Patents

Literature

678 results about "Involute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

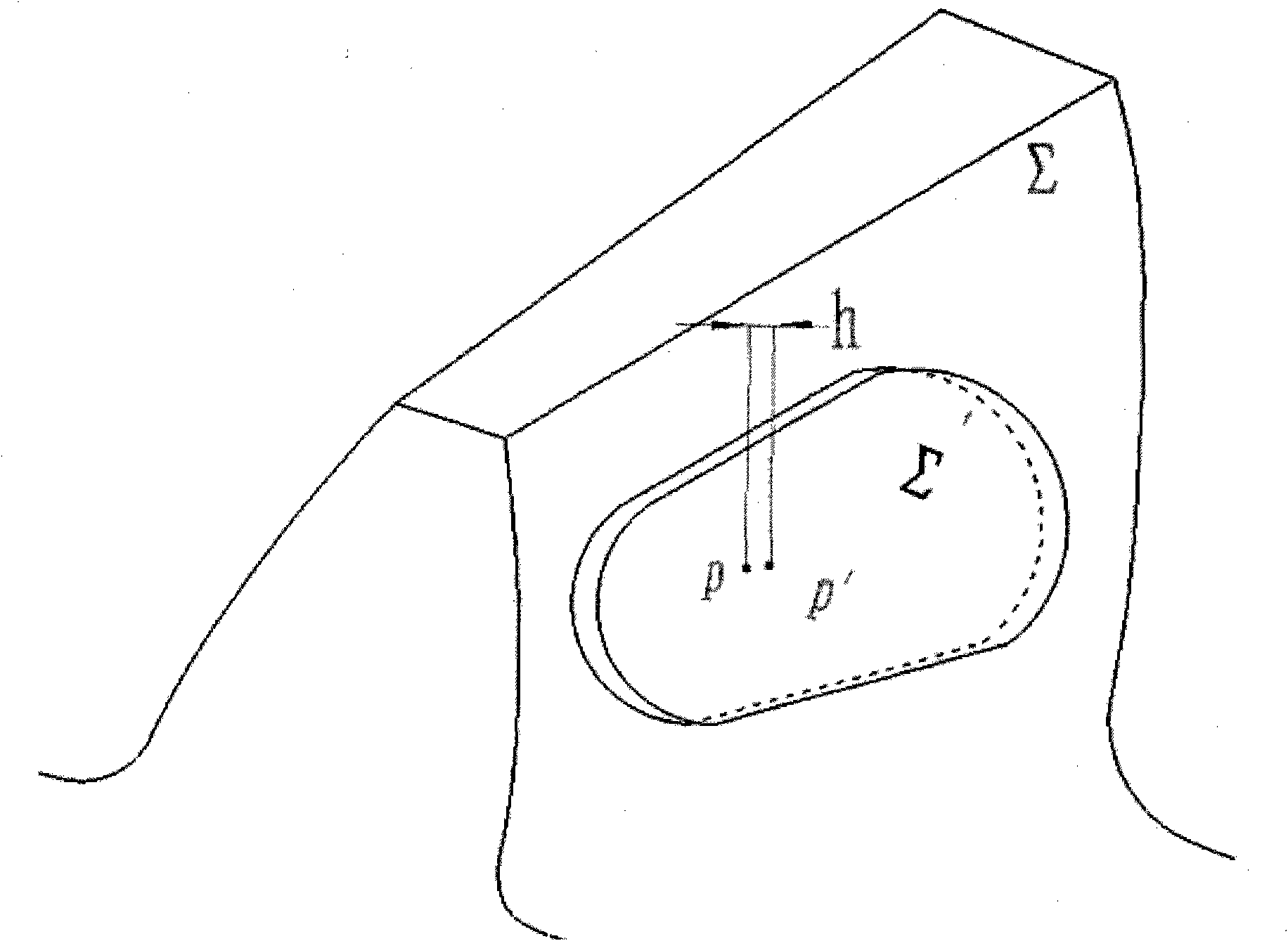

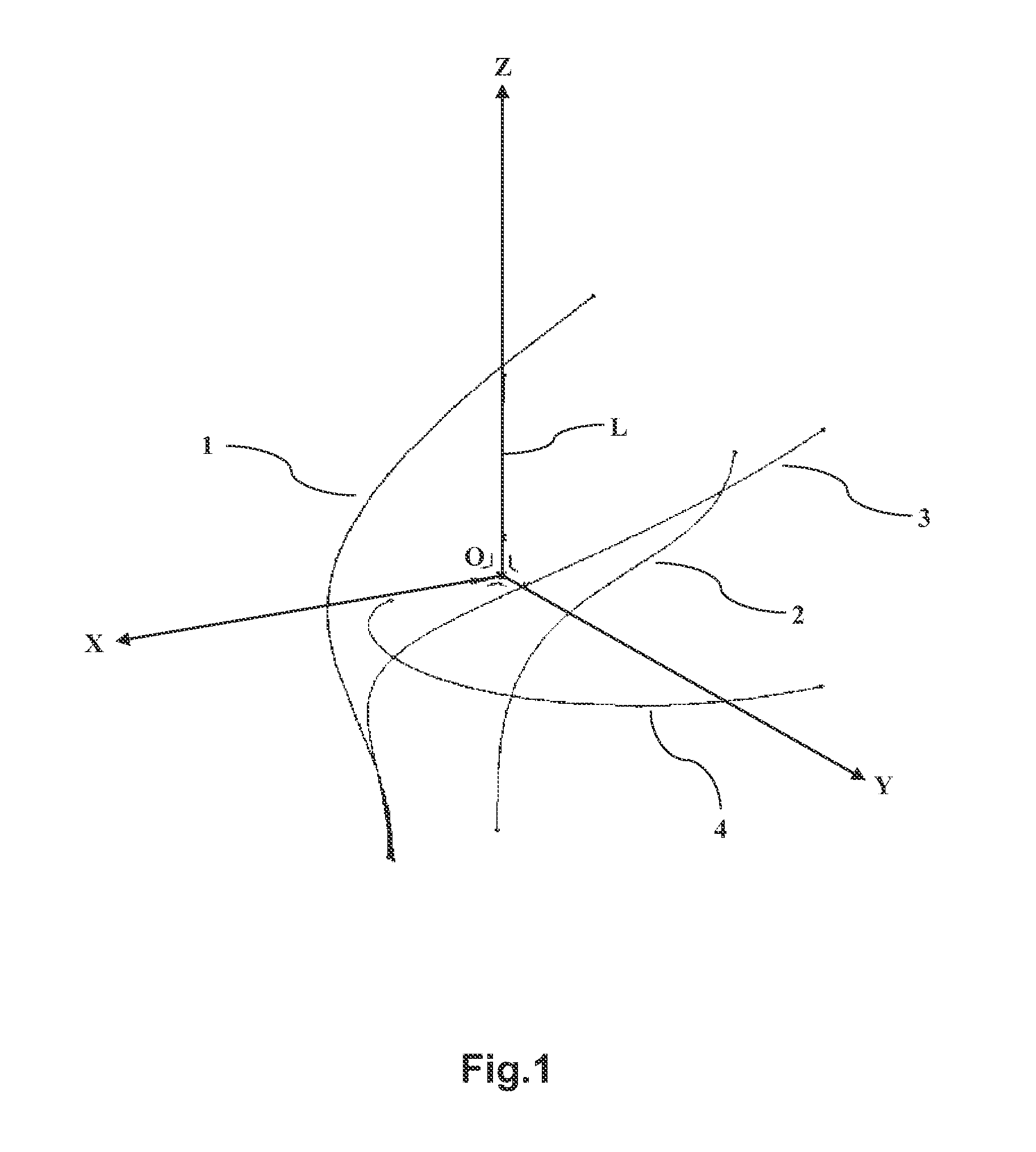

In mathematics, an involute (also known as an evolvent) is a particular type of curve that is dependent on another shape or curve. An involute of a curve is the locus of a point on a piece of taut string as the string is either unwrapped from or wrapped around the curve.

