Drilling fluid plugging agent while drilling

A technology of plugging while drilling and drilling fluid, applied in the directions of reagents, drilling compositions, chemical instruments and methods, etc., can solve the problems of increasing the occurrence of downhole accidents, reducing drilling speed, running slurry, etc., and improving fracture expansion resistance. , Improve the wellbore fracture pressure, the effect of small influence on rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

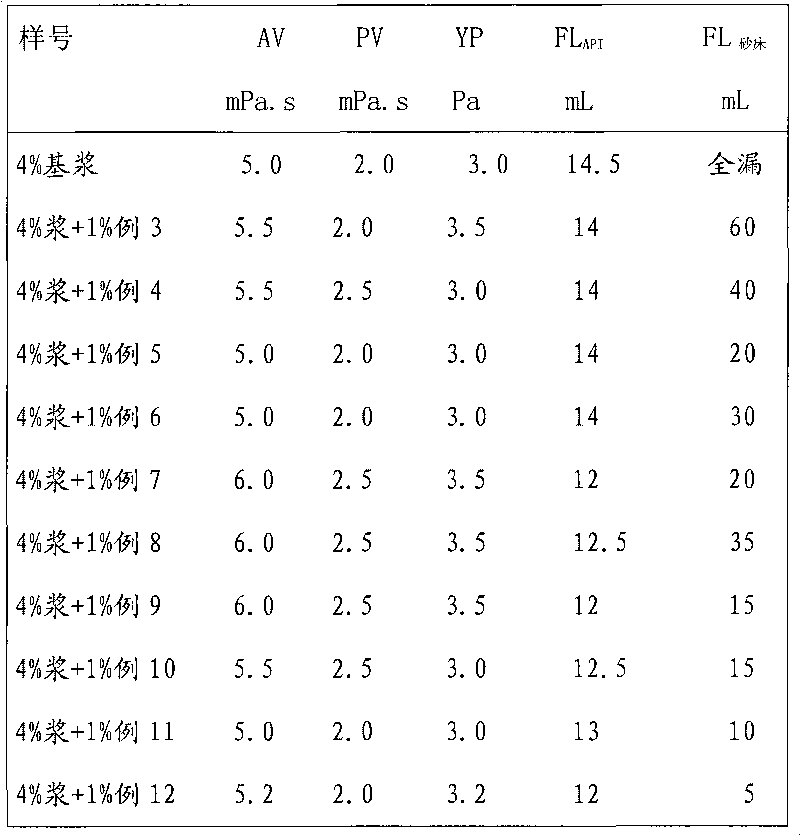

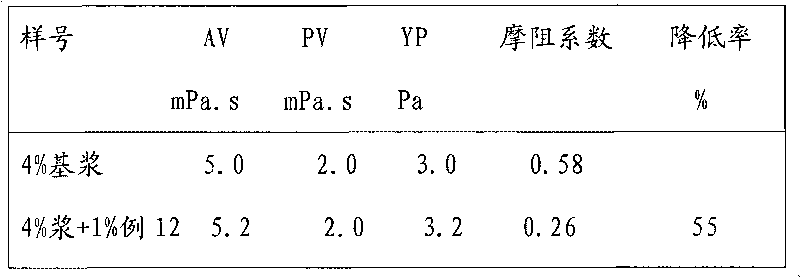

Examples

Embodiment 1

[0036] Add an appropriate amount of sodium hydroxide to 30 grams of 10% acrylic acid solution for neutralization to make a sodium acrylate solution, add 10 grams of acrylamide, 12 grams of 2-acrylamide-2-methylpropanesulfonic acid, 5 grams of Anqiu bentonite and 10 grams of water, after mixing evenly, fill with nitrogen for 20 minutes,

[0037] To drive away dissolved oxygen, 0.05 g of potassium persulfate, 0.05 g of sodium bisulfite, and 0.05 g of methylenebisacrylamide were added at room temperature to initiate the reaction. After the reaction product is dried, it is granulated, pulverized and sieved through a 100-mesh sieve to obtain a product with a water absorption ratio of 20.

[0038] Note the test method of water absorption multiple

[0039] Accurately weigh a sample of a certain quality, place it in a 500ml beaker, add 400ml of water-absorbing medium, and stir thoroughly. After the sample absorbs water and swells constant (the time is greater than 24h), filter it wit...

Embodiment 2

[0045] Add an appropriate amount of sodium hydroxide to 30 grams of 10% acrylic acid solution for neutralization to make a sodium acrylate solution, add 10 grams of acrylammonium, 10 grams of dimethyl diallyl ammonium chloride, 5 grams of Anqiu bentonite and 10 grams of water, after mixing evenly, fill with nitrogen for 20 minutes to drive away dissolved oxygen, add 0.05 grams of potassium persulfate, 0.05 grams of sodium bisulfite, and 0.05 grams of methylenebisacrylamide at room temperature to initiate the reaction . After the reaction product is dried, it is granulated, pulverized and sieved through a 100-mesh sieve to obtain a product with a water absorption ratio of 38.

Embodiment 3

[0047] Take 60 parts of dried and pulverized corncobs passing through 80 meshes, 5 parts by weight of the weakly gelled polymer of Example 1, 20 parts by weight of asphalt raw powder (140°C), and 15 parts by weight of graphite in a mixer and mix them evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com