Patents

Literature

76results about How to "Reduce the amount of bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of straightening wire rods of titanium and titanium alloy

InactiveUS6077369ALow costImprove production yieldFurnace typesHeat treatment furnacesWire rodTitanium

PCT No. PCT / JP95 / 01897 Sec. 371 Date Mar. 19, 1997 Sec. 102(e) Date Mar. 19, 1997 PCT Filed Sep. 20, 1995A method of straightening a wire rod of titanium or titanium alloy wherein the rod is hot-straightened to a straight rod at the straightening temperature T and elongation epsilon satisfying the expression (1) or (2). The method includes hot rolling a titanium billet of beta titanium alloy, ( alpha + beta ) titanium alloy or a near alpha titanium alloy into a wire rod, winding the hot rolled wire rod into a coil, cold drawing the wire rod, cutting the wire rod to obtain a bent wire rod, heating the bent wire rod to a straightening temperature T while both end portions of the bent wire rod are fixed, applying a predetermined elongation epsilon to the wire rod, maintaining a straightening temperature T, hot-straightening the wire in accordance with the expression (2) epsilon (T-400)> / =400(1) epsilon (T-500)> / =200(2) and cooling the wire rod while applying tension. The method is suitable for preparing a straight rod for use in an engine valve.

Owner:NIPPON STEEL CORP

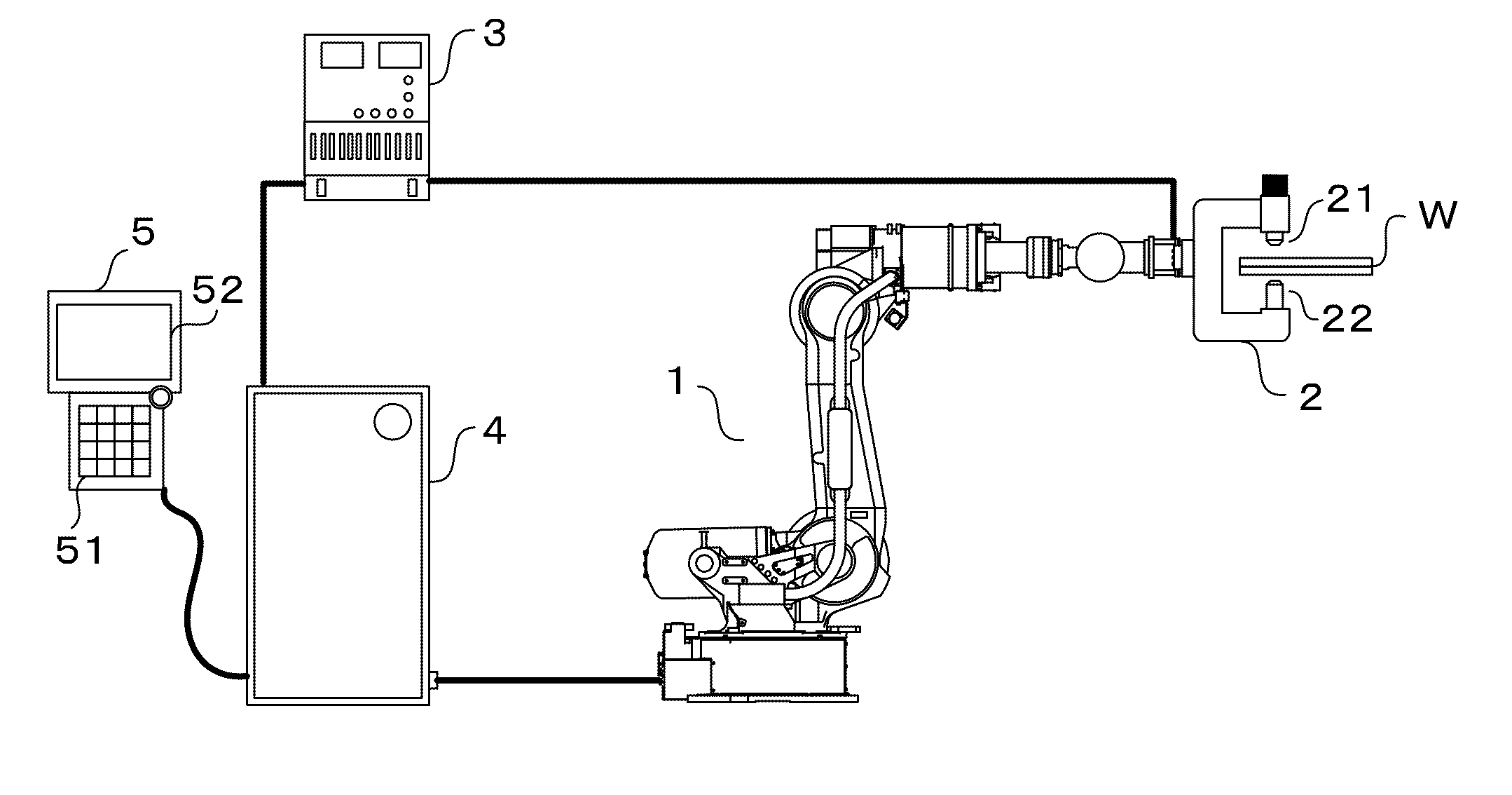

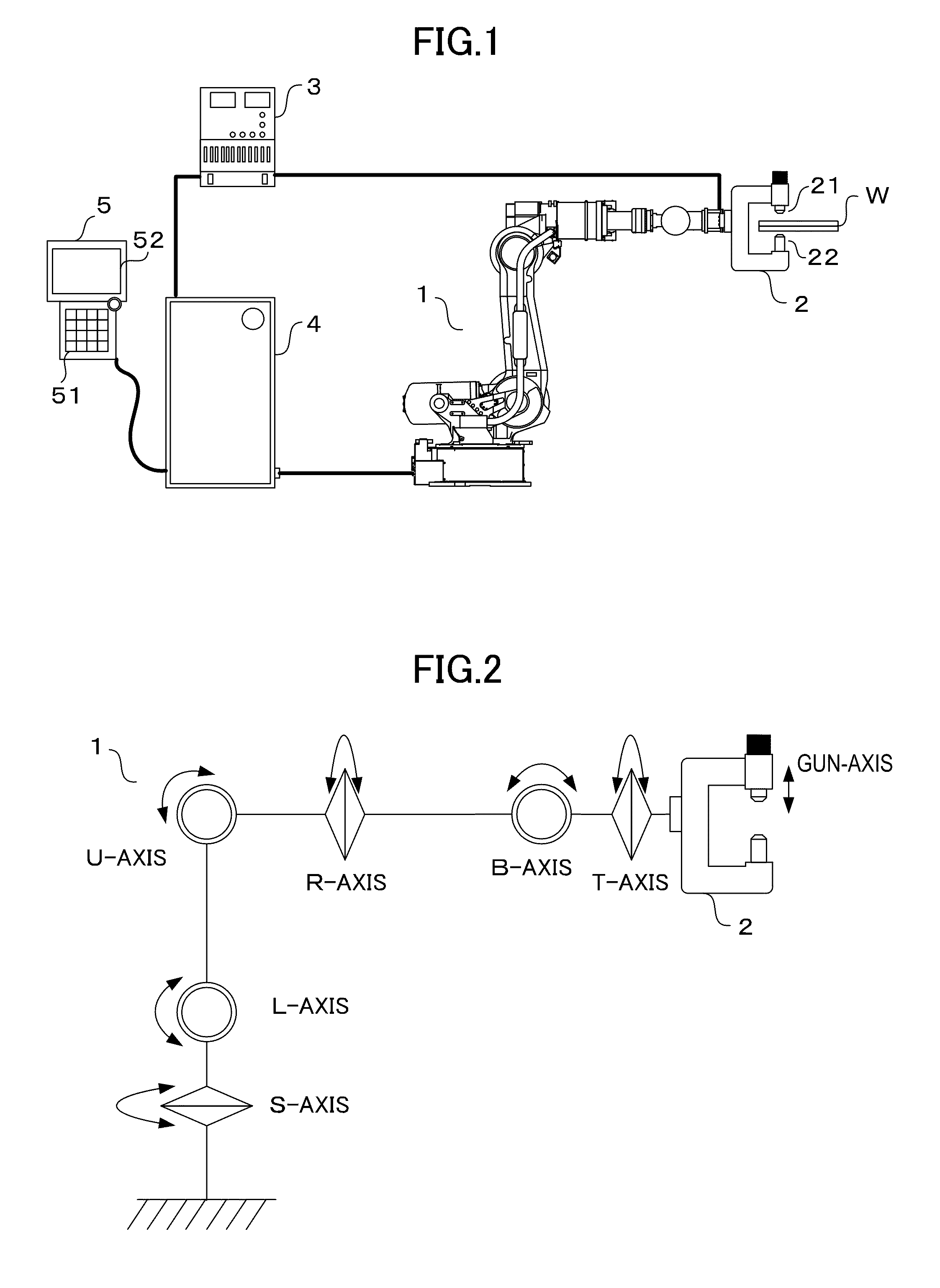

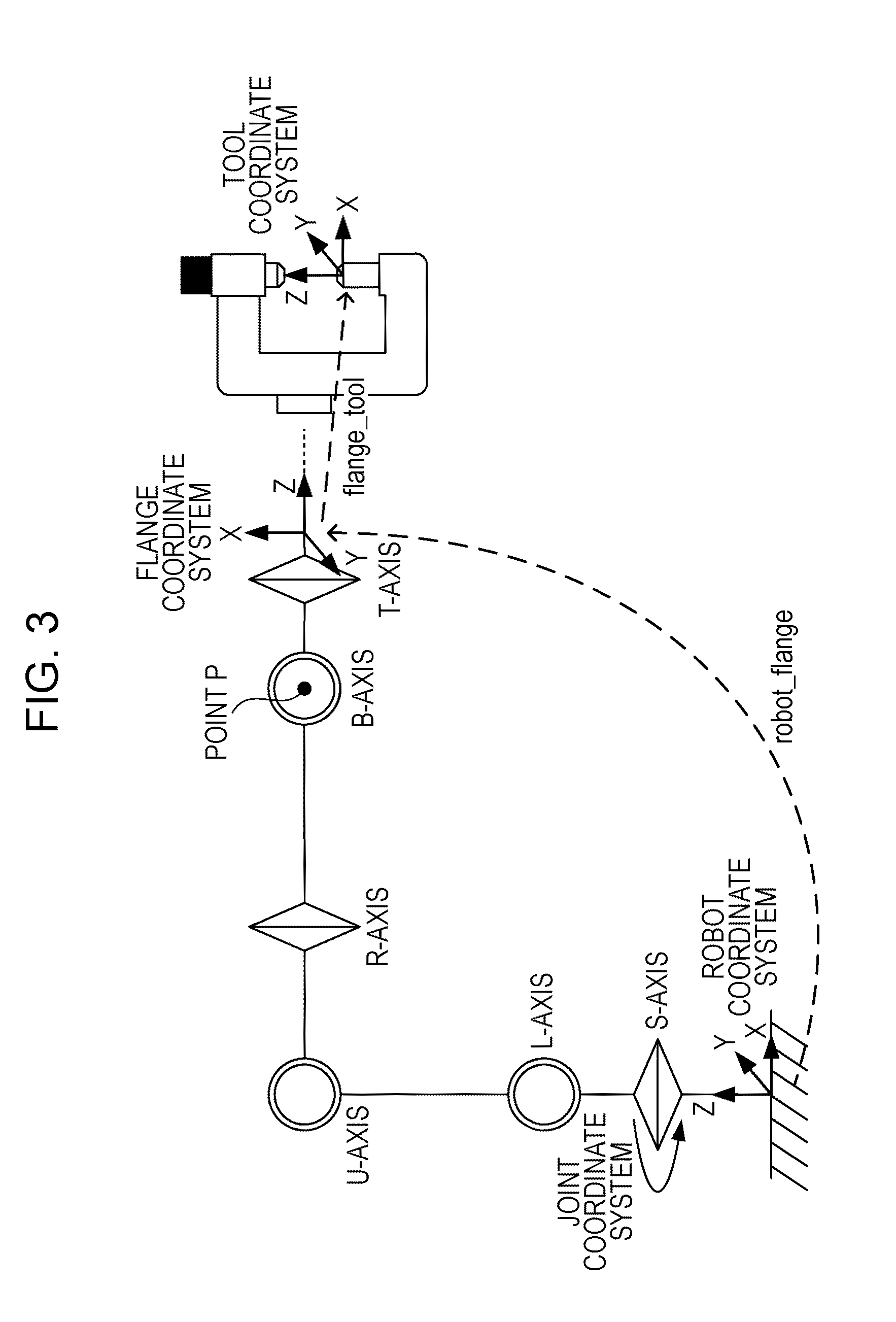

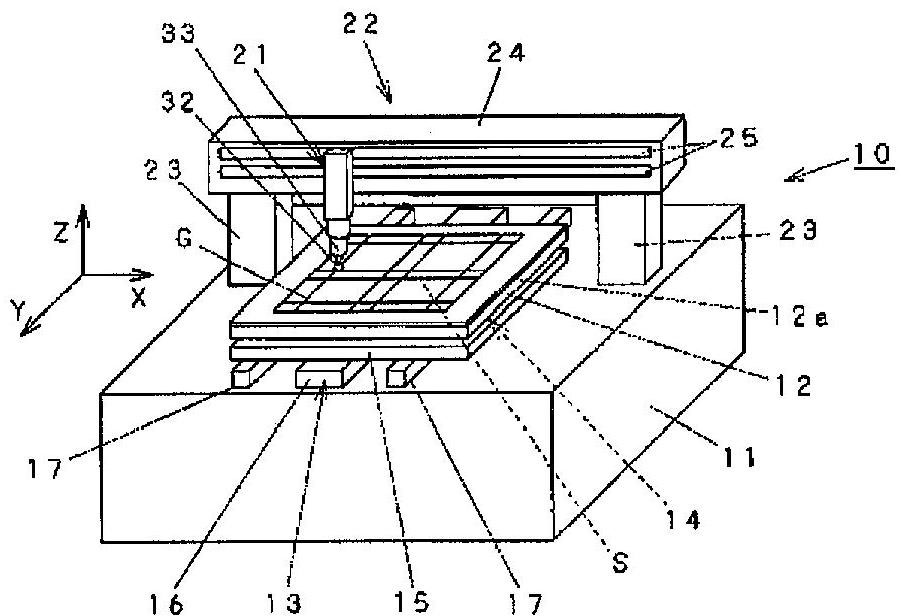

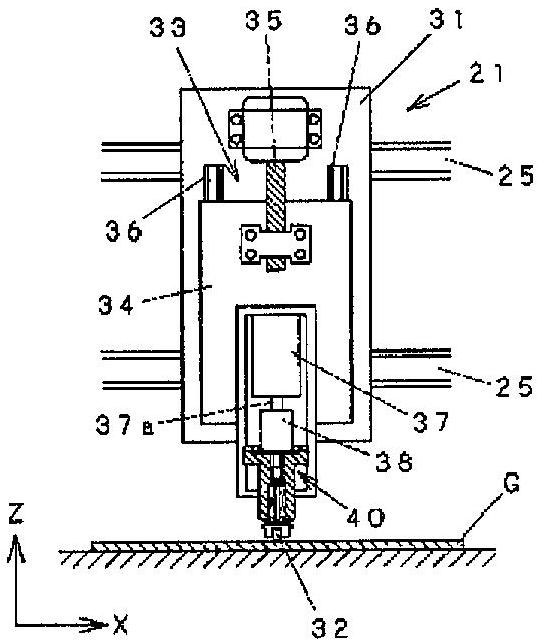

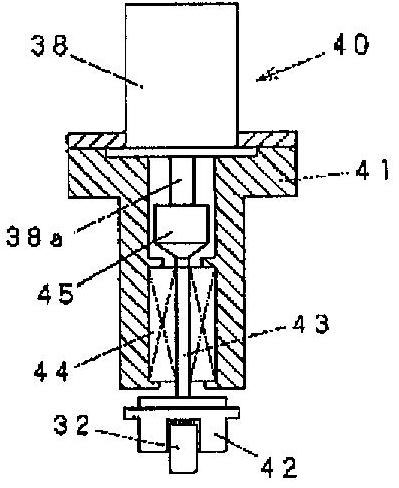

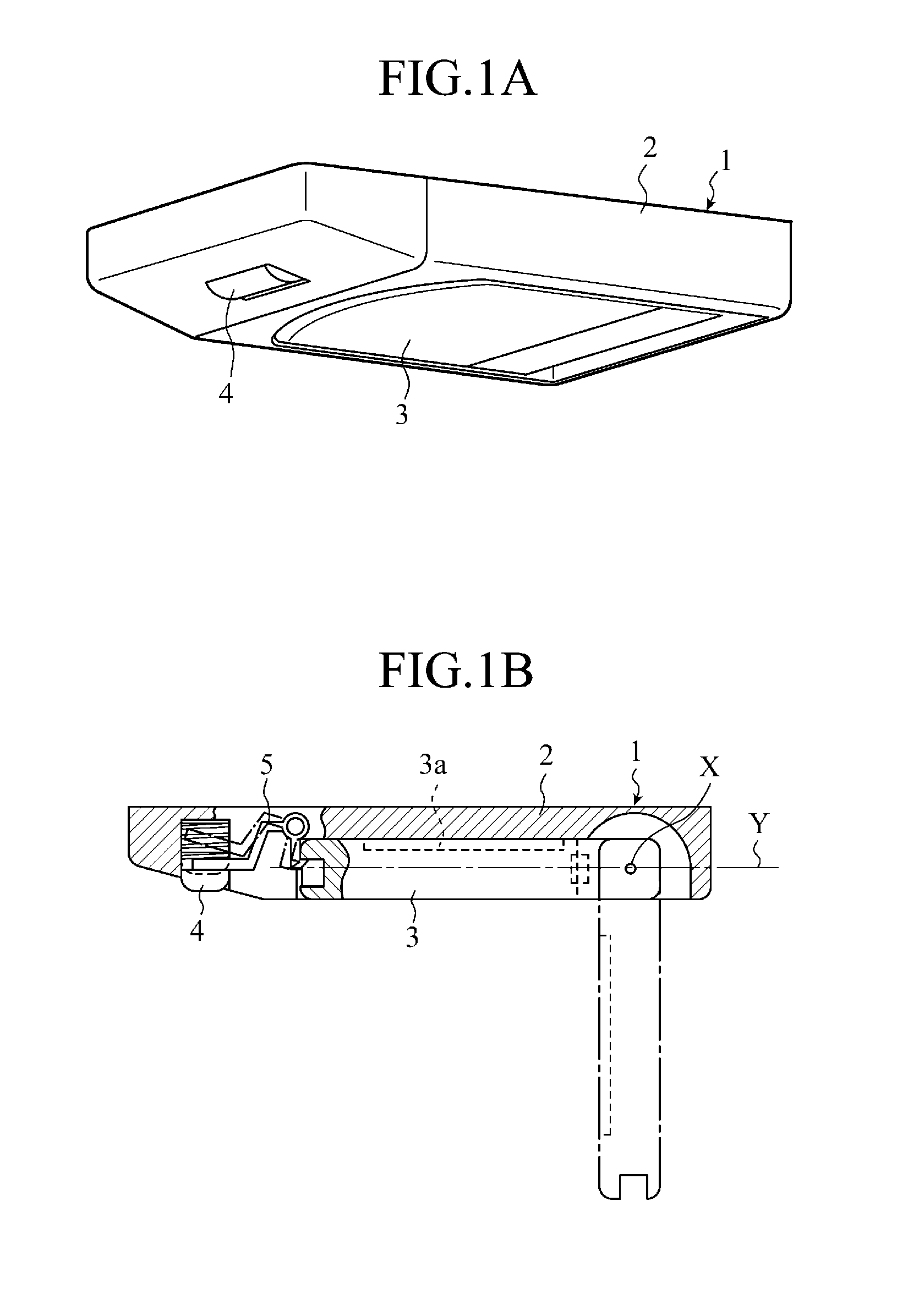

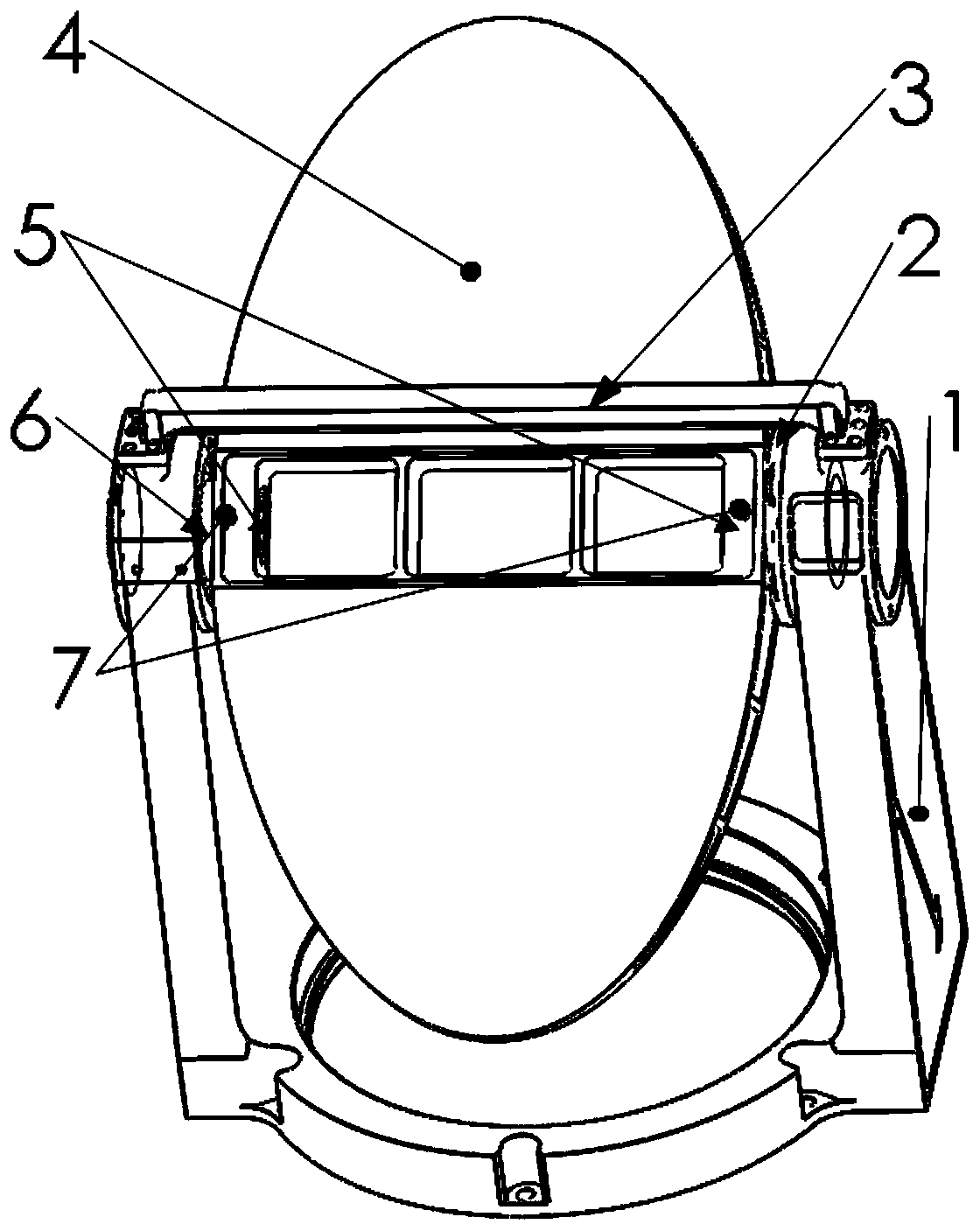

Robot system

InactiveUS20120000891A1Easy to correctBending amountWelding/cutting auxillary devicesAuxillary welding devicesRobotic systemsSpot welding

For teaching a welding-point position for a robot, processing of a robot system includes first processing for moving a spot welding gun to a position at which movable and fixed electrodes pinch the welding point; second processing for extending the movable electrode toward a member to be welded by driving of a motor, detecting contact between the movable electrode and the member based on a torque command to the motor, and stopping the movable electrode after the contact is detected; and third processing for operating the robot toward the movable electrode to move the fixed electrode toward the member while maintaining the contact between the movable electrode and the member by the driving of the motor, detecting contact between the fixed electrode and the member based on a disturbance torque acting on a joint of the robot, and stopping the operation of the robot after the contact is detected.

