Patents

Literature

143results about How to "Reduce local deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-conducting plastic and preparation method thereof

ActiveCN102746560AImprove thermal conductivityEasy injection moldingHeat conductingDegrees of freedom

The invention discloses a heat-conducting plastic and a preparation method thereof, wherein the heat-conducting plastic comprises, by weight, 25% to 80% of matrix resins, 5% to 40% of heat-conducting fillers, 5% to 10% of coupling agents and 5% to 30% of halogen-free flame retardants. According to the heat-conducting plastic, the coefficient of heat conductivity is high, the injection molding is convenient, the cost is low, heat dissipation is even, hot spots can be avoided, local deformation of parts caused by the high temperature is reduced, the weight is light and lighter than the weight of aluminum materials by 40% to 50%, the molding processing is convenient, secondary processing is not needed, and the product design degree of freedom is high.

Owner:SHENZHEN FRD SCI & TECH

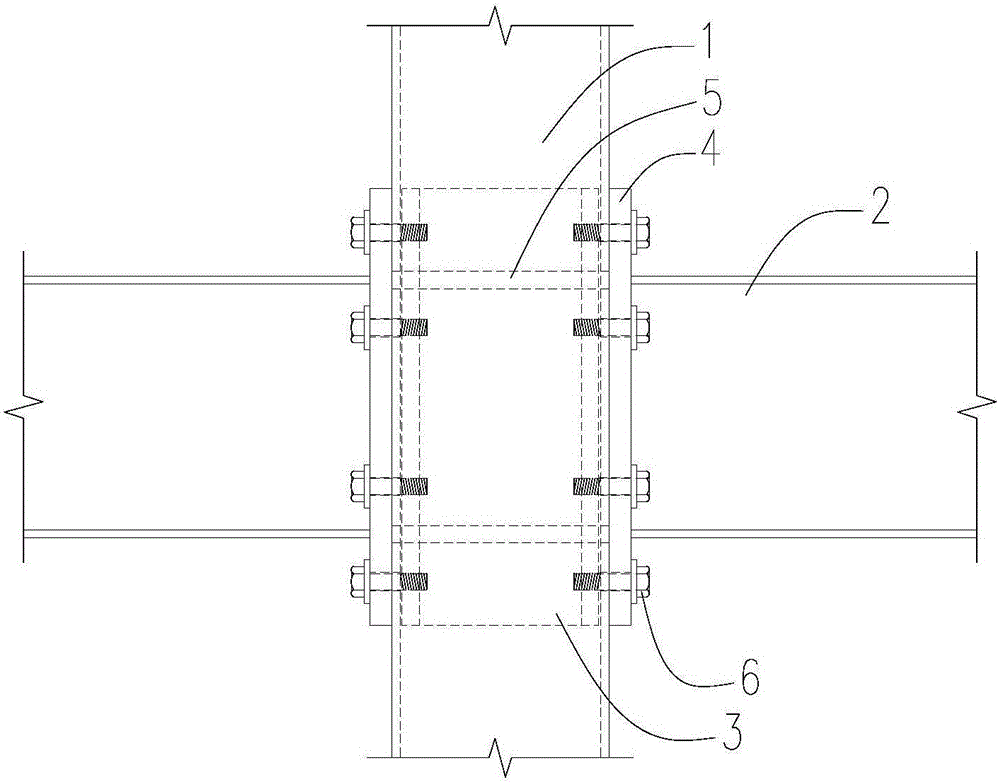

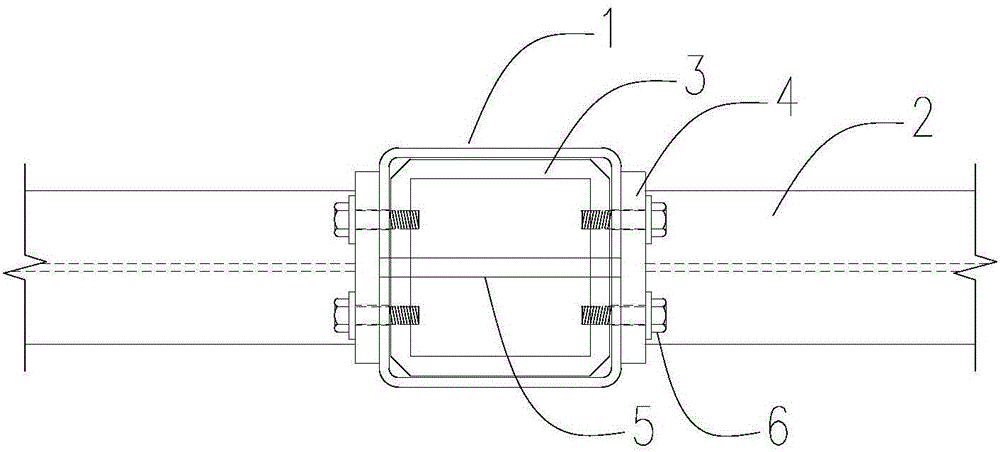

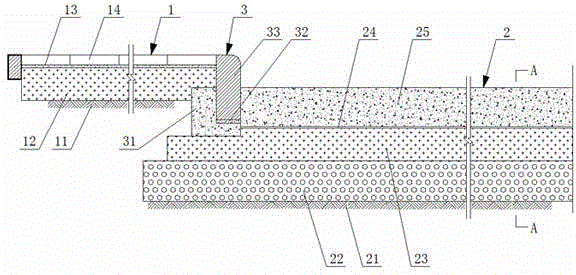

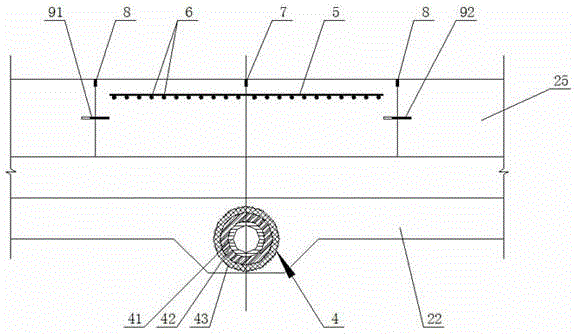

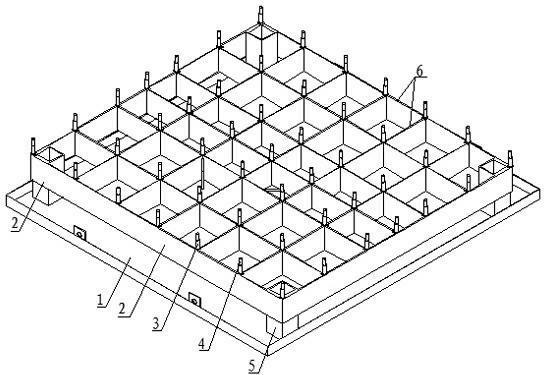

Rectangular steel pipe column and H-shaped steel beam inner sleeve type unilateral bolt connection node

ActiveCN105971118AEasy to fixIncreased shear capacityBuilding constructionsMaterials scienceBolt connection

The invention relates to a rectangular steel pipe column and H-shaped steel beam inner sleeve type unilateral bolt connection node. The structure is simple, the performance is good, the defect that a unilateral bolt is prone to be pulled out is overcome, and the assemblage degree is high. The node comprises a rectangular steel pipe column, H-shaped steel beams, a through pull rod and high-strength bolts; a steel sleeve is coaxially arranged in the rectangular steel pipe column, and extended end-plates are welded to the ends of the H-shaped steel beams; the steel sleeve is provided with positioning circular holes and tapping bolt holes; the extended end-plates and the rectangular steel pipe column are provided with multiple bolt holes in a paired mode in the axial direction of the rectangular steel pipe column, and a connecting wall panel and an opposite wall panel of the rectangular steel pipe column are each provided at least two positioning circular holes in the axial direction of the rectangular steel pipe column; the bolt holes are formed corresponding to the tapping bolt holes and the positioning circular holes on the same side, and the through pull rod penetrates through the positioning circular holes and is used for positioning the steel sleeve and the rectangular steel pipe column; the high-strength bolts sequentially penetrate through the bolts holes in the extended end-plates and the bolt holes in the rectangular steel pipe column to be fixedly connected with the corresponding tapping bolt holes in the steel sleeve.

Owner:CHANGAN UNIV

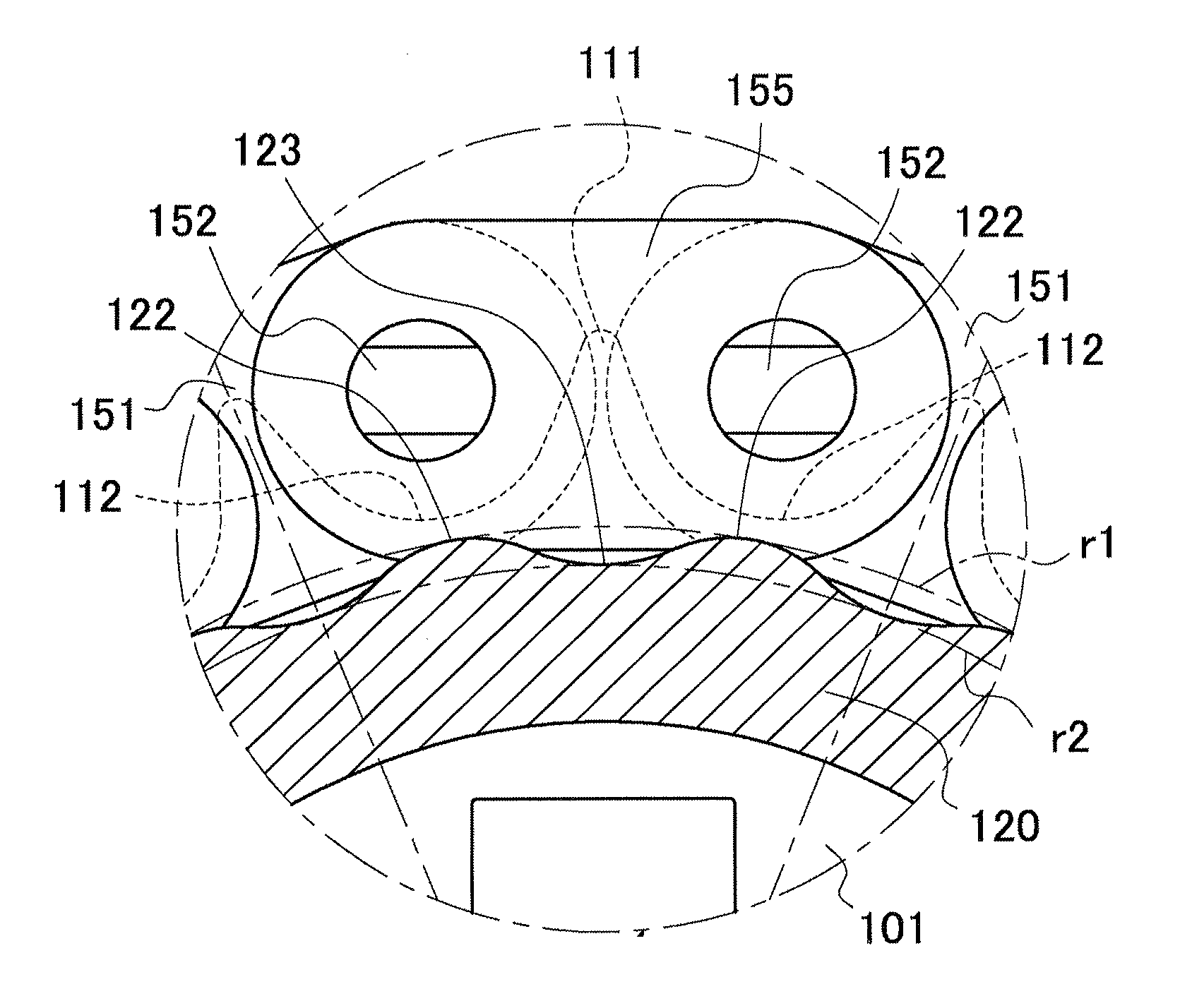

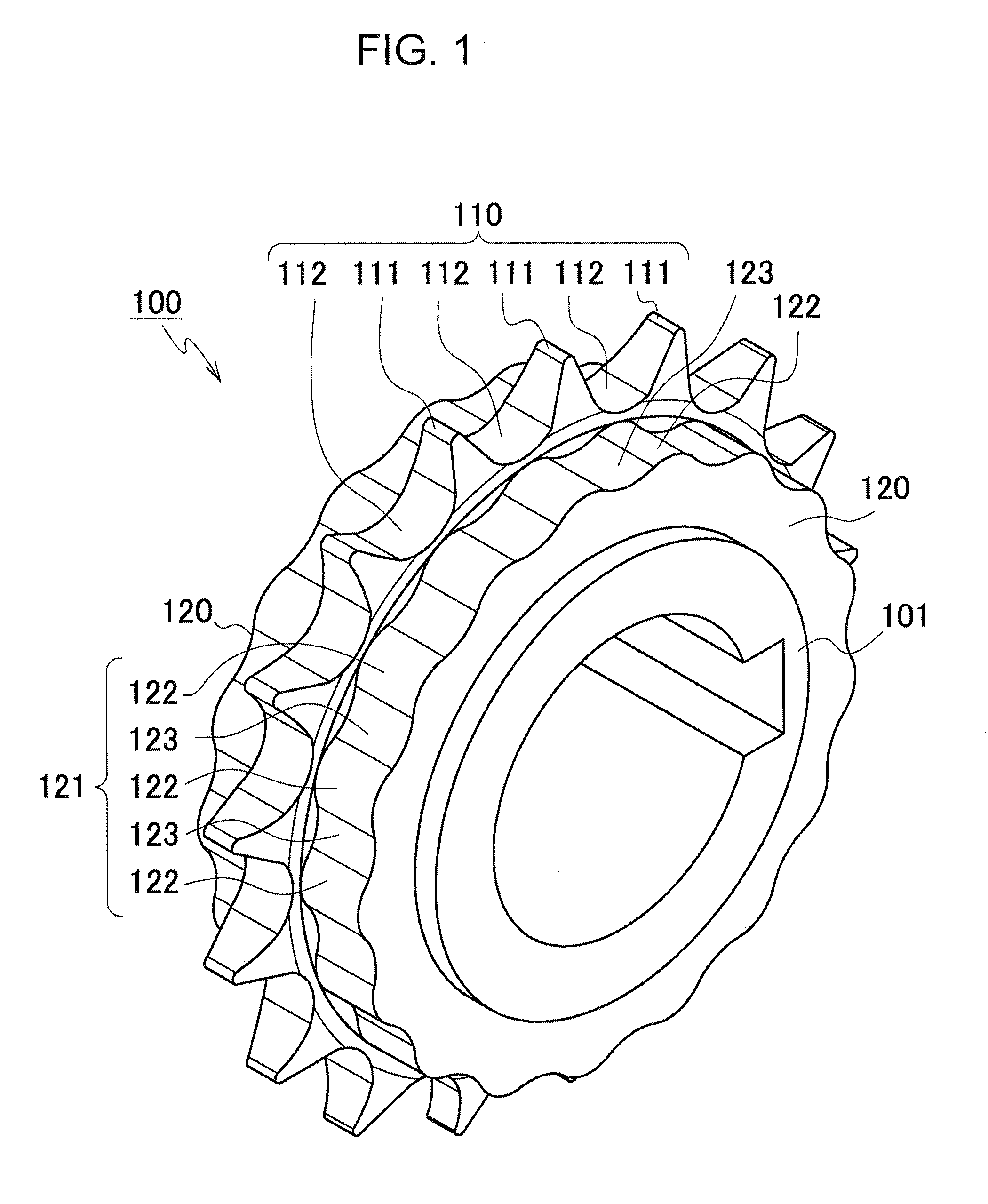

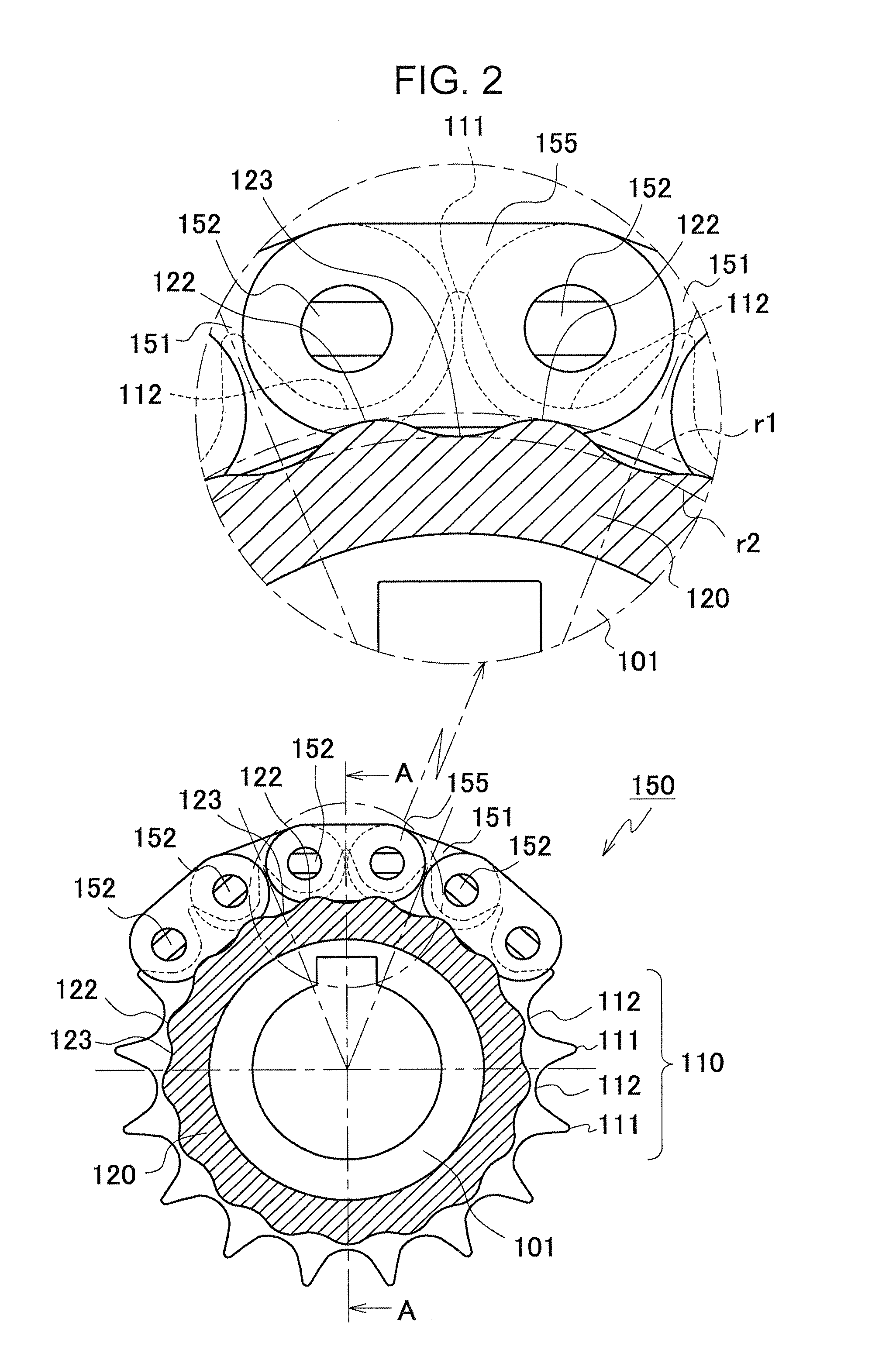

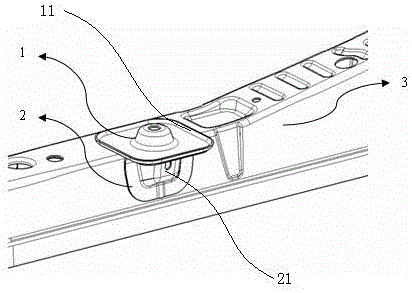

Sprocket

InactiveUS20110300977A1Reduce contact pressureReduce tearingPortable liftingGearing elementsContact pressureEngineering

In a sprocket comprising a sprocket hub, sprocket teeth and a cushion plate for contacting link plates of a transmission chain, the cushion plate is formed with concave portions at angular positions corresponding to the angular positions of the tips of the sprocket teeth, thereby avoiding contact, or reducing contact pressure, between the cushion plate and the middle parts of link plates of the chain.

