Patents

Literature

12735 results about "Ammonium chloride mixture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium chloride is a chemical compound composed of ammonium and chloride ions. It is a colorless crystalline compound. It is used in soldering. It is also used as an electrolyte in the Leclanche cell, a type of primary cell. Ammonium chloride can be deprotonated by strong bases such as sodium hydroxide to produce ammonia gas.

Hemostatic compositions for arresting blood flow from an open wound or surgical site

A hemostatic composition for stopping or decreasing blood flow from an open wound or medical or surgical procedure. Compositions of the invention comprise a mixture of a cationic polymer and a cation exchange material. In one embodiment, the composition comprises a mixture: (1) a high molecular weight copolymer of diallyl dimethyl ammonium chloride (DADMAC) and acrylamide [DADMAC copolymer], and (2) the hydrogen form of a crosslinked, sulfonated polystyrene (hydrogen resin). In an exemplified embodiment, a composition of the invention comprises the mixture of DADMAC copolymer and hydrogen resin provided in a dry powdered form. The compositions of the invention may be applied directly to a wound or treatment site, or they may be incorporated into a wound dressing, such as a bandage. The seal formed at a wound or treatment site treated with the present invention is adhesive and exhibits considerable toughness.

Owner:BIOLIFE

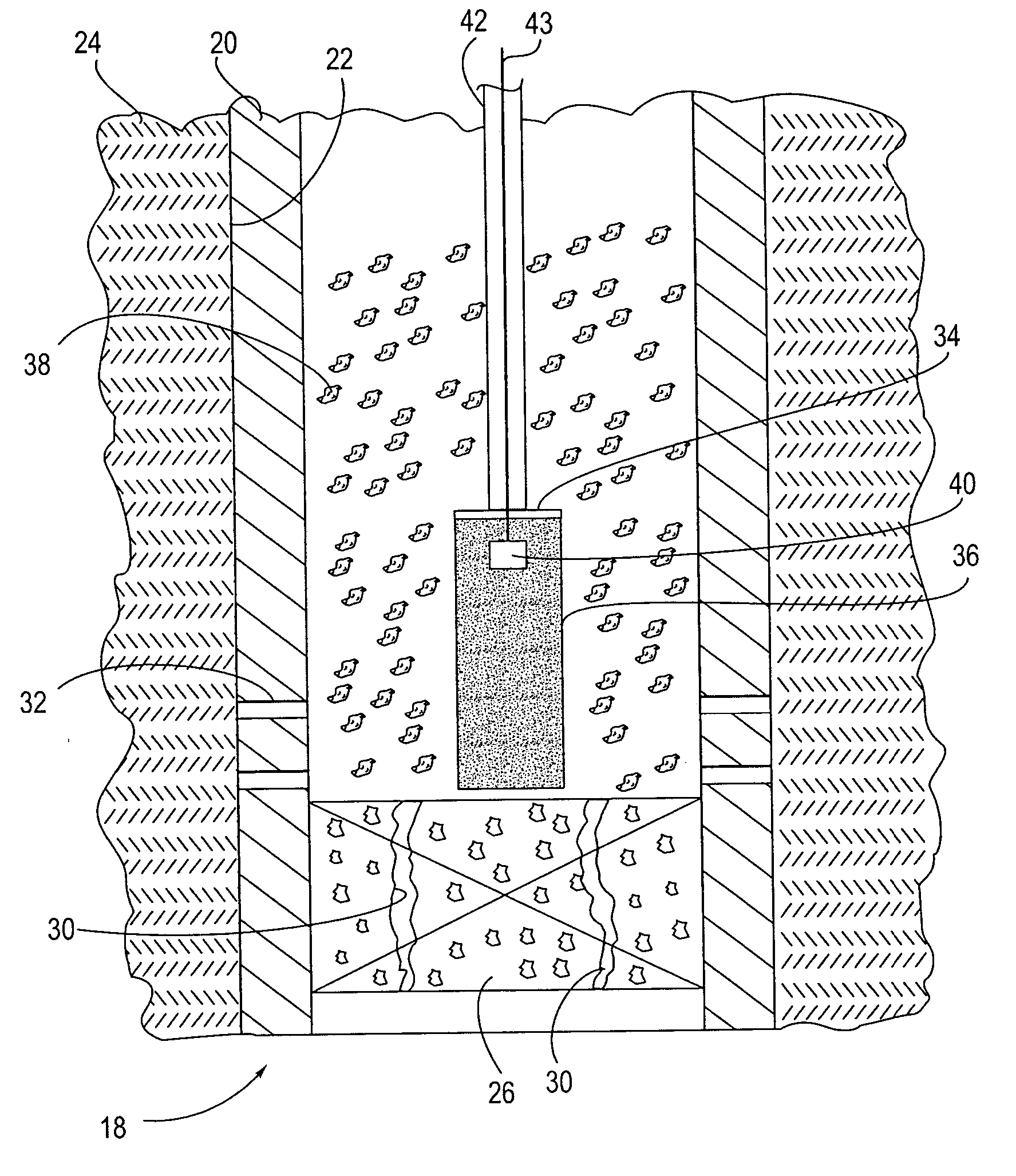

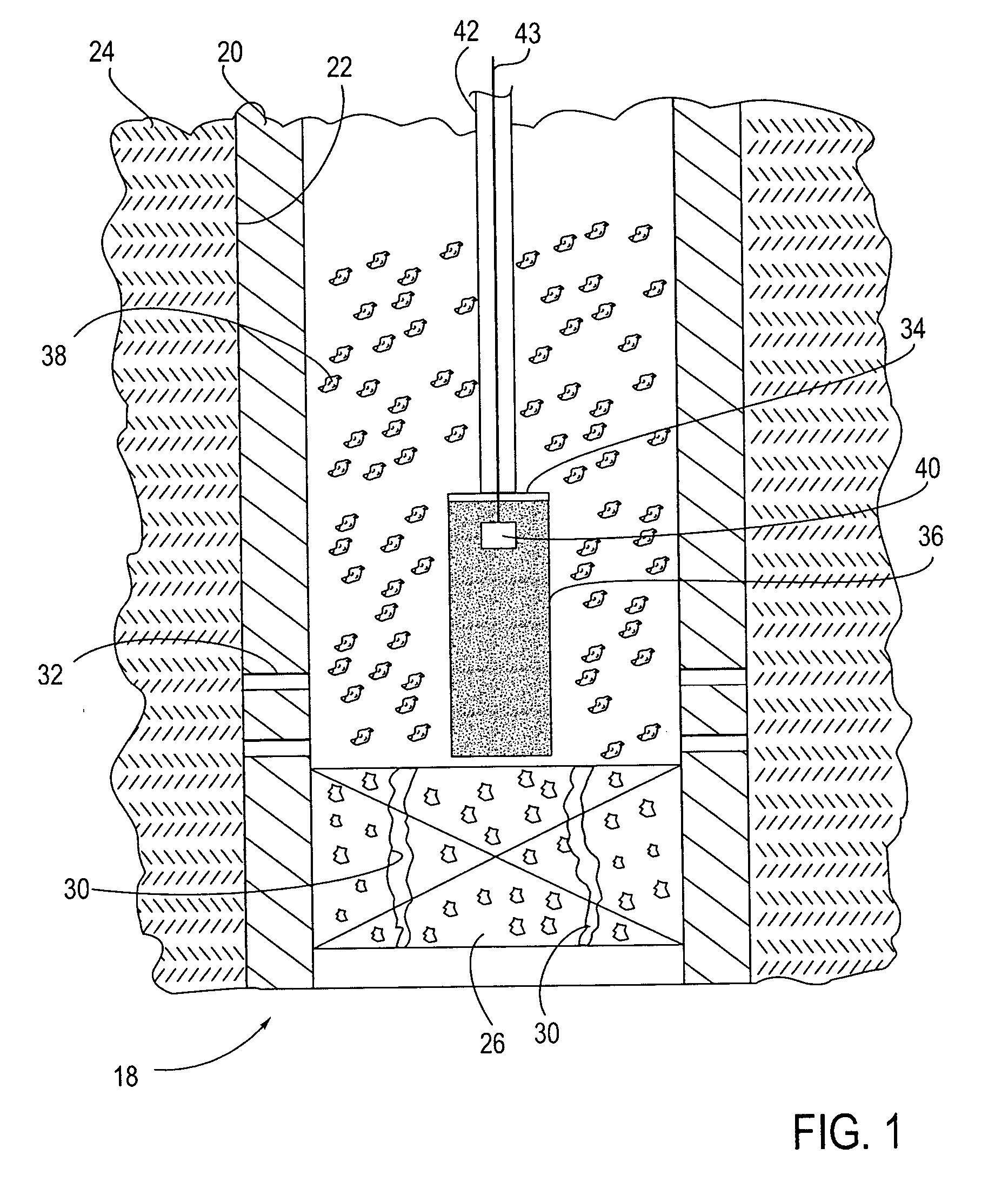

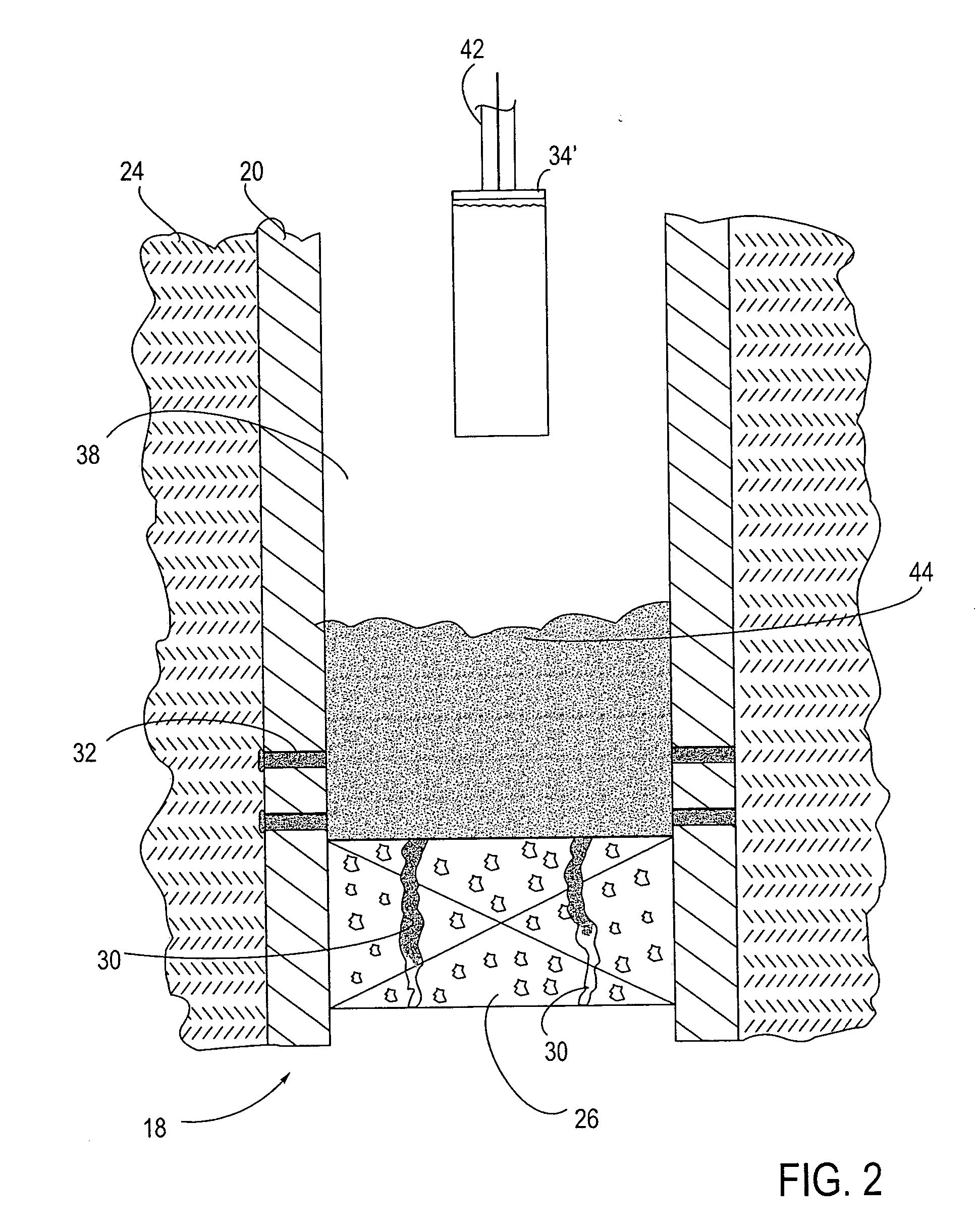

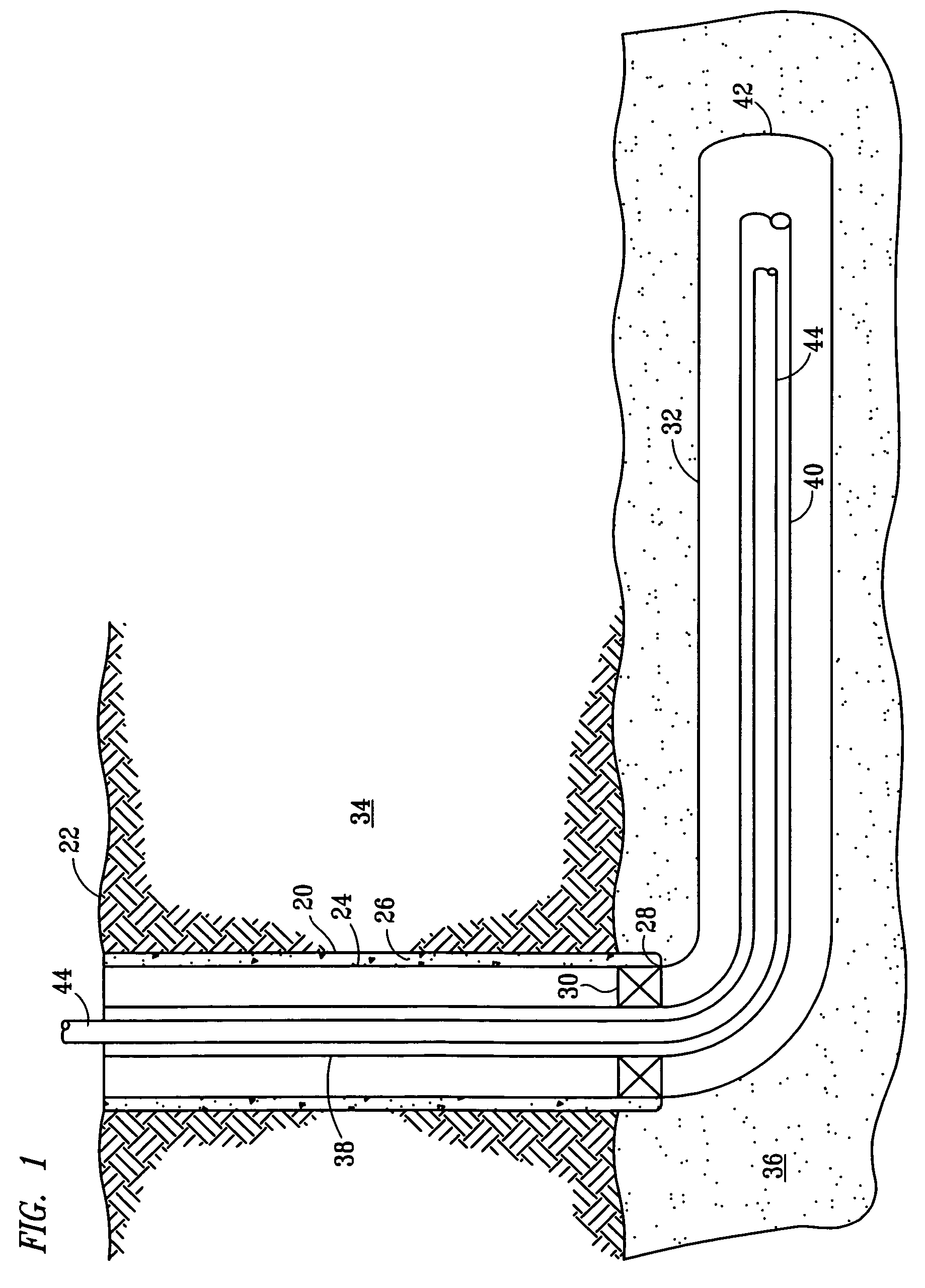

Method and apparatus for repair of wells utilizing meltable repair materials and exothermic reactants as heating agents

A method and apparatus are described for creating a fluid seal in a subterranean well structure having a fluid seal defect. The method comprises introducing a meltable repair material proximate a structure in a subterranean well which has a fluid seal defect or enhanced seal capacity is required or it is desired to temporarily or permanently hydraulically isolate a portion the well or strengthen the structural integrity of well tubulars or tubular hangers. Exothermic reactant materials are located proximate the meltable repair material. The exothermic reactant material is ignited or an exothermic reaction otherwise initiated which supplies heat to and melts the meltable repair material into a molten mass. The molten mass flows and solidifies across the structure and the fluid seal defect to effect a fluid seal in the subterranean well structure or the structural integrity is enhanced. Examples of preferred exothermic reactant materials include thermite, thermate, fusible chemical reactants such as ammonium chloride and sodium nitrate, and oxidizers and accompanying hydrocarbon based fuels. Examples of preferred meltable repair materials include solder or brazing materials and eutectic metals which expand upon cooling and solidifying from a molten state.

