Silane crosslinked polyethylene plastic for low shrinkage anti-crack tube and its preparation method

A polyethylene plastic, low-shrinkage and anti-resistance technology, applied in applications, household utensils, tubular objects, etc., can solve the problems of large shrinkage rate, poor resistance to environmental stress cracking, etc., achieve extended service life, solve continuous production cycle Short and stable sex high effect

Active Publication Date: 2006-12-13

上海高分子功能材料研究所

View PDF0 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The object of the present invention is to improve the disadvantages of large shrinkage rate and poor resistance to environmental stress cracking while retaining all the advantages of common cross-linked polyethylene

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] Example 1 is used in occasions requiring a higher degree of crosslinking.

Embodiment 2

[0036] Example 2 is used in occasions that have higher requirements on the appearance of pipes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Login to View More

Abstract

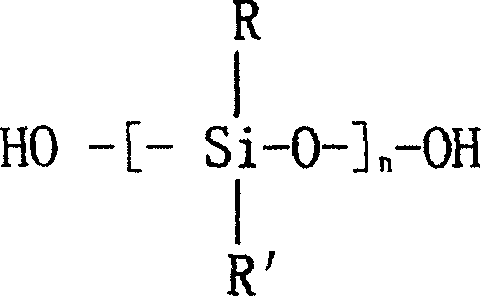

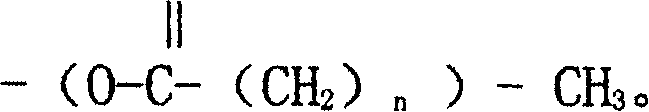

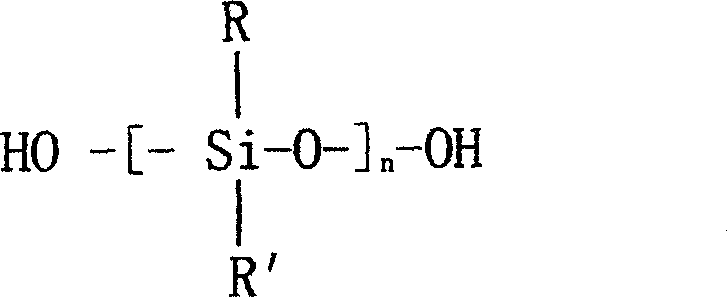

The invention relates the silicon alky cross-linking low-middle-high density vinyon. The components comprises 0.8-3.0wt% silicon alky cross linking agent, 0.02-2.0wt% cross linking initiating agent, 0.02-1.0wt% cross linking catalyst, 0.01-3.0wt% anti-oxidant and 0.05-3.0wt% modified auxiliary agent. The method comprises the following steps: preparing silicon alky grafting material A, mixing A and B materials, handing with extrusion machine to get tubing product, keeping it in water bath at 85Deg.C or vaporium for 8 hours, and getting the product. The invention overcomes the defects of big contraction percentage and degelatinizing phenomena between polythene layer and metal layer; the invention has the advantages of short production circle, stable technology and high rate of finished products.

Description

technical field [0001] The invention relates to a low-medium-high-density polyethylene material used for the inner and outer layers of all-plastic pipes, aluminum-plastic composite pipes and steel-plastic pipes. Specifically, it relates to a material with low shrinkage rate, anti-cracking in various environments, and improving the mechanical properties and heat resistance properties of polyethylene plastics through silane crosslinking. Background technique [0002] Traditional drinking water pipes, industrial gas transmission, and oil pipelines are generally made of galvanized steel pipes. For decades, galvanized steel pipes have often been rusted and scaled, causing secondary pollution of drinking water, and the liquid flow resistance is large, which is relatively useless. Short life. So people seek a new material to replace the original galvanized steel pipe. PPR and cross-linked polyethylene have become popular materials. [0003] The strength of PPR is low under hot c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/06C08K5/54C08J3/24B29C47/00B29D23/00

CPCY02P20/52

Inventor 穆肖斌项华丽贾建平

Owner 上海高分子功能材料研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com