Patents

Literature

717results about How to "Smooth braking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile brake control method for improving lateral stability of turning/braking vehicles

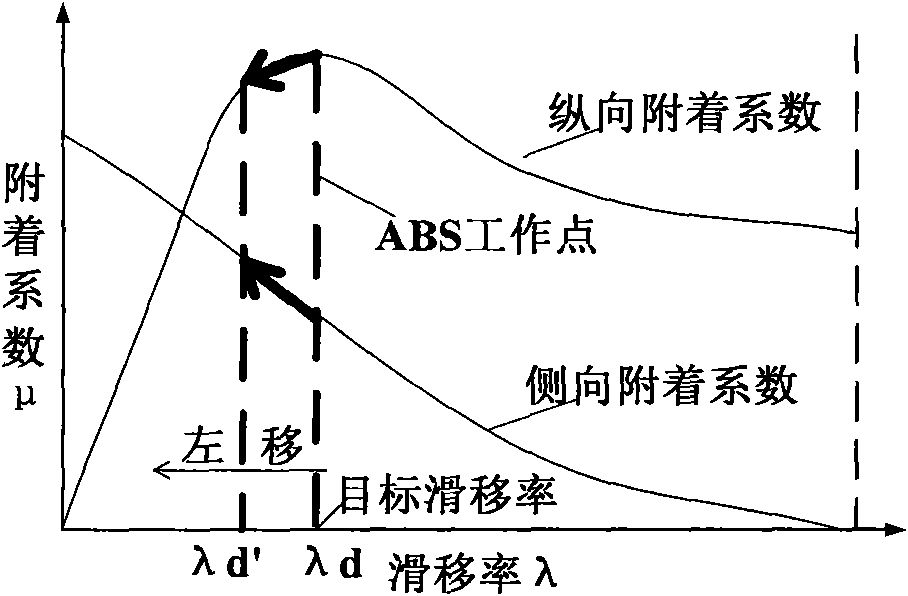

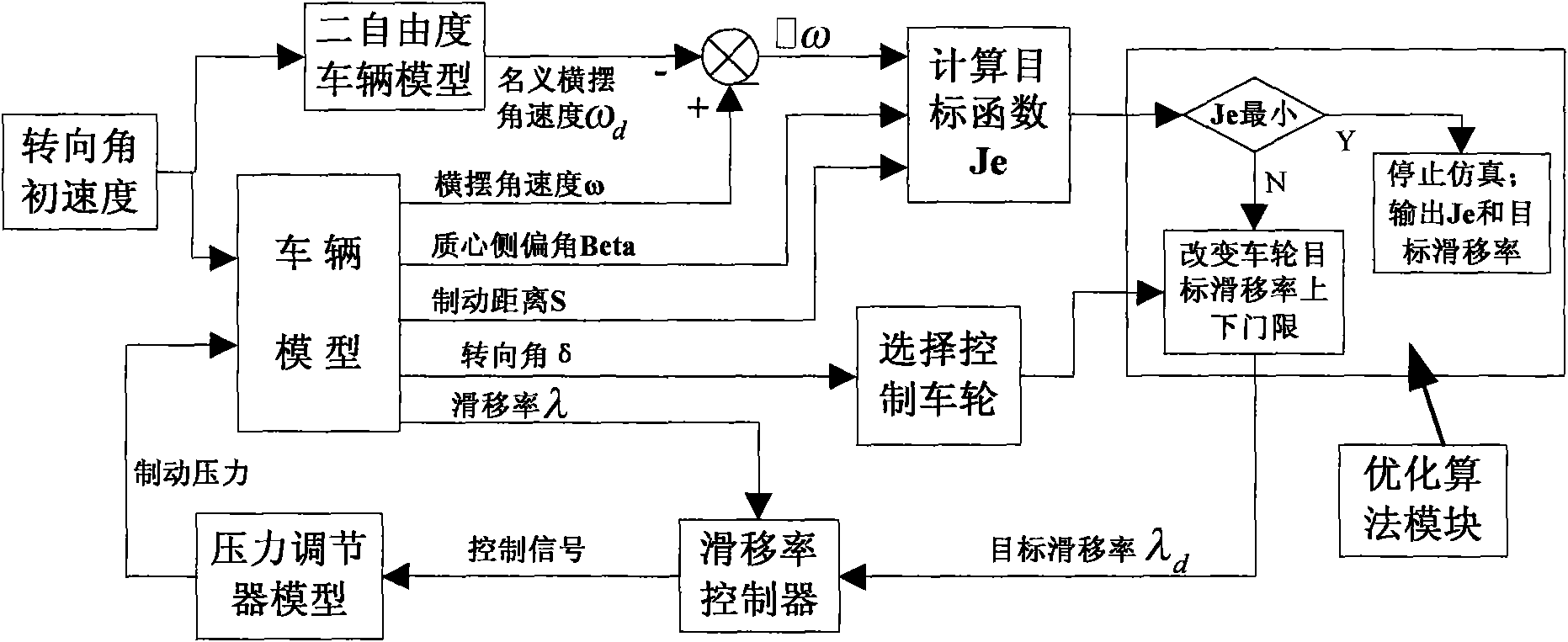

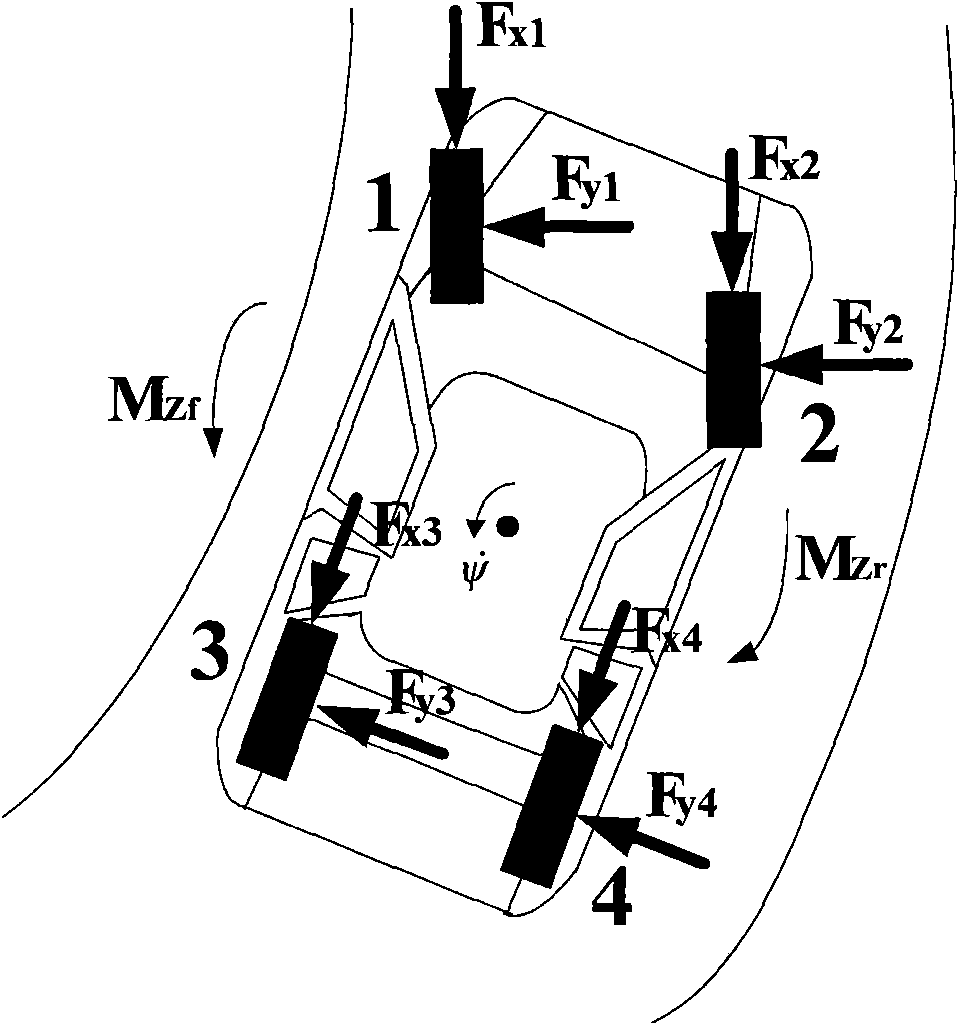

The invention relates to a method for improving lateral stability under the condition of turning / braking vehicles, in particular to an automobile brake control method for improving lateral stability of turning / braking vehicles. By an off-line simulation method, from the angle of whole-vehicle dynamics, based on optimization technology, the invention calibrates an optimal target slip-rate working interval of an automobile ABS system comprehensively considering both longitudinal braking performance and lateral braking performance under the turning / braking condition, forms a curved surface from target slip rate to steering angle to initial braking speed, and then supplies the target slip rate for dynamically adjusting wheels inside and outside a bend to an online ABS system. The online ABS system adjusts the pressure of a braking wheel cylinder to reasonably allocate longitudinal force and lateral force that every wheel bears when a vehicle turns / brakes so as to improve the lateral stability of the vehicle. On the basis of the prior ABS system, the method has the advantage of allowing the ABS system to have part of the functions of an ESP system without increasing any cost.

Owner:JILIN UNIV

Electromagnet and friction composite disc type brake and brake method

InactiveCN102128227AShort duration of actionReduce usage intensityAxially engaging brakesBrake actuating mechanismsFriction reductionElectromagnetic field

The invention provides an electromagnet and friction composite disc type brake and a brake method. Both a steering knuckle and a brake caliper bracket are fixedly connected with an electromagnet brake fixing device, and the electromagnet brake fixing device is fixedly connected with magnet cores. The magnet cores are symmetrically arranged on the two sides of a brake disc, and coil windings are wound on the magnet cores. Permanent magnet bodies and the magnet cores are oppositely arranged, and air gaps are arranged between the permanent magnet bodies and the magnet cores. When an automobile brakes, electromagnet fields distributed on the axes of the coil windings are generated after the coil windings are electrified, and the directions of the electromagnet fields generated by the coil windings on the two sides of the brake disc are consistent. The permanent magnet bodies rotate 90 DEG, the directions of the permanent magnet fields of the permanent magnet bodies are consistent with the directions of the electromagnet fields of the coil windings, and the brake disc is braked by the superposition of the electromagnet fields and the permanent magnet fields. The size of the brake force is adjusted by adjusting the different rotating angles of the permanent magnet bodies or the size of electrifying current in the coil windings. The action time of the brake is shortened, the brake efficiency is enhanced, the use strength of the friction brake is reduced, the abrasion of brake pads is alleviated, and the brake force is easy to control.

Owner:JIANGSU UNIV

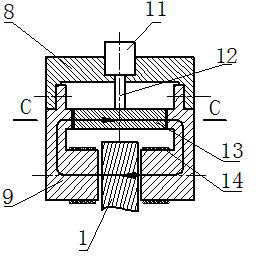

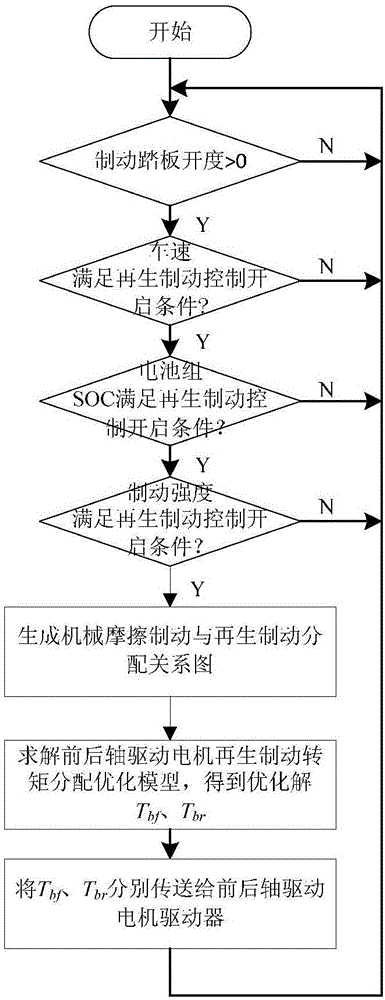

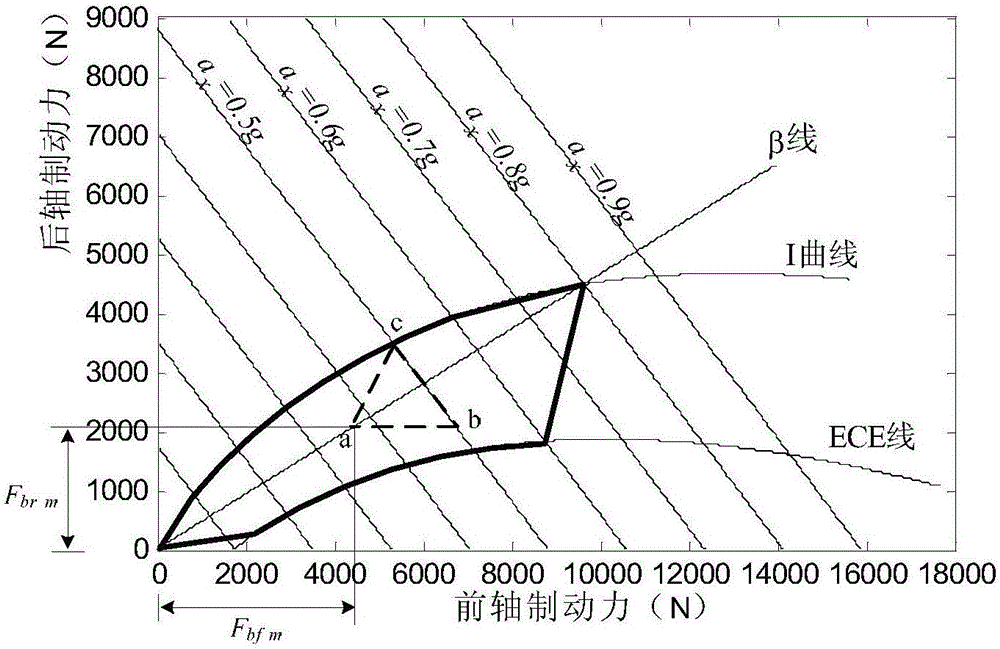

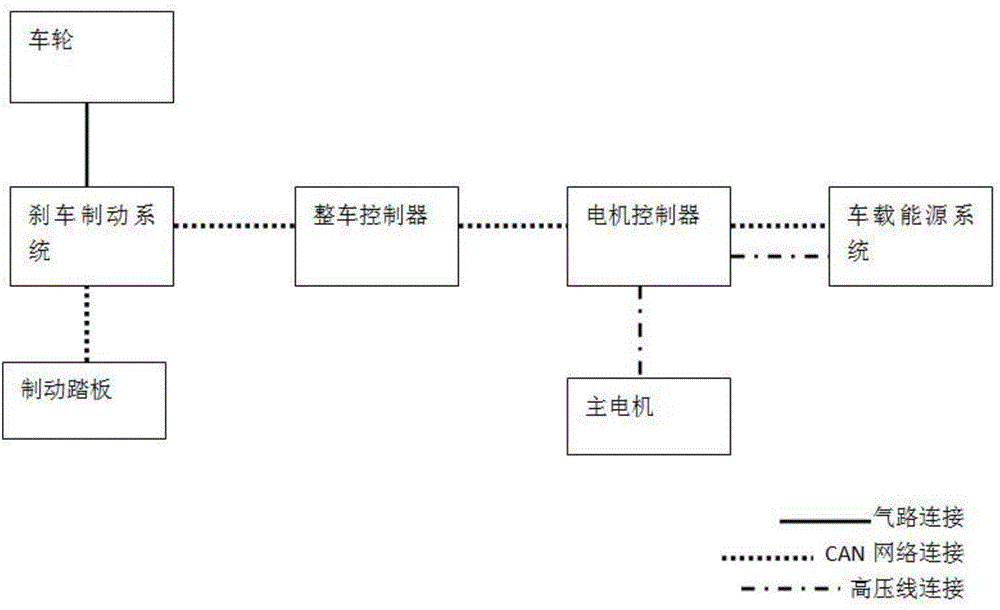

Control method of regeneration brake process of front and back axle driving electric automobile

ActiveCN106218419ABraking process safetySmooth brakingSpeed controllerElectric devicesBrake torqueAutomotive engineering

The invention provides a control method of a regeneration brake process of a front and back axle driving electric automobile. The control method is characterized in that firstly, whether the brake requirement exists or not is judged through detecting the opening degree of a brake pedal; then, whether the automobile speed, the battery pack SOC and the brake intensity meet the regeneration brake control starting conditions or not is judged; then, a regeneration brake torque distribution optimization model of a front and back axle driving motor is built; T<bf> and T are obtained through solution. The control method provided by the invention has the advantages that the safety and the stability of the front and back axle driving electric automobile in the brake process can be ensured; meanwhile, the brake energy is recovered to the maximum degree; the running mileage of the electric automobile is further prolonged.

Owner:佛山佑尔汽车智能技术有限公司 +1

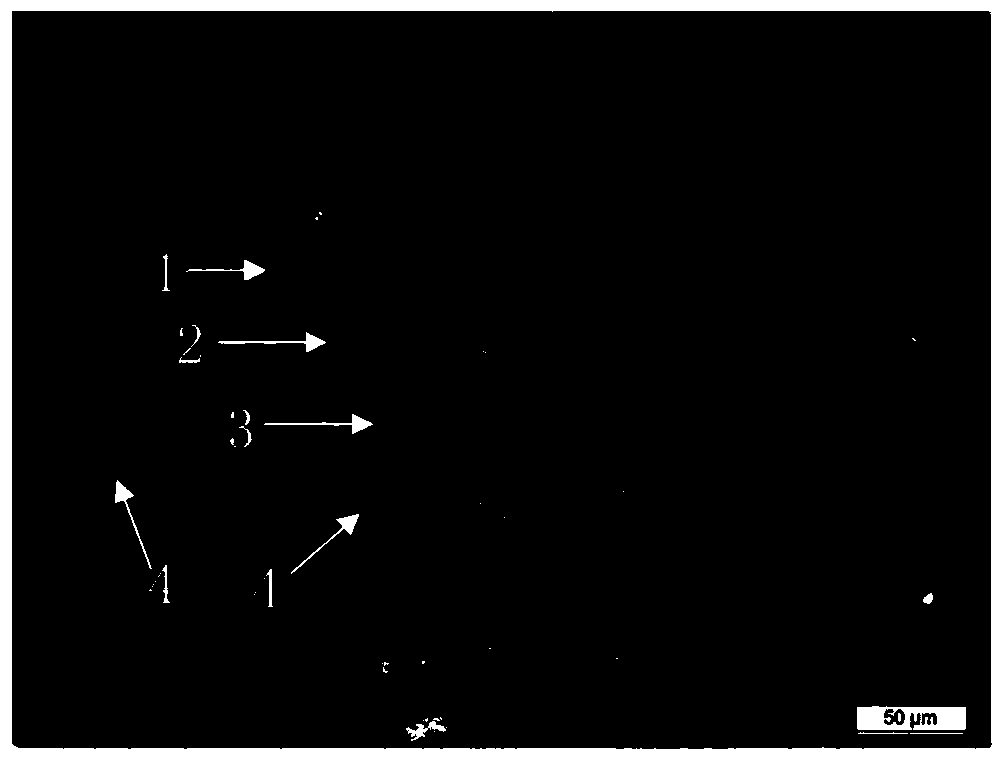

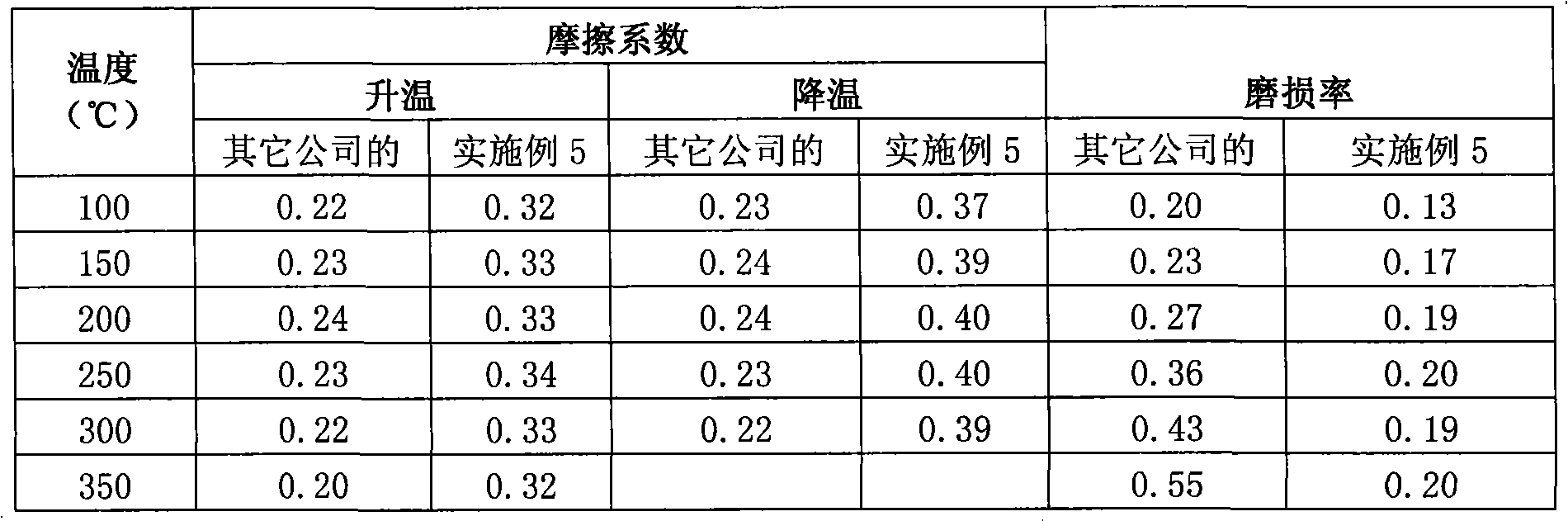

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

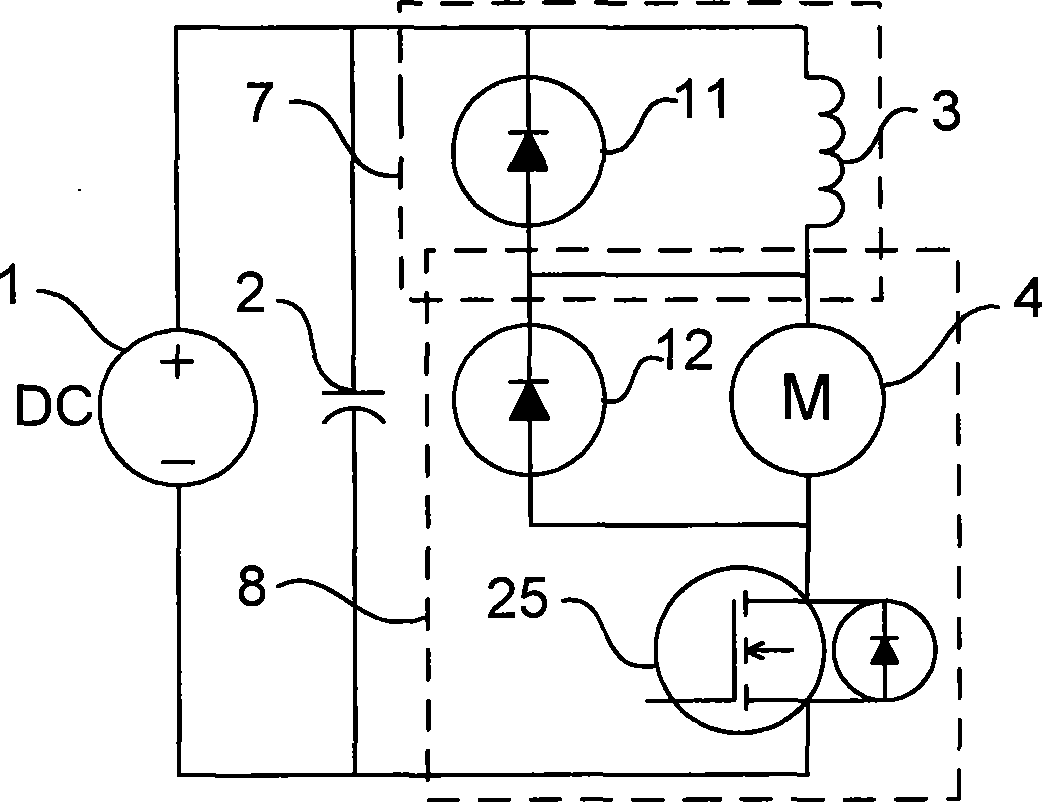

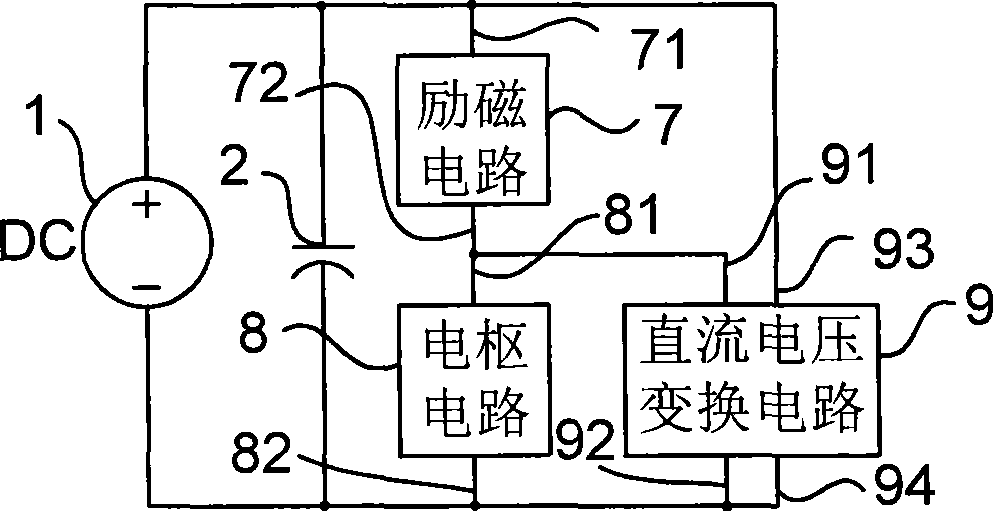

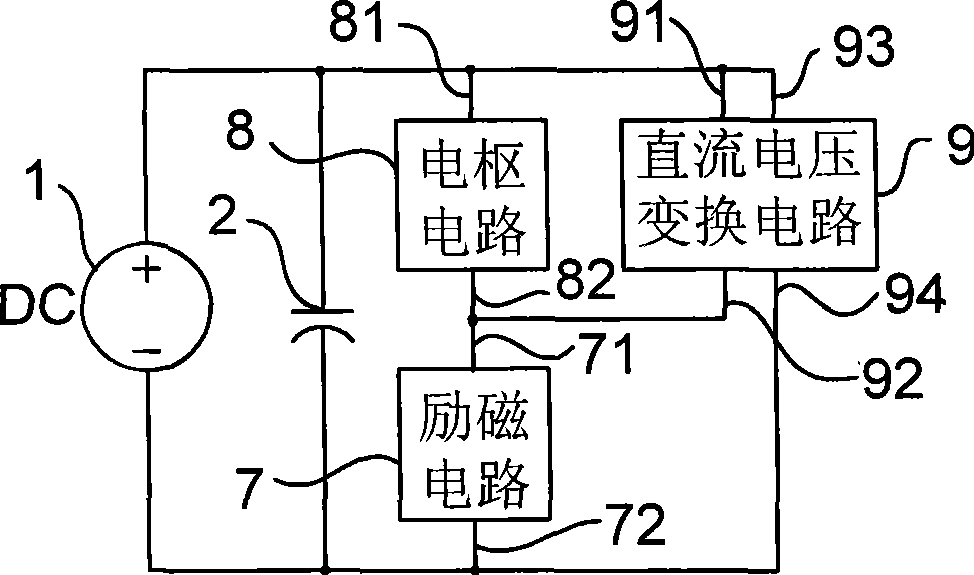

Control circuit, braking method, energy production method and device for DC motor

InactiveCN101425771ASmooth startSmooth brakingField or armature current controlDc motor stoppersElectricityDc motor control

The invention relates to a DC motor control circuit, a braking method, an electricity generating method and a device thereof, in particular to the problems of the starting, the speed regulation, the braking and the reversal rotation of a series excitation DC motor. The control circuit comprises an excitation circuit (7), an armature circuit (8) and a DC voltage transforming circuit (9), and has the characteristics of reusing the braking energy and no mechanical contact point in reversal rotating control. The braking method reuses the braking energy, and the electricity generating method utilizes the rotation of the series excitation DC motor to generate electricity. The device of the invention realizes the stable starting, the stepless speed control, the stepless braking and the running of reversal rotation, the energy in braking is fed back or reused, and the energy in braking can be effectively controlled if the series excitation DC motor rotates when the electricity is cut off. No input electric source exists. If the series excitation DC motor continuously rotates under the action of external force, the device is an electricity generator of the series excitation DC motor and can provide an electric source for the outside.