Owner:CHEVROU USA INC

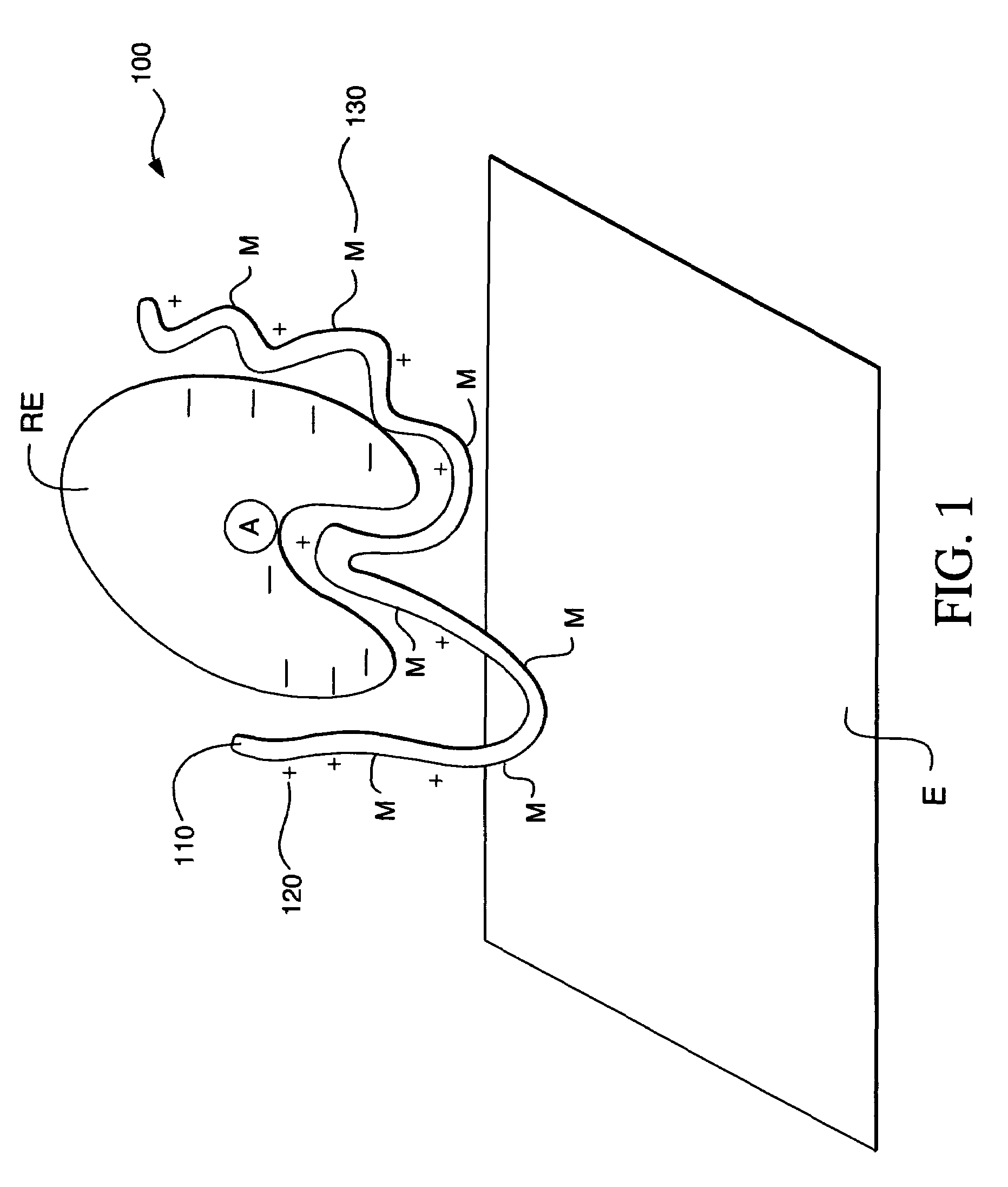

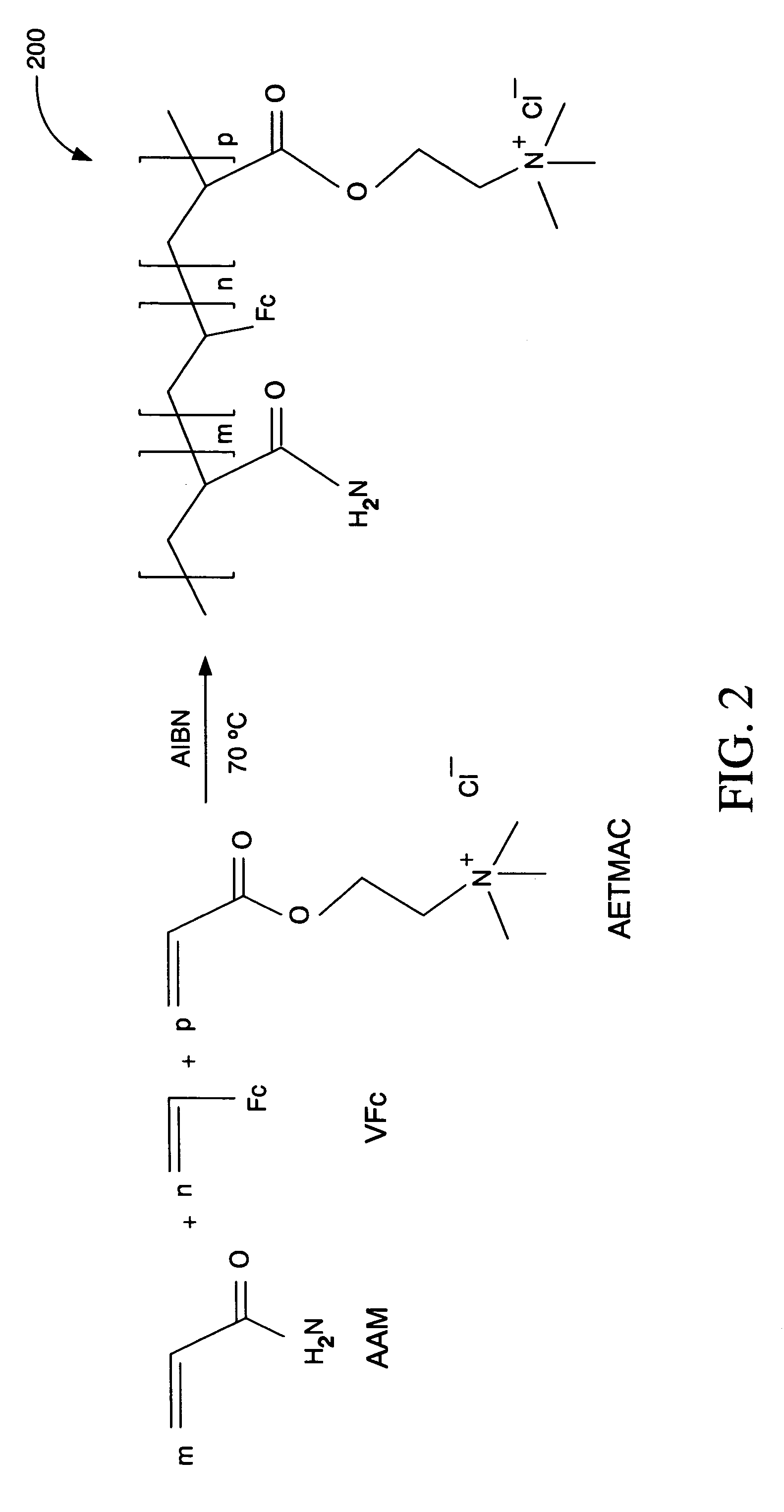

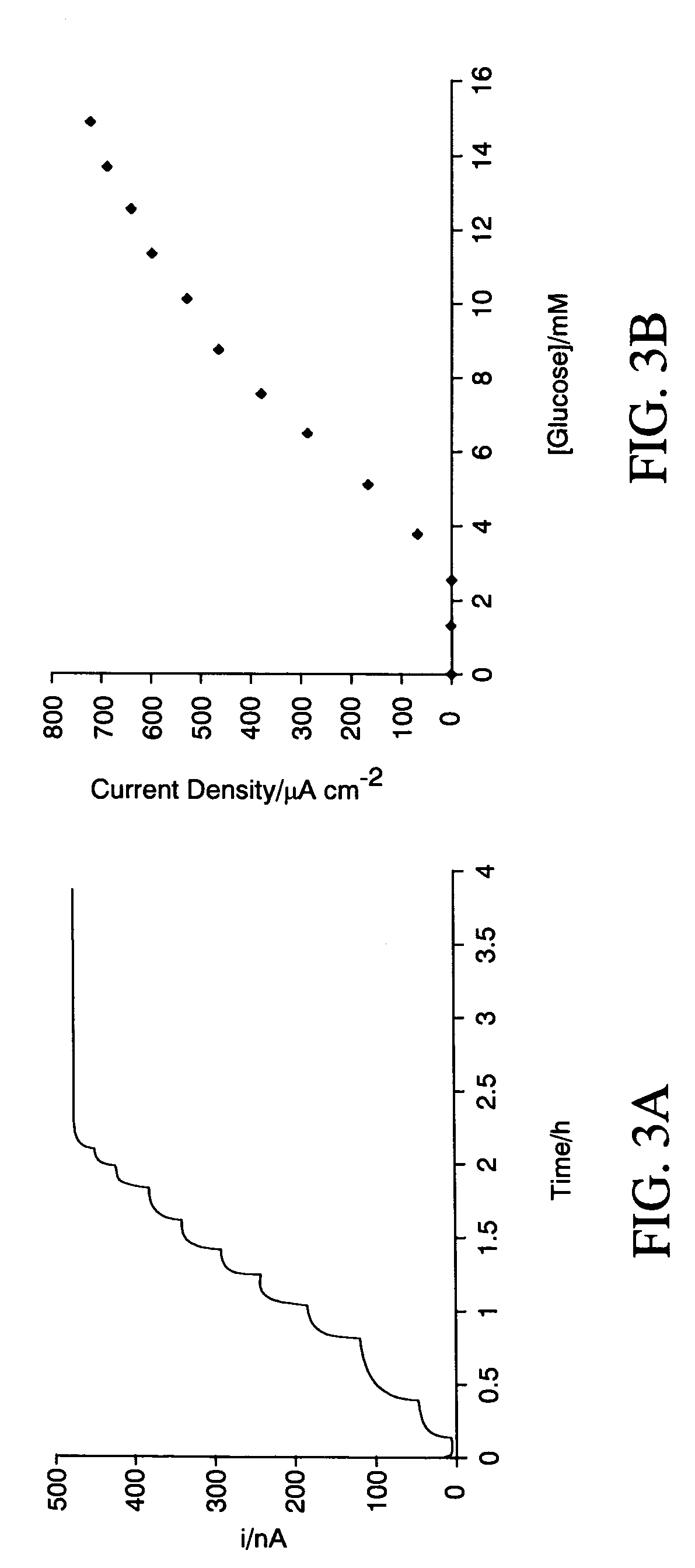

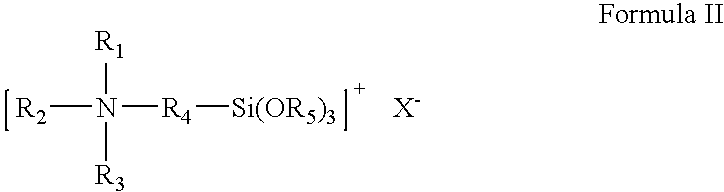

Ionic hydrophilic high molecular weight redox polymers for use in enzymatic electrochemical-based sensors

ActiveUS7351770B2Solve the lack of activityReduce leachingMicrobiological testing/measurementHydrophilic polymersFerrocene

Ionic hydrophilic high molecular weight redox polymers for use in enzymatic electrochemical-based sensors include a hydrophilic polymer (such as a hydrophilic polymer backbone) with ionic portions (e.g., cationic monomers incorporated in the hydrophilic polymer backbone) and a plurality of attached redox mediators. The redox mediators can be, for example, covalently attached to the hydrophilic polymer in a pendant manner. An exemplary cationic hydrophilic high molecular weight redox polymer is synthesized by co-polymerization of a hydrophilic acrylamide monomer, [2-(acryloyloxy)ethyl]trimethyl ammonium chloride and vinyl ferrocene.

Owner:CILAG GMBH INT +1

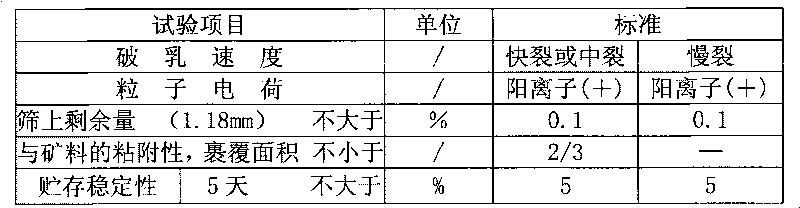

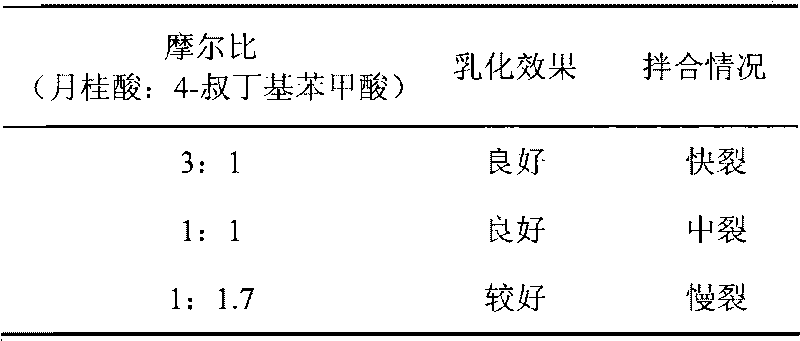

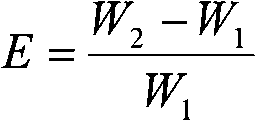

Cationic asphalt emulsifier and preparation method and application thereof

ActiveCN101745340AWide selectionWide applicabilityTransportation and packagingMixingChloroacetic acidsFatty alcohol

The invention relates to cationic asphalt emulsifier and preparation method and application thereof. The main agent of the cationic asphalt emulsifier is prepared through the reaction of quaternarization reagent and intermediate at molar ratio of 0.5-3:1, wherein the intermediate is produced in the reaction of organic acid mixture and organic amine at molar ratio of 1: 1-3. The adjuvant agent of the cationic asphalt emulsifier is the combination of, based on the main agent by weight, 0.1-2.5% of nonionic surfactant and 0.1-2.5% of modifier. The organic acid mixture is the mixture of linear, branched or naphthene-containing organic acid with small relative pace steric effect and organic acid with big relative space steric effect at molar ratio of 1: 3- 3: 1. The quaternarization reagent is epichlorohydrin, hydrochloric acid, chloromethane, dimethyl sulfate or chloroacetic acid. The modifier is one or more of aluminum sulfate, ammonium chloride and calcium chloride and the nonionic surfactant is fatty alcohol-polyoxyethylene ether. The emulsifier has no bad effects to the property of the asphalt, has wide application range and can satisfy different construction conditions.

Owner:PETROCHINA CO LTD +1

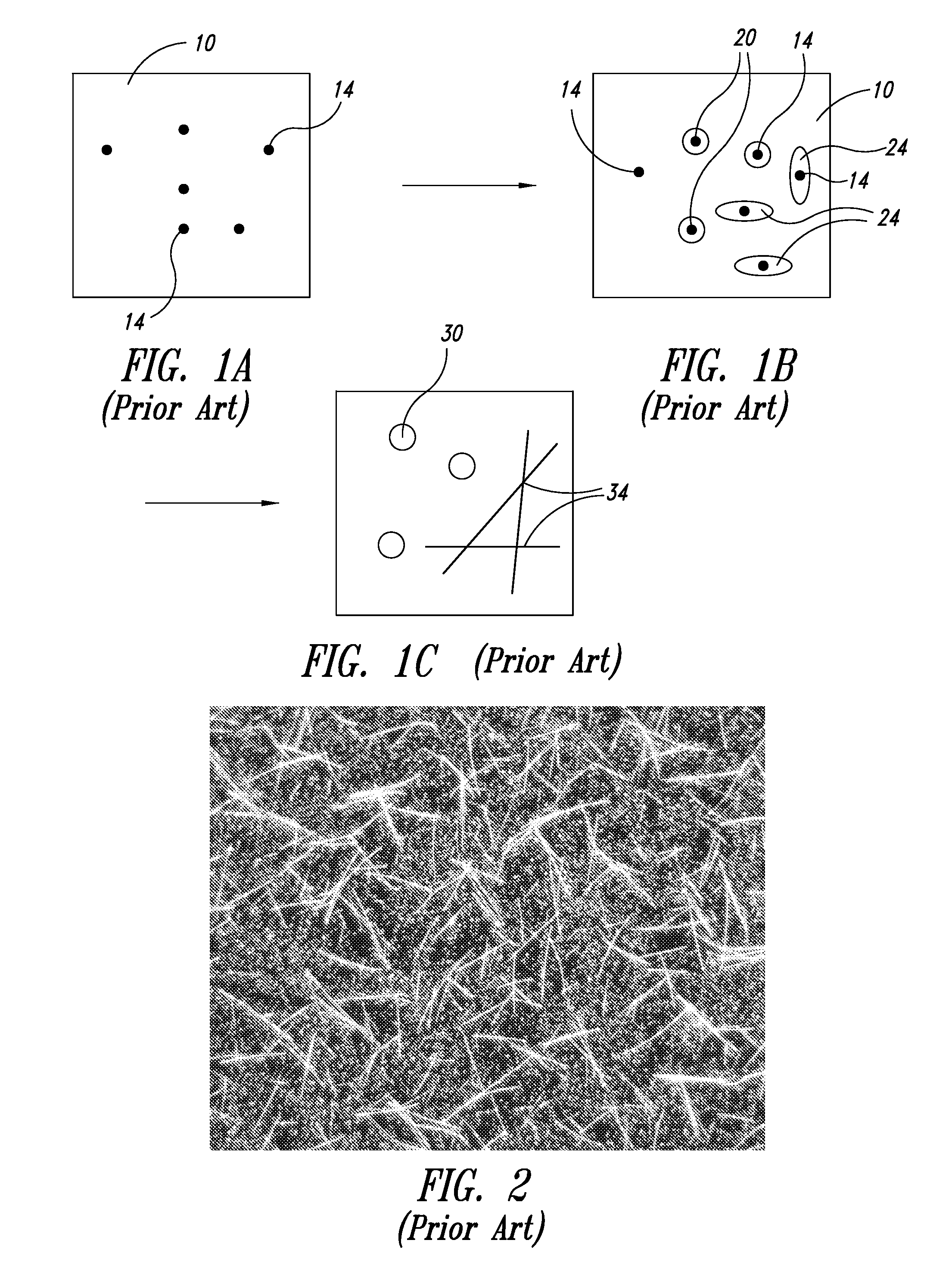

Drilling fluid plugging agent while drilling

The invention relates to a drilling fluid plugging agent while drilling, comprising 60-100 parts of plant fibers, 5-20 parts of asphalt, 5-15 parts of graphite and 5-20 parts of weak water absorbent gel by weight. The weak water absorbent gel is a polymer which has mean grain size of 200-20 meshes and water absorbent multiple of 10-100g.g-1 and is prepared by reacting 20-60 parts of monomer, 0.05-1.0 part of potassium peroxydisulfate, 0.05-1.0 part of sodium bisulfite, 0.005-0.5 part of methylene-bis-acrylamide and 2-10 parts of inorganic fillers by weight under constant temperature of 20-60 DEG C for 8-12h by way of aqueous solution polymerization, drying and pelleting, wherein the polymeric monomer is one or more of acrylamide, acrylic acid, dimethyl diallyl ammonium chloride and 2-acrylamide-2-methyl propanesulfonic acid. The plugging agent has little effect on the rheological property of the drilling fluid, can reduce the API filtration and the coefficient of friction resistance of the drilling fluid in an auxiliary manner and is suitable for controlling leakage of and plugging the windows with high density and narrow pressure.

