Patents

Literature

308 results about "Gear manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gear manufacturing refers to the making of gears. Gears can be manufactured by a variety of processes, including casting, forging, extrusion, powder metallurgy, and blanking. As a general rule, however, machining is applied to achieve the final dimensions, shape and surface finish in the gear. The initial operations that produce a semifinishing part ready for gear machining as referred to as blanking operations; the starting product in gear machining is called a gear blank.

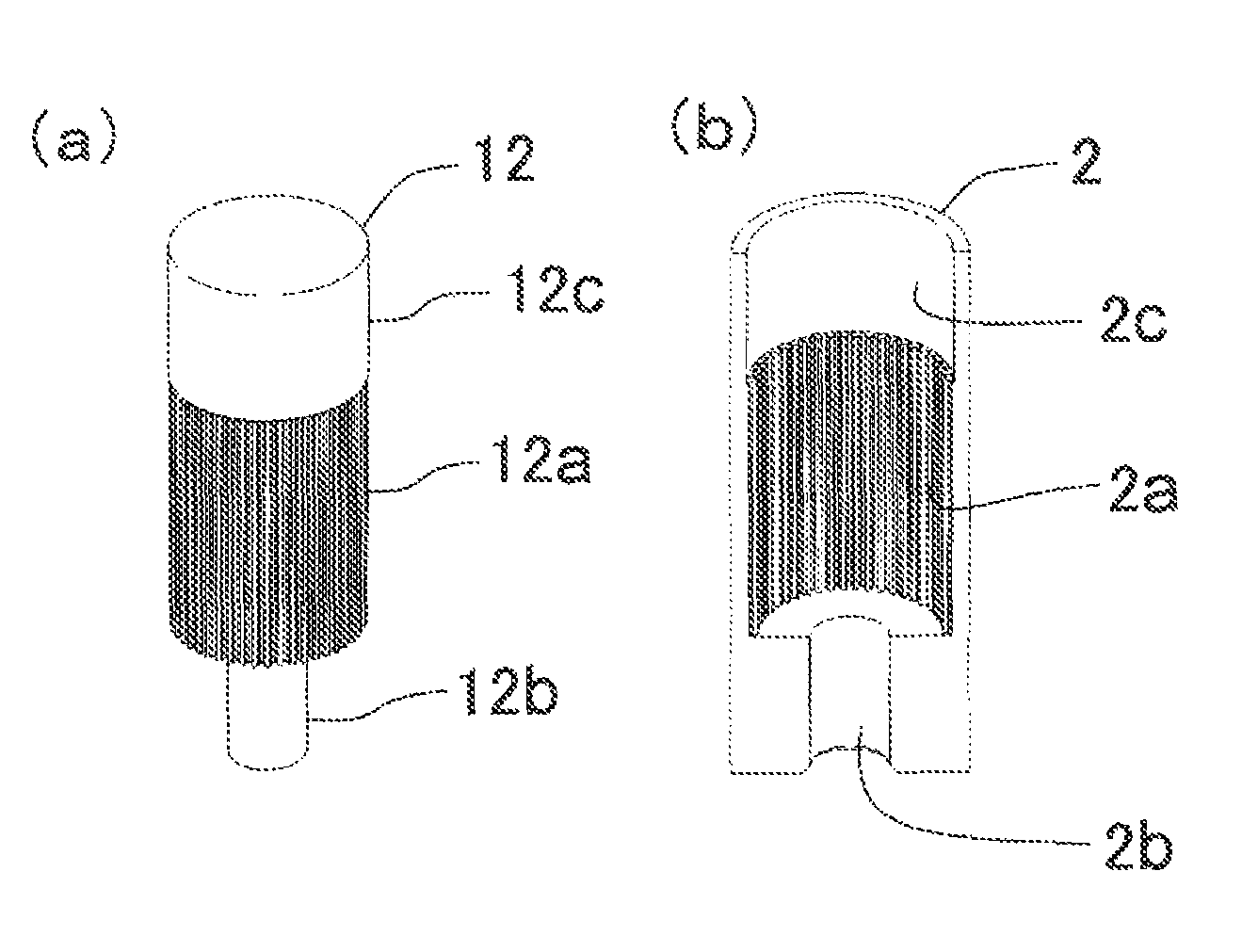

Internal gear manufacturing method and metallic glass internal gear manufactured thereby

InactiveUS20100313704A1Accurately formed into external gearHigh-precision internal gear manufacturingGearingGear wheelsMetallic materialsGear manufacturing

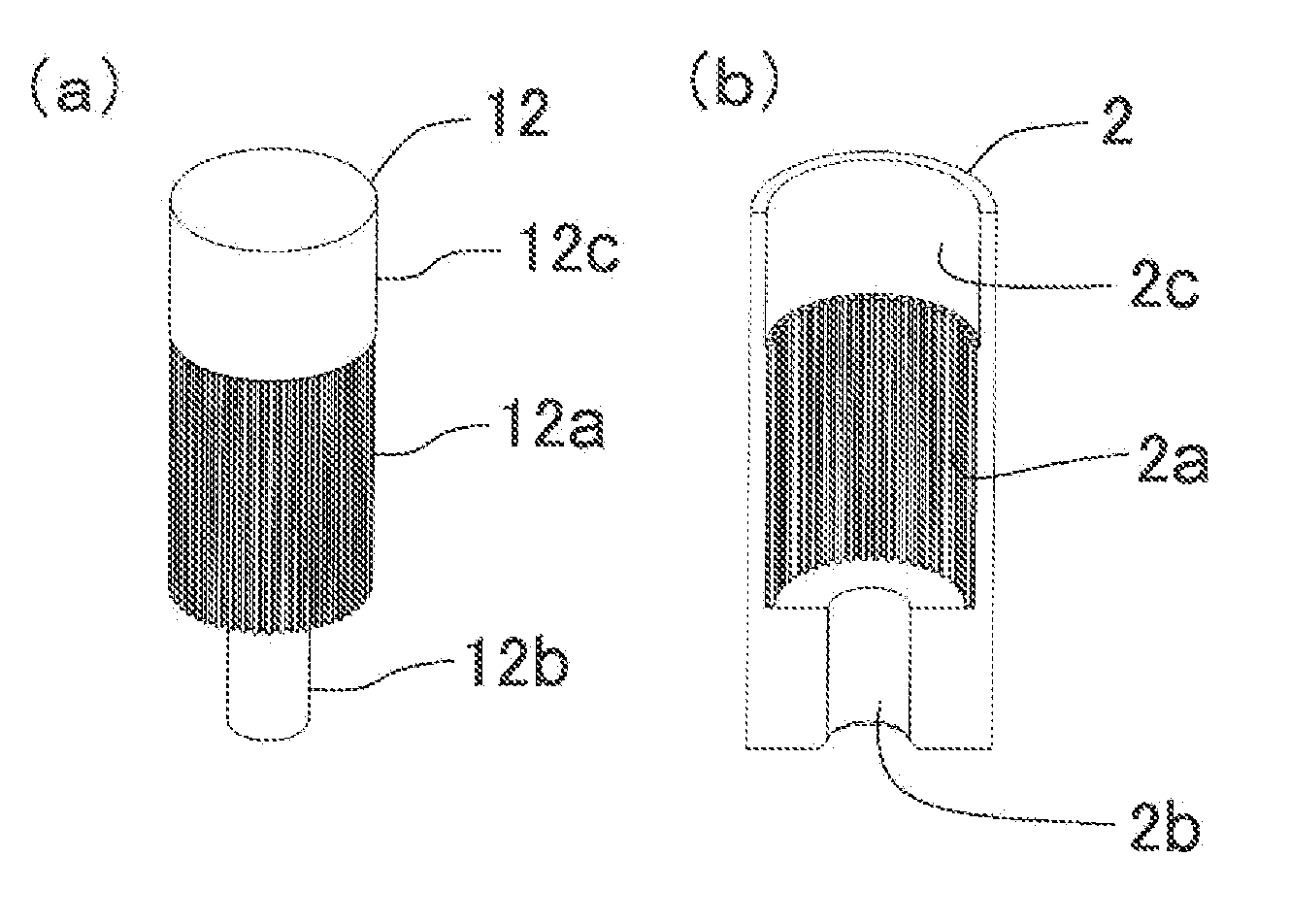

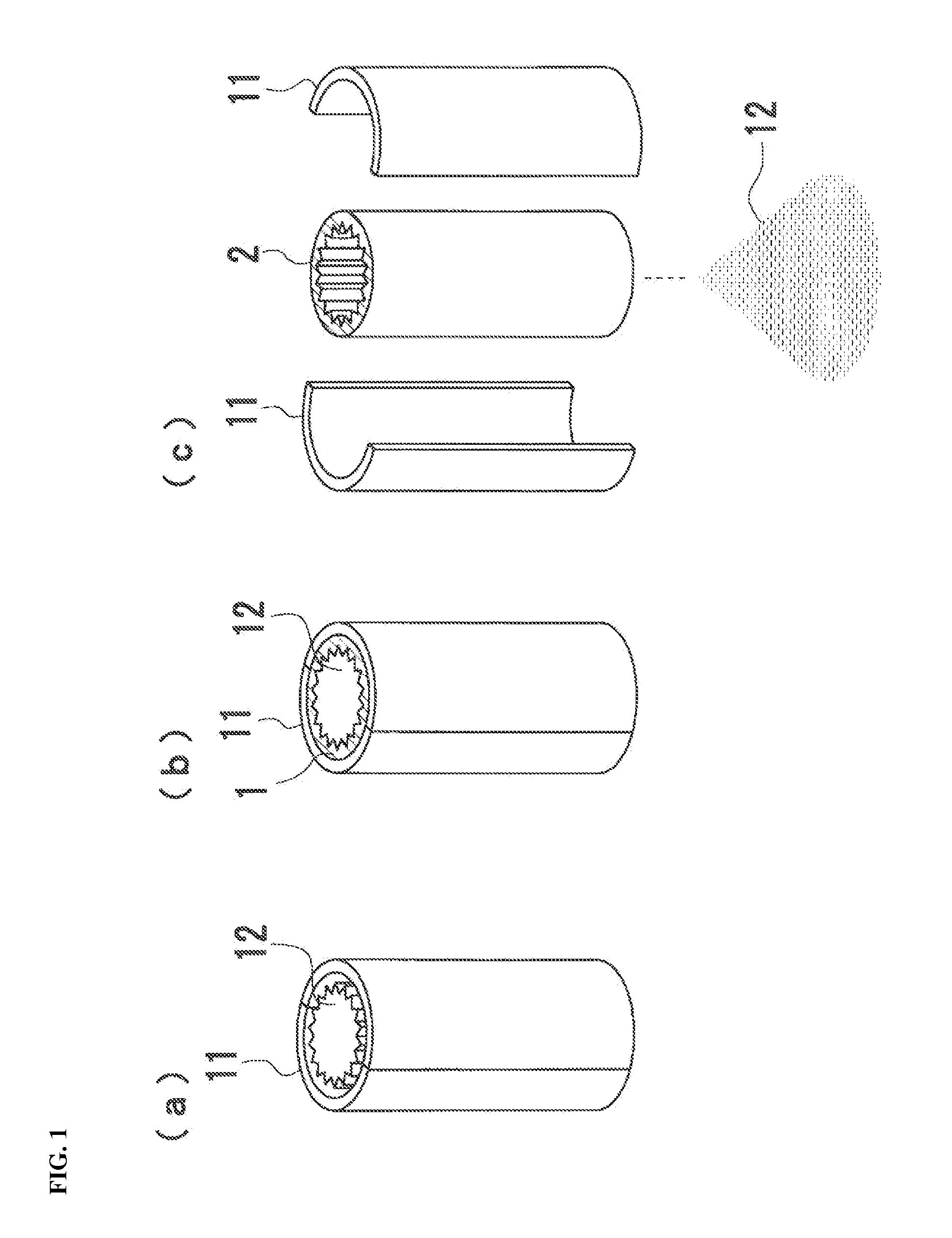

An internal gear manufacturing method capable of manufacturing time reduction and easy core removal, and a metallic glass internal gear manufactured thereby. A carbon core formed into a shape of an external gear is arranged in a thin, long tubular mold of a length equal thereto with a space extending longitudinally therealong. A molten metal material is pressure-injected under a temperature higher than a melting point thereof into the space between the mold and the core. The molten metal material is resolidified by rapid cooling at or above a critical cooling rate thereof together with the mold and the core. After resolidification of the molten metal material, the core is removed by pulverization or dissolution. Along internal gear formed of the resolidified metal material is cut into a plurality of segments of a prescribed length.

Owner:NAMIKI SEIMITSU HOSEKI KK +1

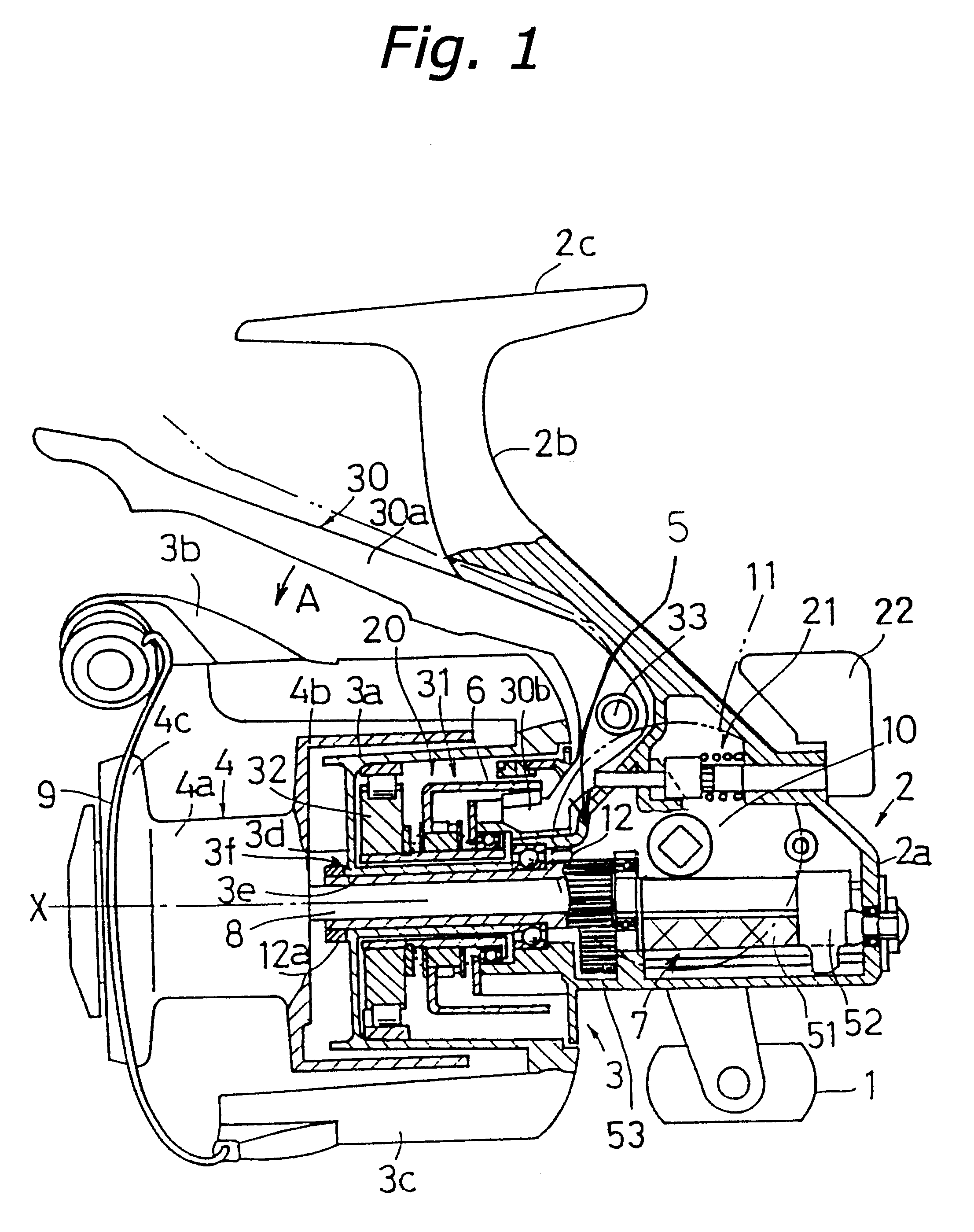

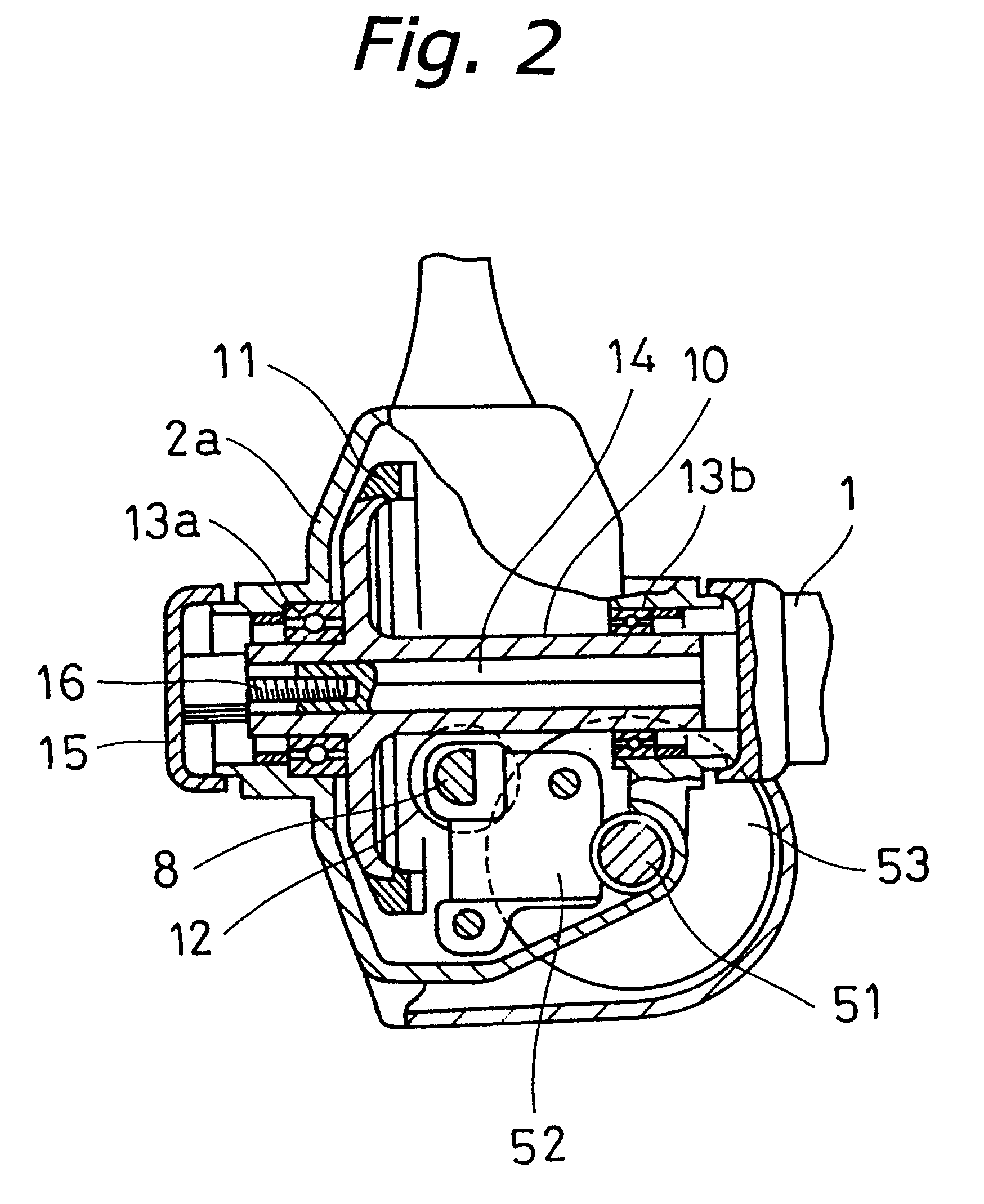

Spinning reel face gear manufacturing method

InactiveUS6343418B1Improve corrosion resistancePrecision manufacturingMetal-working apparatusPortable liftingHigh intensityEngineering

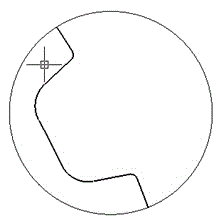

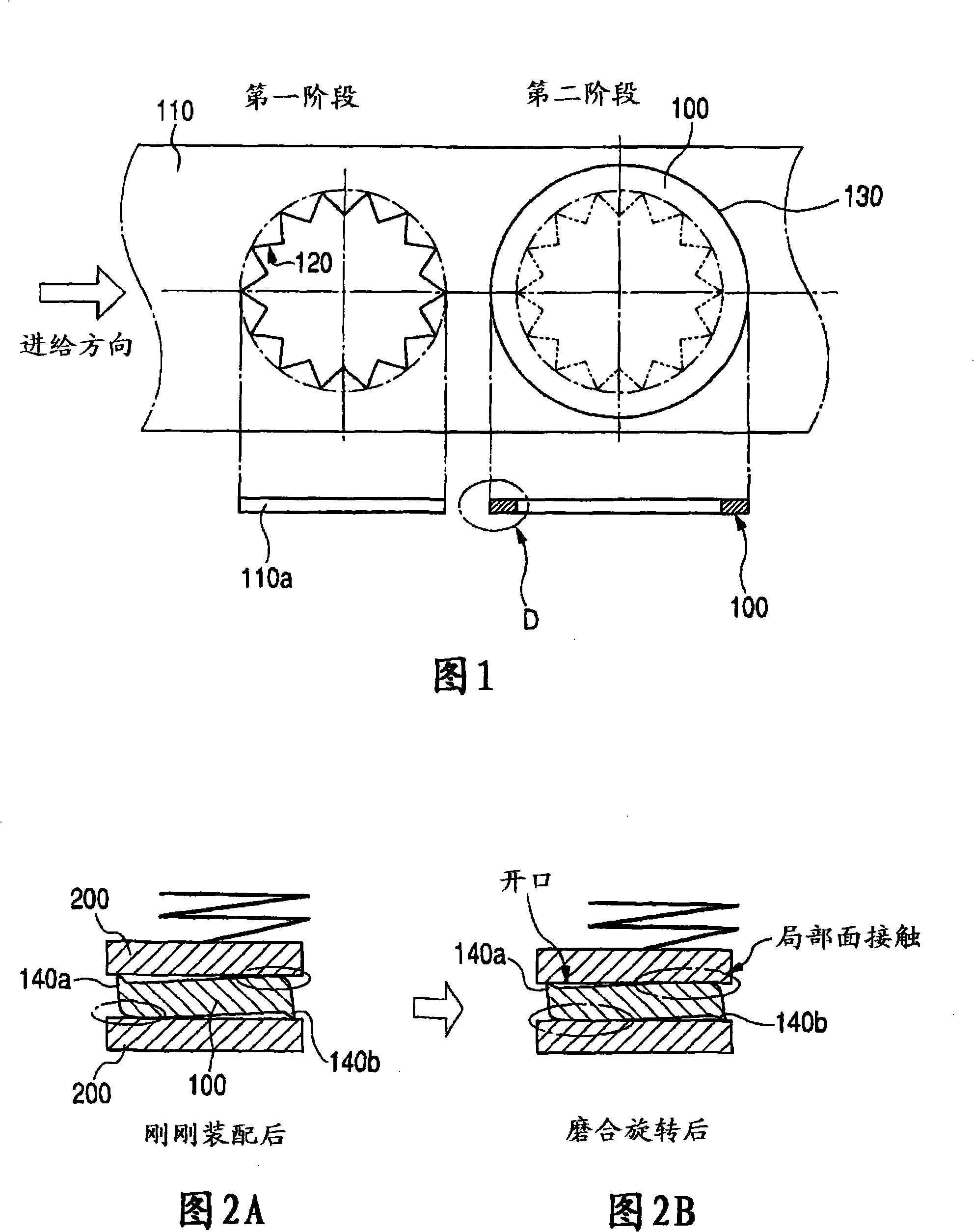

A spinning reel face gear is manufactured by a method of molding tooth-ring bearing, obverse-facing gear teeth onto a separately formed gear disk after the gear disk is made. The gear disk is specially configured with circumferentially spaced peripheral indentations to retain the tooth ring strongly against torque when the face gear meshes with a pinion gear in operation in a spinning reel. Manufacturing the face gear in two separate stages adds a degree of freedom in material selection, allowing a lightweight material to be employed for the gear disk, and a high-strength material for forming precision gear teeth to be employed for the tooth ring. The two-stage manufacturing method also enables the tooth ring to be formed onto the gear disk in a mold that does not leave a parting line on the obverse, teeth-bearing face of the tooth-ring when the mold plates are parted.

Owner:SHIMANO INC

Process for manufacturing backward gear of automobile gearbox

ActiveCN101695806AAvoid overheating and oxidationHigh forming precisionWheelsHeating/cooling devicesGear wheelAustenite

The invention discloses a process for manufacturing a backward gear of an automobile gearbox, comprising the following procedures of blanking, blank forming, shot blasting, warm forging forming, annealing, shot blasting, lubricating, cold finished shaping, turning, gear shaving and carburizing. In the invention, the difference between the warm forging forming, a hot precise forging and a cold precise forging is the heating temperature of the blank, the heating temperature is 750-800 DEG C, under the temperature, the blank just exceeds eutectoid reaction isothermal line, after the material structure is just transformed into Austenite, the blank is sent to the preheated mould to carry out a forging shaping process. The lubricating procedure is that the outer surface of the blank is coated with a macromolecular lubricant. The clod finished shaping procedure is that a standard gear mould is used for correcting the gear formed by the warm forging forming procedure at the normal temperature. In the invention, the advantages of the hot precise forging and the cold precise forging are comprehensively applied, and the process is especially suitable for the technique for manufacturing the backward gear of the automobile gearbox in large scale.

