Patents

Literature

692results about How to "Guaranteed length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

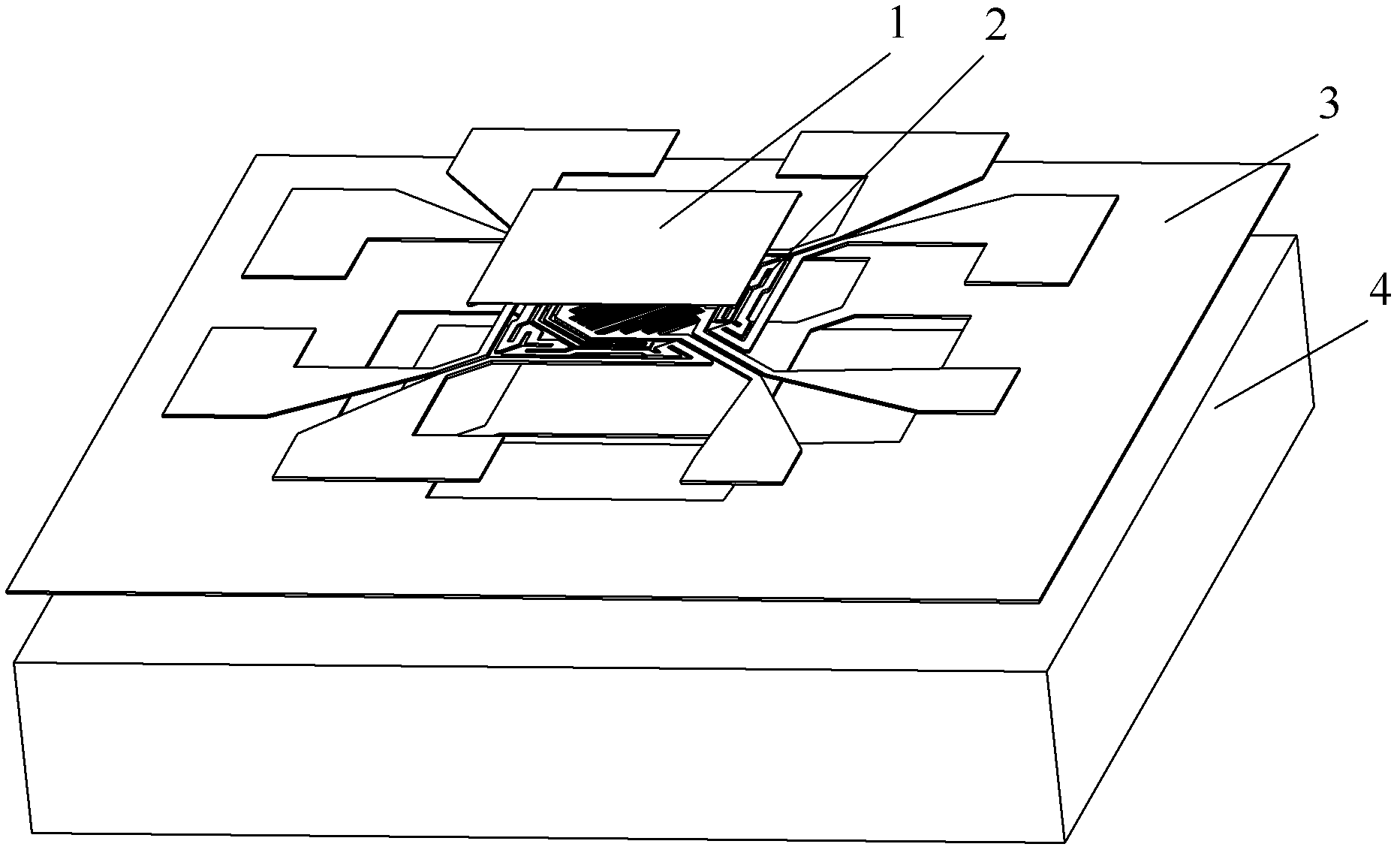

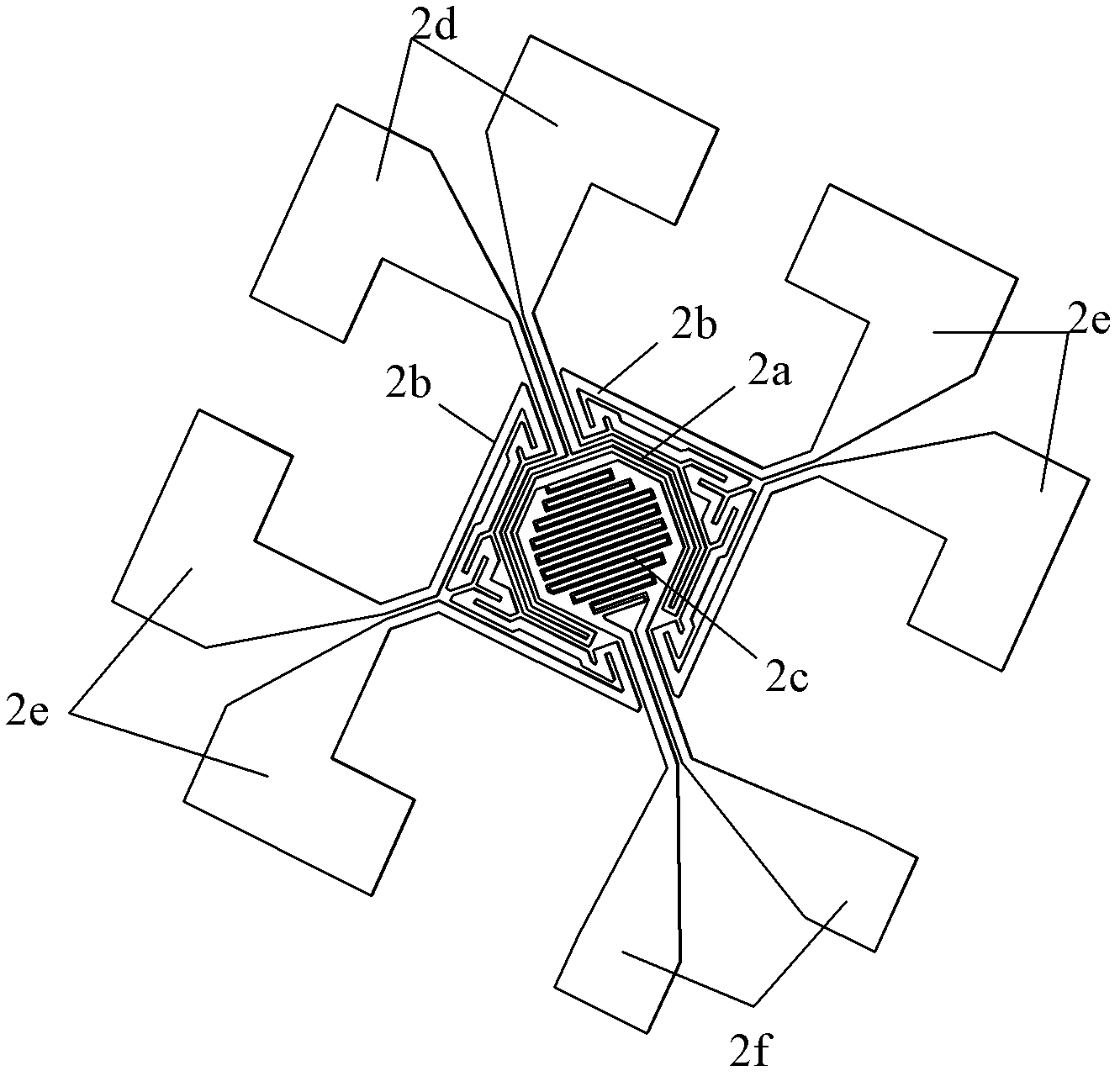

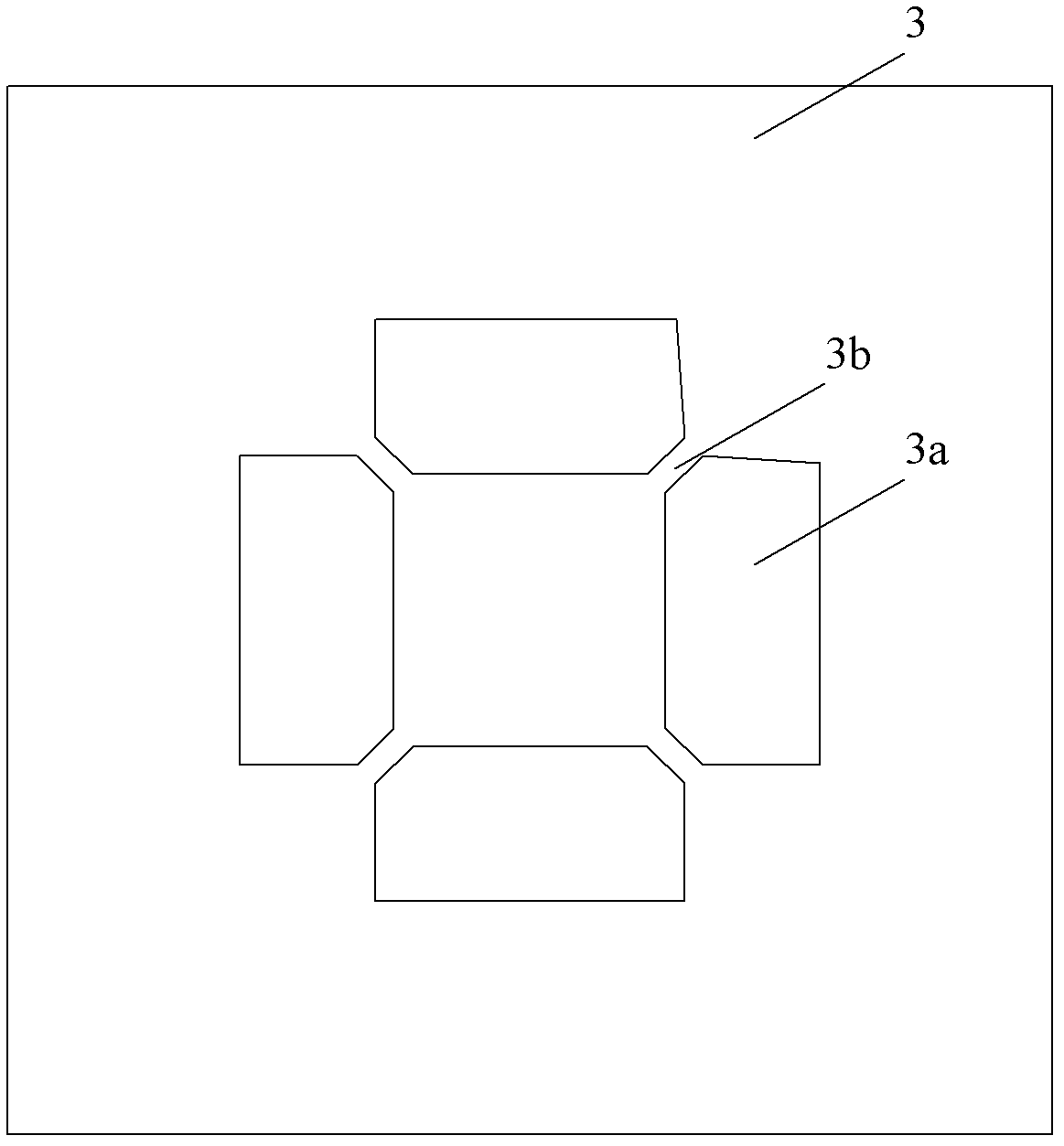

Gas sensor and manufacturing technique thereof

InactiveCN102426176ADecrease the resistance value to measure the change in resistanceReduce volumeDecorative surface effectsMaterial analysis by electric/magnetic meansTin dioxideHeat transmission

The invention discloses a gas sensor and a manufacturing technique of the gas sensor; the gas sensor comprises a silicon substrate, a silicon dioxide heat insulation stop layer, an interdigital signal electrode, a temperature measurement electrode and a heating electrode, wherein the silicon substrate is provided with a structure of a through hole; the upper surface of the silicon substrate comprises a silicon dioxide layer arranged on the top of the through hole; and the silicon dioxide layer is processed into a cantilever structure by a surface technique. The upper surface of the silicon dioxide layer is provided with an electrode group formed by the interdigital signal electrode, the temperature measurement electrode and the heating electrode, and the upper surface of the electrode group is provided with a tin dioxide layer. The technique disclosed by the invention leads the heating electrode, the interdigital signal electrode and the temperature measurement electrode to be manufactured in the same layer, so that the manufacturing complexity is reduced, and the yield is reduced; and the silicon dioxide layer of the sensor is corroded so as to form the cantilever structure, and a heat transmission channel is reduced, so that the power consumption of the sensor is lower.

