Patents

Literature

109 results about "Vaterite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

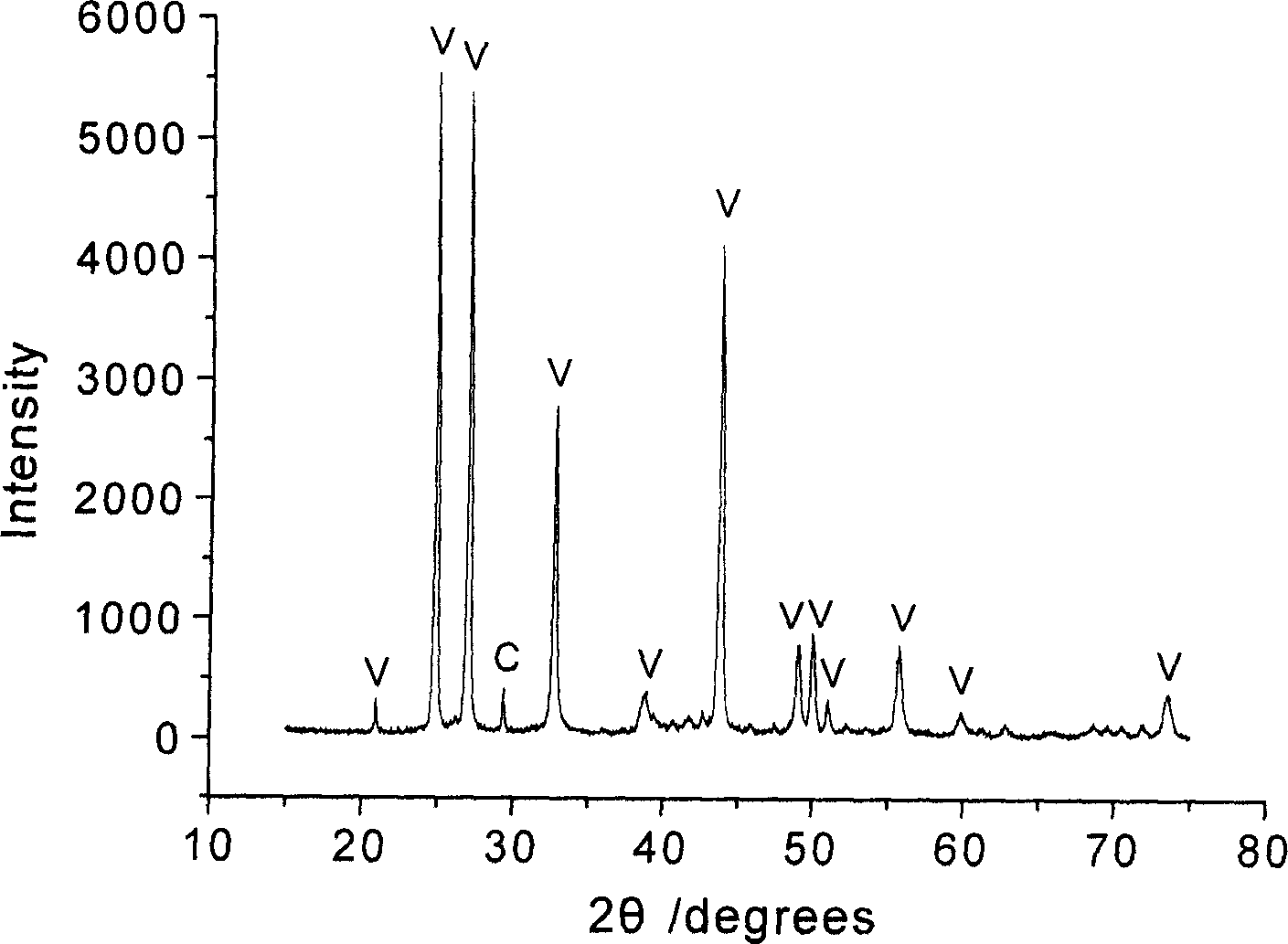

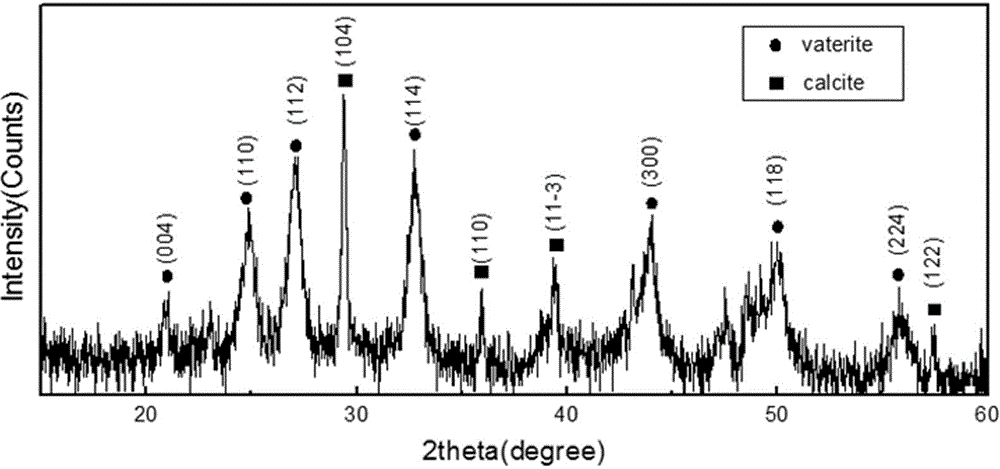

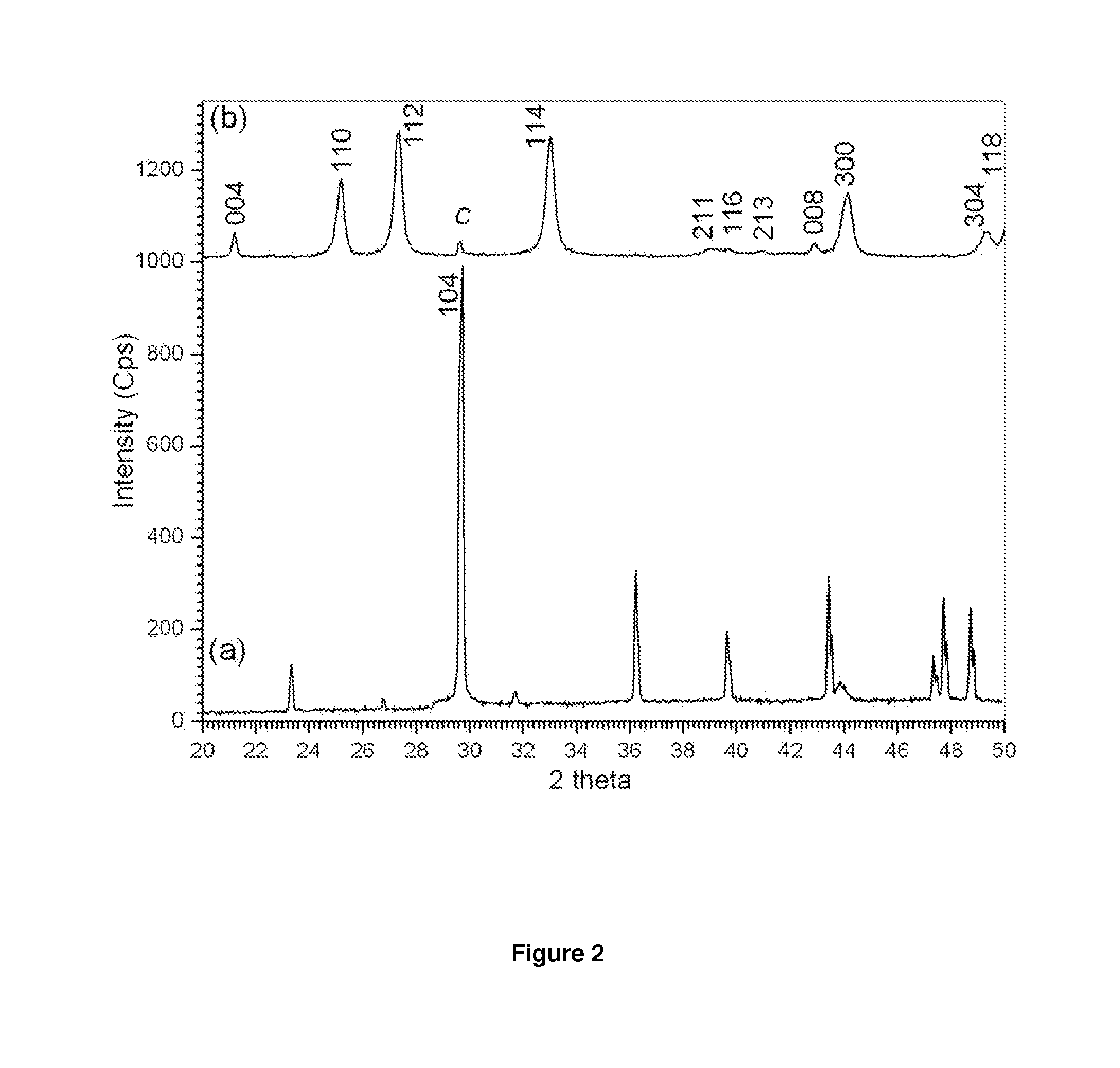

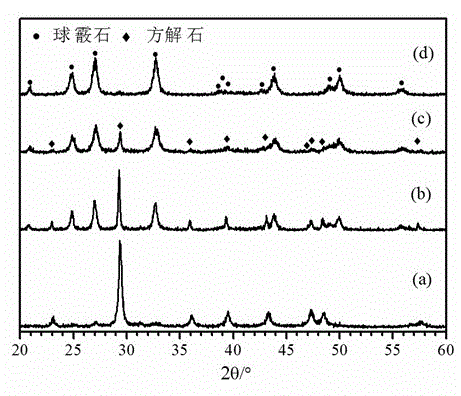

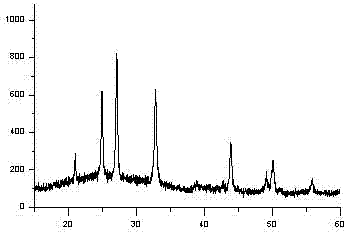

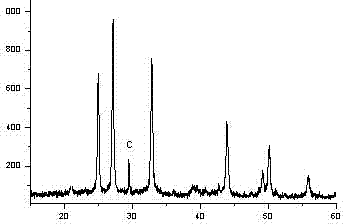

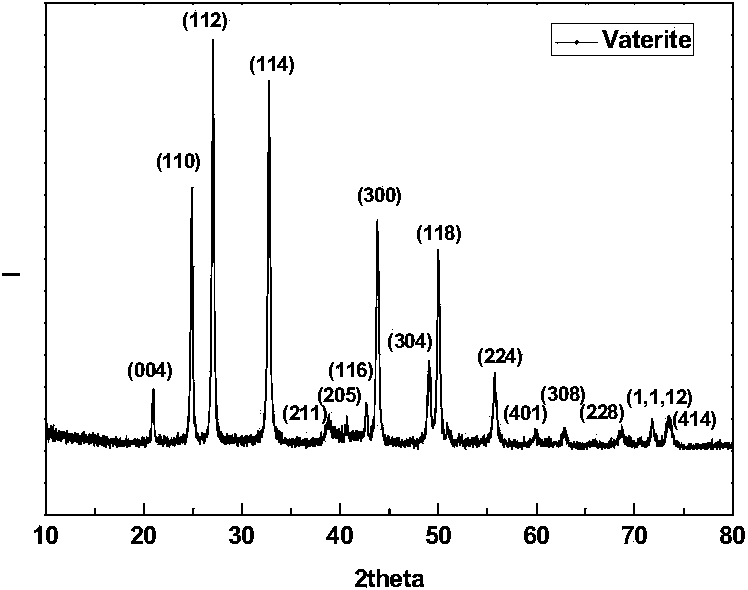

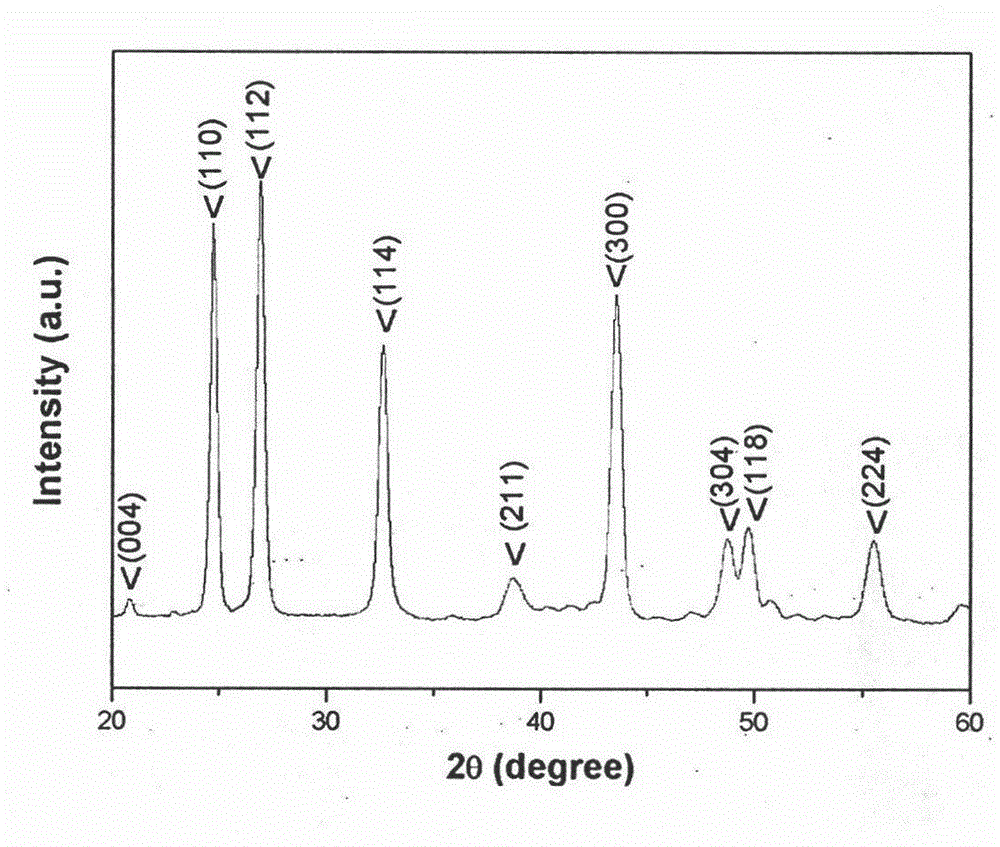

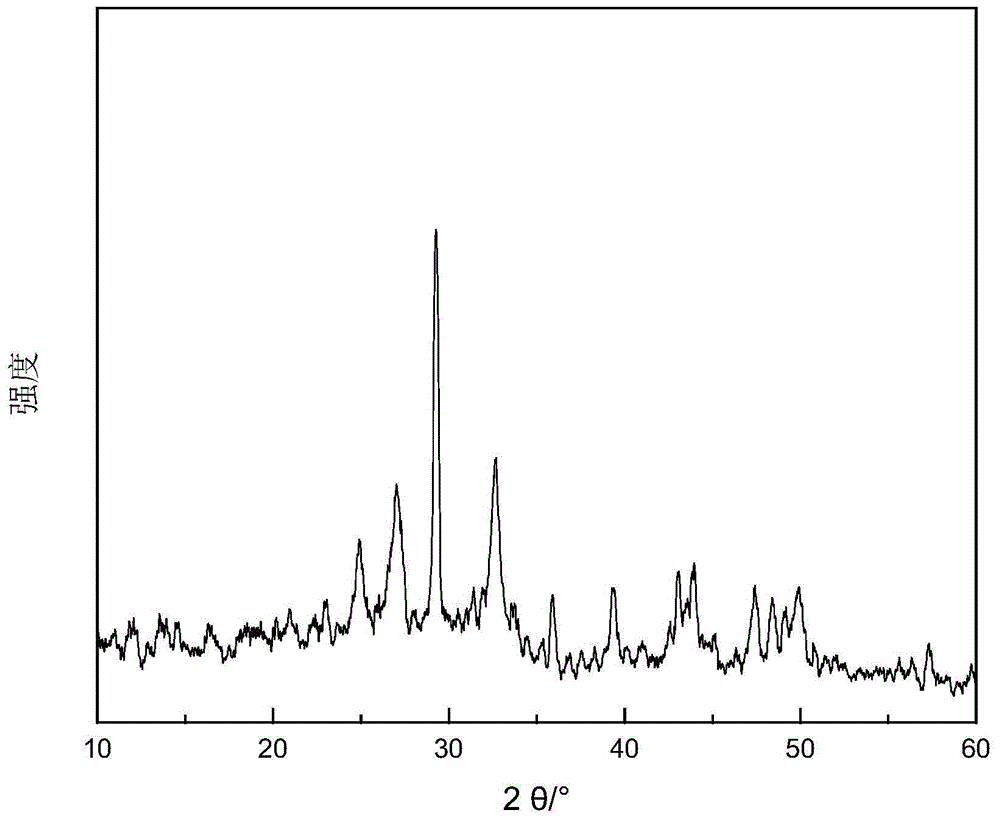

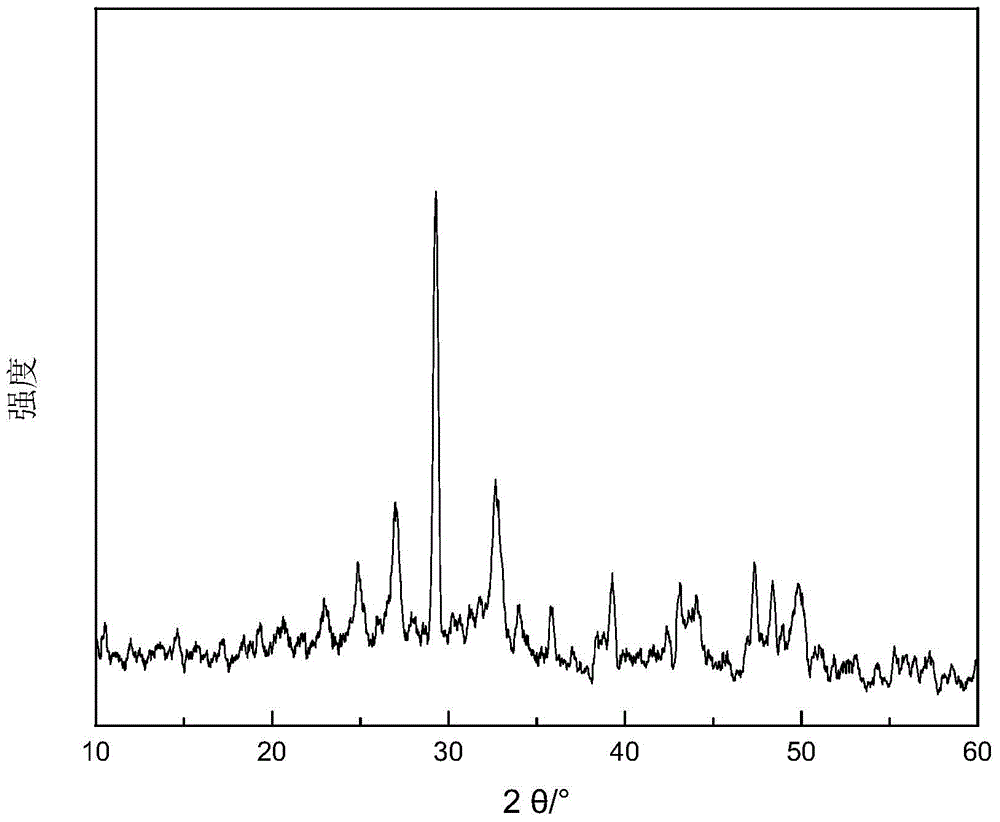

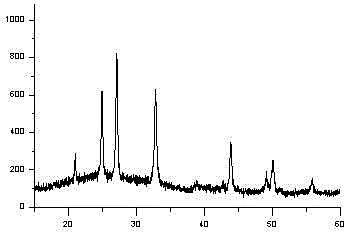

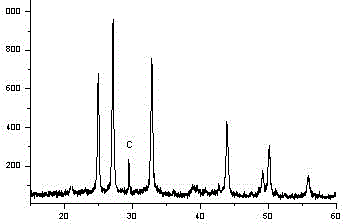

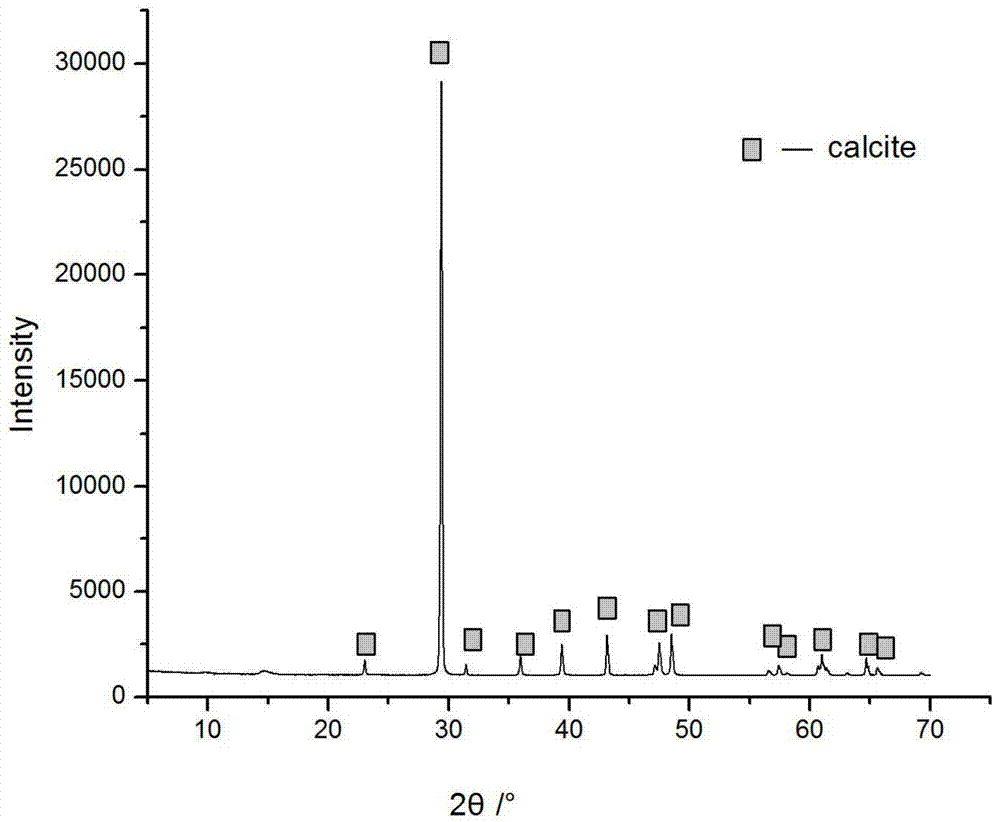

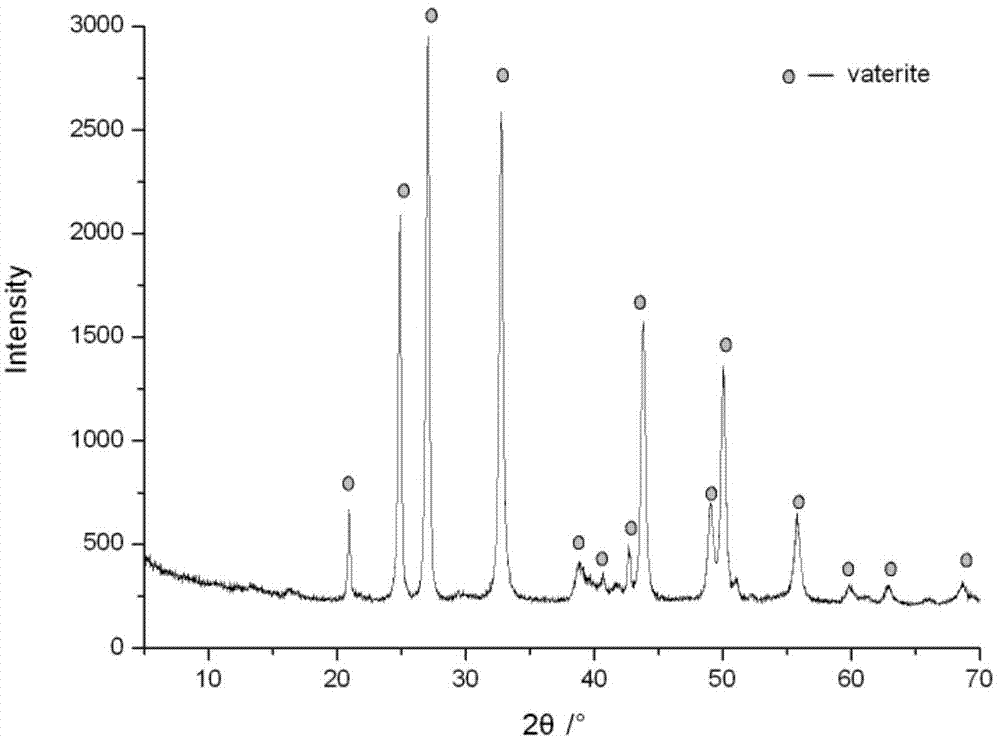

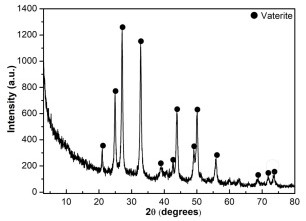

Vaterite is a mineral, a polymorph of calcium carbonate (CaCO₃). It was named after the German mineralogist Heinrich Vater. It is also known as mu-calcium carbonate (μ-CaCO₃) and has a JCPDS number of 13-192. Vaterite belongs to the hexagonal crystal system, whereas calcite is trigonal and aragonite is orthorhombic.