Owner:YASKAWA DENKI KK

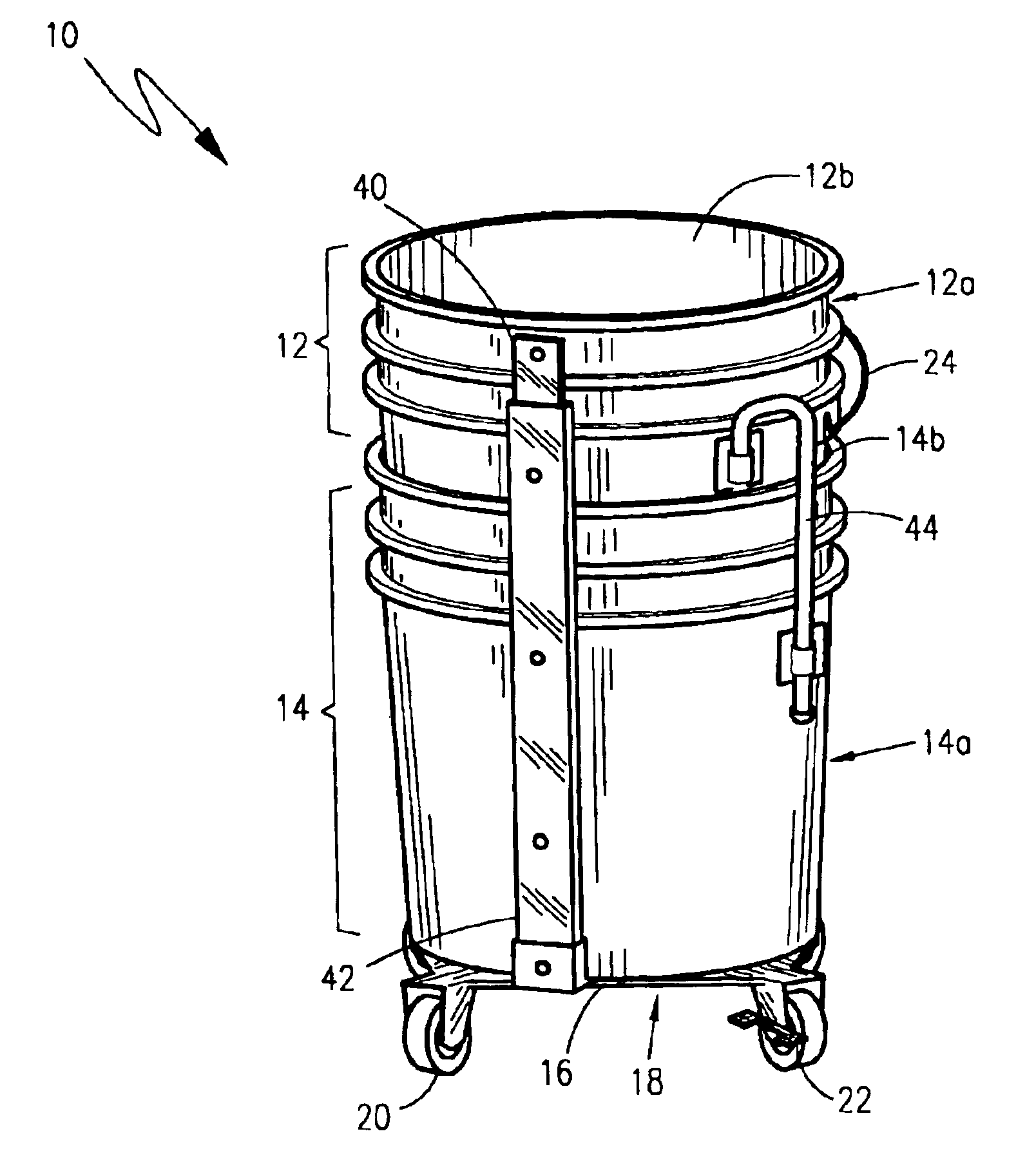

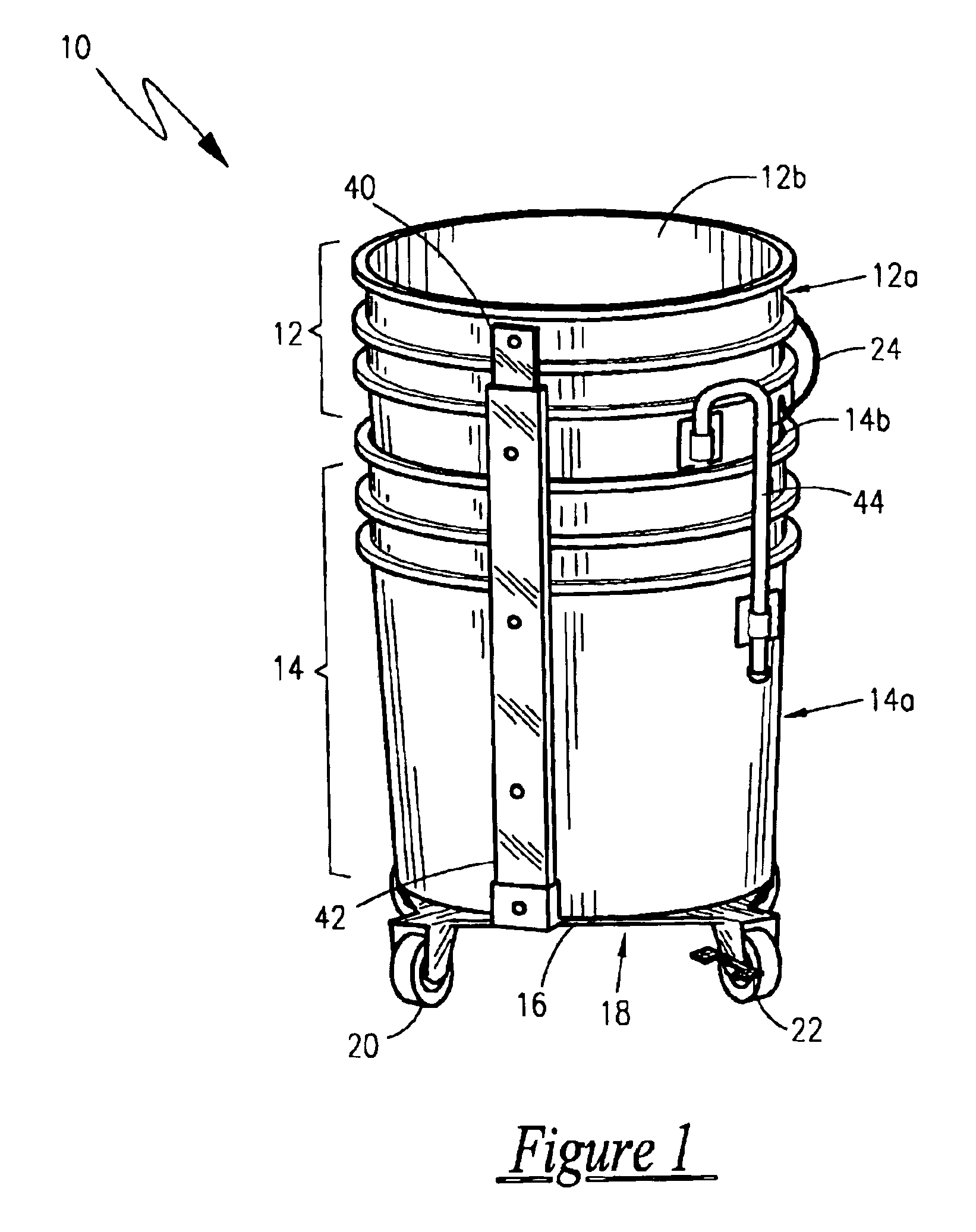

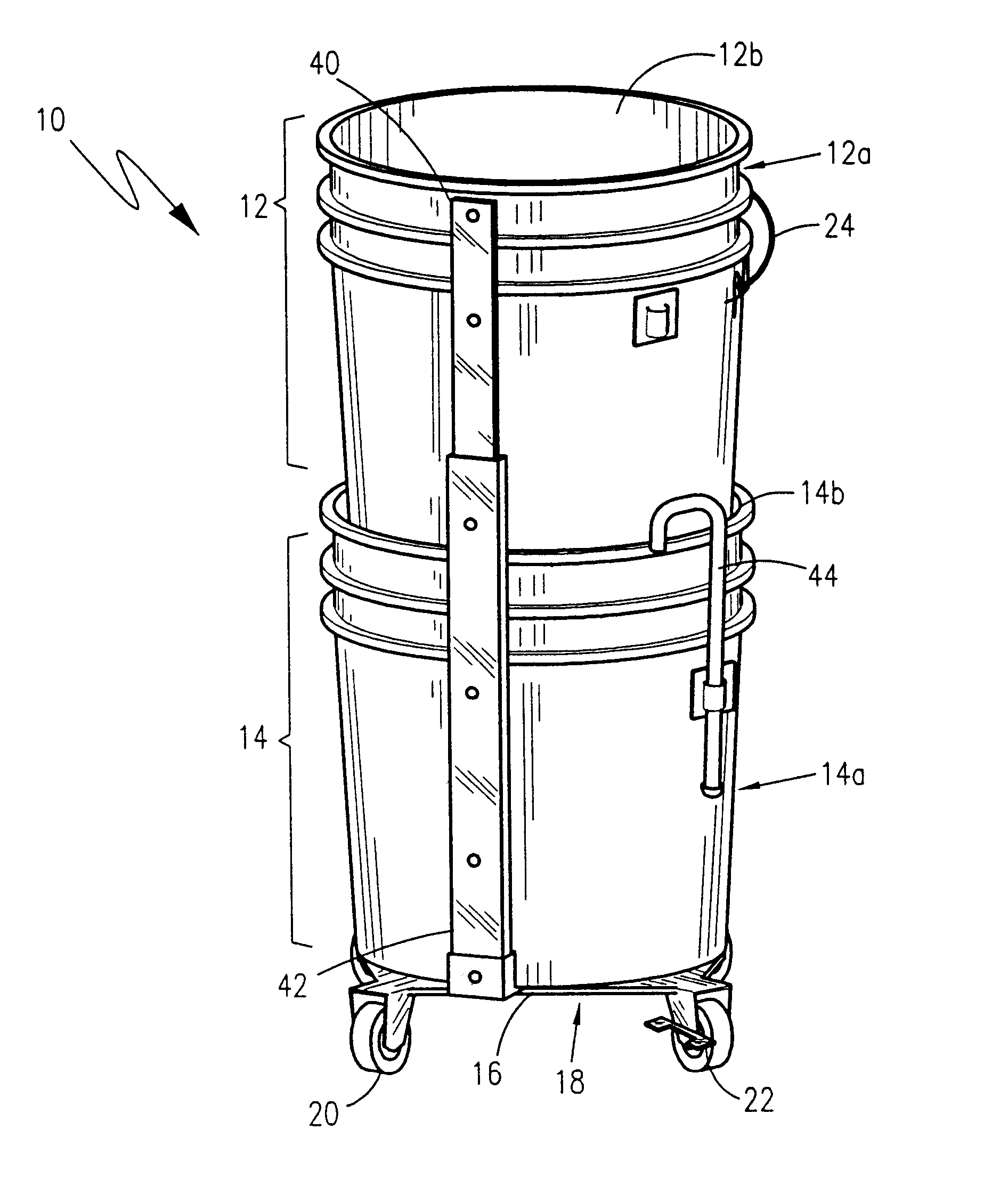

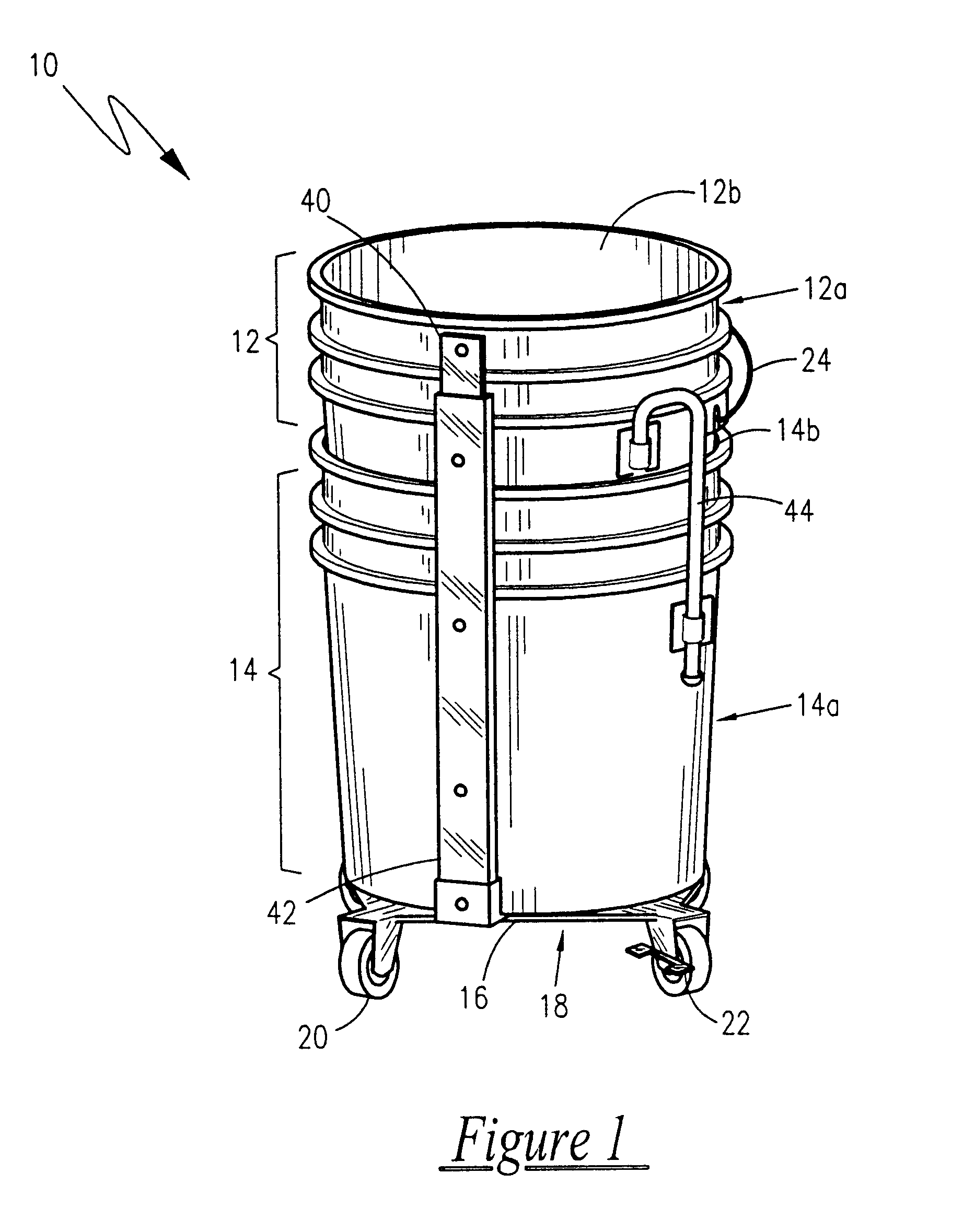

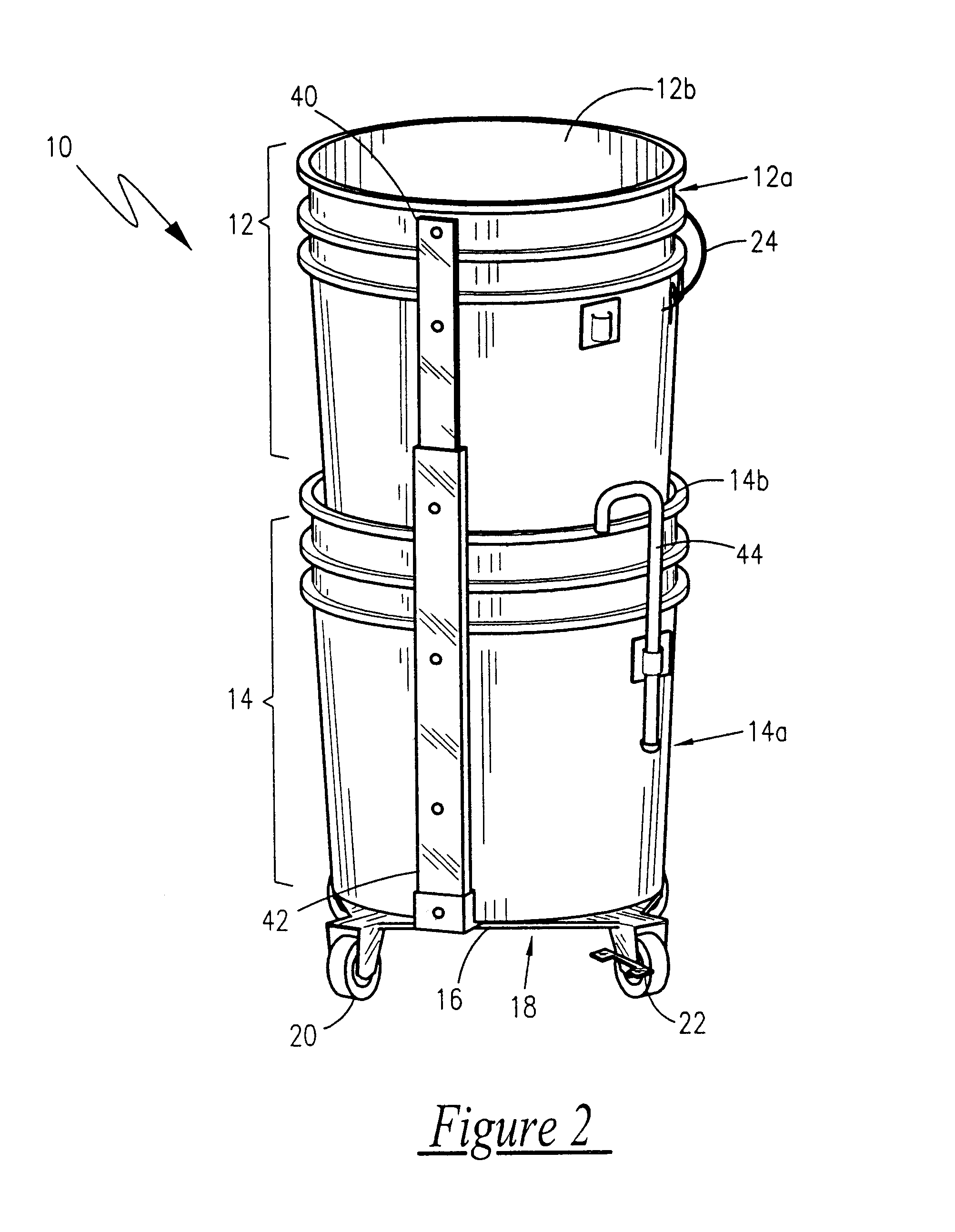

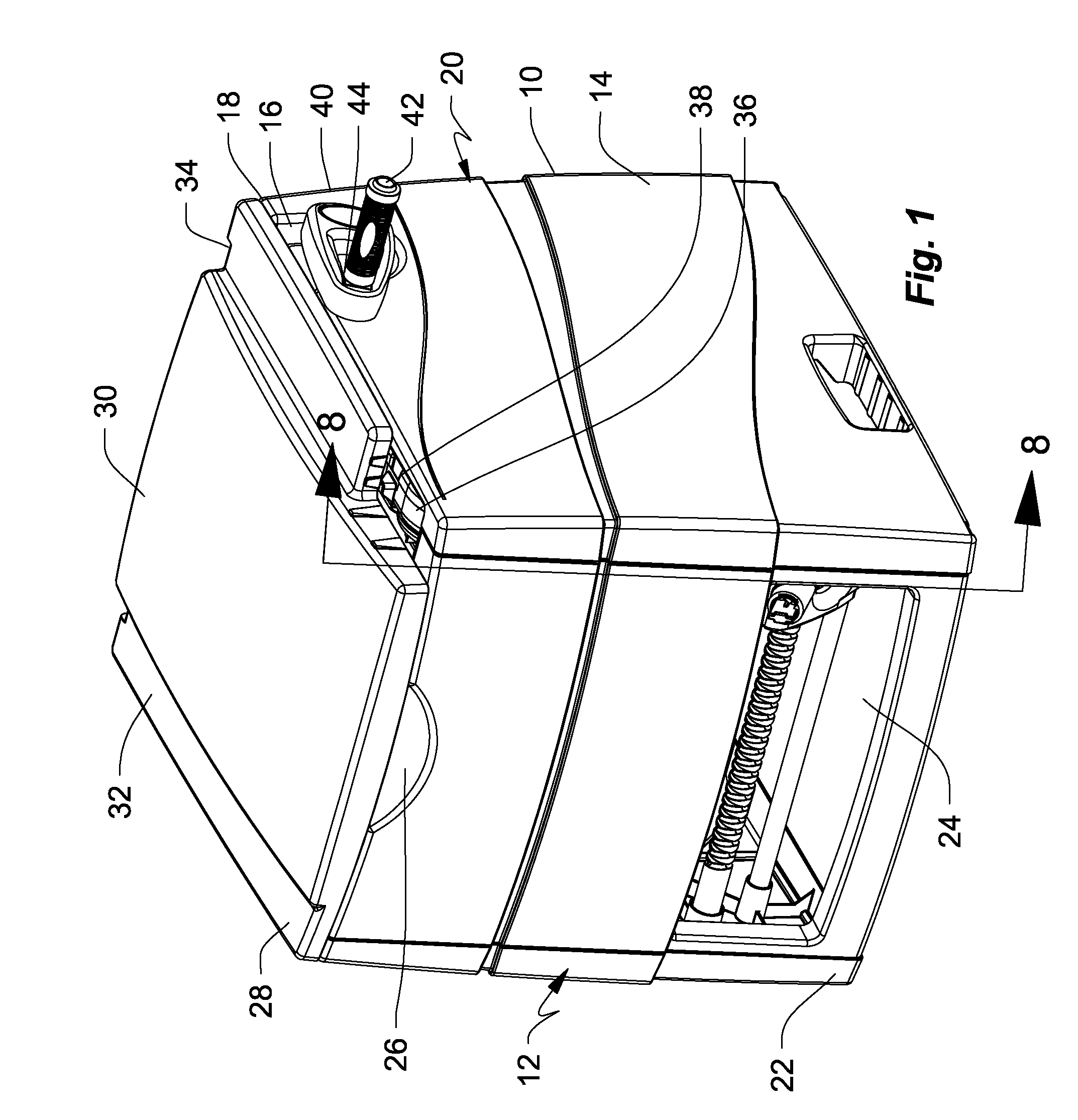

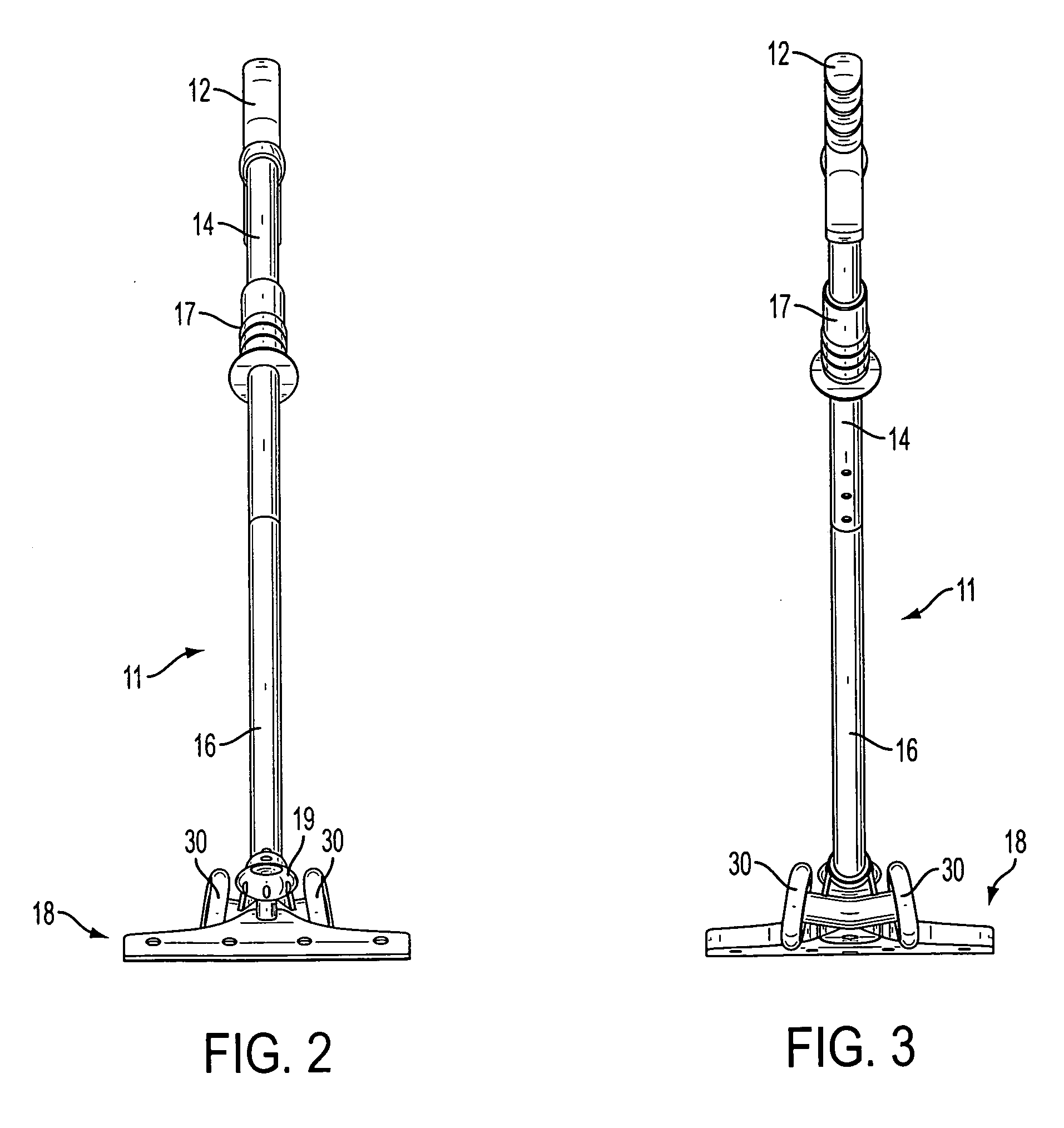

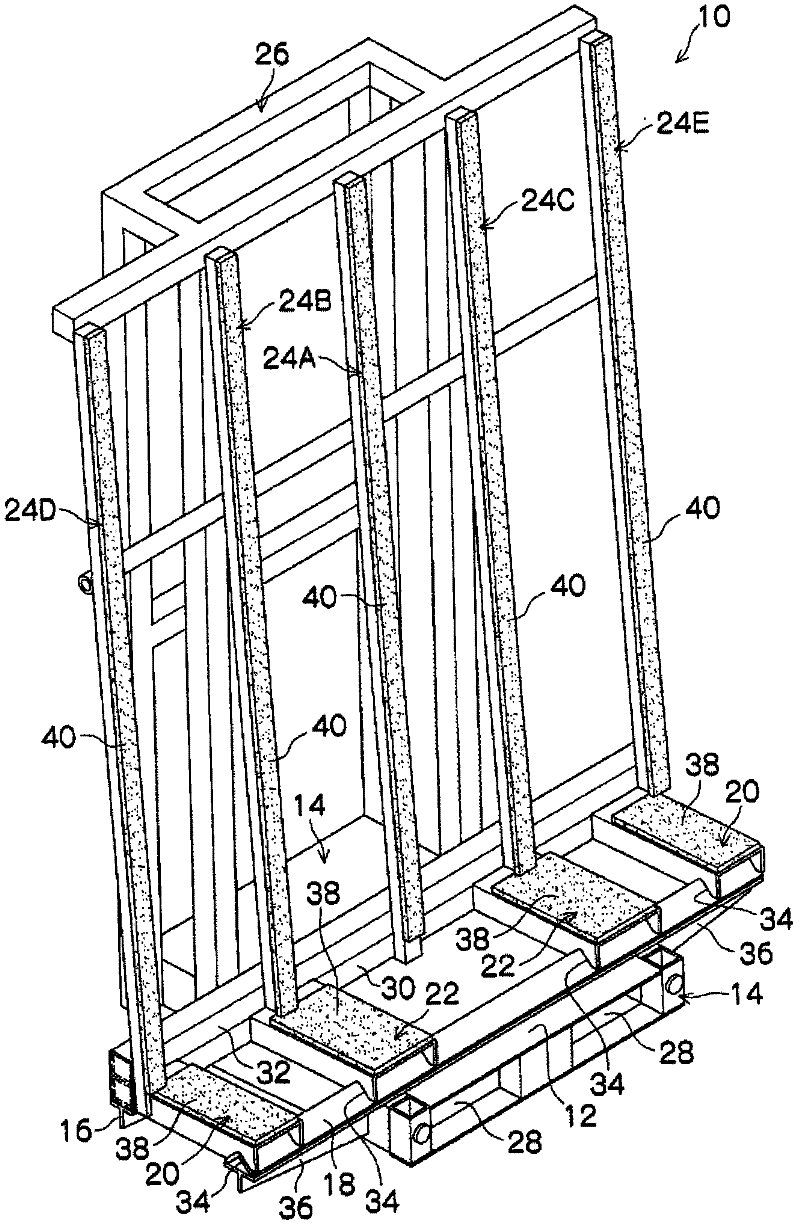

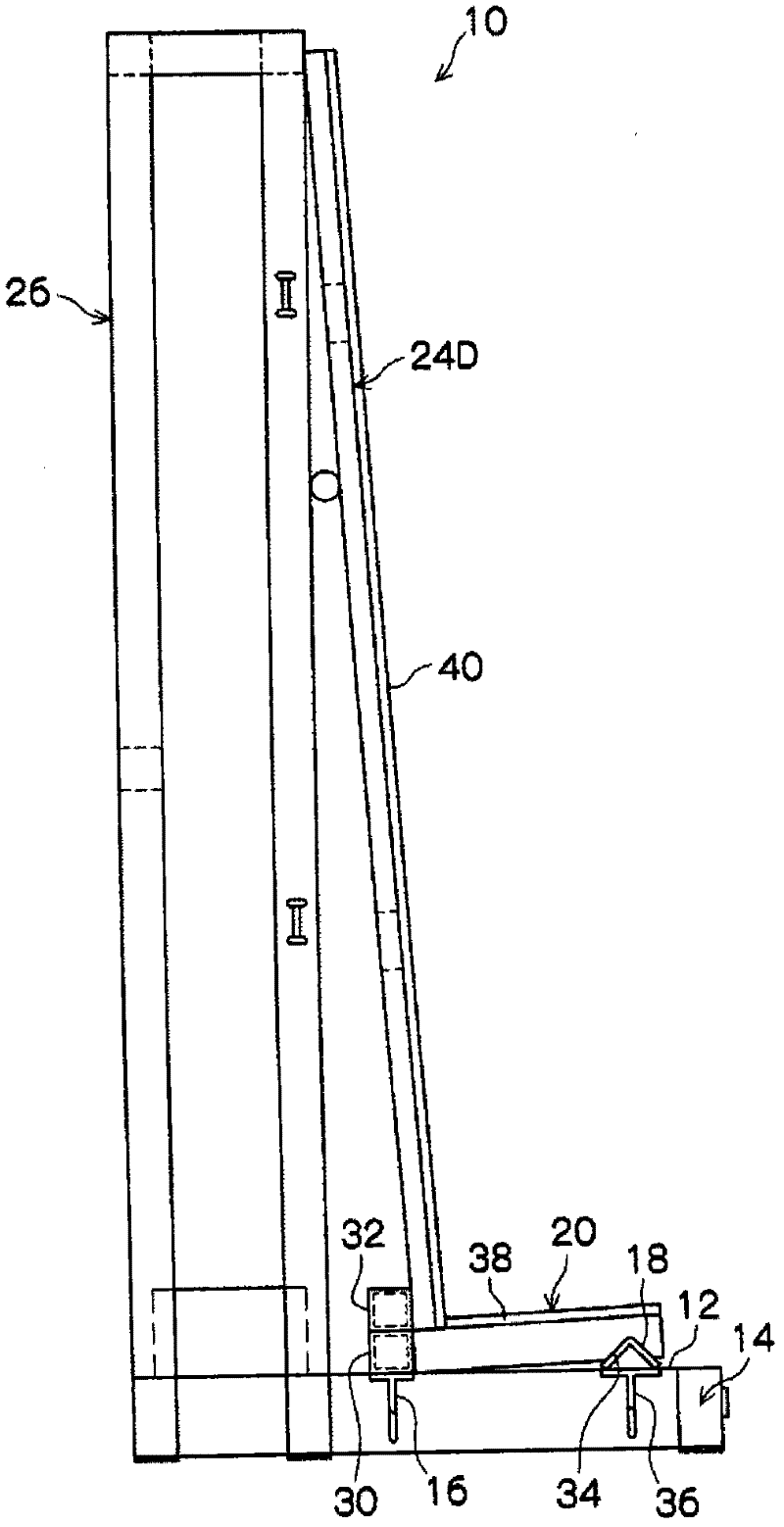

Work bucket vertical extension apparatus

InactiveUS6851566B1Relieve pressureReduce the amount of bendingKitchen equipmentHand carts with one axisEngineeringMechanical engineering

Owner:BONNER JAMES D

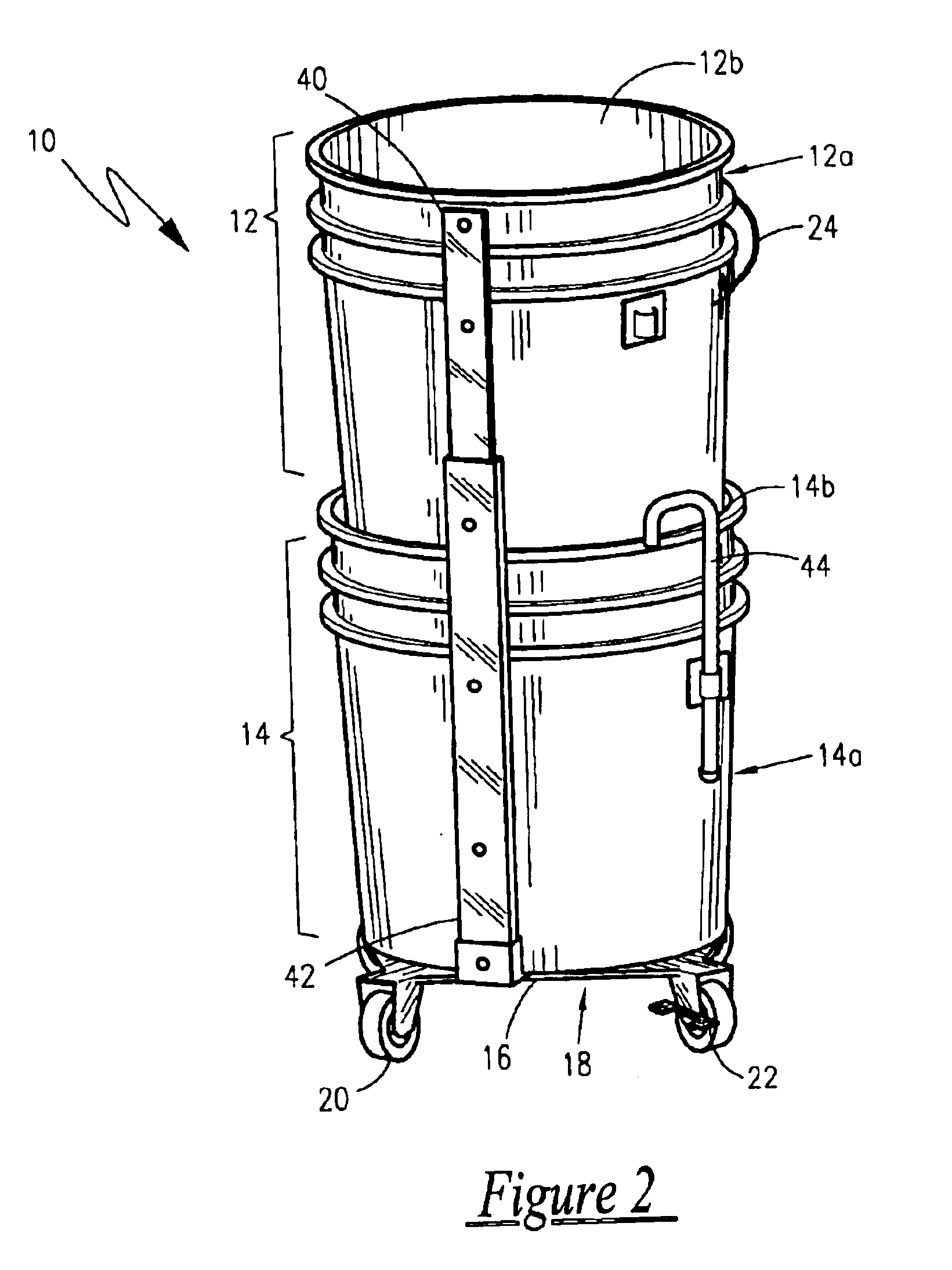

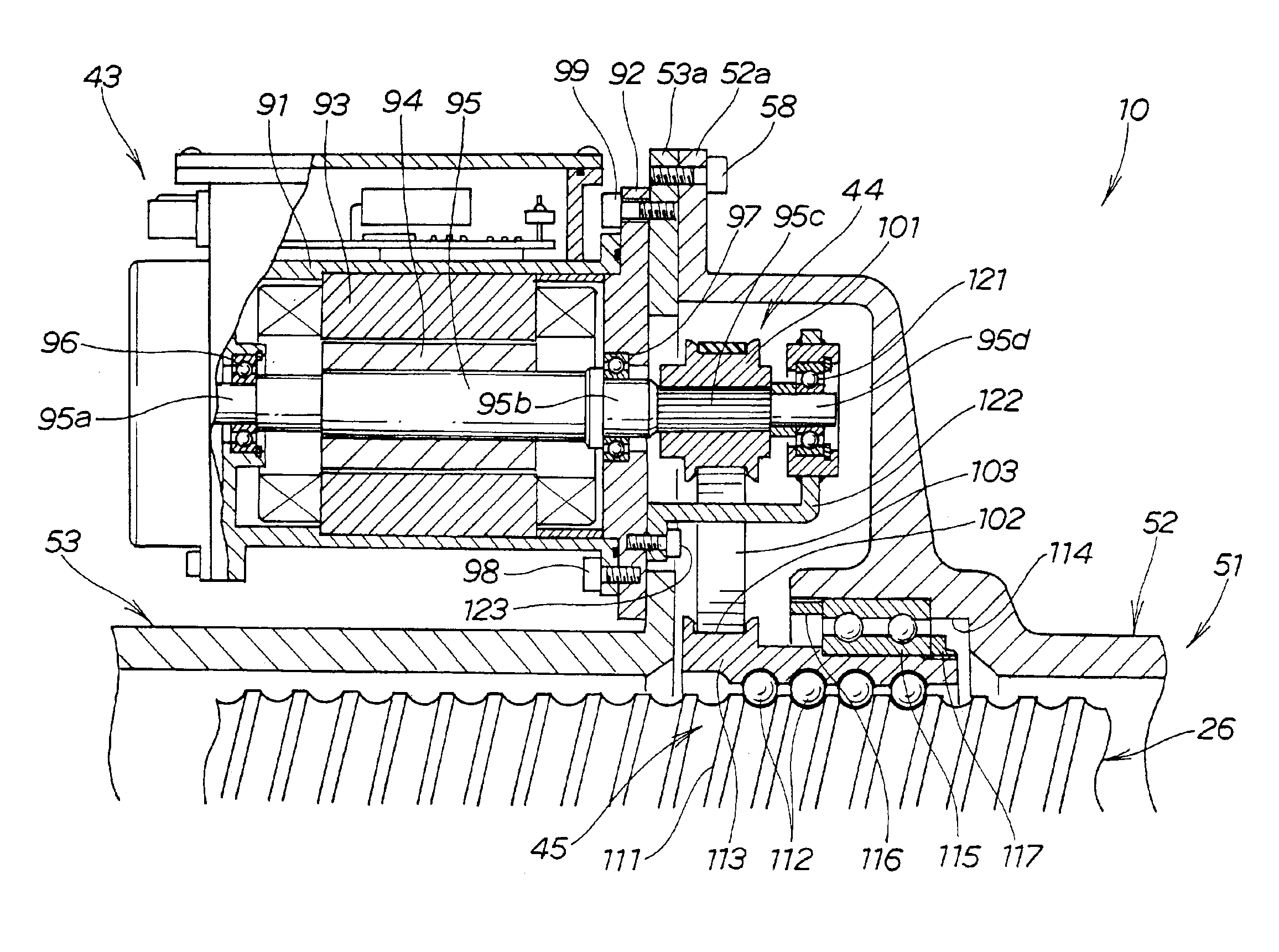

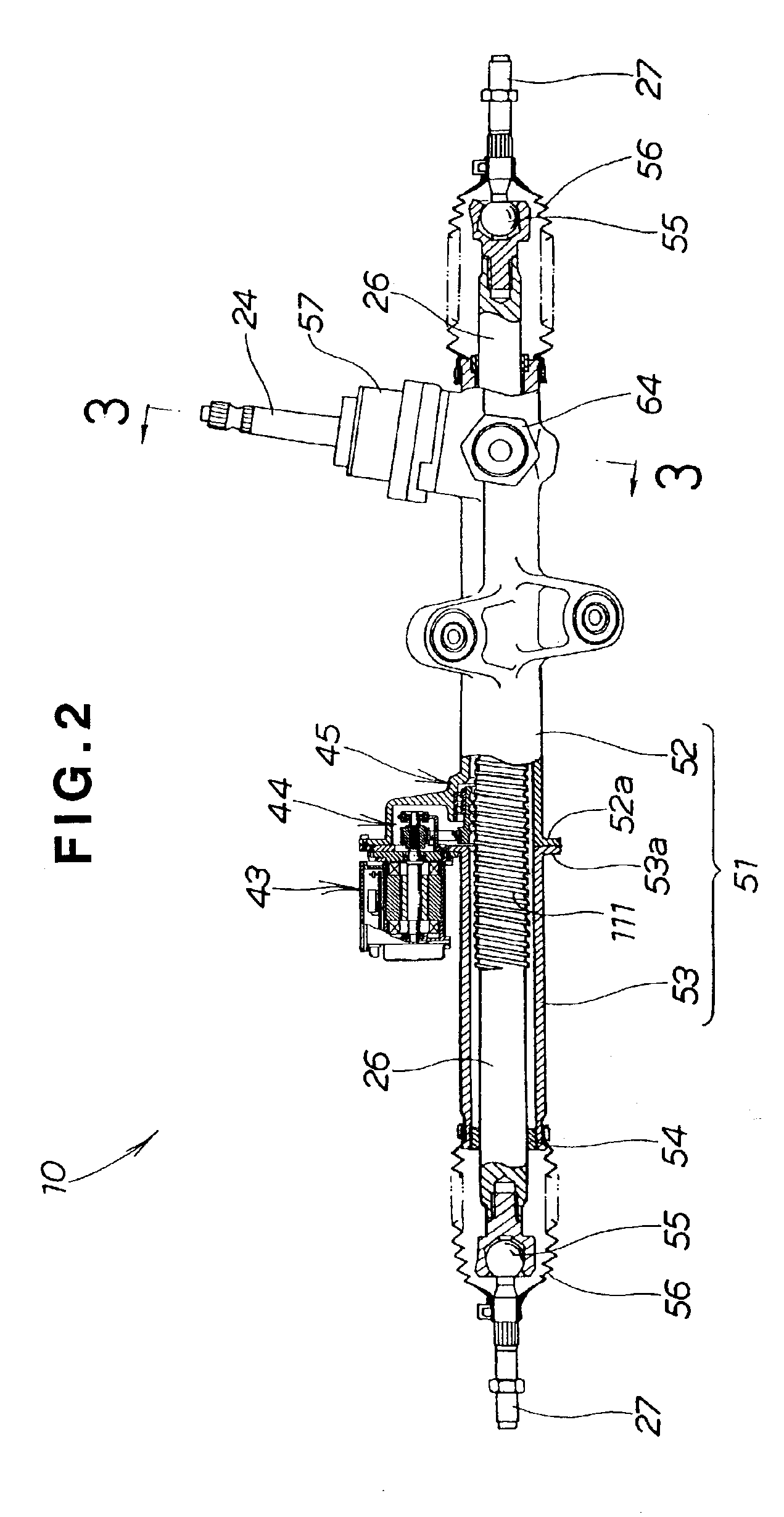

Electric power steering apparatus

InactiveUS6868936B2Improve responsivenessIncreased bending stiffnessDigital data processing detailsSteering initiationsElectric power steeringControl theory

An improvement to an electric power steering apparatus which applies an assisting torque produced by an electric motor in correspondence with a steering torque to a rack shaft by way of a belt type transmission mechanism. A driving pulley of the belt type transmission mechanism is mounted to an output shaft part of the motor shaft of the electric motor. This output shaft part is rotatably supported at locations on both sides of the driving pulley.

