Patents

Literature

21667results about "Bridge erection/assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sensor devices for structural health monitoring

InactiveUS7034660B2Reduce needEasy to compareThermometers using mean/integrated valuesWeather/light/corrosion resistanceStructural health monitoringCurrent sensor

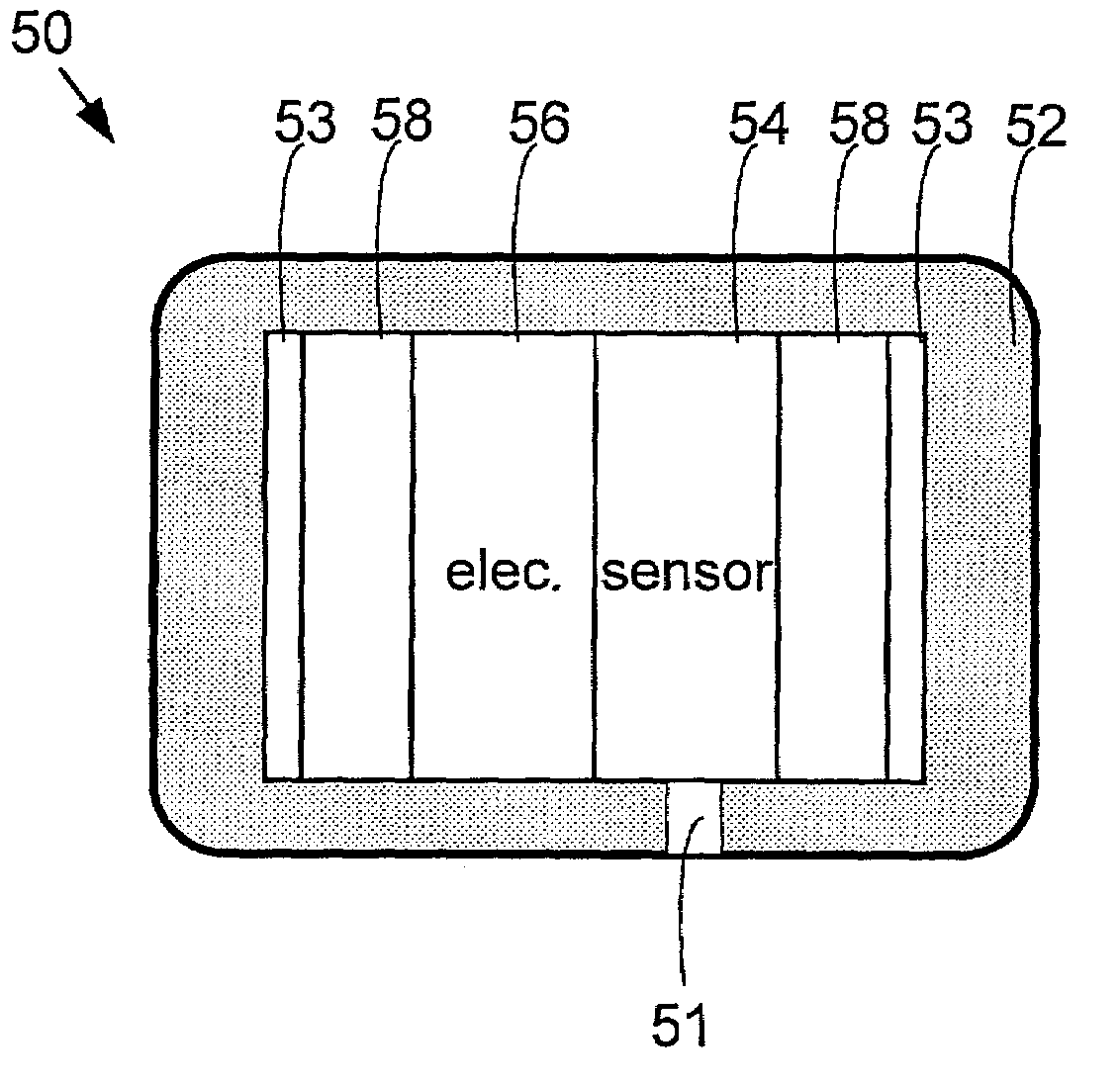

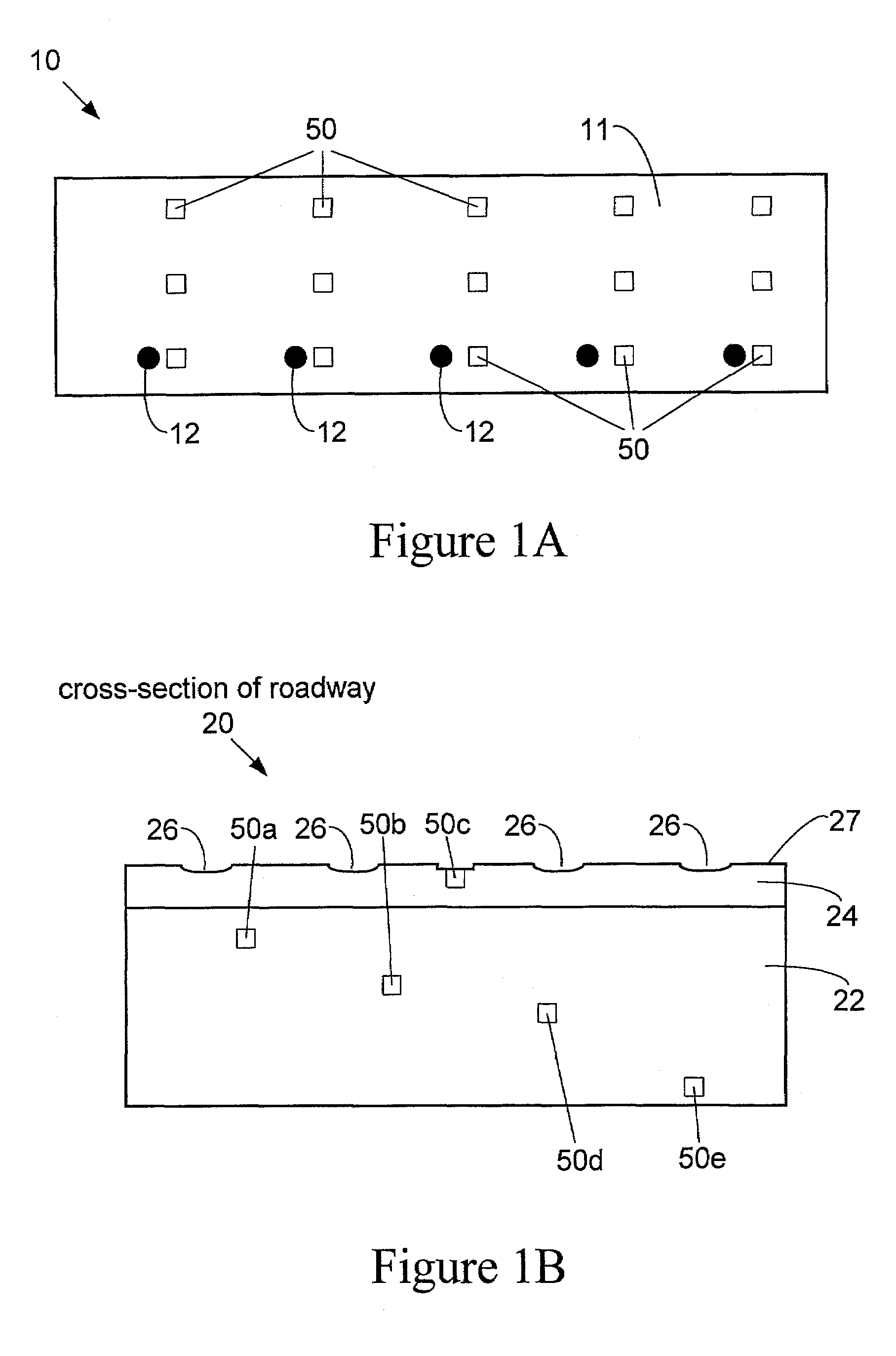

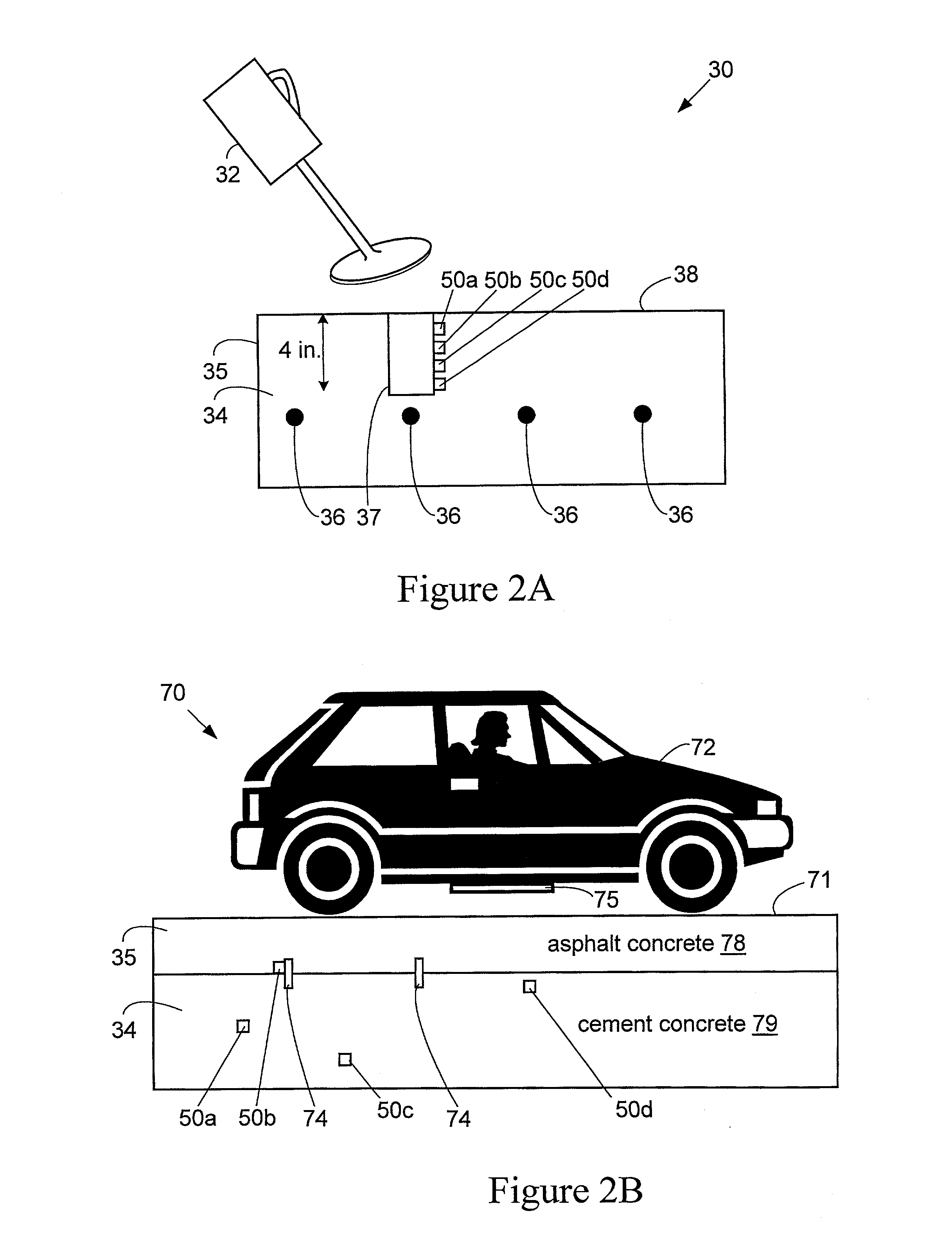

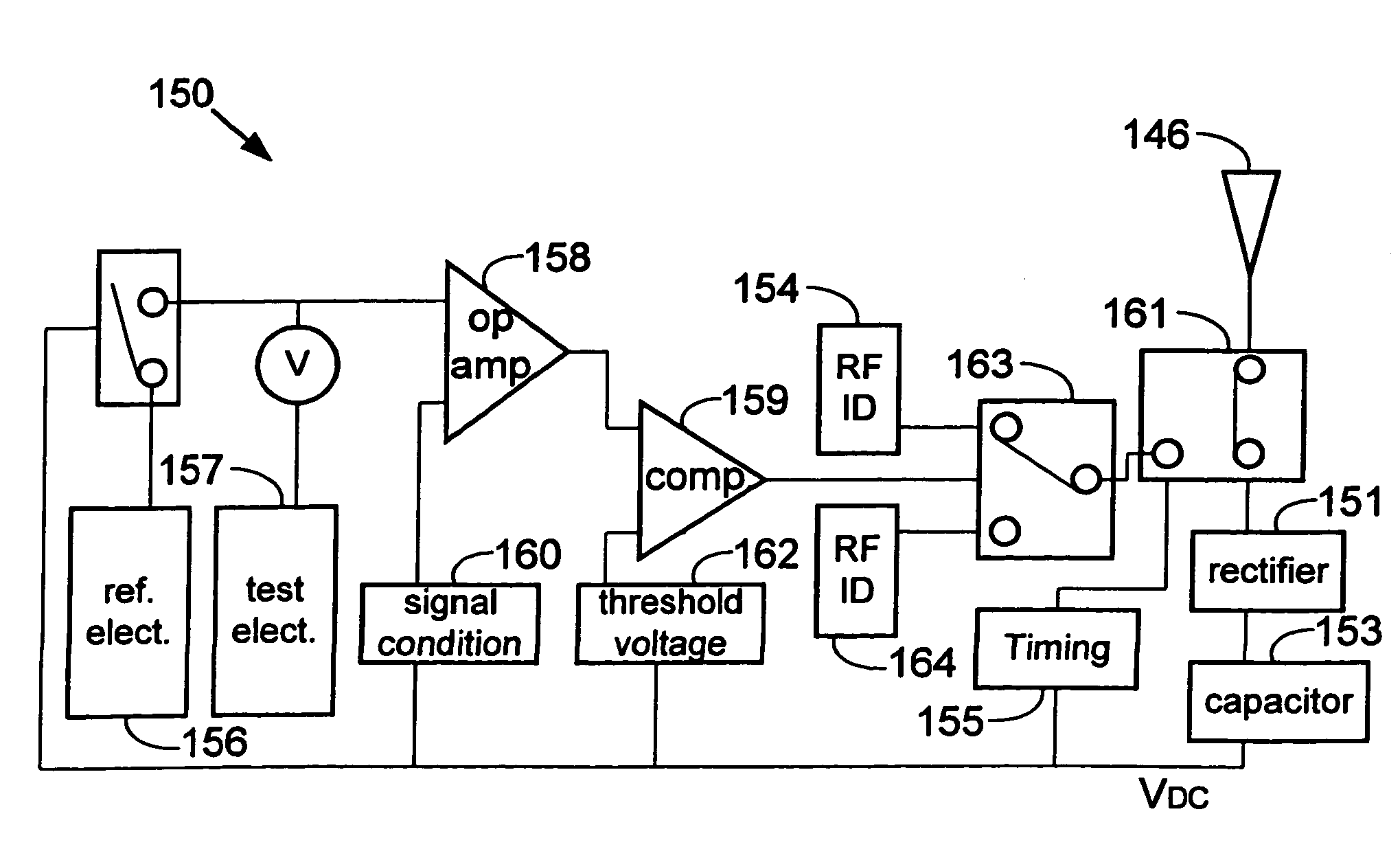

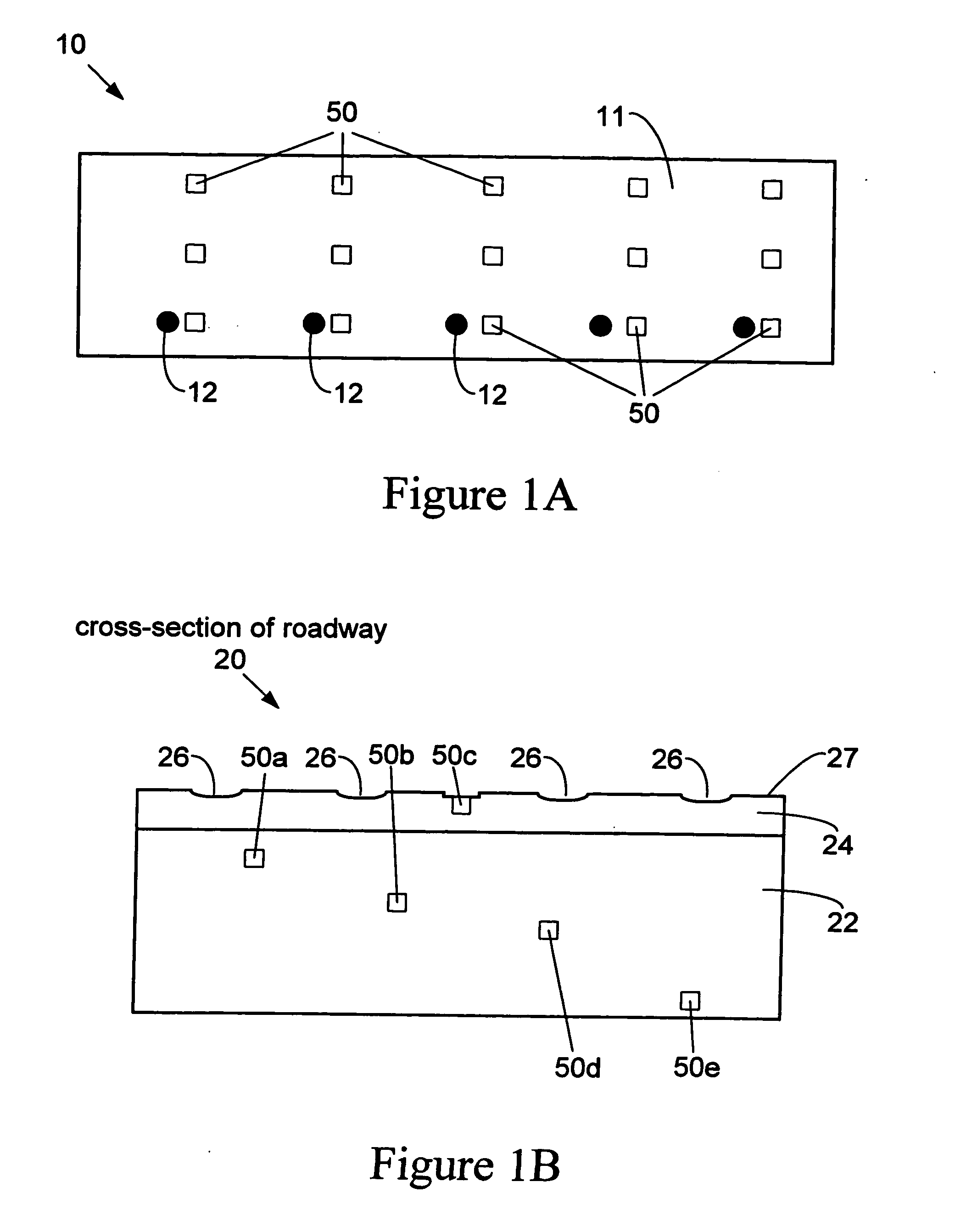

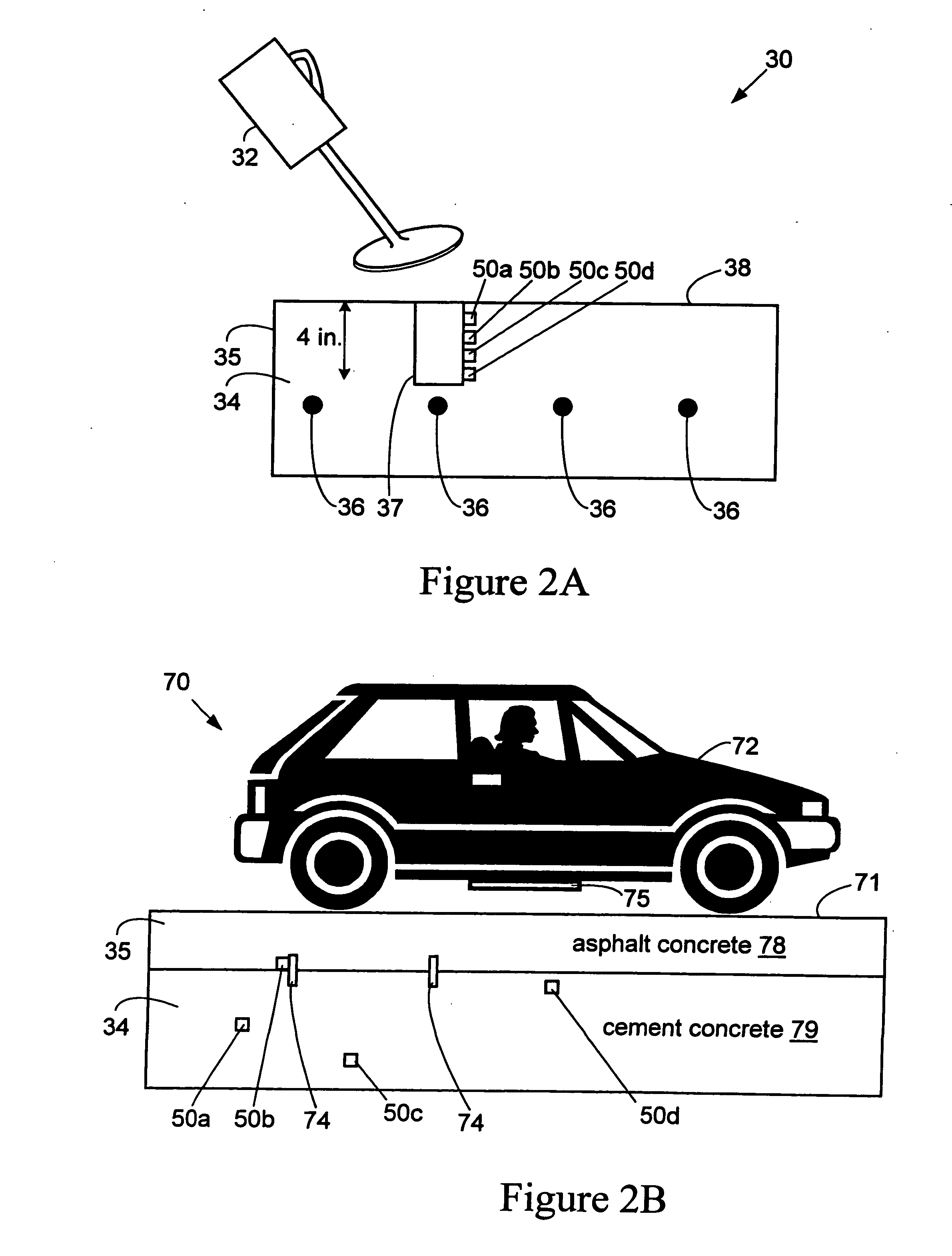

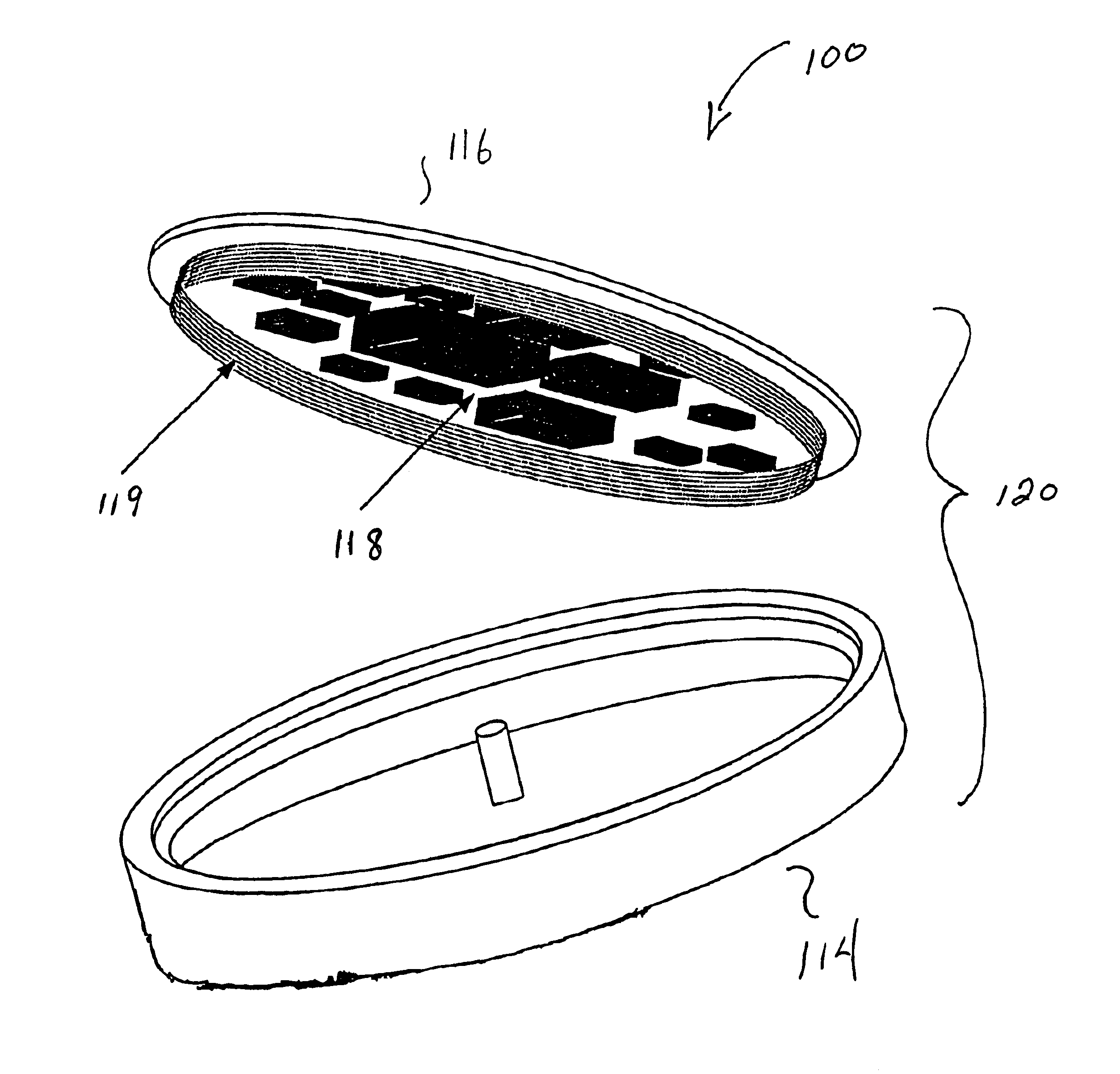

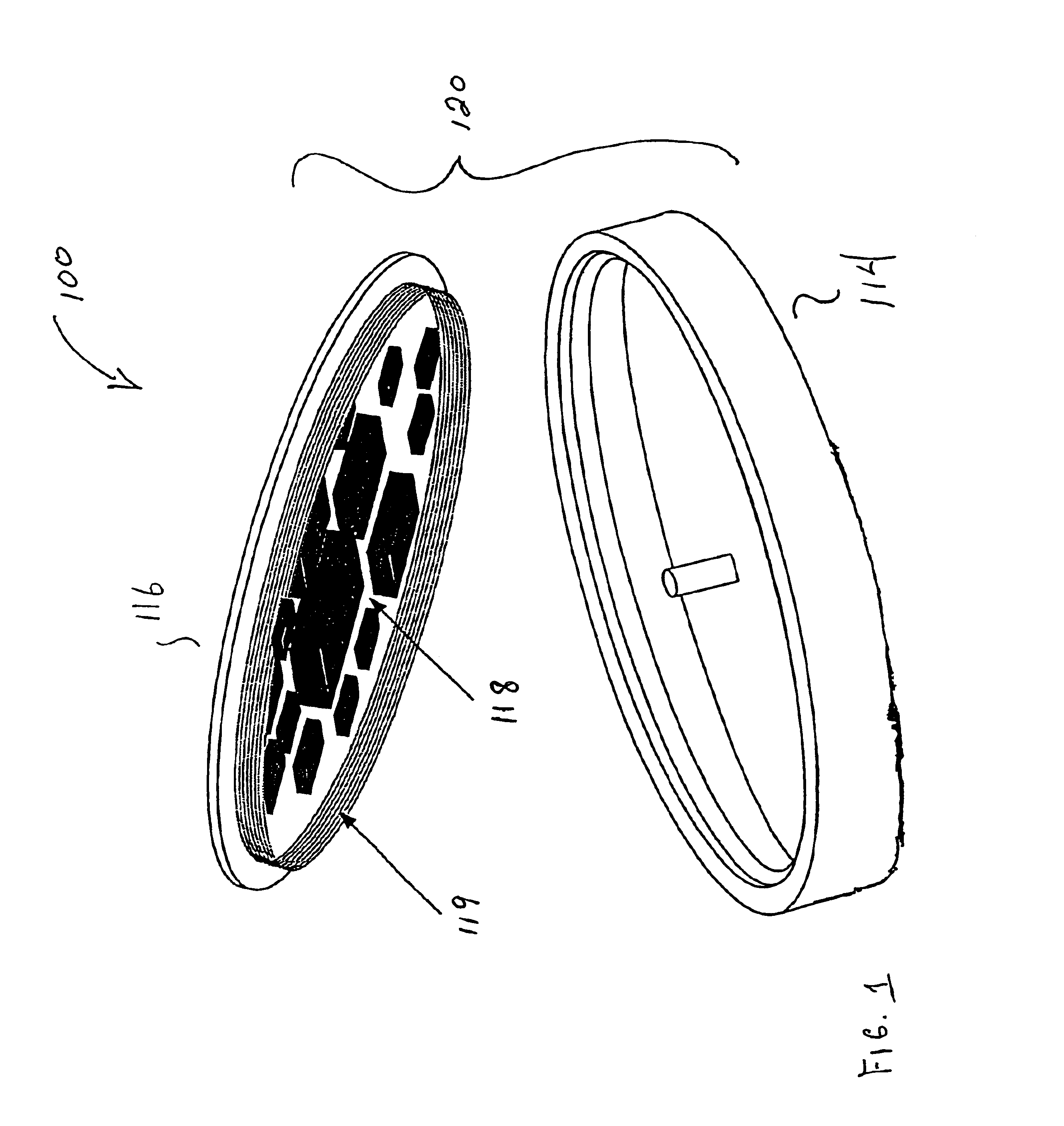

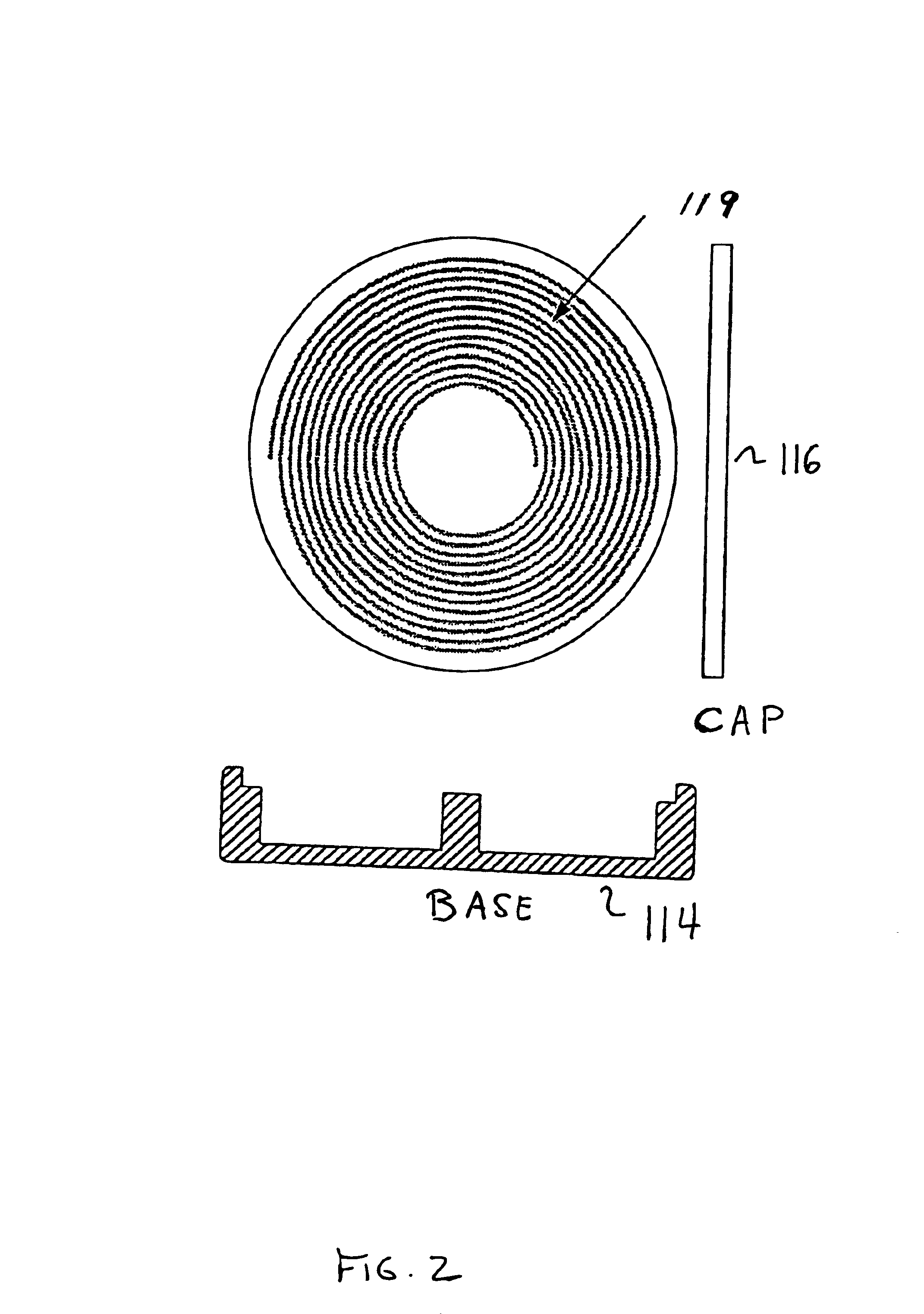

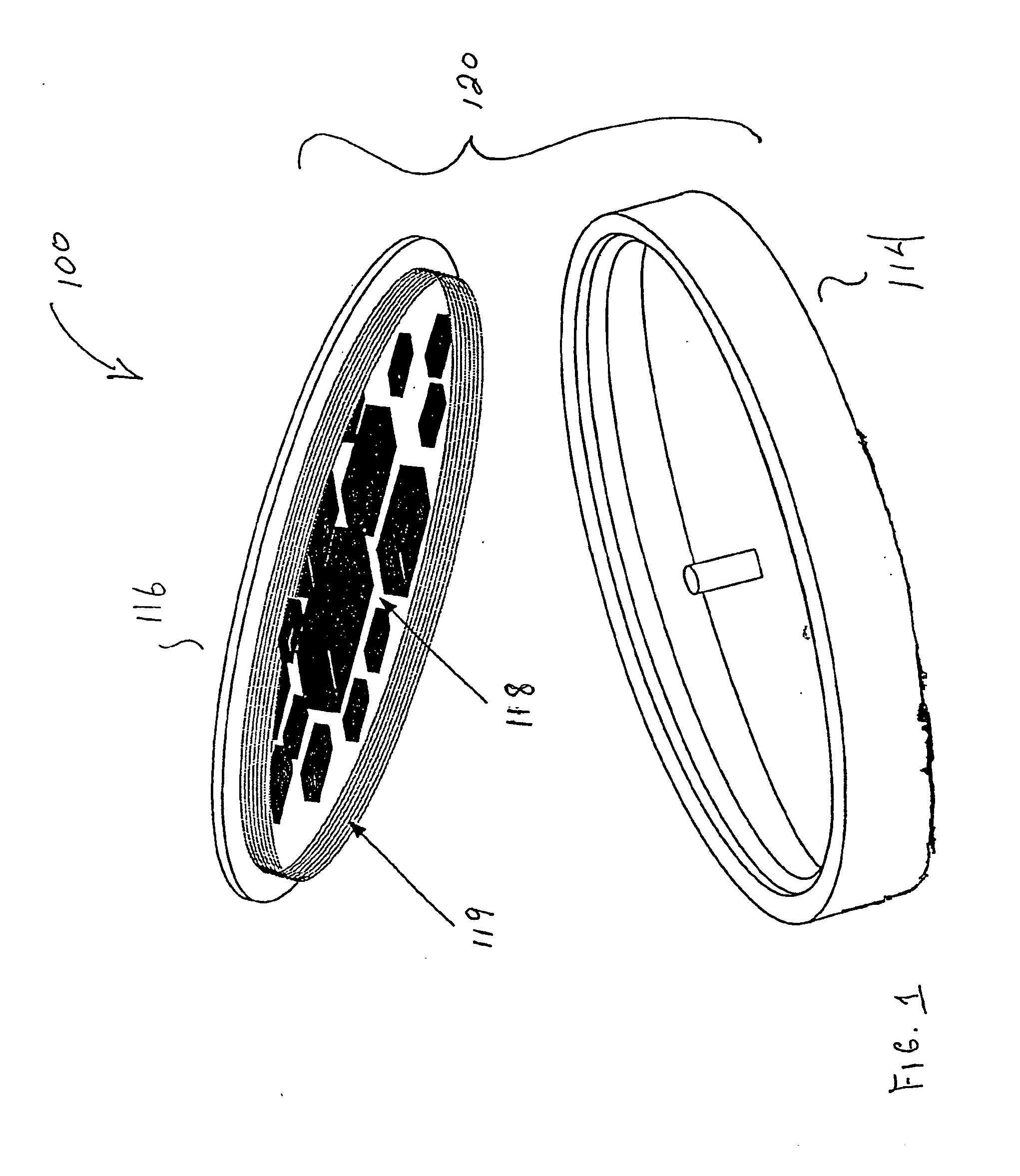

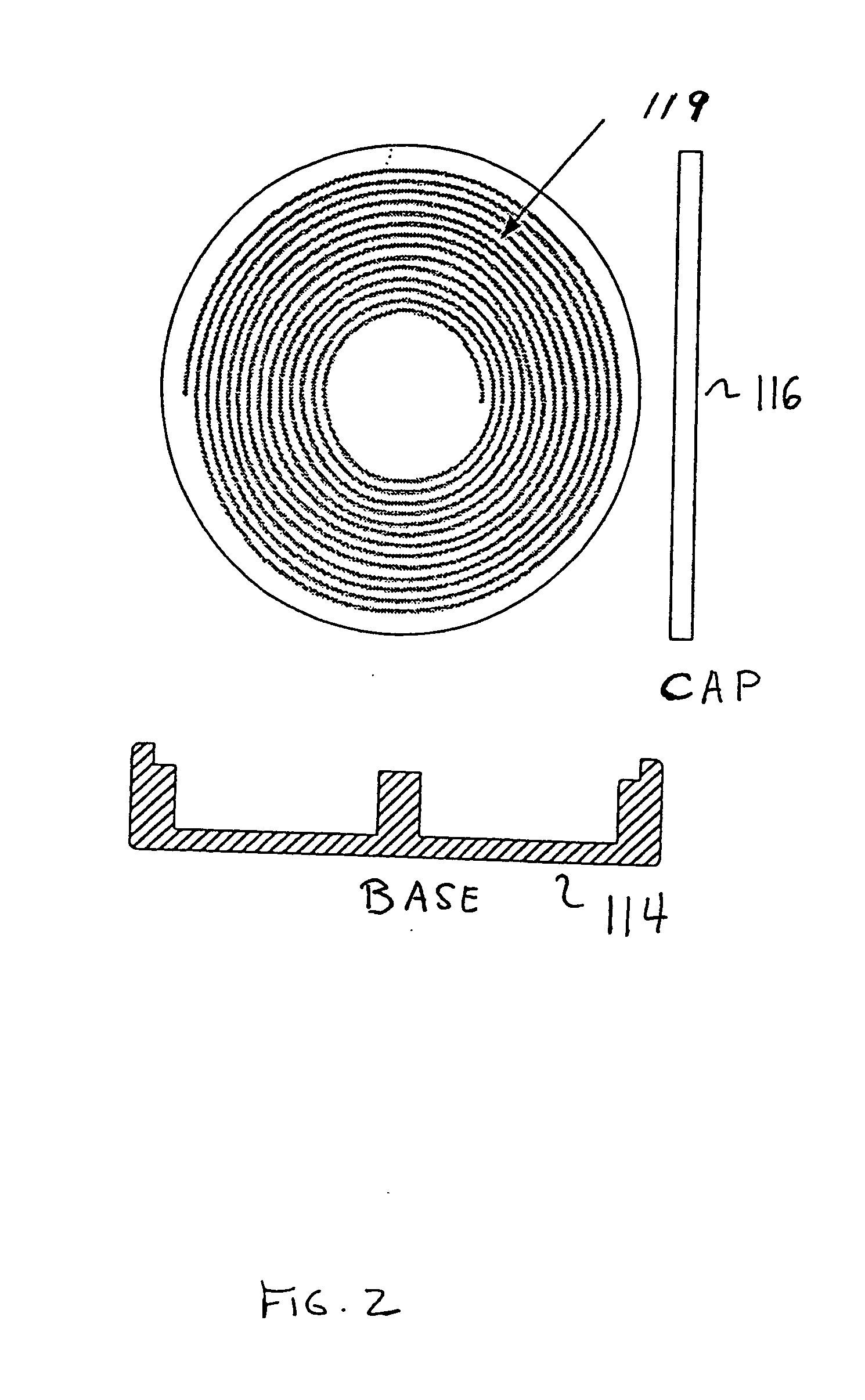

Described herein are wireless interrogation systems and methods that rely on a complementary sensing device and interrogator. The sensing device is disposed to measure a parameter indicative of the health of a structure. A sensor reading from the sensor indicates the level of a parameter being monitored or whether one or more particular physical or chemical events have taken place. Using wireless techniques, the interrogator probes the device to determine its identity and its current sensor reading. This often includes transmission of a wireless signal through portions of the structure. When activated, the device responds with a wireless signal that identifies the device and contains information about the parameter being measured or a particular sensor state corresponding to the parameter. The identity of the device allows it to be distinguished from a number of similar devices. Thus this invention finds particular usefulness in the context of an array of devices that can be probed by a wireless interrogation unit. In one embodiment, the devices are passive and derive power from the interrogation signal.

