Method of utilizing electric furnace slag to prepare spherical vaterite calcium carbonate centralized in granularity distribution

A particle size distribution and electric furnace slag technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of calcium carbonate's unstable performance and low application value, and achieve added value High, high application value, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

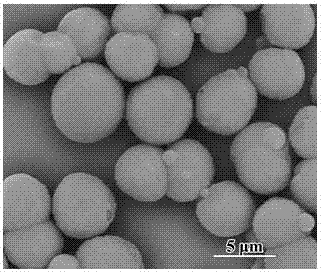

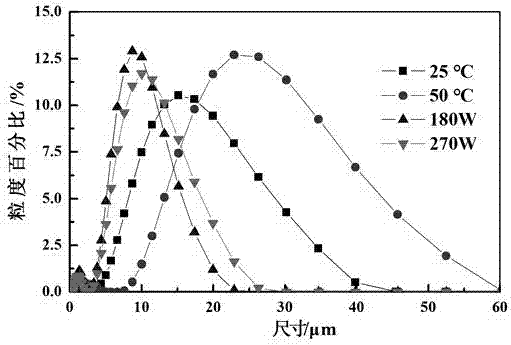

[0037] A method for preparing spherical vaterite calcium carbonate with concentrated particle size distribution by using electric furnace slag. The concrete steps of described method are:

[0038]Step 1. The pulverized electric furnace slag is mixed and reacted for 150-300 min with a solid-to-liquid ratio of 1Kg: (15-25) L and 2-4 mol / L ammonium chloride solution, and the stirring speed of the reaction is 150-300 rpm. The reaction is completed at a temperature of 50-60° C., and filtered after the reaction is completed to obtain a leaching solution containing calcium ions.

[0039] Step 2. Cool the leaching solution containing calcium ions to 15-25°C, add a certain amount of ammonia water to the leaching solution containing calcium ions, place it in a microwave device, and then pass pure carbon dioxide gas to react 100-200min, the reaction is completed under the conditions that the stirring speed is 150-350rpm, the ventilation rate is 200-350ml / min, and the microwave output po...

Embodiment 2

[0041] Step 1. Mix the pulverized electric furnace slag with a solid-to-liquid ratio of 1Kg: (20-30) L and 1.5-3.5 mol / L ammonium chloride solution for 60-180 minutes, and the reaction is carried out at a stirring speed of 200-400 rpm , the reaction temperature is completed under the condition of 45-60° C., and the reaction is filtered after completion to obtain the leaching solution containing calcium ions.

[0042] Step 2, cooling the leaching solution containing calcium ions to 10-20°C, adding a certain amount of ammonia water to the cooling leaching solution containing calcium ions, and then introducing pure carbon dioxide gas to react for 50-180 minutes, and the reaction was stirred The speed is 180-320rpm, the air flow is 180-320ml / min, and the microwave output power is 500-800 watts / liter solution. After the reaction is completed, it is filtered to obtain spherical vaterite calcium carbonate with concentrated particle size distribution.

Embodiment 3

[0044] Step 1. The pulverized electric furnace slag is mixed with 1Kg:(25-35)L of ammonium chloride solution of 1-3mol / L according to the solid-to-liquid ratio for 30-150min, and the stirring speed of the reaction is 300-500rpm, The reaction is completed under the condition of 40-55° C., and the reaction is filtered after completion to obtain calcium ion-containing leaching solution.

[0045] Step 2, cooling the leaching solution containing calcium ions to 10-20°C, adding a certain amount of ammonia water to the cooling leaching solution containing calcium ions, and then introducing pure carbon dioxide gas to react for 20-150 minutes, and the reaction was stirred The speed is 150-300rpm, the ventilation rate is 150-300ml / min, and the microwave output power is 450-750 watts / liter solution. After the reaction is completed, it is filtered to obtain spherical vaterite calcium carbonate with concentrated particle size distribution.

[0046] Compared with the prior art, the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com