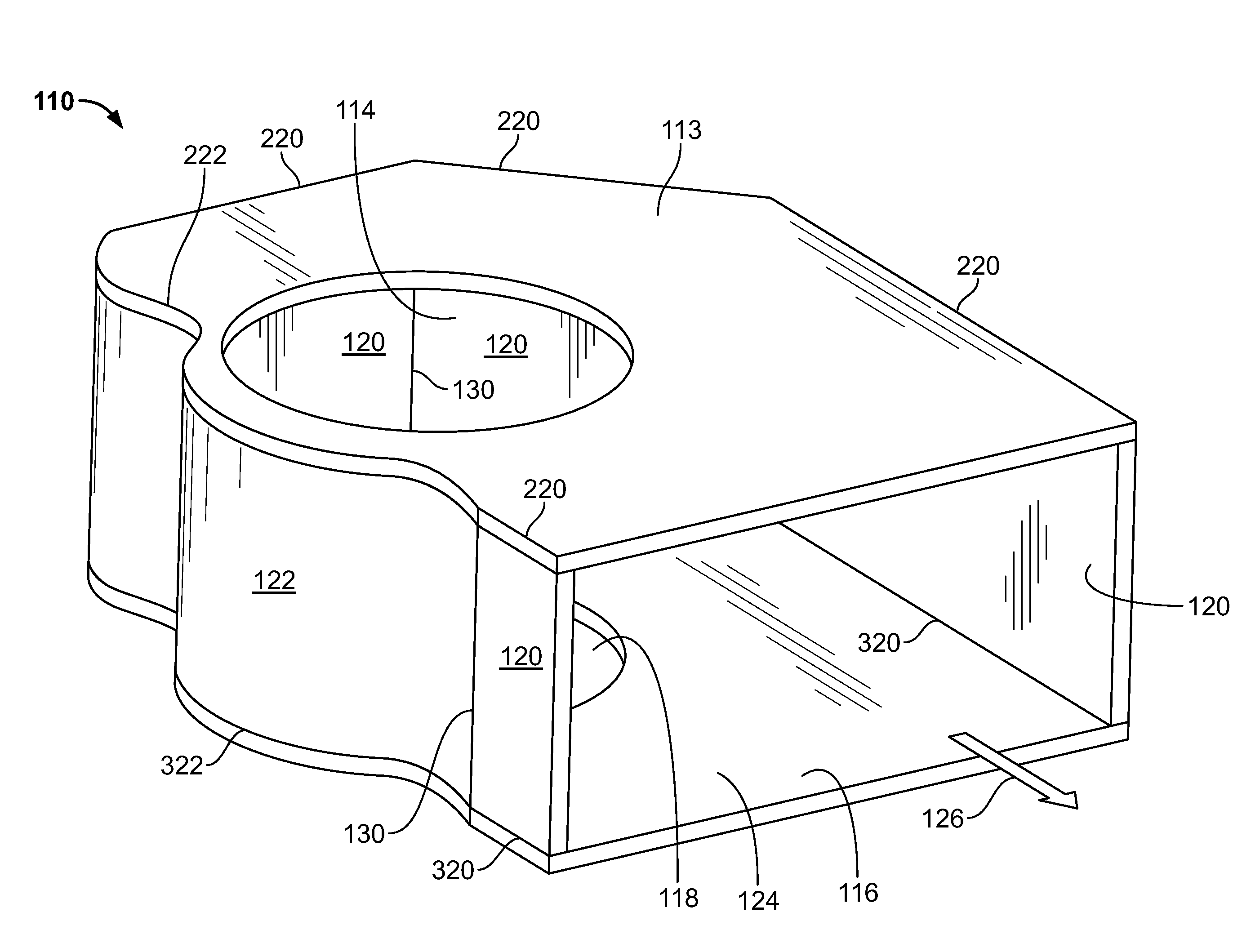

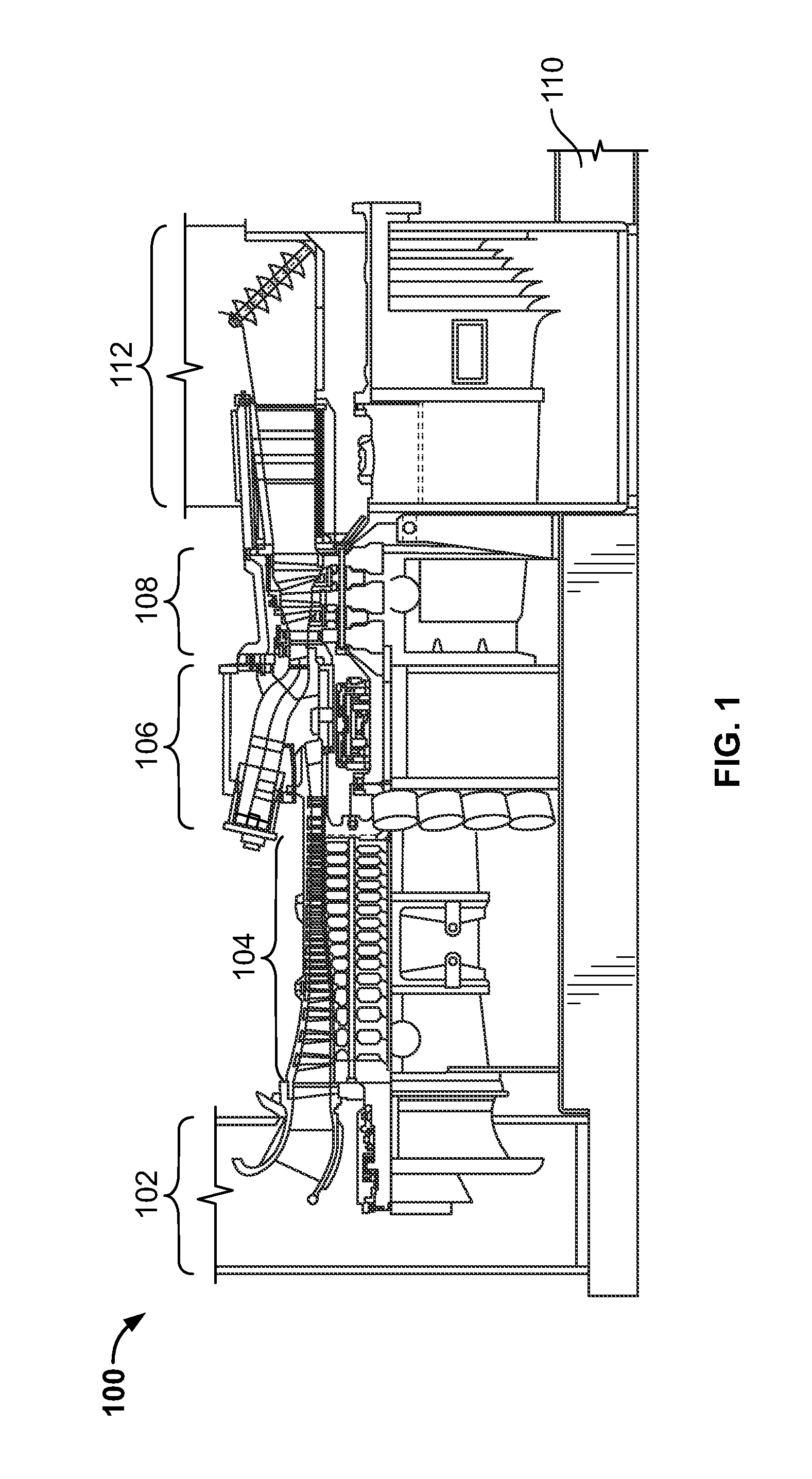

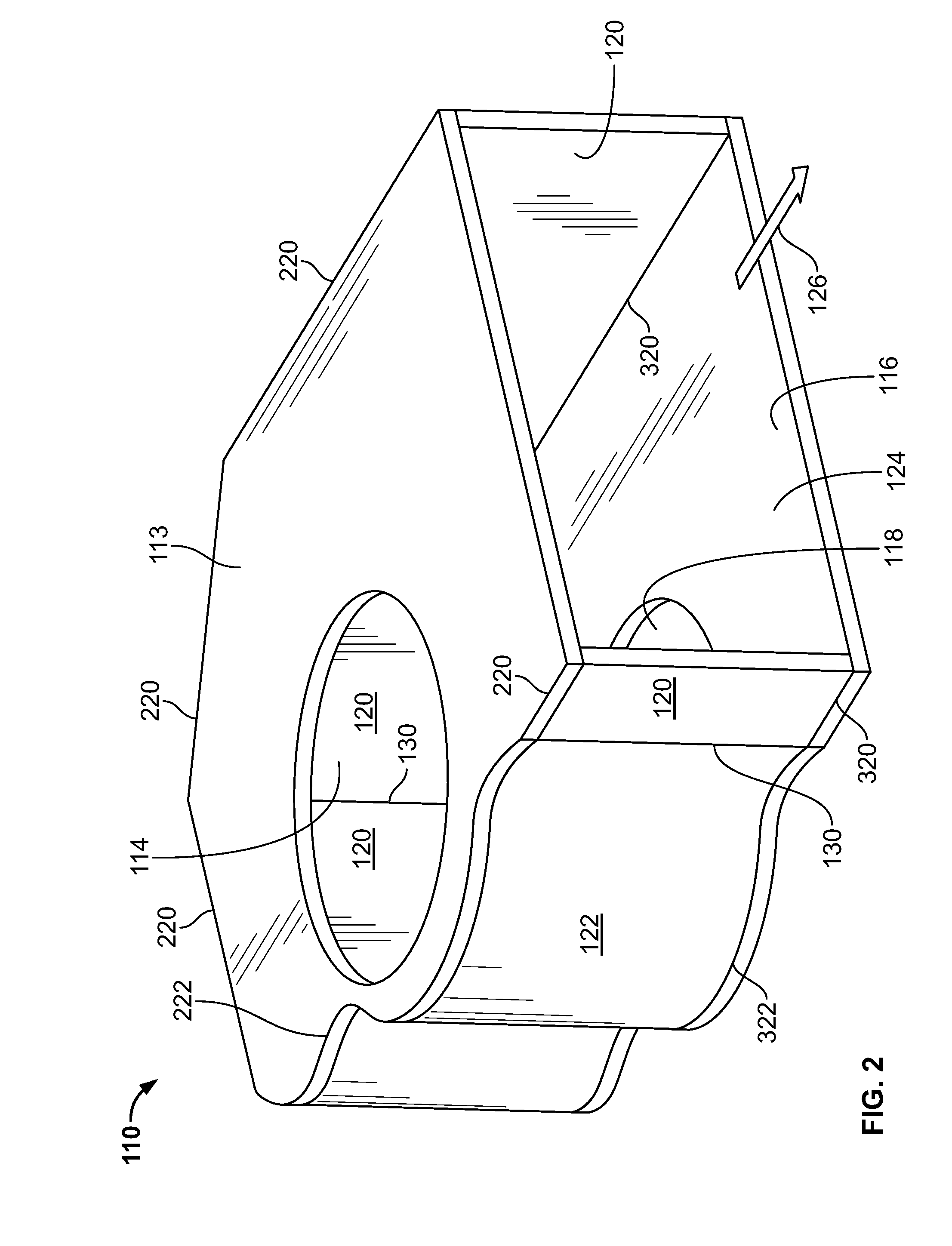

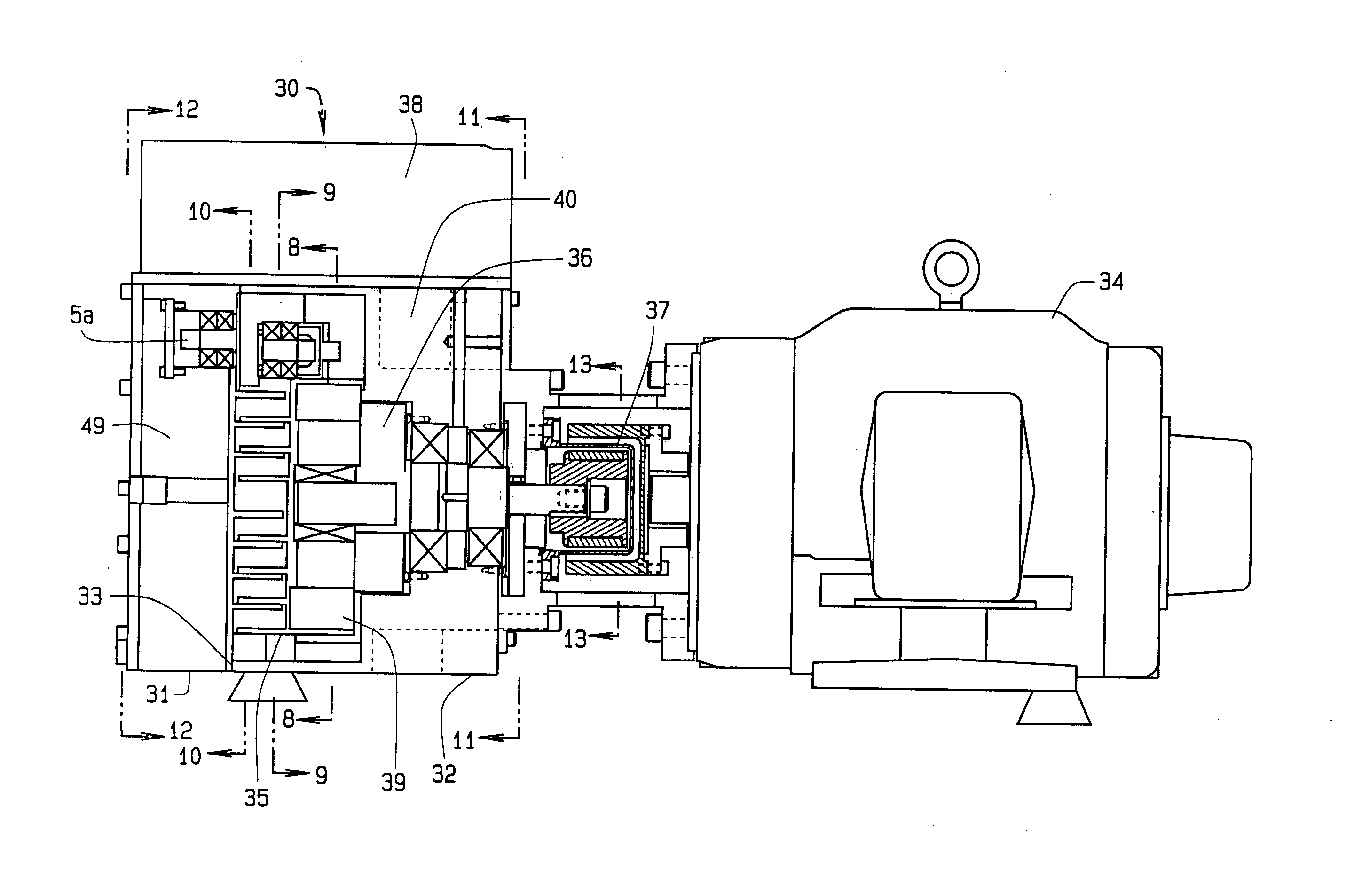

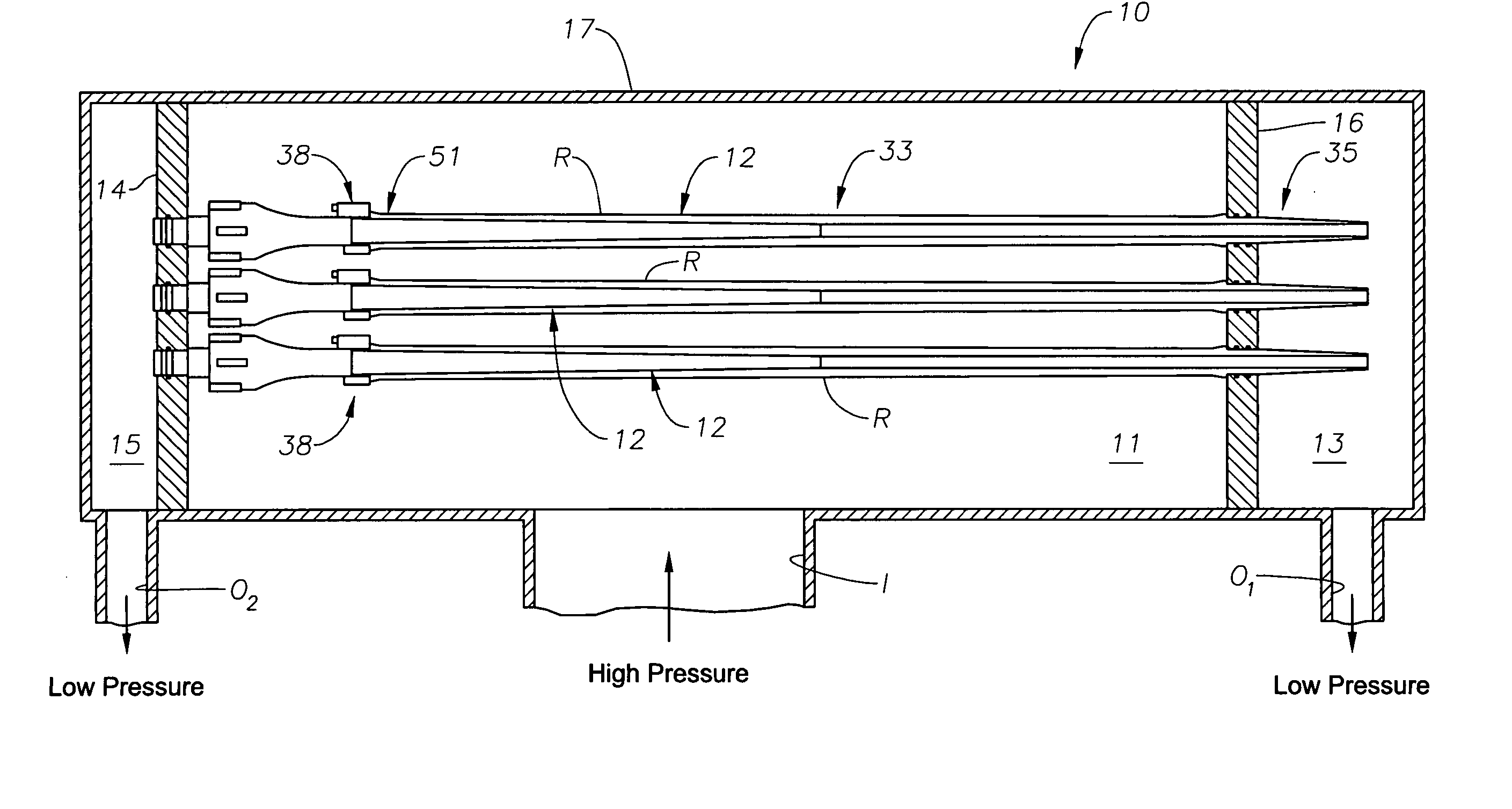

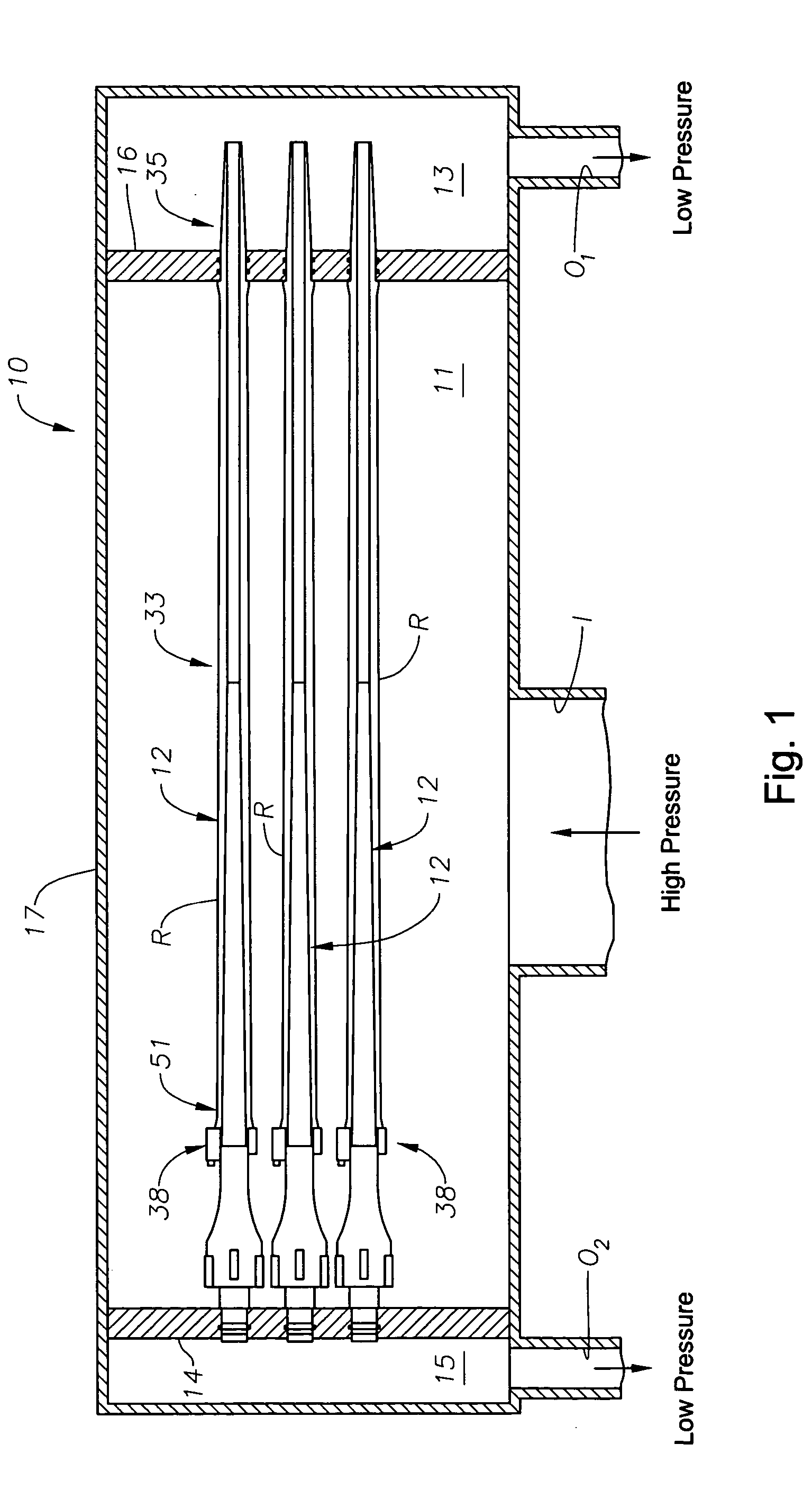

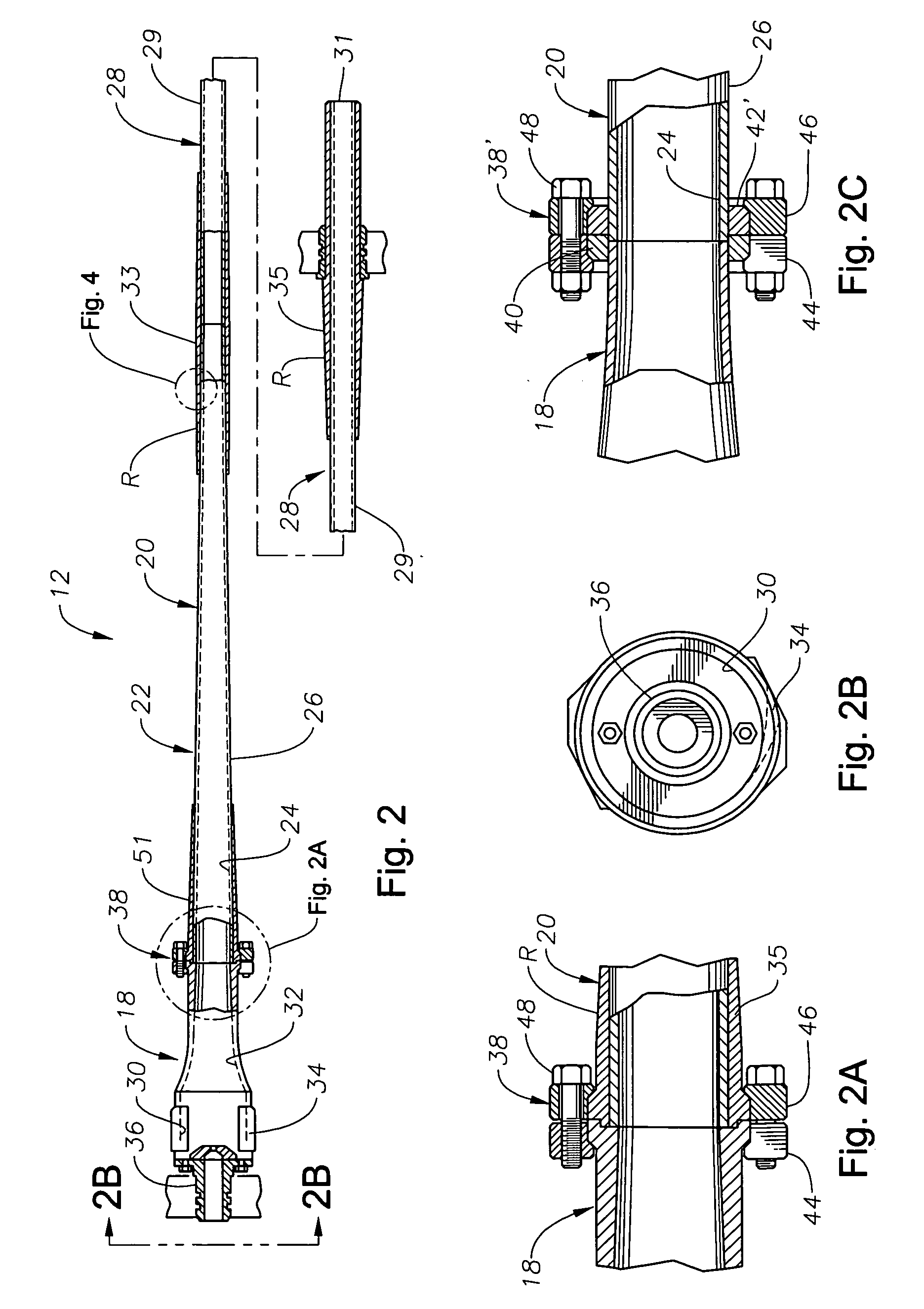

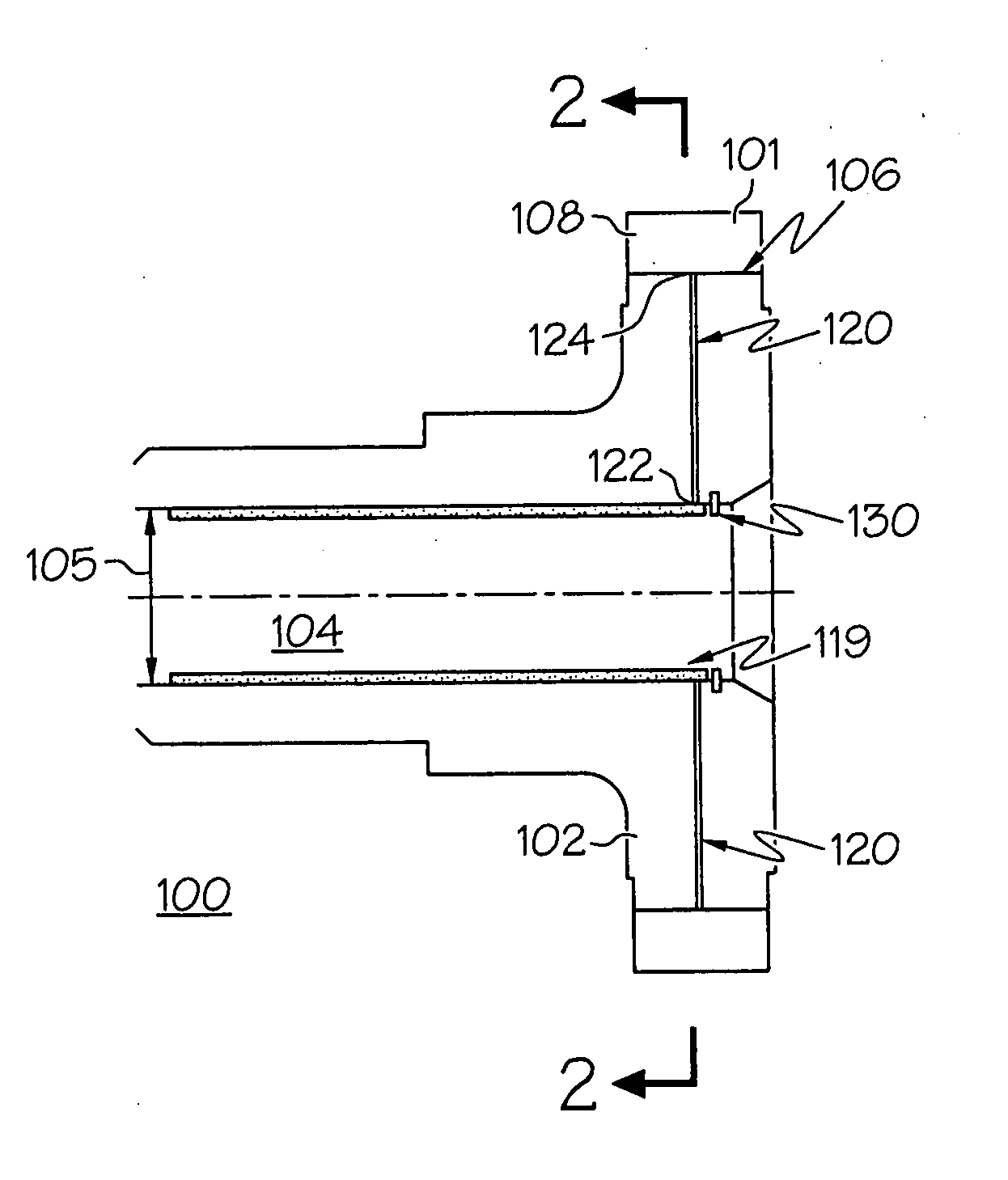

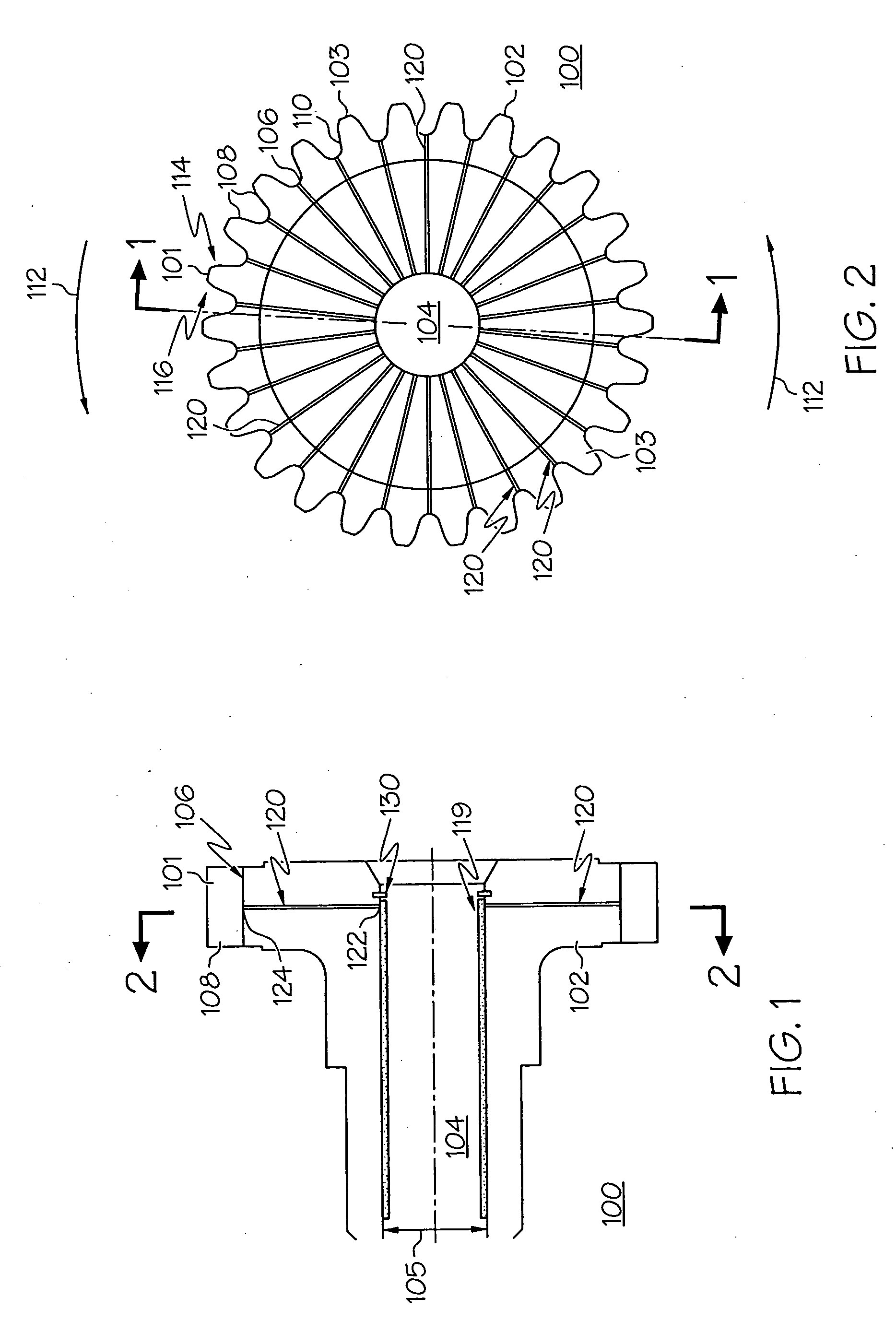

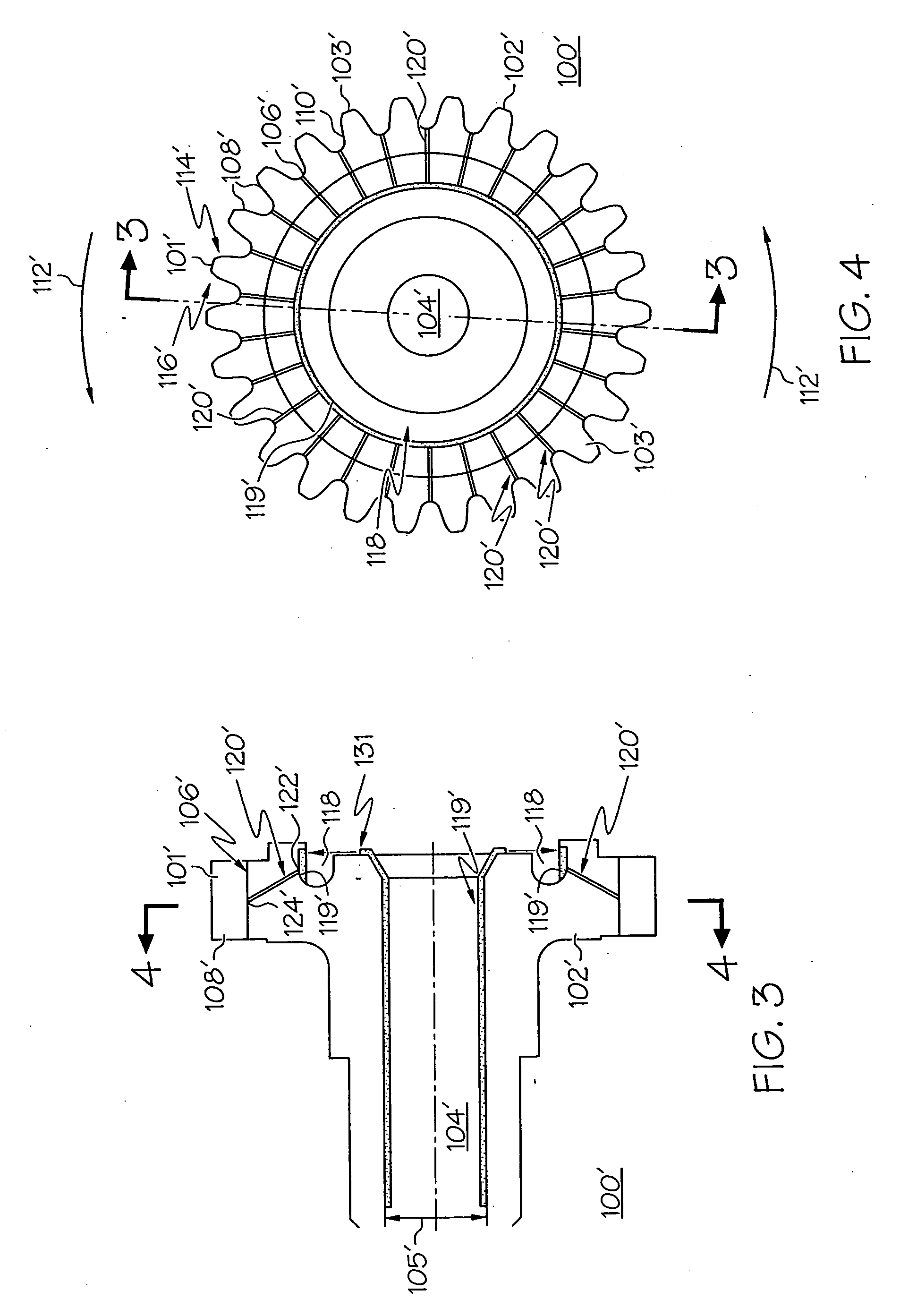

Method and apparatus for radial exhaust gas turbine

A radial exhaust gas turbine apparatus has a gas turbine engine that includes a radial exhaust diffuser section and a casing apparatus consisting essentially of polygonal walls, substantially straight plates, and substantially straight sidewalls. The casing apparatus encloses the radial exhaust diffuser section and is configured to direct at least a substantial portion of the gas exiting the radial exhaust diffuser section to an exit in the casing apparatus via an approximately involute path.

Owner:GENERAL ELECTRIC CO

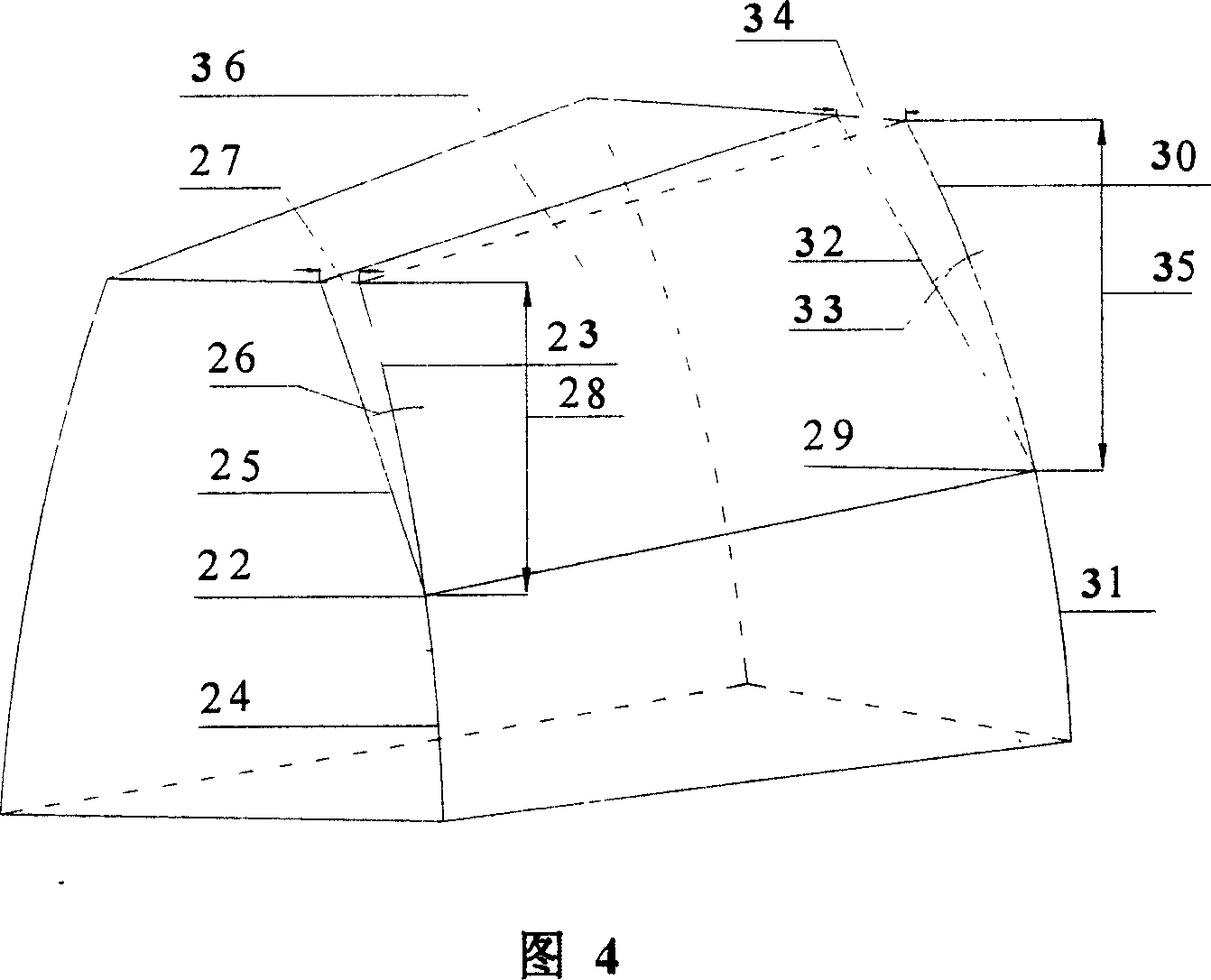

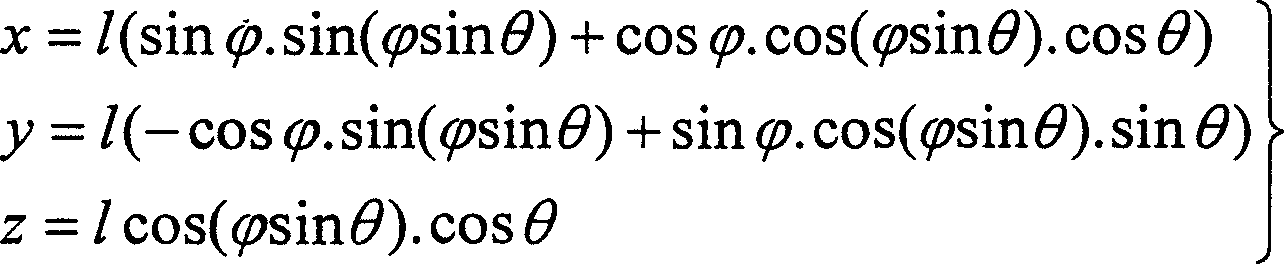

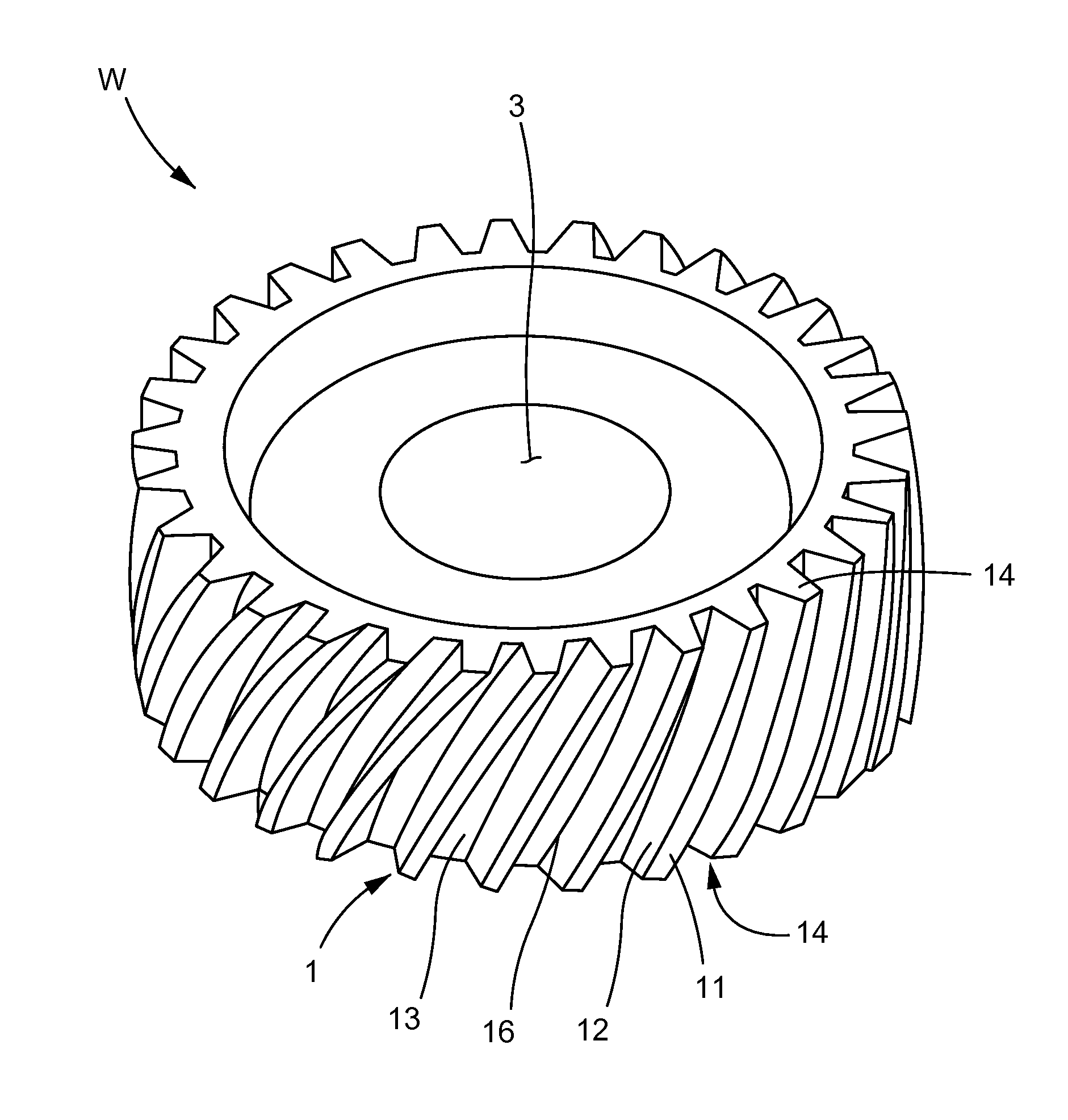

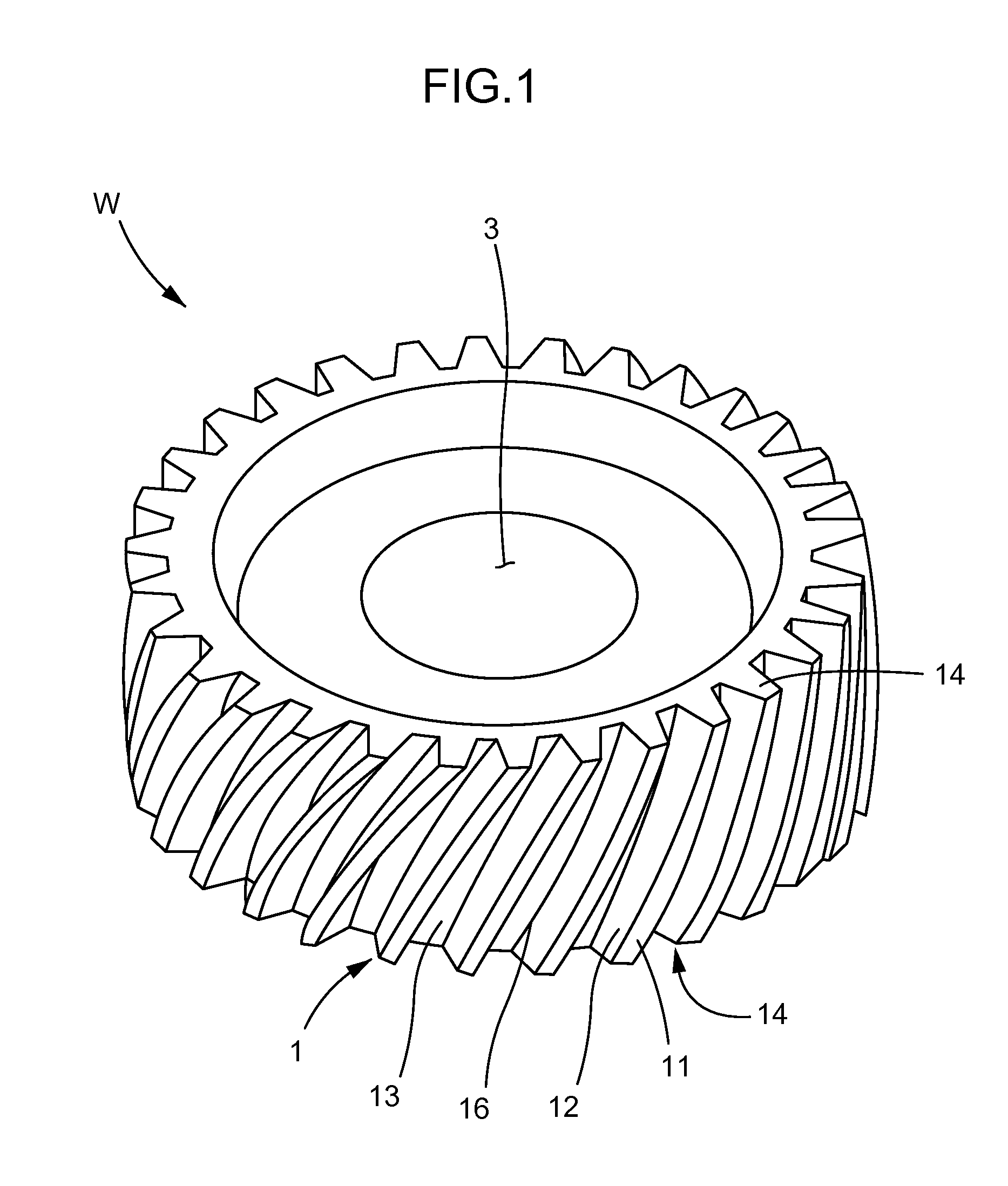

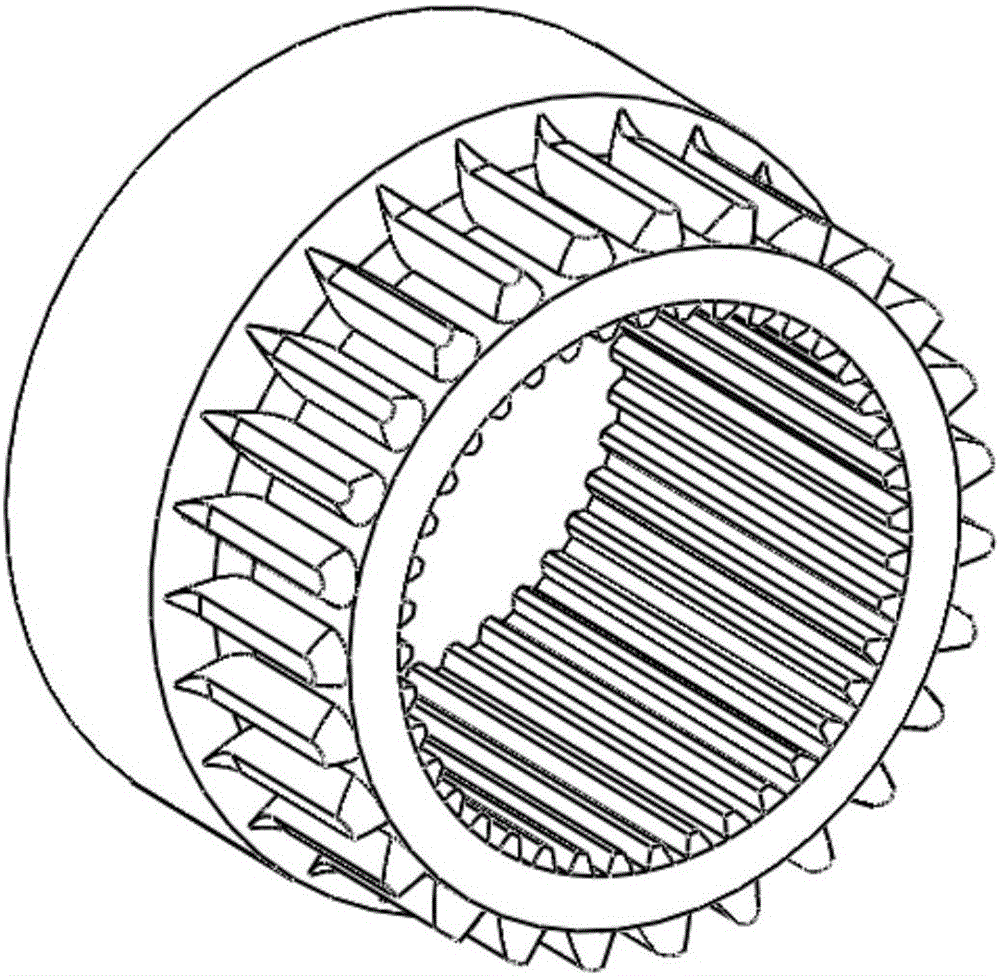

High precision modeling method of involute helical gear

ActiveCN102289534ACombine accuratelyAvoid errorsSpecial data processing applicationsInvoluteEngineering

A method for modeling an involute helical gear accurately comprises the following steps: first step: setting related parameters; second step: establishing an involute and a transition curve by a curve equation, setting a toothspace center line and drawing a dimensional tooth profile; third step: inputting a spiral line equation and establishing a spiral line; fourth step: generating a toothspace by mixed scanning and an array, and cutting a gear blank by Boolean operation to form a gear model; and fifth step: applying a gear model to practical gear machining or simulation analysis. According to the method, a formula suitable for three-dimensional software is deduced based on the basic principle of the involute helical gear and the engagement of a rack and a gear, the original fussy programming computation is saved; besides, the formation of the entity can be highly fitted to provide technical support for the subsequent manufacture and analysis of the helical gear; and the method is not only suitable for a standard profile gear but also a non-standard gear profile, and has remarkable scientific research value and economic efficiency.

Owner:WUXI YONGKAIDA GEAR

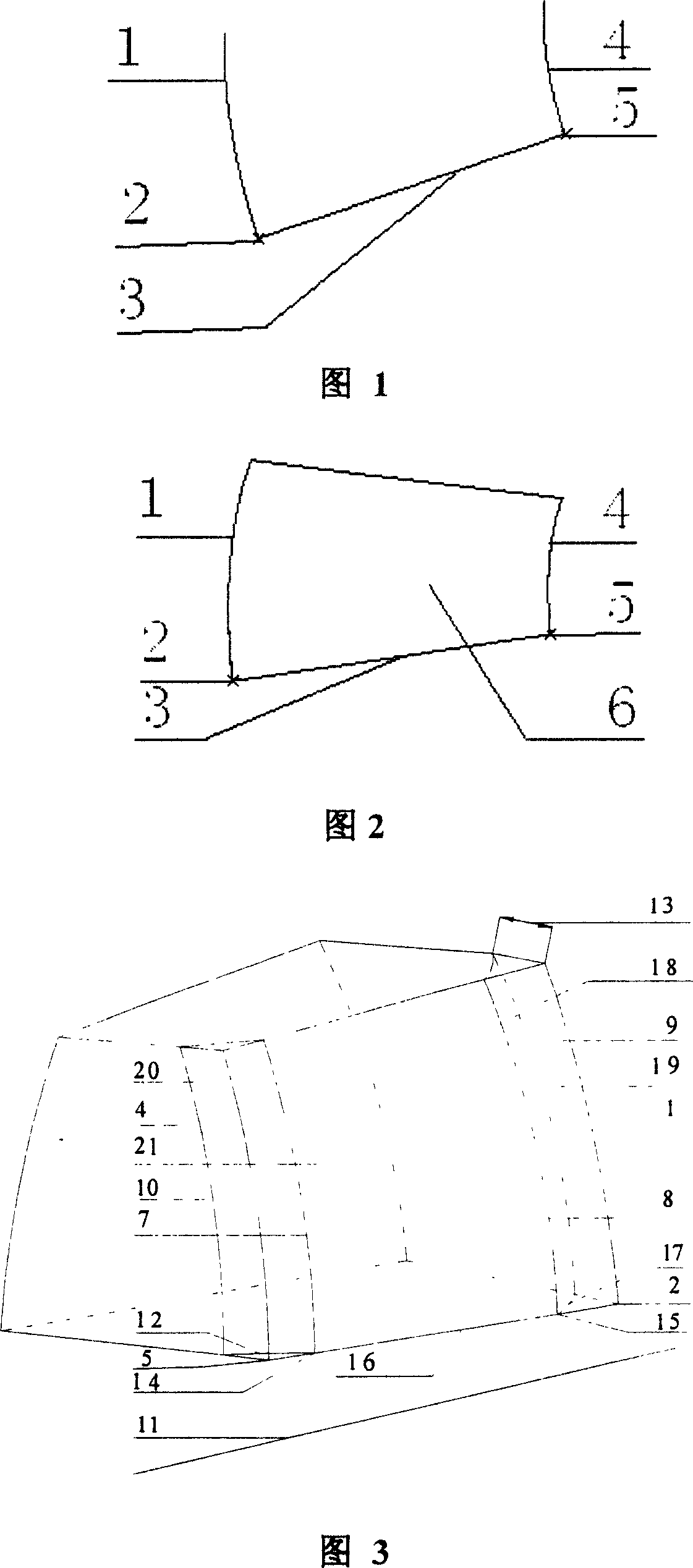

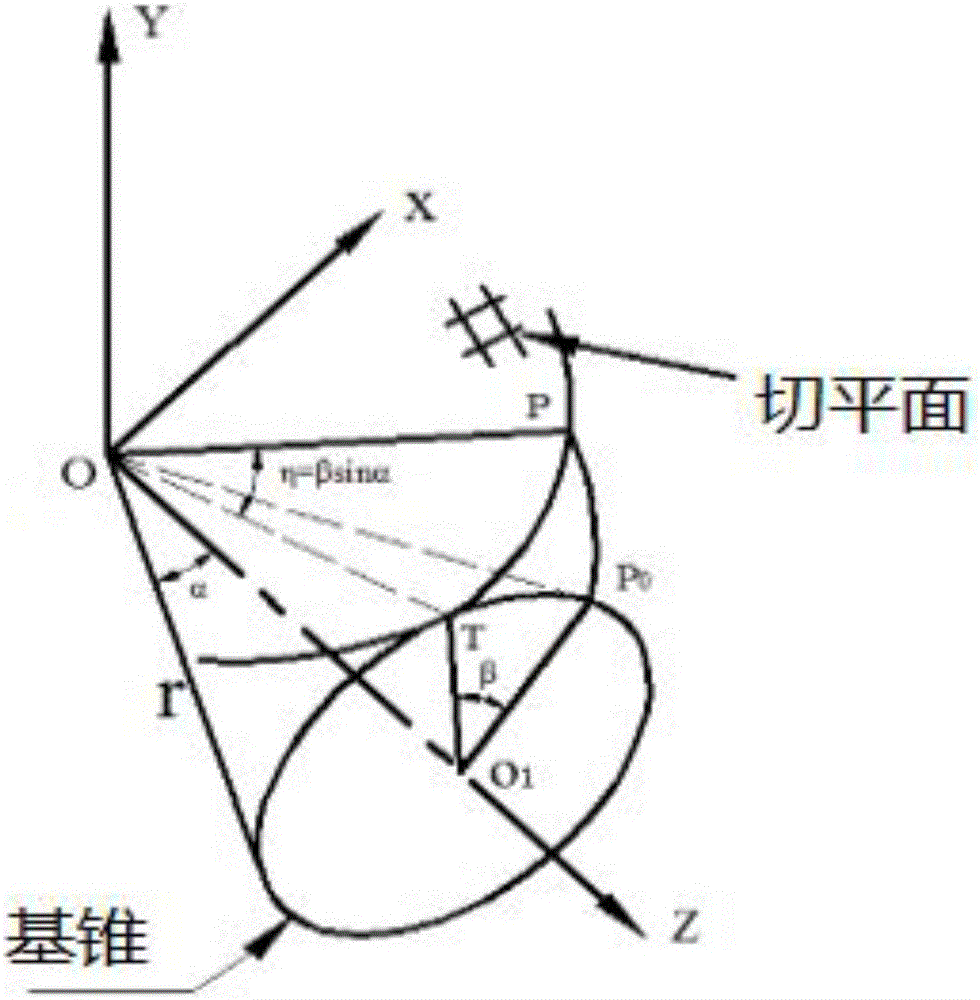

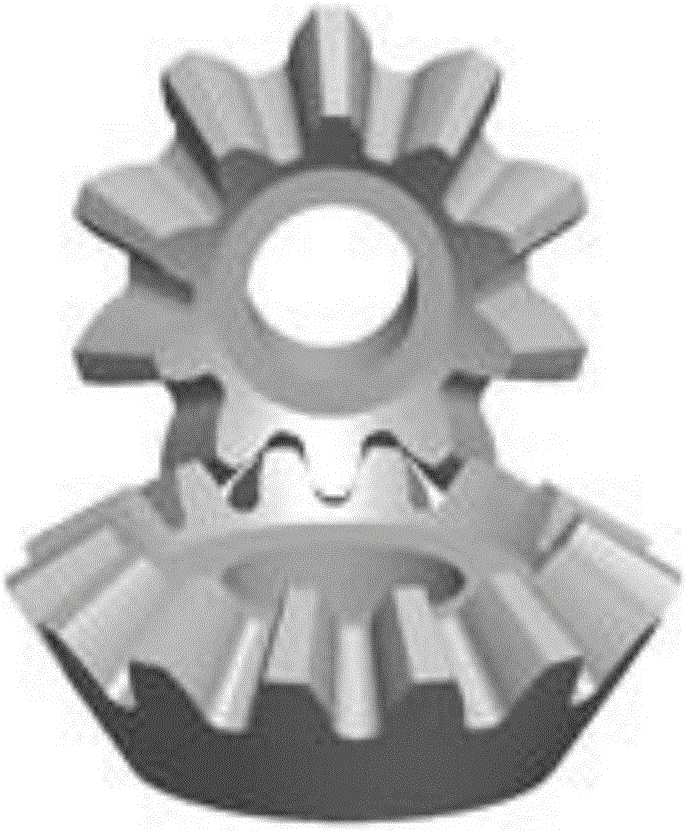

Involute straight tooth cone gear trimming method

InactiveCN101937211AExtend your lifeCompensation for deformationProgramme controlComputer controlNumerical controlStress distribution

The invention provides a technical scheme, in particular an involute straight tooth cone gear trimming method. The method comprises the following steps of: determining a tooth trimming position, a trimming quantity and a tooth profile quantity; solving for a spherical space involute Decare coordinate equation; generating a spherical involute in three-dimensional modeling software, forming a spherical involute plane through curve filling, and realizing straight tooth cone gear solid modeling on the basis of the spherical involute; forming a tooth trimming profile on the central cross section of the gear, and isometrically stretching the profile to the tooth surface to realize tooth isometric trimming; carrying out tooth top arc trimming on the tooth profile; and converting a trimming gear model into a digital control code imported into a digital control machine tool to realize the processing of the trimming cone gear. The invention better controls the stress distribution of the gear through controlling the position and the trimming quantity of the isometric trimming so as to compensate the deformation of the gear and reduces the sensitivity of a cone gear pair to errors and load changes as well as improves the transmission precision of the cone gear pair, reduces the vibration and the noise and prolongs the service life of the gear.

