Patents

Literature

90 results about "Scale height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In various scientific contexts, a scale height, usually denoted by the capital letter H, is a distance over which a quantity decreases by a factor of e (the base of natural logarithms, approximately 2.718).

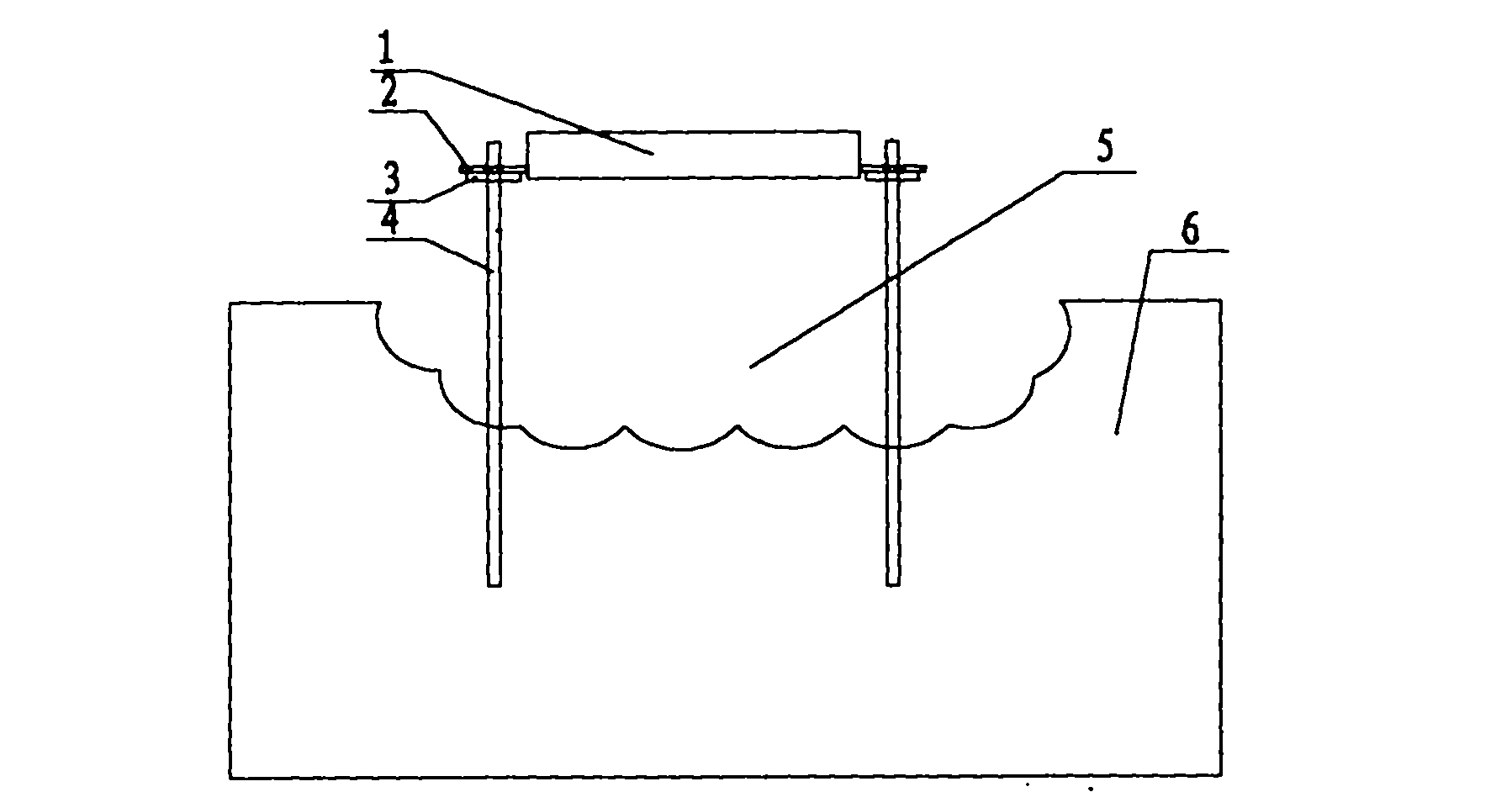

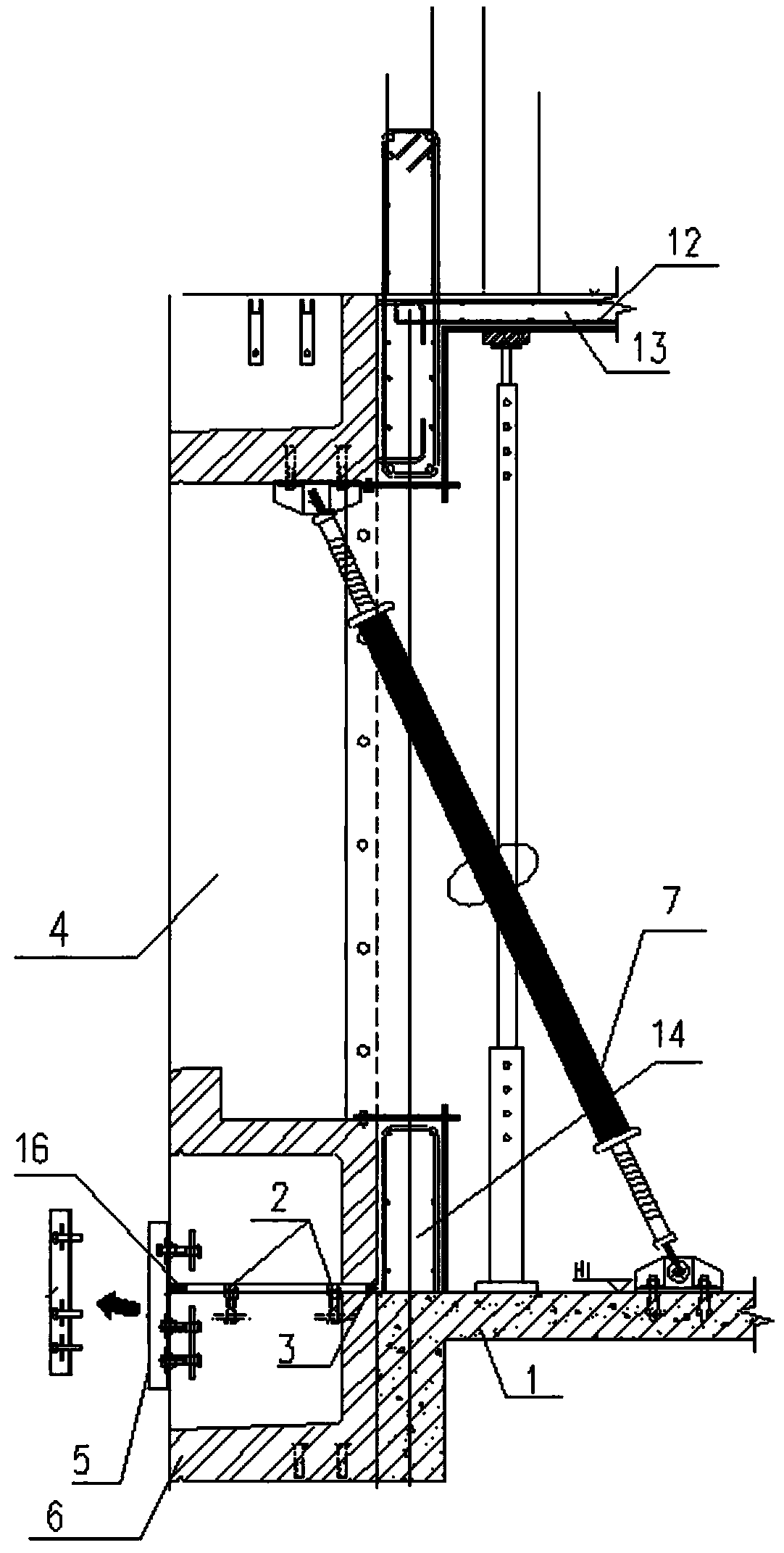

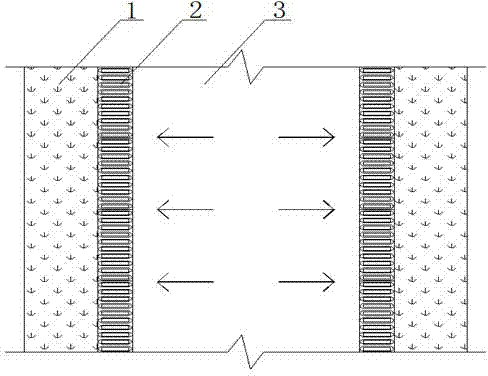

Diaphragm wall and construction method thereof

InactiveCN102312445AGuarantee the stability of the tank wallBreak hydraulic connectionArtificial islandsExcavationsSlurry wallSlag

The invention discloses a diaphragm wall and a construction method thereof, wherein the construction method is carried out according to the following steps: step 1, the underground obstacles at the trench section position and the two sides of the trench section of the diaphragm wall are cleared; step 2, two ranges of cement stirring piles are respectively and symmetrically distributed at the two inner sides of the trench section of the diaphragm wall to reinforce; step 3, an integral pouring type concrete guide wall is formed at the top parts of the cement stirring piles, the cross section of the guide wall is L-shaped, one end of the guide wall is arranged at the inner sides of the cement stirring piles, and the other end of the guide wall crosses the top parts of the cement stirring piles; after the guide wall is built, an integral pouring type concrete rigid terrace is formed at the other end of the guide wall; step 4, the trench construction is carried out between the two ranges of cement stirring piles through a trench machine, and the bentonite mud is adopted in the trench section to protect the wall during the trenching; step 5, after the trenching is completed and reaches the scale height, slags of the trench bottom are removed, a diaphragm wall reinforcement cage is hoisted to be placed in the trench section, and a guide pipe method is adopted to carry out underwater concrete pouring; and step 6, after the concrete reaches the design strength, high pressure grouting is carried out on the bottom of the diaphragm wall. The diaphragm wall can integrate soil blocking, water resisting and bearing into a whole through the method, so good social and economic benefits are obtained.

Owner:CCCC THIRD HARBOR CONSULTANTS

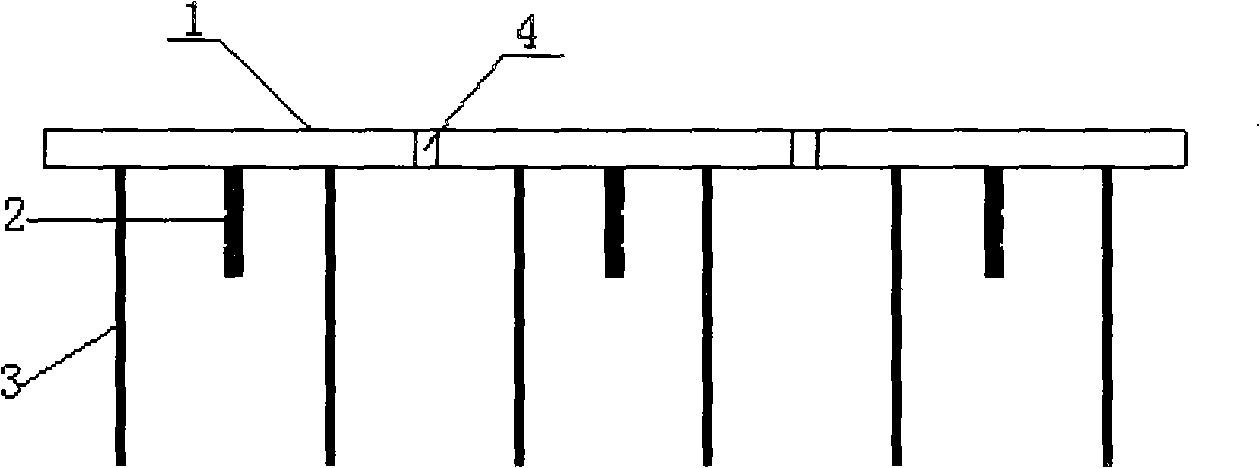

Flat shim plate-adjustable grouting installation method

ActiveCN101871265AImprove construction qualityShort construction periodFoundation engineeringBuilding material handlingSteel columnsScale height

The invention relates to a flat shim plate-adjustable grouting installation method, belonging to a method for installing a steel column or a device. The method comprises the following steps: symmetrically welding rectangular plates with holes on the back and forth of the left side and the right side of a flat shim plate at intervals; cutting a grouting pit outside the foundation bolt or the preset hole of the concrete foundation of an installation device; arranging four screw holes which are arranged into a rectangle in the grouting pit; correspondingly and vertically plugging four screws the upper ends of which are respectively screwed with a regulating nut into the four screw holes; correspondingly sheathing the holes on the four rectangular plates of the flat shim plate onto the four screw in a penetrating mode so that the flat shim plate is supported on the regulating nuts; utilizing the regulating nuts to regulate the scale height and the levelness of the flat shim plate; leveling the flat shim plate for the fist time, arranging a grouting box on the foundation surface at the periphery of the grouting pit and placing a grouting material into the grouting box; when the grouting material is prehardened, utilizing the regulating nuts to accurately level the flat shim plate so that both the scale height and the levelness of the flat shim plate reach the installation requirements. When the steel column or the device is installed, an inclined shim plate is not needed for leveling, thus the method is convenient and speedy.

Owner:CHINA MCC17 GRP

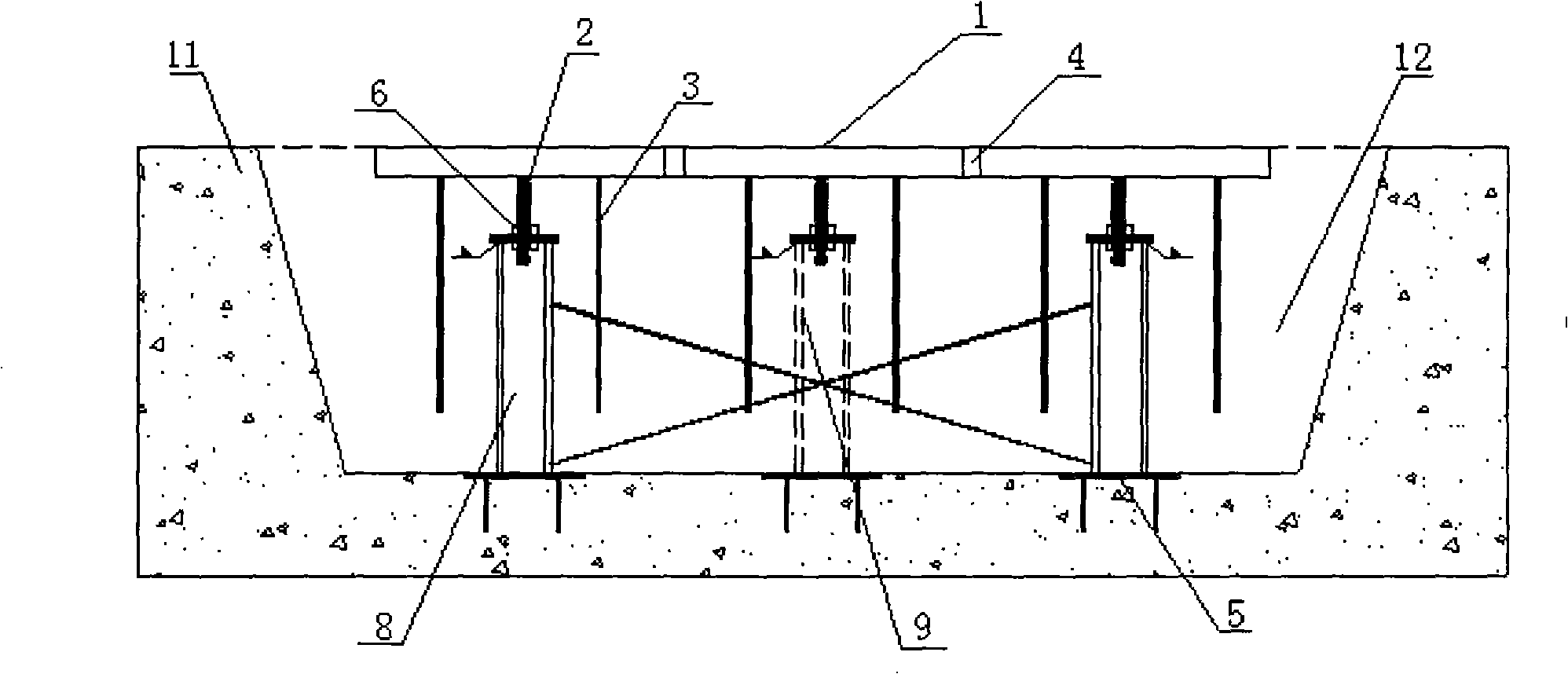

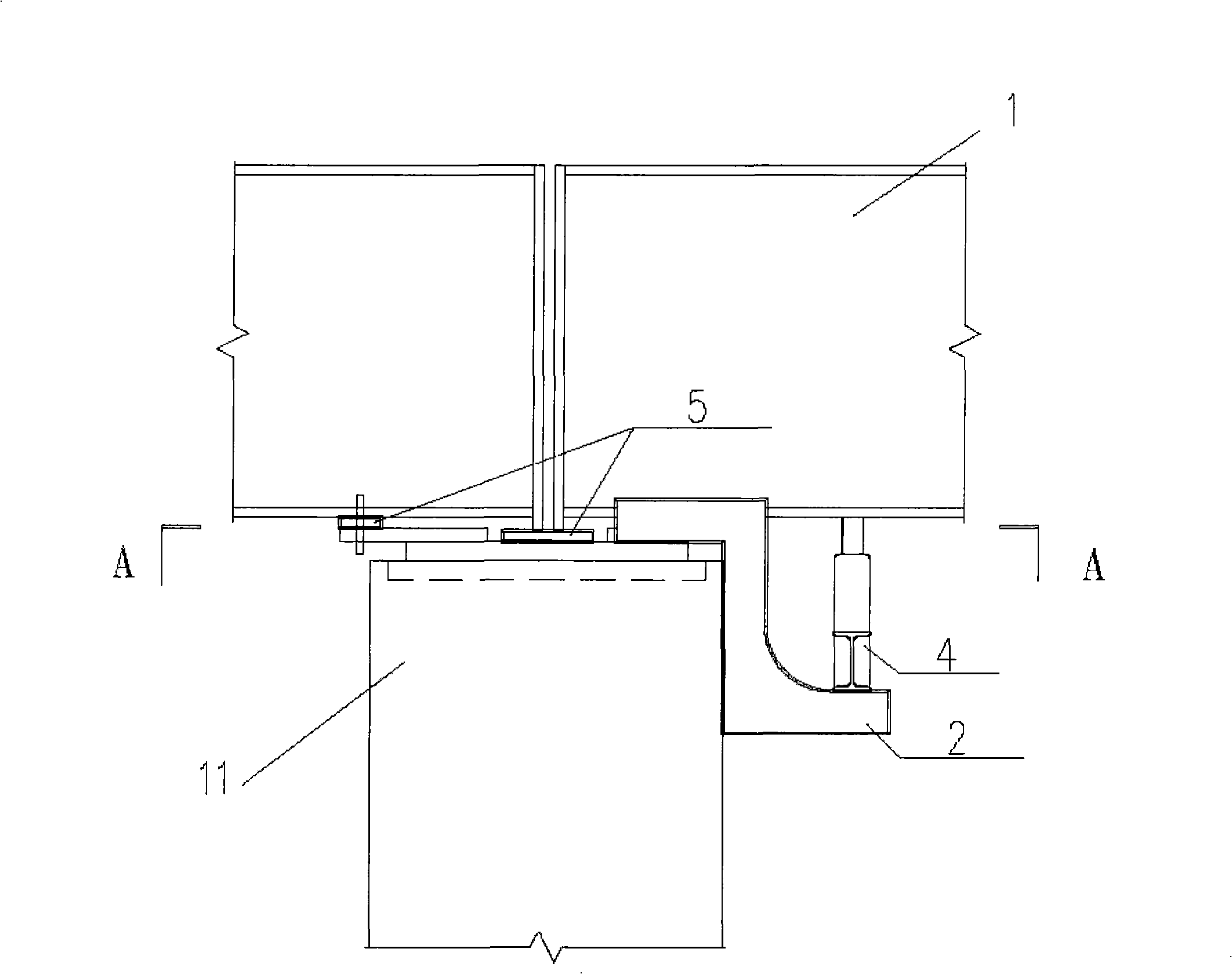

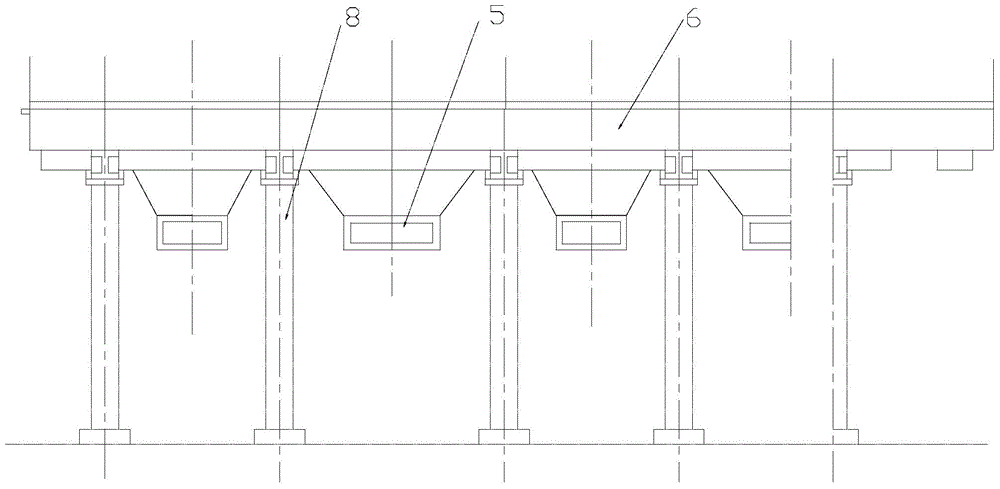

High precision apparatus foundation mounting method

InactiveCN101307605AMeet the installation requirementsHigh precisionFoundation engineeringFixed frameEngineering

The invention relates to a method for assembling a high-precision equipment pedestal, comprising the following steps that: firstly, the flatness of the pedestal (1) is inspected; secondly, the pedestal is placed into structural concrete (11); thirdly, the pedestal (1) is adjusted initially for being in place; fourthly, the pedestal (1) is adjusted accurately; fifthly, concrete (12) is placed. The method adopts equipment pedestal auxiliary bolts and mounting of fixed frames for high-precision adjustment of the scale height and the flatness of the pedestal so as to meet the requirements of equipment assembly, thereby the assembly precision is greatly improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

