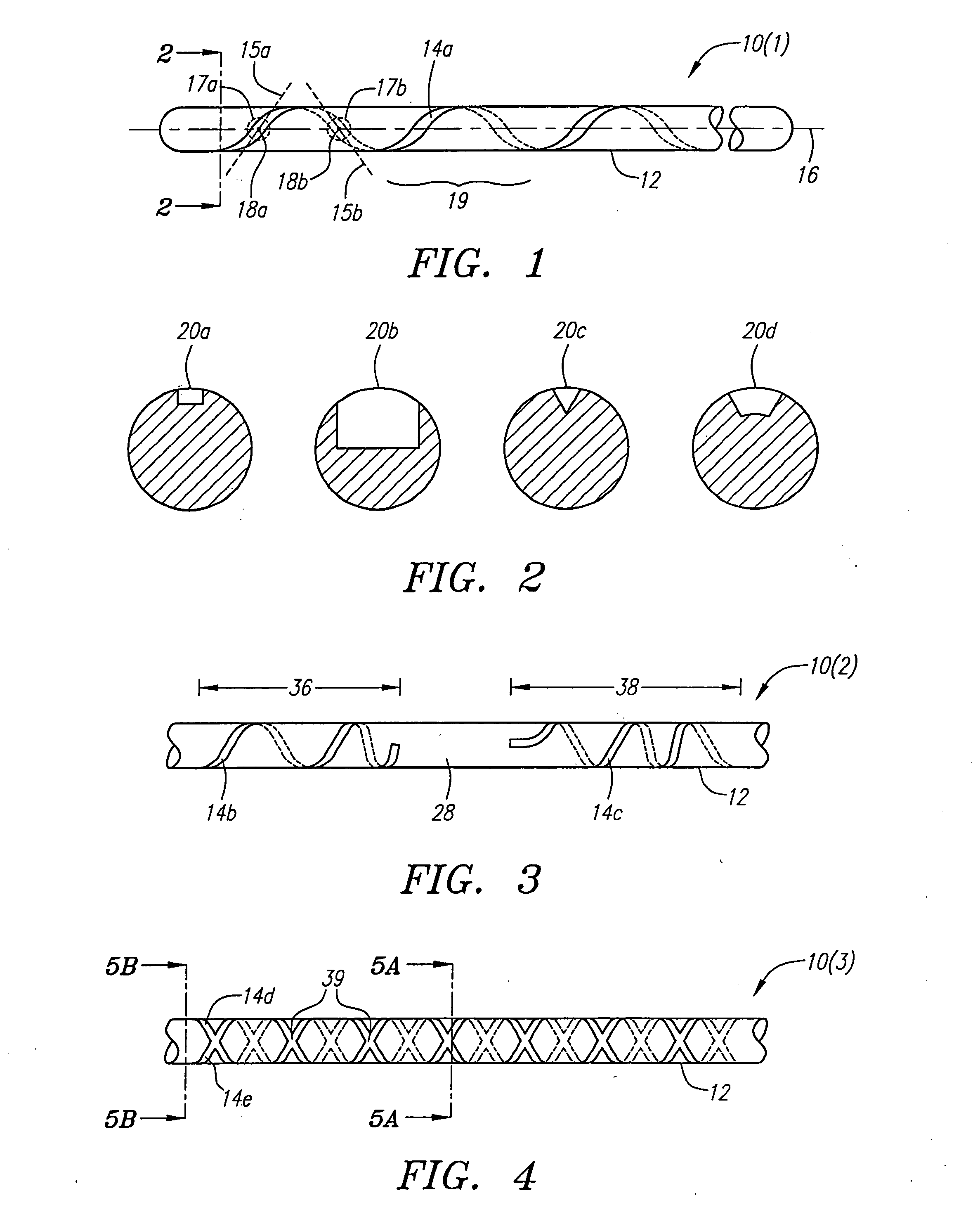

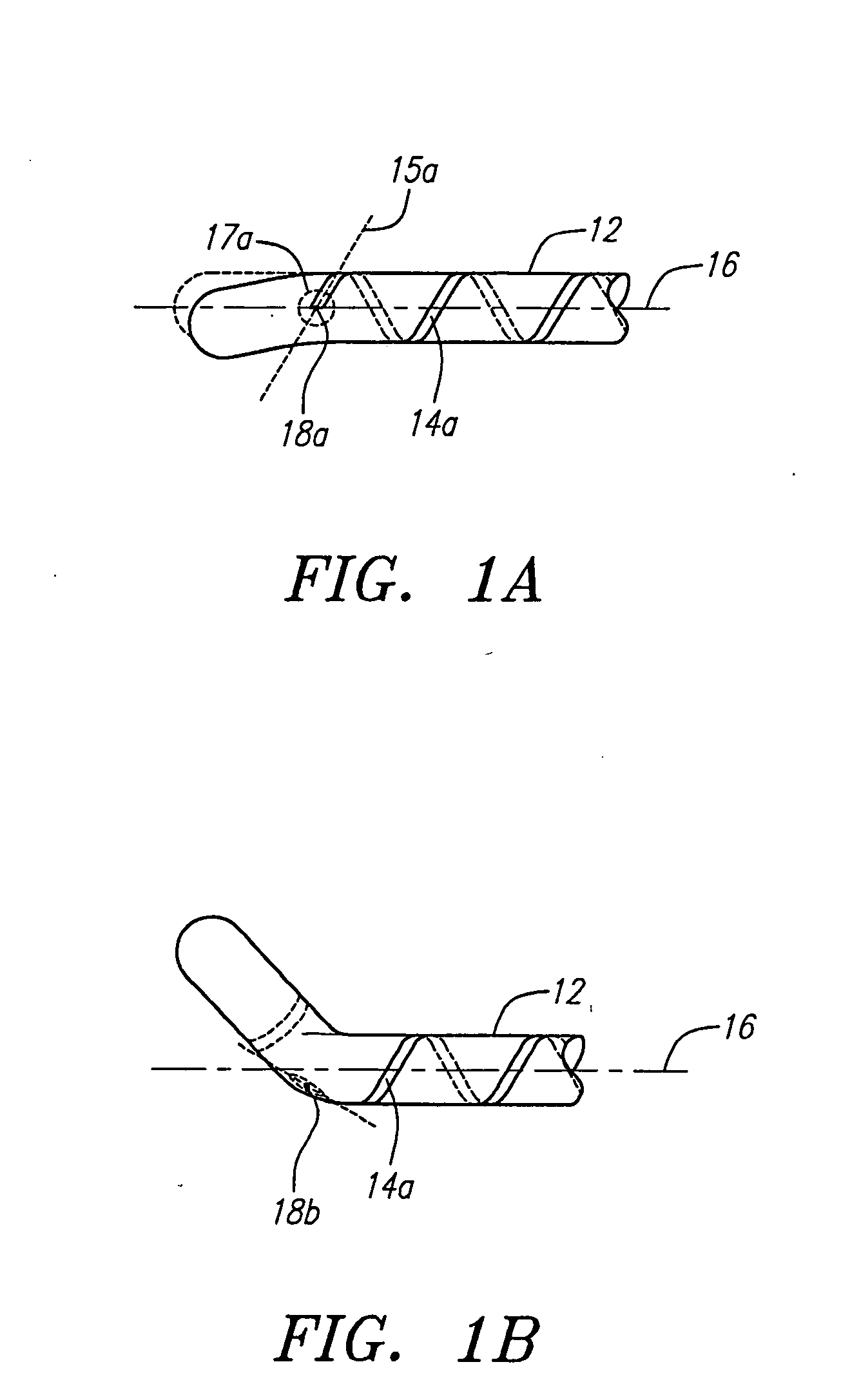

Foldable vaso-occlusive member

InactiveUS7060083B2Efficiently and easily fillGood filling effectDilatorsOcculdersMedicineBiomedical engineering

Vaso-occlusive devices for occlusion of a body cavity are provided. The vaso-occlusive devices include an elongate vaso-occlusive member having one or more fold lines. Methods of using the vaso-occlusive devices are also described.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

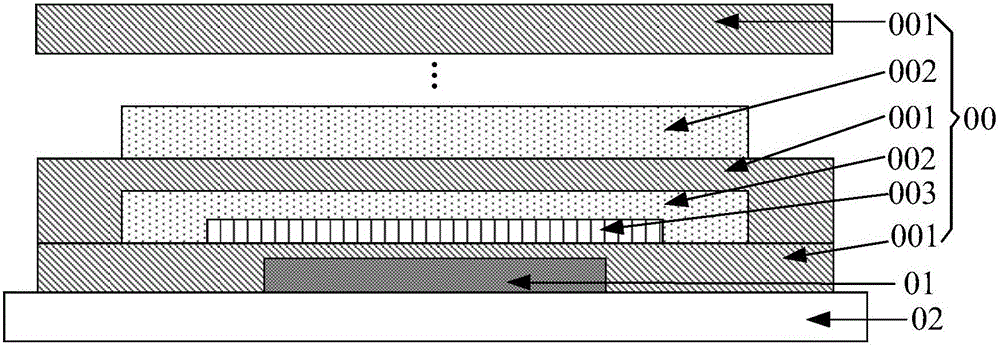

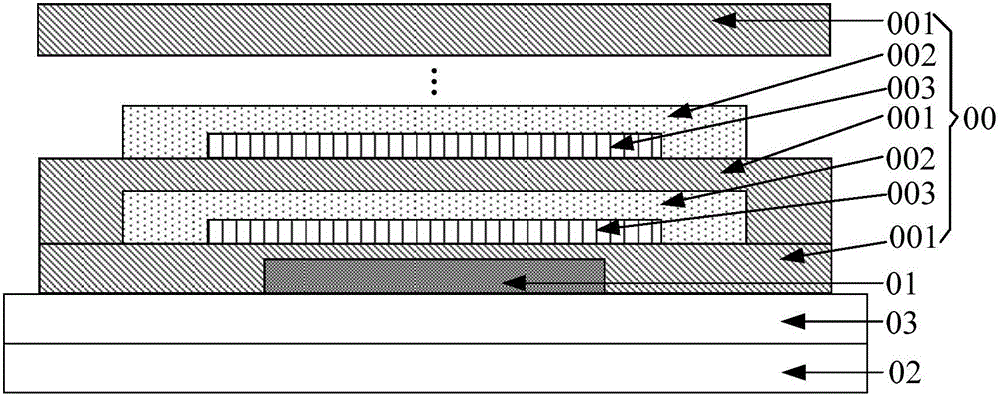

Thin-film packaging structure and display device

InactiveCN105789257AEasy to crackEasy to fillSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a thin-film packaging structure and a display device, and belongs to the technical field of packaging of display devices. The thin-film packaging structure comprises a plurality of film layers, wherein the plurality of film layers coat the outer side of a to-be-packaged device and include alternately stacked inorganic layers and organic layers; in the plurality of film layers, the film layers at the inner sides and the outer sides of the plurality of film layers all are inorganic layers; in the plurality of film layers, an auxiliary spreading layer is formed between the first inorganic layer and the first organic layer; the hydrophilic-hydrophobic property of the auxiliary spreading layer is the same as that of the first organic layer; the first inorganic layer is the film layer, in contact with the to-be-packaged device, in the plurality of film layers; and the first organic layer is the organic layer in contact with the first inorganic layer. According to the thin-film packaging structure, the problem of relatively poor filling effects of the organic layers on cracks and defects in the inorganic layers is solved; improvement of the filling effects of the organic layers on the cracks and defects in the inorganic layers is achieved; and the thin-film packaging structure is suitable for packaging of the display device.

Owner:BOE TECH GRP CO LTD

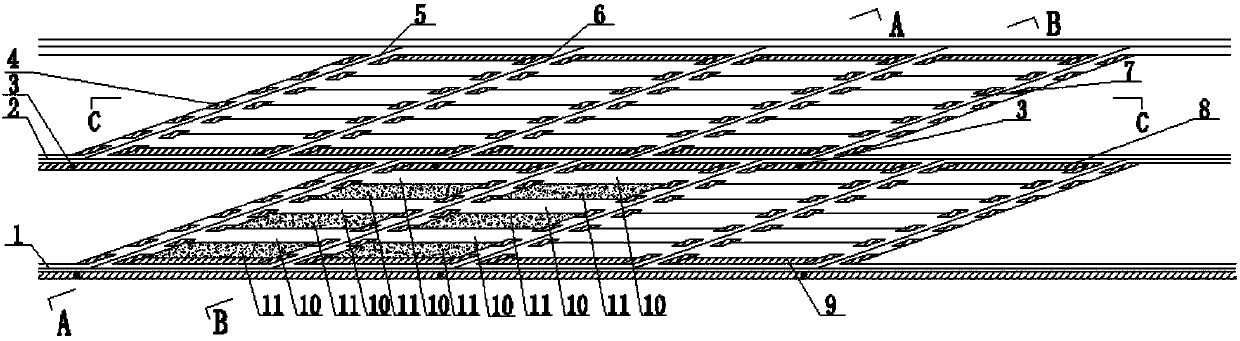

Mechanized mining method for gently-inclined medium-thick ore body

ActiveCN107869349AContinuous and efficient miningIncrease production capacityUnderground miningSurface miningMineralogyLoss rate

The invention provides a mechanized mining method for a gently-inclined medium-thick ore body, and belongs to the technical field of mining. The method comprises the following steps: dividing a gently-inclined medium-thick ore body into a panel area, dividing the ore body in the panel area into strips in a heading direction, driving a pseudo-inclined mining uphill roadway and a return air uphill roadway in the inclining direction of the ore body, driving a stope connecting roadway in a mining uphill direction and a return air uphill direction respectively, reserving a top safety ore pillar anda bottom safety ore pillar at the top and the bottom of each section respectively, and reserving a safety ore pillar between adjacent stopes in the heading direction of the ore body. The strips in the panel area is divided into one-step stopes and two-step stopes, the ore body is stoped at intervals sequentially from bottom to top, the one-step stopes are mined first, and then the two-step stopesare mined. After filling and final setting of all one-step and two-step stopes, uphill safety ore pillars, top safety ore pillars and bottom safety ore pillars are recovered. The method provided by the invention has the advantages of high mechanization degree, large production capacity, small mining and cutting work amount, high ore recovery rate, low lean loss rate and good safety.