Owner:TSUBAKIMOTO CHAIN CO

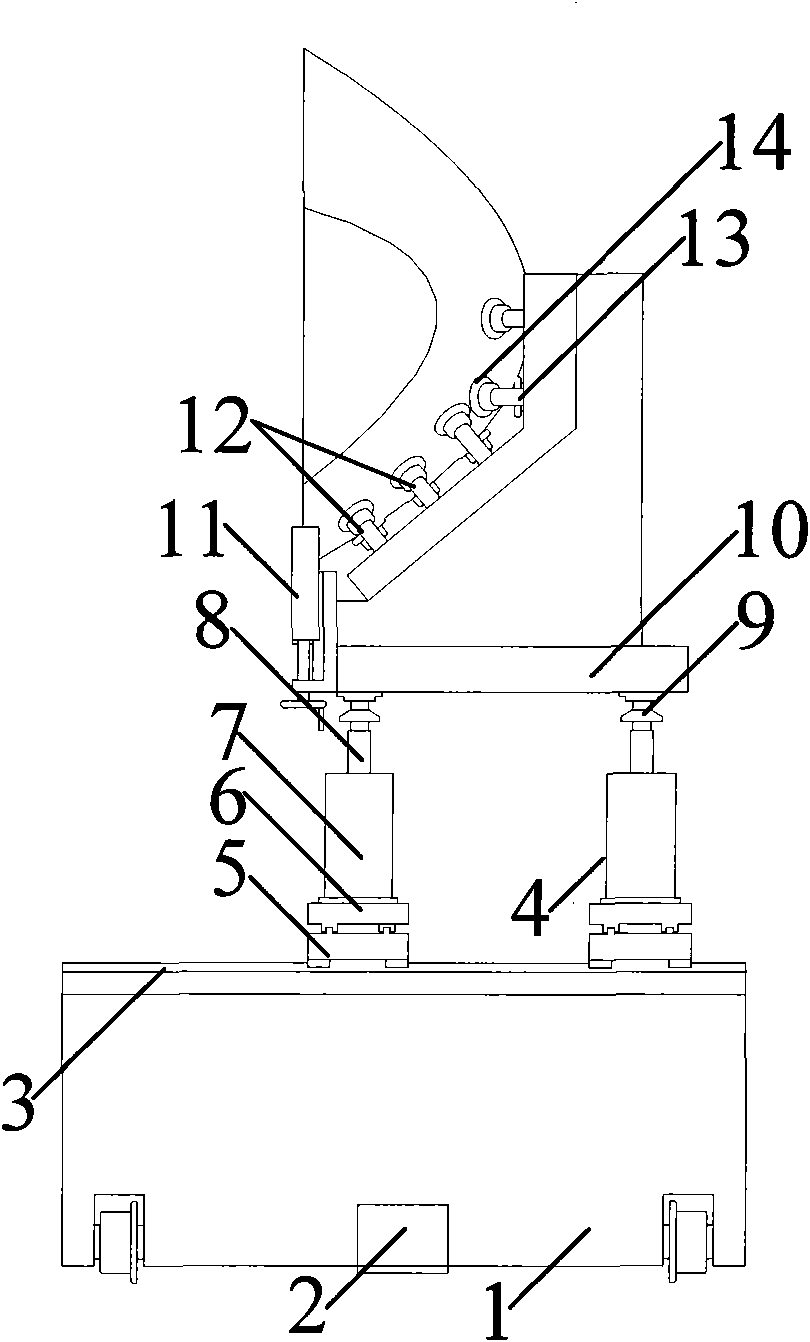

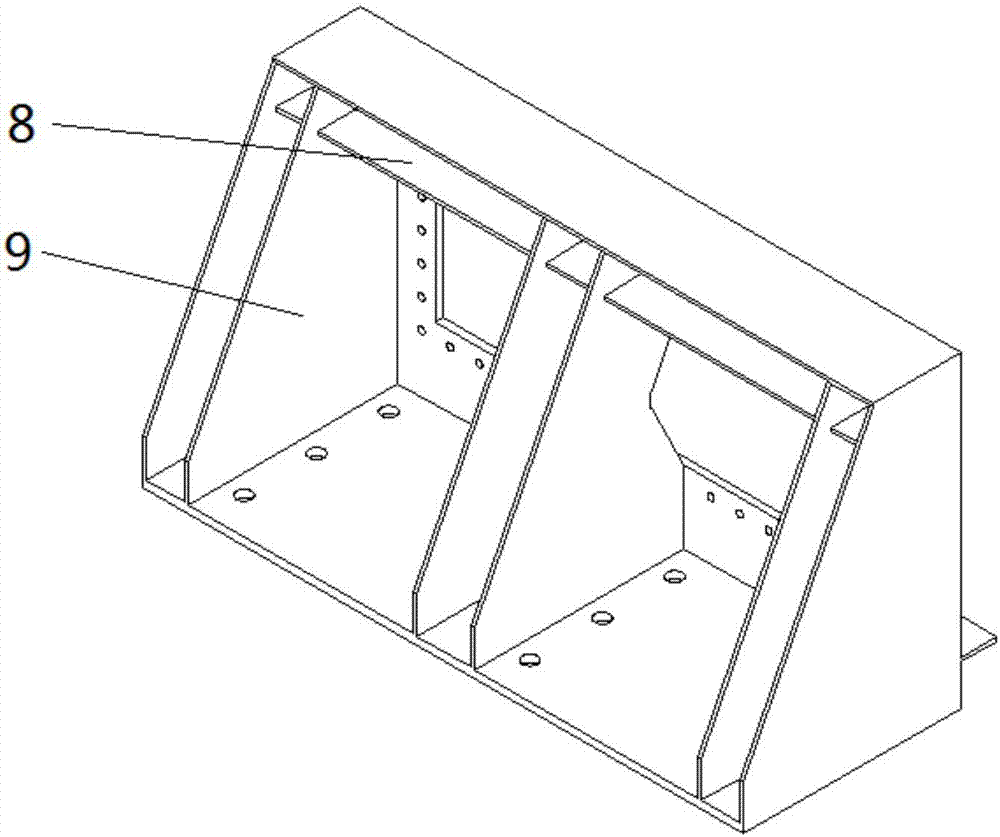

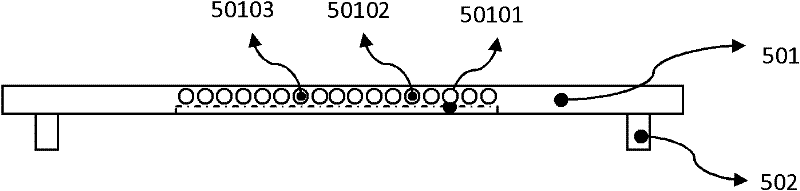

Radome installation bogie based on array absorption unit

The invention discloses a radome installation bogie based on an array absorption unit. An iron core permanently magnetic linear motor is embedded into the bottom of a bogie box body; a linear guide rail is arranged on the top of the bogie; four gesture adjusting three-coordinate positioners are arranged on the linear guide rail; the bottoms of the gesture adjusting three-coordinate positioners arevertical and horizontal slide plates on which an upper slide plate and a support column are arranged; a first telescopic rod is arranged inside the support columns; and the top of the first telescopic rod is provided with a three-coordinate positioner adapter. A flexible bracket is arranged above the four gesture adjusting three-coordinate positiners; and a stop device is arranged on the side ofthe flexible bracket. A dot matrix type passive three-coordinate positioner is arranged on the flexible bracket; a second telescopic rod is arranged inside the dot matrix type passive three-coordinatepositioner; and a round head vacuum absorption disc is arranged on the top of the dot matrix type passive three-coordinate positioner. The radome installation bogie can fix a radome in a multipoint vacuum absorption mode, and achieve the gesture adjustment of the radome through the movement of the gesture adjusting three-coordinate positioners in the X,Y, and Z directions.

Owner:ZHEJIANG UNIV +1

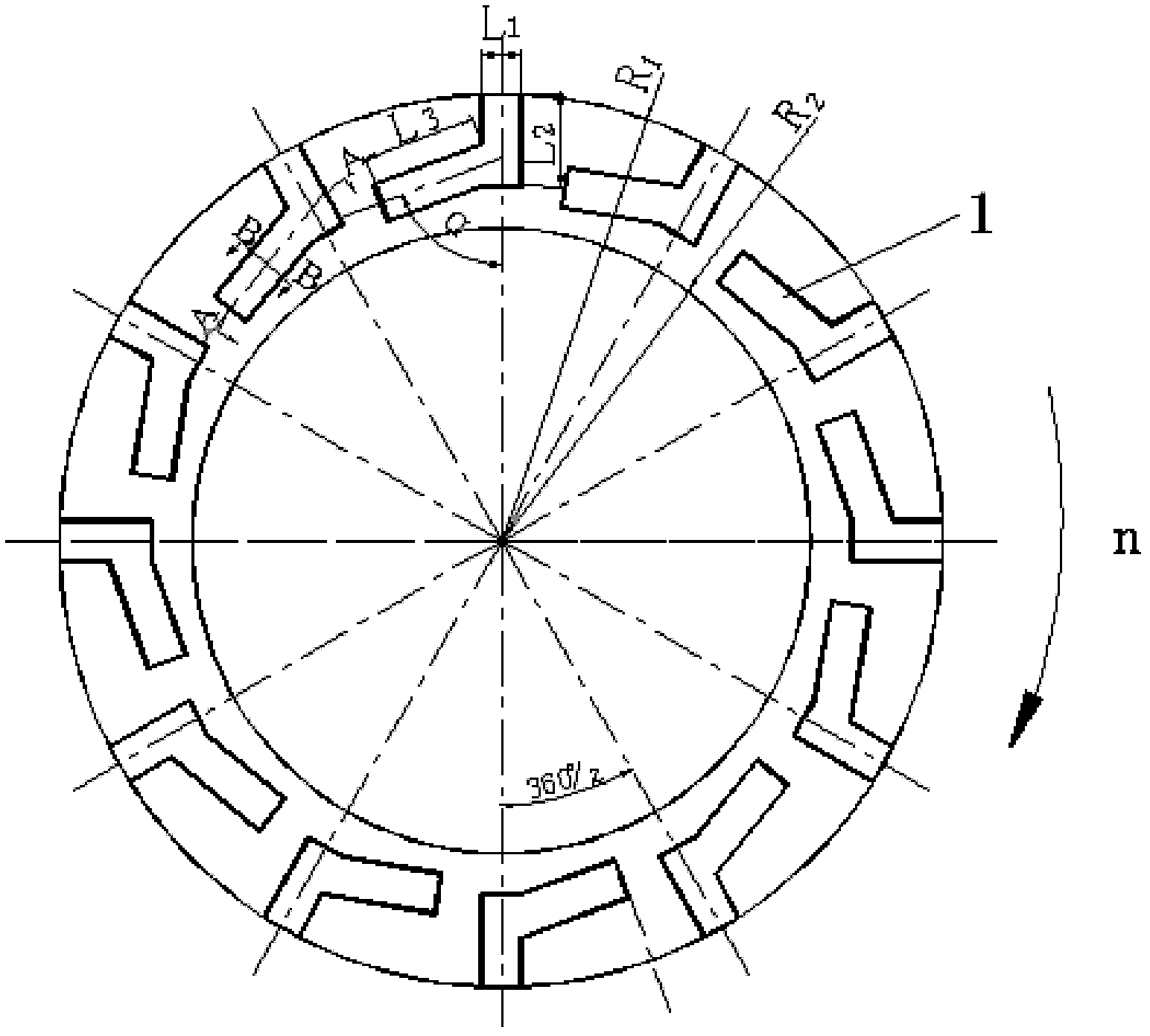

Seal structure with unidirectionally-rotatable three-dimensional L-shaped groove end face

The invention discloses a seal structure with a unidirectional-rotatable three-dimensional L-shaped groove end face. The seal structure is characterized in that the sealing end face of a stationary ring or a rotating ring is provided with three-dimensional L-shaped grooves, wherein the three-dimensional L-shaped groove and the radial direction of the stationary ring or rotating ring have inclined angles of 20-70 degrees and are uniformly distributed along a circumferential direction; each three-dimensional L-shaped groove is composed of a flow-supplying groove and an unequal-deep rectangular tank, and each three-dimensional L-shaped groove is processed by adopting a grinding method so as to improve the fatigue strengthen, can be used for the seal structure with the rotating ring or the stationary ring as a compensation ring, and can also be used for face to face dual seal, back to back dual seal, two-stage series seal, three-stage series seal, combined seal of dual seal and single seal, or combined seal of the single seal and the two-stage seal; and if a low pressure exists at the outside of the seal and a high pressure exist at the inside of the seal, each three-dimensional L-shaped groove is also formed on the circumference surface of the inside of the seal. The seal structure provided by the invention has the advantages of realizing the larger kinetic pressure carrying capacity, reducing the frictional wear, prolonging the service life, and realizing the static seal of a sealing ring at a dike field.

Owner:TSINGHUA UNIV

High strength crack resistant concrete and preparation method, composition and application thereof

The invention discloses high strength crack resistant concrete and a preparation method, a composition and application thereof, the composition includes a component A, a component B, a component C and a component D, the component A is isocyanate, the component B includes polyester polyol, polyether polyol, polyvinyl alcohol, a lauric acid type organic tin catalyst and a cyclopentane foaming agent; the component C includes cement, fly ash and mineral powder, and the component D includes quartz sand and gravel. The invention also provides a method for preparing the high strength crack resistant concrete from the composition used for the high strength crack resistant concrete. The invention further provides the application of the high strength crack resistant concrete, including application in the engineering construction and maintenance and reinforcement. The high strength crack resistant concrete has the characteristics of high strength, strong steel bridge surface adhesion steel bridge, rich toughness, corrosion resistance, water resistance, permeability resistance, frost resistance, impact resistance, aging resistance, simple construction, short construction period and suitable construction costs.

Owner:BEIJING ZHONGKE JIAGU BUILDING MATERIAL SCI &TECH CO LTD

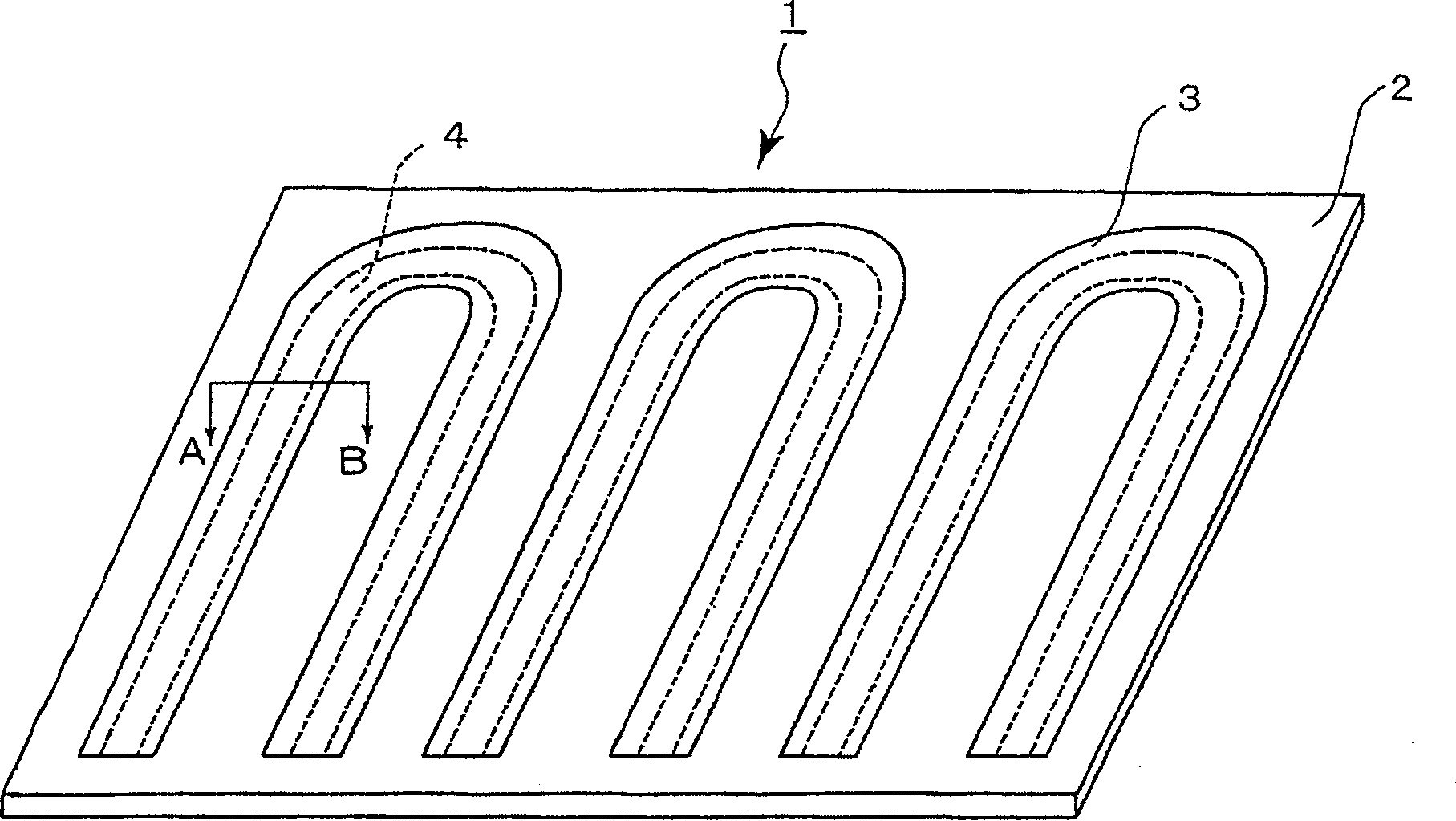

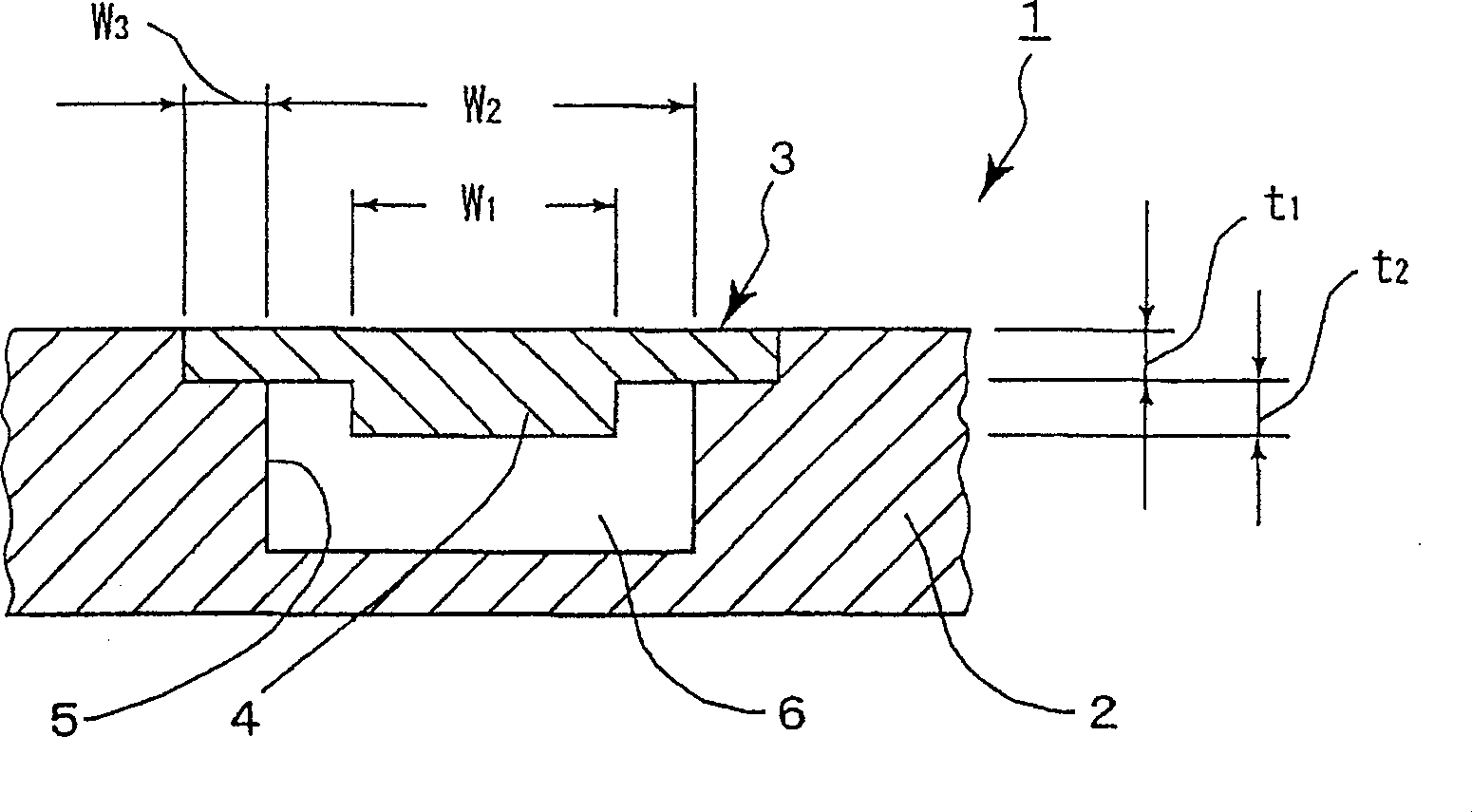

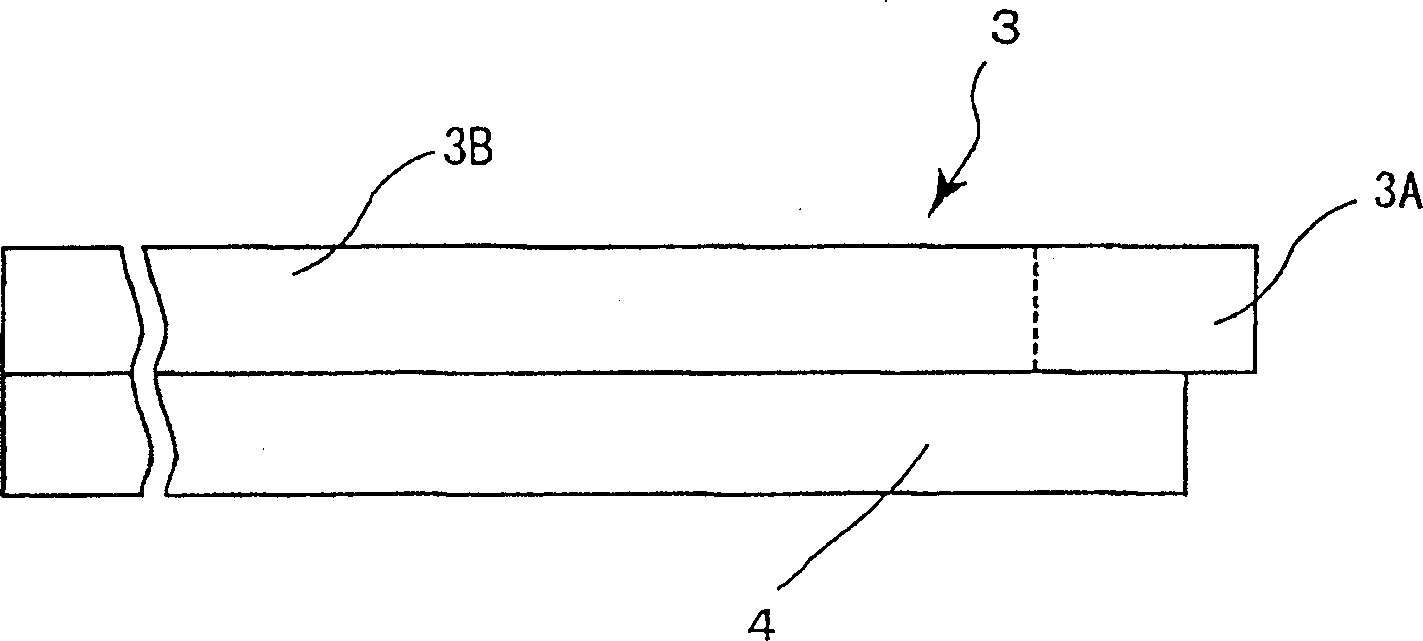

Cooling plate

InactiveCN1880907AReduce local deformationLong replacement lifeVacuum evaporation coatingSputtering coatingEngineeringCoolant