Owner:PETROCHINA CO LTD

Aerosol Cream Mousse and Method of Treating Hair

ActiveUS20080131378A1Low and reduced greasyLow and reduced and oily hair feelBiocideCosmetic preparationsAmmonium compoundsFatty alcohol

The present invention provides stable aerosol cream mousse composition, preferably hair care composition, that can provide enhanced touch, combability, alignment and volume reduction to the hair, with low or reduced greasy, oily hair feel, while being formulated having a thick, rich, creamy, mousse-type rheology with excellent spreading, perception of spreading, and feel. The aerosol composition is based on the combination of component (A) a cationic surfactant, which is generally a quaternary ammonium compound such as e.g., ditallow dimethyl ammonium chloride; (B) a fatty alcohol, such as cetyl and stearyl alcohol; and (C) carbon dioxide.

Owner:THE PROCTER & GAMBLE COMPANY

Antimicrobial substrate, a method and a composition for producing it

InactiveUS20070042198A1Improve adhesionIncrease surface charge densityBiocideBiochemical fibre treatmentHydrophilic polymersPolyethylenimine

Owner:APPEARTEX AB CHALMERS INNOVATION

Flux and process for hot dip galvanization

InactiveUS20030219543A1Improve the immunityConvenient coatingHot-dipping/immersion processesLiquid surface applicatorsAlkaline earth metalChloride

A flux for hot dip galvanization comprises from:&Circlesolid;60 to 80 wt. % of zinc chloride (ZnCl2); 7 to 20 wt. % of ammonium chloride (NH4Cl); 2 to 20 wt. % of a fluidity modifying agent comprising at least one alkali or alkaline earth metal; 0.1 to 5 wt. % of a least one of the following compounds: NiCl2, CoCl2, MnCl2; and 0.1 to 1.5 wt. % of at least one of the following compounds: PbCl2, SnCl2, BiCl3, SbCl3.

Owner:FONTAINE HLDG NV

Method for recovering tungsten trioxide and ammonium metavanadate from selective catalytic reduction (SCR) denitration catalyst

ActiveCN102557142AEmission reductionTungsten oxides/hydroxidesDispersed particle separationWarm waterAmmonium paratungstate

The invention relates to a method for recovering tungsten trioxide and ammonium metavanadate from a selective catalytic reduction (SCR) denitration catalyst. The method comprises the following steps of: crushing the SCR denitration catalyst, sieving to obtain catalyst powder, mixing with sodium carbonate, and stirring fully and uniformly; putting the mixed powder into a sintering furnace, and sintering to obtain a sintered material; keeping temperature for 1 hour, and sieving to obtain sintered material powder; pouring warm water, so that Na2WO4 and NaVO3 in the sintered material powder are dissolved fully, filtering, and removing precipitates to obtain a mixed solution of Na2WO4 and NaVO3; regulating the pH value to be 6.5-7.5, adding an ammonium bicarbonate solution or an ammonium chloride solution, and precipitating ammonium metavanadate precipitate; filtering, washing by using a diluted ammonium bicarbonate solution for 2 to 3 times, washing by using 30 percent ethanol for 1 to 2 times, and drying to obtain an ammonium metavanadate finished product; and converting the Na2WO4 in the residual solution into ammonium paratungstate, evaporating the residual solution to obtain ammonium paratungstate crystals, and calcining to obtain the tungsten trioxide. By the method, the ammonium metavanadate and the tungsten trioxide can be recovered, and the discharge of pollutants is reduced.

Owner:江苏万德环保科技有限公司

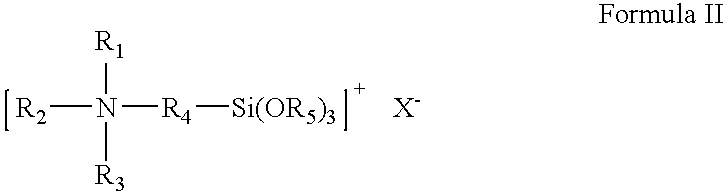

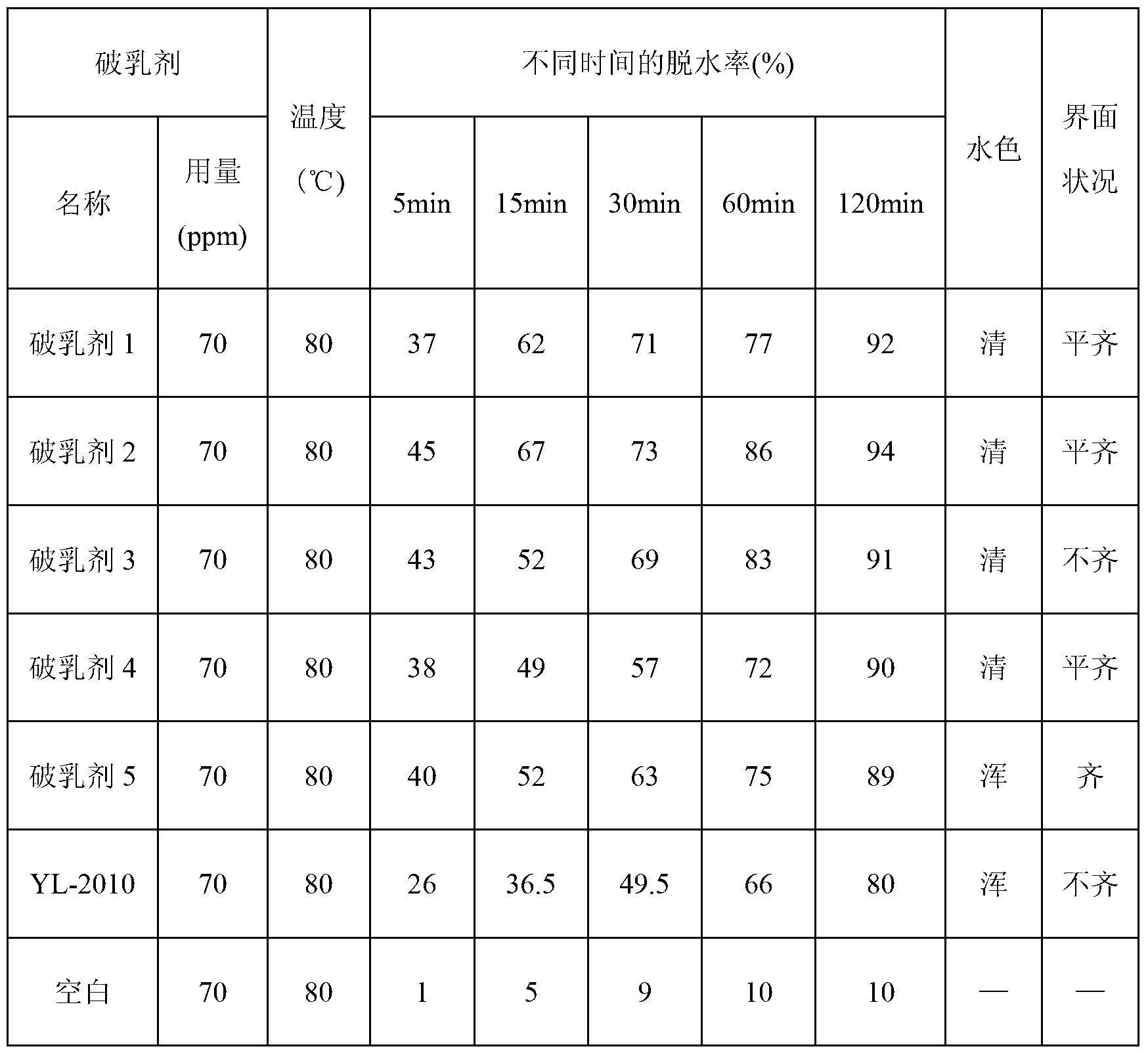

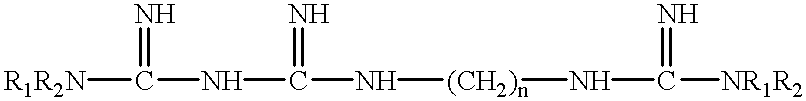

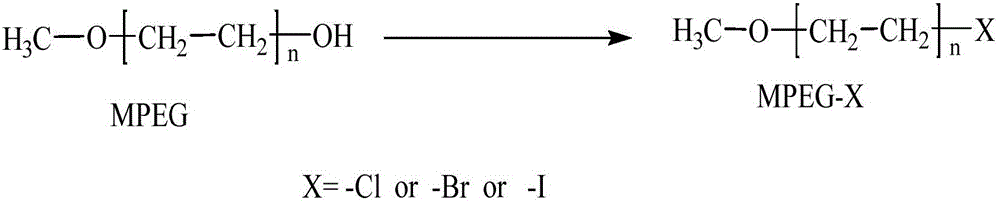

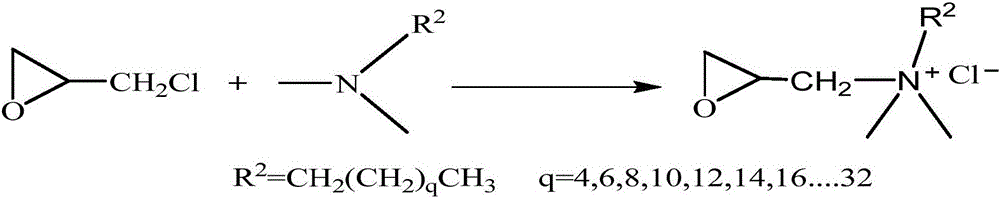

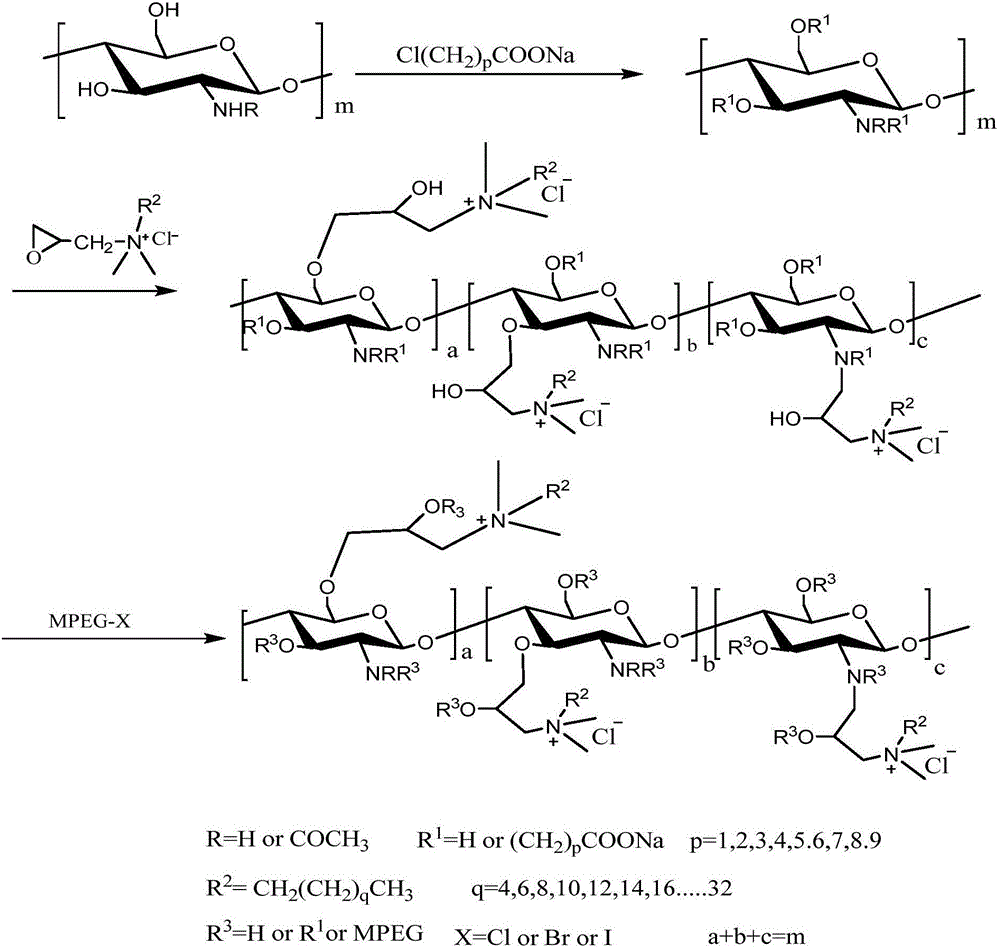

Natural polysaccharide macromolecule-modified crude oil demulsifier

InactiveCN103320158ASustainableWide variety of sourcesDewatering/demulsification with chemical meansAminationIsocyanic acid

The invention relates to a crude oil demulsifier, and discloses a natural polysaccharide macromolecule-modified crude oil demulsifier. The demulsifier is prepared by adopting the following operation steps: (1) conducting halogenation modification, carboxylation modification, amination modification, formylation modification, or isocyanic acid esterification modification on polyethylene glycol monomethyl ether; (2) preparing glycidyl dimethyl alkyl ammonium chloride; (3) preparing quaternized polysaccharide; and (4) reacting the modified polyethylene glycol monomethyl ether with quaternized polysaccharide to obtain a product, namely the natural polysaccharide macromolecule-modified crude oil demulsifier. According to the crude oil demulsifier, as the raw material, the natural polysaccharide macromolecule compound has multiple advantages of being wide in source, natural, non-toxic, sustainable, good in usage safety and the like; and the prepared demulsifier has good demulsifying and dewatering effects; in addition, the molecules of the demulsifier contain a great deal of groups of hydroxyl and the like, which have certain chelating capability to metal ions, thus being capable of removing a certain amount of metal ions while demulsifying.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method to decrease iron sulfide deposits in pipe lines

InactiveUS6866048B2Inorganic/elemental detergent compounding agentsAnionic surface-active compoundsPhosphoniumSulfate

This invention provides a method of treating a dry or processed fluid pipe line susceptible to the build-up of iron sulfide deposits by complexing the iron sulfide in the pipe lines. The method of the present invention introduces the composition on a continuous or a batch basis to a gas pipe line. The composition is made of a solution of 1) water, 2) [tetrakis(hydroxymethyl)phosphonium]sulfate or chloride, and 3) a soluble ammonium salt, such as ammonium chloride or the like.

Owner:COASTAL CHEM CO L L C

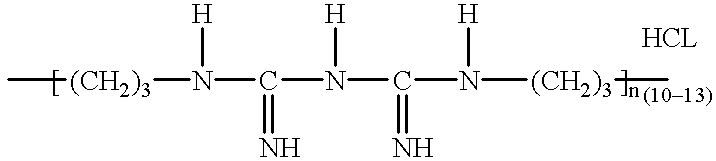

Fast acting disinfectant and cleaner containing a polymeric biguanide

InactiveUS6303557B1Improve effectivenessImprove efficiencyBiocideOrganic detergent compounding agentsSolventNon ionic

A cleaning and biocidal composition in liquid form comprising a solvent, a polymeric biguanide, a single quaternary ammonium salt, a sequestrant, and at least one surfactant. The composition comprising the solvent including water, the polymeric biguanide including a polyhexamethylene biguanide hydrochloride, the quaternary ammonium salt including a didecyldimethyl ammonium chloride, the sequestrant including an amino acid chelating agent selected from the group consisting of: ethylenediaminetetraacetic acid, nitrilotriacetic acid, tetrasodium ethylenediaminetetraacetic acid, or mixtures thereof, the surfactant including a non-ionic surfactant and an amphoteric surfactant.

