Reflecting mirror axis system supporting and clamping device operated at low temperature

A clamping device and mirror technology, applied in installation, optics, instruments, etc., can solve problems such as inability to effectively solve problems, and achieve the effects of improving optical surface accuracy, improving surface accuracy, and reducing thermal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

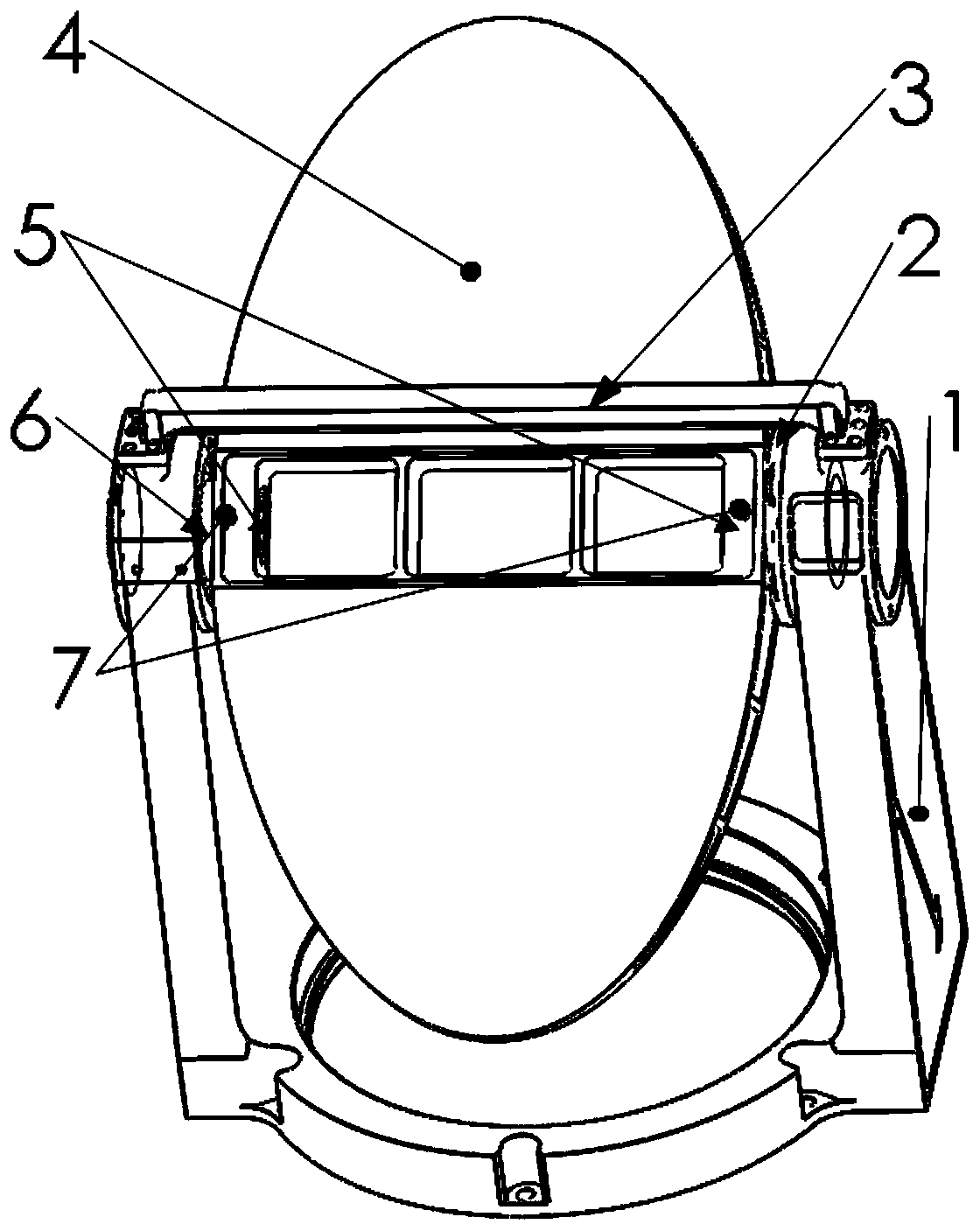

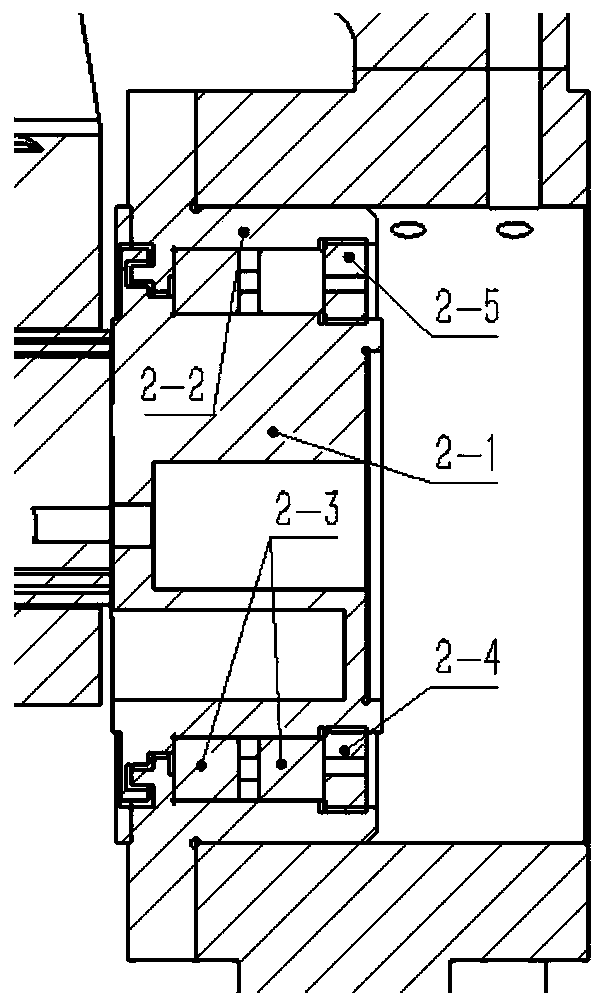

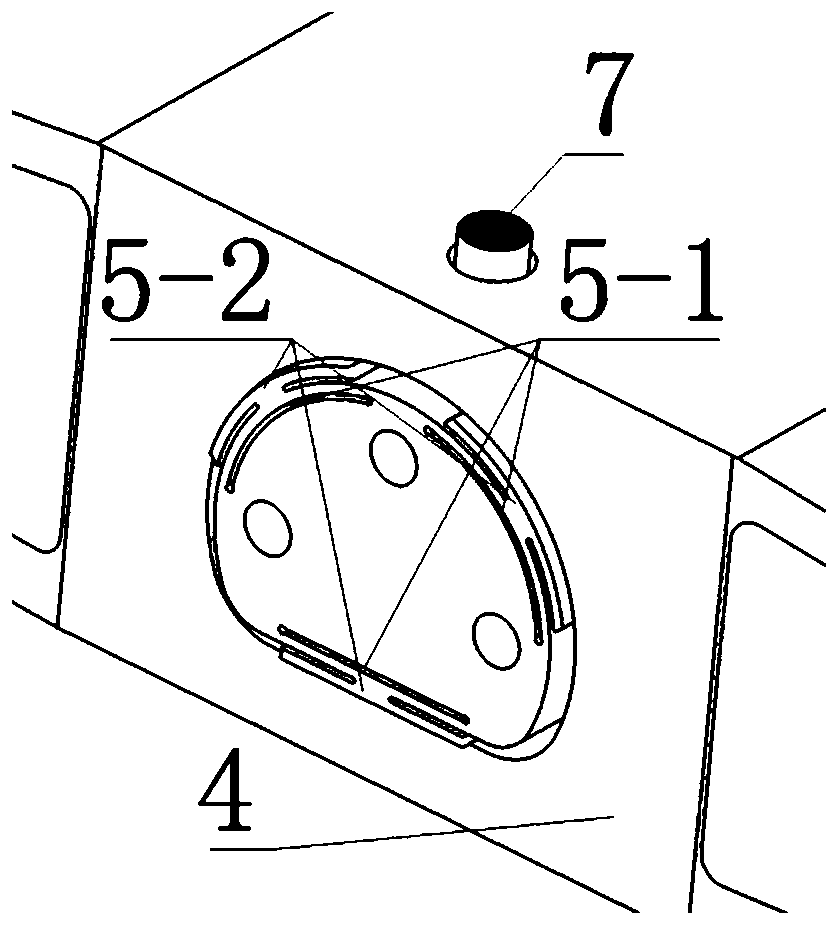

[0043] The following is based on Figure 1 to Figure 4 A preferred embodiment of the present invention is given to illustrate the structural features and implementation methods of the present invention, but not to limit the scope of the present invention.

[0044] In this embodiment, the mirror shaft support and clamping device used at low temperature is applied to the pre-pointing mechanism of an optical instrument for surface detection of a planet that lacks resources and has no active temperature control at all. The total angular range of mirror rotation is 110°, and the beam diameter is 100mm. The working temperature is -80°C, the maximum overload acceleration reaches 30 gravitational accelerations during launch and landing of the aircraft, the root mean square acceleration of random vibration is 23g, and the impact reaches 1800g. The device specifically includes the following parts: U-shaped frame 1 , fixed support shaft system 2 , beam 3 , reflector 4 , mirror body inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com