Owner:JIANGSU PACIFIC PRECISION FORGING

Abrasion-proof energy-saving polyethylene fishing net

The invention discloses a polythene fishing net with wear resistance and energy saving and relates to the filed of fishing gear manufacturing. The wear resistance of the fishing net needs to be improved. The invention adopts the preparation technology of the polythene fishing net and is characterized in that ultra-high molecular weight silicane and high molecular weight polyolefin are mixed with master batches of polyvinyl resin in proportion, wear resistant master batches which are blended in proportion and the polyvinyl resin are blended according to weight proportion, the weight of the wear resistant master batches is 2 percent to 5 percent of the weight of the polythene, the mixture is melt-extruded by an extruding machine, the fiber which is melt-extruded is put into a flume to be cooled and pre-drafted, and the cooled monofilament fiber is drafted. The drafting temperature is 90 to 105 DEG C, the drafting multiple is 11 to 13 times, the setting temperature of the drafted monofilament is 90 to 120 DEG C, the set monofilament fiber is coiled by the wrapping tension of 200 plus or minus 30cN and the coiling speed of 120 to 150 meters per min, and the monofilament is made into net wire of the twist number of 36 to 216 twists per meter and is woven into the wear resistant fishing net with the mesh size of 10mm to 1200mm.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Internal gear manufacturing method and metallic glass internal gear manufactured thereby

InactiveUS8418366B2Shorten production timeImprove productivityMetal rolling stand detailsGearingMetallic materialsDissolution

Owner:NAMIKI PRECISION JEWEL CO LTD +1

Manufacturing method of high-strength sintered umbrella gear

The invention provides a method for making angular wheel. It comprises the following steps: preparing raw materials include ferromolybdenum powder, nickel powder, graphite powder and zinc stearate, wherein ferromolybdenum powder is basic powder and contains molybdenum 0.5-1úÑ; the content of nickel powder is 2-3úÑ, the content of graphite powder is 0.4-0.8úÑ, the content of zinc stearate is 0.8úÑ; mixing raw materials; putting the mixed raw materials into mold and pressing it to form pressed compact with the density above 7.15g / cm.3.; putting pressed compact on high temperature net and heating it with the temperature between 650 deg. and 750 deg., then agglomerating it with the temperature between 1110 deg. and 1120 deg.; annealing pressed compact with the temperature at 840í‚20 deg.; drawing temper it with the temperature at160í‚20 deg..

Owner:SAIC MOTOR

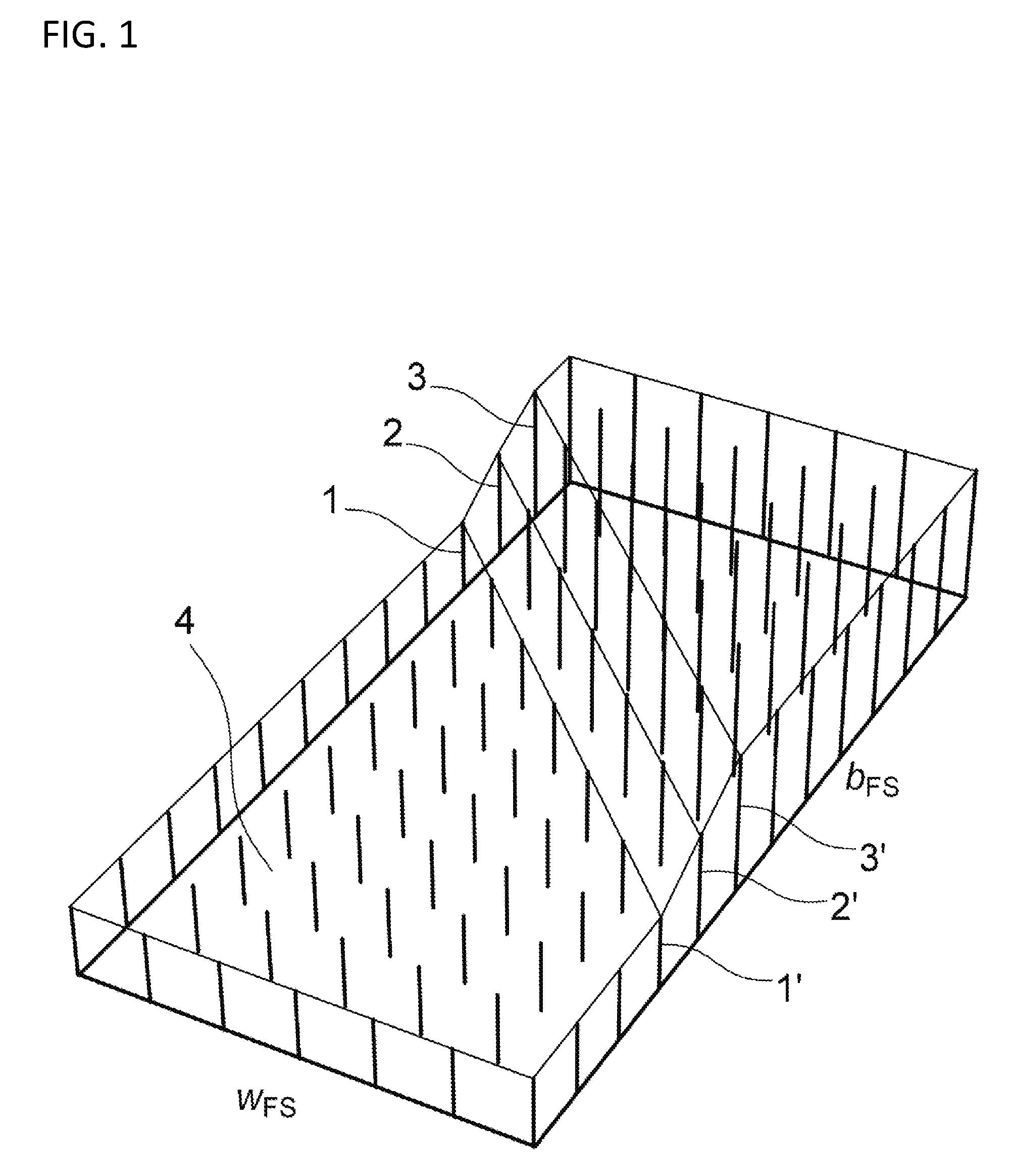

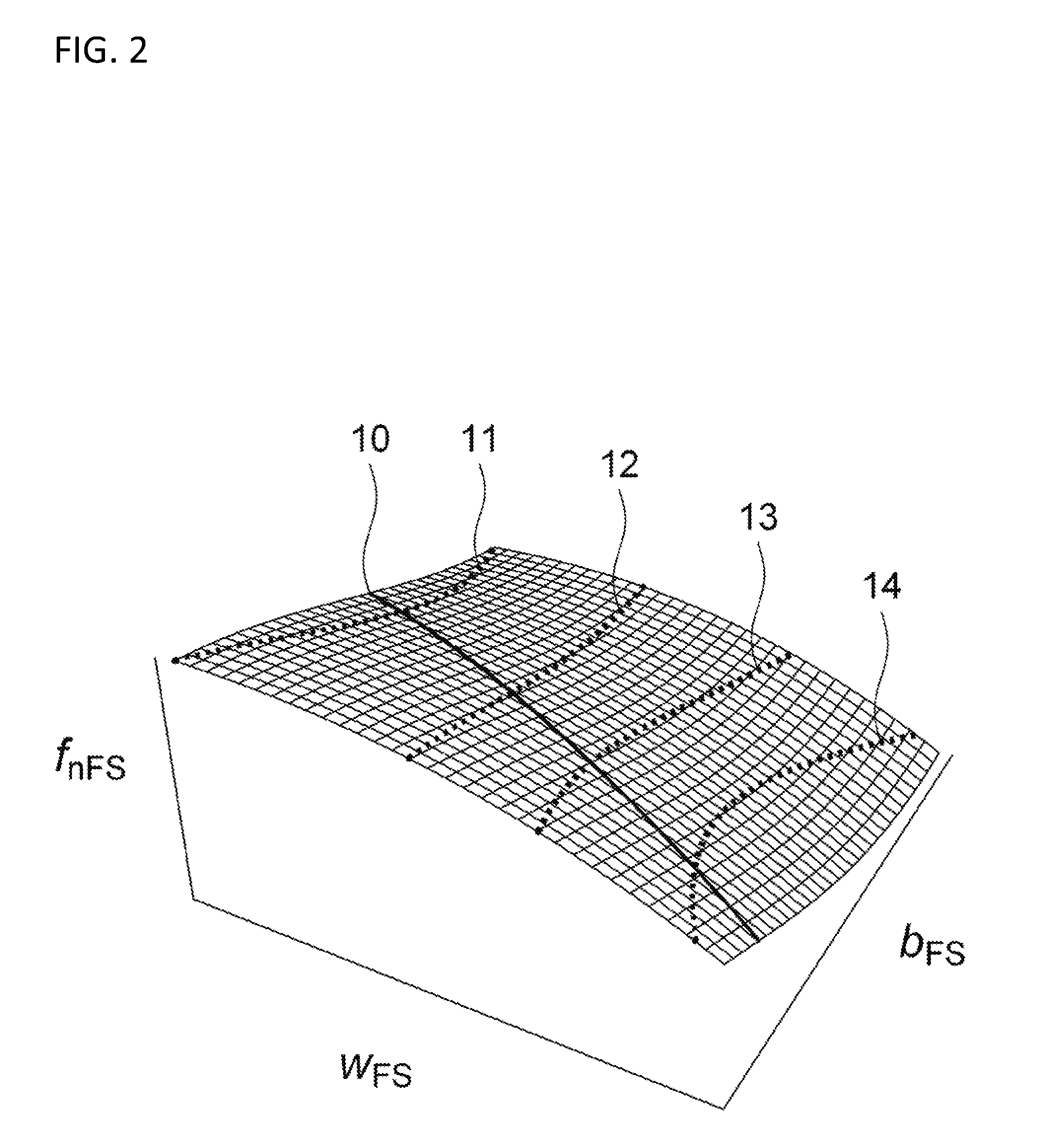

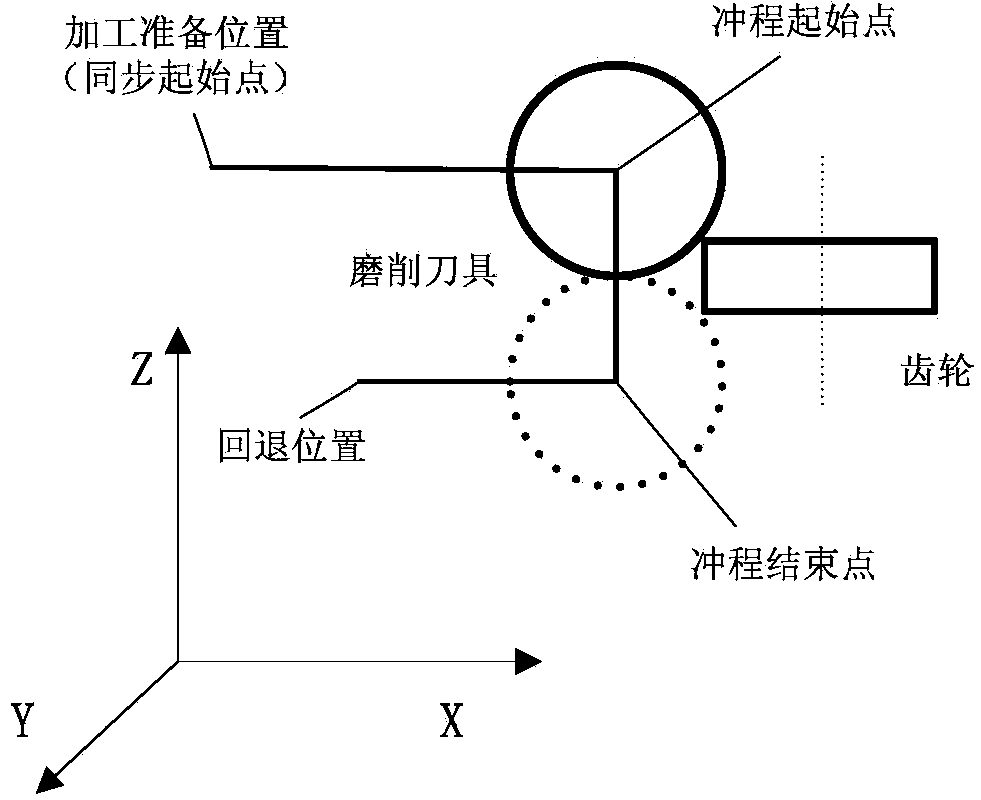

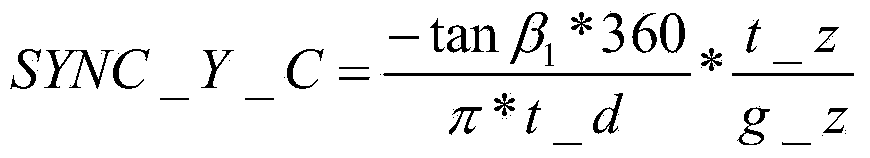

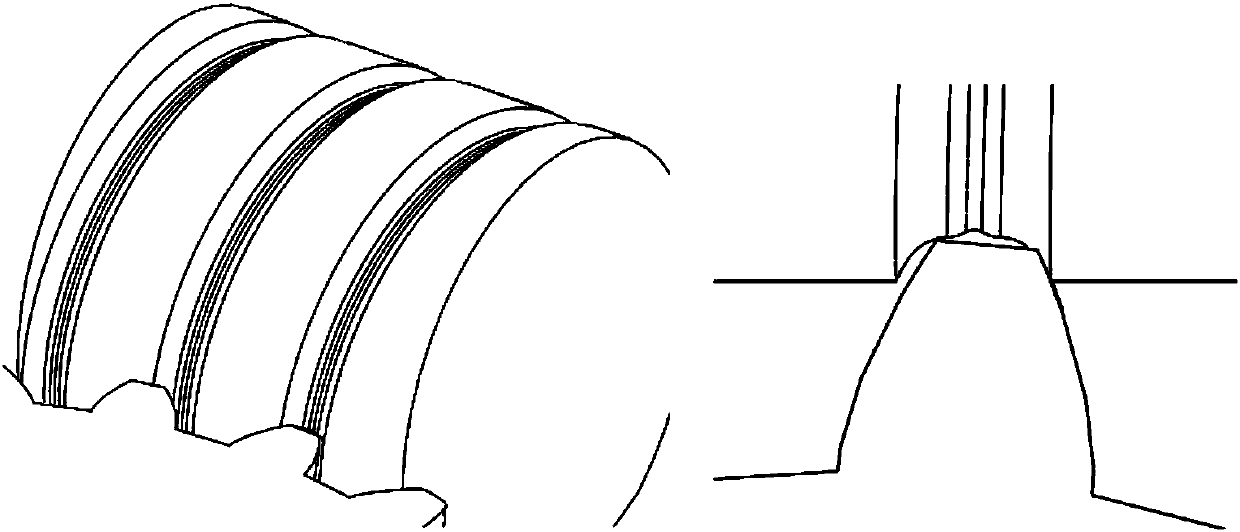

Worm grinding wheel gear grinding surface distortion compensation method

ActiveCN104942380ACompensate distortion errorAbrasive surface conditioning devicesGear teeth manufacturing toolsGear grindingGear wheel

The invention belongs to the field of gear manufacturing, and relates to a worm grinding wheel gear grinding surface distortion compensation method which solves the problem of tooth surface distortion of a bevel wheel gear with axial modification in the grinding process. According to the worm grinding wheel gear grinding surface distortion compensation method, dressing movement is different from a standard worm grinding wheel dressing process, deflection movement of a diamond rolling wheel is needed, and axial screw lead and a spiral angle of the grinding wheel are changed. The method comprises the steps that firstly, according to the wheel gear grinding technology, the worm grinding wheel is divided into a coarse grinding zone, a fine grinding zone and a middle transition zone in the width direction, the diagonal grinding principle is utilized, and appropriate diagonal ratio is selected to make a strict mapping relation exist between the section in the width direction of the wheel gear and the section in the width direction of the worm grinding wheel; secondly, according to distortion amounts of the left tooth surface and the right tooth surface of each section of the wheel gear to be machined, distortion compensation of each tooth surface is achieved by utilizing two methods of combining a deflecting rolling wheel and changing the axial screw lead of the grinding wheel. Due to the fact that excursion exists in the deflection center of the diamond rolling wheel, when deflection exists on the rolling wheel, calculation and compensation need to be conducted on the position variation quantity of a tooth profile of the rolling wheel.