Owner:杨宇强

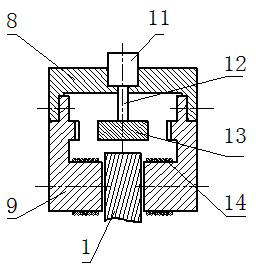

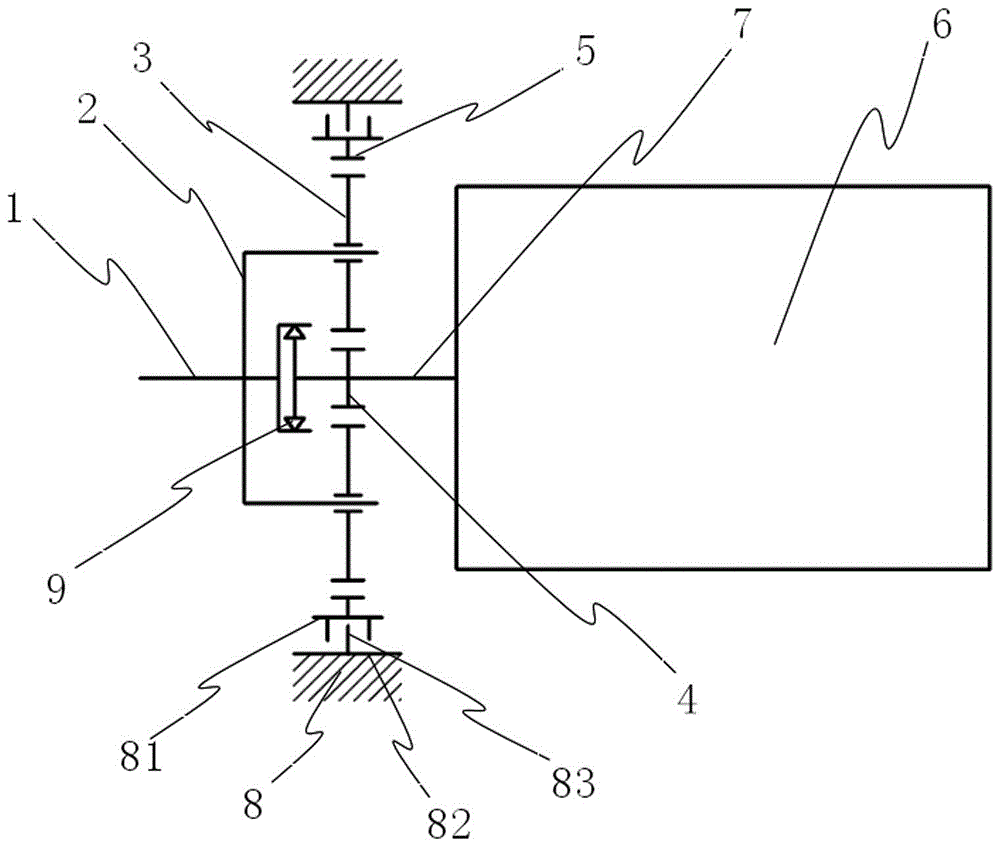

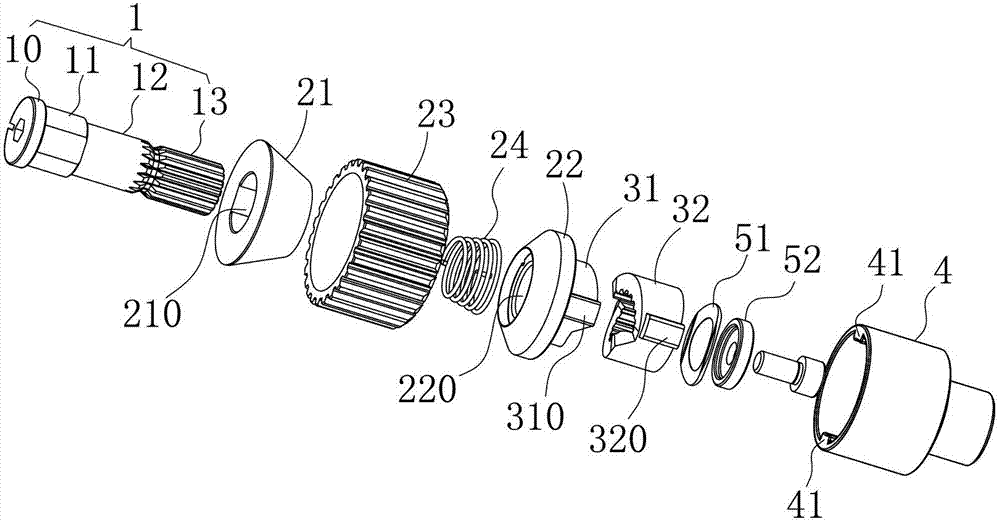

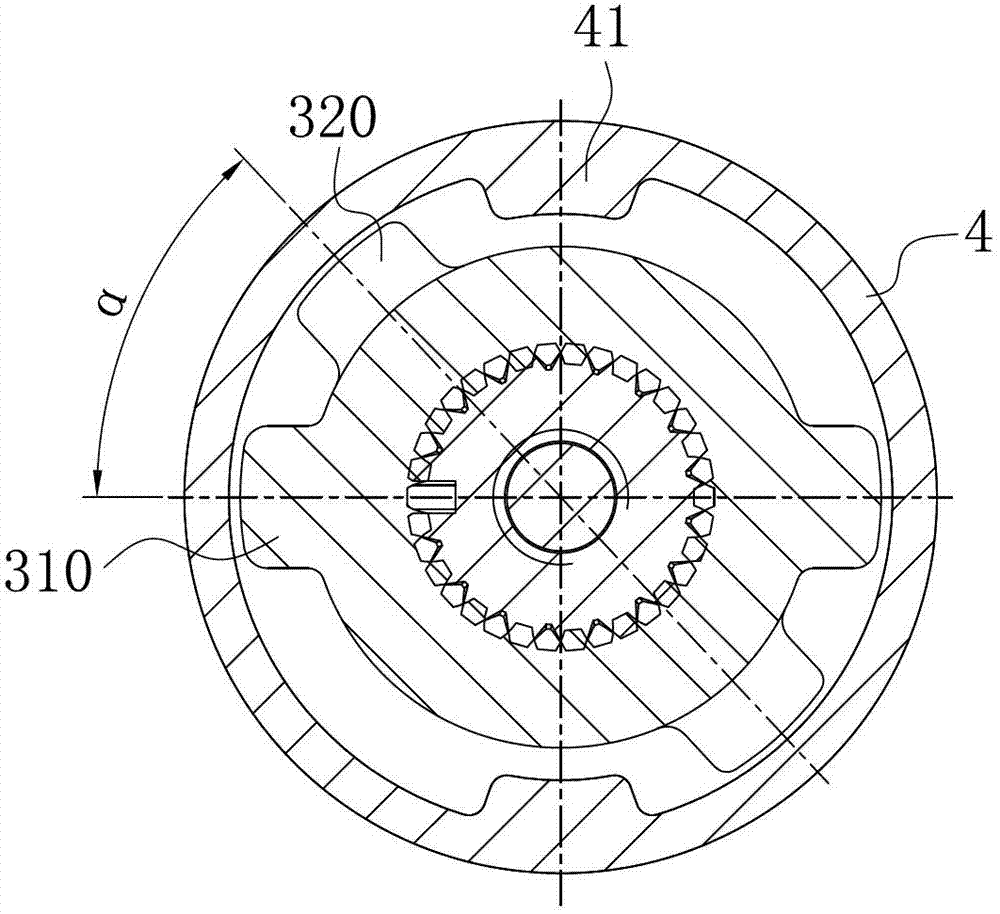

Pure electric two-speed transmission

InactiveCN106438880AReduce control difficultyImprove shift smoothnessToothed gearingsTransmission elementsReducerEngineering

The invention provides a pure electric two-speed transmission. The pure electric two-speed transmission comprises an input shaft (1), a reducer (6), an output shaft (7) and a brake (8), and a planetary mechanism which comprises a sun gear (4), a planet gear (3), a gear ring (5) and a planet carrier (2), wherein the planet carrier (2) is fixedly assembled to the input shaft (1), the sun gear (4) is fixedly assembled to the output shaft (7), and the right end of the output shaft (7) is fixedly connected with the reducer (6), the pure electric two-speed transmission is characterized by further comprising a one-way clutch (9), the right end of the output shaft (1) is connected with the left end of the output shaft (7) through the one-way clutch (9), and the gear ring (5) of the planetary mechanism is connected with the brake (8). According to the invention, gears can be shifted only by using one one-way clutch 9 and one brake 8, and one one-way clutch 9 and one brake 8 are only required to be controlled when the gears are shifted, so that the control difficulty is smaller.

Owner:CHONGQING TSINGSHAN IND

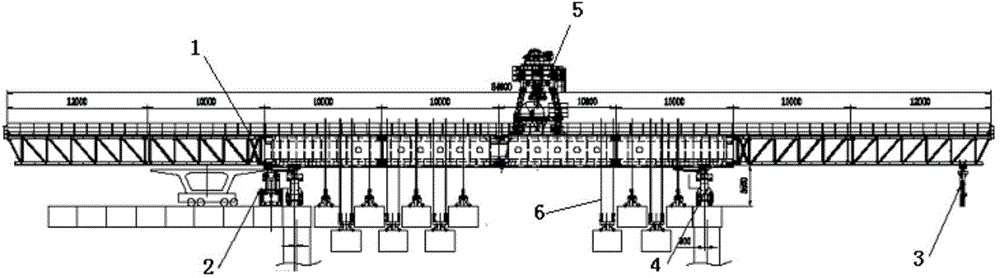

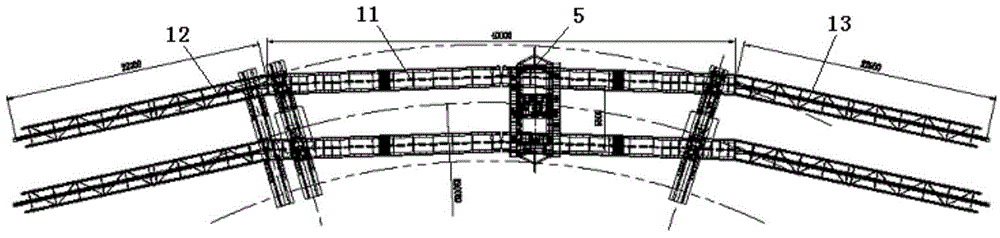

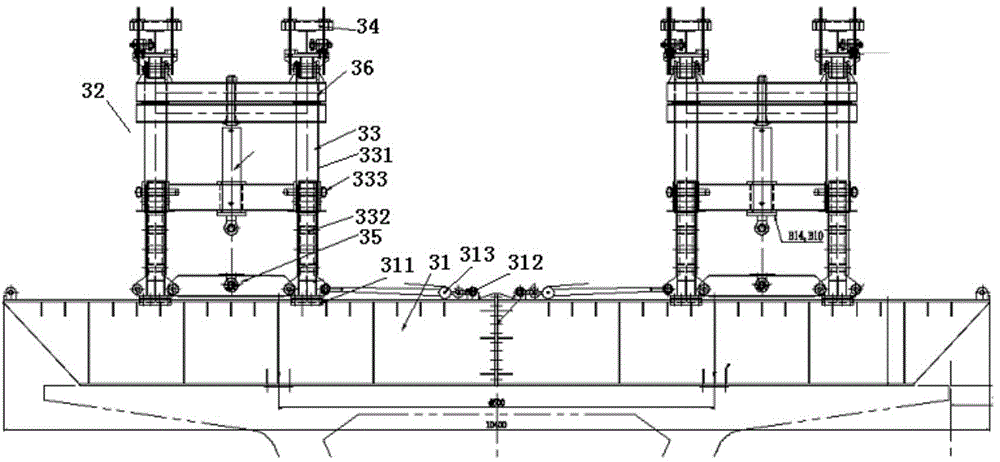

Segmental assembled bridge girder erection machine for construction of small curved bridge

ActiveCN104805773AAutomatically adjust chamfersMeet various spansBridge erection/assemblySocial benefitsPolygonal line

A segmental assembled bridge girder erection machine for the construction of a small curved bridge at least comprises girders which can be automatically bent, a rear support leg, a front support leg, at least one middle support leg, a hoisting crown block which can move along a broken line, and a plurality of hoists, wherein the girders which can be automatically bent comprise two parallel steel girders, and transverse bracings are not arranged between the two steel girders; each steel girder comprises a middle steel box girder, and a front guide girder and a rear guide girder which are located on the two sides of the middle box girder; the girders which can be automatically bent are supported through the rear support leg and the front support leg which are arranged below the girders, as well as the middle support leg located between the front support leg and the rear support leg; the hoisting crown block which can move along the broken line is arranged at the upper parts of the girders which can be automatically bent, and can move back and forth; the hoists are further arranged on the girders which can be automatically bent. Therefore, the mini-sized curved bridge with a radius of at least 60 m can be passed and erected through the segmental assembled bridge girder erection machine; the segmental assembled bridge girder erection machine satisfies various performance requirements, achieves remarkable economic and social benefits, and fills the gaps of small-curvature girder erection and cross bridge girder erection machines at home and abroad.