Stabilized vaterite

InactiveUS20050106110A1Calcium/strontium/barium carbonatesCosmetic preparationsPrecipitated calcium carbonateChemistry

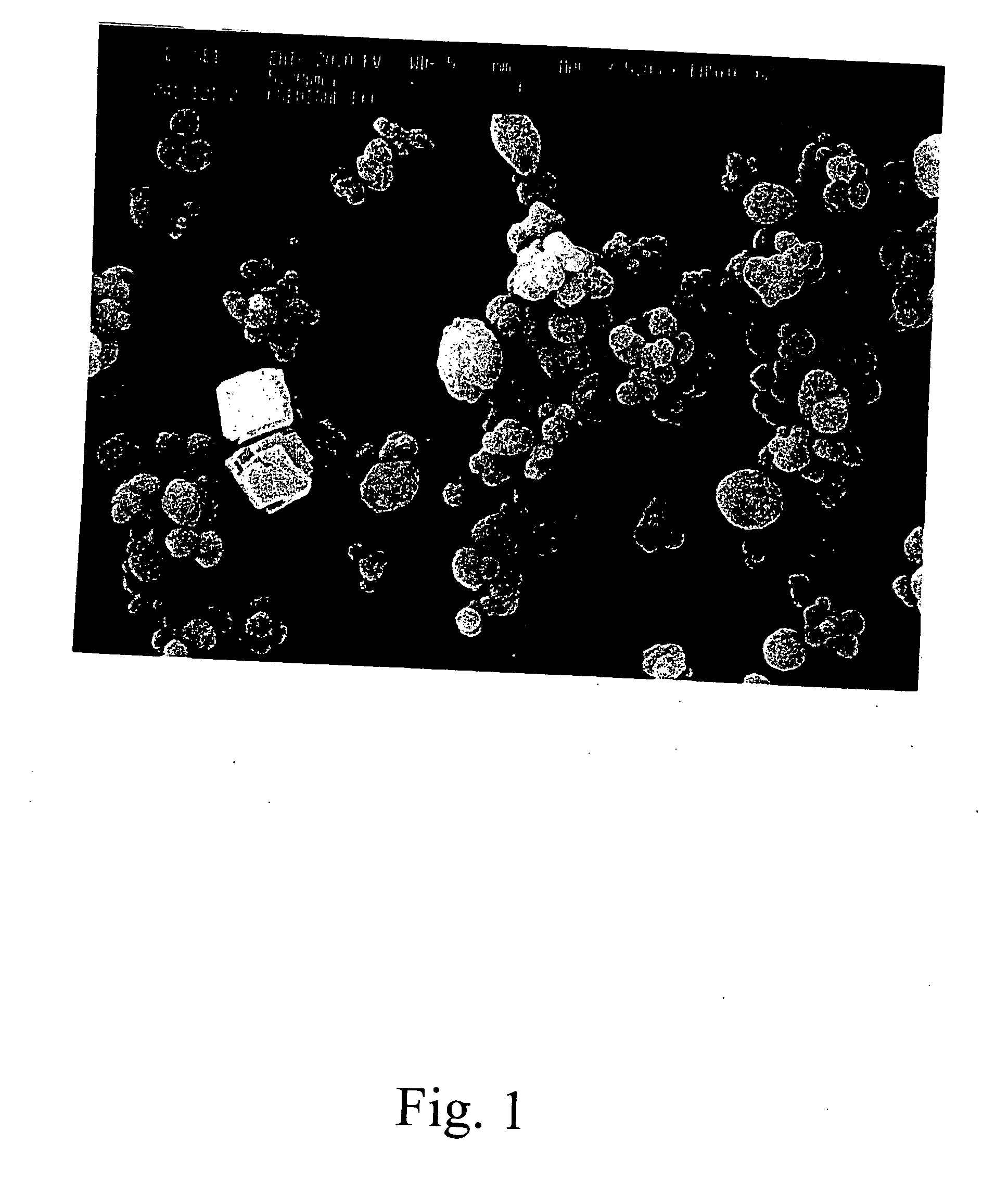

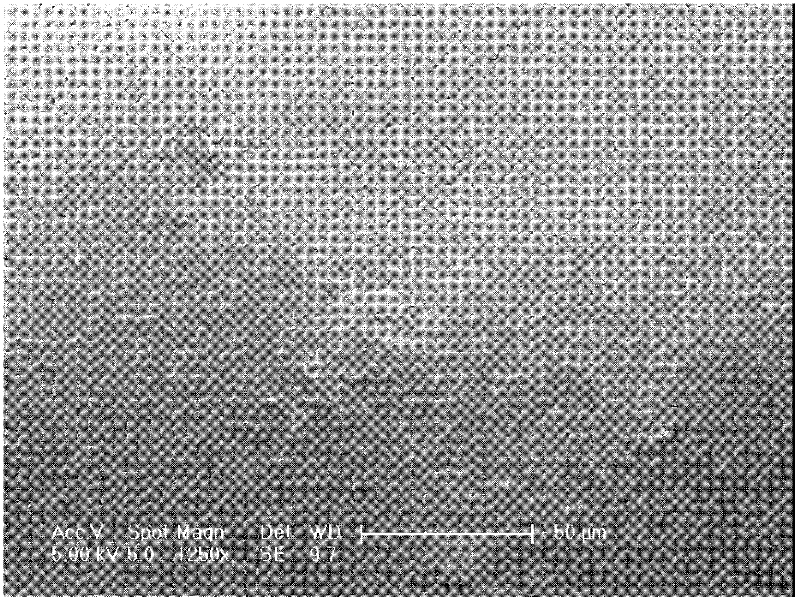

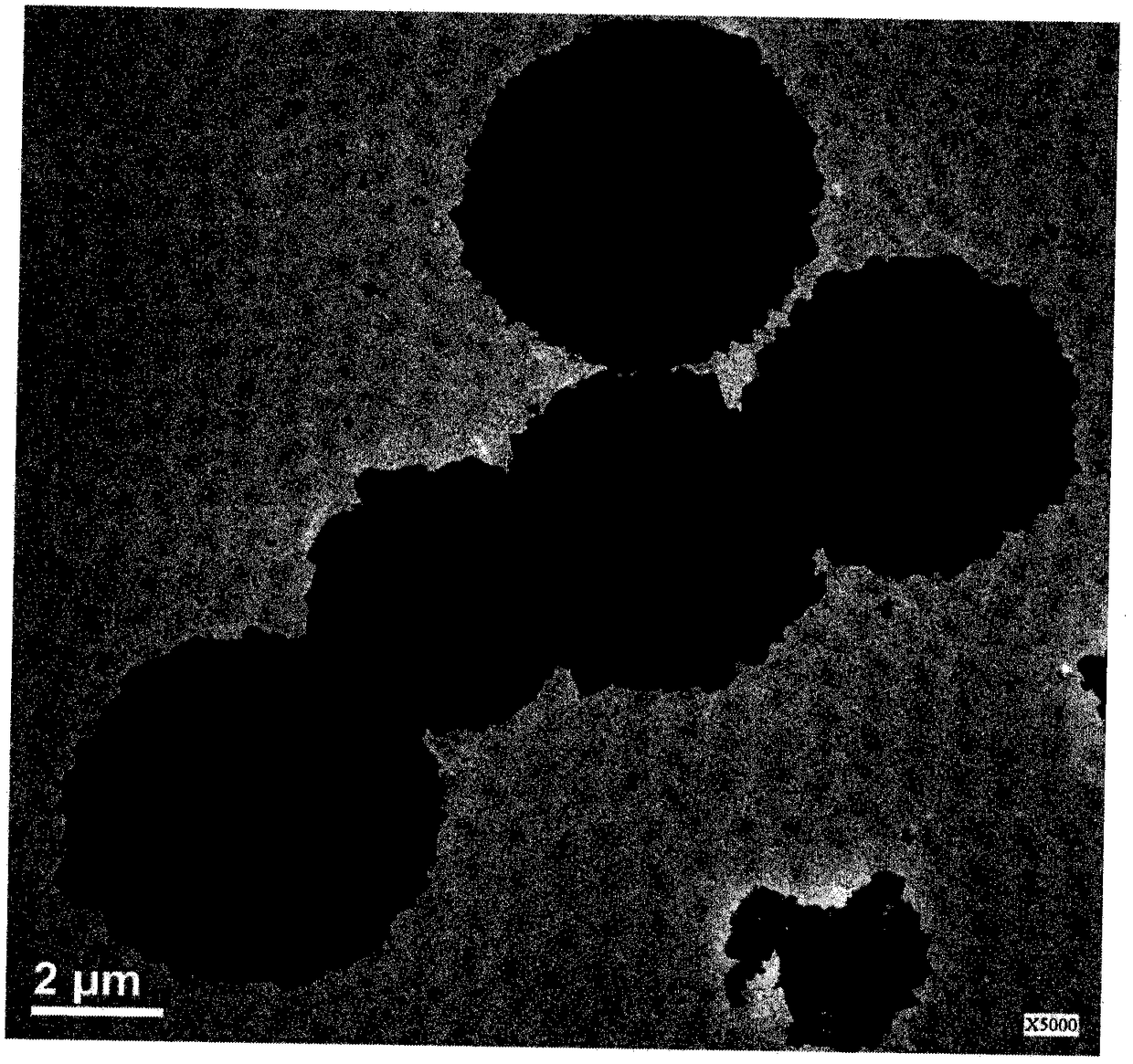

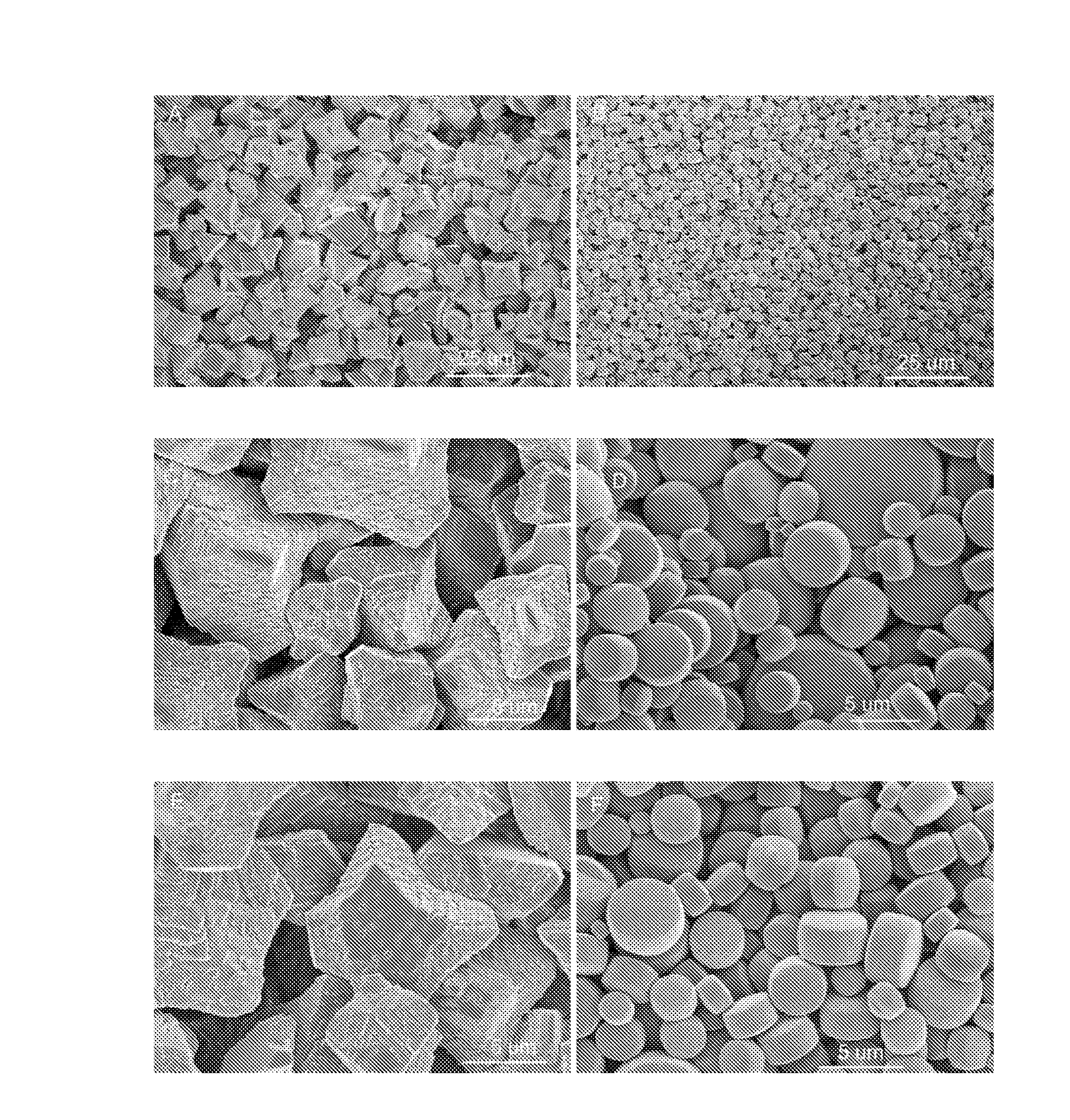

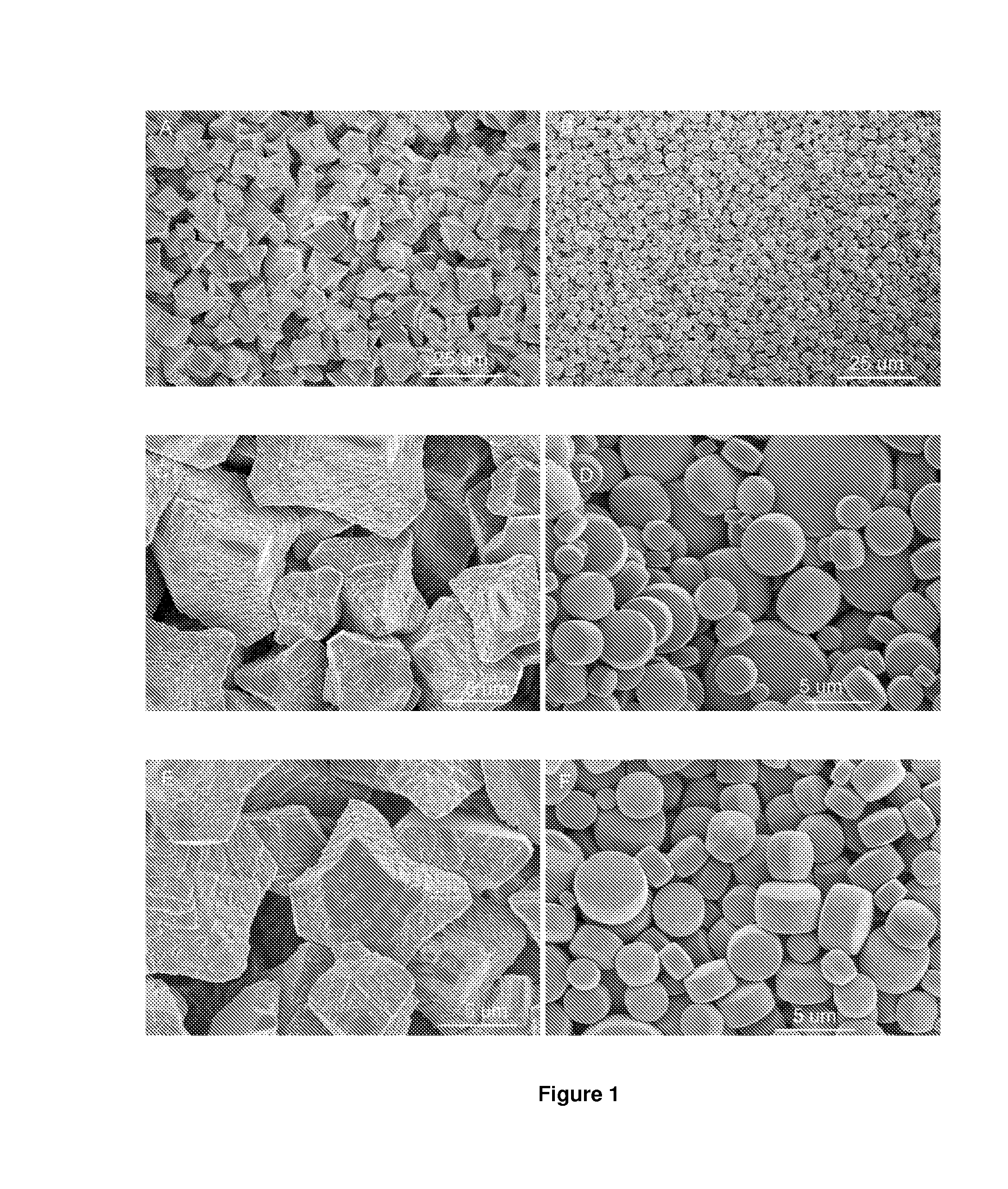

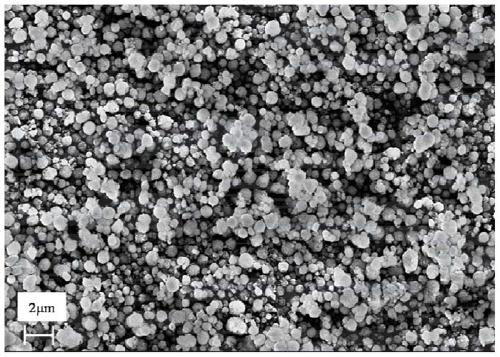

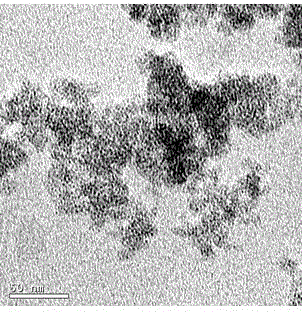

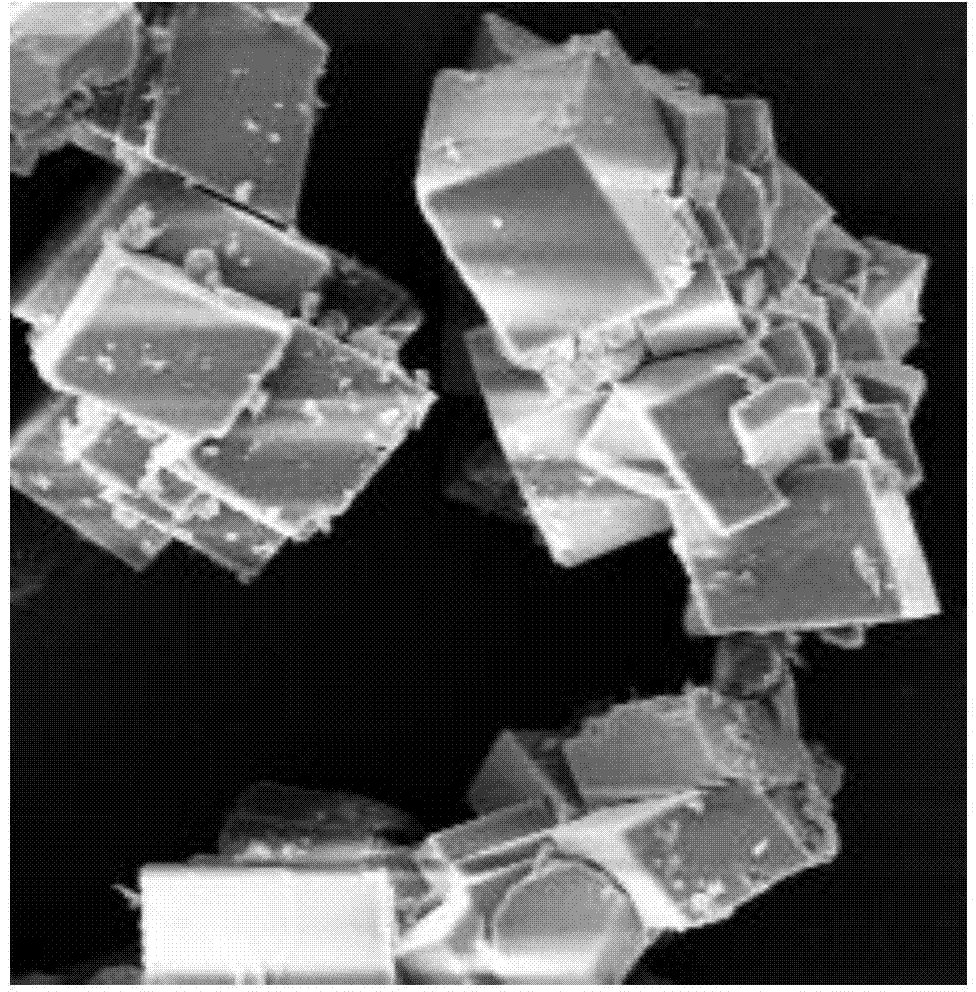

A precipitated calcium carbonate provides excellent cleaning properties without being excessively abrasive. The precipitated calcium carbonate has a vaterite crystalline form, a primary particle size of about 0.2 μm to about 3 μm, and an aggregate particle size of less than about 4 μm.

