Tooth error vision measurement method for involute of straight toothed spur gear

A technology of spur gear and tooth profile error is applied in the field of visual measurement of involute tooth profile error of spur gears to achieve the effects of improving measurement accuracy, simplifying calculation process and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

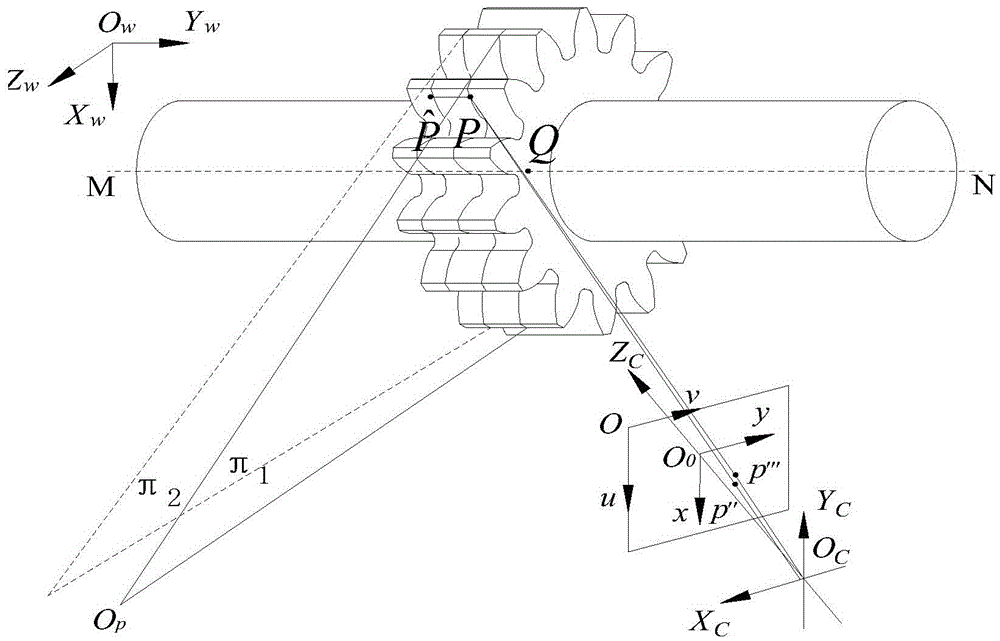

[0045] Invention idea of the present invention is:

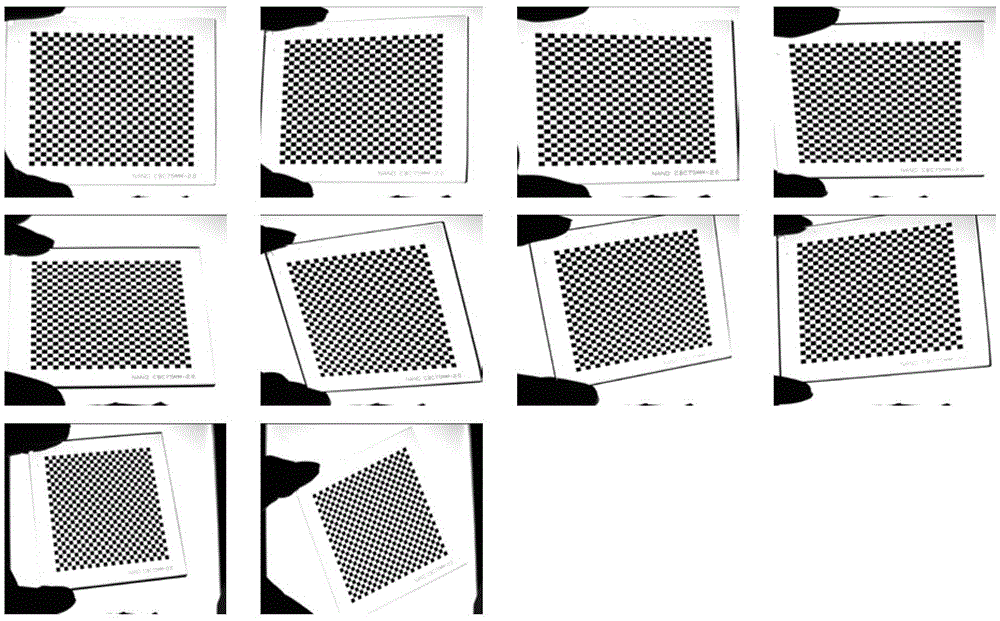

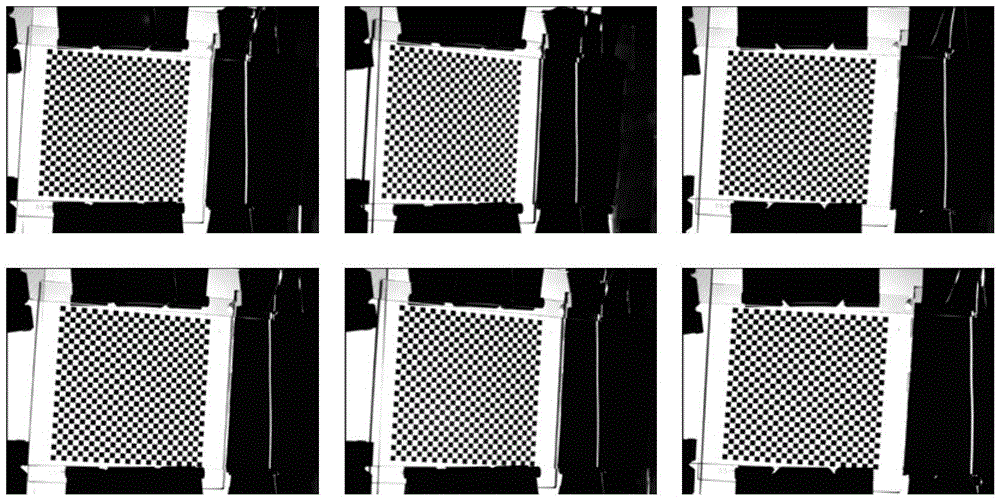

[0046] The invention adopts the principle of visual imaging under active laser lighting, and considers the positional relationship between the CCD camera, the line laser and the measured gear, and comprehensively uses methods such as camera calibration, light strip center line detection and corner point detection to realize measurement. This method uses a CCD camera to detect the position change of the light spot irradiated by the inline laser on the object, and calculates the involute tooth profile error according to the calibration model of the system. In the calibration process, this method takes into account the distortion of the light strip image, which can effectively improve the calibration accuracy. During the measurement process, the measured gear does not require a specific positional relationship with the measurement system, which relaxes the placement requirements of the measurement system and is more conducive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com