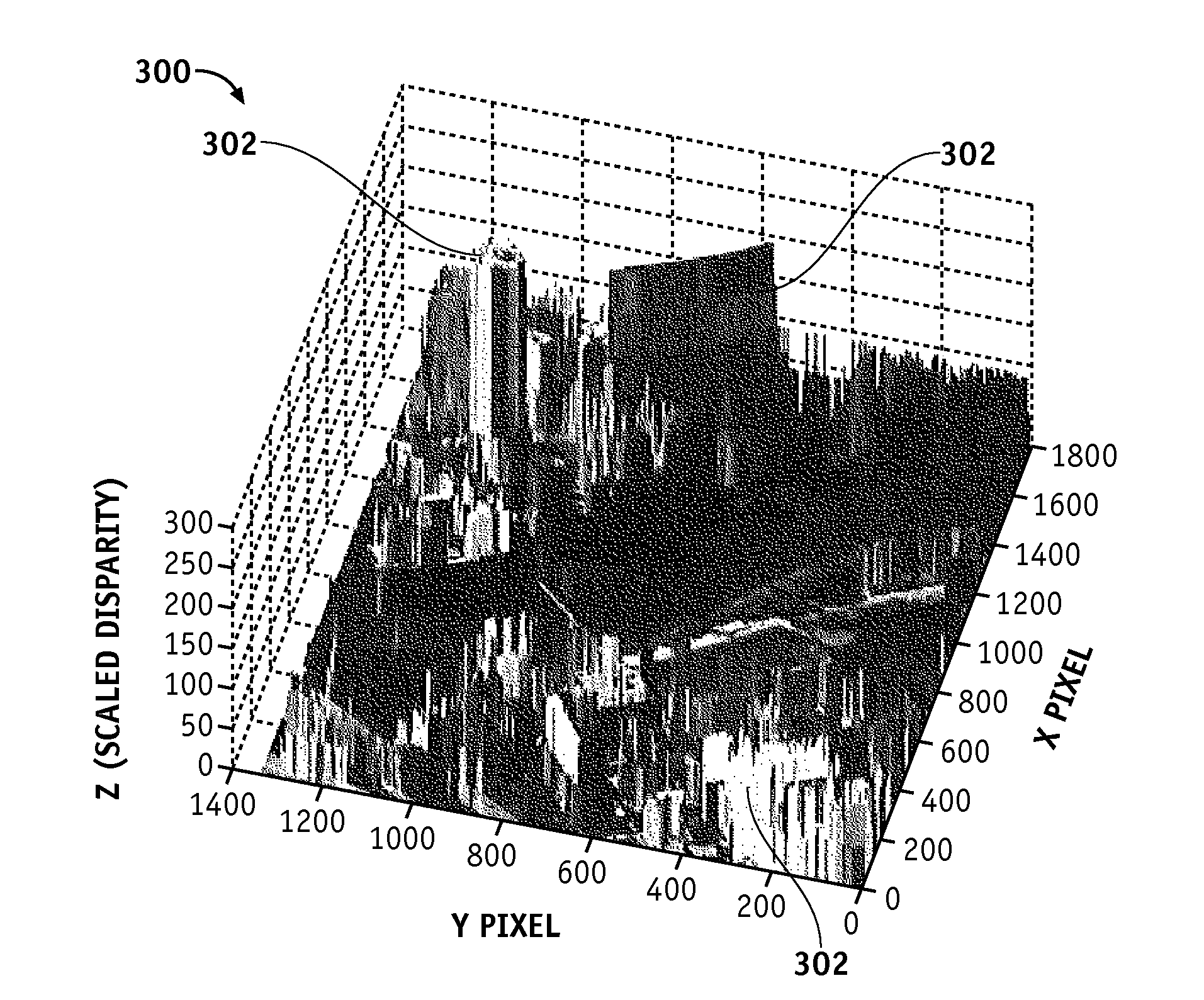

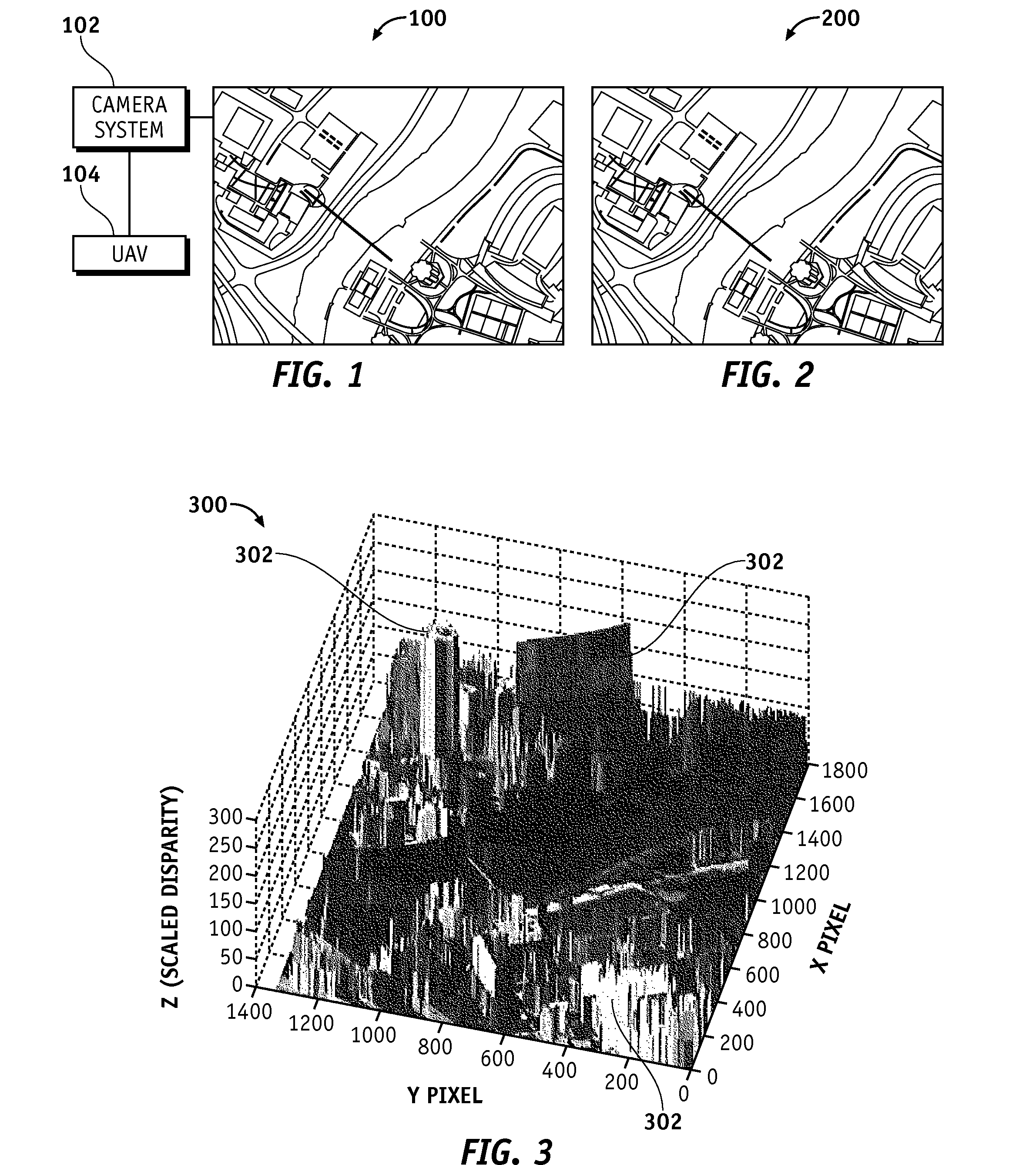

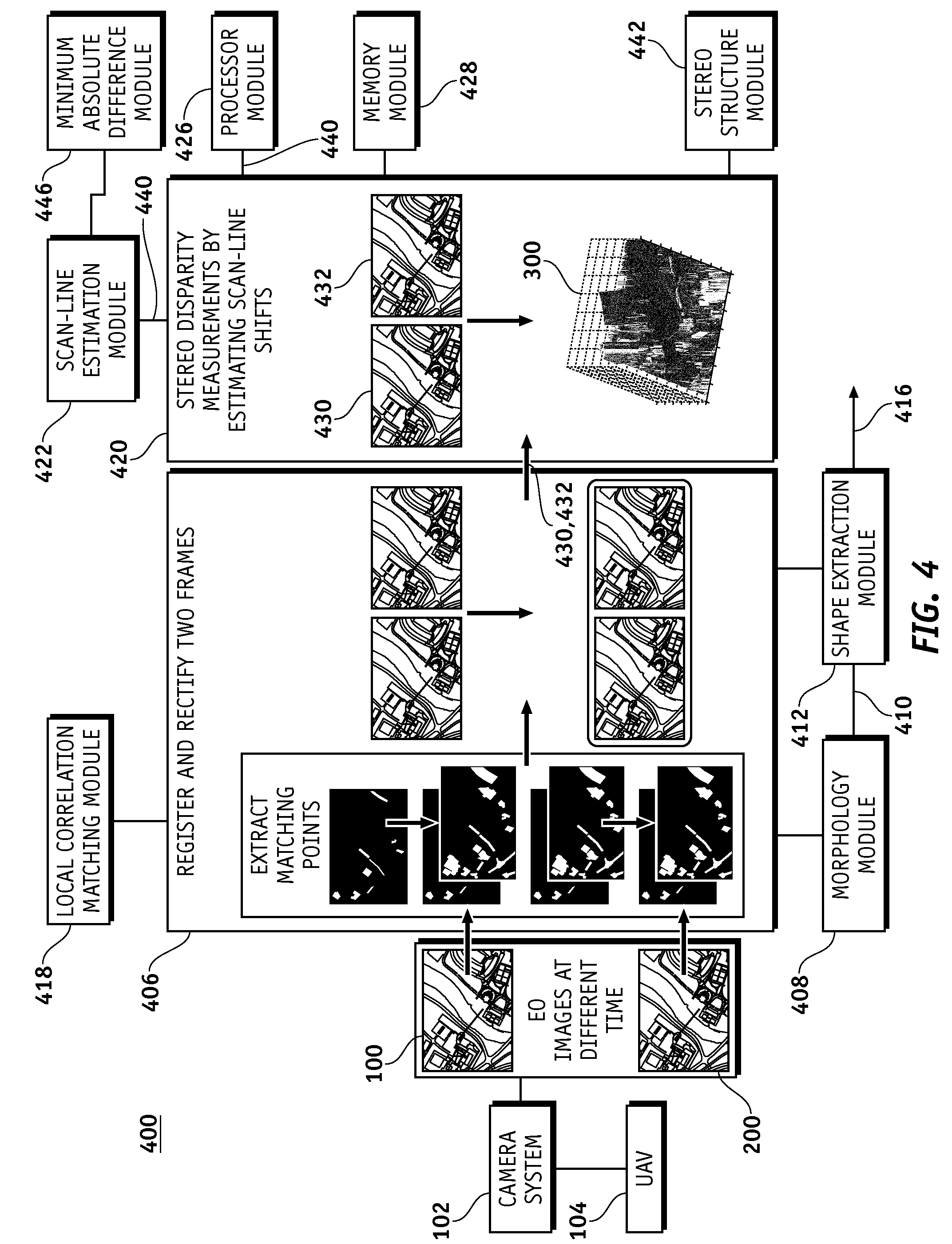

Stereo-motion method of three-dimensional (3-d) structure information extraction from a video for fusion with 3-d point cloud data

According to an embodiment, a method for generating a 3-D stereo structure comprises registering and rectifying a first image frame and a second image frame by local correction matching, extracting a first scan line from the first image frame, extracting a second scan line from the second image frame corresponding to the first scan line, calculating a pixel distance between the first scan line and the second scan line for each pixel for a plurality of pixel shifts, calculating a smoothed pixel distance for each pixel for the pixel shifts by filtering the pixel distance for each pixel over the pixel shifts, and determining a scaled height for each pixel of the first scan line, the scaled height comprising a pixel shift from among the pixel shifts corresponding to a minimal distance of the smoothed pixel distance for the pixel.

Owner:THE BOEING CO

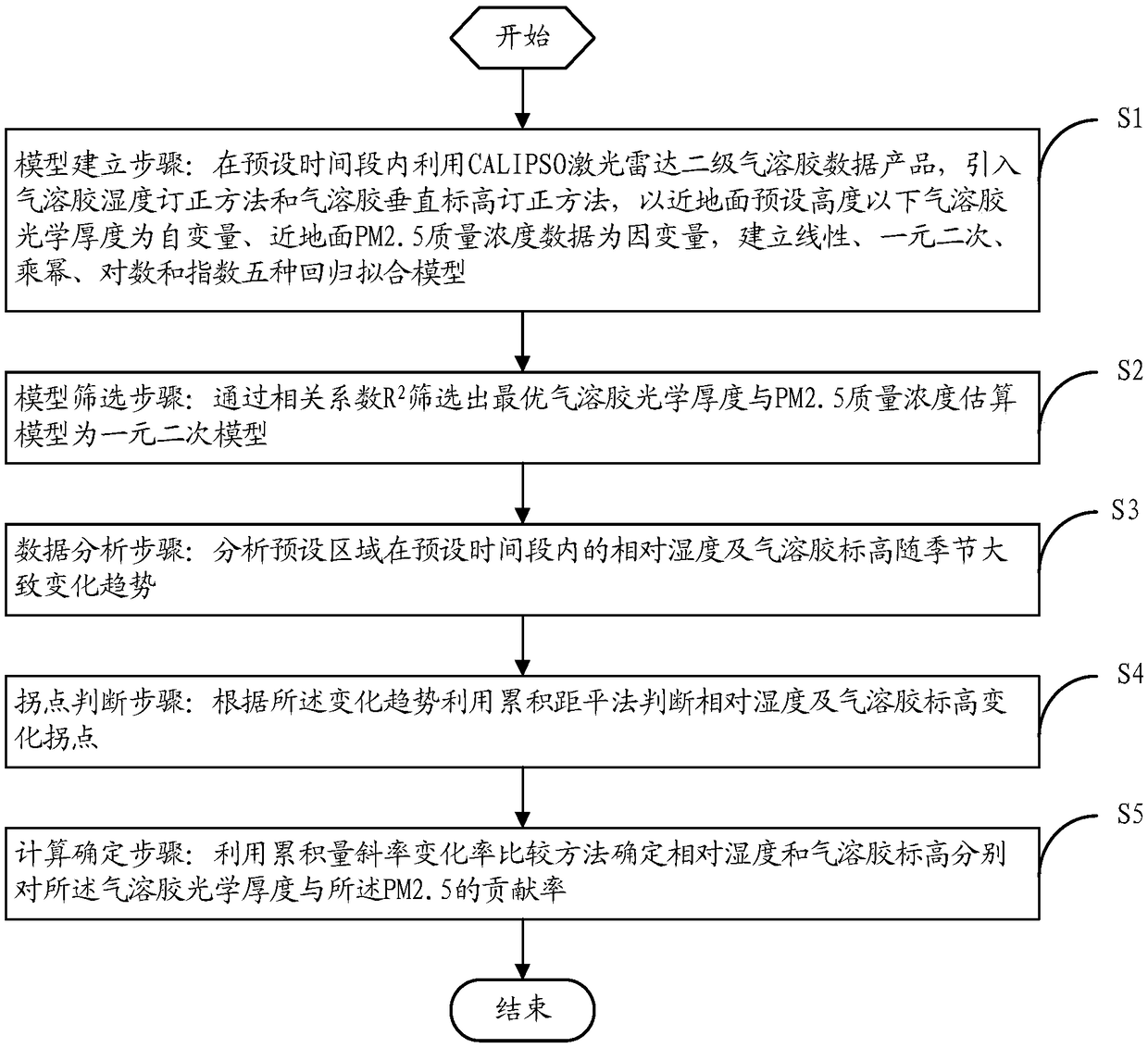

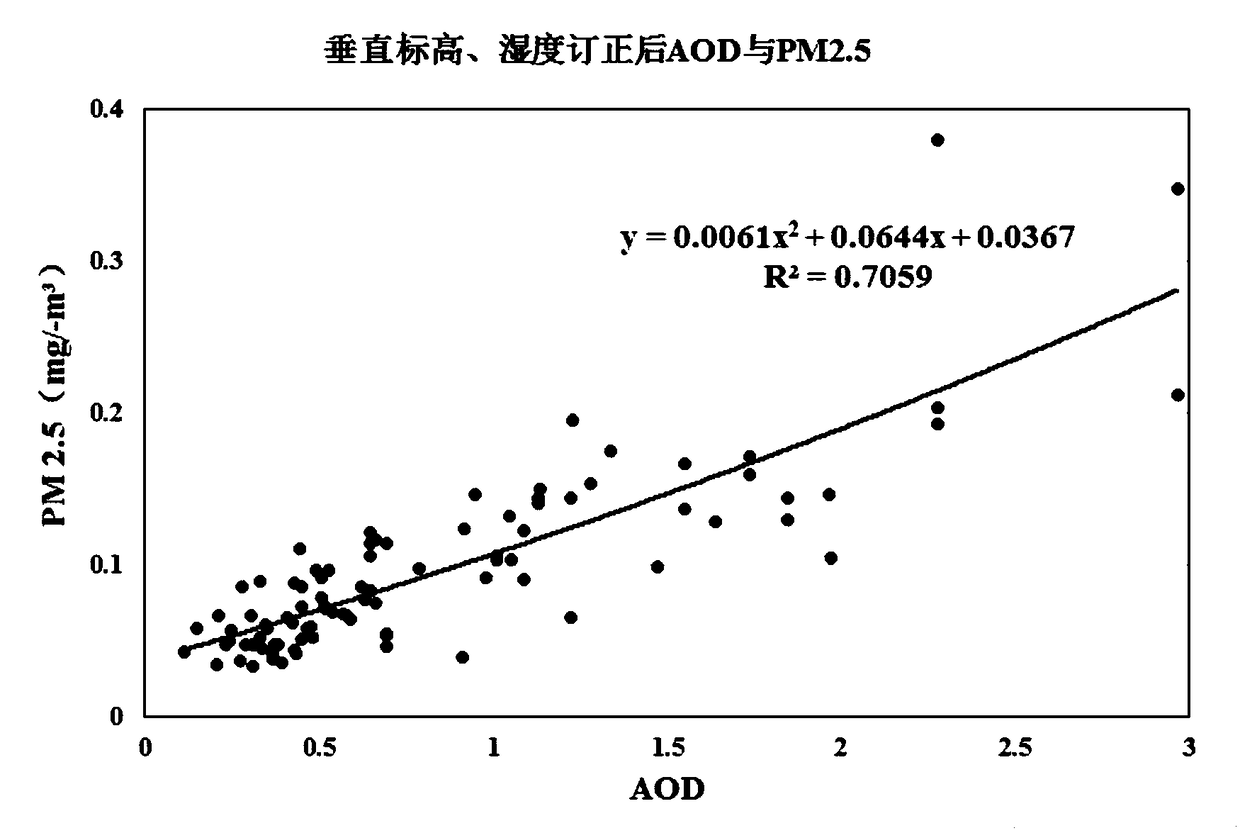

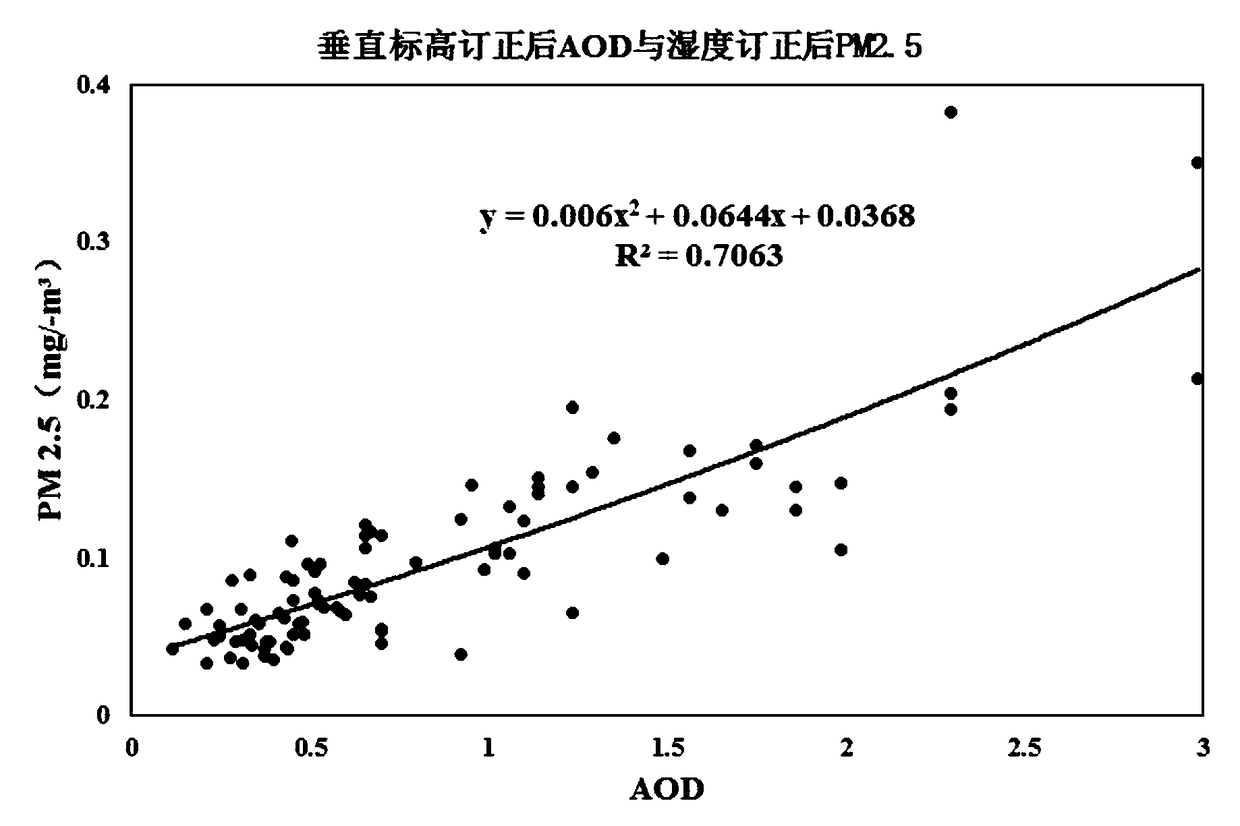

Aerosol optical thickness and PM2.5 inversion correction method and system

ActiveCN108763756ADesign optimisation/simulationSpecial data processing applicationsCorrection methodComputer science

The embodiment of the invention discloses an aerosol optical thickness and PM2.5 inversion correction method and system and relates to the field of environment protection. Through the method, a basiscan be provided for the accuracy and precision of PM2.5 inversion in a research region, and meanwhile the influence degrees of other climatic conditions on an inversion result can be judged indirectly. The method comprises a data analysis step, wherein relative humidity of a preset region in a preset time period and the rough change trend of aerosol scale height over seasons are analyzed; an inflection point judgment step, wherein according to the change trend, a cumulative anomaly method is utilized to judge inflection points of the relative humidity and the aerosol scale height; and a calculation determination step, wherein a cumulant slope change rate comparison method is utilized to determine respective contribution rates of the relative humidity and the aerosol scale height to aerosoloptical thickness and PM2.5.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

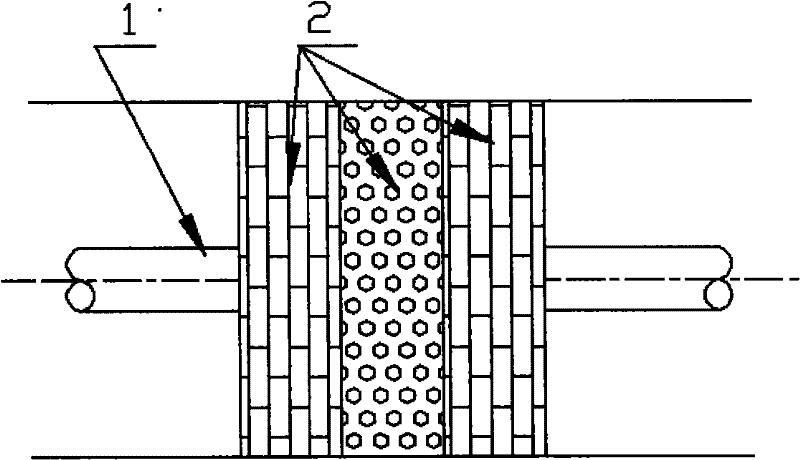

One-time leveling method for installation of large bridge support

InactiveCN101514541AAvoid the defects of repeated loading and unloading levelingImprove construction qualityBridge structural detailsAbutmentBeam bridge

The invention relates to a one-time leveling method for the installation of a large bridge support, the bridge support, as an important constituent part of a beam bridge structure, is a force transferring device arranged at the support location of a bridge-span structure and a bridge pier or the supporting position of a bridge abutment. As the large bridge support limits the operating space on the top of a pier column, the support is difficult to meet the leveling demand during construction. At present, dry hard mortar is used as an anchorage leveling grouting material of the bridge support during the erection of the bridge, so normative level and standard are hardly reached, leaving potential safety hazards to post-operation of the bridge. The invention embeds in advance a plurality of leveling bolts in a pad stone to rotatably level the bolts so that the height of the topmark thereof is consistent in scale height of bottom surface of a lower filler plate of the support; the support is suspended on the leveling bolts and is regulated to be consistent with the axial line of the pad stone; a bonding material is poured between the pad stone and the support. The invention can, without being impacted by inconsistent compression of the dry hard mortar, level the support via the leveling bolts at one time, thus avoiding the defect of current method that repeated loading / unloading and leveling are required.