Owner:CHONGQING UNIV

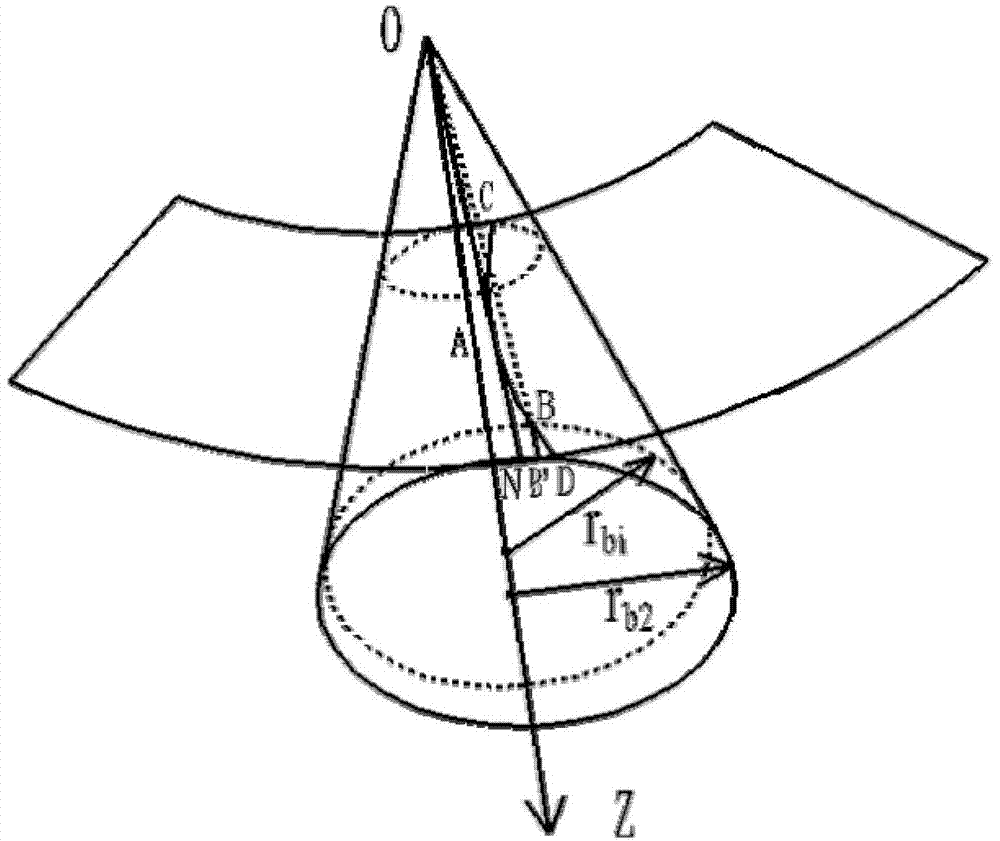

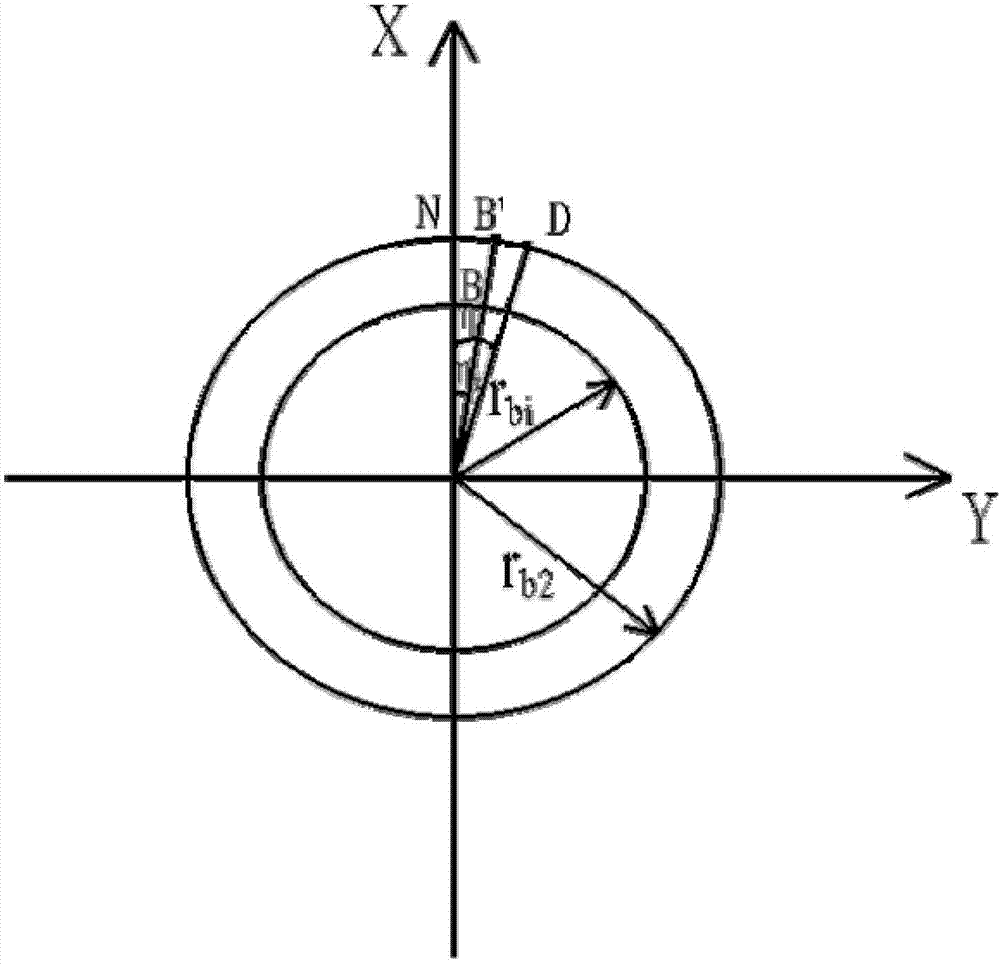

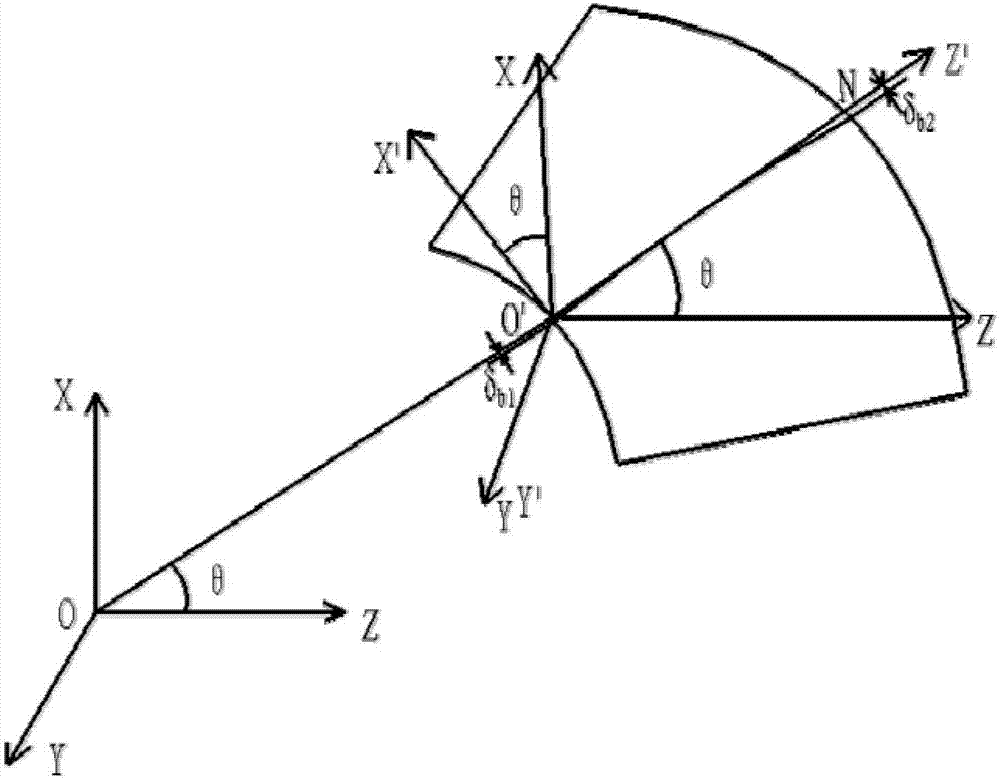

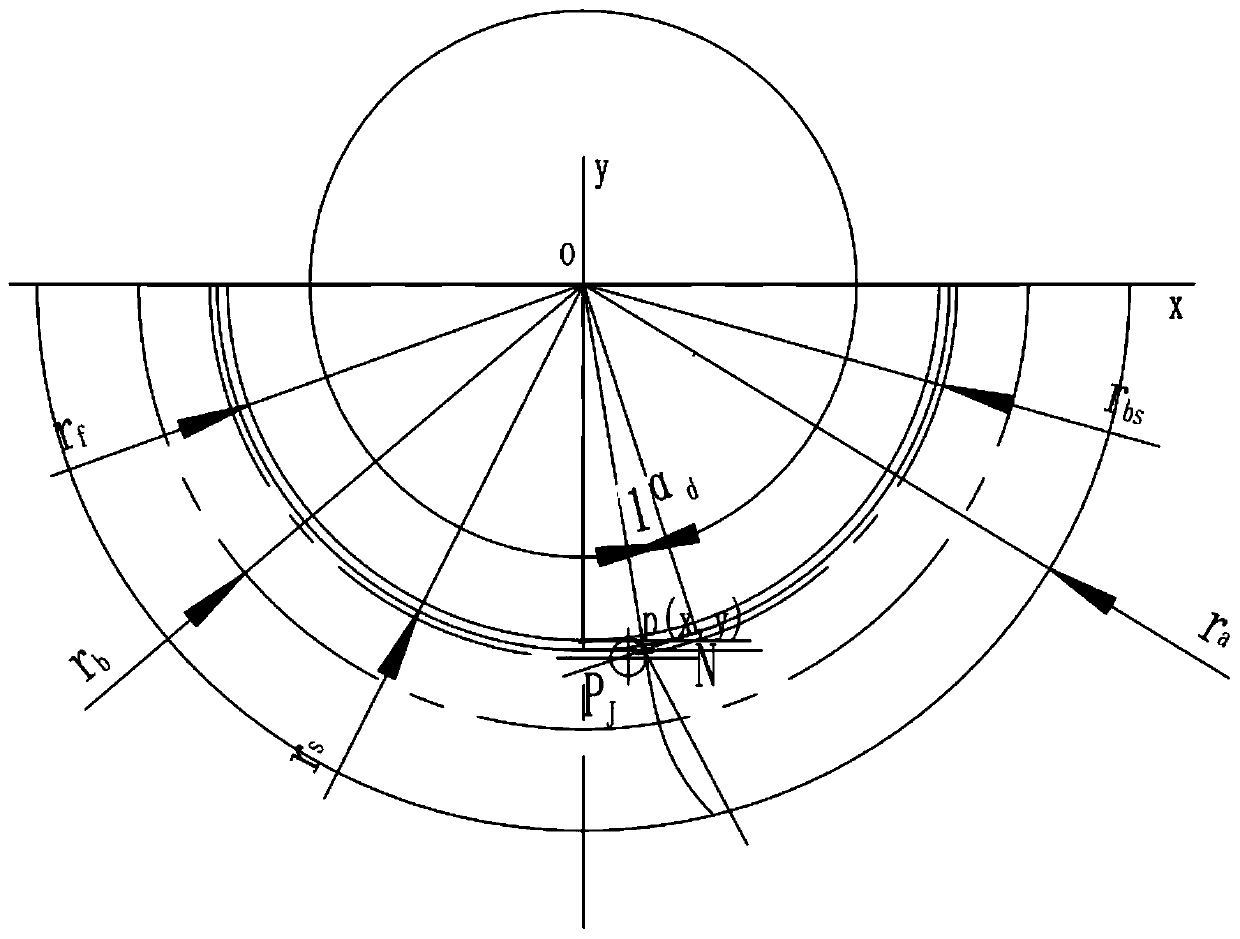

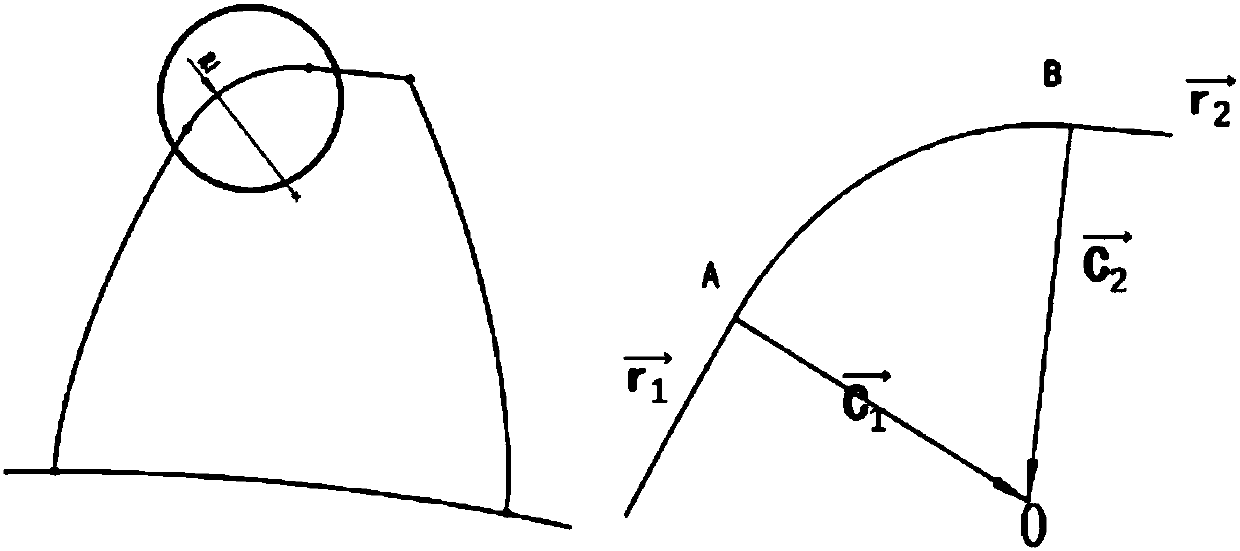

Method for conveniently realizing variable curvature accurate drum correcting of parameterized involute straight bevel gear

InactiveCN103034751AEasy to implement parametric modelingImprove carrying capacitySpecial data processing applicationsNumerical controlElement modeling

A method for conveniently realizing the variable curvature accurate drum correcting of a parameterized involute straight bevel gear belongs to the field of gear production. The scheme fully utilizes ANSYS / LS-DYNA, Imageware, Matlab and Solid works to realize the accurate modeling of a variable curvature drum shape correcting straight bevel gear model, moreover, according to a variable curvature drum shape tooth surface equation which is derived by the method, programming is carried out based on the uniform B-spline surface equation theory so as to realize the parametric modeling of a variable curvature drum correcting tooth surface, the accuracies of the shape correcting straight bevel gear model and subsequent finite element modeling are improved, and shape correcting straight bevel gear products or die electrodes are directly processed through a numerical control technique; and for a straight bevel gear pair, a drive gear is only subjected to the variable curvature shape correcting, a driven gear is not corrected, so that the design and processing difficulty of the shape correcting gear are reduced.

Owner:UNIV OF JINAN

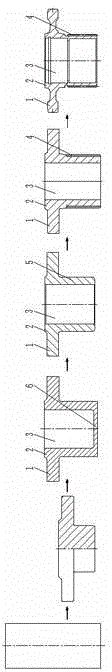

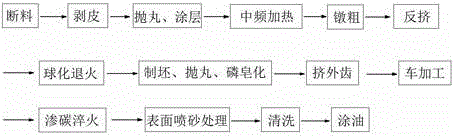

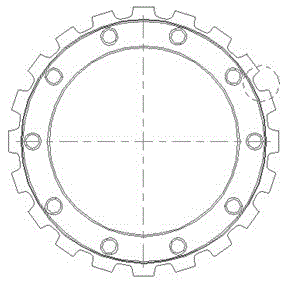

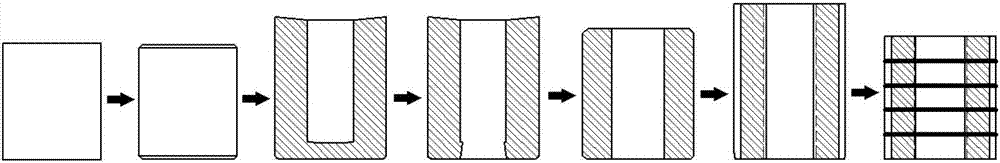

Manufacturing technology of hollow outer gear of electric forklift driving flange

The invention discloses a manufacturing technology of a hollow outer gear of an electric forklift driving flange. The manufacturing technology includes the following steps that material cut-off is performed, skinning is performed, shot blasting is performed, coating is performed, upsetting is performed, a center hole is extruded, spheroidizing annealing is performed, blank making is performed, shot blasting is performed, phosphorus saponification treatment is performed, cold extrusion is performed on outer teeth, turning is performed, carburizing and quenching are performed, surface sand blasting is performed, and cleaning and oiling are performed. The hollow outer gear produced through the technology is stable in quality, and the accumulation error between tooth profiles is small. The finished product rate is high, production efficiency is improved, the production period is short, the method that after hot forging, a machine tool is mainly adopted for machining is replaced, the operation quantity of machine tool machining is reduced, the requirement for precision can be met, the manufacturing cost is lowered, and the manufacturing period is shortened.

Owner:江苏威鹰机械有限公司

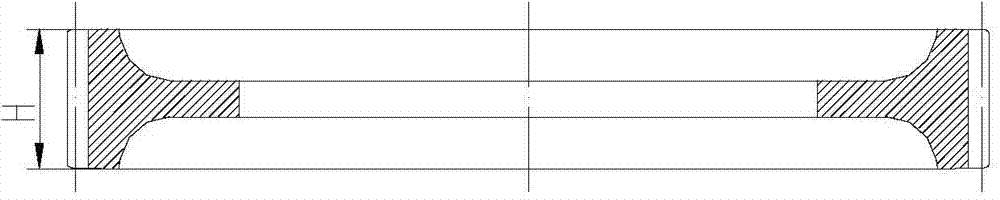

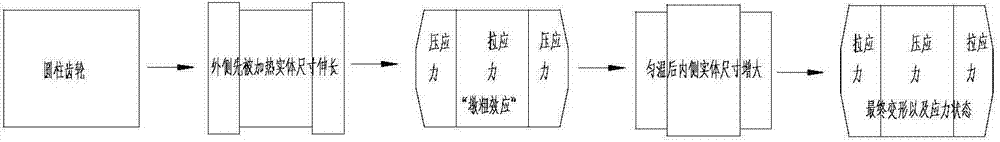

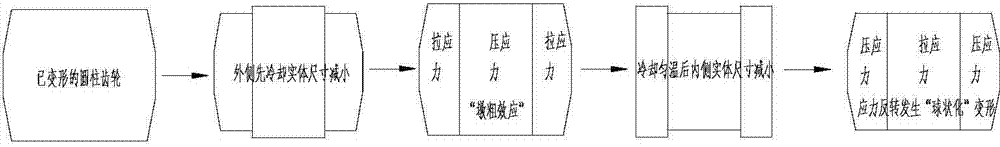

Carburizing and quenching method for cylindrical gear

InactiveCN104498965ACompensation corrects cone distortionEliminate internal stressSolid state diffusion coatingFurnace typesGear grindingElastic plastic

The invention relates to a carburizing and quenching method for a cylindrical gear, and belongs to the technical field of heat treatment. The method comprises the following steps: heating until the temperature exceeds elastic-plastic transformation temperature of low-carbon steel for primary preheating; heating until the temperature is less than the phase-transition temperature Ac1 of the low-carbon steel for preheating again; performing carburizing, high-temperature tempering, quenching, and low-temperature tempering. According to the carburizing and quenching method for the cylindrical gear, effective measures for inhibiting or removing deformation are respectively performed for a plurality of process stages and supplement each other and are organically combined, so that the deformation of the cylindrical gear carburizing and quenching thermal treatment can be obviously reduced, the preset grinding allowance of the gear can be properly decreased, and as a result, the gear grinding time is reduced, and conditions are created for lowering the gear manufacturing cost.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