Owner:UNIV OF JINAN

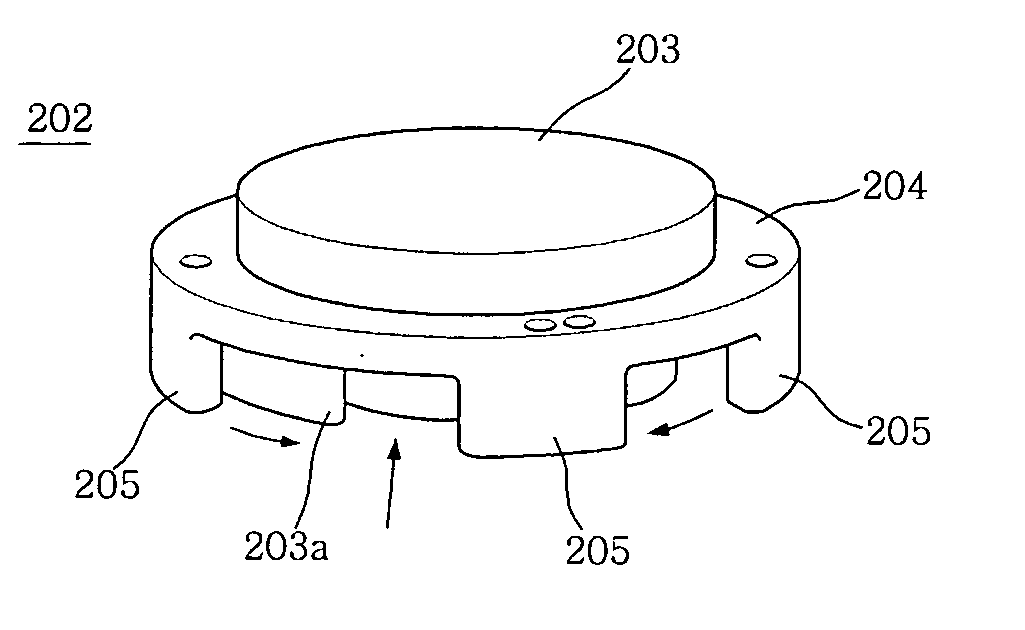

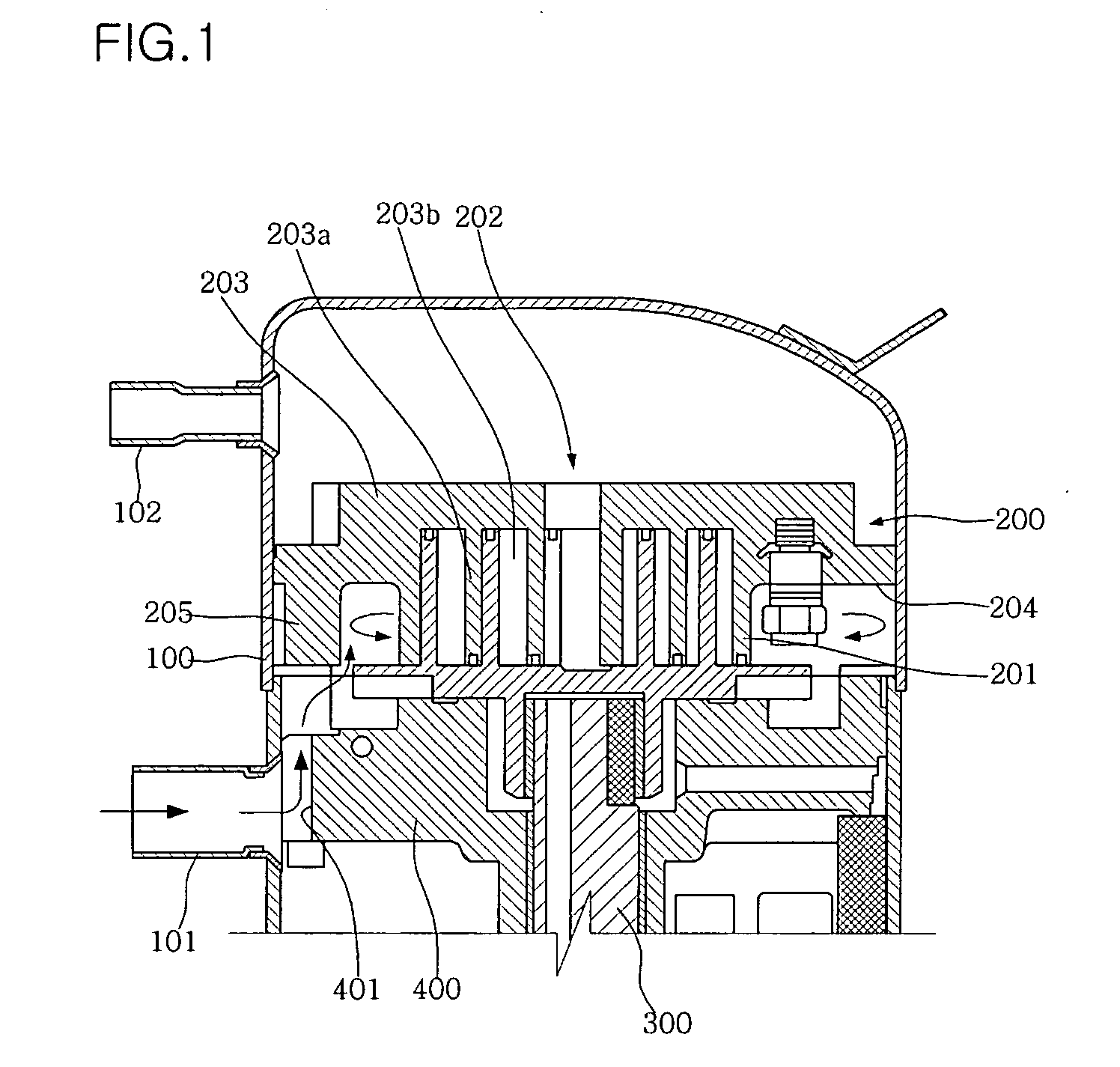

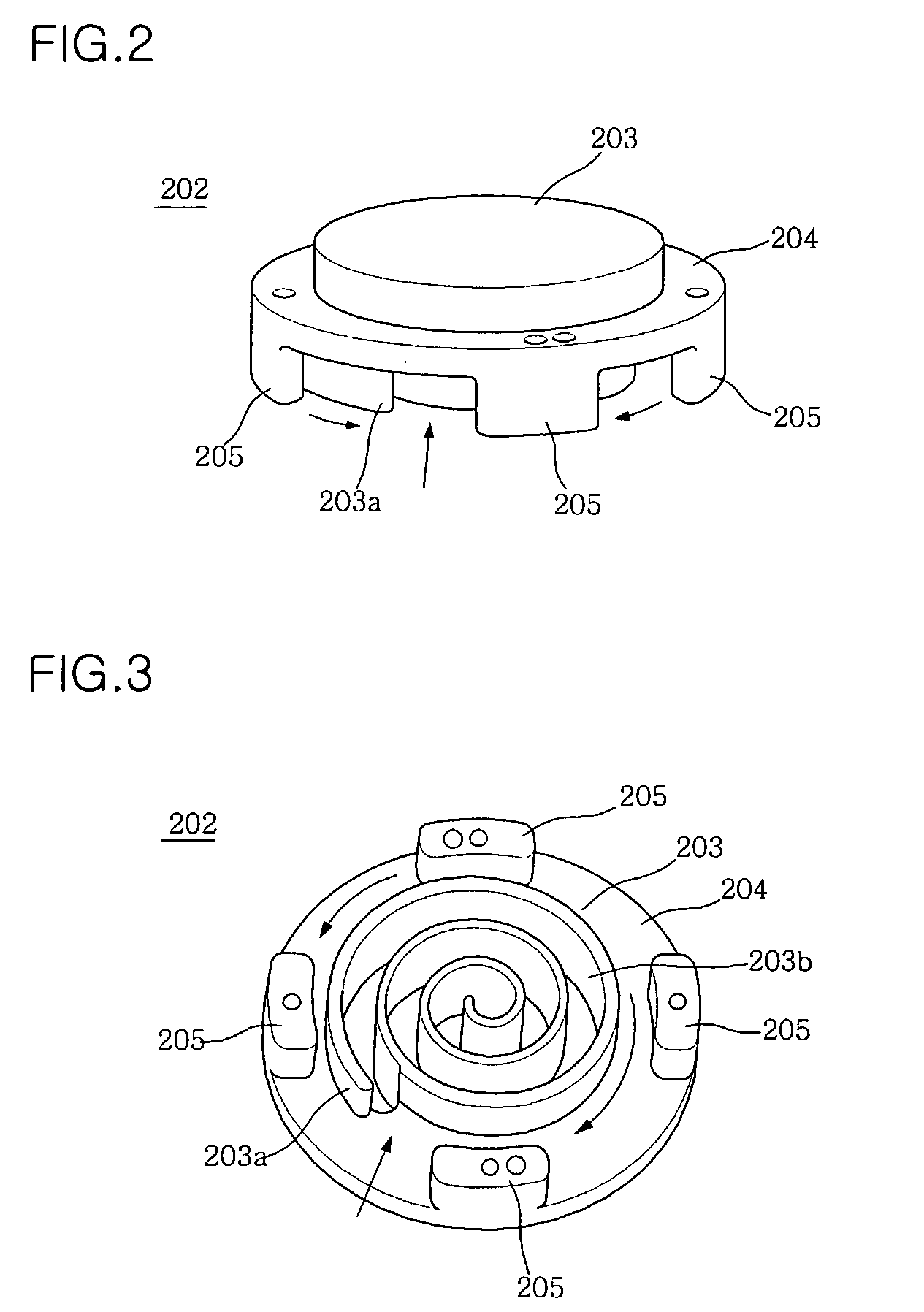

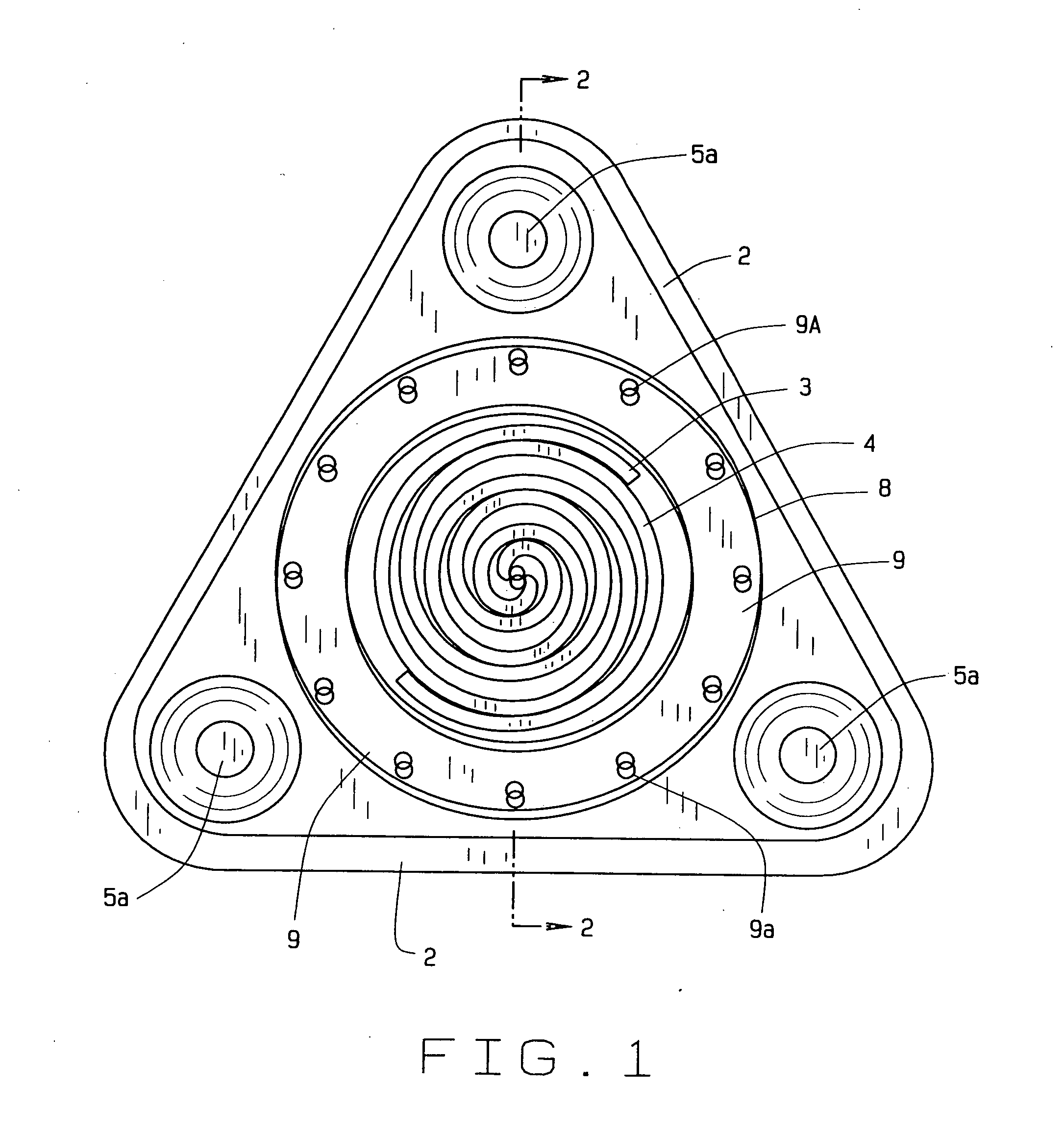

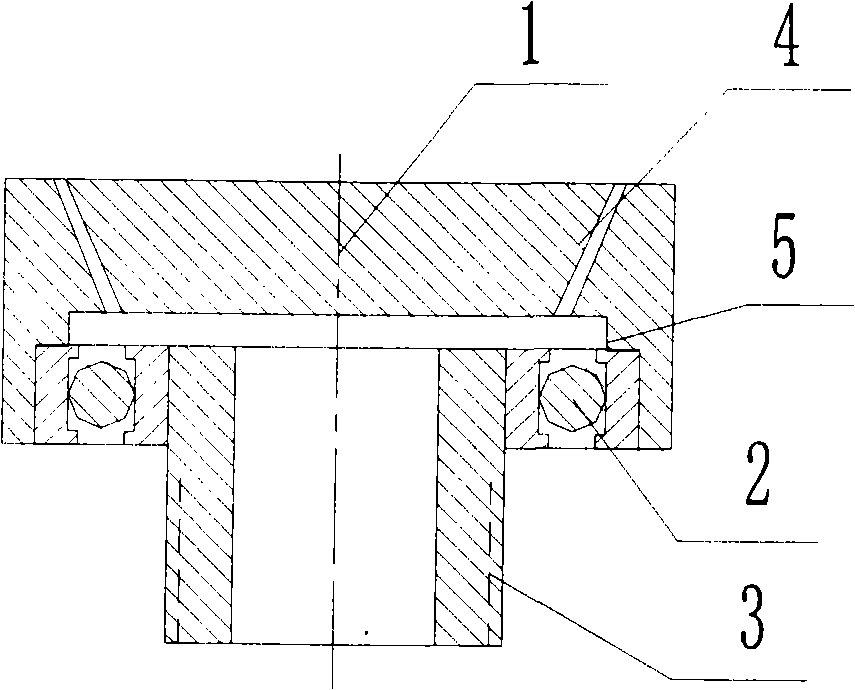

Fixed scroll of scroll compressor

ActiveUS20060222546A1Avoid compressionAvoid introducingEngine of arcuate-engagement typePump componentsInvoluteEngineering

Disclosed herein is a fixed scroll of a scroll compressor capable of preventing gaseous refrigerant, that is heated in the compressor or contains a large amount of oil scatted in a compression unit, from being introduced into a compression chamber. The fixed scroll includes an open involuted wrap provided at a lower surface thereof, a compression chamber defined in the wrap, a plurality of mounting legs formed at a lower surface of a flange portion around the wrap, and an interceptive guiding portion configured to guide suctioned gaseous refrigerant, introduced to the lower surface of the flange portion, to a tip end of the wrap while preventing the gaseous refrigerant from being circulated between the mounting legs underneath the lower surface of the flange portion, thereby allowing the refrigerant to be introduced into the compression chamber.

Owner:LG ELECTRONICS INC

Evolent straight-gear conic-gear direct-finishing method

InactiveCN1936749AResolve Mesh ContactsSolve the noiseProgramme controlComputer controlNumerical controlEdge effects

This invention is about the directly repair shape method, belongs to the manufacturing process of the gear wheel. This can make out the fixed-shape gear wheel straightly by numerical control machine, and no need to fix any more. The process is that: ensuring the fixed-magnitude, the max fix-length of the tooth profile and the longitudinal. It uses the three-dimensional shaping CAD software to build the four theoretical involutes. It has the tip relief by using conjugate gear three-dimensional model. It transforms the fixed-shape gear three-dimensional model into numerical code inputting, and then the numerical machine can directly fix the blank. This invention is easy to carry out, and can reduce the noise and shake, and at the same time it can reduce the edge-effect.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Gear construction method and digital apparatus

InactiveUS20150106063A1Accurate of tooth profileImprove efficiencyGeometric CADGearing detailsInvolute

Owner:AIRBUS SAS

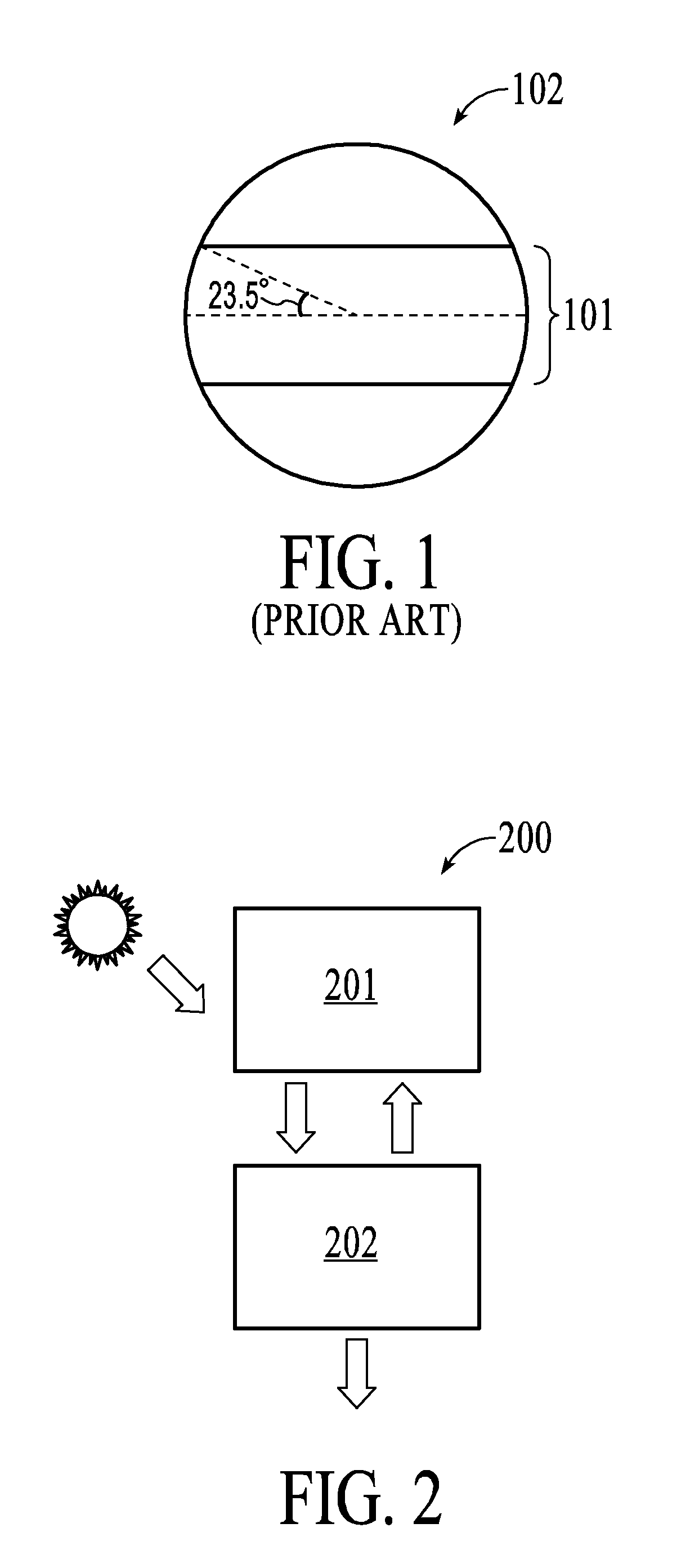

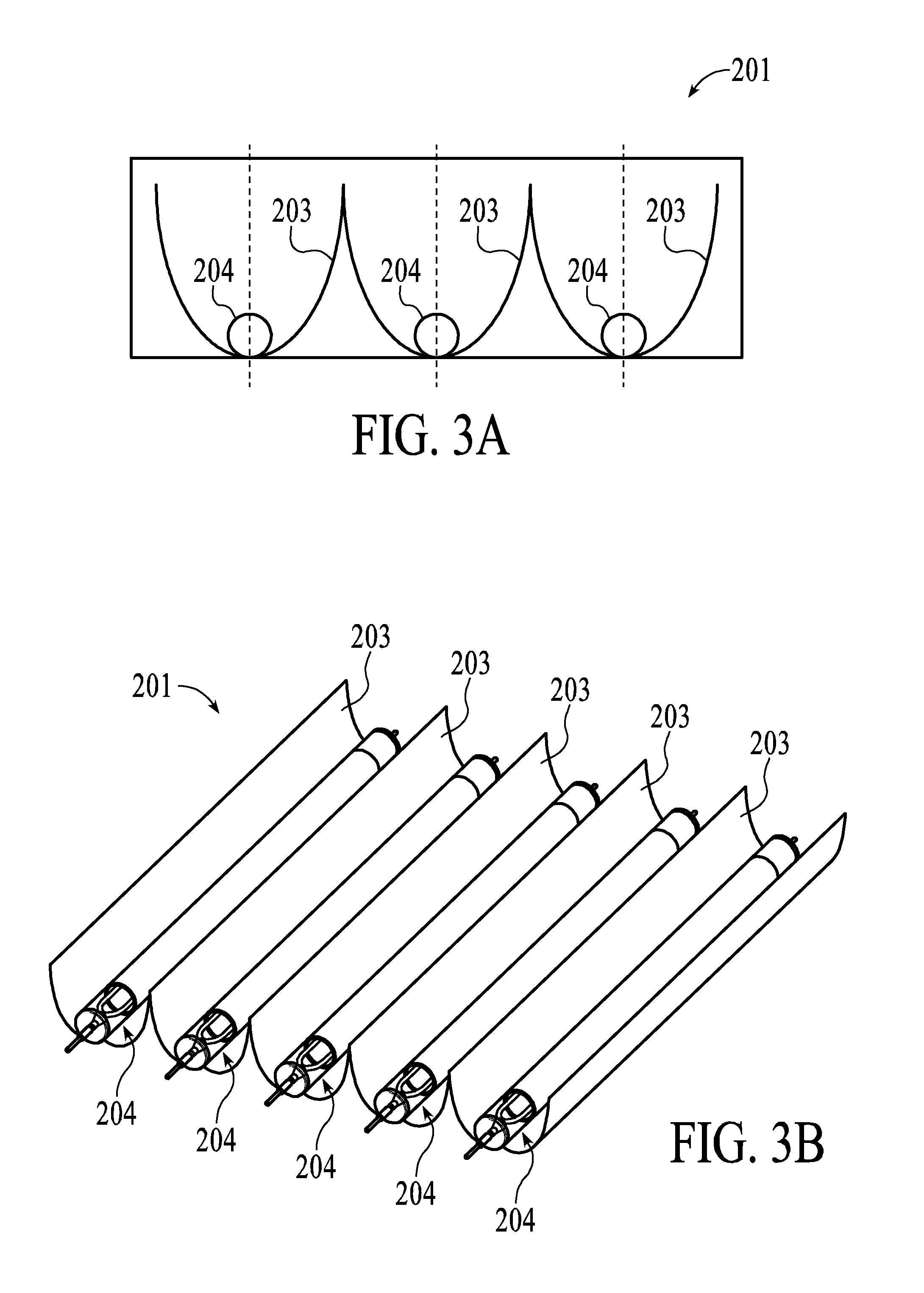

Solar thermal concentrator apparatus, system, and method

InactiveUS20120073567A1Improve collection efficiencyWide acceptance angleSolar heating energySolar heat devicesInvoluteConcentrator

Owner:WINSTON CONE OPTICS

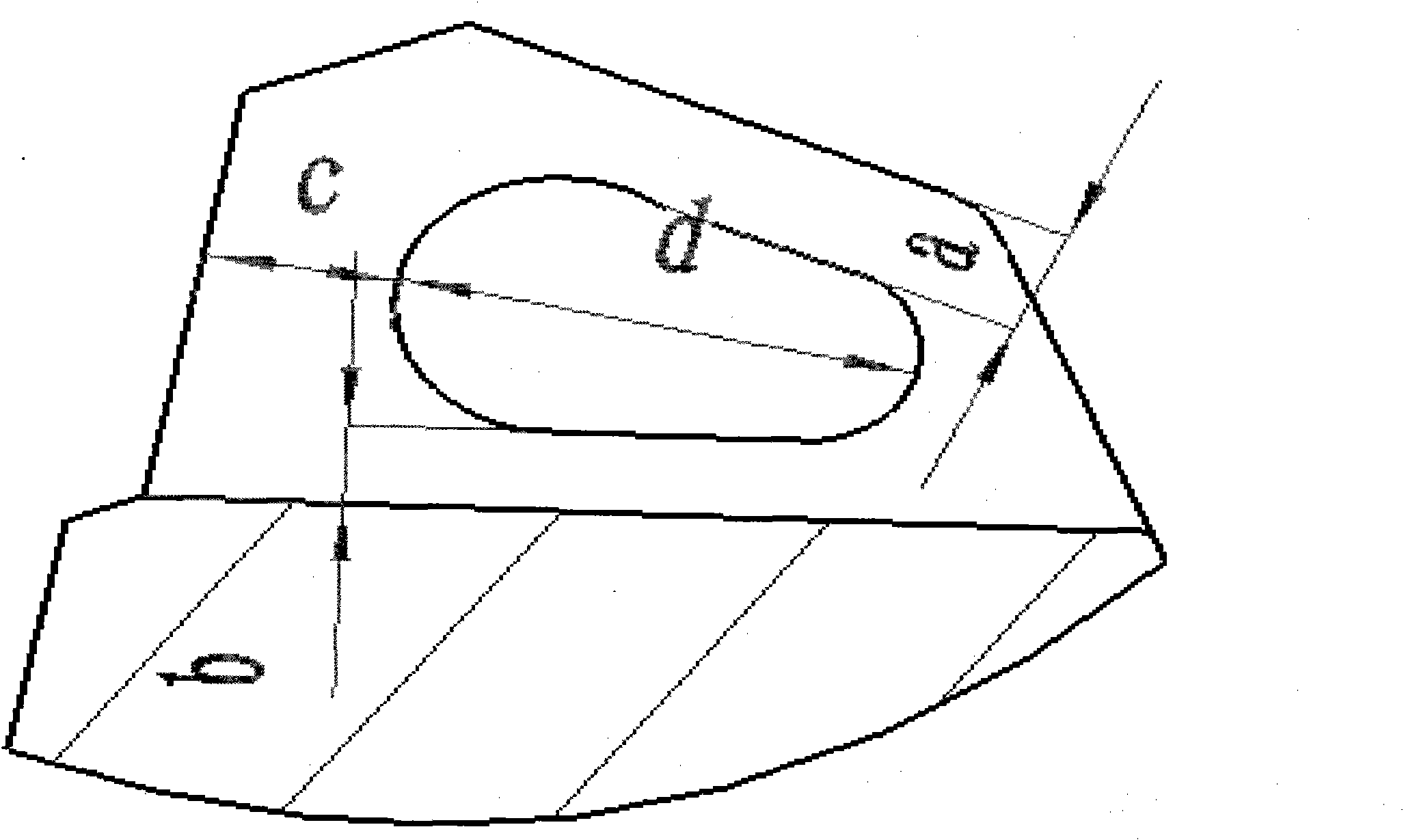

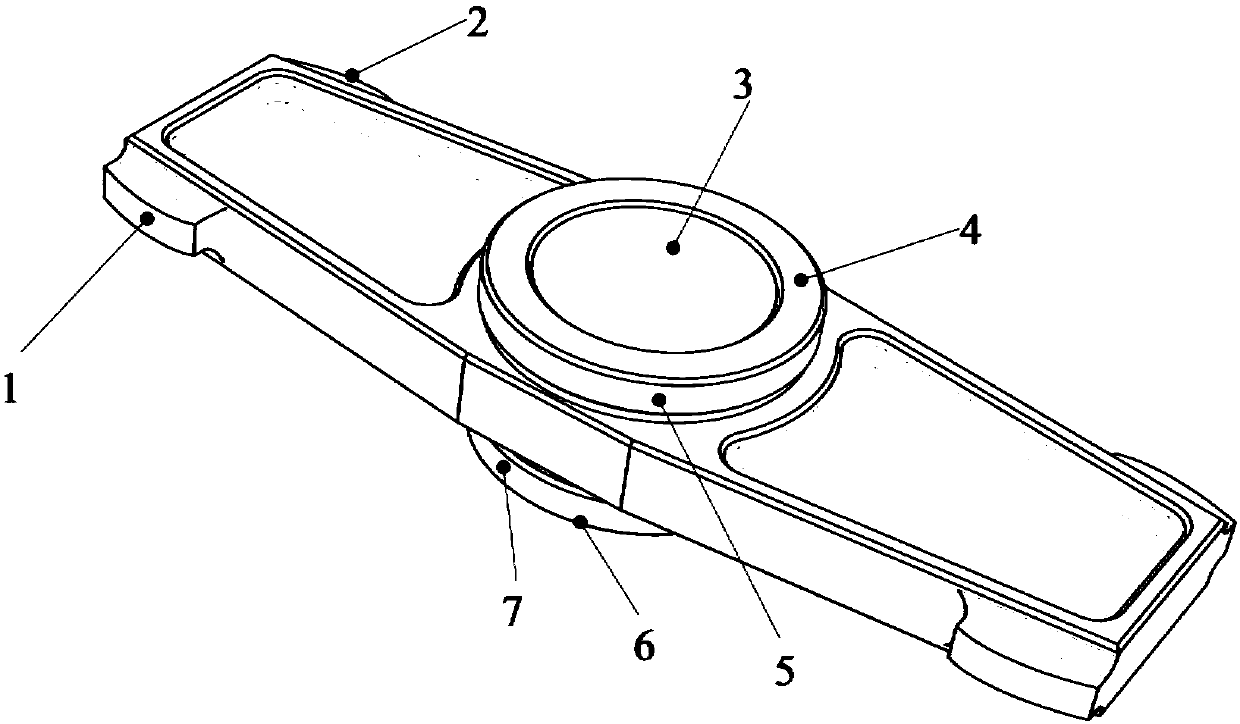

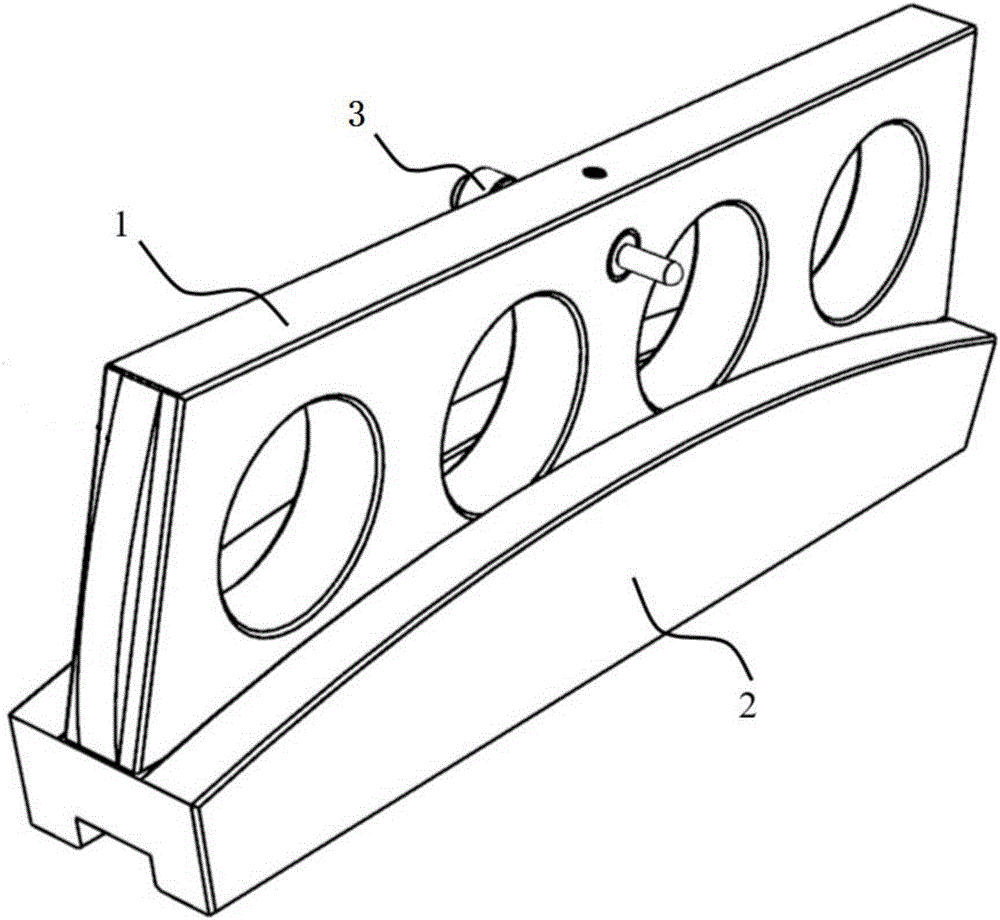

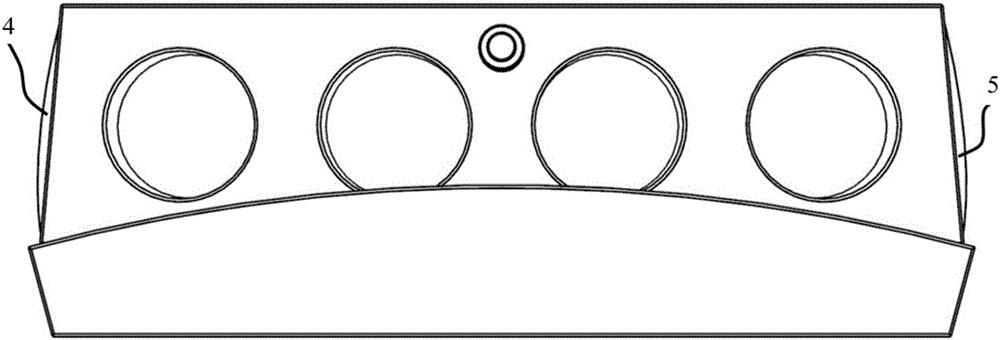

Self-mounting-reference equal-common-normal-line gear involute template

ActiveCN108061651AEasy to processEasy to testMachine gearing/transmission testingShape deviationInvolute

