Damage-controllable self-resetting section prefabricated assembled steel pipe concrete bridge pier and manufacturing method thereof

A technology of steel tube concrete and prefabricated assembly, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., which can solve the problems of less research and engineering practice, less research and development and application of steel tube concrete, and achieve convenient installation and construction, save formwork cost, The effect of reducing the amount of pouring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

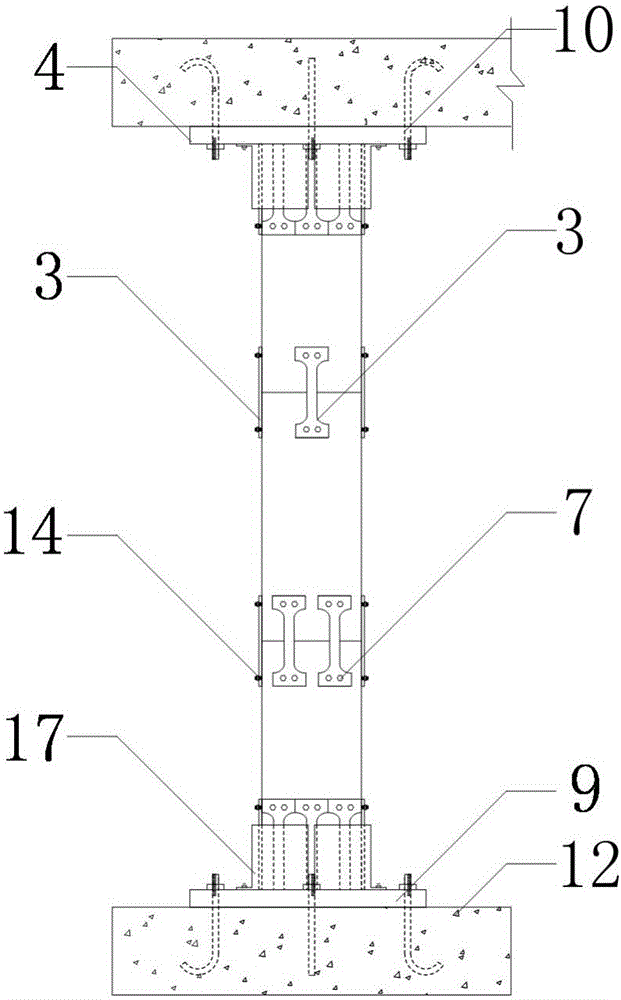

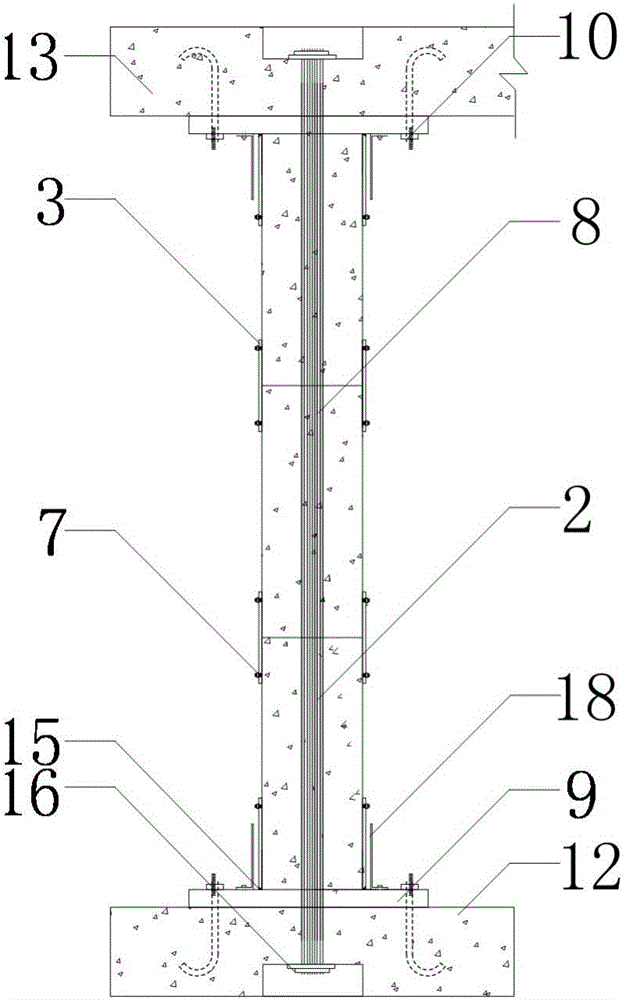

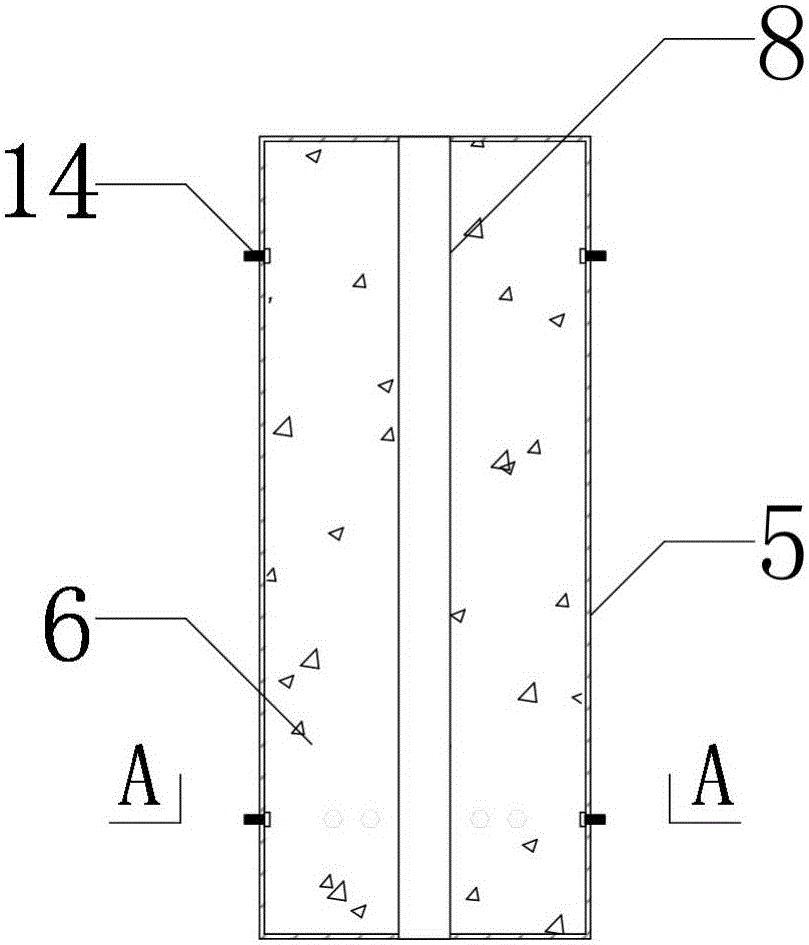

[0036] like Figure 1-7 As shown, a damage-controllable self-resetting section prefabricated assembled concrete-filled steel pipe pier includes a prefabricated steel-filled steel pipe concrete section 1, prestressed tendons 2, energy-dissipating connectors 3, exposed node connectors 4, caps 12 and Cover beam 13.

[0037] The end faces of the adjacent prefabricated steel pipe concrete sections 1 are aligned, and the steel pipe section 5 is the external structure of the prefabricated steel pipe concrete section 1, which is arranged at the junction of adjacent steel pipe sections 5 through energy-dissipating connectors 3, and is connected by high-strength bolts The nut 7 connects and fixes the energy dissipation connector 3 and the steel pipe segment 5 .

[0038] When pouring the platform 12 and the cover beam 13 , the pre-embedded anchor bolts 10 of the exposed node connectors 4 are pre-embedded in the platform 12 and the cover beam 13 . The foot plate 9 is respectively anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com