Owner:HONDA MOTOR CO LTD

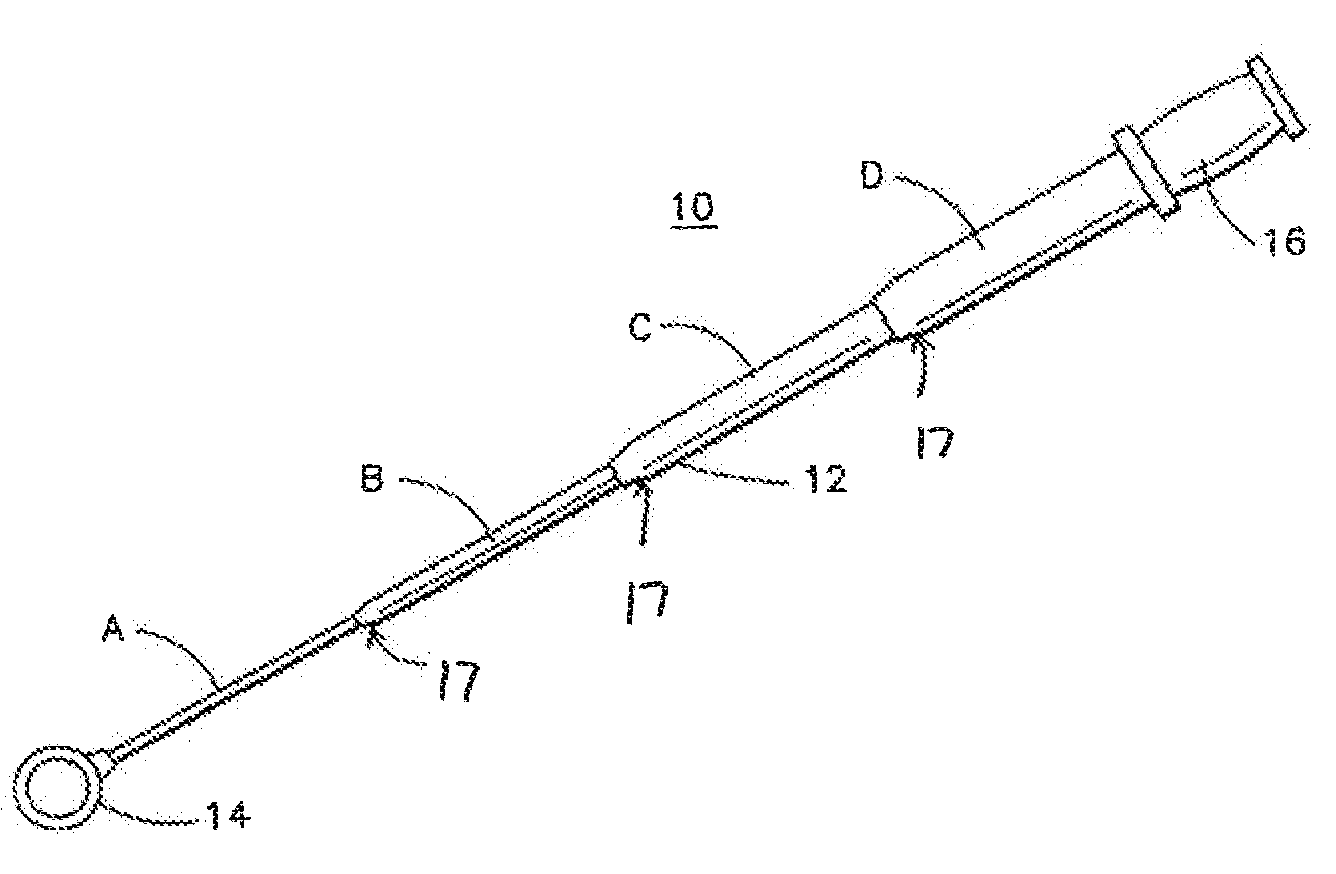

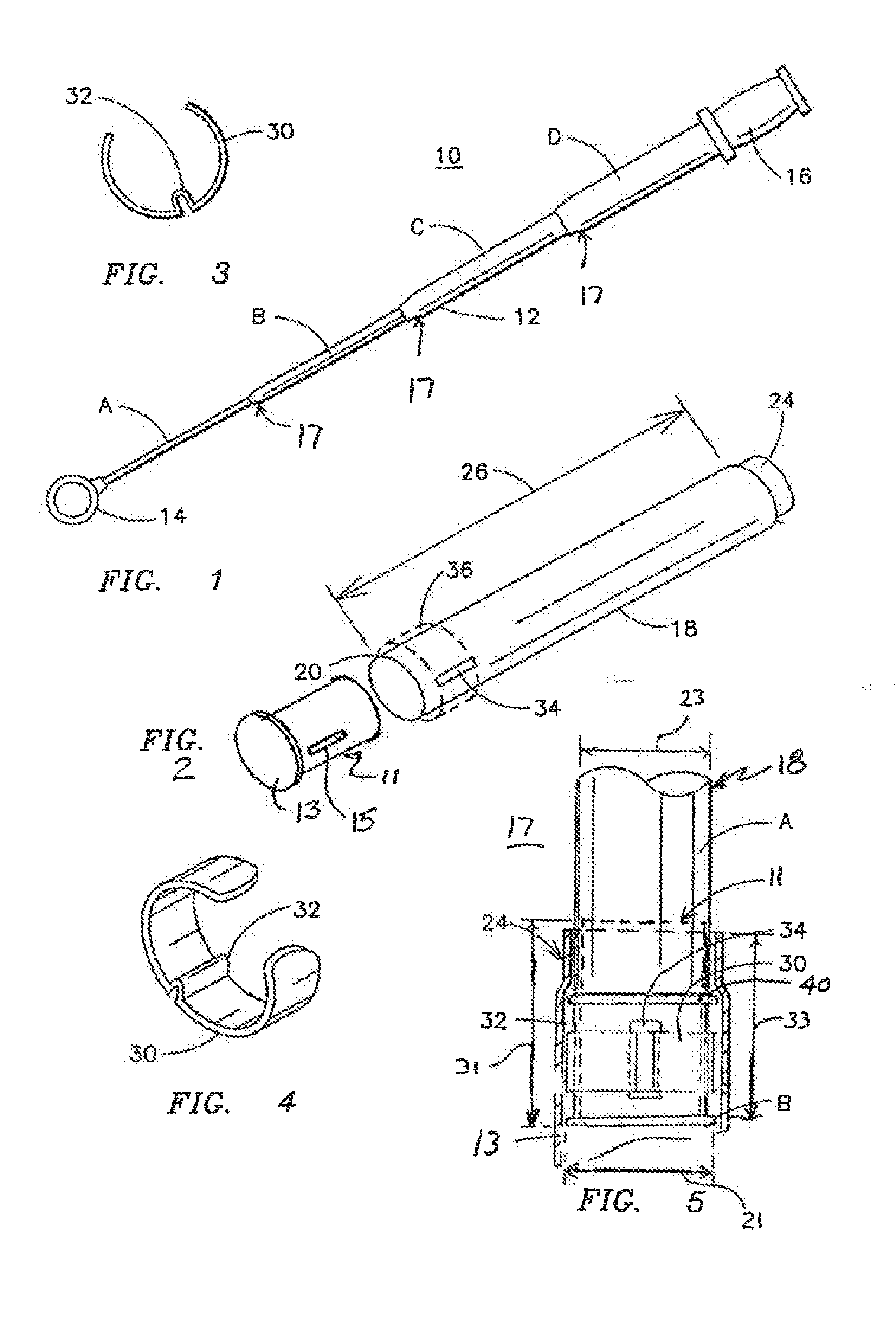

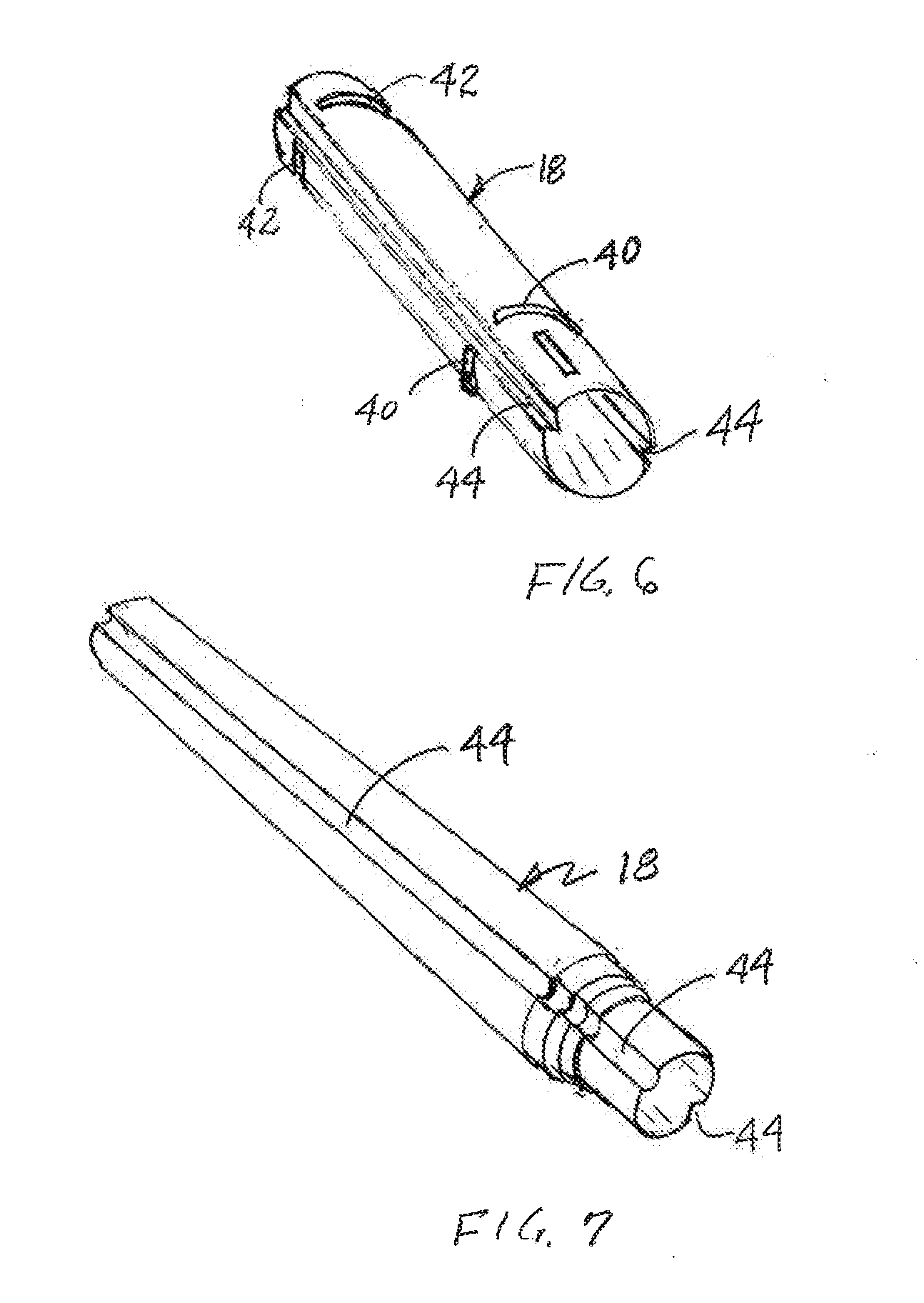

Non-Rotatable Telescopic Handle Construction

ActiveUS20150202766A1Reduce the amount of bendingHigh strengthTravelling carriersHoldersGolf BallBuilding construction

A golf ball retriever handle having a plurality of telescoping segments, each segment comprising a tubular member configured to fit relatively snugly about an adjacent member in sliding engagement therewith, each of the members between the smallest diameter member and the largest diameter member being formed with a radially extending annular rib in proximity to a first end thereof and being formed with a radially inward extending annular depression in proximity to a second end thereof, whereby separation of the tubular members in a handle extending direction is inhibited. The handle also having at least one axial groove formed in each section such that overlapping grooves engage each other to prevent rotation of one section with respect to another.

Owner:BAG BOY

Work bucket vertical extension apparatus

InactiveUS6715627B1Relieve pressureReduce the amount of bendingKitchen equipmentHand carts with one axisEngineeringMechanical engineering

Owner:BONNER JAMES D

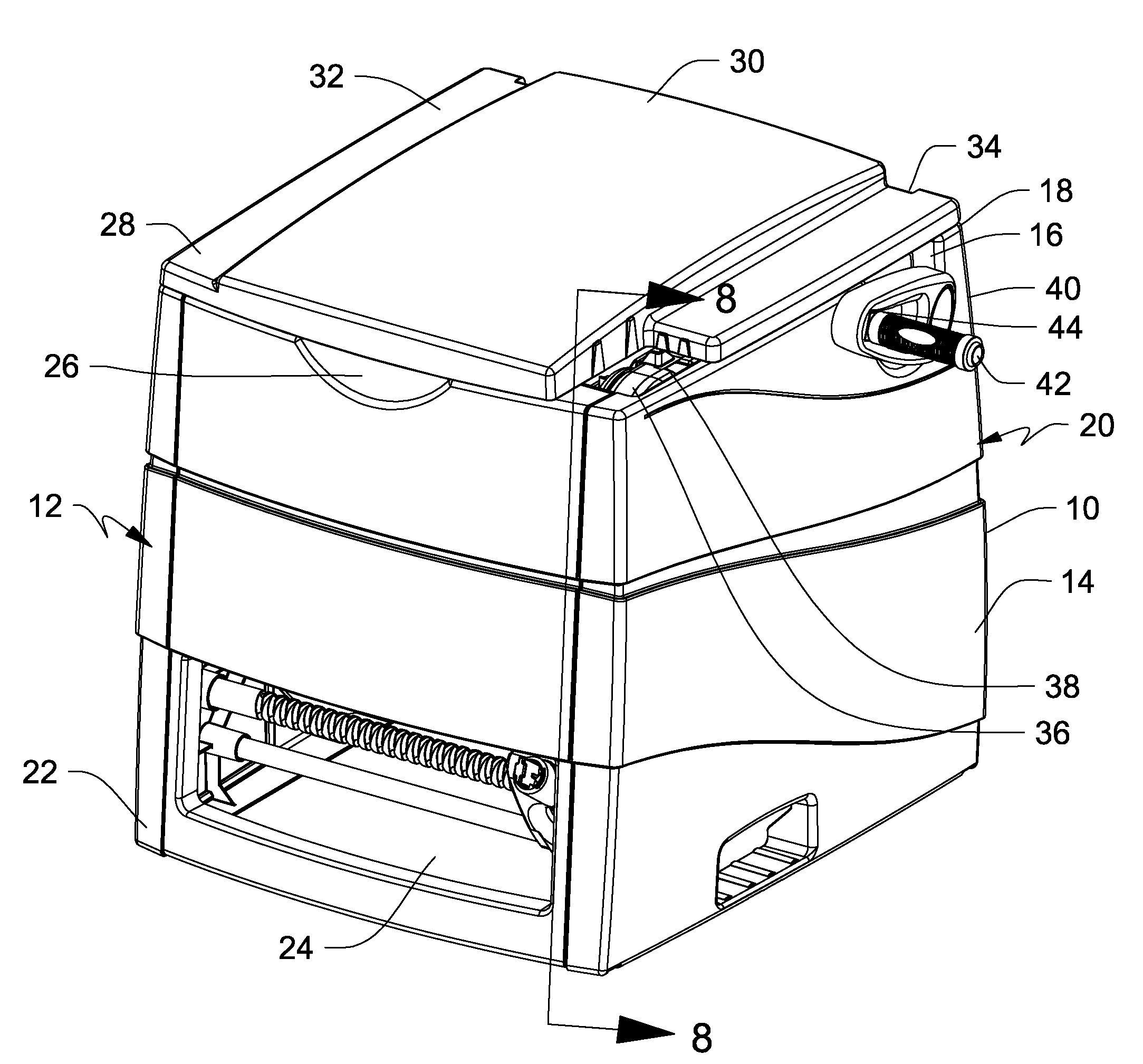

Hose Reel Cart With Multi-Position Crank Handle

ActiveUS20100155520A1Reduce the amount of bendingEliminate needFilament handlingFire rescueGear wheelEngineering

The present invention relates to hose reel carts for handling and storage of flexible hoses, such as garden or air hoses. The hose reel cart is primarily constructed of plastic components having a centrally rotatable spool for winding of the flexible hose, a frame for supporting the spool and a multi-position crank arm assembly allowing the consumer to place the crank handle in a lowered position or a raised position. The crank remotely drives the spool, for winding the hose, through a series of gears located within the crank arm assembly. The device may further include a reciprocating guide assembly that operates during rotation of the spool to rewind the hose into a compact configuration.

Owner:SUNCAST TECH

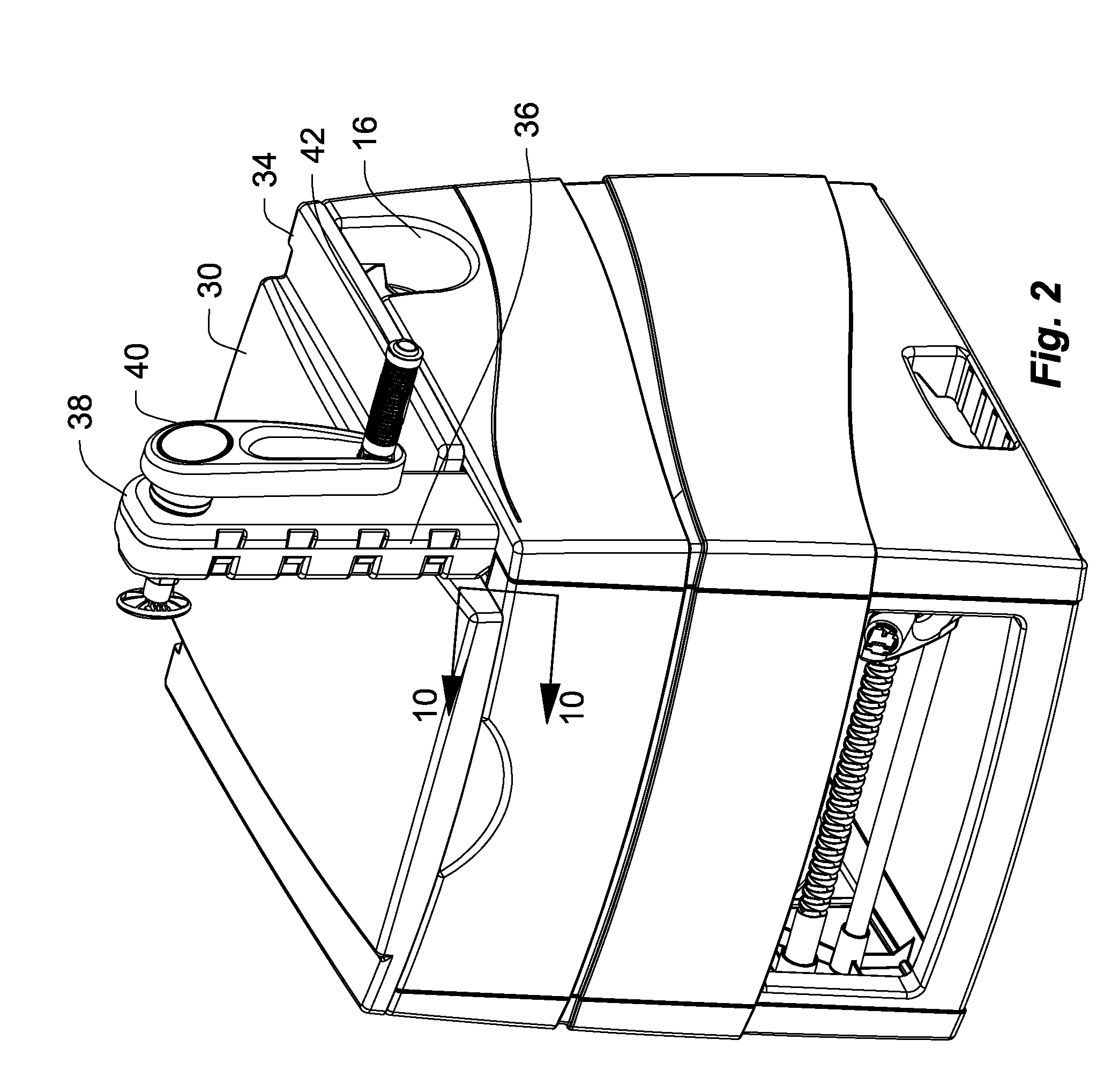

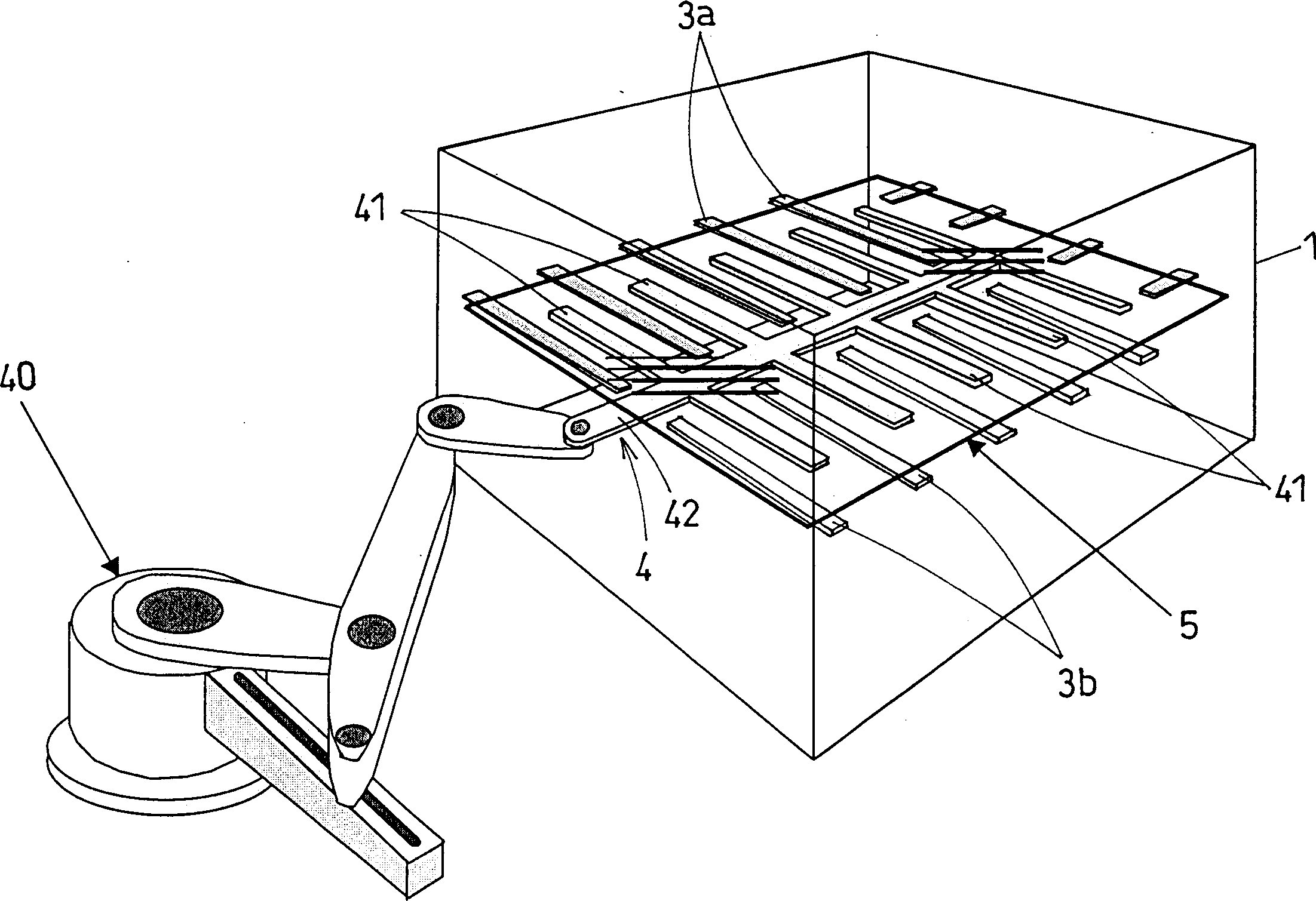

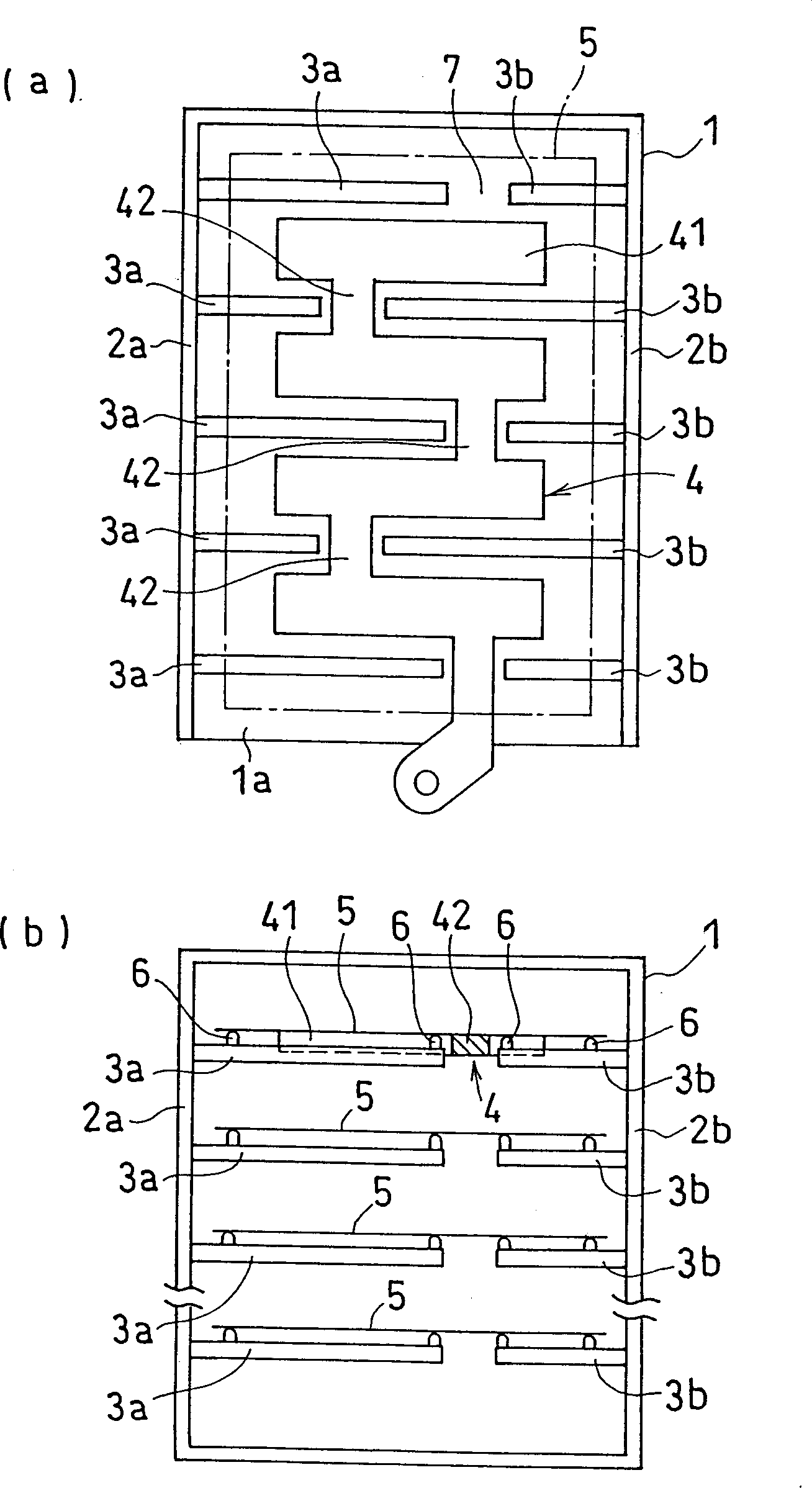

Moving loading device for plate shape substrates and its storing device

InactiveCN1393385AAvoid deformationAvoid breakingGripping headsSemiconductor/solid-state device manufacturingEngineeringManipulator