Owner:NO 3 ENG LIMITED OF CR20G

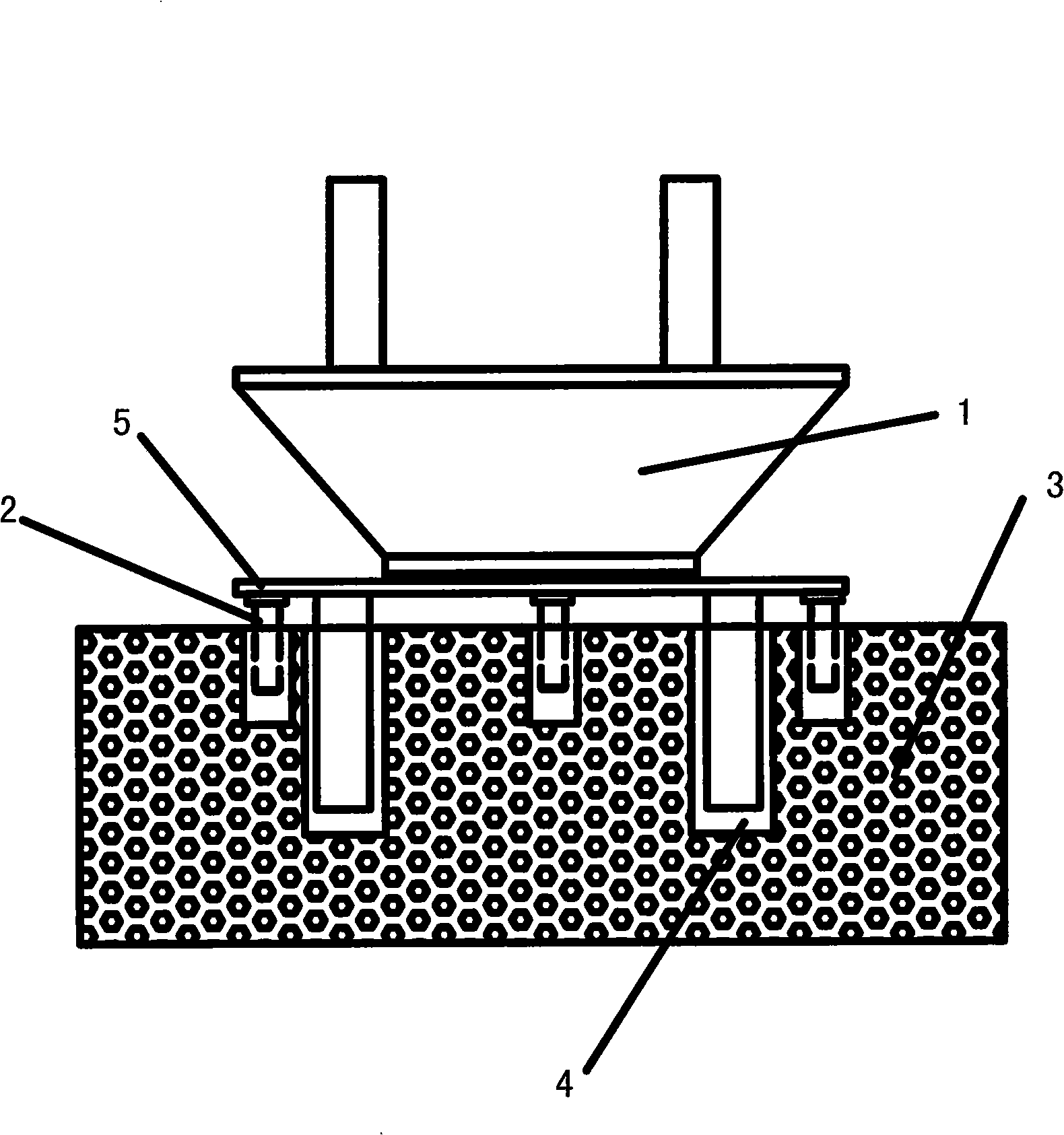

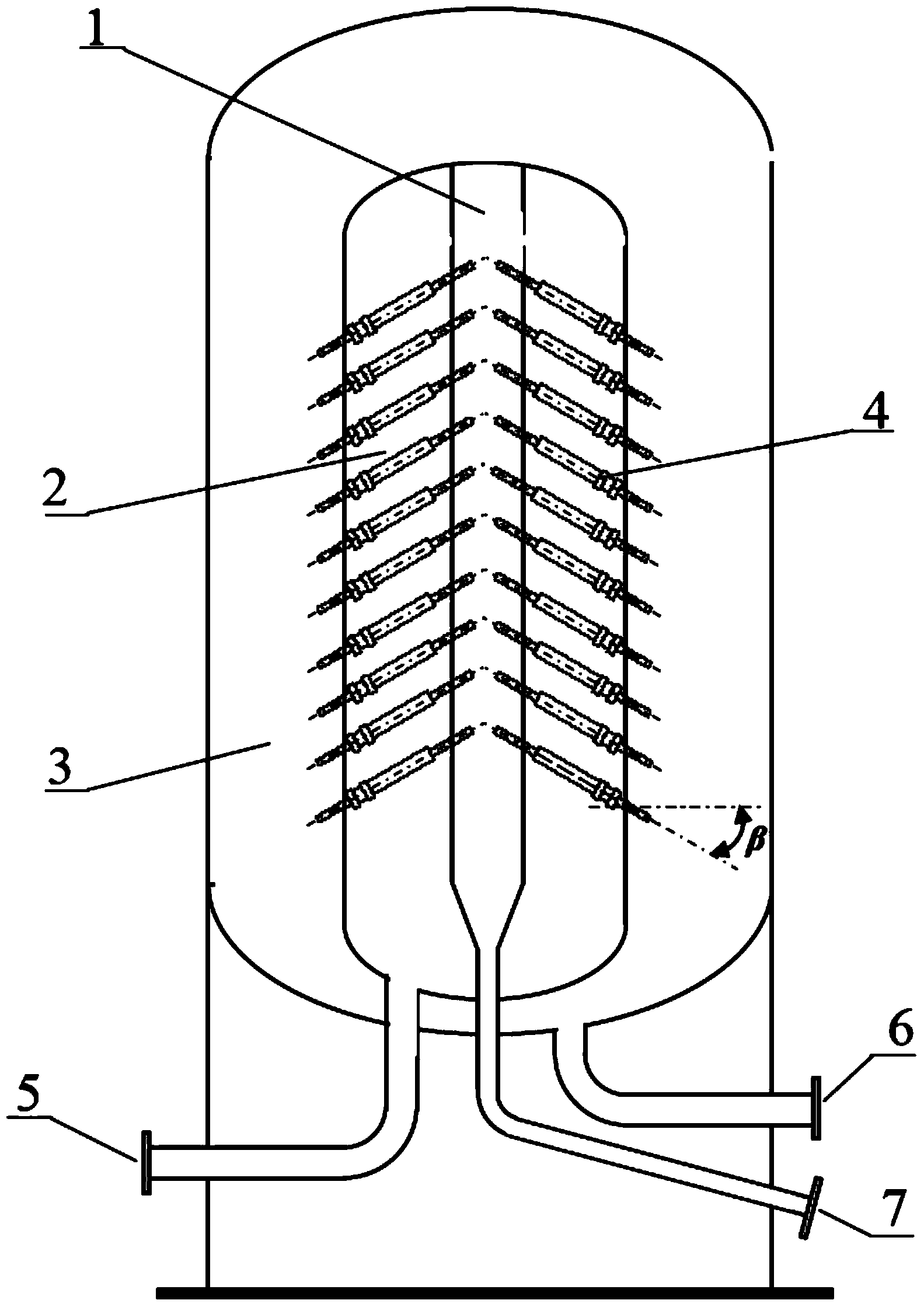

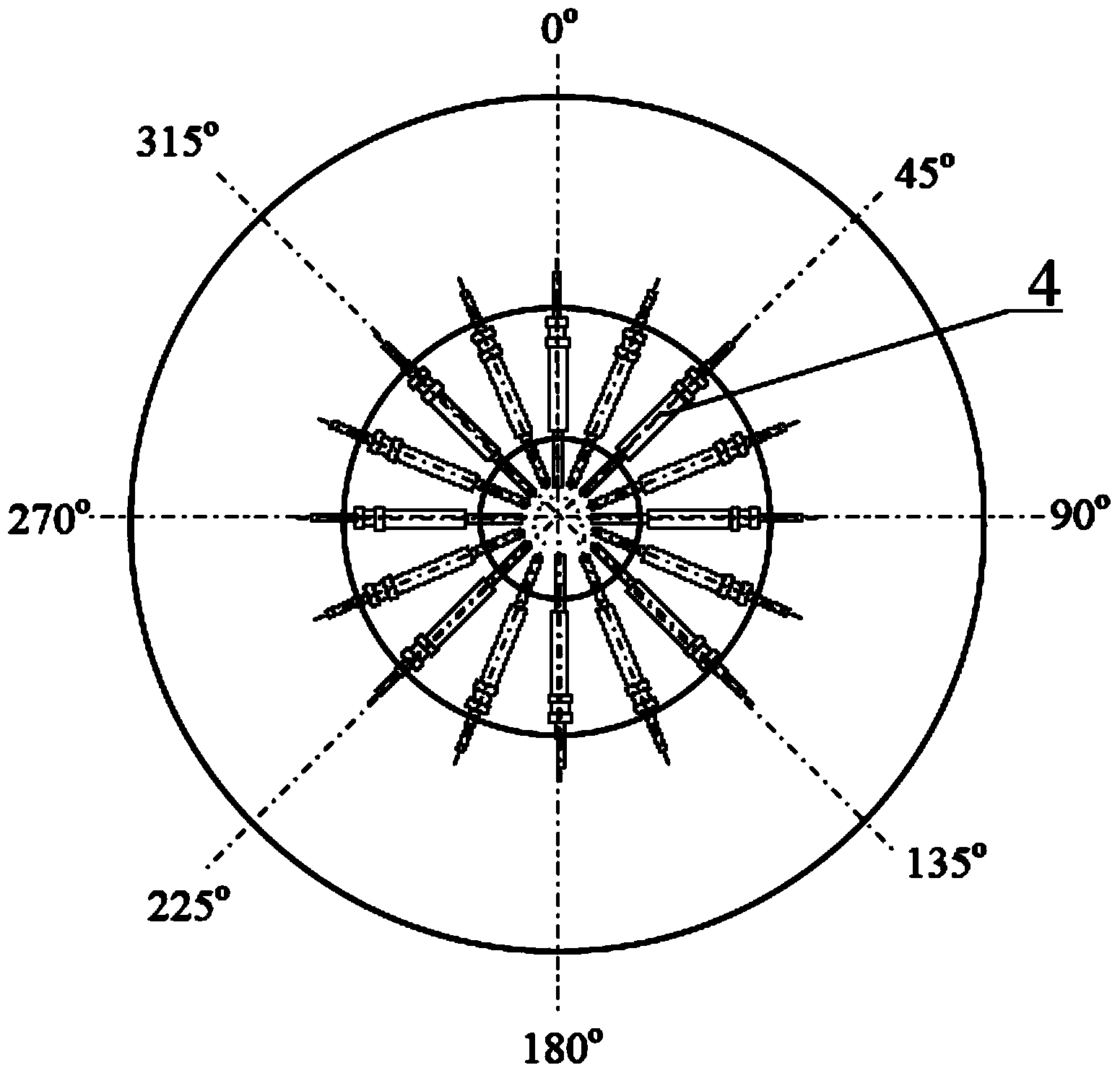

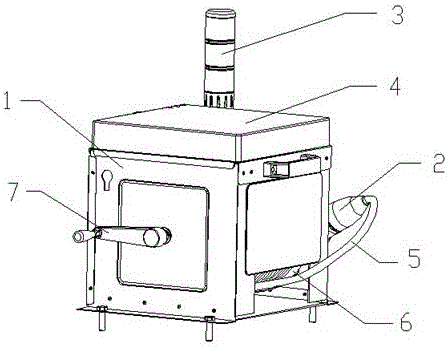

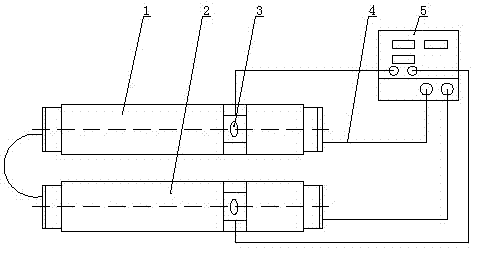

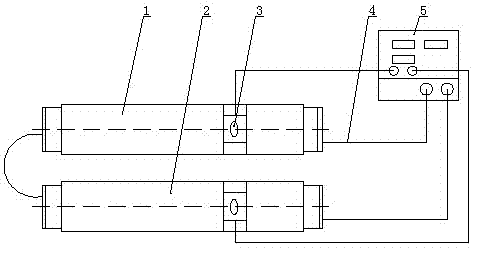

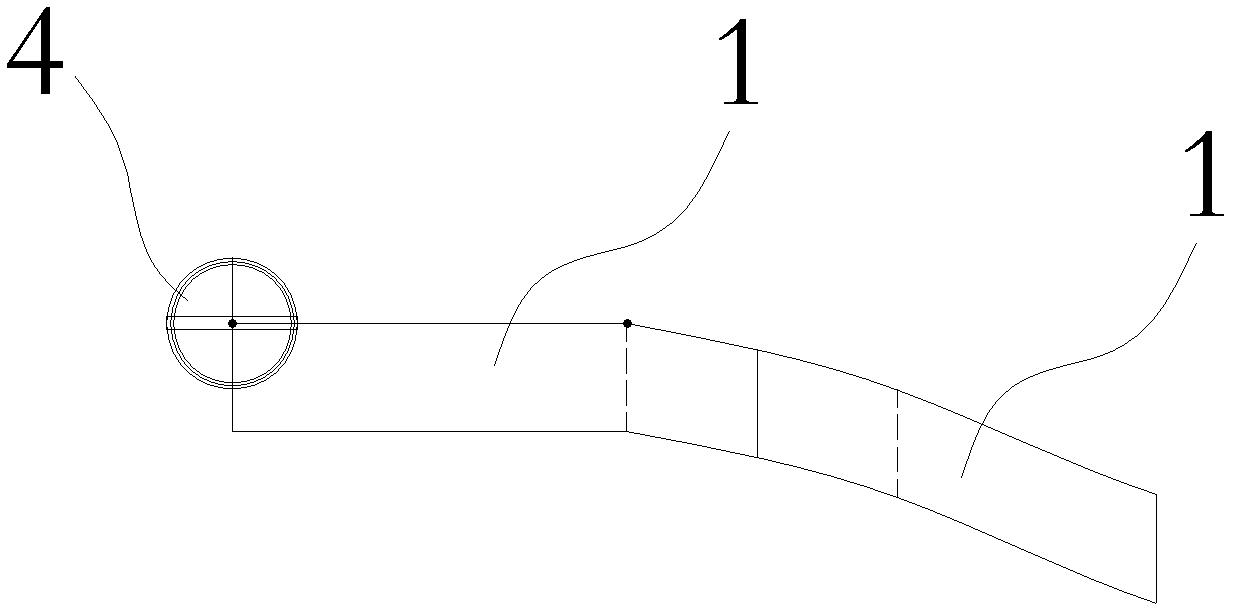

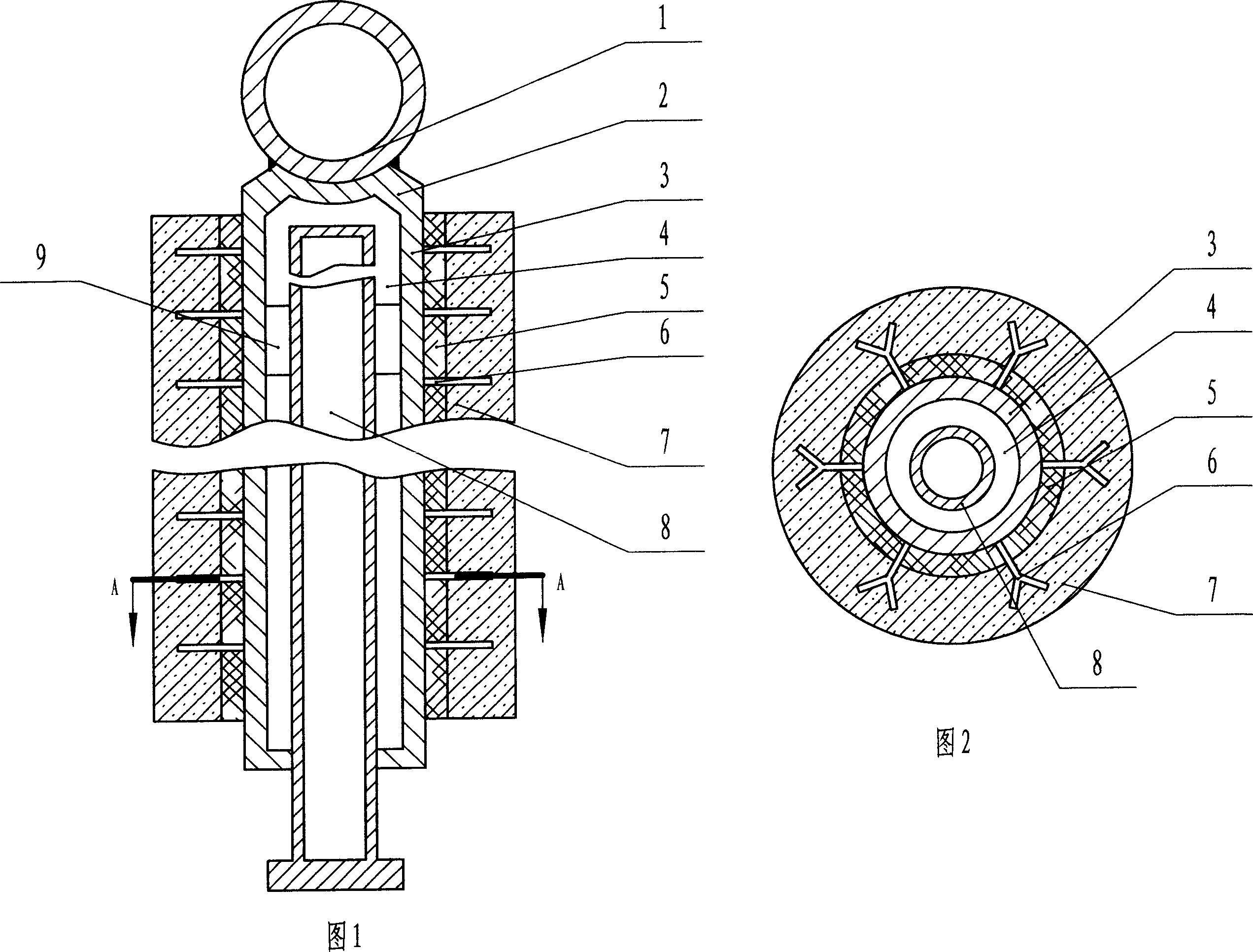

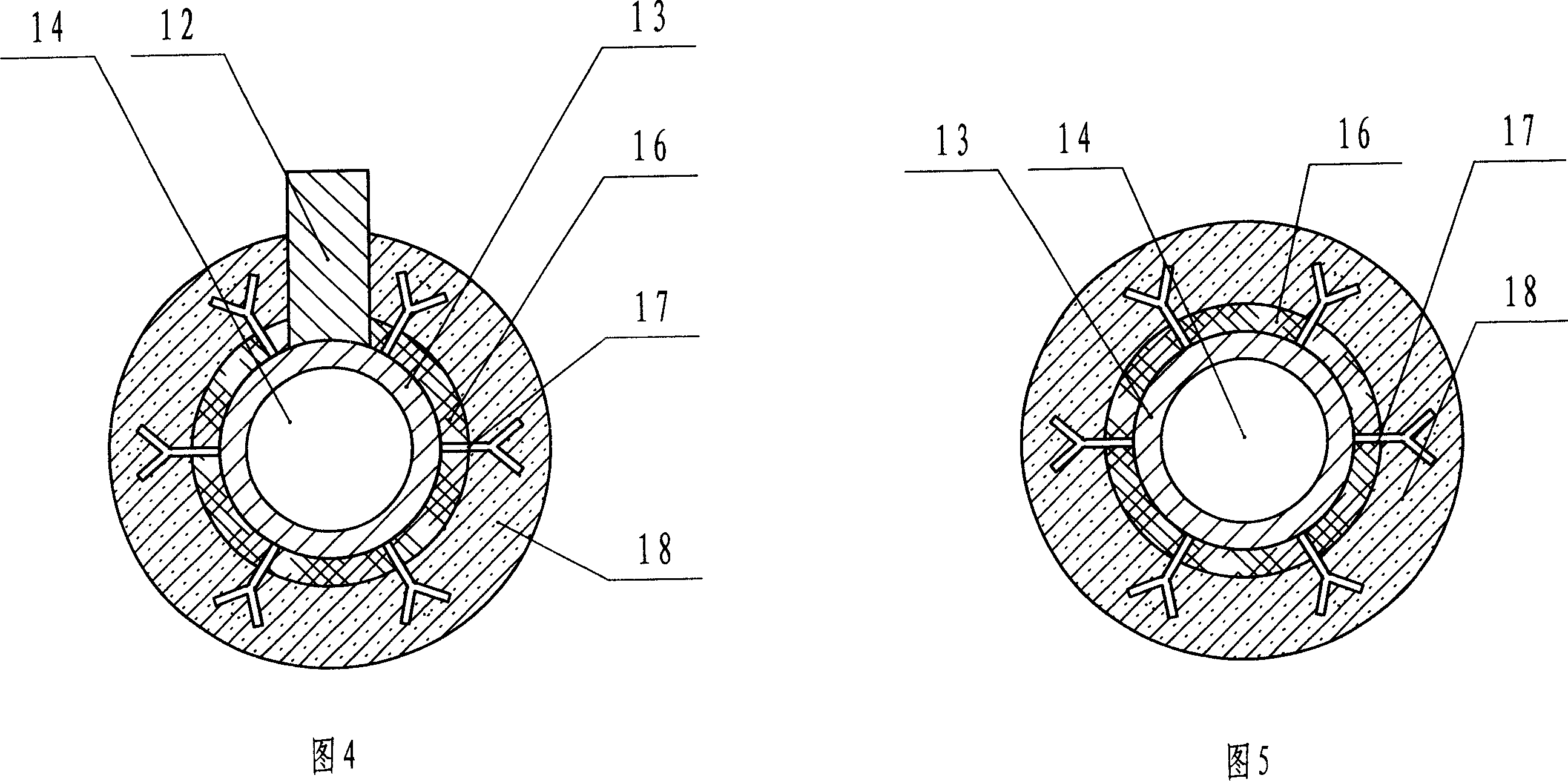

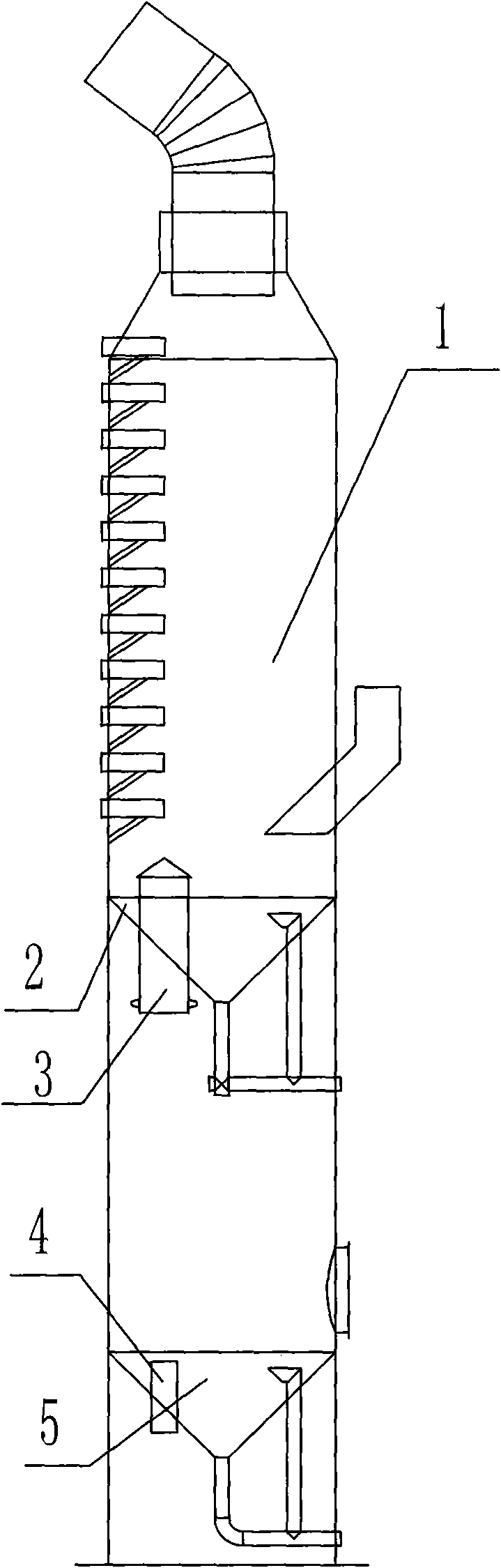

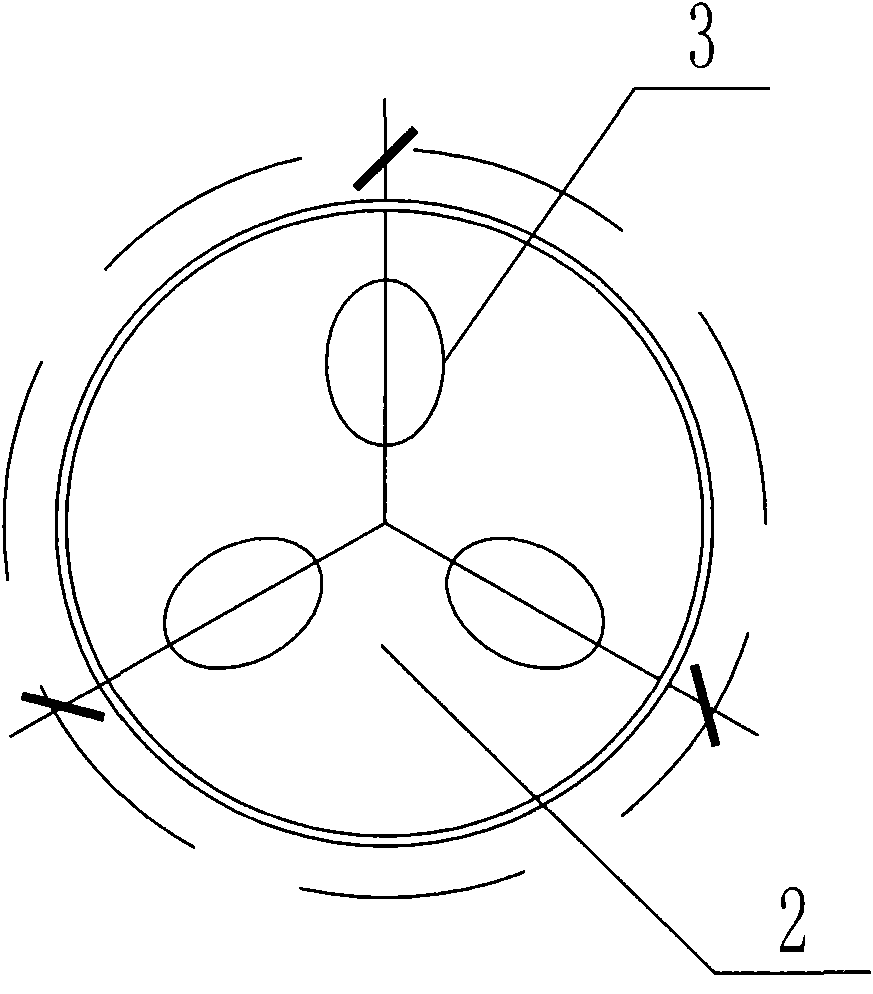

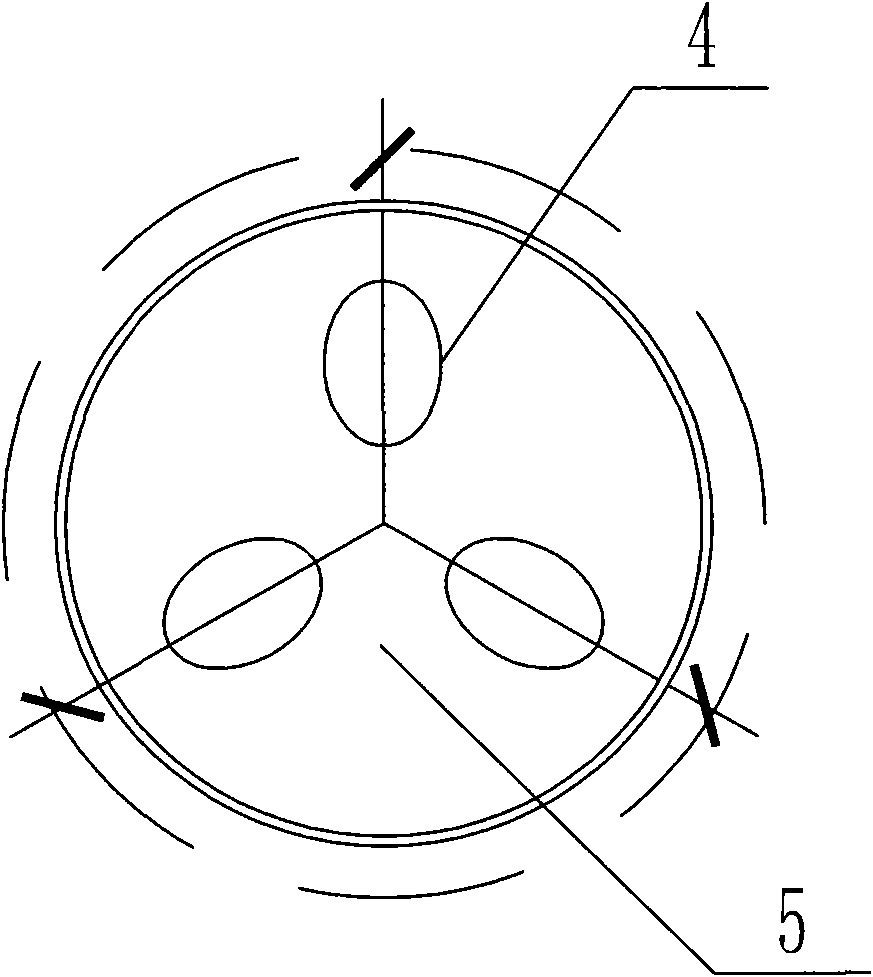

Inverted inclined installation method and device for long-period continuous stable operation of liquid-solid micro cyclone separator