Owner:NANJING UNIV OF TECH

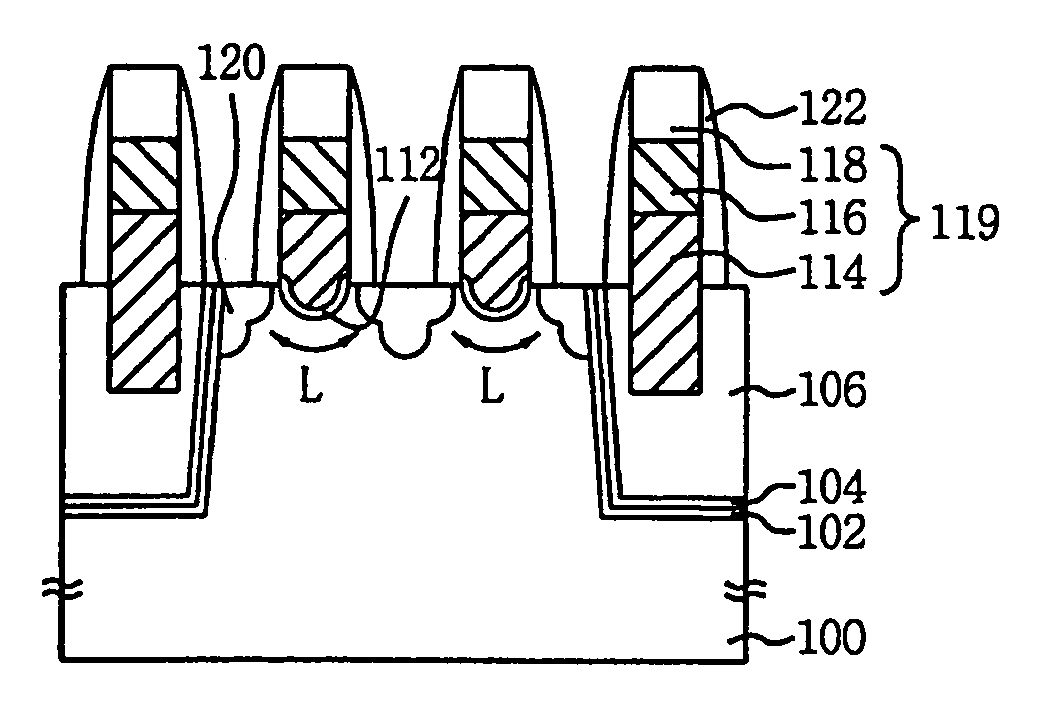

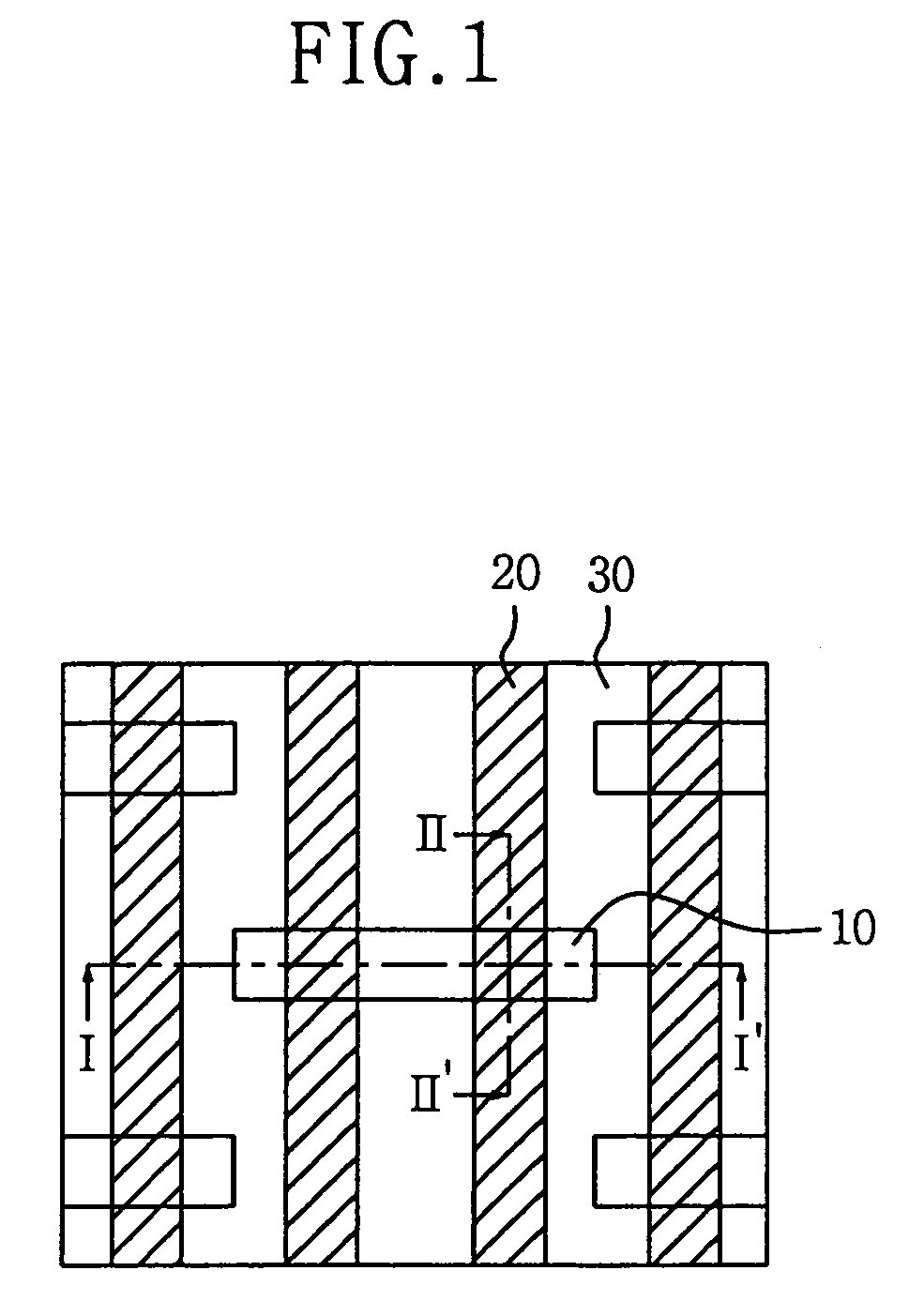

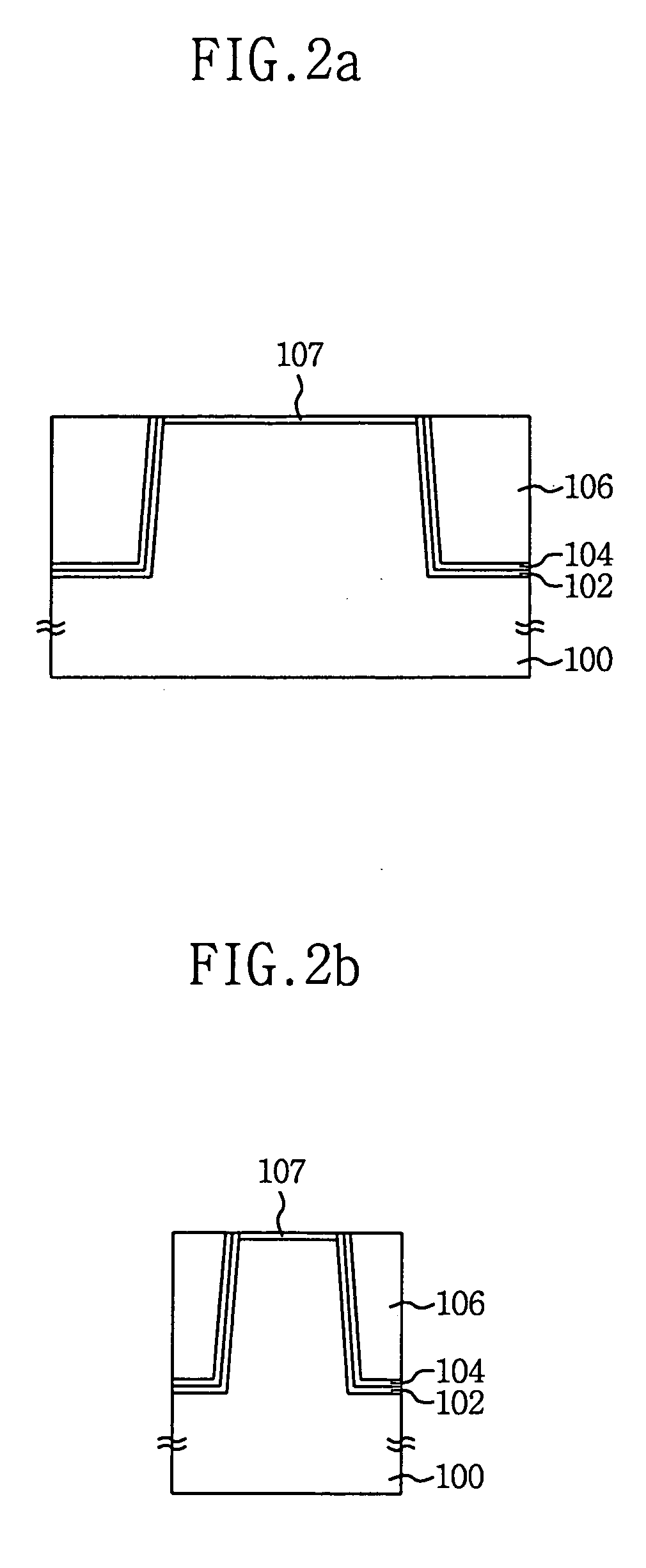

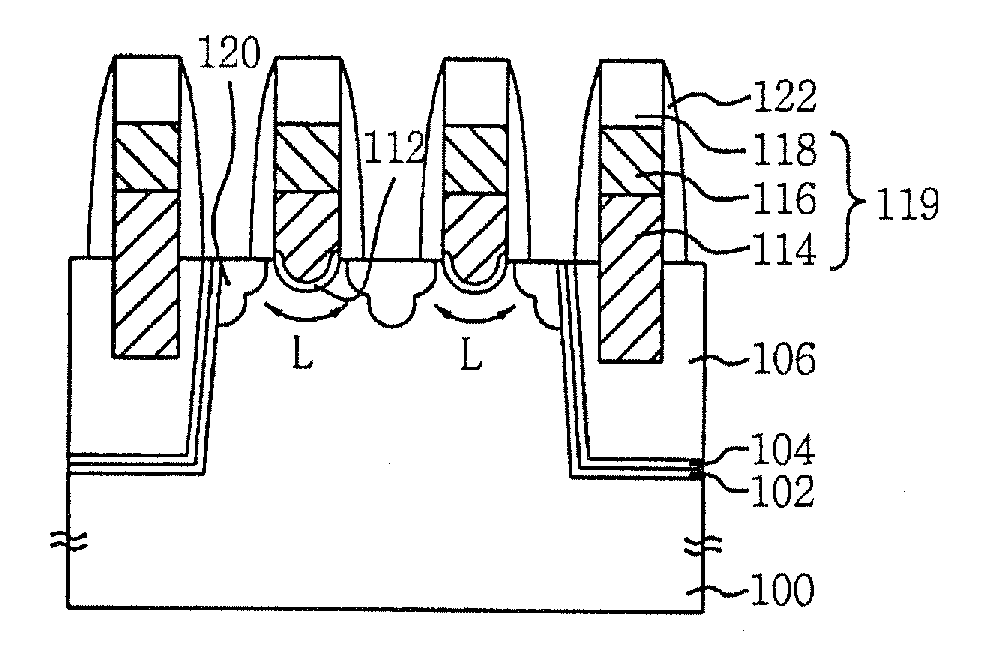

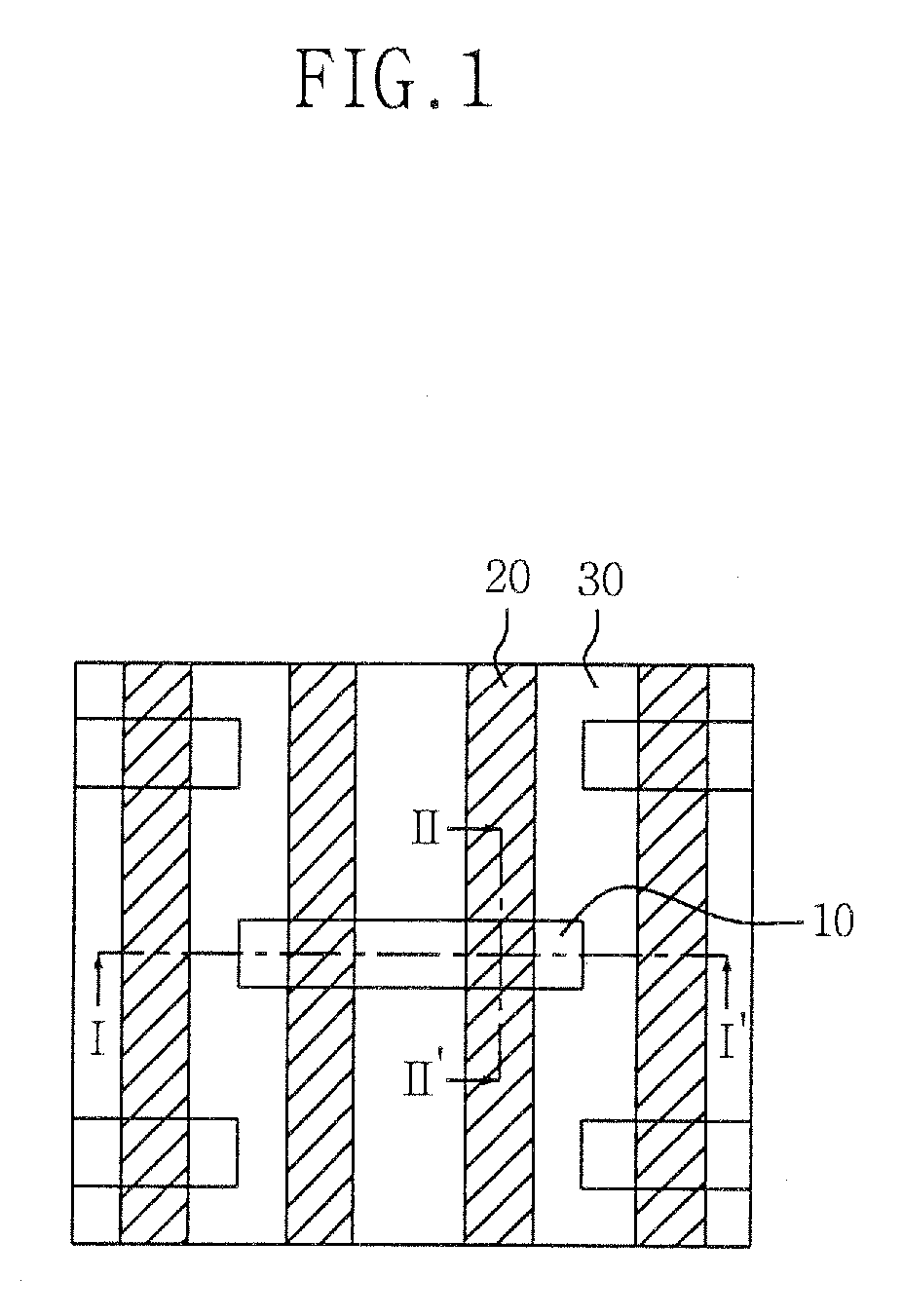

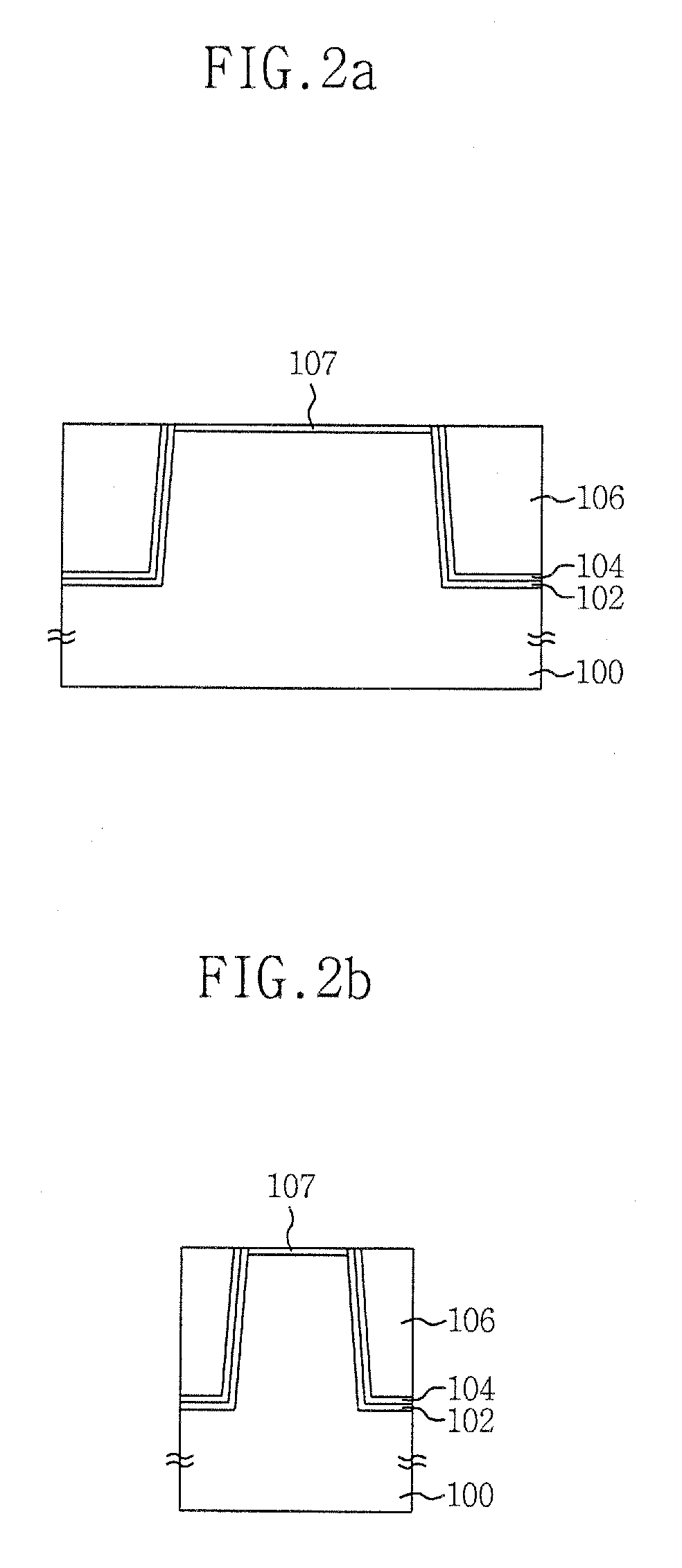

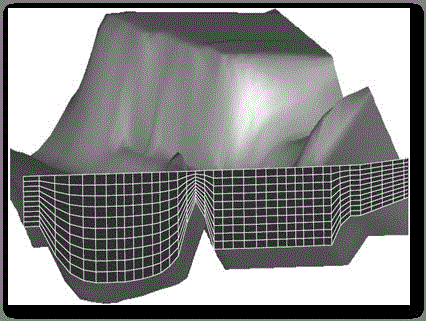

Fin FET and method of fabricating same

ActiveUS7217623B2Improving swing characteristicReducing electric fieldTransistorSolid-state devicesInsulation layerEngineering

A fin field effect transistor (fin FET) is formed using a bulk silicon substrate and sufficiently guarantees a top channel length formed under a gate, by forming a recess having a predetermined depth in a fin active region and then by forming the gate in an upper part of the recess. A device isolation film is formed to define a non-active region and a fin active region in a predetermined region of the substrate. In a portion of the device isolation film a first recess is formed, and in a portion of the fin active region a second recess having a depth shallower than the first recess is formed. A gate insulation layer is formed within the second recess, and a gate is formed in an upper part of the second recess. A source / drain region is formed in the fin active region of both sides of a gate electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

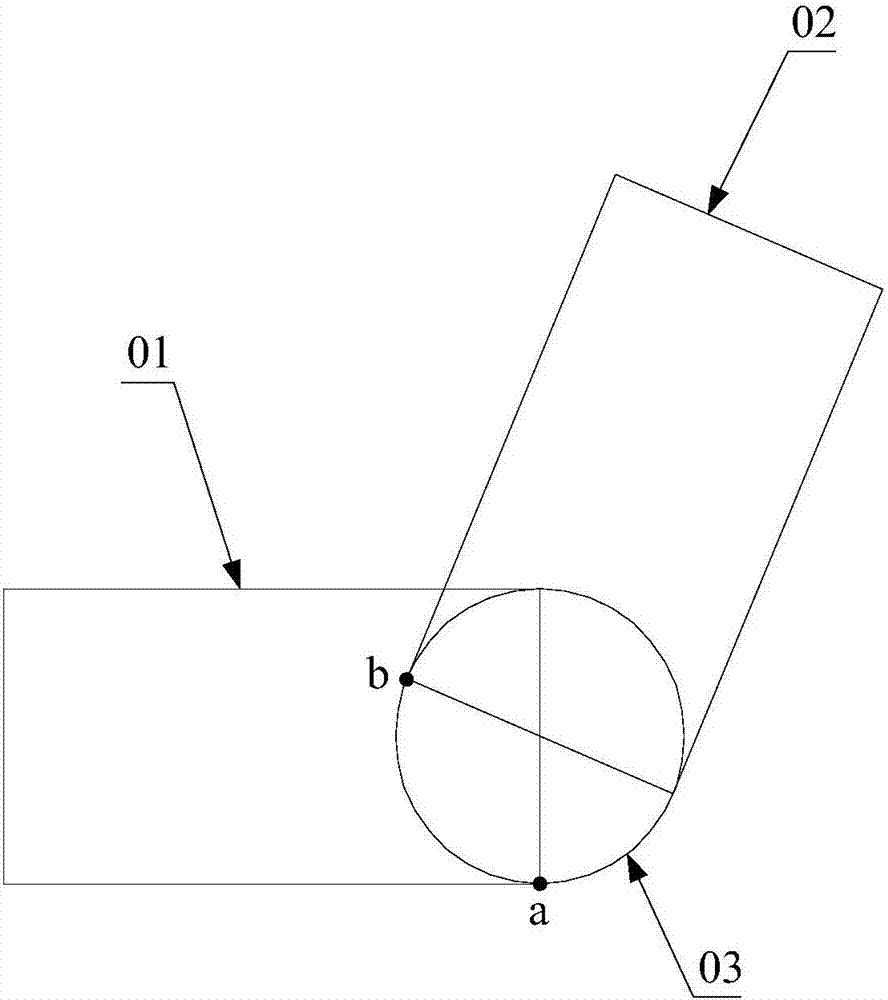

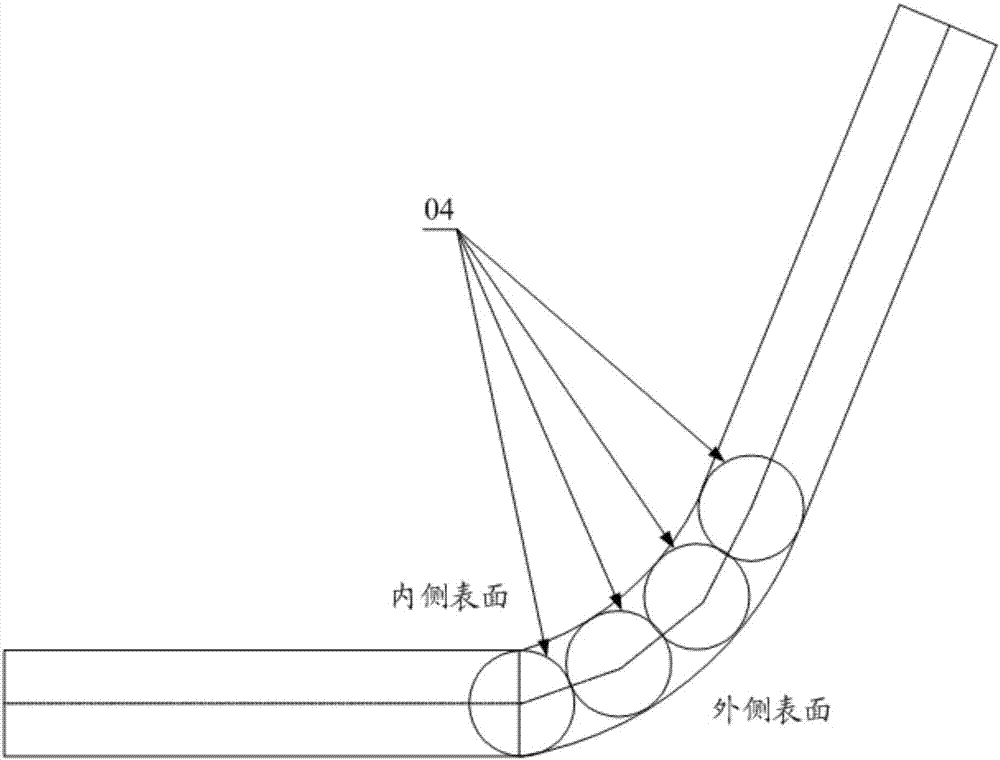

Electronic product and rotating shaft mechanism thereof

ActiveCN107288991AConstant lengthGuaranteed lengthDigital data processing detailsCasings with display/control unitsEngineeringMechanical engineering

Owner:LENOVO (BEIJING) CO LTD

Manufacturing method of bast fiber nonwoven fabric

InactiveCN101324012AEasy to manufactureAvoid breakingNon-woven fabricsAdhesivesNonwoven fabricMaterials science

The invention discloses a production method of a fibrilia non-woven fabric and comprises following steps: (1) opening and mixing: the fibrilia is opened once, bonding fiber and other fibers are opened for two or more times, and the opened fibrilia, bonding fiber and other fibers are mixed; (2) the mixed fibers are processed into a meshwork; (3) prickling shaping: the fiber meshwork that is obtained from step (2) is prickled by a needle machine; (4) hot rolling shaping: the fiber meshwork that is obtained after the prickling is transmitted onto a roll squeezer to be rolled, and the hot rolling shaping is implemented. The production method of the fibrilia non-woven fabric is simple, and the opening times of the fibrilia is limited, thus avoiding fibrilia break that is caused by a plurality of opening times, and consequently ensuring the length of the fibers and being convenient for the production of the non-woven fabric; simultaneously the opening of other fibers excluding the fibrilia is implemented for two or more times, thus ensuring full opening of the fibers and being convenient for the production of the non-woven fabric.

Owner:SUZHOU MOWEI NATURAL FIBER MATERIAL

Vehicle-mounted Doppler laser radar distance measuring method

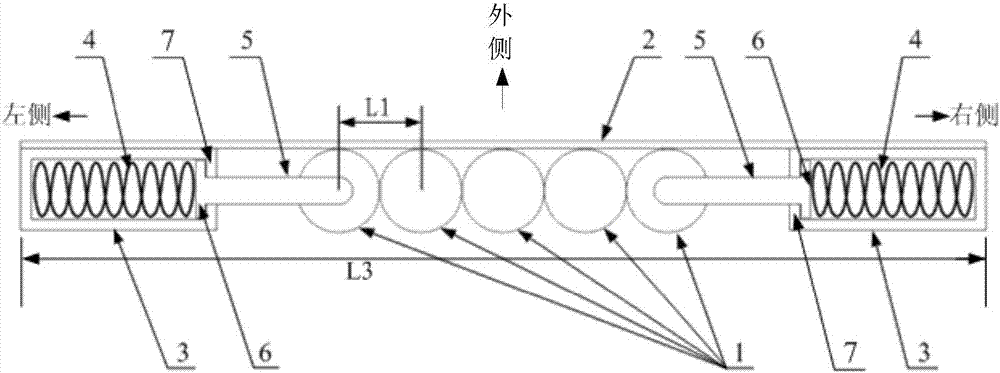

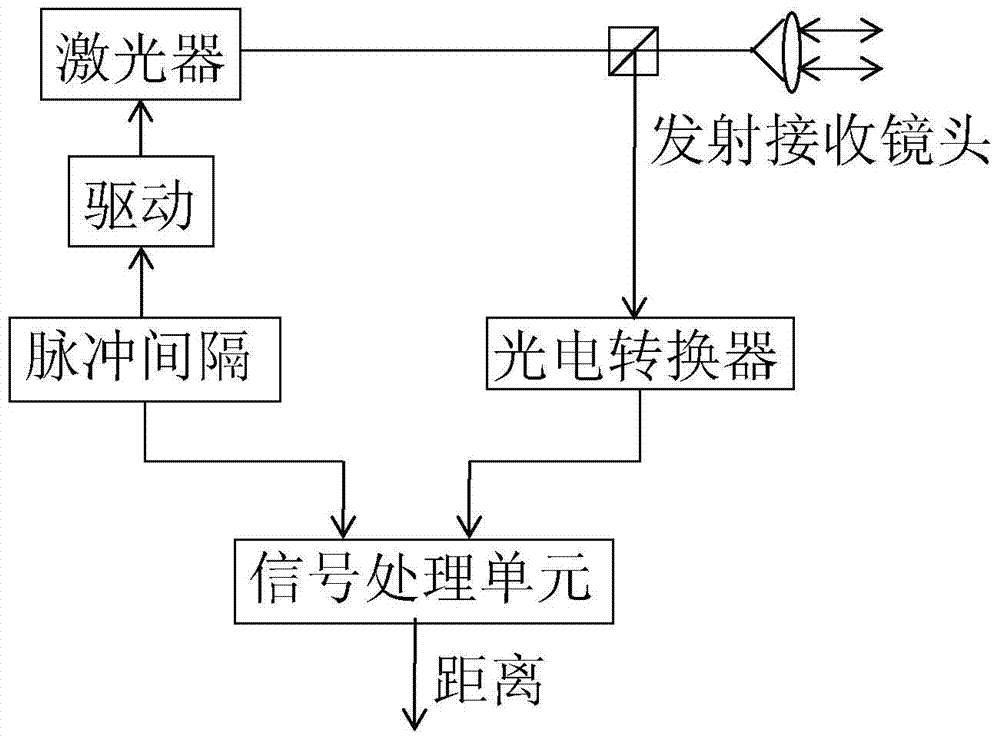

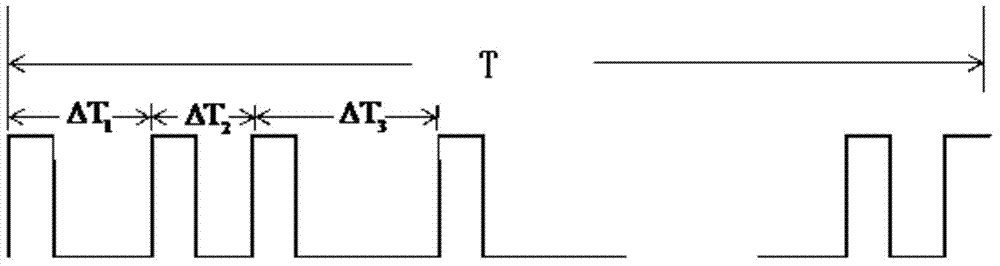

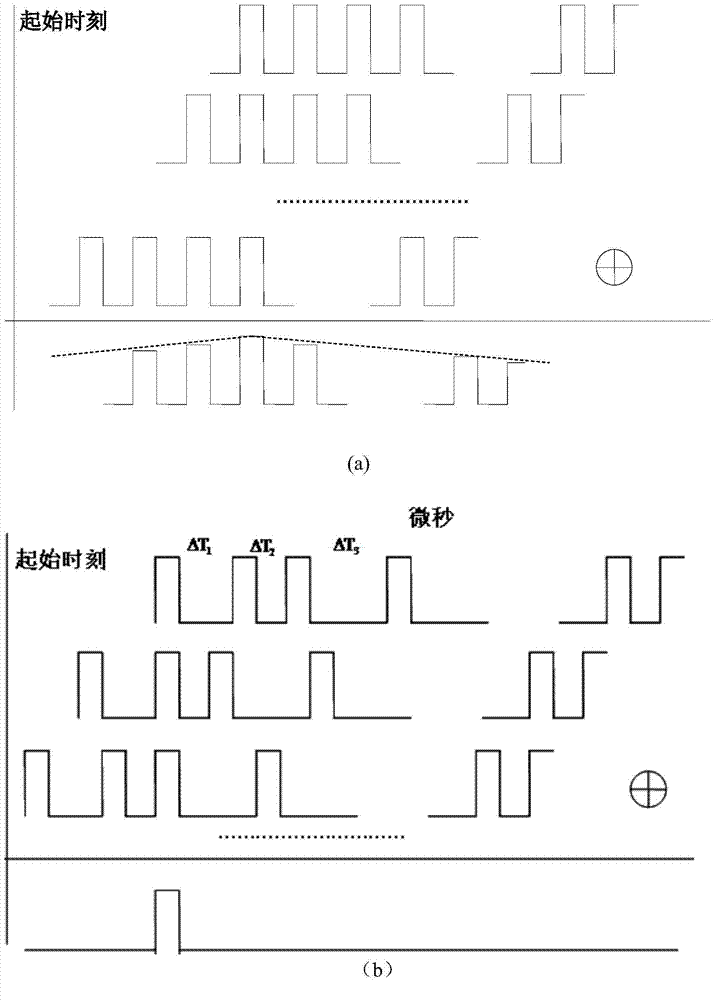

InactiveCN104730535AMiniaturizationGuaranteed lengthElectromagnetic wave reradiationBeam splitterOptoelectronics

The invention discloses a vehicle-mounted Doppler laser radar distance measuring method. A pulse separation module stores the number of transmission pulses and pulse separation information. A drive module decides the laser activation pulse transmission time according to the pulse separation information. The laser transmission pulses are projected to a lens through a beam splitter 100-percent passing light path and transmitted to a target through the lens in a collimation mode. Optical signals reflected by the target are collected through the lens and arrive at a photoelectric converter through a beam splitter 100-percent reflecting light path. The optical signals are converted into electric signals through the photoelectric converter. A signal processing unit module carries out pulse position modulation processing on the electric signals generated by the photoelectric converter through the pulse separation information, and the distance of the target is worked out. The vehicle-mounted Doppler laser radar distance measuring method has the advantages that the transmission pulse separation is modulated and adjusted through the pulse position at a vehicle-mounted Doppler laser radar transmitting end, a receiving end measures the road target distance through an improved data integration method, and the miniature of vehicle-mounted laser radar is achieved while the length of transmitted signals meets the high-speed scanning requirement.

Owner:WUHAN UNIV OF SCI & TECH

Genetic algorithm-based MIMO-SAR planar array antenna array element position optimization method

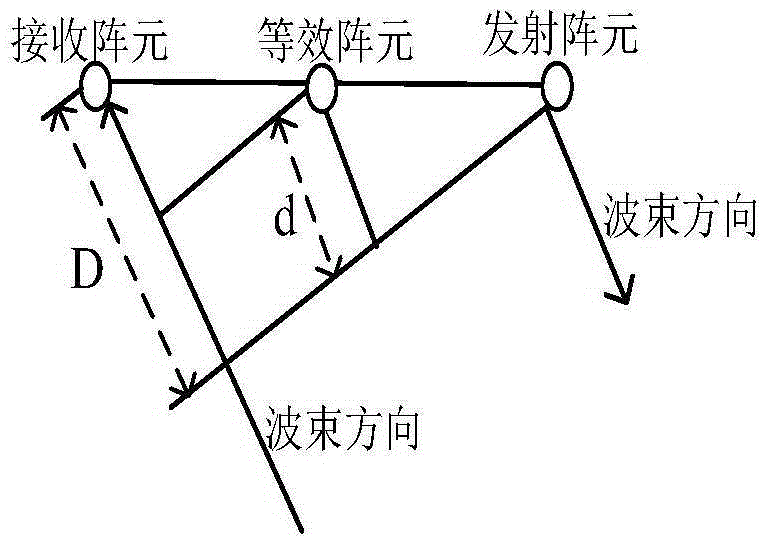

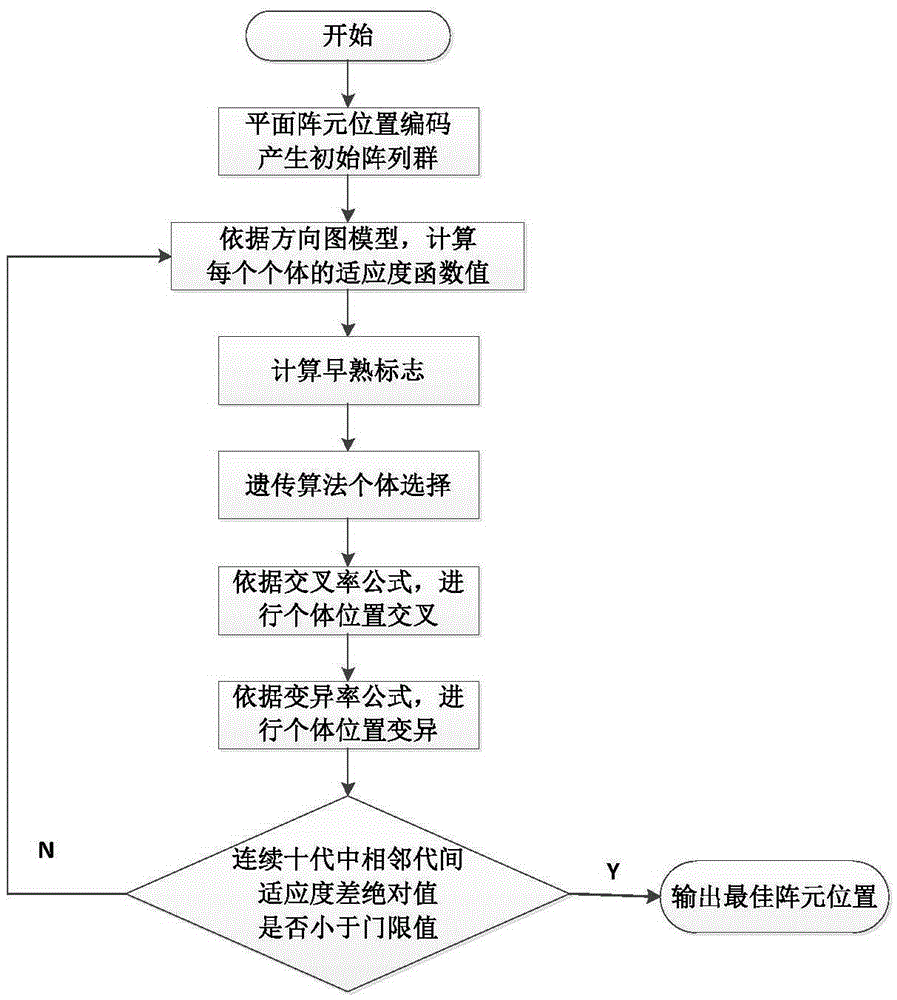

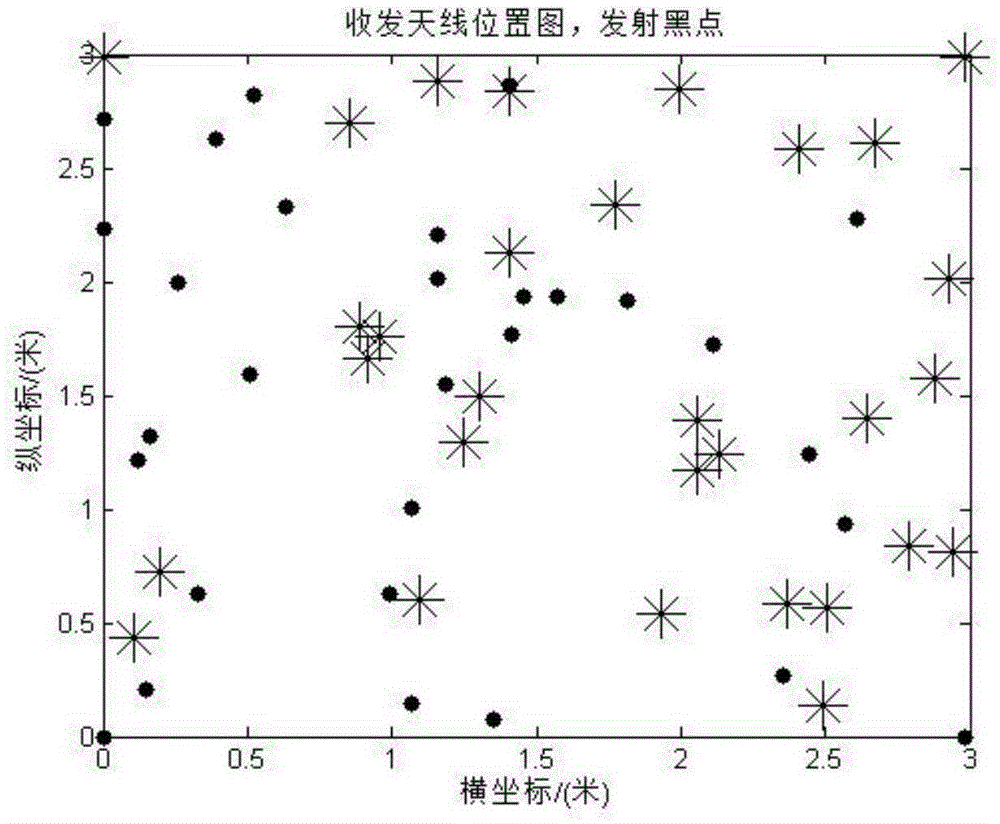

ActiveCN105426578AGuaranteed lengthPrecocious inhibitionDesign optimisation/simulationSpecial data processing applicationsPhysicsGenetic algorithm