Owner:UNIV OF SCI & TECH BEIJING +1

PVC (polyvinyl chloride) coated fabric paste and preparation method thereof

The invention discloses a functional PVC (polyvinyl chloride) paste. The functional PVC paste comprises the following components: PVC paste resin, PVC doped resin, a plasticizing agent, a filling agent, a heat stabilizer, a light stabilizer, an antioxidant, a mildew-proof antibacterial agent, a gas-phase silicon dioxide and the like. A preparation method of the functional PVC paste comprises the following steps of: (1) stirring: firstly mixing and stirring a part of the plasticizing agent and a liquid component uniformly, then adding a solid component, stirring uniformly, finally adding coloring stock and the remaining plasticizing agent, and stirring uniformly, so as to obtain plasticized paste; (2) grinding: grinding the plasticized paste on a three-roll grinding machine; and (3) defoaming and ageing. The paste has the advantages that the viscosity stability is good; and the paste can remain low viscosity under the action of the shearing force of a scraper in the process of producing PVC coated fabric, so that the normal production of the PVC coated fabric is guaranteed, and the surface of the prepared PVC coated fabric is smooth without the phenomena of pin holes and the like.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

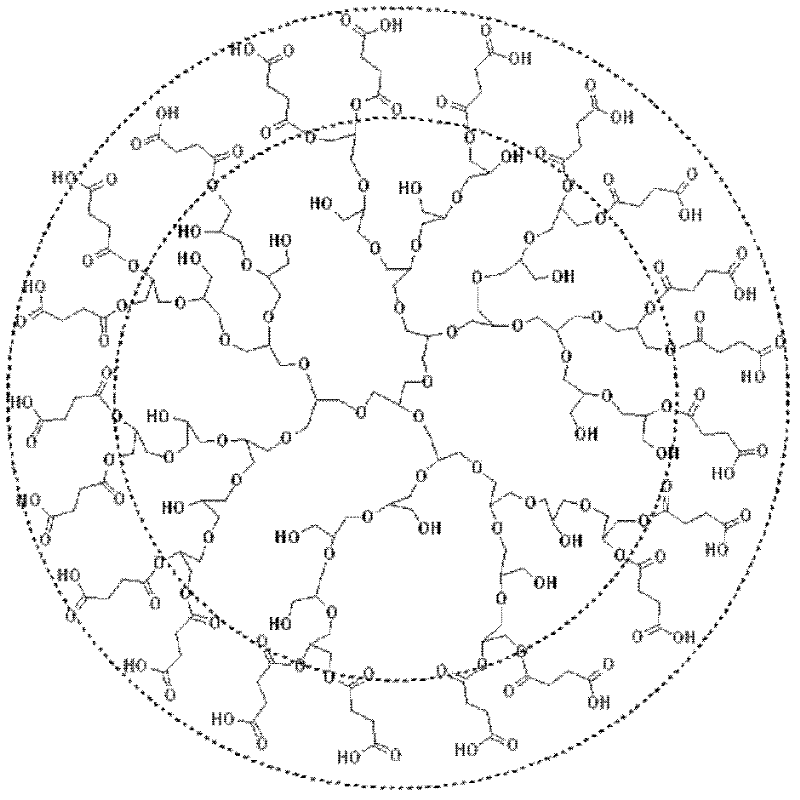

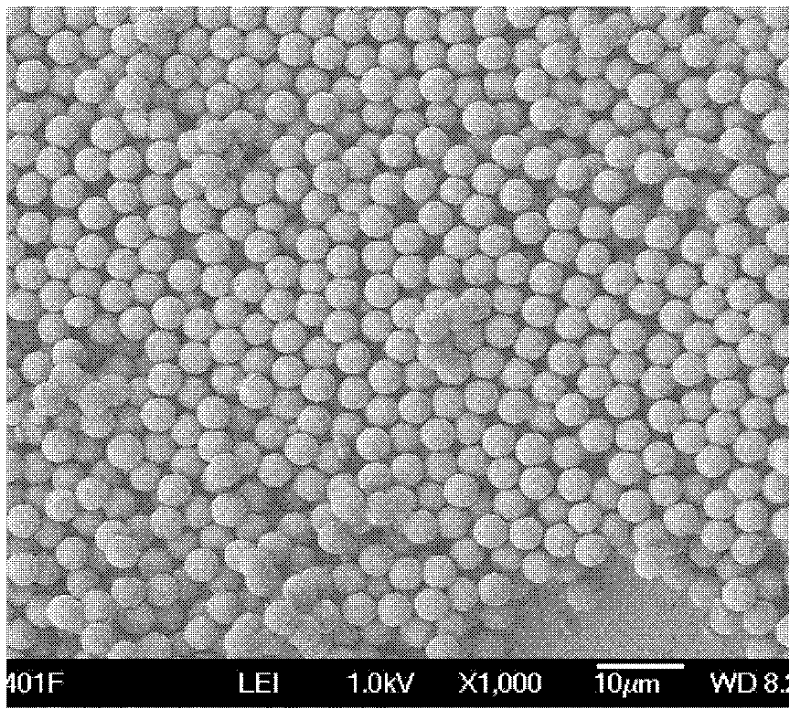

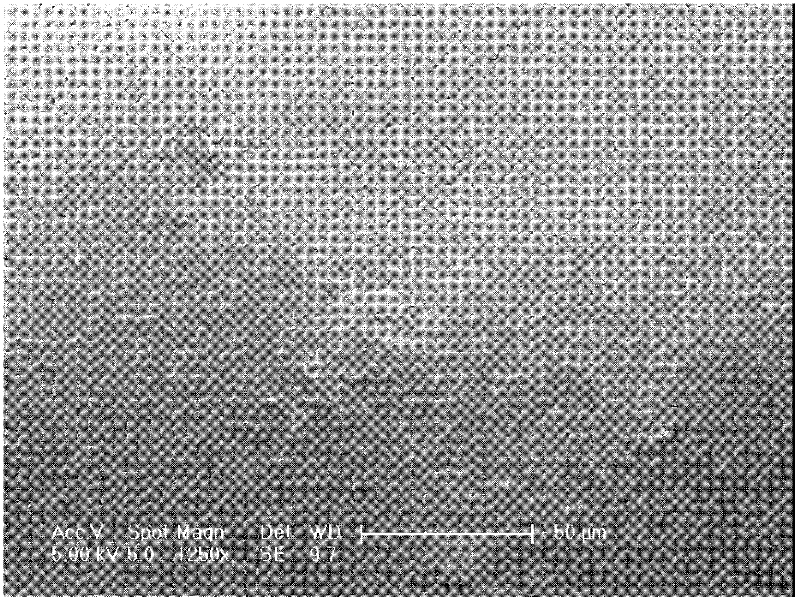

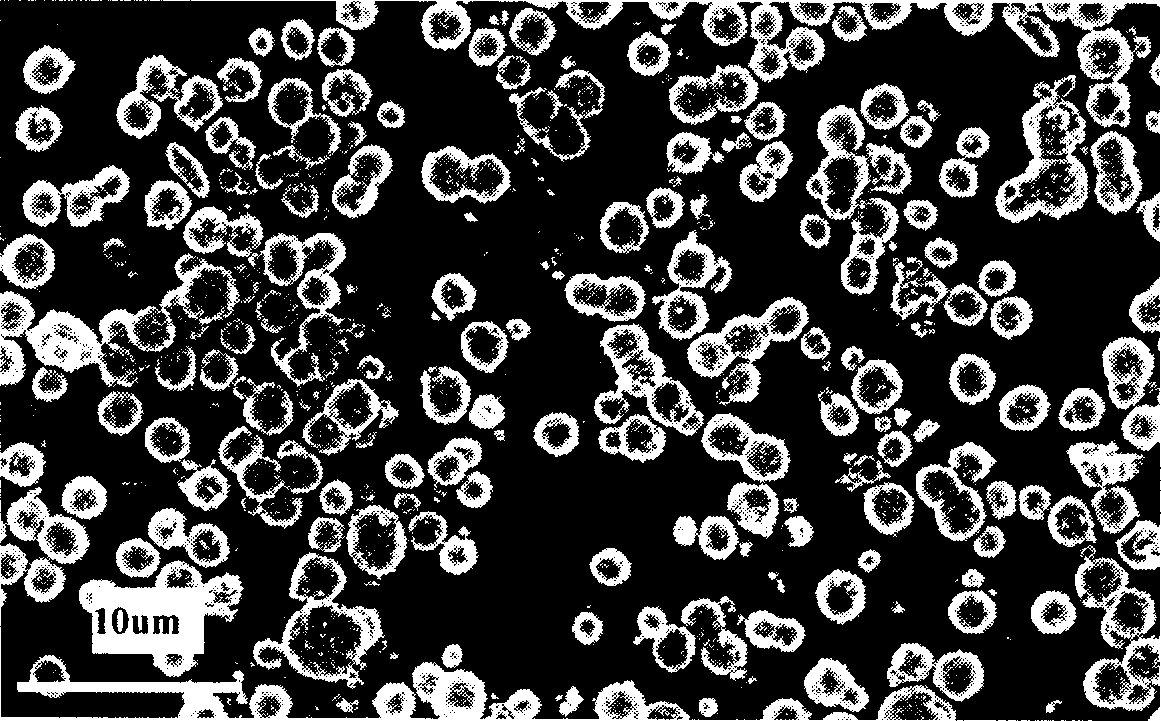

Preparation method for vaterite-phase calcium carbonate microspheres with uniform size

InactiveCN102515236ASimple and fast manufacturing methodUniform size and heightCalcium/strontium/barium carbonatesNanotechnologyMicrosphereHybrid material

The invention discloses a preparation method for vaterite-phase calcium carbonate microspheres with a uniform size, comprising the following step of: using a double-hydrophilic hyperbranched polymer molecule as a template, and performing precipitation reaction between water-soluble calcium salt and carbonate to prepare. The calcium carbonate microspheres prepared by the method are organic-inorganic hybrid materials containing 7-10 wt% of hyperbranched polymer. The particle size of the microspheres can be adjusted in a range between 2 to 4.5 microns by controlling reaction conditions. The product prepared by the method disclosed by the invention is highly uniform in size, green and environment-friendly in synthesis process, and with a certain application prospect.

Owner:HANGZHOU NORMAL UNIVERSITY

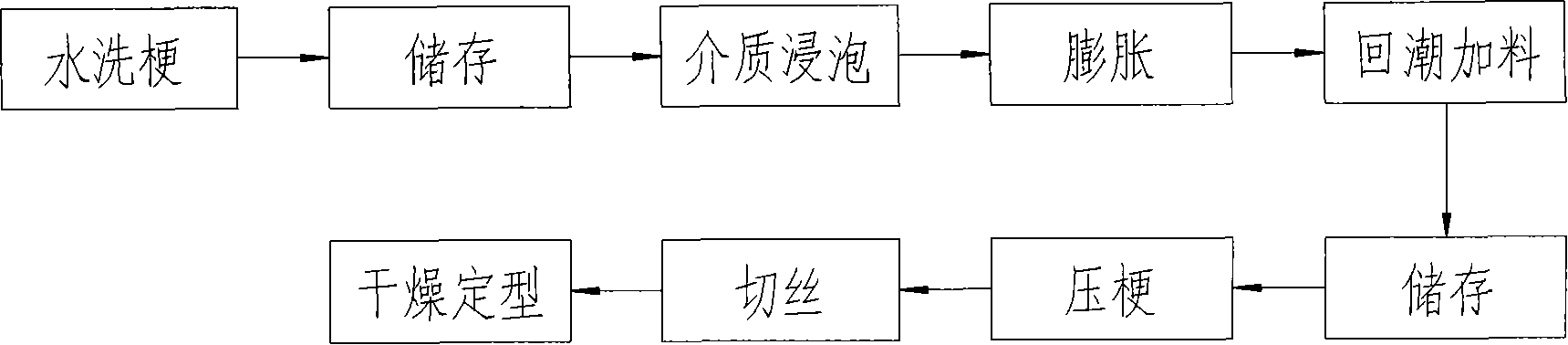

Technique of pre-expanding treating cabo

ActiveCN101108028AFully removedLarge specific surface areaTobacco preparationTobacco treatmentFilling materialsEngineering

A tobacco stalk pre-expending processing technics is provided, which is characterized in that: the technics comprises the following procedures: washing, storing, expanding in liquid and marinating with interface the tobacco stalk, expanding the stalk strips, moisture regaining and feeding, storing, pressing sticks and drying for shaping. The technics method of the invention changes the expanding of cut rolled stem into expanding the tobacco stick by using marinating with high temperature and low pressure and then expanding with high temperature and reduced preddure, thus sufficiently eliminating the bad flatus in the tobacco stick as the flatus of the wood or the corrupt straws; the tobacco stick after expanded has increased cells and remarkably enhanced ratio surface, thus the material liquid can filter into the tobacco sticks sufficiently to becoming a natural filling material and adaptation carrier for adjusting the cigarette fragrance and style; the cigarette stick after expanded is large in volume, which, after pressed, is easy being cut into silkiness (similar as the physical behavior of tobacco shred); after dried and shaped normally, the cut rolled stem can crisp naturally, thus increasing the filling capacity. The cut rolled stem processed by the technics method of the invention is basically similar with tobacco shred in color and shape and the alloying evenness of the tobacco shred is increased; besides, the tobacco shred has no bad aftertaste when smoking, but has strong filling capacity and enhanced internal quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

