Patents

Literature

147results about How to "Increase burst pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

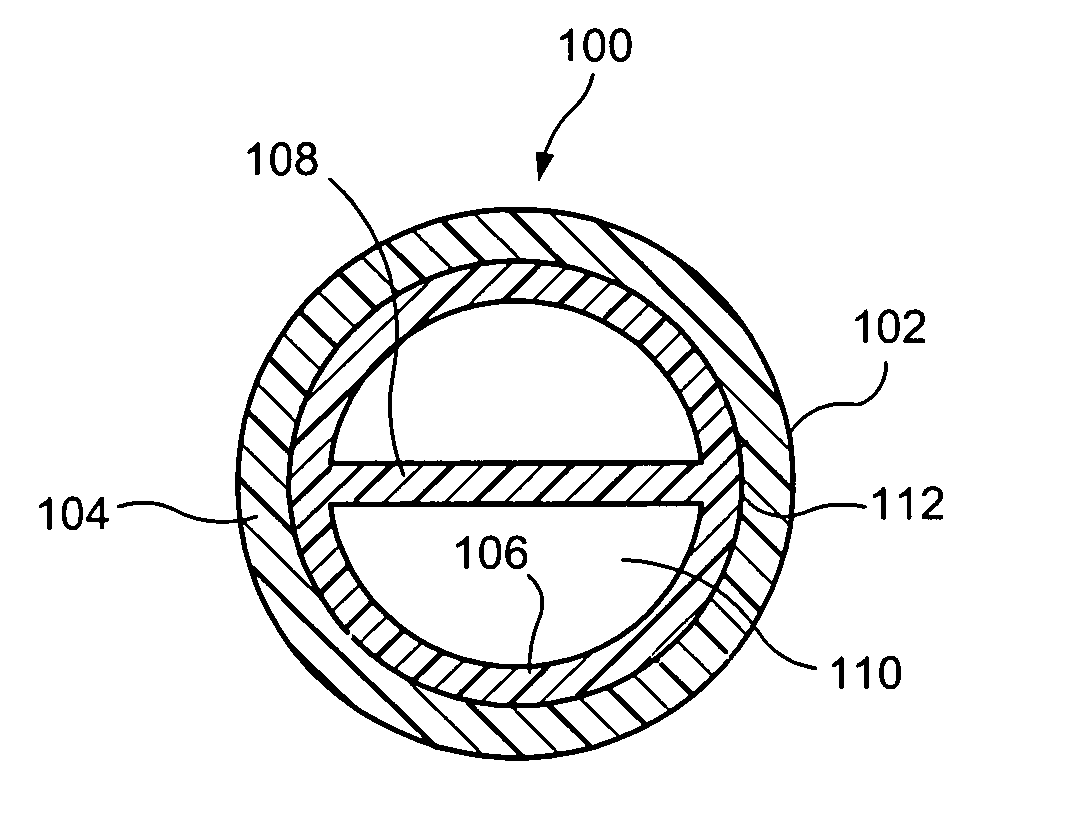

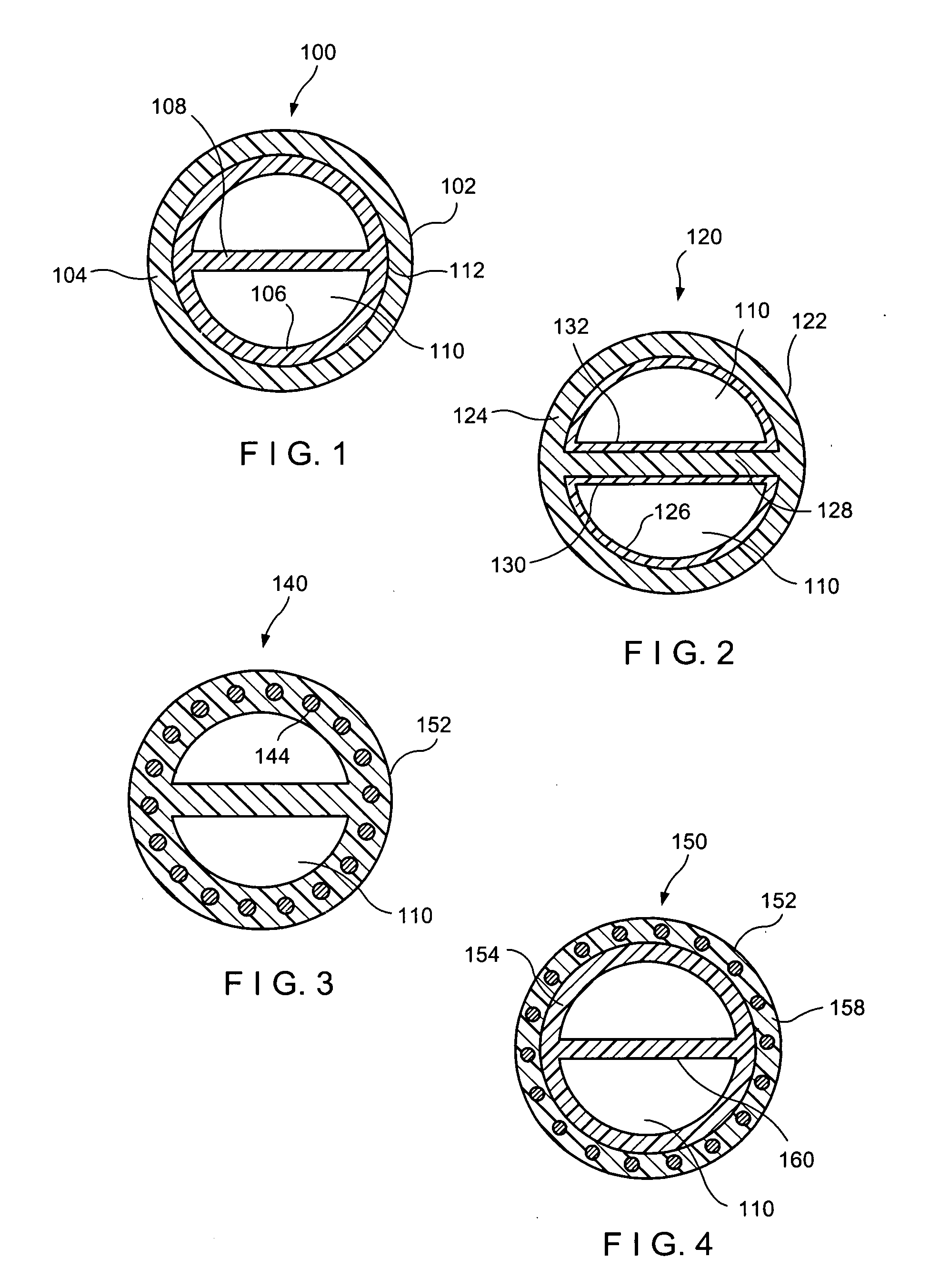

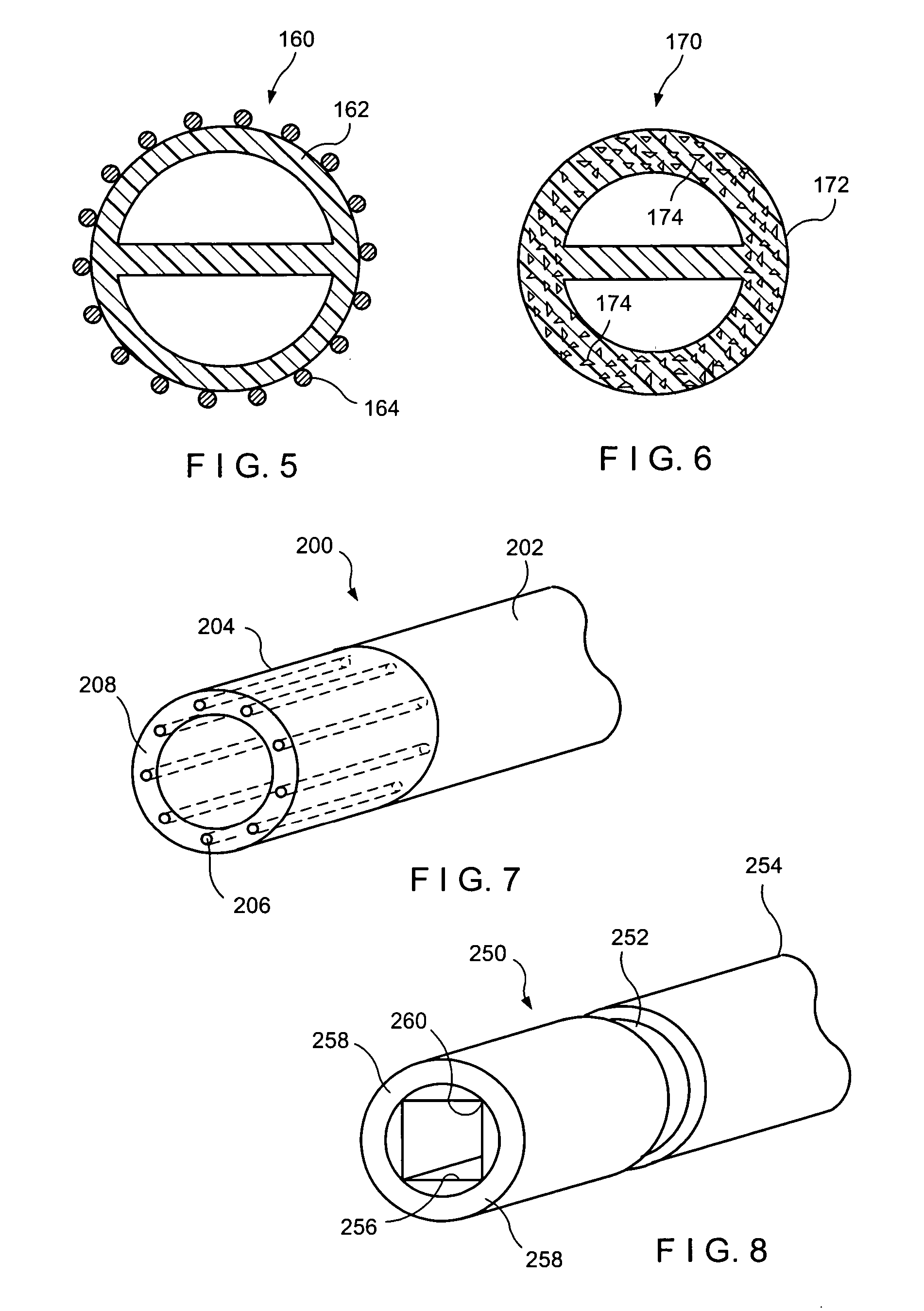

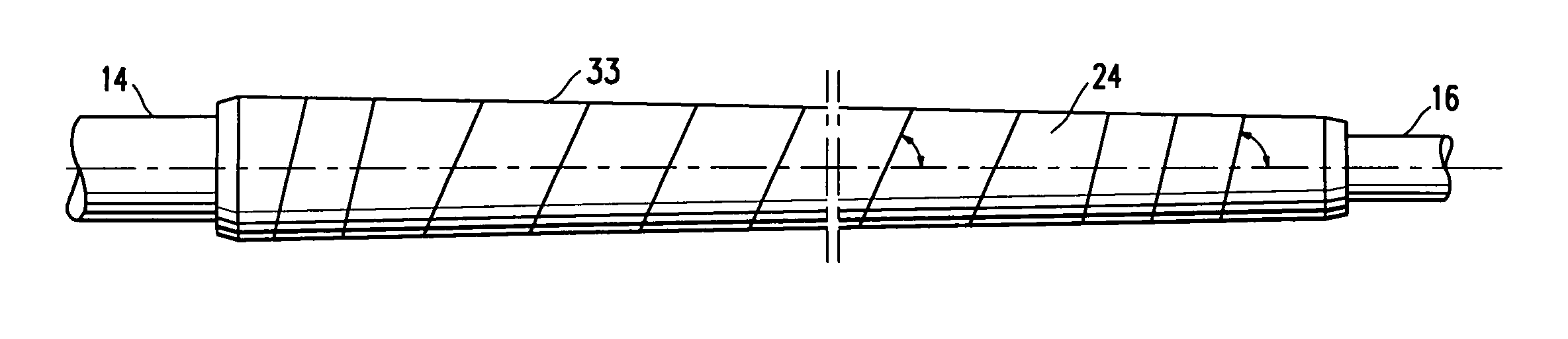

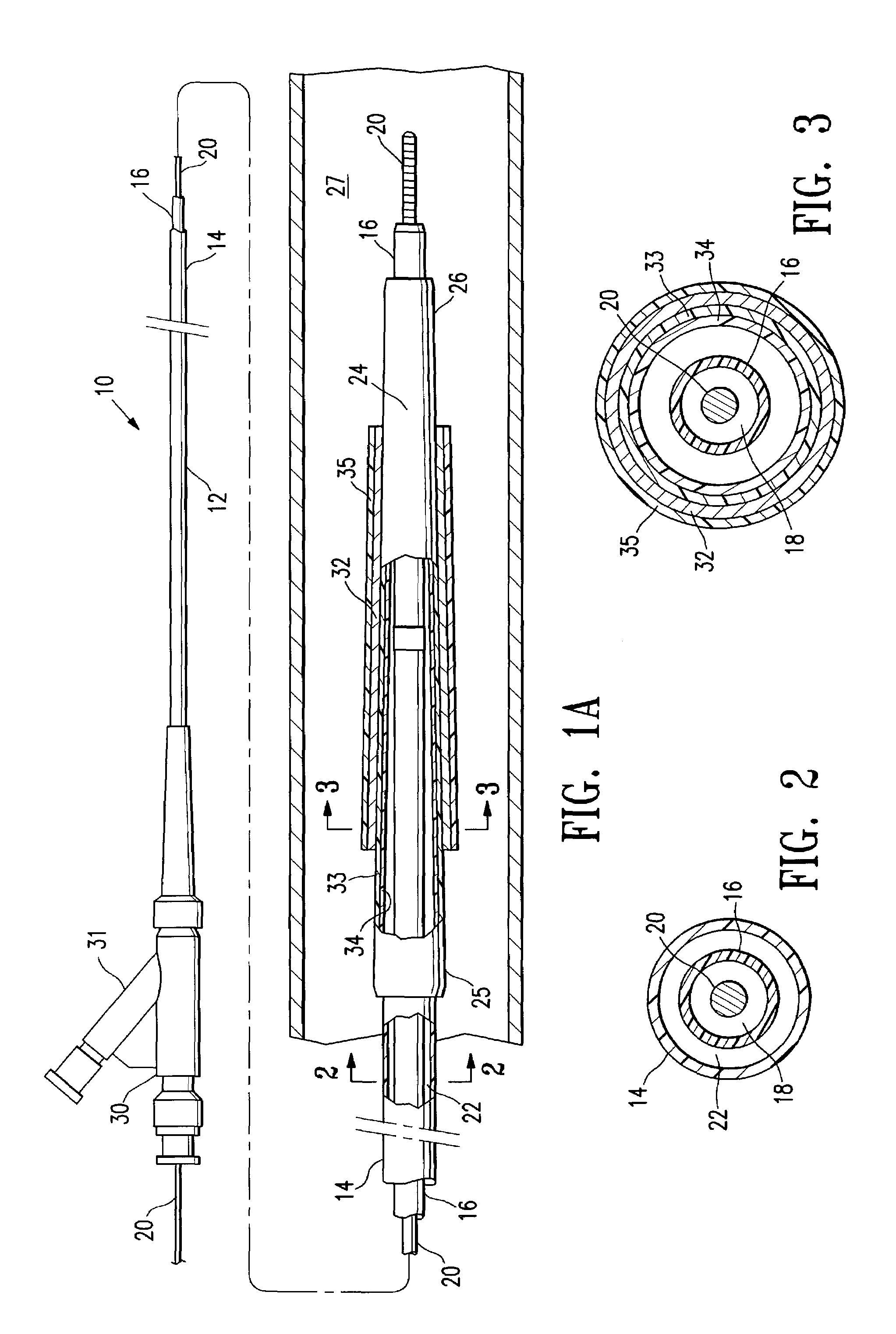

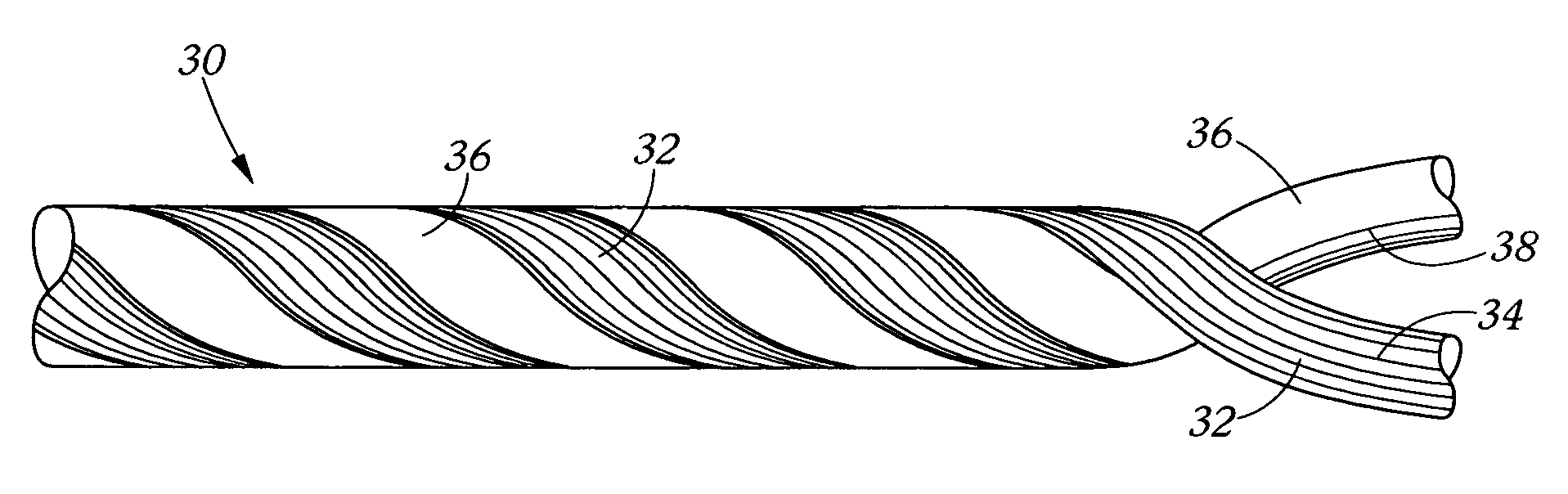

Reinforced venous access catheter

ActiveUS20060020256A1Increase burst pressureMulti-lumen catheterMedical syringesBurst pressureVenous access

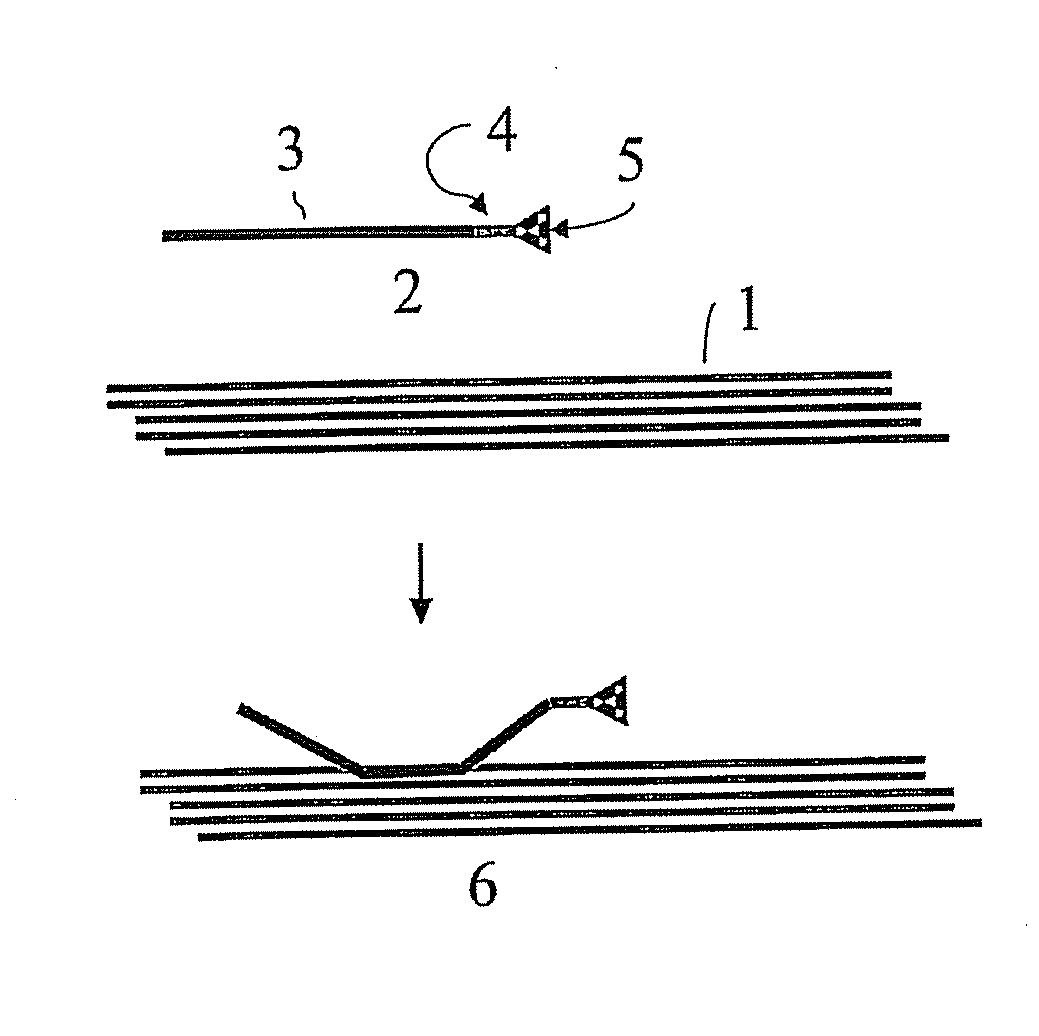

A catheter for medical procedures comprises a shaft portion having a distal end insertable into a body lumen, the shaft portion having a wall defining a working lumen extending therewithin and a first strengthening element coupled to the wall to increase a burst pressure of the shaft portion, wherein the first strengthening element cooperates with a base material of the wall to define a flexible region of the shaft portion allowing the shaft portion to be atraumatically inserted into the body lumen.

Owner:ANGIODYNAMICS INC

Catheter balloon

An expandable medical device or component thereof including a tubular body formed of a wrapped sheet of porous polymeric material fused together, the tubular body having a fused seam at an angle relative to the longitudinal axis of the tubular body which changes along the length of the tubular body from a first angle to a second angle greater than the first angle. The sheet of porous polymeric material is wound and then fused together such that the winding angle is less in a first longitudinal section of the tubular body compared with the winding angle in a second longitudinal section of the tubular body, in order to provide the second section with greater resistance to expansion (i.e., lower compliance) than the first section.