Owner:SH COPPER PROD CO LTD

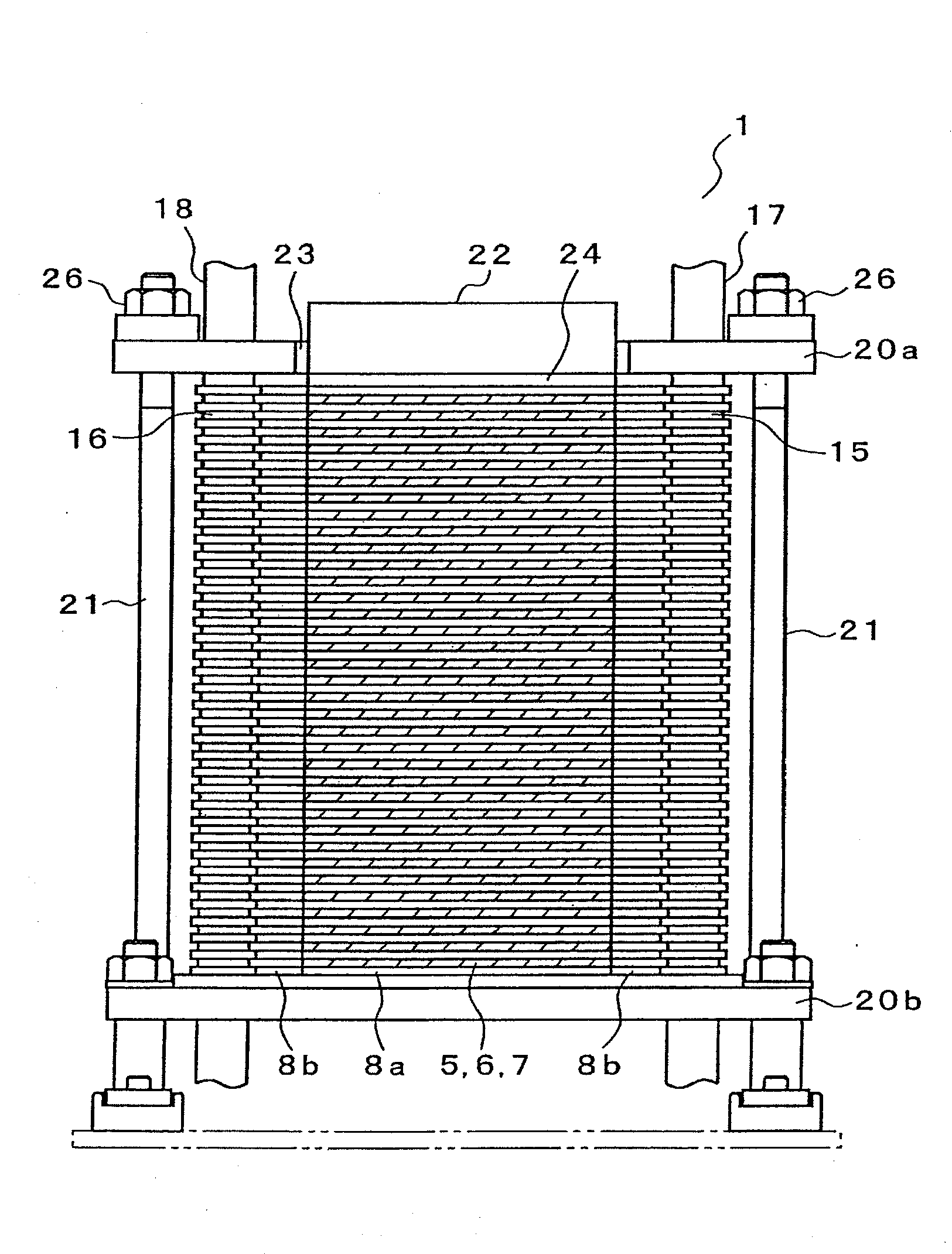

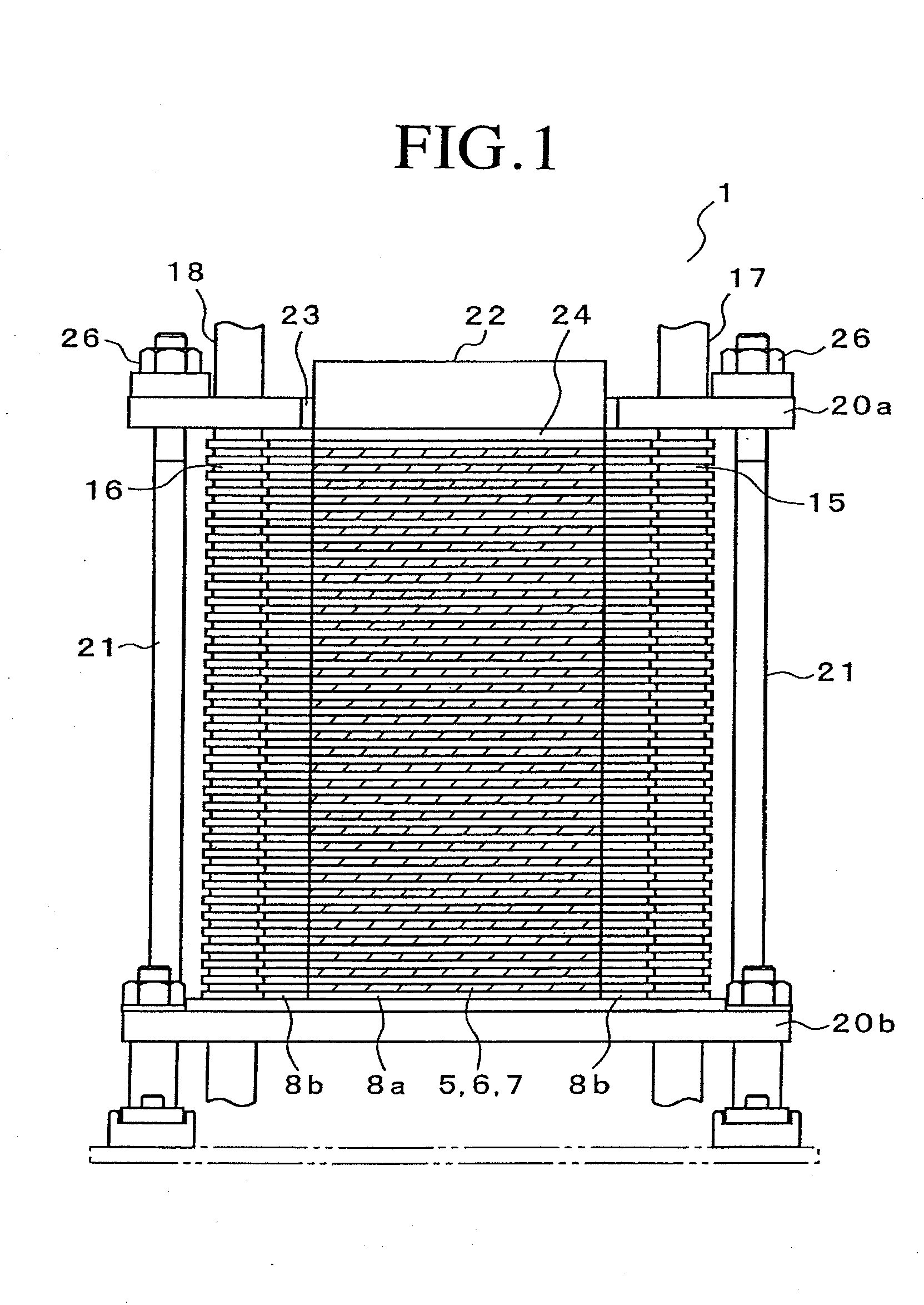

Plate-laminated type fuel cell

InactiveUS20100092837A1Avoid damageSufficient length of armFuel cells groupingCell component detailsFuel cellsEngineering

Owner:AKBAY TANER +3

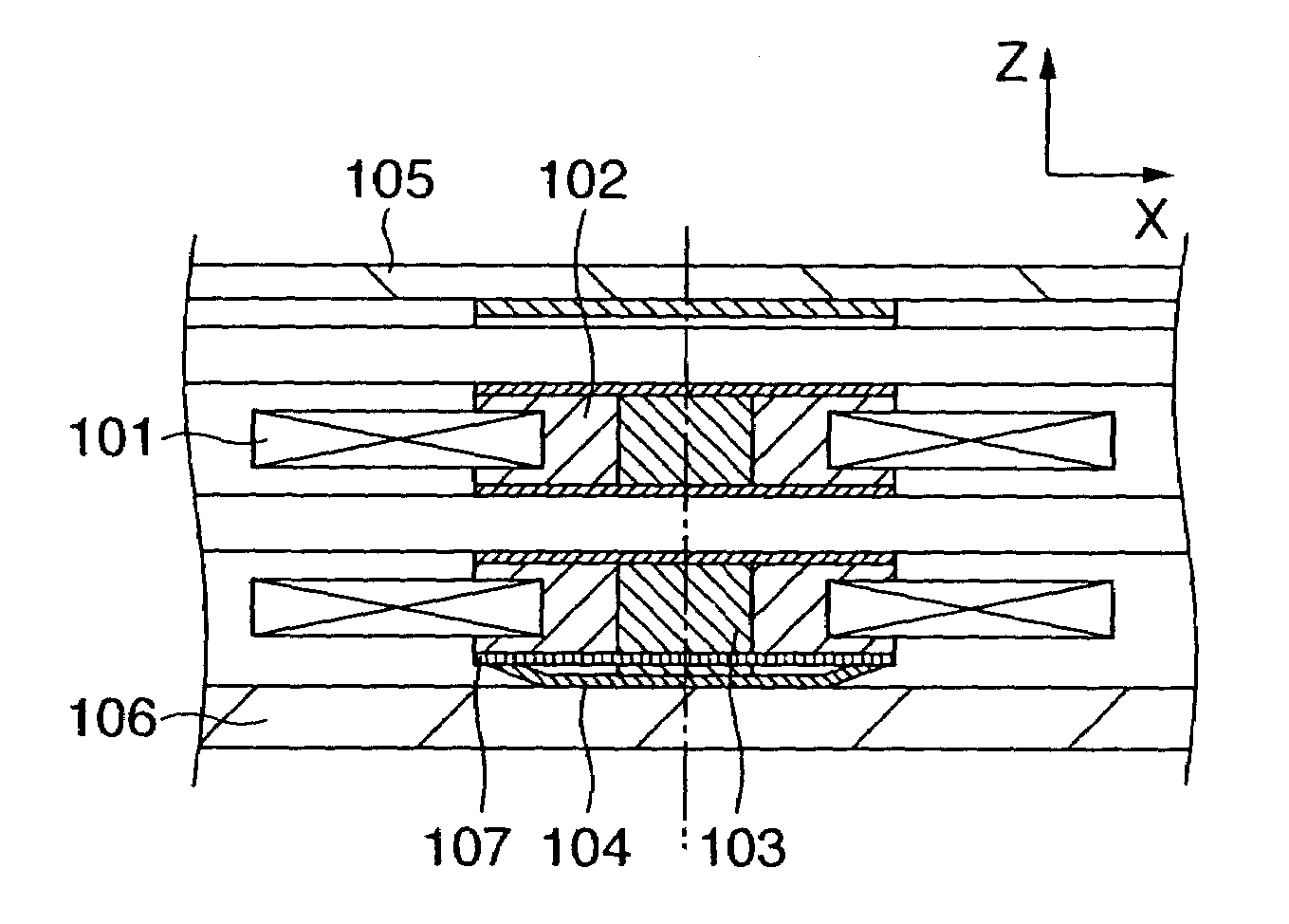

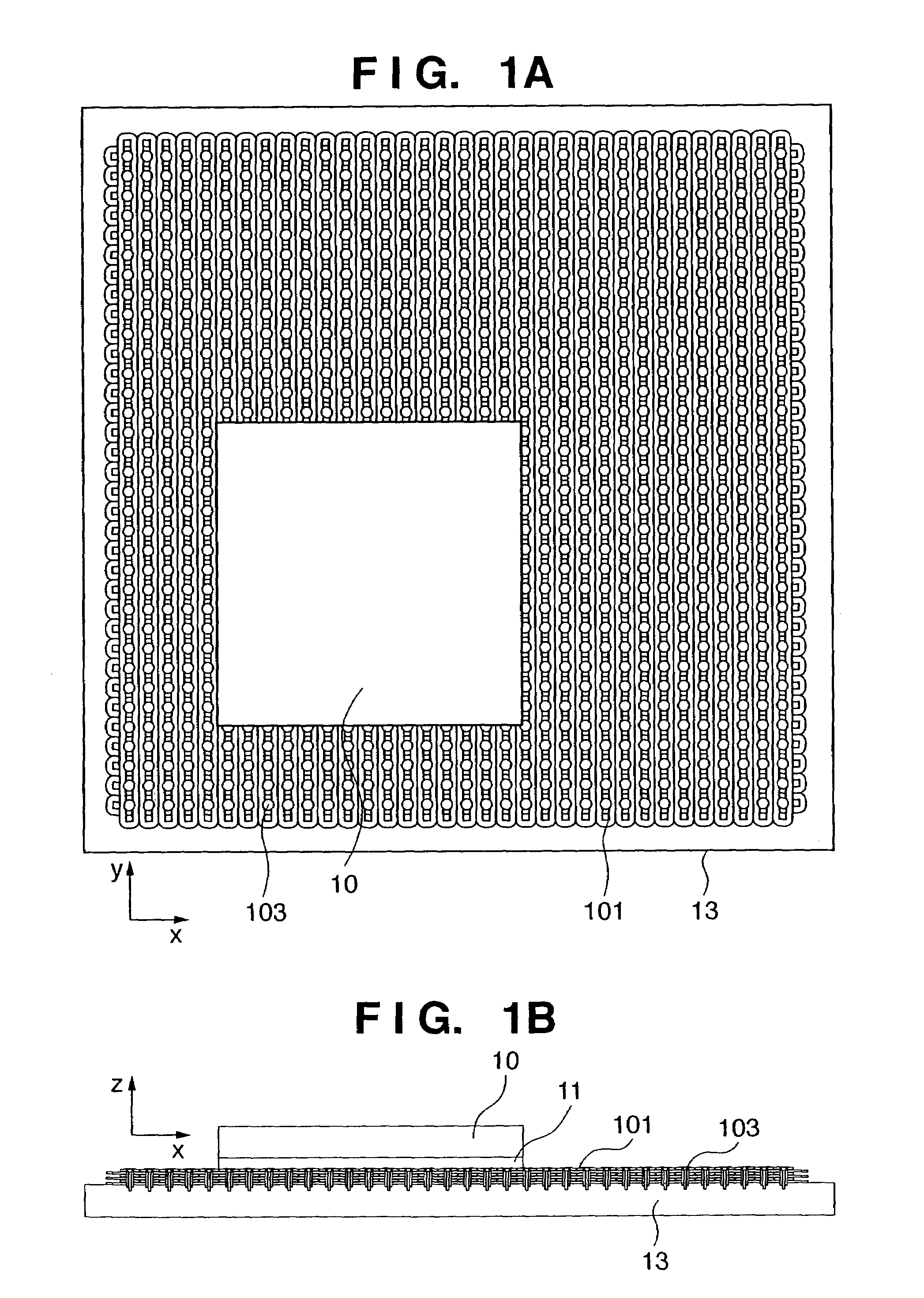

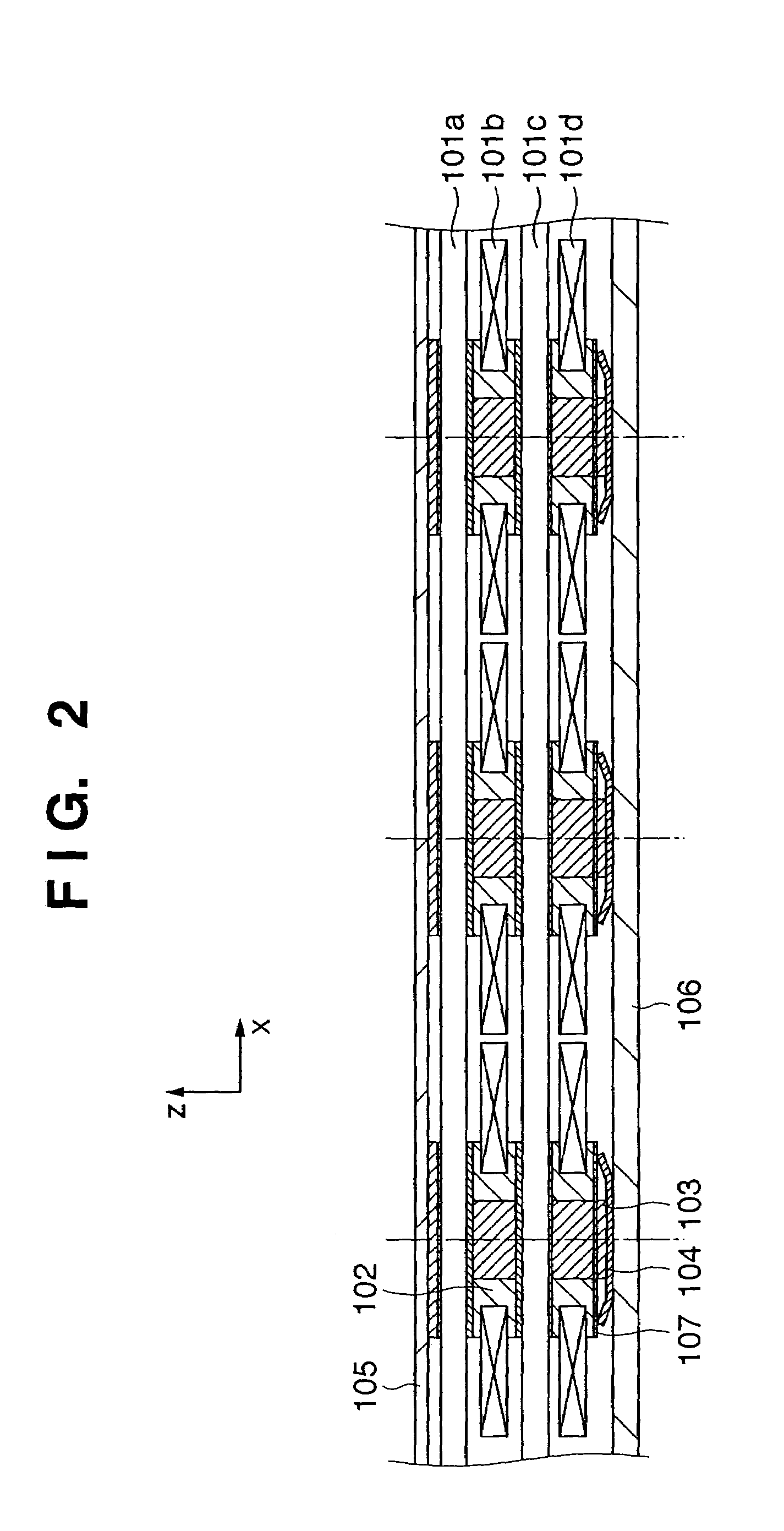

Coil support unit, motor and exposure apparatus using the same, and device manufacturing method

InactiveUS7329972B2Reduce the possibilityPrevent movementMagnetic circuitSemiconductor/solid-state device manufacturingMechanical engineeringEngineering

Owner:CANON KK

Automobile rear suspension spring installation point structure

InactiveCN105966185AIncreased durabilityStrong torsional rigidityResilient suspensionsVehicle springsDynamic stiffnessEngineering

The invention provides a structure of an automobile rear suspension spring installation point with strong dynamic rigidity, high durability and light weight. The structure includes a rear suspension spring seat mounting plate, a support plate and a rear floor side longitudinal beam body, and also includes a first partition plate and a second partition plate. The rear floor side longitudinal beam body is a U-shaped channel steel beam in section, and the support plate It is an L-shaped support plate, the side of the L-shaped support plate is fixedly connected with the side of the rear floor side longitudinal beam body, and the top surface of the L-shaped support plate is respectively connected with the bottom surface of the rear suspension spring seat mounting plate and the groove top of the rear floor side longitudinal beam body The surface is fixed, the first partition and the second partition are respectively arranged on the sides of the rear floor side longitudinal beam body corresponding to the installation point of the L-shaped support plate, and the first partition and the second partition are both U-shaped in cross section channel steel, the groove tops of the first partition and the second partition are respectively vertical and flush with the groove tops of the side longitudinal beam body of the rear floor, and the sides of the first partition and the second partition are vertically aligned with the side longitudinal beams of the rear floor The sides of the beam body are fixed.

Owner:CHERY AUTOMOBILE CO LTD

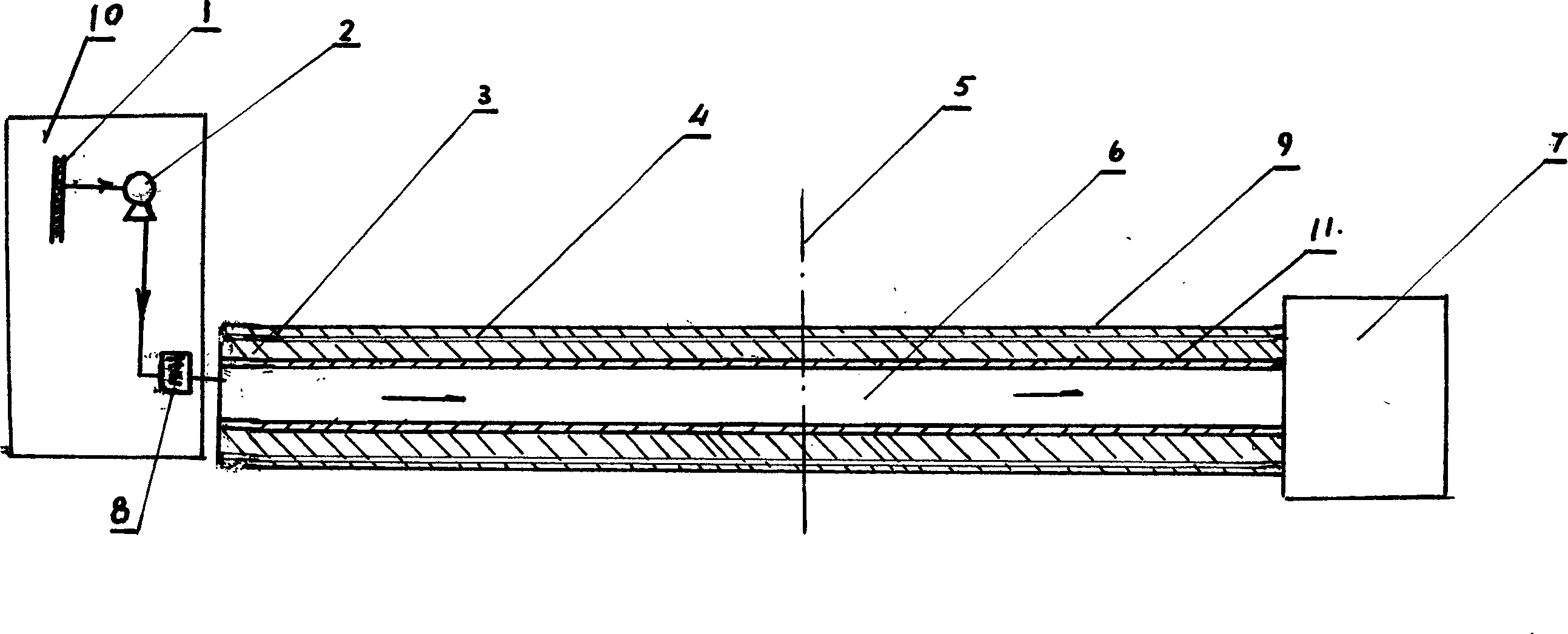

Dehydrated ultra thick oil pipeline transportation method and corollary arrangement

ActiveCN1699822AImprove oil delivery timeReduce energy consumptionPipeline systemsPipeline transportSkin effect

The invention relates to an apparatus and method for pipeline transportation of the dehydrating super heavy crude which belongs to the art of pipeline crude transportation. The invention adopts the thermal insulating pipeline with skin effect, having fuel delivery pump, filter and heat exchanger installed on the oil pipelines which are lay under the ground; performing pre-heating before transportation, injecting oil after the water temperature in the pipeline comes to 75 degree. The method can ensure transporting dehydrating heavy crude in the pipeline of 30 kilometers length and 406 millimeters diameter.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