Owner:LIU SUNG TSUEN

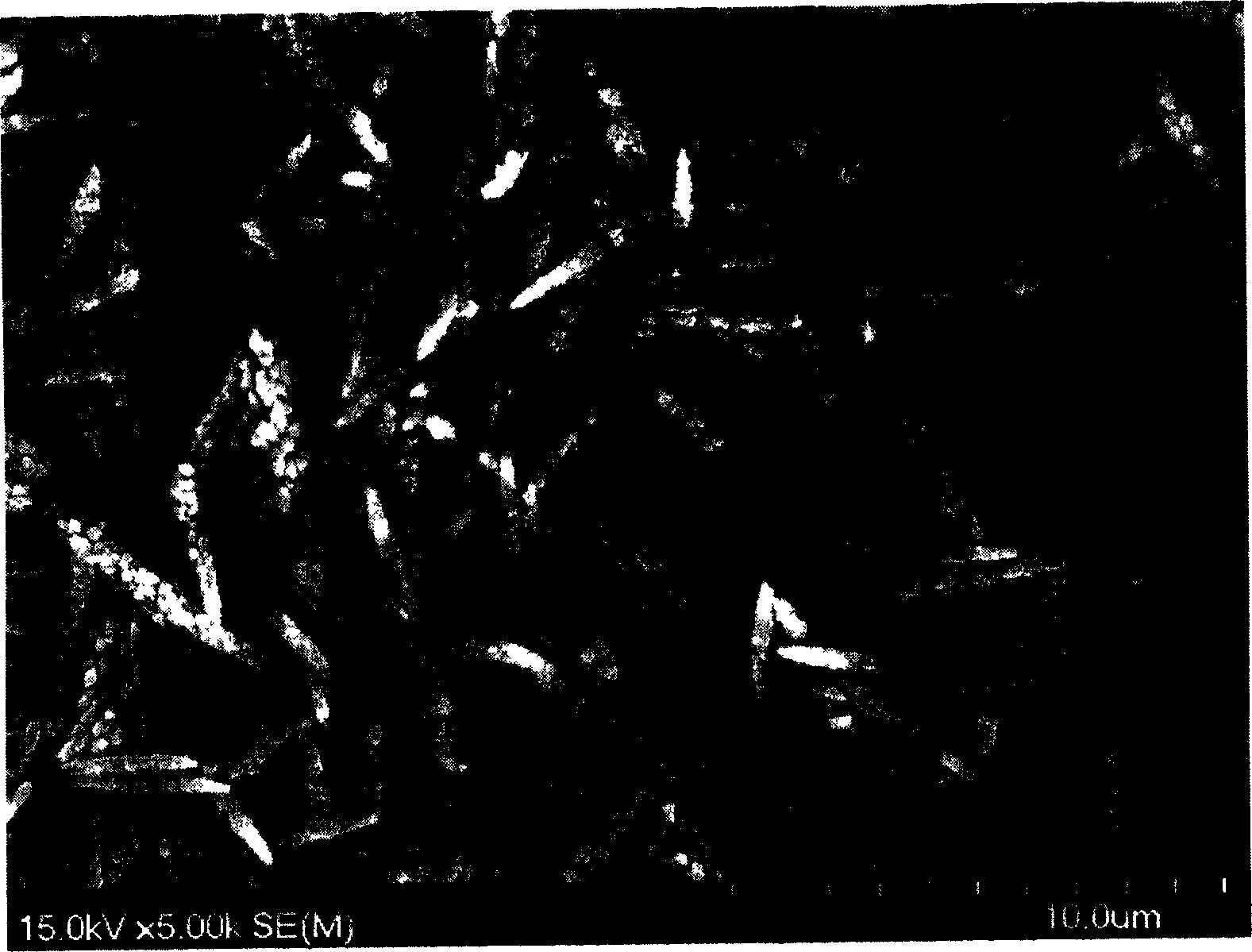

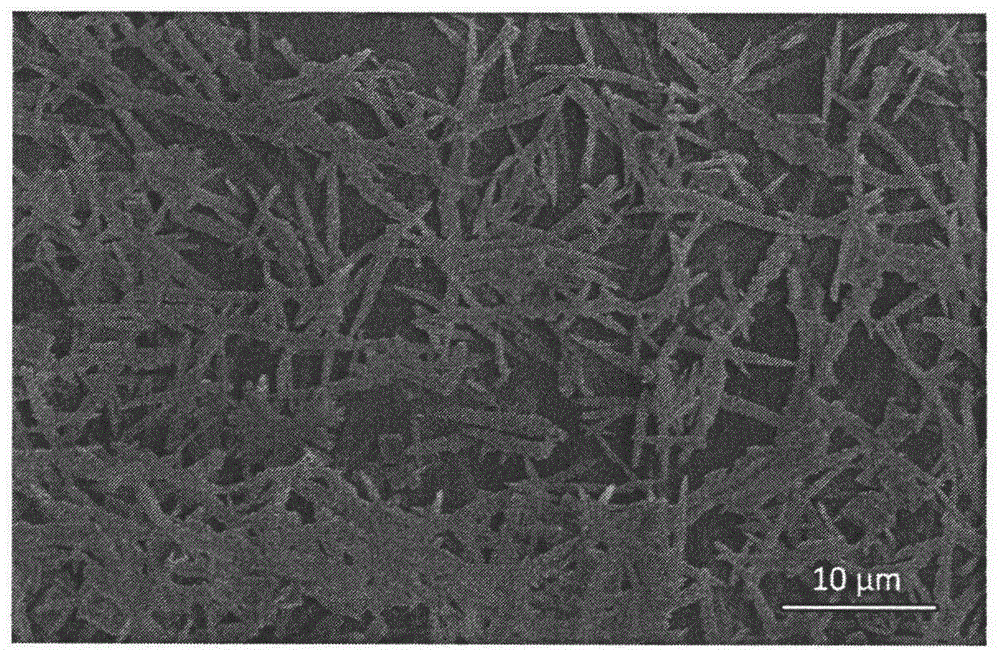

Single dispersing micron chopped fiber-like aragonite type calcium carbonate and preparation method thereof

InactiveCN1631792ASimple methodThe method is simple and controllableCalcium/strontium/barium carbonatesSolubilityPrinting ink

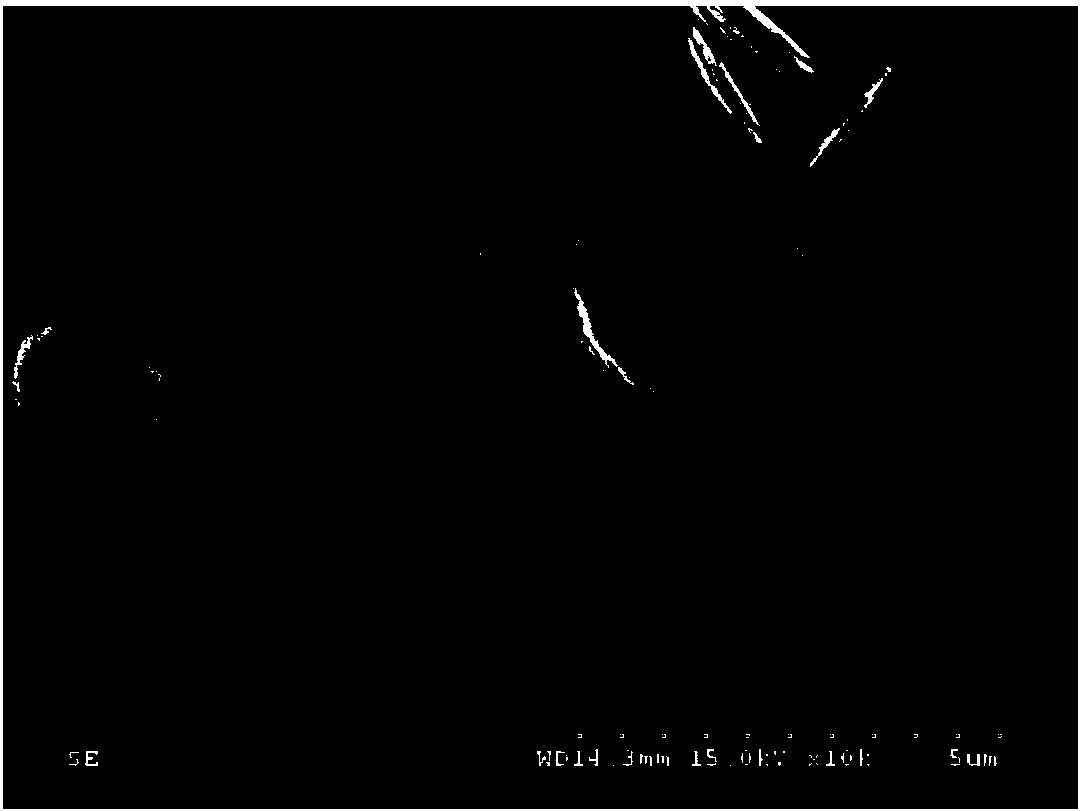

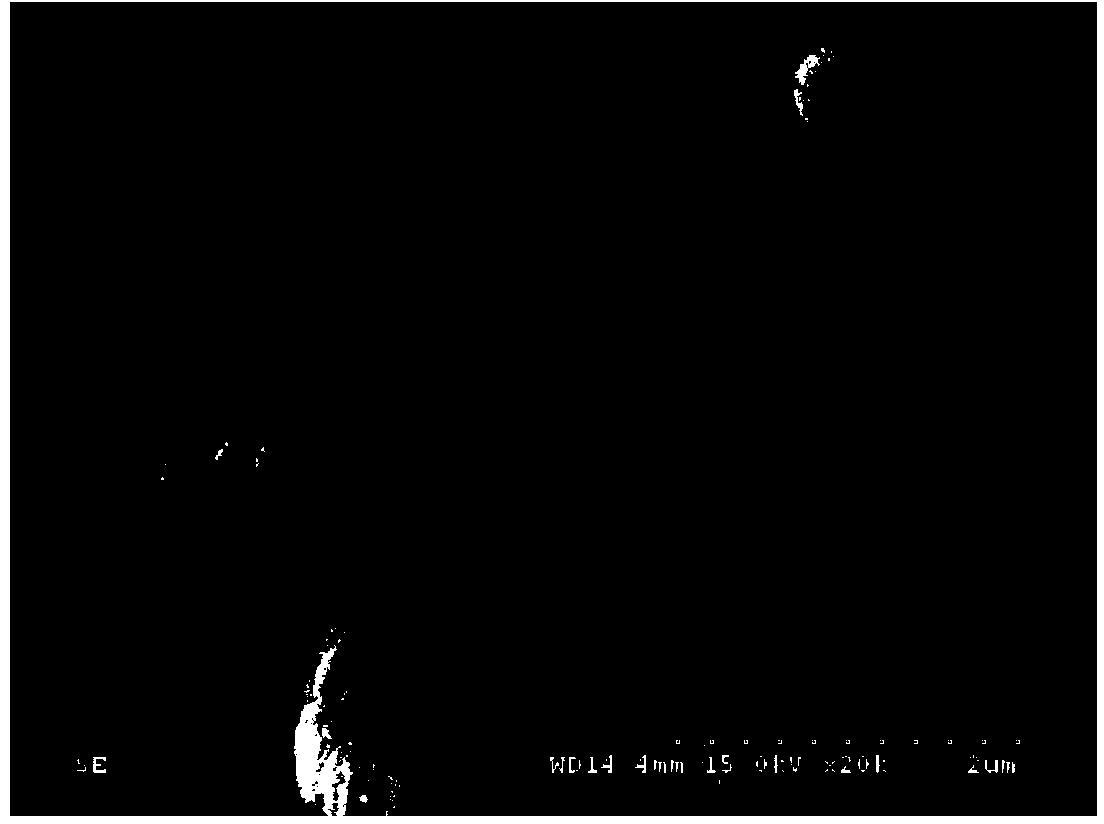

The invention relates to a single-distributive micron short fiber-typed vaterite calcium carbonate and its preparing method. The calcium carbonate crystal is needle short fiber-typed, its length is 2-8 micron and width is 0.3-1.5 micron, the ratio of length and diameter is 5-10, its content of vaterite calcium carbonate is larger than 90% with small particle on the surface of. The preparing method includes mix the aqueous solution of carbonate containing water soluble organic solvent with aqueous solution of calcium salt also containing that, make use of the different dissolubility of carbonate and calcium salt in water soluble organic solvent and water, and the different solvation to calcium ion, compound the product. The calcium carbonate has remarkable single distribution, large ratio of length and diameter, high activity of surface, suitable for coating on paper, filling plastic, coating, printing ink and paper, as well as the raw material for calcium preparations.

Owner:ZHEJIANG UNIV

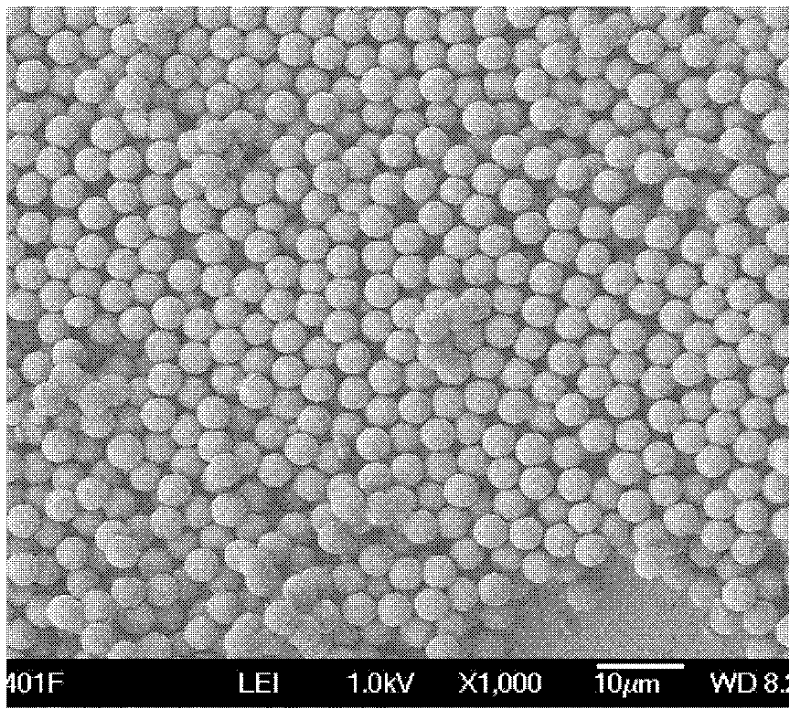

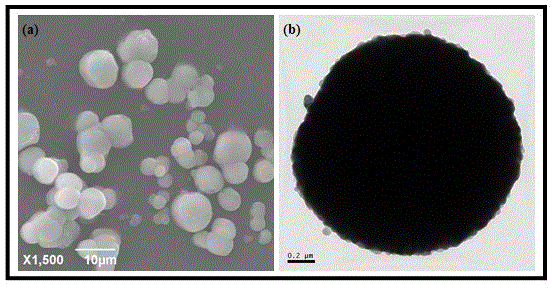

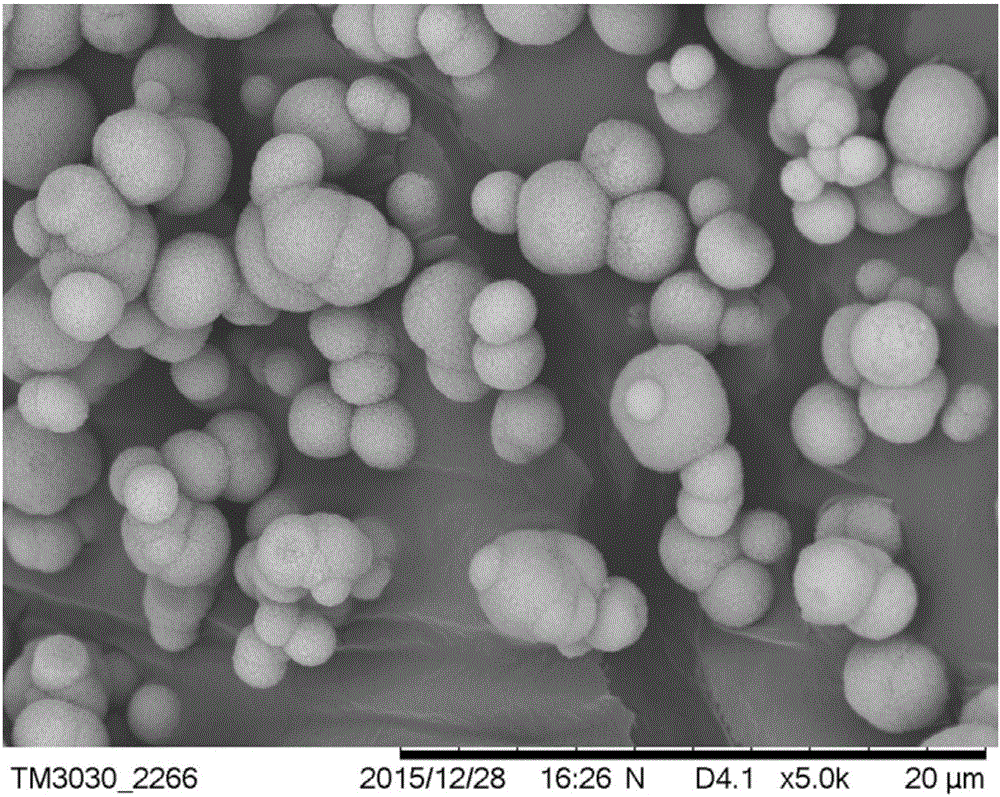

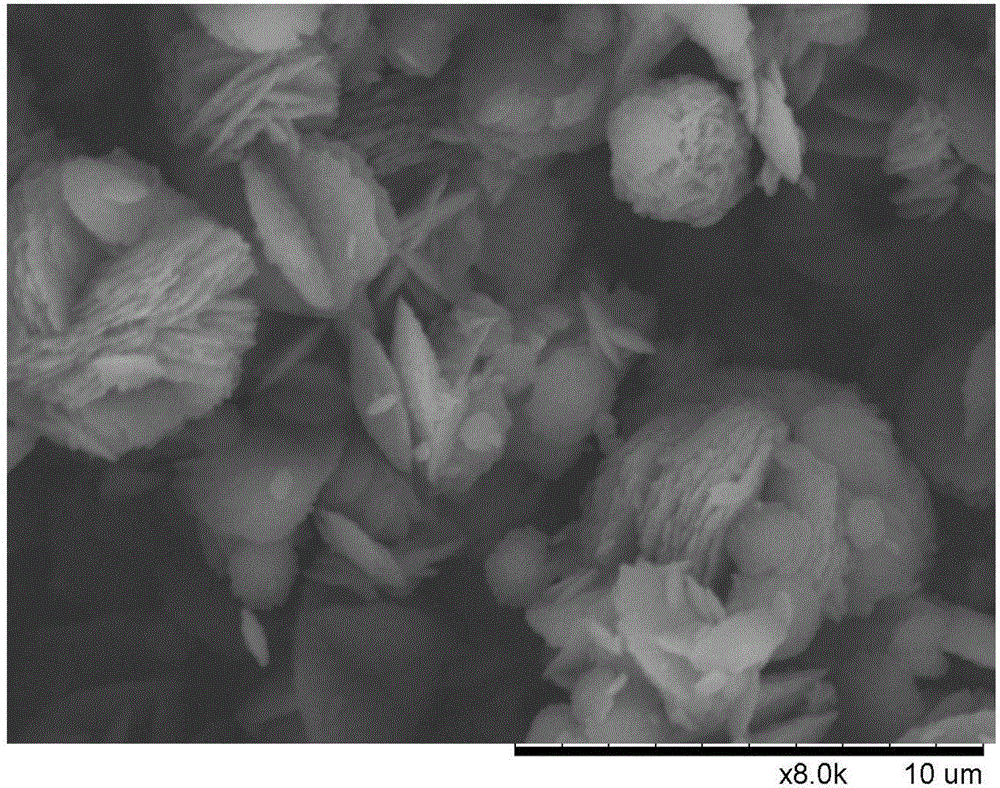

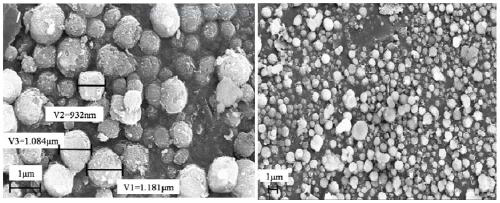

Preparation method for vaterite-phase calcium carbonate microspheres with uniform size

InactiveCN102515236ASimple and fast manufacturing methodUniform size and heightCalcium/strontium/barium carbonatesNanotechnologyMicrosphereHybrid material