Owner:ABBOTT CARDIOVASCULAR

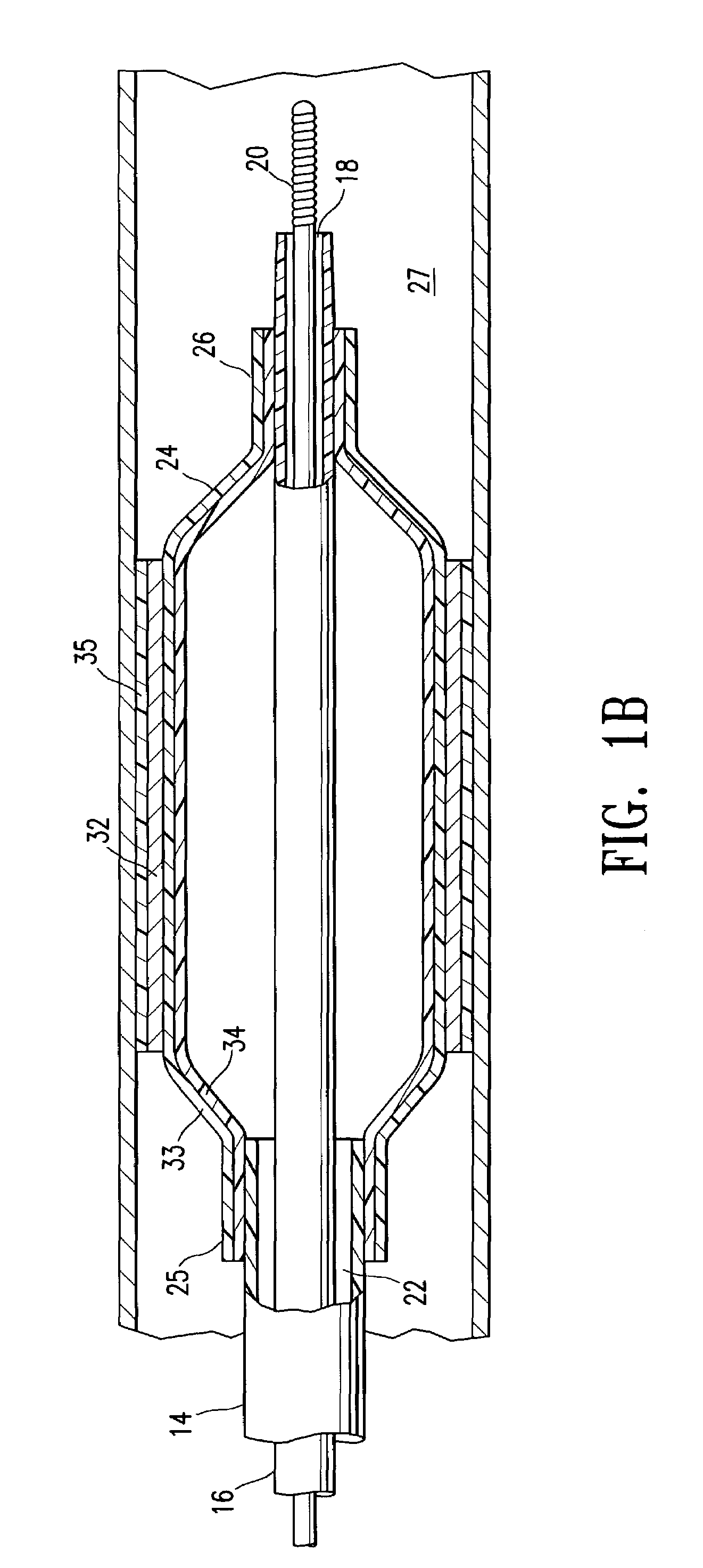

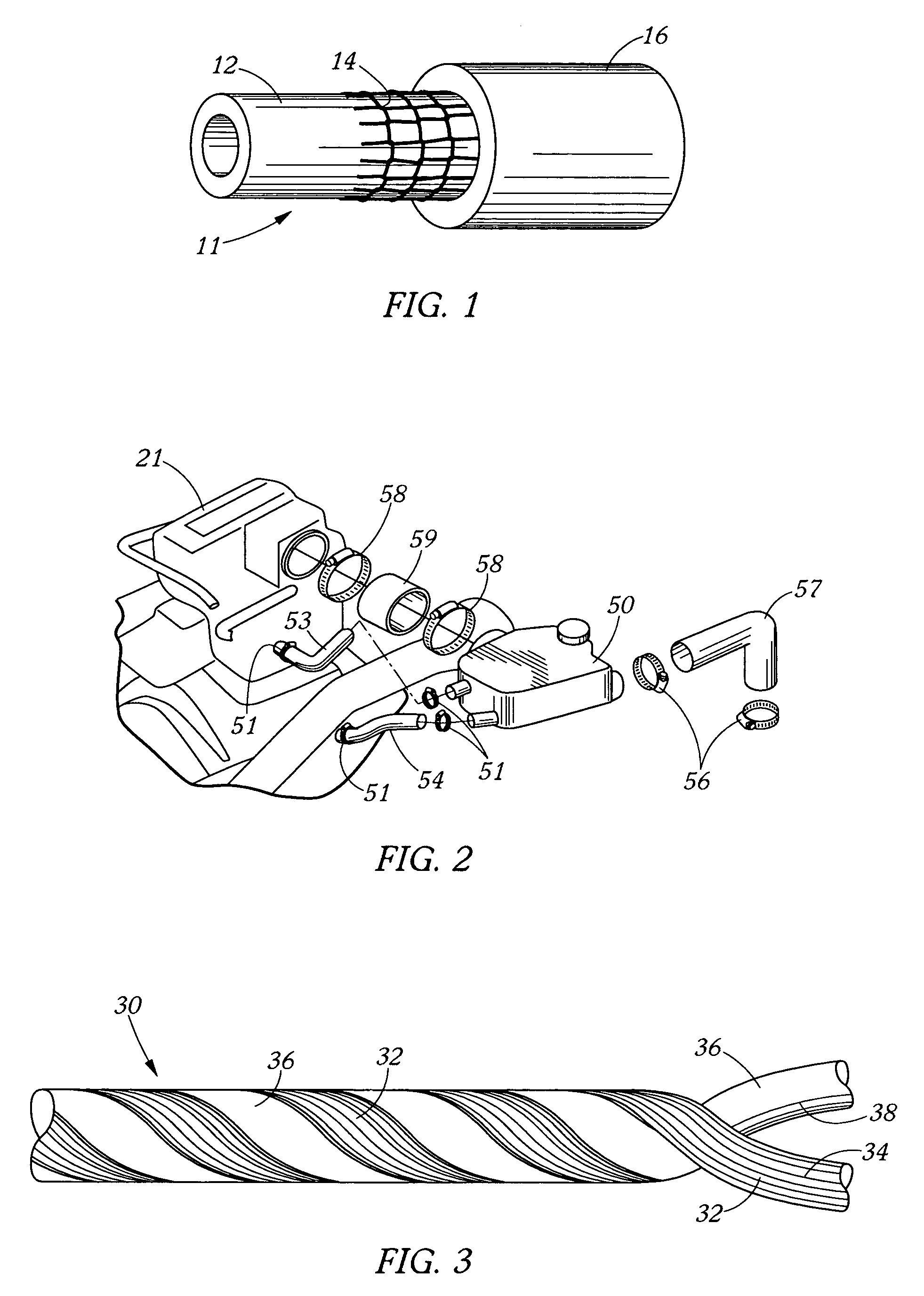

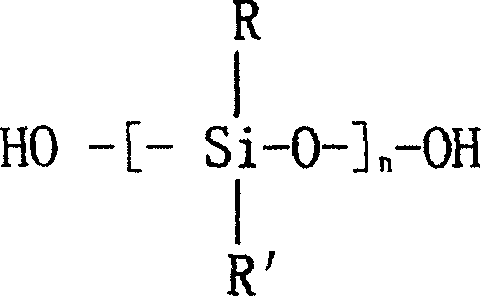

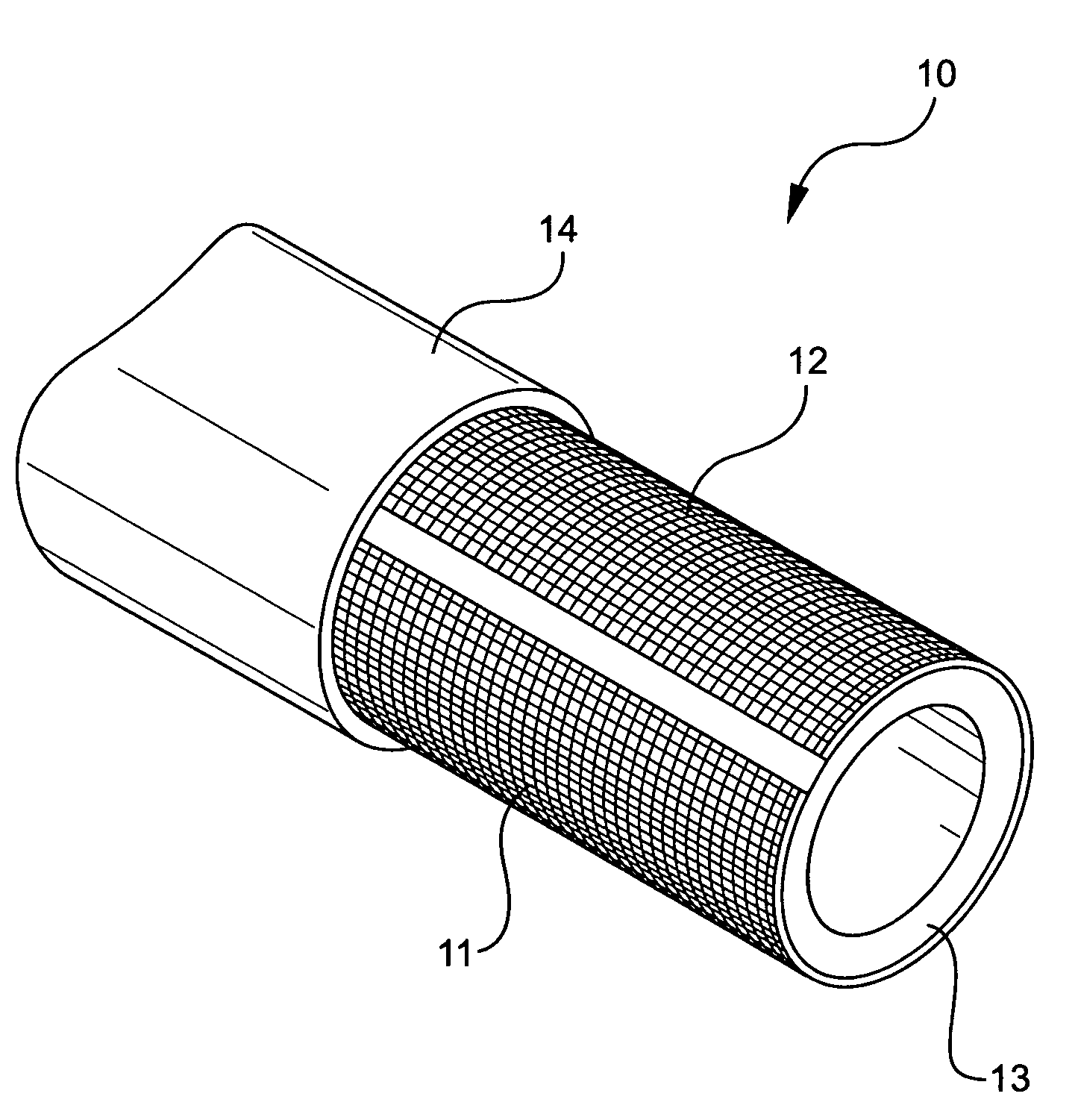

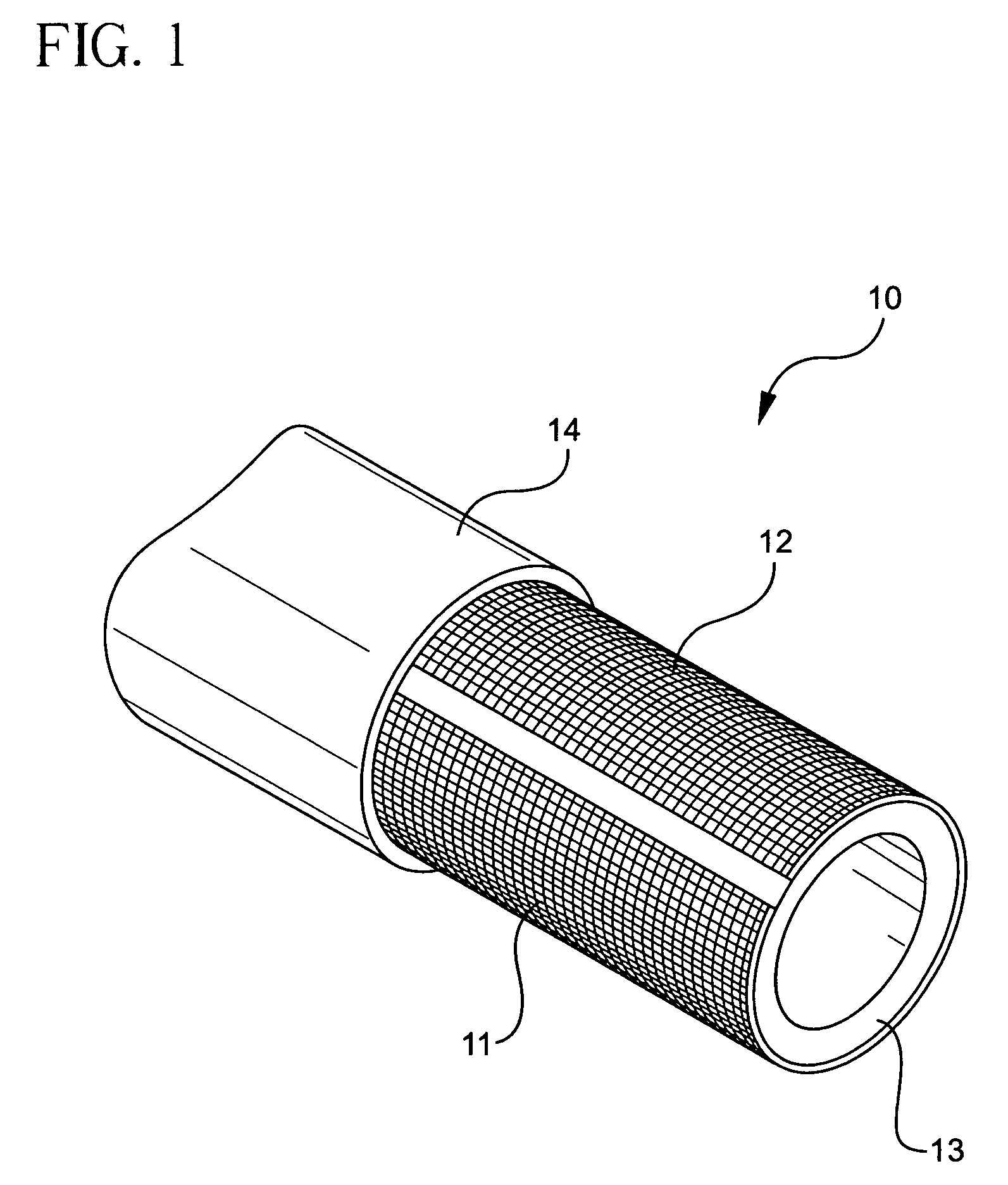

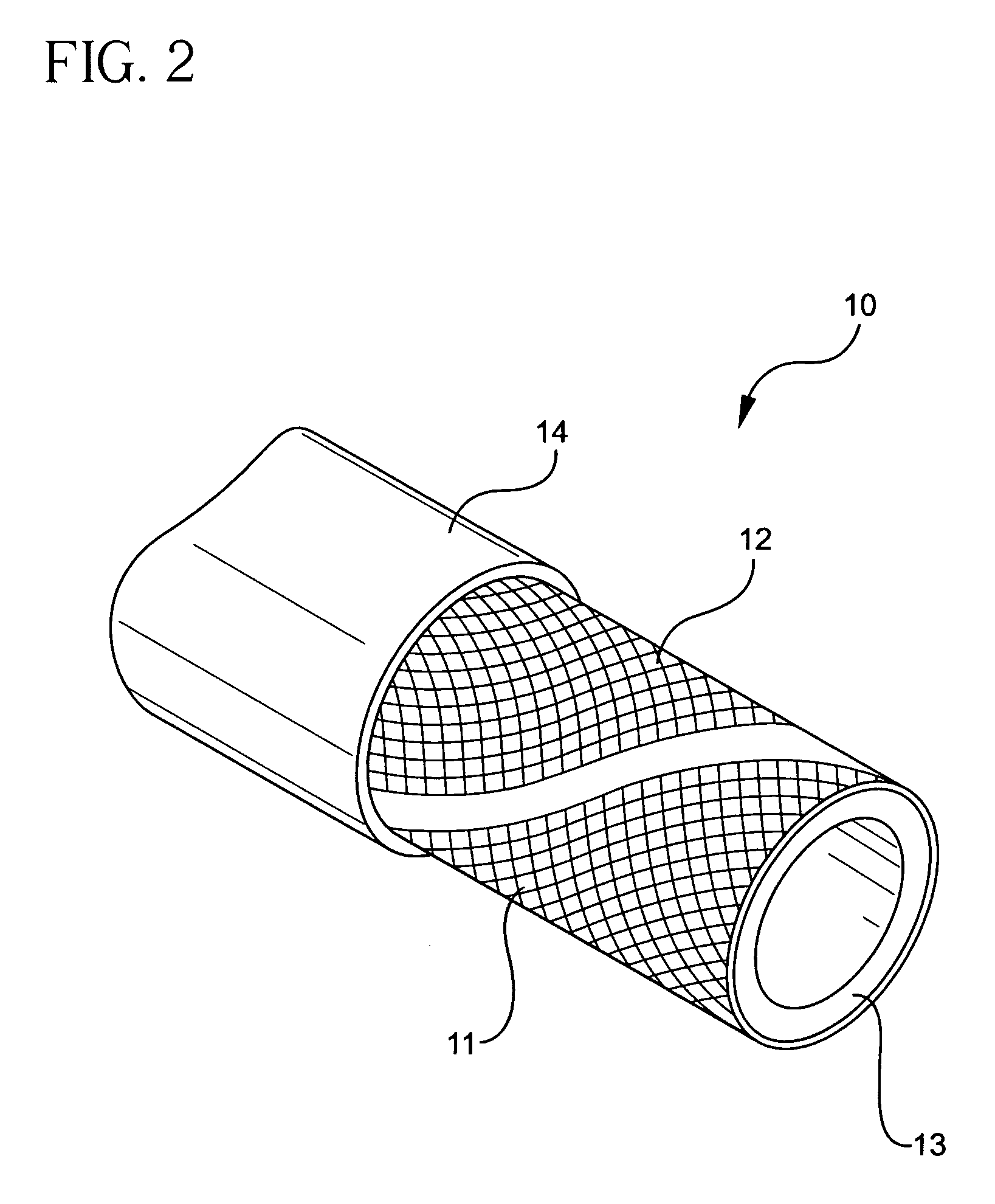

Fluid transfer hose reinforced with hybrid yarn

ActiveUS20080072984A1Improve adhesionDramatic performance improvementEngine sealsInternal combustion piston enginesYarnAramides

A flexible hose comprising a tube, a knit fabric, and a cover. The knit fabric comprises a hybrid yarn which comprises a first yarn of co-para-aramid fibers and a second yarn of meta-aramid fibers. The hose exhibits significantly improved burst pressure and / or improved impulse fatigue resistance.

Owner:THE GATES CORP

Low carbon alloy steel tube having ultra high strength and excellent toughness at low temperature and method of manufacturing the same

InactiveUS20090101242A1Improve toughnessHigh tensile strengthFurnace typesHeat treatment furnacesWater basedNiobium

Owner:TENARIS CONNECTIONS

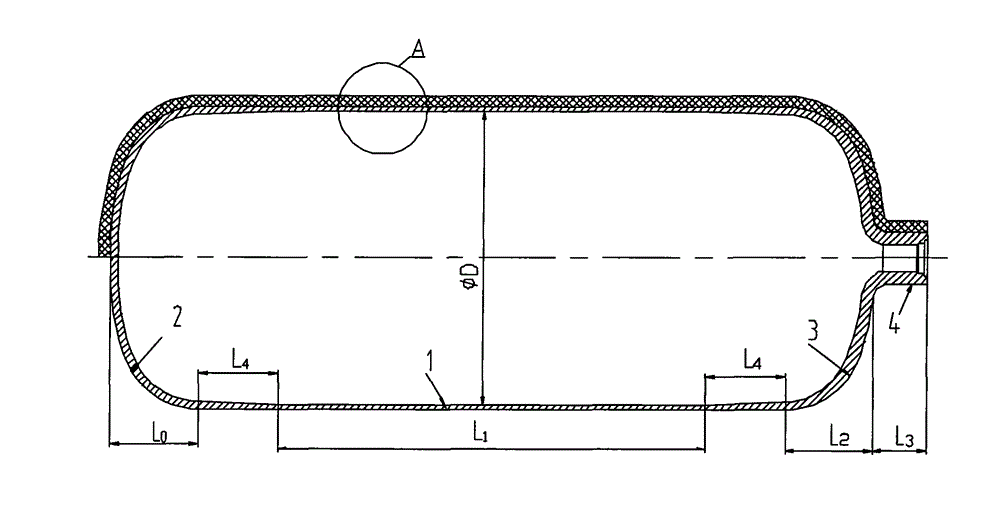

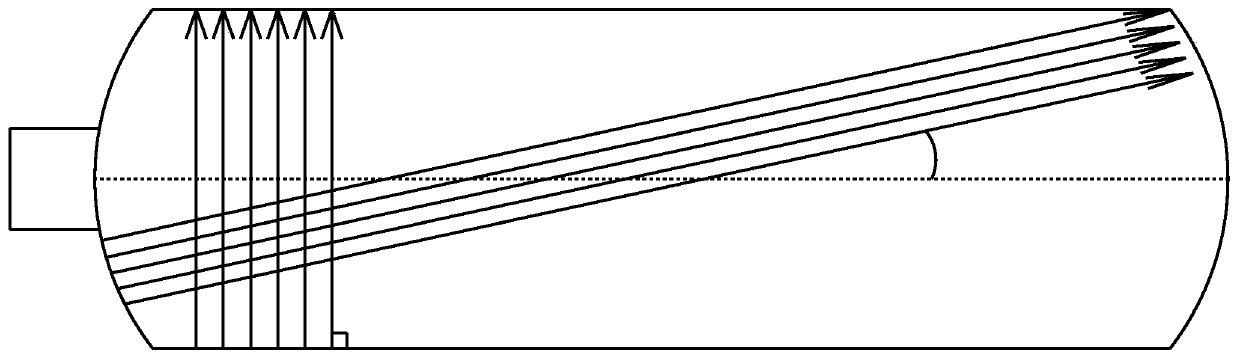

Method for producing carbon fiber-completely winded composite gas cylinder with aluminum inner container

InactiveCN102748584AIncrease burst pressureImprove air tightnessPressure vesselsGlass fiberCarbon fibers

The invention relates to a method for producing a carbon fiber-completely winded composite gas cylinder with an aluminum inner container. The carbon fiber-completely winded composite gas cylinder with the aluminum inner container has main bearing structures of the aluminum inner container and a carbon fiber completely-winding layer. The carbon fiber completely-winding layer on a cylinder body is prepared by alternately winding longitudinally spirally winding fiber layers and circumferentially winding fiber layers in a laying order designed optimally. Glass fiber layers are winded on the surface of the carbon fiber completely-winding layer and are used as impact resistant protective layers of the carbon fiber-completely winded composite gas cylinder with the aluminum inner container. The carbon fiber-completely winded composite gas cylinder with the aluminum inner container has main technical indexes of a safety factor great than or equal to 3.4 and fatigue cycle number N great than or equal to 10000. The method provided by the invention satisfies reasonable stress field distribution, and guarantees that the carbon fiber-completely winded composite gas cylinder with the aluminum inner container can bear maximum burst pressure under the condition of a minimum fiber use amount, produces cracks located at a cylinder body and does not produce fragments. The method guarantees that the aluminum inner container of the carbon fiber-completely winded composite gas cylinder with the aluminum inner container is always in an elastic deformation state under preset work pressure, and guarantees that the carbon fiber-completely winded composite gas cylinder with the aluminum inner container has lasting and good gas tightness and optimal safety.