Owner:YASUMI CAPITAL

Sensor devices for structural health monitoring

InactiveUS20060170535A1Reduce needEasy to compareElectric signal transmission systemsThermometers using mean/integrated valuesStructural health monitoringCurrent sensor

Described herein are wireless interrogation systems and methods that rely on a complementary sensing device and interrogator. The sensing device is disposed to measure a parameter indicative of the health of a structure. A sensor reading from the sensor indicates the level of a parameter being monitored or whether one or more particular physical or chemical events have taken place. Using wireless techniques, the interrogator probes the device to determine its identity and its current sensor reading. This often includes transmission of a wireless signal through portions of the structure. When activated, the device responds with a wireless signal that identifies the device and contains information about the parameter being measured or a particular sensor state corresponding to the parameter. The identity of the device allows it to be distinguished from a number of similar devices. Thus this invention finds particular usefulness in the context of an array of devices that can be probed by a wireless interrogation unit. In one embodiment, the devices are passive and derive power from the interrogation signal.

Owner:YASUMI CAPITAL

Wireless multi-functional sensor platform, system containing same and method for its use

InactiveUS6796187B2Small sizeLow costElectric signal transmission systemsForce measurementLine sensorTransmitted power

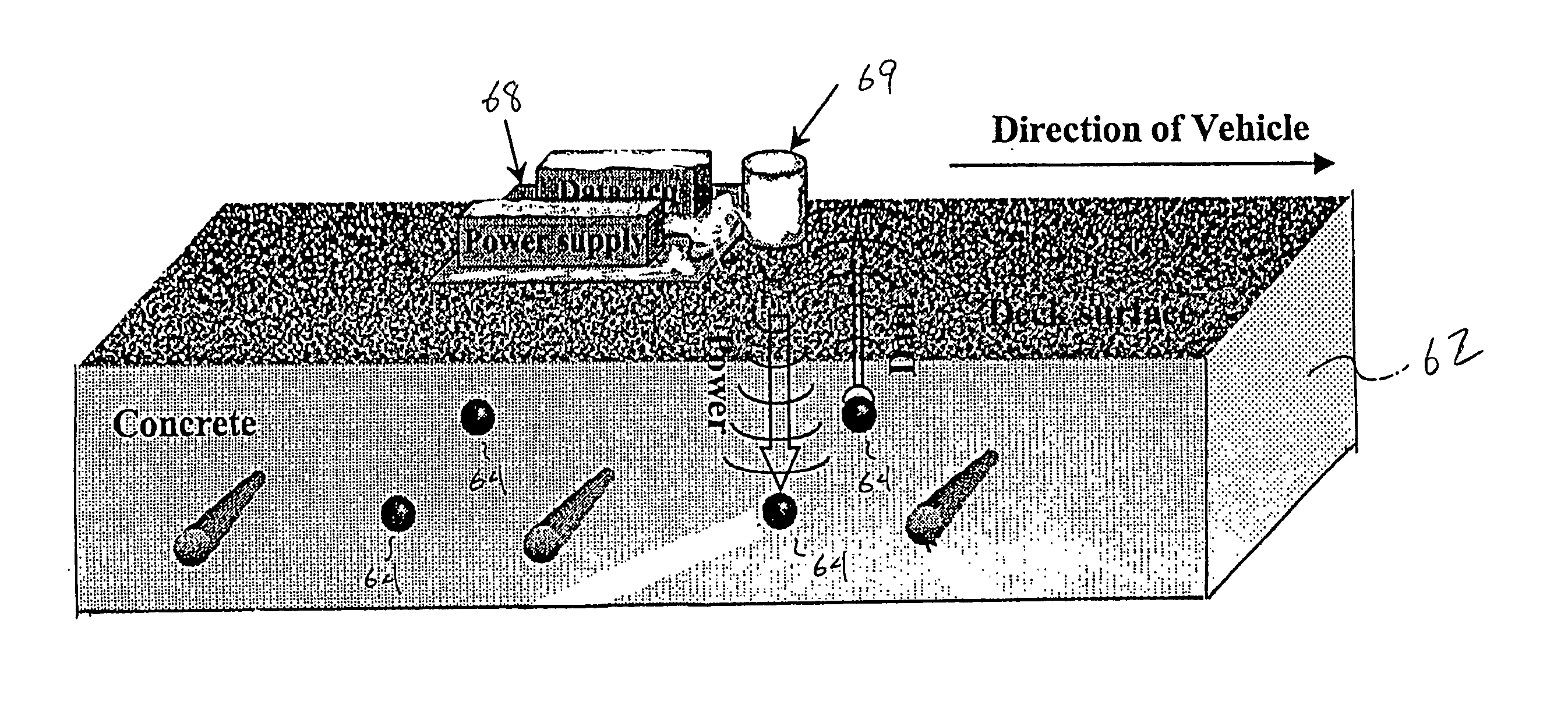

A multi-functional sensor system for simultaneously monitoring various parameters such as the structural, chemical and environmental conditions associated with a medium to be monitored, e.g., bridges, high-rise buildings, pollution zones, is provided wherein the system includes at least a plurality of wireless multi-functional sensor platforms embedded in the medium in which an interrogation unit transmits power and receives responses. Each wireless multi-functional sensor platform includes multiple channels for accommodating a plurality of sensor types to simultaneously monitor the parameters associated with the medium. Thus, the wireless sensor platforms are formed to include those sensor types which are considered germane to the intended medium to be monitored.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Wireless multi-funtional sensor platform, system containing same and method for its use

InactiveUS20040004554A1Electric signal transmission systemsForce measurementLine sensorTransmitted power

A multi-functional sensor system for simultaneously monitoring various parameters such as the structural, chemical and environmental conditions associated with a medium to be monitored, e.g., bridges, high-rise buildings, pollution zones, is provided wherein the system includes at least a plurality of wireless multi-functional sensor platforms embedded in the medium in which an interrogation unit transmits power and receives responses. Each wireless multi-functional sensor platform includes multiple channels for accommodating a plurality of sensor types to simultaneously monitor the parameters associated with the medium. Thus, the wireless sensor platforms are formed to include those sensor types which are considered germane to the intended medium to be monitored.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

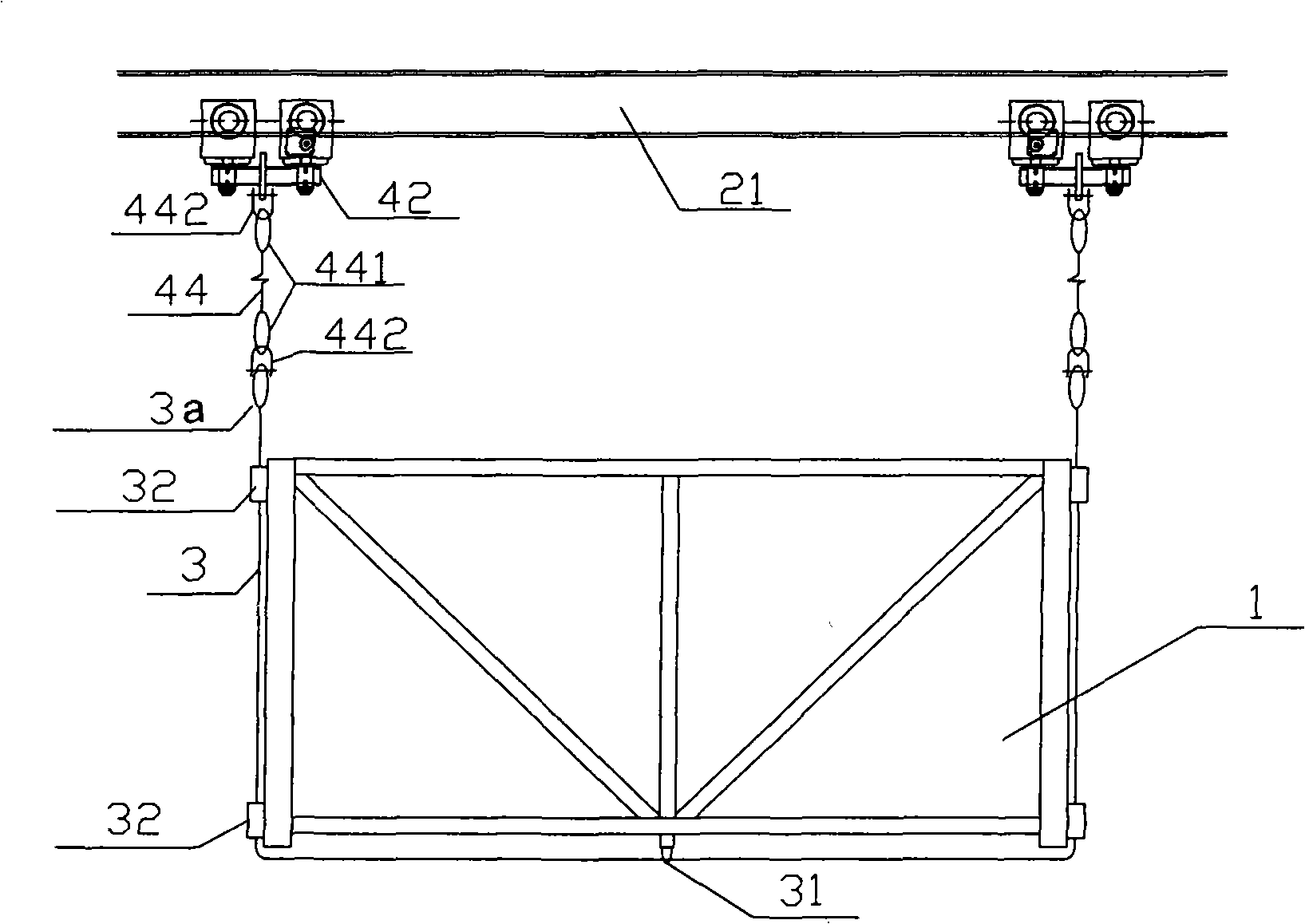

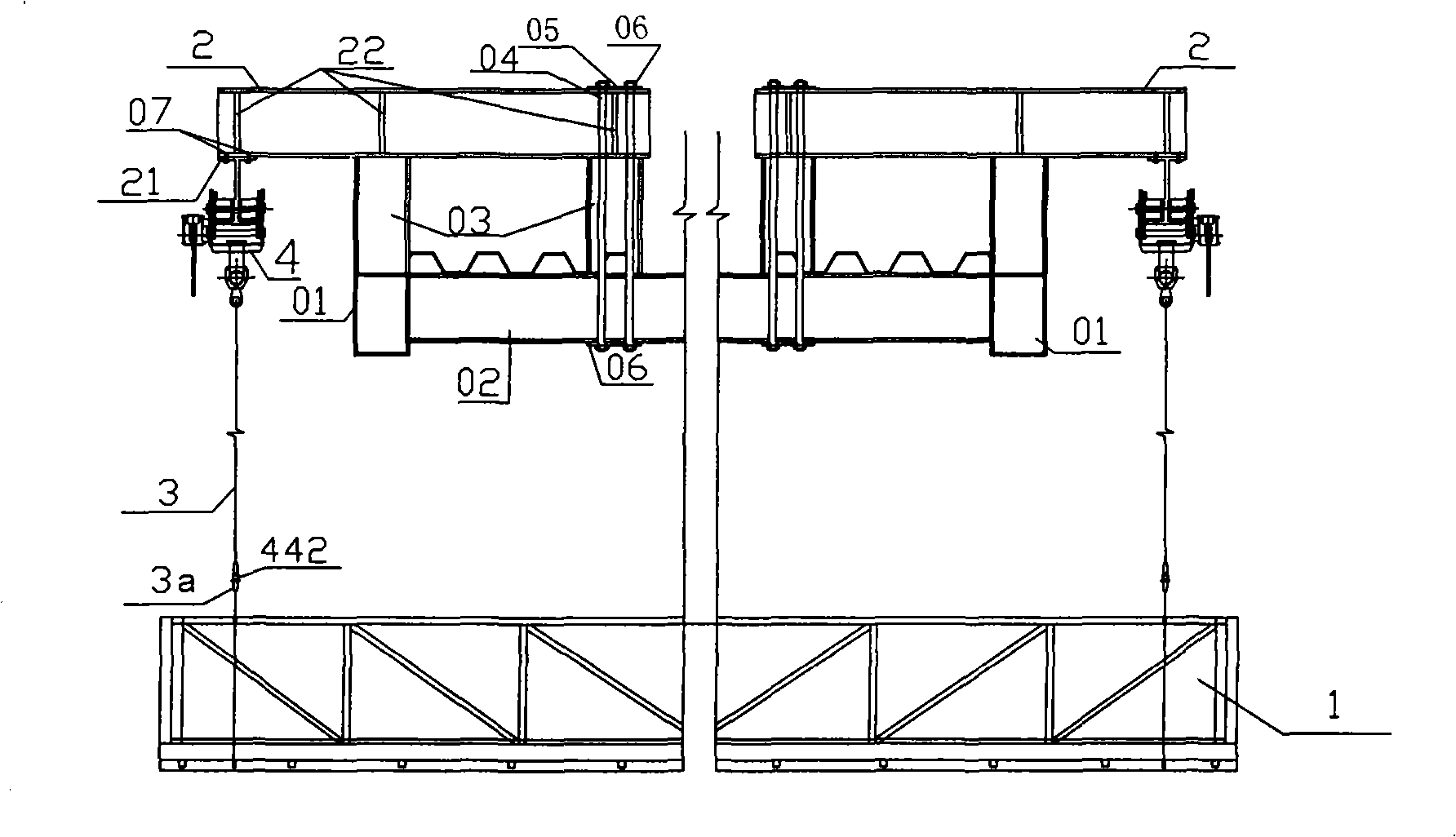

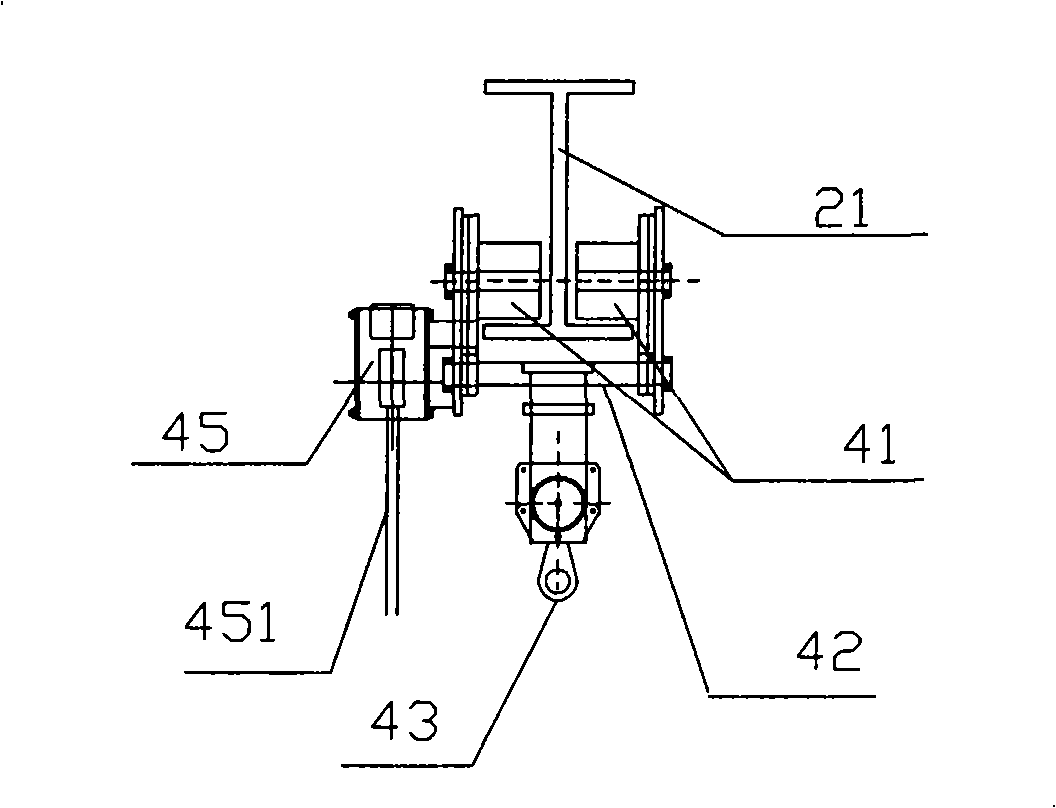

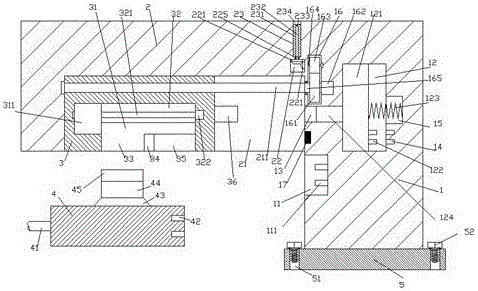

Hanger rail type electric hanging boat and high-rise long span house, bridge building construction method and use thereof

ActiveCN101514586AFirmly connectedImprove securityBridge erection/assemblyBuilding material handlingArchitectural engineeringLong span

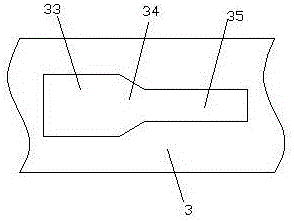

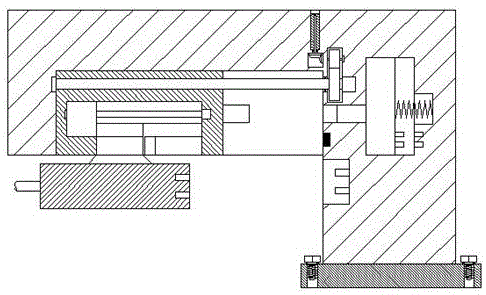

The invention provides a hanger rail type electric hanging boat, comprising an overhung hanger rail fixed on a building main component, a construction operation hanging boat, a hanging boat horizontal walking system and a hanging boat lifting system, wherein the overhung hanger rail is fixed on the building main component, the hanging boat is fixed on the hanger rail via a walking device, and a detachable fixedly connecting structure is formed between the hanging boat and a hanger rod via the hanger rod. The invention further provides a method for high-rise building outside wall construction by the hanger rail type electric hanging boat, including a mounting method and a demolishing method. The use of the hanger rail type electric hanging boat and the construction method is further provided. The invention provides the safe and practical hanging boat with reasonable structure, thereby solving the problem that the hanging boat cannot move horizontally in the prior art, and facilitating outside wall ceiling construction of various special buildings such as long span vestibule.

Owner:JANGHO GRP

Bridge equipment

ActiveCN106812072AAvoid damageImprove work efficiencyBridge erection/assemblyBridge strengtheningEngineeringScrew thread

Owner:江苏源清环保科技有限公司

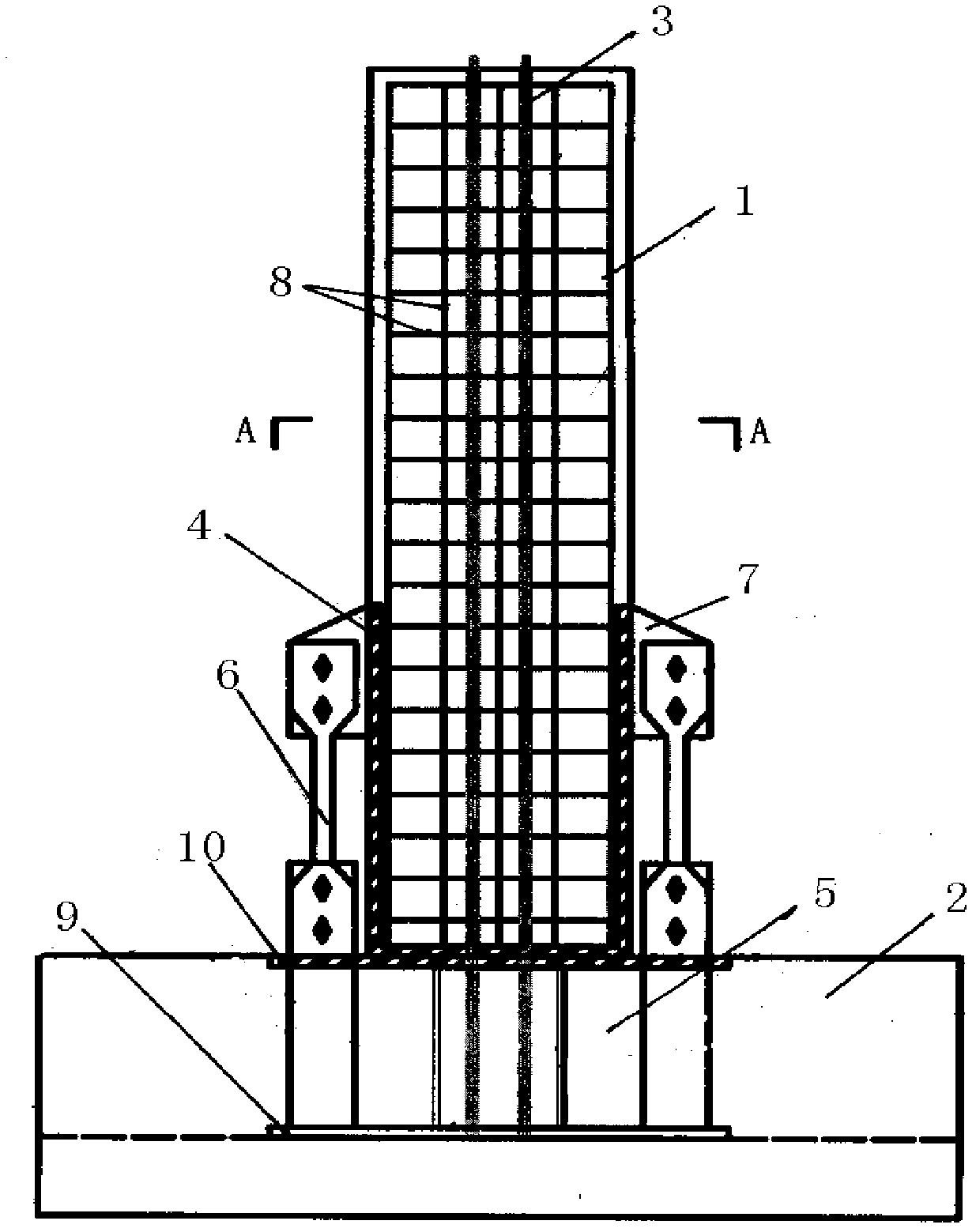

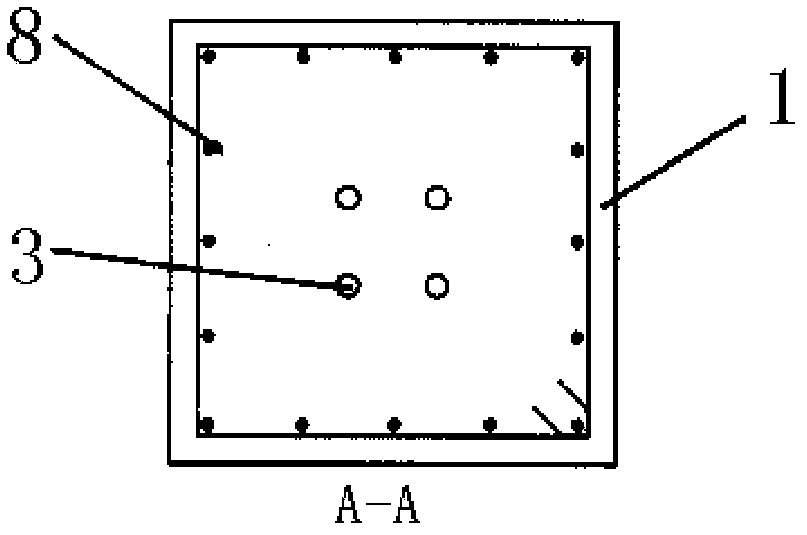

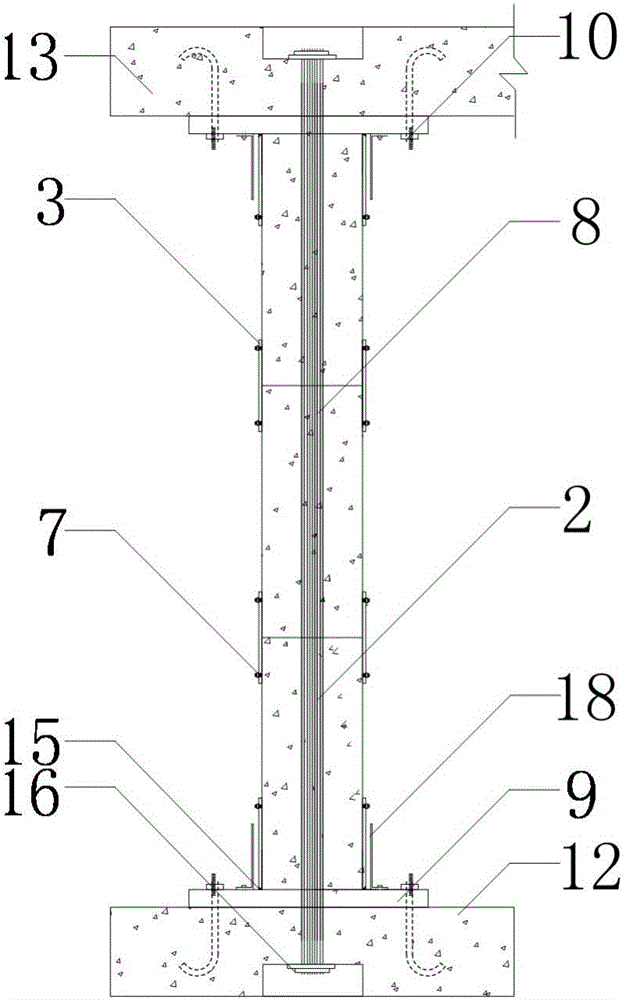

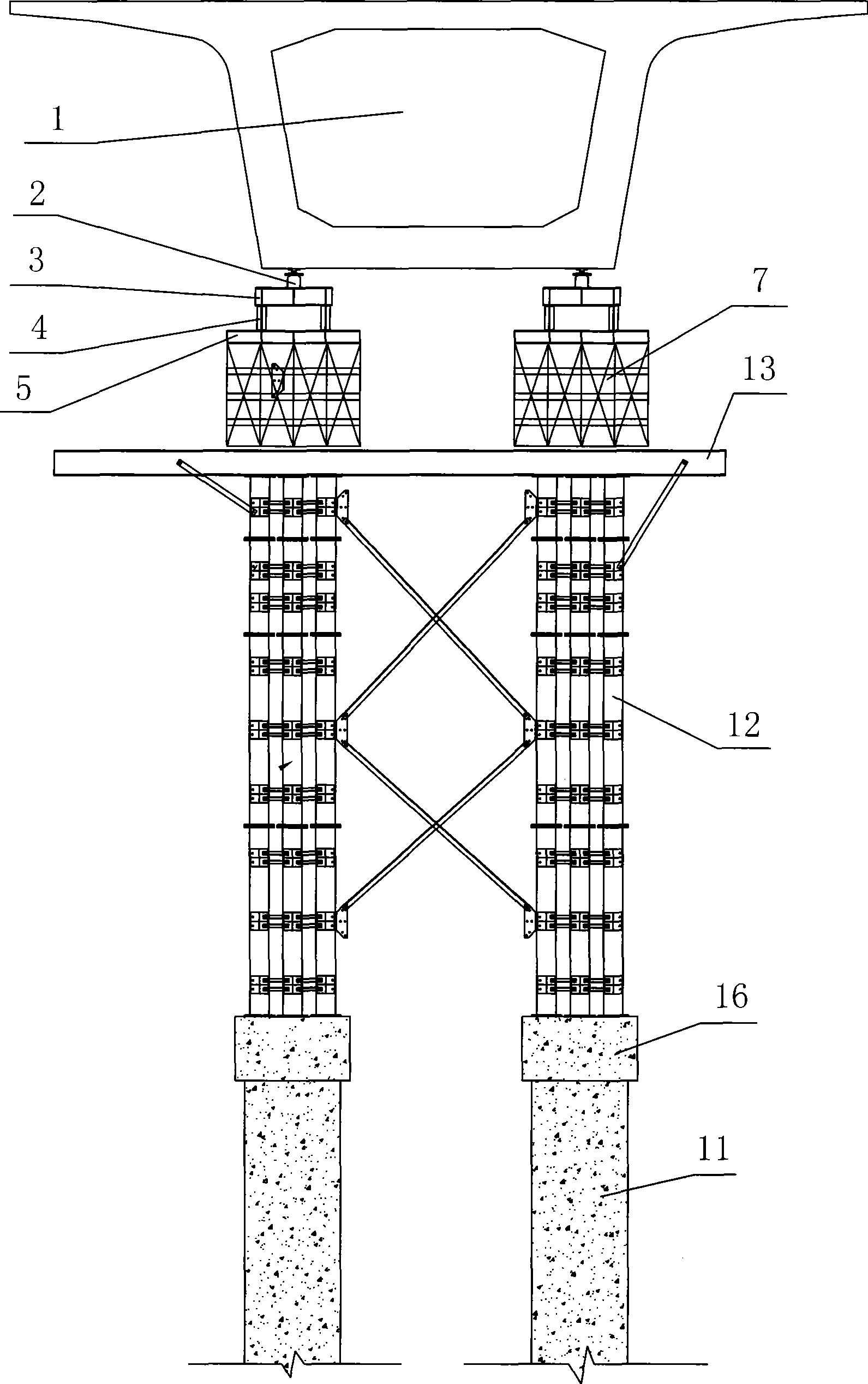

Self-resetting pier column structural system with built-in energy dissipation assembly and implementing method for self-resetting piper column structural system

InactiveCN102409606ASufficient ductility and energy dissipation capacityStrong enoughBridge structural detailsBridge erection/assemblyBridge engineeringResidual deformation

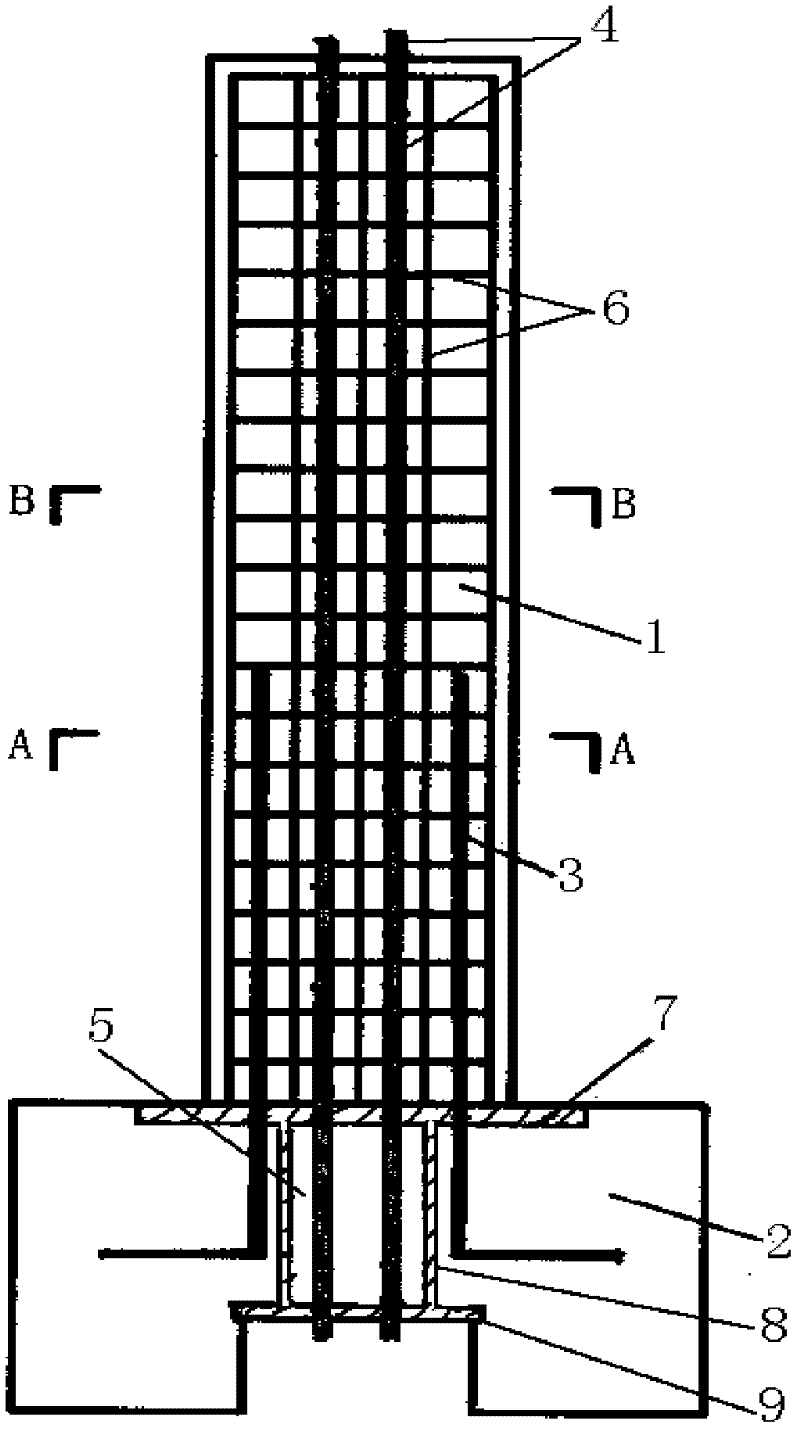

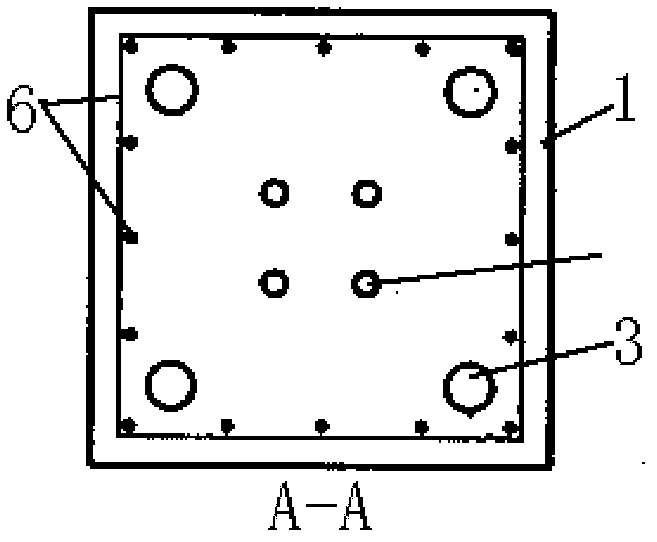

The invention discloses a self-resetting pier column structural system with a built-in energy dissipation assembly and an implementing method for the self-resetting pier column structural system, and belongs to the field of bridge engineering. The self-resetting pier column structural system consists of a pier column, a bridge abutment, energy dissipation steel bars, non-adhesion prestressed steel bars with an elastic resetting function and an embedded part; in the novel pier column structural system capable of effectively reducing residual deformation and ensuring sufficient energy dissipation, a pier is connected with the bridge abutment through the energy dissipation steel bars and the non-adhesion prestressed steel bars. Compared with the conventional pier column node, the self-resetting pier column structural system has the advantages that: the non-adhesion prestressed steel bars are positioned in the axle center of the pier column, a self-resetting restoring force can be generated, and the problem that the conventional pier has large residual deformation under the action of an earthquake load and cannot serve people any longer can be solved well; the self-resetting pier column structural system is flexible in design and definite in structural stress; the pier is ensured to have sufficient strength and rigidity; and the self-resetting pier column structural system can be implemented by a prefabricating or on-site pouring method, is easy and convenient to construct, and is an advanced and practical novel pier column system.