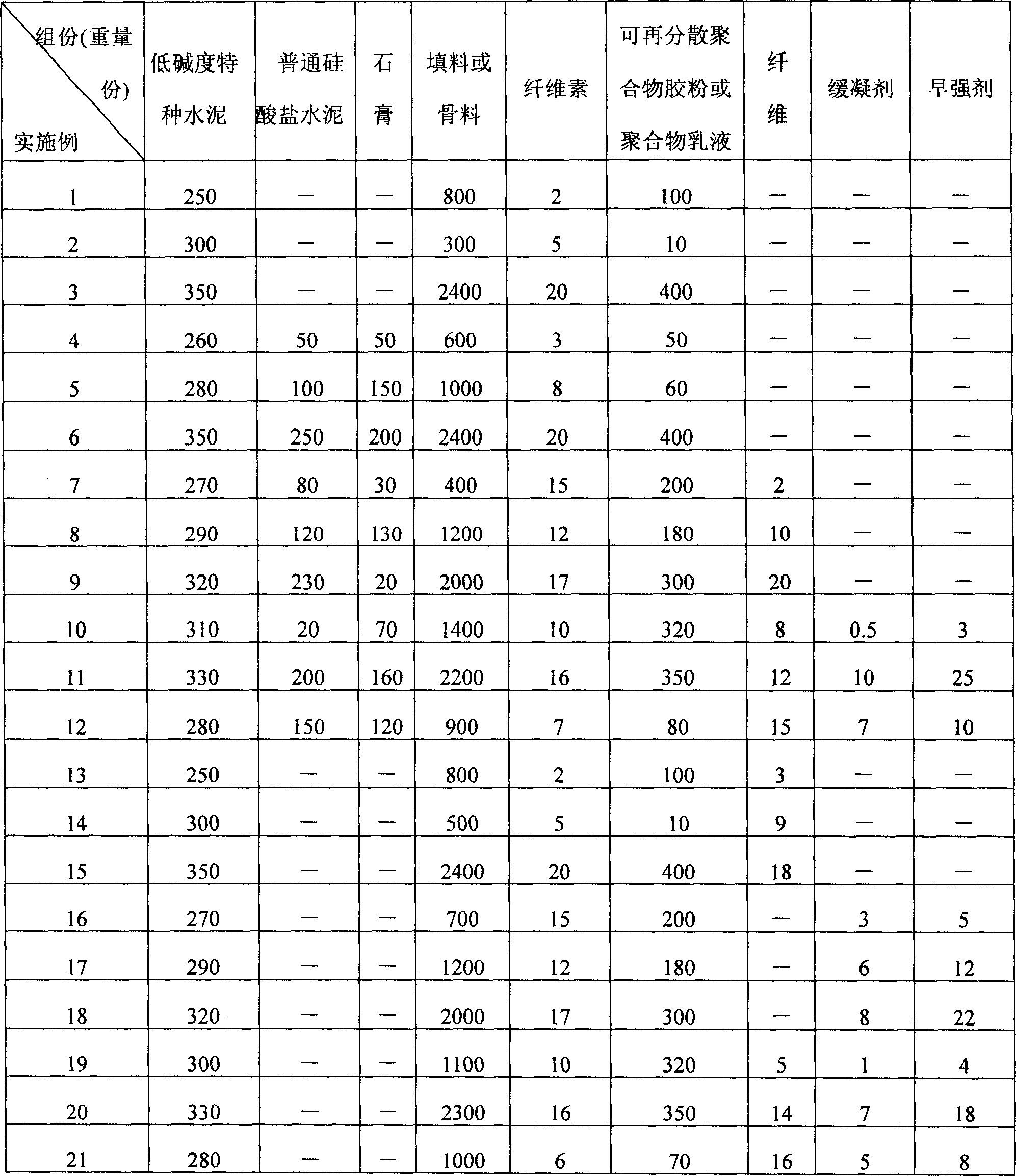

Mortar

InactiveCN1951858AOvercoming brittlenessOvercome defects such as cracking and drummingFiberCellulose

The invention discloses a mortar, which comprises the following parts: 250-350 parts of low-alkaline special typed cement, 0-250 parts of common silicate cement, 0-200 parts of calcium sulfate, 300-2400 parts of filler or aggregate, 2-20 parts of cellulose, 10-400 parts of redispersion polymer gel powder or 10-400 parts of polymer emulsion, 2-20 parts of fiber, 0.5-10 parts of retarder and 3-25 parts of instant coagulant. The low-alkaline cement contains the following clinker with 15%-35% C4A3S, 15%-35% C2S, 0%-35% C3S, 4%-15% CaSO4, 0%-15% C4AF and 0%-5% C3A . The mortar with low-alkaline cement and water can be preserved for 1-7d, whose pH value is 8-9.5.

Owner:王红

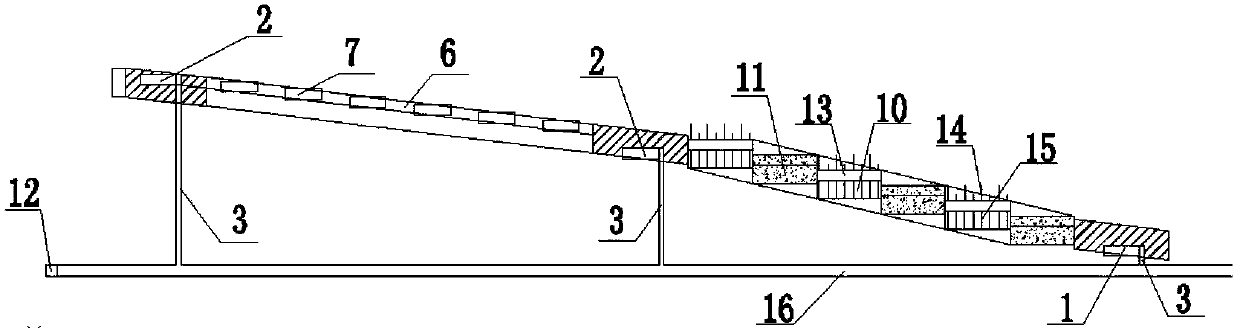

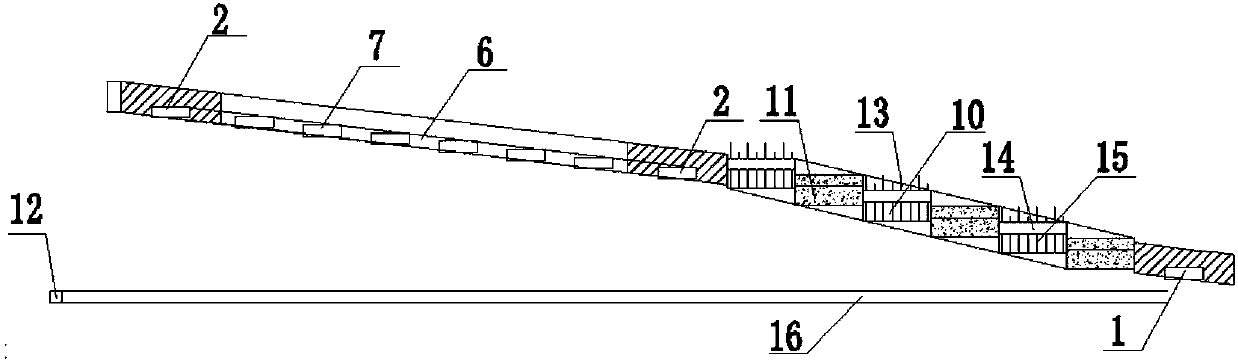

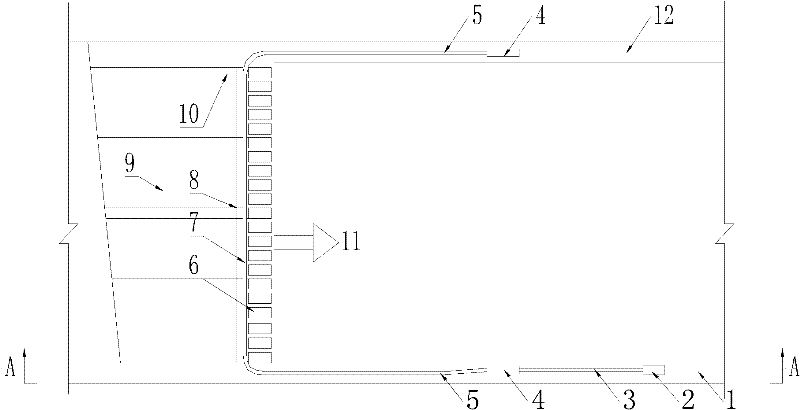

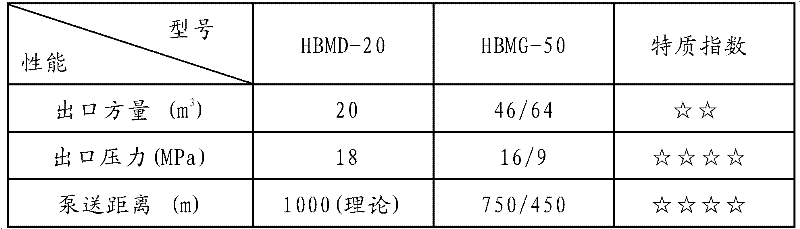

Filling method capable of exploring while filling coal mine goaf

The invention discloses a filling method capable of exploring while filling coal mine goafs, solving the existing problem by that a buttress is filled before direct top inbreak after a working face is boosted. The technical method for construction comprises the following steps: determining the amount and thickness parameters of the buttress; preparing a paste-like material; arranging a transmission pipeline below working surface supporting equipment; installing a paste-like fill pump, a crossheading filling pipeline and the like in a working surface rail crossheading and a conveying crossheading; communicating the fill pump with each group of filling templates in the goaf by the crossheading filling pipeline; after one or two webs are explored for the working face, conveying the paste-like material by the fill pump to serve as the first group of filling buttresses; and after the buttresses filling material is solidified and the working face is boosted for one web, filling the second group of buttresses again. The filling method has the beneficial effect that because the filling method capable of exploring while filling by the paste-like material is adopted, the paste-like material can be filled in time, the breaking range of a roof becomes small, advance mine pressure is obviously weakened, and filling effect is good.

Owner:DALIAN UNIV

Fast preparation method of silk fibroin-hyaluronic acid complex gel

InactiveCN106492279AIncreased external resistance to enzymatic hydrolysisReduce the rate of degradationProsthesisOperabilityRapid prototyping

The invention relates to a fast preparation method of silk fibroin-hyaluronic acid complex gel. The fast preparation method comprises the following steps: dissolving silk fibroin obtained by degumming, preparing a regenerated silk fibroin solution through dialysis, mixing the regenerated silk fibroin solution with hyaluronic acid, and finally preparing the fast complex gel under the action of a crosslinking agent. Compared with a conventional hyaluronic acid gel formed by pure crosslinking, the complex gel can be fast formed and has the advantages that by adding the silk fibroin, the gelating time is effectively shortened, the degrading speed of the gel is reduced, the stay time for tissue repairing and filling is prolonged, and the operability is improved; compared with pure silk fibroin hydrogel, the complex gel has the advantage that by adding the hyaluronic acid, the shortcomings of low toughness, fragility and the like of the silk fibroin hydrogel are overcome. The method for preparing the complex gel is simple in process and short in gelating time; a novel method is provided for the preparation of functional complex gel; the prepared complex gel can be used in the field of medicinal health, tissue engineering, environment protection and the like.

Owner:WUHAN TEXTILE UNIV

Semiconductor device and method for manufacturing the same

ActiveUS8357989B2Good filling effectEliminate needTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor device which eliminates the need for high fillability through a simple process and a method for manufacturing the same. A high breakdown voltage lateral MOS transistor including a source region and a drain region is completed on a surface of a semiconductor substrate. A trench which surrounds the transistor when seen in a plan view is made in the surface of the semiconductor substrate. An insulating film is formed over the transistor and in the trench so as to cover the transistor and form an air-gap space in the trench. Contact holes which reach the source region and drain region of the transistor respectively are made in an interlayer insulating film.

Owner:RENESAS ELECTRONICS CORP

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

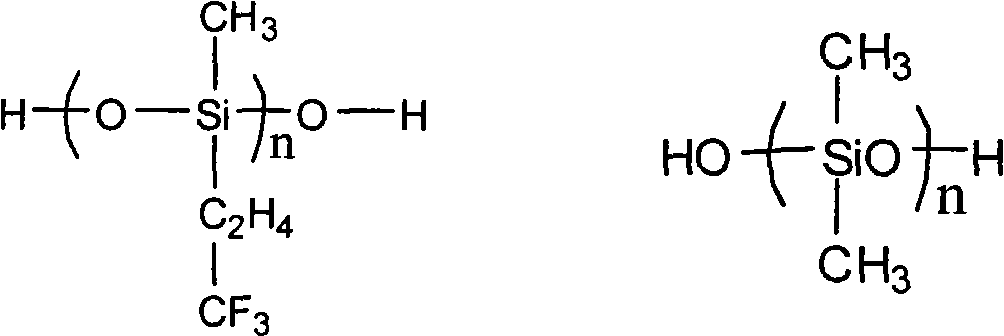

Fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and preparation method thereof

ActiveCN101597463ALower surface energyReduce adhesionCoatingsDecabromobiphenyl etherAluminium hydroxide

The invention provides a fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and a preparation method thereof; the fluorinated silicone rubber anti-pollution flashover coating (short for FRTV) has the following compositions by mass percent: 5-30 percent of fluorinated silicone rubber, 10-30 percent of silicon rubber, 4-8 percent of nanometer grade gas-phase white carbon black, 0.5-8 percent of compound fire retardants, 0.2-0.5 percent of firming agent, 0.01-0.05 percent of catalyst, 0.02-0.08 percent of antioxidant, 2-8 percent of flatting agents, 0.2-0.4 percent of de-foaming agent, 0.1-0.5 percent of paint and 30-60 percent of solvent. The compound fire retardant is composed of inorganic aluminium hydroxide and organic decabromodiphenyl oxide, wherein comprising 1-6 percent of the inorganic aluminium hydroxide and 0.5-3 percent of the organic decabromodiphenyl oxide. The preparing process of the coating is simple, and the coating has good weather ability, oil resistance and longer service life.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

Isolation structure of shallow plough groove and manufacturing method thereof

InactiveCN101330035AImprove compactnessImprove uniformitySemiconductor/solid-state device manufacturingElectrical conductorGas phase

The invention discloses a manufacturing method of a shallow groove isolating structure, which comprises the following steps of: providing a semiconductor underlay; forming a mat oxide layer and a mat azotization layer on the surface of the semiconductor underlay; carrying out the etch of the mat oxide layer, the mat azotization layer and the semiconductor underlay so as to form grooves; carrying out the sedimentation of a first medium layer at the grooves and the surface of the underlay by a first high density plasma chemical gas deposition technology; and carrying out high-temperature thermal annealing and introduction of oxygen to form a silicon oxide layer on the surface of the first medium layer; carrying out the sedimentation of a second medium layer on the surface of the silicon oxide layer by a second high density plasma chemical gas deposition technology; carrying out rapid thermal annealing; grinding the first medium layer and the second medium layer to the mat azotization layer; and removing the mat azotization layer and the mat oxide layer. The STI isolating structure and the manufacturing method of the invention can realize void-free and zero-defect filling of a high depth-width ratio STI isolating groove.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Luminant white paint and preparation method thereof

ActiveCN102533070AHigh hiding powerGood filling effectPolyester coatingsKetone solventsToluene diisocyanate

The invention discloses a luminant white paint. The luminant white paint is obtained by mixing a main paint, a curing agent and a diluent according to a mass ratio, wherein the main paint comprises the following components in parts by weight: 35-40 parts of alkyd resin, 3-5 parts of dispersing agent, 30-40 parts of titanium white powder, 10-20 parts of extender pigment, 0.2-0.5 parts of anti-setting agent, 0.2-0.4 parts of leveling agent, 0.2-0.5 parts of antifoaming agent, 0.5-1.0 parts of anti-yellowing agent and 20-25 parts of main paint solvent; the curing agent comprises the following components in parts by weight: 10-20 parts of curing agent solvent, 0.1-0.2 parts of dehydrating agent, 60-70 parts of HDI (Hexamethylene Diisocyanate) type curing agent and 30-40 parts of TDI (Toluene Diisocyanate) type curing agent; and the diluent comprises the following components in parts by weight: 60-70 parts of ester solvent and 30-40 parts of ketone solvent. The luminant white paint disclosed by the invention has the advantages of rapidness for leveling after being sprayed, full paint film, rockiness and scratch resistance. Meanwhile, the invention also discloses a preparation method of the luminant white paint.