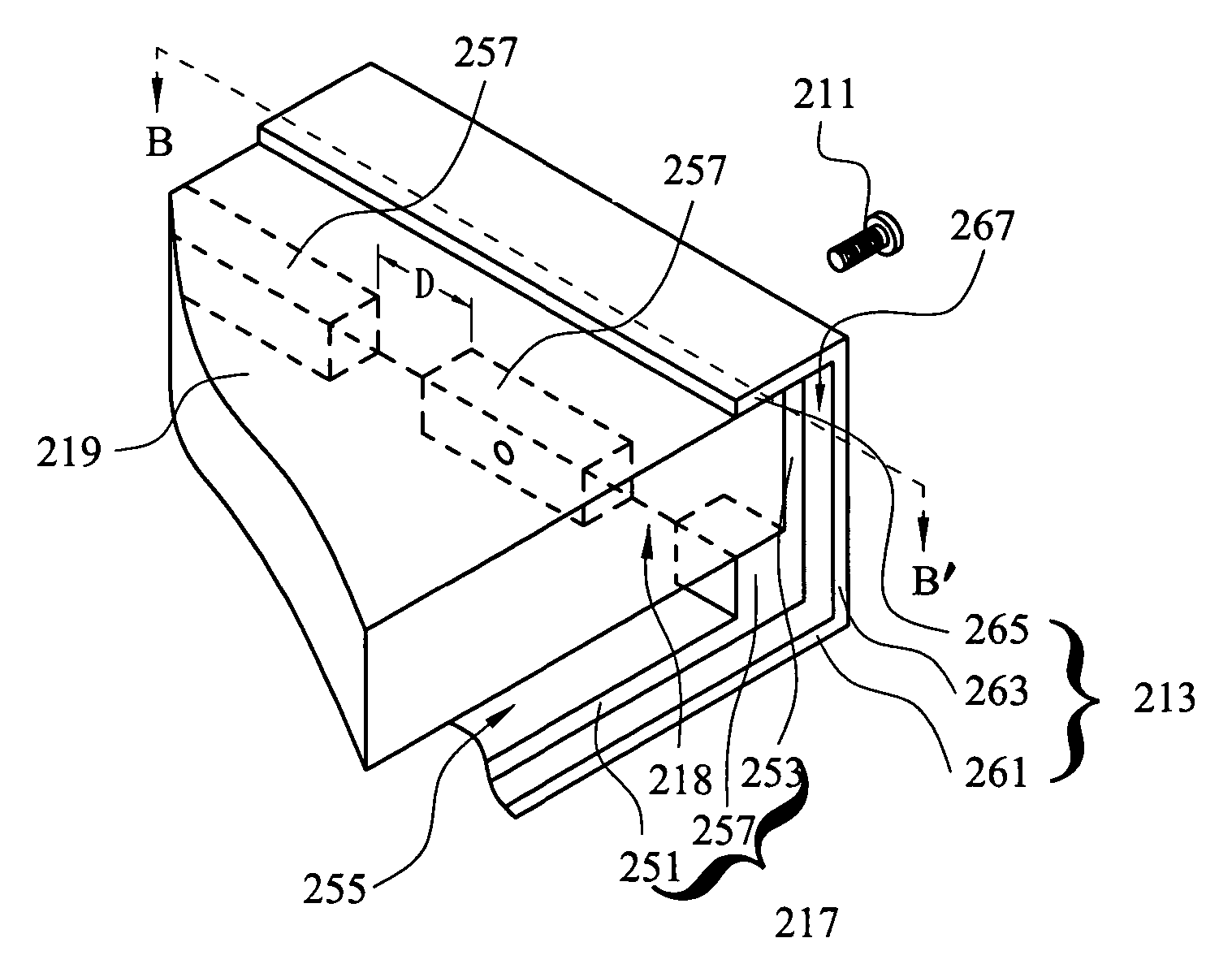

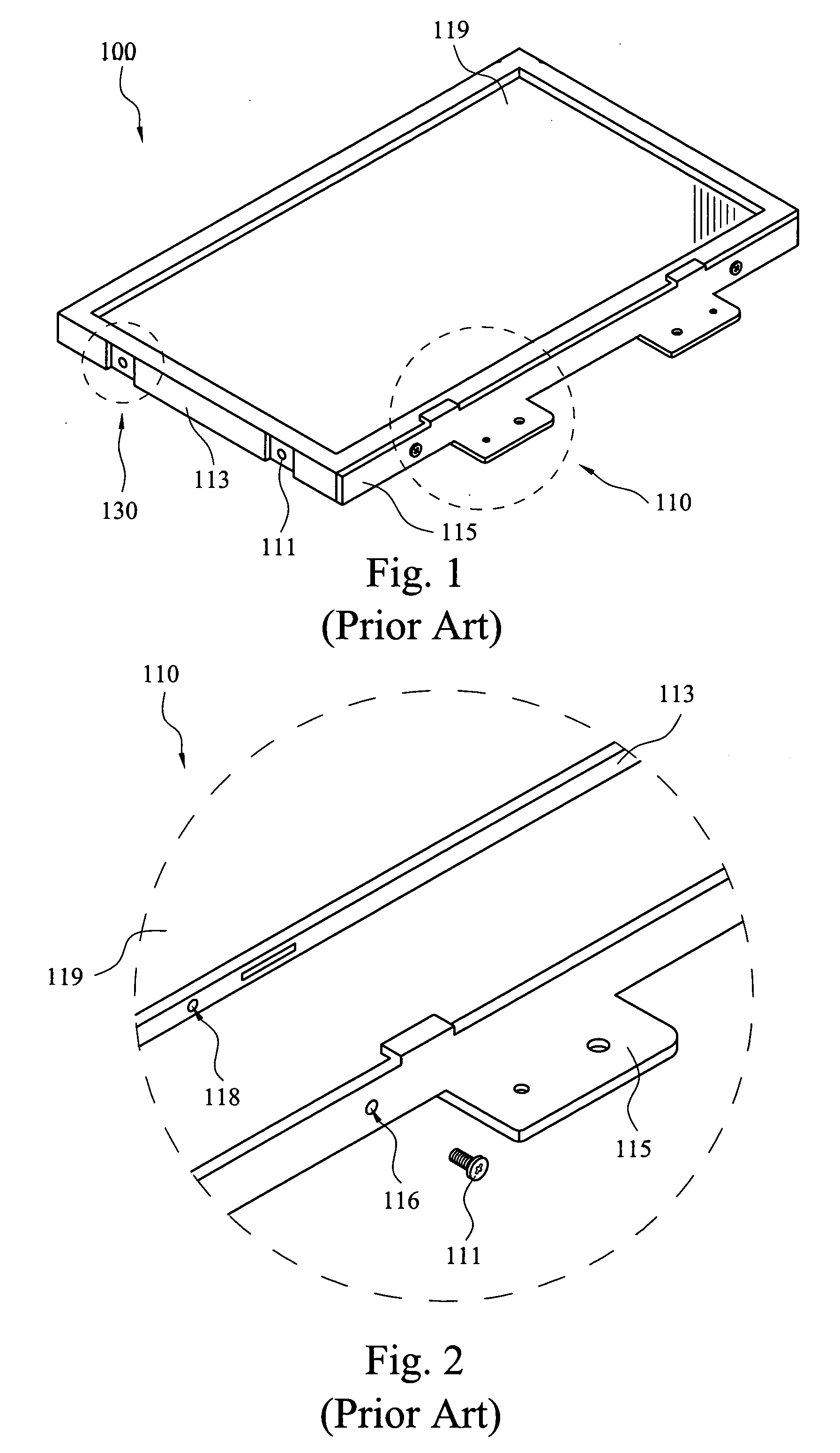

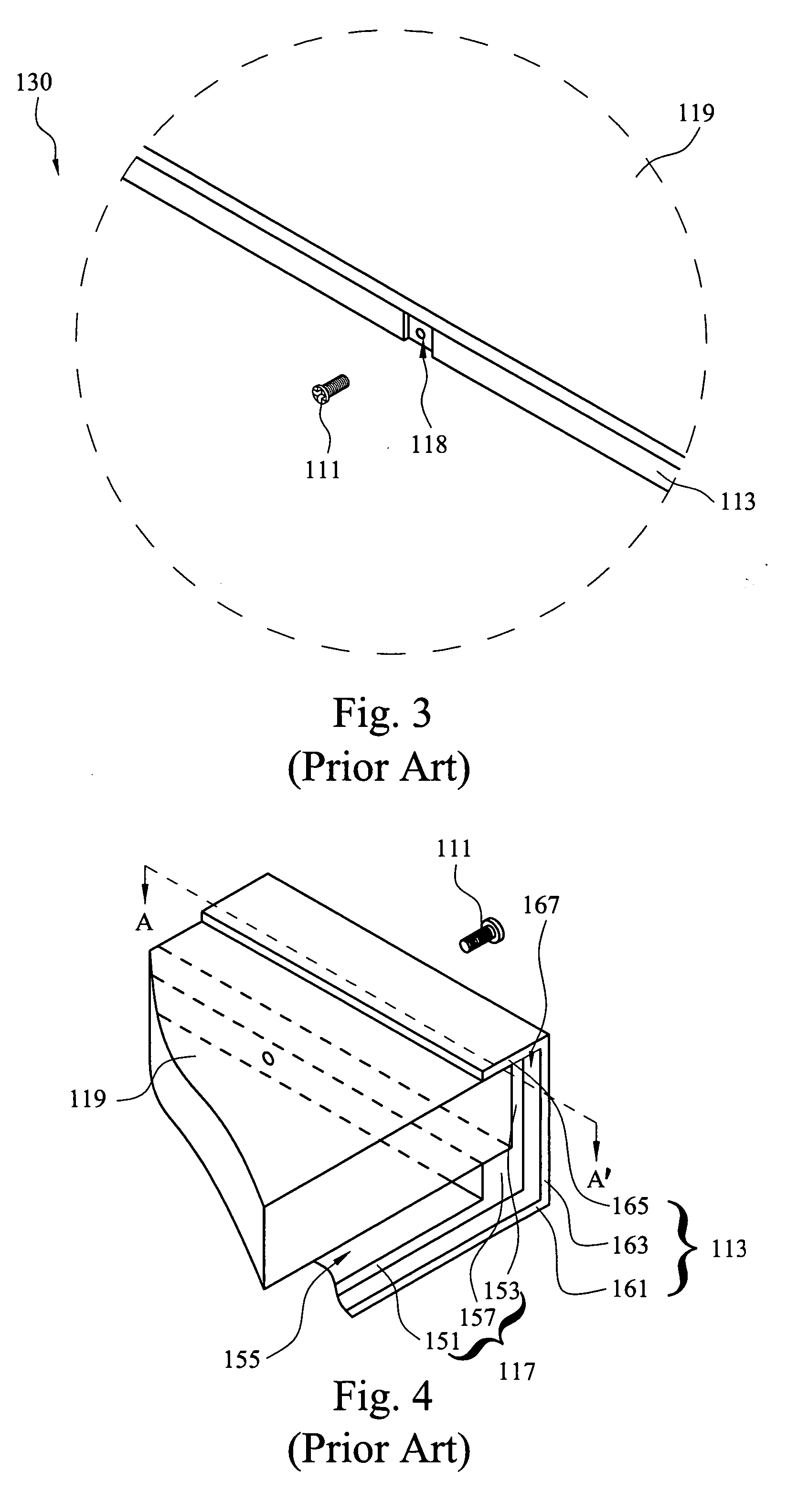

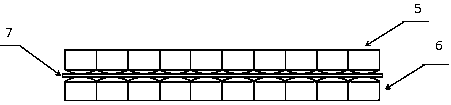

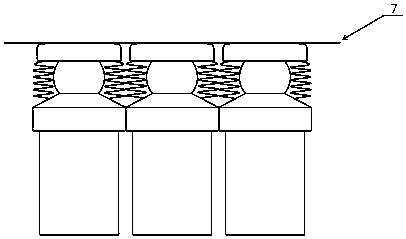

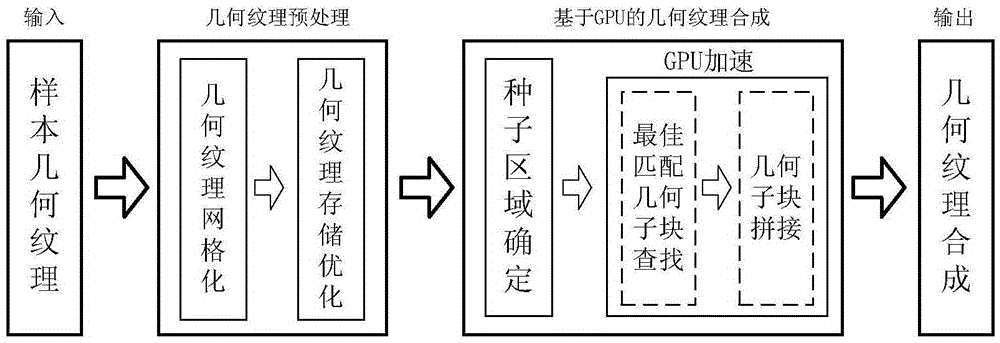

Mold frame for liquid crystal display module

ActiveUS20060033858A1Reduce local deformationReduce impactNon-linear opticsLiquid-crystal displayEngineering

A mold frame liquid crystal display module is disclosed. Supporting stands of the mold frame for supporting a LCD (liquid crystal display) panel, which are separated from each other by a spacer, can reduce the influence resulting from local deformation by releasing torque generated by turning screws in, and solve the ill phenomena of oppressive light leakage and ripple due to interference generated by the mold frame and the LCD panel in the conventional backlight module.

Owner:NYTELL SOFTWARE LLC

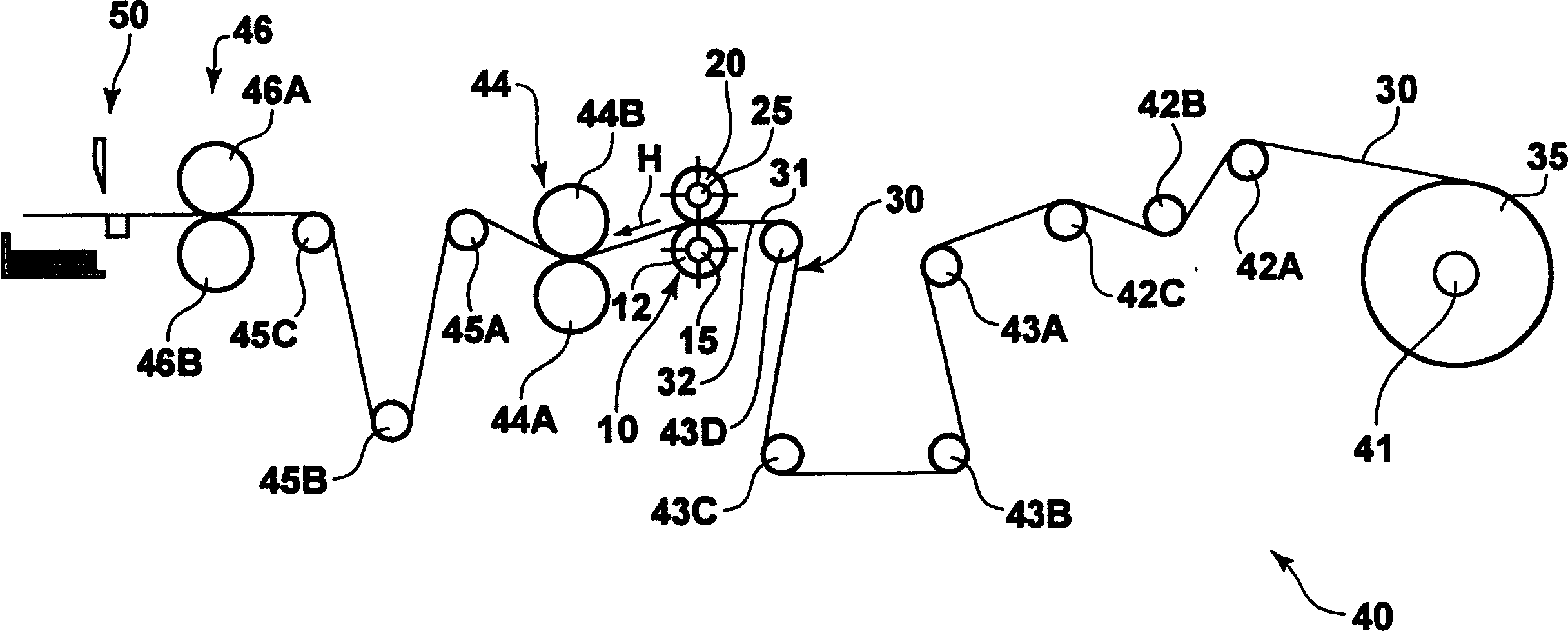

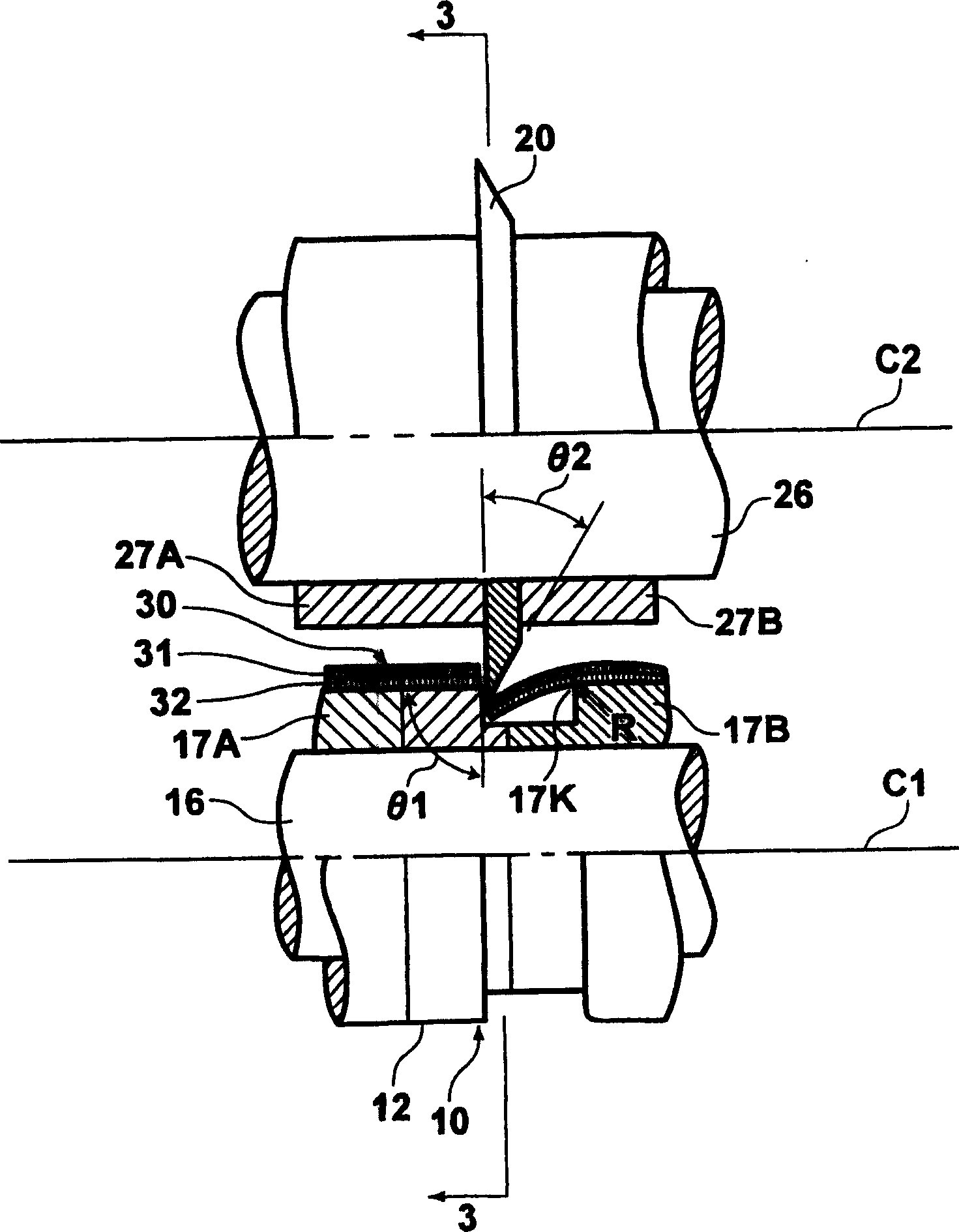

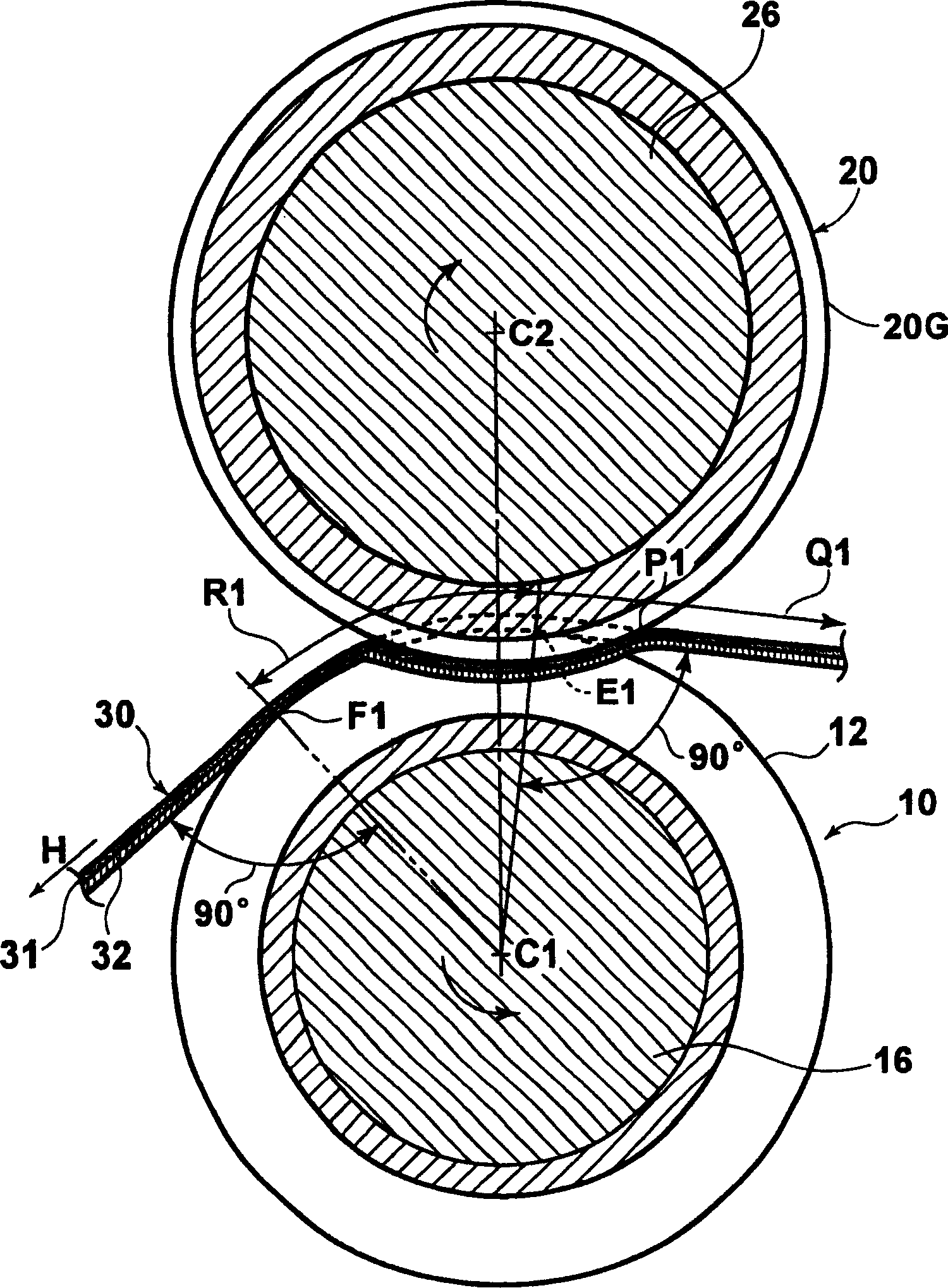

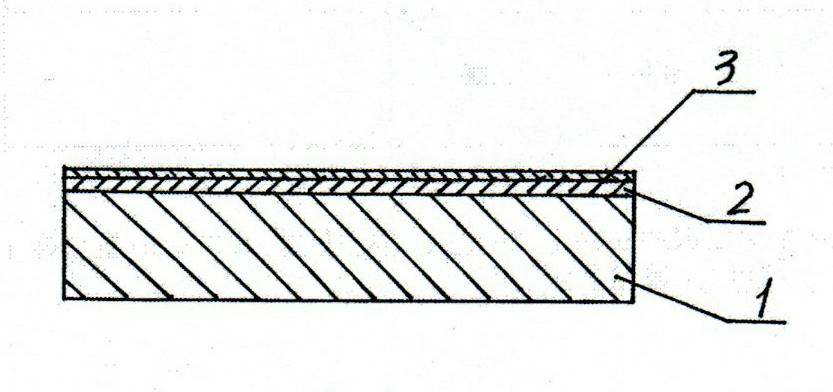

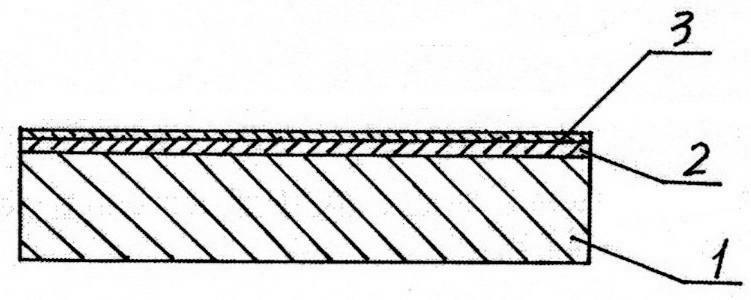

Coated sheet cutting method and apparatus

ActiveCN1572446AReduce the amount of bendingReduce local deformationMetal working apparatusEngineeringMechanical engineering