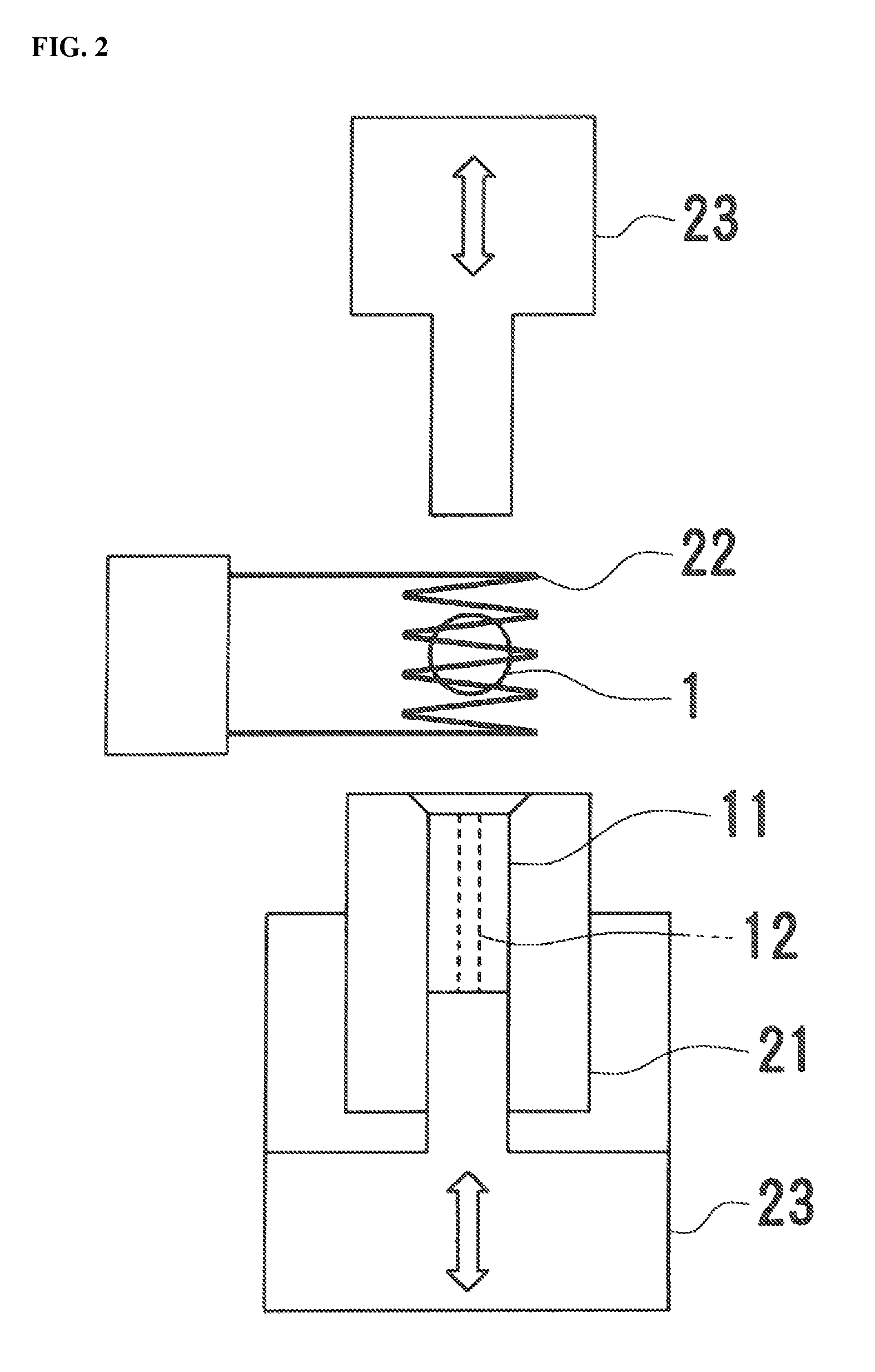

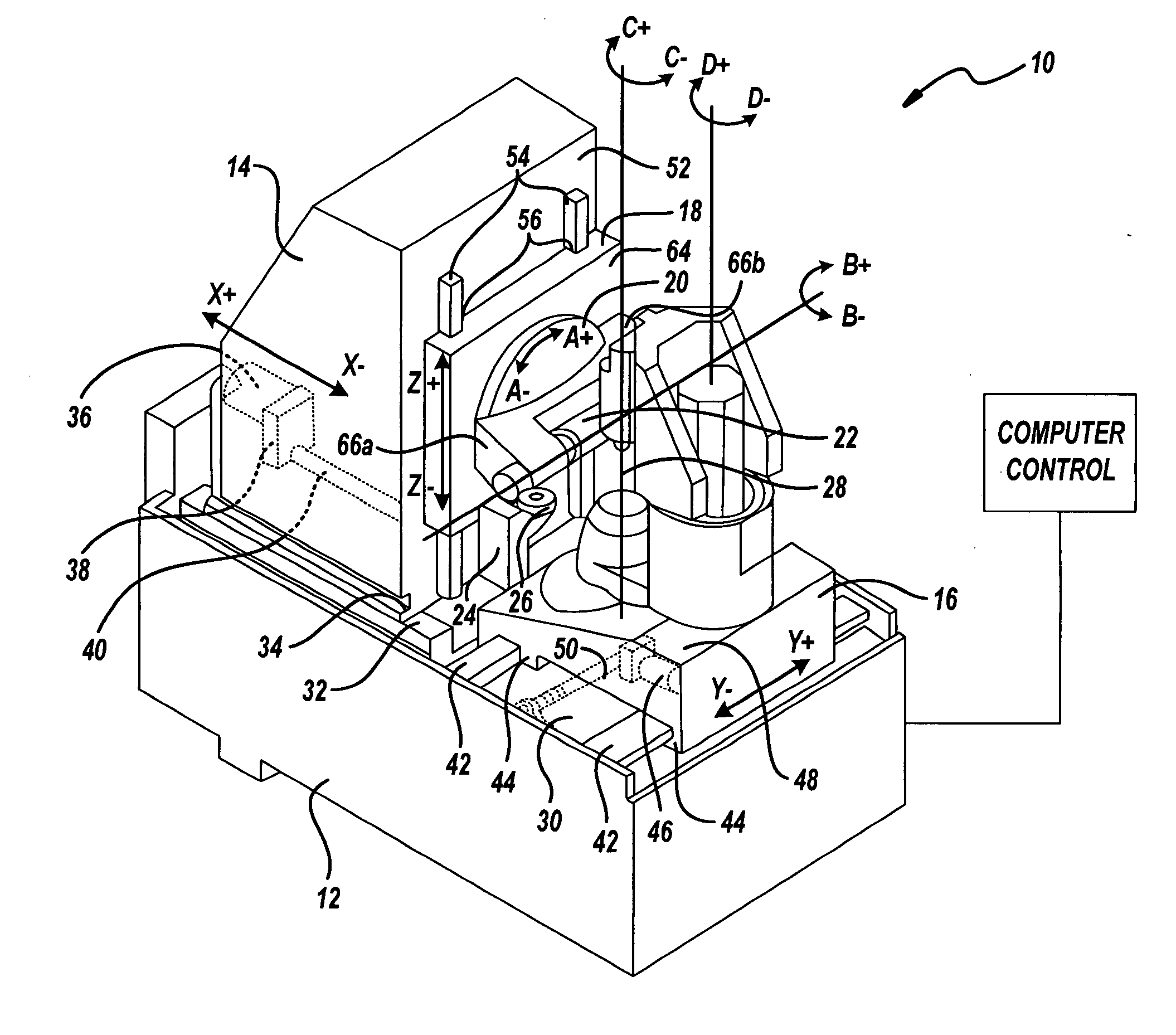

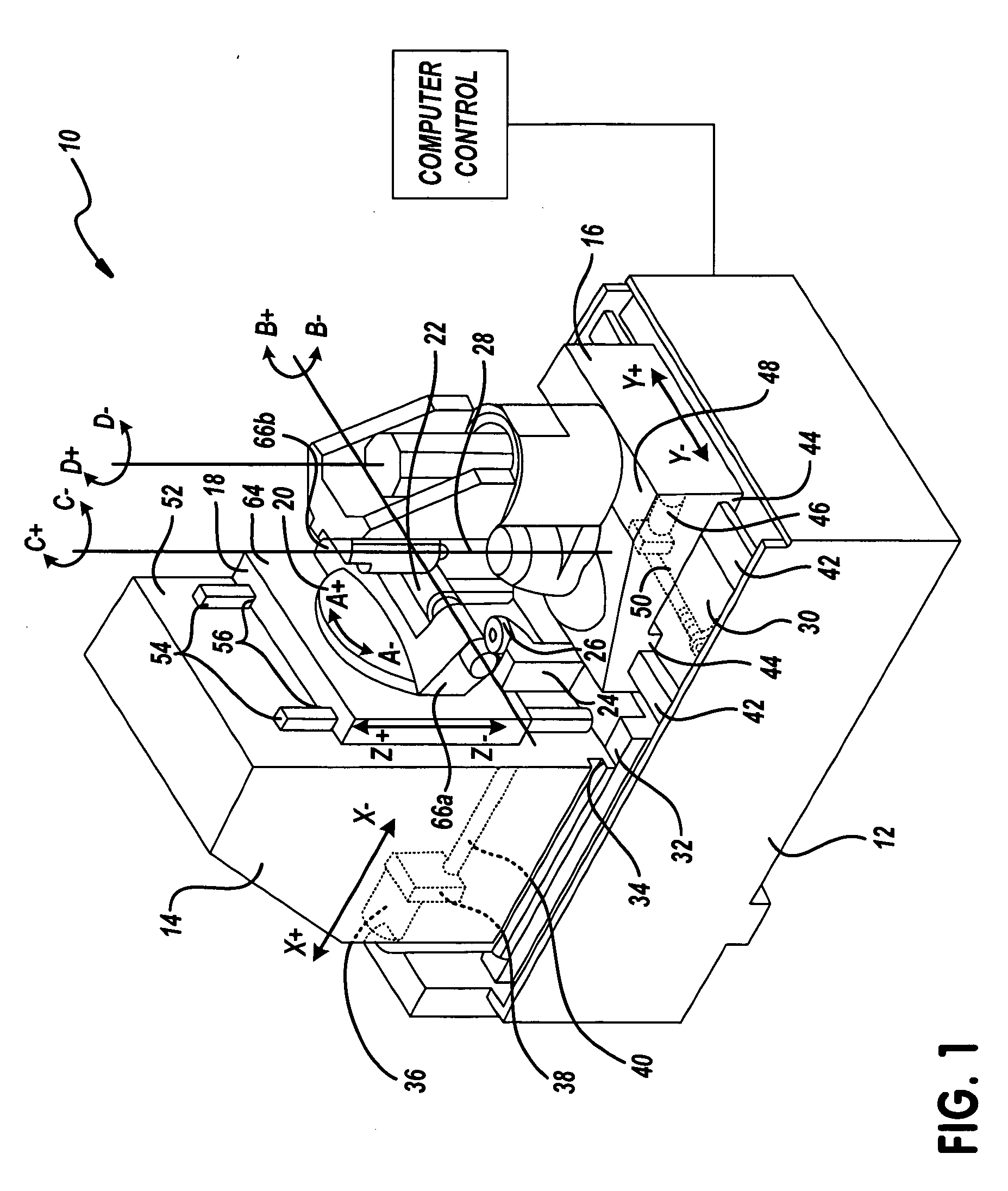

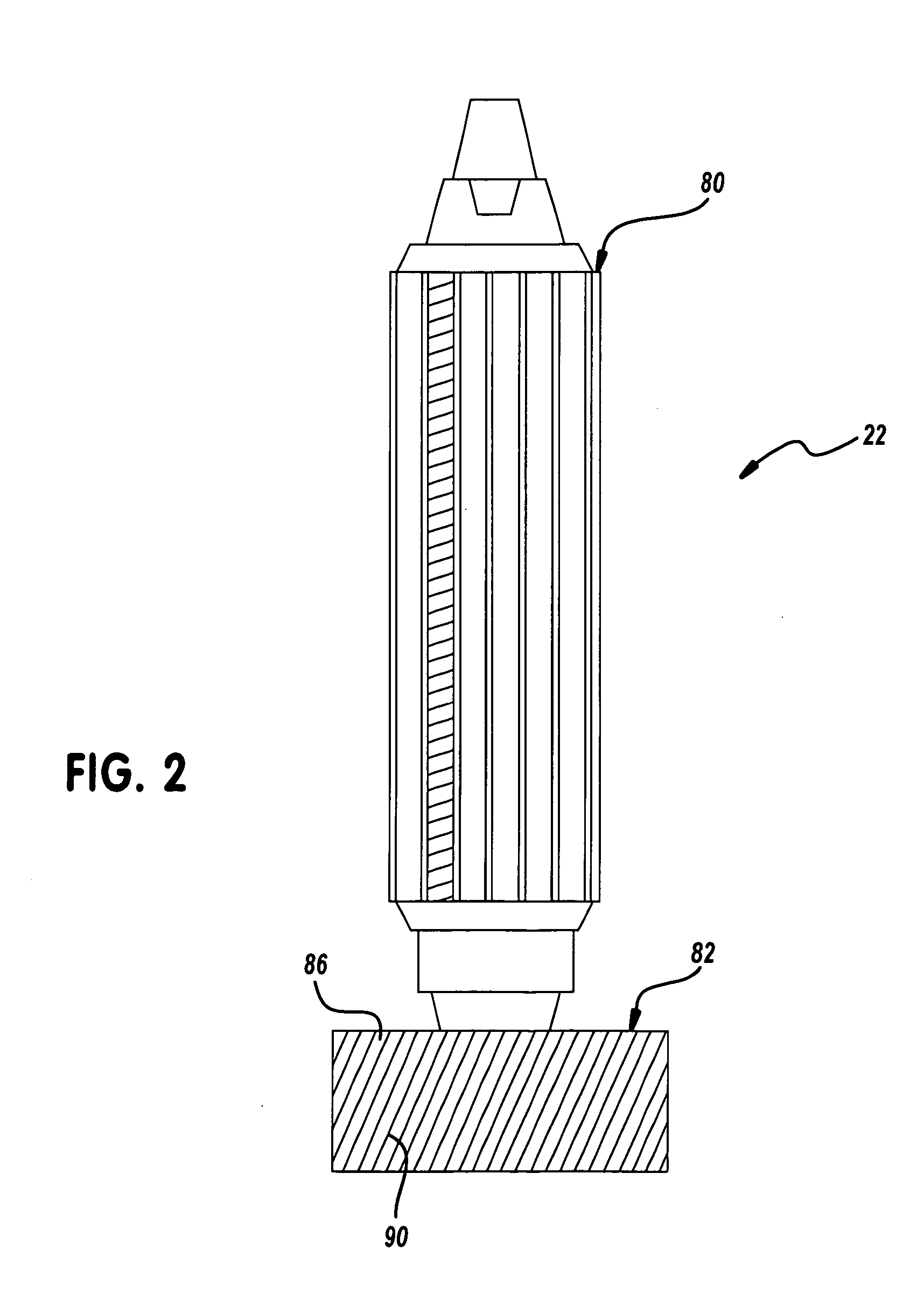

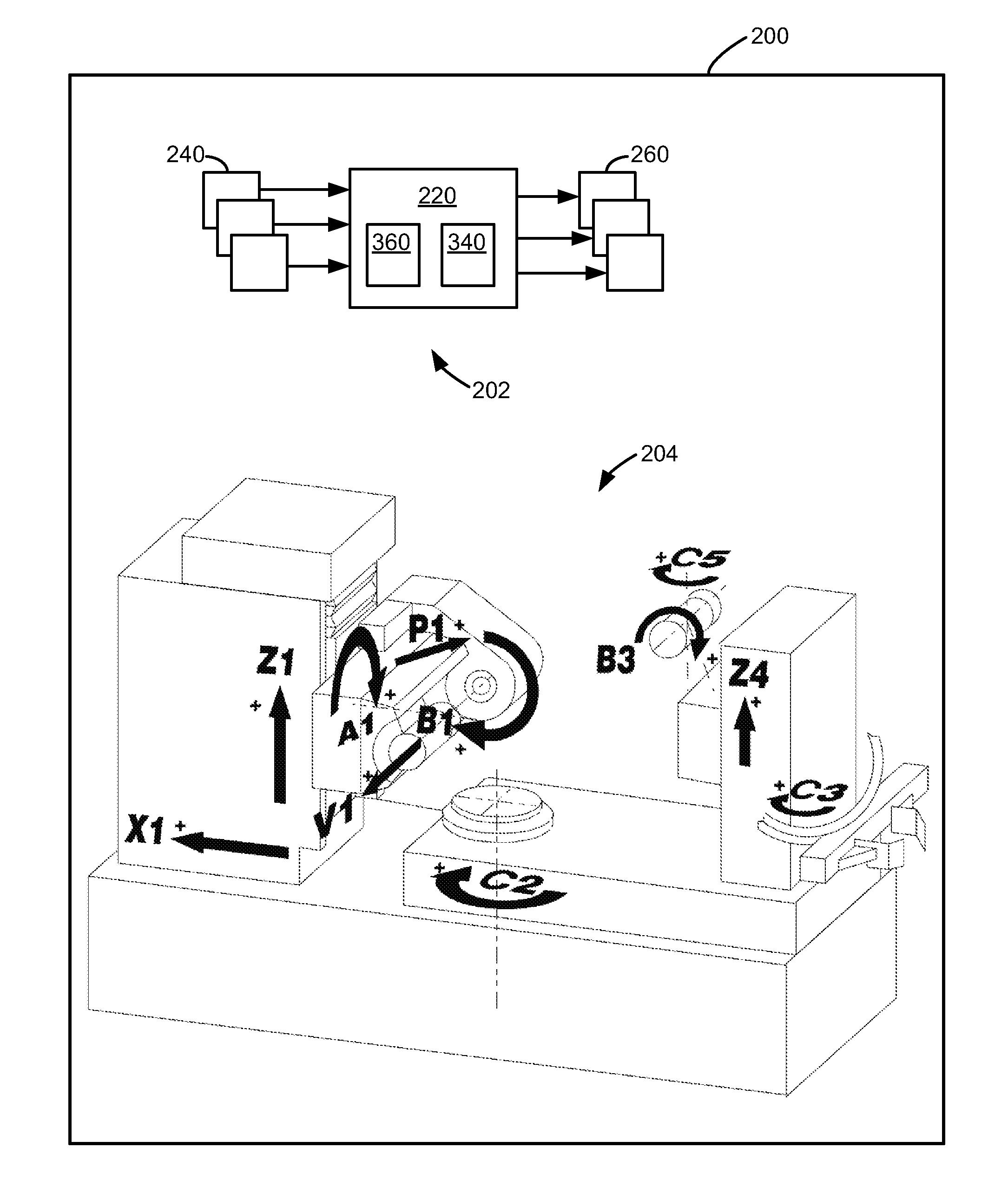

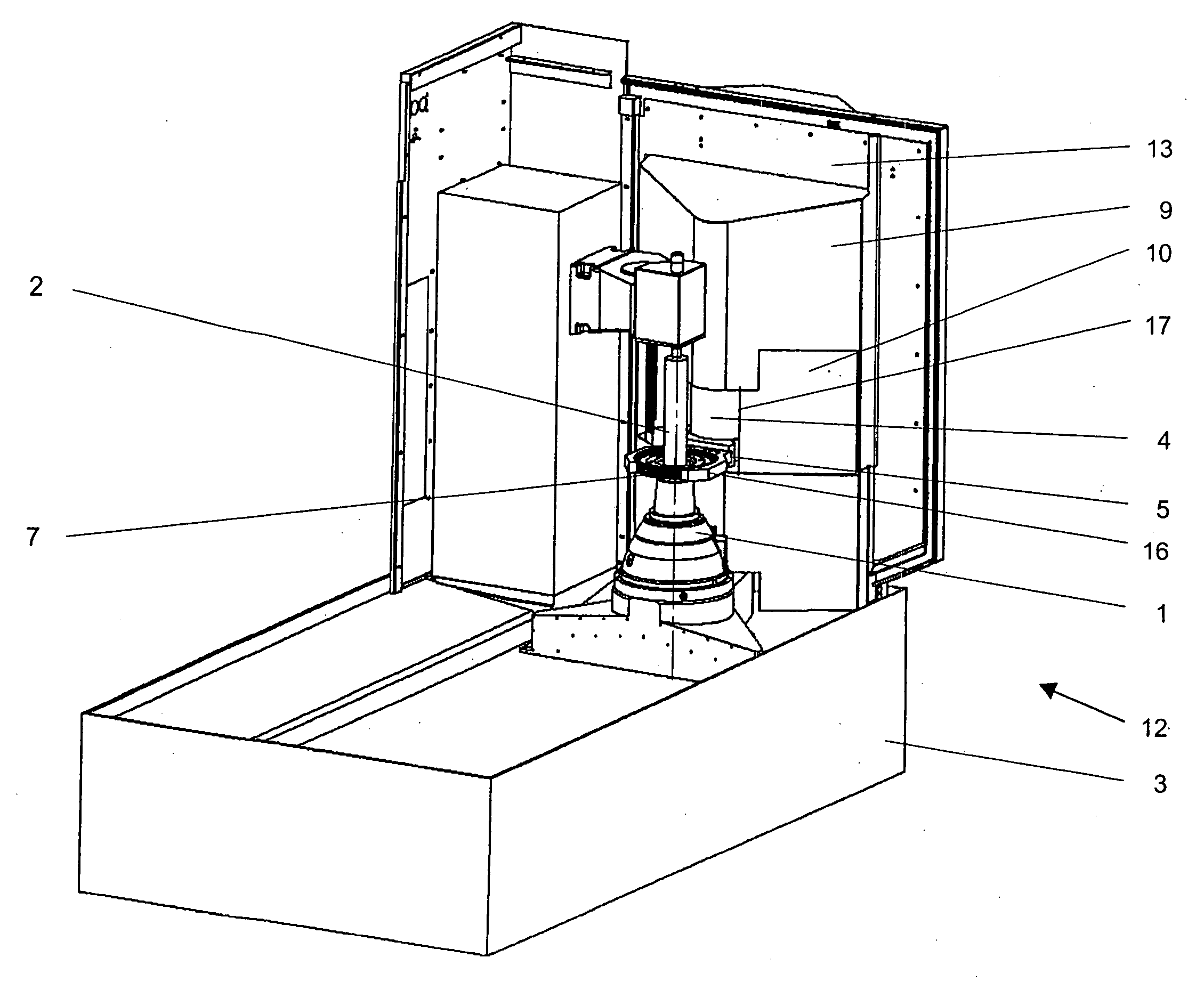

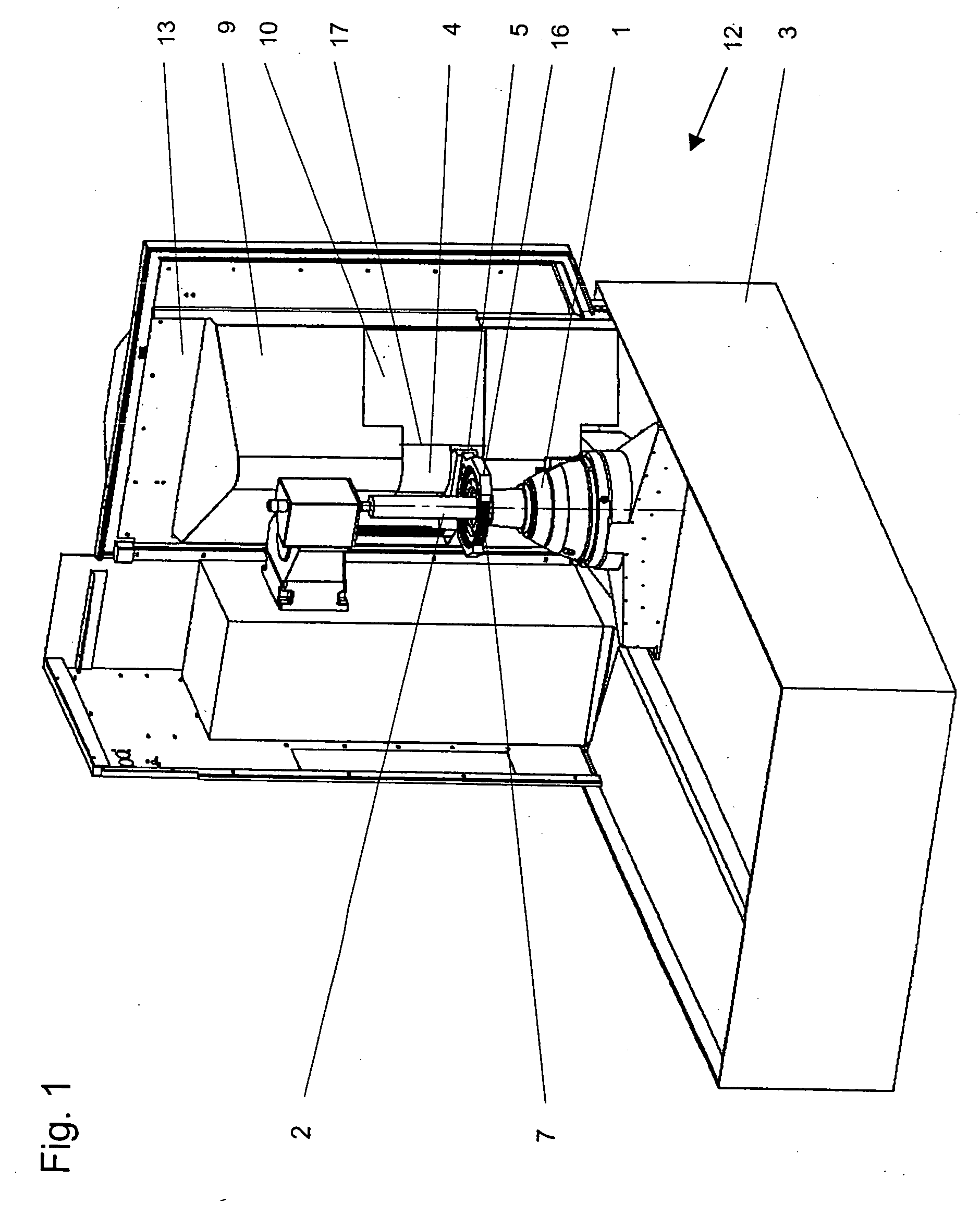

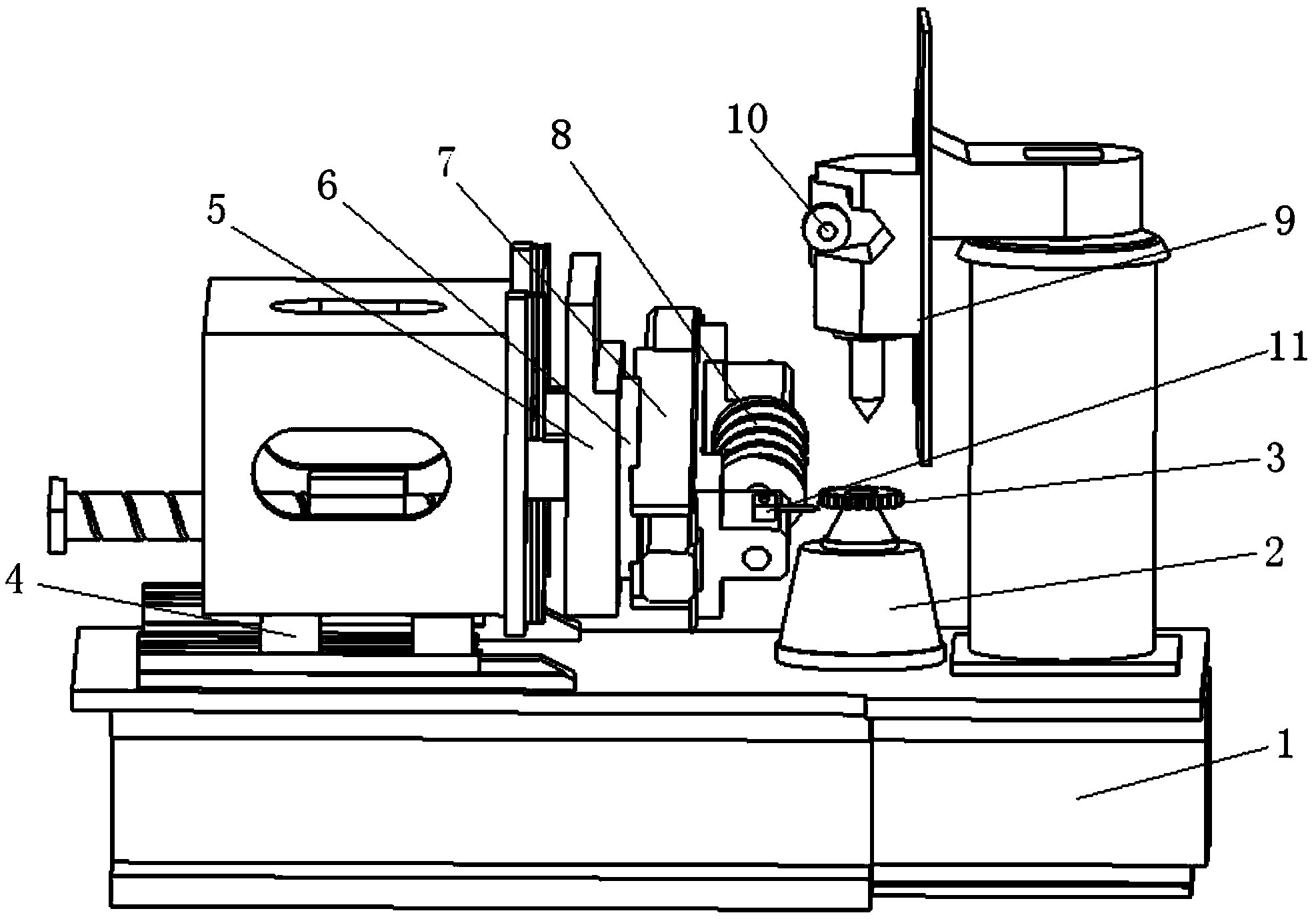

Multiple operation gear manufacturing apparatus with common work axis

A gear production apparatus for producing a gear from a blank includes a base, a first stock slidable along a longitudinal axis of the base and including a first tool rotatably supported thereon and a second stock slidable along a first transverse axis of the base and including a second tool rotatably supported thereon. A blank retainer rotatably supports and selectively drives the blank about a first rotational axis. The first stock slides along the longitudinal axis to engage the first tool with the blank and to form rough teeth in the blank. The second stock slides along the transverse axis to engage the first tool with the blank, which rotatably drives the second tool to operate on the blank.

Owner:MAGNA DRIVETRAIN OF AMERICA

Large scale gear production process

The invention discloses a big-size gear manufacturing method. The manufacturing method includes the following steps: a certain quantity of steel is cut and heated to 1100 to 1300 DEG C, and then the steel is stamped into cake-shaped structure; a through hole with the diameter of 50 to 100 mm is punched at the middle part of the cake-shaped steel; the steel is placed on a ring-rolling machine for hole rolling and enlarging to lead the cake-shaped steel to be a ring-shaped billet with the internal diameter of 550 to 580 mm; the ring-shaped billet is placed between an upper mould and a lower mould of a punching die machine for mould-combing and die to get a wheel blank; the wheel blank is shaped in a temperature of 200 to 500 DEG C after overlaps and burrs are removed; the wheel blank is treated in the temperature of 830 to 880 DEG C to lead the hardness to reach HRC 30 to 38; a medium quenching is carried out after the quality is regulated to lead the hardness to reach HRC 50 to 58 and the depth of a quenching layer is 6 to 12 mm; a final processing can be carried out in the end to get a finished gear. The gear has equal strength distribution and long service life.

Owner:泉州江新机械有限公司

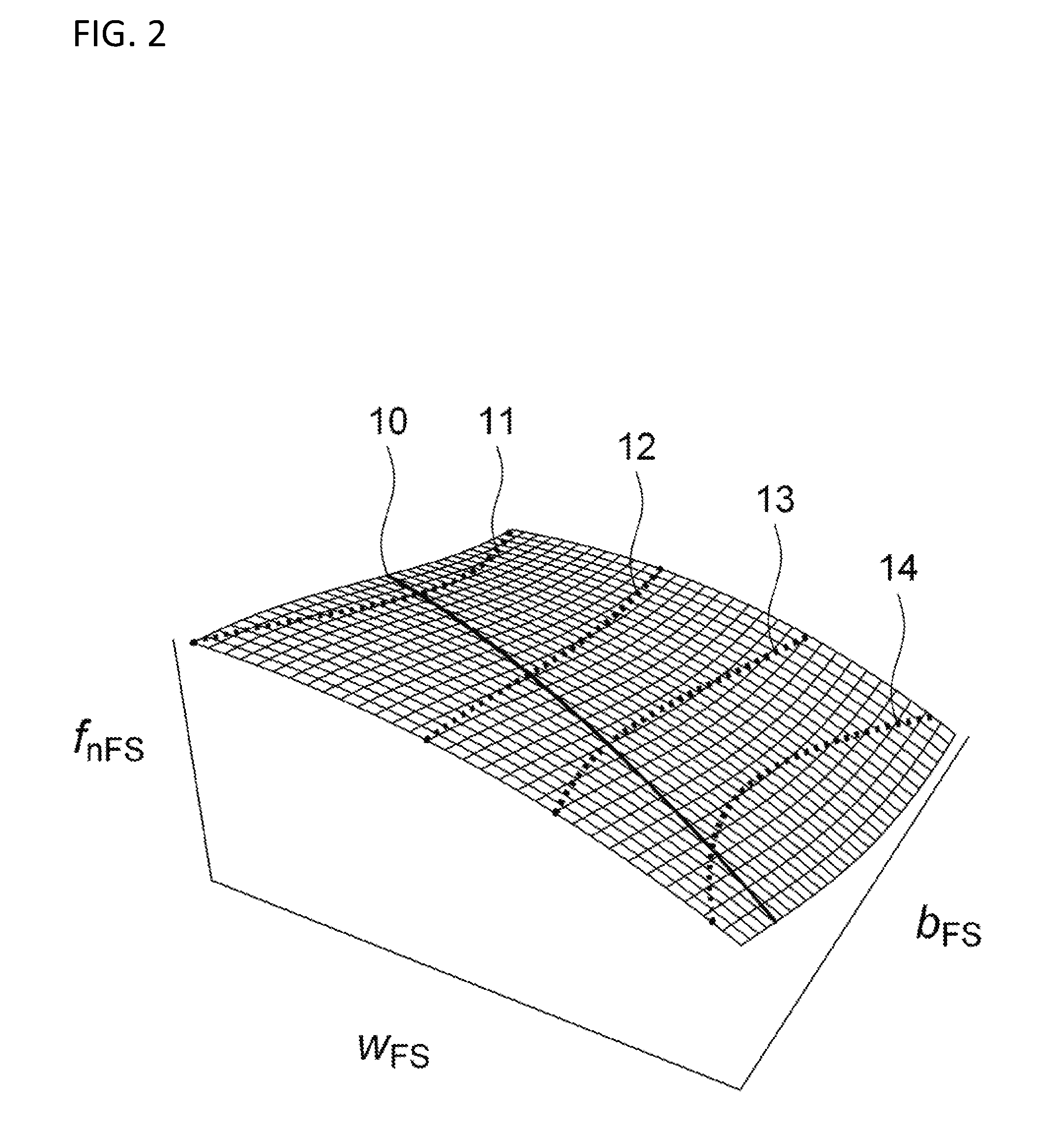

Method of dressing a tool

ActiveUS20170008109A1Avoid undercutEasy to controlAbrasive surface conditioning devicesTotal factory controlEngineeringSurface geometry

A tool which can be used for gear manufacturing machining of a workpiece may be dressed on a dressing machine, and the dressing may take place with line contact between the dresser and the tool. A specific modification of the surface geometry of the tool is produced by the suitable selection of the position of the dresser with respect to the tool during dressing. The specific modification of the surface geometry of the workpiece is specifiable with regard to various parameters.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

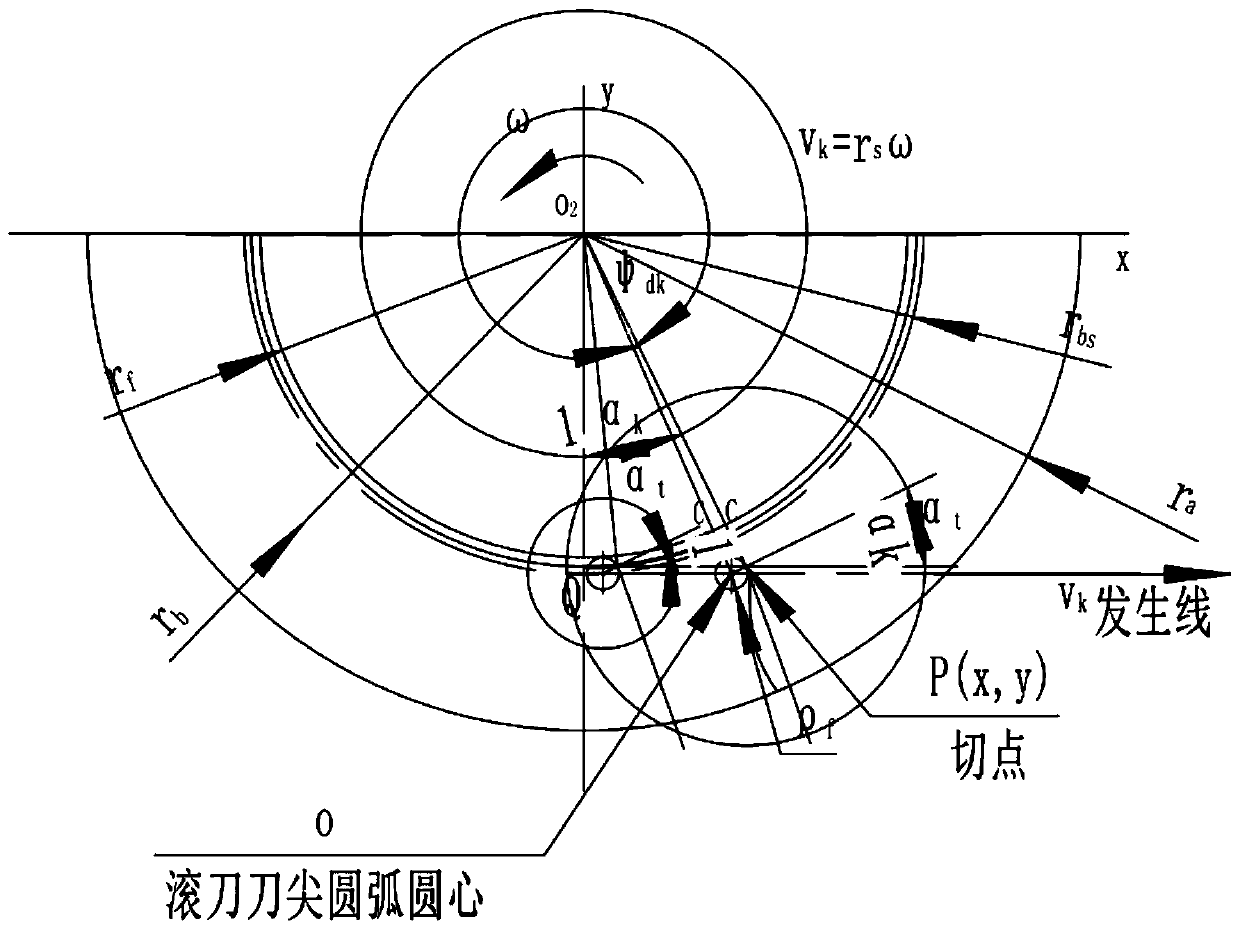

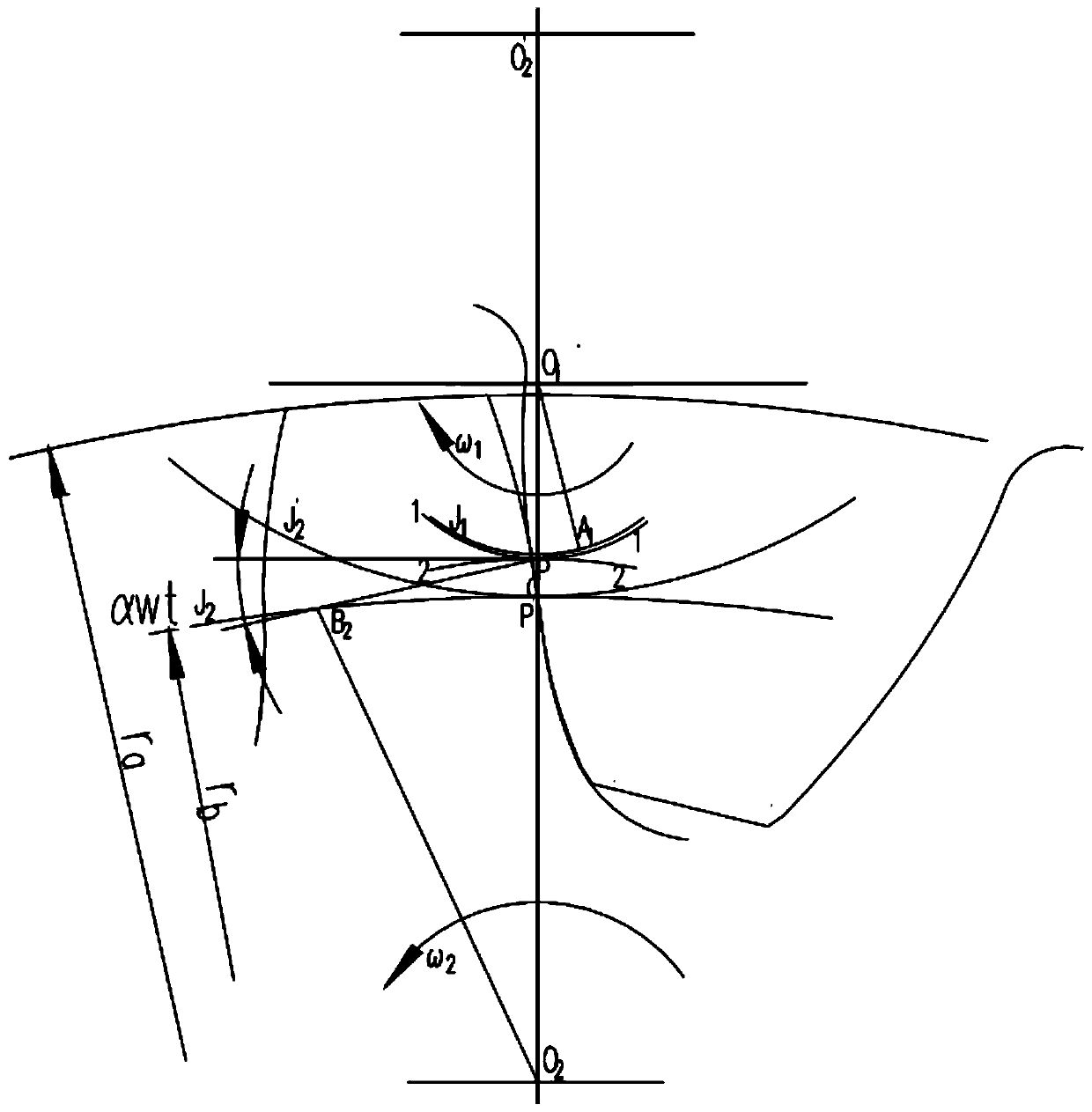

Design calculation method for reverse involute gear transmission meshing

ActiveCN109751386ARelaxation errorReduce difficultyPortable liftingSpecial data processing applicationsInvolute gearEngineering

The invention discloses a design calculation method for reverse involute gear transmission meshing. The design calculation method for the reverse involute gear transmission meshing comprises the following steps that modeling is carried out based on a gear base circle to establish a functional relation of a reverse involute; related meshing equations are deduced; the value of the gear modificationcoefficient of the reverse involute is confirmed; transmission parameters of the reverse involute are calculated; the calculated transmission parameters are checked; and the gear machining quality ischecked. A meshing track of a reverse involute tooth profile is designed on an involute gear, the bearing capacity of a main working face can be improved. Because the elastic deformation is consideredin the design, and the stress deformation of the gear is corrected by using the elastic deformation amount, the requirement of an elastic conjugate tooth profile curve is further met, the manufacturing error of the gear can be relaxed appropriately, and the difficulty of the gear manufacturing meeting the precision requirement is reduced.