Owner:HITACHI LTD +1

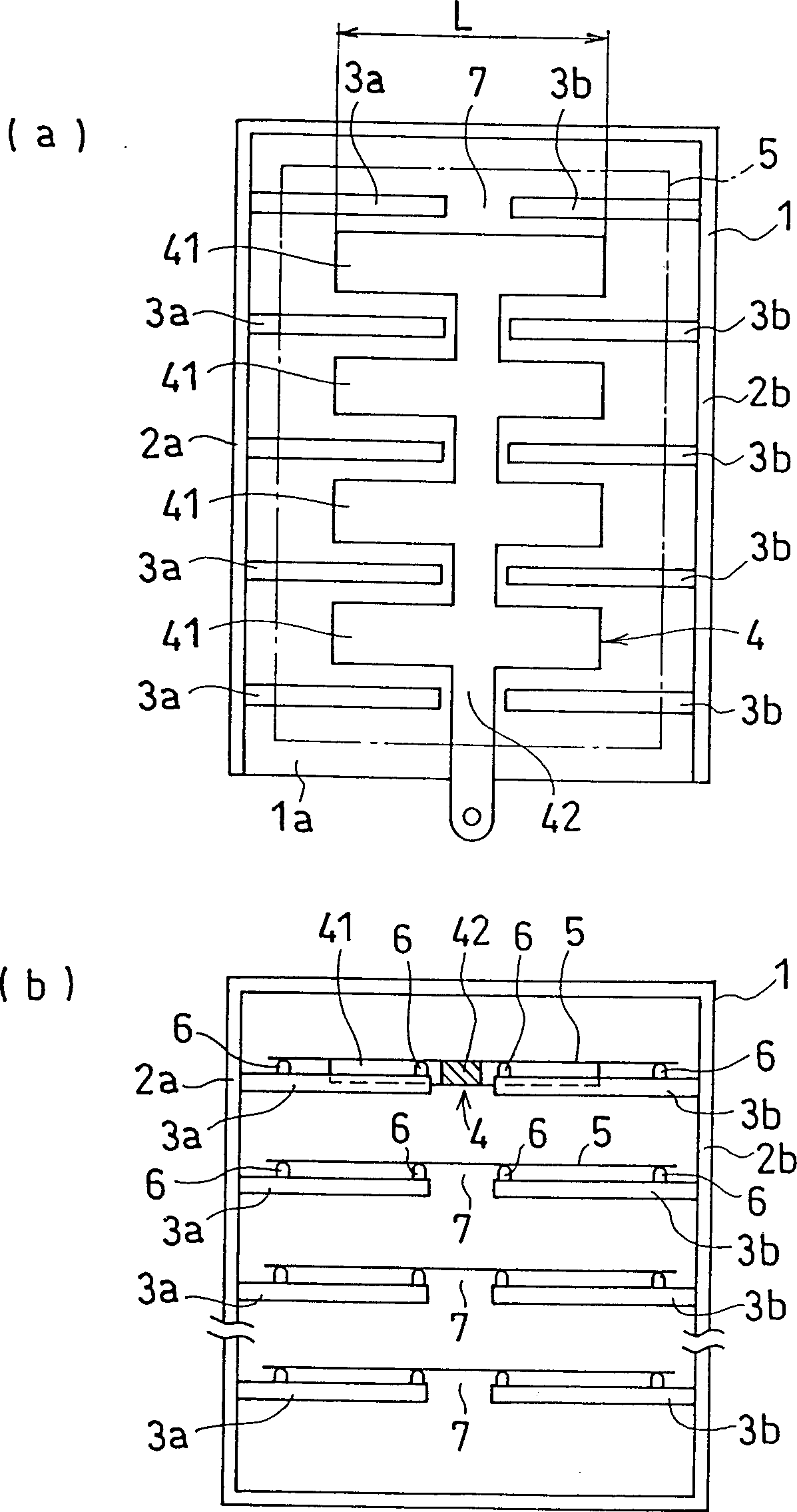

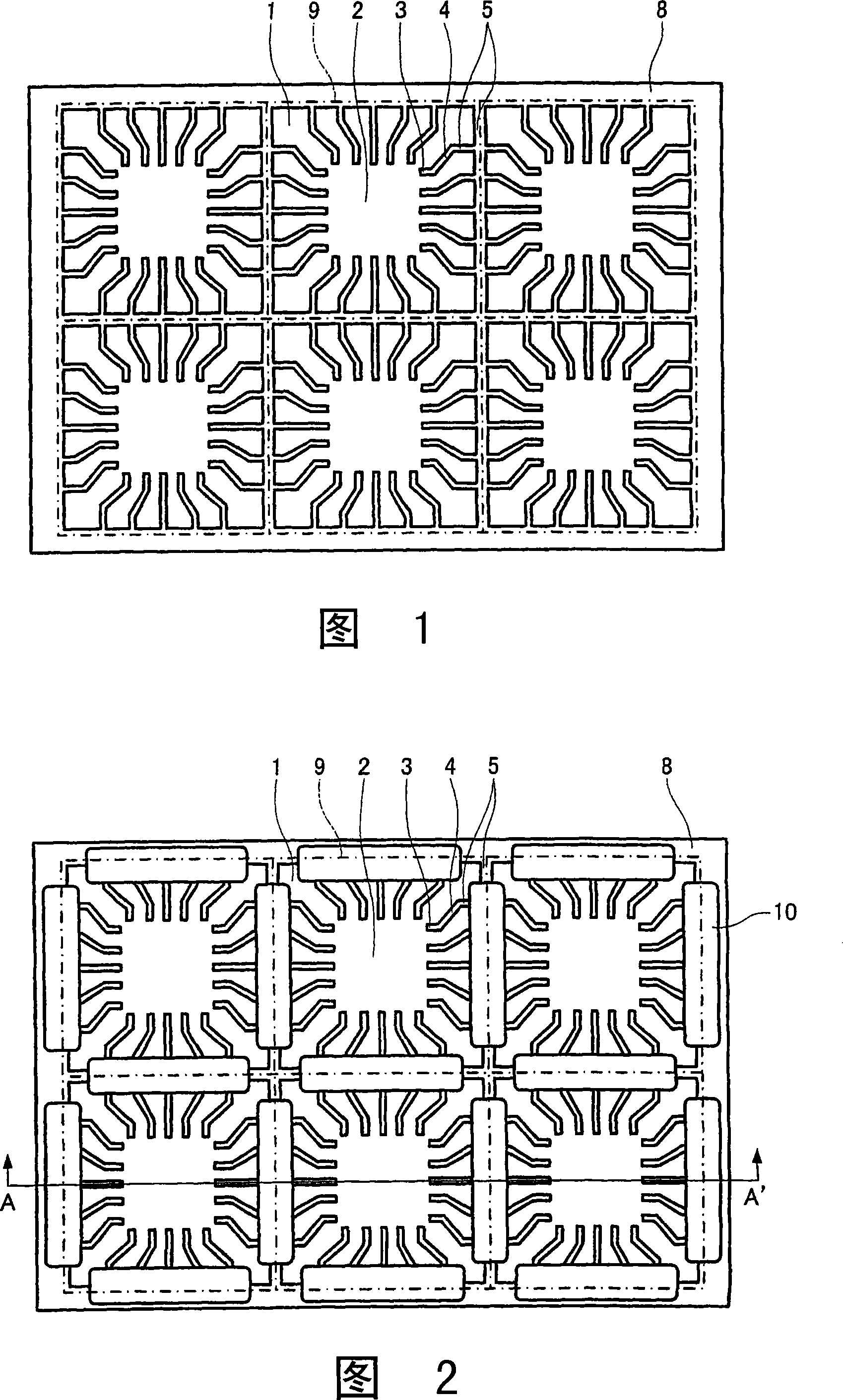

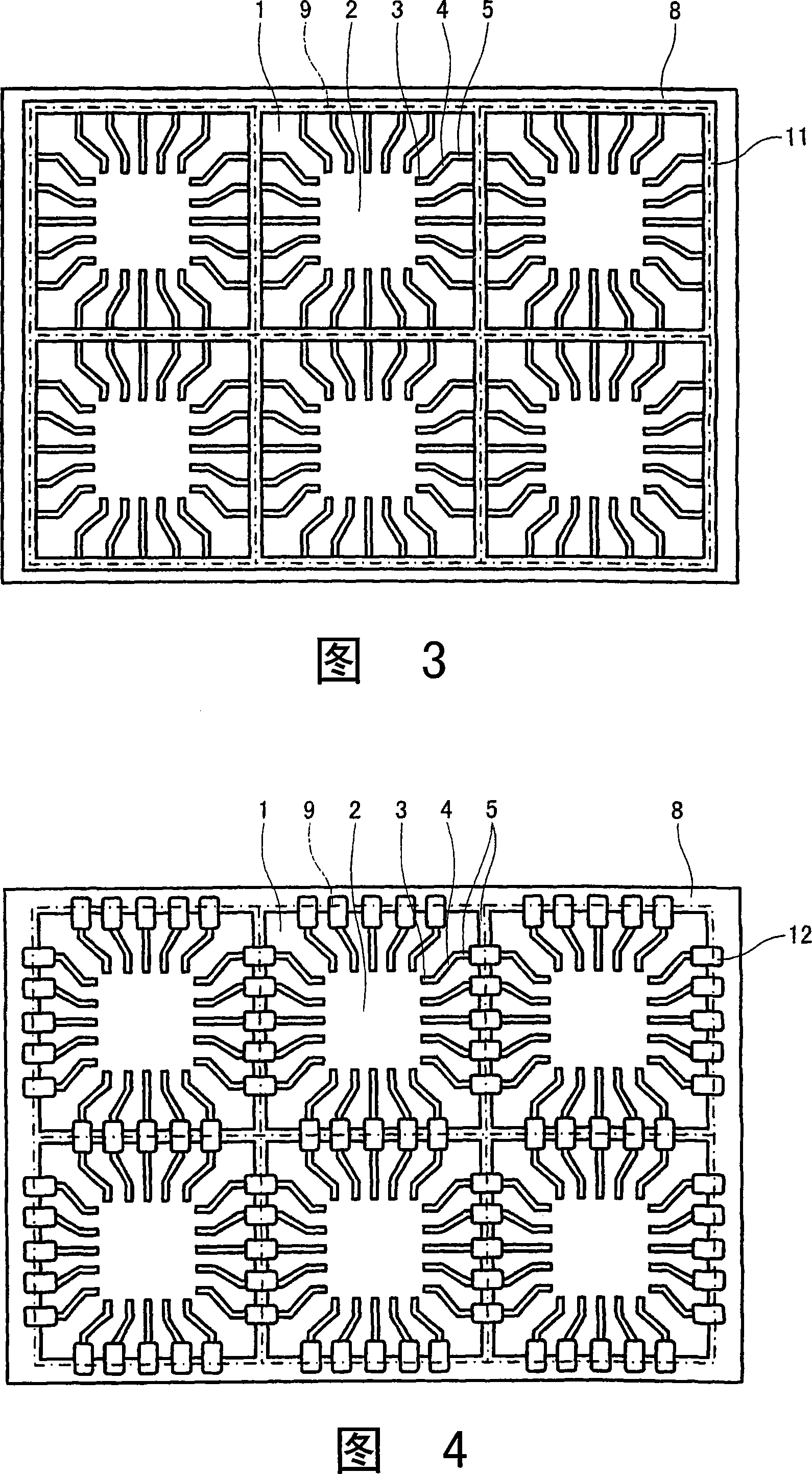

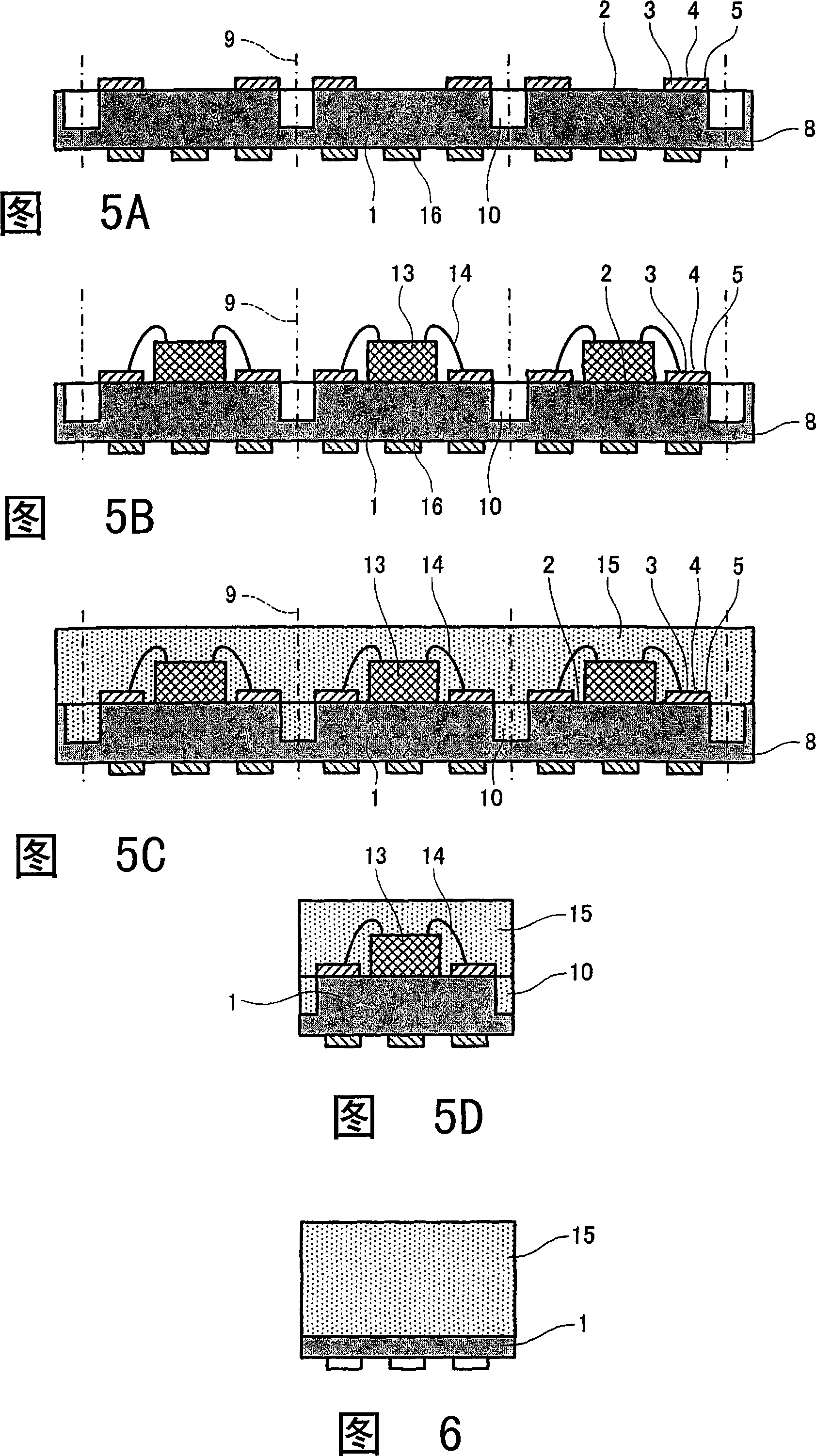

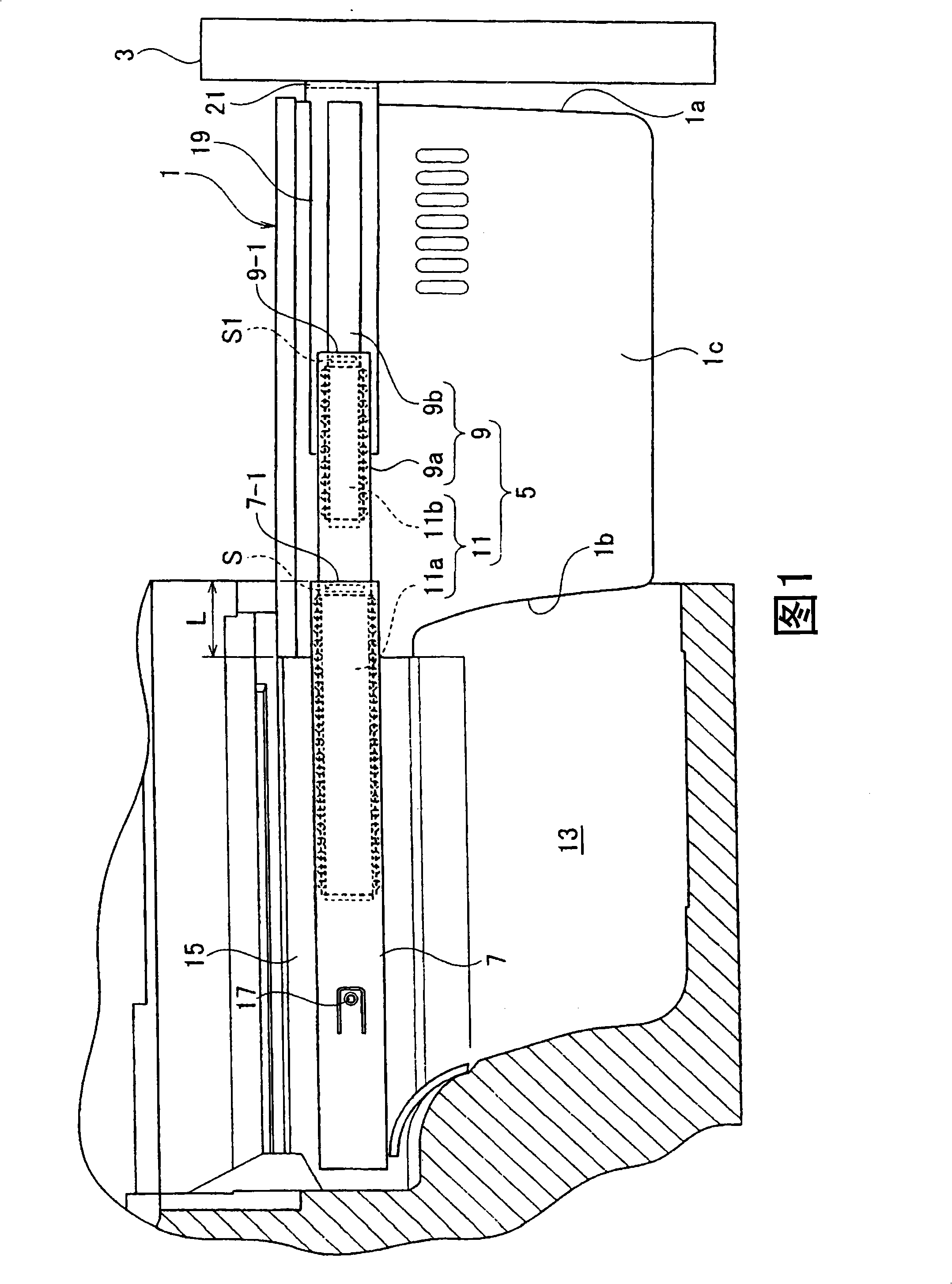

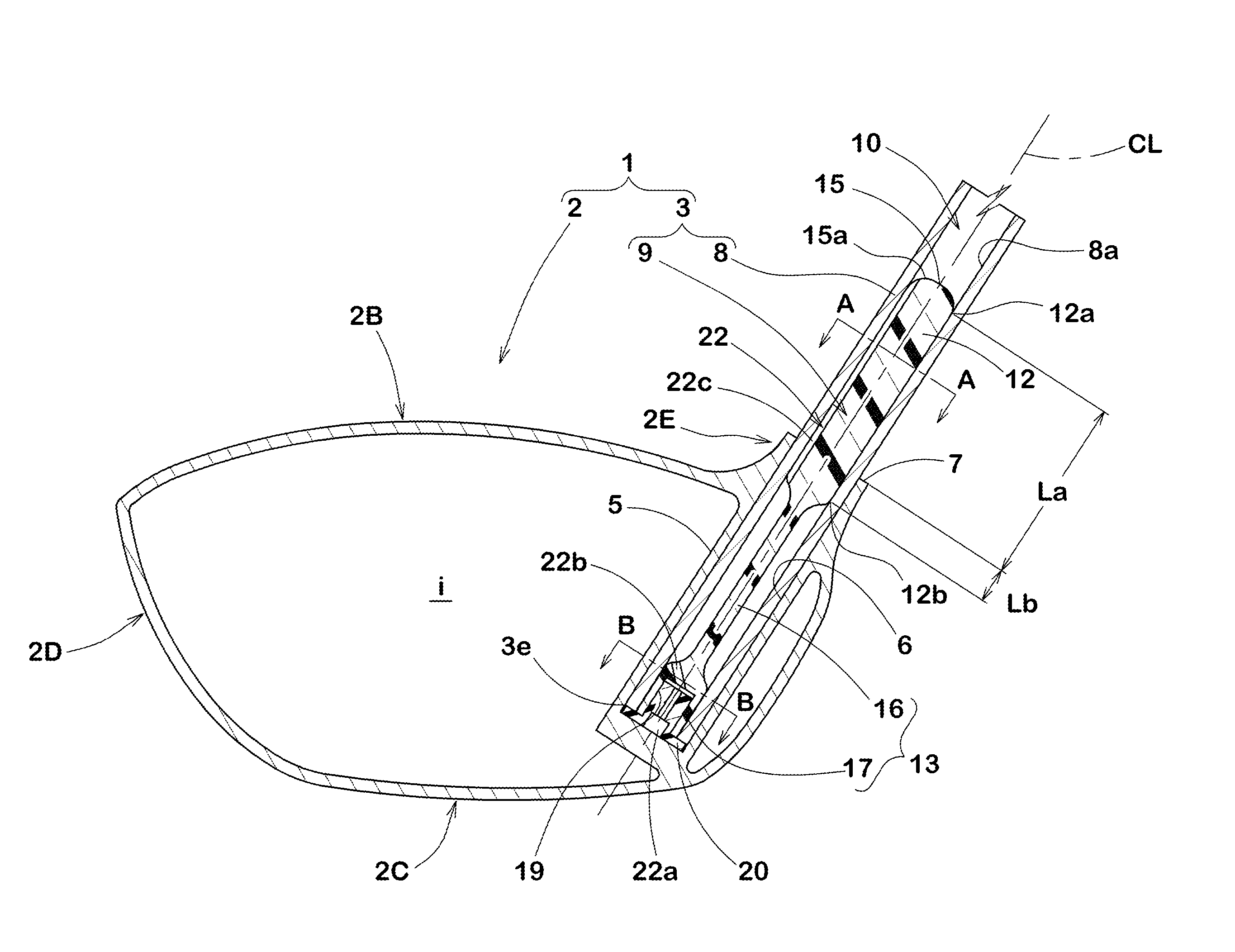

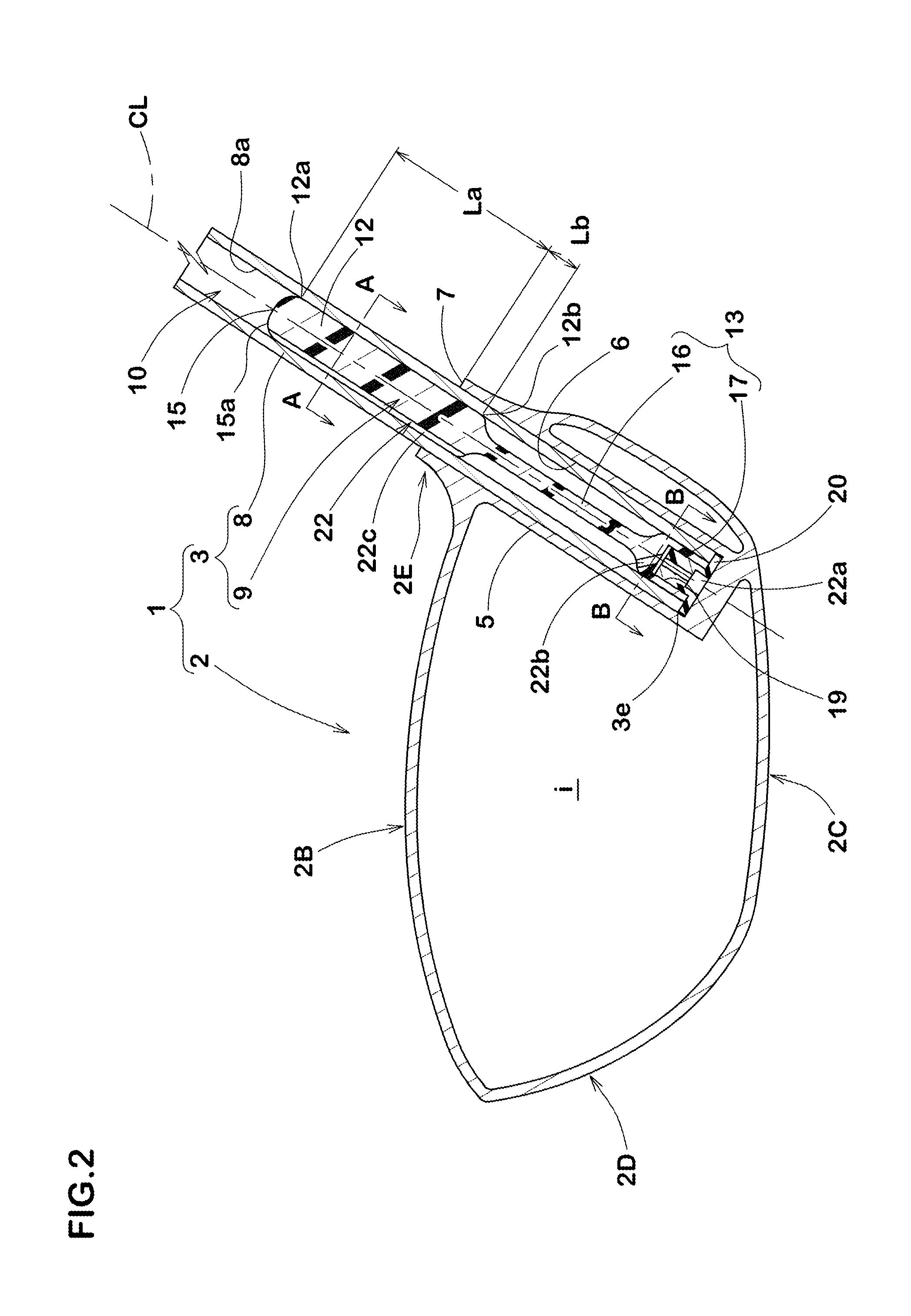

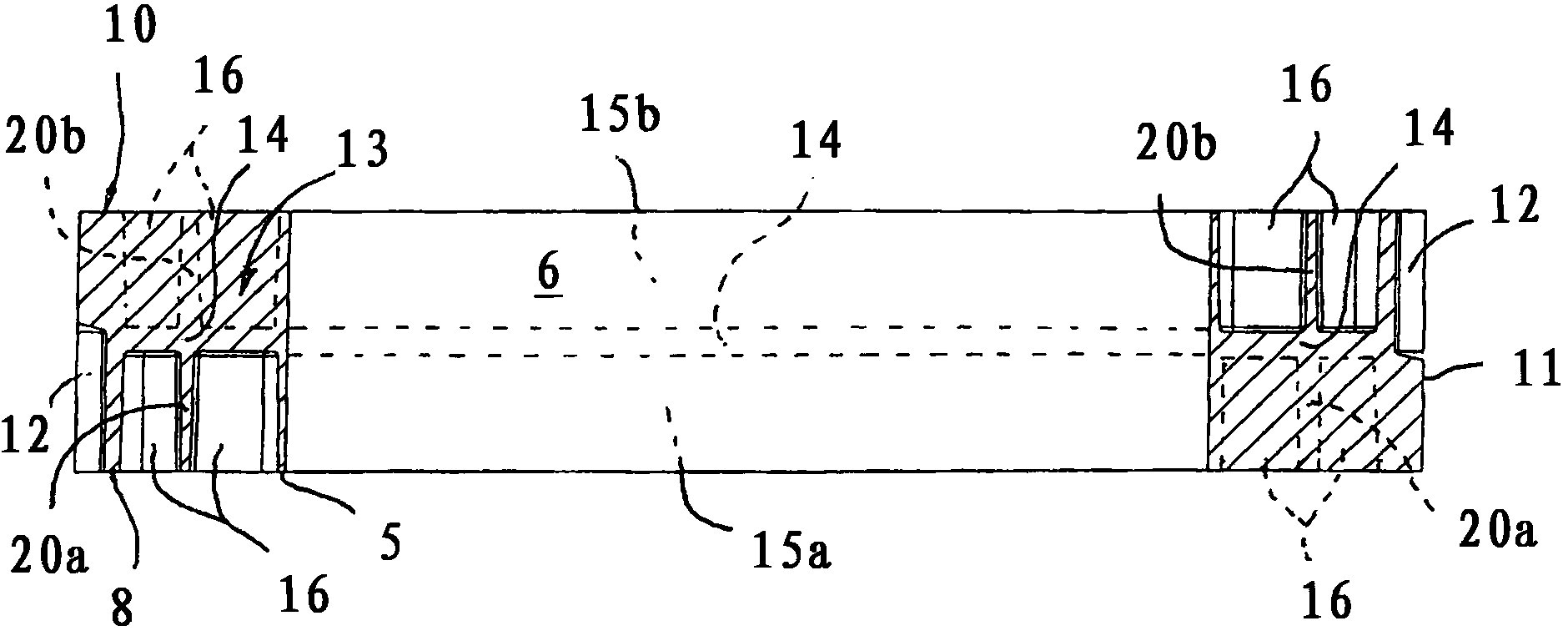

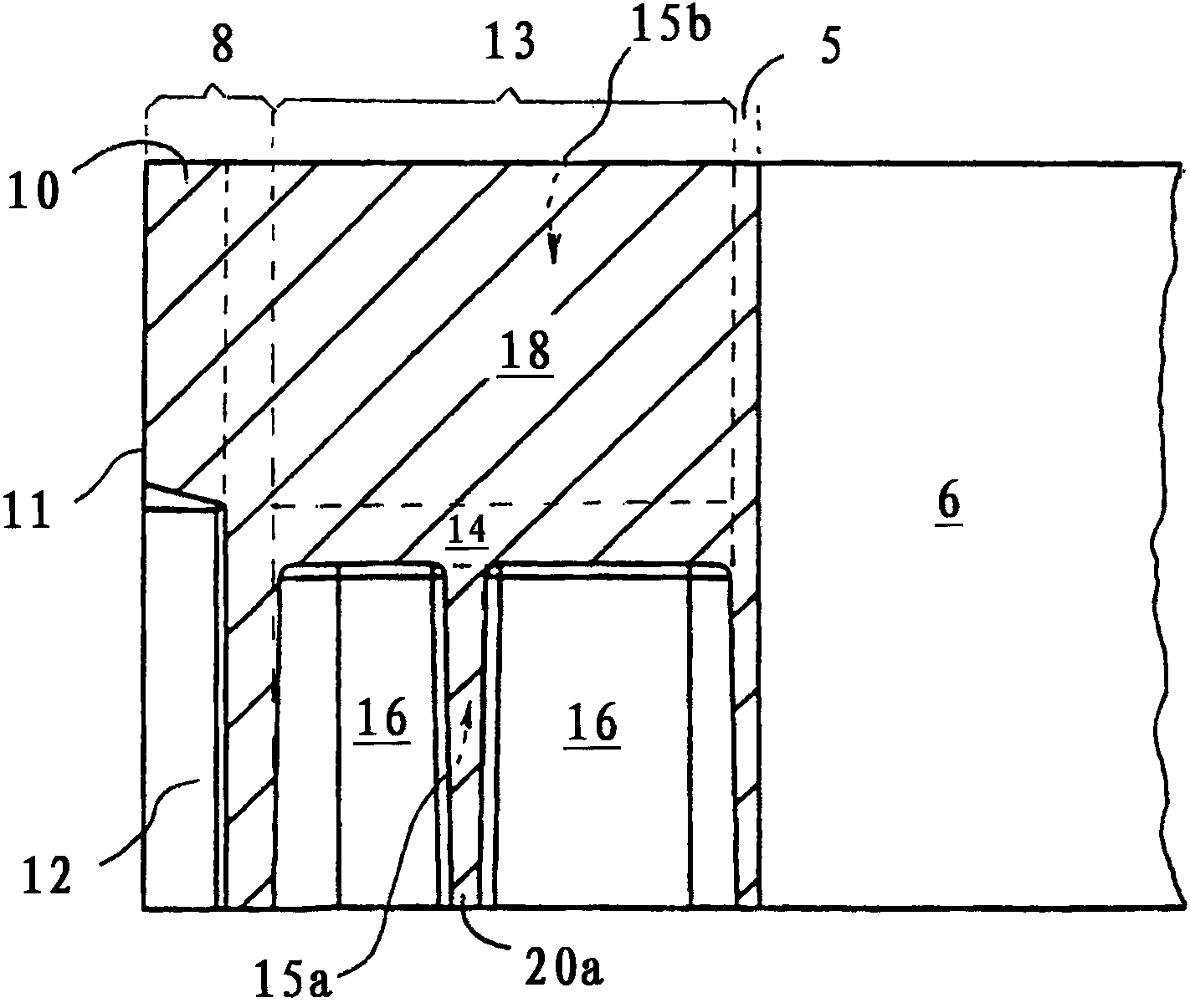

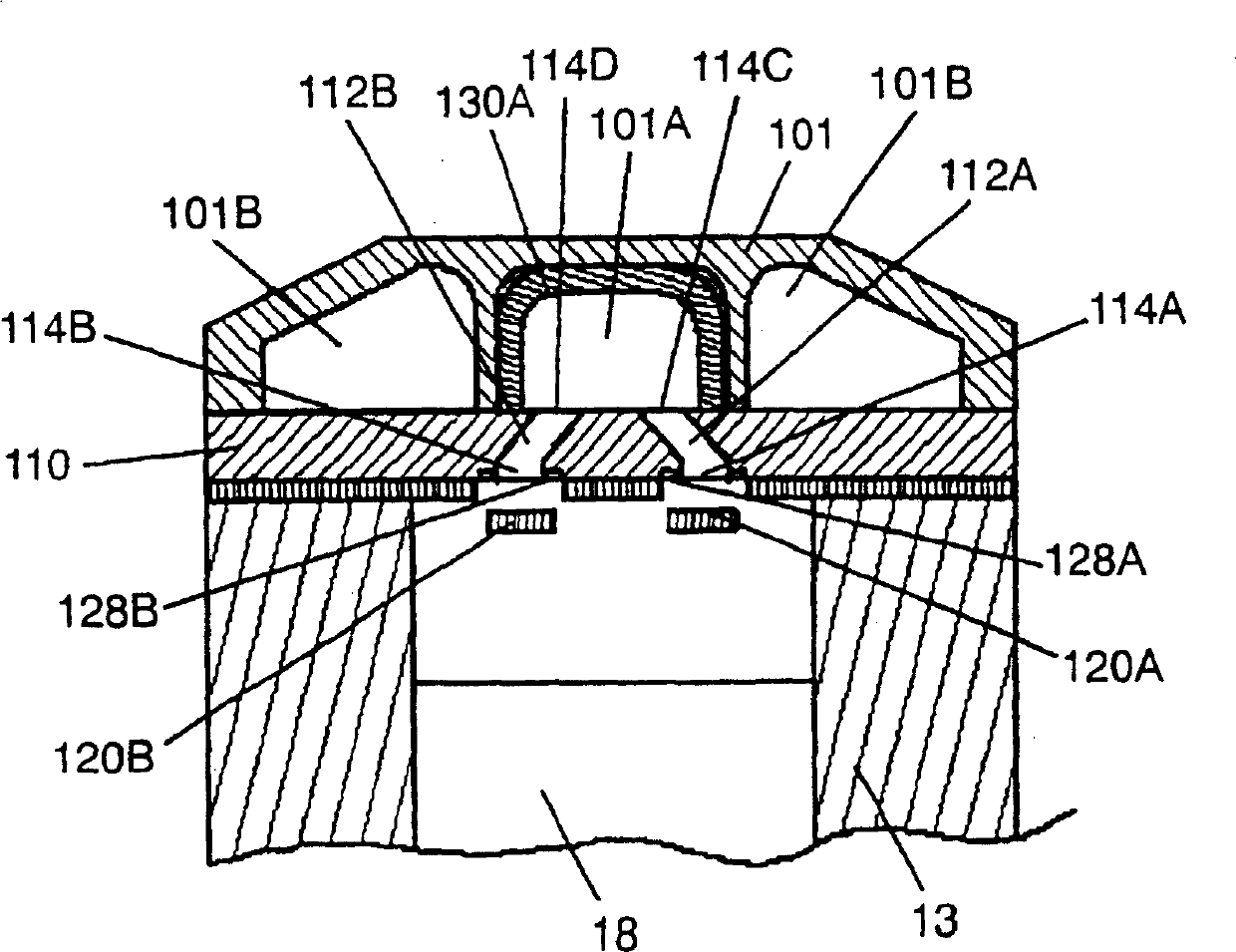

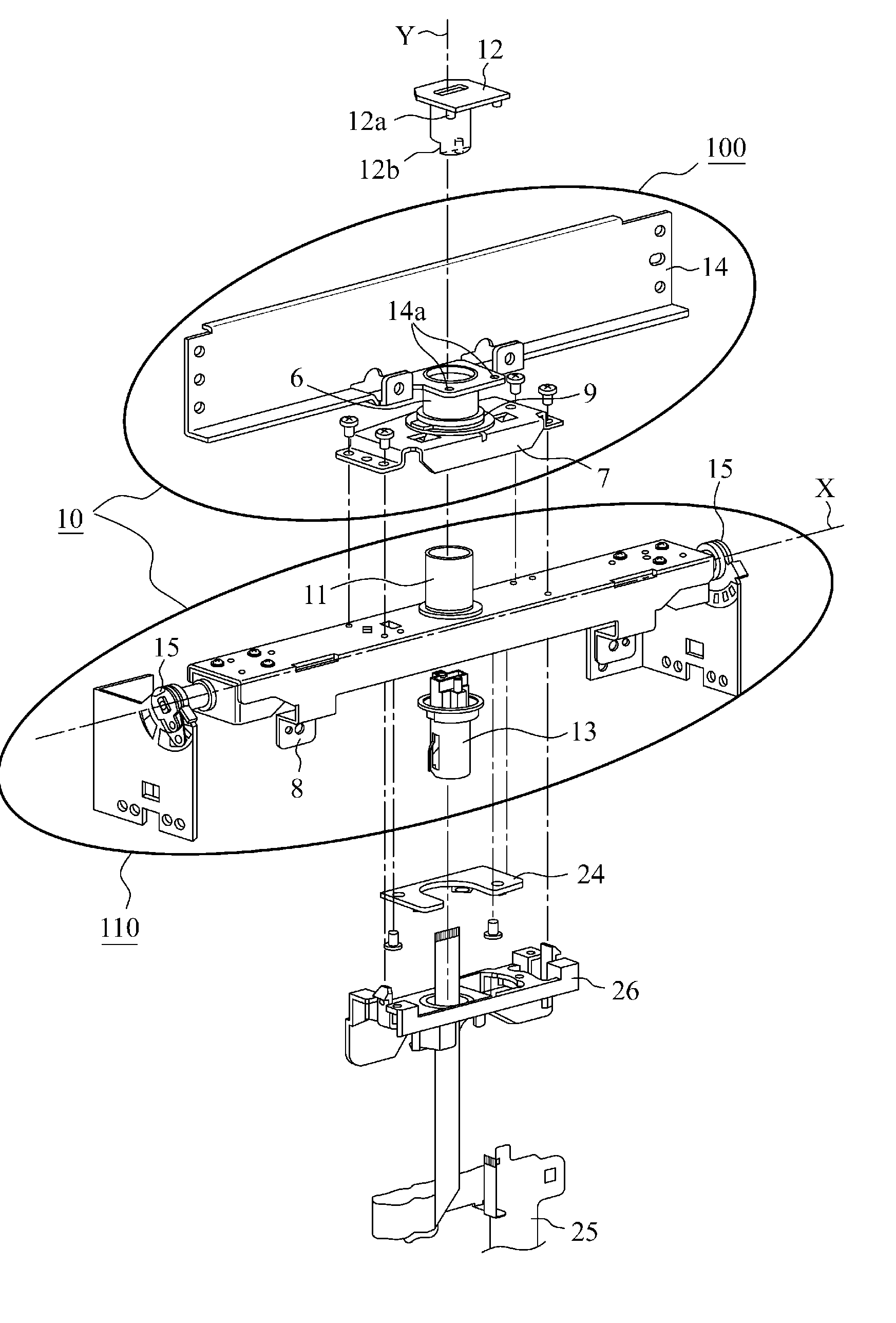

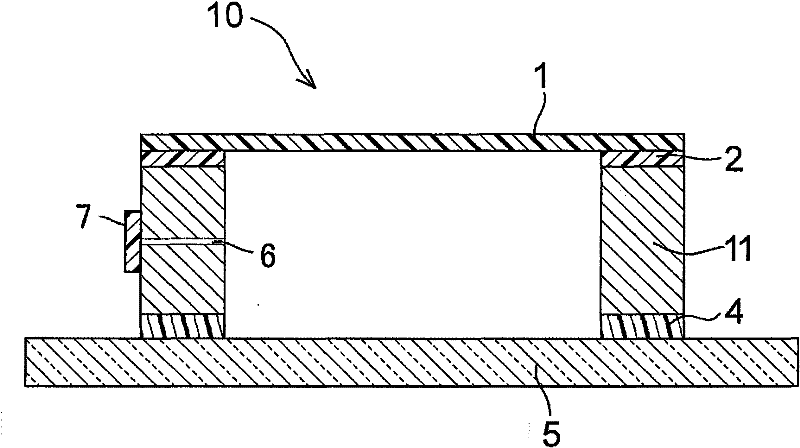

Wiring substrate and semiconductor device using the same

InactiveCN101188221AReduce the amount of bendingImprove installation qualitySemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipSemiconductor package

According to the present invention, a plurality of semiconductor devices having semiconductor chips 13 molded on a semiconductor package substrate 1 by a molding resin 15 can be manufactured by forming recesses 10 around each semiconductor package substrate 1 composing a substrate 8 for a BGA package, and in the state where a molding resin 15 is filled on the substrate 8 including the recesses 10 for resin molding, cutting the substrate 8 and the molding resin 15 along partition lines 9.