The invention provides a genetic algorithm-based MIMO-SAR planar array antenna array element position optimization method. According to the method, an array directional diagram optimization model is established on the basis of an antenna phase center approximation principle; array element positions are selected on grid points in the encoding process of a genetic algorithm by taking the minimum peak side lobe ratio and the minimum main lobe width as optimization objectives; two transmission array elements and two reception array elements are laid at four end points of a laying area to ensure the maximum length of the array; the early-maturing of the genetic algorithm is inhibited to obtain the optimal array element positions; by adopting the planar array form constrained by the array element minimum distance, the number of the required array elements is greatly decreased, so that the cost and calculated amount of an antenna system are effectively reduced, the method is more suitable for the engineering design, and convenience is provided for the MIMO-SAR three-dimensional imaging and objective detection and recognition.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

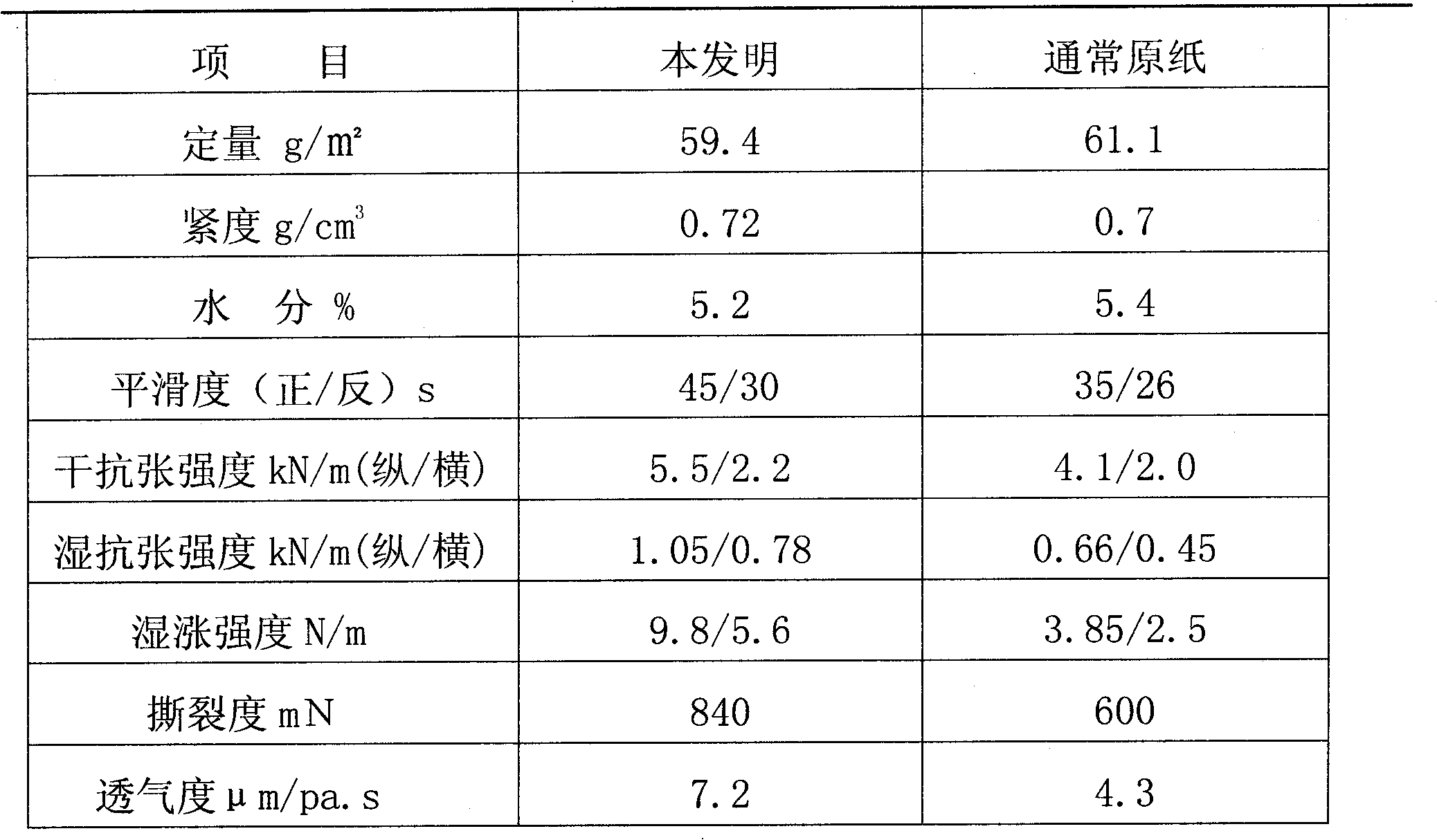

Production method for bactericidal packing paper

ActiveCN102154944AImprove breathabilityHigh strengthPaper coatingReinforcing agents additionBursting strengthCarboxymethyl cellulose

The invention discloses a production method for bactericidal packing paper, which comprises the following steps of: (1) preparation working procedure of applying glue solution to pulp; (2) preparation working procedure of applying glue solution to a surface; (3) working procedure of sizing agent repulping, selecting Southern pipes produced in America to make pulp, adding sodium carbonate and carboxymethyl cellulose into a repulping liquid; (4) working procedure of pulp matching, adding a wet strength agent; (5) working procedure of webbing and forming; (6) working procedure of applying glue solution to the surface, using modified tapicoa starch and polyvinyl alcohol for applying the glue solution to the surface; and (7) completion working procedure. The bactericidal packing paper has good air permeability, high surface strength, tearing resistance after disinfection and high bursting strength and can block bacterium invasion.

Owner:安徽华邦古楼新材料有限公司

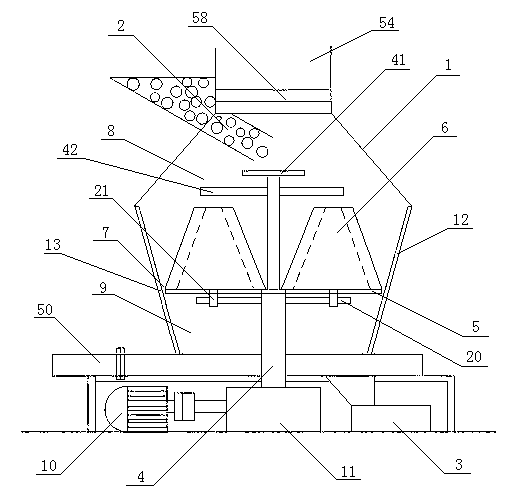

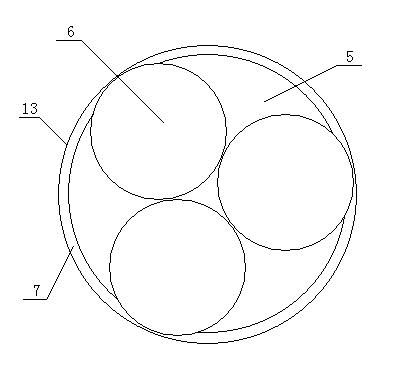

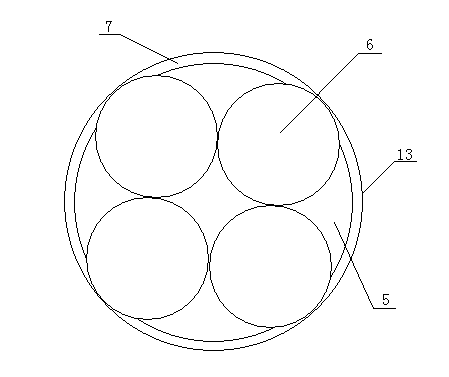

Drying and sorting integrated crusher and process

InactiveCN102698835ASimple production processLess investmentDrying gas arrangementsGrain treatmentsEngineeringHardness

The invention discloses a drying and sorting integrated crusher and a process thereof. The crusher comprises a crushing device, an air blast device, a sorting device and a drying preheating device. Ores are preheated by the drying preheating device and are crushed by the crushing device, and dust formed after the ores are crushed by the crushing device is raised by air which is blown by the air blast device into the sorting device; and a finished product is obtained by the settlement of the dust in the sorting device. According to the drying and sorting integrated crusher, the crushing device comprises a spindle, a crushing disc and 3 to 8 grinding rollers; the spindle is vertical; the crushing disc is horizontal; the grinding rollers are erected on the crushing disc and are meshed with the inner wall of a crushing cavity; and the adjacent grinding rollers are meshed with each other. When the crushing device runs, the grinding rollers revolve on the own axis while rotating around the spindle. The crushing device has a high-efficiency crushing effect on low-hardness ores, and is particularly suitable for crushing asbestos ores. When the drying and sorting integrated crusher is applied to the asbestos ores, the process can be simplified, investment of equipment and capital construction can be reduced, energy consumption and cost can be reduced, and the production efficiency can be improved greatly.

Owner:NANJING EFFUL

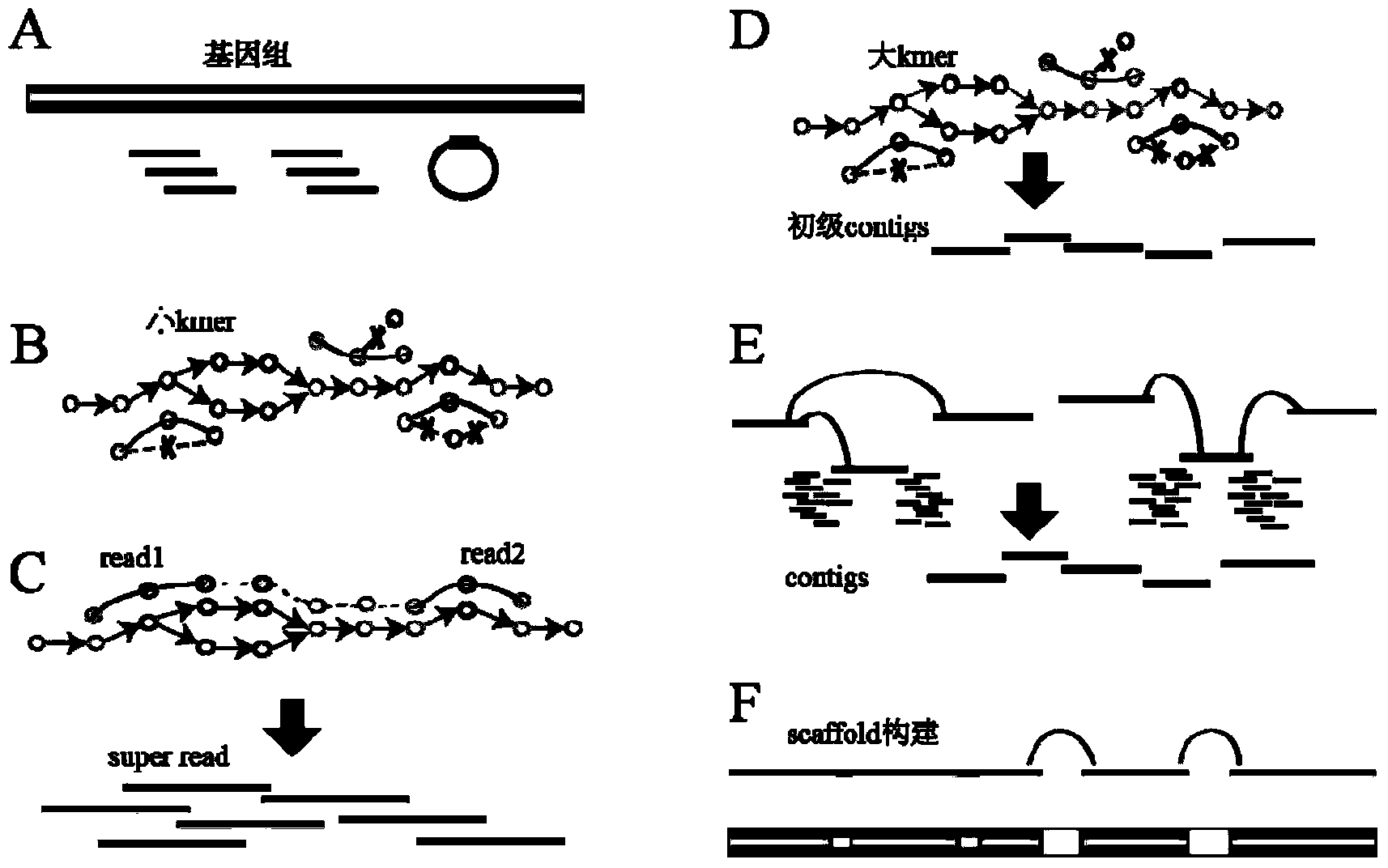

High-throughput sequencing data-based genome de novo assembly method

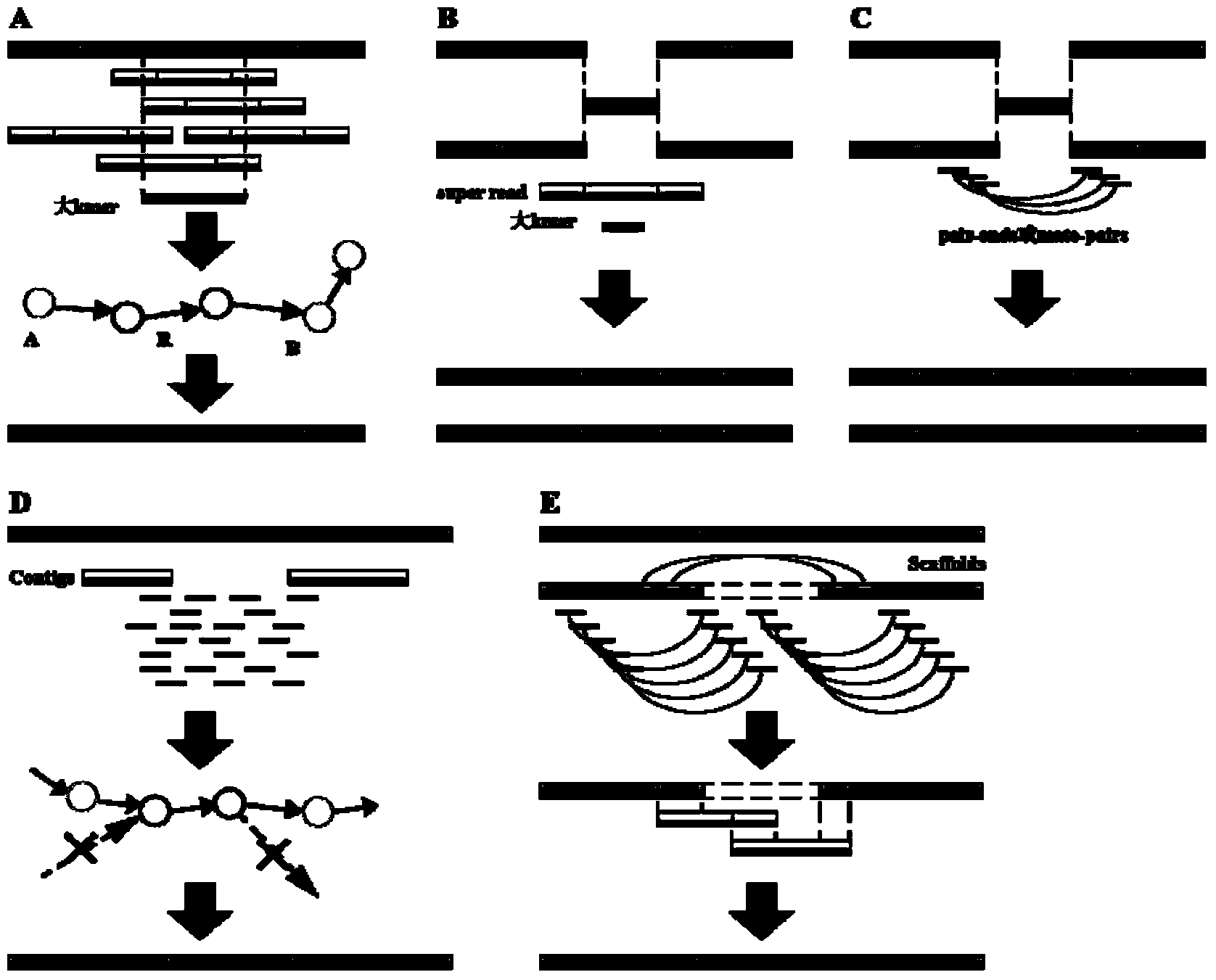

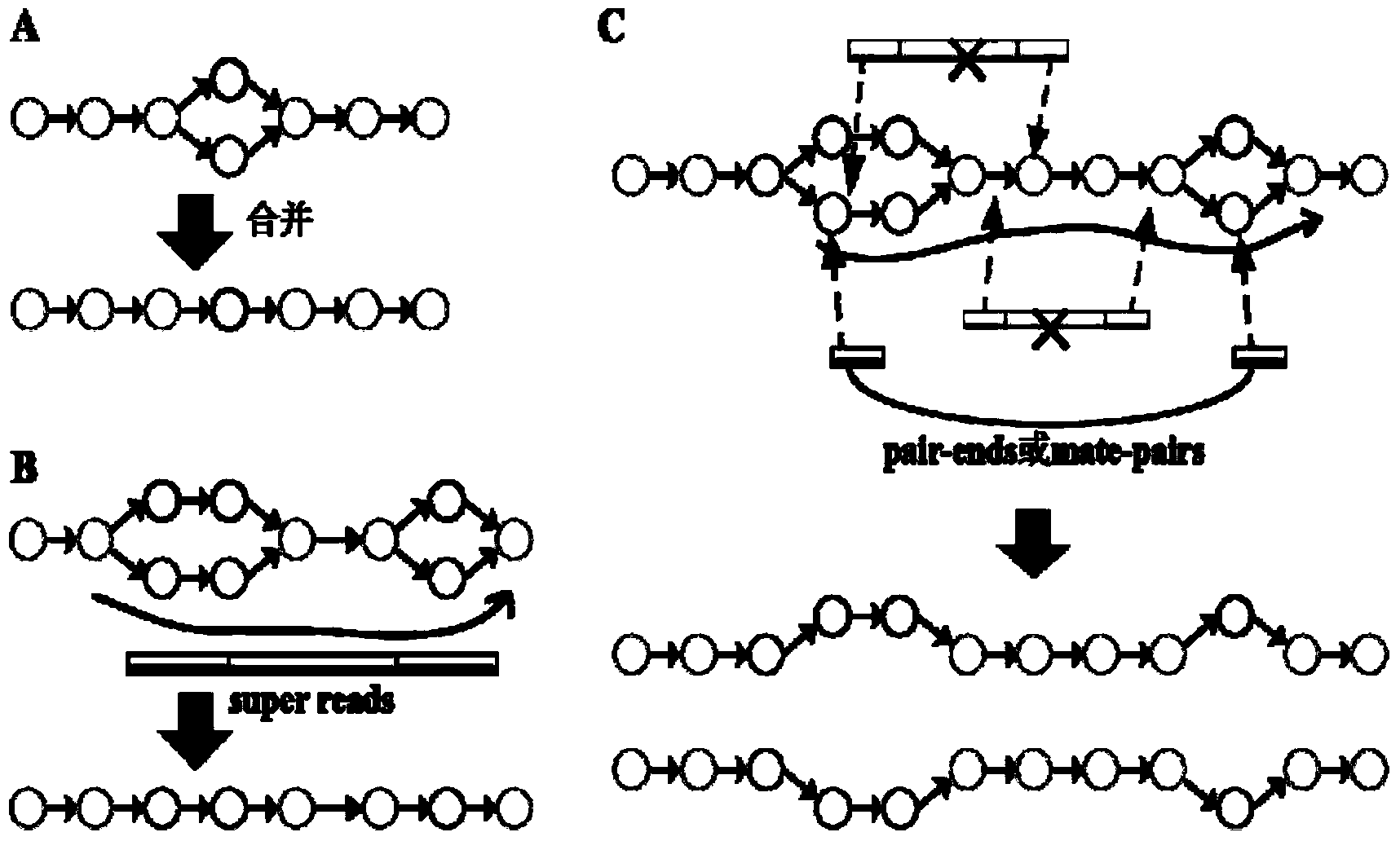

ActiveCN104239750AGuaranteed accuracyReduce the difficulty of assemblySpecial data processing applicationsContigData error

The invention provides a high-throughput sequencing data-based genome de novo assembly method, which comprises the following steps: (1) establishing a de Bruijn graph according to high-throughput sequencing data, and carrying out sequencing data error correction and super read assembly on the basis of the corrected de Bruijn graph; (2) utilizing super read to carry out primary contigs assembly; (3) taking specifically local primary contigs and reads, locally assembling, and combining all local assembly results; (4) sequencing contigs by a sub-graph segmentation algorithm and a simulated annealing algorithm to obtain final scaffolds. The errors brought by high-throughput sequencing are eliminated by de Bruijn graph correction, so that the data accuracy is improved; the sequencing read length is improved by establishing a super read method, and the contigs length is obviously enhanced; the processing capacity of repeated sequences is greatly enhanced by local assembly.

Owner:BIOMARKER TECH

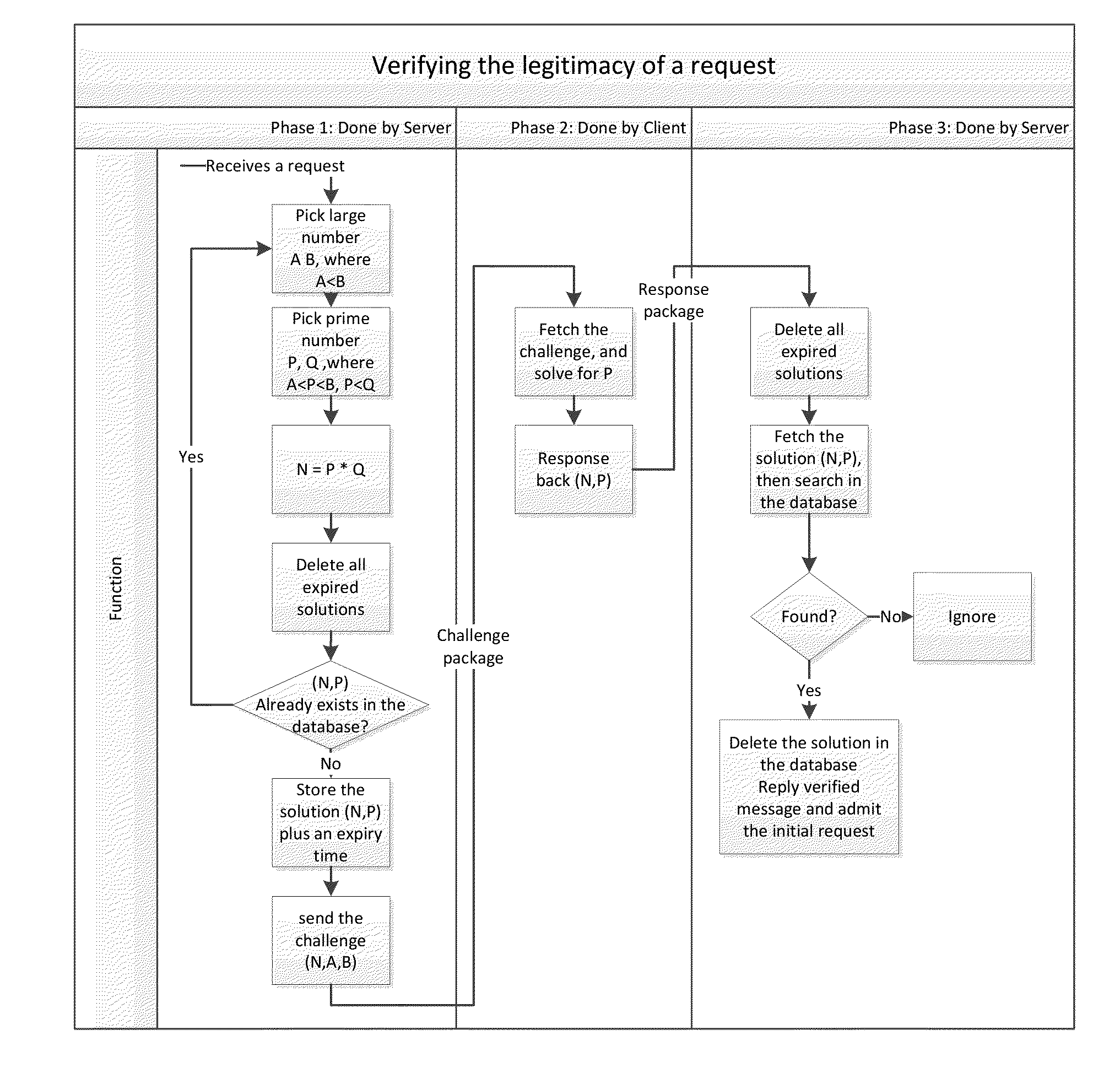

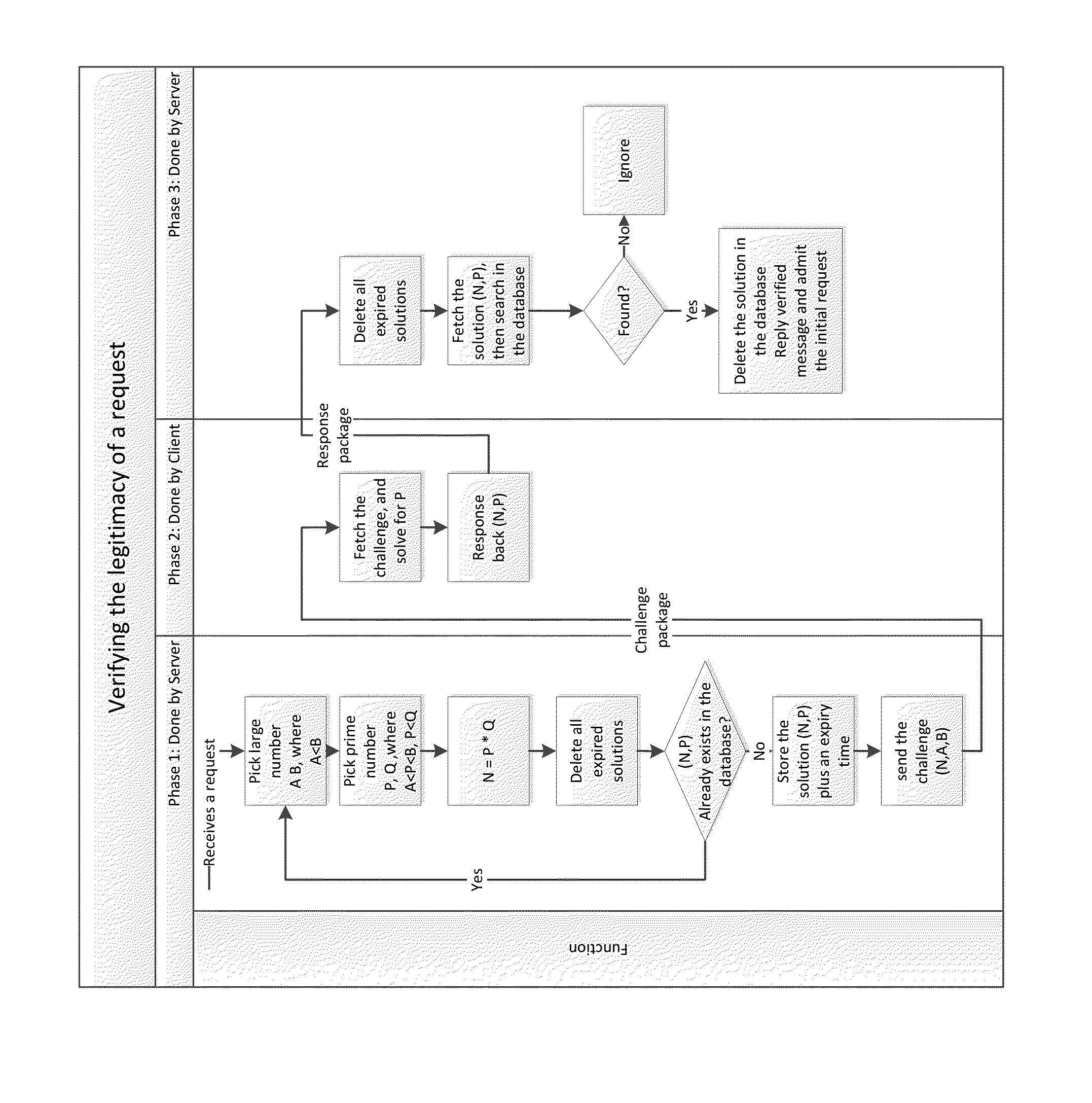

System and method for verifying the legitimacy of requests sent from clients to server

InactiveUS20140380418A1Preventing brute force attack against passwordImprove reliabilityDigital data processing detailsMultiple digital computer combinationsBrute forceComputation complexity

Disclosed herein are method and system that can be used for: preventing brute force attacks against passwords; preventing denial of service attacks by flooding; restricting bots from spamming emails, registering resources, and collecting sensitive information; and possibly in other challenge-response tests. It also can be used to replace CAPTCHA in some situations, with advantages of better reliability and spares human participation during the process. This present invention considers a request as legitimate when the requesting client has paid certain amount of computation resource required by the server, in exchange for the server to admit the request. It performs a challenge-response test. The subject challenged is the sincerity of the client to make that request, which is measured by computation resources the client willing to spend in exchange for the service provided by the server. The invention also gives a method to control and guarantee the computation complexity of the challenge problem of the test.