Owner:JOHNSONDIVERSEY INC

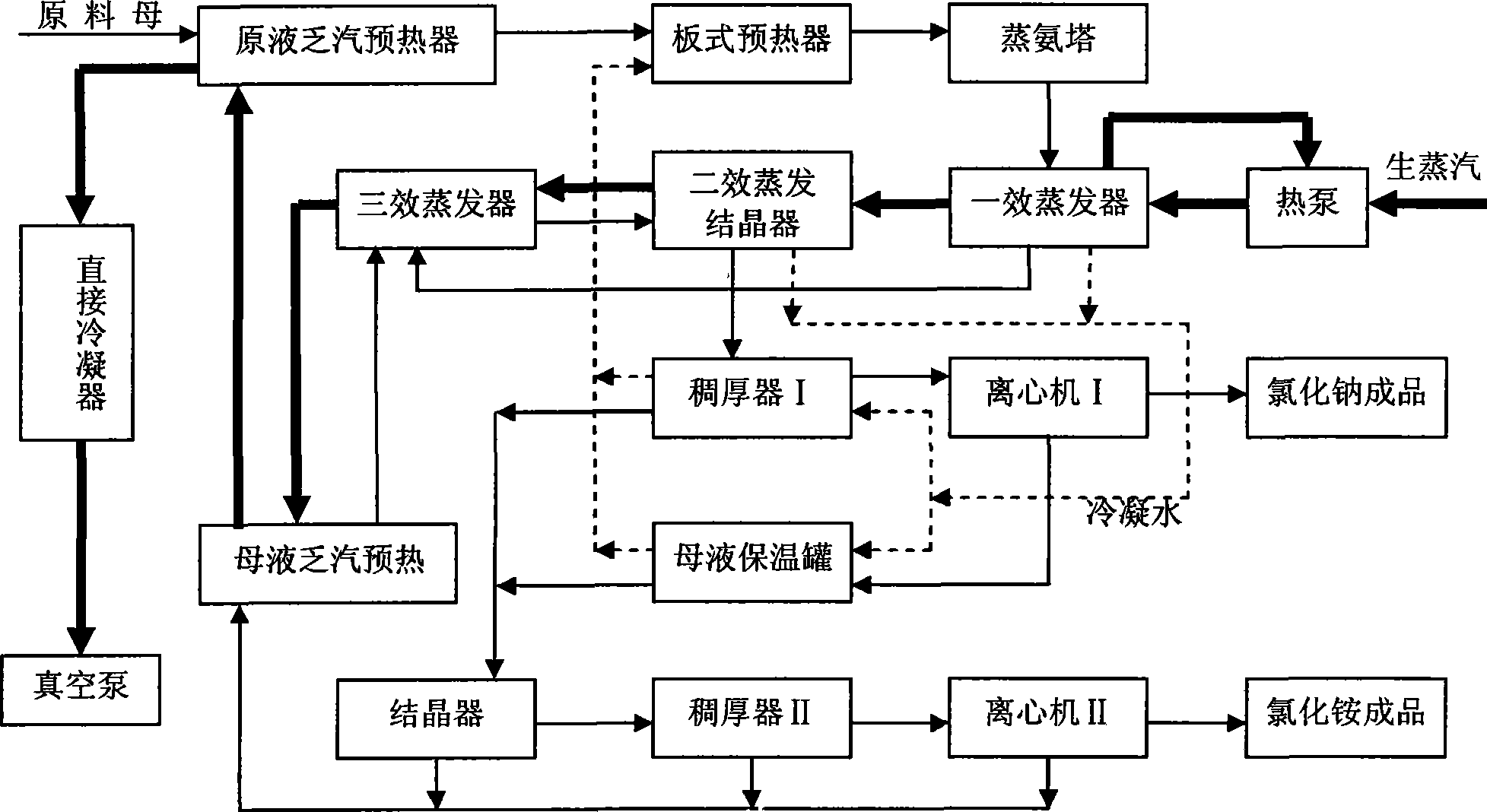

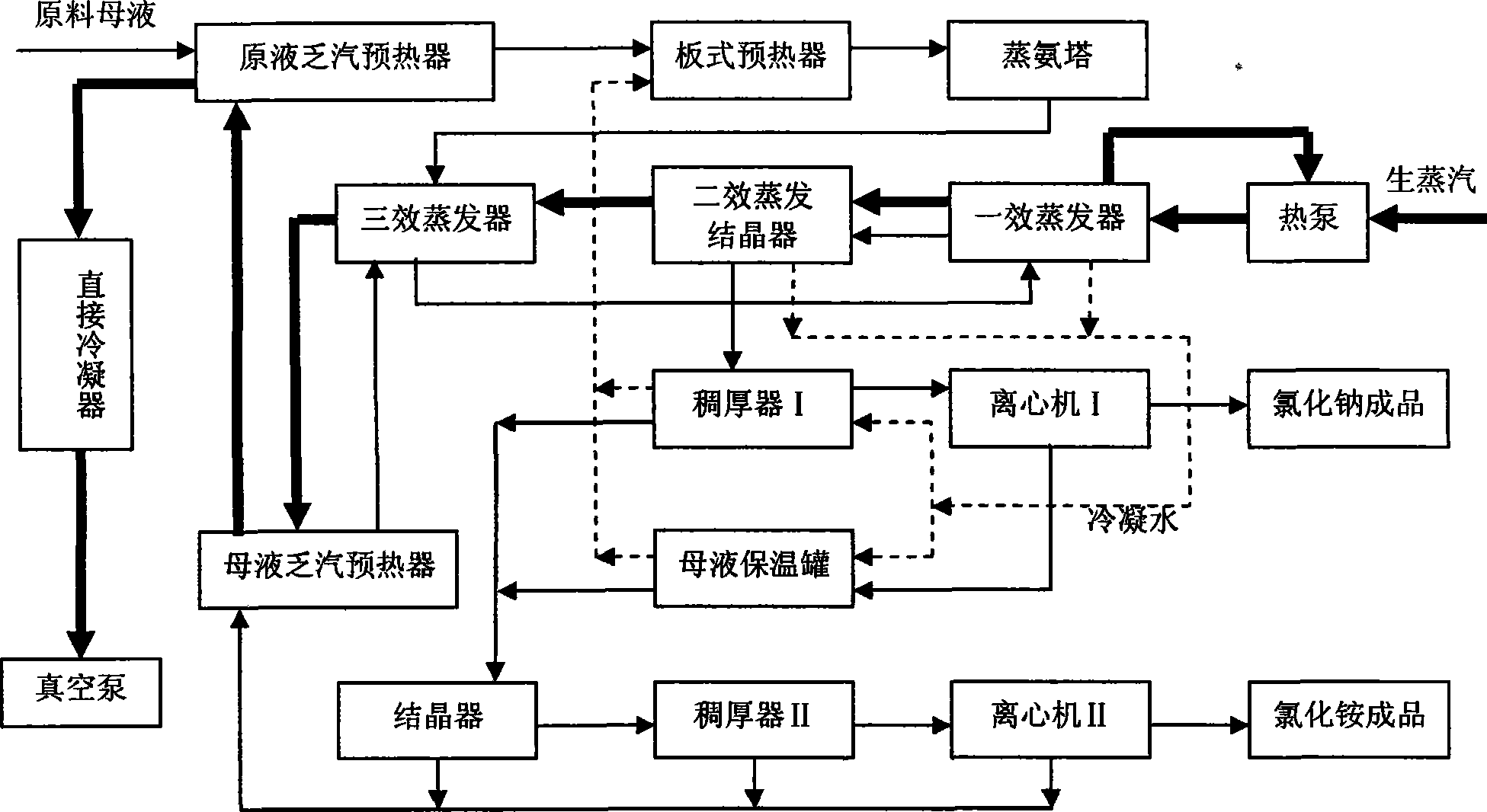

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

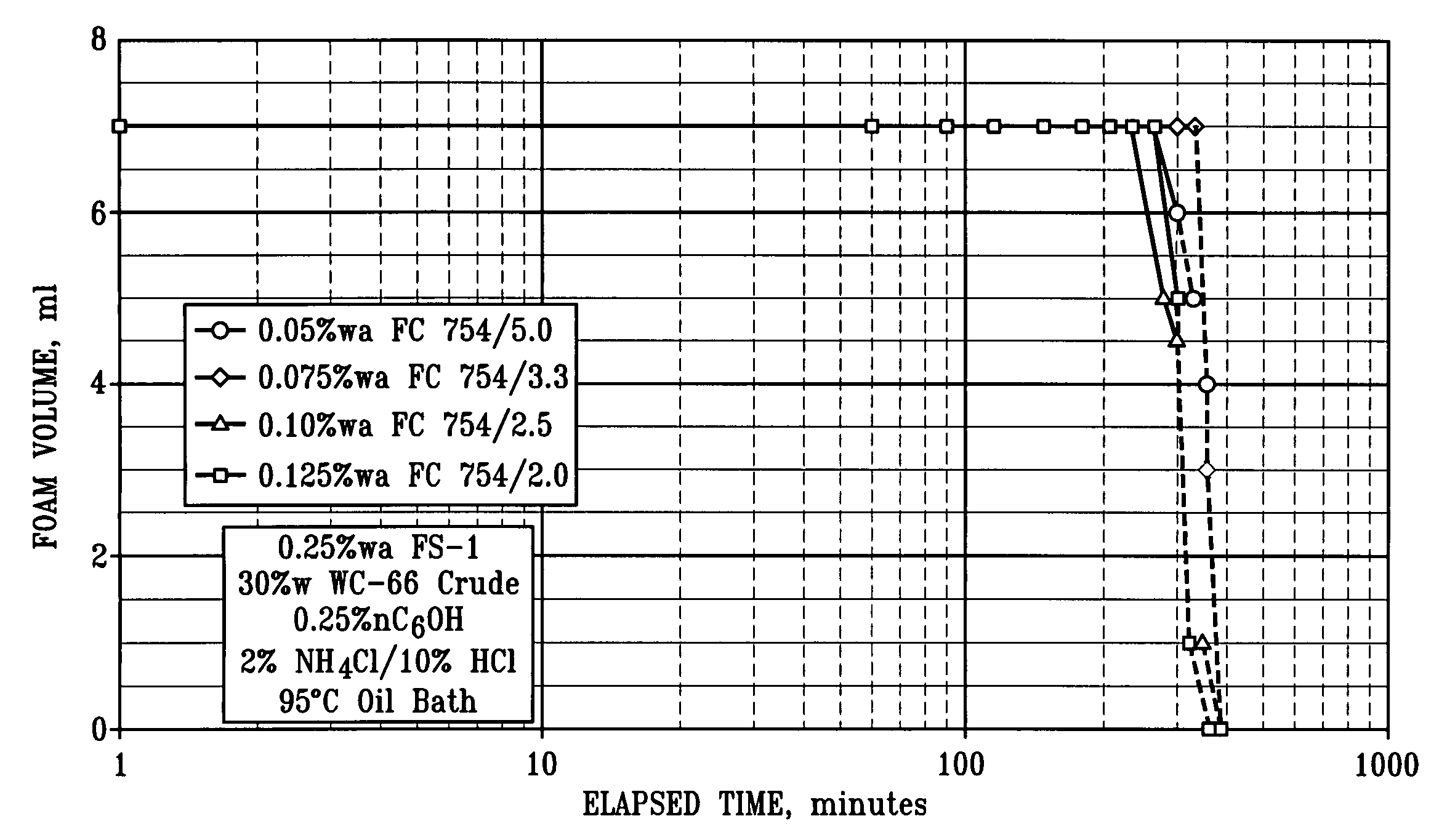

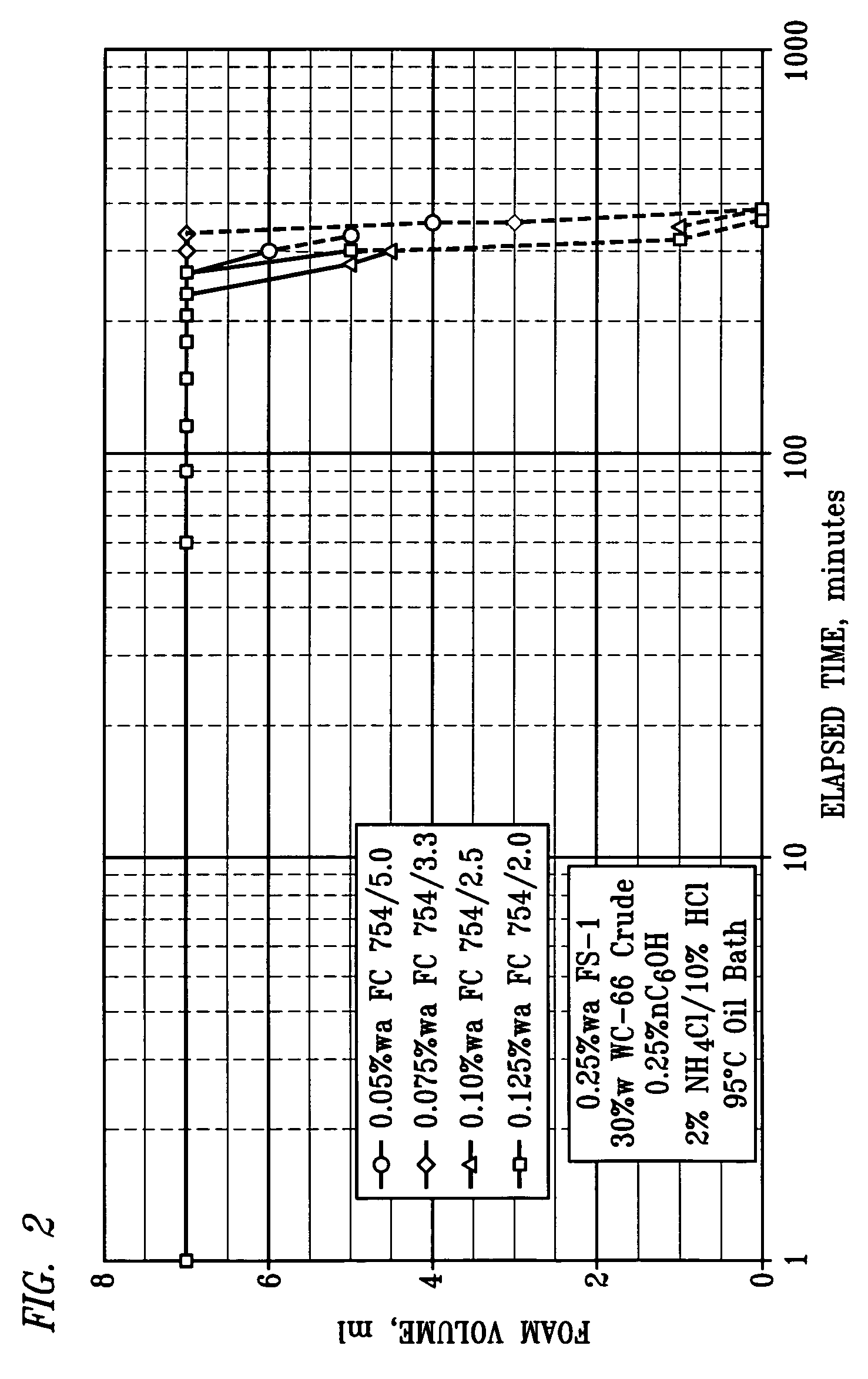

Method for removing filter cake from a horizontal wellbore using acid foam

A composition and method for removing a filter cake from a horizontal wellbore in a subterranean formation using a composition containing a inorganic or organic acidic material, a cationic fluorocarbon surfactant, an alkyl alcohol, water optionally containing ammonium chloride and at least one of an alkyl polyglycoside and a betaine surfactant to produce a stable foam used to remove filter cake from a horizontal wellbore.