Owner:NIPPON PAINT GUANGZHOU

Protective cinder for special-shaped blank continuous casting

The invention belongs to metal continuous casting, in particular relates to protecting slag used for pouring medium carbon steel in a shaped blank continuous casting crystallizer. The protecting slag of the invention has the following compositions, based on weight percent: CaO of 31-37%, SiO2 of 30-37%, Al2O3 of 4.5-10.5%, F- of 2.5-6.5%, R2O(Na2O+K2O) of 2.5-8.5%, and fixation C of 4-7%. Physical property of the protecting slag is in the melting point of 1100-1170 DEG C. and viscosity (1300 DEG C.) of 0.3-0.5Pa.s. The advantages of the invention are of: good physical property of the protecting slag, e.g. low melting point and low viscosity; fine lubrication and filling performance of the protecting slag to satisfy process requirements for continuously casting the shaped blank; reducing surface longitudinal crack of the casting blank greatly, increasing surface quality of the shaped blank, remarkably reducing rejection ratio, with low cost, thus the invention can substitute for imported protecting slag.

Owner:MAANSHAN IRON & STEEL CO LTD +1

Foldable vaso-occlusive member

ActiveUS20060116716A1Efficiently and easily fillGood filling effectDilatorsOcculdersBiomedical engineeringBlood vessel

Vaso-occlusive devices for occlusion of a body cavity are provided. The vaso-occlusive devices include an elongate vaso-occlusive member having one or more fold lines. Methods of using the vaso-occlusive devices are also described.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

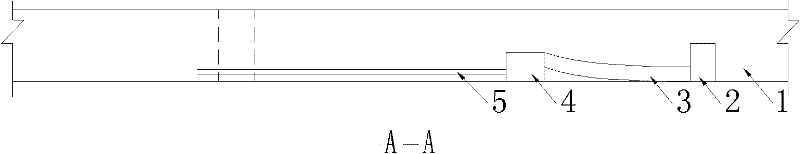

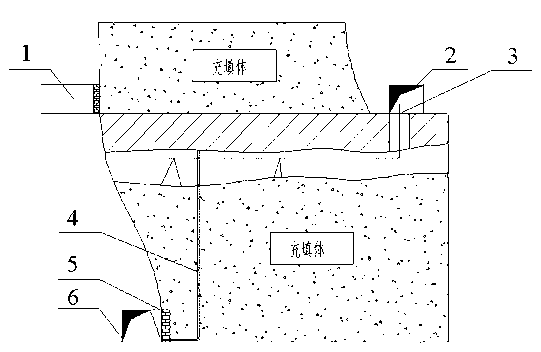

Roof contacting process in goaf filling treating procedure

InactiveCN103233771ALow costGuarantee normal productionMaterial fill-upEngineeringUltimate tensile strength

The invention relates to a roof contacting process in a goaf filling treating procedure and belongs to the technical field of mining engineering. The technical scheme of the roof contacting process in the goaf filling treating procedure includes: detecting a goaf to obtain the coordinate of the top point position of a top plate; drilling a filling drill hole at the top point position of the top plate, and performing cementing filling; installing a three-way plug valve on a filling pipe of the filling drill hole, and guiding a washing pipeline out on the filling pipe through the three-way plug valve; when the position with 1m away from the top point of the top plate is filled, extending the filling pipe to the position farthest from the filling drill hole, and simultaneously, arranging a 1-1.5m temporary retaining wall on the filling drill hole portion; when cement body is full, continuing to fill; and finally opening the three-way plug valve, guiding water away through the washing pipeline and finishing the filling roof contacting work. The roof contacting process is particularly suitable for filling the goaf generated during the filling exploitation process afterwards, is good in filling roof contacting effect and low in working intensity, saves filling roof contacting cost, achieves the roof contacting maximumly, is high in roof contacting efficiency, and ensures normal production of mines.

Owner:HEBEI IRON & STEEL GRP MINING +2

High-strength, thermo-oxidative-aging-resistant and insulating silicone rubber and preparation method thereof

The invention provides high-strength, thermo-oxidative-aging-resistant and insulating silicone rubber and a preparation method thereof. The preparation method includes the following steps of aluminum hydroxide modification, wherein aluminum hydroxide of different grain diameters is mixed according to a certain proportion, and then surfactant is added for modification; calcium carbonate modification; fumed silica modification; mixing; discharging, remilling and straining to complete preparation of the high-strength, thermo-oxidative-aging-resistant and insulating silicone rubber. Aluminum hydroxide of different grain diameters is mixed, a better filling effect is achieved on gaps between molecular chains of silicone rubber raw rubber, cost is lower, the compatibility is further improved through modification, clustering is reduced, and the electrical insulation property and the flame-retardant property of the silicone rubber are guaranteed; nano calcium carbonate and fumed silica are modified, the silicone rubber has a better dispersion effect, the filling effect is improved accordingly, the mechanical performance and thermo-oxidative-aging-resistant performance of the silicone rubber are remarkably improved, the modification process is simple, and cost is low.