The invention belongs to the field of precise gear testing technology, and discloses a self-mounting-reference equal-common-normal-line gear involute template. The self-mounting-reference equal-common-normal-line involute template comprises a left tooth surface, a right tooth surface, an upper reference cylindrical surface, a lower reference cylindrical surface, an upper end surface, a lower end surface and a reference hole. The gear involute template satisfies a basic requirement for a grade-1 precise gear involute template in a gear involute template national standard. Furthermore the involutes of the left special-shaped tooth surface and the right special-shaped tooth surface of the template have a common normal line and a unified expanded basic circle arc. The self-mounting-reference equal-common-normal-line gear involute template facilitates subsequent ultra-precise processing and testing of the gear involute template. Furthermore, the self-mounting-reference is used for processing and measuring and is furthermore used as a magnitude transmission reference in use of the gear involute template. The measurement results of the structure tooth profile shape deviation ffalpha and atoth profile inclination deviation offset fHalpha are not closely related with the processing error and the mounting deviation error of a measuring core shaft in a use process, thereby ensuring highconvenience in use and high dimension stability in magnitude transmission.

Owner:金齿传动科技(大连)有限公司

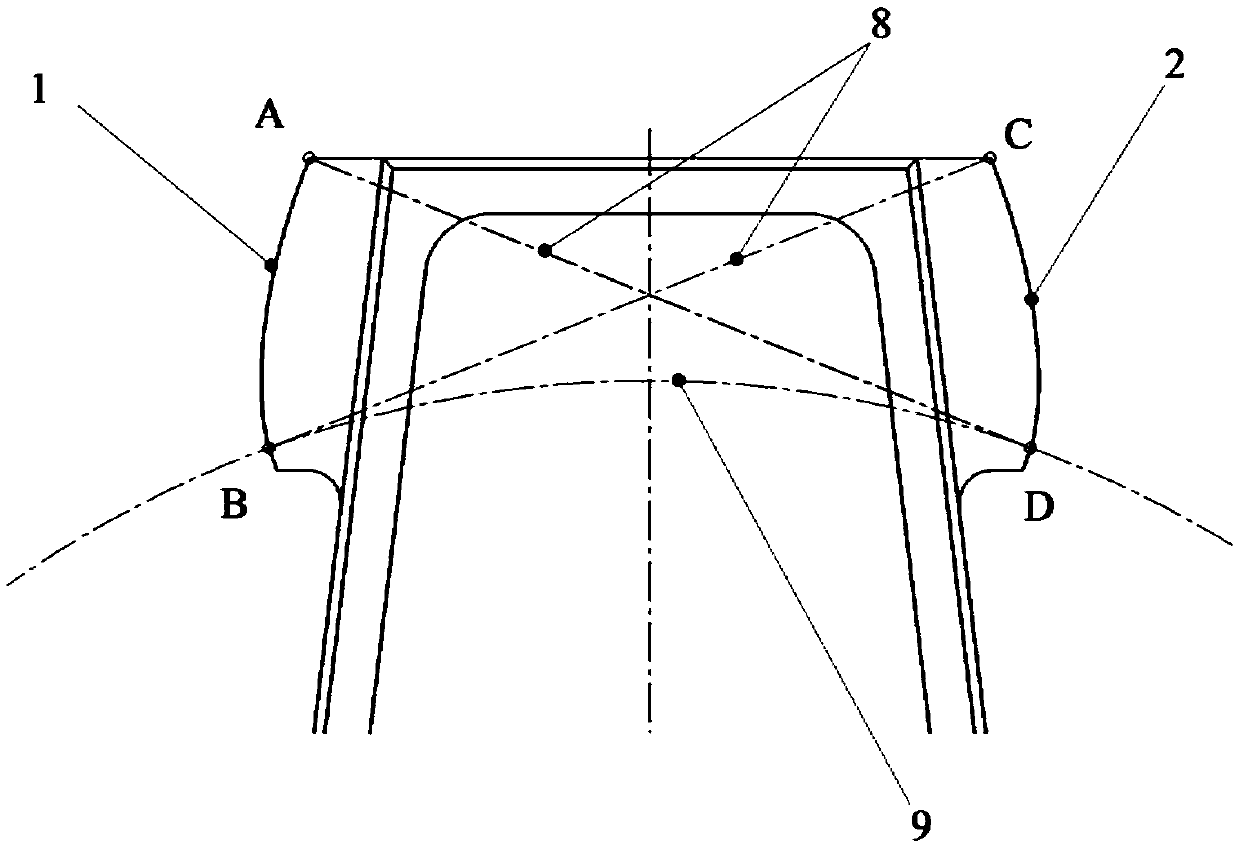

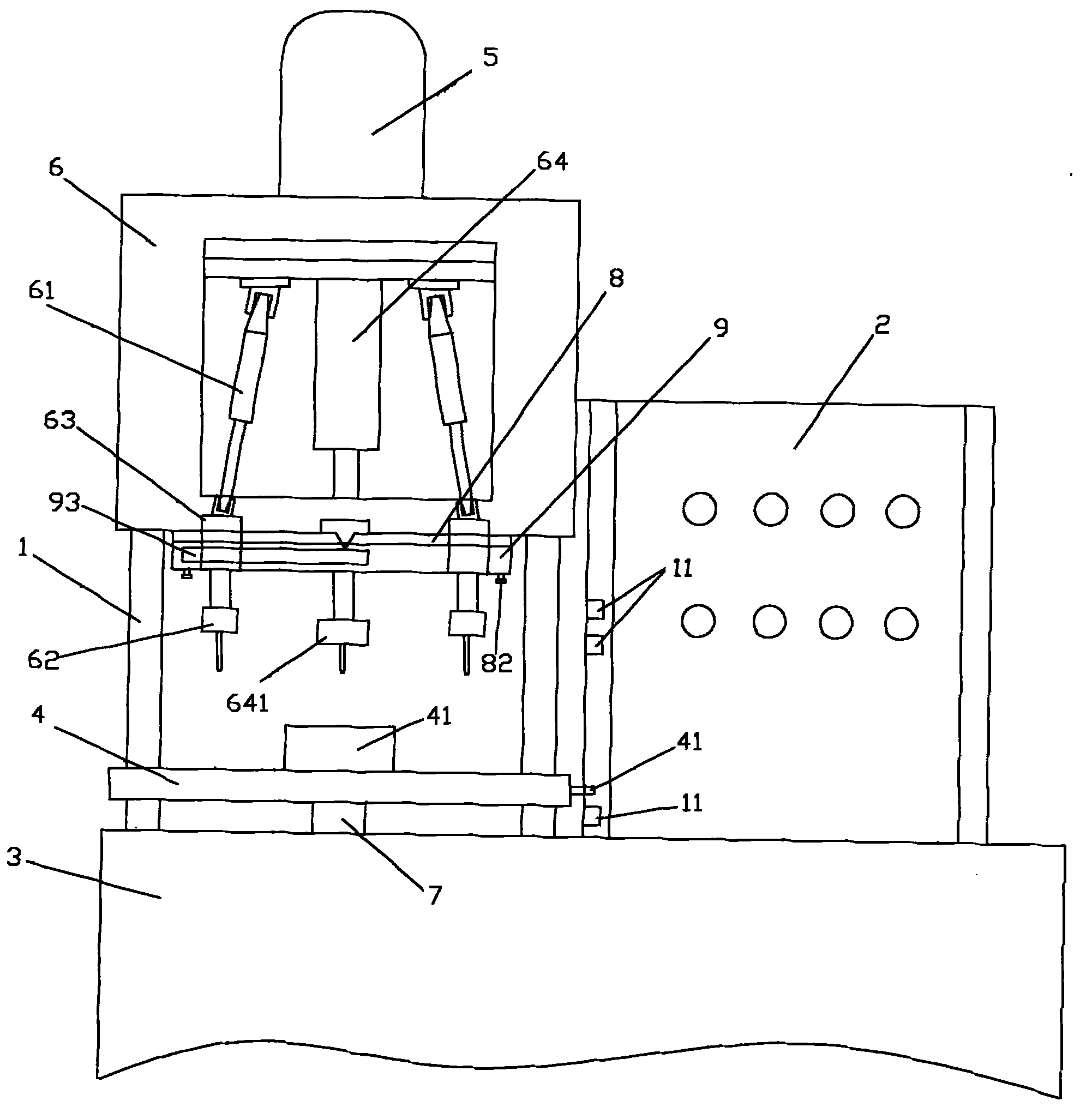

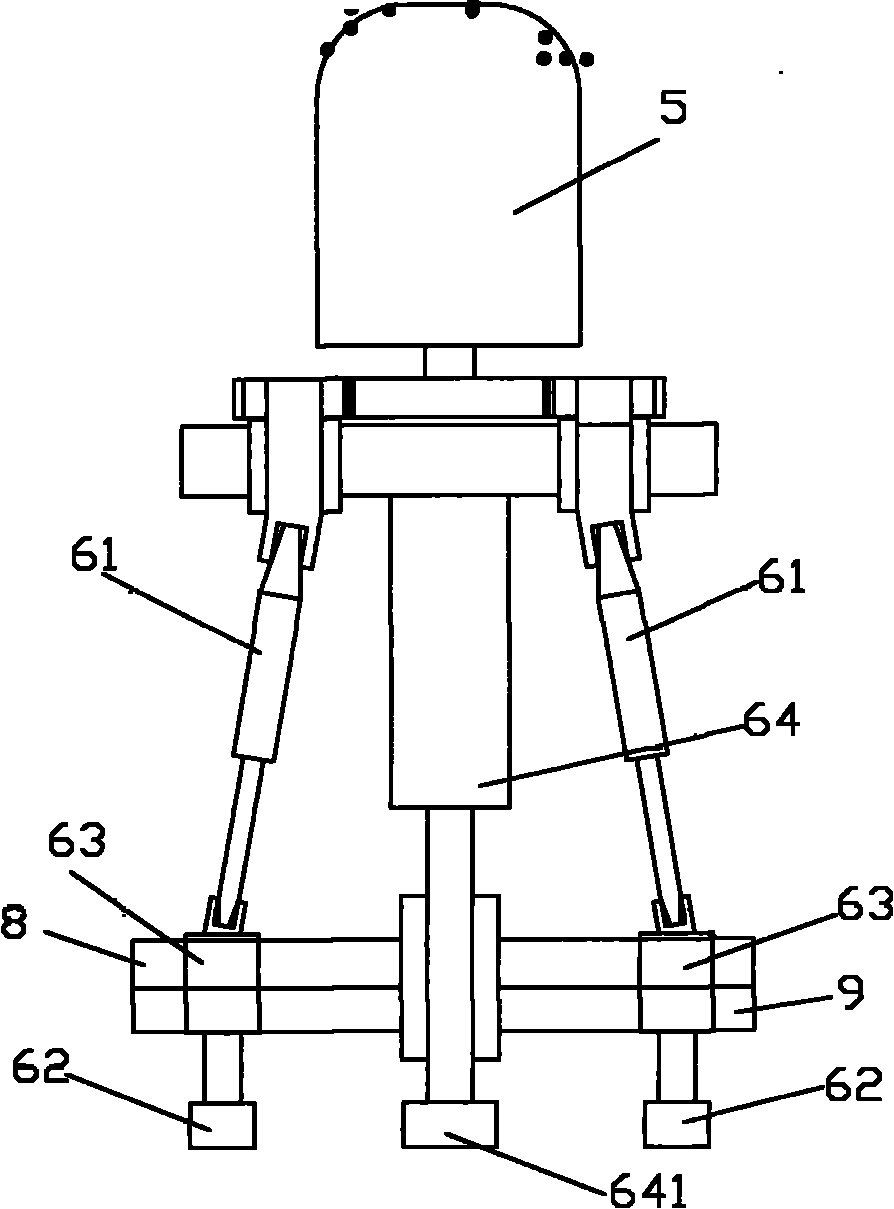

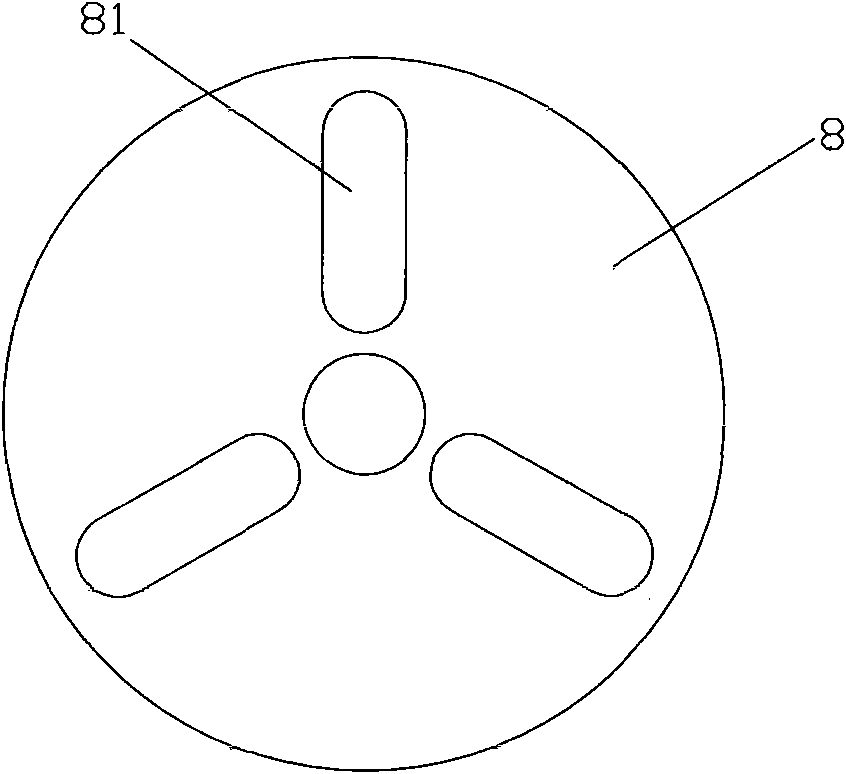

Multi-axis drilling machine with adjustable interval

InactiveCN102101183AImprove work efficiencyEasy to adjustBoring/drilling machinesUniversal jointGear wheel

The invention relates to a multi-axis drilling machine with an adjustable interval, which comprises a machine body, a control box, a base, a workbench, a main motor and a spindle box, wherein a workbench lifting mechanism is arranged between the workbench and the base; the spindle box is arranged on the machine body and above the workbench; the spindle box is internally provided with a universal joint; the upper end of the universal joint is connected with the main motor through a gear or a belt wheel, and the lower end of the universal joint is connected with a drill bit spindle; the bottom of the spindle box is sequentially provided with a fixed regulating plate and a rotary regulating plate; a radial slotted hole is arranged on the fixed regulating plate, and an involute-shaped slotted hole corresponding to the radial regulating slotted hole is arranged on the rotary regulating plate; the periphery of the involute-shaped slotted hole is provided with positioning slotted holes; the drill bit spindle is arranged in the radial slotted hole and the involute-shaped slotted hole through a bearing; and fastening screws are arranged in the positioning slotted holes and connected with the fixed regulating plate. The machine has the characteristics of convenience of regulation and high precision.

Owner:林如华

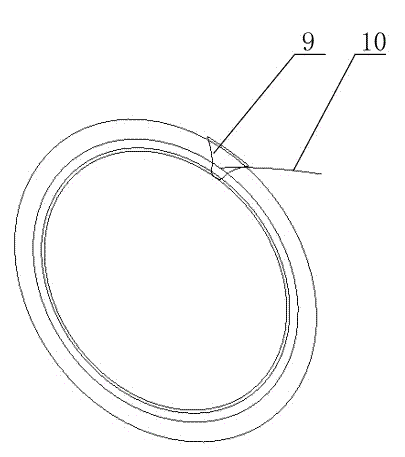

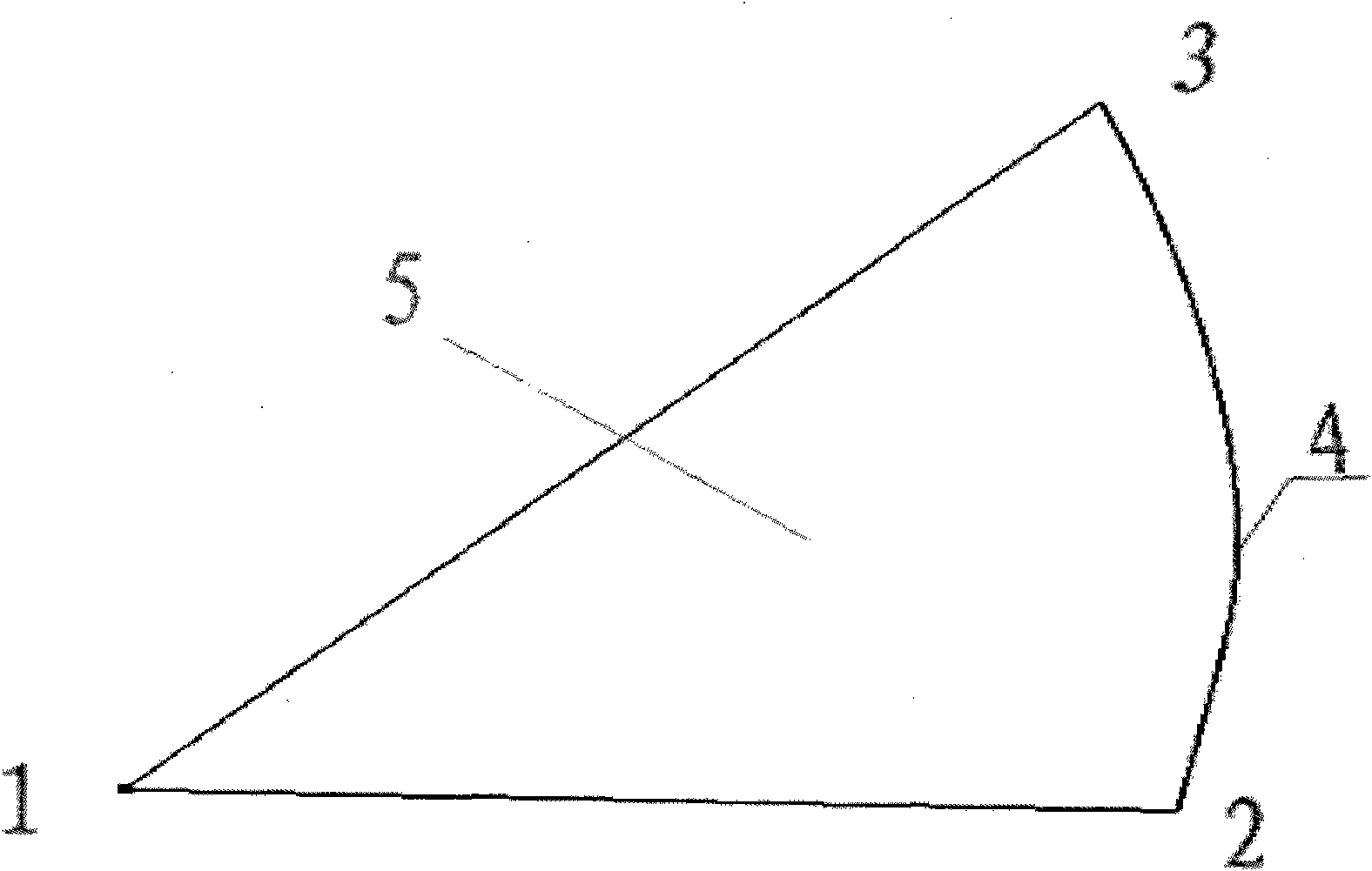

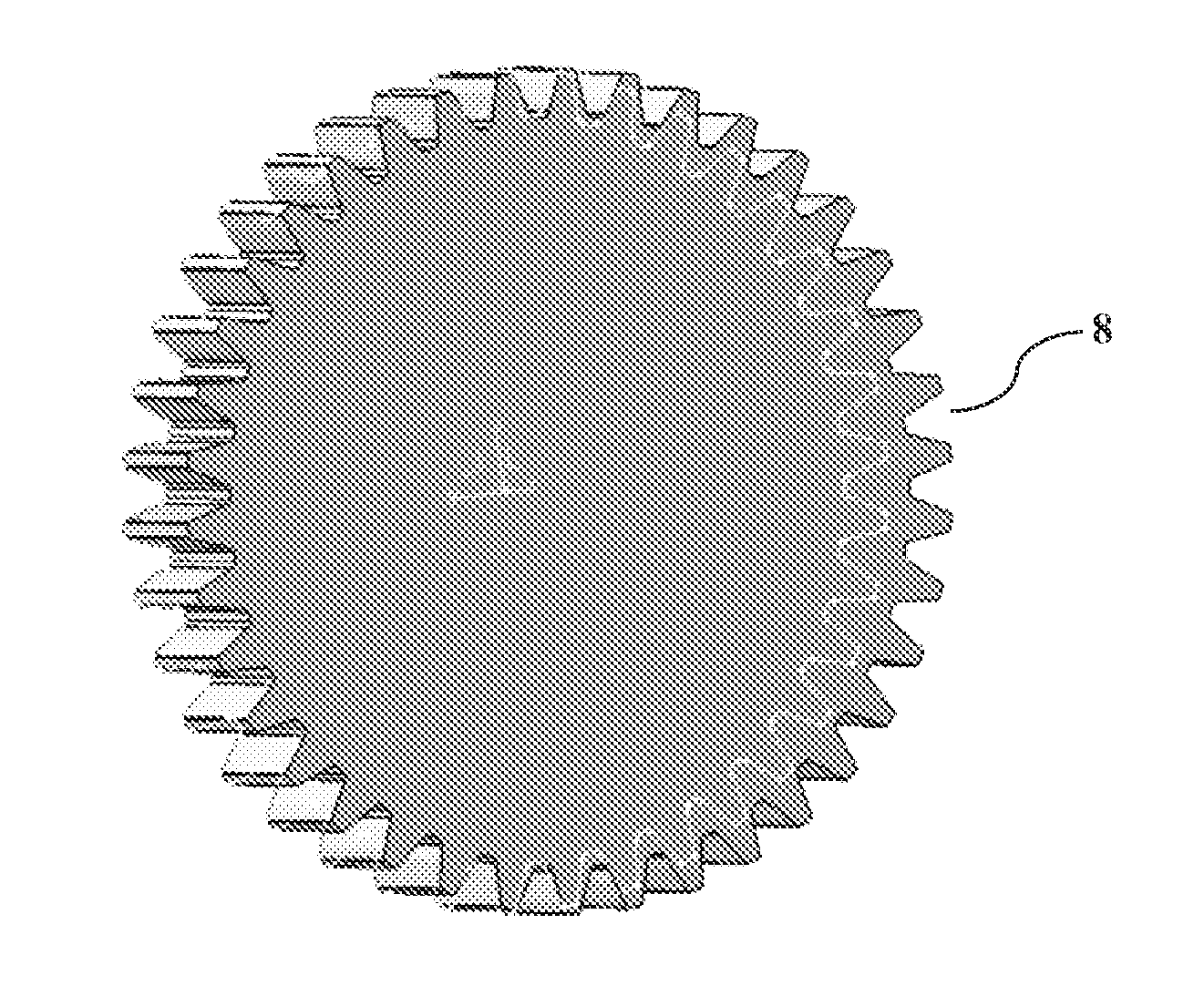

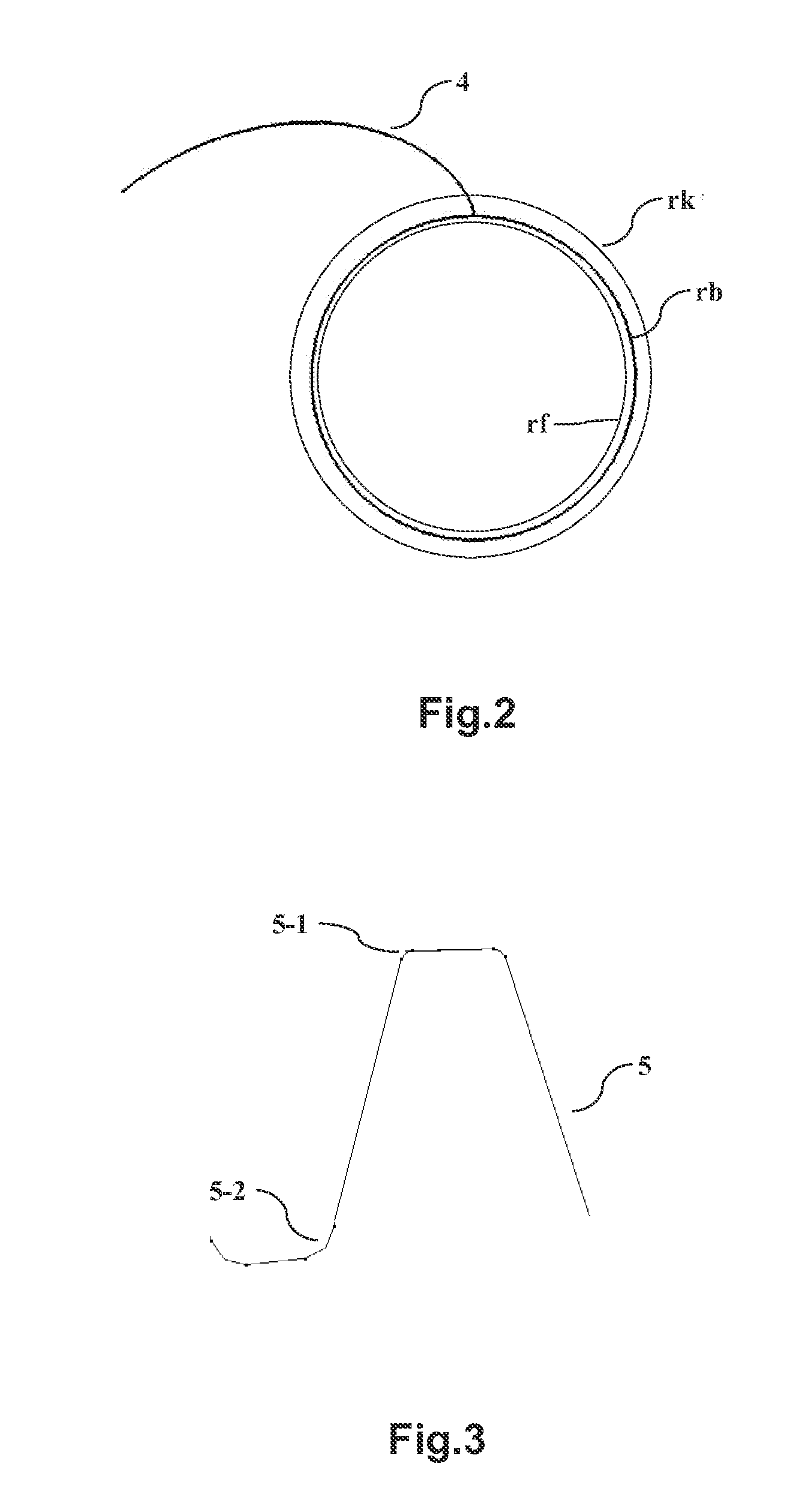

Bull gear involute sample plate

ActiveCN106482690AReduce measurement uncertaintySmall structure sizeMechanical counters/curvatures measurementsMeasuring instrumentGear wheel

The invention belongs to the precision gear test technology field and relates to a bull gear involute sample plate used for calibrating a bull gear measuring instrument. The invention provides the bull gear involute sample plate. Aiming at a base circle radius rb which is greater than 400mm, the bull gear involute sample plate comprises an involute sample plate block, a sector base circle block, an auxiliary supporting ball screw, a positioning pin and a connection screw. The bull gear involute sample plate is used for calibrating gear measuring instrument involute tooth profile deviation measurement precision. The bull gear involute sample plate is provided with the sector base circle block which is taken as a processing reference, a measuring reference and a positioning reference of an involute. Because of unification of the references, measurement precision of a bull gear involute is increased. Through measuring coordinates of a base circle of at least three points or radial jump, a center of circle position of the sample plate base circle is determined. The sample plate is used for calibration of the bull gear measuring instrument with or without revolving platform used for measuring a bull gear. The sample plate possesses advantages that the structure is simple, the size is small, involute precision is high and so on. The sample plate satisfies calibration of the bull gear measuring instrument with more than 4 level precision, and a good market application prospect and a good popularization value are possessed.