Owner:PANASONIC CORP

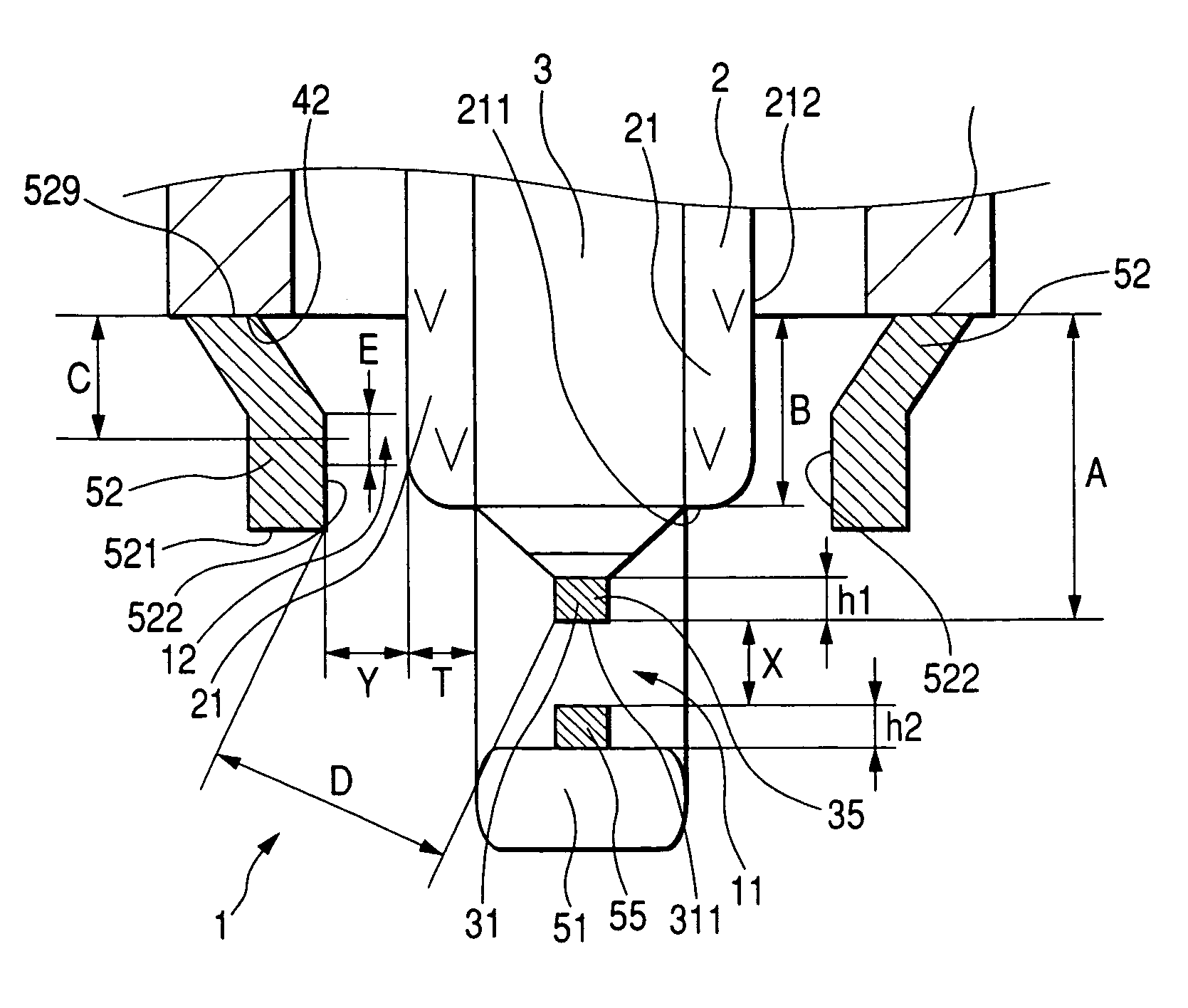

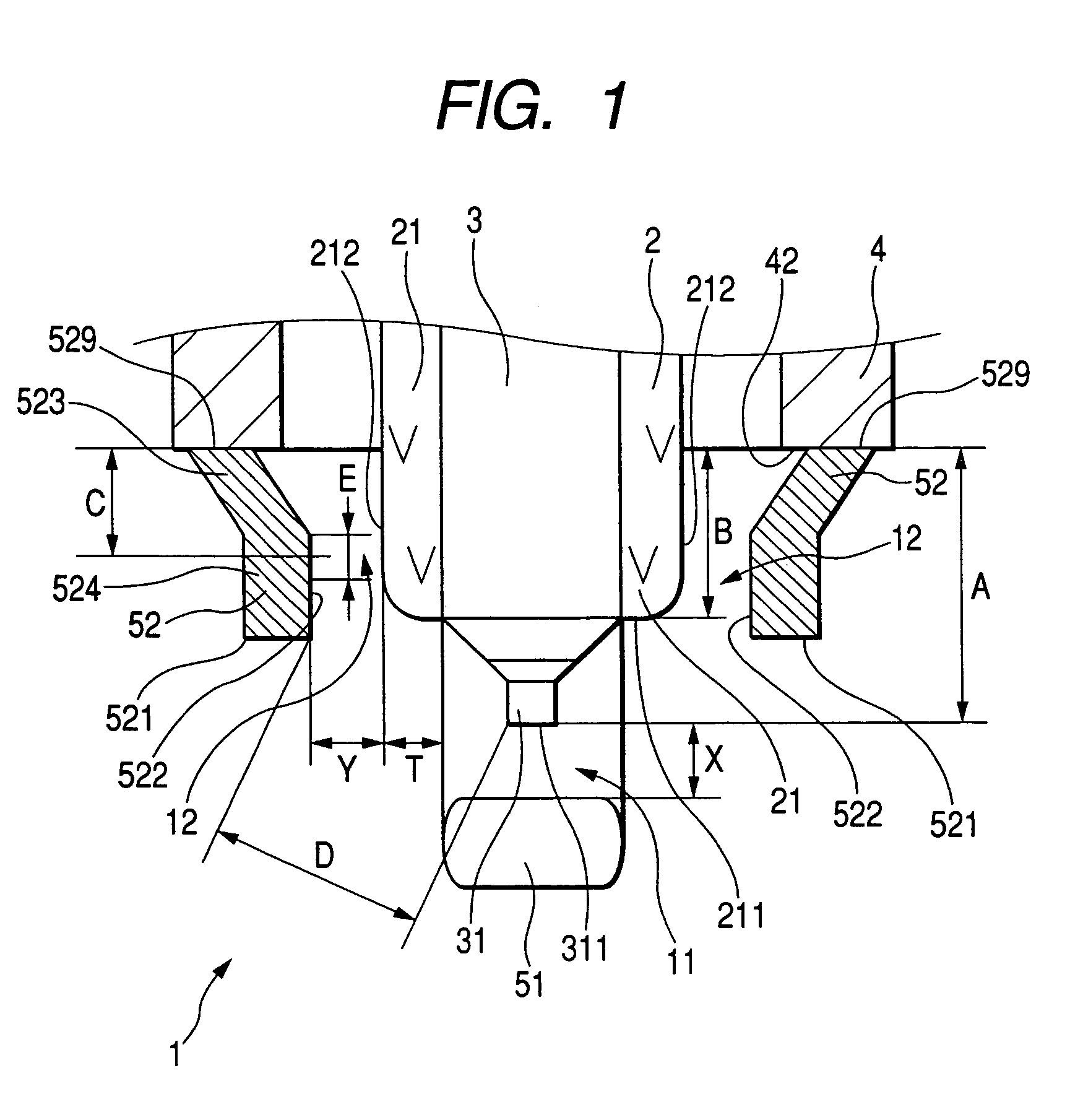

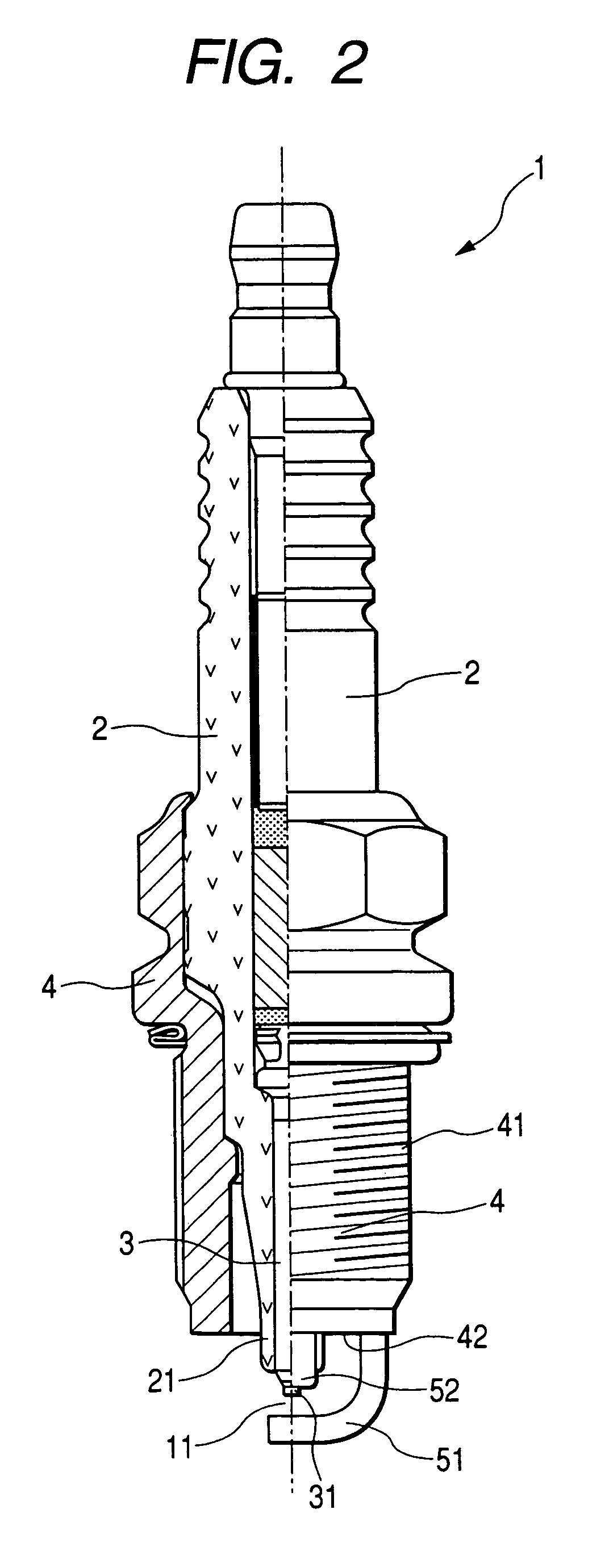

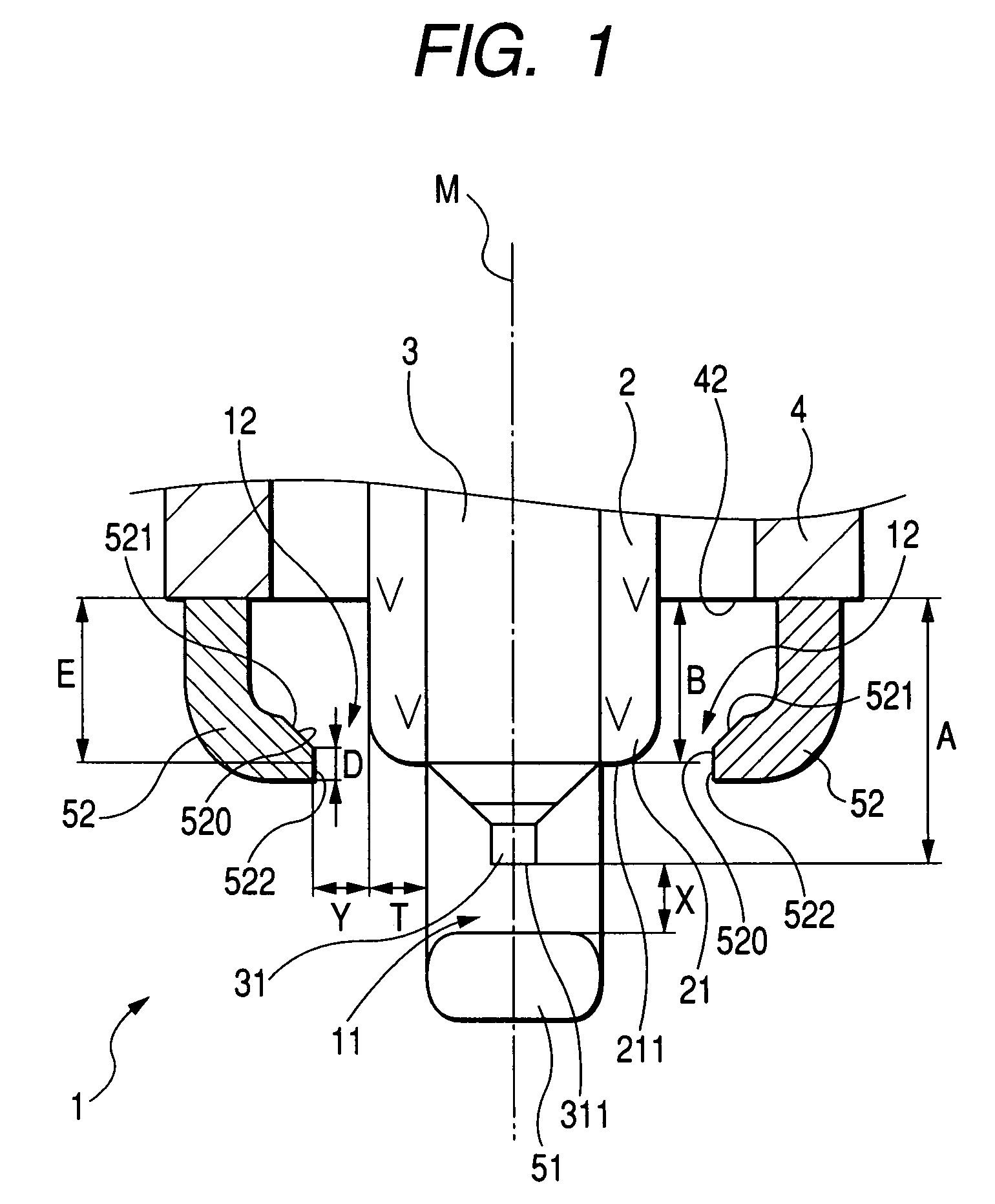

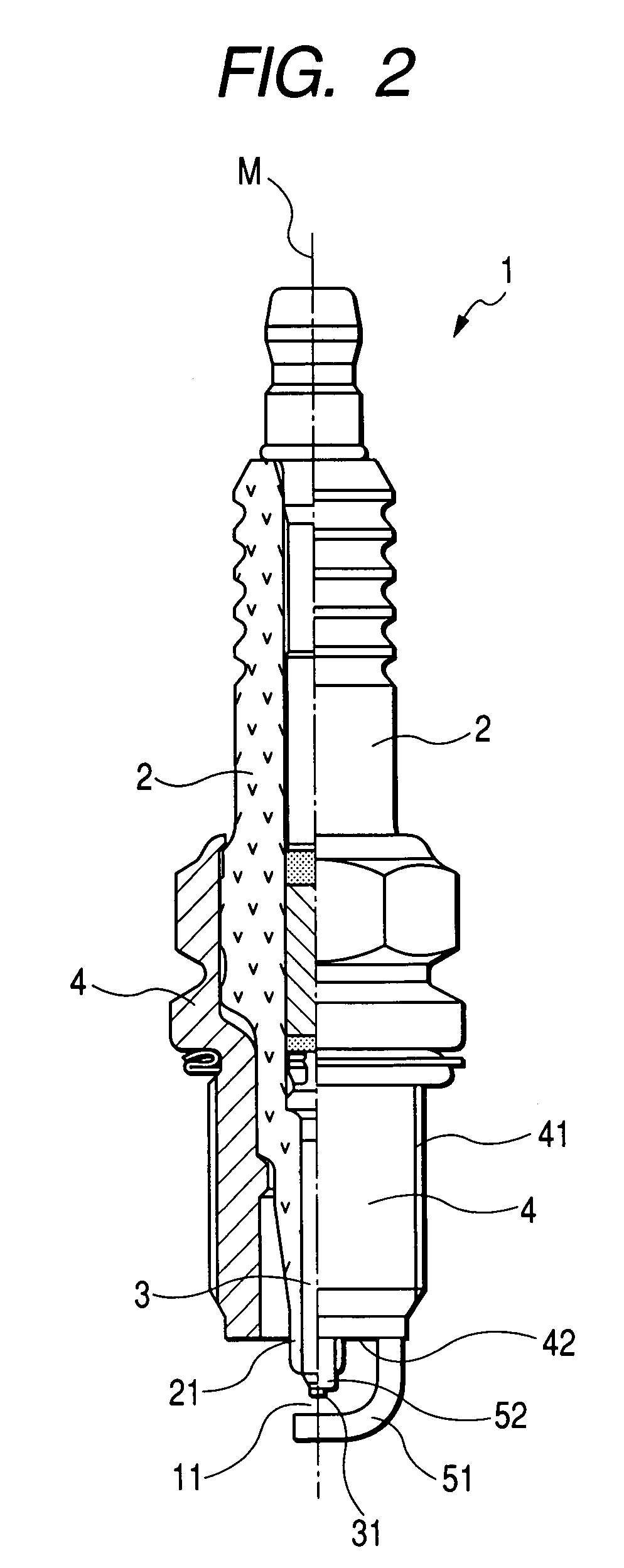

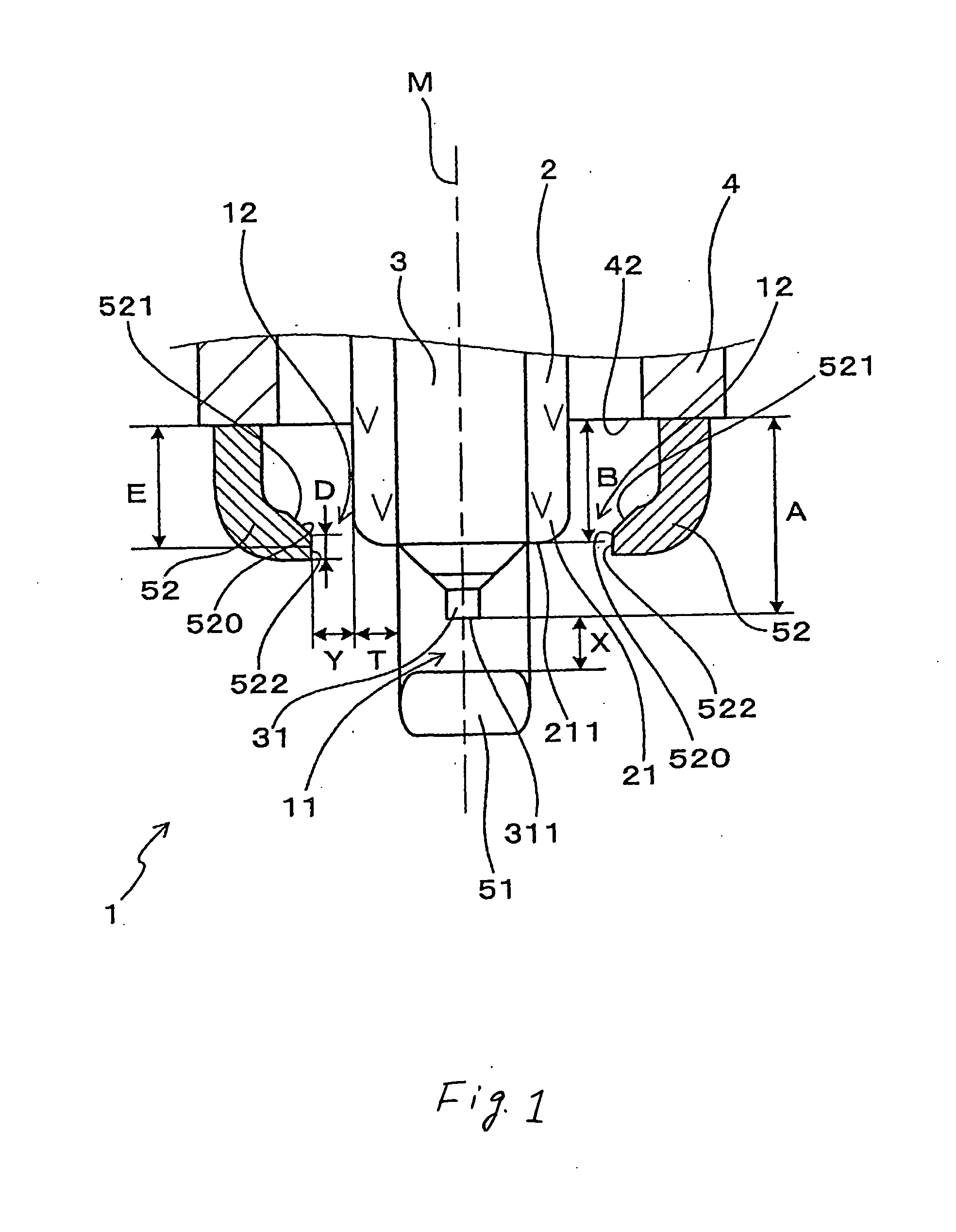

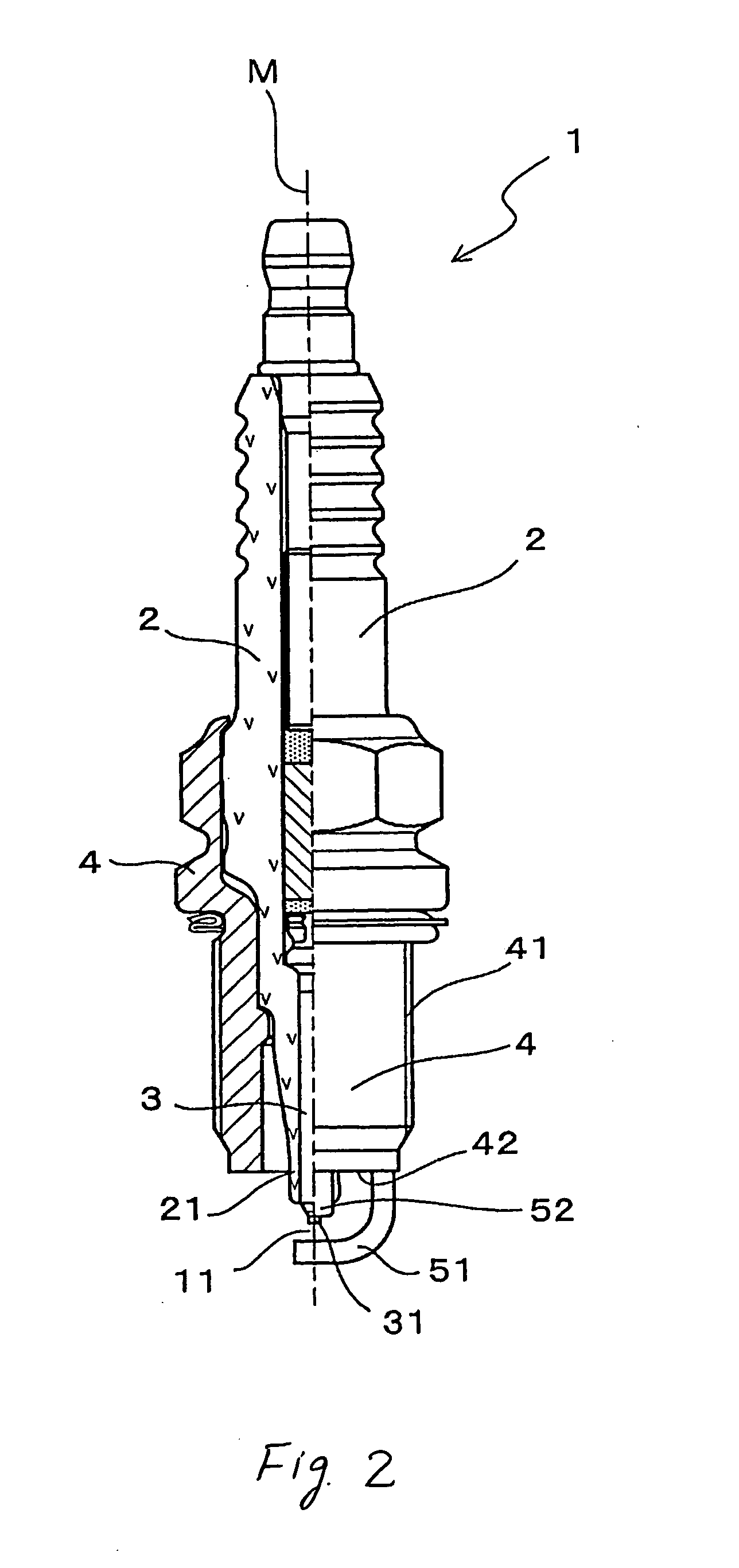

Spark plug with increased durability and carbon fouling resistance

ActiveUS7250711B2Enhanced carbon fouling resistance and durabilitySimple structureSparking plugsFuel injection apparatusElectrical field strengthInternal combustion engine

A spark plug for an internal combustion engine is provided which includes a metal shell, a porcelain insulator, a center electrode, a main ground electrode, and auxiliary ground electrodes. Each of the auxiliary ground electrodes has an inner side surface facing the center electrode through the porcelain insulator to define an auxiliary spark gap between itself and a nose of the porcelain insulator so as to occupy a minimum distance between the porcelain insulator and the auxiliary ground electrode. This avoids a great local increase in electrical field strength on the auxiliary ground electrode to minimize excessive discharge within the auxiliary spark gap to enhance carbon fouling resistance and durability of the spark plug.

Owner:DENSO CORP

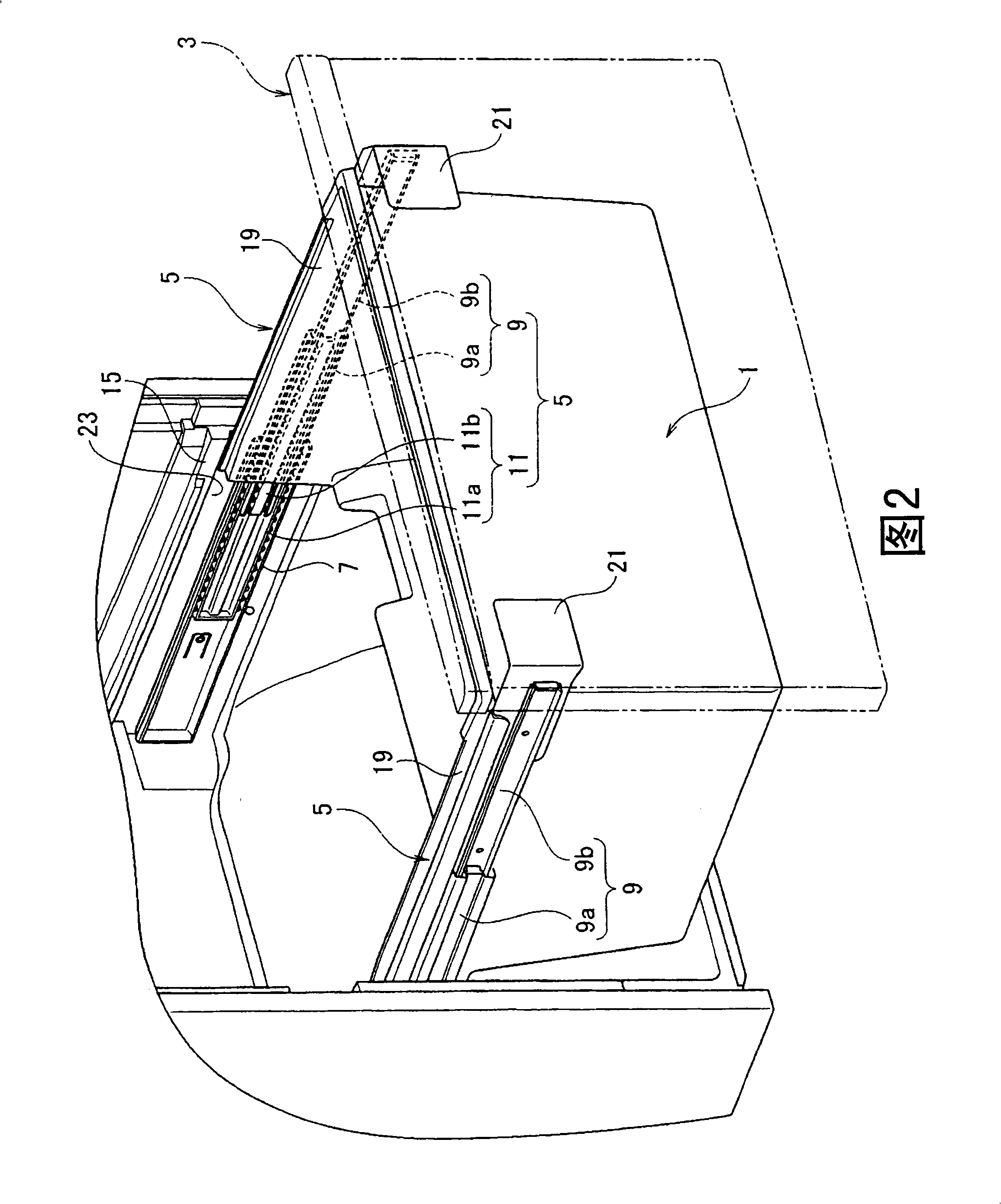

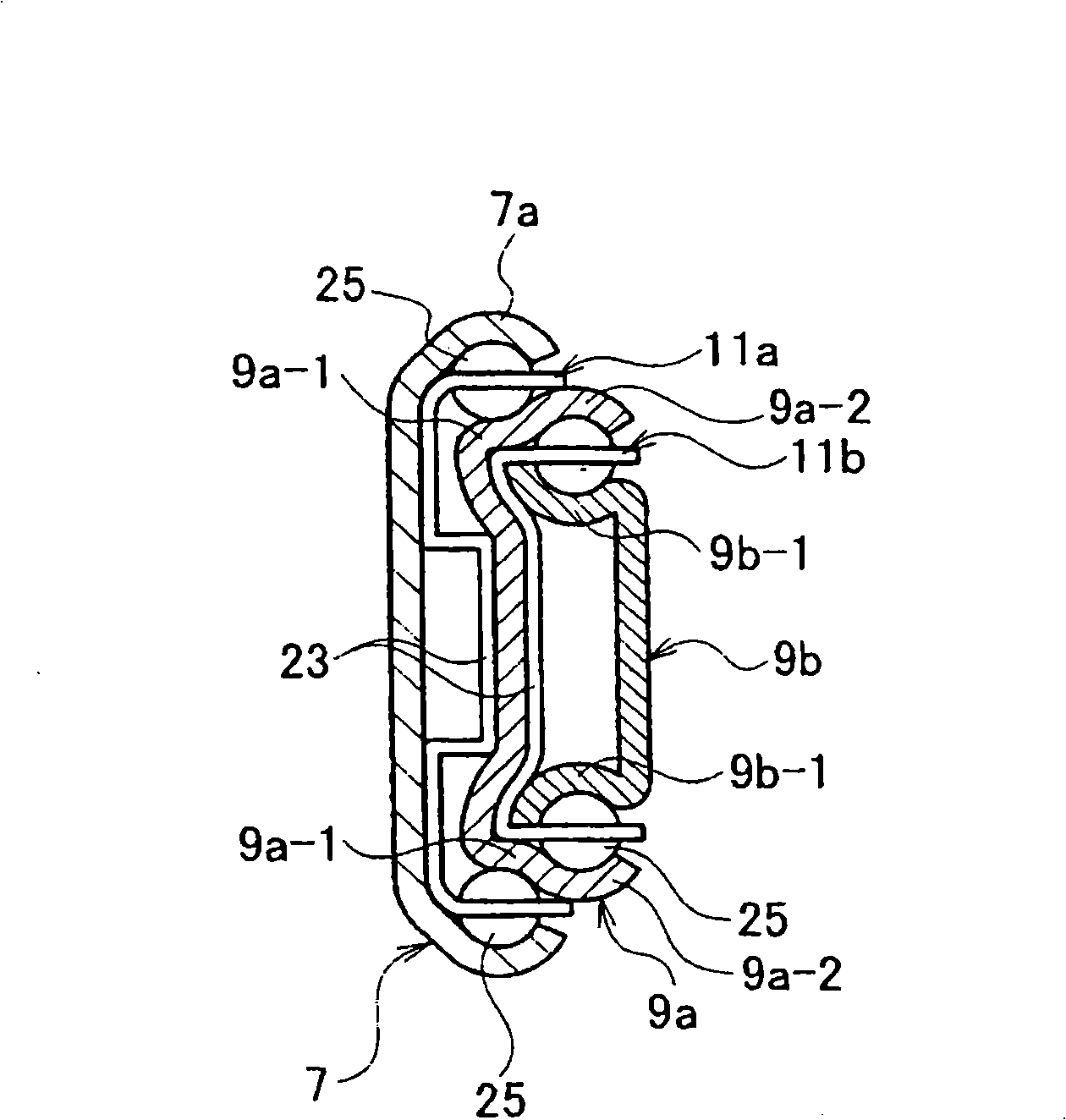

Refrigerator

InactiveCN101354208AReduce loadReduce the amount of bendingLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

Owner:KK TOSHIBA +2

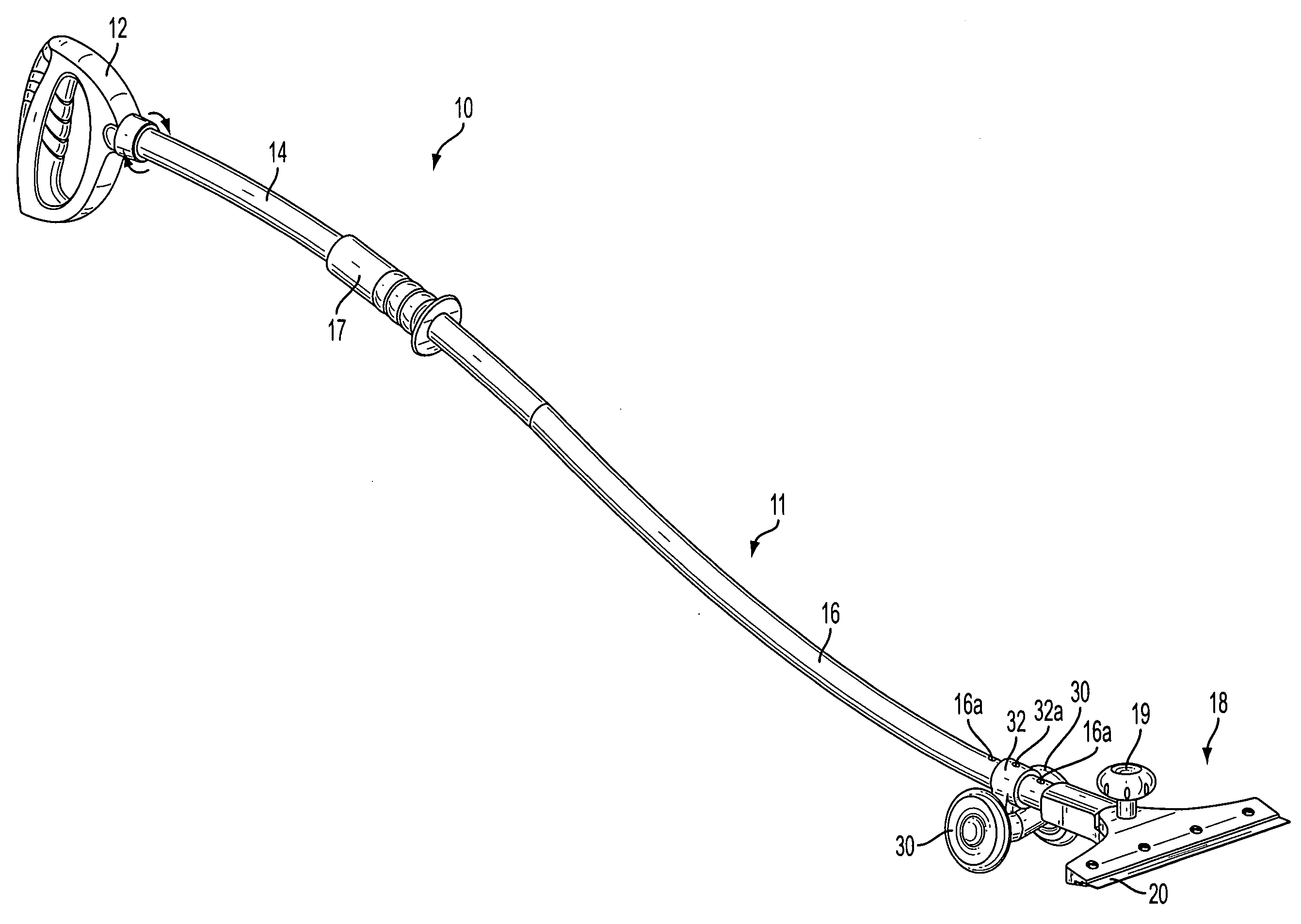

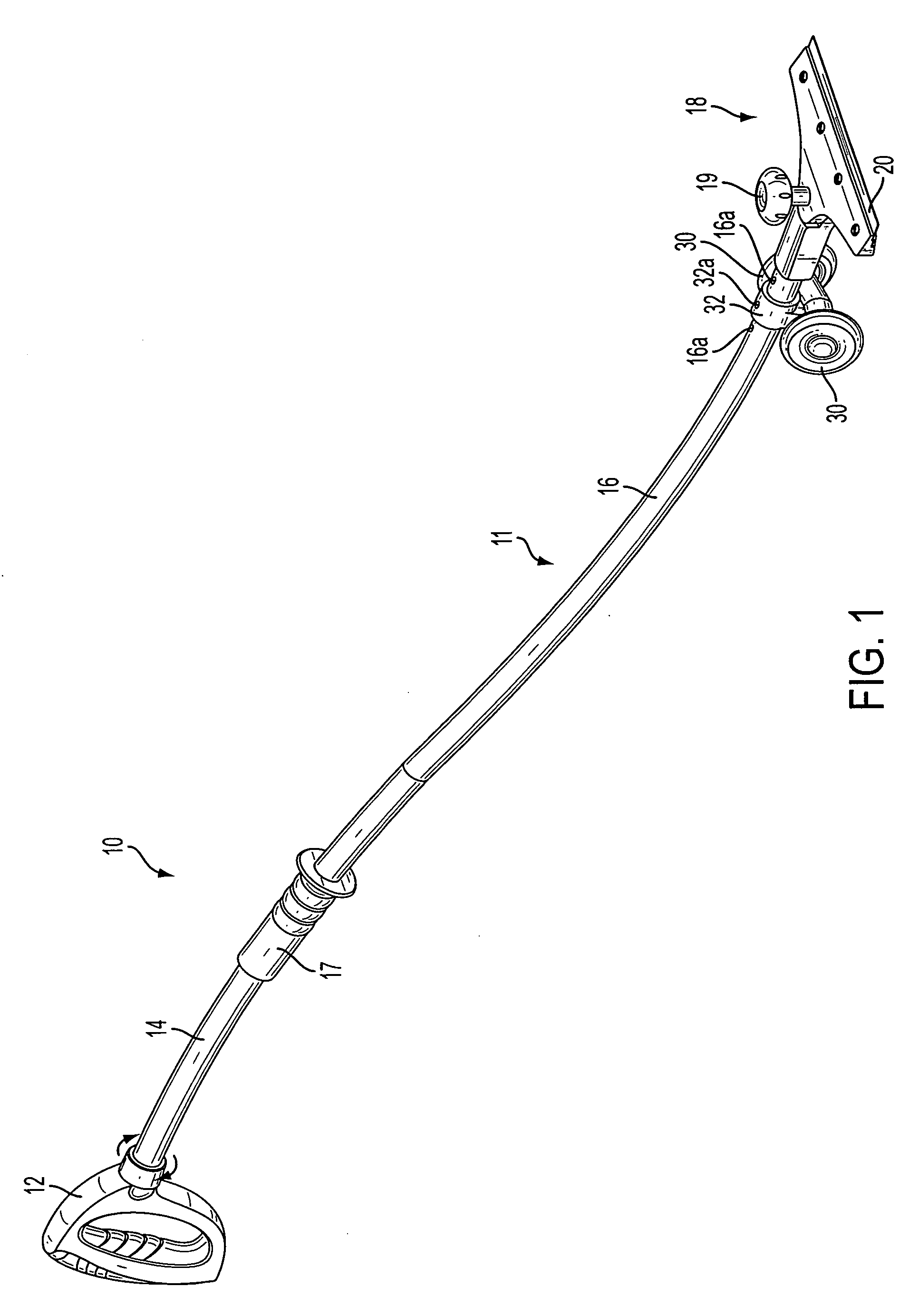

Floor scraper

InactiveUS20090188116A1Amount of bending be reduceEasily adjustCarpet cleanersFloor cleanersEngineeringKnife blades

An ergonomic scraper, such as a floor scraper using a standard replaceable blade, is provided. Embodiments include a scraper having an elongated handle, a scraper head for fixedly holding a blade mounted to a first end of the handle, an upper hand grip at a second end of the handle, and a lower hand grip between the first and second ends of the handle. The handle has an S-shape to reduce the angle between the blade and a workpiece. A pair of wheels is mounted near the scraper head for easily adjusting the blade attack angle. The scraper head is adjustable for changing the scraping angle of the blade to suit the user and / or the job.

