Section steel concrete- punched steel plate-concrete combined shear wall and method for producing the same

A combined shear wall and concrete technology, applied to walls, building components, and earthquake resistance, can solve problems such as concrete spalling and reduce the seismic resistance of shear walls, so as to improve the shear bearing capacity, stabilize the seismic performance in the later stage, and improve the bearing capacity effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

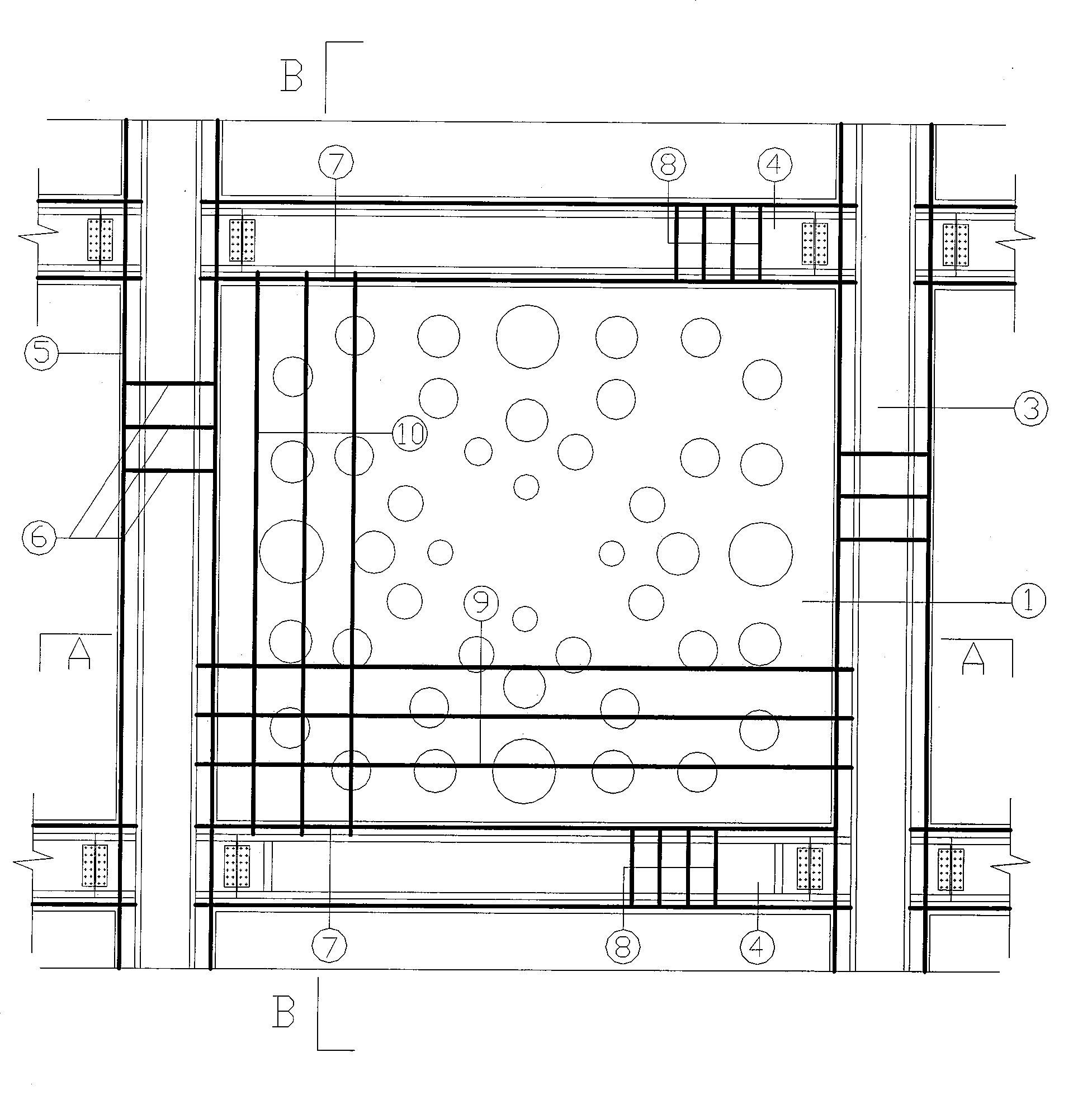

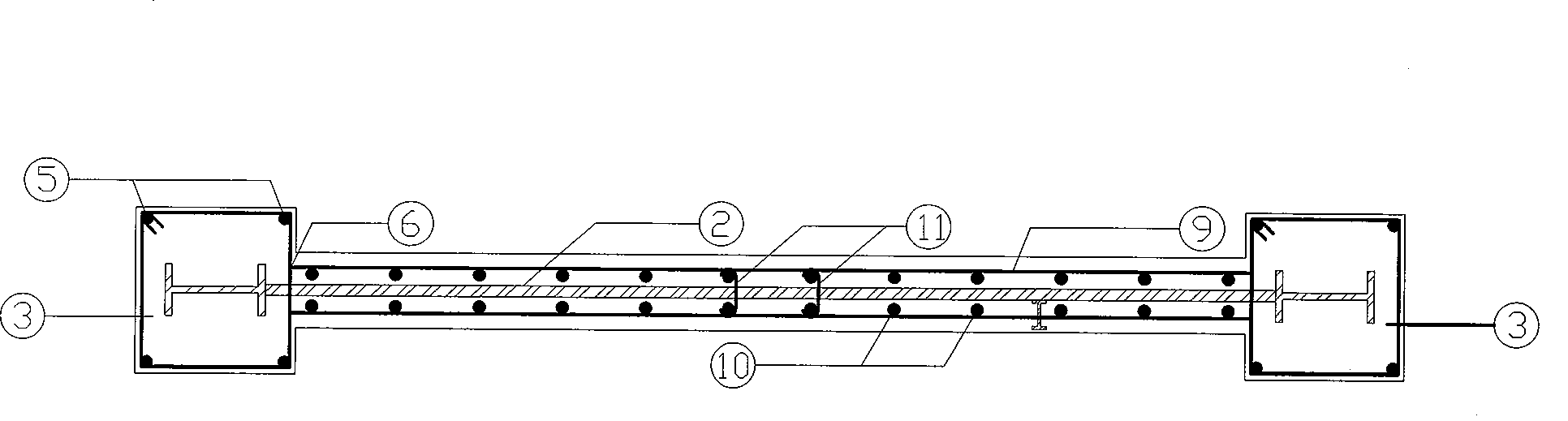

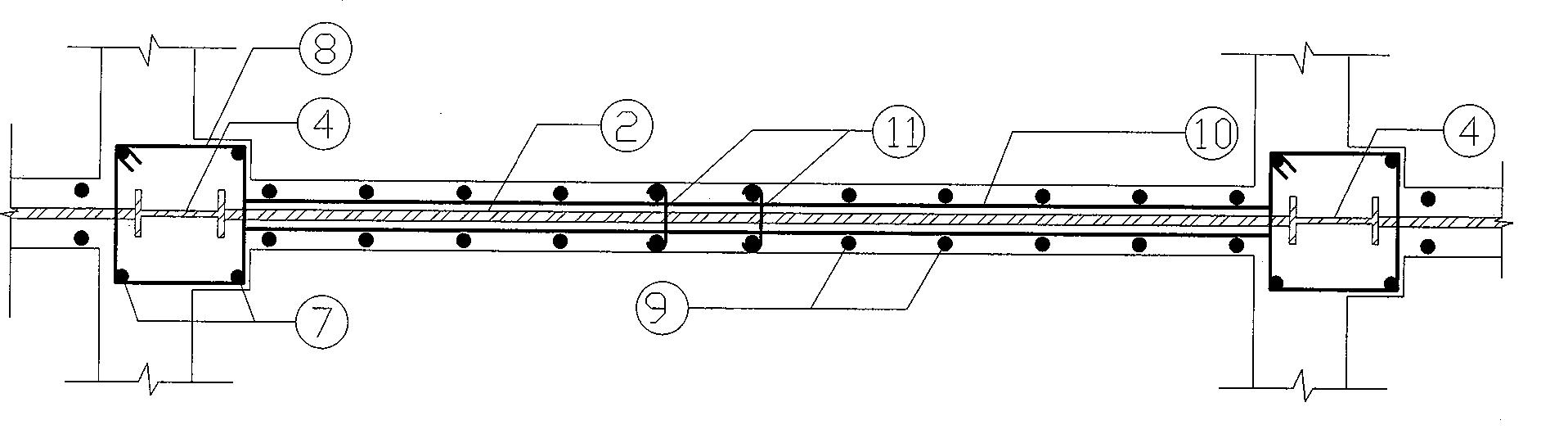

[0022] Combine below Figure 1 ~ Figure 3 The present invention is described further:

[0023] Schematic diagram of the structural reinforcement of a structural unit of steel concrete-opened steel plate-concrete composite shear wall Figure 1 ~ Figure 3 As shown, it includes frame beams, steel concrete columns 3 and steel plates 2. Steel concrete columns 3 are arranged at both ends of the shear wall, and the steel concrete columns 3 are consolidated with frame beams, and steel plates 2 are arranged between the frame beams and frame columns, and the steel plates are arranged in the shear wall, and holes are reserved at the edges of the steel plates 2 Or cut out slots. The frame beam of the shear wall is provided with a shaped steel beam 4, and the frame beam longitudinal reinforcement 7 is arranged on the periphery of the shaped steel beam 4, and the rectangular stirrup 8 is evenly bound along the frame beam longitudinal reinforcement 7, and the rectangular stirrup 8 of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com