ActiveCN103588260AReduce cloggingGreat operating flexibilityWater/sewage treatment by centrifugal separationCycloneProcess engineering

The invention relates to an inverted inclined installation method and device for long-period continuous stable operation of a liquid-solid micro cyclone separator, and provides the inverted inclined installation method for long-period continuous stable operation of the liquid-solid micro cyclone separator. The method comprises the following steps: liquid-solid micro cyclone core tubes (4) are mounted in a feeding cavity (2) of a three-layer pressure vessel in an inverted and inclined manner, wherein the bottom flow port of each liquid-solid micro cyclone core tube (4) is connected into the bottom flow cavity (1) of the vessel, and the overflow port of each liquid-solid micro cyclone core tube (4) is connected into the overflow cavity (3) of the vessel; the scale height of the bottom flow port of each liquid-solid micro cyclone core tube (4) is higher than the scale height of the overflow port; an sharp included angle beta of the axis of each liquid-solid micro cyclone core tube (4) and the horizontal plane is larger than an accumulation angle of repose of particle materials. The invention also provides the inverted inclined installation device for long-period stable operation of the liquid-solid micro cyclone separator.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Determination method for root position of soft heat belt in blast furnace

The invention relates to a determination method for root position of a soft heat belt in a blast furnace, which is characterized by connecting a gas collection pipeline and a dust removal purification system on net pressure holes installed at different heights of a blast furnace body, analyzing clean gas after dust removal filtering purification, analyzing the content of CO2 and CO of the clean gas, calculating CO2 / (CO2+CO) in the component of coal gas, solving a scale height position of CO2 / (CO2+CO)=0 in the blast furnace by utilizing an extrapolation calculating method, carrying out linear regression on the static pressure data of the furnace body with different scale heights, working out the functional relationship between the static pressure and the scale height of the blast furnace, comparing the functional relational expressions of the static pressures of the furnace body and the scale heights of the blast furnace in different operation conditions of the blast furnace, contrasting the functional relational expression with the scale height position of CO2 / (CO2+CO)=0 calculated with the component of the coal gas, and calculating the scale height of the root position of the soft heat belt in the blast furnace after function rectification. By the method of the invention, the position of the soft heat belt can be accurate in the range of 0.2-1.5m.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

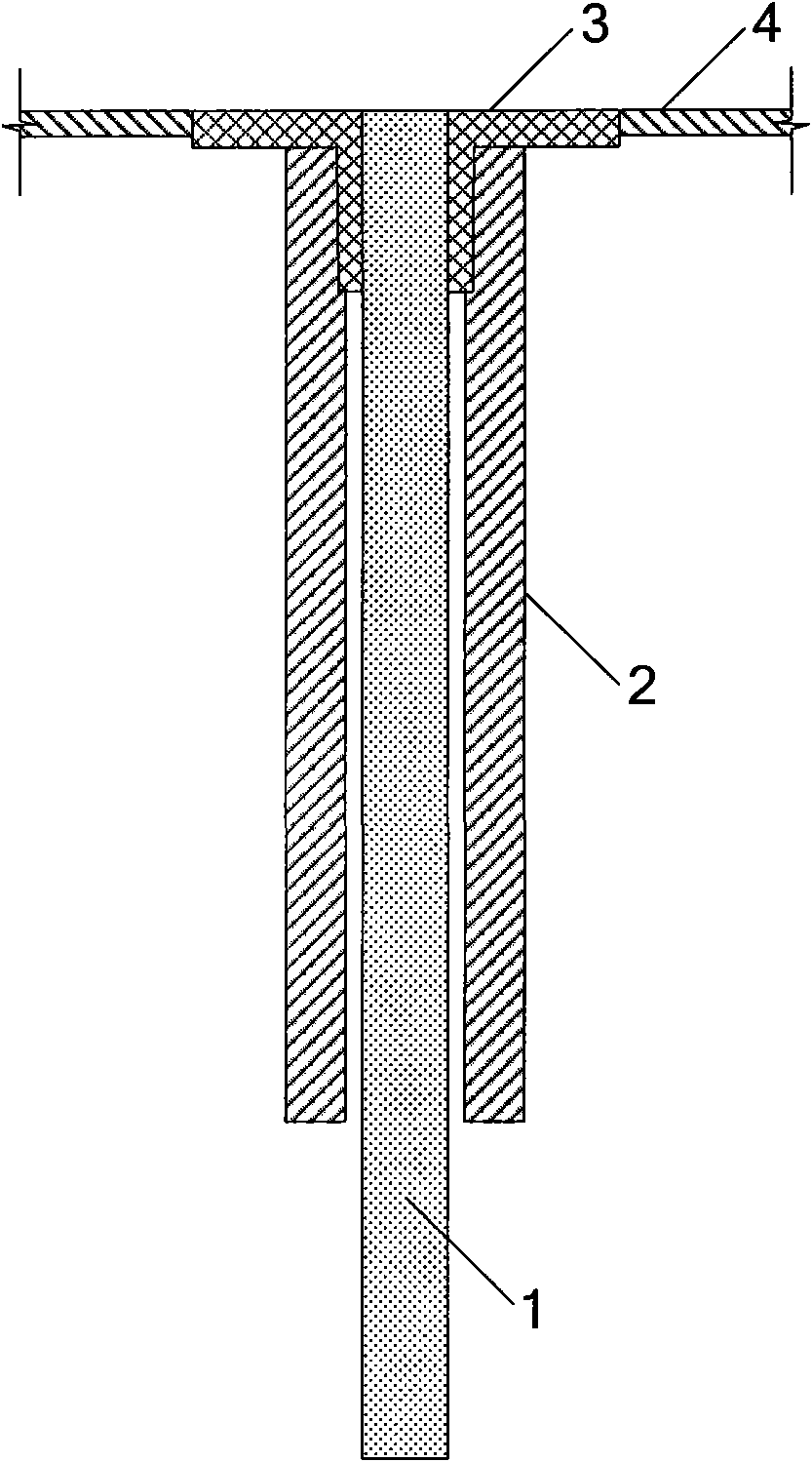

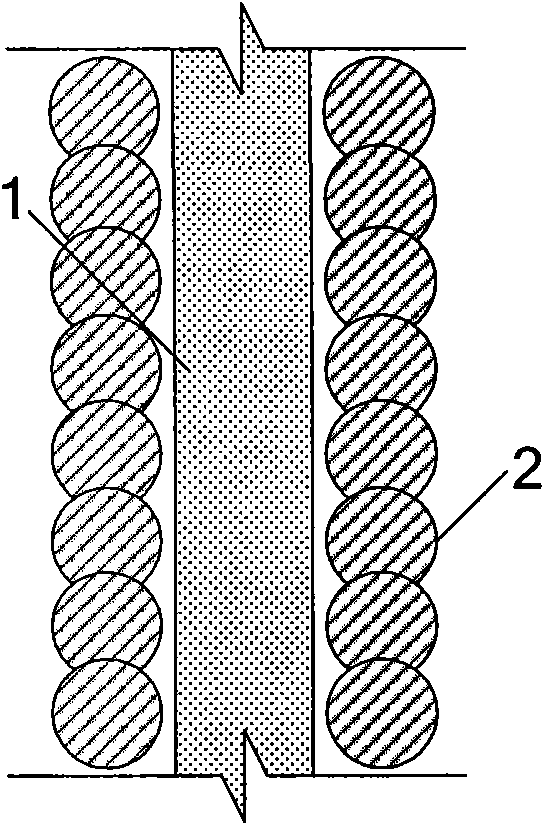

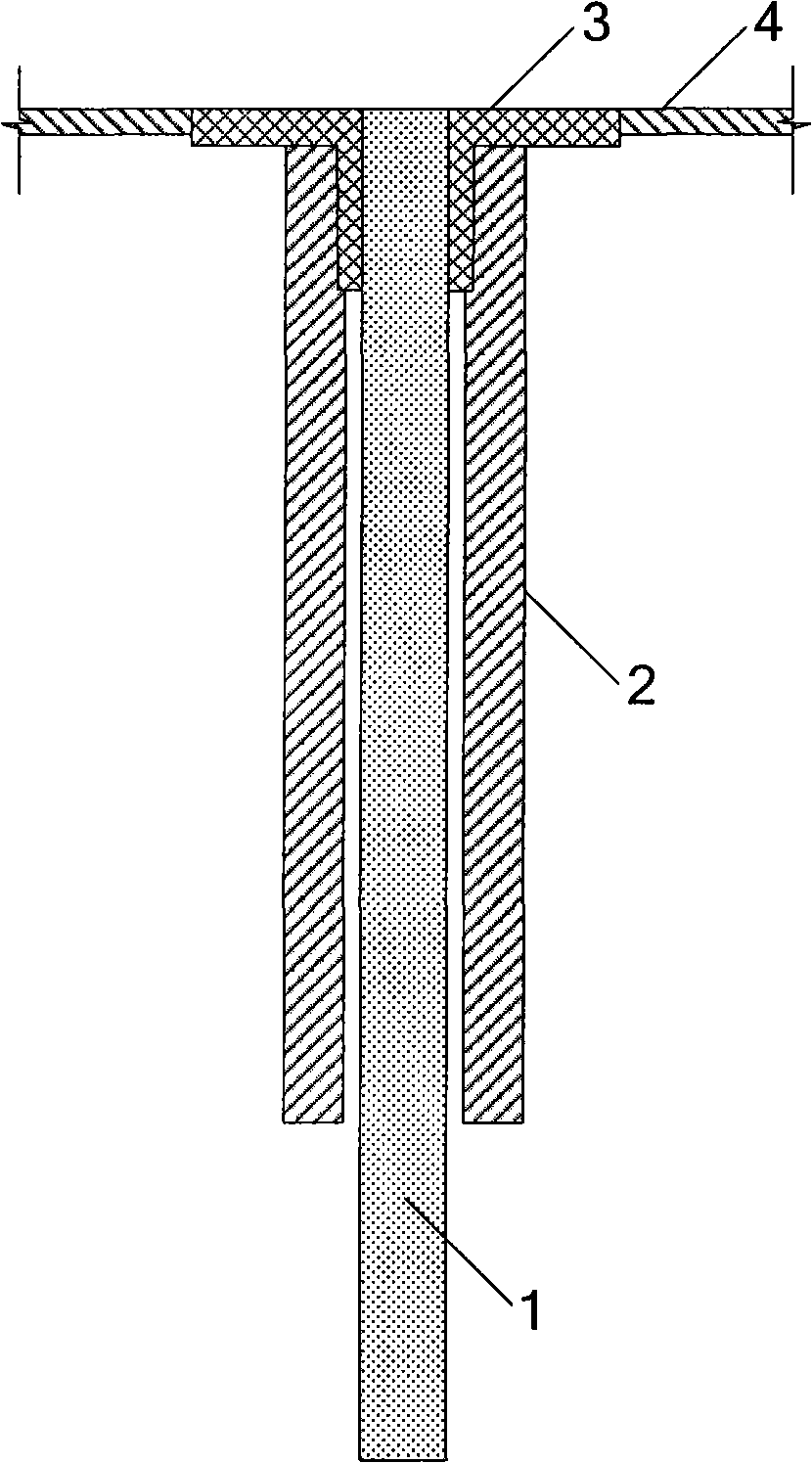

Cast-in-place pile overfilling monitoring device and using method thereof

ActiveCN106759537AGuaranteed effective perfusion heightReduce wasteFoundation testingEngineeringWater content

The invention relates to a cast-in-place pile overfilling monitoring device. The device comprises an equipment bracket, a monitoring sensor, an alarm assembly and a center control host; the monitoring sensor is used for achieving conducting real-time monitoring on a concrete spouting height; the alarm assembly is fixedly arranged on the equipment bracket, electrically connected to the monitoring sensor and used for feeding back monitoring results of the monitoring sensor; the monitoring sensor is connected to the equipment bracket with the help of a connecting assembly arranged on the equipment bracket; the center control host is fixedly arranged on the equipment bracket, in signal connection to the monitoring sensor and the alarm assembly and used for achieving signal transfer between the monitoring sensor and the alarm assembly. Through the cast-in-place pile overfilling monitoring device, the water content of different liquids can be detected through the sensor, accordingly whether concrete reaches a set scale height or not is judged, and after the concrete reaches the set scale height, an alarm is given timely. In this way, not only is the valid spouting height of a cast-in-place pile ensured, but also the overfilling amount is reduced to the greatest extent, and the subsequent chiseling and removing difficulty is lowered.