Owner:武汉通联路桥机械技术有限公司

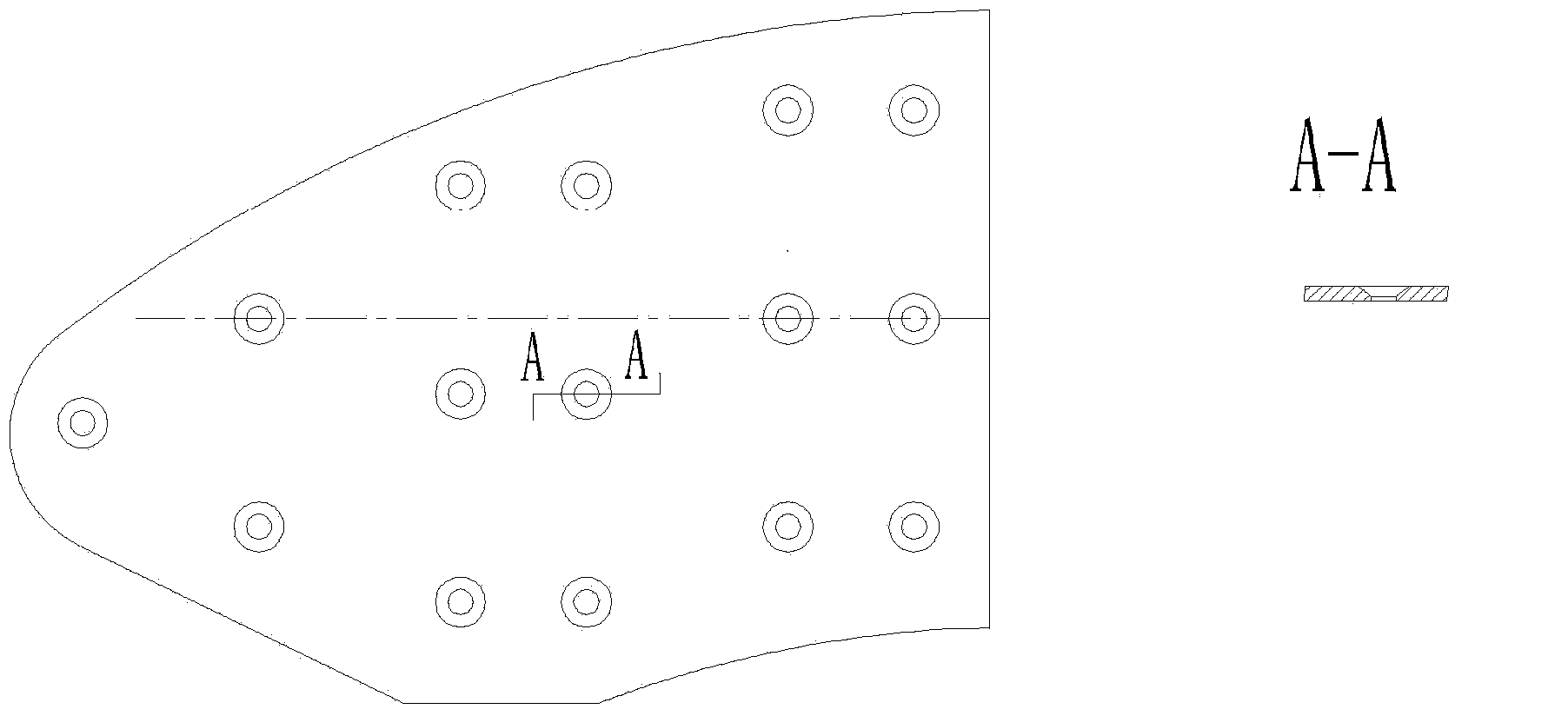

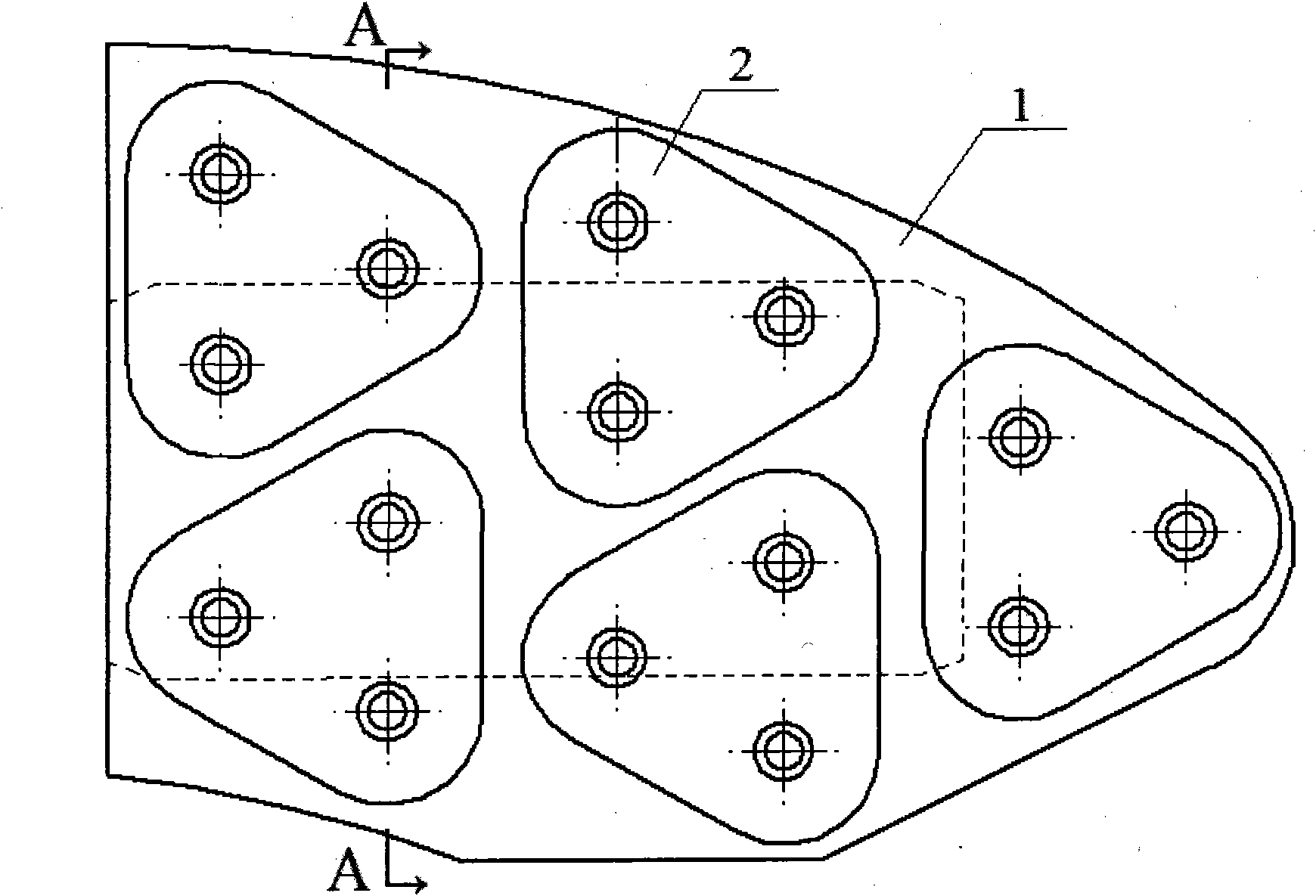

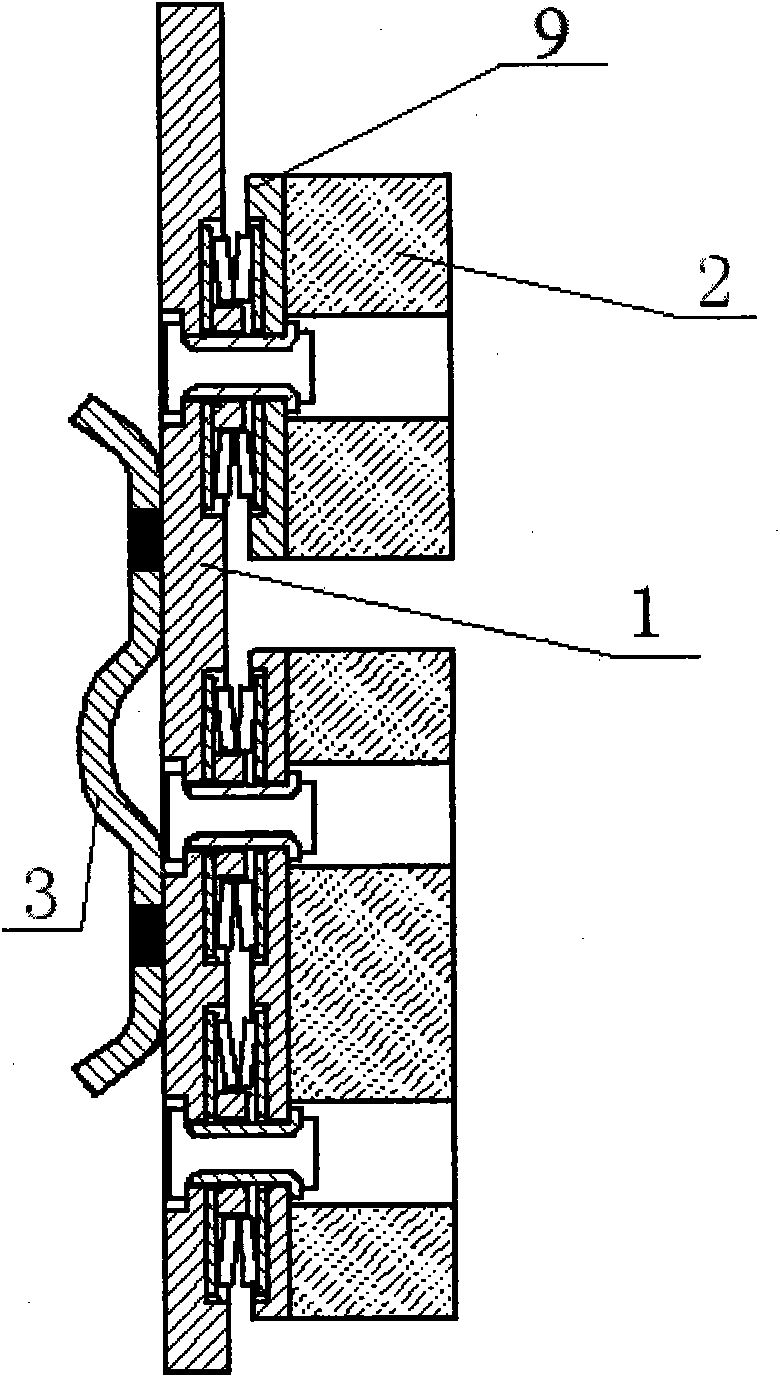

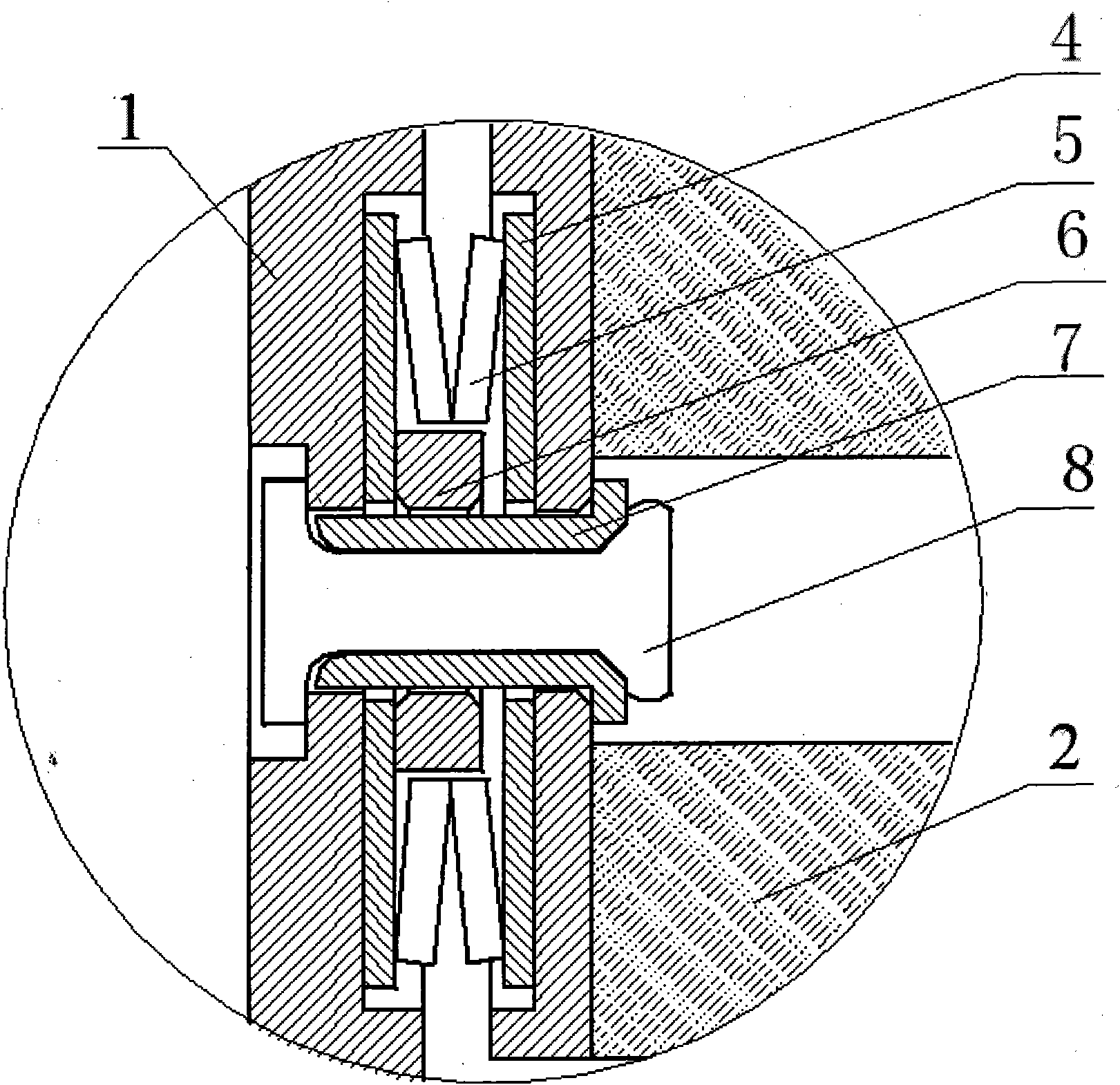

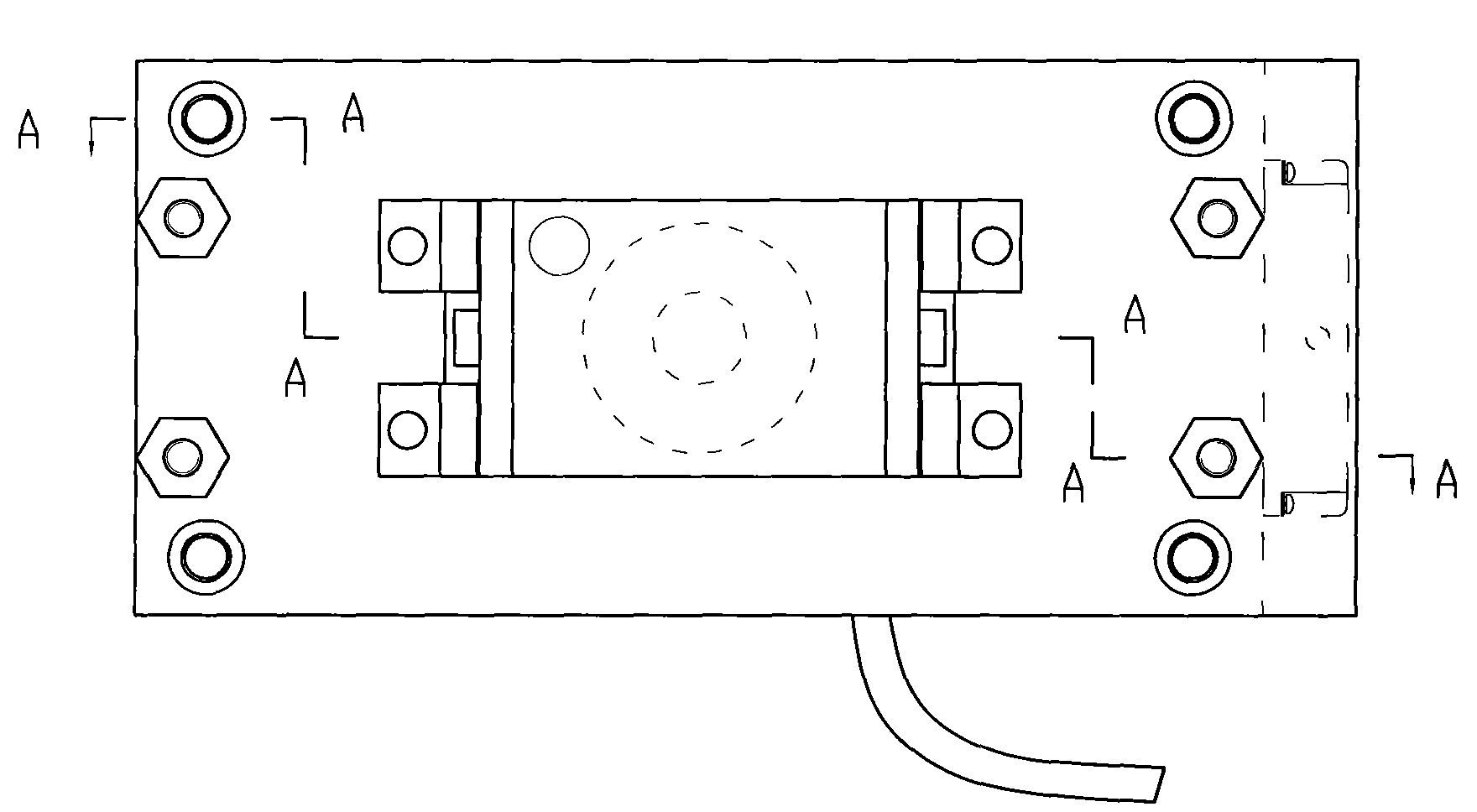

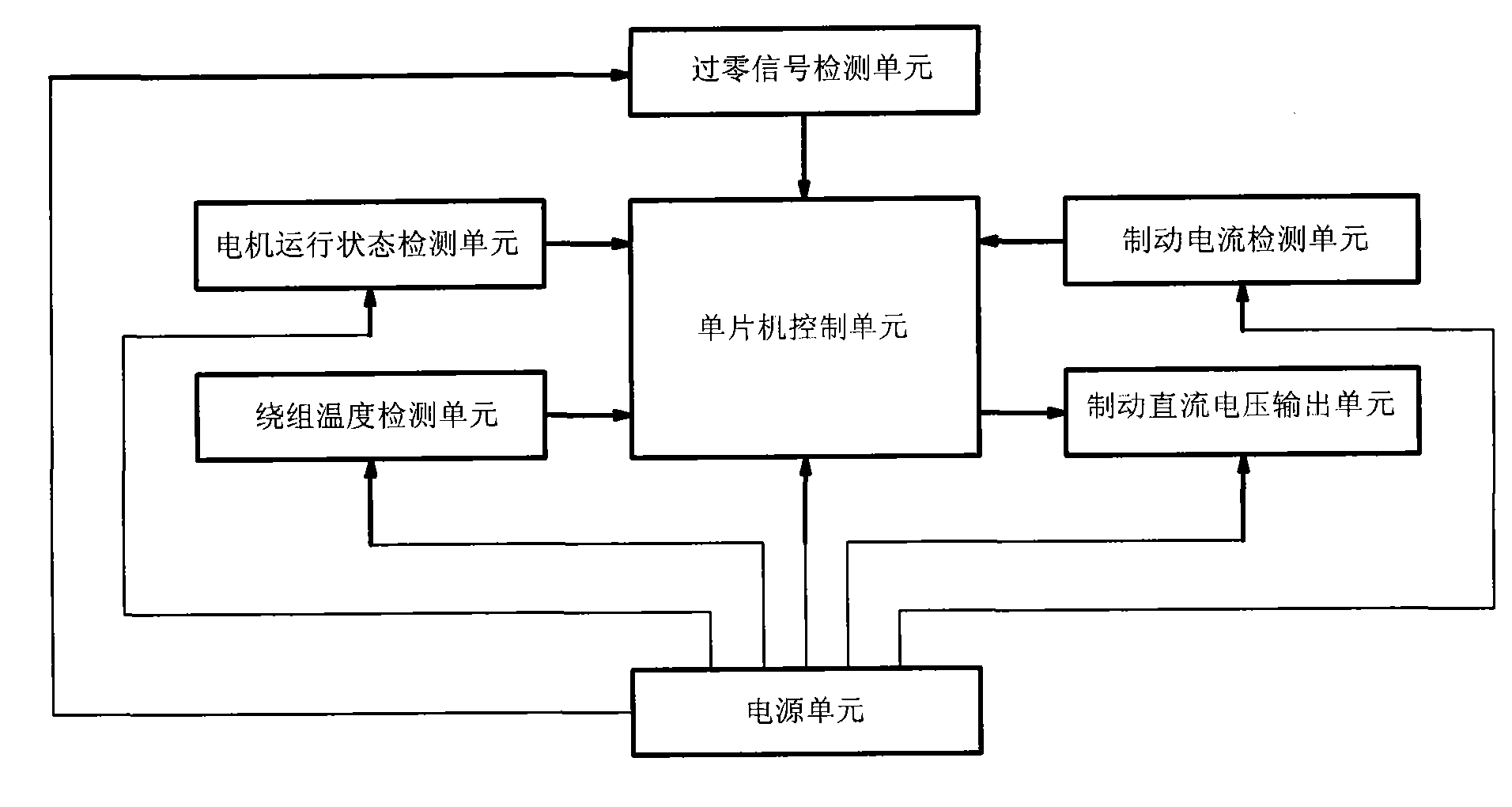

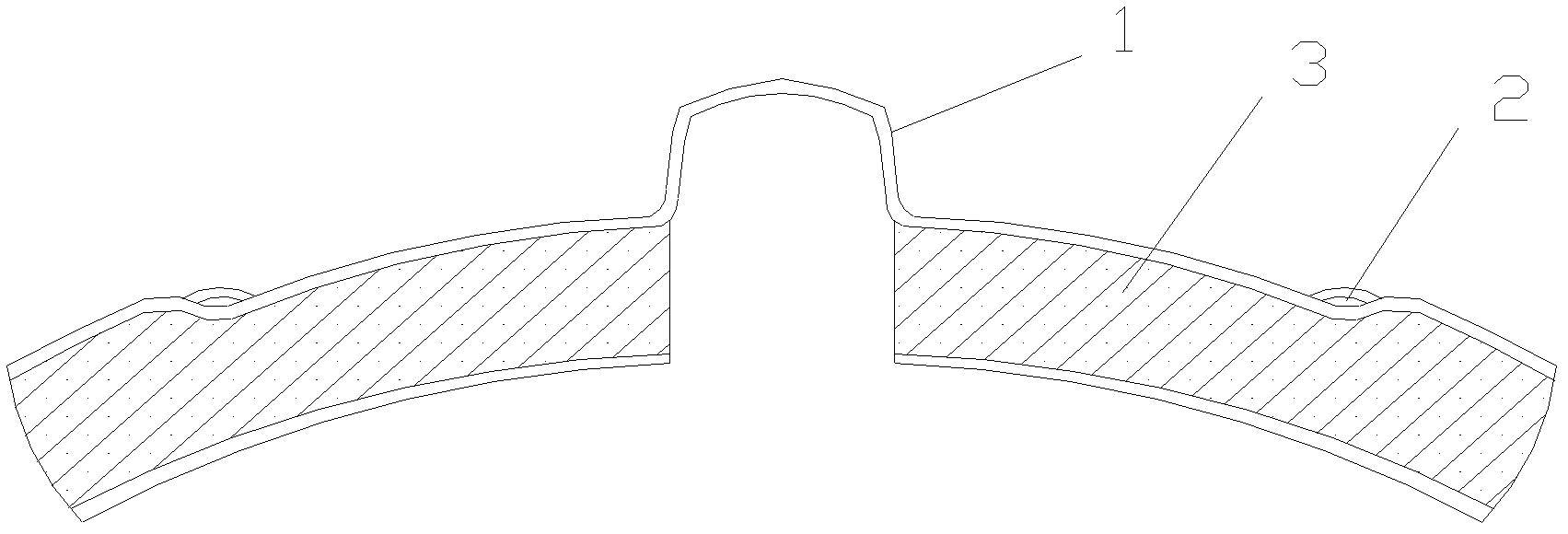

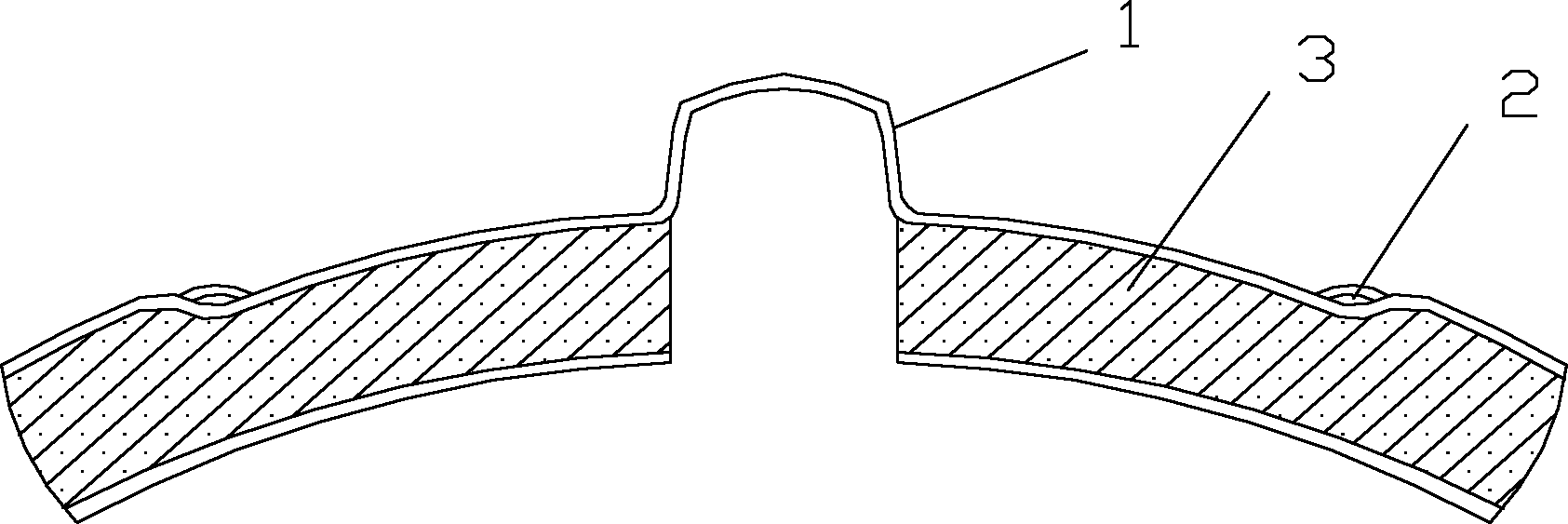

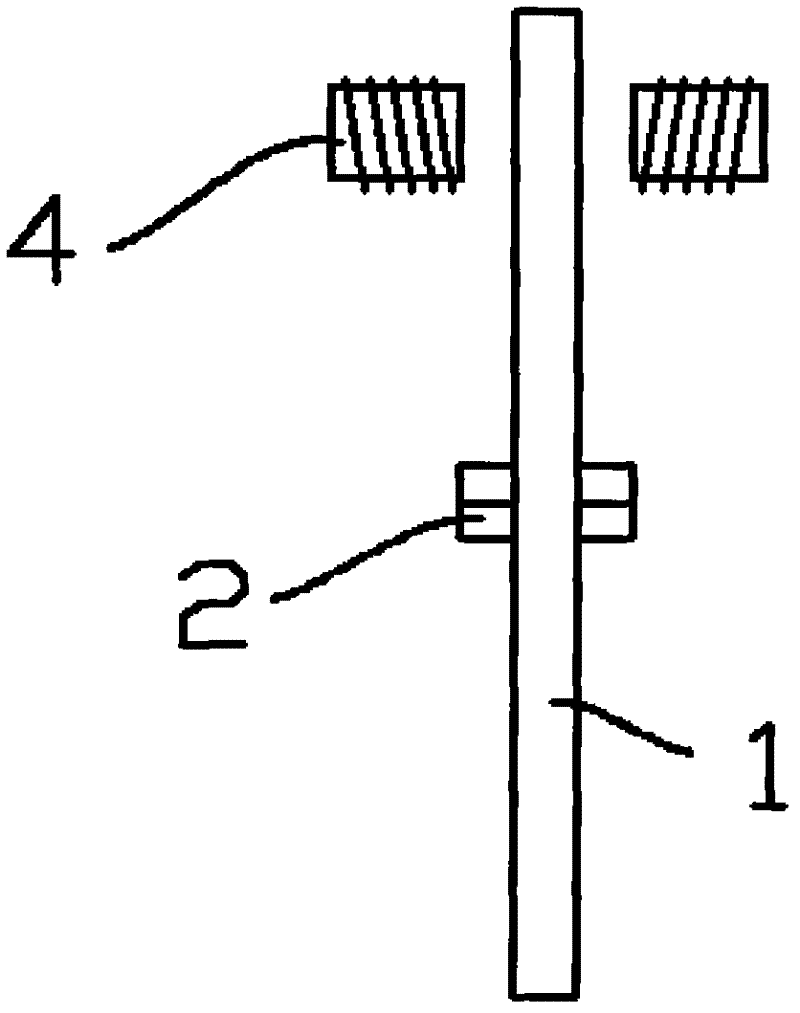

High-speed brake lining with elastic structure

ActiveCN102107665AHigh mechanical strengthReduce wearBrakes for specific applicationsEngineeringThermal stability

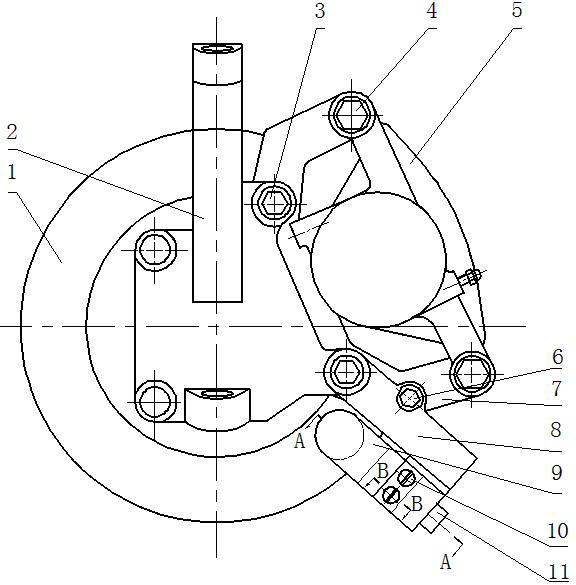

The invention provides an elastic high-speed brake lining, consisting of a steel backing (1), a brake block (2), a dovetail plate (3), a gasket (4), a disk spring (5), a guide sleeve (6), a bushing (7) and a rivet (8). The elastic structure high-speed brake lining provided by the invention has the advantages of high mechanical strength, small wearing capacity, stable friction performance, good thermal stability, good heat conductive performance, high dynamic moment and static moment, no noise, seawater corrosion resistance, sand wind prevention, excellent salt mist resistance and the like. Due to the elastic structure, the brake block of the high-speed brake lining is protected from eccentric wear caused by insufficient contact of the brake block of the high-speed brake lining and the surface of a brake disc, so that a high-speed train can brake smoothly, and the braking distance is short.

Owner:贵州新安航空机械有限责任公司

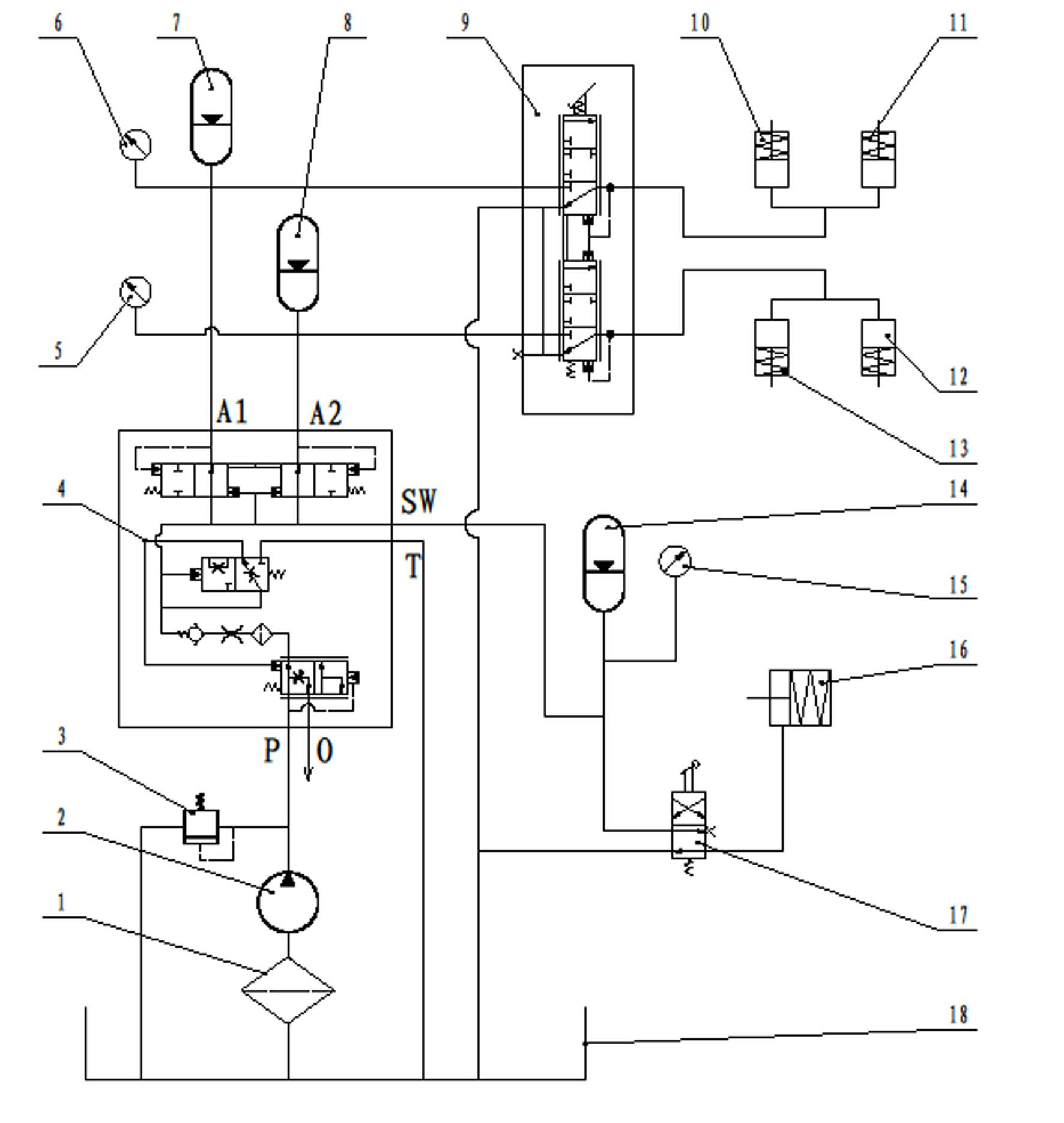

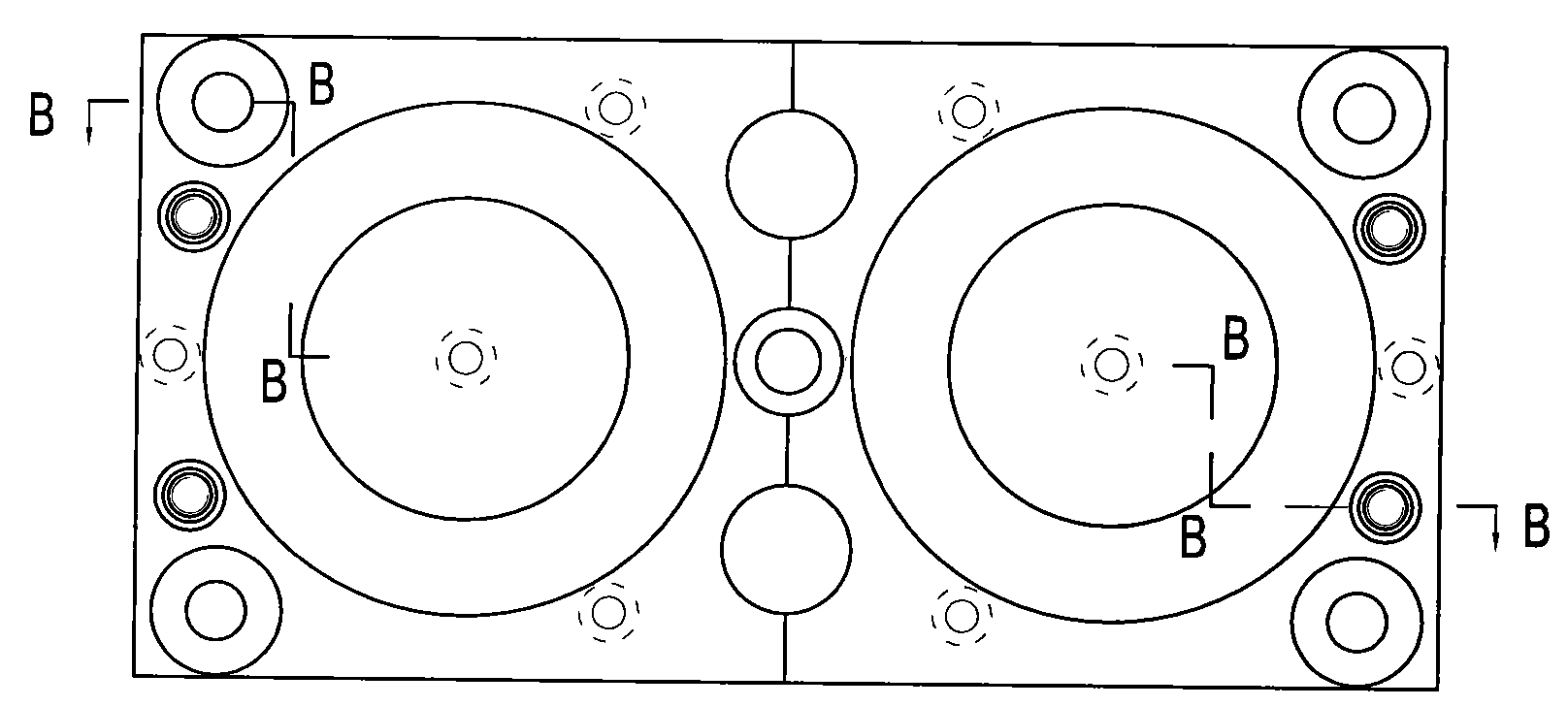

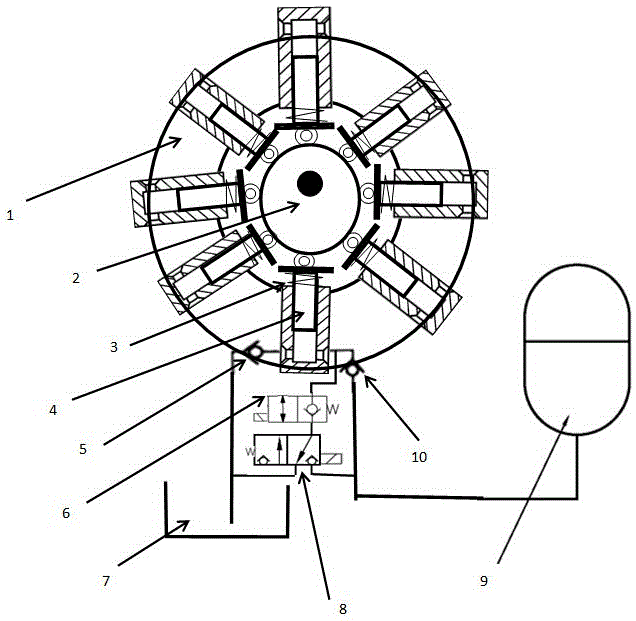

Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

ActiveCN102514562AImprove braking effectReduce labor intensityFluid braking transmissionDouble tubeHydraulic pump

The invention belongs to the technical field of braking devices of coal mine auxiliary conveying machinery, in particular to a double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for a coal mine explosion-proof vehicle. The invention aims to provide an explosion-proof, antipollution, stable, reliable and sensitive brand-new braking system. The braking device comprises a charging valve, wherein an oil feeding opening P of the charging valve is connected with a hydraulic pump, the oil opening A1 and opening A2 of the charging valve are connected with a front brake energy accumulator and a rear brake energy accumulator, and the oil opening SW is communicated with a parking braking oil pipe; the front and rear braking energy accumulators are connected with serial pedal braking valves respectively; the serial pedal braking valves are connected with a front service brake and a rear service brake respectively; parking braking energy accumulators are connected with parking braking valves; and parking braking valves are connected with parking brakes. The braking device meets the conditions for use in a special underground environment, can improve the braking efficiency and working efficiency and safety of the underground explosion-proof vehicle, reduce labor intensity, reduce casualty and accident rates and make underground conveying safer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