Owner:YICHANG XINGZHIXIN PLASTIC ELECTRONICS TECH CO LTD

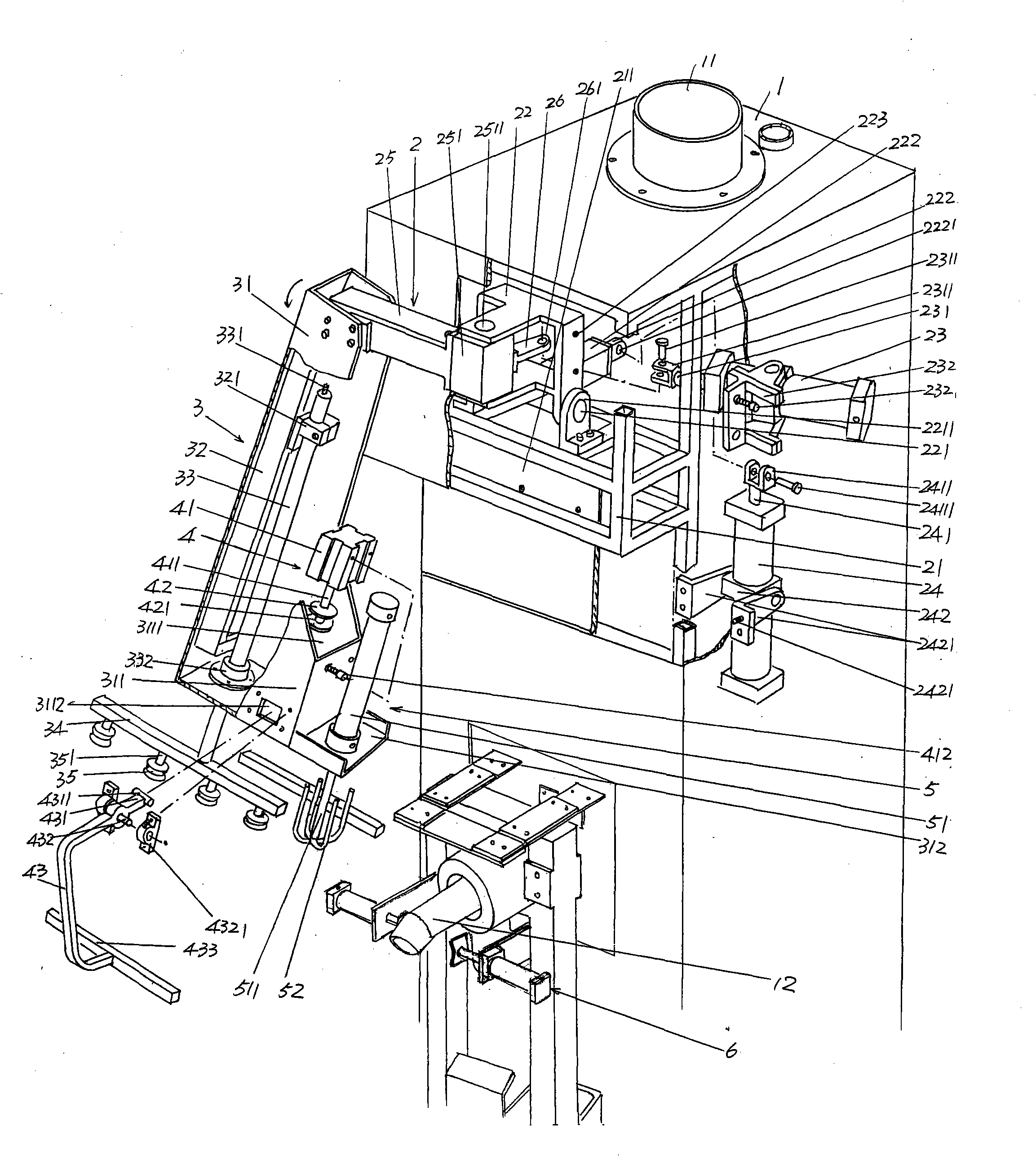

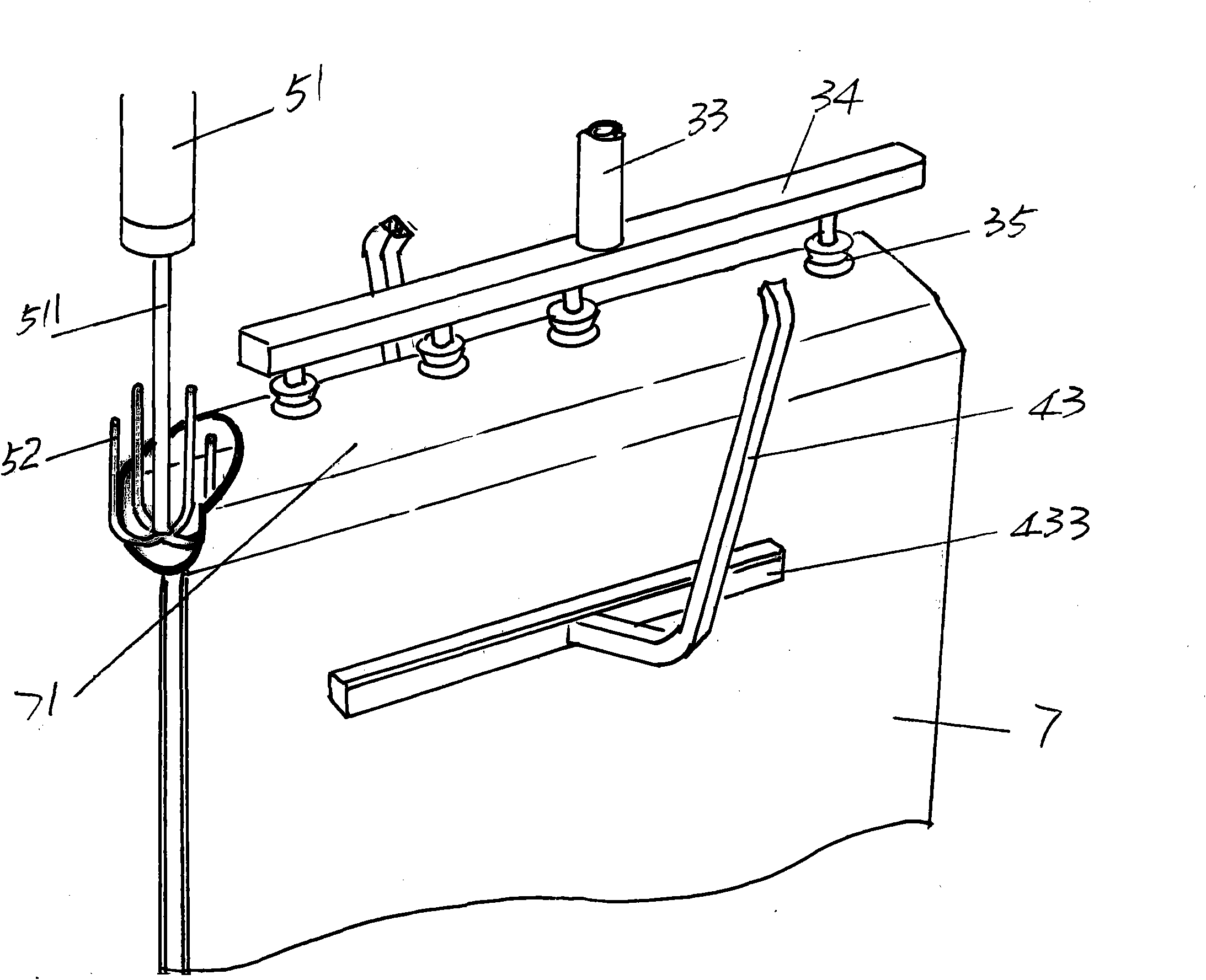

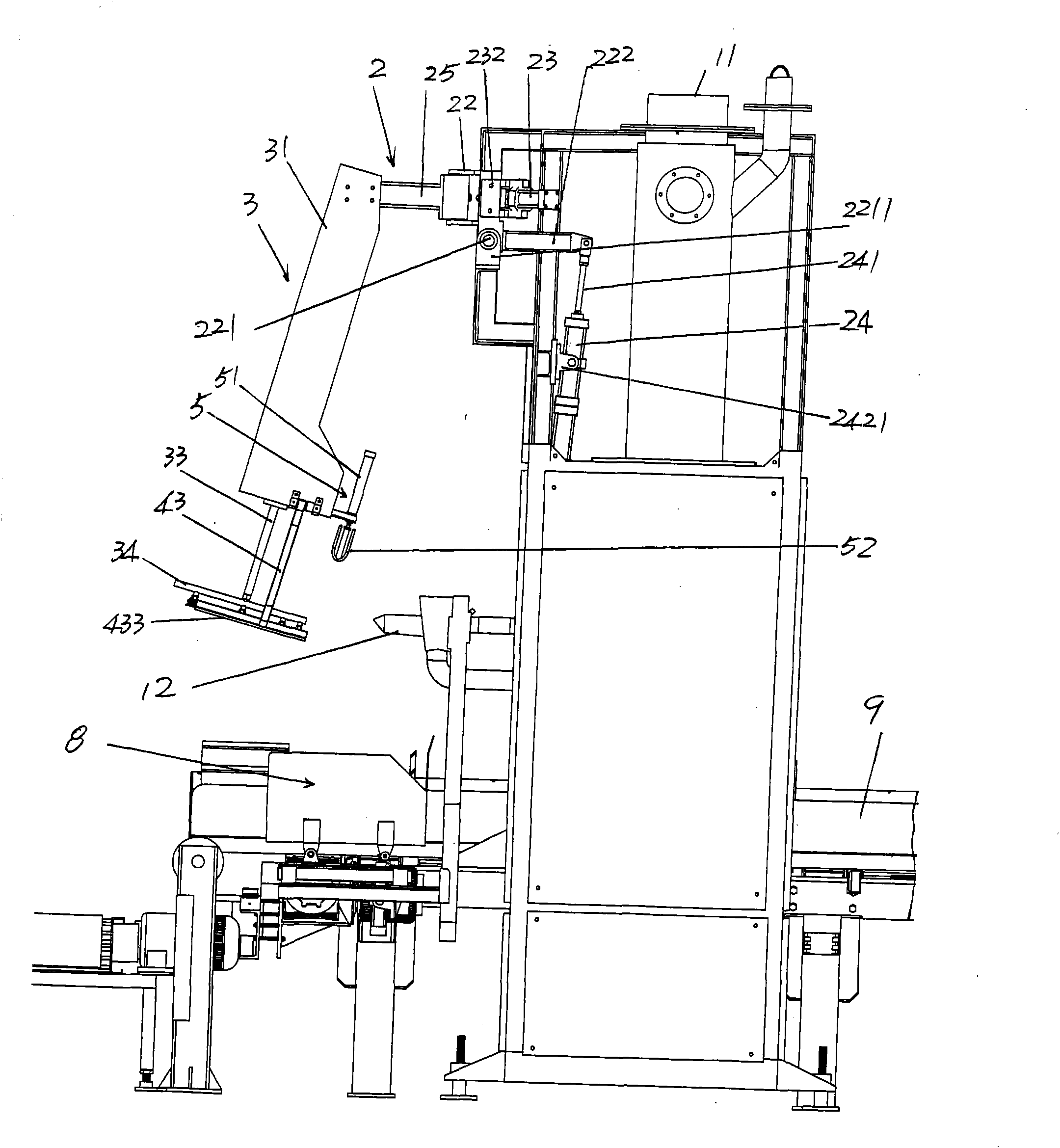

Swing arm type automatic bagging mechanism of valve bag filling machine

ActiveCN101870376AReduce labor intensityAvoid Dust InvasionPackagingMouth openingMechanical engineering

The invention relates to a swing arm type automatic bagging mechanism of a valve bag filling machine, belonging to the technical field of packing machinery. The valve bag filling machine comprises a stand provided with a feed port and a discharge pipe communicated with the feed port. The swing arm type automatic bagging mechanism comprises a swing arm actuating device, a valve bag lifting device, a valve bag mouth clamping device and a valve bag mouth opening device, wherein the swing arm actuating device is arranged on the stand and is positioned at the upper part of the stand in the height direction; the valve bag lifting device is connected with the swing arm actuating device; the valve bag mouth clamping device is used for clamping the mouth of a valve bag lifted by the valve bag lifting device and is arranged on the valve bag lifting device; and the valve bag mouth opening device is used for opening the mouth of the valve bag clamped by the valve bag mouth clamping device, is arranged on the valve bag lifting device, and corresponds to the discharge pipe. The swing arm type automatic bagging mechanism of the valve bag filling machine can reduce the labor intensity of workers, enable the overall processes of bag lifting, bagging and bag filling to be automatically completed by machinery, improve the filling effect, and protect workers from the invasion of dust and other impurities.

Owner:CHANGSHU SANHE PRECISION MACHINERY & TECH CO LTD

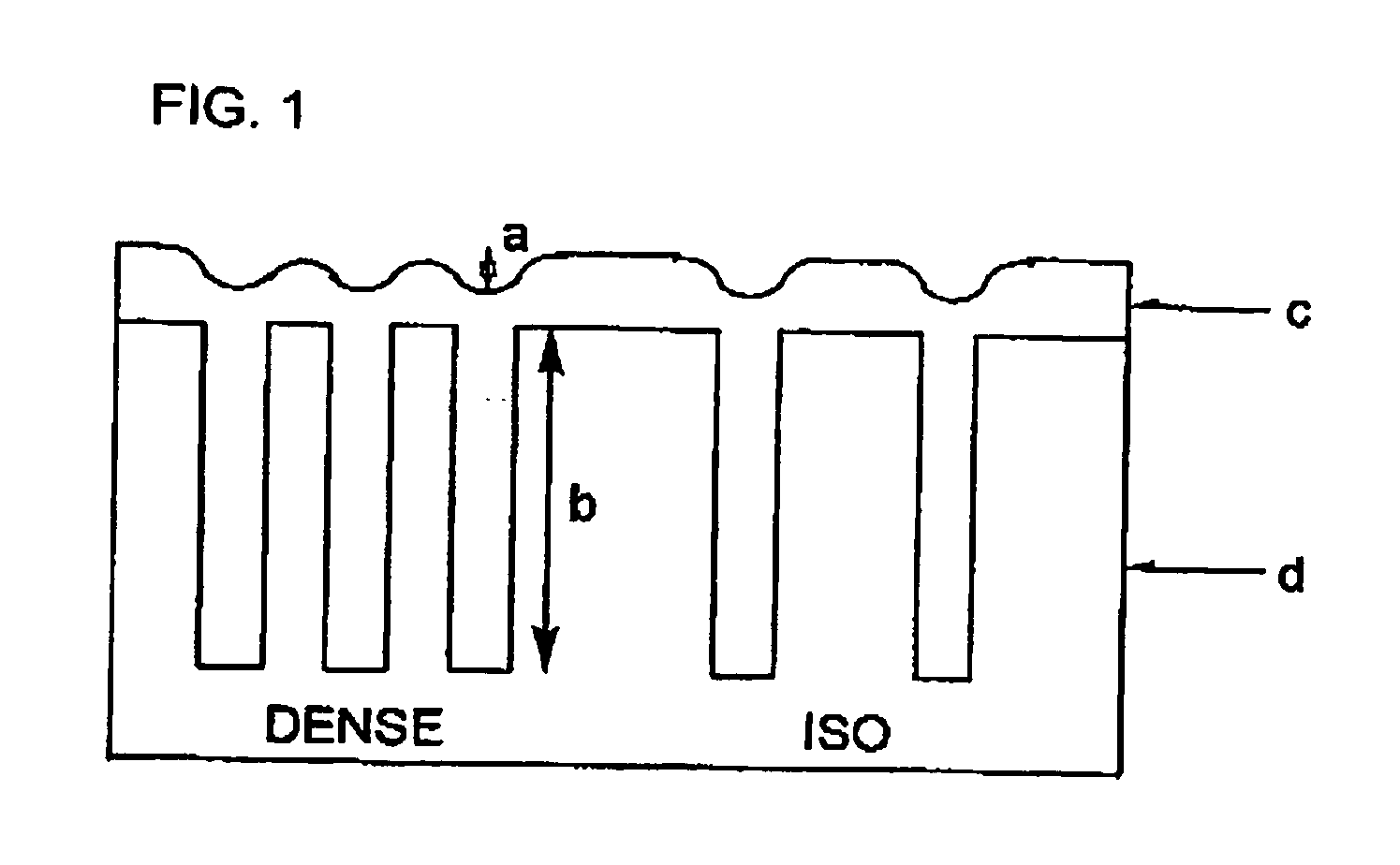

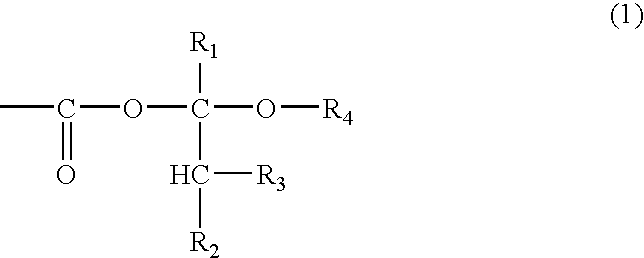

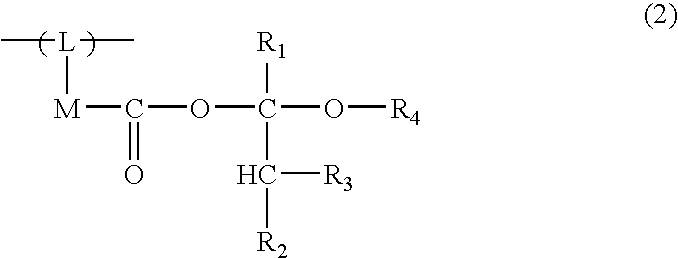

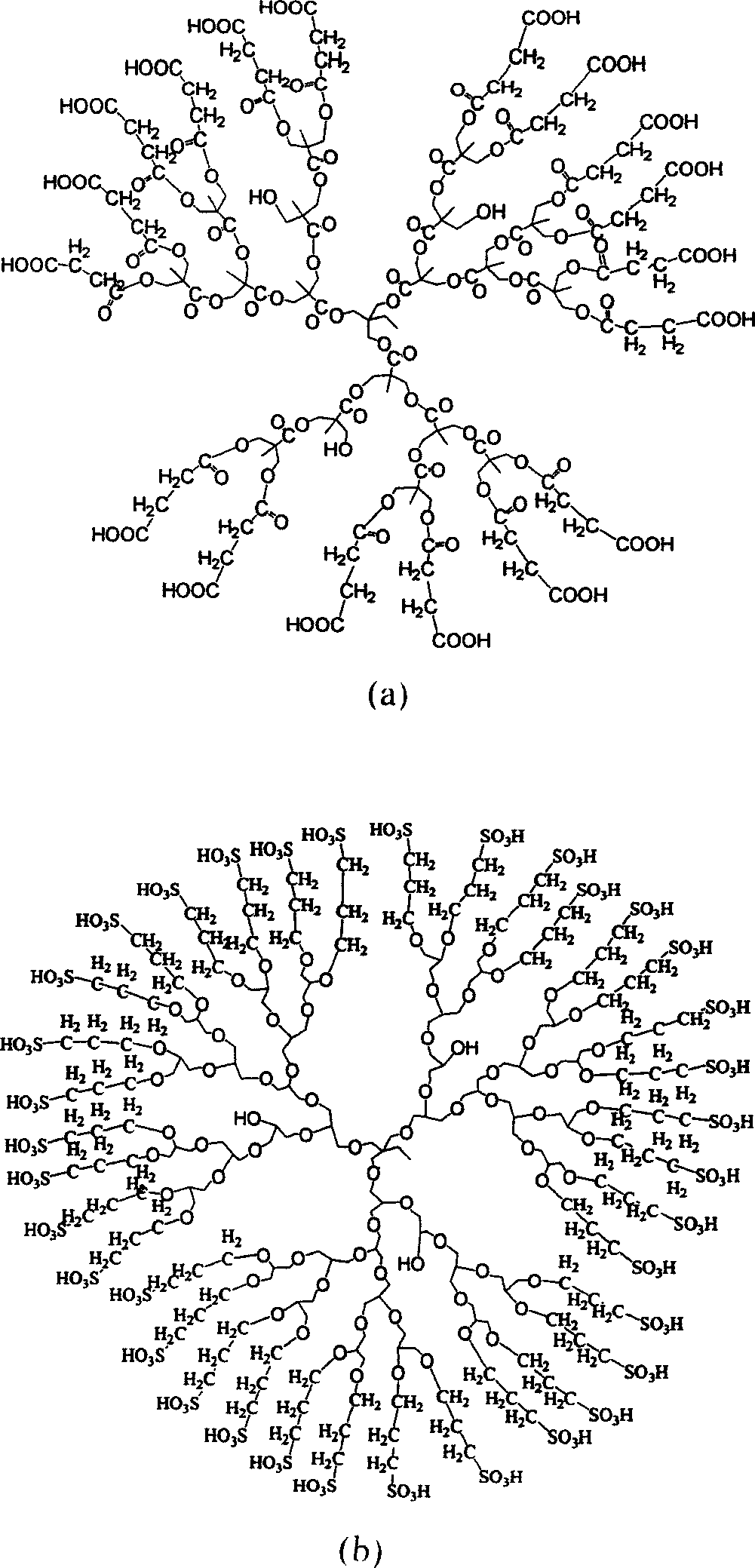

Composition for forming lower layer film for lithography comprising compound having protected carboxyl group

ActiveUS20060210915A1Increased shelf stabilityReduce sublimation substance producedRadiation applicationsPhotosensitive material auxillary/base layersLithography processDevice material

There is provided an underlayer coating forming composition for lithography, and an underlayer coating having a high dry-etching rate compared with photoresist, and causing no intermixing with the photoresist, which are used in lithography process of manufacture of semiconductor device. Concretely it is an underlayer coating forming composition comprising a compound having a protected carboxyl group, a compound having a group capable of reacting with a carboxyl group and a solvent, and an underlayer coating forming composition comprising a compound having a group capable of reacting with a carboxyl group and a protected carboxyl group and a solvent.