Owner:WANG HAOXU

Fin FET and method of fabricating same

ActiveUS20070176245A1Improving swing characteristicReducing electric fieldTransistorSolid-state devicesInsulation layerSilicon

A fin field effect transistor (fin FET) is formed using a bulk silicon substrate and sufficiently guarantees a top channel length formed under a gate, by forming a recess having a predetermined depth in a fin active region and then by forming the gate in an upper part of the recess. A device isolation film is formed to define a non-active region and a fin active region in a predetermined region of the substrate. In a portion of the device isolation film a first recess is formed, and in a portion of the fin active region a second recess having a depth shallower than the first recess is formed. A gate insulation layer is formed within the second recess, and a gate is formed in an upper part of the second recess. A source / drain region is formed in the fin active region of both sides of a gate electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

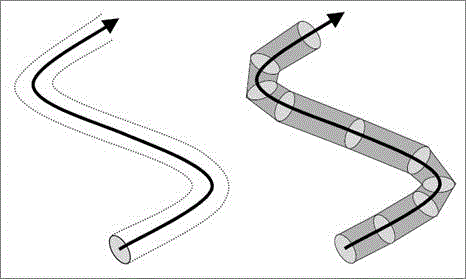

Three-dimensional streamline dynamic visualization algorithm facing irregular ocean flow field data

InactiveCN104658027AClear and vivid streamline structureGuaranteed lengthDetails involving 3D image dataAnimationTime dynamicsInformation technology

The invention belongs to the field of marine information technology and computer visualization, in particular relates to a three-dimensional streamline dynamic visualization algorithm facing irregular ocean flow field data. The algorithm comprises the following steps: firstly establishing a tetrahedral control network based on the irregular flow field data, and obtaining a streamline prototype of a three-dimensional flow field through a seed point generating algorithm based on spatial distribution probability and a Runge-Kutta second-order integral algorithm based on dynamic adaptive integration step; on that basis, compiling GPU drawing codes and performing real-time dynamic rendering treatment to the streamline through a Geometry Shader to obtain dynamic lifelike streamline visual representation capable of quantitatively expressing information such as flow rate and flow direction of the irregular flow field. The algorithm provided by the invention can be used for dynamic visual analysis and expression on various irregular ocean flow field pattern data such as POM pattern data, the streamline and path line of measured data and the like, and has the characteristics of being high in stability and feasibility to solve urgent practical problems and the like.