Owner:BEIJING TIANHAI IND

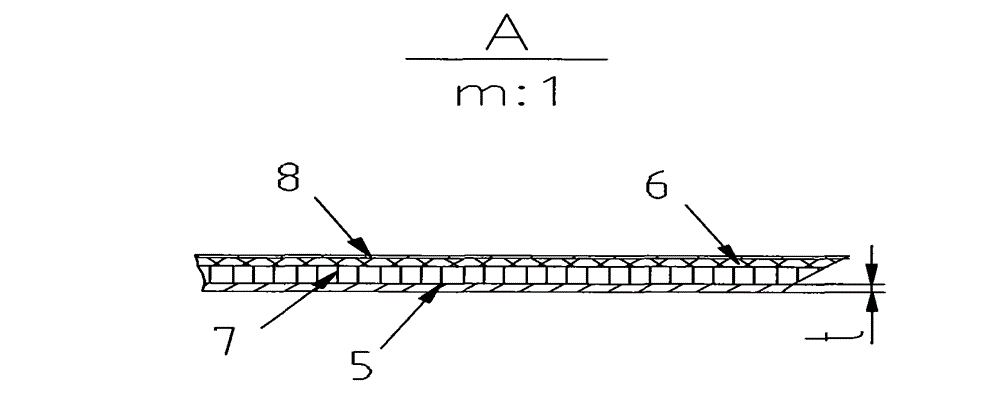

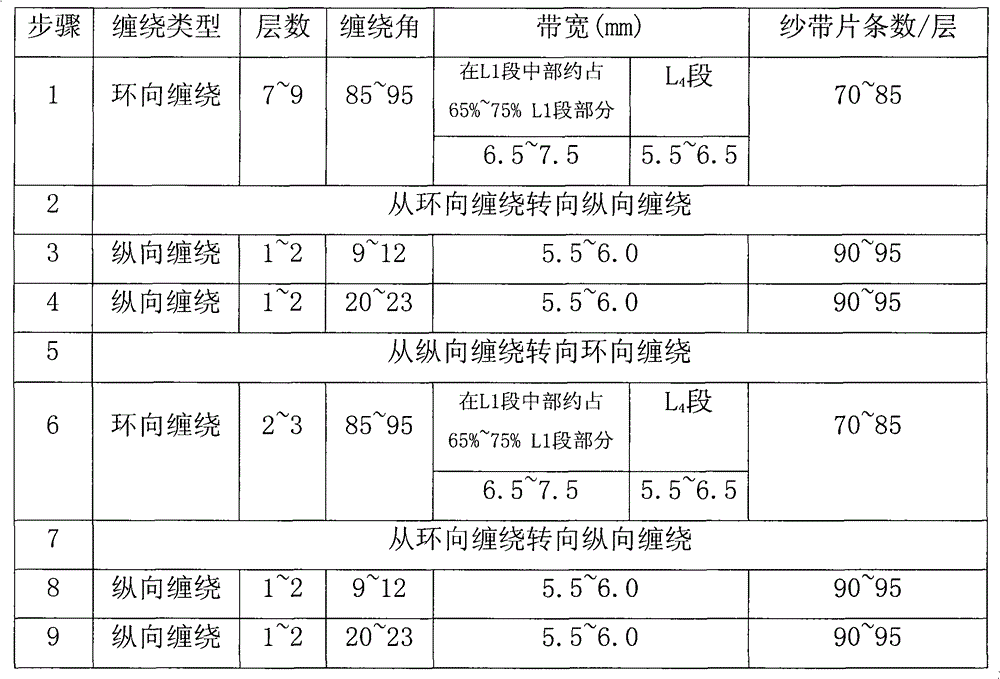

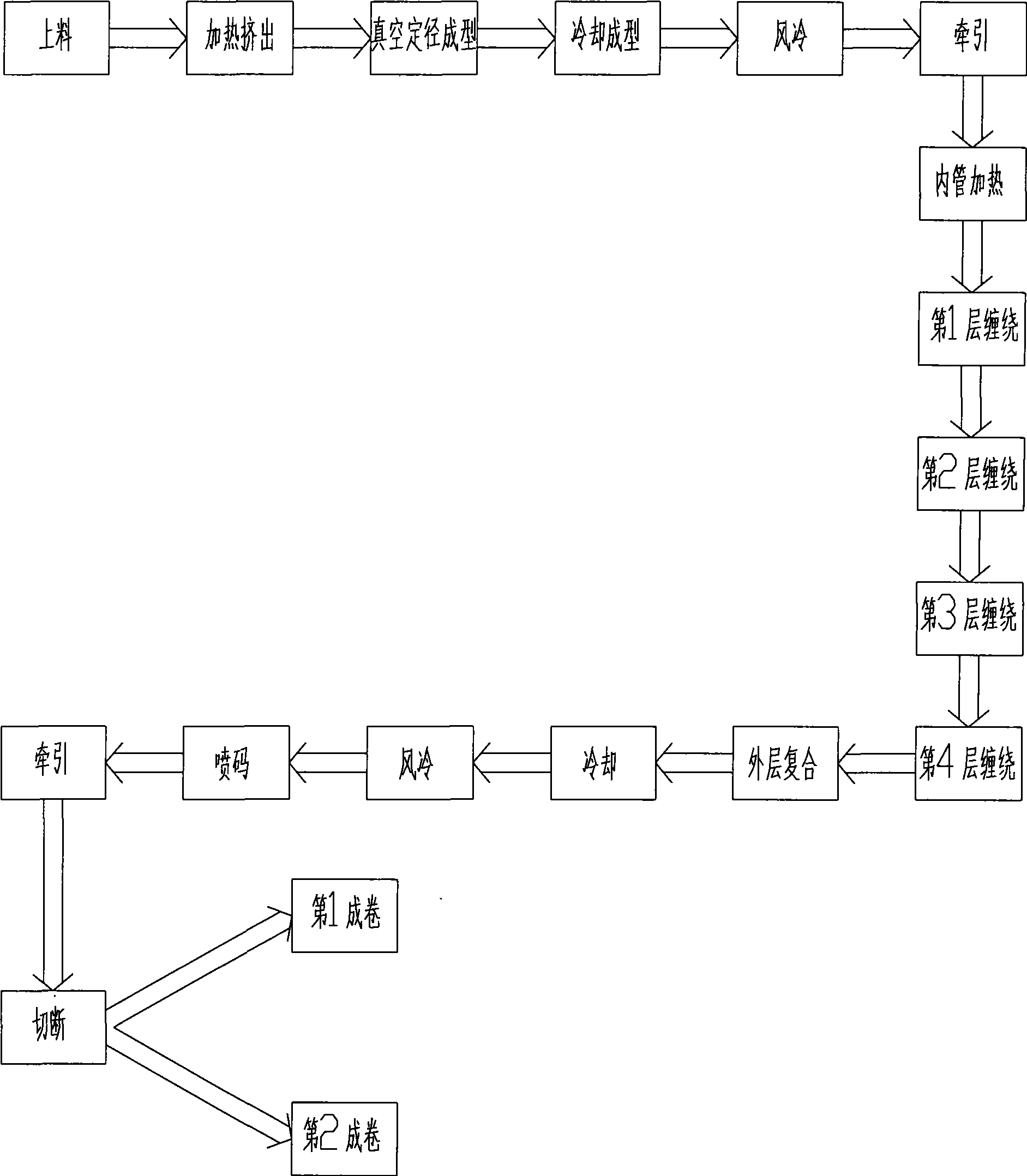

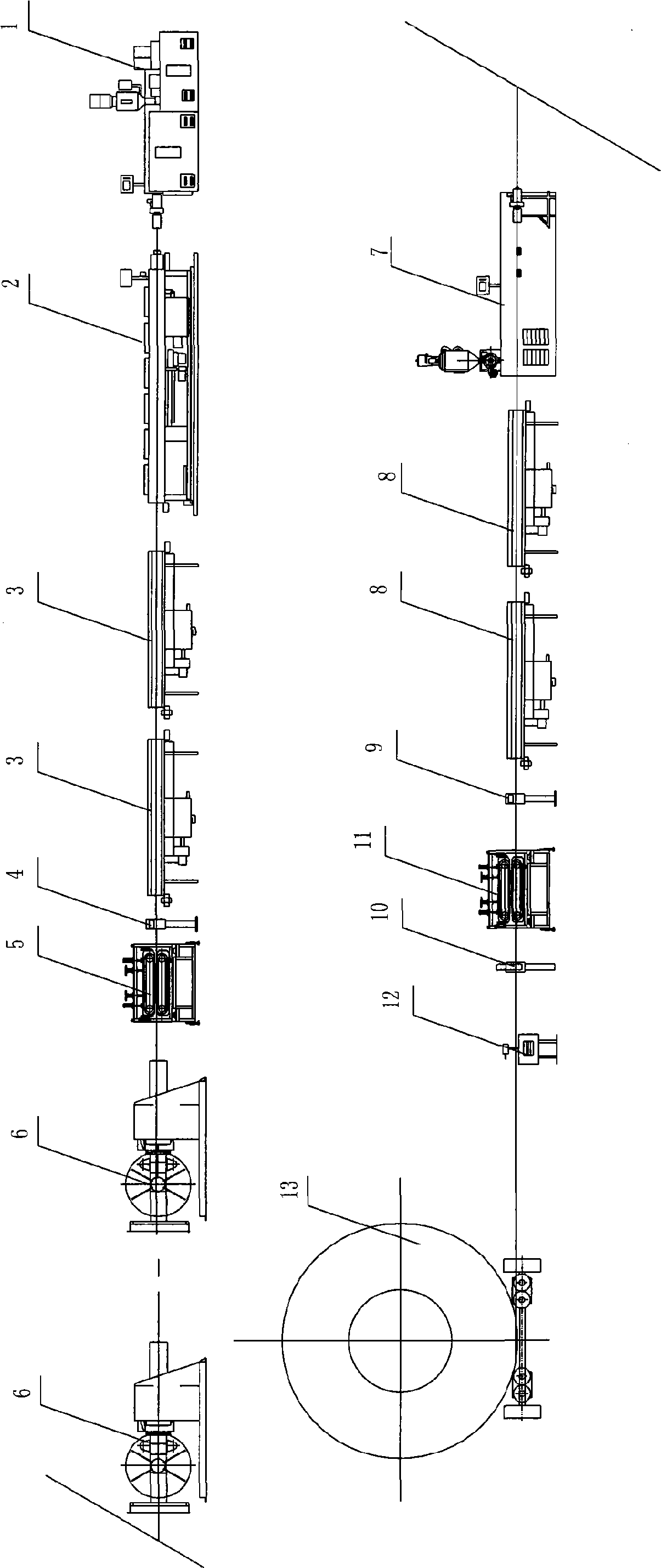

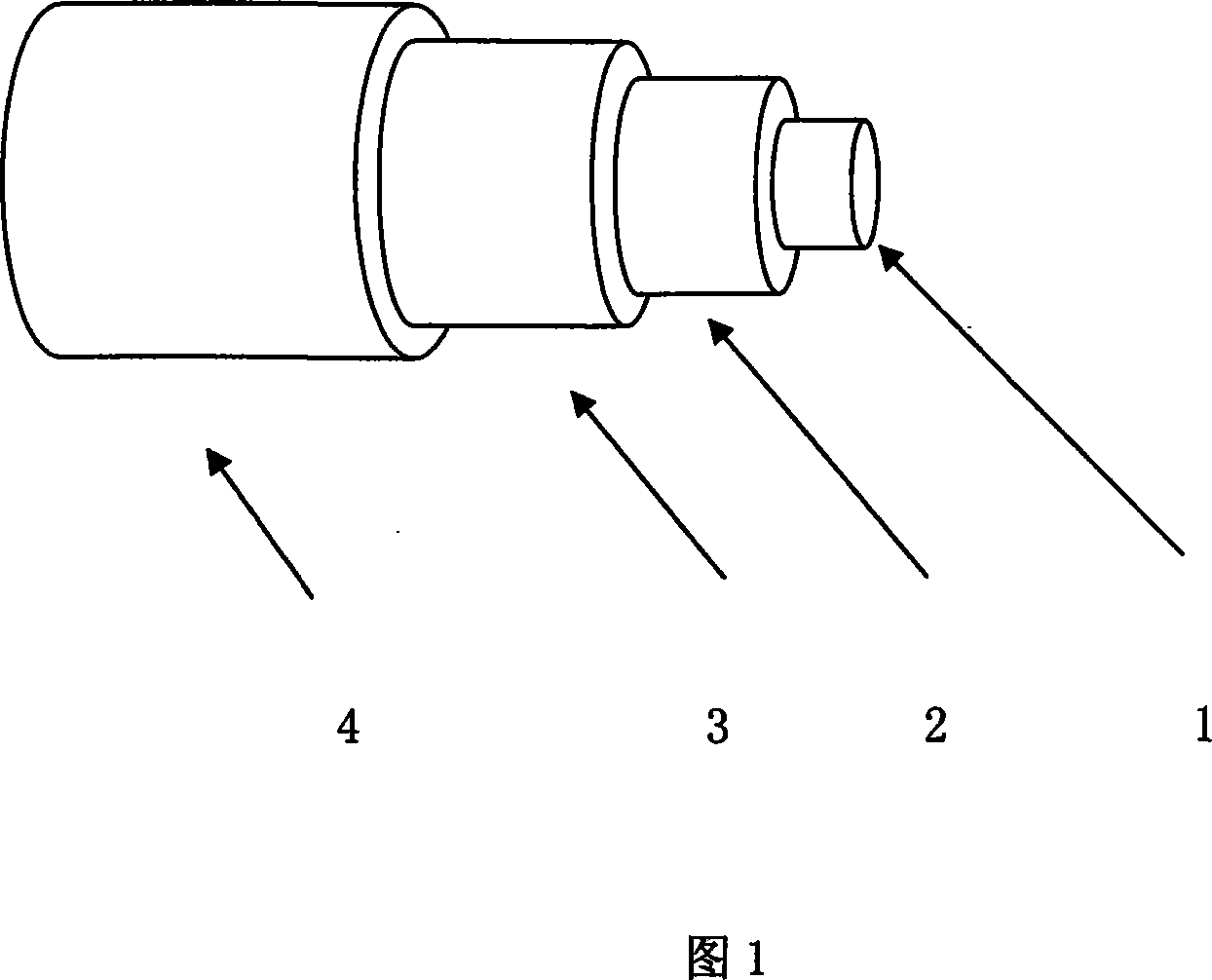

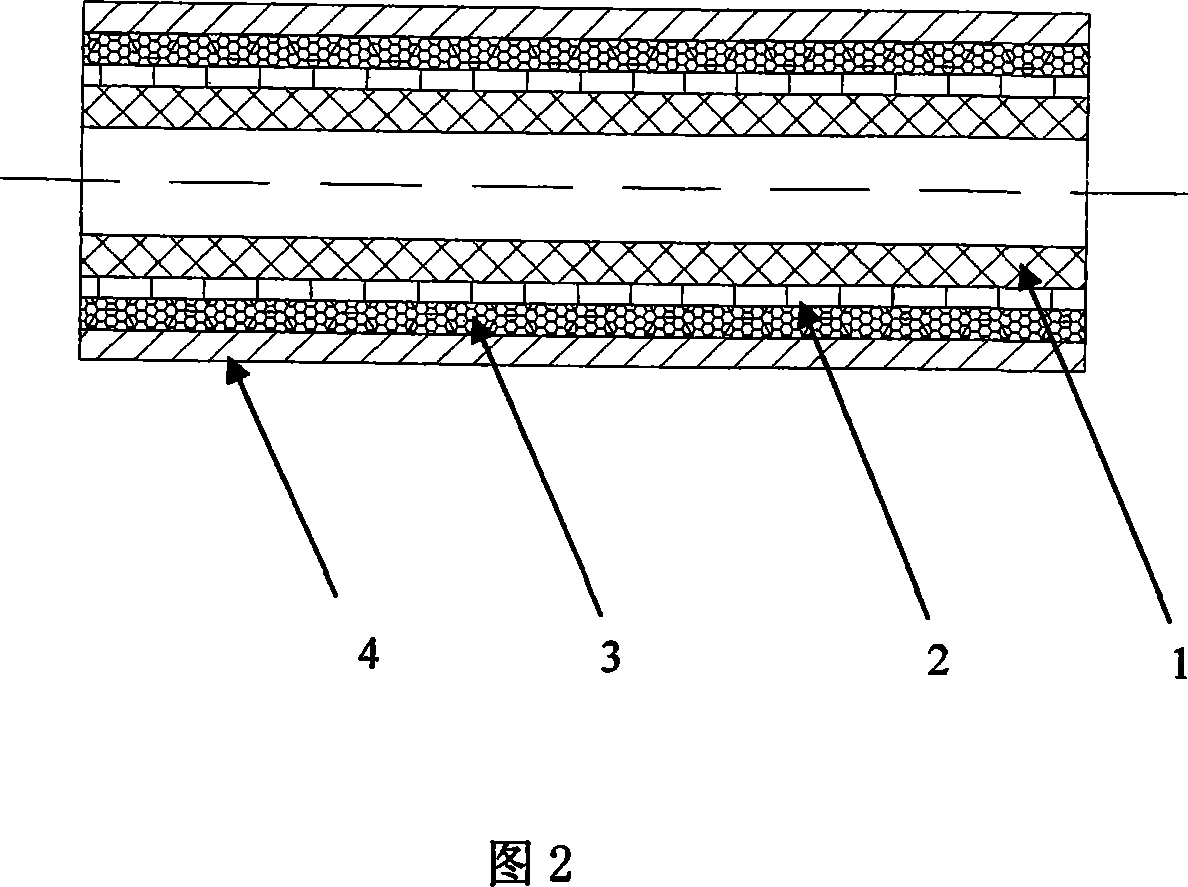

Technique and equipment for processing reinforced thermoplastic plastic pipe

The invention provides a technique and an apparatus for producing a reinforced thermoplastic pipe. The technique comprises the following steps: 1) sending granular PE to a hopper of an extruding machine by negative pressure; 2) heating PE plastic by a first extruding machine, and continuously extruding the PE plastic by a die head with high pressure; 3) cooling the molten PE by water into a PE internal pipe under negative pressure through a vacuum calibrating sleeve of a vacuum water tank; 4) cooling and forming the PE internal pipe continuously in a spray water tank; 5) drying the surface of the PE internal pipe taken from the spray water tank by a first air cooler; 6) pulling the PE internal pipe continuously and stably by a hauling machine which provides power for forming the PE internal pipe; 7) winding a plastic covered reinforcing band made of steel wire or fiber yarn twisted ropes by a winding machine with constant tensile force in opposite directions respectively on the PE internal pipe or the outermost layer of the PE internal pipe; 8) wrapping the molten PE plastic on the outside of the wound reinforcing band through an external composite die head by a second extruding machine to form a wrapped RTP pipe; 9) spraying and cooling to form the wrapped RTP pipe in the water tank; and 10) drying the surface of the RTP pipe taken from the water tank by a second air cooler. The technique is simple and feasible. The apparatus has simple structure, good operating performance and stable and reliable operation.

Owner:李志雄

Fluid transfer hose reinforced with hybrid yarn

ActiveUS7572745B2Retained tensile strengthIncrease burst pressureEngine sealsInternal combustion piston enginesYarnAramides

A flexible hose comprising a tube, a knit fabric, and a cover. The knit fabric comprises a hybrid yarn which comprises a first yarn of co-para-aramid fibers and a second yarn of meta-aramid fibers. The hose exhibits significantly improved burst pressure and / or improved impulse fatigue resistance.

Owner:THE GATES CORP

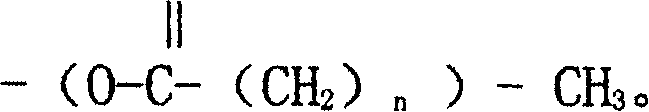

Silane crosslinked polyethylene plastic for low shrinkage anti-crack tube and its preparation method

ActiveCN1876706ASolve the defect of excessive shrinkageOvercome degummingBulk chemical productionTubular articlesCross-linkWater baths

The invention relates the silicon alky cross-linking low-middle-high density vinyon. The components comprises 0.8-3.0wt% silicon alky cross linking agent, 0.02-2.0wt% cross linking initiating agent, 0.02-1.0wt% cross linking catalyst, 0.01-3.0wt% anti-oxidant and 0.05-3.0wt% modified auxiliary agent. The method comprises the following steps: preparing silicon alky grafting material A, mixing A and B materials, handing with extrusion machine to get tubing product, keeping it in water bath at 85Deg.C or vaporium for 8 hours, and getting the product. The invention overcomes the defects of big contraction percentage and degelatinizing phenomena between polythene layer and metal layer; the invention has the advantages of short production circle, stable technology and high rate of finished products.