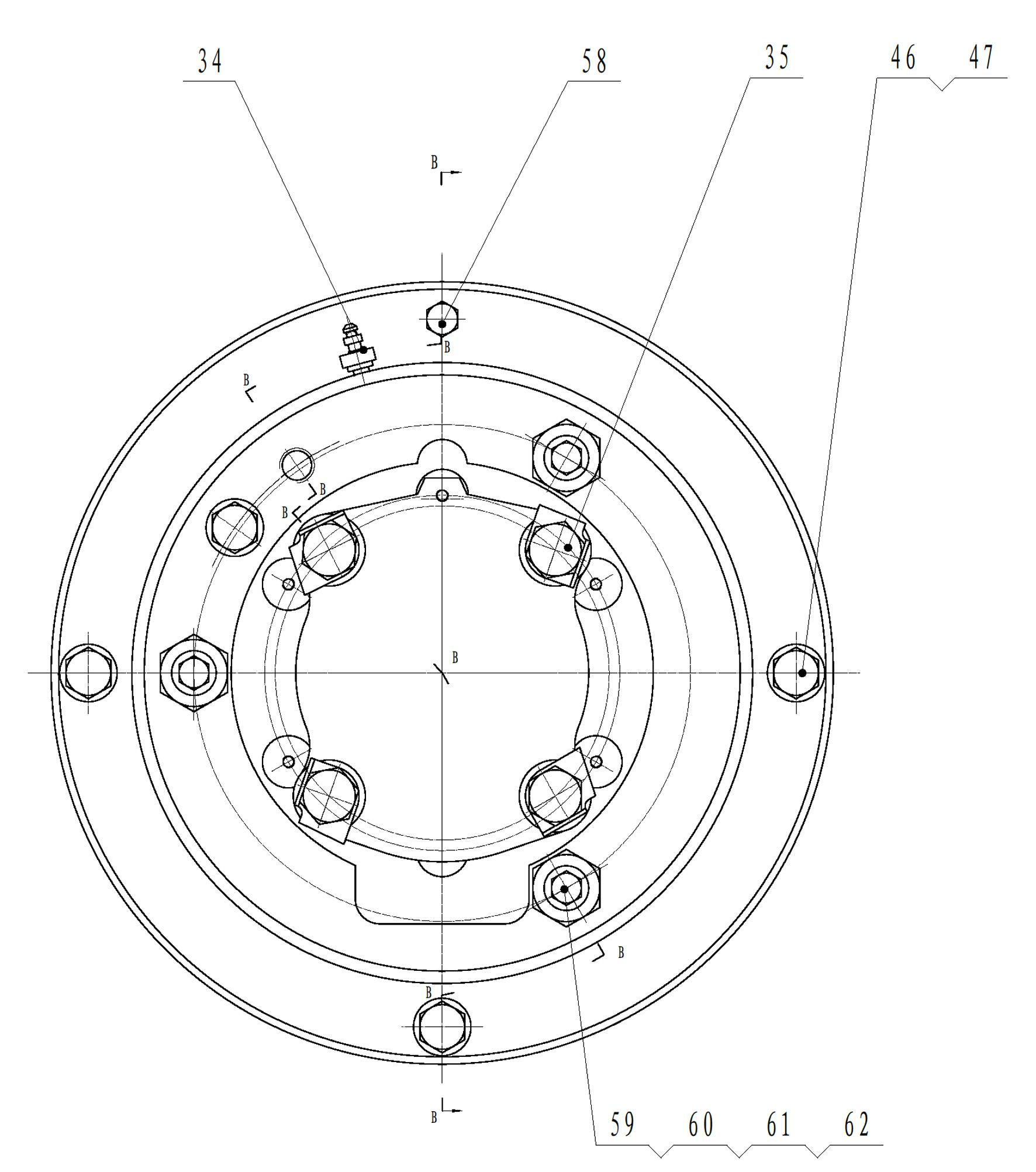

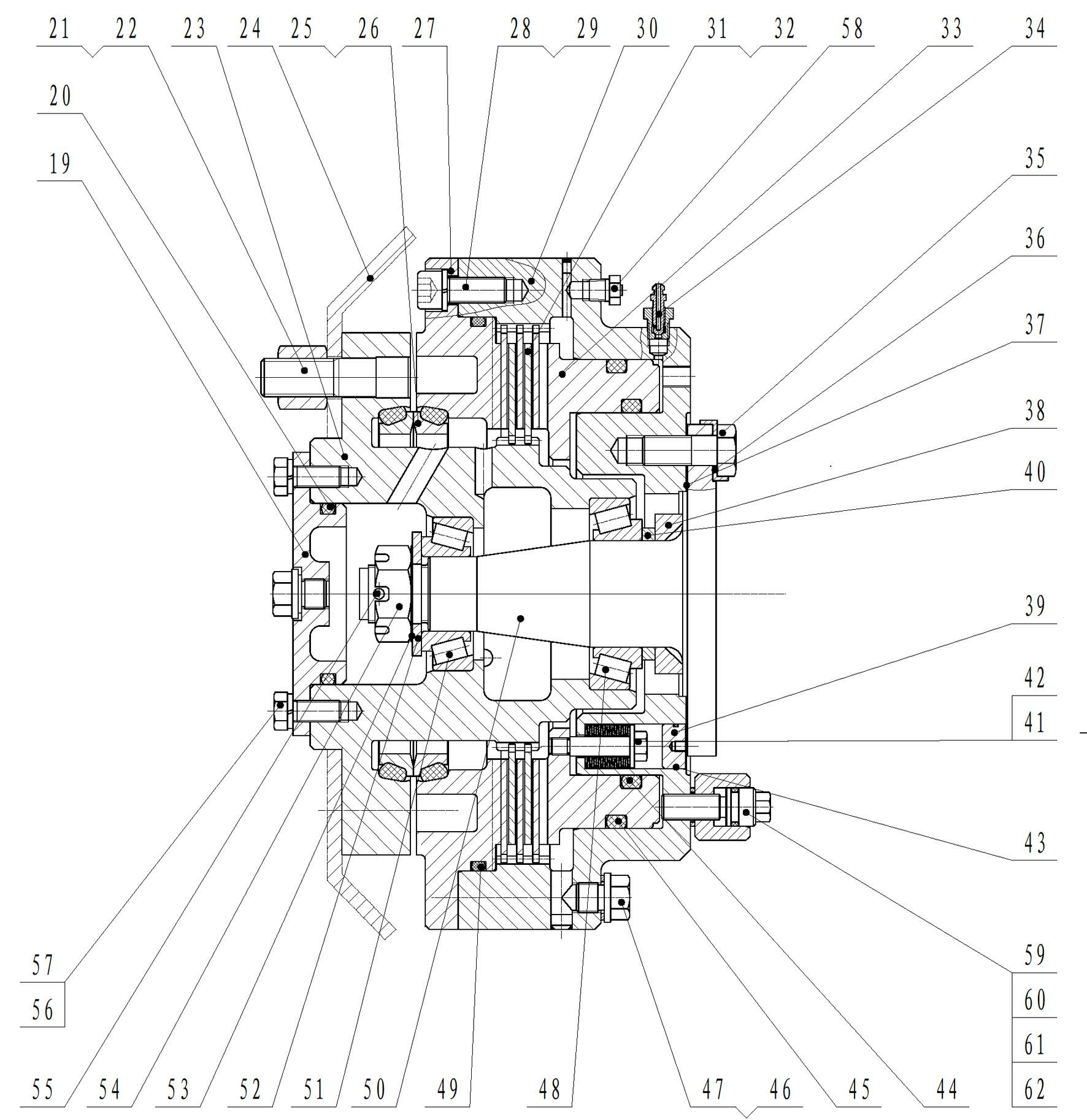

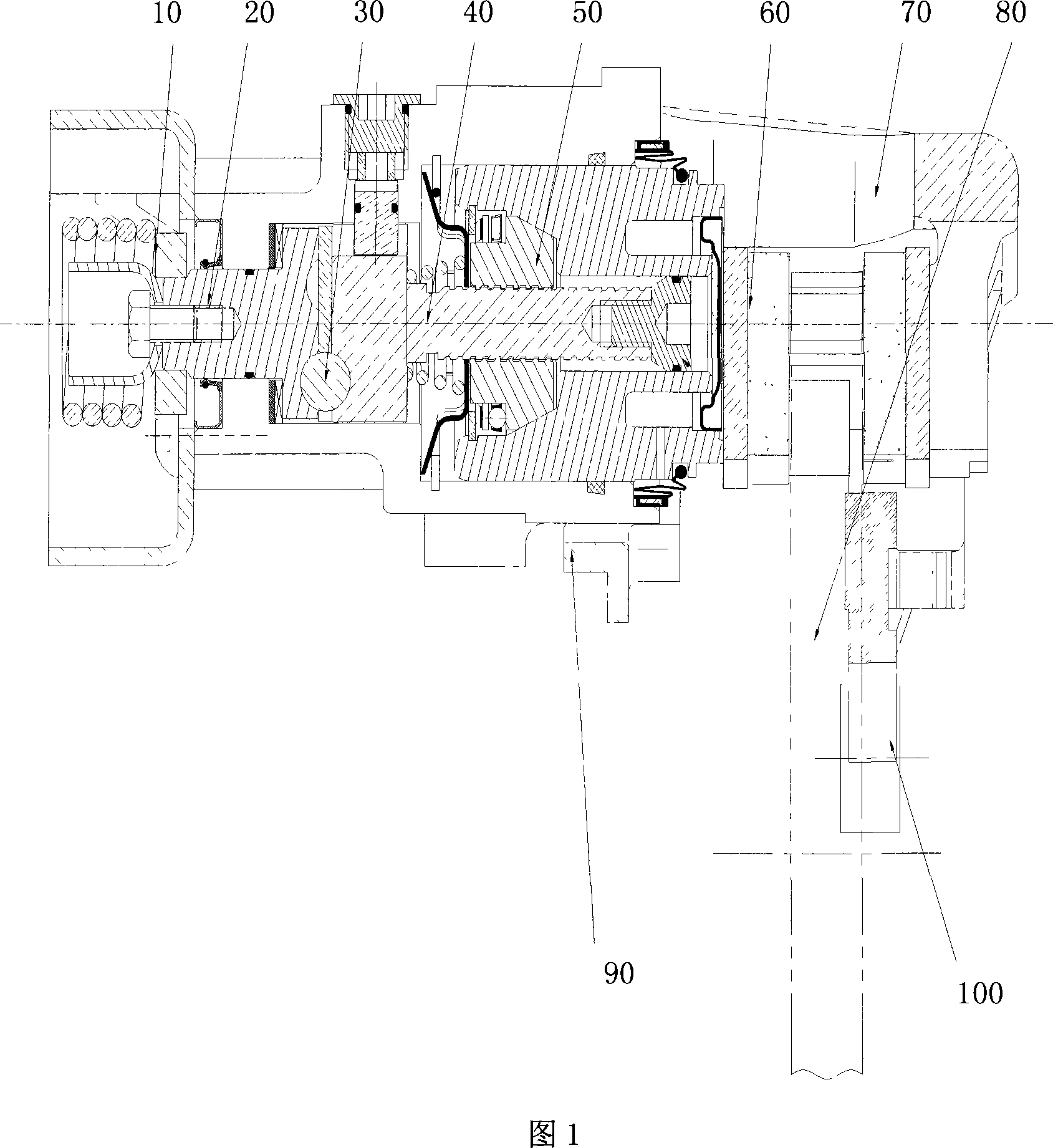

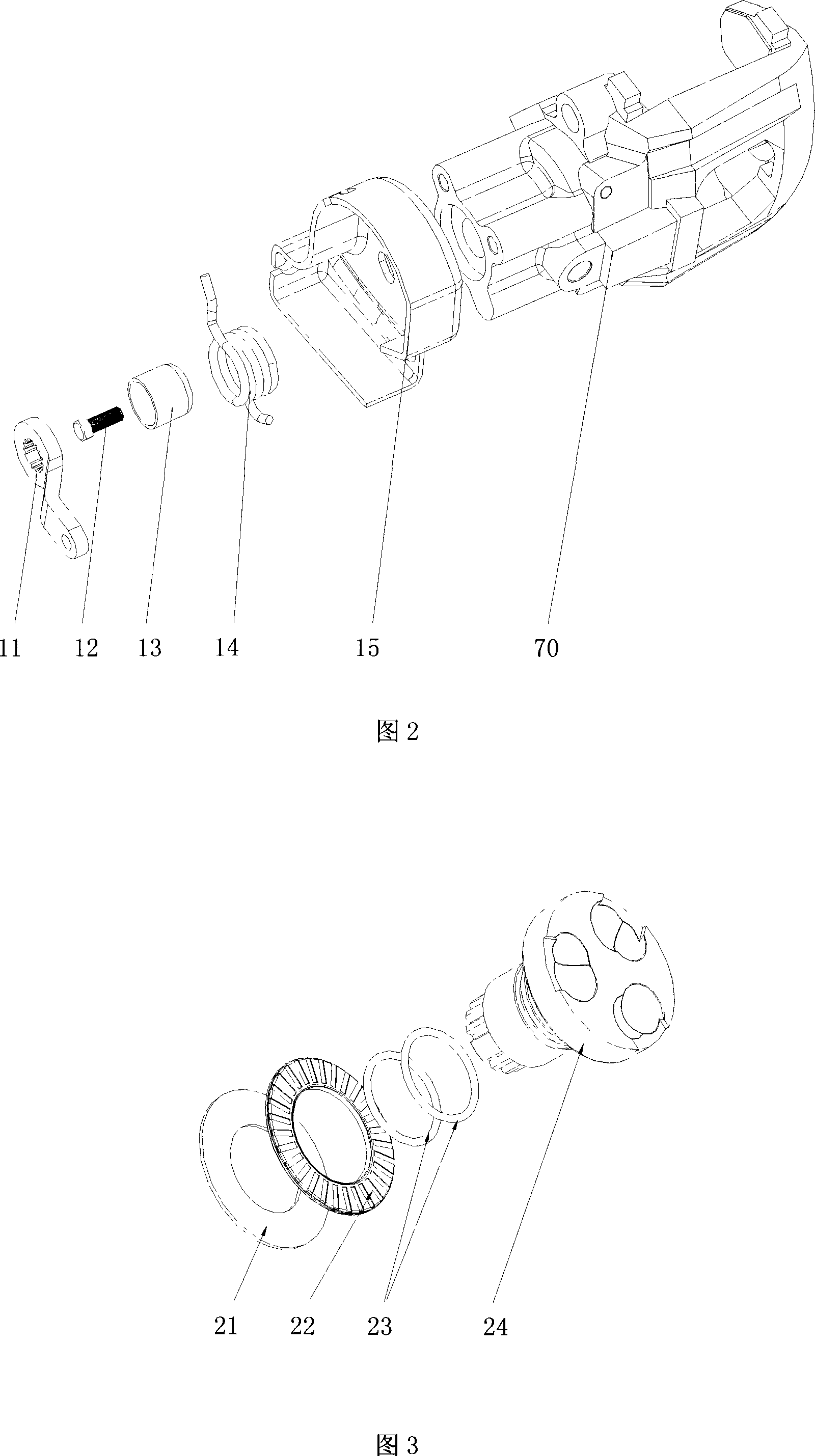

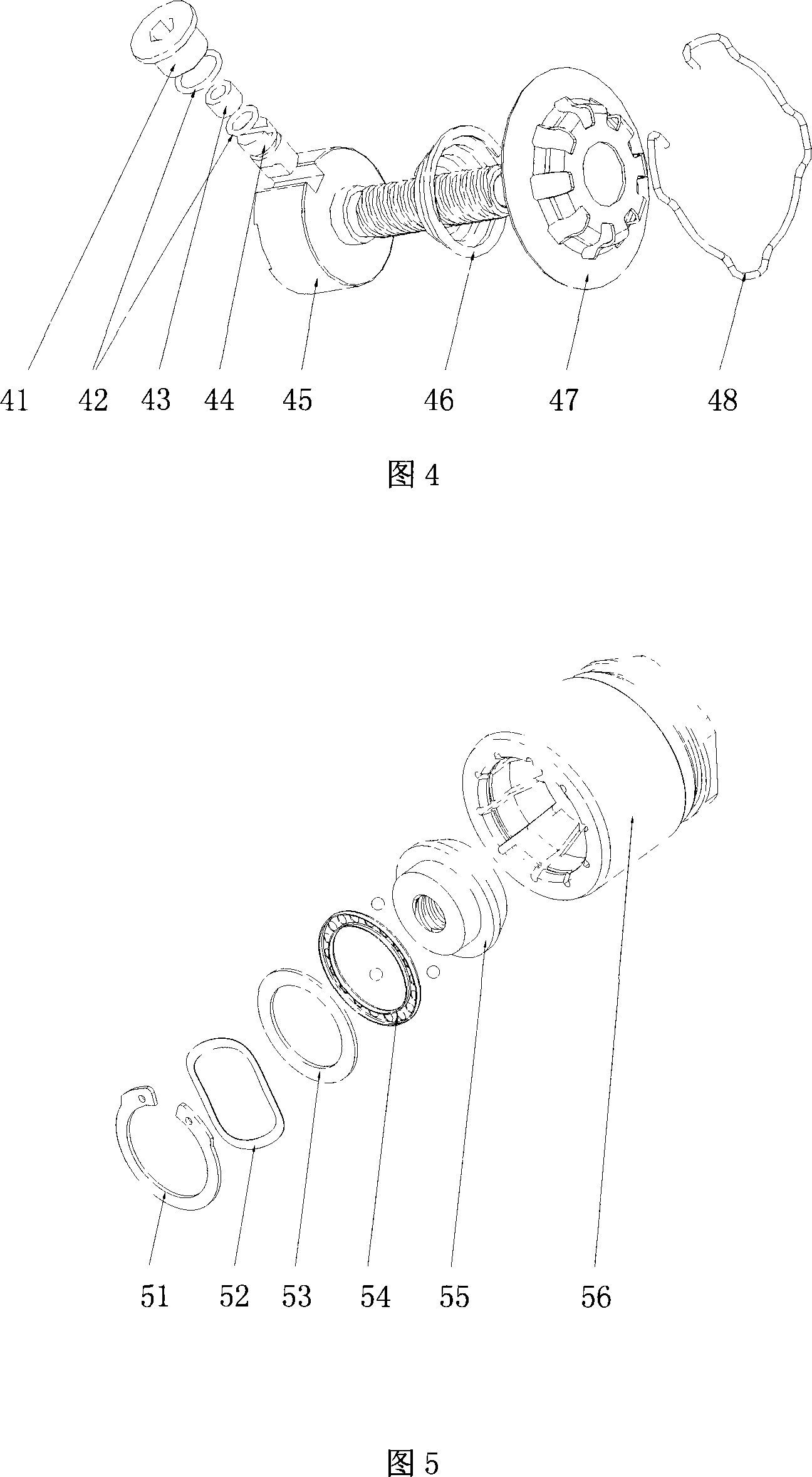

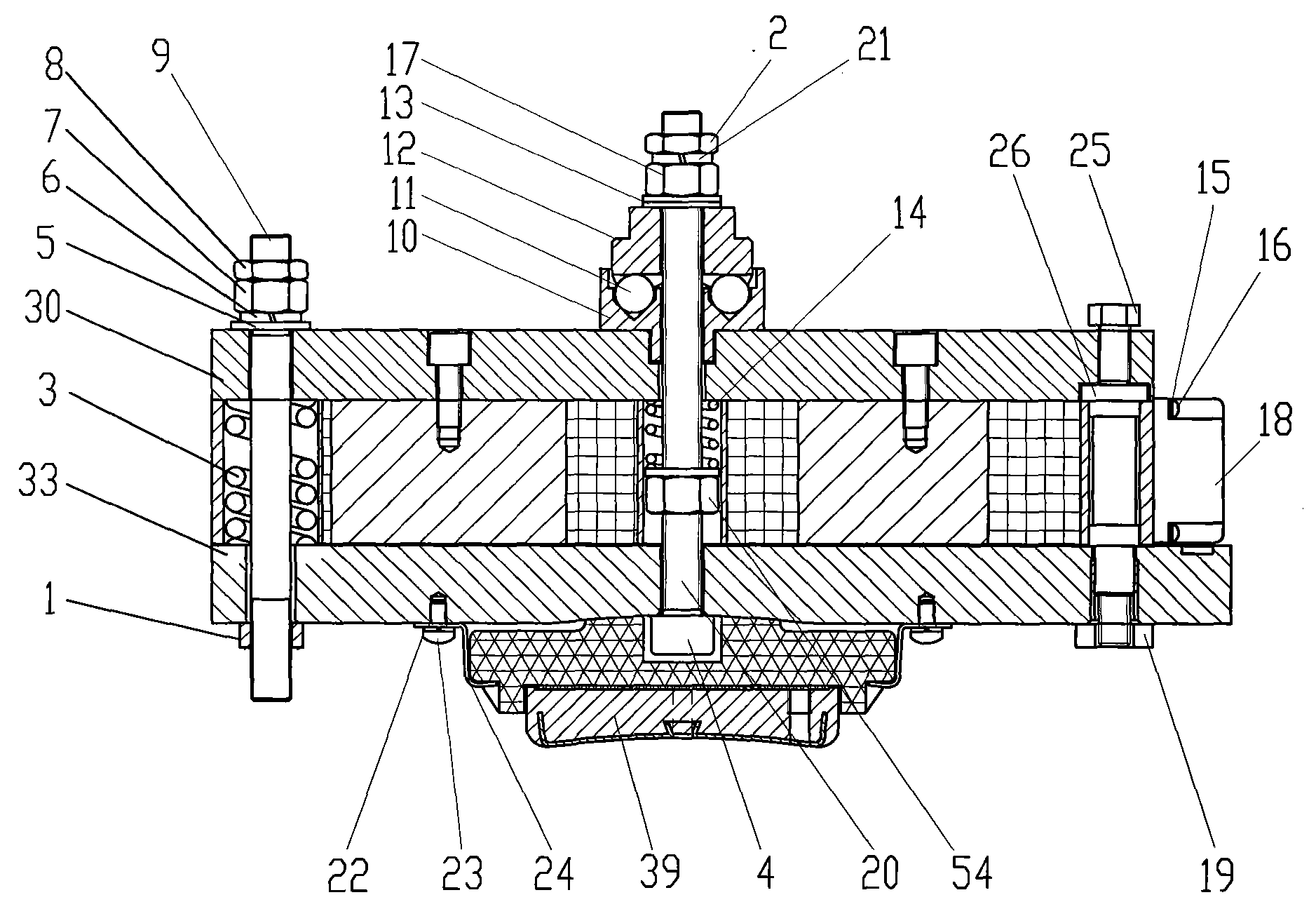

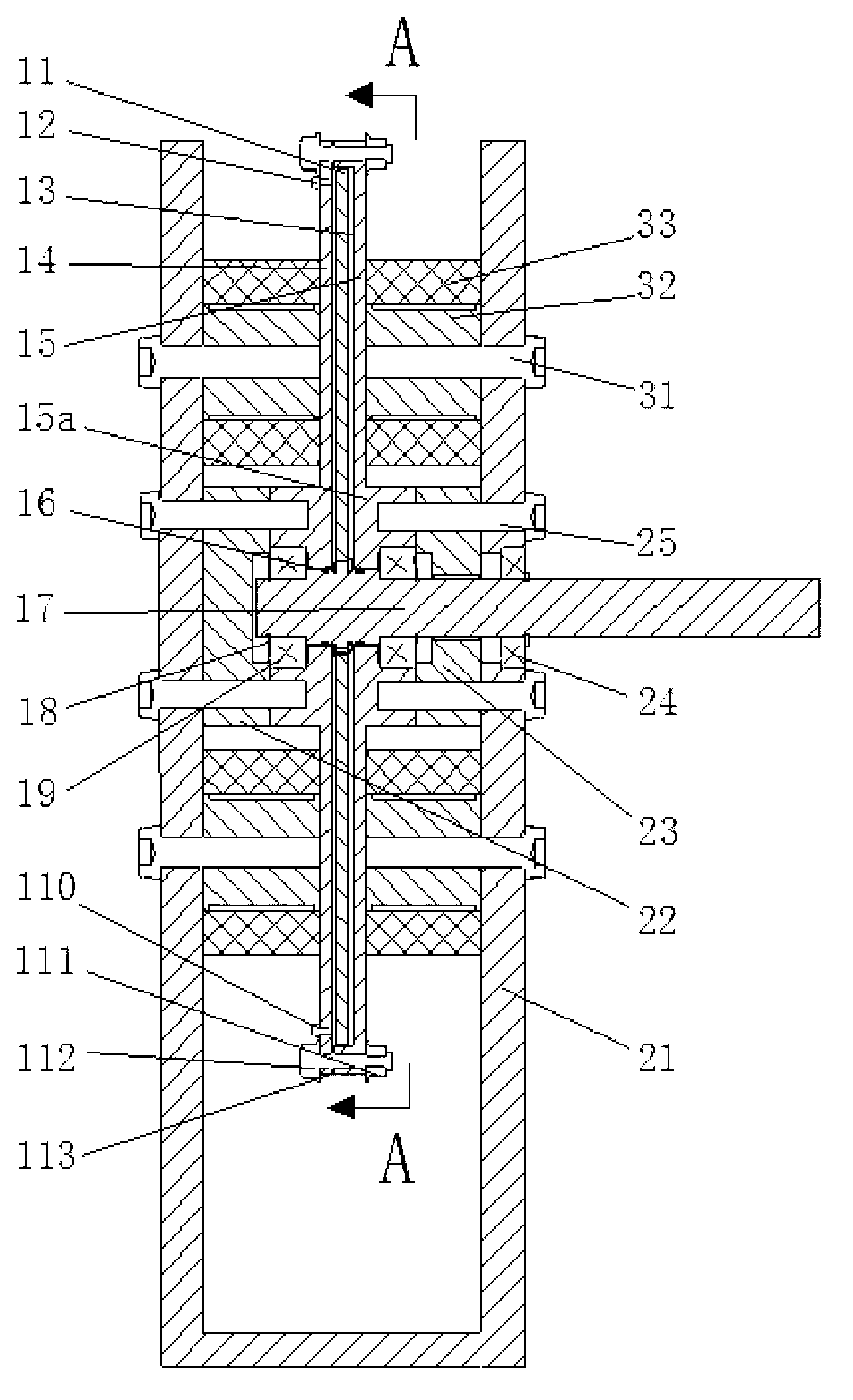

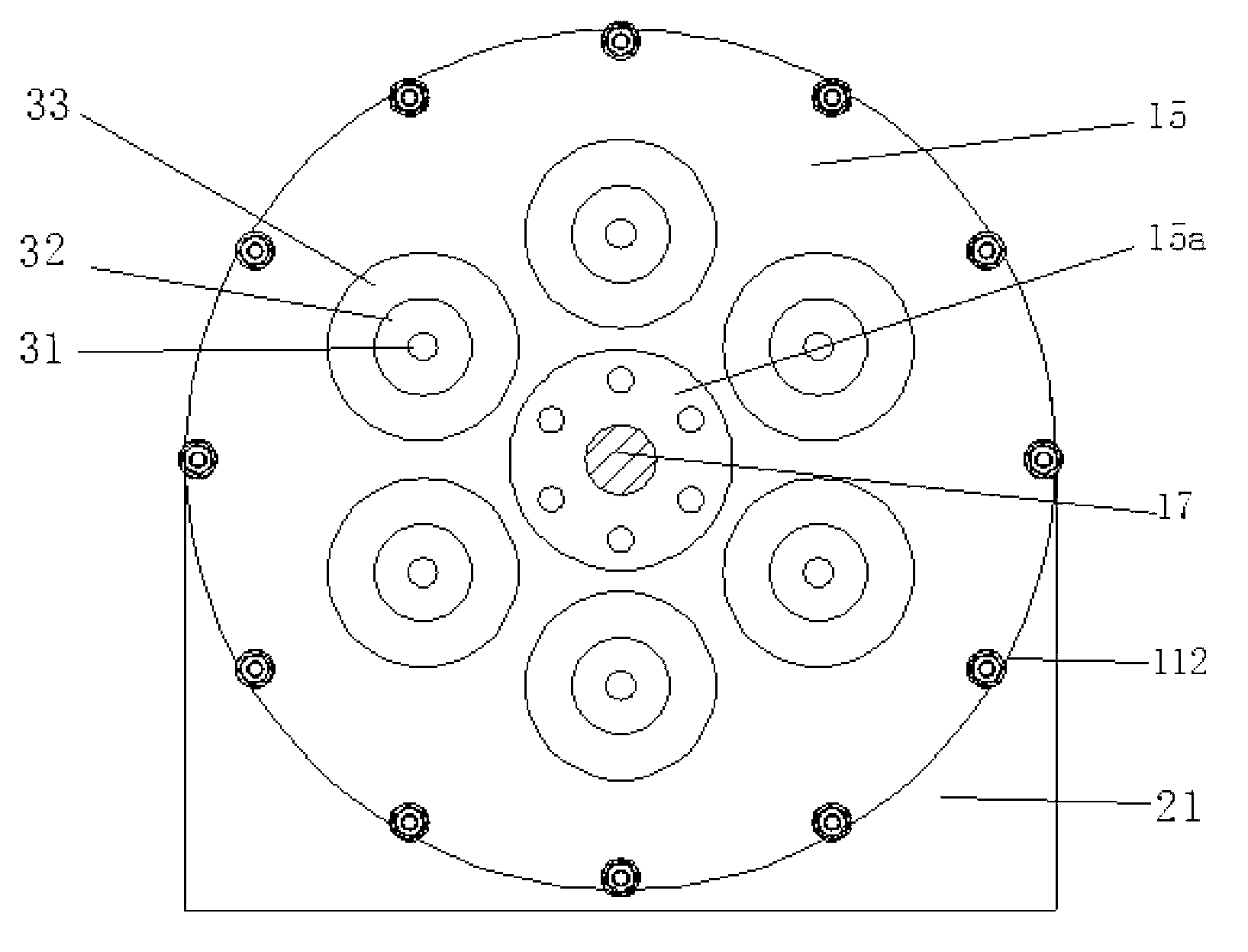

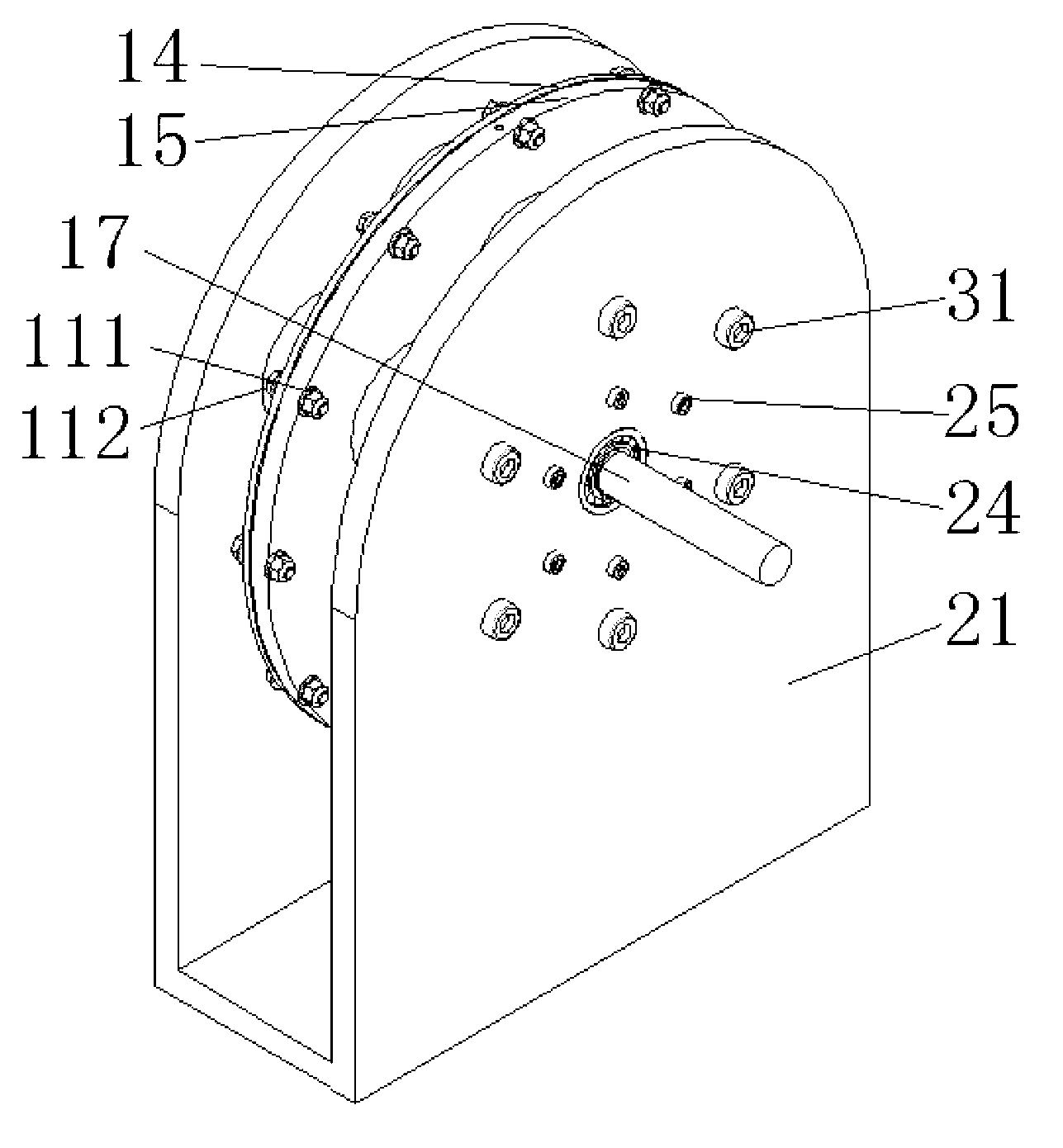

Hydraulic disk type integrated arrestor of floating clamp based on screw drive

ActiveCN101093000AOptimize layoutSmall footprintAxially engaging brakesBrake actuating mechanismsSteel ballEngineering

This invention discloses a hydraulic disk integrated arrester based on a screw driven floating clamp composed of a pull arm component, a mandril component, a steel ball component, a push rod, a piston, a friction block, a caliper and a brake disk connected orderly, in which a clamp floating bracket is connected with the clamp by a guiding bolt, an installation bracket is connected with the floating bracket and fixed on a car bridge by bolts, which applies a special three-lockless screw structure to realize calm transfer of brake force and adjusts the working gap between a friction block and a brake disk automatically.

Owner:WUHAN YOUFIN AUTOPARTS

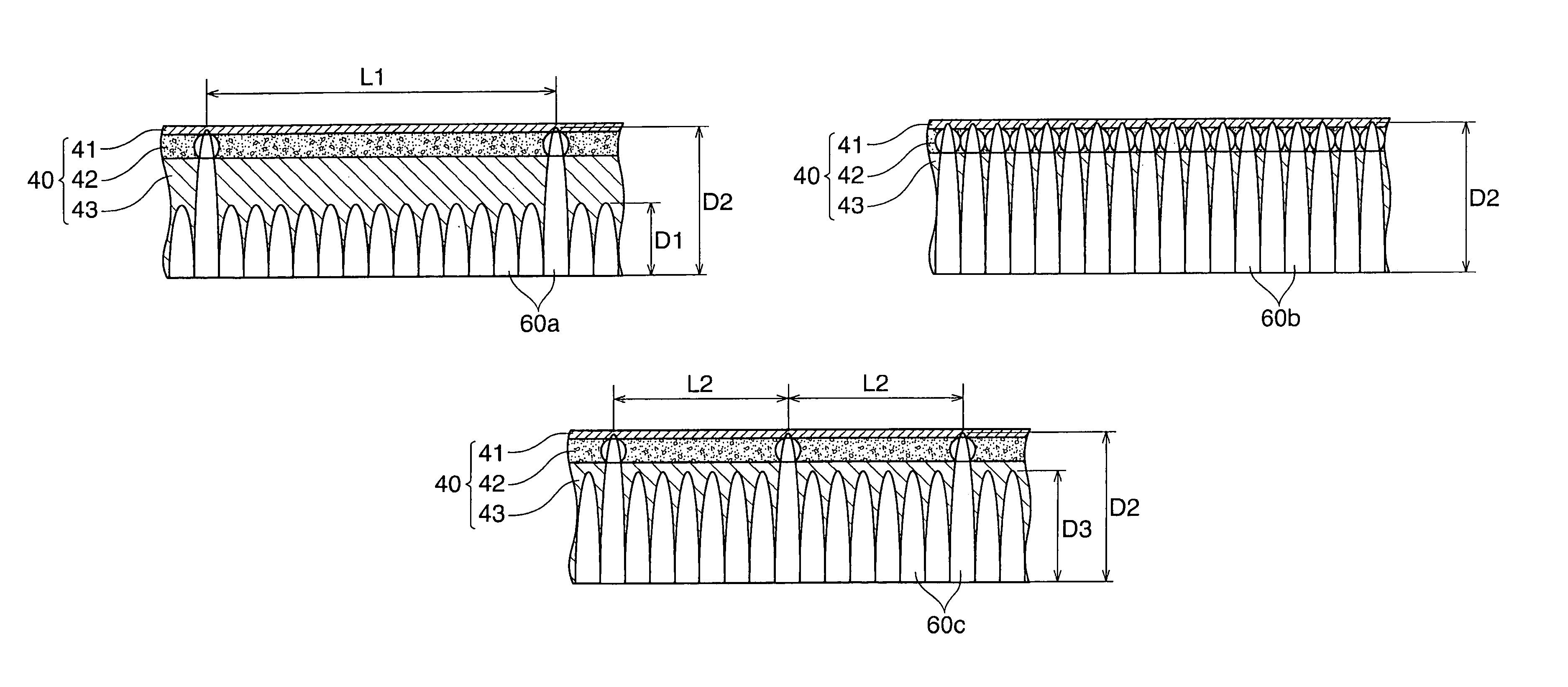

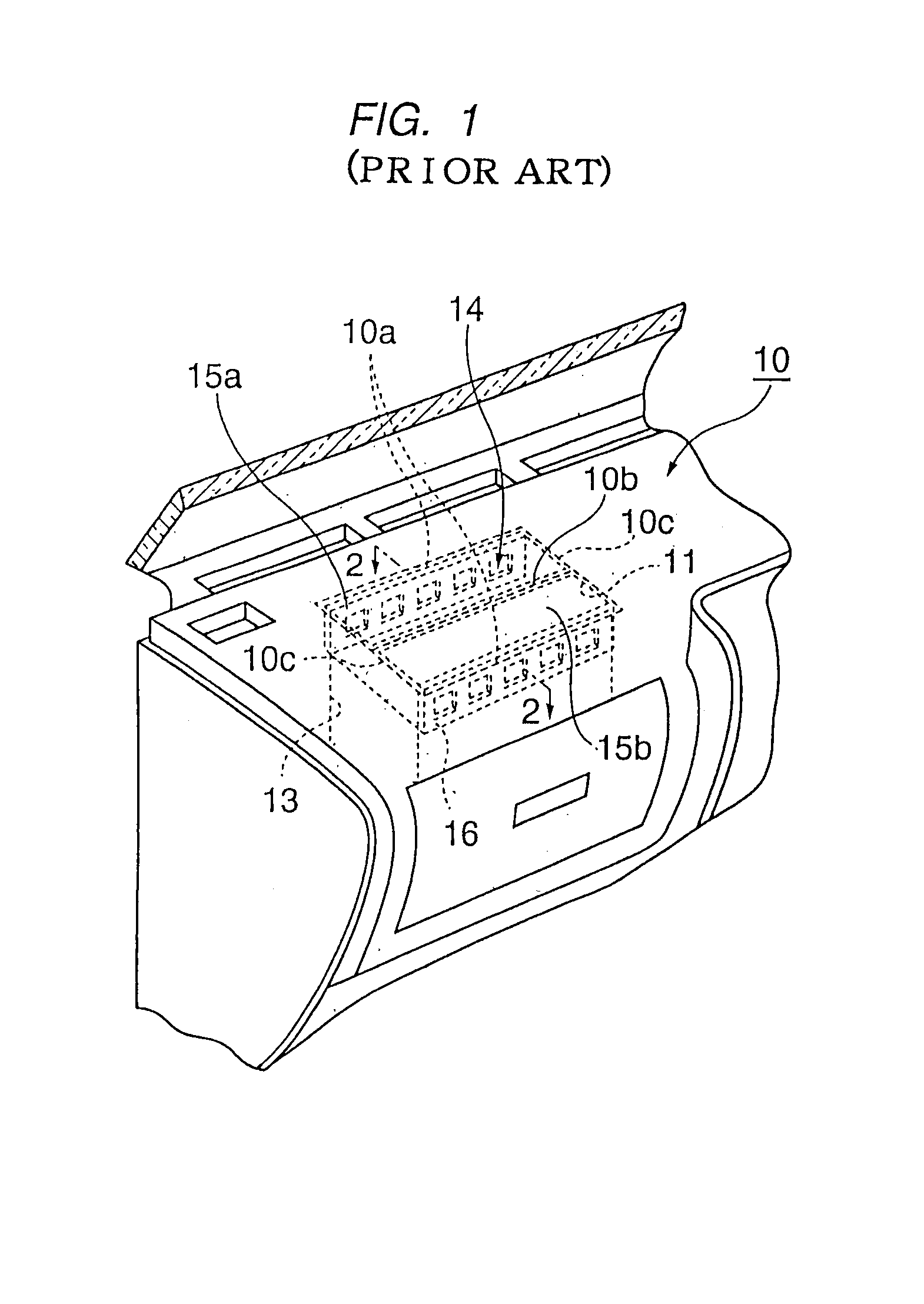

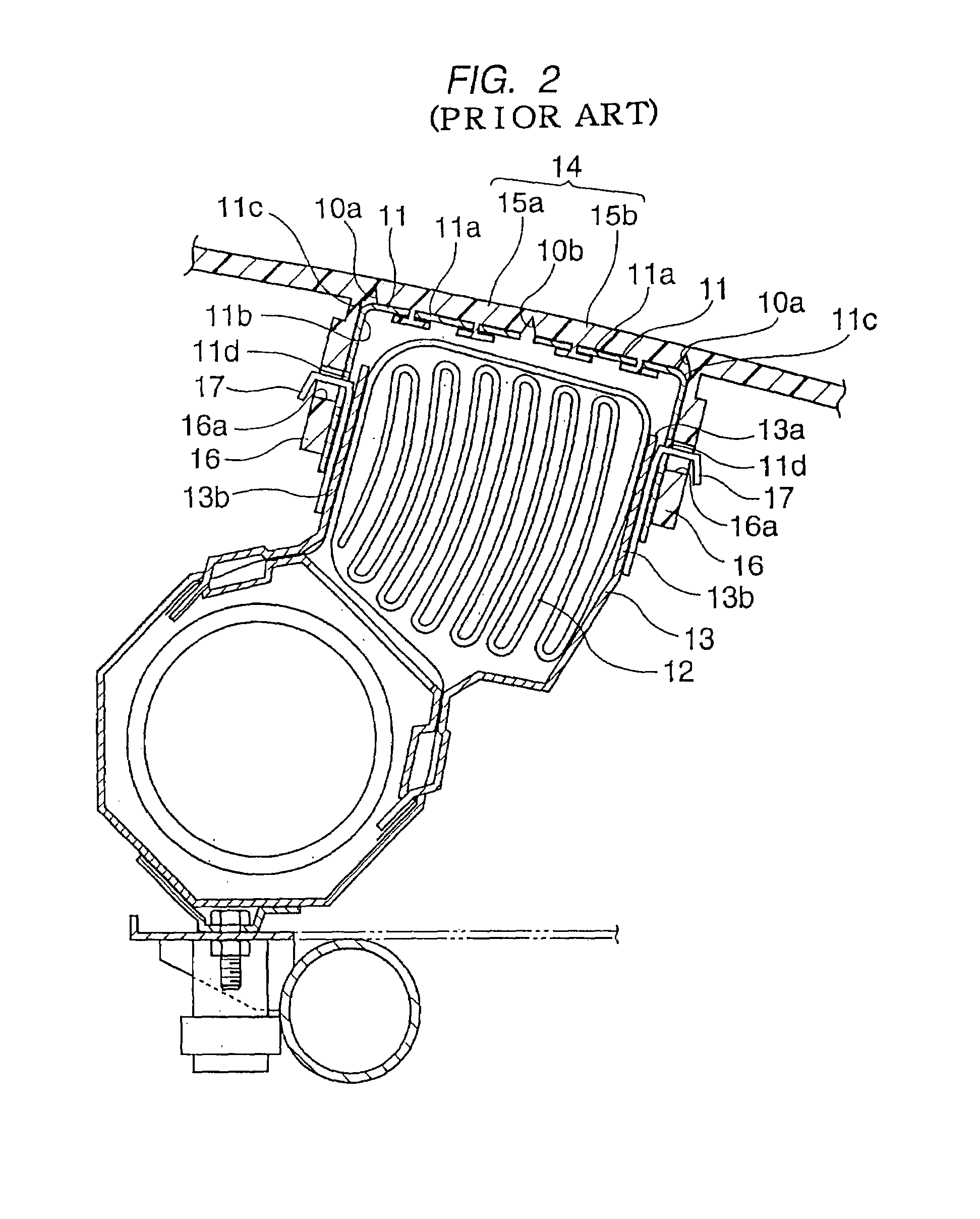

Airbag apparatus for automobile

ActiveUS7168731B2Smooth brakingGood lookingPedestrian/occupant safety arrangementSurface layerEngineering

An airbag apparatus uses an interior panel of an automobile. The interior panel is formed of a multi-layer sheet including a surface layer, an intermediate foam layer, and a base layer. The interior panel has front and rear hinge grooves and left and right fracture grooves for defining a fracture-opening section, and a center fracture groove for dividing the fracture-opening section into front and rear fracture-opening subsections to be split apart from each other in a casement condition. The hinge grooves, the center fracture groove, and the left and right fracture grooves are formed of laser-machined holes which have different depths and do not pass through the surface layer of the interior panel.

Owner:SANGO GOSEI

Cross-country friction material composition for disc friction blocks and preparation method

The invention relates to a cross-country friction material composition for air discs, and the cross-country friction material composition for air discs is characterized by being composed of the following raw materials in parts by weight: 20-52 parts of reinforced fibers, 4-16 parts of an adhesive and 23-86 parts of a friction performance modifier. The cross-country friction material composition for air discs is prepared by the steps of weighing the reinforced fiber, the adhesive and the friction performance modifier by weight to prepare a molding compound, paving a base-layer material formed by weighed fiber material and adhesive on a mold, paving weighed friction material on the base layer to carry out thermocompression, and finally carrying out thermosetting. The cross-country friction material composition for air discs is used for the air disc brakes in complicated road conditions, particularly the cold highland area and wading road conditions, so that a friction material which has good heat recession resistance, high wading restoration performance, temperature alternation repeated impact resistance and stable friction performance is provided.