Owner:TSINGHUA UNIV

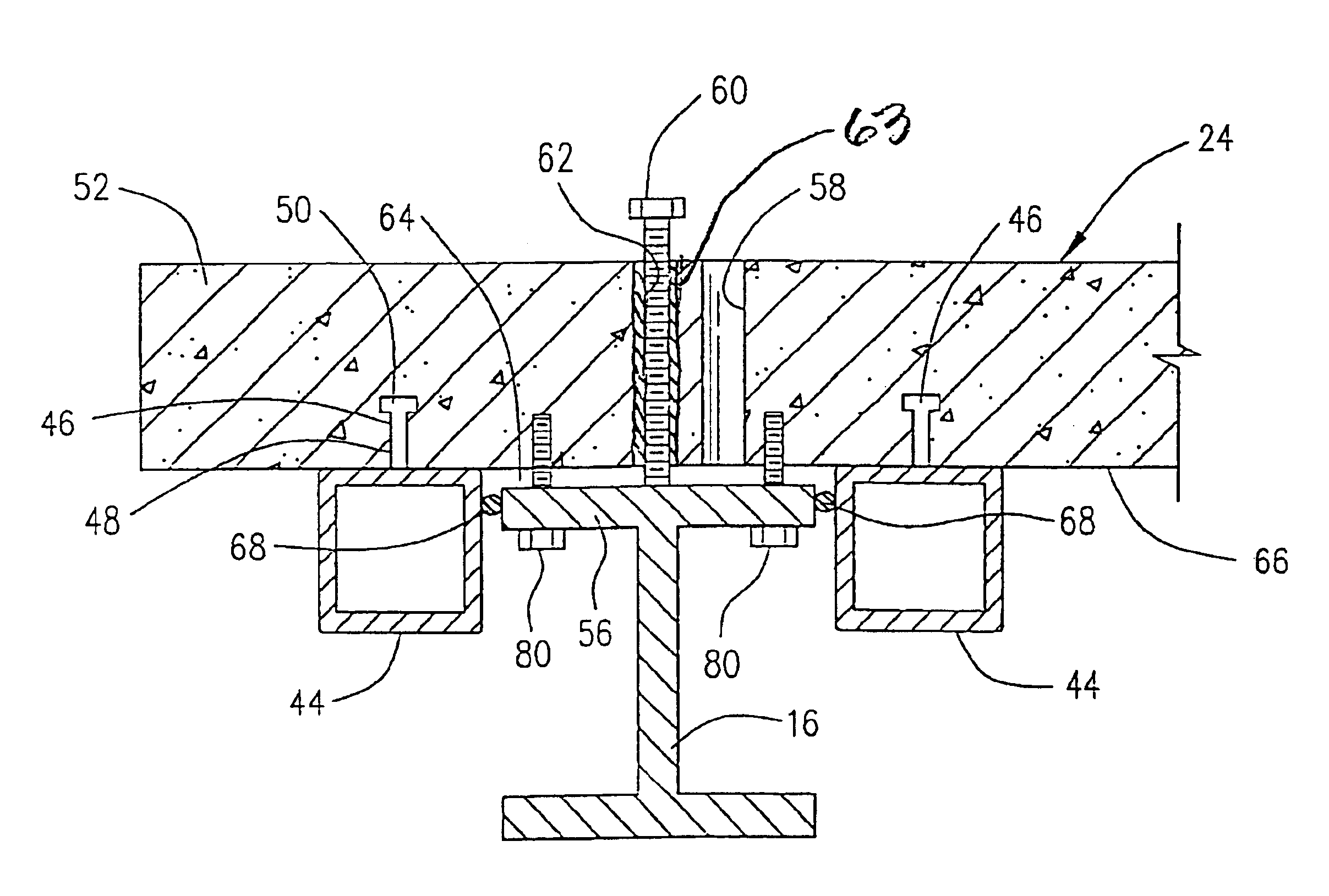

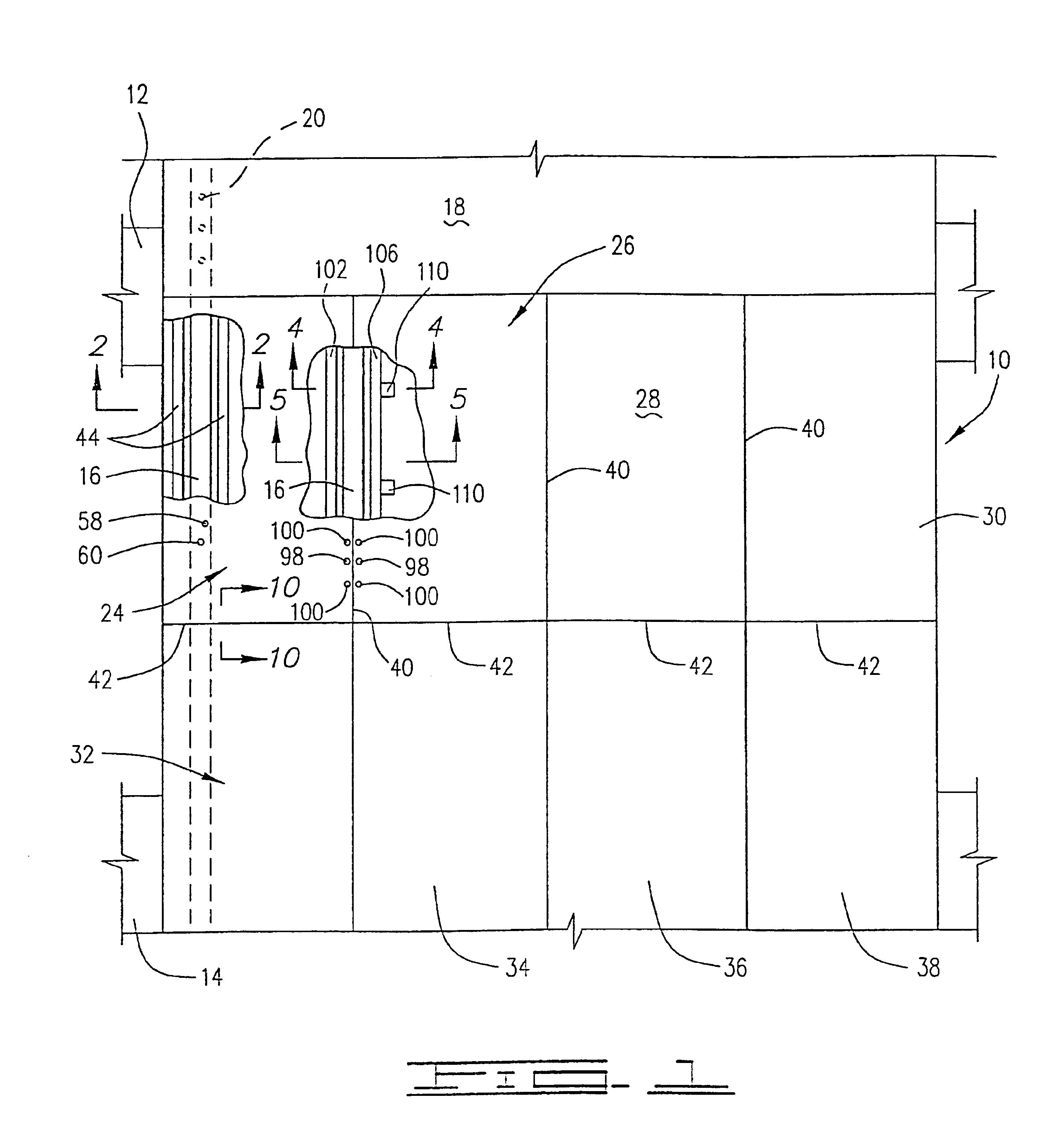

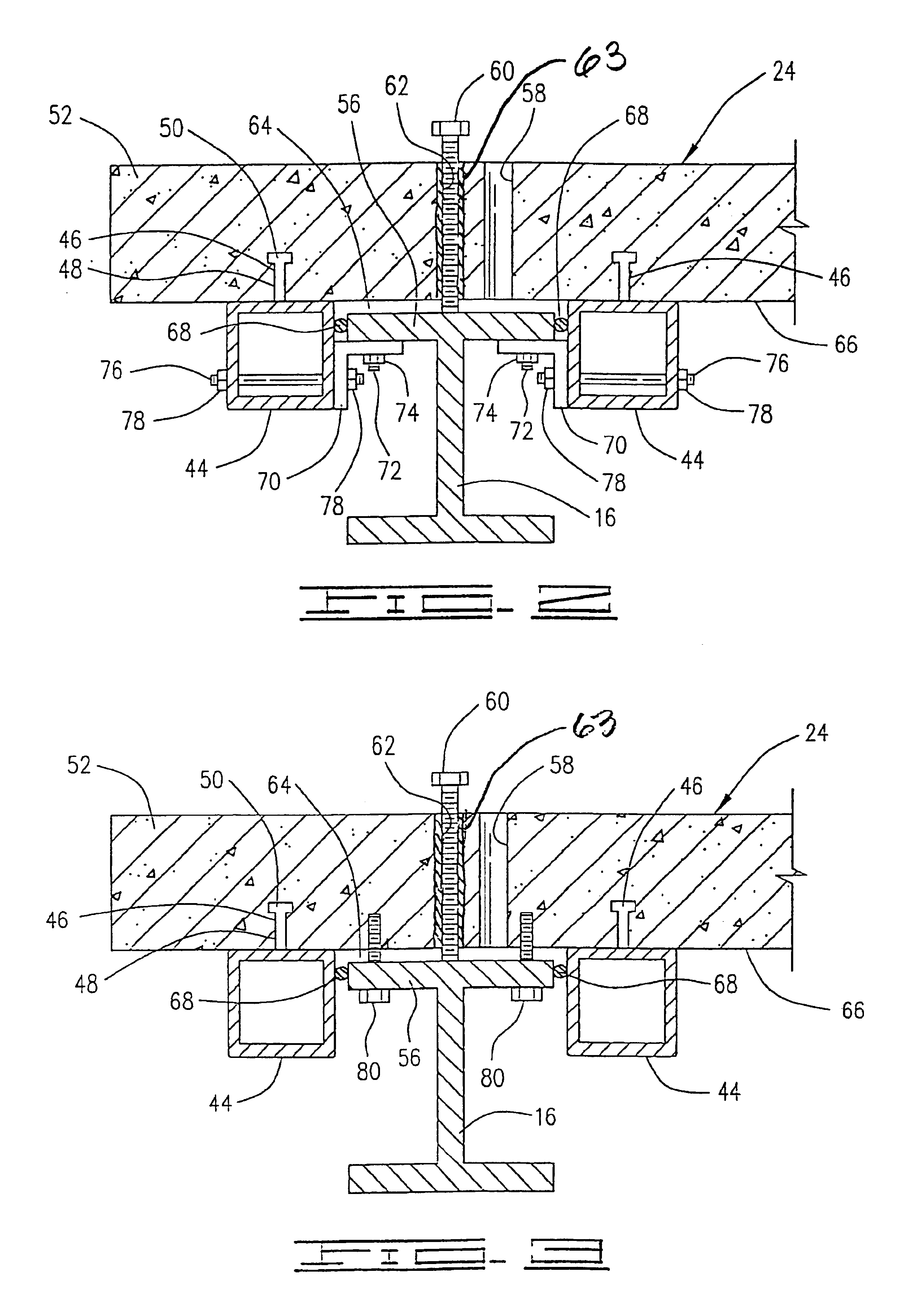

Modular bridge structure construction and repair system

InactiveUS6857156B1Fast and efficient constructionFast and efficient and repair processBridge structural detailsBridge erection/assemblyModular structureEngineering

A modular structure construction and repair system for use in new bridge construction and old bridge repair. The invention comprises a plurality of prefabricated modules which have a plurality of longitudinally extending beams and deck portions molded thereto. The modules are positioned over a plurality of girders so that longitudinal joints are formed above the girder. In the repair of an old bridge, an old section of the bridge deck is removed, and the modules are positioned on the existing girders. The modules are attached to the girders such that a shear connection is provided therebetween. Precompression may also be applied to clamp the sides of adjacent deck portions together. Various embodiments disclose this precompression and the shear connections.

Owner:GROSSMAN STANLEY J

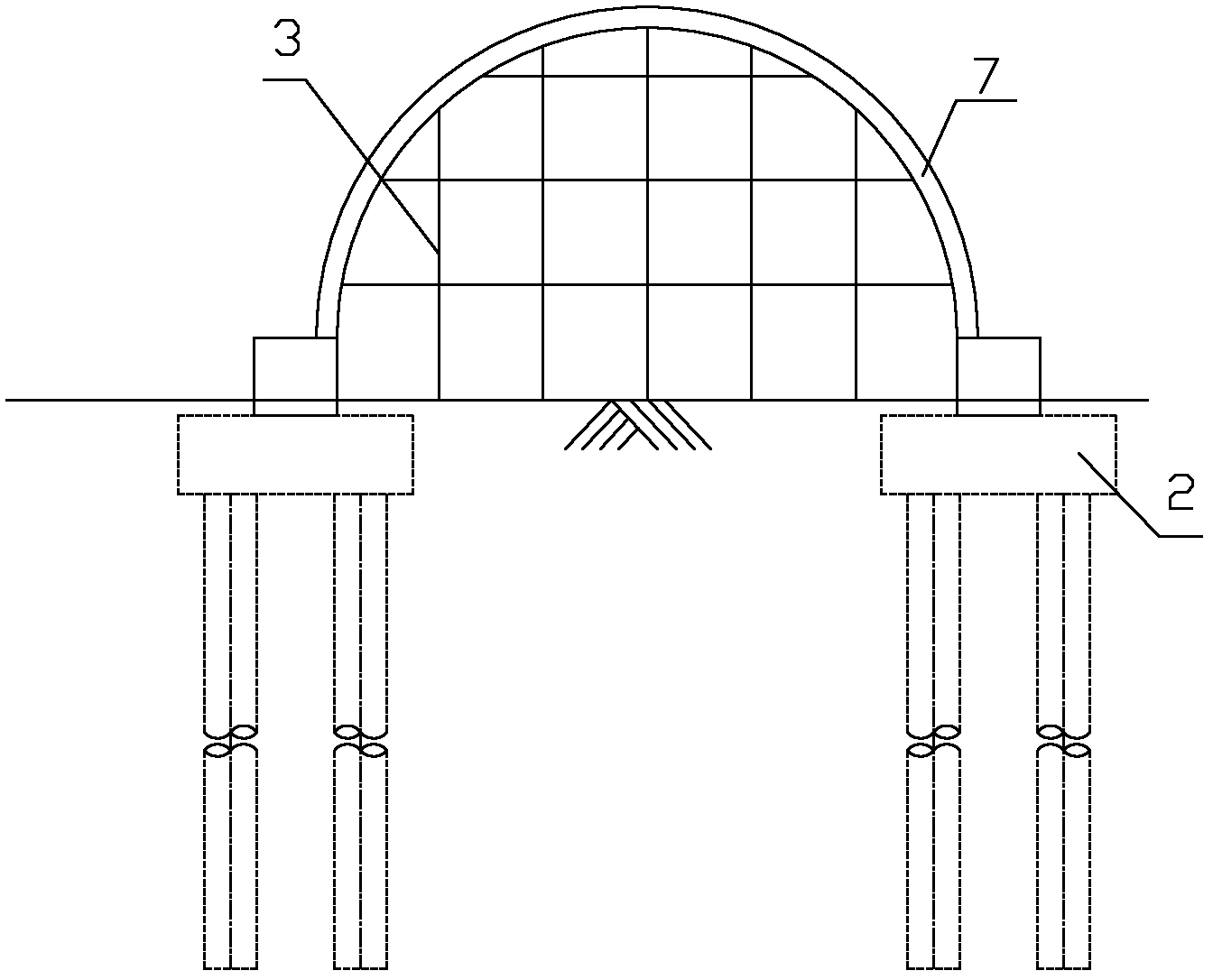

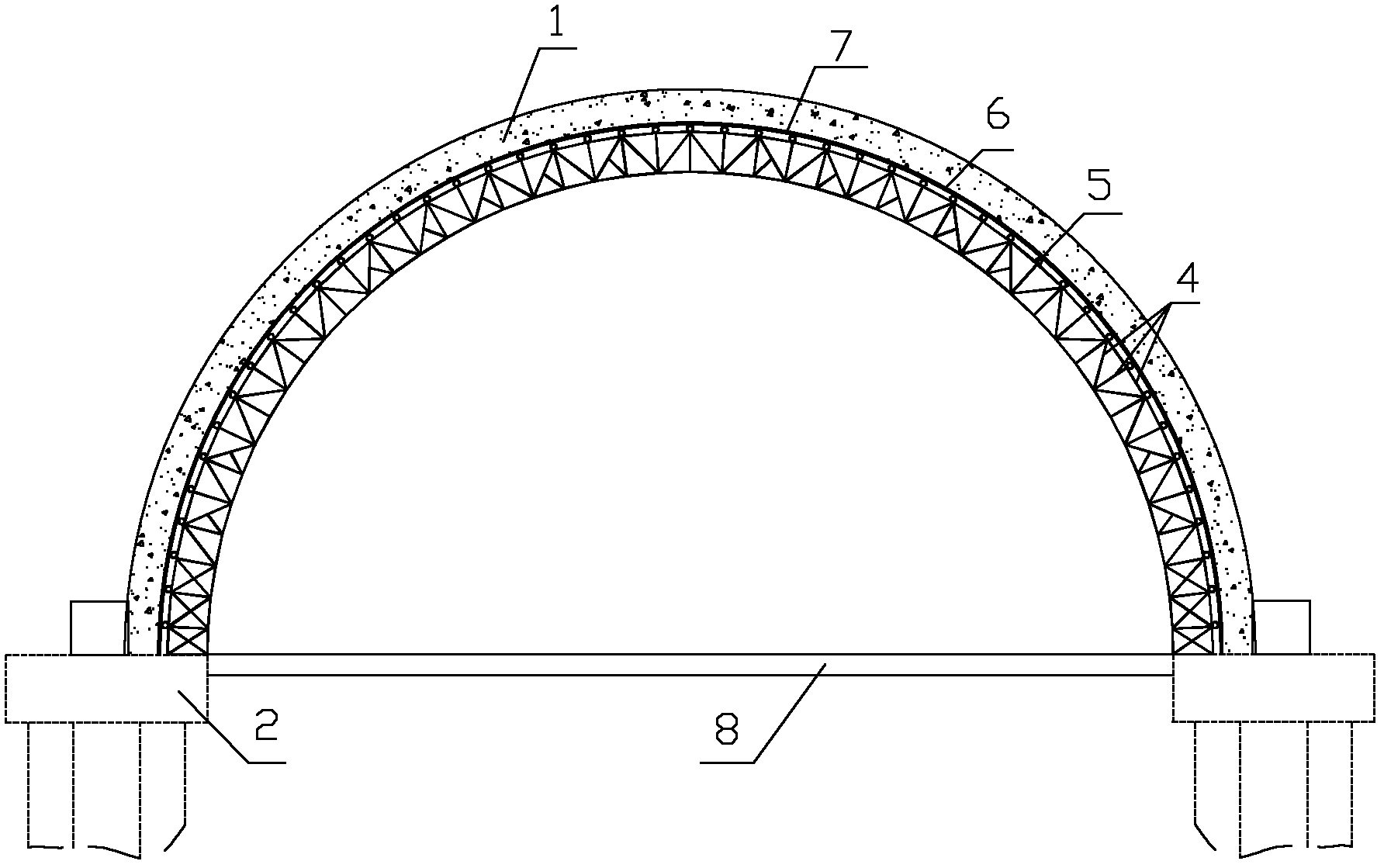

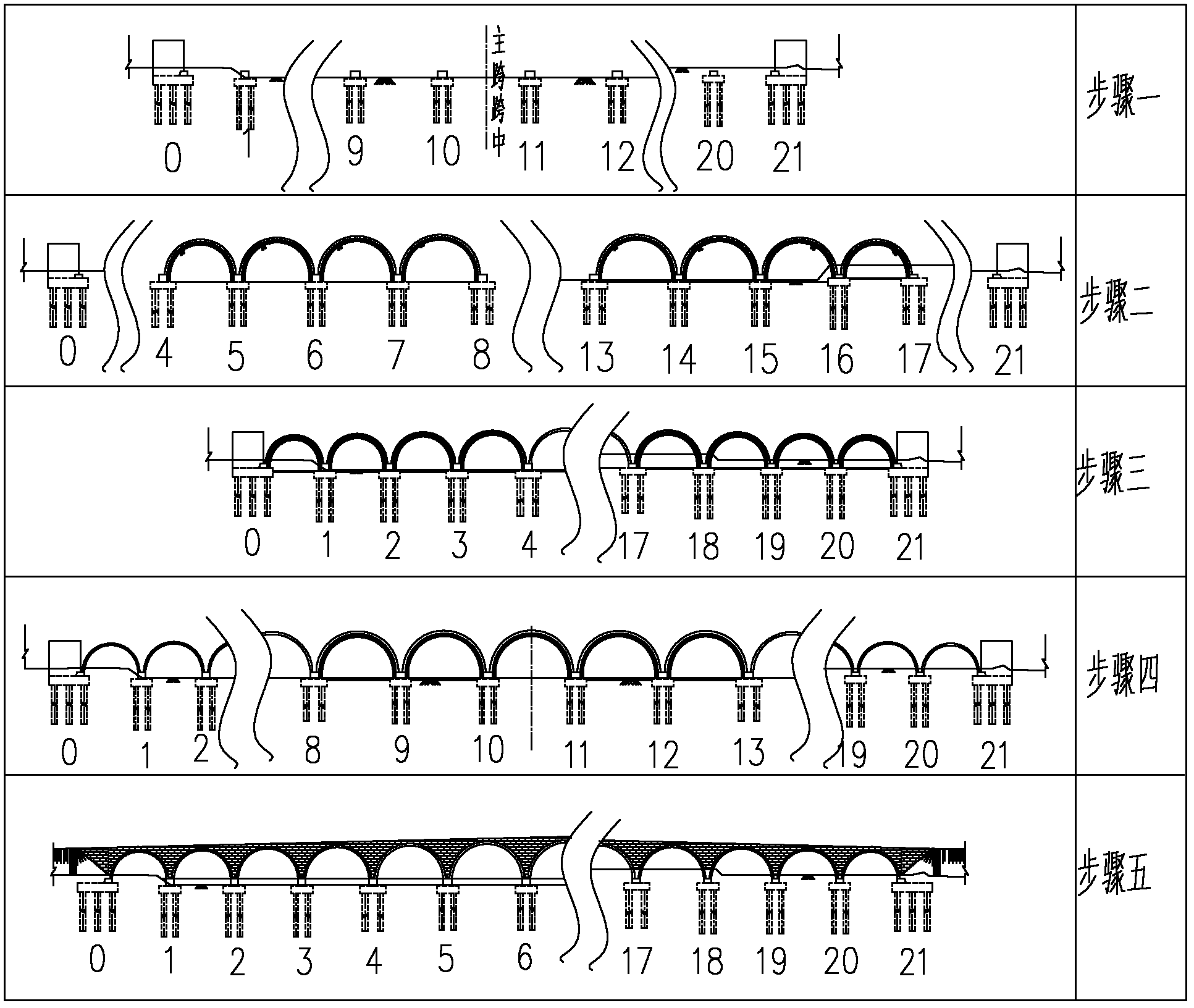

Reinforced concrete arch bridge construction method

ActiveCN102493360AAvoid deformationStable structureBridge erection/assemblyArch-type bridgeReinforced concreteAbutment

The invention discloses a reinforced concrete arch bridge construction method, which comprises the following steps of: 1, constructing a pile foundation, a pile cap, a bridge abutment body side wall and a bridge pier body; 2, erecting arch ring supports from the fourth hole to the eighth hole and from the thirteenth hole to the seventeenth hole on two sides of an arch bridge, arranging a locking system, and finally pouring concrete to arch rings of the eight holes; 3, detaching the arch ring supports in the step 2, erecting arch ring supports from the zero hole to the fourth hole and from theseventeenth hole to the twenty-first hole on the bridge abutment side, arranging a locking system and finally pouring concrete to arch rings of the eight holes; and 4, detaching the arch ring supports erected in the step 3, erecting arch ring supports from the eighth hole to the thirteenth hole in the span, arranging a locking system, pouring concrete to arch rings of the five holes, and folding the whole bridge. Main bodies of the arch ring supports have arch truss structures, a characteristic that steel bars are tensioned is utilized, the structures are firm, the middles of the structures are not required to be supported, materials are saved, the arch ring supports are convenient to detach, and constriction time is saved.

Owner:浙江大东吴集团建设有限公司

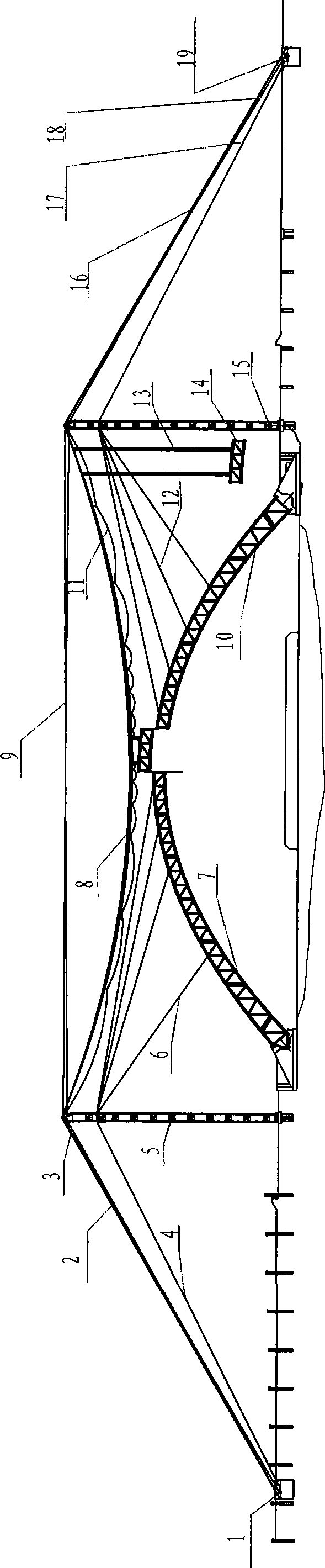

Non-stand construction method for large bridge arch rib

InactiveCN101476293AReduce constructionSave spaceCable-stayed bridgeBridge erection/assemblyPipe supportSteel tube

The invention relates to a large-scale bridge (steel pipe concrete arch bridge) arch rib non-support construction method, which is characterized in that: the fastening tower process and hanging tower process are combined; the fastening anchor process and hanging anchor process are combined; rubber support is applied in the tower articulation (steel structure); steel twisted wire is used as the fastening-hanging tower -anti-wind rope (tower pressing cable); centralized working surfaces and steel twisted wires are adopted in the fastening-hanging process; steel pipe support are used in tower; and less fastening cables are used in the fastening-hanging process. The construction method reduces arch rib assembling places and mounting supports, accelerates the construction progress; the stayed-fastening cable construction uses the masts type tower hung by the cable to mount arch rib, reduces construction of a group of tower and anchor; by adopting less cable construction method, the invention reduces the anchor box segment positions on the tower and reduces anchor cable quantity; and by adopting one-time forming, monitoring and measuring method, the invention simplifies the arch rib mounting construction process and the cable adjusting construction engineering, increases production efficiency, accelerates construction progress and ensures arch rib mounting quality.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

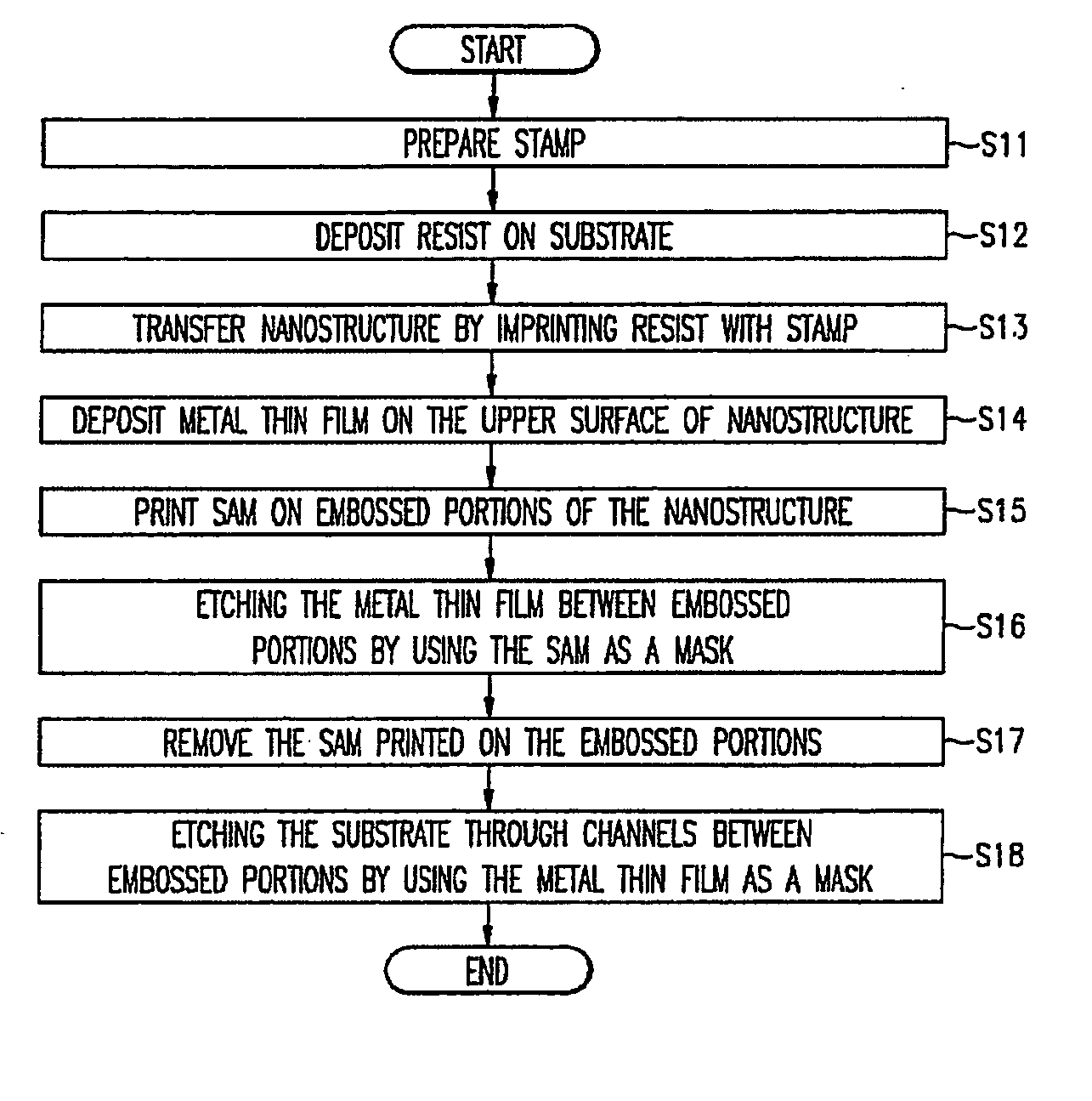

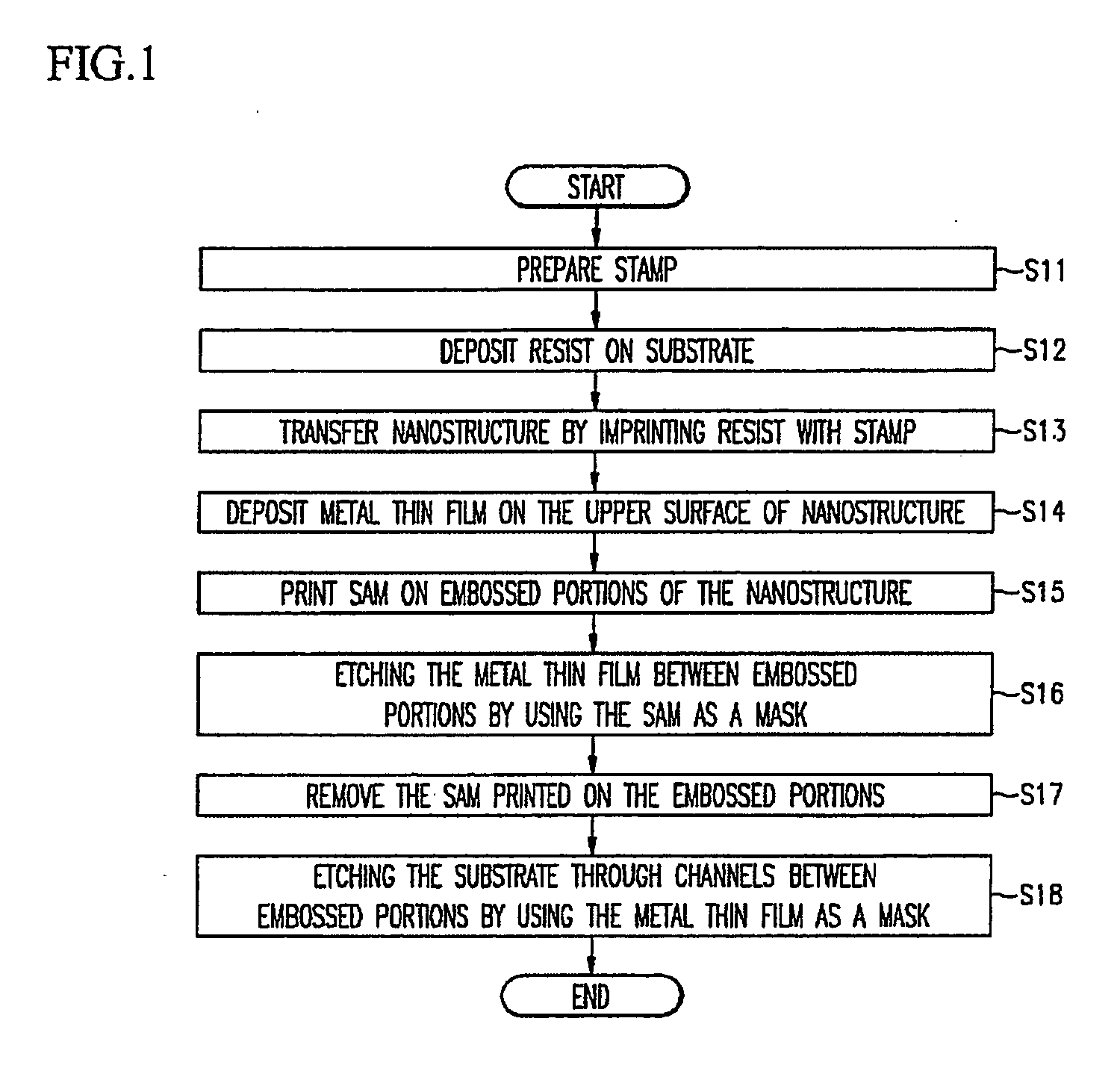

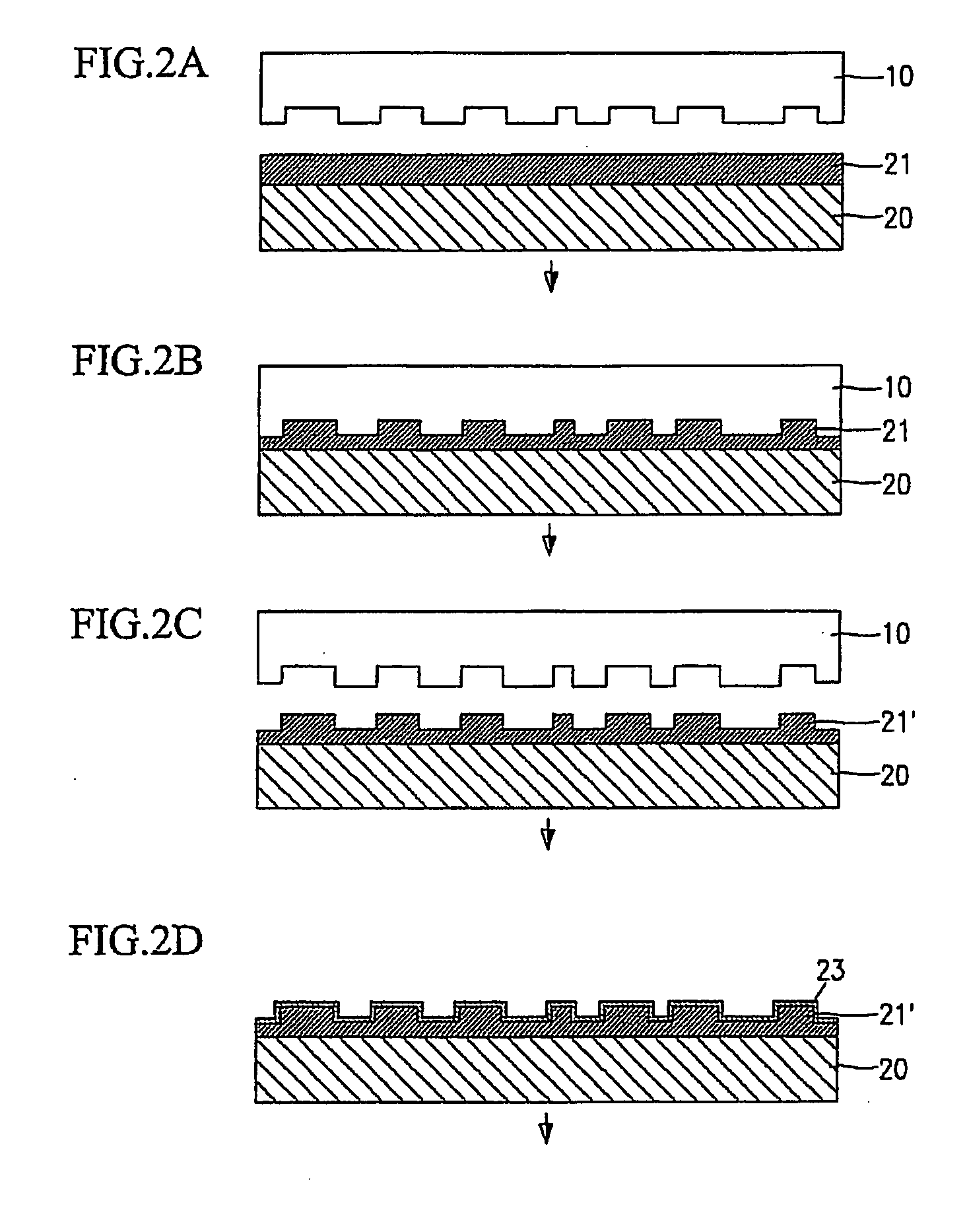

Microcontact printing method using imprinted nanostructure and nanostructure thereof

InactiveUS20050186405A1Material nanotechnologyDecorative surface effectsMicrocontact printingSelf-assembled monolayer

A microcontact printing method using an imprinted nanostructure is provided, wherein the microcontact printing is introduced to a nanoimprint lithography process to pattern a self-assembled monolayer (SAM) The method includes forming a nanostructure on a substrate by using the nanoimprint lithography process; and patterning the nanostructure with the microcontact printing method. The operation of patterning includes: depositing a metal thin film on the nanostructure; contacting a plate with the nanostructure to selectively print the SAM on the nanostructure, wherein the SAM is inked on the plate and the metal thin film is deposited on the nanostructure; selectively removing the metal thin film by using the SAM as a mask; removing the SAM from the nanostructure; and patterning the substrate by using the remaining metal thin film on the nanostructure as a mask.