Owner:上海高分子功能材料研究所

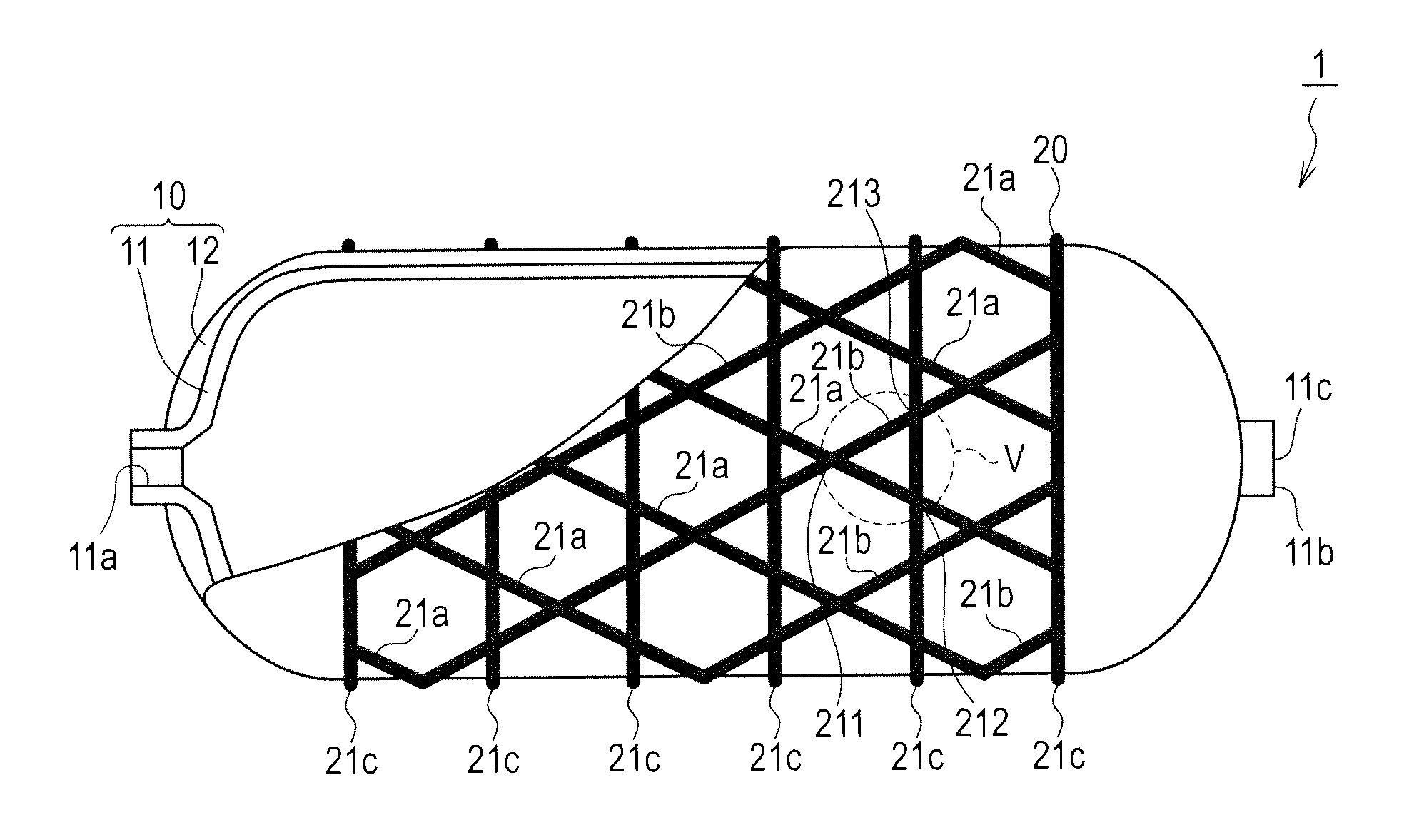

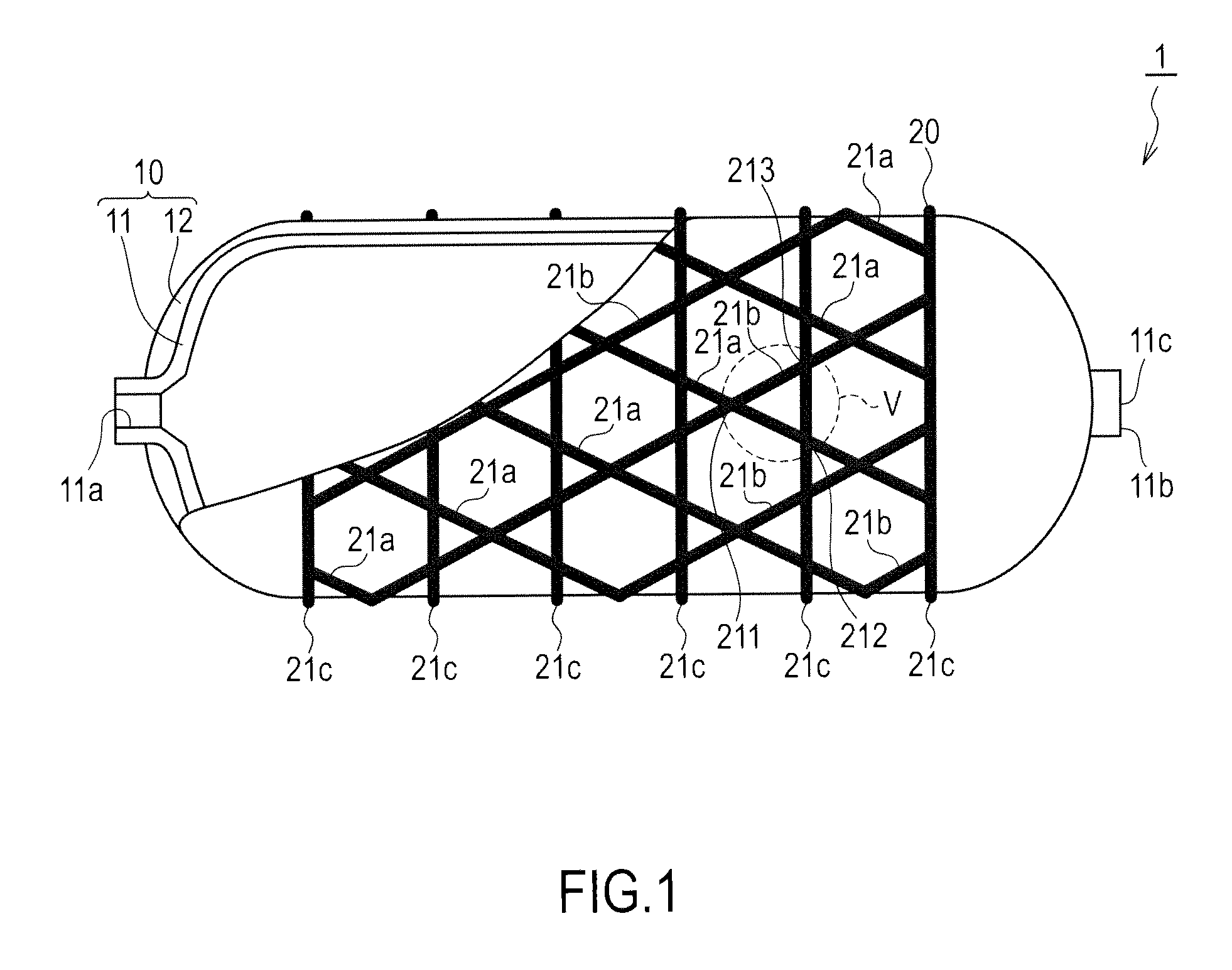

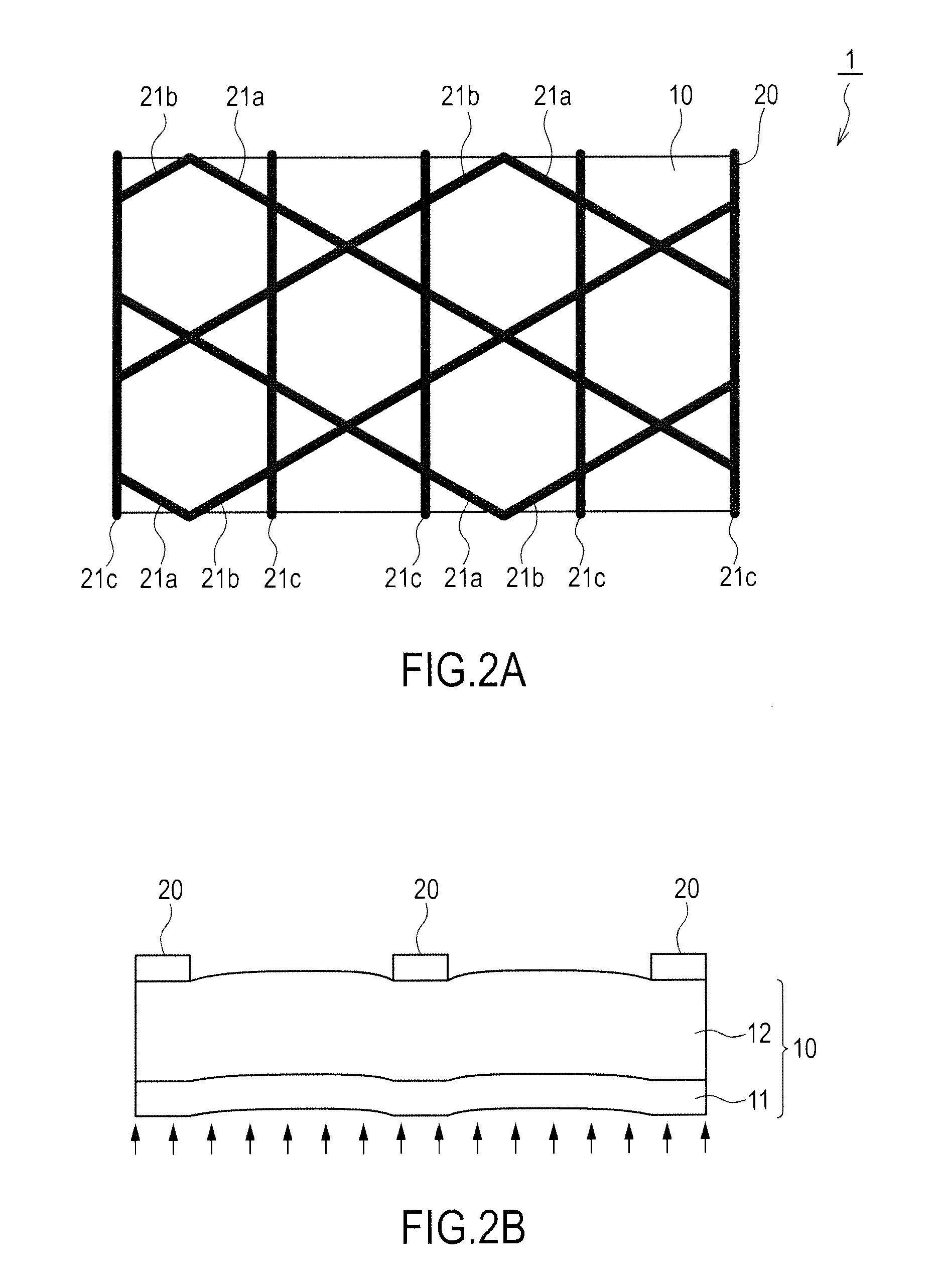

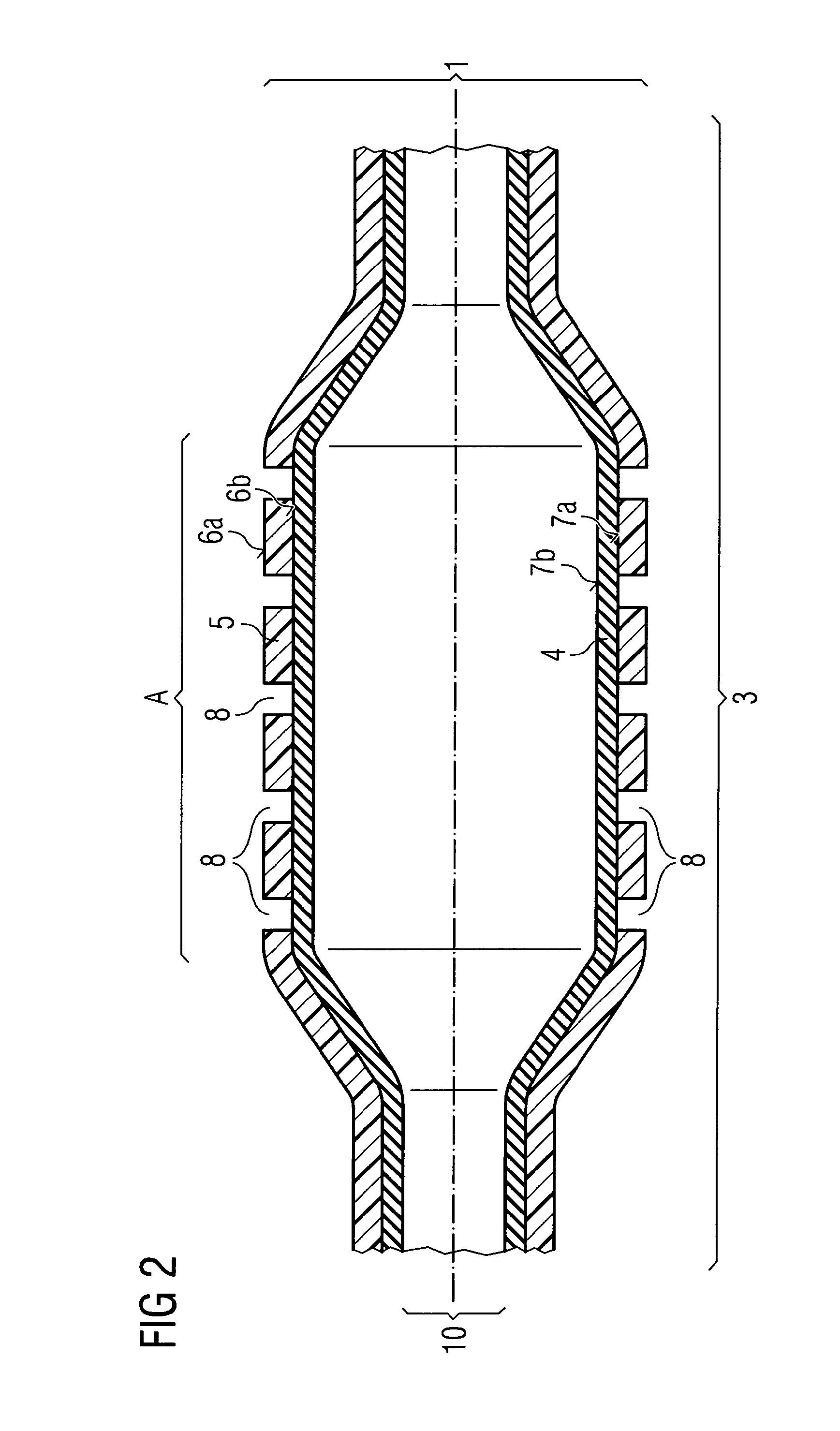

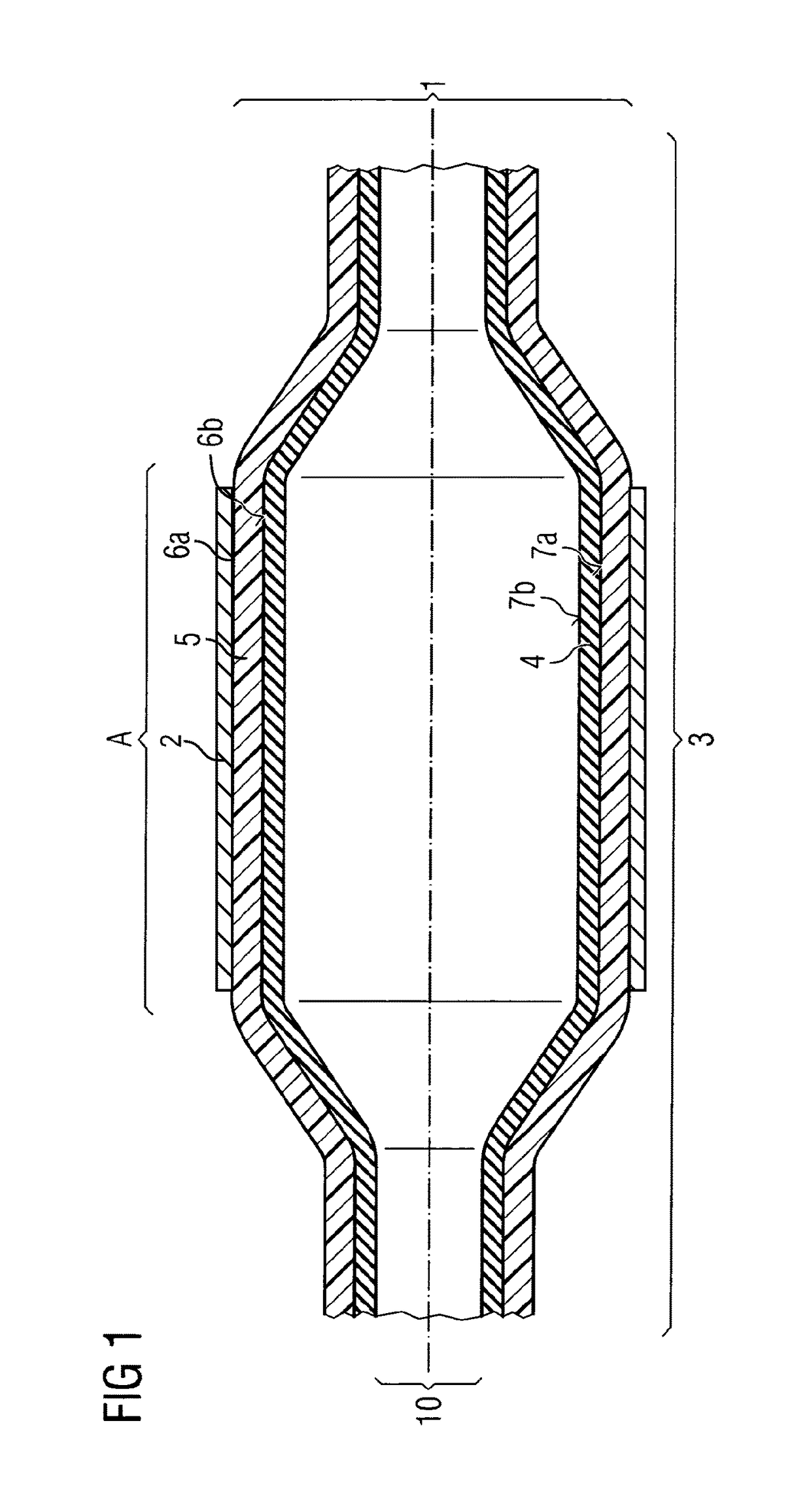

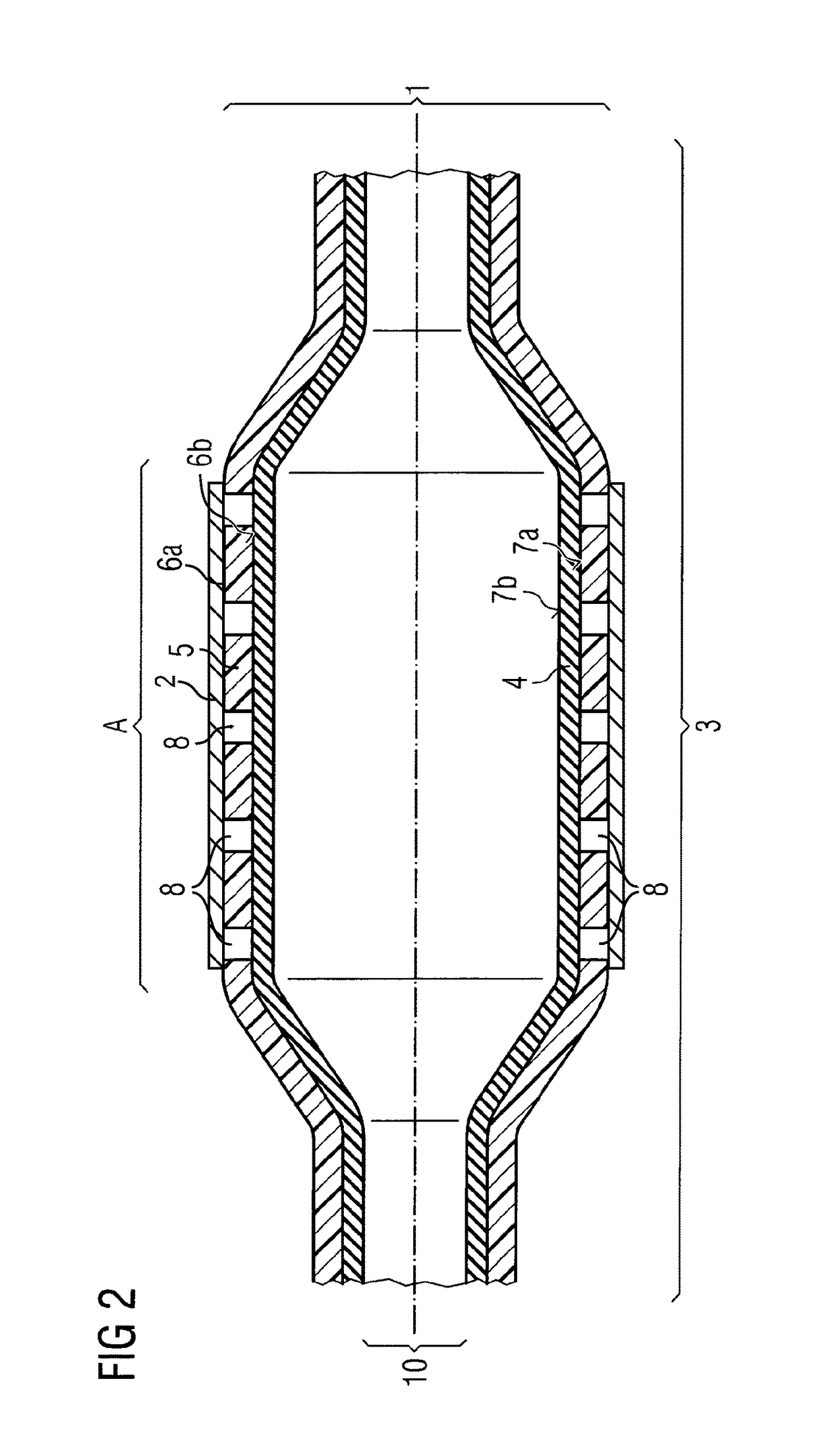

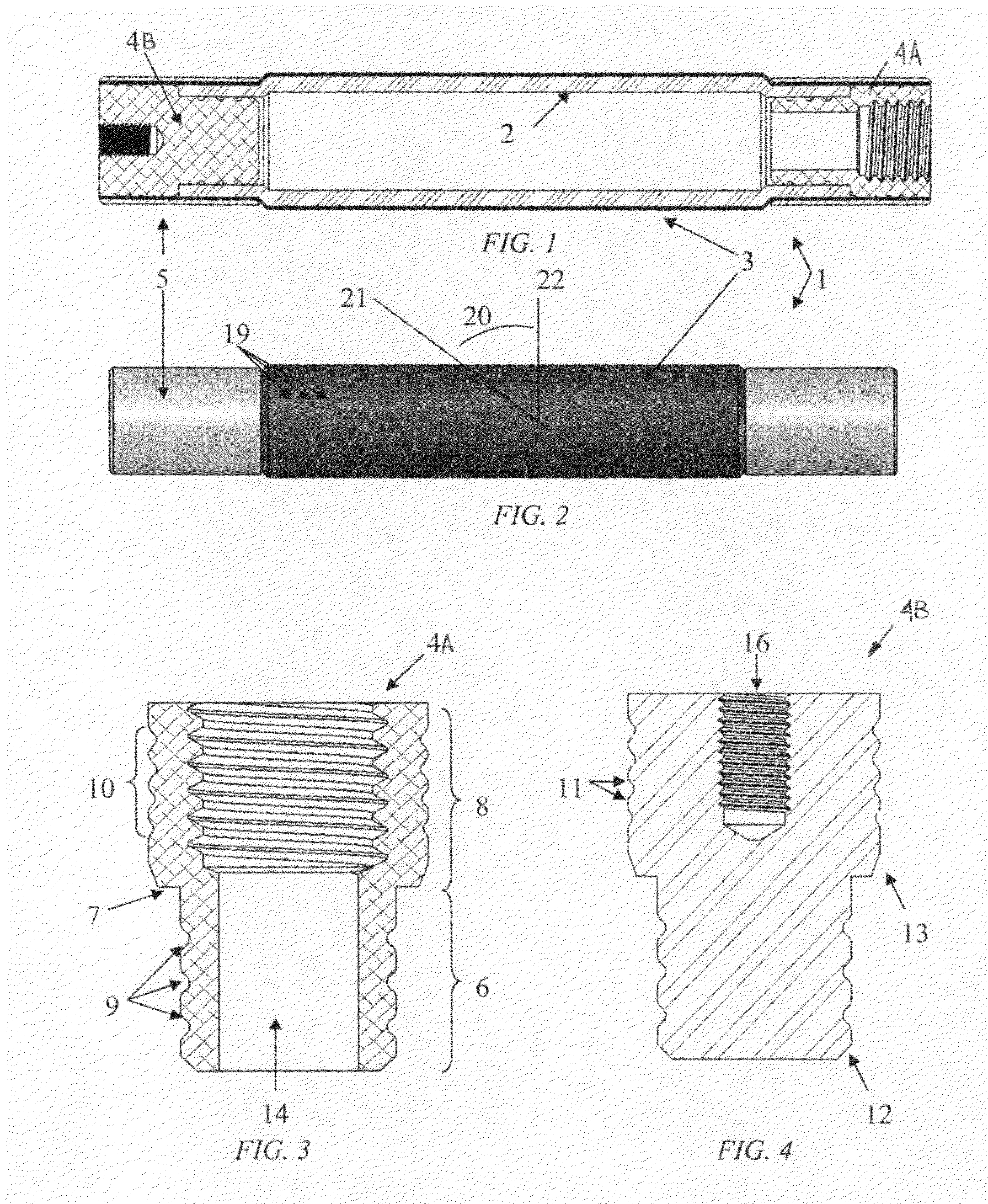

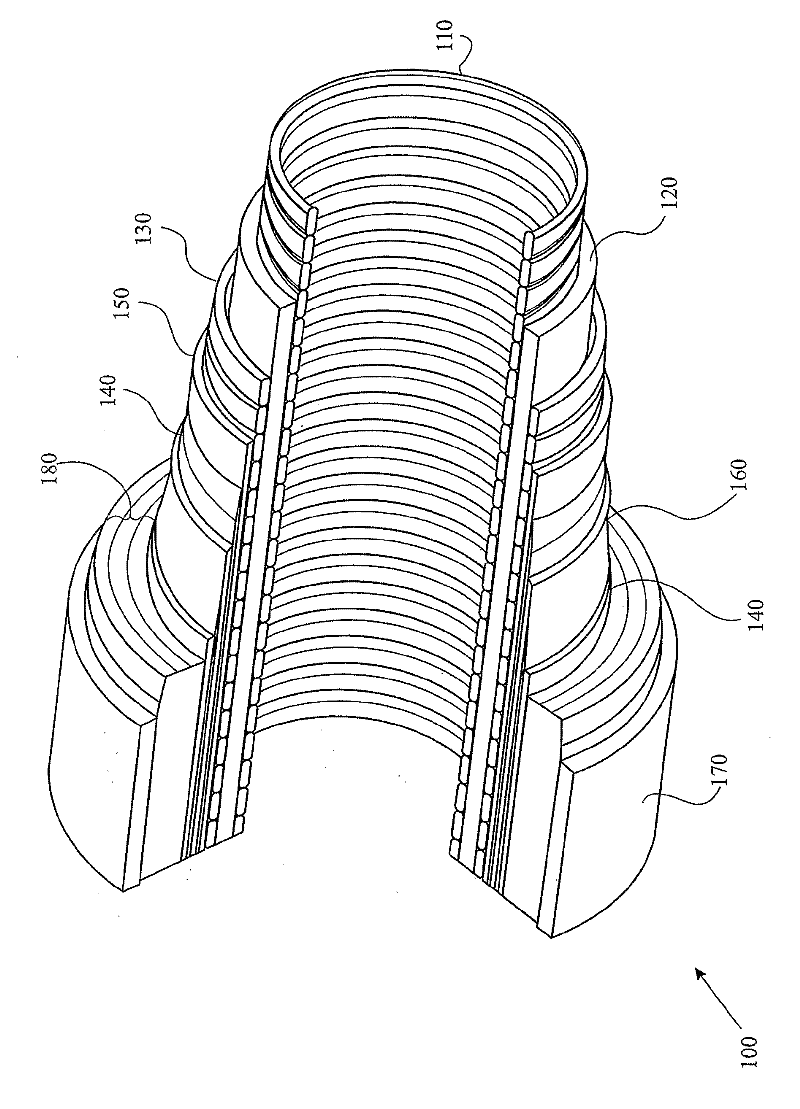

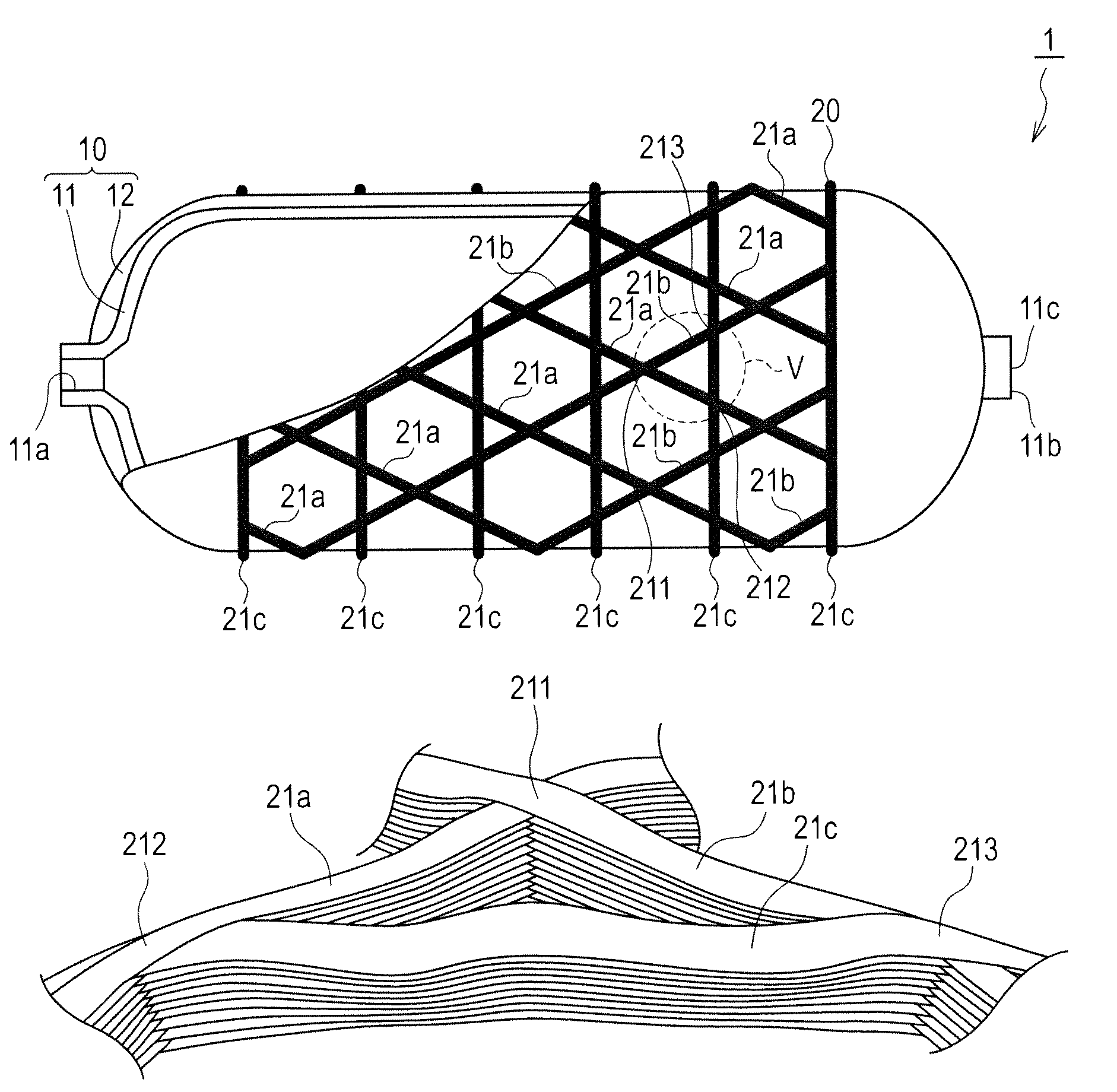

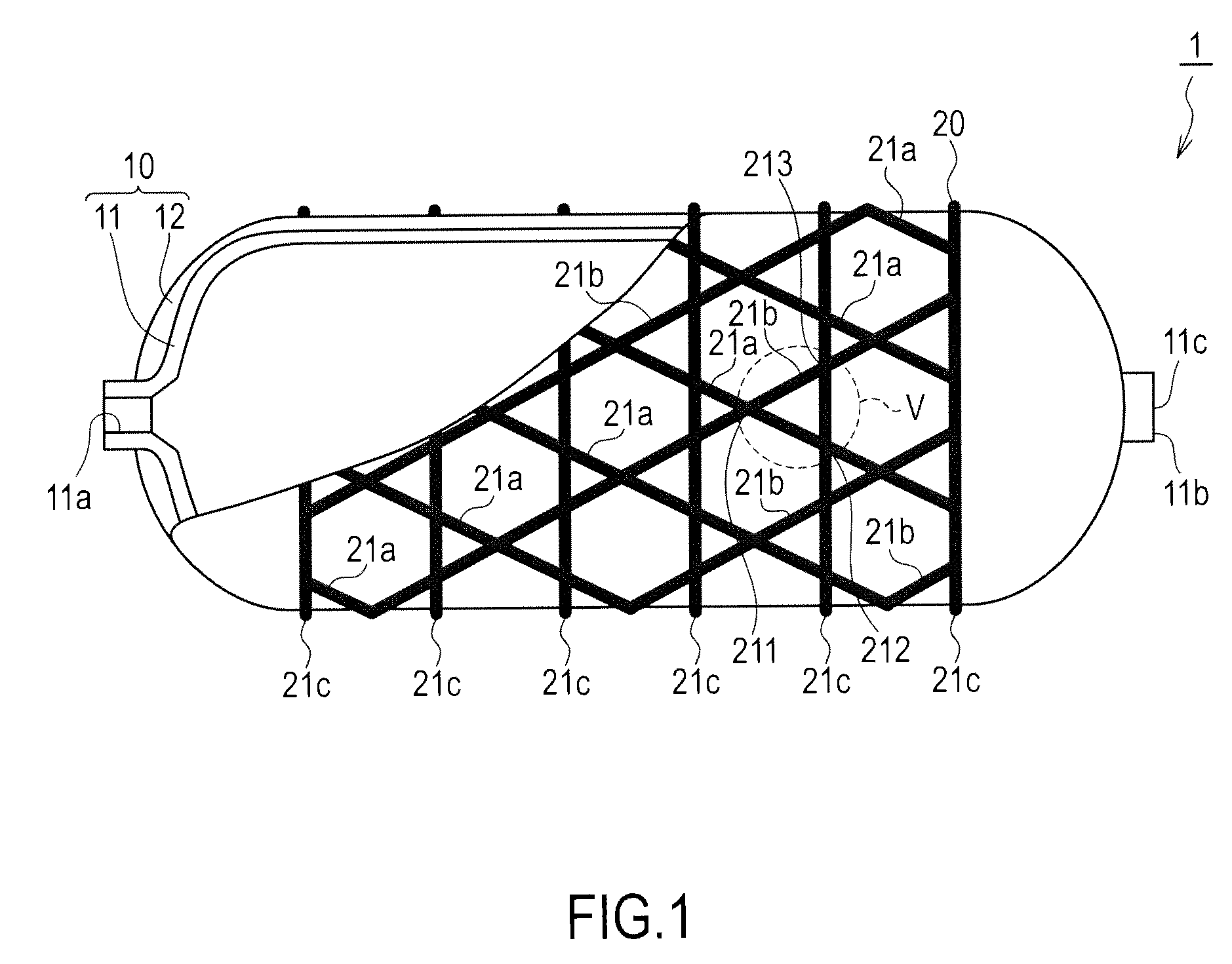

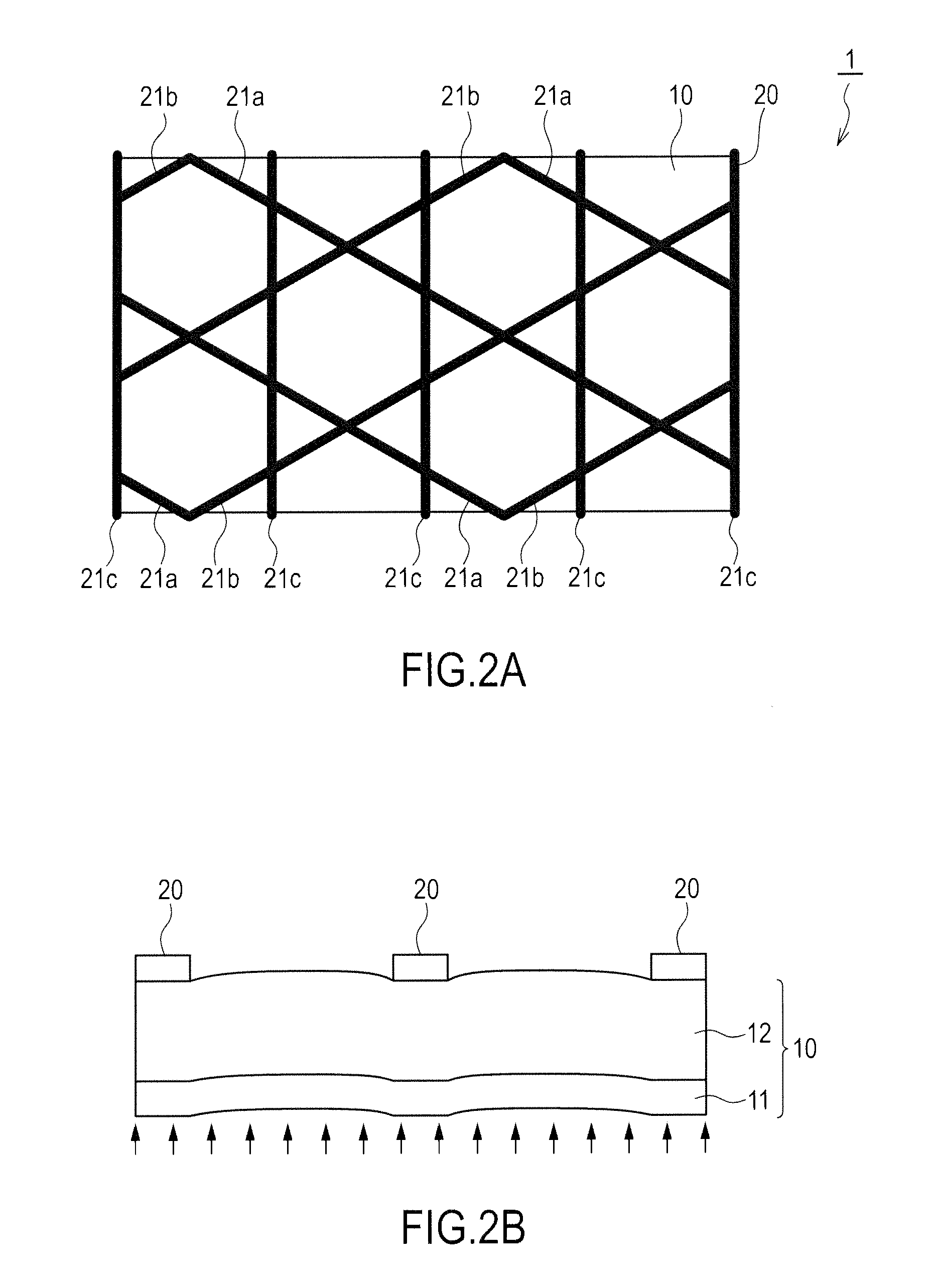

Structure and manufacturing method for pressure vessel

InactiveUS20120012593A1Increase burst pressureVessel manufacturingLarge containersEngineeringPressure vessel

A pressure vessel structure includes a vessel main body, and a grid layer provided on a periphery of the vessel main body and including a plurality of grid lines formed by intersecting strip-form raw materials so as to overlap alternately. Thus, a burst pressure of the pressure vessel is increased.

Owner:NISSAN MOTOR CO LTD +1

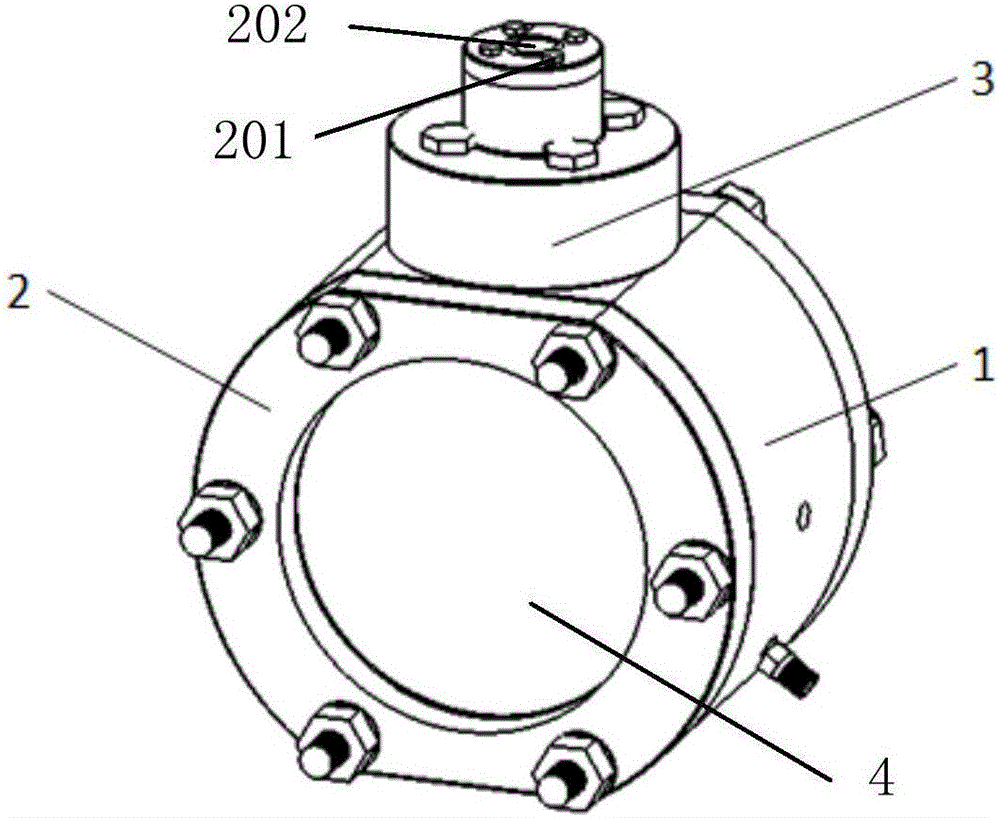

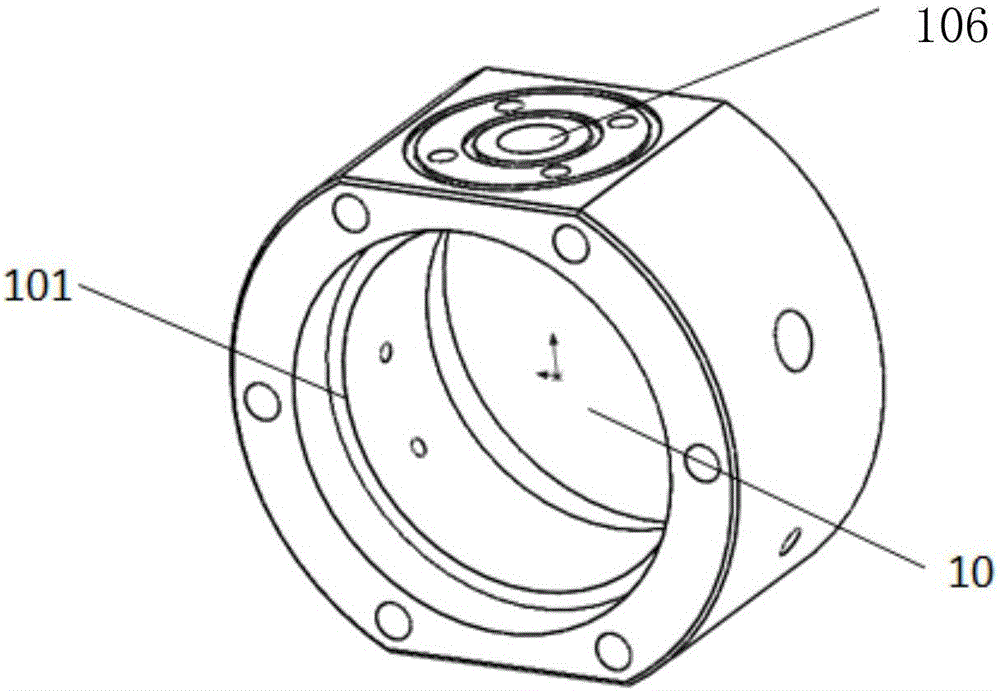

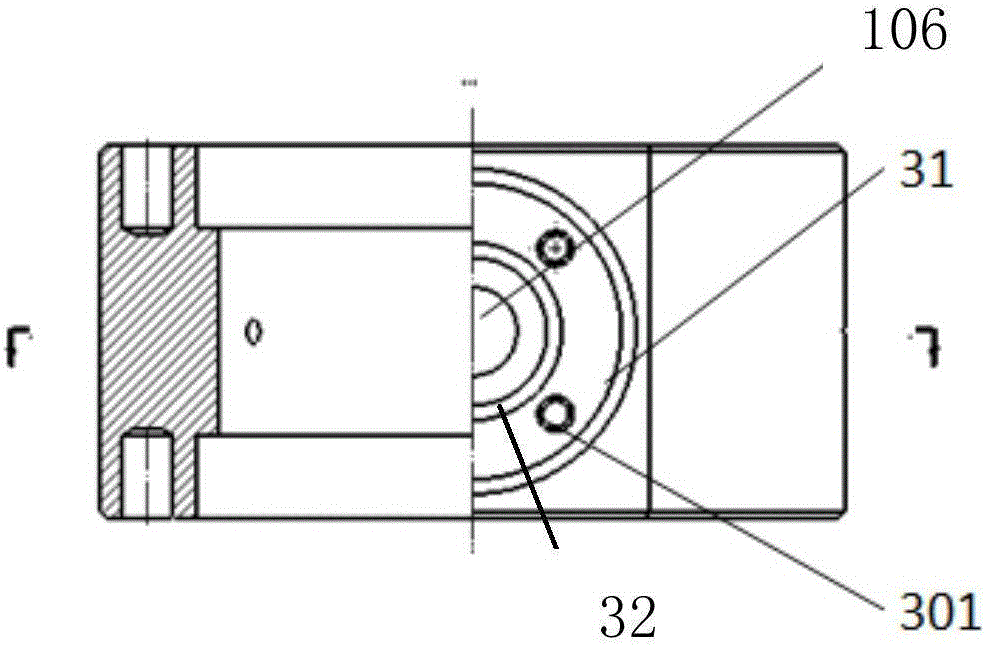

Constant volume bomb for diesel spraying and burning visualization experiment

ActiveCN106353098ASimple structureEasy to processInternal-combustion engine testingDiesel sprayLaser-induced fluorescence

The invention provides a constant volume bomb for a diesel spraying and burning visualization experiment. The constant volume bomb comprises a constant volume bomb body. The constant volume bomb body uses the circular-cake-shaped structure, the interior is hollow and used for forming the visualization experiment area, two sides of the circular cake are opened with visualization window holes and the end faces of the windows are pressed by sealing cover plates for sealing. The quartz glass is clamped between the body and the sealing cover plates. The upper end face is opened with a positioning hole for an oil sprayer installing base, and the unique design is suitable for use of various oil sprayers. The lower end face is opened with a positioning threaded hole for fixing the position of the constant volume bomb. The constant volume bomb body is radially opened with various installing through holes for installing various data collecting devices. The visualization spraying constant volume napalm bomb has the characteristics of simple structure, wide experiment area and transparent light path, and is capable of observing and measuring the spraying and burning processes through cooperating the schlieren method and the laser-induced fluorescence technology, remarkably improving the experiment efficiency, performing the spraying feature test to different oil sprayers and improving the adaptability of the spraying constant volume test bomb.