Owner:CHINA FIRST AUTOMOBILE

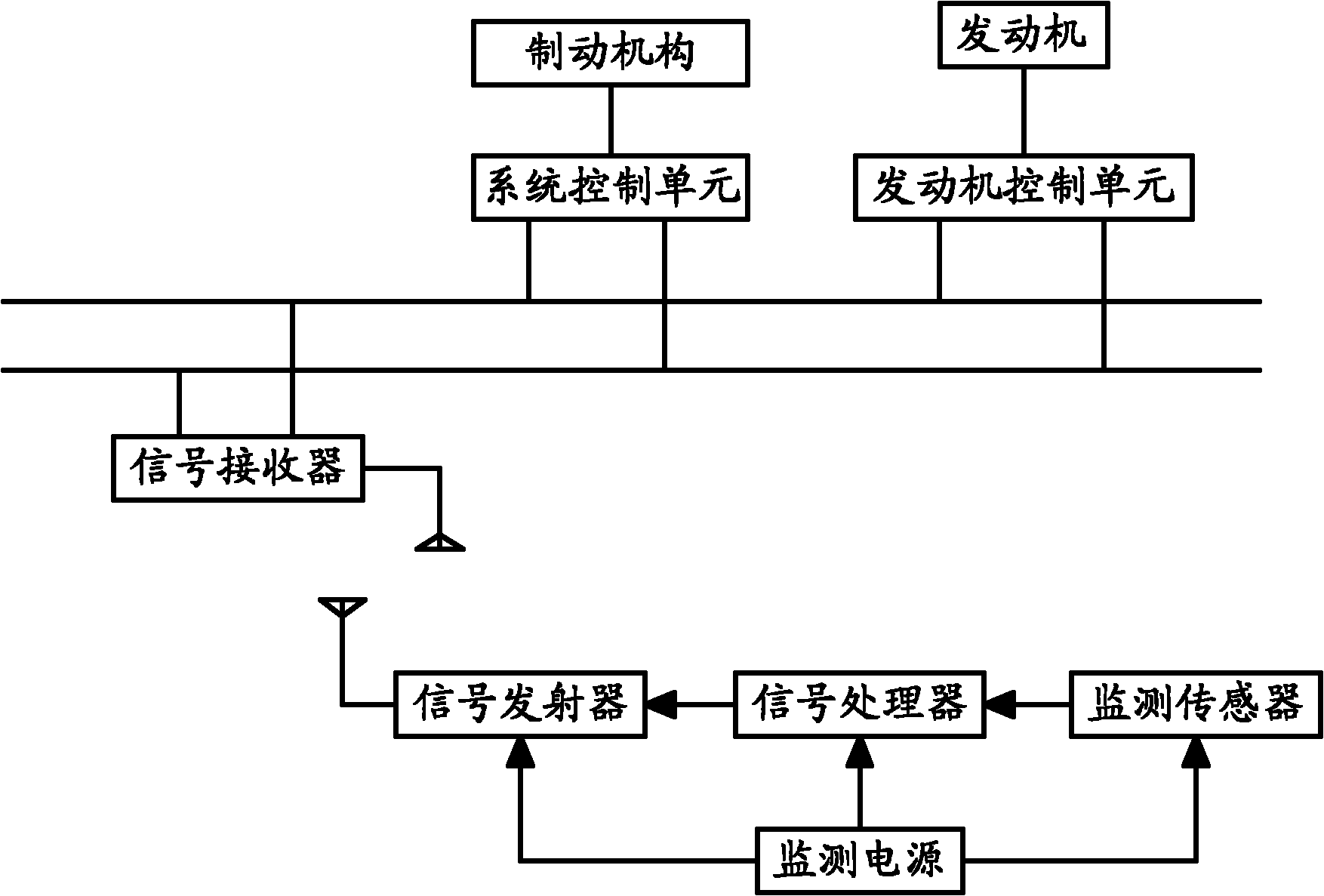

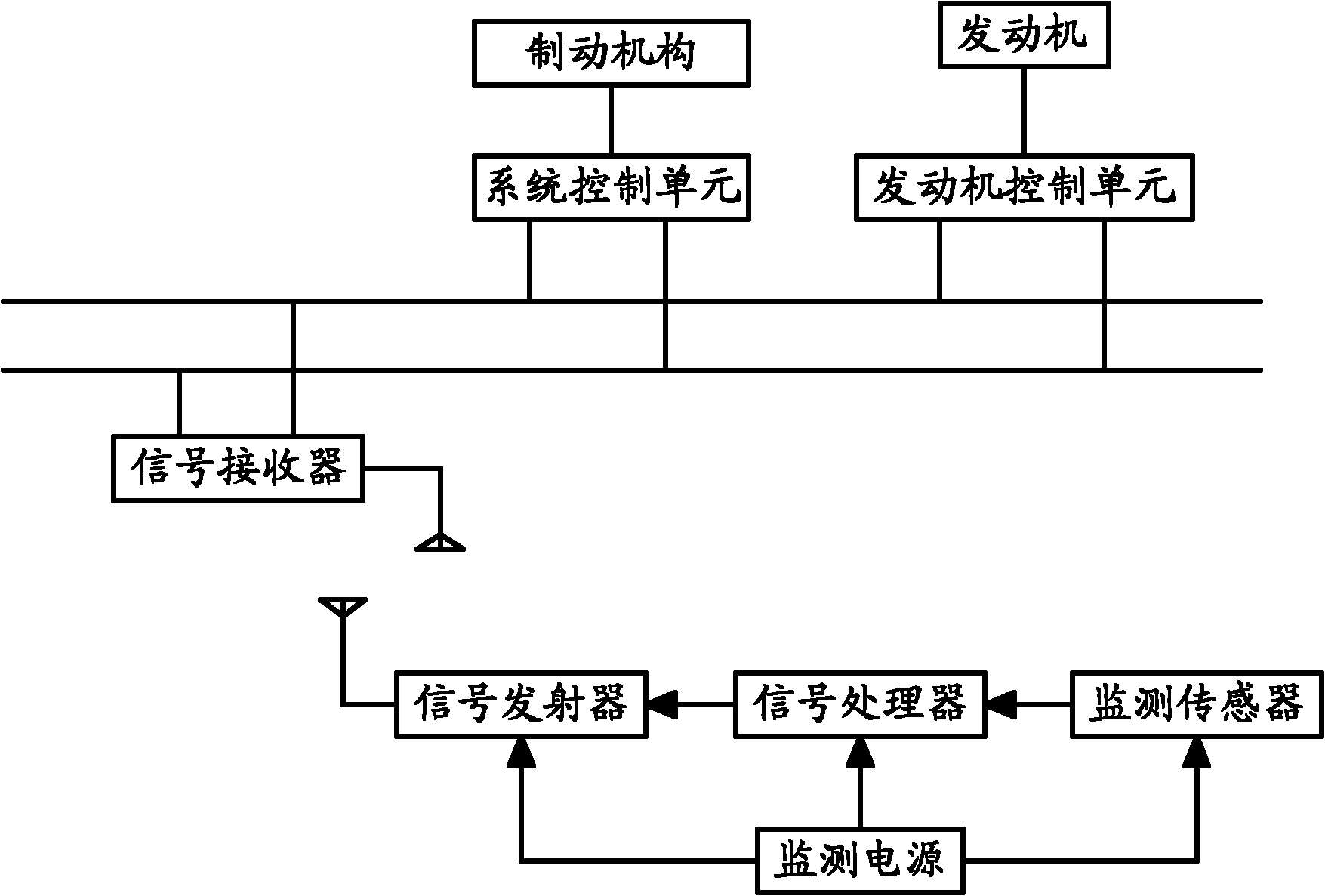

Tire blowout braking control system

InactiveCN102050096AReduce engine torqueReduce speedAutomatic initiationsTyre measurementsAutomobile safetyBrake control

The invention provides a tire blowout braking control system, belonging to the field of automobile safety technique. The invention solves the problems of ruder and crueler braking action and stability deficiency of the existing automobile tire blowout braking system of. The tire blowout braking control system provided by the invention comprises a control device and a tire pressure monitoring unit for detecting the tire blowout state, wherein the control device is connected with an engine control unit and the tire pressure monitoring unit; and the control device can control the tire braking and reduces the engine torque through the engine control unit when the tire blowout signal fed back by the tire pressure monitoring unit is received. The invention has the advantages that when the tire blowout braking control system inducts the occurrence of tire blowout, on one hand, the emergent braking is carried out, on the other hand, the engine torque is reduced, thereby reducing the speed of the automobile; and the two hands are simultaneously carried out, thus the tire blowout braking course is milder and the stability is higher.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Copper-free high-performance environment-friendly type friction material for saloon car and preparation method thereof

A copper-free high-performance environment-friendly type friction material for a saloon car and a preparation method thereof are provided. The friction material comprises the following components in parts by weight: 6-8 parts of phenolic resin, 2-4 parts of aramid fiber, 13-18 parts of an RB205 mixture, 15-20 parts of potassium titanate, 5-8 parts of calcium hydroxide, 20-25 parts of barium sulfate, 1-3 parts of artificial graphite, 3-5 parts of a cashew nut oil friction powder, 3-5 parts of antimony sulfide, 1-3 parts of a butyronityile rubber powder, 3-5 parts of mica, 4-6 parts of calcium silicate, and 1-3 parts of zirconia. The preparation method comprises the steps: a) weighing the component materials according to the formula ratio, and then dispersing into a uniform mixture; b) loading the mixture into a saloon car friction block dedicated die, carrying out hot press molding with the hot press duration time of not less than 5 minutes; and c) carrying out conventional heat treatment on the friction material after hot press molding, and after being fully cured, carrying out size and appearance machining into the product. The friction material has the advantages of excellent high-temperature characteristic, good abrasive resistance performance, good braking performance, reasonable price, recession resistance, high life, stable friction coefficient and the like.