Owner:AMERICAN SAFETY RAZOR CO

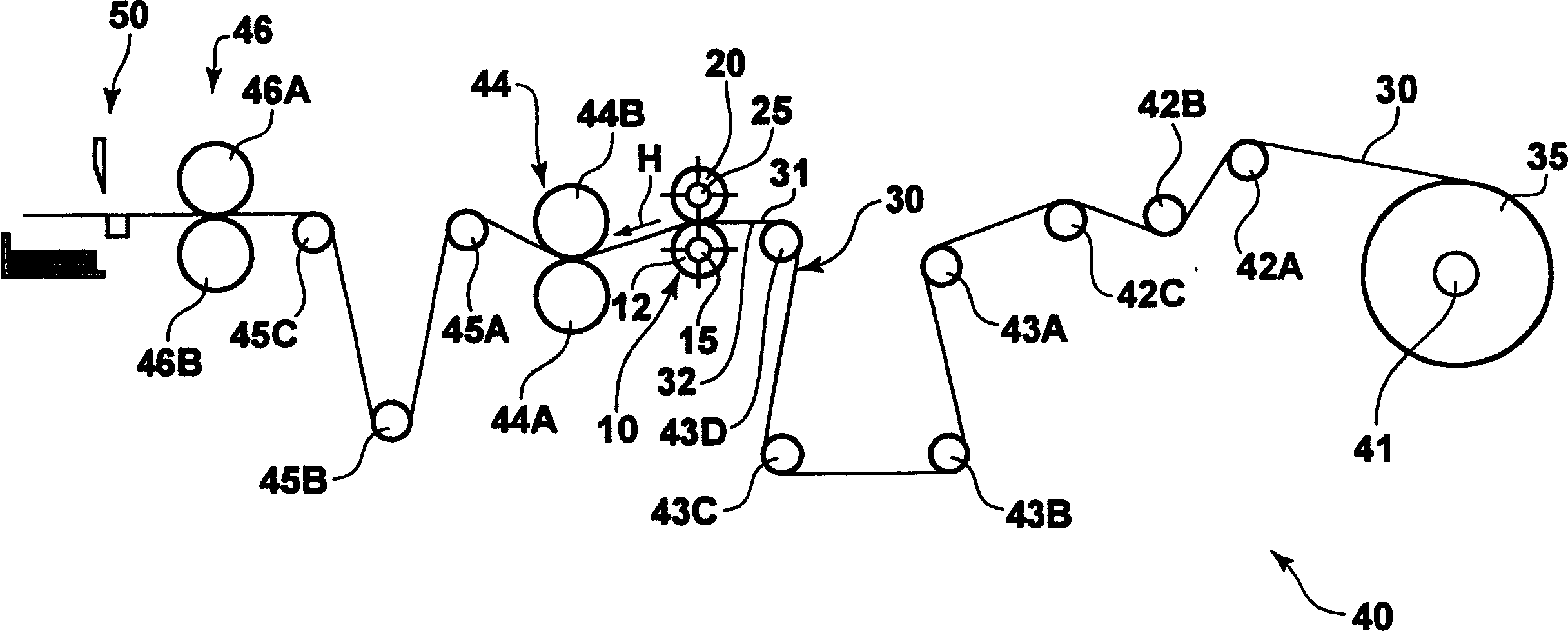

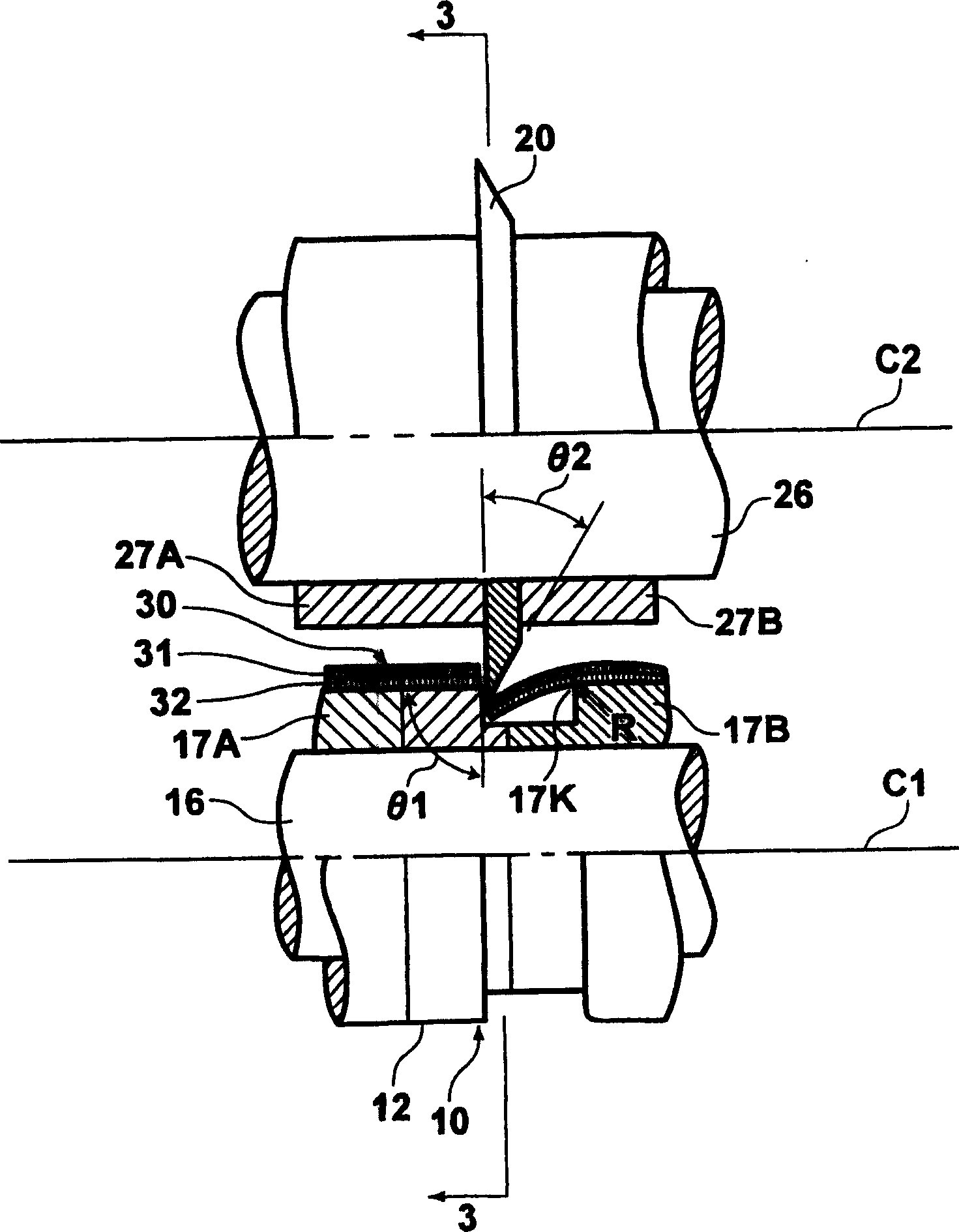

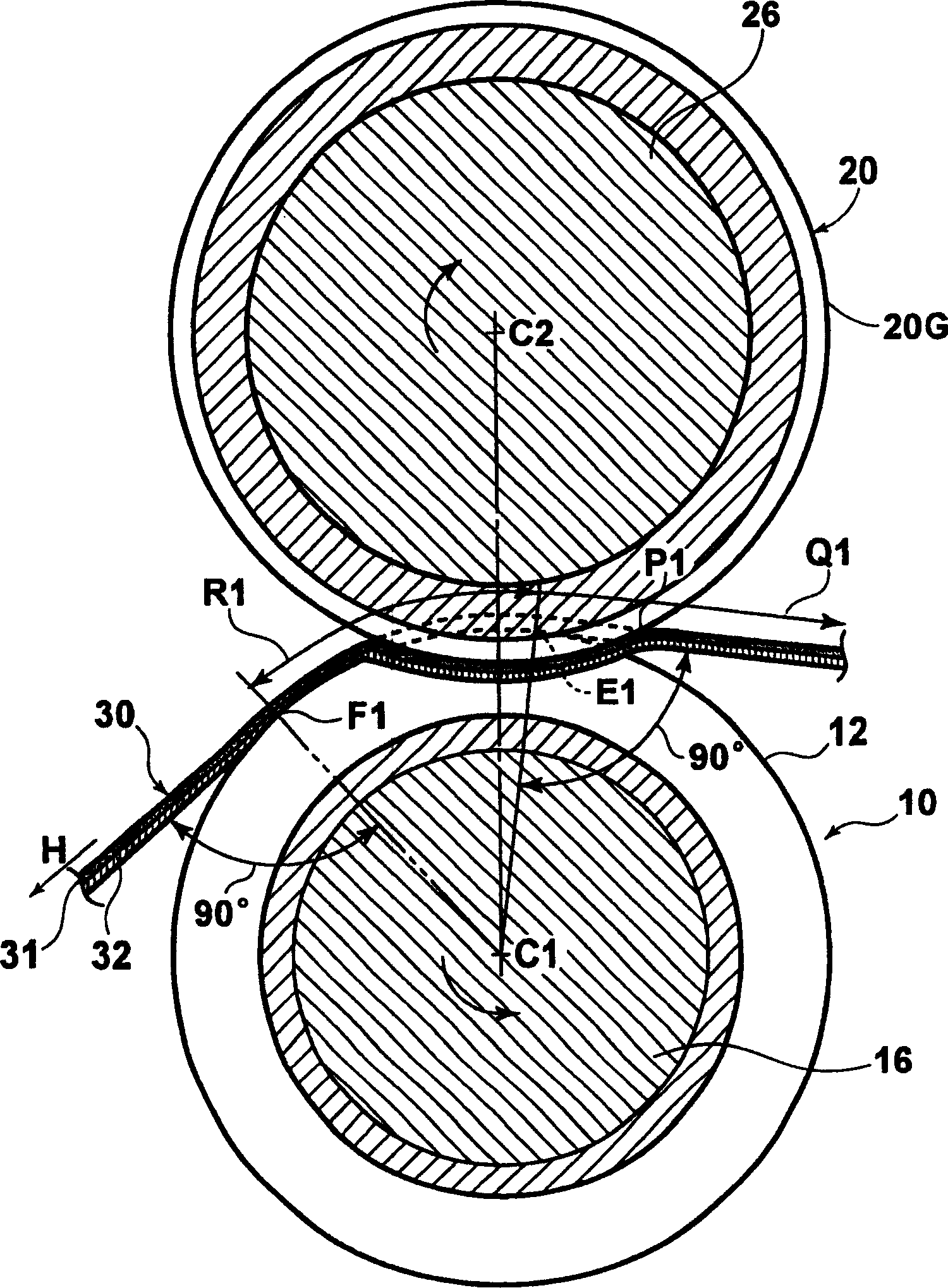

Coated sheet cutting method and apparatus

ActiveCN1572446AReduce the amount of bendingReduce local deformationMetal working apparatusEngineeringMechanical engineering

Owner:FUJIFILM CORP

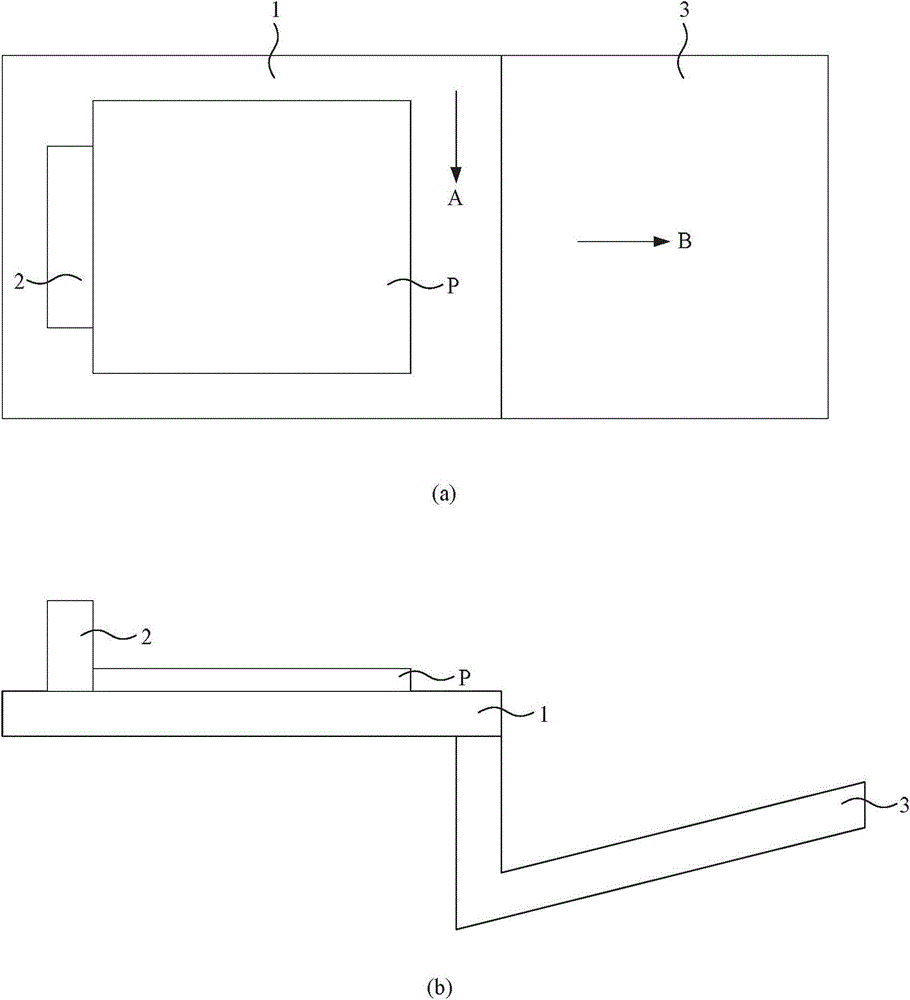

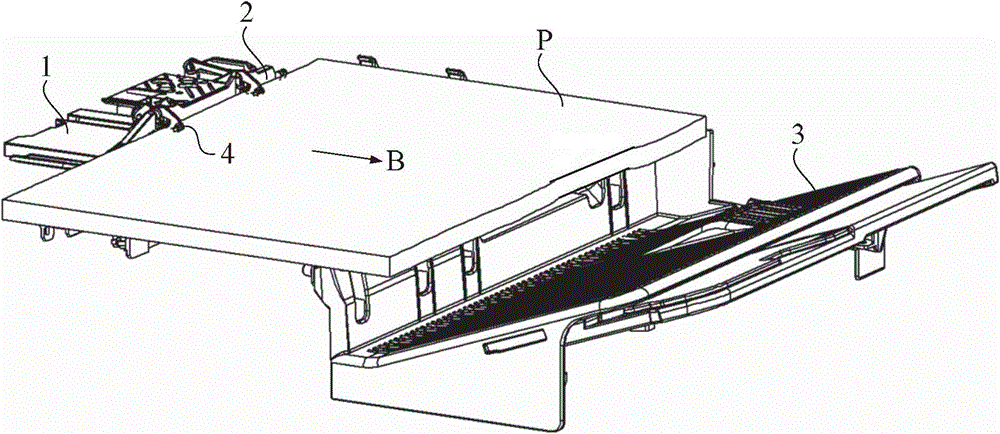

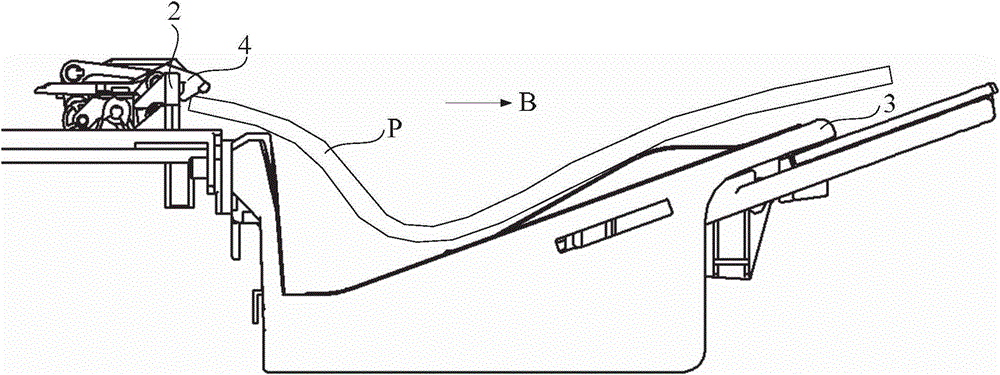

Image forming device and paper discharging mechanism thereof

The invention discloses an image forming device and a paper discharging mechanism thereof. The paper discharging mechanism comprises a first tray, a pushing part, a second tray, a pressure part and a protrusion part, wherein the first tray is used for bearing paper discharged from a paper outlet in the discharging direction; the pushing part is used for pushing out the paper on the first tray in the paper discharging direction; the second tray is located on the downstream part of the first tray in the paper discharging direction to bear the paper pushed out by the pushing part, and the upstream end of the second tray is lower than the downstream end of the first tray; the pressure part is used for pressing the paper on the first tray; the protrusion part is located on the side, near the second tray, of the first tray in the paper discharging direction, and the paper can be supported on the protrusion part when discharged in the paper discharging direction and forms an arch shape extending in the paper discharging direction. The novel paper discharging mechanism is invented and does not damage paper, and the problem that the waist part collapses when the paper is discharged in the paper discharging direction is avoided.

Owner:KONICA MINOLTA TECH DEV WUXI

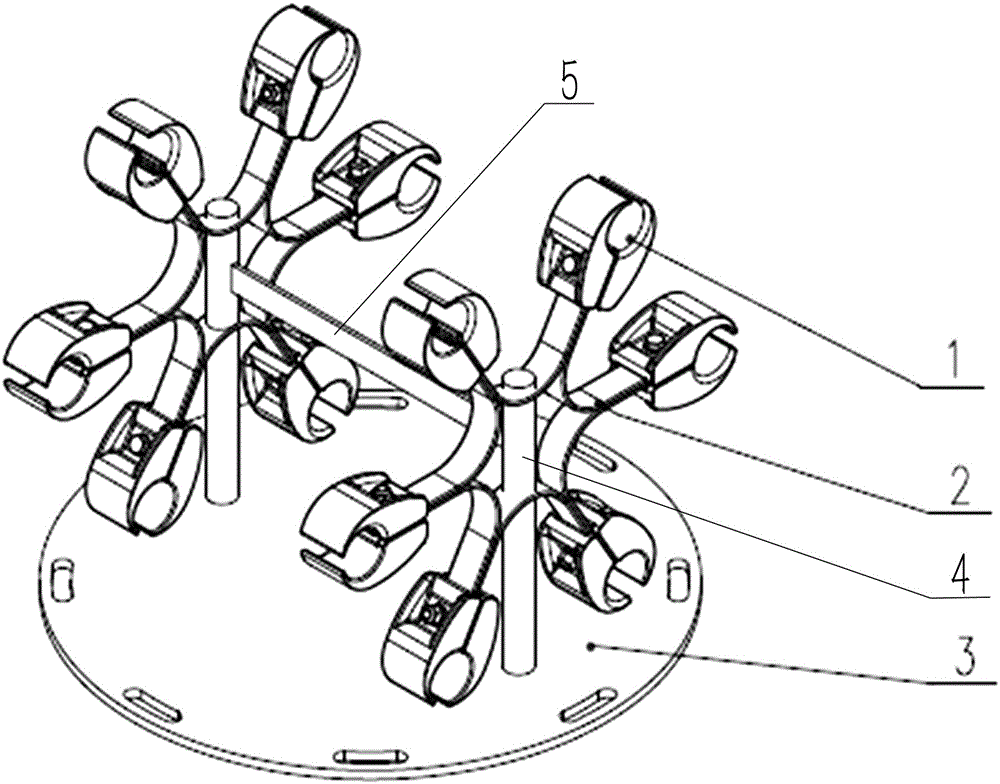

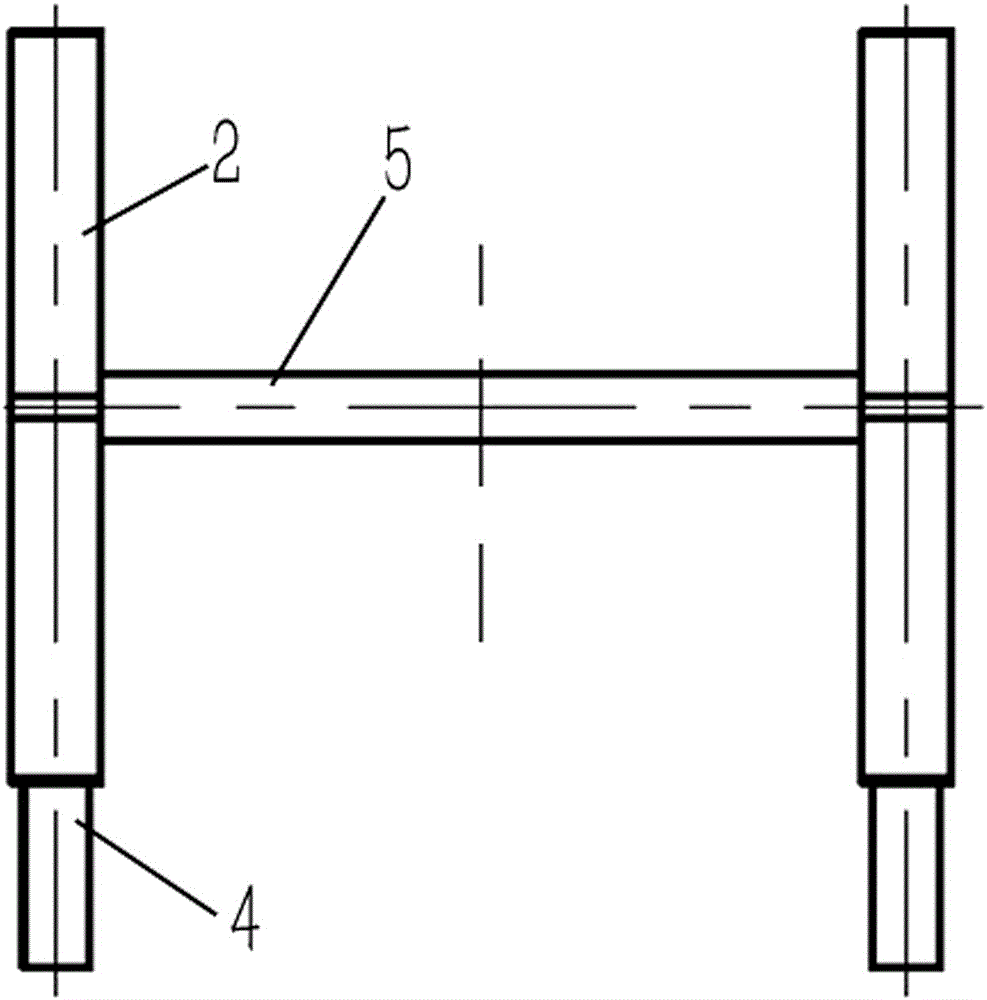

Lead supporting and fixing fitting and interval rod brackets thereof

ActiveCN105048386AReduce the amount of bendingImprove stabilityMaintaining distance between parallel conductorsSuspension arrangements for electric cablesElectric power transmissionElectric power

The invention discloses a lead supporting and fixing fitting and the interval rod brackets thereof. More than two basic bodies of the interval rod brackets are arranged along the horizontal linear direction at intervals, and fixing brackets are fixedly connected between the basic bodies. The wire clamping positions corresponding to the conductor clamps for clamping a same split conductor on the basic bodies are aligned along the arranging direction. In the process of erecting the split conductor, the split conductor is supported by two or more fulcrums clamp on a same lead supporting and fixing fitting, and the fulcrums are relatively fixed. The relative shaking amplitude of each lead supporting and fixing fitting is reduced under the effect of wind, thermal stress and manpower dragging factors, since the length of split conductor clamped by the lead supporting and fixing fitting increases. Bending of the incoming / exiting portions of the split conductor on the lead supporting and fixing fitting is minimized, and the stability and reliability of power transmission of the split conductor are improved.

Owner:PINGGAO GRP +1

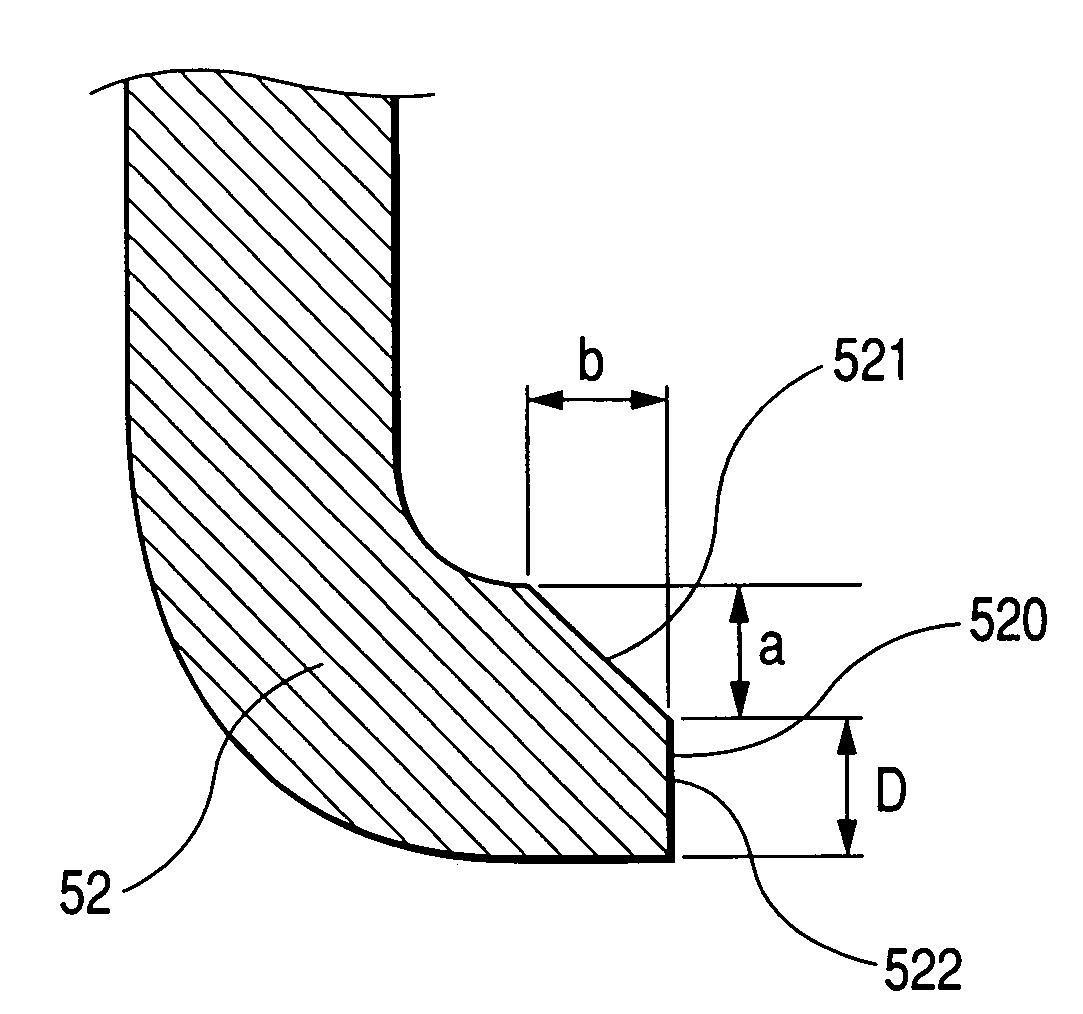

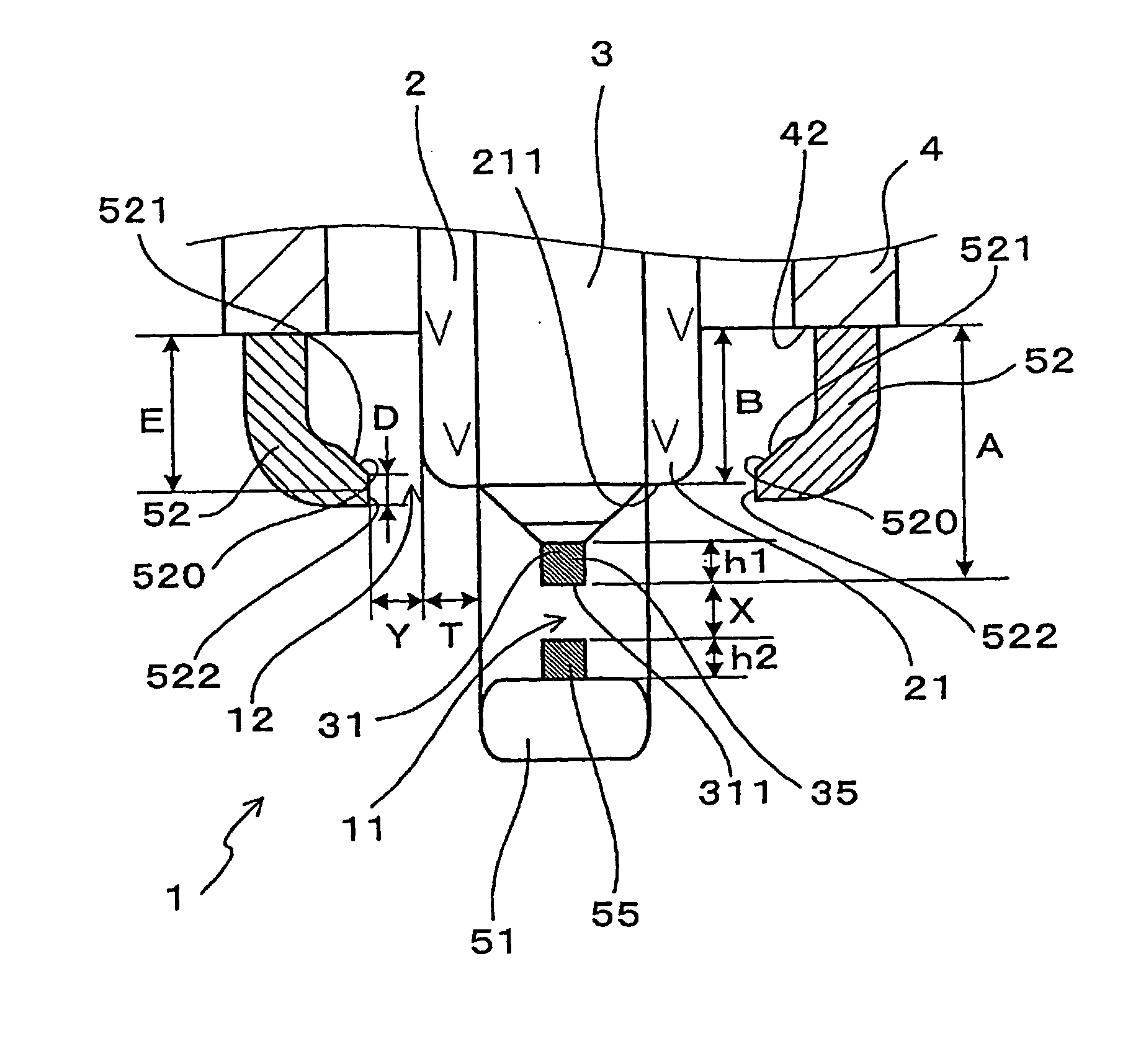

Spark plug with increased durability and carbon fouling resistance

ActiveUS7554253B2Enhanced carbon fouling resistance and durabilitySimple structureSpark gapsSparking plugs manufactureElectrical field strengthEngineering

A spark plug for an internal combustion engine is provided which includes a metal shell, a porcelain insulator, a center electrode, a main ground electrode, and auxiliary ground electrodes. Each of the auxiliary ground electrodes has an end face facing the insulator to define an auxiliary spark gap. The end face includes an increasing-radial distance surface which is located at a distance from a longitudinal center line of the spark plug in a radial direction thereof which increases as approaching to the metal shell. The insulator nose has a wall thickness T meeting a relation of 0.3 mm≦T≦0.7 mm. This avoids a great local increase in electrical field strength on the auxiliary ground electrode to minimize excessive discharge within the auxiliary spark gap to enhance carbon fouling resistance and durability of the spark plug.