Owner:FUJIFILM CORP

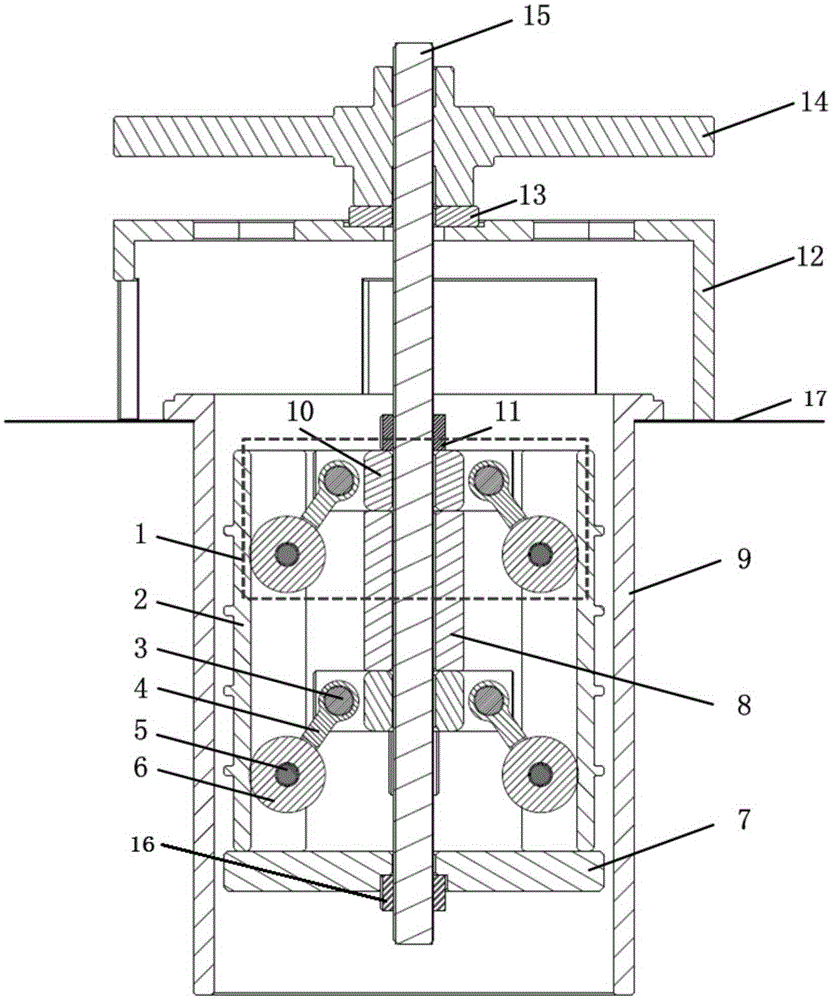

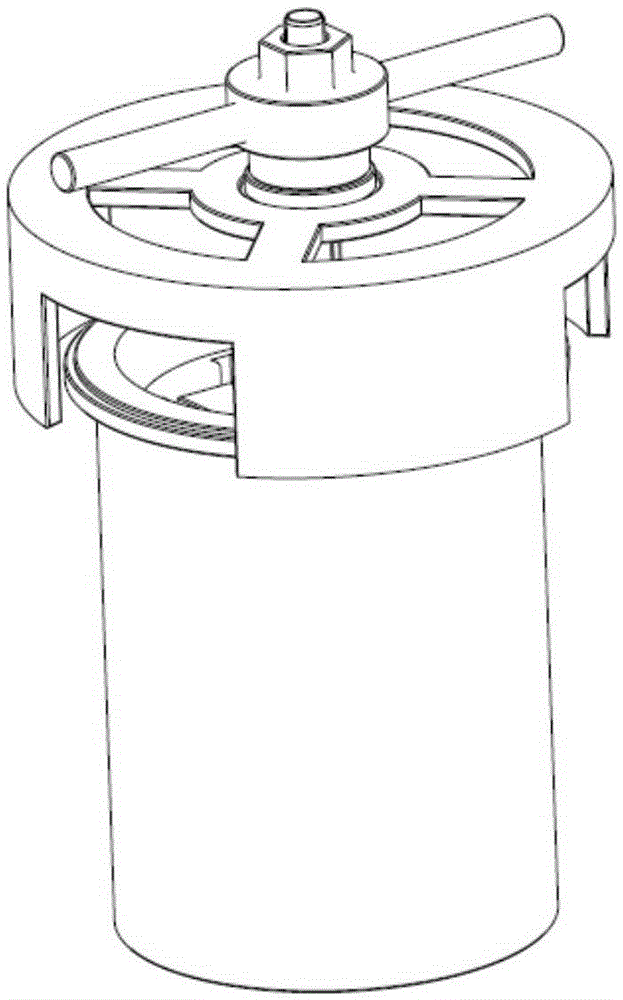

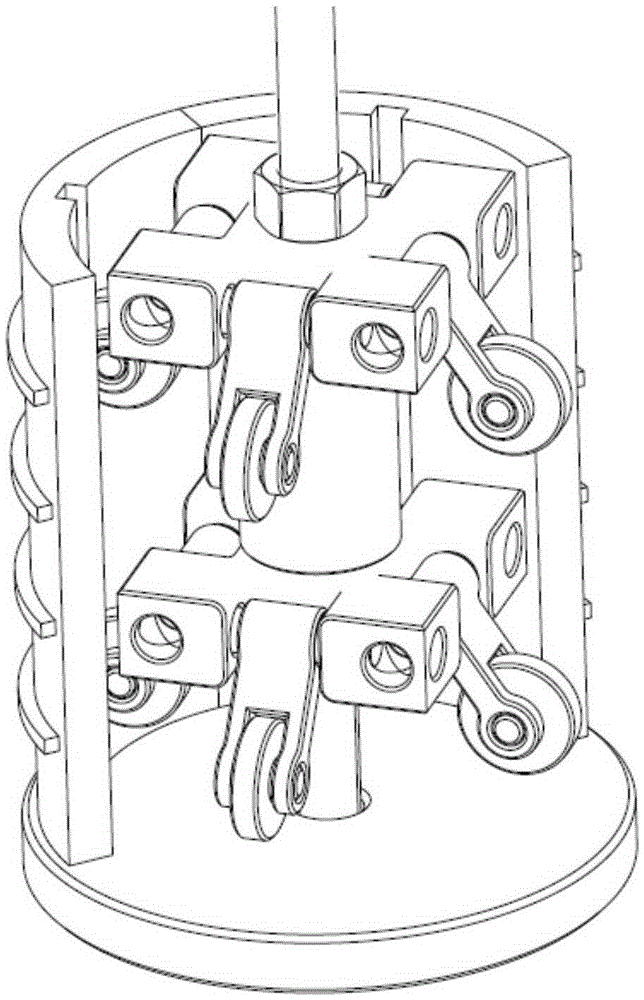

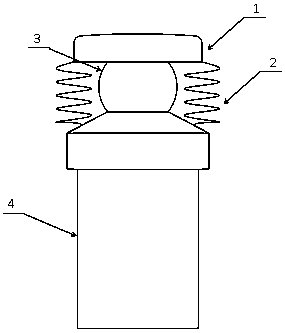

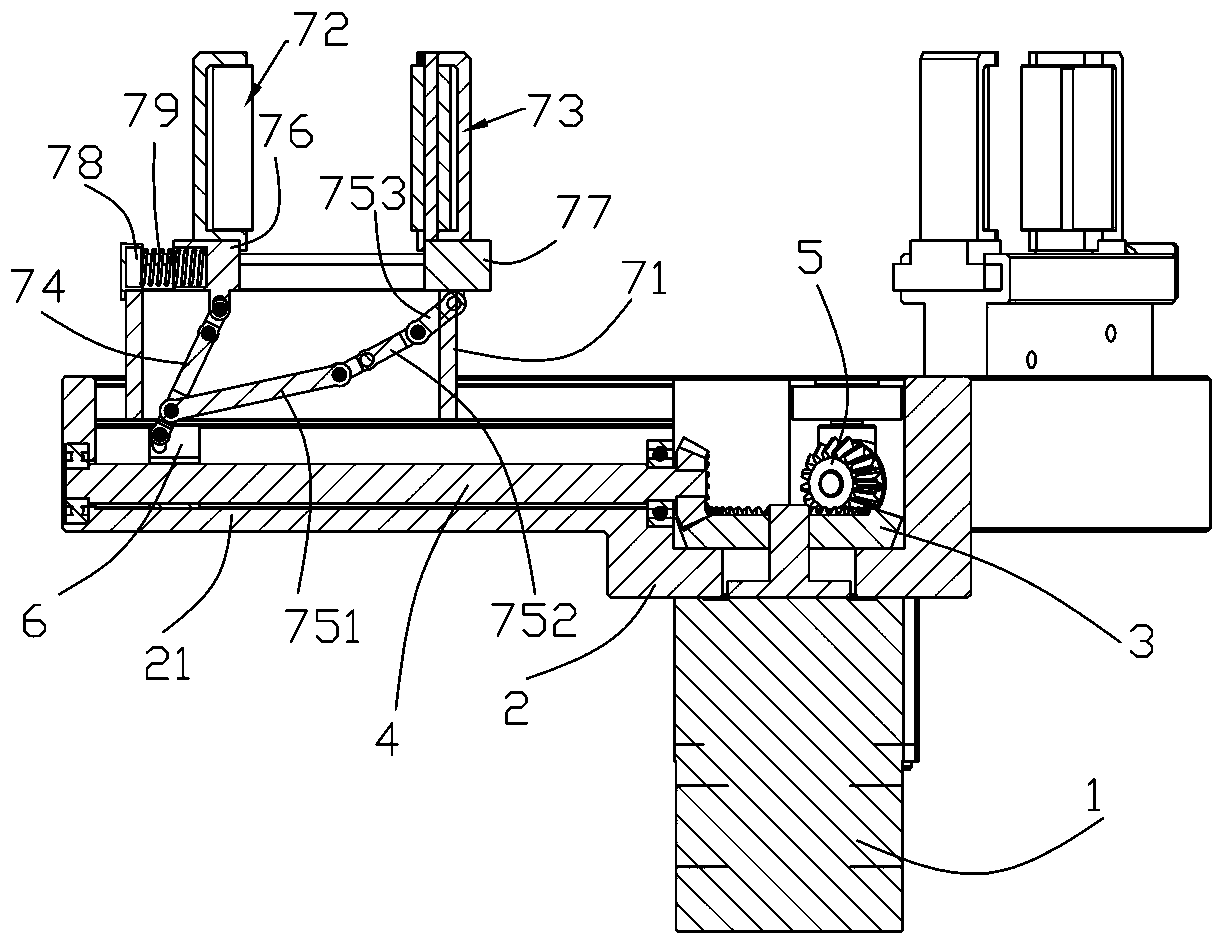

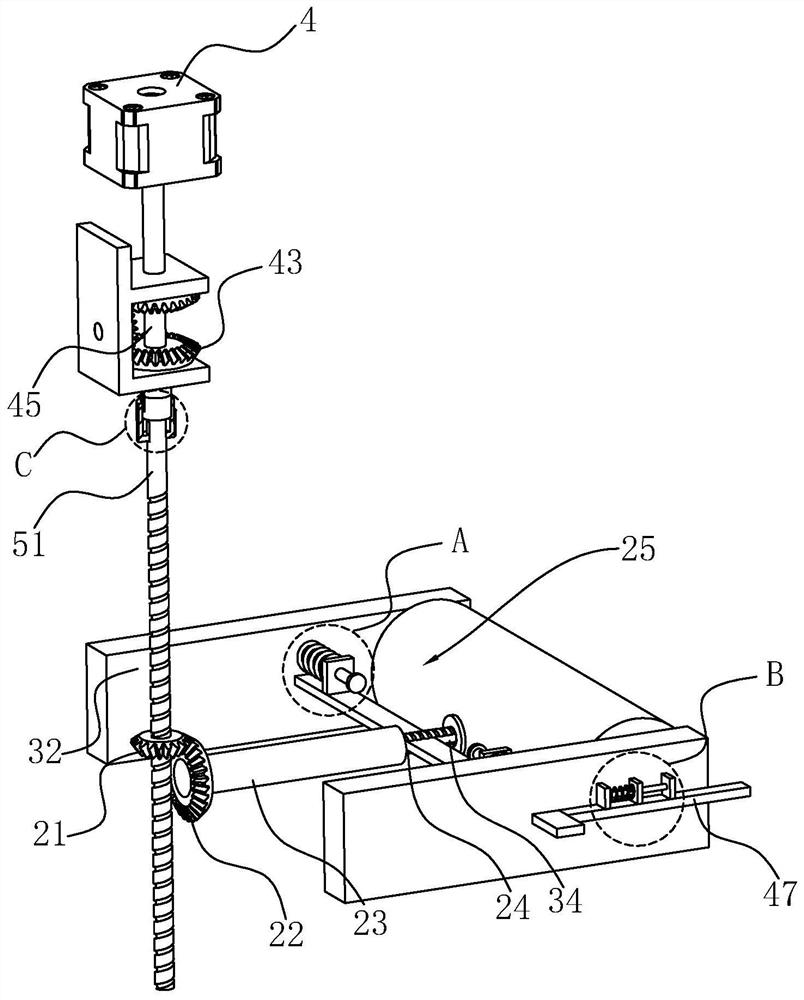

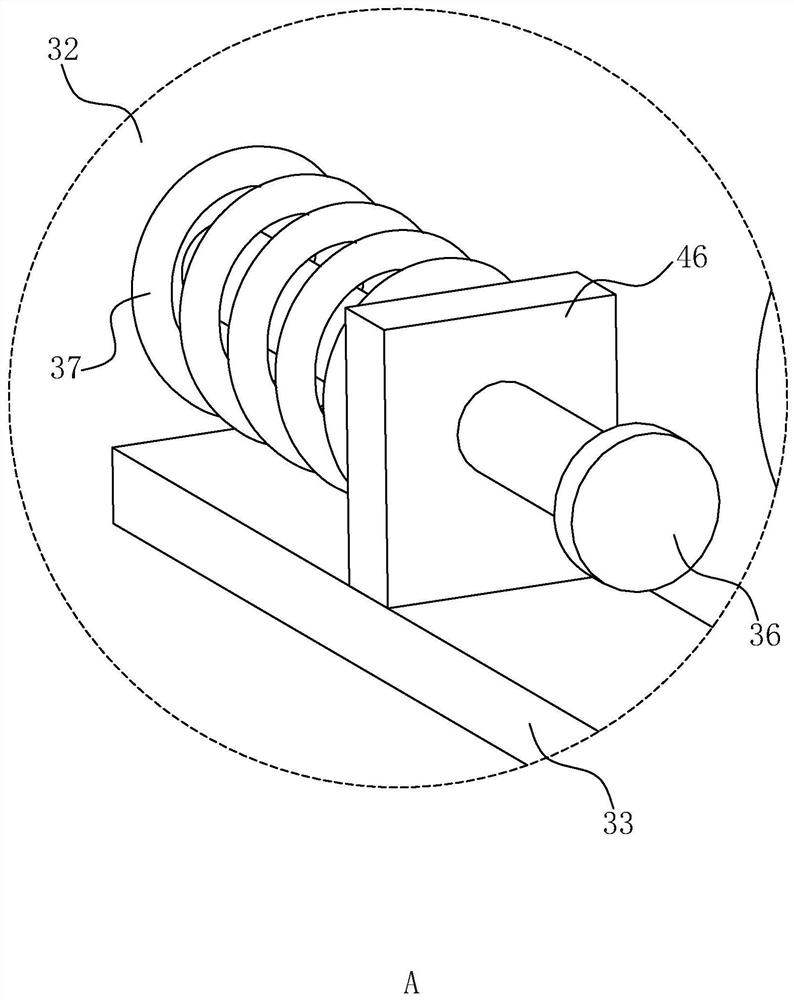

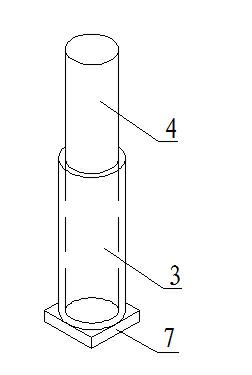

Cylinder sleeve dismounting device

ActiveCN105345735AReasonable structural designEven by forceMetal-working hand toolsEngineeringScrew thread

The invention provides a cylinder sleeve dismounting device. The cylinder sleeve dismounting device comprises pressing devices, friction plates, a base, regulating liner tubes, a pressing nut, a supporting block, a wear reducing device, a rocking bar and a center stud, wherein the center stud is used for sequentially mounting the base, a plurality of pressing device, the pressing nut, the supporting block and the rocking bar from bottom to top; the rocking bar and the pressing nut are both in threaded connection with the center stud; each regulating liner tube is arranged between every two adjacent pressing devices; a cylindrical structure consisting of a plurality of friction plates of which the sections are arc-shaped is arranged at the outer side of each pressing device; the bottom of each friction plate is in contact with the base. The device disclosed by the invention can be used for realizing dismounting of a general cylinder sleeve and also realizing the dismounting of the cylinder sleeve at a condition that the width of a large head of a connecting rod is larger than the inner diameter of the cylinder sleeve; the cylinder sleeve dismounting device is reasonable in structural design and easy to implement.

Owner:CHINA NORTH ENGINE INST TIANJIN

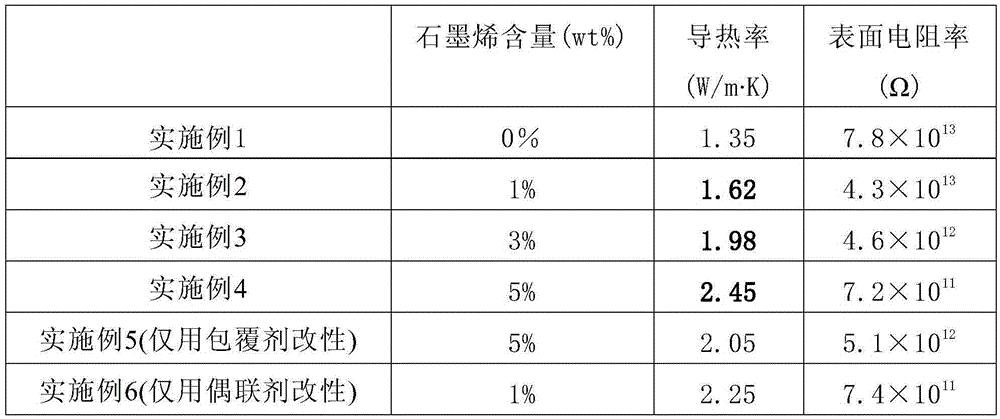

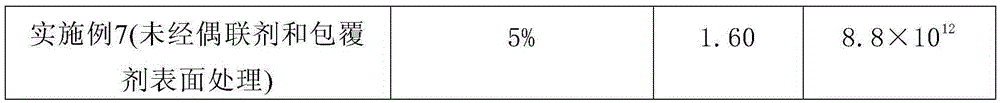

High heat conductivity and insulation plastic as well as preparation method and application thereof

The invention relates to high heat conductivity and insulation plastic as well as a preparation method and application thereof. The invention specifically discloses the high heat conductivity and insulation plastic. The high heat conductivity and insulation plastic comprises thermoplastic plastic and a compound heat conductivity filler uniformly distributed in the thermoplastic plastic, wherein the compound heat conductivity filler is prepared from graphene and an inorganic insulation type heat conductivity filler. The invention further discloses the preparation method and the application of the high heat conductivity and insulation plastic. Under a condition of keeping the mechanical property and the insulation performance of the high heat conductivity and insulation plastic, by adding of the specific compound heat conductivity filler, the heat conductivity of the high heat conductivity and insulation plastic is obviously improved, and the obvious improvement has an important significance for extending the application field of heat conductivity plastic.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