Owner:重庆模源齿轮有限公司

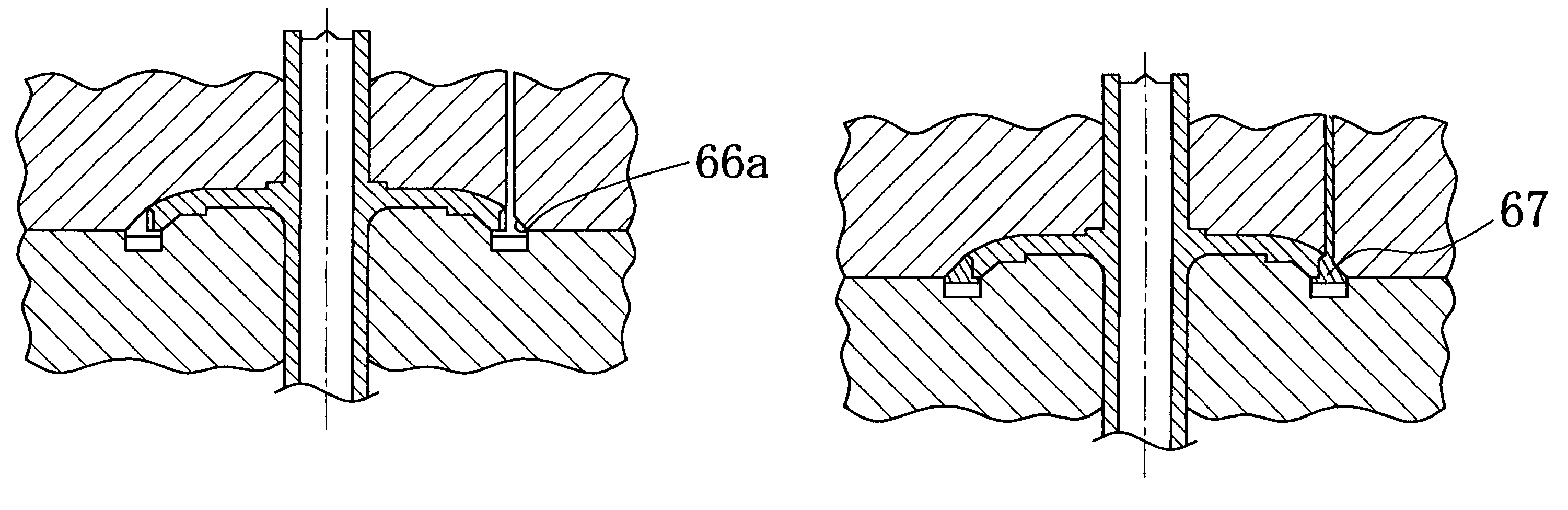

Automobile gearbox P-gear gear manufacturing method

The invention provides an automobile gearbox P-gear gear manufacturing method. An automobile gearbox P-gear gear is finally formed by conducting cold extruding after warm forging is conducted in a warm forging manufacturing mode. The automobile gearbox P-gear gear is characterized in that positive and negative combined extrusion is adopted for cold extruding, and outer teeth are extruded while extrusion forming of the petal portion in a product is finished. The product made through the method is high in accuracy, less in oxidation, good in internal metal organization and more refined in crystalline grain, and harmful structures of coarse crystals, mixed crystals and the like can be avoided; the required equipment is small in tonnage and less in forming force, tooth filling is easier, unit intensity of pressure born by a die is remarkably lowered, the service life of the die is very long, the process can be reduced, and the manufacturing time is greatly shortened (increased by 10 times compared with a gear hobbing machine). The product hardness ranges from HB 140 to HB 180, the tooth profile is fully filled and full, and it is guaranteed that large deformation cannot be generated in subsequent heat treatment of cold extrusion forming.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

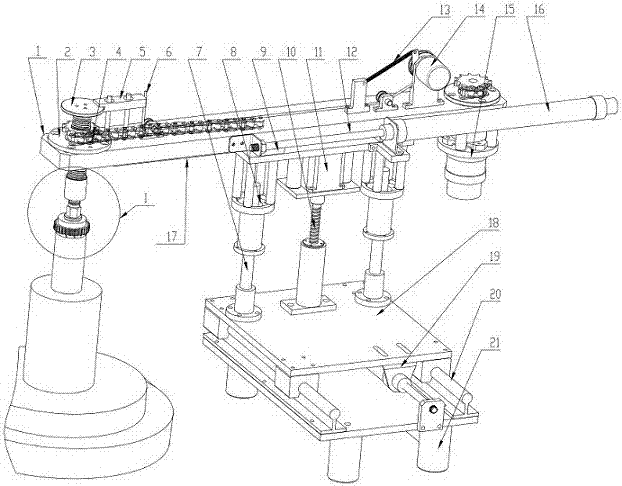

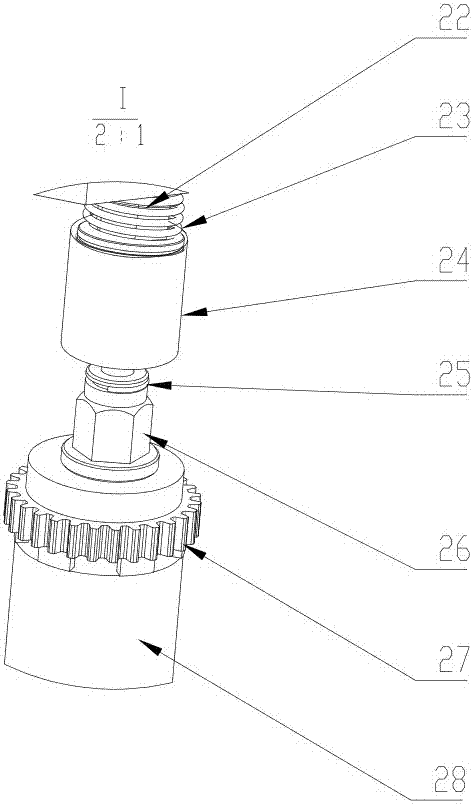

Automatic locking and disassembling device for work piece clamping and locking nut of gear manufacturing equipment

InactiveCN106914749AImprove processing efficiencyReduce labor costsMetal working apparatusGear-cutting machinesEngineeringIndustrial manipulator

The invention discloses an automatic locking and disassembling device for a work piece clamping and locking nut of gear manufacturing equipment. The automatic locking and disassembling device comprises a mechanical arm, a rotary transmission mechanism, a sleeve spring mechanism, a sleeve displacement sensor, an elastic clamping nut and a control circuit, wherein the mechanical arm is driven by an air cylinder to move a sleeve towards to or away from a tooling screw, the sleeve is driven by a motor to rotate to drive the nut to be locked or disassembled, elastic force of a retainer ring spring of the elastic clamping nut can keep the disassembled nut in the sleeve, the displacement sensor can detect longitudinal displacement of the sleeve and reports the displacement to the control circuit, and the control circuit can control action course according to the displacement. The device can be used together with an industrial manipulator to finish automatic work piece feeding and discharging of the gear manufacturing equipment.

Owner:李倩 +1

High-precision gear manufacturing method

The invention relates to a high-precision gear manufacturing method. By optimizing nitrogen process parameters and adopting a flexible positioning net, parts are nitrogenized in a free state, a sandblasting machining method is adopted in a subsequent process to uniform residual stress on the surface of a spoke plate, and by taking measures of using a self-adaptive gear grinding fixture, increasing a sandblasting process and the like, the problems that deformation occurs during gear machining and the precision cannot be guaranteed are solved. The method provided by the invention has the advantages that the stability of nitrogenization is guaranteed, the cutting precision is improved, the spoke plate is prevented from being deformed, the deformation during machining and nitrogenization is effectively controlled and the machining quality of the part is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

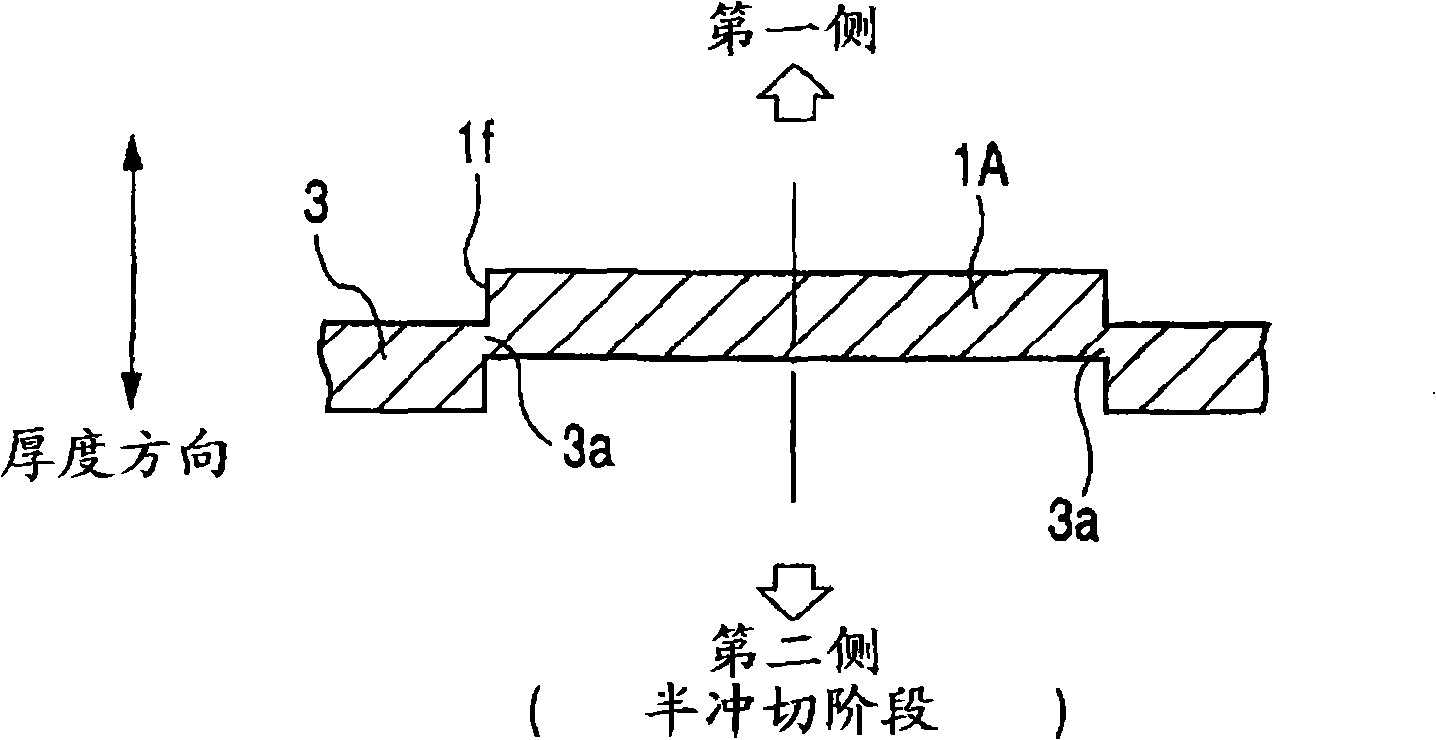

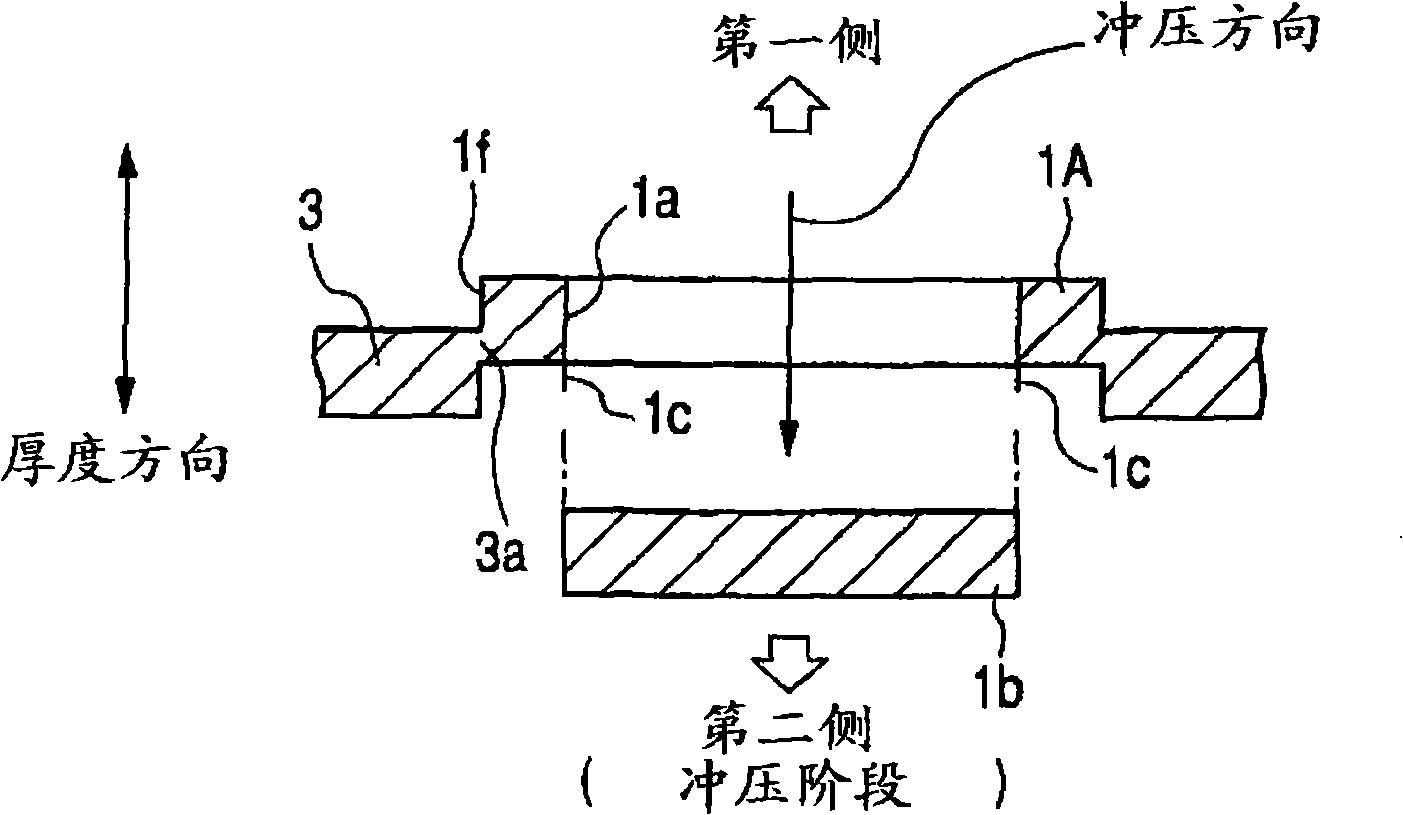

Method of manufacturing gear from metal sheet and the gear manufactured by the method

Owner:DENSO CORP

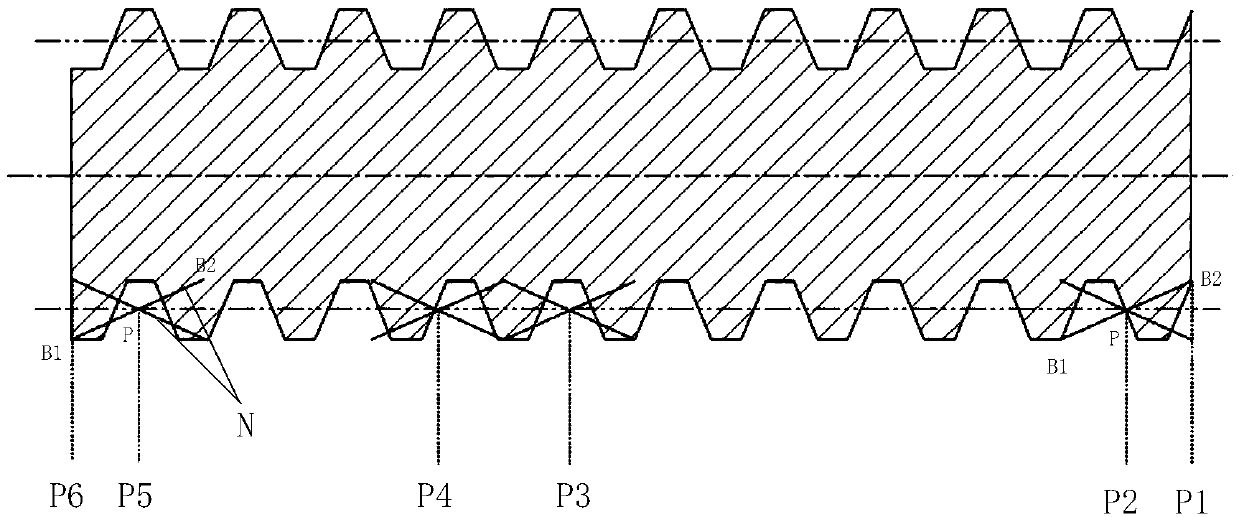

Gear processing technology

The invention discloses a gear processing technology, and belongs to the field of mechanical manufacturing. According to the gear processing technology, a tooth crest basic circle P turned in the first process provides a reliable positioning and clamping replacing standard for machining after heating, and therefore a workpiece can be positioned and clamped reliably, the workpiece is convenient to clamp, and the quality of gears is more stable. A film clamping claw directly clamps the tooth crest basic circle P, compared with an original method, the clamping method has the advantages that the capability to overcome the reciprocating axial acting force is obviously enhanced, the effect of grinding wheel powder on machining quality is reduced in the positioning and clamping process, the phenomenon that because of abrasion and deformation of drum-shaped cylinders on a full pitch circle clamp, relevant machining quality is affected is thoroughly eliminated, and therefore the machining quality of the gears can be stable. Besides, the rejection rate is reduced, the clamping speed of the workpiece is increased, cost of the full pitch circle clamp is saved, and machining cost of the gears is lowered correspondingly.

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

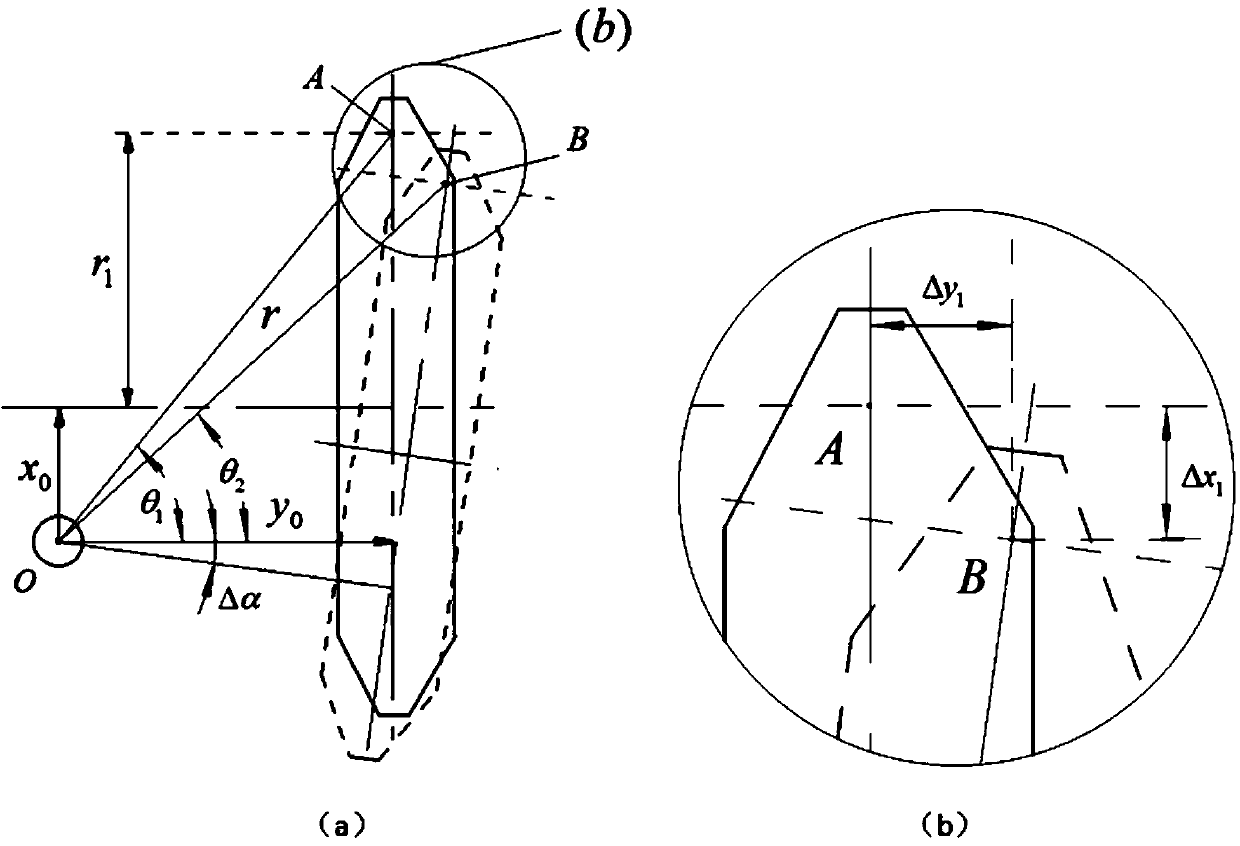

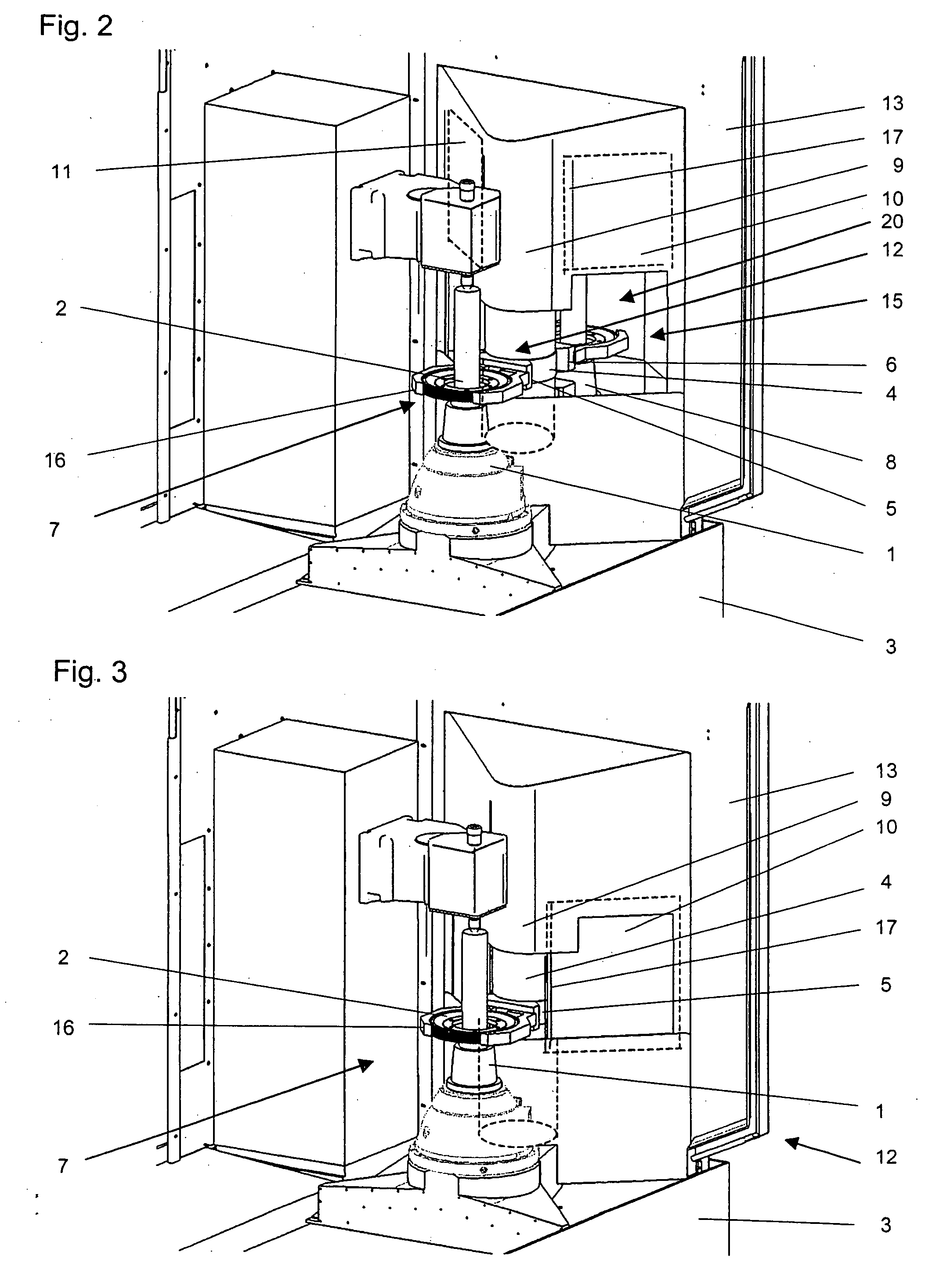

Method for processing spiral bevel gear and apparatus for forming large wheel of bevel gear thereof

A method for manufacturing the spiral bevel gear is characterized by that a semi-hobbing method is used, the teeth of small gear are made by generation method, and the big gear is made by shaping method. The concave-convex surface of big gear is shaped by multiple cutterheads with different shapes. Each cutter head has own axle and holder installed on own vertical track. All cutter heads have common transverse track and feeding track and are controlled by numerally controlled motor.