Owner:金齿传动科技(大连)有限公司

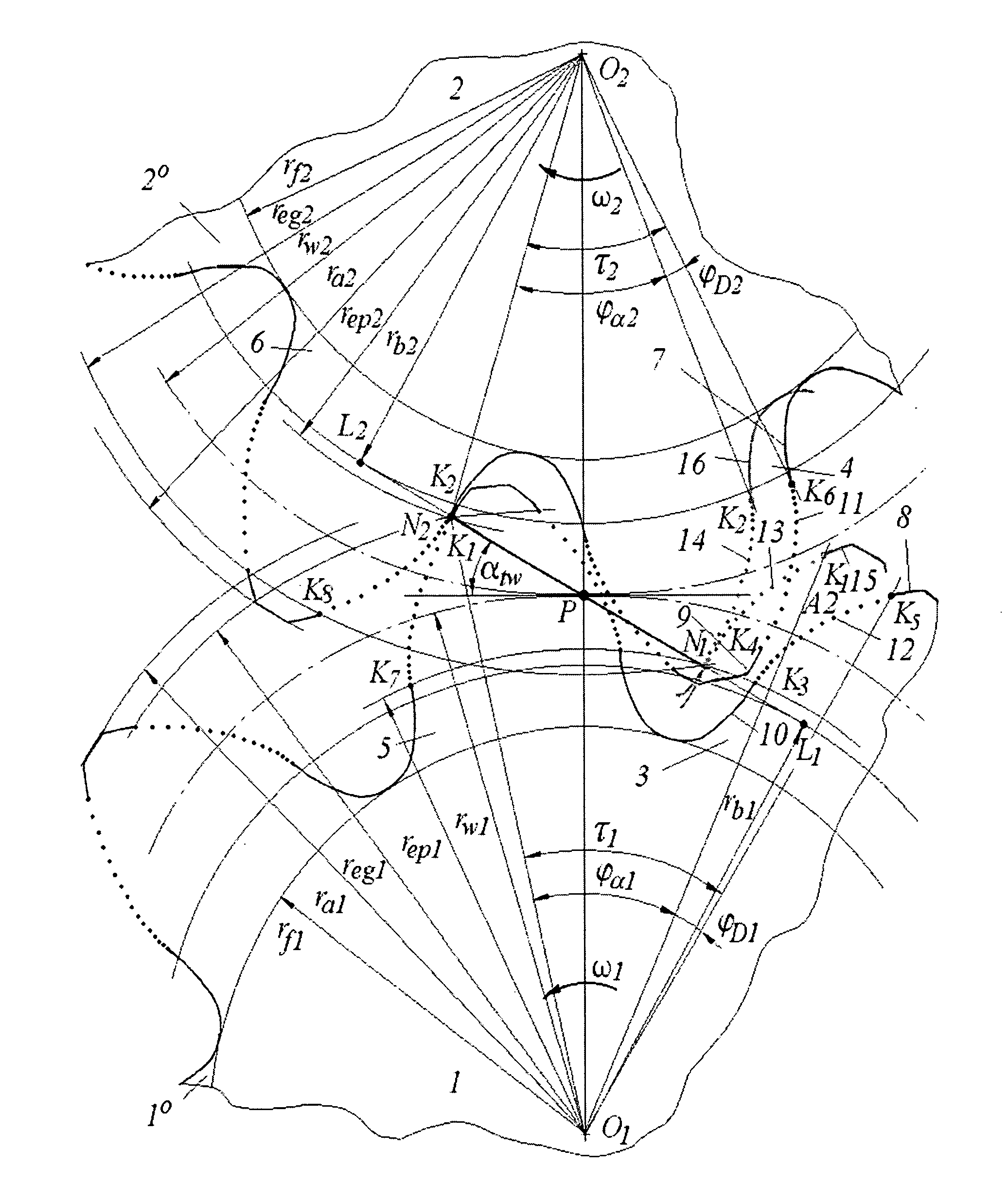

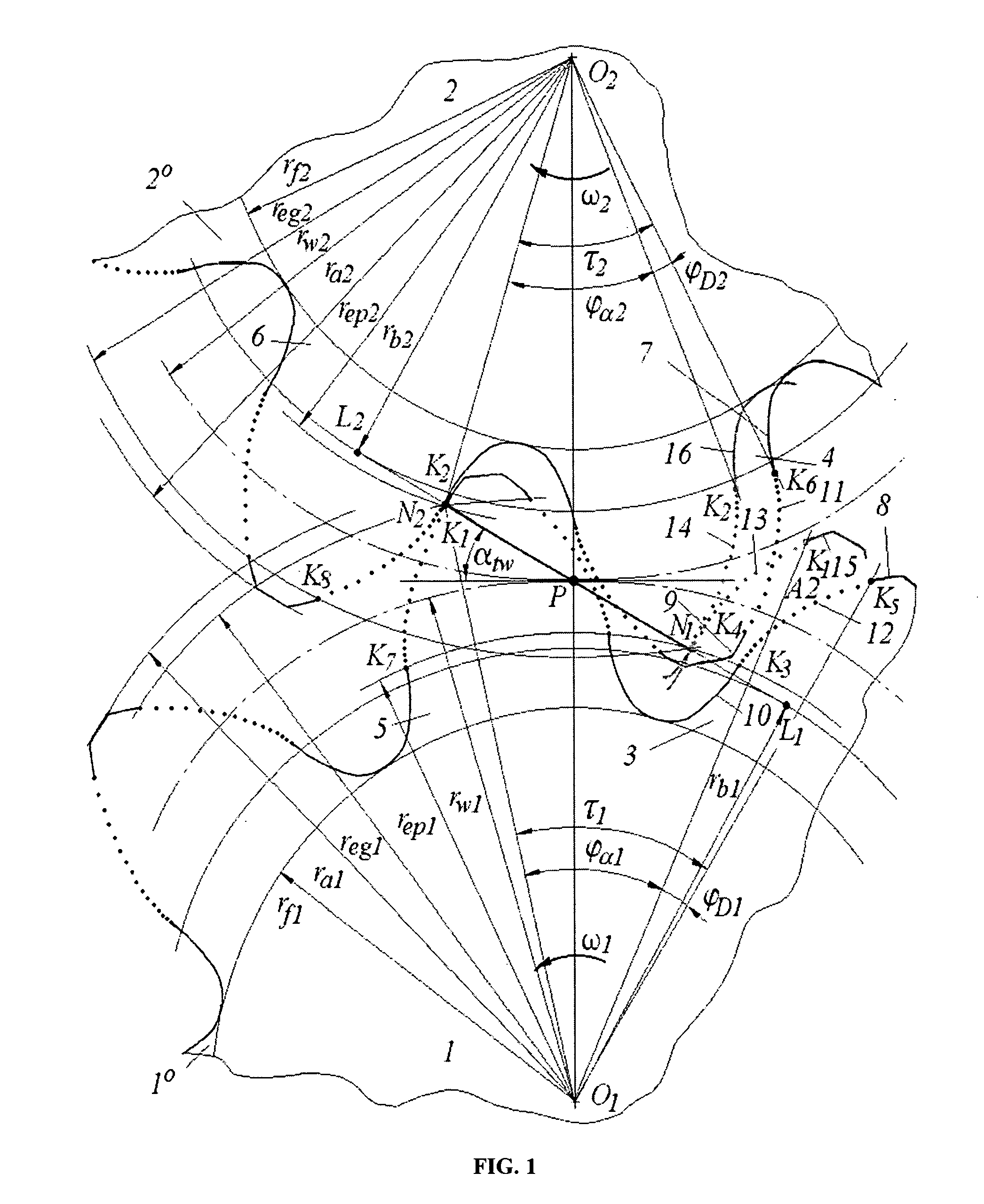

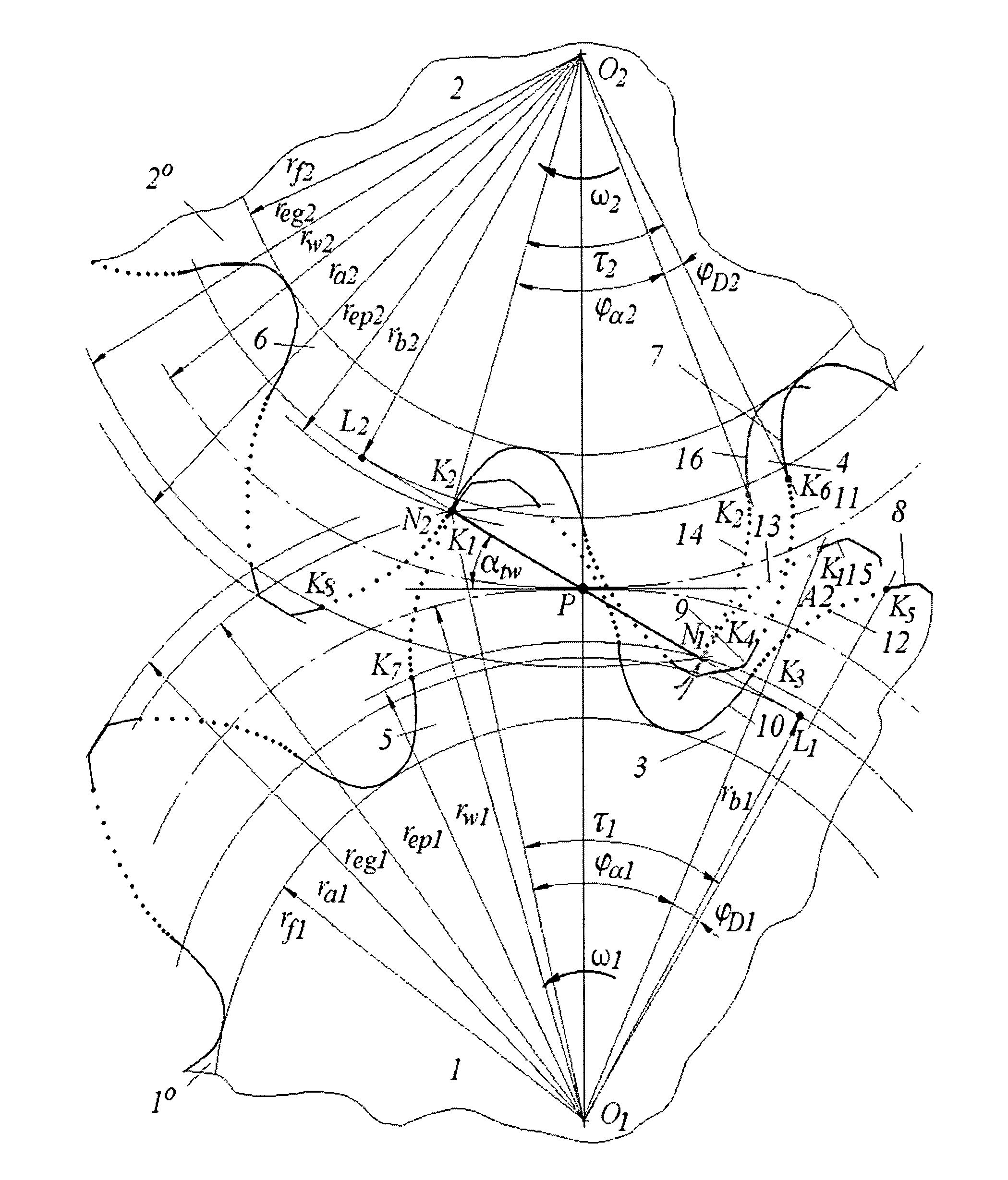

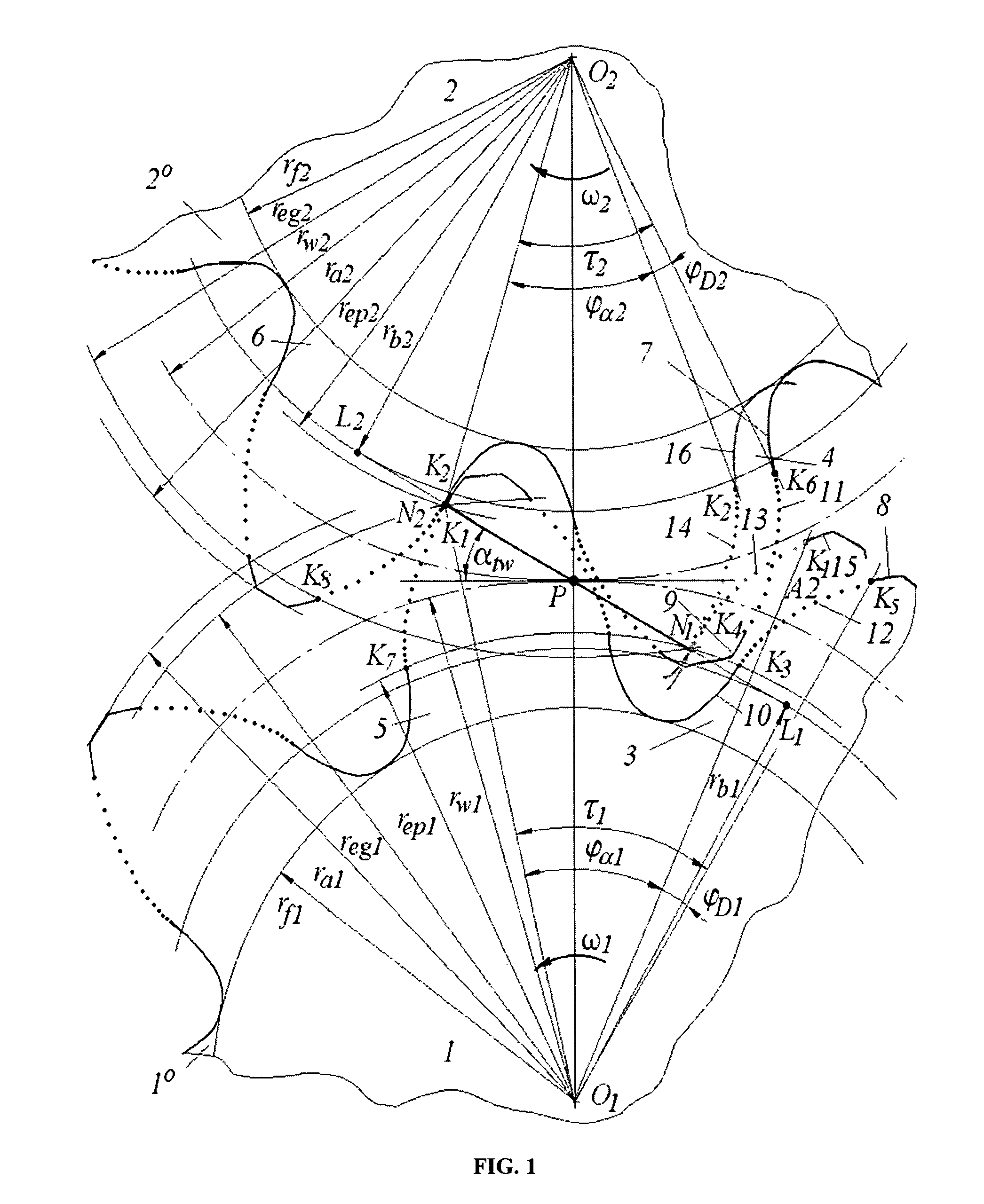

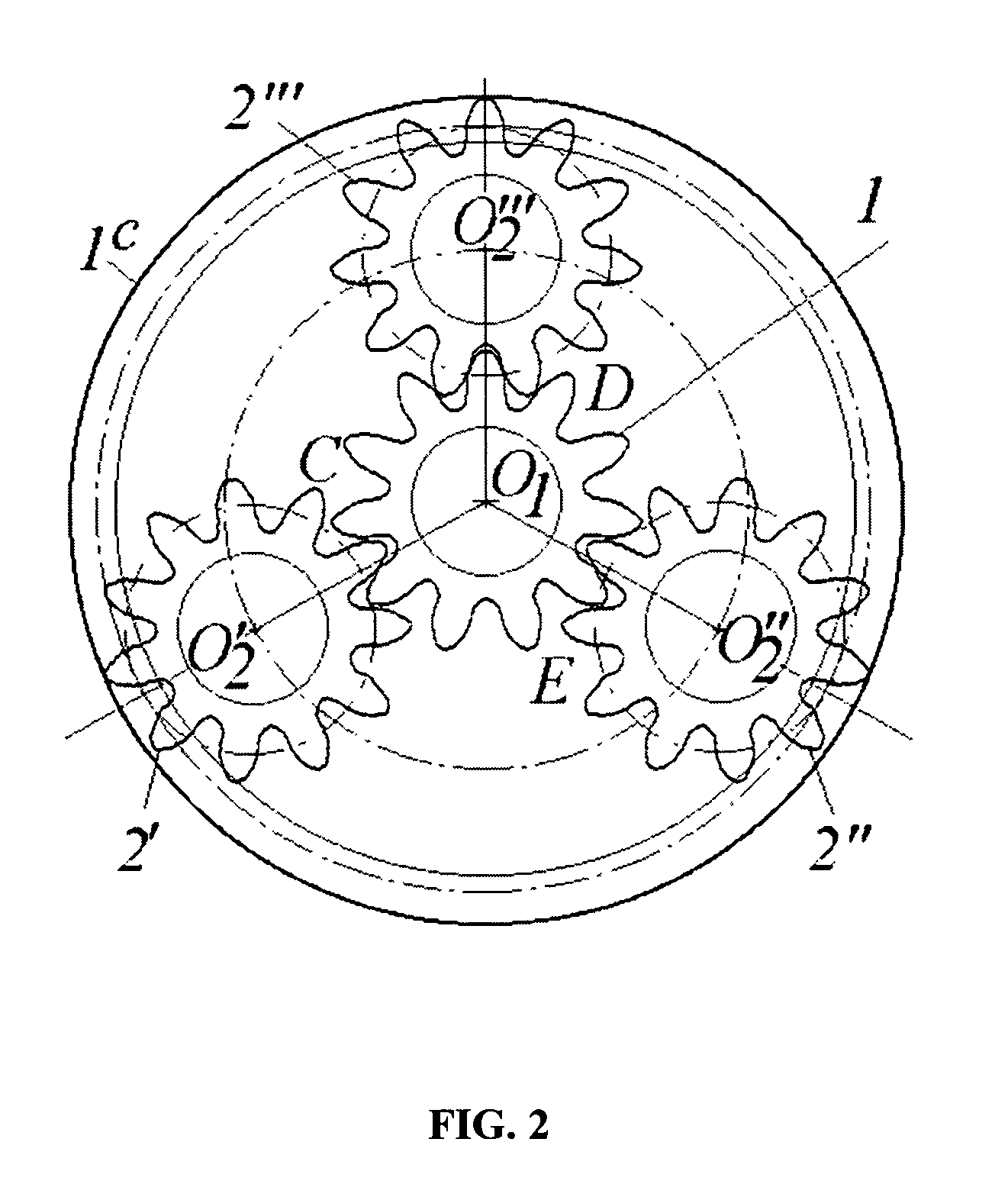

Zhuravlev Gear Drive

InactiveUS20090165585A1Convenient heightIncrease structural flexibility and contact tightnessPortable liftingGearing elementsGear driveGear wheel

The inventive gear drive comprises toothed wheels with teeth of toothed crowns interacting with single- or multi-flow elements. Working profiles of the interacting teeth comprise piecewise and / or pointwise conjugate, convex at a tooth point and concave at a tooth root arc-shaped sections continuously connectable to each other or to involute sections. The interacting toothed crowns are so embodied that a phase gap of the face tooth intermating at a discrete angle from a point, where the interaction of profiles ends at a point, where the interaction of the face profiles of the next tooth pair starts. The drive is so embodied that the face tooth overlap ratio thereof is less than 1. The so improved teeth provide for high level of the contact tightness and absence of axial forces at engagement, increase the structural flexibility of the gear drive teeth in order to improve their qualities.

Owner:NOVIKOV ROMAN VASILYEVICH

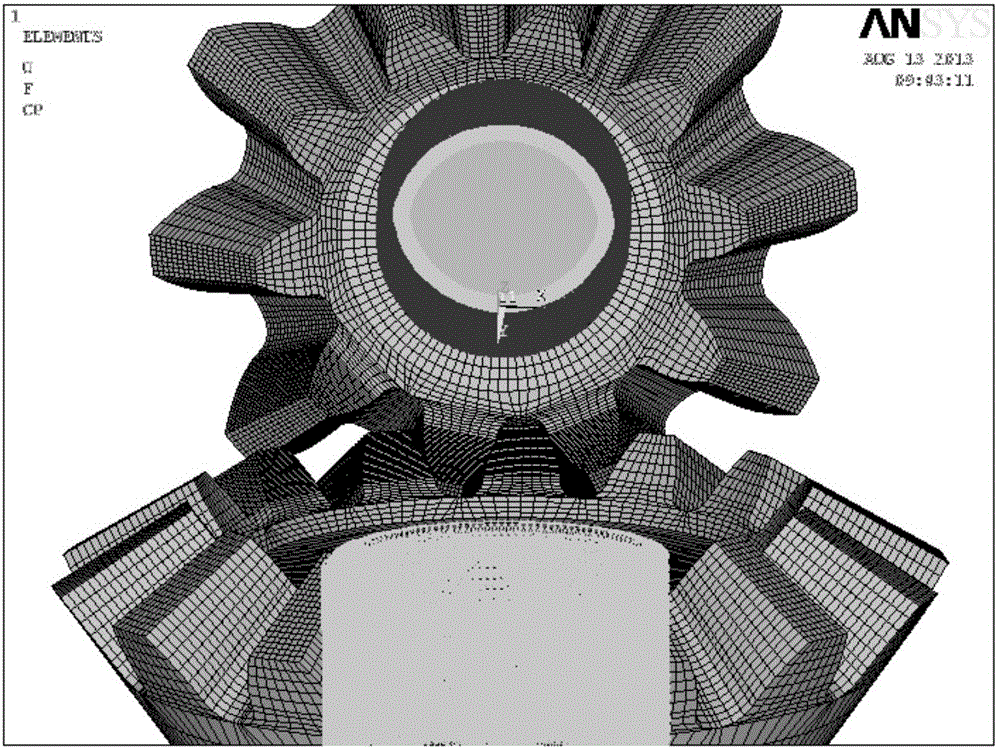

Involute bevel gear tooth end relief and parametric modeling method

ActiveCN105843985AImprove uneven load distributionIncrease stressDesign optimisation/simulationSpecial data processing applicationsStress distributionElement model

The invention disclose s an involute bevel gear tooth end relief and parametric modeling method which includes the steps of building a three-dimensional model of a bevel gear without the relief; building a finite element model of the bevel gear without the relief; determining 4 key engaging positions in the gear engaging process according to the gear engaging period to obtain the gear circumferential displacement difference value and the tooth width-direction equivalent contact stress distribution; determining the relief amount and the relief length of the tooth end relief; building a relief curve equation and a relief tooth surface equation; realizing the primary modeling of the relief curve and the tooth surface after the relief, and building a three-dimensional model of the relief gear; analyzing the gear after the relief by finite element analysis software and comparing the gear after the relief with a gear without the relief. The tooth surface contact condition is improved, the vibration noise in the gear engagement is reduced, and the NVH quality of the gear is improved.

Owner:WUHAN UNIV OF TECH

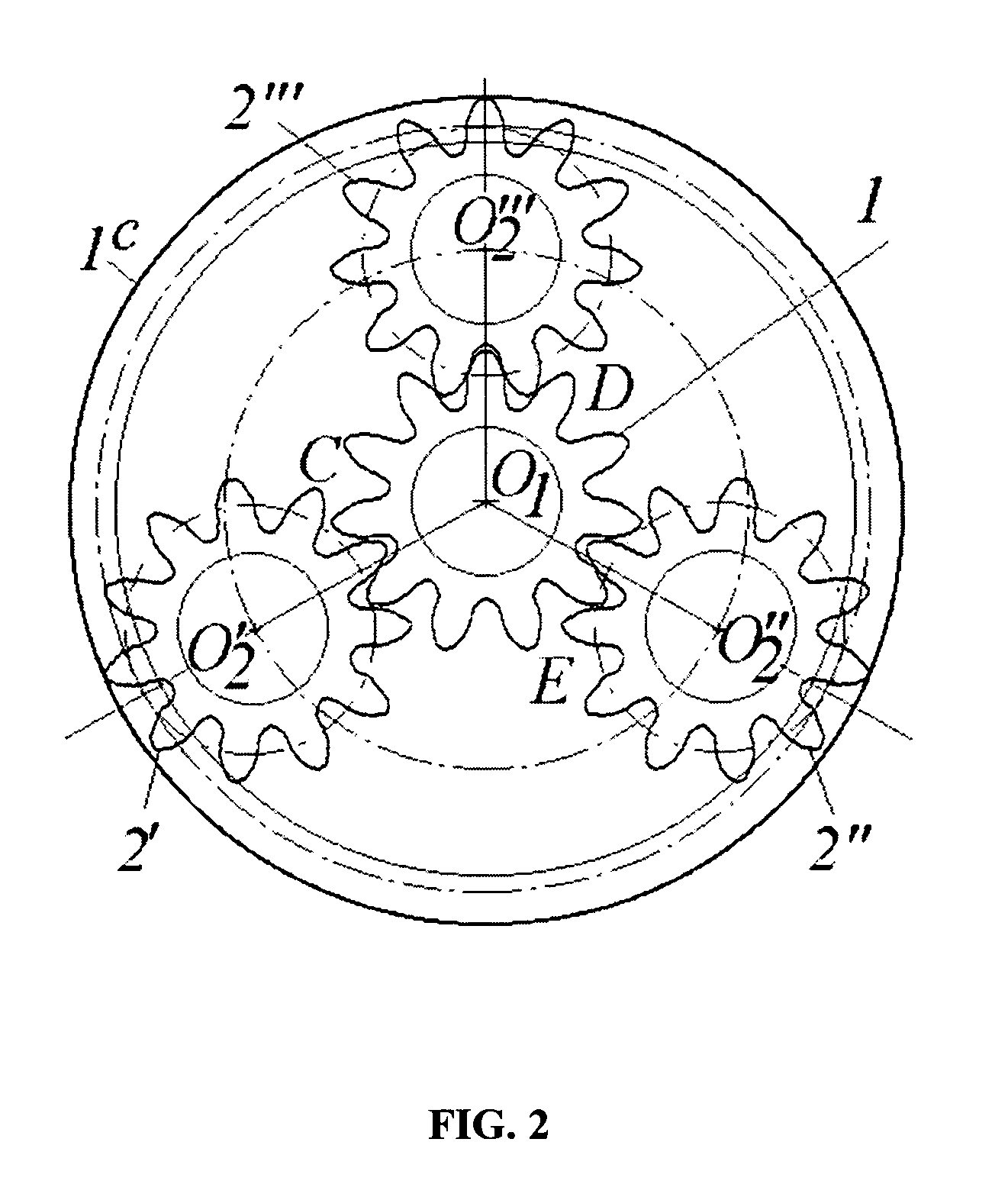

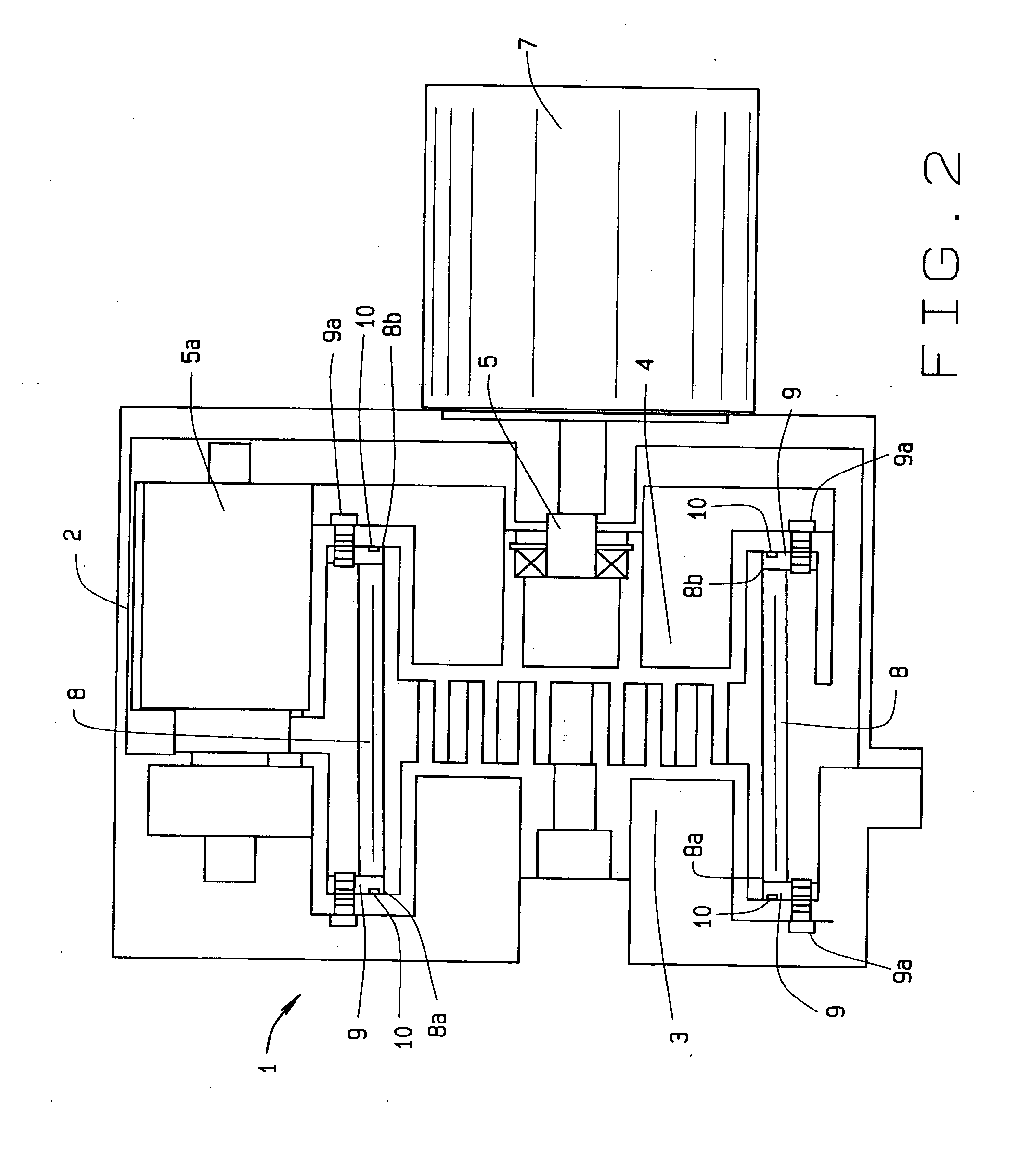

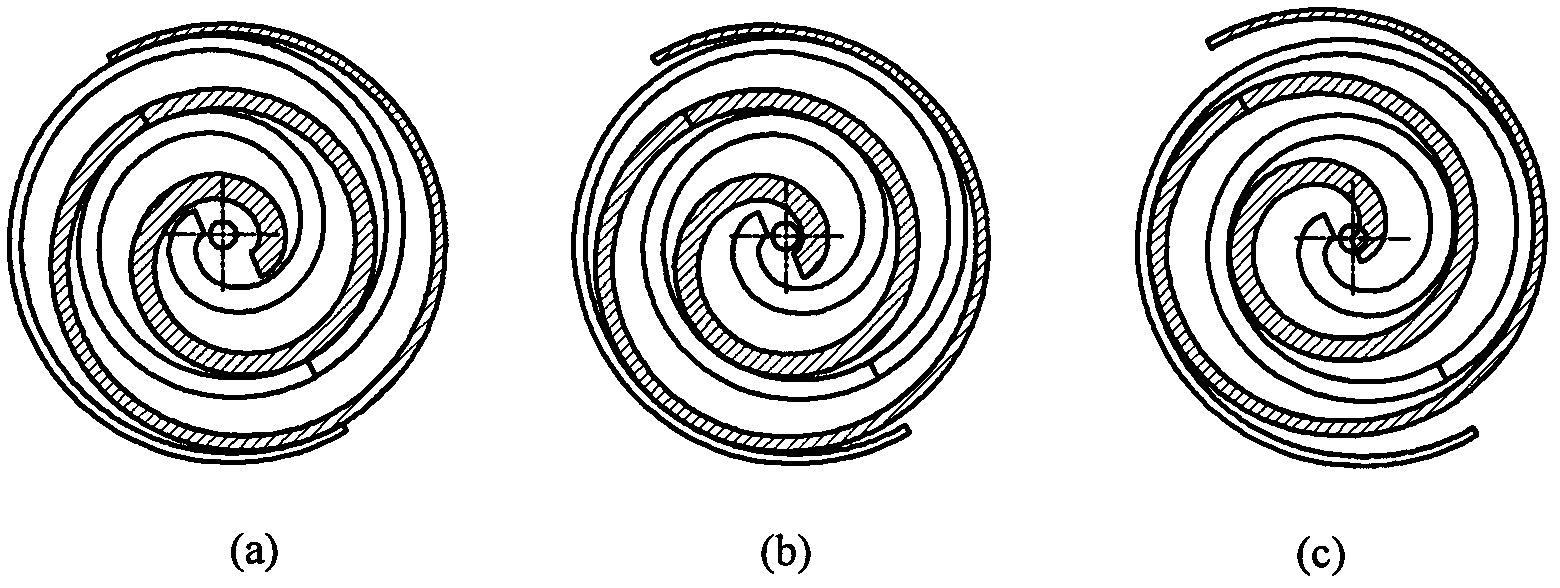

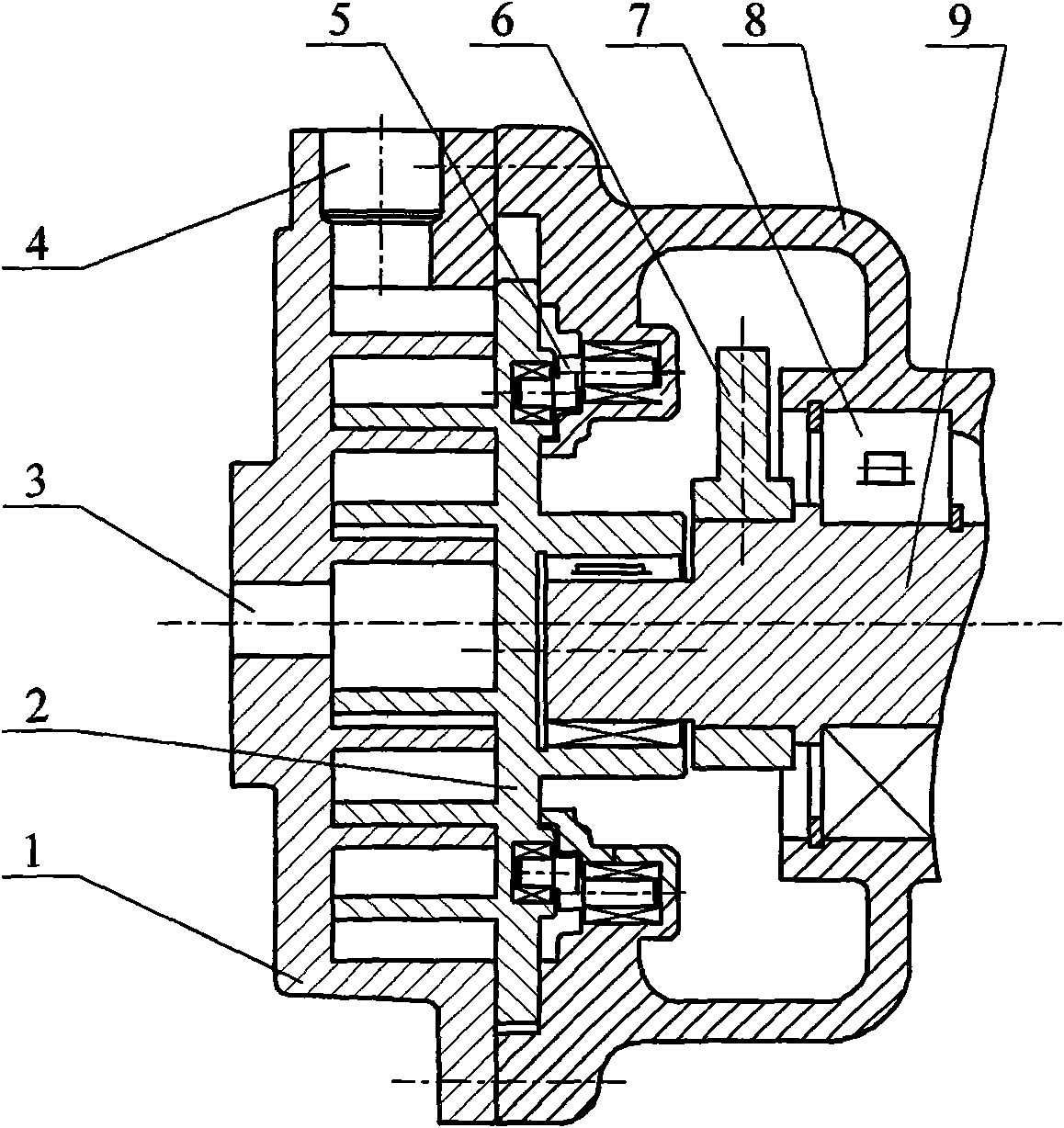

Three stage scroll vacuum pump

ActiveUS20110256007A1Improve heat transfer performanceImprove efficiencyRotary/oscillating piston combinations for elastic fluidsYielding couplingMotor driveThree stage

A three stage vacuum pump has three stages of fixed scrolls and orbiting scrolls that operate simultaneously. A motor drives the second orbiting scroll within the third fixed scroll upon three equally spaced idlers. One idler then transmits rotation and torque into the second stage. The second orbiting scroll to has involutes upon both surfaces to engage the second fixed scroll inwardly and the first fixed scroll outwardly. The first fixed scroll has fins upon its back that extend into the atmosphere to transfer heat to air cool the invention. This pump also has a fan accelerating heat transfer. The pump operates the scrolls directly from a motor or from a motor and magnetic coupling so that the atmosphere does not infiltrate the pump.