Owner:ZHEJIANG HANGMO OUYI AUTOMOTIVE COMPONENTS

Electromagnetic brake, friction piece thereof and friction piece manufacture method

The invention discloses an electromagnetic brake, a friction piece thereof and a friction piece manufacture method. The electromagnetic brake comprises an iron core assembly, a magnetic roof assembly, a friction member and a manual brake release assembly, wherein the magnetic roof assembly comprises a magnetic roof; the manual brake release assembly comprises a bolt; the iron core assembly comprises an iron core bottom plate, an iron core outer ring, an iron core inner ring, a coil and a skeleton; the friction member is arranged on the outer side surface of the magnetic roof; the friction member and the magnetic roof are transversally positioned; the friction member is made of metal; the middle part of the outer side surface of the magnetic roof concaves inwards to form a spherical surface shape; the middle part of the outer side surface of the friction member convexes outwards to form the spherical surface shape which fits the inwards concave spherical surface part of the outer side surface of the magnetic roof, or, the middle part of the outer side surface of the magnetic roof outwards convexes to form the spherical surface shape, and the middle part of the outer side surface of the friction member concaves inwards to form the spherical surface shape which fits the outwards convex spherical surface part of the outer side surface of the magnetic roof. The electromagnetic brake has the advantages of big braking force, stable and reliable braking, convenient and simple assembly, energy saving, fast release, short time delay, low noise and the like.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

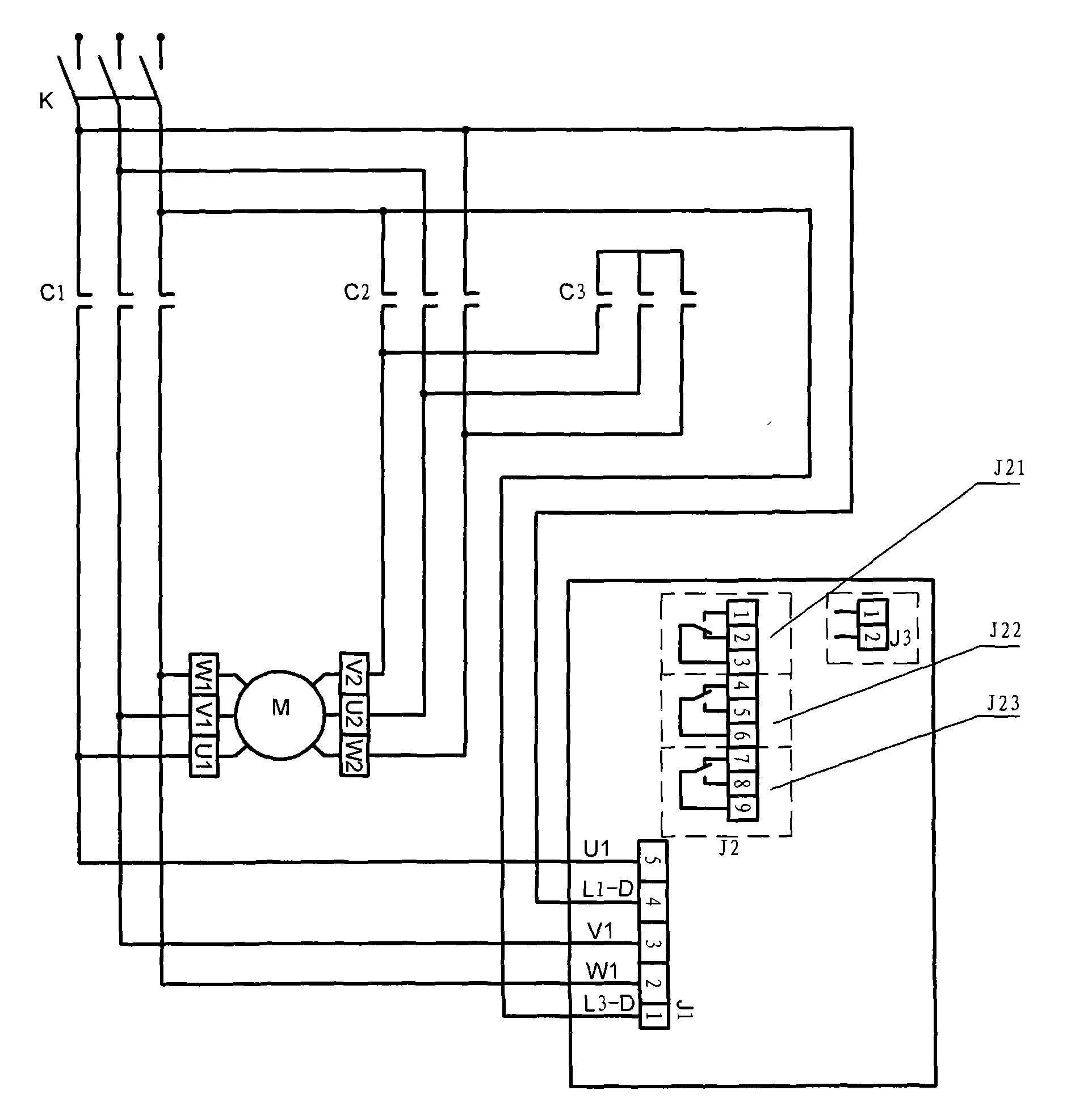

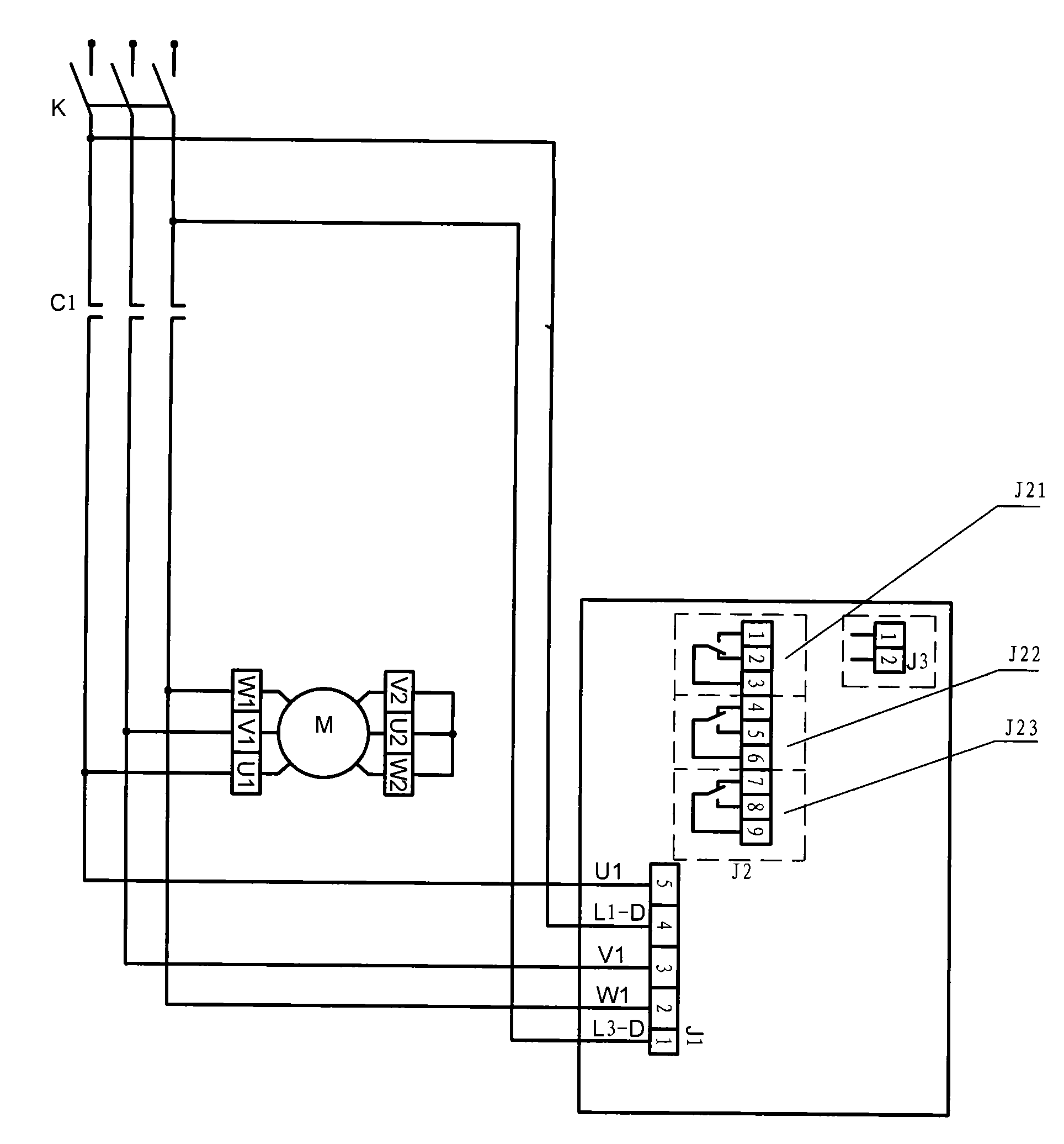

Energy-consumption braking control module of three-phase asynchronous motor

InactiveCN101604944AReduce in quantitySafe and reliable brakingAc motor stoppersMicrocontrollerBrake torque

The invention relates to an energy-consumption braking control module of a three-phase asynchronous motor, comprising a power supply unit, a single chip control unit and a braking direct-current voltage output unit, wherein direct-current voltage output by the braking direct-current voltage output unit is transmitted to a two-phase stator winding of a motor when the motor stops so as to generate braking torque. The energy-consumption braking control module of a three-phase asynchronous motor is characterized in that the single chip control unit detects the work state of the motor by the work conduction angle of the voltage output unit, and a preset program controls the size of the conduction angle so as to regulate the output time and magnitude of the direct-current voltage required by braking. The energy-consumption braking control module of a three-phase asynchronous motor also comprises a zero cross signal detection unit, a running state detection unit, a winding temperature detection unit and a braking current detection unit, wherein each unit respectively outputs a corresponding signal transmitted to the single chip control unit for processing. The invention adopts integrated IC, has little used elements, compact structure, independent products and convenient installation and use and is beneficial to popularization and application; and the single chip is flexible to control, the intellectualized degree is high, and the braking of the motor is safe and stable.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

Winch brake device

InactiveCN102730591AImprove braking performanceIncrease the areaHoisting equipmentsWinchFriction force

The invention discloses a winch brake device which comprises a brake shaft, an outer brake cone plate, an inner brake cone plate, a brake hub, a spiral clutch mechanism and a brake coupling band, wherein the outer brake cone plate, the inner brake cone plate, the brake hub, the spiral clutch mechanism and the brake coupling band are arranged on the brake shaft; a brake drum is meshed with drum key teeth of the winch; the brake shaft drives the spiral clutch mechanism to separate; the outer brake cone plate and the inner brake cone plate respectively clamp the brake hub by the separating process of the spiral clutch mechanism; the outer brake cone plate and the inner brake cone plate are adopted to clamp the brake hub; and the brake hub and the cone plate are in conical contact, the area is larger, the friction force is increased, and brake is reliable. Compared with the existing conical drum tensioning brake, the brake hub is meshed with the drum key teeth of the winch, so the brake force loss is small, the brake response is effectively improved, and the brake performance of the winch is comprehensively improved.

Owner:ZHEJIANG NOWVOW MECHANICAL & ELECTRICAL

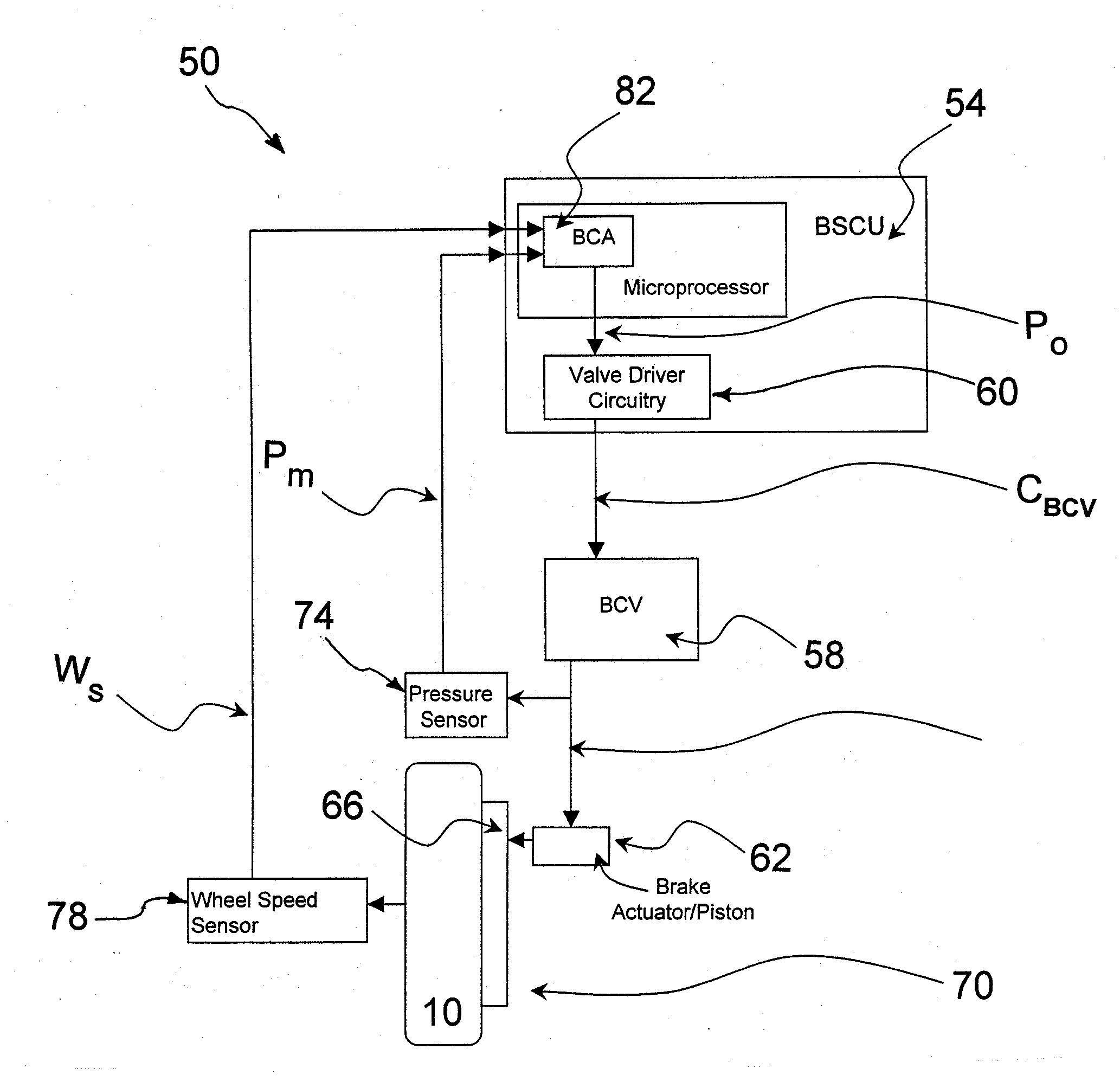

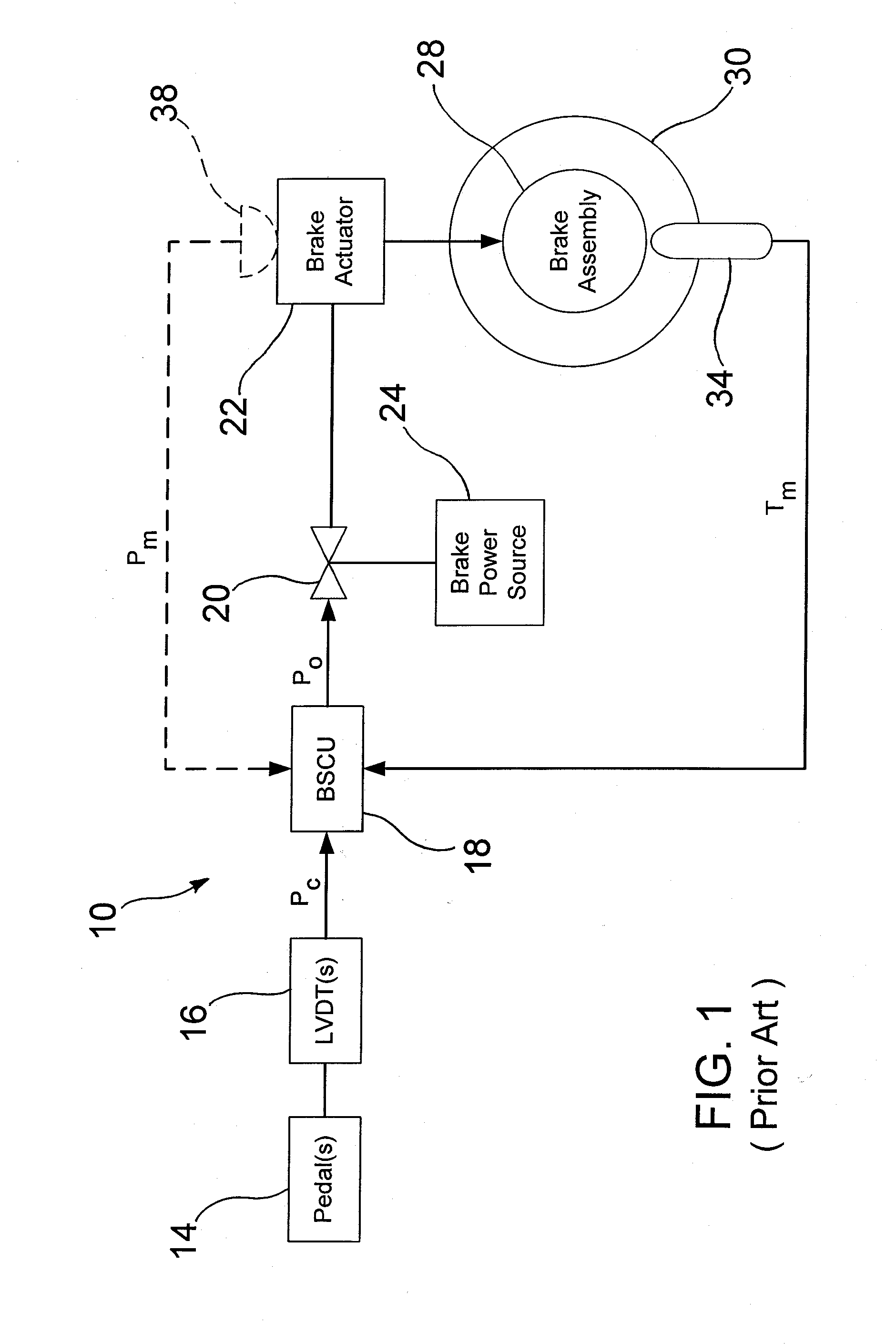

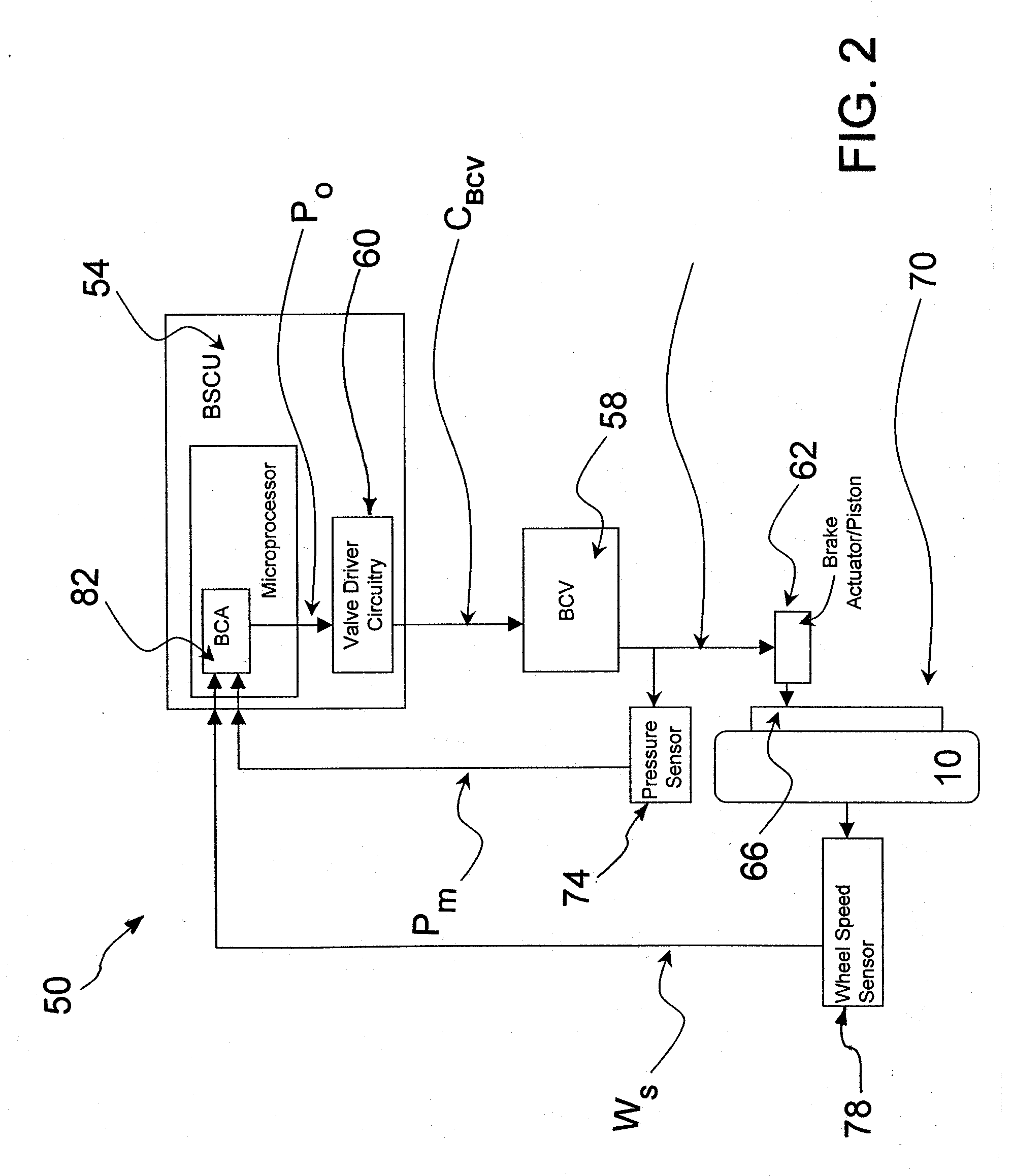

Brake fill effect minimization function

ActiveUS20100276989A1Preventing and reducing controller windupReduces error inputBraking action transmissionAircraft braking arrangementsAutomotive engineeringHydraulic brake

A brake fill effect minimization function for preventing or reducing brake controller windup during a brake fill condition or the like that may commonly occur in hydraulic or electromechanical brake systems, particularly during initial application of the brakes or during anti-skid conditions. The function temporarily reduces error input to the brake controller during a perceived brake fill condition (hydraulic brakes) or running clearance condition (electromechanical brakes) thereby facilitating smooth application of the brakes during initial braking and / or under anti-skid conditions.