Owner:OCEAN UNIV OF CHINA

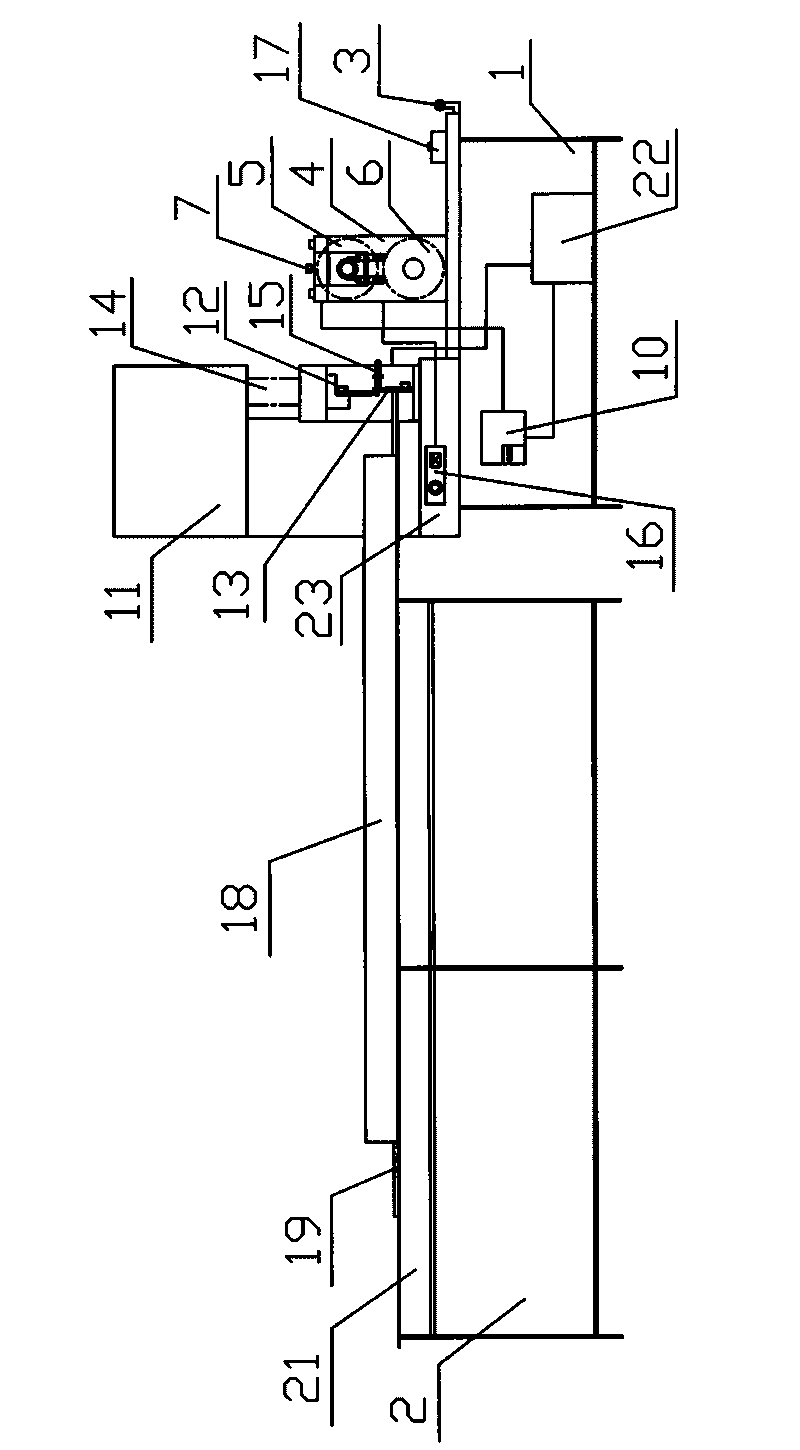

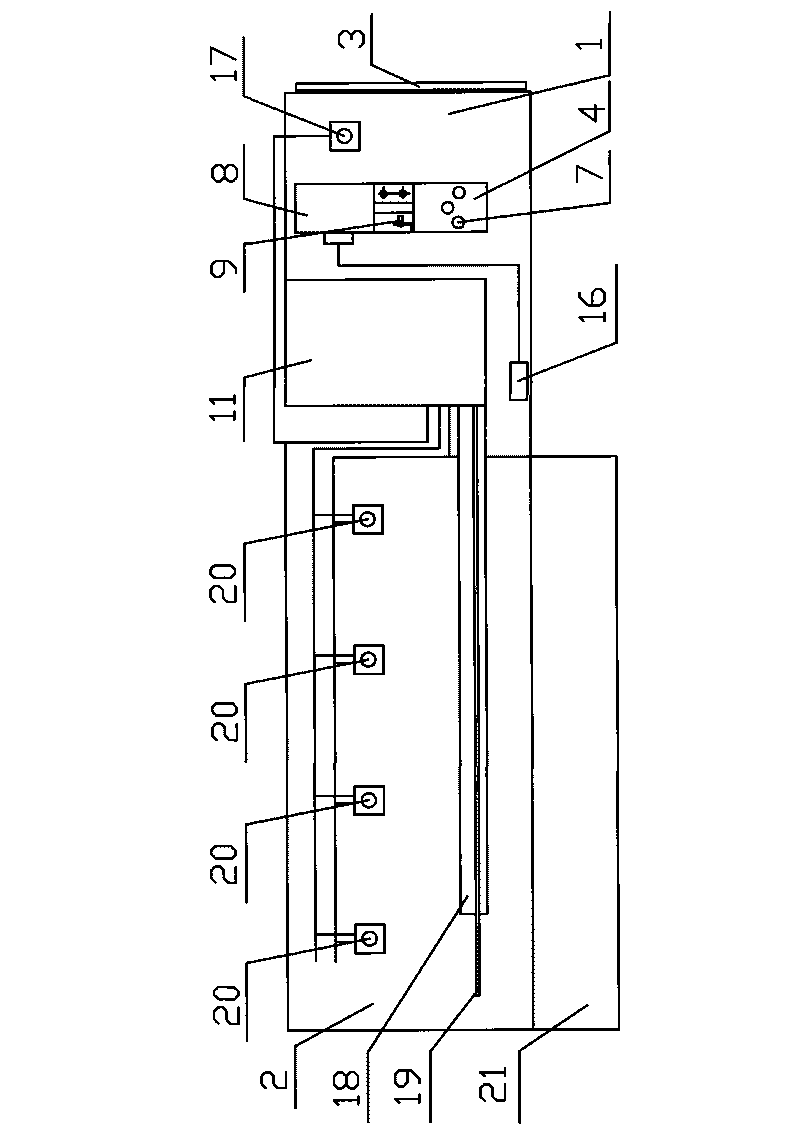

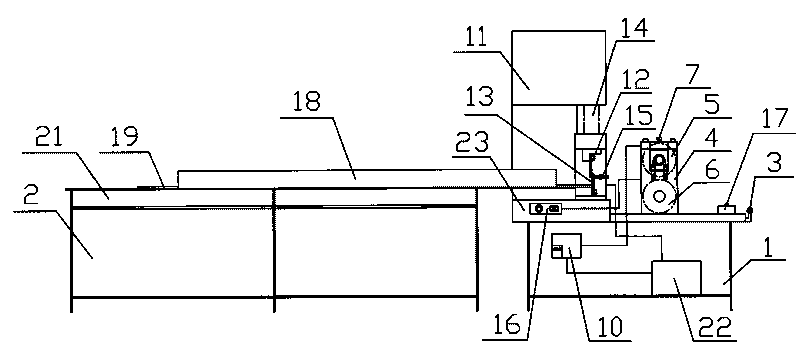

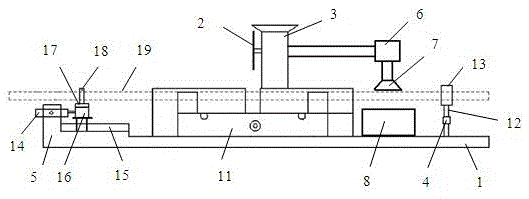

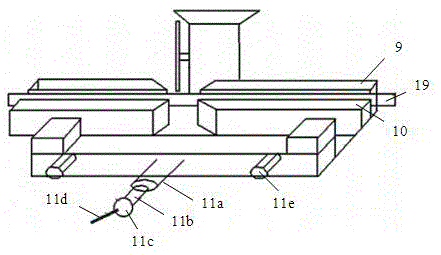

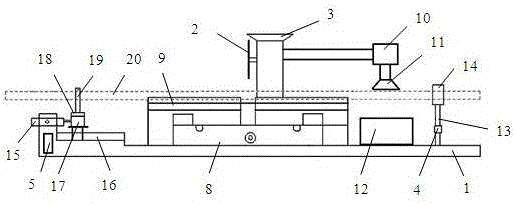

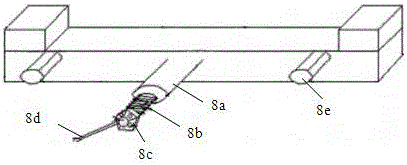

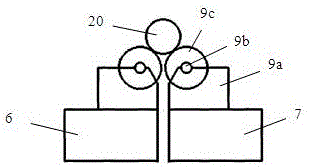

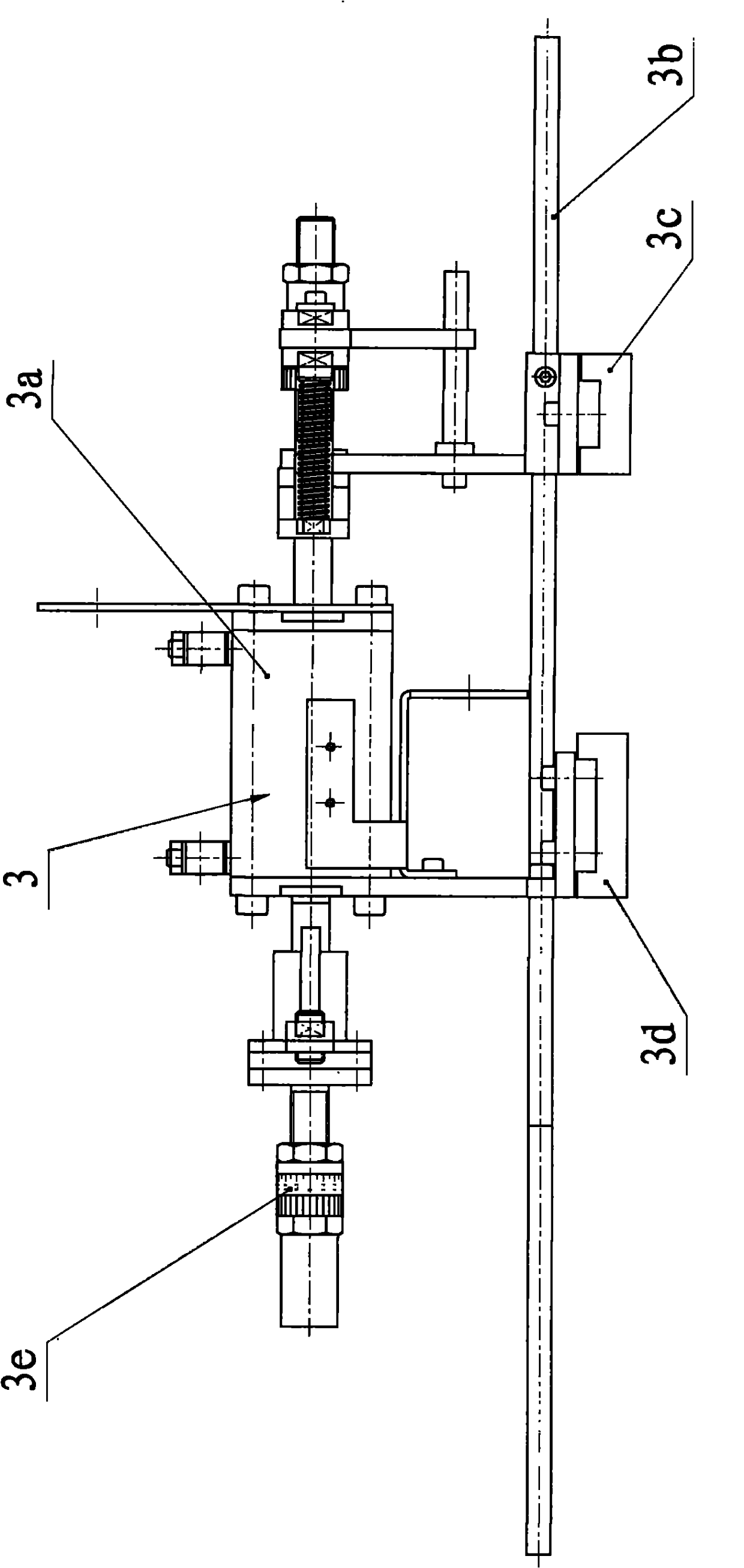

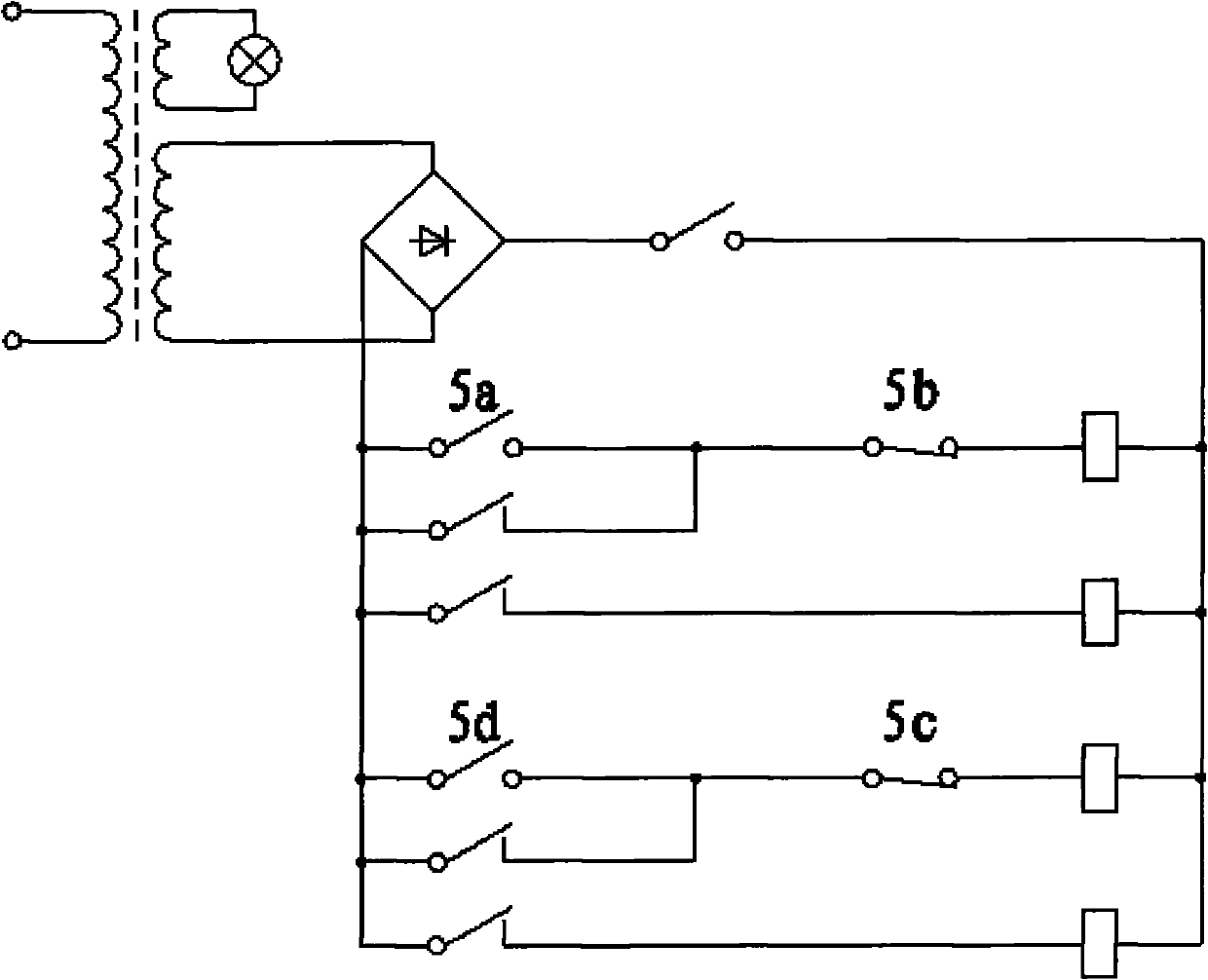

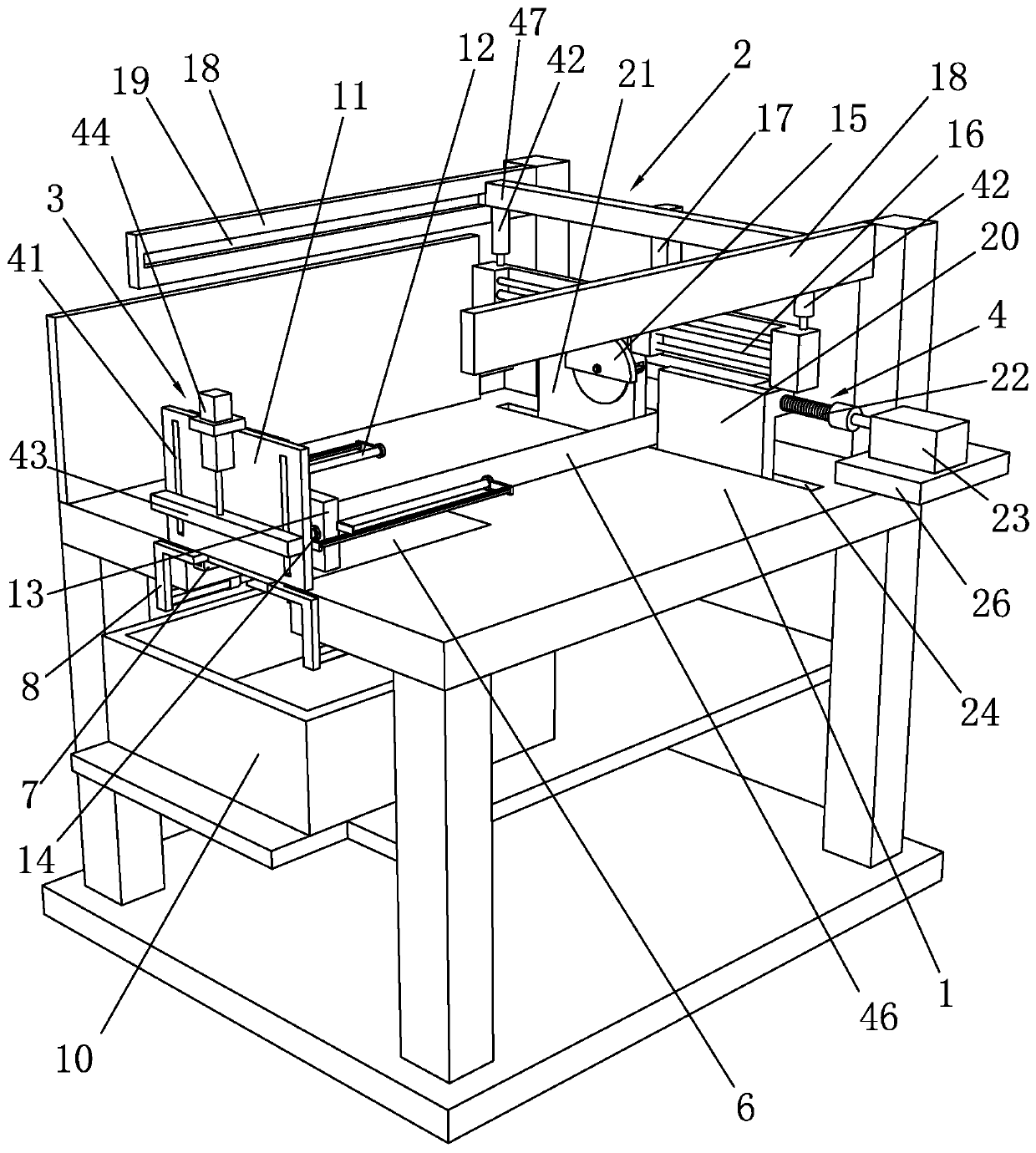

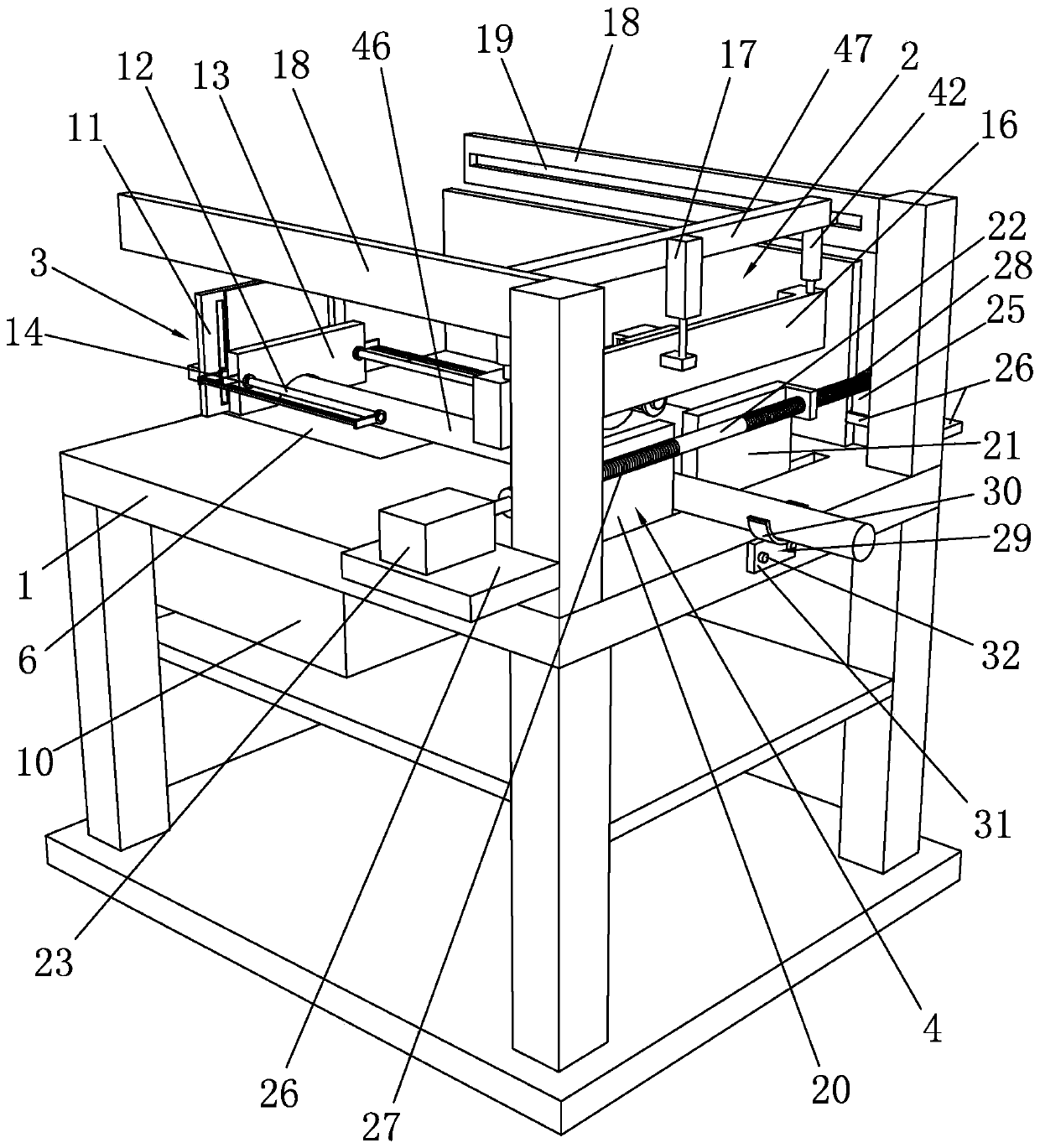

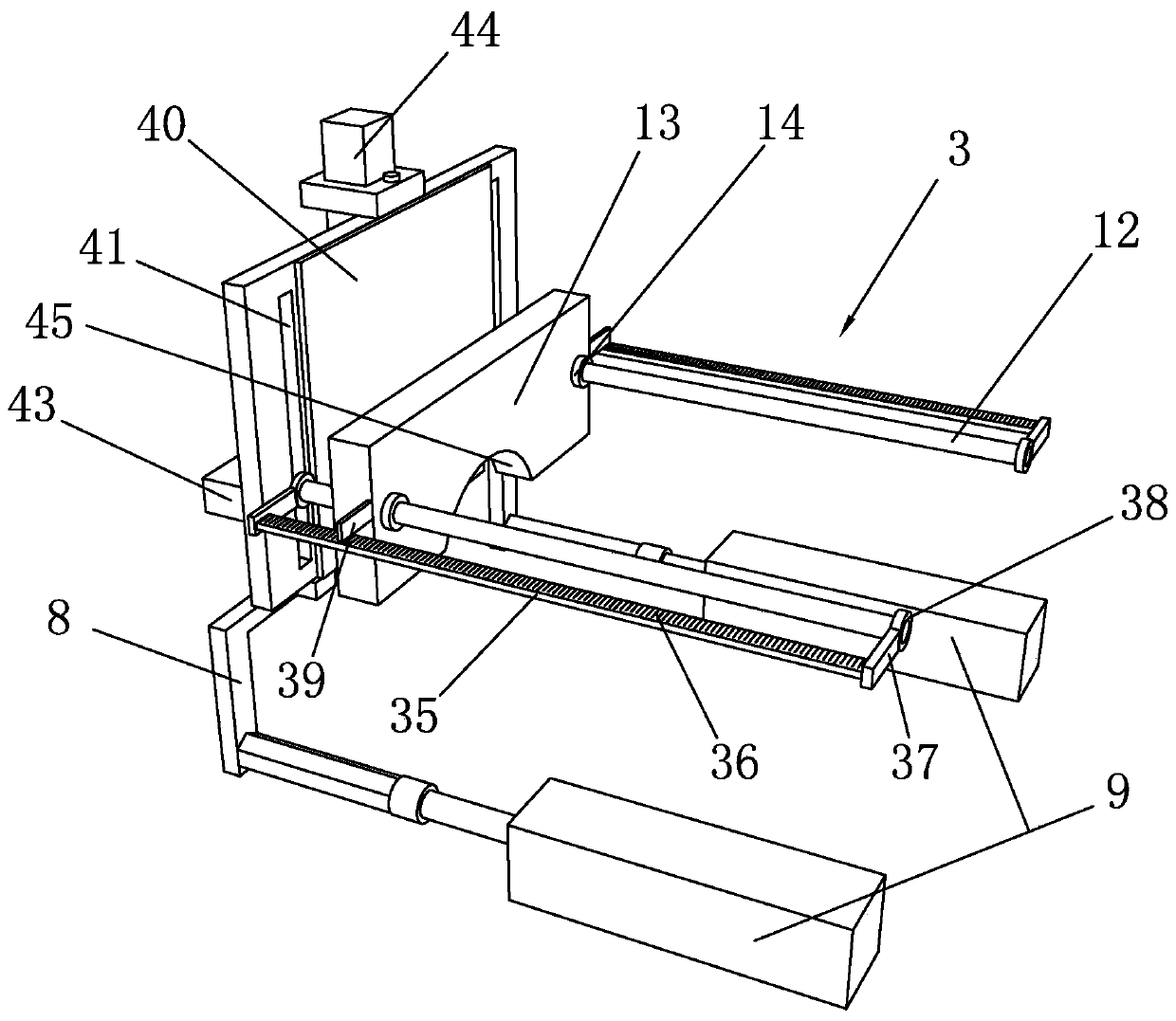

Fixed-length line automatic feeding and cutting device

The invention discloses a fixed-length line automatic feeding and cutting device which comprises a first workbench and a second workbench, the top of one end of the first workbench is provided with an idler wheel, the first workbench is provided with a feeder, the feeder is connected with a motor and provided with an inductive switch, a counter is arranged below the first workbench and connected with the inductive switch, a crimping machine is arranged on one side of the first workbench, a cutting device is arranged in the crimping machine, a speed governing switch is arranged on the front part of the seat of the crimping machine, a guide chute is arranged in front of the upper surface of the second workbench, a length measuring scale is arranged on the bottom inside the guide chute, a plurality of linkage control switches are arranged at the back part of the upper surface of the second workbench, and the linkage control switches are all connected with the cutting device. The invention has the advantages of saved human resource, high accuracy and improved production efficiency, and is applicable for cutting special lines such as shielding line, twisted-pair line and the like.

Owner:南通大地电气股份有限公司

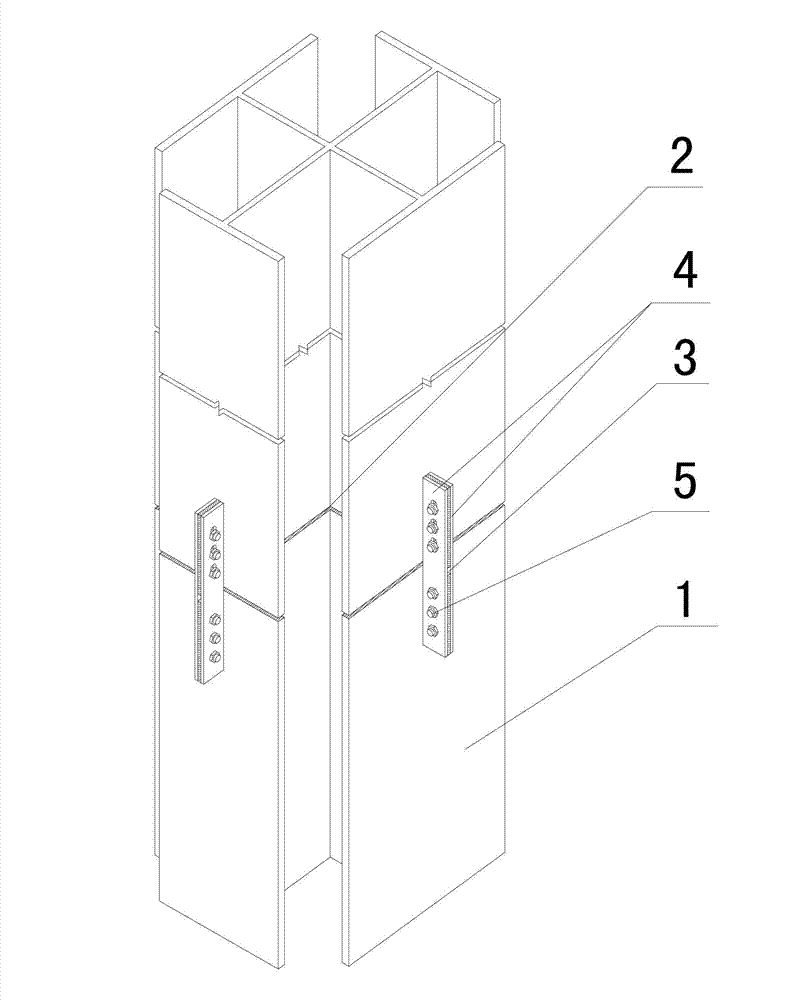

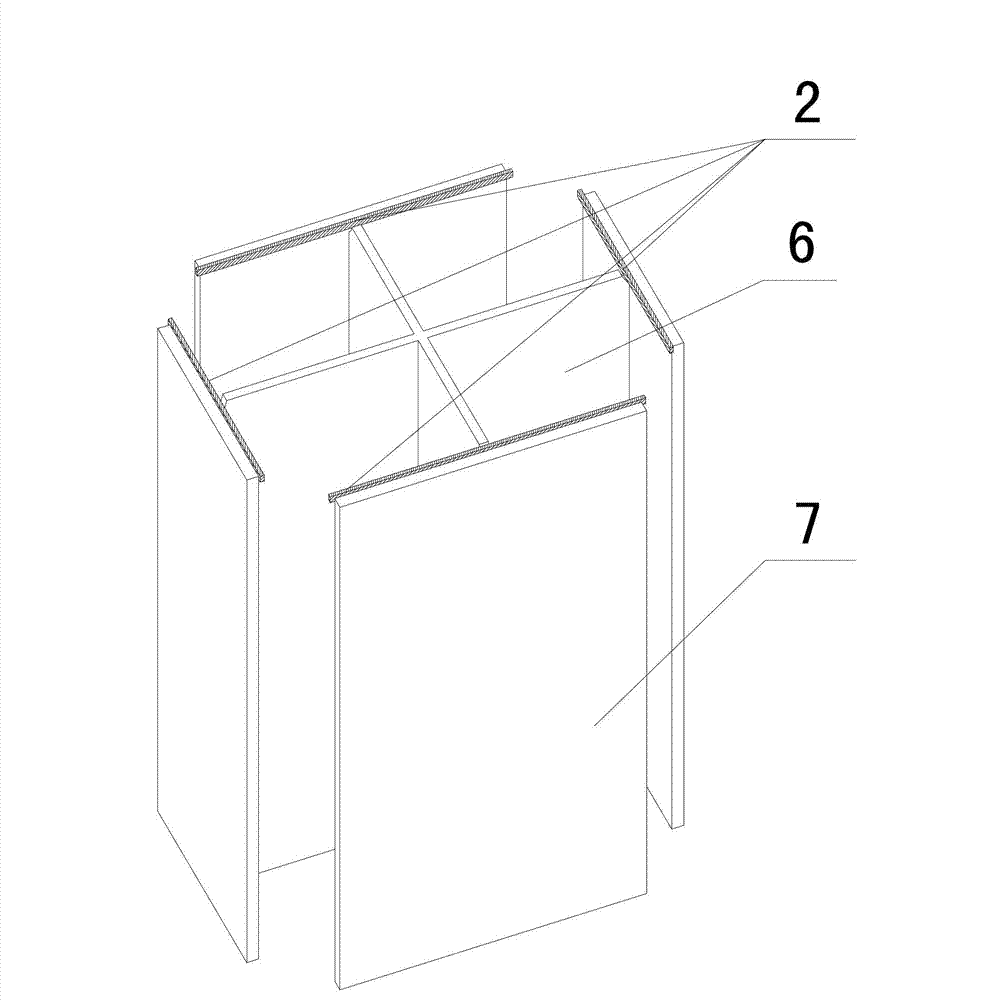

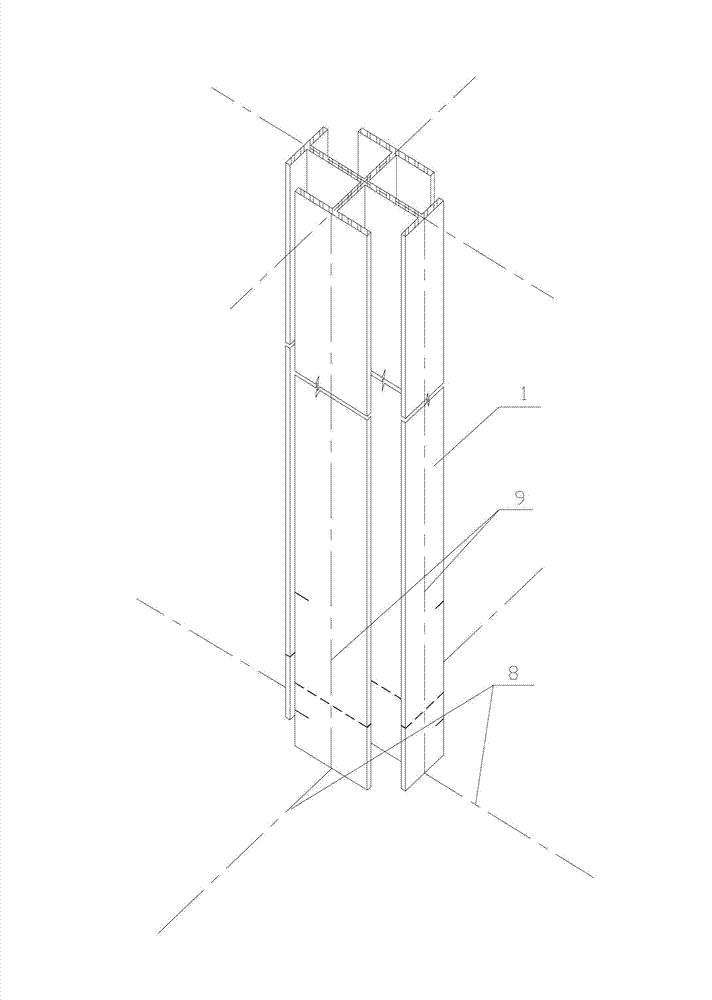

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

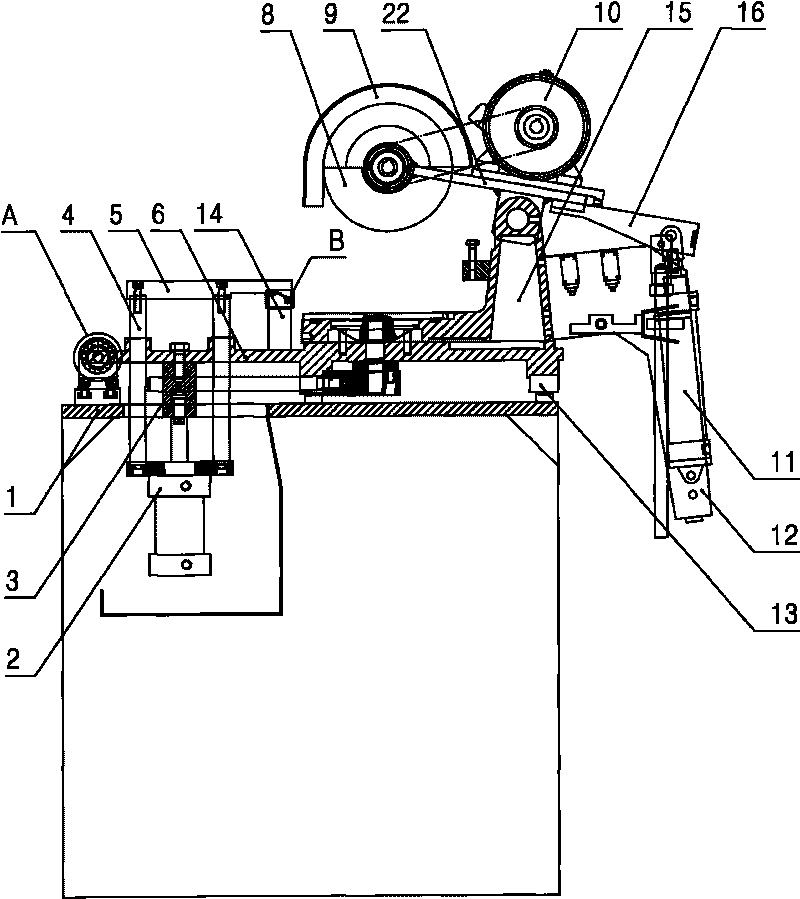

Steel pipe cutting grinding machine

InactiveCN105619086AGuaranteed lengthQuality improvementOther manufacturing equipments/toolsPositioning apparatusEngineeringPipe support

The invention discloses a steel pipe cutting grinding machine. The steel pipe cutting grinding machine comprises a stander, an adjusting fixing device, a cutting cutter and a cutter supporting frame, wherein a power device is installed in the cutter supporting frame, two ends of the stander are provided with a height adjusting device and a steel pipe supporting device and a control device, respectively; the right side of the power device is connected with a grinding device by virtue of the drive of a gear box, and a chipping box is arranged on the stander and is corresponding to the grinding device; and the adjusting fixing device comprises two fixed metal plates, two movable metal plates and an adjusting mechanism. The steel pipe cutting grinding machine is simple in structure, reasonable in design and convenient to operate; and a motor is controlled by virtue of the control device to convey a steel pipe, so that the cutting of the steel pipe to be cut can be rapidly and effectively completed, and the length of the steel pipe can be guaranteed. Moreover, steel pipes of different diameters can be fixed by virtue of simple adjustment, and the fixing device does not need to be replaced. By virtue of the grinding device, burrs produced due to the cutting can be removed, and the quality of the cut steel pipe is good.

Owner:TIANJIN XINDAYUAN METAL PROD

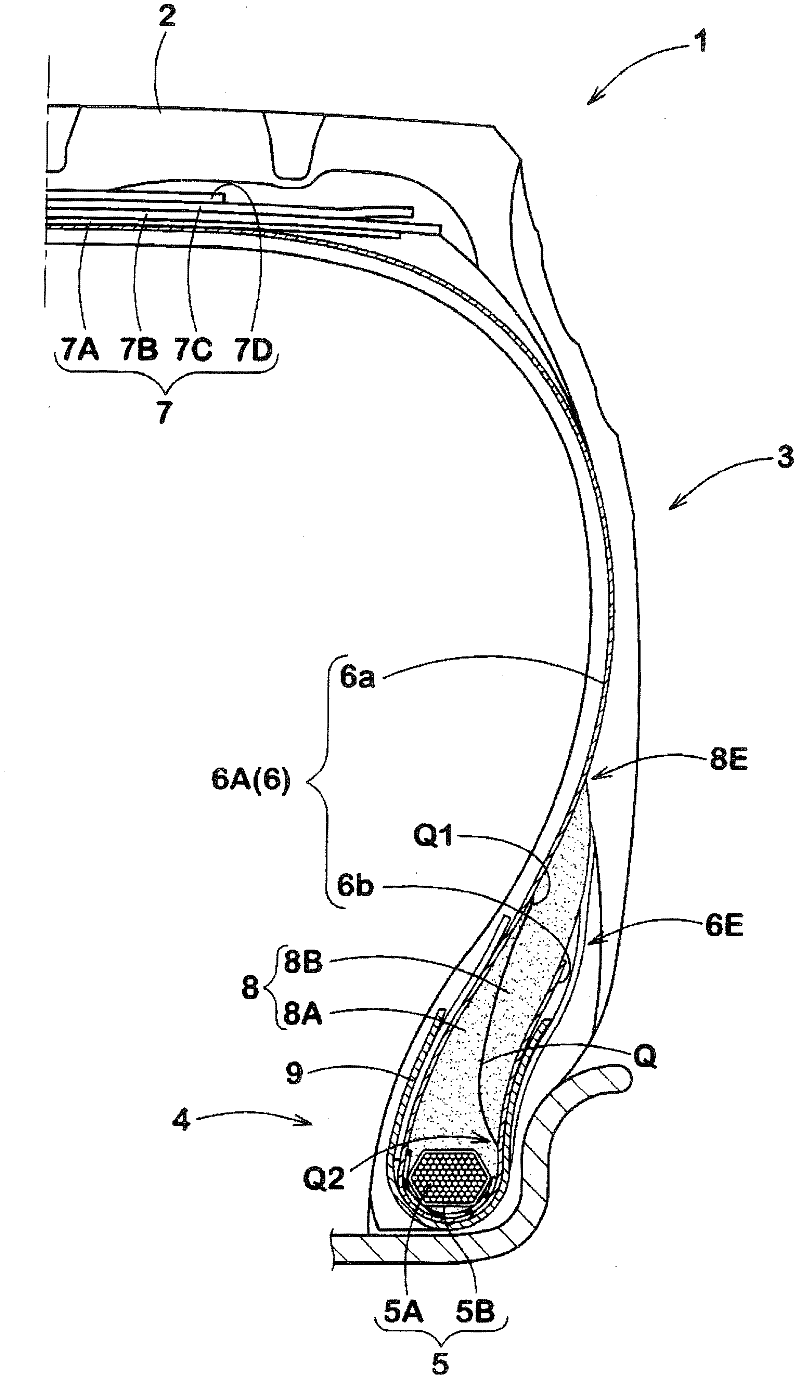

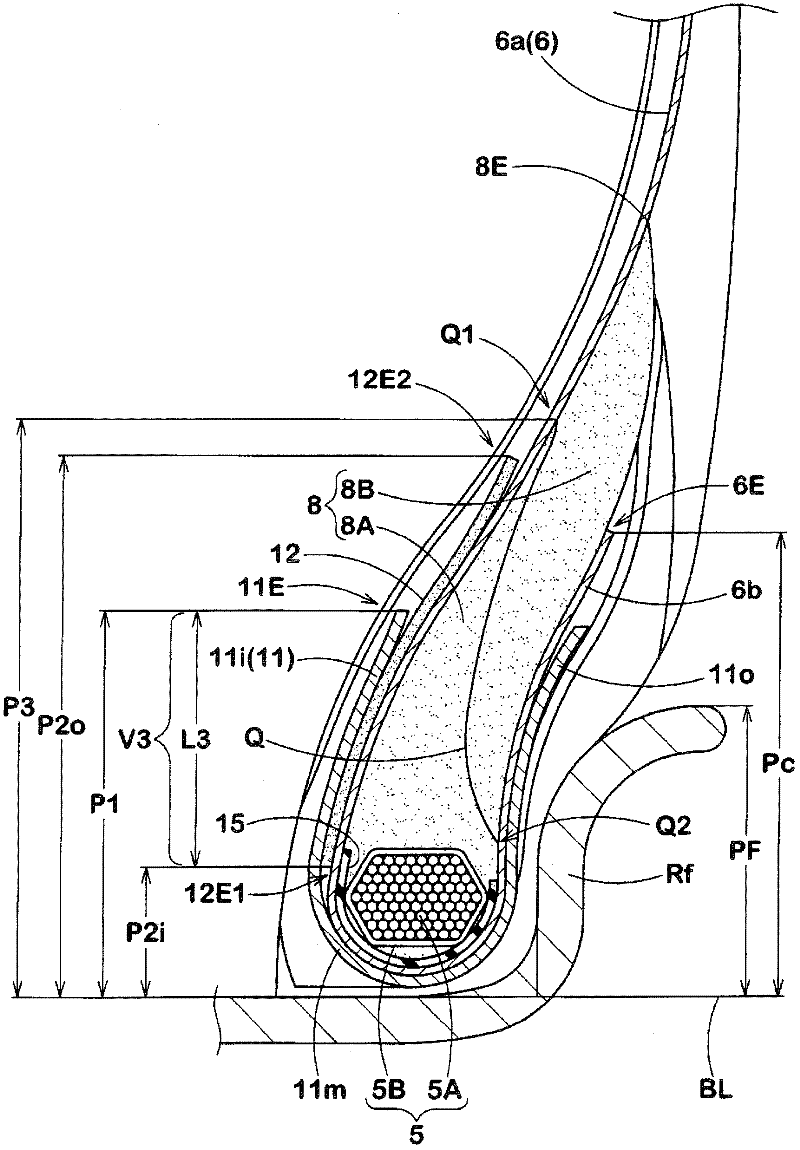

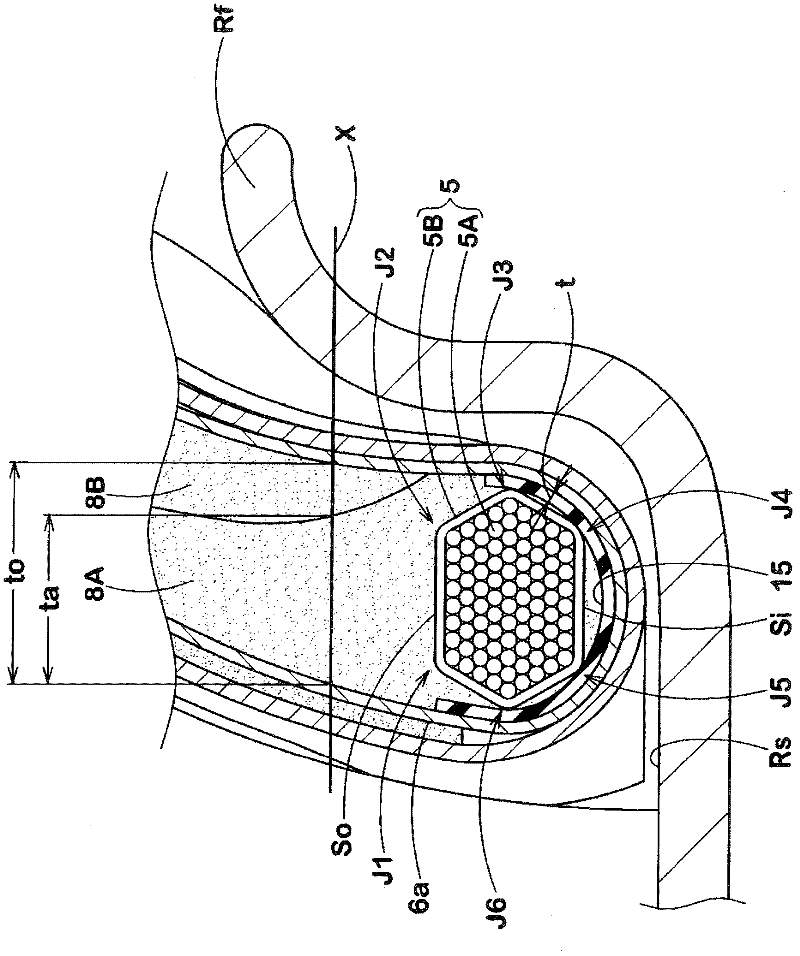

Truck tire

The truck tire of the invention allows the endurance of an ordianry tire not to be damaged and helps to improve the wearing resistance. A tire bead is provided with a first tire bead reinforcing cord layer, a second tire bead reinforcing cord layer and an anti-wearing rubber layer. The first tire bead reinforcing cord layer is U-shaped for connecting an internal portion and an external portion via a bottom portion, wherein the internal portion is arranged along the internal side of the cord main body of a tire body, and the external portion is arranged along the external side of the cord returning portion of the tire body. From an internal end clamped between the internal portion and the cord main body, the second tire bead reinforcing cord layer extends toward an radial external side beyond the internal portion along the cord main body. The anti-wearing rubber layer comprises a rubber sheet which is 0.5-1.5mm in thickness, has a complex modulus of 6.0-10.0MPa, and is arranged between a tire body cord and a tire bead core along the tire body cord. The difference between the height of the external end of the second tire bead reinforcing cord layer and the height of the external end of the cord returning portion is 5-25mm. The difference between the height of the external end of the internal portion and the height of the internal end of the second tire bead reinforcing cord layer is 10-40mm.