Owner:AIR SQUARED

Erosion-resistant hydrocyclone liner

ActiveUS20050016904A1Less brittleReversed direction vortexSingle direction vortexComposite constructionInvolute

Erosion-resistant liquid / liquid hydrocyclone liners, wherein the weight and cost of the liners are kept within acceptable parameters through the construction of a composite hydrocyclone liner, comprised of two or more different materials. The hydrocyclone liner includes a head section that is fashioned, primarily, of a highly erosion-resistant material, such as tungsten carbide. The liner also includes a separate separation section that is primarily fashioned of a material that may be less erosion-resistant but which is less brittle and more physically durable than that used to construct the head section. As a result of this composite construction, the liner is less likely to fail mechanically during installation or use. The head and separation sections are removably affixed to one another. The separation section of the hydrocyclone liner is provided with one or more structural supports to provide mechanical strength and resistance to bending. A liner is also described having a removable involute insert of highly erosion resistant material.

Owner:PETRECO INT

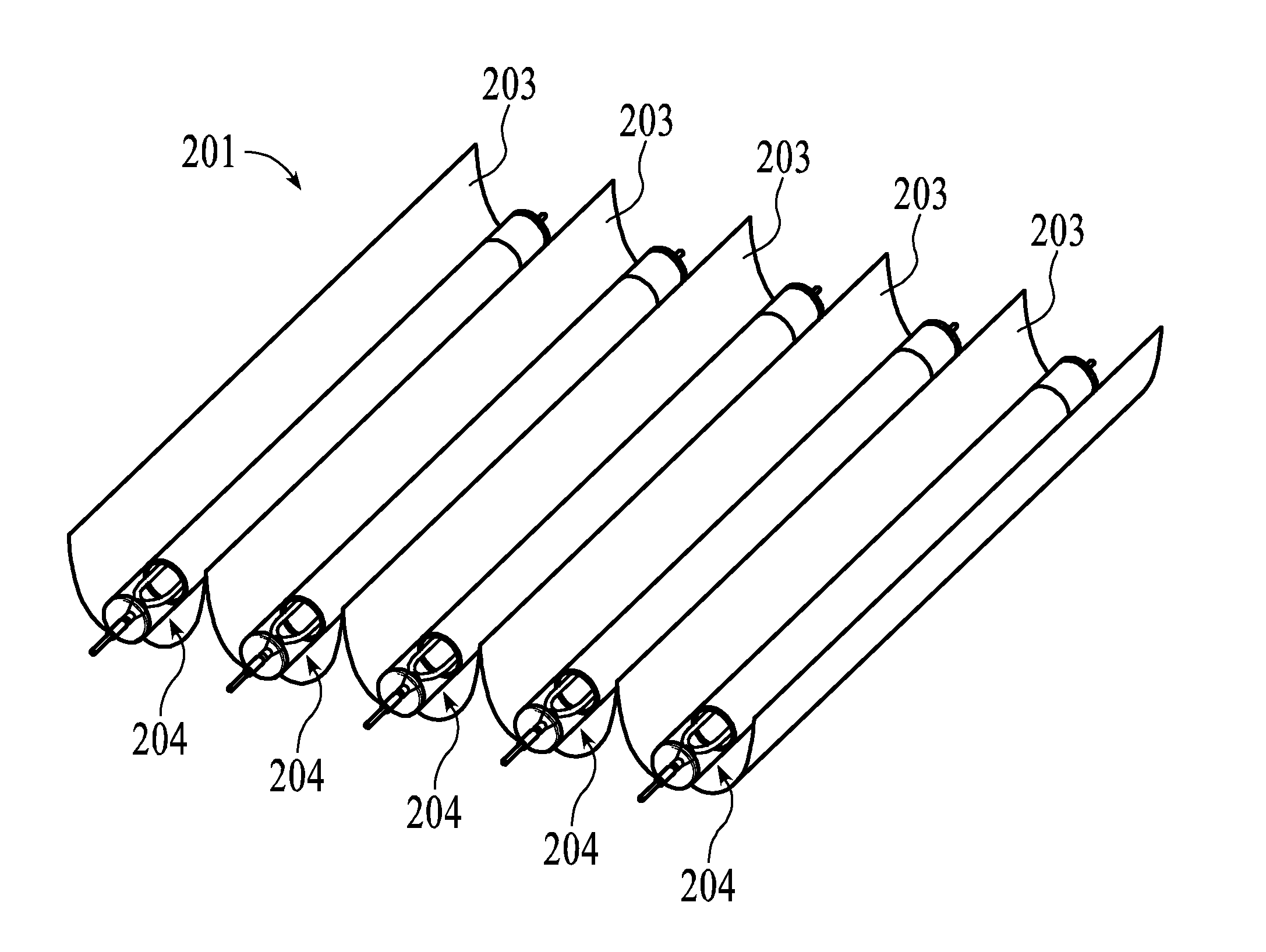

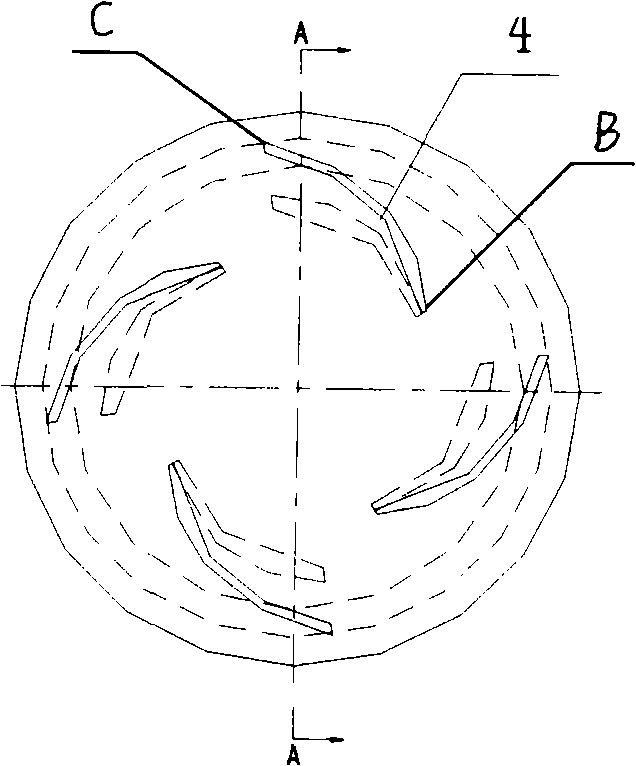

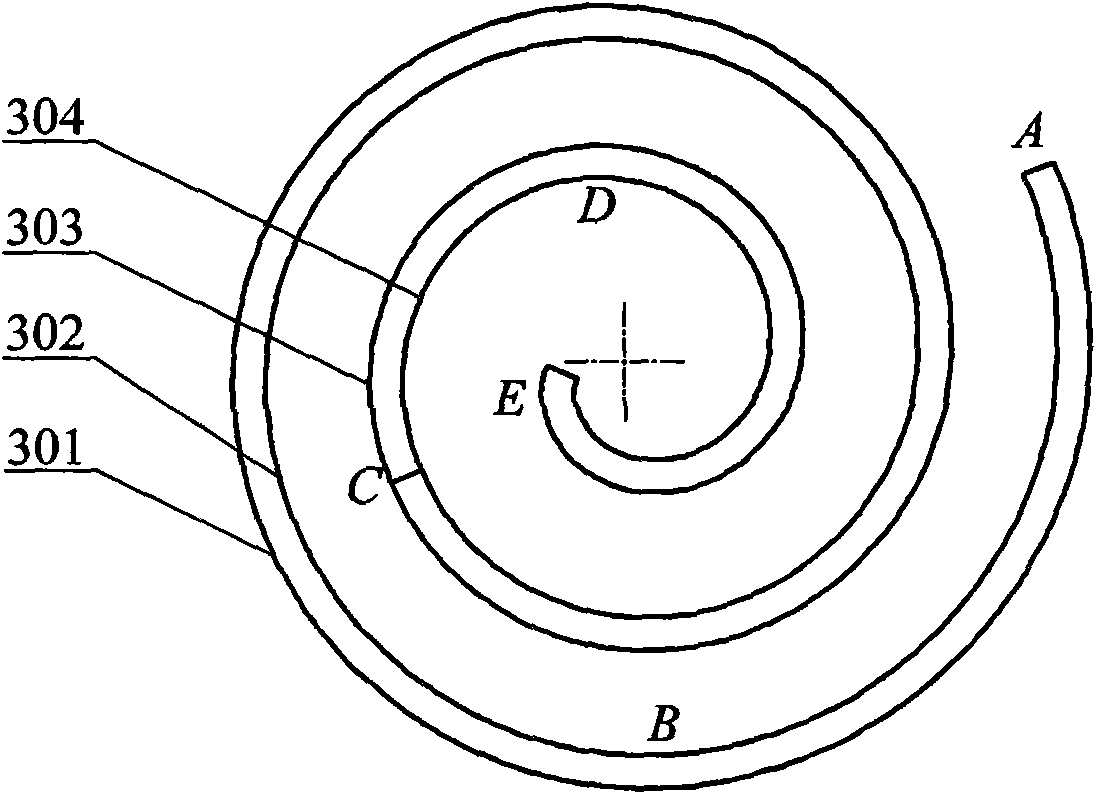

Involute arc spout fire-fighting extinguishing spray-head

InactiveCN101357255AReduce firefighting costsImprove fire extinguishing efficiencyFire rescueInvoluteEngineering

The invention relates to an involute arc spout fire extinguishing sprinkler head of a fire extinguishing device with a mechanical liquid sprinkling fire extinguishing agent, which solves the problem that the existing circular spout groove sprinkler head costs fire extinguishing agent and delays fire extinguishing time. The sprinkler head comprises a sprinkler head body, a bearing and a connecting pipe; the spout groove is involute arc along the radial direction; the spraying angle of B end which is the starting end of the involute arc spout groove 4 is 70-85 degrees, the spraying angle of C end which is the ending end of the involute arc spout groove 4 is 40-45 degrees, and the base radius r of the involute is 10-15mm. The spout groove is in the involute shape, thus the sprayed fire extinguishing agent forms a round cake shape while being sprayed, which is good for fire extinguishing. The sprinkler head is applied to liquid extinguishing agents comprising water, aqueous film forming foam concentrate, and the like. The sprinkler head has the advantages of extinguishing fire in a short time with a few fire extinguishing agents, low fire extinguishing cost, high fire extinguishing efficiency, convenient use, flexible action, saving time and high efficiency, and is applied to oil fire of aerosheds, etc.

Owner:UNIV OF SCI & TECH OF CHINA

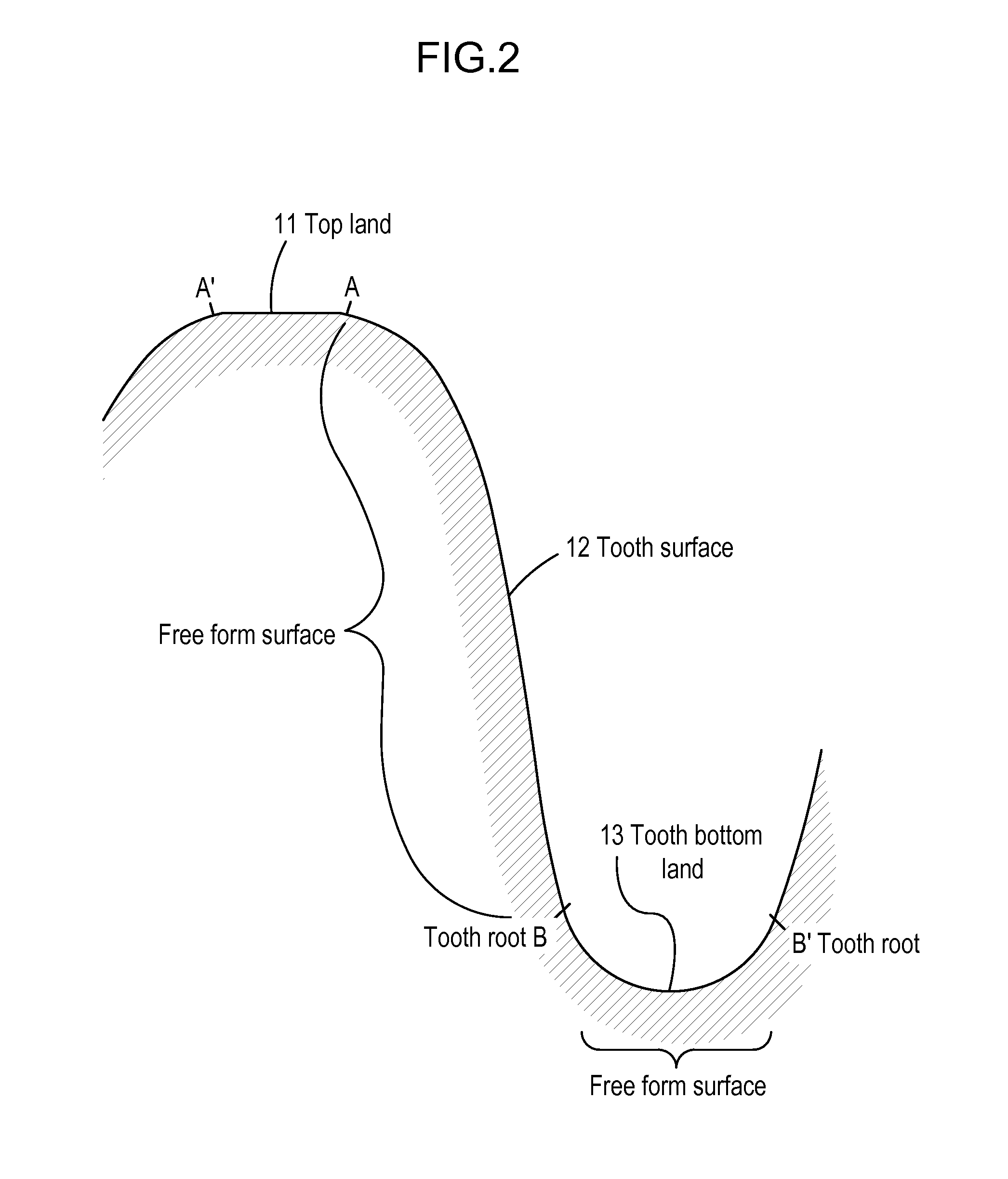

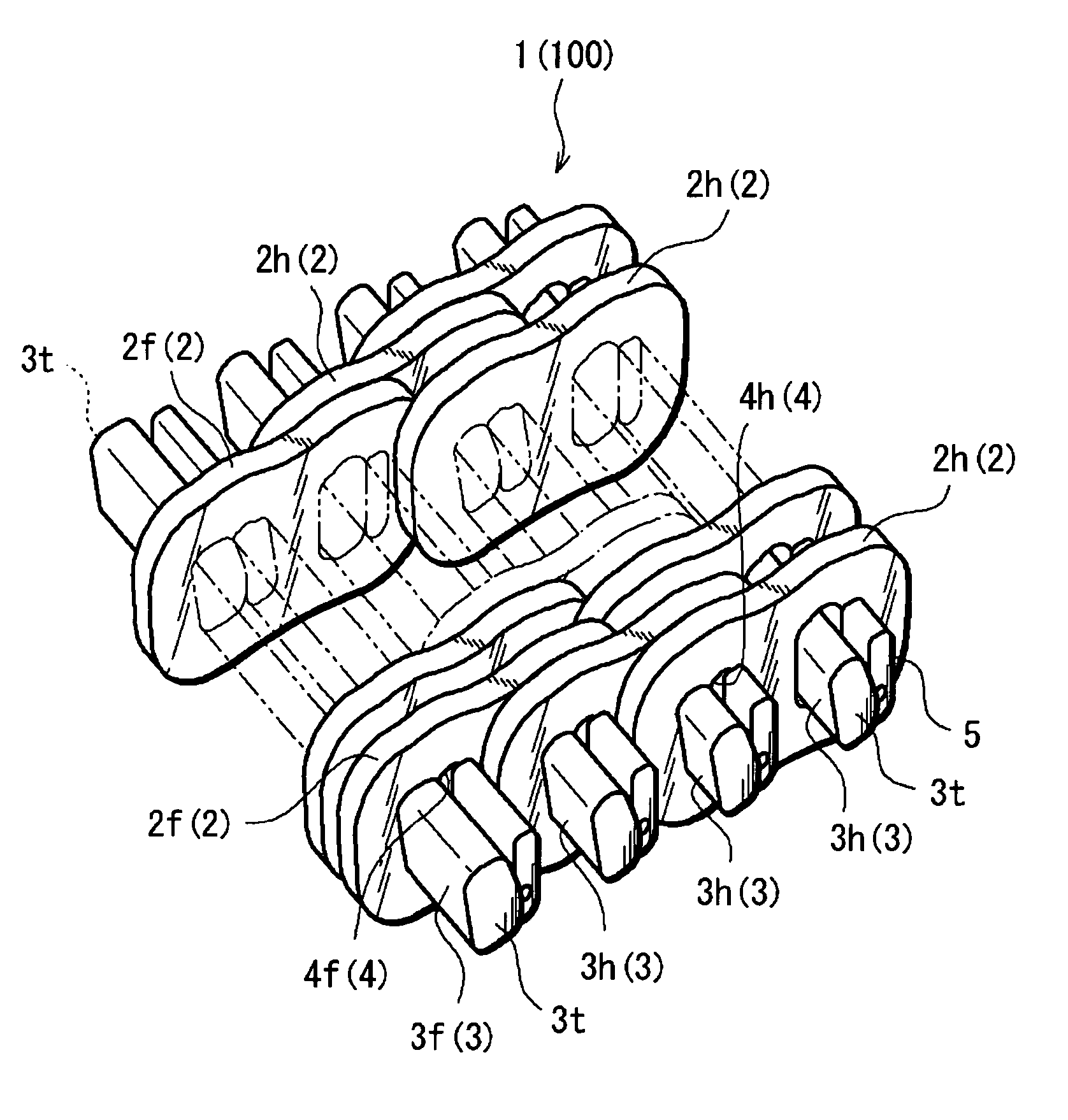

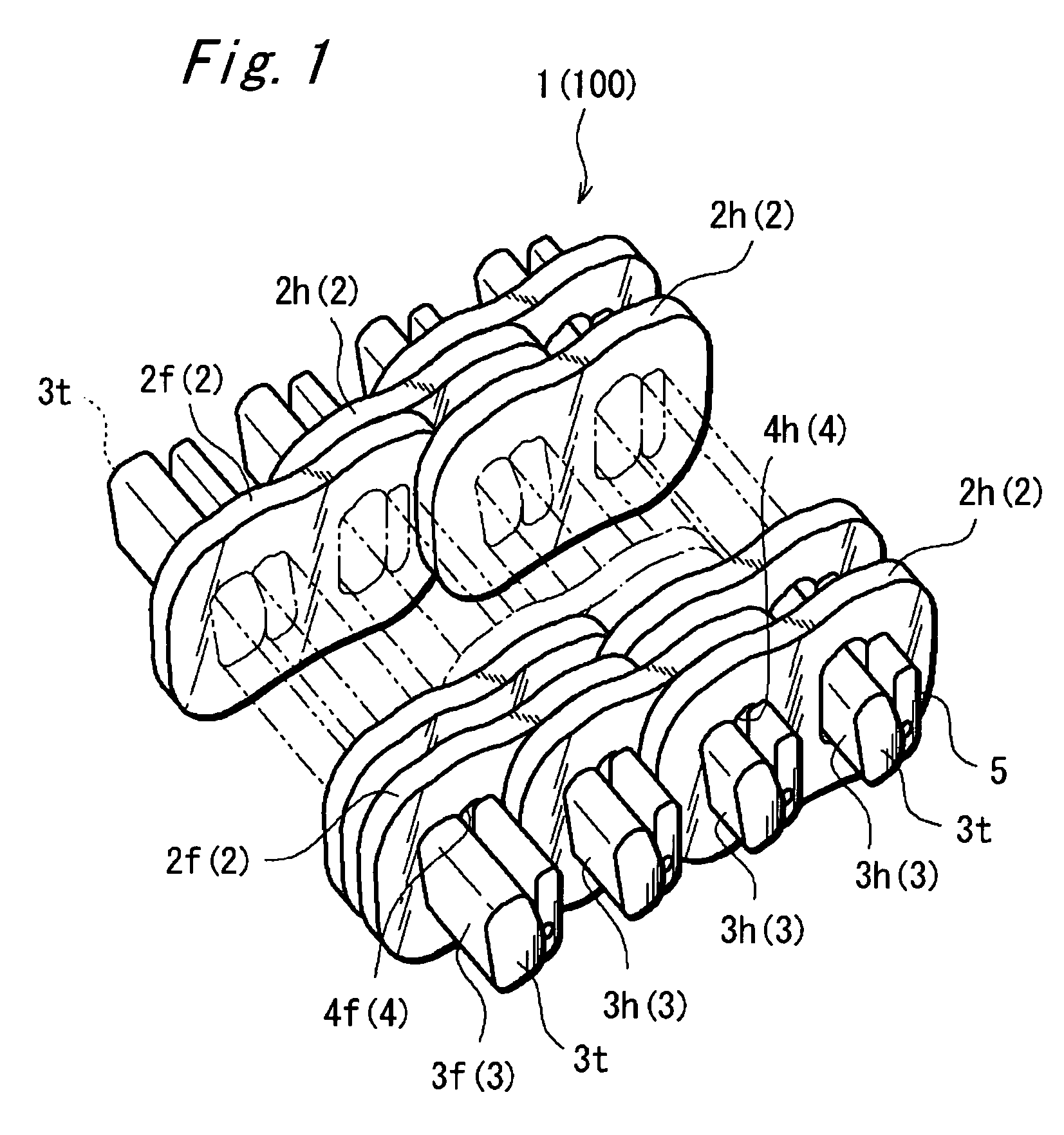

Free-form surface gear

ActiveUS20130091970A1Improve fatigue strengthIncrease contact pressureMetal-working apparatusPortable liftingContact pressureFree form

A transmission gear has a tooth surface formed of a free-form surface instead of an involute surface and a root area formed of a free-form surface instead of a trochoid surface. With such a transmission gear, the fatigue strength against contact pressure can be increased by reducing the Hertzian stress in the area around the meshing point of the tooth surface. The tooth surface is formed of a free-form surface in which the smallest radius of curvature in an area around a mating pitch point is maximized, and the fatigue strength against bending can be increased by reducing the bending stress at a tooth root portion of the bottom land. In addition, the gear noise can be reduced. The bottom land is formed of a free-form surface in which the smallest radius of curvature in an area around a tooth root is maximized.