Owner:KOREA INST OF MACHINERY & MATERIALS

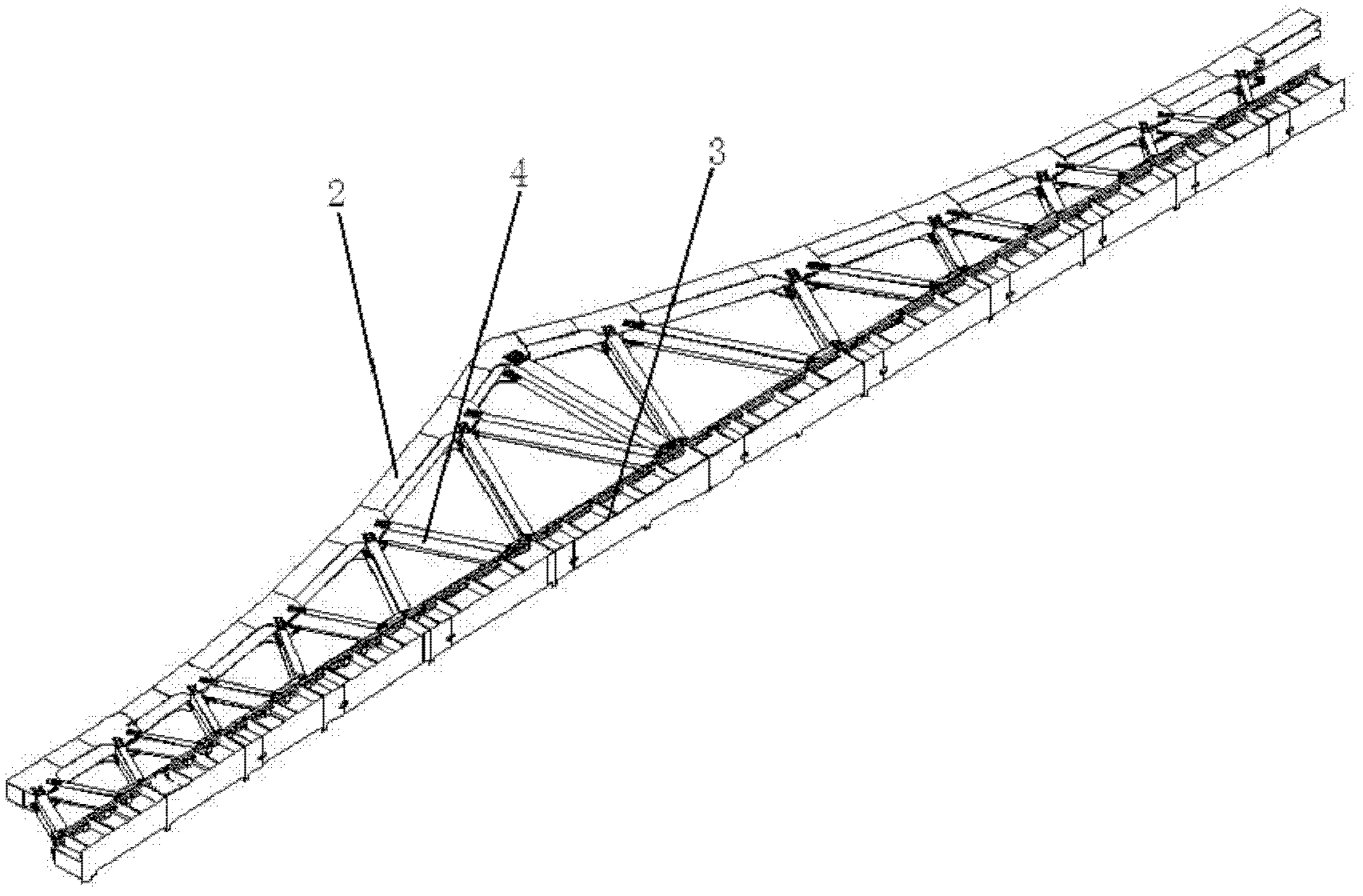

A kind of steel truss bridge and its manufacturing method

ActiveCN102277825AImprove stabilityImprove securityTruss-type bridgeBridge structural detailsBridge deckEngineering

The invention discloses a steel truss bridge and a method for fabricating the same. The steel truss bridge comprises a steel box girder bridge deck, a main truss composed of two steel trusses, and a steel portal frame. The steel truss comprises an upper chord member, a lower chord member, and a web member which is connected with the upper chord member and the lower chord member through bolts. A sidewalk bracket is arranged outside each steel truss. The lower chord member is connected to the steel box girder bridge deck and the sidewalk bracket, respectively. Besides, the two steel trusses are connected through the steel portal frame. During fabrication, all the sections of the steel trusses, the steel portal frame and the bridge deck are independently fabricated, respectively; all the sections of the upper and lower chord members of the steel truss are pre-assembled circularly with the corresponding web members, and all the sections of the steel box girder bridge deck are pre-assembled with the corresponding lower chord members by an orthotectonic method, respectively; and the steel portal frame is pre-assembled with the steel trusses. The steel truss bridge disclosed by the invention completely meets the design requirements so that the stability and safety factor of the bridge can be enhanced; and by employing the fabricating method, positioning is accurate so that the risks during the field assembling can be reduced; and the construction period can be shortened.

Owner:JIANGSU JINGHU HEAVY IND

External energy-consumption self-resetting bridge pier stud structure system and realization method thereof

InactiveCN102304892AStable energy consumptionEnsure safetyBridge structural detailsBridge erection/assemblyBridge engineeringExternal energy

The invention discloses an external energy-consumption self-resetting bridge pier stud structure system and a realization method thereof, belonging to the field of bridgework. The structure system mainly comprises a bridge pier stud, a bridge abutment, an unbonded prestressed reinforcement, an external energy consumption device, a pier embedded part and a bridge abutment embedded part, wherein the bridge pier stud and the bridge abutment are connected by the unbonded prestressed reinforcement and the external energy consumption device, so that residual deformation can be effectively reduced, and energy consumption can be guaranteed. The external energy-consumption self-resetting bridge pier stud structure system is flexible in design and has specific structure stress. The unbonded prestressed reinforcement on the axis position of the pier stud can be used for generating self-resetting restoring force. The problem that the traditional bridge pier has larger residual deformation and cannot continuously serve after the earthquake loading action is solved. The bridge pier has enough strength and rigidity. The external energy-consumption self-resetting bridge pier stud structure system is realized in a cast-in-situ or prefabricating mode and is easy to construct and is a novel pier stud structure system which is advanced and practical and can realize quick replacement and repair after the earthquake..

Owner:TSINGHUA UNIV

Multipoint synchronous push construction method for porous large-span continuous steel truss girder

ActiveCN101831874AEasy constructionReduce labor intensityBridge erection/assemblyControl systemEngineering

The invention discloses a multipoint synchronous push construction method for a porous large-span continuous steel truss girder, which comprises the following steps of: (1) assembling a steel truss girder assembling platform and a push slideway in a shoreside bridge pier position; (2) assembling a section of steel truss girder and a guide girder on the steel truss girder assembling platform; (3) installing a vertical jack for carrying out support conversion on the steel truss girder and then installing a continuous push jack, a steel strand and an electrohydraulic integrated control system; (4) operating the electrohydraulic integrated control system for carrying out push operation on the steel truss girder; and (5) after the push operation of the section of steel truss girder is finished, continuously assembling the steel truss girder on the steel truss girder assembling platform, carrying out next push operation, repeating the step for circulating operation and finishing the push construction of the porous large-span steel truss girder. The invention has the advantages of short construction period, safe construction, quality guarantee, low cost, and the like, realizes the push operation of the large-span steel truss girder, saves the construction cost, and reduces the pollution to a river channel.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

Bridge structural health monitoring car

InactiveCN101713167AEasy maintenanceCollection directlyOptically investigating flaws/contaminationBridge structural detailsInformation processingStructural health monitoring

The invention provides a bridge structural health monitoring car. A mechanical hand capable of being bent to extend into the lower part of a bridge is arranged on the bridge structural health monitoring car, wherein at least one camera is arranged on the mechanical hand and used for collecting the image information of the bottom and the side face of the bridge; a high-precision GPS positioning device is arranged and used for determining a current detection position and measuring the line shape of the bridge surface; a bridge structure dynamic information collecting device is arranged and used for collecting the dynamic characteristic information data of the bridge structure; an information processing device is arranged and used for storing the image information collected by the cameras, the GPS data and the dynamic characteristic information data, judging the health conditions and the disease development conditions of the bridge structure according to the analysis and the comparison of the monitoring data of each time and definitely indicating the disease conditions and parts by visual images. The bridge structural health monitoring car can carry out health monitoring on a plurality of bridges at the same time.

Owner:周劲宇 +1

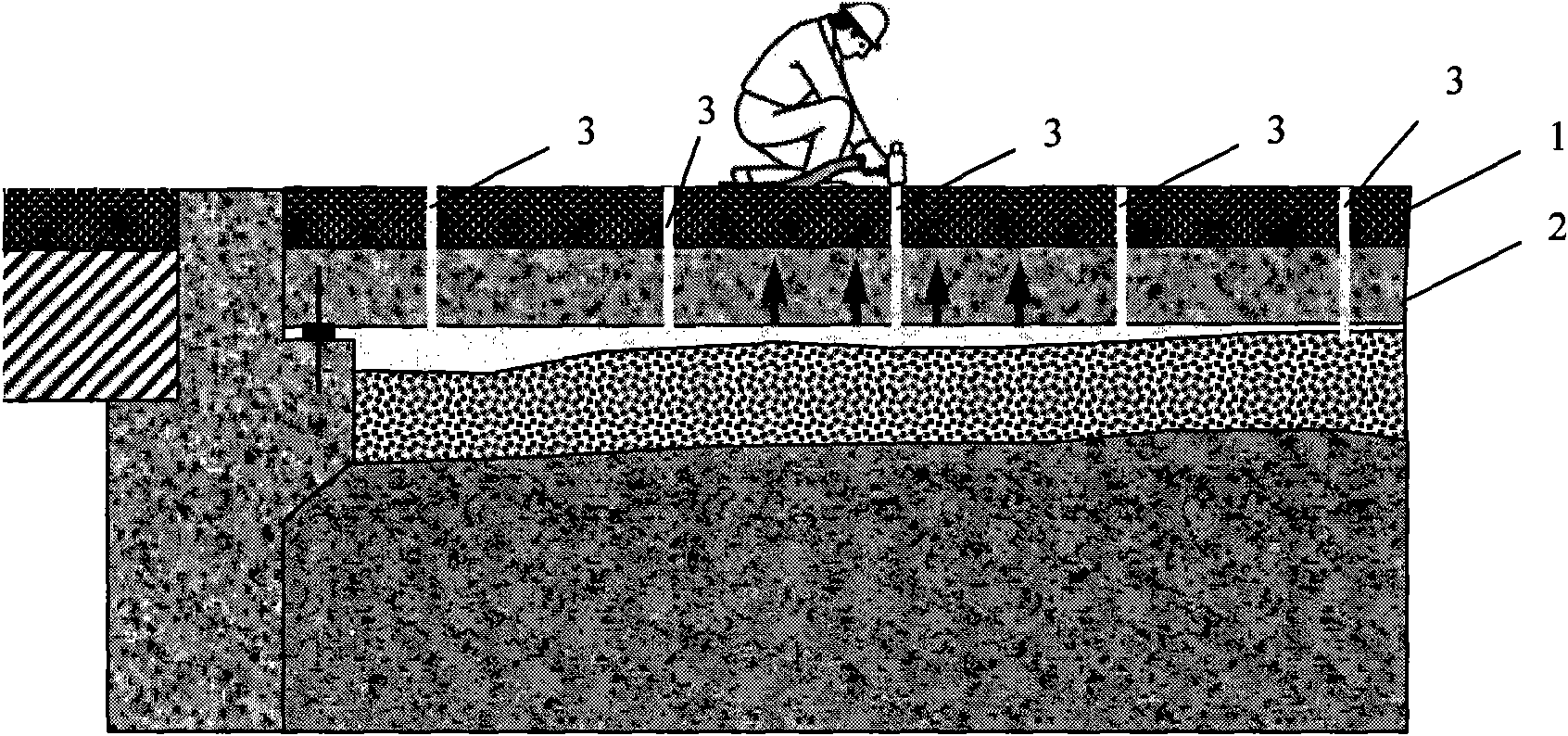

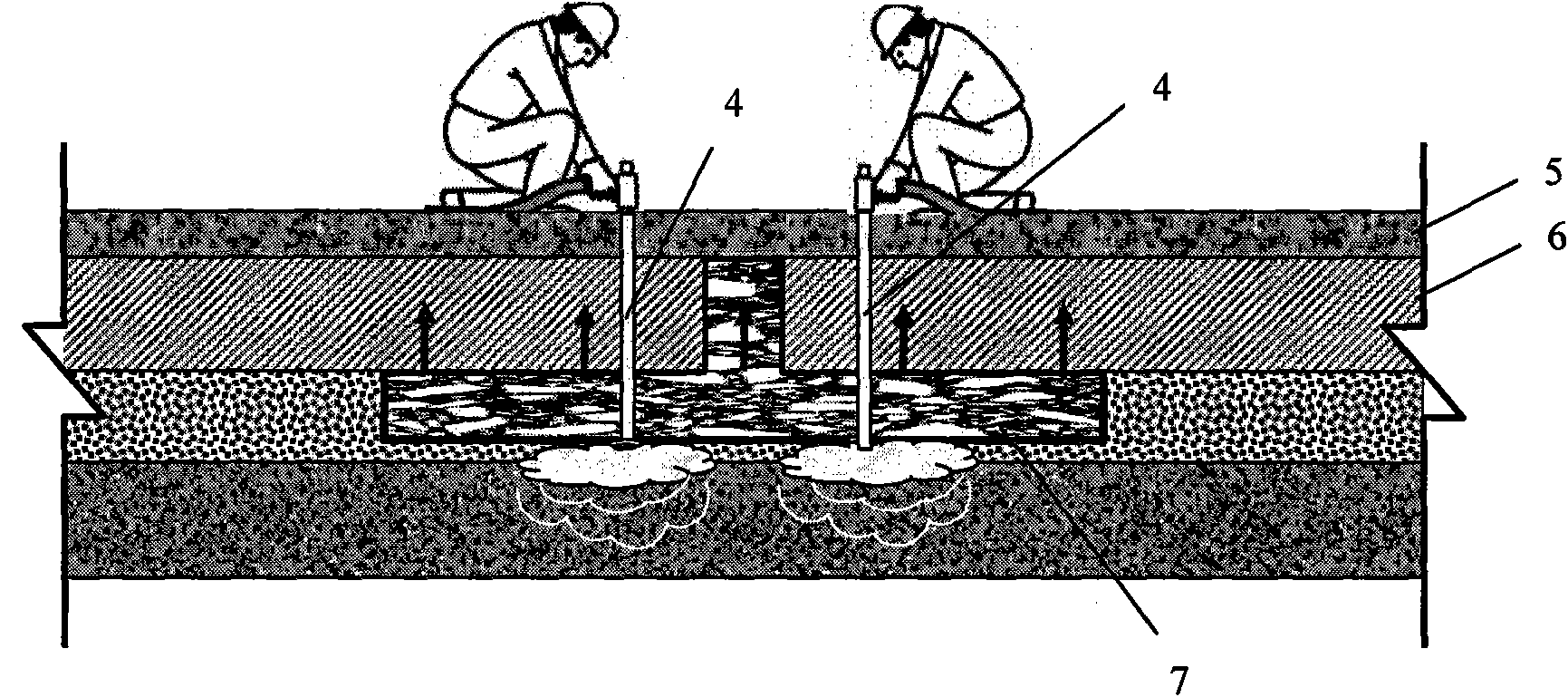

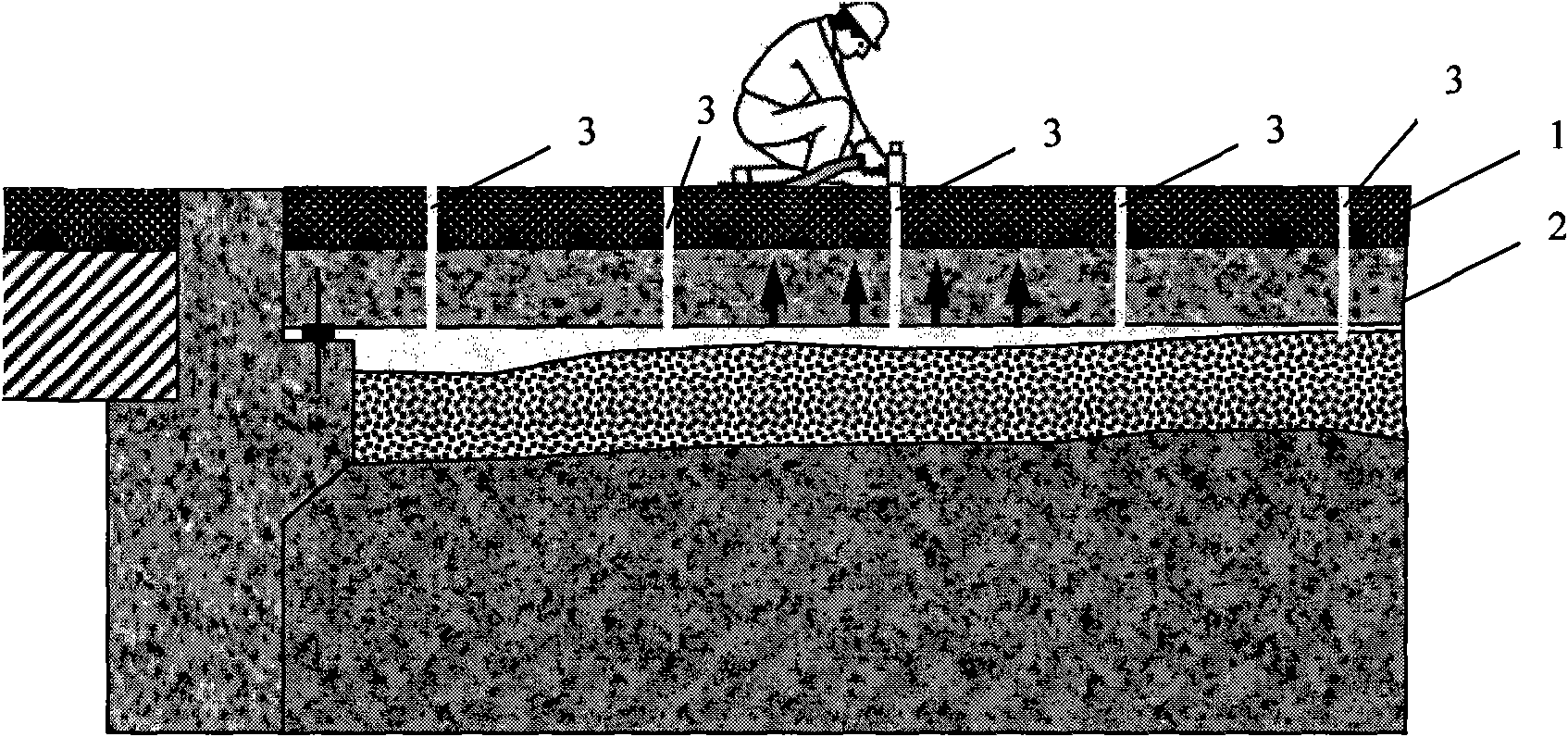

Bridgehead vehicle bump prevention and control high polymer grouting technique and construction method thereof

ActiveCN102051861AIncreased durabilityIncrease elasticityBridge erection/assemblyBridge strengtheningChemical reactionEngineering

The invention discloses a bridgehead vehicle bump prevention and control high polymer grouting technique and a construction method thereof. Aiming at the problems of bridgehead butt strap gapping and sinking problems, nondestructive detection systems of a ground penetrating radar (GPR), a falling weight deflectometer (FWD), a laser level and the like are comprehensively applied to detection and monitoring; and a high polymer material is injected to the bottom of a bridgehead butt strap or the bottom of a sleeper beam, the volume of the material is quickly expanded and the material is cured after chemical reaction, so that the gapped butt strap is quickly filled and raised, the roadbed is reinforced, and bridgehead vehicle bump is radically prevented and controlled. Compared with the conventional treatment method, the technique has obvious innovation on the aspects of technical principles and construction methods, has the characteristics of good durability, short construction period, strong pertinence and the like, and initiates a new advanced, efficient, economic and practical bridgehead bump prevention and control path.

Owner:王复明

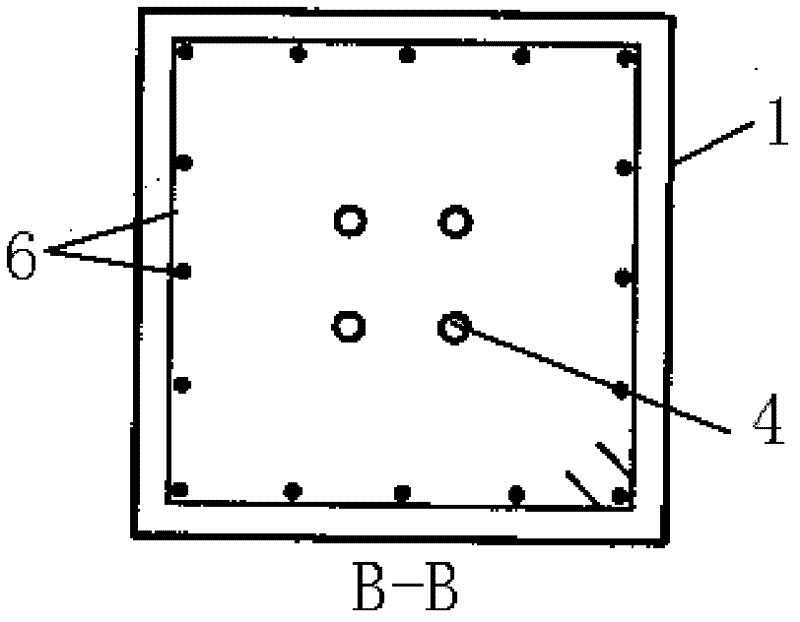

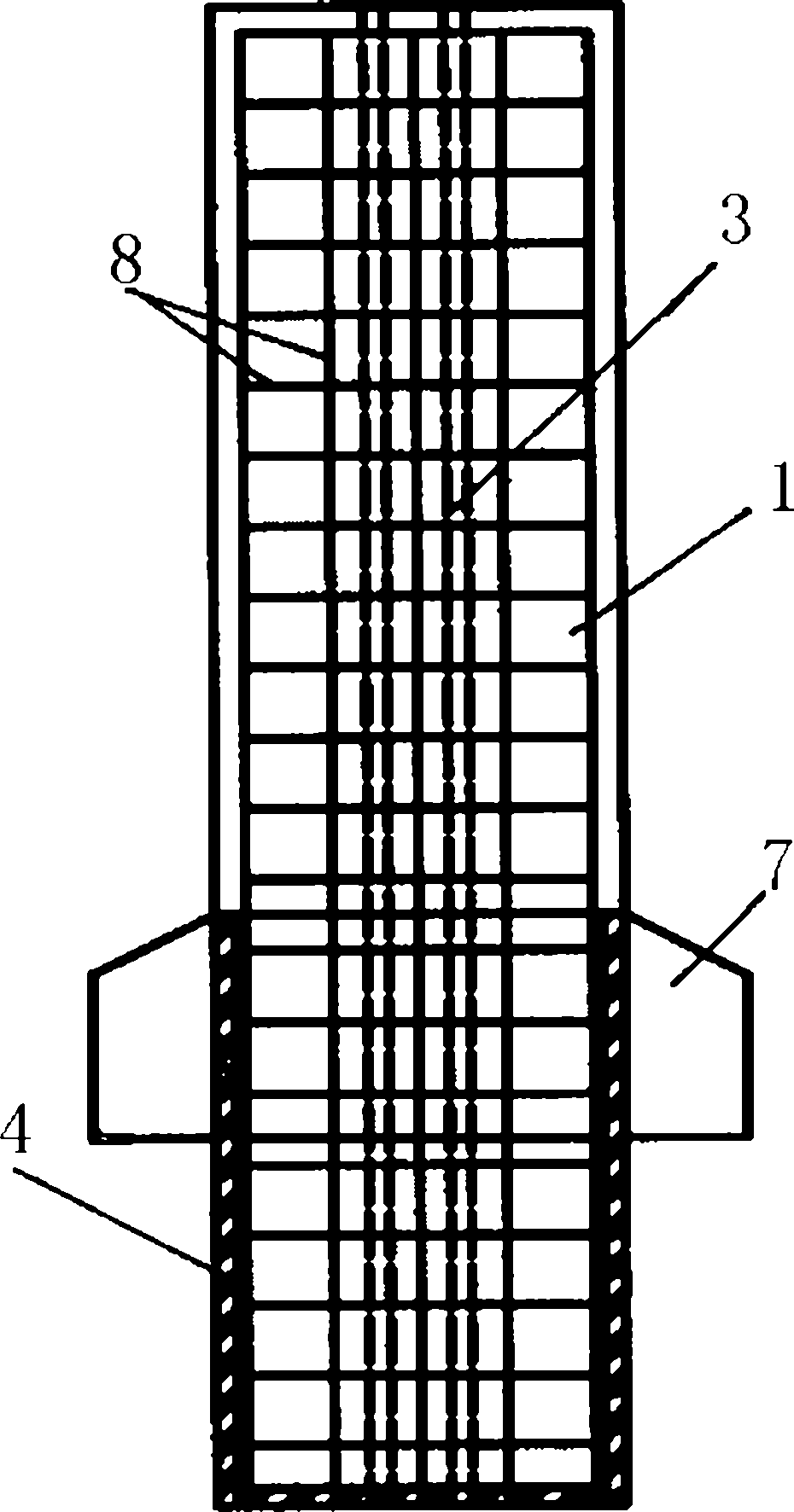

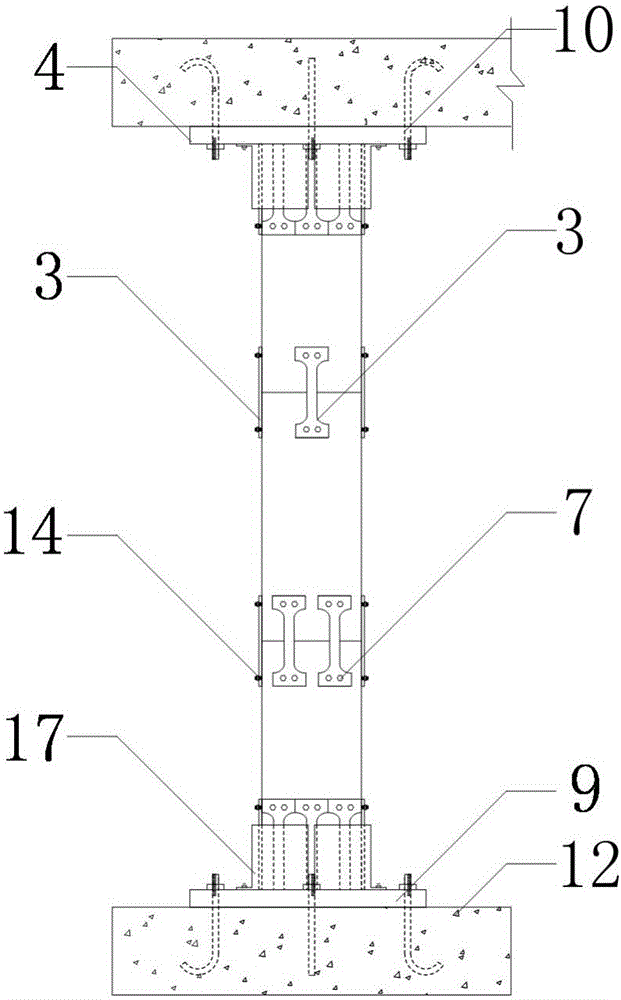

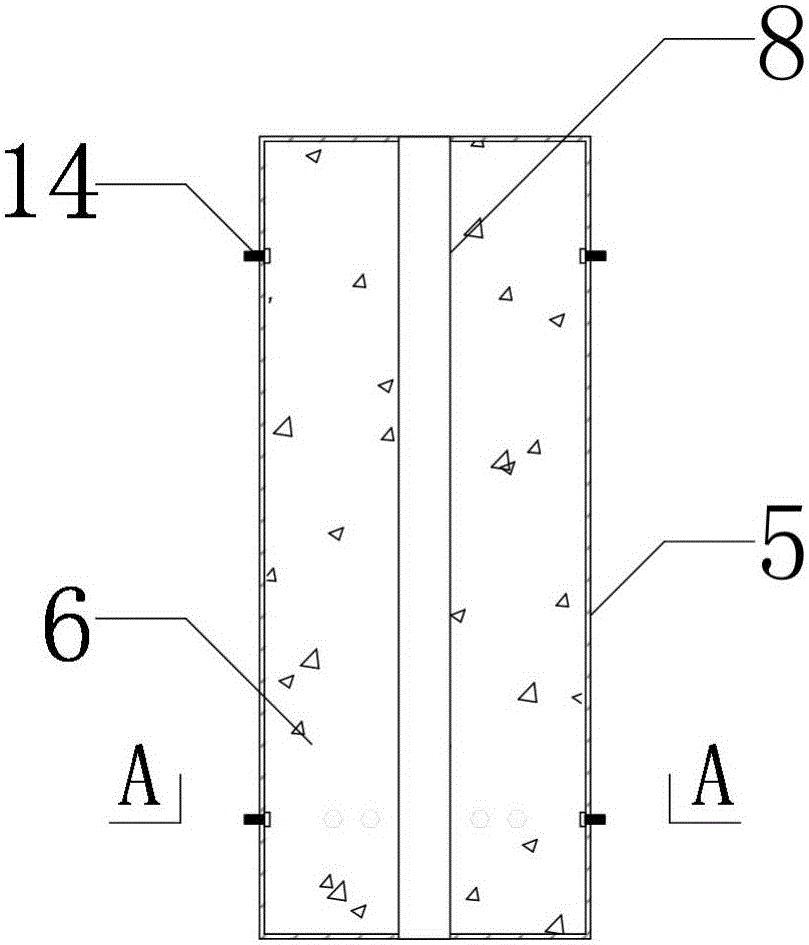

Damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and manufacturing method thereof

ActiveCN105908621ASmall residual displacement after earthquakeImprove bearing capacityBridge structural detailsBridge erection/assemblyBridge engineeringHigh energy

The invention discloses a damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and a manufacturing method thereof, and belongs to the field of bridge engineering. An exposed node connecting piece consists of a foot plate, anchor bolts, end connecting plates and buckling restraining sleeves. A connecting plate is mounted between prefabricated steel pipe concrete sections through high-strength bolts; the exposed node connecting piece is connected with each of a cover beam and a bearing platform by utilizing the anchor bolts, and is connected with a prefabricated steel pipe concrete section through the high-strength bolts relying on the end connecting plates. A pre-stressed tendon penetrates through a section prefabricated steel pipe concrete pier; the two ends of the pre-stressed tendon are respectively anchored to the interiors of the bearing platform and the cover beam by using anchorage devices. The energy consumption-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier disclosed by the invention has the characteristics of small post-seismic residual displacement, high energy consumption capacity, controllable energy consumption, high assembling degree, convenience and quickness in construction process, greenness, high efficiency, energy conservation, environment friendliness, easiness in factory production, convenience and quickness in construction, and the like; the construction period of the pier can be remarkably shortened.