Owner:潘旭华

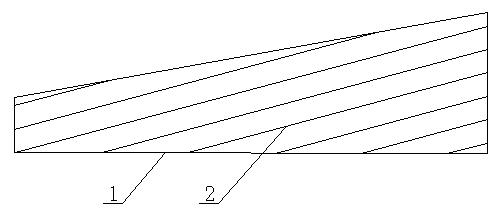

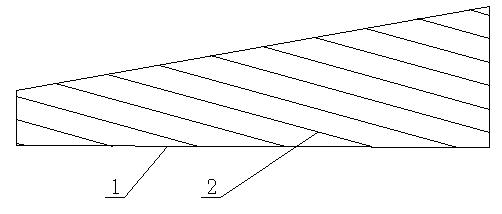

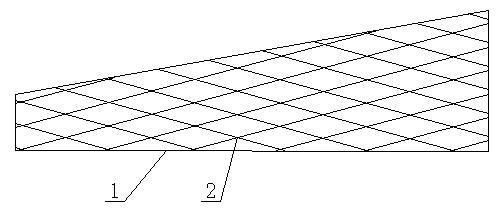

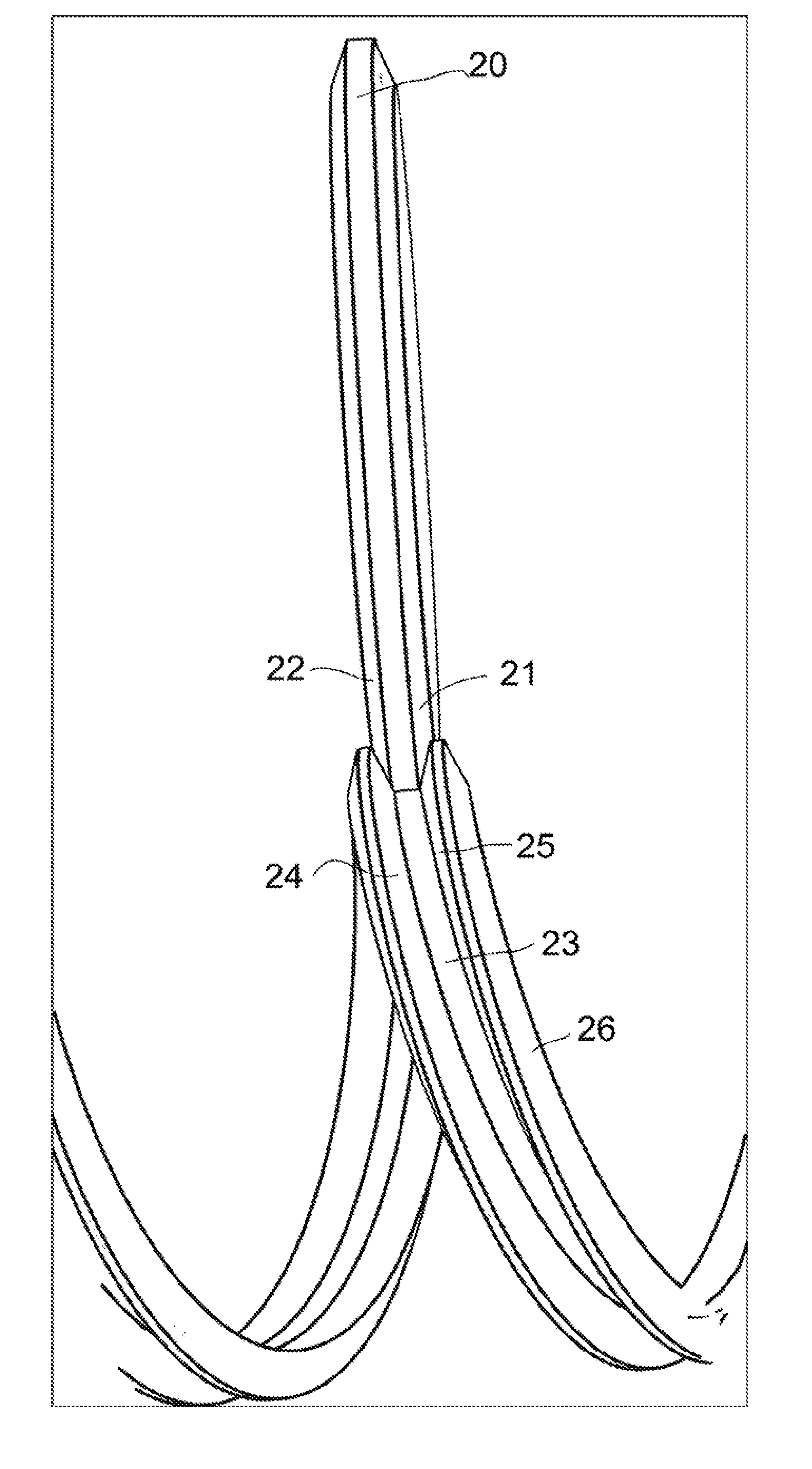

A method of manufacturing a fishing rod

A method for manufacturing a fishing rod, which relates to a method for manufacturing a fishing tool. According to the size required by the design, at least two main cloths with an included angle of 5°-25° between the reference side and the carbon fiber pattern of the carbon fiber cloth are cut out; the main cloths are superimposed Lay together, the carbon fiber lines of the two adjacent main fabrics are in a cross shape; on the mold, use a carbon tape to form an inner winding layer at an angle of 10°-30° to the radial direction of the mold to form an inner winding layer; The final main cloth roll is rolled on the inner winding layer; then an outer winding layer is wound clockwise with a carbon tape and the radial direction of the mold at an angle of 10°-30°; finally, the BOPP release tape is wound and baked at high temperature. Exit the mold, remove the BOPP release tape, trim, polish, paint, and assemble to become a fishing rod. The fishing rod has good toughness, high strength, good conductivity to force, high sensitivity, and good pressure resistance. The tip of the fishing rod is not easy to break when it is twisted by force, and the rod body is not easy to break when it is squeezed by external force.

Owner:威海市海明威集团股份有限公司

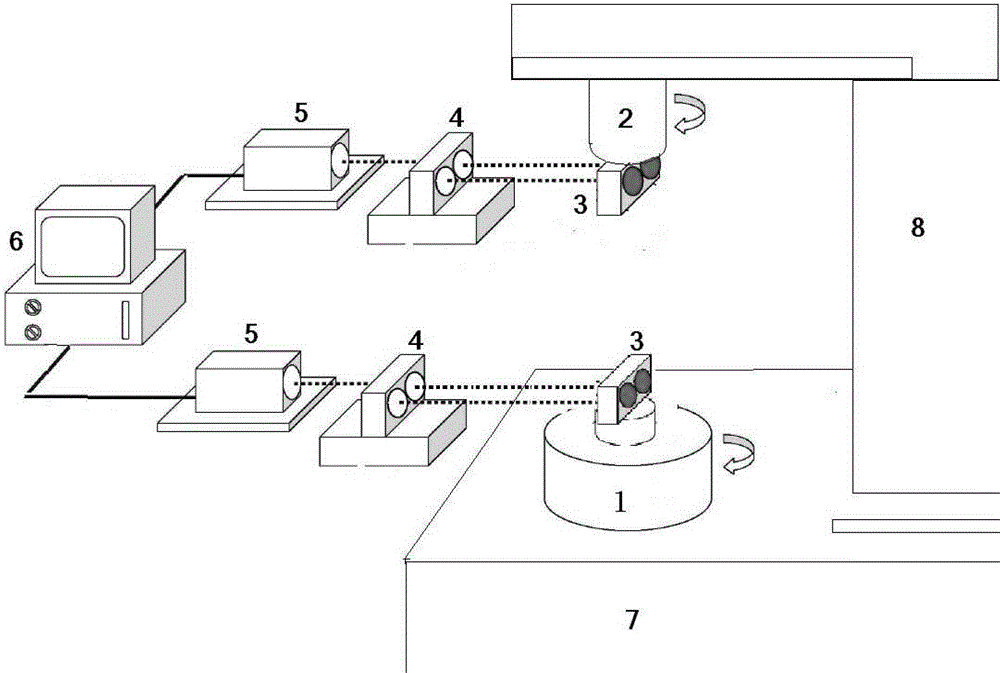

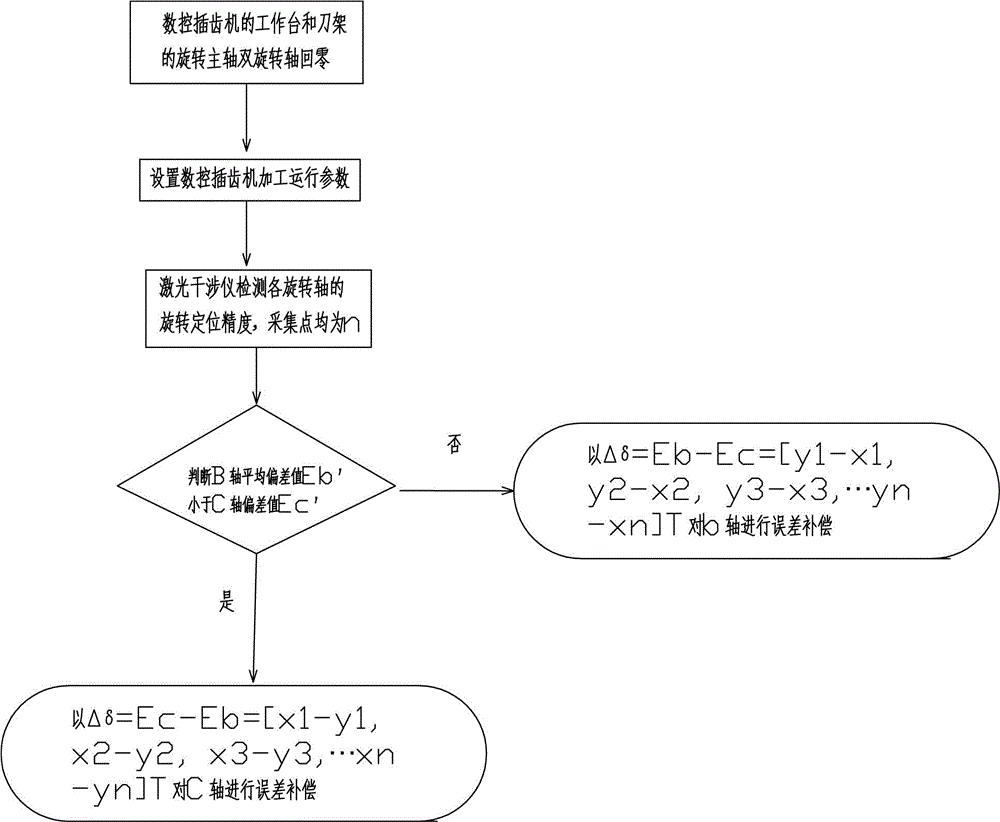

Method and device for compensating for errors of synchronous rotating shafts of numerical control gear shaping machine

InactiveCN105215479AGuaranteed positioning accuracyGuaranteed repeat positioning accuracyGear-cutting machinesGear teethNumerical controlManufacturing technology

The invention relates to a method for compensating for errors of synchronous rotating shafts of a numerical control gear shaping machine, belongs to the technical field of gear machining and manufacturing, and relates to a high-precision gear digital manufacturing technology, in particular to a method for improving the gear machining accuracy through compensation for errors of synchronous shafts of a gear manufacturing machine tool. A moving workbench and a rotating shaft of a tool rest are measured at the same time through two laser interferometer measuring assemblies, a measuring system obtains movement data of the double synchronous shafts at the same time, and then data processing and error compensation are conducted, so that the machining accuracy of gears is improved.

Owner:HUBEI THREE GORGES POLYTECHNIC

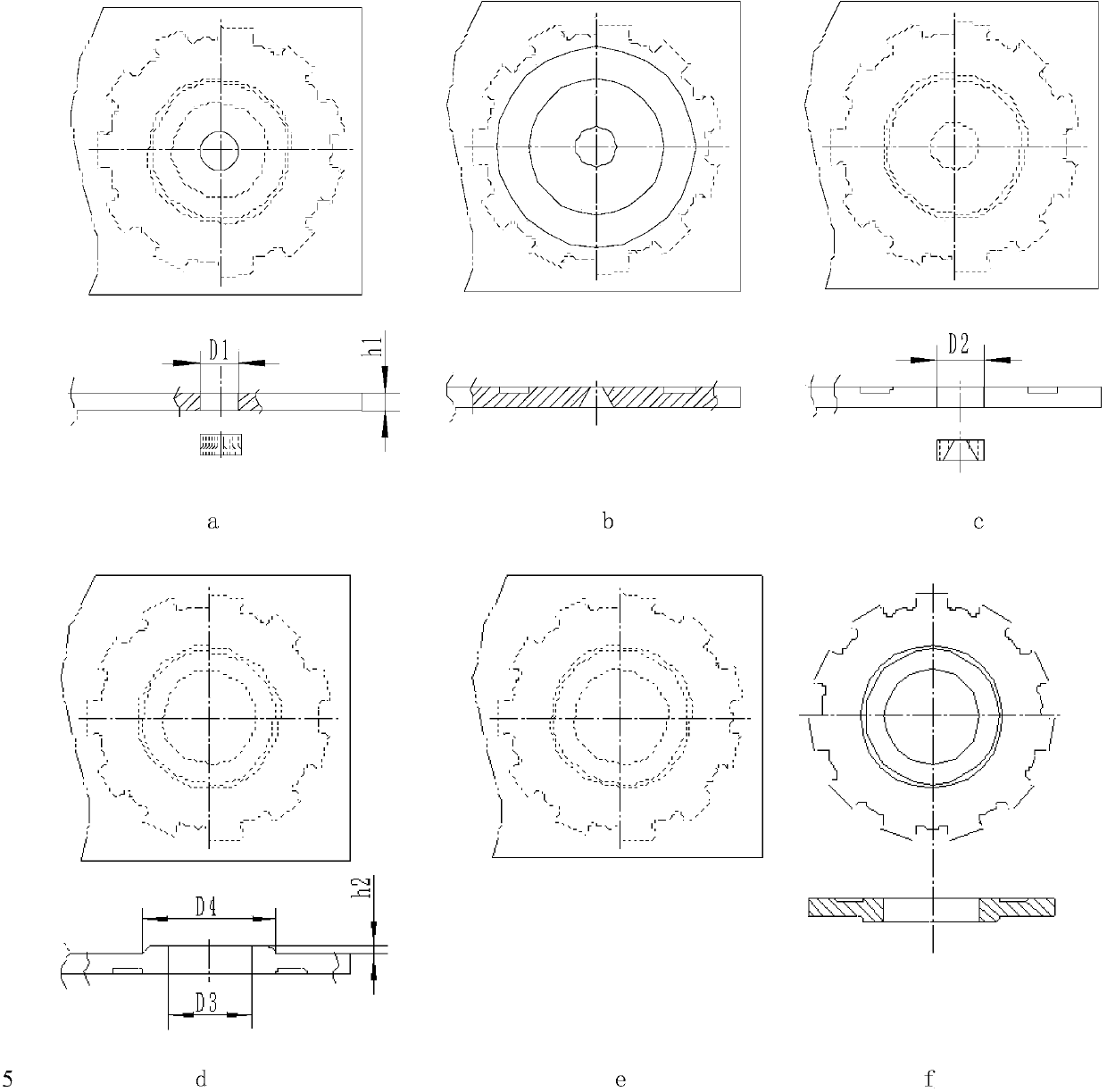

Precision forming method and device of flanged flat gears

ActiveCN103736903AAvoid interrupted cutsGuaranteed lifeForging/hammering/pressing machinesWheelsPunchingGear wheel

Disclosed is a precision forming method and device of flanged flat gears. A blank for manufacturing a gear is punched first to obtain an auxiliary center hole which functions in distributing in the forming process; compression deforming is performed to obtain a circular groove so as to form an upper flange of the gear, flanging and upsetting are performed after pre-punching, and the edge material pre-punched transfers to move a lower flange; a gear ring press plate is used for precision punching to obtain a gear shape. The precision forming method and device of flanged flat gears has the advantages that batch continuous production of gears is achieved, cutting steps are effectively decreased, materials are more available, production efficiency is improved, and cost of a single product is reduced.