Owner:SUMITOMO RUBBER IND LTD

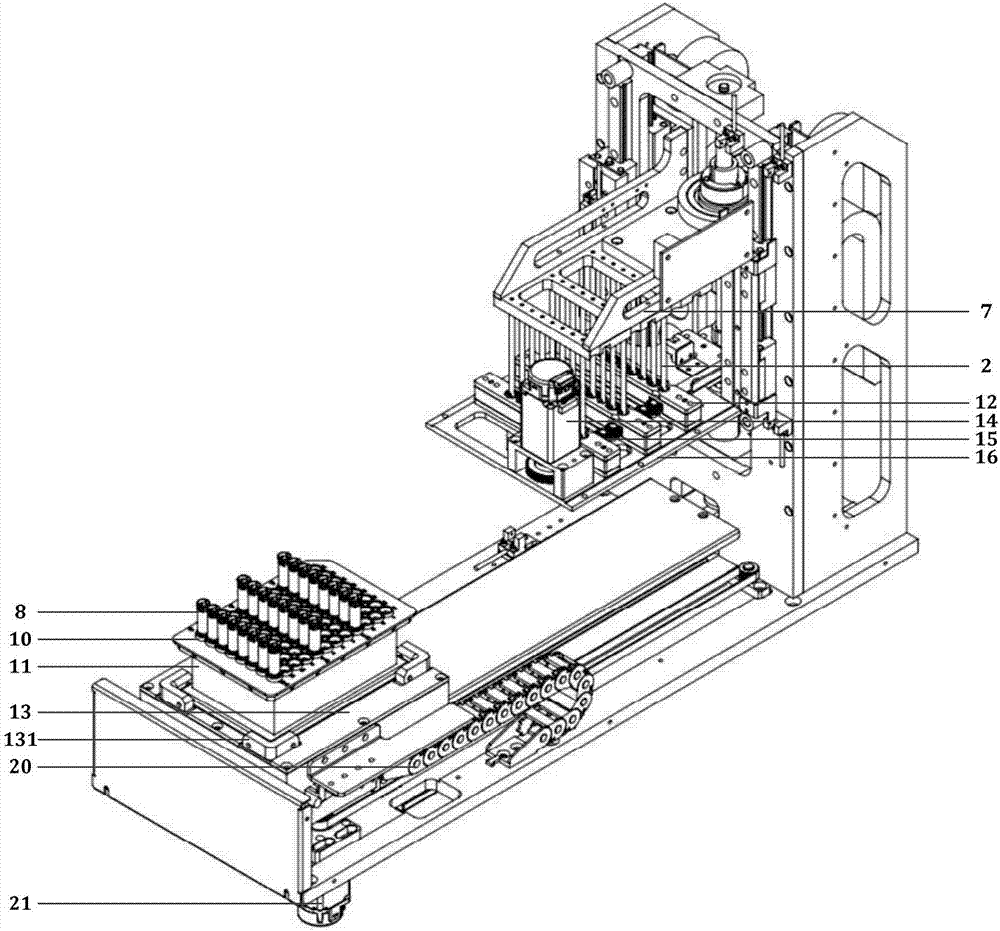

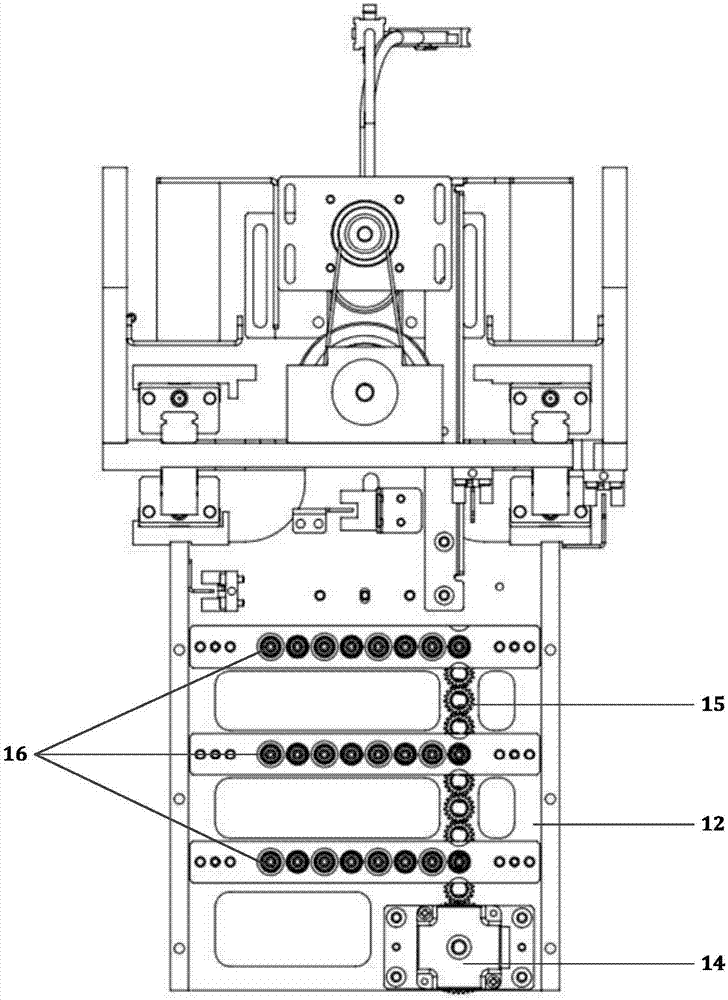

Rotary type nucleic acid extraction device and control method thereof

ActiveCN107058062AIncrease mixing speedImprove the mixing effectBioreactor/fermenter combinationsBiological substance pretreatmentsContamination rateEngineering

The invention discloses a rotary type nucleic acid extraction device and a control method thereof. The device comprises a multiflux extraction device, a plurality of extraction consumable components, a vertical device which is connected with the multiflux extraction device and a horizontal device which is connected with the extraction consumable components, wherein the multiflux extraction device adopts a rotary mode to mix samples and required extraction reagents uniformly, and the device can provide external force such as magnetic drawing, mixing and heating which is required by nucleic acid extraction and coordinate with a motion in a vertical and / or horizontal direction at the same time, so that the whole process of the nucleic acid extraction is achieved. According to the device, the blending efficiency of the samples and the required extraction reagents is improved, the cross contamination rate between extraction holes is lowered, and the length and the integrity degree of nucleic acid fragments in extraction product are guaranteed.

Owner:苏州天隆生物科技有限公司

Astragalus membranaceus cultivation method

InactiveCN104488509AOvercome solidityImproves the efficiency of root developmentSeed and root treatmentPlant cultivationQuality levelInsect pest

The invention discloses an astragalus membranaceus cultivation method which comprises the following steps: step I: carrying out pre-seeding processing to overcome the hard and solid property of astragalus membranaceus seeds and improve the rooting and developing efficiency of the astragalus membranaceus seeds; step II: selecting and preparing a piece of land; step III: seeding; step IV: managing the field; step V: dredging, storing and transplanting seedlings; step VI: preventing and controlling plant diseases and insect pests as well as weeds; step VII: picking and dredging; step VIII: processing after picking and dredging. The cultivation method provided by the invention can effectively improve the yield and quality of the astragalus membranaceus; by implementing scientific management, providing technical service support and subdividing product quality levels, the cultivation method can improve the planting technological level of farmers and promote astragalus membranaceus planting bases to develop towards large-scale, standardization and industrialization directions.

Owner:曹牛

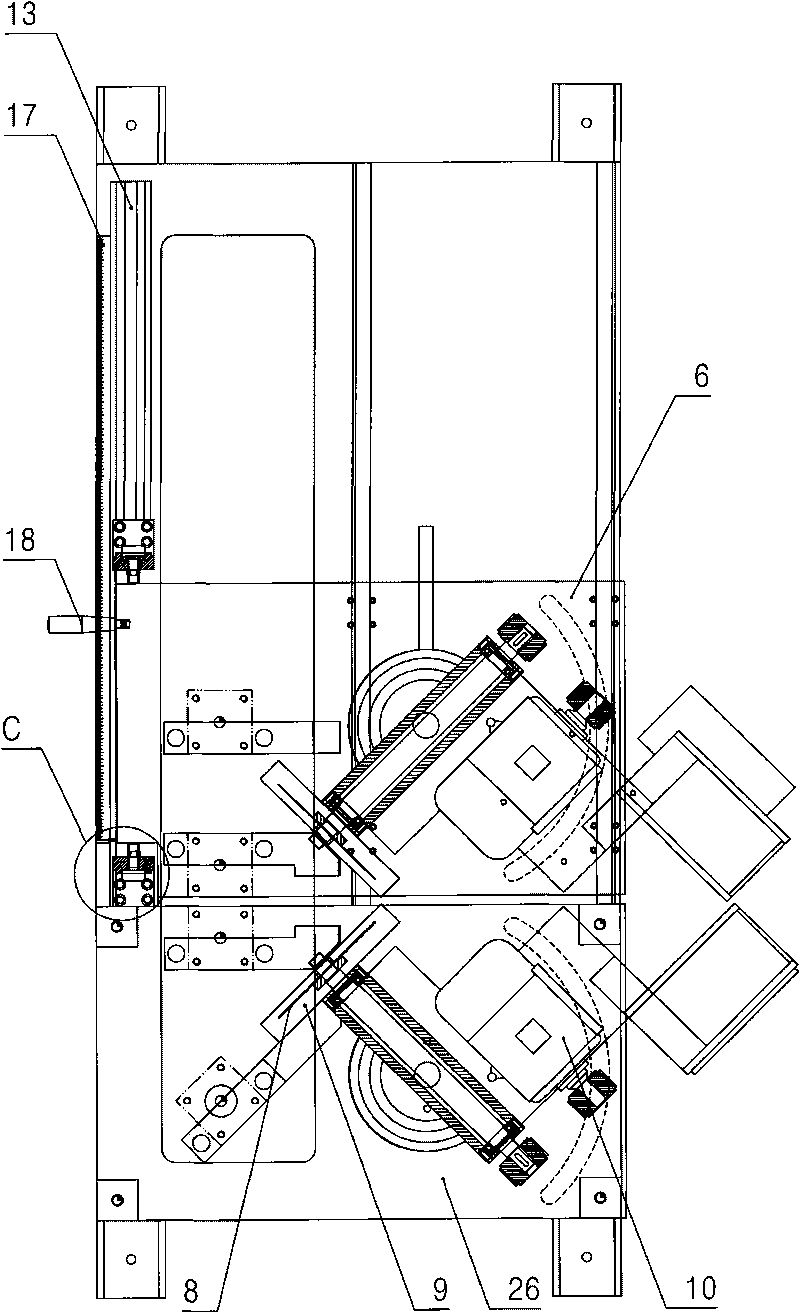

Chipless cutting and grinding machine for steel pipe

InactiveCN105817895AGuaranteed lengthQuality improvementEdge grinding machinesOther manufacturing equipments/toolsEngineeringPipe support

The invention discloses a chipless cutting and grinding machine for a steel pipe. The chipless cutting and grinding machine comprises a rack, an adjusting and fixing device, a cutting cutter and a cutter supporting frame. A power device is arranged in the cutter supporting frame. A height adjusting device is arranged at one end of the rack, and a steel pipe supporting device and a control device are arranged at the other end of the rack. The adjusting and fixing device comprises two fixed metal plates, two movable metal plates, an adjusting mechanism and a chipless mechanism. The right side of the power device is in drive connection with a grinding device through a gear case. The rack is provided with a chipping box corresponding to the grinding device. The chipless cutting and grinding machine is simple in structure, reasonable in design, convenient to operate and capable of rapidly and effectively cutting the steel pipe needing to be cut. A fixing function can be achieved for steel pipes with different diameters through simple operation and adjustment, and no fixing device needs to be replaced. During cutting, the steel pipe and the cutter synchronously rotate, and generation of metal chippings is reduced. By means of arrangement of the grinding device, burrs generated due to cutting are removed, and the quality of the cut steel pipe is good.

Owner:TIANJIN XINDAYUAN METAL PROD

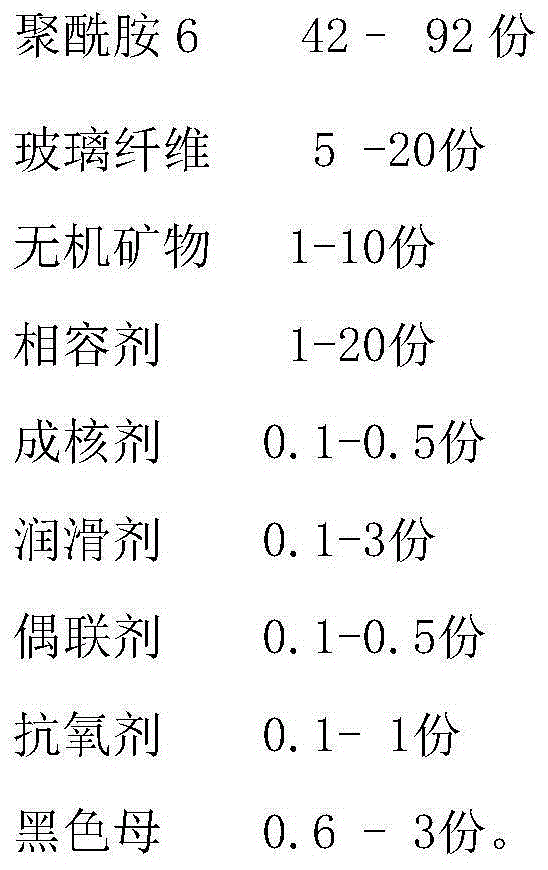

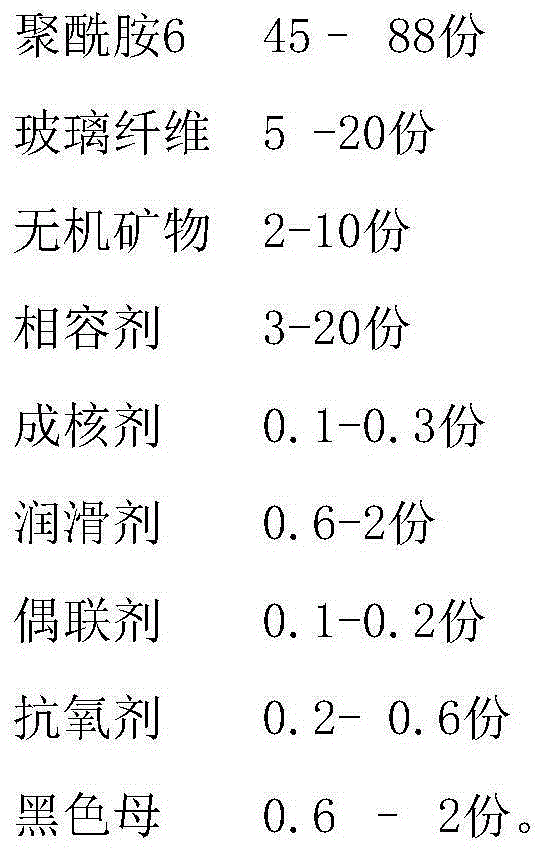

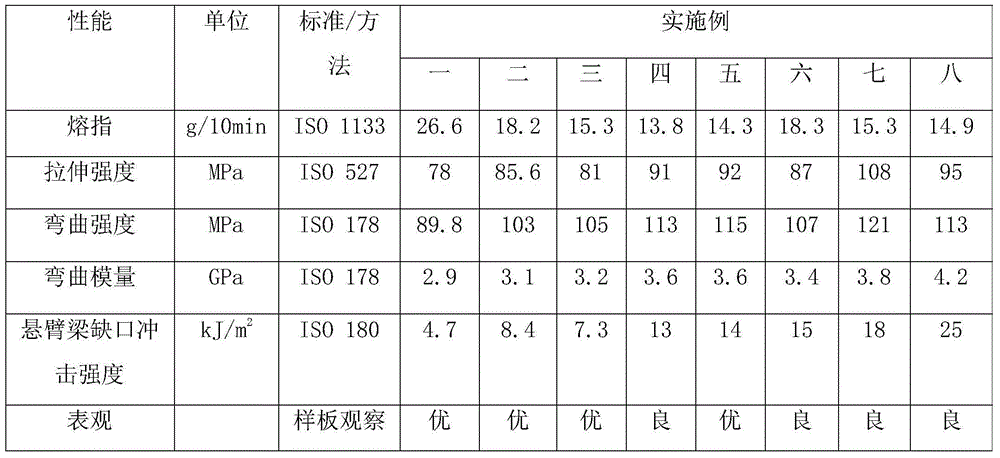

Polyamide 6 composite and preparation method thereof

The invention relates to a composite and a preparation method thereof, in particular to a polyamide 6 composite and a preparation method thereof. Non-alkali chopped fibers are selected to serve as a reinforcing agent of the pyamide 6 composite, and compatilizer is added to improve fatigue durability and low-temperature brittleness of glass fiber reinforcing materials. Coupling reagents, lubricating agents and inorganic minerals are added to improve the combination of the polyamide 6 composite and the glass fibers, and dispersion of the glass fibers in the polyamide 6 composite is enhanced, so that the glass fibers are not prone to being exposed outside the surface, and a good surface is achieved. The polyamide 6 composite and the eparation method thereof have the advantages that the polyamide 6 composite can be used for injection molding of automobile doors and window frame decoration strips.

Owner:NANJING JULONG SCI&TECH CO LTD

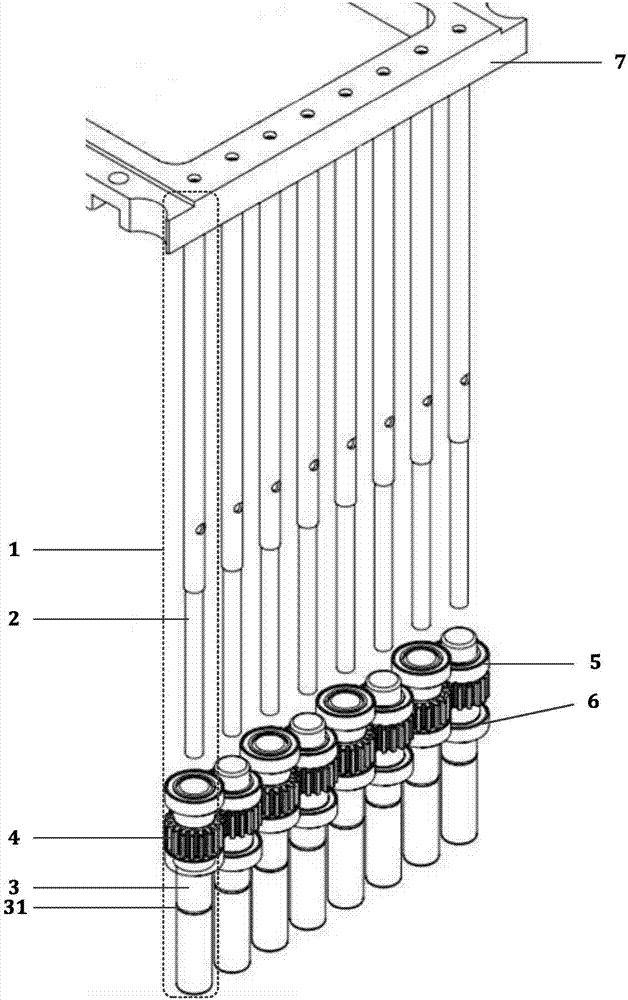

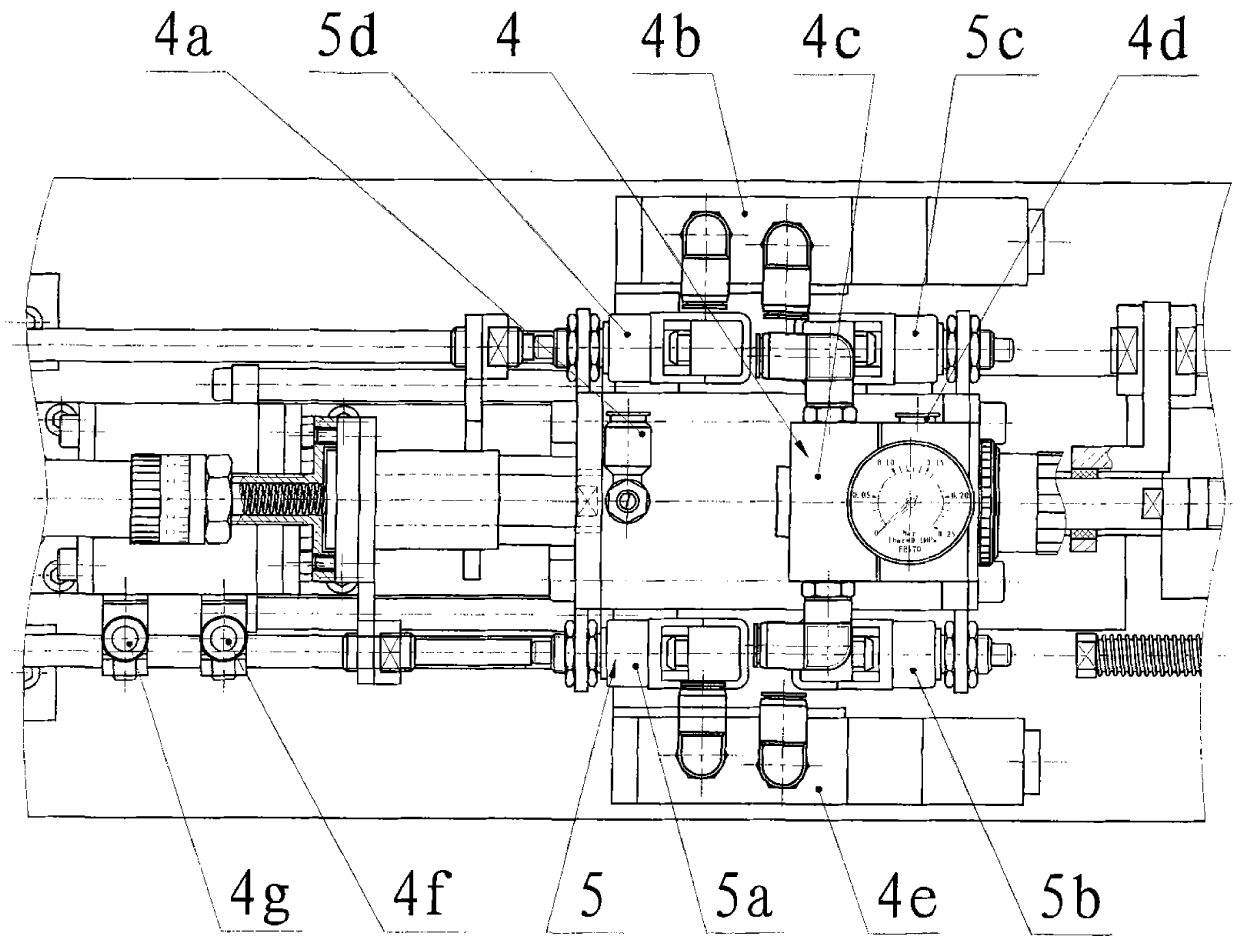

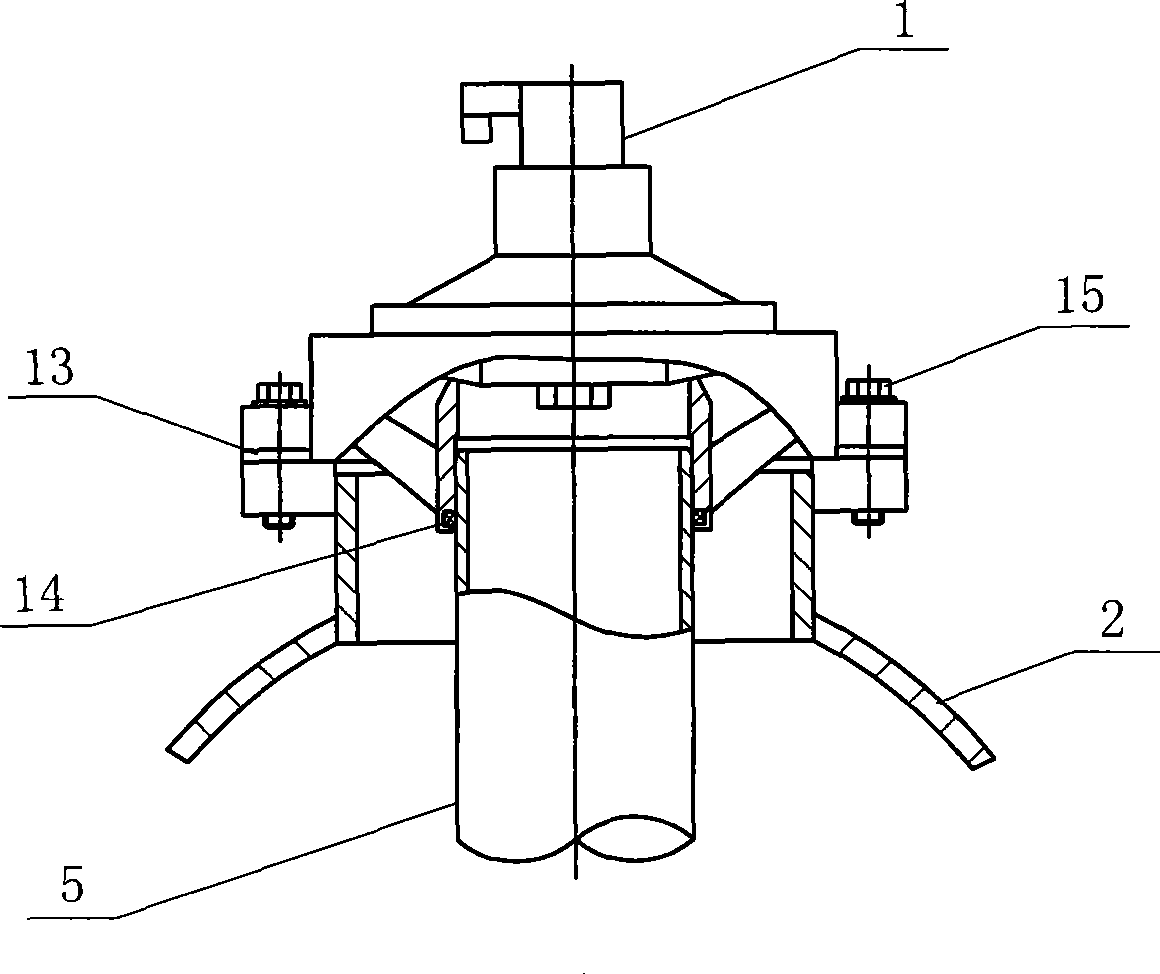

Pre-gluing machine of bolt

ActiveCN101816996AGuaranteed lengthGuaranteed positionLiquid surface applicatorsCoatingsGas cylinderElectric control

The invention discloses a pre-gluing machine of a bolt. The machine is characterized in comprising a gluing head, a gluing opening turning on-off mechanism, a pushing mechanism, an electric control device system, a glue storing cylinder and an adjusting component, wherein the glue storing cylinder is connected with a glue inlet of the gluing head; the gluing head comprises a baffle ring of an opening of a gluing cavity, a gluing cavity sleeve, a gluing cavity sleeve seat, a pushing rod, a gluing cavity, a gluing opening and a glue storing cavity; an annular gluing opening is formed between the baffle ring of the gluing cavity and the gluing cavity sleeve; the pushing mechanism and the gluing opening turning on-off mechanism respectively comprises a gas cylinder; the gluing opening turning on-off mechanism and the pushing mechanism are driven by the gas cylinders to realize the sequential linkage; the pushing rod gradually and axially pushes a bolt of a work piece; glue liquid is peripherally, axially and continuously injected among screw thread teeth of the bolt of the work piece from the gluing opening along the bolt of the work piece; and the adjusting component can adjust the action position of the pushing rod, the turning on-off position of the gluing opening, the opening width of the gluing opening, and the opening pressure of the gluing opening. The pre-gluing machine can peripherally, axially and fast inject the glue into an elastic die cavity, can evenly and exactly glue, guarantees the gluing length and position, and guarantees the quality.