Owner:BEIJING UNIV OF TECH

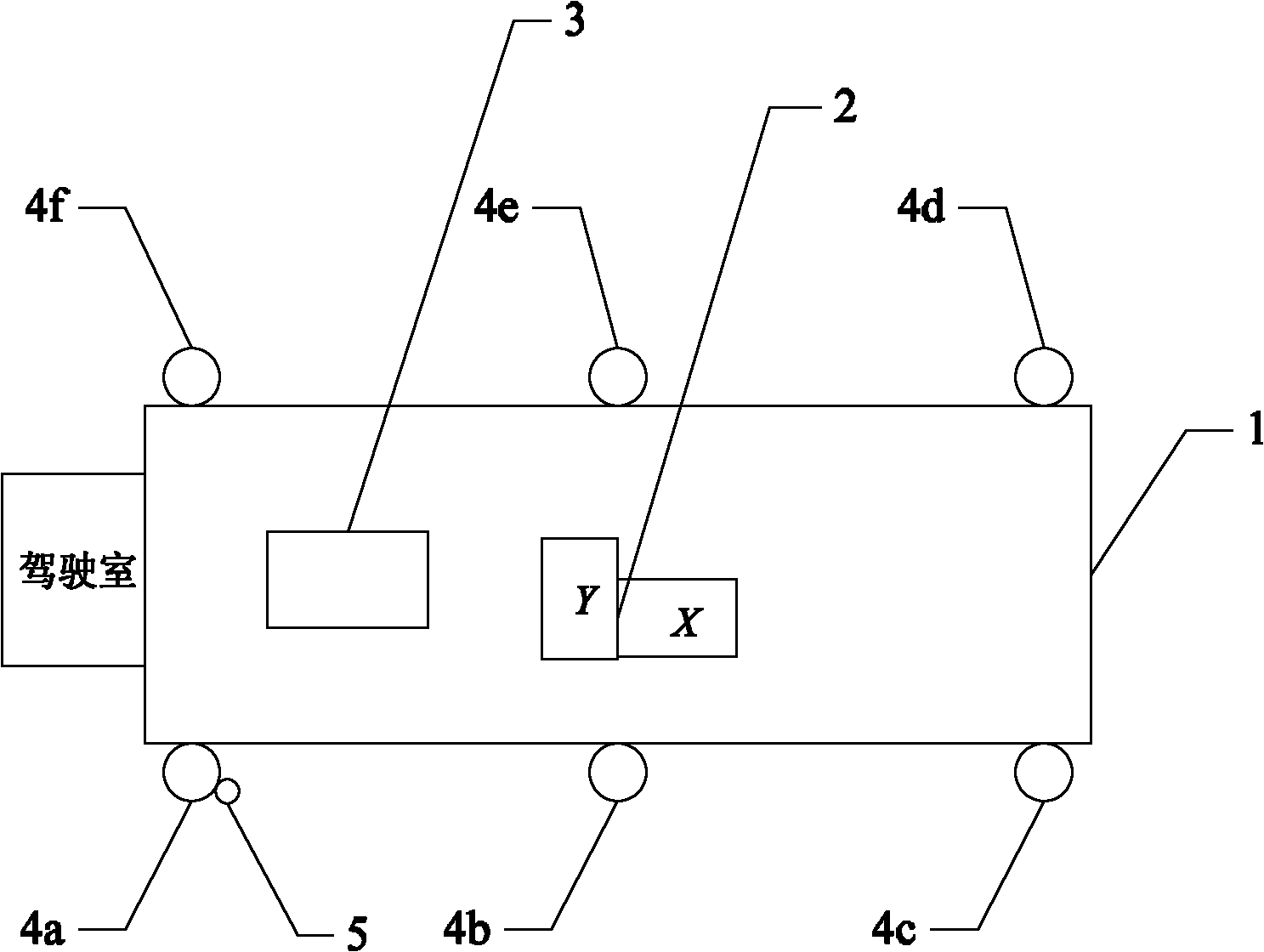

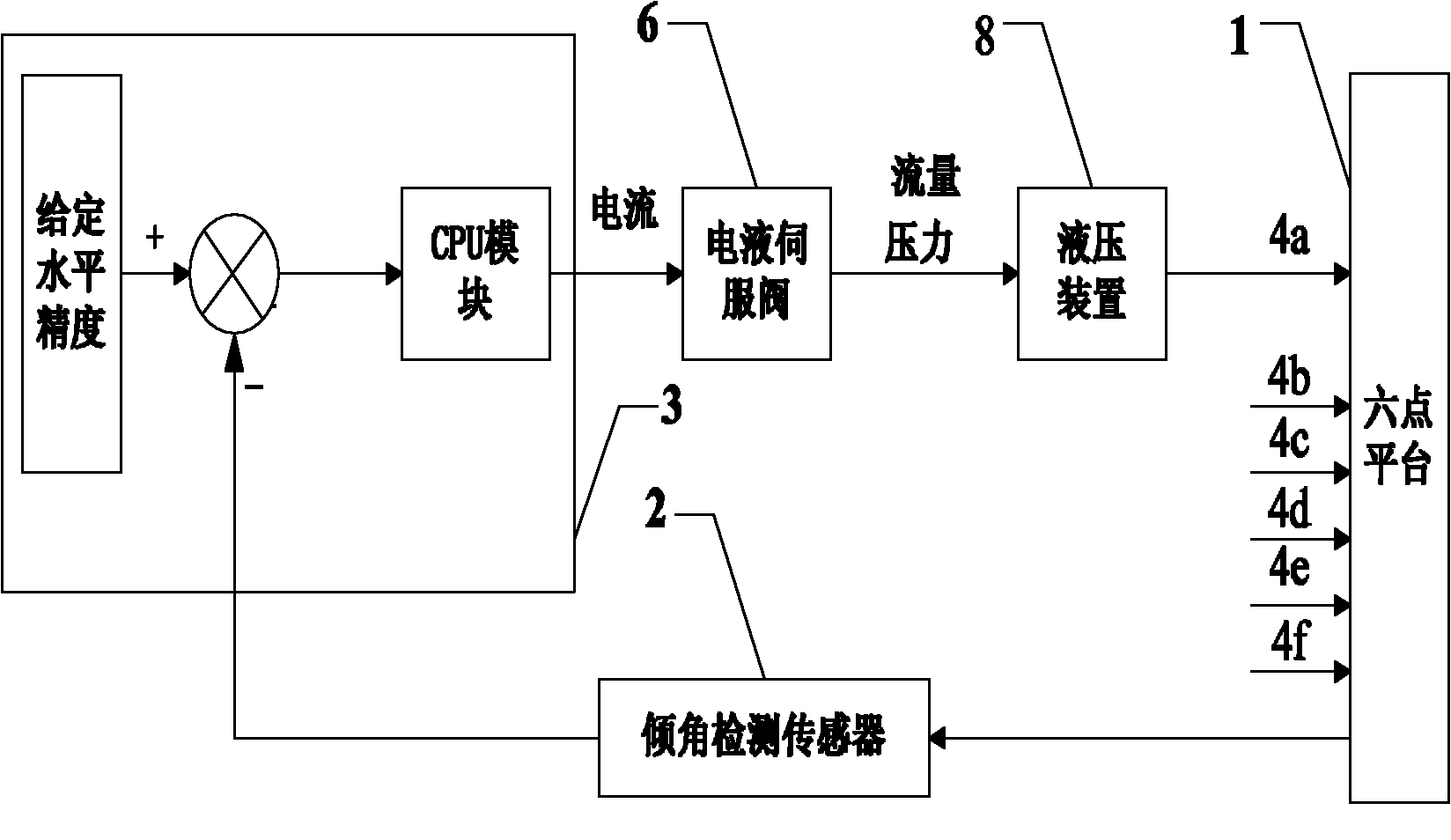

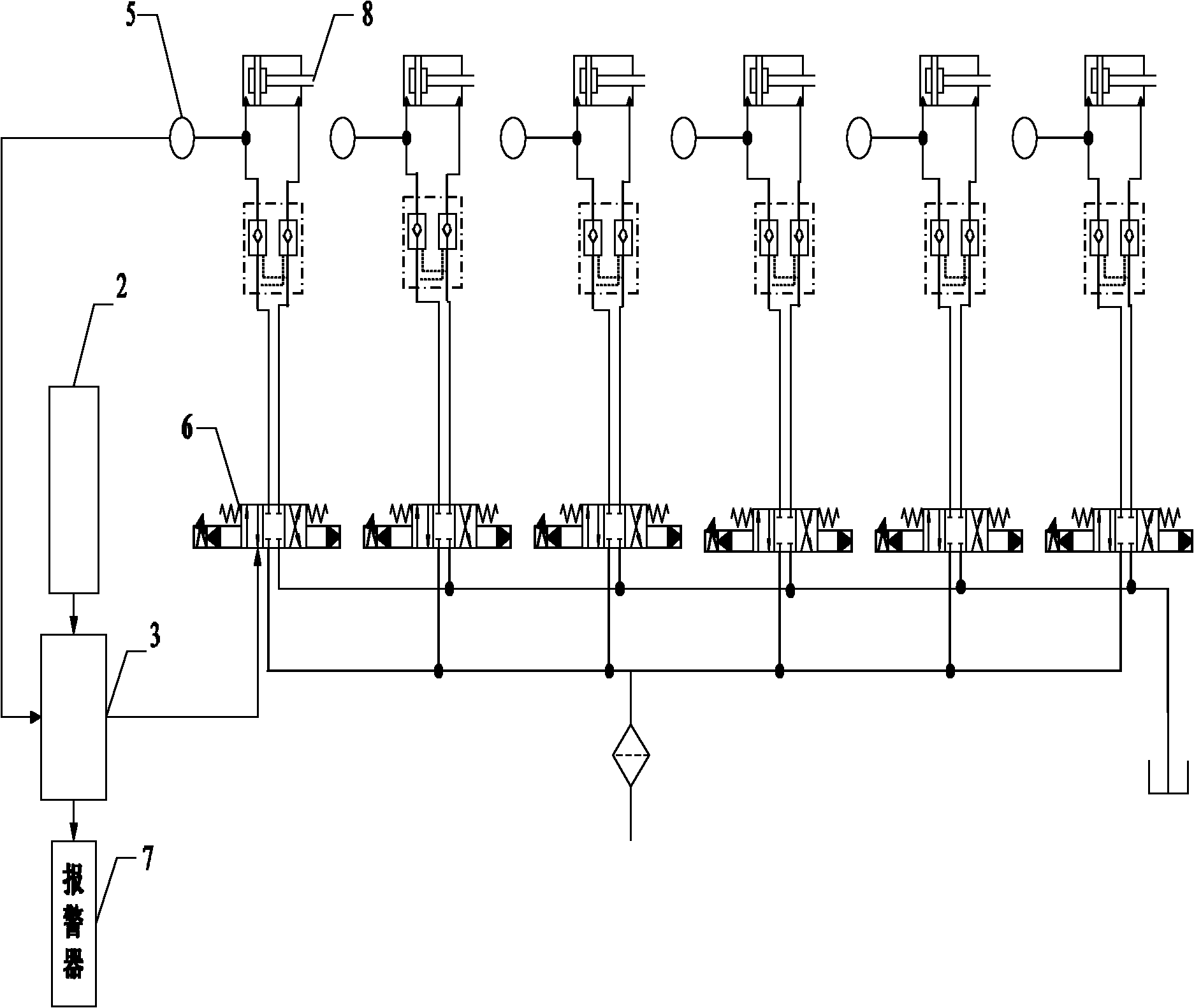

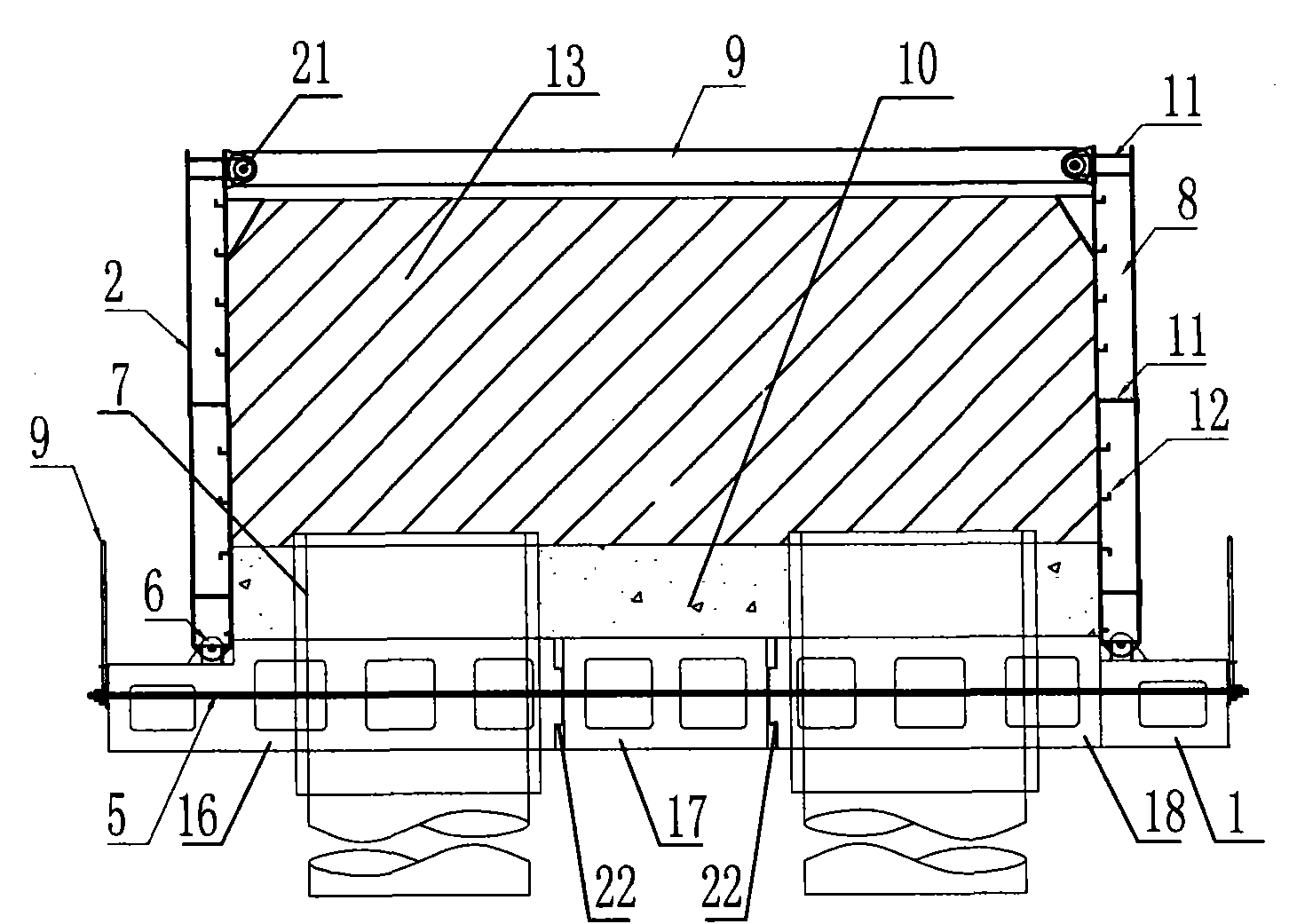

Automatic leveling system and method for six-point support bridging platform

InactiveCN102174794AGuaranteed self-levelingHigh speedBridge erection/assemblyElectro hydraulicEngineering

The invention discloses an automatic leveling system and method for a six-point support bridging platform; six supporting legs are respectively provided with a pressure sensor and respectively connected with a hydraulic device; each hydraulic device is connected with the pressure sensor and an electro-hydraulic servo valve; and a controller is respectively connected with an alarm, a double-shaft tilt sensor, each pressure sensor and each electro-hydraulic servo valve. Coarse adjustment is performed firstly, and then fine adjustment is performed; the coarse adjustment comprises the steps of: inputting a sensed pressure signal of each supporting leg to the controller by the corresponding pressure sensor on the supporting leg, if the pressure value of the supporting leg is less than a preset value in the controller, controlling the alarm to emit an alarm by the controller, or else, performing the fine adjustment; and the fine adjustment comprises the steps of: keeping two middle auxiliary supporting legs still, adjusting two forward supporting legs and two backward supporting legs, keeping the highest supporting leg still, firstly leveling an X direction, and then leveling a Y direction. The automatic leveling system and method for the six-point support bridging platform can ensure that the platform can be automatically leveled in an outdoor severe environment, the good leveling precision and speed can be obtained, and strong environmental applicability and safety are provided.

Owner:JIANGSU UNIV OF SCI & TECH

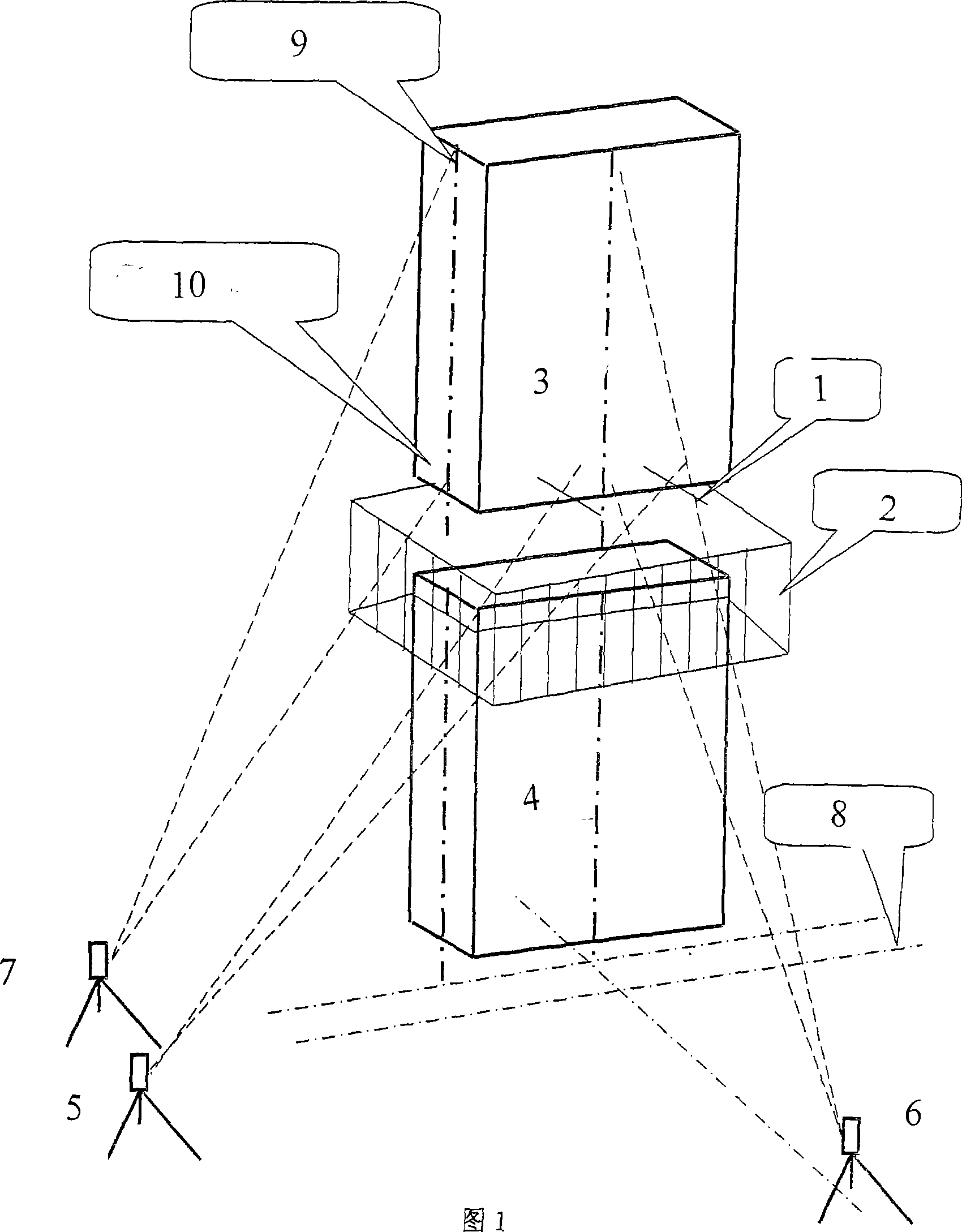

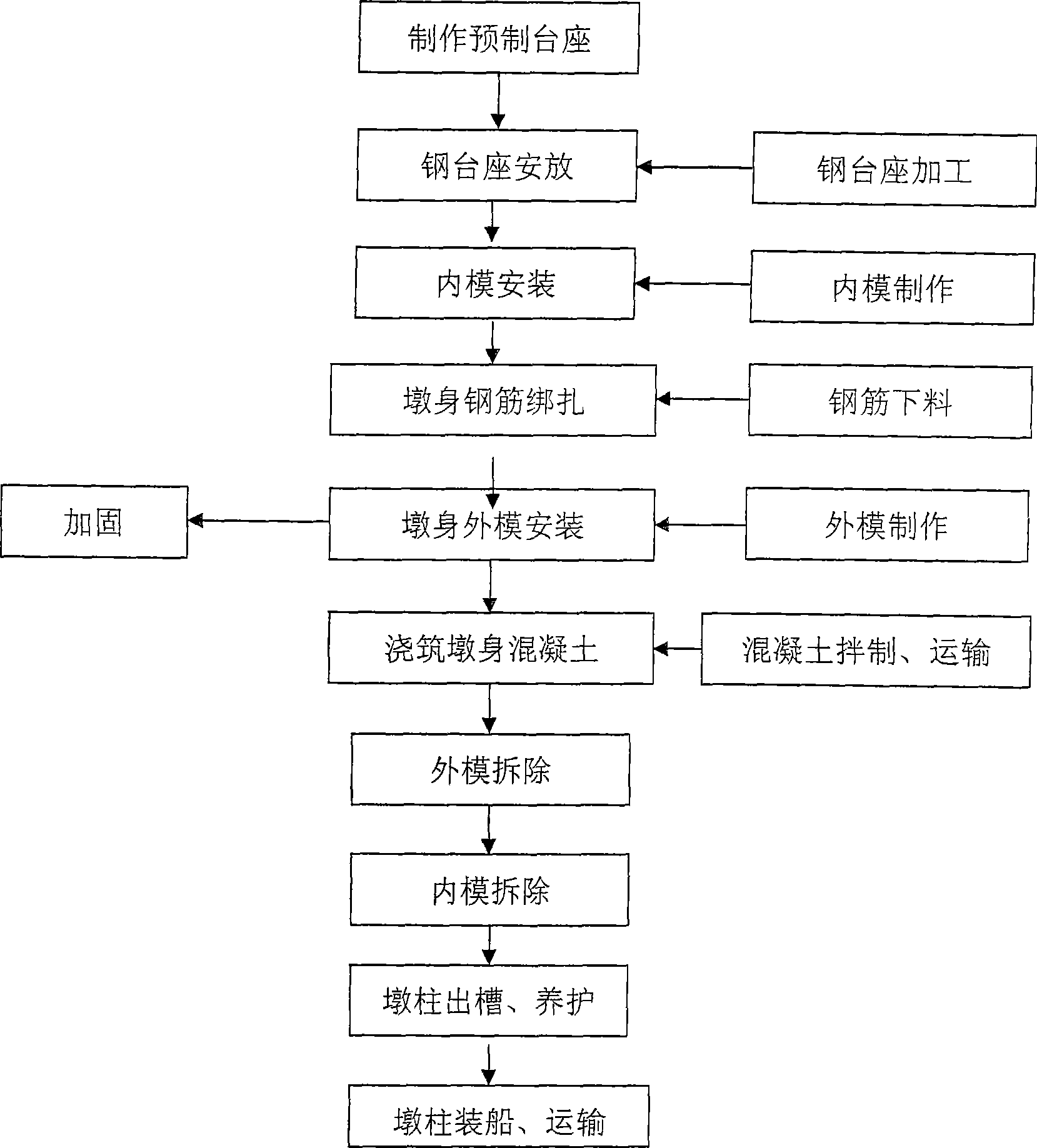

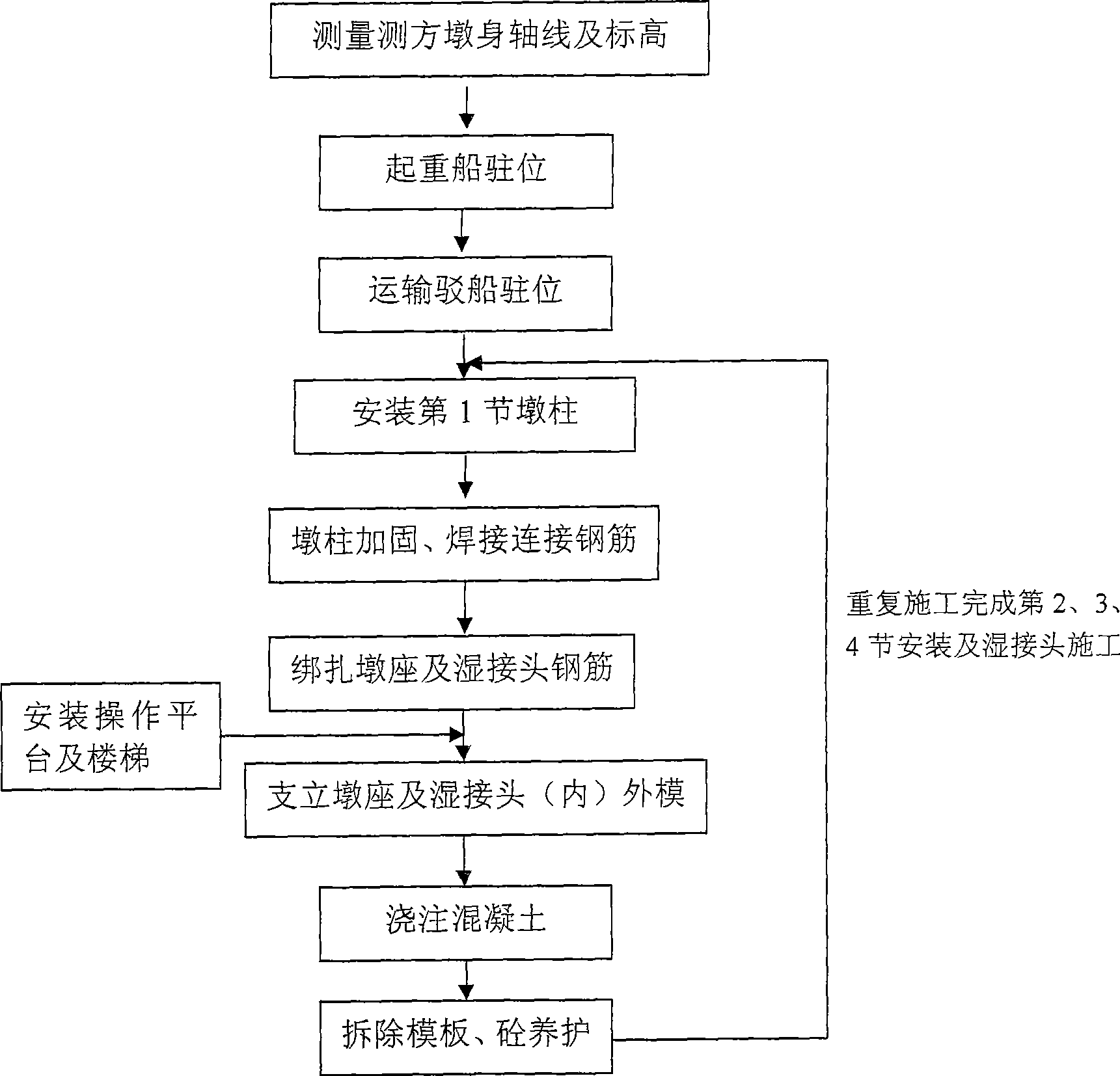

Pier column prefabrication splicing building technology

ActiveCN101429752AInspection is easy to implementImprove construction qualityBridge structural detailsBridge erection/assemblyHigh strength concreteBridge engineering