Owner:CONOCOPHILLIPS CO

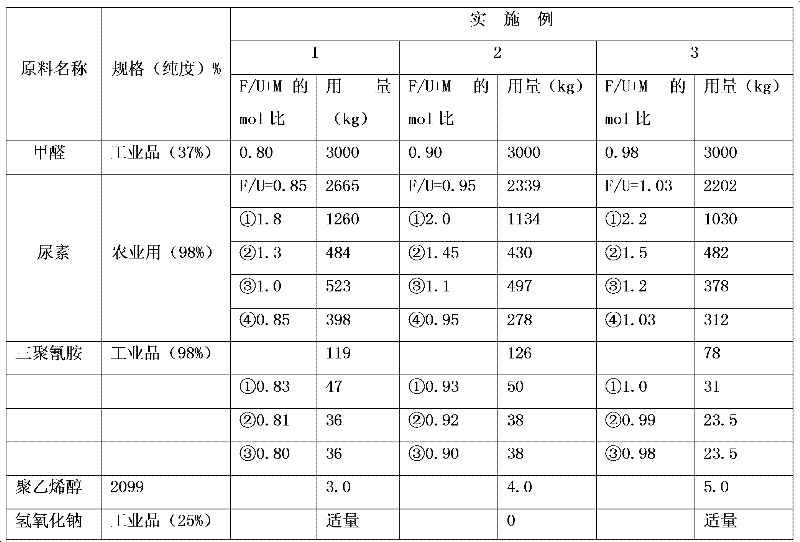

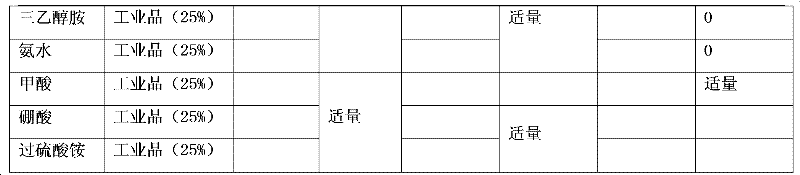

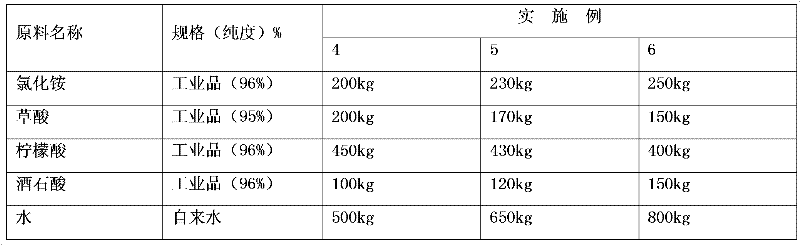

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

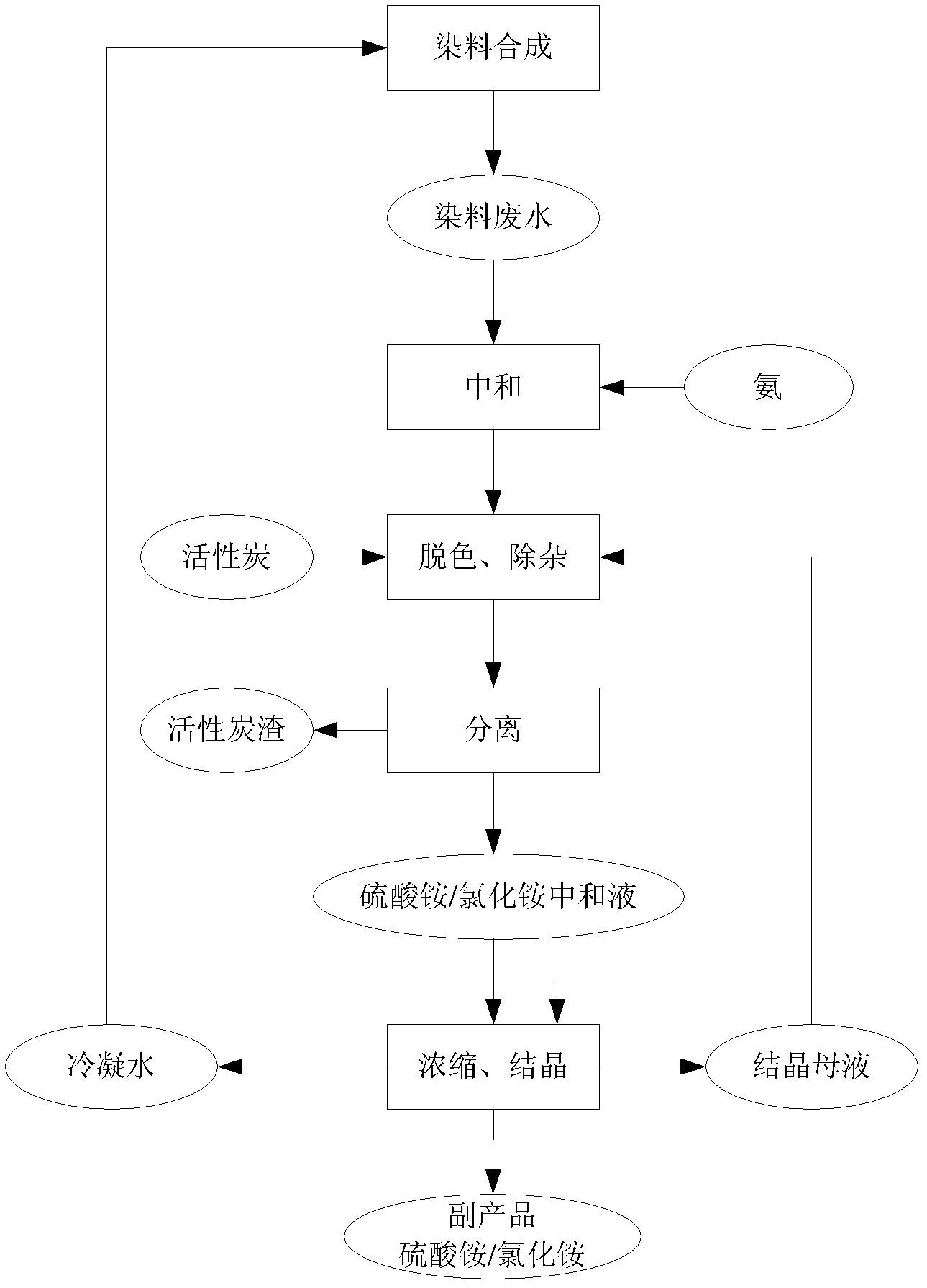

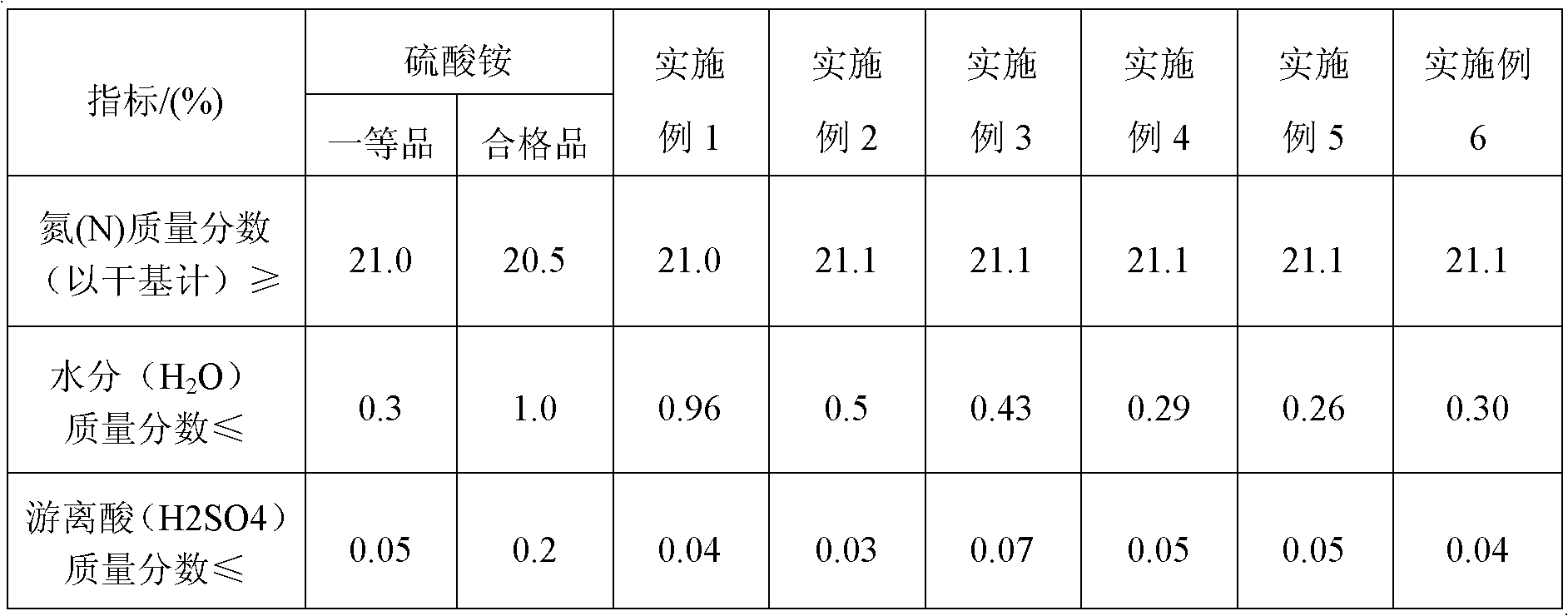

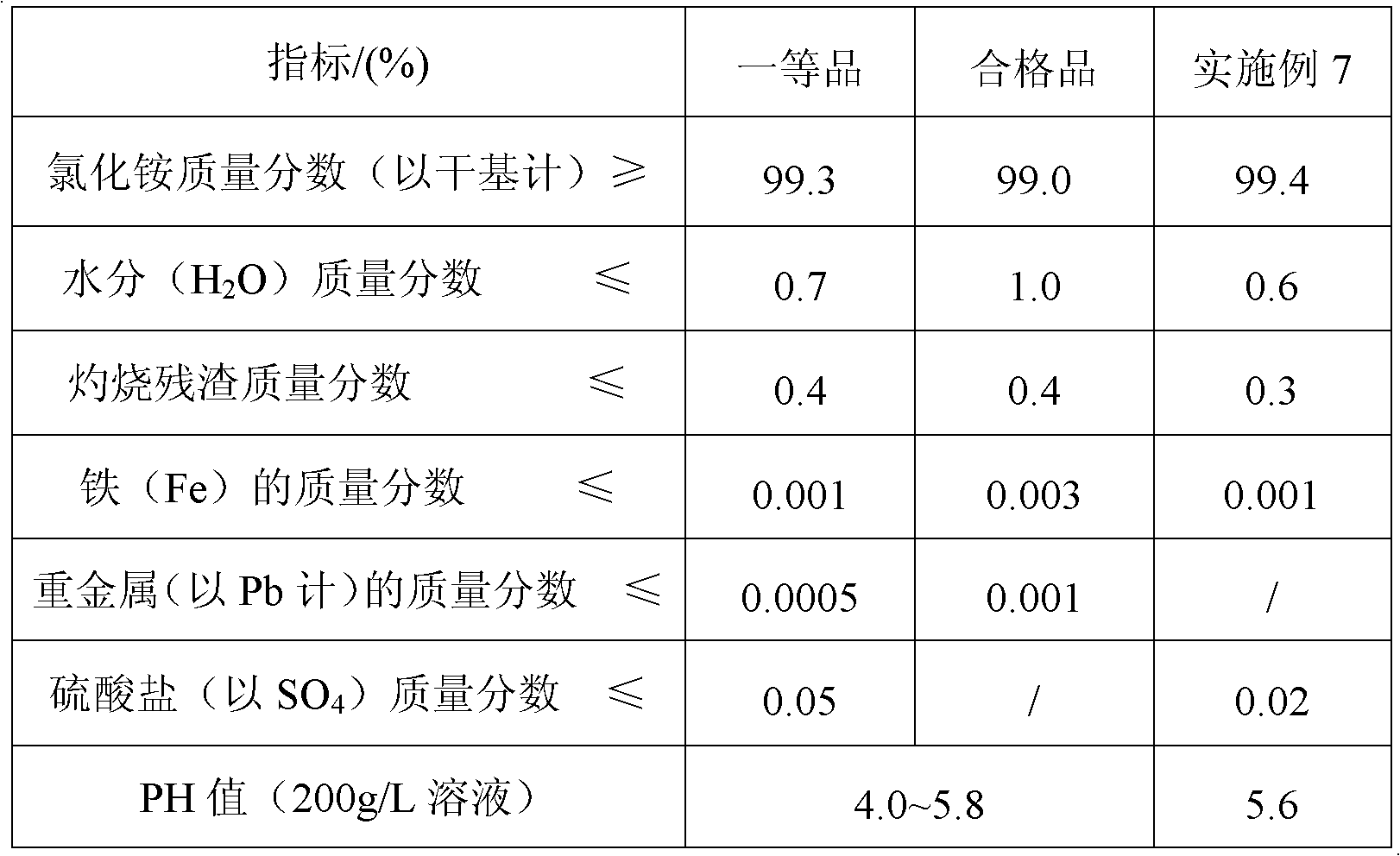

Cleaning treatment method of dying industrial acidic wastewater

ActiveCN102826673AAchieve recyclingAvoid it happening againAmmonium sulfatesMultistage water/sewage treatmentSulfateWastewater

The invention provides a cleaning treatment method of dying industrial acidic wastewater. After purified by measurements of neutralization, decolouring, oxidation, condensation, separation and the like, wastewater is reused as synthetic bottom water and dye filter cake washing water for dye production, thus avoiding discharge of a lot of colored wastewater with high COD value during a traditional dye production process. By a method of using a by-product ammonium sulfate or ammonium chloride, generation of calcium sulfate is avoided during neutralization of wastewater by the use of lime. Therefore, the dangerous solid waste calcium sulfate slug treatment problem is solved, and the cleaning production purposes of water saving, emission reduction and synergy are reflected.

Owner:ZHEJIANG LONGSHENG GROUP +1

Organic fertilizer produced by comprehensively utilizing straw, and preparation method for organic fertilizer

InactiveCN102531756AIncrease profitImprove resistance to pests and diseasesFertilizer mixturesPhosphoric acidAmmonium chloride mixture

The invention discloses an organic fertilizer produced by comprehensively utilizing straw, and a preparation method for the organic fertilizer, and relates to the technical field of agricultural fertilizers. The organic fertilizer is prepared from composted straw, 34 to 44 parts of rice hulls, 20 to 30 parts of composted animal dung, 10 to 15 parts of potassium chloride, 10 to 15 parts of humic acid, 0.4 to 0.6 part of medium and trace elements, 0.4 to 0.6 part of microorganism, 10 to 15 parts of calcium superphosphate and 5 to 10 parts of ammonium chloride through mixing and granulating. The organic fertilizer has the characteristics of low production cost, high bioactivity, high fertilizer efficiency, wide sources of raw materials and the like, can serve as a fertilizer for rice and a fertilizer for dry crops, vegetables, melons, fruits and fruit trees, and also can serve as a fertilizer for flowers.