Owner:JIANGSU CSSIOT TECH CO LTD

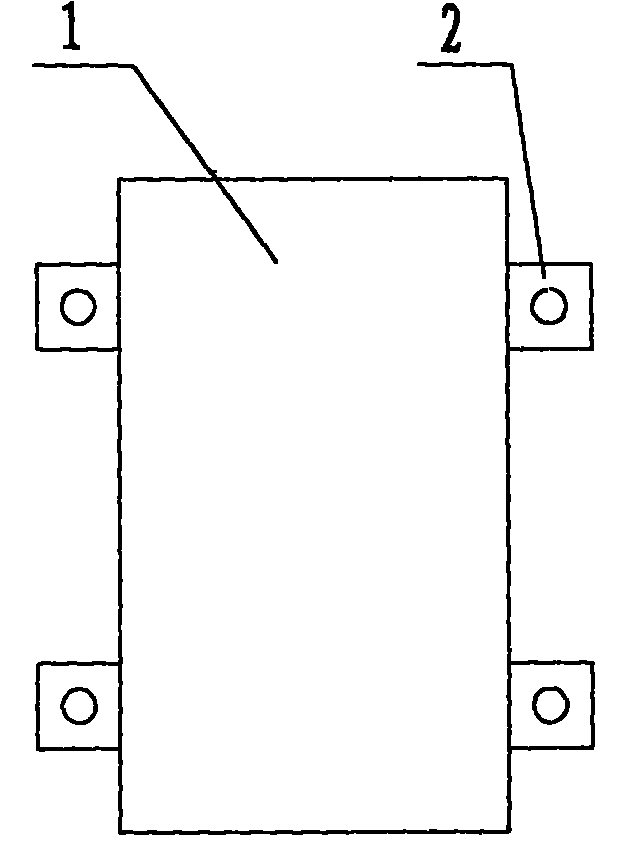

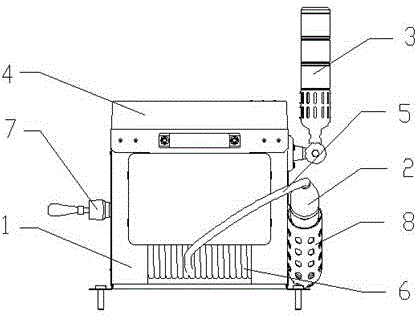

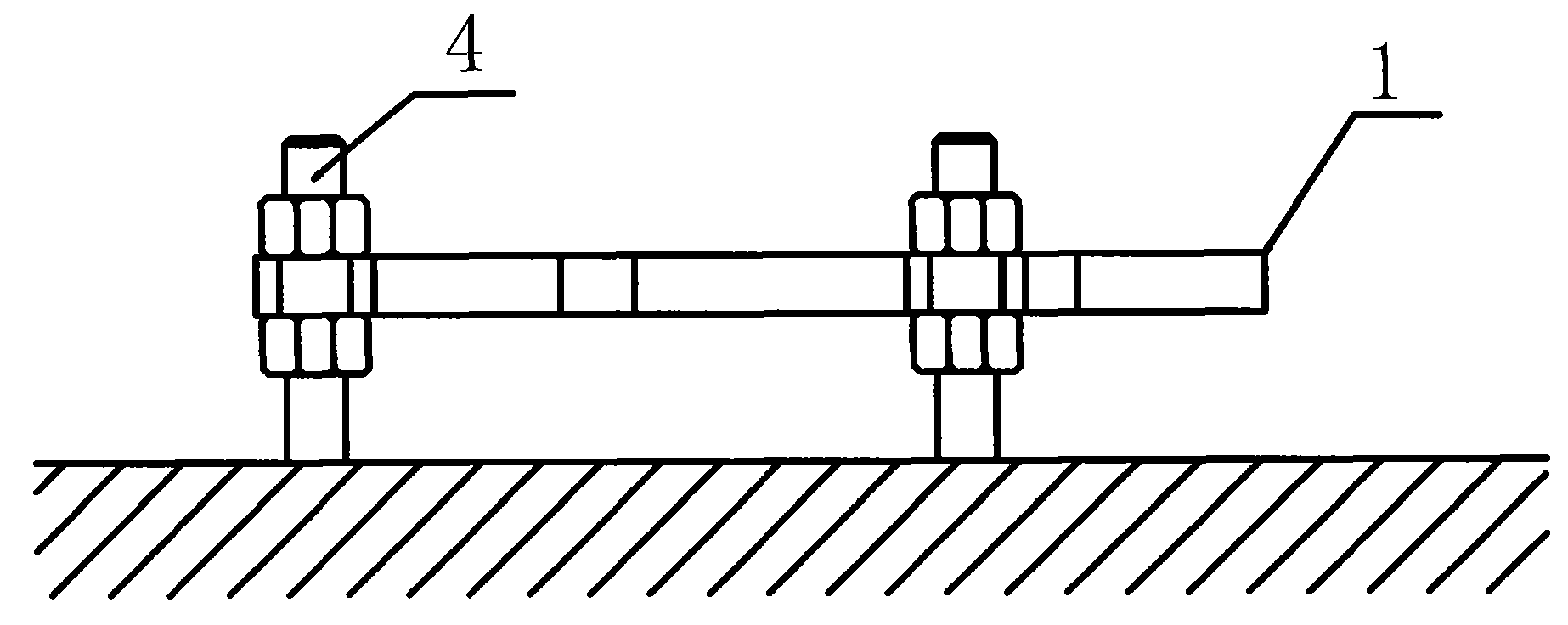

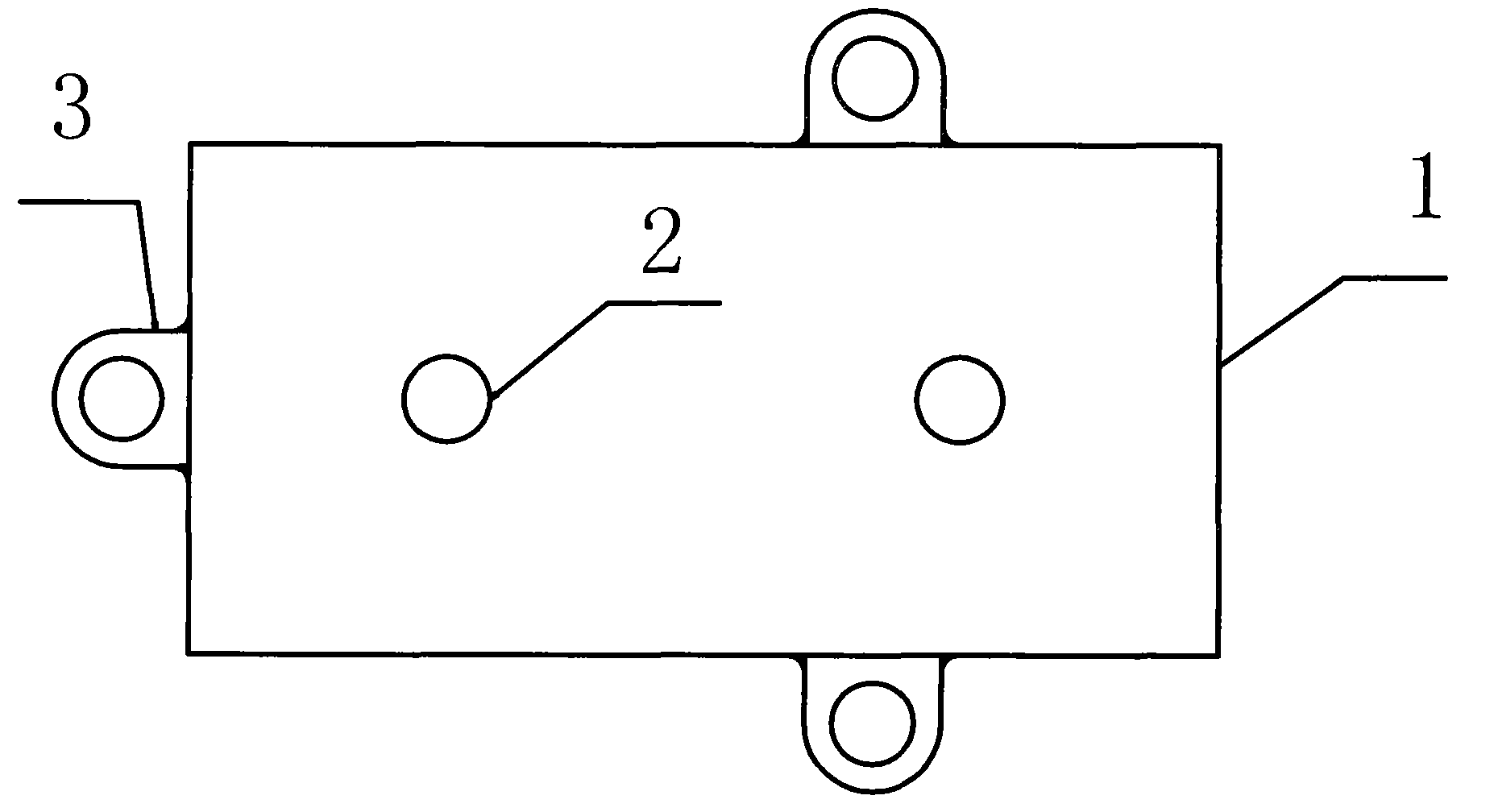

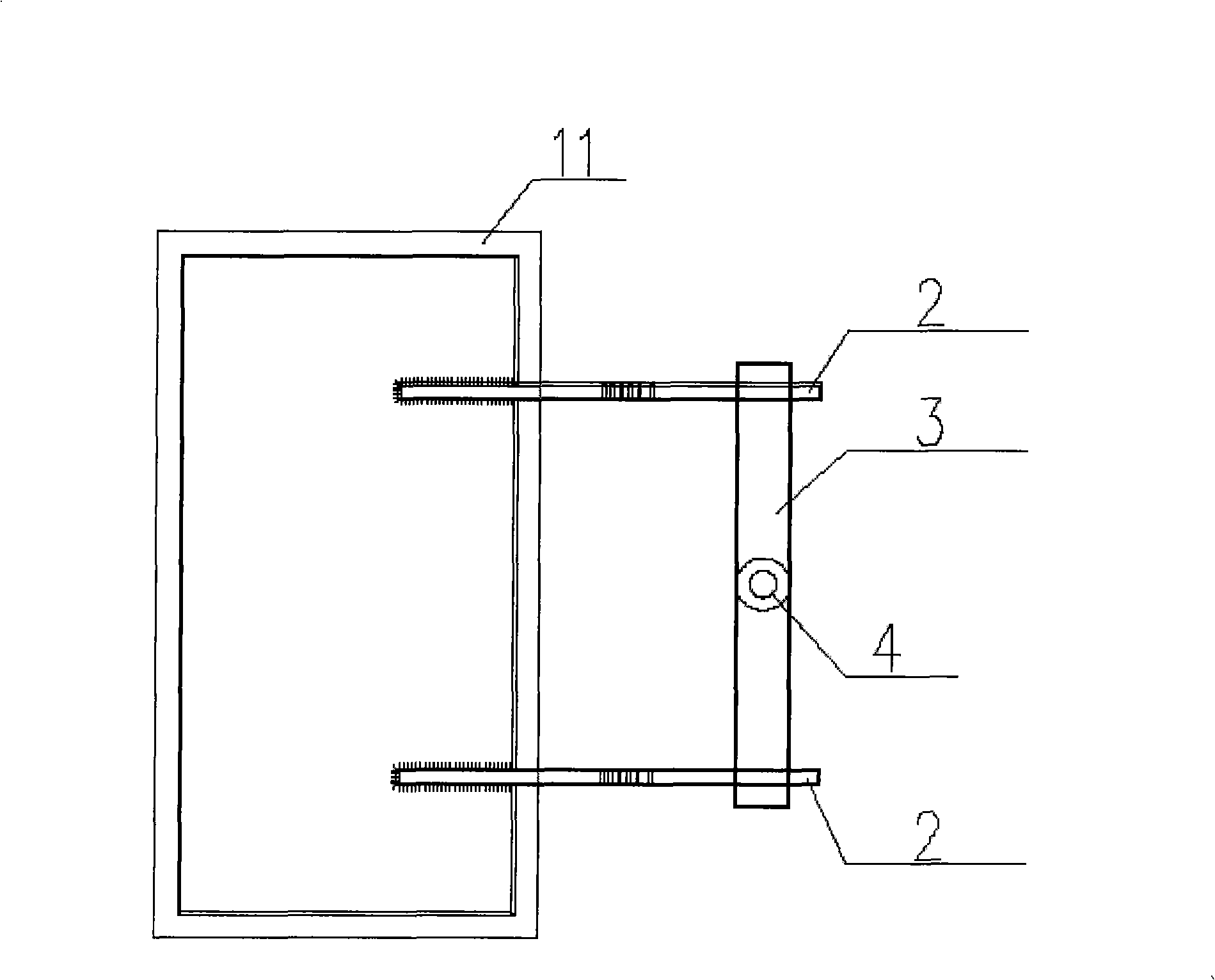

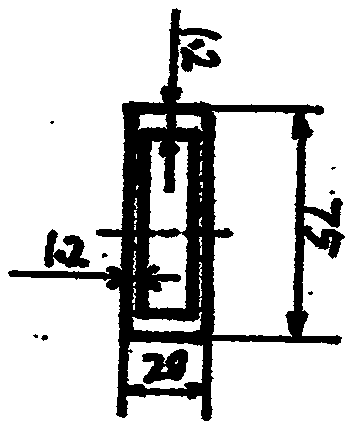

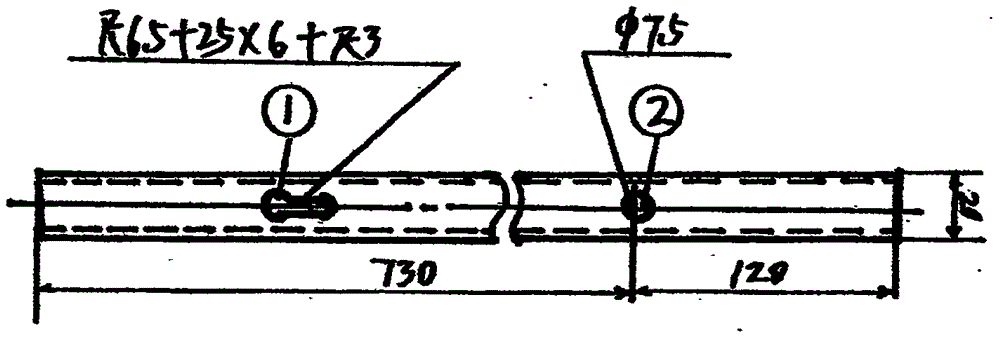

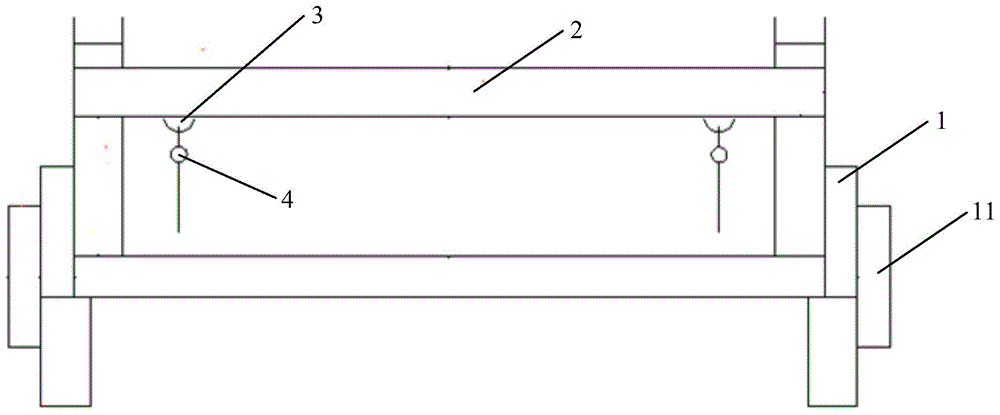

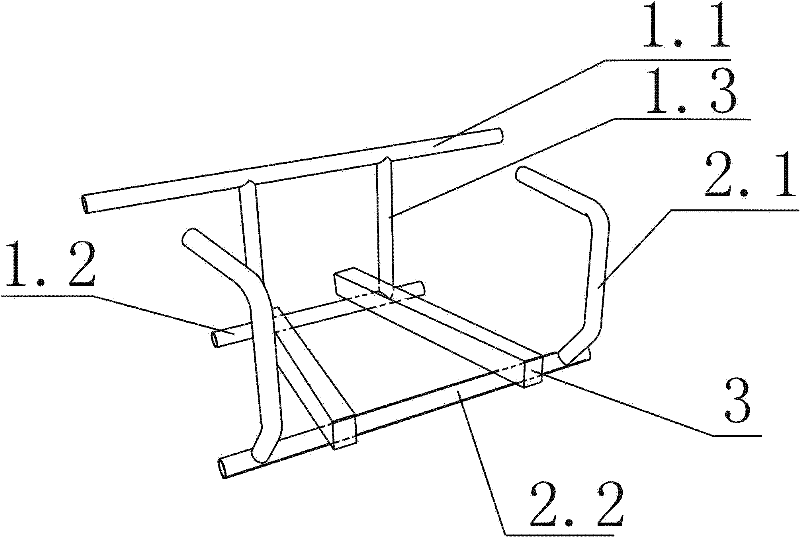

Method for adjusting base plates for high-accuracy machinery installation

The invention relates to a method for adjusting base plates in high-accuracy machinery installation. The method is characterized by comprising the following steps: a) providing a plurality of base plates for the high-accuracy machinery installation, wherein each base plate (1) comprises a rectangular steel plate, a steel earhole plate (3) is welded on one short side of the rectangular steel plate, and the earhole of the earhole plate (3) is used for penetrating adjusting bolts (4); and welding the steel earhole plates (3) respectively on two long sides of the rectangular steel plate close to the other short side end of the rectangular steel plate, and drilling air exhaust holes respectively (2) at two sides of the middle point of the central line of the rectangular steel plate; b) placing the base plates (1) at corresponding foundation parts, driving the adjusting bolts respectively in the earhole positions of three earhole plates (3), and adjusting the scale height and horizontality at the upper surface of each base plate (1); and c) after secondary grouting, cutting a screw rod and a nut on the upper part of each earhole plate, rubbing down, hoisting the machinery device and carrying out accurate adjustment further.

Owner:MCC5 GROUP CORP SHANGHAI

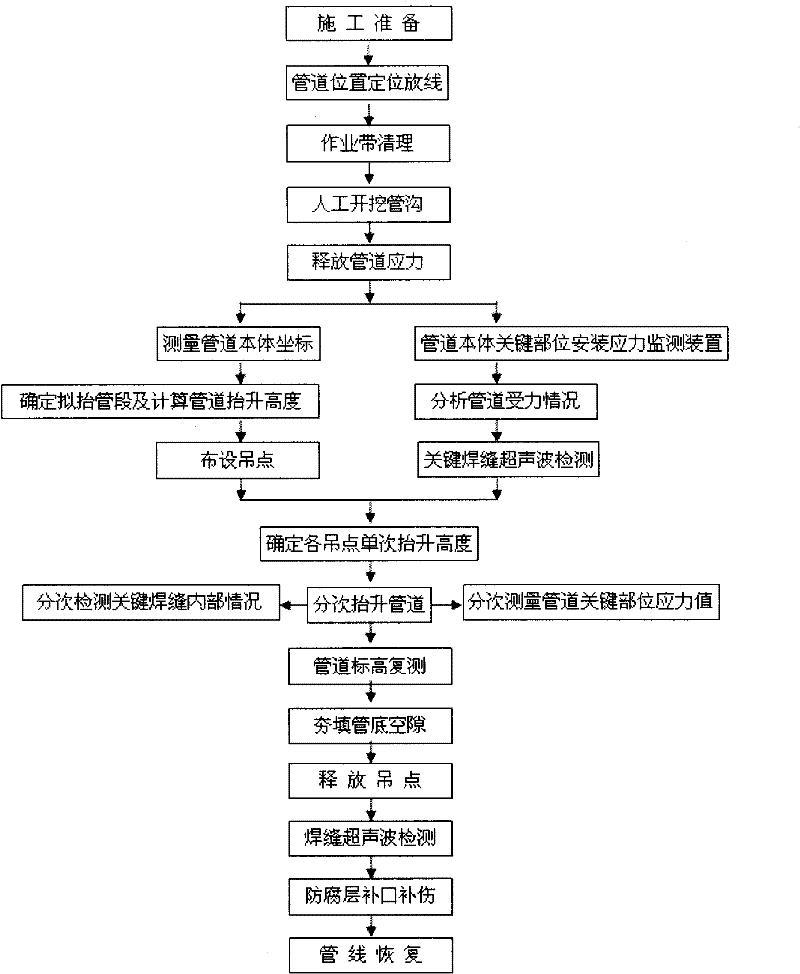

Construction method of in-service oil and gas pipelines encountering goaf collapse and damage

ActiveCN102261518ARestore elevationReduce riskPipe laying and repairPipe elementsStress conditionsEngineering

The invention relates to a restoration construction method for an in-service oil gas pipeline which encounters with the collapse and destruction of a worked-out section, and relates to the technical field of pipeline systems. The restoration construction method comprises the following steps of: 1) preparing construction; 2) performing Redi positioning on the pipeline, and laying the pipeline; 3) cleaning an operating zone and excavating a pipe ditch artificially; 4) releasing the stress of the pipeline; 5) measuring coordinates of a pipeline body and arranging a stress monitoring device at the key position of the pipeline body; 6) analyzing the stressed condition of the pipeline, and determining a pipe section to be lifted and calculating the lifting height of the pipeline; 7) distributing hanging points, and performing ultrasonic detection on key weld joints; 8) determining the single-pass lifting height of each hanging point; 9) lifting the pipeline for multiple times, and detecting the internal condition of the key weld joints and stress values at key positions of the pipeline for multiple times; 10) retesting the scale height of the pipeline; 11) ramming and filling gaps at the pipe bottom; 12) releasing the hanging points; 13) performing the ultrasonic detection on the weld joints; 14) repairing cuts of an anticorrosive coating; and 15) restoring the pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

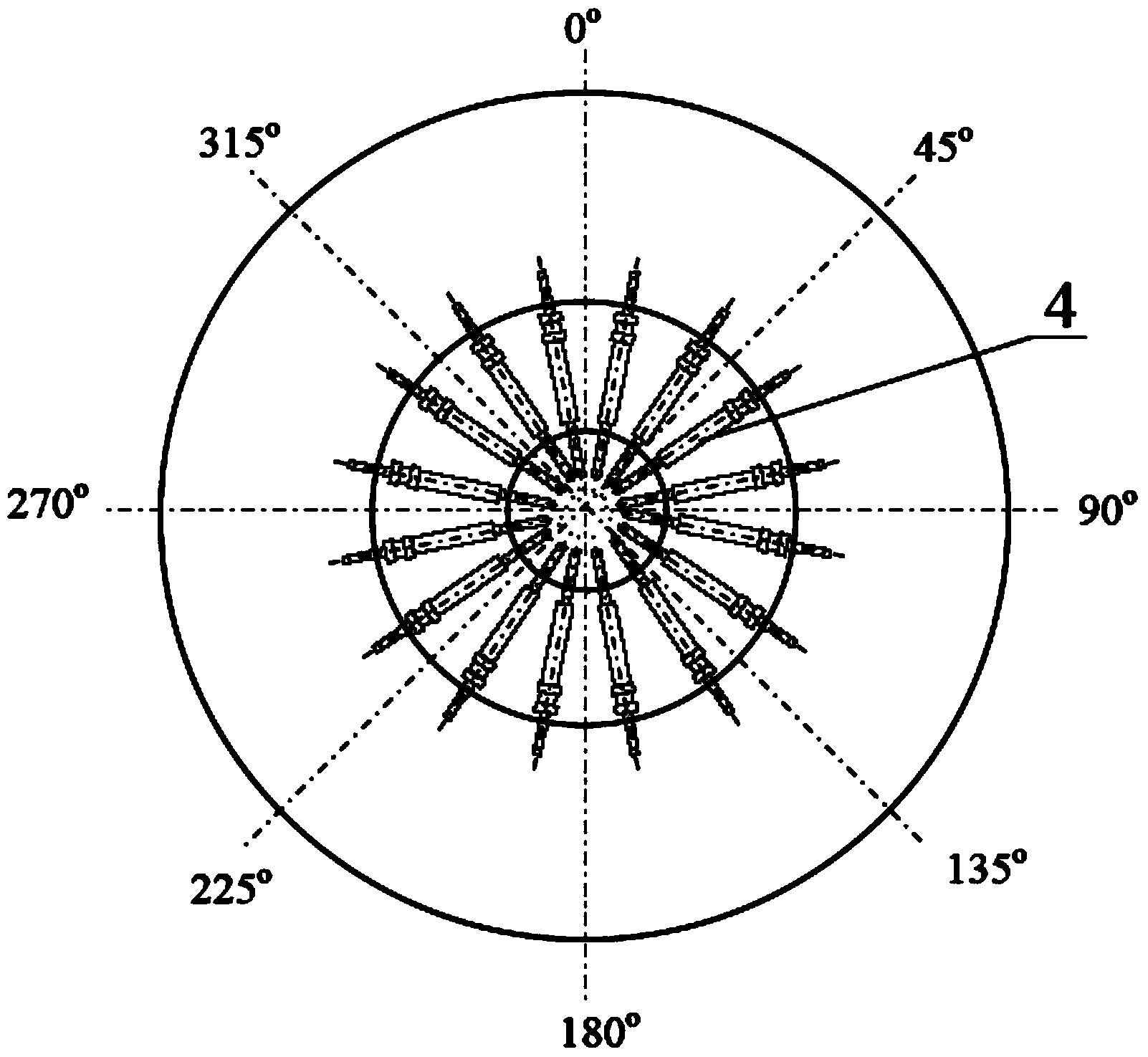

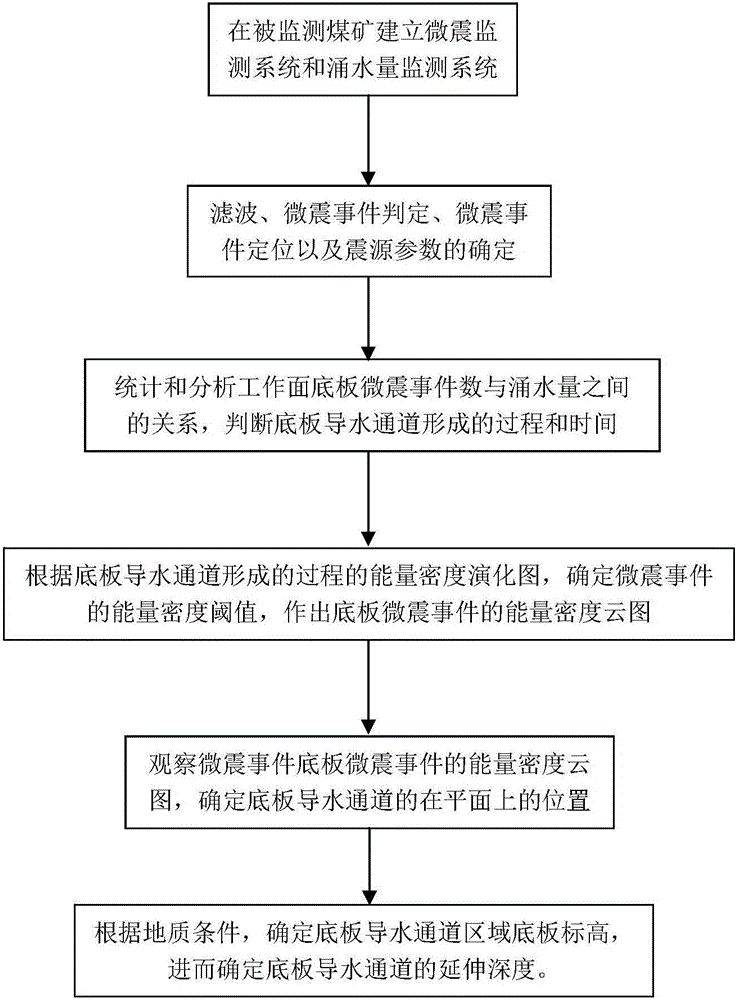

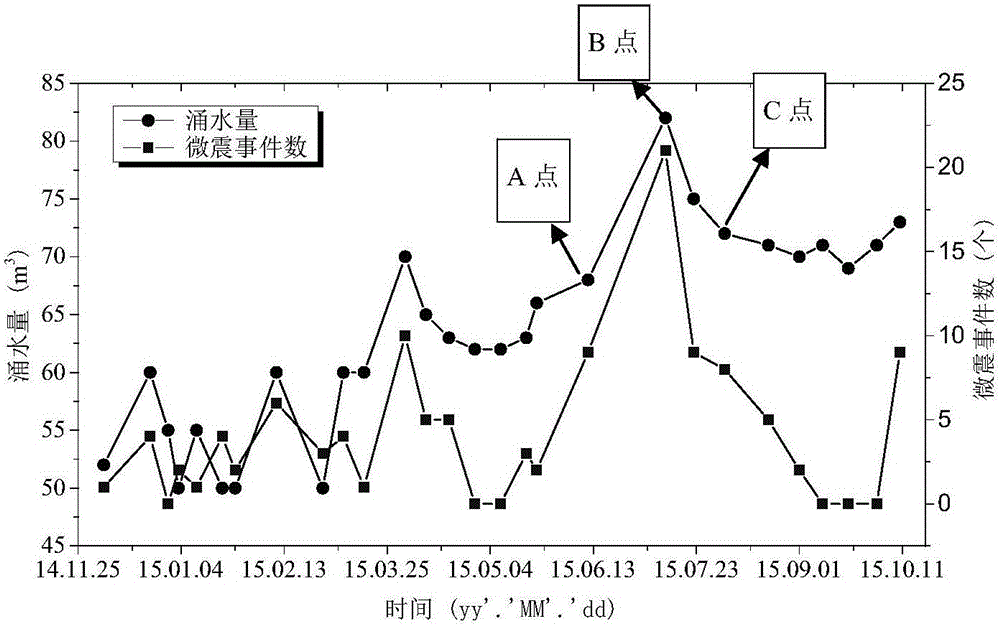

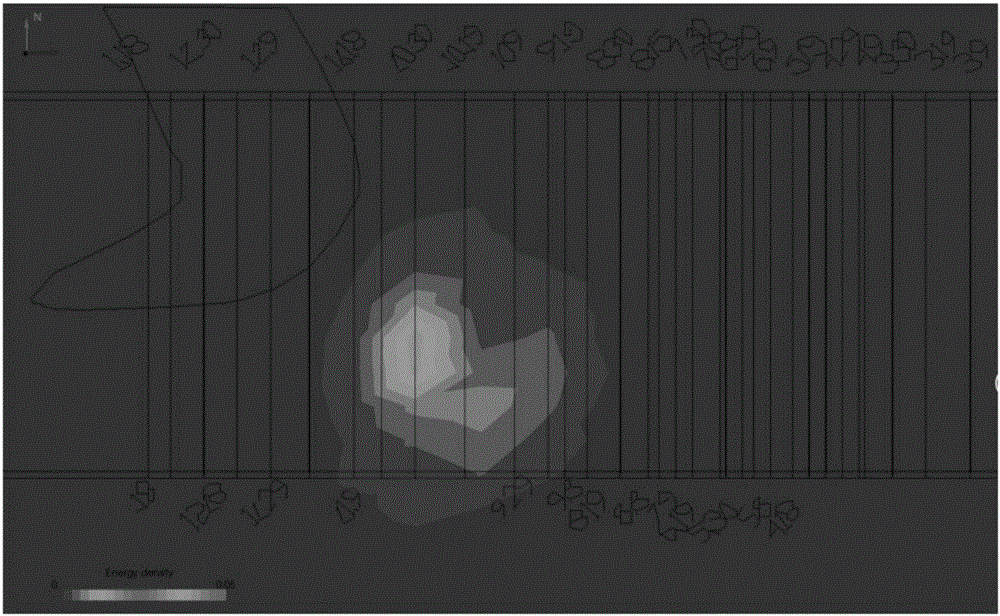

Coal mine bottom plate water guiding channel identification method based on micro-seismic monitoring

The invention discloses a coal mine bottom plate water guiding channel identification method. The method comprises the steps that a micro-seismic monitoring system obtains micro-seismic event locating information and seismic source parameters through monitoring; a water inflow monitoring system monitors the water inflow every day; the forming process and time of a bottom plate water guiding channel are obtained through the rapid increasing of the number of micro-seismic events within a short time on the basis that the water inflow of a working face is increased rapidly; then an energy density cloud picture is made, and the position of the bottom plate water guiding channel on a plane is obtained finally by observing the energy density cloud picture; and at last, the area bottom plate scale height is determined according to the position and geological conditions of the bottom plate water guiding channel on the plane, and therefore the extending depth of the bottom plate water guiding channel is determined. The coal mine bottom plate water guiding channel identification method has high economical value and social significance to widening of the application range of micro-seismic monitoring, reduction of coal mine capital investment and guaranteeing of mine safety production.

Owner:DALIAN UNIV OF TECH

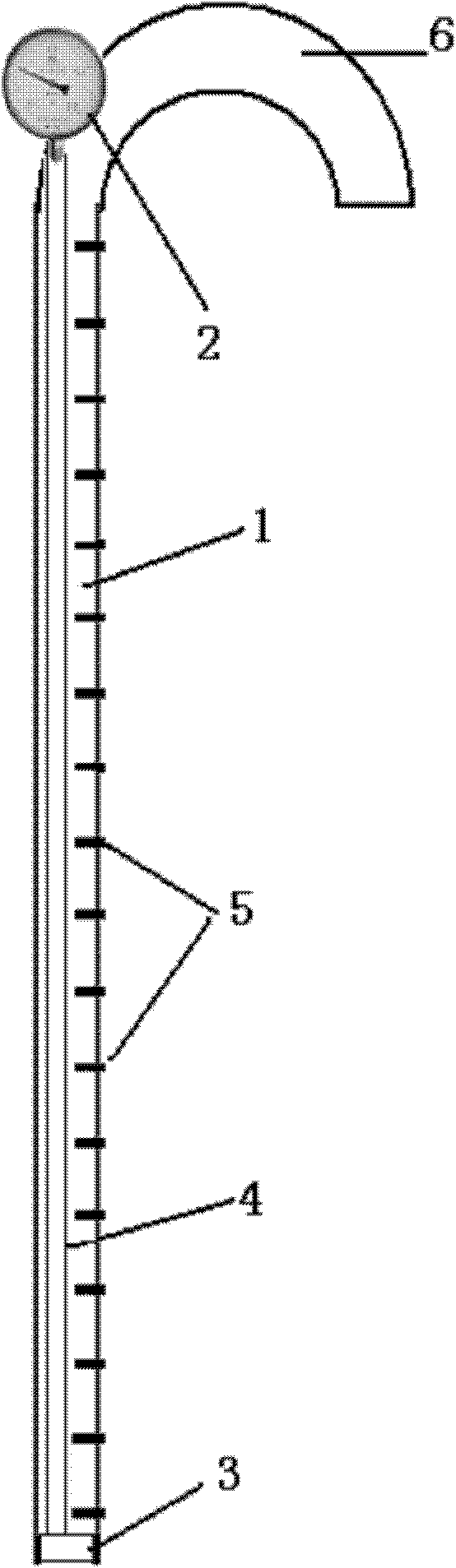

Method and device for measuring oil-water content in oil storage tank

InactiveCN102262036AEasy to useSimple structureVolume measurement apparatus/methodsSpecific gravity measurementWater storage tankLiquid storage tank

A method and device for measuring oil-water content in an oil storage tank. The measuring device is a hollow cylinder with a pressure gauge, the test head of the pressure gauge is located at the bottom opening of the cylinder, and the display head of the pressure gauge is located at the bottom of the cylinder. The top is open, and there is a size scale on the outer wall of the cylinder for reading the liquid height of the oil storage tank; the measurement method is, at first, insert the measuring stick of the present invention into the oil storage tank, and read out the height of the oil storage tank from the pressure gauge of the device. The pressure P at the bottom of filling; then read the liquid level height H in the oil storage tank from the scale of the measuring stick; then according to the formula P=ρ water H water g+ρ oil H oil g, and H=H water+H oil, Calculate the height H of the water in the oil storage tank and the height H of the oil, where ρ water refers to the density of water, and ρ oil refers to the density of oil, which is set to a known value; finally, according to the formula V water = SH water, V Oil=SH oil, the content of oil and water in the oil storage tank can be obtained, where S refers to the cross-sectional area of the inner cavity of the oil storage tank; Measurement of water content in smaller oil storage tanks.

Owner:XI'AN PETROLEUM UNIVERSITY

Construction method for prefabricating directly-buried uncompensated centralized heat supply pipeline by electrically preheating

InactiveCN102444750AImprove running stabilityGuaranteed elongationPipe laying and repairElectricityEngineering

The invention relates to a construction method for prefabricating a directly-buried uncompensated centralized heat supply pipeline by electrically preheating. The method comprises the following steps of: (1) grooving, adjusting the coordinate and scale height of the heat supply pipeline, and computing the preheating temperature and the designed elongation of the heat supply pipeline; (2) controlling the sand refilling height at a half to three quarters of the pipeline height H; (3) connecting the same-side end of the heat supply pipeline with preheating equipment through a cable respectively, and short-circuiting the other side of the heat supply pipeline through a cable; (4) arranging temperature sensors on the heat supply pipeline respectively; (5) recording the initial temperature of the heat supply pipeline and the initial position of a measuring point, starting temperature raising, controlling the temperature raising gradient within 1 DEG C per hour, and preserving heat after a preheating temperature is reached; (6) refilling sand into both sides of the heat supply pipeline, tamping, and controlling the preheating temperature within the range of + / -2 DEG C; (7) after the designed elongation is reached, shutting down the preheating equipment; and (8) performing subsequent construction according to the steps (1)-(7). The construction method disclosed by the invention is safe, reliable, easy and practical, is easy for accurately controlling construction equipment, and is consistent with the national policy of energy saving and emission reduction.