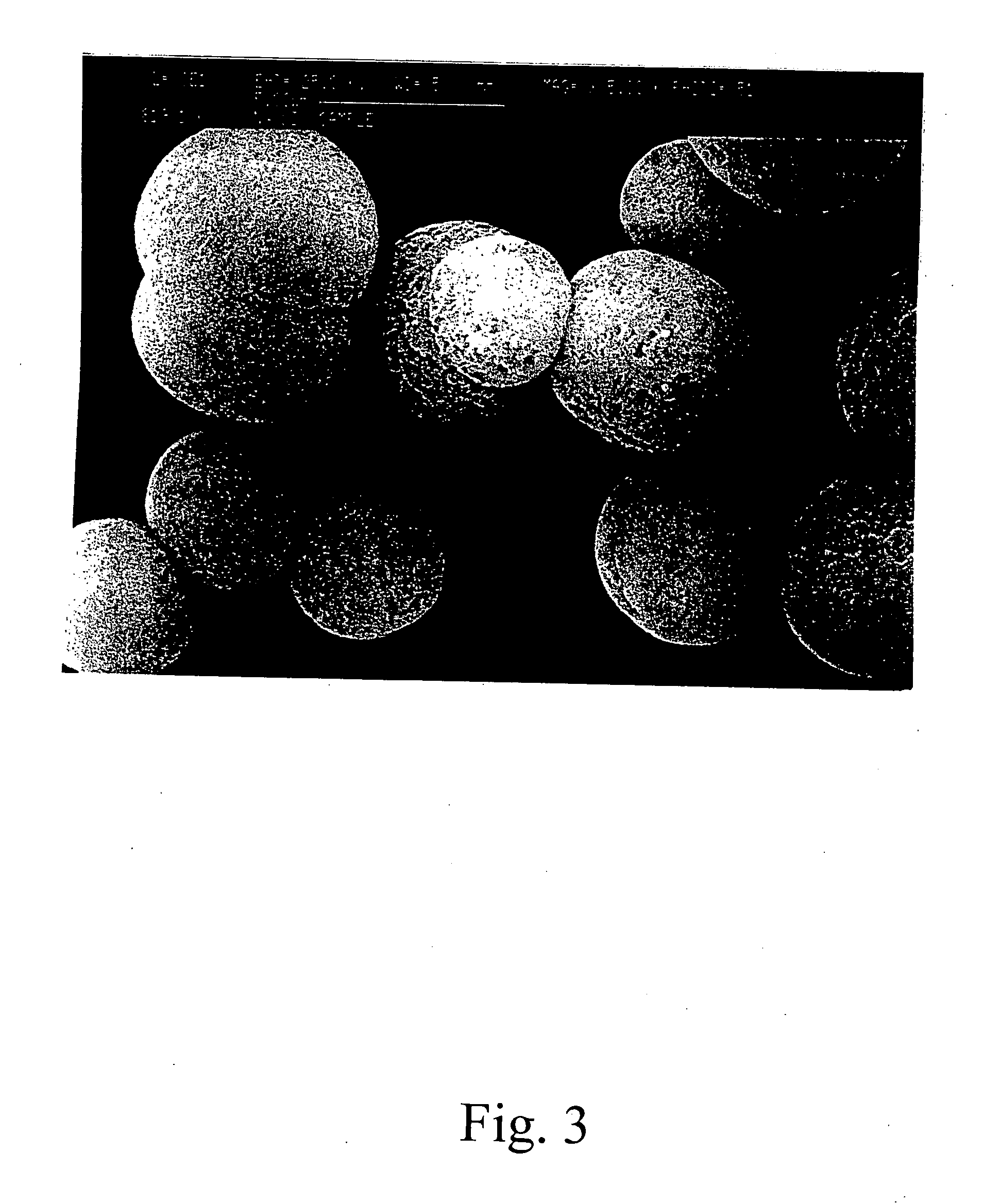

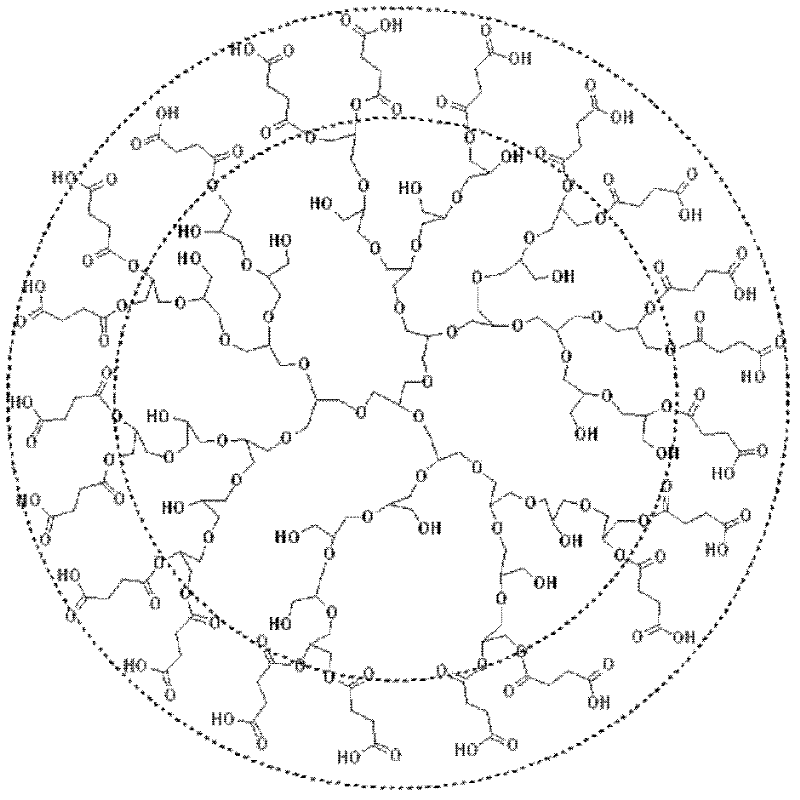

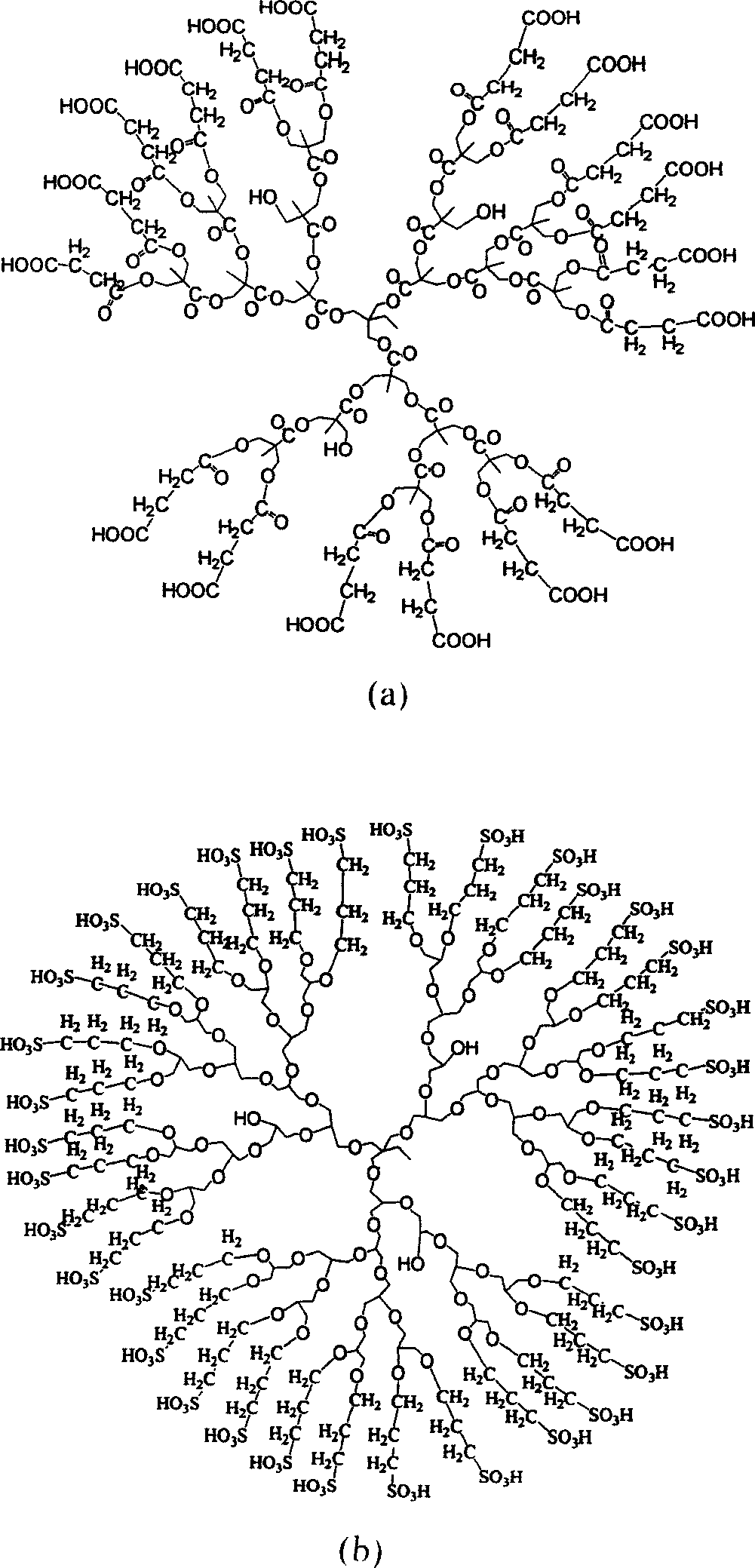

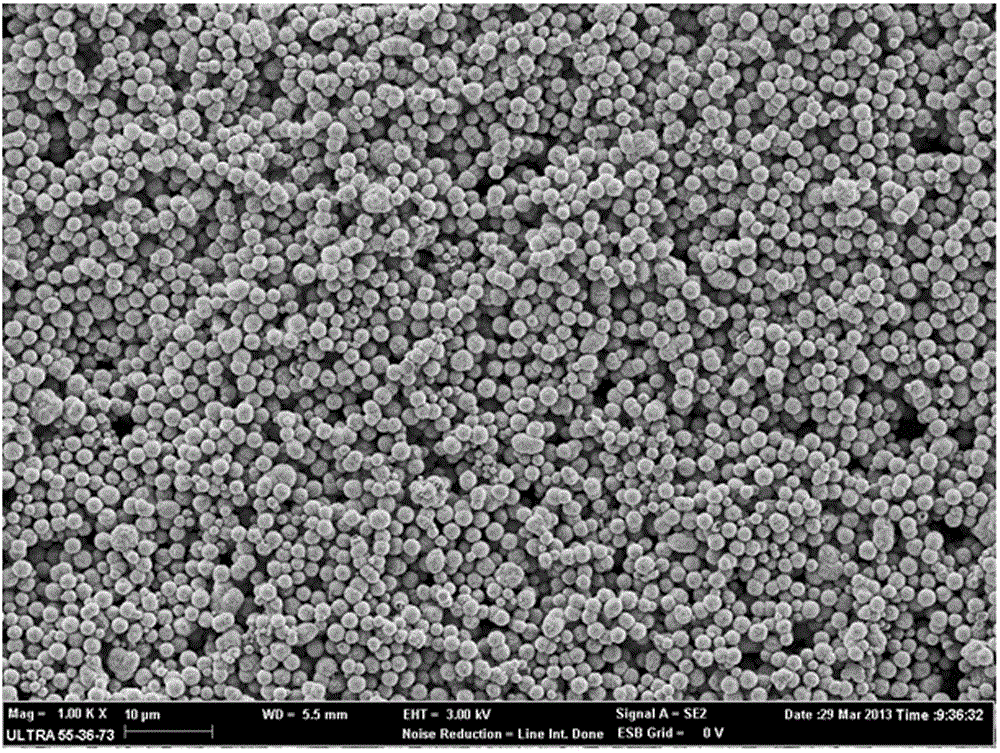

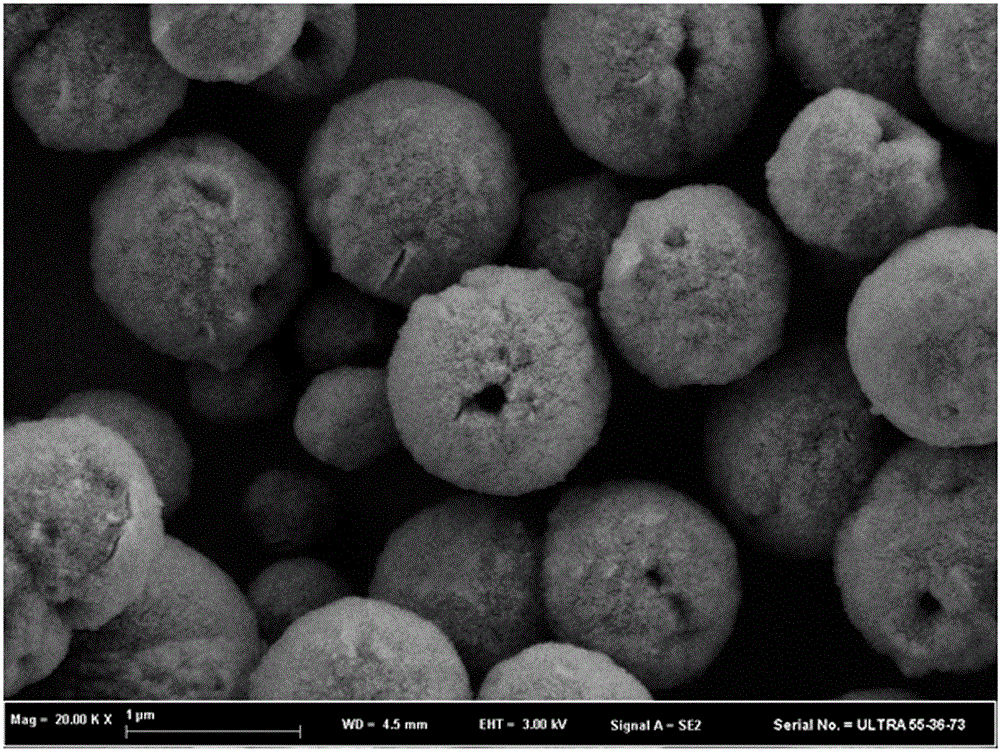

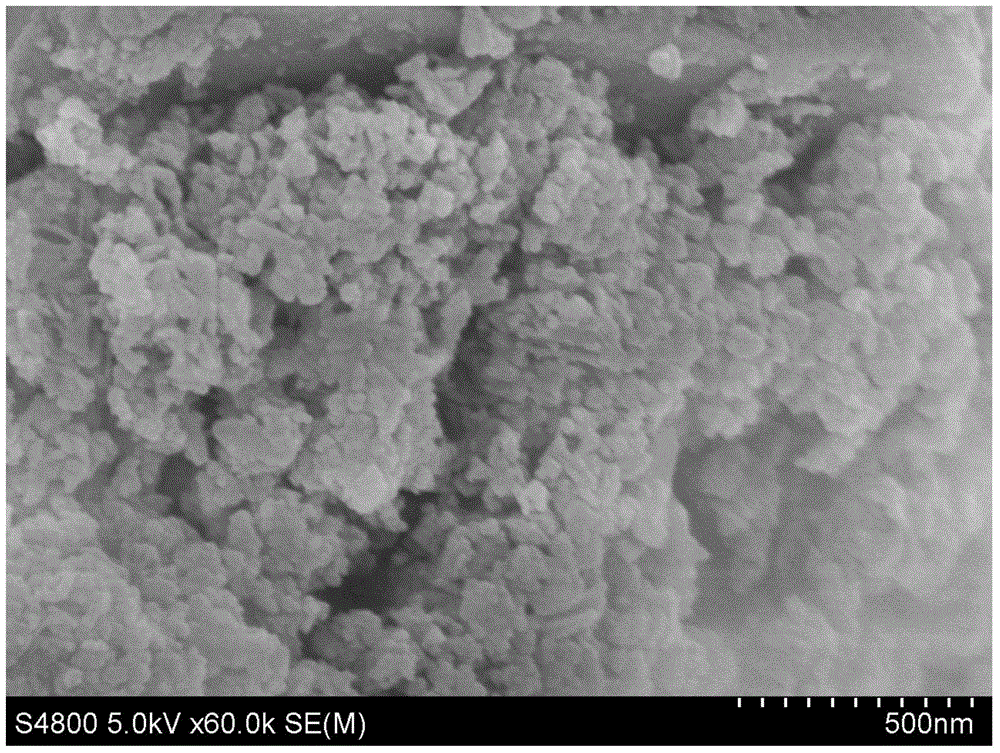

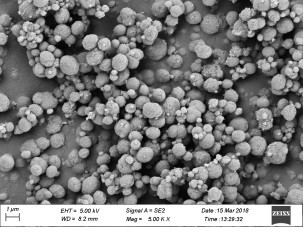

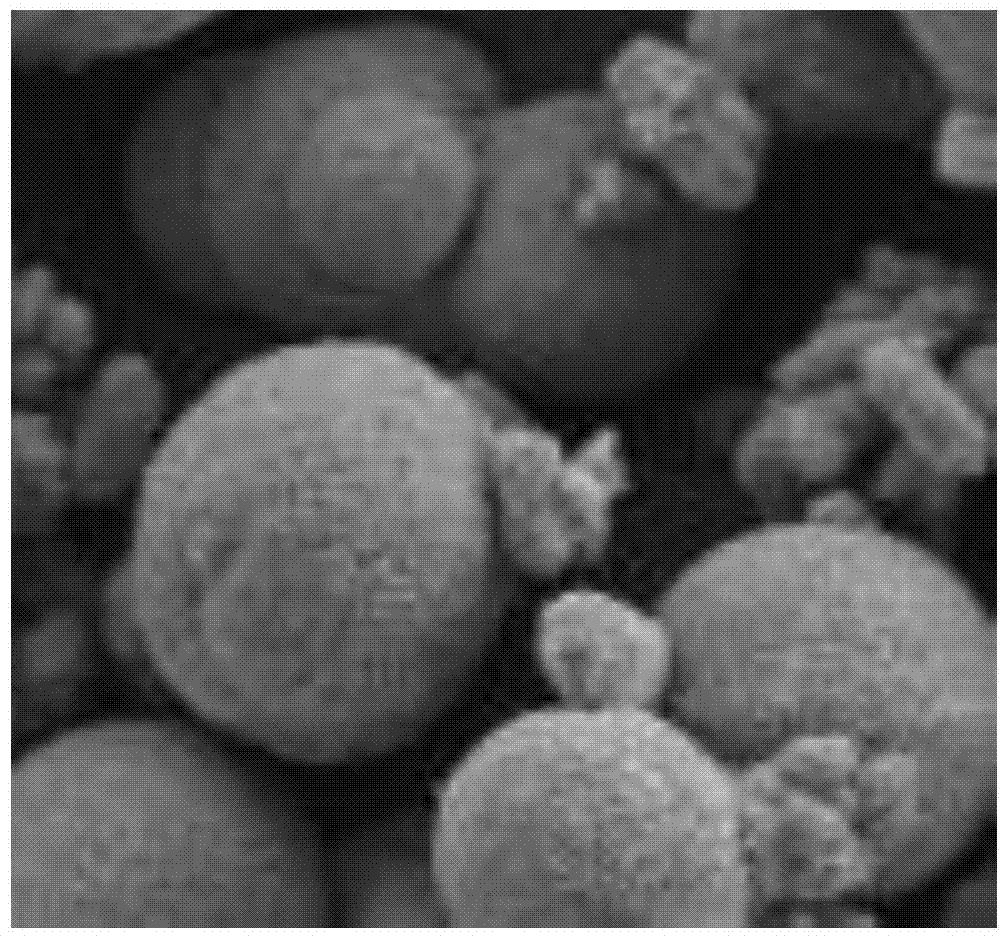

The invention discloses a preparation method for vaterite-phase calcium carbonate microspheres with a uniform size, comprising the following step of: using a double-hydrophilic hyperbranched polymer molecule as a template, and performing precipitation reaction between water-soluble calcium salt and carbonate to prepare. The calcium carbonate microspheres prepared by the method are organic-inorganic hybrid materials containing 7-10 wt% of hyperbranched polymer. The particle size of the microspheres can be adjusted in a range between 2 to 4.5 microns by controlling reaction conditions. The product prepared by the method disclosed by the invention is highly uniform in size, green and environment-friendly in synthesis process, and with a certain application prospect.

Owner:HANGZHOU NORMAL UNIVERSITY

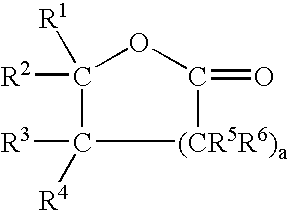

Functionalized polymer composition for grease

A grease composition containing: (a) the reaction product of: (i) a calcium containing overbased organic acid; and (ii) at least one acid producing compound or derivatives thereof selected from the group consisting of: (1) a non-polymeric hydrocarbyl substituted dicarbonyl derivative selected from the group consisting of an acid, an ester, a salt, an anhydride, ester-acid, acid-salt and mixtures thereof; (2) a copolymer derived from monomers containing (1) an olefin; and (2) an unsaturated dicarboxylic acid anhydride or derivatives thereof; and (3) an inorganic acid containing about 2 or more acidic hydrogens; and (b) an oil of lubricating viscosity, wherein the overbased calcium sulphonate contains colloidally dispersed calcium carbonate is selected from the group consisting of calcite, vaterite and mixtures thereof. The invention further relates to the process to make the composition and its use in greases to increase water resistance.

Owner:THE LUBRIZOL CORP

Monodisperse micron level spherical vaterite-type calcium carbonate and its prepn process

InactiveCN1887716ASimple methodReaction conditions are easy to controlCalcium/strontium/barium carbonatesAqueous solutionCarbonate