Owner:HUNAN ZHONGKE AGRI

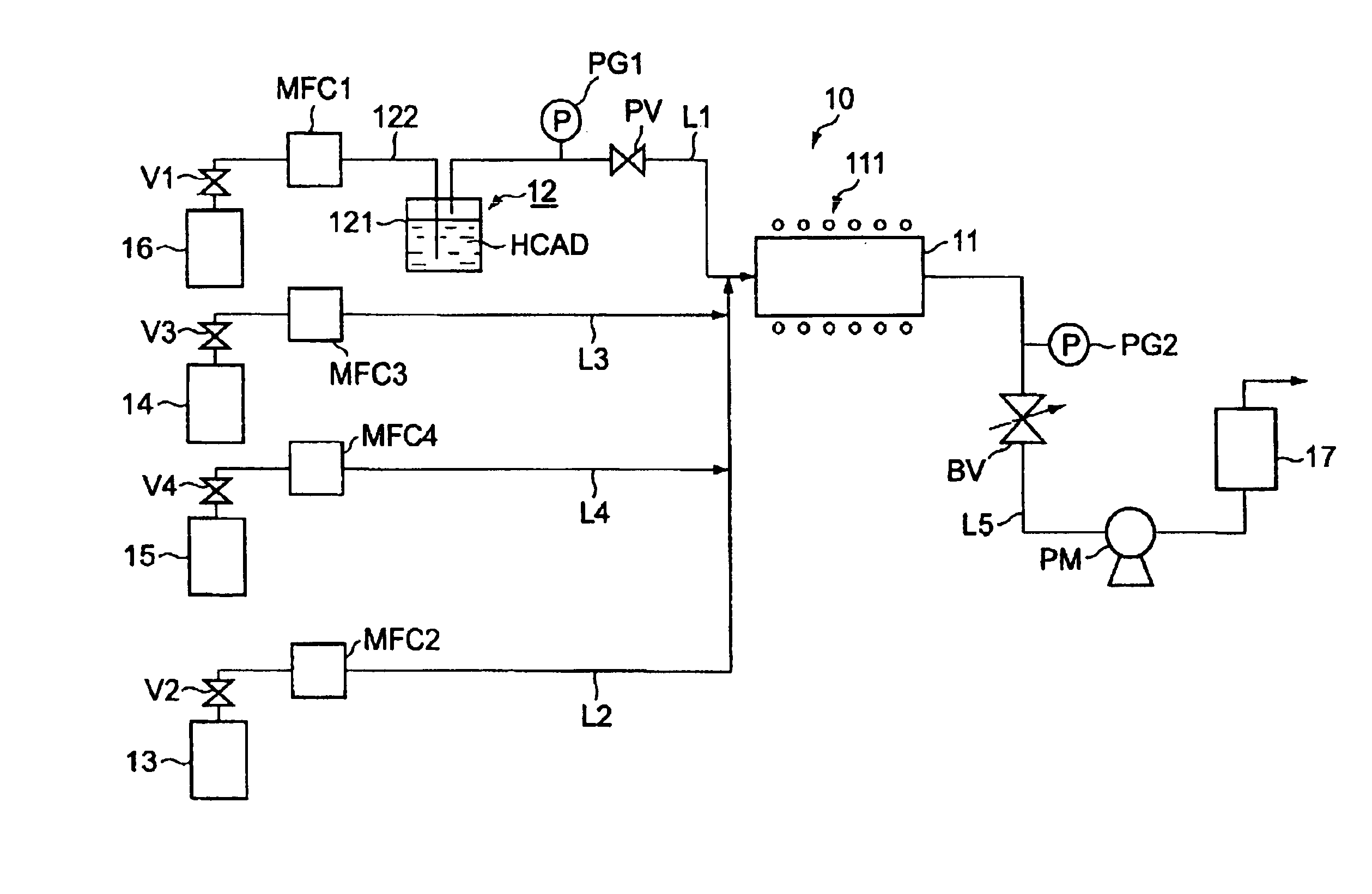

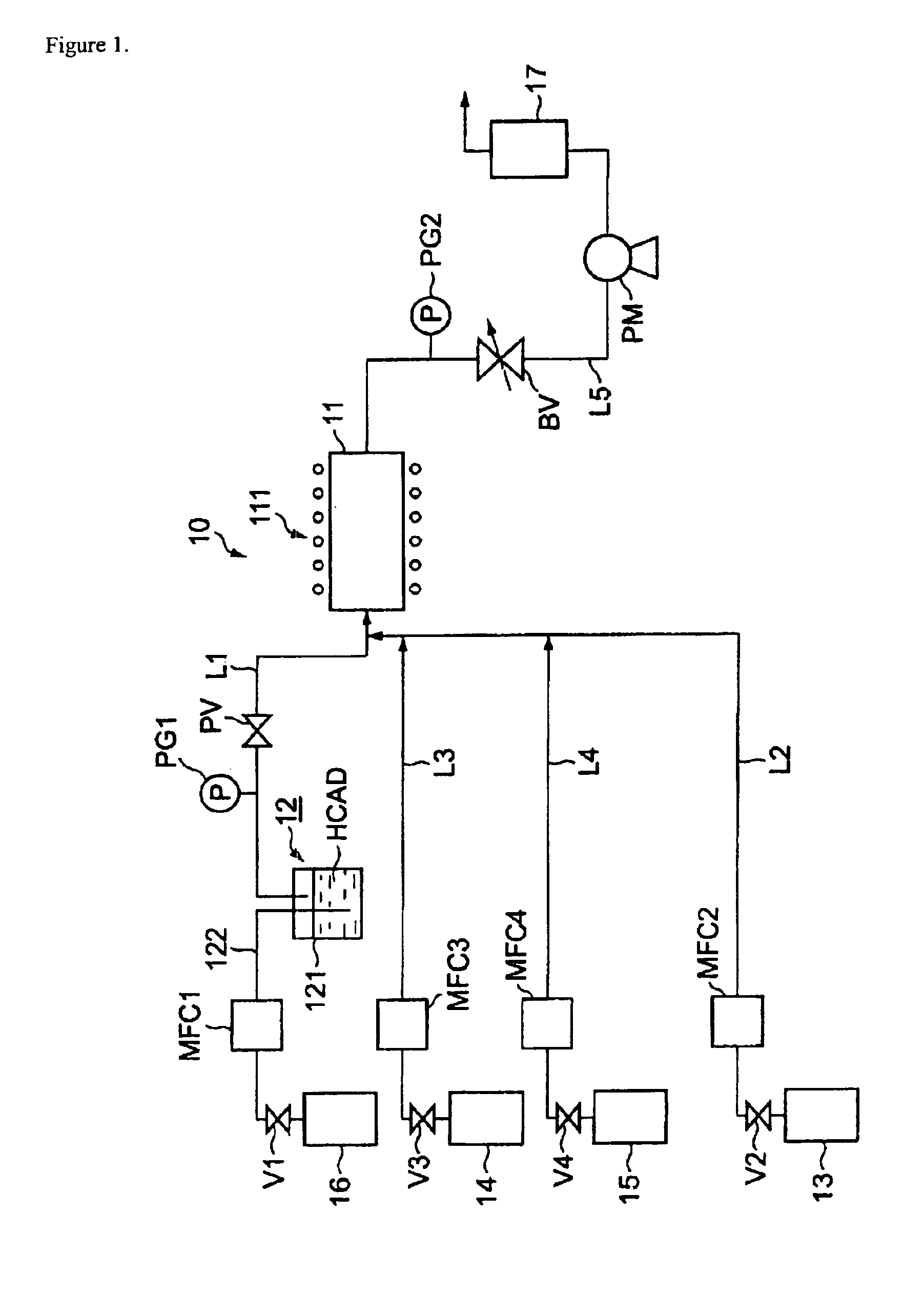

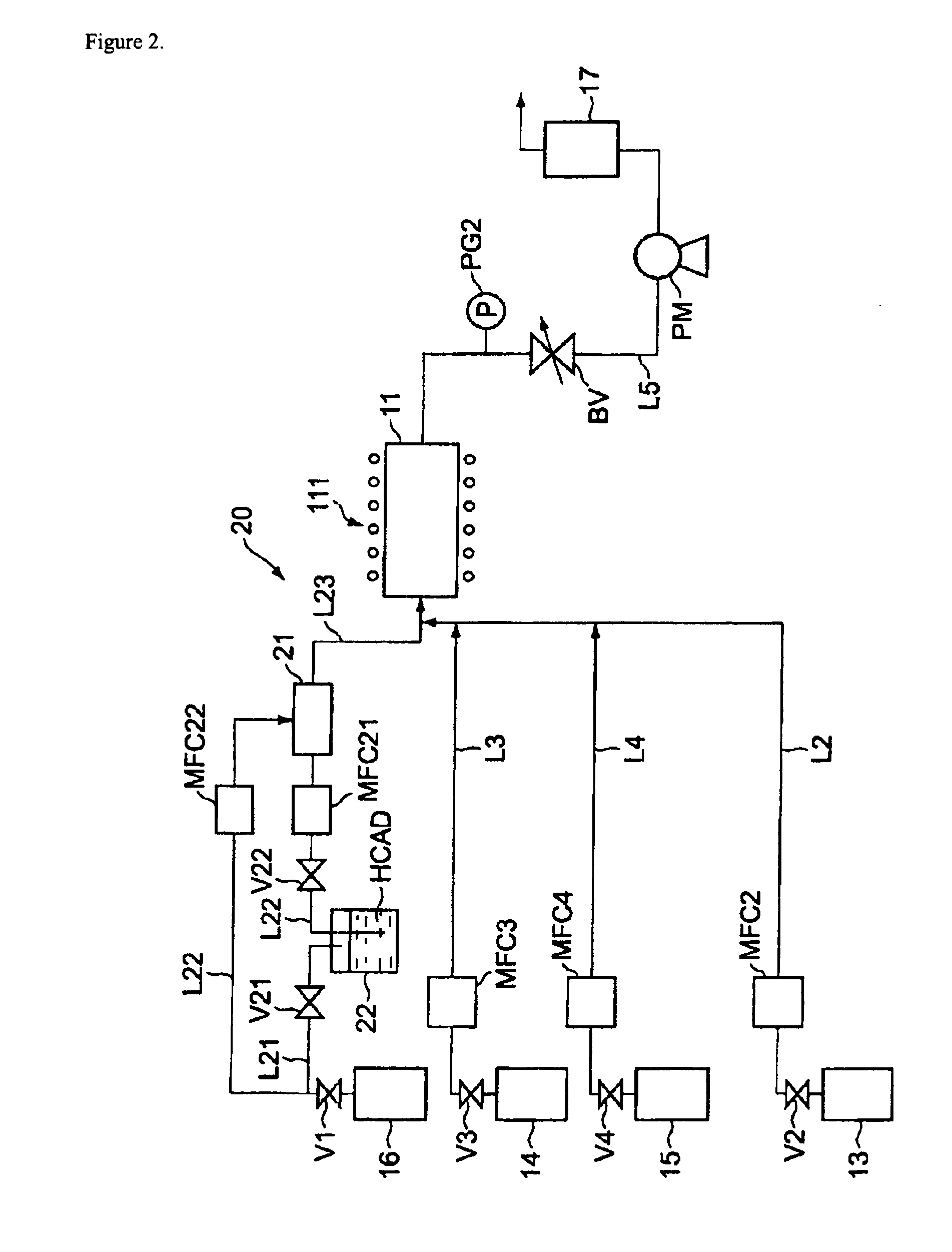

Method for depositing silicon nitride films and silicon oxynitride films by chemical vapor deposition

InactiveUS6936548B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical vapor depositionSilicon oxynitride

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for preparing vanadium pentoxide

InactiveCN1843938AMeet the needs of domestic chemical productionVanadium oxidesCalcium hydroxideSodium aluminate

The invention relates to a method for preparing vanadic anhydride. It comprises following steps: employing ammonium vanadate, vanadic anhydride of technical grade or waste catalyst discharged in sulfuric acid preparation process; treating with ammonium hydroxide, sulfuric acid and ammonium chloride, washing with water; getting fine active vanadic anhydride; removing foreign matter with ammonium hydroxide, calcium hydroxide, sodium aluminate, sodium silicate, sulfuric acid and ammonium chloride; washing with water again; drying; calcing at 670 Deg. C and getting high-purity vanadic anhydride. The invention is characterized in that it makes use of current material to prepare chemical materials urgently needed by industrial production, and saves a large amount of foreigh exchange.

Owner:宿素满

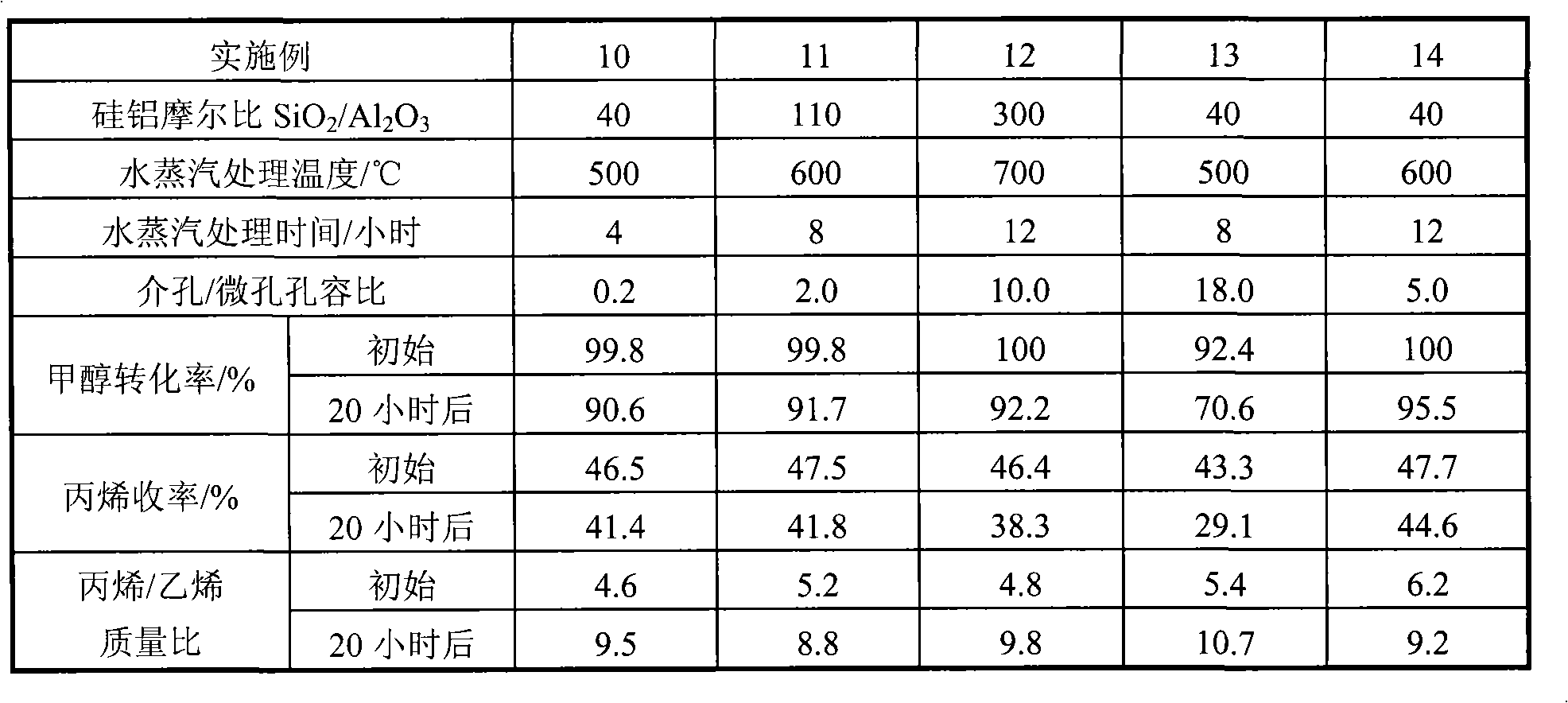

ZSM-5 mesoporous molecular sieve catalyst for preparing propylene from methanol and preparation thereof

ActiveCN101279282AMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMaleopimaric acidAmmonium nitrate

The present invention relates to a ZSM-5 mesoporous molecular sieve catalyst used for manufacturing propylene by methanol and a preparation method thereof, which mainly solves the problems of low propylene selectivity, low propylene / ethylene mass ratio as well as poor thermal stability of molecular sieve and poor water thermal stability in the prior art. The present invention adopts the technical proposal of adopting ZSM-5 mesoporous molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 20 to 100 percent as well as at least one caking agent selected from SiO2, clay and Al2O3 to extrude, tablet or spray into shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol or acetic acid under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid or maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing composite nanofiltration membrane

The invention relates to a method for preparing composite nanofiltration membrane, to the field of film separating technology. The electrolyte multilayer film is assembled on the substrate film as an ultrathin separating film using layers static self-assembly technology, to obtain the composite nanofiltration membrane. The preparation method alternately immerges the substrate film into the polyanion solution and the polycation solution to alternately and repeatedly aggrade on the surface of the substrate film to get the composite nanofiltration membrane ultrathin separating layer after the assemble of a certain layers. The said polyanion solution is sodium polystyrene sulfonate or sodium polyacrylate; the said polycation solution is poly dimethyl diallyl ammonium chloride or polyallyl ammonium chloride, and the said substrate film is polyethersulfone ultrafiltration film or polysulfone ultrafiltration film. The method of the invention has a simple process, and the thickness of ultrathin separating layer is controlled. The compositenanofiltration membrane has a using foreground in the field of sea water and bitter desalination, sewage disposal and callback, ultra pure water preparation and so on.

Owner:SHANGHAI UNIV

Low pervasion oilfield thermochemical cleanup additive and use thereof

InactiveCN101323780AComplete flowbackNo pollution in the processDrilling compositionPhosphoric acidNitrogen gas

The invention discloses a low permeability oil field thermochemical cleanup additive and applications thereof in acidification and fracturing technologies of low permeability oil field oil and water wells. The thermochemical cleanup additive consists of an agent A and an agent B. The agent A consists of certain parts by weight of phosphoric acid, sodium nitrite, dodecyl benzene sulphonic acid, emulsifier, surfactant and water; the agent B consists of certain parts by weight of urea, ammonium chloride and water. The agent A and the agent B thermally react under certain conditions to produce a large amount of nitrogen, carbon dioxide and high-temperature-hot-water and a large amount of heat simultaneously; in addition, the nitrogen and the carbon dioxide with certain pressure can form a large amount of bubbles under the function of a highly efficient active foaming agent for residues to be drained out of the oil and water wells. The thermochemical cleanup agent does not burn or explode easily and is mainly applied to the cleanup technology of the acidification and fracturing techniques of the low permeability oil and water wells for solving the problems such as inadequate drainage strength, reducing pollutions of remaining operating fluid to reservoir stratums and effectively enhancing the acidification and fracturing effects.

Owner:XI'AN PETROLEUM UNIVERSITY

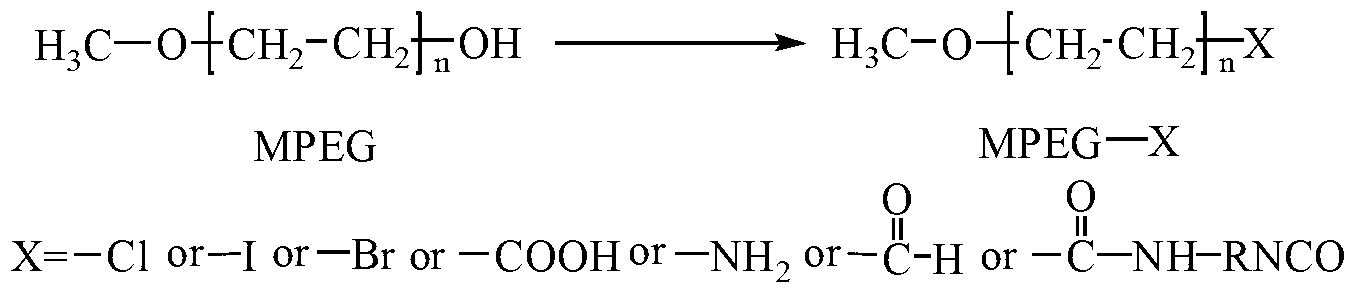

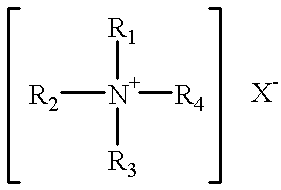

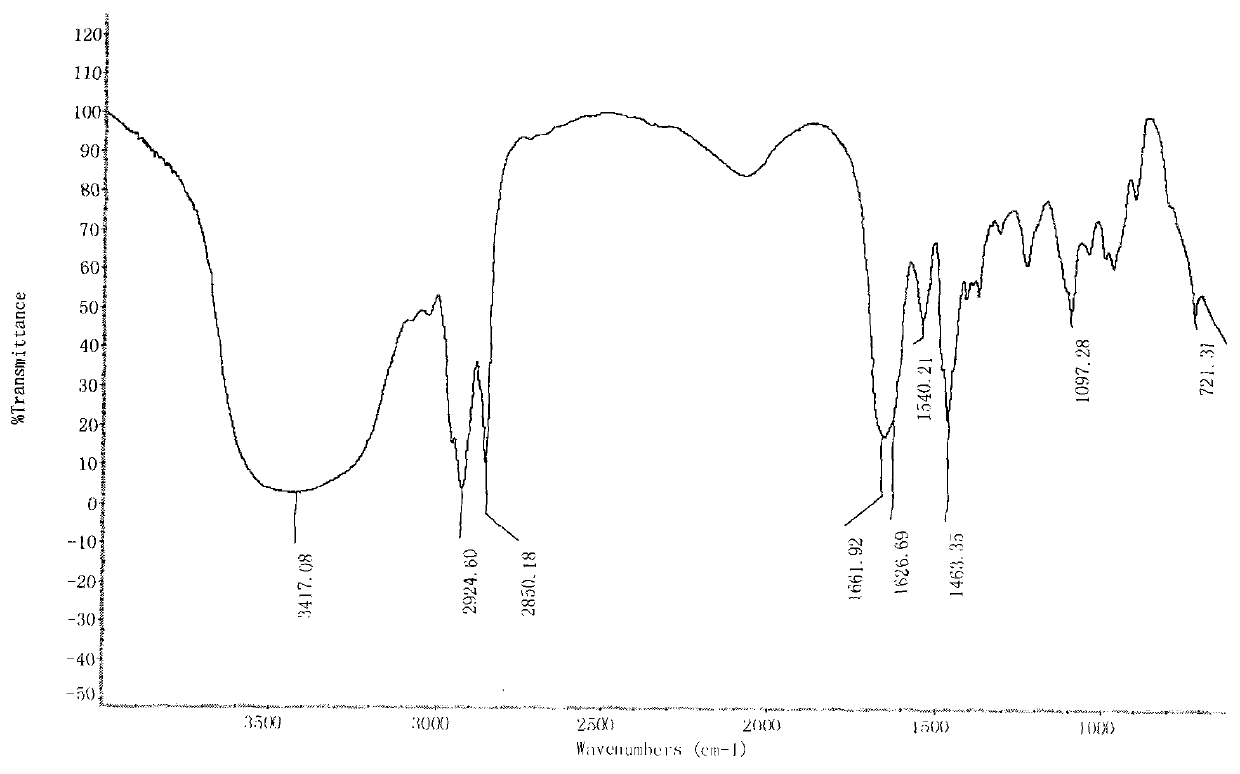

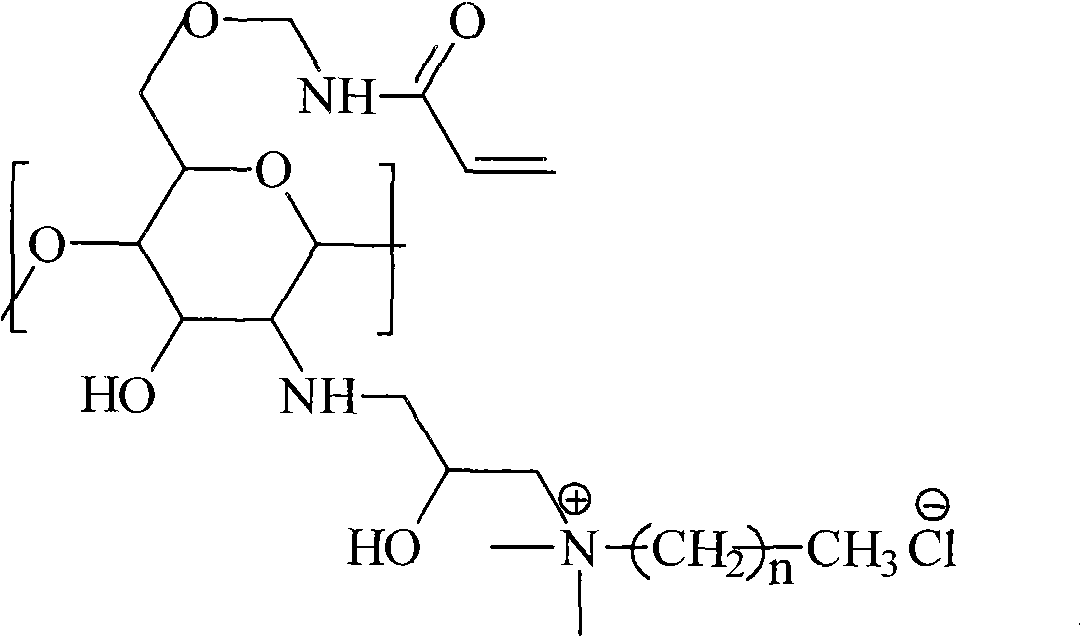

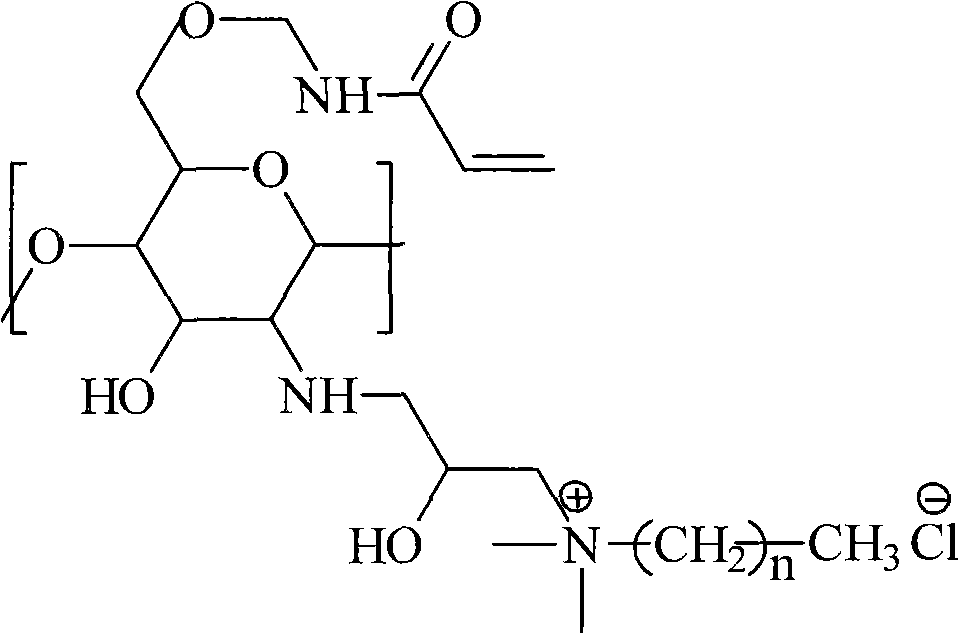

Water-soluble chitosan quaternary ammonium salt antibiotic finishing agent and preparation and application thereof

The invention relates to a water-soluble chitosan quaternary ammonium salt antibiotic finishing agent. The invention is characterized in that the antibiotic finishing agent is names as O-methacrylamide-N-hydroxypropyl alkyl dimethyl ammonium chloride chitosan and the concrete structural formula is as follows. The preparation thereof includes that: alkyl dimethyl tertiary amide and epichlorohydrin are taken as raw materials to synthesize 2, 3-epoxy alkyl dimethyl ammonium chloride, then the 2, 3-epoxy alkyl dimethyl ammonium chloride is introduce onto the ammonium group of chitosan, so as to obtain N-hydroxypropyl alkyl dimethyl ammonium chloride chitosan HDCC, and then crosslinking is carried out on the HDCC and hydroxymethyl acrylamide is carried out, thus obtaining NMA-HDCC. The quaternary ammonium salt antibiotic finishing agent contains water-soluble group and fibrous reactivity group and has good water solubility, the bacterial inhibition rate of finished cotton fabrics is close to 100%, and the finishing agent can be combined with cellulose fiber by covalent bond and is wash-resistant; and cost is low, raw material is environmental friendly, environmental pollution is less, thus having industrialization application prospect.