Owner:MCC TIANGONG GROUP

Crane beam scale height regulation method

InactiveCN101492147AGuaranteed safe operationAchieve regulationLifting framesRunwaysEngineeringBolt connection

Owner:SHANGHAI BAOYE GRP CORP

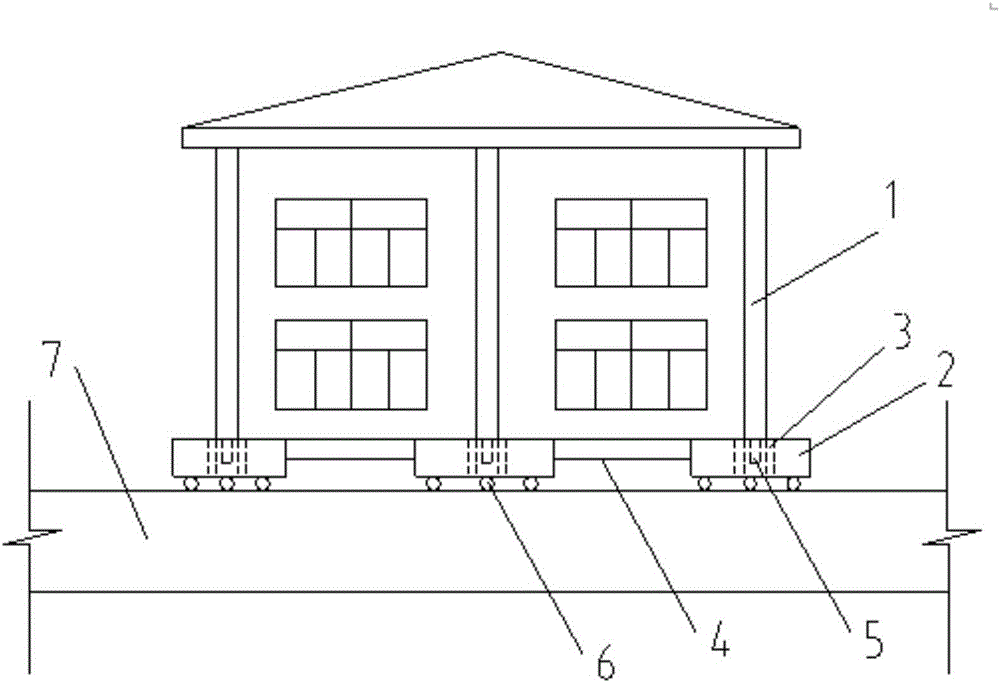

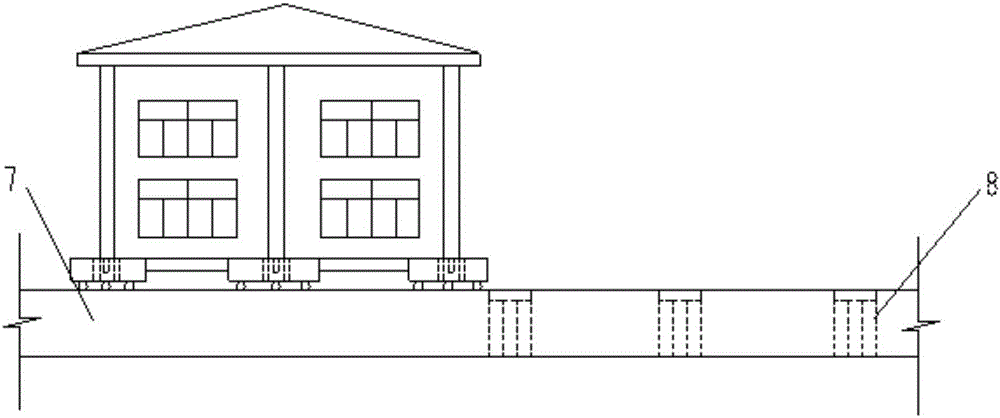

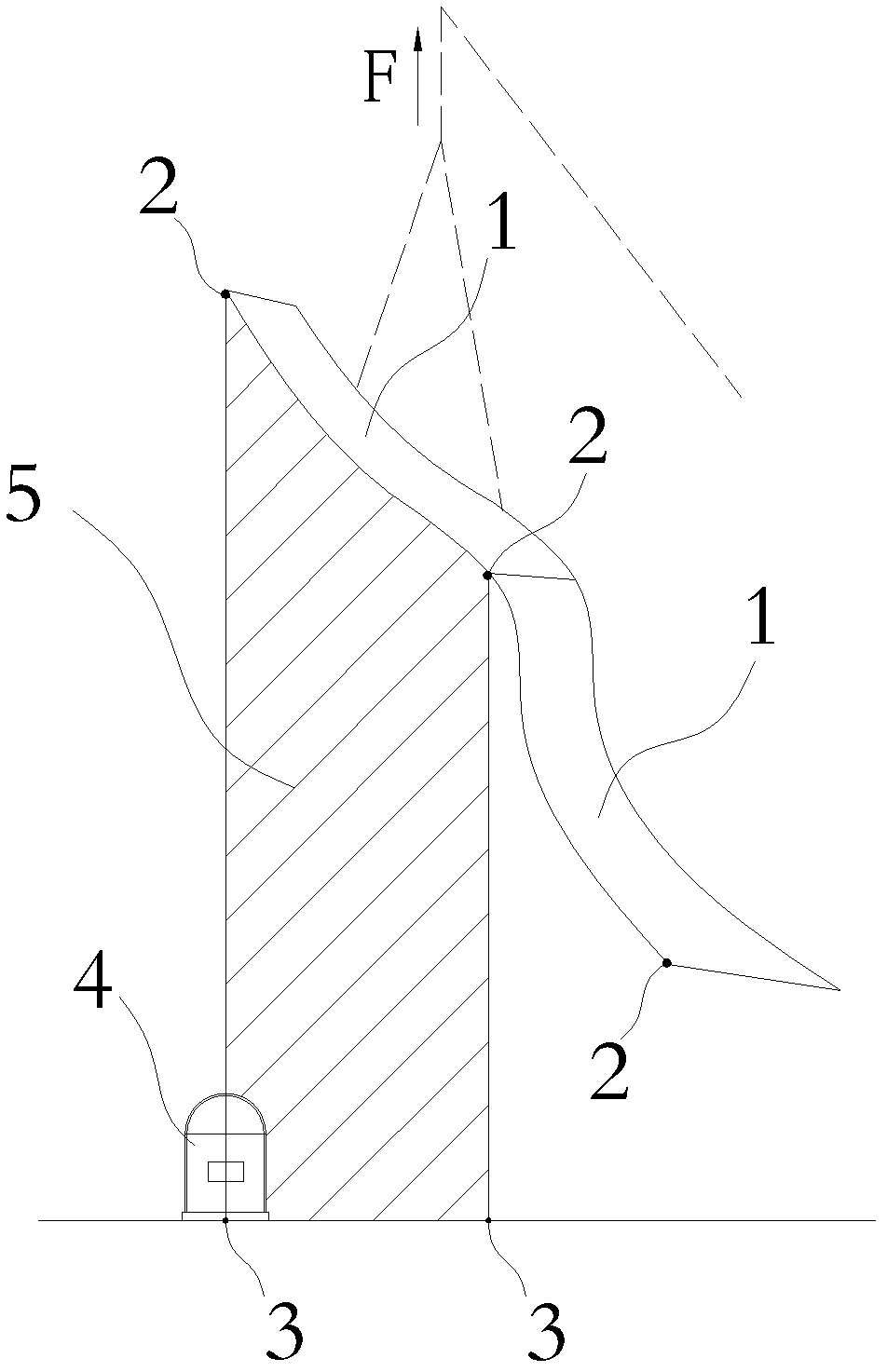

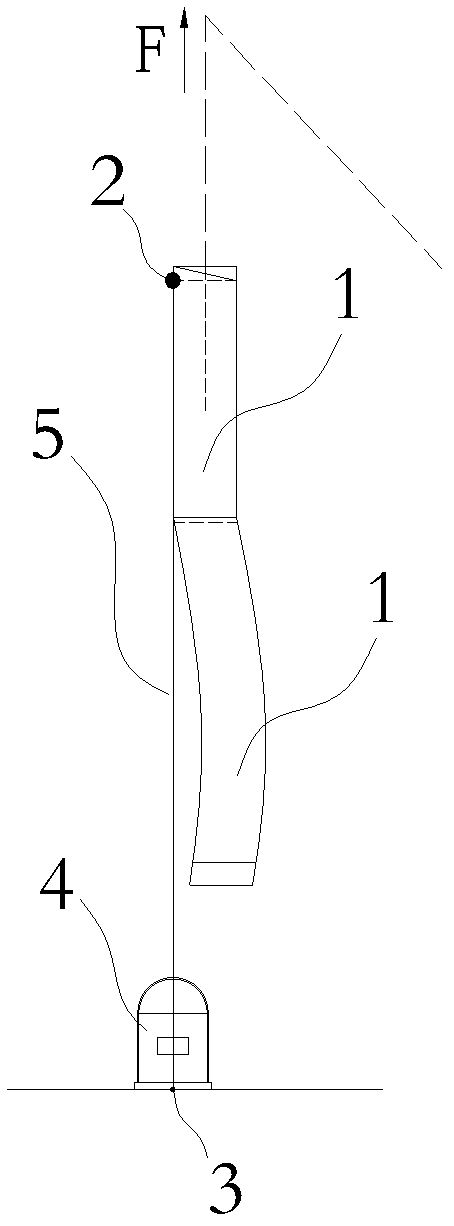

Method for achieving building moving steering by means of track height differences

ActiveCN106285040AAvoid additional internal forceShorten the construction periodBuilding repairsHeight differenceControl theory

The invention discloses a method for achieving building moving steering by means of track height differences. The method comprises the steps that 1, before building moving, a moving track before steering and a moving track after steering are poured on a building moving path, and the scale height of the moving track after steering is lower than that of the moving track before steering; 2, an underpinning beam before steering and an underpinning beam after steering are poured, and the bottoms of the two underpinning beams are on the same scale height; 3, the moving building is transferred to the moving track before steering through the underpinning beam before steering and a roller; 4, before the moving building reaches the moving steering position, moving is stopped; the moving track at the steering position is leveled up through a filler; 5, the building continues to be moved to the steering position, and the roller is placed under the underpinning beam after steering above the moving track after steering; 7, the roller below the underpinning beam before steering is taken out; 8, the filler for leveling up the intersection of the tracks before steering and after steering is removed; 9, the building continues to be moved to the designated position on the track after steering.

Owner:SHANDONG JIANZHU UNIV

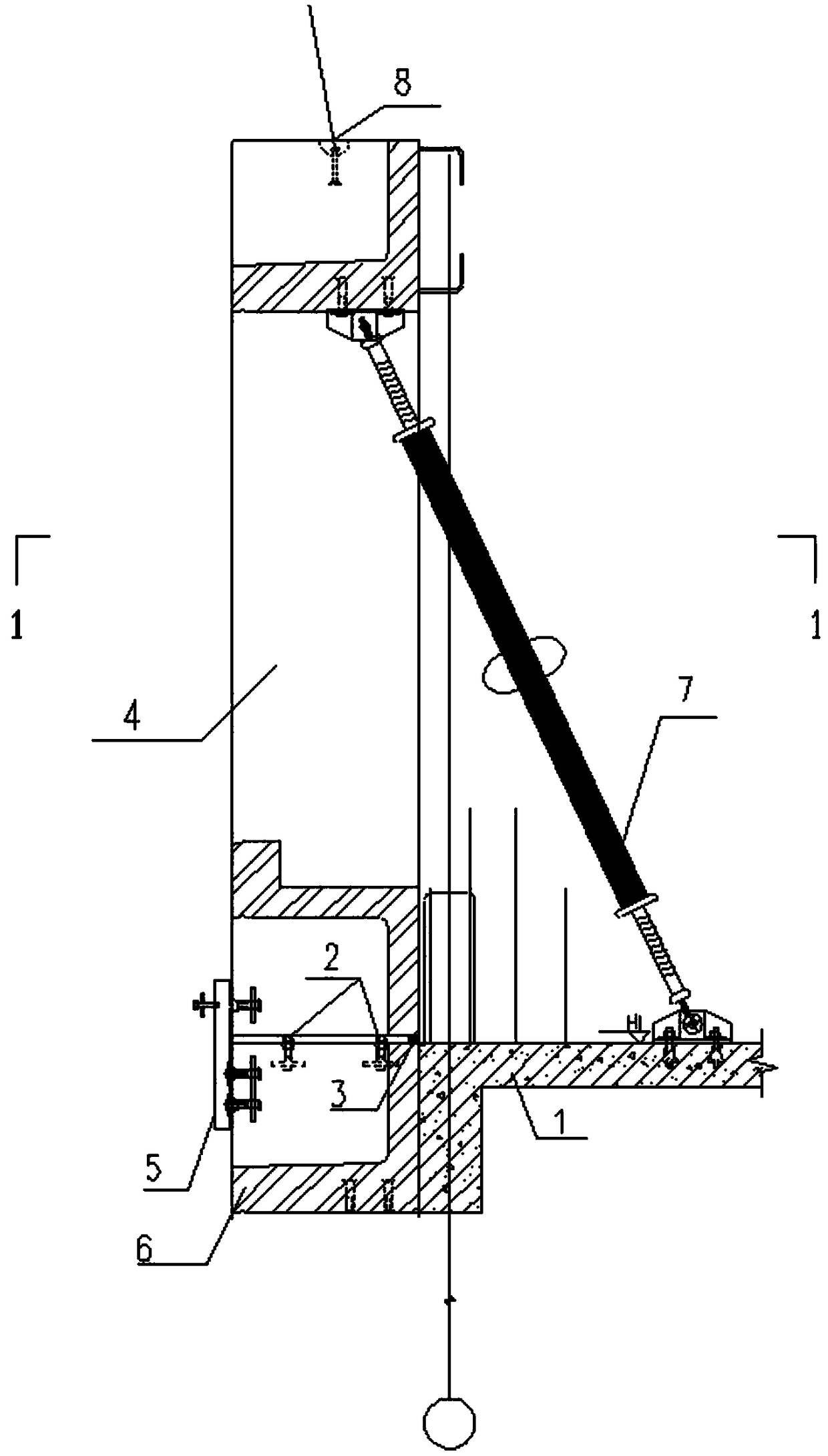

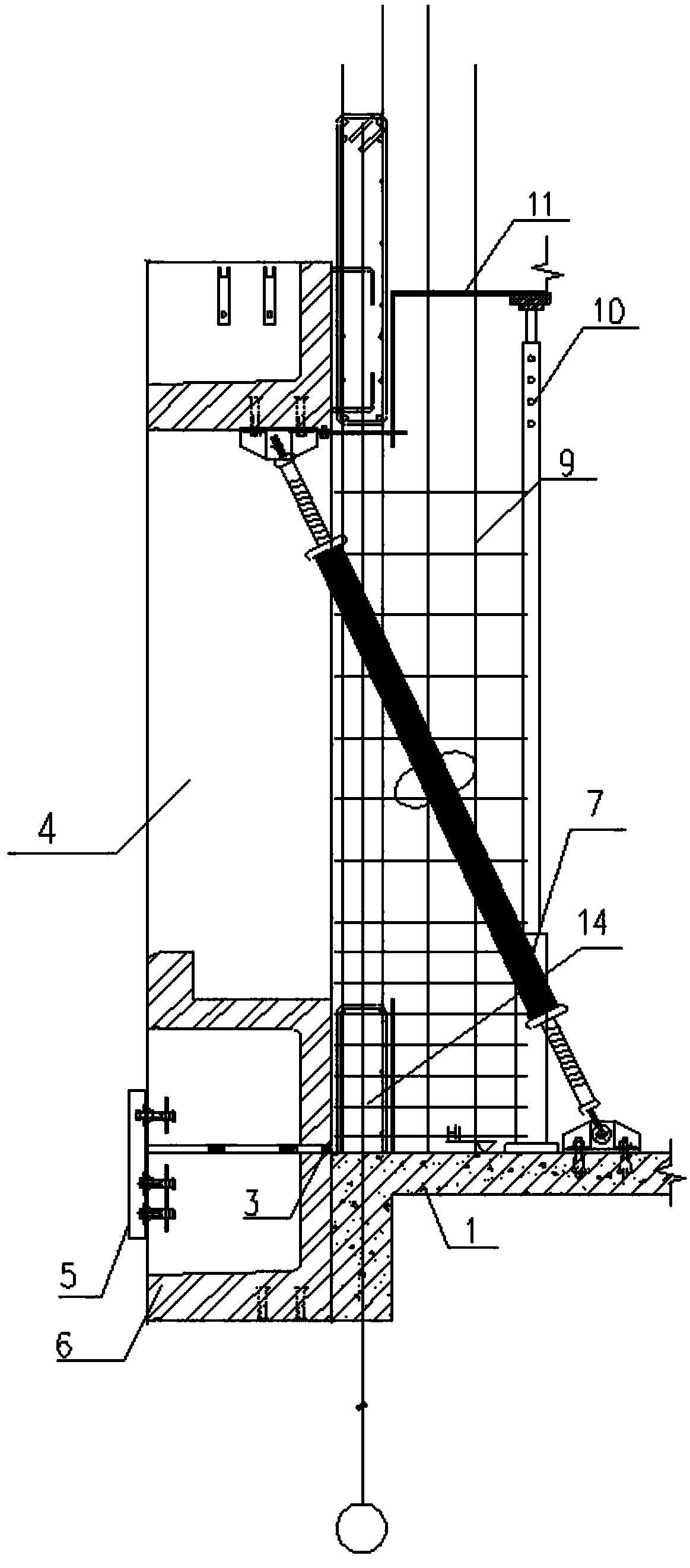

Residential building prefabricated bay-window construction structure and method

PendingCN108824632AImprove molding qualitySolve the problem of easy mold expansionForms/shuttering/falseworksArchitectural engineeringWater seepage

The invention provides a residential building prefabricated bay-window construction structure and method. The residential building prefabricated bay-window construction structure comprises a lower layer PC poured on the exterior side of a lower layer beam slab, a bolt is screwed into the upper end of the lower layer PC in the vertical direction, and the scale height of the top portion of the boltis Hi+0.020. An upper layer component is installed above the lower layer PC in an abutting joint mode, a PE stick is arranged on the interior side of a seam crossing between the lower layer PC and theupper layer component in a pressing mode, and the lower layer PC is fixedly connected with the exterior side of the upper layer component through a connecting piece. An inclined strut is installed between the upper layer component and the lower layer beam slab, the lower end of the inclined strut is fixed to the indoor lower layer beam slab, and the upper end of the inclined strut is fixed to theupper portion of the upper layer component. The problems that a traditional cast-in-place bay-window is prone to rising mould and leaking grout in the construction process, the molding quality is notsteady, and a post-installed window frame edge is subjected to water seepage are solved, and the invention belongs to the technical field of building main body construction.

Owner:CHINA CONSTR FOURTH ENG DIV +1

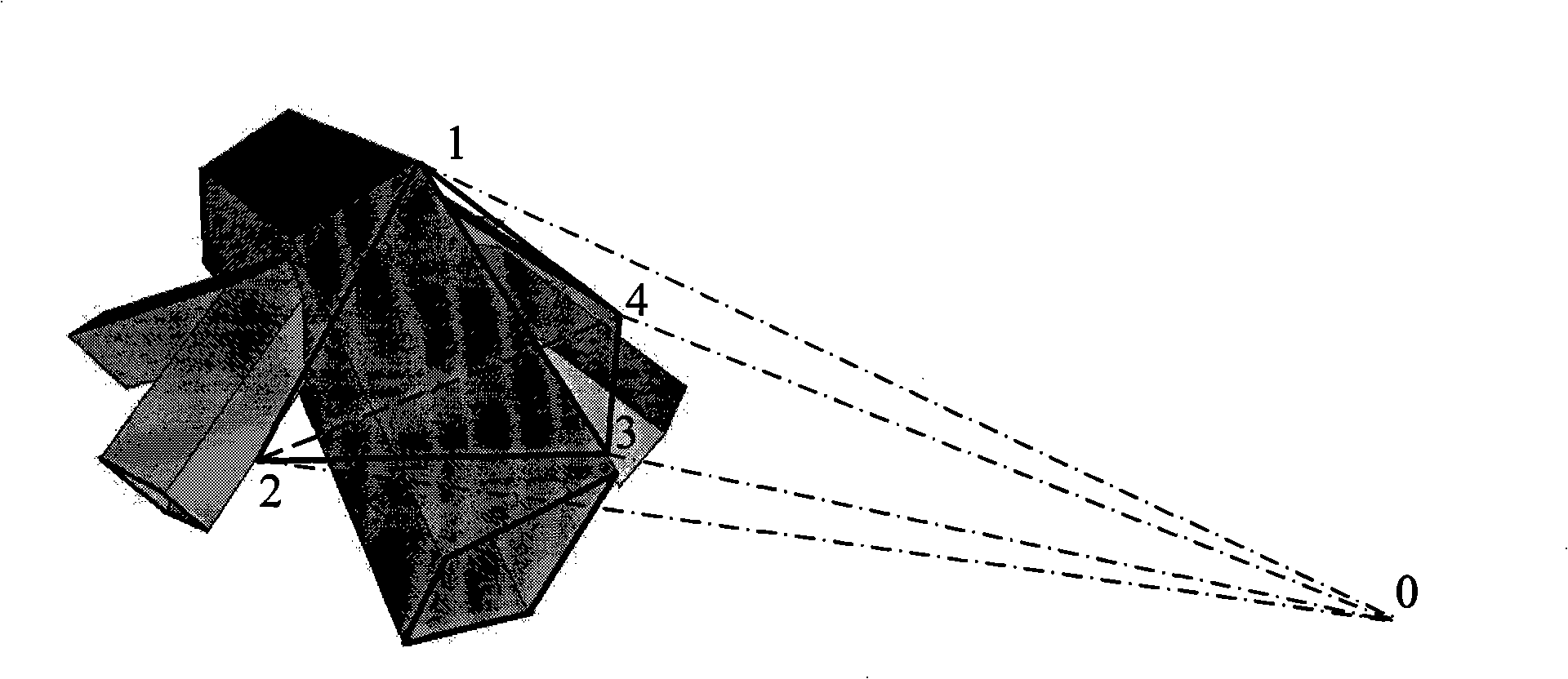

Method for measuring and locating virtual tetrahedron top of abnormity component

InactiveCN101255767AThe principle is simpleReliable methodSurveying instrumentsBuilding material handlingMeasurement pointTotal station

The present invention discloses a method for measuring and locating the tops of the virtual tetrahedron of the special-shaped component. In a special-shaped node three-dimensional body, four points which are not in a same surface are chosen to form a virtual tetrahedron. The three-dimensional coordinates of the four points are calculated and the corresponding marks of the four points are marked on the real object of the node. A random point is chosen as a main control point of the node and other points are taken as auxiliary control points. When the node is hanged to the station, firstly the three-dimensional coordinate of the main control point is monitored with an electronic total station at the position of the measuring point, and on the moulding bed of the node, the adjustment is executed by means of equipment to accurately control the plan position and scale height of the main control point. The planar and vertical three-dimensional rotation adjustments are executed while the node takes the main control point as a center until when the monitored reading number of the coordinate of other three auxiliary control points is fit with the calculated value. When the node is measured and is accurately mounted, the node is welded on the positioning device of the moulding bed for temporary fixing. The method of the invention has the advantages of simple principle, reliable method, convenient realization, high work efficiency and broad application sphere.

Owner:ZHEJIANG UNIV +2

A method of inspecting steel welding quality

InactiveCN105651791AProcess arrangement is reasonableProcess Arrangement CoordinationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by transmitting radiationCrazingX-ray

A method of inspecting steel welding quality is disclosed. The method mainly comprises 1) a step of determining whether the type and the size of a welded joint meet regulations of related patterns and standards, 2) subjecting all weld seams to outer checking to determine whether unallowed defects comprising burning through, cracks, non-uniform scale heights, disconnected weld seams, exposure of craters, and undercuts the depth of which is more than 0.5 mm and the length of which is more than 15% of the length of weld seams exist or not, 3) subjecting important butt weld seams (such as cover plates and webs of a tension zone of a girder of a crane) to nondestructive inspection, with quality of the butt weld seams being not lower than quality specified in the II grade in the GB3323 during radiographic inspection, and quality of the butt weld seams being not lower than quality specified in the I grade in the JB1152 during ultrasonic inspection, and 4) designating a part to be subjected to X-ray shooting inspection through a technical department, if an unallowed defect is found through shooting, performing supplementary shooting at the extending direction or a questionable direction of the defect, and if doubt exits after the supplementary shooting, shooting the full part of each weld seam. The method can effectively reduce the reject rate and products are high in quality.