Owner:O OKA CORP

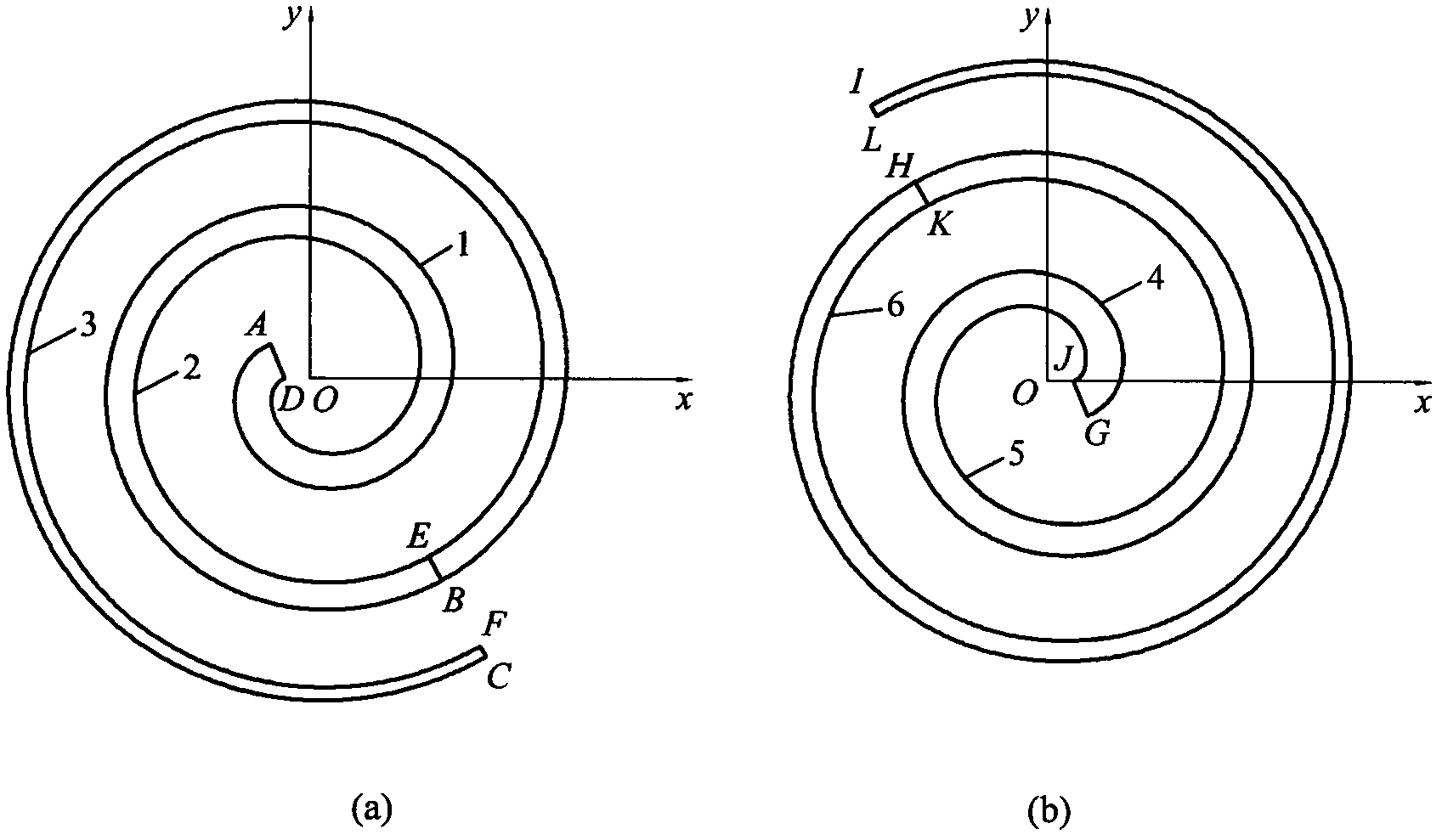

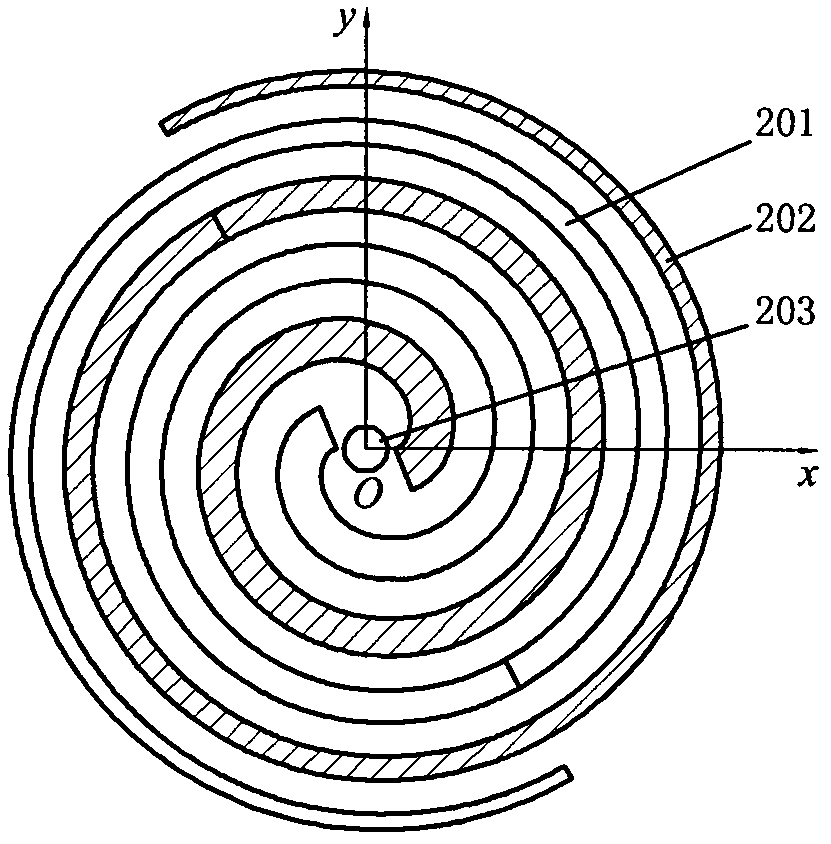

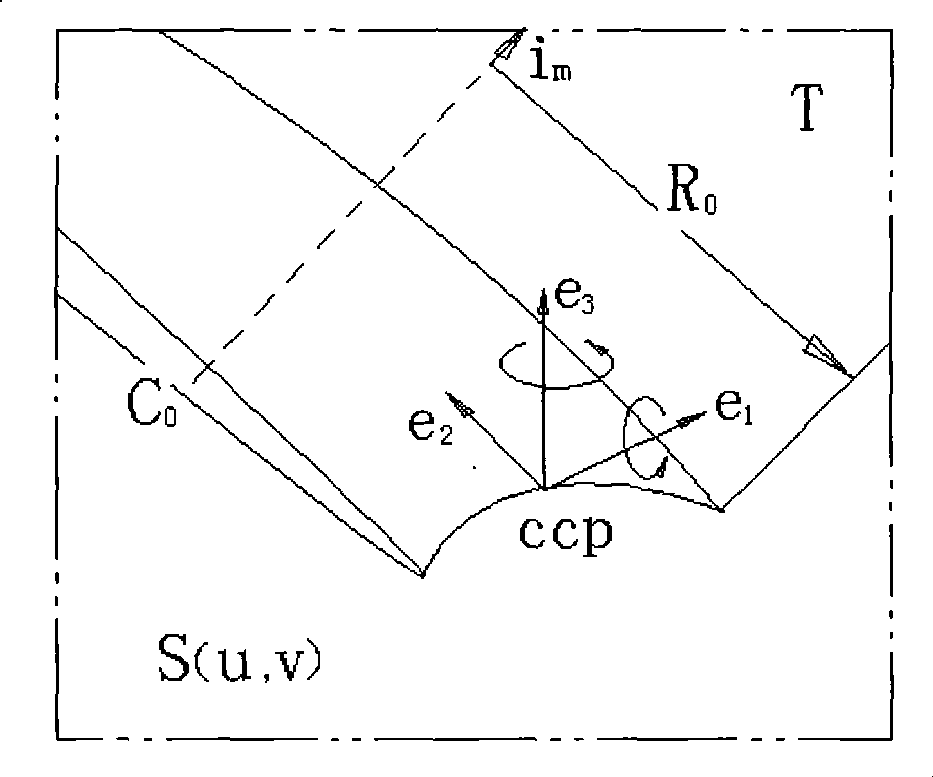

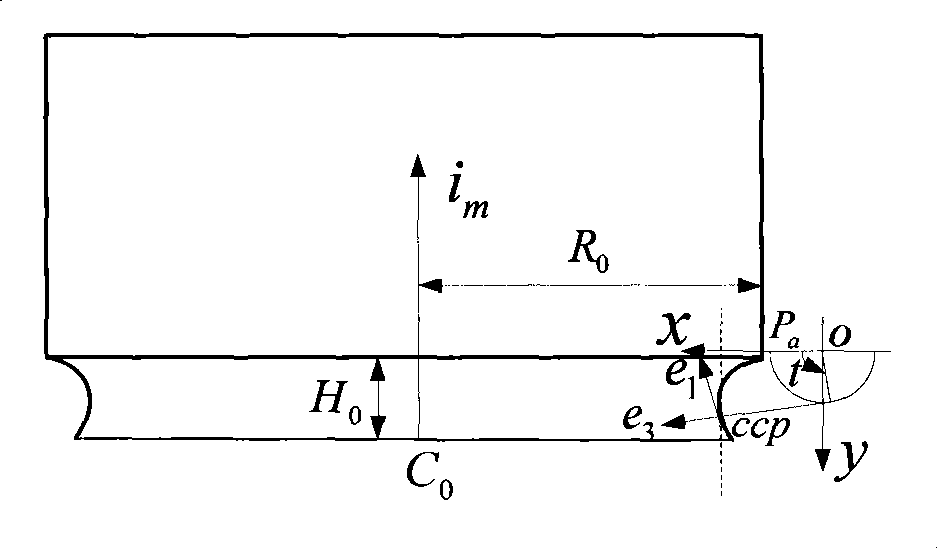

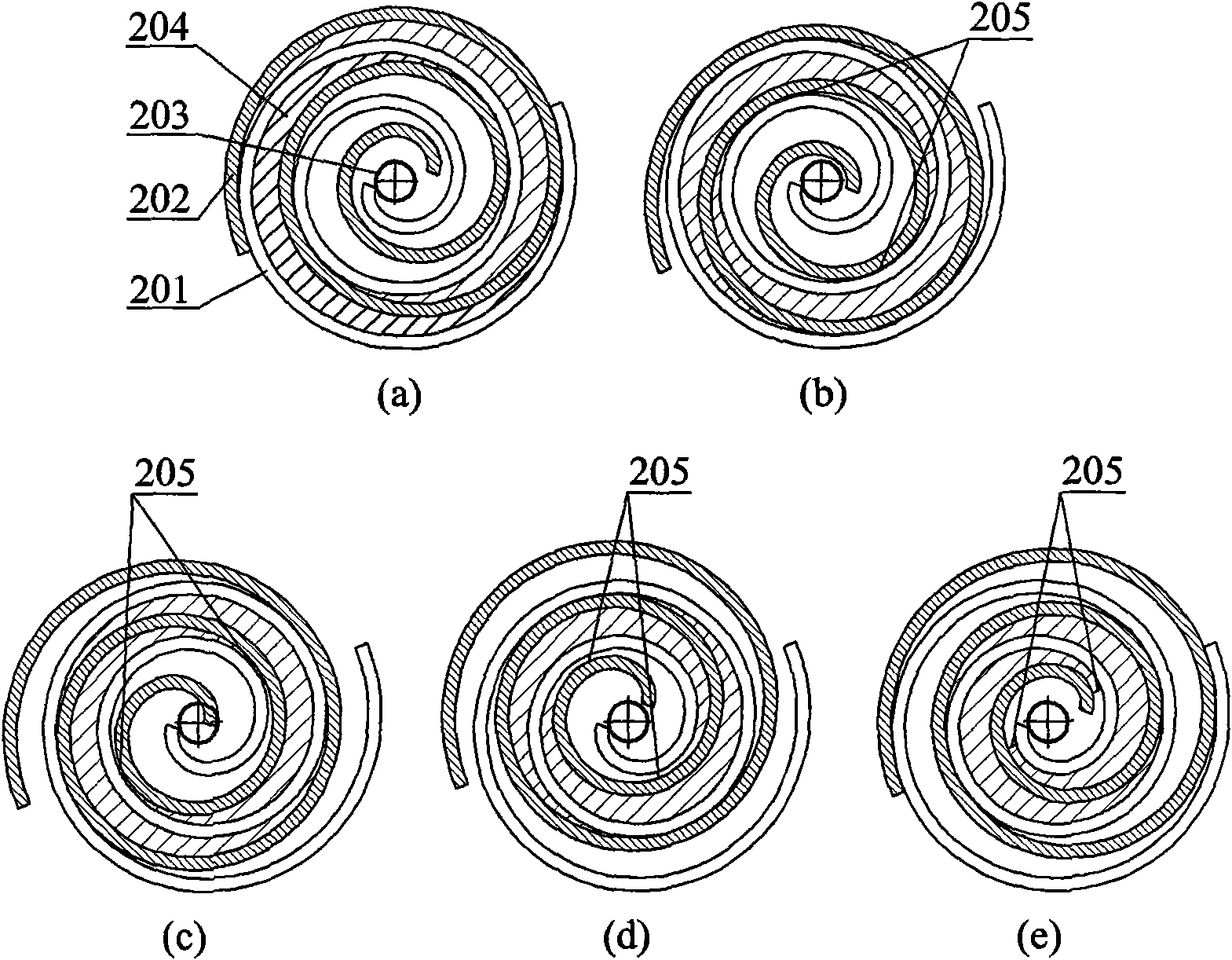

Scroll wrap profile of liquid-injected scroll compressor

InactiveCN103047135AStrong enoughExtended service lifeRotary piston pumpsRotary piston liquid enginesInvoluteEngineering

The invention relates to a scroll wrap profile of a liquid-injected scroll compressor. Outer profiles of a static scroll wrap and a dynamic scroll wrap are composed of a section of a variable diameter base circle involute, and the inner profiles of the static scroll wrap and the dynamic scroll wrap are composed by smoothly connecting a variable diameter base circle involute at a center part and normal equidistant curves of the variable diameter base circle involute of the outer ring. The scroll wrap refers to a scroll wrap with compression chamber variational meshing clearance and the wall thickness of the scroll wrap changing gradually. The meshing part close to a central air outlet of the compression chamber is provided with the meshing clearance which forms a pressure unloading channel to the air outlet with small clearance internal leakage, so that the problems of surge pressure in the compression chamber or liquid impacting which are produced by incompressible liquid with relatively large spraying volume. The meshing point of a suction cavity formed by the scroll wrap has no meshing clearance, so that the suction cavity is completely isolated from the compression chamber; at the same time, the wall thickness of the scroll wrap changes thinner gradually from the center to the outer ring, so that the central part of the scroll wrap has enough strength; and the wall thickness at the outer ring of the scroll wrap is relatively thin, so that area utilization rate of a scroll plate is effectively increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

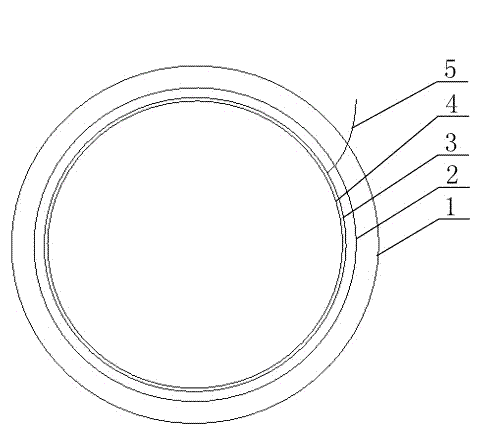

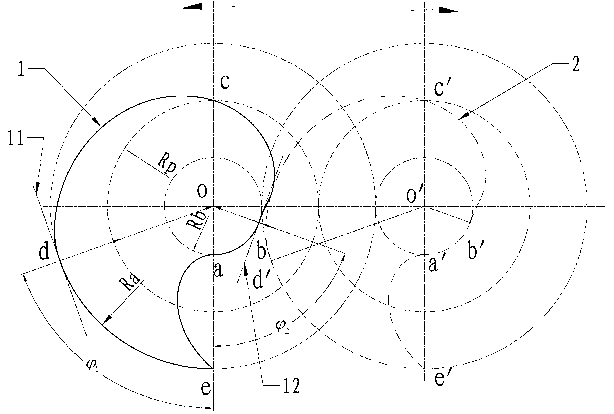

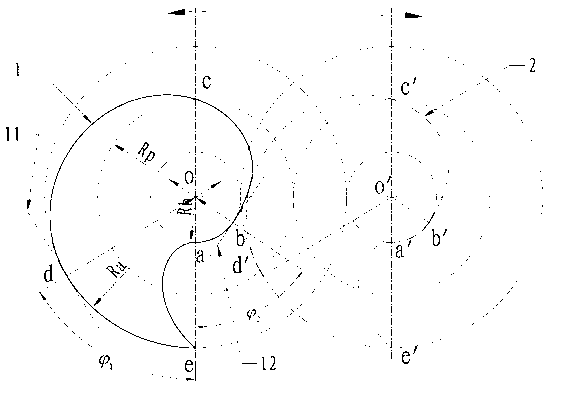

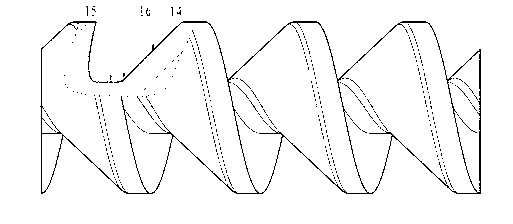

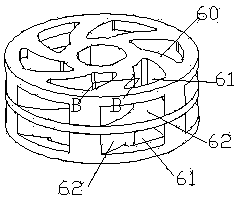

Novel tooth-shaped screw type wire

ActiveCN103195716AAvoid formingImprove dynamic performanceRotary piston pumpsRotary piston liquid enginesManufacturing cost reductionChemical industry

The invention discloses a novel tooth-shaped screw type wire, which belongs to the technical field of dry type screw vacuum pumps. The screw type wire disclosed by the invention comprises 5 curve segments, including a dedendum arc ab, a deformed involute bc, an envelop curve cd of a deformed involute b'c', an addendum arc de and a long cycloid ea, wherein the dedendum arc ab and the deformed involute bc are in smooth transition, and the envelop curve cd and the addendum arc are in smooth transition. According to the screw type wire disclosed by the invention, the deformed involutes and the envelop curve are taken as transition curves between the dedendum arc and the addendum arc, so that the dedendum arc and the addendum arc are in smooth connection with the transition curves to prevent a leakage zone and a stagnation zone and to form tight sealing, and the change of a formed end face prompts the improvement of dynamic performance; and simultaneously, the dedendum and the tooth profile part of a rotor are in smooth connection by virtue of the transition curves, and thus manufacturing costs are effectively reduced. The dry type screw vacuum pump provided by the invention can be widely applied to the fields of electronics, semiconductors, chemical industry, food, aerospace and the like.

Owner:ZHEJIANG MOTEC SCREW VACUUM PUMP

Positive lubrication of a meshing gear

A device and method for the lubrication of teeth in a meshing gear. A plurality of teeth are formed about a periphery of a toothed wheel. Each tooth is defined by a root portion, an involute profile portion, and a minimal stress portion. The device and method includes the formation of a plurality of fluidic passages, each including an inlet and an outlet, in fluidic communication with a lubricant and the minimal stress portion of at least one of the plurality of teeth. During operation, the lubricant contained flows via centrifugal force to the minimal stress portion of each of the plurality of teeth via the fluidic passages. The fabrication of the outlet of the fluidic passages at a minimal stress portion of at least one of the plurality of teeth eliminates any further stress fabrication on the portion of the tooth structure that is under stress during operation.

Owner:HONEYWELL INT INC

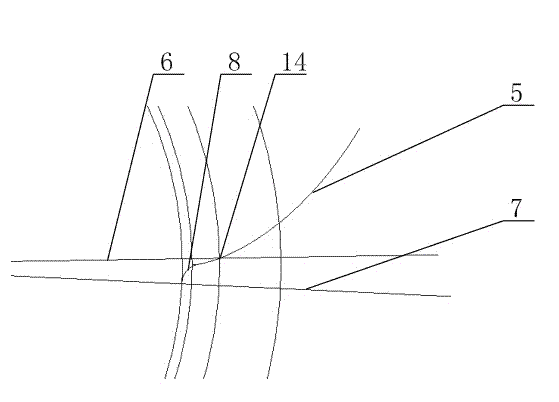

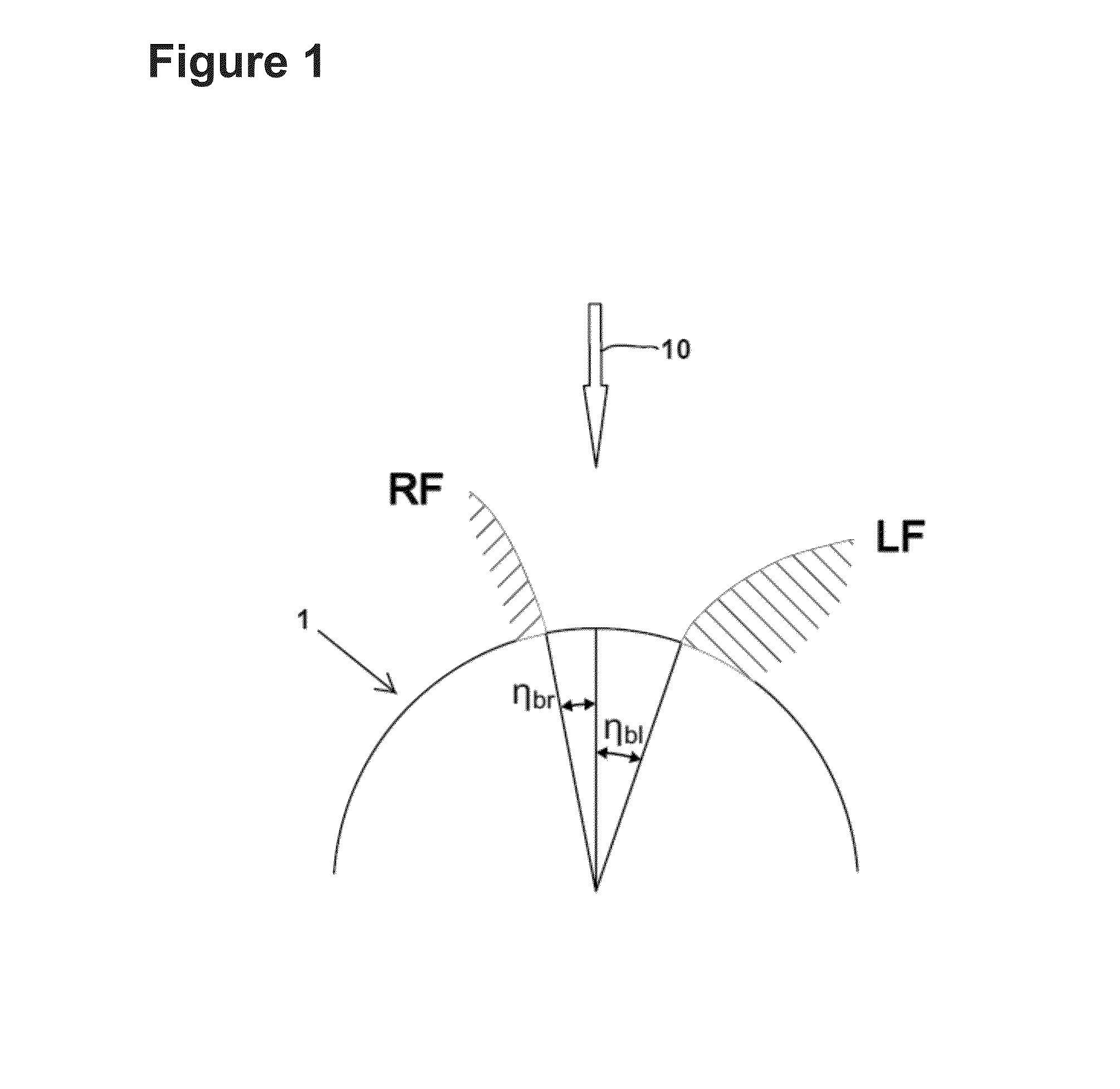

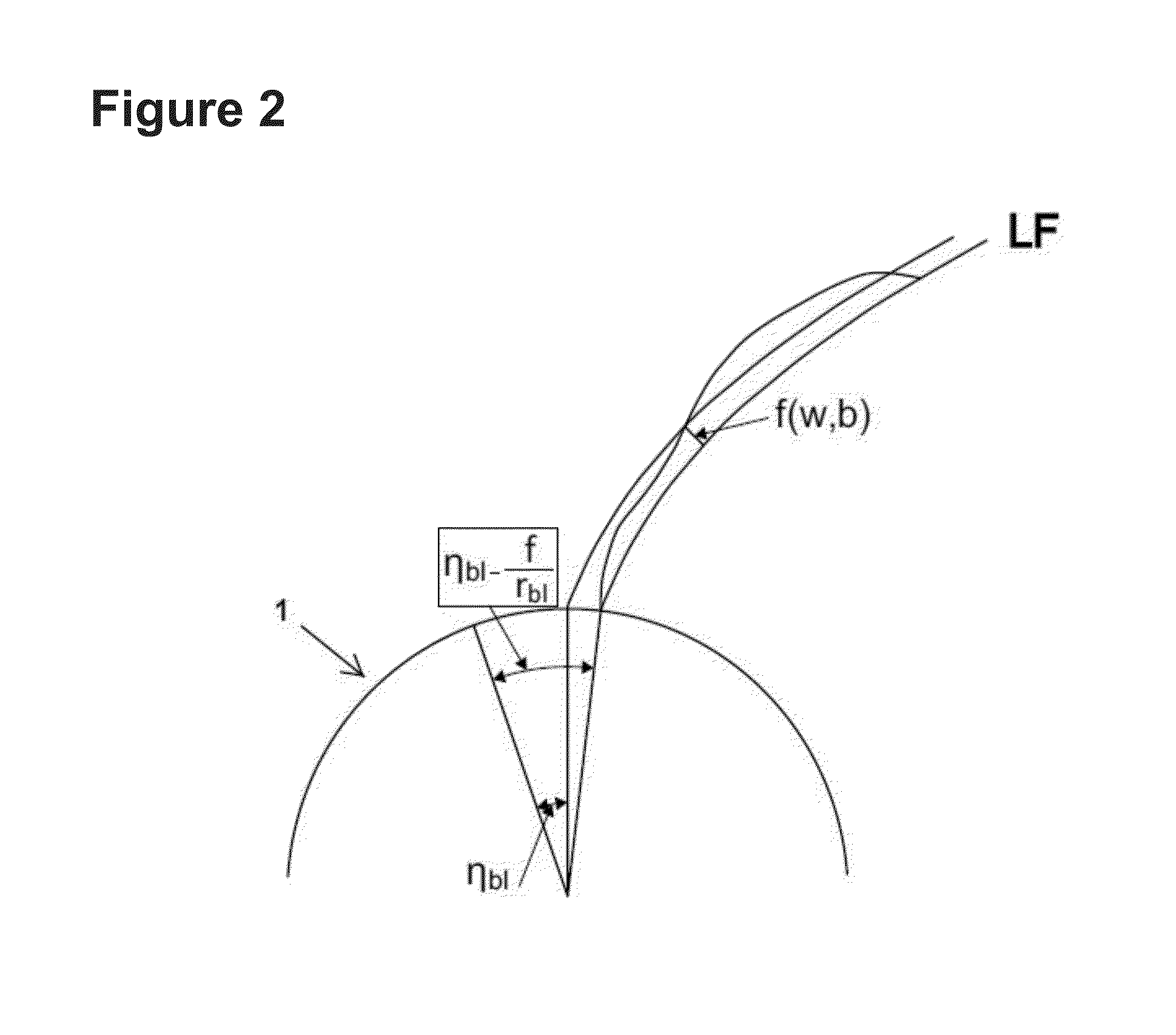

Method for the location determination of the involutes in gears

ActiveUS20150338201A1Angles/taper measurementsMeasurement/indication equipmentsInvoluteRelative motion

A method for the location determination of the involutes of a pre-gear cut workpiece within a gear-cutting machine using a gear-cut tool comprising the method steps: generating first and second relative movements between the workpiece and the tool; detecting respective, resulting first and second contact between a first tooth flank of the tool and a first tooth flank of the workpiece; and detecting a respective first and second set of coordinates for representing the relative movement of the workpiece and the tool; and determining the angles of rotation, the feeds, the axial distance and the crossed-axes angle of the tool and the workpiece based on the first and second set of coordinates and subsequent calculation of the location of the involutes on the basis of the angles of rotation, the feeds, the axial distance and the crossed-axes angle.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

Power transmission chain and power transmission assembly using the same

An object of the invention is to provide a power transmission chain capable of effectively reducing noises and a power transmission assembly using the same. In the power transmission chain including plural links each possessing through-holes and plural pins inserted through the through-holes for interconnecting the plural links, all the plural pins substantially have the same longitudinal length while the plural pins include plural types of pins which have mutually different rigidities against force acting in the pin longitudinal direction. Furthermore, a locus of contact position between the pin and a strip is defined by an involute of a circle. The pins and strips are combined to form two or more types of pairs which provide the involutes of base circles having different radii.

Owner:JTEKT CORP

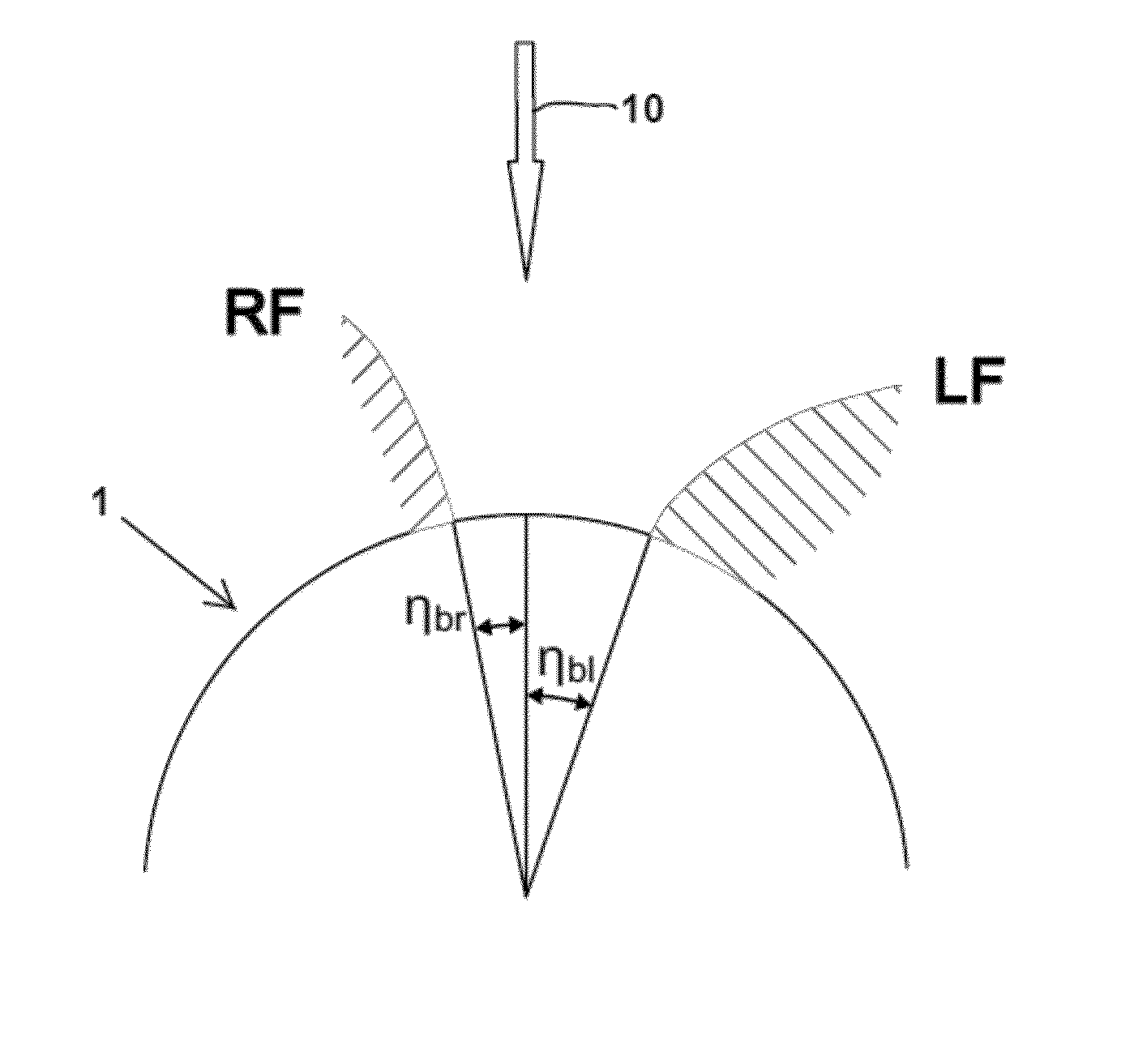

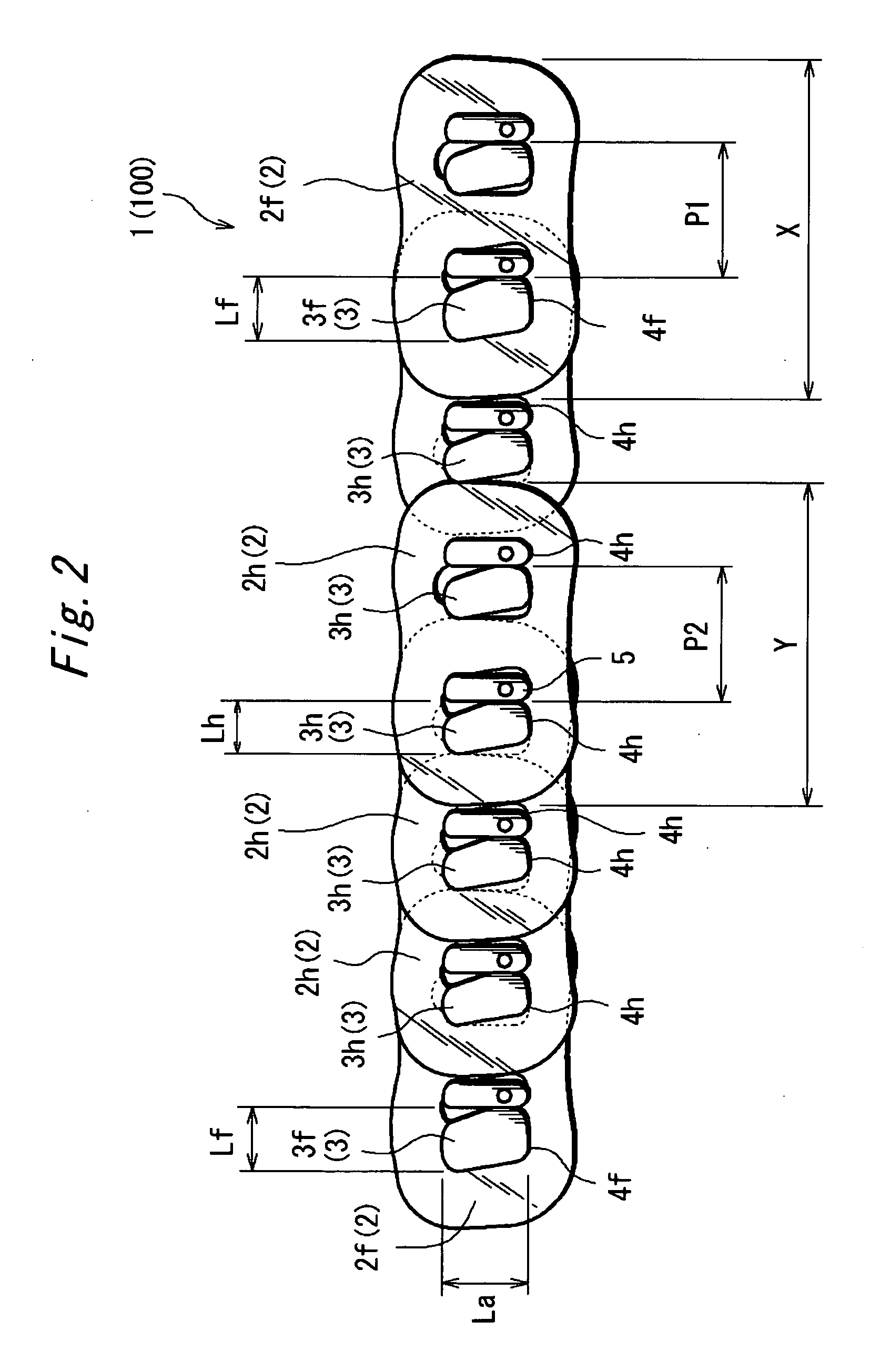

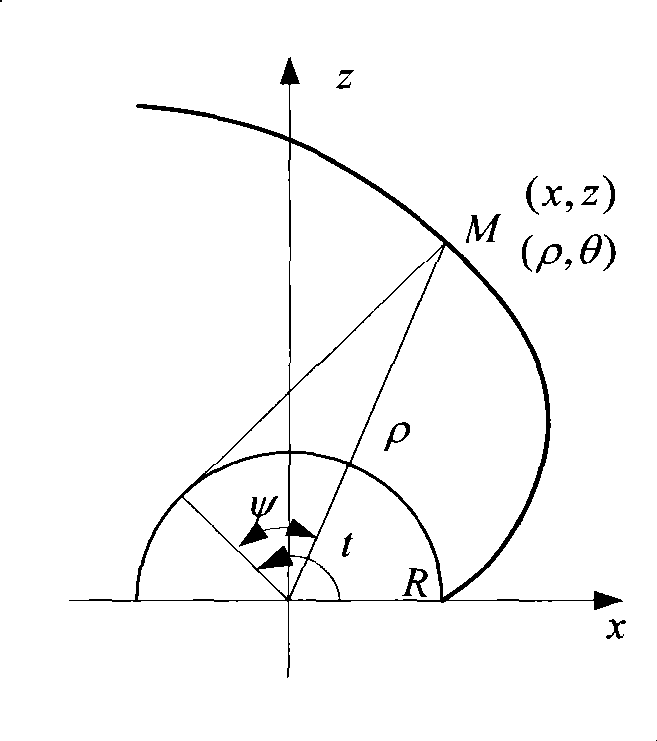

Modeling method for compound parabolic concentrator for linear Fresnel light condensing and heat collecting system on basis of matlab

ActiveCN103810352AAccurate calculation of convergence rateSimple modeling methodSpecial data processing applicationsModel methodInvolute

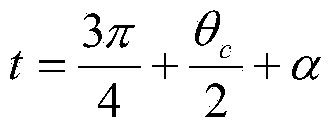

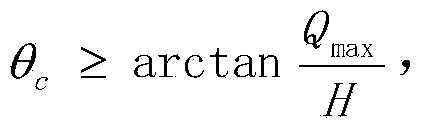

The invention relates to a modeling method for a compound parabolic concentrator (CPC) for a linear Fresnel light condensing and heat collecting system on the basis of matlab. The modeling method comprises the following steps: 1, determining the maximum receiving half angle theta c of the CPC; 2, using an outer diameter circle of a metal inner pipe of a vacuum heat collecting tube as a base circle of an involute; 3, rotating the involute by an angle alpha by using a circle center O as the center, so that a point C on the involute, which meets the condition that t=t0, is positioned on a center shaft of the CPC and the distance between the point C and the metal inner tube of the heat collecting tube is the sum of the distance between the point and a glass outer tube of the heat collecting tube and the distance between the glass outer tube and the metal inner tube of the heat collecting tube; 4, using a point on the involute, which meets the condition (refer to the specification), as a junction point of an involute CFB and a parabola A; 5, rotating the parabola by an angle theta c around the vertex of the parabola to enable the parabola to pass through a left junction point FB and using a right junction point FA as a focus to obtain a parabolic equation; 6, carrying out simulating calculation on a relation of a convergence rate and an intercepting ratio of the CPC by utilizing a ray tracing method, and selecting the suitable intercepting ratio.