Owner:THE BF GOODRICH CO

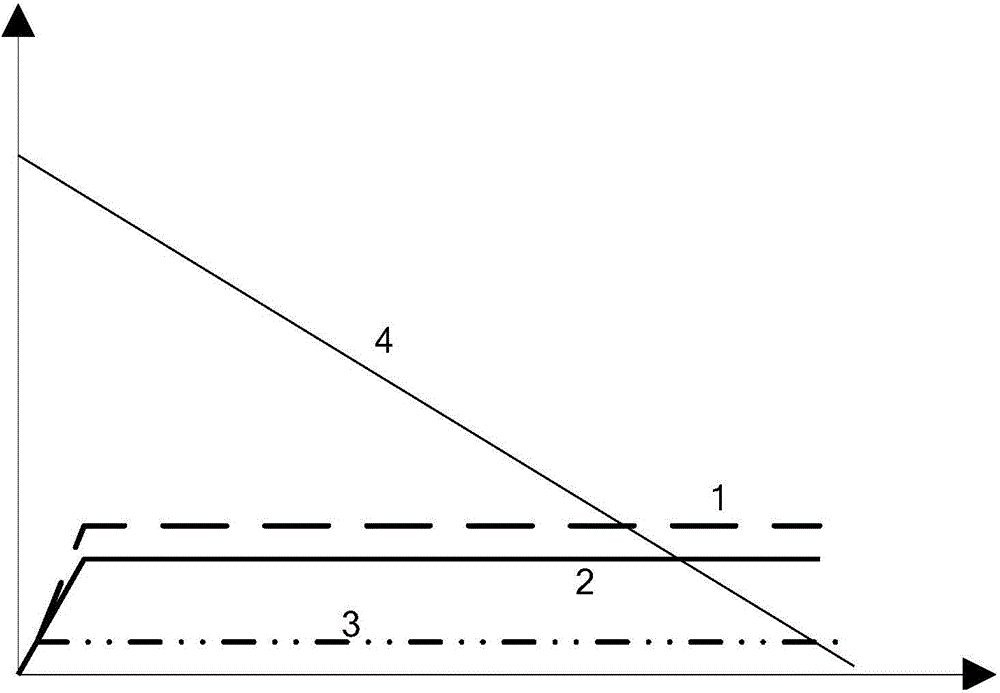

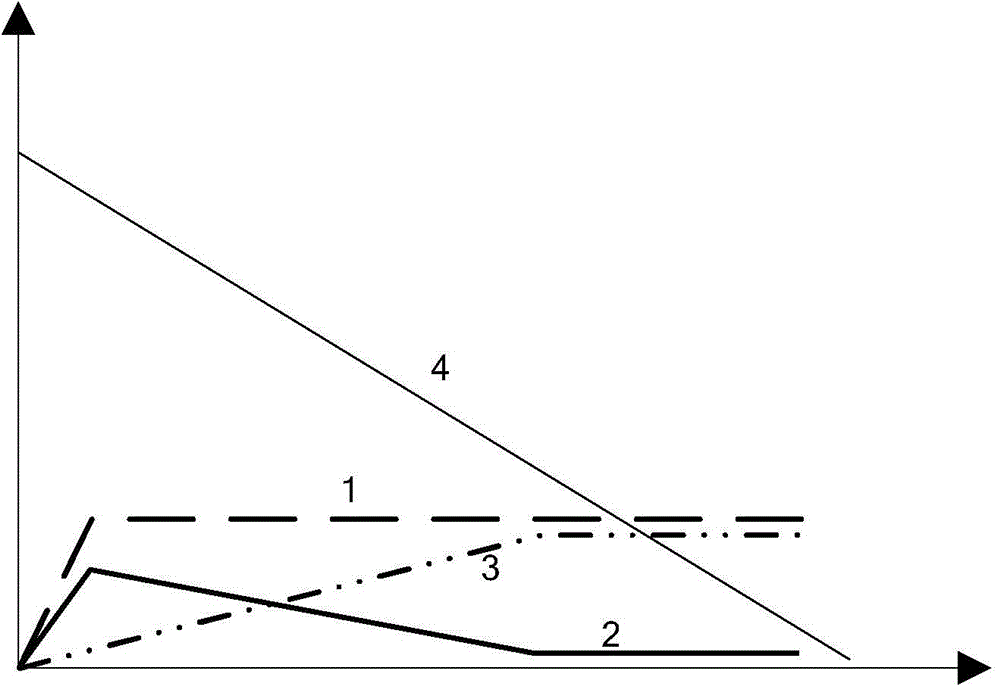

Compound braking method

ActiveCN104890521AImprove riding performanceImprove stabilityElectrodynamic brake systemsEngineeringBrake force

Owner:ZHENGZHOU YUTONG BUS CO LTD

Carbon ceramic brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN102659443ANo pollution in the processGuaranteed reliabilityBraking membersGas phaseBrake shoe

The invention discloses a carbon ceramic brake shoe for an urban rail vehicle and a manufacturing method thereof. In the method, a continuous carbon fiber is taken as an enhanced fiber; pyrolytic carbon and an SiC ceramic material are taken as substrates; a pyrolytic carbon substrate is prepared with a chemical gas phase osmosis process; a ceramic substrate is prepared by adopting an orientation fused silicon impregnation method; and the ceramic substrate comprises the following components in percentage by weight: 12-24 percent of carbon fiber, 16-32 percent of pyrolytic carbon, 18-46 percentof silicon carbide, 6-19 percent of silicon-copper compound, 1-5 percent of titanized carbon and 2-12 percent of simple substance copper. The carbon ceramic brake shoe for the urban rail vehicle has higher heat resistance, wear resistance, moderate friction coefficient, stable braking and high environmental suitability. The manufacturing method is simple and practicable.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Corrosion resistant low noise semi-metallic brake pad

ActiveCN101555916AImprove heat resistanceGood instantaneous high temperature resistanceFriction liningLow noiseFiber

A corrosion resistant low noise semi-metallic brake pad comprises the following components according to weight percentages: 2-4% of nitrile rubber buna, 3-5% of tyre powder, 3-5% of expandable graphite, 9-13% of phenolic resin, 10-15% of stainless steel chopped fibre, 4-7% of red copper fibre, 2-3% of cashew nut oil friction powder, 3-5% of graphite particle, 7-10% of superfine ferric oxide powder, 3-5% of diatomite, 7-12% of acicular wollastonite fibre, 10-15% of barite, 3-5% of chromite, 4-8% of sepiolite fibre, 0.2-0.5% of zinc stearate, 2-3% of zirconite, 3-5% of boron nitride and 2-3% of supramoly; the brake pad has the characteristics of corrosion resistant performance, high frictional coefficient, satisfactory high temperature and thermal decay resistant performance, long service life, and the like. After the brake pad is used, the car brake is sensitive, the braking is stable and brake noise is low, and the brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

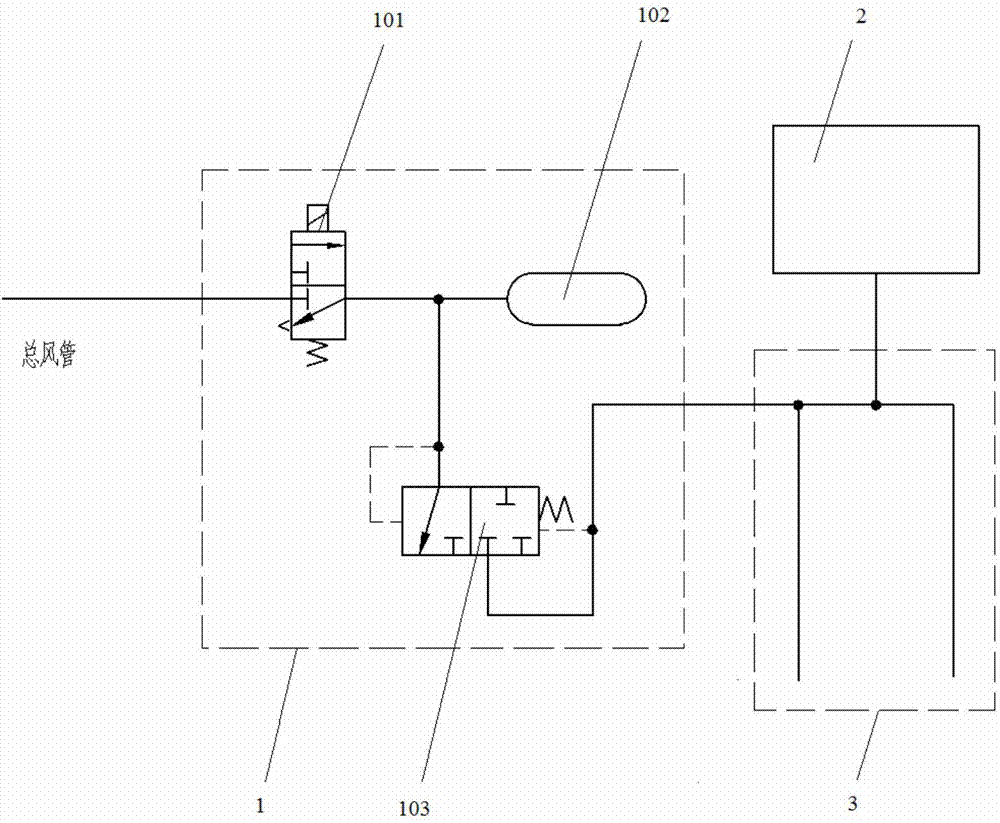

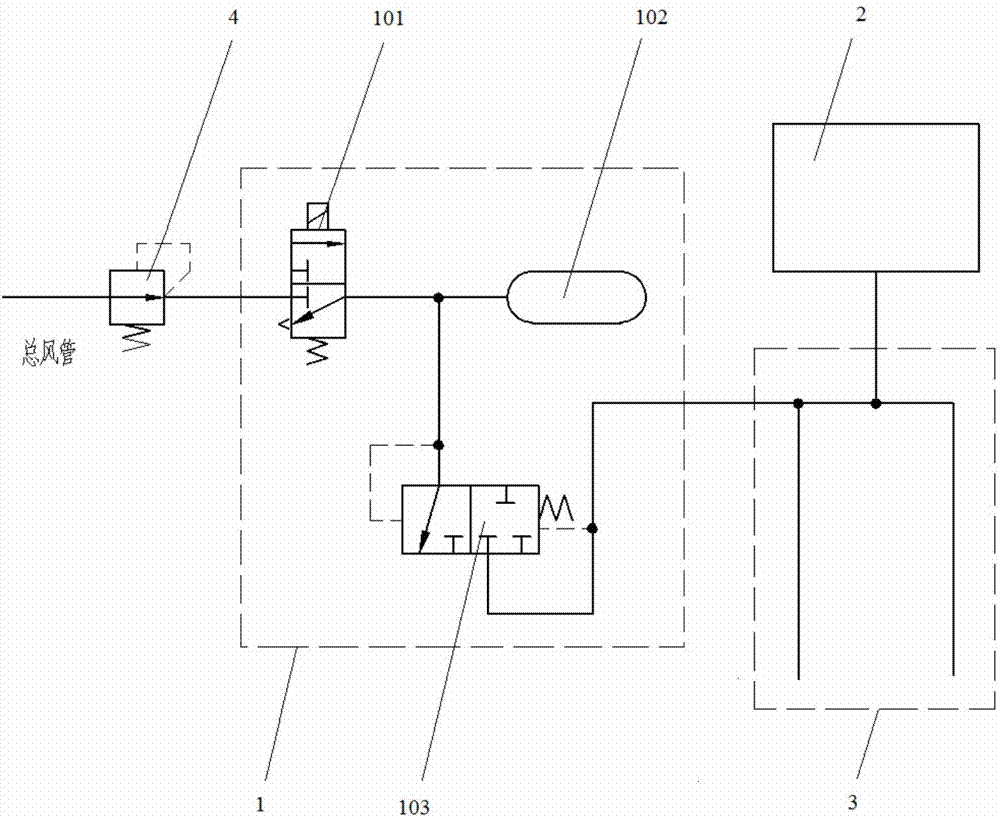

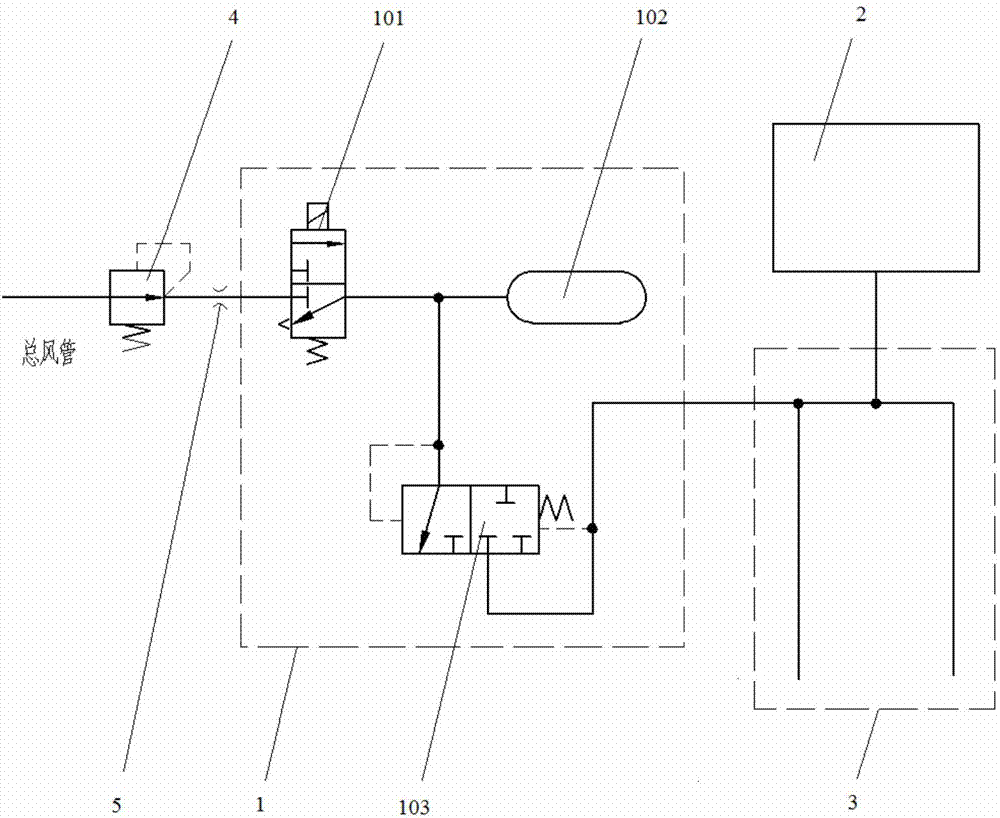

Air braking system and control method thereof

ActiveCN104228804ASmooth brakingImprove securityBraking action transmissionVitrified clay pipeAtmospheric pressure

The embodiment of the invention provides an air braking system and a control method of the air braking system. The air braking system comprises a redundancy channel, a distribution valve and a braking vitrified clay pipe, wherein one end of the redundancy channel is connected with a main blast line and the other end of the redundancy channel is connected with the braking vitrified clay pipe; when a railway locomotive is emergently braked, the redundancy channel receives main blasts in the main blast line; when the air pressure of the main blasts received by the redundancy channel is higher than the air pressure of compressed air in the braking vitrified clay pipe for a preset threshold value, the redundancy channel conveys the received main blasts into the braking vitrified clay pipe, and the air pressure in the braking vitrified clay pipe is increased. The distribution valve is connected with a control vitrified clay pipe and used for inflating the braking vitrified clay pipe with the compressed air, so that the air pressure in the braking vitrified clay pipe is increased. When the value of the air pressure in the braking vitrified clay pipe is not smaller than a preset numerical value, the railway locomotive is braked.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

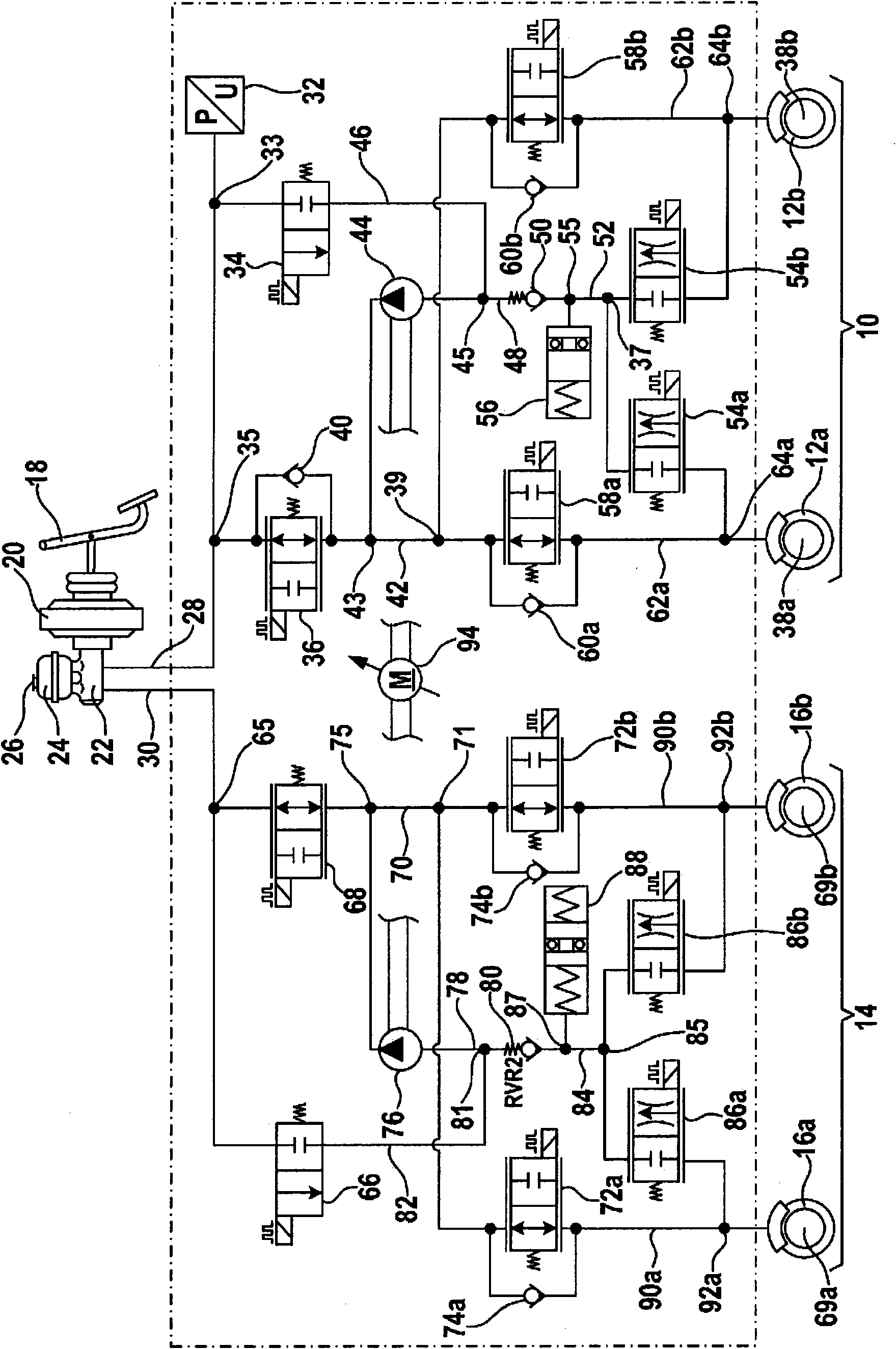

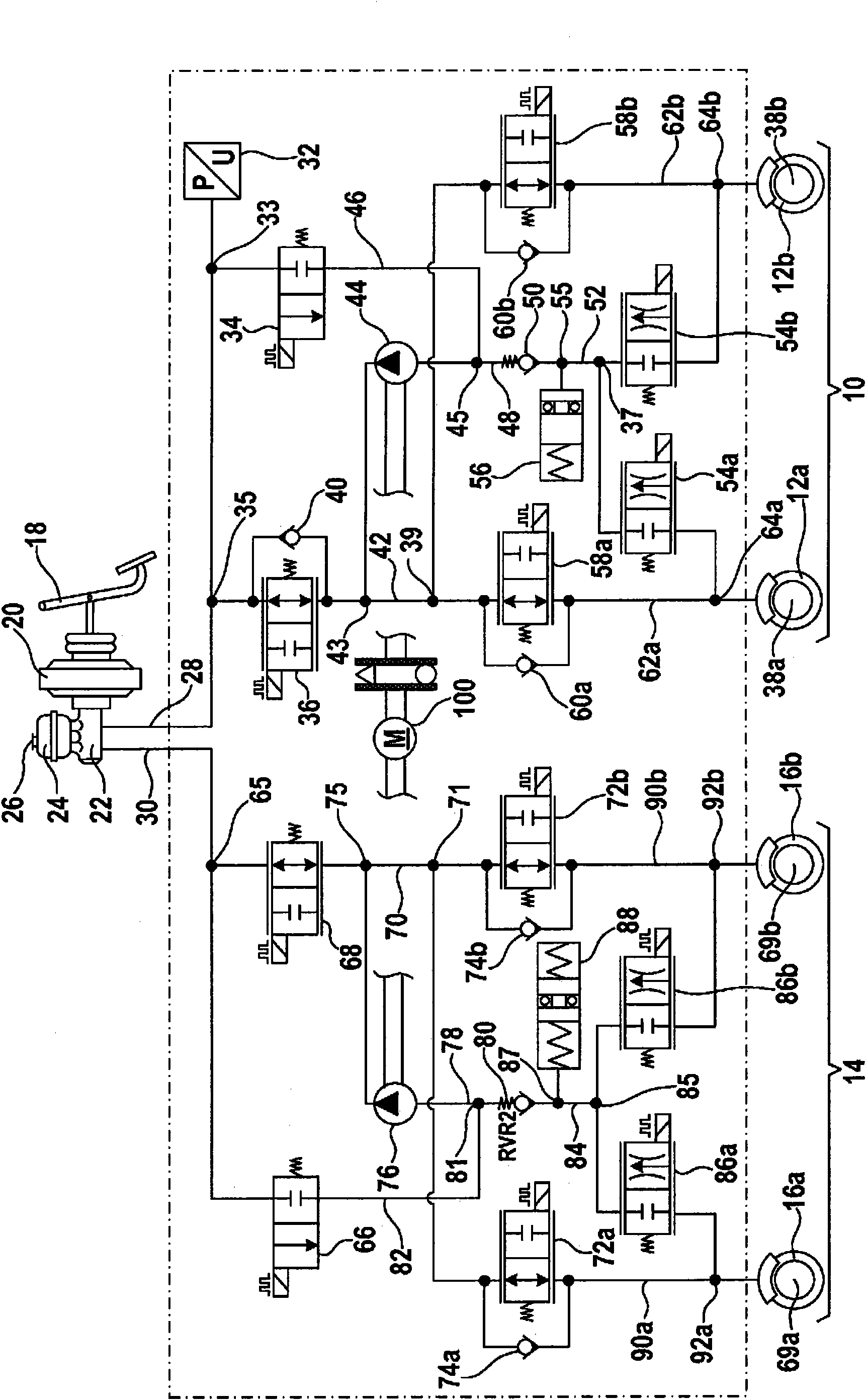

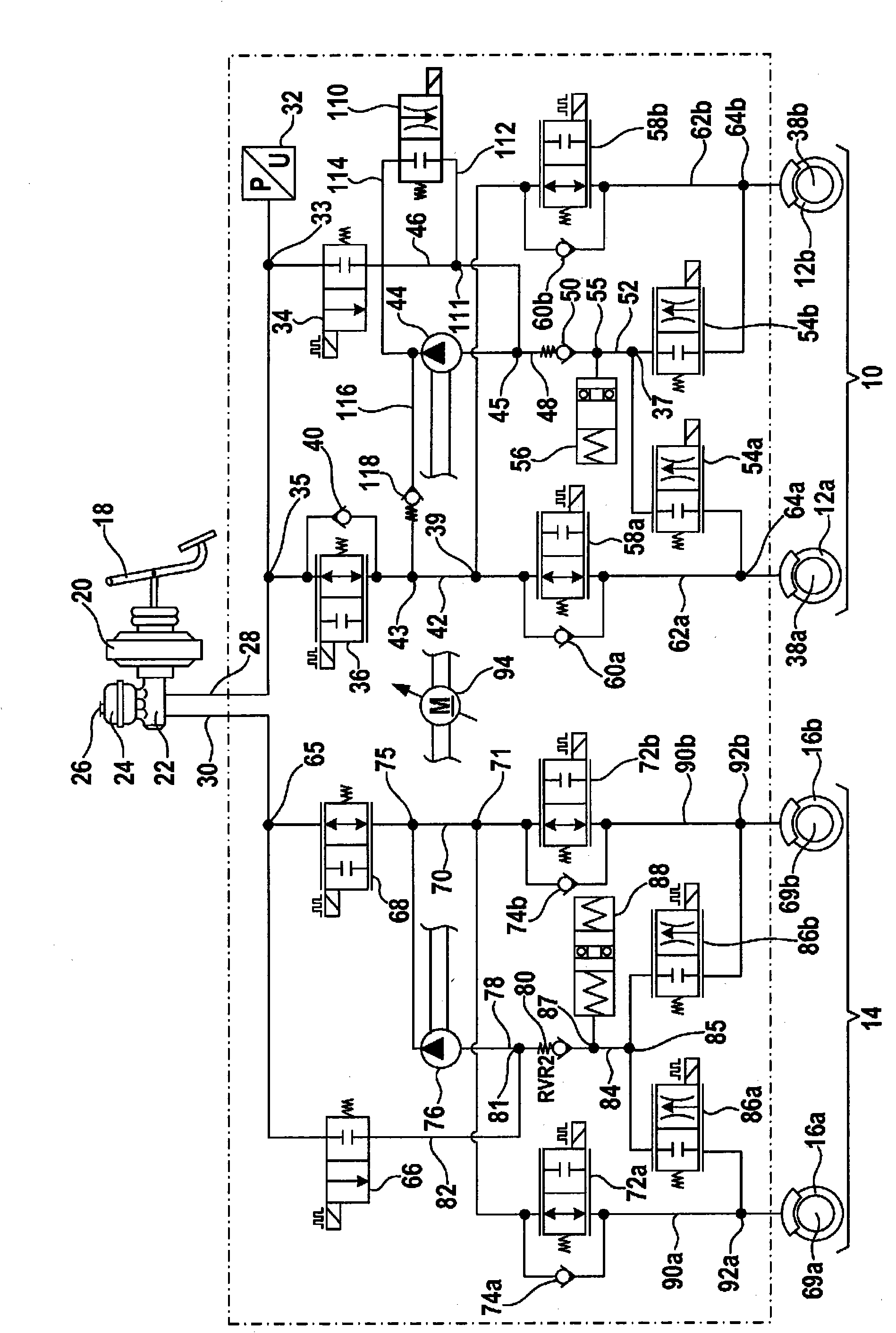

Brake system and method for operating a brake system

InactiveCN101909956ASave construction spaceLow costElectrodynamic brake systemsBraking systemsWheel cylinderBraking system

The present invention relates to a brake system for a vehicle, comprising a main brake cylinder (22), which is configured to detect an actuation of a brake input element (18) and to provide a pressure signal corresponding to the actuation of the brake input element (18), and a first brake circuit (14) having a first wheel brake cylinder (69a,69b), which is configured to exert a force corresponding to the pressure signal onto a first wheel (16a, 16b), a first switching valve (68) disposed between the main brake cylinder (22) and the first wheel brake cylinder (69a,69b), said switching valve being configured as a separating valve, a first pump (76), and a storage chamber (88), wherein the storage chamber (88) has a storage volume on a side facing the first pump (76) in the idle state, and a first wheel outlet valve (86a,86b), which is associated with the first wheel (16a, 16b) and configured to control a brake medium flow between the first wheel cylinder (69a,69b) and the storage chamber (88). The invention further relates to a method for controlling a corresponding brake system.