Owner:DONGHUA UNIV

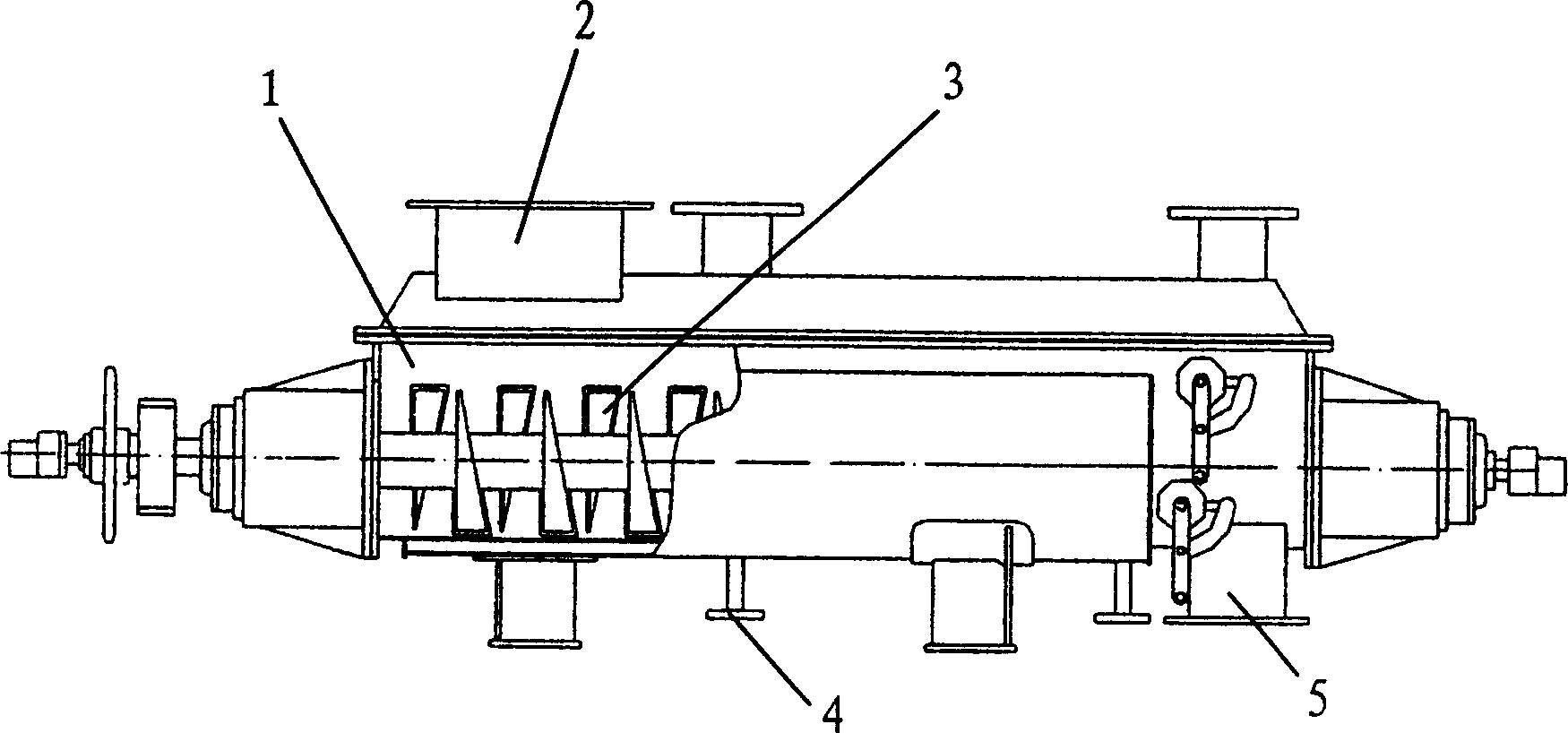

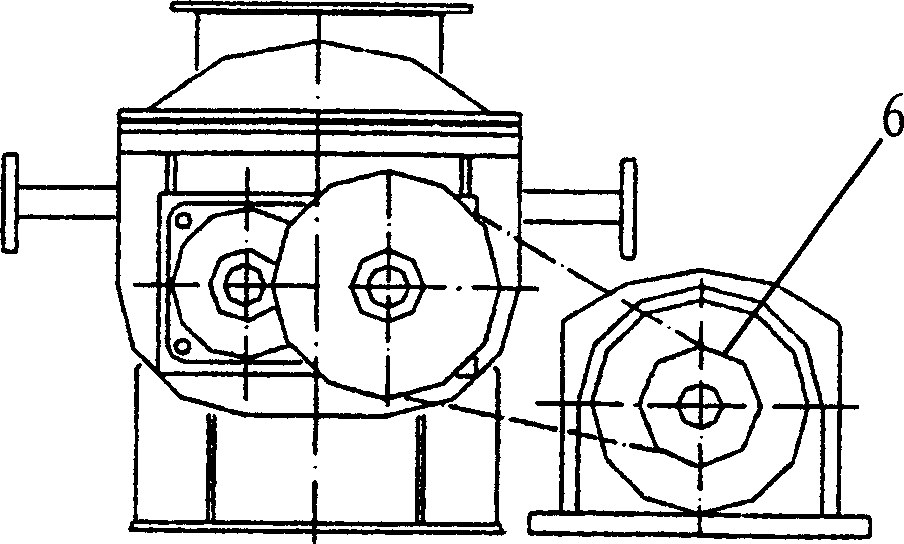

Method of producing ranadium pentoxide using vanadium containing waste catalyst

InactiveCN1752021ACatalyst regeneration/reactivationVanadium oxidesAmmonium chloride mixtureVanadium(V) oxide

A process for preparing V2O5 from the used catalyst containing V includes such steps as removing deposited oil from said catalyst, pulverizing, immersing in water, oxidizing, adding alkali to regulate pH=8.5-9.5, extracting at 50-60 deg.C for 1-2 hr, solid-liquid separation, recovering the solution of sodium vanadate and sodium molybdate, washing filtered dregs, calcining in rotary furnace, dissolving the calcined material in water, stirring, solid-liquid separation, recovering the solution of sodium vanadate and sodium molybdate, collecting said solution, removing impurity P, adding ammonium chloride to generate ammonium metavanadate deposit, solid-liquid separation, adding ammonium metavanadate in flake-making furnace, decomposing at 800-850 deg.C to obtain fused V2O5, and preparing V2O5 flakes.

Owner:刘亚光

Method for recycling ammonia from low concentration ammonium chloride wastewater

The invention discloses a method for recovering ammonia from low-concentration ammonium chloride wastewater, which comprises the following steps that: an alkaline substance is added into the low-concentration ammonium chloride wastewater to prepare mixed slurry containing ammonia water and chloride salt; the mixed slurry is subjected to the separation and concentration of the ammonia water in an ammonia water distillation concentration tower to obtain ammonia vapor and a drained waste liquid; the ammonia vapor is conveyed to an ammonia water cooler for cooling treatment, and the ammonia water obtained by the cooling treatment is stored for standby; and the drained waste liquid is subjected to solid-liquid separation to obtain solid-phase residue and a waste liquid containing the chloride salt. The method evaporates the ammonia in the low-concentration ammonium chloride wastewater and concentrates the ammonia to an industrial grade concentration, and has the advantages of broad source of auxiliary materials, low cost, completely sealed technical process, and low energy consumption; and drained substances meet the requirement of no pollution and no nuisance.