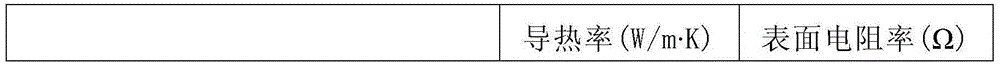

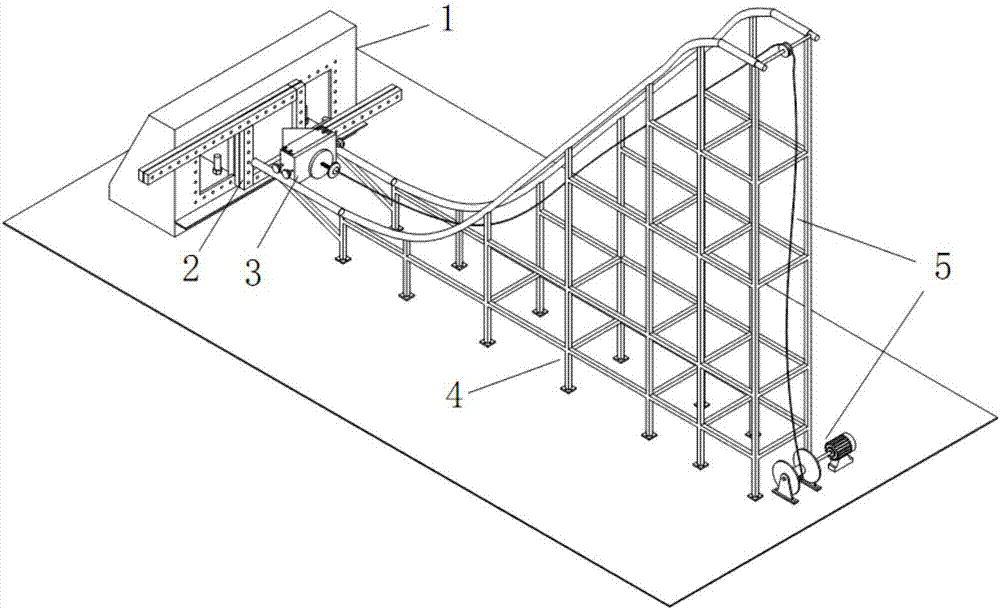

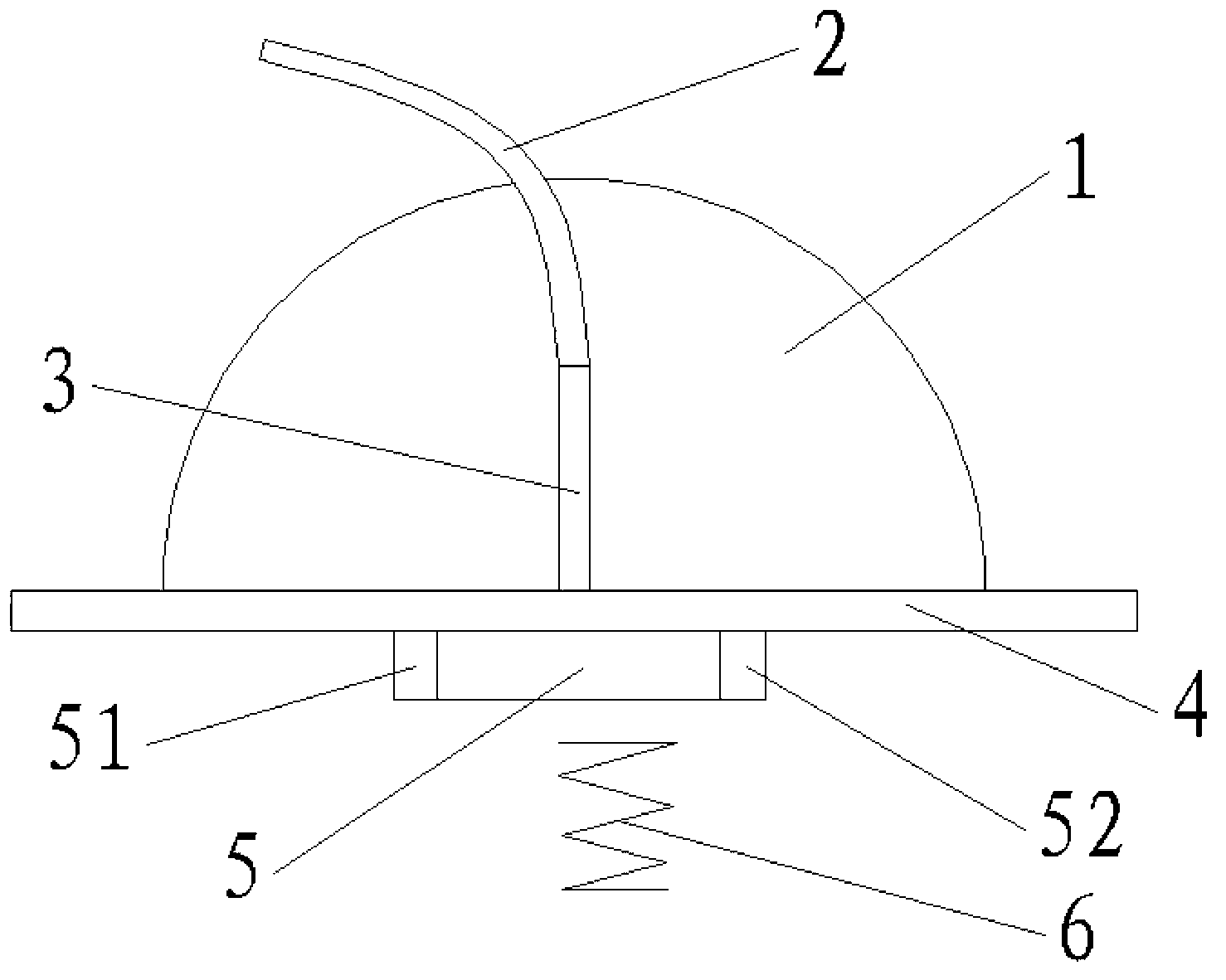

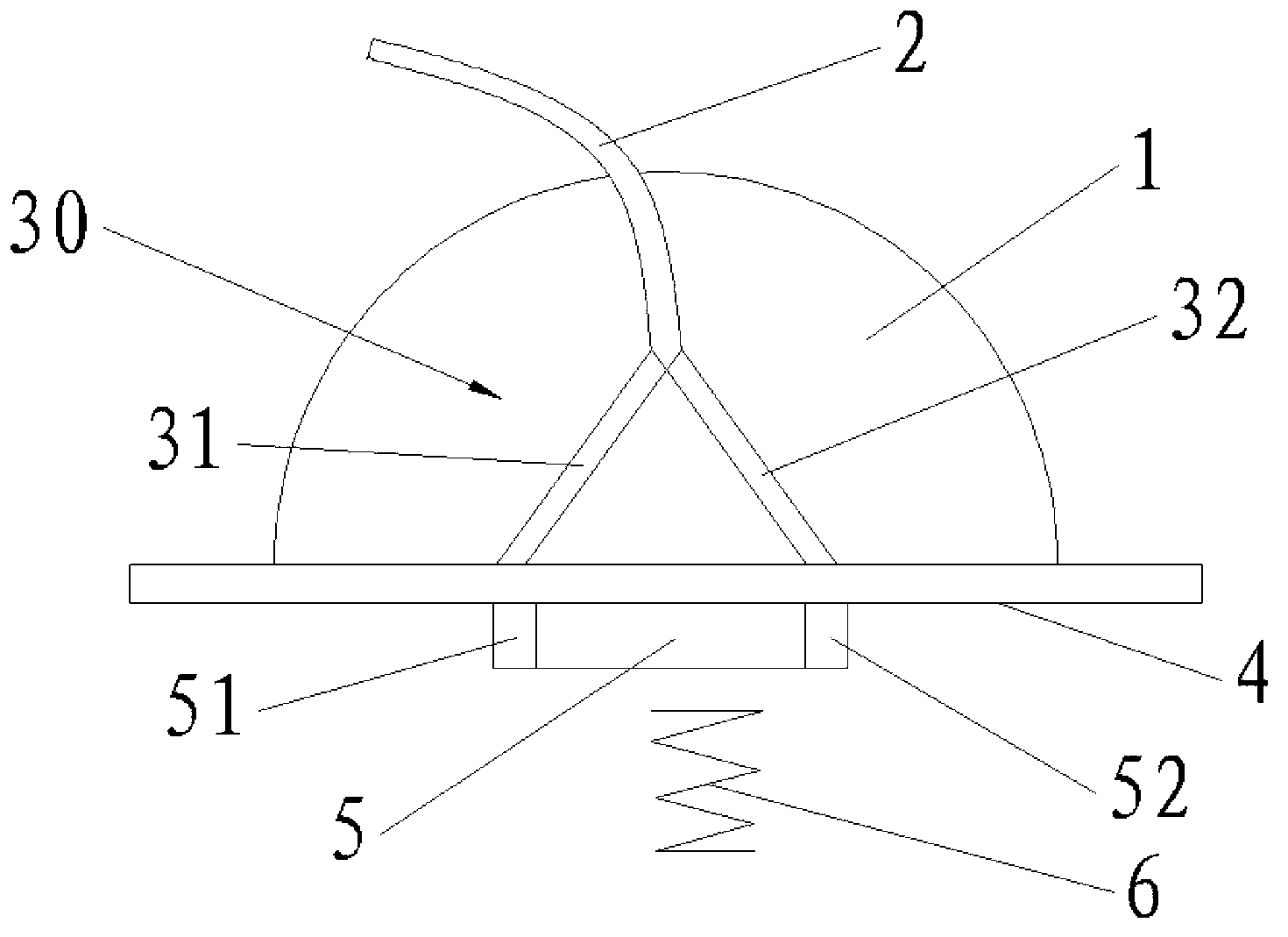

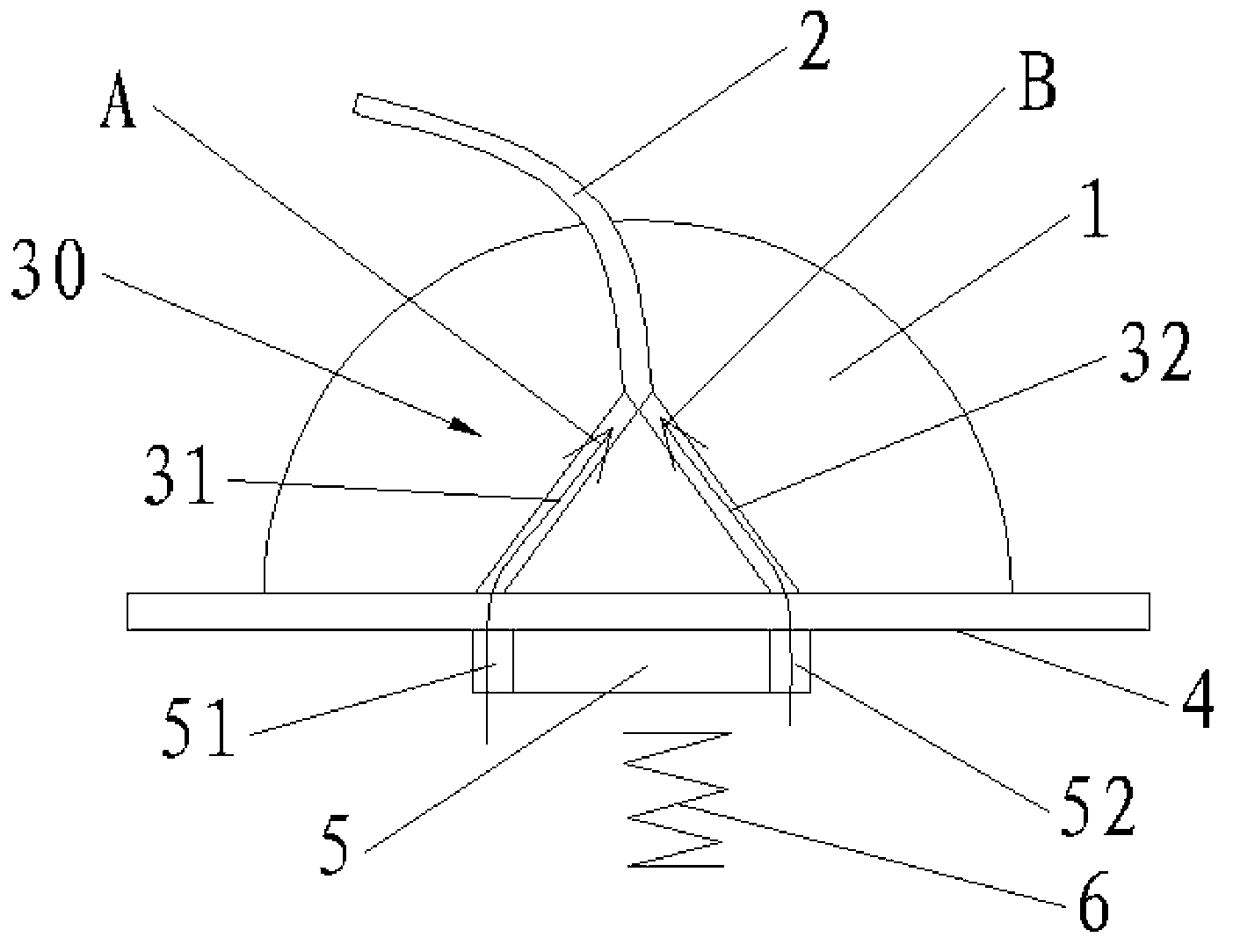

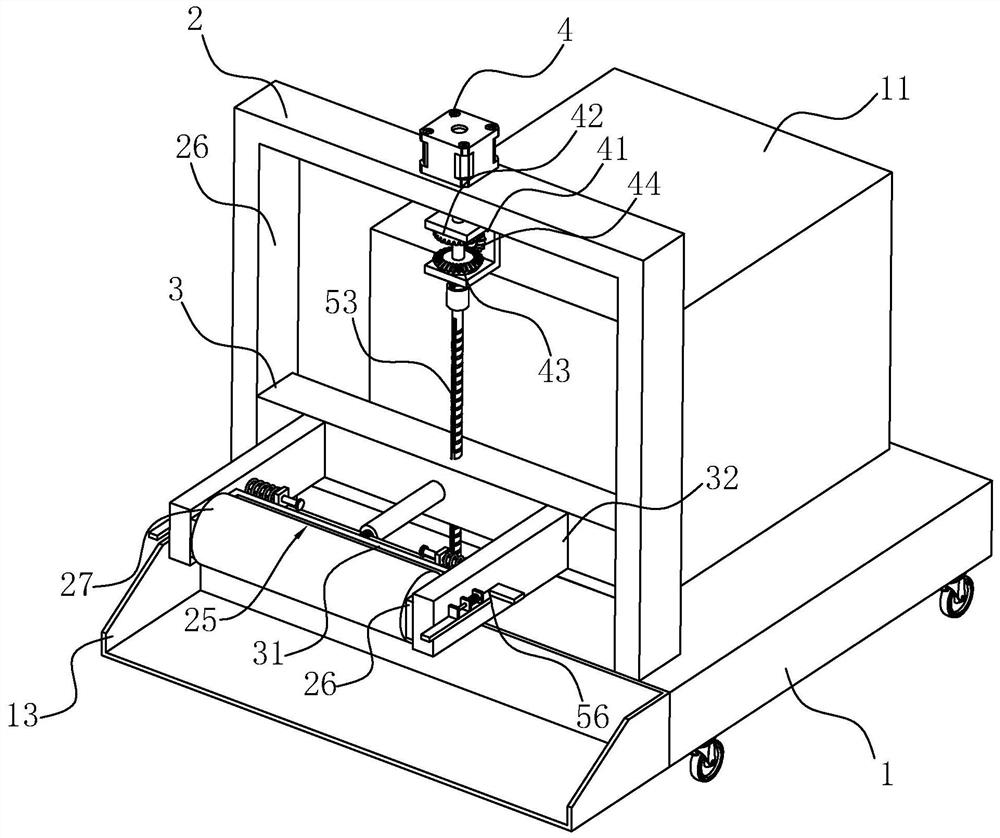

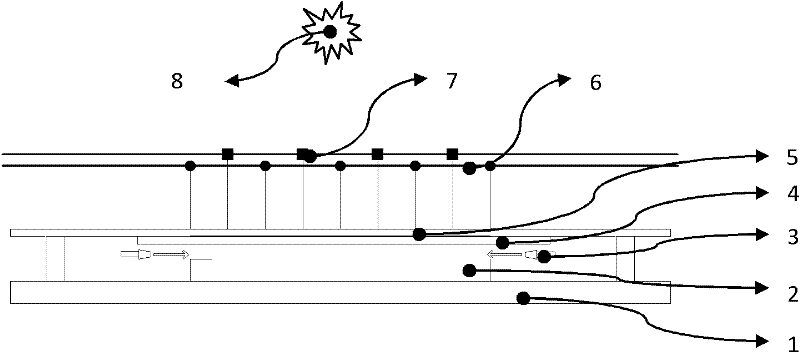

Device capable of carrying out horizontal impact test

PendingCN106950027AImprove versatilityAvoid secondary collisionsShock testingTraction (engineering)Engineering

The invention discloses a device capable of carrying out a horizontal impact test. The device comprises a base (1), a fixture mechanism (2), an impact vehicle (3), a track (4) and a matched traction mechanism (5), and is characterized in that the base (1), the fixture mechanism (2), the impact vehicle (3), the track (4) and the traction mechanism (5) are sequentially arranged in space and operate in a collaborative manner so as to realize a low-speed impact test for different sizes of structures under different boundary conditions, wherein the structures are mainly rectangular plates, square plates or stiffened plates. The device disclosed by the invention is reliable in structure, convenient to operate, high in universality, capable of carrying out a horizontal impact test and preventing secondary impact during the impact test, and capable of simulating horizontal impact in engineering more authentically; the device can realize fixed-end boundary conditions of different sizes of experimental plates or structures; the base is matched with the foundation and small in local deformation when being subjected to strong impact, and can be used for a long time; and the base and the track are high in universality.

Owner:WUHAN UNIV OF TECH

Circuit board and manufacturing method thereof

ActiveCN111901971AConnectivity Alignment Accuracy ImprovementReduce local heatCircuit board tools positioningElectrical connection printed elementsEngineeringLaser drilling

The invention provides a manufacturing method of a circuit board, which comprises the following steps of: 1) providing a core board which is provided with a first surface and a second surface which are opposite to each other; 2) forming positioning holes in the core plate; (3) positioning is carried out through the positioning holes, performing laser drilling on the core plate, machining a plurality of first blind holes in the first face, and distributing and drilling the drilling lines of the first blind holes according to a spiral path from outside to inside when the first face is drilled; and (4) turning over the core plate, performing positioning through the positioning holes, machining a plurality of second blind holes in the second face, and when the second blind holes are drilled inthe second face, drilling lines correspondingly drill holes according to a spiral path from outside to inside, so that the first blind holes drilled in the first face and the second blind holes drilled in the corresponding second face are coaxially communicated. The paths for drilling the blind holes in the two surfaces of the core plate are the spiral lines from outside to inside, so that the core plate is deformed into uniform shrinkage, deformation caused by local overheating of the core plate is avoided, and the communication accuracy of each first blind hole and the corresponding secondblind hole is improved.

Owner:DONGGUAN SHENGYI ELECTRONICS

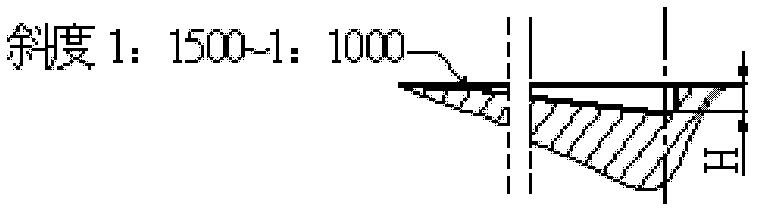

Concrete road pavement structure

InactiveCN104631268AImprove integrityLess bendingPaving reinforcementsIn situ pavingsBrickSurface layer

The invention relates to a concrete road pavement structure which comprises a sidewalk pavement and a roadway pavement, wherein an isolation road edge is arranged between the sidewalk pavement and the roadway pavement; the sidewalk pavement comprises a first base soil layer; a first cement macadam base layer is laid on the first base soil layer; a first mortar layer is laid on the first cement macadam base layer; a water permeable brick layer is laid on the first mortar layer; the roadway pavement comprises a second base soil layer; a macadam sub-base layer is laid on the second base soil layer; a second cement macadam base layer is laid on the macadam sub-base layer; an asphalt seal layer is laid on the second cement macadam base layer; a concrete surface layer is laid on the asphalt seal layer; an embedded pipe is arranged in the macadam sub-base layer; a connecting reinforcing steel bar is arranged in the concrete surface layer just above the embedded pipe along the transverse direction; a kerf is formed in the concrete surface layer. The concrete road pavement structure has the advantages of being good in overall strength, low in construction difficulty and good in bearing capability.

Owner:CHONGQING CREATION VOCATIONAL COLLEGE

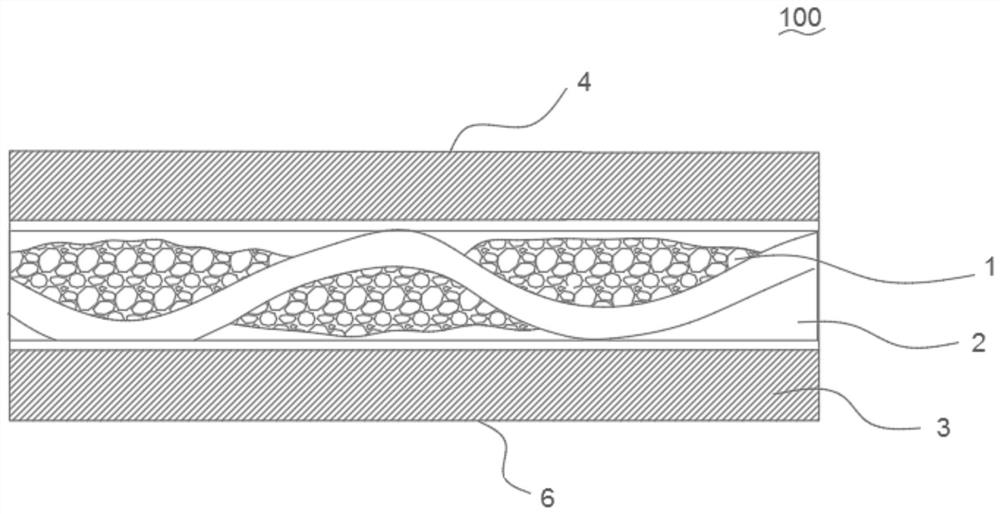

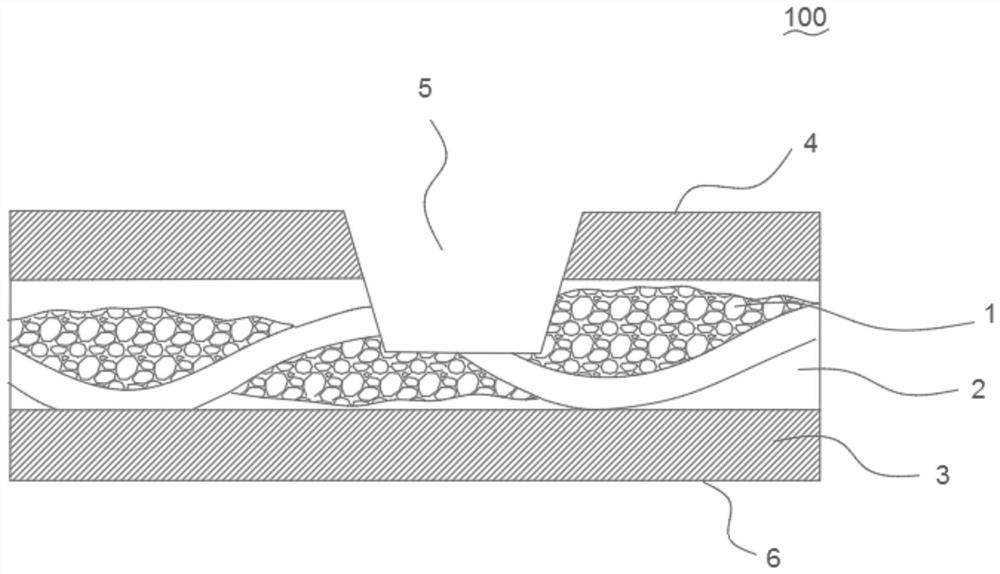

Elastic running board for running machine

InactiveCN102275360ALarge plastic deformationNot much use valueSynthetic resin layered productsMovement coordination devicesHeat resistanceEngineering

The invention discloses an elastic running board for a running machine. The elastic running board is formed by adhering an elastic layer on a bottom plate surface which is manufactured by a medium density fiberboard or a plywood board and then adhering a friction layer on the outer surface of the elastic layer. The elastic running board can buffer and absorb impact force and vibration force which are generated by running, has high intensity, toughness and heat resistance, and greatly reduces noise emitted during running.