Owner:FAWER AUTOMOTIVE PARTS

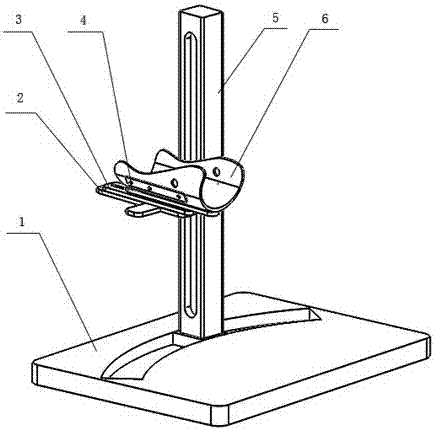

Horizontal leg rehabilitation robot used after lower limb fracture surgery

The invention relates to a horizontal leg rehabilitation robot used after lower limb fracture surgery, and relates to the field of rehabilitation medical instruments. The horizontal leg rehabilitation robot is composed of a base, a lifting platform, a first-stage telescopic rod, a second-stage telescopic rod, a stand column and a protection tool. The lower limb rehabilitation robot has four degrees of freedom, the overall mechanism is controlled by a controller and driven by three servo motor and achieves needed movement through a ball screw structure, a gear-rack structure and the like. When a patient uses the lower limb rehabilitation robot, the robot can be placed on a bed, the patient lies on the bed, the leg needing training is fixed to the protection tool, and after the robot is started, effective training of leg lifting movement, leg stretching and bending movement and lateral direction movement of the leg can be conducted.

Owner:HARBIN UNIV OF SCI & TECH

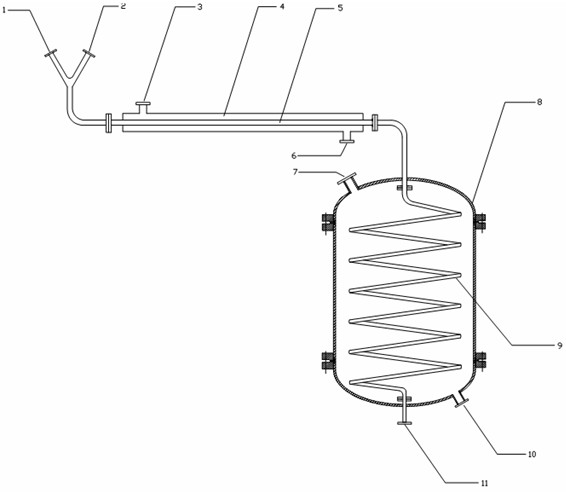

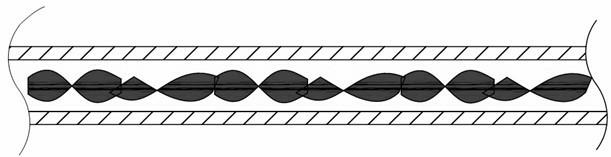

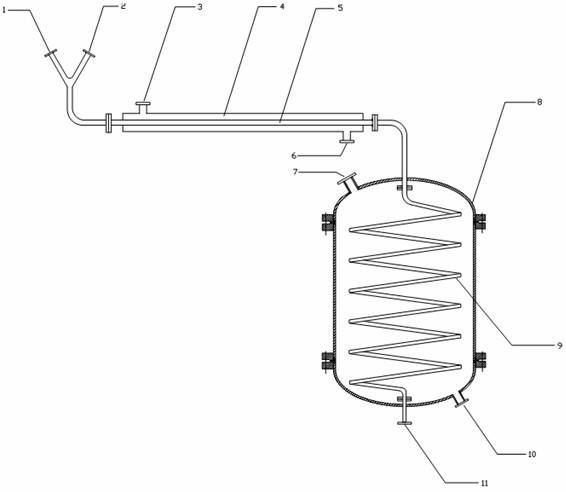

Pipe reactor with static mixing device

InactiveCN102553512AEasy to processImprove the mixing effectFlow mixersChemical/physical/physico-chemical stationary reactorsHeat carrierProcess engineering

The invention discloses a pipe reactor with a static mixing device. The pipe reactor with the static mixing device comprises a Y-shaped fluid feed port, a static mixing device, and a pipe reacting device, wherein the Y-shaped fluid feed port is provided with a fluid inlet A and a fluid inlet B, and the static mixing device comprises a jacket and an SK-type static mixer; a jacketed inlet and a jacket outlet are arranged on the jacket, and the pipe reacting device comprises a reacting device shell and a pipe reactor; a heat carrier inlet and a heat carrier outlet are arranged on the reacting device shell, and one end of the SK-type static mixer is connected with the Y-shaped fluid feed port; and the other end of the SK-type static mixer is connected with the pipe reactor. According to the pipe reactor with the static mixing device, two streams of fluids have a good mixing effect at a low flow and a flow rate, the mixing and the reaction process of the two streams of fluids are carried out at different temperatures, and part of raw material is avoided being pre-reacted, so that the mixing and the reaction process of the two streams of fluids are safer and more stable. The pipe reactor with the static mixing device is suitable for the mixing reaction process of the two streams of fluids at a low flow and a flow rate.

Owner:ZHEJIANG UNIV

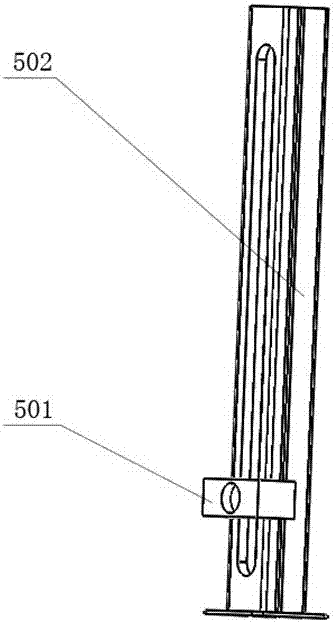

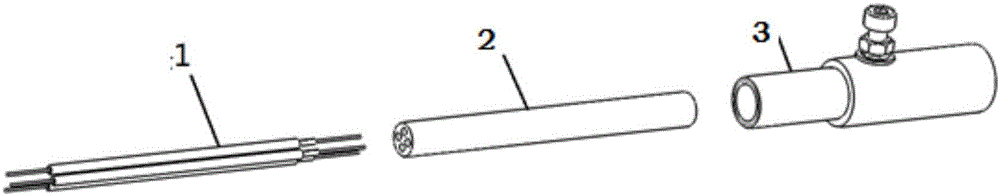

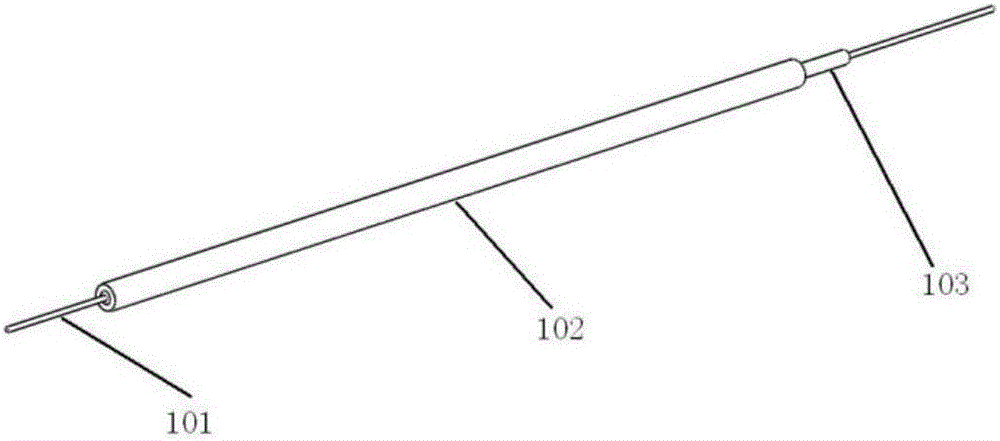

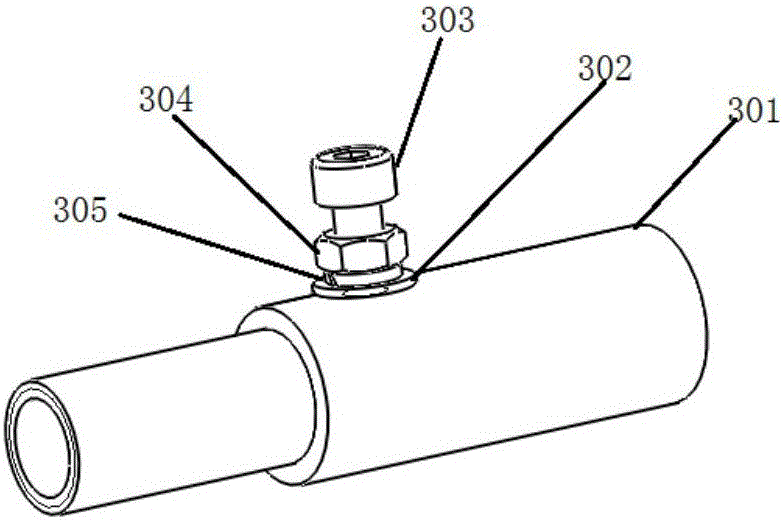

Cylindrical probe used for plume measurement of magnetic plasma thrustor

The invention discloses a cylindrical probe used for plume measurement of a magnetic plasma thrustor. The cylindrical probe includes single probe modules, a four-hole ceramic tube and a Langmuir probe protection tube module. The single probe module includes a thick single-hole ceramic tube, a thin single-hole ceramic tube and a tungsten filament. One end of the thin single-hole ceramic tube and one end of the thick single-hole ceramic tube are flush to each other and are fixed to each other. The tungsten filament is inserted to the thin single-hole ceramic tube. An end face of the four-hole ceramic tube is provided with four through holes. Three identical single probe modules are inserted into three of the four through holes. The Langmuir probe protection tube module includes a protection tube, a flat gasket, a fastening screw, a nut and a spring gasket. The four-hole ceramic tube with the fixed single probe modules is inserted from the protection tube and gets fixed. The cylindrical probe provided by the invention has advantages that the four-hole ceramic tube, the thick single-hole ceramic tube, the thin single-hole ceramic tube and the tungsten filament made of aluminum oxide which is common in market can bear plume temperature of the magnetic plasma thrustor; structural stability can be kept through clearance fit; and the cylindrical probe is simple in structure.

Owner:BEIHANG UNIV

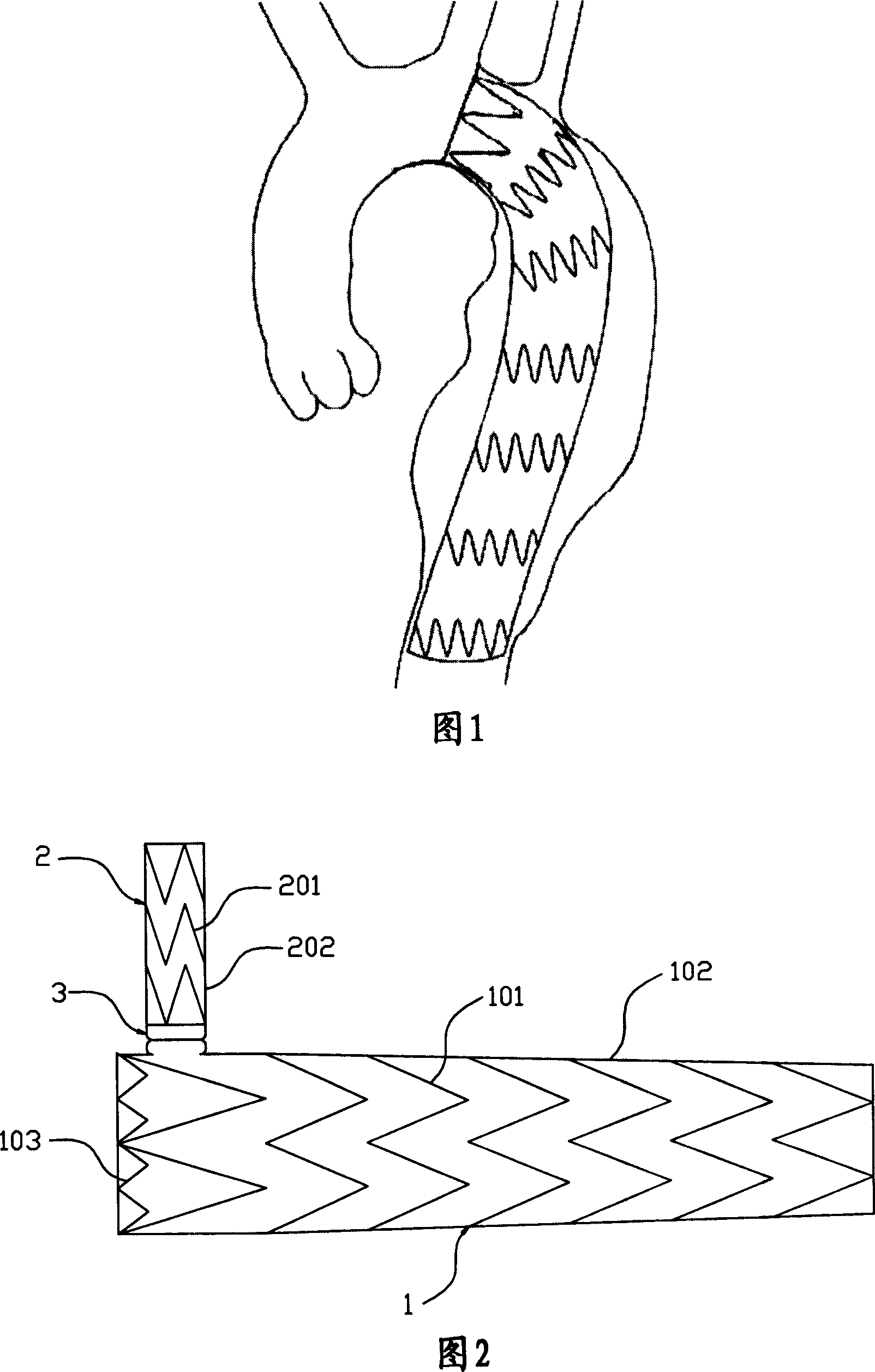

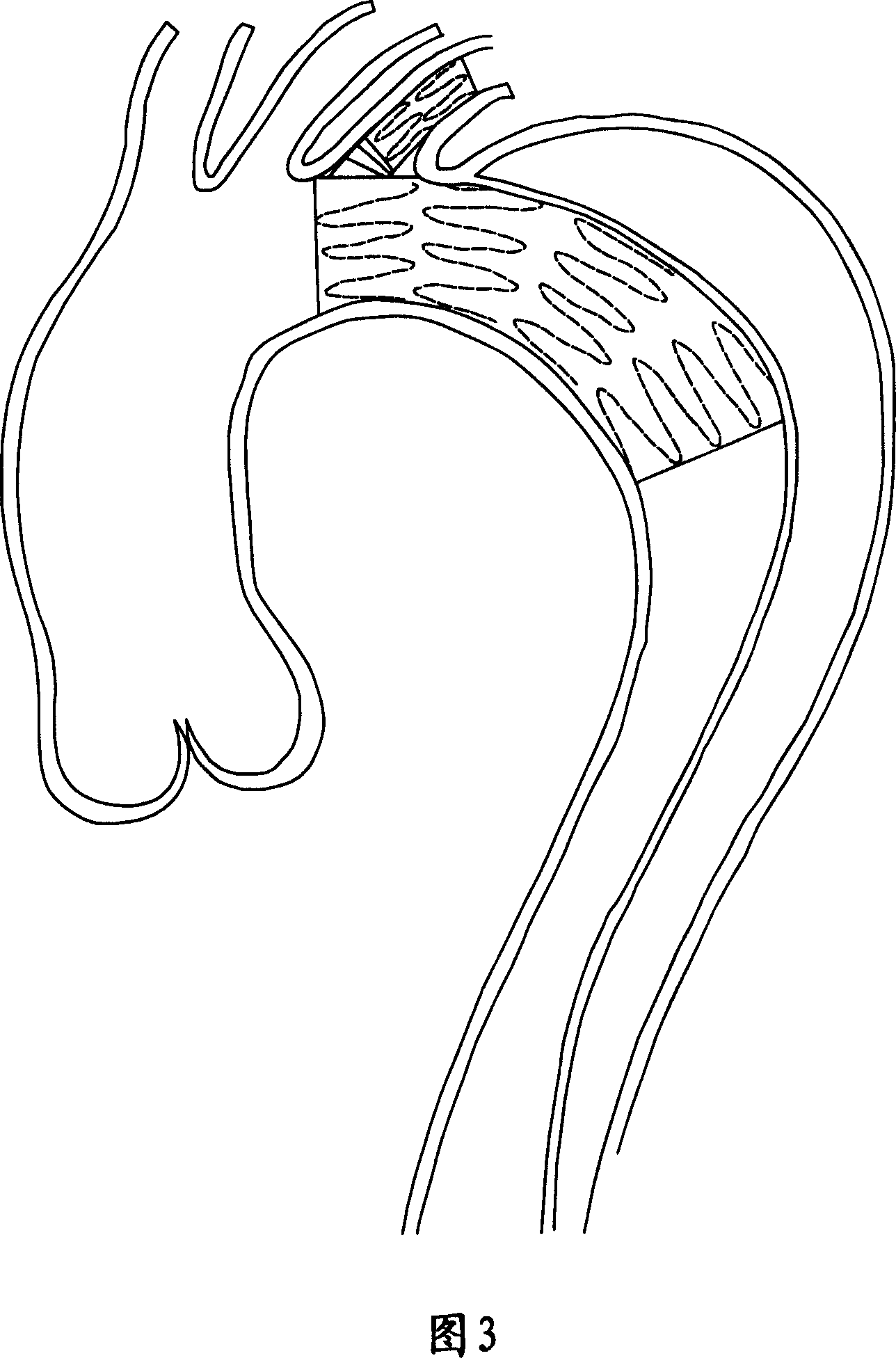

Collateral covered graft-stent and releasing method thereof

The invention discloses a collateral typed tectorial rack, which comprises the following parts: host, collateral, flexible connecting part of host and collateral, wherein the flexible connecting part is artificial vessel. The invention also provides releasing method of collateral typed tectorial rack, which comprises the following steps: loading the rack into transmitter pipe; making collateral on the front end of host; overlapping flexible connecting part and adjacent end of host; separating collateral from host when reducing main artery; leading the collateral into left claviculate lower artery; releasing host and collateral with random angle after the host reaches the position; fitting for any patient to be transplanted into main artery easily.

Owner:许尚栋 +1

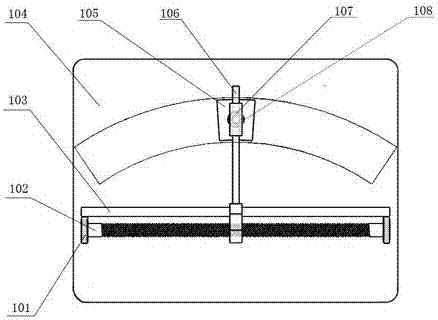

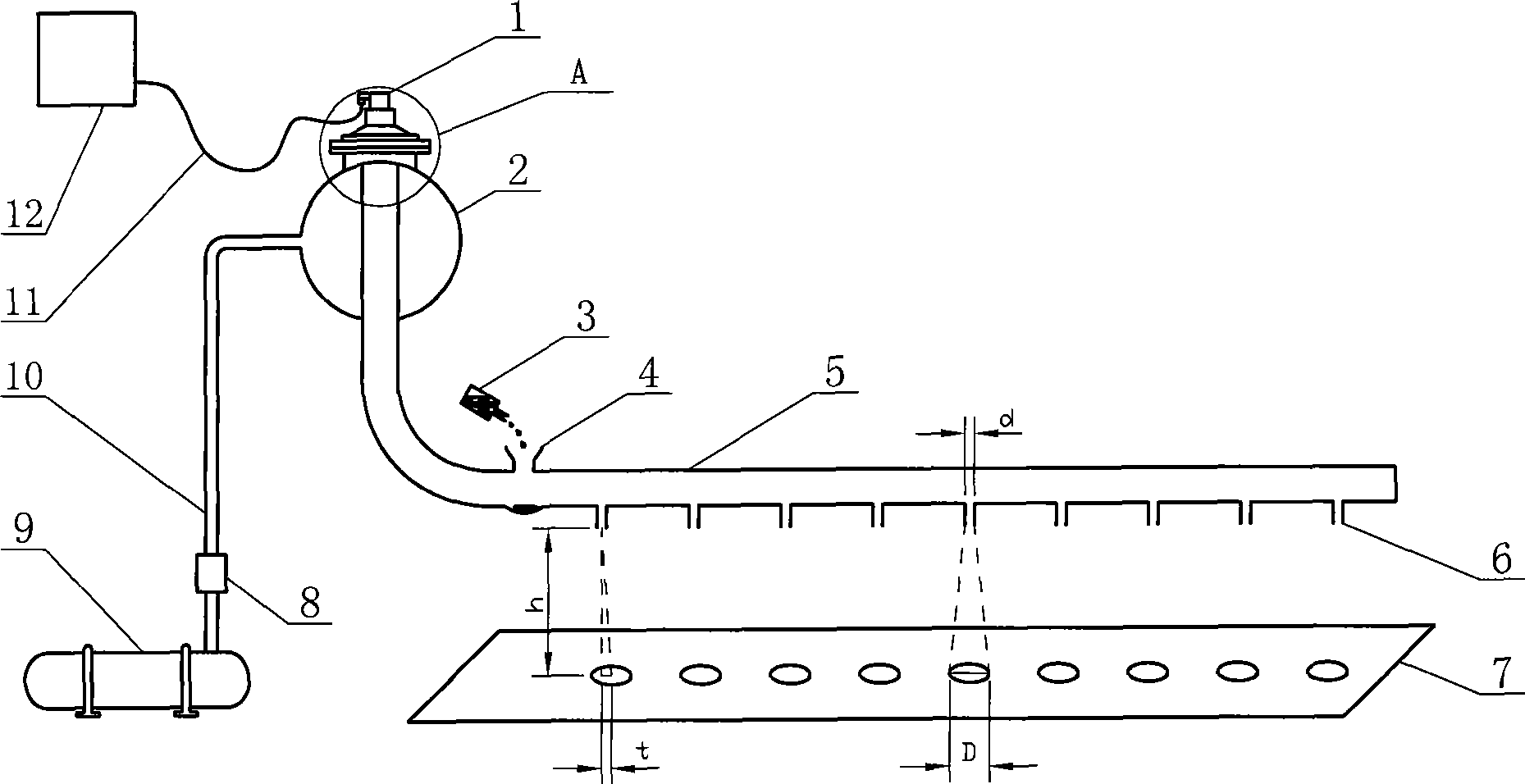

Test device and method for impulse blowing jet stream included angle and jet stream declination angle

InactiveCN101504281AExtended service lifeGuaranteed lengthUsing fluid meansEngineeringAir compressor

The invention discloses a device and a method for testing the pulse blowing jet included angle and the jet offset angle. The test device comprises a pulse valve, a gas bag, a blow pipe provided with a plurality of nozzles, a gas source processor, an air compressor and a pulse controller, wherein a filling port is arranged on the blow pipe; and an image net board is arranged below the blow pipe. The test method comprises: firstly, filling a colorful developing solution into the filling port, releasing air through pulse of the pulse valve, and spraying the colorful developing solution onto the image net board through the nozzles to form a jet image; secondly, measuring the diameter D and the offset t of the image; and thirdly, calculating the jet included angle and the jet offset angle according to the diameter d of the nozzles and the distance h between the nozzles and the image net board, namely through a formula 2arctan((D-d) / 2h) and arctan(t / h). The invention can accurately calculate the jet included angle and the jet offset angle and apply the obtained data to engineering design, makes blown air flow capable of covering the length of the whole filter bag, strengthens the ash removal effect, and prolongs the service life of the filter bag.