Owner:包头市西骏环保科技有限公司

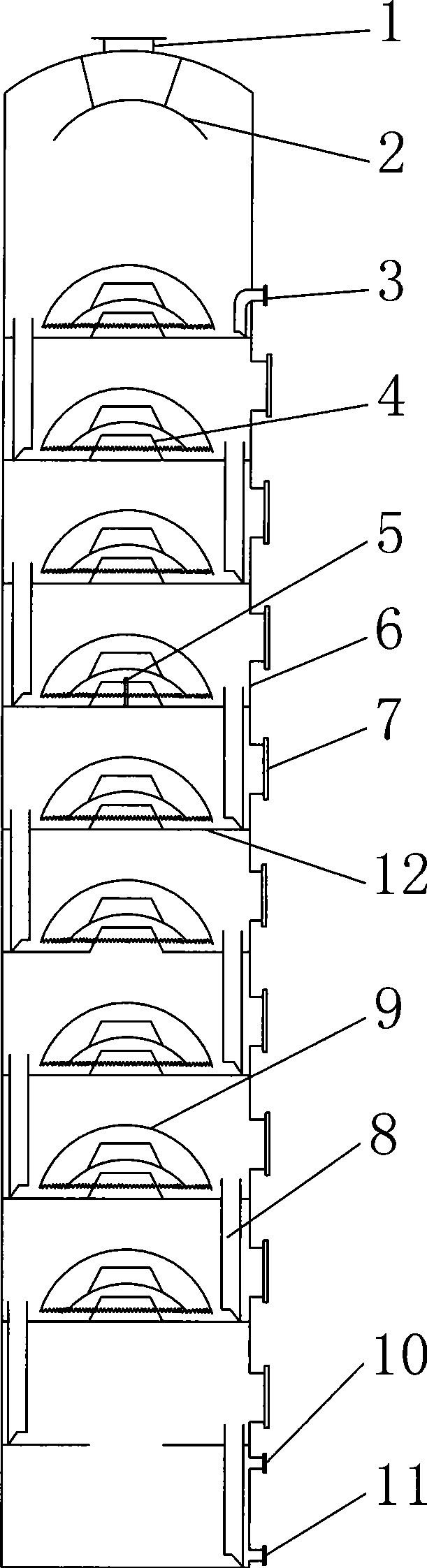

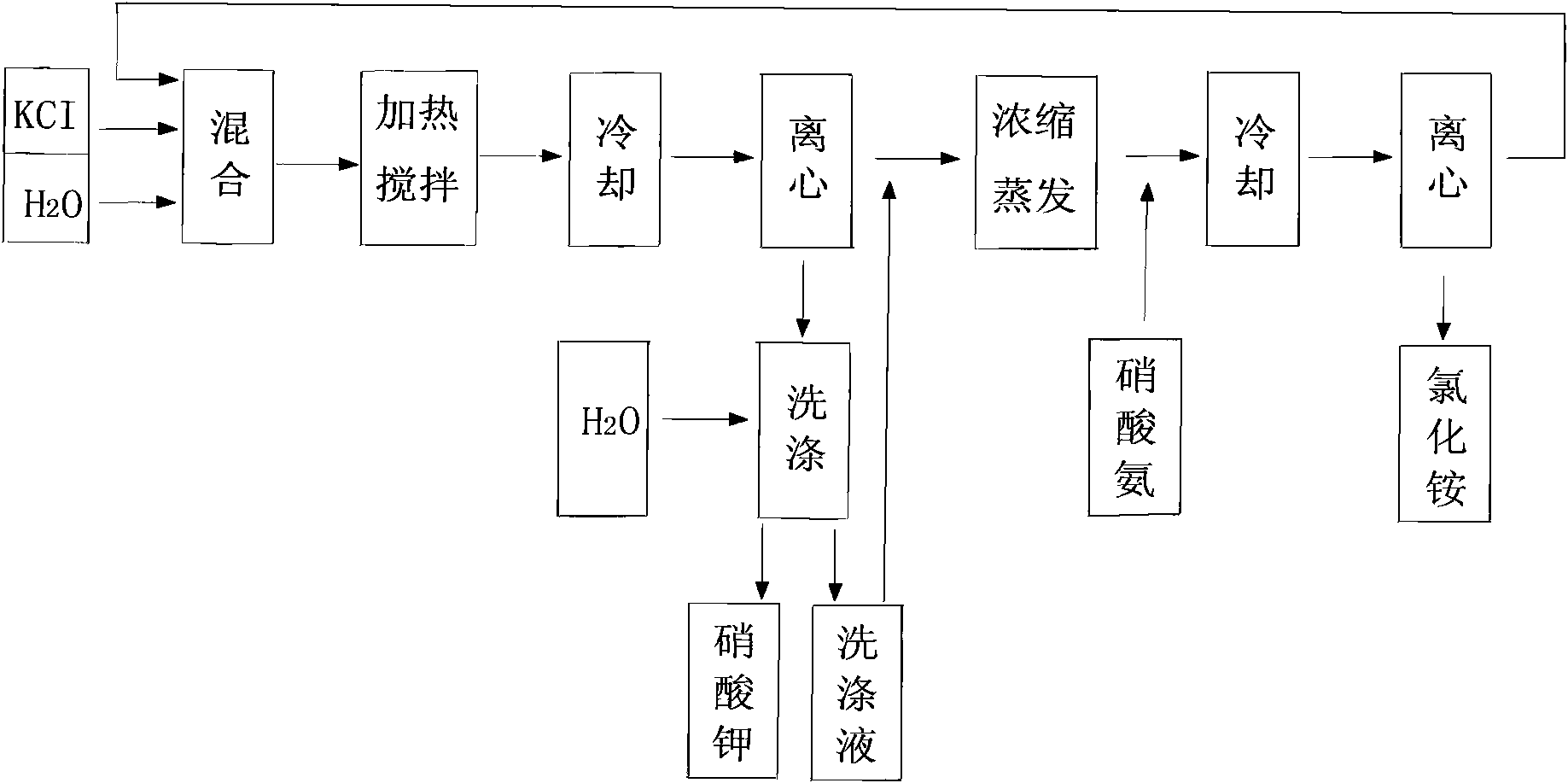

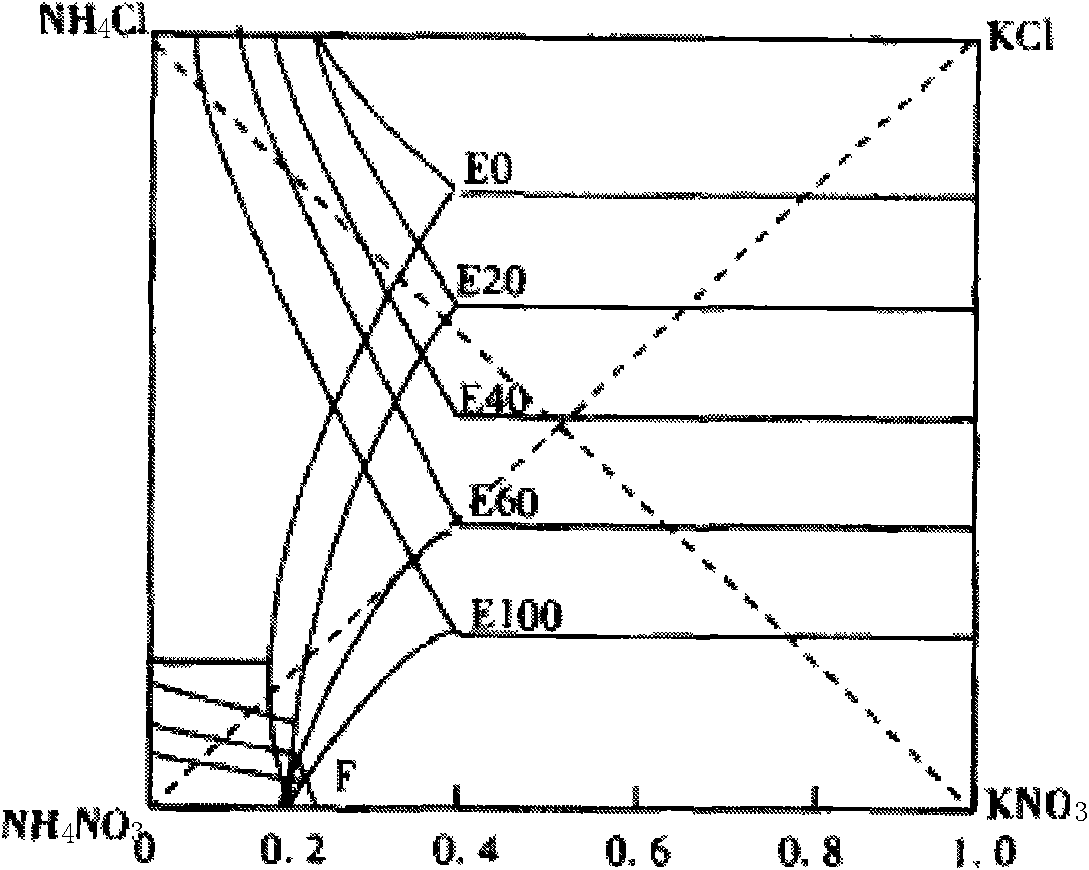

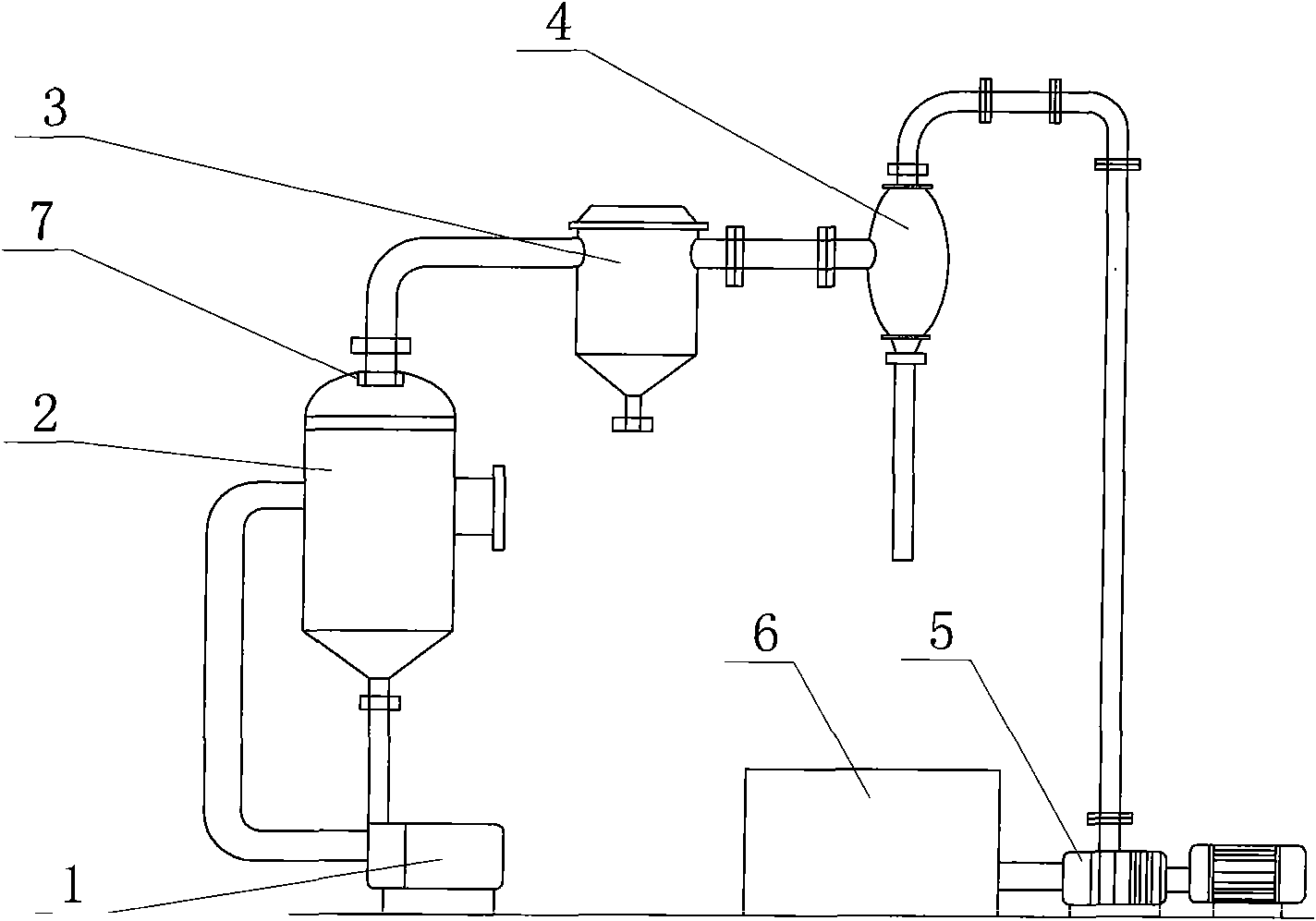

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

Preparation method for chitosan natural polymer modified crude oil desalting demulsifier

ActiveCN106188552ALimited demulsibilityIntensify the degree of emulsificationDewatering/demulsification with chemical meansQuaternary ammonium cationNon toxicity

The invention relates to a preparation method for a chitosan natural polymer modified crude oil desalting demulsifier. The method comprises the following steps: 1) modifying polyethylene glycol monomethyl ether by halogenating; 2) preparing glycidyl dimethyl alkyl ammonium chloride; 3) preparing quaternized carboxy alkyl chitosan; 4) causing the modified polyethylene glycol monomethyl ether to react with the quaternized carboxy alkyl chitosan, thereby obtaining a target product, polyethylene glycol monomethyl ether grafted quaternized carboxy alkyl chitosan. According to the invention, the chitosan natural high-molecular compound is taken as the raw material and has the advantages of wide resource, naturality, non-toxicity, sustainability, excellent biological compatibility of products, degradability, and the like. The demulsifier prepared according to the invention has excellent demulsification dewatering effect; the molecule of the demulsifier contains a large amount of carboxy alkyl groups and quaternary ammonium salt groups and the electronegative ions, including metal cation, naphthene acid radicals, and surfaces are electronegative grains and have strong combining capacity, so that the demulsifier has the capacities of demulsifying while removing oil-soluble salt.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

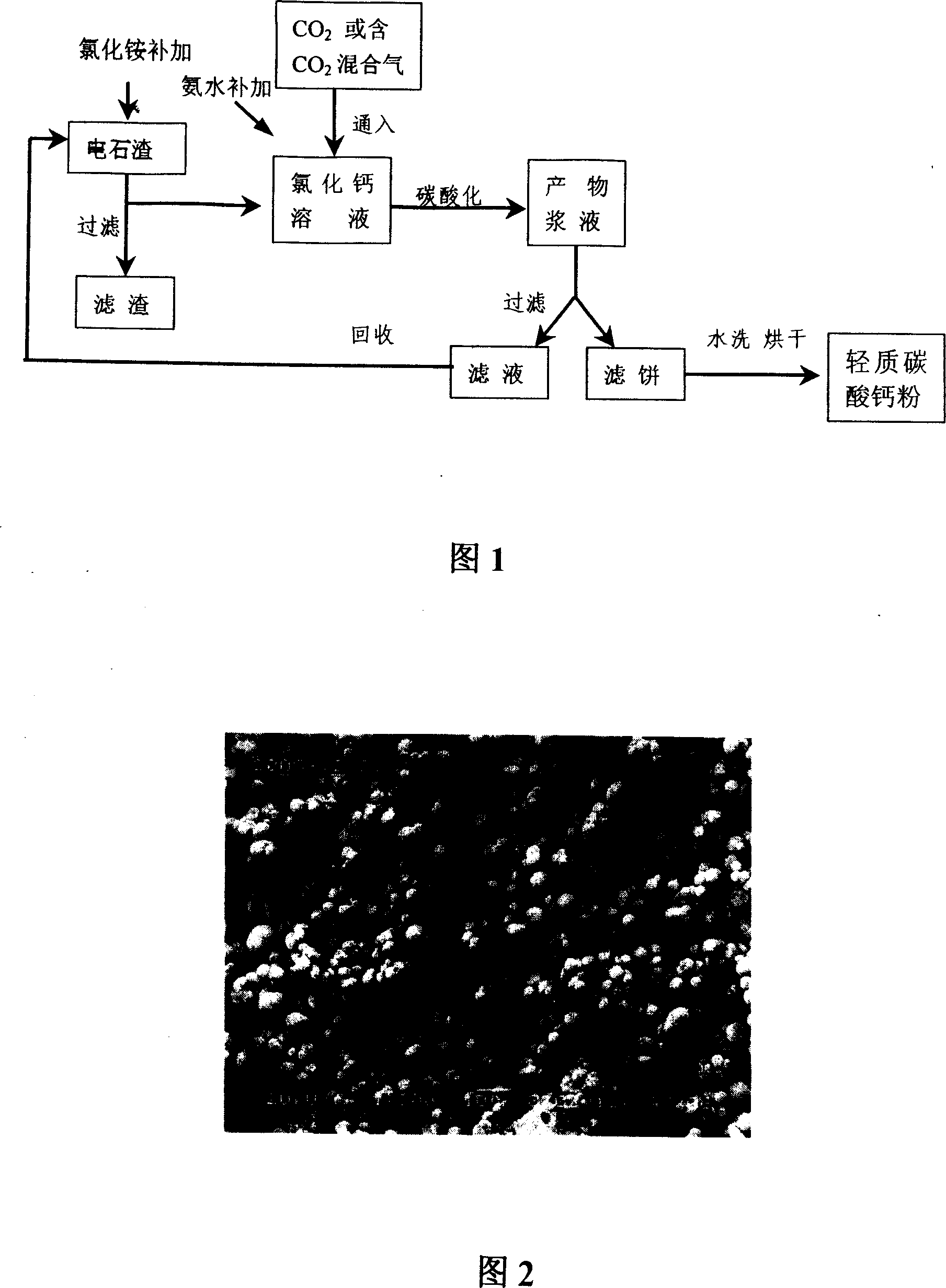

Process of preparing high purity light calcium carbonate fine powder with carbide residue

InactiveCN101020579AHigh purityReduce the difficulty of manufacturing processCalcium/strontium/barium carbonatesCalciteSlurry

The process of preparing high purity light calcium carbonate fine powder with carbide residue includes reacting carbide residue as one kind of industrial waste directly with ammonium chloride solution to produce mixture solution of calcium chloride and ammonia water, filtering, introducing CO2 gas for carbonating reaction, filtering the produced slurry, water washing the filter cake and stoving to obtain calcite type spherical light calcium carbonate fine powder, and circulating ammonium chloride solution for reuse. The present invention has simple technological process, lowered production cost, high product purity and high product quality.

Owner:NAT UNIV OF DEFENSE TECH

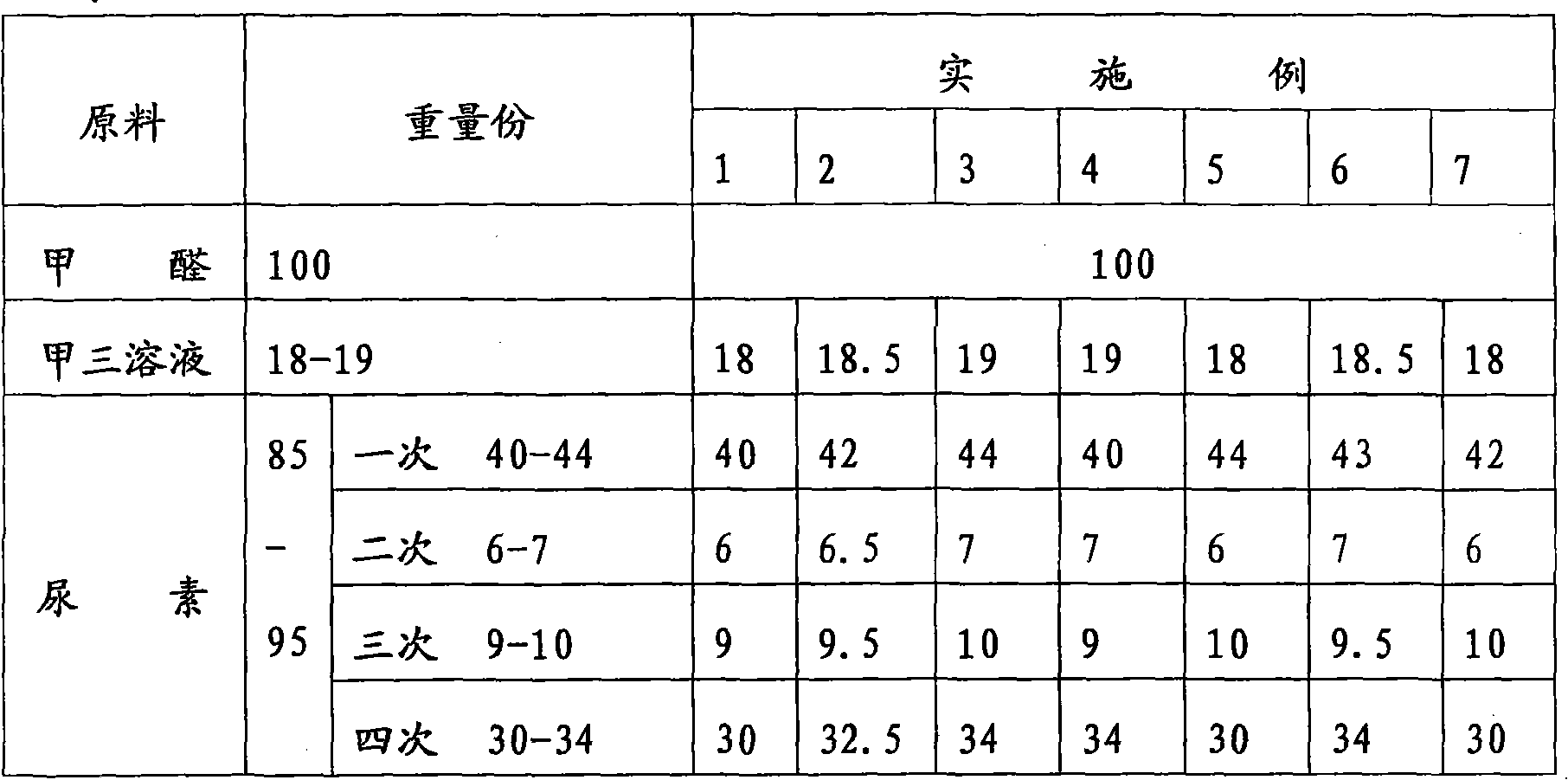

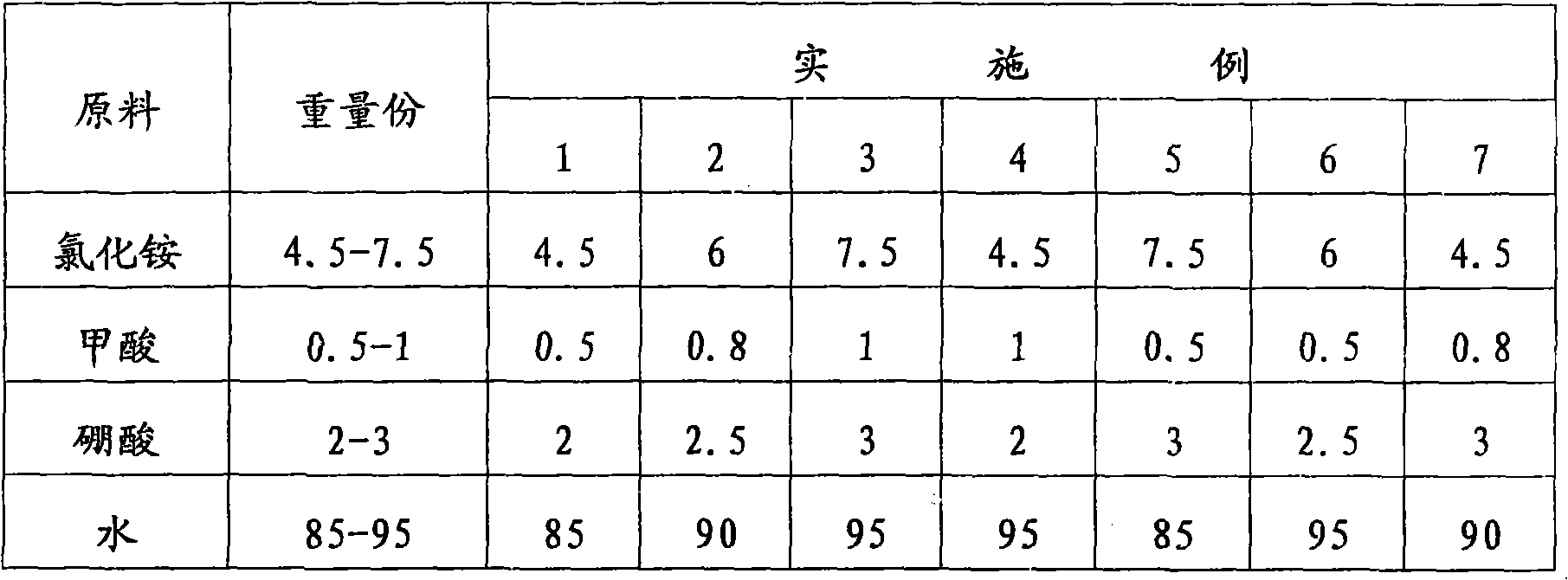

Production method of environmental-friendly type low-cost middle and high density fiber board

ActiveCN101791817AReduce formaldehyde contentReduce releaseNon-macromolecular adhesive additivesWood working apparatusOXALIC ACID DIHYDRATEFiber

The invention relates to a production method of an environmental-friendly type low-cost middle and high density fiber board. Self-made modified urea-formaldehyde glue, a composite curing agent and a formaldehyde trapping agent are used in a glue blending procedure, wherein the modified urea-formaldehyde glue is prepared by heating formaldehyde, melamine and urea in a reaction kettle through a chemical reaction; the composite curing agent is prepared by mixing ammonium chloride, boric acid, oxalic acid and water; and the formaldehyde trapping agent is prepared from phosphoric acid, urea, a catalyst and water under a certain temperature condition. When the middle and high density fiber is produced, the application amount of the formaldehyde trapping agent is 3 percent or 4 percent of the weight of modified urea-formaldehyde glue solid, the application amount of the modified urea-formaldehyde glue solution is 12.5 percent of the weight of absolute dried fiber, and the application amount of the composite curing agent is 3 percent or 2 percent of the weight of the modified urea-formaldehyde glue solution. The middle and high density fiber board produced using the three ingredients can completely meet Eo level environmental-friendly requirements, has good compatibility and high bonding strength and greatly reduces production cost of the fiber board.

Owner:ZHEJIANG FORESTRY ACAD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com