Owner:兰州大成科技股份有限公司 +2

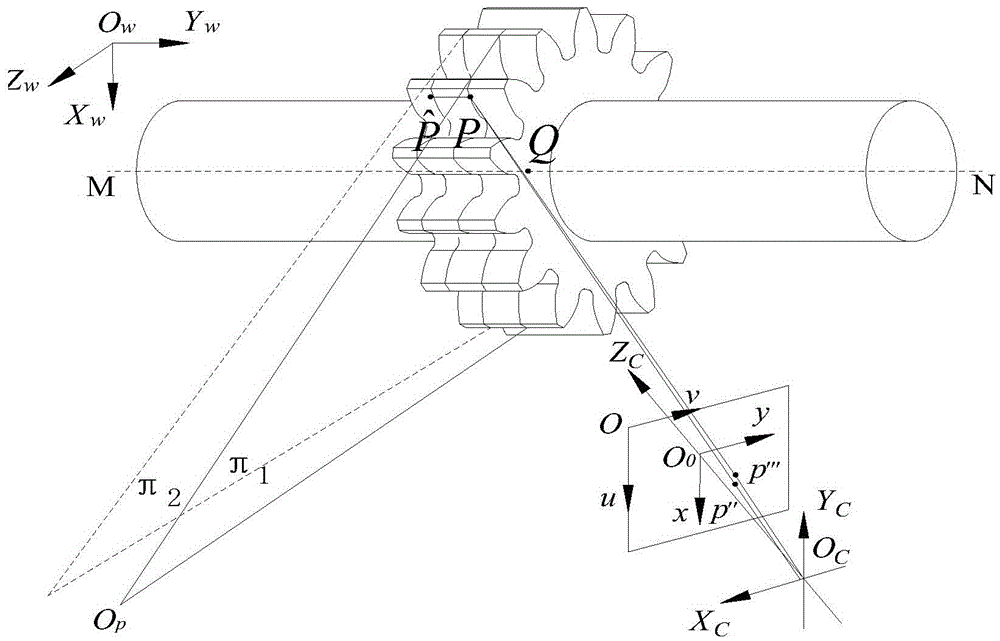

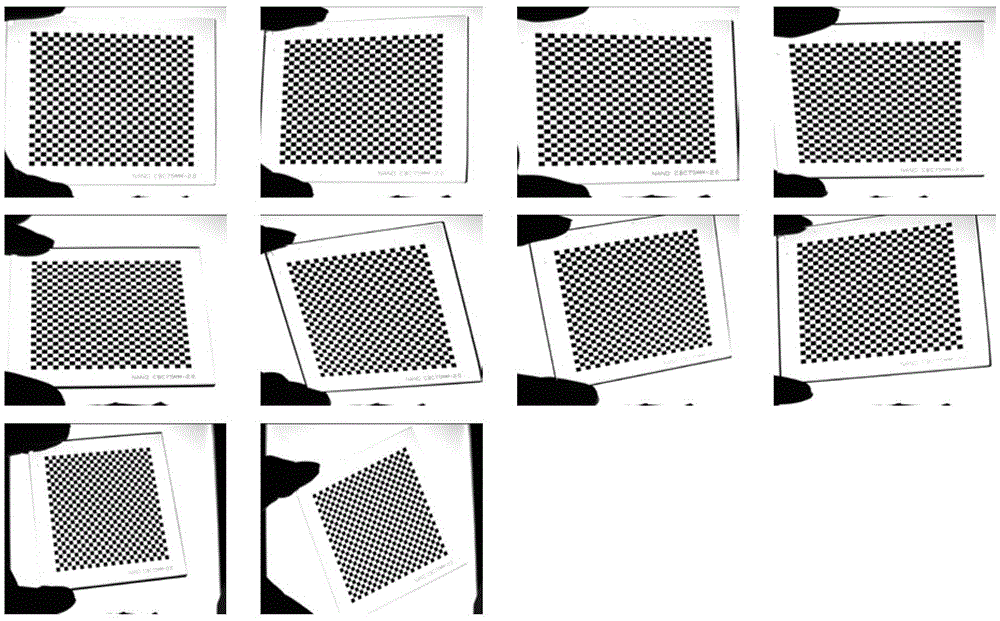

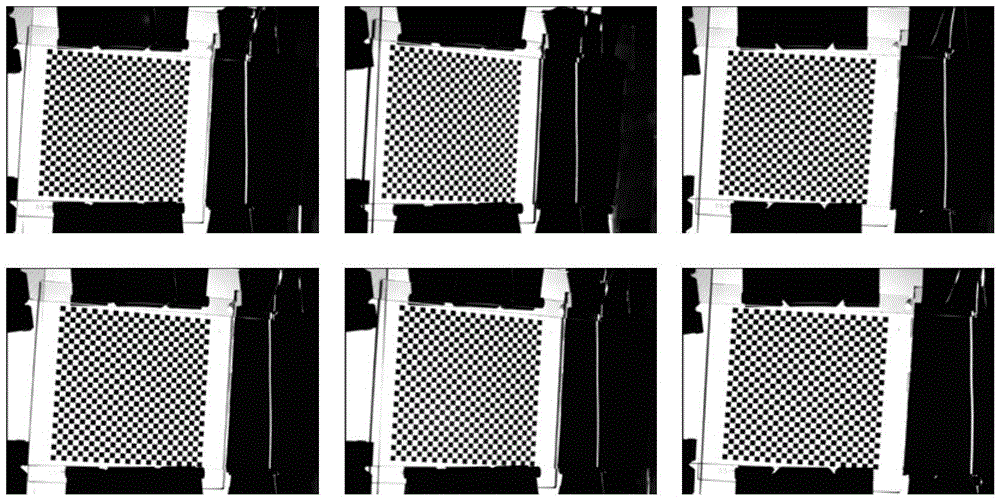

Tooth error vision measurement method for involute of straight toothed spur gear

InactiveCN105571523ASimple calculationRelaxed placement requirementsUsing optical meansInvolutePlane equation

The invention relates to a tooth error vision measurement method for the involute of a straight toothed spur gear. According to the method, an involute tooth error measurement model is established based on a linear laser vision imaging system. In combination with the light stripe centric line detection technique, the corner point detection technique, the camera calibration technique and the like, the measurement of a to-be-measured object is realized. The method comprises the steps of 1) calibrating a vision imaging model under the effect of laser active illumination; 2) calibrating the parameters of a pseudo light plane equation; 3) calculating the three-dimensional coordinates of a to-be-measured point on the surface of a tooth profile; 4) calculating the tooth error for the involute of the surface of the tooth profile. According to the method, based on the vision measurement technique, the online non-contact detection is implemented. Meanwhile, based on the precise laser active illumination technique, the high measurement accuracy is ensured. The measurement accuracy of the method for gears of IT 6-8 level in accuracy is smaller than or equal to 0.015 mm.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Single-parameter variable-camber barrel-type knife tool as well as posture confirming method and use thereof

InactiveCN101412123AEfficient processingImprove machining accuracyAutomatic control devicesMilling cuttersAlgorithmCurve shape

The invention discloses a one-parameter variable camber drum-shaped cutter, a method for determining the pose thereof, and application thereof. The variable camber bus bar of the cutter comprises curves such as involute of circle, ellipse line, hyperbola, parabola, logarithmic curve. The equation of the variable camber bus bar can be selected properly according to the property of the curved surface to be processed. If the involute is used as the bus bar of the cutter, because the only parameter determining the shape of the curve is the radius of a base circle, the involute is called as a one-parameter variable camber bus bar; contact points with the same curvature on the cutter can be determined according to the curvature of the curved surface to be processed; and through the position of the only determined contact point of the curve on the cutter by the equation, the pose of the cutter can be optimized by taking the largest processing line width as an objective function. The cutter has high processing precision and high processing efficiency, and can achieve the highly-efficient processing to the edge part of a blade.

Owner:BEIHANG UNIV

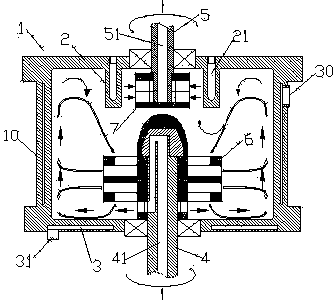

Scroll gas-liquid multiphase mixing transmission pump

InactiveCN101603530ABroaden the range of gas-liquid ratioNo reduction in volumetric efficiencyRotary piston pumpsRotary piston liquid enginesLiquid mediumInvolute

The invention discloses a scroll gas-liquid multiphase mixing transmission pump composed of a movable scroll pan, a fixed scroll pan, a frame body, a crankshaft, and a small crank anti-rotation mechanism; the movable scroll pan and the fixed scroll pan with the same shaped wires relatively rotate 90 degrees, and are offset for certain distance, and then the movable scroll pan and the fixed scroll pan are inserted into each other to form a plurality of working cavities; under the driving of the crankshaft, the movable scroll pan realizes revolution and translation with the fixed scroll pan under the constraint of the anti-rotation mechanism of the small crank so as to form the working cavity volume with cyclic variation, and the absorption, compression and discharging of gas-liquid medium are realized. The movable scroll pan and the fixed scroll pan are both provided with a section of variable back lash scroll wrap composed of reducing base circle involute; during working, back lash exists, so that a pressure relief path exists in the discharging port direction from a compression cavity; in the pressurizing process, a small quantity of gas-liquid medium generates internal leakage via the path from the compression cavity to the discharging port so as to realize random unloading for liquid phase compression, which solves the problems that pressure surge and liquid impact are easy to appear during pressurizing mixing transmission gas-liquid medium when liquid holdup is higher.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

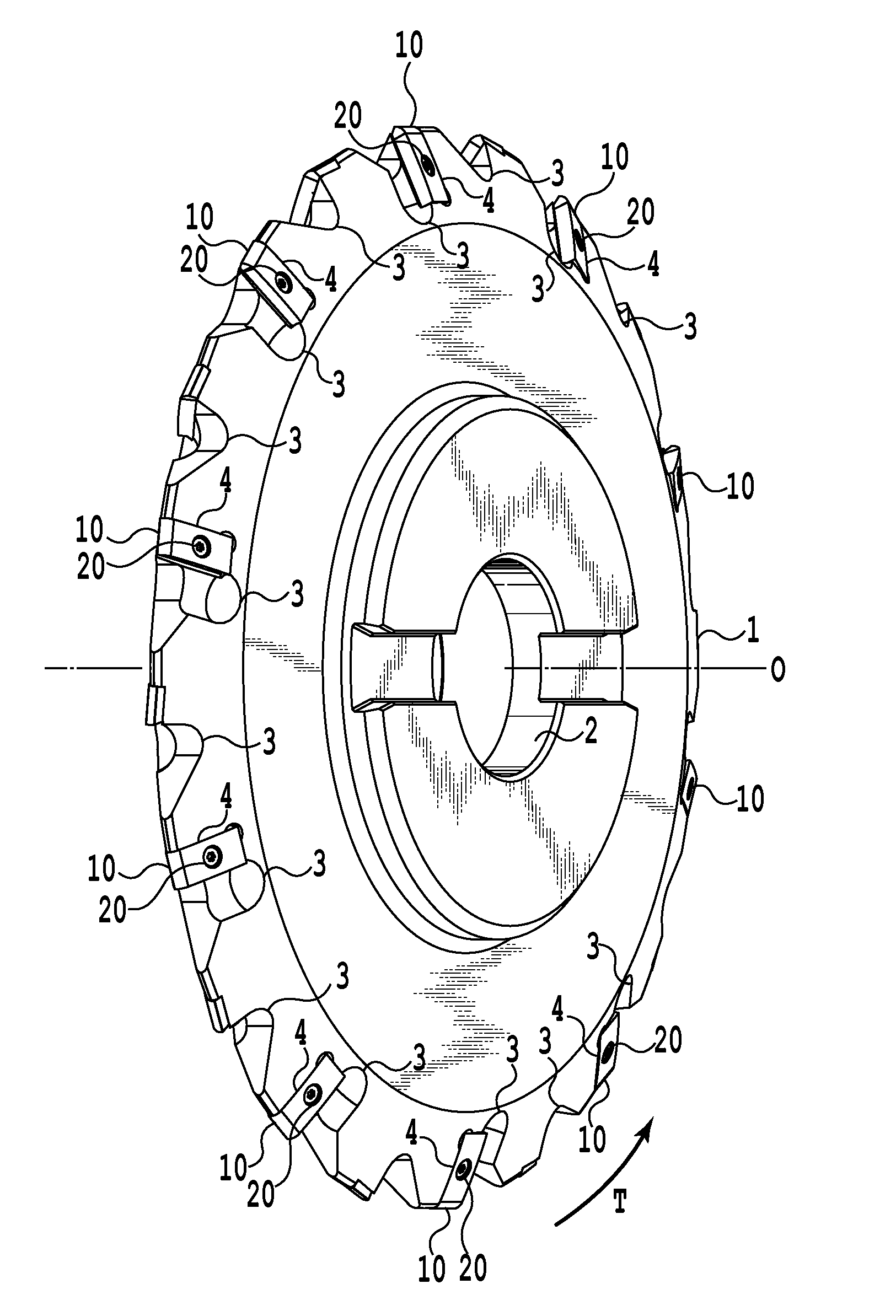

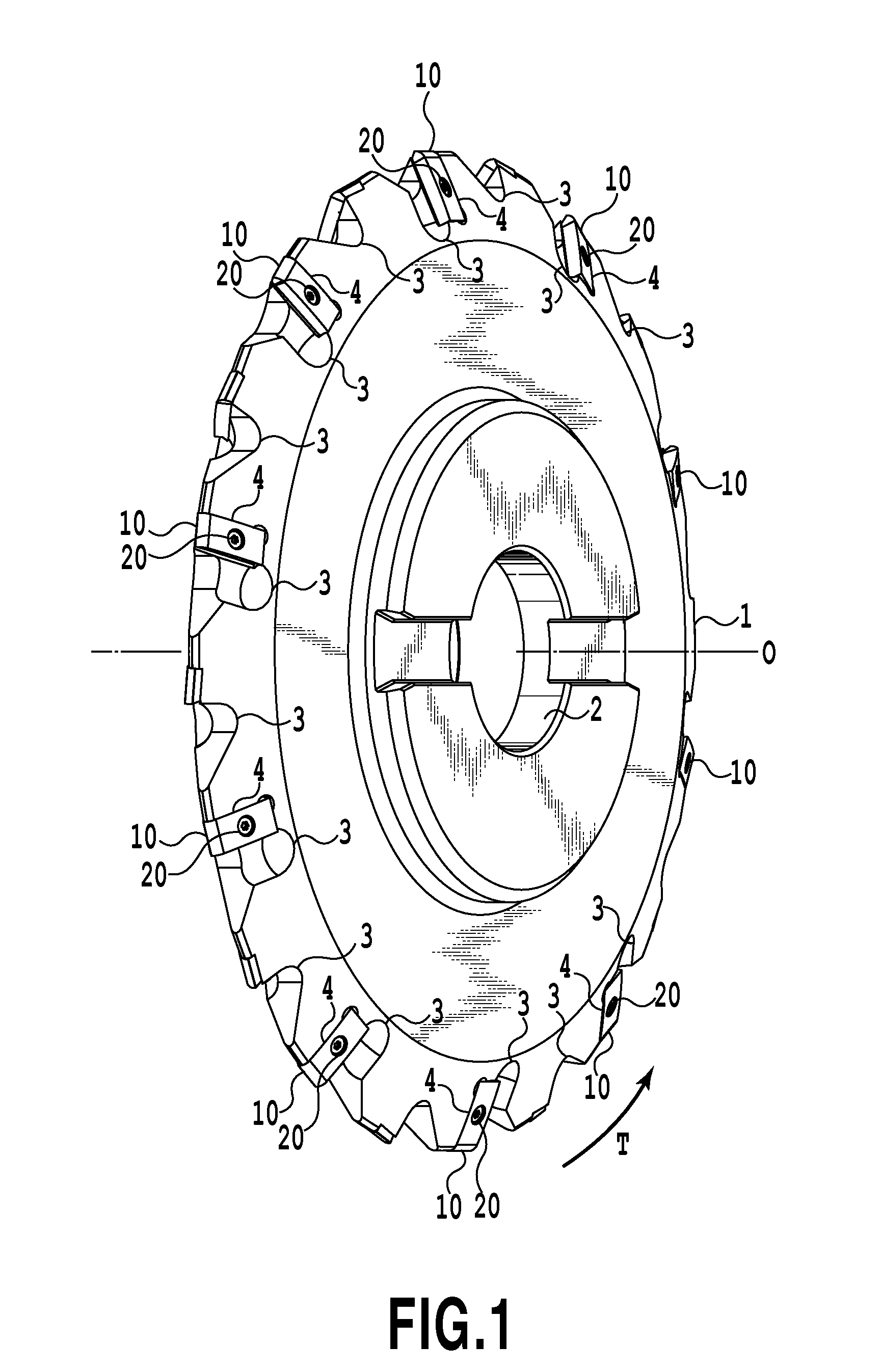

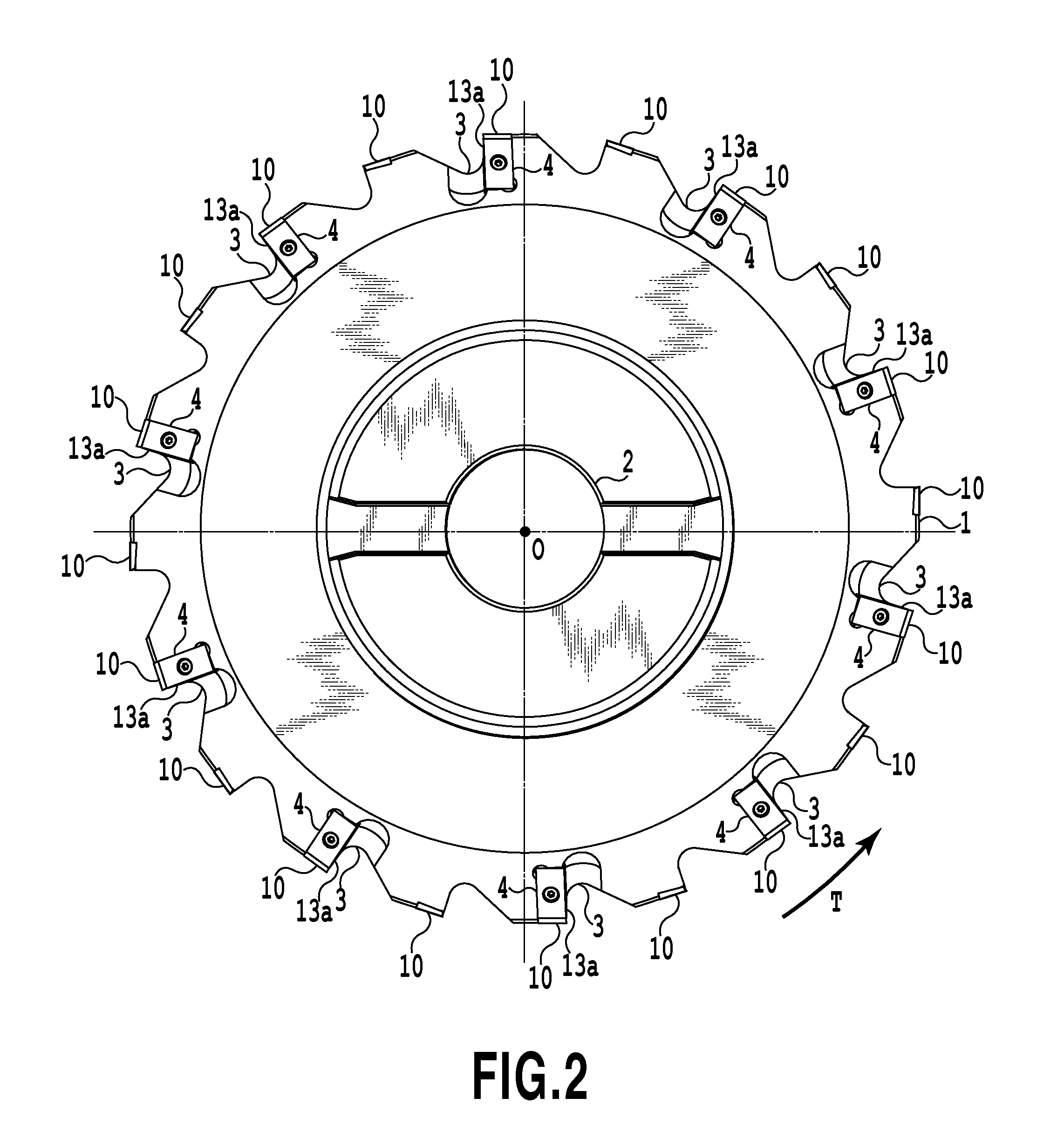

Cutting Insert and Indexable Tooth Cutting Tool Using the Same

A cutting insert is removably mountable on an insert seat formed in a peripheral of a tool body rotated around an axis O and of substantial disc shape. The cutting insert includes a substantially planar insert body of a substantially square shape in plan view, a flank at an upper face of the body, a rake face at a side of the body intersecting with the flank, and a cutting edge at an intersection ridge between the rake face and the flank. The cutting edge is a substantial involute in side view of the body, the rake face is inclined to an inside of the body from an upper toward a lower face, and at least a front end arranged in a peripheral of the tool body is concave constituting a part of a substantially conical side face.

Owner:TUNGALOY CORP

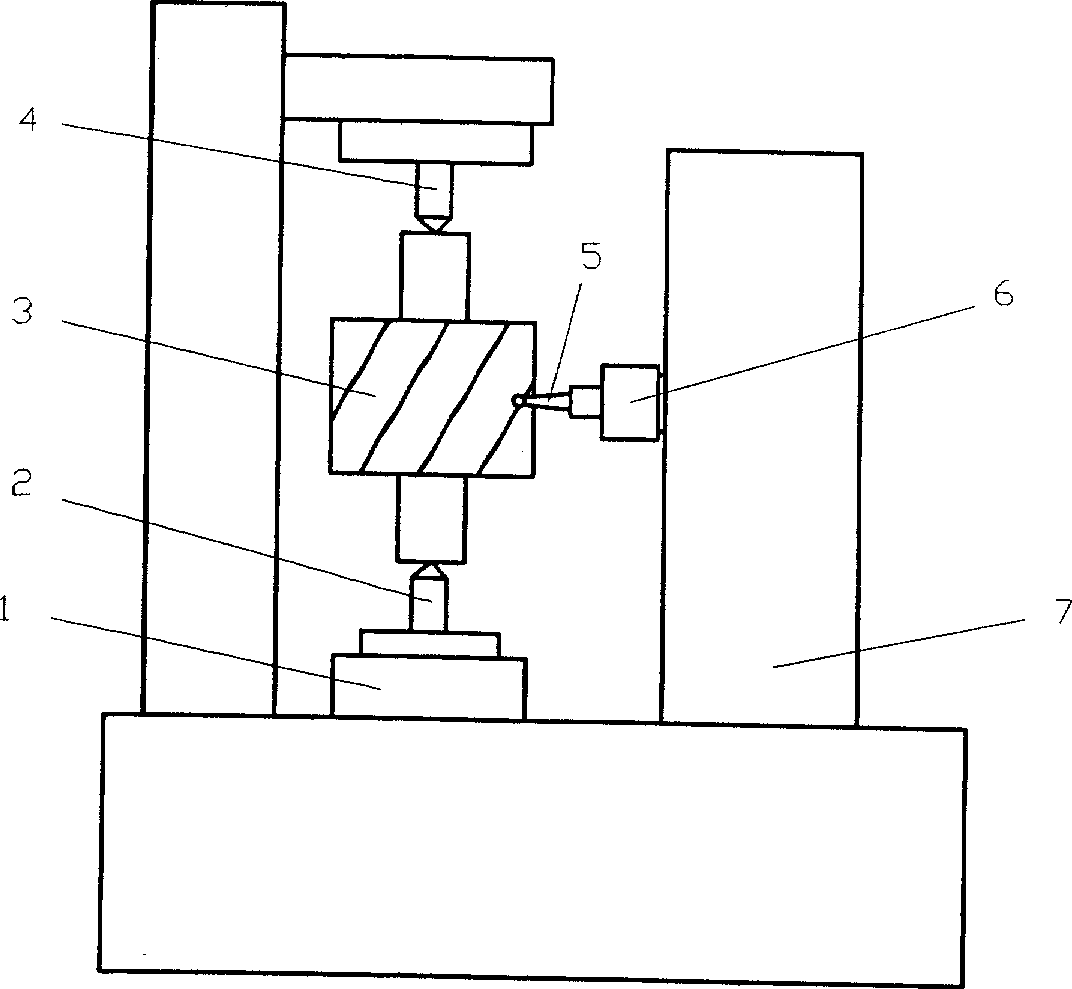

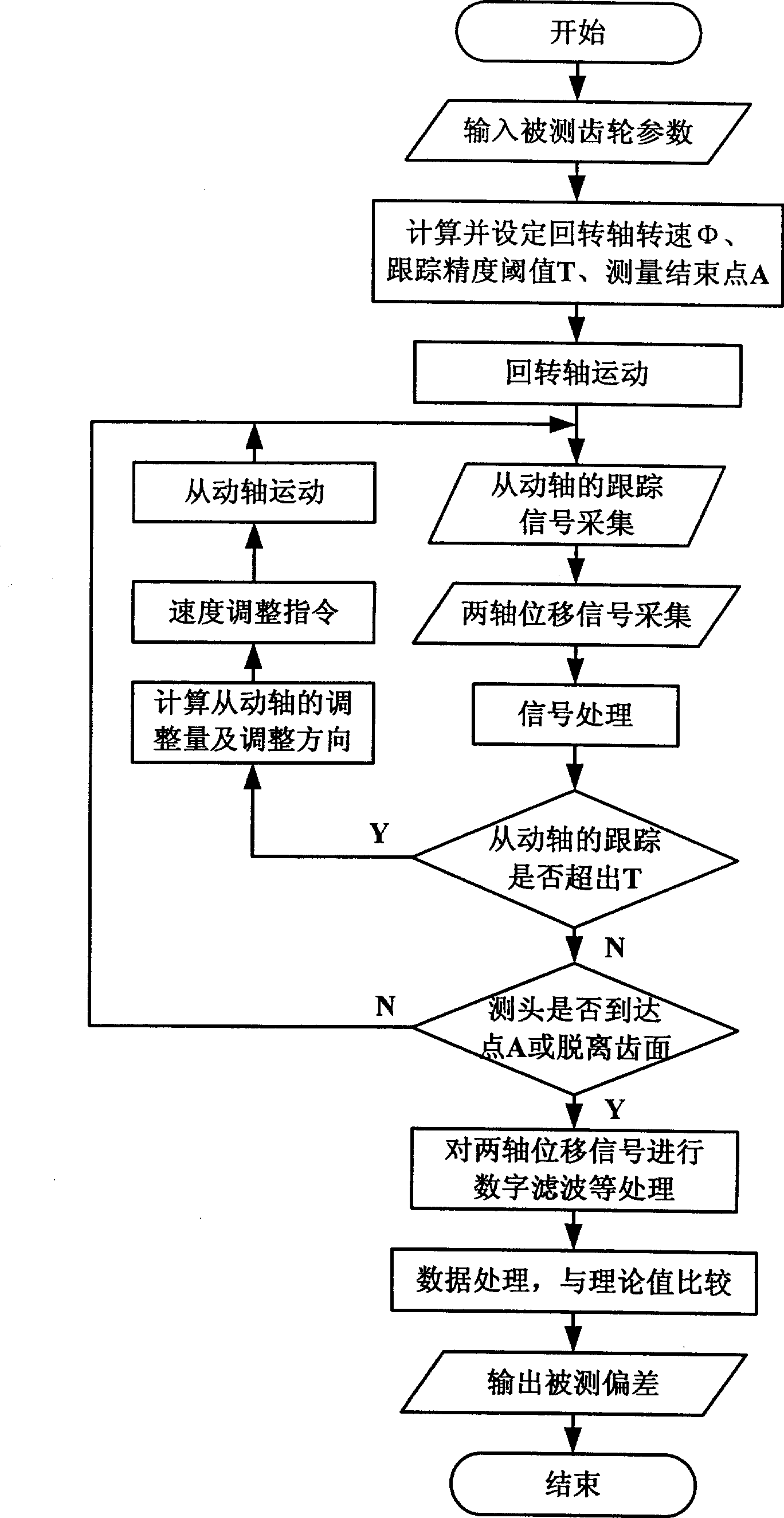

Method for detecting gear tooth profile and spiral line by diaxon servocontrol

InactiveCN101419066AIncrease varietyReduce mechanical structureMeasurement devicesCircular discInvolute

The invention discloses a two-axis follow-up control method for detecting gear tooth profiles and helices. The method acquires relative displacement signals of a measured curve and a gauge head in real time through a displacement sensor, so as to control the motion of a driven shaft; meanwhile, a angular displacement sensor and a linear displacement sensor acquire the displacement signals of two axes respectively, and then the measured curve can be drawn; and the measured curve is compared with a theoretical curve in a computer, so as to obtain the deviation of the measured curve. In the measurement method, the displacement sensor follows the measured curve to move, so as to ensure that the deviation range of the detectable measured curve is no longer constrained by the range of the displacement sensor, and expand measurement range. The measurement method can detect various types of continuous curves on gears, including circular arc profiles, involutes, helices and the like, increases the species of detectable curves, and expands application fields. In the measurement method, the two axes do not need to simulate the precise theoretical curve, thereby leaving out not only base circle plates and other mechanical structures in a mechanical generation method but also motion control cards and other components in an electronic generation method, and simplifying circuit design.

Owner:CHINA JILIANG UNIV

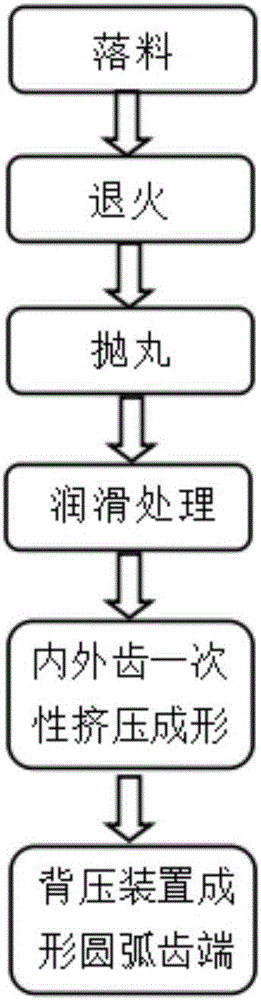

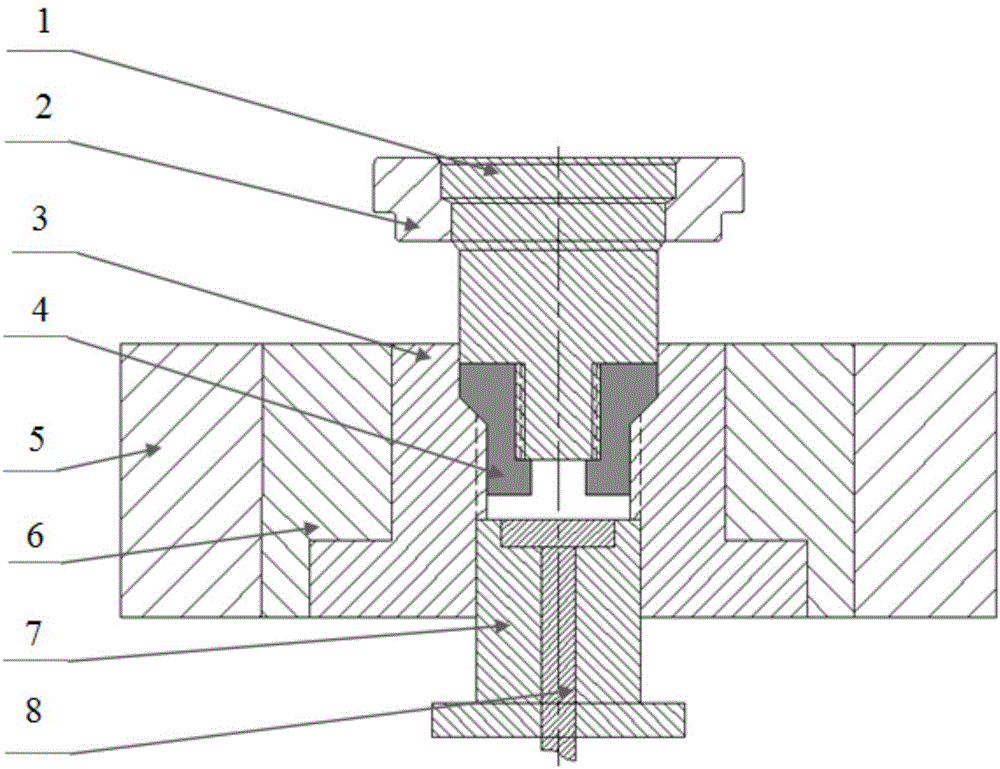

Cold extruding forming method used for automotive spline sleeve part

InactiveCN105880304AIncrease profitImprove mechanical propertiesExtrusion diesExtrusion control devicesInvoluteMechanical property

The invention relates to a cold extruding forming method used for an automotive spline sleeve part. The spline sleeve is in an axisymmetrical cylinder shape. Axial involute spline tooth are formed in the inner surface of the body of a cylinder and the outer surface of the body of the cylinder. The end surfaces of outer spline tooth are in an arc shape. The method comprises the following steps: (1) preparing billets of the spline sleeve part; (2) annealing the billets to soften the billets; (3) conducting slot blasting treatment of the annealed billets to remove burrs and scale; (4) conducting lubricating treatment of the billets which is subjected to the slot blasting treatment; (5) conducting extruding and forming treatment of the billets which is treated by step (4) to make inner spline tooth and the outer spline tooth be extruded and formed all at once; (6) forming the arc-shaped end surfaces of the outer spline tooth by using a back pressure device. Compared with the prior art, the spline sleeve part produced by utilizing the cold extruding forming method has the advantages that the mechanical property is good, the material utilization rate is high, the defect that tooth-shaped die cavity can not be fully filled can be avoided and the production process flow is short.

Owner:SHANGHAI UNIV OF ENG SCI +1

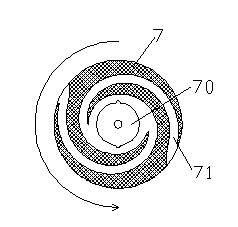

Stirring type grinding separator and grinding device

ActiveCN103657801AImprove discharge efficiencySpeed up dischargeGrain treatmentsElectric machineryInvolute

The invention relates to the technical field of grinding, and discloses a grinding separator. The grinding separator comprises a cylindrical separation wheel, wherein a cavity is formed in the separation wheel; and a separation groove in a spiral involute shape is formed in the wall of the cavity, one end of the separation groove is communicated with the outer side of the separation wheel, and the other end is communicated with a separation port in the separation wheel. During operation, the separator rotates at a high speed under the driving of a motor, when materials are separated and enter the separator, the materials separated from separation barrels move towards the separation port along the separation groove in the spiral involute shape under the action of centrifugal force of the separator, and the materials are vertically distributed from small to large in the cavity of the separator. Materials with smaller grains are distributed on the upper layer, so that larger gains and smaller grains of materials in the separator cannot gather at the separation port simultaneously, material discharge efficiency and speed are increased, and the technical effect of improvement of grinding efficiency is realized.

Owner:BOYEE SHENZHEN IND TECH CO LTD

Gear drive

InactiveUS8061229B2Increase structural flexibility and contact tightnessQuality improvementPortable liftingGearing elementsGear driveGear wheel

The inventive gear drive comprises toothed wheels with teeth of toothed crowns interacting with single- or multi-flow elements. Working profiles of the interacting teeth comprise piecewise and / or pointwise conjugate, convex at a tooth point and concave at a tooth root arc-shaped sections continuously connectable to each other or to involute sections. The interacting toothed crowns are so embodied that a phase gap of the face tooth intermating at a discrete angle from a point, where the interaction of profiles ends at a point, where the interaction of the face profiles of the next tooth pair starts. The drive is so embodied that the face tooth overlap ratio thereof is less than 1. The so improved teeth provide for high level of the contact tightness and absence of axial forces at engagement, increase the structural flexibility of the gear drive teeth in order to improve their qualities.

Owner:NOVIKOV ROMAN VASILYEVICH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com