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

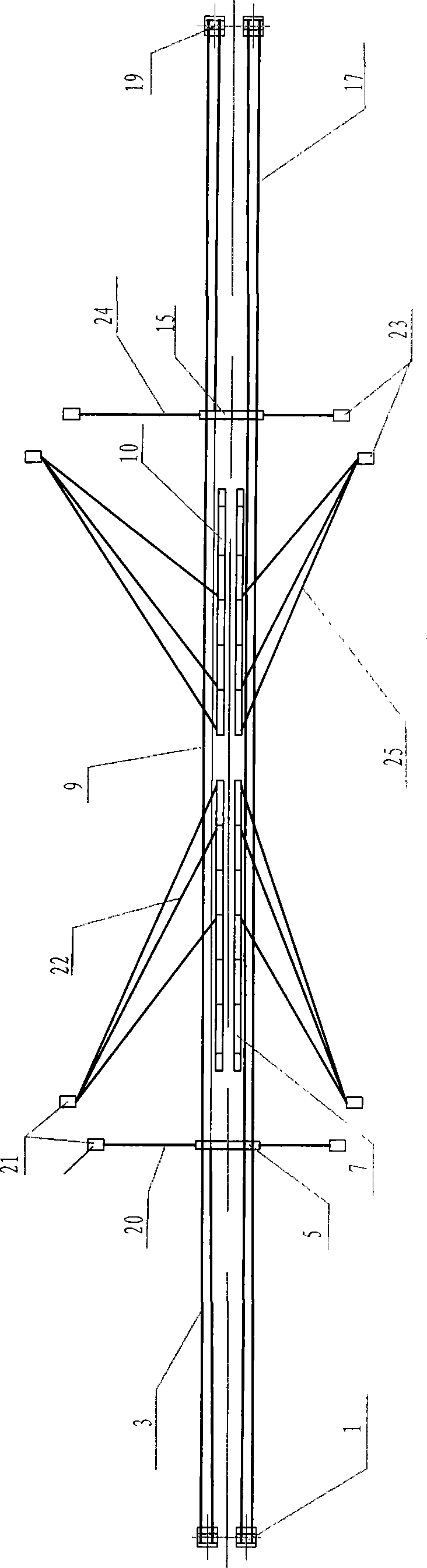

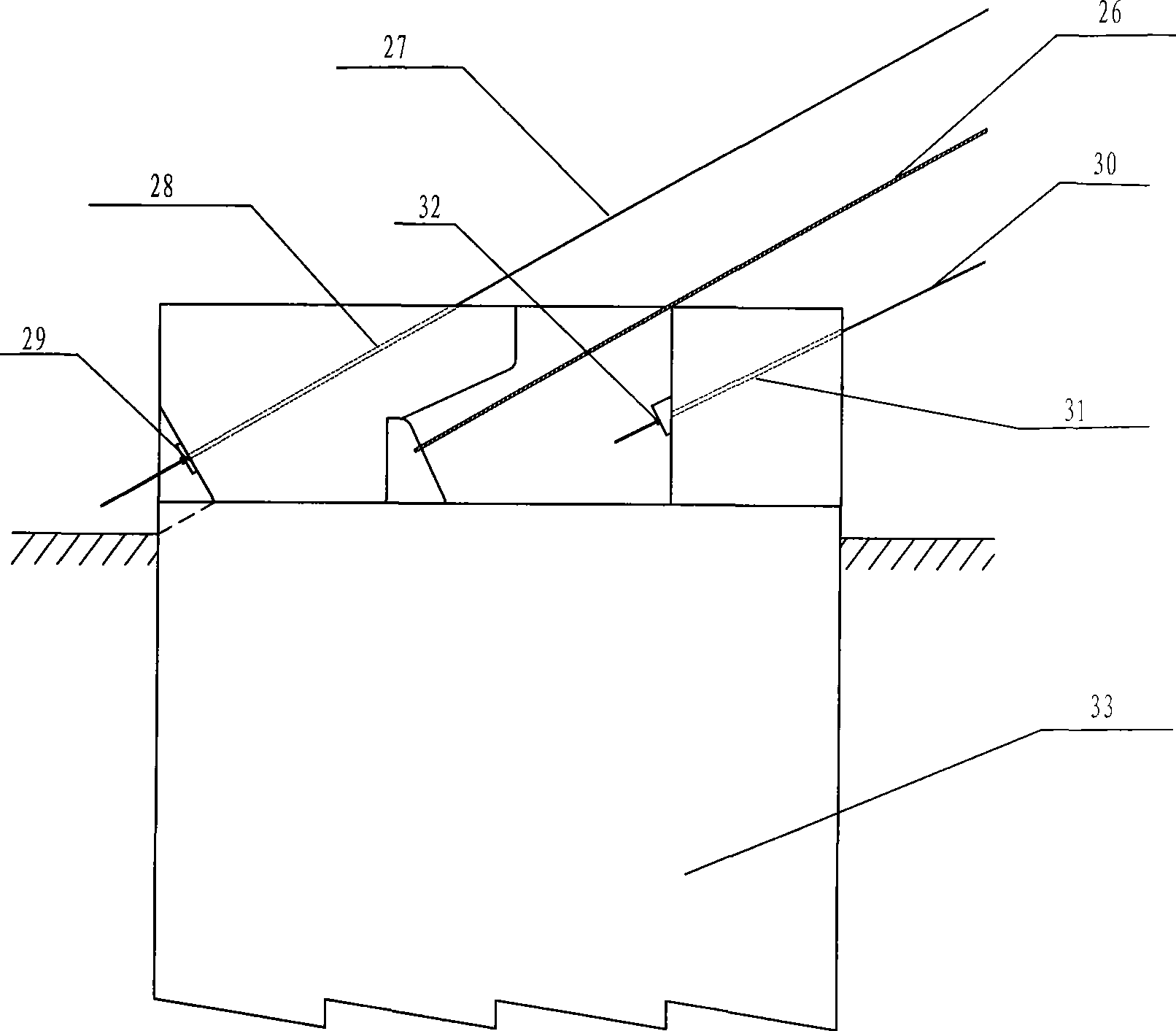

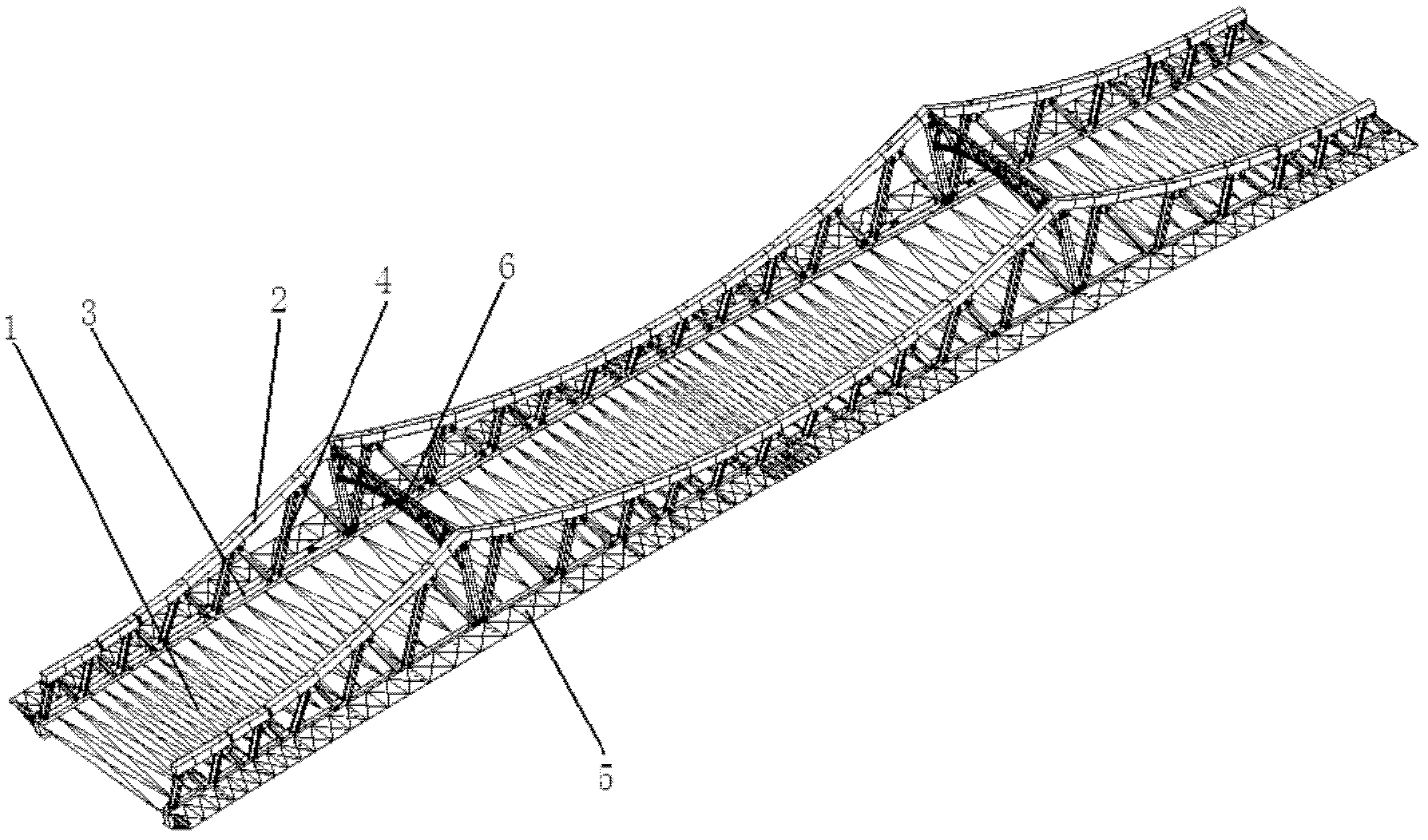

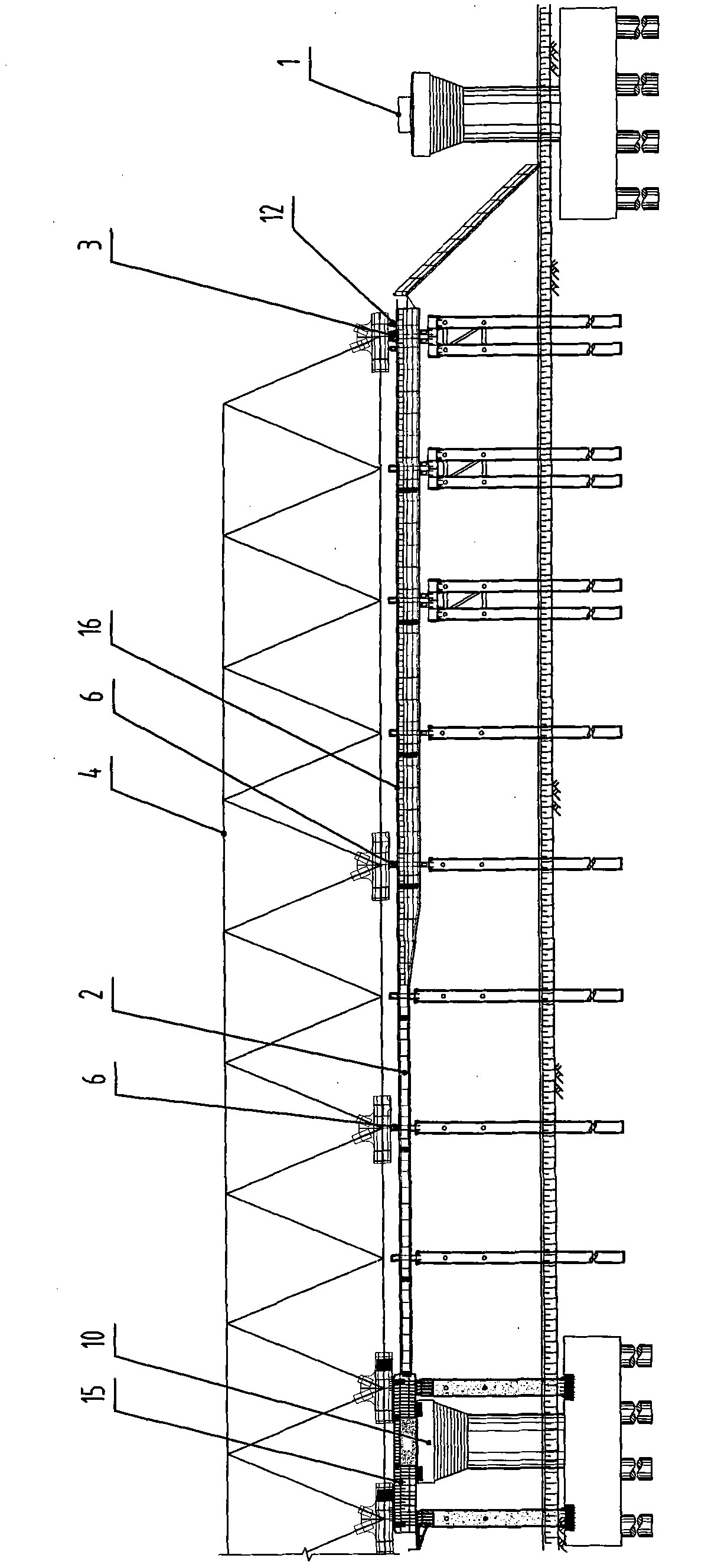

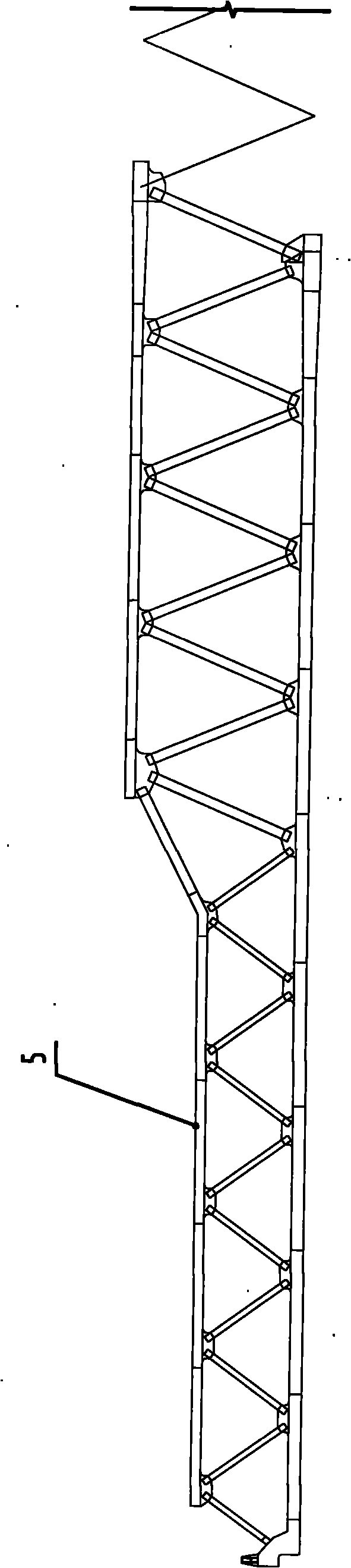

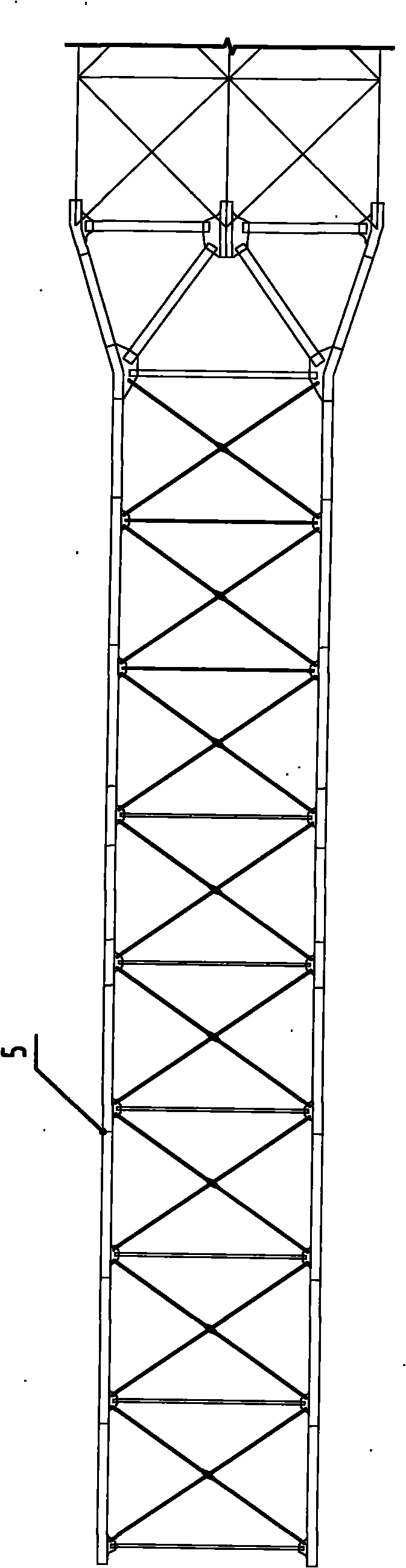

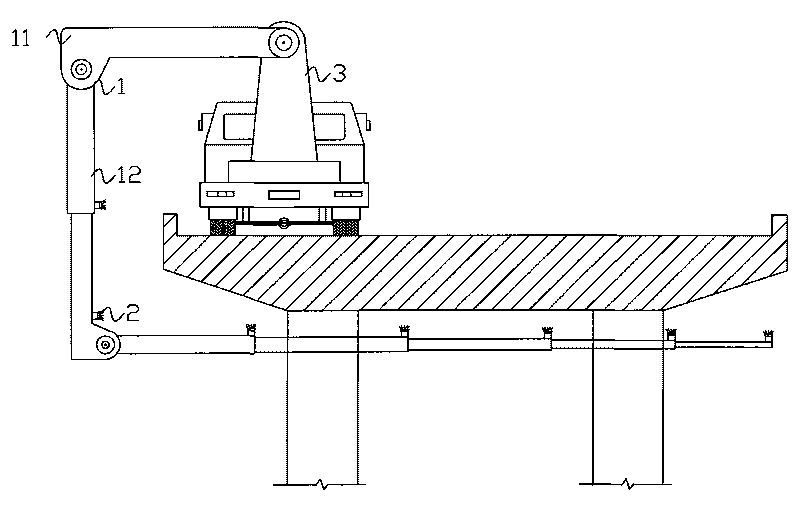

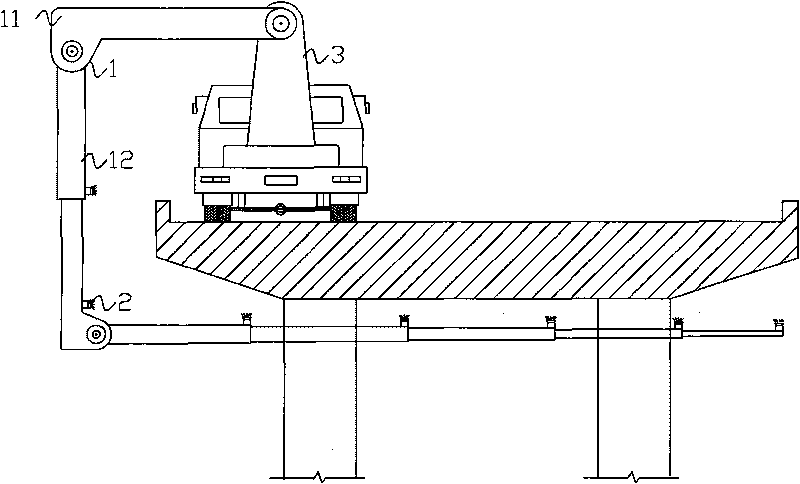

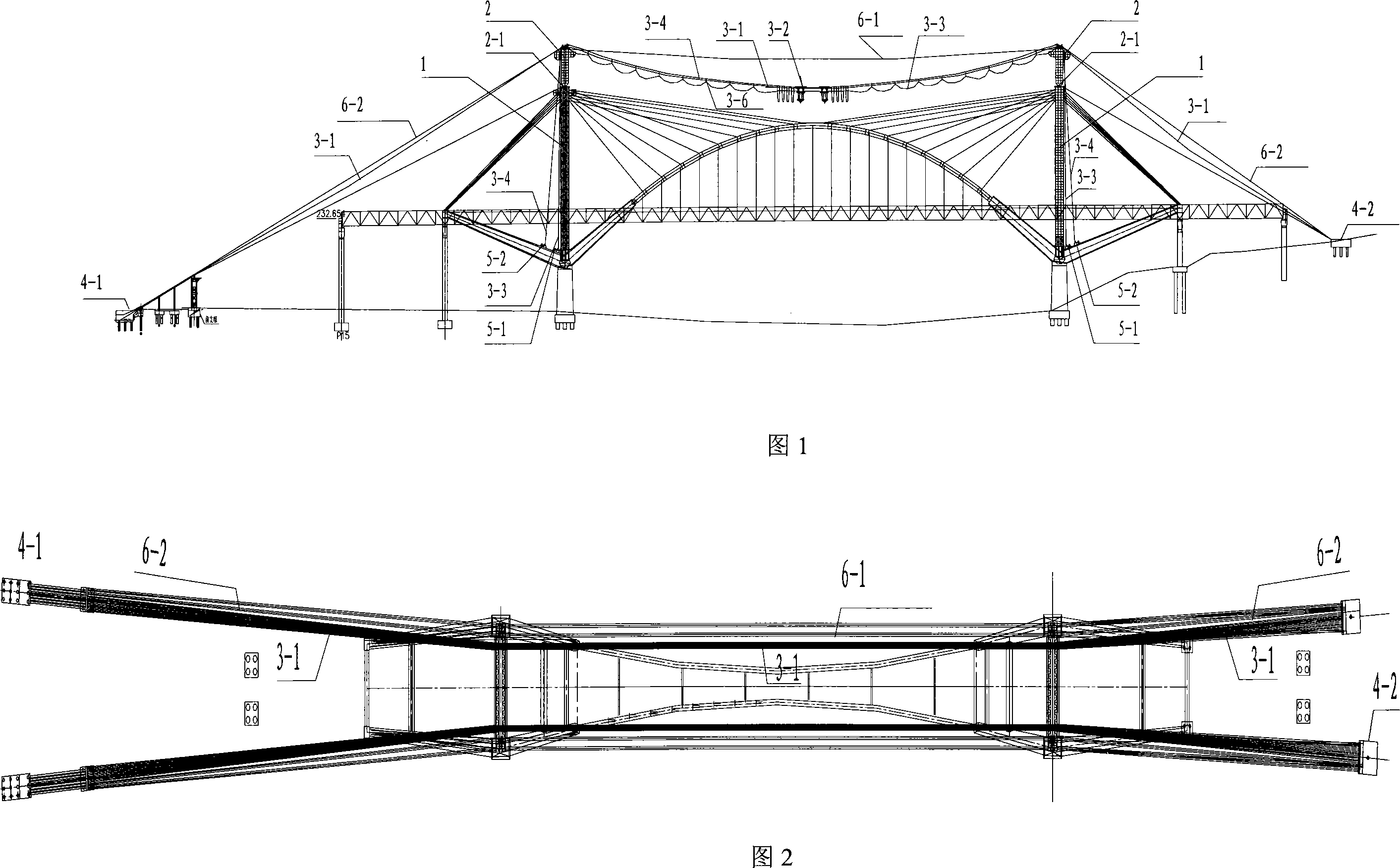

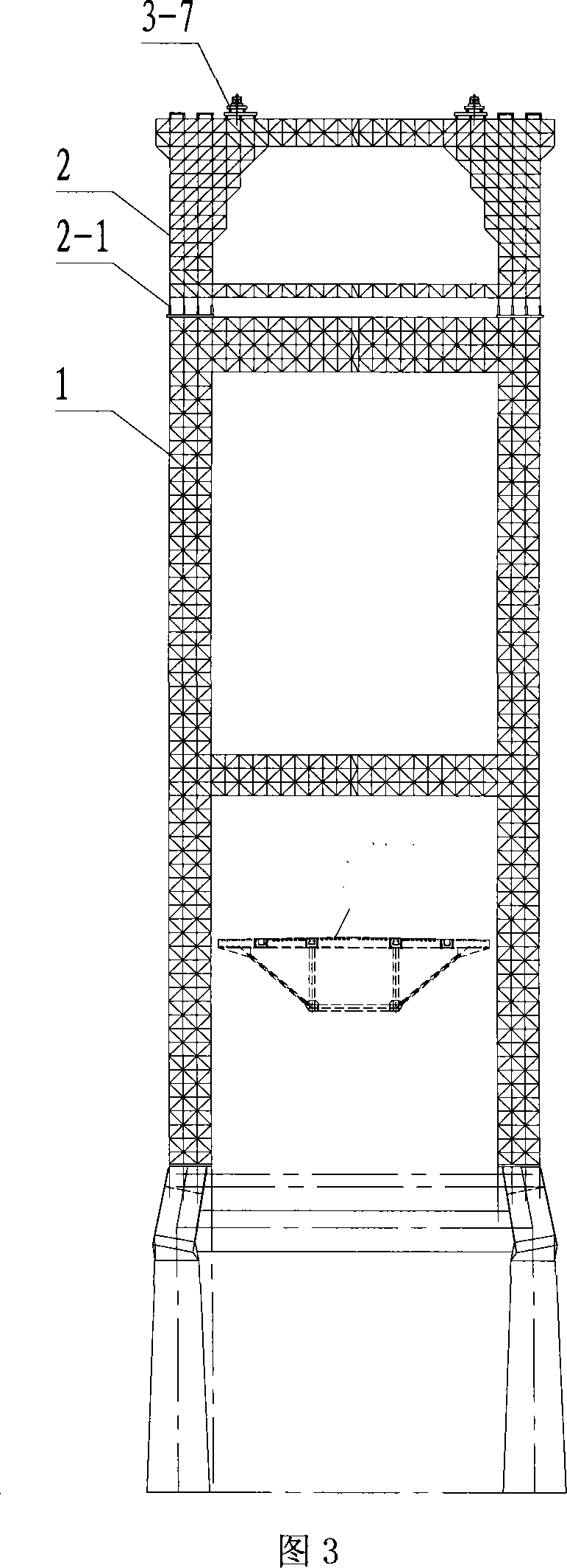

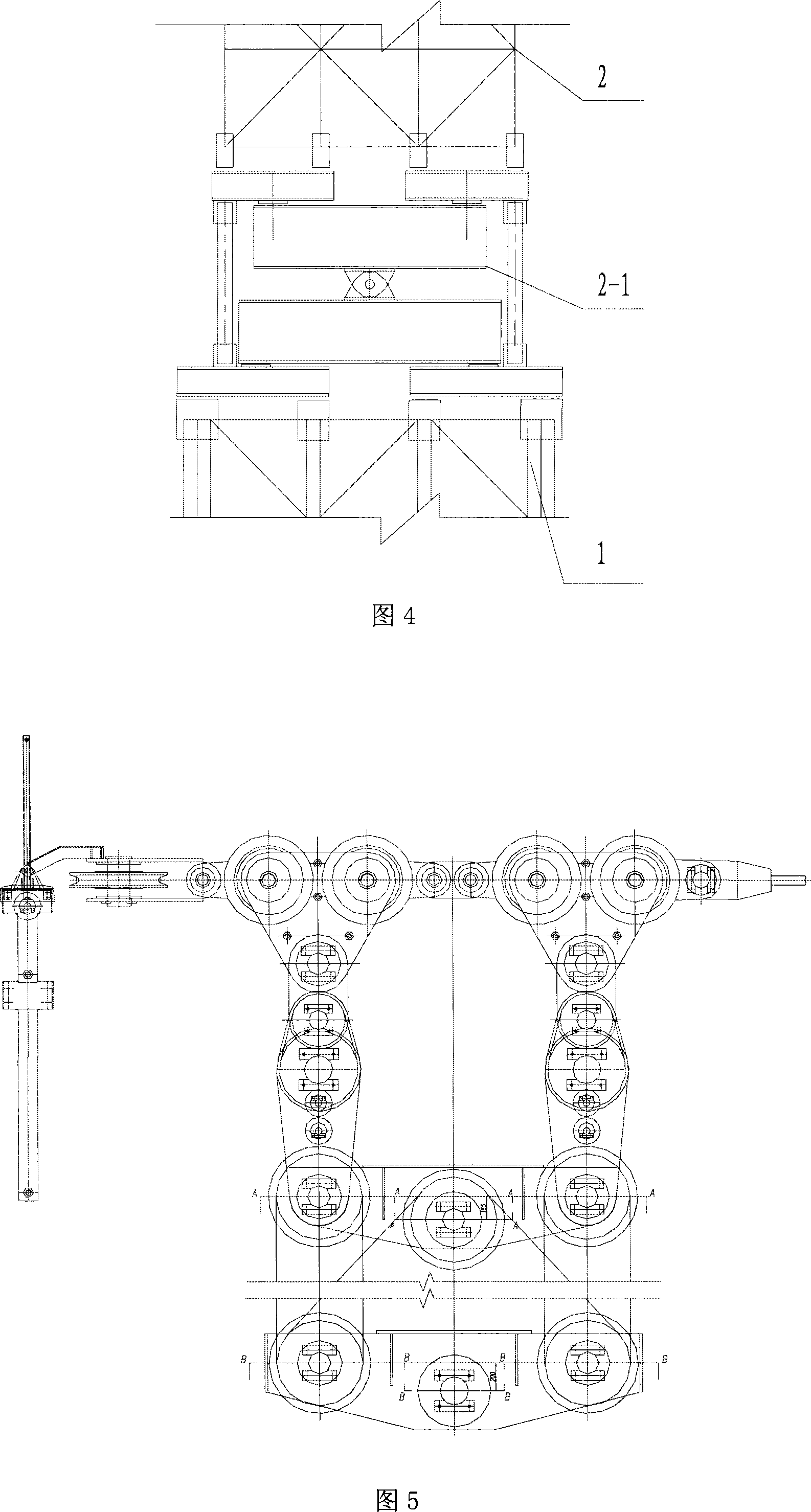

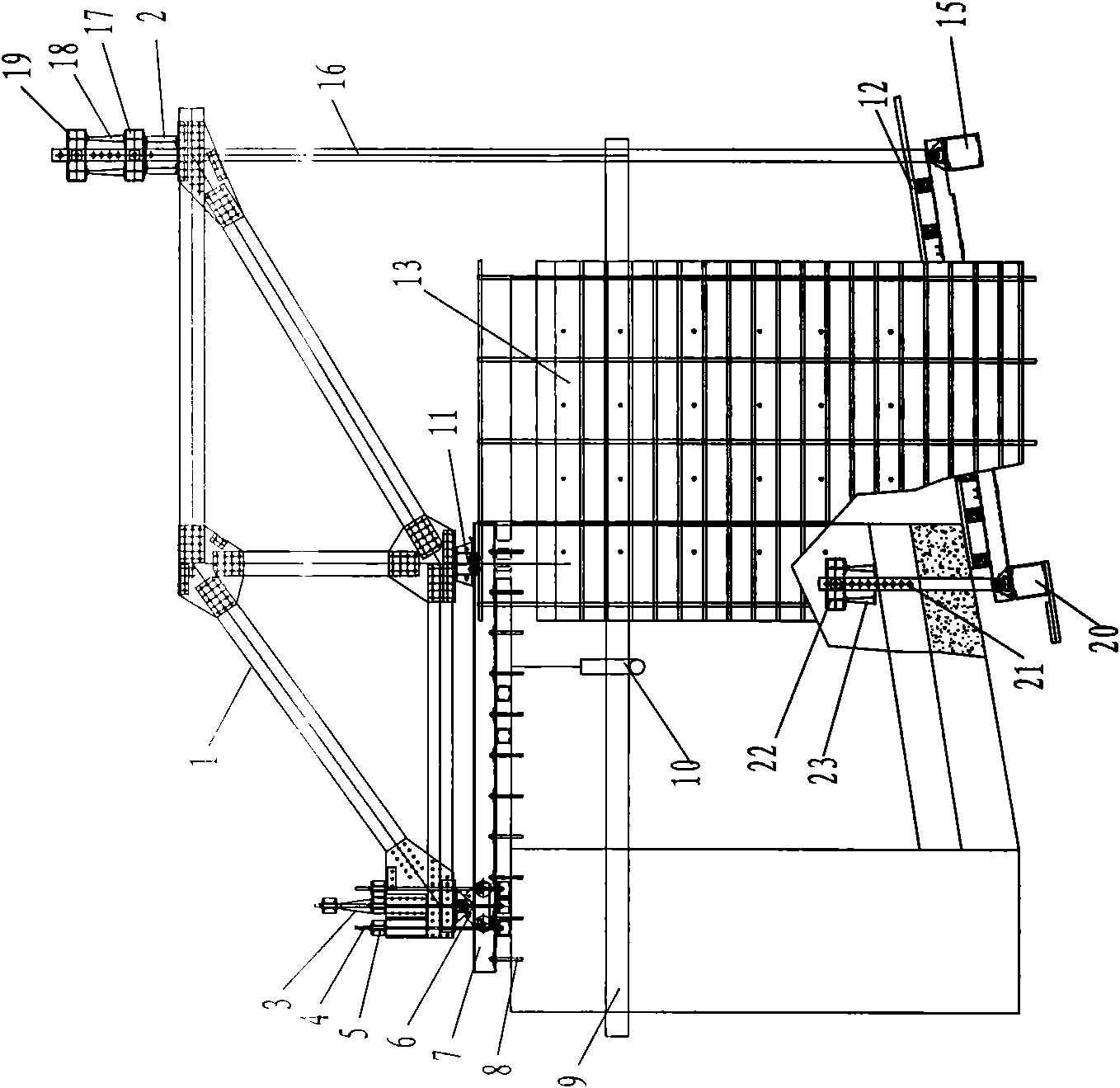

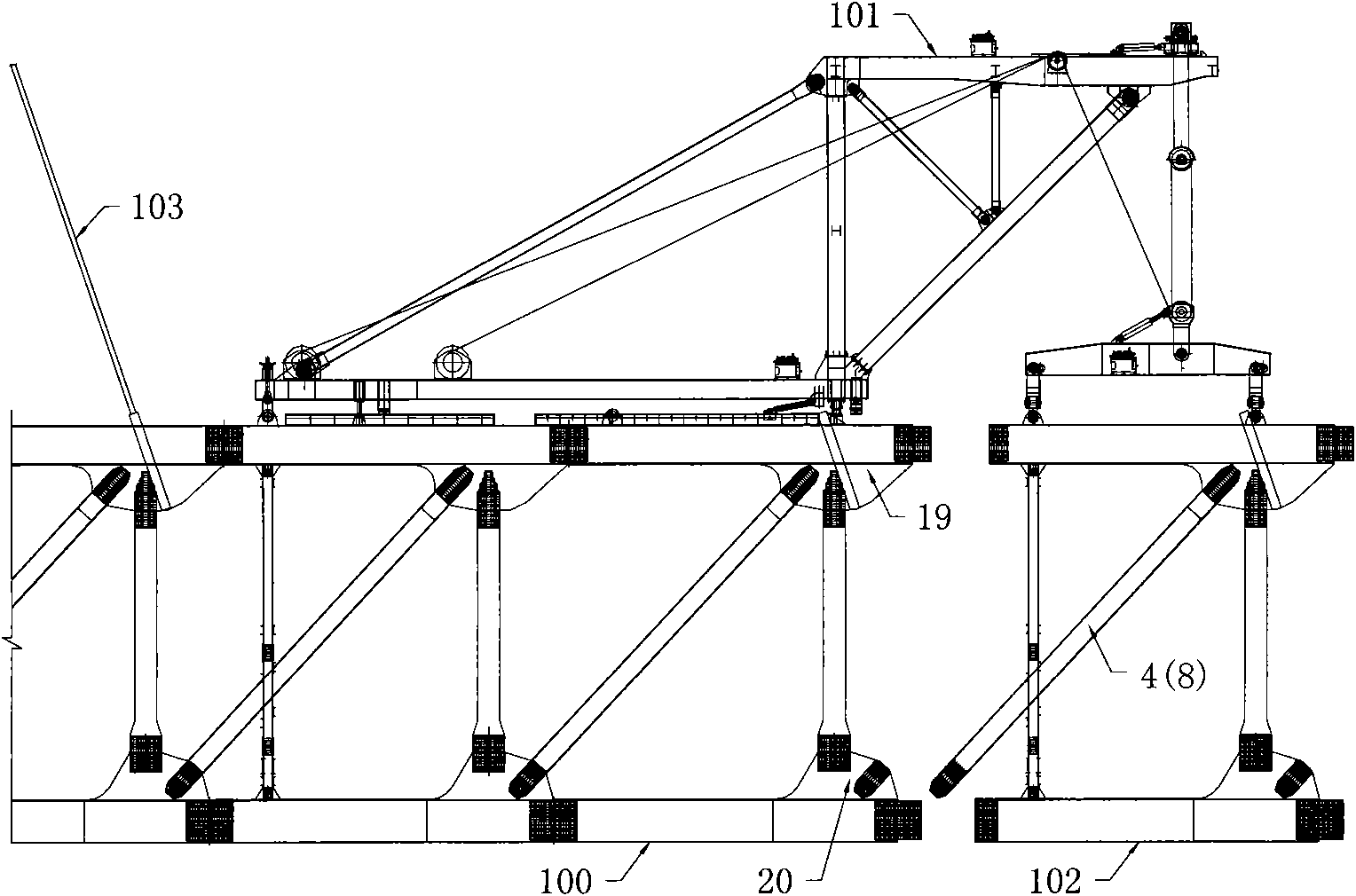

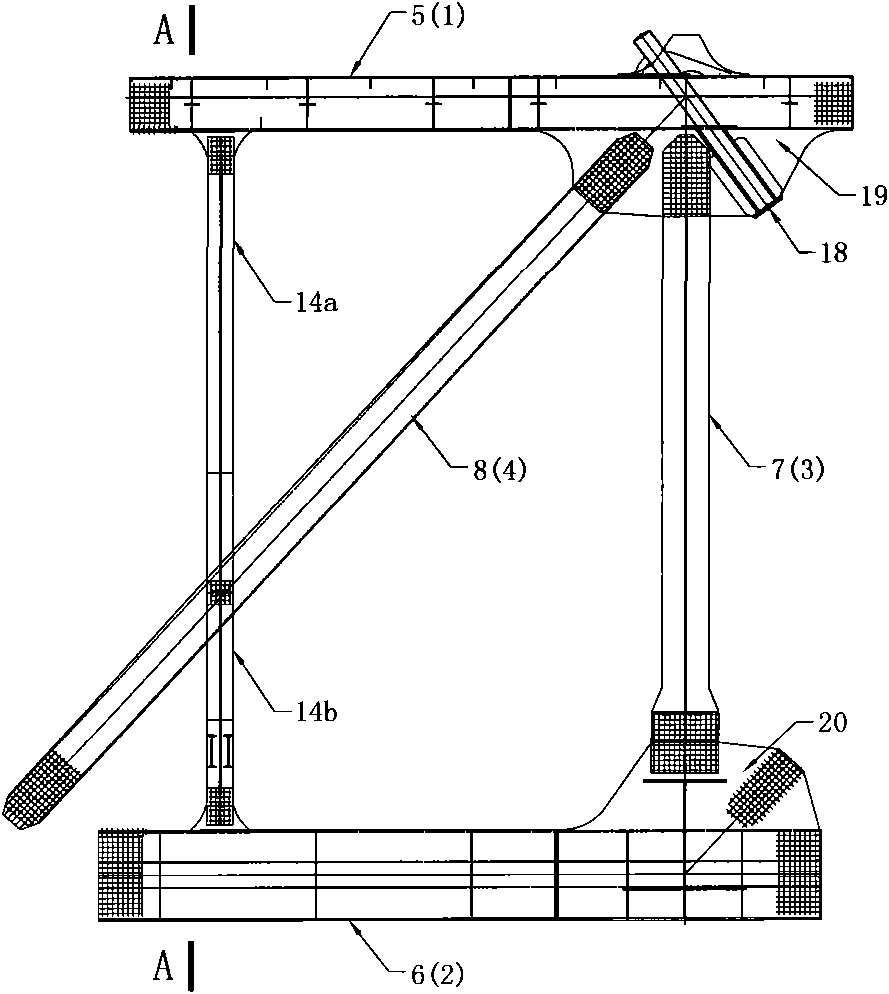

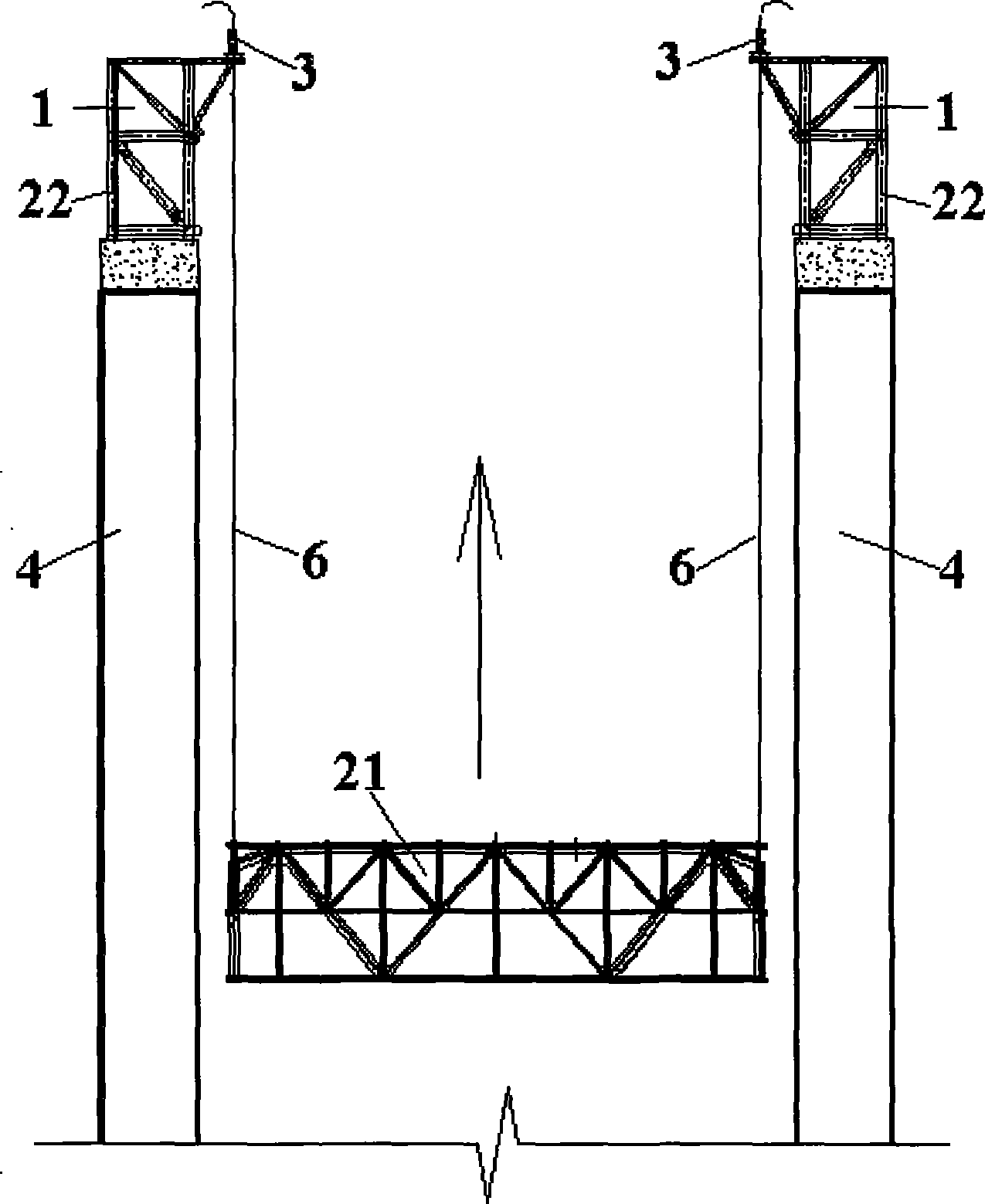

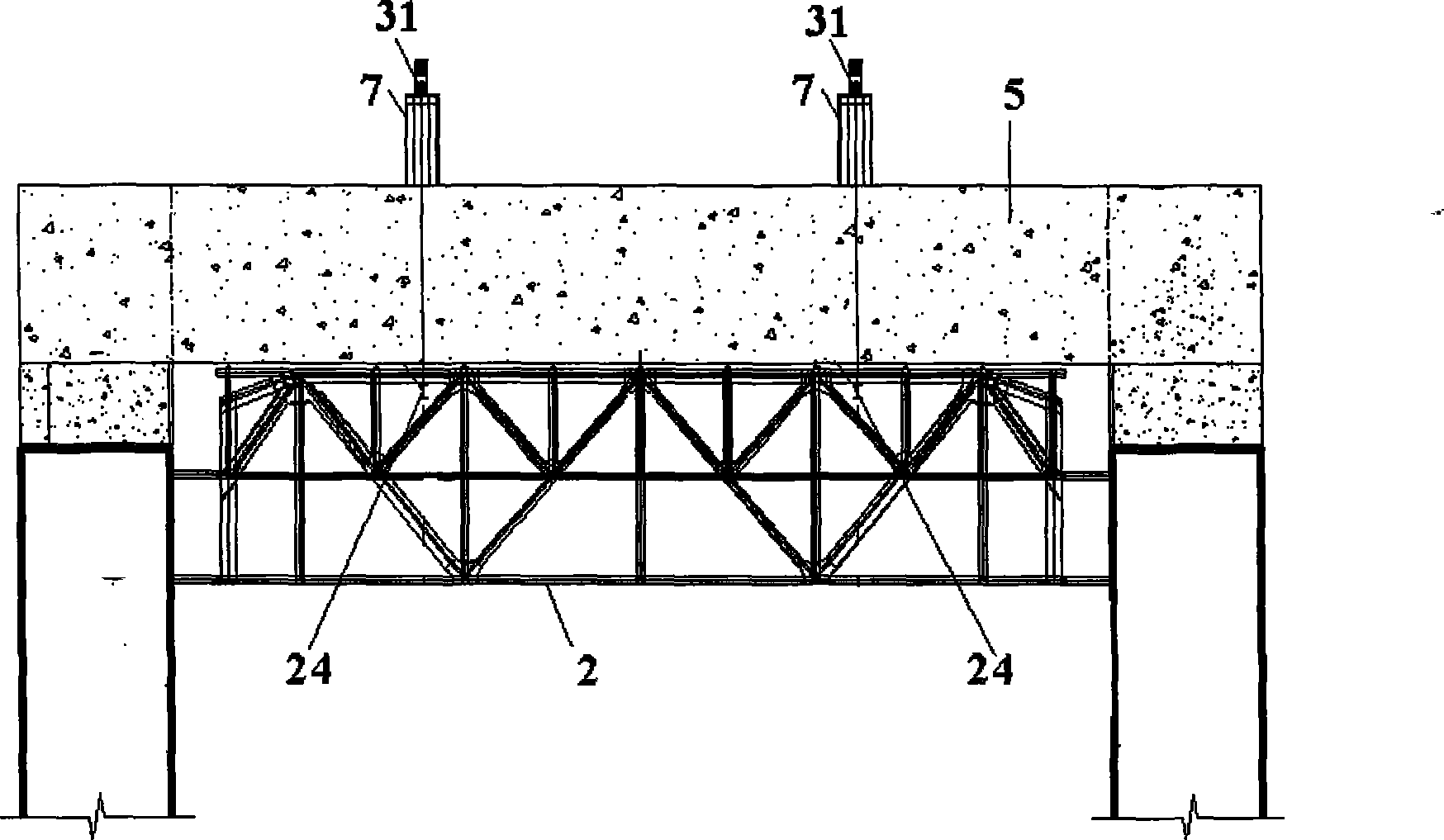

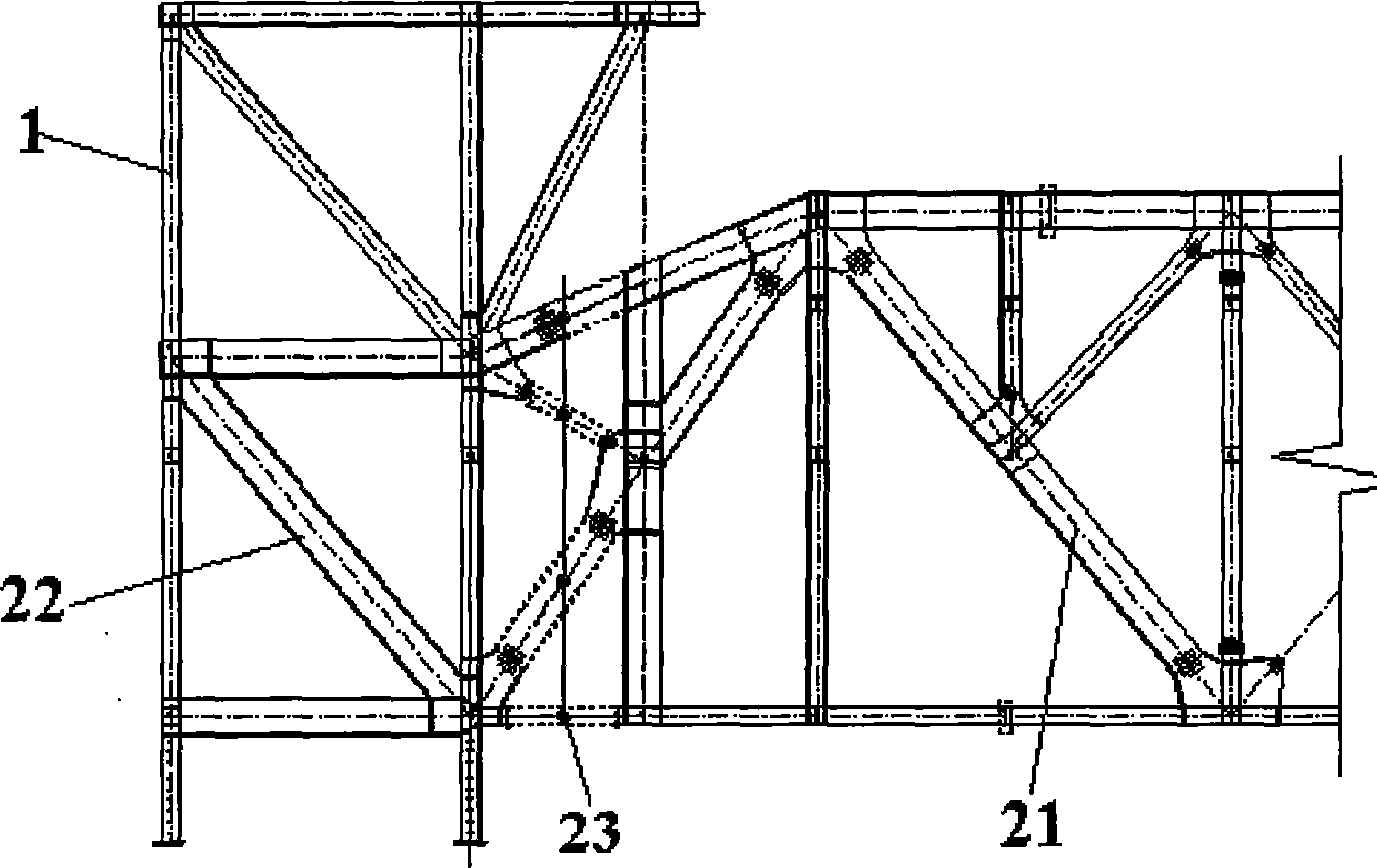

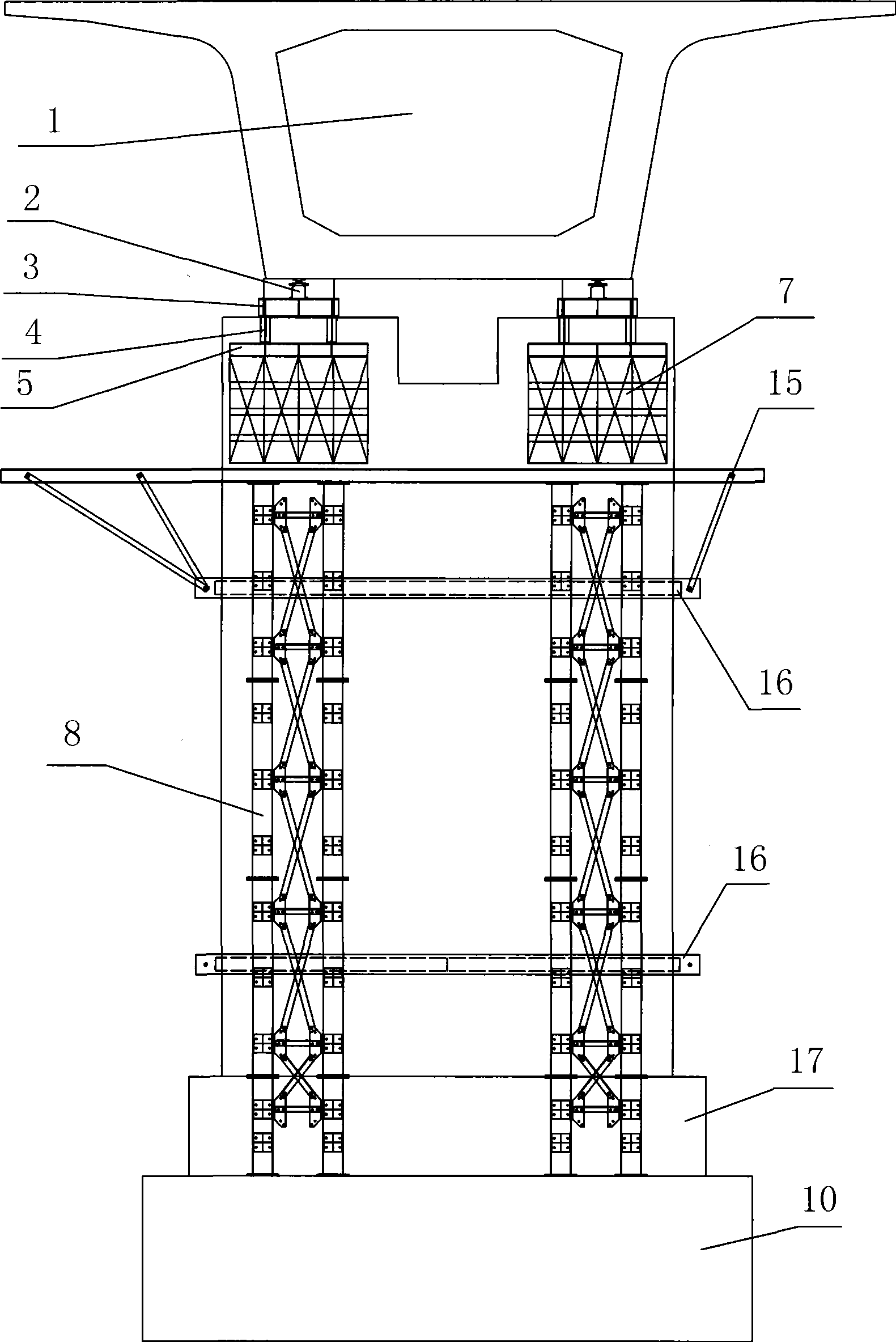

Long-span load-carrying cable lifting machine and mounting method therefor

InactiveCN101224856AReduce the impactReduce misalignmentBridge erection/assemblyCable carsHorizontal forceTraction system

The invention provides a long-span over loading cable crane and an installation method thereof which relates to a cable crane used in bridge construction and consists of a guy rope tower 1, a cable tower 2, a main cable and a hoisting traction system 3, an anchoring system 4, an electromechanical system 5 and a wind cable system 6. The tower of the cable crane consists of the guy rope tower 1 and the cable tower 2 which is hinged on the top of the guy rope tower 1 and fixedly connected with the bottom of the guy rope tower 1. The invention adopts the techniques of the parallel bearing of a plurality of main cables, the wind cables connected in series, the joint construction of the cable towel and the guy rope tower, etc., thereby greatly improving the loading capability of the long-span cable crane and lowering the manufacturing cost as much as possible. The invention can reduce the influence of the unbalanced horizontal force on the top of the cable tower 2 on the guy rope tower 1 and greatly save the construction cost of the guy rope tower 1. The loading cable crane has strong load-carrying capability, wide loading range and high economic performance.