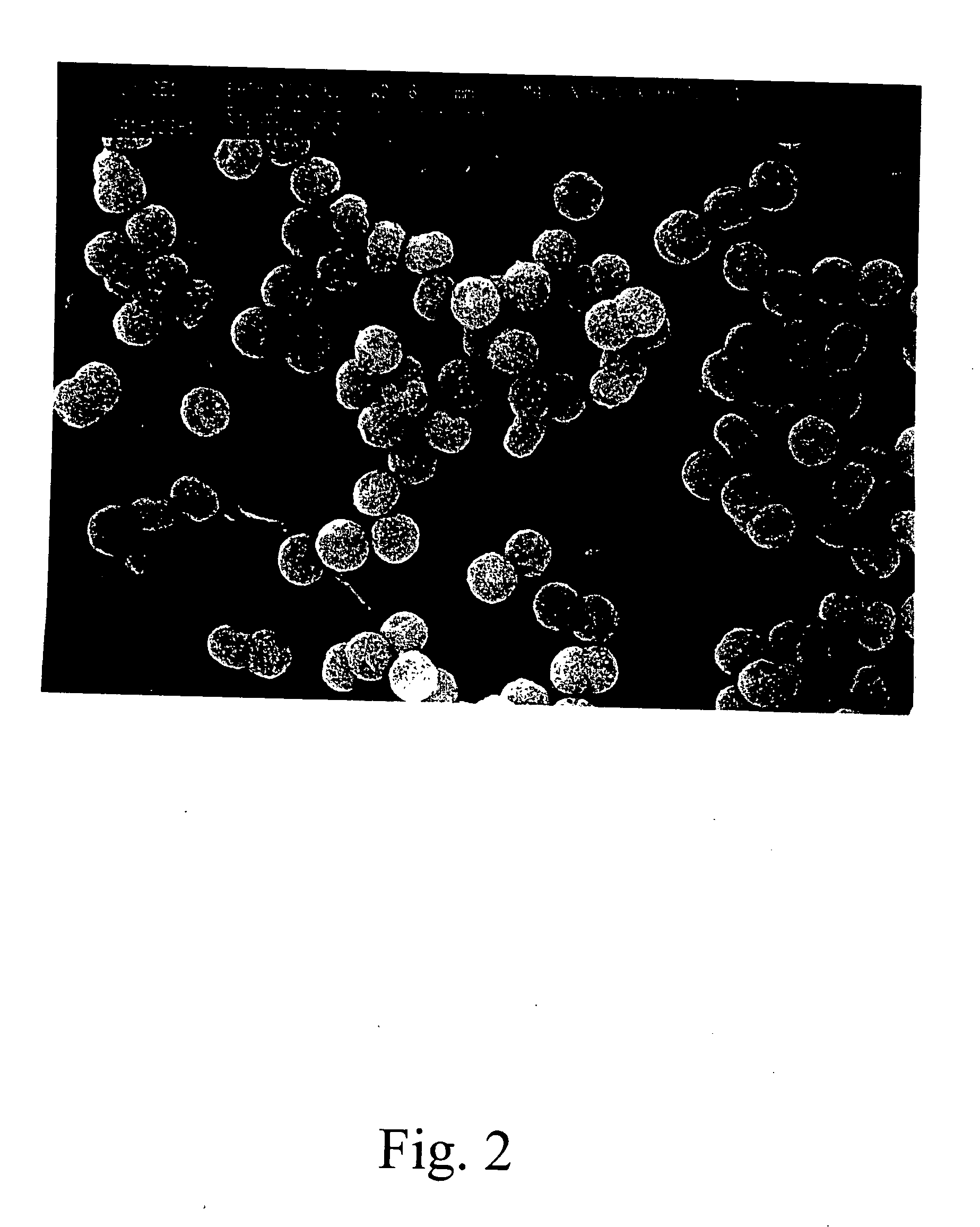

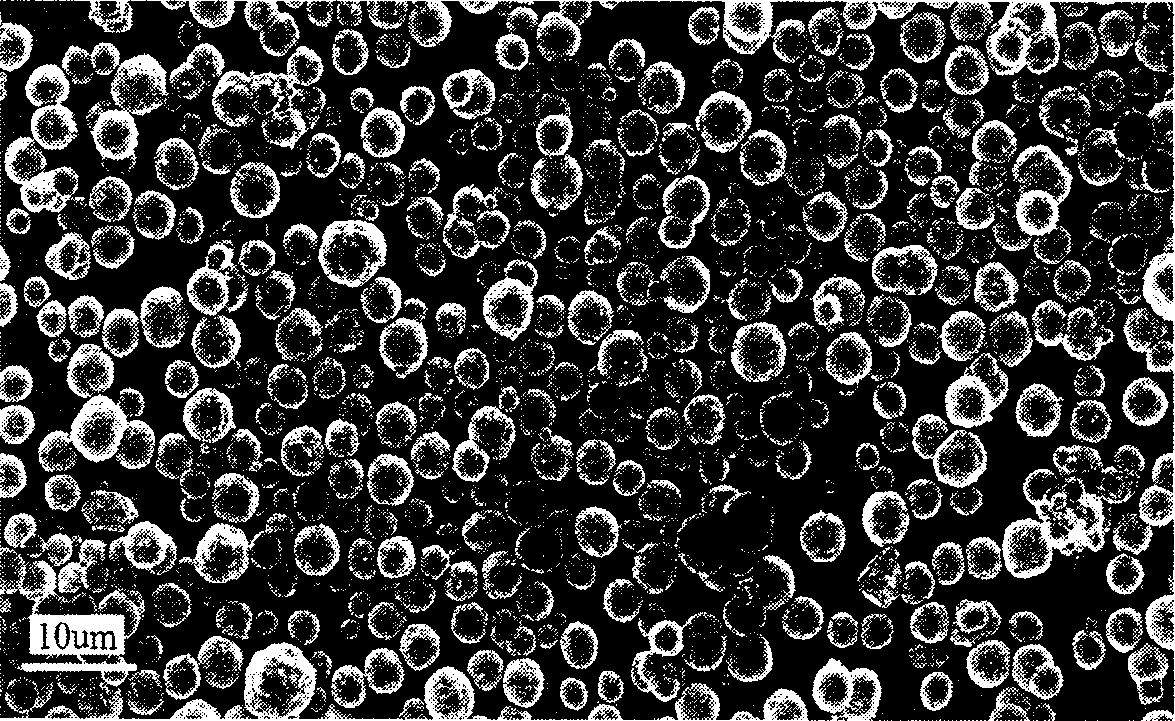

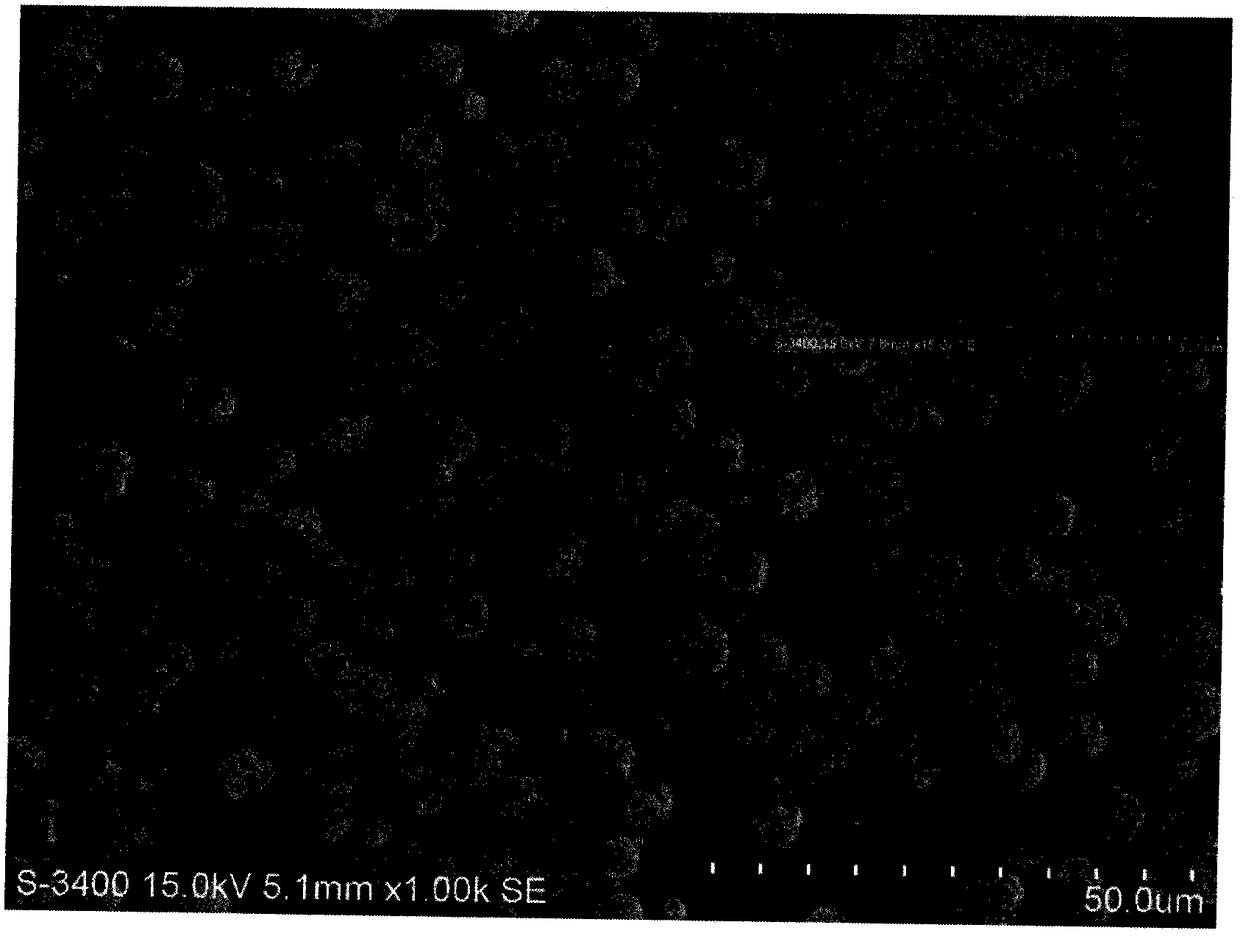

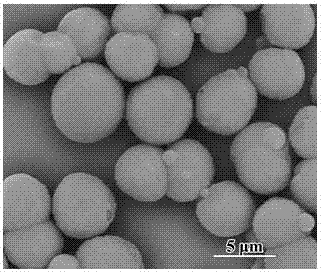

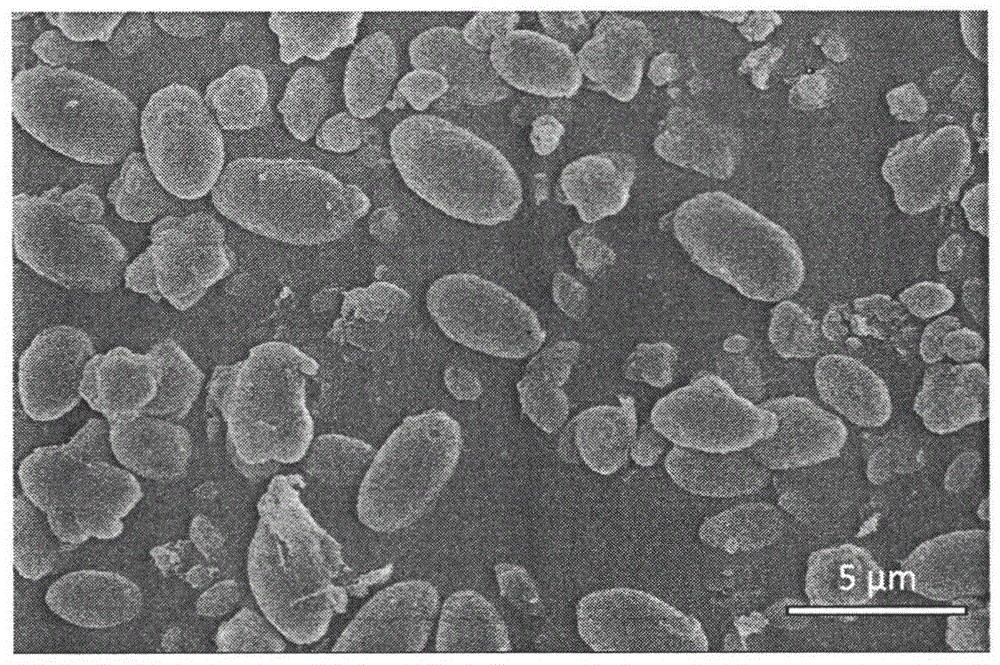

The present invention relates to one kind of monodisperse micron level spherical vaterite-type calcium carbonate, which is one kind of organic-inorganic hybridized material comprising inorganic calcium carbonate component with calcium carbonate content of 95-100 wt% and organic component of super branched polymer accounting for 3-10 wt%. The preparation process of the monodisperse micron level spherical vaterite-type calcium carbonate includes the following steps: preparing water solution of calcium salt; preparing water solution of carbonate or bicarbonate; preparing water solution of functional super branched polymer; fast mixing the water solution of calcium salt, the water solution of calcium salt and the water solution of functional super branched polymer at 5-40 deg.c via stirring; ageing for 1-24 hr; centrifugal or filtering separation, washing and stoving to obtain the monodisperse micron level spherical vaterite-type calcium carbonate.

Owner:NANJING UNIV

Hollow calcium carbonate microsphere and preparation method thereof

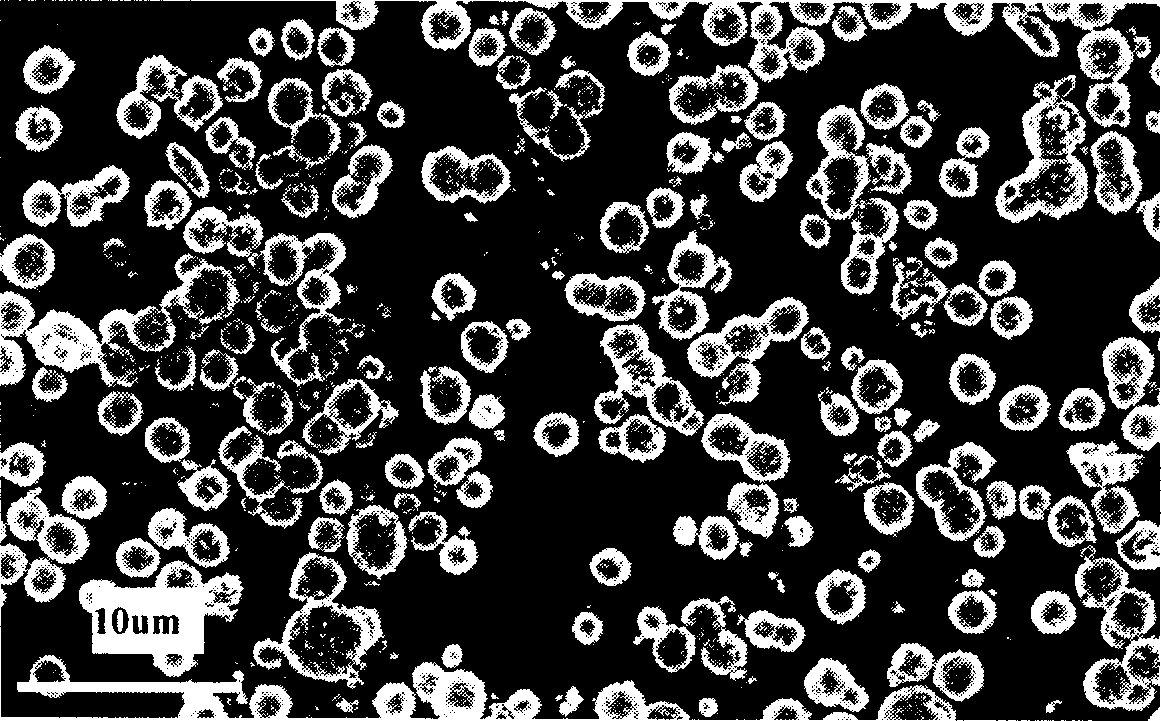

The invention discloses a hollow calcium carbonate microsphere and a preparation method thereof. The preparation method comprises the following steps: 1, preparing solutions of calcium chloride (CaCl2), sodium carbonate (Na2CO3), polyacrylic acid (PAA) and sodium dodecyl sulfate (SDS); 2, adding the prepared PAA in constant volume into the Na2CO3 solution and the CaCl2 solution; 3, adding the SDSsolution into a mixed solution containing the Na2CO3 and PAA only, and adding the solution into a mixed solution of CaCl2 and PAA; 4, filtering, washing and drying the reaction product, thereby obtaining the white powdered hollow calcium carbonate microsphere with excellent monodispersity. The obtained hollow calcium carbonate microsphere has a compound crystal form of calcite and vaterite, is uniform in particle size distribution, does not have an agglomeration phenomenon, and has the mean grain size of 5-8 microns and the specific surface area of 30-60m<2> / g. The preparation method is simplein process, low in cost, easy to control, green, environmentally friendly and capable of realizing industrialized production; the prepared hollow calcium carbonate microsphere has huge application value in the fields of drug sustained release and the like.

Owner:SHANGHAI HUAMING HI TECH GRP

Vaterite calcium carbonate microspheres and preparation method thereof

InactiveCN104692439ARich sourcesSolve the problem of wastewater useCalcium/strontium/barium carbonatesCalcium crystalsChemical reaction

The invention discloses a method for simply preparing vaterite calcium carbonate microspheres. The preparation method comprises the steps of 1, preparing a sericin solution; 2, preparing a sericin solution with a certain concentration as a template regulation system through the dialyzed sericin solution according to the chemical equation shown in the specification, and dropping calcium salt and carbonate which have the same concentration into a reaction system in a certain proportion; 3, agitating the reaction system for a period of time, centrifuging to remove precipitate, and washing with water at three times; 4, drying the CaCO3 precipitate through a drying box after water washing, so as to obtain the finished product of vaterite calcium carbonate microspheres. The granularity of the CaCO3 microspheres is 1 to 1.5 microns; the vaterite calcium crystal form in the obtained material is more than 80%; the natural sericin solution is used as the template regulation system to regulate CaCO3 crystal form.

Owner:ZHEJIANG SCI-TECH UNIV

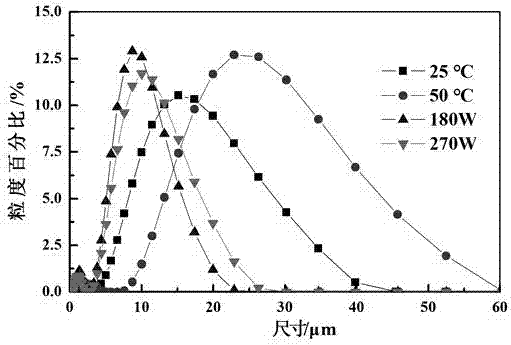

Method of utilizing electric furnace slag to prepare spherical vaterite calcium carbonate centralized in granularity distribution

InactiveCN107128963AImprove performanceLow application valueCalcium/strontium/barium carbonatesSlagGranularity

The invention discloses a method of utilizing electric furnace slag to prepare spherical vaterite calcium carbonate centralized in granularity distribution. The method includes steps: mixing the electric furnace slag with ammonium chloride solution for reaction to obtain leachate containing calcium ions; feeding carbon dioxide gas into the leachate for reaction to generate calcium carbonate granules. The method is characterized by adding ammonia water into the leachate and feeding carbon dioxide in a microwave radiation state for reaction at the same time. Calcium carbonate prepared by the method has a centralized granularity distribution range and is spherical, stable in performance and high in added value, and crystal form of calcium carbonate has the characteristics of vaterite.

Owner:YANGTZE NORMAL UNIVERSITY

Calcium carbonate microtablets and method for the preparation thereof

The invention discloses a method of preparing monodisperse microtablets of calcium carbonate in aqueous solutions containing calcium, gelatin and urea. Calcium carbonate powders of a unique tablet-like morphology were produced by simply ageing the prerefrigerated (at 4° C. for at least 24 hours) CaCI2-gelatin-urea solutions at 70° C. for 24 h in ordinary glass media bottles. Thermal decomposition of dissolved urea was used to supply aqueous carbonate (CO32−) ions to the calcium (Ca2+) ion and gelatin-containing solutions. Monodisperse CaCO3 microtablets have the particle sizes from 1 to 8 microns. CaCO3 microtablets were biphasic in nature and consist of 93 to 98% vaterite and 2 to 7% calcite. Identical solutions used without prerefrigeration yielded only trigonal prismatic calcite crystals upon ageing at 70° C. for 24 h.

Owner:TAS AHMET CUNEYT

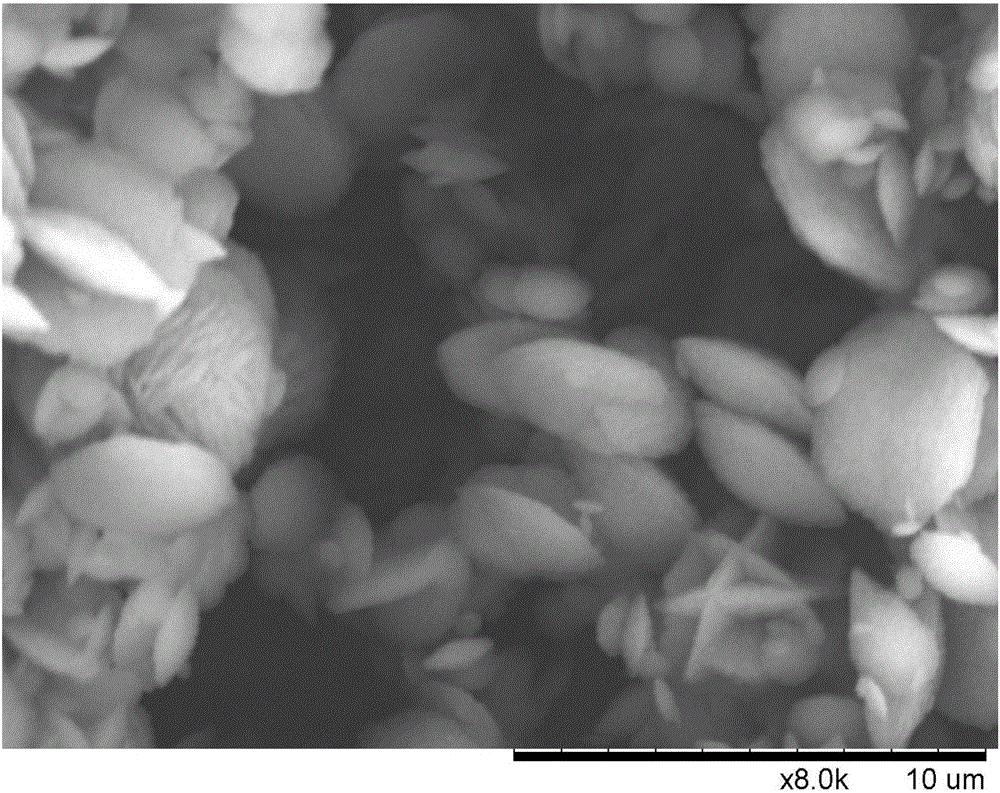

Micron spindle-fiber-like structure vaterite calcium carbonate preparation method

InactiveCN105399128AGood dispersionUniform size distributionCalcium/strontium/barium carbonatesFiberPotassium carbonate

The present invention relates to a calcium carbonate inorganic mineral preparation method, particularly to a micron spindle-fiber-like structure vaterite calcium carbonate crystal preparation method, which comprises: 1) dissolving pluronic (F127) in a deionized water / ethanol system having a certain ratio (V / V); 2) adding a certain amount of sodium dodecyl sulfate (SDS) to the system; 3) preparing a calcium chloride aqueous solution with a certain concentration; 4) preparing a potassium carbonate aqueous solution with a certain concentration; 5) rapidly pouring the solution in the step 3) into the solution prepared in the step 2); 6) slowly adding the solution prepared in the step 4) into the solution in the step 5) in a dropwise manner, and aging at a certain temperature; and 7) carrying out centrifugation separation on the mixing solution obtained after the aging, and washing to obtain the micron spindle-fiber-like structure vaterite calcium carbonate crystal. According to the present invention, the prepared micron spindle-fiber-like structure vaterite calcium carbonate has characteristics of good purity, high yield and good monodisperse property, the preparation reaction conditions are easy to control, and the industrial production is easily achieved.

Owner:TIANJIN POLYTECHNIC UNIV

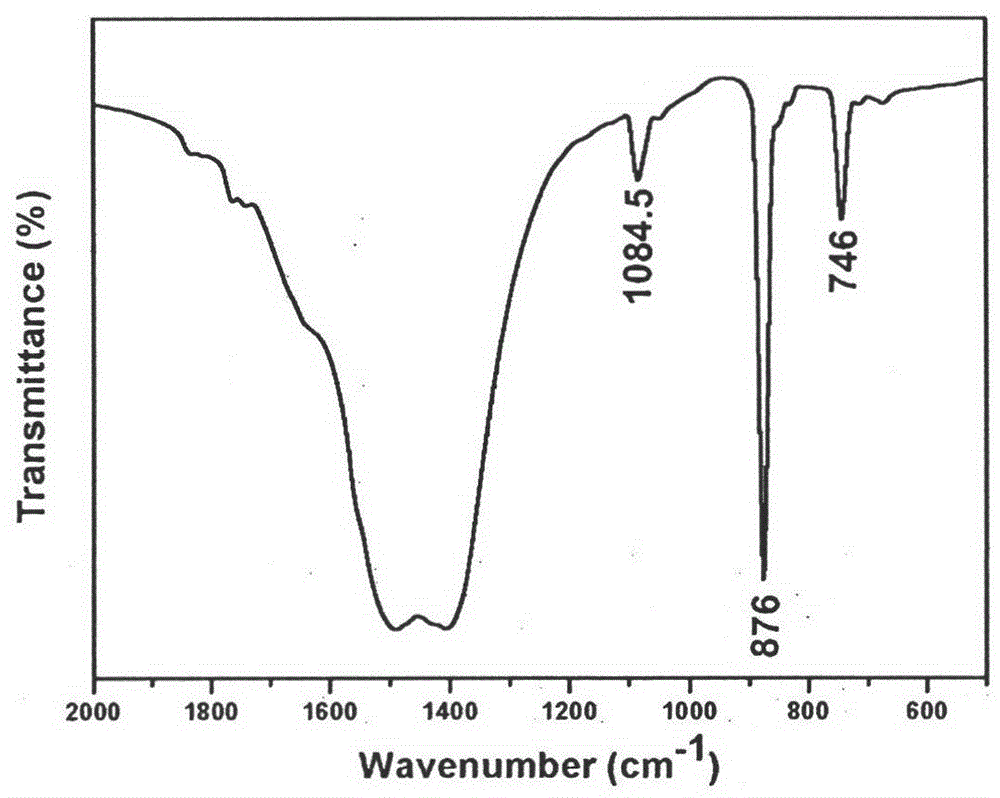

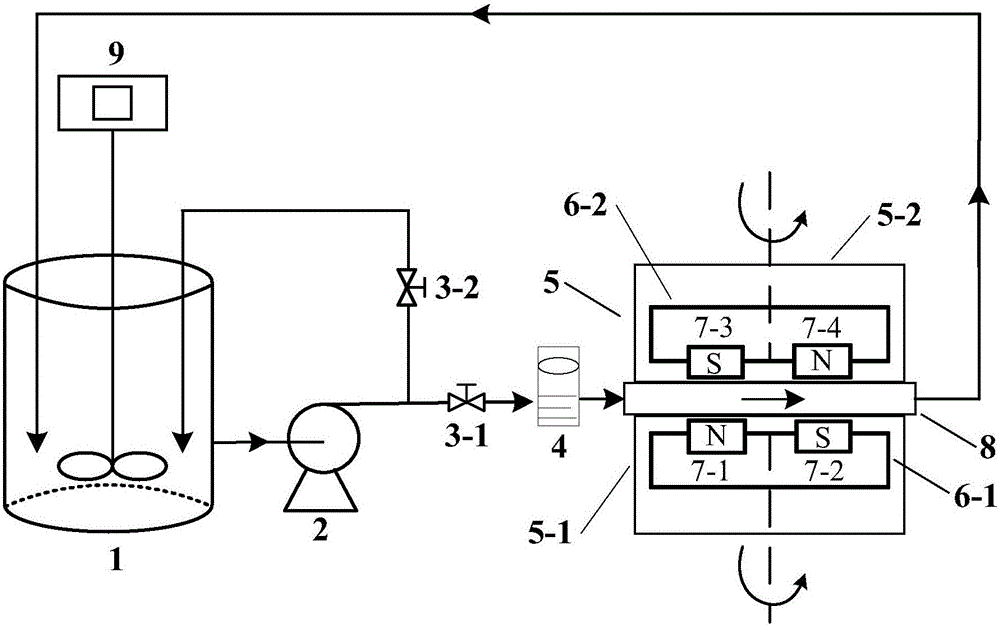

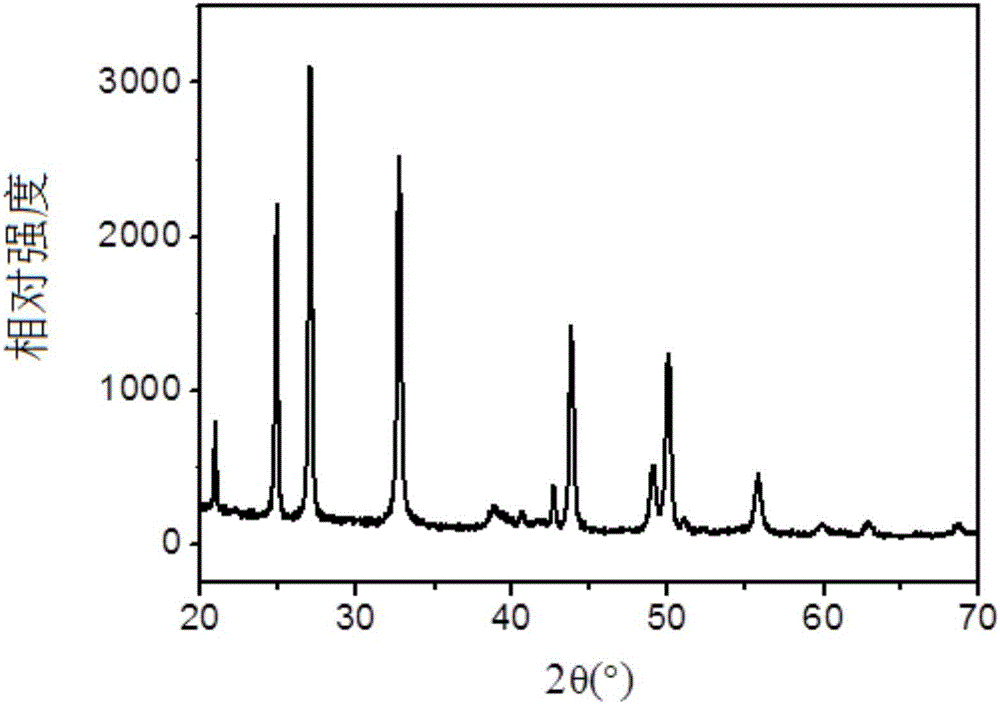

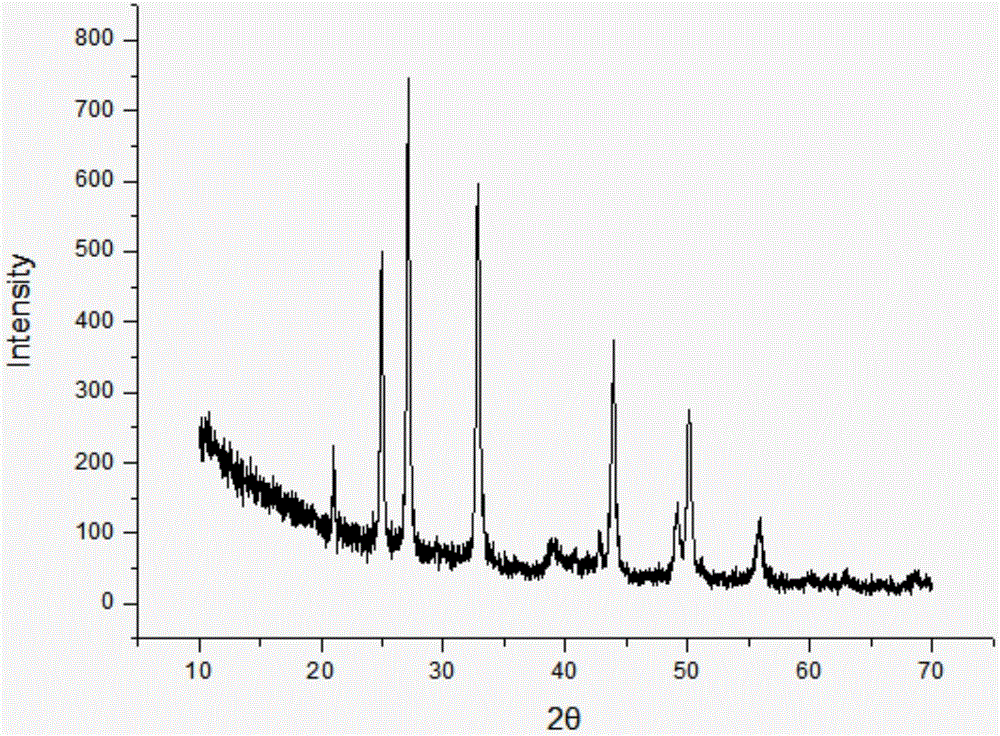

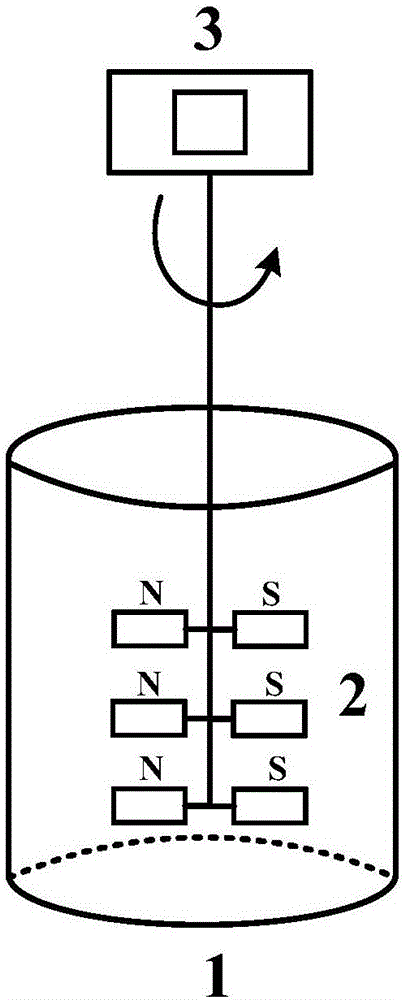

Method and device for preparing vaterite by using magnetic field

ActiveCN106495196ASimple processEasy to operateCalcium/strontium/barium carbonatesFiltrationMagnetic line

