Double-sided laminator driving mechanism

A driving mechanism and laminating machine technology, which is applied in the directions of packaging machines, packaging, transportation and packaging, etc., can solve the problems of lower production efficiency, double-sided machine cardboard creases, degumming, etc., to overcome cardboard creases and degumming, extend Effects of service life and maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

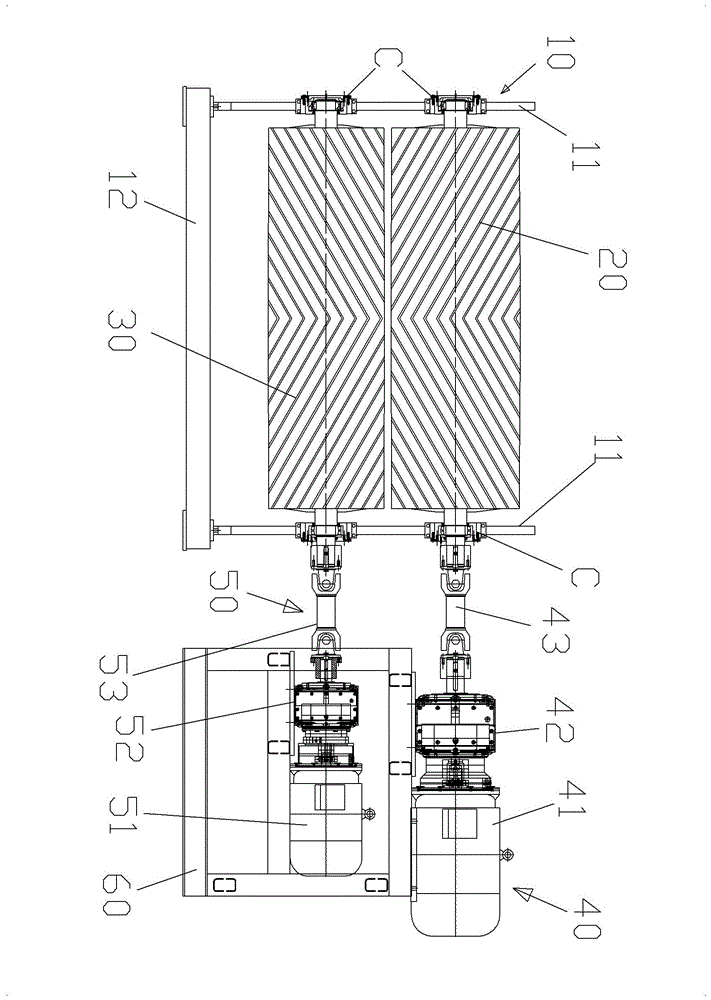

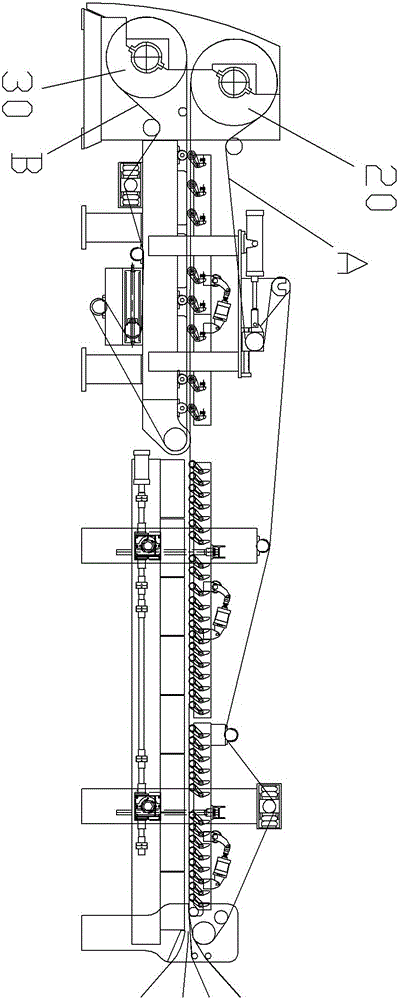

[0013] Such as Figure 1 to Figure 2 Shown is a preferred specific implementation example of the present invention, a double-sided laminating machine drive mechanism, including a frame 10, a rubber wheel 20 rotatably installed in the frame 10, a rotatably mounted The lower rubber wheel 30 located below the upper rubber wheel 10 in the frame 10, the first power mechanism 40 for driving the upper rubber wheel 20 to rotate and the lower rubber wheel for driving the The second power mechanism 50 that the wheel 30 rotates drives the upper rubber wheel 10 and the lower rubber wheel 20 through the first power mechanism 30 and the second power mechanism 50 to control the speed synchronously, so that the upper rubber wheel 20 is driven The upper conveyor belt A and the lower conveyor belt B driven by the lower rubber wheel 20 realize synchronous operation.

[0014] Further, the shaft heads at the left and right ends of the upper rubber wheel 20 and the lower rubber wheel 30 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com