Owner:NISSAN CHEM IND LTD

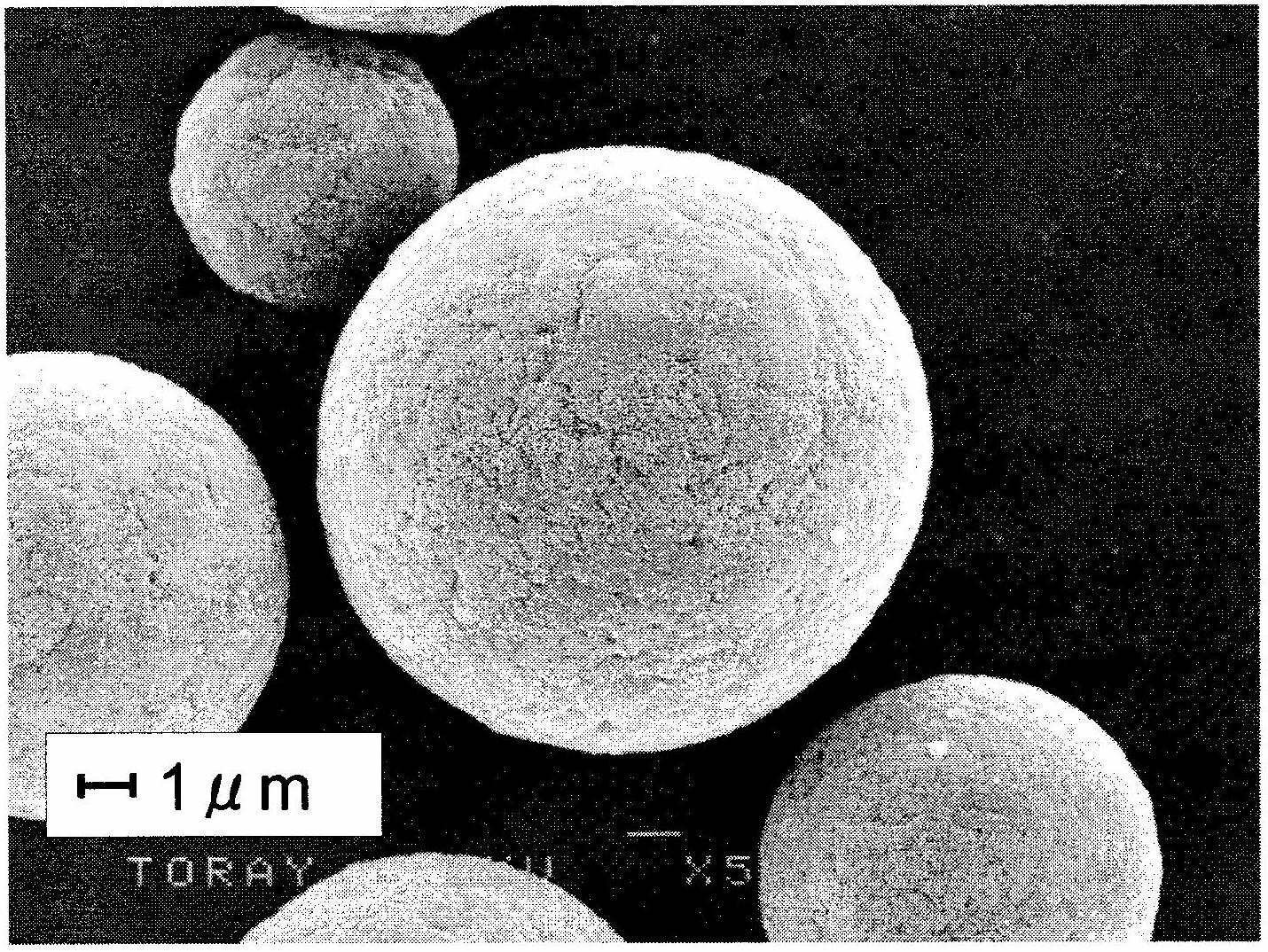

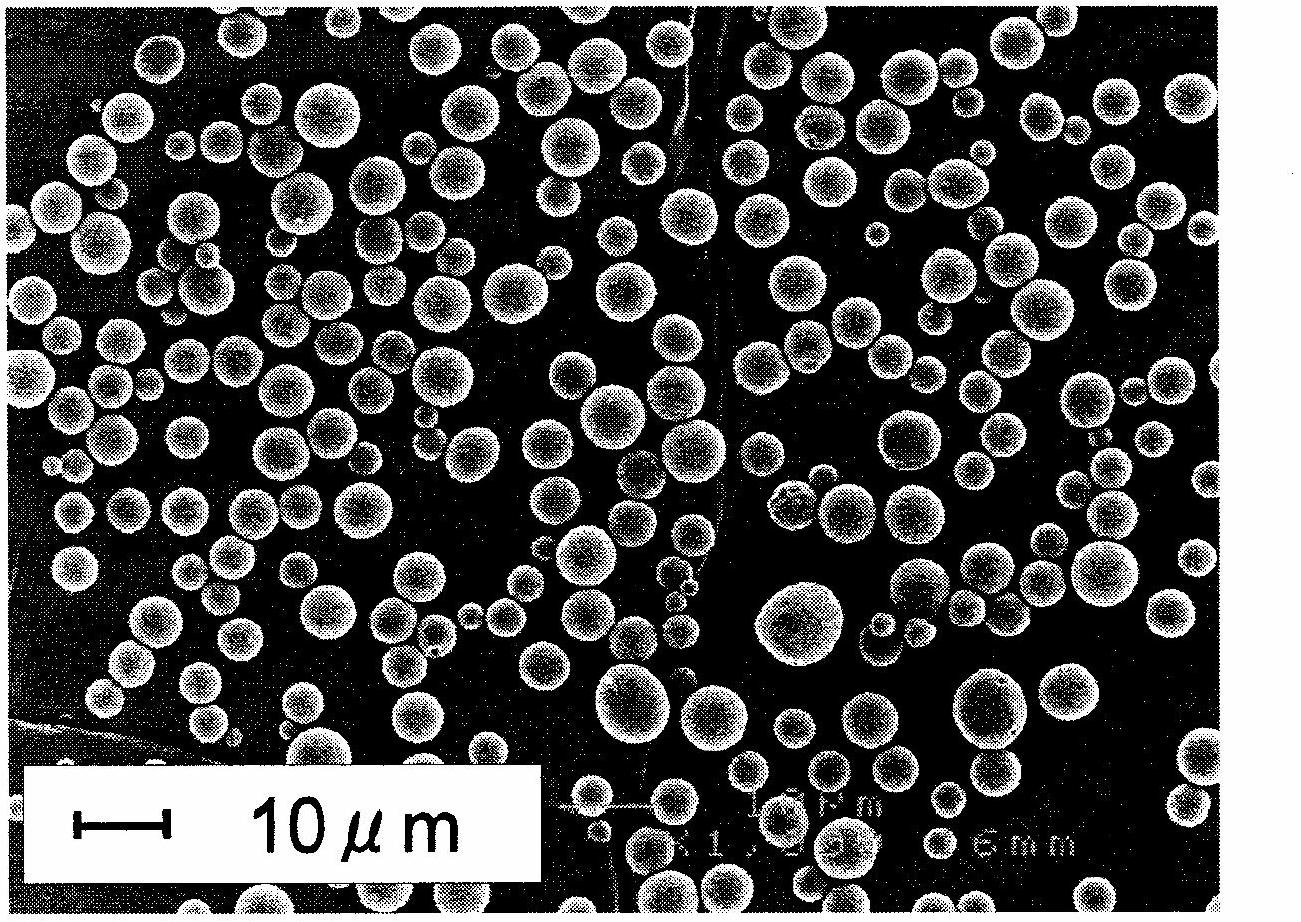

Carbon microparticle and process for production thereof

InactiveCN102666376ANarrow particle size distributionImprove the degree of graphitizationCell electrodesFinal product manufacturePolymer scienceEmulsion

A process for producing carbon microparticles, characterized in that synthetic resin microparticles, metal-containing synthetic resin microparticles or child-particle-containing synthetic resin microparticles are subjected to carbonization baking, wherein the synthetic resin microparticles, the metal-containing synthetic resin microparticles or the child-particle-containing synthetic resin microparticles are produced by a process comprising mixing a polymer (A) such as polyacrylonitrile copolymer microparticles composed of a copolymer of an acrylonitrile monomer and a hydrophilic vinyl monomer with a polymer (B) that is different from the polymer (A) in an organic solvent to produce an emulsion and bringing the emulsion into contact with a poor solvent for the polymer (A), thereby causing the polymer (A) to precipitate; and the carbon microparticles.