The invention discloses a method and a device for preparing vaterite by using a magnetic field. The method comprises: enabling a reaction solution of carbonate and calcium salt to pass through a strong magnetic field by means of vertically cutting magnetic lines of force, and then performing suction filtration, cleaning and drying treatment to obtain vaterite-typed calcium carbonate powder. The prepared vaterite has a particle diameter ranging from 1 mu m to 5 mu m, and a purity of 100%. The method for preparing the vaterite is a pure physical promotion method; compared with conventional methods, in which a crystal-formed control agent requires to be added and a pH value is adjusted and controlled, the method has a simple process, is easy to operate, has a low cost without adding any additive, a preparing process is green and environment-friendly, product purity is high, and large-scale industrial production can be achieved easily.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

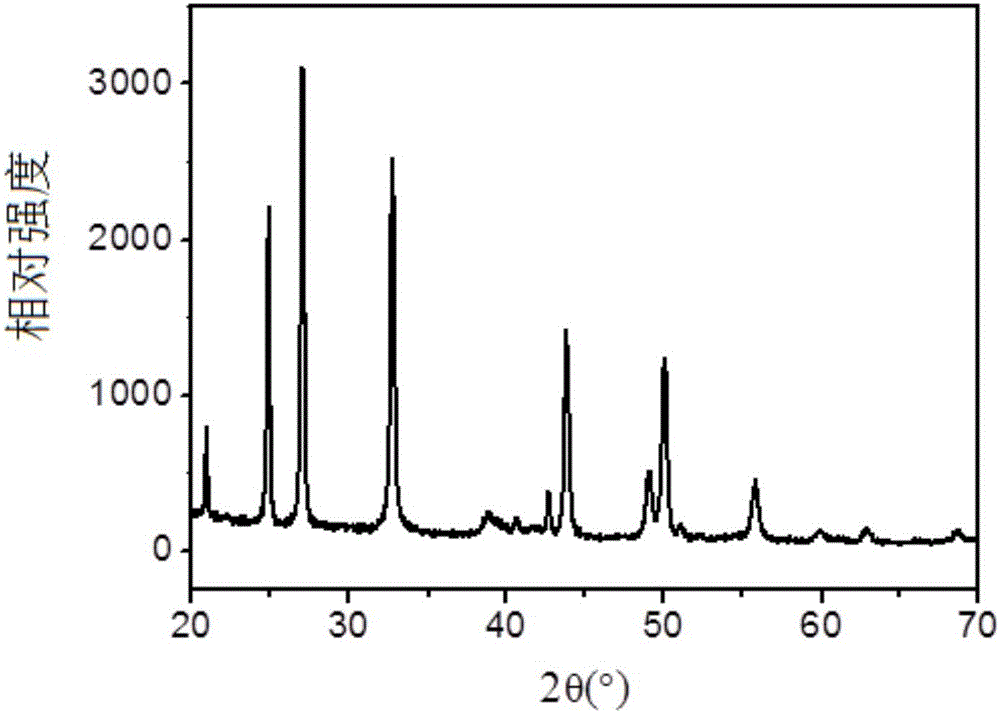

Method and device for preparing vaterite-type calcium carbonate powder

InactiveCN103553108AShort cycleOvercome the disadvantage of low concentrationCalcium/strontium/barium carbonatesCarbonizationChloride

The invention discloses a method and a device for preparing vaterite-type calcium carbonate powder. The method comprises the following steps: introducing a CO2 gas to a calcium chloride aqueous solution of which the pH value is adjusted by ammonia water, so as to prepare pure vaterite-type calcium carbonate powder; and preparing the pure vaterite-type calcium carbonate powder from the reacted solution through a multi-stage carbonization device. By adopting the method, the prepared calcium carbonate powder is controlled into a pure vaterite type through the concentration of calcium chloride, and the solution system after each stage of reaction is fully utilized through the multi-stage carbonization device. Thus, the device disclosed by the invention has the characteristics of being controllable in calcium carbonate powder crystal type, short in reflection period, simple in reaction system, energy-saving and environment-friendly and the like.

Owner:HUBEI UNIV OF TECH

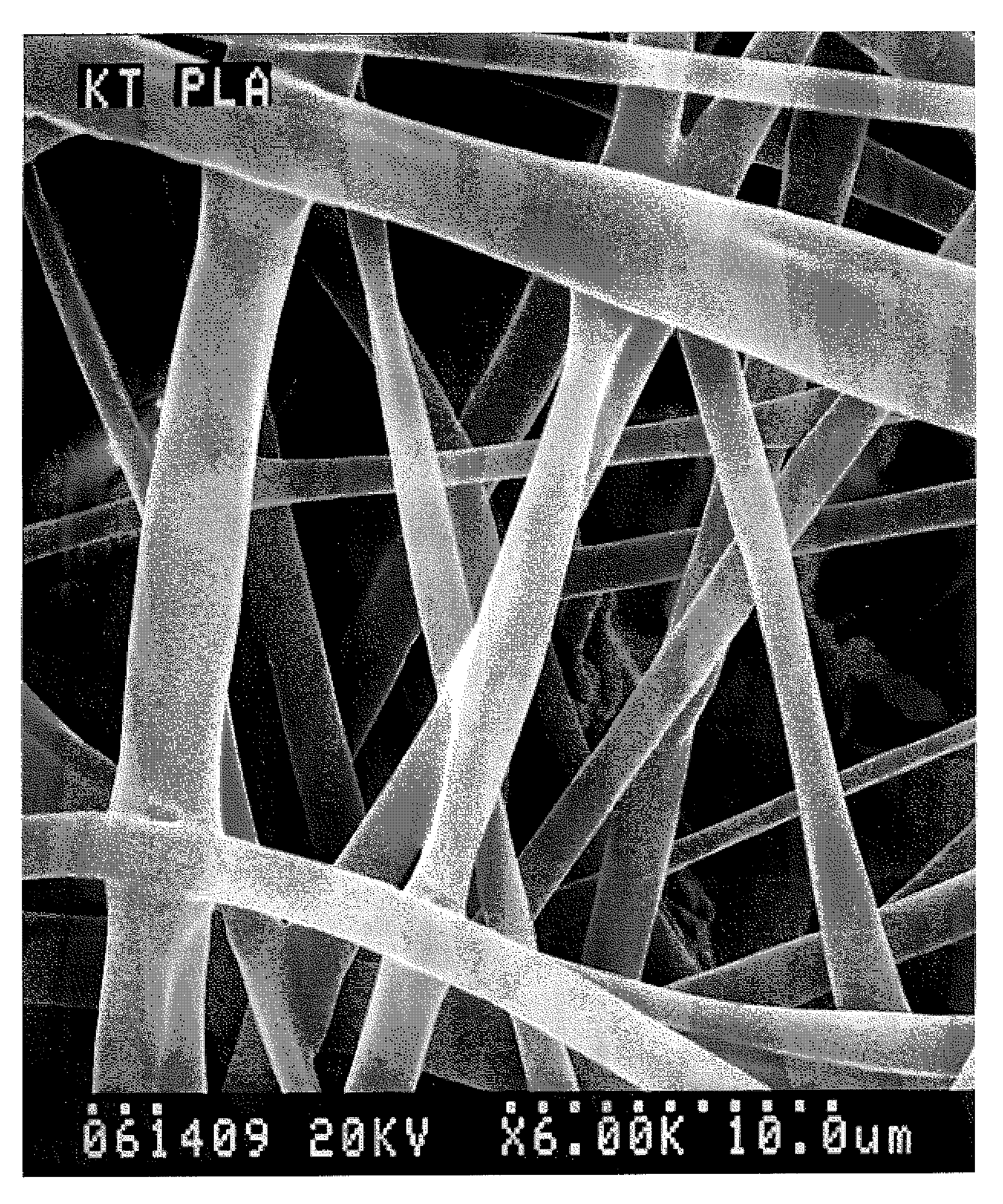

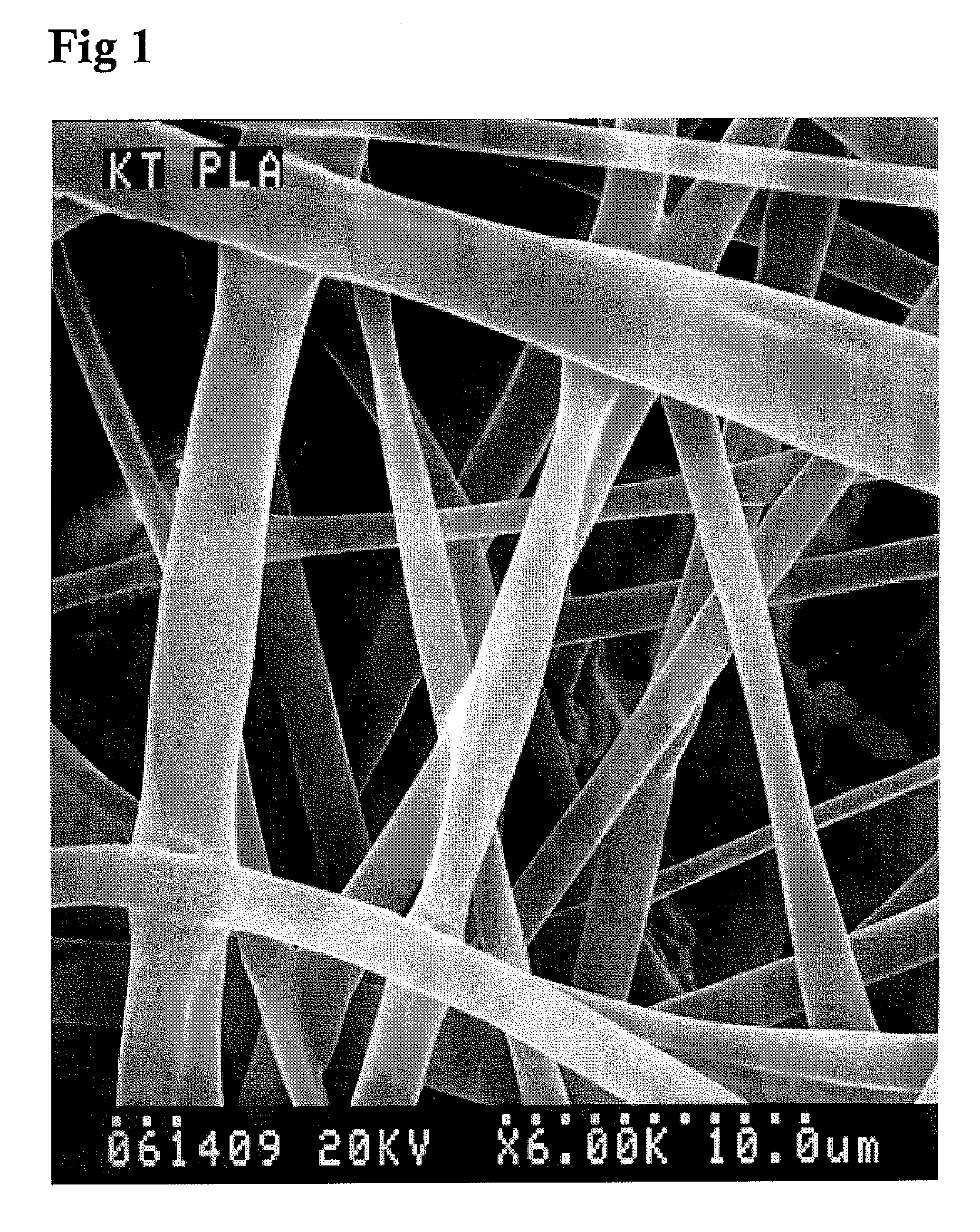

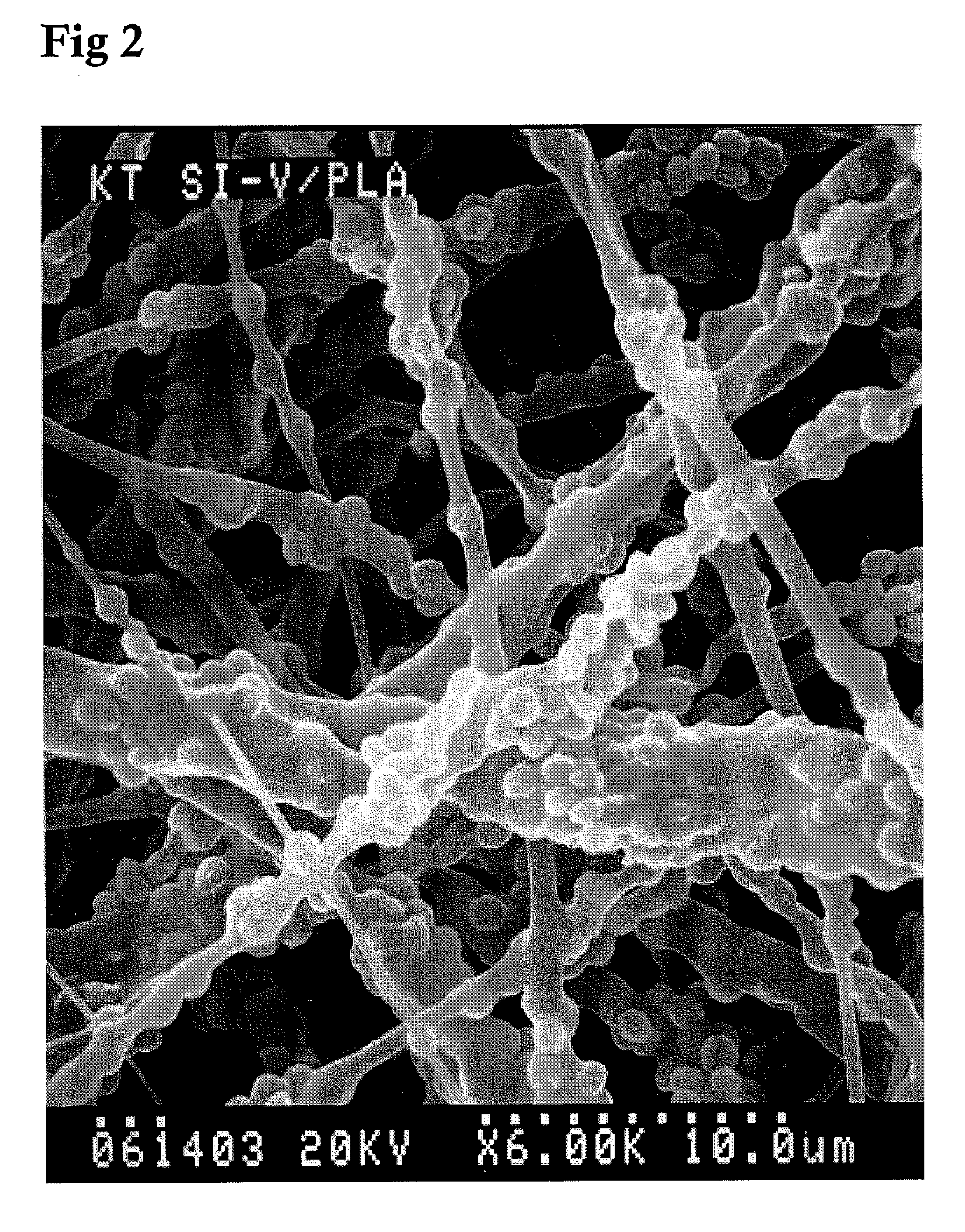

Guided bone regeneration membrane and manufacturing method thereof

InactiveUS20120315319A1Efficient inductionImprove performanceBiocideElectric discharge heatingFiberApatite

A guided bone regeneration material is disclosed. The guided bone regeneration material includes biodegradable fibers produced by an electro spinning method. The biodegradable fibers produced by the method include a silicon-releasing calcium carbonate and a biodegradable polymer. The silicon-releasing calcium carbonate is a composite of siloxane and calcium carbonate of vaterite phase. The biodegradable fibers may be coated with apatite. When the guided bone regeneration material is immersed in a neutral aqueous solution, silicon species ions are eluted from the calcium carbonate. The guided bone regeneration material excels in bone reconstruction ability.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +3

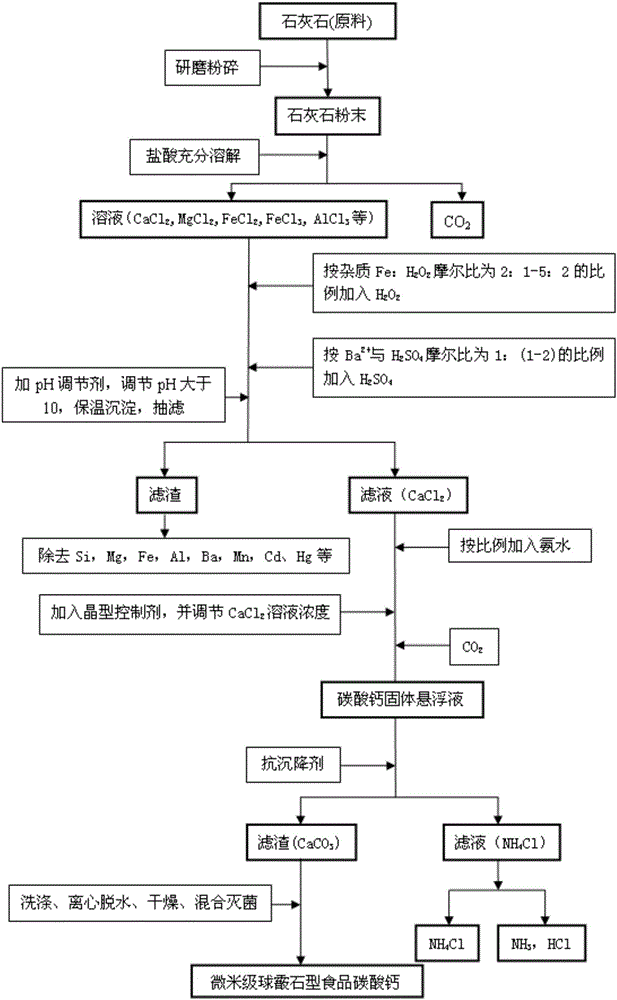

Preparation method and application for micron vaterite type food-grade calcium carbonate

InactiveCN105858696ALower requirementFriendly productionCalcium/strontium/barium carbonatesFood ingredientsDispersityPrill

The invention discloses a preparation method and application for micron vaterite type food-grade calcium carbonate. By adopting a gas-liquid two-phase carbonization process and an in-situ surface modification process to prepare vaterite type food-grade calcium carbonate, the preparation method concretely comprises the following steps: with limestone as a raw material, grinding the raw material into powder, carrying out dissolving by utilizing acid, then adding H2O2, H2SO4, Ca(OH)2 and the like, and removing impurities like Fe, Ba, Mg, Al, Cd and Hg so as to obtain a pure calcium solution; and adding ammonia water, a controlling agent with a food-grade crystal form and an anti-settling agent into a CaCl2 solution, introducing CO2, and carrying out gas-liquid two-phase carbonization reaction so as to prepare the micron vaterite type food-grade calcium carbonate with good dispersion and suspension performances, wherein the micron vaterite type food-grade calcium carbonate is micron spherical calcium carbonate and has a stable crystal form. The calcium carbonate product prepared by using the method provided by the invention is spherical particles, is fine and uniform, has good dispersity and suspension property and strong settlement resistance, can be directly used as a calcium strengthening agent in liquid beverages like milk, soymilk and fruit juice.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

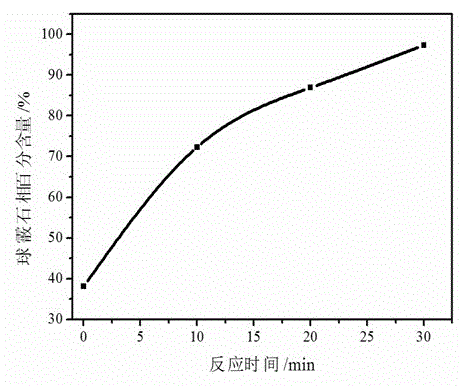

Calcium-based carbon dioxide adsorbent and preparation method thereof

ActiveCN103623768AIncrease reaction rateImprove conversion rateOther chemical processesDispersed particle separationReaction rateSorbent

The invention discloses a calcium-based carbon dioxide adsorbent and a preparation method thereof. The preparation method comprises the steps of taking sodium carbonate and calcium chloride at equal molar weight as raw materials, tween 80 80 and polyethylene glycol as additives, performing reaction and precipitation in an aqueous solution to form an adsorbent precursor, and roasting the adsorbent precursor to form the calcium-based carbon dioxide adsorbent. The calcium-based carbon dioxide adsorbent obtained by the method has a higher vaterite content, and a high reaction rate with carbon dioxide; 80% of total conversion rate can be reached in 10 minutes basically; the energy consumption is greatly reduced; compared with natural limestone and other synthesized calcium-based adsorbents, the calcium-based carbon dioxide adsorbent has a higher conversion rate and a higher recycling rate, can separate a carbon dioxide component from tail gas of a thermal power plant more effectively, and lowers the total operation cost; and the method has the characteristics of simplicity in operation and low cost.

Owner:王岩

Method for preparing single-crystal-form ball aragonite nano calcium carbonate through microemulsion system

The invention discloses a method for preparing single-crystal-form ball aragonite nano calcium carbonate through a microemulsion system, and belongs to the technical field of nanometer materials. According to the method, a non-aqueous xylene / emulsifier / co-emulsifier microemulsion system is firstly prepared, then a calcium chloride microemulsion is prepared in a microemulsion area, then a sodium carbonate aqueous solution at certain concentration is slowly added into the calcium chloride microemulsion and reacts to finally obtain a ball aragonite nano calcium carbonate emulsion; or demulsification, precipitation, washing and drying are conducted to obtain the ball aragonite nano calcium carbonate powder. The ball aragonite nano calcium carbonate prepared according to the method provided by the invention has the characteristics such as small particle size, single crystal form, and good stability of crystal form. The reaction condition is mild, the equipment is simple and easy to operate, meanwhile, the chosen materials are low in cost and are easy to get, so that the method is easy in promotion and application.