Owner:吴小凤

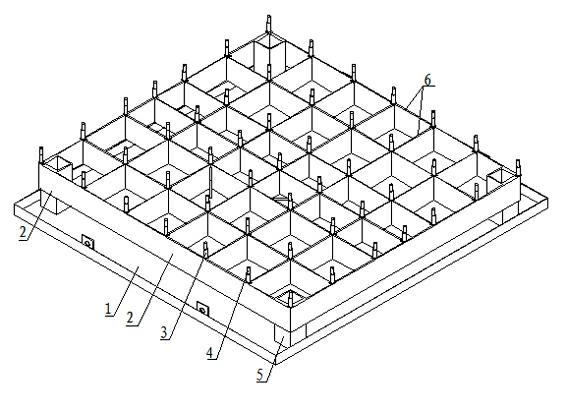

Multi-point swinging head press forming method for panel three-dimensional curved surface forming

The invention relates to a multi-point swinging head press forming method for panel three-dimensional curved surface forming, and belongs to the field of mechanical engineering. In the forming process, multi-point reconfigurable die profiles are constantly converted, and metal plate materials are gradually and continuously formed into a curved surface; a multi-point reconfigurable die is composedof discretized swinging heads which are adjustable in height and are arranged regularly; and multi-point press forming serves as a basis, swinging bodies of the swinging heads can restrain plate materials in a self-coordination manner along with deformation of the plate materials in the forming process, and accordingly the plate materials are formed. The multi-point swinging head press forming method has the beneficial effects that during forming, the state of suspension of the plate materials does not exist, the plate materials are constantly restrained by base bodies, stress is more uniform,and generation of defects can be effectively prevented. The swinging bodies are sufficiently attached to the plate materials, forming faces are continuously increased, stress of the plate materials is more uniform and stable, local deformation is reduced, and the surface quality is obviously improved. Dislocation between acting force of the upper base body and the lower base body is reduced, thelocal bending effect is weakened, and the forming precision is obviously improved.

Owner:JILIN UNIV

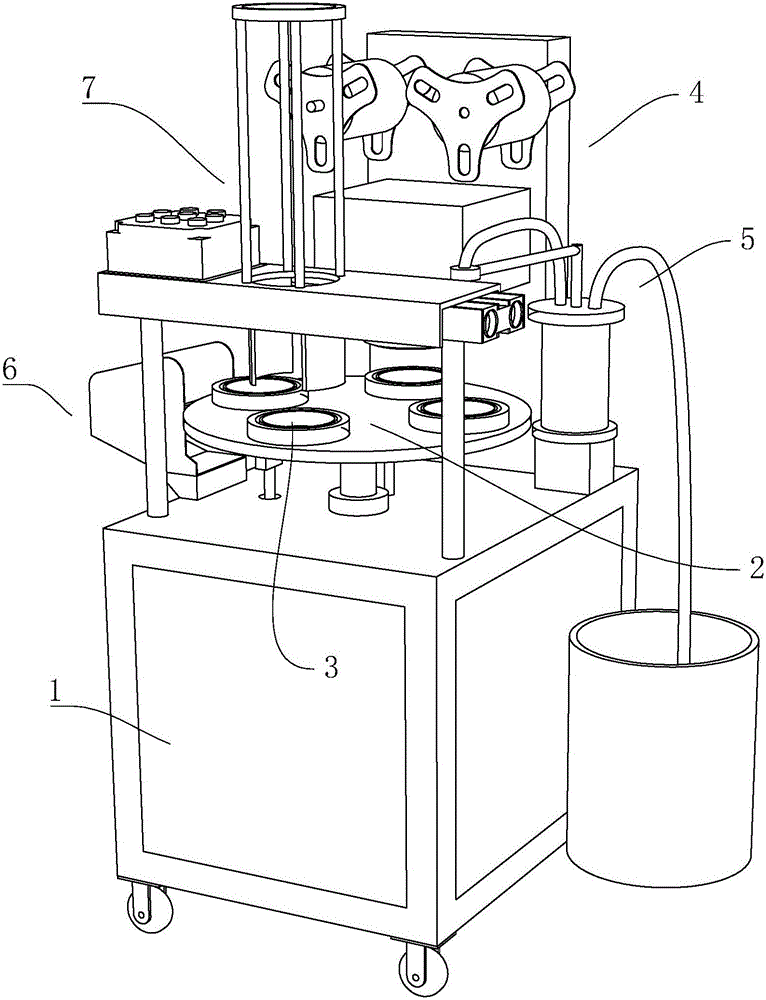

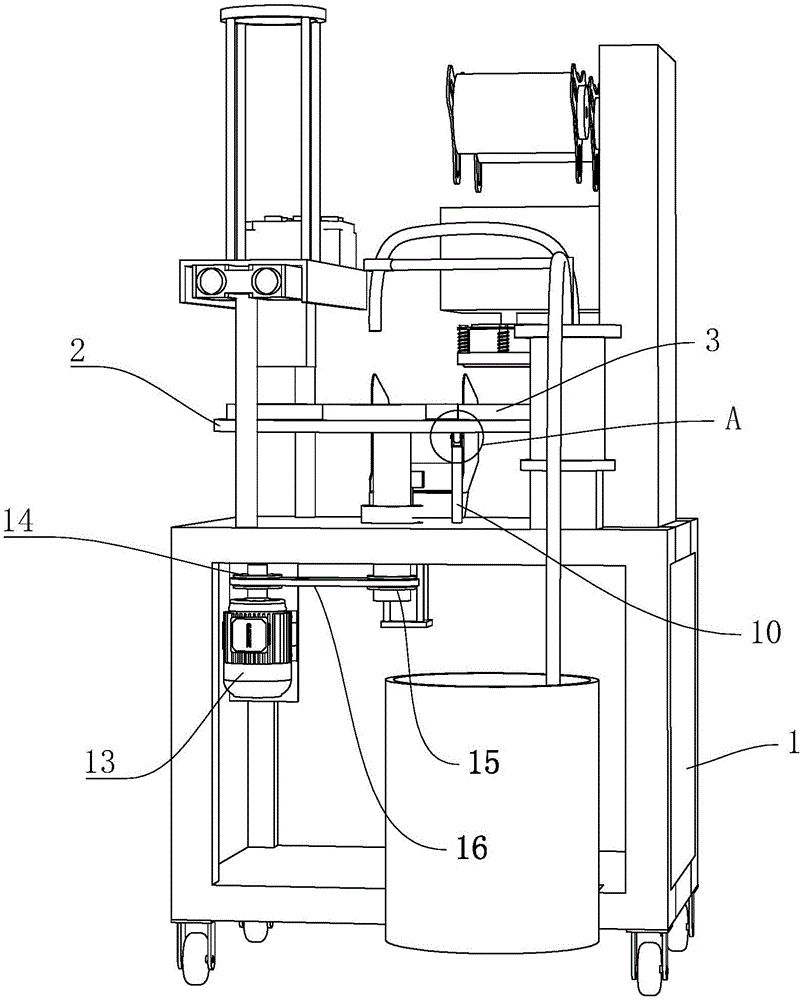

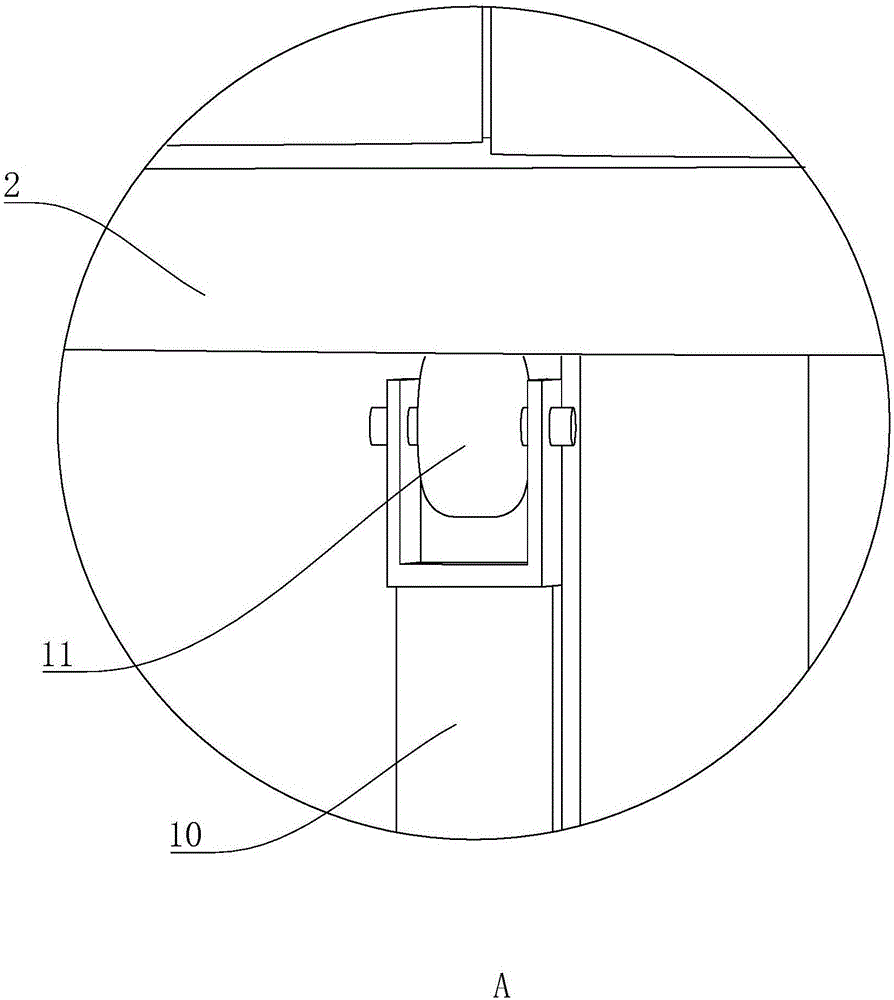

Cup body sealing machine

InactiveCN107176344AImprove processing efficiencyFully automatedLiquid materialEngineeringAutomation

The invention discloses a cup body sealing machine. The cup body sealing machine comprises a machine frame, a rotary plate and container bases, wherein the rotary plate is rotatably arranged above the machine frame and horizontally disposed, and the container bases are arranged on the rotary plate and distributed around the circle center of the rotary plate in the circumferential direction; the machine frame is provided with a sealing mechanism and a liquid supply mechanism, the machine frame is provided with a discharging mechanism, and the liquid supply mechanism, the sealing mechanism and the discharging mechanism are arranged in sequence; the discharging mechanism comprises a driving part which is arranged on the machine frame and used for driving plastic cups to be ejected out of the container bases. The cup body sealing machine has the following advantages and effects that by using a new mechanical structure, the rotary plate is arranged and matched with a cup feed mechanism, the liquid supply mechanism, the sealing mechanism and the discharging mechanism, and the cup feed mechanism, the liquid supply mechanism, the sealing mechanism and the discharging mechanism are sequentially arranged around the rotary plate in the circumferential direction, thus the cup body sealing machine can automatically finish plastic cup processing, processing automation is achieved, and the processing efficiency of plastic cups is improved.

Owner:浙江伊瑞机械有限公司

Special heat-conductive insulating material for new energy automobile battery

InactiveCN108659327AImprove thermal conductivityGood insulation and heat conductionHeat-exchange elementsFiberHexagonal boron nitride

The invention discloses a special heat-conductive insulating material for a new energy automobile battery. The heat-conductive insulating material comprises the main raw materials in parts by weight:30-40 parts of POM plastics, 6-11 parts of hexagonal boron nitride micropowder, 5-10 parts of nanometer SiO2 powder, 3-4 parts of chopped carbon fiber particles, 1-2 parts of zinc oxide, 0.5-1 part ofpolyglycerol fatty acid ester, 0.5-1 part of cresyl diphenyl phosphate and 0.5-1 part of ethylene bisstearamide. The invention further discloses a preparation method of the special heat-conductive insulating material, and the preparation method comprises the continuous production processes: blending treatment, double-screw extrusion and injection molding by an injection molding machine. Due to the selection of a formula in which POM plastics, hexagonal boron nitride / calcium carbonate nanometer composite particles and modified silicon dioxide are adopted, the prepared composite has high heat conductivity, good insulativity, low density, low cost and good machinability and can be better adapted to the new energy automobile battery, the battery is uniform in heat radiation and capable of avoiding hot spots, local deformation caused by high temperature can be effectively reduced, and the service life can be prolonged.

Owner:湖北娅安科技开发有限公司

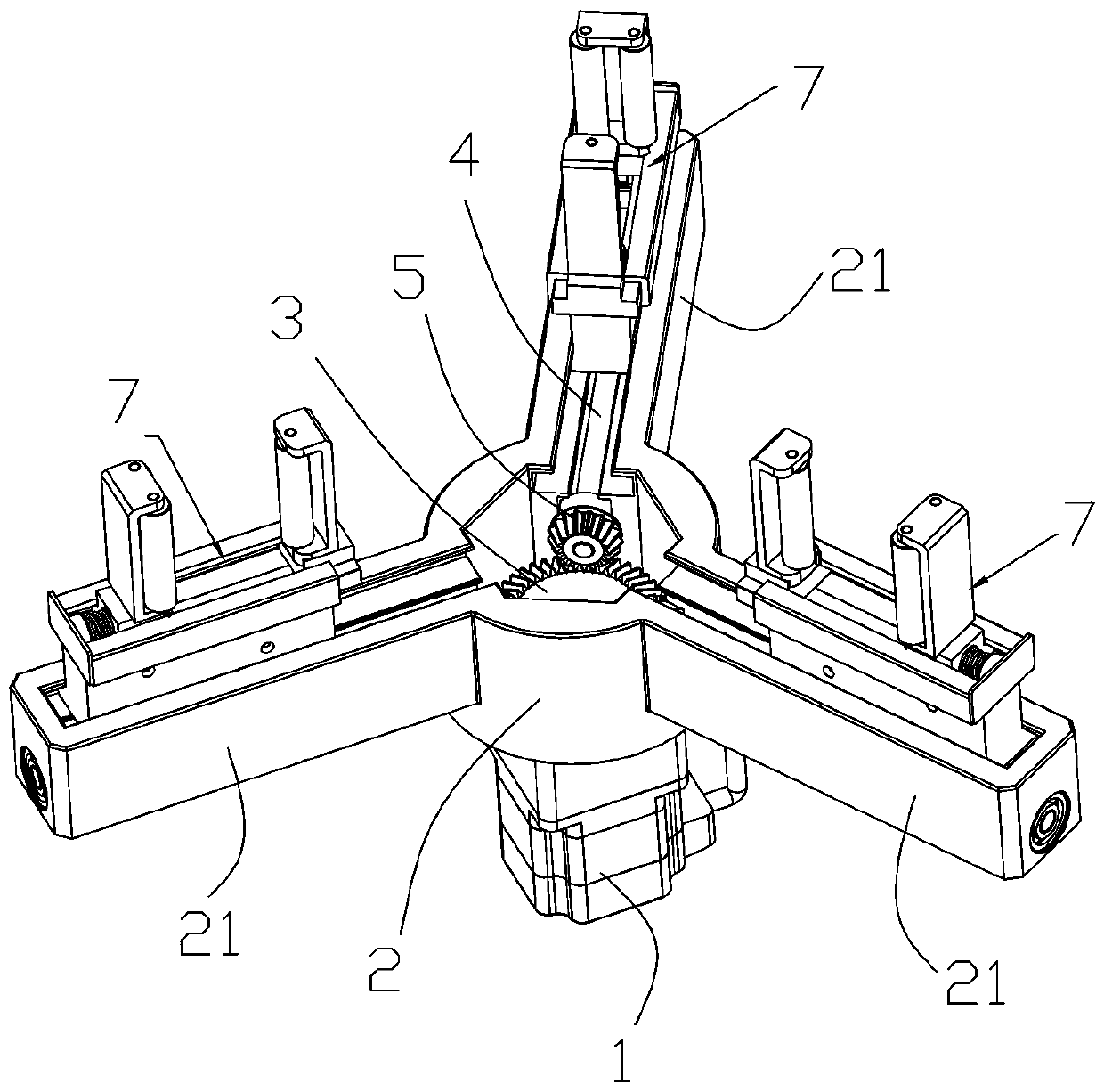

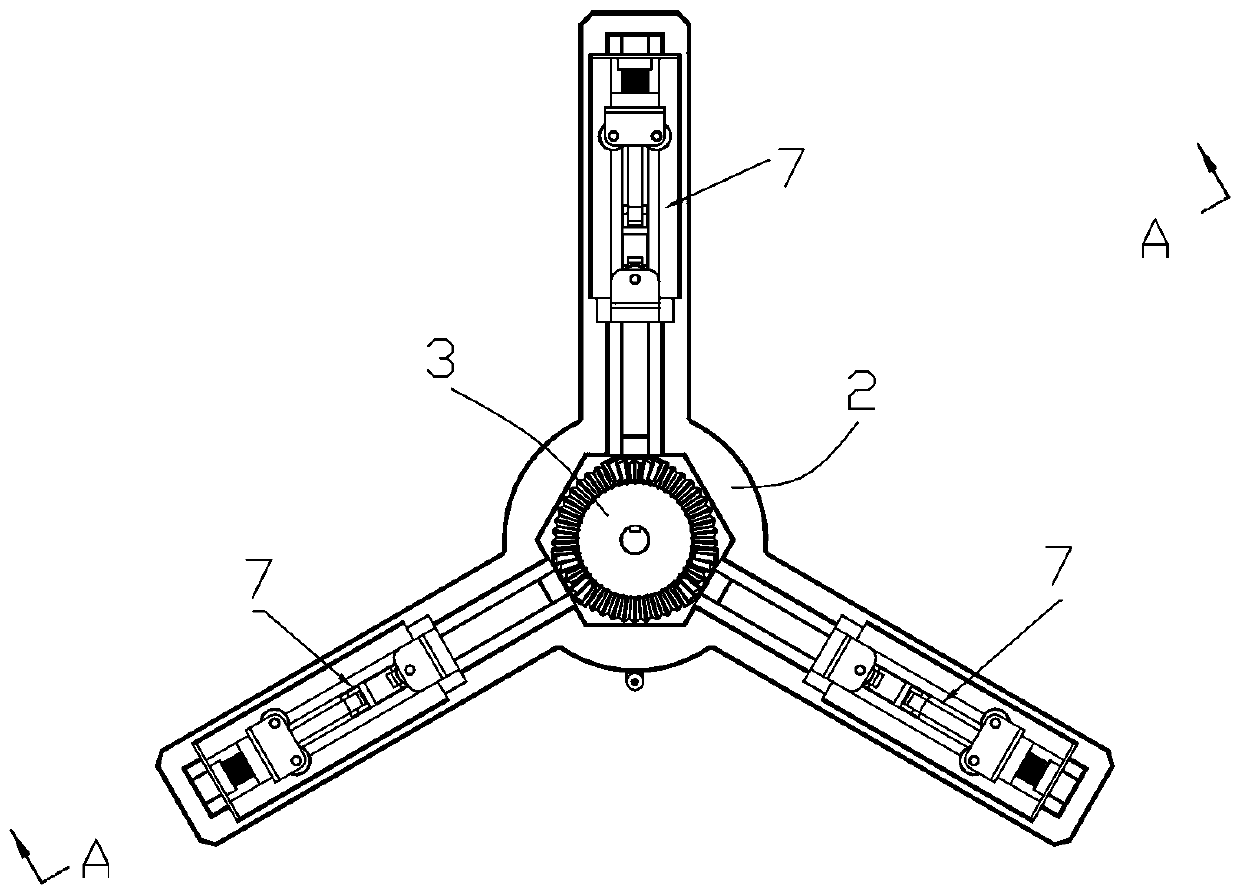

Self-adaptive circular tubular thin-wall part clamping jaw

InactiveCN110842958AReduce local deformationReduce the possibility of deformationGripping headsElectric machineryEngineering