Owner:HARBIN ENG UNIV

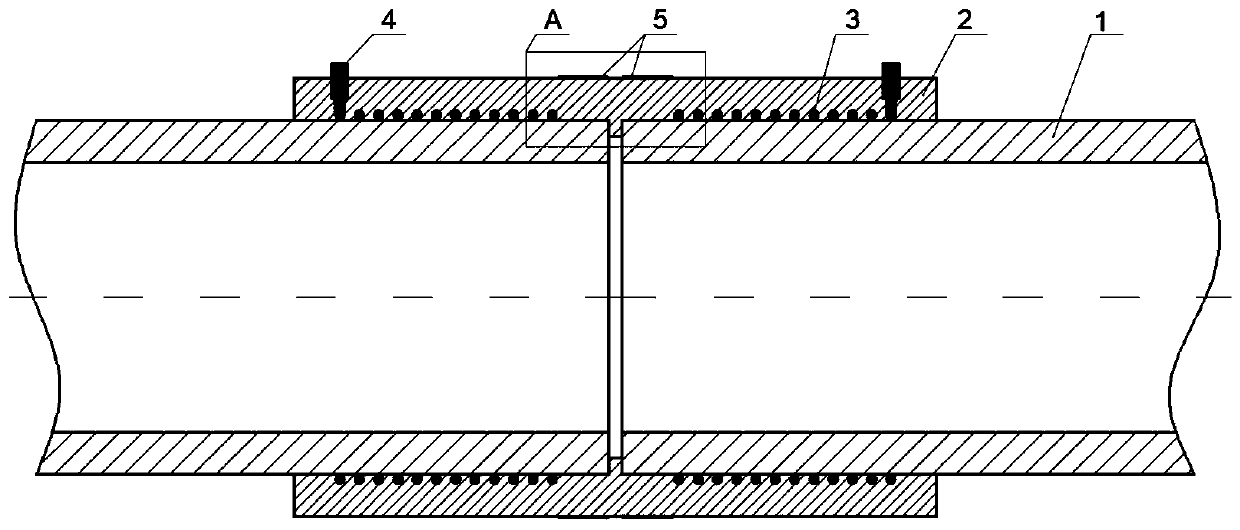

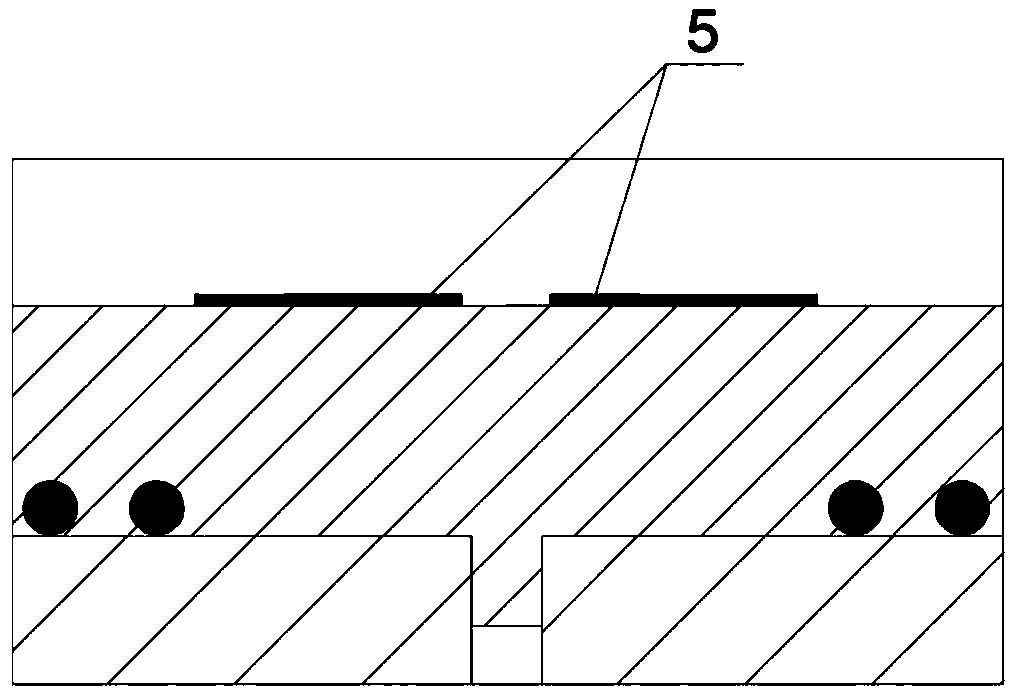

Carbon fiber reinforced plastic electric-smelting pipe fitting with strain self-monitoring function

ActiveCN109827014AIncrease elasticityHigh yield strengthElectrical/magnetic solid deformation measurementPipe connection arrangementsThermoplasticFiber

The invention relates to the field of thermoplastic plastic electric-smelting pipe fittings, and aims to provide a carbon fiber reinforced plastic electric-smelting pipe fitting with the strain self-monitoring function. The carbon fiber reinforced plastic electric-smelting pipe fitting comprises an electric-smelting pipe fitting body with a resistor wire buried, and two binding posts respectivelyconnected to the two ends of the resistor wire are arranged on the electric-smelting pipe fitting body. The carbon fiber reinforced plastic electric-smelting pipe fitting is characterized in that theelectric-smelting pipe fitting body is made of thermoplastic plastic filled with the carbon fiber, at least one set of paired electrodes is arranged on the surface of the electric-smelting pipe fitting body and used for monitoring the changes of the resistance values due to thermal temperature rising or internal pressure deformation in the suing process so as to achieve the strain monitoring of the electric-smelting pipe fitting. The carbon fiber reinforced plastic electric-smelting pipe fitting can improve the elastic modulus and yield strength of the material, has higher mechanical strength,higher blasting pressure, and can improve the operating pressure, the strain of the electric-smelting pipe fitting and the pressure inside the electric-smelting pipe fitting can be monitored, the additional equipment does not need, the intelligence and safety of the electric-smelting pipe fitting are improved, and the manufacturing process is simple, the stability is high, and the cost of the process is reduced.

Owner:ZHEJIANG UNIV

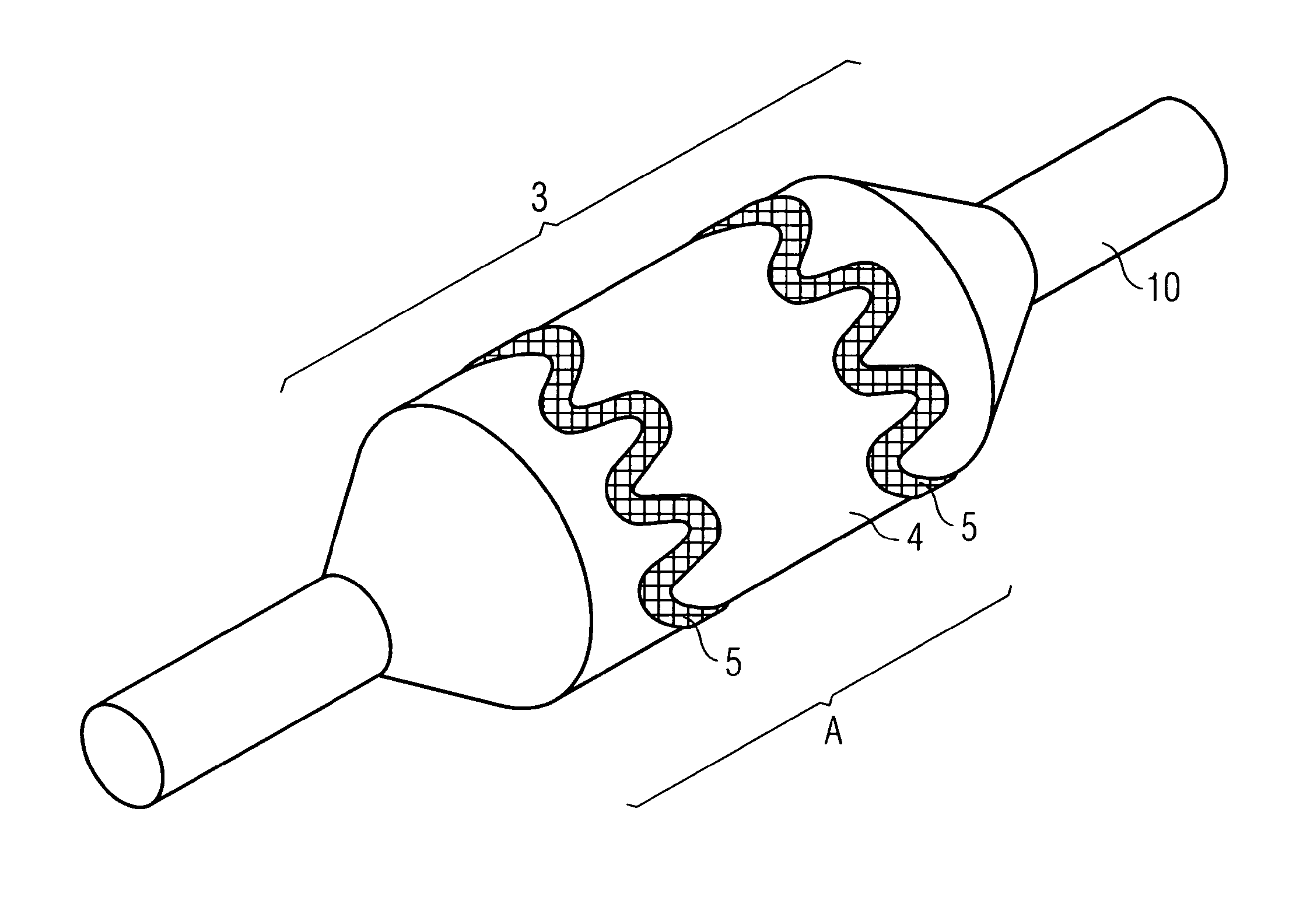

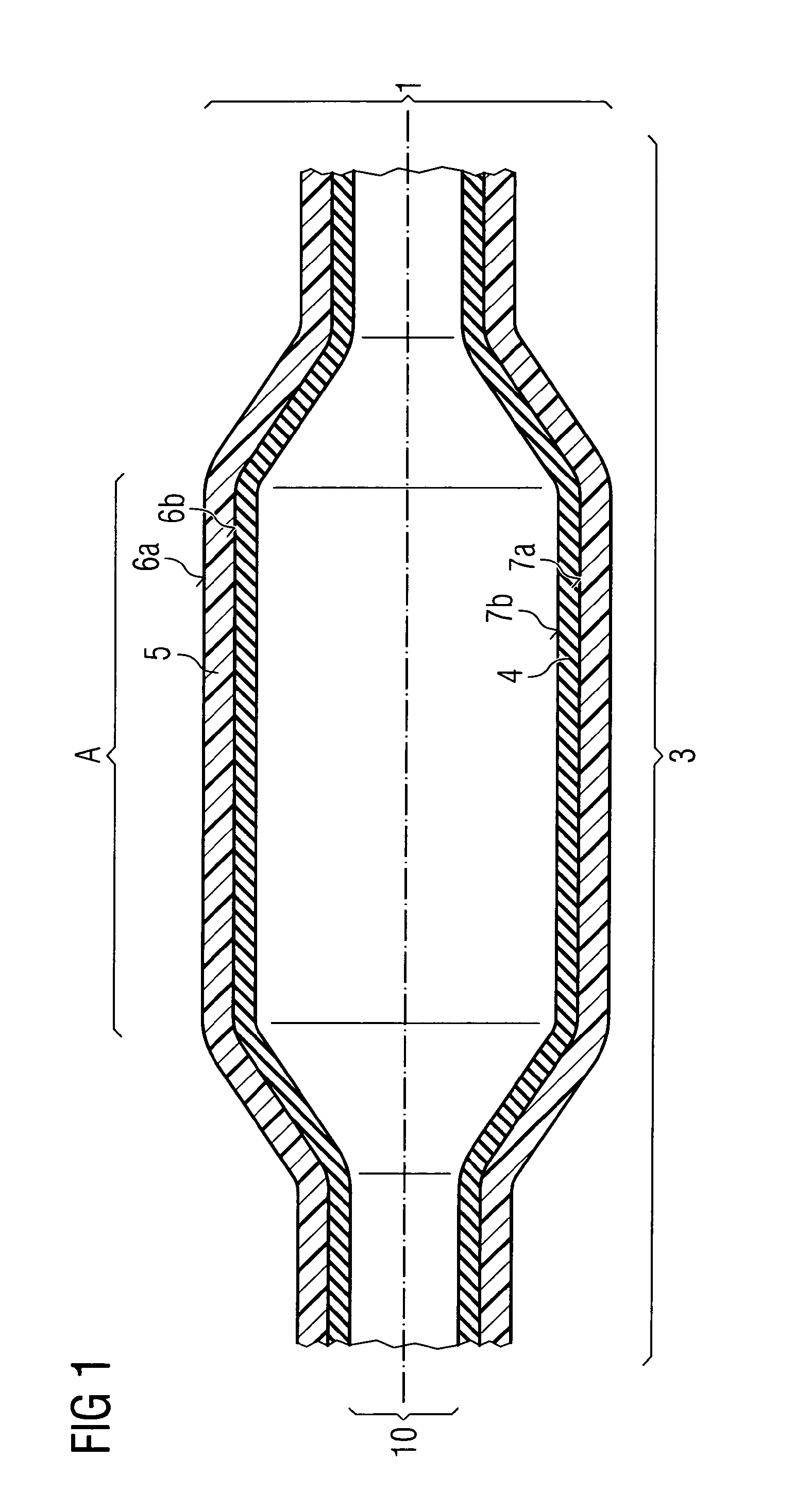

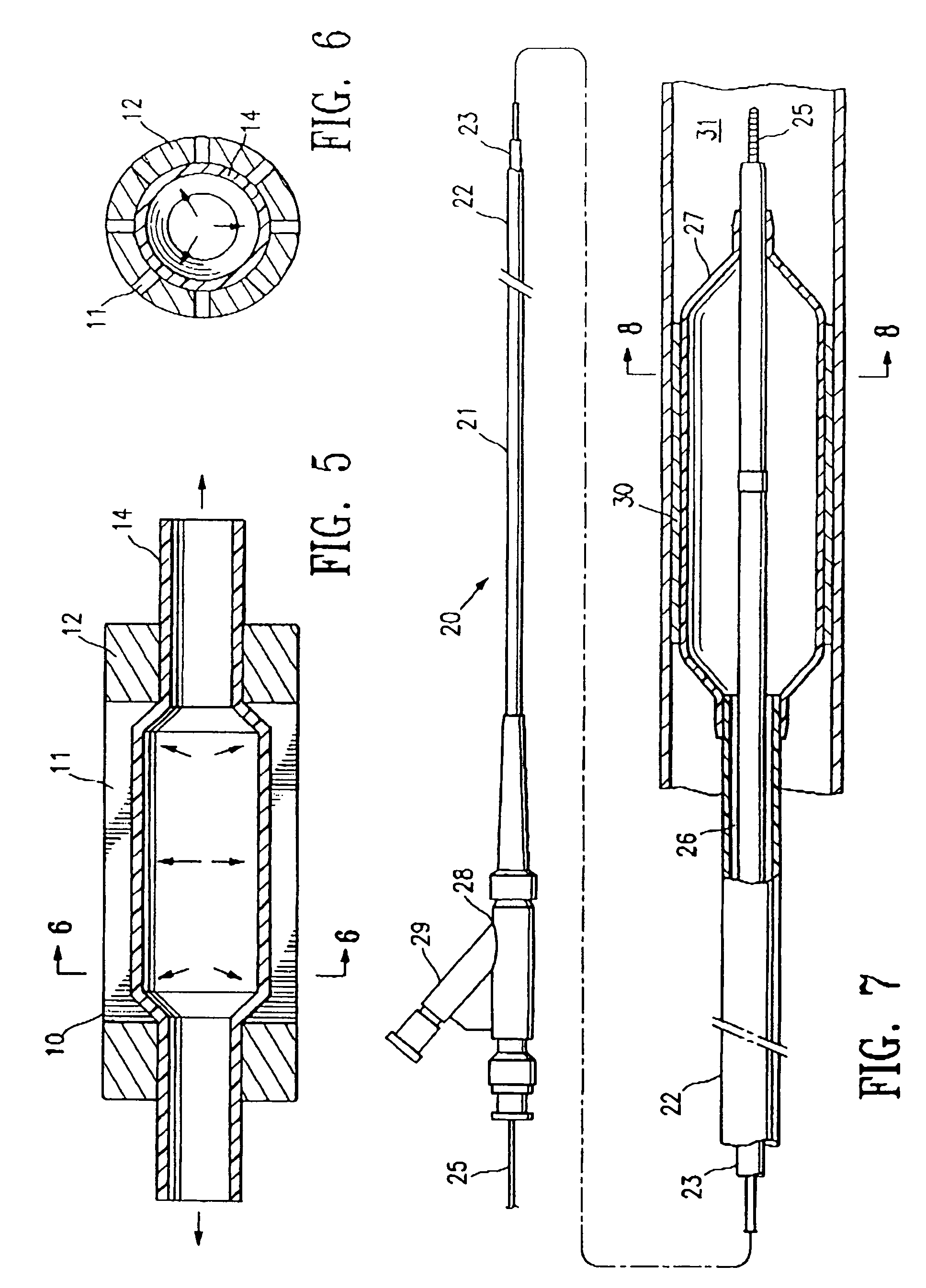

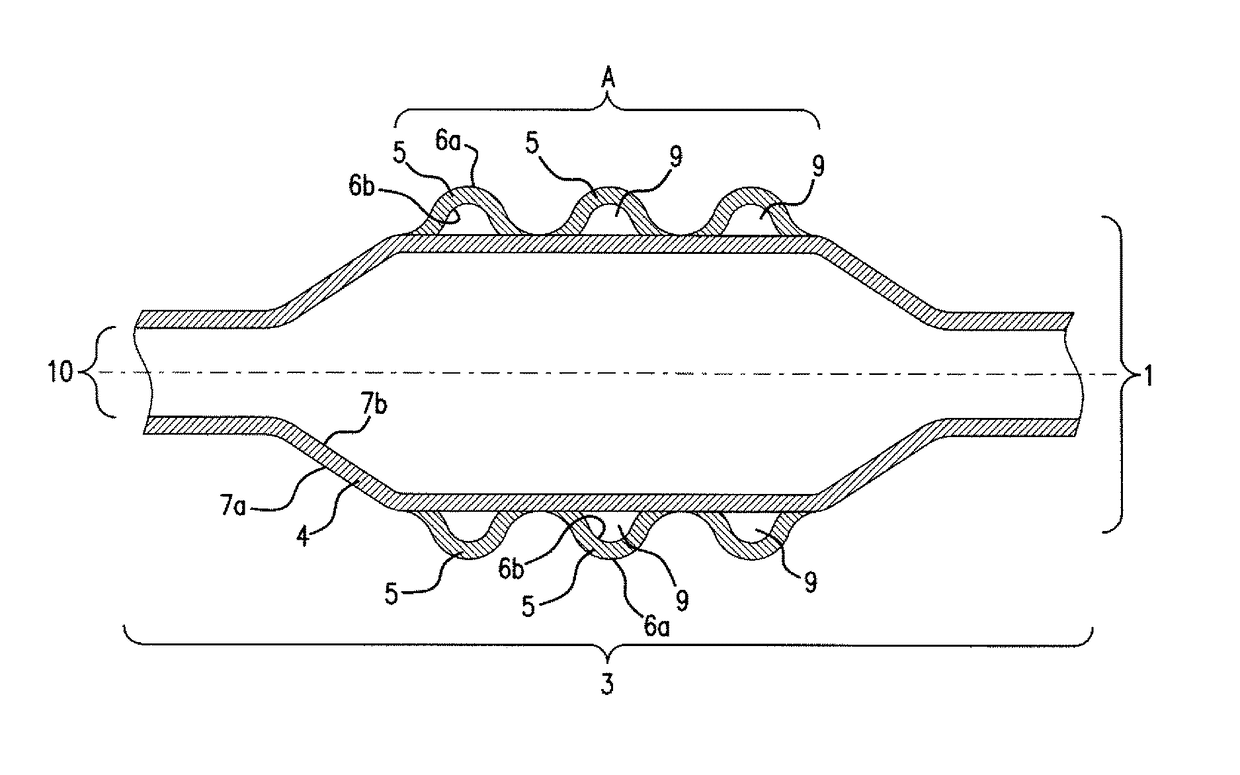

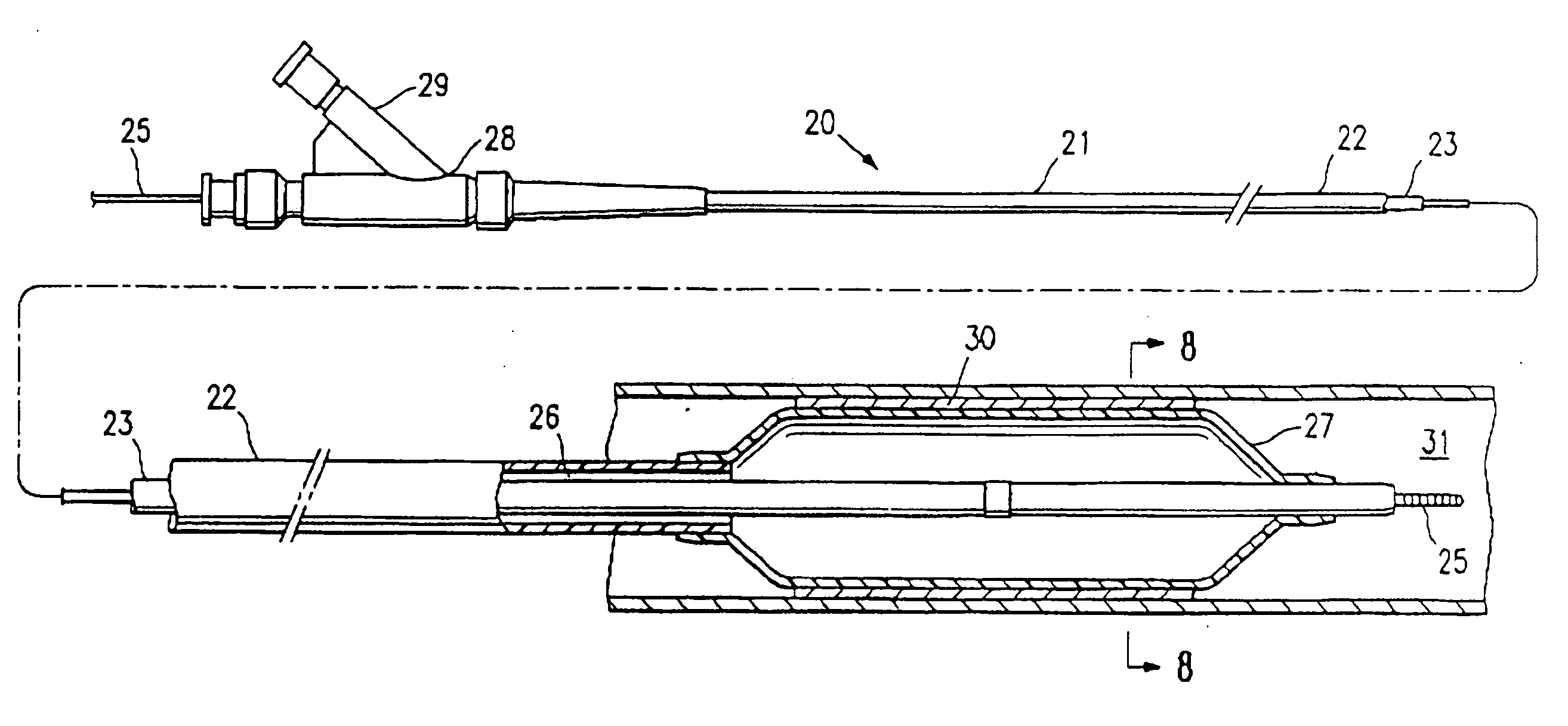

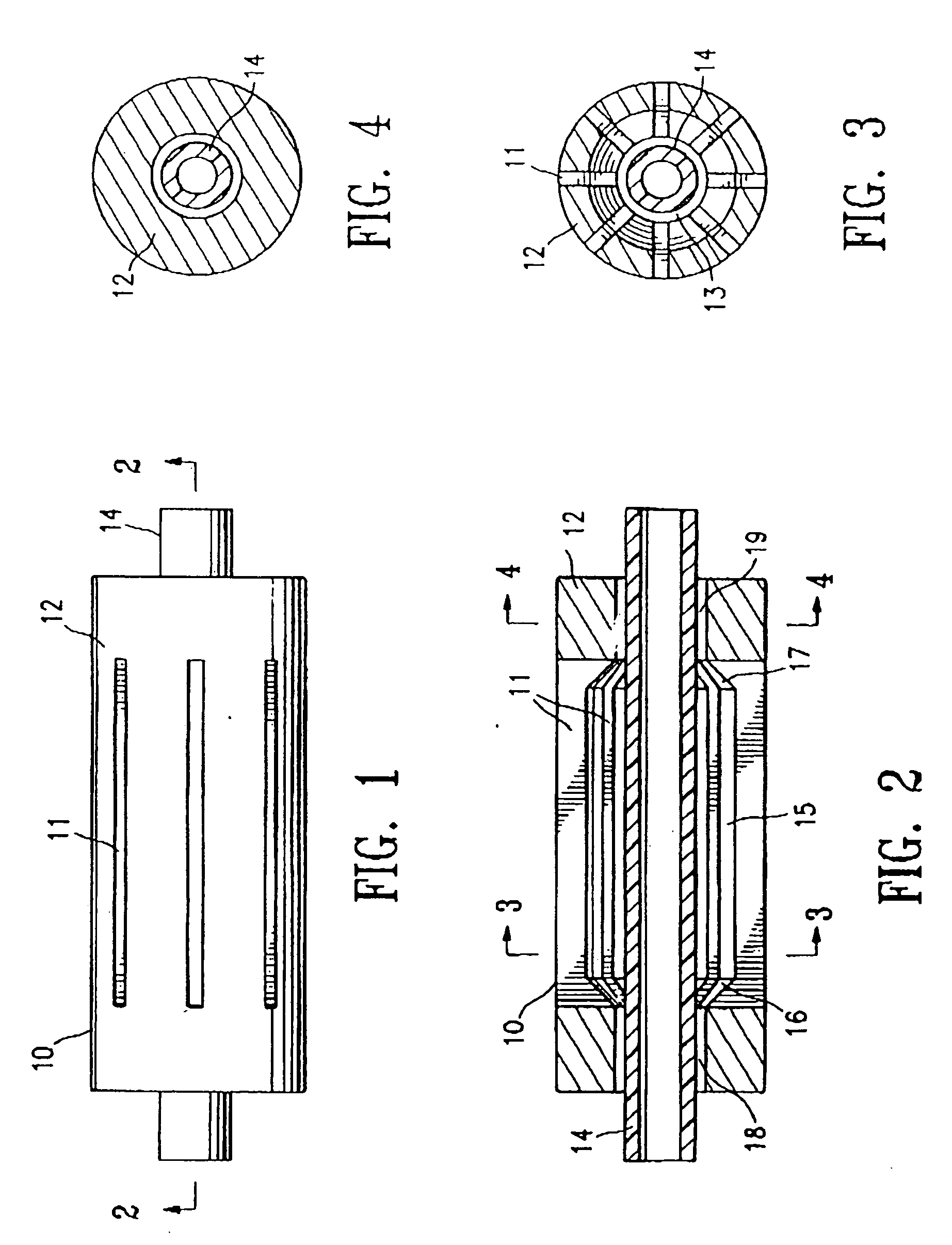

Double layered balloons in medical devices

ActiveUS20110022152A1Decreases compliance rateIncrease burst pressureStentsSurgeryHuman patientBalloon catheter

The present invention refers to medical devices. Particularly it relates to stent devices and balloon catheter devices. In the most particular aspect of the invention it relates to balloon catheter devices carrying stents (2) with the medical balloon (3) comprising an inner layer (4) having a lower compliance rate and / or burst pressure than the outer layer (5) and an outer layer (5) having on the outer surface (6a) a higher adhesion strength than the inner layer (4), and its use in a variety of medical procedures to treat medical conditions in animal and human patients.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

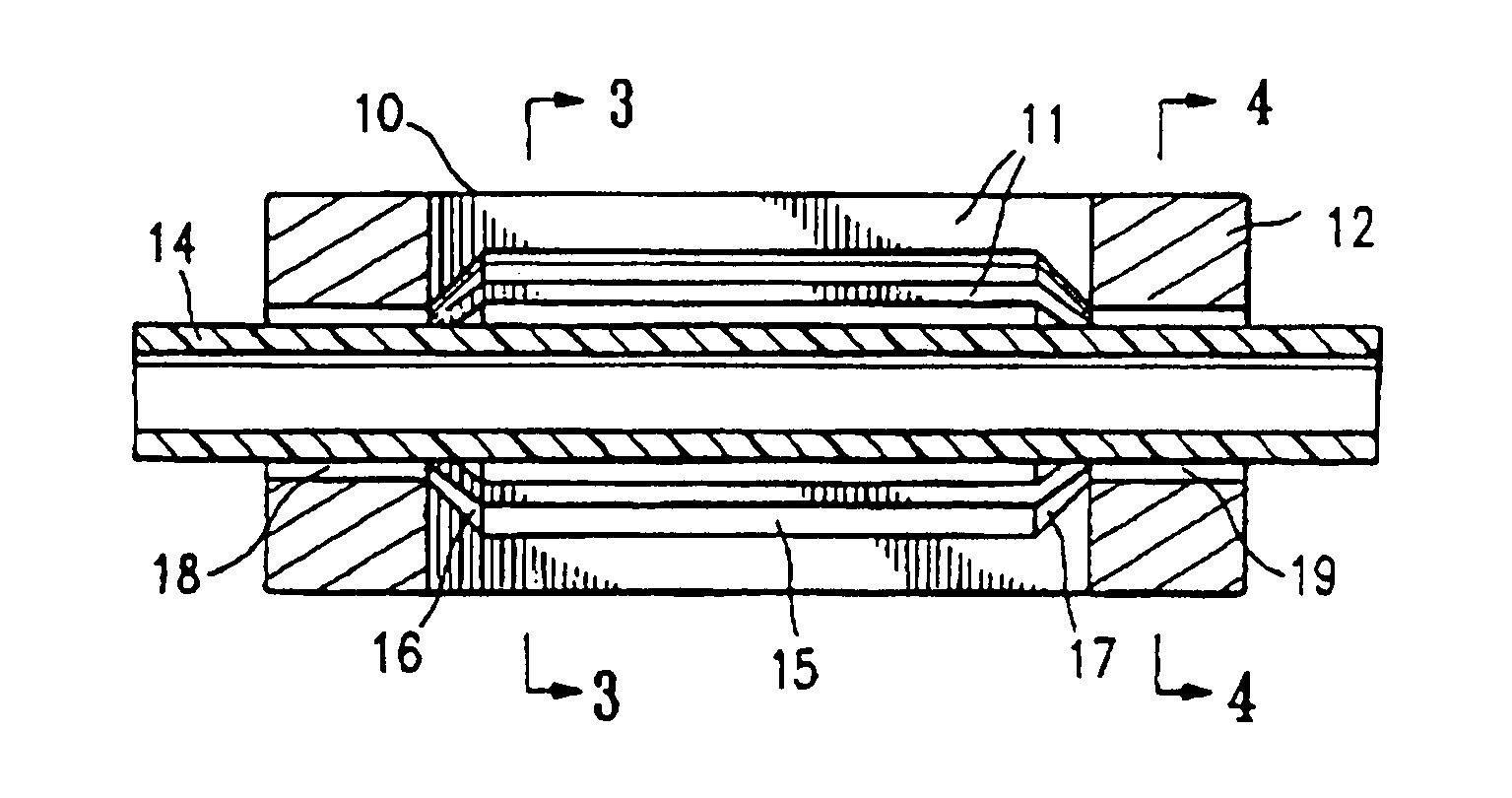

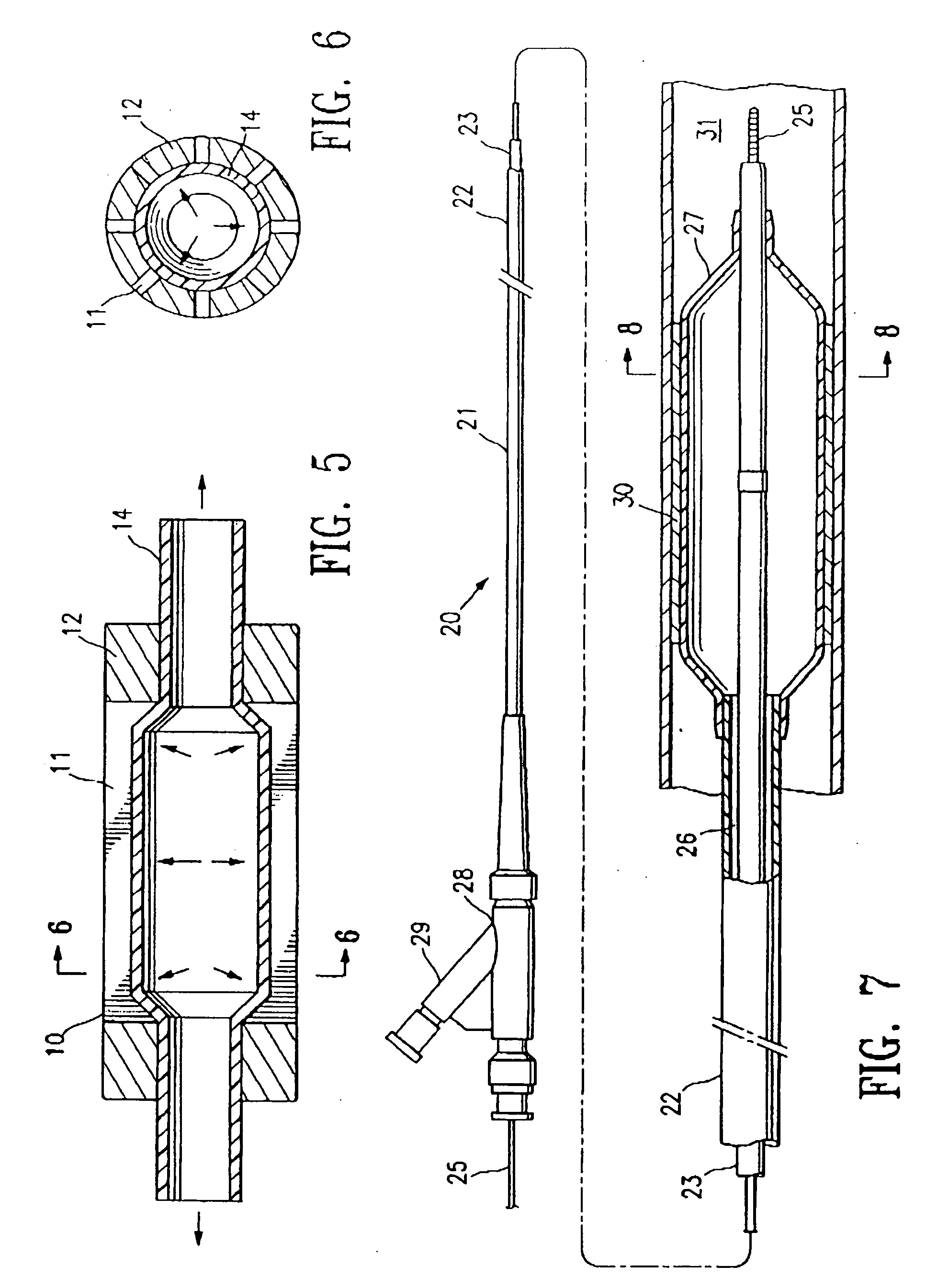

Slotted mold for making a balloon catheter

InactiveUS7314364B2Improve heat transfer performanceHeating evenly and quicklyConfectioneryCatheterBlow moldingMedicine

A method of making a catheter balloon, and a balloon formed thereby, in which a polymeric tube is radially expanded in a mold having a wall with an outer surface and an inner surface defining a chamber, and having at least a section with one or more channels in the wall. The channels result in improved transfer of heat to the polymeric tube within the chamber of the mold during blow molding of the tube to form a balloon, so that the tube is heated more quickly and evenly. One aspect of the invention is directed to a balloon having sections with improved thin walls.

