Method for measuring and locating virtual tetrahedron top of abnormity component

A positioning method and a technology of special-shaped components, which are applied in the direction of measuring instruments, measuring devices, mechanical measuring devices, etc., can solve the problems of being impossible or very inconvenient to apply, and achieve the effects of simplifying the work of measuring, positioning and correcting, improving work efficiency, and reliable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

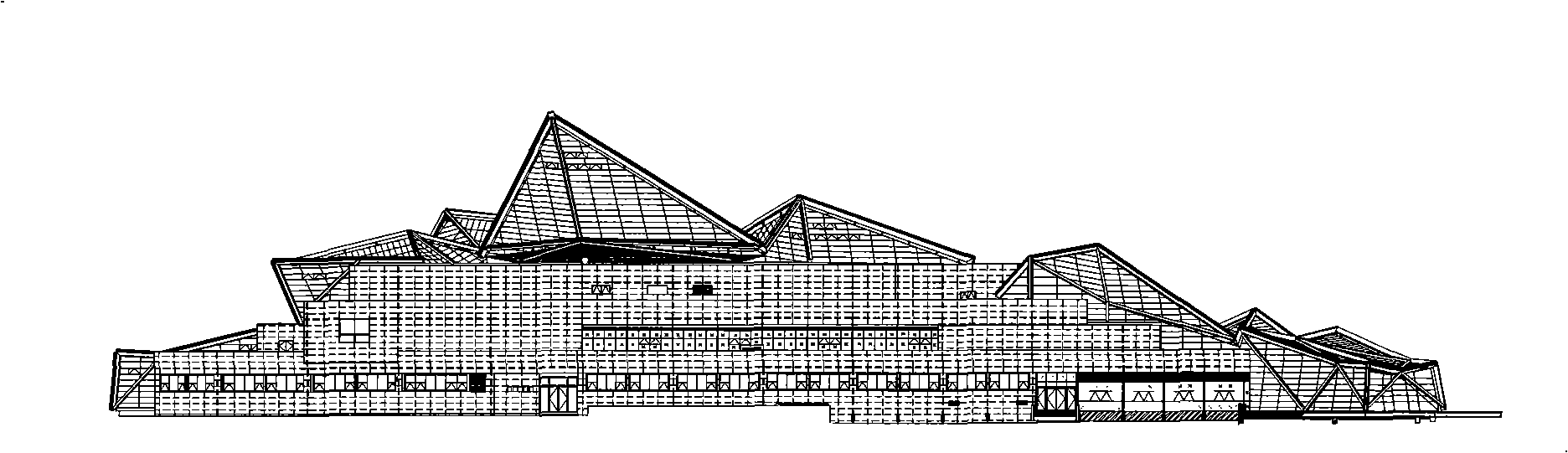

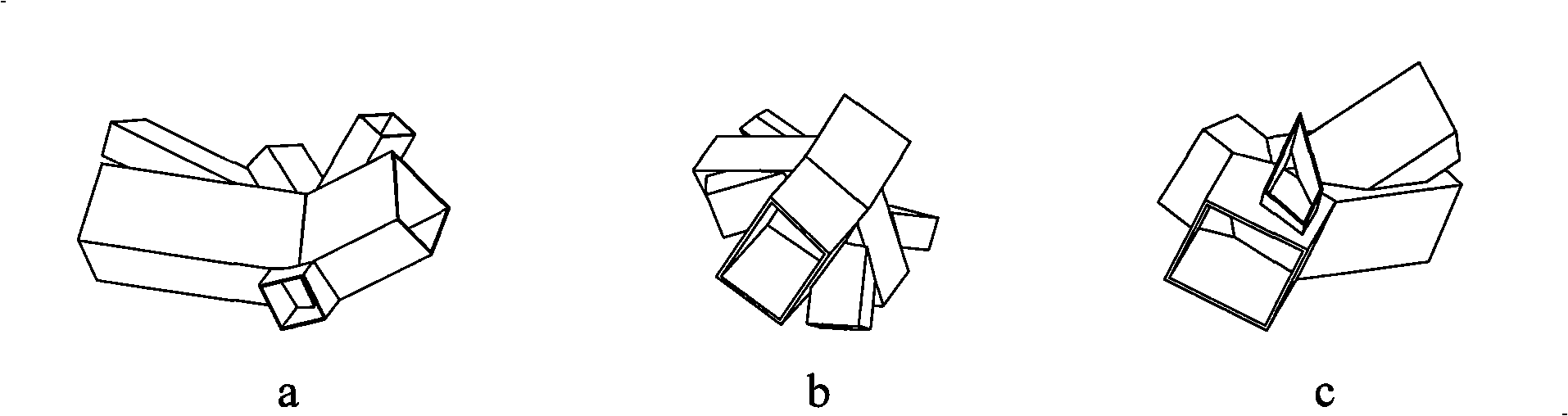

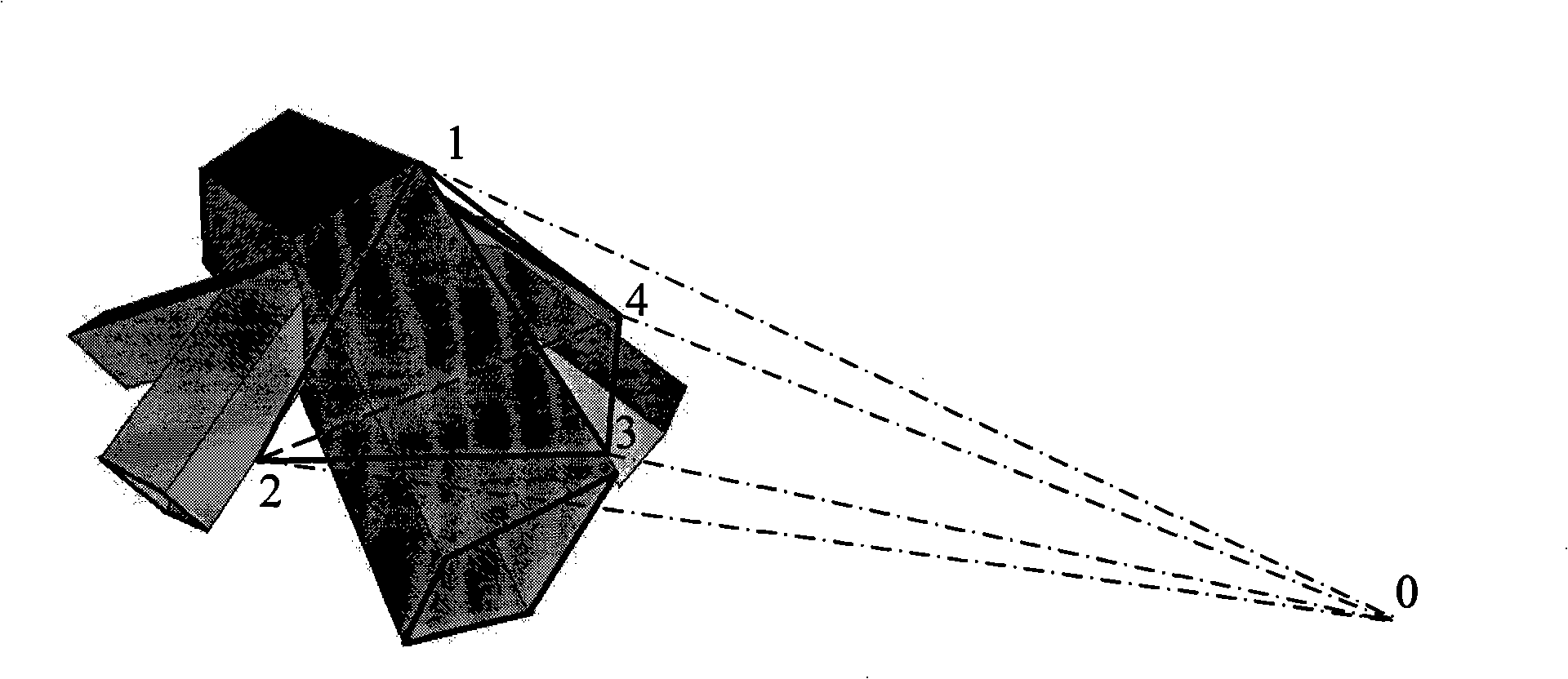

[0017] Such as figure 1 shows a heteromorphic structure whose nodes are composed of similar figure 2 The three-dimensional body composed of profiled nodes is shown. as image 3 Take a three-dimensional body with special-shaped nodes as an example, take four points 1, 2, 3, and 4 that are not in the same plane on the design drawing of the three-dimensional body with special-shaped nodes to form a virtual tetrahedron, and point 1 is the highest point, according to the design The drawing calculates the three-dimensional coordinates of these four points, and then makes the corresponding marks of these four points on the three-dimensional object of the special-shaped node. In addition to considering the convenience of measurement readings, when selecting a virtual tetrahedron, the lengths of the six sides should be as close as possible and as long as possible. Select the highest point 1 of the three-dimensional body of the special-shaped node as the main control point for measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com