Owner:SHANGHAI JIAO TONG UNIV

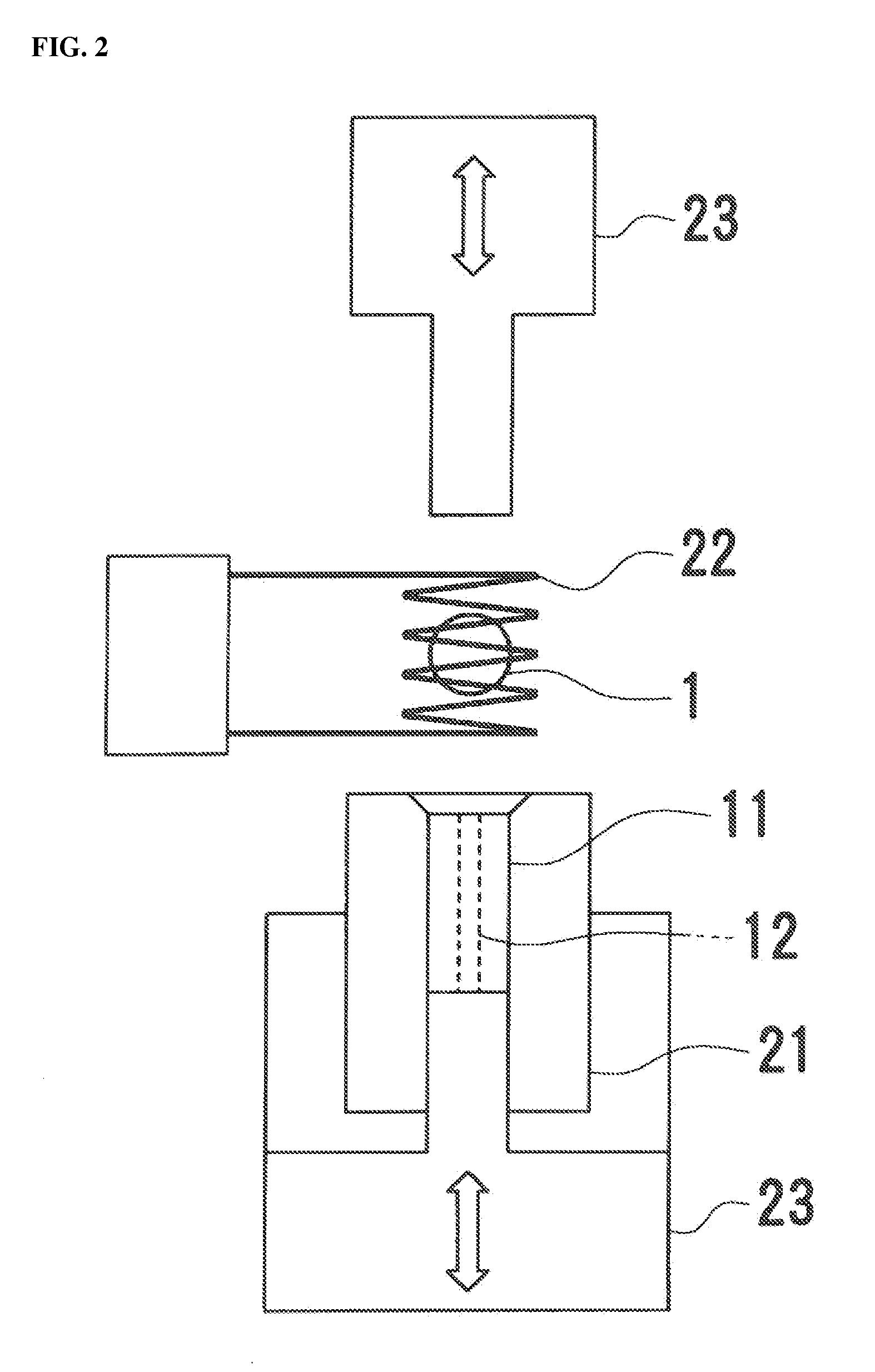

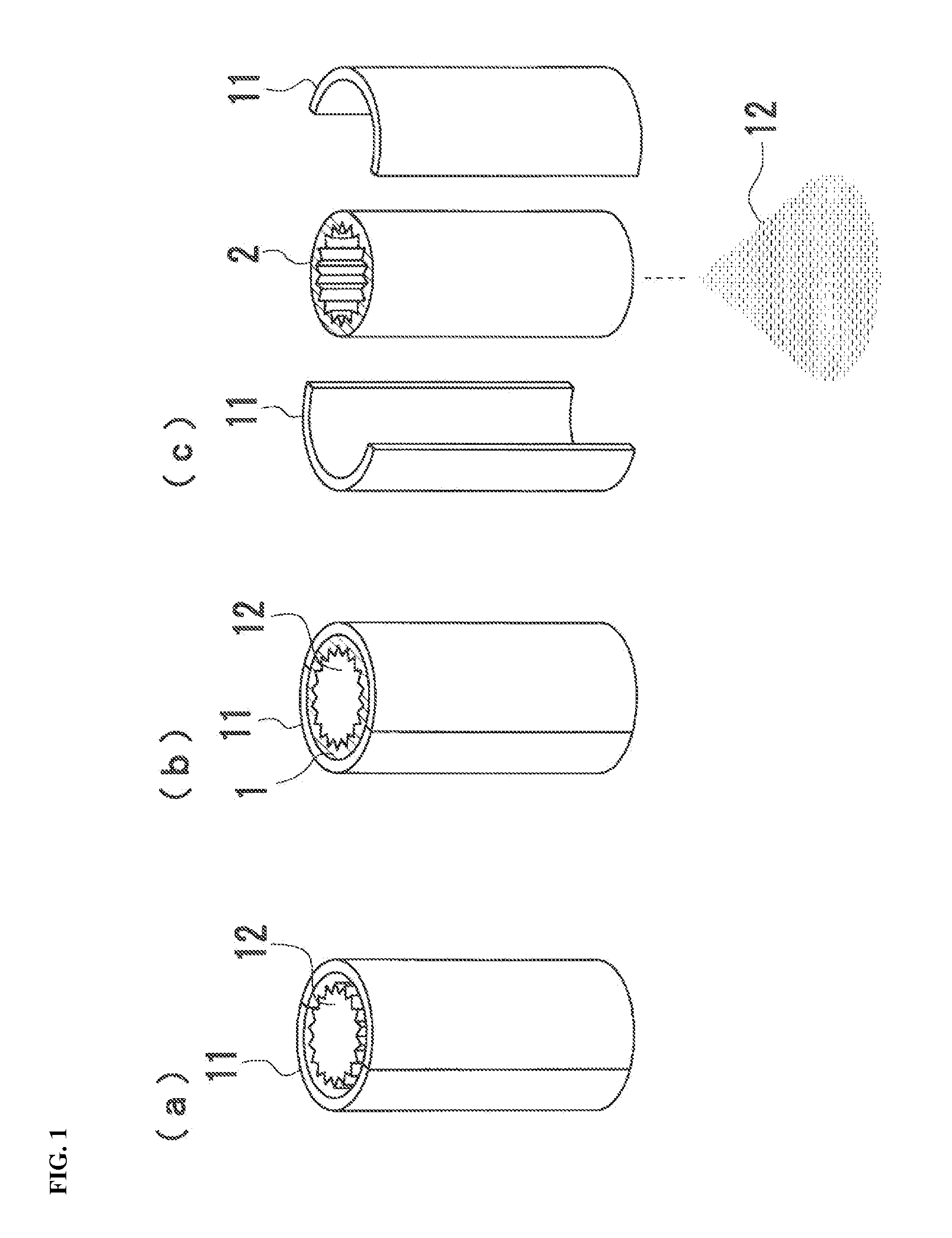

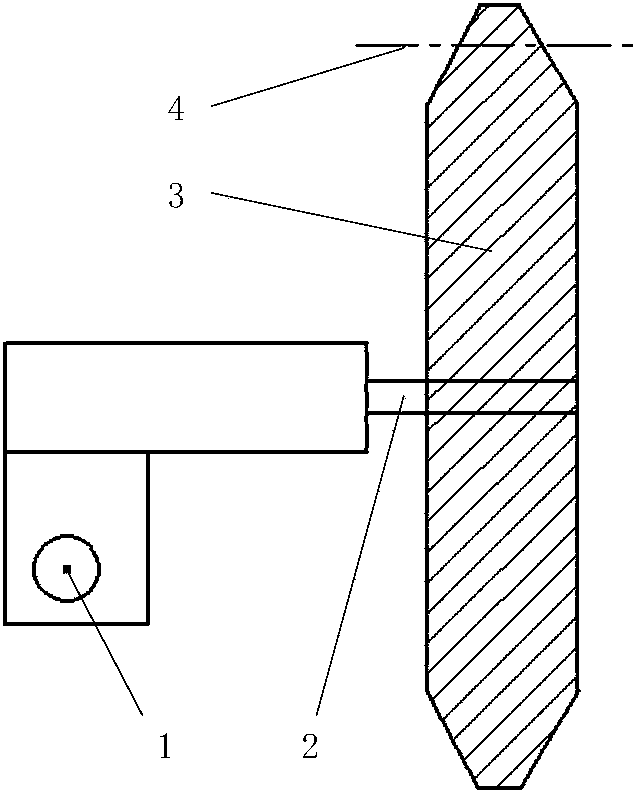

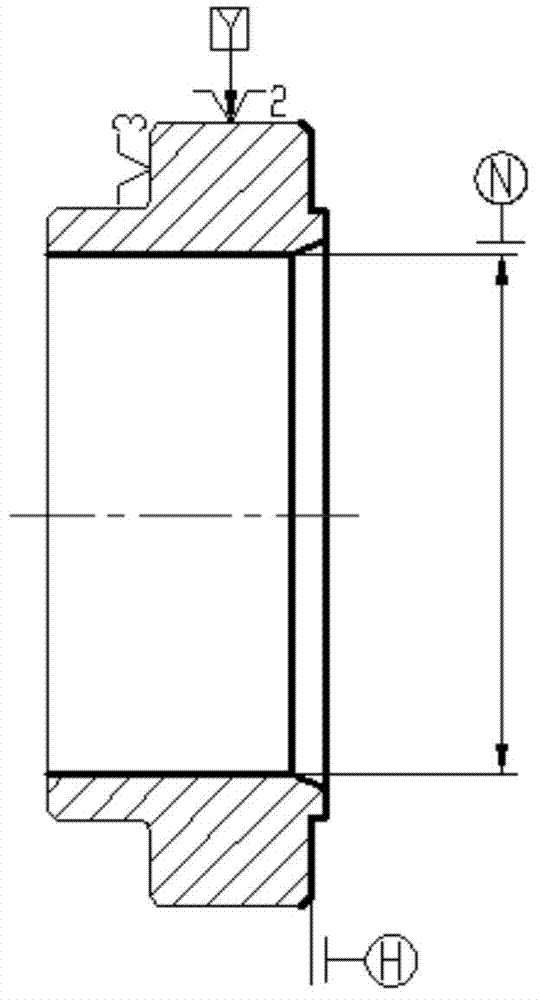

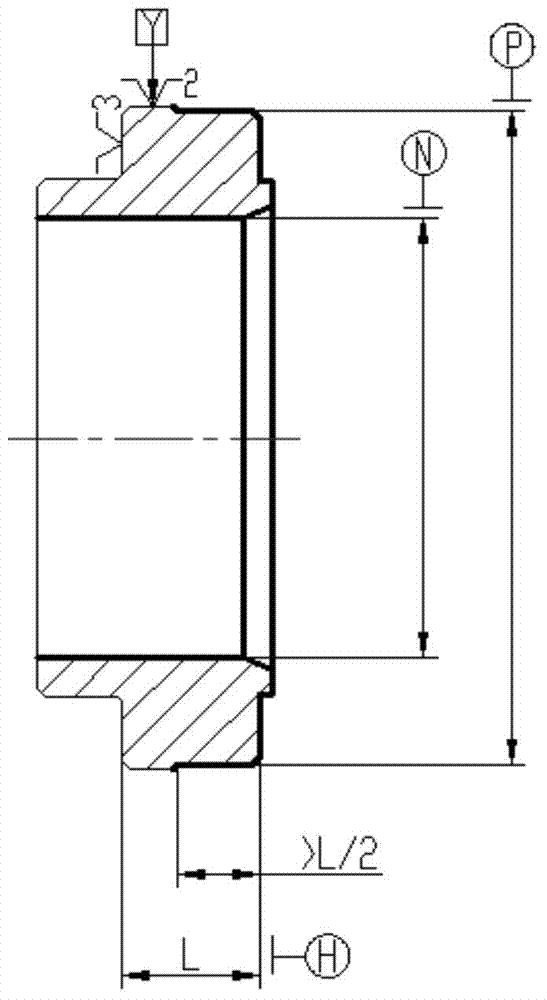

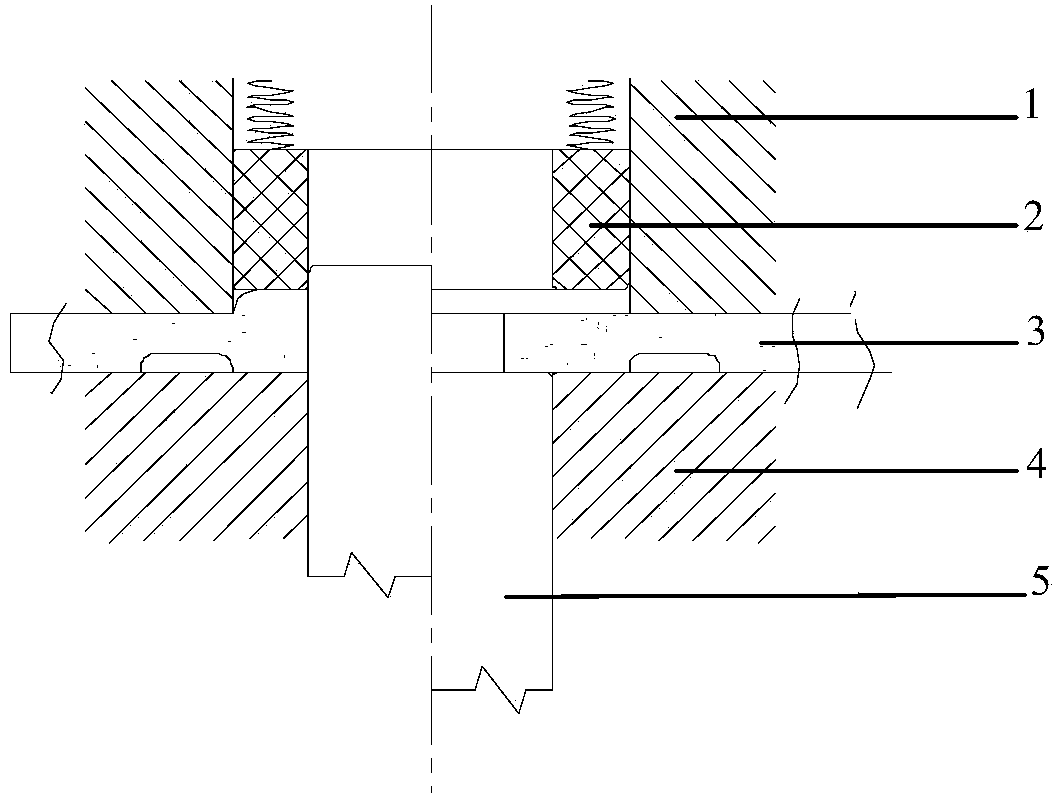

Gear manufacturing machine and process for the operation of such a gear manufacturing machine

ActiveUS20070060022A1Reduce idle timeEasy and time-savingGrinding feed controlAutomatic grinding controlEngineeringMachining process

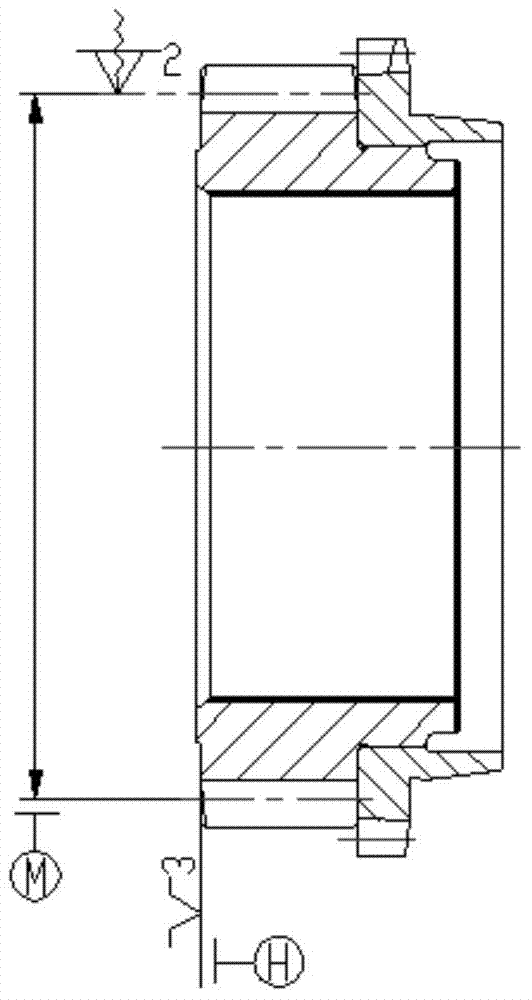

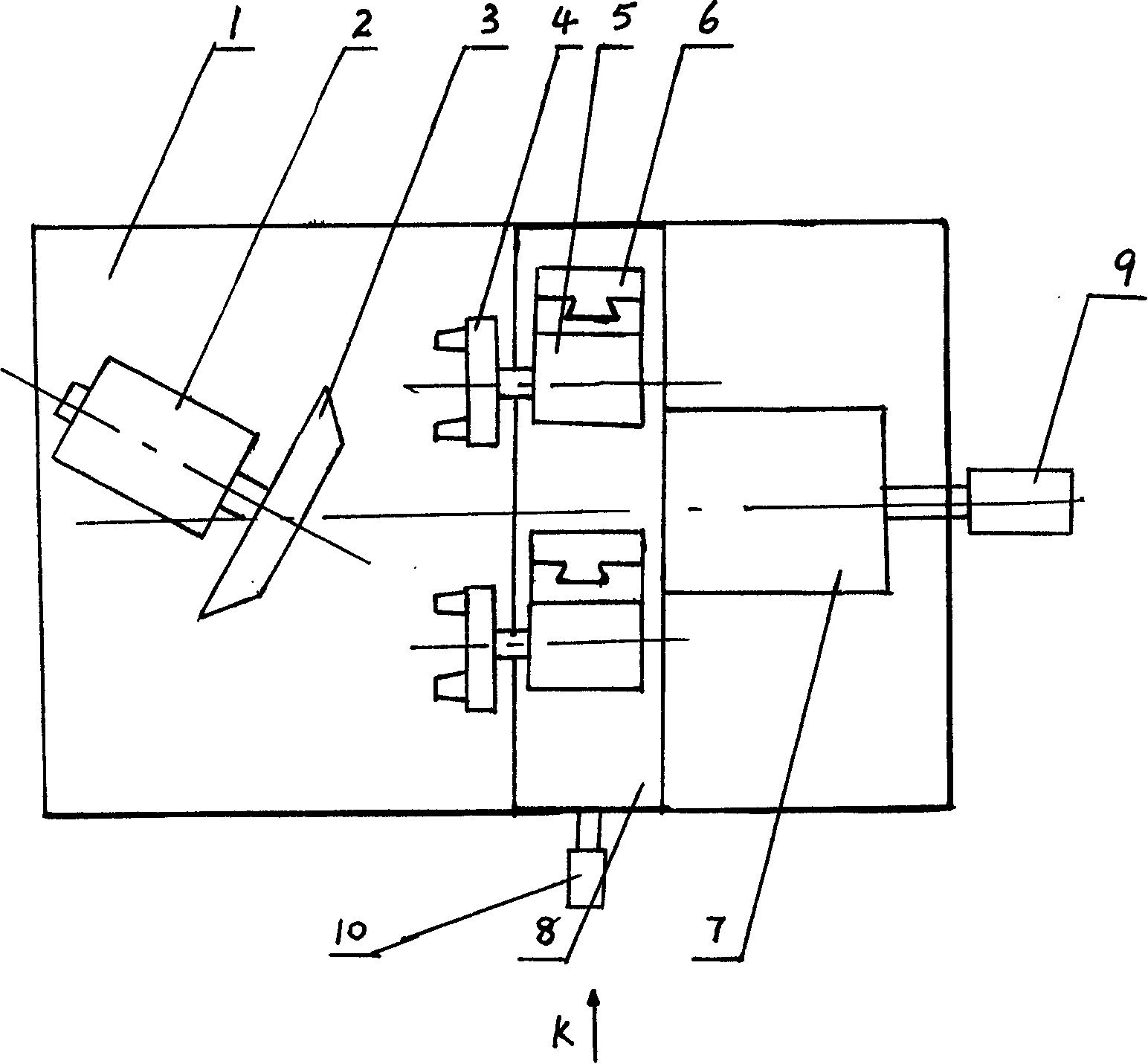

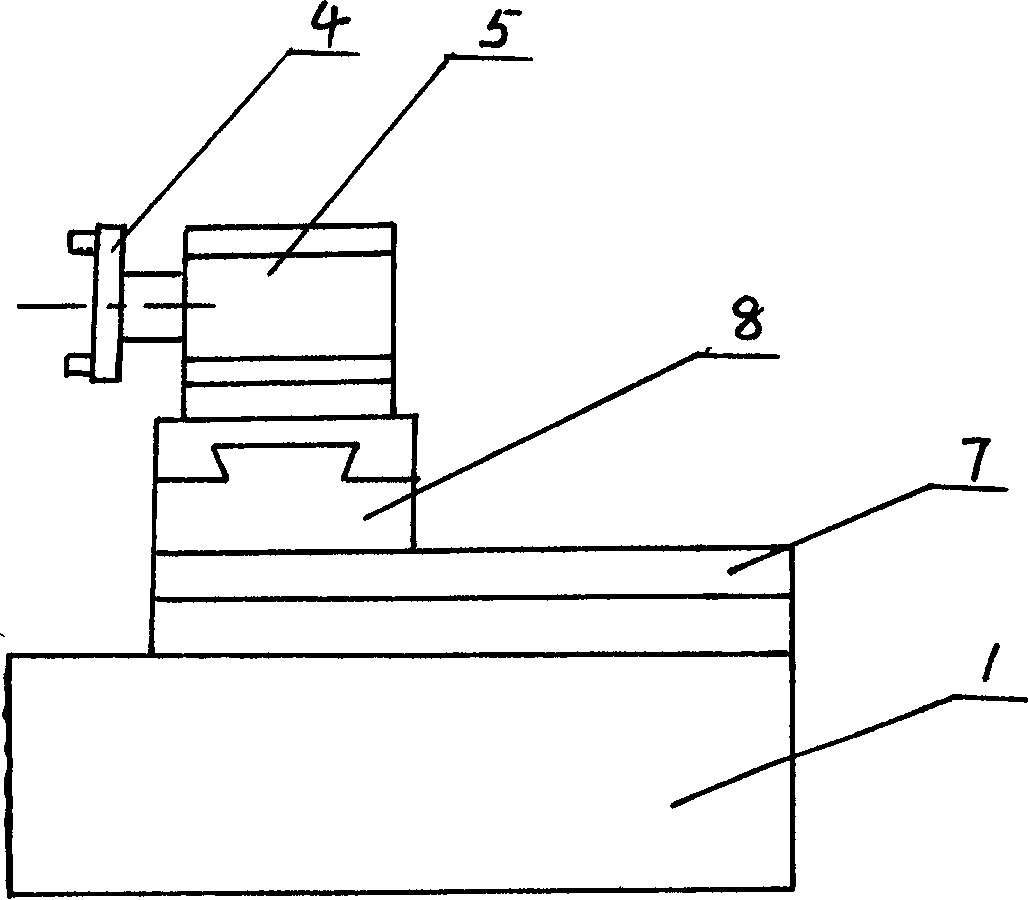

The invention concerns a device for the automatic loading of workpieces into a gear manufacturing machine, in particular a hard state finishing machine, by means of a swivel device arranged on the machine, where simultaneous with the machining process of a work piece blank (2) clamped on the work spindle (1) a finish machined work piece (2) on the transfer platform (8) located opposite the work spindle is de-oiled in a work piece loading lock, removed, and a fresh work piece blank fed in. The transfer platform (8) is designed as a centrifuge station.

Owner:REISHAUER

Method of dressing a tool

ActiveUS20170008148A1Programme controlAbrasive surface conditioning devicesEngineeringSurface geometry

The present disclosure relates to a method of dressing a tool which can be used for the gear manufacturing machining of a workpiece on a dressing machine, wherein the dressing takes place with line contact between the dresser and the tool; wherein a specific modification of the surface geometry of the tool is produced in that the position of the dresser with respect to the tool during dressing is varied in dependence on the tool width position.

Owner:LIEBHERR VERZAHNTECHNIK GMBH

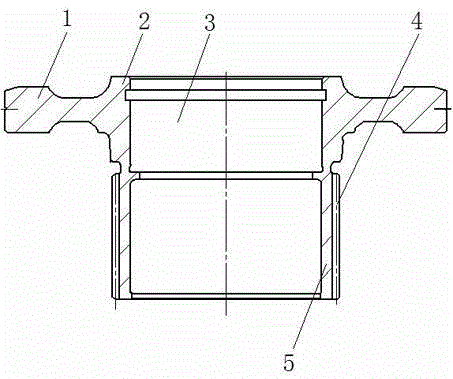

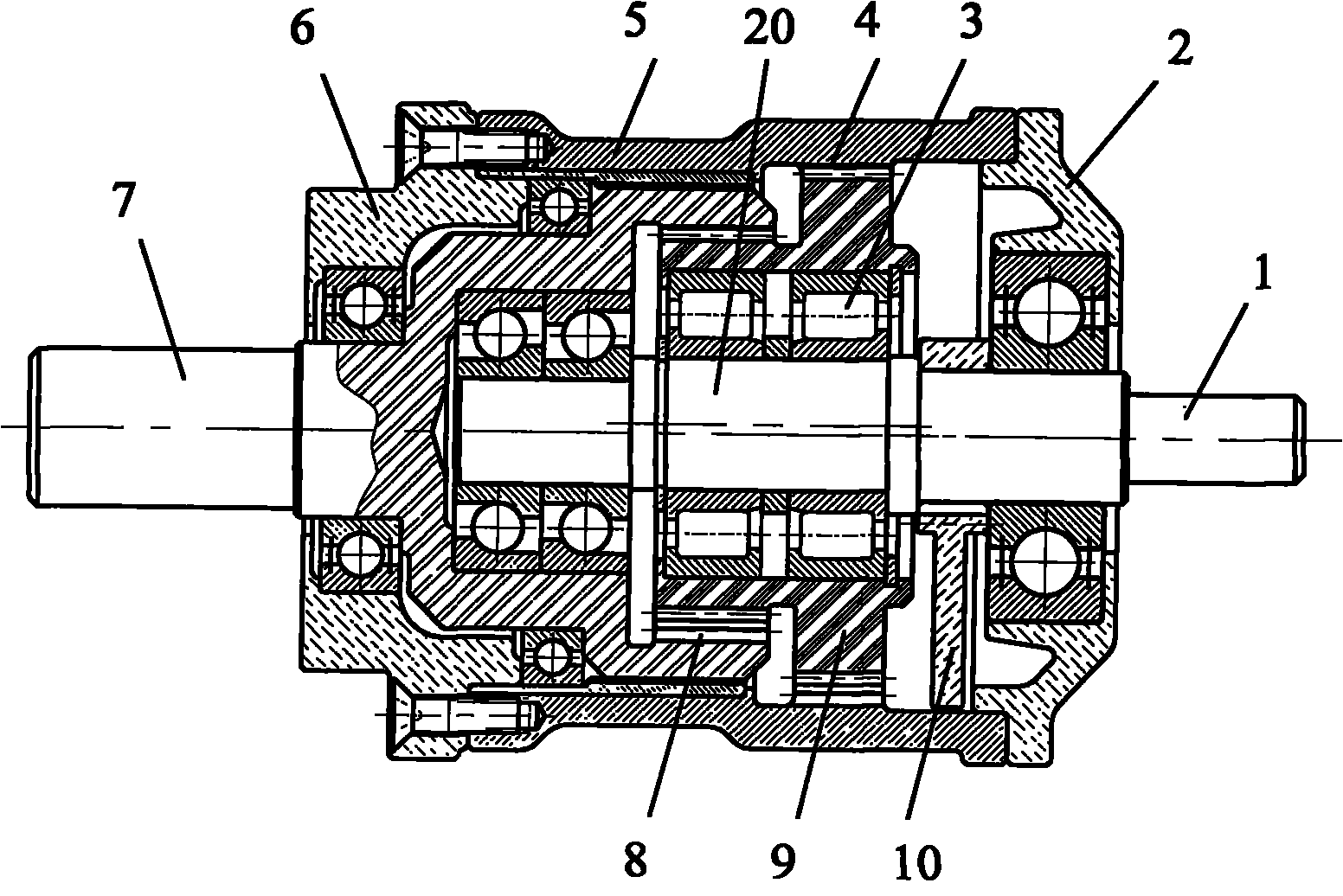

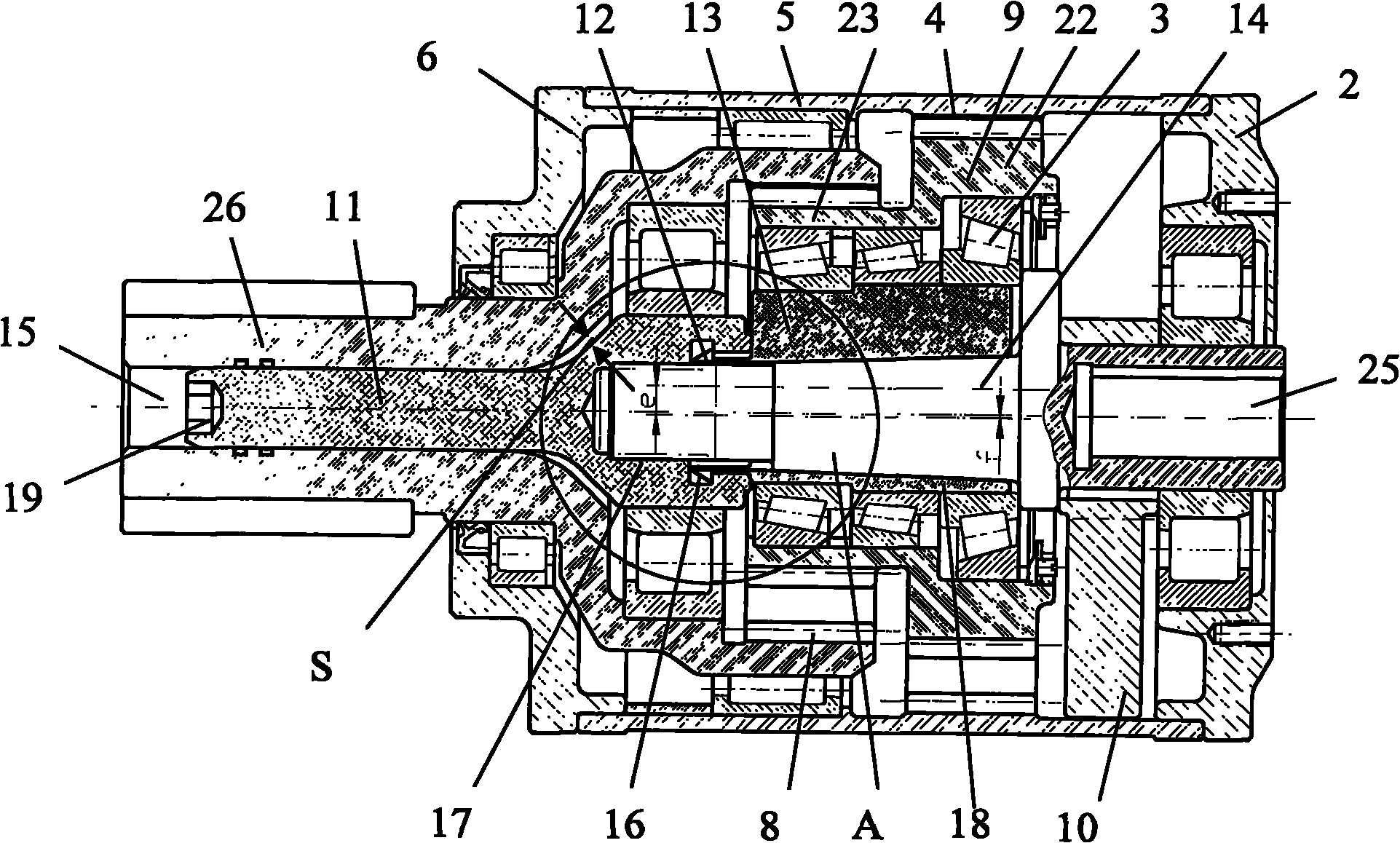

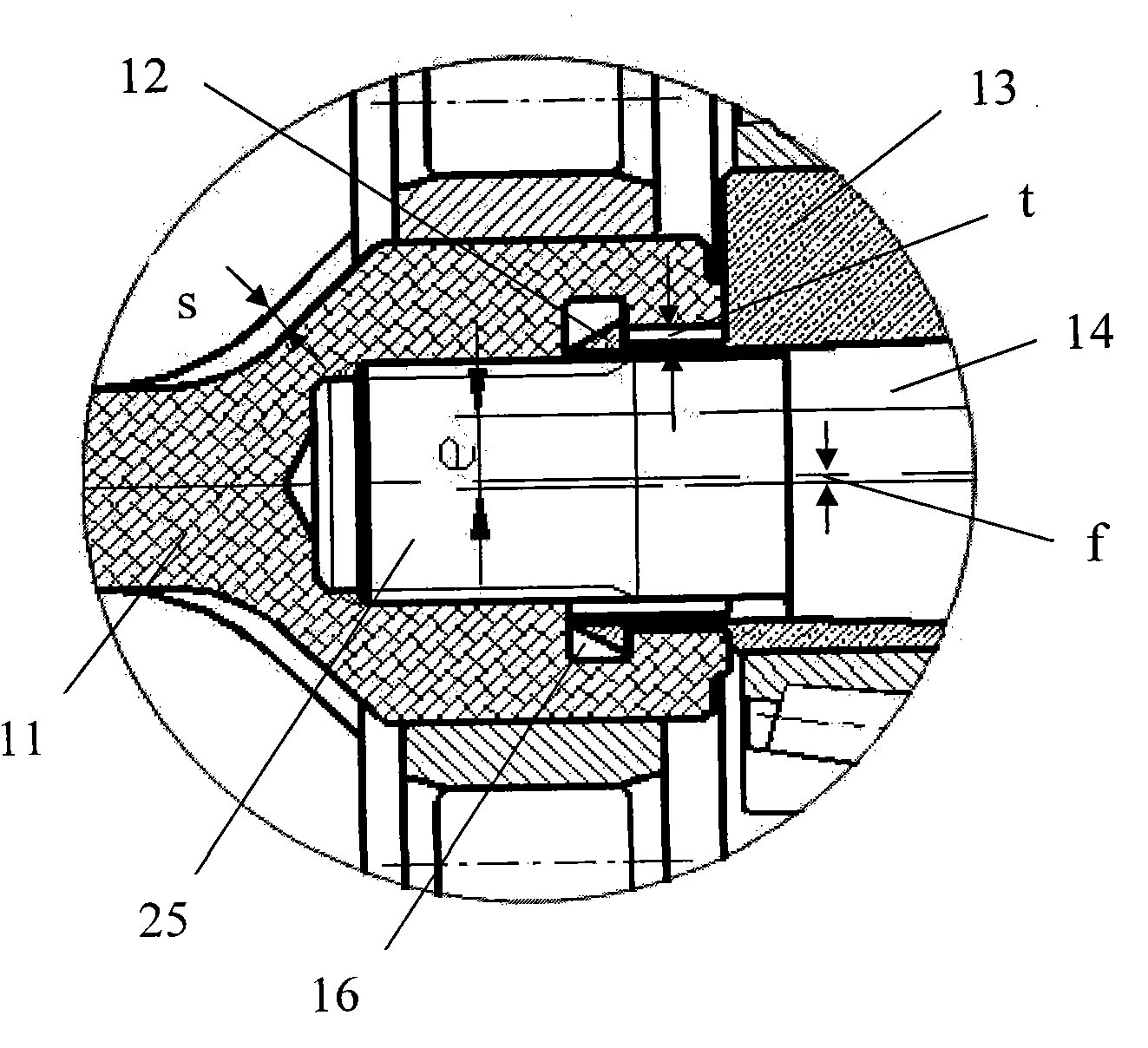

Reducer capable of regulating return difference

InactiveCN101893064AReduce manufacturing costExtended service lifeToothed gearingsGearing detailsGear wheelReducer