Owner:ABBOTT CARDIOVASCULAR

Turbine booster hose of fluorine rubber, oil-resisting silicon rubber and silicon rubber and its production

The invention discloses an extrusion production, the fluorine rubber inner layer (1), resistance oil silicone rubber middle (2), kevlar line (3) and the outer layer of silicone rubber (4) composed of automobile turbocharged hose, broke the previous three-layer structure of the turbocharged, four- layer structure used, and uses advanced extrusion technology, braided hose to a molding process, the turbocharged hose reached appearance no impurities, without defects, flat and smooth. Not only increase production efficiency, but also through our compound formula, the structure of several aspects of research and development, so that the hose can meet the performance requirements of use, the hose improve the oil resistance, high temperature resistant, resistant infiltration, and improve the bursting pressure, the hose of the service life is extension.

Owner:TIANJIN PENGYI GRP CO LTD

Double layered balloons in medical devices

ActiveUS9717615B2Low complianceIncrease burst pressureStentsBalloon catheterAdhesion strengthMedical treatment

Owner:ABBOTT LAB VASCULAR ENTERPRISE

Plastic tube, especially a pneumatic tube

InactiveUS7040351B2Simple and economical to manufactureSimpler contact making functionFlexible pipesPipe-jointsElectrical conductorPlastic materials

A plastic hose, and more particularly a pneumatic hose, is provided with at least two electrical conductors extending along the hose body. These conductors are in the form of strips (11 and 12) of a metallized braid of plastic material or of natural fiber with a spacing apart on the hose body (13). Accordingly high flexibility of the plastic hose (10) is achieved with satisfactory electrical conductivity of the strips ensuring safety as regards breakage.

Owner:FESTO AG & CO KG

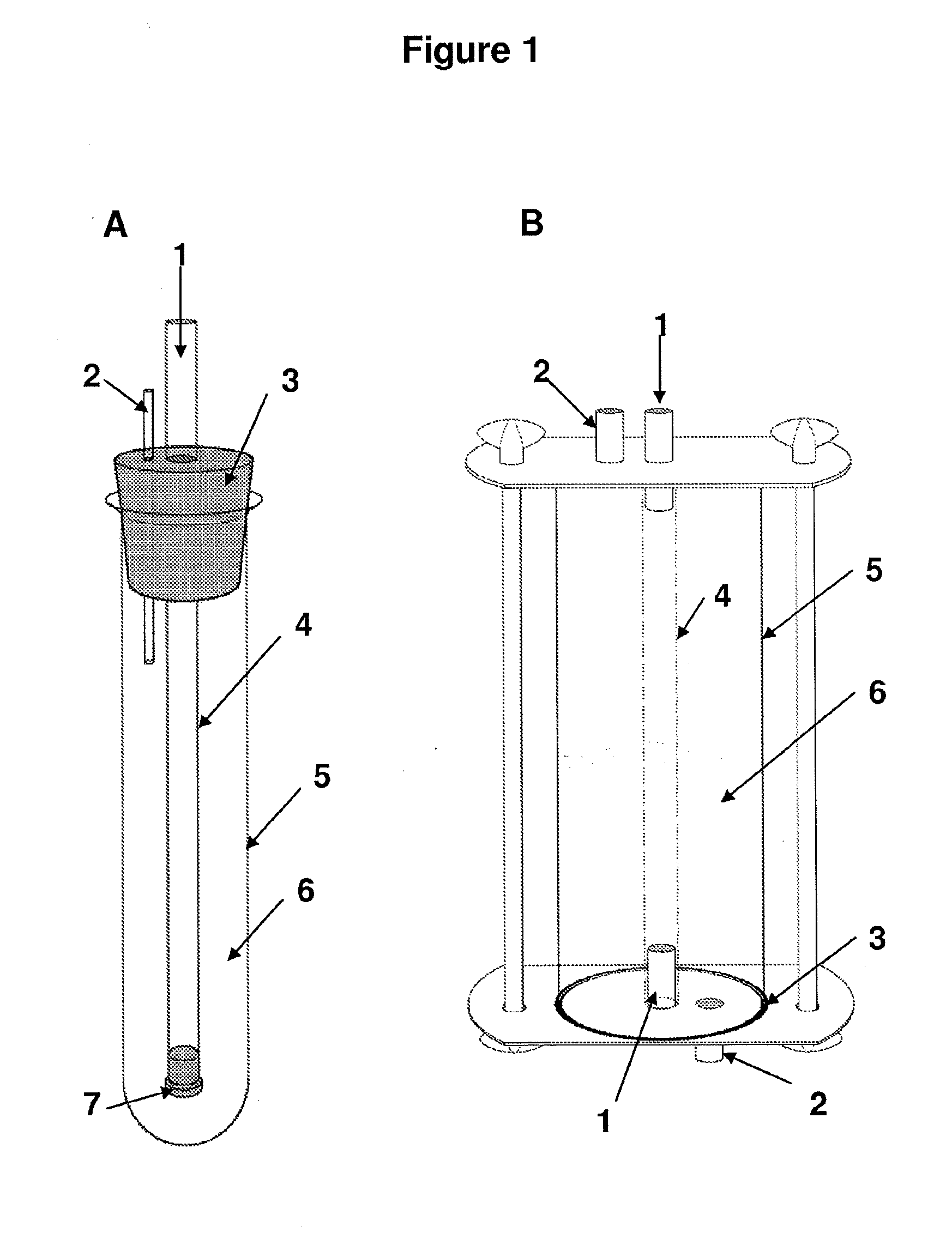

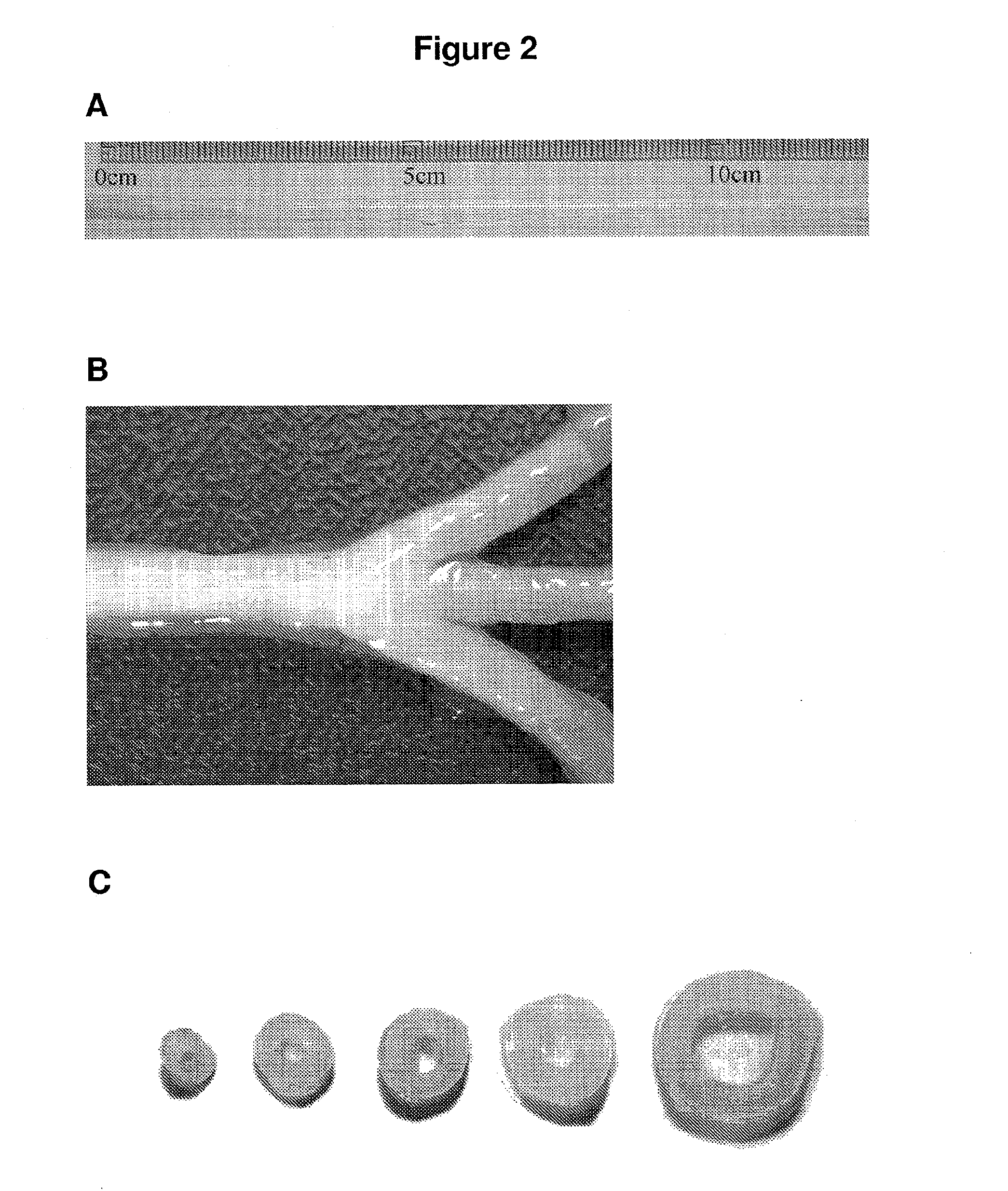

Preparation of hollow cellulose vessels

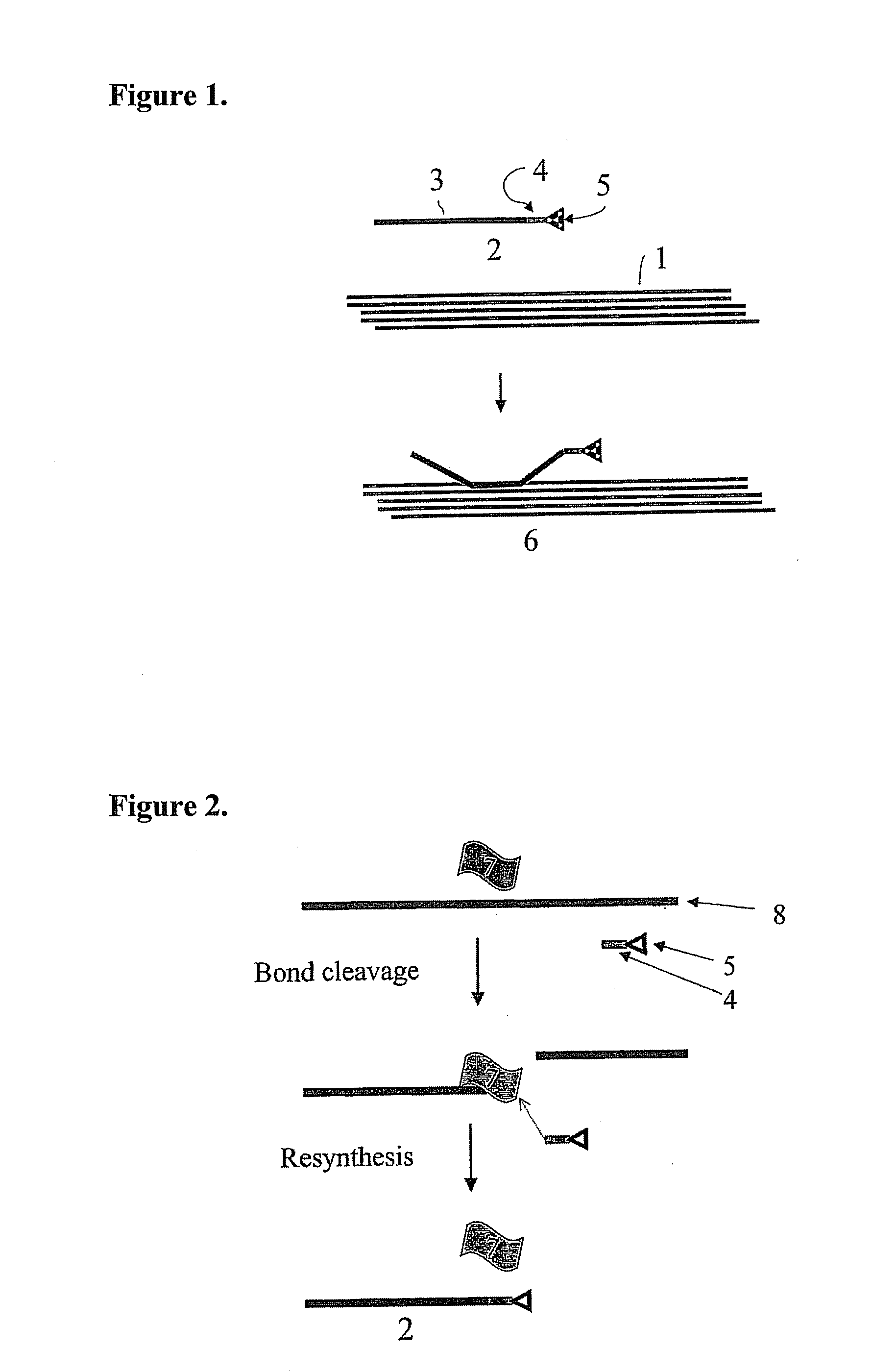

InactiveUS20100042197A1Good mechanical resistanceIncrease burst pressureEnvelopes/bags making machineryLayered productsHollow fibreLymphatic vessel

The present invention relates to an improved method for the preparation of hollow cellulose vessels produced by a microorganism, and hollow cellulose vessels prepared by this method. The method is characterized by the culturing of the cellulose-producing microorganisms being performed on the outer surface of a hollow carrier, and providing an oxygen containing gas on the inner side of the hollow carrier, the oxygen containing gas having an oxygen level higher than atmospheric oxygen. The hollow microbial cellulose vessels of the present invention are characterized by improved mechanical properties and can be used in surgical procedures to replace or repair an internal hollow organ such as the urethra, ureter, the trachea, a digestive tract, a lymphatic vessel or a blood vessel

Owner:ARTERION AB

Slotted mold for making a balloon catheter

InactiveUS20050123640A1Improve heat transfer performanceHeating evenly and quicklySurgeryDilatorsBlow moldingMedicine

A method of making a catheter balloon, and a balloon formed thereby, in which a polymeric tube is radially expanded in a mold having a wall with an outer surface and an inner surface defining a chamber, and having at least a section with one or more channels in the wall. The channels result in improved transfer of heat to the polymeric tube within the chamber of the mold during blow molding of the tube to form a balloon, so that the tube is heated more quickly and evenly. One aspect of the invention is directed to a balloon having sections with improved thin walls.