Owner:HENAN ANALYSIS TESTING CENT

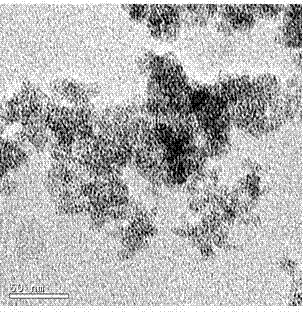

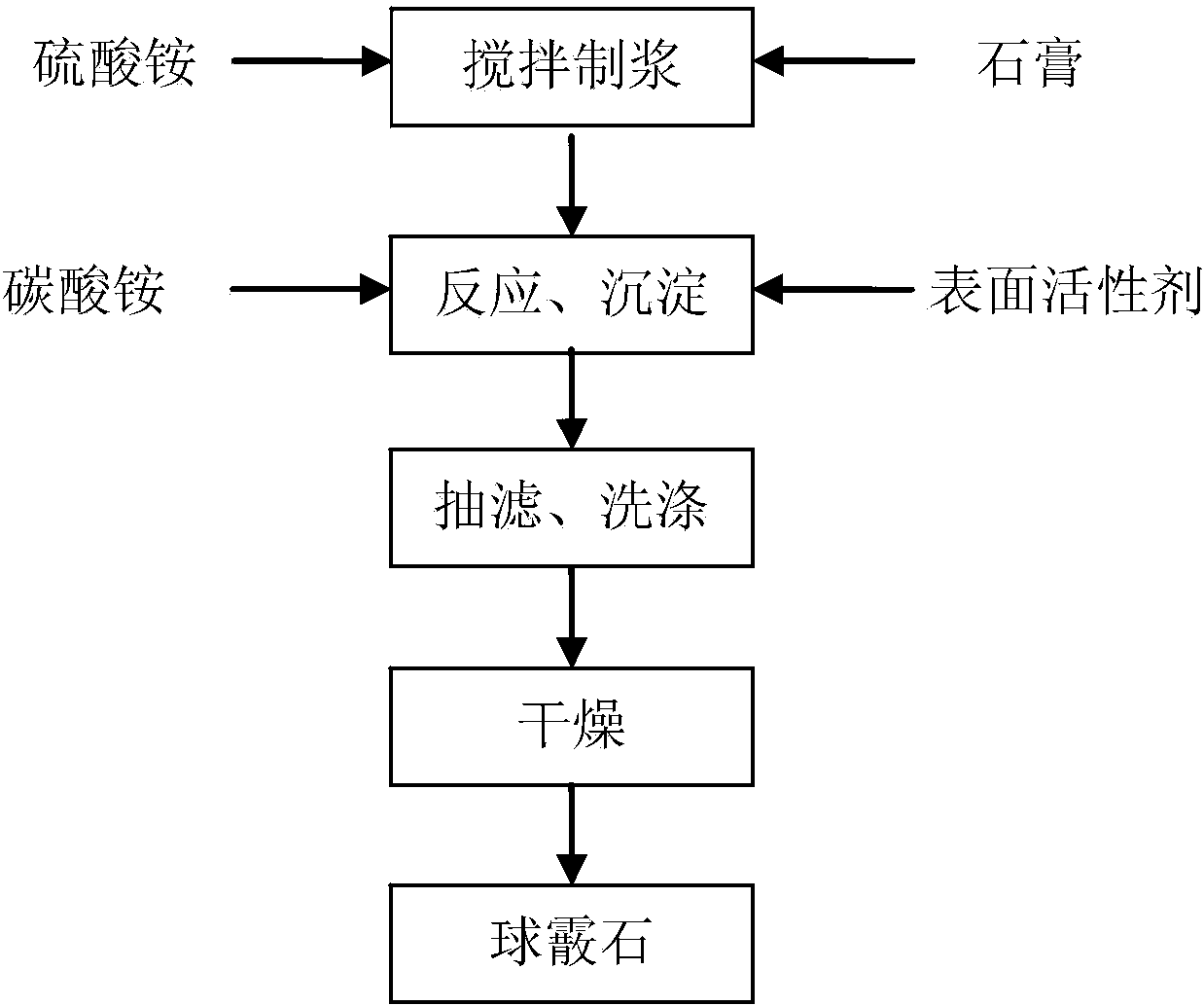

Method for preparing high-purity metastable vaterite calcium carbonate from gypsum

ActiveCN103922378ASolve the problem of low-quality utilizationEase of industrial productionCalcium/strontium/barium carbonatesHigh concentrationReaction temperature

The invention relates to a method for preparing high-purity metastable vaterite calcium carbonate from gypsum. The method comprises the following concrete steps: (1) adding an ammonium sulfate solution into a reactor from the constant temperature to the reaction temperature, adding the gypsum into the reactor, and stirring for pulping for 25-35 minutes; (2) adding an ammonium carbonate solution into the reactor; (3) adding an anionic surfactant accounting for 0.1%-5% by mass of the gypsum into the reactor in the step (1); (4) adjusting the rotary speed of a stirring paddle and reacting at the constant temperature to obtain a reaction product; and (5) filtering the reaction product in the step (4) in a conventional way, washing, and drying to obtain the high-purity metastable vaterite calcium carbonate. The vaterite calcium carbonate produced by adopting the method adopts the gypsum as a raw material, a technical support can be provided for solving the problem of recycling of industrial solid wastes-gypsum, and wastes are turned into wealth; the vaterite calcium carbonate is high in crystal purity and easy to prepare, the yield of the vaterite calcium carbonate is increased due to high-concentration ammonium carbonate reaction, and the production cost of the vaterite calcium carbonate can be greatly reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Method and device for utilizing dynamic magnetic stirring paddle to prepare vaterite

ActiveCN106348332ASimple processEasy to operateCalcium/strontium/barium carbonatesEngineeringHigh intensity

The invention discloses a method and a device for utilizing a dynamic magnetic stirring paddle to prepare vaterite. The method comprises the following steps of arraying permanent magnets according to the sequence to prepare the magnetic stirring paddle; placing the magnetic stirring paddle into a reactor; under the condition of stirring, feeding a carbonate solution into a calcium salt solution in the reactor at a constant speed; utilizing a high-intensity magnetic field formed by the permanent magnets on the magnetic stirring paddle for enabling the solution in the reactor to cut magnetic lines; then pumping filtering, washing and drying the reaction solution to obtain the vaterite. The method for preparing the vaterite is a pure physical promotion method, which is simple in process, easy to operate, low in cost, dispensed with any additive, and green and environment-friendly in production process compared with traditional methods requiring adding crystal form control agents and regulating pH. A dynamic rotation magnetic stirring method is adopted, so that the action of the magnetic field is strong, the product purity is high, 100 percent of vaterite type calcium carbonate can be generated, and the method and the device can be largely applied in preparing the vaterite type calcium carbonate.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

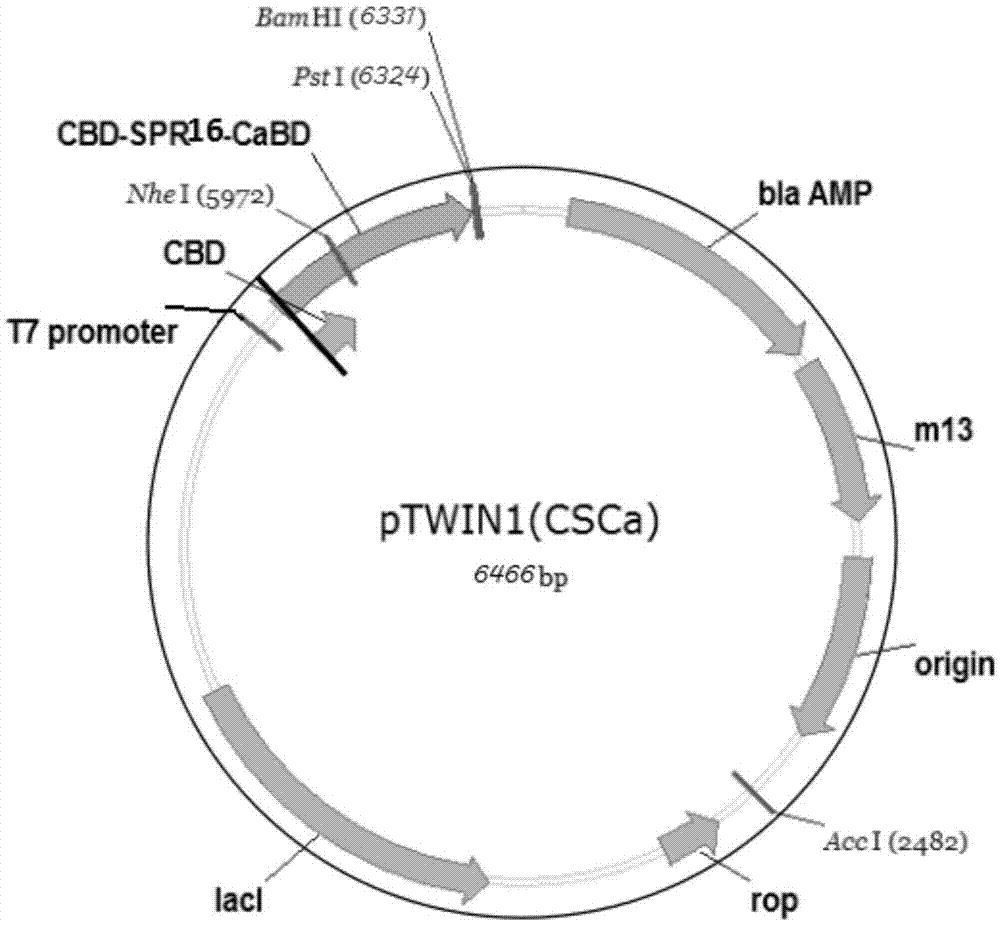

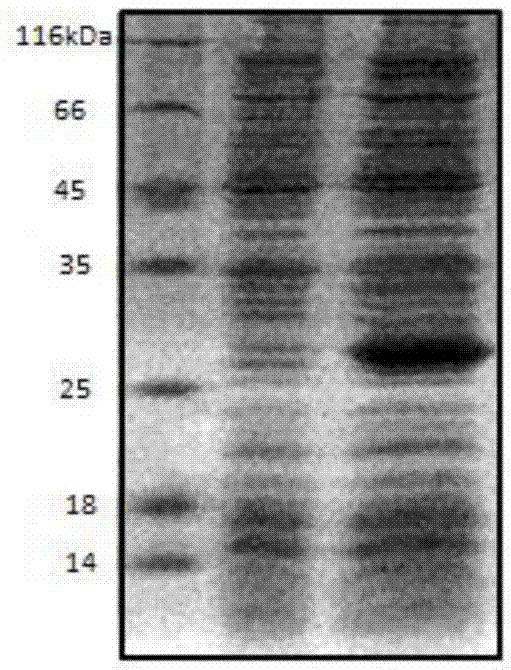

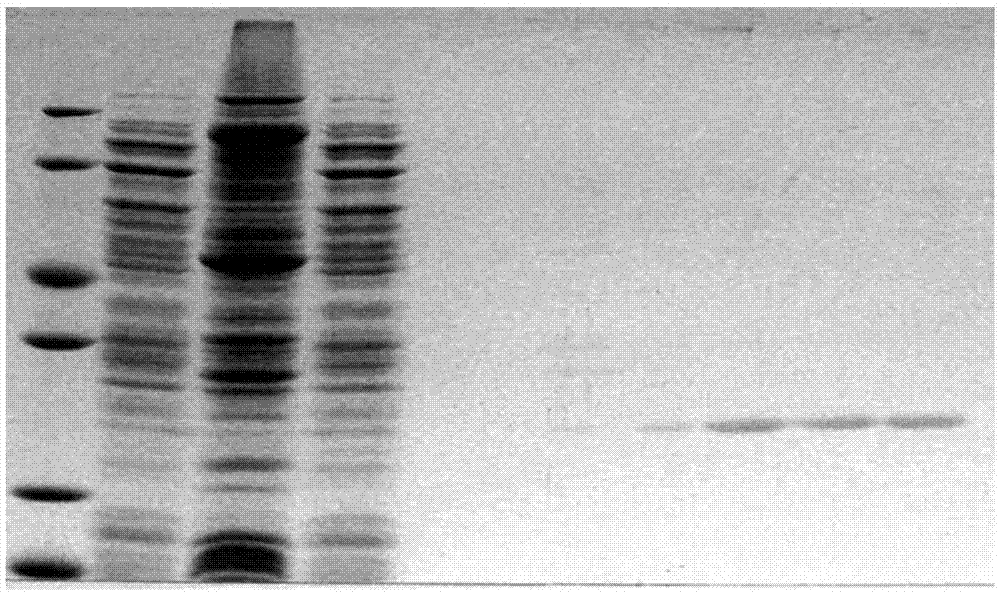

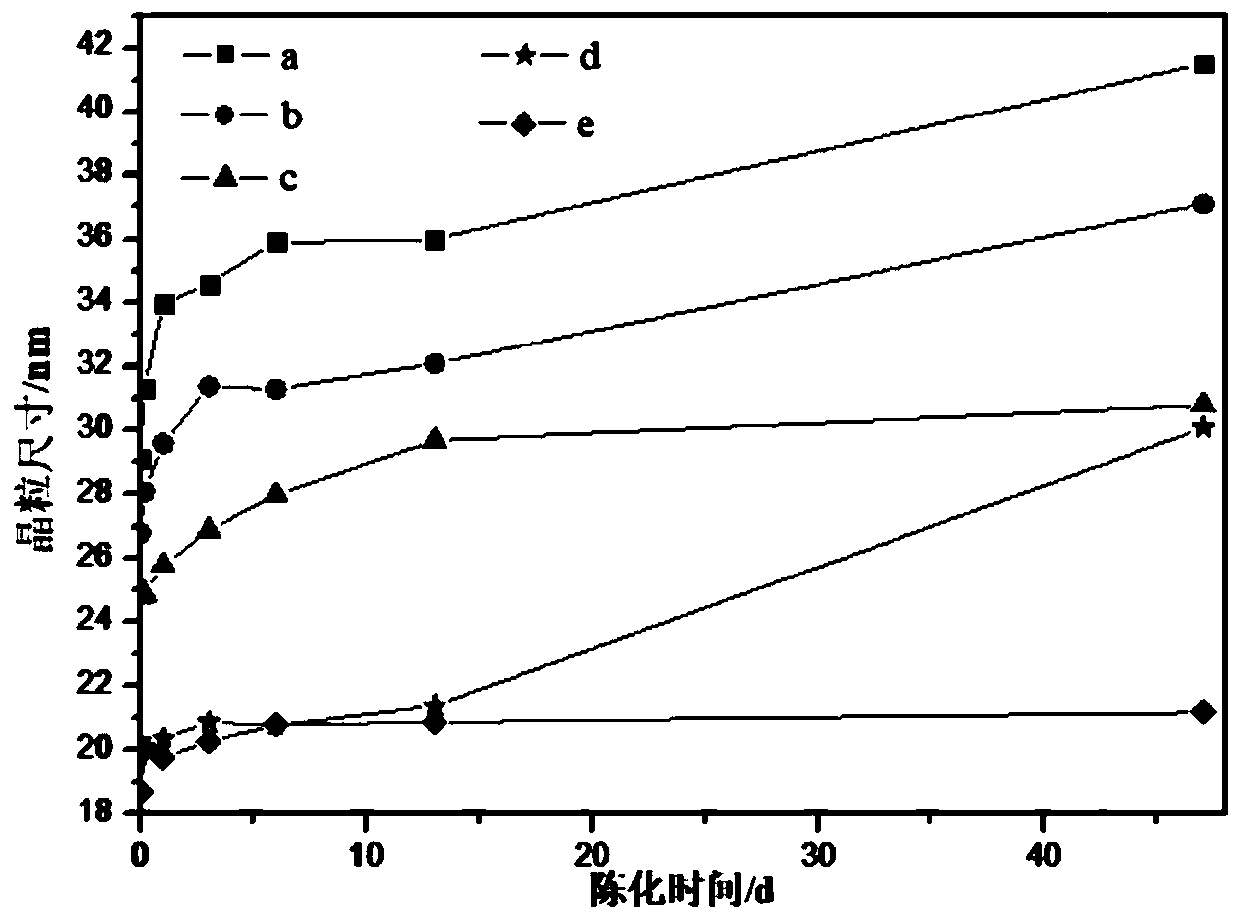

Shell nacre-like recombinant protein CSCa and method for regulating and preparing calcium carbonate by using same

ActiveCN105440140AEasy to prepareEasy to operateCalcium/strontium/barium carbonatesAntibody mimetics/scaffoldsRepetitive SequencesMaterials preparation

The invention specifically relates to a shell nacre-like recombinant protein CSCa and a method for regulating and preparing calcium carbonate by using the same, belonging to the field of material preparation. The recombinant protein CSCa is composed of a chitin binding domain, a silk protein repetitive sequence and a calcium ion binding domain. The method for regulating and preparing calcium carbonate by using the same comprises the following steps: uniformly mixing chitin with a recombinant protein CSCa solution; adding a NaHCO3 solution when chitin and recombinant protein CSCa are fully combined together and carrying out uniform mixing under stirring; then adjusting a pH value to 8.5 to 9.5 and adding a CaCl2.2H2O solution; and carrying out a mineralization reaction under the condition of stirring so as to obtain mineralized calcium carbonate. Vaterite-phase calcium carbonate can be prepared by using the method provided by the invention and can be stably maintained for a period of time under the action of the recombinant protein CSCa, which is an unusual phenomenon in the process of mineralization and is of great promotion significance to deeper understanding of the mechanism of mineralization.

Owner:WUHAN UNIV OF TECH

Method for preparing micron-grade acicular vaterite calcium carbonate

InactiveCN105883877AGood dispersionSimple processCalcium/strontium/barium carbonatesMicrometerDrug carrier

The invention relates to a method for preparing micron-grade acicular vaterite calcium carbonate. According to the invention, wherein a chemical precipitation method is used to obtain the acicular vaterite calcium carbonate with size distribution of 15-20 micrometers at different aging times by using regulation and control of organic additives. The obtained acicular acicular vaterite calcium carbonate has relative large specific surface area. The method has characteristics of simple process, safe operation, low cost and good repeatability, and can provide high potential application value as the drug carrier in the field of medicine after the suitable scale production.

Owner:TIANJIN POLYTECHNIC UNIV

Polymer modified nano calcium carbonate novel product series

ActiveCN109867986AGood value for moneyReduce sizeCalcium/strontium/barium carbonatesPigment treatment with macromolecular organic compoundsPolymer modifiedSingle crystal

The invention relates to a polymer modified nano calcium carbonate novel product series, and specifically provides polymer in-situ modified nano calcium carbonate novel products, wherein the novel products are obtained by adding a water-soluble polymer or a polymer emulsion as a template agent and a modification agent for controlling a crystallization process and reducing the size of single crystals and aggregates; and the invention provides a novel method for synthesizing the modified nano materials which are easy to produce and have low cost. A vaterite-type calcium carbonate product with asingle-crystal particle size of less than 10 nm and a calcite-type calcium carbonate product with a single-crystal particle size of less than 25 nm can be obtained, the particles are uniform, dispersity is good, the use amount of the novel products in a composite material can be remarkably increased, meanwhile, strengthening and toughing are achieved, and performance of the composite material is maintained and improved. The modified vaterite-type calcium carbonate and calcite-type calcium carbonate can simultaneously improve or maintain toughness and strength of the material in the polypropylene composite material under the condition of high addition amount, and a huge application development potential is displayed.

Owner:XIAMEN UNIV +2

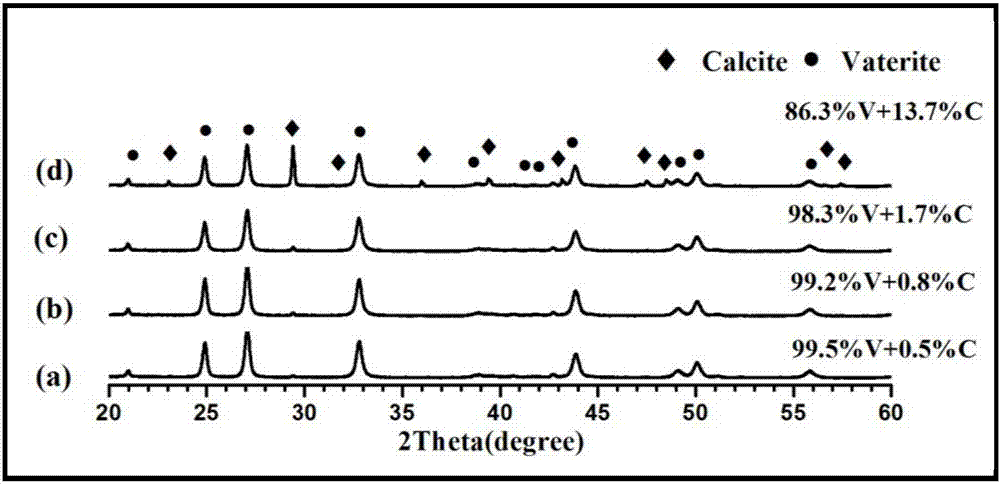

Content-controllable mixed crystal form nano calcium carbonate synthesis method

InactiveCN104961148AControl the content of vaterite calcium carbonateUniform particle size distributionCalcium/strontium/barium carbonatesMaterial nanotechnologySynthesis methodsMixed crystal

The invention provides a content-controllable mixed crystal form nano calcium carbonate synthesis method, and relates to a method for preparing nano calcium carbonate materials. The method aims to solve the problems that in the prior art, nano materials with various mixed calcium carbonate crystal forms cannot be prepared, and the content of the alcium carbonate crystal forms in the materials cannot be controlled. The synthesis method includes the steps that 1, a calcium chloride-polyaspartic acid mixed solution is prepared; 2, a sodium carbonate solution is prepared; 3, mixed microemulsion is prepared; 4, sodium carbonate emulsion is prepared; 5, the mixed microemulsion is mixed with the sodium carbonate emulsion, centrifugal separation, ethyl alcohol washing and drying are sequentially conducted on the mixture, and mixed crystal form nano calcium carbonate is obtained. The synthesis method has the advantages that the content of vaterite type calcium carbonate in the calcite and vaterite mixed crystal form nano calcium carbonate is controlled by adjusting concentration of polyaspartic acid in the calcium chloride-polyaspartic acid mixed solution prepared in step 1. The synthesis method is mainly used for preparing the mixed crystal form nano calcium carbonate.

Owner:HEILONGJIANG UNIV

Method for preparing single-crystal-form ball aragonite nano calcium carbonate through microemulsion system

The invention discloses a method for preparing single-crystal-form ball aragonite nano calcium carbonate through a microemulsion system, and belongs to the technical field of nanometer materials. According to the method, a non-aqueous xylene / emulsifier / co-emulsifier microemulsion system is firstly prepared, then a calcium chloride microemulsion is prepared in a microemulsion area, then a sodium carbonate aqueous solution at certain concentration is slowly added into the calcium chloride microemulsion and reacts to finally obtain a ball aragonite nano calcium carbonate emulsion; or demulsification, precipitation, washing and drying are conducted to obtain the ball aragonite nano calcium carbonate powder. The ball aragonite nano calcium carbonate prepared according to the method provided by the invention has the characteristics such as small particle size, single crystal form, and good stability of crystal form. The reaction condition is mild, the equipment is simple and easy to operate, meanwhile, the chosen materials are low in cost and are easy to get, so that the method is easy in promotion and application.

Owner:HENAN ANALYSIS TESTING CENT

Overbased vaterite containing salt composition

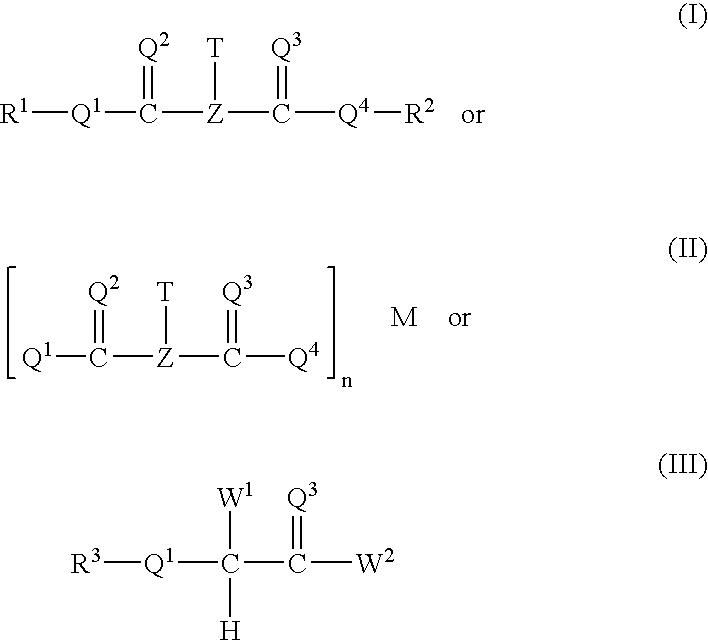

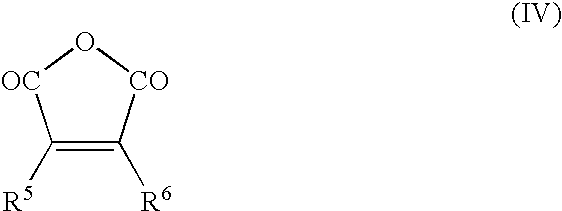

InactiveUS20060183650A1Organic chemistryOrganic compound preparationDispersed mediaNuclear chemistry

This invention relates to an overbased vaterite containing composition, comprising: a disperse medium, and a calcium salt and calcium carbonate dispersed in the disperse medium, at least about 50% by weight of the calcium carbonate being in the form of vaterite, the composition being substantially haze free.