Owner:JIEHUA HLDG

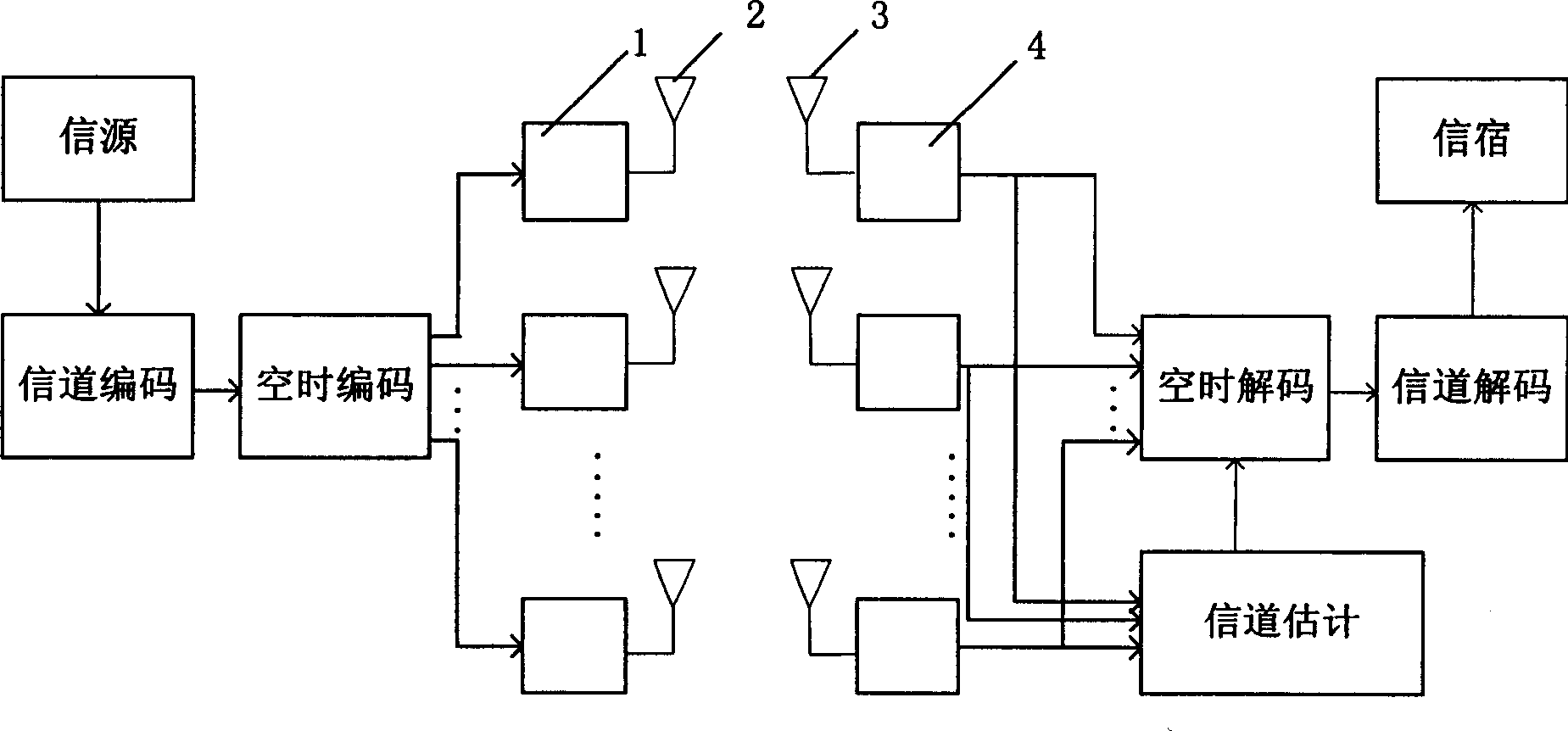

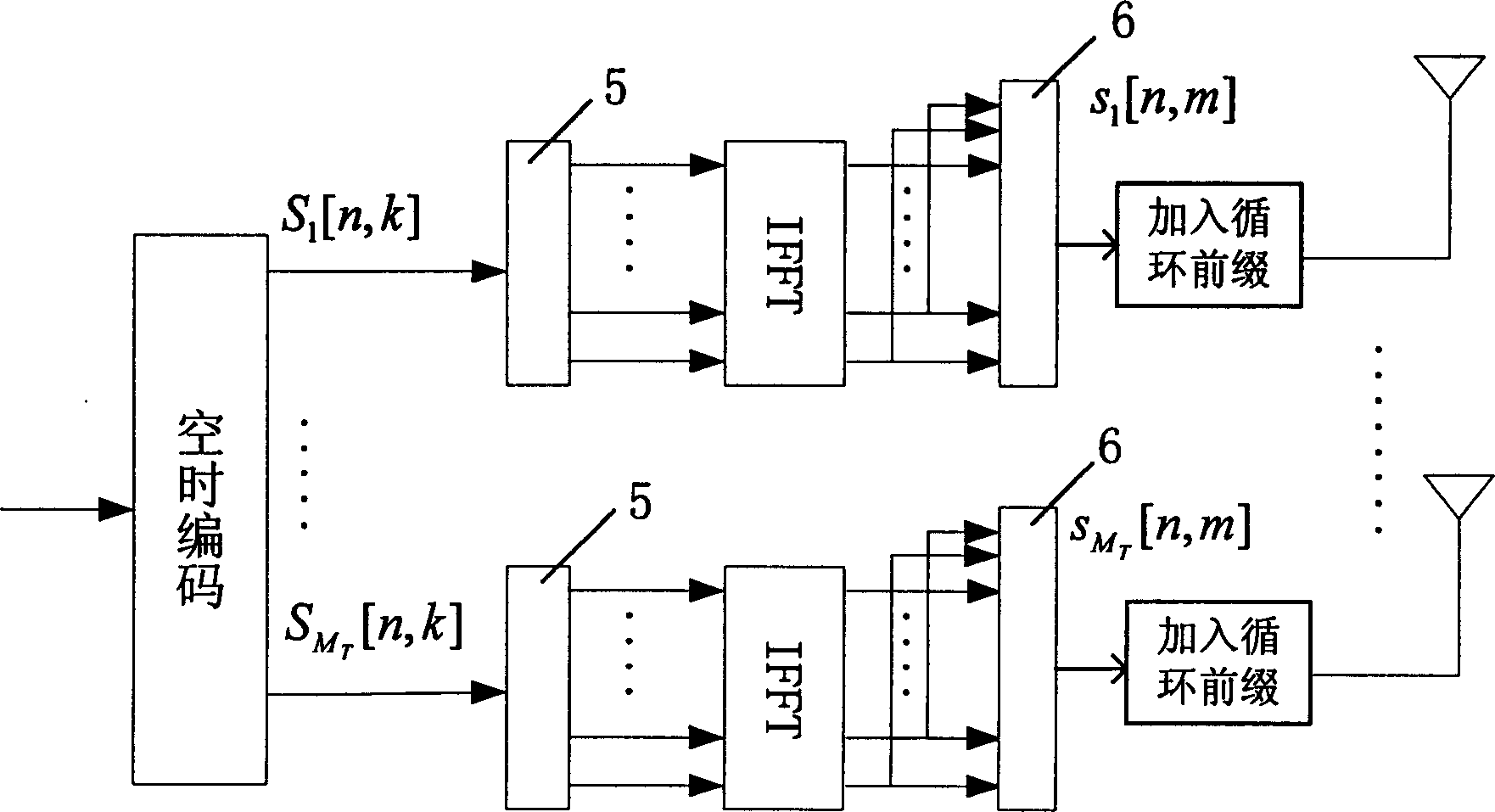

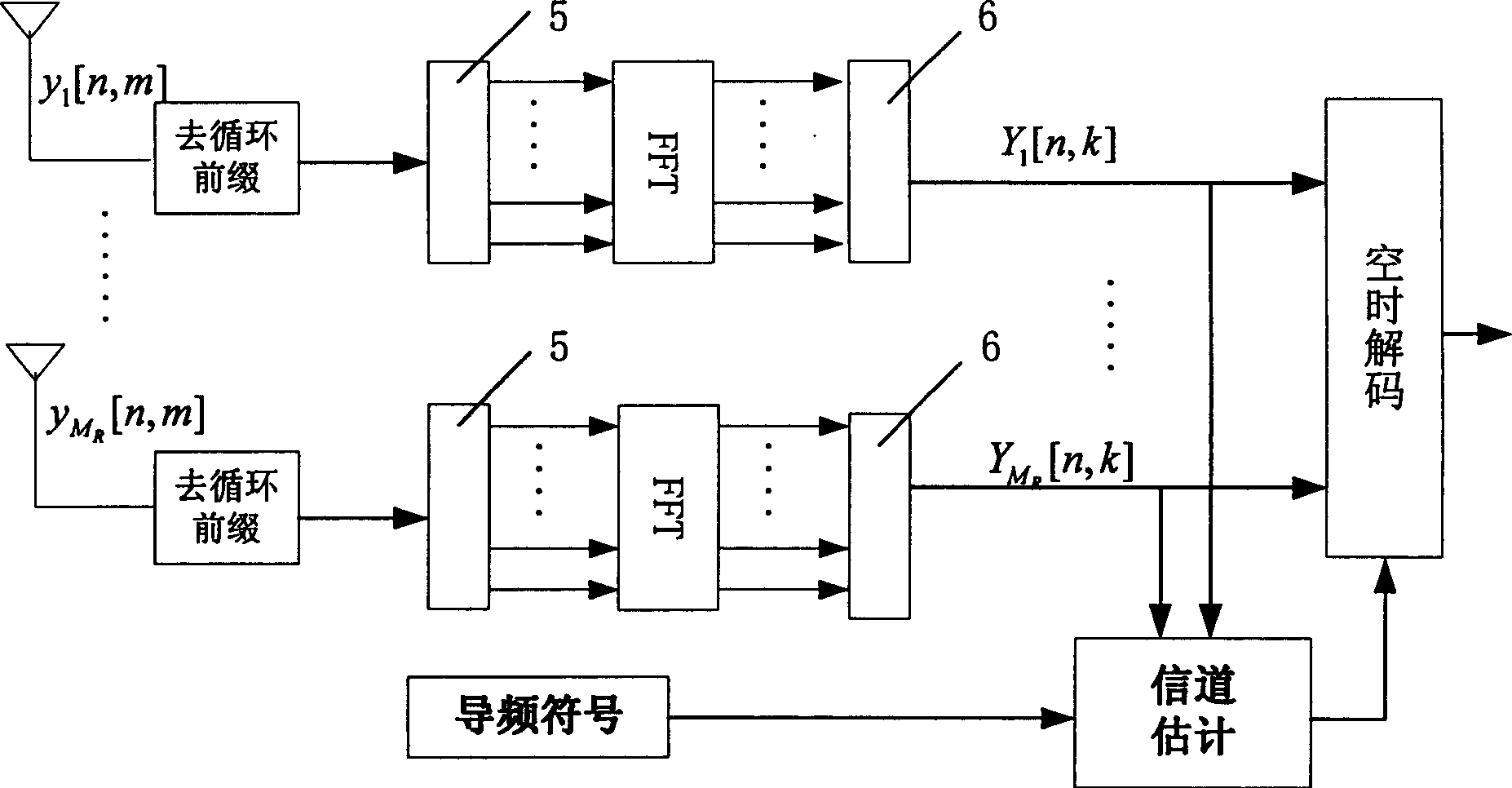

Channel estimating method in MIMO-OFDM system

InactiveCN1801792ASave Spectrum ResourcesImprove spectrum utilizationBaseband system detailsRound complexityFrequency spectrum

Present invention discloses semi-blind channel estimation method in MIMO -OFDM system. It contains replacing original OFDM circulate prefixion to training sign to estimate channel. Transmitted-data is divided into training sign and data transmission OFDM sign, wherein training sign constituting fine self-correlation and poor cross-correlation sequence for substituting circulate prefixion, resisting ISI and ICI and establishing channel estimated initial parameter, data transmission OFDM sign composed of data sign channel estimate algorithm adopting Wiener's algorithm. Said invention has higher frequency spectrum efficiency and data-signalling rate and lower operating complexity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Double-headed cutting machine

InactiveCN101695772AHigh positioning accuracyGuaranteed lengthMetal sawing devicesEngineeringFuselage

The invention discloses a double-headed cutting machine which can regulate the cutting range. The double-headed cutting machine comprises a machine body and two sets of cutting devices, wherein a fixing platform is arranged on the machine body, a pair of mutually parallel guide rails are also arranged on the machine body, a movable platform is arranged on the pair of guide rails in a sliding way, a fine-regulating positioning device is arranged between the guide rails and the movable platform, the fixing platform and the movable platform are respectively provided with a pair of clamps, and the two sets of cutting devices are respectively arranged on the fixing platform and the movable platform. The invention can regulate the distance between the movable platform and the fixing platform according to actual requirements, thereby broadening the application range of the double-headed cutting machine.

Owner:ZHANGJIAGANG MINGHUA MACHINERY MFG

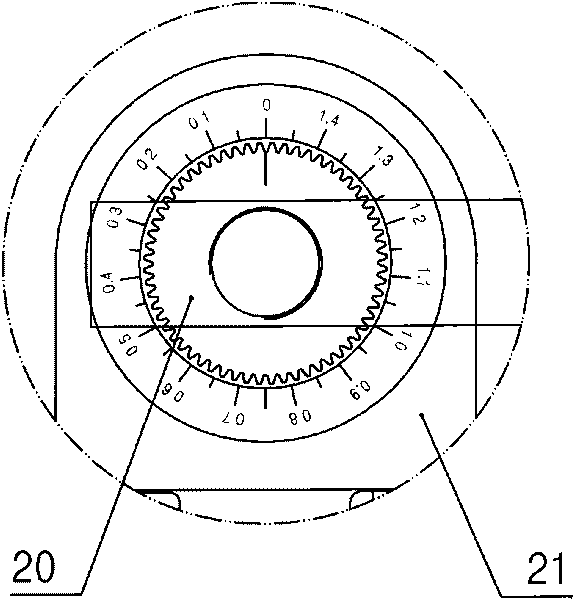

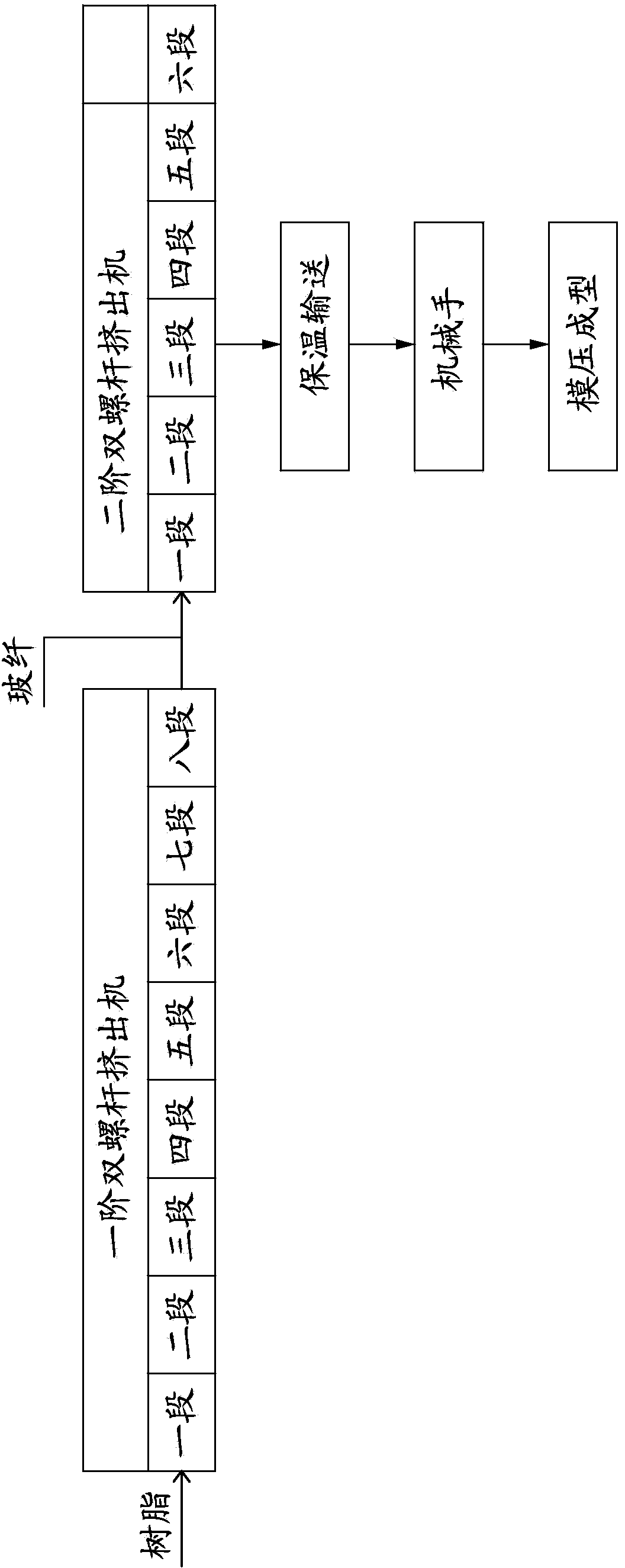

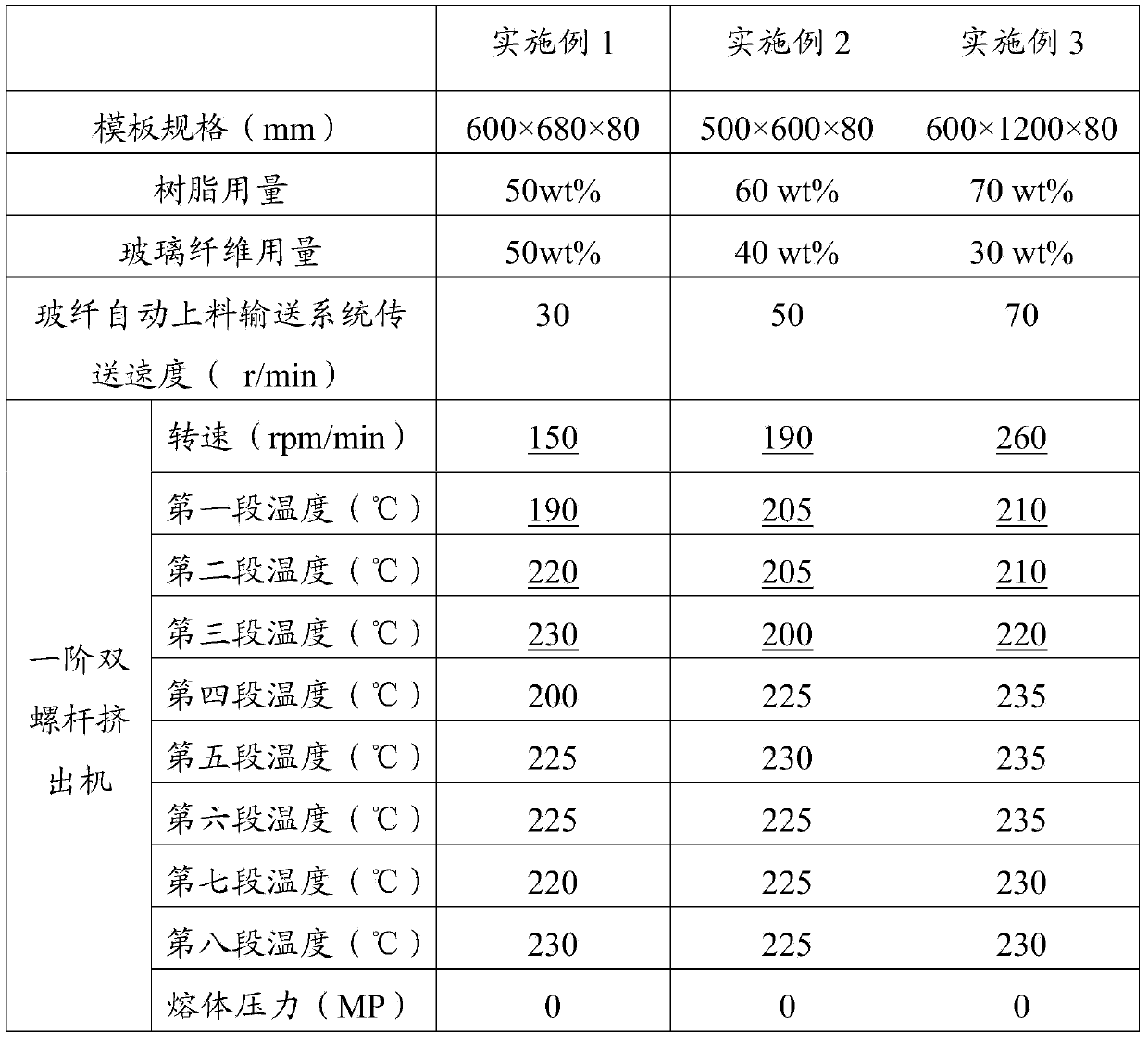

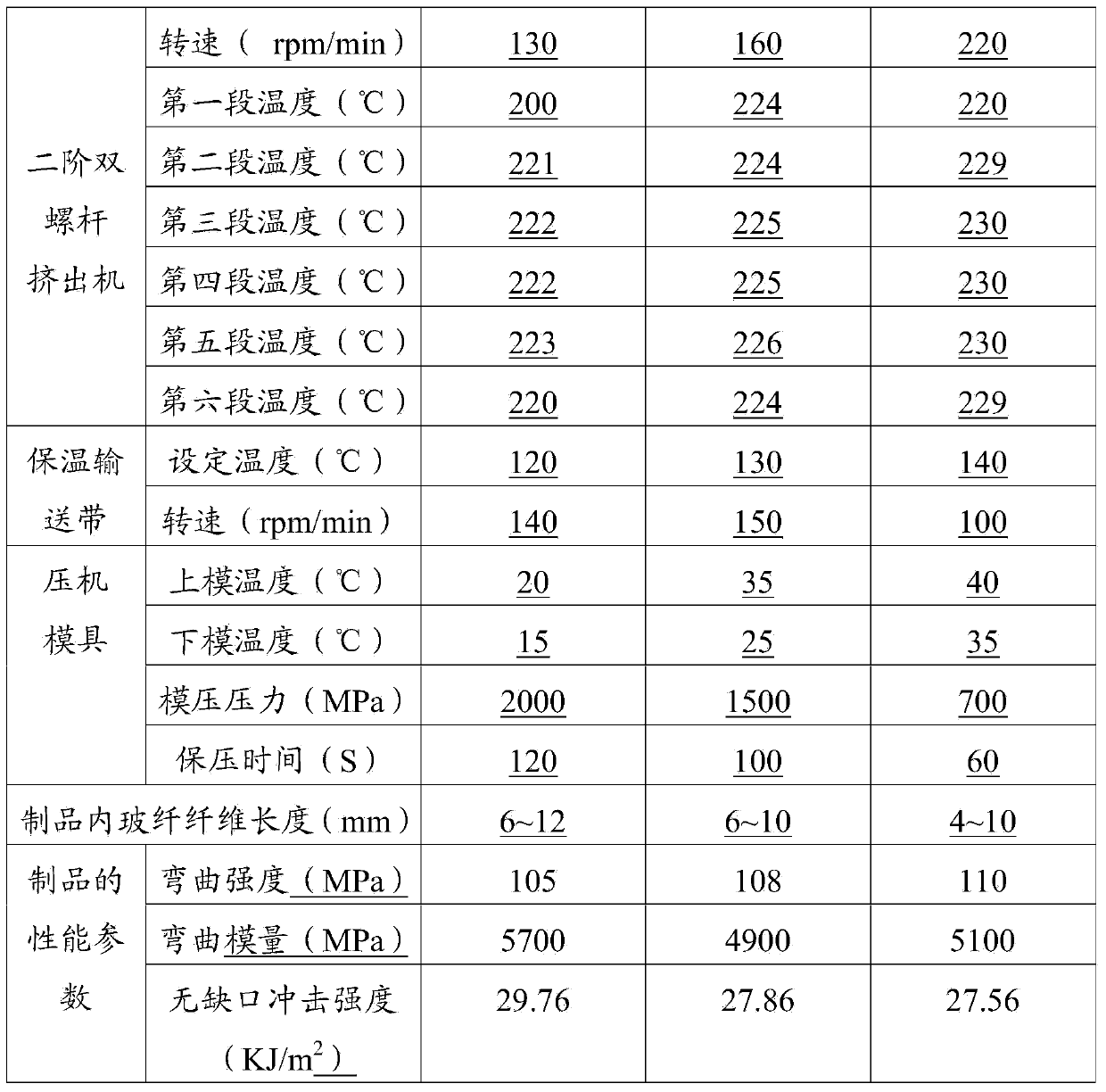

LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of composite building template

The invention provides an LFT-D (Long Fiber Reinforced Thermoplastic Direct) forming process of a composite building template. The forming process comprises the following steps of (10) performing quantitative measurement on resin from a vacuum feeding system to a vector type weighing system according to the weight of the template; then feeding the resin to a first-stage twin-screw extruder to be heated and fused; feeding into a second-stage twin-screw extruder in a feed opening of the second-stage twin-screw extruder together with glass fibers, so as to be mixed and plasticized, wherein the glass fibers are cut according to the set length of 24 to 25mm by a glass fiber measuring and cutting device and then are added into the fused resin; performing the secondary length change under the shearing action of the fused resin; and (20) uniformly plasticizing by the second-stage twin-screw extruder, cutting raw materials by a second-stage screw die cutter according to the weight of the template, then insulating and conveying to a material taking and displacement position and putting the raw materials into a press mold by a manipulator for pressing and forming. By using the forming process, the glass fibers in a product are long, and the performance of a product is effectively improved.

Owner:福建易安特新型建材有限公司

Fixed-length cutting device for stainless steel tube

ActiveCN109719570ACompact and reasonable structure designEasy to useMeasurement/indication equipmentsFeeding apparatusEngineeringLength measurement

The invention discloses a fixed-length cutting device for a stainless steel tube. The fixed-length cutting device for a stainless steel tube comprises a cutting platform and a cutting head group, andfurther comprises a length determining assembly and a clamping assembly; the left side end of the cutting platform is provided with an opening groove, a cutting panel is arranged in the opening groove, and a material collecting box is arranged under the cutting panel; and the length determining assembly comprises a fixed side plate, positioning screws and a positioning pressing plate, the fixed side plate is located over the left end of the opening groove and fixedly connected with the top face of the cutting platform, the positioning screws are symmetrically arranged on the front side and theback side of the fixed side plate, and the two ends of the positioning pressing plates are arranged on the two positioning screws in a sleeving mode separately. According to the fixed-length cuttingdevice for the stainless steel tube, the structure is simple, the practicability is high, operation is easy, use is convenient, not only can the cutting rate and the cutting precision of the stainlesssteel tube be improved, but also the cutting length standard can be guaranteed every time only through one time of cutting length measurement, the manual labor intensity is effectively reduced, the error rate brought by each time of manual measurement is decreased, and resources and the cost are saved.

Owner:ANHUI KINGWE PIPE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com