Owner:ABBOTT CARDIOVASCULAR

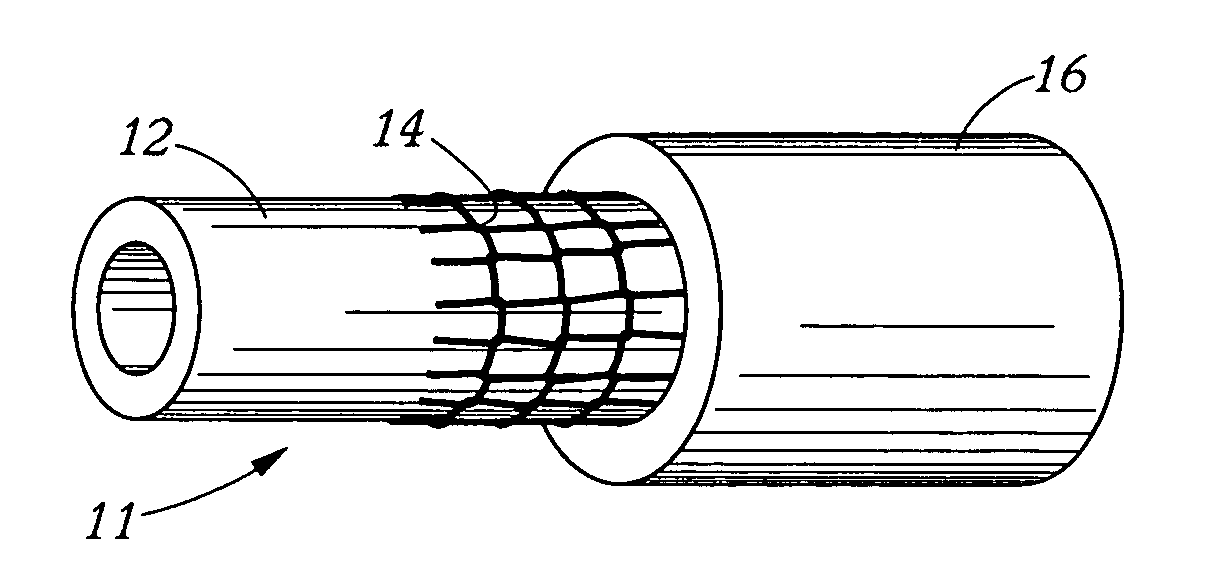

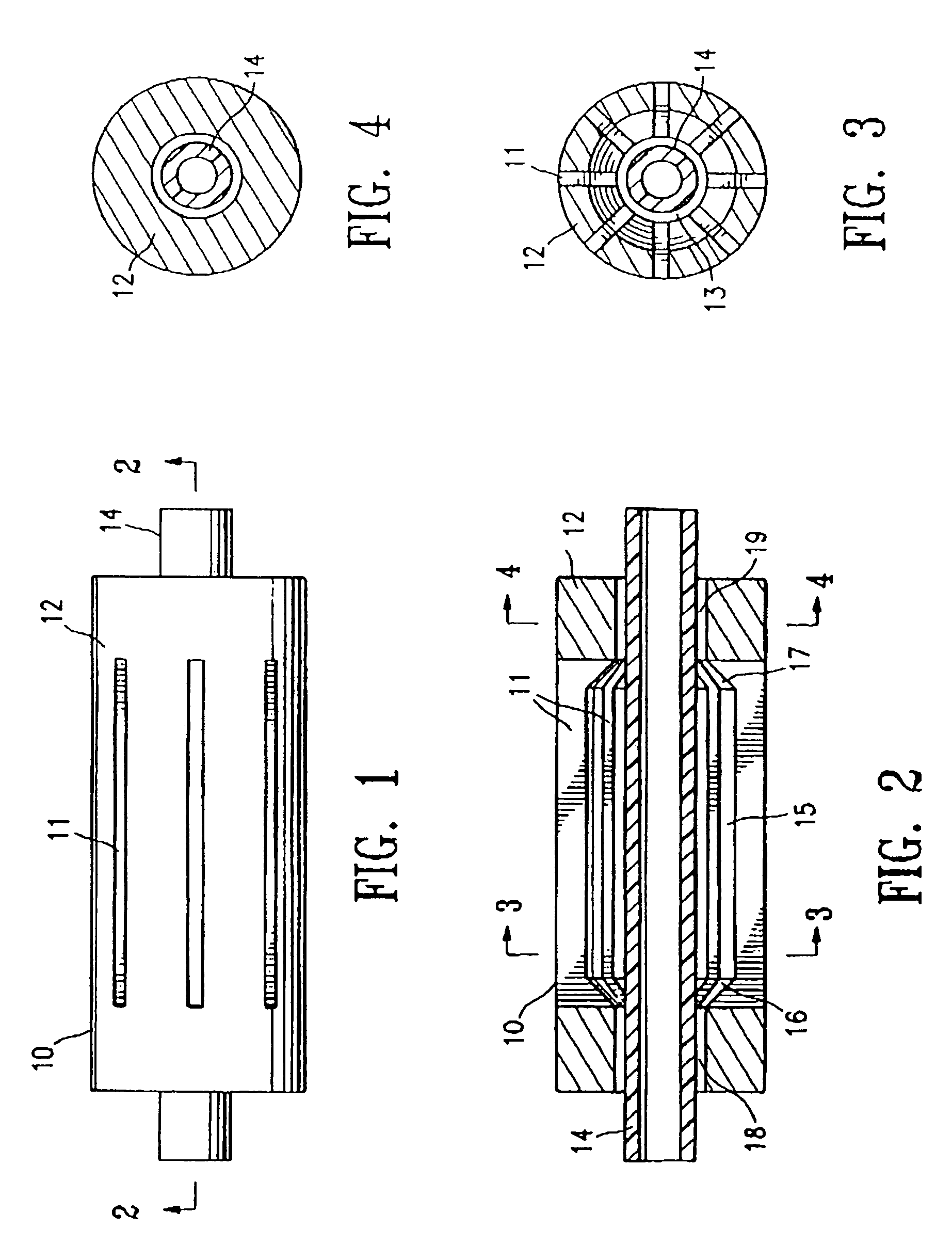

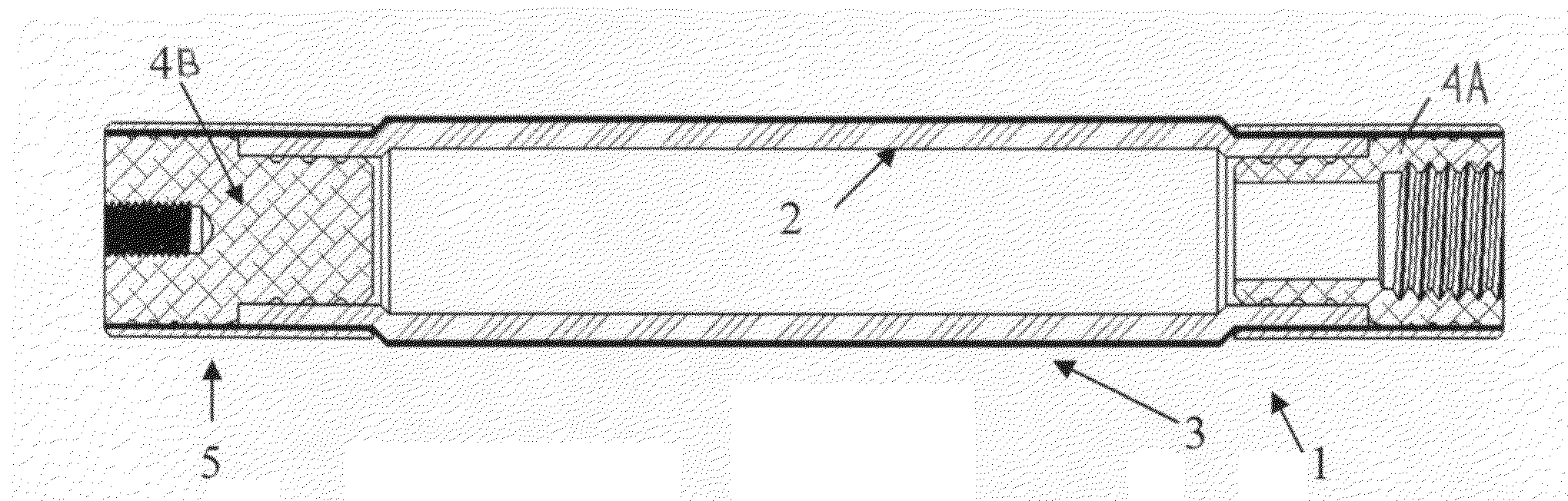

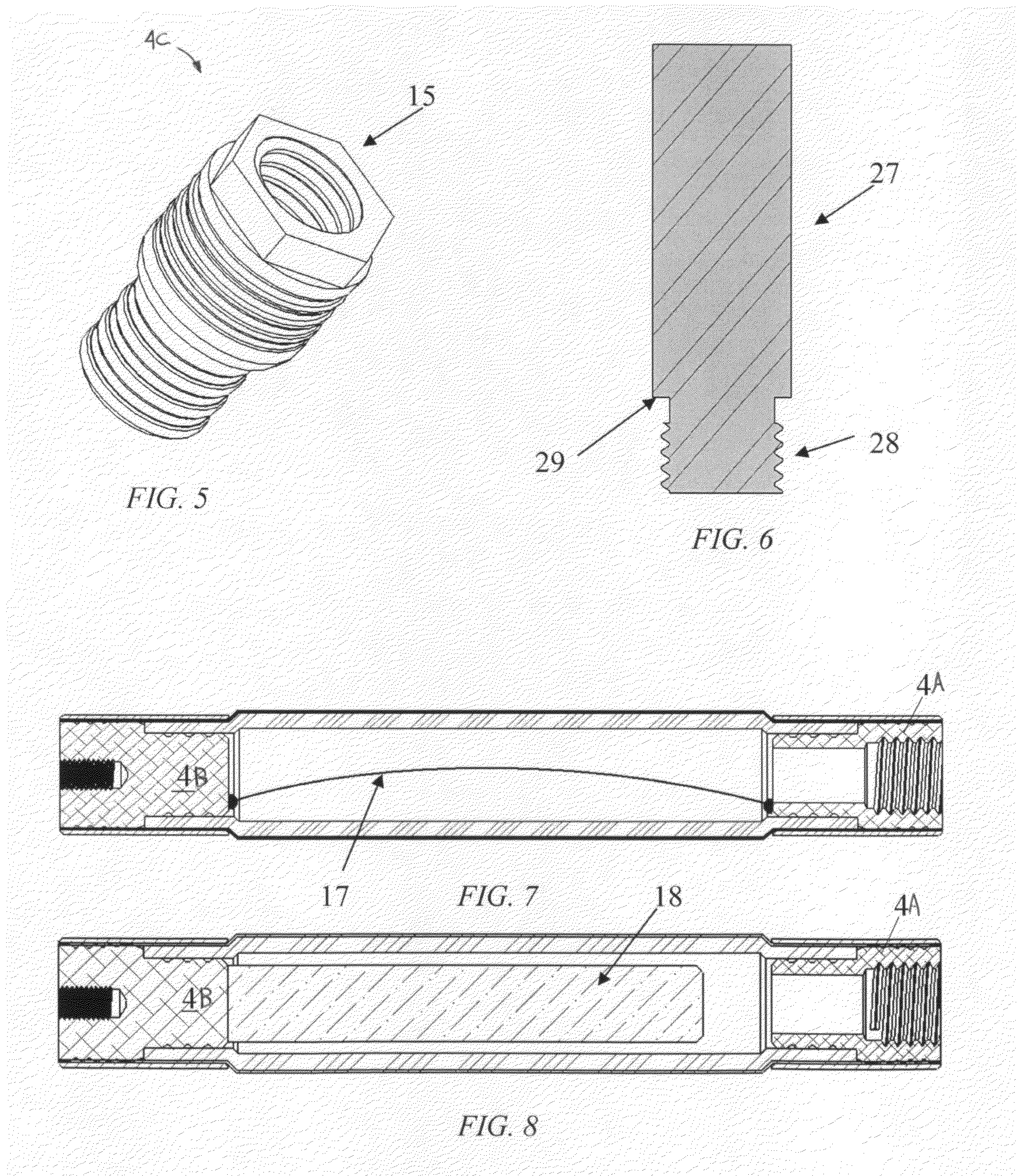

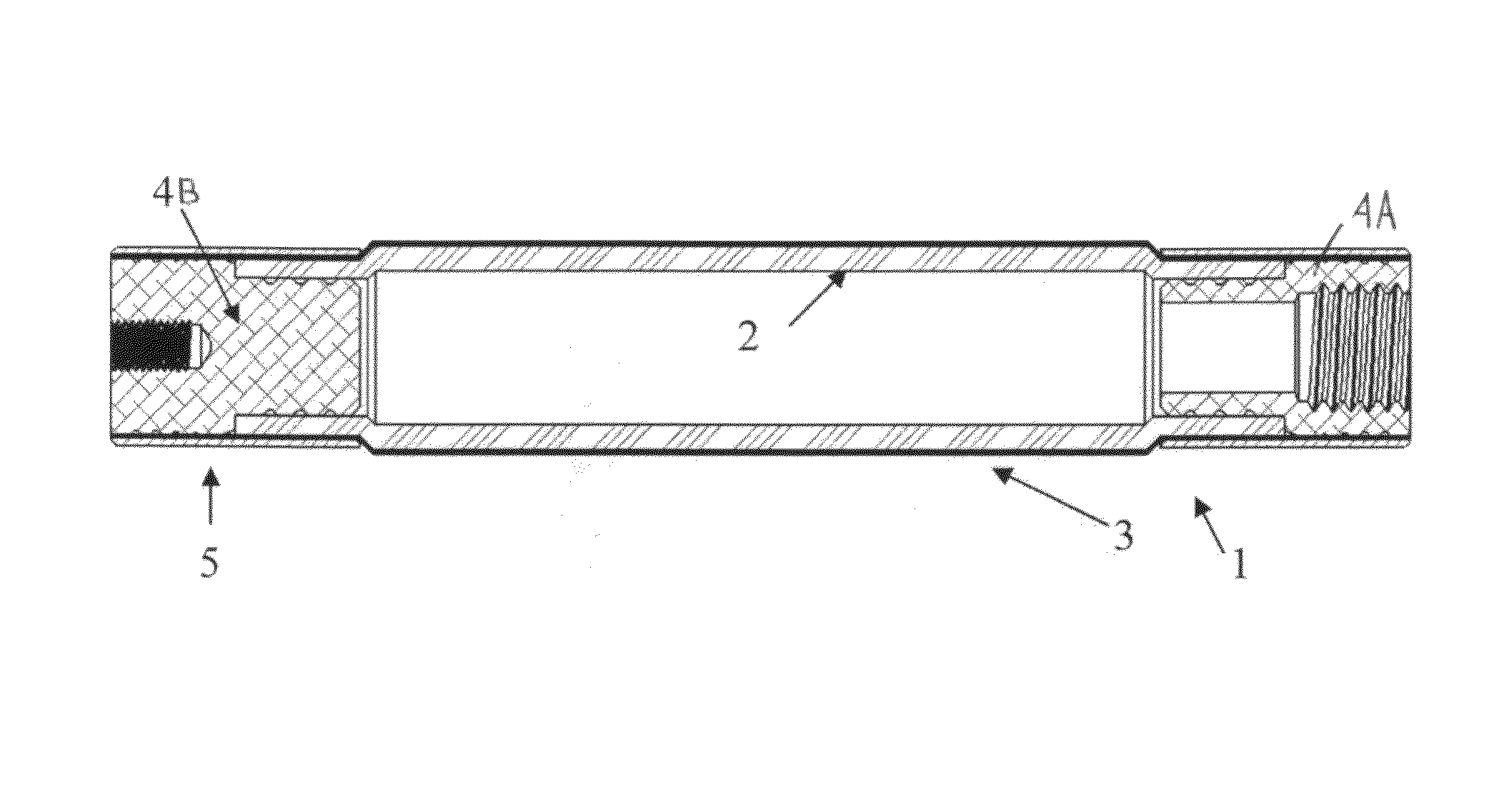

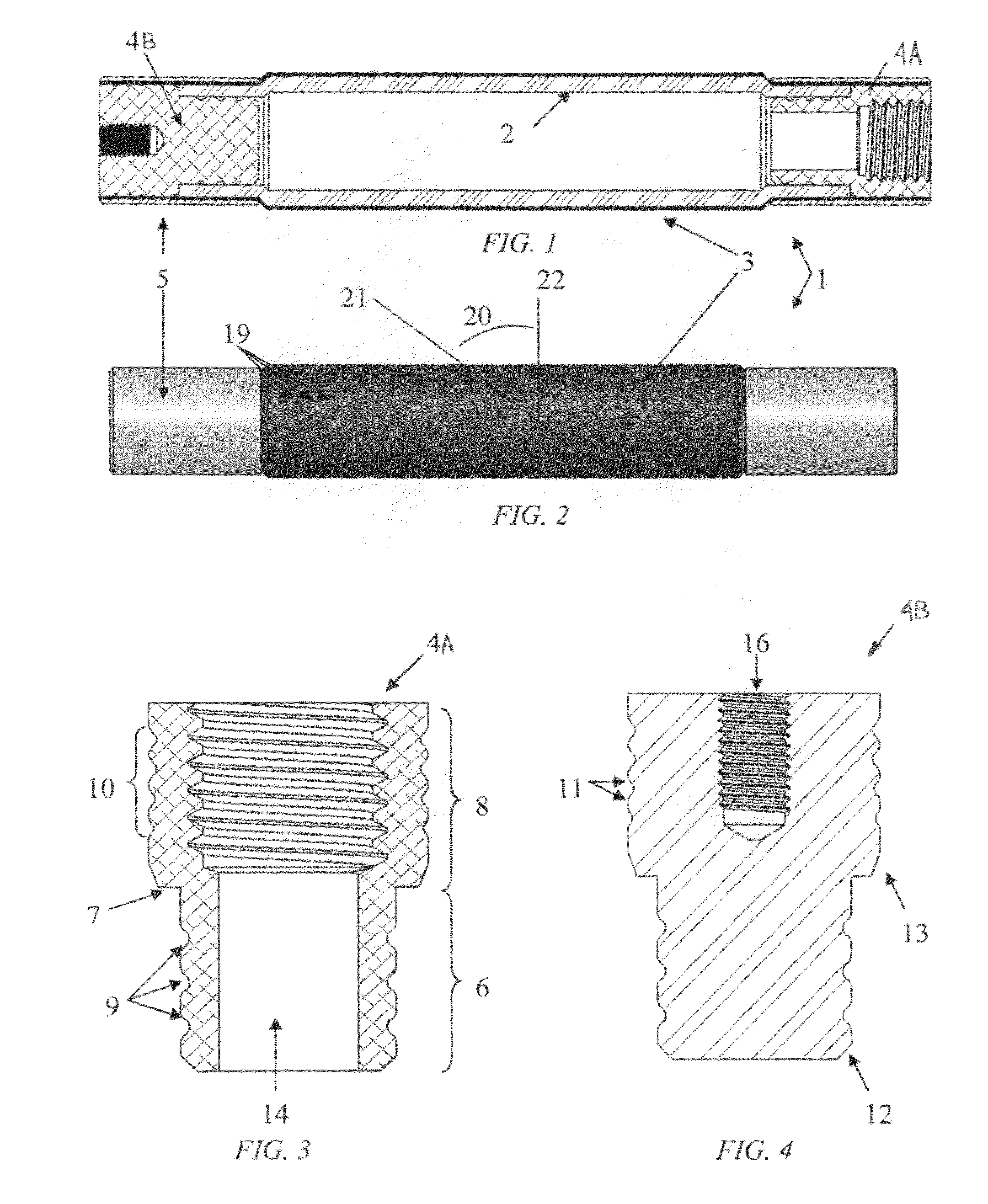

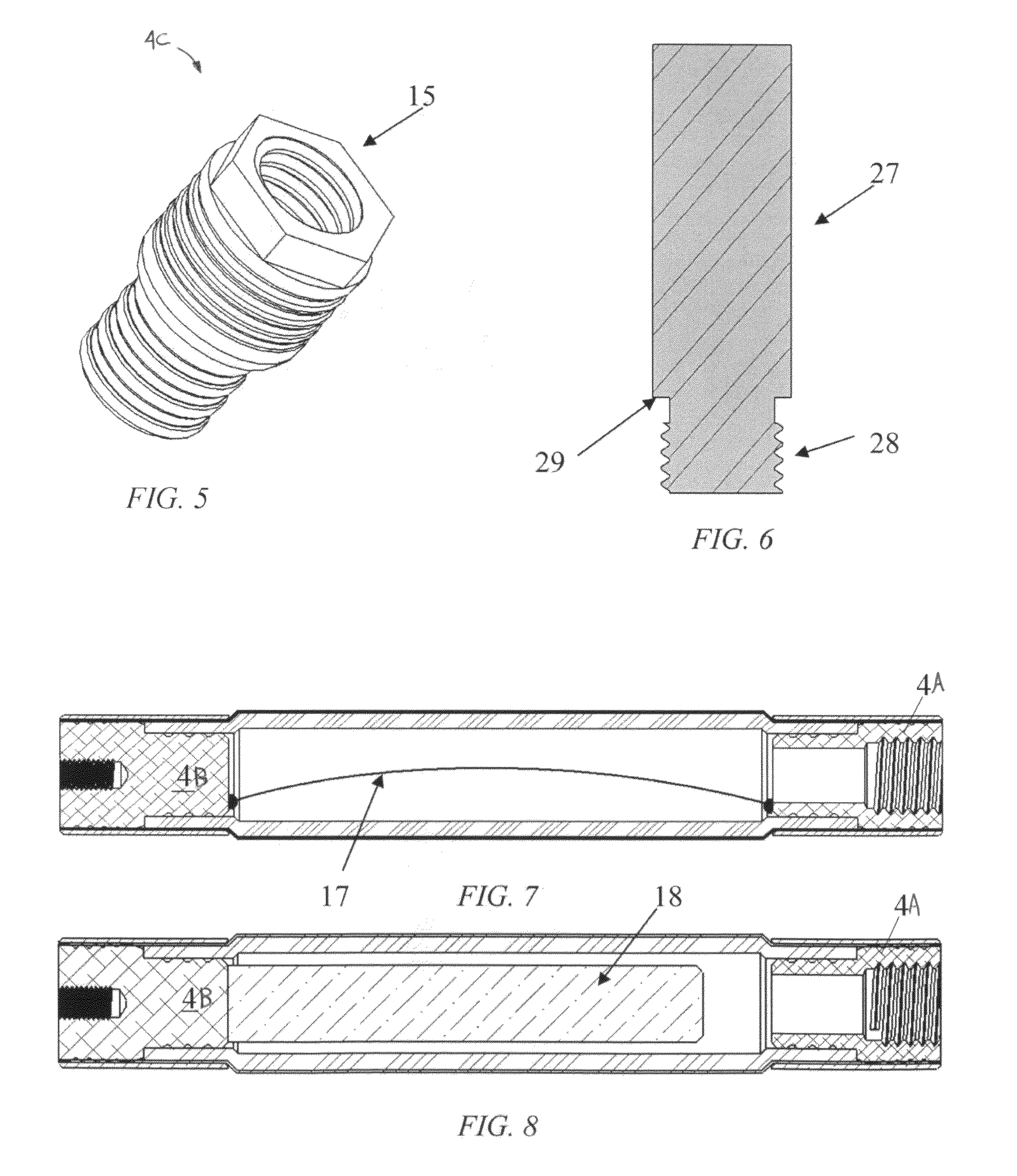

Fluidic artificial muscle actuator and swaging process therefor

ActiveUS20090301292A1Simple and robust connectionHigh tensile strengthShaping toolsFlexible wall reciprocating enginesEngineeringSwaging

A fluidic artificial muscle actuator consisting of an inner elastic bladder surrounded by a braided filament sleeve and sealed off on either end with end fittings. Pressurization of the actuator produces force and / or motion through radial movement of the bladder and sleeve which forces the sleeve to move axially. Both contractile and extensile motions are possible depending on the geometry of the braided sleeve. The fluidic artificial muscle actuator is manufactured using a swaging process which plastically deforms swage tubes around the end fittings, braided sleeve, and pressure bladder, creating a strong mechanical clamping action that may be augmented with adhesive bonding of the components. The swaging system includes the swaging die and associated components which are used to plastically deform the swage tube during assembly of the actuator.

Owner:INNOVITAL LLC +1

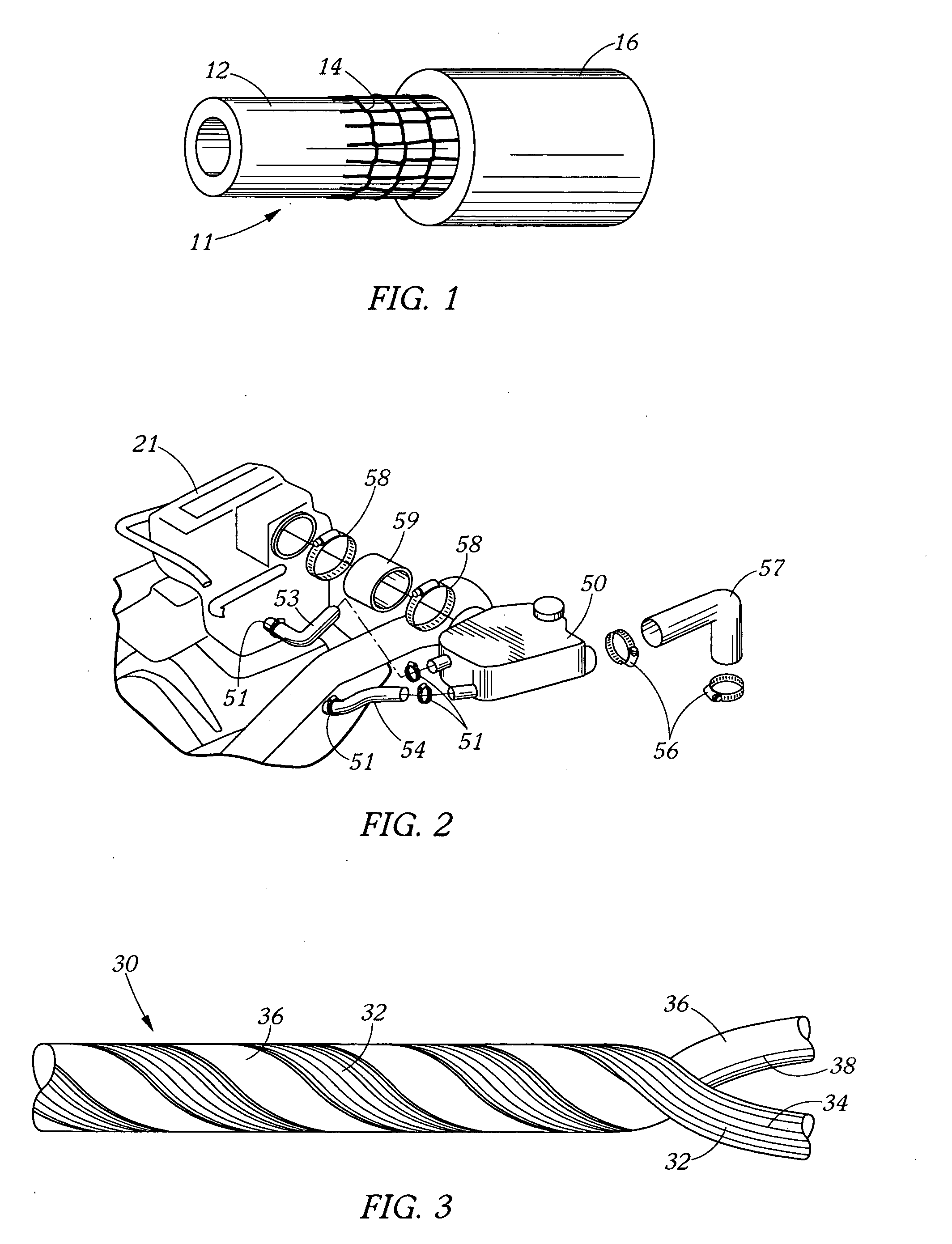

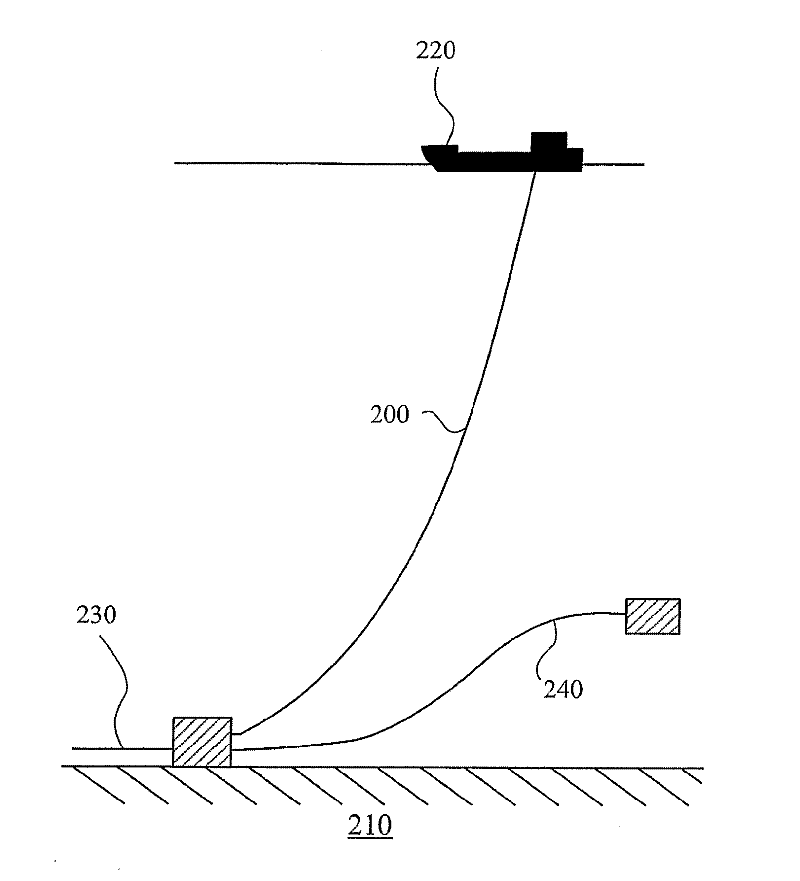

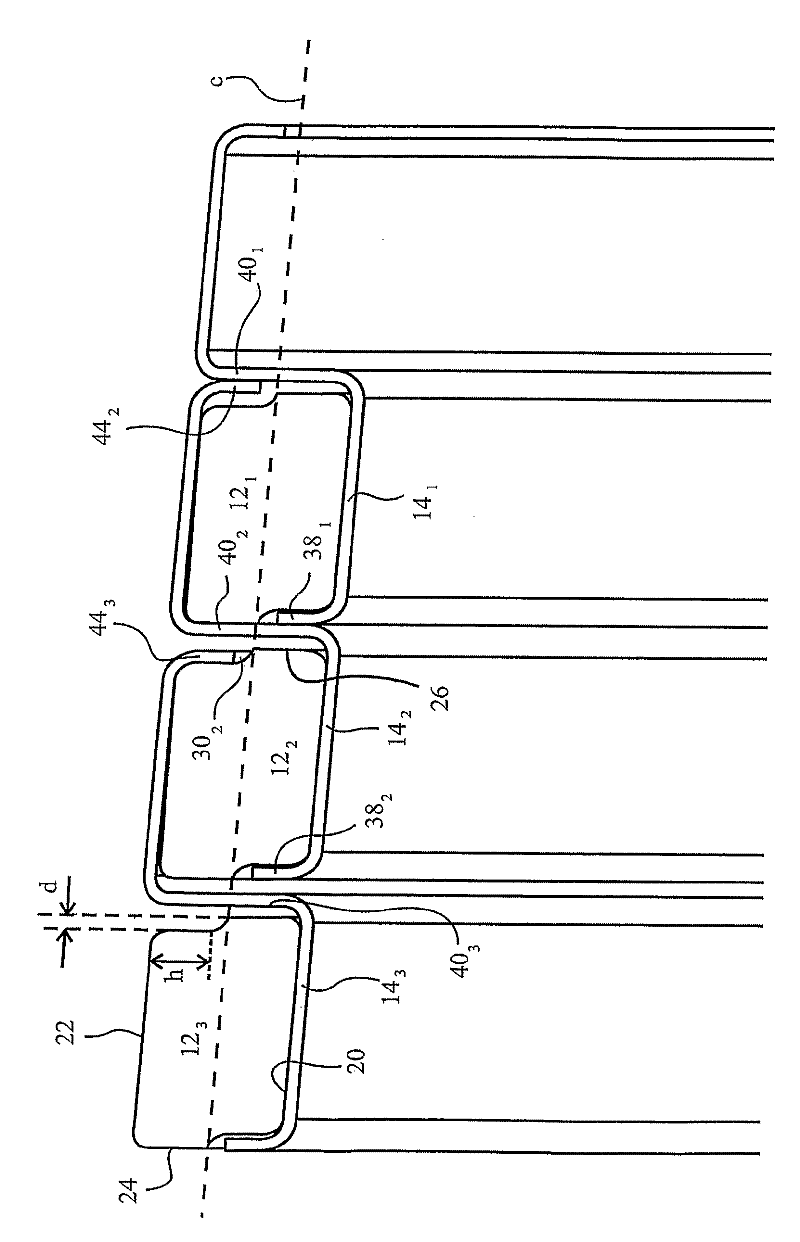

Flexible pipe having pressure armour layer and components thereof

InactiveCN102245953AIncrease hydrostatic external pressureIncrease static external pressureFlexible pipesMechanical engineeringClassical mechanics

An elongate tape element and method of manufacturing flexible pipe body are disclosed. The elongate tape element (12) which is for providing at least one helically wound layer of windings in a flexible pipe body (10), comprises an elongate body having a base surface (20), a top surface (22) opposed to the base surface and opposed first and second side walls (24, 26) extending between the base and tope surface wherein at least one surface and / or side wall of the body comprises a recessed region for receiving a respective portion of a tape element holder member when said tape element is wound to form a layer of windings.

Owner:GE OIL & GAS UK LTD

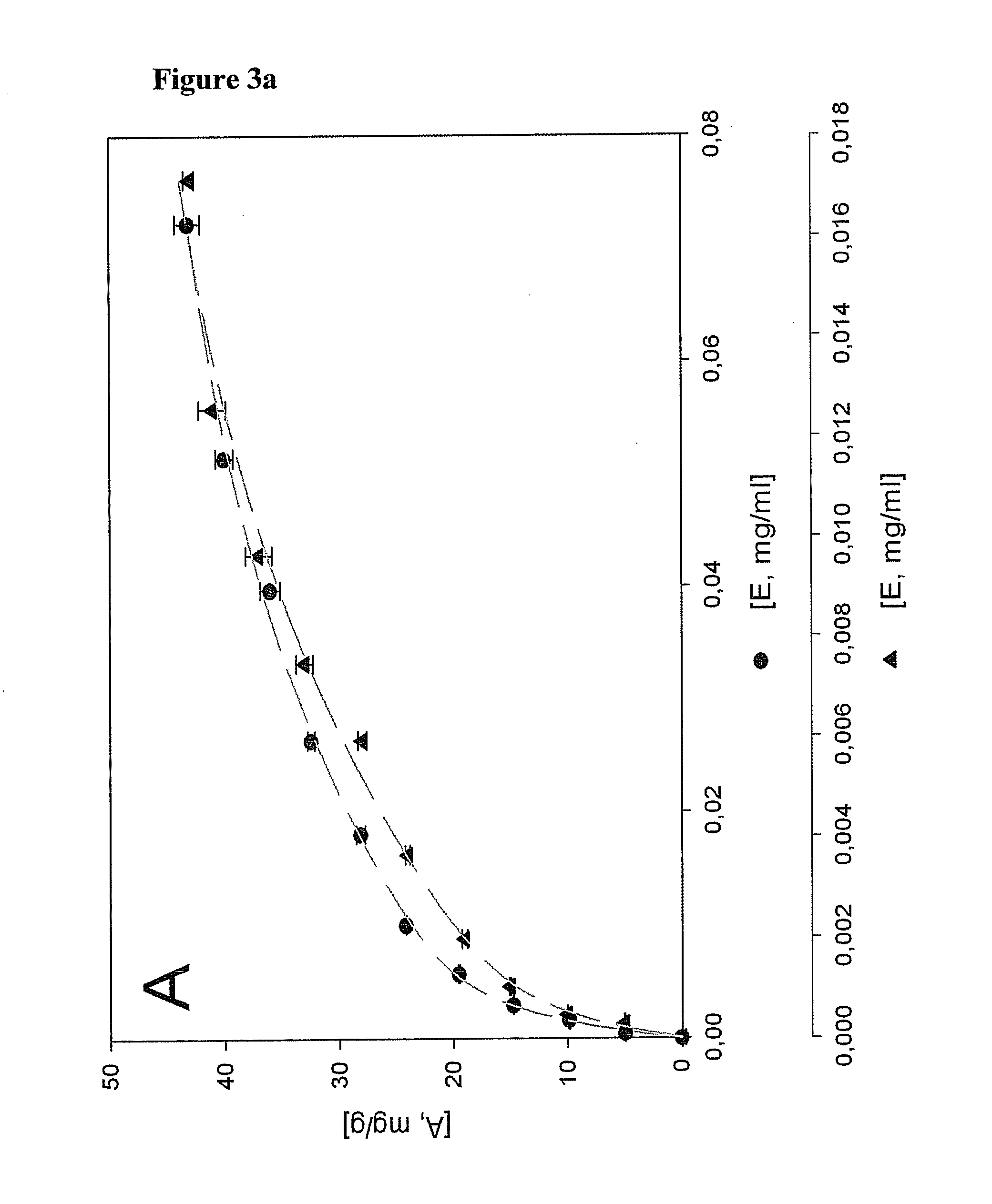

Implantable material comprising cellulose and the glycopeptide xyloglucan-grgds

InactiveUS20100278893A1Good biocompatibilityAlter confirmation and orientationBiocideTransferasesMedicineGlycopeptide

Owner:SWETREE TECHOLOGIES AB

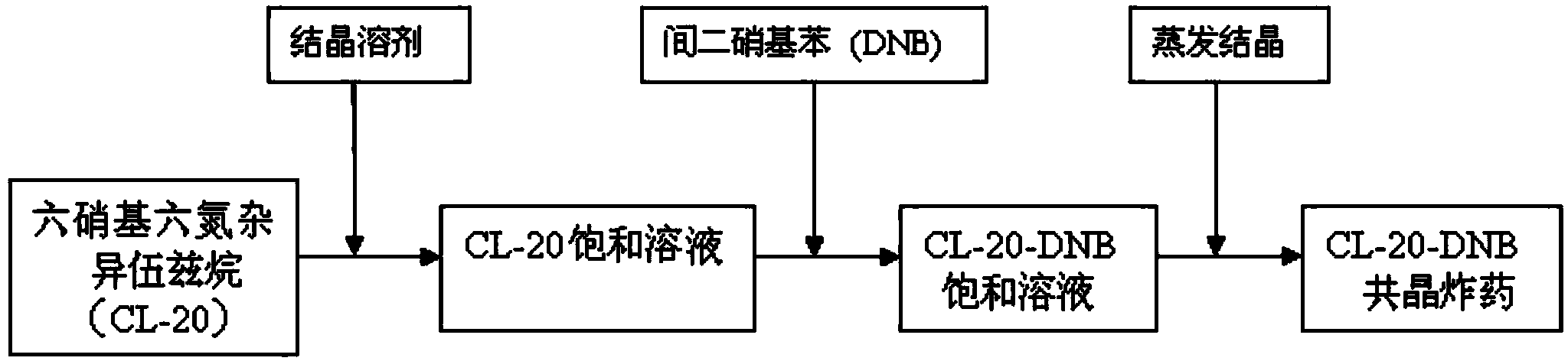

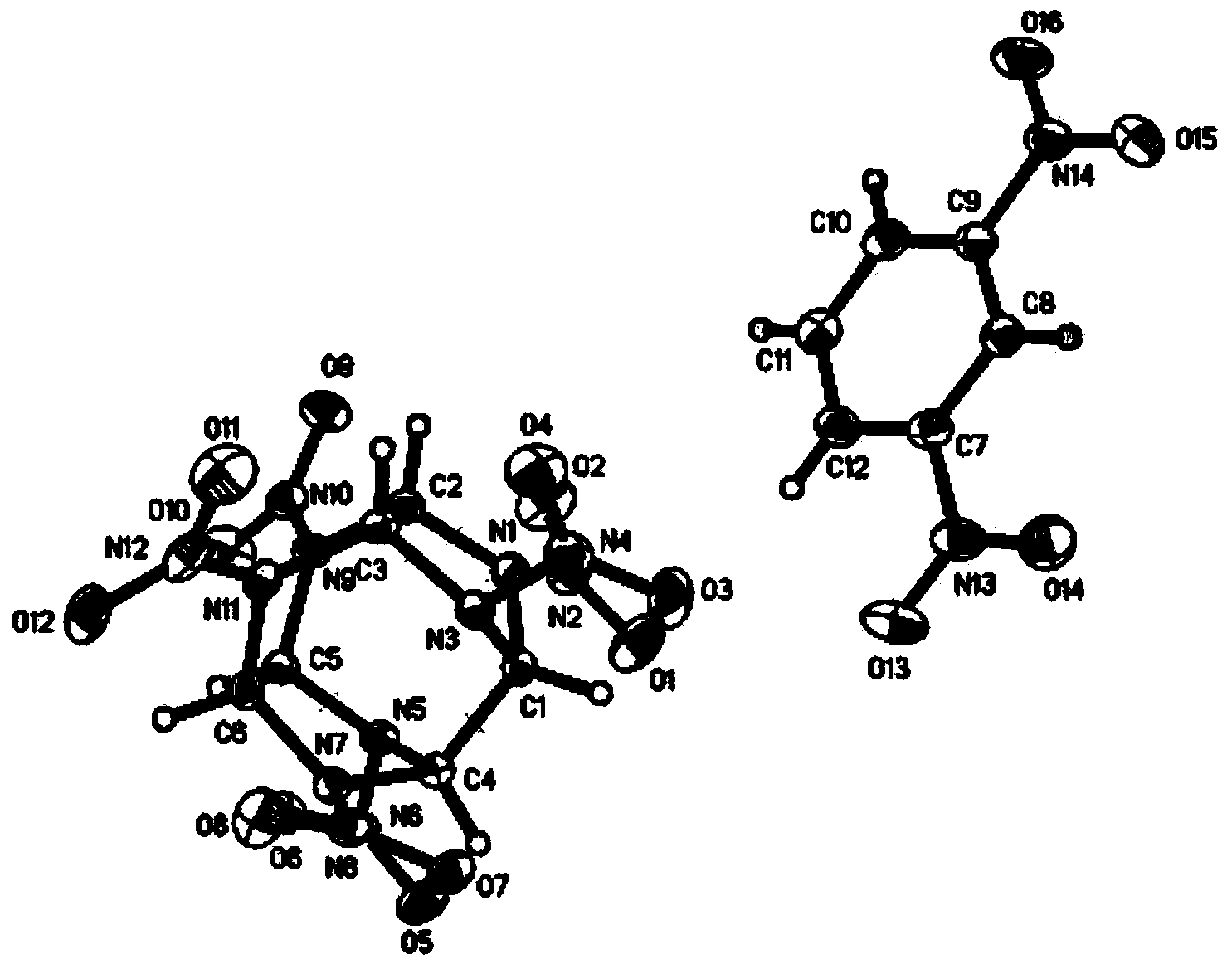

Preparation method for hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive

ActiveCN103396274AHigh detonation velocityIncrease burst pressureNitroparaffin explosive compositionsSolvent evaporationSolvent