Owner:CHINA MAJOR BRIDGE ENG

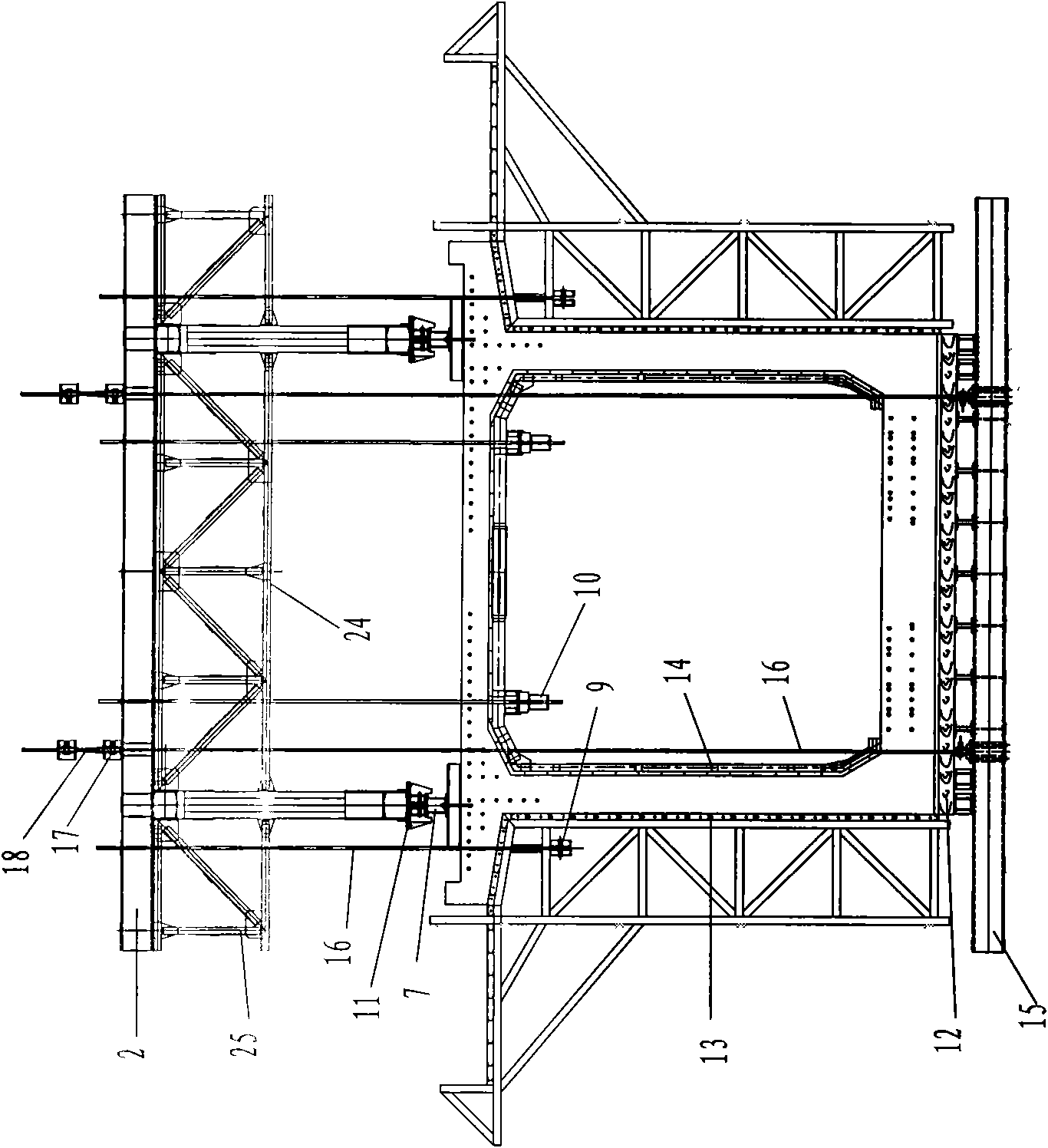

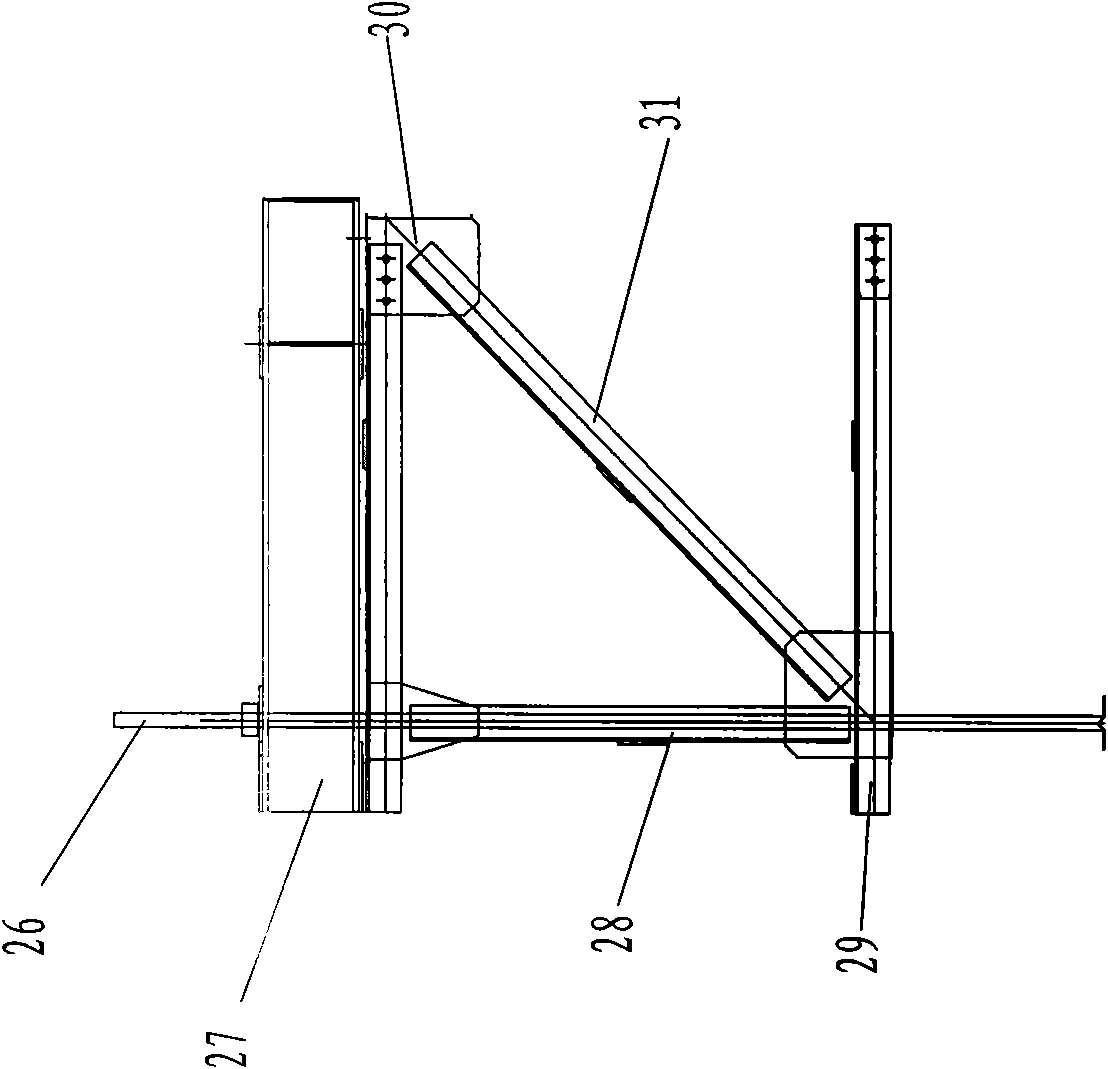

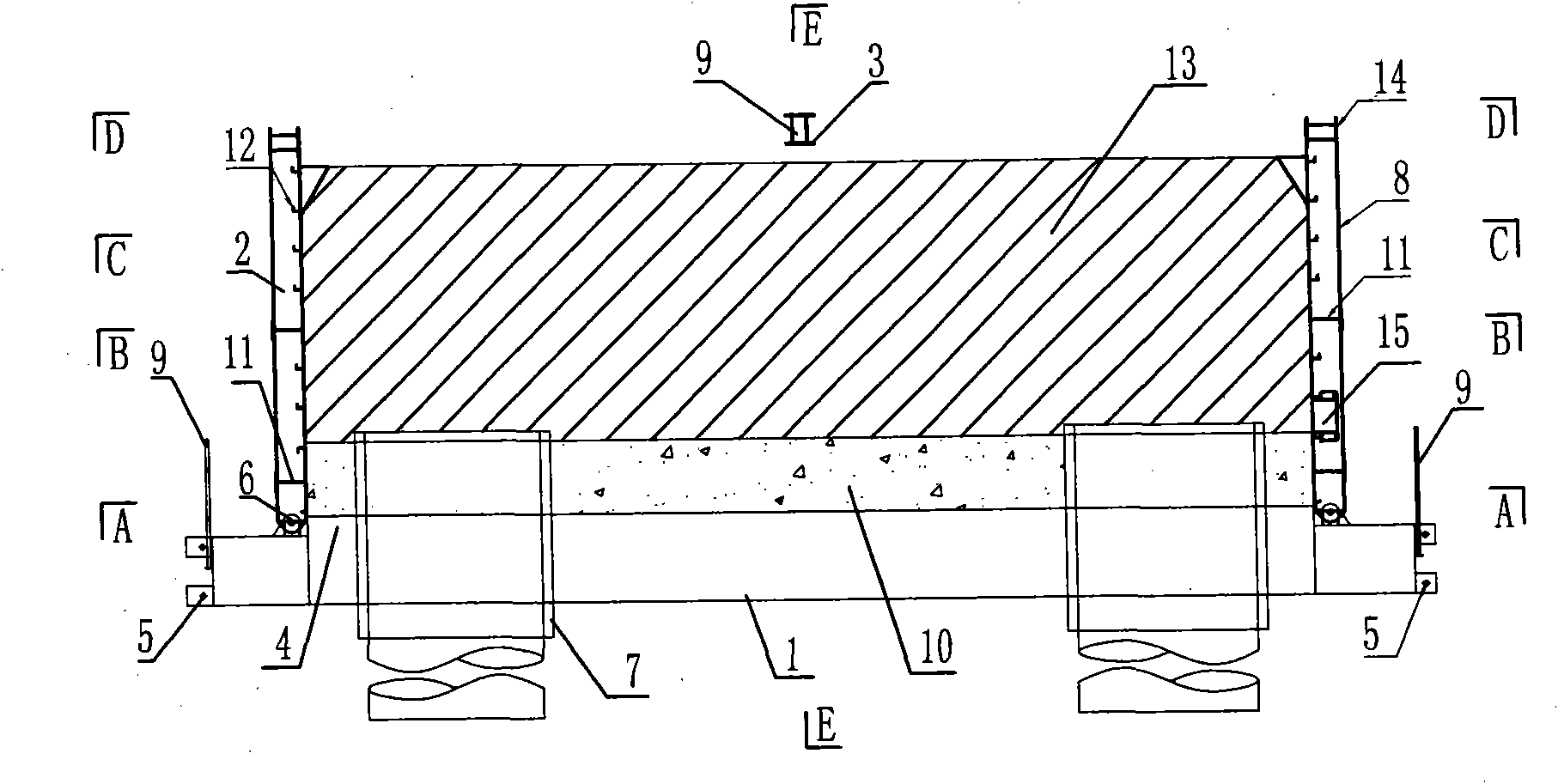

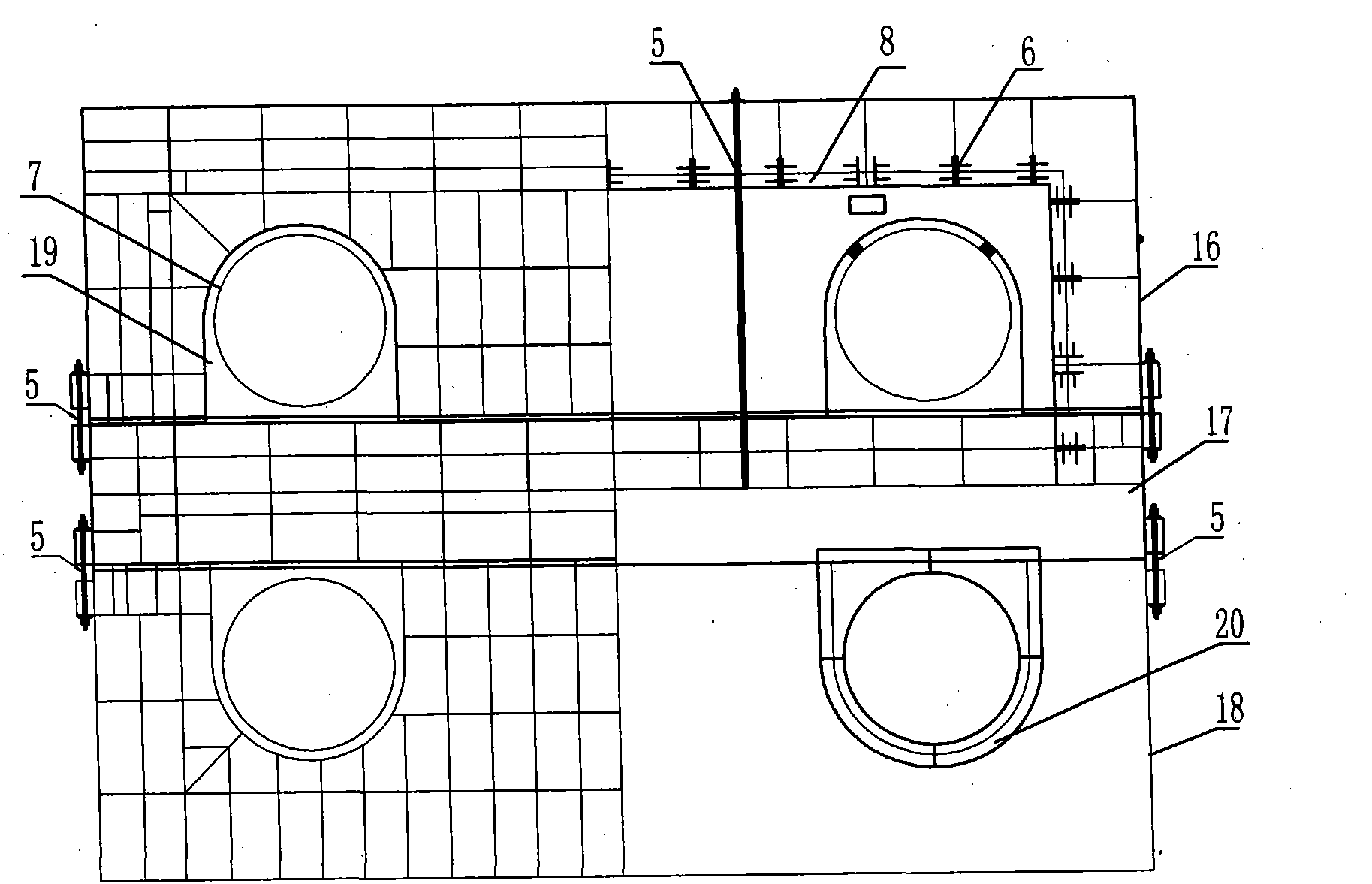

Receding construction method of cradle of continuous girder bridge made of prestressing concrete

The invention relates to a receding construction method of a cradle of a continuous girder bridge made of prestressing concrete, which is characterized in that the bridge surface of a bridge prefabricated by concrete is provided with a track and a door-shaped truss traveling device, and the width of a ceiling girder inside the door-shaped truss traveling device is wider than that of the bridge surface by 90cm-110cm; a front bottom cross beam and a rear bottom cross beam must extend to the outer side of an external mold by 45cm-55cm to form a main cradle truss, and an overhanging auxiliary door frame is additionally arranged outside the main cradle truss, after the construction of a closure segment of the bridge prefabricated by concrete is finished, and precise rolling deformed steel bars with the diameter of 32 outside a box girder positioned on the overhanging auxiliary door frame are connected with the rear bottom cross beam to disassemble a rear hanging strip; a bottom mold frame is separated from a beam body by utilizing a manual spiral type jack to loose the precise rolling deformed steel bars positioned on the door frame and the front bottom cross beam; a leading chain or a hoist are utilized to drive the main cradle truss so that the cradle recedes in a slideway to a first cast-in-situ segment; and a bottom mold and the external mold are fallen by the leading chain or the hoist to disassemble the main truss.

Owner:NO 1 ENG CO LTD OF CR11BG +1

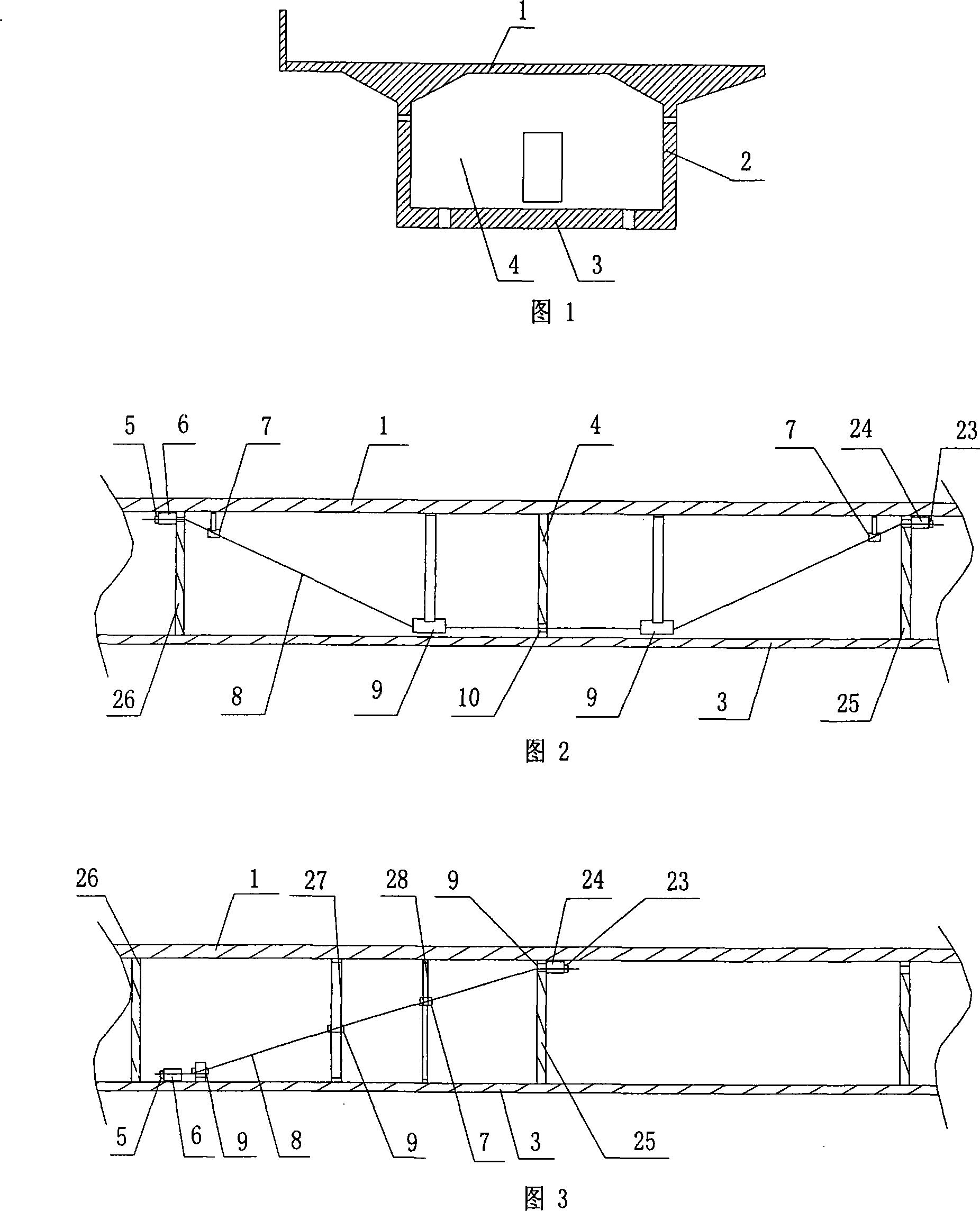

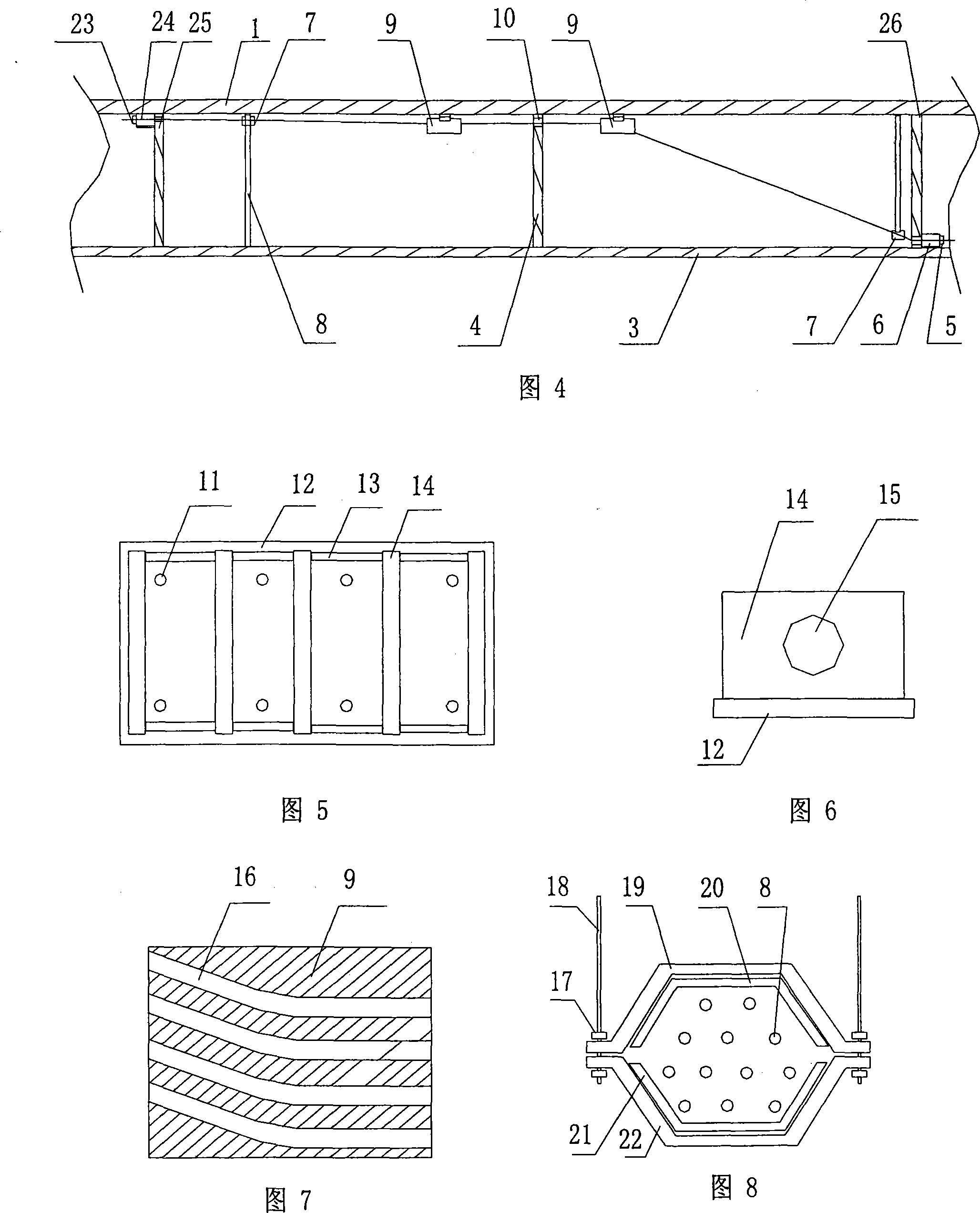

Construction method of marine self-floating type steel soleplate single-wall suspension box cofferdam and single-wall suspension box cofferdam

ActiveCN101775809AIncrease stiffnessReduce assembly processBridge structural detailsFoundation engineeringCofferdamAcceleration Unit

The invention discloses a construction method of a marine self-floating type steel soleplate single-wall suspension box cofferdam and a single-wall suspension box cofferdam, wherein the construction method comprises the following steps of: firstly installing a soleplate suspended shoulder pole girder and lowered guiding device of the cofferdam, then installing a steel soleplate, a lateral plate and an inner support, then carrying out the construction of lowering, fixing and bottom sealing by concrete of the cofferdam and finally carrying out the construction of a bearing platform. The cofferdam can be repeatedly used after being dismantled. The marine self-floating type steel soleplate single-wall suspension box cofferdam comprises the steel soleplate, the lateral plate, the inner support and the soleplate suspended shoulder pole girder and lowered guiding device. The steel soleplate of the invention is of a self-floating type assembled structure, an inner inclined strut of the cofferdam is utilized as a distributing girder suspended on the cofferdam when in the construction of bottom sealing by concrete, the lateral plate adopts a massive integral design, and meanwhile, an inner guide girder and the lateral plate are combined into a whole, thereby improving the integral rigidity of the lateral plate and also reducing the assembled working procedures of the cofferdam. The invention has the advantages of effective acceleration of construction schedule, simple and convenient construction operation, high repeated use ratio, safety, reliability and less cost investment.

Owner:THE 5TH ENG MBEC

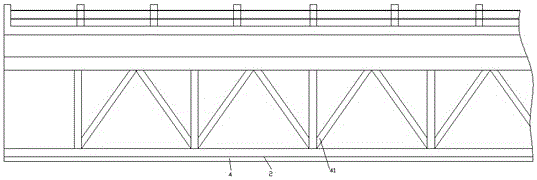

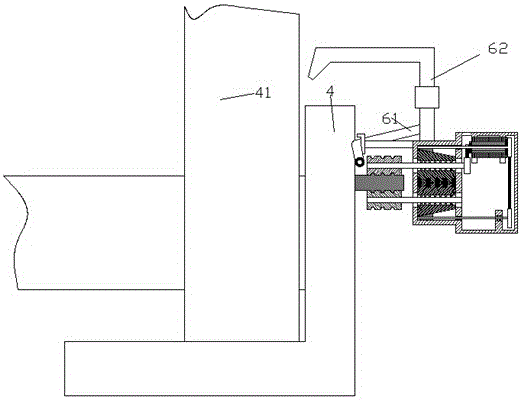

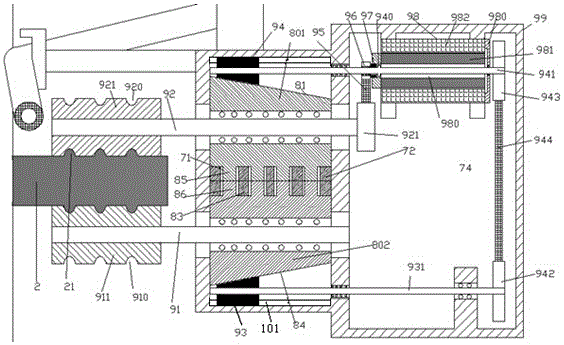

Automatic cleaning and maintaining device for building bridge

InactiveCN105040618AAvoid Large Dangling AreasPrevent excessive compressionRoad cleaningBridge erection/assemblySpray nozzleEngineering

The invention relates to an automatic cleaning and maintaining device for a building bridge. The automatic cleaning and maintaining device is used for cleaning and maintaining the bridge. The bridge comprises a cross main beam (4) and an auxiliary beam (41), wherein the cross main beam (4) is provided with a guide rib (2) extending transversely, and the auxiliary beam (41) is supported by the cross main beam (4). The automatic cleaning and maintaining device comprises a supporting frame (99), a water supply pipe (61) and a spray nozzle (62) communicated with the water supply pipe (61) to be aligned with the part, needing to the cleaned, of the bridge to carry water spraying cleaning, wherein the water supply pipe (61) is supported by the supporting frame (99) and is close to the main beam (4). The upper surface and the lower surface of the guide rib (2) are provided with a plurality of guide protrusions extending along the guide rib (2).