Owner:THE LUBRIZOL CORP

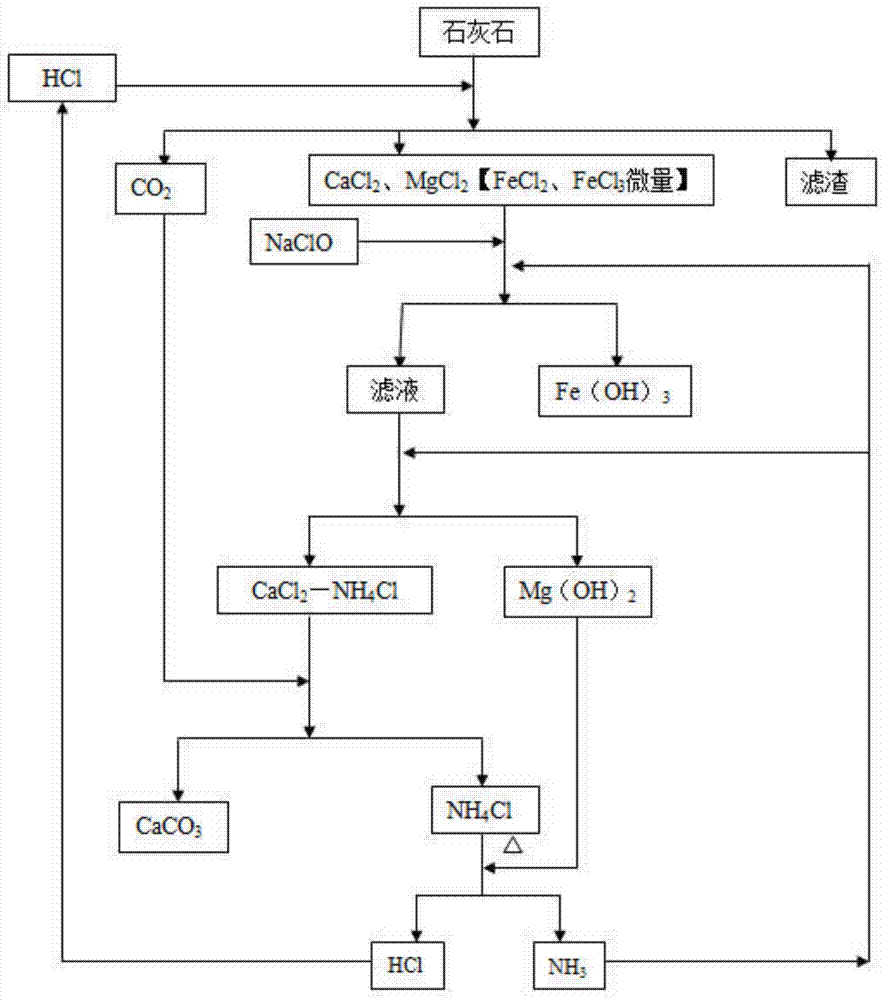

Method for preparing homogenous nano vaterite type calcium carbonate through limestone acidolysis

ActiveCN104118895AInhibit transformationCrystal stableCalcium/strontium/barium carbonatesPrillResource utilization

The invention discloses a method for preparing homogenous nano vaterite type calcium carbonate through limestone acidolysis, which comprises the following steps: crushing limestone, and pulverizing into powder; dissolving with hydrochloric acid, thus obtaining a solution containing main components CaCl2, MgCl2, FeCl2, FeCl3 and the like; adding NaClO to oxidize Fe<2+> into Fe<3+>; adding ammonia water to gradually regulate the pH value, and ensuring that the Fe<3+> and Mg<2+> in the solution are removed in the form of Fe(OH)3 and Mg(OH)2, thus obtaining a CaCl2-NH4Cl solution; and finally introducing CO2, reacting to form a CaCO3 precipitate, filtering, washing, and drying to obtain the high-purity homogenous nano vaterite type calcium carbonate. According to the invention, the homogenous calcium carbonate metastable state crystal form vaterite type can be prepared without adding any additive and crystal form control agent; and the prepared nano vaterite is self-assembled into a spherical particle, thus effectively inhibiting conversion of the vaterite to calcite and ensuring the stable crystal form. The acidolysis process disclosed by the invention is more friendly to environment, low in energy consumption, high in resource utilization rate and simple in method.

Owner:BEIJING UNIV OF CHEM TECH

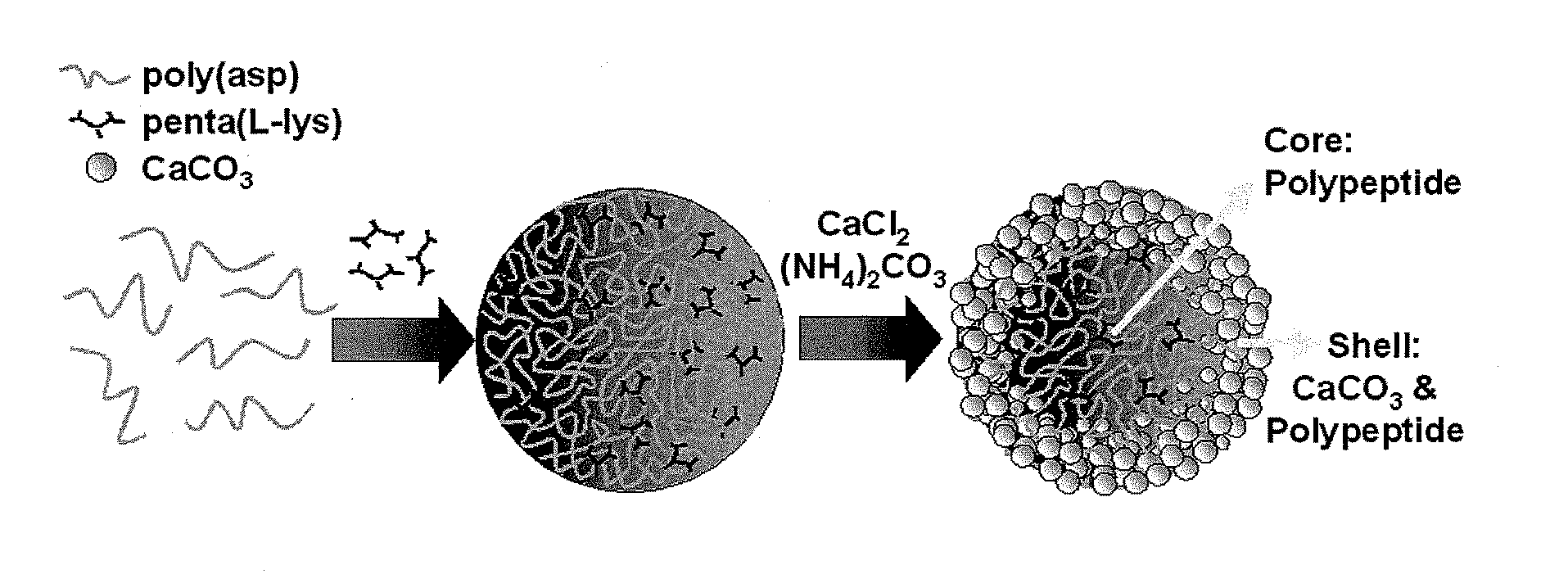

Calcium carbonate microstructures useful in encapsulation applications and a process for the preparation thereof

InactiveUS20110223111A1Useful applicationUltrasonic/sonic/infrasonic diagnosticsPowder deliveryFluorescenceAntibacterial activity

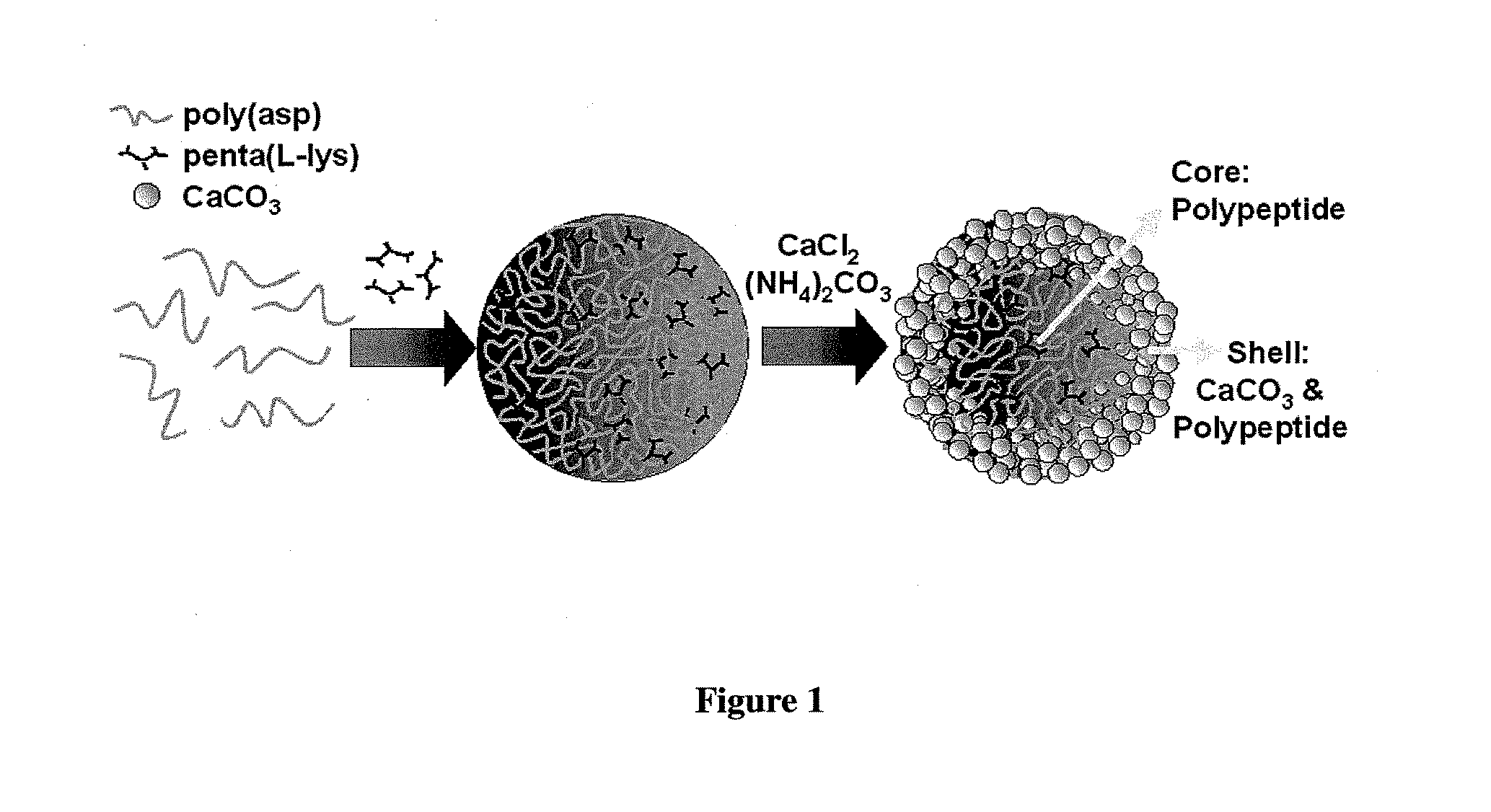

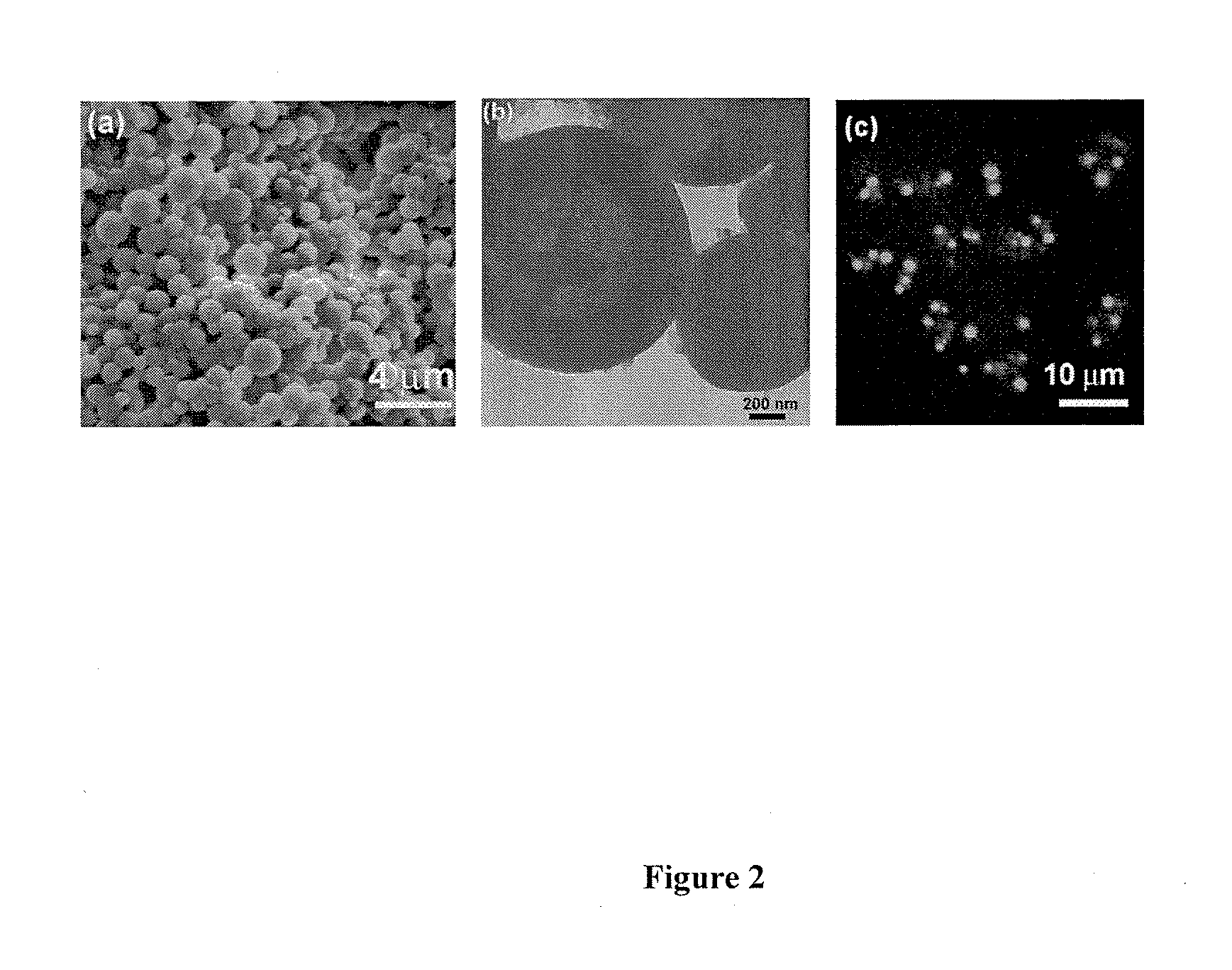

A facile method to synthesize stable calcium carbonate microstructures is demonstrated which allows in situ encapsulation of sensitive molecules like drugs. The methodology involves a macromolecular assembly of anionic polypeptide with cationic peptide oligomer to concurrently template and hold to stabilize the mineralized structure. The heterogeneously distributed mixture of anionic and cationic residues in the macromolecular assembly, similar to that is found in natural systems assists in recognizing and coassembling Ca2+ and CO32− ionic clusters, especially for formation of a disordered precursor phase such as amorphous calcium carbonate (ACC) and further crystallization to form a metastable vaterite phase. The assembly also facilitates encapsulation of a guest molecule such as tetracycline at ambient conditions without affecting the mineralization process. The tetracycline-loaded microstructures show excellent antibacterial activities against many Gram-positive and Gram-negative bacterial strains and hence together with the fluorescence property of tetracycline and appropriate drug release profile, they can be used as multifunctional materials for therapeutic and imaging applications.

Owner:COUNCIL OF SCI & IND RES

Preparation method of high-purity vaterite type calcium carbonate microspheres

PendingCN111777089AReduce dosageRaw materials are easy to getCalcium/strontium/barium carbonatesMicrosphereSulfate

The invention relates to a method for preparing high-purity vaterite type calcium carbonate microspheres from a calcium sulfate raw material. The method comprises the following steps of: 1) grinding the calcium sulfate raw material to obtain a powder raw material; 2) proportioning the powder raw material obtained in the step 1) and a leaching aid, putting the mixture into a reaction container witha stirring function for reaction, and carrying out solid-liquid separation on a reaction product after the reaction is finished so as to obtain filtrate rich in calcium ions and a solid product; and3) burdening the filtrate obtained in the step 2) and ammonia water, introducing CO2 gas, carrying out reaction in a reaction container with a stirring function, controlling process conditions to obtain the high-purity vaterite type calcium carbonate microspheres, and further recycling the filtrate for leaching the calcium sulfate raw material. The calcium carbonate microsphere material is non-toxic, safe and fine in particles, has the characteristics of high whiteness, good fluidity and the like, and can be applied to the industries of rubber, plastics, chemical engineering and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

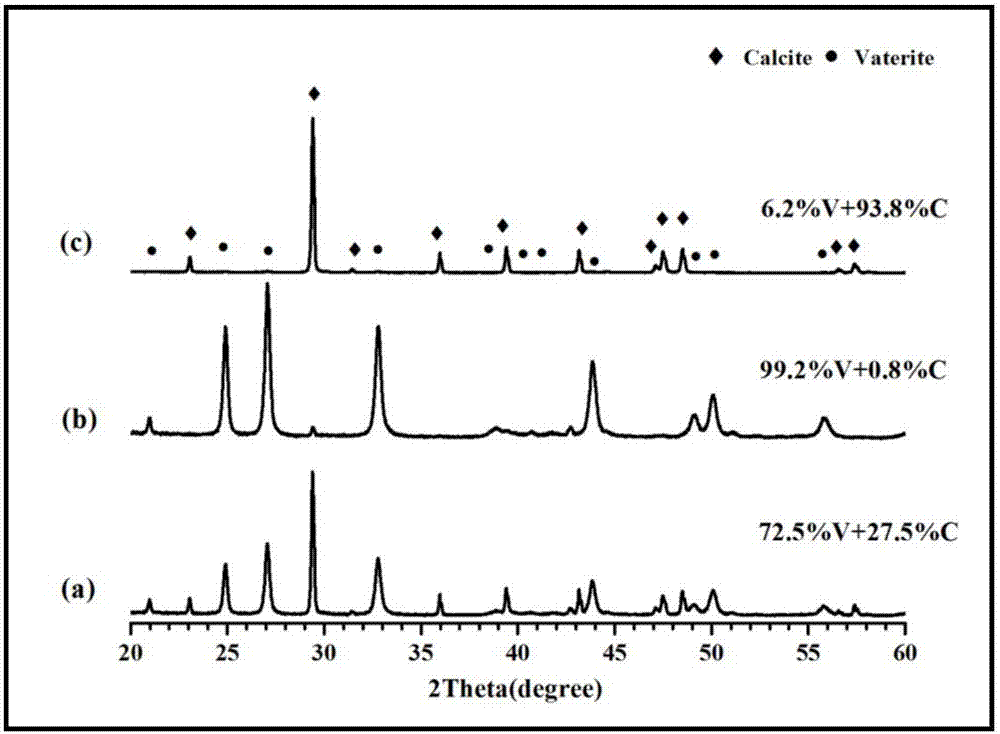

Indirect process of preparing light calcium carbonate based on medium strengthening

InactiveCN103539187AWide variety of sourcesLow costCalcium/strontium/barium carbonatesAtherion elymusReaction temperature

The invention relates to an indirect process of preparing light calcium carbonate based on medium strengthening. The indirect process comprises the following steps of: adding calcium-rich ion liquor containing inorganic soluble calcium salt into insoluble organic amine as well as a phase regulator, stirring to uniformly mix the liquor until pH of the mixed liquor is kept stable, wherein pH of the mixed liquor is over 9.5; ventilating a CO2 gas or purified industrial smoke gas into the mixed liquor to react with the mixed liquor, controlling a reaction temperature at 5 DEG C-40 DEG C, and stopping the reaction when pH is lowered to 7-8; filtering, drying and grinding the prepared calcium carbonate precipitates to obtain calcium carbonate of different crystalline forms. According to the indirect process disclosed by the invention, the liquor rich in calcium ions and carbon dioxide react under a higher pH environment and an oil-water mixed state which are respectively provided and created by insoluble organic amine and the phase regulator; temperature is controlled, so that preparation of calcite type as well as vaterite type fine light calcium carbonate is realized.

Owner:SHANDONG UNIV

Preparation method for vaterite calcium carbonate crystals with layered structure

InactiveCN103787398AHigh yieldLarge specific surface areaCalcium/strontium/barium carbonatesCooking & bakingPapermaking

The invention relates to a preparation method for inorganic calcium carbonate minerals, and in particular relates to a preparation method for vaterite calcium carbonate crystals with a layered structure. The method comprises the following steps: (1) adding a sodium sulfonate polymer into de-ionized water, and stirring and dissolving the sodium sulfonate polymer; (2) adding water-soluble calcium salt into the sodium sulfonate polymer solution, adding urea, and performing stirring and dissolving to obtain a mixed solution; (3) transferring the mixed solution to a sealed container, and placing the sealed container in a thermostatic baking oven for thermostatic treatment; (4) performing solid-liquid separation and washing on the mixed solution subjected to the thermostatic treatment so as to obtain the vaterite calcium carbonate crystals with the layered structure. The prepared vaterite calcium carbonate crystals with the layered structure has the purity of 100%, and is high in yield and monodispersion; compared with vaterite calcium carbonate crystals with a spherical structure, the vaterite calcium carbonate crystals with the layered structure are large in specific surface area, high in activity and applicable to the industries of rubber, plastics, papermaking, printing ink, building materials, coatings and the like; the preparation process is simple, reaction conditions are easy to control, and the vaterite calcium carbonate crystals with the layered structure are easy to industrially produce.

Owner:BEIJING UNIV OF TECH

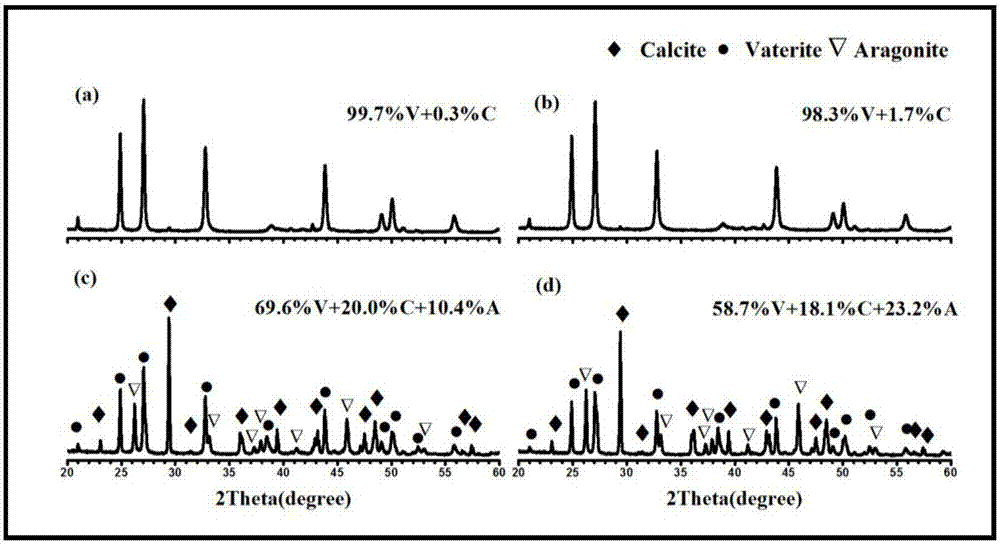

Method for preparing metastable-state vaterite calcium carbonate based on calciumethylene glycolate calcium method

ActiveCN107416882ALow costSimple process conditionsCalcium/strontium/barium carbonatesAlcoholDecomposition

The invention provides a method for preparing metastable-state vaterite calcium carbonate based on an ethylene glycol calcium calcium glycolate method. The method comprises the following steps: step (1) preparing an ethylene glycol calcium calcium glycolate solution (with the concentration of 0.01mol / L to 1.0mol / L) and a sodium carbonate solution (with the concentration of 0.025mol / L to 2.5mol / L); step (2) mixing and stirring the calcium glycolateethylene glycol calcium solution and the sodium carbonate solution in step (1) at 0 DEG C to 100 DEG C and sufficiently reacting; standing and ageing for 0 to 42h to obtain turbid liquid; step (3) carrying out centrifuging treatment on the turbid liquid obtained by step (2) and washing with absolute ethyl alcohol and de-ionized water; finally, centrifuging and filtering sediments, and drying. According to the method provided by the invention, a relatively simple double decomposition system is adopted; the whole preparation method has the advantages of simple technological conditions, low requirements on equipment and a green and environment-friendly preparation process; the weight ratio of vaterite CaCO3 in a product can be changed through adjusting experimental parameters (the concentration of reactants, mixed reaction temperature and standing and ageing time), and the weight ratio of the vaterite CaCO3 in the calcium carbonate product reaches 99.7 percent.

Owner:HUBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com