The present invention discloses a preparation method for a hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive, wherein a crystallization solvent is adopted to prepare a hexanitrohexaazaisowurtzitane and m-dinitrobenzene saturated solution, and a constant temperature incubator is adopted to perform solvent evaporation and crystallization to obtain the hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive. According to the present invention, crystal density of the hexanitrohexaazaisowurtzitane and m-dinitrobenzene (CL-20-DNB) co-crystallized explosive is significantly increased by 19.6% compared with crystal density of DNB, detonation velocity and detonation pressure of the CL-20-DNB co-crystallized explosive are respectively increased by 46.2% and 147.5% compared to detonation velocity and detonation pressure of DNB, and the CL-20-DNB co-crystallized explosive has characteristics of a good detonation performance and high safety performance, and can be used for preparing low sensitivity ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

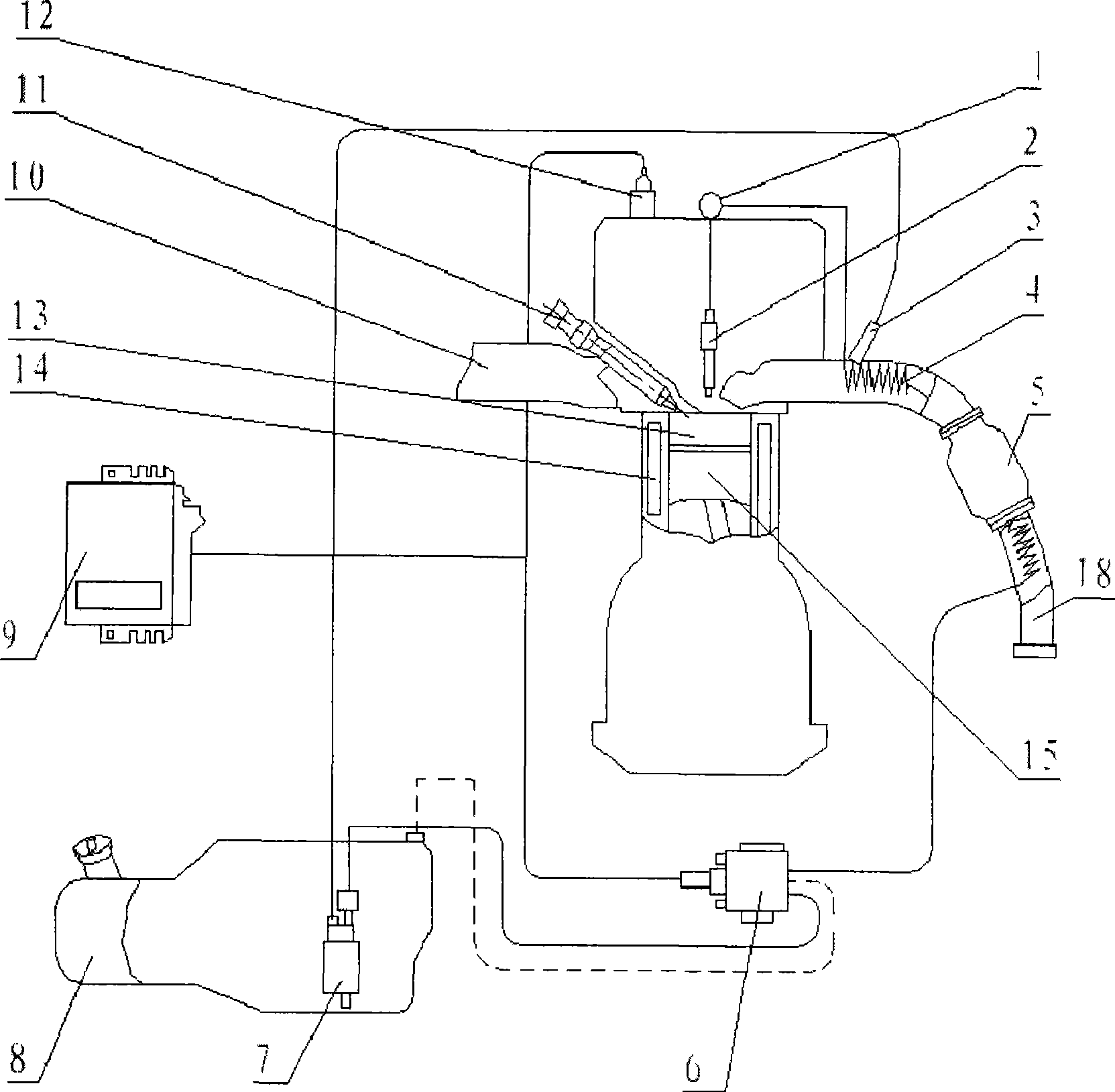

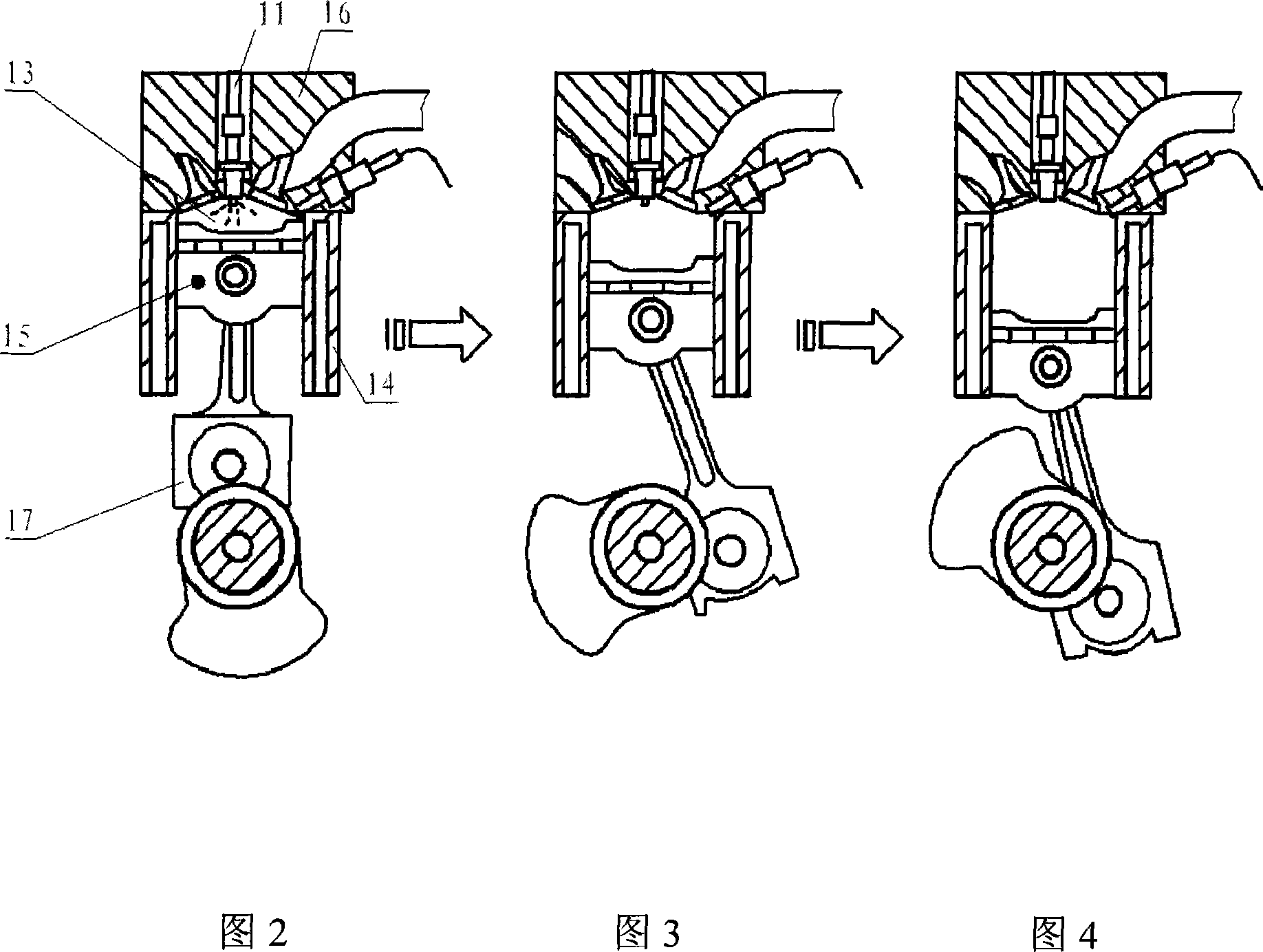

Subcritical steam auxiliary power gasoline engine

InactiveCN101457713AEfficient emissionsReduce fuel consumptionInternal combustion piston enginesNon-fuel substance addition to fuelPipingInjector

The invention relates to a subcritical vapor auxiliary work done gasoline engine which comprises a water injector in a cylinder of the gasoline engine, wherein, the water injector comprises a water tank, an electric control unit, and water pumps, a water guideway, a water injection nozzle and a temperature sensor which are controlled by the electric control unit. The water injector is characterized in that the water pumps comprise a low pressure water pump and a high pressure water pump pressurizing water to be above 200bar, the low pressure water pump is arranged in the water tank and is communicated with the high pressure water pump, the high pressure water pump is communicated with the water guideway by a high pressure water pipe, the water injection nozzle is communicated with the water guideway, and a water injection opening extends into a combustion chamber of the gasoline engine. The gasoline engine also comprises a gasoline engine exhaust pipe used for heating water to above 250 DEG C and not more than 374.2 DEG C, and a high pressure water pipe penetrates through the exhaust pipe and then is communicated with the water guideway. The gasoline engine utilizes the waste heat of engine tail gas to do work circularly, thereby saving oil; the temperature of water injected into the cylinder is in a subcritical state, and the water is instantaneously vaporized in the cylinder under the pressure condition, thereby increasing the explosion pressure of the cylinder; and the torque output and the power are improved under the premise that the oil injection amount is not increased.

Owner:MIANYANG XINCHEN ENGINE

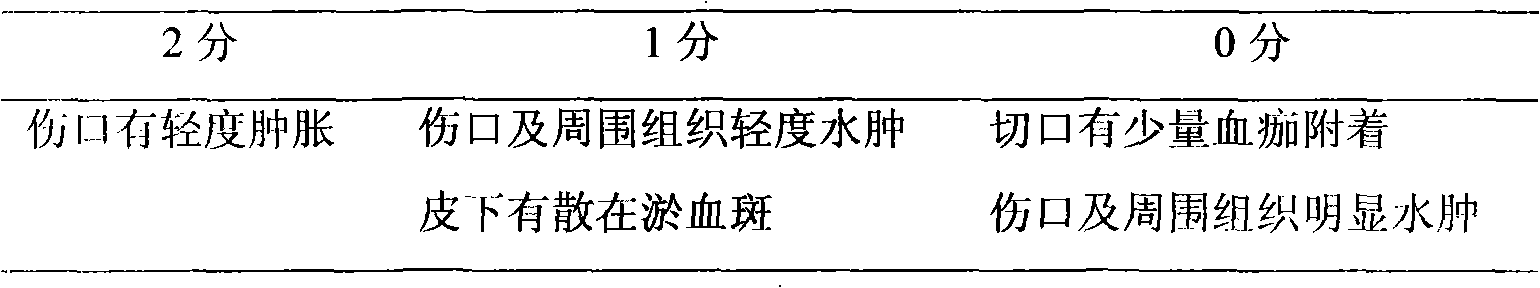

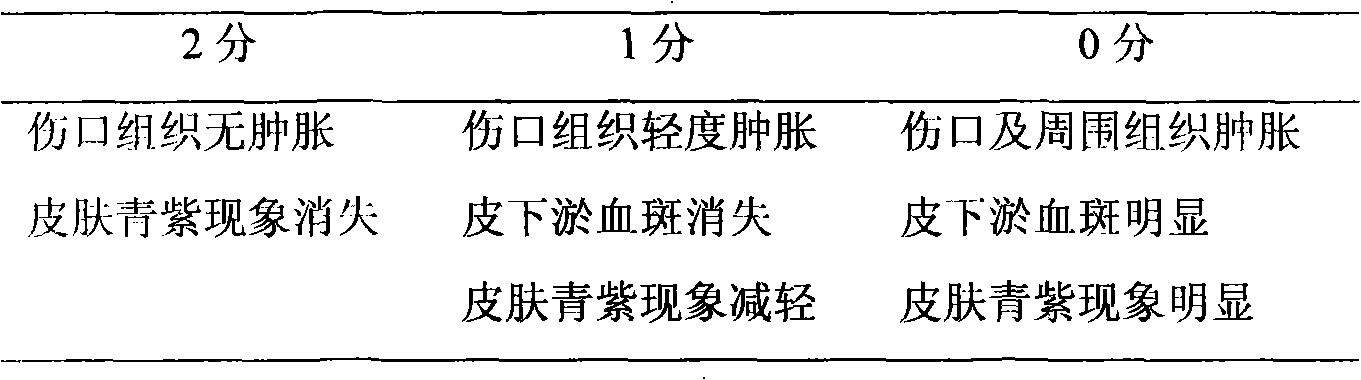

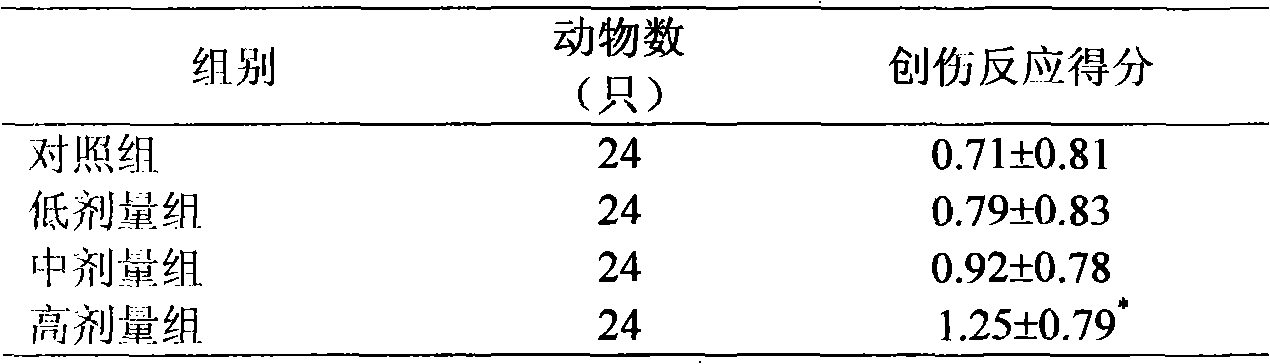

Application of marine peptide in preparing medicament for promoting caesarean section postoperation recovery and health food

InactiveCN101797373APromote absorptionFast absorptionPeptide/protein ingredientsDermatological disorderSolubilityUterus

The invention relates to a marine peptide product and application thereof in preparing a medicament for promoting caesarean section postoperation recovery, a health food or food. The marine peptide is a group of low-molecular weight oligopeptide mixture which adopts fish skin, fish bones or fish flesh of marine fishes as main raw materials, is produced by hydrolysis through an enzyme method, can be dissolved by trichloroacetic acid, has the relative molecular mass of smaller than 1,000 and comprises marine collagen peptide (derived from the fish skin), marine bone-derived peptide (derived from the fish bones) and marine protein peptide (derived from the fish flesh). The invention has the characteristics of easy and rapid absorption, low viscosity, good water solubility, and the like. Animal tests prove that the marine peptide has the effects of promoting skin peptide wound healing after a caesarean section operation and promoting the wound healing of the uterus.

Owner:HEILONGJIANG SUNCARE NUTRITIONAL TECH +1

Drilling fluid plugging agent while drilling

Owner:PETROCHINA CO LTD

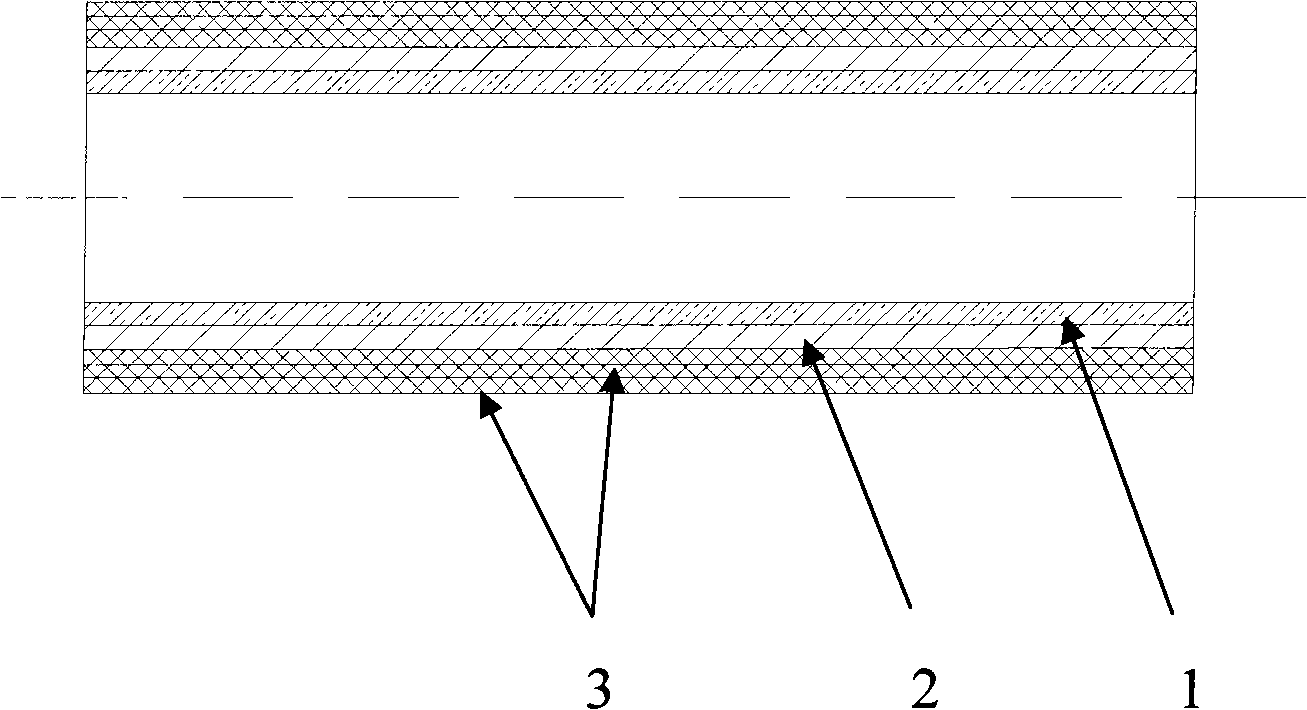

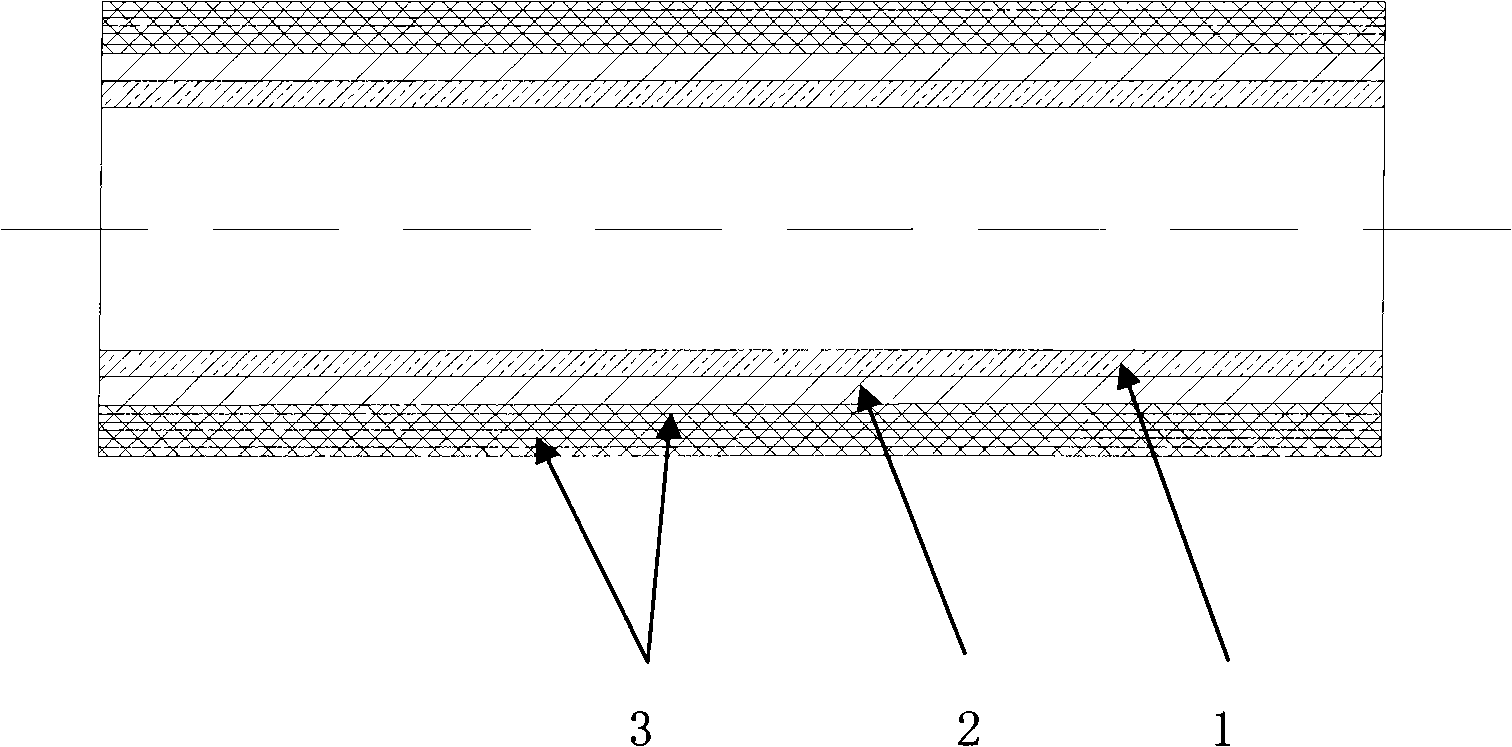

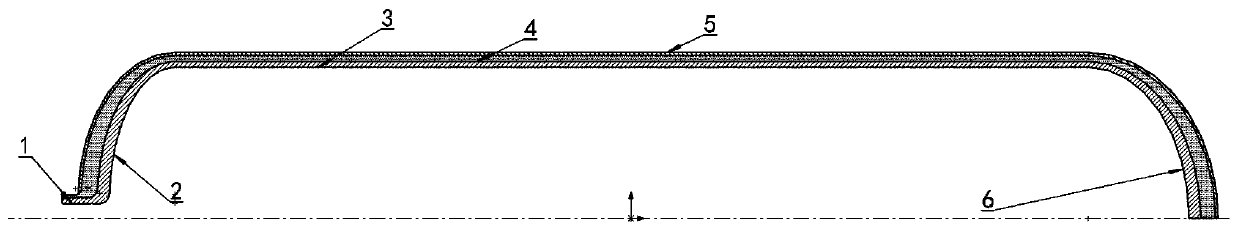

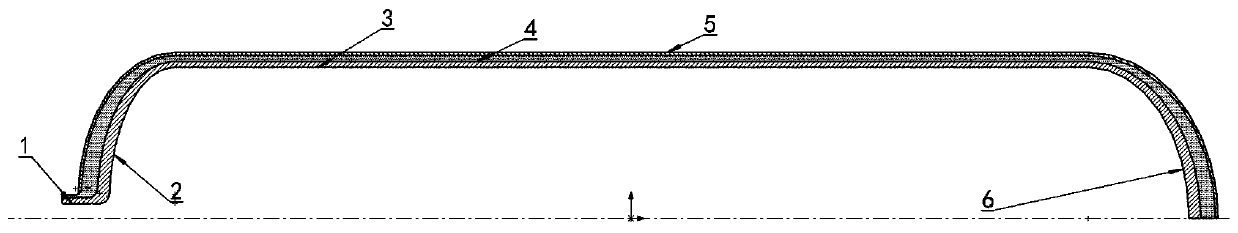

Cloth re-winding rubber pipe of fluororubber and silicon rubber composite extrusion and preparation method thereof

The invention relates to a cloth winding rubber hose compositely extruded by fluorubber and silastic, and a preparation method thereof; the turbo charging rubber hose made of the fluorubber, oil-proof silastic and cloth winding silica gel comprises a fluorubber inner layer 1, an oil-proof silica gel middle layer 2, and a silica gel cloth outer layer 3, wherein, the thickness of the inner layer is 0.4mm to 1.0mm, the thickness of the middle layer is 1mm to 3mm, and the thickness of each silica gel cloth is 0.5mm to 1.5mm. The preparation method of the invention comprises the following steps of the tube blank manufacturing operation, the reinforcement layer preparation, and the vulcanization and forming process. The invention adopts the silica gel cloth as the reinforcement layer instead of the previous aramid yarns, one layer of cloth winding can be carried out when the aramid yarns are adopted, a plurality of layers of cloth winding can be carried out according to the requirements when the silica gel cloth is adopted, and the rubber hose adopts the technology of firstly and compositely extruding the fluorubber and the oil-proof silica gel, then winding the silica gel aramid cloth, thus further improving the bursting pressure and long-term pulse performance of the turbo charging rubber hose of a heavy-duty vehicle, and prolonging the service life of the rubber hose used in the heavy-duty vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

Method for casting aluminum piston of gasoline engine

The invention discloses a method for casting an aluminum piston of a gasoline engine. Based on the traditional gravity casting method, the method also comprises the following steps of: adopting powder metallurgy material with good air permeability to manufacture a mould; carrying out optimization and simulation on the structure of the mould and the casting technology by MAGMAsoft solidification simulation analysis software; after moldassembly, introducing inert gas into a mold cavity of the mould before the mould is poured; and carrying out gas pressurization on molten aluminum in the stage of piston solidification. The method further improves the casting quality of the piston, thus providing the aluminum piston of the gasoline engine which is suitable for various complex structures and high in explosion pressure, strength and performance.

Owner:SHANDONG BINZHOU BOHAI PISTON

Fluidic artificial muscle actuator and swaging process therefor

ActiveUS8307753B2High mechanical strengthSimple and robust connectionShaping toolsFlexible wall reciprocating enginesEngineeringSwaging

Owner:INNOVITAL LLC +1

Compressed natural gas bottle with 35MPa aluminum alloy inner container fully wound with basalt fiber

PendingCN109838682AHigh compressive strengthHigh strengthPressure vesselsCompressed natural gasMetallurgy

The invention discloses a compressed natural gas bottle with a 35MPa aluminum alloy inner container fully wound with basalt fiber. The compressed natural gas bottle comprises a natural gas bottle bodywith the aluminum alloy inner container. A basalt fiber winding layer is arranged on the outer surface of the aluminum alloy inner container in a layered order in a fully winding mode, the basalt fiber winding layer comprises a circumferential winding layer winding around a aluminum alloy inner container cylinder body and a spiral winding layer winding around the aluminum alloy inner container cylinder body and heads at the two ends, and the spiral winding direction of the aluminum alloy inner container cylinder body and the heads at the two ends is consistent and continuous; and the aluminumalloy inner container is first subjected to shot blasting, and then is wound with the basalt fiber winding layer , after winding the aluminum alloy inner container, the outer surface of the basalt fiber winding layer is coated with a protective layer, and the protective layer is bisphenol A epoxy resin. The natural gas bottle can increase the working pressure of a CNG bottle for the vehicle to 35MPa, the utilization rate of the gas storage can be improved, the driving range of CNG vehicles is increased to reach the same mileage as gasoline vehicles, the strength of the aluminum alloy inner container is strengthened, and the anti-pressure ability, yield pressure, burst pressure and anti-fatigue ability of the natural gas bottle are improved.

Owner:XIHUA UNIV

Structure and manufacturing method for pressure vessel

InactiveUS8931661B2Increase burst pressureVessel manufacturingLarge containersEngineeringPressure vessel

A pressure vessel structure includes a vessel main body, and a grid layer provided on a periphery of the vessel main body and including a plurality of grid lines formed by intersecting strip-form raw materials so as to overlap alternately. Thus, a burst pressure of the pressure vessel is increased.

Owner:NISSAN MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com