Owner:罗瑛

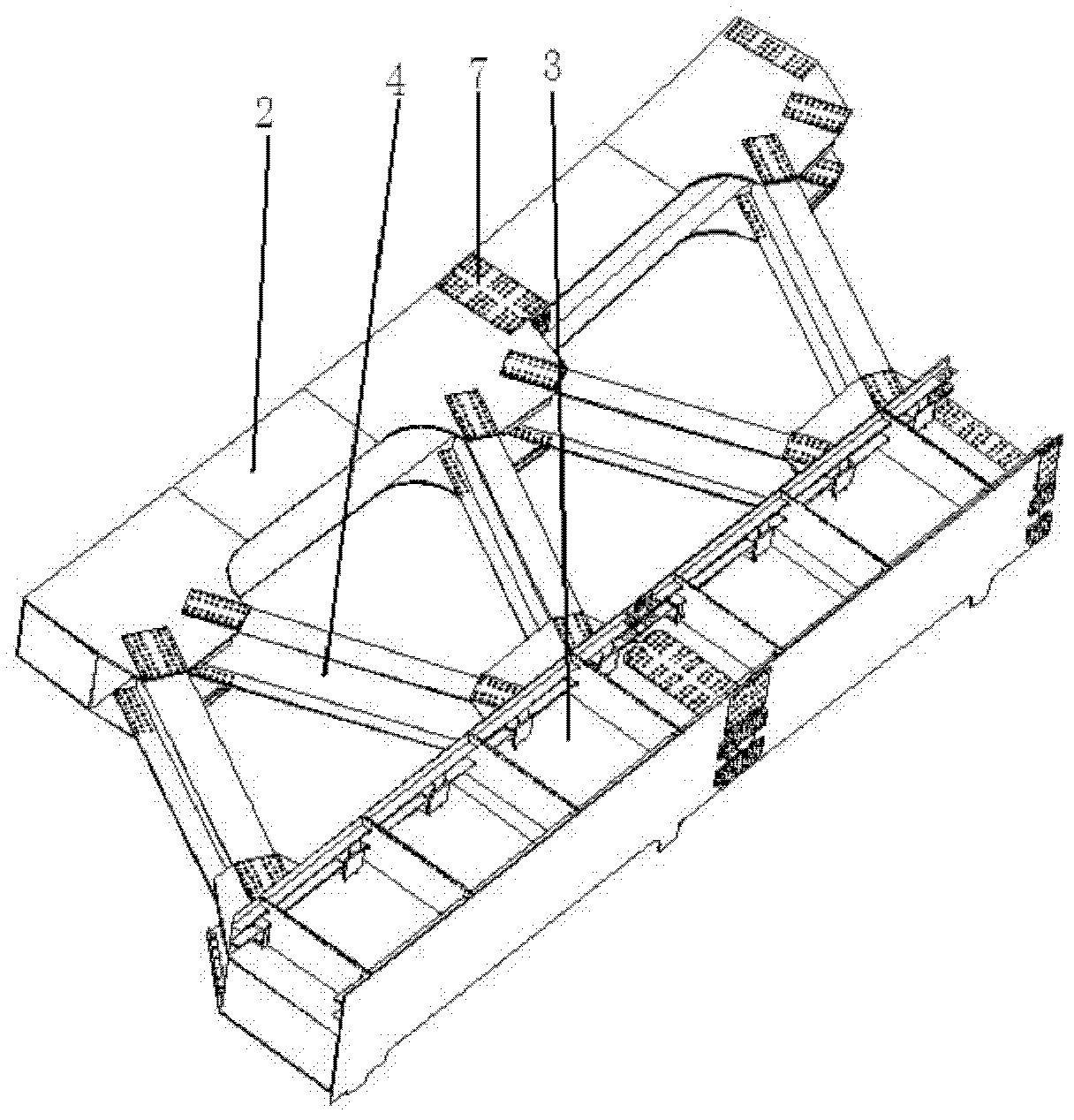

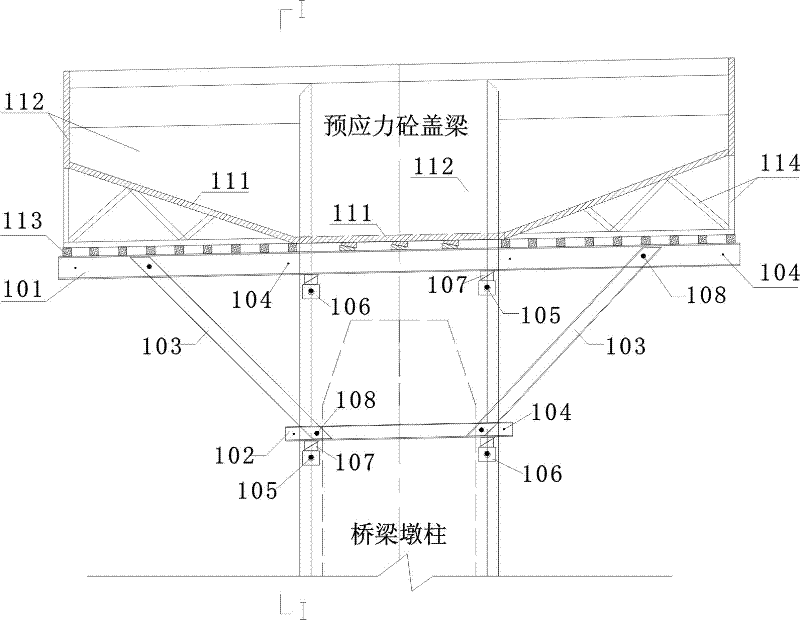

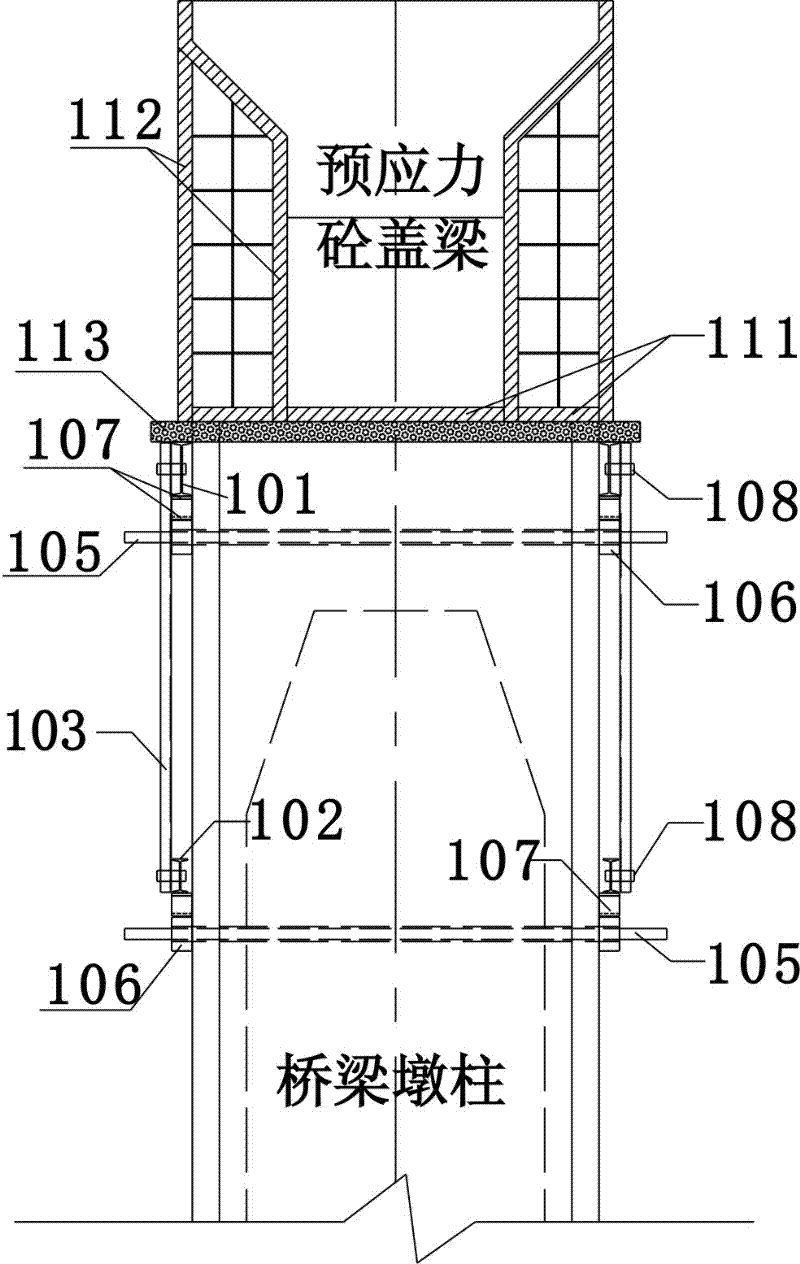

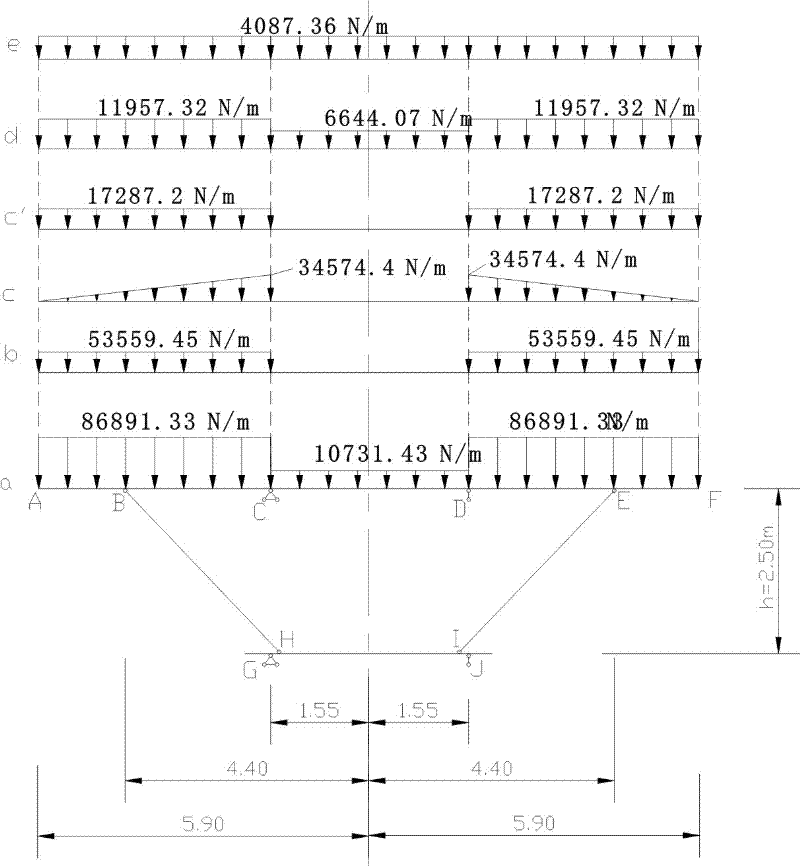

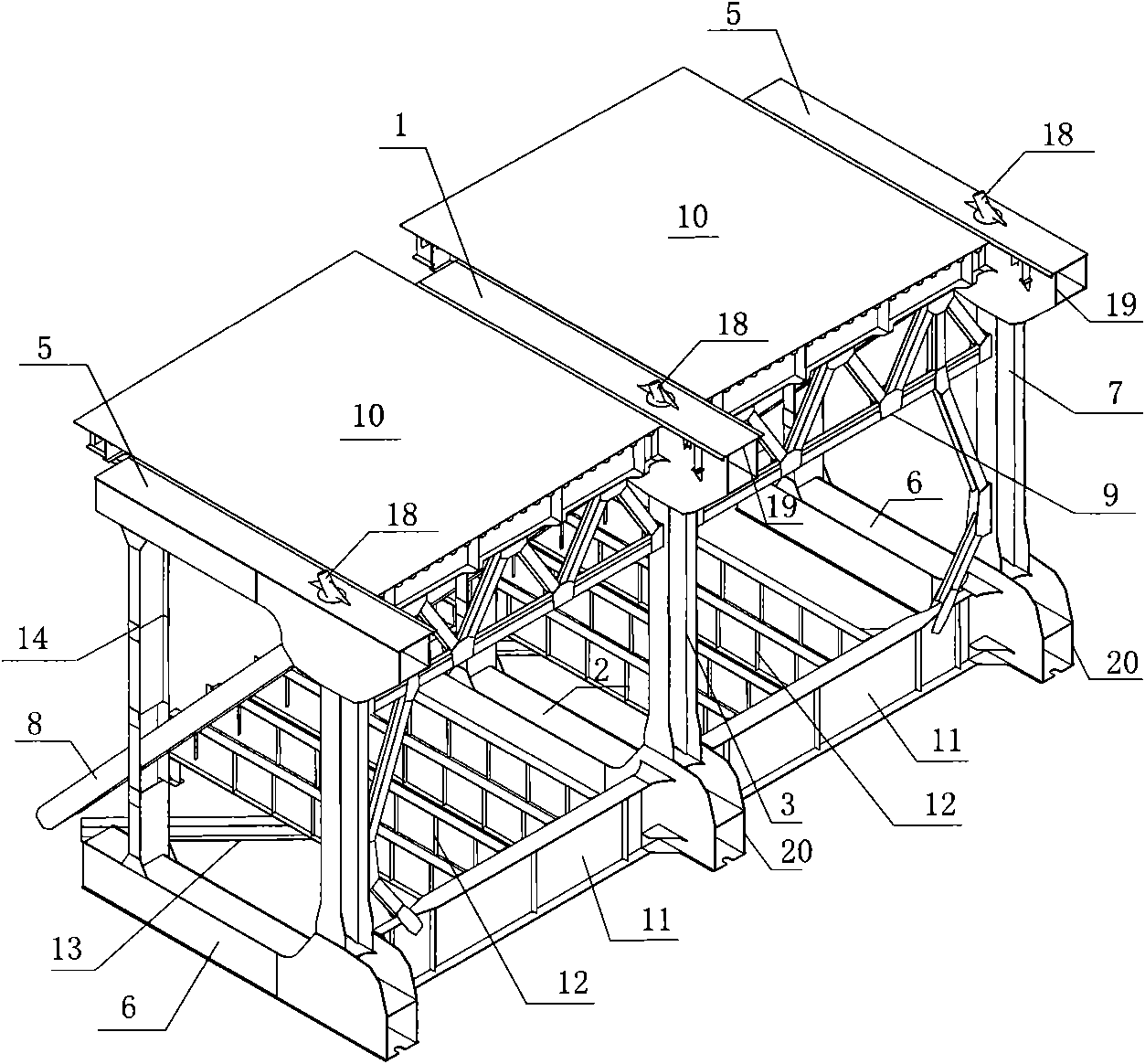

Box-shaped bracket system and its installation method for single-column pier groups of bridges

ActiveCN102286925ASimple structureEasy structure calculationBridge erection/assemblyTerrainMaterial consumption

The invention discloses a bridge single column pier assembled box bracket system, which is characterized in that box bracket plates are arranged on two sides of a pier below a capping beam; and each bracket plate comprises an upper longitudinal beam, a lower longitudinal beam and diagonal bracings symmetrically arranged, wherein the upper longitudinal beam, the lower longitudinal beam and the diagonal bracings are manufactured by profile steels; and the bracket plates on the two sides of the pier are pulled and fastened by a round steel pull rod to form an integrated bearing system in order to improve the whole stability of the bracket. The system is stably supported on the pier by a round steel rod, so that the anti-overturning capability of the bearing system is improved in the construction process of the capping beam. The box bracket has the advantages of simple and convenient structural calculation, good stressing condition and safety and stability, little material consumption, high working efficiency, low cost, good economy and the like, and the construction is not limited by terrain.

Owner:四川路航建设工程有限责任公司

Three-truss main girder structure of highway and railway bi-purpose cable-stayed bridge and installation method thereof

ActiveCN101603288AImprove installation efficiencySave installation timeBridge erection/assemblyLoad-engaging elementsButt jointCable stayed

The invention relates to a three-truss main girder structure of a highway and railway bi-purpose cable-stayed bridge and an installation method thereof, relating to the technologies of designing and constructing a heavy load and long span highway and railway bi-purpose cable-stayed bridge. The structure of three main trusses comprises a middle truss piece and side truss pieces arranged on both sides of the middle truss piece, wherein an orthotropic slab and a transverse bracing truss are arranged between the upper edges of the middle truss piece and each side truss piece, and a railroad transverse girder, a railroad longitudinal girder and a horizontal bracing cross bridging are arranged between the lower edges of the middle truss piece and each side truss piece; and the invention provides the installation method adopting adaptive pre-splicing of multiple truss-sections, arrangement of temporary constructional rod pieces, integral lifting of each truss section and multi-node simultaneous alignment. The invention has the beneficial effects of: 1. pushing the highway and railway bi-purpose cable-stayed bridge to develop towards the direction of large span and heavy loading, 2. improving the installation efficiency and quality, 3. reducing the quantity of welding lines of construction sites, 4. innovatively practicing the multi-point simultaneous butt joint technology, 5. adopting the temporary rod pieces for solving the problems of unstability and large deformation in the processes of delivering and lifting the truss sections, 6. strengthening the adaptability of adjacent truss sections, and 7. solving the problems of inconsistent deformation of the middle and the side trusses and inconsistent centre-of-gravity positions of the truss sections.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

Construction method for chamber type bridge maintaining external pre-stress

InactiveCN101173505AEasy constructionFlexible constructionBridge erection/assemblyBridge strengtheningPre stressPre stressing

The invention discloses an external prestressing construction method for box bridge maintenance, which is characterized in that: 1). The position of an anchor block, a redirector and a shock absorber are decided according to external cable arranging mode for external prestressing; 2). The installation of the anchor block: 2.1). concrete base surface processing; 2.2). hole drilling, hole cleaning and reinforcing bar planting; 2.3). the installation of steel-bonded steel plate: the anchor block comprises a steel-bonded steel plate, a connecting plate and a stiffening plate; all anchor bolts are penetrated through a corresponding fixing hole on the steel-bonded steel plate; 2.4). the installation of other steel plates for the anchor block; the connecting plate is welded with the steel-bonded steel plate, the stiffening plate is welded with the steel-bonded steel plate and is provided with a through hole for external cable; 2.5). glue pouring for the steel-bonded steel plate: glue pouring is made between the steel-bonded steel plate and the concrete base surface for the anchor block; 3). Horizontal partition wall perforation; 4). The installation of a redirecting support and a damping support; 5). The installation of the redirector; 6). Penetrating and tension of prestressing steel strand; 7). The installation of the shock absorber. The invention has the advantages of convenient construction, flexibility and stronger reliability.

Owner:CHINA FIRST METALLURGICAL GROUP

Integral hoisting system for superaltitude overlong jumbo beam by truss method and construction method thereof

InactiveCN101446135AImprove construction progressReduce safety hazards of falling objectsBridge erection/assemblyBuilding material handlingLow altitudeFalling Objects

Owner:SHANGHAI CONSTR NO 1 GRP

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

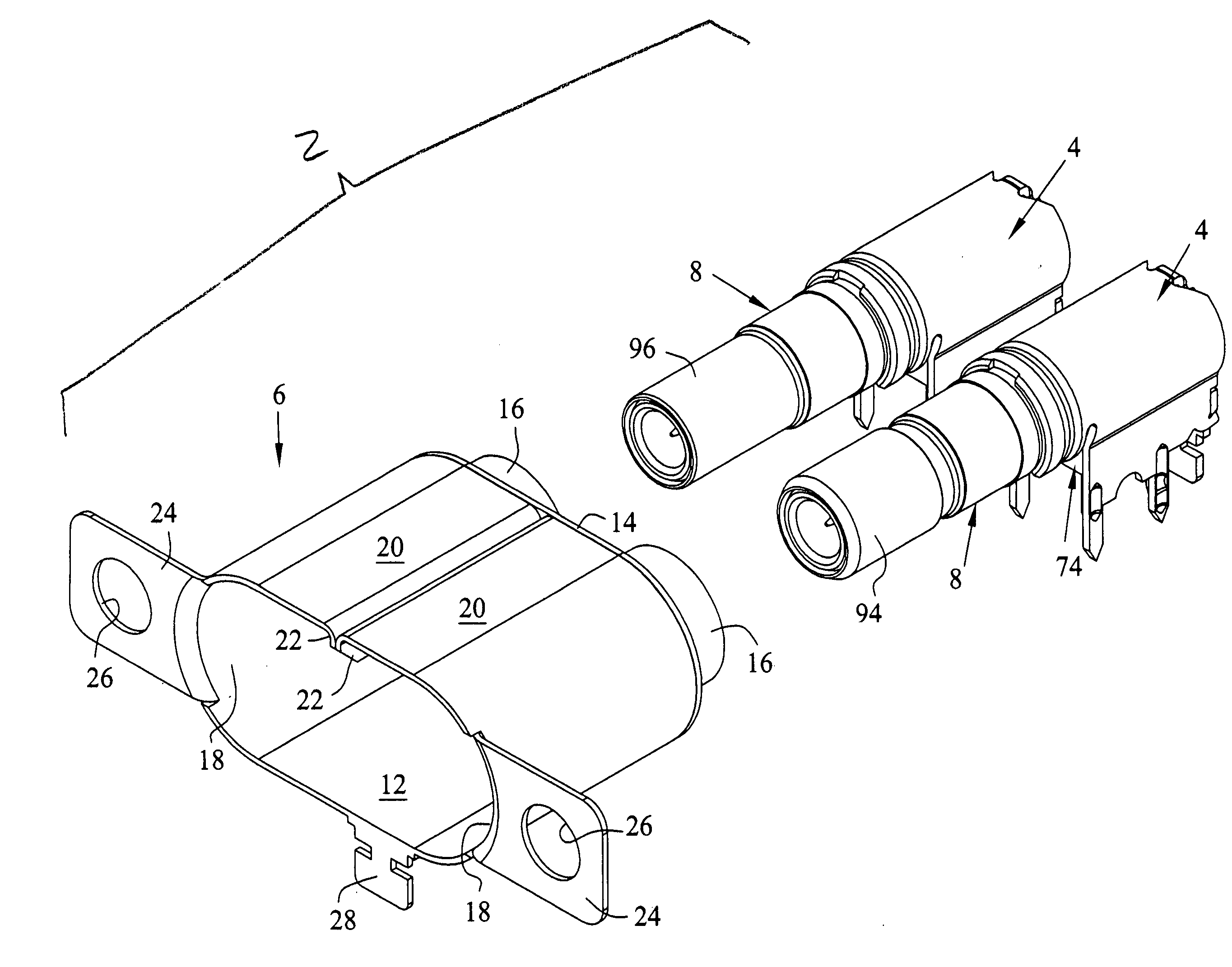

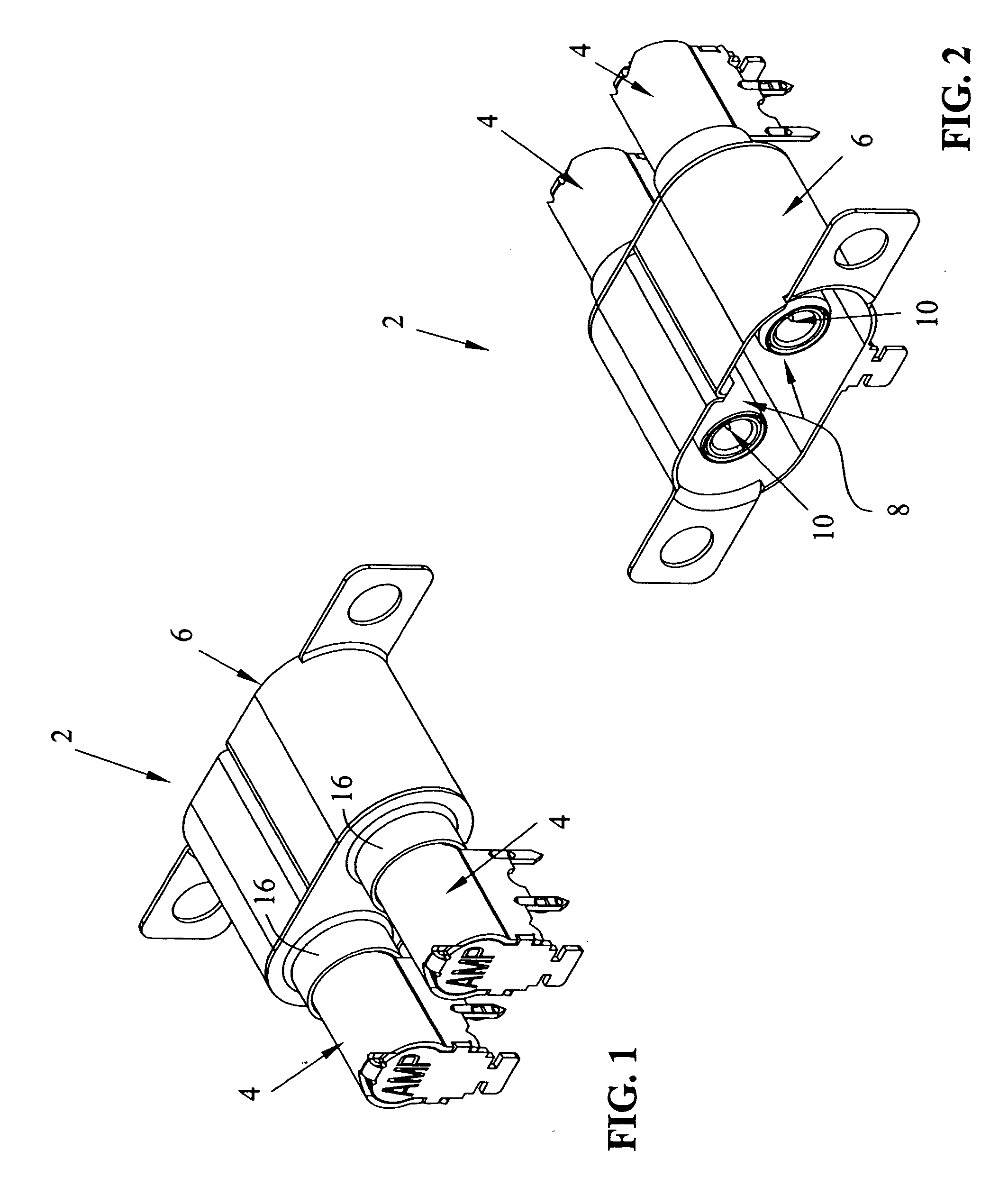

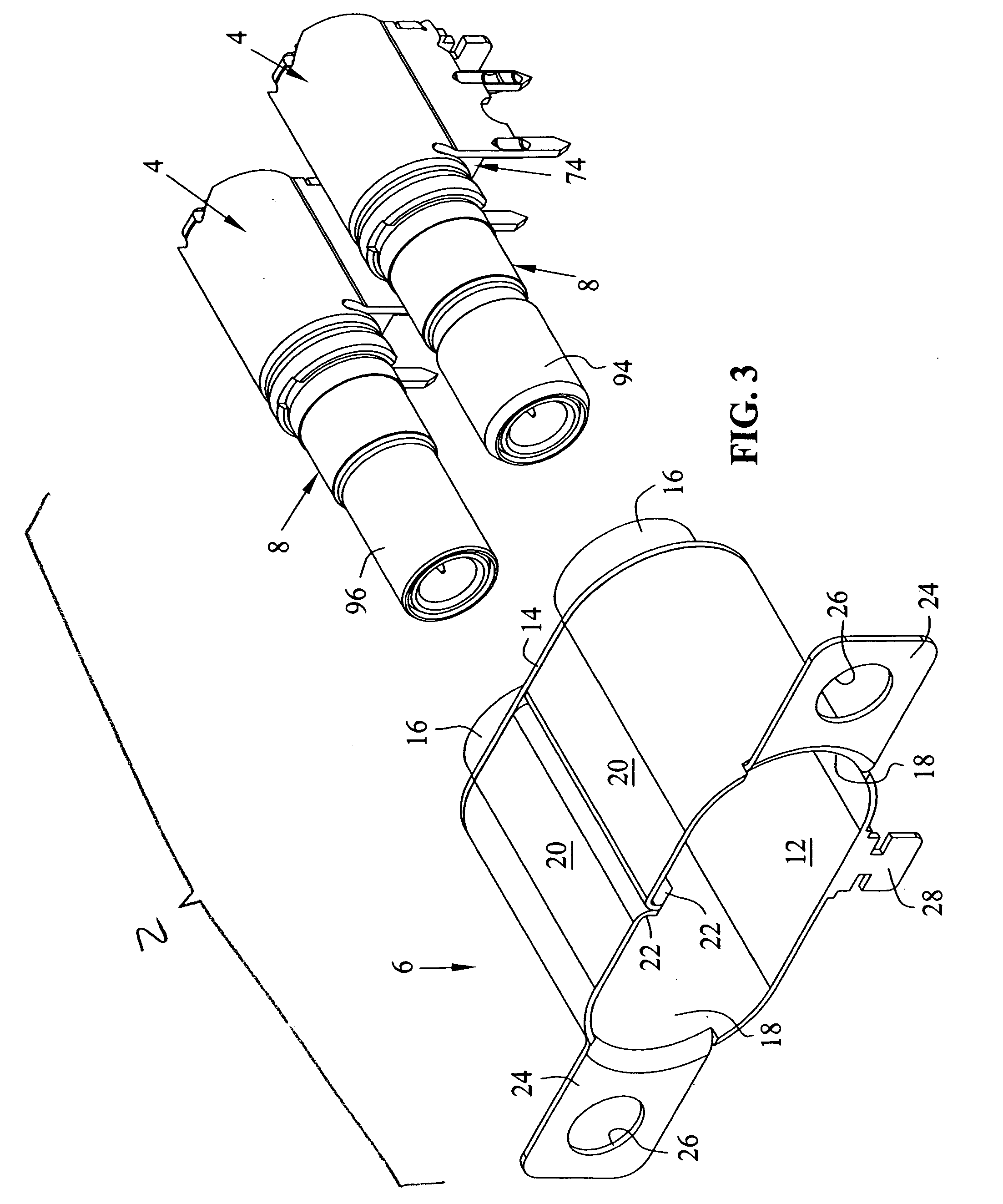

Shielded electrical jack connector

InactiveUS20050221673A1Two pole connectionsContact member cases/bases manufactureEngineeringMechanical engineering

A shielded jack assembly is shown having a front cylindrical tube, and a rear ground shell portion. The rear ground shell is stamped and formed from pre-plated metal, and includes a partial cylindrical portion, plate portions extending downwardly therefrom, and printed circuit board portions depending from the plate portions. A rear wall portion is integral with the partial cylindrical portion, and depends therefrom via a hinge. The rear wall portion is bent to cover the end opening in the partial cylindrical portion.

Owner:TE CONNECTIVITY CORP

Bridge span replacement system

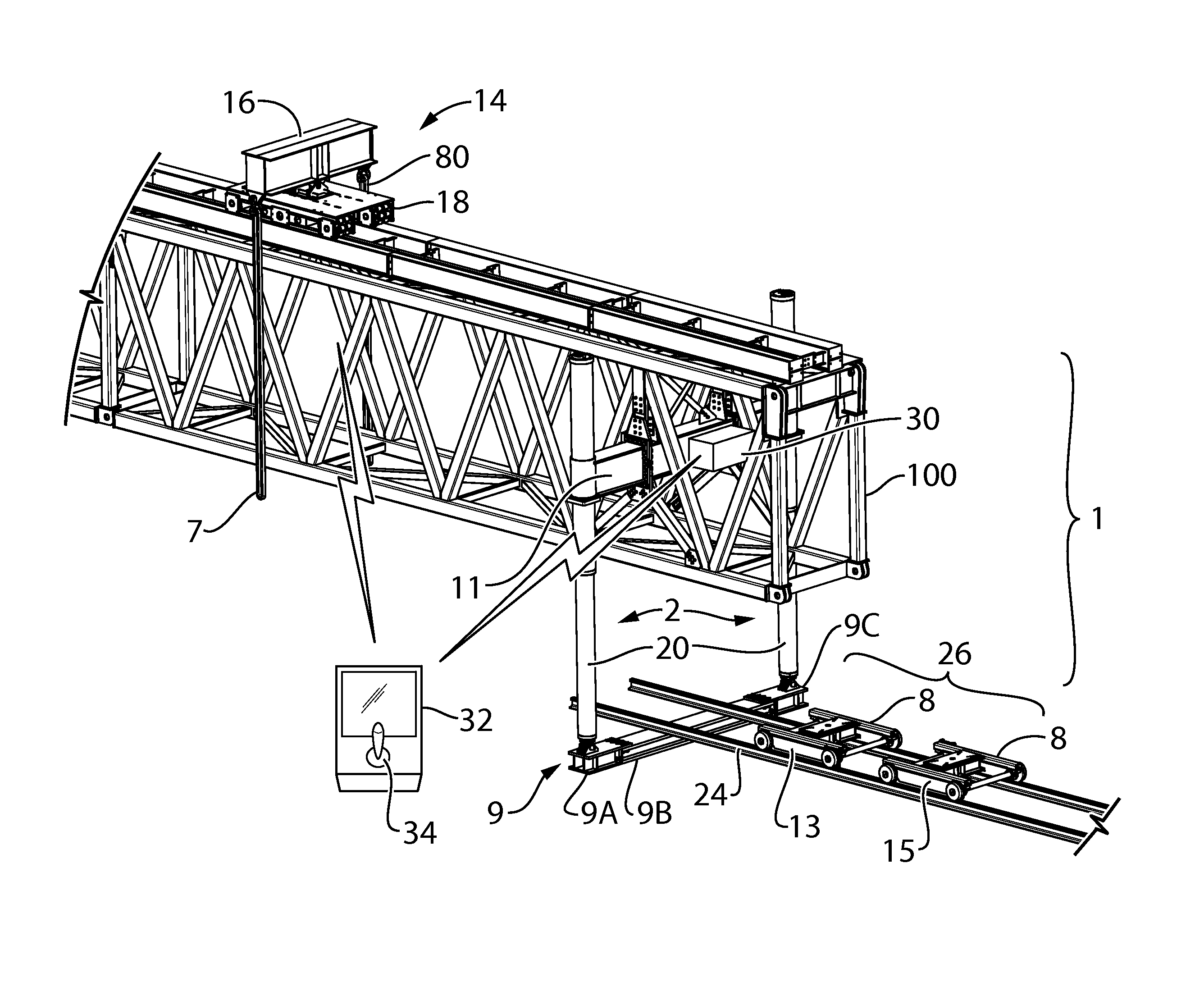

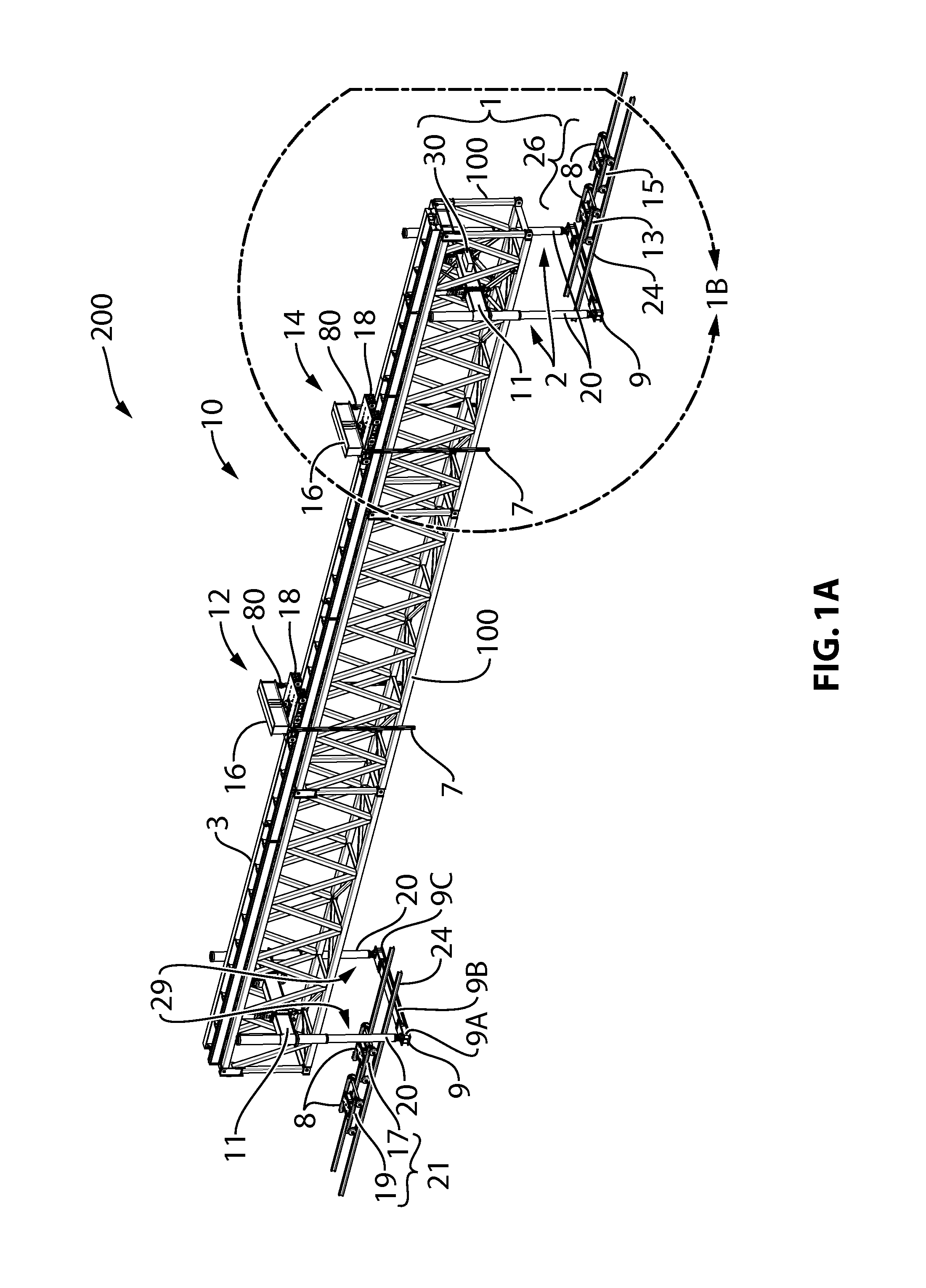

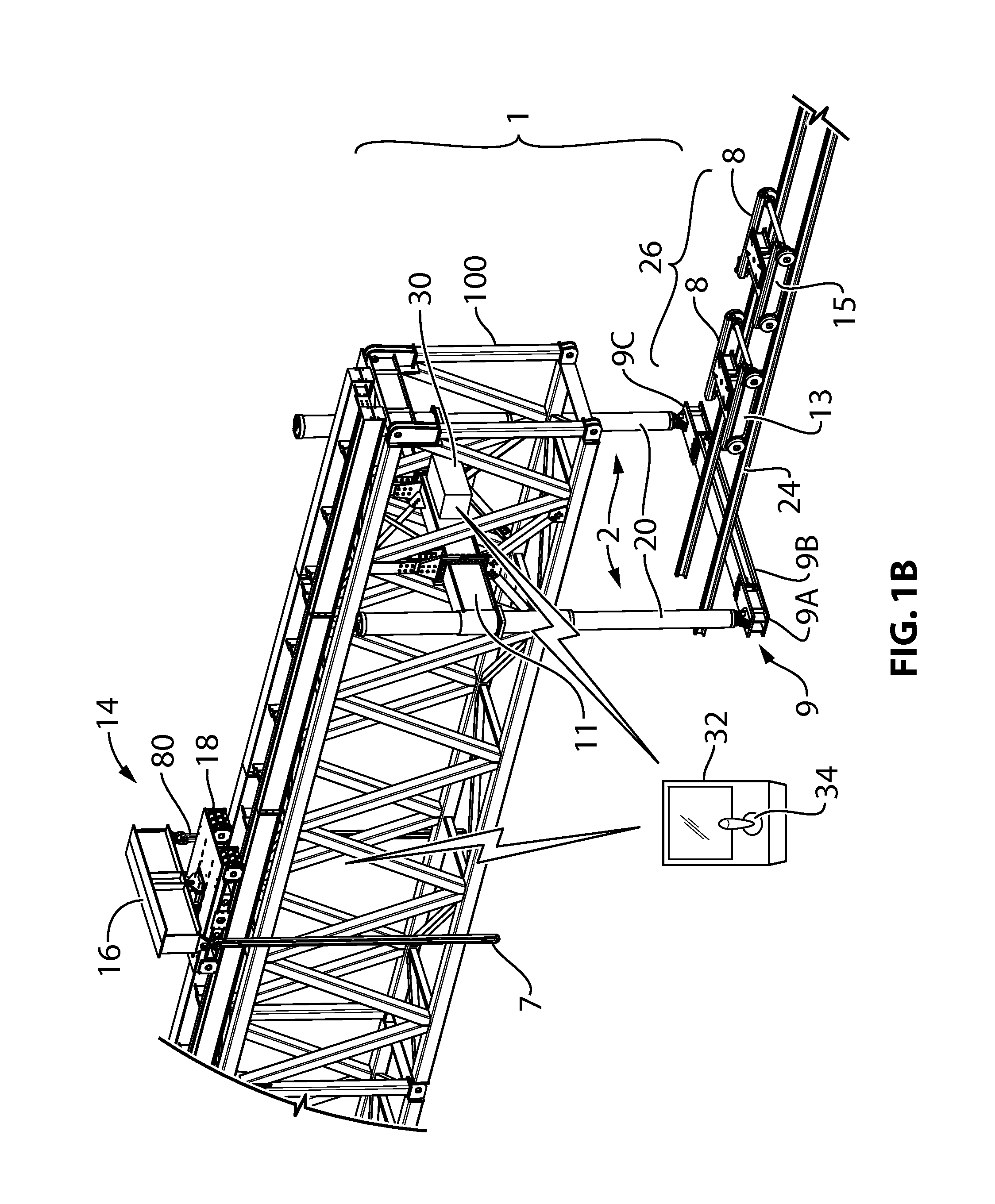

InactiveUS8671490B1Compact configurationPrecise positioningPortable bridgeBase supporting structuresEngineeringSupport surface

A vertically-adjustable gantry assembly installation adapted for removal or placement of a train bridge-span of the type which spans and is supported by two piers, comprises a gantry assembly positioned on load-bearing first ground-support locations, the gantry assembly comprising a gantry and a ground-engaging vertical support and lift system, the vertical support and lift system adapted for supporting a combined weight of the gantry and a bridge span in at least one operational vertical position above respective bridge span support-surfaces of the piers including a position corresponding to a disembarking plane in which the leg portions are extended from a stowed position to an extent at least sufficient for the gantry assembly to self-liftoff the pre-installation conveyance system onto the first ground-support locations to effect the gantry assembly installation.

Owner:WESTERN MECHANICAL ELECTRICAL MILLWRIGHT SERVICES

Popular searches

Thermometers using material expansion/contaction Converting sensor ouput using wave/particle radiation Volume/mass flow measurement Material analysis by electric/magnetic means Alarms Subscribers indirect connection Transmission systems Wireless architecture usage Record carriers used with machines Bridge repair

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com