Owner:荆门禾硕精密机械有限公司

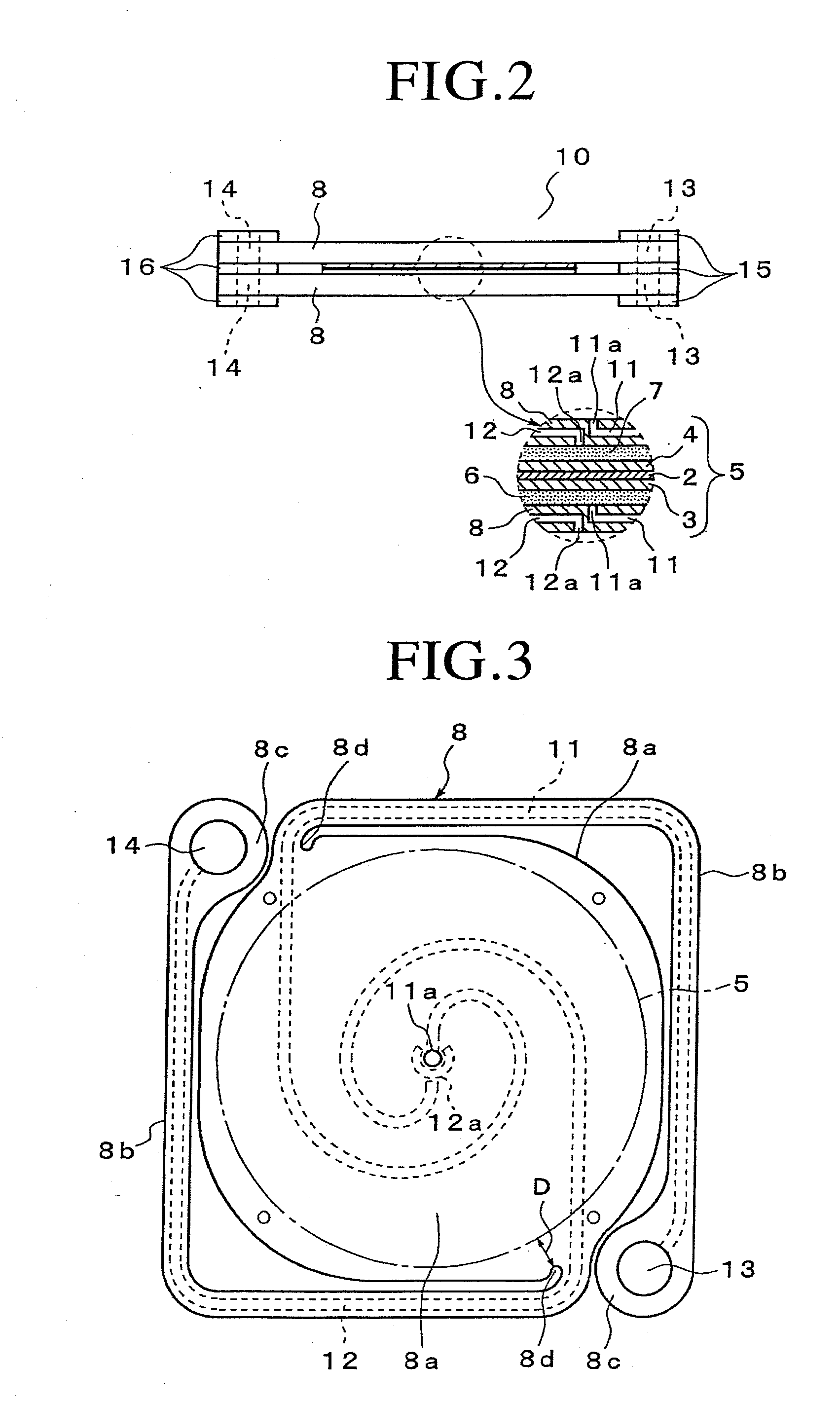

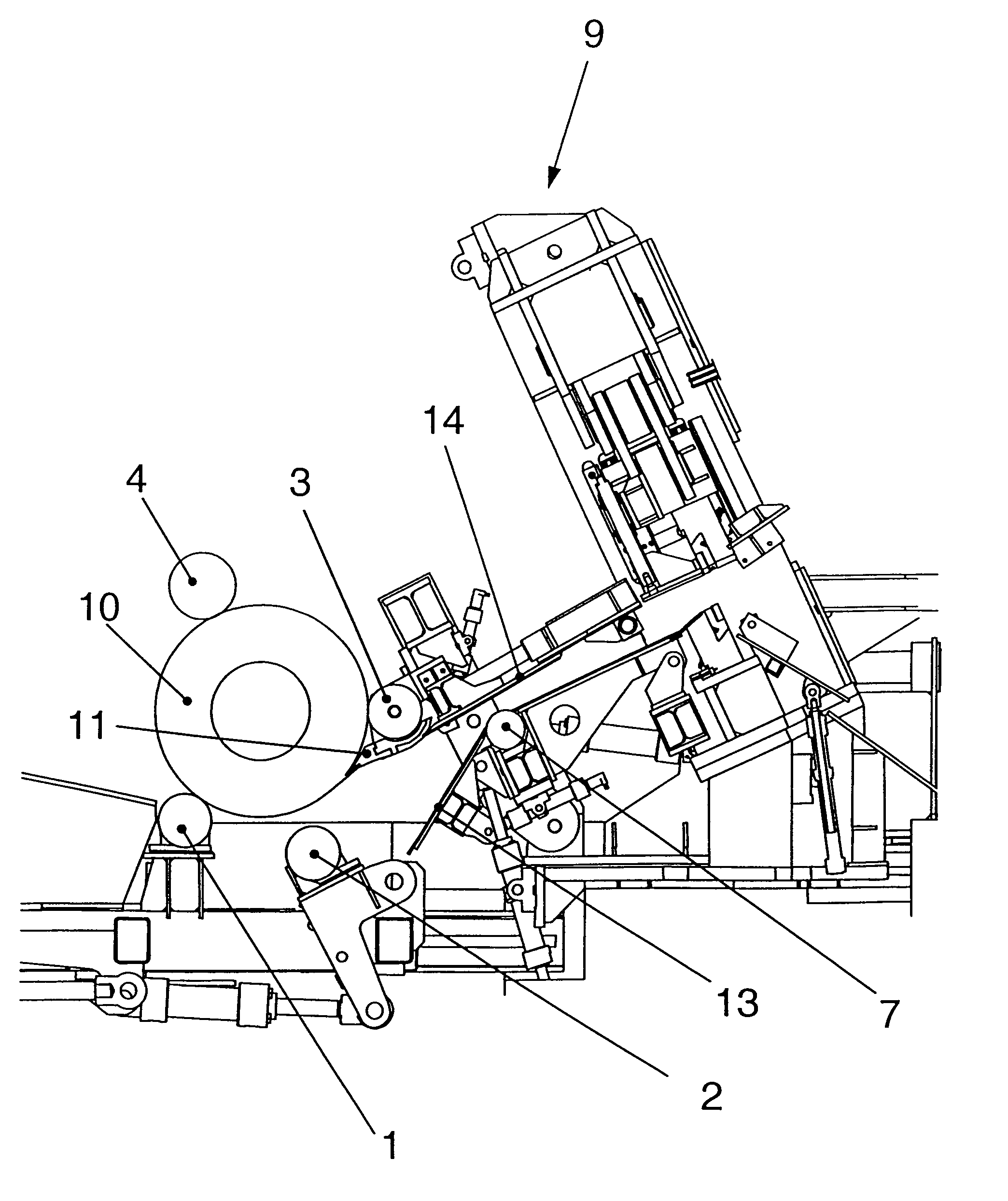

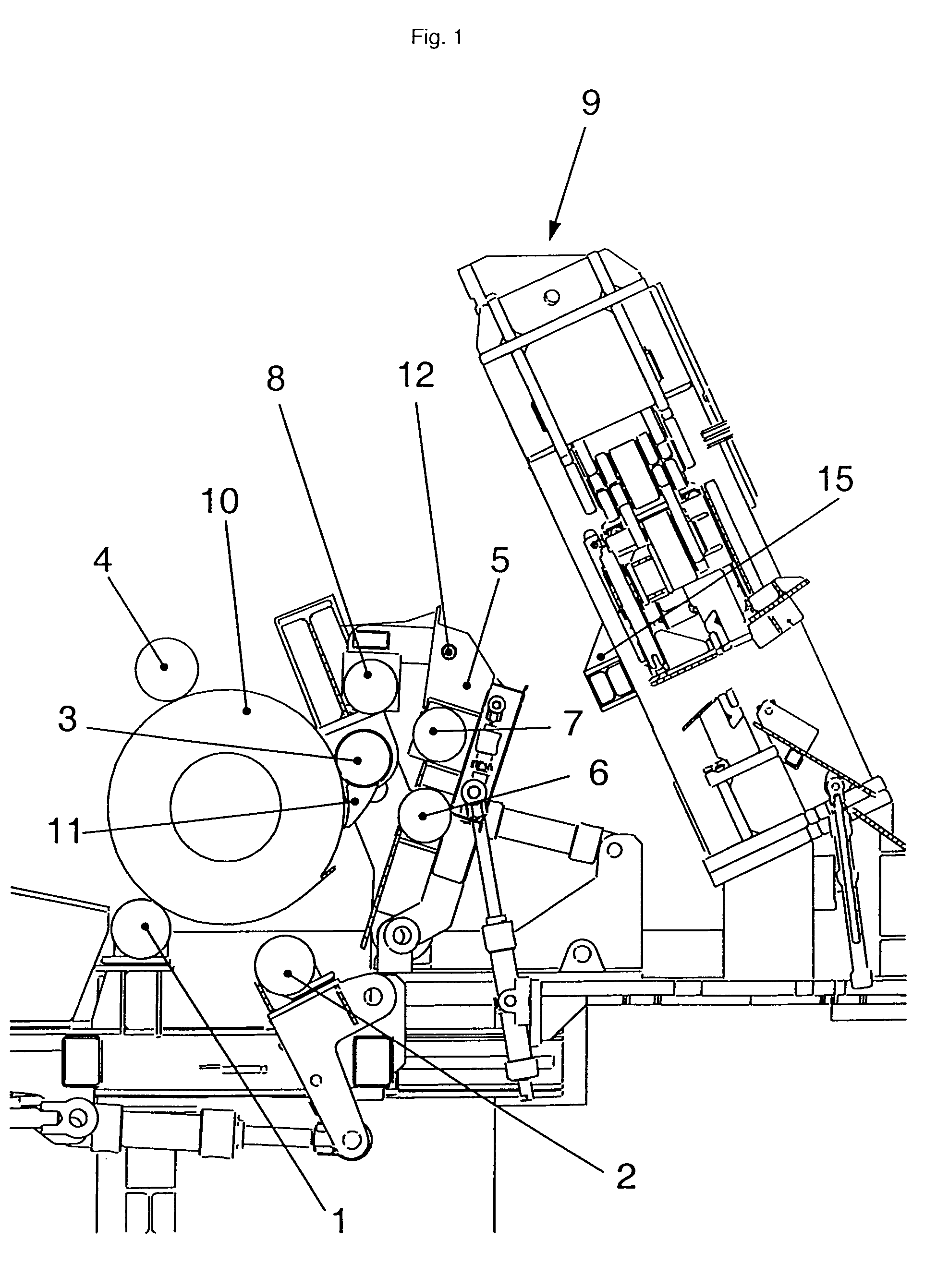

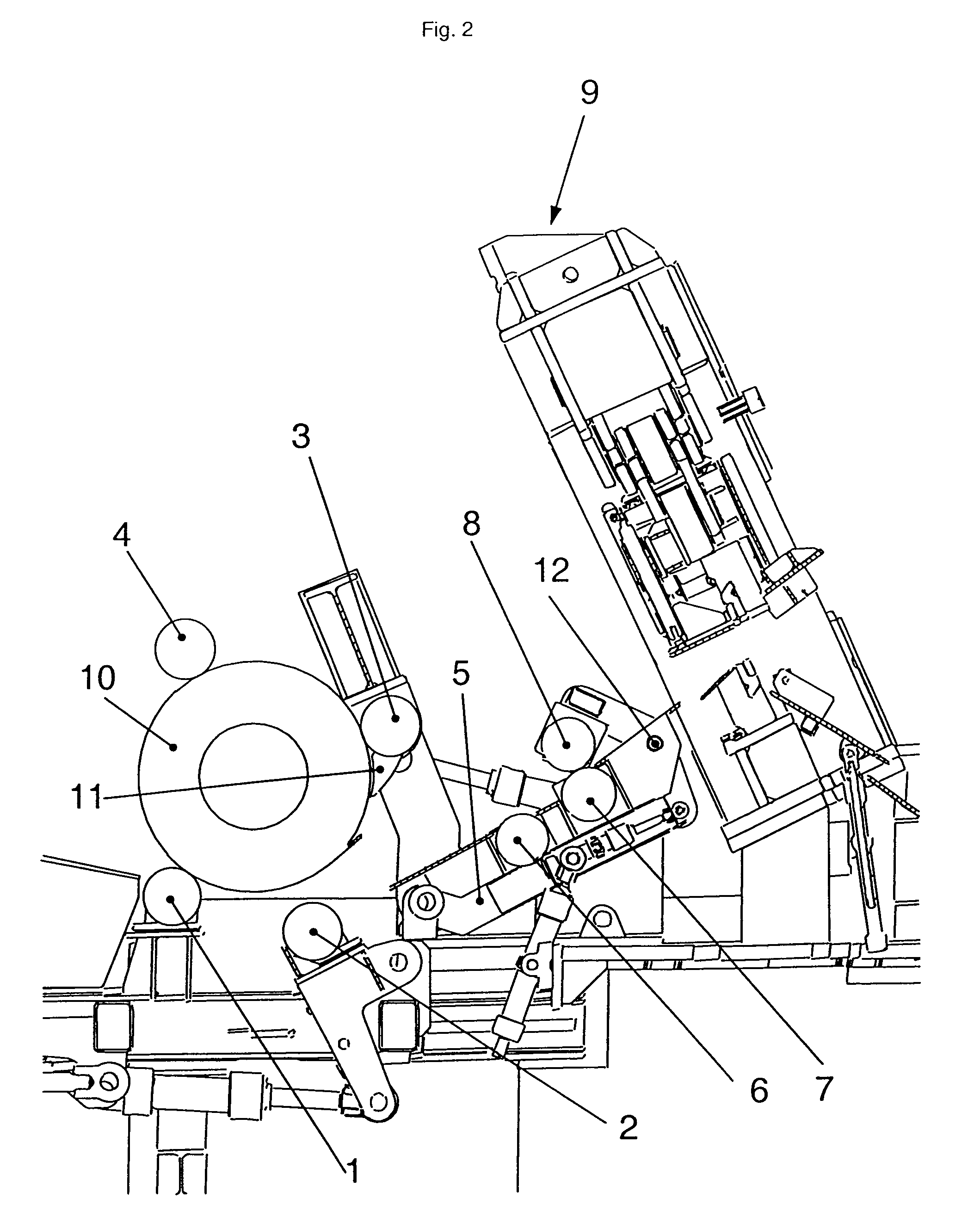

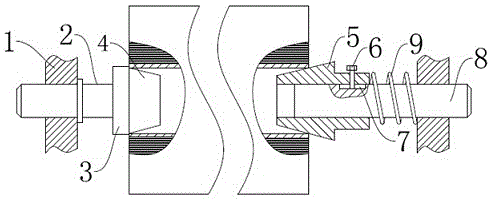

Sampling apparatus and method

InactiveUS8096158B2Reliable croppingReliable samplingShearing machinesMetal working apparatusBiomedical engineering

The invention relates to an apparatus and a method for cropping the ends of or for separating test pieces from rolled strip wound into bundles. An apparatus is disclosed which, by means of an outwardly pivotable bottom roller (2) and guide devices (5, 6, 7, 8, 13, 14) for guiding the strip end to the shears, also makes it possible to process strips which are thicker or of greater firmness and are wound into bundles (10). Furthermore, a method is specified, which allows a reliable sampling and, if appropriate, inspection of the sample from strips wound into bundles, a closed bundle being obtained again after sampling.

Owner:PRIMETALS TECH AUSTRIA GMBH

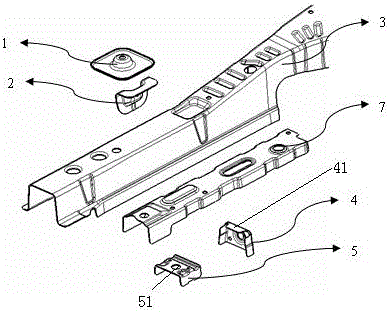

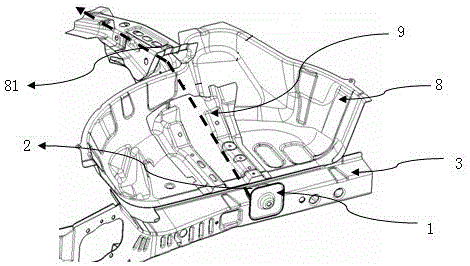

Rear force transmission structure of automobile

ActiveCN103318265AReduce risk of damageReduced impact strengthSuperstructure subunitsBumpersEngineeringUltimate tensile strength

The invention relates to the field of automobiles, and discloses a rear force transmission structure of an automobile. The rear force transmission structure comprises a longitudinal floor beam, a force transmission beam and a column C; the longitudinal floor beam is connected with a shock absorber; one end of the column C is connected with an automobile body, the other end of the column C is connected with the longitudinal floor beam by the force transmission beam, and the force transmission beam is connected with a rear wheel cover; the force transmission beam comprises a first force transmission rod and a force transmission rod. Parts of longitudinal force are transmitted by the first force transmission rod and the second force transmission rod respectively, the strength of impact on a part, which is connected with the force transmission beam, of the rear wheel cover is reduced, and accordingly the rear wheel cover is protected. The rear force transmission structure has the advantages that the first force transmission rod and the second force transmission rod are arranged in a splay manner, and a hollow triangular structure is formed between the force transmission beam and the longitudinal floor beam, so that the stability of the force transmission beam is improved, and the rigidity of the rear wheel cover is further improved; the triangular structure is favorable for improving the ability of transmitting rear collision force to the automobile body via the force transmission beam and the column C after rear collision of the automobile occurs; the force transmission beam is connected with two rear transverse floor beams, and accordingly energy of lateral collision force can be advantageously absorbed by the automobile.

Owner:GREAT WALL MOTOR CO LTD

Anti-crack thermal insulation wall and construction process

The invention relates to an anti-crack thermal insulation wall and a construction process. The construction process of the anti-crack thermal insulation wall comprises the following steps that polyurethane adhesive is coated to form an adhesive layer, and a polystyrene plastic plate is pasted on the surface of the adhesive layer; and fiber mortar is coated on the surface of the polystyrene plastic plate, and air-drying is carried out for 15-20 minutes at normal temperature to form a surface layer. The wall construction device for coating the adhesive layer and the surface layer comprises a supporting frame; a connecting seat is slidably connected in the supporting frame, the connecting seat is rotatably connected with an internal thread pipe, and a screw rod is in threaded connection in the internal thread pipe; the screw rod is fixedly connected with a fixing frame, and a painting wheel is rotationally installed in the fixing frame; the connecting seat is fixedly connected with a guide plate, a guide piece penetrates through the guide plate, and an inserting groove is formed in the peripheral face of the screw rod; the guide plate is provided with a separation assembly used for driving the guide piece to be separated from the inserting groove; and a driving mechanism used for driving the inner threaded pipe to rotate is arranged in the supporting frame. The problem that a brush is locally deformed due to the fact that the brush is tightly attached to the outer wall can be solved.

Owner:合肥国泓建设工程有限公司

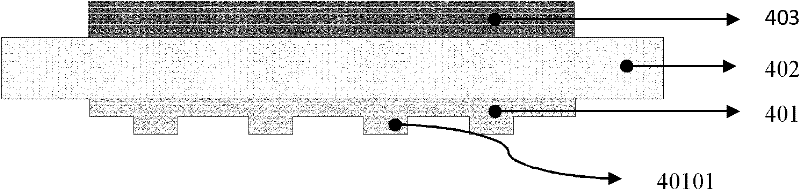

Device and method for nanoimprinting of full wafer

ActiveCN102096315BNo tensile deformationReduce local deformationPhotomechanical apparatusResistUltraviolet lights

The invention relates to a device and a method for nanoimprinting of a full wafer, comprising a working platform, a full wafer coated with an etchant resist, a nozzle for demoulding, a template, an imprinting head, a pressure pipeline, a vacuum pipeline and an ultraviolet light source, wherein the template is fixed on the bottom surface of the imprinting head; the side surface on the lower part of the template is equipped with the nozzle for demoulding; the pressure pipeline and the vacuum pipeline are connected to air inlet holes which are arranged on two side surfaces of the working platform of the imprinting head; the full wafer coated with the etchant resist is fixed on a wafer working platform; and the ultraviolet light source is arranged over the imprinting head. The method providedby the invention comprises the following steps of: 1) pre-treating process; 2) imprinting process; 3) curing process; and 4) demoulding process. The device and the method for nanoimprinting of the full wafer provided by the invention have the characteristics that the structure is simple, the cost is low, the production efficiency is high, the accuracy is high, the imprinting area is large, and the suitability for the batch production and the imprinting of the full uneven wafer can be obtained. The device and the method can be applied to the large-scale manufacturing of high-density disc, micro-optic device and micro-fluidic device and the like, and the device and the method are particularly suitable for the imaging of the full wafer of a photonic crystal LED (Light Emitting Diode).

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

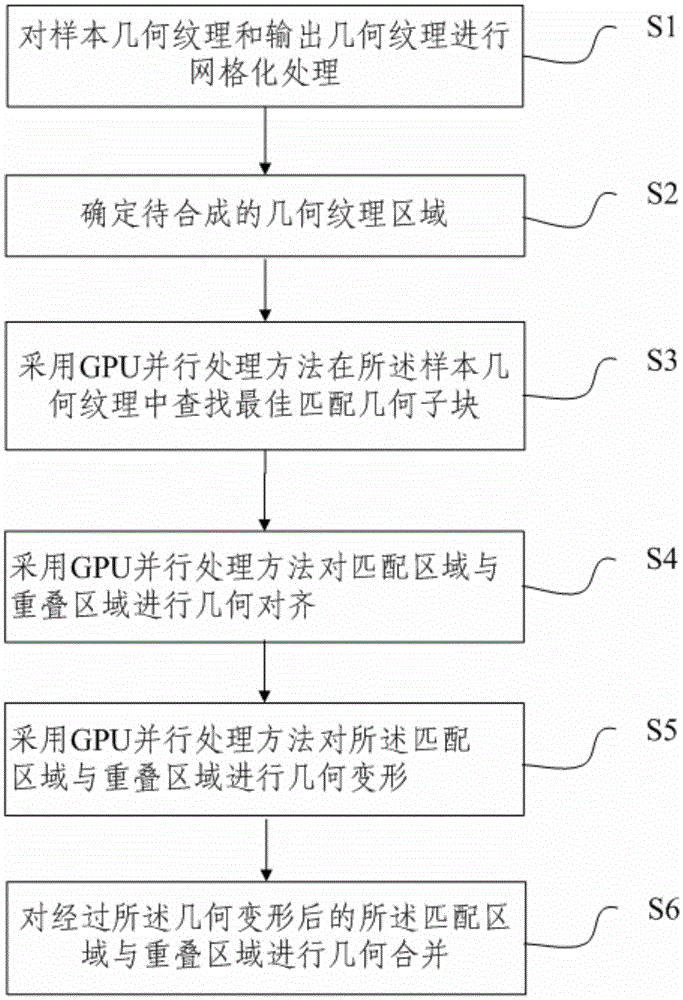

Geometric texture synthesis method and system based on GPU (Graphics Processing Unit) acceleration

ActiveCN105574903ASynthesis speedReduce local deformationTexturing/coloringProcessor architectures/configurationGeometric alignmentTexture synthesis

The invention relates to a geometric texture synthesis method and system based on GPU (Graphics Processing Unit) acceleration. The method comprises the following steps of performing gridding processing on a sample geometric texture M<in> and an output geometric texture M<out>; determining a region on which the geometric textures are to be synthesized; finding optimal matching geometric sub-blocks m<out> from the sample geometric texture M<in> through a GPU parallel processing method; performing geometric alignment on a matching region P<out> and an overlapping region shown in the description through the GPU parallel processing method; performing geometric deformation on the matching region P<out> and the overlapping region shown in the description through the GPU parallel processing method; and performing geometric combination on the matching region P<out> and the overlapping region shown in the description which are subjected to the geometric deformation. According to the geometric texture synthesis method and system, the sample geometric texture is subjected to geometric sub-block subdivision, and the geometric sub-blocks are taken as basic synthesis units, so that the quality of a synthesis result is enhanced. The GPU parallel processing method is adopted, so that the calculation complexity in finding of the optimal matching geometric sub-blocks and splicing of the geometric sub-blocks is lowered, and the geometric texture synthesis speed is increased.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Round steel replaced cutting platform

InactiveCN102489827AEasy to operateReduce replacement costsGas flame welding apparatusVertical projectionPipe fitting

The invention relates to a cutting platform, in particular to a round steel replaced cutting platform applied to cutting medium-thickness and large-thickness steel plates. The cutting platform comprises a supporting frame of which the bottom is provided with a support; the supporting frame consists of transverse and longitudinal supporting plates which are connected with each other; steel pipe fittings are fixed at connecting points of the transverse and longitudinal supporting plates; supporting round steels are sleeved in the steel pipe fittings; and the supporting frame is arranged in a water tank below. Due to the structure, the cut steel plate is directly contacted with the round steel only, the damage of high-intensity flame to the cutting platform is avoided, the cutting platform has a small vertical projection area, and a little flowing high-temperature adhering slag drops on the cutting platform in the process of cutting the steel plates, so that the cutting platform is prevented from being locally deformed due to a high temperature. Moreover, the high-temperature adhering slag can drop into the water tank at the bottom and is rapidly cooled, and the ground in a workshop cannot be damaged. In addition, supporting round steels with various heights are selected to be arranged in a working area of a cutting machine simultaneously, and steel plates with various thicknesses can be cut simultaneously.

Owner:CHINA 22MCC GROUP CORP +1

Kraft paper roll mounting base

InactiveCN105059972AReduce local deformationPrevent rotationWebs handlingKraft paperPulp and paper industry

The invention discloses a kraft paper roll mounting base, and relates to a support base. The kraft paper roll mounting base comprises a support frame and a support shaft, wherein the support shaft is arranged on the support frame, and comprises a positioning shaft and a pressing shaft; a positioning piece is arranged at the shaft end of the positioning shaft; the pressing shaft is coated with a pressing piece connecting part; the pressing piece connecting part is coated with a pressing piece; and the pressing piece and the pressing shaft are connected through a fixed bolt. The kraft paper roll mounting base solves the problem of inconvenience for loading and unloading kraft paper rolls, and saves materials compared with the prior art.

Owner:CHONGQING XINSHENG CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com