Owner:重庆江东摩托车配件有限公司

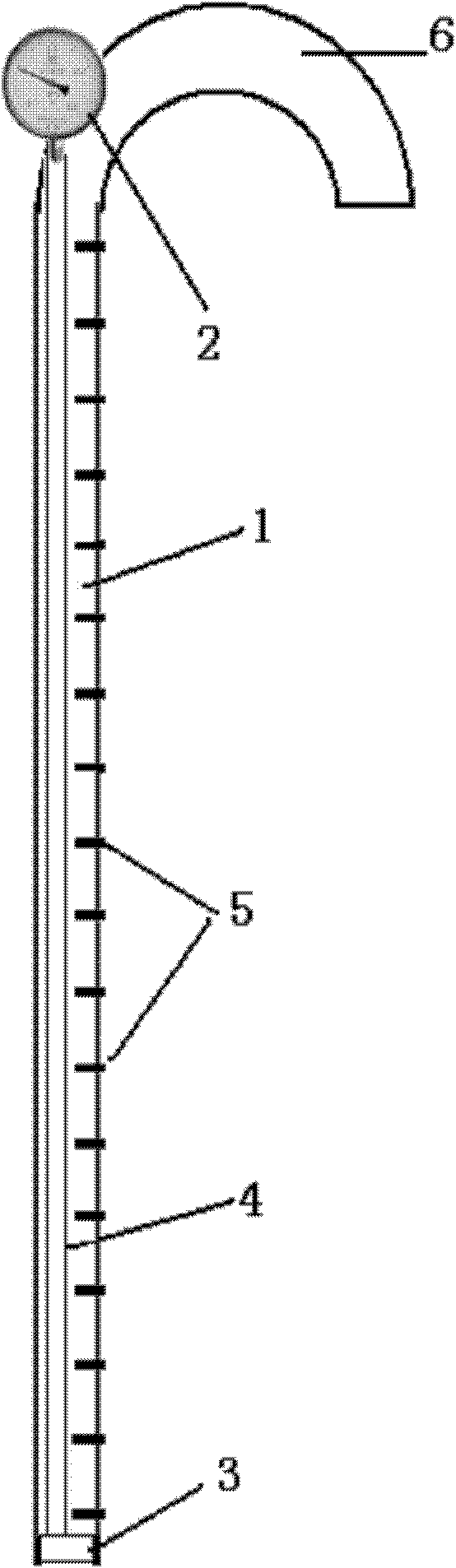

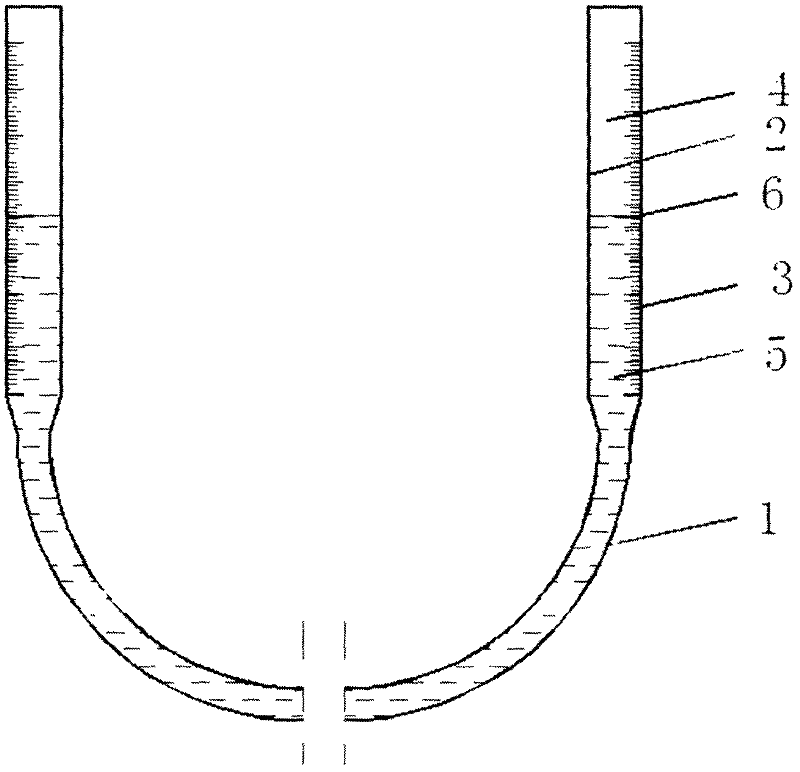

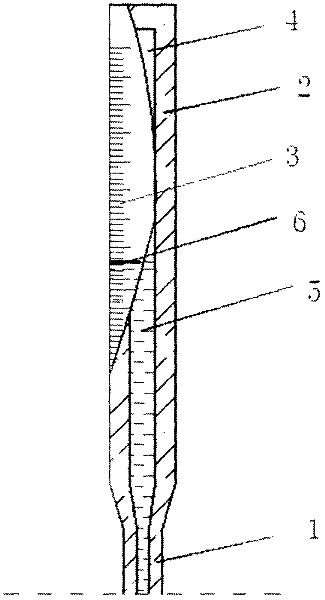

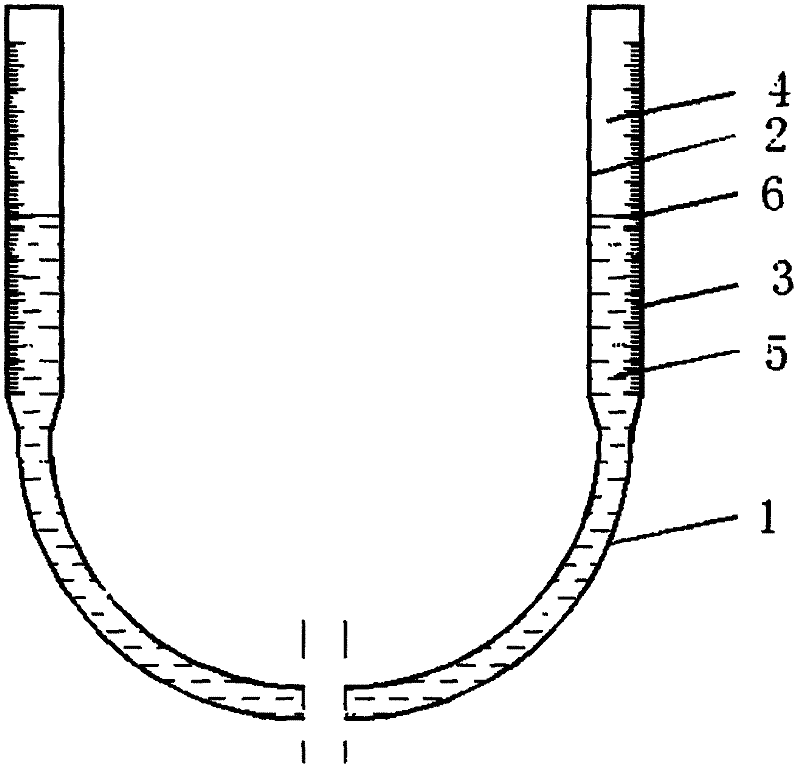

Leveling instrument for building

InactiveCN102445185ASimple structureEasy to operateHydrostatic levellingAnti freezingHeight difference

The invention discloses a liquid communicated leveling instrument for a building. The leveling instrument consists of thick transparent pipes, a thin transparent pipe and a colored anti-freezing liquid. A device is only filled with a liquid without any air, and the device is not full of the liquid, so that the upper sides of liquid surfaces at two ends in the device are in the vacuum state. The leveling instrument is structurally characterized by comprising a thin transparent pipe, wherein the two ends of the thin transparent pipe are connected with relatively thick transparent pipes; and the outer sides of the thick transparent pipes are provided with graduations for indicating liquid surface heights. The pipe wall of the device is of a certain thickness, so that the inside of the device is in the vacuum state, and the device is prevented from being damaged and deformed under the condition of an external atmospheric pressure. The leveling instrument is suitable for scale height measurement in small-distance and small-height-difference construction, and has the characteristics of convenience for operating, simple structure and prevention of the liquid from leaking easily.

Owner:孙培峰 +1

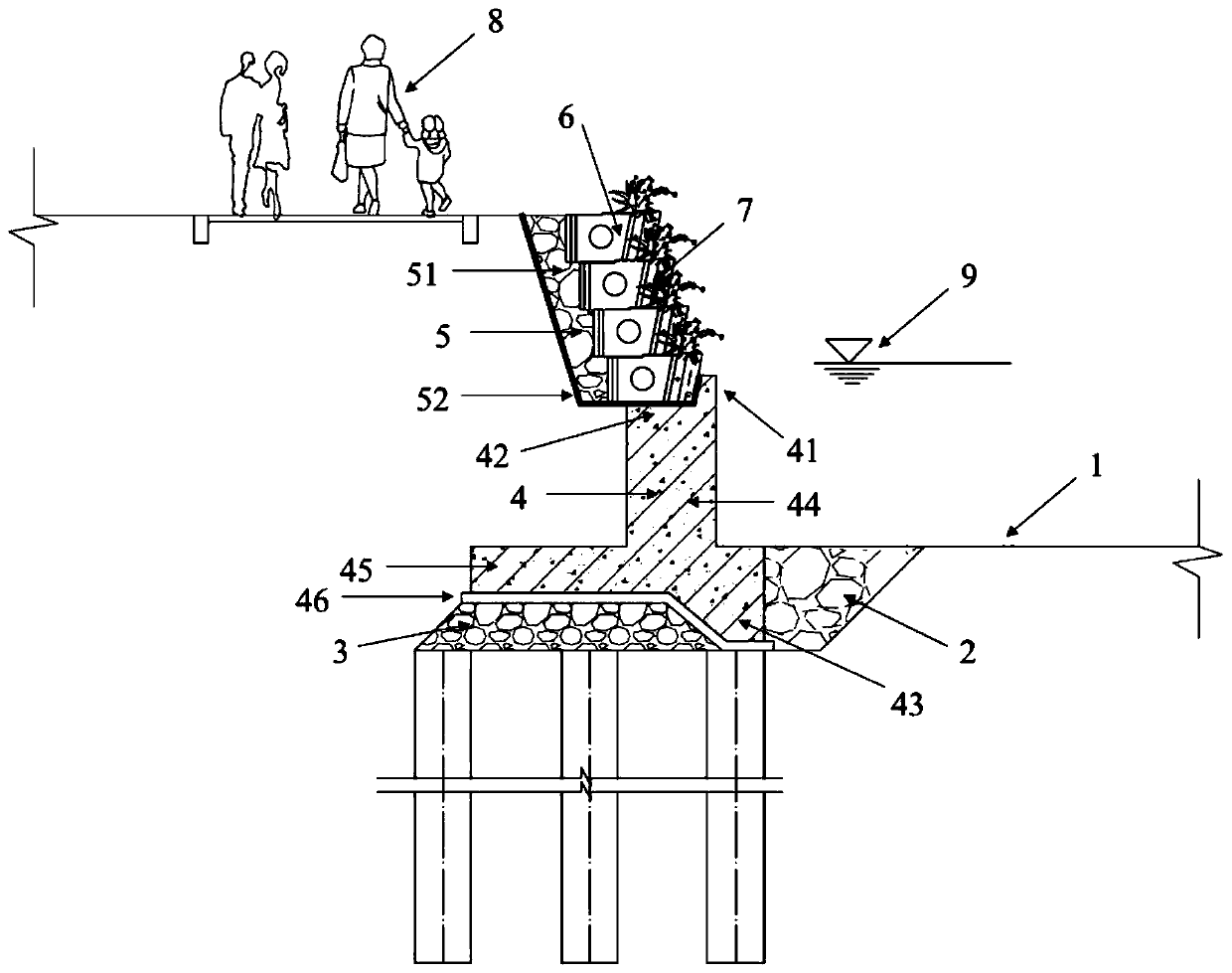

Water and soil loss resistant stepped ecological frame revetment structure and construction method thereof

PendingCN110485369AAvoid churnEcologically goodClimate change adaptationCoastlines protectionReinforced concreteSlope ratio

The invention provides a water and soil loss resistant stepped ecological frame revetment structure and a construction method thereof. The water and soil loss resistant stepped ecological frame revetment structure is arranged at a riverway bank and comprises a reinforced concrete revetment base, the base is provided with a water and soil loss resistant stepped ecological frame, the ecological frame is provided with a greenery landscape, the ecological frame top scale height is flush with the revetment top scale height, and the slope top is provided with a flood protection passage. By means ofthe water and soil loss resistant stepped ecological frame revetment structure and the construction method thereof, the water and soil loss resistant ecological frame is designed, and the ecological frame can be planted green, is attractive and generous in appearance and has good ecological and landscape effects; the front edge of the outer portion of the ecological frame is provided with soil-retaining structures, the ecological frame is internally and fixedly provided with three-dimensional soil and water conservation blankets, and generation of the revetment water and soil loss situation can be effectively prevented; and the ecological frame is provided with two stages of slide-resistant tooth ridges, different step combination can be formed, and the water and soil loss resistant stepped ecological frame revetment structure and the construction method thereof can well adapt to revetments of different slope ratios.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

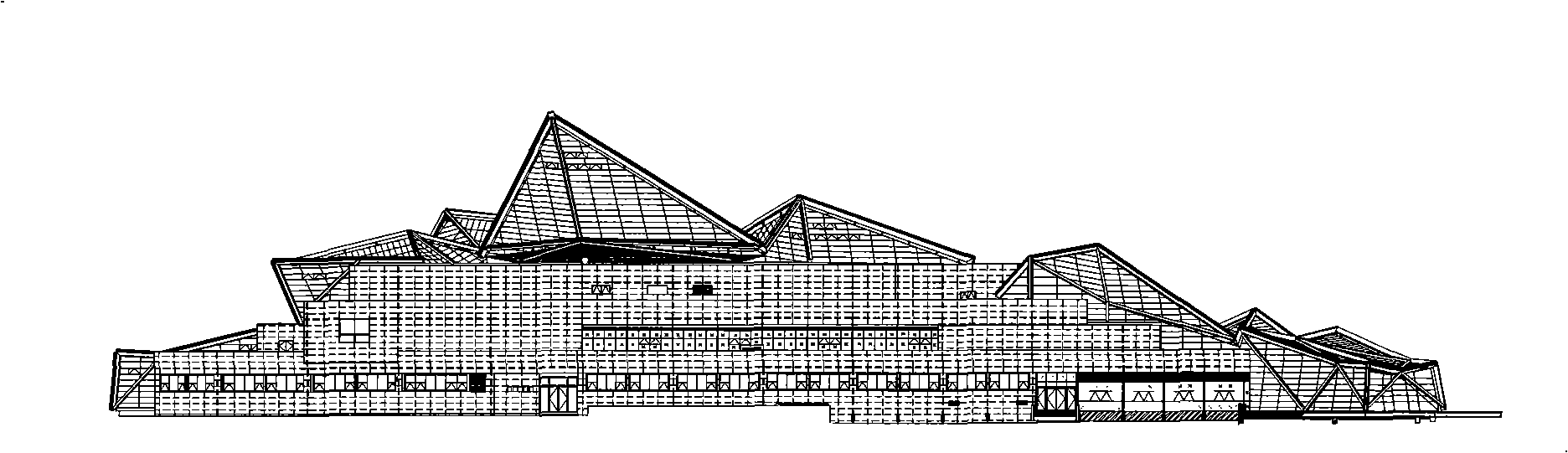

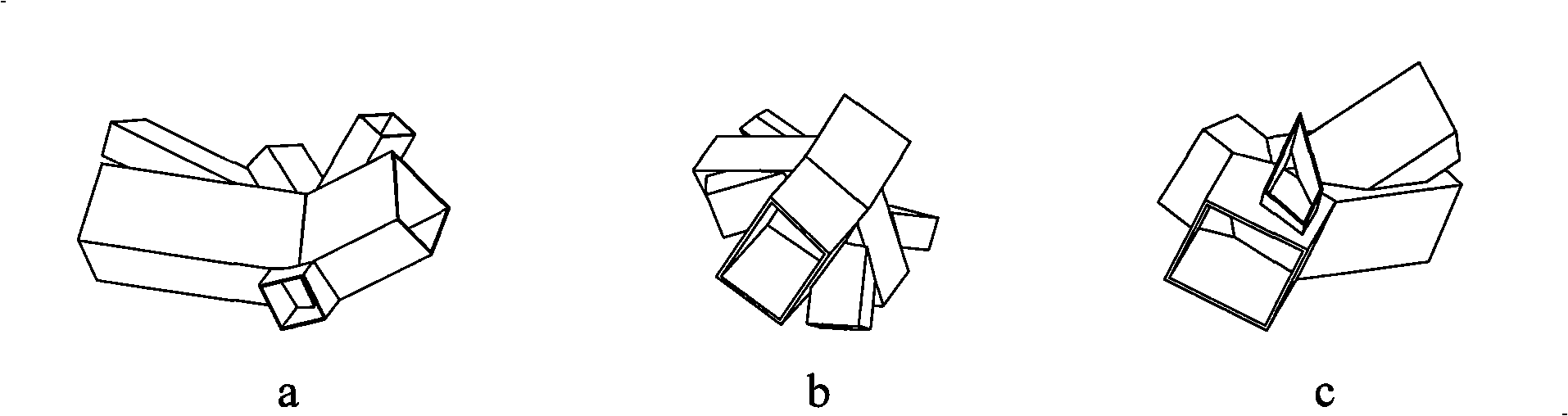

Method for manufacturing and mounting irregular abnormally-shaped large space steel structure

ActiveCN102535863AControl productionControl installationExtraordinary structuresBuilding material handlingManufacturing technologyMeasuring instrument

The invention discloses a method for manufacturing and mounting an irregular abnormally-shaped large space steel structure, and belongs to the technical field of manufacturing of metallurgy and construction. The method for manufacturing and mounting the irregular abnormally-shaped large space steel structure is high in manufacturing and mounting quality and low in labor intensity and is convenient to operate. The method for manufacturing and mounting the steel structure comprises the following steps of: according to structural characteristics of a large number of nodes in the irregular abnormally-shaped large space steel structure, detaching the irregular abnormally-shaped large space steel structure into a plurality of steel structure manufacturing units; marking a node on the end part of each steel structure manufacturing unit as a measurement coordinate control point; projecting to a horizontal ground at the mounting position of the irregular abnormally-shaped large space steel structure to form the measurement coordinate control point; and controlling and measuring the central line and the scale height of each steel structure manufacturing unit by using a laser marked line distance measuring instrument arranged on the horizontal ground to ensure the mounting quality of the irregular abnormally-shaped large space steel structure. By the method, the cost is saved, and construction periods are shortened.

Owner:CHINA 19TH METALLURGICAL CORP

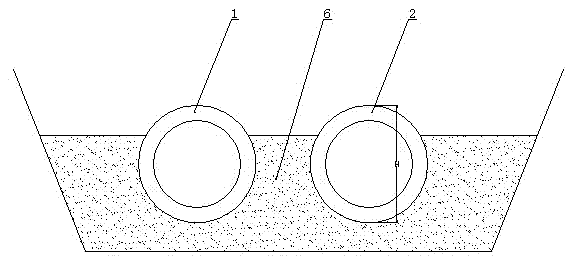

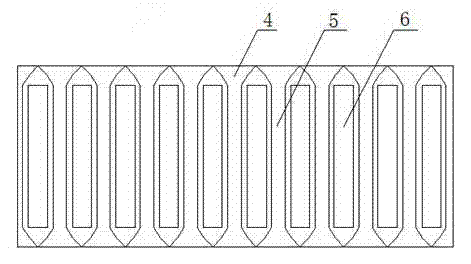

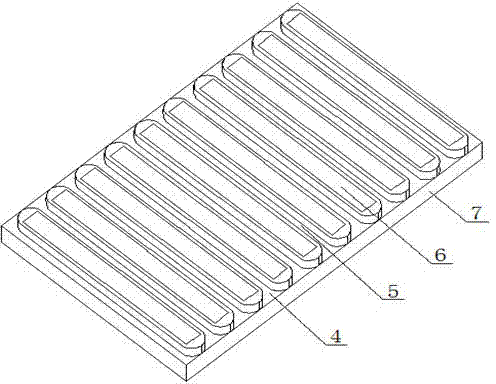

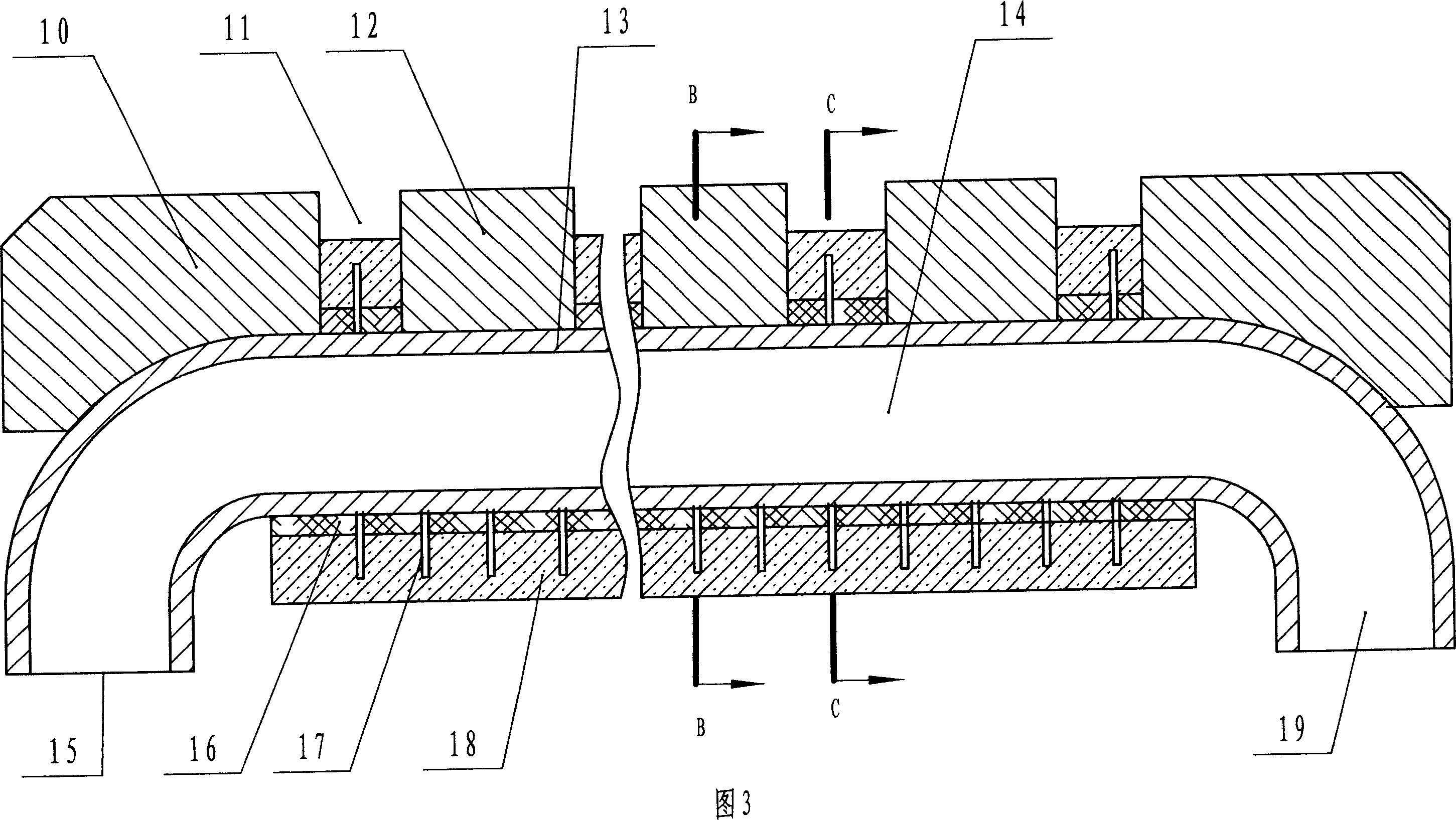

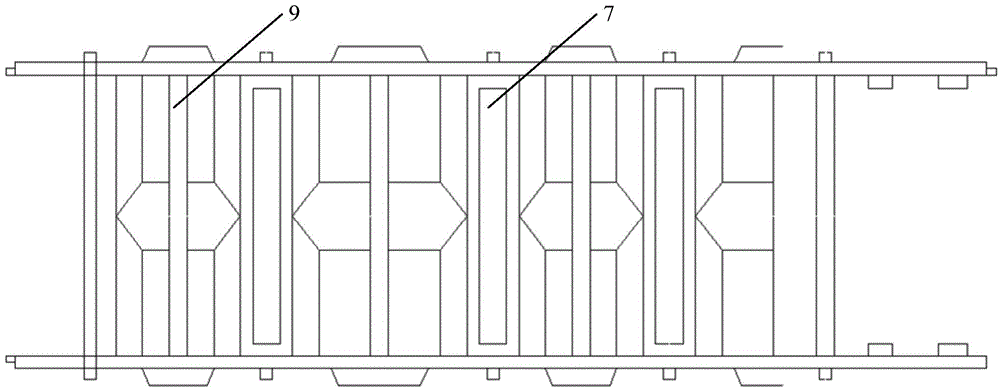

Rainwater grates capable of separating initial rainwater runoffs

InactiveCN103498505AReduce processing loadReduce runoff coefficientSewerage structuresRainfall runoffSewage

The invention relates to rainwater grates capable of separating initial rainwater runoffs. The rainwater grates capable of separating initial rainwater runoffs comprises a concrete base plate (7) and water-permeable ports (6) formed in the concrete base plate, wherein water passing galleries (5) are formed at the two sides of each water-permeable port (6), the scale height of each water-permeable port (6) is larger than that of each water passing gallery (5), and arc water catchment ports (4) are formed in the two ends of each water passing gallery (5). The rainwater grates capable of separating initial rainwater runoffs has the advantages of being capable of separating the initial rainwater runoffs from the runoffs in the middle and later periods, reducing the water amount entering the city rainwater pipe network and lightening the water processing load of sewage plants on one hand, making full use of the potency that roadside green detain and absorb the initial rainwater runoffs so that road surface source pollutants can be reduced on the other hand, and being capable of effectively relieving even solving the problem of city surface source pollution due to the fact that rainwater runoffs scour roads in the rainfall process.