Owner:DENSO CORP

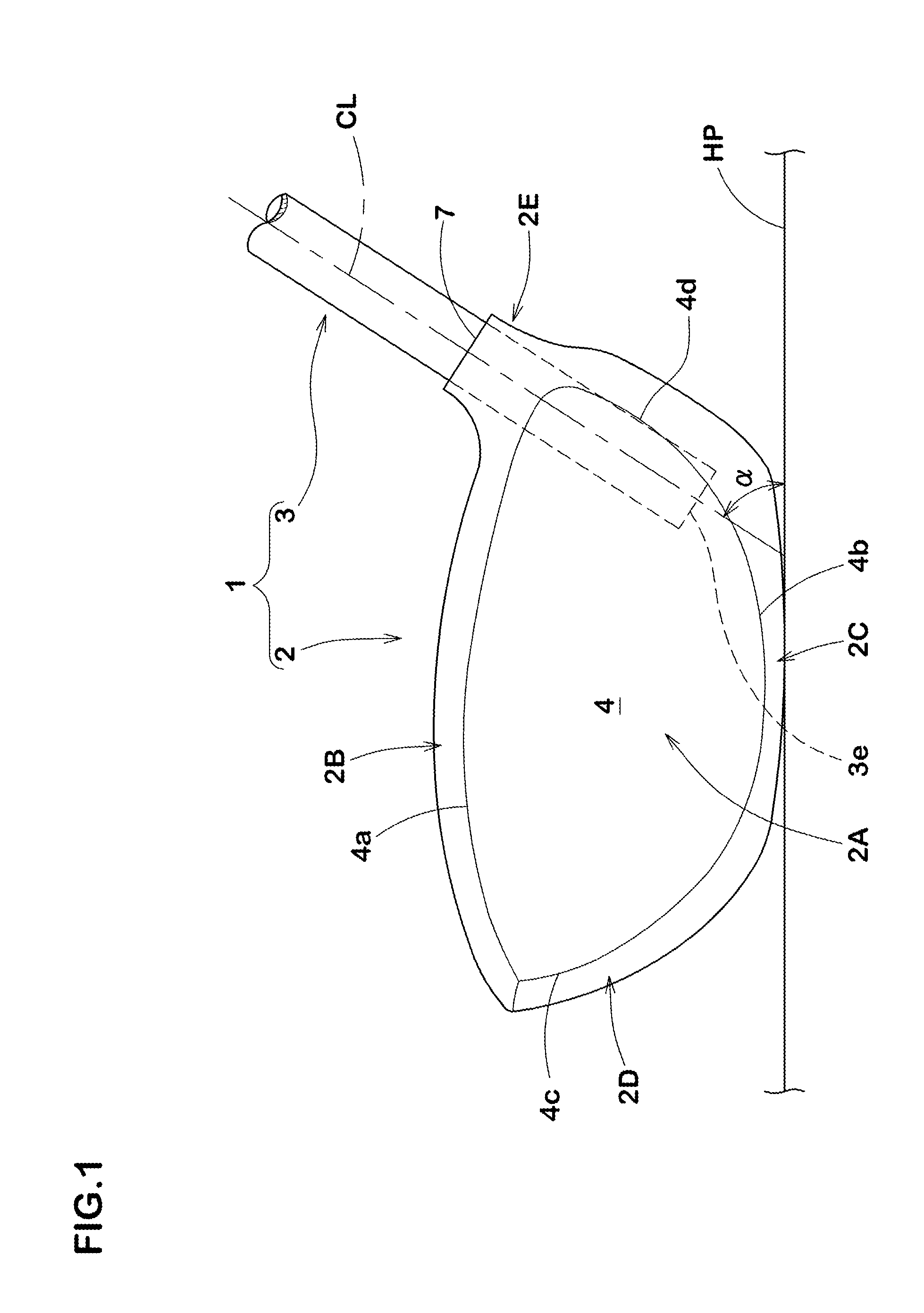

Golf club

ActiveUS20140357398A1Increase massAmount of bending be reduceGolf clubsRacket sportsEngineeringGolf club

Owner:SUMITOMO RUBBER IND LTD

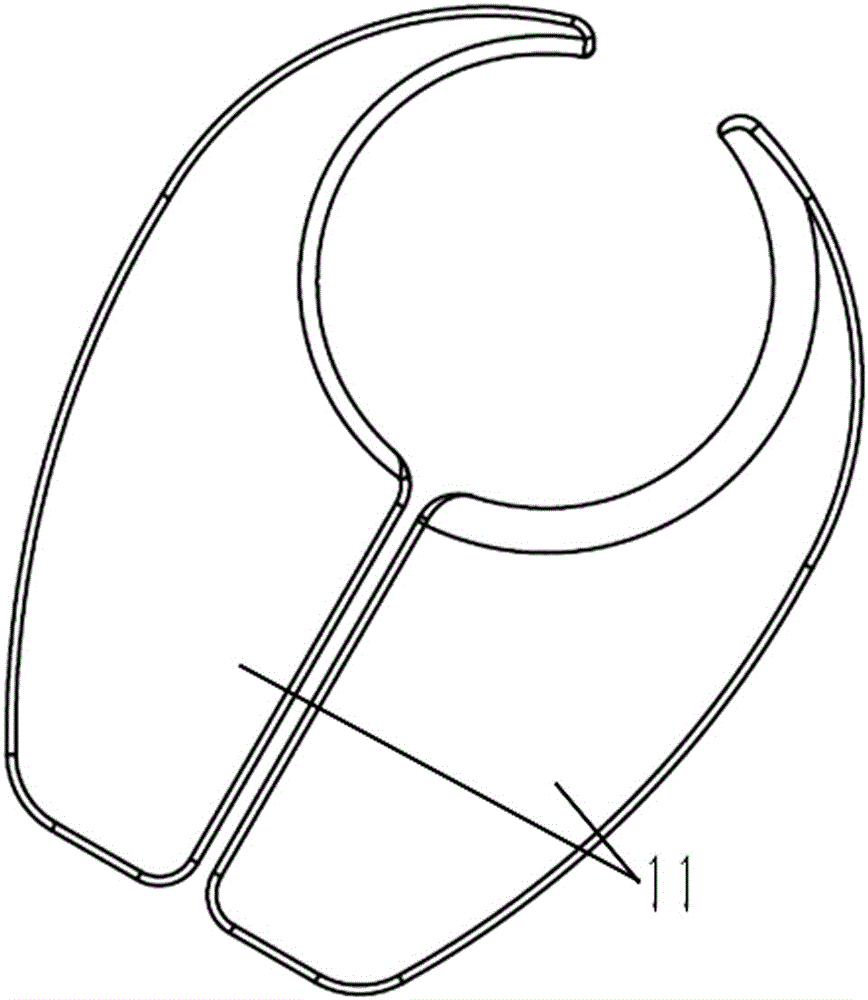

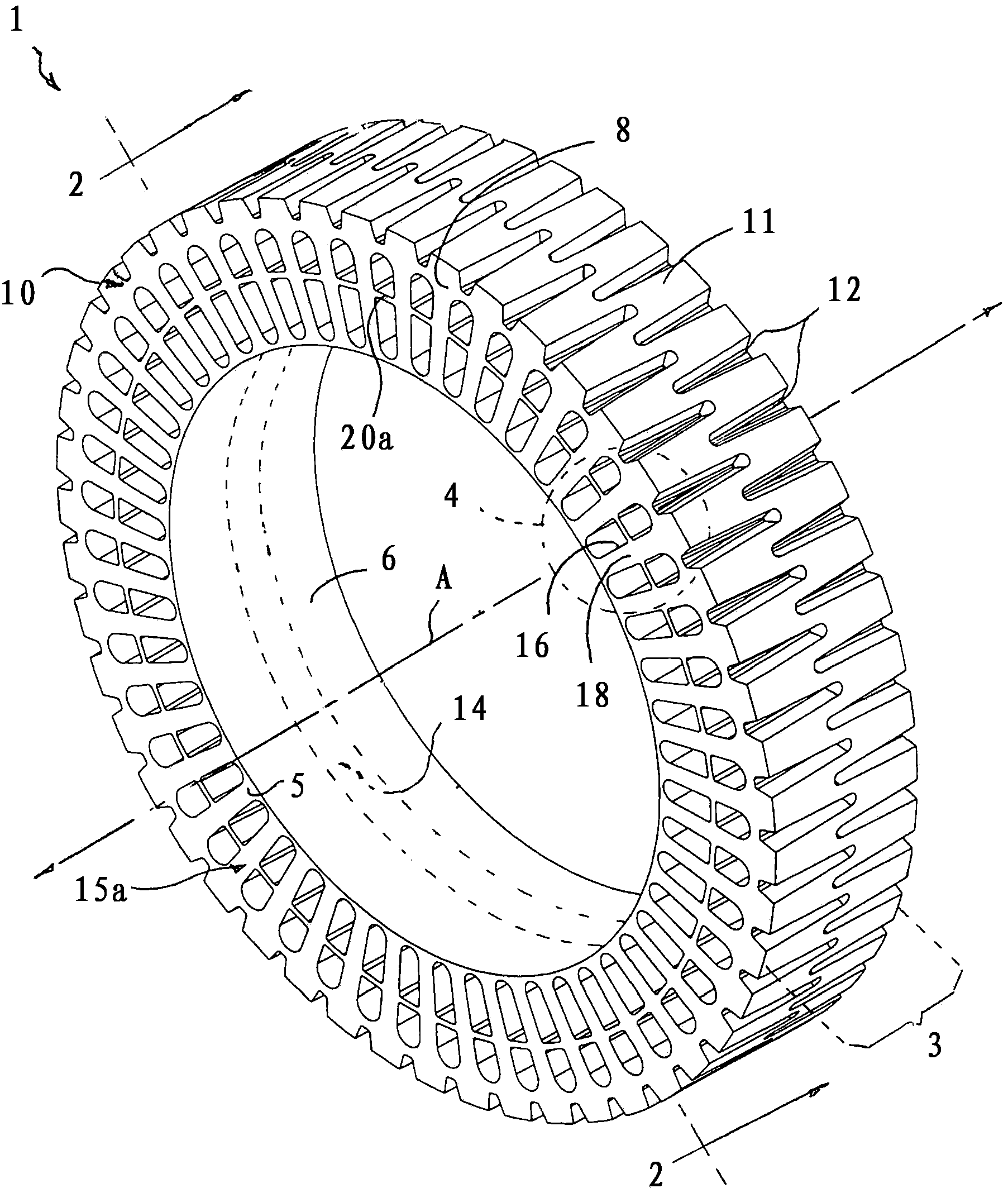

Non- pneumatic tire with annular spoke reinforcement

InactiveCN103429439AHeavy loadReduce the amount of bendingNon-inflatable tyresEngineeringMechanical engineering

Owner:CATERPILLAR INC

Spark plug with increased durability and carbon fouling resistance

ActiveUS20060055299A1Improve flammabilityEasy to igniteSpark gapsSparking plugs manufactureElectrical field strengthEngineering

A spark plug for an internal combustion engine is provided which includes a metal shell, a porcelain insulator, a center electrode, a main ground electrode, and auxiliary ground electrodes. Each of the auxiliary ground electrodes has an end face facing the insulator to define an auxiliary spark gap. The end face includes an increasing-radial distance surface which is located at a distance from a longitudinal center line of the spark plug in a radial direction thereof which increases as approaching to the metal shell. The insulator nose has a wall thickness T meeting a relation of 0.3 mm≦T≦0.7 mm. This avoids a great local increase in electrical field strength on the auxiliary ground electrode to minimize excessive discharge within the auxiliary spark gap to enhance carbon fouling resistance and durability of the spark plug.

Owner:DENSO CORP

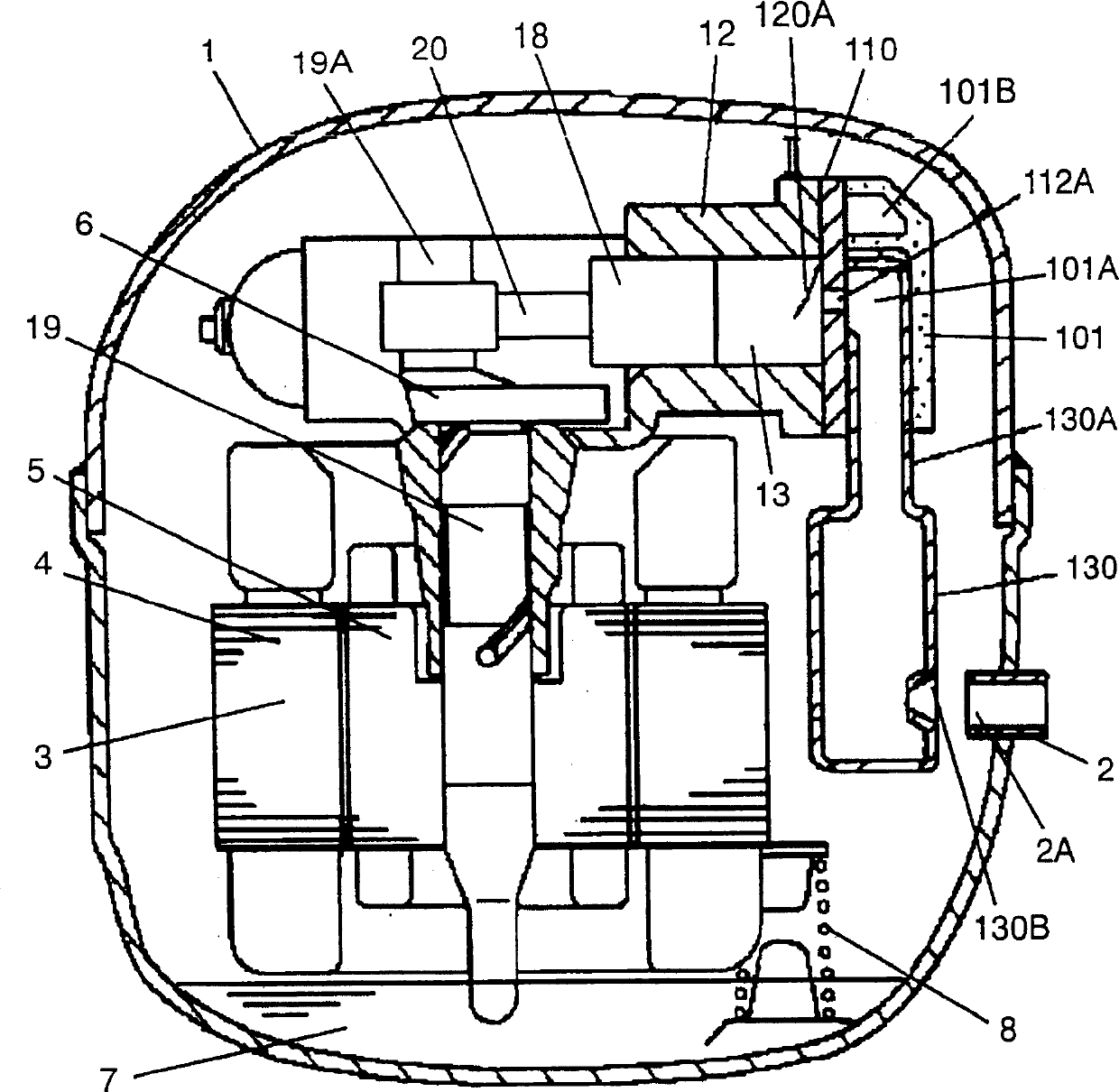

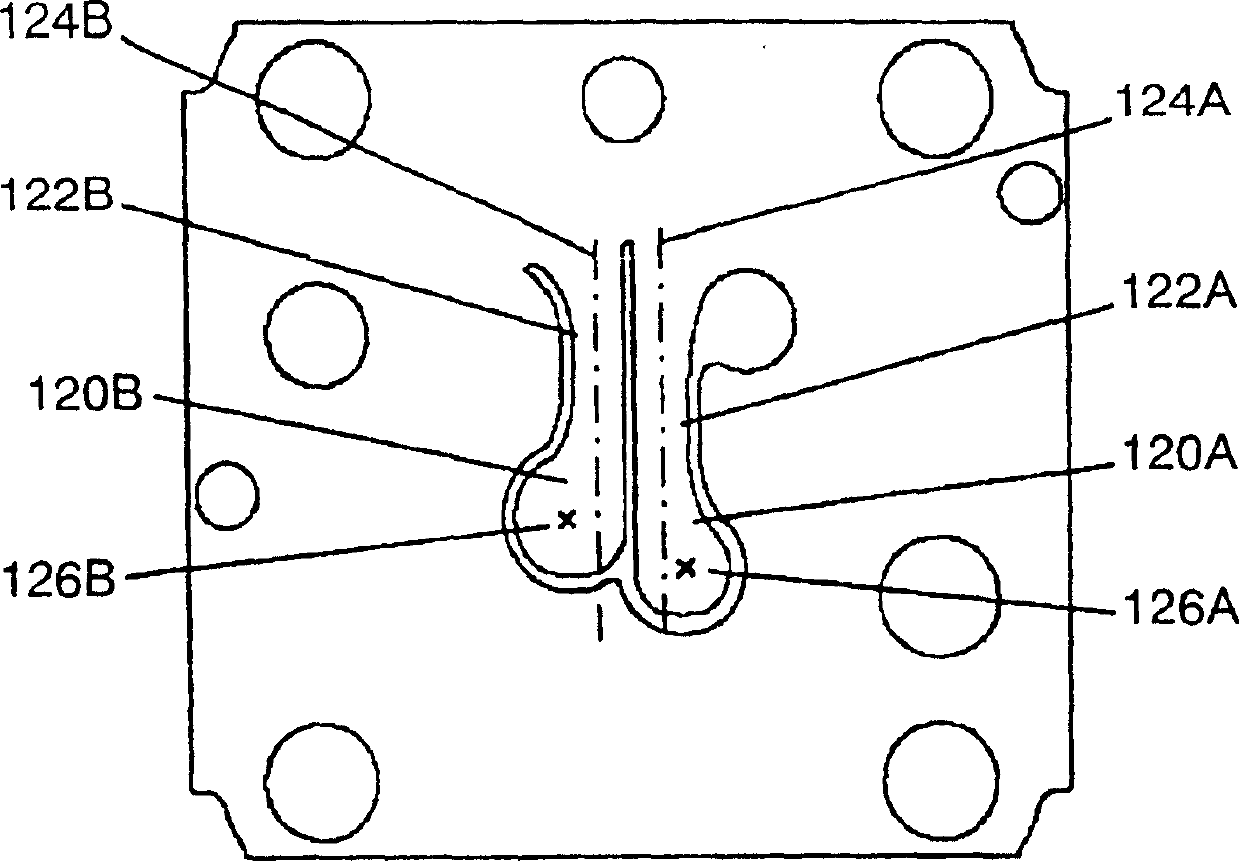

Refrigerant compressor

InactiveCN1697930AReduced shutdown delayReduce the amount of bendingPositive displacement pump componentsPositive-displacement liquid enginesEngineeringReed valve

A valve plate includes a plurality of suction holes and a plurality of suction reed valves for opening and closing them. At least two of theses suction reed valves have different natural frequencies. In this configuration, a natural frequency of one reed valve is larger. Therefore, even when an operation frequency is changed to a higher frequency, the compressor can suck a refrigerant gas into a cylinder efficiently without occurring delayed closing and reduction of a lift amount. Thus, refrigerating capacity and compression efficiency can be increased.

Owner:PANASONIC CORP

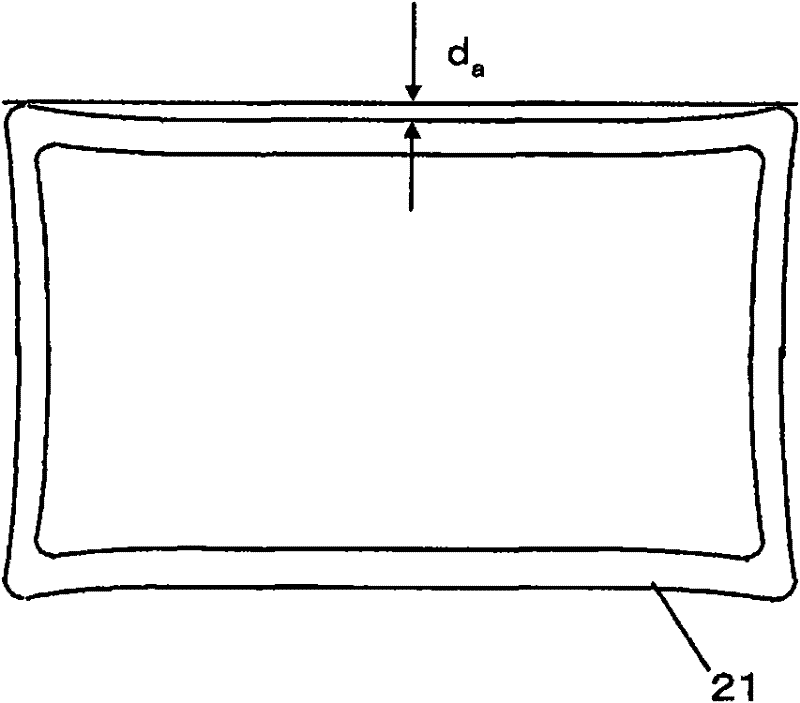

Method for breaking brittle material substrate

InactiveCN102596523AReduce vibration effectsReduce the amount of bendingFine working devicesGlass severing apparatusEngineeringUltimate tensile strength

Provided is a breaking method by which an end surface strength can be stronger. A method for breaking a brittle material substrate comprises a step for forming a scribe line on the brittle material substrate, and a breaking step for breaking along the scribe line. In the breaking step, a break roller is pressed on and applies a load to the brittle material substrate placed on a table by rolling the break roller near the scribe line along a position separate from the scribe line to one side, so as to fold at a low load and divide the substrate.

Owner:MITSUBOSHI DIAMOND IND CO LTD

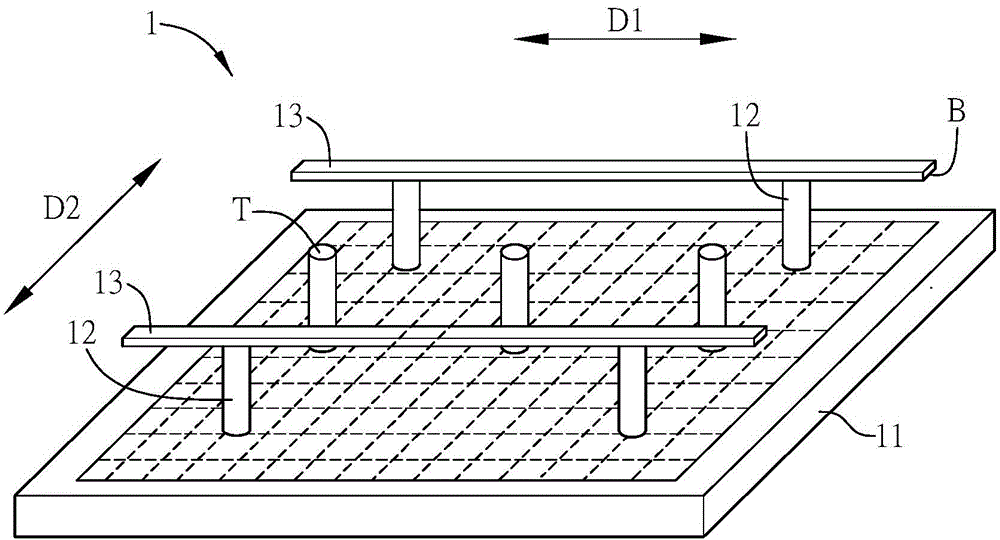

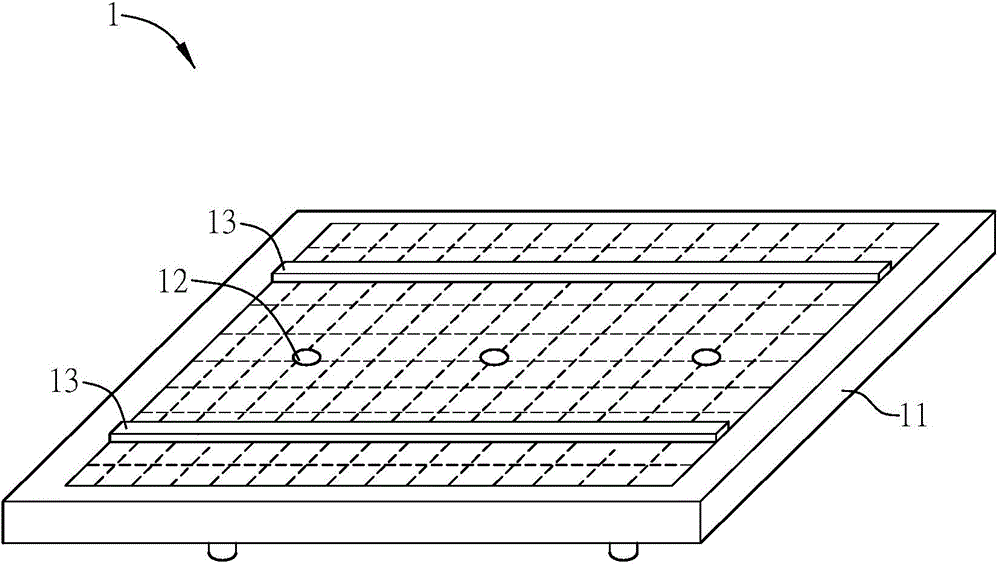

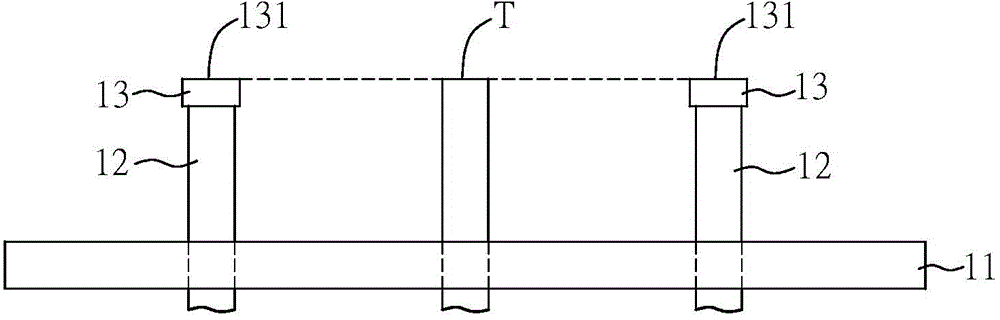

Substrate supporting device

InactiveCN105810628AReduce the amount of bendingSufficient support effectSemiconductor/solid-state device manufacturingEngineering

Owner:HANNSTAR DISPLAY NANJING +1

Apparatus for packing glass plates

InactiveCN102414092AReduce the amount of bendingAvoid damageRigid containersDamagable goods packagingEngineeringUltimate tensile strength