Owner:TORAY IND INC

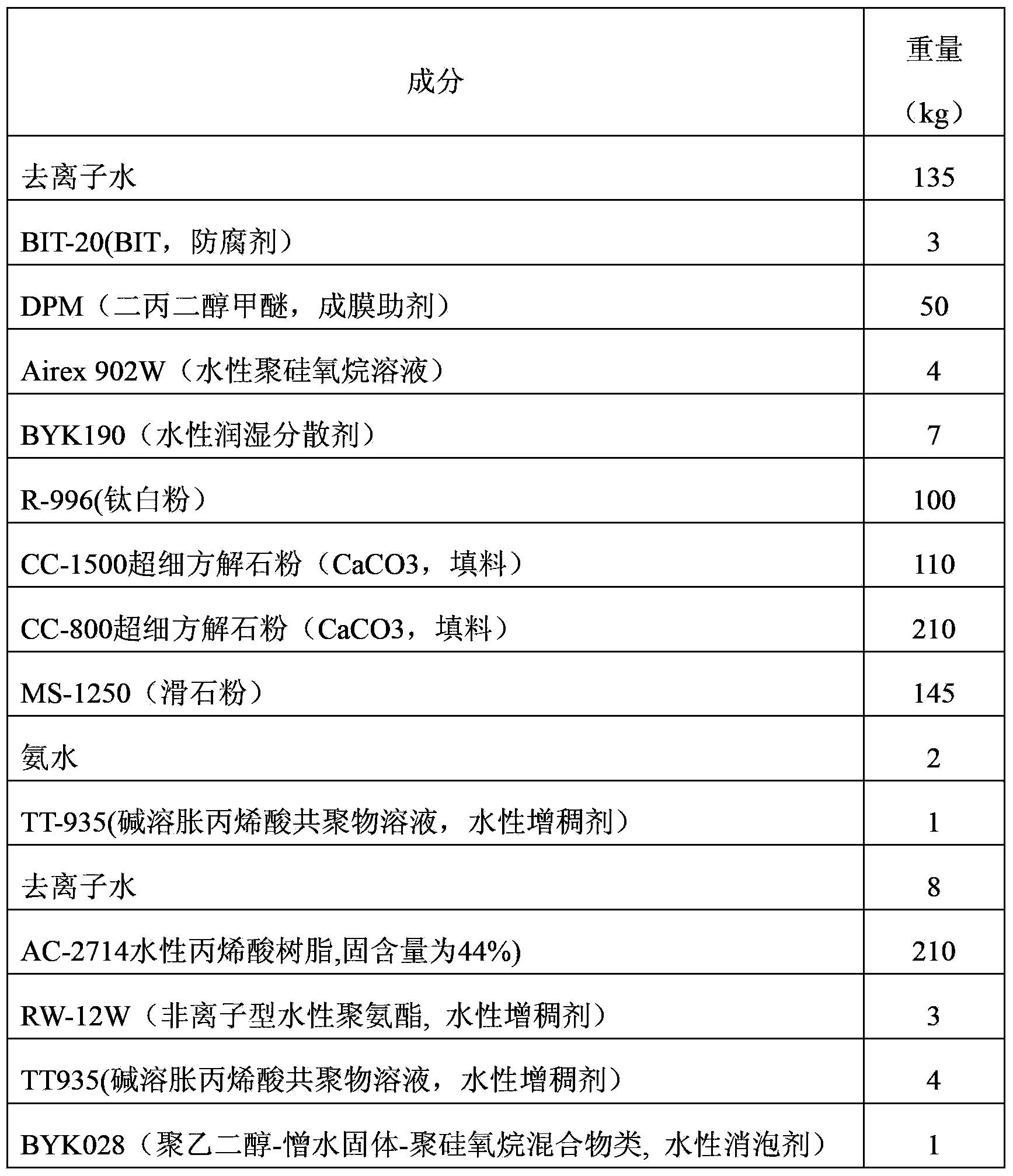

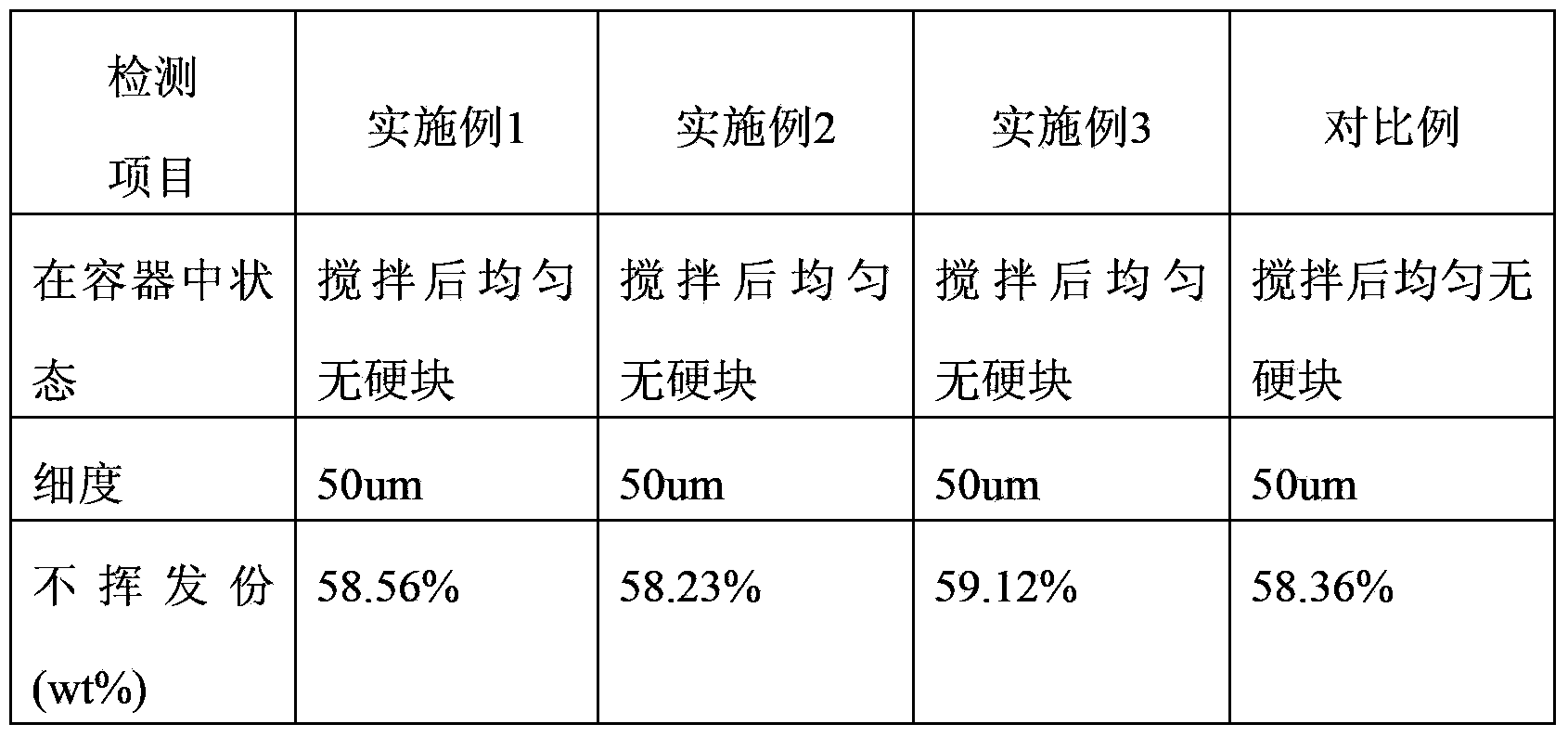

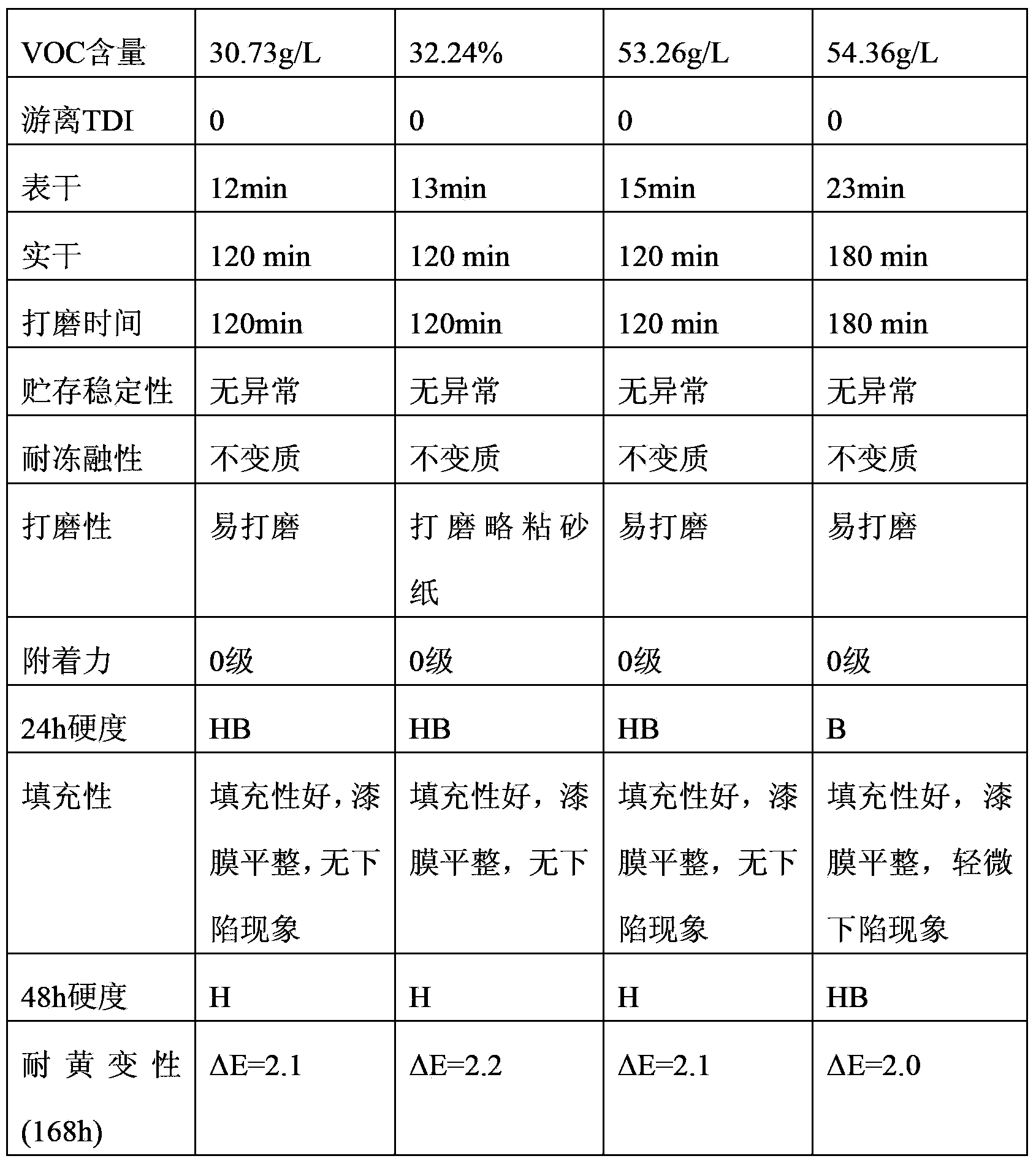

Water-based high-filling white paint

InactiveCN104098967AGood filling effectGood sealingFilling pastesWater basedEnvironmental resistance

The invention belongs to the field of water-based paints, and particularly relates to a water-based high-filling white paint. The water-based high-filling white paint comprises the following raw materials by weight: 150 ~ 300 parts of water-based resin, 22 ~ 60 parts of a film forming auxiliary agent, 60-150 parts of titanium dioxide, 100-250 parts of talcum powder, 280-350 parts of a filler, 100 ~ 300 parts of deionized water, 2 pH parts of a regulator, 2-4 parts of a preservative, 6-10 parts of a water-based defoaming agent and 4-10 parts of a water-based thickening agent. The water-based high-filling white paint is a water-based product, safe, environmentally friendly, high in solid content, high in base material filling property, and high in hardness, does not sink, is good in board sealing property, does not bleed, can be used with all kinds of oily and water-based paints, is fast in drying and good in grinding property, can levelly fill plate gaps, and is convenient in construction.

