Buckling concrete split head for supporting upper and lower layers of steel bars

A technology of concrete horse stools and buckle locks, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of low production efficiency, large and bulky, and difficult demoulding, so as to reduce construction costs, save steel resources, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment, the content of the present invention will be further described:

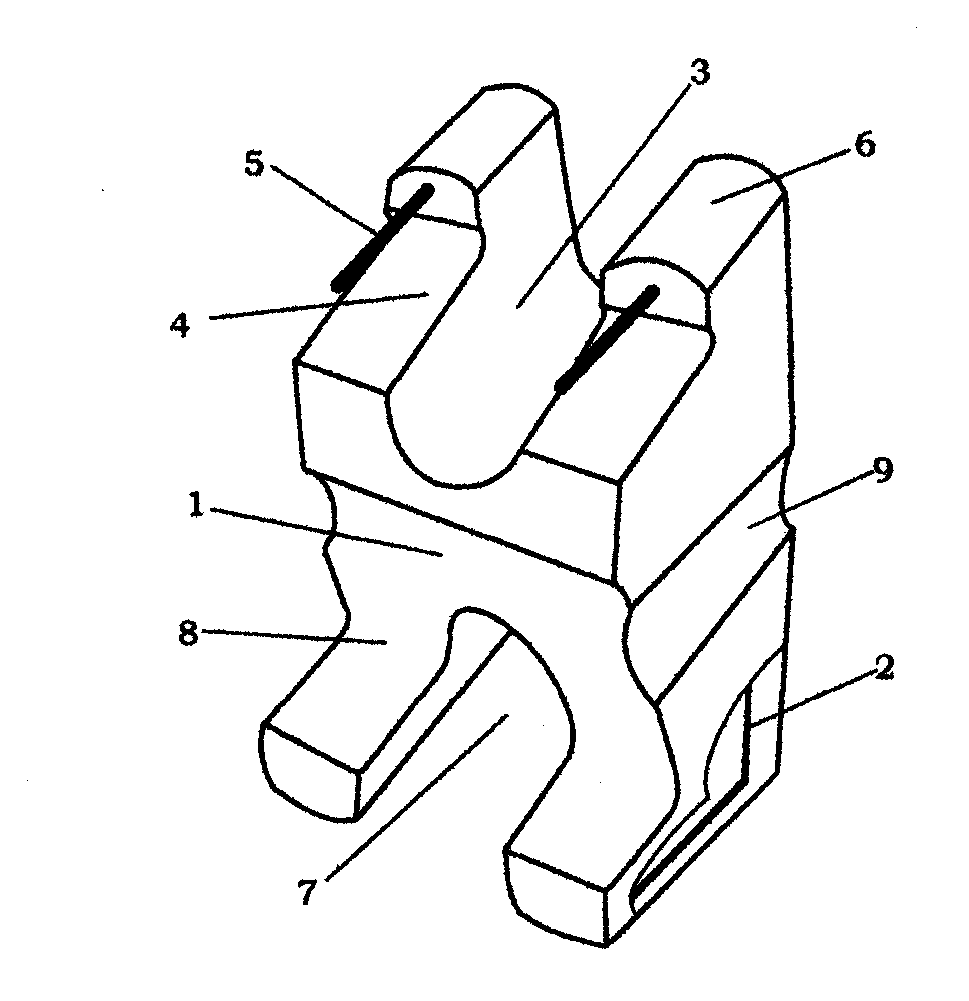

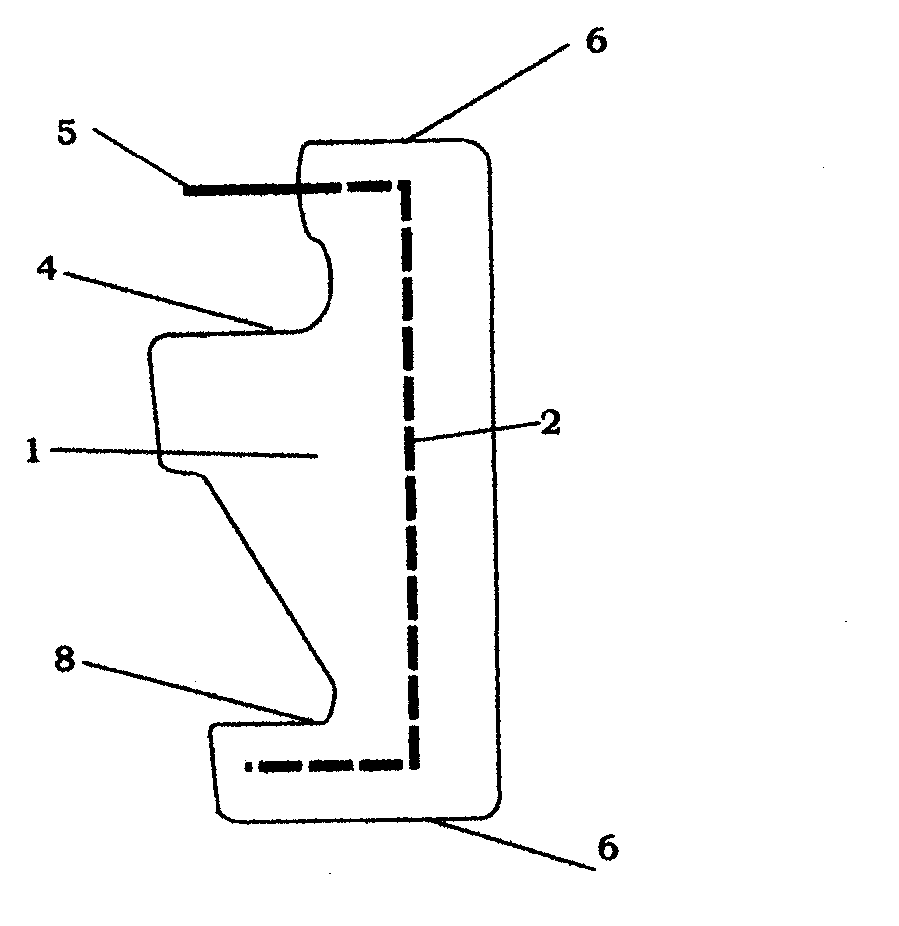

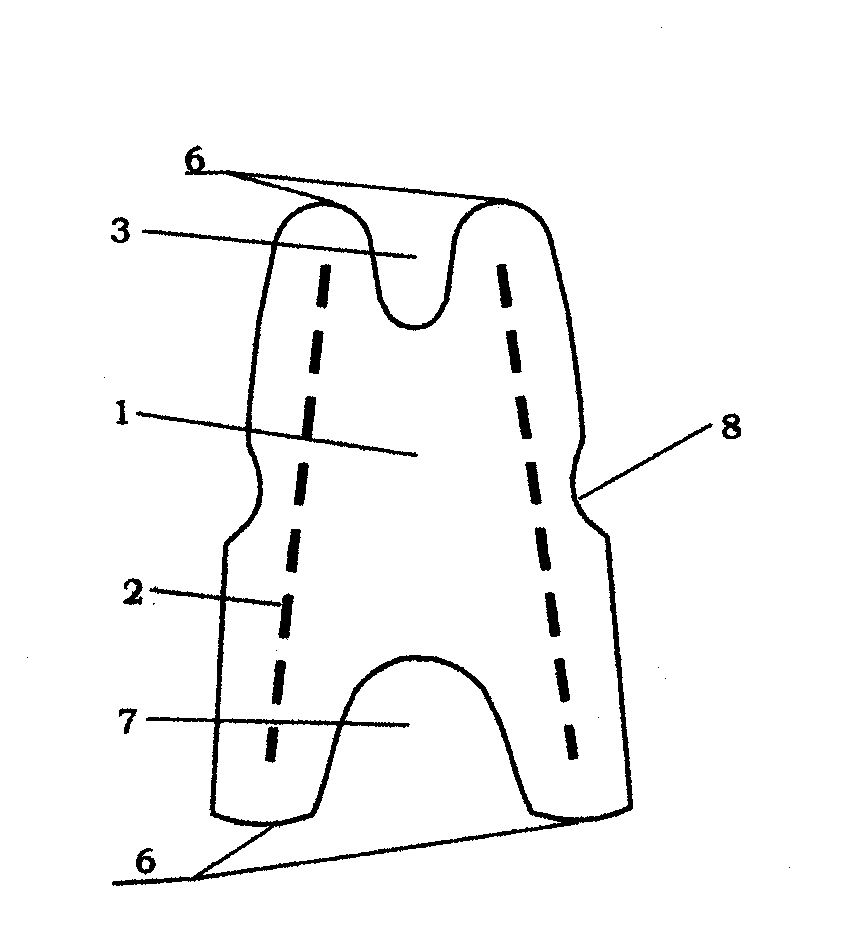

[0019] like Figure 1 to Figure 4 Shown is a schematic diagram of an embodiment of a buckled concrete horse stool supporting upper and lower steel bars provided by the present invention.

[0020] A buckled concrete horse stool supporting upper and lower steel bars is characterized in that: a concrete stool body 1, Type metal rib 2, upper end through involute notch 3, L-shaped step 4, buckle metal rib 5, elevation of protective layer thickness 6, lower end through involute notch 7, acute angle or U-shaped groove 8, rough uneven Composition of face 9: it is set on both sides of the concrete stool body 1 respectively The metal rib 2 increases the strength of the concrete stool body 1; the upper end of the concrete stool body 1 is provided with an involute notch 3 that penetrates through the upper end, and L-shaped steps 4 are respectively arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com