Owner:ASAHI GLASS CO LTD

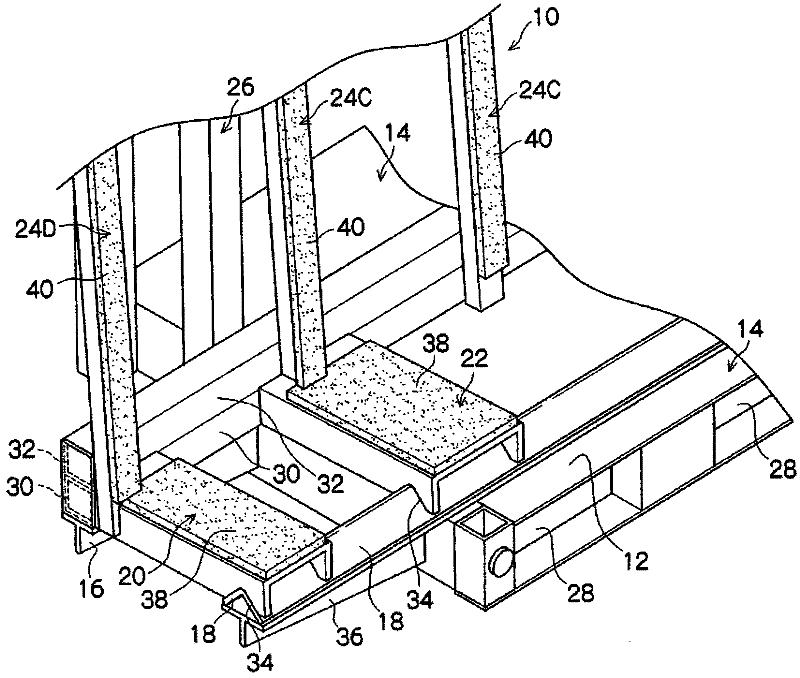

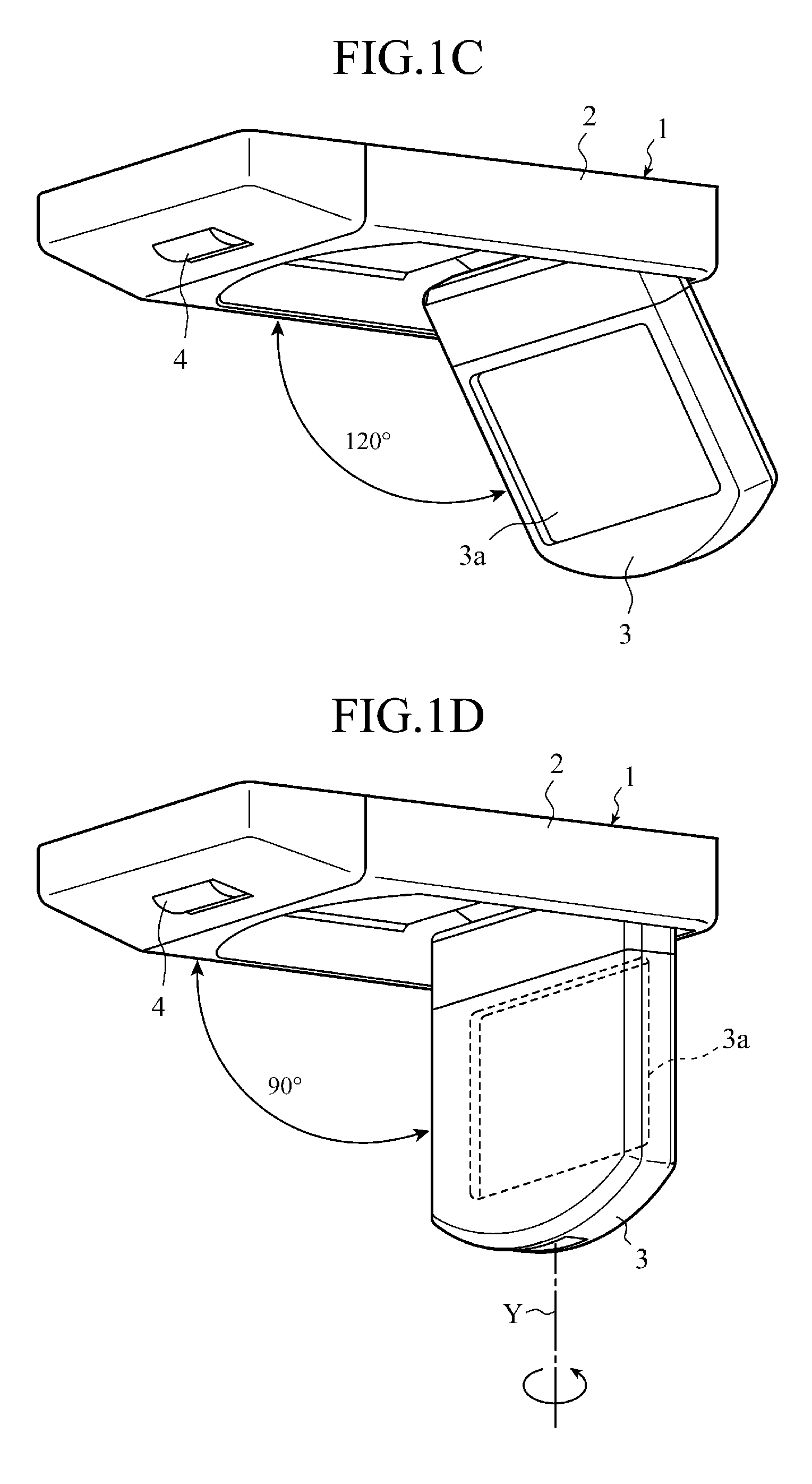

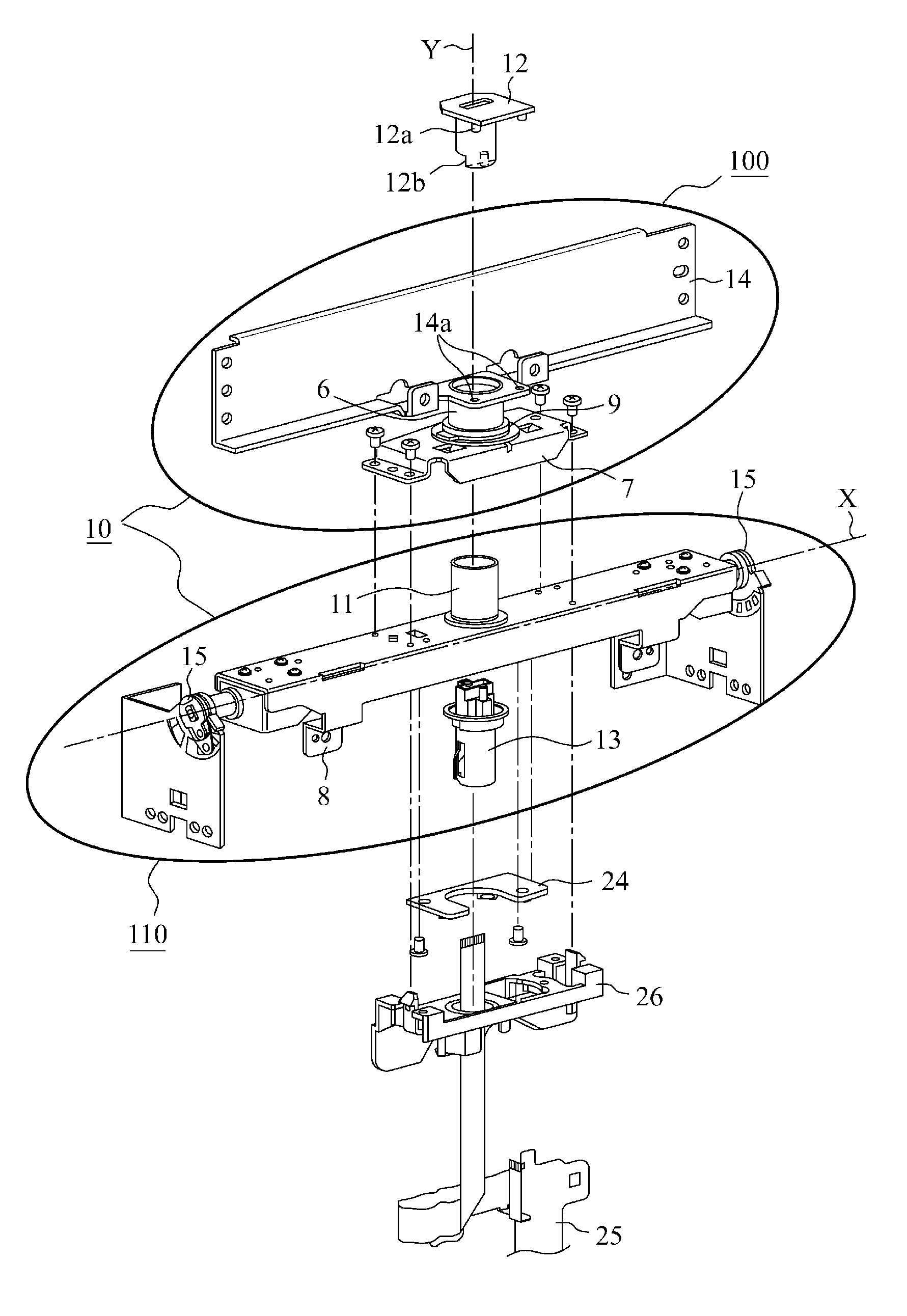

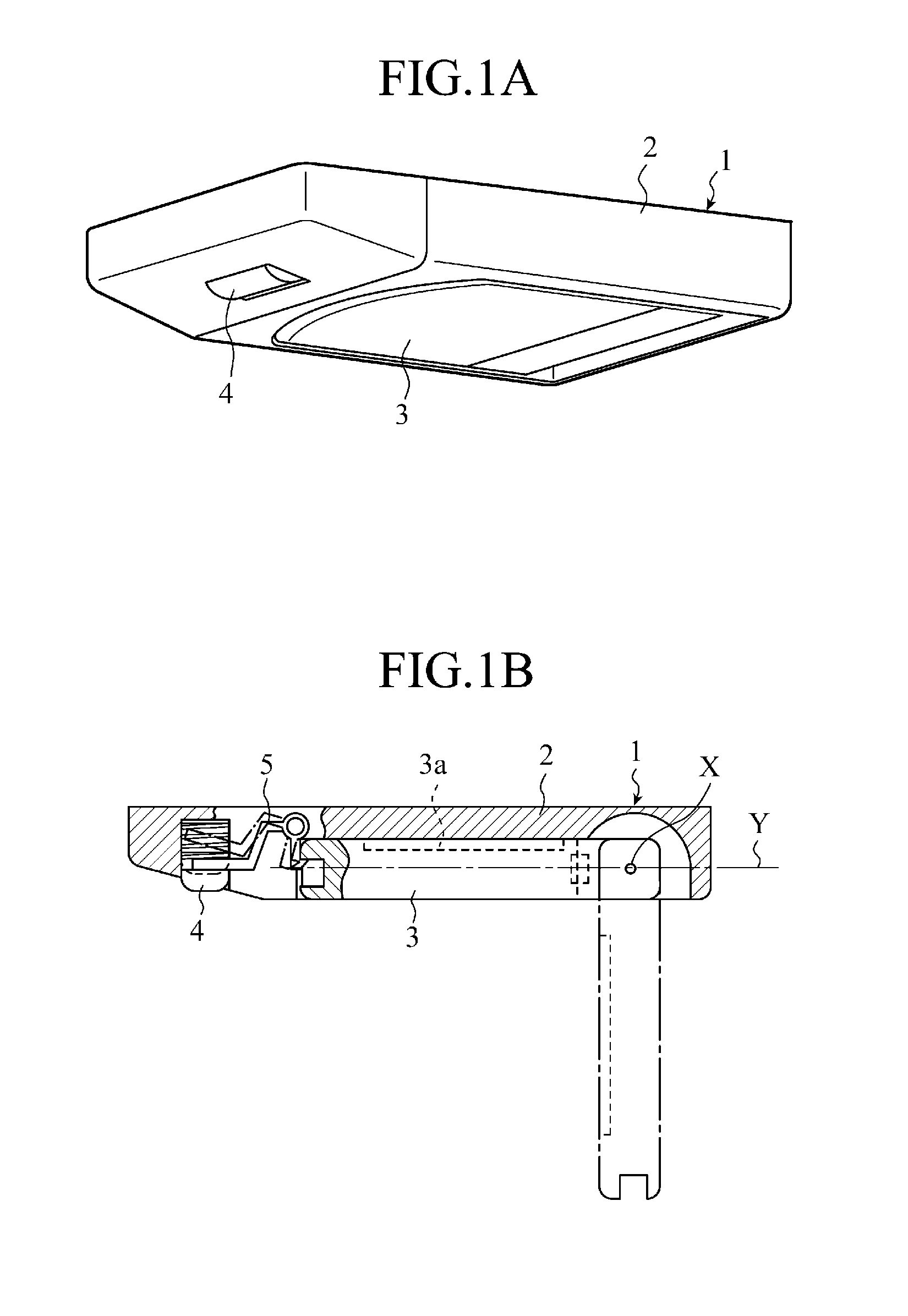

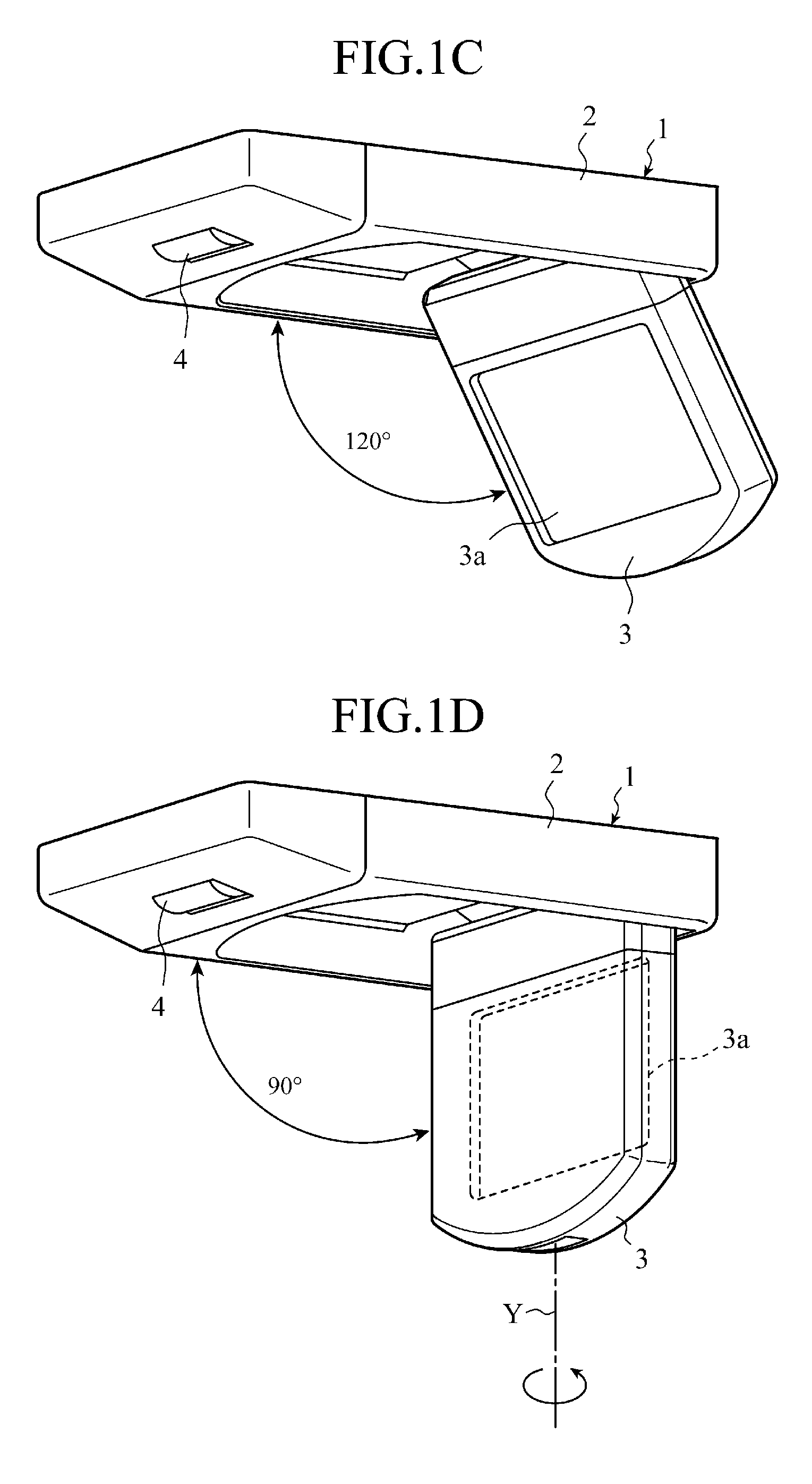

FPC fixing structure for two-axis hinge mechanism

InactiveUS20110146029A1Reduce amount of flexureReduce stressDigital data processing detailsWing accessoriesStructural engineering

Owner:MITSUBISHI ELECTRIC CORP

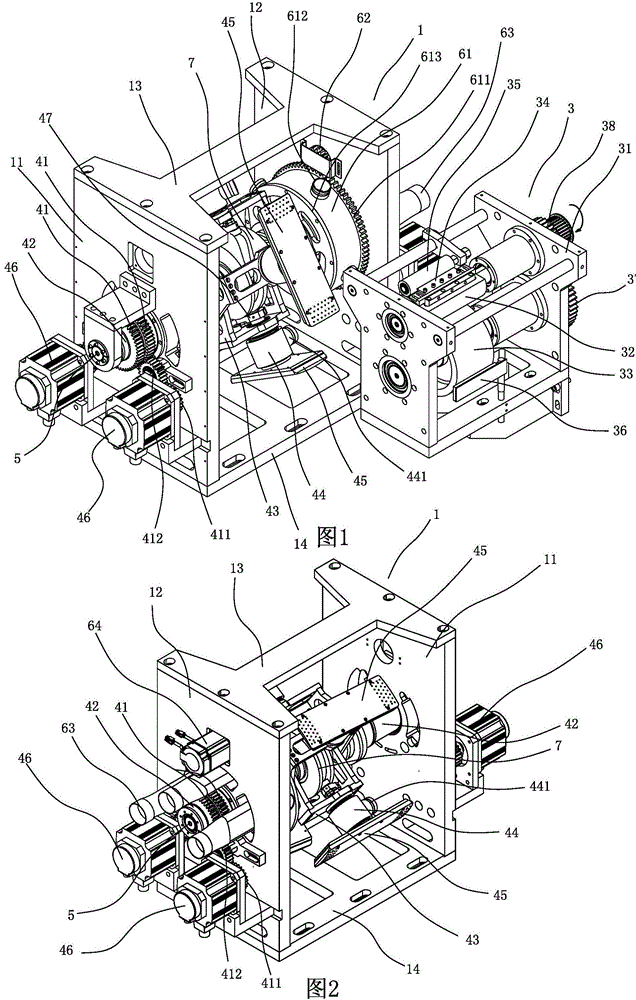

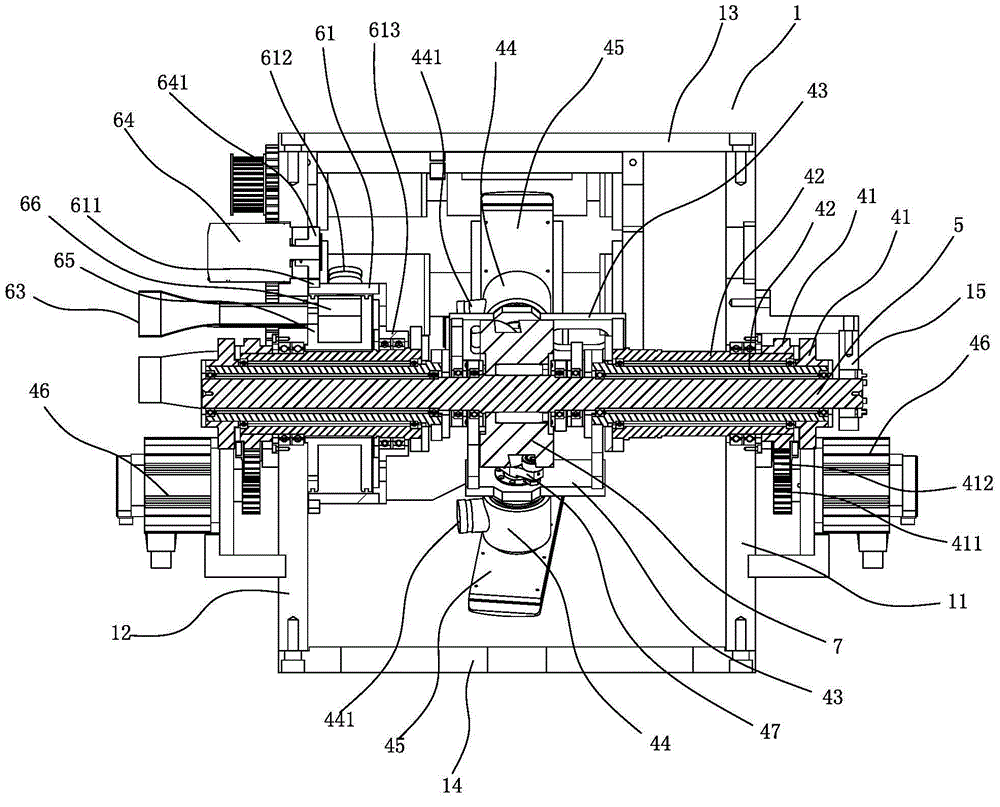

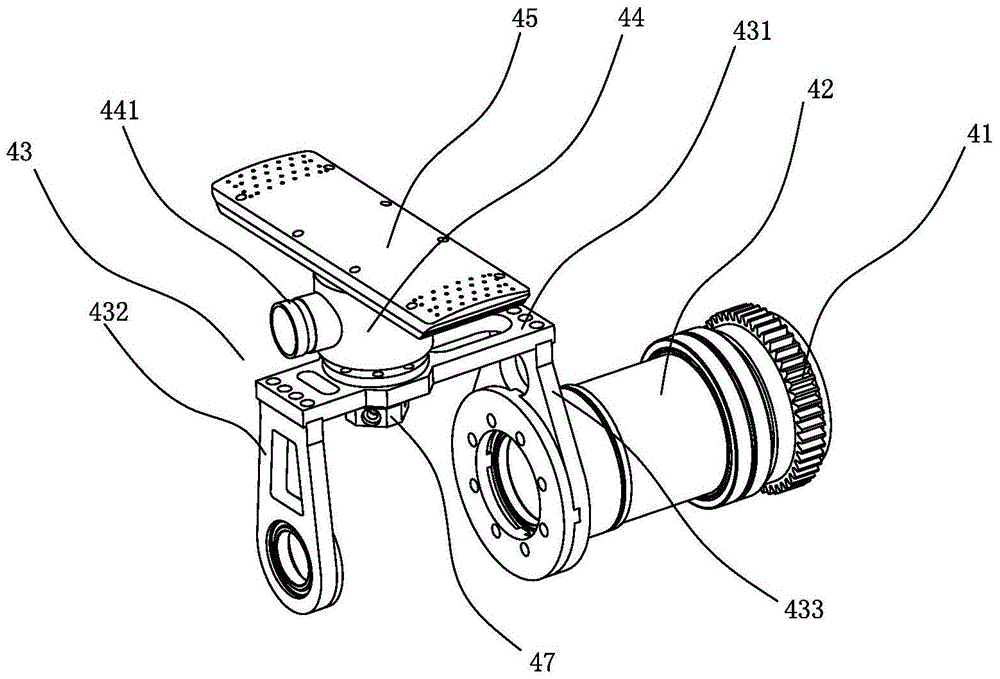

Slitting transposition variable speed conveying device and method

ActiveCN104002328ASlicing to achieveRealize variable speed conveyingMetal working apparatusEngineeringCam

The invention provides a slitting transposition variable speed conveying device and method. The device is used for conveying a flexible material at a variable speed and achieving slitting and transposition in the conveying process. The device comprises a machine frame, a dotted line slitting mechanism, a supporting shaft, a plurality of rotation sleeves, a plurality of first servo motors, rotation frames, negative-pressure absorbing blocks, a cylindrical cam, a swing arm and a rotation negative-pressure mechanism, wherein the dotted line slitting mechanism is used for machining easily-broken dotted lines on the flexible material, the supporting shaft is fixedly arranged on the machine frame, the rotation sleeves are arranged on the supporting shaft in a rotating and sleeved mode, the first servo motors are arranged on the machine frame to drive the rotation sleeves to rotate at a variable speed, the rotation frames are arranged on all the rotation sleeves, the negative-pressure absorbing blocks are arranged on the rotation frames in a rotating mode through a pivoting shaft, the cylindrical cam is arranged on the supporting shaft, the swing arm is connected between the cylindrical cam and the pivoting shaft and used for driving the negative-pressure absorbing blocks to carry out transposition, and the rotation negative-pressure mechanism is respectively communicated with all the negative-pressure absorbing blocks through hoses. The dotted line slitting mechanism is arranged on the input side of the flexible material. The device has the advantages of being simple in structure, accurate in movement, high in adaptability and the like.

Owner:JINJIANG HAINA MACHINERY

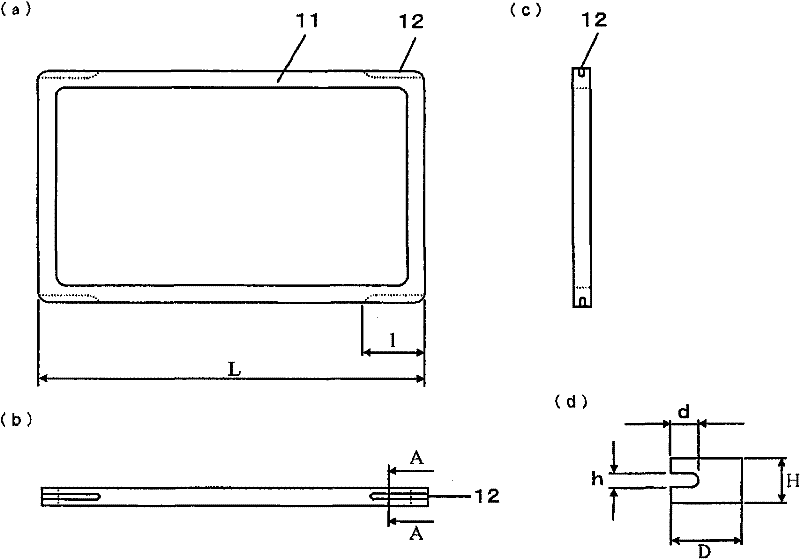

Dustproof film assembly and framework thereof

InactiveCN102053483AReduce the amount of bendingControl bend shapeSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentMechanical engineeringAdverse conditions

The invention provides a dustproof film assembly and a framework thereof.Due to the dustproof film assembly framework adopted by the dustproof film assembly, adverse conditions caused by tension difference and the small bending thereof due to the tension force of the dustproof film are avoided.According to the invention, the dustproof film assembly framework extending from both ends toward the middle point thereof is arranged at the outer sides of at least one pair of opposite edges of the frame body, which does not pass through the recess portion.The dustproof film assembly is arranged on the dustproof film assembly framework, wherein the recess portion is preferably arranged on a longer pair of sides or on all sides.

Owner:SHIN ETSU CHEM IND CO LTD

Reflecting mirror axis system supporting and clamping device operated at low temperature

PendingCN109946812AReduce the amount of bendingImprove optical surface accuracyMountingsAdhesiveEngineering

The invention discloses a reflecting mirror axis system supporting and clamping device operated at low temperature. Main supporting of a mirror body and axis systems is performed through a U-shaped frame, and symmetric deformation at low temperature is realized through mounting of a cross beam at the top of the U-shaped frame; rotation of a reflecting mirror is realized through mounting of the axis systems in inner holes in the two sides of the U-shaped frame; the two axis systems are respectively designed to be fixed and moved; insert blocks with double-layer flexible structures are bonded inthe holes in the two sides of the reflecting mirror through an adhesive and are connected with the two axis systems through screws; and pins are arranged between the insert blocks and the mirror body, so that the connection firmness is improved. The device can be applied to clamping and supporting of the reflecting mirror requiring still keeping excellent optical surface type and high performanceat extremely low temperature after going through vibration and impact environment; and the device is applicable to outboard tracking and pointing mechanisms for satellite-carried optical communication and scanning pointing mechanism reflecting mirrors for deep space detection. The device is compact in structure, light in mass, wide in applicable temperature range and good in reflecting mirror surface type maintenance.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

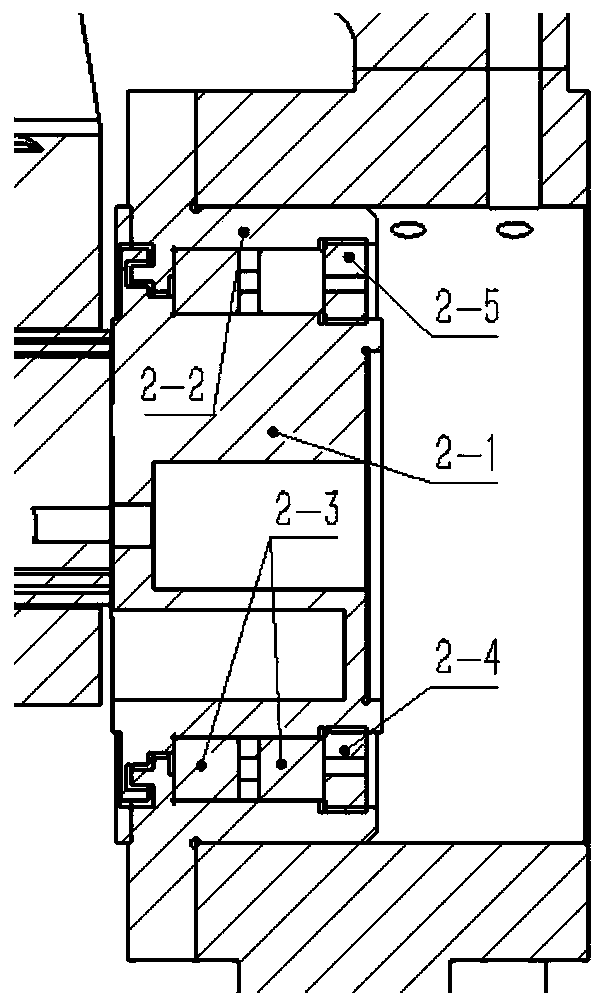

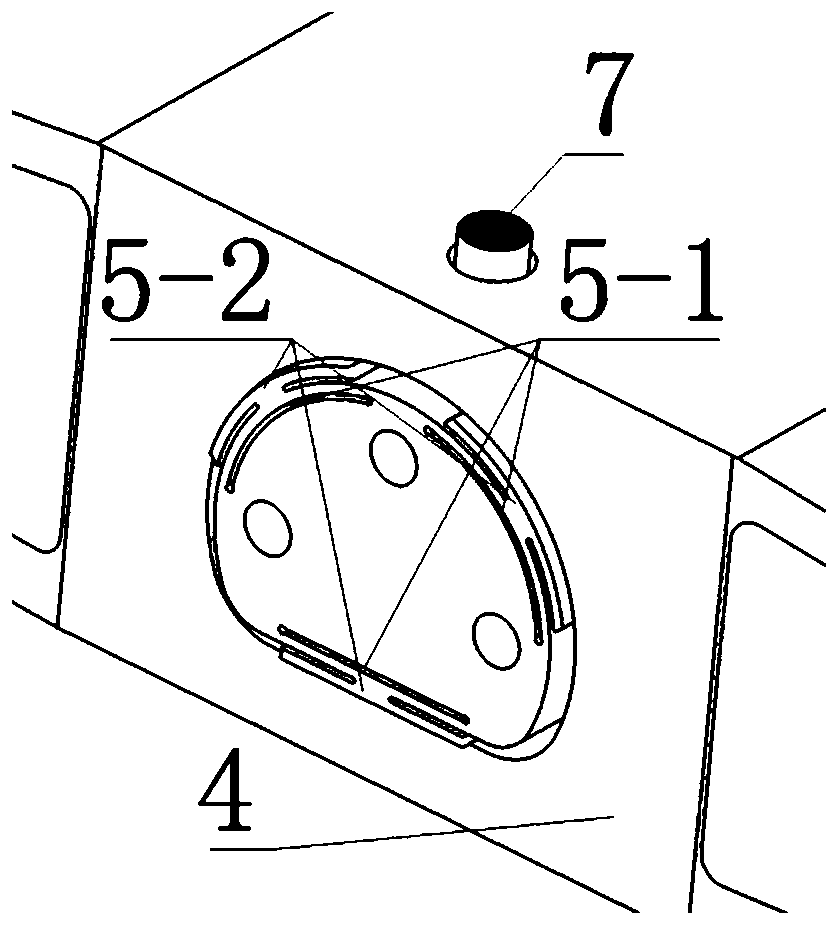

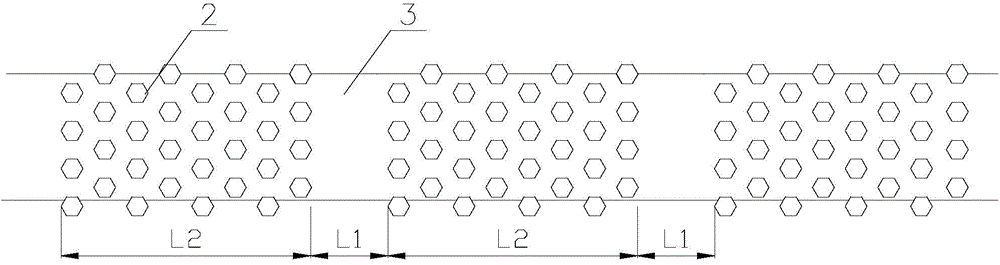

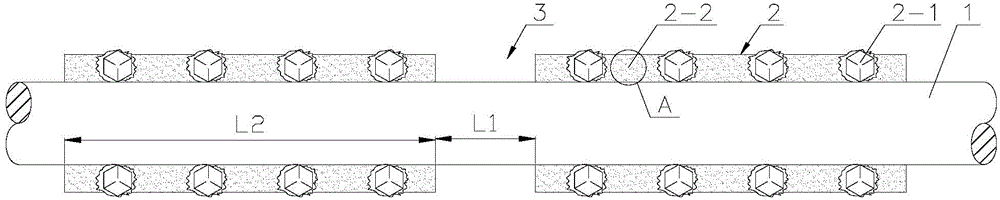

Heterogeneous fixed abrasive wire saw for multi-line cutting

ActiveCN104647618AGuaranteed lengthReduce crackingFine working devicesStress concentrationWire cutting

The invention relates to a heterogeneous fixed abrasive wire saw which is applicable to machining hard materials such as crystal silicon, silicon carbide, crystal and sapphire by a multi-line cutting method. According to the wire saw, a metal wire with a circular or similarly circular section is used as a generating line, a stress release clearance is reasonably reserved between abrasive cutting fixed layers, and stress concentration of the abrasive cutting fixed layers in the cutting process is reduced. By relieving stress concentration in the abrasive cutting fixed layers, the risk of cracking of the abrasive cutting fixed layers and adjoint abrasive cutting particle detachment in existing wire saw technology is remarkably reduced, and the breakage rate of the fixed abrasive wire saw can be reduced.

Owner:FUNDANT JIANGSU ADVANCED MATERIALS CO LTD

Fascia gun

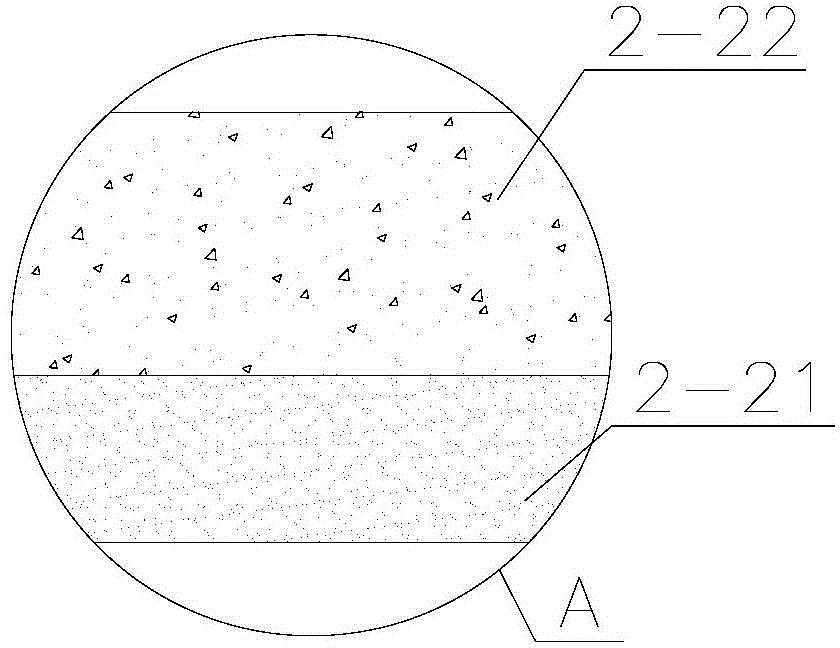

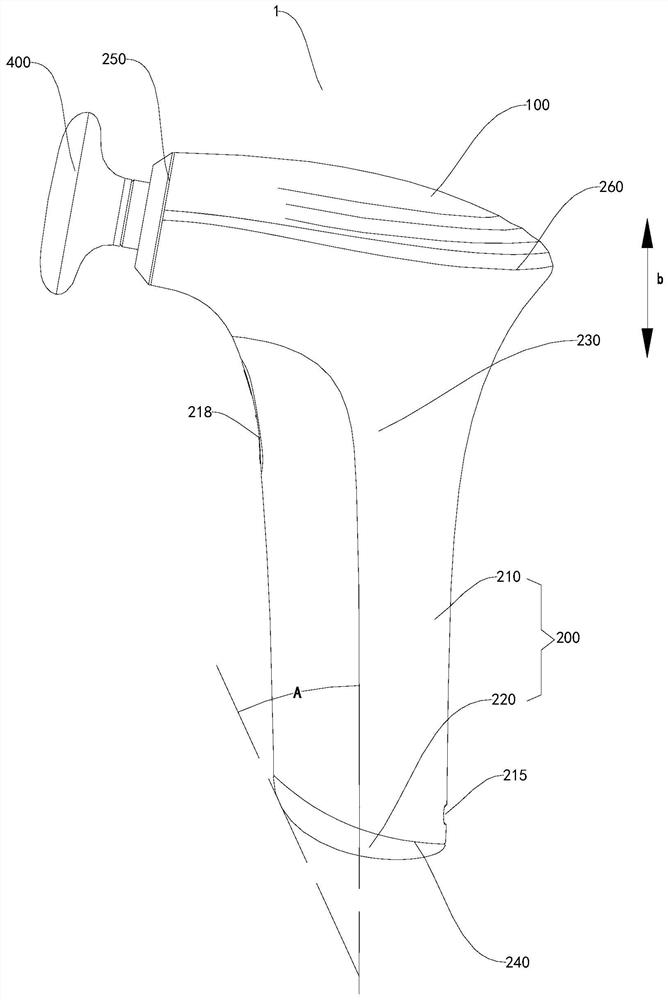

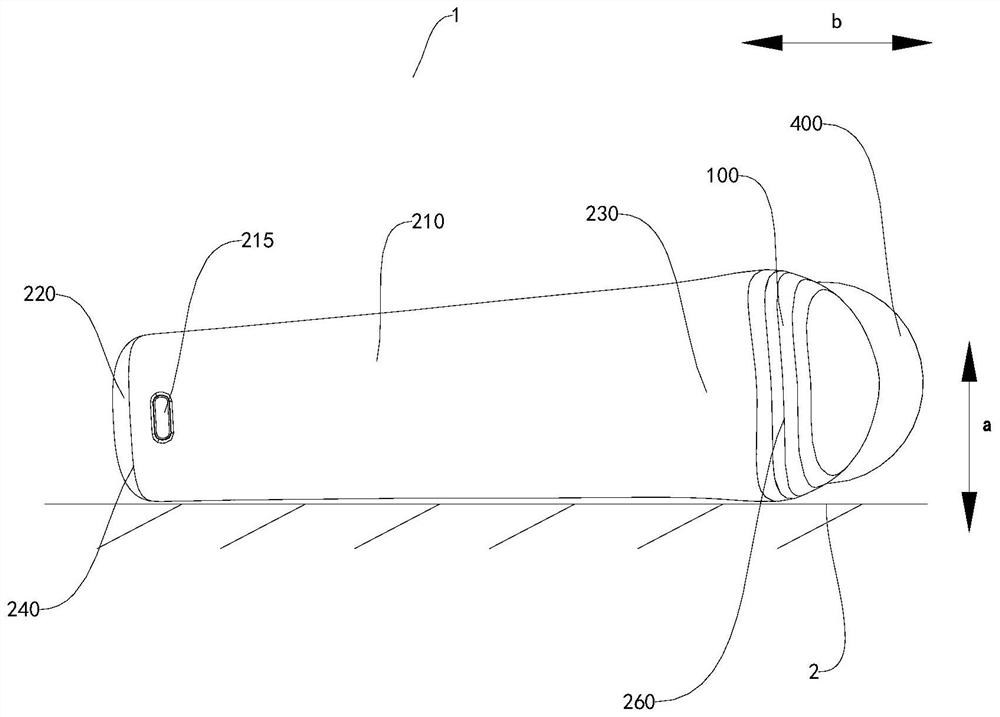

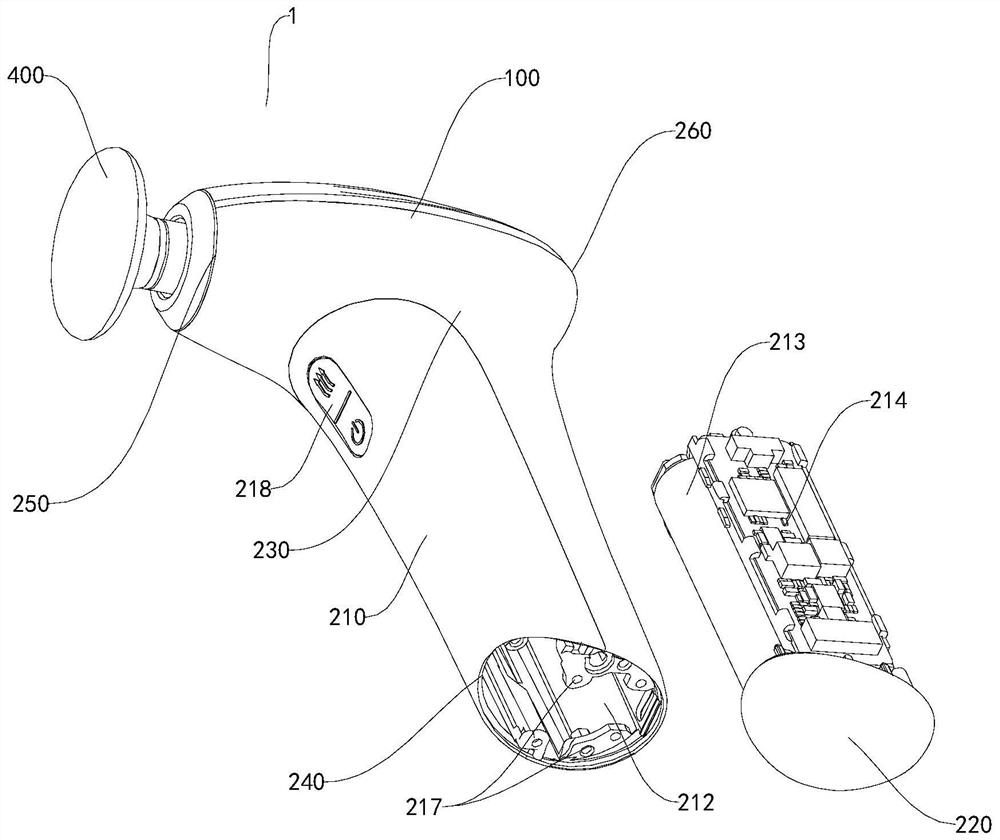

InactiveCN112089615AReduce the amount of bendingReduce fatigueVibration massageTherapeutic coolingHuman bodyPhysical medicine and rehabilitation

The invention discloses a fascia gun. The fascia gun comprises a machine body, a massage head, a handle and a heat exchange part, wherein the machine body comprises a head end and a tail end which areopposite; the massage head is arranged close to the head end and used for exerting a tapping effect on a human body; the handle comprises a handle part and a cover part; the handle part is used for being held by a hand and comprises a first end and a second end which are opposite; the first end is connected with the machine body, the head end extends out relative to the edge of the handle, the cover part is installed at the second end, and in the direction from the head end to the tail end, the end face of the cover part gradually extends in the direction away from the machine body; and the heat exchange part is arranged in the handle and is close to the second end, and the heat exchange part exchanges heat through the cover part. According to the fascia gun provided by the embodiment ofthe invention, the hot compress effect and the holding experience can be both taken into consideration, and tiredness does not occur after long-time holding during long-time hot compress.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

FPC fixing structure for two-axis hinge mechanism

InactiveUS8434198B2Reduce stressAvoid damageDigital data processing detailsWing accessoriesStructural engineeringEngineering

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com