The invention relates to a reducer capable of regulating return difference. The reducer comprises an outer shell, a compound planet gear, an input shaft and output shaft, wherein a first gear I of the compound planet gear is meshed with the fixed gear ring of the outer shell, and a second gear II thereof is meshed with the gear of the output shaft; the input shaft and the output shaft are in the same straight line, the eccentric shaft neck of the input shaft is provided with taper, and an eccentric sleeve is arranged between the eccentric shaft neck of the input shaft and the bearing of the compound planet gear; the eccentric sleeve is provided with a tapered hole, and the front end of the eccentric sleeve is provided with an elastic hanger; the eccentric shaft neck of the input shaft is tightly matched with the tapered hole of the eccentric sleeve; the centre hole of the output shaft is internally provided with an adjusting screw rod, a screwed hole at the large end of the adjusting screw rod is connected with an external thread at the other end of the input shaft; and the elastic hanger of the eccentric sleeve is inserted into a hanger groove at the larger end of the adjusting screw rod, and the larger end of the adjusting screw rod is connected with the output shaft through a bearing. The invention can carry out adjustment to enable the gear return difference to restore to an expected value, has simple, convenient and feasible adjustment, reduced gear manufacturing cost and prolonged service life. The second embodiment of the invention can realize automatically regulating return difference.

Owner:张爱华

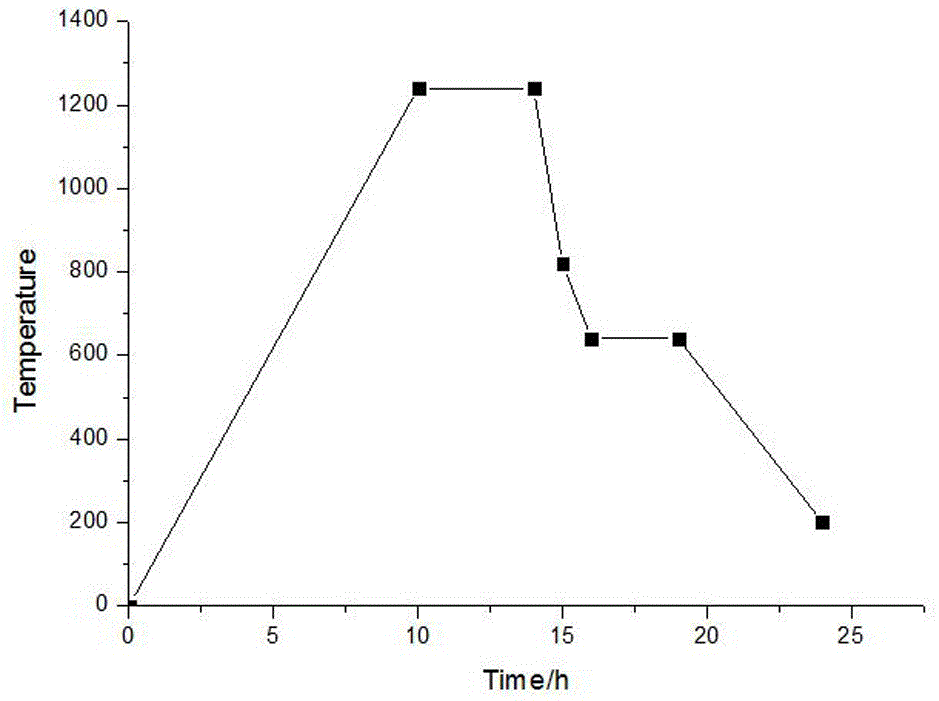

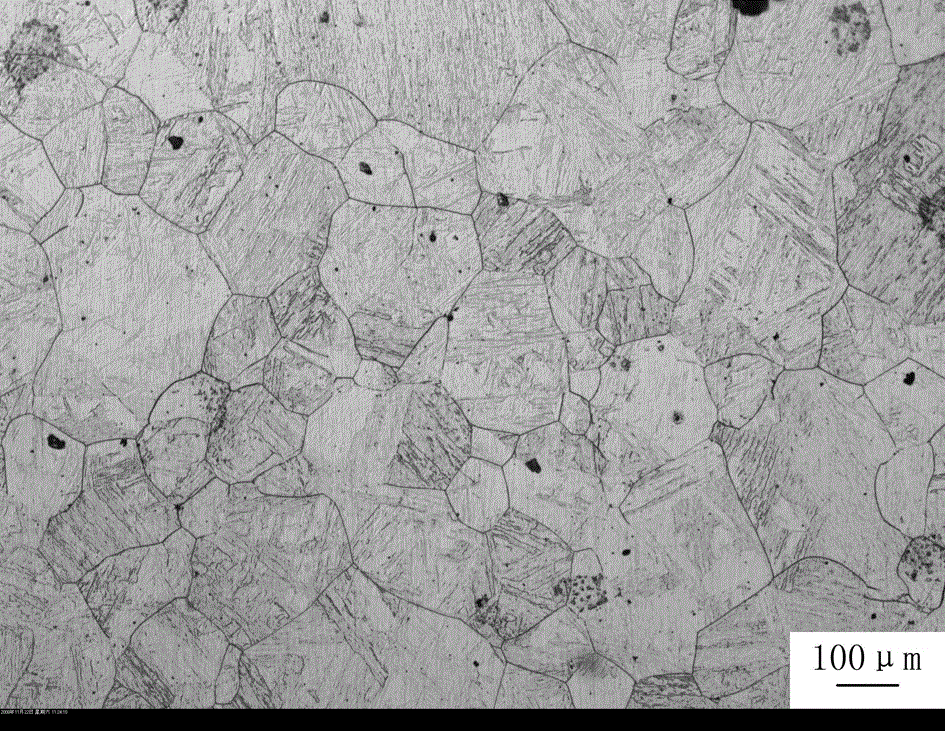

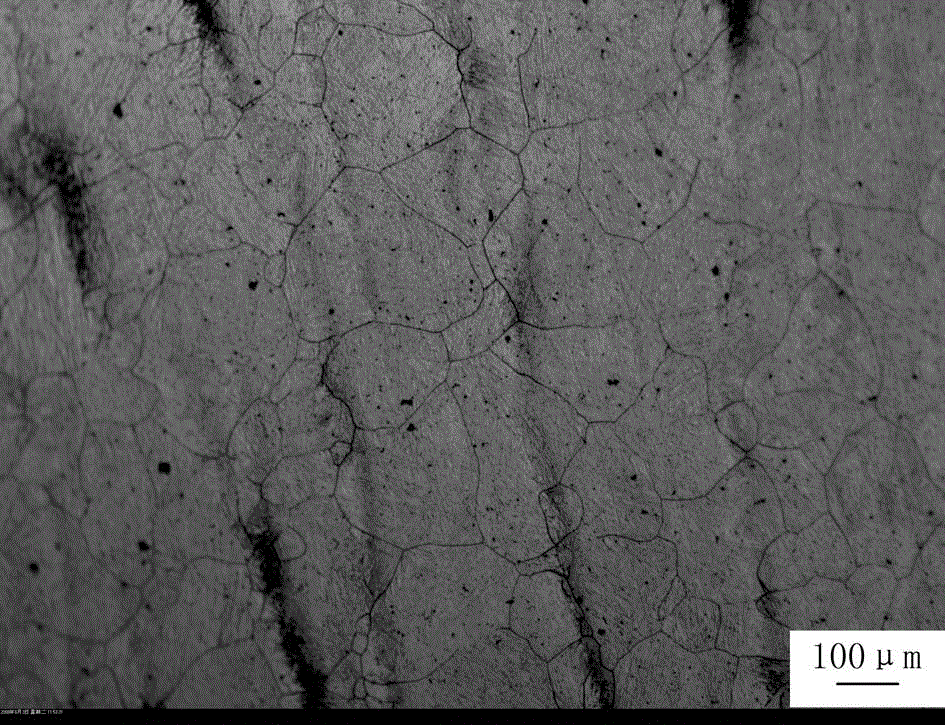

Method for forging 17CrNiMo6 steel wind power generation gear

InactiveCN106424524AEvenly diffused tissueAvoid crackingMetal-working apparatusWheelsManufacturing technologyRoom temperature

The invention belongs to the wind power generation gear manufacturing technology, and relates to a method for forging a 17CrNiMo6 steel wind power generation gear. The method is characterized by comprising the steps of treatment before forging, wherein after the temperature of a heating furnace is raised, a forged piece blank is placed in the heating furnace to be heated and subjected to heat preservation; forging forming, wherein the forging temperature is 1240+ / -10 DEG C-830+ / -10 DEG C, the single-heating-number single-pass forging ratio ranges from 1.5 to 2, the last-pass forging ratio ranges from 1.8 to 2, the total forging ratio is larger than 4, and a blank gathering material is formed at the deformation rate being 0.1-1 s<-1>; and cooling after forging, wherein the gear is fast cooled to 650+ / -10 DEG C after being forged for isothermal tempering, and furnace cooling is carried out after heat preservation to achieve the room temperature. A forged piece is heated before being forged, and the inner structure of the forged piece is more dispersed and uniform; the forging forming process parameters are controlled, and therefore the inner structure of the forged piece can form tiny equiaxial grains quite easily, and the comprehensive mechanical property of the forged piece is improved; and by means of the manner of cooling after forging, energy consumption is reduced, and meanwhile the stress of the inner structure of the forged piece is eliminated.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

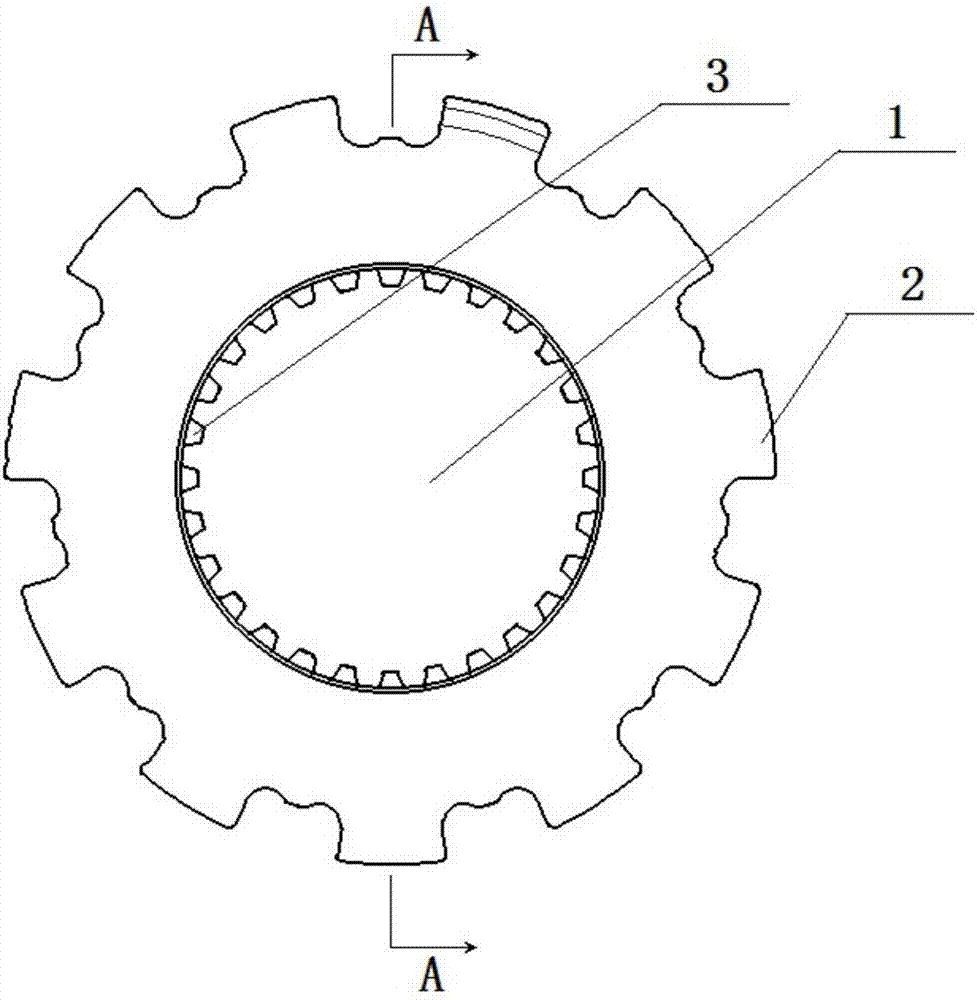

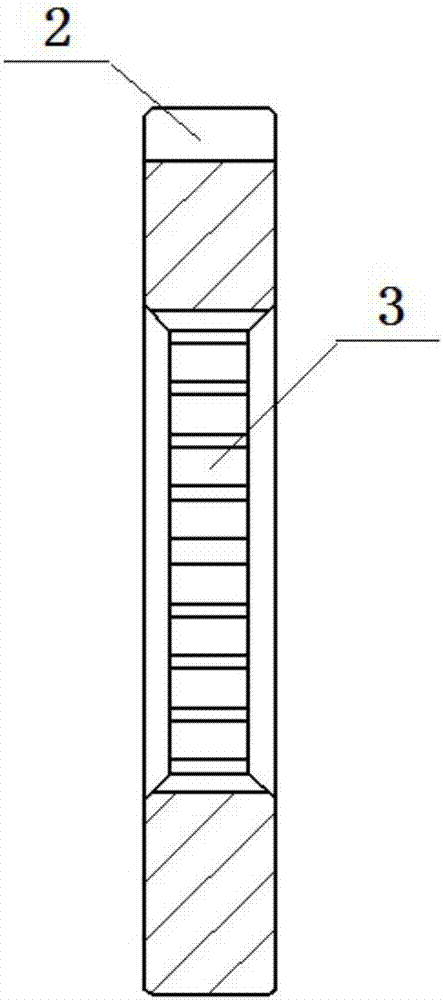

Synchronizing shaft error compensation method of numerical control gear manufacturing machine tool

ActiveCN103817380AImprove machining accuracyTo achieve error compensationGear-cutting machinesGear teethNumerical controlDrive shaft

The invention discloses a synchronizing shaft error compensation method of a numerical control gear manufacturing machine tool. A virtual shaft which is additionally arranged in an electronic gearbox of the numerical control gear manufacturing machine tool is taken as a driving shaft, and coincides with a following shaft in synchronizing shafts; the error compensation amount of each shaft in the synchronizing shafts is converted into an equivalent compensation amount of the virtual shaft by the corresponding synchronization coefficients; the total equivalent compensation amount of the synchronizing shafts is obtained by linear superposition, and finally, the error compensation of the synchronizing shafts is realized by utilizing the theoretical motion of the virtual shaft. According to the method, after the error of each shaft is obtained, the compensation to a single shaft is not needed, the hardware and system parameters of the machine tool are not changed, and the precision needed by the engagement motion of the gear manufacturing can be ensured by only arranging one virtual shaft in the electronic gearbox for compensation; the method is good in flexibility and adaptation, strong in expansion and high in compensation precision, and the composition error at any point in the coordinate system of the machine tool can be compensated; especially, when the dynamic error compensation of the machine tool is carried out, the real-time exchange data amount is small, and the response speed is rapid.

Owner:CHONGQING UNIV

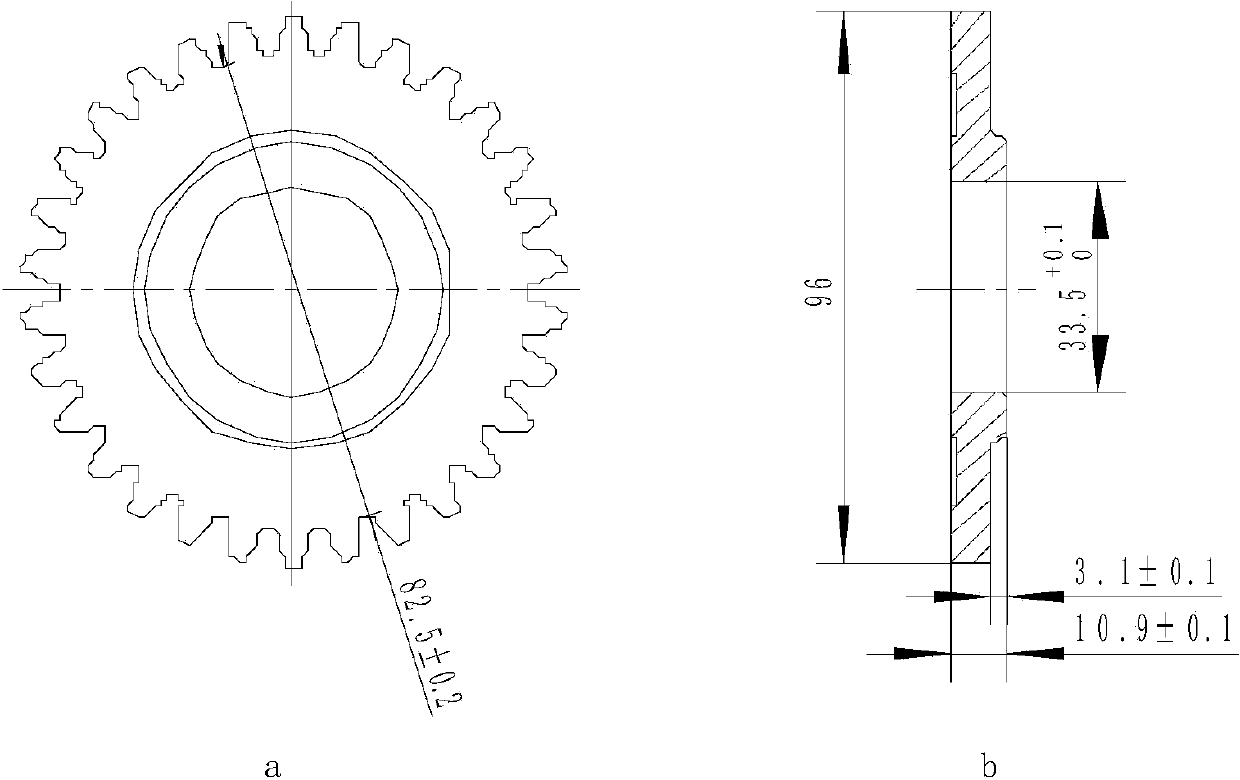

New-energy car speed reducer parking gear manufacturing technology

InactiveCN107984182AThe technical route of the manufacturing process is reasonableHigh strengthManufacturing technologyNew energy

The invention discloses a new-energy car speed reducer parking gear manufacturing technology. According to the technology, at first, cold extruding is carried out to remove the bottom so that a hollowcylindrical shaft can be formed, then the outer tooth face and the inner tooth face of the hollow cylindrical shaft are formed in a cold forging and extruding manner, and finally cutting is carried out, so that a plurality of new-energy car speed reducer parking gears are formed. The manufacturing technology is reasonable in technical route, metal flow is not cut off, the strength of product tooth faces is high, raw materials are saved, and the production efficiency is high.

Owner:江苏威鹰机械有限公司

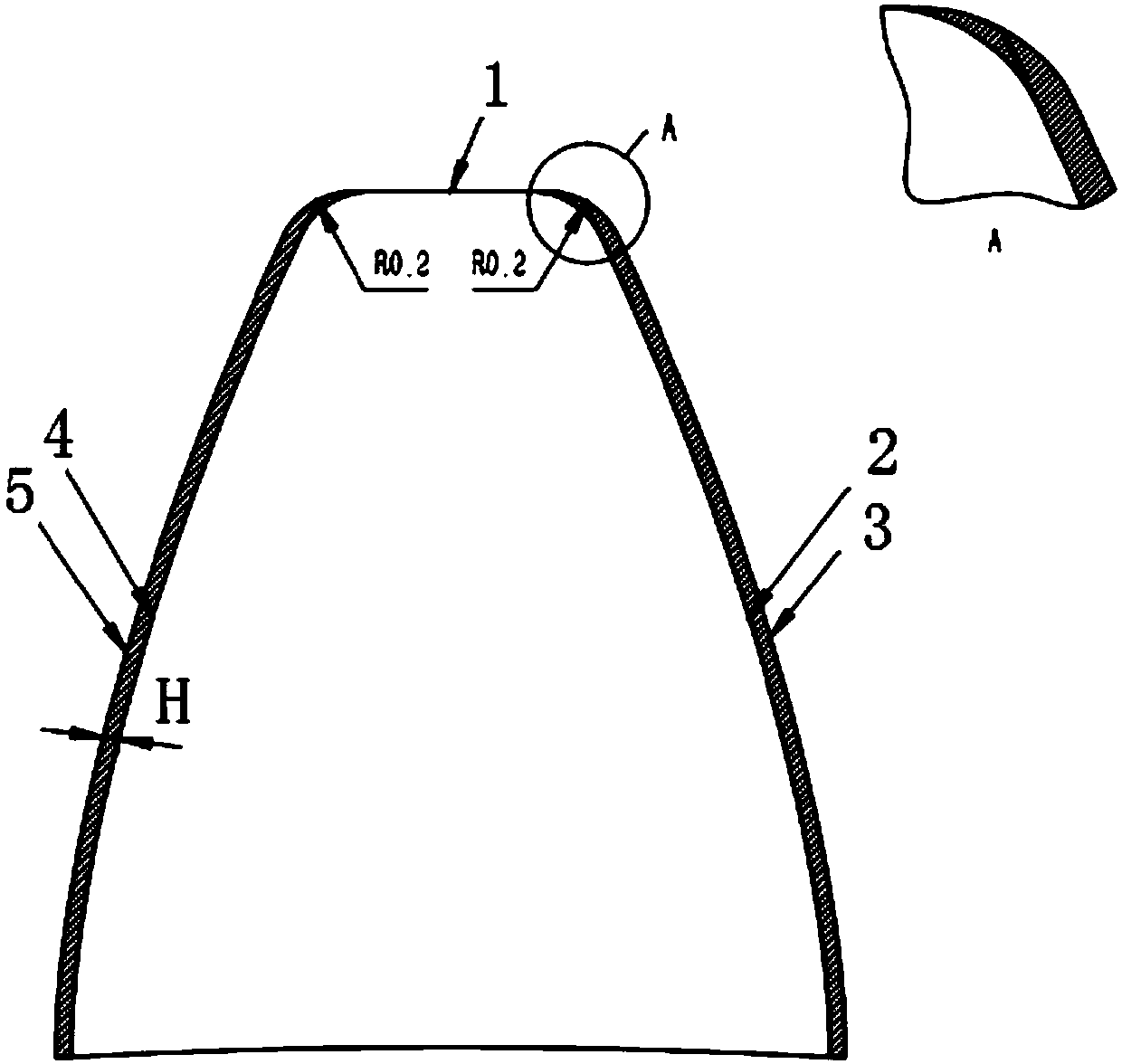

Tooth crest rounding method

The invention belongs to the field of gear manufacturing, relates to a design method for calculating a grinding wheel profile according to a gear profile and provides a novel tooth crest rounding method. The problem is solved that tooth crest rounding needs manual grinding at present. The tooth crest rounding method adopts a special rounding grinding wheel to machine tooth crest round corners on aworm grinding wheel gear-grinding machine. Compared with a traditional manual grinding for tooth crest rounding, the machining efficiency and machining quality are greatly improved. Firstly, an independent tooth crest rounding process needing to be performed after gear machining completion is analyzed according to a present-stage gear manufacturing process, and then the design method for calculating a special grinding wheel profile according to geometric parameters of a gear and rounding size is proposed.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com