Owner:展辰新材料集团股份有限公司 +4

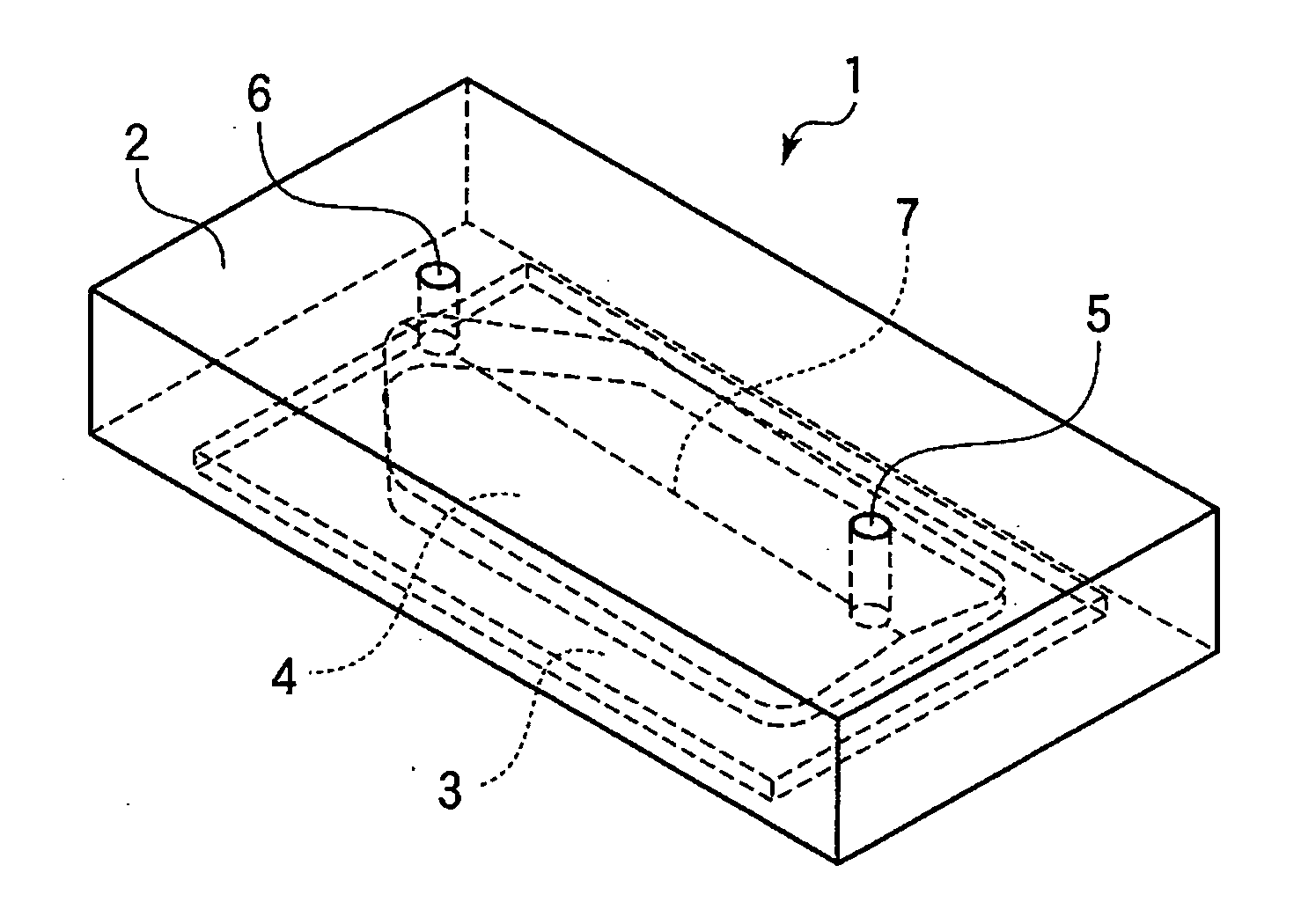

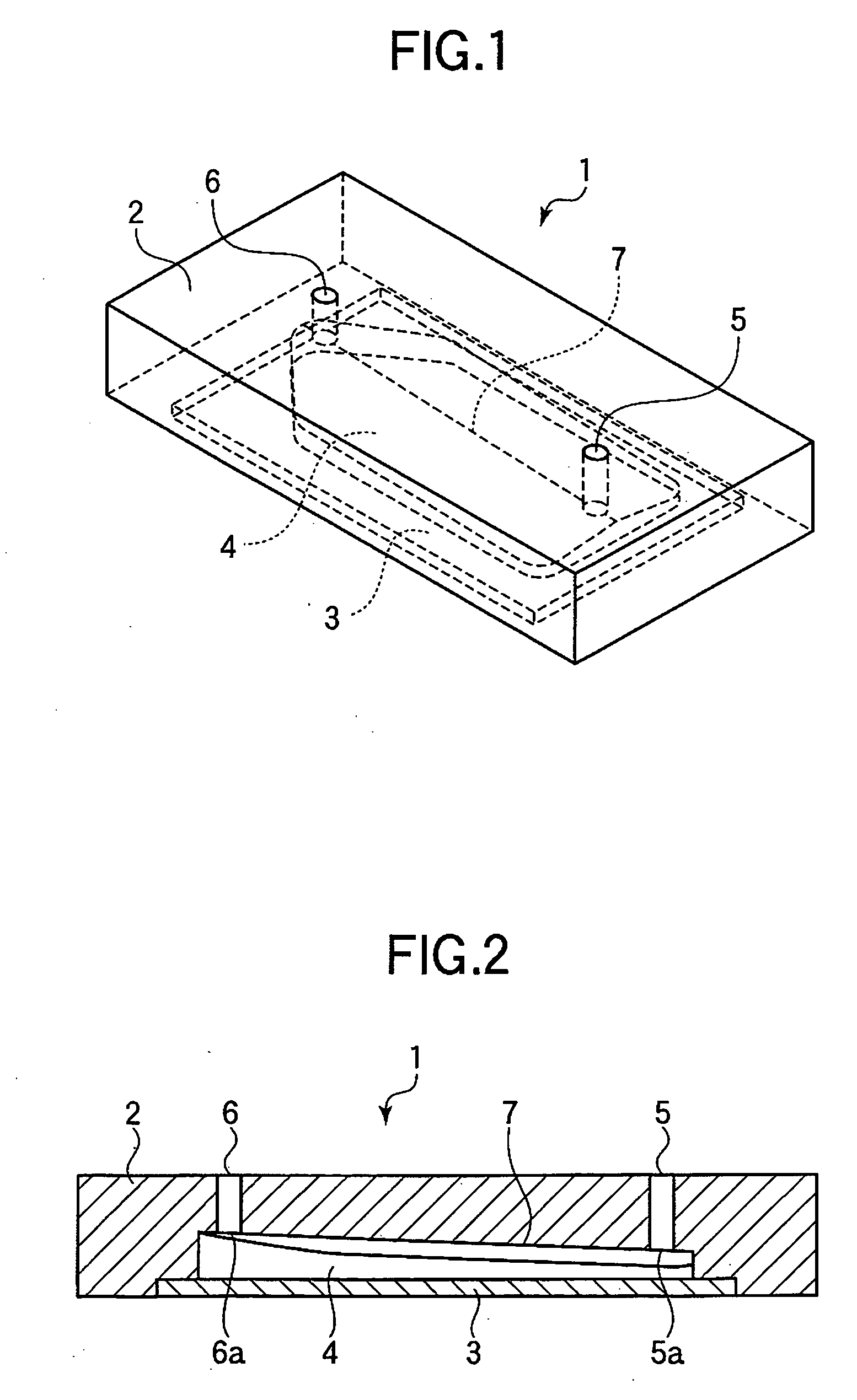

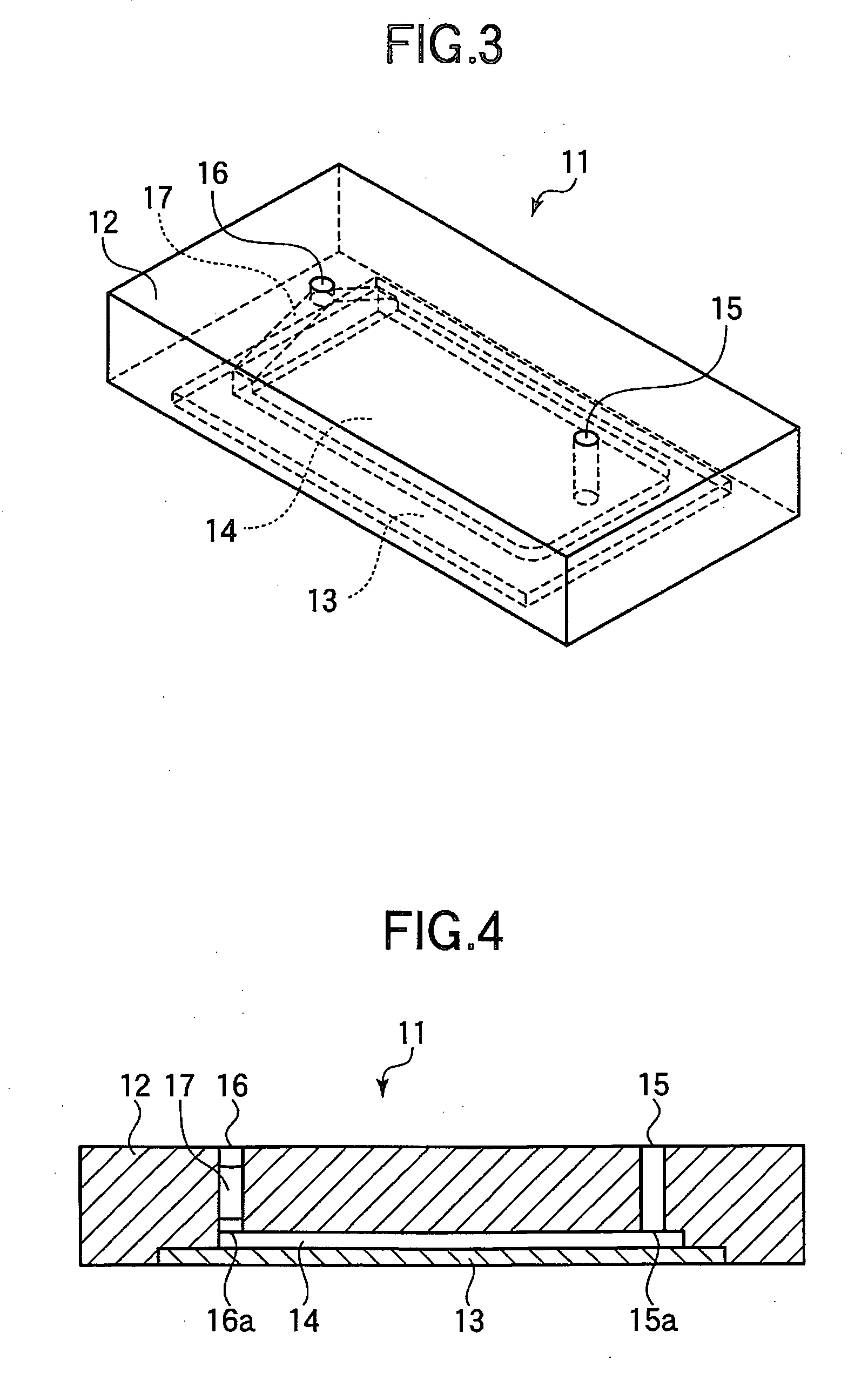

Biochemical reaction cassette with improved liquid filling performance

InactiveUS20070059817A1Improve performanceReliable conductionBioreactor/fermenter combinationsHeating or cooling apparatusInjection portBiochemical engineering

A biochemical reaction cassette comprises a housing member, a reaction chamber arranged in the housing member and having a bottom section and a ceiling facing the bottom section, an injection port arranged at the ceiling of the reaction chamber, a discharge port arranged at the ceiling of the reaction chamber and a probe carrier arranged at the bottom section of the reaction chamber, the ceiling having an inclination with the highest part located at the discharge port in the vertical direction.

Owner:CANON KK

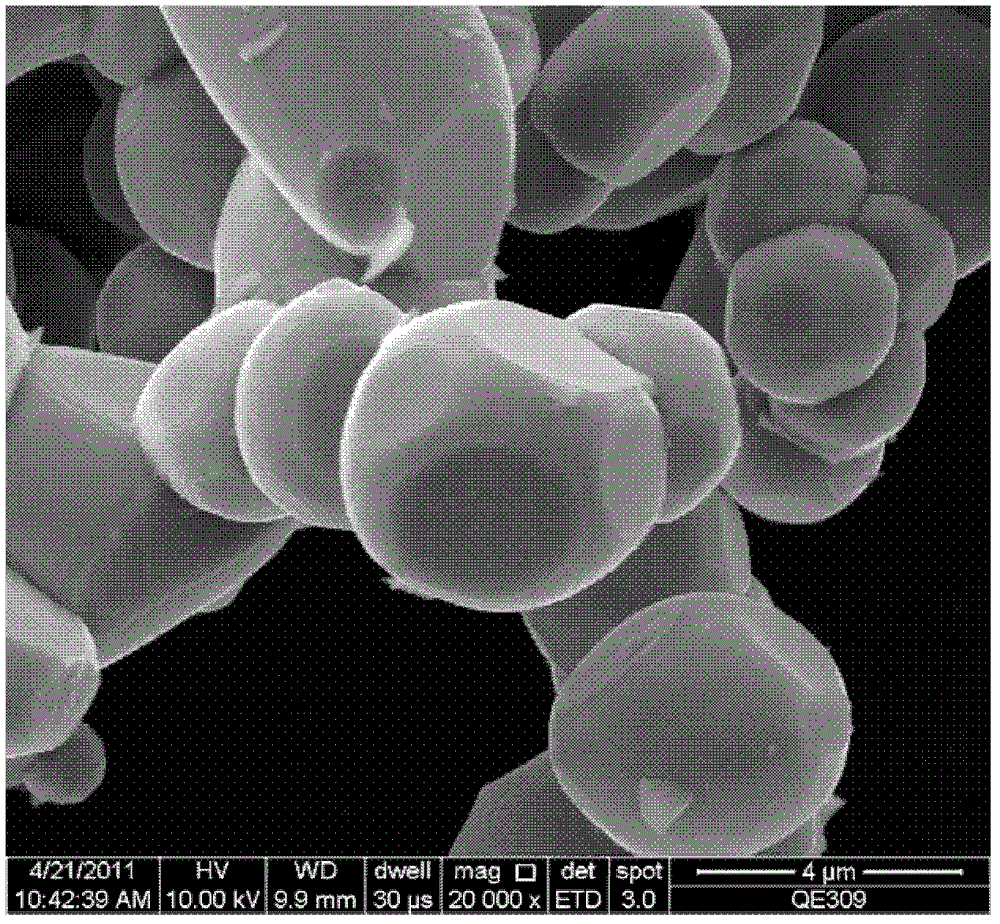

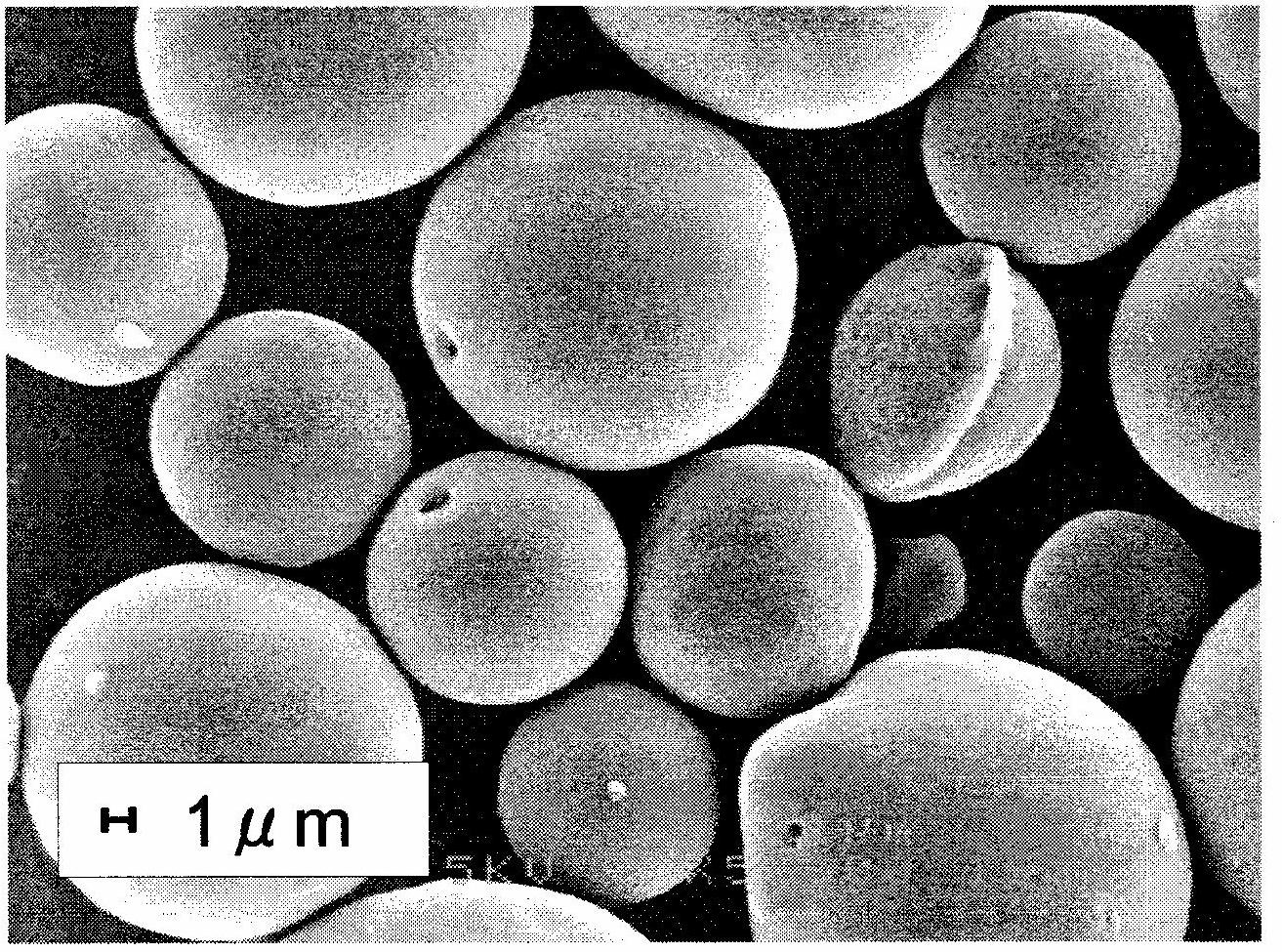

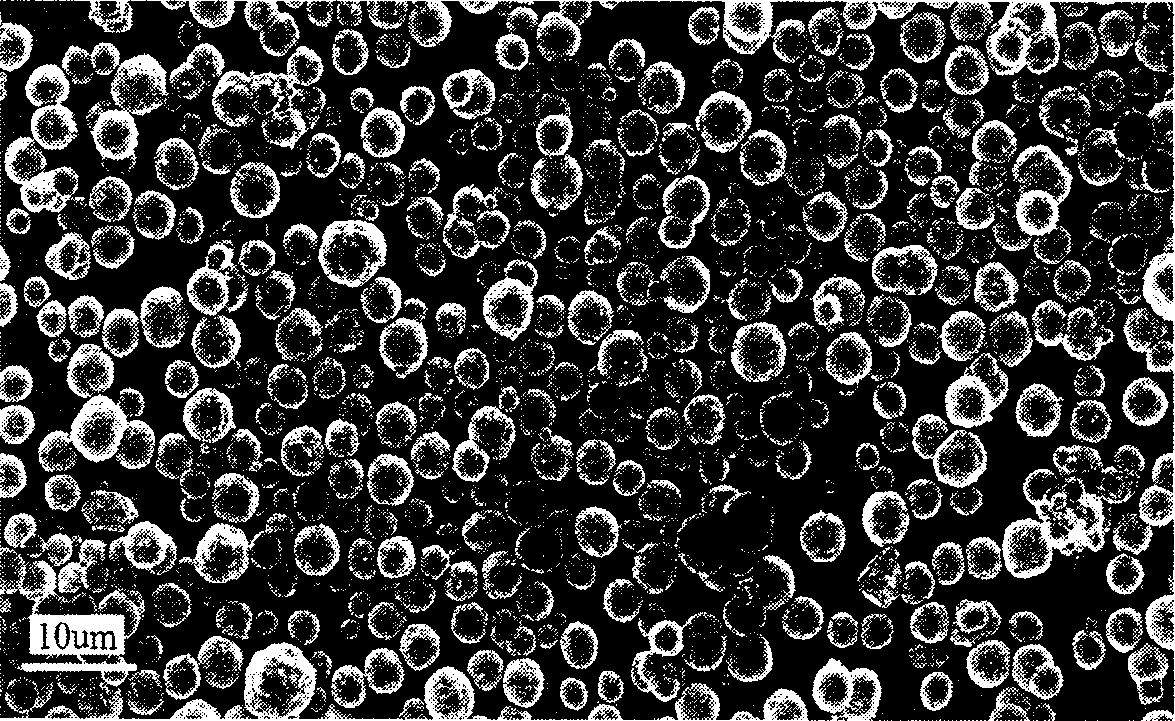

Monodisperse micron level spherical vaterite-type calcium carbonate and its prepn process

InactiveCN1887716ASimple methodReaction conditions are easy to controlCalcium/strontium/barium carbonatesAqueous solutionCarbonate

The present invention relates to one kind of monodisperse micron level spherical vaterite-type calcium carbonate, which is one kind of organic-inorganic hybridized material comprising inorganic calcium carbonate component with calcium carbonate content of 95-100 wt% and organic component of super branched polymer accounting for 3-10 wt%. The preparation process of the monodisperse micron level spherical vaterite-type calcium carbonate includes the following steps: preparing water solution of calcium salt; preparing water solution of carbonate or bicarbonate; preparing water solution of functional super branched polymer; fast mixing the water solution of calcium salt, the water solution of calcium salt and the water solution of functional super branched polymer at 5-40 deg.c via stirring; ageing for 1-24 hr; centrifugal or filtering separation, washing and stoving to obtain the monodisperse micron level spherical vaterite-type calcium carbonate.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com