Owner:CHONGQING UNIV +1

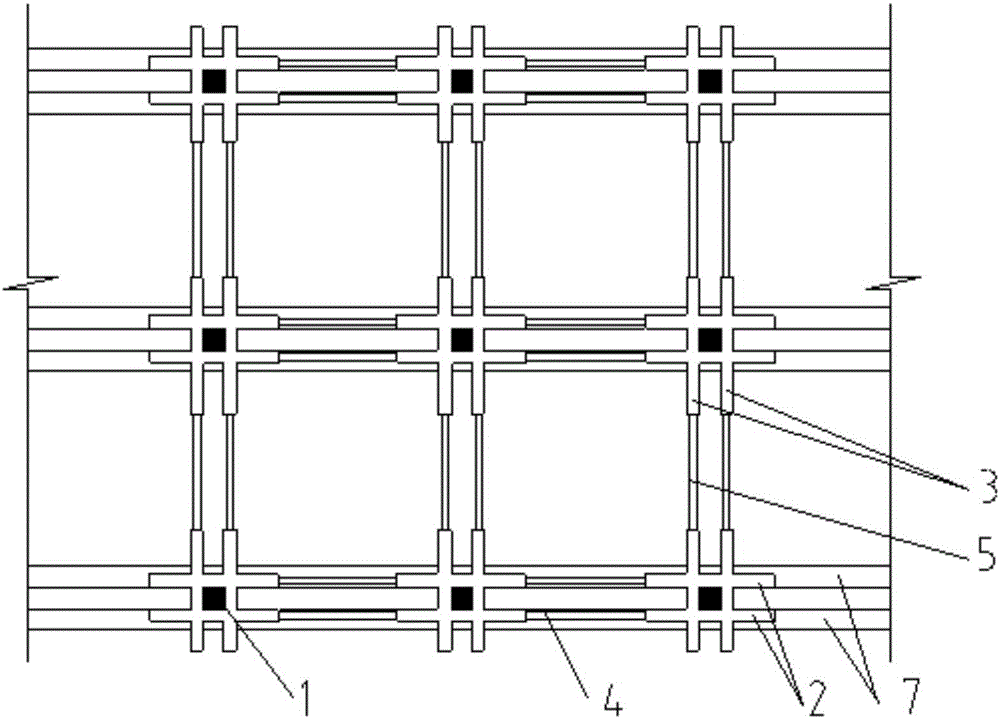

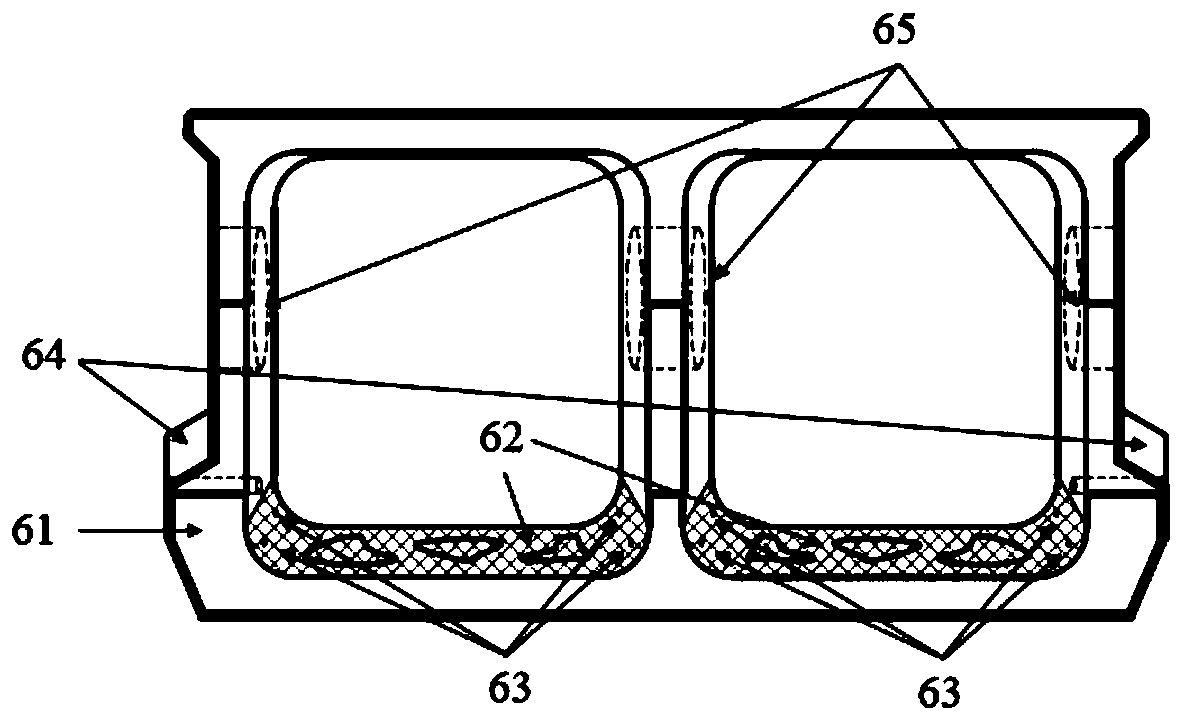

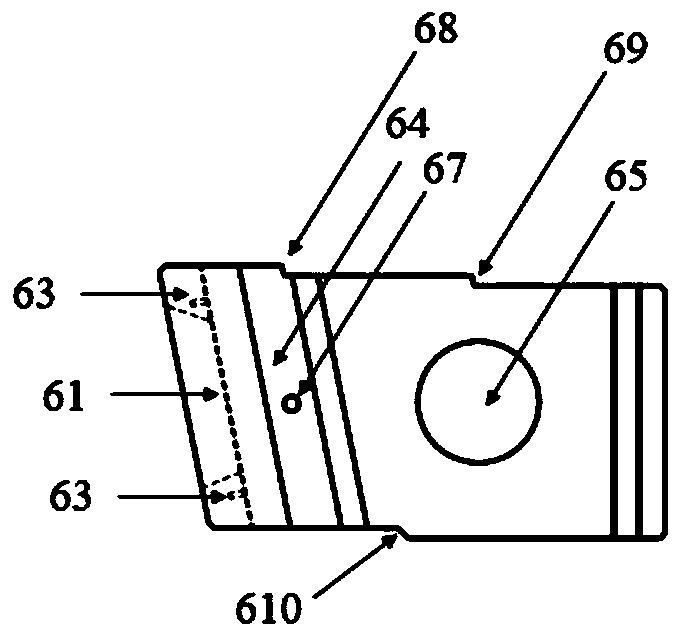

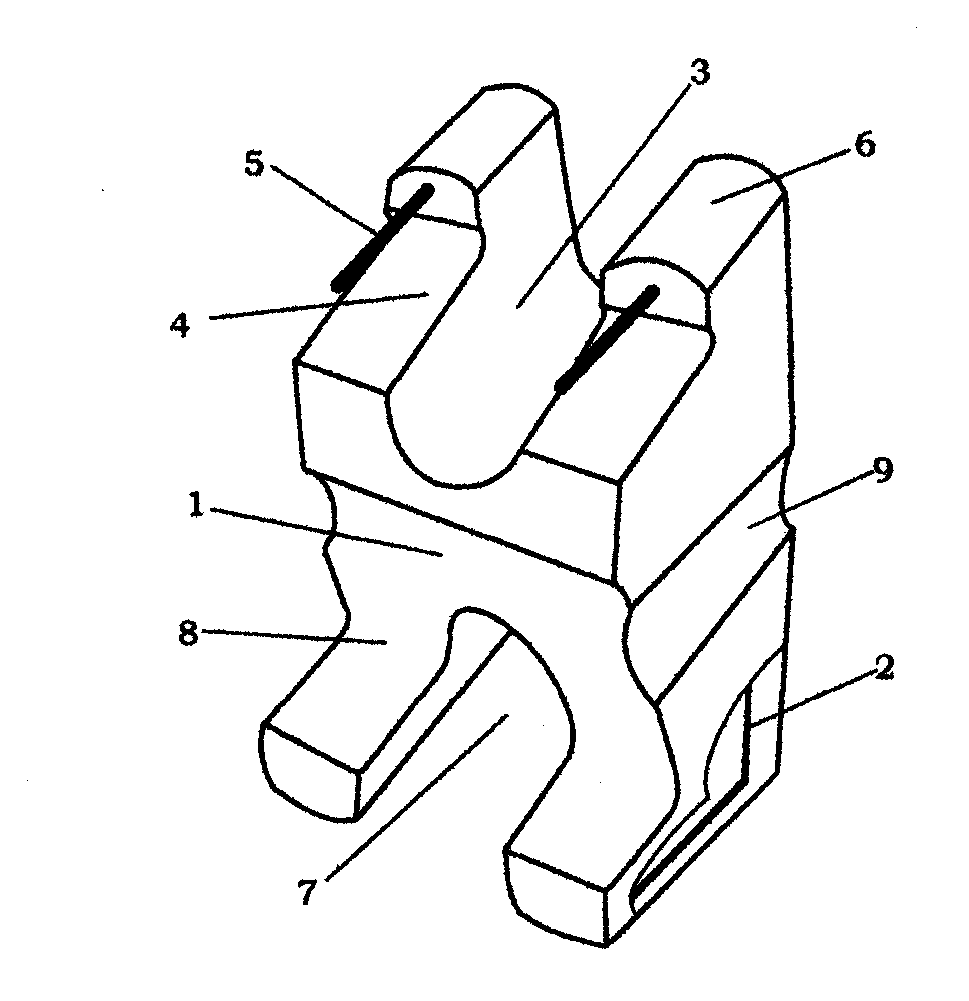

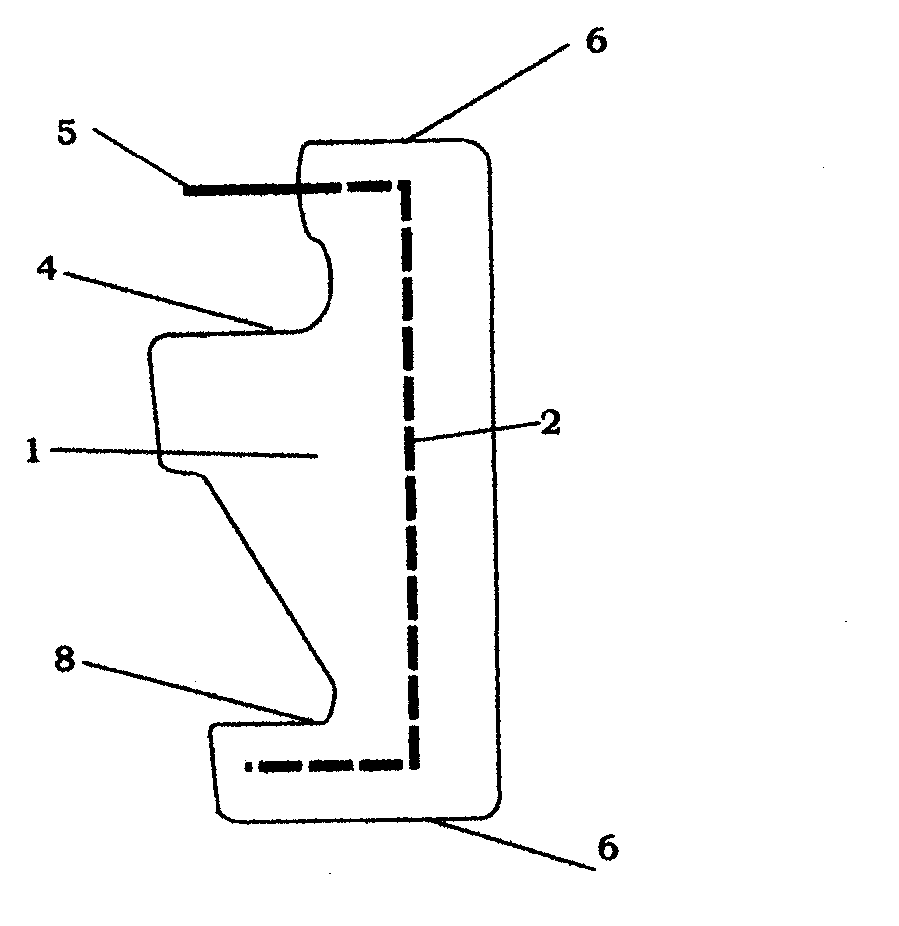

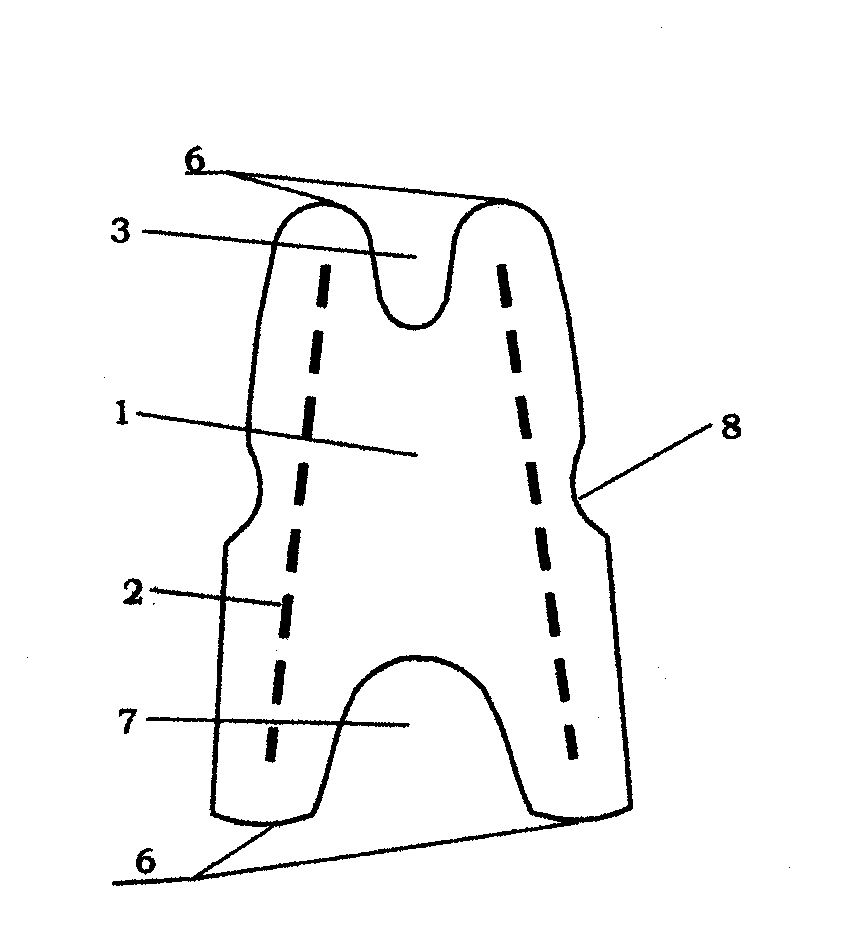

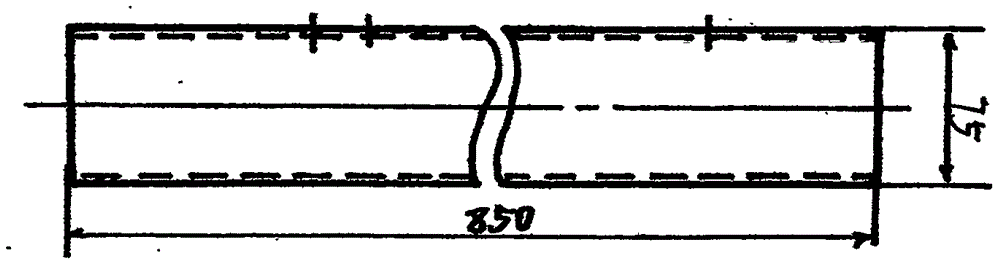

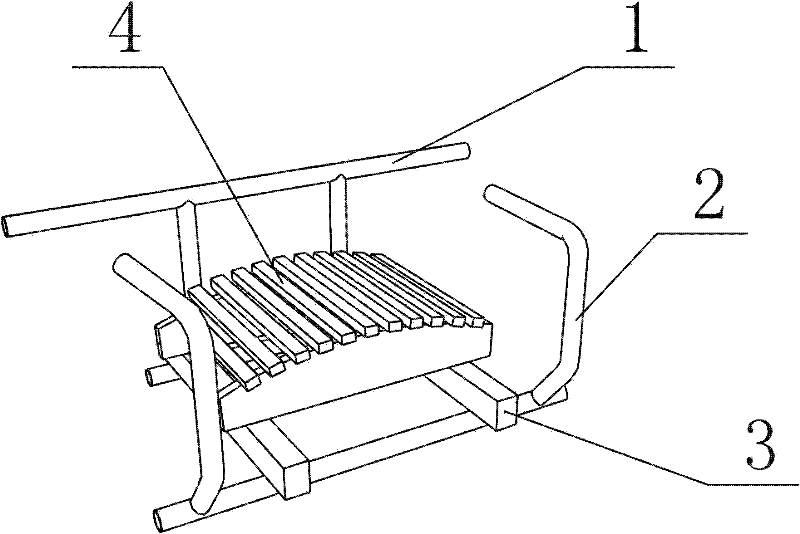

Buckling concrete split head for supporting upper and lower layers of steel bars

A buckling concrete split head for supporting upper and lower layers of steel bars is characterized in that ']' shaped metal bars are arranged on two sides of the inside of a concrete split head body to enhance the strength of the concrete split head body; an upper-through and gradually-opening notch and L-shaped steps are formed in the upper end of the concrete split head body and used for crossing the upper steel bars in an avoidance manner and realizing supporting positioning, a lower-through and gradually-opening notch and acute angles or U-shaped slots are formed in the lower end of the concrete split head body and used for crossing the lower steel bars in an avoidance manner and realizing supporting positioning, so that space between the upper and the lower steel bars is kept, the center of the concrete split head body can be supported for stressing, and the stability is improved; buckling metal bars are arranged on two walls of the upper ends of the L-shaped steps, and buckle the upper steel bars and further stabilize the concrete split head body, so that the concrete split head body cannot be moved or knocked down during construction treading; upper and lower end surfaces of the concrete split head body are scale heights for indicating the thicknesses of protective layers of steel bars; and rough concave and convex surfaces which are convenient to tightly combine concrete are arranged on the surface of the concrete split head body. The buckling concrete split head is used for realizing once supporting positioning of double layers of bidirectional steel bars and is convenient to mount, and the work efficiency and the project quality are improved.

Owner:贺绍勤

Laser-ray-following wall ground leveling darby

With the invention of the laser line wall and ground leveling scraper, the metal processing technology is used to drastically improve the original scraper, and it is used with the existing laser line thrower. The existing leveling scraper is difficult to carry, the deviation of the leveled ground is 20mm-40mm, and the application range is small. The present invention consists of two scrapers (Fig. 1-Fig. 6), which are connected into a long scraper through a connector (Fig. 7-Fig. 9), and an L-shaped adjustable scale is installed on both ends of the top (Fig. 10-Fig. 9). 12), used to observe the laser level and elevation. The new tool is used harmoniously with the existing laser line projectors on the market. For ground leveling and slope leveling, laser horizontal lines are used; for vertical wall leveling, laser vertical lines are used. The new tool is easy to carry and store, and the accuracy of wall and ground leveling is increased by 10 times, the scope of use is expanded. After the technical solution is transformed into actual production, the economic and social benefits are huge.

Owner:贺国林

Walking beam changing method of step-by-steep heating furnace

The invention relaters to walking beam exchanging method for the walking beam reheating furnace. It includes the following steps: removing the refractory materials covered on the level beam flame section; removing the fireclay insulating refractory covered on its stand column; fixing walking beam frame to make the error be not more than + / -2mm for all slides along the elevation direction; fixing the stand column each of which upper end is welded strip steel; removing the flame section level beam; cutting flame section saddle shape bracket; welding the bracket of which upper arc surface bottom error is + / -1mm; setting welded level beam tube of which heat resisting cushion block scale height error is not more than + / -2mm; checking the welding port; welding the heat resisting cushion; welding the anchor fixing hook; binding up fiber blanket; pouring; and drying oven. The invention has the advantages of short exchanging construction period, and low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for replacing sintering machine air box chutes and air box girders

The invention provides a method for replacing sintering machine air box chutes and air box girders. The method includes the steps: manufacturing a hoisting tool; preassembling the air box girders; hanging the preassembled air box girders on the hoisting tool, and conveying the air box girders to the inside of an ignition furnace for mounting when the air box girders are mounted inside the ignition furnace; transporting the preassembled air box girders to a framework of a sintering machine by a crane for mounting when the air box girders are mounted outside the ignition furnace; mounting the air box chutes below the air box girders. The hoisting tool comprises two groups of supporting rods which are arranged on two trolleys respectively, the height of each supporting rod is lower than the scale height of the ignition furnace or a heat preserving furnace, a square frame is arranged at the top ends of two groups of supporting rods, and a lifting device is arranged on the square frame. The method can greatly shorten construction time and effectively solves the problem of difficulty in dismounting and mounting an air box and air box girders in the ignition furnace and the heat preserving furnace, labor intensity is reduced, and working efficiency and safety are improved.

Owner:MCC BAOSTEEL TECH SERVICE

Installation method of ring seam scrubbing tower AGE tube

ActiveCN101574604AControl deviationGuaranteed concentricityUsing liquid separation agentEngineeringTower

The invention provides an installation method of a ring seam scrubbing tower AGE tube, comprising an upper cone and a lower cone which are arranged inside the ring seam scrubbing tower, an AGE tube, and a baseplate which is arranged on the bottom of the scrubbing tower. The installation method is as follows: a. making a tube tapping sample plate; b. measuring and centering of the AGE tube center; c. determining the cross center line of the tube tapping; d. determining the concentric rate; e. opening a tube hole; f. mounting the tube; g. adjusting the tube and h. welding the tube. Compared with the prior art, the invention has the advantages of simple method and easy operation; the invention can effectively control the deviation of the upper tube and the lower tube, ensure the concentric rate, scale height and perpendicularity of the upper and lower tubes, avoid the secondary rework and improve working efficiency.

Owner:CHINA 22MCC GROUP CORP

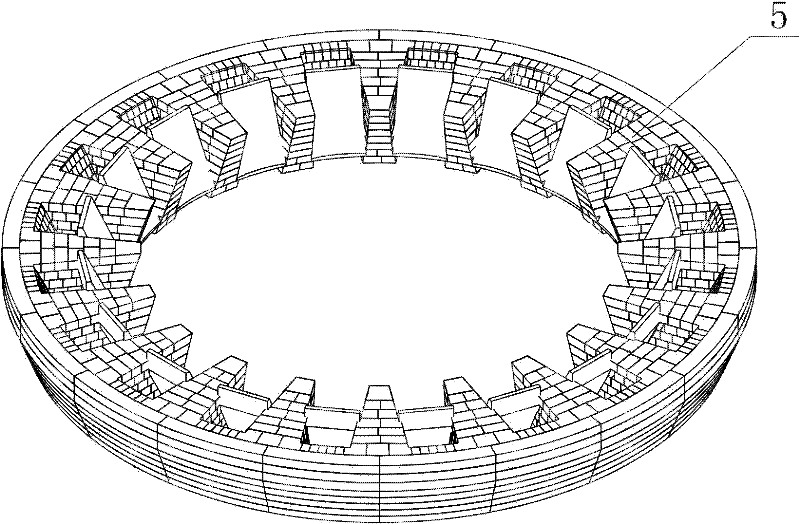

Method for supporting arch tire for building overhead brick in inclined duct of dry quenching furnace

ActiveCN102504838AEasy to set upReduce support processCoke quenchingBuilding material handlingBrickQuenching

The invention relates to a method for building a kiln lining, in particular to a method for supporting an arch tire for building an overhead brick in an inclined duct of a dry quenching furnace. The method for supporting the arch tire for building the overhead brick in the inclined duct of the dry quenching furnace comprises the following steps of: I, building partition walls in the inclined duct, and putting a device special for supporting the arch tile between adjacent partition walls; II, putting the arch tire on the device special for supporting the arch tile; and III, pre-arranging an overhead brick on the arch tire, adjusting the scale height of the arch tire, and combining the pre-arranged overhead brick with arch springing bricks at the front ends of the partition walls. The method has the beneficial effects that: 1, due to the adoption of the method, supporting of the arch tire is easy, and building of the overhead brick is easy; 2, during supporting of the arch tire, a steelpipe is not required to be taken as a bracket, so that the using amount of steel pipe is saved, and the supporting procedures of the arch tire are reduced; and 3, the device special for supporting the arch tile can be used repeatedly, so that materials are saved; and the structure of the device is small, so that construction space is saved.

Owner:CHINA FIRST METALLURGICAL GROUP

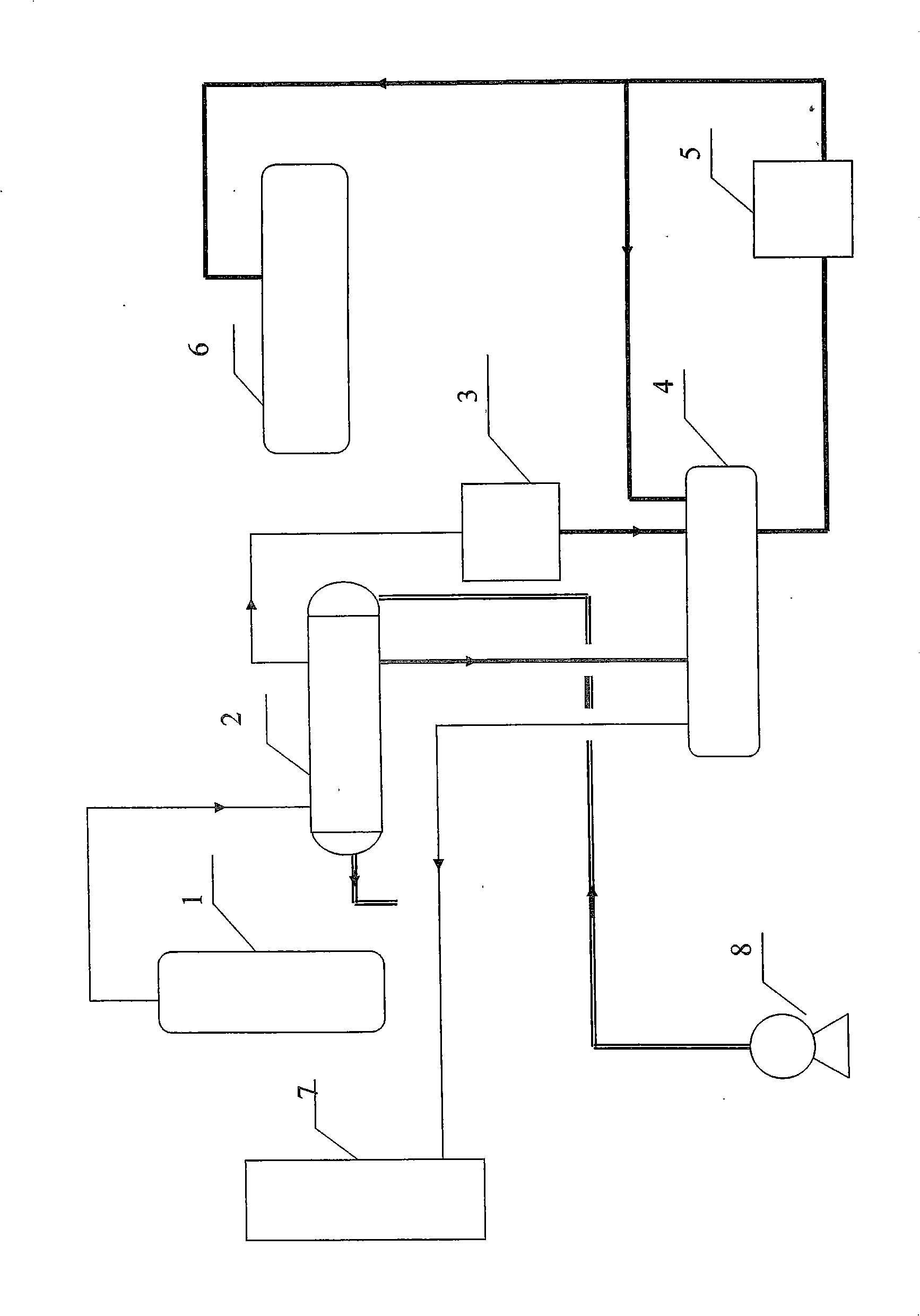

Novel process of medium-pressure ammine recovery system for urea water solution complete cycle production

InactiveCN101348447AReduced medium pressure vent volumePrevent scalingUrea derivatives preparationOrganic compound preparationWater useAmmonia storage

A novel process is used in a recovery system for manufacturing medium pressure ammonia by a urea aqueous solution complete cycle method. The medium pressure system for manufacturing urea by the aqueous solution complete cycle method adopts the following technological transformations that facilities including an evaporative condenser, an ammonia pump, an ammonia storage tank and matched pipes, valves and electrical apparatuses and instruments are added; meanwhile, the scale height of an ammonia cooler A is reduced and a urea circulating pump matched with the ammonia cooler is arranged; and the novel process abandons an ammonia cooler B\C, and changes the cooling water used in the evaporative condenser into desalted water. The invention provides the technological transformations for a medium pressure system by the urea aqueous solution complete cycle method during production and application, and has the advantages of less investment, quick returns, convenient implementation and operation, and the like.

Owner:ANHUI JINMEI ZHONGNENG CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com