Owner:ROBERT BOSCH GMBH

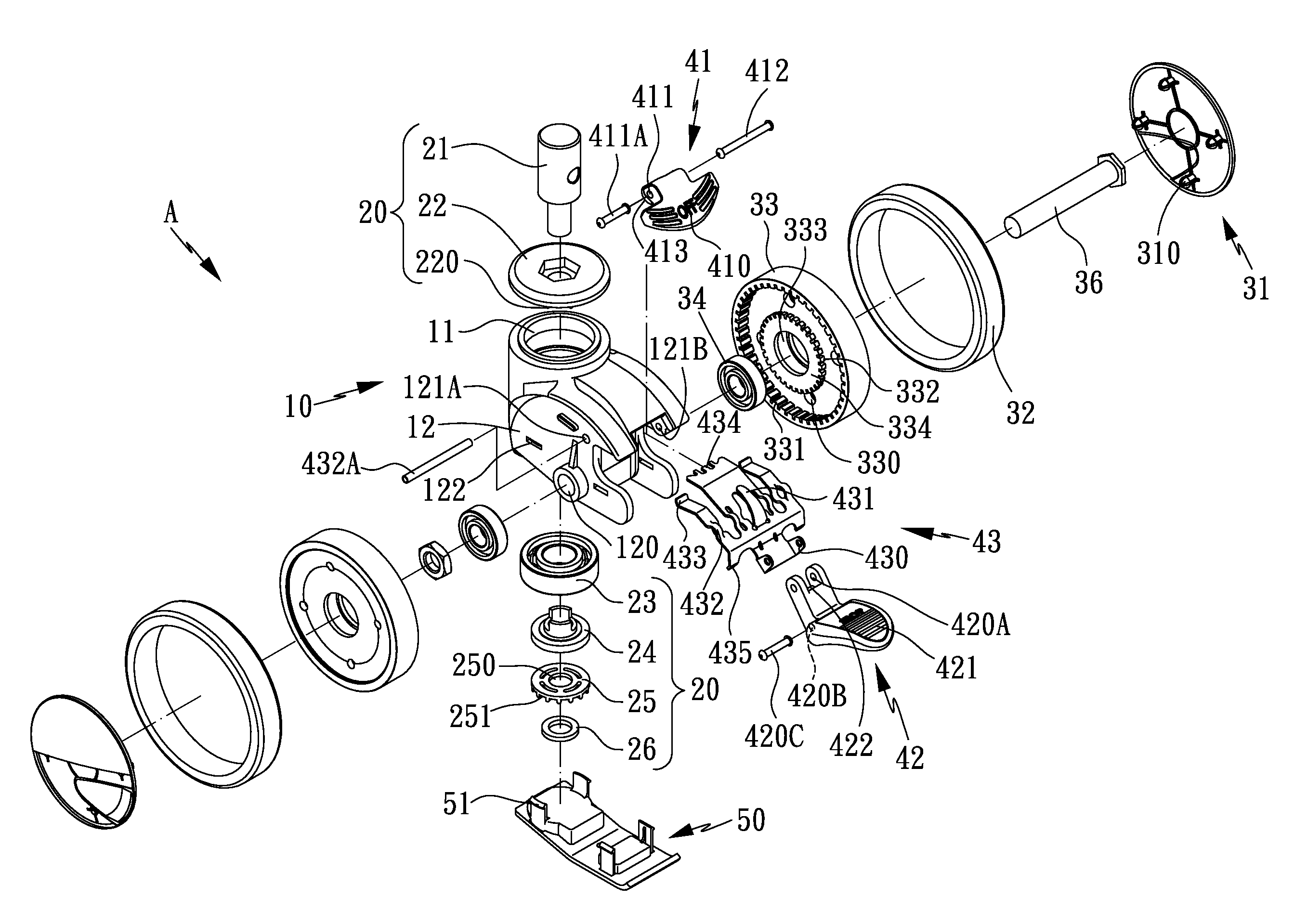

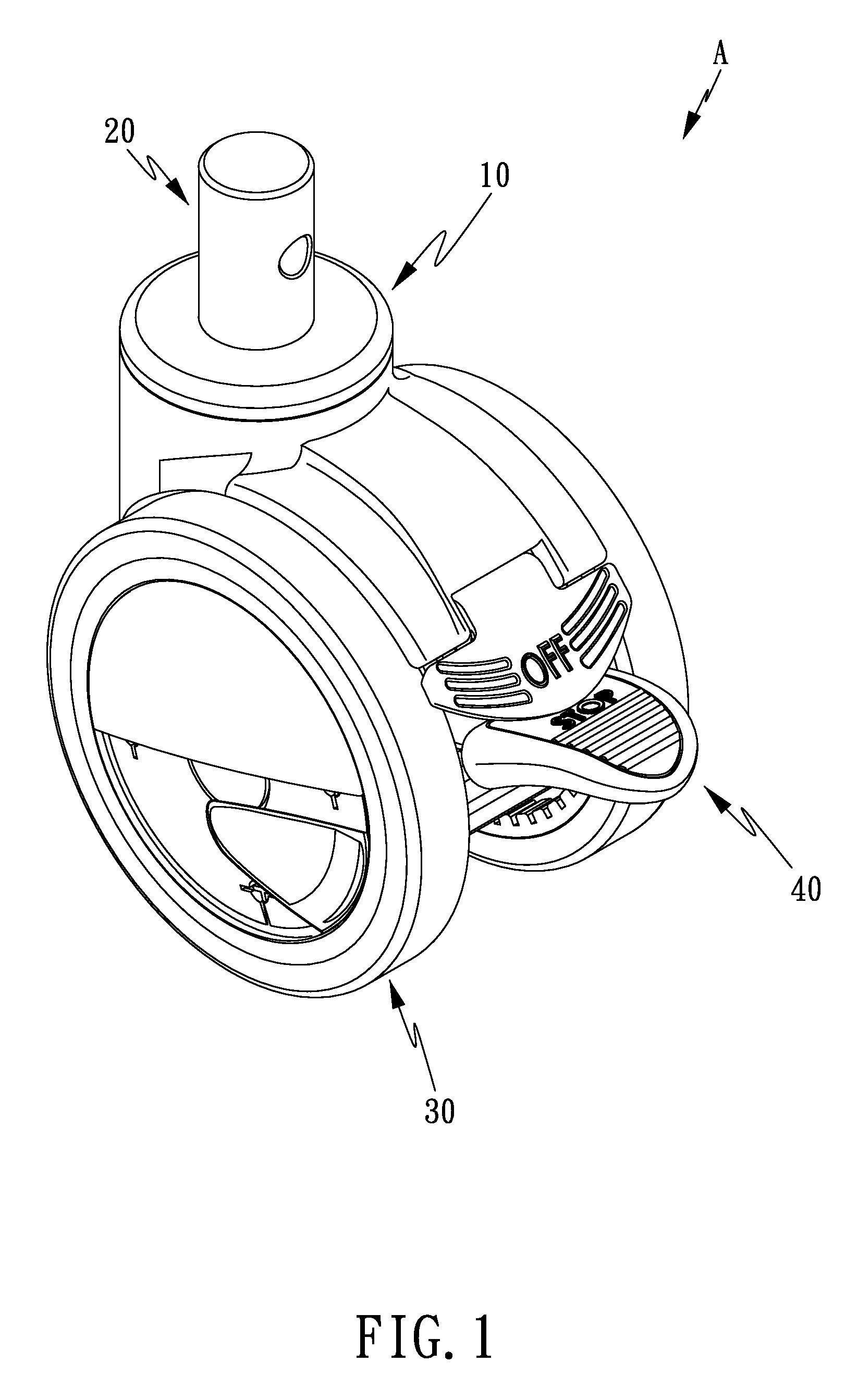

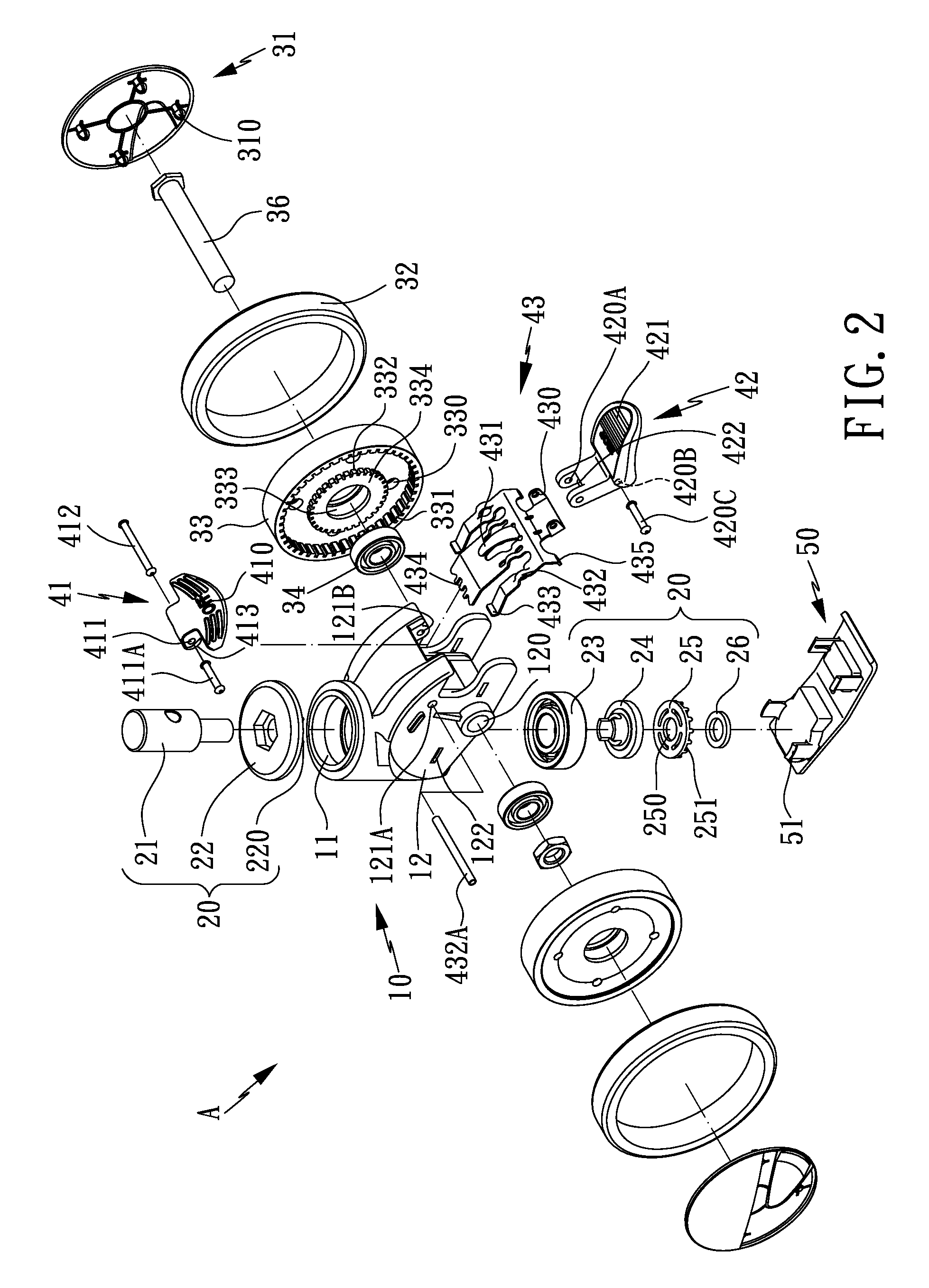

Double-pedal double-wheel truckle with independent braking and releasing functions

Owner:CATIS PACIFIC MFG CORP

Automobile kinetic energy conversion and recovery device

ActiveCN105059274AImprove efficiencyIncrease energy densityHybrid vehiclesBraking element arrangementsHydraulic motorRadial motion

The invention discloses an automobile kinetic energy conversion and recovery device. The automobile kinetic energy conversion and recovery device is used for storing energy during subway braking and recovering kinetic energy during starting. The automobile kinetic energy conversion and recovery device mainly comprises an eccentric wheel, hydraulic plungers and a corresponding hydraulic loop. During subway braking, the eccentric wheel and an axle rotate synchronously, so that the built-in hydraulic plungers conducts reciprocating radial motion; hydraulic oil is pressed into an energy accumulator through the hydraulic plungers on the basis of the design of the corresponding hydraulic loop, and therefore kinetic energy of the automobile is converted into hydraulic energy to be stored. During subway starting, the device is used as a low-speed large-torque hydraulic motor on the basis of switching control over an electromagnetic valve to push a subway to achieve kinetic energy recovery. According to the automobile kinetic energy conversion and recovery device, the hydraulic mode is utilized for energy storage, braking energy is not converted into electric energy and is just stored as hydraulic energy, and the efficiency is much higher than that of the existing energy storage mode.

Owner:王林翔

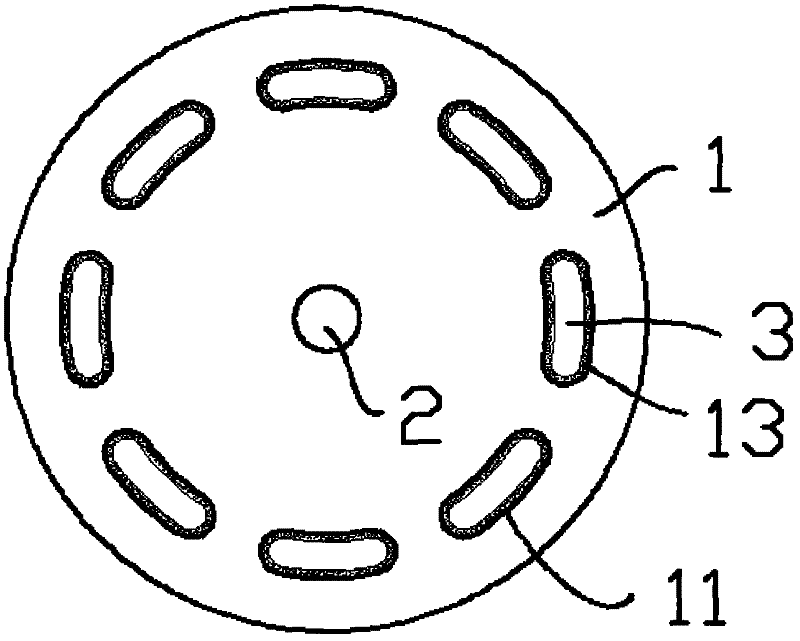

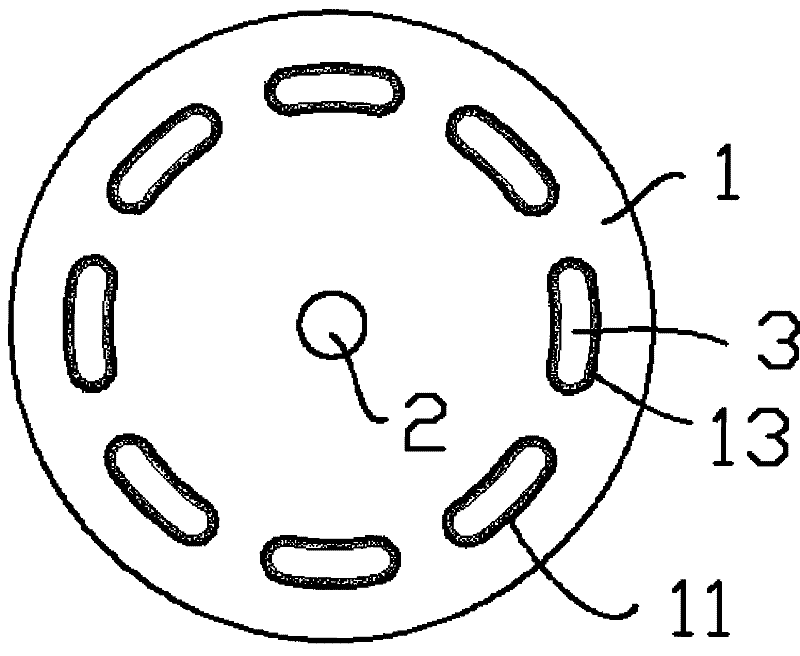

Magnetic-control brake

InactiveCN102303591ASmooth brakingReduce wearBraking element arrangementsDynamo-electric brakes/clutchesFriction lossSoft magnet

The invention provides a magnetic-control brake, which is applied to a vehicle. The magnetic-control brake comprises a metal brake disc, wherein through holes are uniformly and circumferentially distributed on the brake disc; soft magnets are arranged in the through holes; insulators are arranged outside the soft magnets and inside the through holes for insulation; and a pair of coils is respectively arranged on two sides of circumferences of the through holes and generates a magnetic field orthogonal to the brake disc during energization. The magnetic-control brake provided by the invention has the advantages of stableness, no vibration, brake noise and friction loss, and longer service life.

Owner:郑霞

Magneto-rheological hydraulic brake executing device for electric vehicles

ActiveCN103057427AShorter braking distanceIncrease shear stressElectrodynamic brake systemsDrive shaftCar manufacturing

The invention relates to a magneto-rheological hydraulic brake executing device for electric vehicles and belongs to the technical field of electric vehicles. The magneto-rheological hydraulic brake executing device comprises a driving shaft, a brake disk, magneto-rheological liquid, a shell, an electromagnetic coil, connecting plates and a support structure from the inside to the outside. The driving shaft and the brake disk are fixedly connected with a spline and transmit torque to wheels. A left shell piece and a right shell piece are integrally connected through bolts, the brake disk is horizontally disposed in the shell, and the magneto-rheological liquid is filled into the shell. The electromagnetic coil takes an iron core as a support, is limited and fixed by bolts distributed on the support and fits with the outer surface of the shell to form a magnetic loop. The support structure comprises a left portion and a right portion, is fixedly connected with a car body, transmits brake force to the vehicle body, supports the electromagnetic coil through bolts and fixes the brake structure by bolts. The magneto-rheological hydraulic brake executing device is simple and compact in structure, accordant with requirements of the vehicles, capable of setting pressure at millisecond magnitude and convenient to adjust and can meet the requirements for brake strength of the vehicles.

Owner:TSINGHUA UNIV

Friction grain and watering prilling process therefor

The invention discloses a friction granule and the granulation technology thereof. Firstly, resin, toughener, rubber, antifriction, fiber, molding agent, filling, and friction material waste machining material are weight according to a certain proportion, mixed and added into a mixing plant to be stirred by adding water, so a wet mixture is obtained; granulation is carried out on the wet mixture on a granulation device to obtain a granular matter; the granular matter is roasted for many hours under the temperature of 100-200 DEG C to obtain a dried granular material; and at last, the dried granular material is screened according to the requirement to obtain the granular material with needed grit number. The invention utilizes waste materials, reduces the production cost and facilitates the environment protection; in addition, the wearable performance, the vibration resistance and the anti-attenuation of the obtained friction granule are all improved; the brake is sensitive and stable with little noise; and the damage caused for a braking disc drum is little.

Owner:NINGGUO FEIYING AUTO SPARE PARTS +2

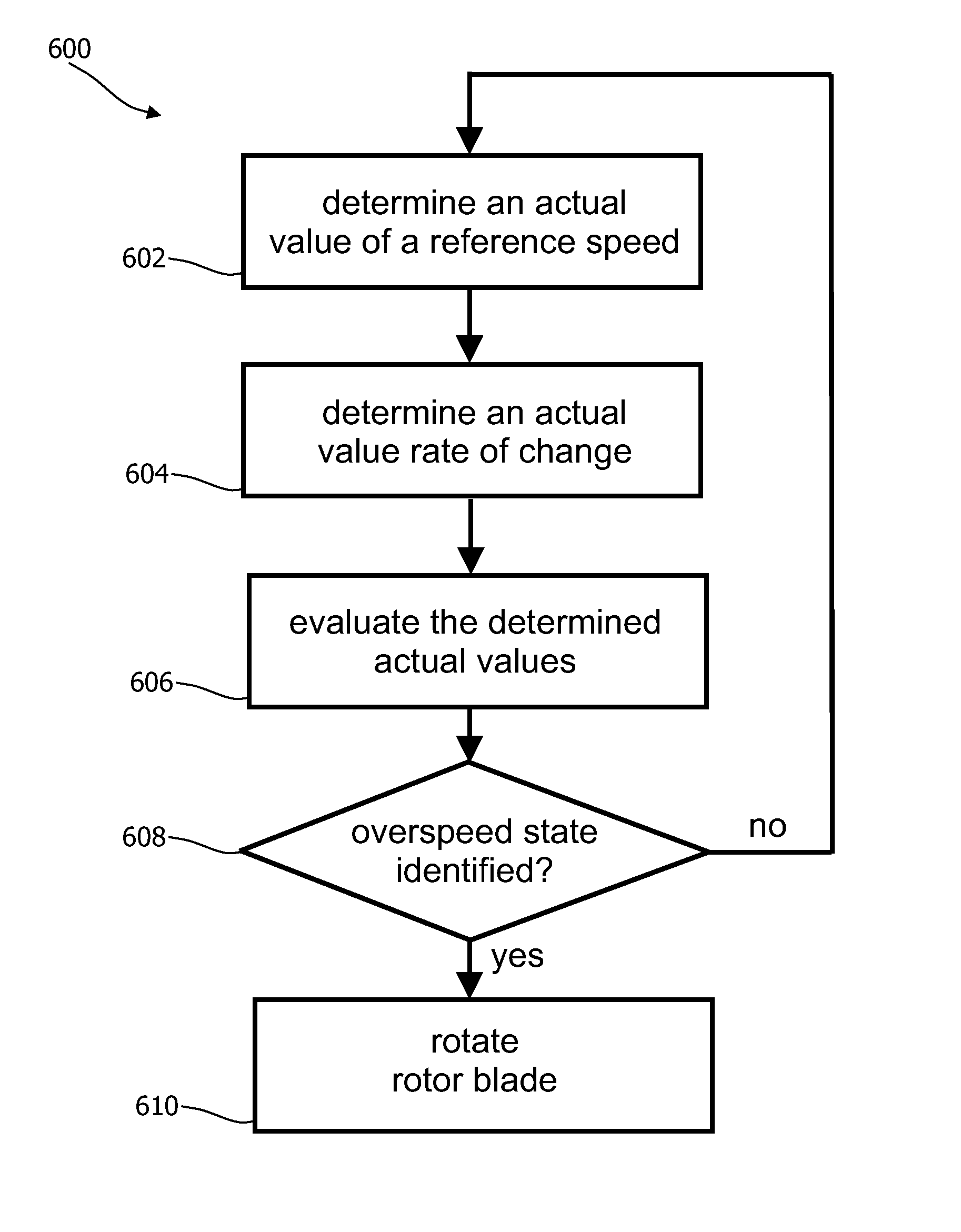

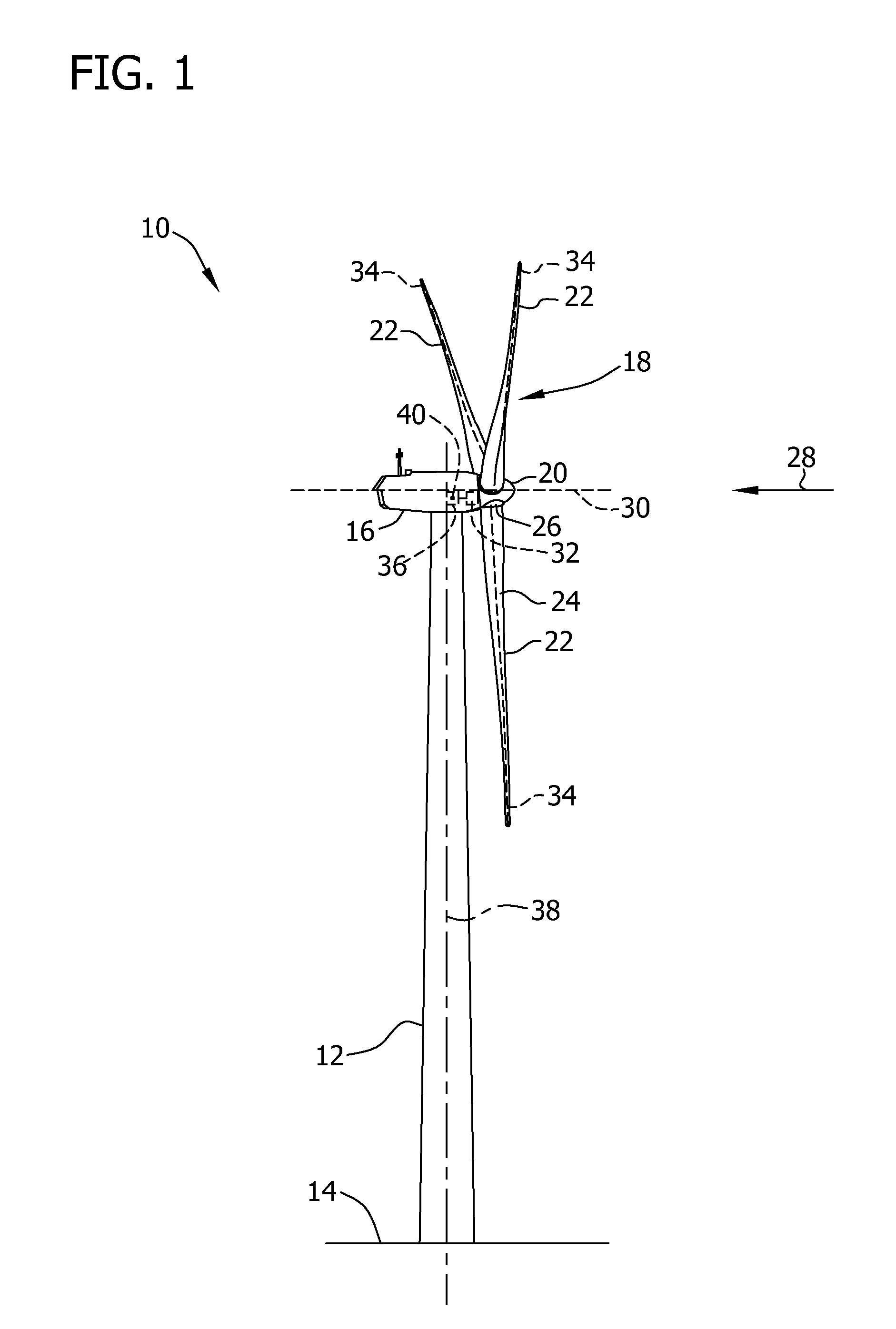

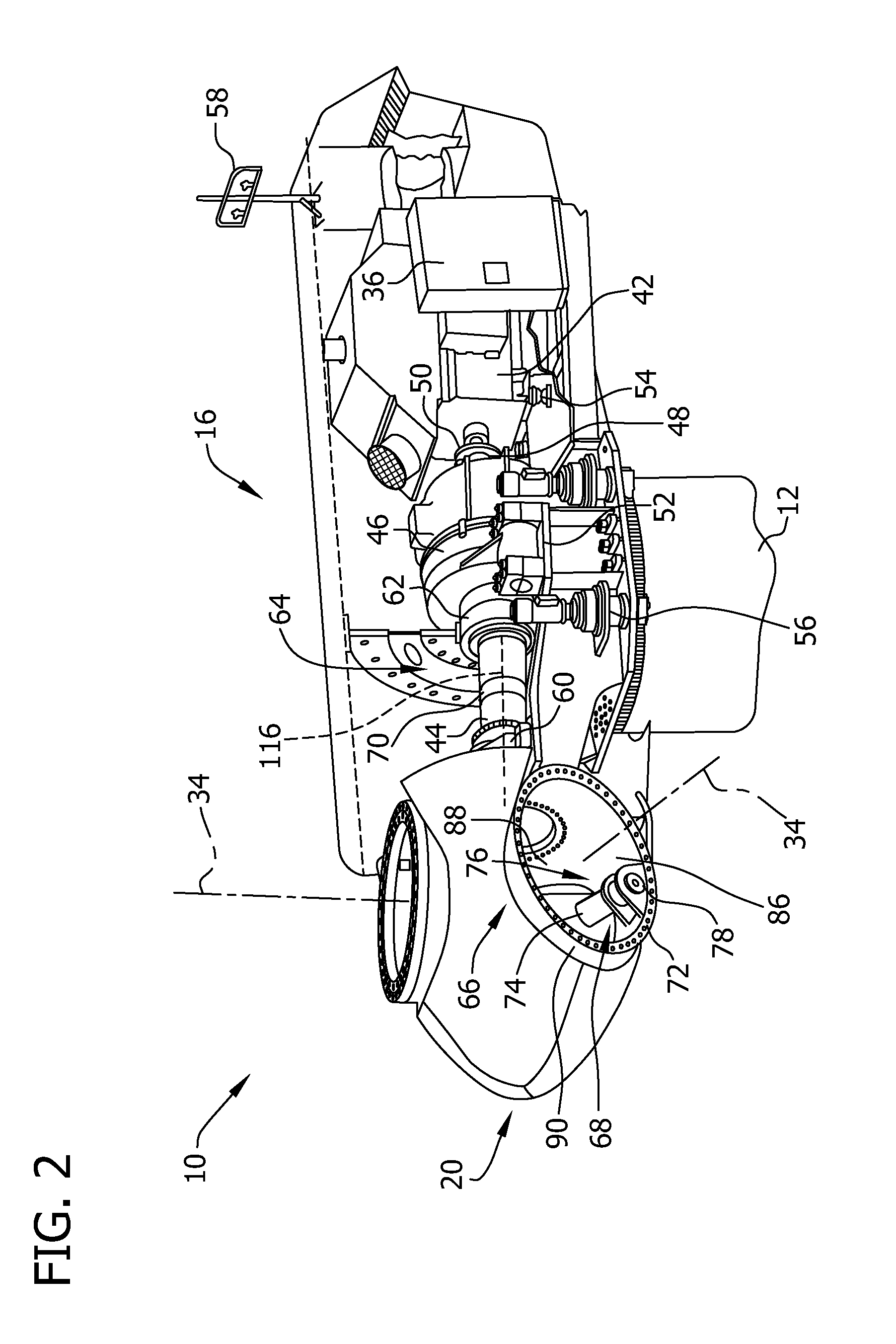

Apparatus and method for operation of a wind turbine

Owner:GE INFRASTRUCTURE TECH INT LLC

Car brake block mixed with piemarker fiber and preparing method of car brake block

InactiveCN103836098AHigh melting pointModerate hardnessOther chemical processesFriction liningRare earthRenewable resource

The invention discloses a car brake block with a piemarker fiber and a preparing method of the car brake block. The car brake block comprises the natural piemarker fiber, aramid fiber pulp, rare-earth modified phenolic resin, a friction performance modifier, padding and the like, and comprises, by weight, 30-35 parts of reinforced fiber, 13-16 parts of binding agent, 9-12 parts of friction performance modifier and 40-45 parts of padding. The piemarker fiber on which the alkali treatment and ultrasonic treatment are carried out is low in price, light, high in specific strength, specific modulus and tensile strength and good in abrasion resistance and has other superior properties, and belongs to renewable resources. The car brake block prepared under the optimal technological condition and mixed with the piemarker fiber has a stable friction coefficient, a good brake effect and brake smoothness, is low in noise, good in comfort and friendly to the environment and is an ideal environment-friendly friction material.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com